Patents

Literature

1256 results about "Plain weave" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

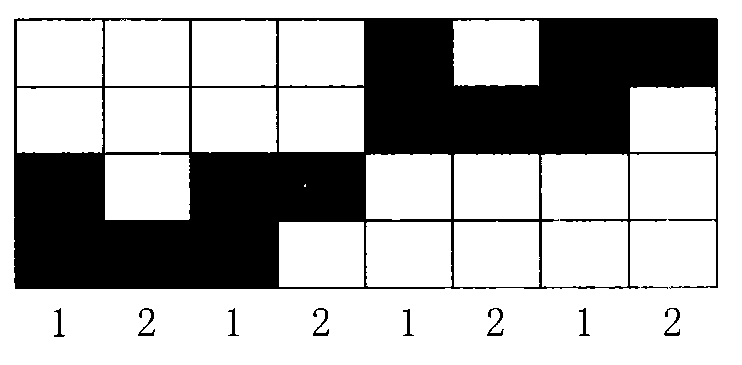

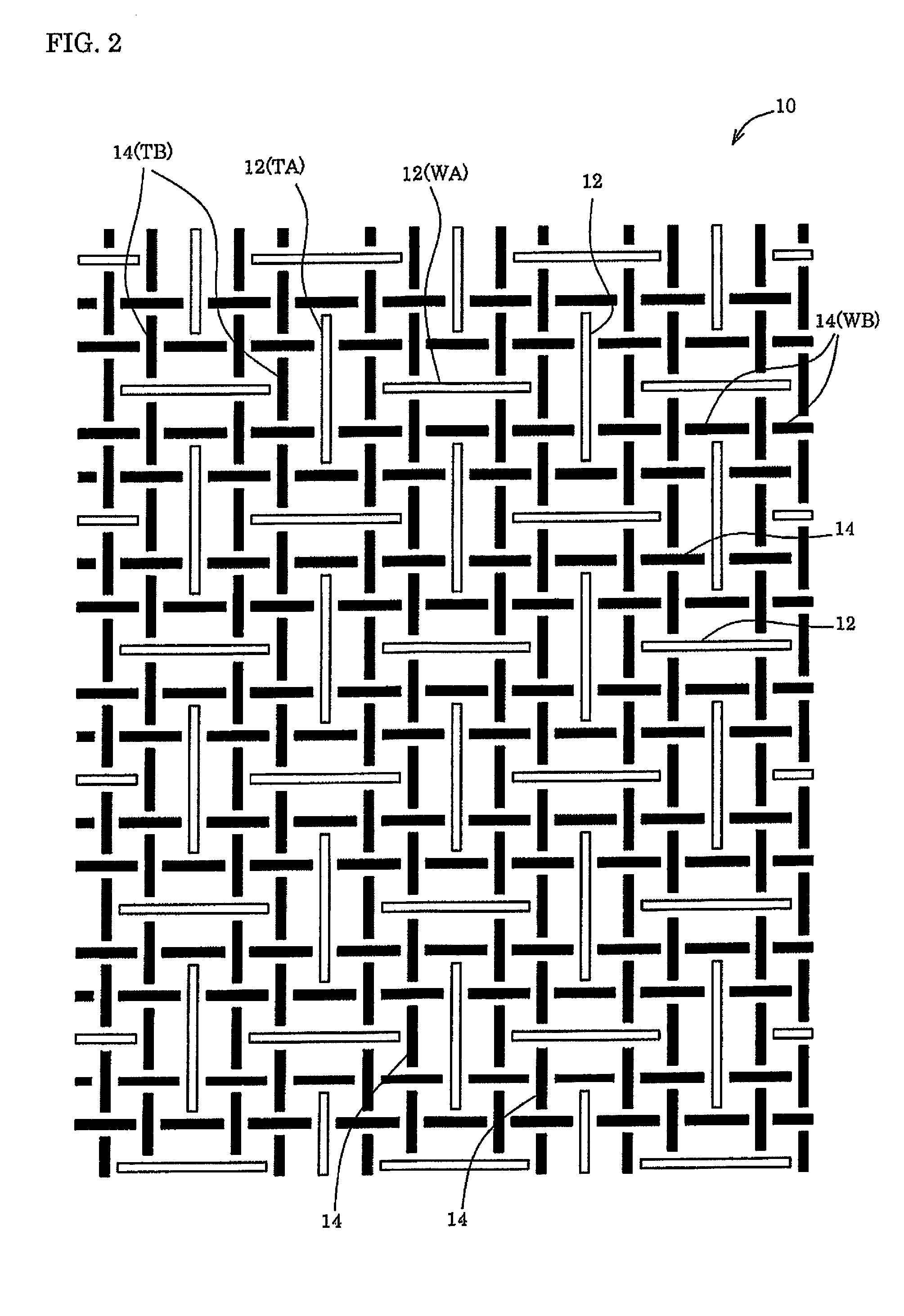

Plain weave (also called tabby weave, linen weave or taffeta weave) is the most basic of three fundamental types of textile weaves (along with satin weave and twill). It is strong and hard-wearing, and is used for fashion and furnishing fabrics.

Industrial multilayer textile

InactiveUS6860299B2Superior in fiber supportabilityMachine wet endMulti-ply fabricsEngineeringPlain weave

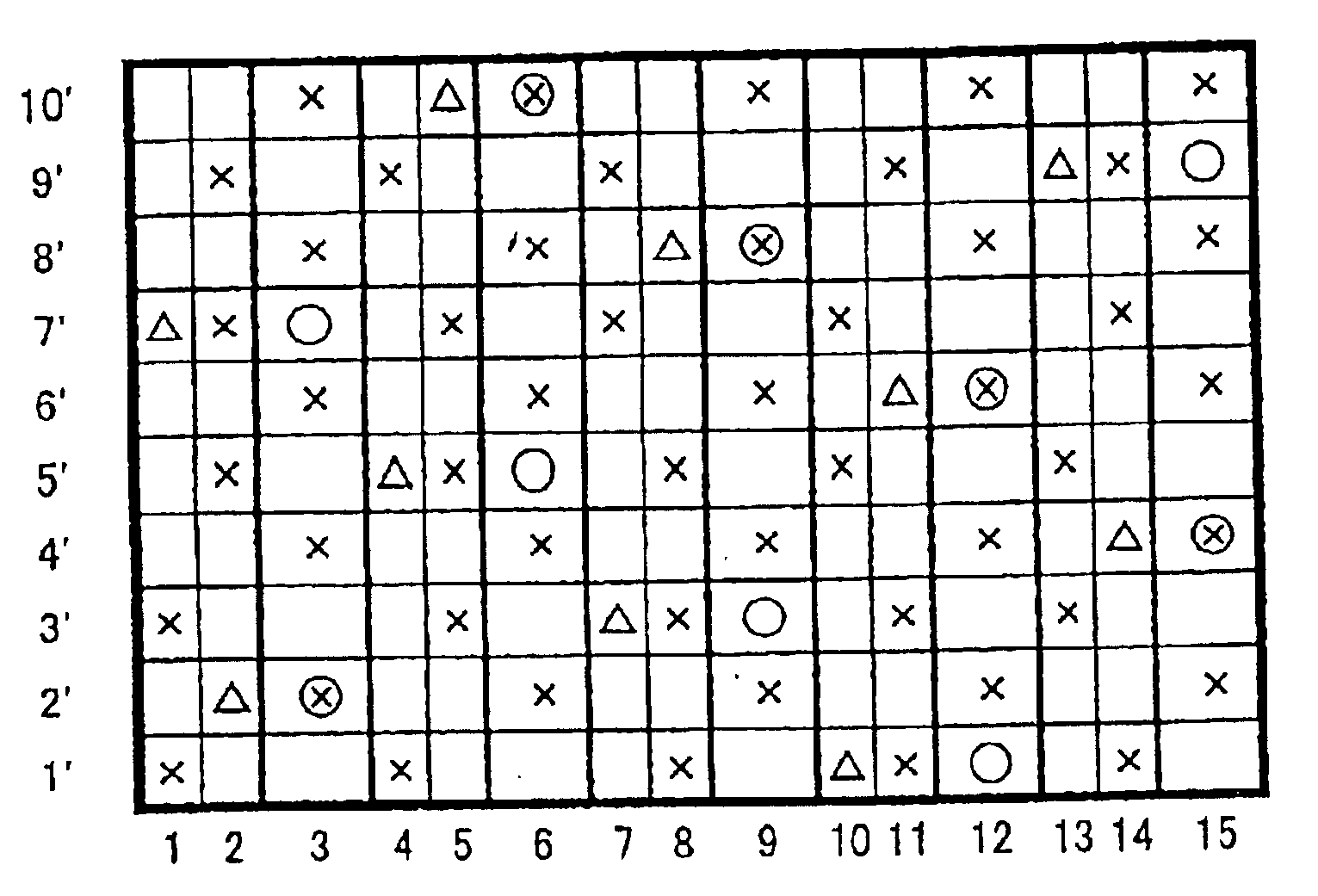

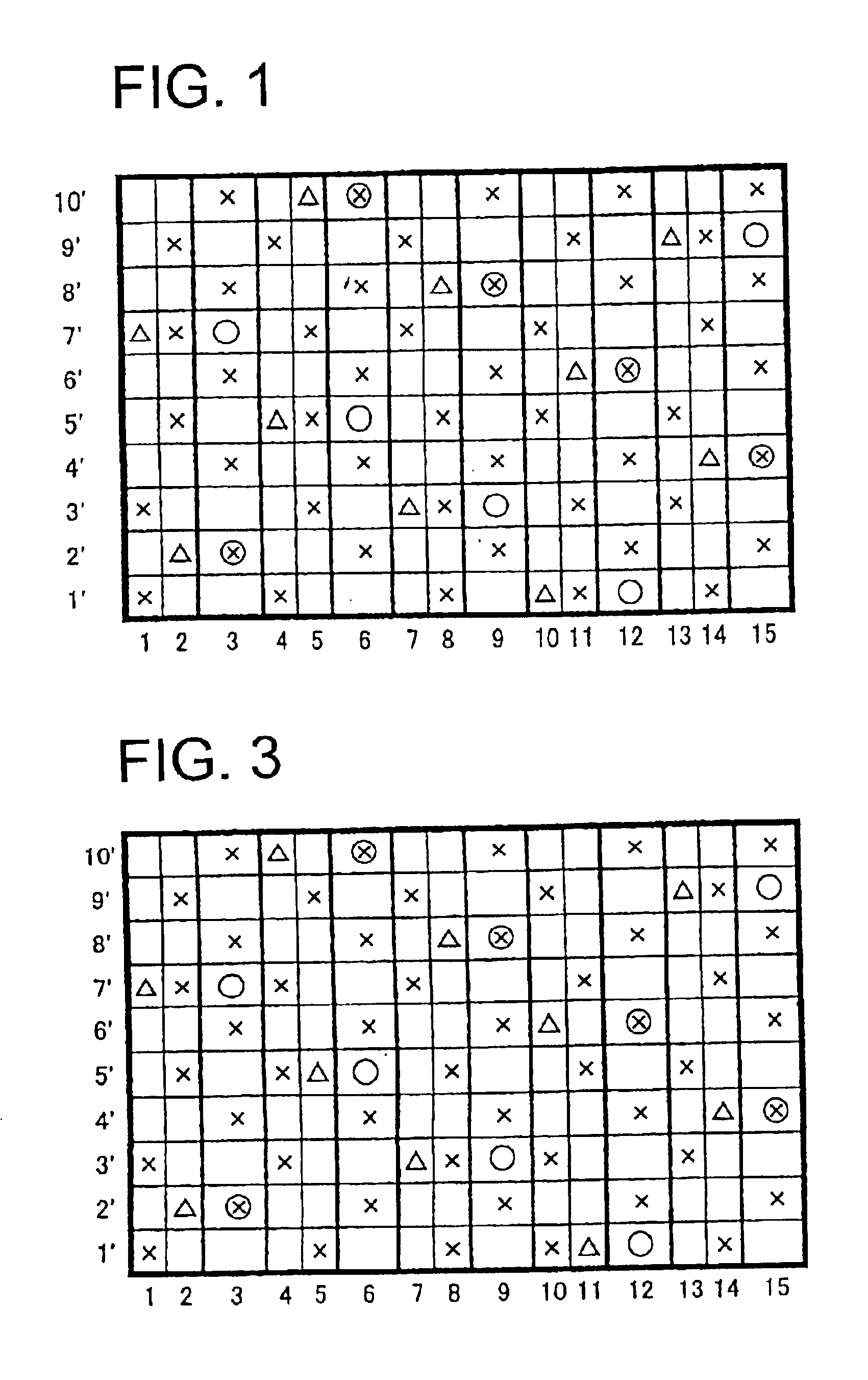

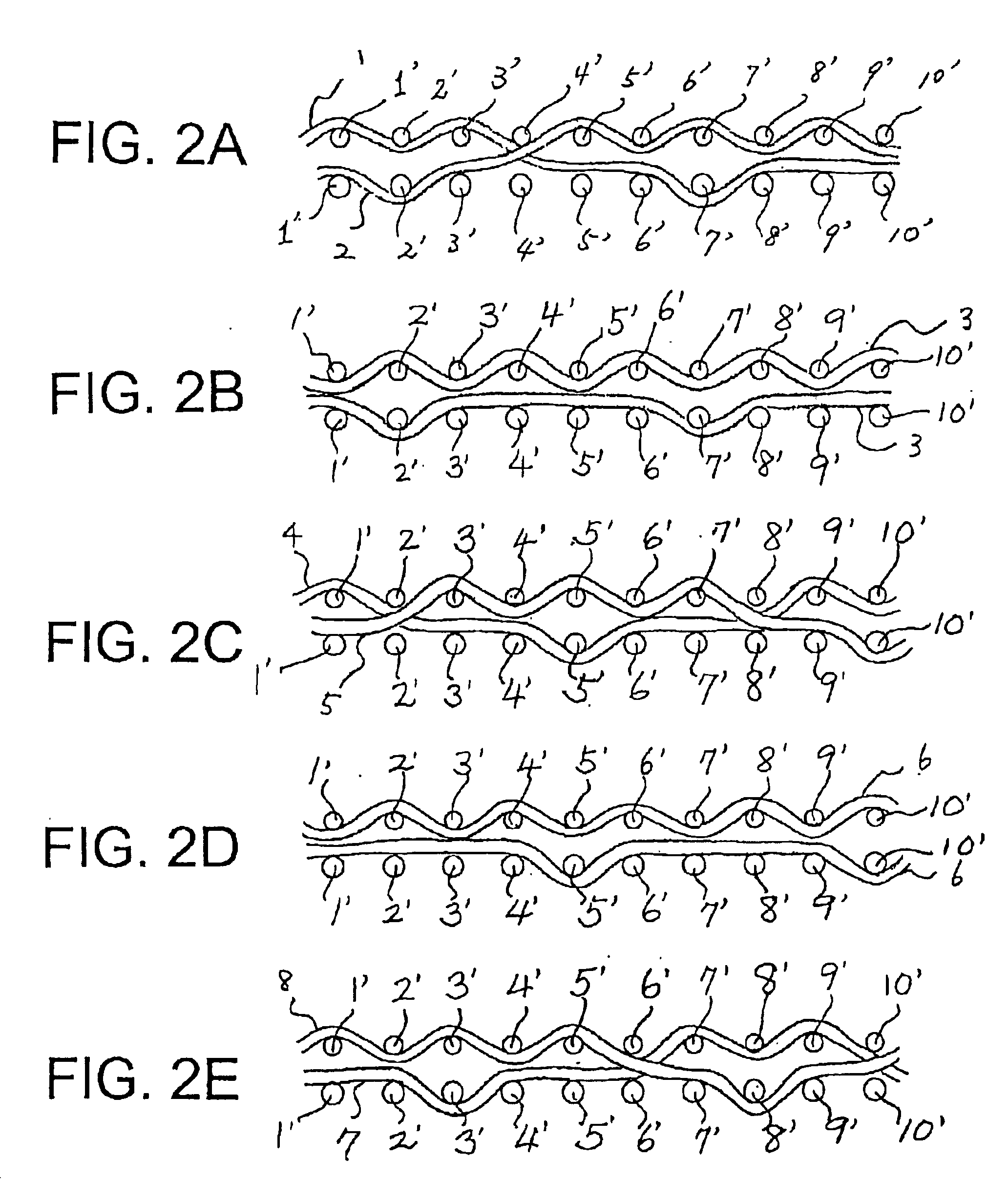

An industrial multilayer textile has at least an upper surface side layer and a lower surface side layer as a running surface. The upper surface side layer and the lower surface side layer are connected by warp ground yarn connecting yarns that weave the upper surface side layer and the lower surface side layer. Among these, a pair of warp ground yarn connecting yarns is made into yarns corresponding to one warp in an upper surface side surface, and the pair of warp ground yarn connecting yarns and another warp are alternately disposed and woven with upper surface side wefts to form a surface of a substantially plain weave texture on the upper surface side layer.

