Patents

Literature

207results about How to "Fast polishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

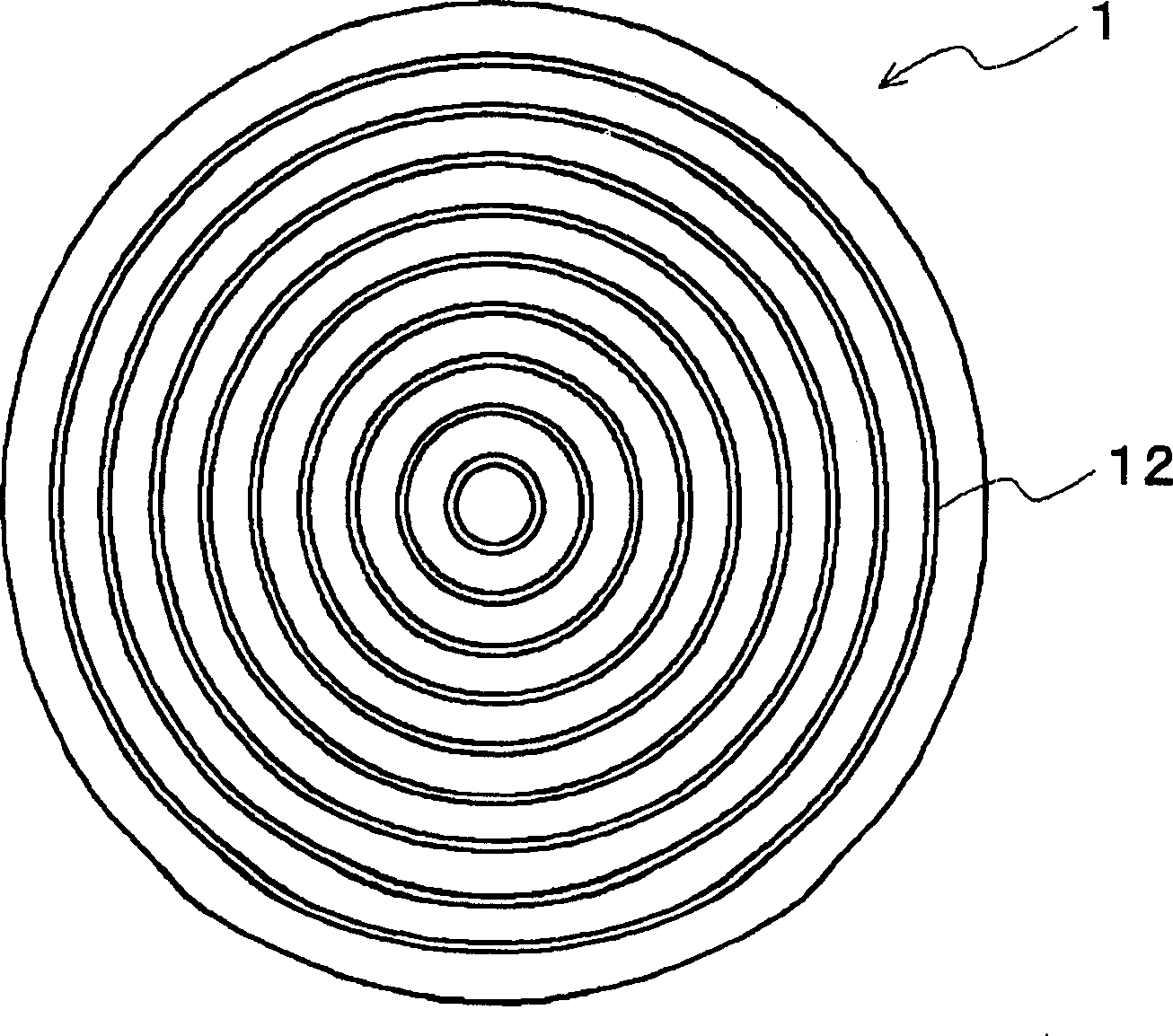

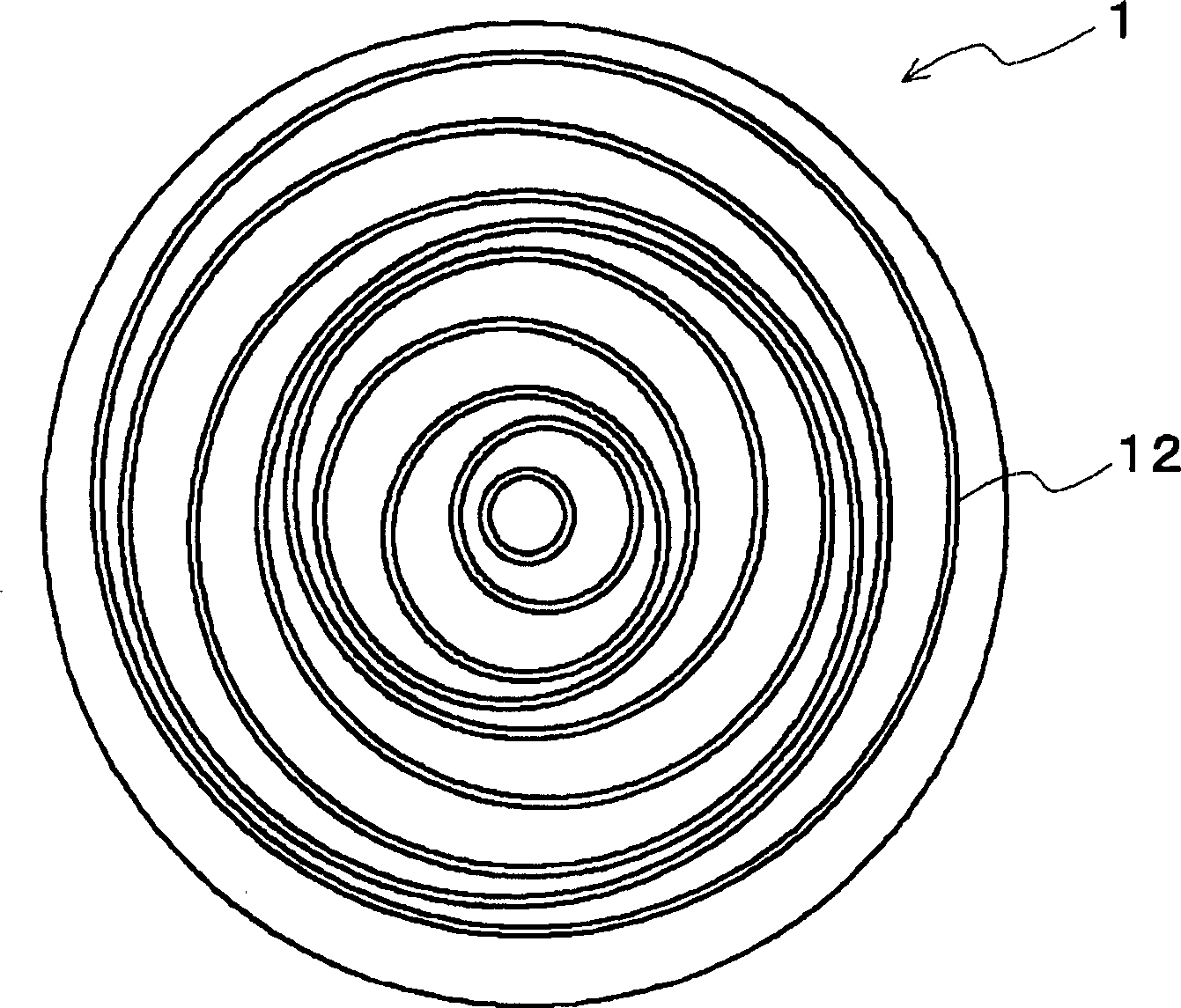

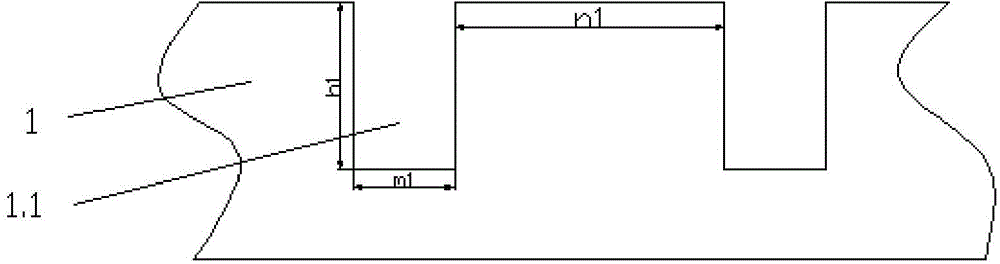

Polishing mattress and multilayer polishing mattress

InactiveCN1494983AInhibit chafingImprove flatnessSemiconductor/solid-state device manufacturingFlexible-parts wheelsSurface roughnessBiomedical engineering

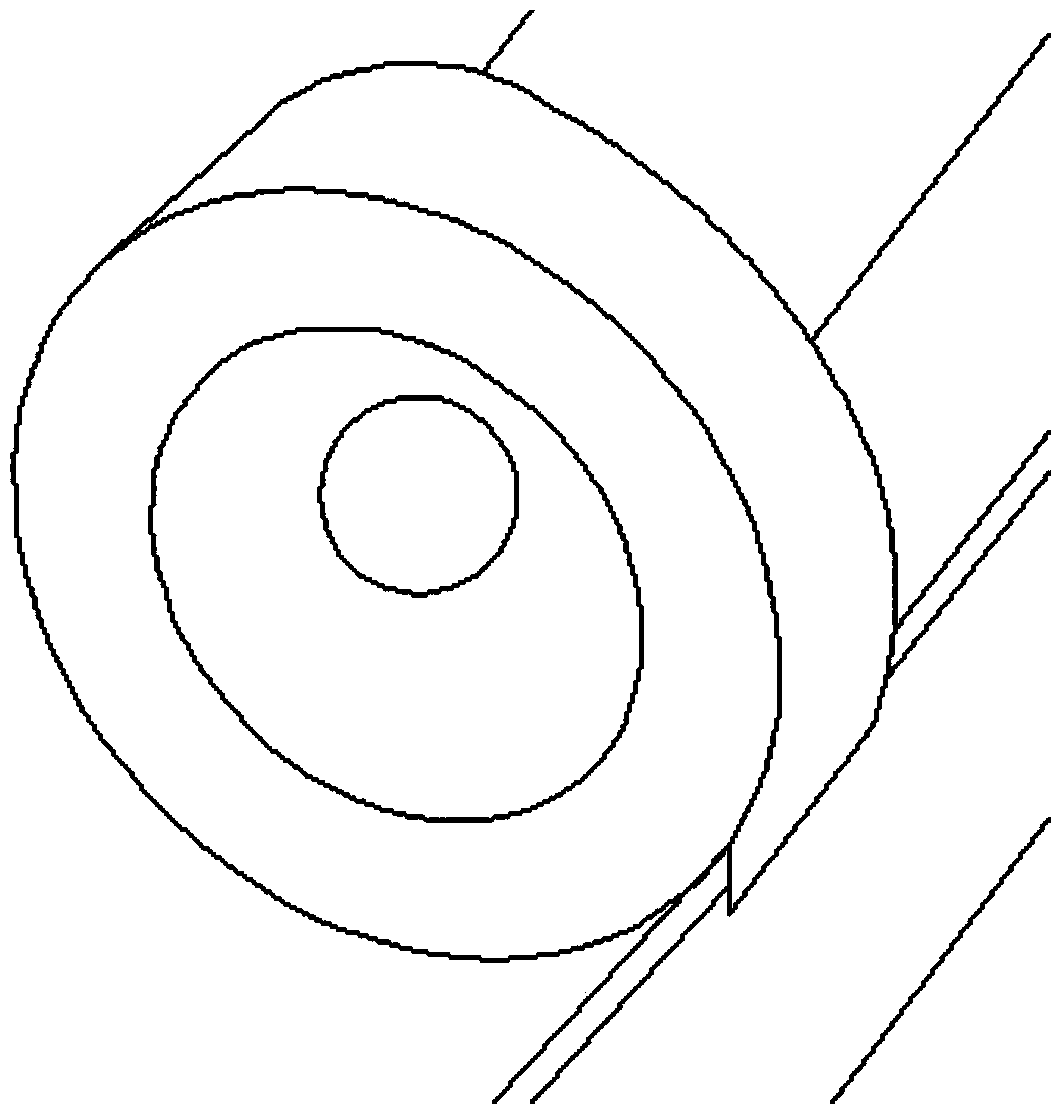

The present invention intends to provide a polishing pad and a multi-layer polishing pad (1) that can particularly effectively suppress scratch from occurring. The polishing pad (1) of the invention comprises at least one part selected from a groove (a) having at least one kind of shape selected from annular, lattice-like and spiral form on a polishing surface side, a concave portion (b) and a through hole (c). In the above, surface roughness of an inner surface of the part is 20 mu m or less and the polishing pad (1) is used for chemical mechanical polishing.

Owner:JSR CORPORATIOON

Polishing liquid for polishing monocrystalline silicon piece chemical machine

InactiveCN101671528ANo surface defectsEfficient ultrafine chemical mechanical polishingPolishing compositions with abrasivesActive agentSurface roughness

The invention discloses a polishing liquid for polishing a monocrystalline silicon piece chemical machine, comprising the raw materials by mass percent: 0.1-20% of grinding material, 0.1-2% of chelating agent, 0.1-5% of dispersing agent, 0.1-5% of active agent, 0.01-10% of pH regulator and less than or equal to 90% of purified water; and the pH value is 9.0-12.0. The polishing liquid can obviouslyimprove the polishing speed (removing rate reaching 710nm), generates lower surface defect for a monocrystalline silicon piece, and reduces the surface roughness (reaching 0.18nm), thus realizing topolish the high-efficiency ultra-precision chemical machine of the monocrystalline silicon piece, and ensuring the fine quality of the surface of the monocrystalline silicon piece. The polishing liquid is alkaline, so as to be conveniently cleaned after polishing; furthermore, the polishing liquid does not corrode equipment, thus prolonging the service life of the equipment and reducing the processing cost.

Owner:DALIAN SANDAAOKE CHEM

Compound polishing powder for polishing optical elements, preparation method and polishing technology

ActiveCN101362925BImprove effectivenessImprove machining accuracyOptical surface grinding machinesOther chemical processesSurface finishGranularity

The invention provides a compound polishing powder of a polishing optical element, a preparation method and a polishing process, belonging to expendable material used for polishing the optical element, the preparation method and the polishing process of the polishing powder; wherein, the polishing powder comprises 0.5-3 of Cr2O3 powder and 1 of Al2O3 according to the weight proportion; the granularity of the Cr2O3 powder is ranging from 0.05 microns to 0.10 microns and the granularity of the Al2O3 powder is ranging from 0.05 microns and 0.10 microns; the polishing process comprises the steps as follows: 1) installing polishing formworks for the optical element; 2) filling the polishing powder; 3) arranging a lens disc; 4) fixing the lens disc; 5) rubbing and polishing. The polishing formwork comprises 500 of polishing asphalt and 20-200 of Al2O3 according to the weight parts; in the polishing process, the polishing powder and the polishing formwork can be used for polishing the optical element which is made of zinc selenide, with the surface smoothness of more than 20-10.

