Patents

Literature

81results about How to "Good molding performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly type moldable aqueous transfer coating, preparation and use thereof

ActiveCN101407656AReduce contentReduce manufacturing costCoatings with pigmentsPolyurea/polyurethane coatingsSolvent basedPolyresin

The invention relates to an environment-friendly moldable waterborne transfer coating, a preparation method and an application thereof, wherein, the waterborne transfer coating takes the following components with the contents (parts by weight) as raw materials: 40 to 70 parts of waterborne resin; 10 to 20 parts of cosolvent; 18 to 40 parts of deionized water; 0.1 to 2 parts of pH value regulator; 0.1 to 0.5 part of wetting agent; 0.1 to 0.2 part of leveling agent; and 0.05 to 0.2 part of defoamer. Compared with the prior art, the environment-friendly moldable waterborne transfer coating has the following advantages of environmental protection and cost advantages, good printing adaptability, relatively wide range of suitable molding temperature during the molding, good molding effect and easy production control; furthermore, the environment-friendly moldable waterborne transfer coating can be directly used for replacing the existing solvent laser transfer coating by the pilot scale production confirmation.

Owner:SHANGHAI WEIKAI CHEM

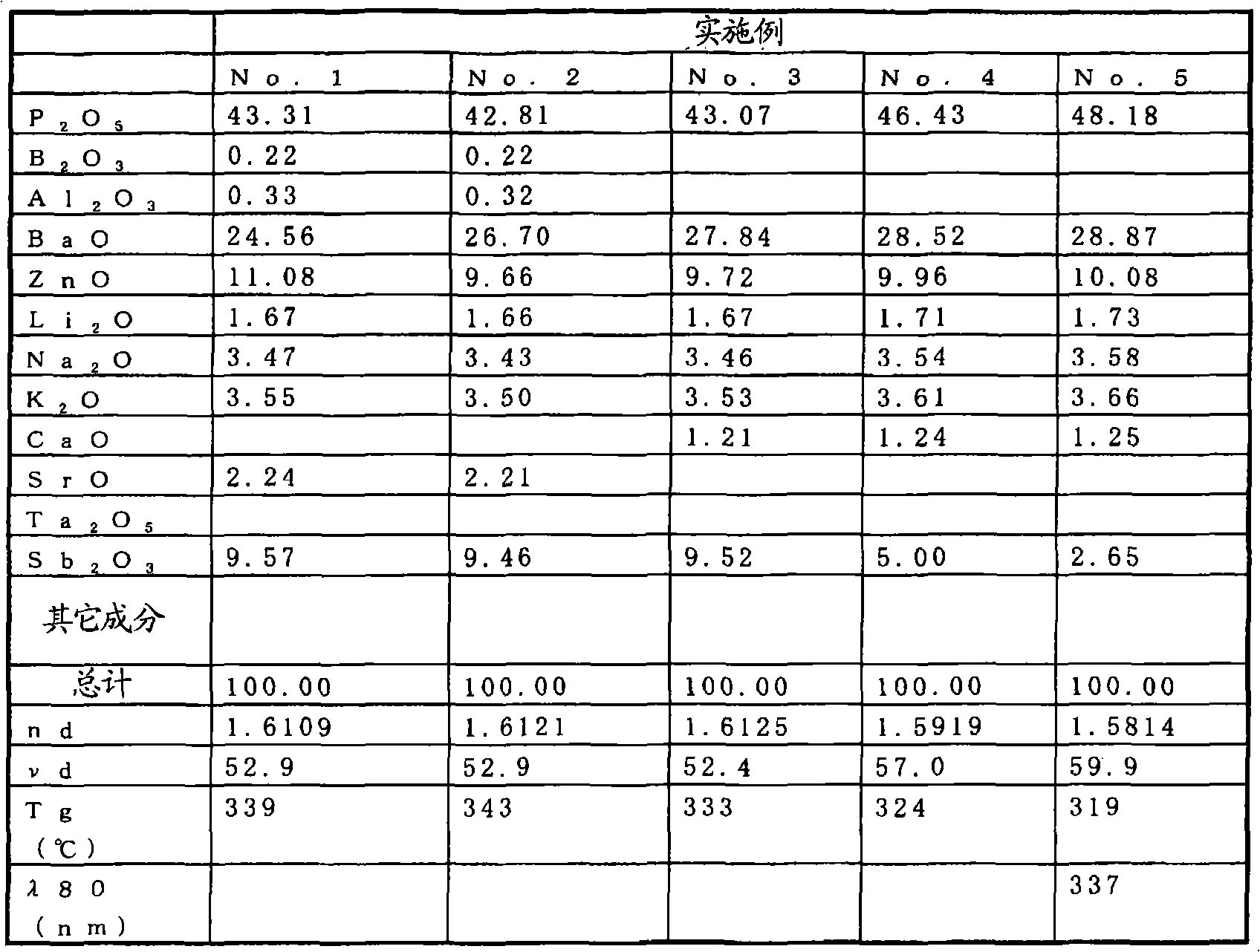

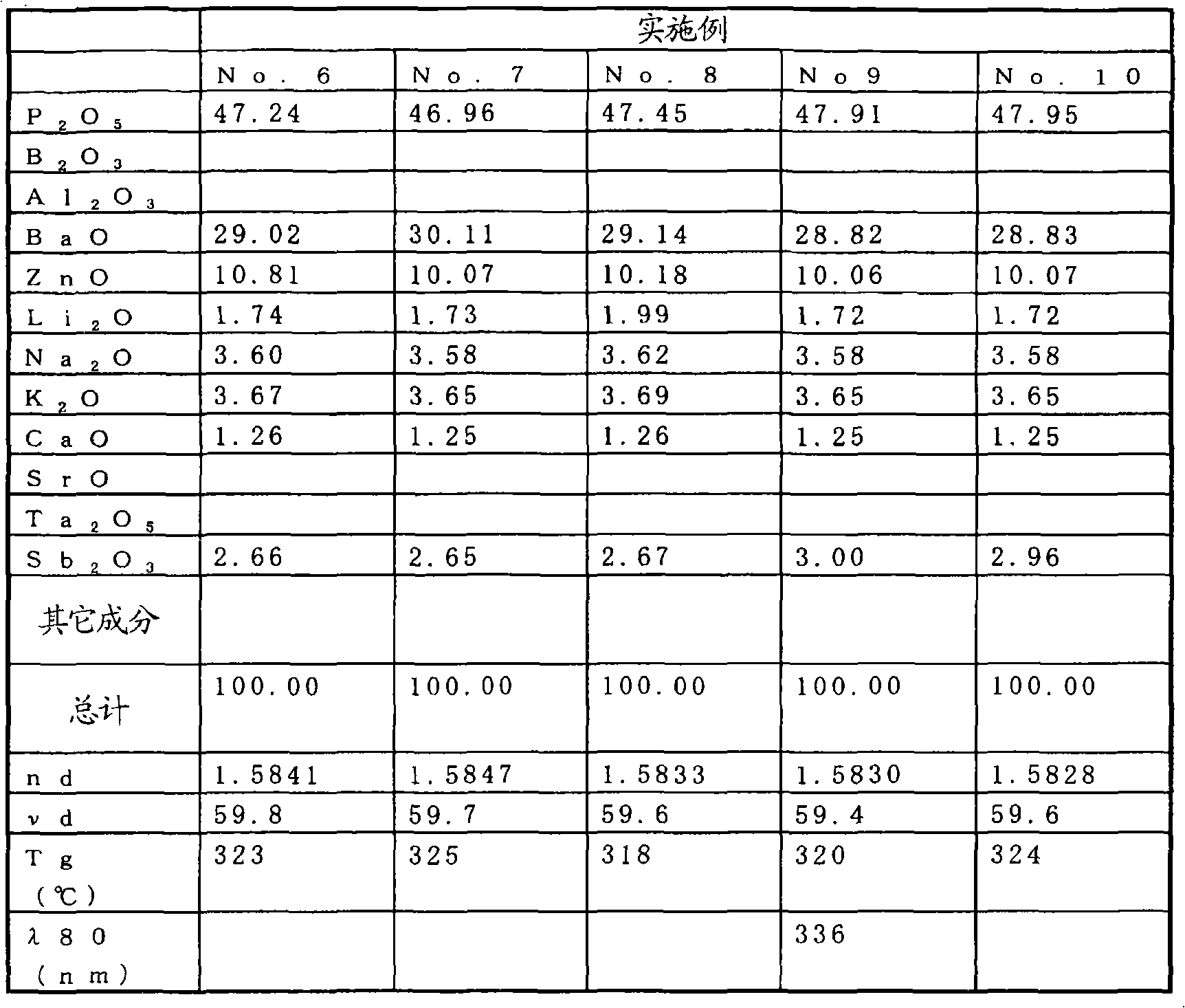

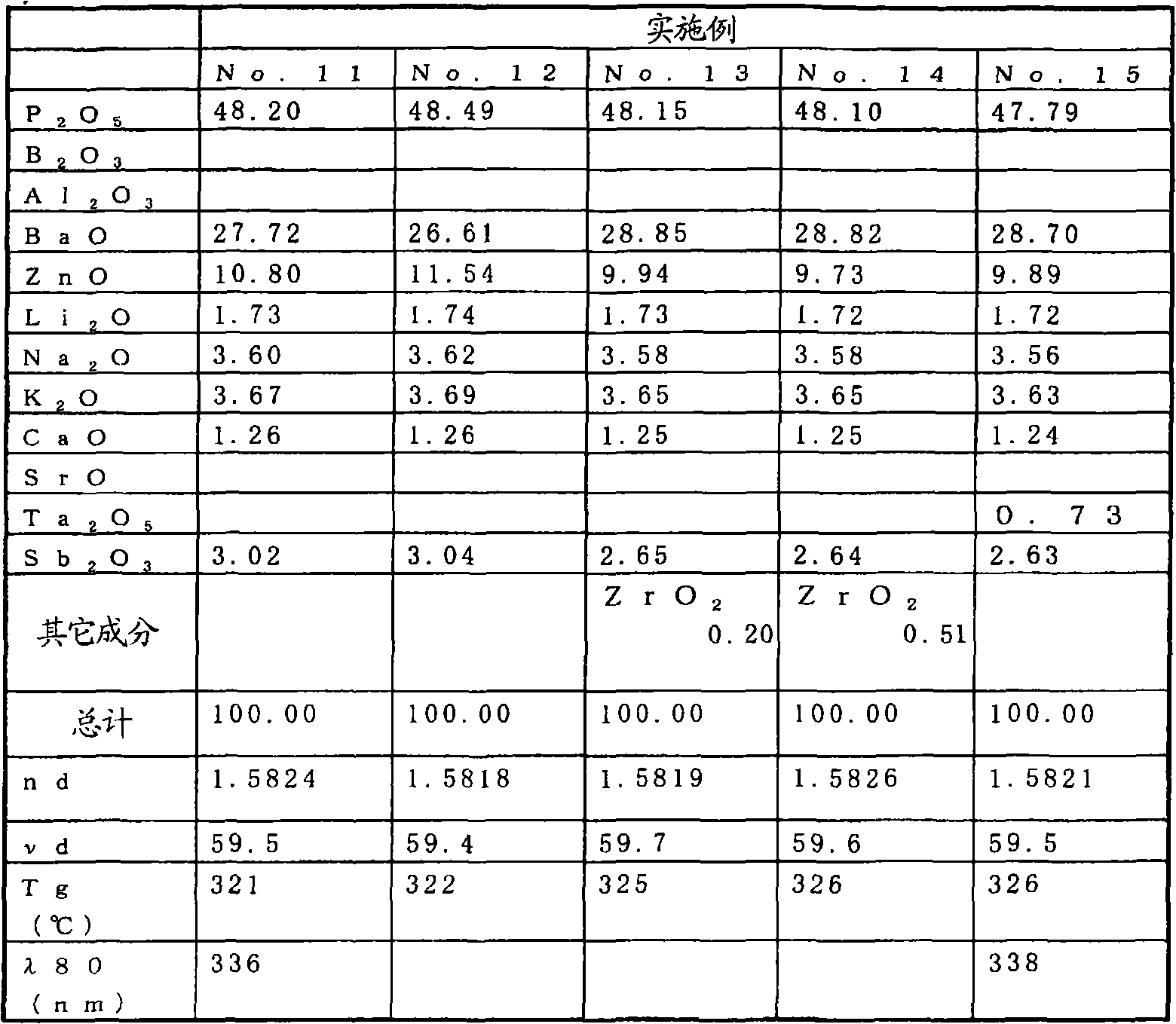

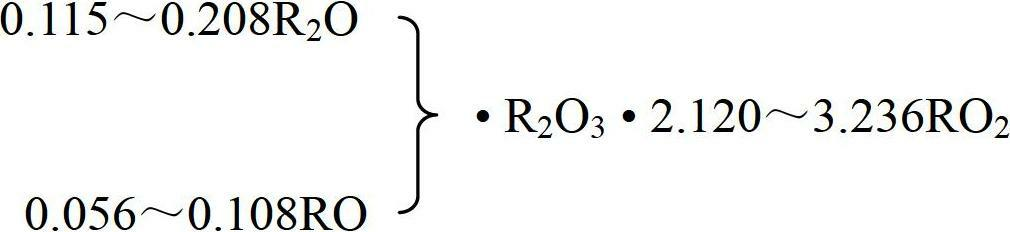

Optical glass

Disclosed is an optical glass having optical constants, namely a refractive index (nd) of 1.50-1.65 and an Abbe number (gamma d) of 50-65, while having a glass transition temperature (Tg) of not more than 400 DEG C. In this optical glass, the shortest wavelength at which the light transmittance reaches 80% (lambda 80) is not more than 370 nm.

Owner:OHARA

Fluororubber cloth clamp combination V seal ring and method for producing the same

The invention provides a V-shaped seal ring with a fluororubber canvas combination which is characterized in that the seal ring is produced by materials with the following portions by weight: 100 portions of peroxide vulcanized fluororubber, 20-50 portions of light-colored filler, 3-5 portions of zinc oxide, 2-5 portions of iron oxide red, 3-5 portions of 2,5-dimethyl-2,5-di-(tert-butyl peroxide) hexane, 4-6 portions of triallyl glycicy isocyanuratel and 0.5-1.5 portion of processing agent. A preparation method of the invention indicates that the materials with the portions by weight are first made into fluororubber dry mix which is then dissolved in mixed solvent so as to prepare adhesive cement; then the adhesive cement is dip coated on glass fiber cloth to prepared the fluororubber glass fiber canvas which is then die pressed by a vulcanized product combination to prepare the V-shaped seal ring with the fluororubber canvas combination. In addition, the obtained V-shaped seal ring with the fluororubber canvas combination has long service life and is resistant to high temperature, high pressure and hydraulic safety fluid.

Owner:GUANGZHOU MECHANICAL ENG RES INST

Reinforcing porcelain blank suitable for Longquan green glaze and preparation method of product thereof

ActiveCN102674804AReduce manufacturing costGood molding performanceClaywaresPromotion effectLoading unloading

The invention discloses a reinforcing porcelain blank suitable for Longquan green glaze and a preparation method of a product of the glaze. The blank is low in cost, good in formability, small in damage and high in yield in the manufacture formation process, remarkably improves product strength performance and is favorable for large-scale production. The obtained product is collision-proof and not easy to damage, reduces unnecessary loss in the transportation loading-unloading process, is capable of well meeting requirements for mechanical washing and the like, is favorable for market expansion, and has great promotion effects on development of green glaze enterprises in Longquan.