Owner:NIPPON FILCON

Weft-filled decorative fabrics in three-layer structure and production process thereof

InactiveCN101649522AStrong three-dimensional flower shapeObvious permanent bump effectWoven fabricsSurface layerEngineering

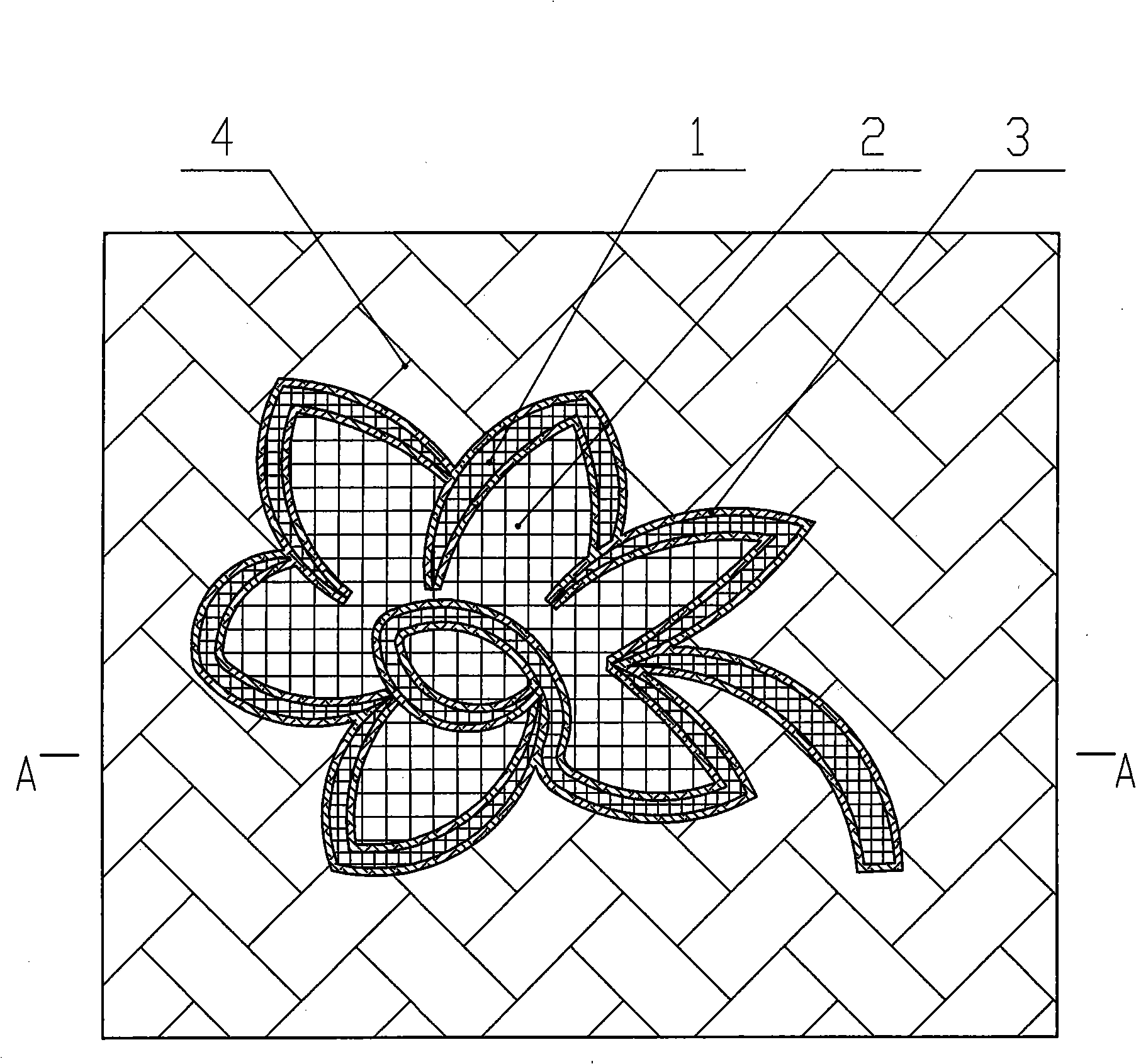

The invention discloses weft-filled decorative fabrics in a three-layer structure and a production process thereof. One of plain weave or twill weave is adopted as basic weave in a surface layer and aliner layer; warp yarns and weft yarns on the surface layer and the liner layer are woven into two-layer fabrics; 3 / 3 warp overlapped plain weave single-layer grid embedded strip yarns and 2 / 2 weft overlapped plain weave single-layer grid embedded strip yarns are respectively embedded and woven in an alternative arrangement mode on the surface layer and the liner layer in the warp direction and the weft direction; weft suspended filling yarns are woven between the surface layer texture of and the liner layer texture; the number R of full-texture circulating warp yarns of the whole fabrics satisfies an equation: R=10-16; and the decorative fabrics in the two-layer texture weft-filled three-layer structure are woven. The whole fabrics integrally have three-dimensional grid effect in a two-layer texture triple structure; under the supporting action of filled wefts in the weft direction, two-layer bag-shaped grids have permanent obvious swelling effect and form an air layer with a thickness of 1.2-1.8 mm in the fabrics, and the air layer has favorable functions of heat insulation, heat maintenance and sound shielding. Accordingly, the novel household decorative fabrics are ideal.

Owner:SHAOXING UNIVERSITY

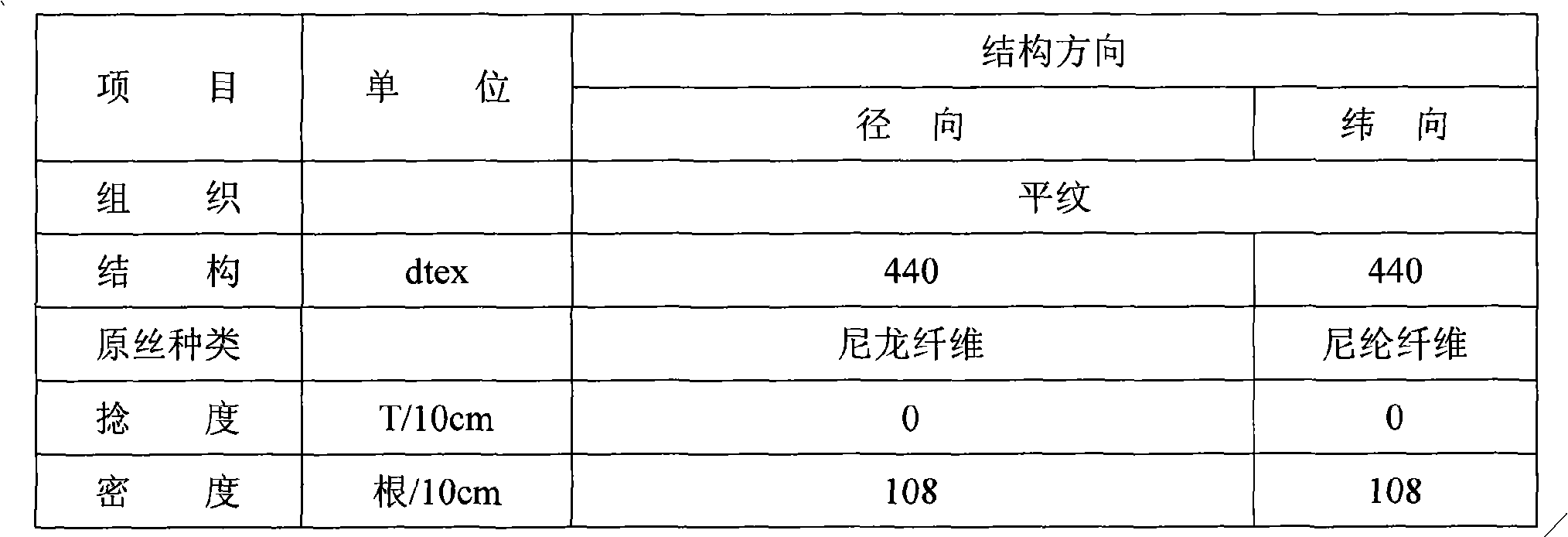

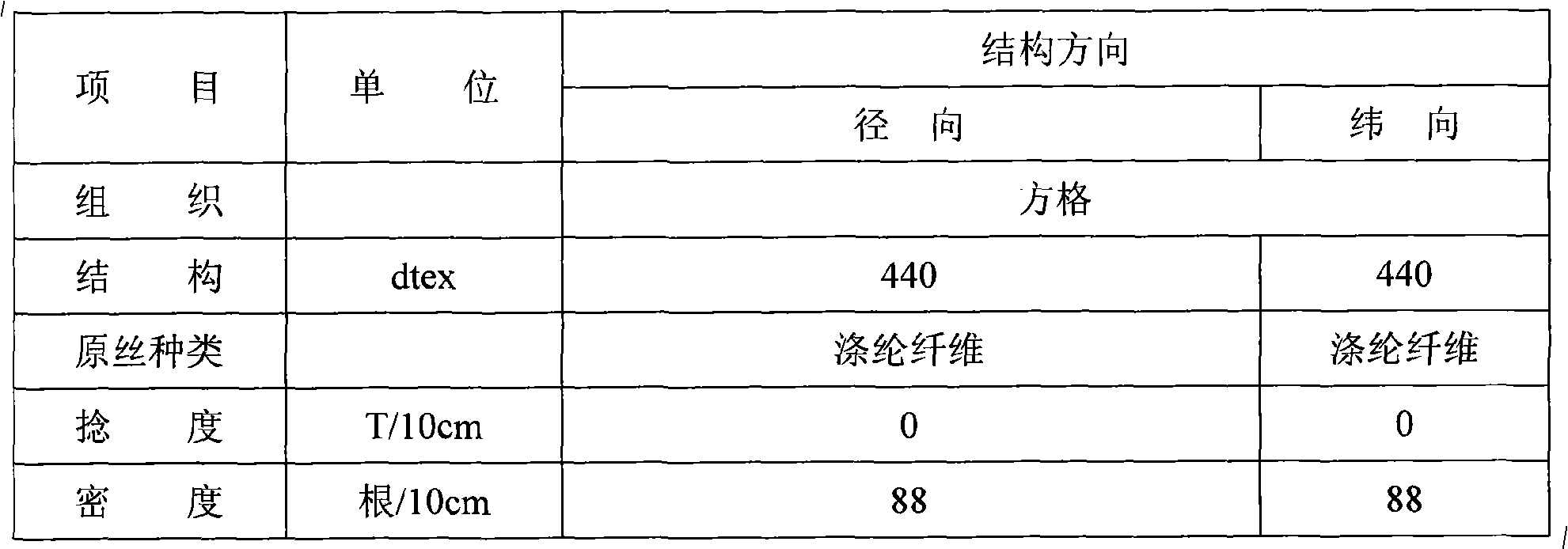

Polyester filament woven fabric for air bags

InactiveUS20060252322A1Pedestrian/occupant safety arrangementSynthetic resin layered productsEngineeringFabric structure

A polyester plain weave fabric construction wherein said fabric has a basis weight of between 150 to 300 g / m2 with tongue tear strength equal to or better than nylon fabrics of the same construction and weight. The present invention relates to both coated and uncoated polyester filament woven fabric. The uncoated fabric is useful for industrial purposes wherein the fabric has a warp tongue tear resistance of at least 0.75 N / g / m2, when the fabric basis weight is between 150 to 300 g / m2 The preferred uncoated polyester filament yarn has a linear density of between about 200 to about 800 dtex, a tenacity of at least 65 cN / tex, a tensile index of at least 350. The fabrics can be coated with chloroprene, neoprene, polyurethane, silicone or other organic coatings to reduce air permeability. The fabric of the present invention may also be constructed with the warp and / or filling yarn having an aspect ratio between 1.2 and 6.

Owner:INV PERFORMANCE MATERIALS LLC +1

High-performance fiber reinforced film composite material

A high-performance fiber reinforced film composite material comprises a bonded fabric and a resin coating layer on the surface of the boned fabric and is characterized in that the boned fabric takes high-strength fiber with the yarn count of 200-600D as warp or weft; the weaved warp and weft density is 22*22-27*27; the boned organization structure is a plain weave or a square grid organization or bi-axial warp-knitting (the warp and weft density is 18*18-18*20) structural fabric; the resin coating layer is characterized in that at least one surface out of two surfaces of the boned fabric is coated by the resin layer with a combination process of clearance coating and transferring coating; the resin layer comprises 85-90 parts of thermoplastic resin, 1-5 parts of nano-inorganic additive and 5-10 parts of organic modifier. The composite material is characterized in that the surface density is less than or equal to 280g / m<2>, the warp and weft elongation breaking strength is 750-1000N / cm, the warp and weft incision tearing strength is 750-850N and the elongation at break is less than or equal to 5%; furthermore, the composite material has the advantages of good weather-resistance and temperature-resistance and self-cleaning performance, strong flexibility and anti-fatigue, and being capable of high-frequency heat sealing; and the peeling strength (fabric / adhesive) is more than or equal to 2500N / m.

