Patents

Literature

60results about How to "Solve the production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microorganism passivator for repairing heavy metal pollution of soil and preparation and application thereof

InactiveCN106867945AIncrease resistanceImprove enrichment capacityBacteriaContaminated soil reclamationMicroorganismResource utilization

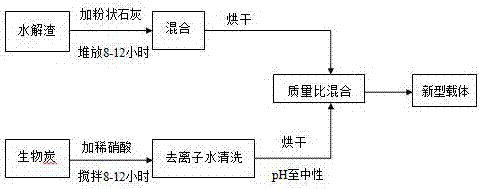

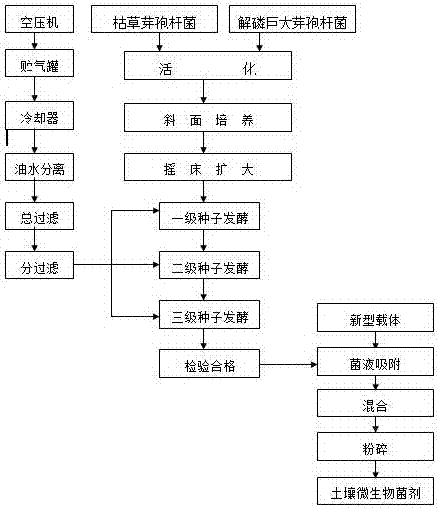

The invention discloses a microorganism passivator for repairing heavy metal pollution of soil and preparation and application thereof. A preparing method comprises the steps of fermentation and adsorption of strains. Specifically, bacteria solutions obtained after fermentation of bacillus megateriumvar.phosphaticum and bacillus subtilis LVLE-14 are mixed in proportion, then adsorption is conducted by means of a special adsorption carrier, and then mixing and smashing are conducted to obtain the microorganism passivator. The adsorption carrier comprises hydrolysis residues and biochar which are mixed and smashed according to a certain mass ratio. By the adoption of the microorganism passivator for repairing heavy metal pollution of soil, the content of available heavy metals in soil can be effectively reduced, and the number of microbial populations and plant yield are increased greatly. The method for repairing heavy metal pollution of soil by means of the microorganism passivator is in-situ repair, operation is easy, the cost is low, and industrialized implementation can be easily achieved; furthermore, the repairing effect is good, soil fertility can not be damaged, and the utilization rate of resources can be increased.

Owner:SHANGHAI LVLE BIO TECH

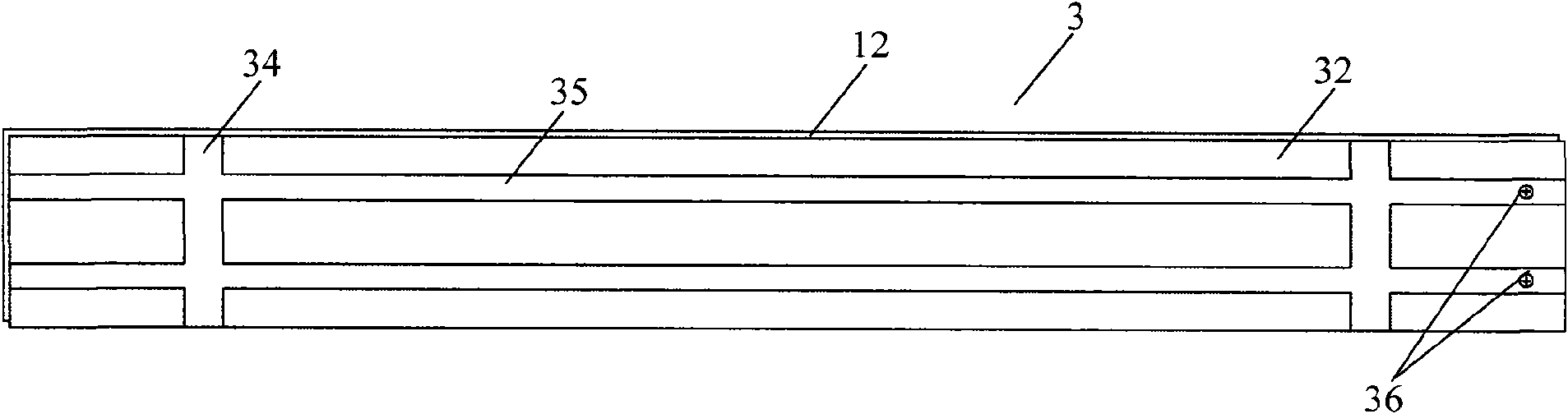

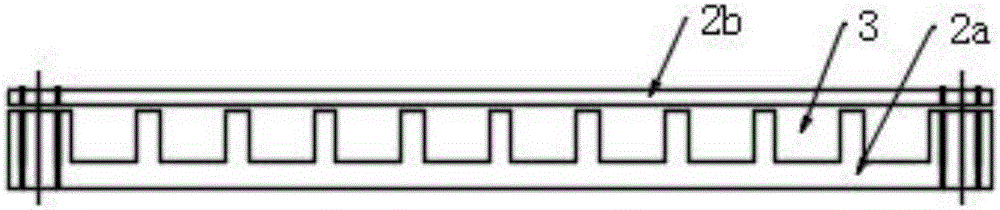

Far-infrared heat energy wood floor and manufacturing method and paving method thereof

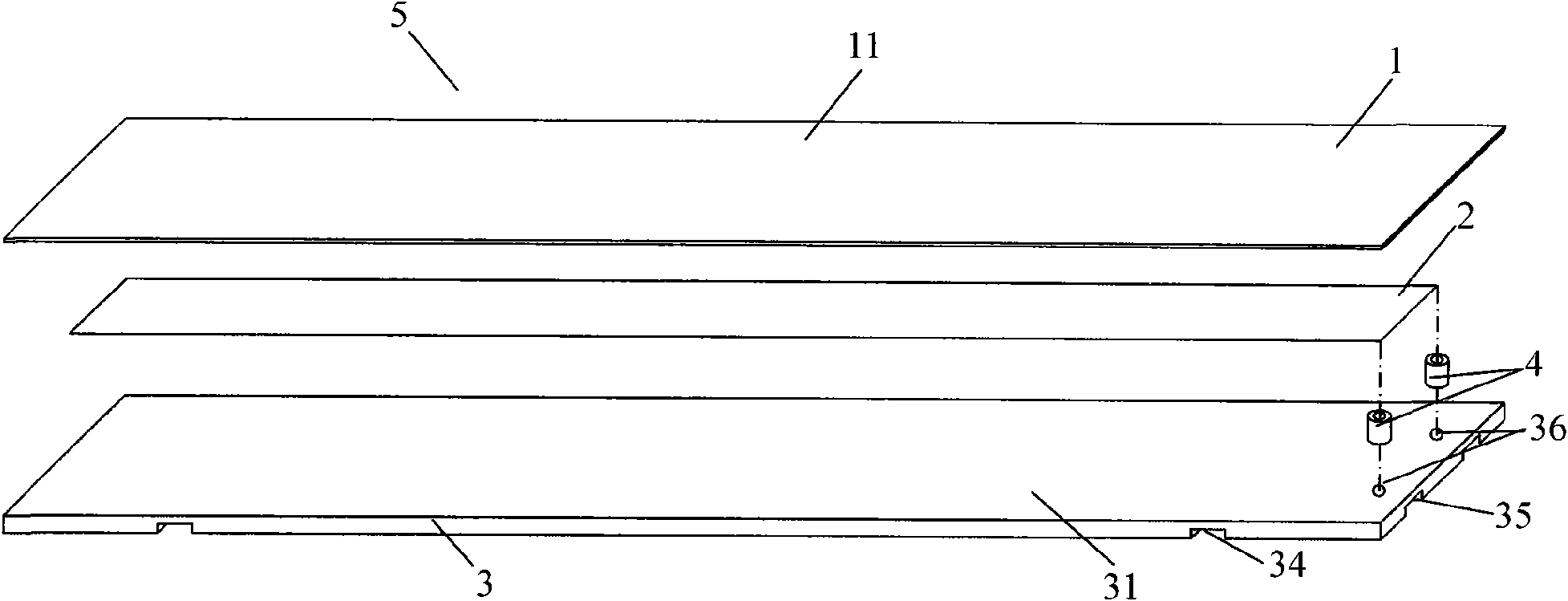

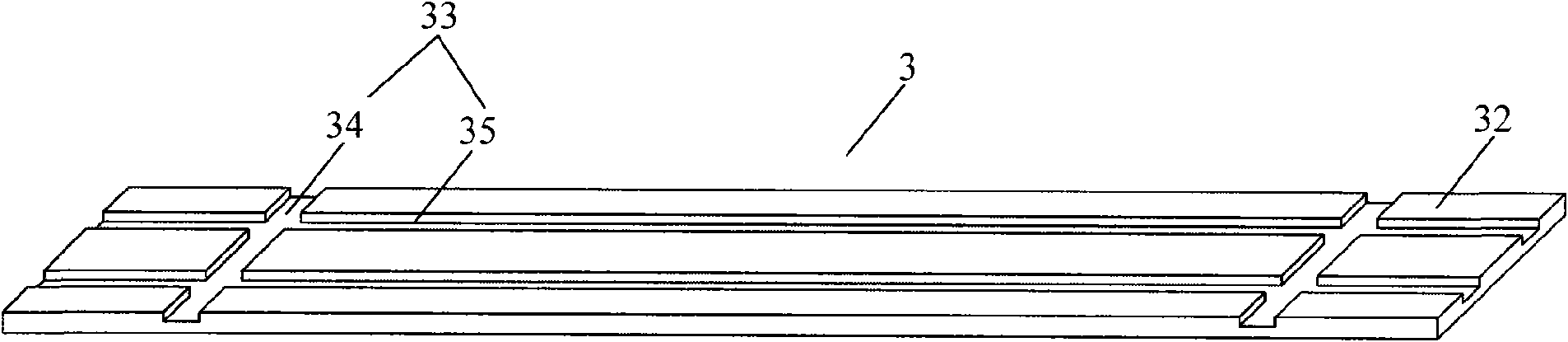

InactiveCN101660803AIngenious designBreak through the natural functionLighting and heating apparatusElectric heating systemElectric heatingHardwood

The invention relates to a far-infrared heat energy wood floor, the carbon crystal electric heating material sheets of which are respectively pasted on the second surface of a surface board of the wood floor and the third surface of a base board of the wood floor. Preferably, the surface board of the wood floor is a hardwood board, the air-dry density of which is 0.5-0.7g / cm<3>, the thickness of which is 2-4mm and the moisture content of which is 6-8%; the thickness of each of the carbon crystal electric heating material sheets is 0.2-0.5mm; and the base board of the wood floor is a softwood board, the air-dry density of which is 0.3-0.6g / cm<3>, the thickness of which is 13-16mm and the moisture content of which is 6-8%. The far-infrared heat energy wood floor comprises an even number of layers of wood boards which are sequentially pasted, and the textures of the wood boards are crisscrossed; and air guiding grooves are arranged on the fourth surface of the base board of the wood floor. The invention also provides a manufacturing method and a paving method. The invention has the advantages of skillful design, safety, environment protection, energy saving and automatic adjustment oftemperature, breaks through the natural functions of the wood floor, organically combines a far-infrared heat energy heating element and the wood floor, has important breakthrough in the aspects of service life, energy saving, safety, environment protection, health, physical therapy and the like of the geothermal heating materials, and is a revolution in the international wood floor industry.

