Patents

Literature

49 results about "Tert-butylcatechol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Efficient natural gas

InactiveCN103710062AGood volatilization effectLess corrosiveGaseous fuelsTert-butylcatecholTurpentine

The invention discloses efficient natural gas. The efficient natural gas consists of natural gas with purity higher than 95% in percentage by weight, and 0.3-0.5% of a liquid-phase synergistic additive in terms of weight percentage of the natural gas, wherein the liquid-phase synergistic additive consists of the following raw materials: 200# solvent oil, isopropanol, petroleum ether, ethylene glycol monoethyl ether, turpentine, tung oil, isooctyl nitrate, dimethyl carbonate, tert-butylferrocene or ferrocene, methyl tertiary butyl ether or n-octyl ferrocene, p-tert-butylcatechol, azodiisobutyronitrile and polyether. The efficient natural gas, through adding little liquid-phase synergistic additive in the natural gas, can obviously improve burning temperature and burning efficiency; meanwhile, the liquid-phase synergistic additive is low in corrosion and good in volatility on containers.

Owner:BEIJING DATONG HONGYE TECH DEV

Method for synthesizing para-tert-butylcatechol by using acid-mixed mixed system containing ionic liquid

InactiveCN102643170AImprove stabilityEasy to recycleOrganic chemistryOrganic compound preparationAlkyl transferDistillation

The invention provides a method for synthesizing para-tert-butylcatechol by using an acid-mixed mixed system containing ionic liquid, which comprises the following steps: stirring, heating and melting catechol and an acid-mixed catalyst, adding an alkylating agent in a droplet mode within 30 min, performing condensation backflow reaction for 60-150 min under the temperature of 110-150 DEG C, extracting reaction liquid to separate the ionic liquid for recycling, performing extract-phase reduced pressure distillation and purification and finally obtaining the para-tert-butylcatechol, wherein the mole ratio of the catechol to the alkylating agent to the acid-mixed catalyst is 1:0.5-2.0:0.01-0.1. The acid-mixed catalyst is formed by mixing two types of acidic ionic liquid or mixing acidic ionic liquid and bronsted acid. The method for synthesizing the para-tert-butylcatechol by using the acid-mixed mixed system containing the ionic liquid overcomes the defect that simple ionic liquid is weak in acidity and poor in catalysis effect, facilitates catalytic alkylation reaction and is small in corrosivity and environmental pollution, the conversion rate of the catechol reaches up to 87.2%, and the selectivity of 4-para-tert-butylcatechol (4-TBC) reaches up to 77.3%.

Owner:HEBEI UNIV OF TECH

Alcohol based fuel additive

InactiveCN106281507AEffective carbon depositionEffectively remove carbon depositsLiquid carbonaceous fuelsFuel additivesAlcoholTert-butylcatechol

The invention belongs to the technical field of fuel additives, and particularly relates to an alcohol based fuel additive. The alcohol based fuel additive is prepared from raw materials in parts by weight as follows: 10-18 parts of hexamethylene tetramine, 8-16 parts of N-acetylimidazole, 6-14 parts of p-tert-butylcatechol, 5-10 parts of polyvinyl alcohol, 4-12 parts of glyceryl triacetate, 3-11 parts of a cetane number improver and 1-8 parts of a combustion promoter. The additive has the functions of being combustion-supporting, clean, anti-corrosion and anti-oxidant, increasing the cetane number of the fuel and the like.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

Antibacterial polyvinyl chloride tube material

InactiveCN105440489AAvoid decompositionImprove heat resistanceRigid pipesLow-density polyethylenePhosphate

The invention discloses an antibacterial polyvinyl chloride tube material. The antibacterial polyvinyl chloride tube material comprises polyvinyl chloride, sulfonated polyethersulfone, styrene-butadiene rubber, butadiene-acrylonitrile rubber, high density polyethylene, nanometer zinc oxide, modified nanometer titanium dioxide, attapulgite, nanometer montmorillonite, epoxidized butyl oleate, tri-isopropylphenyl phosphate, zinc stearate, zinc azelate, calcium pimelate, pentaerythritol, lanthanum 2-ethyloctoate, dimethyltin bis(isooctylmercaptoacetate), an anti-oxidant, 2-n-octyl-4-isothiazolin-3-one and p-tert-butylcatechol. A preparation method of the modified nanometer titanium dioxide comprises adding ferric nitrate and nanometer titanium dioxide into deionized water, stirring the solution at a room temperature for 50-60h, carrying out aging for 25-30h, carrying drying, carrying out grinding, carrying out calcination at a temperature of 450-500 DEG C for 2-3.5h and then cooling the product to the room temperature. The antibacterial polyvinyl chloride tube material has good bacterinertness, heat resistance and aging resistance.

Owner:安徽宁国市高新管业有限公司

Polymerization inhibitor and application thereof in acrylonitrile production device

InactiveCN106905188AInhibition of free radical polymerizationExtend production run timesPreparation by hydrocarbon ammoxidationCarboxylic acid nitrile purification/separationTert-butylcatecholAcrylonitrile

Owner:北京誉天利化工有限公司 +1

Waterproof flame-retardant adhesive and preparation method thereof

InactiveCN107698701AImprove adhesionLower surface energyNon-macromolecular adhesive additivesTriethoxysilanePhosphate

The invention relates to the technical field of adhesives and discloses a waterproof flame-retardant adhesive and a preparation method thereof. The adhesive is prepared from the following raw materials in parts by weight: 45-60 parts of modified hydroxyl acrylic resin, 1-5 parts of butanone, 2-7 parts of tri(2-chloroethyl)phosphate, 1-3 parts of p-tert-butylcatechol, 3-7 parts of dicyandiamide, 2-6 parts of vinyl triethoxysilane, 12-18 parts of talcum powder and 4-9 parts of modified aluminum hydroxide. The adhesive disclosed by the invention has excellent waterproof flame-retardant performances.

Owner:浙江星丰科技有限公司

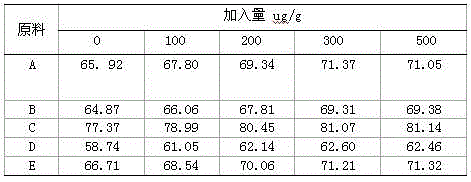

Complex solvent and application thereof

ActiveCN108728155AImprove solubilityHigh selectivityAzeotropic/extractive distillationHydrocarbon oils treatmentHydroxylamineExtractive distillation

The invention relates to the field of aromatics extraction and discloses a complex solvent and application thereof. The complex solvent comprises a main solvent, a cosolvent and an olefin polymerization inhibitor. Based on the total weight of the complex solvent, the content of the main solvent is 70-99 wt%, the content of the cosolvent is 0.999-29.9 wt%, and the content of the olefin polymerization inhibitor is 10-1000ug / g; the main solvent is selected from sulfone compounds; the cosolvent is selected from at least one of N-methyl pyrrolidone, triglycol monomethyl ether, tetraethylene glycolmonomethyl ether, furfural and dimethylacetamide; the olefin polymerization inhibitor is selected from at least one of p-tert-butylcatechol, diethylhydroxylamine, dipropyl hydroxylamine, 2-sec-butyl-4,6-dinitrophenol and sodium nitrite. The complex solvent has high selectivity on aromatic hydrocarbons and sulfides, is capable of reducing the selectivity of the olefins and inhibiting olefin polymerization, and is very suitable to be used during extractive distillation.

Owner:BEIJING ENERGY ENG TECH

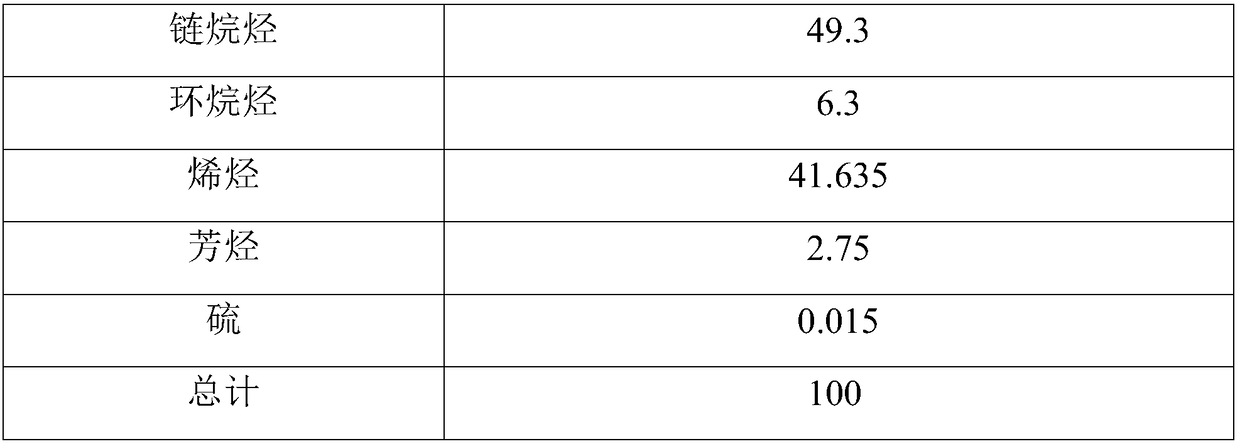

Adhesive for fiber board and preparation method of adhesive

InactiveCN107099268AHigh densityImprove rigidityAldehyde/ketone condensation polymer adhesivesFiberAdhesive cement

The invention discloses an adhesive for a fiber board and a preparation method of the adhesive. The p-tert-butylcatechol is taken as a crosslinking agent to produce dimethylol urea and a urea resin molecule through connection, and a urea resin is synthesized through an acid-neutral-acid-neutral-acid process, so that the molecule of the adhesive is evenly increased, a benzene ring structure is introduced into the molecular structure, the resin curing crosslinking density and rigidity of the urea resin are improved, the capability of capturing free formaldehyde is improved, the bonding strength is very high, and the formaldehyde emission is very low. The adhesive has the advantages that the unconventional p-tert-butylcatechol is used to produce a quinone structure under the actions of a catalyst and an oxidizing agent, the acid-neutral-acid-neutral-acid process is used to gradually increase the molecular chain of the urea resin and finally form a network structure, the formed resin is low in molecular weight and high in reaction activity, the basic procedure is close to the conventional process, the process is simple, the operation is simple, and the existing equipment is not transformed.