Owner:朱守诚

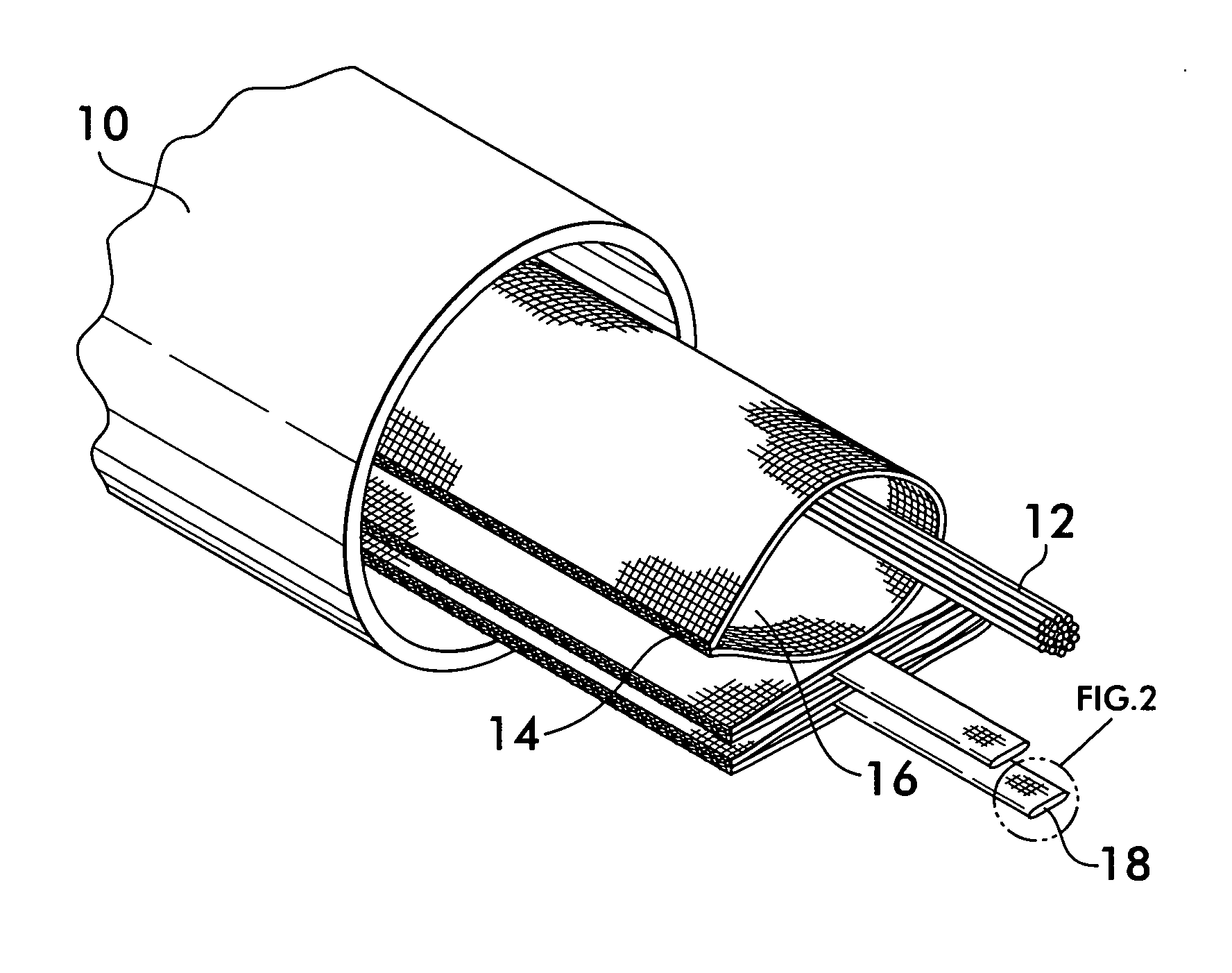

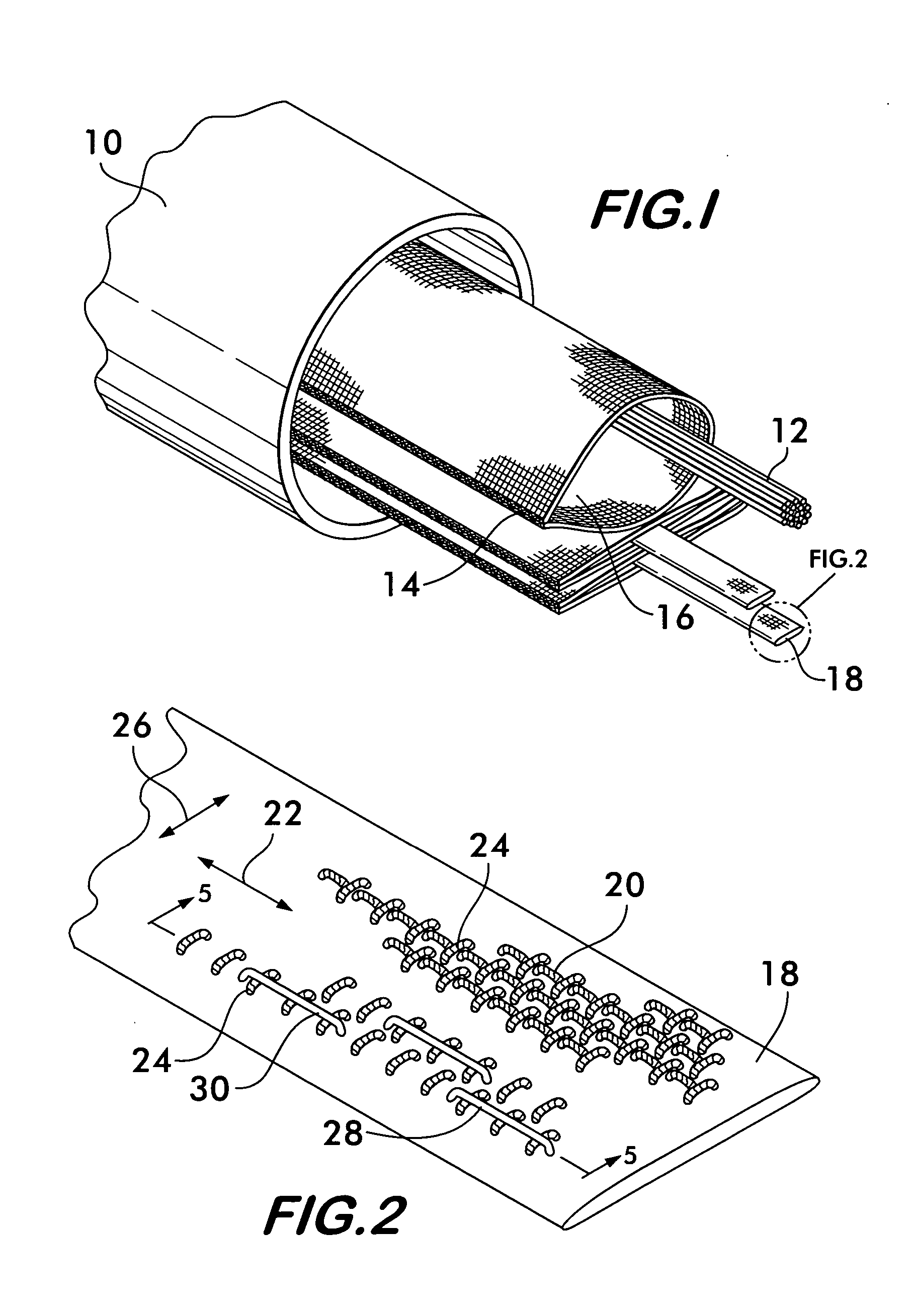

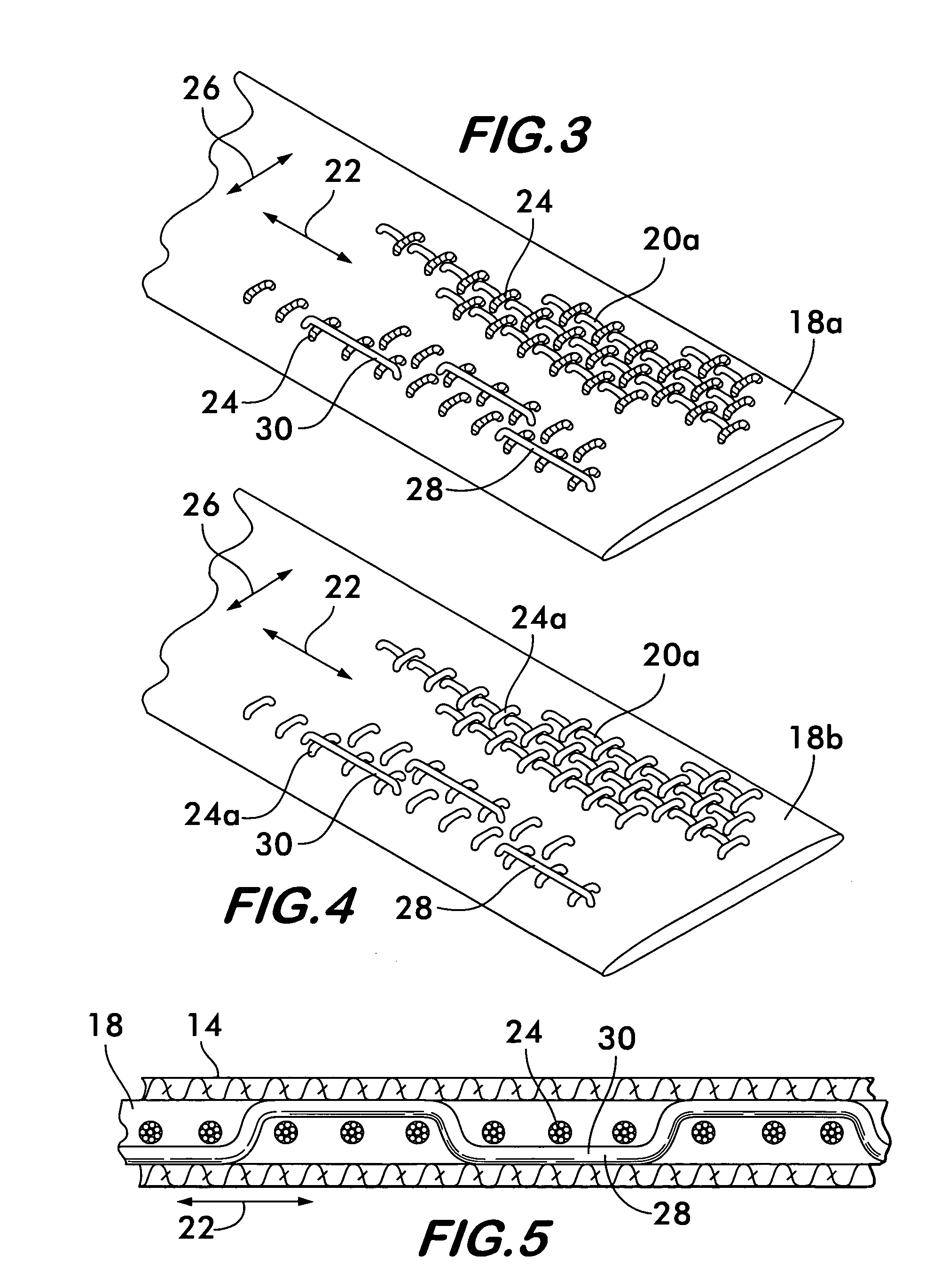

Low-friction pull tape

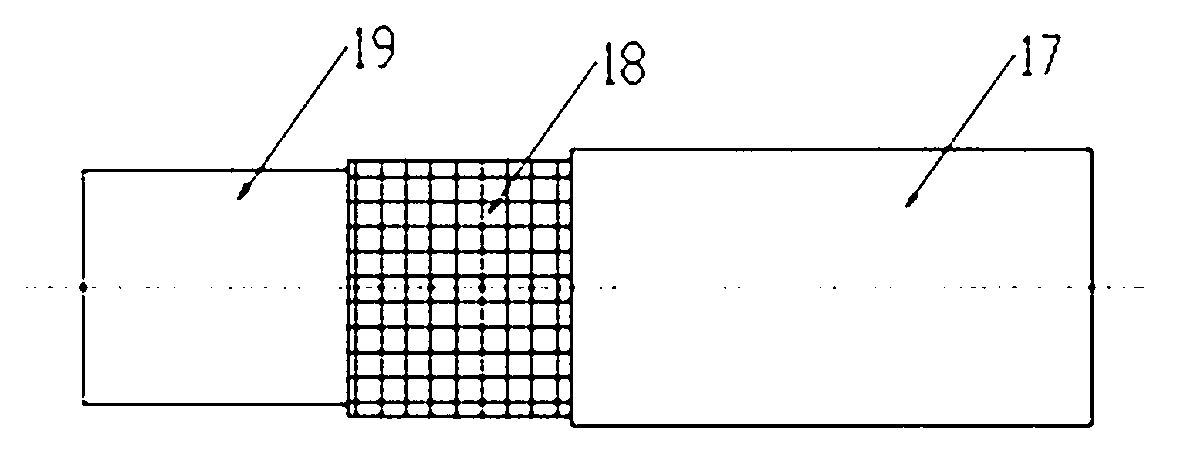

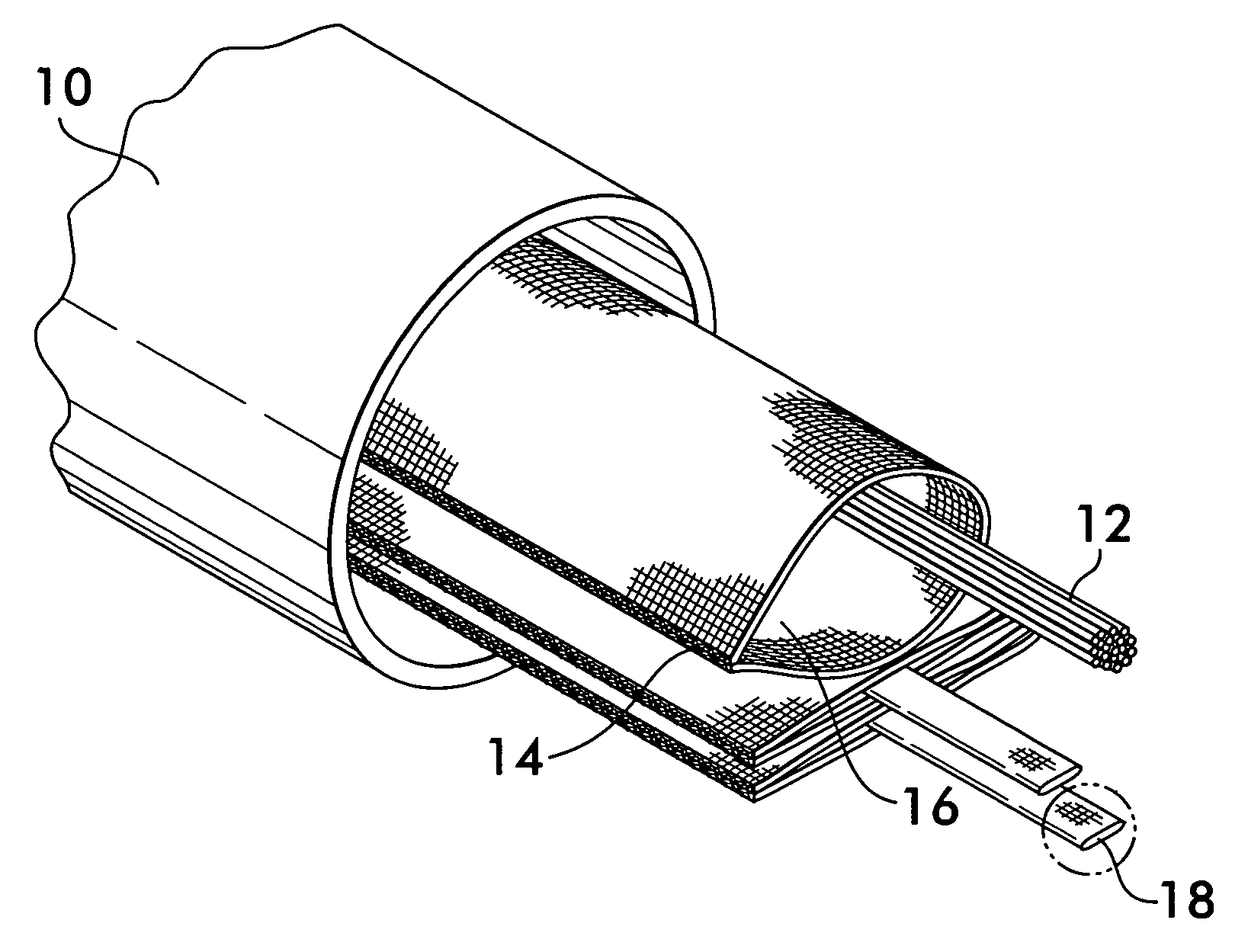

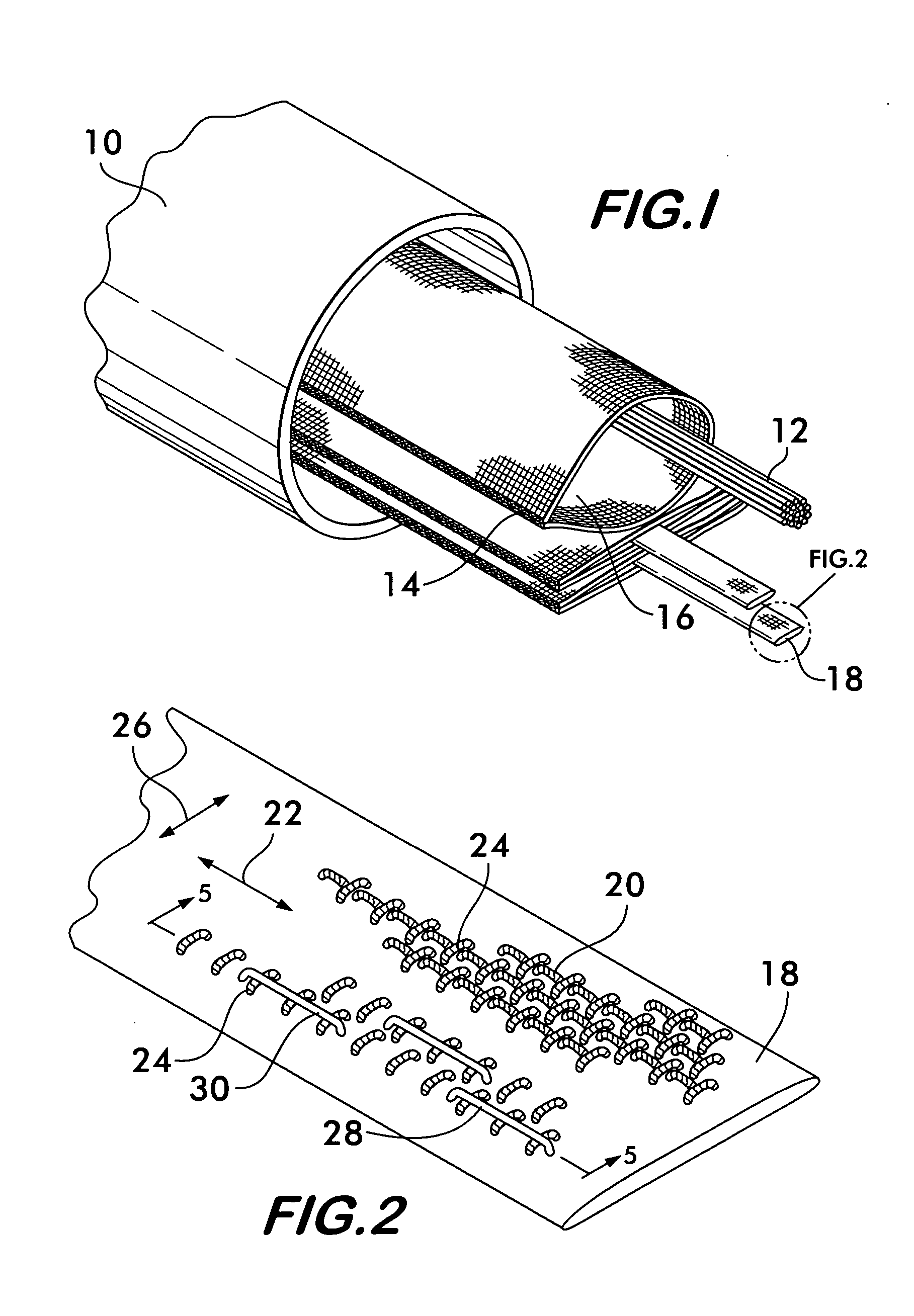

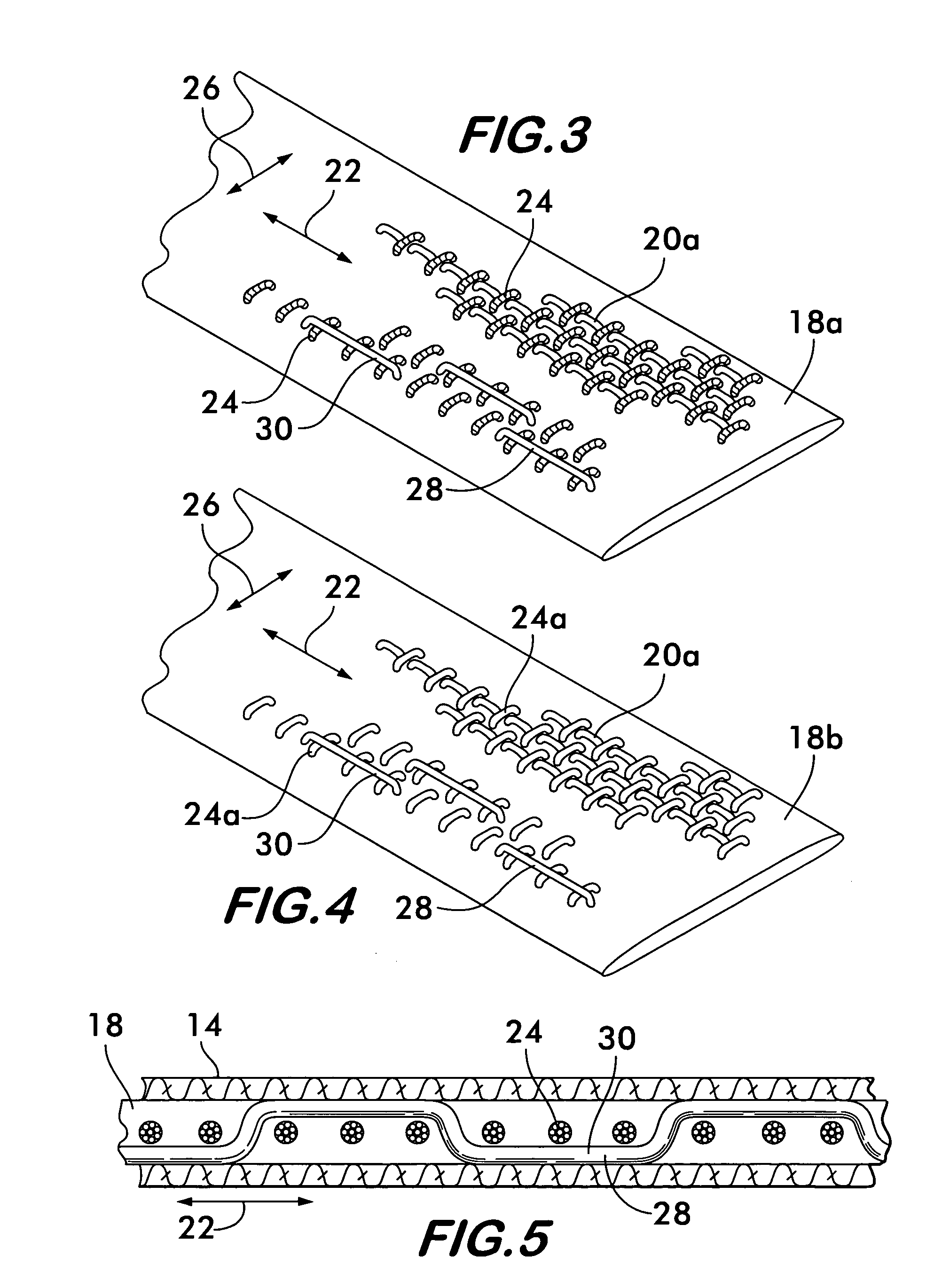

ActiveUS20050185902A1Reduce frictionEasy to drawInsulated cablesFibre mechanical structuresLow frictionPlain weave

A pull tape for facilitating positioning of elongated items within a protective sleeve is disclosed. The pull tape is woven of filamentary members preferably using a twill or satin weave that allows floats to form on the surface of the tape that reduce friction between the tape and the sleeve when the tape is drawn through the sleeve. Preferably, the tape is formed of multifilament warp and weft yarns woven in a plain weave with additional monofilament yarns arranged in the warp direction and woven in a twill or satin weave to form the floats in the warp direction. Additional embodiments include tapes having warp members entirely of monofilaments, as well as both warp and weft members being entirely of monofilaments.

Owner:FEDERAL MOGUL WORLD WIDE LLC

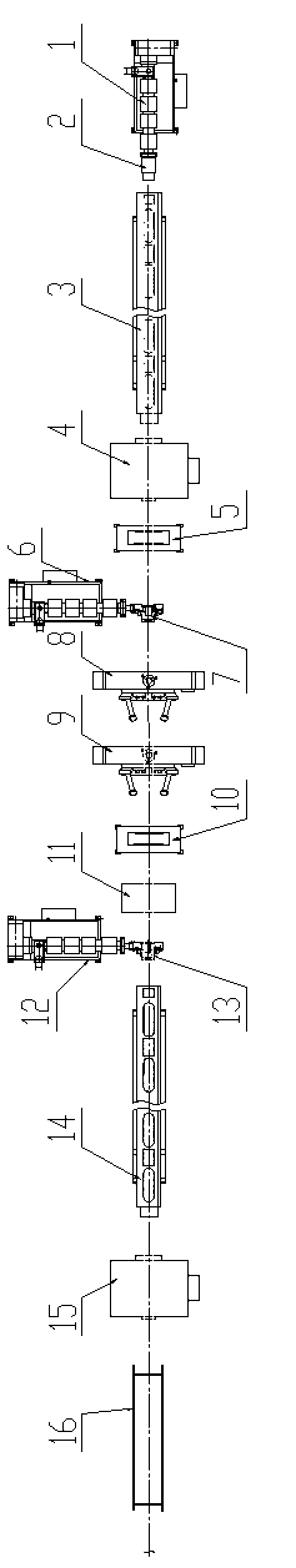

Fiber mesh tape-wound and reinforced composite pipe, preparation process and device

ActiveCN103016856AGuaranteed synchronicitySolve associativityRigid pipesMechanical propertyMaterials science

The invention relates to a fiber mesh tape-wound and reinforced composite pipe, a preparation process and a device, belonging to the technical field of forming processes of composite pipes. The composite pipe comprises an inner-layer core pipe and a post-coated layer, as well as a fiber mesh tape arranged between two layers, wherein the inner-layer core pipe is extruded by a core pipe extruding machine, the adhesive resin fiber mesh tape is heated through a post-heating box, and the composite pipe is finally obtained by traction through a post-traction machine, sizing through a vacuum spraying and sizing box and the like. According to the composite pipe disclosed by the invention, the technology is adopted, the preparation process is simple, the existing tape plastic covering treatment process and the composite pipe forming process are combined into a whole, the number of workers for production is reduced, and the degree of automation is improved; furthermore, the used device is a conventional device, and the cost is reduced; and in addition, adhesive resin is firstly coated on the outer surface of the core pipe, and the plain woven fiber mesh tape is further wounded, so that the interface problem in the pipe is effectively solved, the mechanical properties of the pipe are upgraded and the stability of the pipe during long-term use is also improved.