Owner:陆上驰 +1

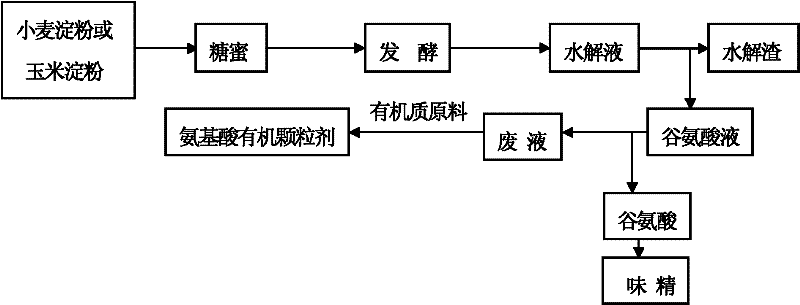

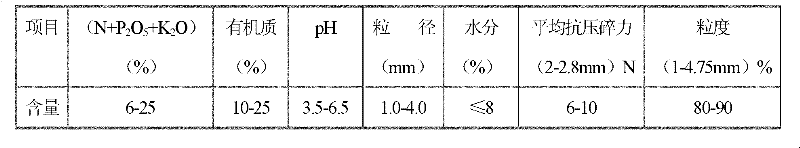

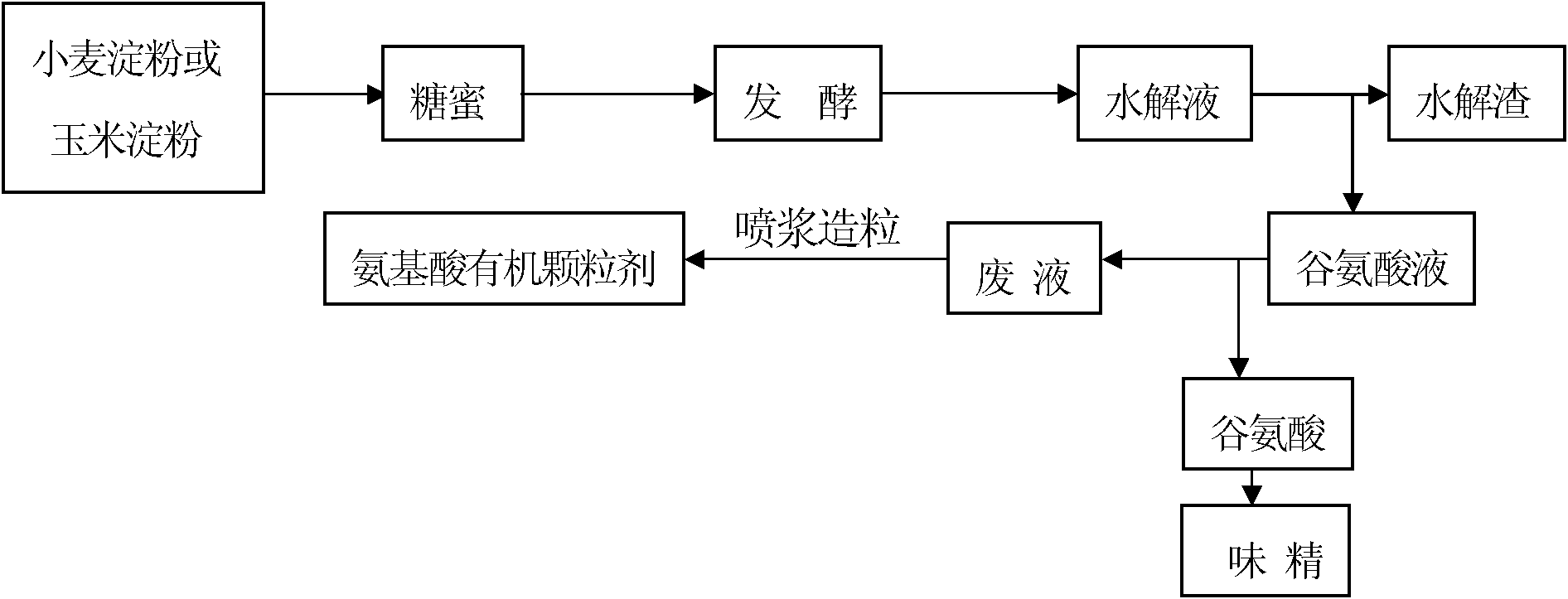

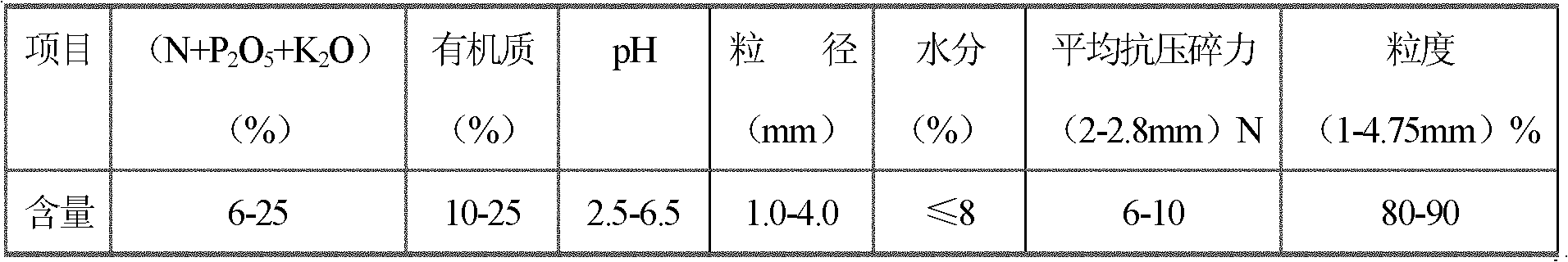

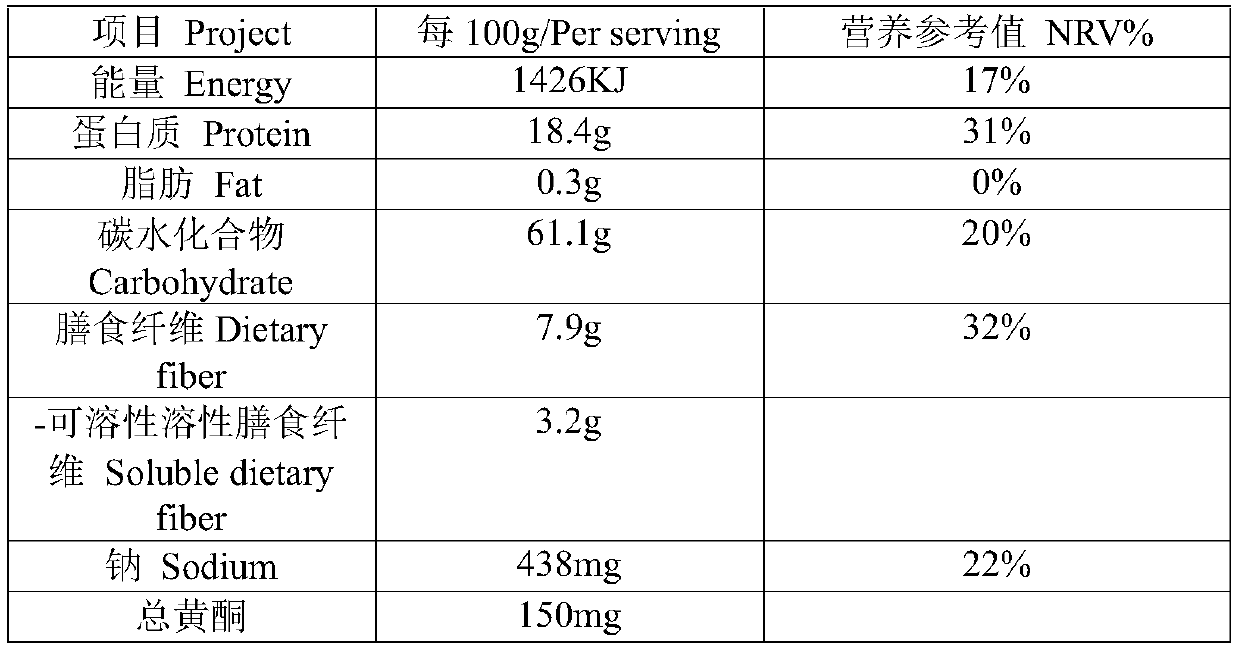

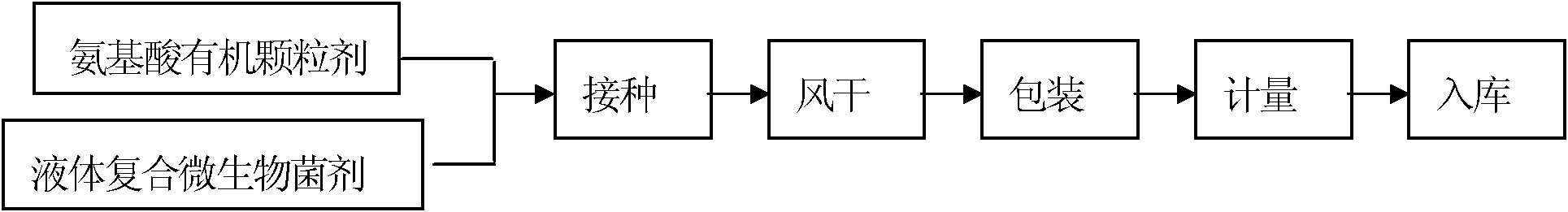

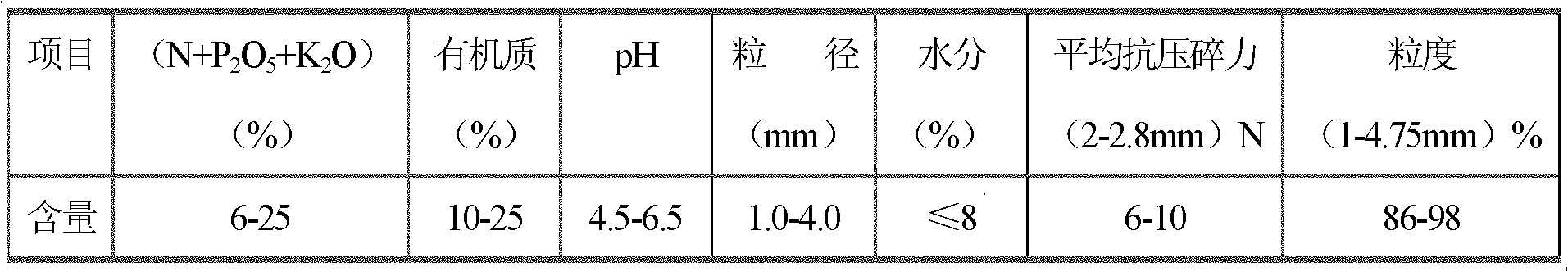

Production method of granular bioorganic fertilizer

ActiveCN102050644AReduce manufacturing costImprove product qualityClimate change adaptationBioloigcal waste fertilisersChemistryOrganic matter

The invention provides a production method of granular bioorganic fertilizer. The preparation method comprises steps of preparing a liquid microbial preparation, making organic granules from amino acid waste liquid and organic matter raw material, and mixing organic granules with the liquid microbial preparation. The liquid microbial preparation is uniformly adsorbed on the surfaces of amino acidorganic granule, and the addition proportion in bioorganic fertilizer finished product is 0.5-1.5 wt%. The production method breaks the normal procedures, adopts granulation of organic granules and adsorption of liquid microbial preparation onto the organic granules, and ensures certain viable count in the bioorganic fertilizer. The bioorganic fertilizer product realizes the breakthrough from powder, pan or drum granulation to spray granulation, and lays a foundation for improving the commercial quality and the effectiveness of the bioorganic fertilizer and promoting the bioorganic fertilizer.

Owner:SHANGHAI LVLE BIO TECH

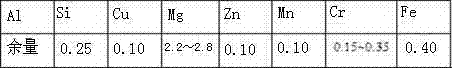

Production and heat treatment method of aluminum alloy continuous-casting continuous-rolling billet

The present invention belongs to the technical field of non-ferrous metal processing, and particularly relates to a production and heat treatment method of a 5052 aluminum alloy continuous-casting continuous-rolling billet. The production and heat treatment method comprises steps such as smelting, continuous casting, continuous rolling, coiling and heat treatment, and is characterized in that the Hazelett continuous-casting continuous-rolling process is used after the smelting, and the smelting step comprises three refining and concretely comprises material preparing, aluminum alloy liquid smelting, first refining, slag skimming, alloy element adding, second refining, alloy component adjusting, third refining, degassing filtration, and standing. With the production and heat treatment method of the present invention, the key technology that the Hazelett process is adopted to produce the 5052 aluminum alloy plate material and perform the heat treatment is solved, the blank of the production process is filled up, and the high economic benefits and the high practical values are provided.

Owner:JIANGSU UNIV

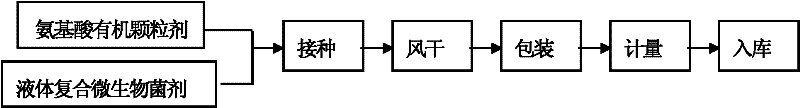

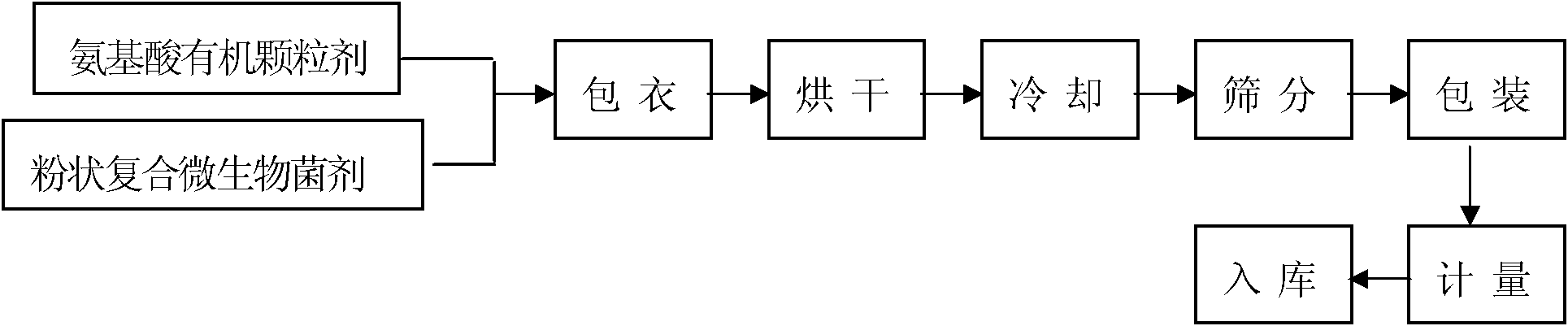

Production method of amino acid complex microorganism fertilizer

ActiveCN102040407ASolve ball problemSolve solubilityOrganic fertilisersSpray GranulationMicroorganism

The invention provides a production method of an amino acid complex microorganism fertilizer, in particular to a method for producing an amino acid complex microorganism fertilizer by using amino acid organic granules. The method comprises the following steps: preparing solid inoculant; pelleting amino acida liquid waste into organic granules; compounding the organic granules with solid powders; when compounding, adding powdery inoculant which accounts for 5-15% of the finished product complex microorganism fertilizer at weight ratio; and mixing, pelleting and drying, wherein the material temperature in a drying cylinder is not higher than 80 DEG C. The production method provided by the invention breaks the normal procedure and is divided into two steps of pelleting of the organic granules and the package of the organic granules, as well as ensures viable count in the complex microorganism fertilizer. The production method of the complex microorganism fertilizer provides a new process which realizes the breakthrough of the process from powder pelleting by a disc and a roller to spraying granulation, thus improving commodity and effectiveness of the complex microorganism fertilizer and laying a foundation for popularization.

Owner:SHANGHAI NUOTONG INFORMATION TECH CO LTD

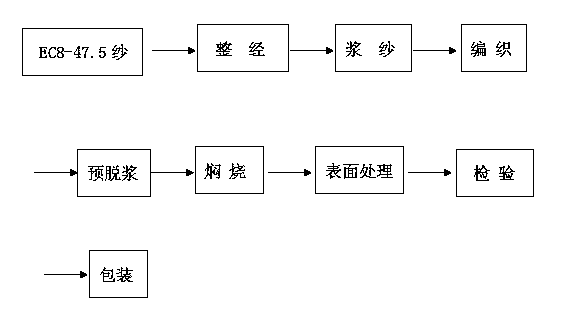

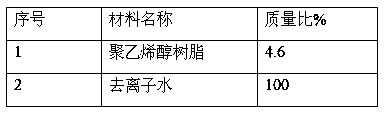

Production technology of glass fiber cloth for insulation

ActiveCN103741319ASolve the production processSimple processFibre treatmentHeating/cooling textile fabricsGlass fiberPolymer science

Provided is a production technology of glass fiber cloth for insulation. The production technology of the glass fiber cloth for insulation comprises the steps that EC8-47.5 glass fiber yarn serves as warp and weft; a warping working procedure technology is carried out, wherein the EC8-47.5 glass fiber yarn is placed on warping creels in sequence; a slashing working procedure technology is carried out; a knitting working procedure technology is carried out, wherein an air jet loom is used for carrying out weaving, drafting, reed insertion, gaiting and weaving are carried out on slashed warp beams in sequence according to plain weave, the warp and weft density is 17.3*14.2 pieces per centimeter, and the cropping length is 2000 meters per roll; a post-processing working procedure is carried out; drying is carried out at the temperature of 200DEG C, and the trimming working procedure, the take-up working procedure, the check working procedure and the packaging working procedure are carried out. The purpose of the production technology for using the EC8-47.5 glass fiber yarn to produce the high-grade glass fiber cloth for insulation is achieved, the warp and weft density of the glass fiber cloth is 17.3*14.2 pieces per centimeter, the thickness of the glass fiber cloth is 0.140mm, the basic weight is 150g / m<2>, the diameter of a filament of the glass fiber cloth is 8 microns, the warp and weft number is 47.5Tex, and the production technology of the glass fiber cloth for insulation has the advantages that the technology is more convenient to use, production management is easy, weaving is convenient, and the foundation is laid for producing the high-grade insulating glass fiber cloth through ordinary devices.

Owner:江西长江化工有限责任公司

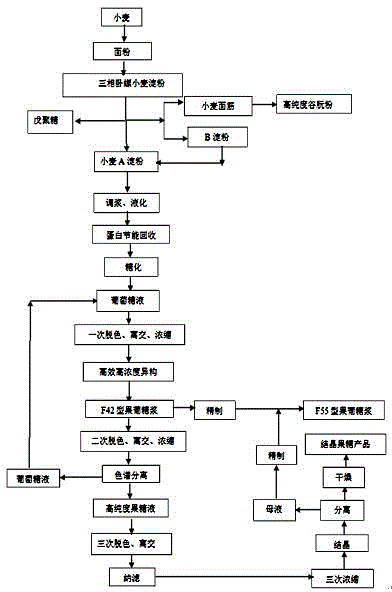

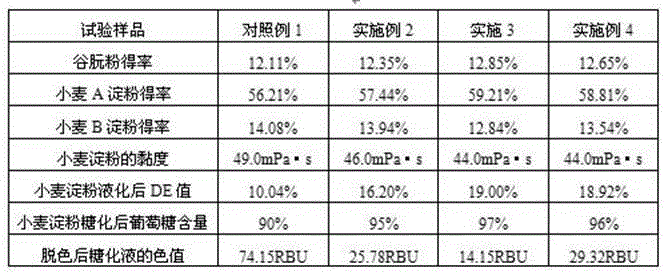

Method for co-producing crystalline fructose and fructose corn syrup by taking wheat as raw material, and preparation method of wheat starch

ActiveCN103146849ASolve constraintsExpand the field of sourcesFructose productionGlucose productionBiotechnologyGluten

The invention discloses a process for co-producing crystalline fructose and F55 fructose corn syrup by taking wheat as a raw material and belongs to the technical field of starch sugar. The process comprises the following steps: grinding the wheat used as the raw material into powder, producing wheat starch by adopting a three-phase horizontal decanter production process, adding a compound enzymic preparation containing lipase into size mixing water to produce by-products such as wheat starch, vital gluten, pentosan and B starch, returning the B starch separated by a three-phase horizontal decanter to a starch finished product tank, subsequently mixing the B starch with A starch and performing a process of producing sugar; acquiring crystalline fructose by mixed wheat starch milk through processes of liquefying, recycling protein, saccharifying, efficiently isomerizing, separating chromatograph, concentrating, crystallizing and drying; and circularly crystallizing mother liquor for a certain number of times, and then compounding the mother liquor with F42 fructose corn syrup acquired by isomerizing to acquire an F55 fructose corn syrup product. By utilizing the preparation method, the problems of high material liquid viscosity, low product yield and poor quality caused by the process of producing starch by taking the wheat as the raw material and sugaring the wheat starch are solved, and the yield and purity of the product are effectively improved.

Owner:BAOLINGBAO BIOLOGY

High-temperature-resistant high-performance alloyed fastener and manufacturing technique thereof

The invention provides a high-temperature-resistant high-performance alloyed fastener comprising following ingredients: 0.42% of C, 0.33% of Si, 0.70% of Mn, 0.030% or less of S, 0.030% or less of P, 1.10% of Cr, 0.025% or less of Ni, 0.025% or less of Cu, 0.20% of Mo, 0.24% of V, and 0.03% of Nb. The invention also provides a manufacturing technique used for production of the alloyed fastener. The manufacturing technique of the high-temperature-resistant high-performance alloyed fastener helps to solve a problem that: manufacturing techniques used for production of alloyed fasteners with a level of 12.9 or above have not been invented in domestic at present. The alloyed fastener produced by the manufacturing technique possesses high strength and hardness which are not possessed by common fasteners, and excellent plasticity, toughness, corrosion resistance, tensile strength, fatigue strength and delayed fracture resistance. The alloyed fastener is capable of ensuring that failures such as break and damage are not easy to happen in manufacturing process and using procedures, and can function normally at a highest temperature of 500 DEG C. Service life of the fastener is extremely prolonged.