Owner:江苏苏林木业有限公司

High-performance sealing curing agent, preparation method thereof and application thereof in concrete

The invention discloses a high-performance sealing curing agent, a preparation method thereof and application thereof in concrete. The high-performance sealing curing agent is prepared from the following raw materials in parts by weight: 40-50 parts of sodium silicate, 10-20 parts of vinyl tri-methoxysilane, 6-8 parts of cement, 5-15 parts of modified bentonite, 16-20 parts of water, 7-9 parts of glycerol, 2-4 parts of trisodium phosphate and 1-3 parts of sodium alginate. A preparation method of the modified bentonite comprises the following steps: adding 25-35 parts of bentonite into 85-95 parts of methylbenzene; stirring for 30-50min, and adding 30-40 parts of benzotriazole, 1-3 parts of p-toluenesulfonic acid, 1-2 parts of p-tert-Butylcatechol and 0.2-0.4 part of beta-phenyl naphthylamine; carrying out refluxing reaction for 4-6h, filtering after cooling, and washing and drying to obtain the modified bentonite. After the high-performance sealing curing agent provided by the invention is painted to the surface of concrete, the abrasion loss of the concrete can be obviously lowered. Compared with the prior art, the high-performance sealing curing agent has outstanding substantial characteristics and prominent progress.

Owner:山东纽迈新材料科技有限公司

Extraction fractional distillation for separating pyrocatechol in furanol

ActiveCN101323561AThe total yield of distillation is improvedHigh purityOrganic chemistryOrganic compound preparationFuranTert-butylcatechol