Owner:ZHEJIANG WEIXING NEW BUILDING MATERIALS CO LTD

Low-friction pull tape

ActiveUS7188642B2Reduce frictionEasy to drawInsulated cablesMulti-ply fabricsEngineeringLow friction

A pull tape for facilitating positioning of elongated items within a protective sleeve is disclosed. The pull tape is woven of filamentary members preferably using a twill or satin weave that allows floats to form on the surface of the tape that reduce friction between the tape and the sleeve when the tape is drawn through the sleeve. Preferably, the tape is formed of multifilament warp and weft yarns woven in a plain weave with additional monofilament yarns arranged in the warp direction and woven in a twill or satin weave to form the floats in the warp direction. Additional embodiments include tapes having warp members entirely of monofilaments, as well as both warp and weft members being entirely of monofilaments.

Owner:FEDERAL MOGUL WORLD WIDE LLC

Moisture-absorption sweat-drainage worsted fabric and method for producing the same

Owner:AOYANG GRP CO LTD

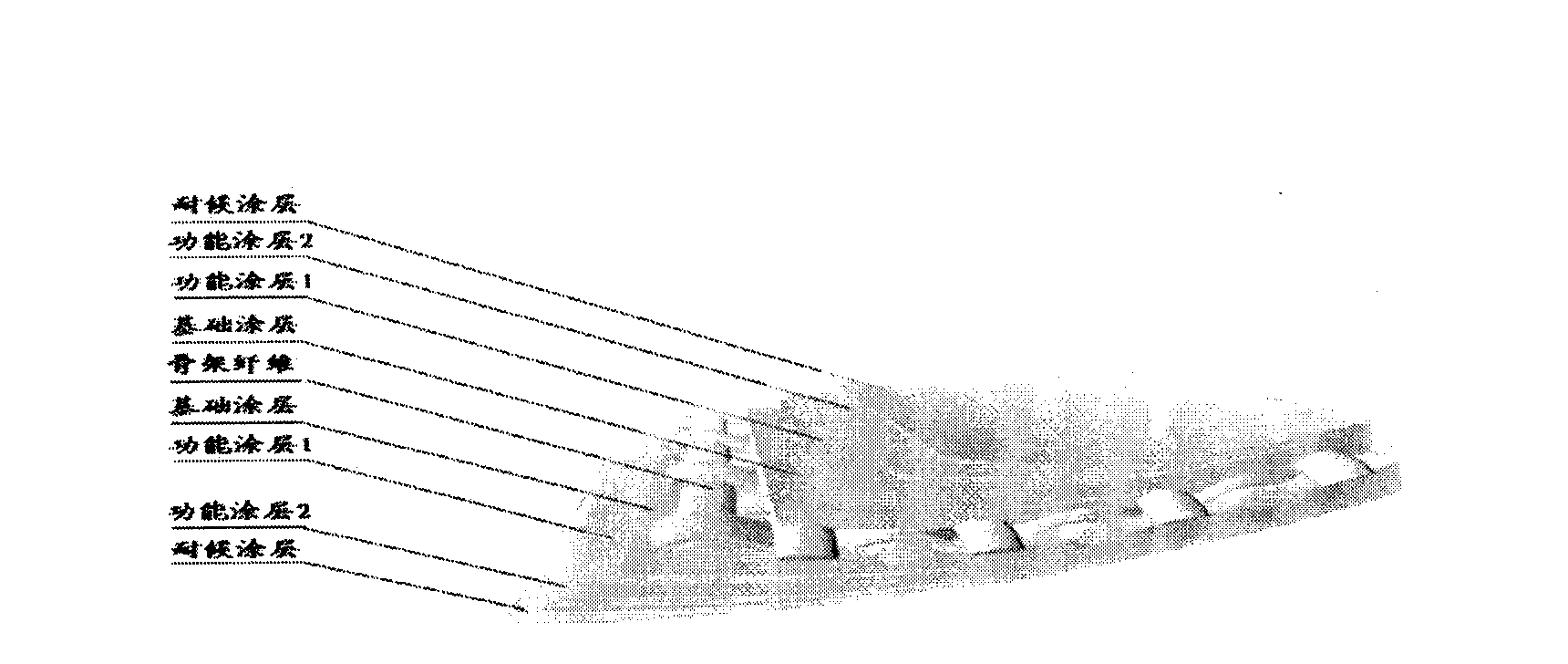

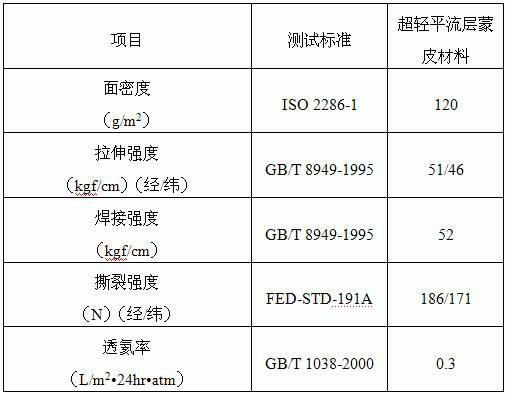

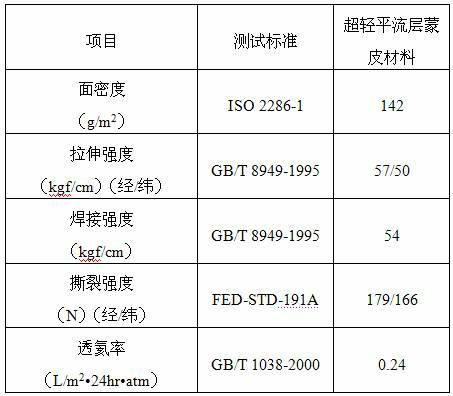

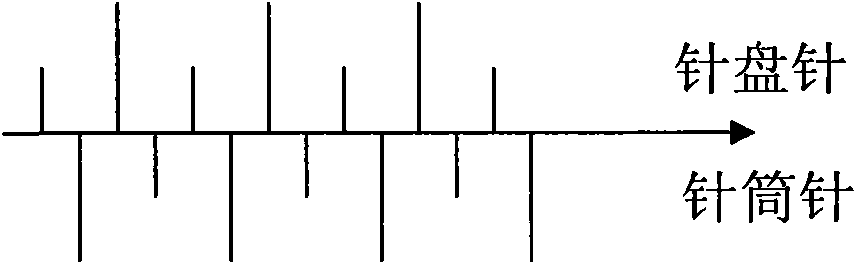

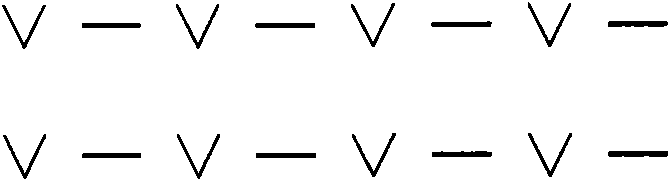

Ultra-light, weather-resistant and high-strength stratosphere skin material

InactiveCN101905557ALight in massGood weather resistanceSynthetic resin layered productsLighter-than-air aircraftPolyesterStratosphere

The invention provides an ultra-light, weather-resistant and high-strength stratosphere skin material which has high strength and weatherability, relating to skin materials. The ultra-light stratosphere skin material consists of a weather-resistant layer, a force bearing layer, a block layer and a heat sealing layer from outside to inside. Vectran fiber 200 Daniel plain woven fabric with ultra-high strength is selected and used as the force bearing layer, the Vectran fiber 200 Daniel plain woven fabric has the strength about 6 times as high as that of common polyesters, and the light weight of 54 g / m<2> and the thickness of 0.16 mm. The produced stratosphere skin material has ultra-light mass.

Owner:HARBIN INST OF TECH

Ice-cold fiber knitted fabric and manufacturing method thereof

InactiveCN101613907AWith cooling functionReduce unit weightWeft knittingWarp knittingUltraviolet protectionPulp and paper industry

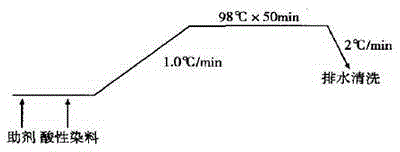

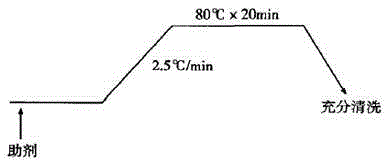

The invention relates to a fabric with a double-sided composite structure interweaved by cooling ice-cold fibers and cotton yarns. The inner layer of the fabric is formed by the ice-cold fibers and has a mesh-like tissue structure; and the outer layer of the fabric has a plain weave tissue structure. Australia AS / NZS 4399:1996 Evaluation and Classification of Ultraviolet Protective Fabric' standard tests show that the ultraviolet protection factor UPF level of the fabric reaches 50 +. A method for manufacturing the fabric comprises the following steps of: weaving, preprocessing, dyeing and scotching forming. The dyeing step comprises cotton dyeing, water washing, dewatering, polyamide fiber dyeing, water washing, color fixing and water washing in sequence. A coolfresh auxiliary agent and an uvioresistant auxiliary agent are added in one bath during dyeing, and the coolfresh auxiliary agent is added again by squeezing when scotching forming. The fabric combines the multiple functions of ice cooling, temperature reduction, coolfresh and uvioresistance into the whole fabric and is an ideal outdoor sportswear fabric.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

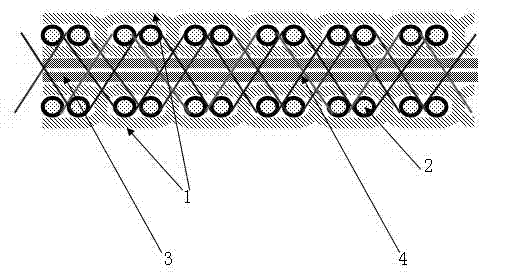

Dipped canvas fabric structure in three-dimensional structure for heavy-duty conveyor belt and production process thereof

ActiveCN102212917ASolve production technical problemsGood physical and mechanical propertiesFibre treatmentTwo or more solvent application treatmentPolyesterEngineering

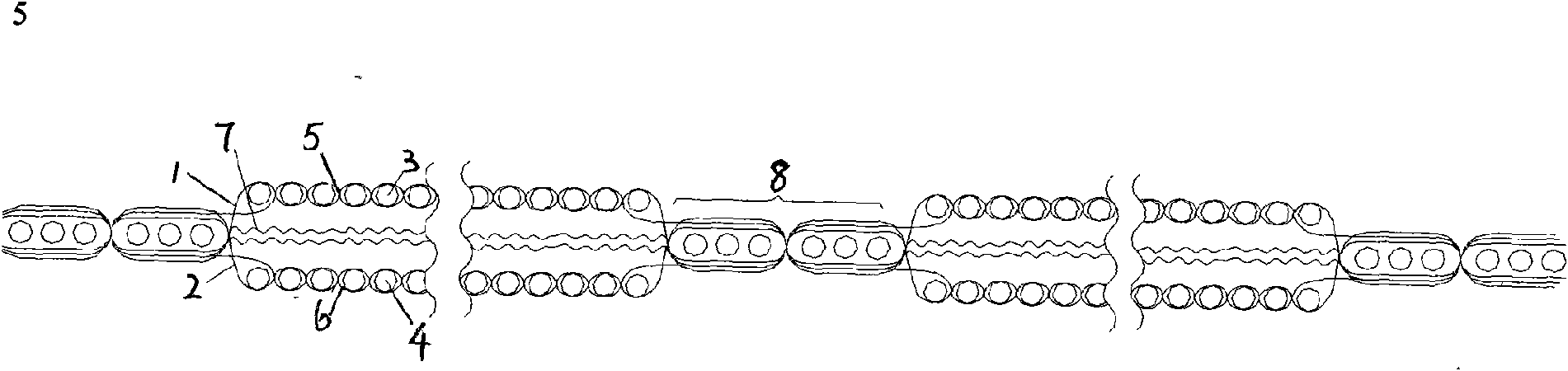

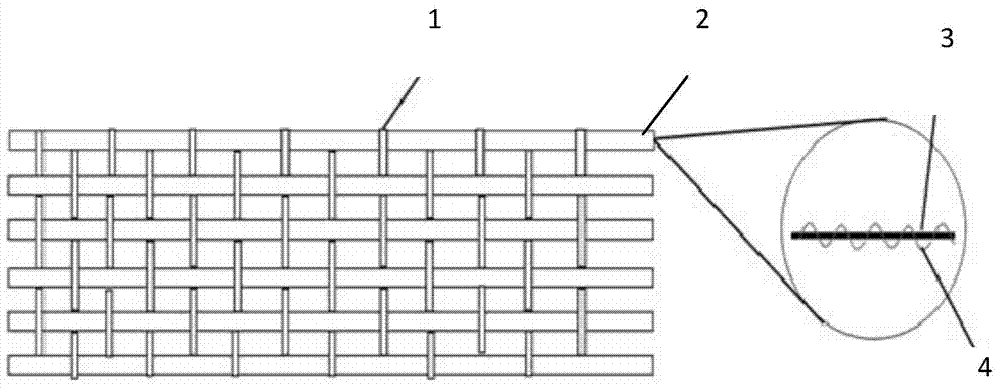

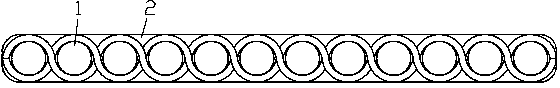

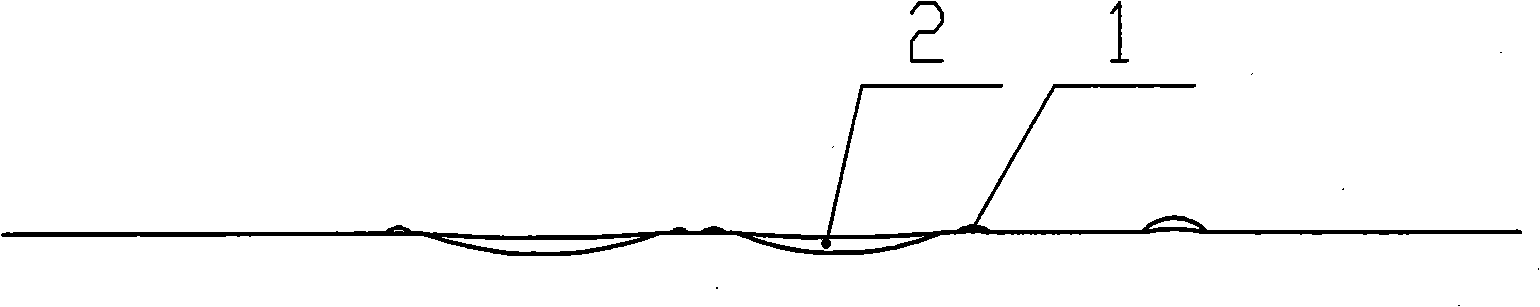

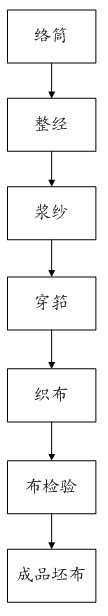

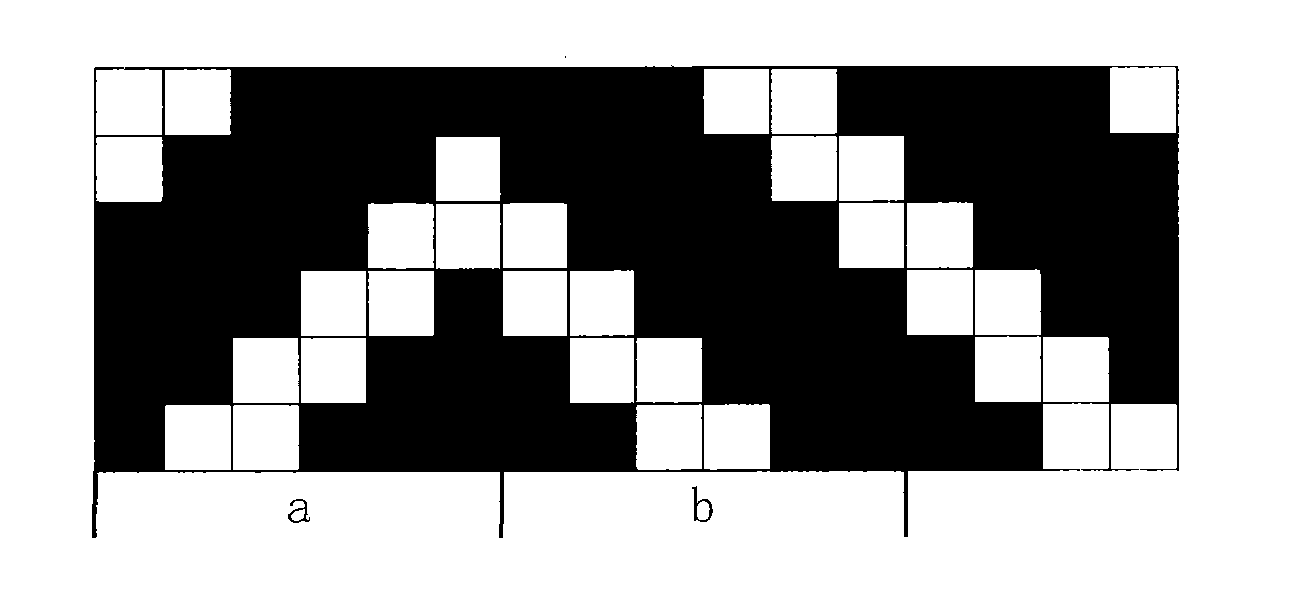

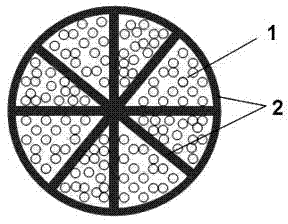

The invention discloses a dipped canvas fabric structure in a three-dimensional structure for a heavy-duty conveyor belt and a production process thereof. The dipped fabric structure is characterized in that an upper layer and a bottom layer adopt ground-facing warps (1) in the plain weave structure and weft (2) interwoven with the ground-facing warp, a straight warp (3) in the straight warp structure is utilized as an intermediate layer, a bundling warp (4) is connected with the weft (2), and the upper layer, the intermediate layer, the bottom layer and the bundling warp form the three-dimensional structure. The production process comprises the following processes: the process of weaving a fabric on a machine: adopting double warp shafts to send a warp woven cloth; and the process of stipulating a dipping formula and preparing, wherein a dipping solution is a mixture of an RF (resorcinol-formaldehyde) resin water solution generated by virtue of condensation polymerization of hydroxyphenol and formaldehyde and VP (vinyl pyridine) latex (L), the total content of solids is 18-22%, the pH value is 9-11, and the ratio of the RF to the L is (1:5)-(1:7). Polyester dipped canvas in the three-dimensional structure is especially applicable to production of the heavy-duty rubber conveyor belts and has the characteristics of tear resistance, puncture resistance and impact resistance.

