Patents

Literature

215 results about "High kinetic energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

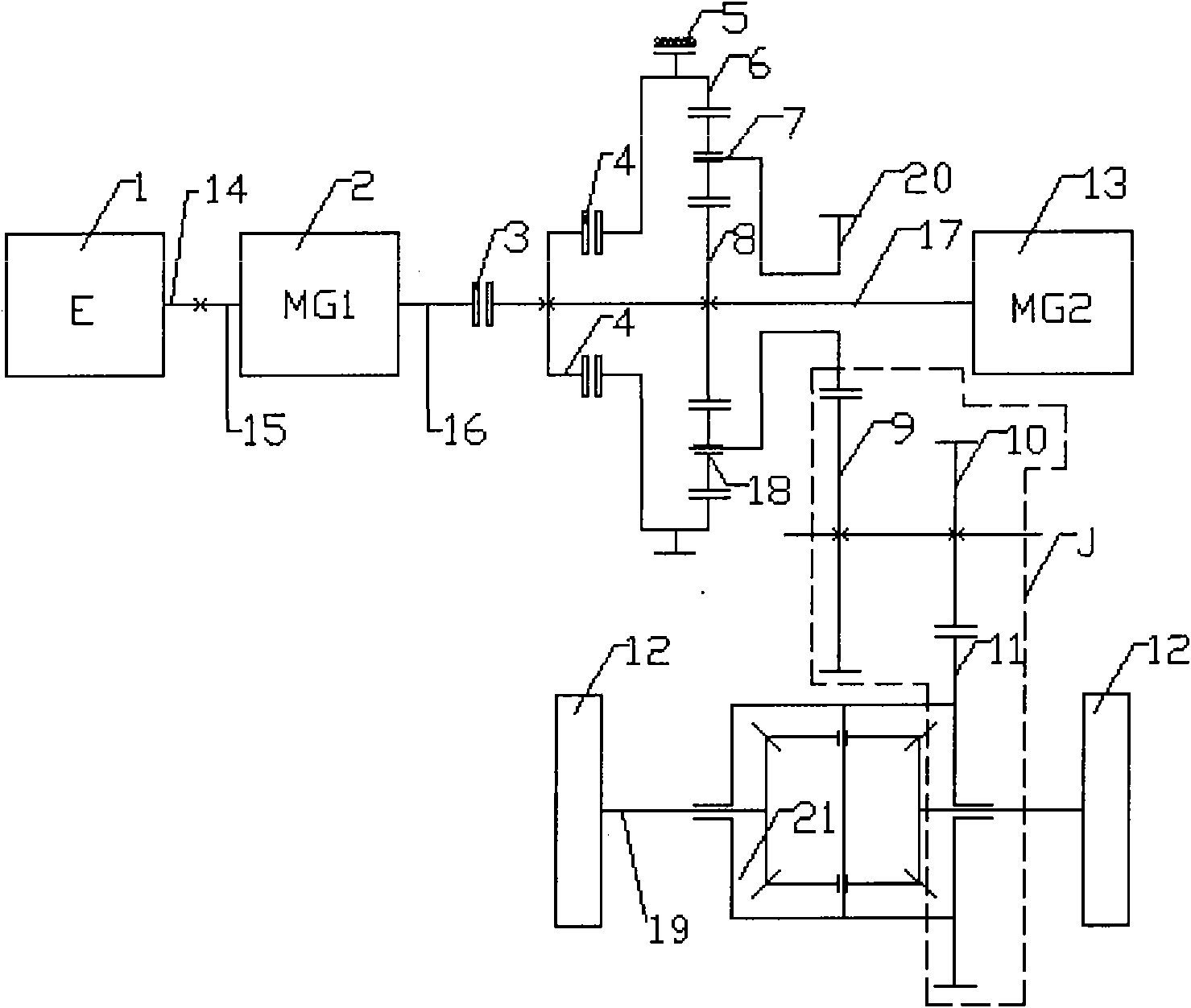

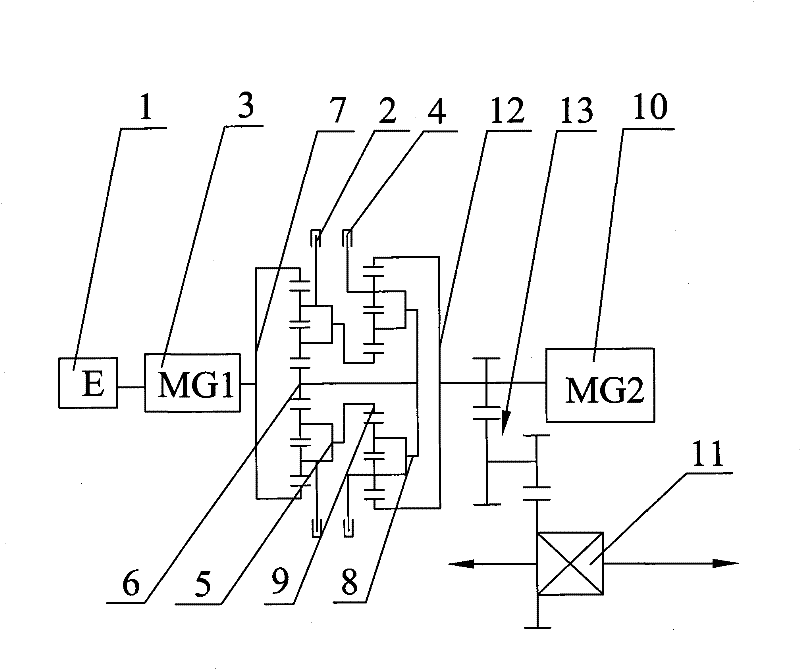

Hybrid driving system for automobile and gear operating method thereof

ActiveCN102107604ASmall reduction ratioReduce in quantityHybrid vehiclesToothed gearingsCouplingInternal combustion engine

The invention relates to a hybrid driving system and a gear operating method thereof. The system comprises an internal-combustion engine, a first motor, a second motor, a planet coupling mechanism, a retarding mechanism and a differential mechanism, wherein an output shaft of the internal-combustion engine is connected with an input shaft of the first motor; an output shaft of the first motor is connected with an output shaft of the second motor by a first clutch; and the output shaft of the second motor is connected with one of a sun wheel and a gear ring of the planet coupling mechanism at the position of the axial direction of the output shaft, and output shaft of the second motor is connected with the other one of the sun wheel with a brake and the gear ring by a second clutch at the other position of the axial direction of the output shaft. In the hybrid driving system, two gear levels of forward gears of an automobile are formed by adjusting the planet coupling mechanism, so that operating modes and corresponding gears are selected flexibly according to different running work conditions of the automobile to achieve the effects of low emission and oil consumption, high kinetic energy and the like of the integral automobile.

Owner:BYD CO LTD

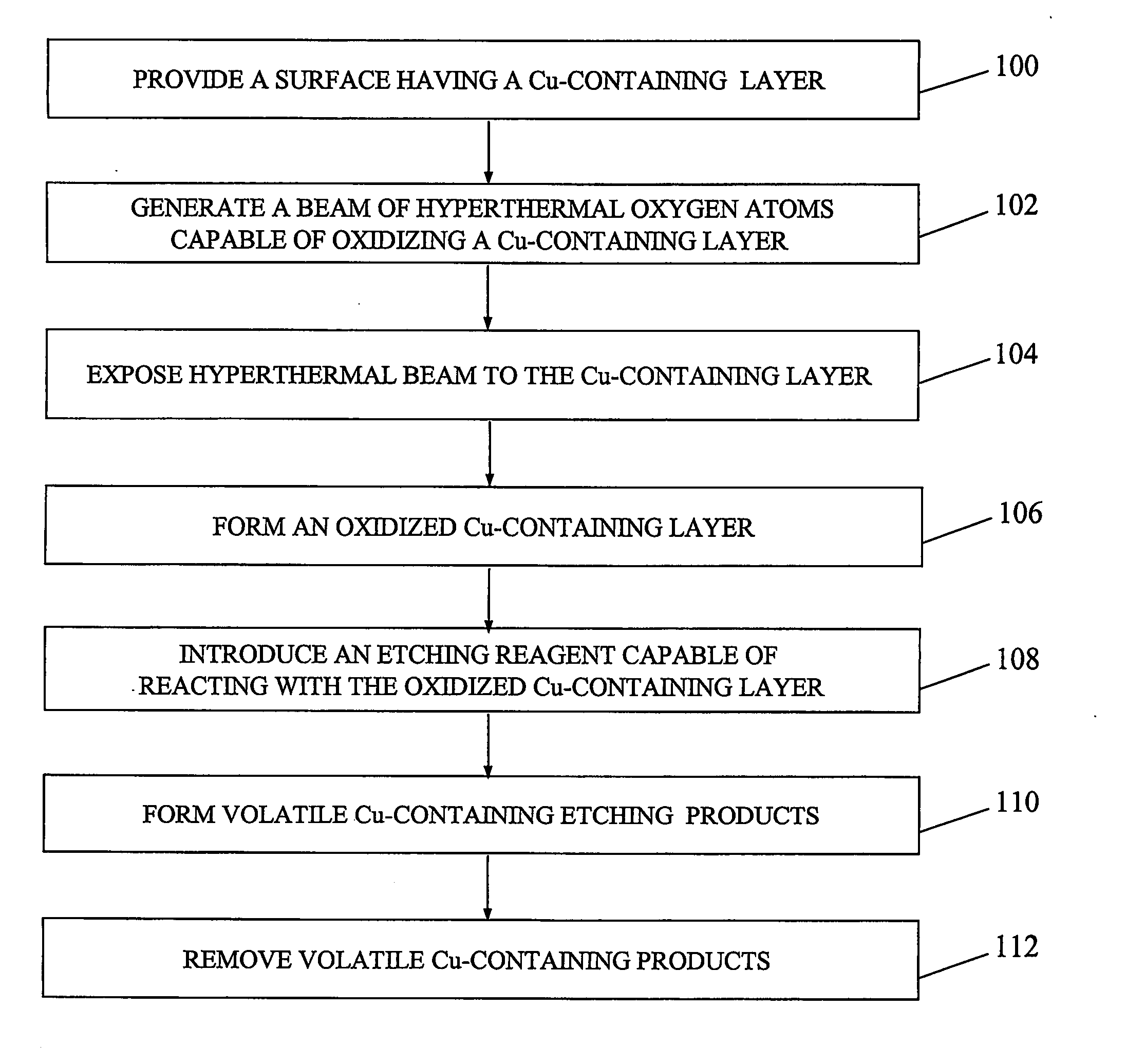

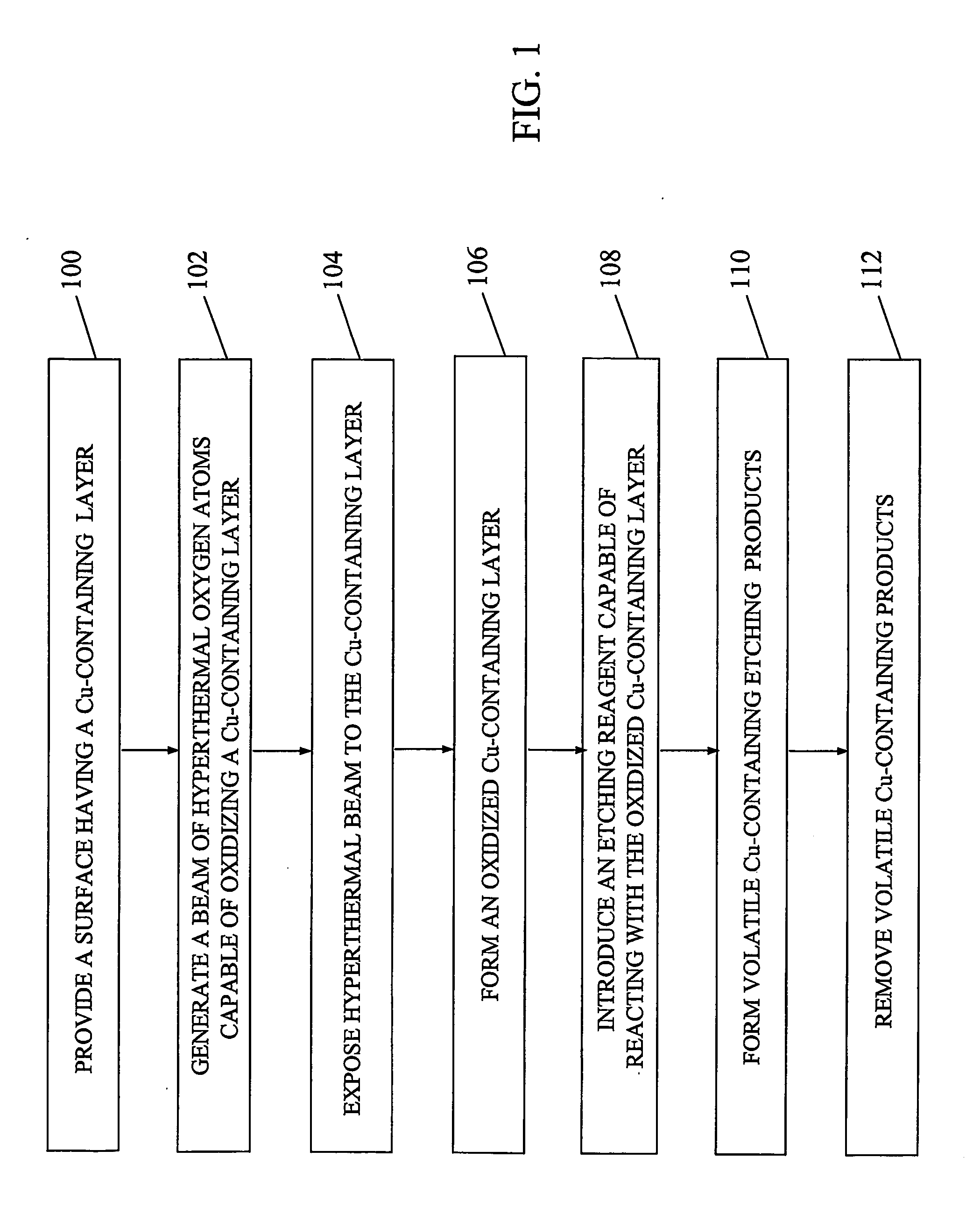

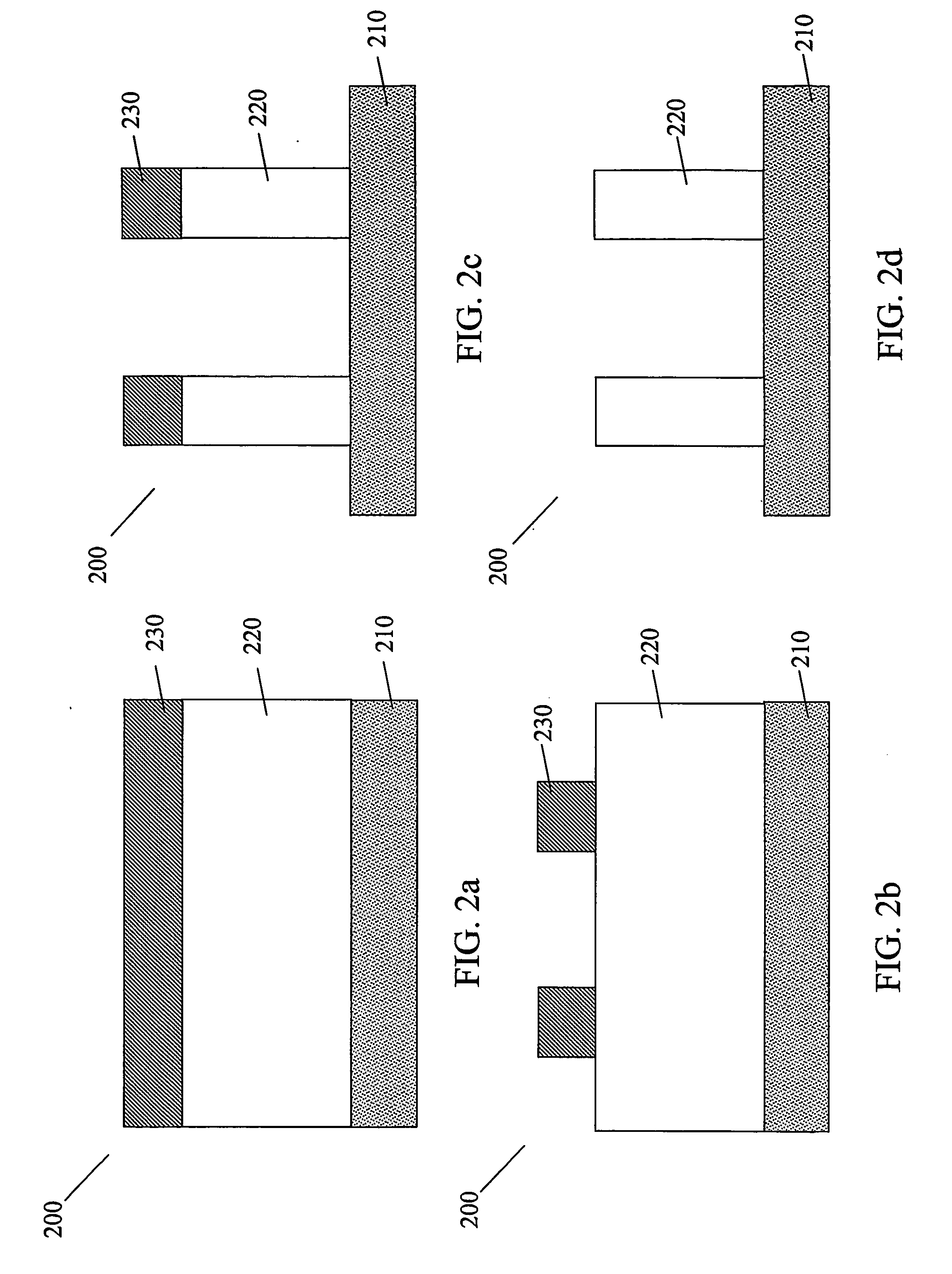

Anisotropic dry etching of cu-containing layers

InactiveUS20050224456A1Improve responseDecorative surface effectsSemiconductor/solid-state device manufacturingCopperAnisotropic etching

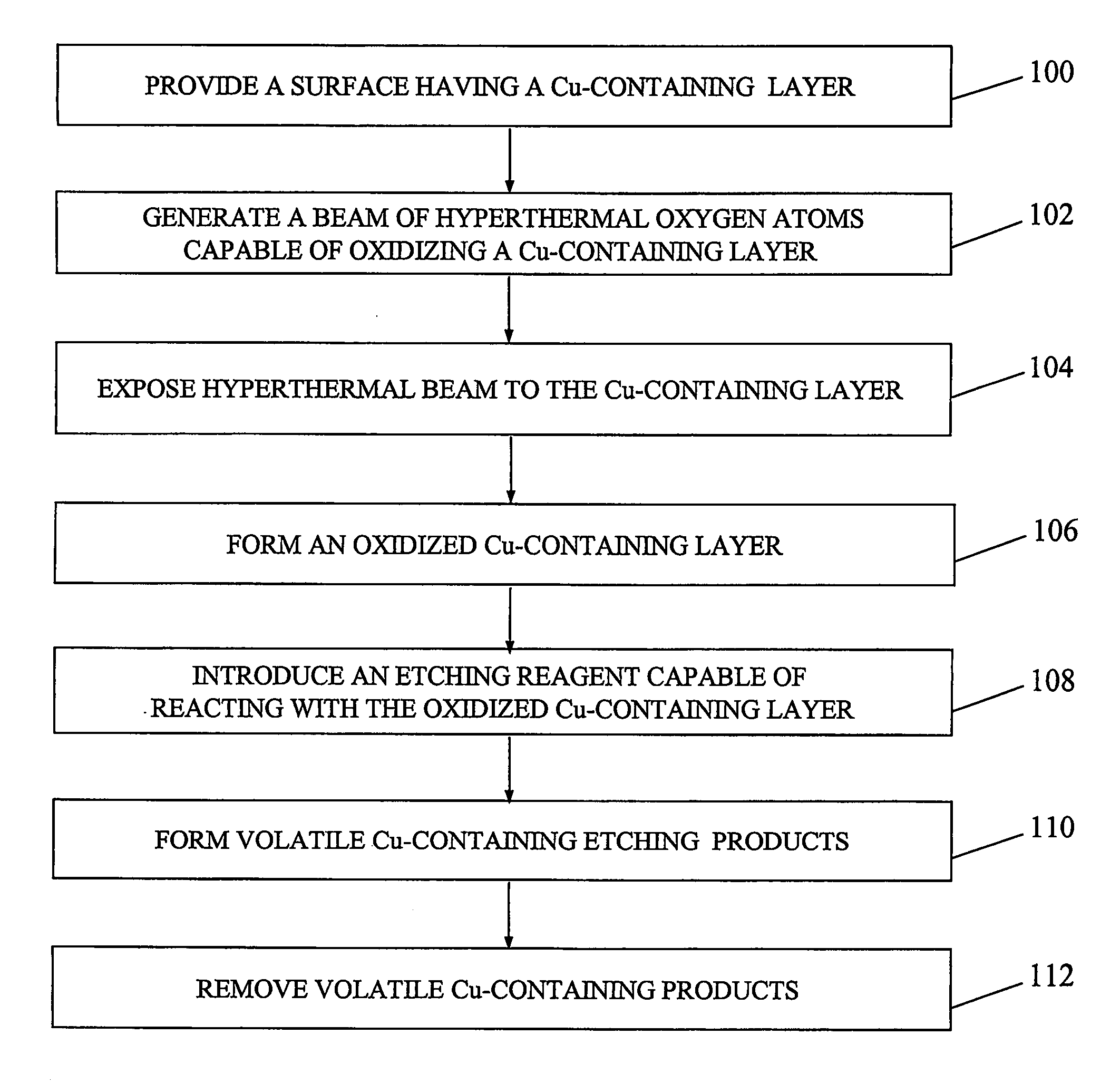

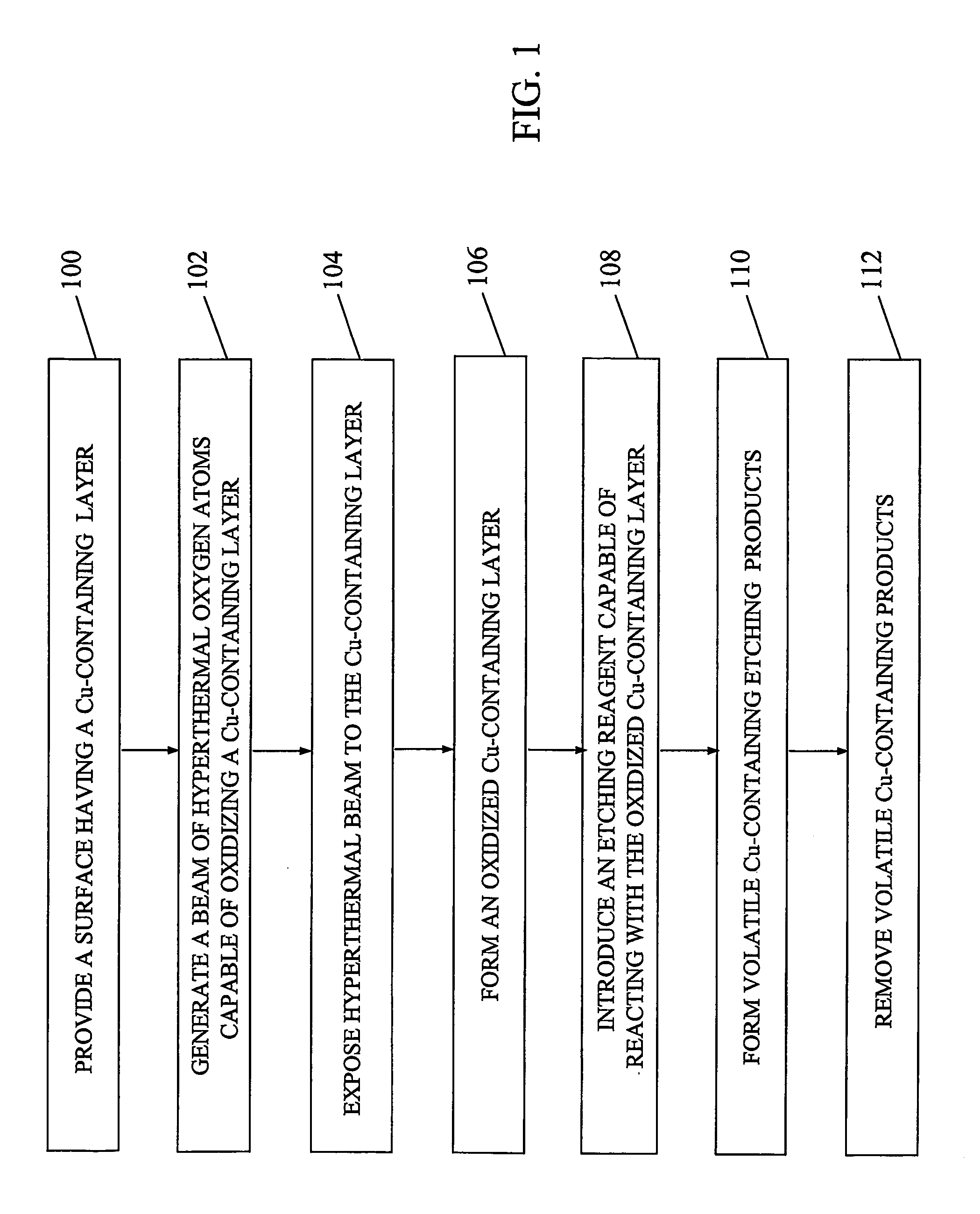

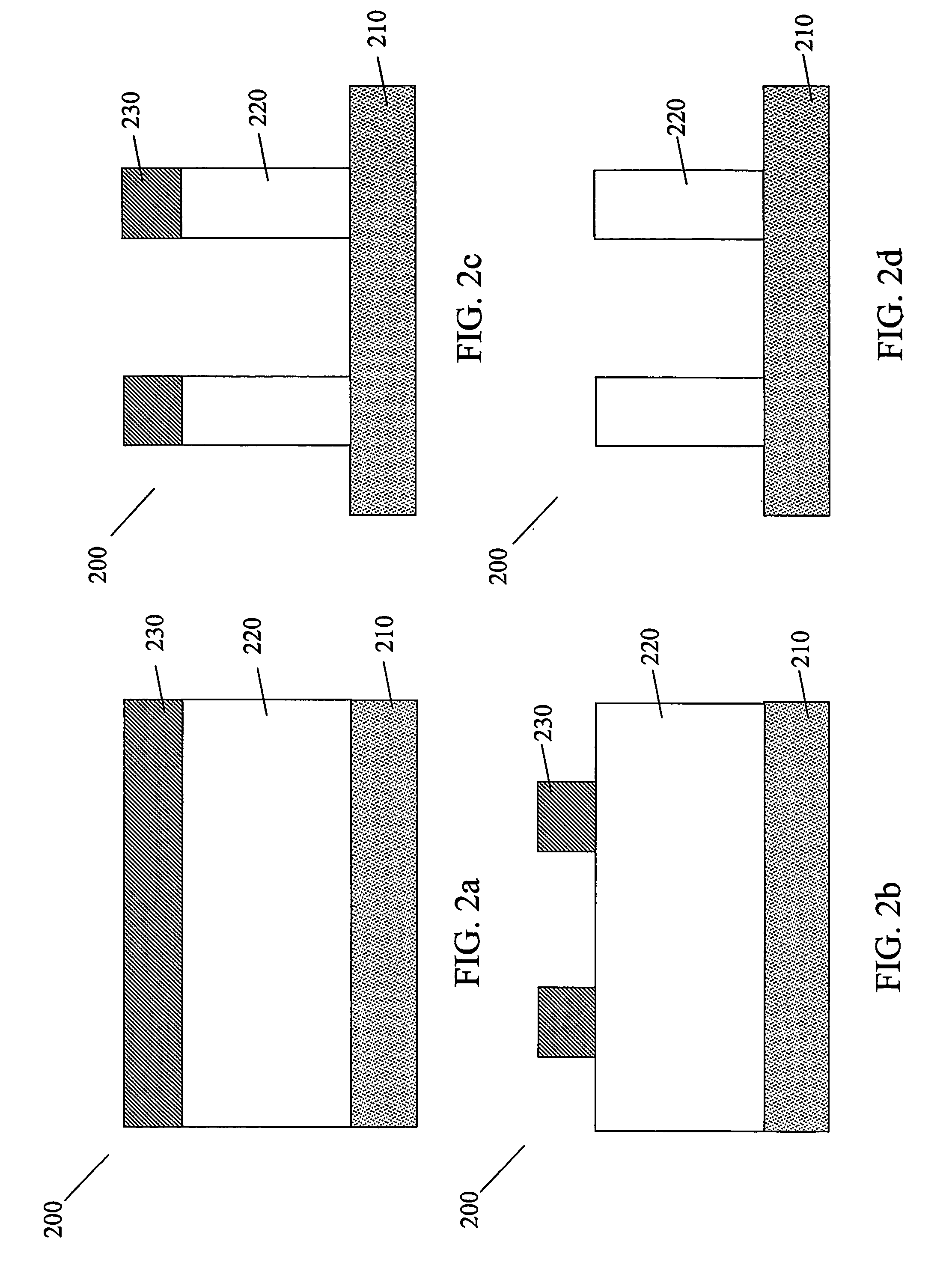

A method and apparatus for dry etching pure Cu and Cu-containing layers (220, 310) for manufacturing integrated circuits. The invention uses a directional beam of O-atoms with high kinetic energy (340) to oxidize the Cu and Cu-containing layers, and etching reagents (370) that react with the oxidized Cu (360) to form volatile Cu-containing etch products (390). The invention allows for low-temperature, anisotropic etching of pure Cu and Cu-containing layers in accordance with a patterned hard mask or photoresist (230, 330).