Owner:汕头经济特区超艺螺丝工业有限公司

Composite slag making industry waste slag energy-saving self-insulating external wall panel and production method thereof

ActiveCN101302095ASolve the production processSolve the production methodSolid waste managementEarthquake resistanceWeather resistance

The invention discloses a composite building slag-industrial residue energy-saving self-heat preservation external wall panel and a production method thereof. The invention provides a production formula and a production method for composite building slag-industrial residue energy-saving self-heat preservation external wall panel with three different thickness ranges. The composite building slag-industrial residue energy-saving self-heat preservation external wall panel and the production method thereof can produce a wall body in one piece by integrating walling materials and insulating materials, allows for mechanically automatic flow line production, and the production method can produce various composite building slag-industrial residue energy-saving self-heat preservation external wall panels which use various kinds of waste slag as main raw materials for an external wall body and use agricultural wheat straw, straw and other slag as insulating materials for the external wall body, thereby making full use of wastes and saving energy and protecting environment; The composite building slag-industrial residue energy-saving self-heat preservation external wall panel has the advantages of earthquake resistance, compression resistance, impact resistance, cold and weathering resistance, corrosion resistance, aging resistance, good abrasion resistance performance, no poison, no pollution, humidity absorption, water absorption, and good expansion constringency, along with simple formula, low cost and higher cost performance.

Owner:四川丰汇环境科技有限公司

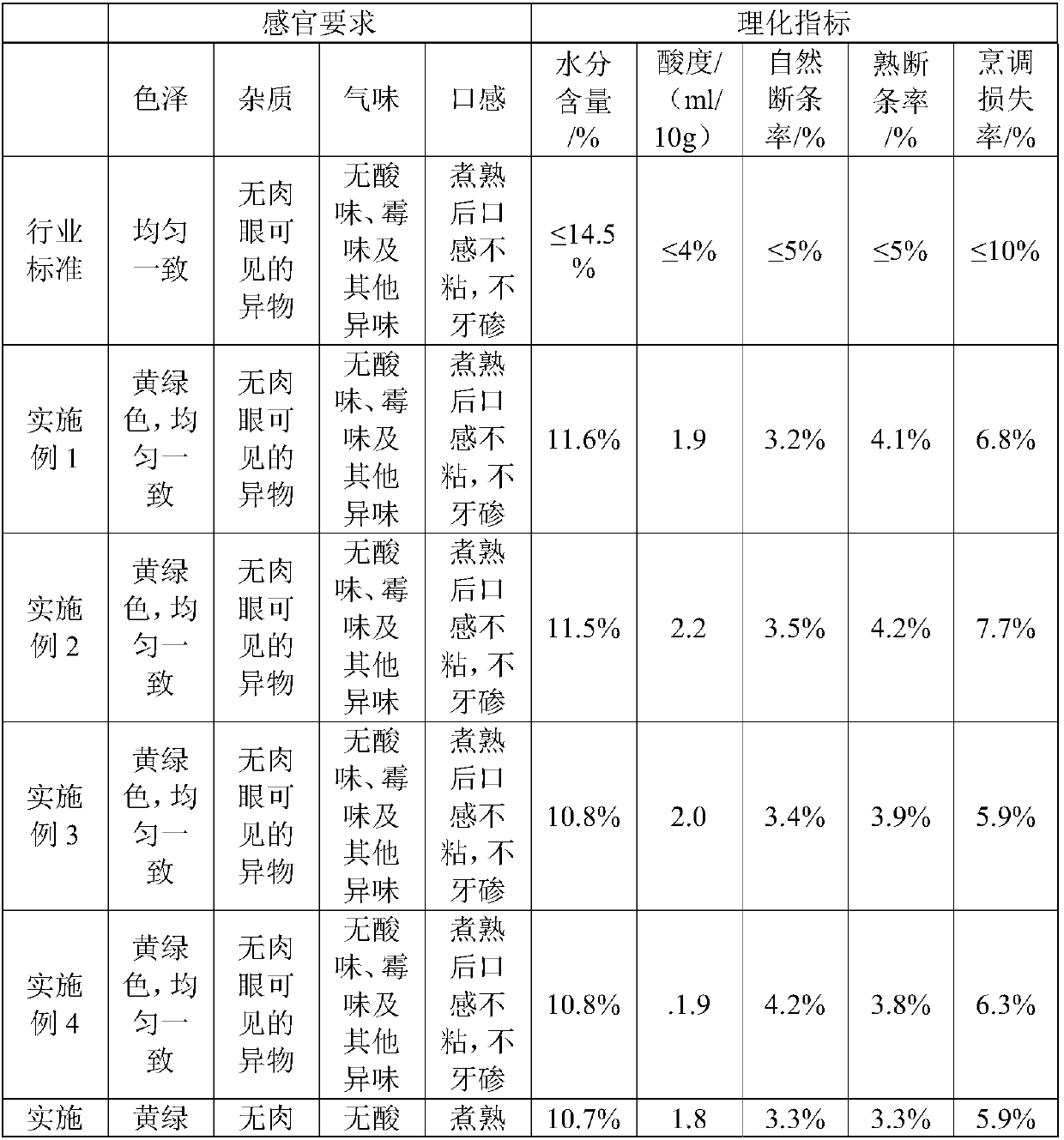

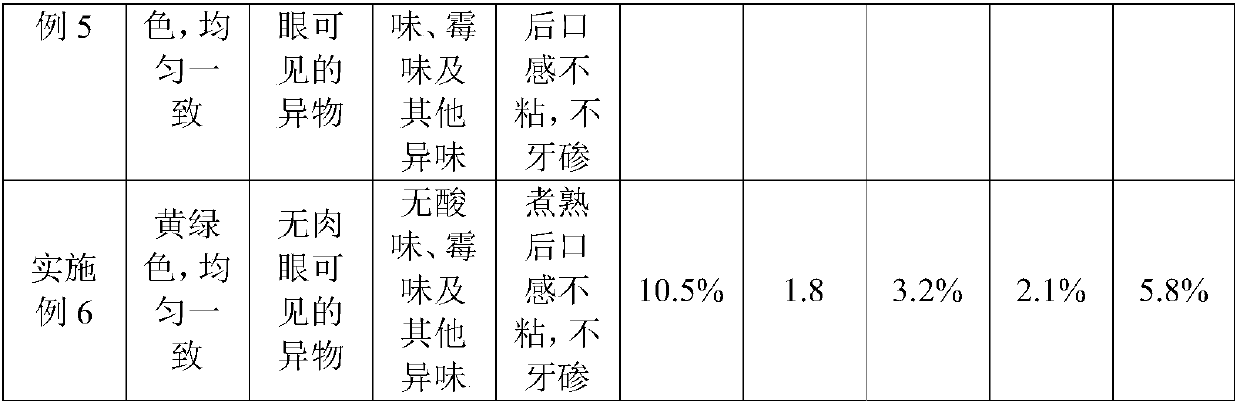

High-fiber high-protein nutrient noodles and making method thereof

InactiveCN107836640AWide adaptabilityReduce absorptionNatural extract food ingredientsFood ingredient functionsFiberWhey protein powder

The invention provides high-fiber high-protein nutrient noodles. The high-fiber high-protein nutrient noodles mainly comprise wheat flour, wheat dietary fiber flour, vital wheat gluten, a radix puerariae extract, a Chinese wolfberry fruit extract, a Chinese yam extract, tartarian buckwheat powder, barley tender leaf powder, resistant starch, konjaku flour, inulin, soy protein isolate powder, wheyprotein powder and L-arabinose. A making method of the high-fiber high-protein nutrient noodles comprises the following steps of performing ethanol extraction on radix puerariae, Chinese wolfberry fruits and Chinese yams, performing decompressed concentration, and performing drying so as to obtain the radix puerariae extract, the Chinese wolfberry fruit extract and the Chinese yam extract for standby application; and adding water to the vital wheat gluten and the konjaku flour, performing uniform mixing and stirring, adding the wheat flour and the tartarian buckwheat powder, then adding the remaining components, and performing stirring so as to obtain the high-fiber high-protein nutrient noodles. The high-fiber high-protein nutrient noodles disclosed by the invention have significant effects, besides, concurrently have the effect of being balanced in nutrients, and are preferable medical nutrient treatment selection for crowds for preventing and controlling diabetes.

Owner:迈纽斯(苏州)生物科技有限公司

Method for producing compound microbial fertilizer from amino acid organic granules

InactiveCN102040406ASimplify the steps of dryingSolve ball problemOrganic fertilisersFertilizer mixturesMicrobial agentSlurry

The invention provides a method for producing compound microbial fertilizer from amino acid organic granules, in particular to a method for producing compound microbial fertilizer by adopting slurry spraying and granulating processes, comprising the following steps: preparing liquid microbial agent, granulating waste amino acid solution into organic granules, and compounding the organic granules with the liquid compound microbial agent, wherein the liquid compound microbial agent is uniformly absorbed on the surfaces of the amino acid organic granules, and fermentation liquid accounts for 0.5-1.5wt% of the finished product of the compound microbial fertilizer. According to the invention, the normal method for producing the compound microbial fertilizer is improved, a novel method for producing the granular compound microbial fertilizer by two steps of granulating waste amino acid solution into organic granules and absorbing the liquid compound microbial agent by the amino acid organic granules is provided, and the number of viable bacteria in the compound microbial fertilizer is ensured. The production of the compound microbial fertilizer by the slurry spraying and granulating processes breaks through the production of the powdery compound microbial fertilizer by the disc and roller granulating process, thus a good foundation is laid for improving the commodity value, effectiveness and large-area popularization of the compound microbial fertilizer.

Owner:SHANGHAI NUOTONG INFORMATION TECH CO LTD

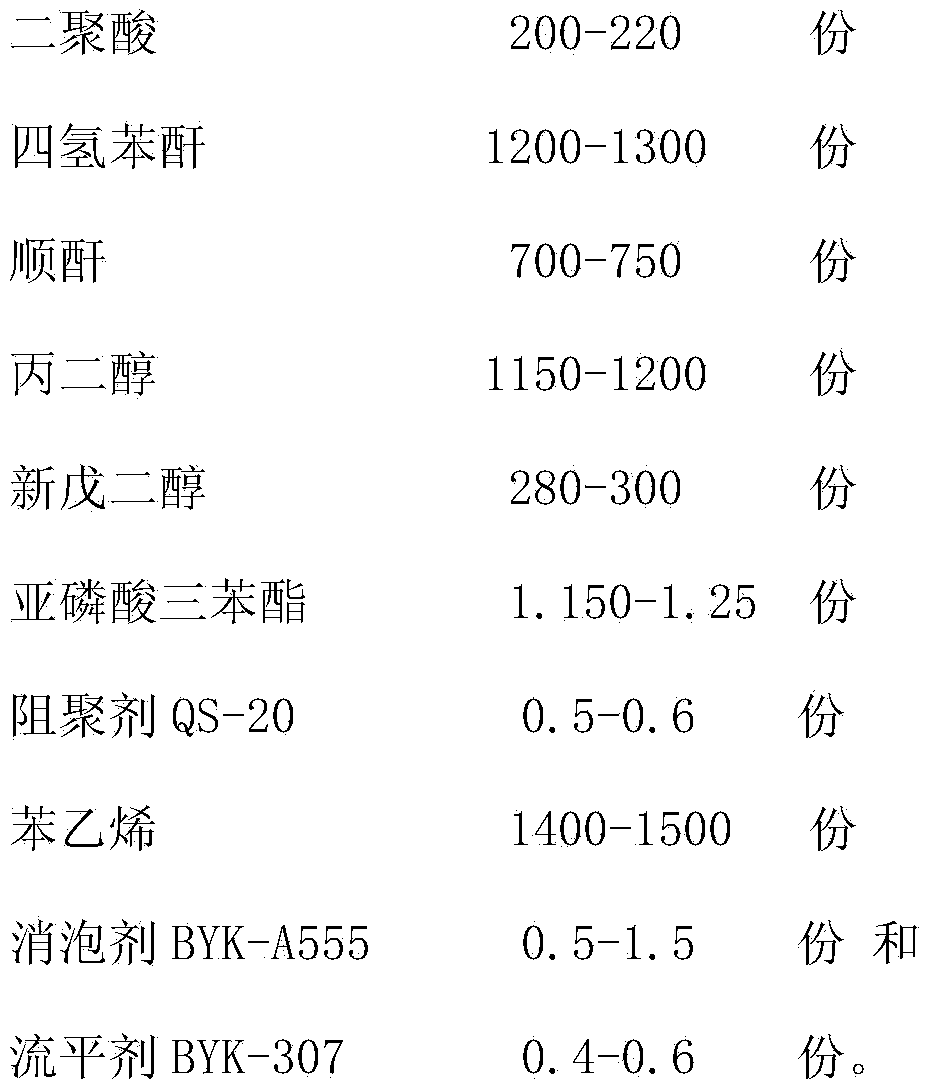

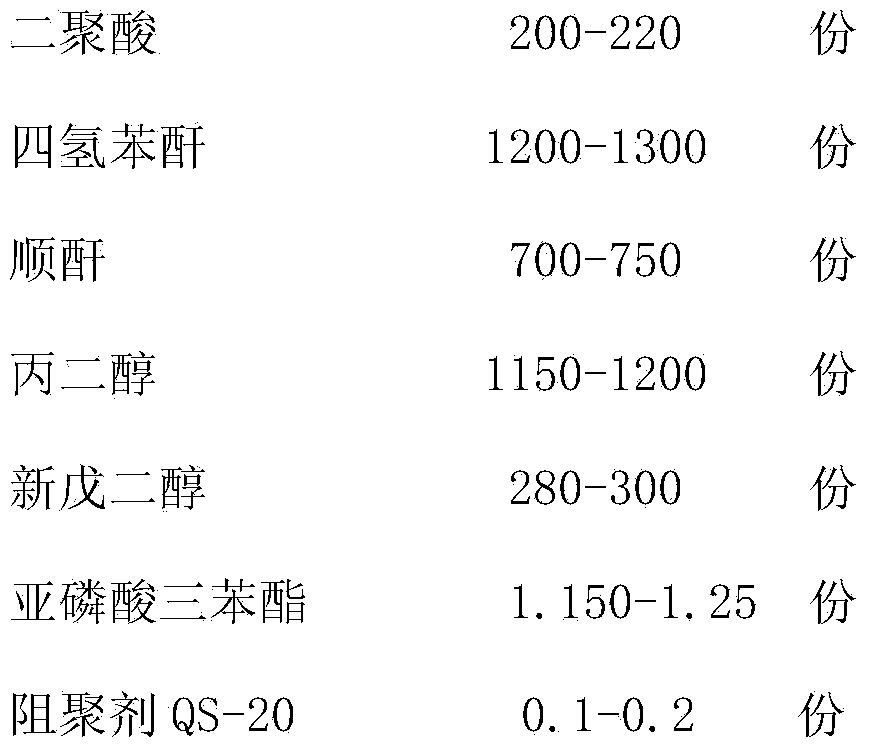

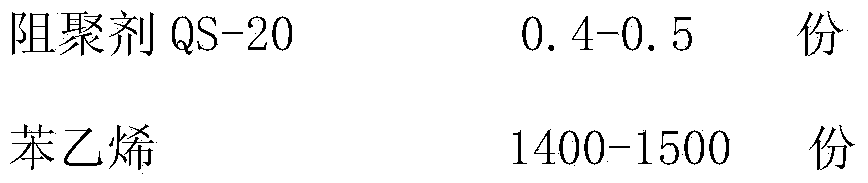

Air-dried unsaturated polyester resin and production method thereof

The invention discloses an air-dried unsaturated polyester resin and a production method thereof. The air-dried unsaturated polyester resin comprises the following raw materials by weight: 200-220 parts of dimer acid; 1200-1300 parts of tetrahydrophthalic anhydride; 700-750 parts of maleic anhydride; 1150-1200 parts of propylene glycol; 280-300 parts of neopentyl glycol; 1.150-1.25 parts of triphenyl phosphite; 0.5-0.6 part of a polymerization inhibitor QS-20; 1400-1500 parts of styrene; 0.5-1.5 parts of an antifoaming agent BYK-A555 and 0.4-0.6 part of a leveling agent BYK-307. The invention also discloses the production method of the resin.