Owner:JINGDEZHEN CERAMIC INSTITUTE

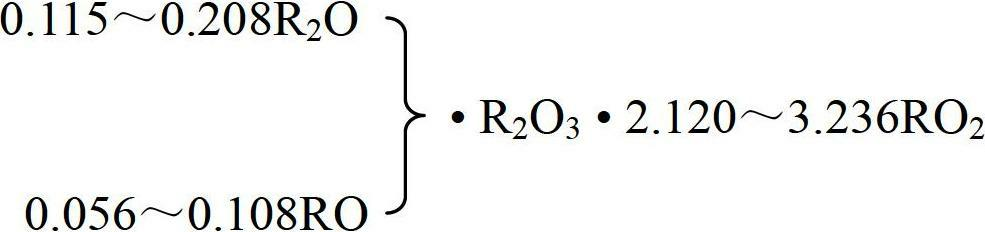

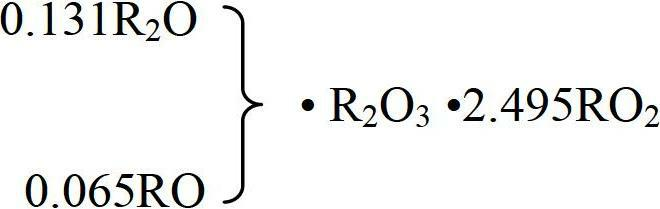

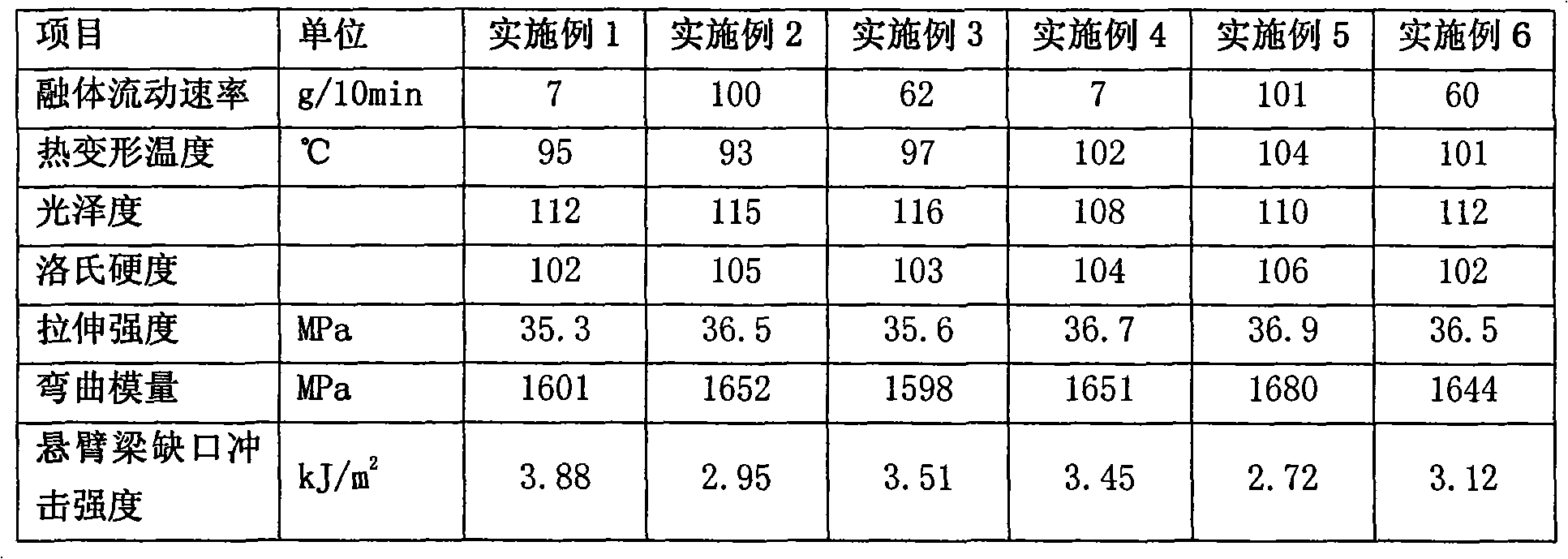

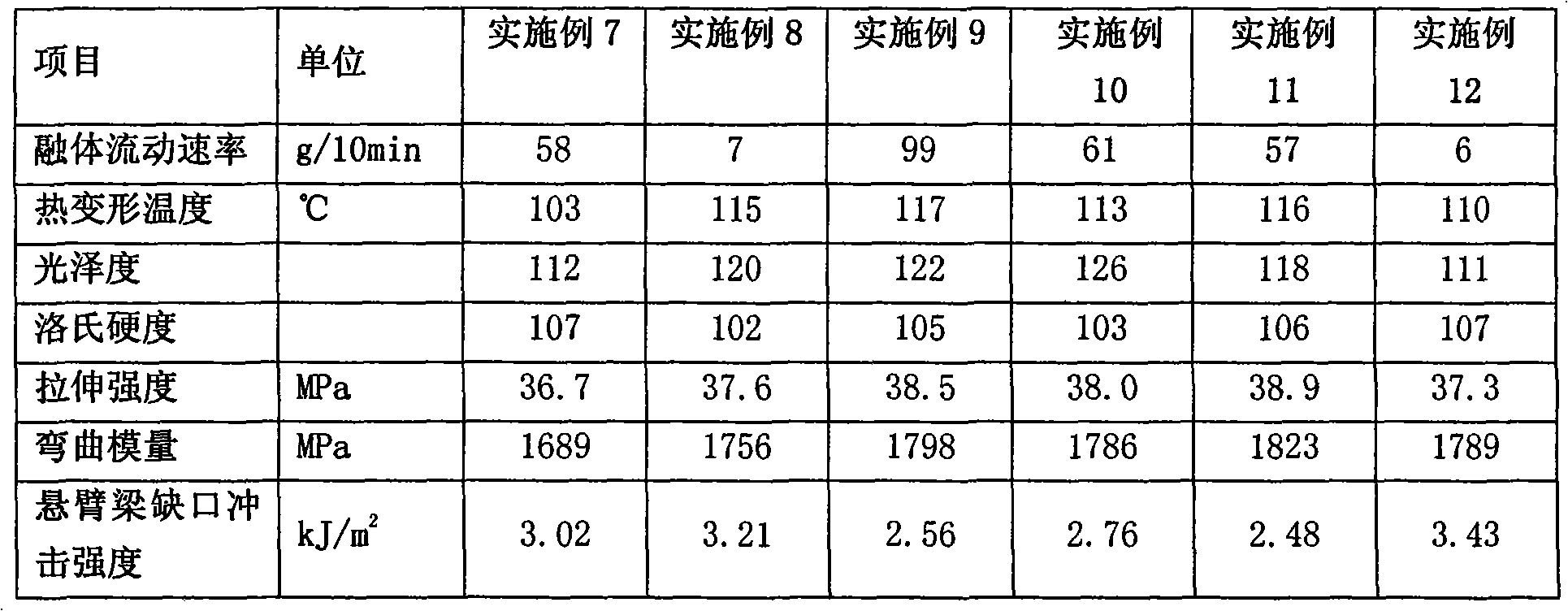

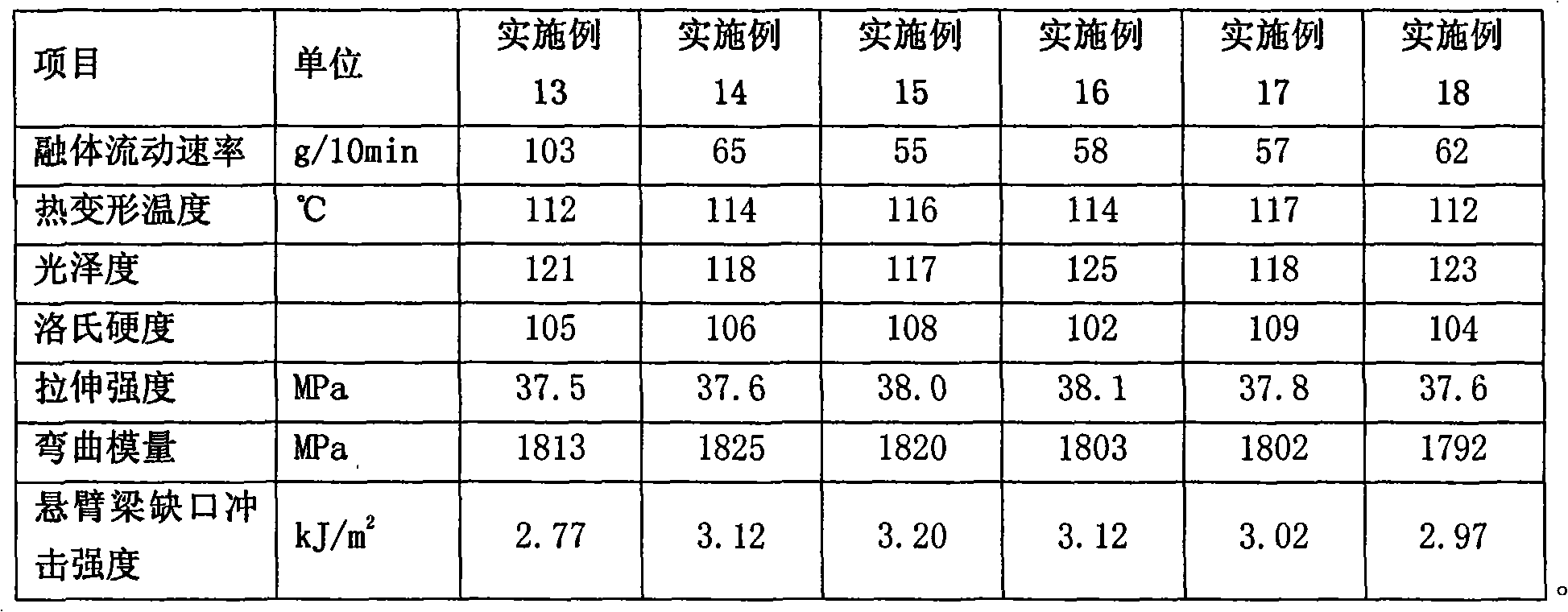

Controllable rheological high-gloss polypropylene resin and preparation method thereof

The invention discloses a controllable rheological high-gloss polypropylene resin which is composed of the following components in parts by weight: 100 parts of homo polypropylene as a base material, 0.1-0.25 part of processing agent, 0.15-0.2 part of nucleating agent, 0-1.5 parts of hardness regulator, 0.05-0.1 part of glossiness regulator and 1-12 parts of oxide master batch, wherein the number-average molar mass of the homo polypropylene is 61235-65210; the oxide master batch is formed by mixing 100 parts of homo polypropylene and 0.1-0.65 part of peroxide. Thus, the rheological behaviour of the resin can be changed by regulating the additive amount of the peroxide master batch. The controllable rheological high-gloss polypropylene resin of the invention has favourable heat resistance (heat distortion temperature is more than or equal to 110 DEG C) and higher rigidity (bending modulus is more than or equal to 1800 MPa). Because of adopting the controllable rheological technology, the invention can flexibly regulate the melt flowing rate of the material, and the material has excellent processability, heat-resistant quality and mechanical property.

Owner:CHINA PETROLEUM & CHEM CORP +1

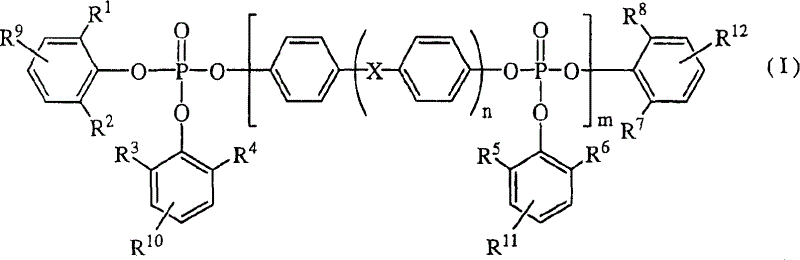

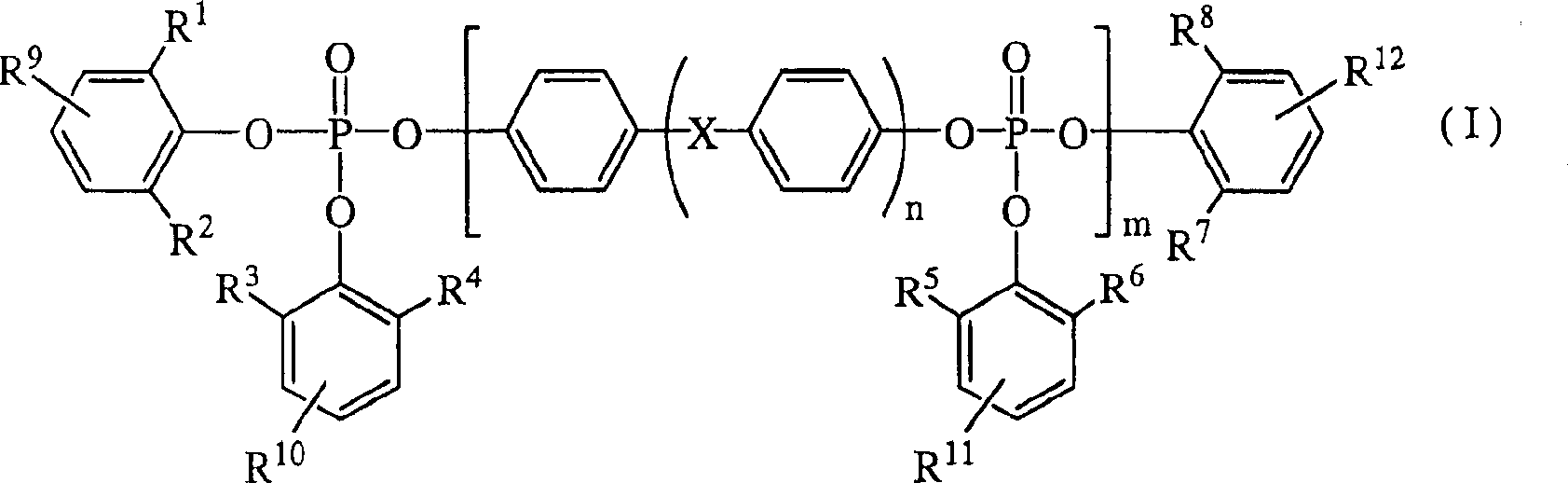

Polyarylene thioether resin composition

Provided is a polyarylene sulfide resin molded article having a good surface state which can be molded at a significantly high crystallization speed without impairing heat resistance, mechanical properties, chemical resistance, dimensional stability and flame retardancy of polyarylene sulfide resins. The resin composition comprises (A) 100 pts. wt. polyarylene sulfide resin, (B) 0.1-10 pts. wt. aromatic phosphate of a specific structure, and (C) 3-35 pts. wt. polyphenylene oxide resin.

Owner:POLYPLASTICS CO LTD

A method for manufacturing an aluminum alloy section bar used for aviation

The invention relates to a method for manufacturing an aluminum alloy section bar, particularly relates to a method for manufacturing an aluminum alloy section bar used for aviation, and overcomes a problem that various aluminum alloy section bars produced by conventional processes are low in tensile strength, low in proof strength at non-proportional extension, low in percentage elongation afterfracture and low in exfoliation corrosion performance. The method includes 1) smelting, 2) casting, 3) cutting off, 4) lathing to remove skin, 5) annealing, 6) heating, 7) extrusion, 8) solution treatment and water quenching, 9) stretching and 10) ageing treatment. Through alloy component optimization and through adoption of optimized solution treatment and ageing treatment processes after extrusion, integrated performance requirements of users on the alloy section bar are met, the prepared aluminum alloy section bar has a good physical dimension, good surface quality, good forming performancein industrial production and excellent comprehensive mechanical performance. The method is used for manufacturing the aluminum alloy section bar used for aviation.

Owner:郝金芳

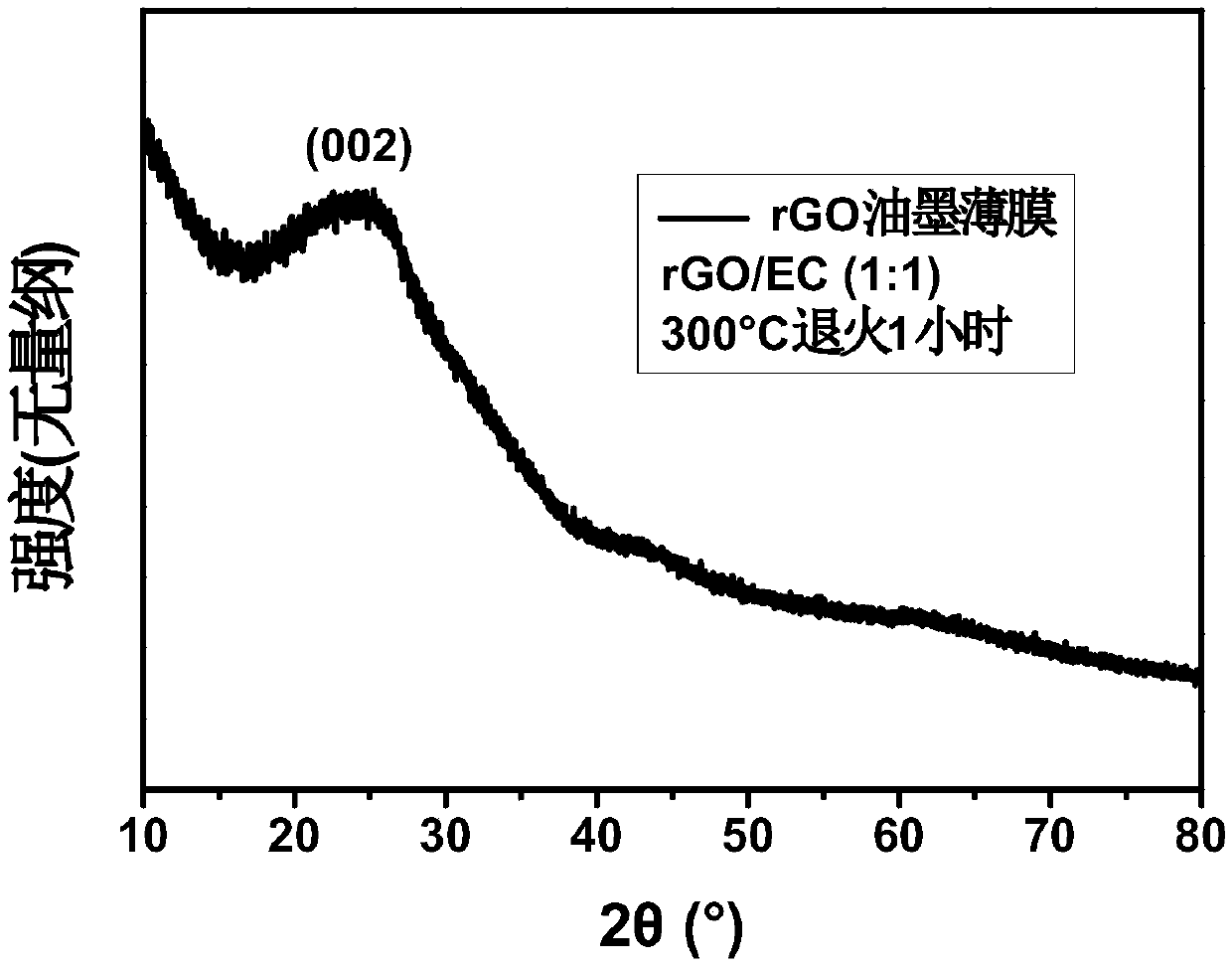

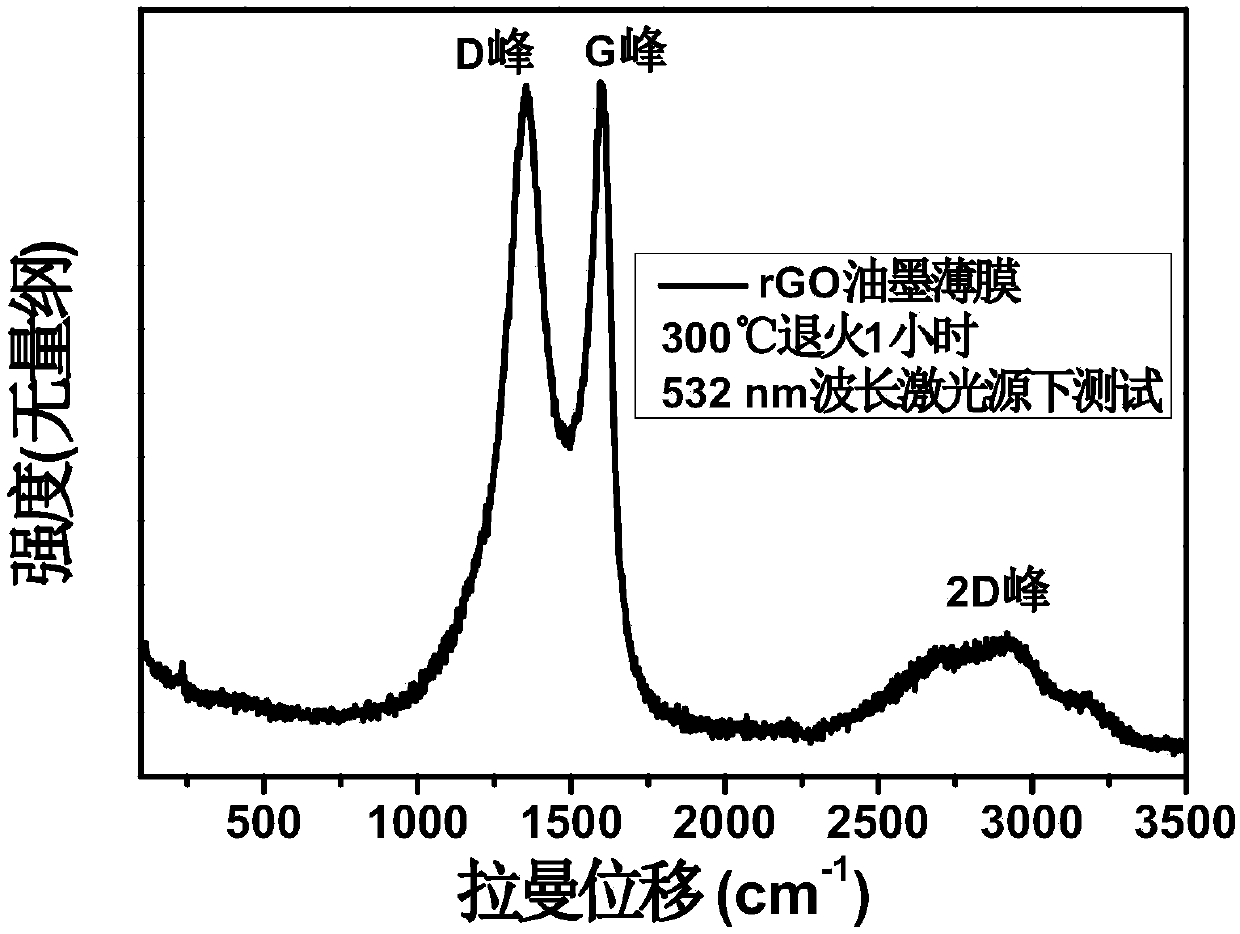

Graphene electric-conduction ink preparation method, graphene electric-conduction ink film and graphene electric-conduction ink film composite material film

