Dark electrochemical aluminium foil with applicable thermoprinting scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

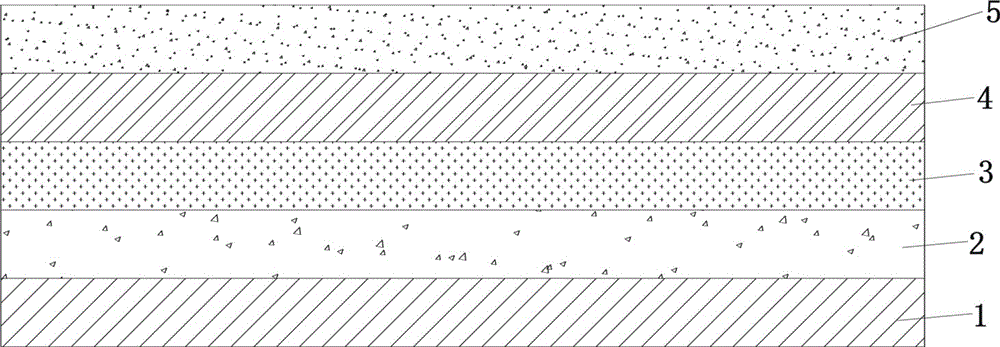

[0016] Fig. 1 shows the dark-colored anodized aluminum foil with wide ironing range without laser effect of the present invention, which includes PET base film 1, release layer 2, imaging layer 3, aluminum-coated layer 4 and adhesive layer 5 from bottom to top, Its preparation method is:

[0017] (1) On the PET base film, use a printing roller with a mesh number of 200 to evenly coat a release layer with a certain release force. The formula of the release layer is amide wax:toluene:butanone 1:64: 35, the wet coating amount is 5.5±0.5g / m 2 , the drying temperature is 140°C;

[0018] (2) On the release layer, use a printing roller with a mesh number of 180 to evenly coat an imaging layer that allows the aluminum layer to adhere. The formula of the imaging layer is aminoacrylic resin (Banggu PET-308-10) : methyl hydroxy modified acrylic resin (Banggu PET-888): nitrocellulose: butanone: butyl ester: color pink: color powder yellow = 16 : 13 : 5 : 37 : 24 : 4:1, the dry coating a...

Embodiment 2

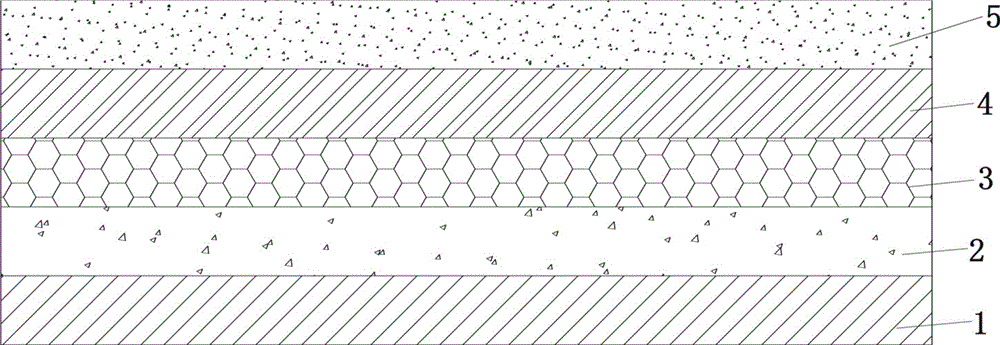

[0022] figure 2 Shown is the dark-colored anodized aluminum foil with laser effect and wide ironing range of the present invention, which includes PET base film 1, release layer 2, imaging layer (with embossed pattern) 3, aluminum coating layer 4 and Adhesive layer 5, its preparation method is:

[0023] (1) On the PET base film, a 200-mesh printing roller is used to evenly coat a release layer with a certain release force. The formula of the release layer is amide wax:toluene:butanone 0.8:66: 33.2, the wet coating amount is 5.5±0.5g / m 2 , the drying temperature is 140°C;

[0024] (2) On the release layer, use a printing roller with a mesh number of 180 to evenly coat an imaging layer that allows the aluminum layer to adhere. The formula of the imaging layer is aminoacrylic resin (Banggu PET-308-10) : methyl hydroxy modified acrylic resin (Banggu PET-888): nitrocellulose: butanone: butyl ester: color pink: color powder yellow = 15 : 13 : 5 : 37 : 25 : 4:1, the dry coating a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com