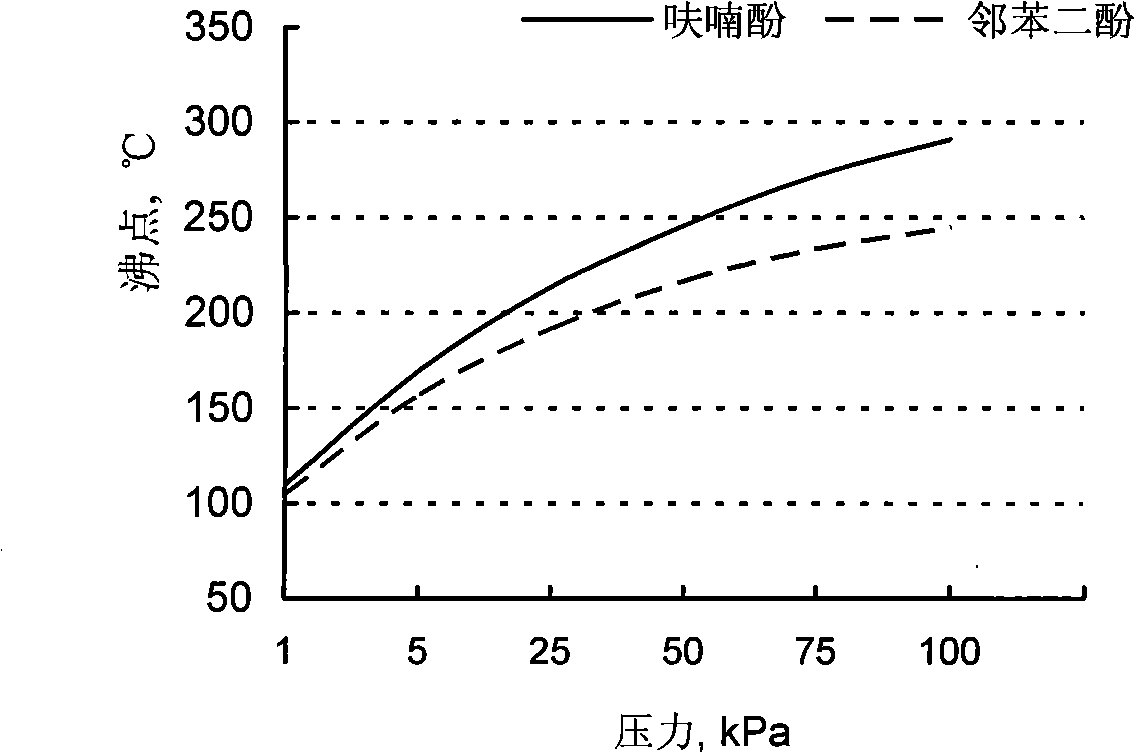

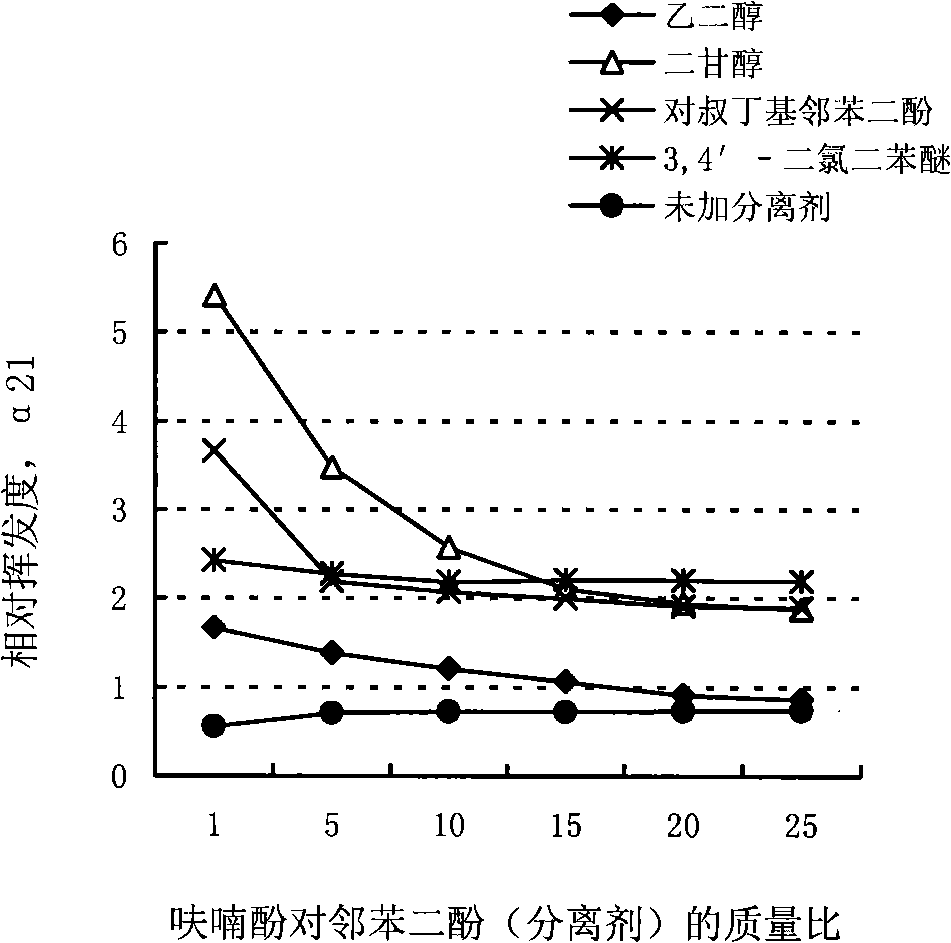

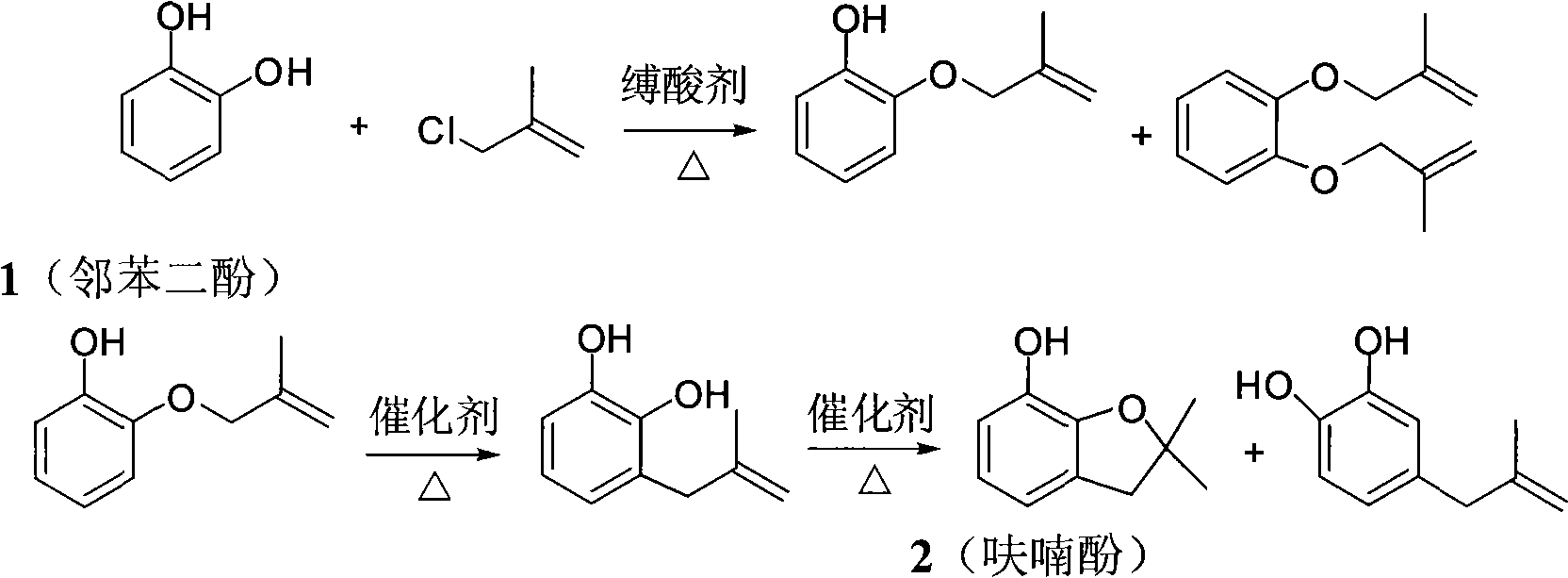

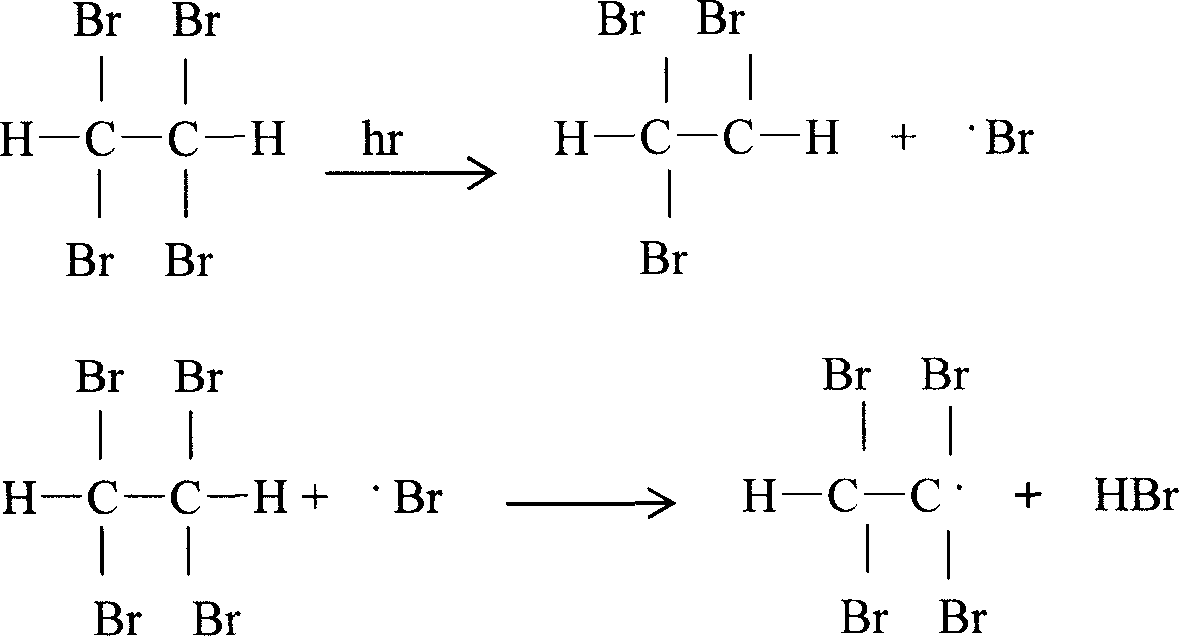

The invention discloses a method for separating catechol pyrocatechol from furan phenol (2, 3-dihydrogen-2, 2-dimethyl-7-hygroxy benzofuran) by the way of extraction and rectification with high efficiency, low cost and simple and convenient unit operation. Separating agent chosen is a compound with small molecular structure and stereospecific blockade and with boiling point of 240 DEG C to 320 DEG C / 101.33KPa, such as phenol, alcohol, ether, phenolic ether, alcohol ether, etc. with hygroxy or ether bond, specifically as diglycol, para-tert-butylcatechol, 3, 4'-dichlorine diphenyl ether, etc., and the dosage of the separating agent is 0.5 percent to 5.0 percent of the mass of crude products. The method of the invention can increase rectification yield by more than 5.0 percent, shorten rectification time by 25 percent and increase product purity to more than 99.0 percent.

Owner:HUNAN CHEM RES INST

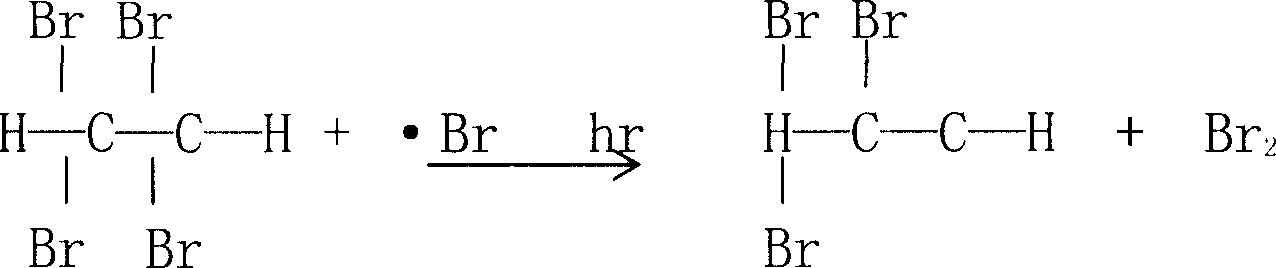

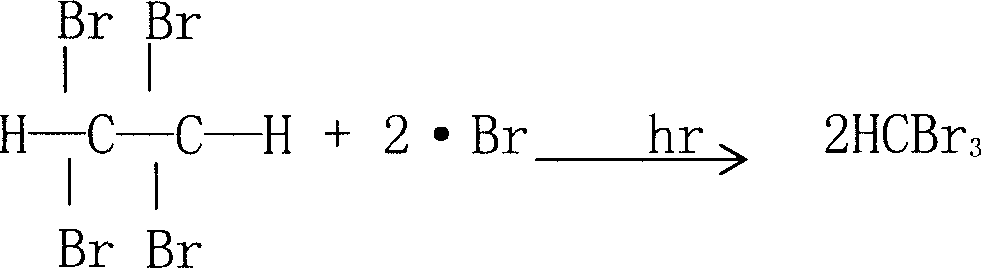

Composite stabilizer for improving stability of tetrabromoethane

ActiveCN1919811AAvoid generatingPrevent discolorationHalogenated hydrocarbon separation/purificationChlorobenzenePolymer science

The invention discloses a composite stabilizer to improve stability of tetrabromoethane, which consists of optical stabilizer and anti-oxidant with weight rate at 1: 1, wherein the optical stabilizer is 2-(3-tertiary-butyl-2-hydroxyl-5-butyl phenylhydrazine)-5-azimido-chlorobenzene; the anti-oxidant is 2, 6-p-tert-butylcatechol or 2, 6-di-tert-butyl-4-butyl-phenol.

Owner:TIANJIN CHANGLU HAIJING GRP CO LTD

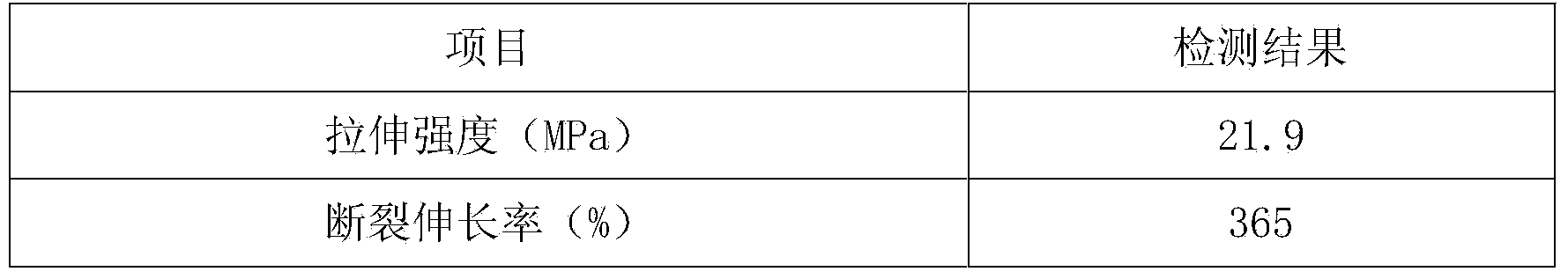

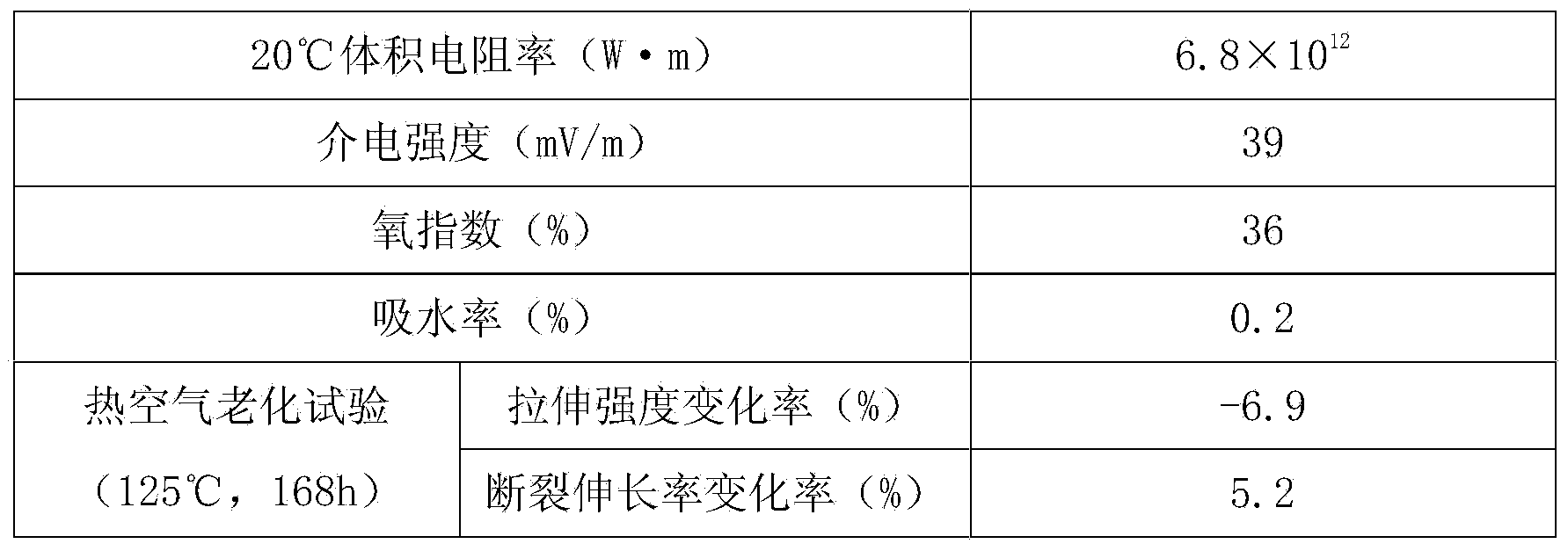

Communication optical cable jacket material for hot and humid areas and preparation method thereof