The invention discloses a graphene electric-conduction ink preparation method, a graphene electric-conduction ink film and a graphene electric-conduction ink film composite material film. According tothe present invention, a graphene electric-conduction filler is uniformly dispersed in an alcohol / ketone / ester / ether solvent under the assisting of a cellulose-based dispersing agent through room-temperature stirring and ultrasonic dispersion to obtain high-quality high-stability high-conductivity graphene ink, and further the high-quality high-stability high-conductivity graphene ink is compounded with other functional materials to obtain graphene-based composite ink; the method has characteristics of simple formula, simple process, high efficiency, environment friendliness, low cost and thelike; and the graphene ink and the composite ink are suitable for scrape coating, screen printing, direct writing, ink-jet printing and other processes, and can firmly form pure graphene or graphenecomposite films and patterns on common hard / soft substrates.

Owner:XI AN JIAOTONG UNIV

Graft copolymer and thermoplastic resin composition

InactiveCN1486347AGood mattingGood lookingDispersed particle separationDisinfectionFunctional monomerMeth-

A thermoplastic resin composition comprising 10 to 98 parts by weight of a graft polymer (1A) containing a rubber-like polymer (1G) having a diene unit content of 50% by weight or less, 2 to 50 parts by weight of a hydroxyl group-containing acrylic copolymer (1B) and 0 to 80 parts by weight of other thermoplastic resin (1F), wherein the rubber-like polymer (1G) is at least one selected from the group consisting of a diene-based rubber, a polyorganosiloxane-based rubber and an olefin-based rubber; and, a graft copolymer (2A) obtained by grafting a vinyl-based polymer to a (meth)acrylate-based rubber-like polymer (2G) expansion-treated with an acid group-containing copolymer latex (2K) wherein the (meth)acrylate-based rubber-like polymer contains two or more poly-functional monomer units.

Owner:MITSUBISHI CHEM CORP

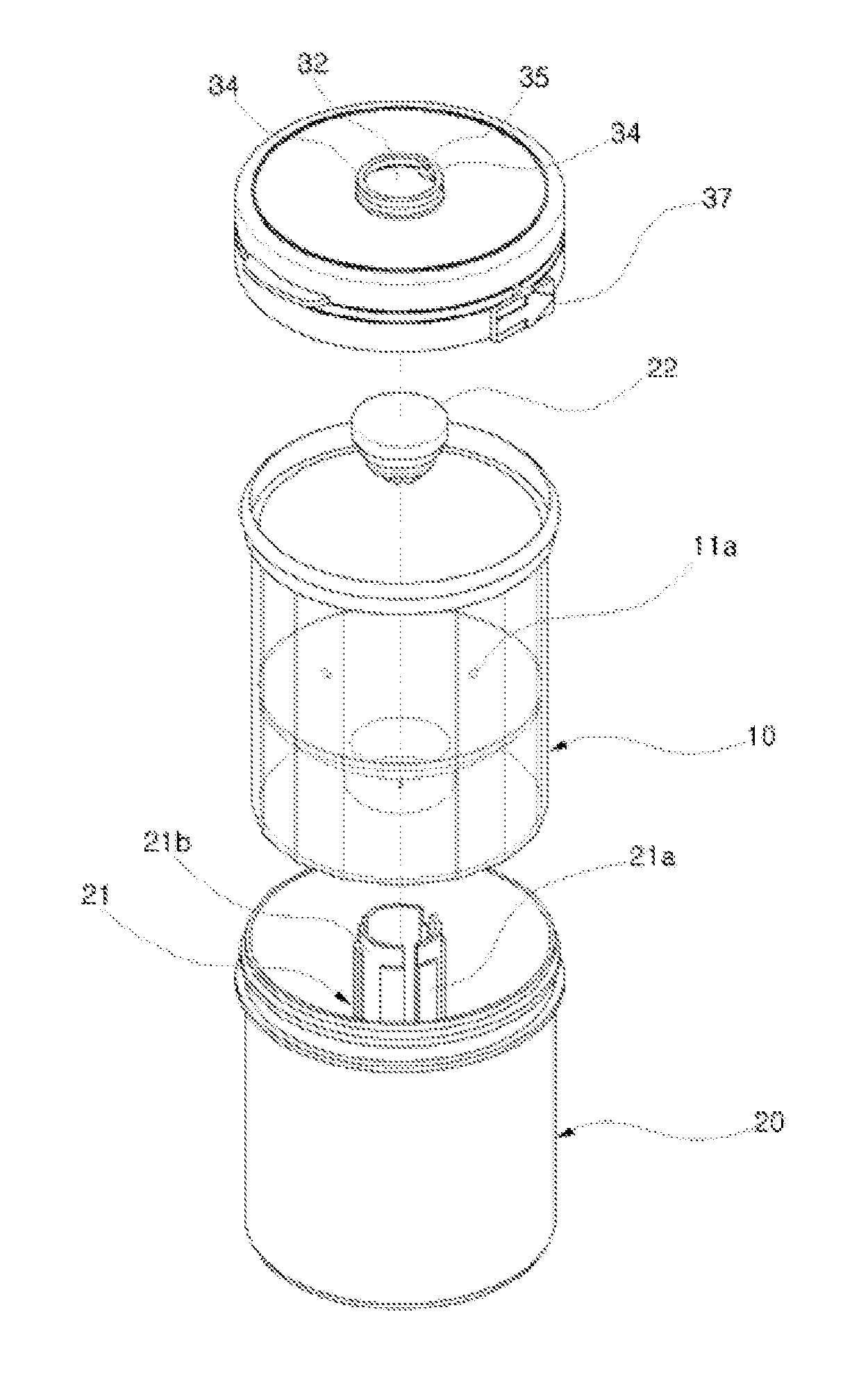

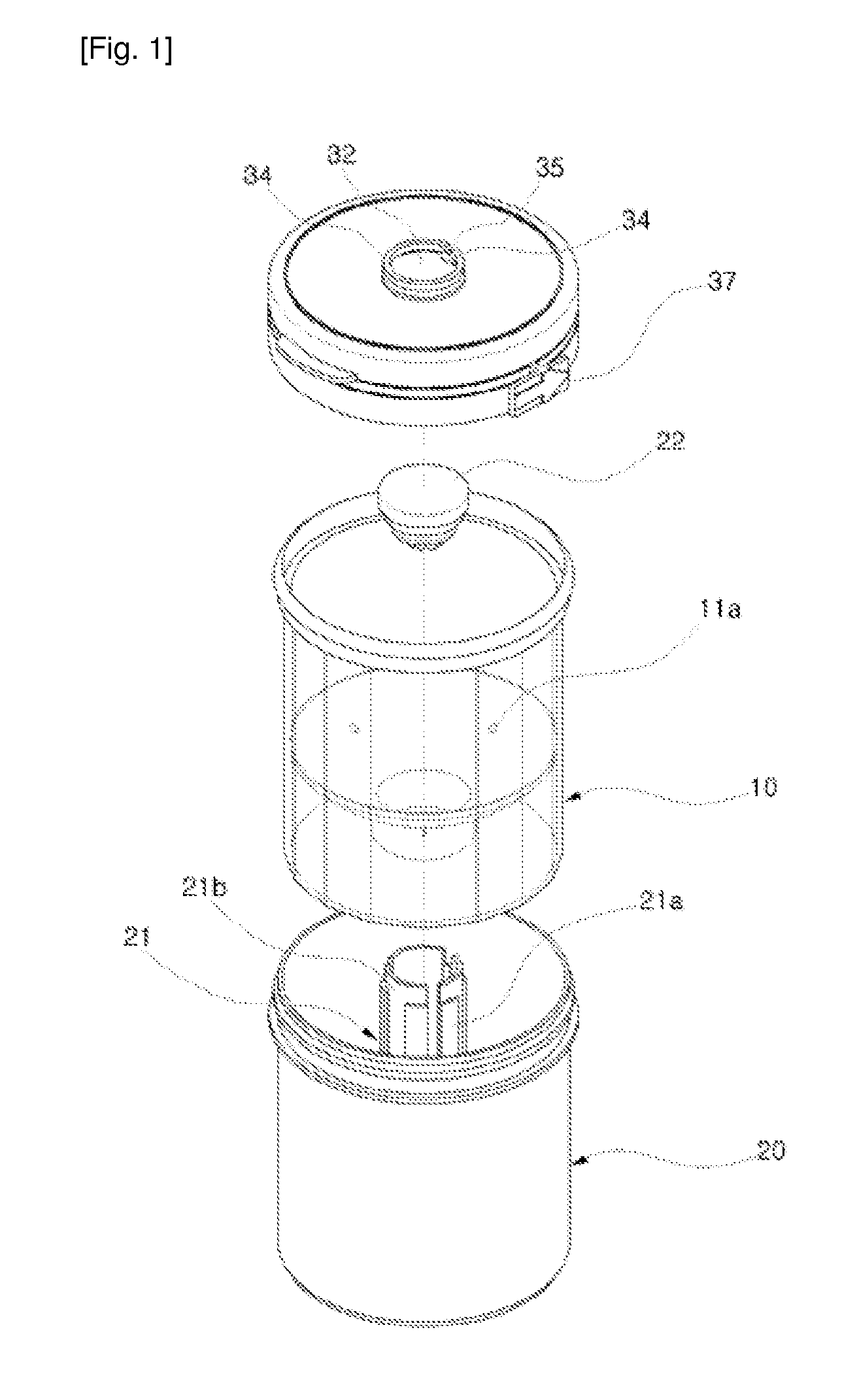

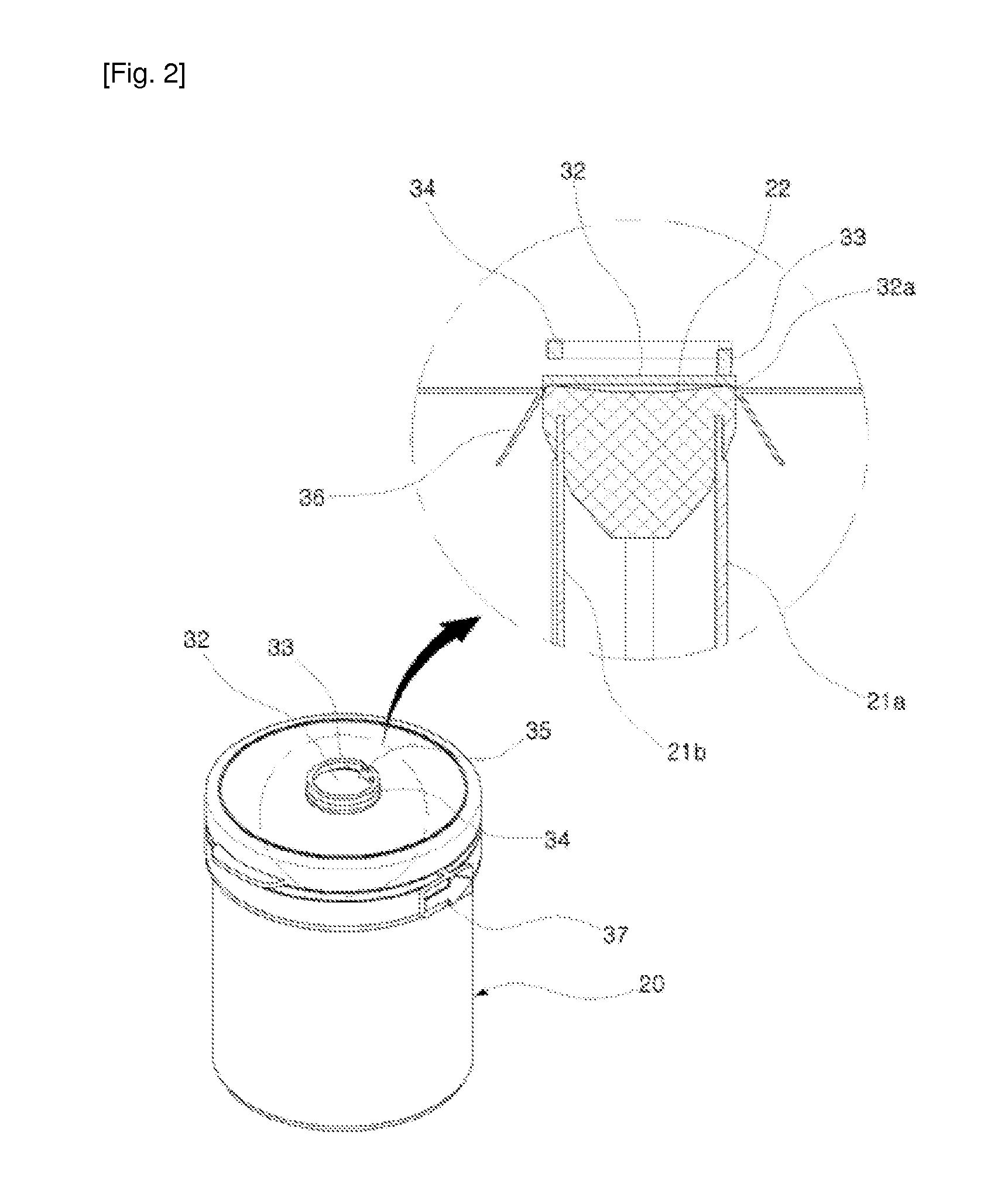

Gum dispenser for dispensing gum by vertical lifting

ActiveUS20120111883A1Reliable in operationGood molding performanceSmall article dispensingCoin-freed apparatus detailsChewing gumEngineering

The present invention relates to a gum dispenser for automatically dispensing gum by the vertical lifting of a gum case. Particularly, the present invention provides a container that has a self-sealing means, accurately dispenses a piece of gum one by one, prevents the generation of container defects, and provides ease of operation and molding. Currently, in the above operation structure, an inner case receiving gum therein is fitted in a lifting shaft of an outer case to be lifted or lowered so that a piece of gum is pushed up to an upper end of the lifting shaft, and then the gum is exposed to a dispensing hole perforated in a lid, which is coupled with the inner case, one by one for a user to enjoy. The above structure, however, has a disadvantage in that if two pieces of gum are lifted to the upper end of the lifting shaft and the lifting shaft is exposed to the perforated hole of the lid, then the lifting shaft and the dispensing hole correspond to each other 1:1 so that the two pieces of gum pop out, which makes the gum difficult to catch. In addition, if the lifting shaft is molded integrally with the outer case, the lifting shaft is likely to be twisted or bent due to the thickness thereof in the cooling procedure during the molding thereof so that it is difficult to achieve a precisely standing structure. Furthermore, if the inner case is repetitively lifted or lowered in the outer case, an outer force may be applied in the lifting motion according to a vacuum state, so that smooth operation becomes impossible and longer molding time is required in the molding. In addition, in the state that the lid is sealingly coupled with the outer case and the inner case for the sealing of the container during storage or delivery thereof, a perforated lid for implementing the dispensing hole may be pressed by the lifting shaft and the container may burst. If the perforated lid is formed to be thick in order to prevent the bursting, a pulling portion to be pulled for cutting the perforated lid is likely to be cut, and implementation of the dispensing hole may fail. As a result, the present invention is aimed at resolving the above problems.