Owner:TOKYO ELECTRON LTD

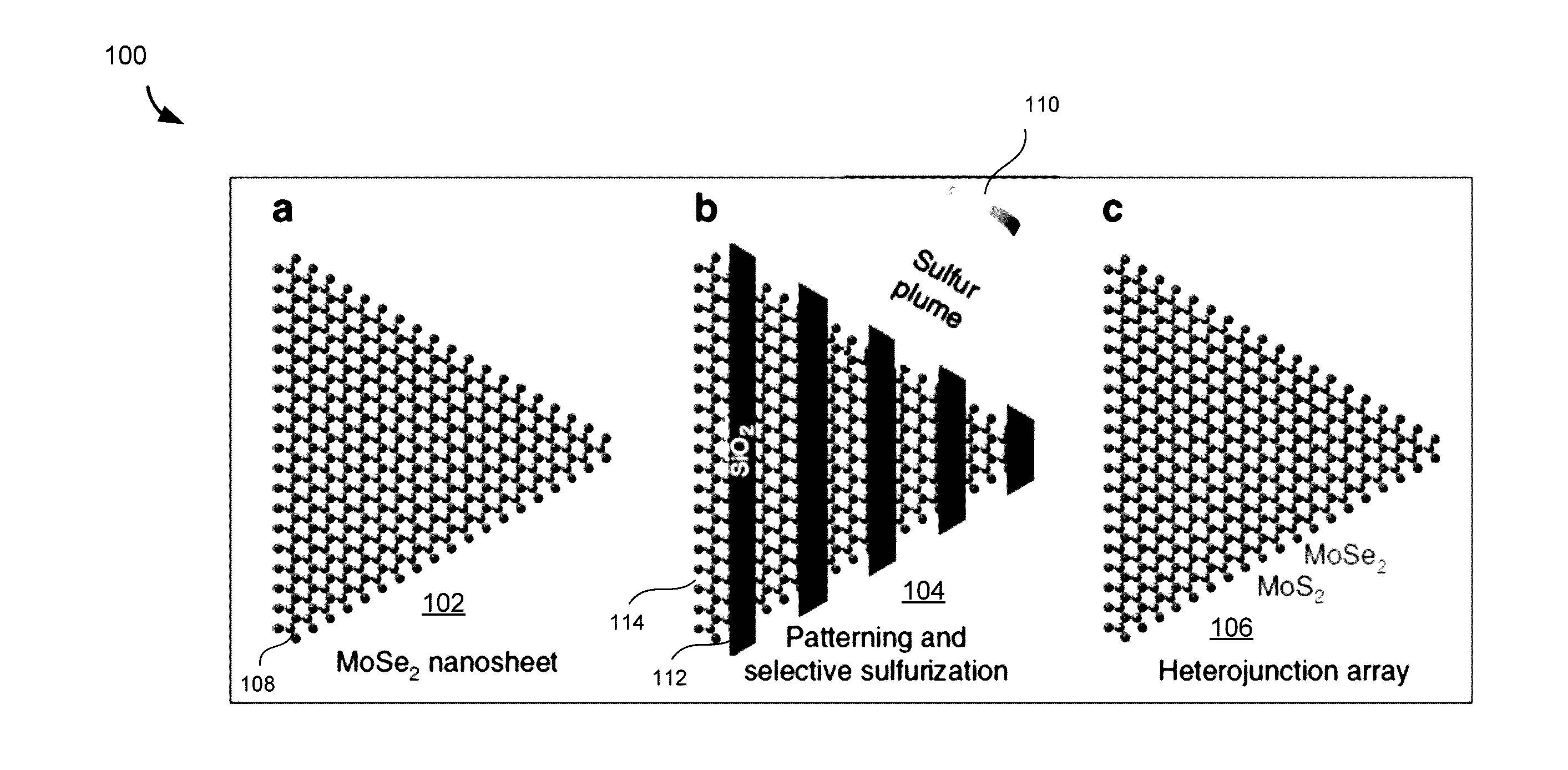

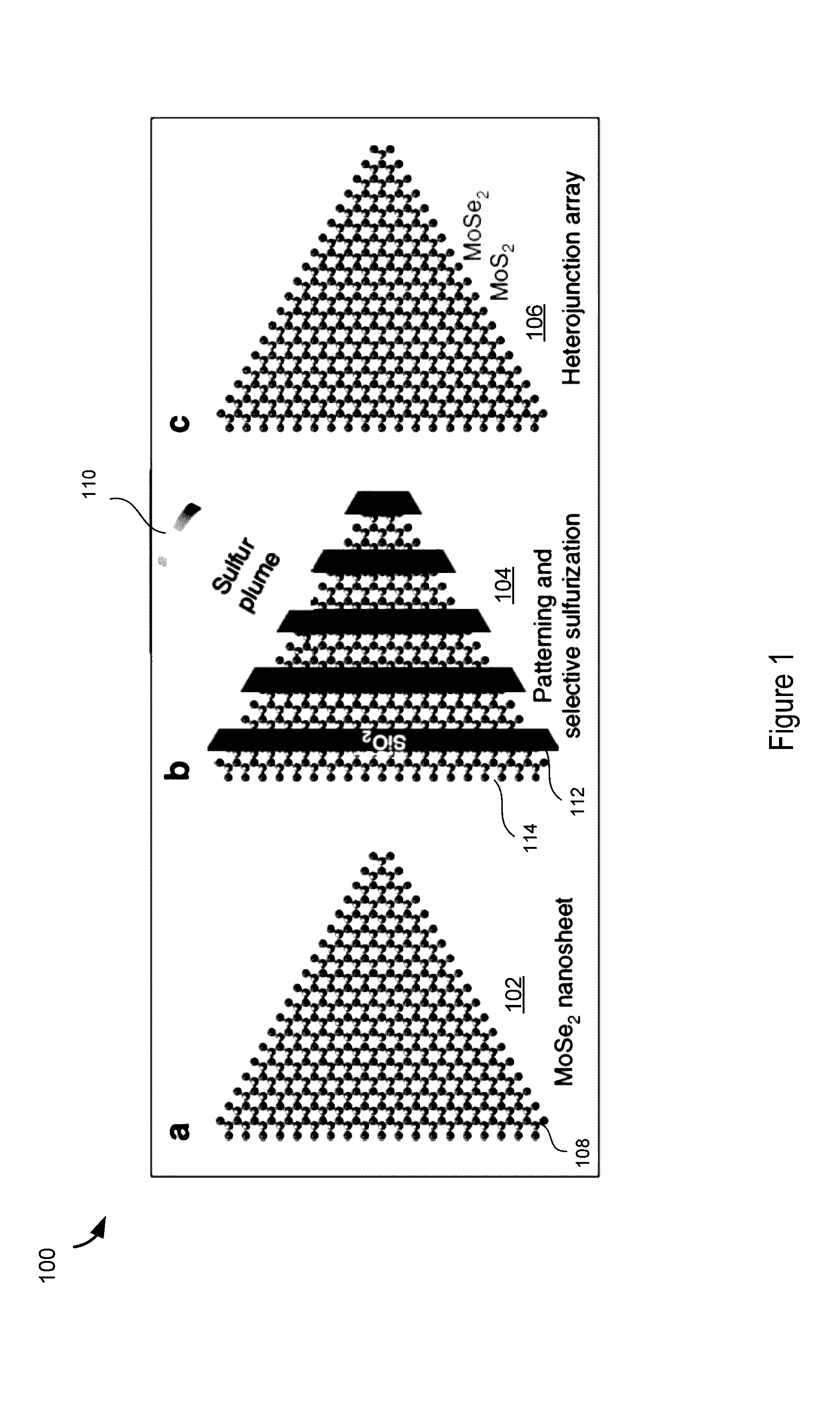

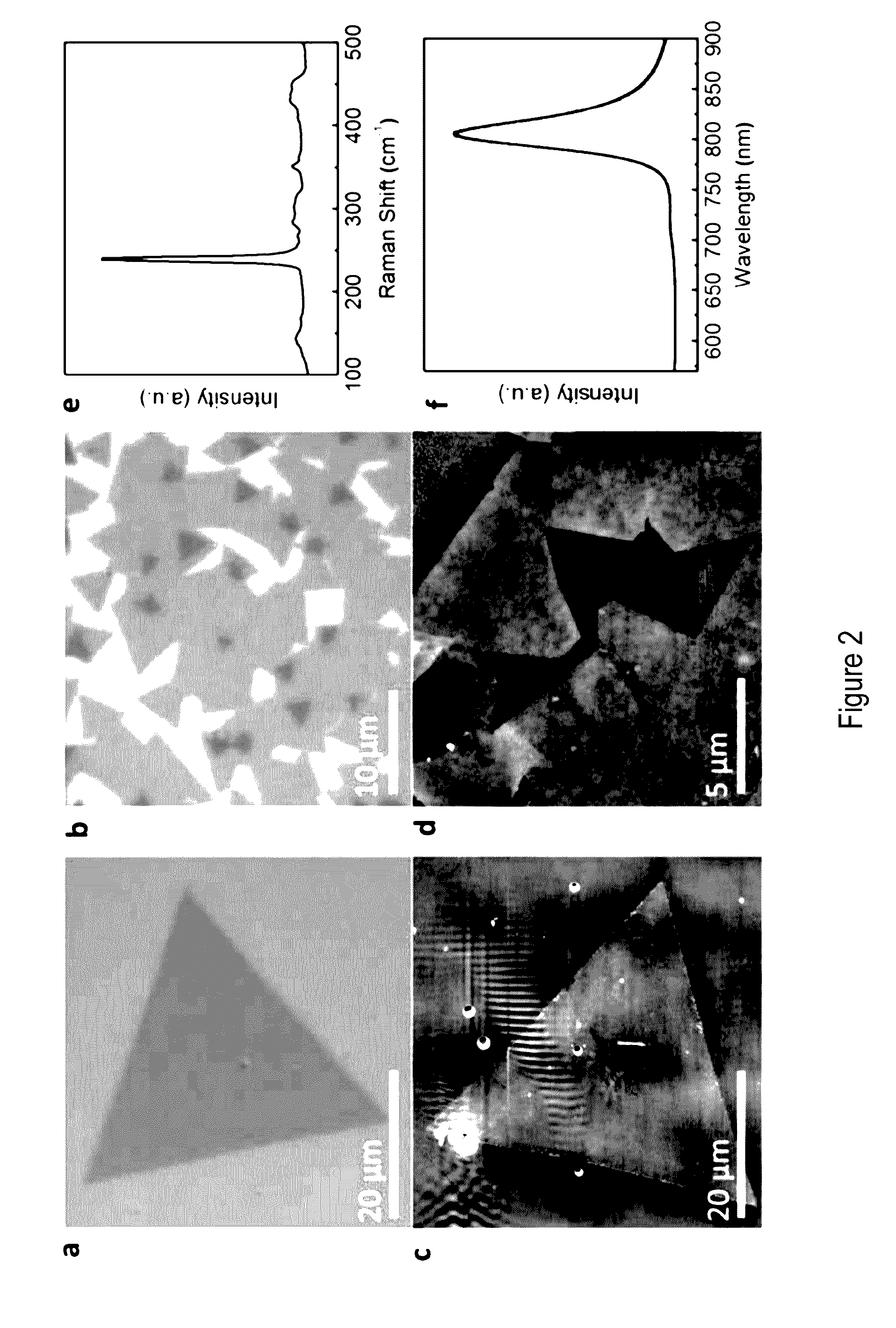

Two-dimensional heterostructure materials

ActiveUS20170025505A1Semiconductor/solid-state device manufacturingOriginals for photomechanical treatmentHeterojunctionNanoscopic scale

Methods, articles of manufacture and systems for creating new nanoscale two dimensional materials comprising designed arrays of lateral or vertical heterojunctions may be fabricated by first lithographically masking a 2D material. Exposed, or unmasked, regions of the 2D material may be converted to a different composition of matter to form lateral or vertical heterojunctions according to the patterned mask. PLD and high kinetic energy impingement of atoms may replace or add atoms in the exposed regions, and a plurality of the exposed regions may be converted concurrently. The process may be repeated one or more times on either side of the same 2D material to form any suitable combination of lateral heterojunctions and / or vertical heterojunctions, comprising semiconductors, metals or insulators or any suitable combination thereof. Furthermore, the resulting 2D material may comprise p-n, n-n, p-p, n-p-n and p-n-p junctions, or any suitable combination thereof.

Owner:UT BATTELLE LLC

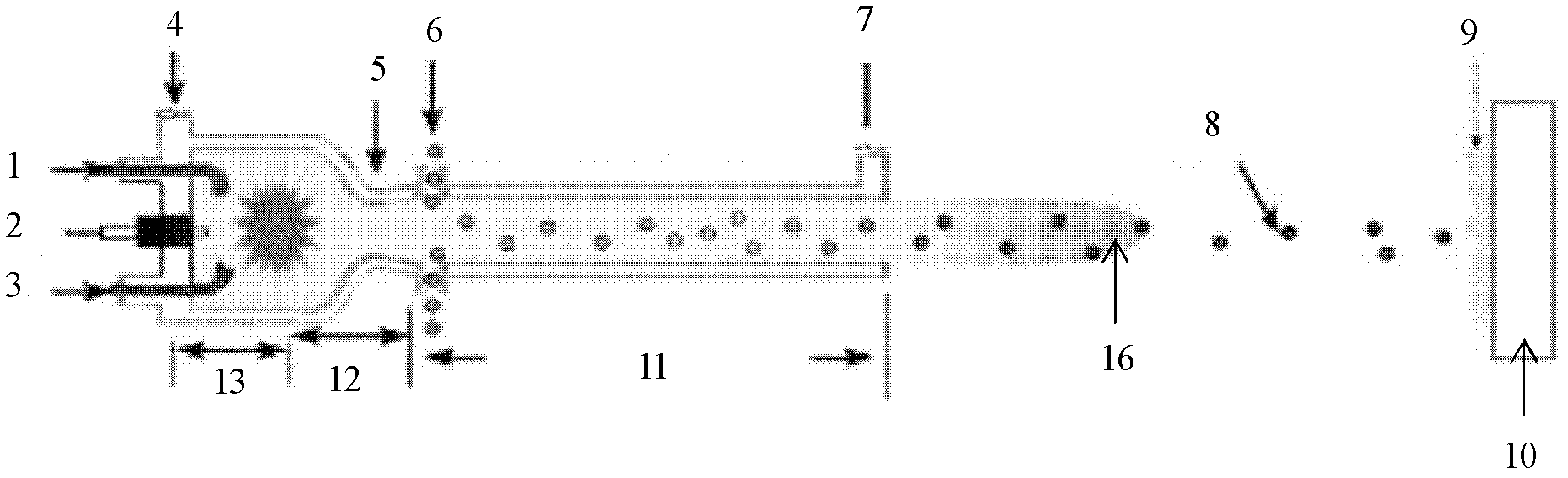

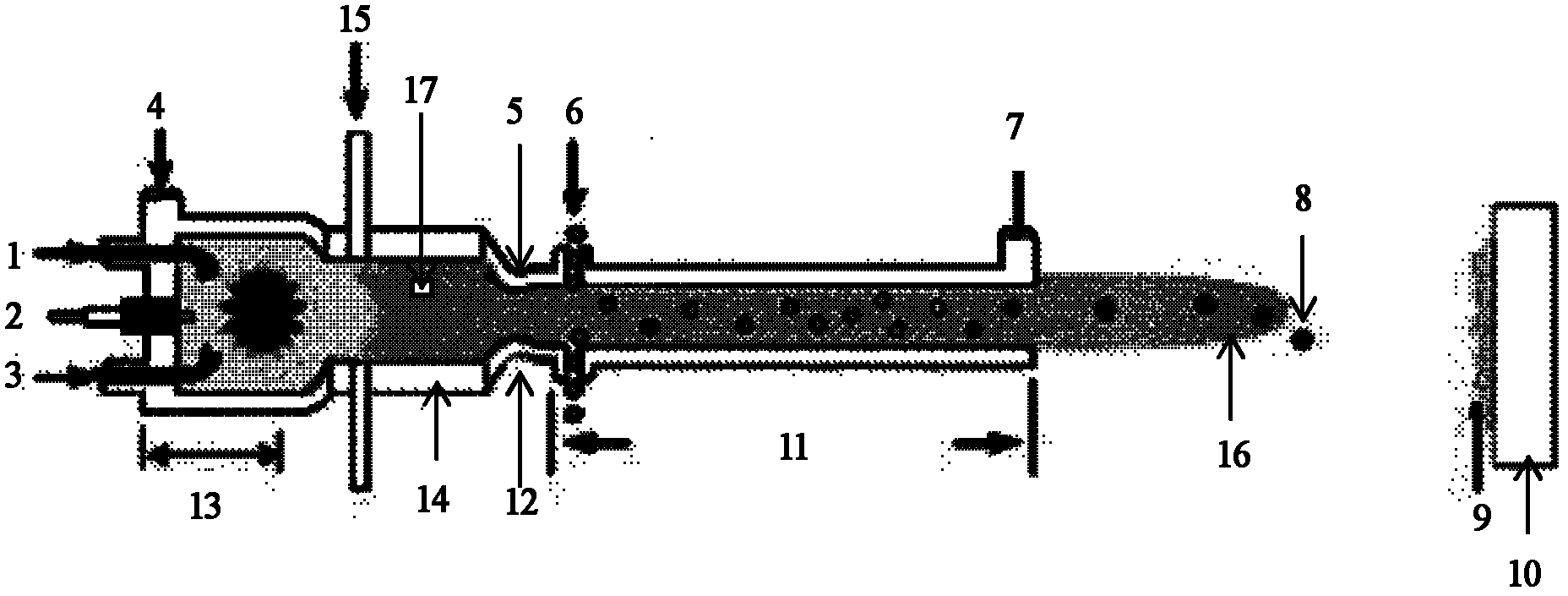

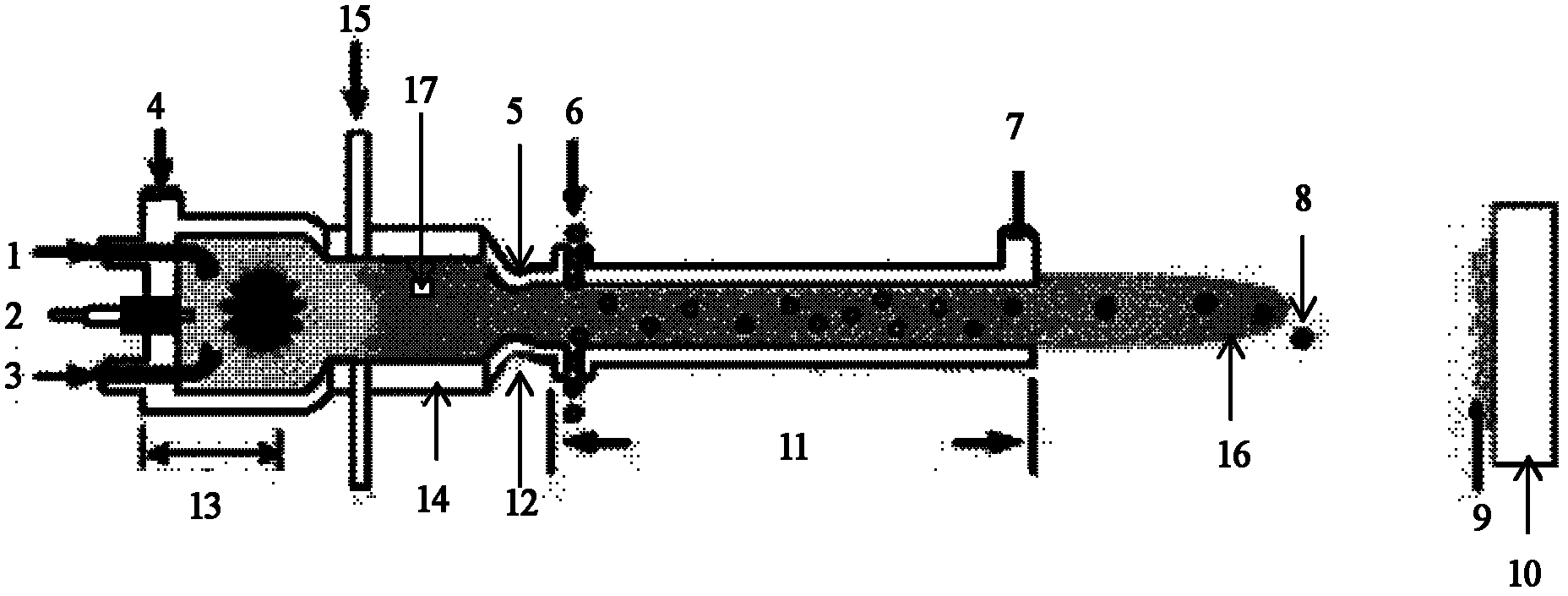

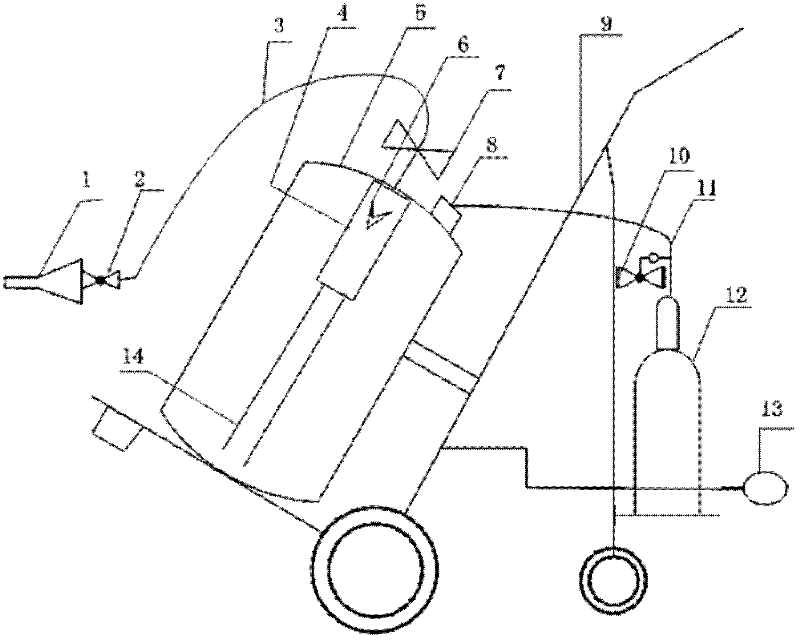

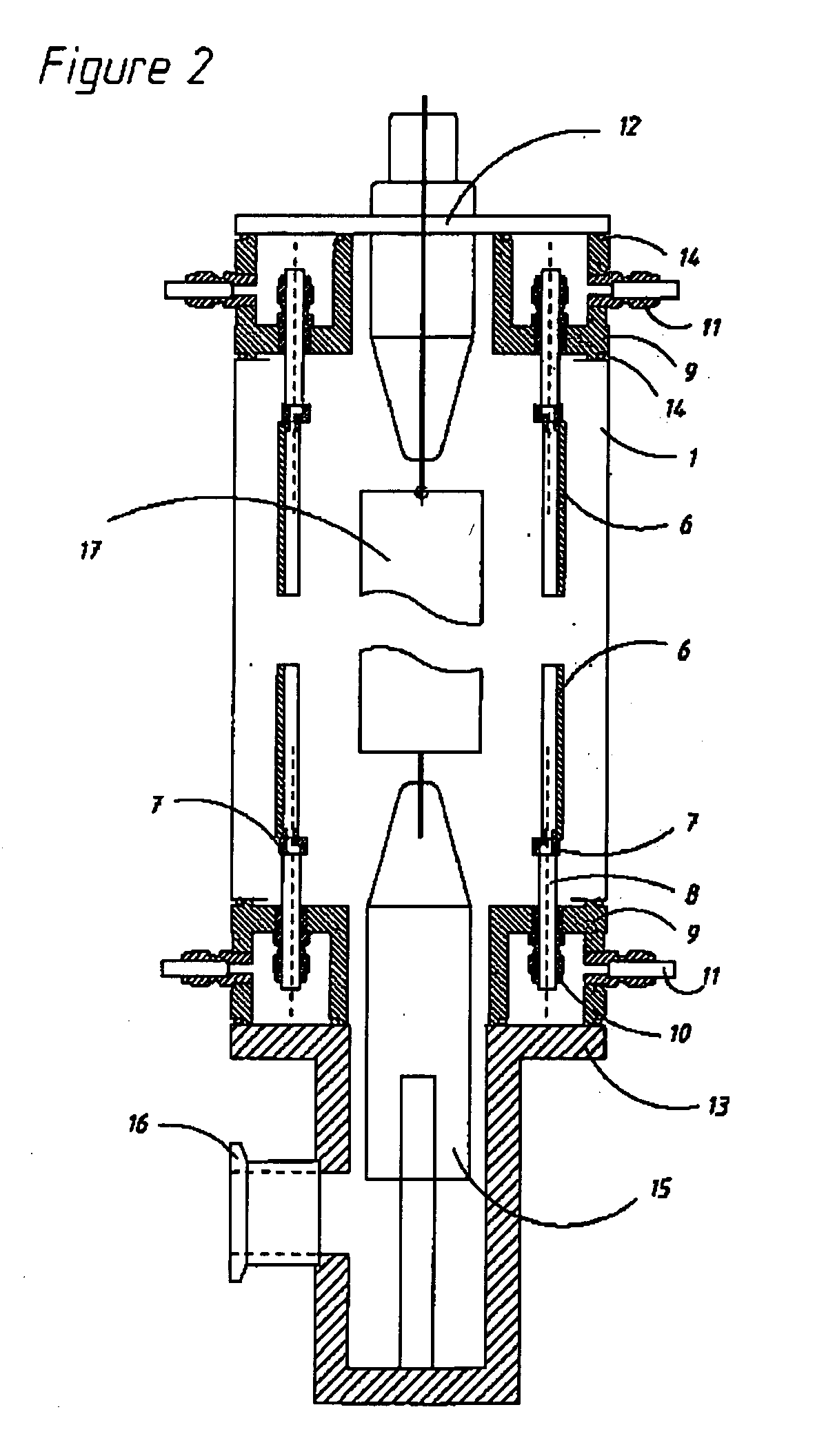

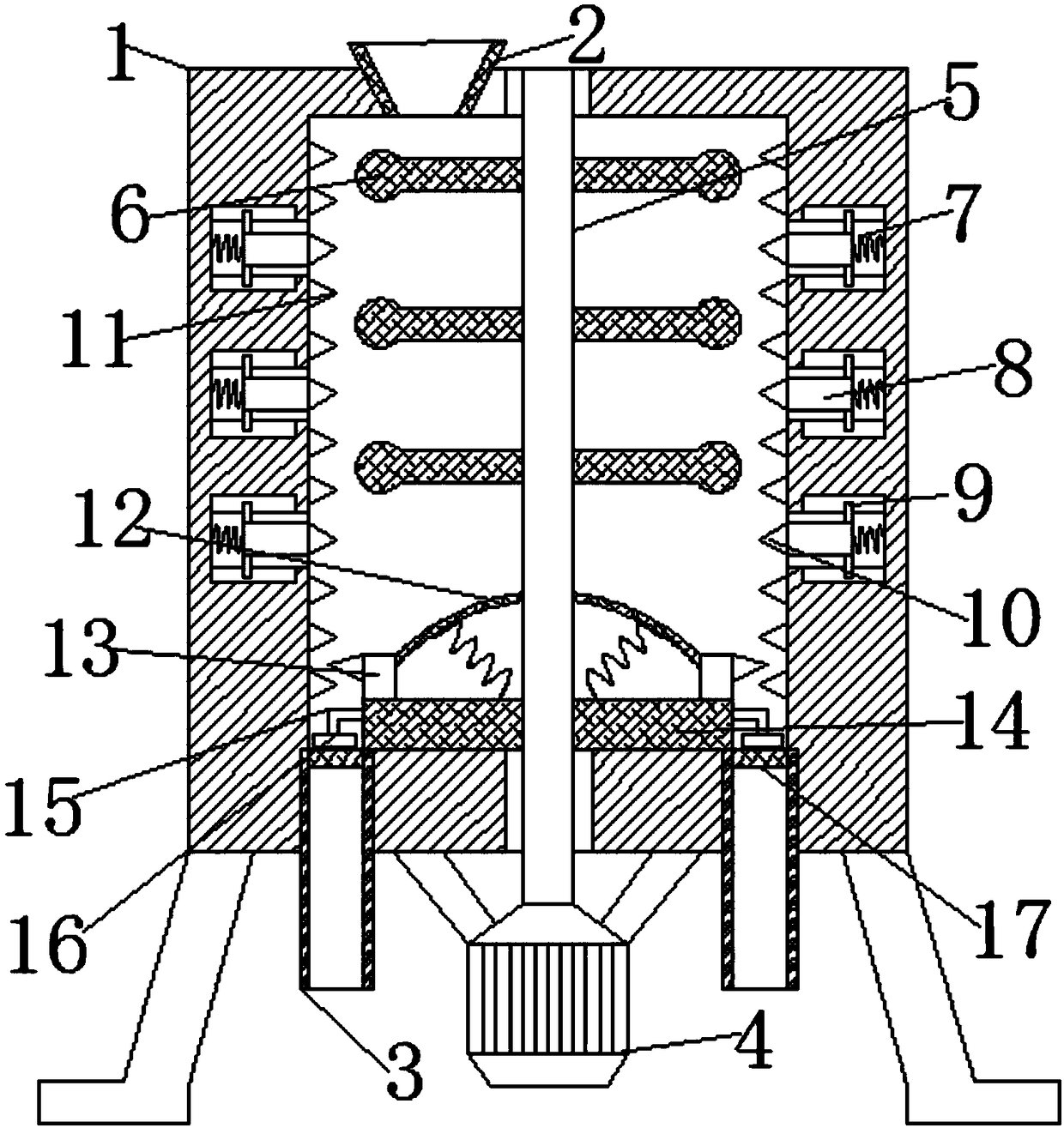

Thermal spraying device and method for manufacturing quasicrystalline coating

InactiveCN102560326AAvoid problems such as easy oxidationEven distribution of constituent phasesMolten spray coatingPorosityThermal spraying

The invention relates to the field of manufacturing of surface coatings, in particular to a thermal spraying device and a thermal spraying method for manufacturing a quasicrystalline coating. A fuel inlet, a spark plug and an oxygen inlet are arranged on one side of a mixing chamber of the thermal spraying device; the other side of the mixing chamber is communicated with a middle mixing chamber; a cooling gas inlet is formed on the middle mixing chamber; middle mixing chamber is communicated with a spray pipe through a supersonic nozzle; and an outlet of the supersonic nozzle and an inlet of the spray pipe are communicated with a quasicrystalline powder inlet. The middle mixing chamber for the cooling gas is added and the flame temperature is reduced, so that the powder and the gas form a gas-solid two-phase flow; solid particles in the gas-solid two-phase flow are sprayed onto the surface of a workpiece, and are plastically deformed seriously and deposited onto the surface of the workpiece; and subsequent particles with high kinetic energy repeat the process and form a quasicrystalline alloy coating. The problems that in the prior art, a crystalline phase is accompanied by a quasicrystalline phase, the porosity of the coating is high and micro-cracks exist are solved; and the thermal spraying device and the thermal spraying method can be used for manufacturing multiple series of quasicrystalline coatings.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

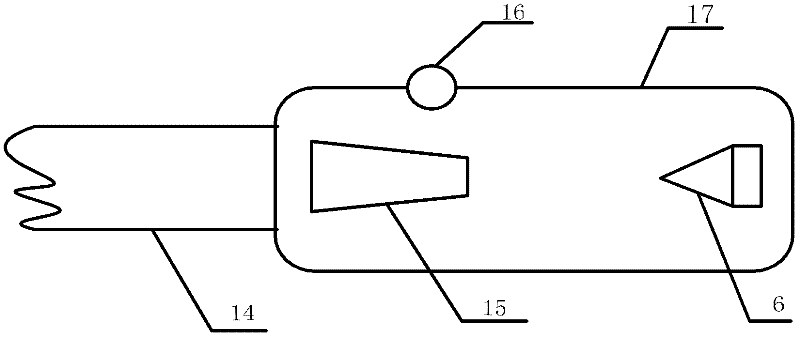

Foam generator for compressed gas

InactiveCN102500079AImprove the mixing effectHigh strengthFire rescueProcess engineeringHigh pressure gas

The invention provides a foam generator for compressed gas. The foam generator comprises a foam generator shell, a liquid nozzle, a turbulator and a compressed gas entrance, wherein the liquid nozzle is used for controlling flow rate of foam extinguishing agent premixed liquid entering the foam generator; and the compressed gas entrance is used for controlling flow rate of compressed gas entering the foam generator. The foam generator is used for enabling the foam extinguishing agent premixed liquid entering the foam generator to form rotating fog liquid, and be impacted with and mixed with the compressed gas entering the foam generator to form foam. Compared with the prior art, the foam generator for the compressed gas provided by the invention can greatly improve the mixing capacity of foam liquid and high-pressure gas, so that the ejected foam has the advantages of high kinetic energy, long ejecting distance, uniform and stable foam, high fire-extinguishing speed, high fire-extinguishing strength, long fire-retarding time, high fire-extinguishing efficiency, small use amount of foam and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