Owner:CHENGDU Z & Z OPTOELECTRONICS TECH

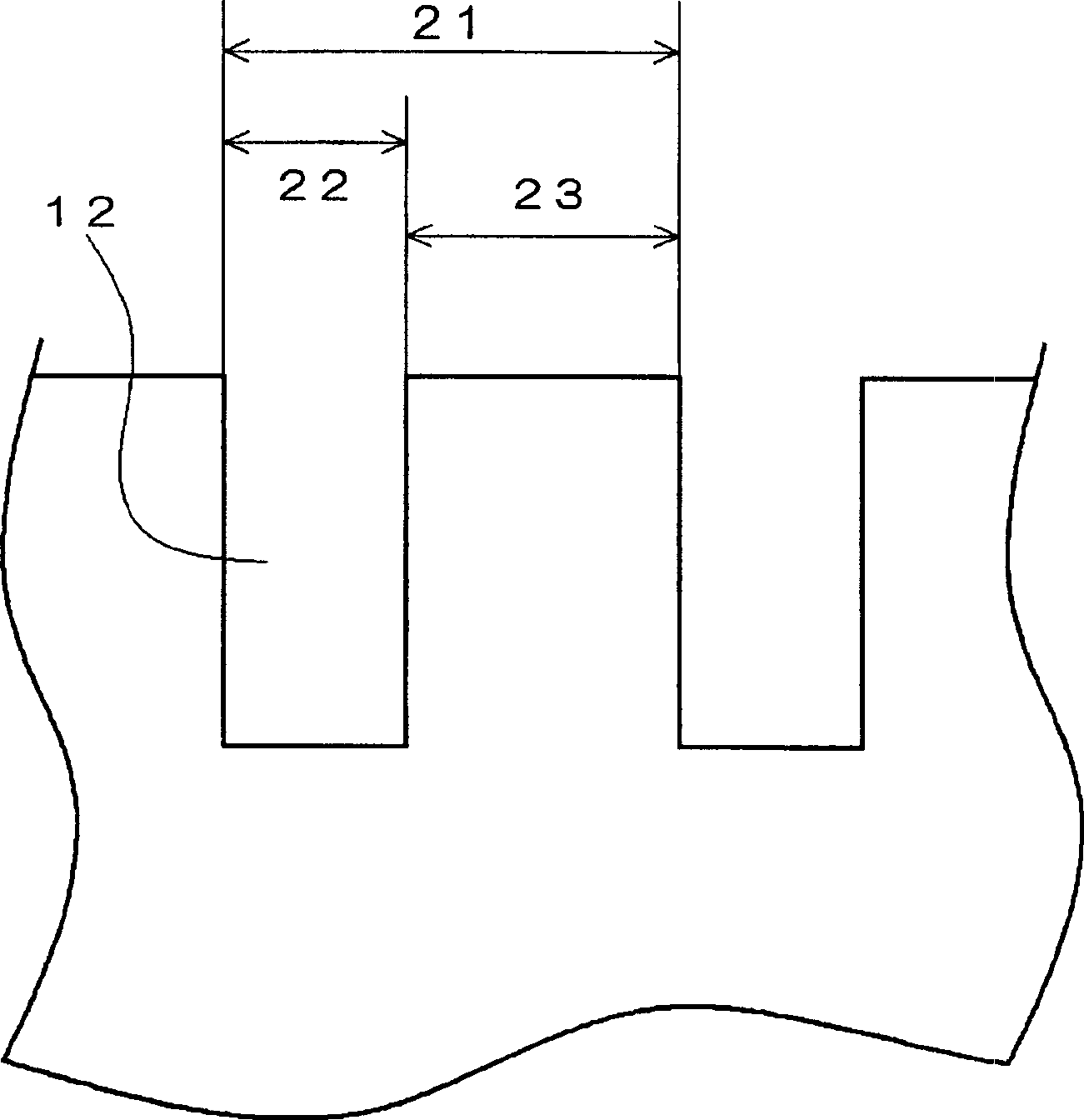

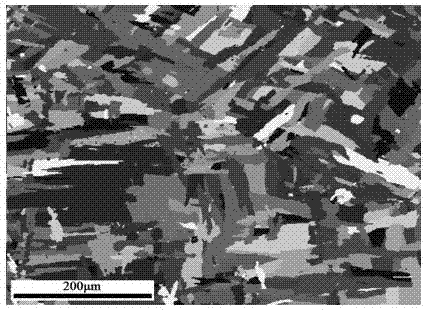

Electrolytic polishing solution for titanium and titanium alloys and electrolytic polishing process

InactiveCN102899711AEasy to get materialsLow costPreparing sample for investigationAcetic acidProcess equipment

The invention discloses electrolytic polishing solution for titanium and titanium alloys and an electrolytic polishing process, wherein the polishing solution is prepared by perchloric acid with volume fraction of 8-15% and acetic acid with volume fraction of 85-92%. The polishing solution is convenient in material selection, easy in preparation and storage, simple in polishing process equipment, easy in operation, smooth in surface, free of obvious scratches and oxide films and high in EBSD (Electron Back-Scattered Diffraction) pattern recognition rate, and has the effects of greatly reducing the superficial stress of the samples and greatly improving the detection precision.

Owner:CHONGQING UNIV

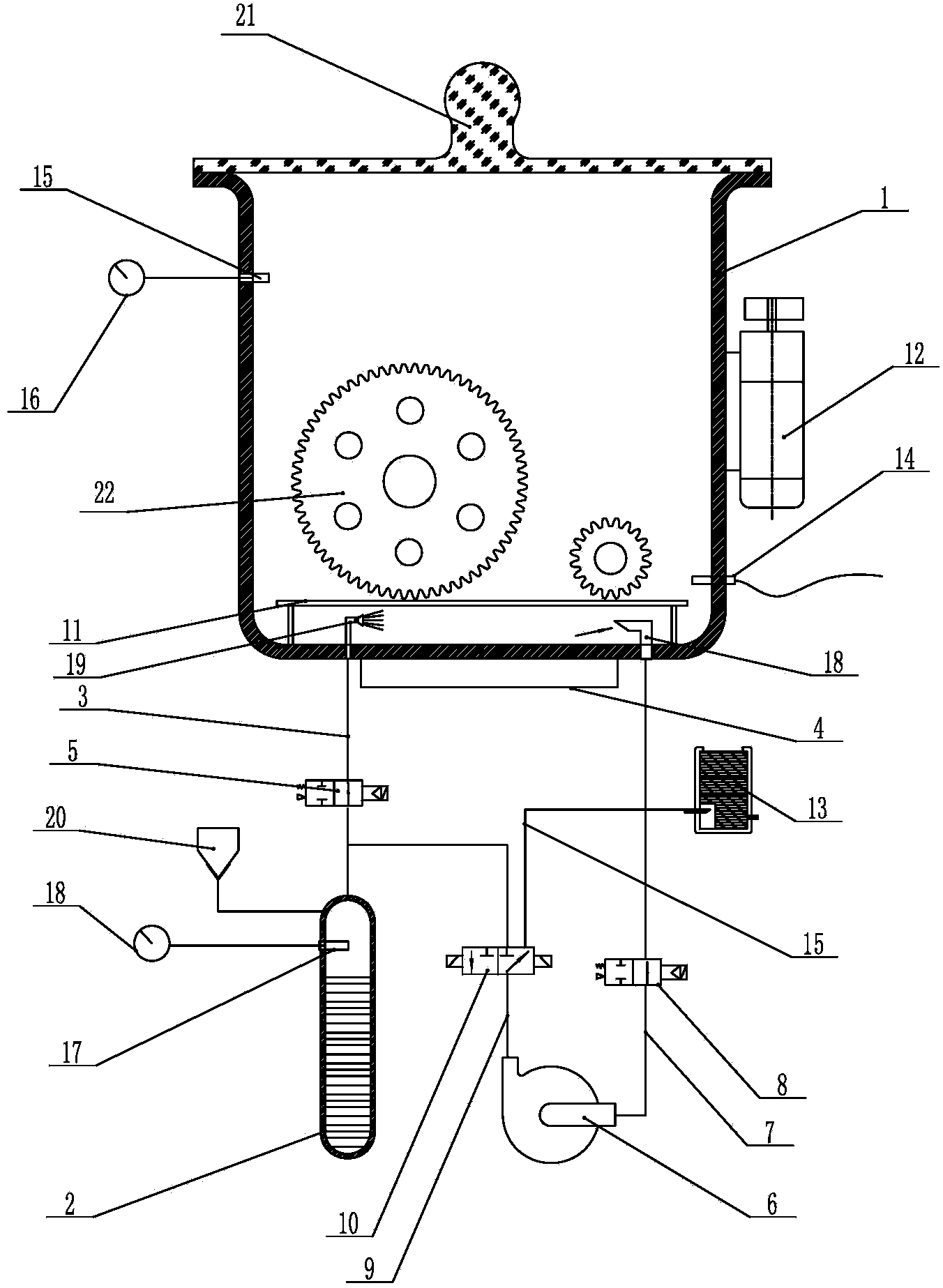

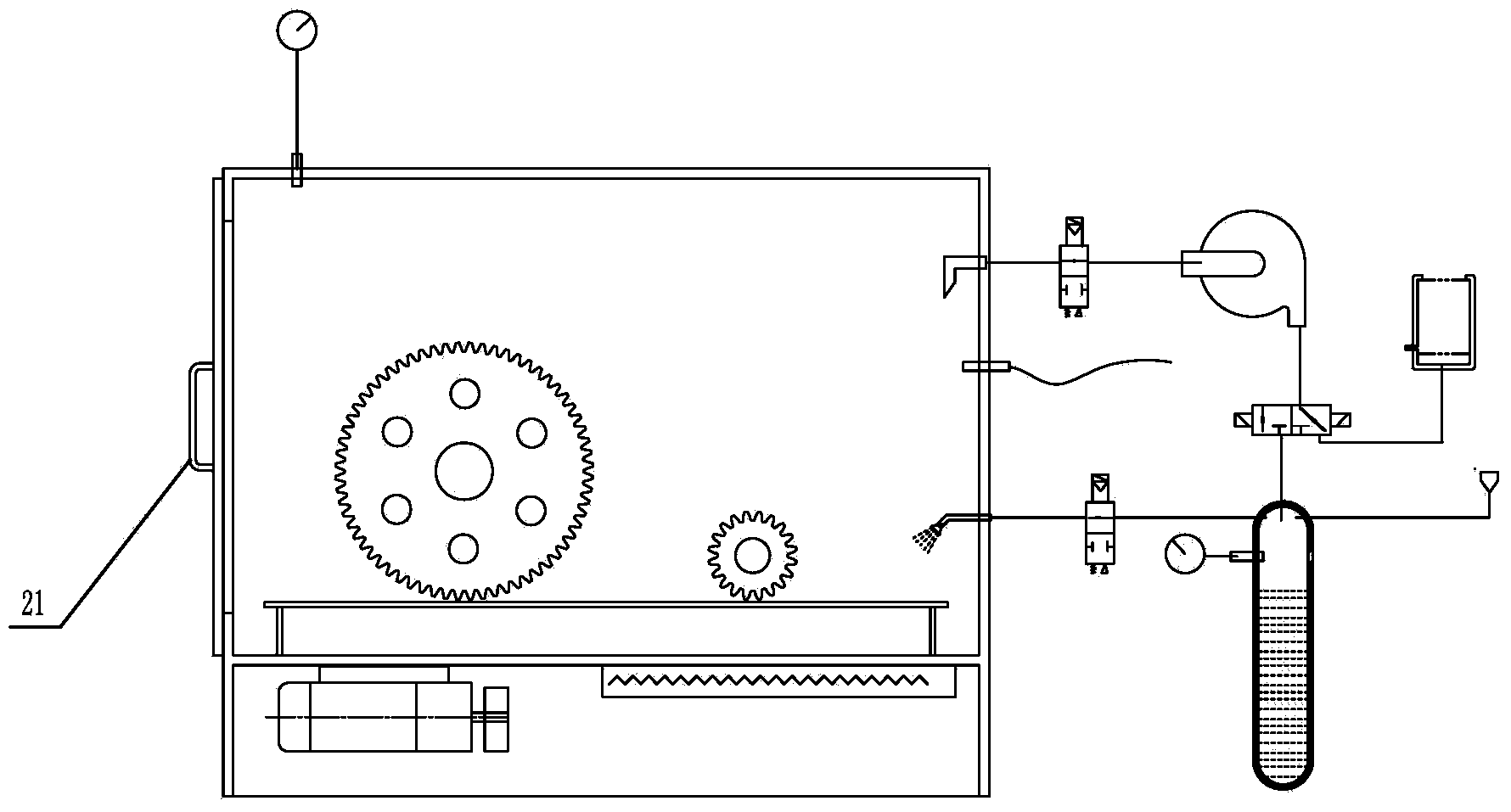

Apparatus and method for polishing three-dimensional printed plastic/resin pieces

The invention provides an apparatus for polishing three-dimensional printed plastic / resin pieces. The apparatus comprises a polishing chamber and a solvent storage tank which are communicated with each other by use of a liquid inlet pipe; the apparatus is characterized in that the polishing chamber is an airtight container, an exhaust opening of the polishing chamber is connected with an air inlet of a vacuum device, an air outlet of the vacuum device is connected to the outside atmosphere and the solvent storage tank, respectively, and a switch is used for controlling the vacuum device to be connected with or disconnected from the polishing chamber, the solvent storage tank and the outside atmosphere, respectively. The apparatus for polishing the three-dimensional printed plastic / resin pieces is environmentally-friendly, capable of effectively polishing to-be-polished pieces with complex structures, and also capable of quickly recovering the hardness of the polished pieces.

Owner:孙韶

Method of preparing alkali resistance ultra-pure silicasol

The invention discloses a making method of alkaline-resistance hyperhigh pure silicasol, which comprises the following steps: 1. adopting distilled pure organic silicane as raw material; dissolving in the inorganic acid or organic acid to obtain acid metasilicate acid solution; 2. dissolving rectified organic silicane in the inorganic alkaline or organic alkaline solution to obtain the alkaline silicon solution; or diluting inorganic alkaline or organic alkaline solution to obtain alkaline solution without silicon; 3. reacting acid metasilicate acid solution and alkaline solution without silicon under 105 deg.c; obtaining the silicasol; 4. heating silicasol under normal pressure or decompressing condition to boil to remove carbinol or alcohol and partial water; obtaining the product with density over 20%.

Owner:苏州西丽卡电子材料有限公司

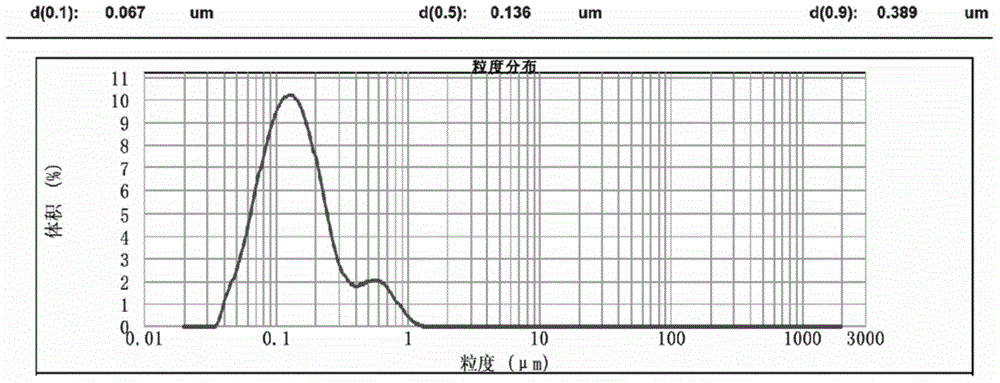

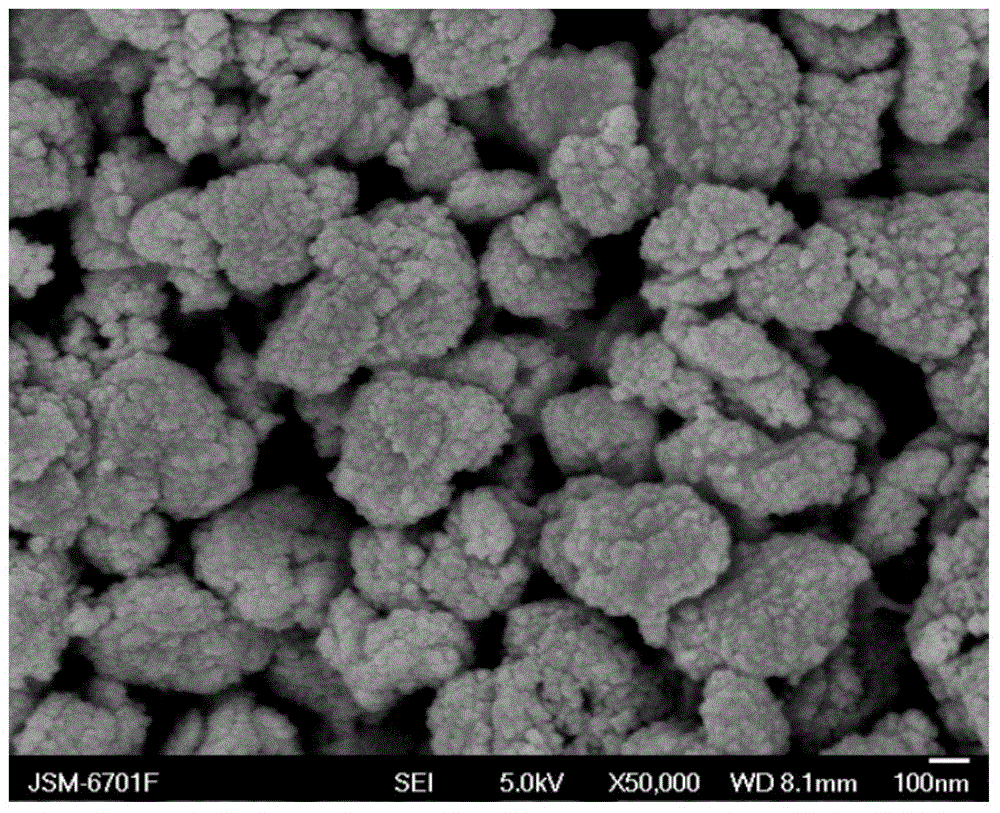

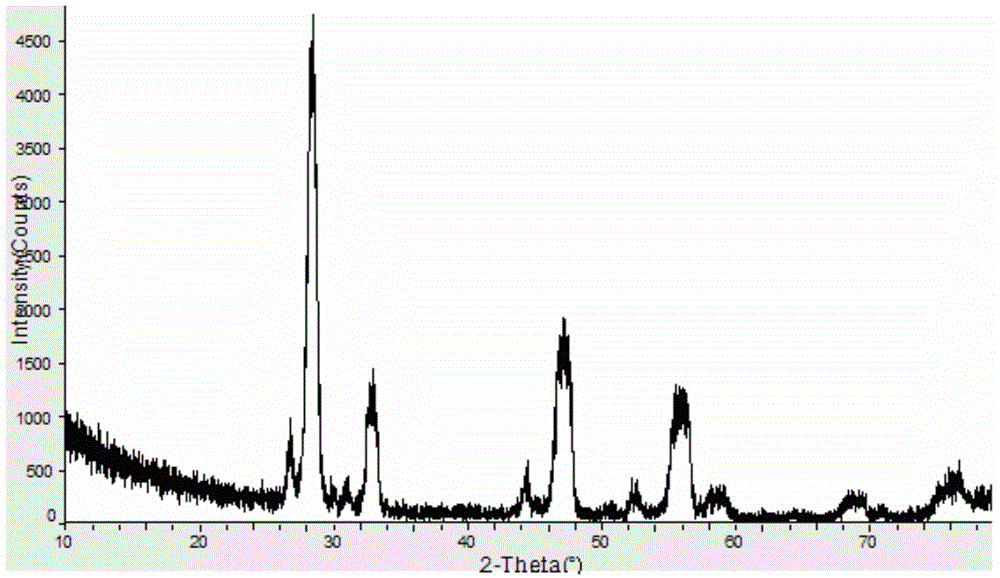

Porous nano composite abrasive particle containing polishing active elements, polishing solution composition and preparation method thereof