Owner:ZHANGZHOU YABANG CHEM

Energy-saving self-heat-insulating composite external wall plate made from building slag and industrial waste residues and production methods thereof

ActiveCN102617087AGood wear resistanceGood expansion and contractionSolid waste managementClimate change adaptationSlagIndustrial waste

The invention discloses an energy-saving self-heat-insulating composite external wall plate made from building slag and industrial waste residues and production methods thereof. The invention provides production formulas of three types of energy-saving self-heat-insulating composite side fasciae which are made from building slag and industrial waste residues and have different thickness ranges, and provides production methods of the side fasciae. According to the energy-saving self-heat-insulating composite side fasciae which are made from building slag and industrial waste residues and the production methods thereof, wall material and heat insulating material are combined together and subjected to one-step production molding; the side fasciae can be produced in a mechanically automatic production line; the composite side fasciae have the advantages that multiple waste residues are used as main raw materials of the side fascia and agricultural wheat straw, crop straw and other waste ash residues are used as the heat insulating materials of the side fasciae, thus recycling waste materials and protecting the environment and saving energy. The energy-saving self-heat-insulating composite external wall plates are capable of resisting vibration, compression, impact, freezing, weathering, corrosion and aging, good in wear resistance, free from toxicity, harmless, capable of absorbing moisture and water, and good in expansion contractility; in addition, the products are simple in formula, low in cost and high in cost performance.

Owner:四川银创再生资源利用股份有限公司

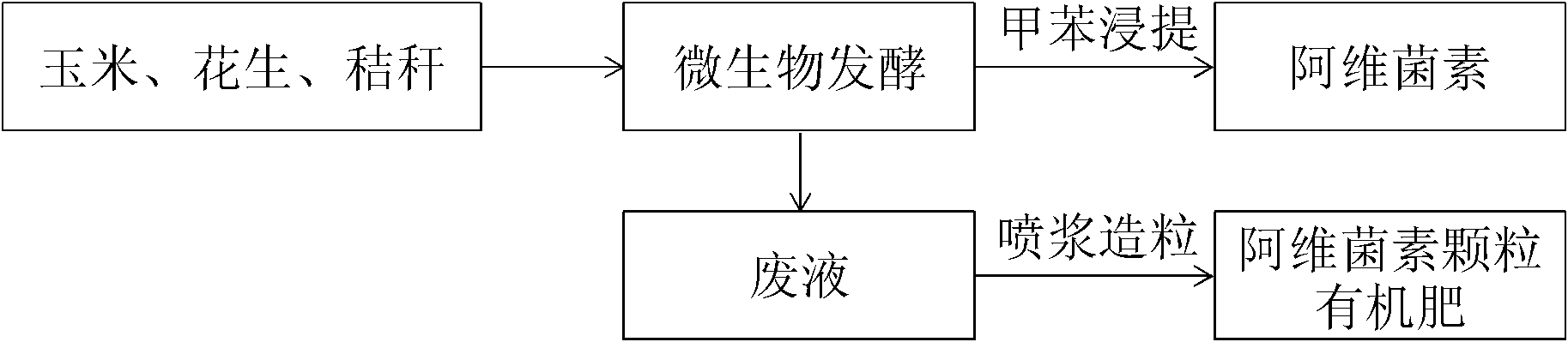

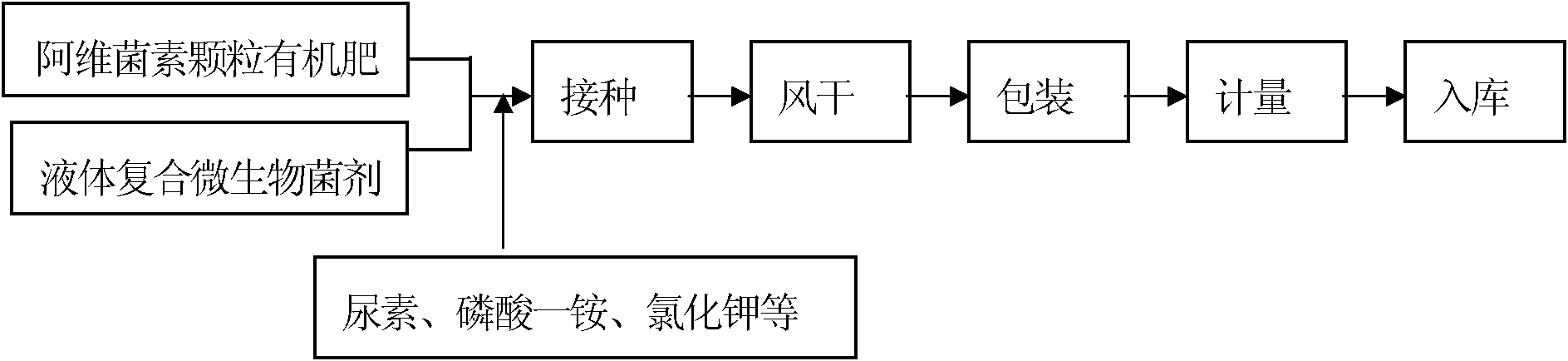

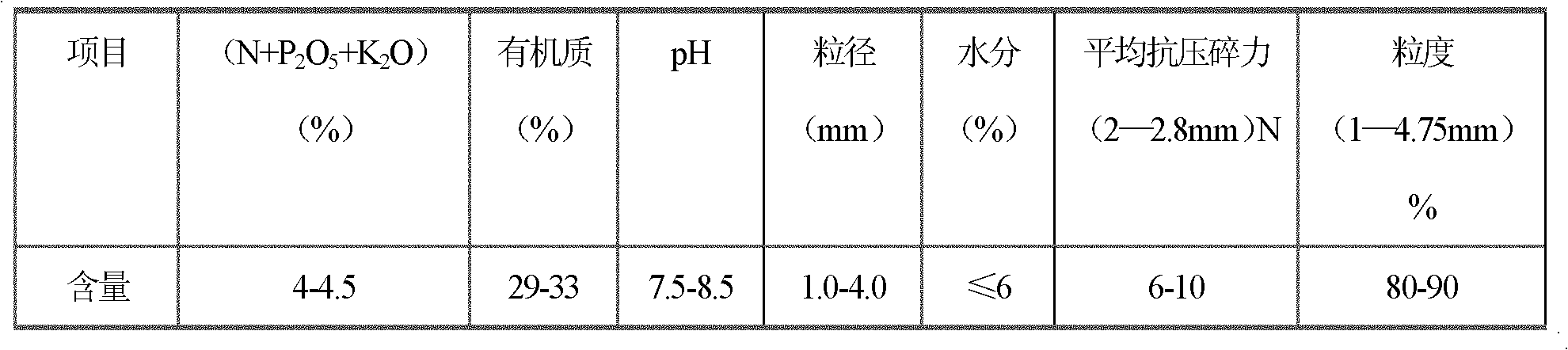

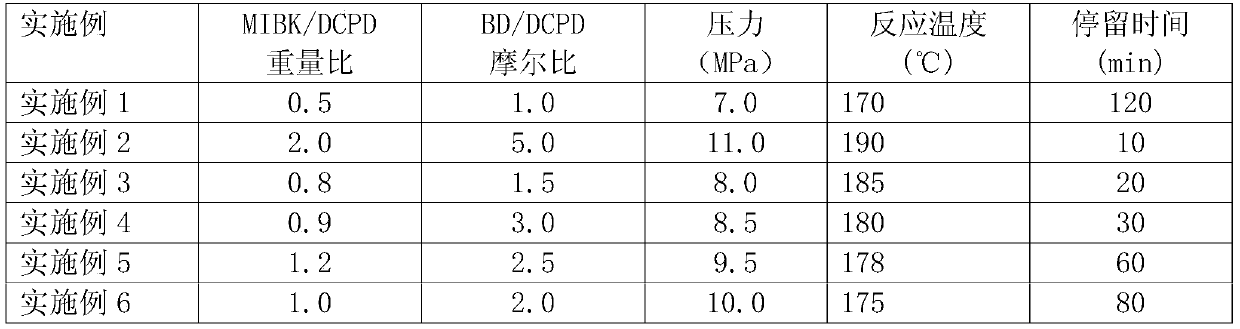

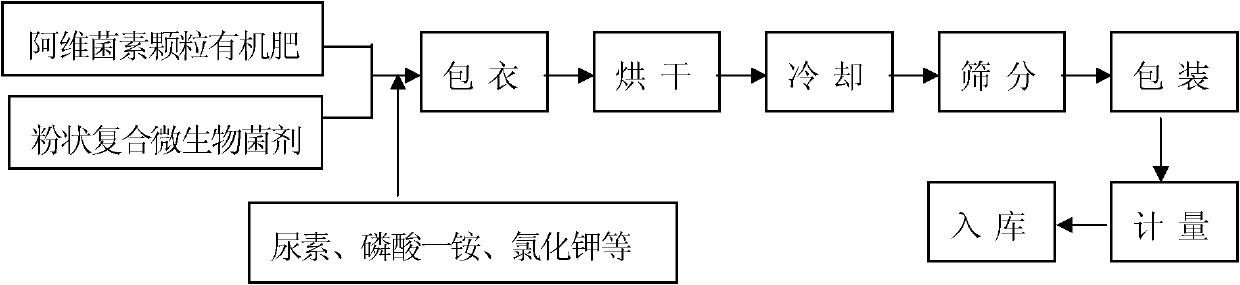

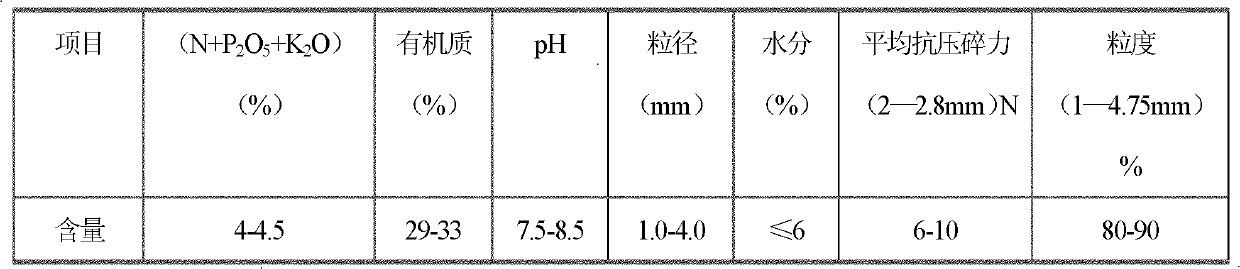

Method for producing compound microbial fertilizer with insecticidal effect

InactiveCN102040430AReduce manufacturing costImprove product qualityFertilizer mixturesMicrobial agentInorganic fertilizer

The invention provides a method for producing a compound microbial fertilizer with insecticidal effect, comprising the following steps: preparing liquid microbial agent; adding waste abamectin liquid to inorganic fertilizer, and granulating the inorganic fertilizer into granular organic fertilizer; compounding the granular organic fertilizer and the liquid microbial agent which is 0.5-1.5 percent of the weight of the finished product of the compound microbial fertilizer; and airing or drying. The invention breaks the normal method for producing the compound microbial fertilizer and provides a novel method for producing the granular compound microbial fertilizer by granulating the inorganic fertilizer into the organic fertilizer and coating the liquid microbial agent by the granular organic fertilizer. The powdery compound microbial fertilizer is replaced by the granular compound microbial fertilizer, and the granular compound microbial fertilizer has a certain activity, thus a good foundation is laid for popularizing the granular compound microbial fertilizer on a large scale. The invention also provides a method for recycling the waste abamectin liquid.

Owner:SHANGHAI NUOTONG INFORMATION TECH CO LTD

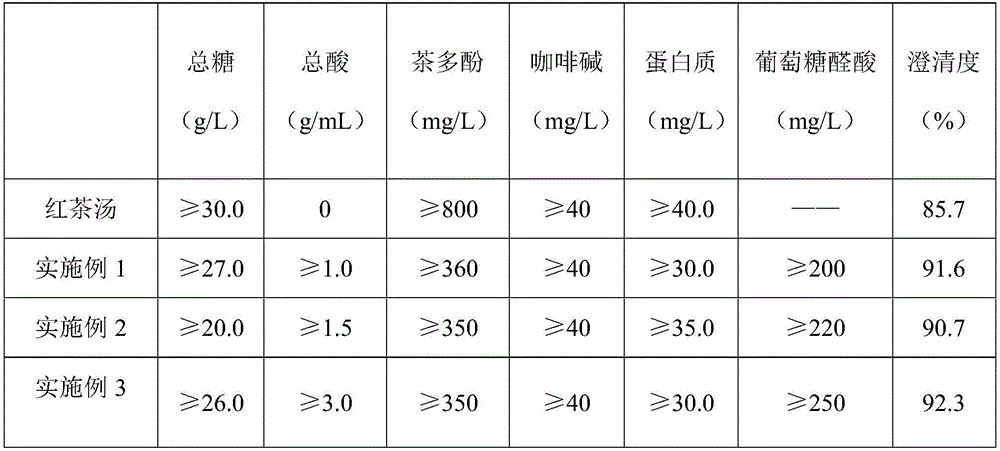

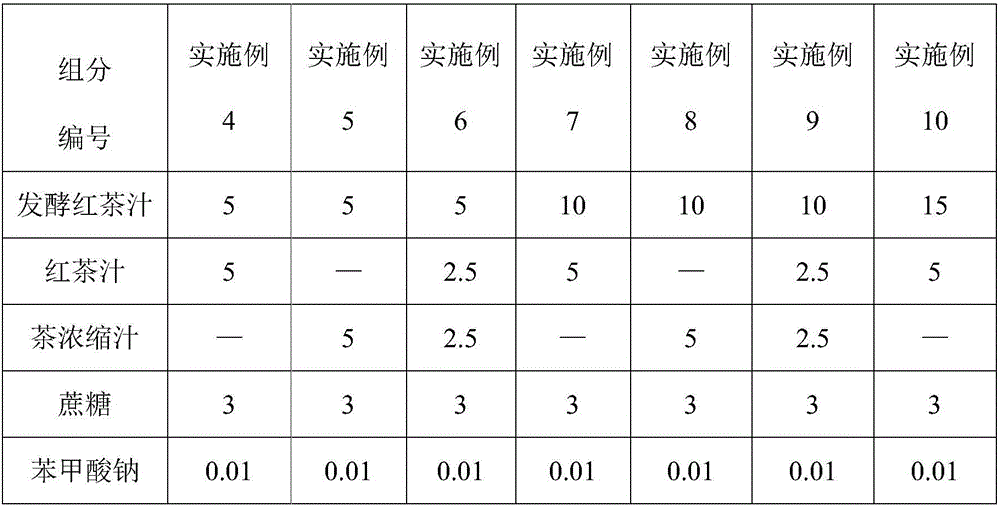

Enzymatic fermented black tea beverage and preparation method thereof

InactiveCN106173025ASolve the production processSolve the problem that product standards are not easy to controlTea extractionPreservativeBlack tea

The invention discloses an enzymatic fermented black tea beverage and a preparation method thereof. The enzymatic fermented black tea beverage comprises the following raw materials in percentage by weight: 1 to 30% of enzymatic fermented black tea juice, 1 to 10% of tea concentrated juice, 0.01 to 10% of a sweetener, 0.01 to 0.1% of a preservative, 0.05 to 0.1% of edible essence and the balance of water, and the sum of the raw materials is 100%. The enzymatic fermented black tea beverage prepared by the invention has rich nutriments and good taste, is nutritional and healthy, not only solves the problems of difficult control on the traditional fermented black tea production process and product standards and quality instability, but also greatly shortens the fermentation production cycle of fermented black tea and solves the problem of large energy consumption of the fermented black tea. The prepared fermented black tea beverage disclosed by the invention has the characteristics of clear and bright color, pure tea fragrance, mellow taste, moderate sweetness and mild sourness, and further has the healthcare functions of promoting appetite, invigorating the stomach, helping digestion, increasing appetite and the like, and the characteristics of enhancing the human immunity, regulating the body acid-base balance, improving chronic fatigue and enhancing physical constitution, thereby being superior to the traditional fermented black tea beverage.