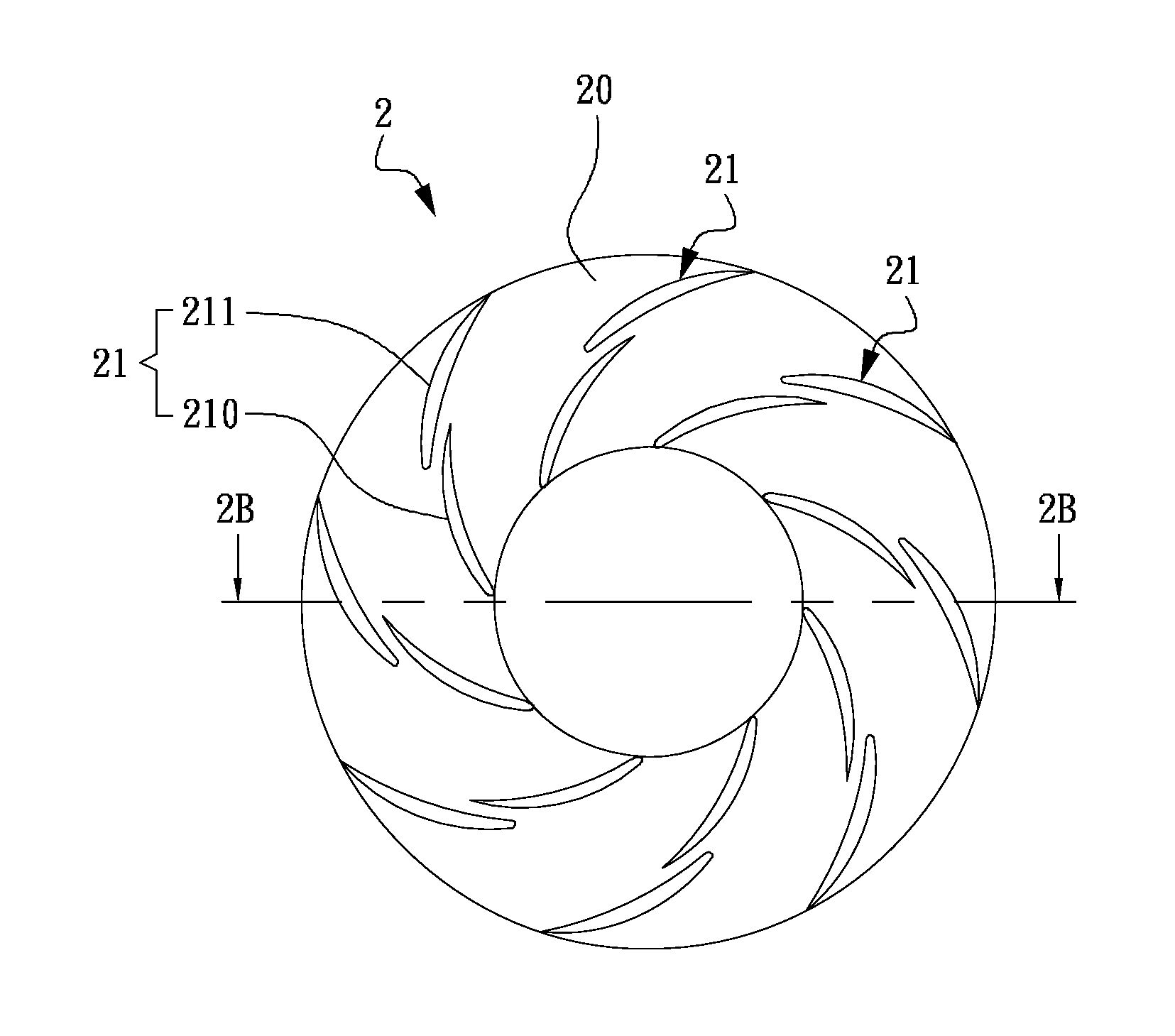

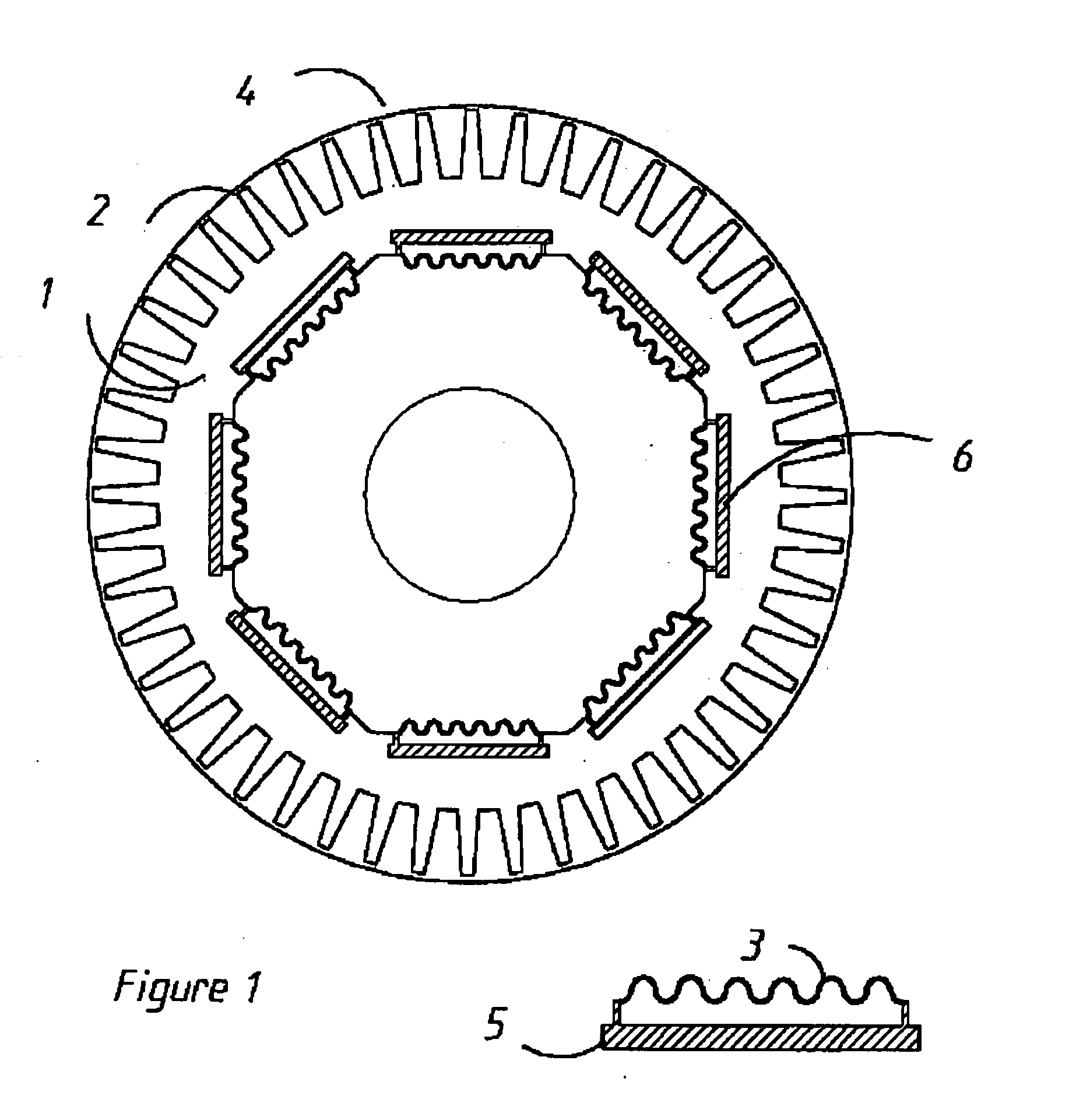

Impeller Structure and the Centrifugal Fan Device Using the Same

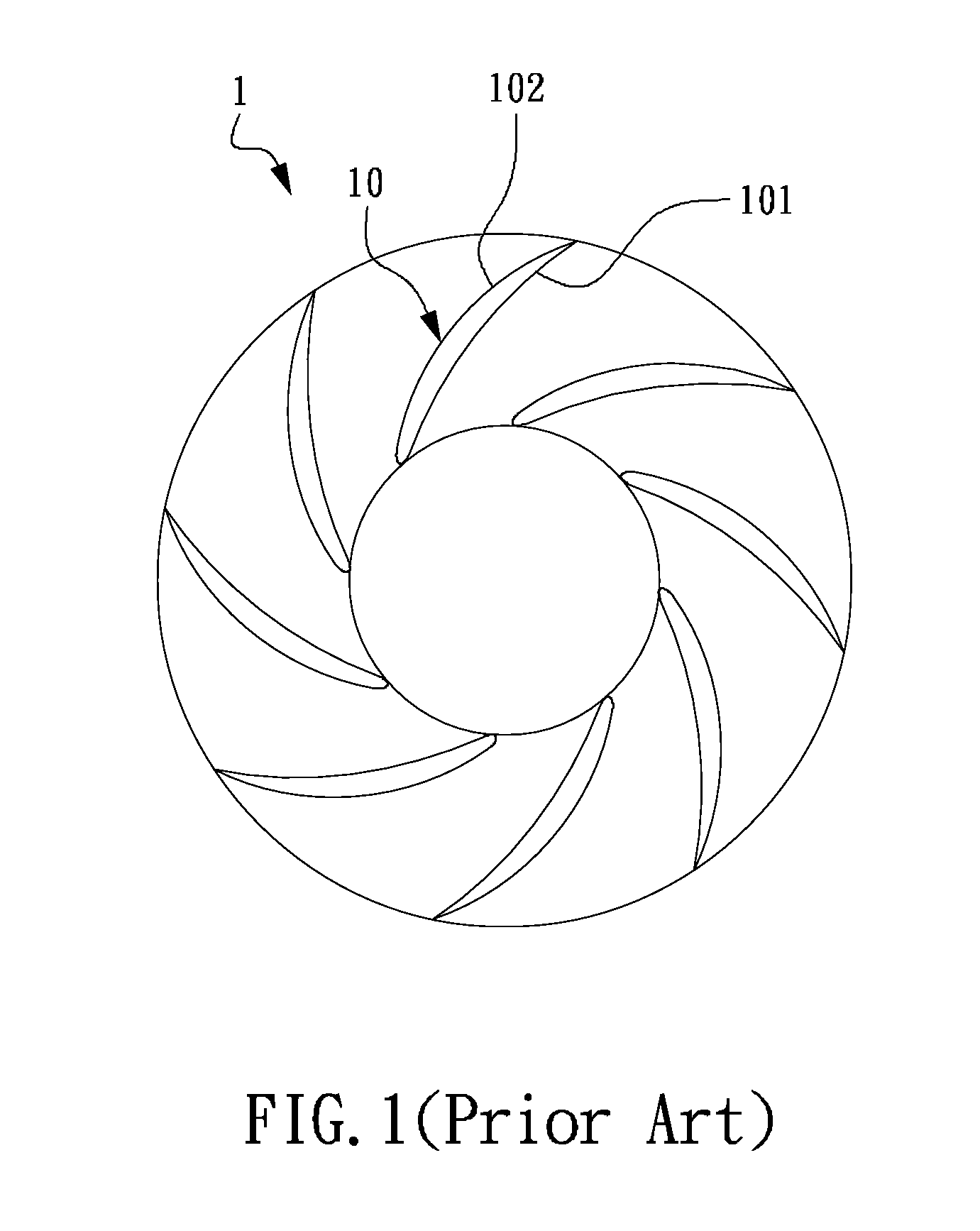

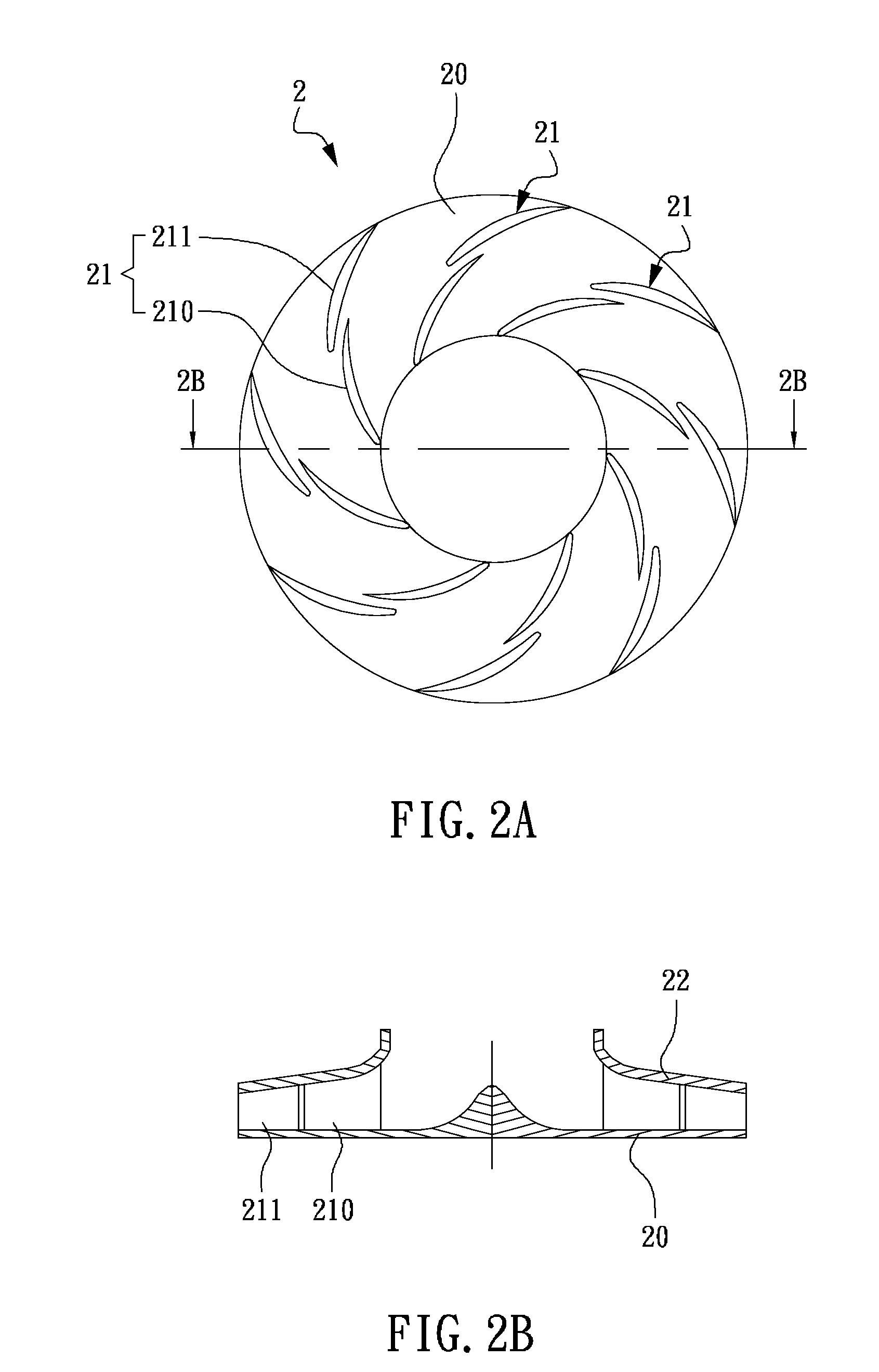

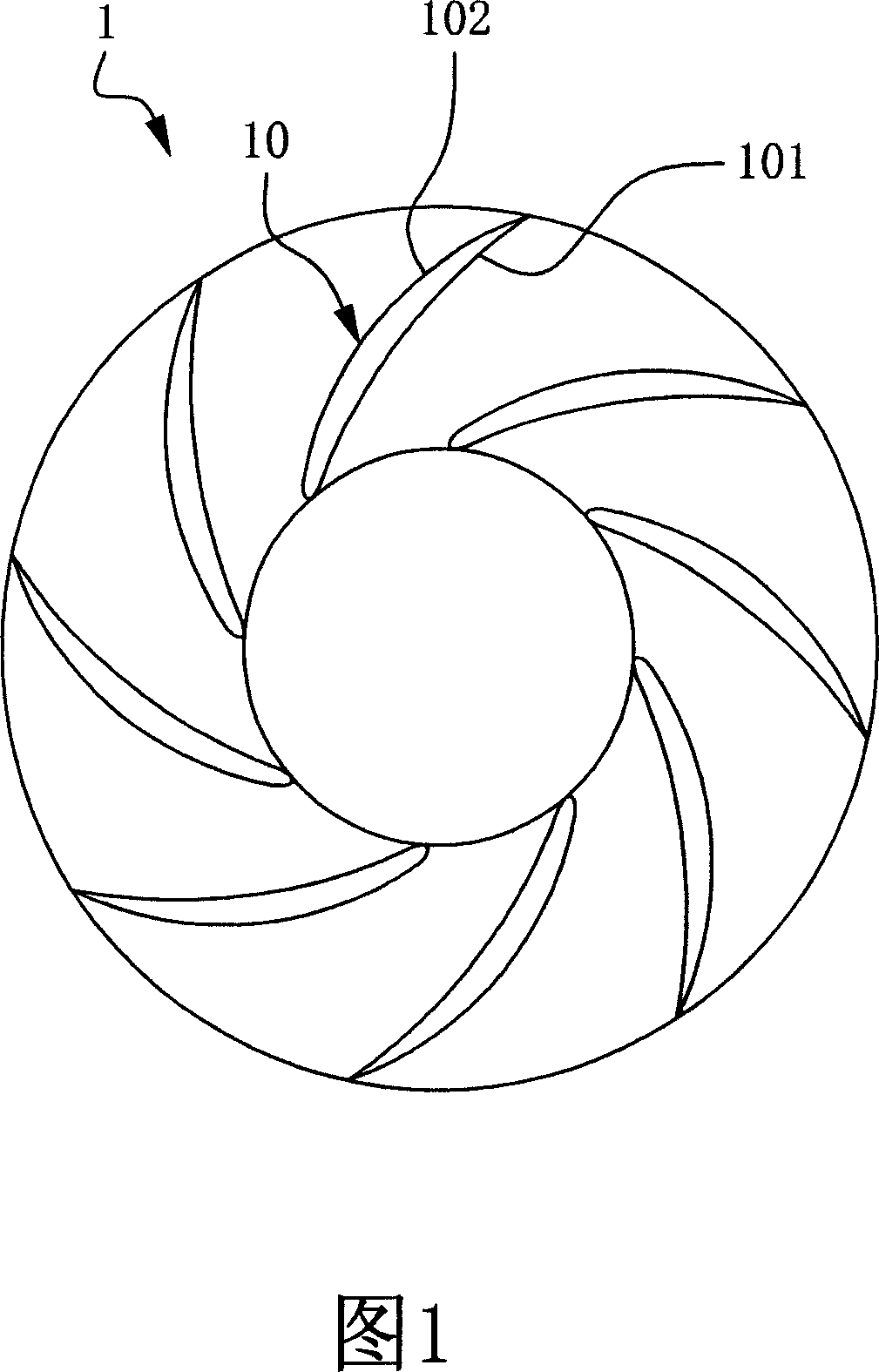

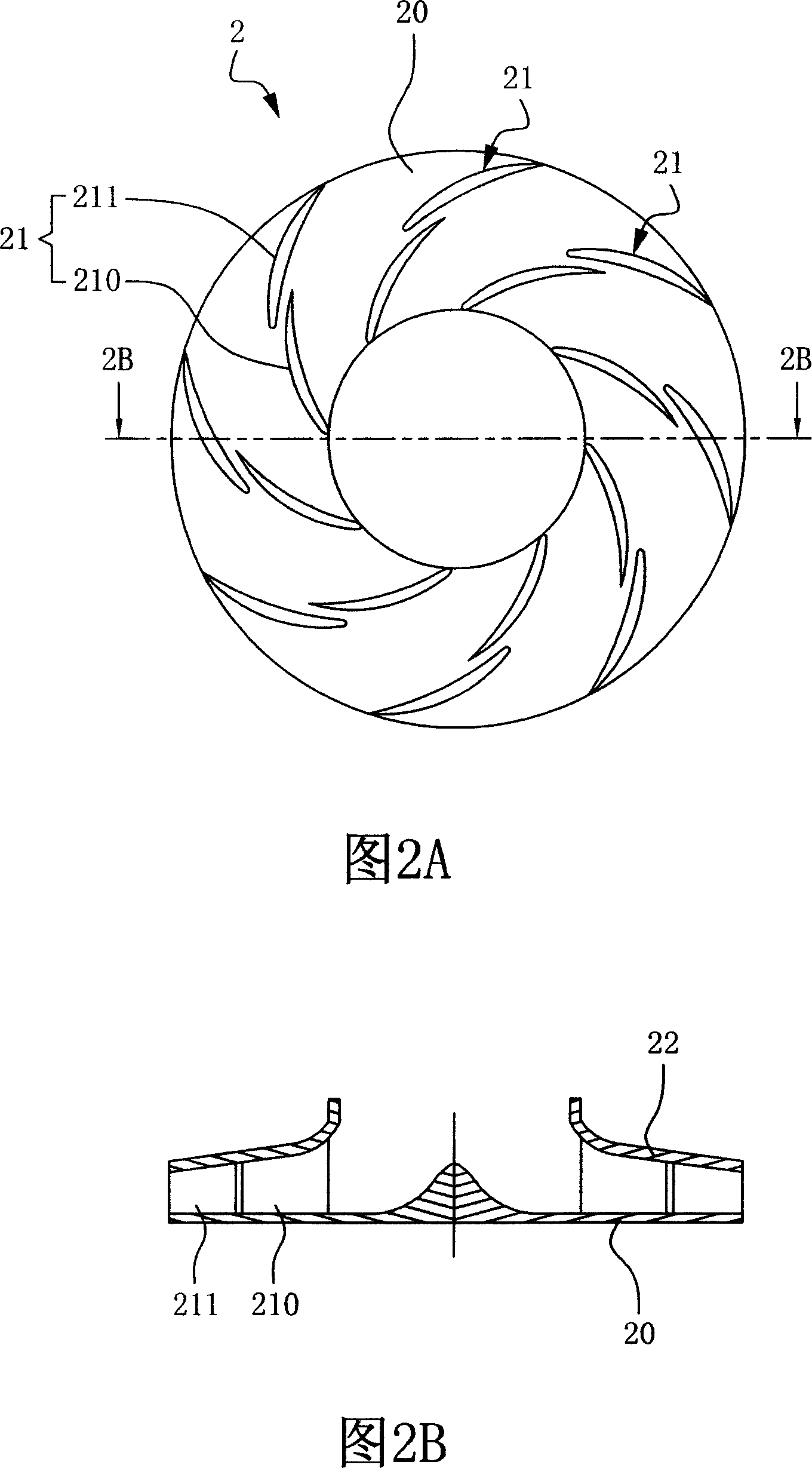

InactiveUS20080050228A1Reduced boundary layer thicknessGrowth can be interruptedPump componentsStatorsImpellerSuction stress

An impeller structure for a centrifugal fan device is disclosed, in which the impeller structure is primarily comprised of: a disc; and a plurality of blade structures, each being arranged on the disc; wherein, each blade structure further comprises: a first blade; and a second blade, arranged at a circumferential length away from a side of the first blade while radially overlapping with the radial of the first blade by a specific overlap area for forming a gap passage functioning as a nozzle. As a fluidic is flowing through and shooting out of the gap passage, not only the growth of the boundary layers on the suction surfaces of front blades are interrupted, but also as the fluidic with high kinetic energy is mixing with the low-kinetic fluidic flowing on the suction surfaces of rear blades, the thickness of the boundary layer is reduced while the separation point is delayed and thus separation can be prevented.

Owner:IND TECH RES INST

Blade wheel structure and centrifugal fan device using the same

The impeller comprises a disk and multiple pairs of blades which are set on the disk and comprises a first blade and a second blade. The second blade is set on one side of the first blade. The first blade and the second blade have an overlapped region each other in radial direction. The overlapped region can form a gap passage acting a function like nozzle. When fluid sprays out from the gap passage, it can interrupt the grow-up of the boundary layer of the suction face of front column blade, and the high kinetic energy fluid mixes with the low kinetic energy fluid on the suction face of back column blade so as to reduce the boundary layer thickness, delay separation point position or overcome separation occurrence.

Owner:IND TECH RES INST

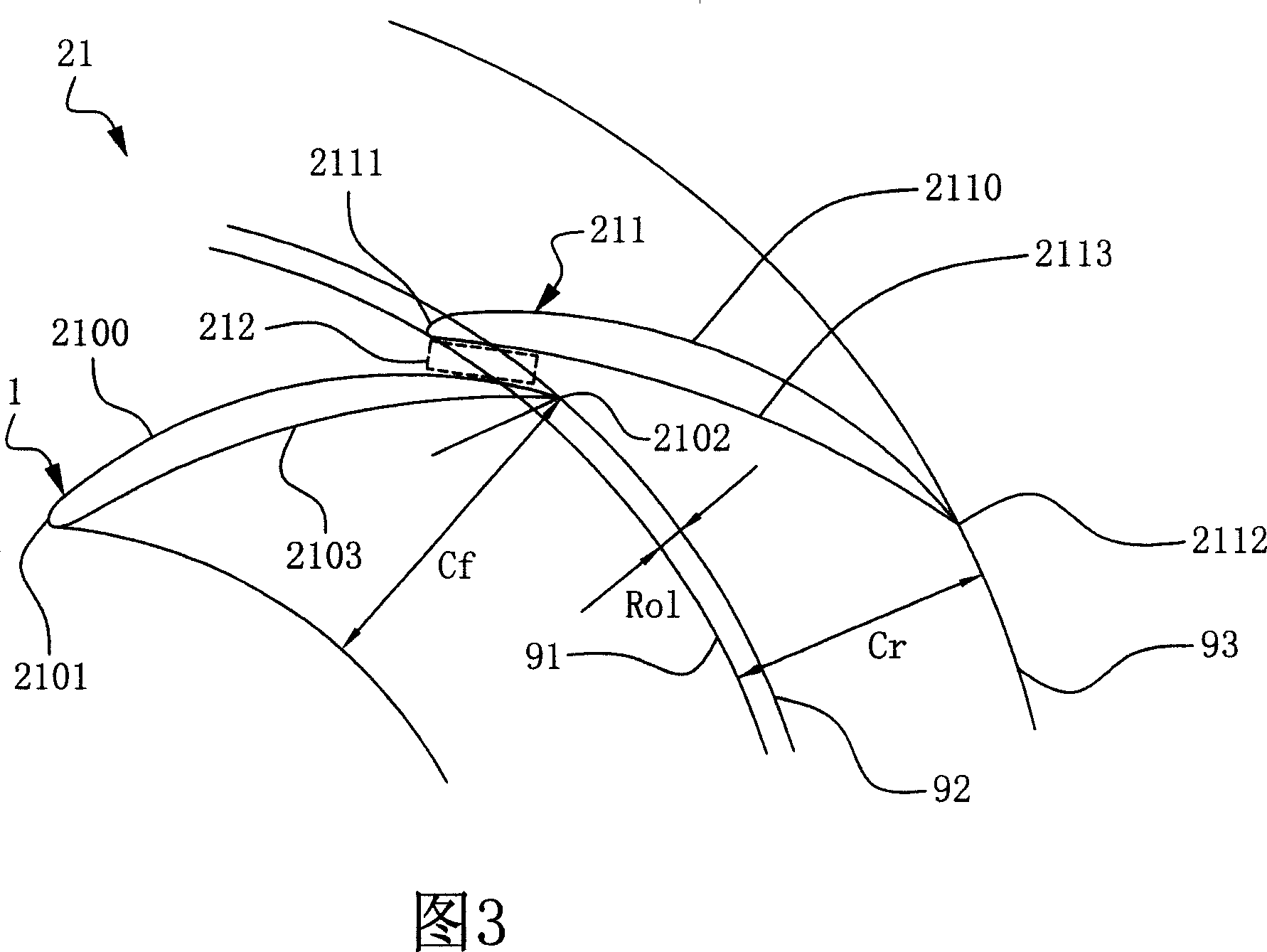

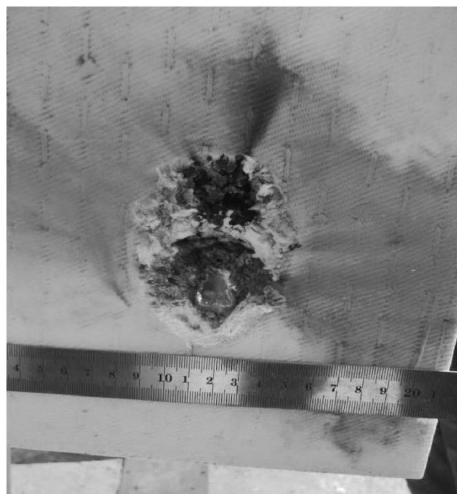

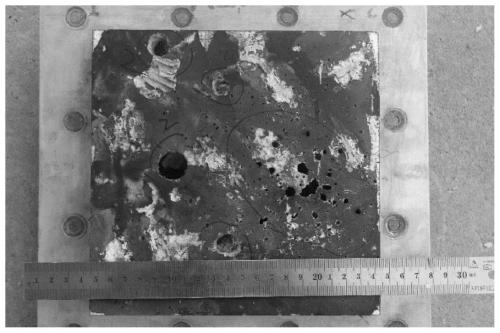

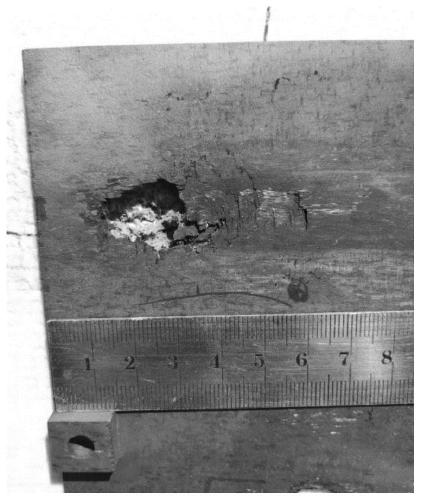

Preparation method of energetic fragment of composite charge structure

ActiveCN110340349AWide variety of sourcesLow costTransportation and packagingMetal-working apparatusCombustionUltimate tensile strength

The invention relates to a preparation method of an energetic fragment of a composite charge structure, and belongs to the field of energetic materials and active fragment materials. The preparation method comprises the following steps of uniformly mixing tungsten powder / PTFE powder in an omnidirectional planetary ball mill; putting the uniform powder in a custom mold, and carrying out pre-press molding to obtain a hollow cylindrical pre-pressing piece A; uniformly mixing aluminum powder, the tungsten powder and polytetrafluoroethylene powder in the omnidirectional planetary ball mill, fillingthe hollow cylindrical pre-pressing piece A with the uniform powder, and carrying out pre-press molding; and sintering to obtain a final product. According to the energetic fragment, as an energeticmaterial, and the energetic fragment is very insensitive and safe in static state, and has a certain toughness and strength, so that the energetic fragment can be directly machined; violent explosionand combustion are generated under the high-speed impact action, and high heat and high temperature are generated; and as a fragment material, high-kinetic energy is utilized to impact high chemical energy released after explosion, and combined damage of penetration, implosion, arson and overpressure can be carried out on a target.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

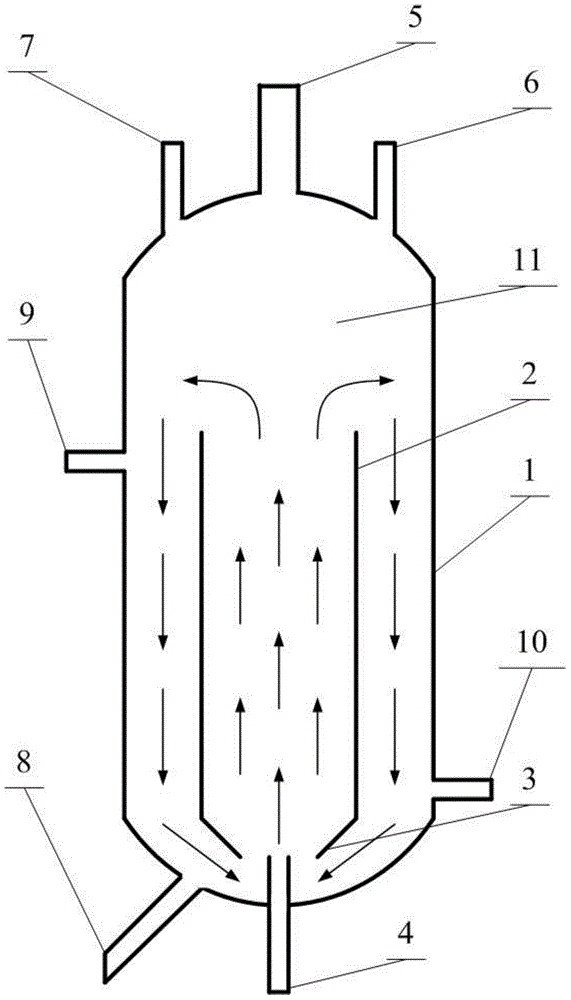

Reactor for mineralization fixation of carbon dioxide by fortified calcium-base solid wastes in ammonia medium system and application method thereof

InactiveCN104907010AReduce consumptionIncrease profitCalcium/strontium/barium carbonatesTransportation and packagingReaction temperatureHigh pressure