ActiveCN102408871AImprove chemical performanceFast polishingOther chemical processesPolishing compositions with abrasivesCeriumSilicon oxide

The invention relates to a porous nano composite abrasive particle containing polishing active elements, a polishing solution composition and a preparation method thereof. The composite abrasive particle is: a. composite silicon oxide abrasive particle formed by silicon oxide and oxide containing polishing active elements; or b. composite aluminum oxide abrasive particle formed by aluminum oxide and oxide containing polishing active elements. The composite abrasive particle is in a nano pore structure, and can lower the abrasive hardness and reduce the excess collision of the inorganic compact abrasive particle onto the substrate, thereby reducing the polishing damage; the abrasive particle contains iron or copper, cerium, nickel, titanium, silver or any other polishing active element in the aspect of chemical composition, and can enhance the chemical action of the abrasive particle; and the porous structure of the abrasive particle can adsorb and store the polishing solution component to enhance the chemical activity of the abrasive particle. The enhancement of the chemical action can increase the polishing speed of the abrasive particle, and the abrasive particle designed in such a way can simultaneously achieve the goals of high speed and high precision in polishing. When being used for polishing an electronic device, such as a hard disk substrate, the polishing solution provided by the invention can effectively lower the surface roughness of the memory hard disk substrate, and has high polishing speed.

Owner:昆山捷纳电子材料有限公司

Brass chemical polishing solution and preparation method thereof

The invention discloses a brass chemical polishing solution and a preparation method thereof, and one liter of the polishing solution contains 60-140g of persulfate, 200-350ml of 92.5 wt%-98.0 wt% concentrated sulfuric acid, 0-60ml of 85.0wt% strong phosphoric acid, 1-10g of citric acid, 2-10g of 7.H2O ferrous sulfate, 0-3g of sodium chloride, 0-6g of urea, 0.2-1.0g of sodium lauryl sulfate and balance of water. The invention adopts persulfate (kalium, sodium, ammonium and the like) as an oxidant to replace strong nitric acid, hydrogen peroxide and the like adopted for traditional chemical polishing, avoiding using the oxidant harmful to the environment and generating nitrogen oxide gas with strong toxicity for humans in the prior art; the brass chemical polishing solution has the characteristics of environmental protection, more stability (greatly improved by being compared with the stability of a hydrogen peroxide polishing solution), high polishing speed, good polishing effect andthe like. The brass polished through the brass chemical polishing solution has a flat and smooth surface and golden appearance.

Owner:HUAQIAO UNIVERSITY

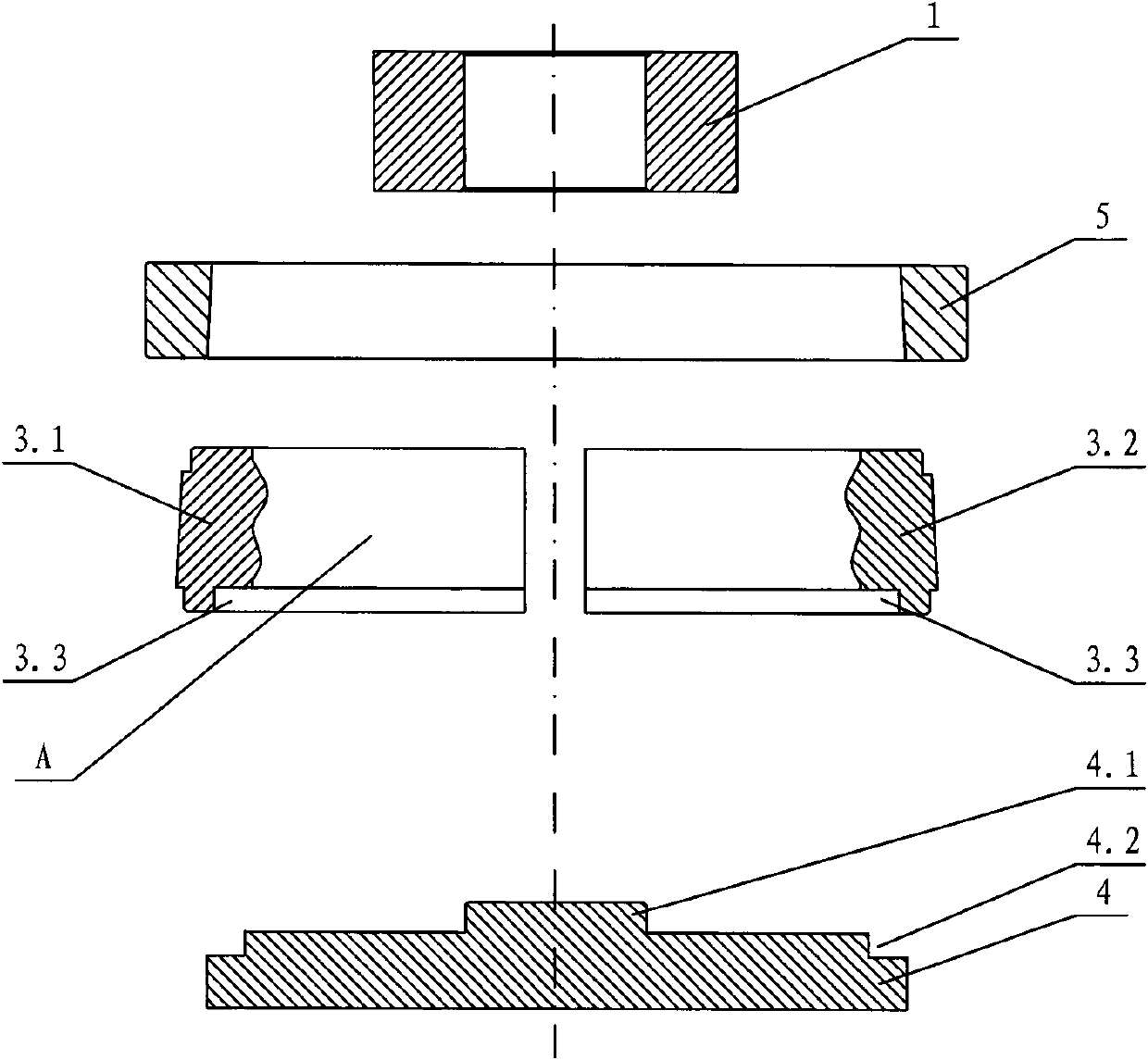

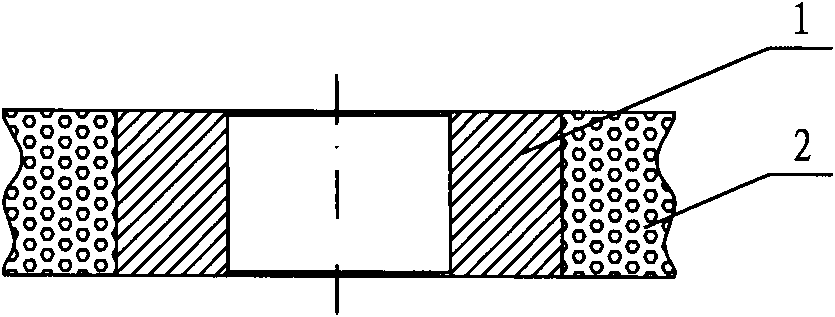

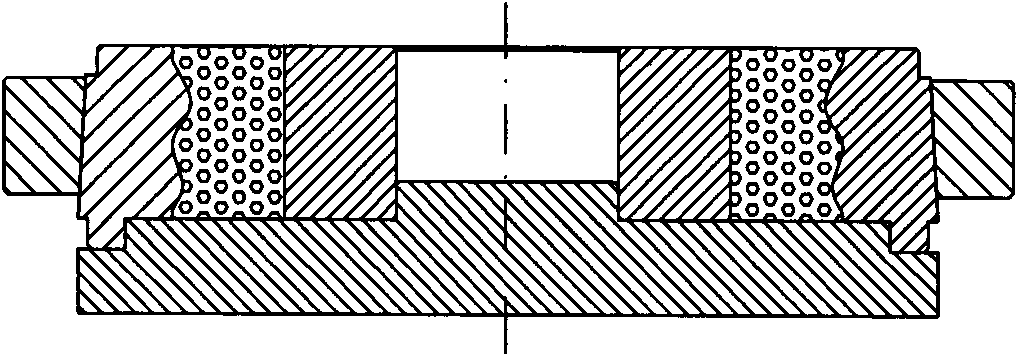

Resin-bonded diamond abrasive tool, method and mold for producing resin-bonded diamond abrasive tool

The invention discloses a resin-bonded diamond abrasive tool, a method and a mold for producing the resin-bonded diamond abrasive tool. The resin-bonded diamond abrasive tool comprises a matrix and an abrasive layer, and the abrasive layer is prepared from binder, abrasive and packing by way of mixed casting, wherein the binder is prepared from epoxy novalac type vinyl ester resin liquid, initiating agent and accelerating agent through mixing; the abrasive comprises diamond and silicon carbide; and the packing is one or more of powdered alumina, quartz powder and cerium oxide polishing powder; and the components above in parts by weight are as follows: 100 parts of epoxy novalac type vinyl ester resin liquid, 2 to 3 parts of initiating agent, 1 to 4 parts of accelerating agent, 10 to 20 parts of diamond, 10 to 30 parts of silicon carbide, and 80 to 120 parts of packing. The invention has the advantages of good sharpness, strong self-sharpness, good grinding and polishing effects, simple and reasonable manufacturing process, precise one-stop special-shaped surface production, high grinding and polishing efficiencies, high comprehensive performance, and low production cost, and is flexible in operation,.

Owner:广东奔朗新材料股份有限公司

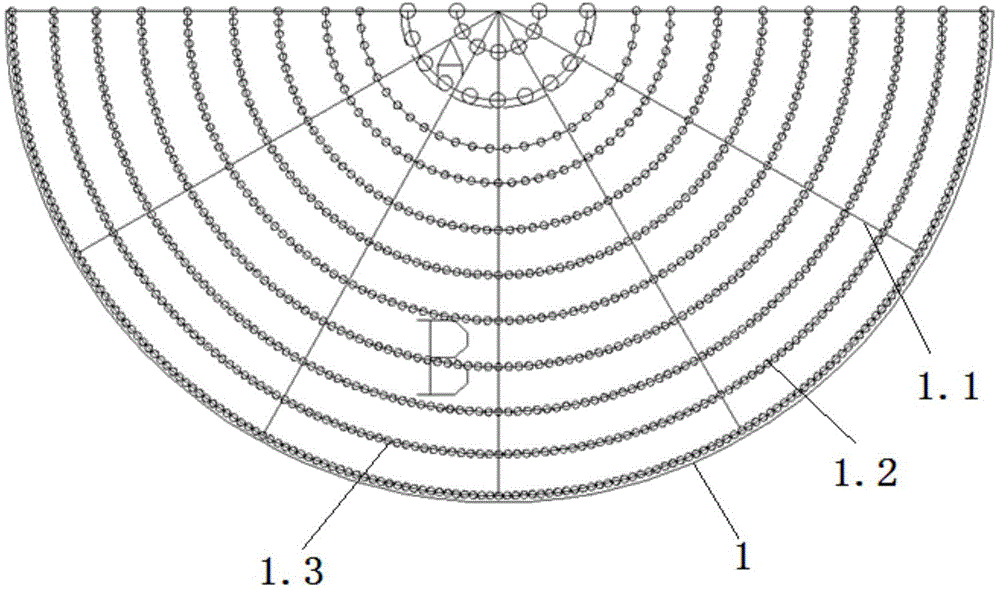

Chemical-mechanical polishing pad

The invention discloses a chemical-mechanical polishing pad and solves the problem that an existing polishing pad is scratched easily and low in polishing efficiency. According to the technical scheme, the chemical-mechanical polishing pad comprises a polishing layer, a plurality of holes are formed in the polishing surface of the polishing layer, the center of the polishing surface is a circle center, and the holes are arranged into multiple rows of concentric rings different in diameter. The center of the polishing surface is an end point, and a plurality of grooves extending to the edge of the polishing surface are evenly radiated from the end point. The surface roughness of the polishing surface is below 15 micrometers. The polishing pad is simple in structure, capable of increased polishing removing efficiency and inhibiting scratches, and long in service life.

Owner:HUBEI DINGLONG CO LTD

Diamond resin binder abrasive disc and preparation method and application thereof

ActiveCN110842800AImprove stabilityThe polishing process is environmentally friendlyAbrasion apparatusGrinding devicesA diamondAbrasive

The invention provides a diamond resin binder abrasive disc and a preparation method and an application thereof and belongs to the technical field of polishing grinding apparatuses. The diamond resinbinder abrasive disc is prepared from the following raw materials in parts by mass: 20-40 parts of thermosetting resin, 4-30 parts of a curing agent, 15-30 parts of a diamond, 10-20 parts of an auxiliary grinding material, 10-30 parts of micro filler, 1-10 parts of nano filler and 1-5 parts of a coupling agent. The diamond resin binder abrasive disc is used for polishing a marble and has the advantages of being good in polishing effect, high in efficiency, environmental-friendly and safe and the like.