Owner:ID PLATECH

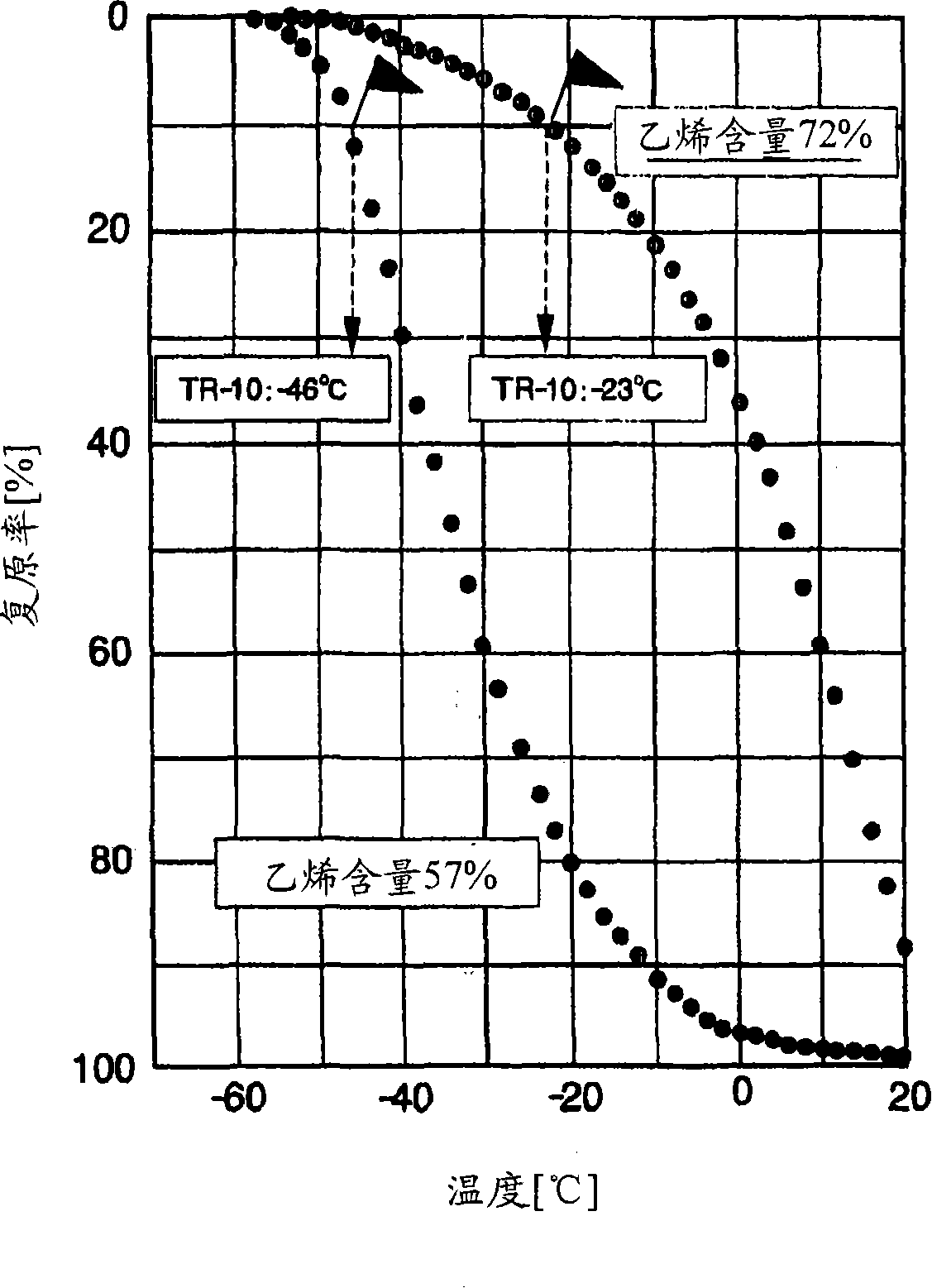

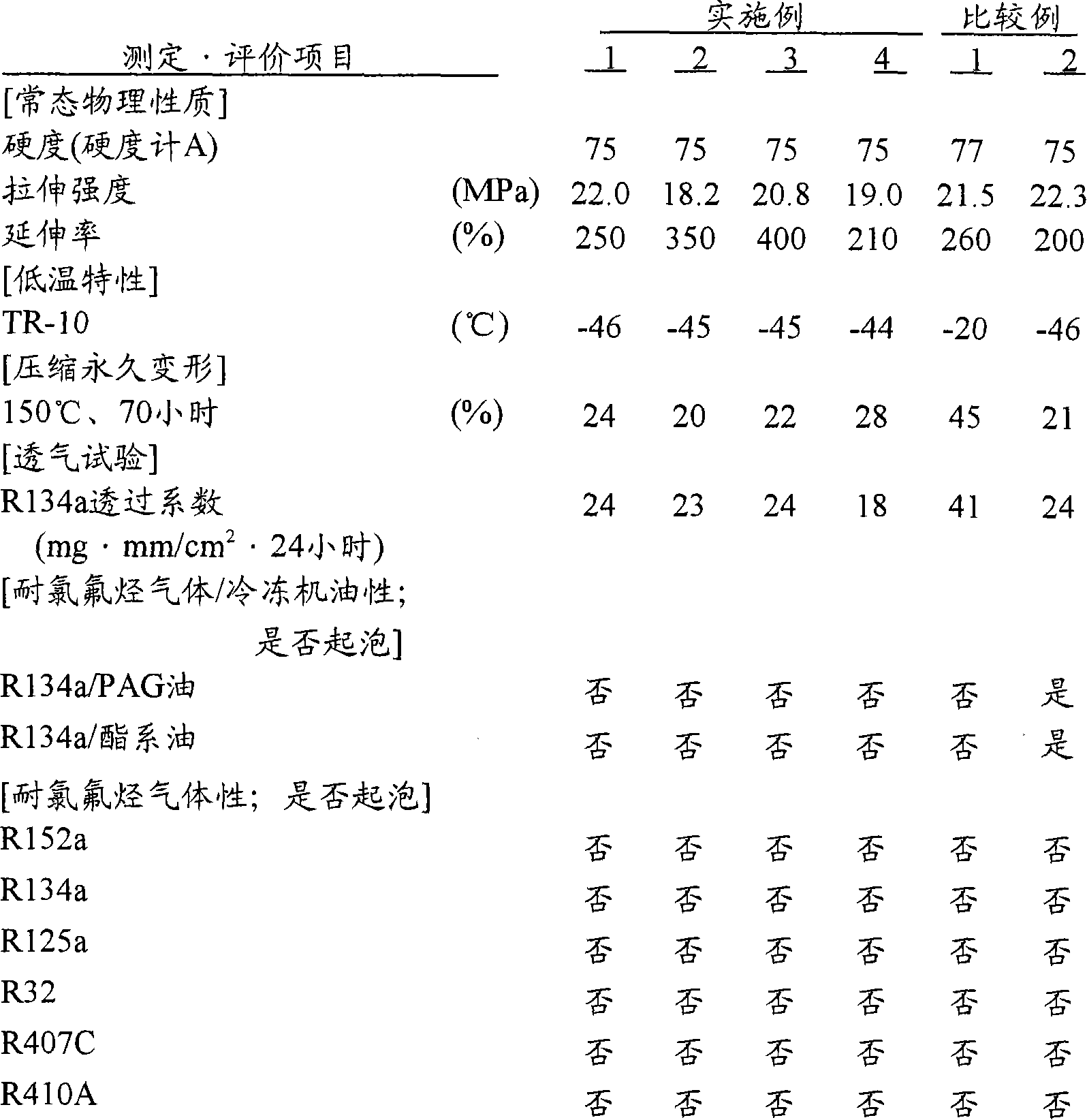

EPDM composition

InactiveCN101203565AGood molding performanceIncrease foam resistanceEngine sealsOther chemical processesVulcanizationChlorofluorocarbon

An EPDM composition which contains, as a crosslinking agent, an organic peroxide in an amount of 0.2 to 4.0 parts by weight relative to 100 parts by weight of EPDM having an ethylene content of 50 to 58% by weight and a Mooney viscosity (ML1+4) (at 100 DEG C) of 10 to 48. The EPDM composition shows an excellent blistering resistance under co-presence of flon gas / refrigerating machine oil which is a matter of concern in practical use as a rubbery material for molding a sealing material for a flon-type cooling medium (e.g., R134a), and also shows an excellent molding property. A sealing material produced by vulcanization-molding the EPDM composition, when used for sealing of a flon-type cooling medium, shows a smaller amount of permeation / leak of the cooling medium compared to that in a sealing material comprising hydrogenated NBR which has been used as a shaft seal for a compressor provided in an automotive air-conditioning system.

Owner:NOK CORP +1

Environment-friendly aquosity composite citicall limited aluminium paint and preparation method thereof

ActiveCN101768399ALow in volatile organic compounds (VOCs)Avoid problems with significantly higher costsCoatingsLow speedEmulsion

The invention relates to an environment-friendly aquosity composite citicall limited aluminium paint and a preparation method thereof. The paint comprises the following components in parts by weight: 5-10 parts of self crosslinking acrylic emulsion and stereoplasm acrylic emulsion, 5-10 parts of aqueous dispersoid of polyurethane, 10-20 parts of cosolvent, 20-40 parts of deionized water, 0.2-0.3 part of pH regulator, 0.1-0.5 part of wetting agents, 0.1-0.2 part of flatting agents and 0.05-0.2 part of defoamers; the resin components are put in a reaction kettle; stirring the mixture at a low speed; adding the pH regulator, the wetting agent, the flatting agent and the defoamer in turn; and stirring the mixture and filtrating to obtain a finished product. Compared with the prior art, the invention has the advantages of environment protection, low cost, good solvent resistance, wider range of suitable mould pressing temperature during the mould pressing, good mould pressing effect, is easy to control during production, and can be directly used to replace the prior solvent type composite citicall limited paint.

Owner:SHANGHAI WEIKAI CHEM

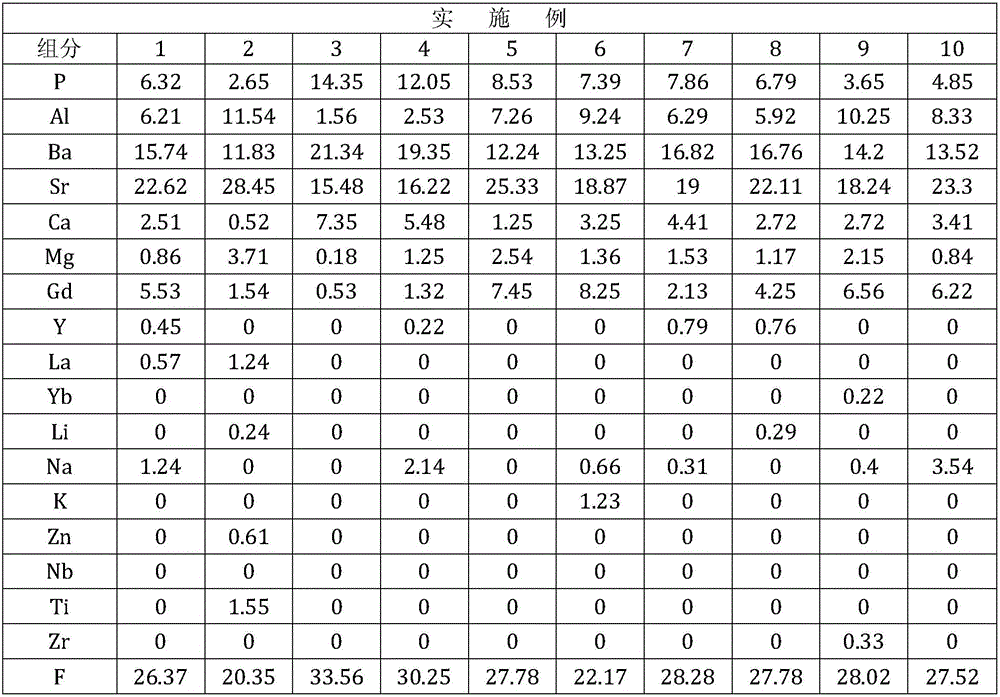

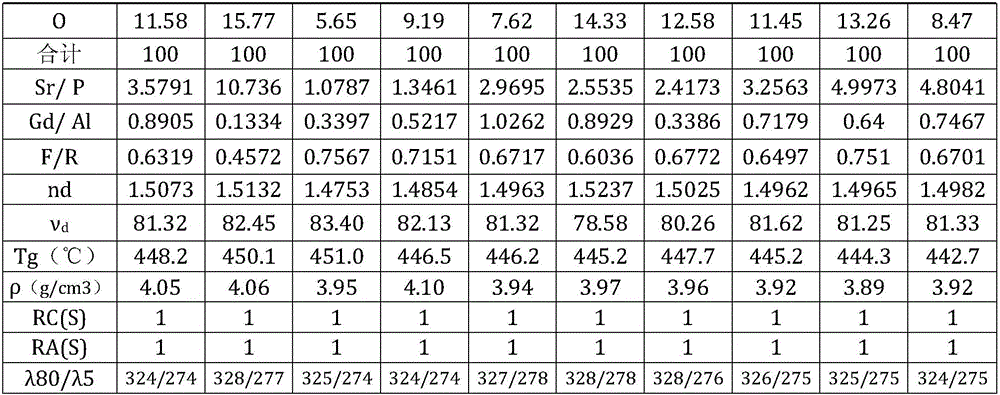

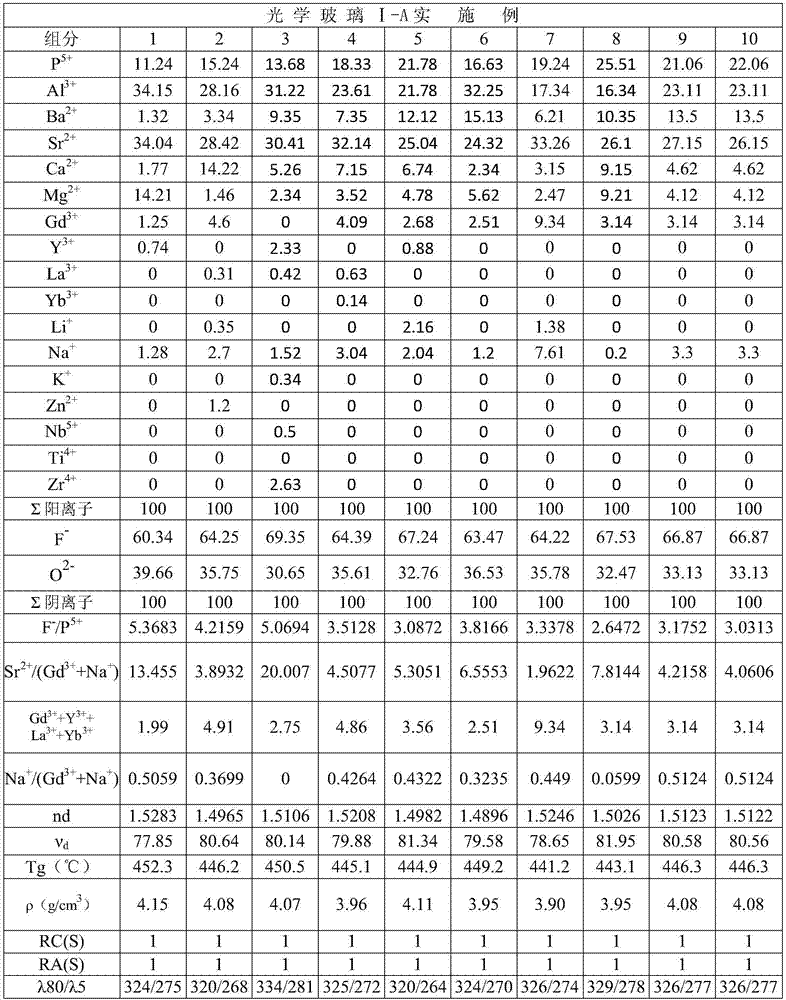

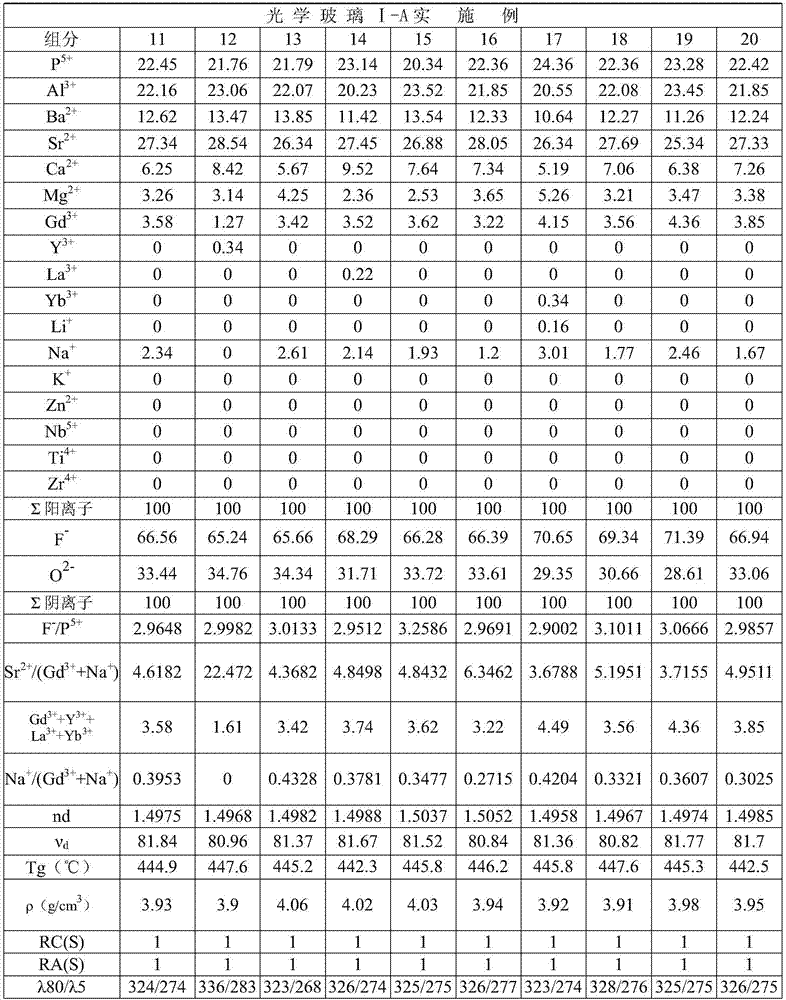

Optical glass, optical prefabricated member and optical element

ActiveCN106082644AGood molding performanceImprove yield rateOptical elementsRefractive indexAbbe number

The invention provides optical glass with excellent precision molding performance, refractive index being 1.46-1.53 and abbe number being 77-84. The optical glass comprises, by weight percentage, 2-15% of P, 1-13% of Al, 10-22% of Ba, 15-30% of Sr, 0.1-8% of Ca, 0-5% of Mg, larger than 0 but not larger than 10% of Gd, 20-35% of F and 5-16% of O. The optical glass has the advantages that the molding performance of the optical glass is improved fundamentally by reasonably regulating the proportion of the components, the problems of damage and fogging of the optical glass with the refractive index being 1.46-1.53 and the abbe number being 77-84 during the molding of the optical glass are solved effectively, and the yield of optical element production is increased greatly.