Owner:NINGBO XINUOYA MARINE BIOTECH CO LTD

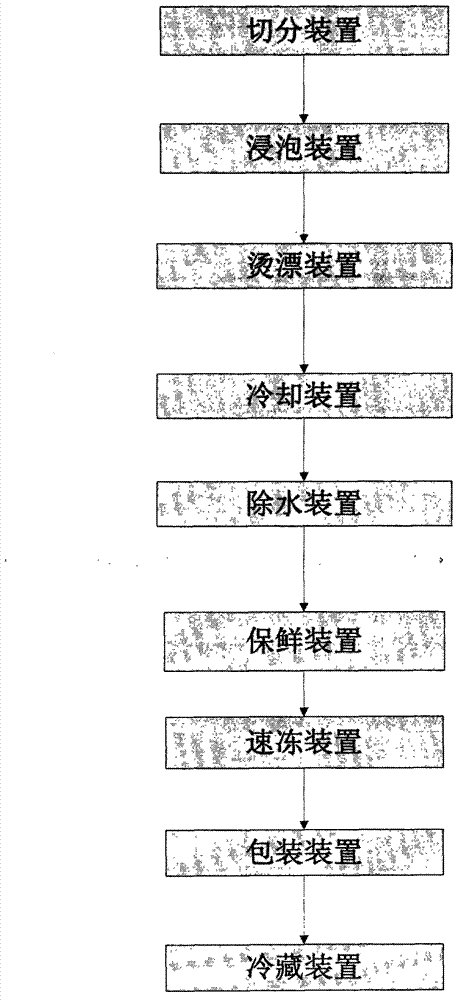

Quick-frozen bolete and a quick-freezing method thereof as well as equipment

InactiveCN102823849ALittle change in colorMaintain colorFood preservationFood preparationRefrigerationComputer engineering

The invention discloses a quick-frozen bolete and a quick-freezing method of the quick-frozen bolete. The quick-frozen bolete is prepared by the following steps of: splitting, color protecting, blanching, dewatering, freshness keeping, quick freezing, packaging and refrigeration; in addition, the invention further discloses equipment for preparing the quick-frozen bolete; and the equipment comprises a splitting device, a soaking device, a blanching device, a cooling device, a dewatering device, a freshness keeping device, a quick freezing device, a packaging device and a refrigeration device.

Owner:LIJIANG ZHONGYUAN GREEN FOOD

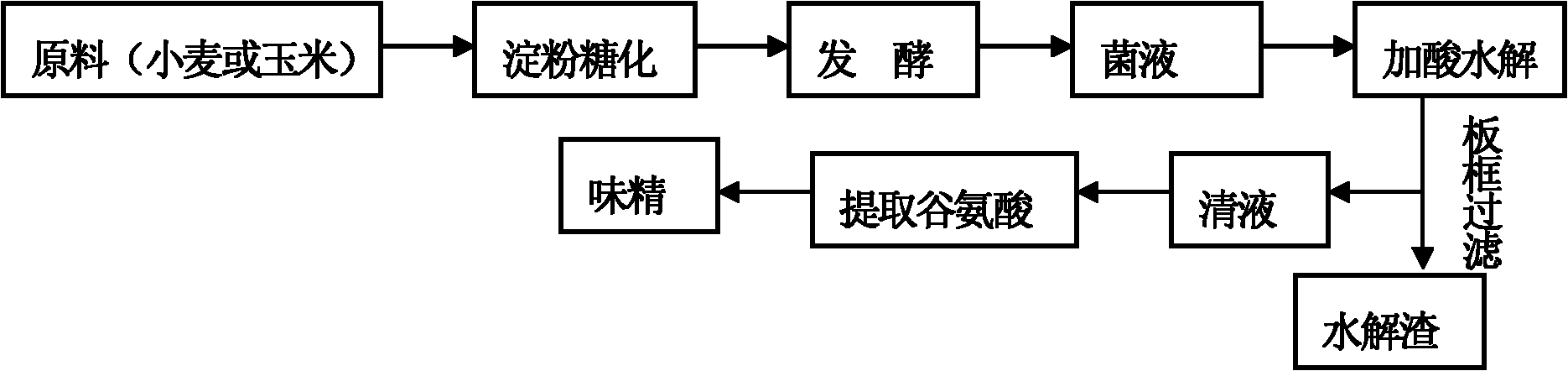

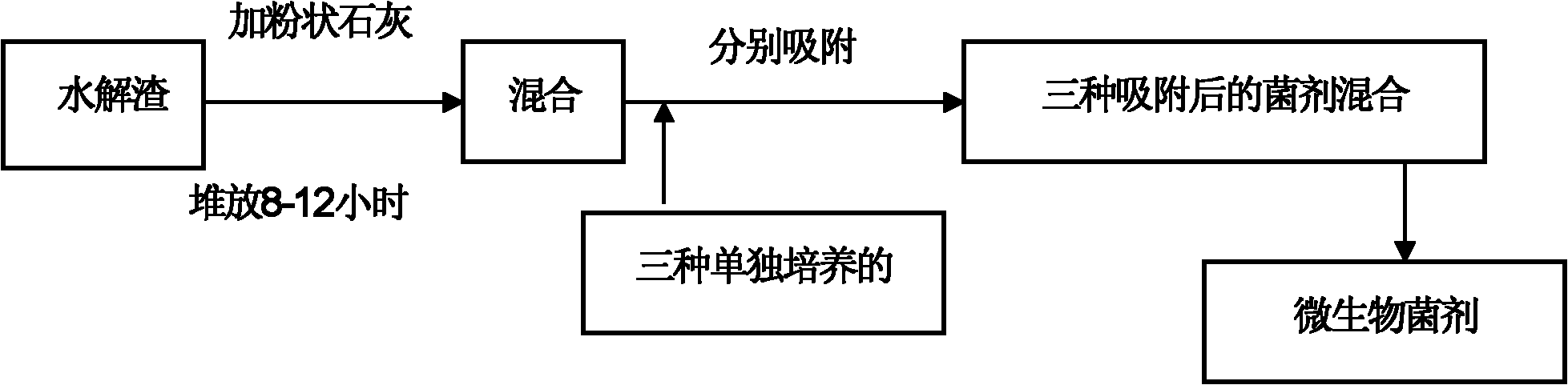

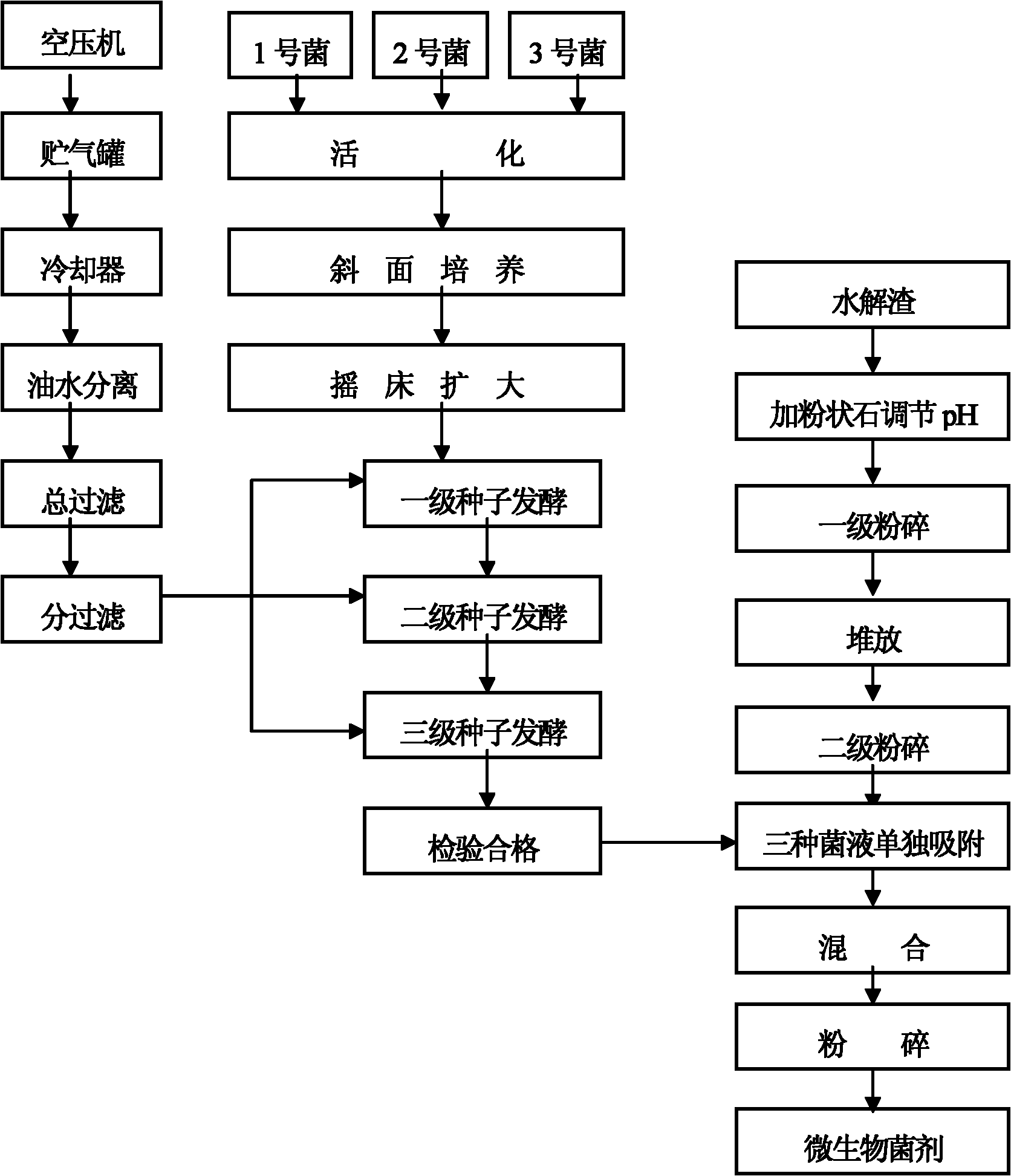

Production method of microbial inoculum

ActiveCN102174443AShort storage timePromote growthBacteriaMicroorganism based processesMicroorganismBacillus megaterium

The invention provides a production method of microbial inoculum and the method contains the fermentation and adsorption of the strain. The method comprises the following steps: utilizing treated hydrolysis residue as a bacterium solution adsorption medium to absorb the fermented bacterium solution of one or more of Bacillus subtilis, Bacillus megaterium and Bacillus mucilaginous krassilm, wherein the weight ratio of the bacterium solution to the hydrolysis residue is 0.3:(2-4); and then mixing and crushing, thus obtaining the microbial inoculum. The invention provides a new powdery microbial inoculum adsorption carrier, and the carrier contains various nutrients for microbial growth, is favorable for microbial proliferation and growth and is environmentally-friendly and low in price.

Owner:SHANGHAI NUOTONG INFORMATION TECH CO LTD

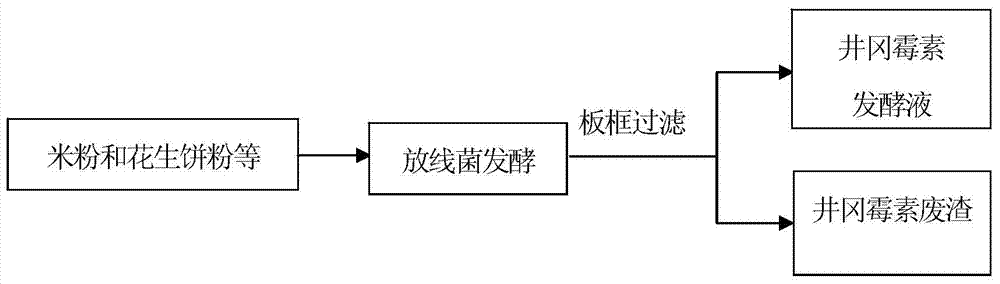

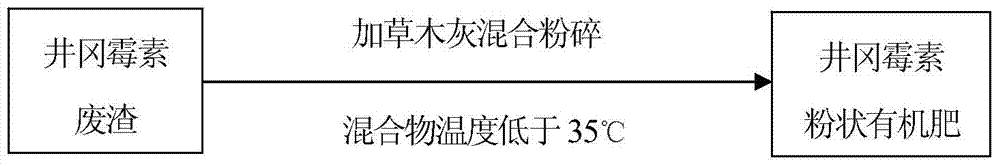

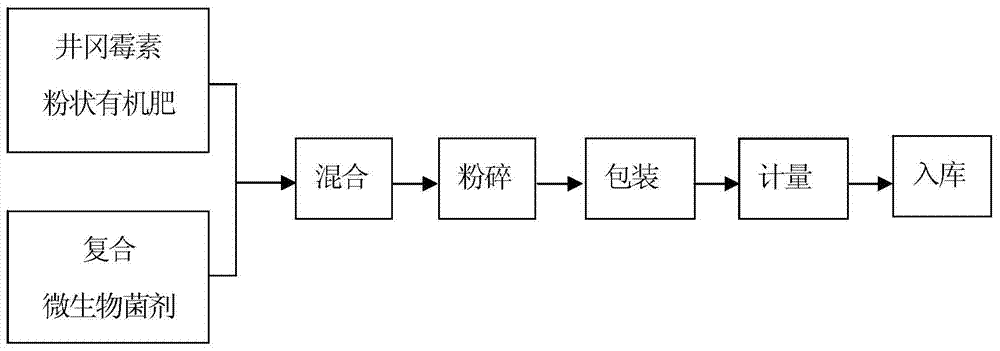

Compound microbial fertilizer with efficient disease prevention function and production method of compound microbial fertilizer

The invention discloses a compound microbial fertilizer with an efficient disease prevention function. The raw material is a mixture of herb residues generated in the production process of validamycin and plant ashes, wherein a fungicide is a composite fungicide prepared from bio-control bacillus subtilis HL259, bacillus megaterium and bacillus mucilaginosus after fermentation and absorption; the mass ratio of the raw material to the fungicide is (50-70):(5-15). Meanwhile, the invention also discloses a production method of the compound microbial fertilizer with the efficient disease prevention function. The method comprises the following procedures: preparation of raw materials of validamycin herb residues, preparation of a compound microbial agent, and preparation of the compound microbial fertilizer after mixing and crushing; the microbial agent accounts for 5-15% of total weight of the compound microbial fertilizer; the raw materials of the validamycin herb residues account for 50-70% of total weight of the compound microbial fertilizer. By adopting the compound microbial fertilizer, the raw material range of the compound microbial fertilizer is expanded, and the obtained compound microbial fertilizer has a good inhibition effect on rhizoctonia solani.