Owner:惠安宇信金刚石工具有限公司 +1

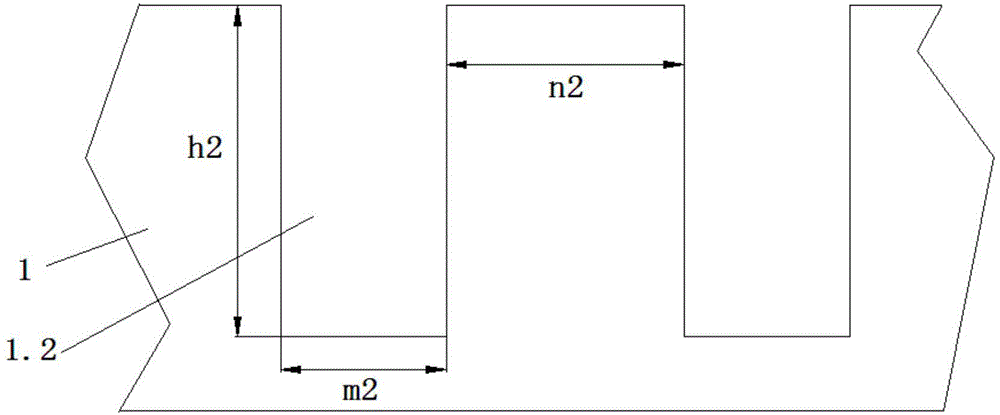

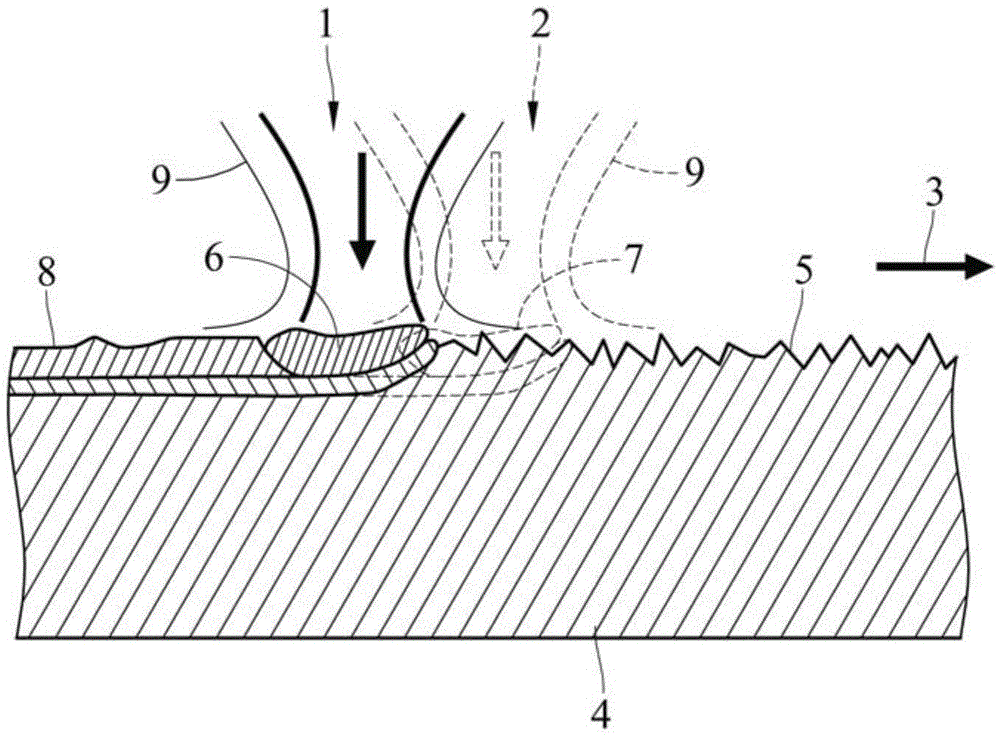

Buffing device and buffing method

ActiveCN106695124AFast polishingIt is difficult to solve the problem of talent trainingLaser beam welding apparatusPhysicsLaser

The invention discloses a buffing device and a buffing method. The buffing method comprises a first pulse laser having first power and a second pulse laser having second power scan a surface to be buffed of a workpiece along a moving path repeatedly and alternately. The first power is different from the second power.

Owner:IND TECH RES INST

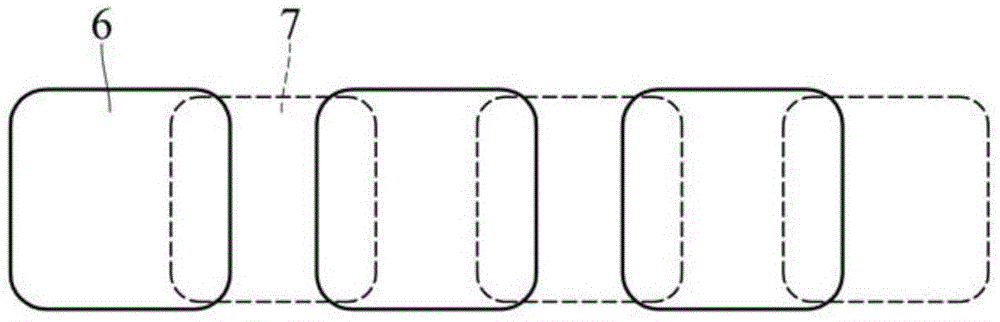

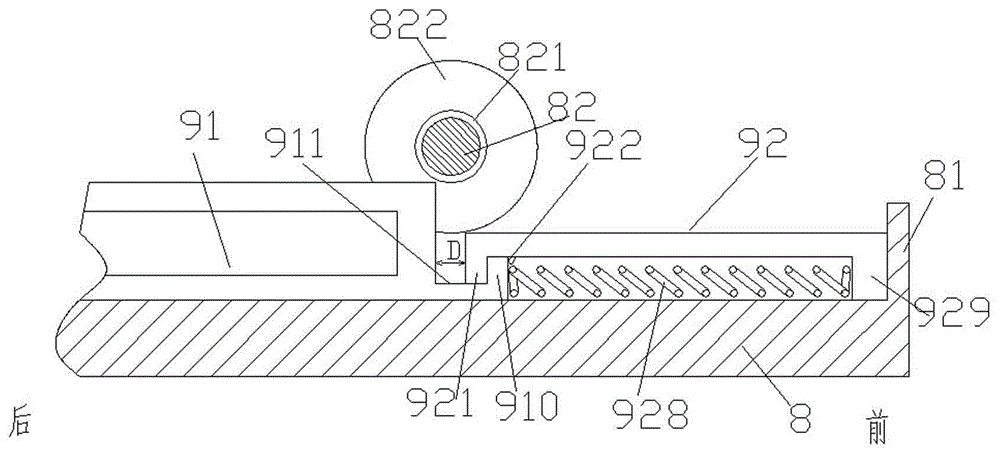

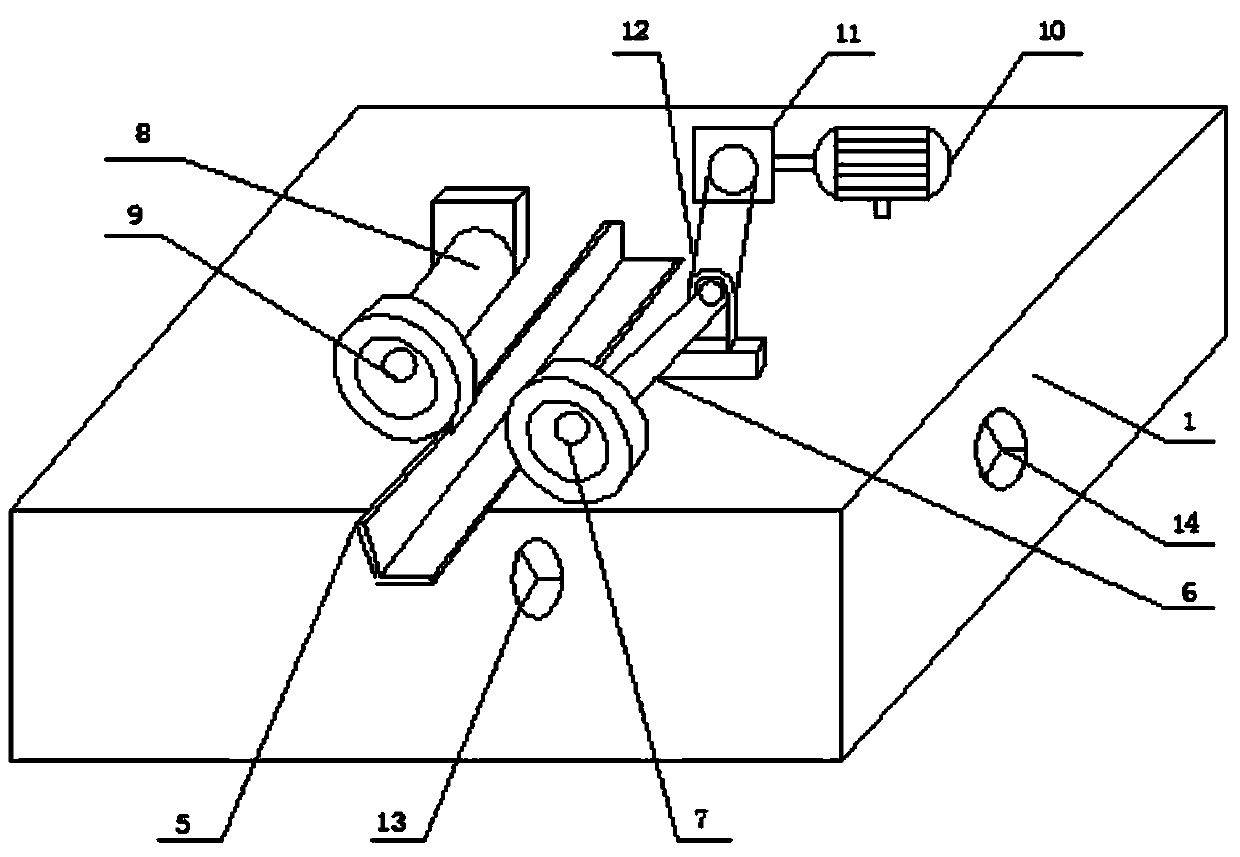

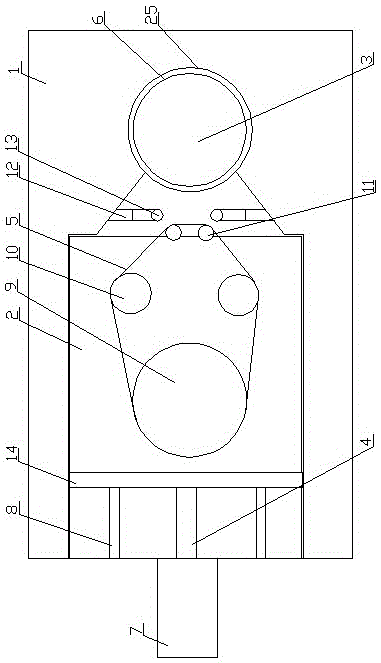

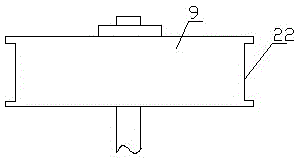

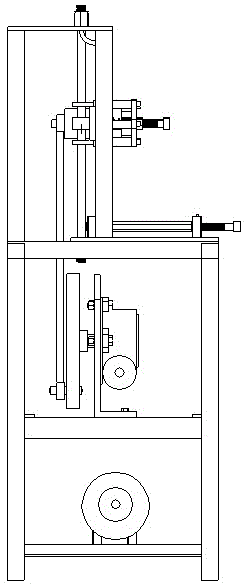

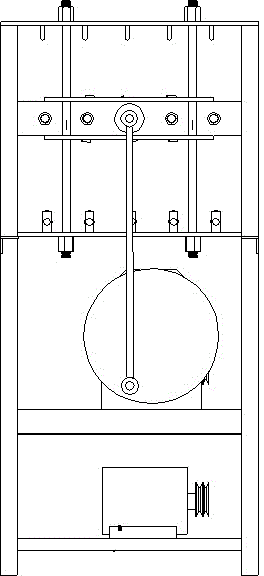

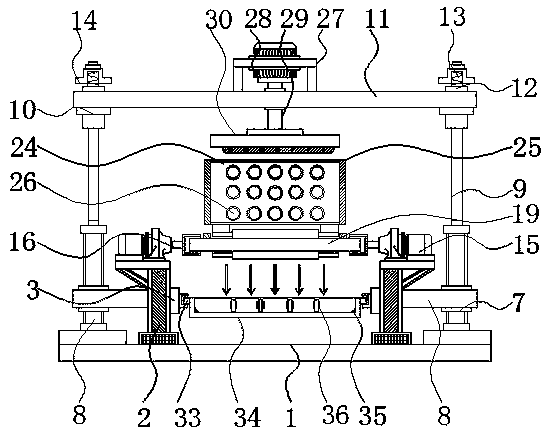

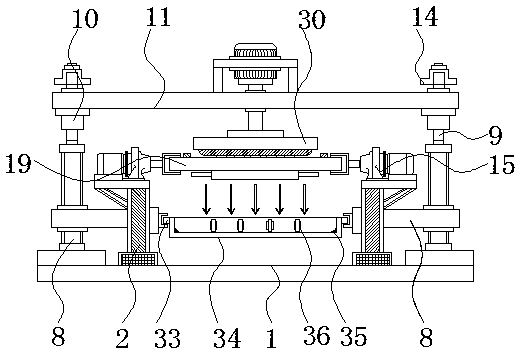

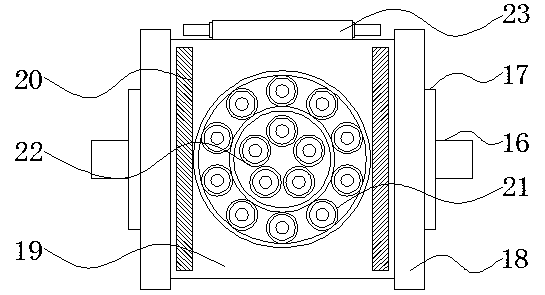

Mechanical iron plate surface double-layer synchronous polishing equipment

ActiveCN108453598APolishing saves time and effortFast polishingGrinding carriagesPolishing machinesMechanical componentsMachine parts

The invention relates to mechanical part machining equipment, in particular to mechanical iron plate surface double-layer synchronous polishing equipment which is provided for achieving the technicaleffects that an iron plate can be automatically polished with less time and effort, the two sides of the iron plate can be polished simultaneously each time, and the polishing speed is high. In orderto achieve the technical effects, the mechanical iron plate surface double-layer synchronous polishing equipment provided by the invention comprises a bottom plate, supporting plates, N-shaped frames,first connecting blocks, first rotating wheels, a conveyor belt, a screw rod, a second connecting block, rolling wheels, a guide rod, a mounting plate, a first bearing block and the like. The supporting plates are arranged on the left and right sides of the bottom plate. The upper ends of the supporting plates are both connected with the N-shaped frames. The mechanical iron plate surface double-layer synchronous polishing equipment achieves the effects that the iron plate is automatically polished with less time and effort, the two sides of the iron plate can be polished simultaneously each time and the polishing speed is high.

Owner:泰州永林机械有限公司

Fluorine doping method of cerium-based rare earth polishing powder

InactiveCN104419378AAdd evenlyEasy to control particle sizeOther chemical processesPolishing compositions with abrasivesFiltrationCerium

The invention discloses a fluorine doping method of cerium-based rare earth polishing powder. The fluorine doping method comprises the following steps: (1) respectively preparing a cerium-based rare earth salt solution, a precipitator and a fluorinating agent; (2) adding the rare earth salt solution, the precipitator and the fluorinating agent into a reaction kettle through parallel flow at a certain flow velocity, controlling the pH of the reaction system through controlling the flow velocity of the precipitator, controlling the fluorine doping proportion through controlling the flow velocity of the fluorinating agent, keeping a certain temperature in the reaction process, stirring violently, carrying out ageing after the reaction, and carrying out filtration, cleaning and drying on the sizing agent to obtain a cerium-based rare earth polishing powder precursor; and (3) calcining the prepared cerium-based rare earth polishing powder precursor, and carrying out natural cooling in the furnace to obtain the cerium-based rare earth polishing powder material. The fluorine doping method is simple in process, convenient to operate and suitable for industrial production. The cerium-based rare earth polishing powder prepared through the method is spherical in particle shape and controllable in particle size of product; and products with different particle sizes and different particle size distributions can be prepared according to the requirements of rare earth polishing powder with different applications.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