Owner:浙江尤夫科技工业有限公司

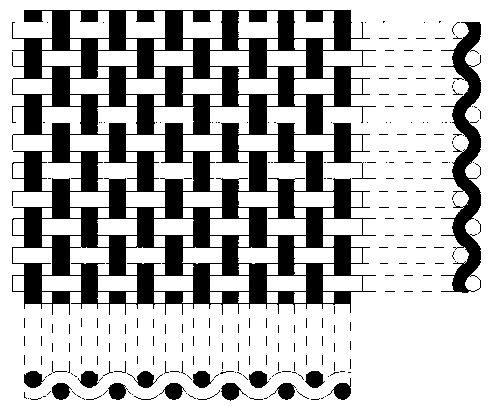

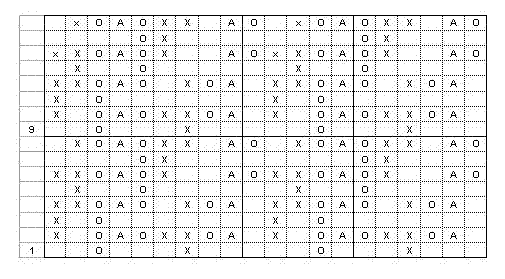

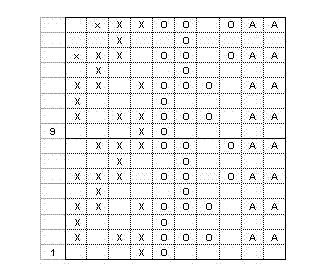

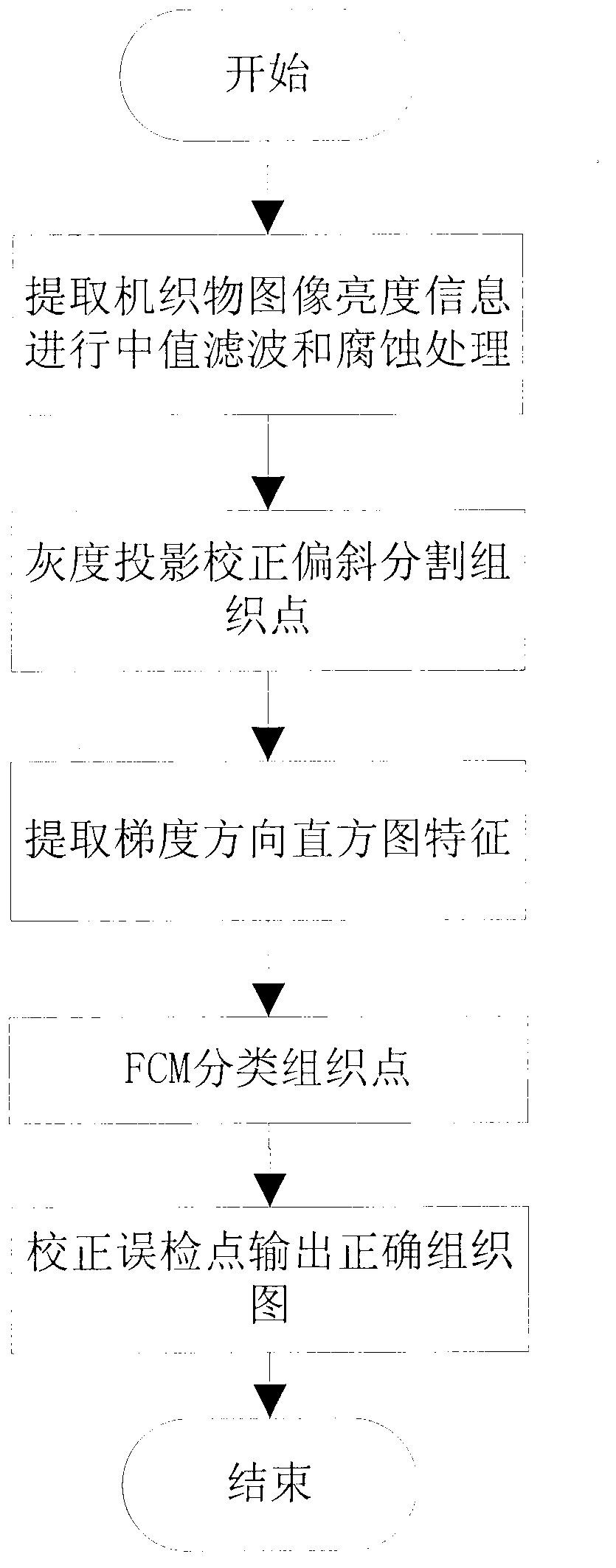

Recognition method for woven fabric structure

InactiveCN103106645ASimple methodEasy to implementImage enhancementImage analysisError checkingStatistical classification

The invention relates to an automatic recognition method for a woven fabric structure based on gradient direction characteristics and Fuzzy C-Means Algorithm (FCM). The automatic recognition method comprises the following steps of: firstly preprocessing a woven fabric brightness image by adopting an image morphology method, then correcting deflection existing in interweaving of warp yarns and weft yarns by utilizing gray projection, simultaneously segmenting a fabric image into a plurality of weave points, extracting gradient direction histogram characteristics on each weave point, classifying the weave points by using an improved FCM, and finally carrying out statistics on classifying results according to the periodicity of the fabric structure and correcting error checking points, thus outputting a correct weave chart. The automatic recognition method can overcome the influence brought by uneven illumination, and difference in thickness and color of yarns by utilizing gradient direction information of the weave points and combining with the FCM method, can achieve recognition of basic weaves (a plain weave, a twill weave and a satin weave) of the woven fabric, and also has a good recognition effect on derivative weaves (a plain derivative weave, a twill derivative weave and a satin derivative weave) in small decorative pattern derivative weaves.

Owner:TIANJIN POLYTECHNIC UNIV

Heavy-twisted stranded elastic pure-cotton jacquard shell fabric and processing process thereof

InactiveCN102560812AGood moisture absorption and air permeabilityHigh resilienceFabric breaking/softeningSingeingEngineeringMoisture absorption

The invention discloses a heavy-twisted stranded elastic pure-cotton jacquard shell fabric, which comprises warps and wefts according to the proportion of 1:1, wherein the warps are JC5.8texX2 high-count stranded heavy-twister yarns, and the wefts are JC / S5.8tex / 5.8tex / 30D(denier) core spun yarns and JC5.8texX2. The fabric weaving structure is the small plain-weave jacquard structure. Special treatment methods are utilized in the steps of slashing, weaving, dyeing and finishing. The heavy-twisted stranded elastic pure-cotton jacquard shell fabric has the characteristics of fine moisture absorption and air permeability of pure cotton while having high elasticity, luster and smoothness, stiffness and high suspension effect, and is applicable to spring and summer clothing due to natural crinkling effect and cambric styles thereof. Besides, the heavy-twisted stranded elastic pure-cotton jacquard shell fabric which is popularized is development from single-yarn heavy twist to heavy strand twist and is the extension from singular plain weaves to jacquard varieties. By the special treatment method utilized in the processing process, quality and grade of the heavy-twisted stranded elastic pure-cotton jacquard shell fabric are improved evidently, and the breakthrough in research and development and process of the heavy-twisted stranded elastic pure-cotton jacquard shell fabric provides reference for development of high-end and individual spinning fabric and guidance for expanding the market.

Owner:TIANJIN TIANFANG INVESTMENT HLDG

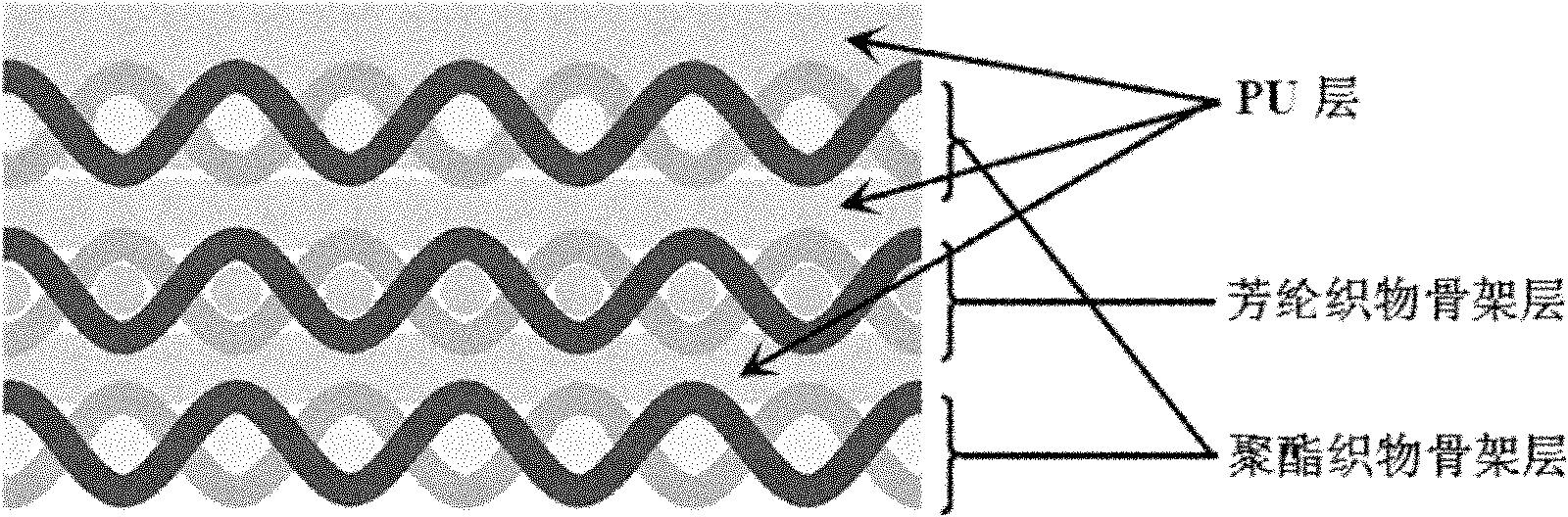

Light conveying belt and preparation method thereof

ActiveCN101979283AHigh warp strengthQuality assuranceConveyorsSynthetic resin layered productsPolyesterEngineering

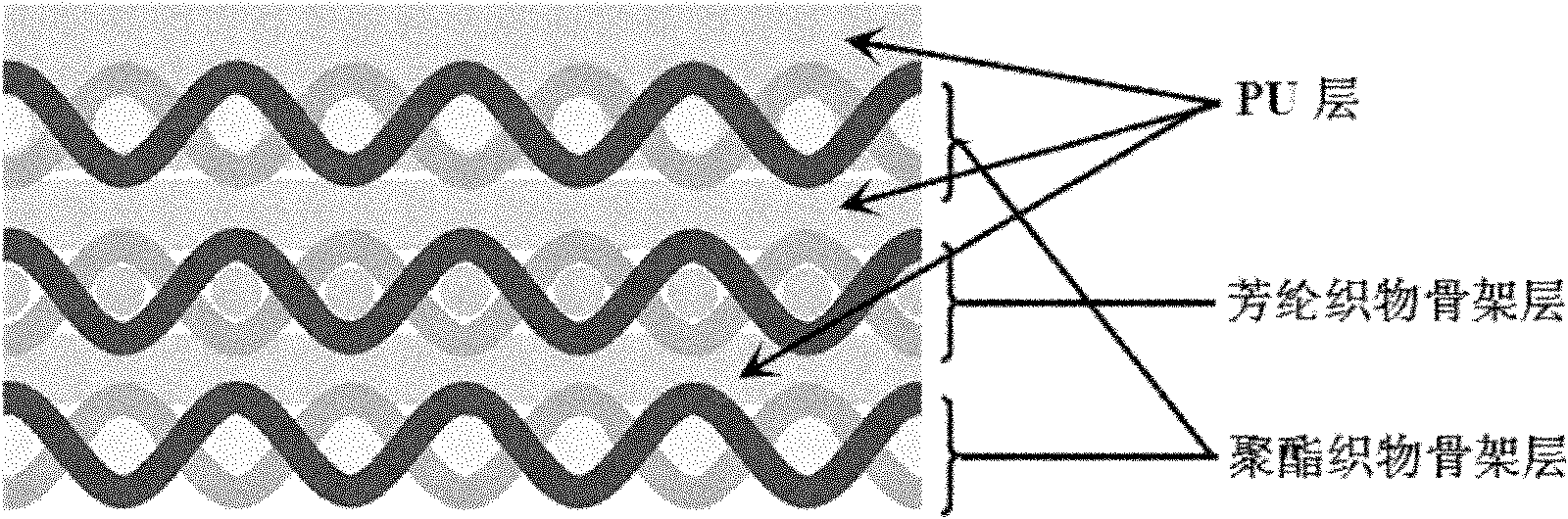

The invention relates to a light conveying belt and a preparation method thereof. The conveying belt comprises a Kevlar woven fabric, polyester woven fabrics and a polyurethane covering adhesive layer, wherein the Kevlar woven fabric is used as a middle framework layer; two layers of the polyester woven fabrics are used as a framework material of an upper framework layer and a framework material of a bottom framework layer; and three framework layers are respectively laminated with conductive polyurethane so as to obtain the three-fabric three-adhesive light conveying belt. The preparation method comprises the following steps of: (1) adopting Kevlar as warps of the Kevlar woven fabric and adopting ultra low shrink polyester multifilament yarns as weft yarns of the Kevlar woven fabric, wherein the basic weave is plain weave; (2) gluing the fabric and then sizing the glued fabric; and (3) coating the materials. The conveying belt of the invention has high strength. The integral tensile strength and the peel strength of the conveying belt are greatly improved. The preparation method is simple, has low cost and is suitable for industrial production.

Owner:DONGHUA UNIV

One-way continuous carbon fiber reinforced polyether-ether-ketone composite material and preparation method thereof

ActiveCN104262900APlay a protective effectAvoid damageMonocomponent synthetic polymer artificial filamentMelt spinning methodsCarbon fibersFiber bundle

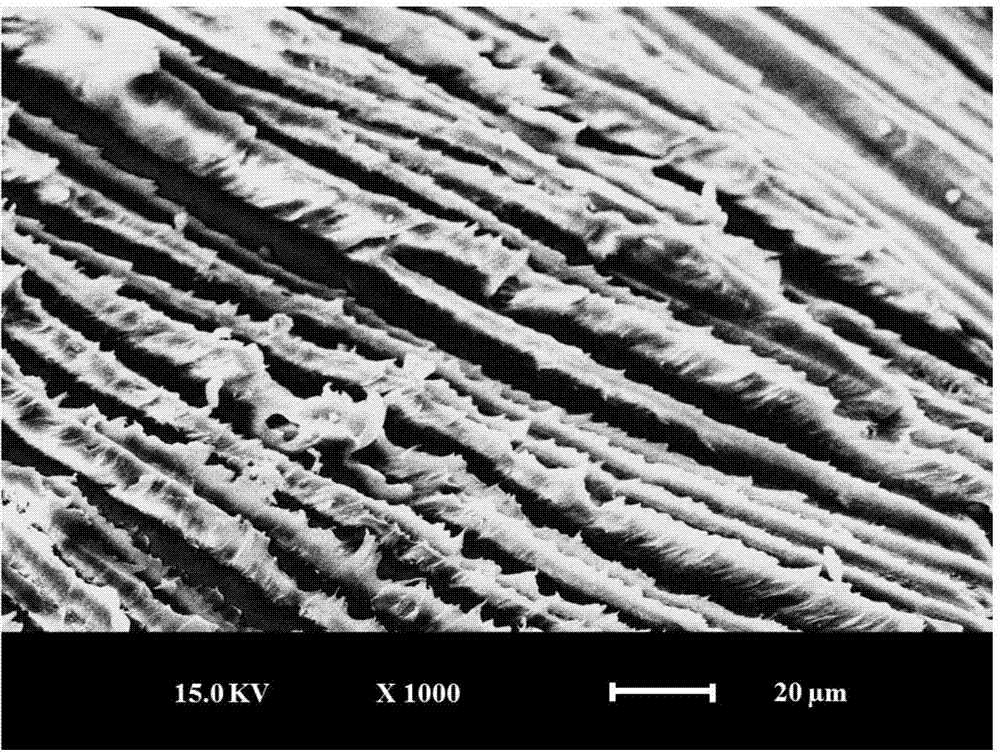

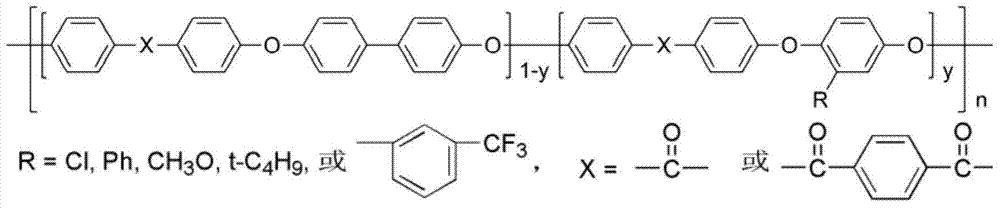

The invention discloses a one-way continuous carbon fiber reinforced polyether-ether-ketone composite material and a preparation method thereof, belonging to the technical field of thermoplastic composite materials. The method comprises the following steps: (1) preparing polyether-ether-ketone multi-filaments with the line density of 10-150tex from special spinning grade polyether-ether-ketone materials by using a melt spinning method; (2) uniformly wrapping continuous carbon fibers with the prepared polyether-ether-ketone multi-filaments through a fancy twister, thereby preparing hybrid fiber bundles; (3) weaving the hybrid fiber bundles as warp fibers and the polyether-ether-ketone multi-filaments as weft fibers to form plain weave fabrics in a plain weaving mode; and (4) overlapping the woven plain weave fabrics, hot-pressing on a hot-pressing machine, exhausting, cooling, and demolding to obtain the one-way continuous carbon fiber reinforced polyether-ether-ketone composite material disclosed by the invention. The preparation method has the advantages that the whole process is free of a solvent, so that the environment is not polluted, the preparation process is relatively simple, and the prepared composite material is relatively high in strength.