Owner:SHANGHAI LVLE BIO TECH

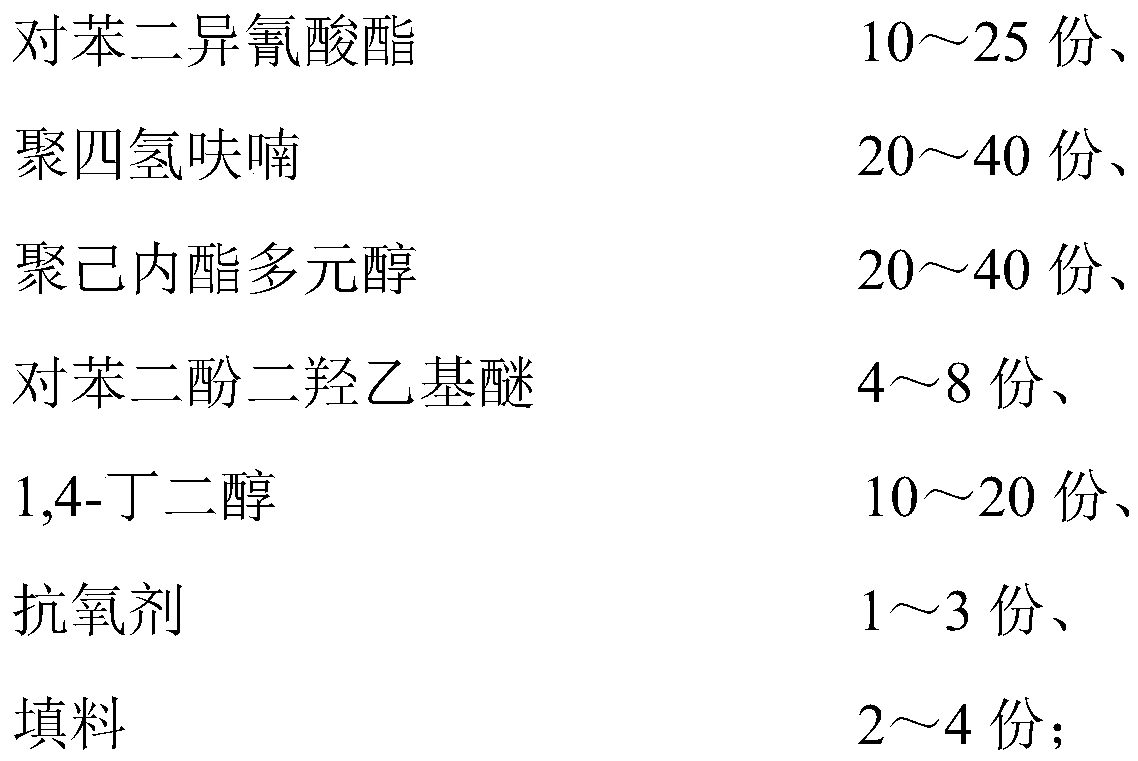

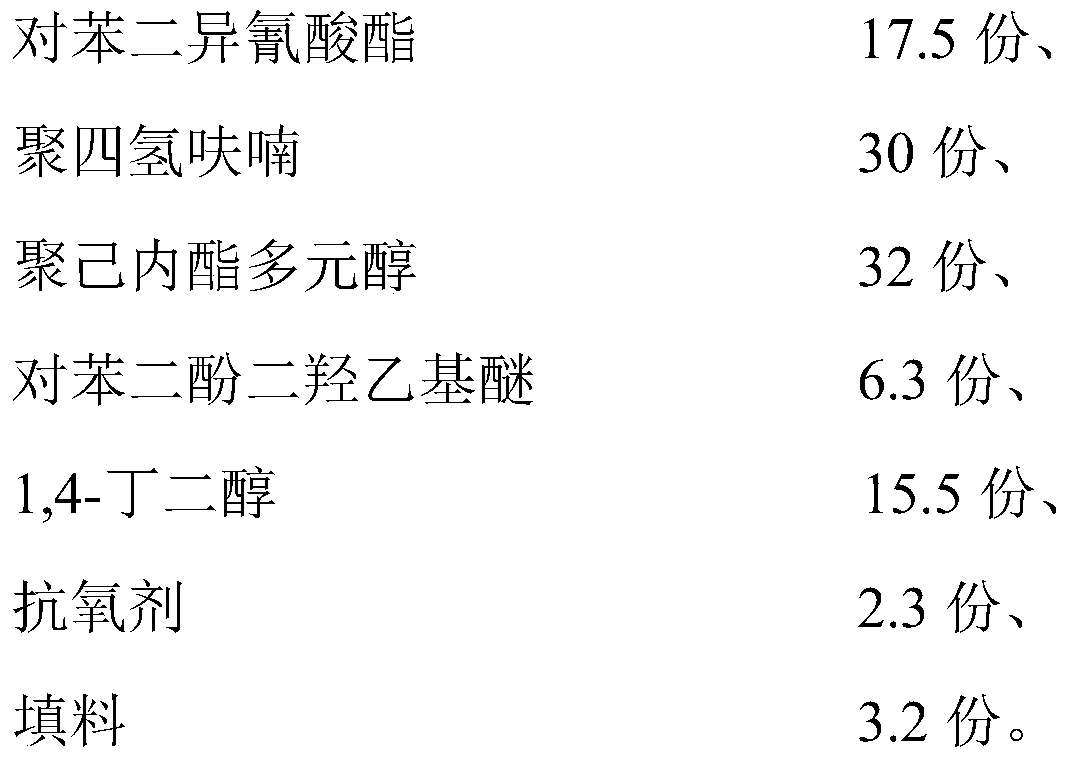

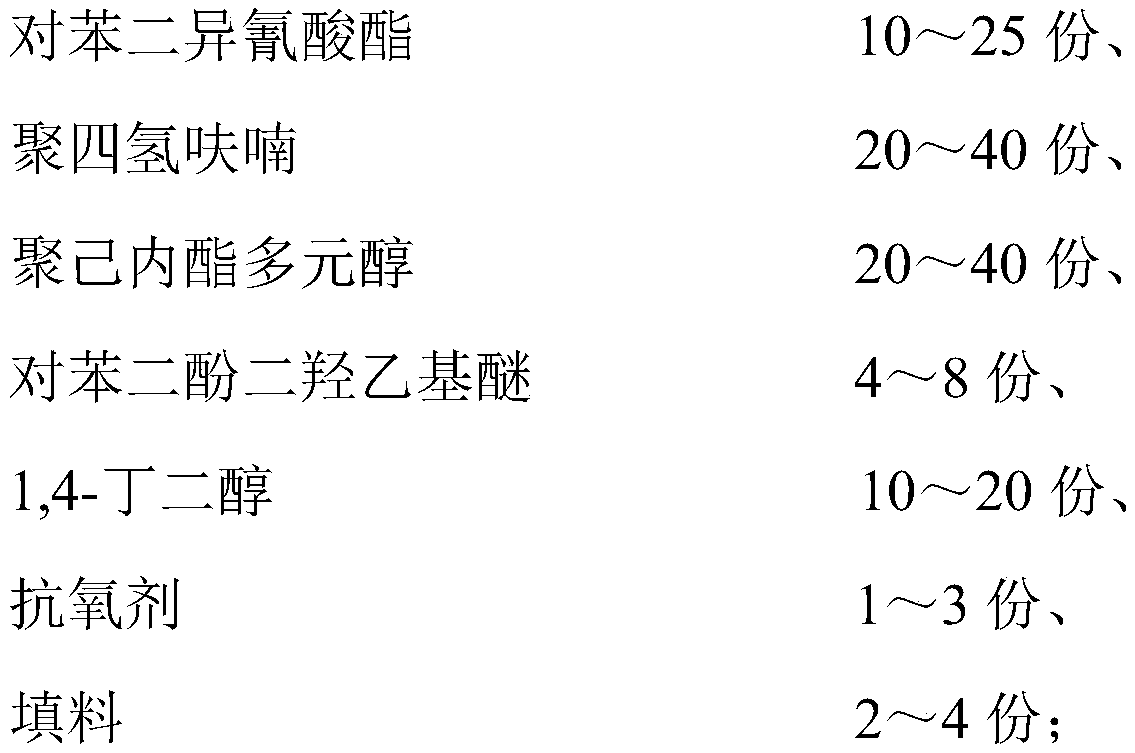

Formula and preparation process for low-temperature-resistant high-elasticity polyurethane used for sealing

The invention discloses a formula for low-temperature-resistant high-elasticity polyurethane used for sealing. The formula comprises the following raw materials by weight: 10-25 parts of p-phenylene diisocyanate, 20-40 parts of polytetrahydrofuran, 20-40 parts of polycaprolactone polyol, 4-8 parts of hydroquinone bis(2-hydroxyethyl)ether, 10-20 parts of 1,4-butanediol, 1-3 parts of an antioxidantand 2-4 parts of a filler, wherein the relative molecular mass of the polytetrahydrofuran is 1400-2000, and the relative molecular mass of the polycaprolactone polyol is 1800-2200. Theow-temperature-resistant high-elasticity polyurethane used for sealing prepared by the invention has good low-temperature resistance and high elasticity, is expanded in the range of use temperature and not liable tothermal ageing, and can be injection-molded.

Owner:上海唯万密封科技股份有限公司

Composite energy-saving self-insulation external wall boards made from building residues and industrial waste residues and production methods thereof

ActiveCN102617088ASolve the production processImprove wear resistanceSolid waste managementClimate change adaptationEnvironmental engineeringGeoponic

The invention discloses composite energy-saving self-insulation external wall boards made from building residues and industrial waste residues and production methods of the energy-saving self-insulation external wall boards. The invention provides production formulations of three composite energy-saving self-insulation external wall boards which are made from building residues and industrial waste residues and have different thickness ranges, and provides production methods of the external wall boards. According to the composite energy-saving self-insulation external wall boards made from building residues and industrial waste residues and the production methods of the external wall boards, wall body material and heat insulation material are combined together and subjected to one-step production molding; the external wall boards can be produced in a mechanically automatic production line; the composite energy-saving self-insulation external wall boards made from building residues and industrial waste residues which take multiple waste residues as main raw materials of the external wall body material and take agricultural wheat straw, crop straw and other waste ash residues as external wall body heat insulation material are developed, thus recycling waste materials and protecting the environment and saving energy. The products are capable of resisting vibration, compression, impact, freezing, weathering, corrosion and aging, good in wear resistance, free from toxicity, harmless, capable of absorbing moisture and water, and good in expansion contractility; in addition, the products are simple in formulation, low in cost and higher in cost performance.

Owner:罗吉祥

Technological method for increasing stability of protein

PendingCN110604213AEasy to operateSolve production process problemsAnimal proteins working-upProtein proteinChemistry

The invention discloses a method for increasing stability of protein. The method comprises the steps of 1, adding water of 40-50 DEG C to protein raw materials, performing dissolving, and performing compounding to obtain a protein solution of which the concentration is 10-30%, wherein protein is one or several of whey protein concentrate, milk protein, calcium caseinate and casein; 2, adding 0.5-1moL / L of pH-regulating agents to the protein solution which dissolves well so that the pH value is 5-9; 3, respectively adding one or more of different sodium-containing minerals, potassium-containingminerals, calcium-containing minerals, magnesium-containing minerals, ferrum-containing minerals and zinc-containing minerals of which the concentration is 20-1500mg / 100g to the protein solution which dissolves well; and 4, putting the protein solution of which the pH value is adjusted and the protein solution to which different kinds of minerals are added in water bath of 70-100 DEG C, and performing stirring and heating at the speed of 200-600rpm for 2 hours. According to the method, the protein sources are wide, the concentration is high, the types of different minerals are researched, through experiment, the denaturation point of protein can be found out, production enterprises can be guided to directly avoid factors which lead to protein denaturation in accordance with the differences of the used proteins, and the stability of products can be increased.

Owner:苏州恒瑞健康科技有限公司

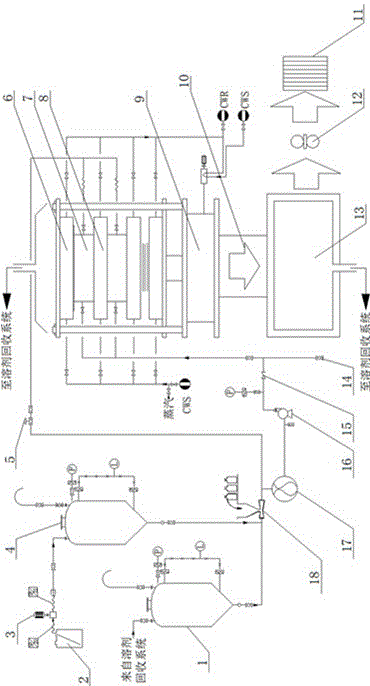

Production technology for hard PVC high foaming plate

The invention discloses a production technology for a hard PVC high foaming plate. A fresh solvent barrel, a diaphragm pump, a fresh solvent storage groove, a charging tank, a kneader, a charge pump, a foaming machine, an automatic conveyor, a hot air circulation oven and a cutting machine, all of which are sequentially connected are included. A solvent recycling storage groove is further formed in front of the charging tank. A heating plate I, a die and a heating plate II are arranged in the foaming machine. The bottom of the heating plate I is connected with the top of the die, and the bottom of the die is connected with the top of the heating plate II. An inlet of the die is connected with an outlet of the charge pump, and an outlet of the die is connected with the kneader. Each of the heating plate I and the heating plate II is provided with a steam heating and circulation water cooling device. According to the production technology, the hardness and foaming ratio of the PVC foaming plate are greatly improved, and the problem that hard high foaming plate materials are unavailable for PVC in China at present is solved.