Owner:CDGM OPTICAL GLASS

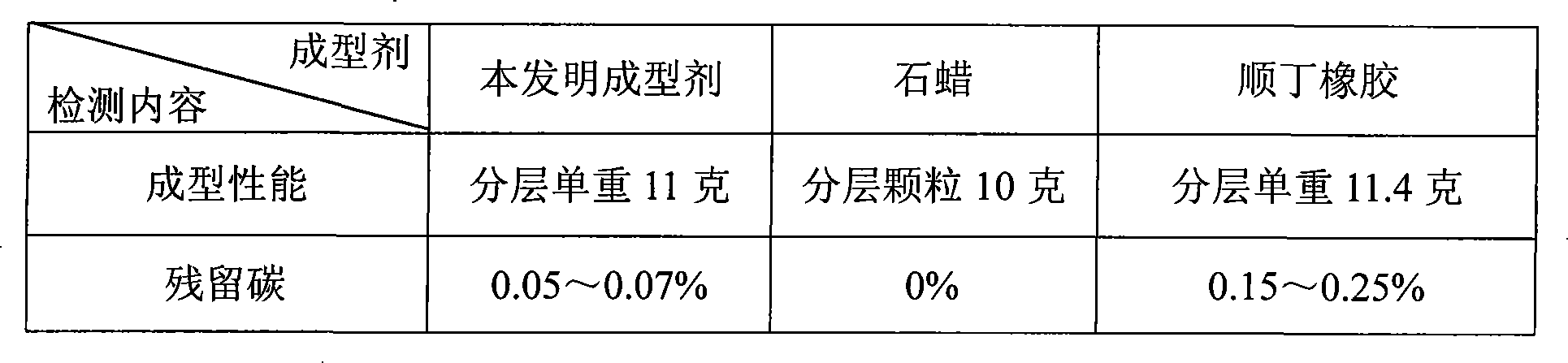

Hard metal complex plasticizer and method of manufacturing the same and method of use thereof

The invention relates to a forming agent of the manufacture of hard metals and the production method and the use method. The components and the weight per cents are 20 per cent to 27 per cent of paraffin, 34 per cent to 42 per cent of SBS solution and 32 per cent to 44 per cent of No. 120 solvent gasoline. The production method is that the solid paraffin is first dissolved into water and then a screen mesh is adopted to remove the solid impurities; the gained pure liquid paraffin is mixed with the gasoline to stir evenly; then the SBS solution is added to stir fully and mixed evenly to gain the forming agent solution; the temperature of the forming agent solution is kept for use. The use methods of in-situ preparation, thermal insulation and short storage are adopted. The invention adopts the gasoline as solvent, which makes the paraffin and the SBS solution dissolved in the same solution system and makes the two play use of forming together with good forming performance. The carbon content remained is greatly reduced and high-carbon WC powder can be used as raw material to produce hard alloy. Meanwhile, because of low viscidity, the forming agent of the invention can not only suitable for manual adhesive-doped technology but also suitable for the preparation technology of the spray drying mixture.

Owner:ZHUZHOU JINGGONG CEMENTED CARBIDE

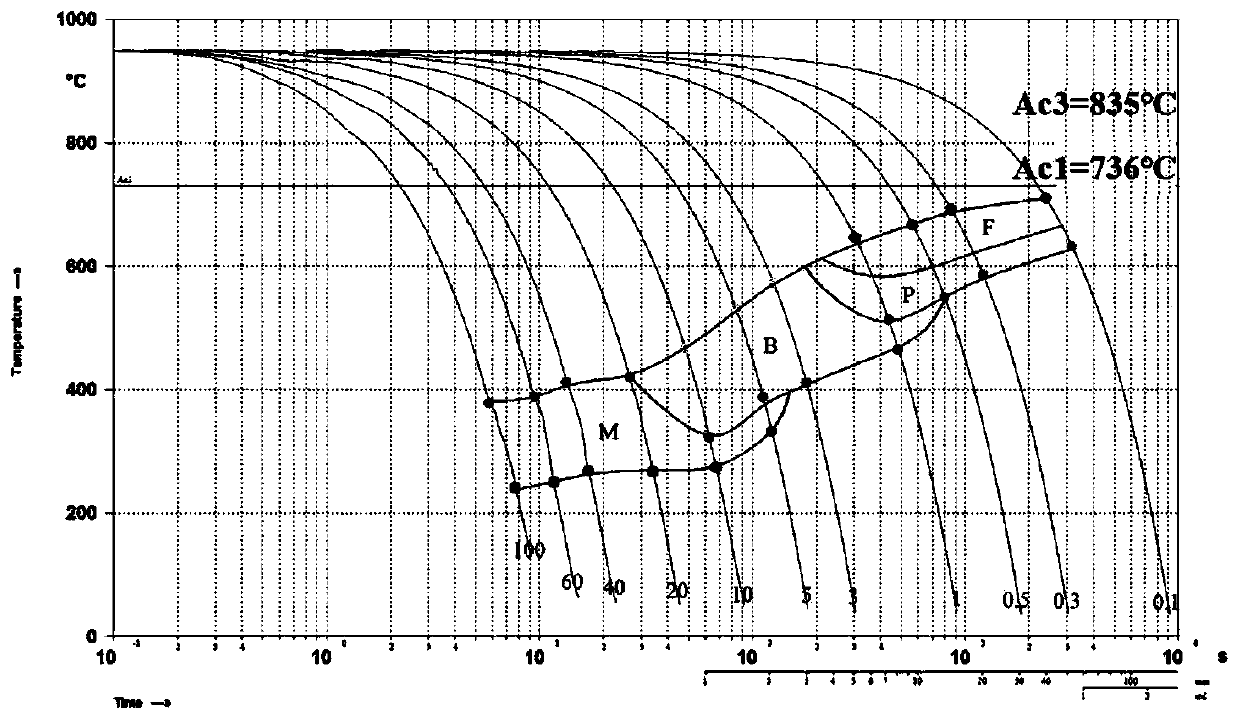

Wear-resistant steel with good forming performance for dumper carriage body and production method thereof

ActiveCN110964979AGood molding performanceEnsure consistencySteel platesMechanical properties of carbon nanotubes

The invention discloses wear-resistant steel with good forming performance for a dumper carriage body. Weight percentages of chemical components of the wear-resistant steel are as follows, 0.16-0.22%of C; 0.15-0.35% of Si; 0.90-1.30% of Mn; less than or equal to 0.018% of P, less than or equal to 0.010% of S, 0.020-0.060% of Als; 0.020-0.060% of Nb; 0.012-0.028% of Ti, 0.30-0.70% of Cr, 0.10-0.20% of Mo, 0.0005-0.0018% of B, less than or equal to 0.0025% of O, less than or equal to 0.0050% of N, less than or equal to 1.8 ppm of H and the balance of Fe and inevitable impurities. In the production method, the controlled rolling process comprises the rough rolling process, and austenite recrystallization zone deformed austenite grain uniformity control is carried out in the rough rolling process, and the pass reduction rate is controlled to gradually increase. The wear-resistant steel is advantaged in that the microstructure of the base plate is mainly composed of fine lath martensite, martensite lath size and mechanical property through plate distribution are uniform, a steel plate uniformly extends in all directions during stretching, cutting and U-shaped bending, consistency of machining and forming is guaranteed, straightness of the steel plate ranges from 1 mm / 2 m to 4 mm / 2 m after the steel plate is cut into narrow strips, straightness of a bent end is not larger than 3 mmafter the steel plate is bent in a U shape, and good forming performance is achieved.

Owner:HANDAN IRON & STEEL GROUP +2

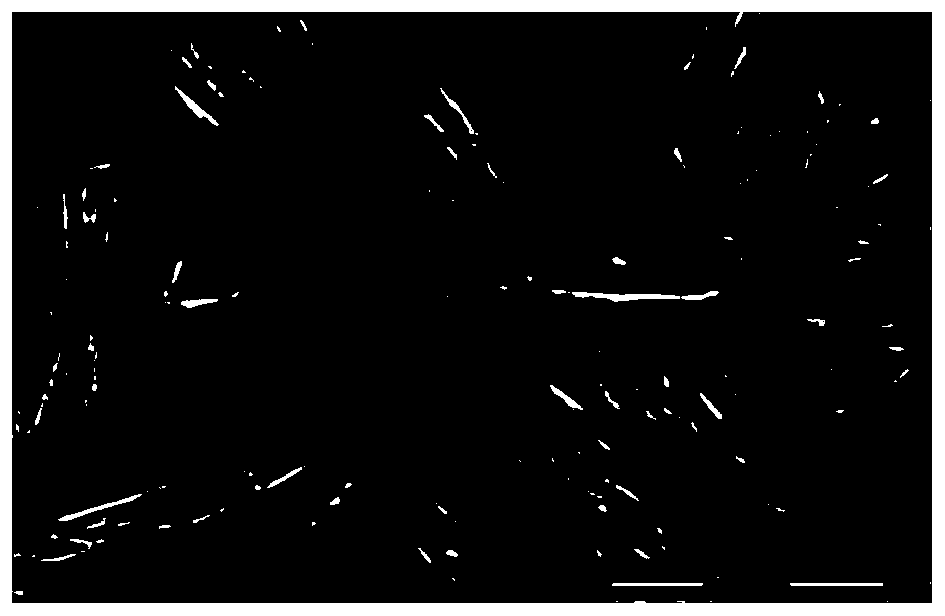

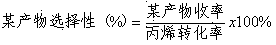

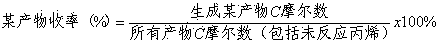

Propylene oxidation catalyst, preparation method thereof and applications thereof

ActiveCN103736498AGood molding performanceImprove the binding effectOrganic compound preparationOxygen compounds preparation by hydrocarbon oxidationActive componentBreakage rate

The invention relates to a propylene oxidation catalyst, a preparation method thereof and applications thereof, mainly solving problems of low mechanical strength and the high breakage rate of catalysts in the prior art. According to the technical scheme adopted by the catalyst and the preparation method, at least one of SiO2 or Al2O3 is selected as a carrier, an active component shown as the general formula Mo[12]Bi[a]Fe[b]Ni[c]Sb[d]X[e]Y[f]Z[g]Q[q]O[x] is contained, wherein the X is at least one selected from Mg, Co, Ca, Be, Cu, Zn, Pb or Mn; the Y is at least one selected from Zr, Th or Ti; the Z is at least one selected from K, Rb, Na, Li, Tl or Cs; the Q is at least one selected from La, Ce, Sm or Th; and the catalyst is subjected to pre-calcination in the preparation process. By the technical scheme, the problems are solved well and the catalyst can be used in the industrial production of the acraldehyde by propylene oxidation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for daily-use ceramic

The invention provides a preparation method for daily-use ceramic. The raw material formula comprises, by weight, 40-45% of kaolin, 15-25% of quartz, 10-15% of potash feldspar, 10-20% of alumina, 4-6% of zinc oxide and 0.6-0.8% of cerium dioxide. The daily-use ceramic integrates characteristics of high strength and high weight, and also has the advantages of good molding performance, wide sintering scope, high thermal stability and the like; the glossiness of ceramic glaze is improved, glaze is smooth, and the ceramic has good hardness, rupture strength and fracture toughness; the disadvantage of bad light transmittance of common strengthen porcelain is overcome, and also the problems of difficult molding and narrow sintering scope are solved.

Owner:吕子玉

Method for manufacturing aluminum alloy rivet rod for aerospace product

The invention relates to a method for manufacturing a high shear-resistant strength and high percentage elongation after fracture aluminum alloy rivet rod for the aerospace product, belonging to the method for manufacturing an aluminum alloy rod, and aiming to solve the problems of low non-proportional extension strength, shearing strength, tensile strength and extension at break of the existing aluminum alloy rivet rod for the aerospace product. The method comprises the following steps: (1) preparing molten alloy; (2) casting an alloy rod; (3) cutting off the cast alloy rod; (4) turning the peel of the cast alloy rod; (5) carrying out homogenizing annealing; (6) heating the cast alloy rod; (7) extruding; (8) carrying out cold-drawing by using a mold; (9) quenching; (10) straightening; and (11) aging to obtain the aluminum alloy rivet rod for the aerospace product. The aluminum alloy rivet rod manufactured by adopting the method has the tensile strength of not less than 431N / mm<2>, the non-proportional extension strength of not less than 265N / mm<2>, the extension at break of not less than 16% and the shearing strength of not less than 255N / mm<2> and meets the application requirement of the aerospace product. The method can be used for processing and manufacturing the aluminum alloy rivet for the aerospace product.

Owner:哈尔滨东轻特种材料有限责任公司

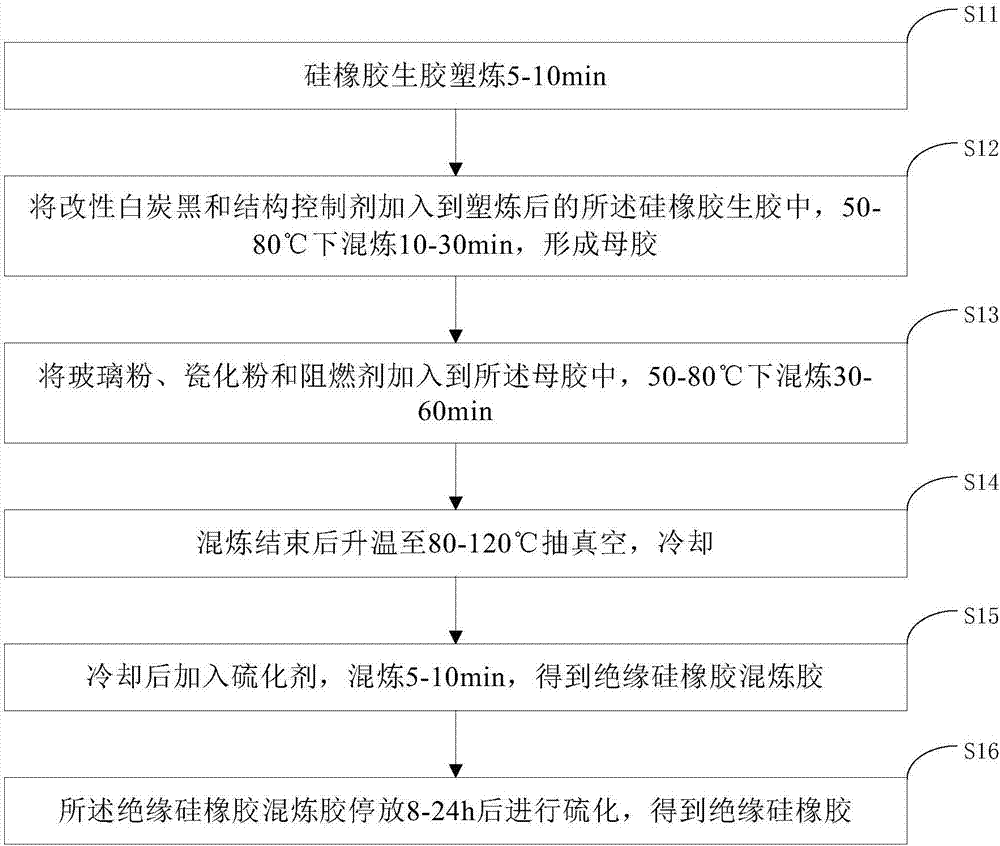

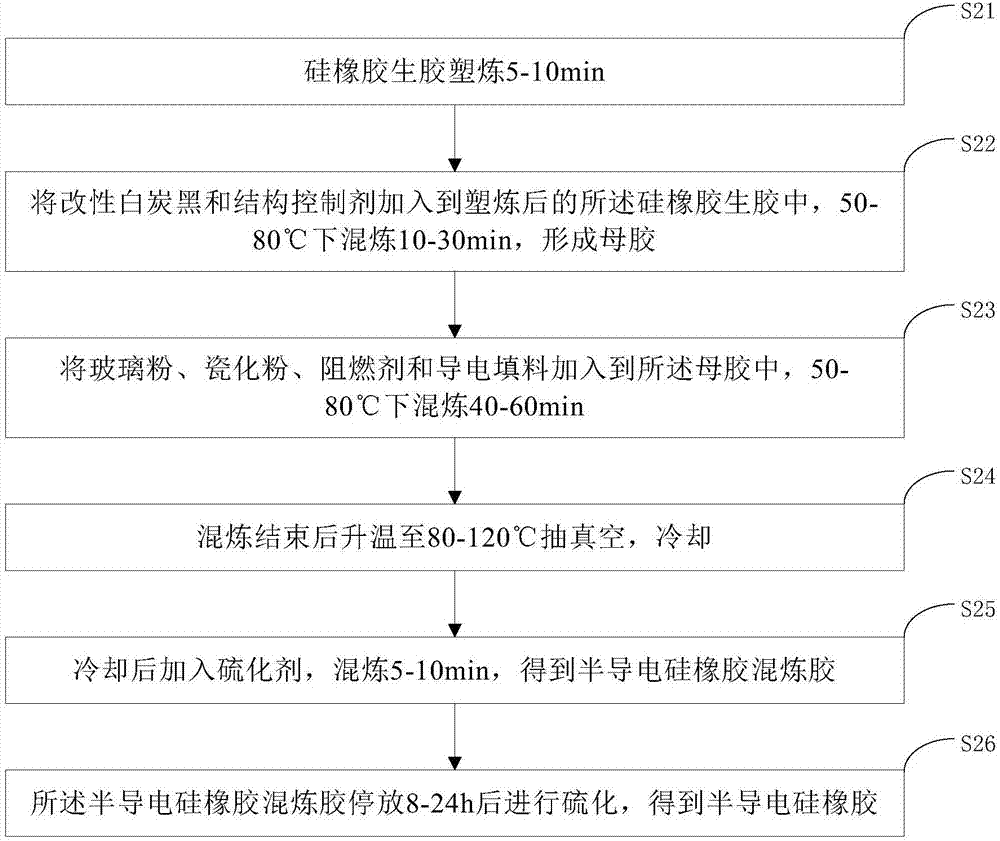

Insulating silicone rubber, semiconductive silicone rubber, a cable head casing pipe and a preparing method

InactiveCN107286664AGood molding performanceReduce manufacturing costRubber insulatorsNon-conductive material with dispersed conductive materialEngineeringThermal decomposition

Insulating silicone rubber, semiconductive silicone rubber, a cable head casing pipe and a preparing method are provided. Ceramic powder allows the insulating silicone rubber to form hard ceramic protection in high-temperature or firing state, thus playing a function of isolating flame. A flame retardant allows the thermal decomposition initial temperature of the insulating silicone rubber to exceed 400 DEG C, the limit oxygen index to exceed 30%, and the UL94 flame retardant grade to be the V-0 grade. On the basis of an insulating silicone rubber raw material, the semiconductive silicone rubber also includes a conductive filler. Through adding the conductive filler, the semiconductive silicone rubber has characteristics of the insulating silicone rubber and also has a conductive characteristic. An inner core layer and an outer skin layer of the cable head casing pipe are prepared from the semiconductive silicone rubber, and an insulating layer is prepared from the insulating silicone rubber. The cable head casing pipe has good thermal stability, flame retardance and conductivity, and can perform insulating protection on a cable connector so as to ensure safe operation of power supply equipment.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

Transferring and compounding dual-purpose coating for waterborne polyurethane, preparation method and application thereof

InactiveCN102363708AAvoid problems such as placement stabilityQuality improvementPretreated surfacesPolyurea/polyurethane coatingsPolyesterXylylene

The invention relates to a transferring and compounding dual-purpose coating for waterborne polyurethane, a preparation method and an application thereof. The preparation method comprises the following steps: copolymerizing polyester polyol and polyether polyol with HMDI (Hexamethylene Diisocyanate), XDI (Xylylene Diisocyanate), IPDI (Isophorone Diisocyanate) and TDI (Toluene Diisocyanate); extending chains by using different chain extenders, thereby acquiring different components (components A and B); and lastly, adding a component C, stirring and milling, thereby preparing the coating. Compared with the prior art, the transferring and compounding dual-purpose coating for the waterborne polyurethane suitable for laser provided by the invention has the advantages of environmental protection and capability of enhancing anti-counterfeiting and illuminating effects and other effects, is suitable for a high-speed transferring aluminizing process, and can be applied to a compound package material, thereby realizing dual purpose of one material and meeting a demand on the packaging of products in modern society. The pilot scale production confirms that the transferring and compounding dual-purpose coating can be directly used for replacing a present related solvent-base coating.