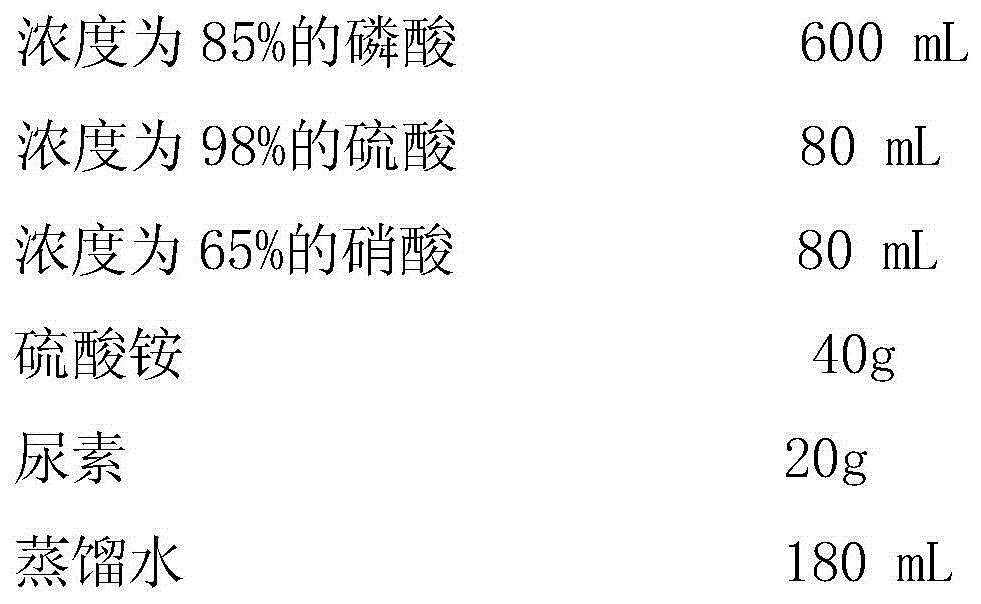

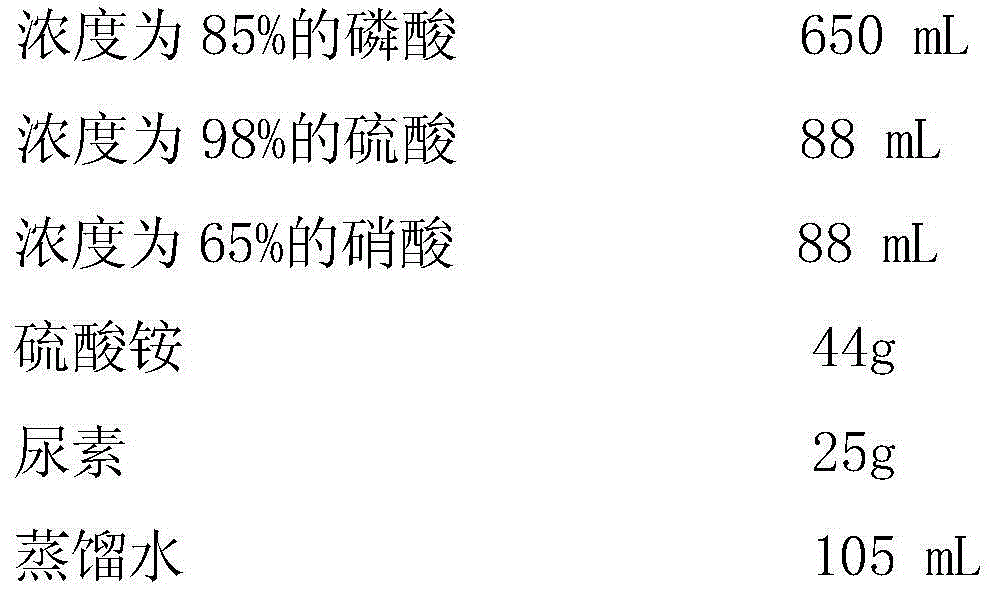

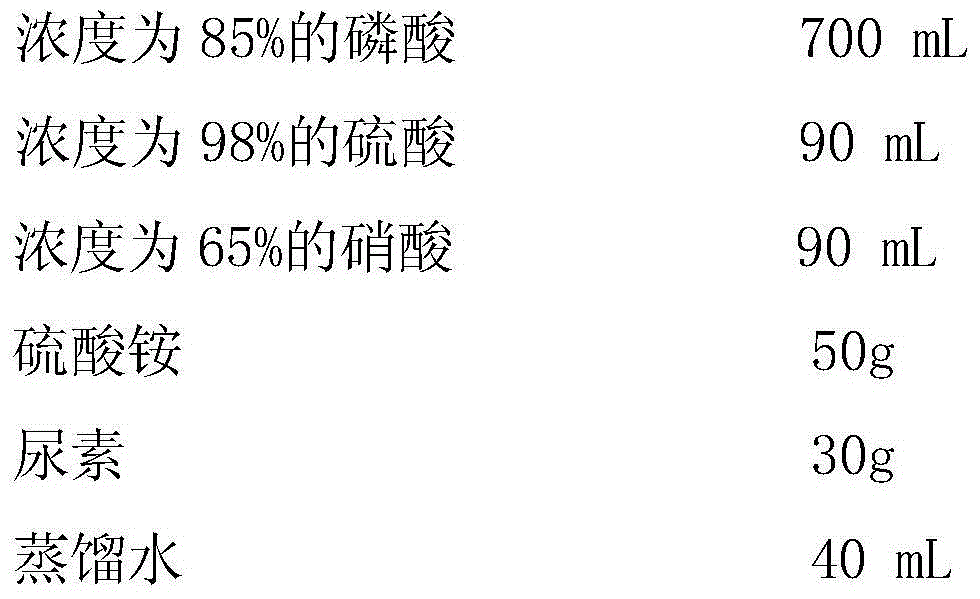

Chemical polishing solution for cast aluminium alloy and polishing technology

InactiveCN104005031AHigh polishing finishImprove polishing efficiencyPhosphoric acidAmmonium sulfate

The invention provides a chemical polishing solution for cast aluminium alloy and a polishing technology. The polishing solution comprises a polishing solution A and a polishing solution B. The polishing solution A comprises the following compositions in percent by volume: 60%-75% of nitric acid and 20%-25% of hydrofluoric acid. The polishing solution B comprises the following compositions in percent by weight: 60%-70% of phosphoric acid, 8%-9% of sulfuric acid, 8%-9% of nitric acid, 2%-3% of urea and 4%-5% of ammonium sulfate. The polishing technology comprises: performing cleaning processing on the surface of a cast aluminium alloy ZL104 product, putting in the polishing solution A to remove silicon on the product surface, and then putting in the polishing solution B for reacting for 2 min, controlling the temperature of the polishing solution B to be 85+ / -5 DEG C, so as to enable the product to be selectively self dissolve in the polishing solution B, and further to level and polish the cast surface and realize the purpose of reducing the surface roughness Ra. The polishing solution and the polishing technology have the advantages that the appearance of cast aluminium alloy shows aluminium natural color, the polishing finish is high, the polishing efficiency is high and the polishing effect is excellent, and the polishing solution and the polishing technology are widely applicable to polishing of cast aluminium alloy materials.

Owner:HUBEI SANJIANG AEROSPACE WANFENG TECH DEV

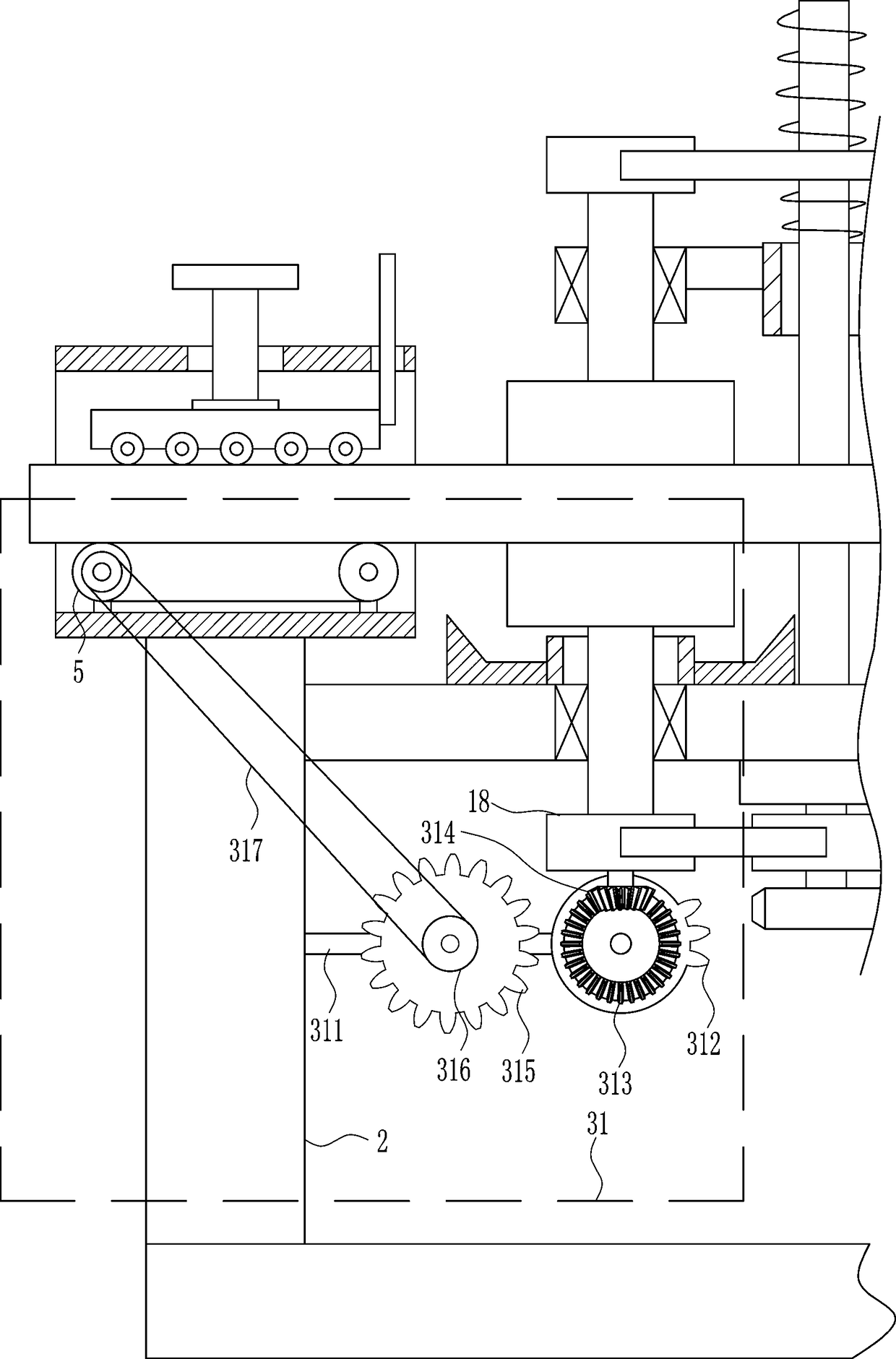

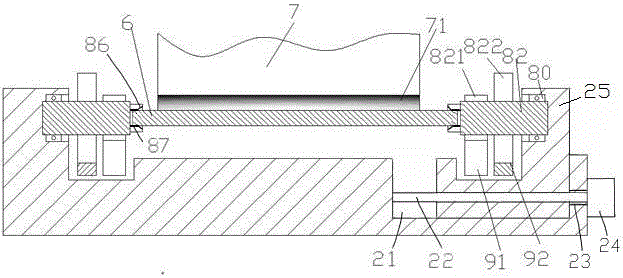

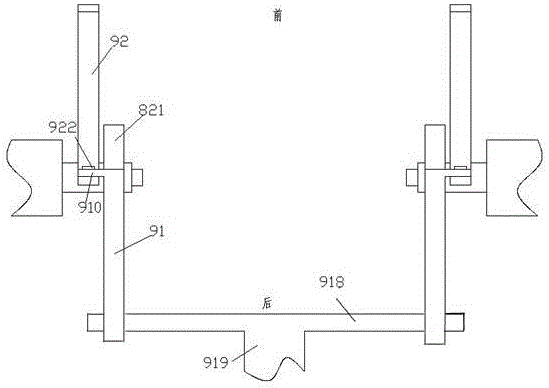

Polishing device applicable to shaft parts of different lengths and using method of polishing device

The invention relates to a polishing device applicable to shaft parts of different lengths and a using method of polishing device. The polishing device comprises a polishing component with a polishing strip and a supporting base. A sliding groove is formed in the right end of the supporting base. A sliding seat is mounted in the sliding groove in a slideable manner. A drive screw is mounted in the sliding seat in a threaded fit manner. The left end of the drive screw is rotatablely mounted on the left side wall of the sliding groove. The right end of the drive screw penetrates through an unthreaded hole in the right side wall of the sliding groove, and is in power connection with a regulating motor mounted at the outer end of the right side wall of the sliding groove. Clamping and driving components are rotatablely supported at the left end of the supporting base and on the sliding seat by virtue of bearings. A gearwheel and a pinion are fixedly mounted on the circumferential surface of each clamping and driving component. The gearwheels are positioned on the outer sides of the clamping and driving components, and the pinions are positioned on the inner sides of the clamping and driving components. The gearwheels and the pinions are used for being meshed with outer racks and inner racks respectively so as to drive the shaft parts to push against the polishing strip and rotate relative to the polishing strip to be polished.

Owner:PUJIANG XIONGDA MACHINERY EQUIP

Copper material pickling polishing solution and preparation method and application method thereof

The invention relates to the technical field of metal polishing, in particular to a copper material pickling polishing solution and a preparation method and application method thereof. The copper material pickling polishing solution is prepared from, by weight percent, 15%-28% of tervalent ferric salt, 10%-15% of sulfuric acid, 0%-5% of chlorate, 0%-7% of peroxysulphate, 0%-0.5% of pypocholoride, 0.9%-2.1% of compound additive and the balance water. The copper material pickling polishing solution is environmentally friendly, free of chromium, yellow fume and nitrogen and phosphorus ingredients, stable in performance, high in polishing speed, capable of being recycled, long in service life and easy to maintain, the brightness is equivalent to the polishing effect of a chromate system process, and use cost is equivalent to that of the chromate system process.

Owner:Dongguan Kaimeng Chemical Co Ltd

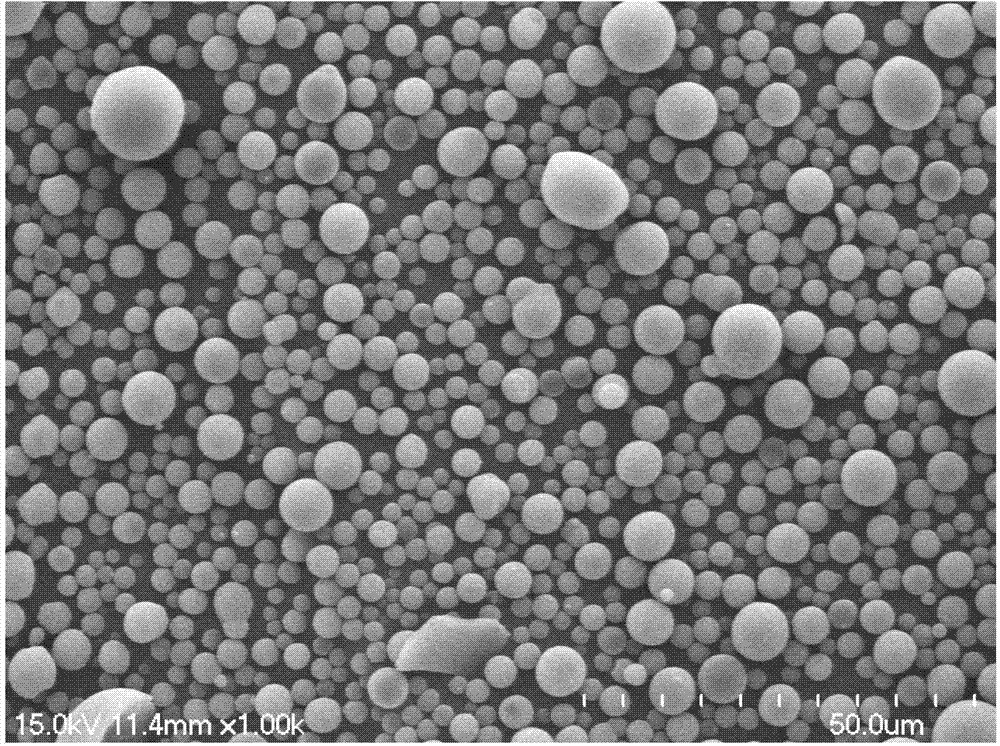

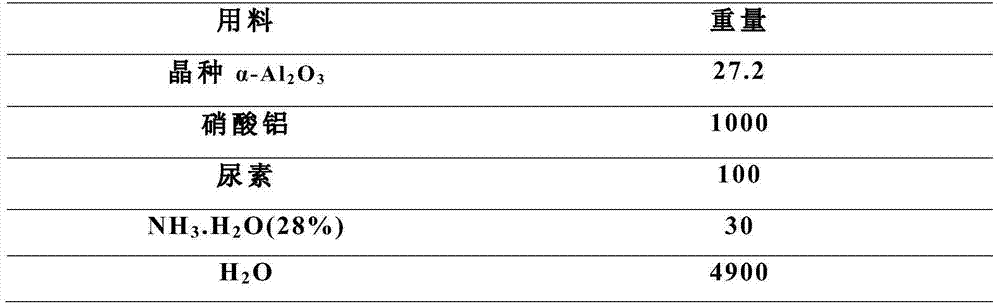

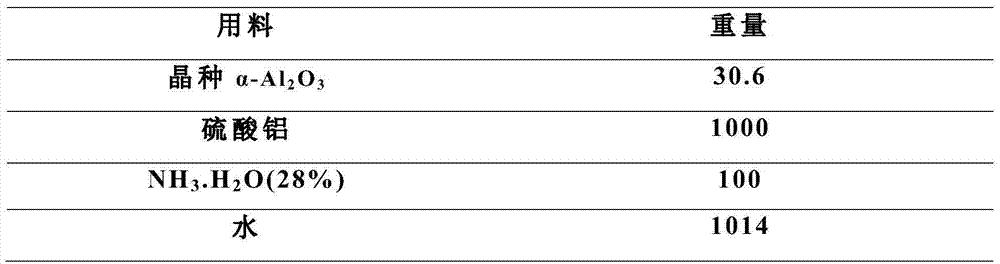

Preparation method of sapphire polishing solution

ActiveCN103881586AReduce the temperatureReduce processing costsPolishing compositions with abrasivesSalt waterNanocrystal

The invention discloses a preparation method of a sapphire polishing solution. The preparation method is characterized by comprising the following steps: (1) uniformly dispersing alpha-Al2O3 nano-crystals which have average particle size in the range of 100-300nm and are taken as crystal seeds in an aluminum salt water solution as a precursor solution; (2) preparing the precursor solution into spherical powder containing the crystal seeds of the alpha-Al2O3 nano-crystals as a precursor by virtue of a spray drying process; (3) sintering the precursor by controlling the temperature range within 900-1200 DEG C to obtain alpha-Al2O3 powder; (4) dispersing the alpha-Al2O3 powder into water, and adjusting the pH value and size of secondary particles to obtain the sapphire polishing solution. According to the preparation method disclosed by the invention, the obtained sapphire polishing solution has the advantages of small average particle size, narrow particle size distribution, good water dispersibility, wide and adjustable range of process parameters and capability of greatly improving the efficiency and the precision of sapphire polishing.