Owner:TIANWEI CHEM +1

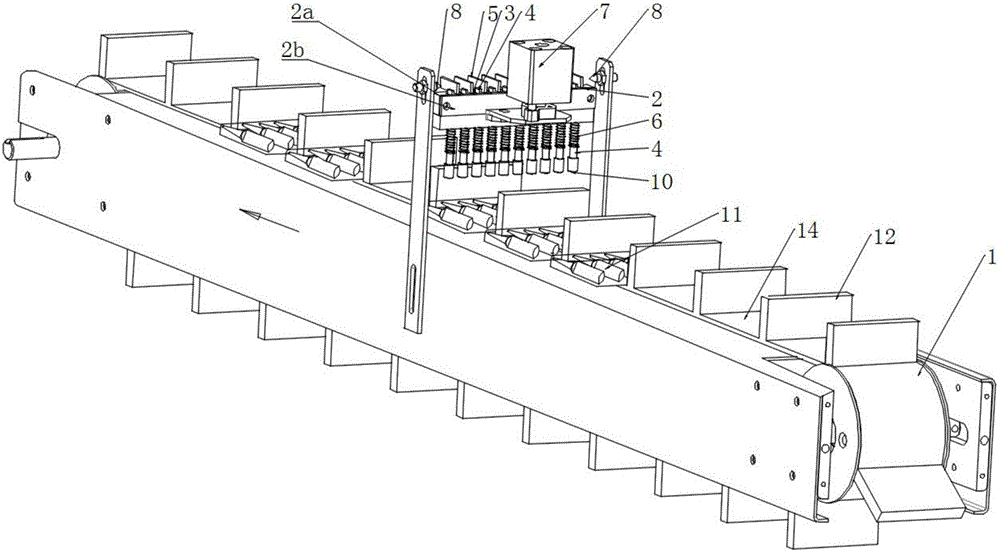

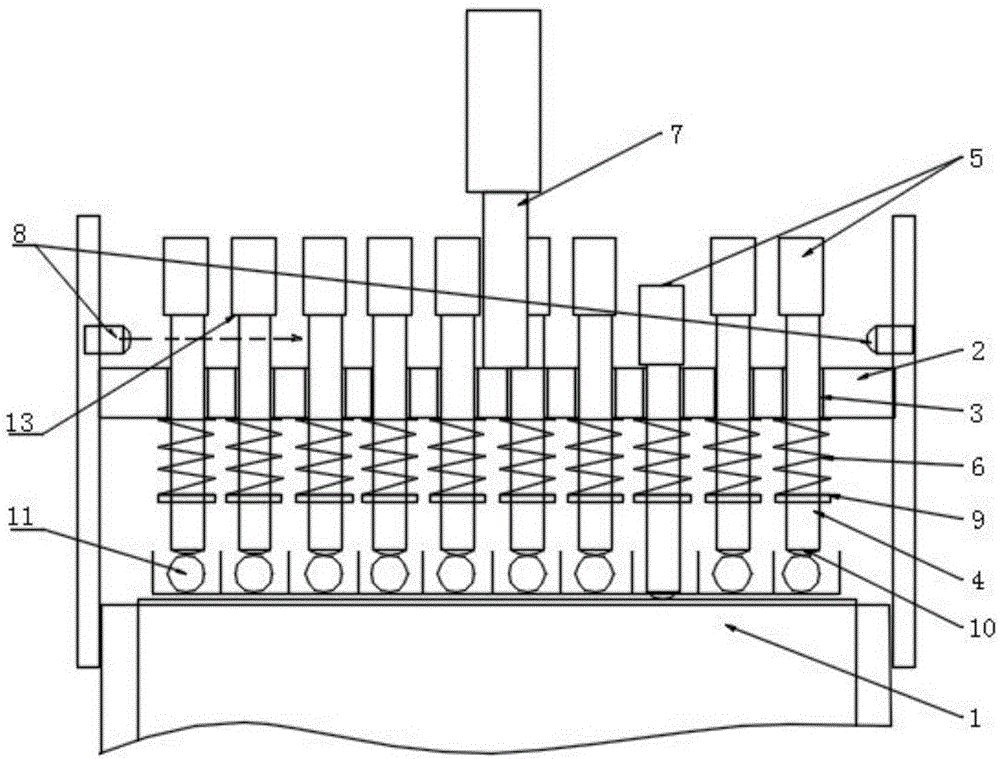

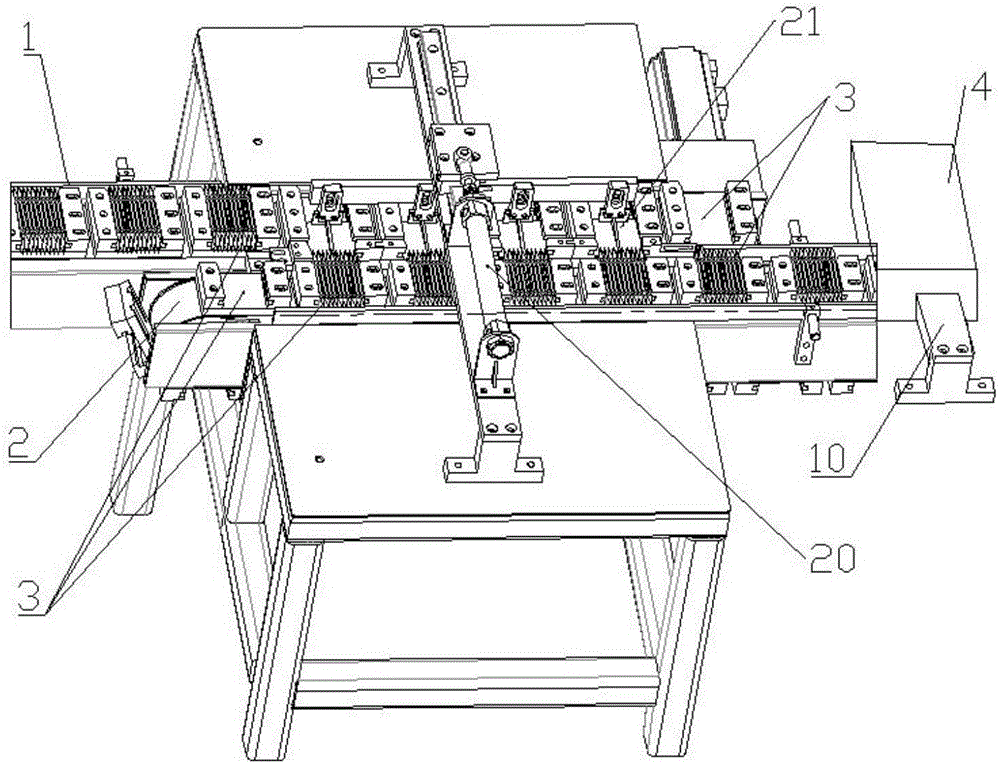

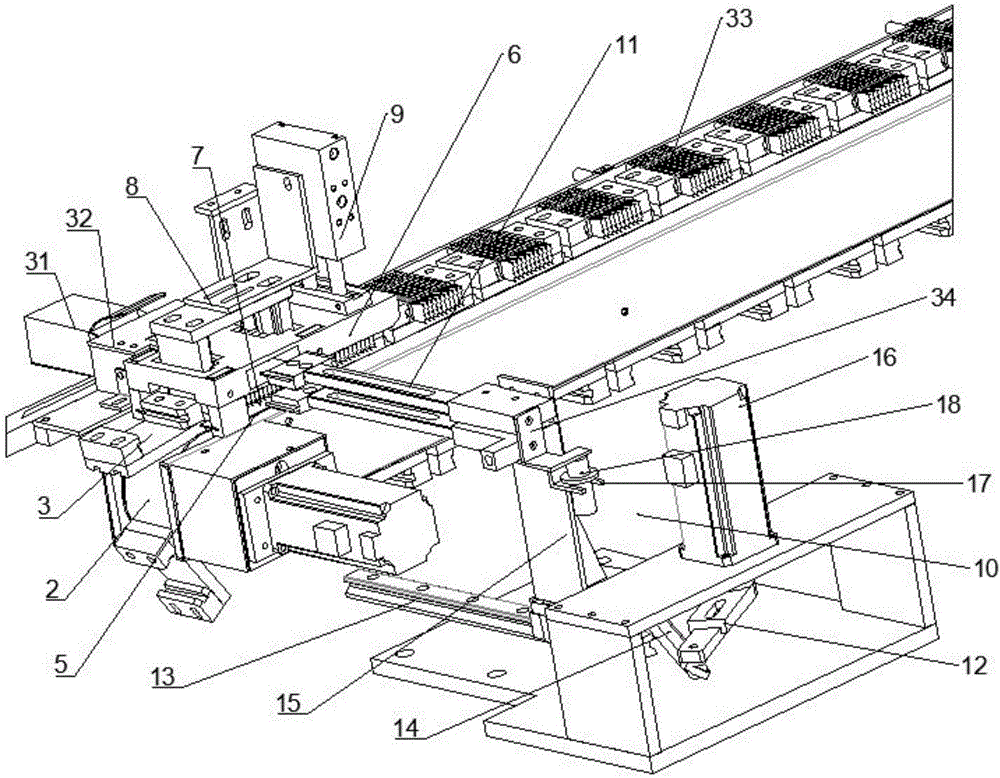

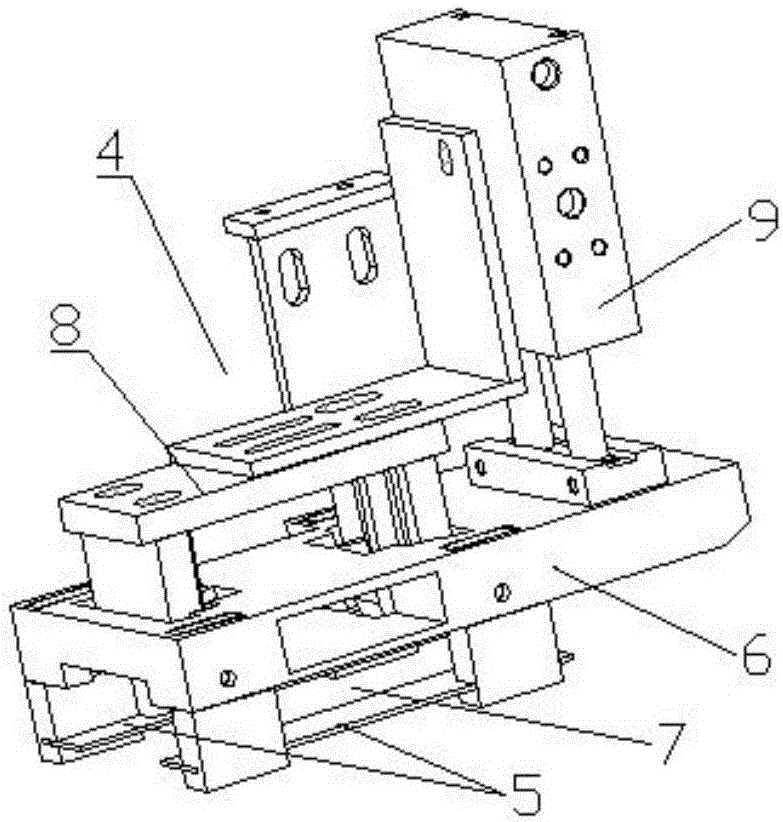

Package shortage detecting device

InactiveCN106275636ASolve the production processReduce the labor intensity of production operationsPackaging automatic controlEngineeringSignal transition

The invention discloses a package shortage detecting device. The package shortage detecting device comprises a detecting device which corresponds to a corresponding conveying device; the detecting device comprises a position detector which is operated correspondingly and synchronously with the conveying device, and a signal converter which corresponds to the position detector; the position detector comprises a driver which is connected with a corresponding intelligent controller, and a plurality of detecting bodies which are connected to the interior of the driver through corresponding guide devices, and correspond to corresponding detected objects on the conveying device. According to the package shortage detecting device, package shortage automatic detection treatment of liquid medicine bottles or injections can be realized; the mechanical automatic bagging and packaging of the liquid medicine bottles are realized; the package efficiency and the production efficiency are improved; moreover, the package shortage detecting device is simple in structure, stable and reliable in operation and high in practicability.

Owner:JIANGXI WANSHEN MACHINERY

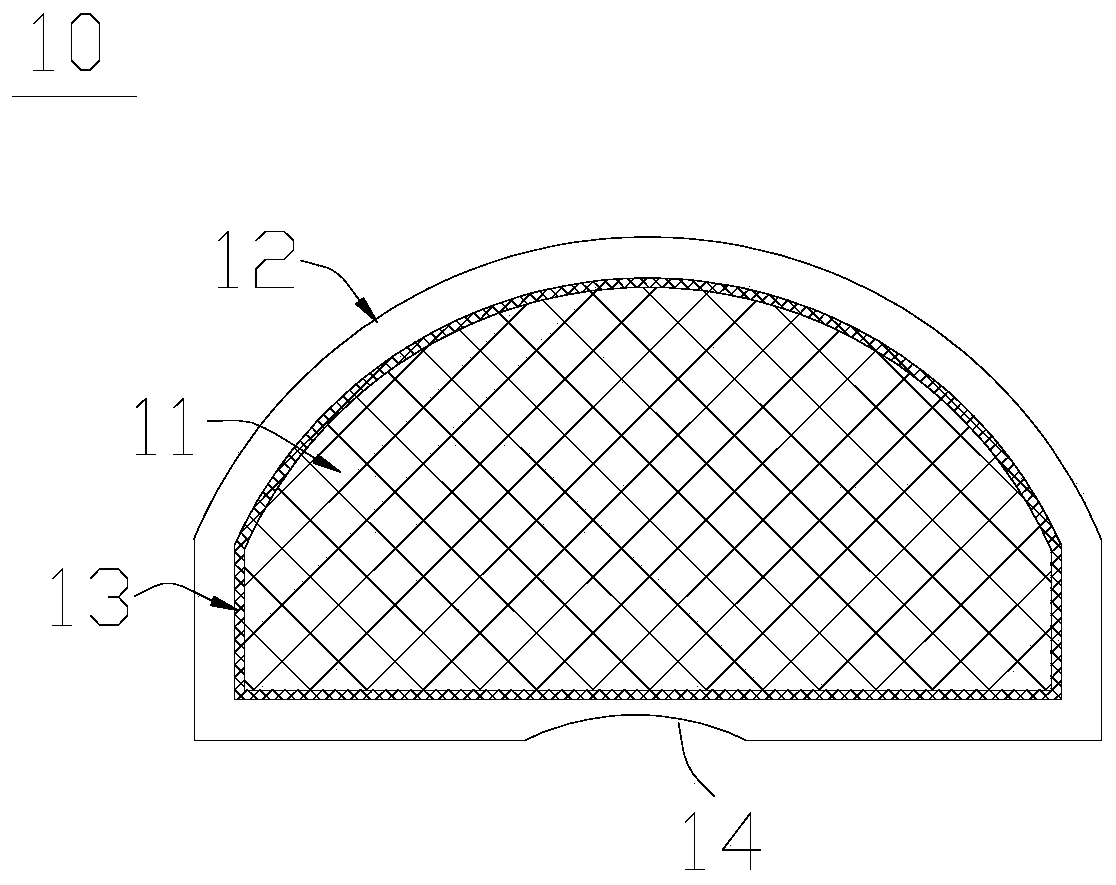

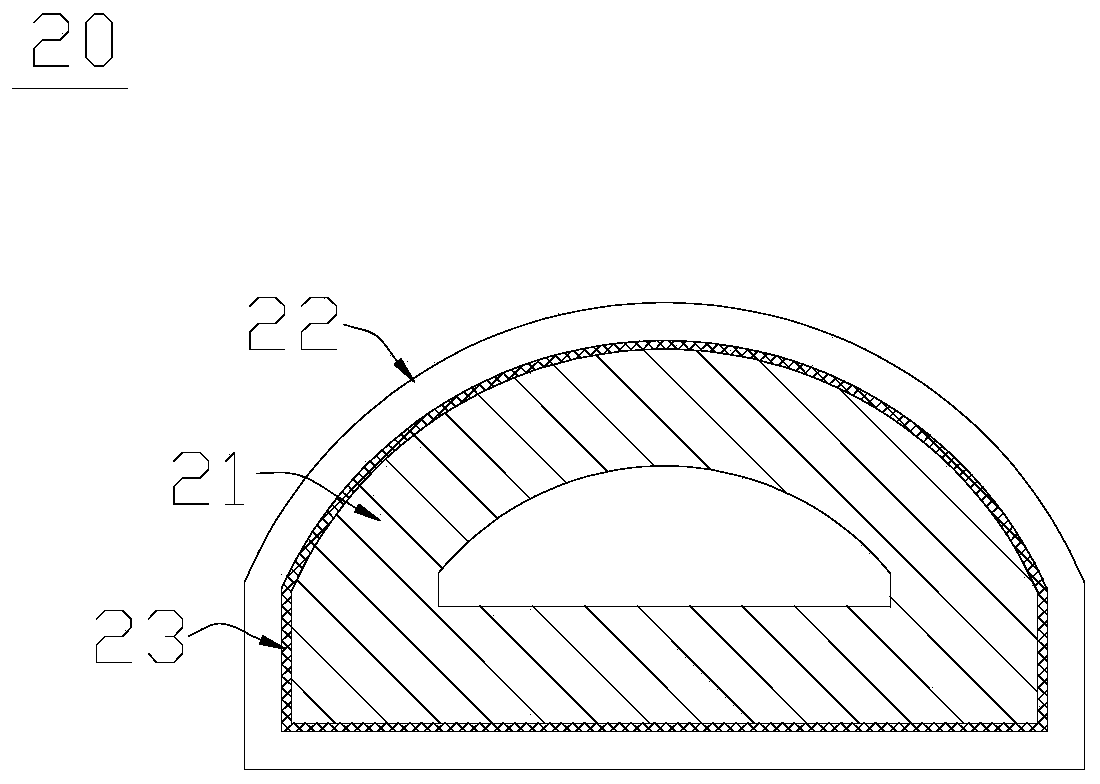

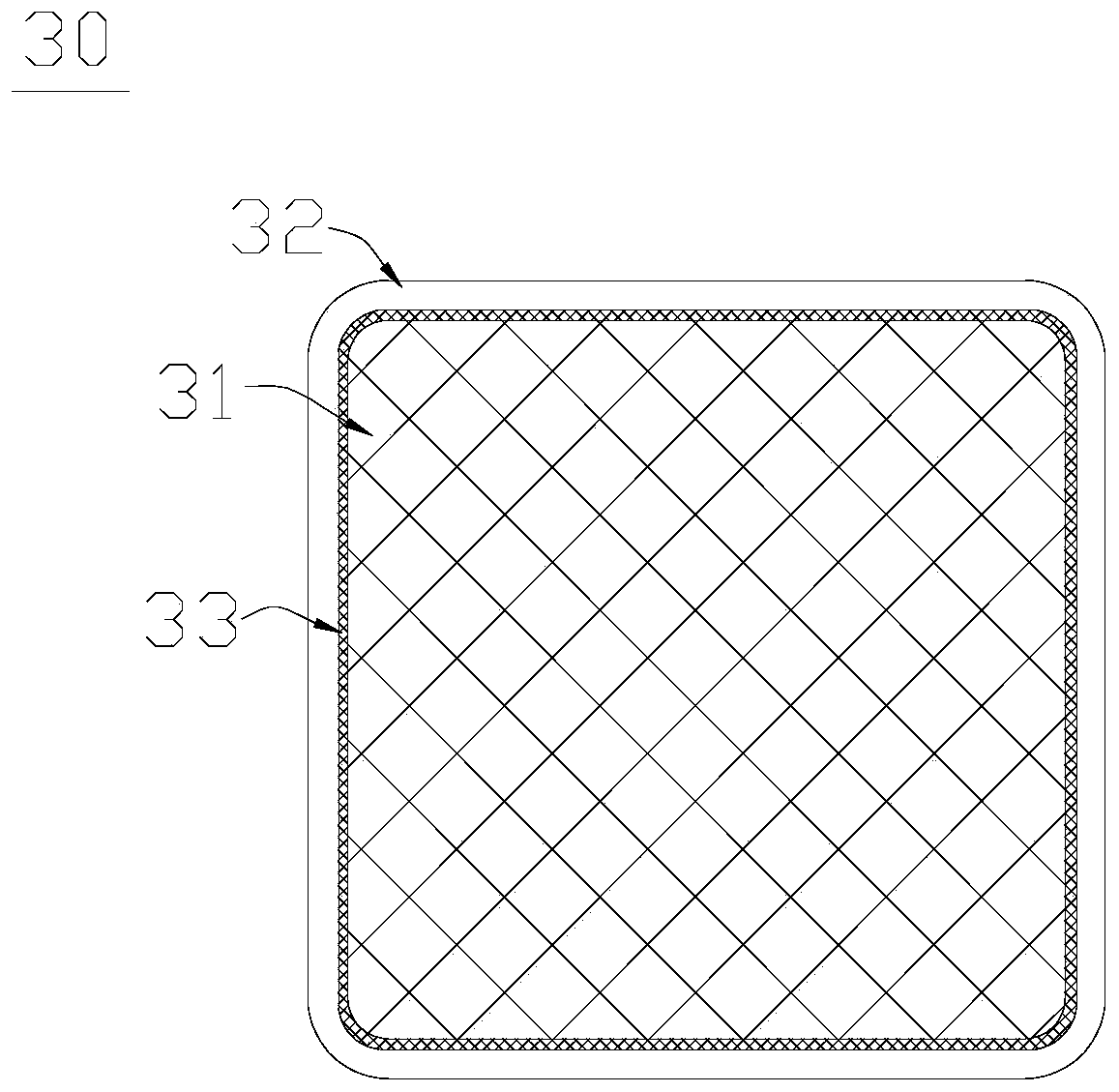

Fabric over foam and manufacturing method thereof

PendingCN109862766ASolve highSolve the production processMagnetic/electric field screeningEngineeringSurface-mount technology

The invention discloses a fabric over foam and a manufacturing method thereof. The fabric over foam comprises an elastic core, a solderable conductive layer and a bonding layer. The outer surface of the elastic core is coated with the solderable conductive layer, the bonding layer is arranged between the solderable conductive layer and the elastic core, and the solderable conductive layer can be bonded on the elastic core. The fabric over foam coats and is fixed on the elastic core in a bonding mode to form a fabric over foam capable of reflow soldering or SMT, the solderable conductive layercan achieve that the fabric over foam is installed on an electronic device in a reflow soldering mode and is used for the reflow soldering surface installation technology so as to solve the problems of limited operation height, the production process, the human influence and quality risk in a traditional fabric over foam.

