Production and heat treatment method of aluminum alloy continuous-casting continuous-rolling billet

A heat treatment method, continuous casting and rolling technology, applied in the field of non-ferrous metal processing, can solve the problems of long production cycle, immature production technology, development restrictions, etc., and achieve increased recrystallization texture, high economic benefits and practical value, The effect of reducing surface segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

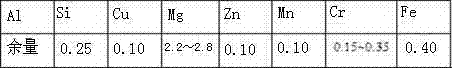

[0049] Using 85% electrolytic aluminum liquid and 15% solid material (99.70% industrial pure aluminum ingot, solid 5052 waste, magnesium ingot, etc.) Chemical composition range implementation. Set the melting temperature to 750~760 0 C, the primary refining temperature is 715 0 C, the second and third refining temperature is 735 0 C; use SNIF degassing, add Al-5Ti-1B grain refining agent through the launder before degassing, the amount of refining agent added is controlled at 10m / min; the hydrogen content in the melt is controlled within 0.12ml / 100gAl; before The casting temperature of the box is 680±5°C. After online testing, the measured chemical composition is

[0050] .

[0051] Hazelett continuous casting machine is adopted, Y-shaped steel strip and SS casting nozzle are used for continuous casting of 5052 aluminum alloy; graphite spraying system is sprayed once half an hour before casting, during the casting process, cracks on the edge of the strip need to be spr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com