Owner:JILIN PROVINCE HUAYU AUTO PARTS

Nice and cool purified cotton yarn dyed fabric manufacturing process

InactiveCN103526391ARaw materials are natural and greenReduce contact surfaceWoven fabricsPulp and paper industryMoisture absorption

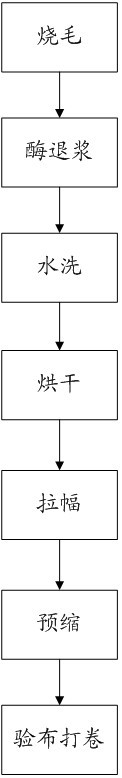

The invention relates to a nice and cool purified cotton yarn dyed fabric manufacturing process. The structure of a nice and cool purified cotton yarn dyed fabric comprises 1 / 1 plain weave, 1 / 1 plain back plus through holes, 1 / 1 plain back plus 3 / 1 twill weave or 2 / 2 basket weave, and the specification of the nice and cool purified cotton yarn dyed fabric comprises that yarn counts range from 35s to 70s, warp density ranges from 110 to 190 per inch, and weft density ranges from 58 to 110 per inch. The nice and cool purified cotton yarn dyed fabric manufacturing process is characterized by sequentially comprising the following processing steps of spinning, yarn setting, yarn dyeing, warping, slashing, weaving, singeing, desizing, mercerizing, liquid ammonium processing, noniron finishing, tentering, preshrinking and finished product obtaining, or spinning, yarn setting, yarn dyeing, warping, slashing, weaving, singeing, desizing, mercerizing, liquid ammonium processing, tentering, preshrinking and finished product obtaining. A finished product fabric processed through the nice and cool purified cotton yarn dyed fabric manufacturing process has a soft hand feel, no special auxiliary which feels cool is added in the production process, the contact area between yarn and the skin is reduced, gaps between the yarn are enlarged, the superficial area for moisture and heat dissipation is enlarged, moisture absorption and air permeability are more than doubled, and therefore a wearer can feel quite cool in summer.

Owner:LUTAI TEXTILE

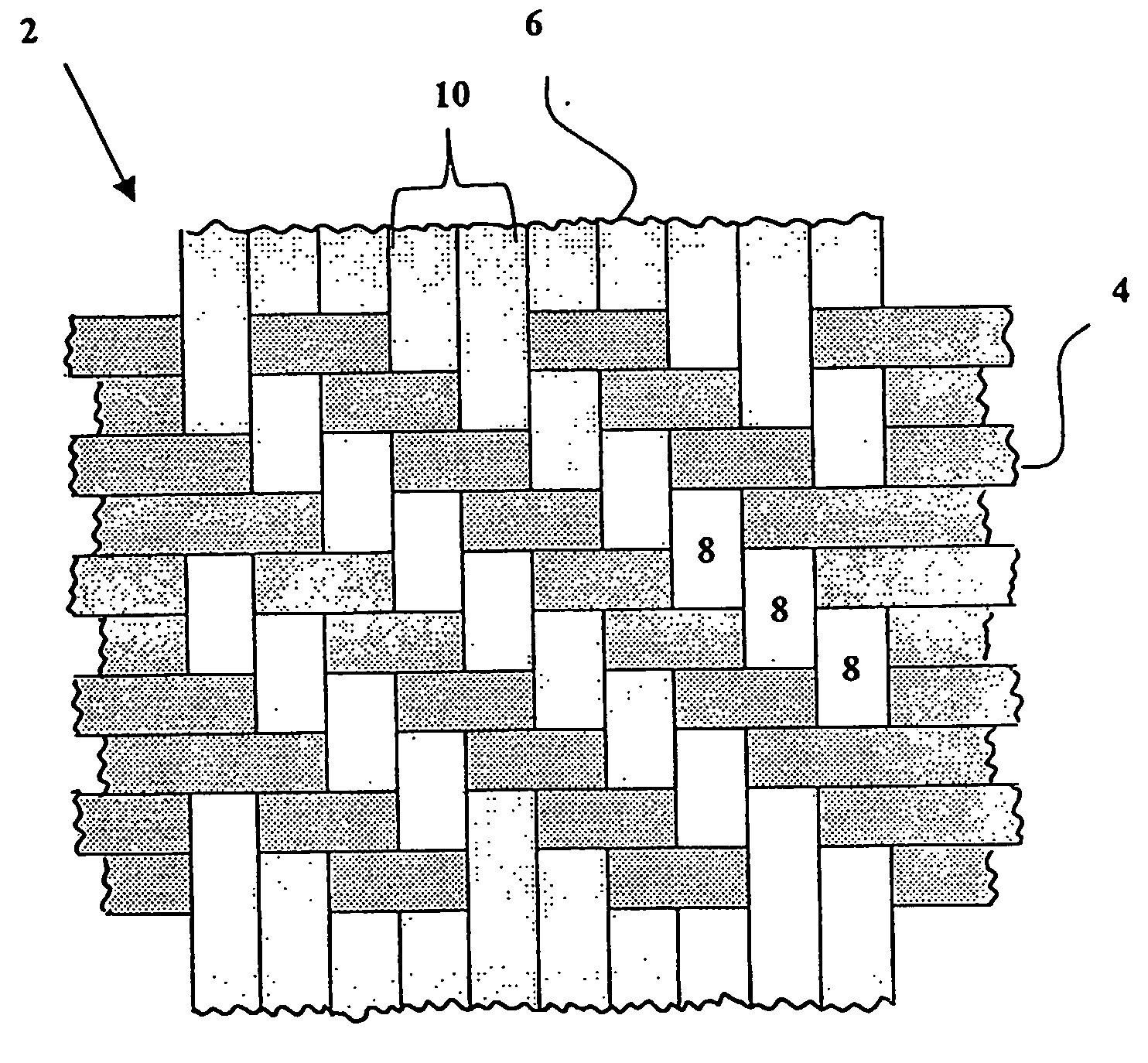

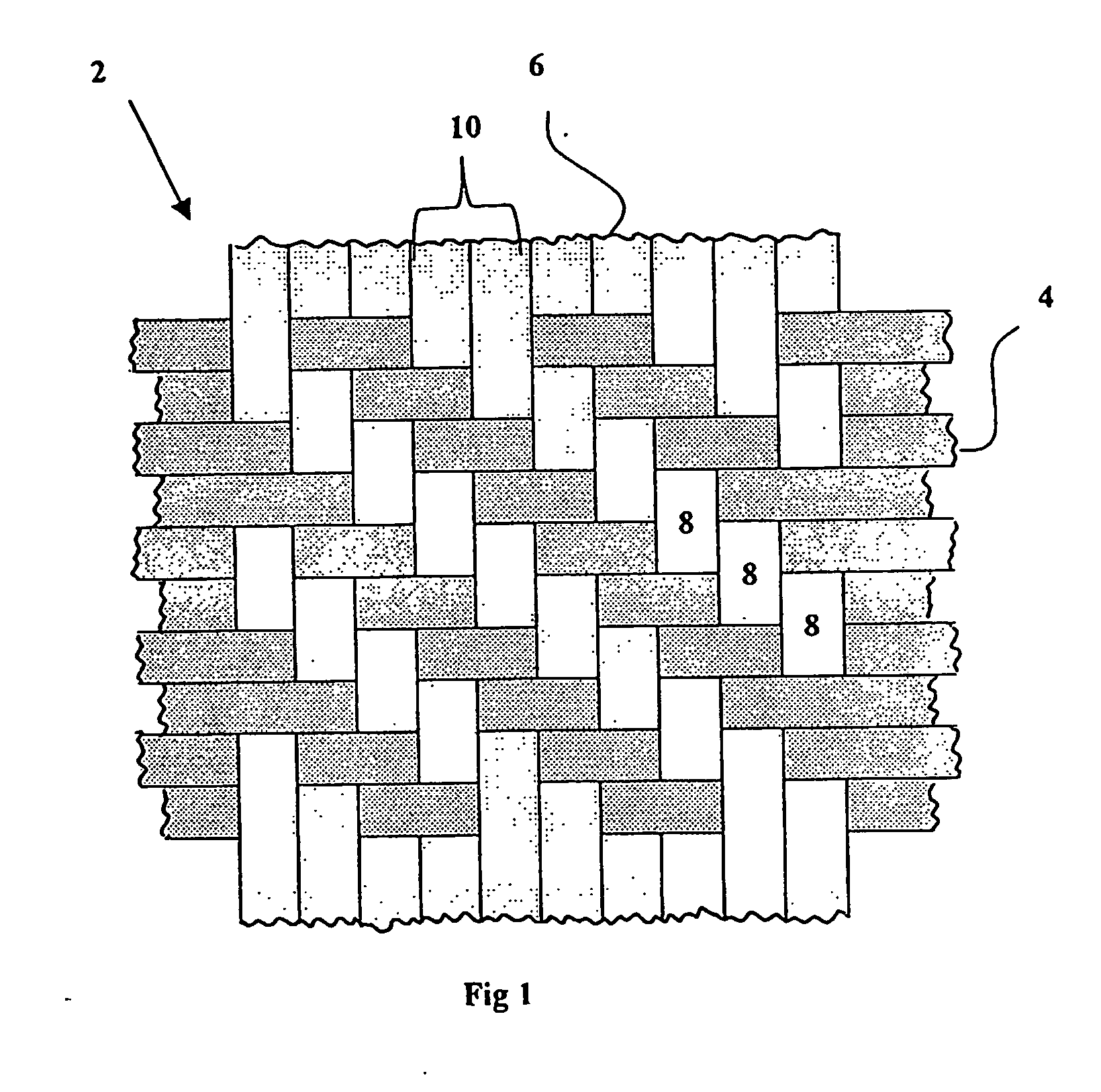

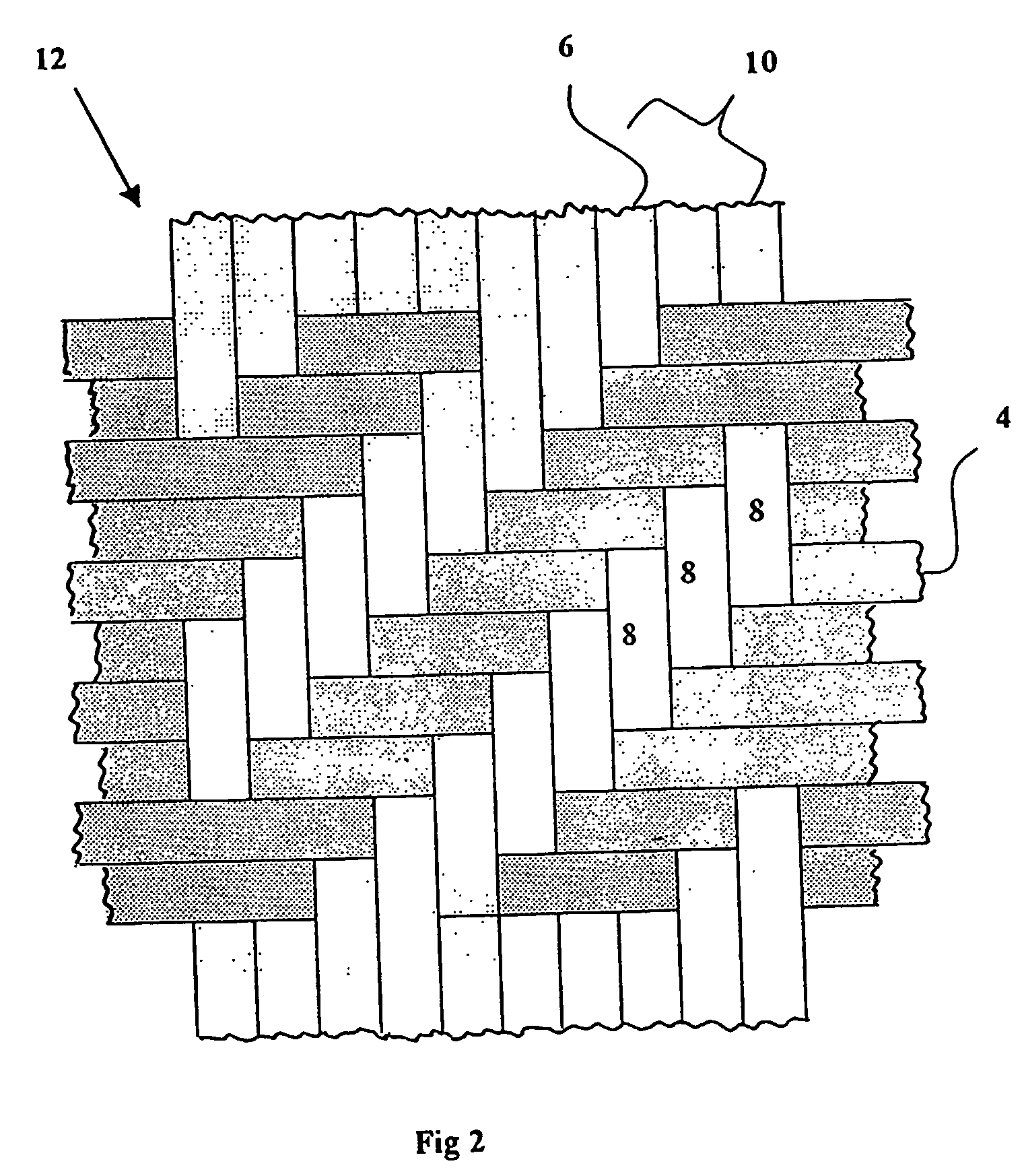

Scrim made of twill-woven thermoplastic tapes

InactiveUS20060166577A1Low tensile strengthHeavy and durableWeft knittingProtective fabricsEngineeringUltimate tensile strength

An industrial-strength scrim is made of thermoplastic tapes woven together in a twill weave, in which the weft tapes cross over at least two successive warp tapes and under at least one successive warp tape, in a repeating pattern. Such weave permits more tapes per inch to be accommodated in the scrim than for a plain weave, producing a scrim having greater mechanical strength, less cramming and folding of tapes and a smoother surface with fewer voids, suitable for coating.

Owner:INTERWRAP INC

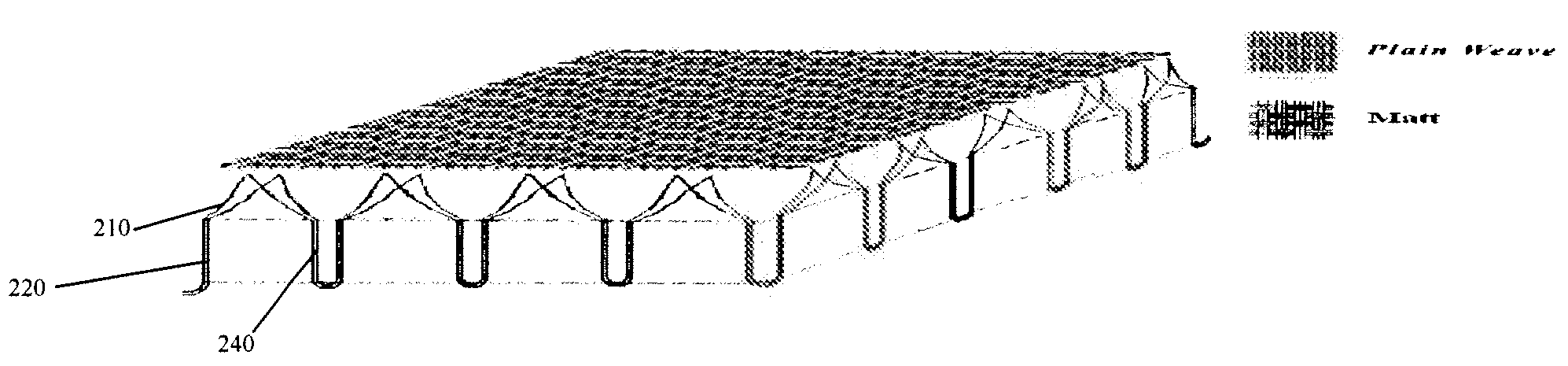

Fabric stimulating the plant structure for moisture management

ActiveUS20080220185A1Excellent water transport propertyKeep coolGarment special featuresDead plant preservationPlant StructuresEngineering