The invention relates to a reactor for mineralization fixation of carbon dioxide by fortified calcium-base solid wastes in an ammonia medium system and an application method thereof. The invention is characterized in that a pressurized loop reactor is used in the ammonia medium system's fortified calcium-base solid wastes mineralization fixation process of carbon dioxide. During the process, the reaction temperature is 60-200 DEG C, duration time of the reaction is 5-60 min, CO2 gas partial pressure is 1-40bar, and CO2 gas concentration is 20-99.99%. By the adoption of the pressurized loop reactor, defects such as high kinetic energy consumption of a stirred-tank reactor, large sealing difficulty of an overpressure system, easy deposition of solid materials in a mechanical agitation-free bubble column reactor and the like are overcome. The reactor provided by the invention has advantages as follows: pneumatic stirring replaces mechanical agitation; energy consumption is low; and the reactor is easy to process and is simple to clean, maintain and operate. The reactor is especially suitable for the ammonia medium system's fortified calcium-base solid wastes mineralization fixation process of carbon dioxide, has characteristics of high pressure gas and high solid content, and is easy for industrial scale-up.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

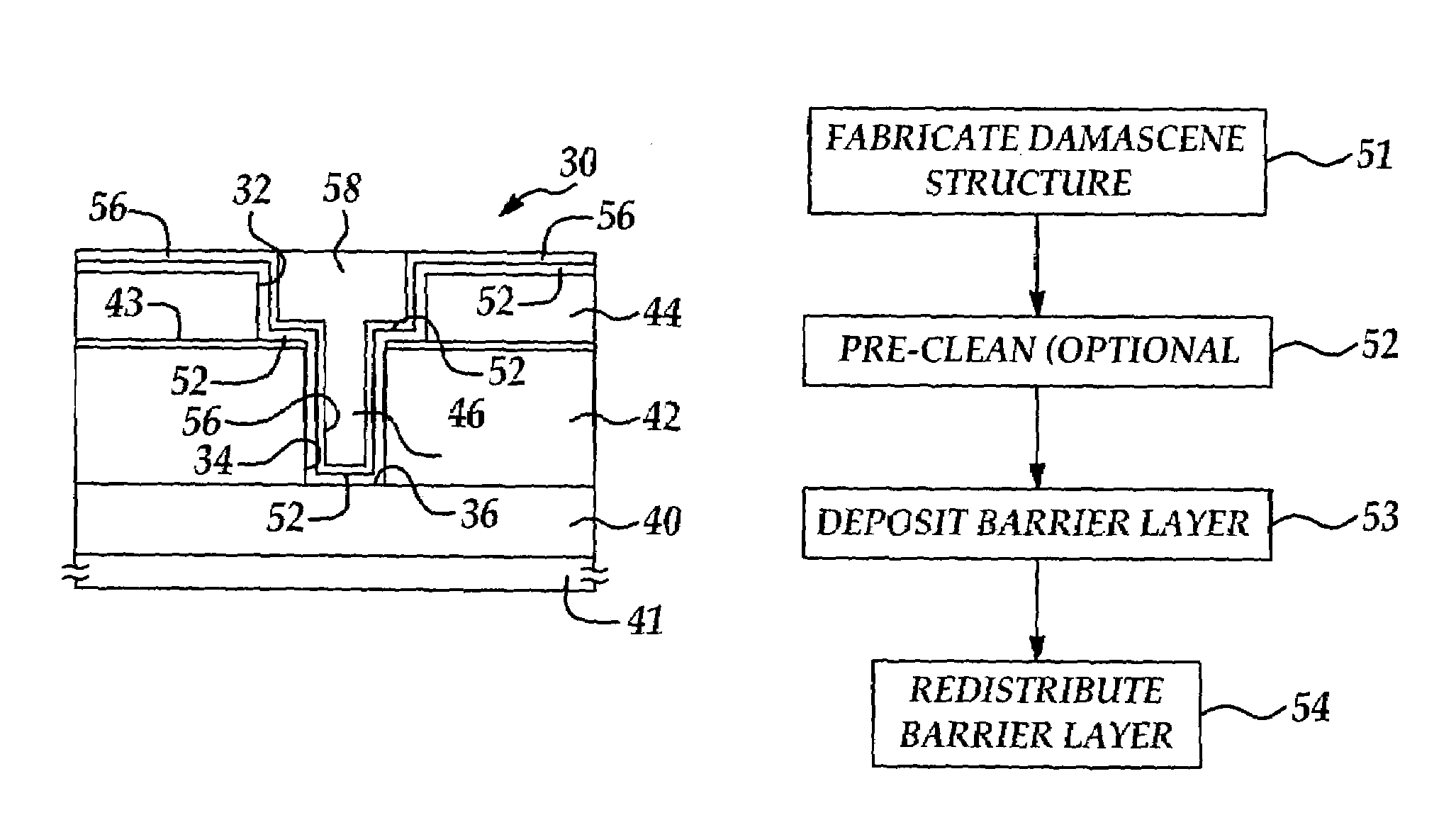

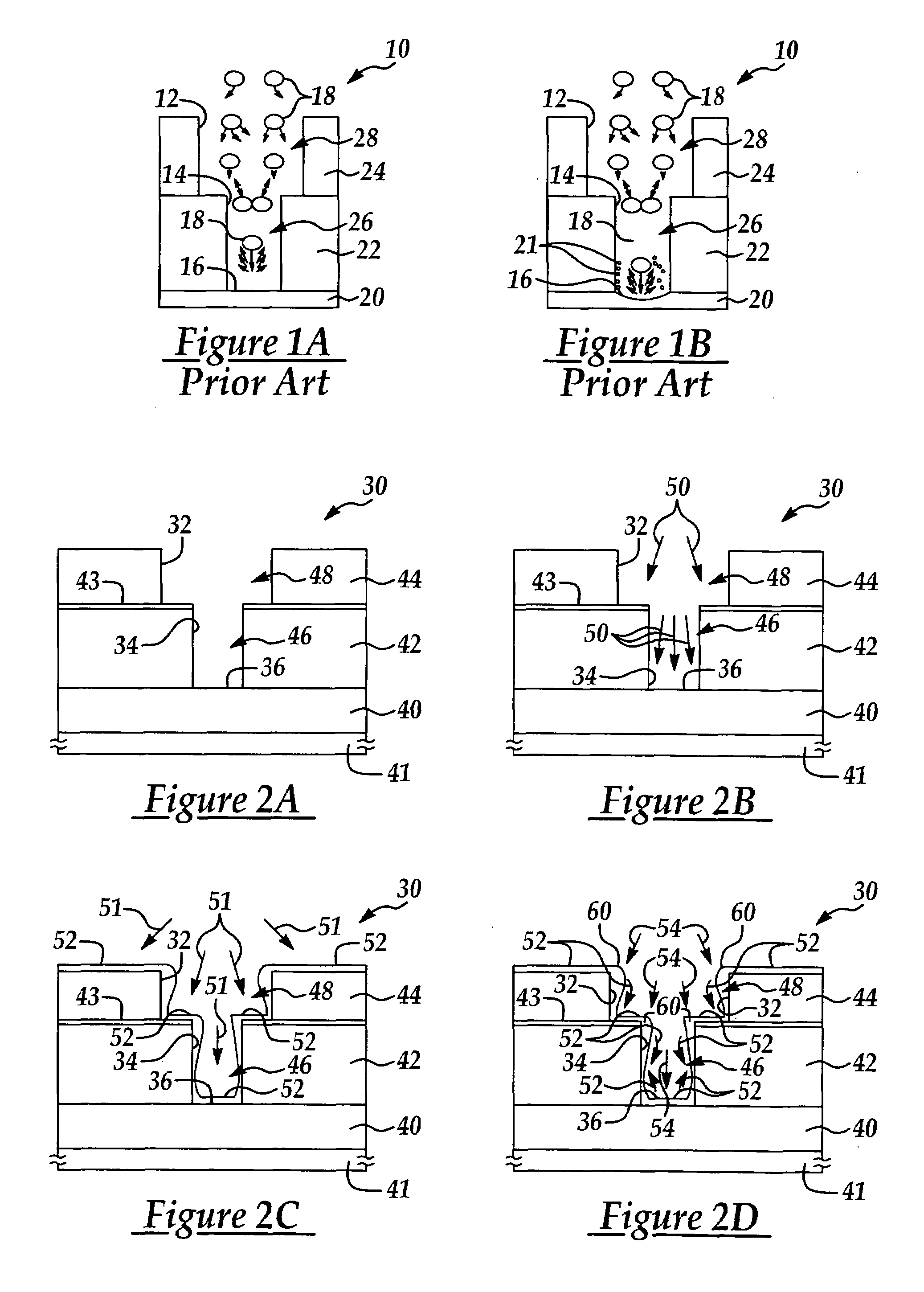

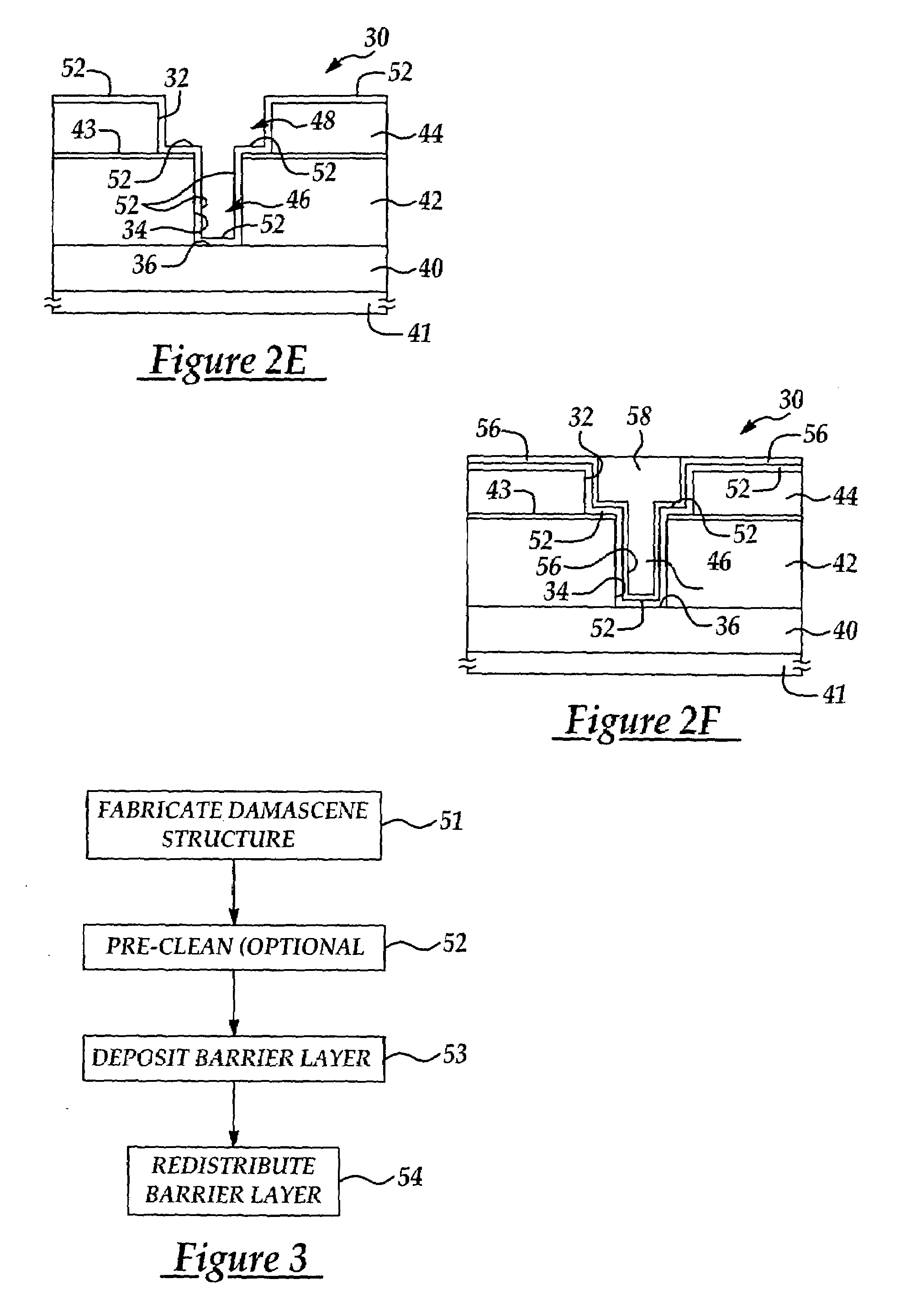

Method for high kinetic energy plasma barrier deposition

ActiveUS6949472B1Reducing and eliminating damageEliminate needSemiconductor/solid-state device manufacturingThin metalHydrogen

A novel method for depositing a barrier layer on a single damascene, dual damascene or other contact opening structure. The method eliminates the need for pre-cleaning argon ion bombardment of the structure, thereby reducing or eliminating damage to the surface of the underlying conductive layer and sputtering of copper particles to the via or other contact opening sidewall. The process includes fabrication of a single damascene, dual damascene or other contact opening structure on a substrate; optionally pre-cleaning the structure typically using nitrogen or hydrogen plasma; depositing a thin metal barrier layer on the sidewalls and bottom of the structure; and redistributing or re-sputtering the barrier layer on the bottom and sidewalls of the structure.