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

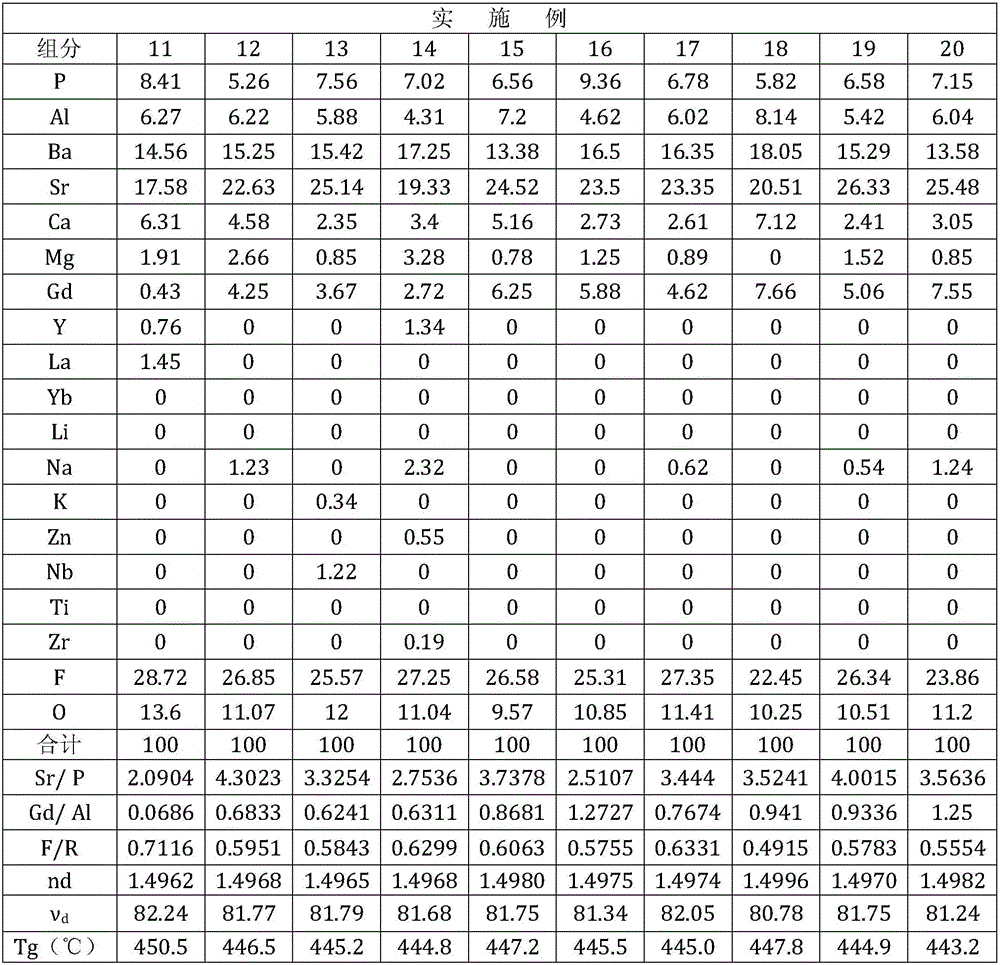

Optical glass, optical preform and optical element

ActiveCN107540214AGood molding performanceImprove yield rateOptical elementsRefractive indexOptical glass

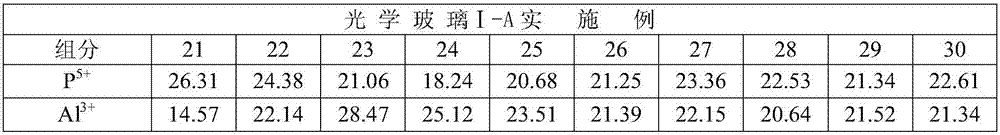

The invention provides optical glass with excellent precise molding properties, a refractive index of 1.46 to 1.53 and an Abbe number of 77 to 84. The optical glass comprises the following cations bymol: 10-30% of P<5+>,10-35% of Al<3+>, 1-20% of Ba<2+>, 15-35% of Sr<2+>, 1-20% of Ca<2+>, 0-10% of Gd<3+> and 0-10% of Na<+>, wherein a ratio of Sr<2+> / (Gd<3+> + Na<+>) is 1-30. The optical glass comprises the following anions: F<-> and O<2->. A ratio F<-> / P<5+> of the molar percentage of F<-> relative to the total amount of the anions and the molar percentage of P<5+> relative to the total amount of the cations is 2.5 or more. According to the invention, through reasonable adjustment of the ratio of components, the moldability of the optical glass is improved, the problems of damage and fogging in the molding process are overcome, and the yield of production of the optical element is greatly improved.

Owner:CDGM OPTICAL GLASS

Holographic transfer single coating material and its preparation method

InactiveCN102816490AStrong adhesionIncrease productivityCellulose derivative coatingsCelluloseInformation layer

The invention relates to a coating material of the holographic anti-counterfeiting printing industry, particularly to a holographic transfer single coating material and its preparation method. The holographic transfer single coating material composition provided in the invention can improve the adhesion force and is suitable for post-printing, and consists of the following components by mass: 8-20 parts of thermoplastic acrylic resin, 2-7 parts of cellulose ester, 1-6 parts of vinyl chloride-vinyl acetate resin, 75-85 parts of solvents, 0.5-1.0 part of auxiliary agents, and 1.5-4.5 parts of a functional additive. The coating material needs only one time coating, and has the characteristics of high production efficiency, energy saving and emission reduction; the obtained holographic pattern is clear, and the anti-counterfeiting effect is strong; an aluminized back adhesive can transfer completely, the transfer paper has good smoothness and high folding endurance, an aluminum layer and an information layer, as well as the information layer and a paper substrate both have strong adhesion; the coating material has good post-printing adaptability, and printing can be carried out directly after transfer and curing, the printing ink can have good leveling property, and the quality defects such as color difference, lifting, color rupture, reverse pull and the like do not exist.

Owner:HUBEI LHTC ANTI COUNTERFEITING TECH CO LTD

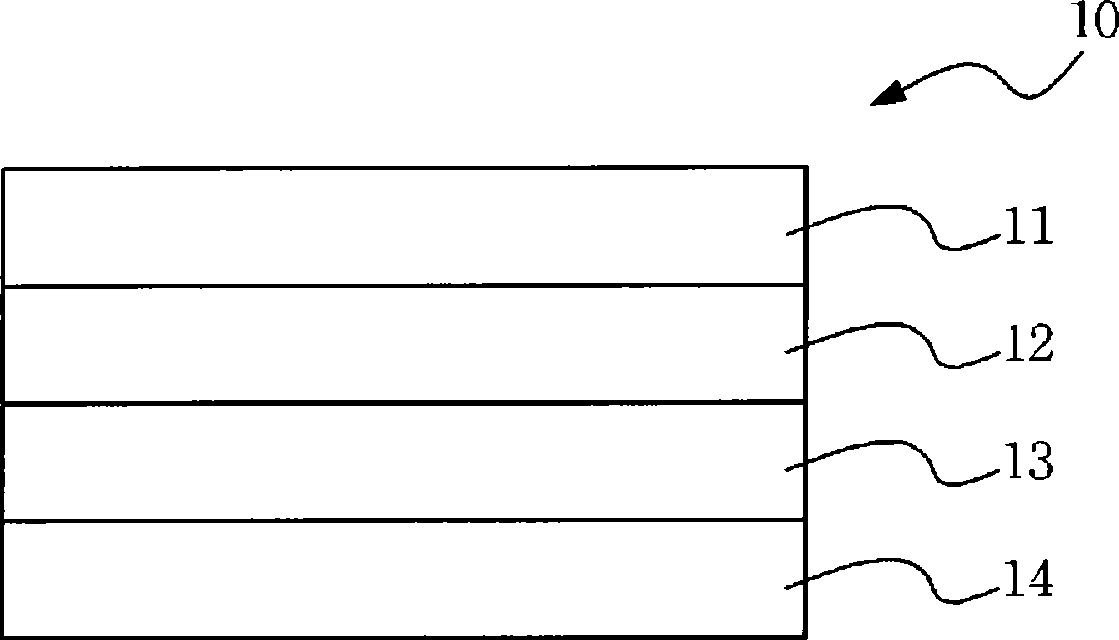

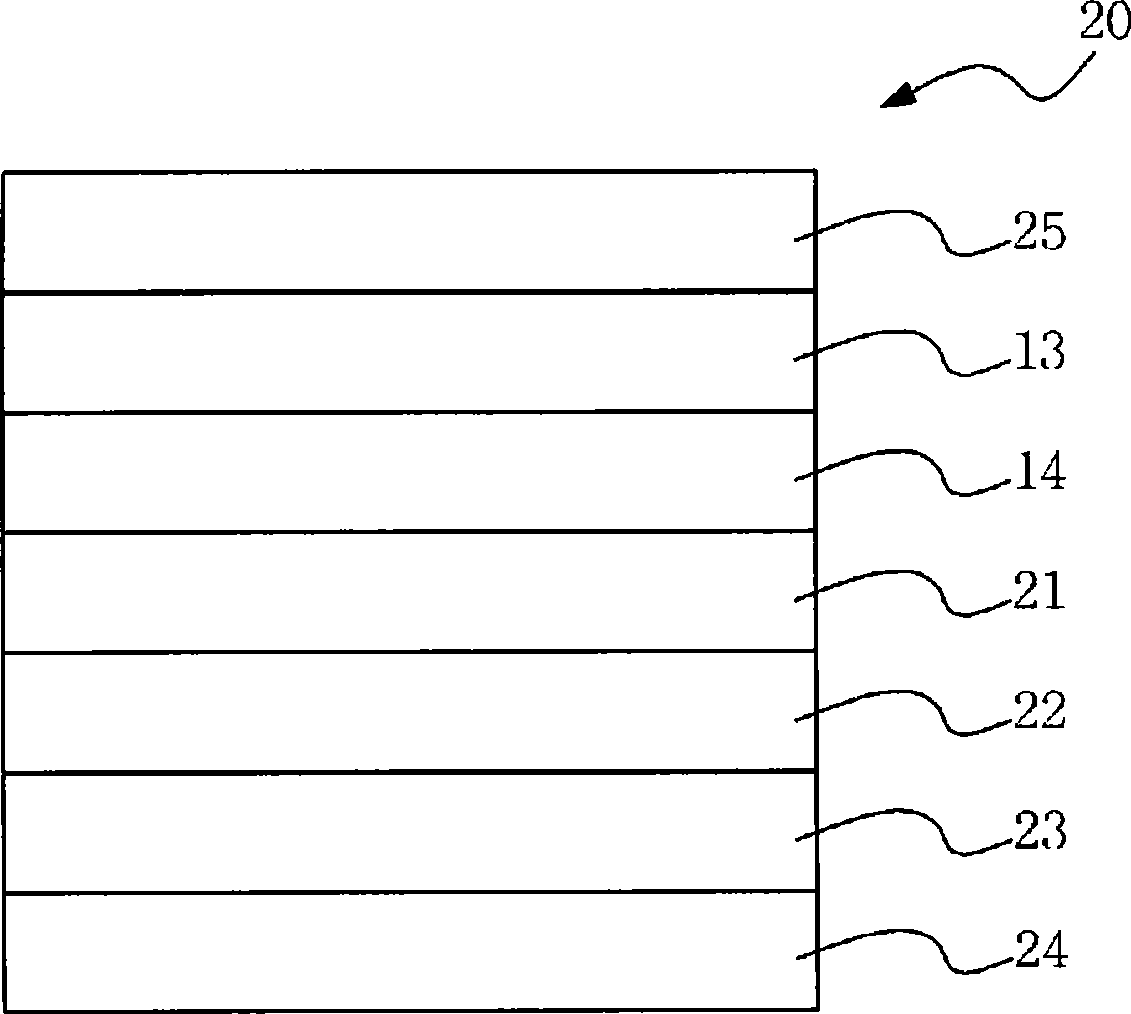

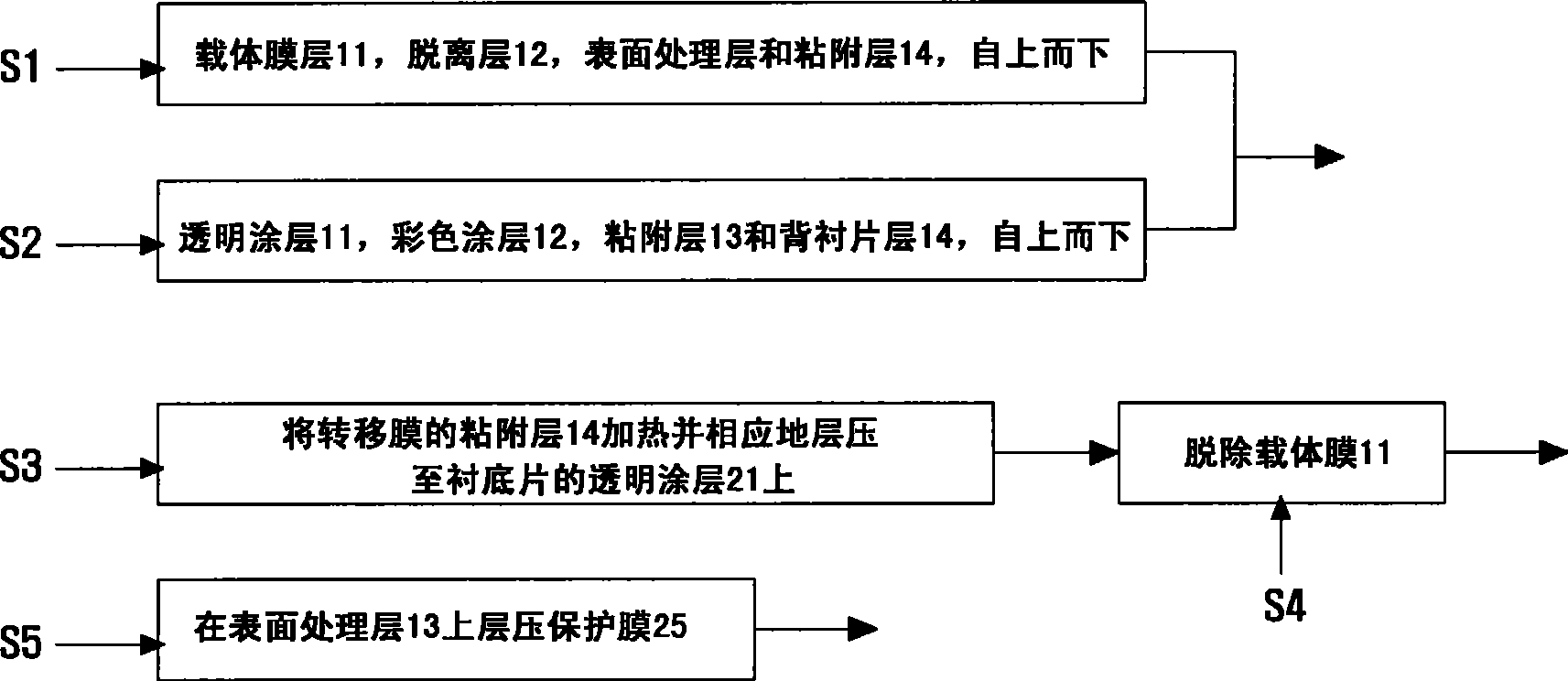

Transferring films, multilayered sheets and manufacturing methods thereof

InactiveCN101479095AExcellent surface hardnessHigh elongationDecorative surface effectsSynthetic resin layered productsAcrylic resinMotor vehicle part

The present invention relates to a transferring film for manufacturing a decorative laminate sheet having an excellent weatherability, scratch resistance and moldability, a laminate sheet manufactured therefrom and a method for manufacturing thereof. The transferring film and the laminate sheet of the present invention combine an excellent scratch resistance and thermo- formability, since a surface treatment layer comprising a modified acrylic resin and vinyl acetate is formed thereon, and thus may be effectively applied to protect and decorate plastic molded articles such as household appliances, furniture and automobile parts, especially, molded articles having a three-dimensional complicated shape.