Owner:苏州柔陶新材料有限公司

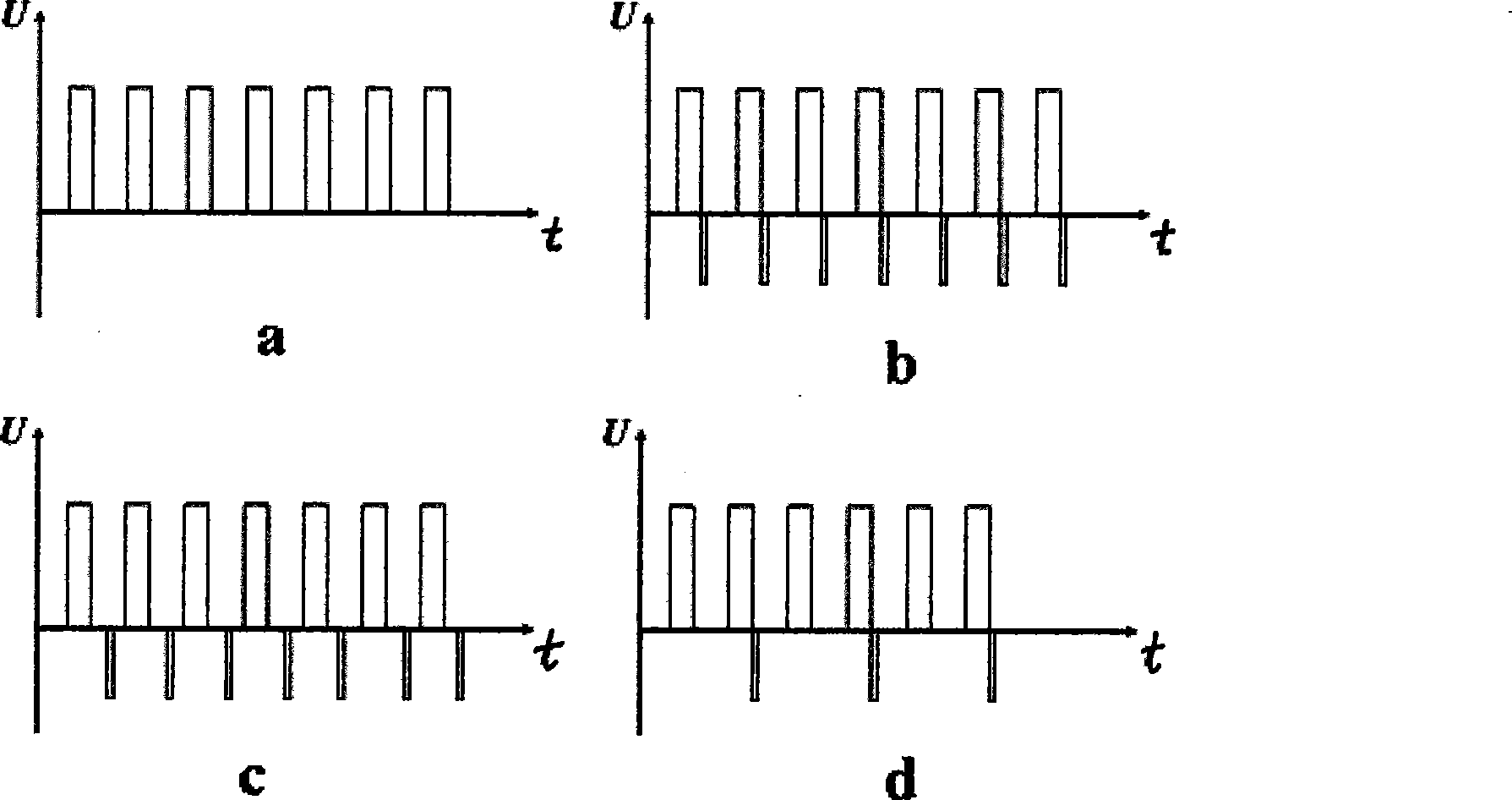

Non-equilibrium liquid condition composite pulse plasma polishing method

A polishing solution disclosed by the present invention is composed of the following components according to mass percentage: component A: (NH4)2SO4 aqueous solution with a concentration of 1% to 10%, component B: ethylene glycol with a concentration of 0.2% to 3% One or a combination of amine tetraacetic acid, ammonium citrate, sodium tartrate or sodium oxalate. The method of using the polishing liquid to carry out non-equilibrium liquid compound pulse plasma polishing, first prepare the polishing solution according to the above formula, then put the workpiece to be treated into the above prepared polishing liquid, add a compound electric pulse or an equivalent different Combination of positive and negative pulses, control positive pulse frequency 0.5-80kHz, duty cycle 5%-95%, voltage 200-480V, make the reaction in the most violent state, treatment for 1-5 minutes, that is to complete the polishing process. In the present invention, pulses are used instead of direct current, which is beneficial to the generation of plasma, so that the discharge plasma can obtain higher kinetic energy, better mirror effect and faster polishing speed.

Owner:XIAN UNIV OF TECH

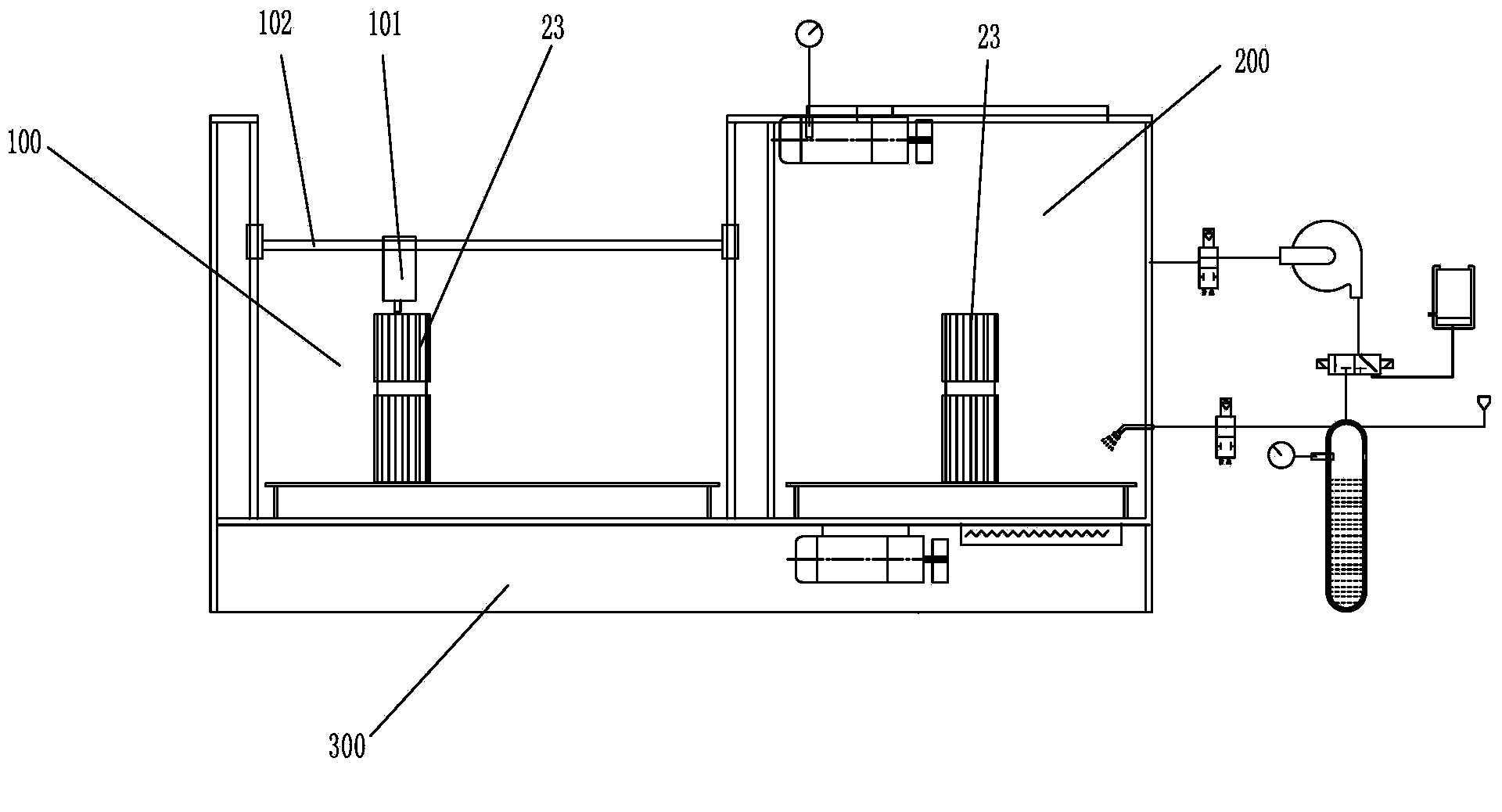

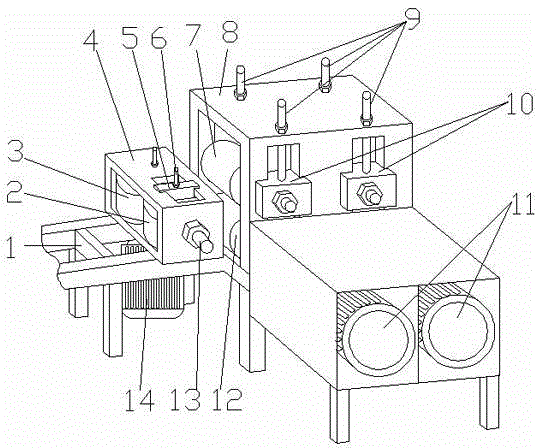

Adjustable four-surface polishing machine for board

InactiveCN104476373AFast polishingIncrease productivityPolishing machinesGrinding machine componentsElectric machineryPolishing

The invention discloses an adjustable four-surface polishing machine for a board, and belongs to the technical field of polishing machines. The machine comprises a rack, a first polishing box and a second polishing box, wherein the first polishing box and the second polishing box are arranged on the rack; a first vertical polishing roller and a second vertical polishing roller are arranged in the polishing box, wherein the first vertical polishing roller is fixed into the first polishing box and is connected with a vertical polishing roller driving motor at the lower end of the rack; two ends of the second vertical polishing roller are respectively connected with a first H-shaped bearing moving seat; two groups of first horizontal polishing rollers and second horizontal polishing rollers are arranged in the second polishing box, wherein the second horizontal polishing rollers are fixed into the second polishing box and are connected with a horizontal polishing roller driving motor on the side surface of the second polishing box; two ends of the first horizontal polishing roller are respectively connected with a second H-shaped bearing moving seat. With the adoption of the machine, four surfaces of the board can be polished, so that the polishing speed and the production efficiency can be raised; in addition, the spacing of the polishing rollers can be adjusted by adjusting the positions of the bearing moving seats, and therefore, the applicable scope is expanded.

Owner:芜湖市海源铜业有限责任公司

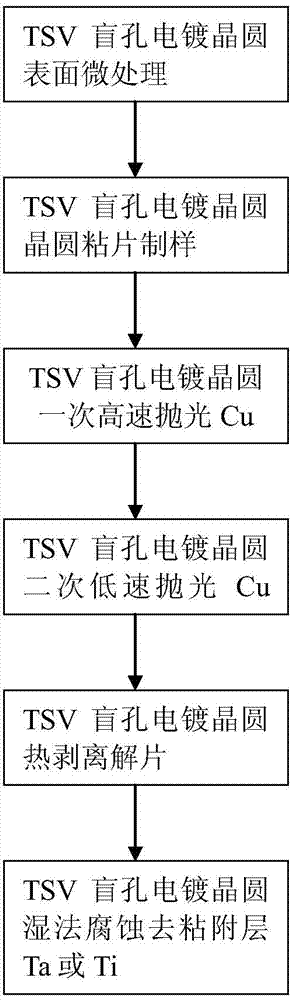

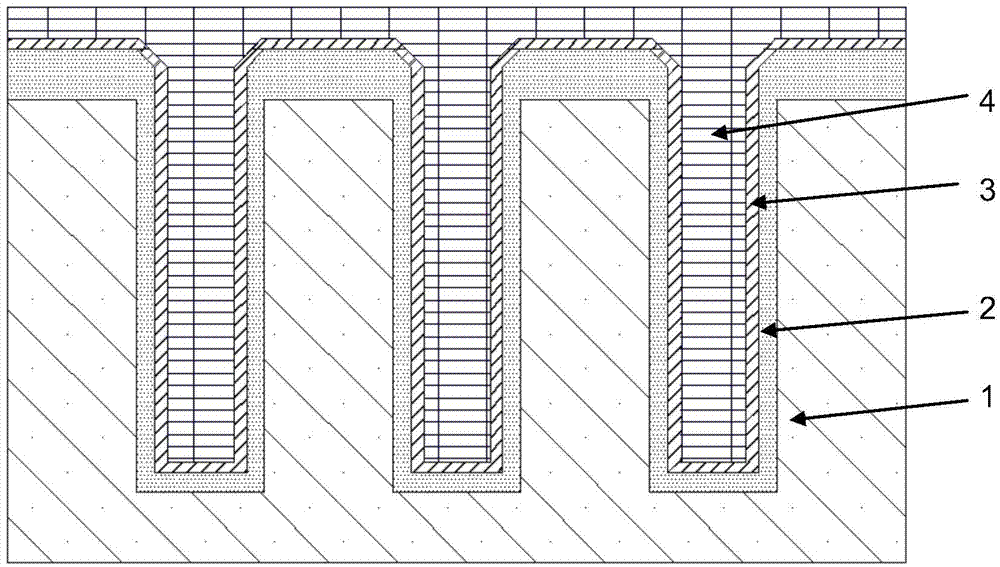

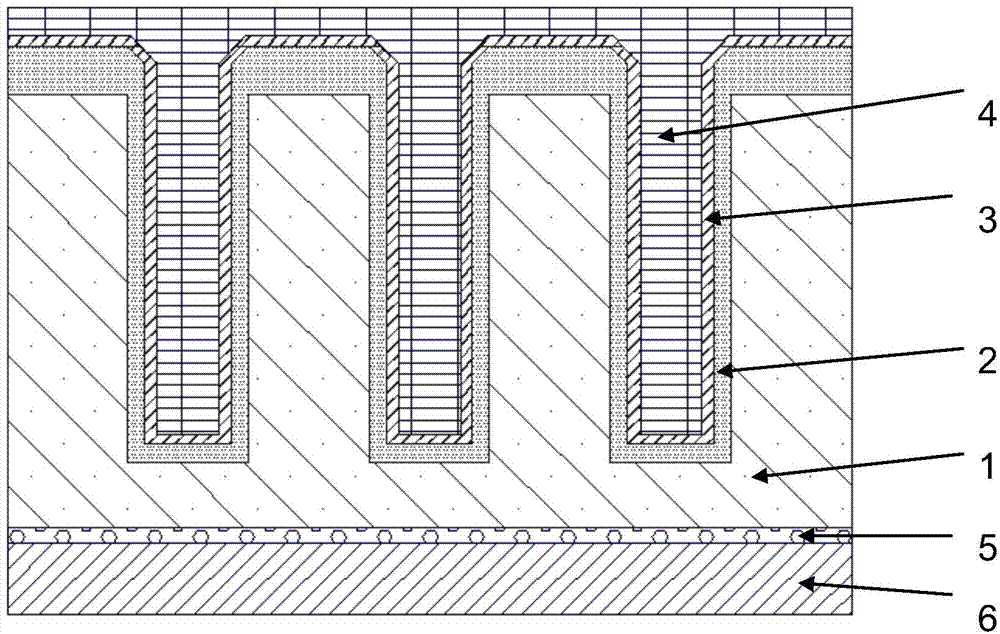

TSV wafer surface polishing method

ActiveCN104716090AGood conditionQuality improvementSemiconductor/solid-state device manufacturingLapping machinesCopperLayer removal

The invention provides a TSV wafer surface polishing method. Firstly, a copper layer on the surface of a TSV blind hole electroplated wafer is corroded through a H2SO4 solution and a hydrogen peroxide mixed solution; then, the wafer adheres to a ceramic plate through thermal spalling double-faced adhesive tape for the wafer sample preparation process; the whole wafer is placed on a rotary plate attached to a polishing pad for polishing and copper layer removal; finally, after the ceramic plate is heated and taken off, Ta or Ti corrosive liquid is adopted, a Ta or Ti blocking layer corresponding to the surface of the TSV blind hole electroplated wafer is removed, and polishing of the surface of the TSV wafer is finished. By adding micro-processing of the surface of the TSV blind hole electroplated wafer, the state of the surface of the blind hole electroplated wafer is improved, polishing of the copper layer is facilitated, and polishing cost is reduced. Process operation is simple, cost is low, and the method is suitable for wafers and fragments of different sizes. By means of the thermal spalling double-faced adhesive tape, thickness uniformity in the wafer sample preparation process can be improved, and quality of the surface of the polished TSV blind hole electroplated wafer is improved.

