High-speed impact resistance composite material

A composite material and high-speed impact technology, applied in the field of composite materials, can solve the problem of poor interlaminar shear and bending resistance of composite materials, affecting the performance and range of use of composite materials, and the decline of shear and bending resistance of composite materials and other problems, to achieve the effects of excellent kinetic energy absorption capacity of the projectile, improved shear resistance and bending resistance, and high kinetic energy absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

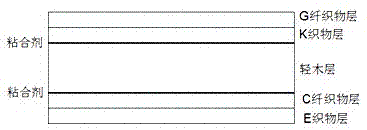

[0018] Such as figure 1 The structure shown is designed for high velocity impact resistant composites. The interlayer hybrid composite material of the impact surface layer adopts glass fiber fabric (G) / aramid fiber 1414 fiber fabric (K) vinyl ester resin interlayer hybrid composite material, the resin content is 40%, and the interlayer hybrid order is G / G / G / K / K / K, ply angle 0 / 90 / 0 / 90 / 0 / 90. The quality of the organic high-performance fiber aramid 1414 in the surface layer accounts for 48.8% of the total reinforced fabric quality. The fabric specification is 210g / m 2 S-2 plain weave fiberglass fabric, 200g / m2 kevlar129 plain weave fabric. The interlayer hybrid composite material of the back impact surface layer adopts carbon fiber fabric (C) / ultra-high molecular weight polyethylene fabric (E) vinyl ester resin interlayer hybrid composite material, the resin content is 40%, and the interlayer hybrid order is C / C / E / E / E / E, ply angle 0 / 90 / 0 / 90 / 0 / 90. The quality of the organi...

Embodiment 2-5

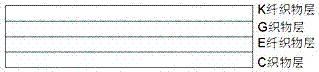

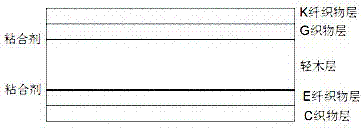

[0031] The materials and structures of the high-speed impact-resistant composite materials of Examples 2 to 5 are shown in Table 2.

[0032] Table 2 Example 2-5 high-speed impact-resistant composite material

[0033]

[0034] Note: C stands for carbon fiber, G stands for glass fiber, K stands for aramid 1414 fiber, E stands for ultra-high molecular weight polyethylene fiber, P stands for polyphenylene benzobisoxazole (PBO) fiber

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com