Owner:LG CHEM LTD

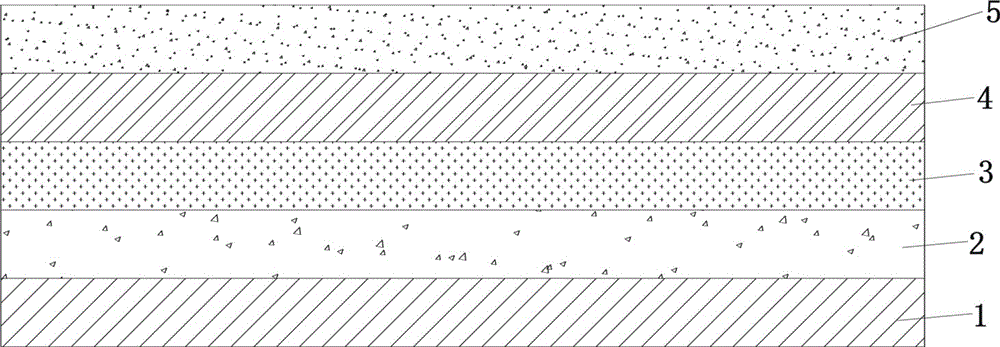

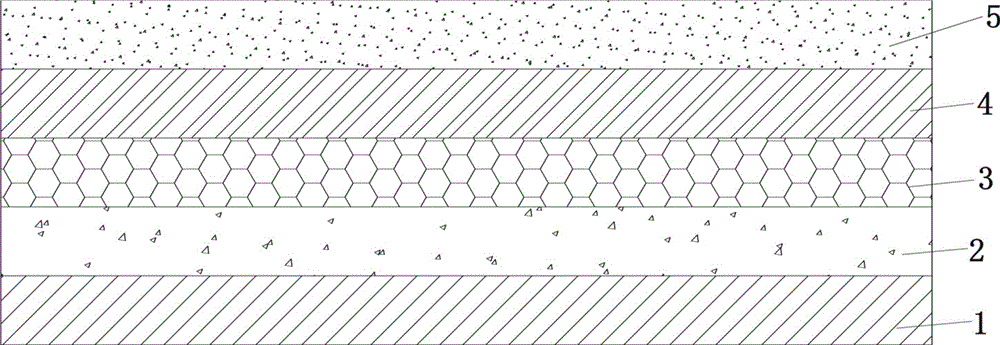

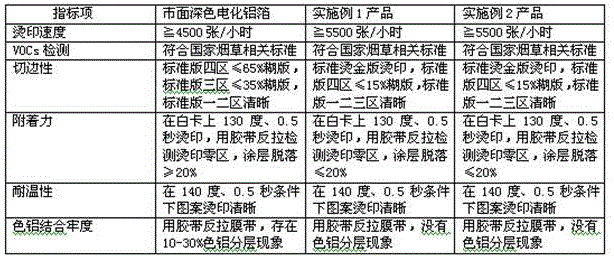

Dark electrochemical aluminium foil with applicable thermoprinting scope

ActiveCN107433814AImprove trimming effectSmall molecular weightNon-macromolecular adhesive additivesDecorative surface effectsFine lineLeveling effect

The invention provides a dark electrochemical aluminium foil with an applicable thermoprinting scope. The electrochemical aluminium foil comprises a carrier membrane, a release layer, an imaging layer, an aluminum plating layer and a glue layer, the imaging layer comprises the following components by weight percentage: 14.5-16% of amino-acrylic resin, 13-14% of methyl hydroxy modified acrylic resin, 5-7% of nitrocellulose, 37-40%of butanone, 24-26% of butyiate, and 4.5-5.5% of color powder; the imaging layer employs template roller printing with 180 meshes, and the dry coating amount is 1.26+ / -0.05 g / m<2>. According to the dark electrochemical aluminium foil, the coating apparent leveling effect of the imaging layer is good, the moulding effect is good, the moulding effect is good, the color aluminium combination fastness is high, moulding is carried out without coating the imaging layer with a layer of protective layer, the dark electrochemical aluminium foil is suitable for thermoprinting the patterns with small area or fine line patterns, the cost is saved, and the applicable thermoprinting scope is widened.

Owner:GUANGDONG XINRUI NEW MATERIAL TECH

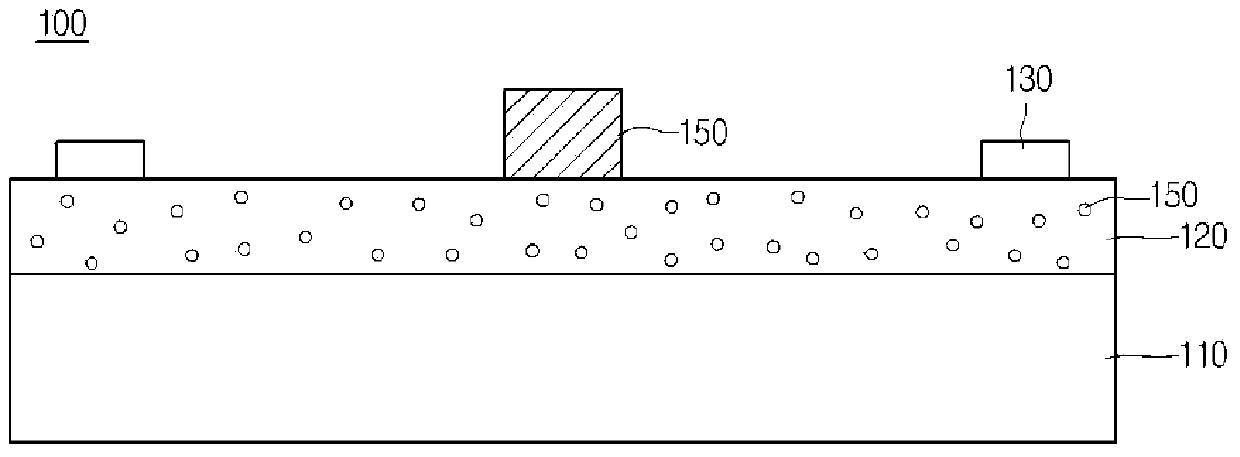

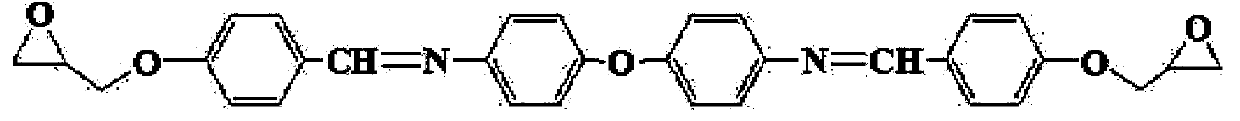

Epoxy resin compound and radiant heat circuit board using the same

ActiveCN103827205AImprove thermal conductivityImprove heat radiation abilityCircuit susbtrate materialsCooling/ventilation/heating modificationsEpoxyRadiant heat

Disclosed are an epoxy resin compound and a radiant heat circuit board using the same. The epoxy resin compound mainly includes an epoxy resin, a curing agent, and an inorganic filler. The epoxy resin includes a crystalline epoxy resin and a rubber additive to disperse the inorganic filler into the epoxy resin. The epoxy resin is used on a printed circuit board as an insulating material, so that a substrate having a high heat radiation property is provided.

Owner:LG INNOTEK CO LTD

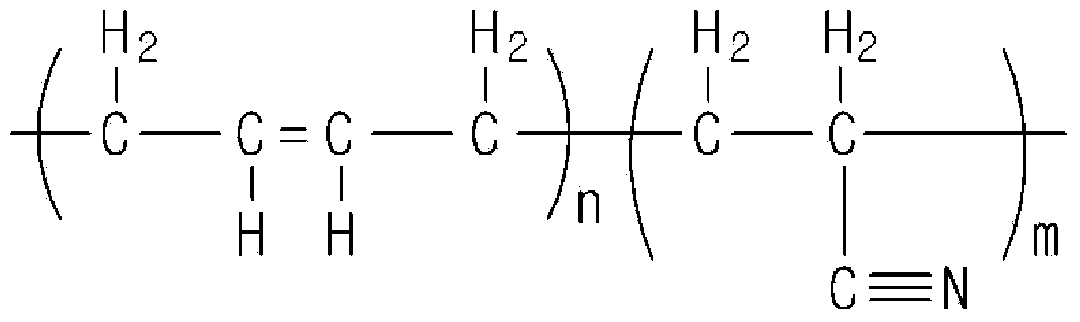

Composite and molded product thereof

InactiveCN103975023AReduce surface resistanceGood molding performanceShielding materialsFiberChemistry

A composite of the present invention comprises: (A) about 10-84 wt% of a thermoplastic resin; (B) about 5-35 wt% of a first filler; (C) about 1-20 wt% of a second filler; and (D) about 10-60 wt% of a third filler, wherein the third filler (D) is a conductive filler, and the melting points of the thermoplastic resin (A), the first filler (B) and the second filler (C) satisfy the following relation 1: [Relation 1] Tma-30 DEG C > Tmb, Tma+500 DEG C < Tmc (wherein, Tma is the melting point ( DEG C) of the thermoplastic resin (A), Tmb is the melting point ( DEG C) of the first filler (B), and Tmc is the melting point ( DEG C) of the second filler (C)).

Owner:CHEIL IND INC

Al-Zn-Mg-Cu series ultrahigh-strength aluminum alloy and preparation method thereof

The invention relates to an Al-Zn-Mg-Cu series ultrahigh-strength aluminum alloy which is prepared from the following components in percentage by mass: 10-12 percent of Zn, 2-3 percent of Mg, 0.5-1.5 percent of Cu, smaller than 0.2 percent of a total amount of Fe and Si, smaller than 0.2 percent of impurity and the balance of Al. A preparation method for the Al-Zn-Mg-Cu series ultrahigh-strength aluminum alloy comprises the following steps of step 1, adding industrial pure aluminum in a crucible resistance furnace for heating and complete melting according to the mass percentage, and then sequentially adding a Cu source, a Zn source and an Mg source until all the materials are thoroughly molten; step 2, performing stirring, refining with degassing and slag skimming; step 3, spraying a prepared metal liquid to a copper roller to prepare a strip; step 4, performing cold isostatic pressing on the strip obtained through rapid solidification to obtain a cold-pressed blank; step 5, performing hot extrusion on the cold-pressed blank to obtain an extruded rod; and step 6, finally, performing heat treatment on the extruded rod. By adopting the technical method provided by the invention, the process flow is simplified, the material utilization rate is high, and the Al-Zn-Mg-Cu series ultrahigh-strength aluminum alloy has high strength and shaping and has a good application prospect in the fields of aerospace, automobiles and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

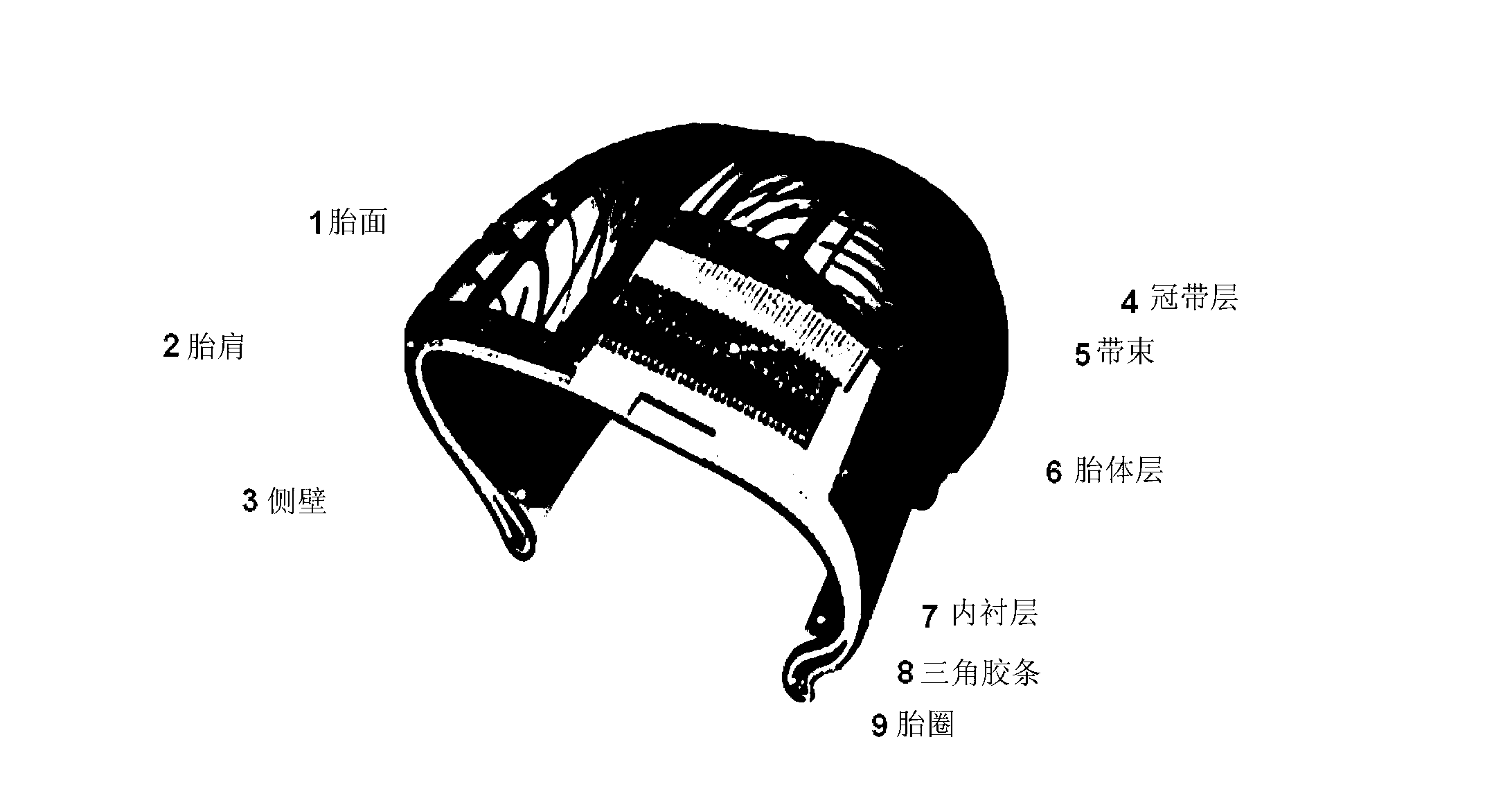

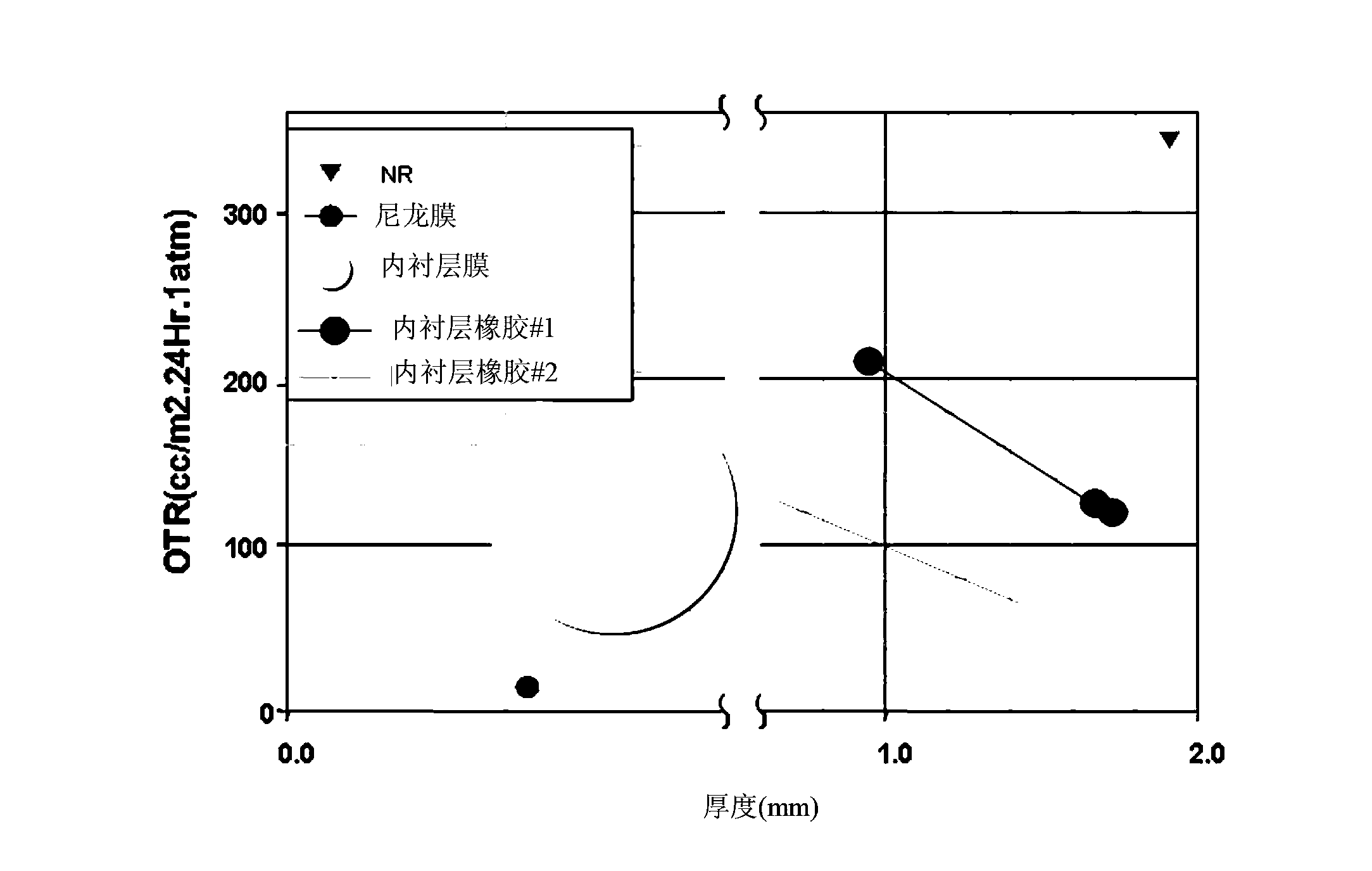

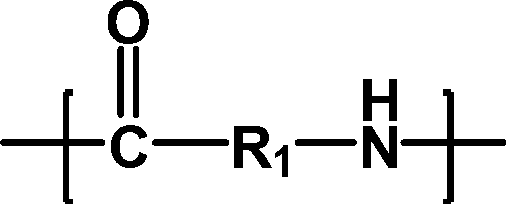

Film for a tyre inner liner and a production method therefor

ActiveCN102933643AImprove air tightnessImprove fuel efficiencyWithout separate inflatable insertsTyresPolymer sciencePolyamide

This invention relates to a film for a tire inner liner, which includes a copolymer including a polyamide-based segment and 5 / 50 wt% of a polyether-based segment relative to the total weight of the film, and has a thickness 30 / 300 [mu] m, and to a method of manufacturing the film for a tire inner liner, including polymerizing a polyamide-based resin or its precursor with 5 / 50 wt% of a polyether-based resin relative to the total weight of the film, thus preparing a copolymer, and melting and extruding the copolymer, thus forming a film.