Owner:常州市飞荣达电子材料有限公司

Automobile axle material

The invention discloses an automobile axle material. The automobile axle material comprises, by weight, 0.25%-0.35% of C, 0.2%-0.5% of Si, 0.5%-0.8% of Mn, 06%-1.2% of Cr, 0.40%-0.60% of Mo, 015%-0.25% of V, 0.001%-0.030% of S, 0.1%-0.5% of Al, 0.25%-0.55% of Cu, 0.6%-1.2% of Ti, 0.05%-0.2% of Ni and the balance Fe and inevitable impurities. In addition, the weight percentage of P is limited below 0.05%, and the weight percentage of O is limited below 0.06%. An axle steel pipe prepared from the material is high in strength and surface hardness, good in impact toughness, excellent in anti-fatigue performance; and steel has excellent hardenability and good comprehensive mechanical performance, and the surface hardness of a nitride layer of the steel is 1000 HV or over.

Owner:ANQING JIAN AUTO PART FORGING & ROLLING

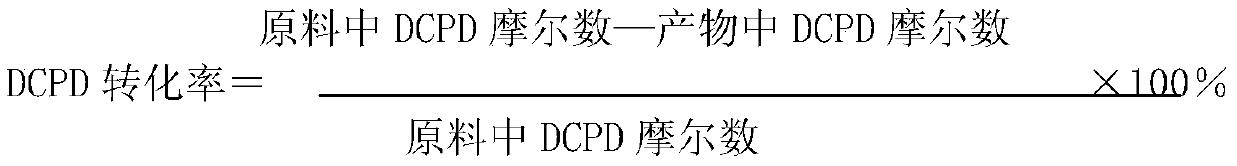

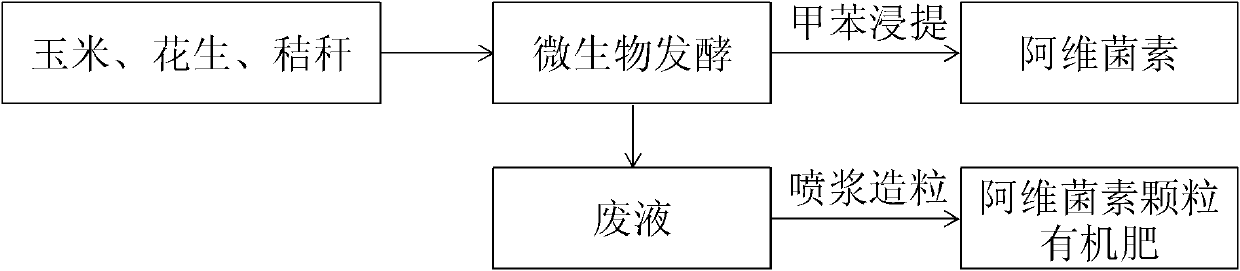

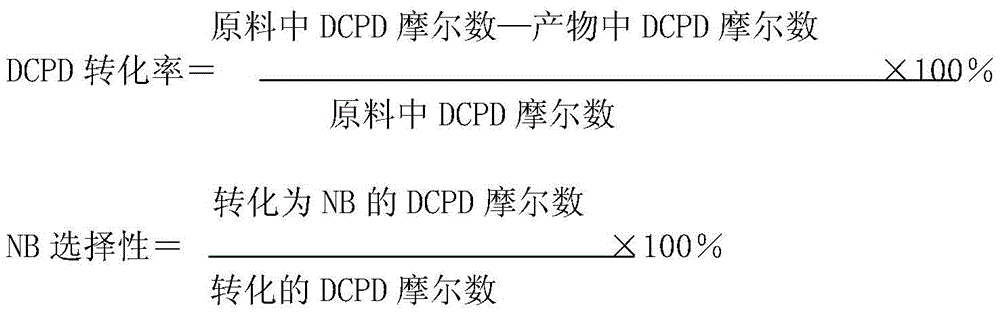

Vinyl norbornene production method

ActiveCN105541529AHigh yieldAvoid generatingHydrocarbons from unsaturated hydrocarbon additionHydrocarbon by depolymerisationTert-butylcatecholSystem pressure

The invention relates to a vinyl norbornene production method. The method utilizes two tank reactors connected in series and through the reactors, dicyclopentadiene undergoes a pyrolysis reaction to produce cyclopentadiene and the cyclopentadiene and 1, 3-butadiene undergo a Diels-Alder reaction to produce the vinyl norbornene. The method comprises 1, feeding dicyclopentadiene, 1, 3-butadiene, methyl isobutyl ketone as a solvent and a p-tert-butylcatechol solution as a polymerization inhibitor from the bottom of the first tank reactor into the first tank reactor through a pump and carrying out a reaction process under conditions of a reaction temperature of 170-190 DEG C, system pressure of 7-11MPa and material staying time of 10-120min, and 2, carrying out a reaction process in the second tank reactor under the conditions of a reaction temperature of 200-220 DEG C, system pressure of 7-10MPa and material staying time of 10-80min, discharging the reaction solution, feeding the reaction solution into a refining system and carrying out refining to obtain refined vinyl norbornene with content of 99.5% or more. The method improves a product vinyl norbornene yield and effectively prevents polymer formation of individual or all of 1, 3-butadiene and cyclopentadiene.

Owner:SHANGHAI PEARLK CHEM

Method for producing compound microbial fertilizer by microbial inoculum packing method

ActiveCN102040434BReduce manufacturing costSolve the production processFertilizer mixturesAgricultural engineeringAbamectin

Owner:SHANGHAI NUOTONG INFORMATION TECH CO LTD

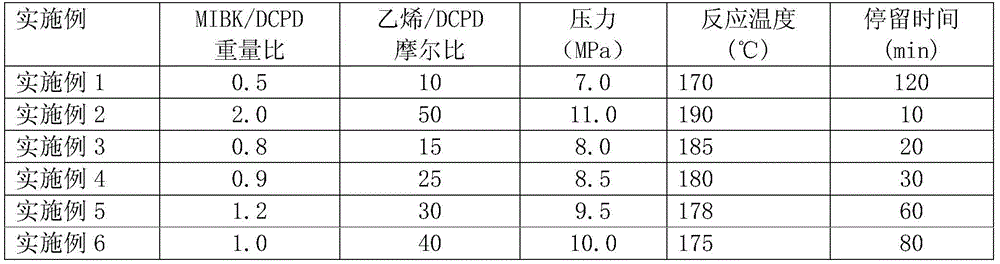

Norbornene production method

ActiveCN105481625AAvoid generatingIncrease NB yieldHydrocarbons from unsaturated hydrocarbon additionHydrocarbon by depolymerisationMethyl isobutyl ketoneNorbornene

A norbornene production method uses two tank reactors in series, so that dicyclopentadiene (DCPD) depolymerizes into cyclopentadiene (CPD), and cyclopentadiene and ethylene are subjected to a Diels-Alder reaction to convert into norbornene (NB). The method is as below: 1) continuously feeding the prepared dicyclopentadiene, a solvent methyl isobutyl ketone (MIBK) and a polymerization inhibitor p-tert-butyl catechol (TBC) solution by a pump from the bottom of a first tank reactor to a reactor, stirring, introducing ethylene gas, reacting at the temperature of 170-190 DEG C and under the pressure of 7-11 MPa, maintaining the materials in the reactor for 10-120 min; 2) maintaining the materials in a second tank reactor for 10-80 min at the reaction temperature of 200-220 DEG C and under the pressure of 7-10 MPa; sending the discharged reaction solution into a refining system to obtain refined norbornene with content of higher than 99.9 wt.%. The method increase the yield of NB and effectively prevents the generation of CPD polymer and polymer.

Owner:SHANGHAI PEARLK CHEM

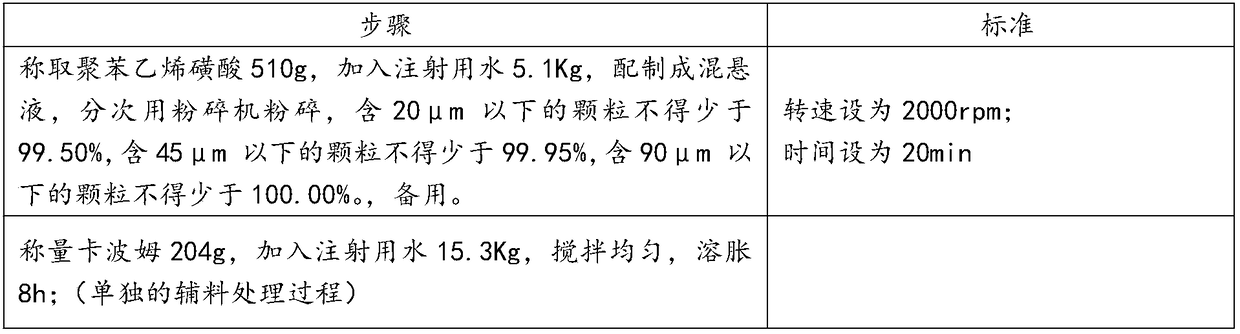

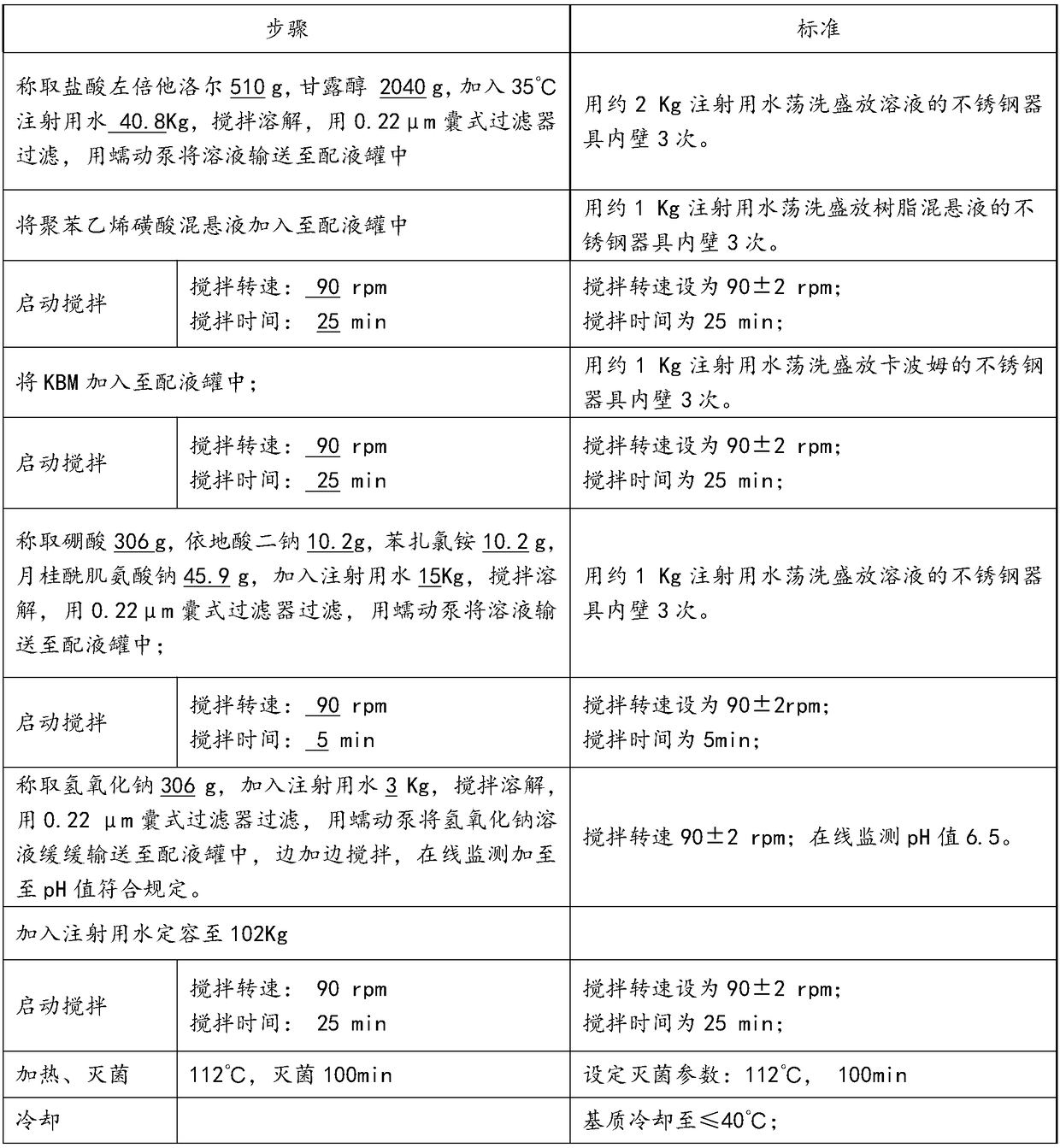

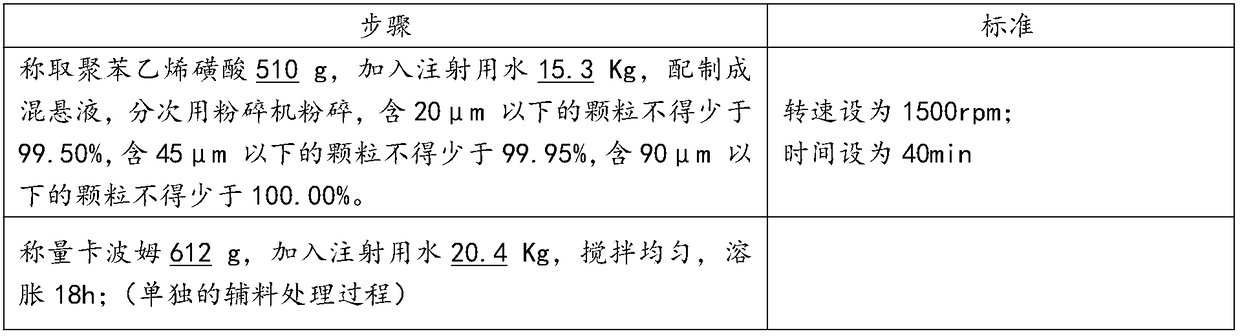

Preparation method of levobetaxolol hydrochloride eye drops

ActiveCN108066283ASolve the production processLess impuritiesOrganic active ingredientsSenses disorderDisodium EdetateInjections water

The invention discloses a preparation method of levobetaxolol hydrochloride eye drops. The method includes: adding 0.5% of polystyrolsulfon acid into 5-15% of injection water, crushing, and stirring to obtain suspension; adding 0.2-0.6% of Carbomer into 15-20% of injection water, evenly stirring, and swelling; adding 0.5% of levobetaxolol hydrochloride and 2-6% of mannitol into 40% of injection water, heating, stirring for dissolving, and filtering to obtain mixed liquid A; adding the suspension into the mixed liquid A, and stirring and mixing to obtain mixed liquid B; adding the Carbomer solution after the swelling into the mixed liquid B, and stirring and mixing to obtain mixed liquid C; adding boric acid, edetate disodium, benzalkonium chloride and sodium lauroyl sarcosine into 15% of injection water, stirring for dissolving, filtering, adding the filtered liquid into the mixed liquid C, and stirring and mixing to obtain mixed liquid D; using 0.03-0.09% of pH regulator to regulate the pH of the mixed liquid D to be 6.5-7.5, adding injection water to achieve constant volume, stirring, heating, sterilizing, and cooling to obtain the levobetaxolol hydrochloride eye drops. The levobetaxolol hydrochloride eye drops are simple in preparation process and good in stability.

Owner:ZHAOKE GUANGZHOU OPTHALMIC DRUG

Multifunctional efficient automatic packing machine

PendingCN107434061ASolve the production processReduce the labor intensity of production operationsIndividual articlesCartoning machineMechanical engineering

The invention discloses a multifunctional efficient automatic packing machine which comprises an inputting synchronous belt and a packing synchronous belt in synchronous correspondence. Loading devices are arranged in corresponding compartments of the packing synchronous belt and include pushers or include pushers and corresponding temporary storage units. The mulitufunctional efficient automatic packing machine realizes automatic packing of one or multiple groups of sacked materials or hard materials to be packed synchronously simultaneously, realizes automatically mechanical packing of the sacked materials in batch, improves packing production efficiency, and has the advantages of simple and reasonable structure, stable and reliable running and high adaptability.

Owner:JIANGXI WANSHEN MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com