InactiveCN104371282AImprove heat resistanceImprove water resistancePlastic/resin/waxes insulatorsDiphenylsilanediolPolybutylene terephthalate

The invention discloses a communication optical cable jacket material for hot and humid areas and a preparation method thereof. The communication optical cable jacket material is prepared from the following raw materials in parts by weight: 37-53 parts of polybutylene terephthalate, 24-38 parts of polyarylene ether ether nitrile, 4-8 parts of triglycidyl isocyanurate, 3-6 parts of diphenylmethyene bismaleimide, 2.5-4.5 parts of zinc tetroxy chromate, 16-22 parts of wollastonite powder, 2-4 parts of triethoxyisobutylsilane, 4-6 parts of ethyl-3-amino crotonic acid ester, 12-18 parts of dioctyl terephthalate, 2-3 parts of p-tert-butylcatechol, 5-10 parts of melamine cyanurate, 3-6 parts of diphenyl silanediol, 10-15 parts of phenol-aralkyl epoxy resin, 1.5-2.5 parts of 2-ethyl acetate lead, 4-8 parts of lignite wax and 5-10 parts of diisobutyl aluminum hypophosphite. The jacket material disclosed by the invention has excellent heat resistance, and also has extremely excellent water resistance; and meanwhile, the jacket material has excellent properties such as chemical corrosion resistance, aging resistance, wear resistance, environmental stress cracking resistance and the like, and can be used in the hot and humid areas for a long time.

Owner:安徽电信器材贸易工业有限责任公司

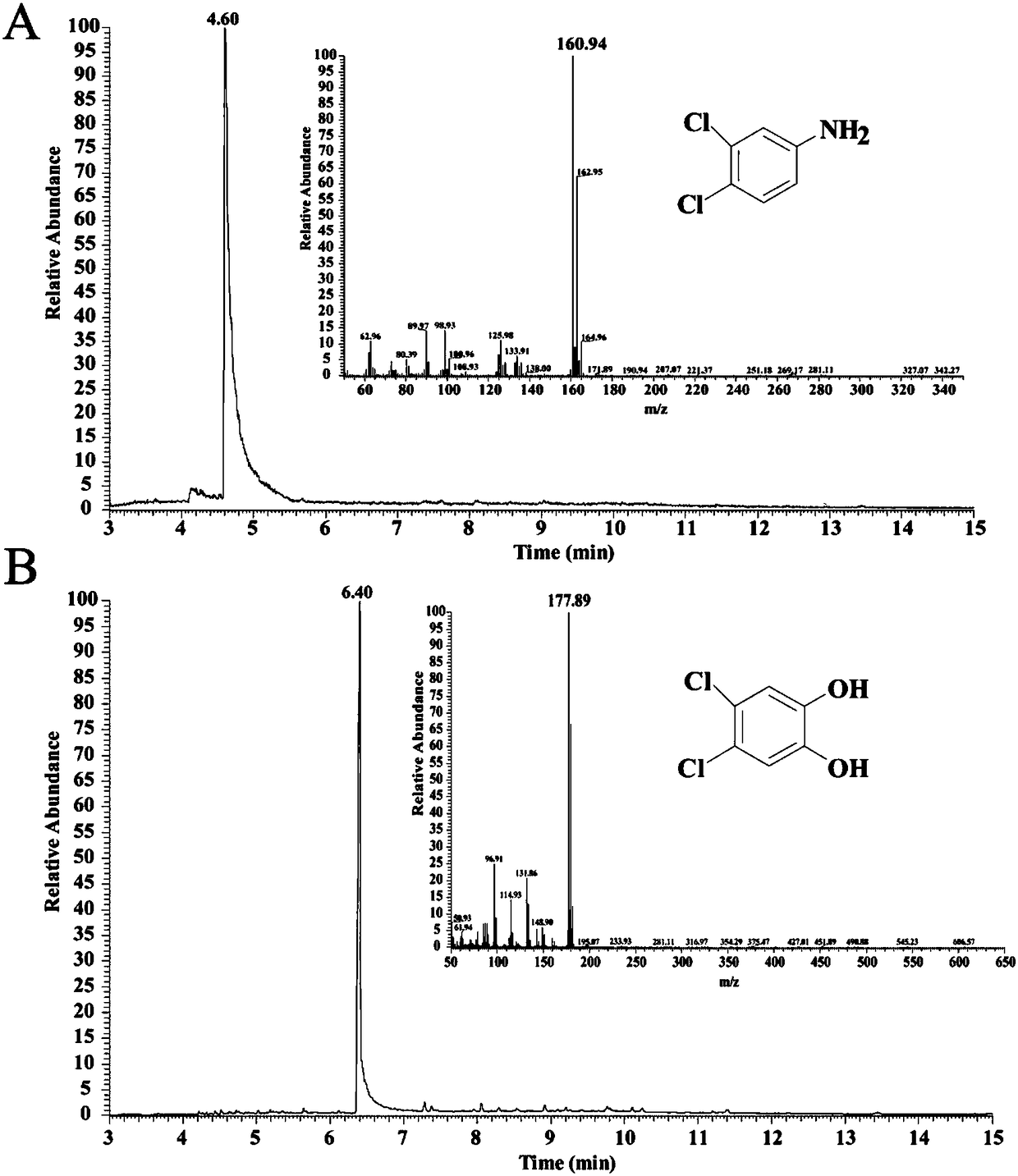

Method for preparing catechol compounds by biotransformation

InactiveCN108486141AWide applicabilityNo environmental burdenFermentationVector-based foreign material introductionEscherichia coliTert-butylcatechol

The invention belongs to the field of biological high technology, and discloses a method for preparing catechol compounds by biotransformation. The method comprises the steps that two kinds of anilineoxidase ATD and ADO are efficiently synthesized by escherichia coli; under normal circumstances, escherichia coli cells containing the ATD and ADO can efficiently convert aniline compounds to producea plurality of catechol compounds which include catechol, 3-methylcatechol, 4-methylcatechol, 3-chlorocatechol, 4-chlorocatechol, 4,5-dichlorocatechol, p-tert-butylcatechol and isopropyl catechol, and the conversion rate is greater than 95%. The waste produced in the scheme is mainly bacterial cells, the bacterial cells can be killed by high temperature, and the environmental burden is almost notproduced.

Owner:南京乐夫朗生物科技有限公司

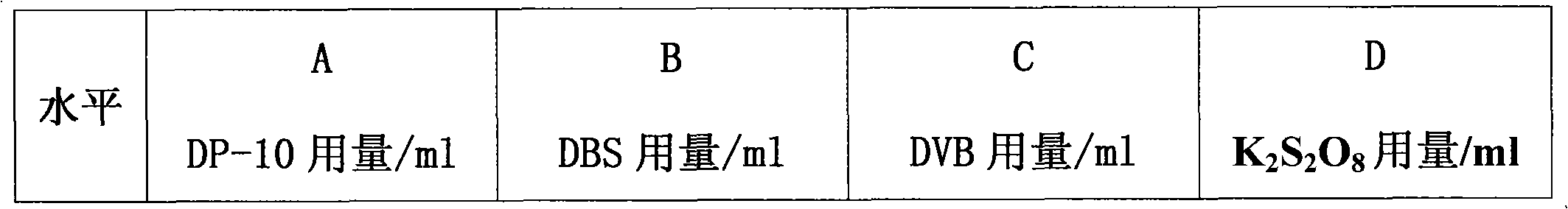

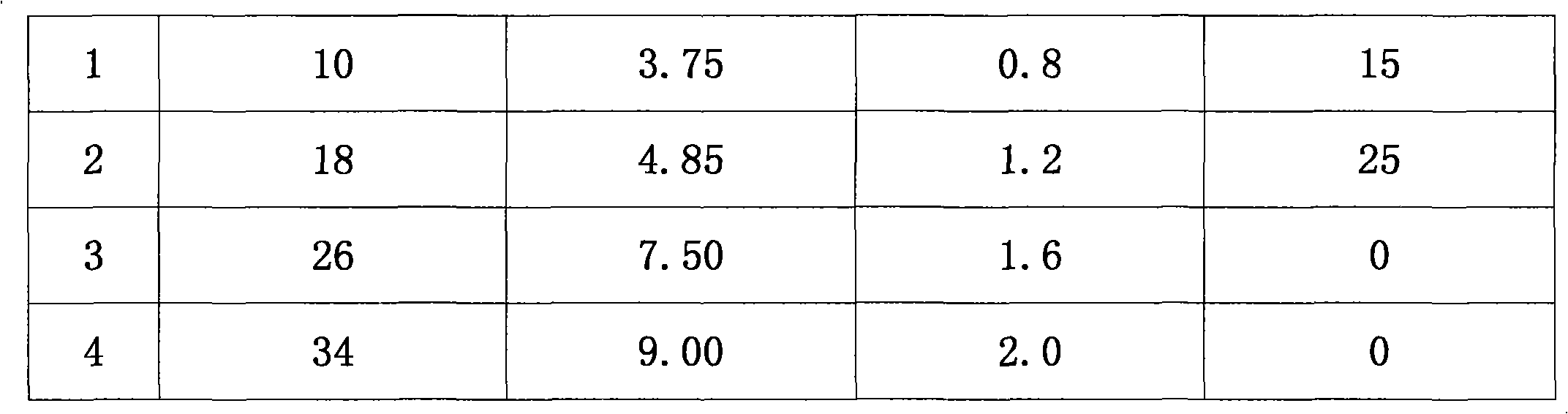

Method for preparing styrene-acrylic ester microemulsion

The invention discloses a method for preparing a styrene-acrylic ester microemulsion, relating to a preparation method of resin. The method for preparing the styrene-acrylic ester microemulsion has the advantages of small consumption of raw materials, high solid content of products and industrial production. In the technical scheme provided by the invention, the preparation method comprises the following process steps of: processing monomer styrene with 8% NaOH before adding so as to remove a polymerization inhibitor p-tert-butylcatechol in the monomer; heating a constant-temperature water bath kettle to 65 DEG C, then adding 10-34ml of emulsifier OP-10, 3.75-9.0ml of assistant emulsifiers DBS, 114ml of monomer styrene, 0.8-2.0ml of cross-linking agent divinyl benzene and 0-25ml of intiator K2S2O8, controlling the reaction temperature to be between 65 DEG C and 70 DEG C, reacting for 6-8h; and taking out the reactant and carrying out laser grain size analysis and electronic microscope analysis.