Owner:KOLON IND INC

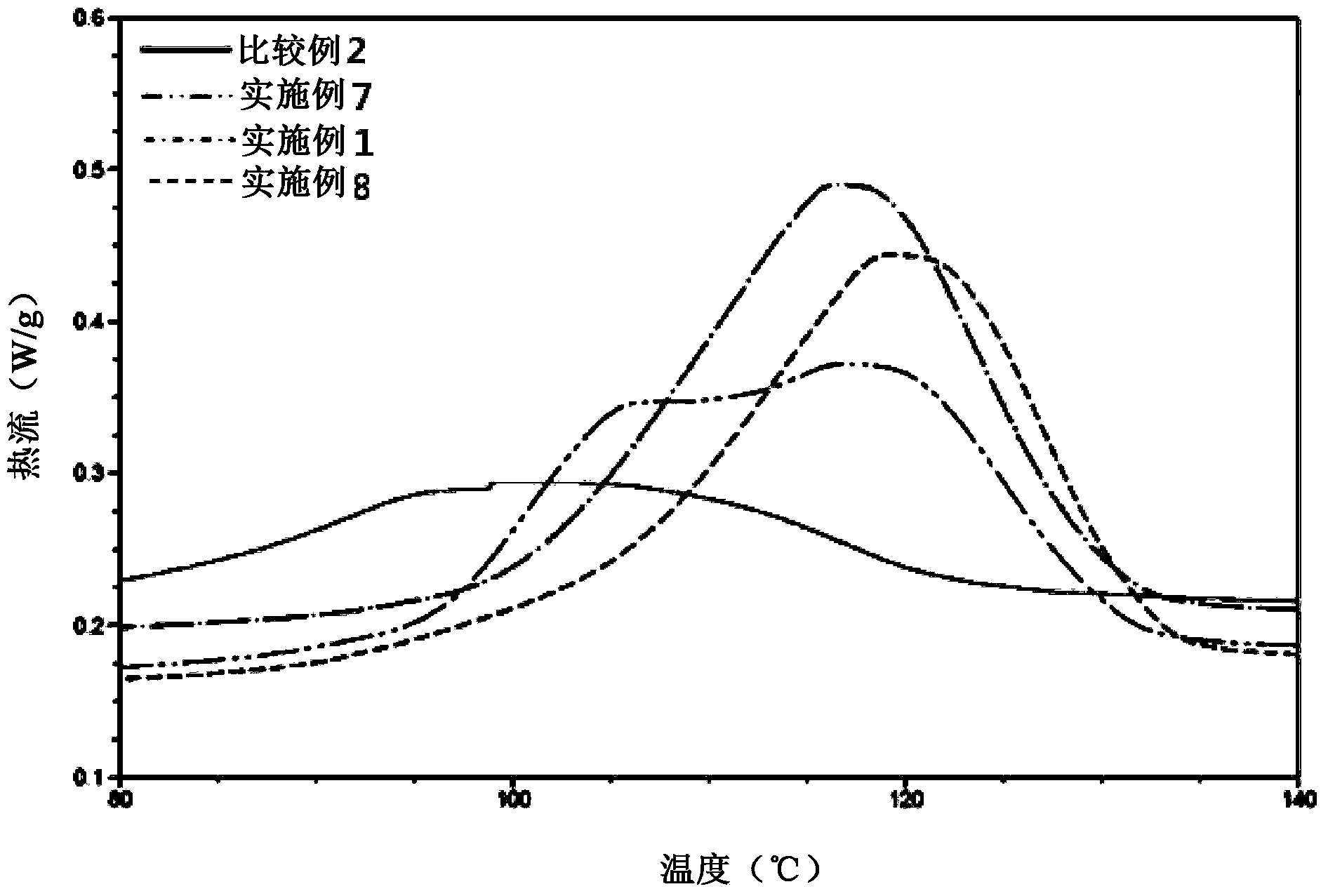

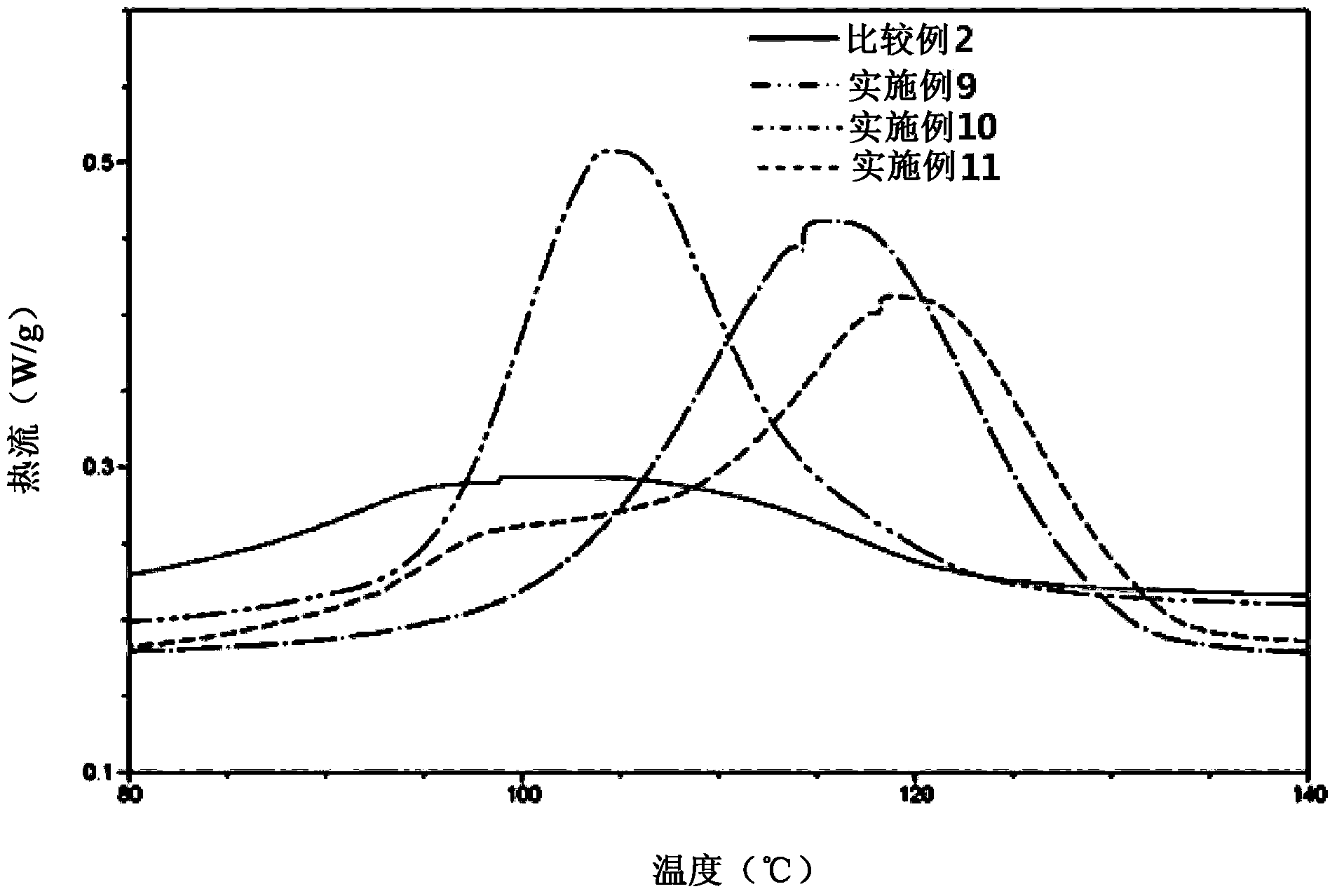

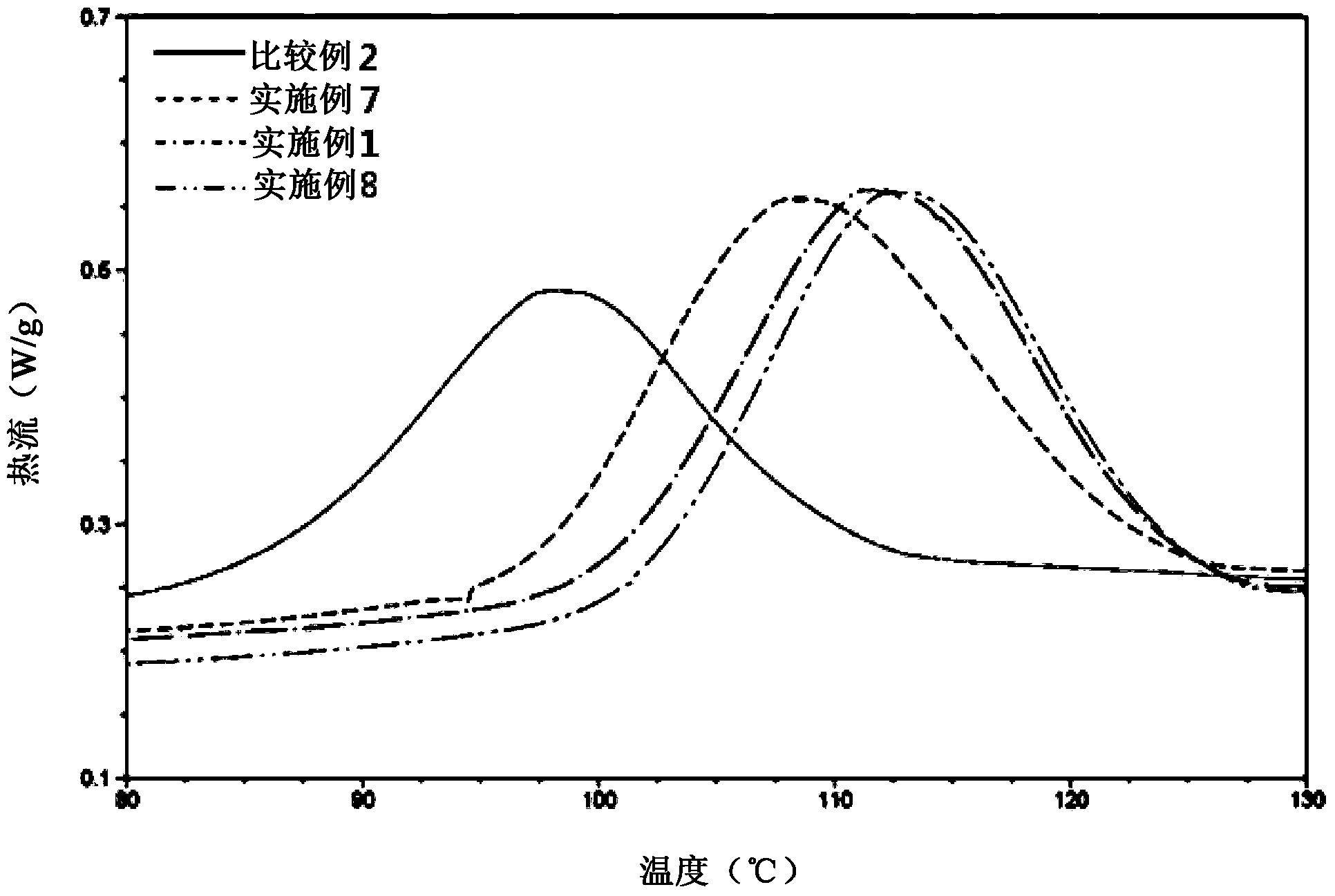

Polylactic acid stereocomplex resin composition having improved crystallization rate and method for molding the same

ActiveCN104231577AIncrease the rate of crystallizationHigh impact strengthHeat resistancePolymer chemistry

Owner:LOTTE CHEM CORP

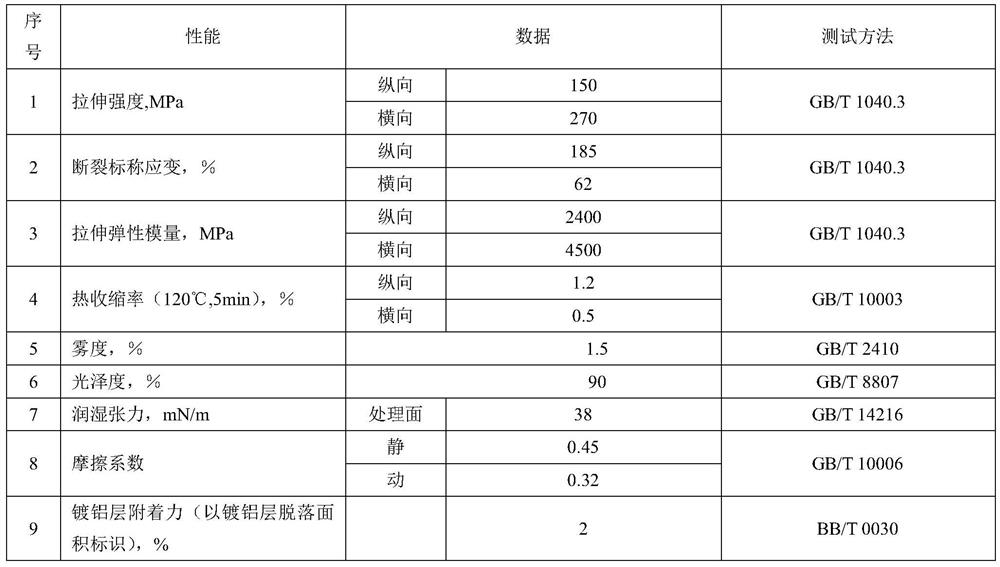

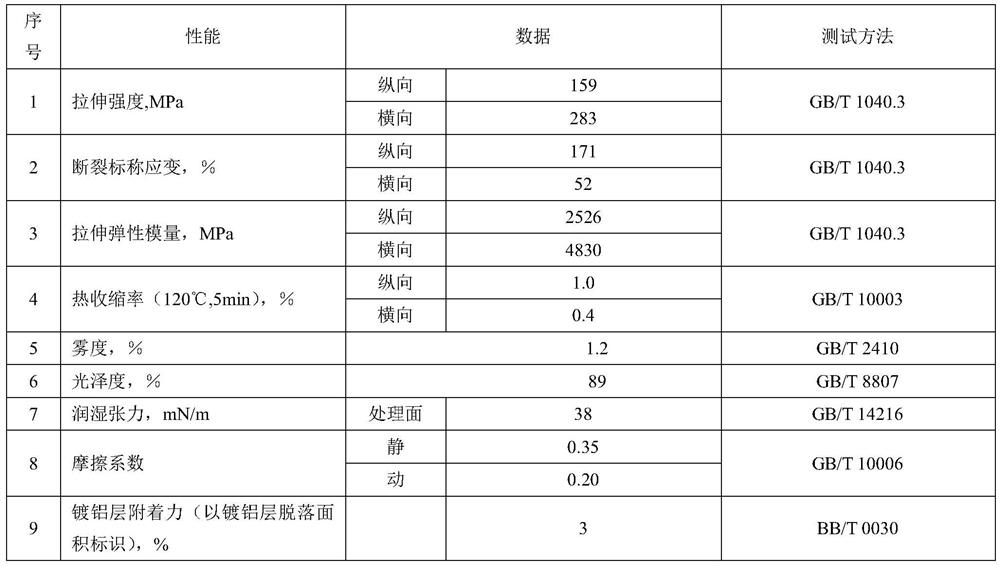

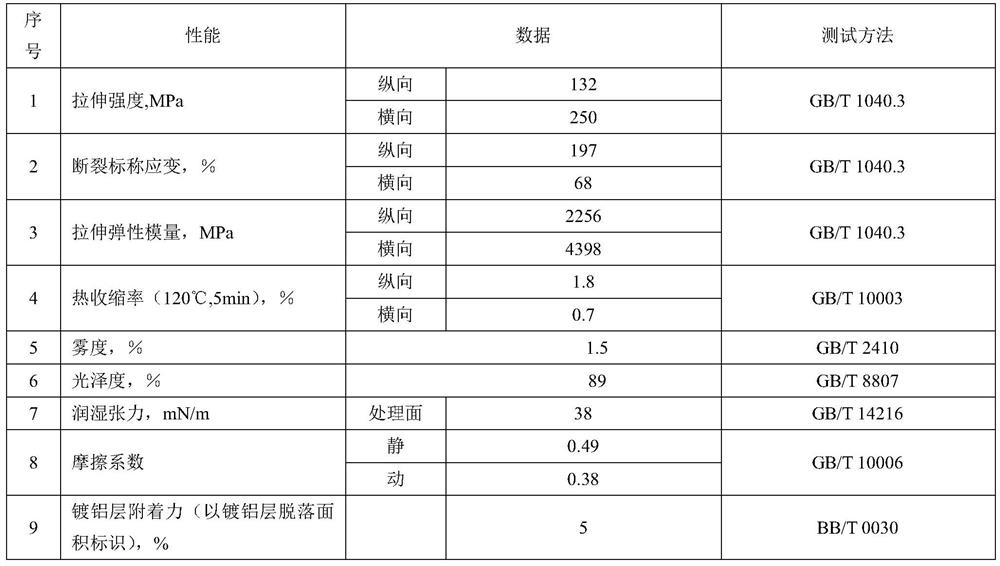

High-aluminizing-fastness BOPP base film for low-temperature laser mold pressing and preparation method thereof

ActiveCN111703159AGood molding performanceGood compatibilitySynthetic resin layered productsFlat articlesLow-density polyethylenePolypropylene

The invention discloses a high-aluminizing-fastness BOPP base film for low-temperature laser mould pressing, which consists of an outer surface layer, a middle layer and an inner surface layer, wherein the inner surface layer is a mould pressing layer and is prepared from the following raw materials in percentage by mass: 1 to 10 percent of anti-blocking master batch, 10 to 20 percent of maleic anhydride grafted modified polypropylene and the balance of modified mould pressing master batch; the modified mould pressing master batch is prepared by blending a propylene-butadiene-ethylene terpolymer, alpha-olefin and metallocene linear low-density polyethylene according to a mass ratio of (40-90) : (20-40) : (20-40). The invention also discloses a preparation method of the BOPP base film withhigh aluminizing fastness for low-temperature laser mould pressing. The BOPP base film disclosed by the invention can be used for mould pressing under a low-temperature condition of 80 DEG C, and thenlaser is carried out; the BOPP base film has the advantages of low mould pressing temperature, low thermal shrinkage rate, high aluminizing fastness, excellent physical properties, excellent opticalproperties and the like.

Owner:ANHUI GUOFENG PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com