Owner:TAIWAN SEMICON MFG CO LTD

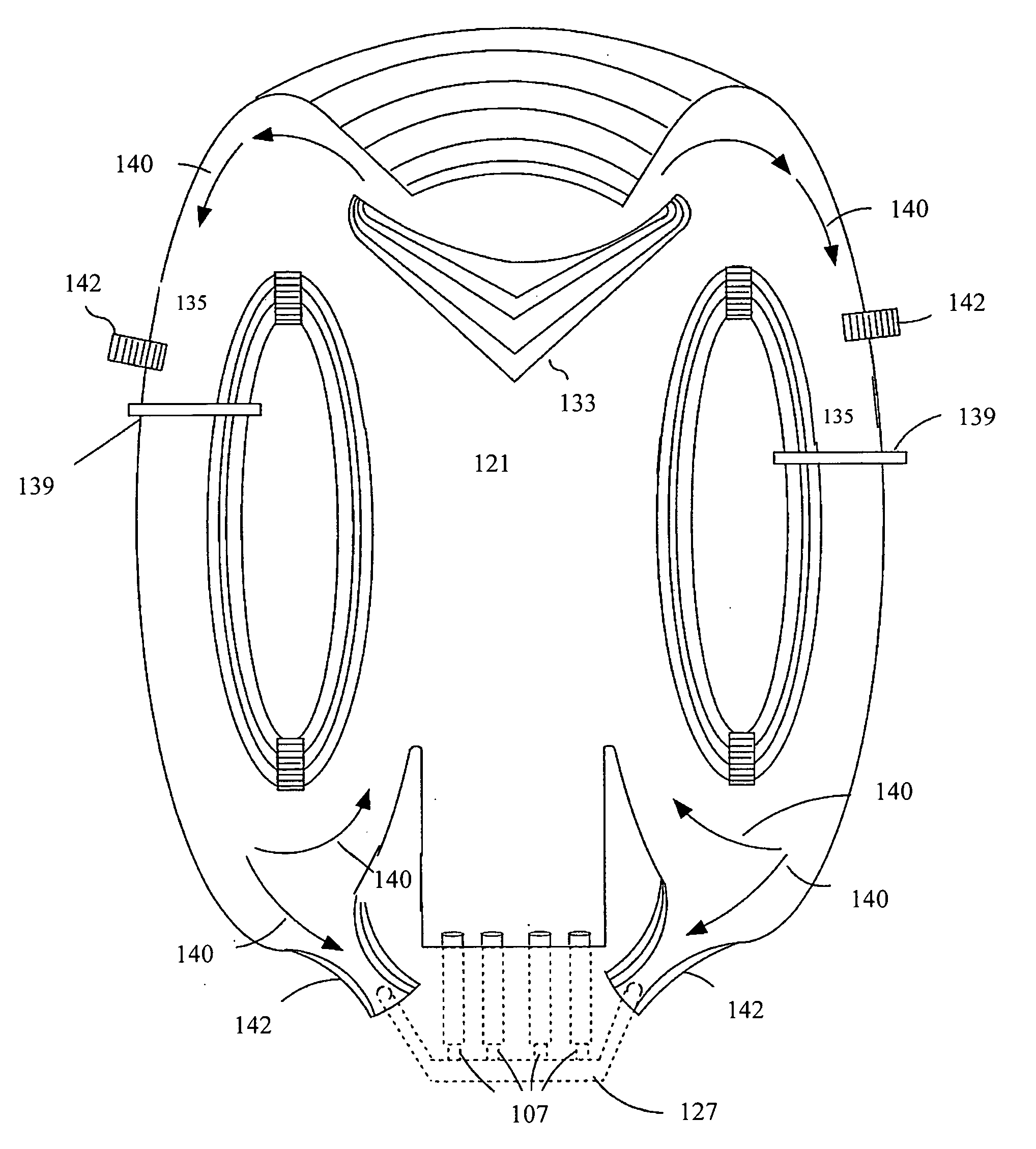

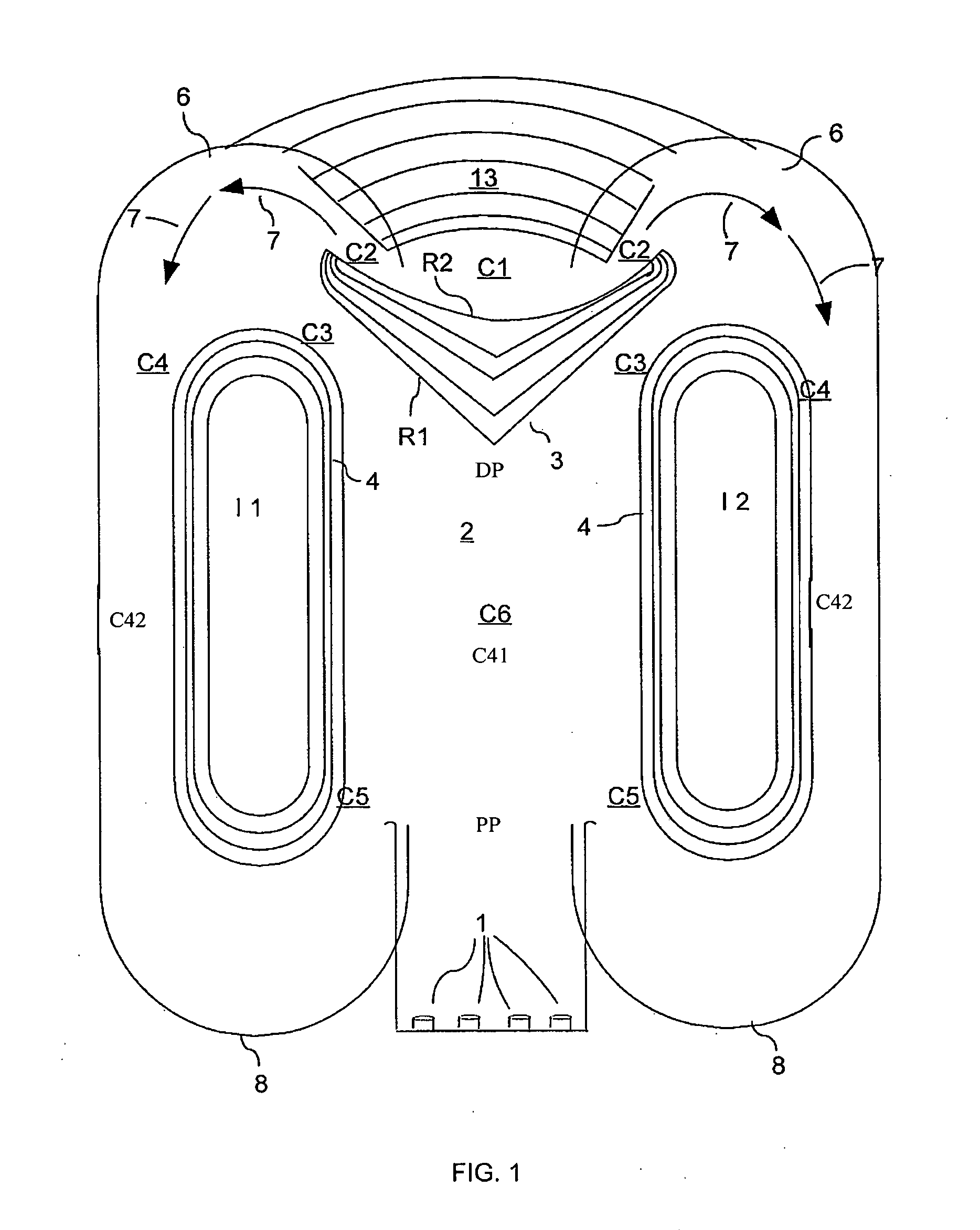

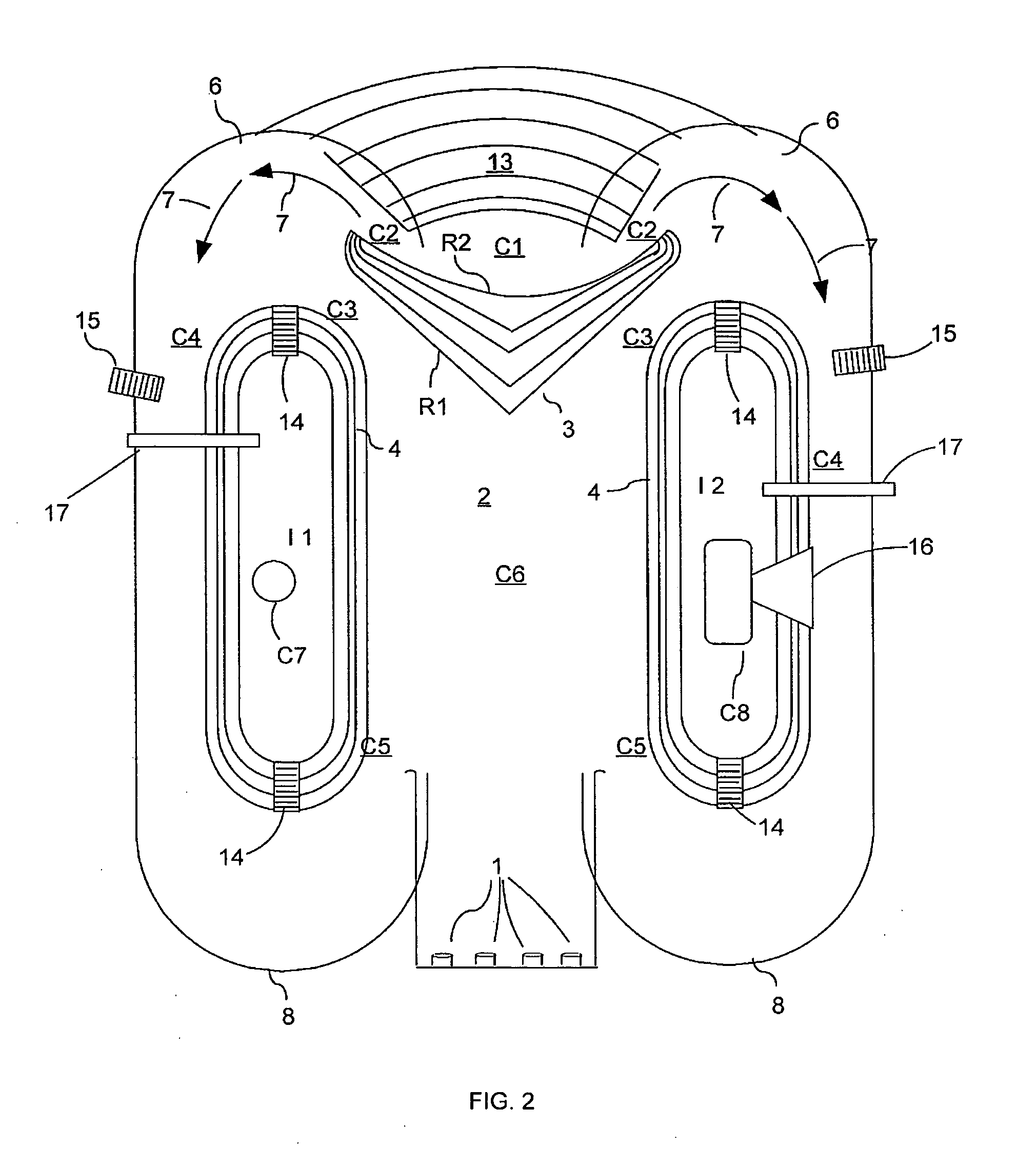

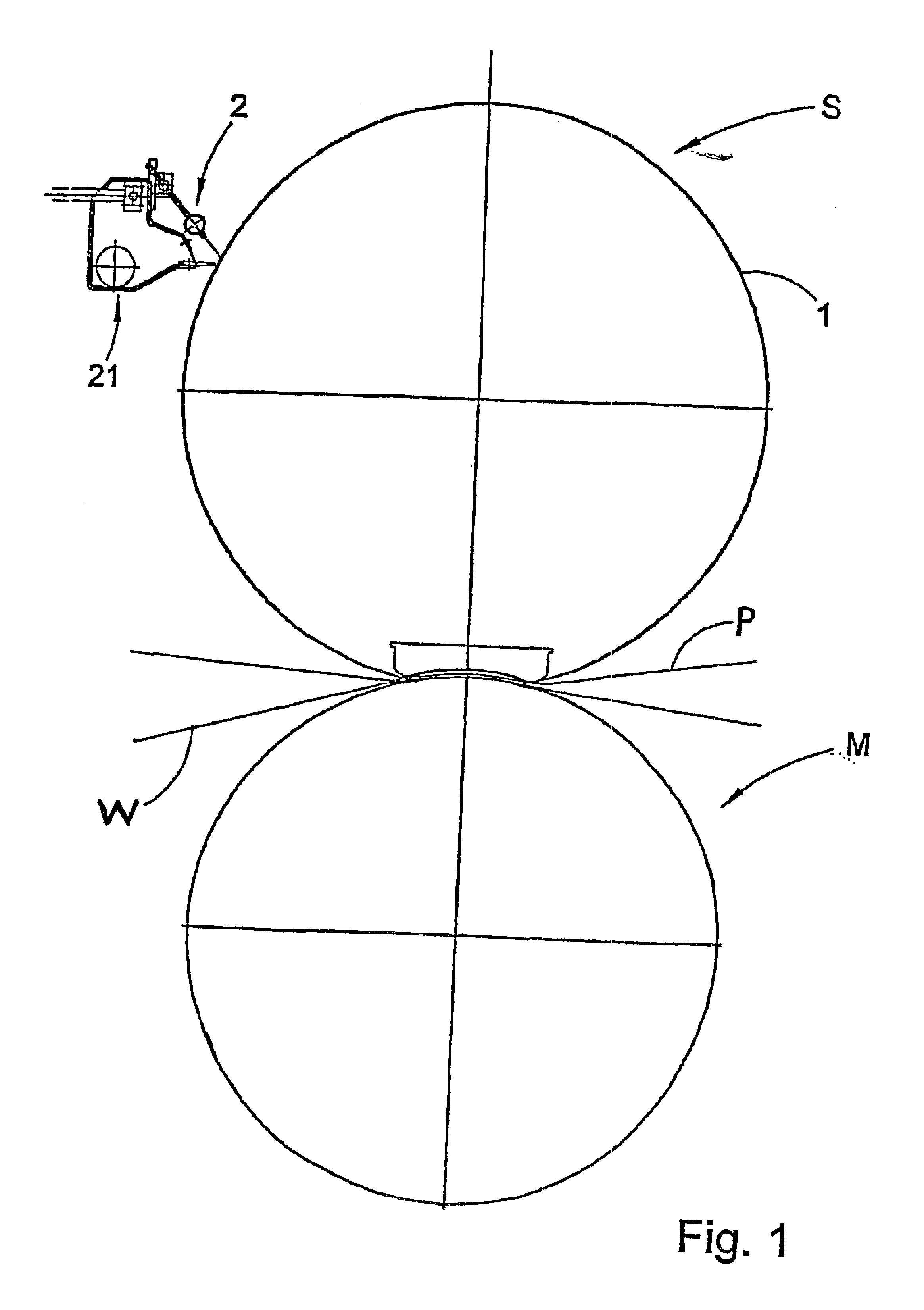

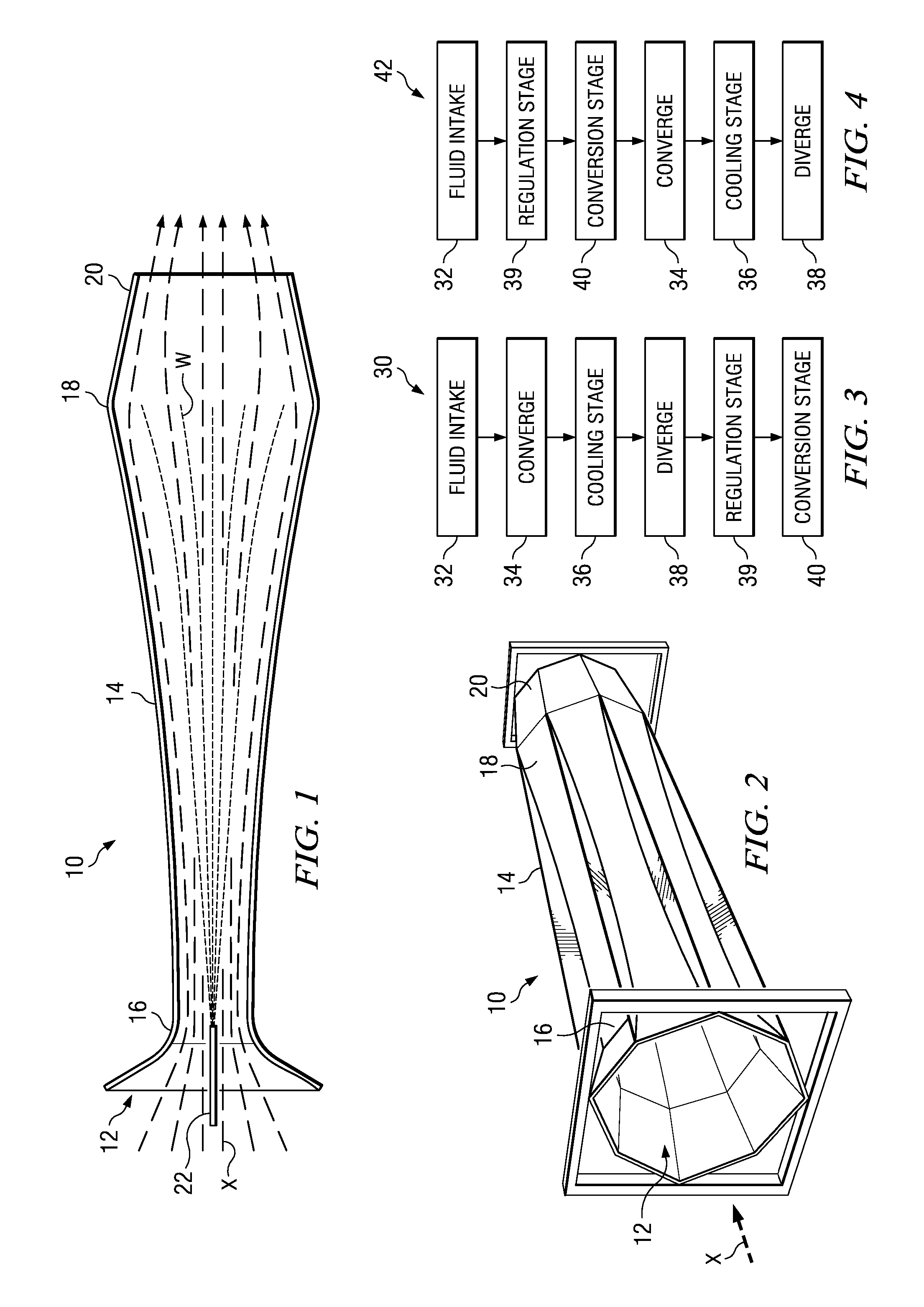

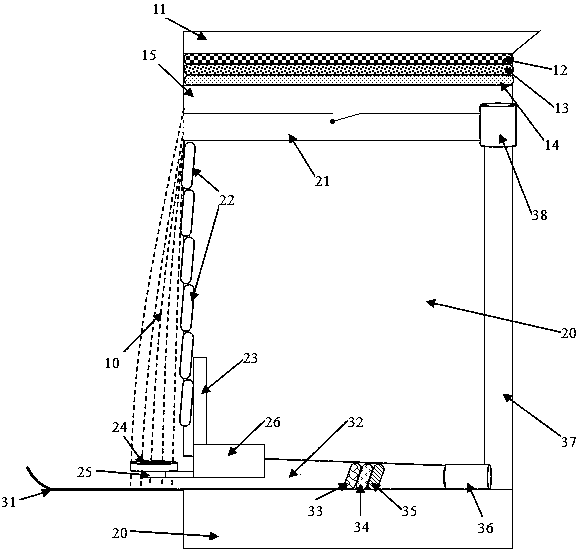

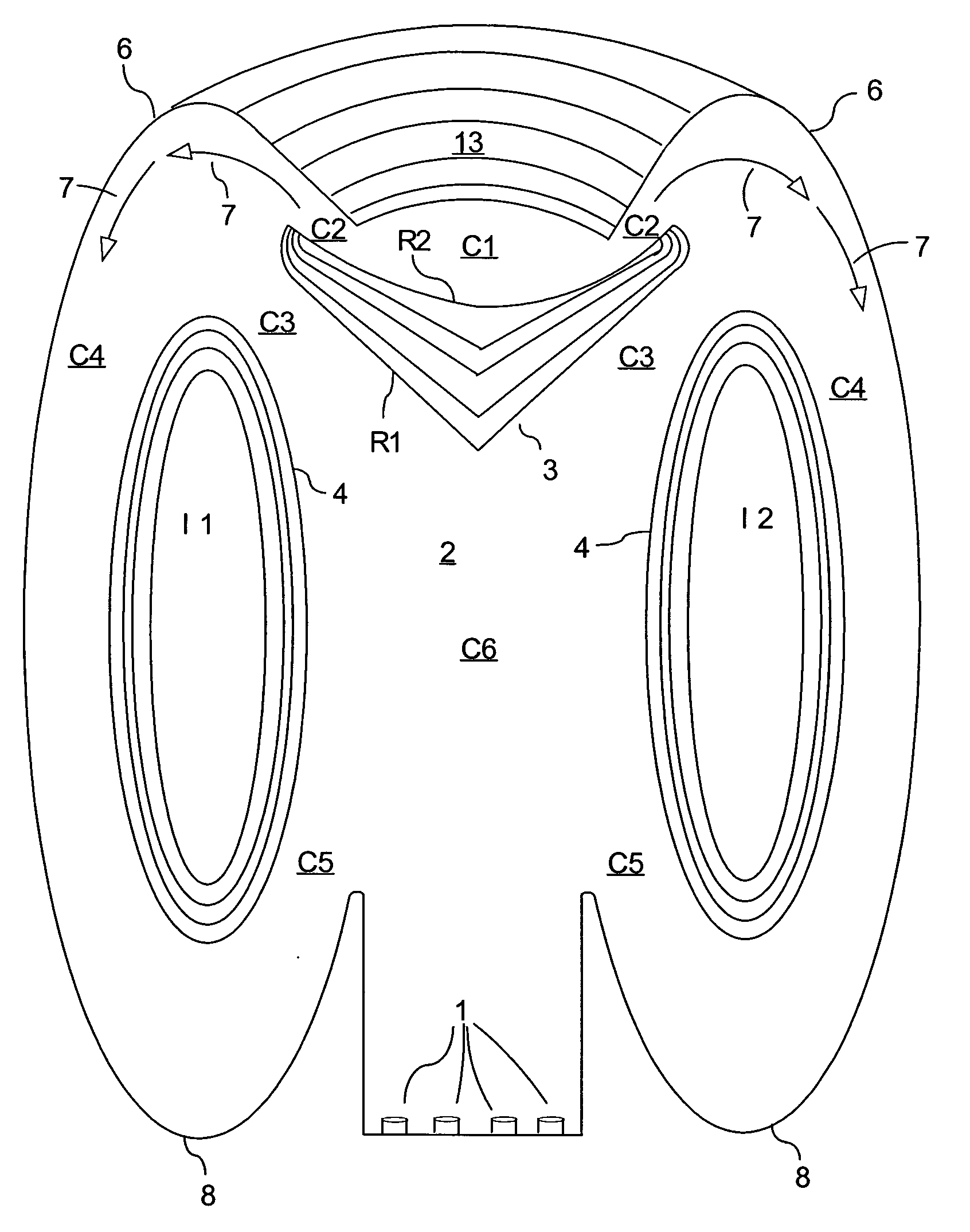

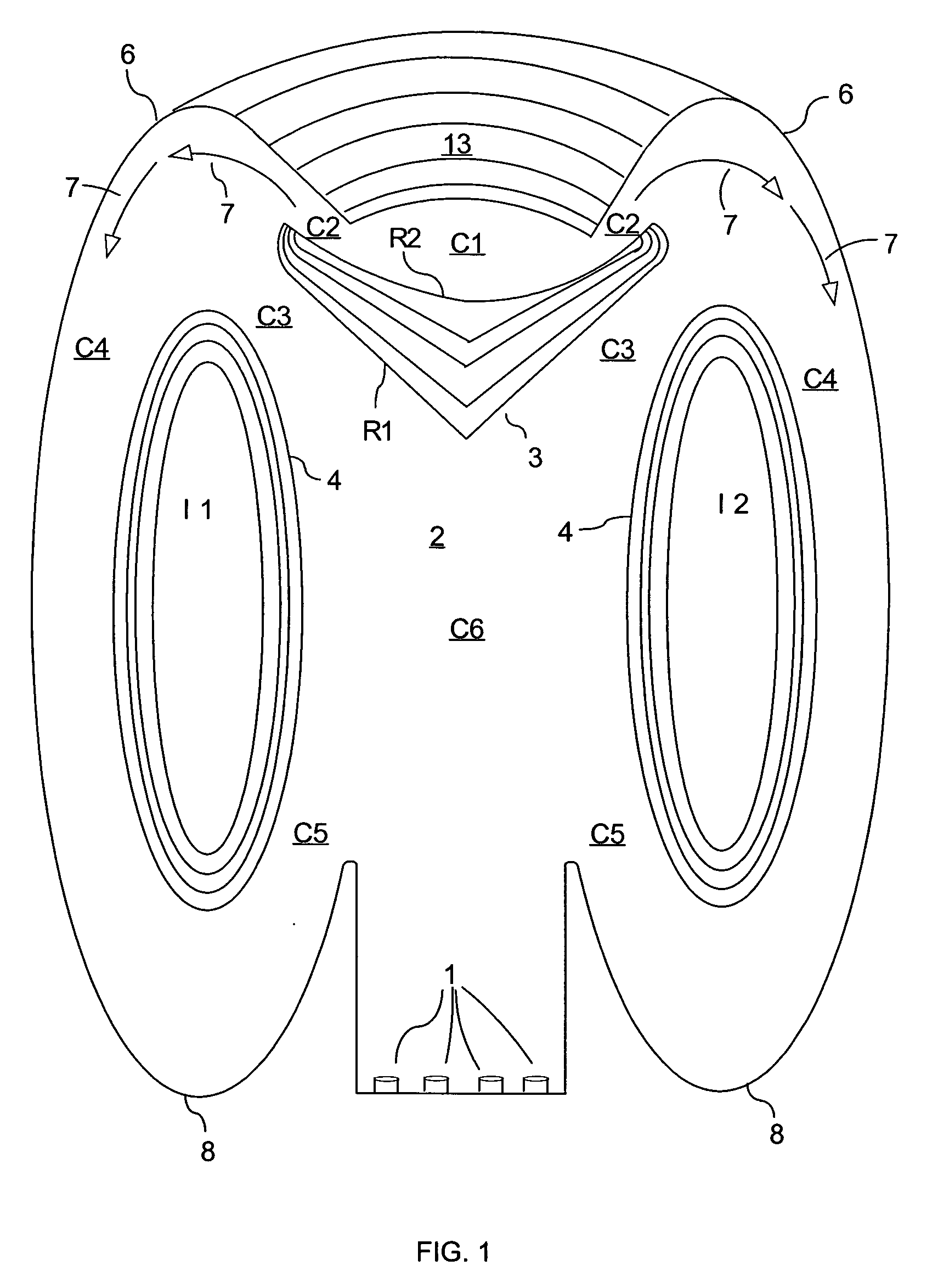

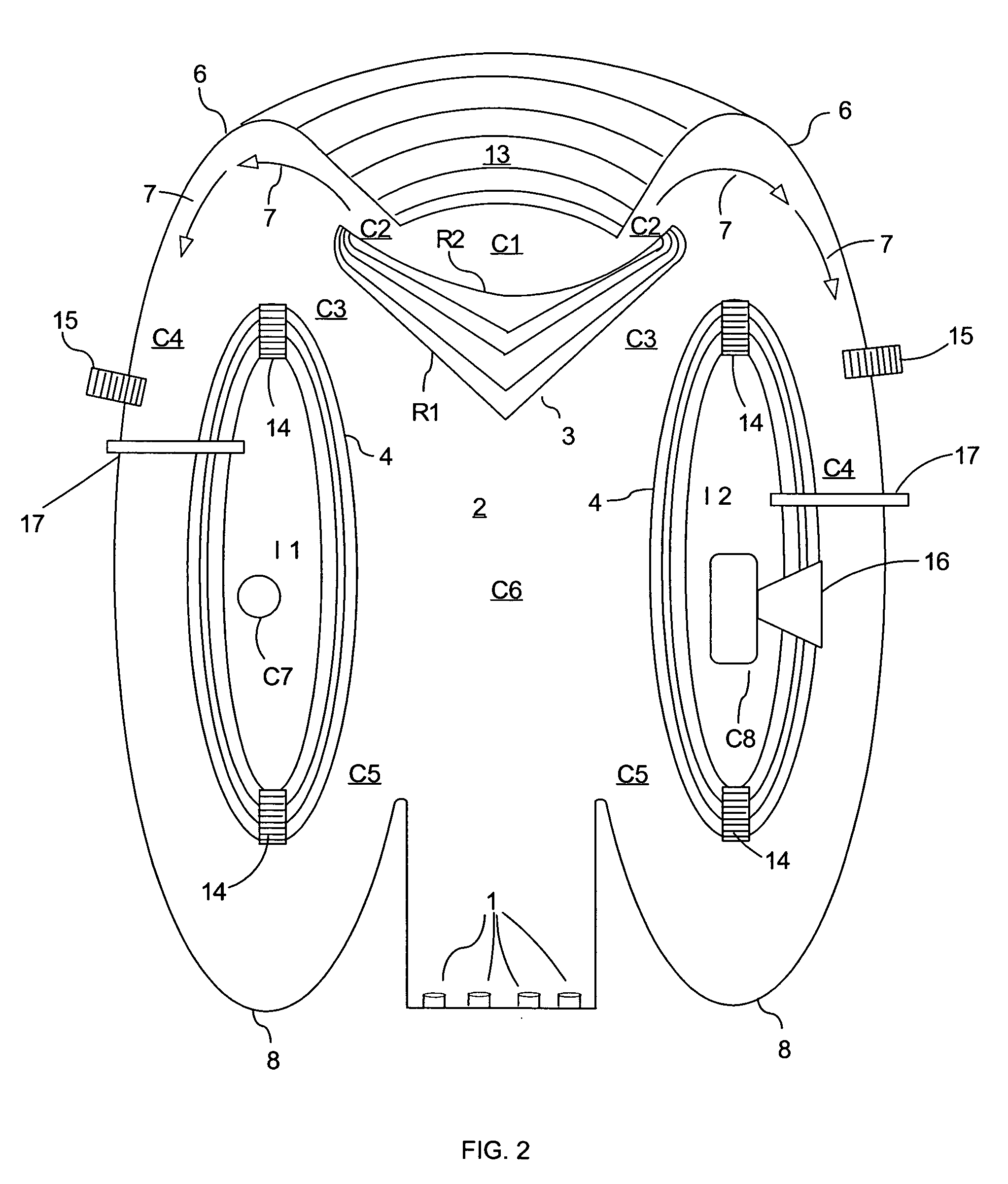

Water feature for wave pools

The present invention relates to wave pools and diversion channels that capture high kinetic energy portions of a wave generated within the wave pool, and redirects the captured wave portions to the vicinity of wave formation, preferably timed so as reinforce a subsequently generated wave. The high kinetic energy within the diversion channel creates an additional feature in the form of an action river for riders of a wave pool to enjoy. At the same time, capturing of portions of the wave reduces the backwash of the wave and stabilizes the level of water within the wave pool, especially for embodiments with wave generators and pools capable of high volume waves. Riders may enter the diversion channel and ride from the distal, beach end of the wave pool to the proximal, wave generating end.

Owner:JOHNSON GARRETT TYLER

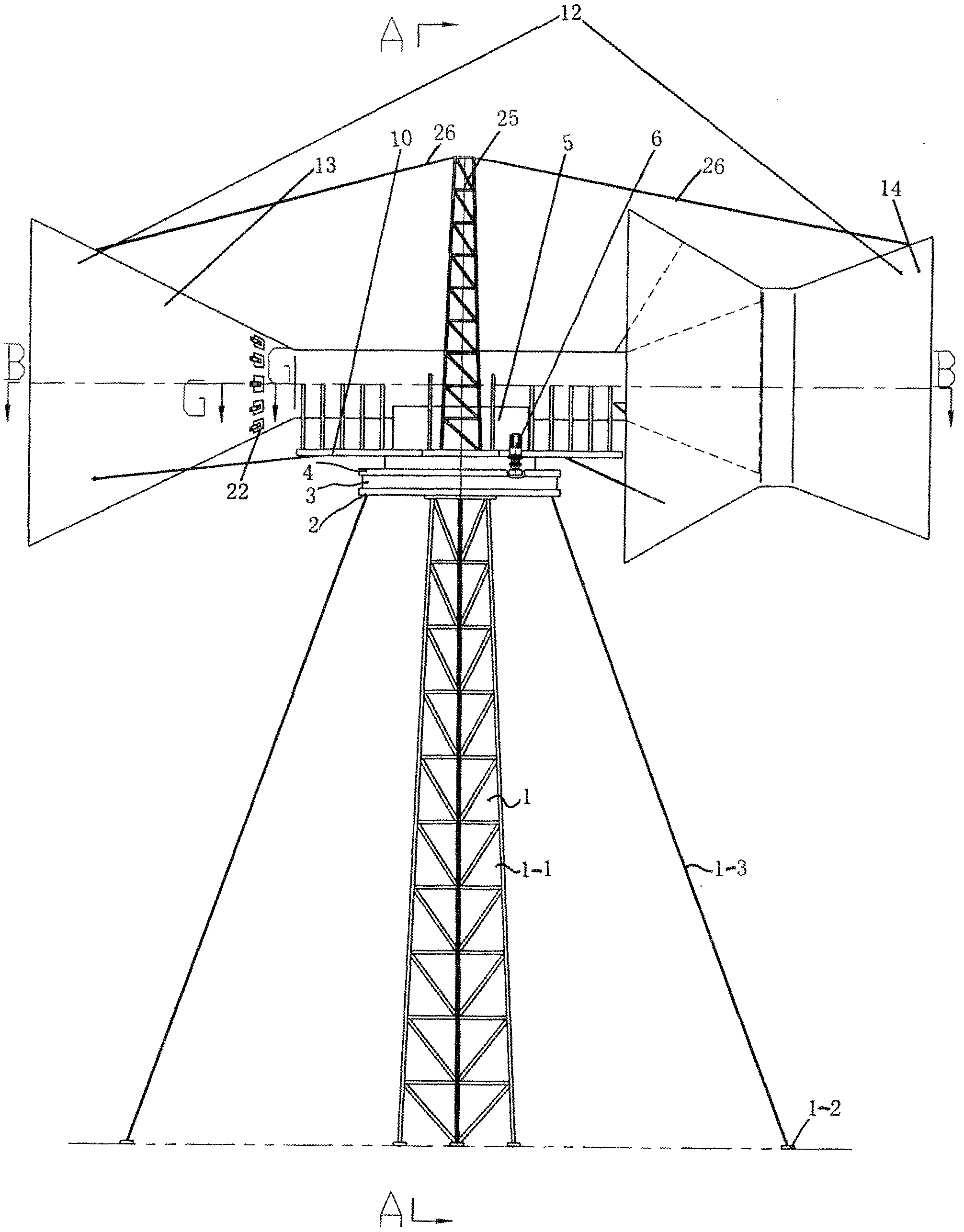

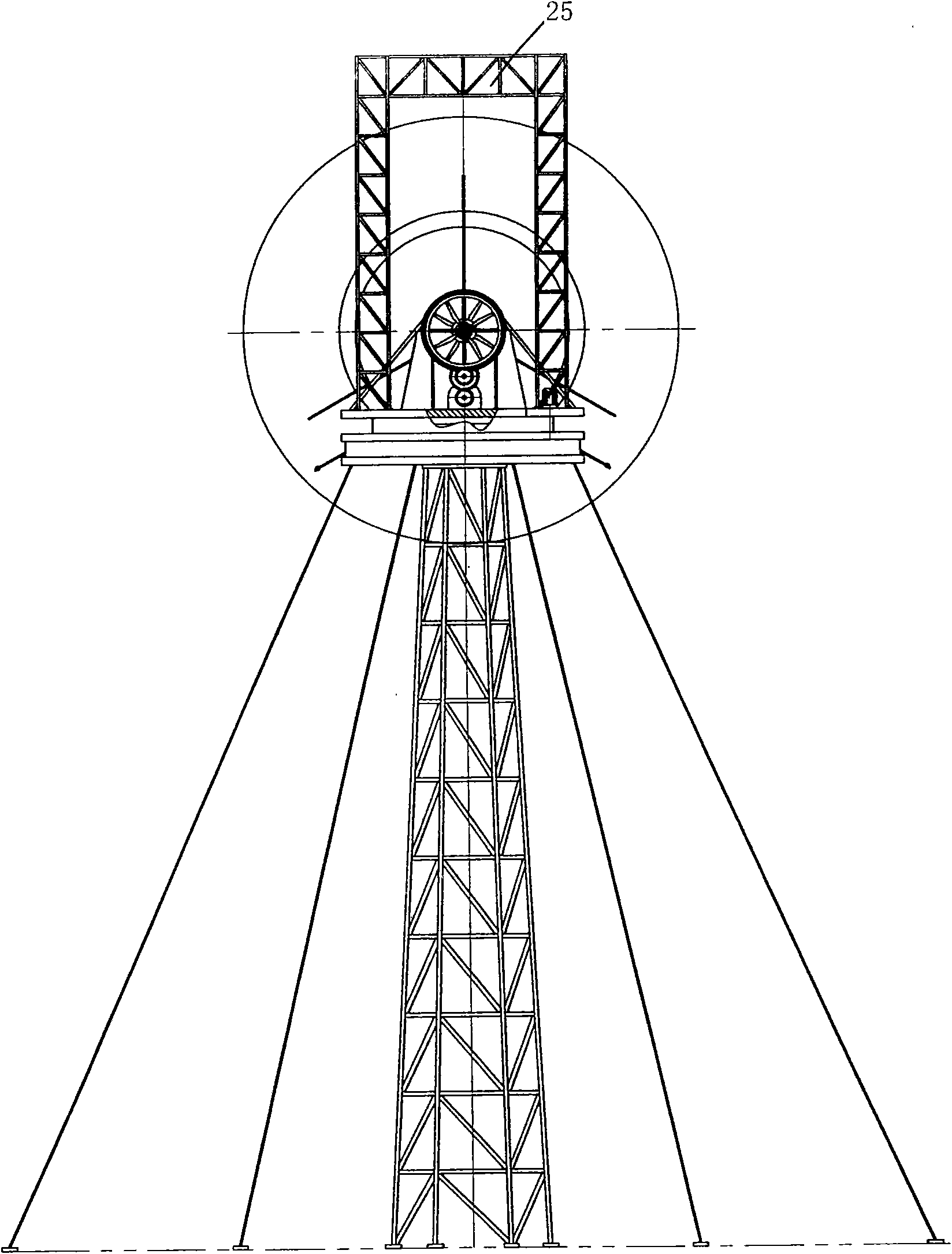

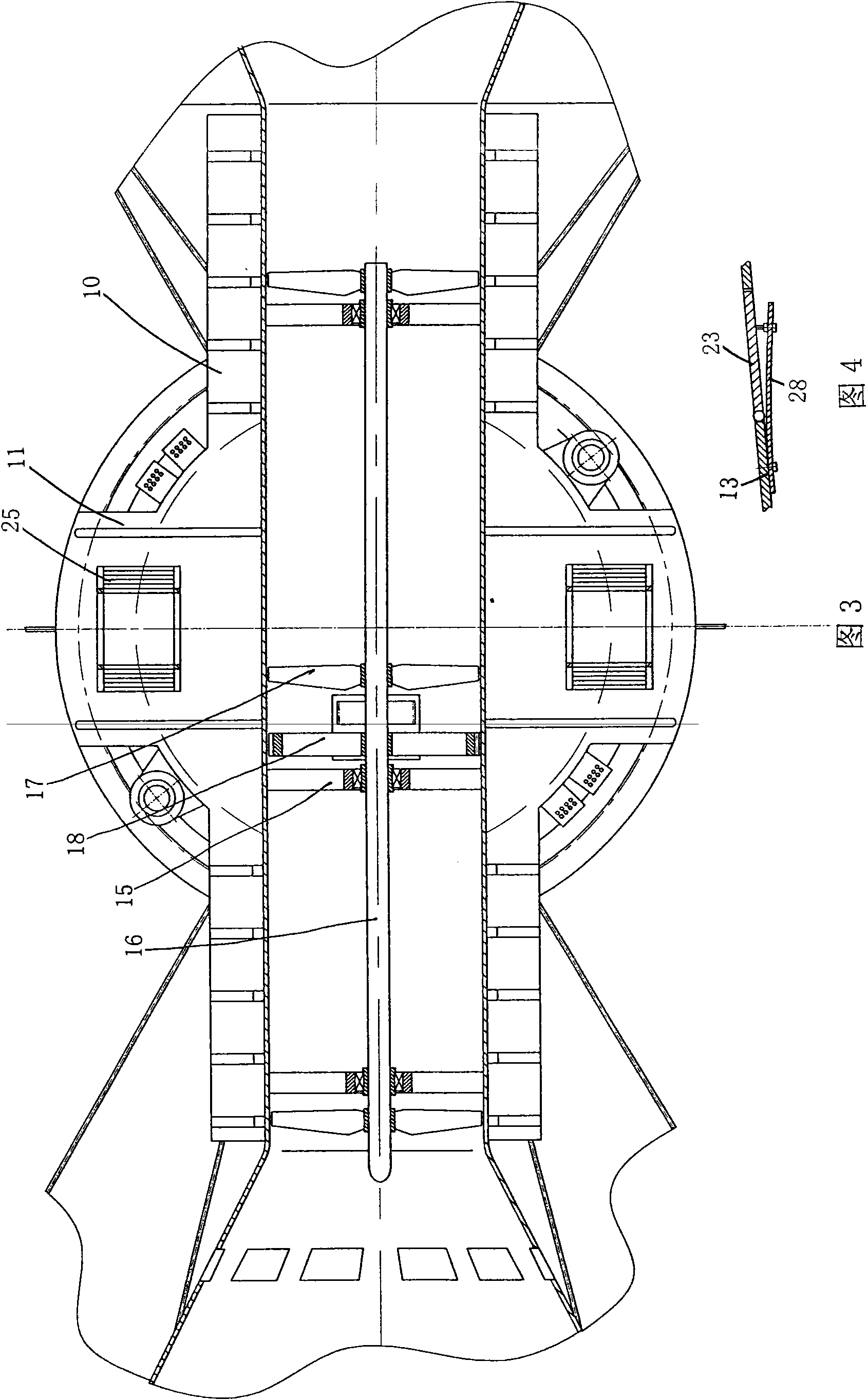

Tunnel diffusion draught fan

InactiveCN101949353AVelocity increasesImprove economyWind motor controlFinal product manufactureImpellerNacelle

The invention discloses a tunnel diffusion draught fan, which comprises a tower, a worktable arranged on the top of the tower, a lower bearing disk arranged on the worktable, an upper bearing disk positioned on the lower bearing disk and a cabin arranged on the upper bearing disk, wherein the upper bearing disk is provided with a supporting bracket which is provided with a tunnel diffusion draught fluid channel with a round cross section; a diffuser is arranged in the tunnel diffusion draught fluid channel; a front diffusion and acceleration section three-dimensional channel, a three-dimensional fluid acting channel and a rear post-action air flow three-dimensional fluid channel, which are communicated in turn, are arranged in the diffuser; and the three-dimensional fluid acting channel is provided with at least two impellers along the axial direction of the fan, and a working machine positioned in the cabin is connected with the impellers through a transmission mechanism. The tunnel diffusion draught fan has high kinetic energy utilization rate and reduced cost and is convenient and safe in manufacturing, transportation, installation and maintenance.

Owner:李平

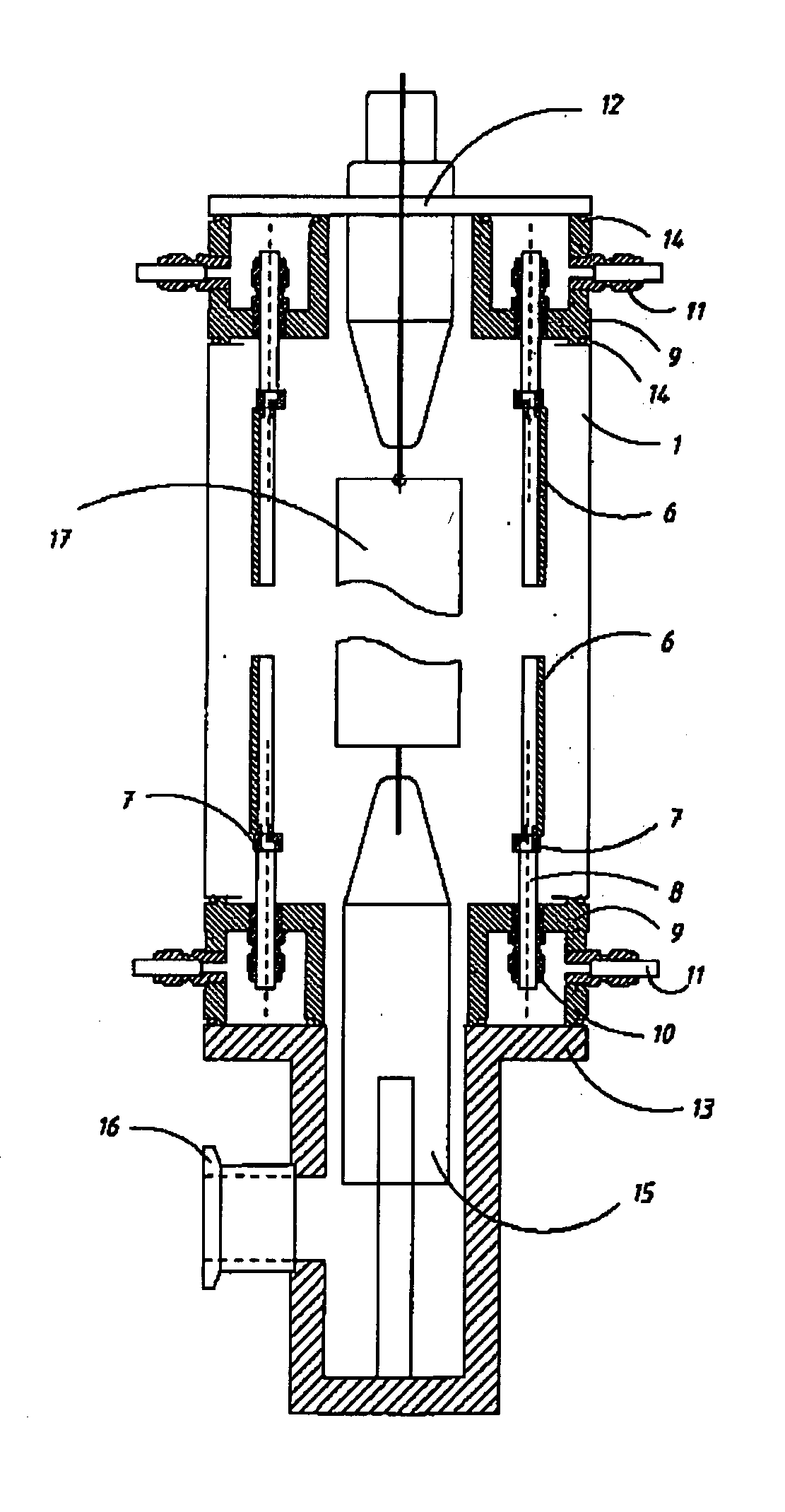

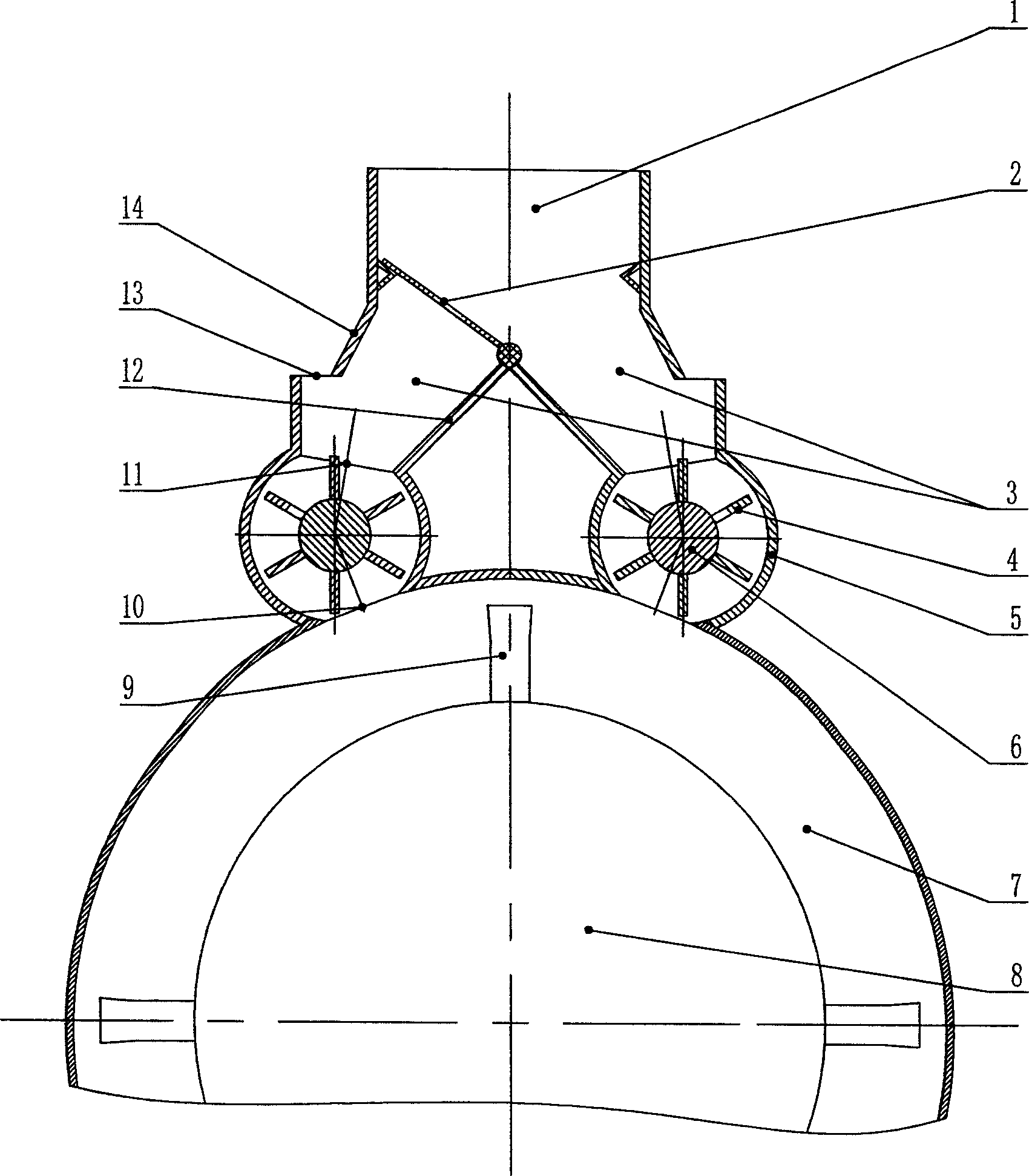

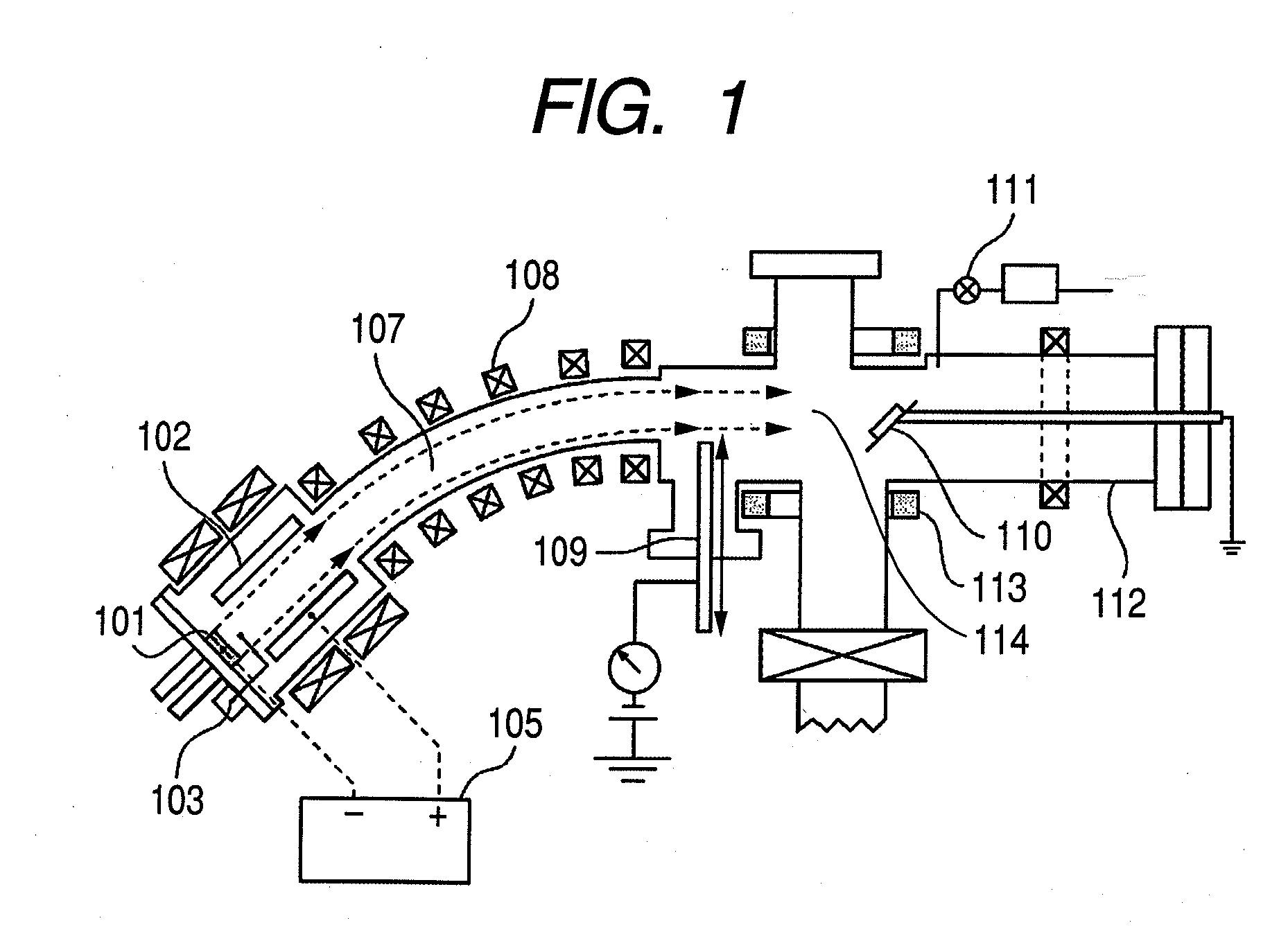

Proton Generator Apparatus for Isotope Production

InactiveUS20080089460A1Easy to operateImprove performanceConversion outside reactor/acceleratorsNuclear energy generationInertial electrostatic confinementIsotope

The invention relates to a particle producing apparatus adapted to utilize a star mode of inertial electrostatic confinement of a glow discharge induced ion and neutral gas mixture of fusible low atomic number isotope species to generate protons or neutrons in a macro linear geometry, the apparatus comprising a hermetically sealed vessel of generally prismatic form having an inner surface and a central axis, within which vessel is disposed an elongate anode electrode structure surrounding an elongate cathode electrode structure having a perimeteral surface provided with apertures therein, the anode and cathode structures being substantially concentric along at least a part of their lengths and substantially coaxial with the vessel such that, during operation, the star mode beams of ions and high kinetic energy neutrals have a general direction of motion which is aligned substantially radially to a central axis of the vessel. The inner vacuum vessel wall incorporates a fluid conduit structure with an inner facing anode wall of a thickness sufficiently minimized to permit the energetic protons to traverse from the inner region of the vessel to the fluid target which incorporates isotopes that can be transmuted by proton collision reactions to become isotopes favored by practitioners of Positron Emission Tomography for example.