Owner:黄军

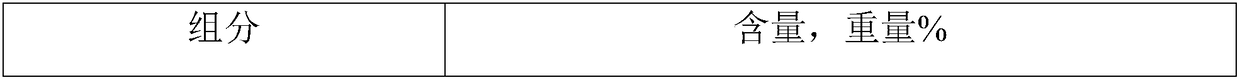

Natural gas for cutting metals

InactiveCN106244270AGood volatilization effectLess corrosiveGaseous fuelsFuel additivesTert-butylcatecholTurpentine

The invention discloses a natural gas used for cutting metals; it comprises natural gas with a purity higher than 95% by weight, and a liquid-phase synergistic additive accounting for 0.3-0.5% by weight of the aforementioned natural gas; the liquid-phase synergistic additive includes the following raw materials : 200# solvent oil, acetylene, petroleum ether, ethylene glycol monoethyl ether, turpentine, tung oil, isooctyl nitrate, dimethyl carbonate, tert-butyl ferrocene or ferrocene, methyl tert-butyl ether or n- Octyl ferrocene, p-tert-butyl catechol, azobisisobutyronitrile, polyether; the natural gas used for cutting metal can obviously increase the combustion temperature and combustion efficiency by adding a small amount of liquid-phase synergistic additives to the natural gas; At the same time, the liquid-phase synergistic additive of the present invention has little corrosion to the container and good volatility.

Owner:谢光玉

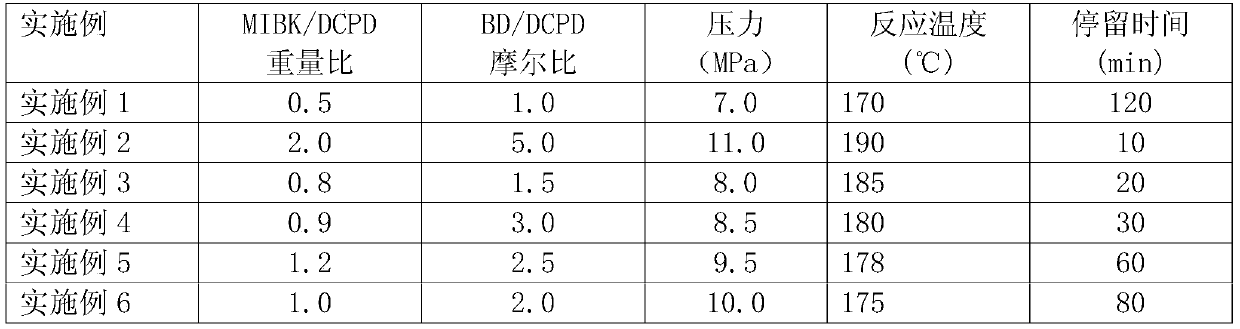

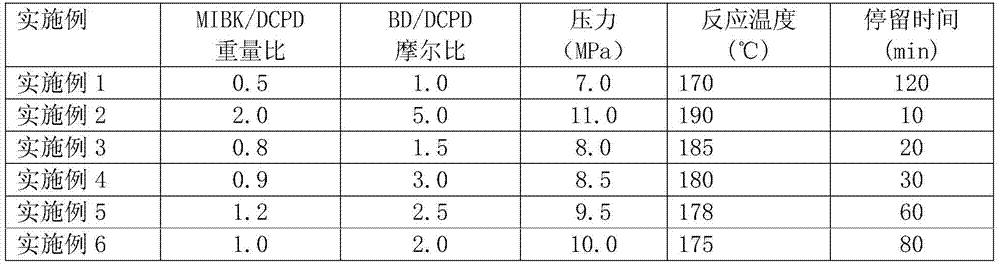

Vinyl norbornene production method

ActiveCN105541529AHigh yieldAvoid generatingHydrocarbons from unsaturated hydrocarbon additionHydrocarbon by depolymerisationTert-butylcatecholSystem pressure

The invention relates to a vinyl norbornene production method. The method utilizes two tank reactors connected in series and through the reactors, dicyclopentadiene undergoes a pyrolysis reaction to produce cyclopentadiene and the cyclopentadiene and 1, 3-butadiene undergo a Diels-Alder reaction to produce the vinyl norbornene. The method comprises 1, feeding dicyclopentadiene, 1, 3-butadiene, methyl isobutyl ketone as a solvent and a p-tert-butylcatechol solution as a polymerization inhibitor from the bottom of the first tank reactor into the first tank reactor through a pump and carrying out a reaction process under conditions of a reaction temperature of 170-190 DEG C, system pressure of 7-11MPa and material staying time of 10-120min, and 2, carrying out a reaction process in the second tank reactor under the conditions of a reaction temperature of 200-220 DEG C, system pressure of 7-10MPa and material staying time of 10-80min, discharging the reaction solution, feeding the reaction solution into a refining system and carrying out refining to obtain refined vinyl norbornene with content of 99.5% or more. The method improves a product vinyl norbornene yield and effectively prevents polymer formation of individual or all of 1, 3-butadiene and cyclopentadiene.

Owner:SHANGHAI PEARLK CHEM

Alcohol-based fuel capable of reducing emission of sulfur dioxide

InactiveCN106281486AGood storage stabilityAntioxidantLiquid carbonaceous fuelsFuel additivesDimethylaniline N-oxideAlcohol

The invention belongs to the technical field of fuels and particularly relates to an alcohol-based fuel capable of reducing the emission of sulfur dioxide. The alcohol-based fuel is prepared from the following raw materials in parts by weight: 62-86 parts of methanol, 12-24 parts of diesel oil, 0.6-1.8 parts of p-tert-butylcatechol, 0.5-1.7 parts of 2,4-dimethylaniline, 0.4-1.6 parts of methyl heptenone, 0.3-0.9 part of glyceryl triacetate, 0.1-0.7 part of glycerin monostearate, 0.01-0.07 part of isoamyl butyrate, 0.03-0.15 part of a cetane number improver and 0.1-1.3 parts of a clearing agent. The alcohol-based fuel has the effects of resisting oxidization, helping combustion, resisting corrosion, dispersing, clearing, increasing the cetane number and the like, and the emission of sulfur dioxide can be remarkably reduced.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

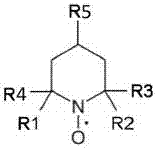

Polymerization inhibitor and glass fiber reinforced plastic profiled bar comprising same

The invention relates to a polymerization inhibitor which comprises the following components in parts by weight: 10 parts of p-tert-butylcatechol, 10 parts of p-benzoquinone and 80 parts of styrene. Meanwhile, the invention further discloses a glass fiber reinforced plastic profiled bar comprising the polymerization inhibitor. The glass fiber reinforced plastic profiled bar comprises 60-70% of glass fibers and 30-40% of a resin formula material, wherein the resin formula material comprises the following components in parts by weight: 100 parts of resin, 10-30 parts of filler, 2-4 parts of a mill base, 0.8-1.5 parts of a release agent, 0.5-1 part of an initiator, 0.5-2 parts of an accelerant, 0.1-0.3 part of an antioxidant and 0.1-0.2 part of the polymerization inhibitor. According to the invention, the gelling time of the resin formula material under a condition of 35-60 DEG C is prolonged, a cross-linking reaction in advance in a resin trough is avoided, and solid particles are prevented from blocking a die port, so that the continuity of production is guaranteed.

Owner:NANJING HUAGE ELECTRONICS & AUTOMOBILE PLASTIC IND

Anti-rust paint for treating surface of steamship and preparation method of anti-rust paint

The invention relates to a method for preparing anti-rust paint for treating the surface of a steamship. The anti-rust paint is prepared from the following components: zinc powder, methyl ethyl ketone, alkyd resin, methacrylate, sodium tripolyphosphate, polymer polyol glycerin ether defoaming agent, hexanediol butyl ether acetate, triethylene diamine, glycerol, mixed tung oil, dimethylbenzene, dicumyl peroxide, silane coupling agent KH792, triallyl cyanurate, maleic anhydride, styrene, p-benzoquinone and p-tert-butylcatechol. The anti-rust paint for treating the surface of a steamship is wide in raw material sources and low in cost, the compatibility among the components can be improved due to addition of the film forming resin in the prescription, the film forming effect is greatly improved; the component prescription has strong adhesion, high hardness, scratch resistance, acid-alkali resistance, water resistance, oil resistance and excellent anti-rust performance to a metal surface, the painted film has high drying speed under a natural condition, and the service life of the painted film can be 8-10 years.

Owner:ZHANGJIAGANG FREE TRADE ZONE GUANXIANG TRADE

Preparation technology of 4'4'' (5'')-di-tert-butyl-di-benzo-18-crown-6

ActiveCN101928275APromote formationReduced solvationOrganic chemistryReaction rateTert-butylcatechol

The invention discloses a preparation technology of 4'4'' (5'')-di-tert-butyl-di-benzo-18-crown-6, which is characterized by comprising the following steps: selecting para-tert-butylcatechol as a raw material, caesium carbonate as a template agent, and tetrahydrofuran or acetonitrile as a solvent, adding the reaction materials to an agitated reactor, and synthesizing to obtain a mixture containing the expected product 4'4'' (5'')-di-tert-butyl-di-benzo-18-crown-6 at 40-80 DEG C under the protection of nitrogen atmosphere; and after finishing the reaction, adopting a silica gel alumina backflow co-heat technology or an eluant with different compositions and proportioning to perform column chromatography gradient elution, and isolating and purifying the expected product 4'4'' (5'')-di-tert-butyl-di-benzo-18-crown-6. Compared with the reportorial preparation technology, the invention simplifies the procedures of synthesis as well as separation and purification and improves the reaction conversion rate and the purity and yield of the products.