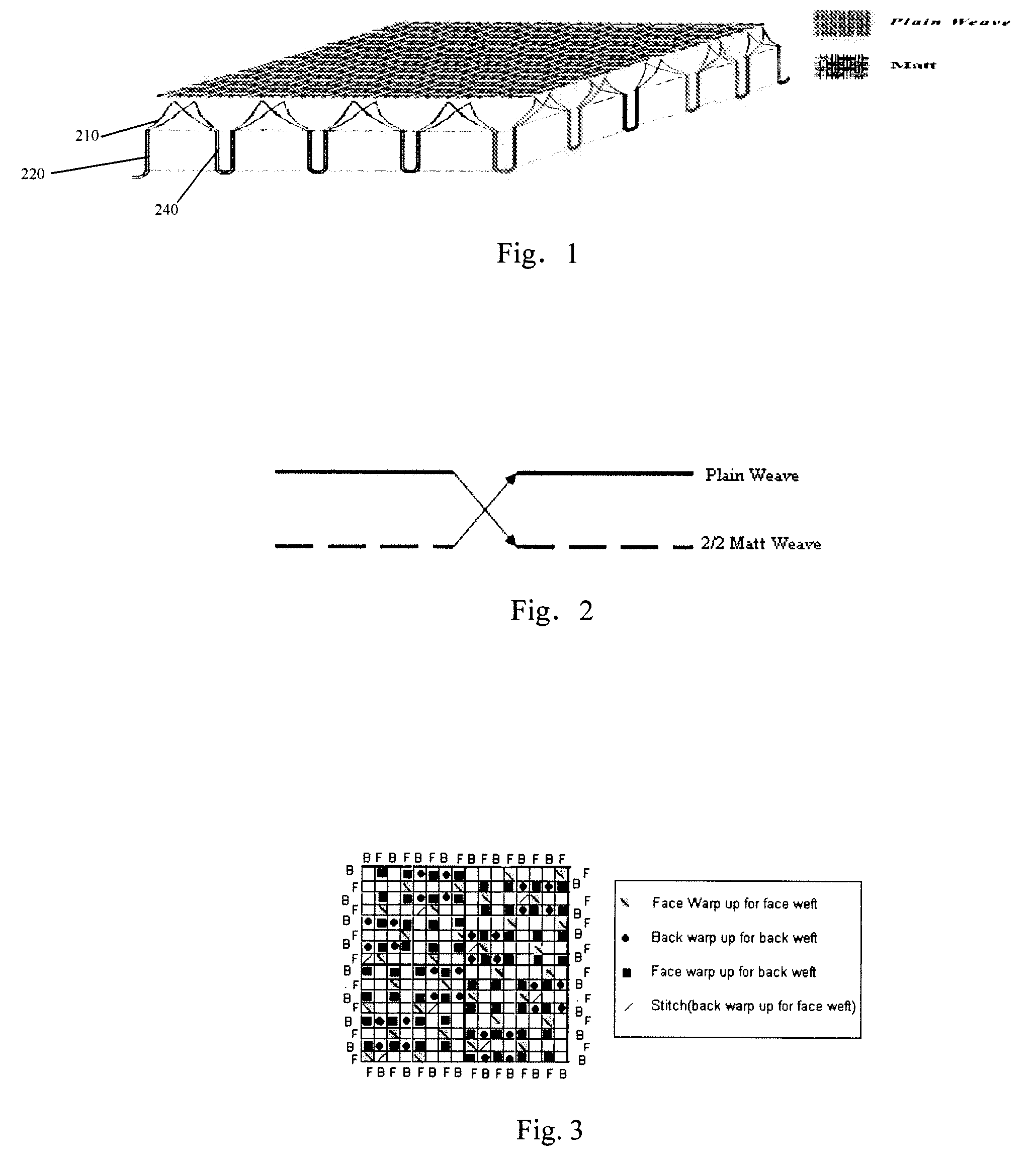

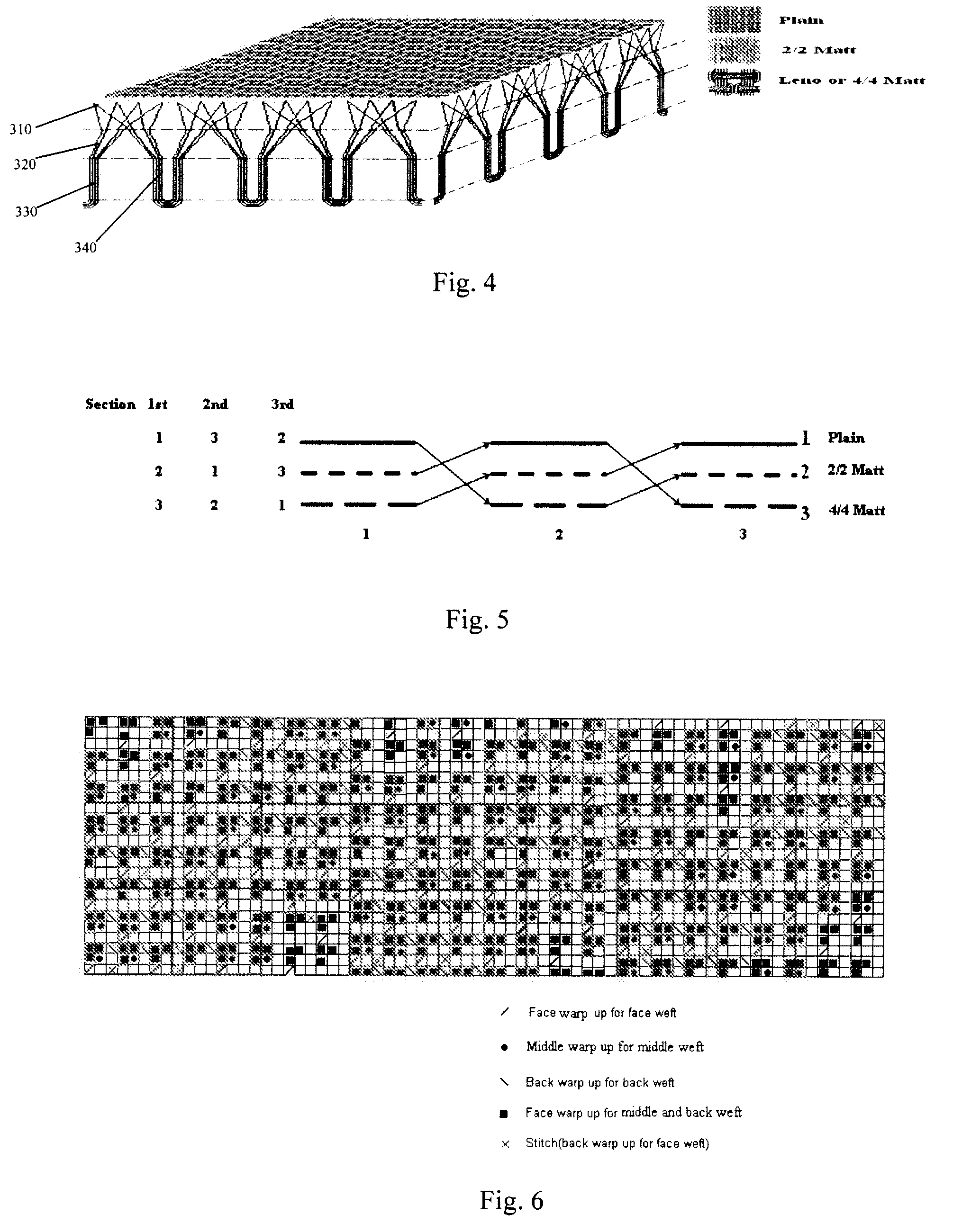

A fabric having moisture management function, which has a structure simulating plant structure and comprises at least two layers as follows: a bottom layer, which is of a leno or matt structure simulating main stem of plant, in which a number of yarns are grouped together to form a plurality of fabric units; said bottom layer can be adapted to be in contact with human skin; a top layer, which is of a plain weave structure, in which the yarns of said fabric unit further split in the top layer to form such a plain weave structure, simulating the branching in plant structure; wherein, in said fabric, water can be transported from the bottom layer to the middle layer and further to the top layer where it evaporates due to the improved capillarity of the yarns so as to provide better moisture management function.

Owner:THE HONG KONG POLYTECHNIC UNIV

Bamboo fiber label tape and production method thereof

ActiveCN103590255ANot easy to wrinkleSoft touchSucessive textile treatmentsVegetal fibresAdhesiveEngineering

The invention relates to label tapes and production methods thereof, particular to a bamboo fiber label tape and a production method thereof. The label tape comprises a base cloth layer and an adhesive layer, the thickness of the label tape is in a range of 0.280-0.300 mm, the base cloth layer is made of a 100% bamboo pulp fiber material, the count of bamboo pulp fiber yarn forming the base cloth layer is 16-40, the warp density is 28-45 warps / cm, and the weft density is 19-35 wefts / cm. The production method comprises the steps of selecting a bamboo fiber semi-finished product as base cloth; performing anti-crease finishing; subjecting the base cloth to two-time immersion and two-time rolling treatment; performing pre-calendering treatment: a calendering surface is a stain-weave surface, the calendering temperature is 50 DEG C to 60 DEG C, the pressure is 10MPa to 12MPa, the calendering speed is 30 m / min to 35 m / min, and the thickness of the base cloth is calendered into 0.285 mm to 0.295 mm; performing coating treatment: a dry type coating method is adopted, coating a plain-weave surface of the base cloth with adhesive, scraping pulp by pulp scraping equipment, the adhesive spread is controlled within 5 g / m<2> to 10 gm<2>, and the total weight is 144 g / m<2> to 148 g / m<2>; and performing post-calendering treatment: the calendering temperature is 70 DEG C to 120 DEG C, the pressure is 10MPa to 12MPa, the calendering speed is 30 m / min to 35 m / min, and the thickness of the coated cloth is calendered into 0.280 mm to 0.300 mm. The label tape touches soft and can be used as a sewn-in label.

Owner:HUZHOU SINY LABEL MATERIAL

Concave-convex jacquard cloth and manufacturing method thereof

InactiveCN101260589AStrong three-dimensional senseAdd dimensionSwivel-woven fabricsLappet-woven fabricsEngineeringSurface structure

The invention relates to a concavo-convex jacquard which has a fabric surface with concavo-convex patterns and a manufacture method thereof. The surface of the concave-convex jacquard is provided with the concavo-convex patterns, warp yarns of the fabric are cotton yarns with two colors of A color and B color, weft yarns are cotton yarns and elastic yarns, wherein the cotton weft yarns are A color and the elastic weft yarns are B color, the convex part and the concave part of the patterns are both plain weave bag structures, the surface structure of the convex part is formed through interlacing the warp yarns with A color and the weft yarns with A color, the surface structure of the concave part is formed through interlacing the warp yarn with B color and the weft yarn with B color, the circumferences of the convex part and the concave part are dobby structures, and other structures of the fabric are jacquard structures formed through interlacing two warp yarns and two weft yarns. The concavo-convex jacquard solves the technical problem that the cloth surface of the prior jacquard is flat lacking vivid third dimension, which can not give persons a fresh feeling. The concavo-convex jacquard has fabric patterns with strong third dimension so as to bring stronger visual impact for the persons, and can be used for high grade home accessories and dress fabrics.

Owner:倪爱东

Production technology of glass fiber cloth for insulation

ActiveCN103741319ASolve the production processSimple processFibre treatmentHeating/cooling textile fabricsGlass fiberPolymer science

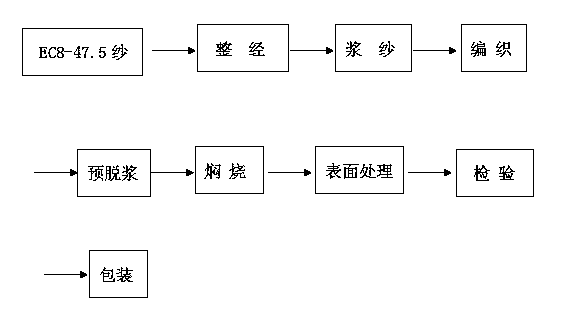

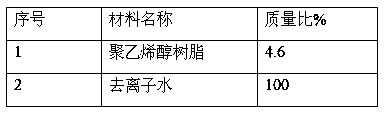

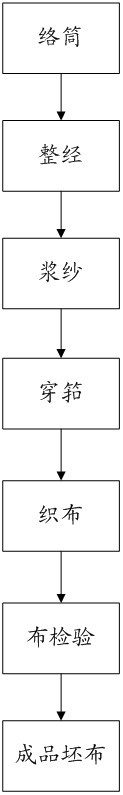

Provided is a production technology of glass fiber cloth for insulation. The production technology of the glass fiber cloth for insulation comprises the steps that EC8-47.5 glass fiber yarn serves as warp and weft; a warping working procedure technology is carried out, wherein the EC8-47.5 glass fiber yarn is placed on warping creels in sequence; a slashing working procedure technology is carried out; a knitting working procedure technology is carried out, wherein an air jet loom is used for carrying out weaving, drafting, reed insertion, gaiting and weaving are carried out on slashed warp beams in sequence according to plain weave, the warp and weft density is 17.3*14.2 pieces per centimeter, and the cropping length is 2000 meters per roll; a post-processing working procedure is carried out; drying is carried out at the temperature of 200DEG C, and the trimming working procedure, the take-up working procedure, the check working procedure and the packaging working procedure are carried out. The purpose of the production technology for using the EC8-47.5 glass fiber yarn to produce the high-grade glass fiber cloth for insulation is achieved, the warp and weft density of the glass fiber cloth is 17.3*14.2 pieces per centimeter, the thickness of the glass fiber cloth is 0.140mm, the basic weight is 150g / m<2>, the diameter of a filament of the glass fiber cloth is 8 microns, the warp and weft number is 47.5Tex, and the production technology of the glass fiber cloth for insulation has the advantages that the technology is more convenient to use, production management is easy, weaving is convenient, and the foundation is laid for producing the high-grade insulating glass fiber cloth through ordinary devices.

Owner:江西长江化工有限责任公司

Textile and production process thereof

ActiveCN102605511AWith thermoregulationAnti-allergicSingeingDry-cleaning apparatus for textilesAntibiosisAllergy prevention

The invention discloses a textile. A plain-weave or diagonal-weave organization unit is interwoven by warps and wefts, the warps are made of colored cotton, the wefts are made of natural colored hemp, the warps and the wefts of the plain-weave or diagonal-weave organization unit are arranged vertically in a layered manner, and the ratio of the warps to the wefts is 5:3. The production process of the textile includes weaving process and finishing process. The warps and the wefts of the textile are properly matched vertically in the layered manner, and mutually make good for deficiency so as to realize perfect combination of appearance and hand feeling. In addition, the textile has functions of temperature regulation, allergy prevention, static elasticity prevention and antibiosis. The production process includes the pure physical finishing process, chemical preparation is omitted, pollution is reduced, and the production process is environment-friendly.

Owner:JIANGSU MENGLAN GROUP

Fabric and production method thereof

InactiveCN101942731AWith super indigo effectWith two-color effectFibre treatmentDyeing processColor effectPolyester

The invention discloses a fabric and a production method thereof. All or partial warps forming the fabric are air-texturing composite yarns, and the air-texturing composite yarns are manufactured by feeding modified polyester pre-orientated yarns serving as decorative yarns and polyester full-drawn yarns serving as core yarns into an air-texturing nozzle and performing thermal treatment under the action of airflow. In the production process of the fabric, variable tissues of plain weave, twill weave, plain weave and twill weave or dual tissues taking the above tissues as surface tissues are adopted. The prepared fabric has super indigo effect, double-color effect and good abrasion resistance and wrinkle resistance.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Textile material in sheet form for technical uses