Owner:SVED JOHN

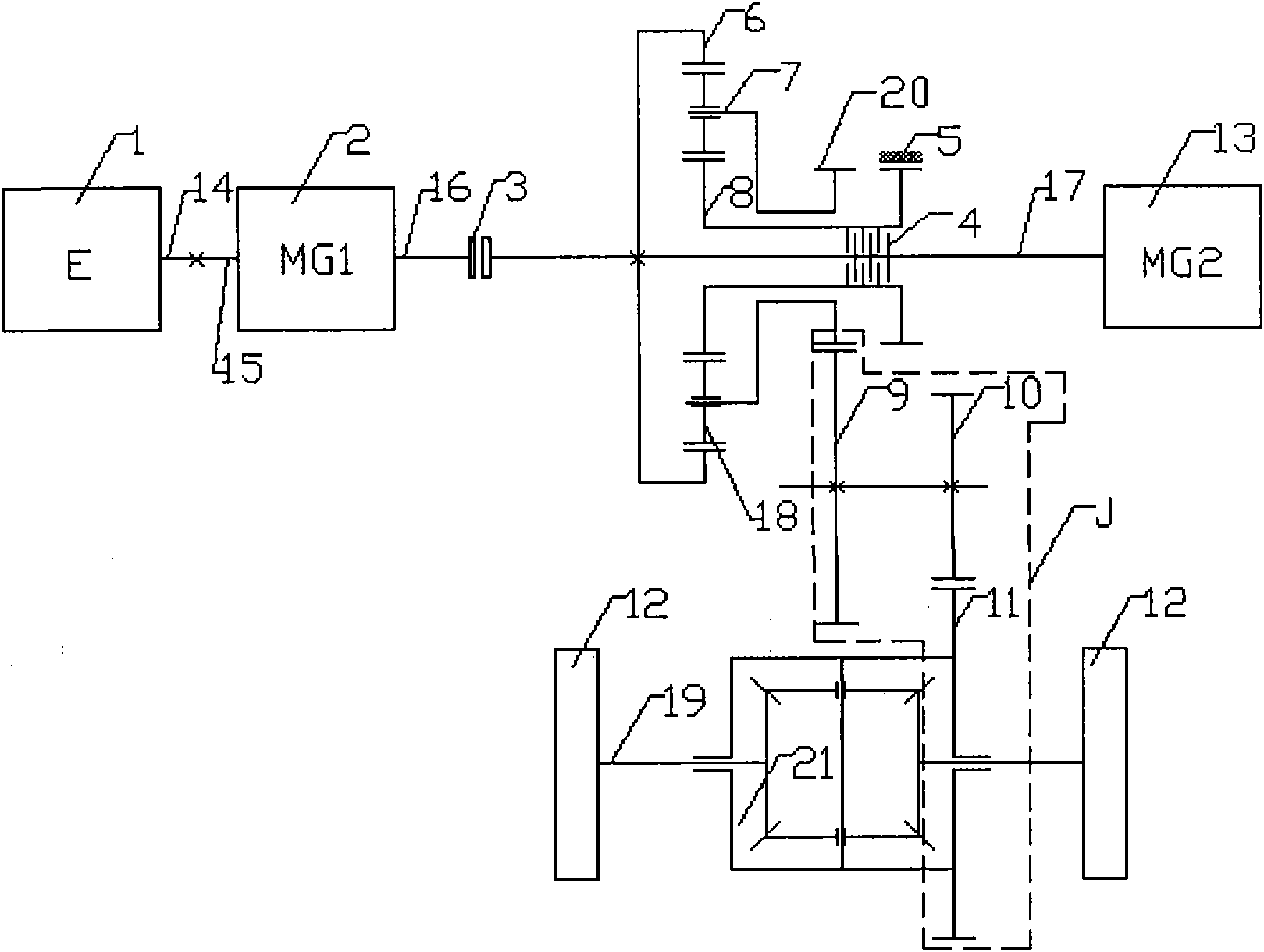

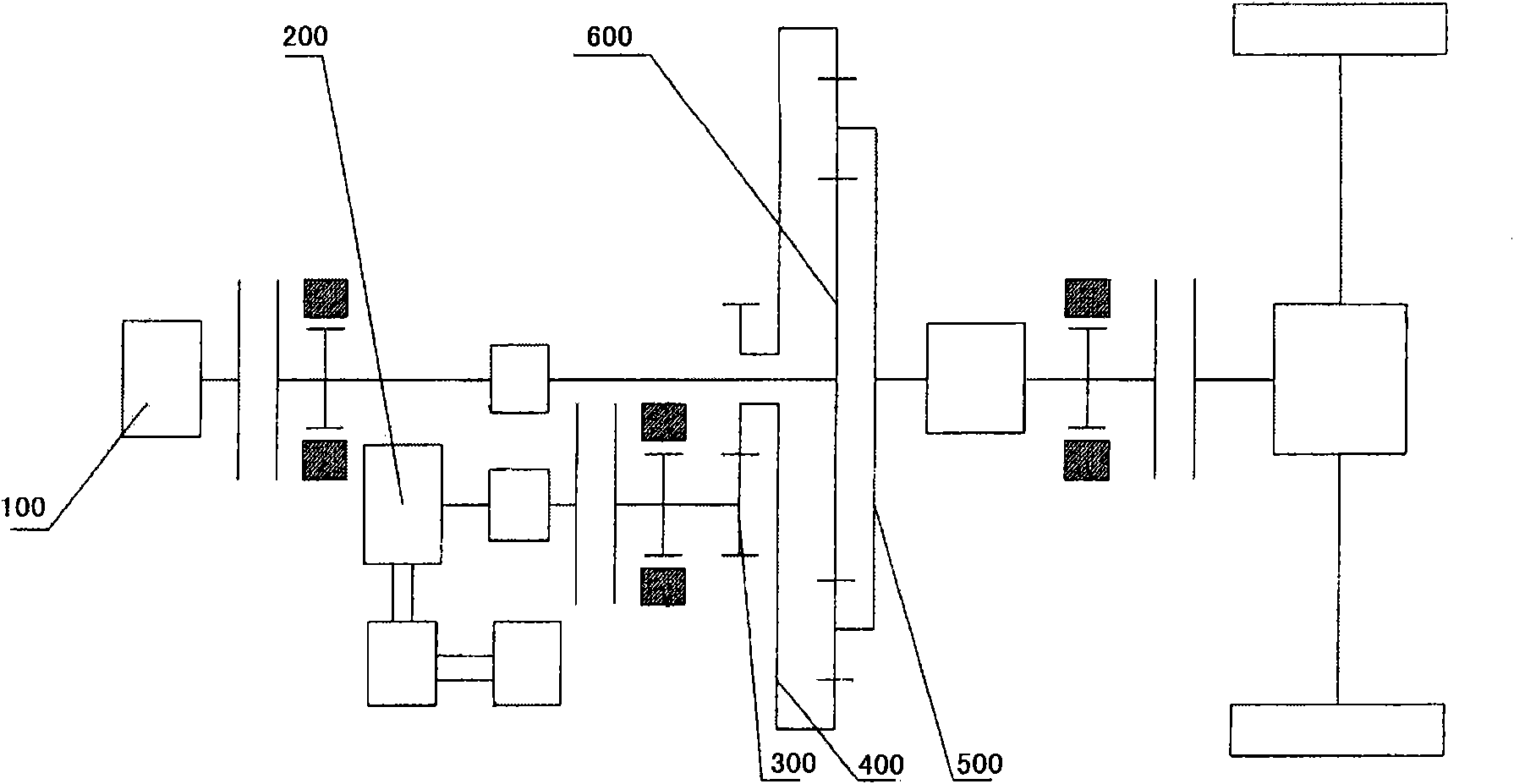

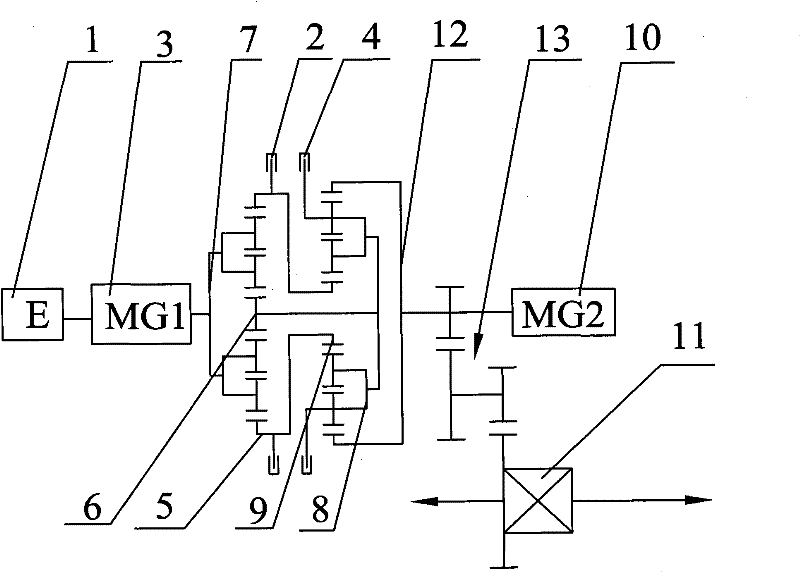

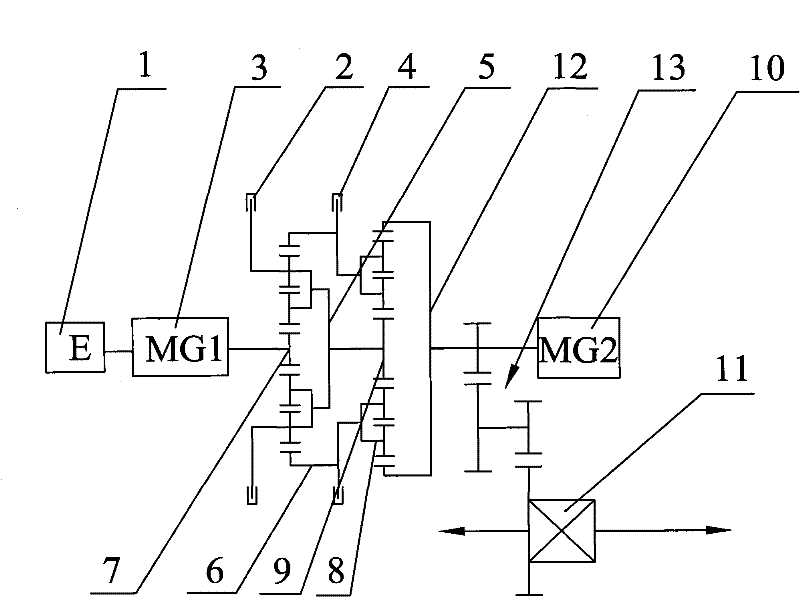

Hybrid driving system and vehicle including same

ActiveCN102343796AMeet the driving needs under different working conditionsEasy dischargeToothed gearingsGas pressure propulsion mountingLow speedInternal combustion engine

