Production technology of glass fiber cloth for insulation

A glass fiber cloth and production process technology, applied in fiber processing, weaving, fabrics and other directions, can solve the problems of difficult production management and high technical requirements, and achieve the effects of easy production management, convenient process, and easy weaving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

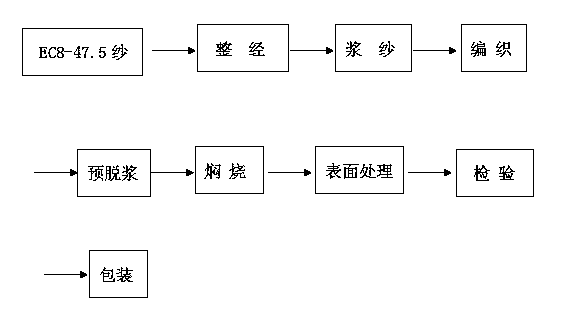

[0033] The insulating cloth produced in this example is produced by using EC8-47.5 glass fiber yarn, the warp and weft density is 17.3×14.2 threads / cm, the thickness is 0.140mm, and the mass per unit area is 150g / m 2 , the diameter of its monofilament yarn is 8um, warp and weft number 47.5Tex, with single warp, single weft, through warping, sizing and then carry out air-jet loom and weave.

[0034] Present embodiment is to utilize common air-jet loom, warping machine and sizing machine to produce high-grade insulating glass fiber cloth.

[0035] In this embodiment, EC8-47.5 glass fiber yarn is used as raw material, which is made by warping and sizing EC8-47.5 glass fiber yarn on an air-jet loom. Composed of firing, surface treatment, inspection and packaging processes, the following production processes can be used to make glass fiber cloth for insulation.

[0036] 1. Yarn selection

[0037] The warp and weft yarns are EC8-47.5 glass fiber yarns;

[0038] 2. Warping proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com