Owner:XI AN JIAOTONG UNIV

High-efficiency and energy-saving alcohol based fuel

InactiveCN106281487AHas a cleansing effectEffective carbon depositionLiquid carbonaceous fuelsFuel additivesBenzoic acidTert-butylcatechol

The invention belongs to the technical field of fuel and particularly relates to high-efficiency and energy-saving alcohol based fuel. The high-efficiency and energy-saving alcohol based fuel is prepared from raw materials in parts by weight as follows: 68-92 parts of methyl alcohol, 16-34 parts of diesel oil, 0.7-1.9 parts of alkanolamide, 0.2-1.4 parts of p-tert-butylcatechol, 0.02-0.14 parts of N-ethylaniline, 0.3-1.5 parts of benzoic acid, 0.1-1.3 parts of 2-methylpentane, 0.01-0.07 parts of polyethylene glycol, 0.03-0.15 parts of isooctyl nitrate and 0.1-1.3 parts of a corrosion inhibitor. The high-efficiency and energy-saving alcohol based fuel is clean, anti-oxidant, combustion-supporting and corrosion-resistant, increases the cetane number, is good in combustion performance and high in combustion efficiency, realizes energy conservation and emission reduction, and reduces the cost.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

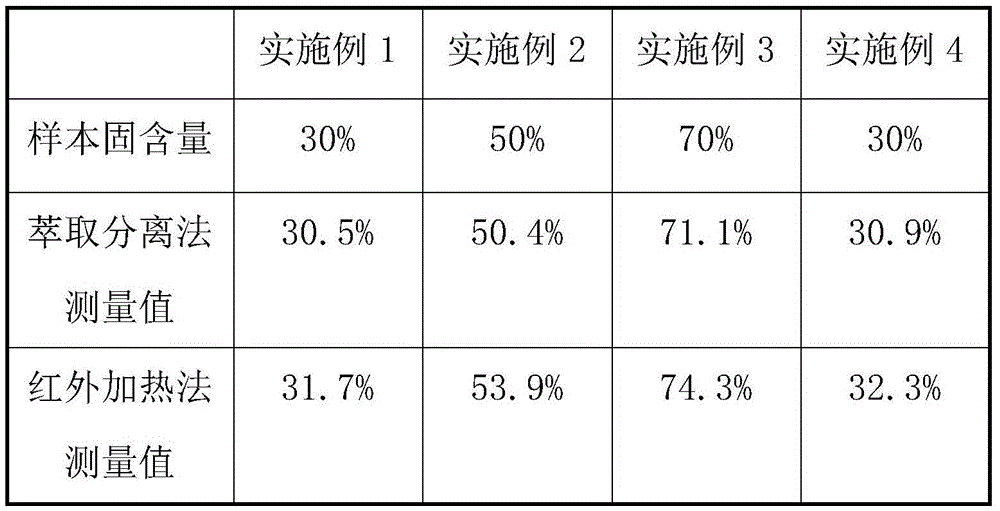

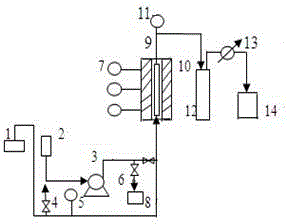

Method for determining solid content of ABS by continuous bulk polymerization process

ActiveCN105547903AThe amount of test samples is smallSample preparation method is simpleWeighing by removing componentTert-butylcatecholSolvent

The invention discloses a method for determining solid content of ABS by continuous bulk polymerization process. A sample is added into a certain amount of a mixed solvent with stirring, in order to dissolve more fully, a micro amount of hydroquinone or TBC (p-tert-Butylcatechol) is added; after the sample is completely dissolved with strong stirring, and the sample is added into a methanol solution drop by drop; the sample is allowed to stand after fully mixing for demixing, and a polymer phase is separated by filtering; the polymer and a filter are placed into a baking oven for drying, and the polymer and the filter are placed in a dryer for natural cooling at room temperature; mass of solids is weighed, and solid content of the sample is calculated. The method can effectively prevent the problem that monomers and a few initiators are remained after treatment of the sample, which can influence the test results.

Owner:NORTH HUAJIN CHEM IND CO LTD

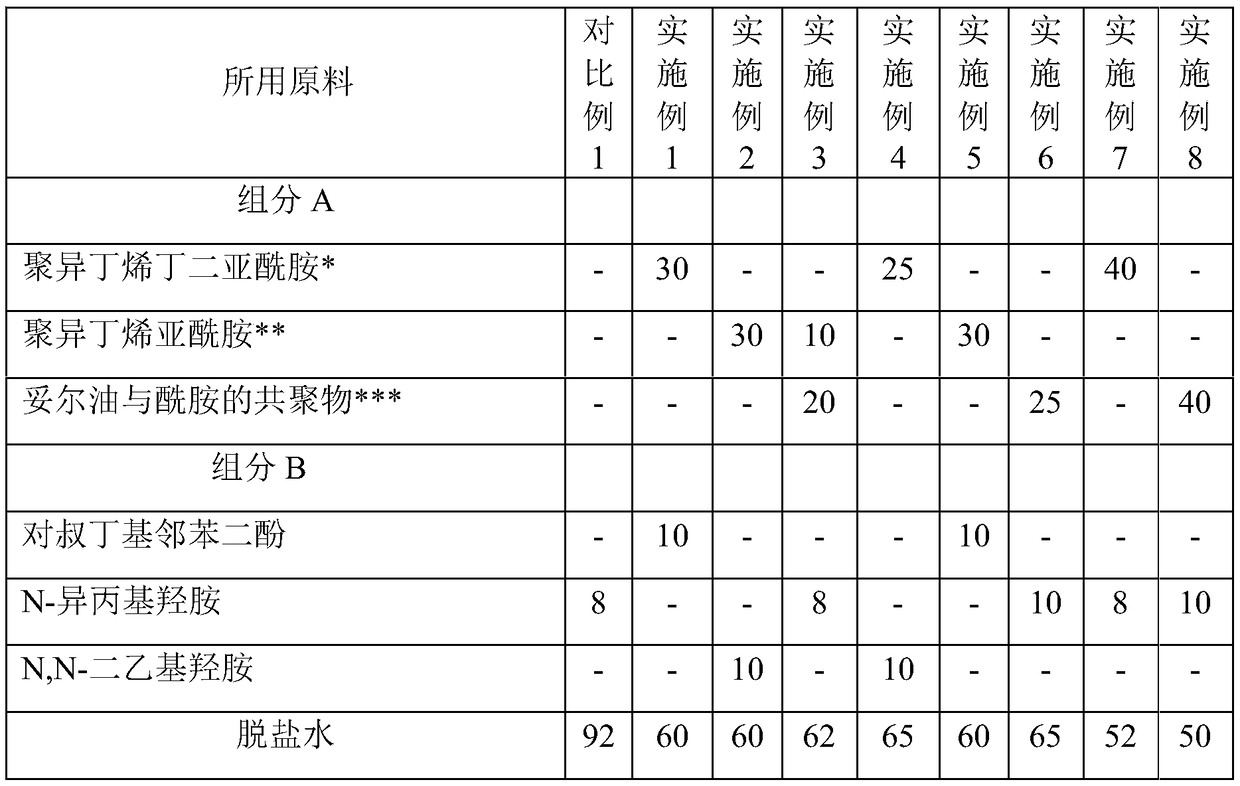

A kind of water-soluble dispersed scale inhibitor and its application

The invention discloses a water soluble dispersion scale inhibitor and an application thereof in a production device of acrylonitrile. The water soluble dispersion scale inhibitor comprises a component A and a component B, wherein the component A is a polymer of imide and / or amide, the component B is one or more of p-tert-butylcatechol, N, N-diethylhydroxylamine and N-isopropylhydroxylamine, and the mass ratio of the component A to the component B is (10-50): (1-10). With the adoption of the water soluble dispersion scale inhibitor, polymerization of radicals can be effectively inhibited, formed scale can be dispersed to be evenly dispersed in an aqueous phase, and accordingly, the scale is prevented from being separated out of the production device of acrylonitrile, and the production cycle of the device can be prolonged.

Owner:北京誉天利化工有限公司 +1

Anti-fake holographic high molecular material

The invention discloses an anti-fake holographic high molecular material which comprises the following components in parts by weight: 55-60 parts of epoxy resin modified polyureathane, 3-6 parts of methylcellulose, 1-3 parts of stannous capric acid, 8-9 parts of polytetramethylene glycol, 11-15 parts of methacrylic acid isopropyl ester, 8-9 parts of methacrylic acid glycerol trilaurate, 9-15 parts of modified polypropylene, 5-9 parts of nano calcium sulfate, 14-16 parts of polyamide resin, 3-7 parts of acrylic resin, 3-4 parts of dicyclohexyl peroxydicarbonate, and 1-2 parts of p-tert-butylcatechol. The raw materials are easily available, the raw materials and the product have excellent stability, and the anti-fake holographic high molecular material is convenient to prepare and is convenient for realization of industrial popularization.

Owner:QINGDAO QIANXIANG ENVIRONMENTAL PROTECTION TECH

Aid for improving yield of liquid oil in oil delayed coking device and preparation method for aid

ActiveCN102888241BAvoid cokingReduce generationThermal non-catalytic crackingEthylene productionPentaerythritolTert-butylcatechol

The invention discloses an aid for improving the yield of liquid oil in an oil delayed coking device and a preparation method for the aid. The aid is prepared from N,N-bis(salicylidene) propylenediamine, p-tert-butylcatechol, tetrapentaerythritol ester, octylphenol polyoxyethylene (30) ether, N,N-di-n-butyl ammonia methylbenzotriazole and a solvent. The aid is directly added into raw material residual oil, so that a phenomenon that a coking device is coked when heating a furnace pipe and the on-stream period is prolonged can be avoided, the generation amount of coke and dry gas is reduced, and the liquid oil yield is improved; the method is simple, convenient and economical, and eventually, aims of increasing economic benefits, saving energy and reducing emission amount of carbon dioxide are fulfilled.