Owner:BYD CO LTD

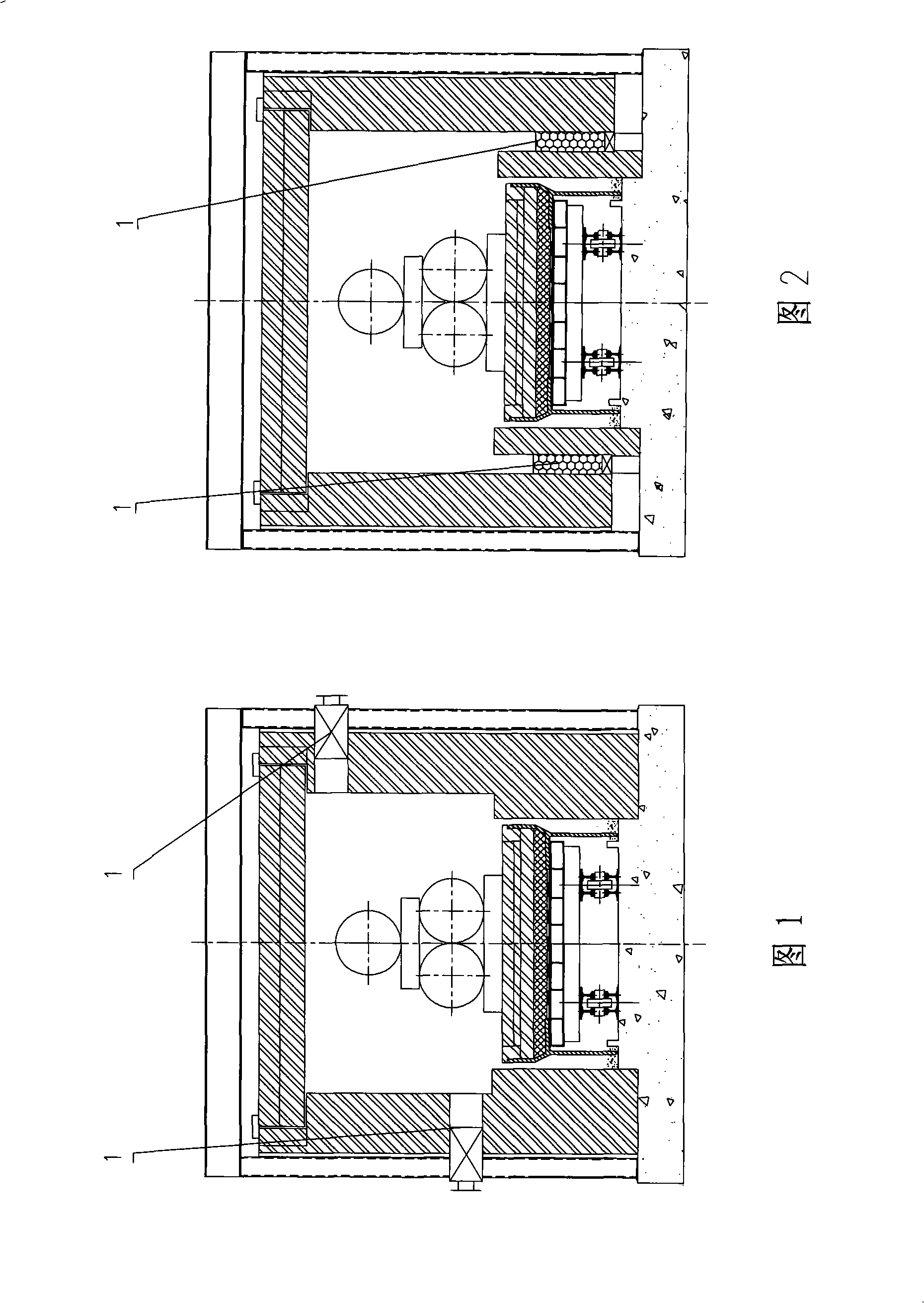

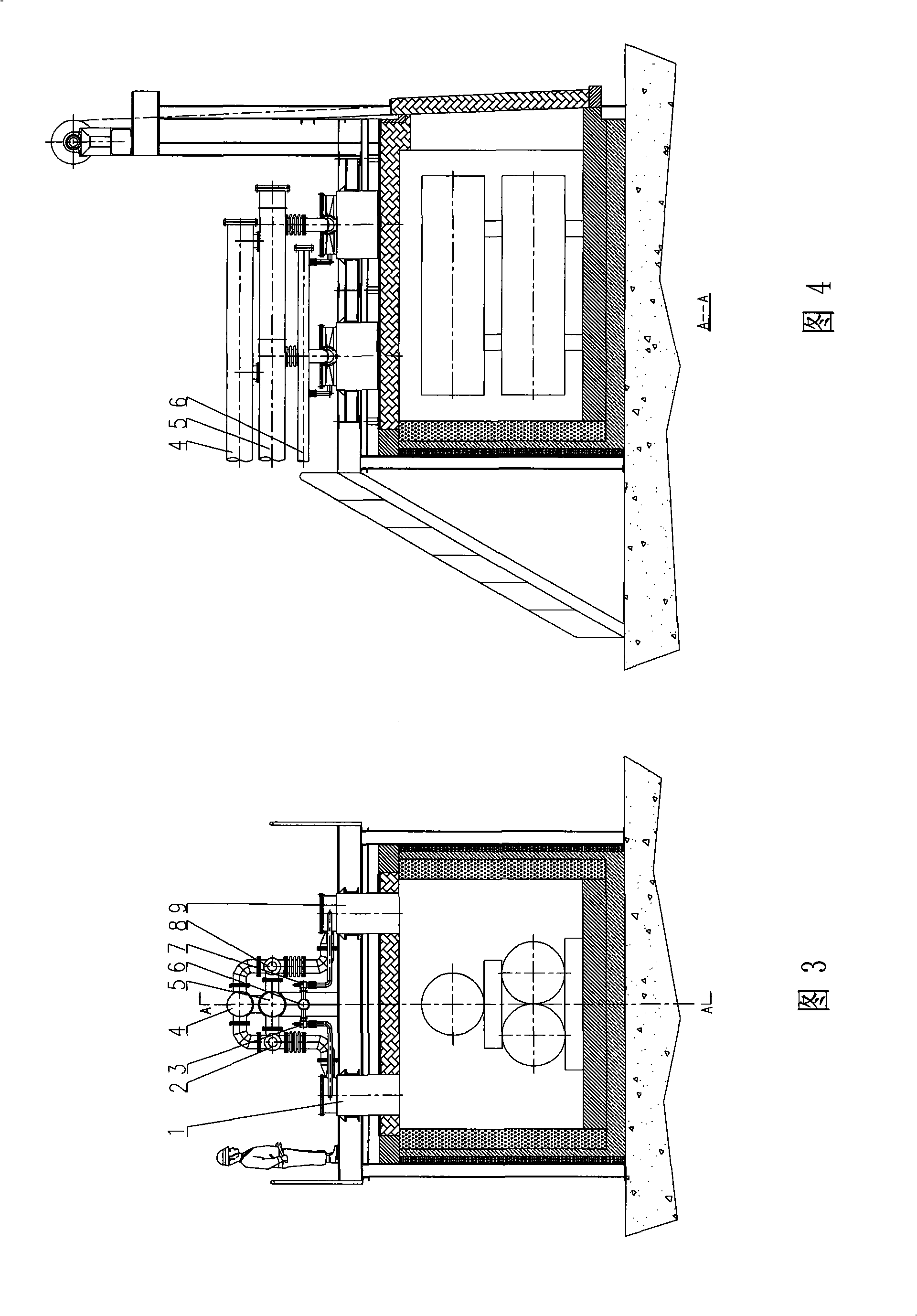

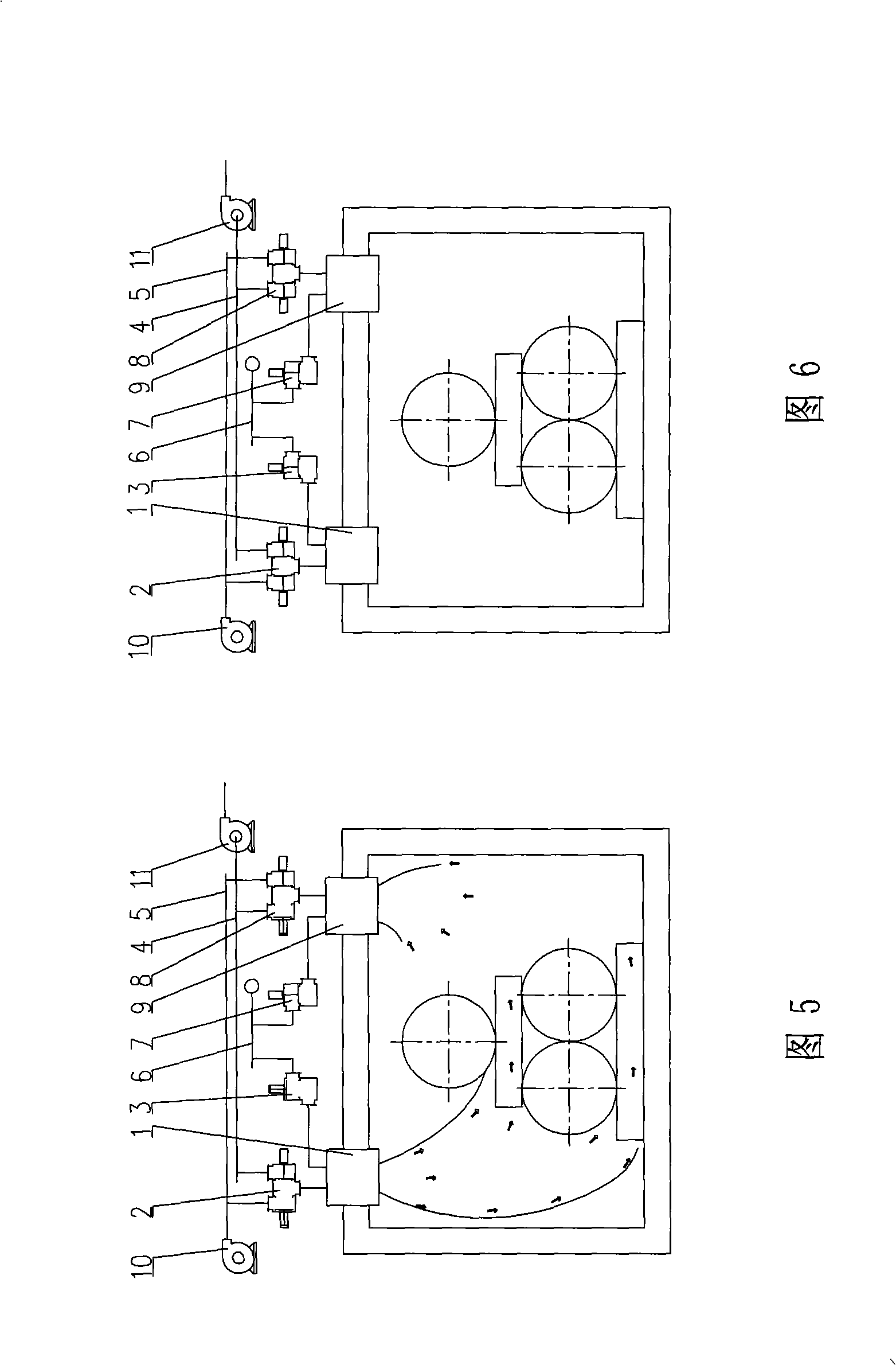

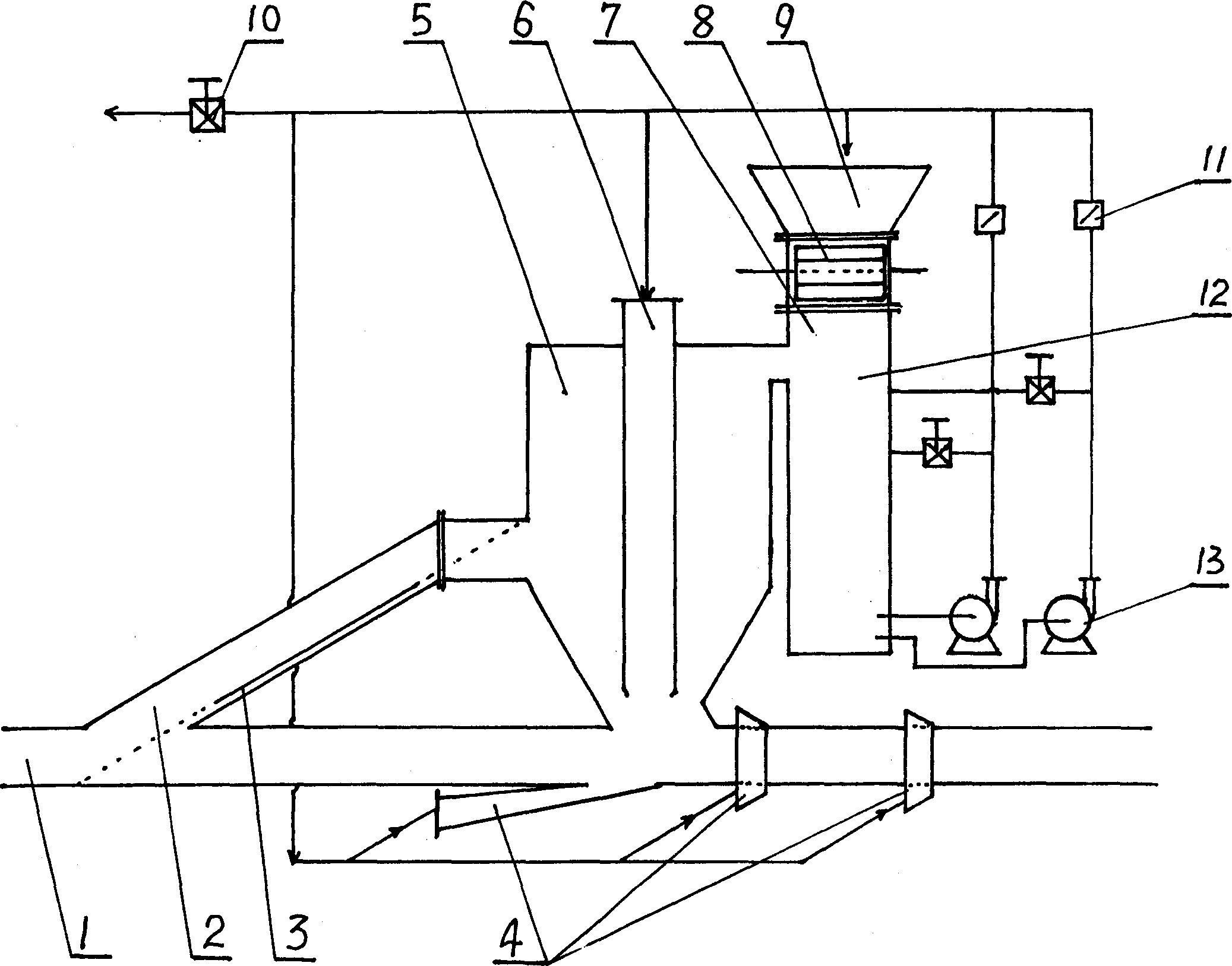

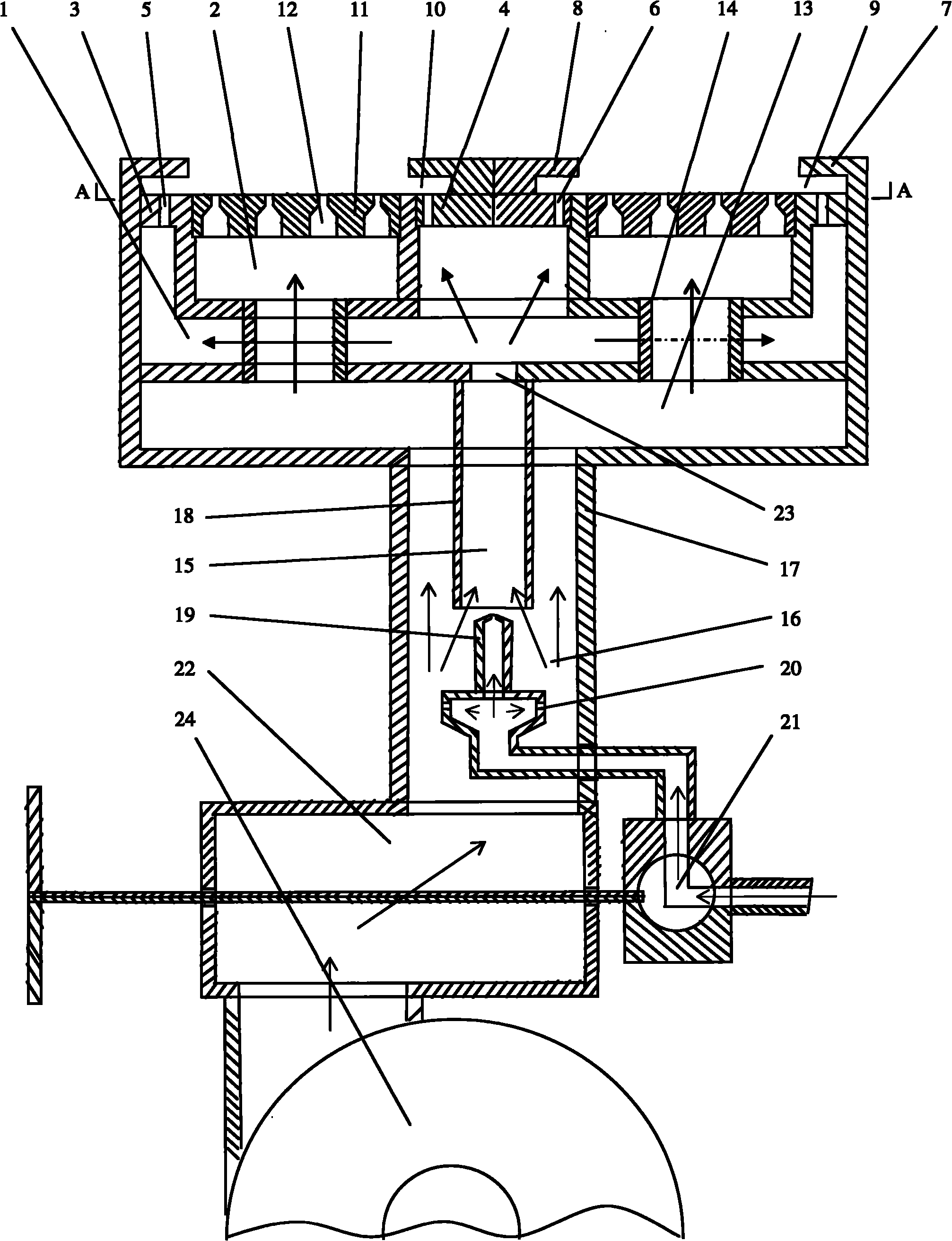

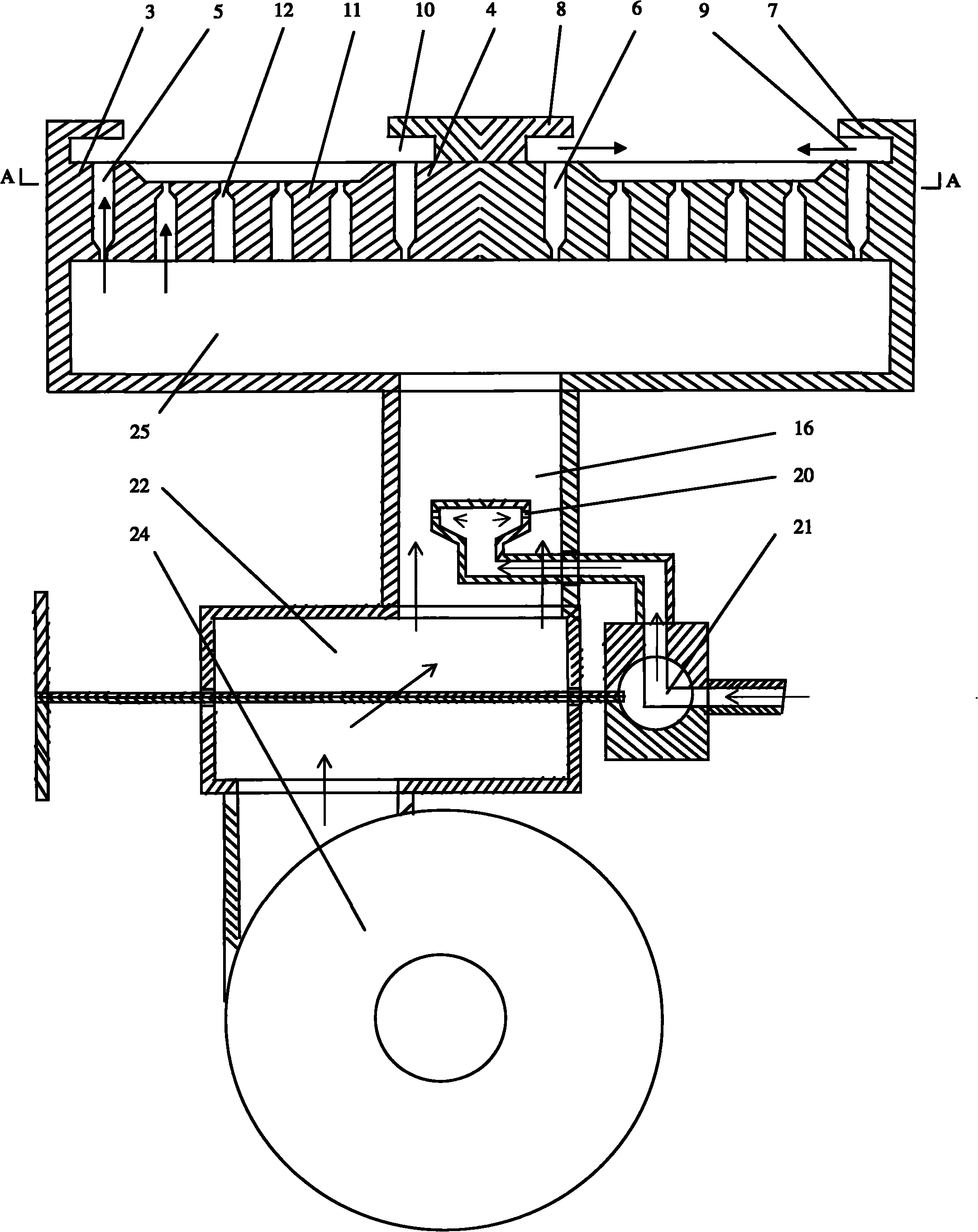

Cell-type car-type heating stove highly effective combustion system

InactiveCN101261089AImprove uniformitySolve easy blockageMechanical apparatusFurnace componentsFurnace temperatureHigh energy

The invention relates to an efficient combustion system of a chamber and car bottom heating furnace, belonging to the energy-saving and environment-protecting heating furnace technique field. The invention comprises a plurality of pairs of heat accumulating left and right sides combustion nozzles which are arranged on the two sides of the furnace top of the heating furnace, wherein, the heat accumulating left side combustion nozzles are connected with a smoke pumping main and an air main through a left side reversing valve and are connected with a gas main through a left side gas quick-switch valve; the heat accumulating right side combustion nozzles are connected with the smoke pumping main and the air main through a right side reversing valve and are connected with the gas main through a right side gas quick-switch valve; the air main is connected with a combustion air fan; the smoke pumping main is connected with a smoking machine. The efficient combustion system forms the high kinetic energy U-shaped air steam inside the furnace, thereby improving the uniformity of the furnace temperature; all the flue gas generated by the combustion of half of the combustion nozzles of the whole furnace is discharged from the other half of the combustion nozzles, thereby abolishing the tail gas duct with high energy consumption and complicated structure of the prior chamber and car bottom heating furnace; the energy consumption is reduced by 40 to 60 percent and the furnace output and the blank heating quality are improved.

Owner:WUXI LONGSHAN TECH

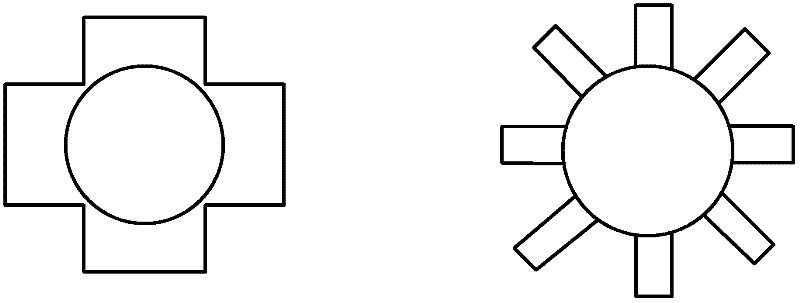

Feeding mechanism of crusher

The present invention relates to crusher technology, and is especially feeding mechanism of crusher. The feeding mechanism includes one feed port with tilted tangent flow passage comprising casing and sliding plate, feed baffle capable of masking the tangent flow passage, horizontal cylindrical casing in the end of the tangent flow passage possessing two axial opening separately to the end of the tangent flow passage and the crushing chamber; and one feeding wheel inside the cylindrical casing and comprising central shaft for power input and radial blades on the shaft. During operation, the central shaft rotates in homogeneous speed for homogeneous feeding to form thin-layer linear feeding flow, and the material may obtain high kinetic energy for fast crushing. The present invention may be applied in hammer crusher.

Owner:JIANGSU MUYANG GRP CO LTD

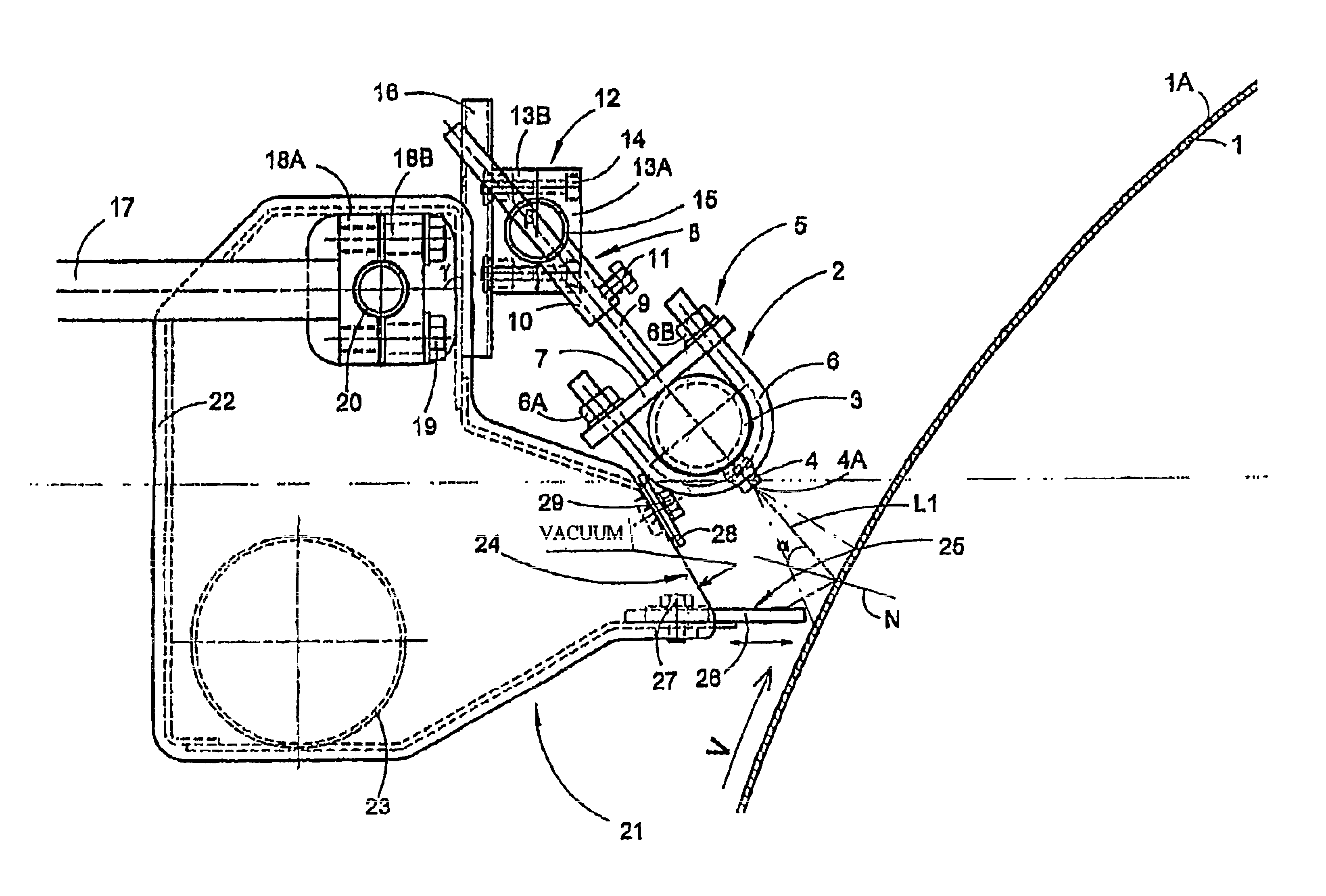

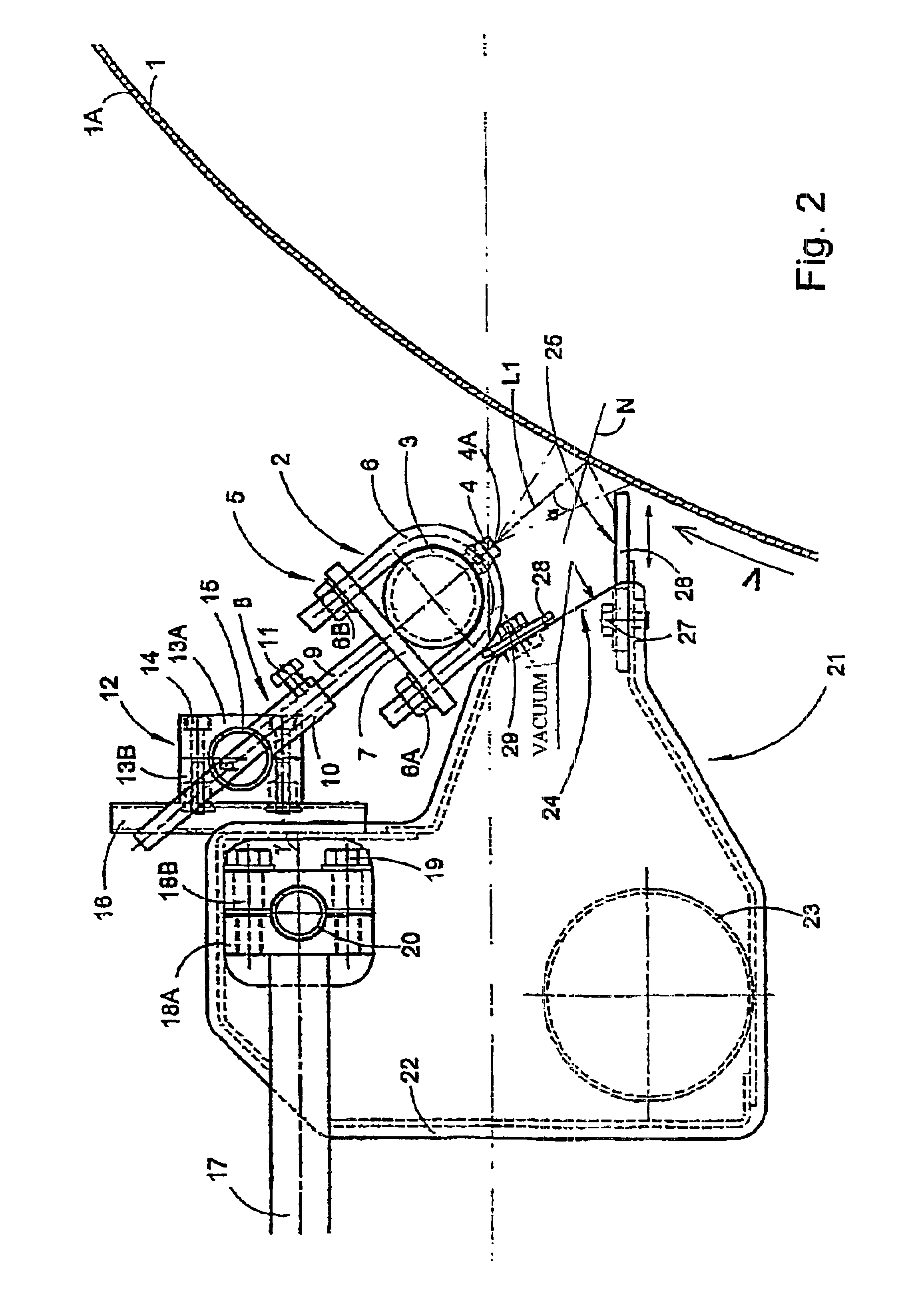

Method and a device for removing water from the surface of a roller jacket

The present invention relates to a method for removing water from a movable roll jacket surface in a wet section of a paper-making machine, which roll jacket surface preferably belongs to a flexible roll jacket in a shoe press, said method comprising the following steps: arranging a spray device next to the roll jacket surface, making available a collecting device which is provided with an opening and collects liquid, moving said roll jacket surface past said spray device, applying a medium onto said roll jacket surface with the aid of said spray device, and collecting liquid in said liquid-collecting device. The invention is characterized in that said medium is sprayed with high kinetic energy onto said roll jacket surface to follow a fluid stream rebounding from the roll jacket surface, so that the liquid is conveyed to said liquid-collecting device.

Owner:VALMET TECH INC

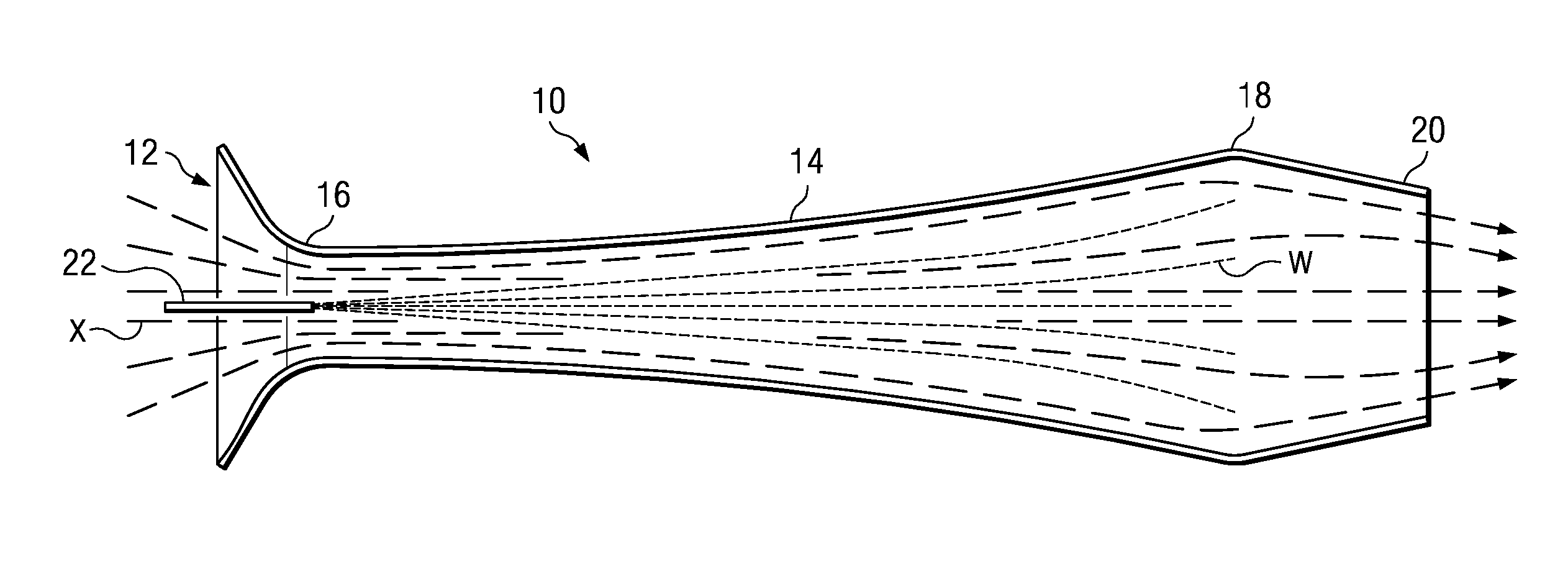

Fluid dynamic power generator and methods

InactiveUS20070277501A1Cosmonautic vehiclesCosmonautic propulsion system apparatusEngineeringElectric generator

Fluid dynamic power generation methods and associated apparatus are disclosed for introducing a fluid through an intake into a convergent-divergent stream duct adapted for accelerating the fluid. The fluid is cooled within the convergent-divergent stream duct and ejected through a variable area exhaust port, the ejected fluid having a higher kinetic energy than the intake fluid, for conversion to useable power.

Owner:SORENSON SIDNEY DALE

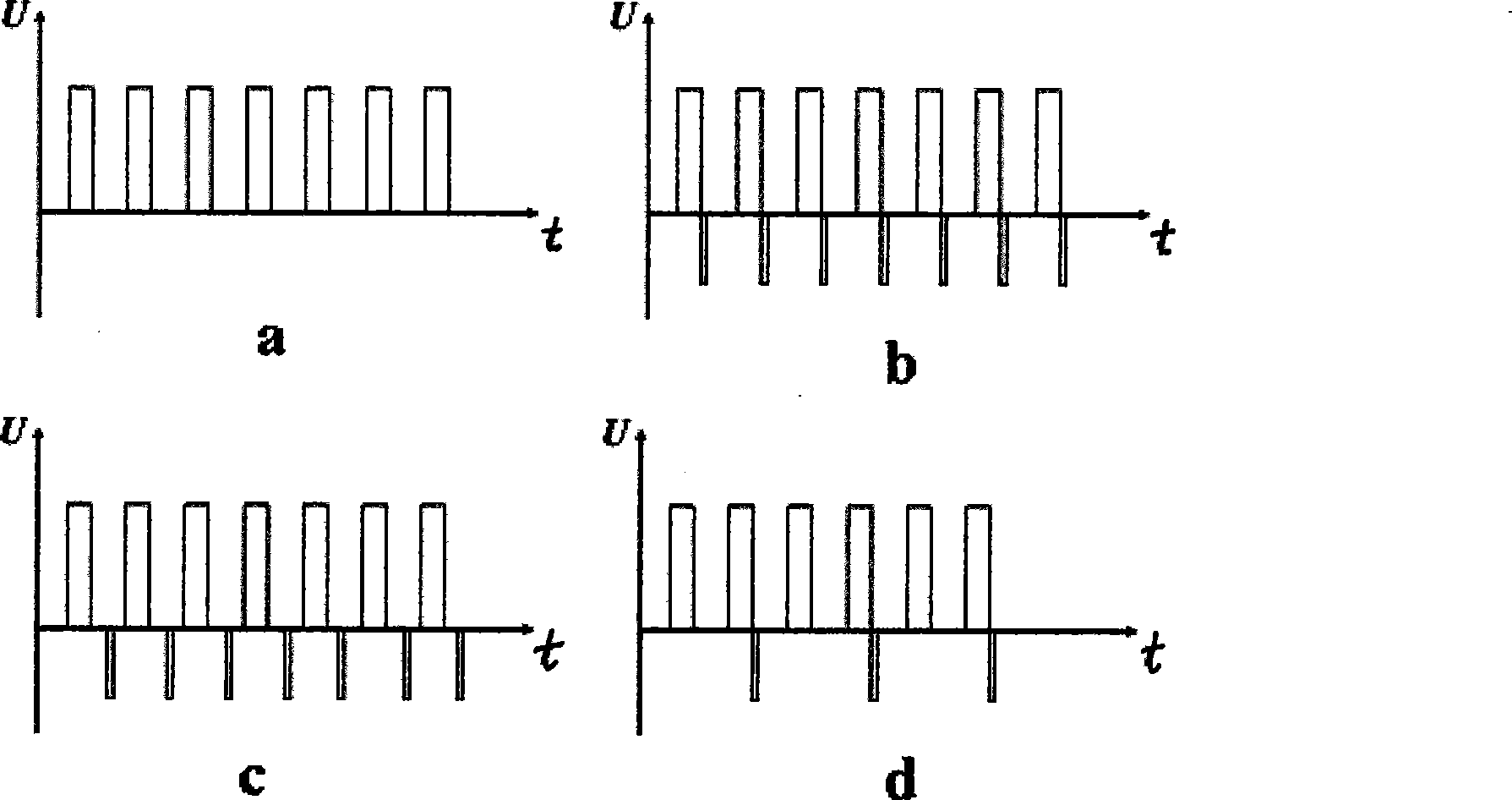

Non-equilibrium liquid condition composite pulse plasma polishing method

A polishing solution disclosed by the present invention is composed of the following components according to mass percentage: component A: (NH4)2SO4 aqueous solution with a concentration of 1% to 10%, component B: ethylene glycol with a concentration of 0.2% to 3% One or a combination of amine tetraacetic acid, ammonium citrate, sodium tartrate or sodium oxalate. The method of using the polishing liquid to carry out non-equilibrium liquid compound pulse plasma polishing, first prepare the polishing solution according to the above formula, then put the workpiece to be treated into the above prepared polishing liquid, add a compound electric pulse or an equivalent different Combination of positive and negative pulses, control positive pulse frequency 0.5-80kHz, duty cycle 5%-95%, voltage 200-480V, make the reaction in the most violent state, treatment for 1-5 minutes, that is to complete the polishing process. In the present invention, pulses are used instead of direct current, which is beneficial to the generation of plasma, so that the discharge plasma can obtain higher kinetic energy, better mirror effect and faster polishing speed.

Owner:XIAN UNIV OF TECH

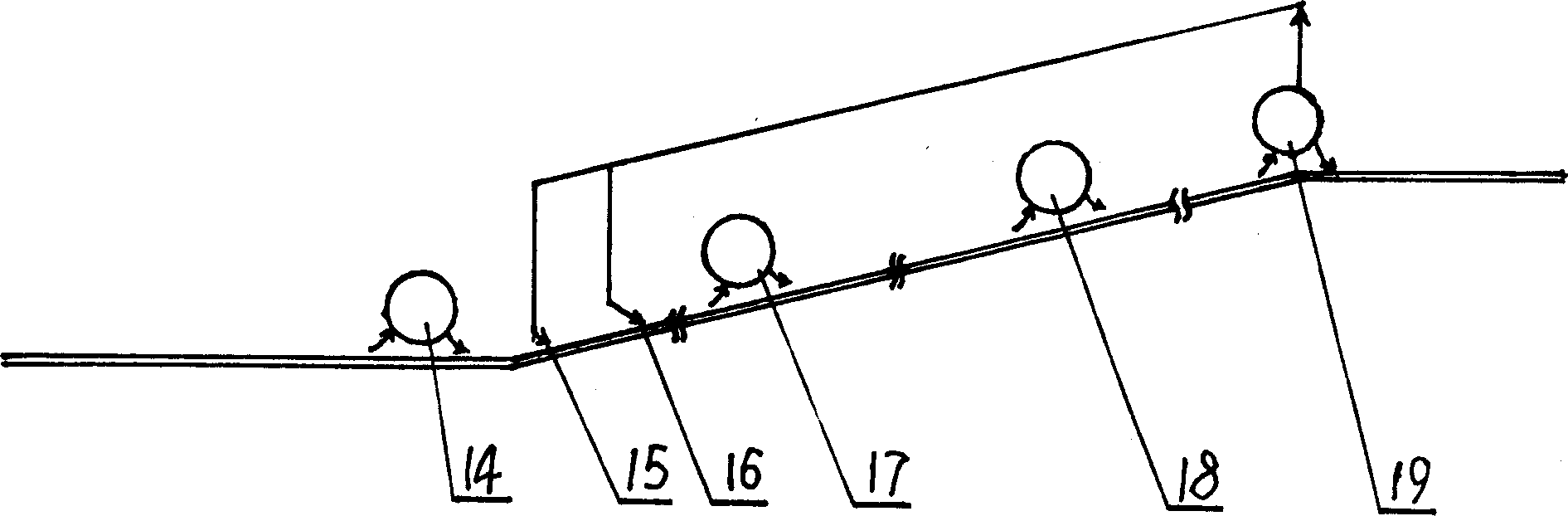

Relay pressurizing method and device for long distance pipeline transport solid/liquid mixture

InactiveCN1749136AEasy to implementEliminate the effects ofBulk conveyorsHigh concentrationSolid component

The present invention discloses one kind of relay pressurizing method and apparatus for long distance pipeline transport of solid / liquid mixture, and solves the technologic problem of continuous, stable, economic and safe transport. On the transport pipeline, one solid / liquid mixture fluid passage is connected serially, pressurizing pump is used to pressurize separated liquid, and the pressurized liquid is then jetted to the solid / liquid mixture in several points. The relay pressurizing apparatus has less resistance to solid / liquid mixture and high kinetic energy transfer effect. The present invention is suitable for pipeline transportation in different topographic conditions, may be used in transporting solid / liquid mixture with high concentration and large grain size solid component in great flow rate and for long distance, and has the features of high system stability, high safety, low power consumption, etc.

Owner:武善东 +1

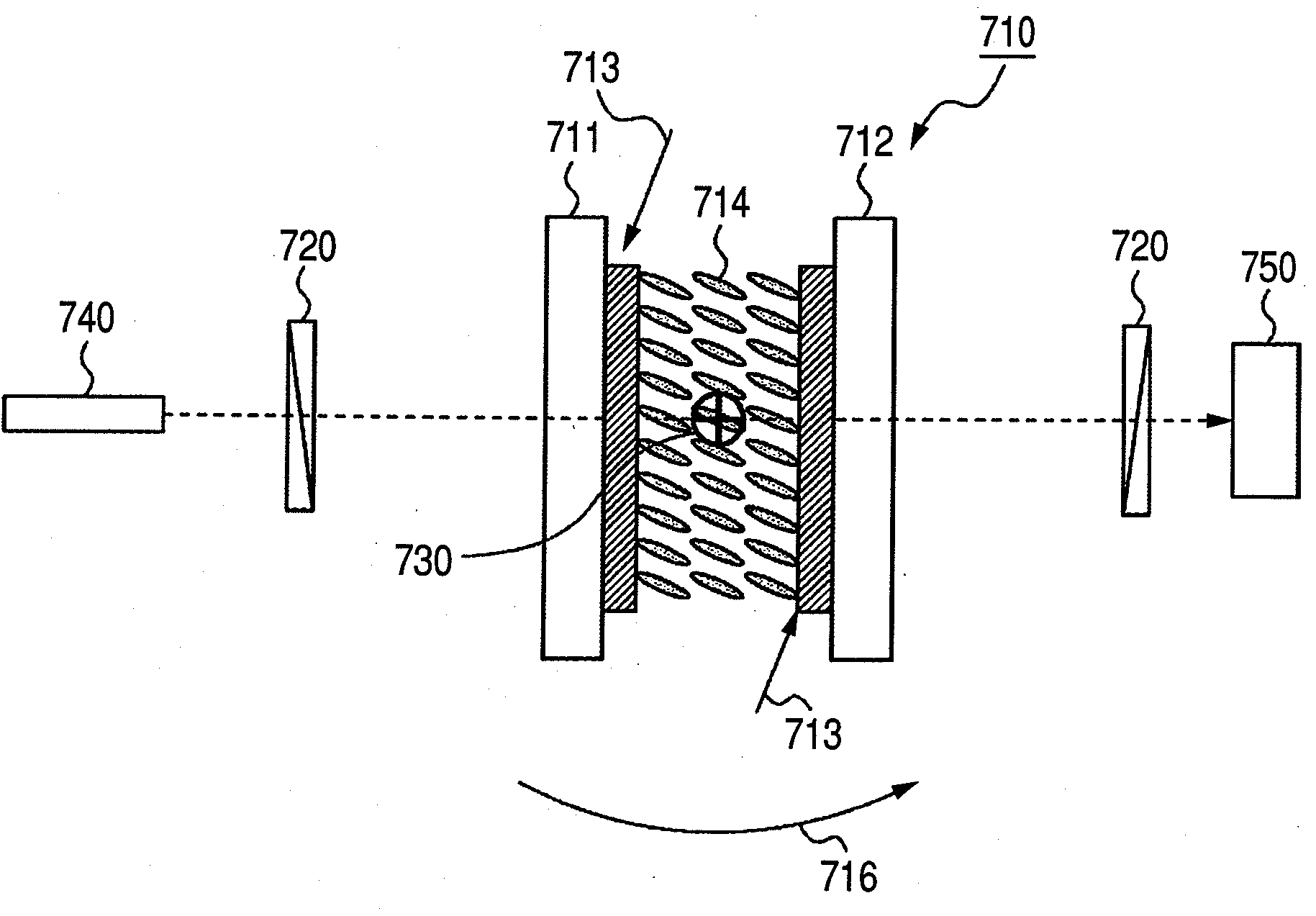

Liquid crystal optical device manufacturing process

InactiveUS20090109387A1Increased durabilityIncrease deposition rateNon-linear opticsHigh fluxEngineering

A manufacturing method of a liquid crystal optical device is provided including an alignment film forming step of forming an alignment film containing silicon oxide on a substrate, and a liquid crystal cell forming step of disposing a pair of substrates at least one of which the alignment film has been formed on, opposite to each other interposing a liquid crystal therebetween. In the alignment film forming step, the substrate surface is bombarded with a plasma beam generated by vacuum arc discharge using a cathode containing silicon, where the substrate is disposed on the course of the plasma beam obliquely with an angle. When the plasma beam bombards the substrate surface, plasma ions in the plasma beam have higher kinetic energy or higher flux density than plasma ions in a plasma beam which, if bombarding the substrate obliquely at the angle, form a film having a column structure.