Owner:珠海天成先进半导体科技有限公司

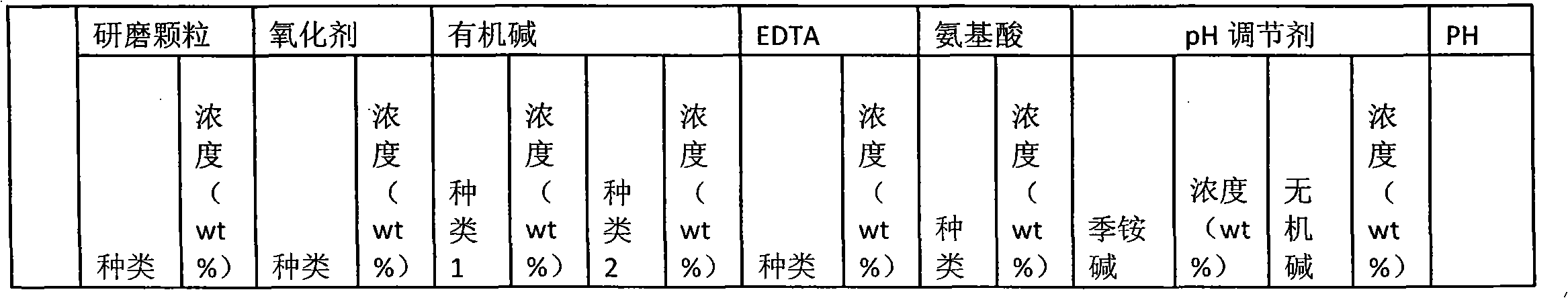

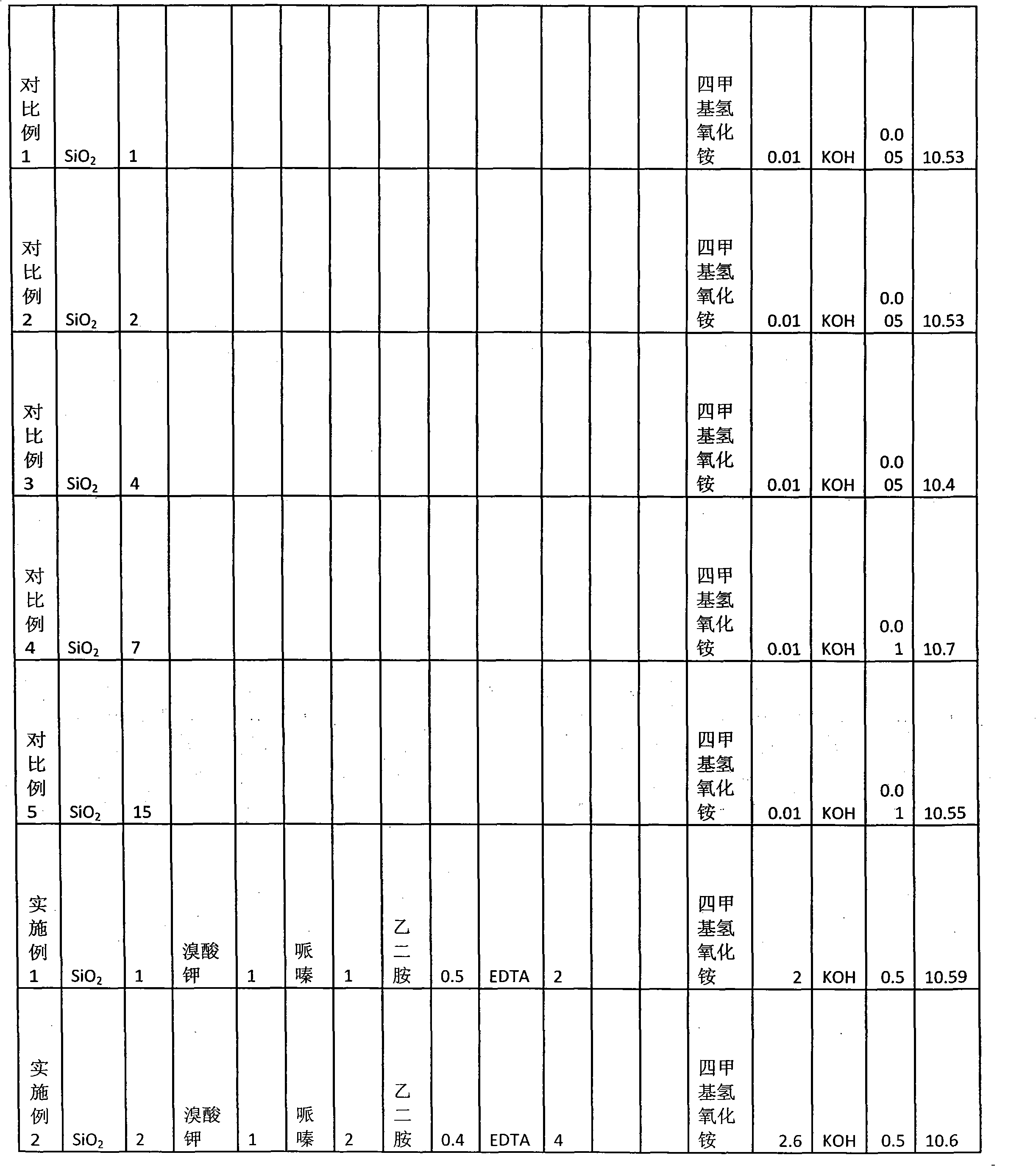

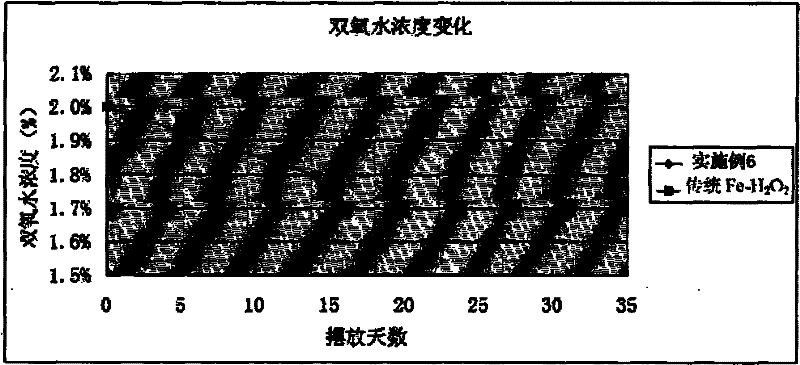

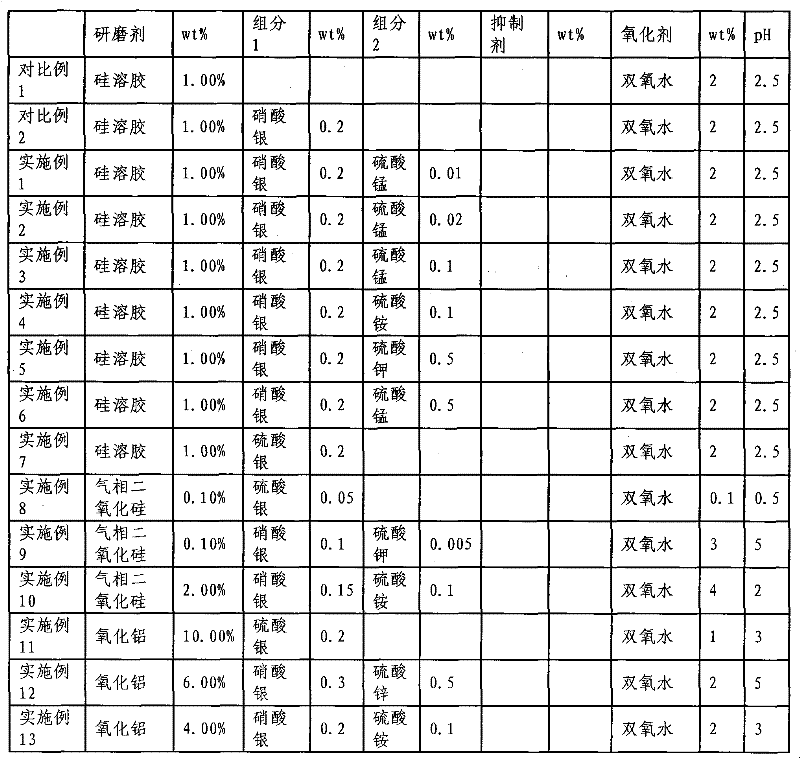

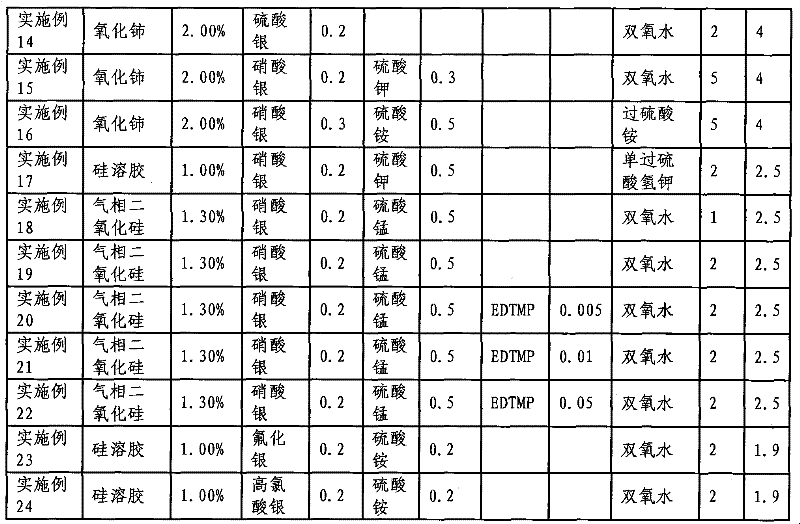

Chemical mechanical polishing solution

ActiveCN102399494AFast polishingStable removal rateSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesHalogenCompound (substance)

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Chemical mechanical polishing solution

ActiveCN102051129AFast polishingIncrease productivityPolishing compositions with abrasivesTungstenMaterials science

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

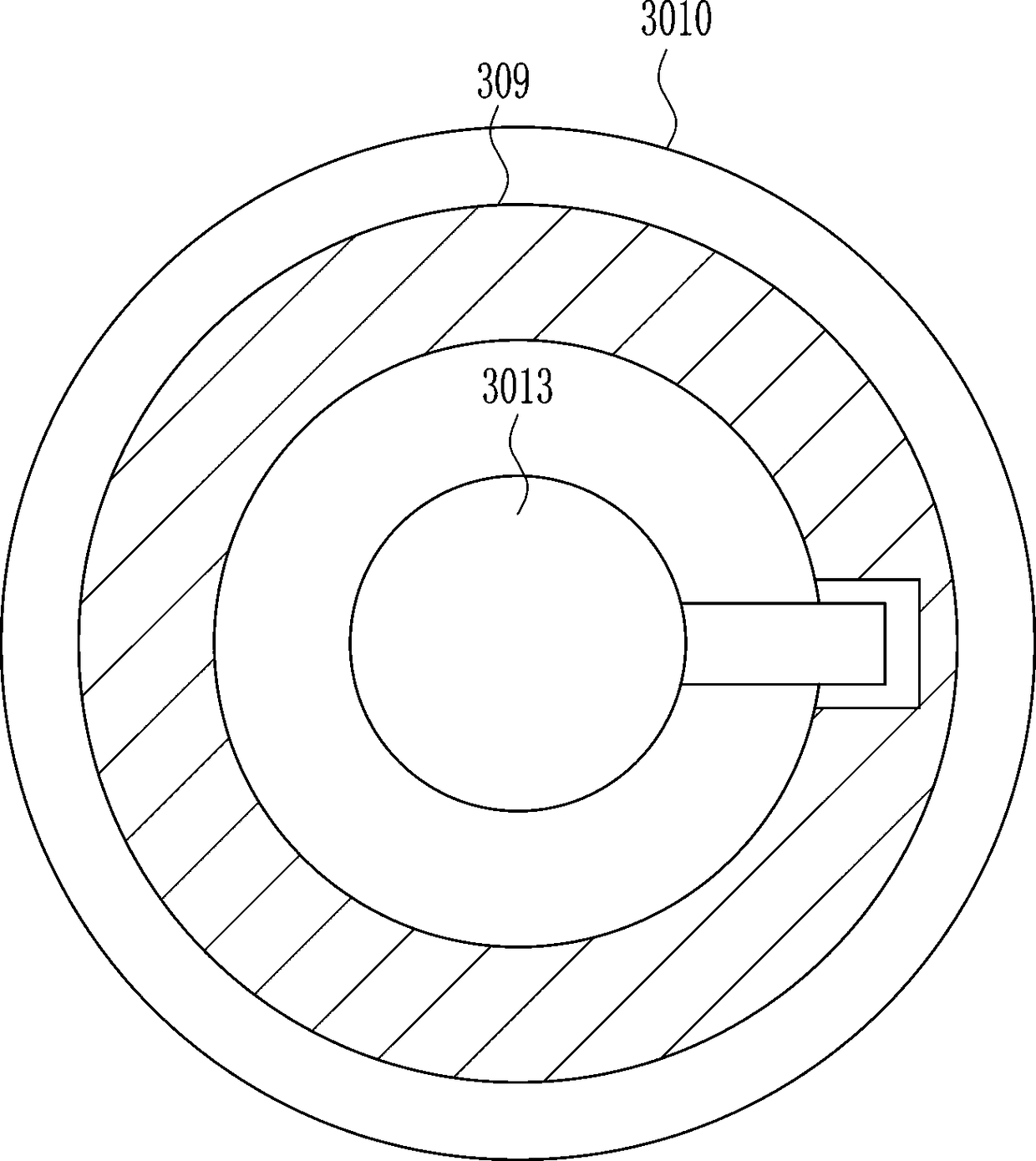

Round pipe polishing machine

The invention provides a round pipe polishing machine and belongs to the field of polishing machinery. The round pipe polishing machine comprises a support, a power mechanism arranged on the support, a transmission mechanism, a polishing mechanism and a slideway, wherein the power mechanism drives the transmission mechanism; the transmission mechanism comprises a connecting shaft and a guiding wheel, one end of the connecting shaft is fixed on the support, and the other end of the connecting shaft is connected with the guiding wheel; the polishing mechanism comprises a main body and a polishing wheel, and the main body is fixed on the support, parallel with the connecting shaft and connected with the polishing wheel; the slideway is arranged between the polishing wheel and the guiding wheel. According to the round pipe polishing machine, machining speeds of pipes and wire rods can be adjusted, the machine is applicable to to-be-machined pieces with various sizes without changing of the polishing wheel, and the machine is simple, convenient to operate, high in polishing speed, low in production cost and high in efficiency.