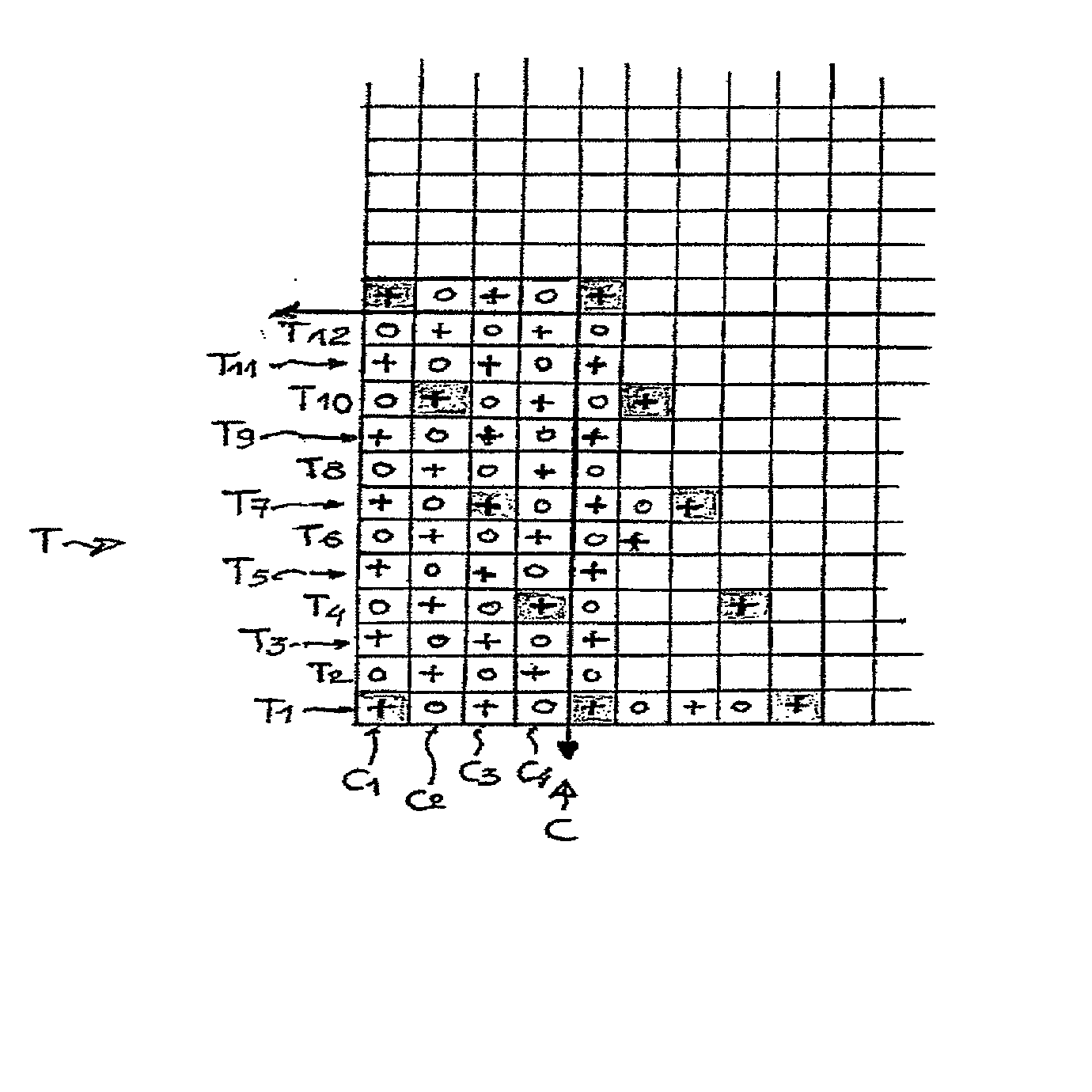

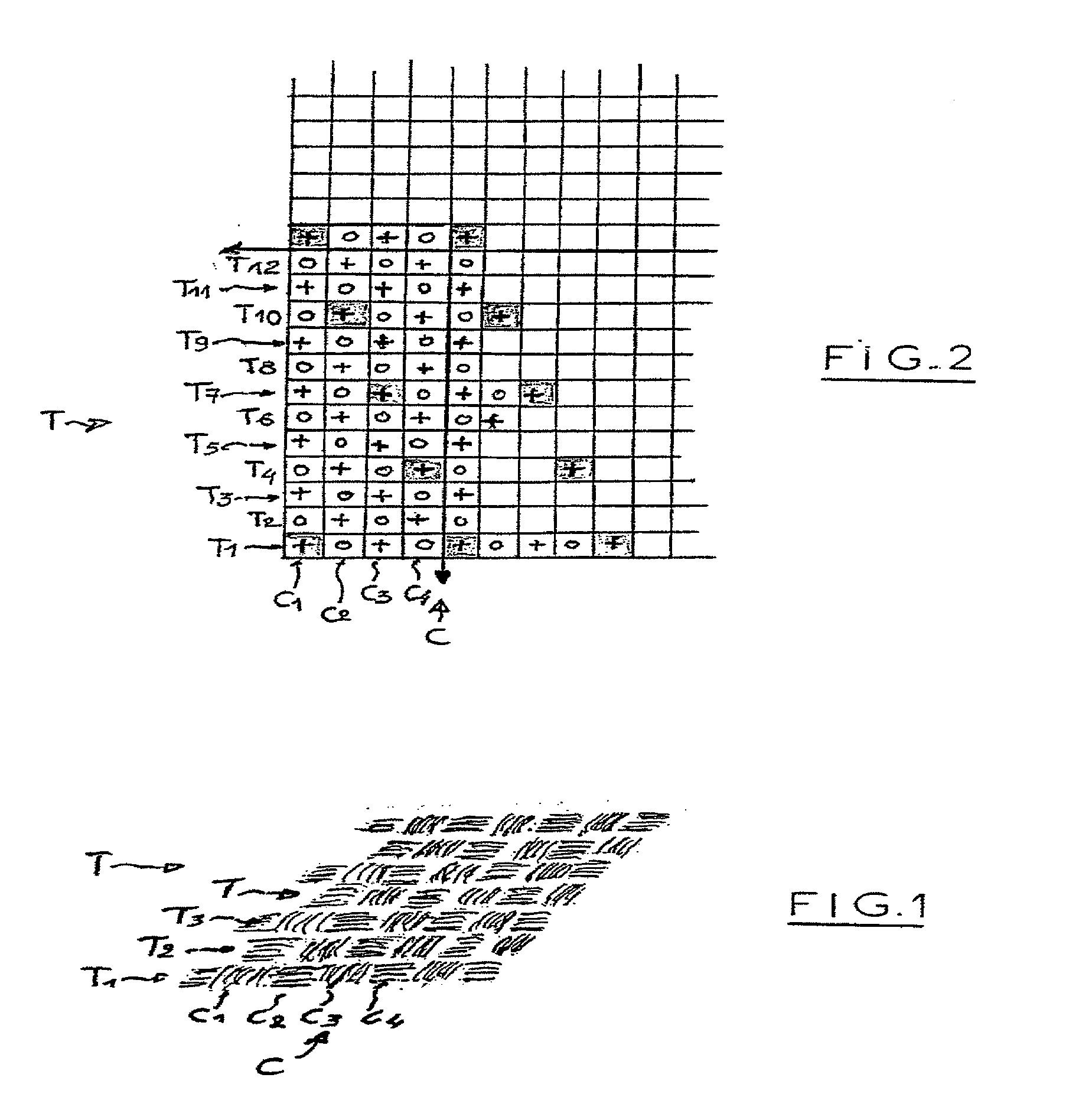

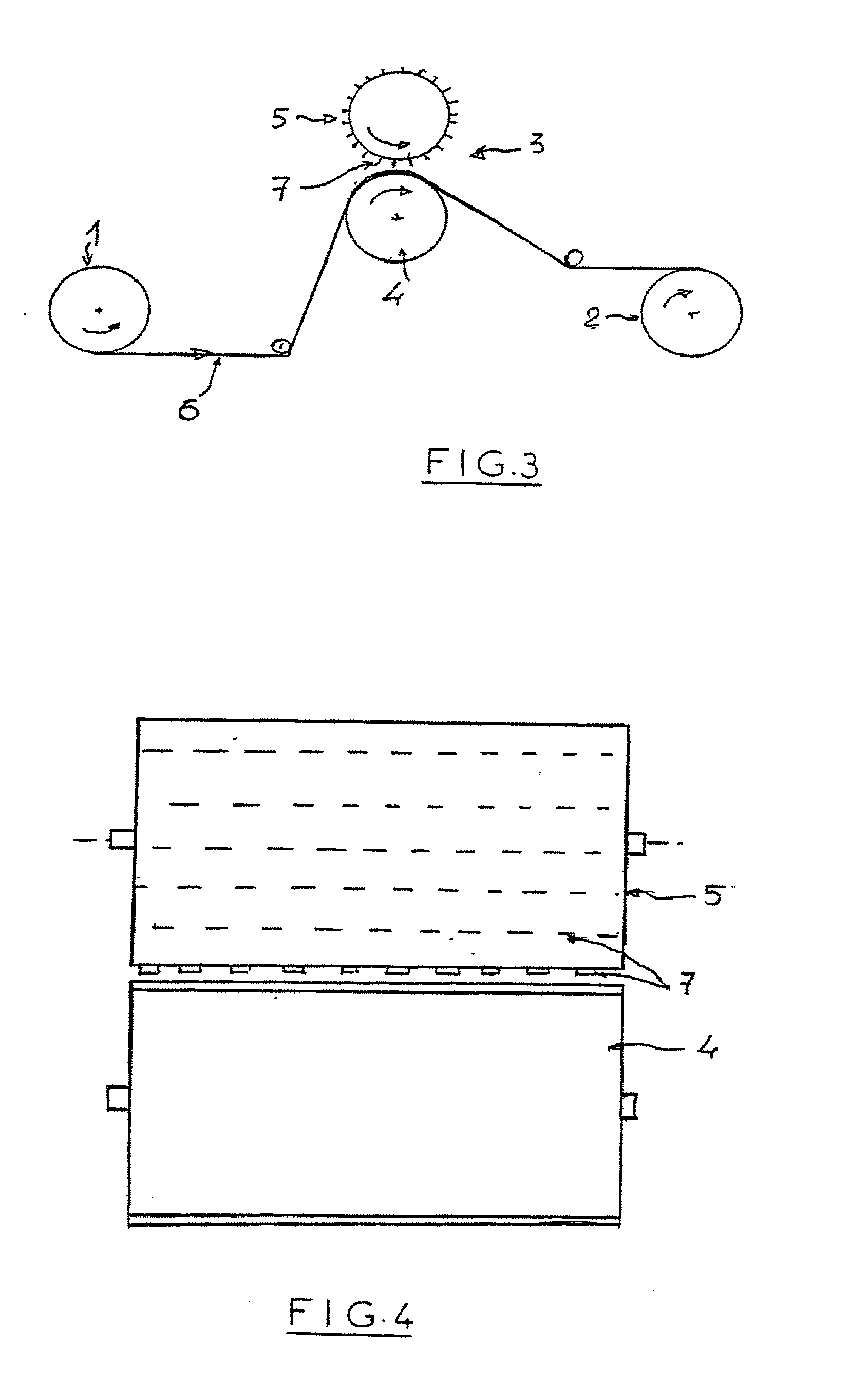

The invention relates to a textile material in sheet form, consisting of a warp and weft fabric produced by rovings of continuous technical filaments (glass, carbon, aramide) without torsion. The invention is characterized in that the fabric is produced according to a plain weave or derivative thereof, the density of the warp (C) and the weft (T) being balanced; the warp threads (C) or weft threads (T) are weakened or cut individually at predetermined intervals without any noticeable deterioration in the characteristics of the weft or warp threads situated beneath the weakening or cutting area; and the areas in which a series of threads of the fabric (C) or (T) are weakened or cut are produced with a lateral and vertical thread course between two consecutive threads.

Owner:ESTAB LES FILS DAUGUSTE CHOMARAT & CO SA

Textile

ActiveUS20150104592A1Improve textureIncreased durabilityPedestrian/occupant safety arrangementSynthetic resin layered productsEngineeringPlain weave

A textile with high weave density which comprises a main-yarn made of a Japanese paper yarn and a sub-yarn thinner than the main-yarn interwoven with each other, wherein the textile has a weave texture structure including warps A and wefts A made of the main-yarn, and warps B and wefts B made of the sub-yarn, wherein in the weave texture structure, warp rows have a repeating row structure where a plurality of warps B are located between two warps A and weft rows have a repeating row structure where a plurality of wefts B are located between two wefts A, and wherein the warps A and the wefts A cross each other in a plain weave texture structure.

Owner:ITOI LIFESTYLE RES

Enhanced flexible solar cell assembly and packaging method thereof

ActiveCN102709366AReduce weightGood flexibility and bendabilityFinal product manufactureGlass/slag layered productsPhysicsPlain weave

The invention relates to a structural piece of a flexible solar cell assembly with an enhanced back plate and a packaging process for the structural piece, belongs to the technical field of solar cells and aims to solve the problem that due to plastic deformation of the flexible solar cell assembly, the output voltage is reduced. The packaging method has the technical characteristics of preparing the front plate and the back plate of the cell assembly by using high polymer materials, fiber fabrics and enhanced fiber fabrics of which the thicknesses are 0.1 to 1.0mm; placing laminated sheets which are made of plain woven materials into a high temperature resistant vacuum sealing bag; vacuumizing the bag to seal the assembly; and heating and pressurizing the bag by using a high-pressure autoclave. The flexible solar cell assembly has the advantages that the weight is reduced greatly, the total weight of a mounting structure is 25 to 30Kg / square meters, the tensile strength of 0.5 percent of elongation variable is over 300MPa, and the flexible solar cell assembly with the flexibility is suitable for curved surface and other non-planar mounting structures.

Owner:SHENZHEN TRONY SOLAR CORP +1

Functional nylon 66 shell fabric and manufacturing method thereof

InactiveCN105332297AGood flexibilityIncrease elasticityHeating/cooling textile fabricsDry-cleaning apparatus for textilesNylon 66Light reflection

The invention relates to a functional nylon 66 shell fabric and a manufacturing method thereof. The method is characterized by comprising the steps of 1, raw material selection and distribution, 2, spinning technology, 3, weaving technology and 4, finishing technology after dyeing. The shell fabric has the advantages of being high in yarn fine denier and large in tightness, and being firm in texture, high in tear resistance and good in wear resistance even though tissue is simple plain weaves. The shell fabric can be used for manufacturing a jacket and a wind coat and can also be used for manufacturing sportswear and leisure wear when used as the high-density nylon fabric shell fabric, and the shell fabric is a best-quality shell fabric of a down jacket in the current trend that winter clothing is portable due to the fact that the warp and weft density is higher; the shell fabric is super strong, capable of resisting gigging and resisting coldness, warm, light, soft, fine, smooth, easy to wash, quick to dry, easy to manage and not likely to fade when used as the down jacket shell fabric; energy losses are reduced through light reflection, the warmth keeping effect is achieved, and cells are activated through resonance and generation of heat by friction, so that the health care effect is achieved.

Owner:JIANGSU YDTEX GRP LTD

One-way wet-guiding and absorbing and quick-drying type cotton/nylon composite knitting fabric

ActiveCN103696110AFeel goodHigh glossWeft knittingHeating/cooling textile fabricsDying processesEngineering

The invention relates to a one-way wet-guiding and absorbing and quick-drying type cotton / nylon composite knitting fabric. The fabric adopts a double-sided plain weave structure, the cotton with higher wet-absorbing capability and poorer wet-guiding capability is weaved into an inner layer of the fabric by a circular knitting machine, and the superfine denier nylon long yarns with good wet-guiding and absorbing capability are weaved into an outer layer of the fabric. The dying process of the one-way wet-guiding and absorbing and quick-drying type cotton / nylon composite knitting fabric adopts the conventional dying process, and comprises the following processing steps of weaving of fabric blanks, preshaping, fiber opening, dyeing, cleaning, hydrophilic softening and arranging and shaping. The fabric has the advantages that the wet can be quickly absorbed and diffused to the outer layer of the fabric, the continuous dryness in the clothes can be maintained, and the fabric is an ideal and environment-friendly type one-way wet-guiding and quick-drying material.

Owner:广东广纺检测技术股份有限公司

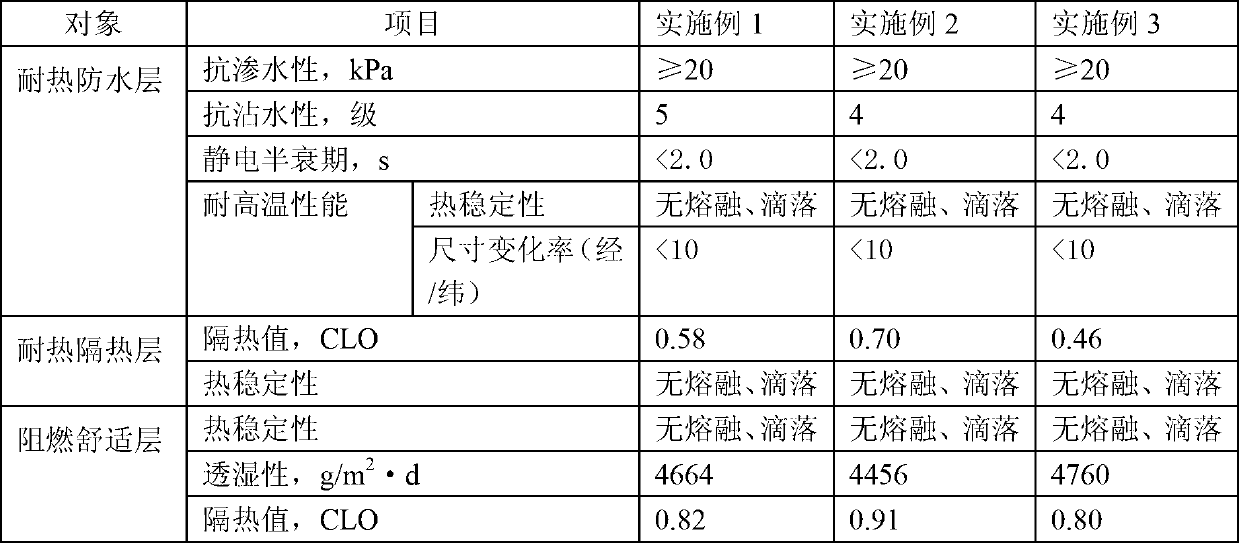

High-temperature-resisting heat-insulating waterproof antistatic multifunctional fabric and application thereof

ActiveCN102896854AHigh temperature resistantWith heat insulationSynthetic resin layered productsWhole bodyNonwoven fabric

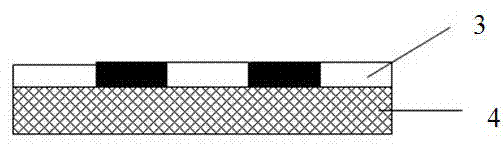

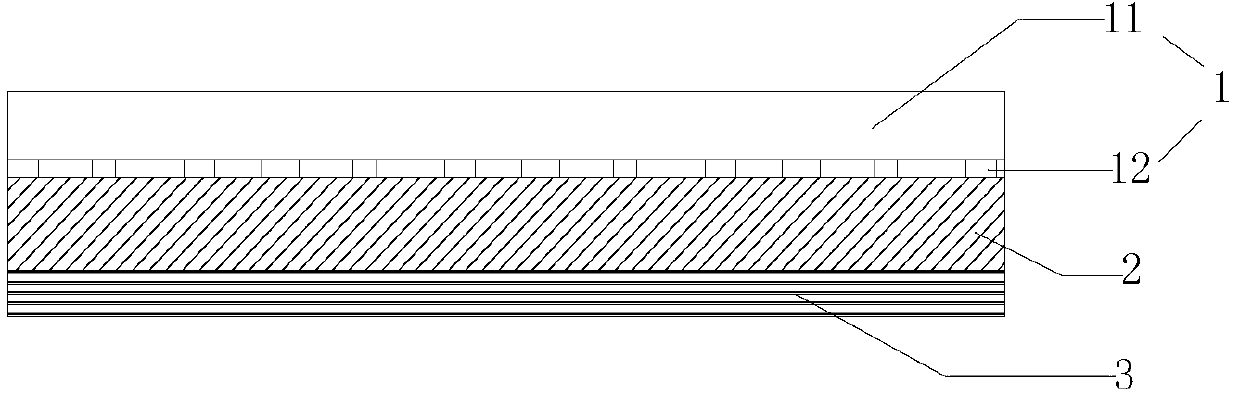

The invention relates to the field of multifunctional materials, in particular to a high-temperature-resisting heat-insulating waterproof antistatic multifunctional fabric. The multifunctional fabric comprises a heat-resisting waterproof layer (1), a heat-resisting heat-insulating layer (2) and a flame-retardant comfortable layer (3) in sequence from top to bottom, wherein the heat-resisting waterproof layer (1) comprises a high-temperature-resisting antistatic fabric (11) which is subjected to waterproof treatment, and a waterproof film (12) which is pasted to a lower surface of the high-temperature-resisting antistatic fabric (11); the heat-resisting heat-insulating layer (2) is a multilayer spunlace nonwoven fabric which is made of a high-temperature-resisting fiber; and the flame-retardant comfortable layer (3) is a flame-retardant plain weave fabric. The multifunctional fabric has a high temperature resisting function, a heat insulating function, a waterproof function, an antistatic function and the like at the same time, can be made into protective articles such as protective garments and protective gloves which have the high temperature resisting function, the heat insulating function, the waterproof function and the antistatic function and are used for whole body protection or local protection during operation under dangerous conditions, and is extremely high in practicability.

Owner:NAVY MEDICINE RES INST OF PLA

High-abrasion-resisting glass fiber fabric and preparation method thereof

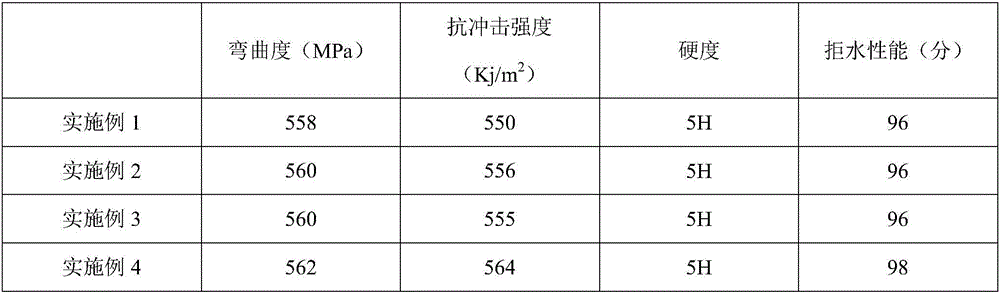

The invention discloses a high-abrasion-resisting glass fiber fabric and a preparation method thereof. The preparation method comprises the steps that 1, glass fiber monofilaments are plain-woven to obtain a basic glass fiber fabric; 2, the basic glass fiber fabric is put in a sizing agent to be dipped for 2-3 hours; 3, the excessive sizing agent on the basic glass fiber fabric is extruded out, and air bubbles are removed to obtain a preformed glass fiber fabric; 4, the glass fiber monofilaments are parallelly concentrated to obtain protofilaments, the protofilaments are cut according to the length of 60-70 mm and are randomly and uniformly laid on the preformed glass fiber fabric, then a bonder is applied, and heating and curing are performed to obtain a basic material; 5, the sizing agent in the step 2 is uniformly applied to two sides of the basic material in a coated mode, and then ultraviolet curing is conducted on the basic material to obtain the high-abrasion-resisting glass fiber fabric. The high-abrasion-resisting glass fiber fabric has high hardness, good mechanical strength and a high water-repellency performance value, and good abrasion resistance is reflected. The curvature and anti-impact strength are ideal, and it is indicated that the high-abrasion-resisting glass fiber fabric has good water repellency.

Owner:嘉兴杰特新材料股份有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com