Owner:CANON KK

Hydraulic power generation device for smart city landscape

ActiveCN108915028AAvoid collisionProtected from long-term impact damageRoof coveringWater/sewage treatment by irradiationExternal energyFiltration

The invention relates to a hydraulic power generation device for a smart city landscape. The hydraulic power generation device includes a rainwater collection and filtration system, an energy supply system and a circulation system. By arranging a hydraulic turbine at the bottom of a landscape waterfall, the very high kinetic energy of a water body with very high potential energy at the bottom is instantly converted into the kinetic energy of the hydraulic turbine rotation, thus the landscape is realized completely without the splash of the waterfall and impact on an external blocking plate; and through the arrangement of hydropower and solar power generation devices, the external energy supply of the whole device is not required; and the water body used in the landscape uses rainwater supply, the external water body supply is not required basically, and the self- sufficiency of energy and resources is really realized.

Owner:吴克峰

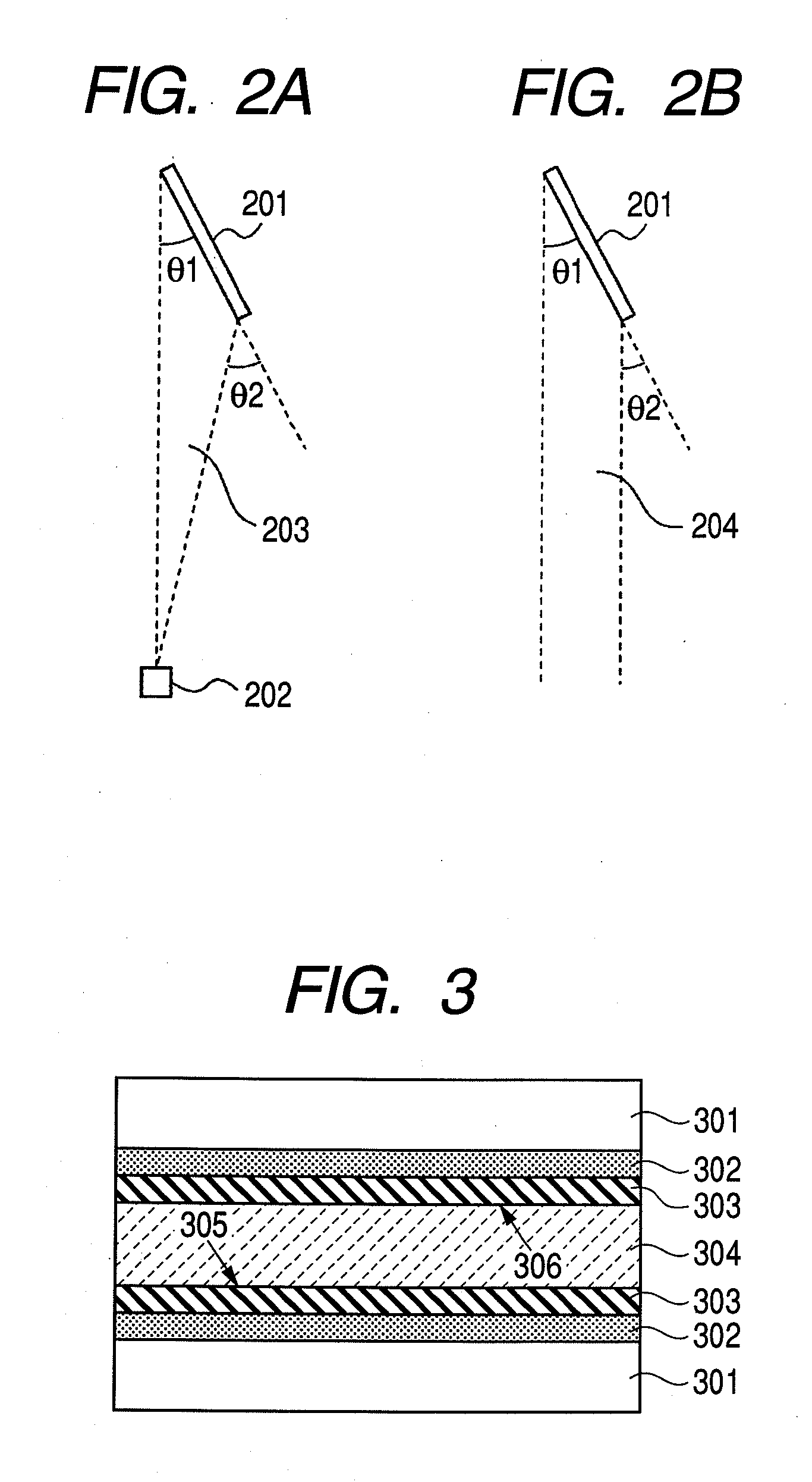

Anisotropic dry etching of Cu-containing layers

InactiveUS7214327B2Improve responseDecorative surface effectsSemiconductor/solid-state device manufacturingResistMetallurgy

A method and apparatus for dry etching pure Cu and Cu-containing layers (220, 310) for manufacturing integrated circuits. The invention uses a directional beam of O-atoms with high kinetic energy (340) to oxidize the Cu and Cu-containing layers, and etching reagents (370) that react with the oxidized Cu (360) to form volatile Cu-containing etch products (390). The invention allows for low-temperature, anisotropic etching of pure Cu and Cu-containing layers in accordance with a patterned hard mask or photoresist (230, 330).

Owner:TOKYO ELECTRON LTD

Sand making machine

The invention discloses a sand making machine. The sand making machine comprises a crushing box, a feed port, a discharge port and a motor; the feed port is fixedly inserted in the top wall of the crushing box; the discharge port is fixedly inserted in the bottom wall of the crushing box; multiple first grinding teeth are fixed on the inner side wall of the crushing box; the hammer sand making machine for rare earth crushing is simple in structure; through additional arrangement of a crushing hammer, a first spring, a slide rod, a limiting block, bore spines and the first grinding teeth, rareearth is crushed by the crushing hammer rotated at high speed; at the same time, the crushed rare earth achieves higher kinetic energy under the effect of the crushing hammer; the rare earth collidesthe inner wall of the crushing box for crushing again under the effect of the first grinding teeth; meanwhile, when the rare earth collides the bore spines, the rare earth is rebounded immediately, sothat the slide rod slides out to collide other rare earth particles; and when massive rare earths are not crushed, but fall onto a spherical rubber plate, the massive rare earth is rebounded for crushing again by the crushing hammer, so that higher practicability is achieved.

Owner:重庆中色新材料有限公司

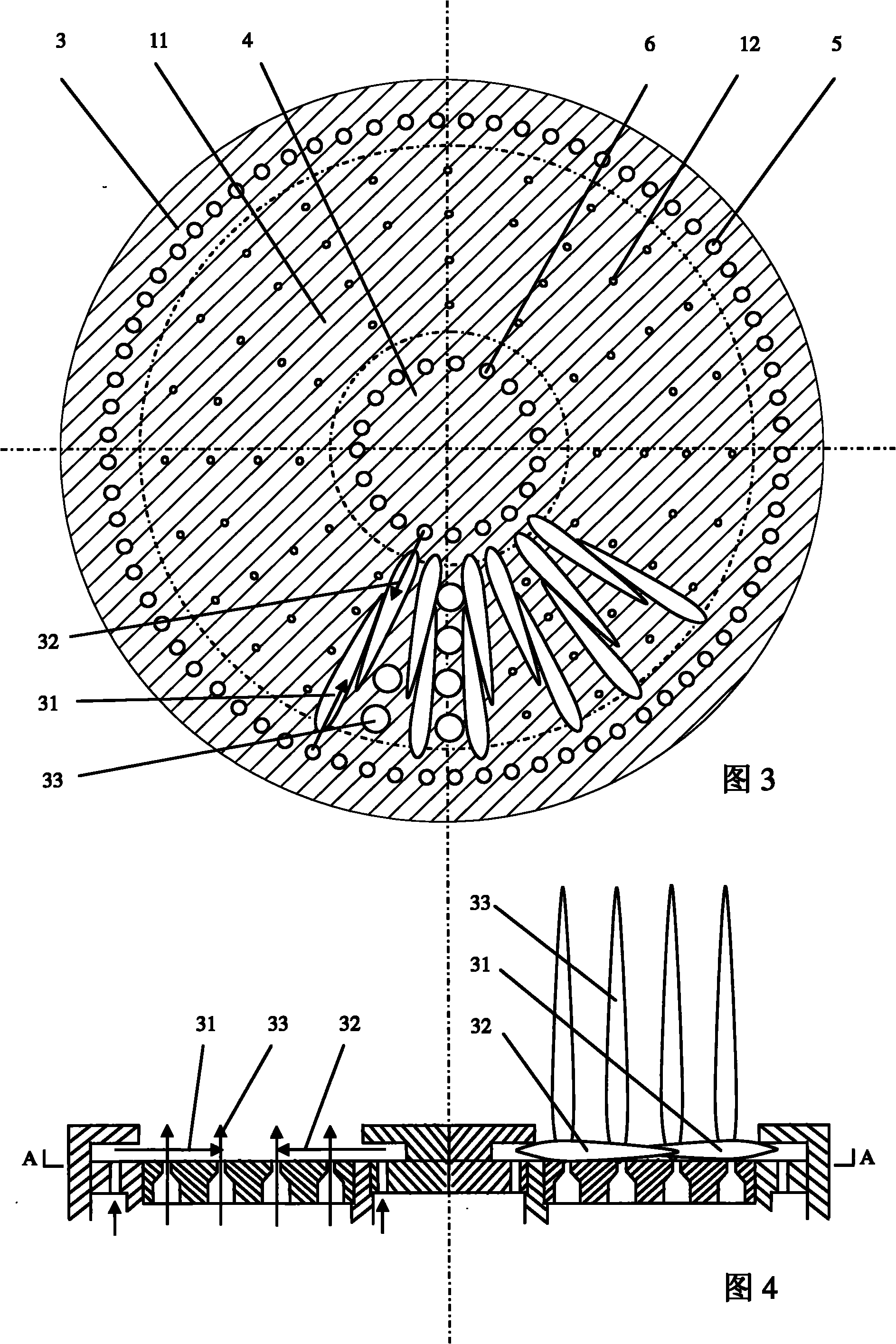

Combustor capable of improving combustion intensity and heat transfer intensity by utilizing auxiliary counter-flow flames

InactiveCN102052671AUniform combustion reactionStable combustion reactionGaseous fuel burnerCounter flowCombustor

The invention discloses a combustor capable of improving combustion intensity and heat transfer intensity by utilizing auxiliary counter-flow flames, which comprises auxiliary fire holes and main combustion fire holes. The combustor is characterized in that: auxiliary outer-circle fire caps, main combustion fire caps and auxiliary inner-circle fire caps are arranged to form a three-circle shape; the main combustion fire caps are positioned between the auxiliary outer-circle fire caps and the auxiliary inner-circle fire caps; an annular cavity between the auxiliary outer-circle fire cap and a corresponding outer-circle rectifier baffle plate is an outer-circle combustion diversion cavity; the annular cavity between the auxiliary inner-circle fire cap and a corresponding inner-circle rectifier baffle plate is an inner-circle combustion diversion cavity; and an opening of the outer-circle combustion diversion cavity is opposite to the opening of the corresponding inner-circle combustion diversion cavity. Outer-circle auxiliary flames flow relative to inner-circle auxiliary flames to form flame nets with more uniformly distributed heat on the surfaces of the main combustion fire caps, so that main combustion premixed gases flowing out of each gas orifice can obtain enough heat required by combustion, the combustion reaction of all the main combustion premixed gases is uniform, consistent and sufficient, and the combustion flames are stable. The main combustion premixed gases flow out at high flow rate and under high pressure, so the combustion intensity and flame temperature of the main combustion premixed gases are correspondingly high. Main combustion flames entrain the auxiliary flames by high kinetic energy to simultaneously transfer the heat, and the high-efficiency heat transfer can make the high temperature combustion flames rapidly reach the bottom of a roasting kettle.

Owner:李芳春

Water feature for wave pools

The present invention relates to wave pools and diversion channels that capture high kinetic energy portions of a wave generated within the wave pool, and redirects the captured wave portions to the vicinity of wave formation, preferably timed so as reinforce a subsequently generated wave. The high kinetic energy within the diversion channel creates an additional feature in the form of an action river for riders of a wave pool to enjoy. At the same time, capturing of portions of the wave reduces the backwash of the wave and stabilizes the level of water within the wave pool, especially for embodiments with wave generators and pools capable of high volume waves. Riders may enter the diversion channel and ride from the distal, beach end of the wave pool to the proximatal, wave generating end.

Owner:JOHNSON GARRETT

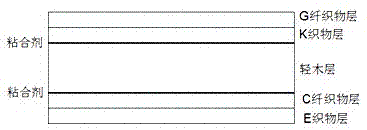

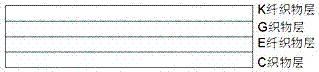

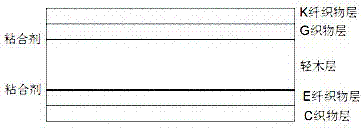

High-speed impact resistance composite material

ActiveCN103660456ALight weightExcellent kinetic energy absorption capacity of projectileSynthetic resin layered productsSurface layerPolyresin

The invention discloses a high-speed impact resistance composite material. An impact surface facing layer, a middle core layer and an impact surface backing layer form a sandwich composite material structure, the core layer consists of microporous materials, the impact surface facing layer and the impact surface backing layer of the sandwich structure composite material are respectively formed by laminating at least four layers of inorganic fiber layers and organic fiber layers, the resin mass content of the inorganic fiber layers is 10 to 40 percent, the inorganic fiber layers need to be near the impact surface facing layer, and the impact surface facing layer, the impact surface backing layer and the core layer are bonded through adhesives. The high-speed impact resistance composite material has the advantages that dynamical anisotropy differences of various high-performance fibers are utilized, and an interlayer hybrid mode is adopted for preparing a surface layer composite material, so the composite material has light weight and excellent elastic body kinetic energy absorption capability; an impact surface facing and impact surface backing asymmetric mode is adopted for designing the sandwich structure composite material, high kinetic energy absorption capability of the composite material is ensured, and the anti-shearing and anti-bending capability of the composite material are also improved.

Owner:ZHEJIANG SCI-TECH UNIV

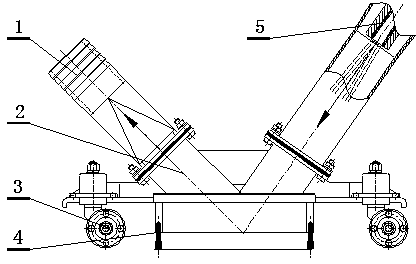

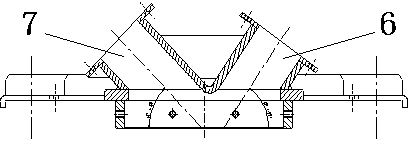

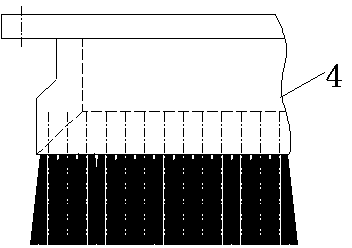

Device for surface cleaning

ActiveCN104084890AStop SpillSports EfficientAbrasive blasting machinesGrinding/polishing apparatusInlet channelSurface cleaning

The invention relates to a device for surface cleaning. The device is characterized in that: a bracket is provided with a closed chamber, which is equipped with a high kinetic energy particle inlet channel and a high kinetic energy particle outlet channel, the high kinetic energy particle inlet channel is connected to an accelerator, the high kinetic energy particle outlet channel is connected to a recovery pipe, and the bottom of the bracket is provided with a universal walking mechanism. During use, the high kinetic energy particles are accelerated by the accelerator, the accelerated high kinetic energy particles enter the closed chamber through the inlet channel. The specially designed particle motion trail guide channel and the reasonable axial angle guarantee that the angle between the high kinetic energy particle motion trail and the normal of a clean surface is 40DEG-55DEG C. The inside of the closed chamber is in a partial vacuum state of certain degree. A hairbrush guard board on the one hand can stop overflow of high kinetic energy particle materials and dust, and on the other hand serves as a supplemental inlet of external gas. The airflow can form a reasonable suspension and recovery rate, thus realizing efficient recovery of high kinetic energy particle materials.

Owner:SHANGHAI SHIPBUILDING TECH RES INST

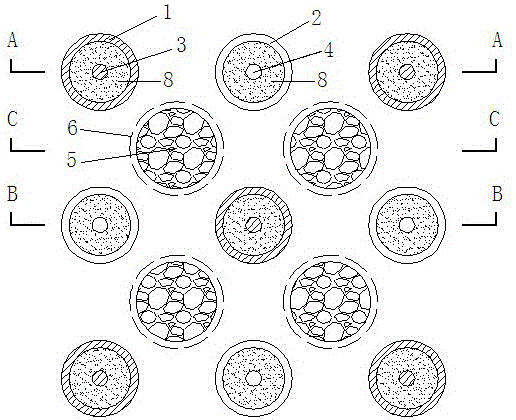

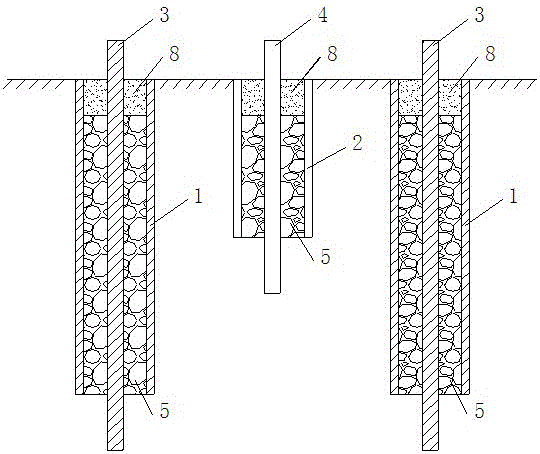

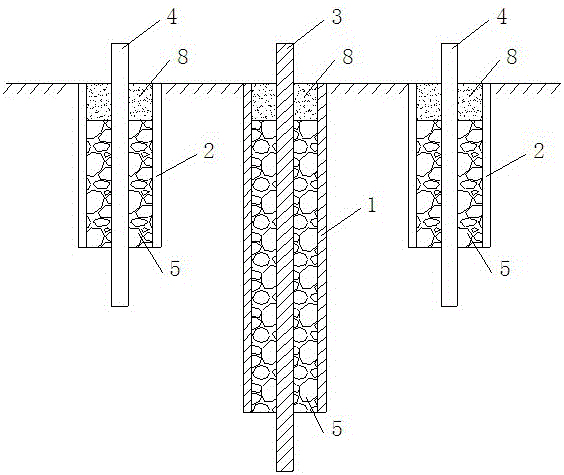

Hybrid power drainage consolidation system applied to deep saturated soft soil foundation and construction method

ActiveCN106049413AAchieve drainage consolidationAchieve replacementSoil preservationAir pollutionHigh kinetic energy

The invention provides a hybrid power drainage consolidation system composed of a vacuum shaft drainage system, a foundation hybrid consolidation system and a full compaction rolling system and a construction method. The bearing capacity of a foundation is remarkably improved, meanwhile, the effects of strong drainage, strong compaction, high kinetic energy, over pressure and the like are integrated, post-construction settlement of the saturated soft soil foundation can be effectively controlled, engineering cost can be reduced, and the construction period can be shortened; and meanwhile the treatment depth of the foundation is large, the foundation is good in reinforcement effect and remarkable in environmental protection effect, that is, vibration, noise, air pollution and the like are reduced, and the later maintenance charge is reduced.

Owner:TANGSHAN IND VOCATIONAL TECHN COLLEGE +1

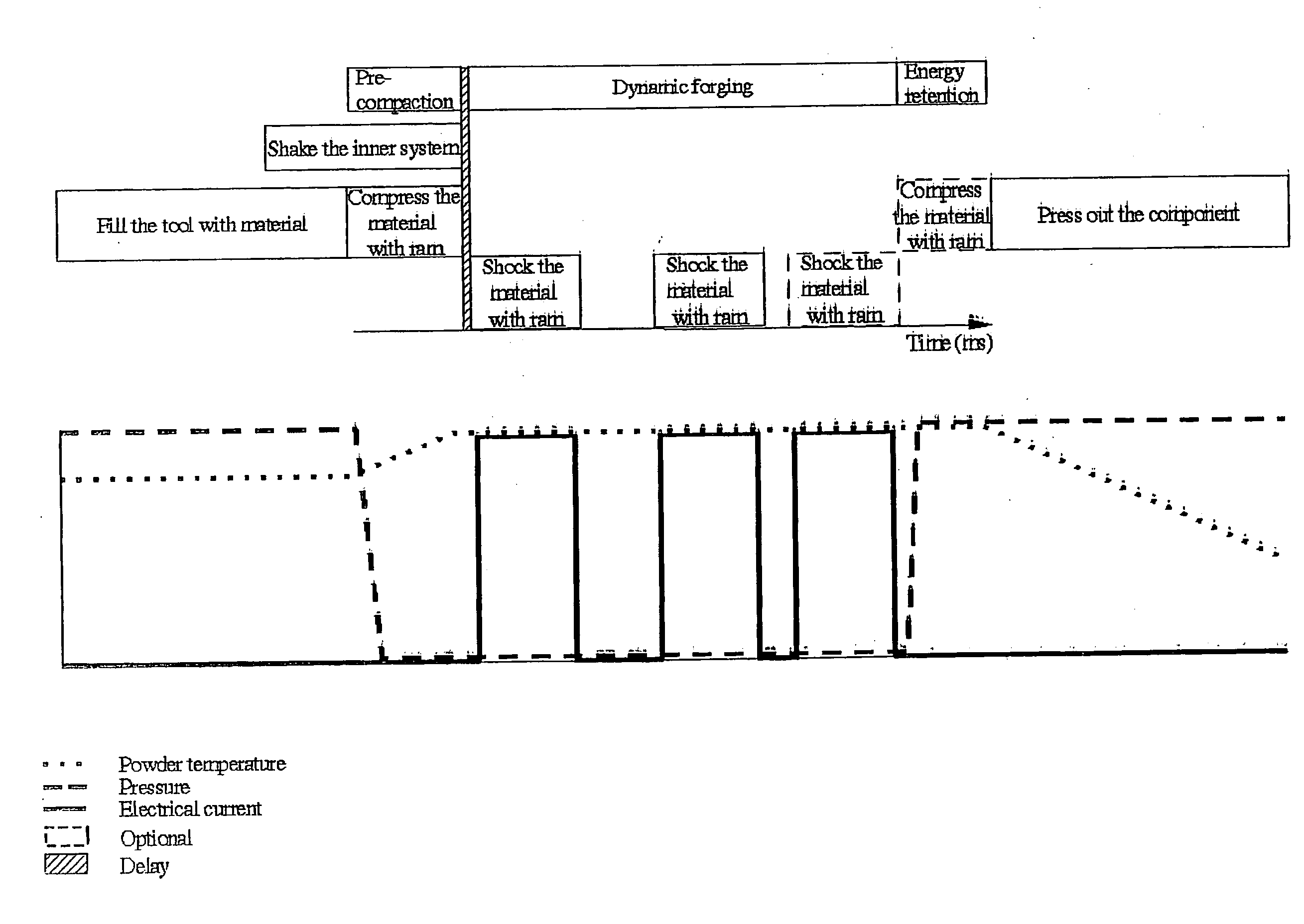

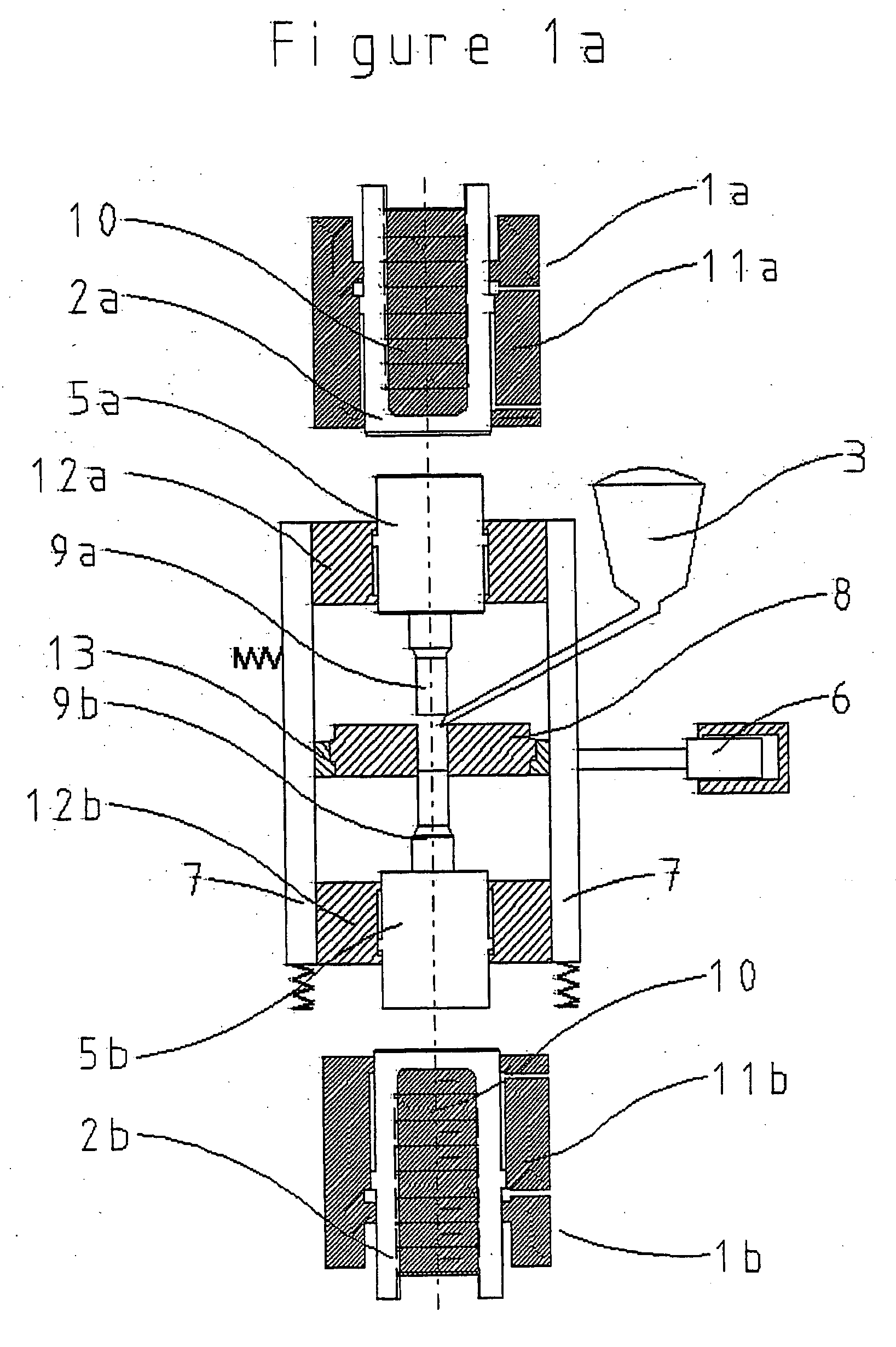

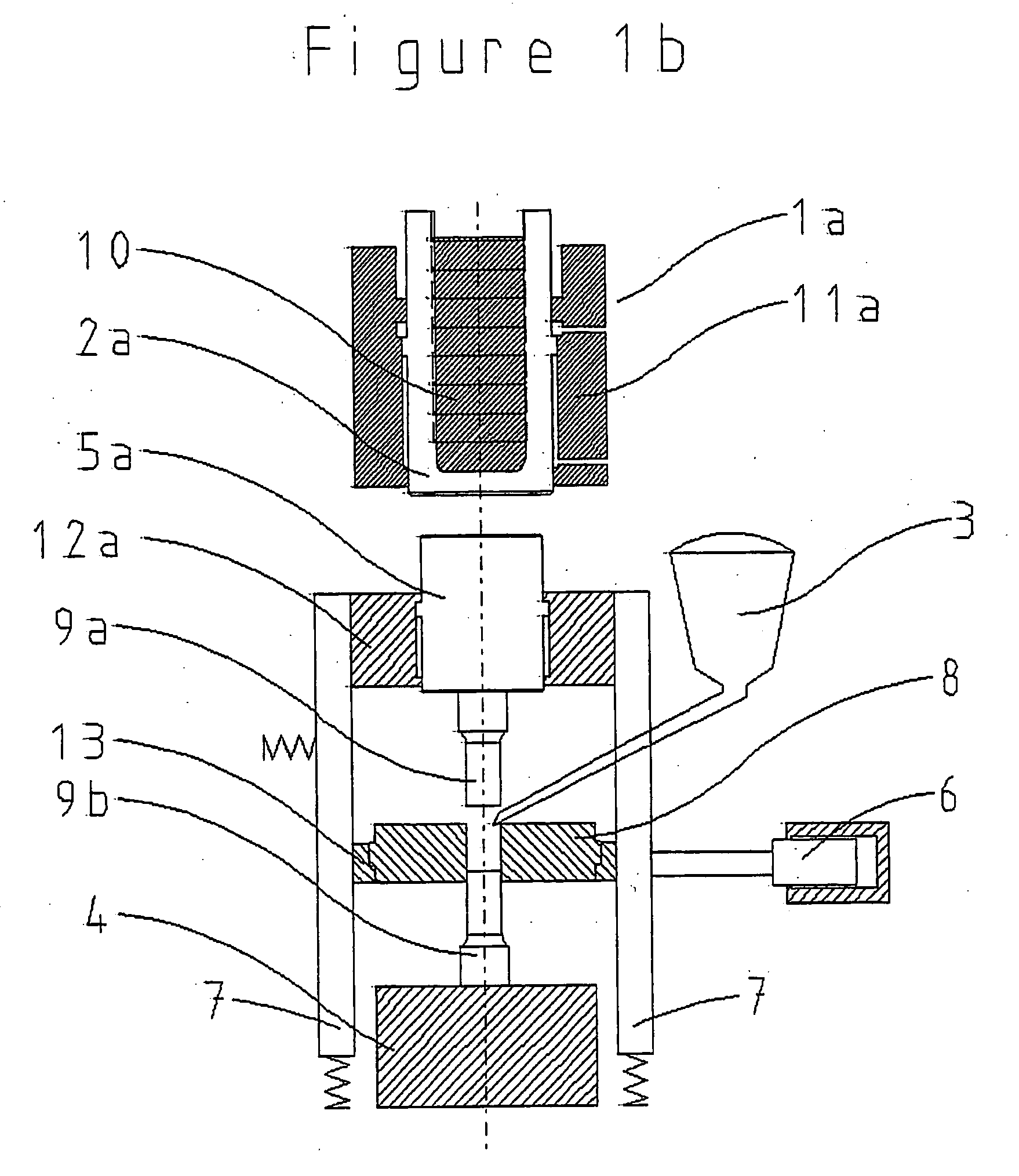

Process for producing a high density by high velocity compacting

InactiveUS20050220658A1Good sequence controlLow running costPower hammersHammer drivesParticulatesHigh density

A method of producing a body from a particulate or solid material comprises filling a precompacting mould with the material, optionally vibrating the mould, pre-compacting the material and compressing it by at least one stroke with high kinetic energy in order to cause coalescence or high density of the material.

Owner:OLSSON KENT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com