Owner:TIANJIN JINGLUN COPPER PROD

Bent pipe outer polishing device

ActiveCN105108614AImprove polishing qualityAchieve the purpose of polishingBelt grinding machinesMachine toolAutomation

The invention discloses a bent pipe outer polishing device. The bent pipe outer polishing device comprises a machine tool body which is provided with a grinding mechanism and a reverse rotating mechanism. The grinding mechanism comprises a grinding driving mechanism and a polishing strap arranged on the grinding driving mechanism. The reverse rotating mechanism comprises a reverse driving mechanism and a rotating plate arranged on the reverse driving mechanism. The polishing strap is matched with the rotating plate. The grinding mechanism and the reverse rotating mechanism are connected with a controller. The bent pipe outer polishing device can automatically polish the outer surfaces of a bent pipe and a straight pipe. A supporting and moving mechanism of the bent pipe is omitted due to the fact that the grinding mechanism is horizontally arranged, the complexity of a traditional outer polishing device is greatly simplified, the automation degree for outer polishing is improved, and all-face dead-angle-free polishing is performed on the surface of the bent pipe.

Owner:HENAN YONGFUDE SCI & TECH CO LTD

Graphene-containing chemical mechanical polishing solution

ActiveCN104592897AReduce surface roughnessCreativeSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesCompound (substance)Surface roughness

The invention discloses a chemical mechanical polishing solution. Based on the total mass, the chemical mechanical polishing solution comprises the following components in percentage by weight: 10-50wt% of inorganic nanoparticles, 0.01-5wt% of chemical additives and the balance of pH regulators and water, wherein the inorganic nanoparticles at least comprise silica and graphene; and the mass percent of the graphene is 0.01-10wt% based on the total mass of the chemical mechanical polishing solution. The chemical mechanical polishing solution disclosed by the invention has the following beneficial effects in the process of polishing sapphire and other high-hardness materials: because the hardness of the graphene particles is high, the polishing speed is high, and the efficiency is high; and moreover, the surface toughness of the polished sapphire and other high-hardness materials is low, and obvious defects such as orange skin, corrosion or scratch and the like are avoided.

Owner:SHANGHAI XINANNA ELECTRONICS TECH +1

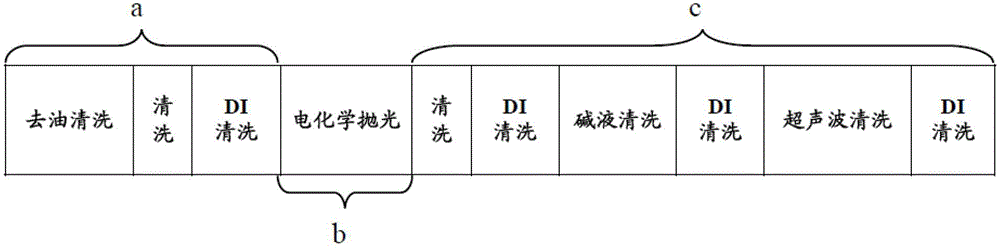

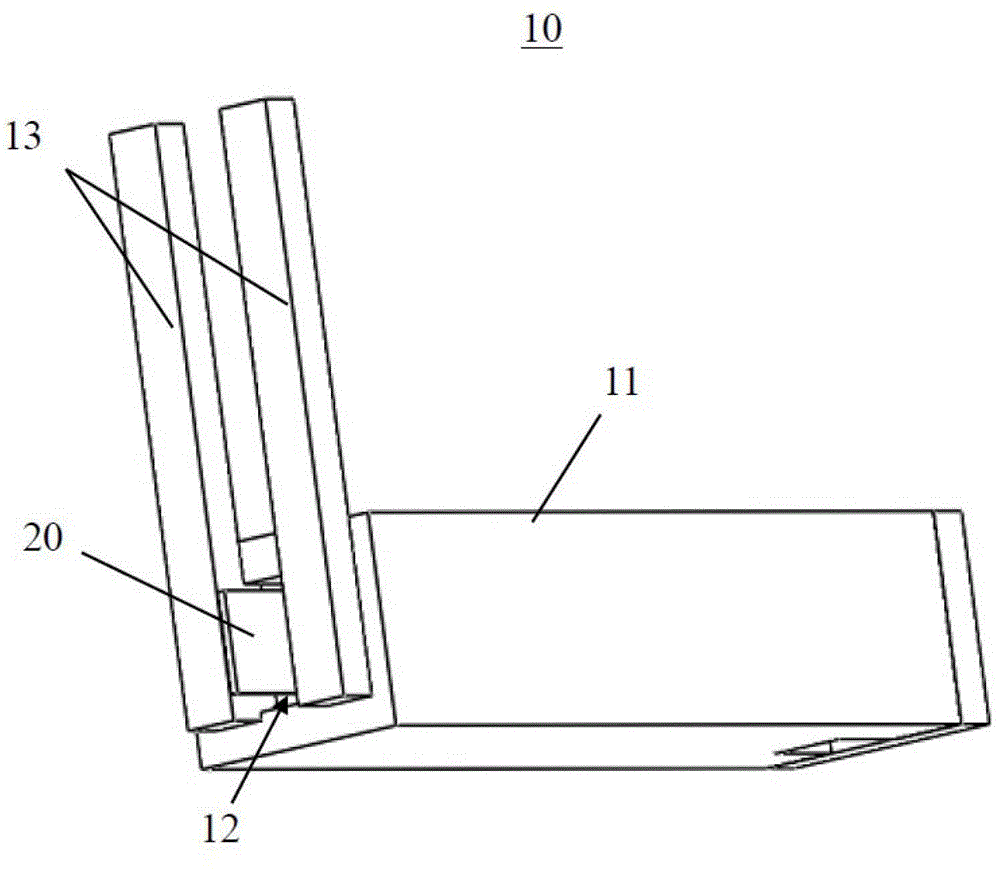

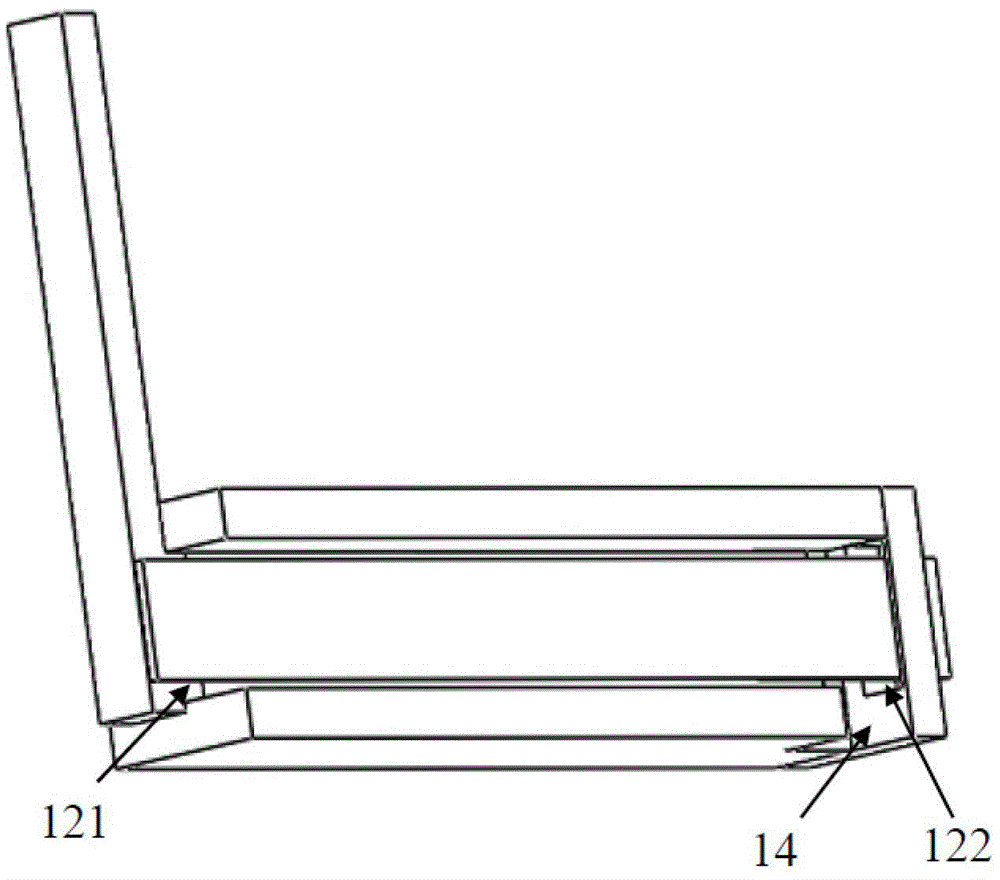

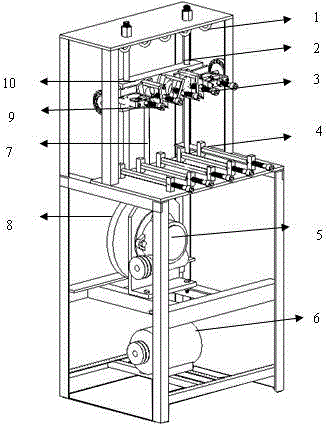

Electrochemical polishing apparatus and method thereof

ActiveCN104032366AEliminate columnar striationsImprove polishing effectElectrolysis componentsEngineeringElectrochemistry

The invention discloses an electrochemical polishing apparatus. The apparatus comprises: a tank body; at least one electrolytic cell horizontally penetrating through the tank body, wherein the electrolytic cell forms an inlet and an outlet at two ends of the tank body respectively, and a workpiece to be polished transversely moves in the electrolytic cell; electrodes positioned at two sides of the electrolytic cell, wherein an electric field formed by the electrodes is shielded in the electrolytic cell; and an electrolyte supply pipeline connected to the electrolytic cell and guiding an electrolyte to flow along the surface of the workpiece to be polished. The invention also discloses an electrochemical polishing method. The apparatus has a simple structure, and can solve the columnar stripes appearing on the surface of a base band, and the polishing method has the advantages of good polishing effect and fast polishing speed.

Owner:SUZHOU NEW MATERIAL INST +2

Surface polishing method of copper musical instrument part

InactiveCN103240661AReduce hardnessImprove toughnessEdge grinding machinesPolishing machinesWalnut NutPolishing

The invention relates to a surface polishing method of a copper musical instrument part. The method is characterized in that a copper device is hung in a polishing rolling barrel through a hanging device, walnut sand micro powder and a brightener which are made specifically are added into the barrel respectively, and a better polishing effect can be achieved by rotating the rolling barrel according to certain rotating speed and time. The method is high in polishing speed, good in effect, even and soft in gloss, free of dust pollution and capable of improving working efficiency greatly.

Owner:河北金音乐器集团有限公司

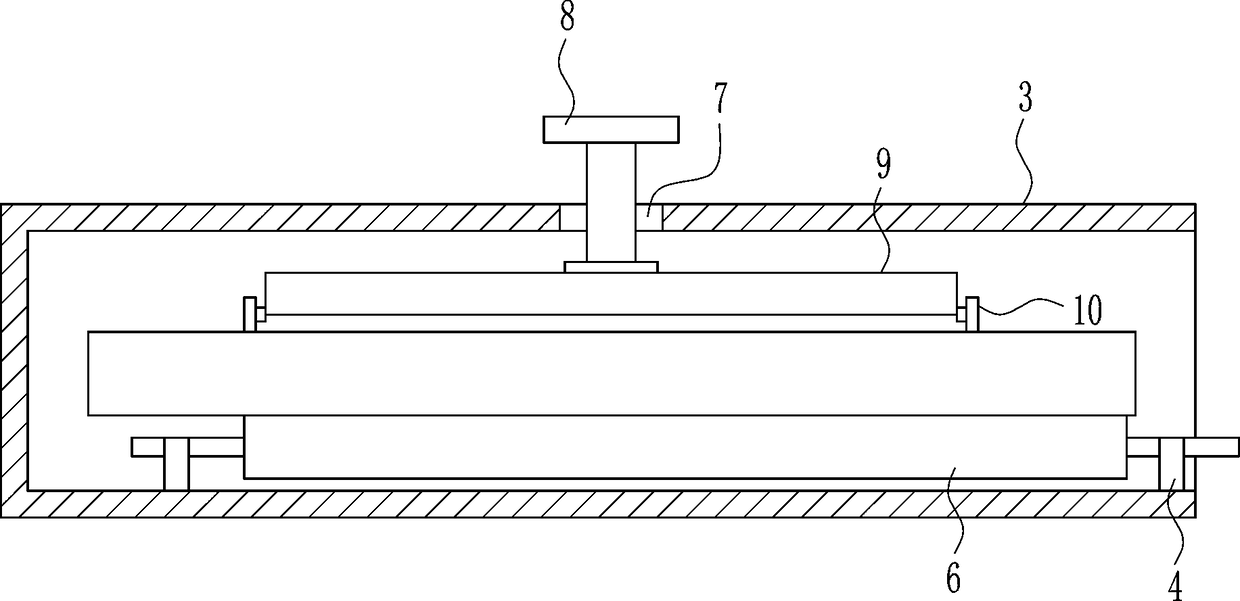

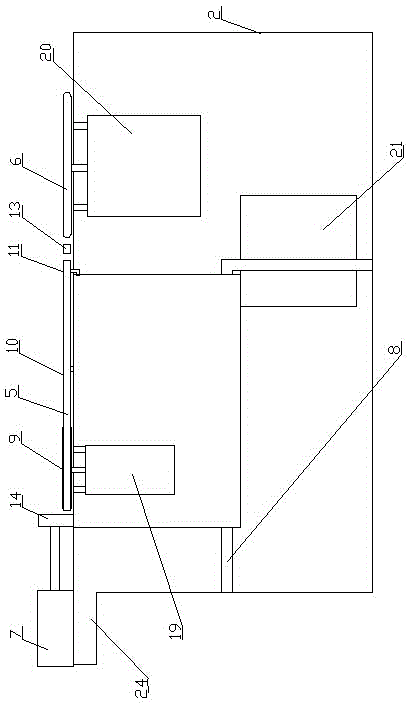

Method and equipment for polishing die

InactiveCN102975104AFast polishingReduce polishing labor intensityBelt grinding machinesGrinding work supportsOperating environmentCam

The invention relates to a method and equipment for polishing a die, which belong to the technical field of electromagnetic wire production. The technical scheme is that a clamp (2) is arranged on each guide rod (2), a plurality of clamps are connected together through a clamp plate, the clamp plate (10) is connected with a cam and rocker mechanism which is formed by a rocker (7) and a cam (8), and the output of a motor (6) is connected with the cam and rocker mechanism through a speed reducer (5); a band fixing ring and a band fixing rod are respectively arranged on the two ends of each guide rod, a polishing band is arranged between the band fixing ring (1) and the band fixing rod (4), the dies which need to be polished are respectively clamped on the clamps and are contacted with the polishing band, and the clamp plate, the clamps and the dies do reciprocating motion on the guide rods together to complete the die polishing. The method and the equipment have the beneficial effects that the polishing die of the die is increased, the die polishing labor intensity is lowered, mechanical power is utilized to polish a plurality of dies, the die polishing precision can be increased, and the polishing operating environment is improved.

Owner:BAODING TIANWEI GRP CO LTD

Polishing device of fixing clamp with rotating mechanism for machining bearing washer

InactiveCN110315414AIncrease flexibilityEasy to installGrinding carriagesGrinding feedersDrive shaftEngineering

The invention discloses a polishing device of a fixing clamp with a rotating mechanism for machining a bearing washer, and relates to the technical field of bearing washer production. The polishing device comprises a supporting seat mechanism, a clamping mechanism and a waste material collecting box, wherein a supporting rod is welded above the supporting seat mechanism, a sliding rail is arrangedin a transverse plate, a first motor is fixedly arranged at the upper end of the supporting rod, the other end of a first transmission shaft is connected with an expansion plate, the clamping mechanism is positioned on the inner side of the expansion plate, and the left side surface and the right side surface of the waste collecting box are integrally connected with a sliding block. According tothe polishing device, through mutual cooperation among a sleeve, a limiting groove, a limiting column and a screw cap, an upper-layer plate can be combined and fixed at the upper end of a hydraulic rod, so that the overall structure of the device is high in flexibility and convenient to mount and dismount; the device is arranged with a storage plate through the clamping mechanism, the bearing washers can be overturned at the same time, and the device can be used for carrying out double-sided polishing on the bearing washers.

Owner:东莞市史雷帝三维数控科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com