Preparation method of metallurgical adhesive

A technology of adhesives and additives, which is applied in the field of preparation of metallurgical adhesives, can solve problems such as difficulty in uniformity and difficulty in obtaining compacted powder, and achieve low cost, prevention of segregation or dust, and low environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

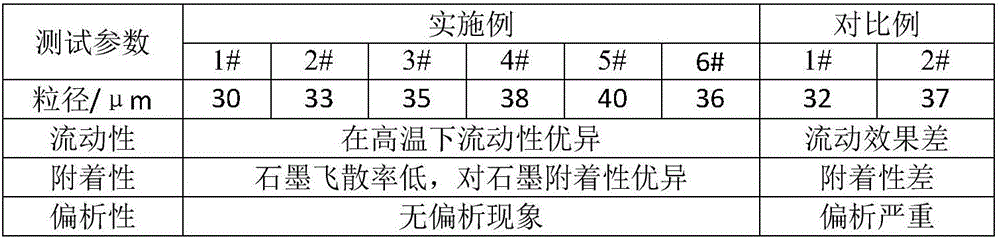

Examples

Embodiment 1

[0022] A method for preparing metallurgical binder, comprising the steps of:

[0023] (1) Add SEBS elastomer, zinc oxide nanorod / mica composite powder, and epoxy castor oil to the mixed solution of methyl ethyl ketone and ethyl acetate, ultrasonically disperse for 20-30min, and add p-tert when heated to 60-80°C Butylcatechol and additives continue to stir and react for 40-60min;

[0024] (2) Continue to increase the temperature of the product of step (1) to 70-90°C, add rosin-modified phenolic resin, bisphenol A epoxy resin, thickener, and mix and stir at a high speed at 800-1000r / min for 1- 2h;

[0025] (3) Add the material prepared in step (2) to a grinder to grind and disperse evenly, filter to obtain a material with a fineness of 30-40 μm, and pack it;

[0026] Wherein, each component composition is counted as in parts by weight:

[0027] 33-38 parts of rosin modified phenolic resin, 3-5 parts of epoxy castor oil, 5-10 parts of SEBS elastomer, 5-10 parts of zinc oxide n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com