Owner:CANGZHOU XINCHANG CHEM CORP

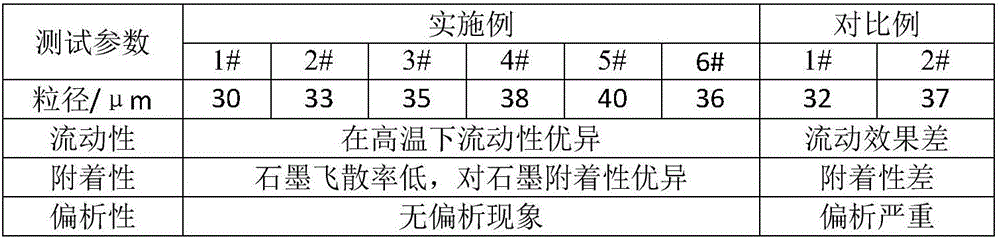

Preparation method of metallurgical adhesive

The invention belongs to the field of adhesives, and particularly relates to a preparation method of a metallurgical adhesive. The preparation method comprises the following steps of (1) adding an SEBS elastomer, ZnO nanorod / mica composite powders, and epoxidized castor oil in a mixed solution of methyl ethyl ketone and ethyl acetate, dispersing ultrasonically, heating, and adding p-tert-Butylcatechol and an additive, and continuously conducting stirring reaction; (2) continuously increasing the temperature of the product prepared in the step (1), adding rosin modified phenolic resin, bisphenol-A epoxy resin and a thickening agent, and conducting high-speed mixing and stirring reaction; and (3) adding the material, prepared in the step (2), in a grinding machine for grinding, dispersing uniformly, filtering to obtain a material of which the fineness is 30-40 [mu]m, and packing. The adhesive prepared according to the preparation method can prevent segregation or dust flying effectively and can improve the flowability of mixed powder. The preparation method is simple, low in cost, and low in environmental pollution, can realize large-scale production, and is suitable for various metallurgical processing fields.

Owner:扬州派德粉末冶金有限公司

Efficient natural gas

InactiveCN103710062BGood volatilization effectLess corrosiveGaseous fuelsTert-butylcatecholTurpentine

The invention discloses efficient natural gas. The efficient natural gas consists of natural gas with purity higher than 95% in percentage by weight, and 0.3-0.5% of a liquid-phase synergistic additive in terms of weight percentage of the natural gas, wherein the liquid-phase synergistic additive consists of the following raw materials: 200# solvent oil, isopropanol, petroleum ether, ethylene glycol monoethyl ether, turpentine, tung oil, isooctyl nitrate, dimethyl carbonate, tert-butylferrocene or ferrocene, methyl tertiary butyl ether or n-octyl ferrocene, p-tert-butylcatechol, azodiisobutyronitrile and polyether. The efficient natural gas, through adding little liquid-phase synergistic additive in the natural gas, can obviously improve burning temperature and burning efficiency; meanwhile, the liquid-phase synergistic additive is low in corrosion and good in volatility on containers.

Owner:BEIJING DATONG HONGYE TECH DEV

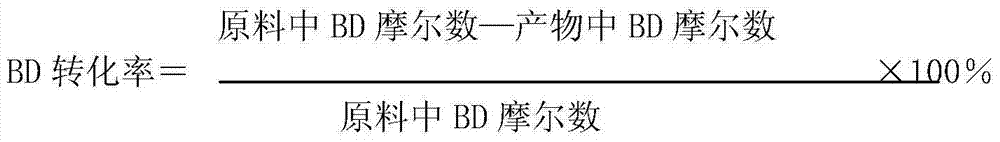

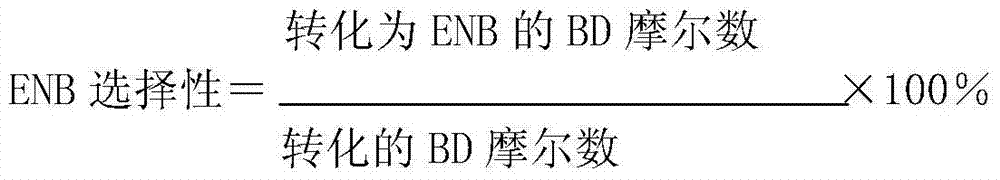

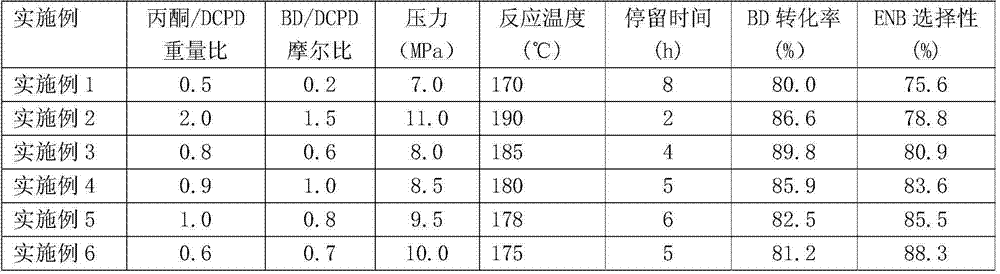

A kind of production method of ethylidene norbornene

ActiveCN105461505BHigh selectivityThe reaction process is simpleHydrocarbon by isomerisationDistillationTert-butylcatechol

A kind of production method of ethylidene norbornene, this method adopts tank reactor, makes dicyclopentadiene (DCPD) cracking becomes cyclopentadiene (CPD), cyclopentadiene (CPD) and 1,2-butane The diene (BD) is converted into ethylidene norbornene (ENB) by a Diels-Alder reaction, and the reaction product is separated by rectification to obtain an ethylidene norbornene product with a content of more than 99.5%. The reaction uses acetone as a solvent, the molar ratio of BD to DCPD is 0.2-1.5:1, the weight ratio of solvent acetone to DCPD is 0.5-2.0:1, and the amount of polymerization inhibitor p-tert-butylcatechol (TBC) is the mass of DCPD 0.003%, the reaction temperature is 170-190°C, the system pressure is 7-11MPa, and the reaction time is 2-8 hours. Compared with the prior art, the reaction process is simple, and the conversion rate of the reaction and the selectivity of ethylidene norbornene are obviously improved.

Owner:SHANGHAI PEARLK CHEM

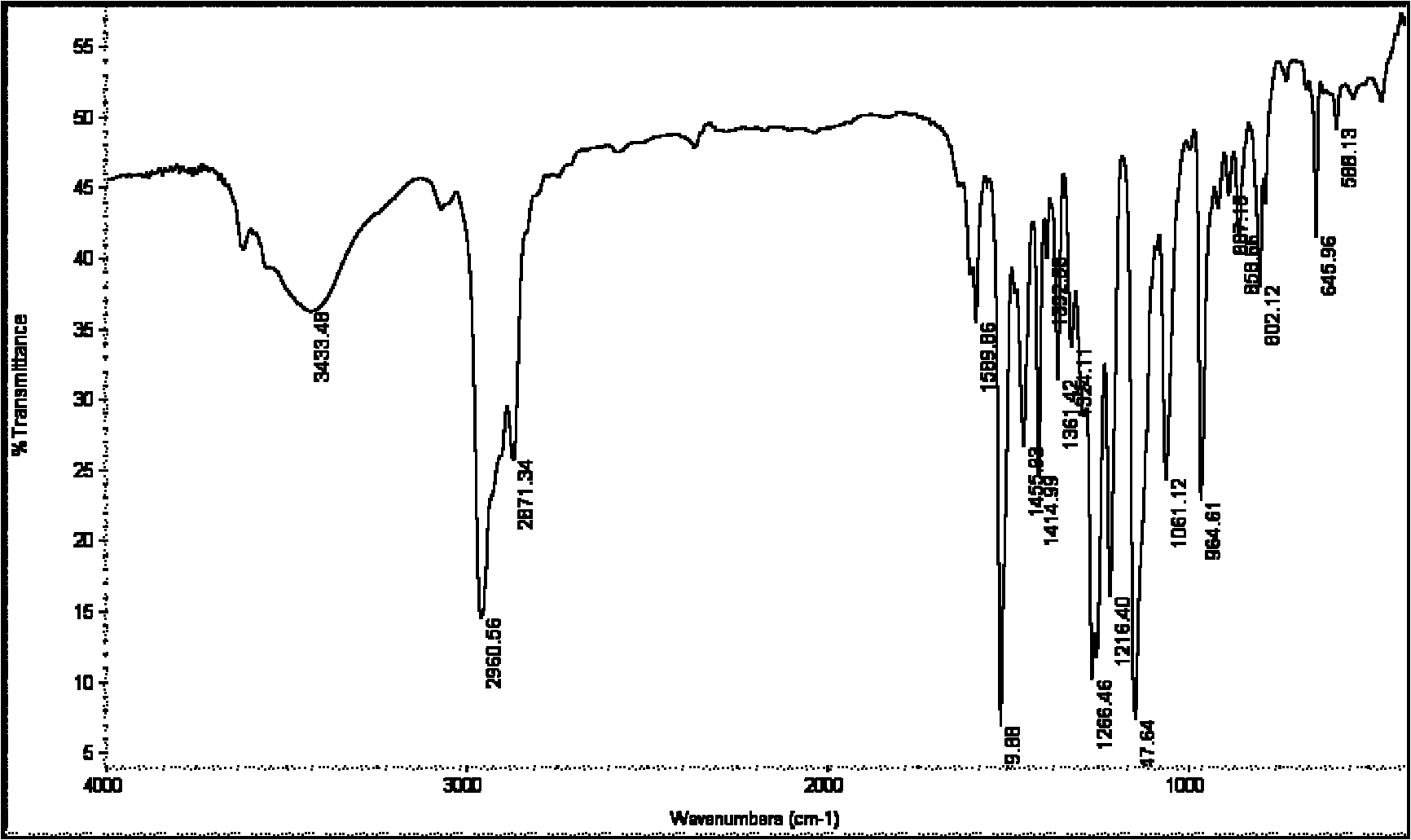

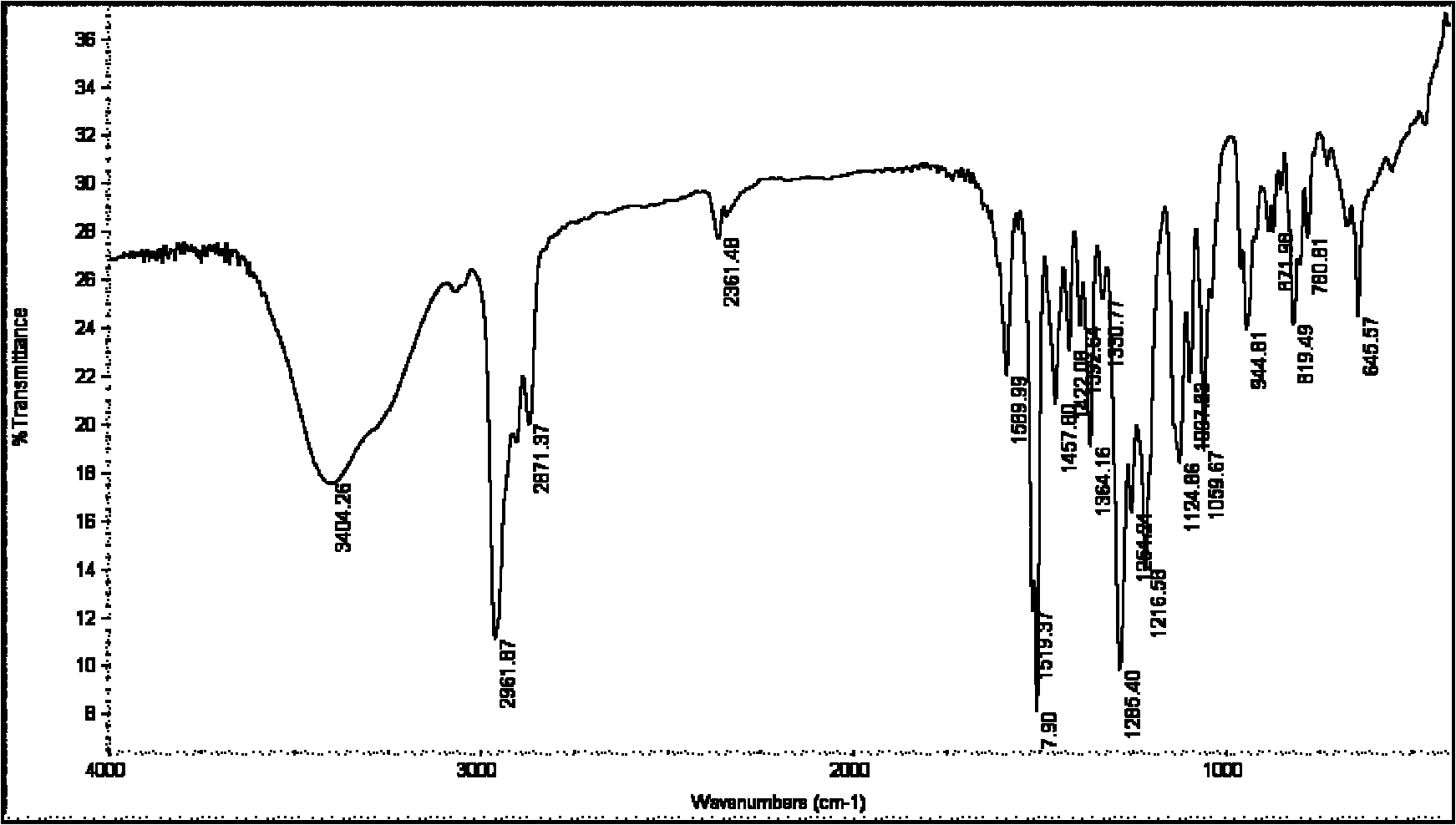

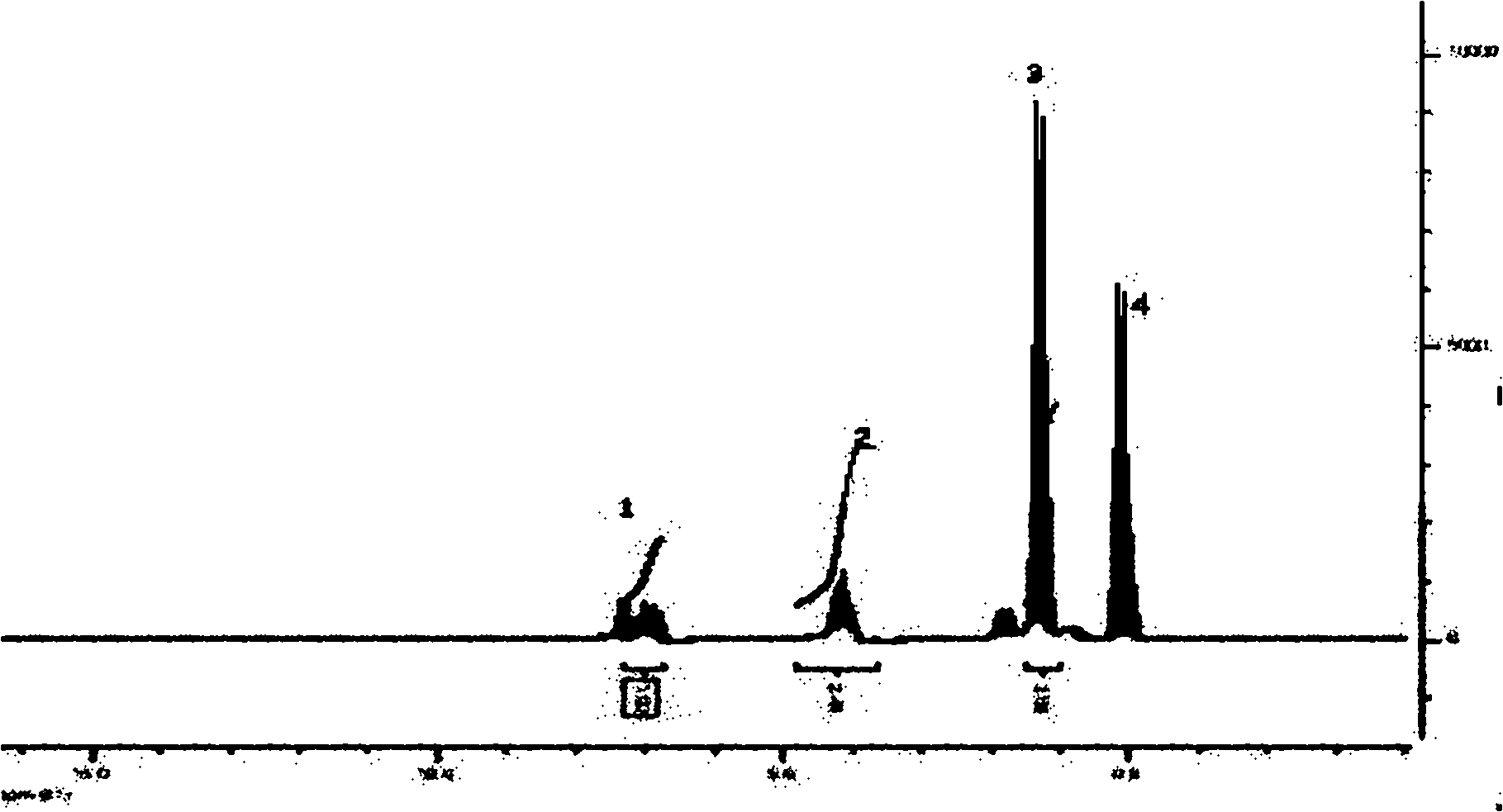

Synthesis method for p-tert-butylcatechol

ActiveCN110041170AReduce dosageHigh selectivityOrganic chemistryOrganic compound preparationThermal insulationSynthesis methods

The invention relates to a synthesis method for p-tert-butylcatechol. The method comprises the following steps that: catechol and isobutene are taken as raw materials; under the existence of an HMT (hexamine) catalyst, N2 is used for replacing air in a reaction still; after catechol is heated and dissolved, isobutene is introduced at a uniform speed at a temperature of 80-120 DEG C, wherein introduction time is controlled within 4-8 h; then, at a temperature of 105-110 DEG C, thermal insulation reaction is carried out, wherein thermal insulation reaction time is controlled within 0-5 h, and the molar ratio of catechol to isobutene is 1:(0.3-0.7); reaction liquid obtained after reaction is finished and the catalyst are subjected to filtering separation; the reaction liquid is subjected to product rectification and fractionation; the HMT catalyst is repeatedly used. According to the method, under the function of the HMT catalyst, 3-TBC (p-tert-butylcatechol) and 3,5-DTBC (3,5-di-tert-butylcatechol) can carry out transposition rearrangement reaction to generate 4-TBC, reaction selectivity can be directly improved, and the synthesis method is a green synthesis method for p-tert-butylcatechol.

Owner:江西兄弟医药有限公司

A kind of production method of vinyl norbornene

ActiveCN105541529BHigh yieldAvoid generatingHydrocarbons from unsaturated hydrocarbon additionHydrocarbon by depolymerisationMethyl isobutyl ketoneTert-butylcatechol

The invention relates to a vinyl norbornene production method. The method utilizes two tank reactors connected in series and through the reactors, dicyclopentadiene undergoes a pyrolysis reaction to produce cyclopentadiene and the cyclopentadiene and 1, 3-butadiene undergo a Diels-Alder reaction to produce the vinyl norbornene. The method comprises 1, feeding dicyclopentadiene, 1, 3-butadiene, methyl isobutyl ketone as a solvent and a p-tert-butylcatechol solution as a polymerization inhibitor from the bottom of the first tank reactor into the first tank reactor through a pump and carrying out a reaction process under conditions of a reaction temperature of 170-190 DEG C, system pressure of 7-11MPa and material staying time of 10-120min, and 2, carrying out a reaction process in the second tank reactor under the conditions of a reaction temperature of 200-220 DEG C, system pressure of 7-10MPa and material staying time of 10-80min, discharging the reaction solution, feeding the reaction solution into a refining system and carrying out refining to obtain refined vinyl norbornene with content of 99.5% or more. The method improves a product vinyl norbornene yield and effectively prevents polymer formation of individual or all of 1, 3-butadiene and cyclopentadiene.

Owner:SHANGHAI PEARLK CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com