Polishing pad finisher used for wafer chemical-mechanical planarization equipment

A chemical machinery, polishing pad technology, used in metal processing equipment, grinding machine parts, grinding/polishing equipment, etc., can solve problems such as polishing pad aging, avoid corrosion, no cross-contamination, structure and control methods simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples are further detailed descriptions of the present invention.

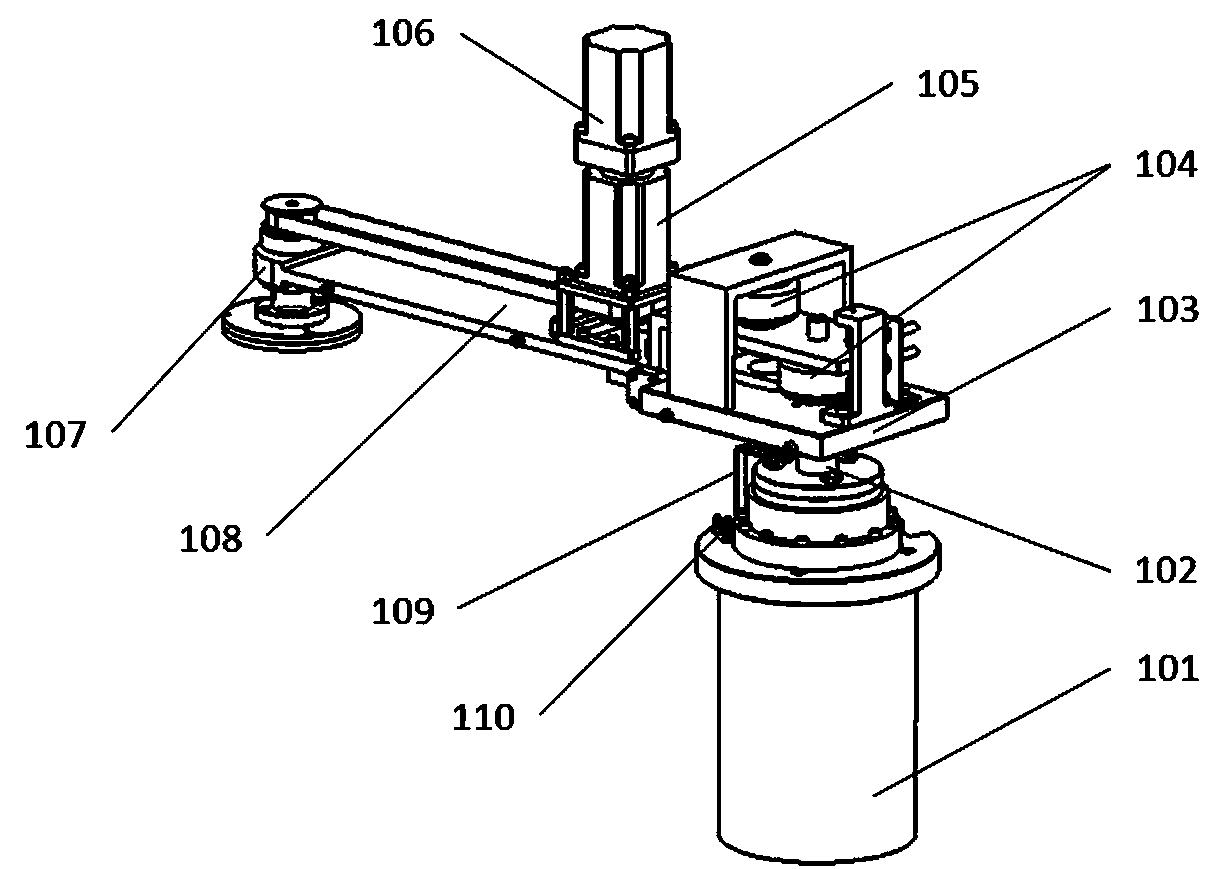

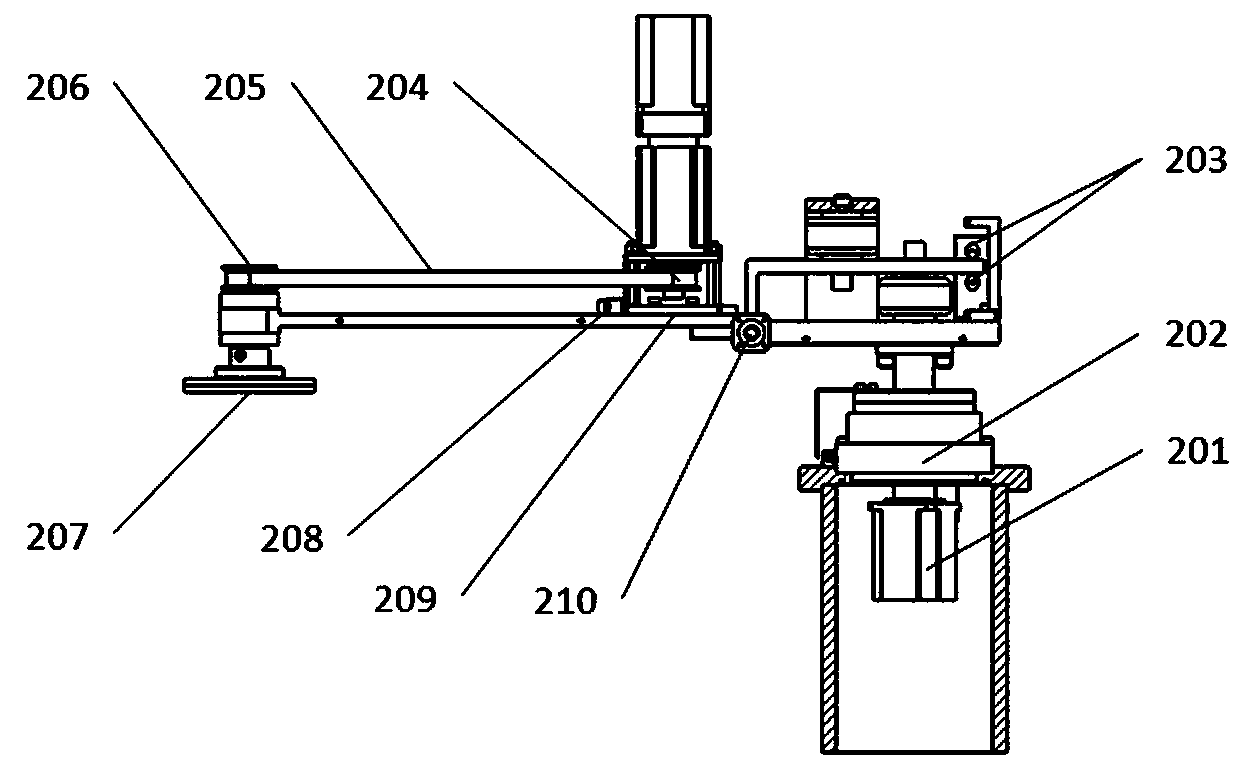

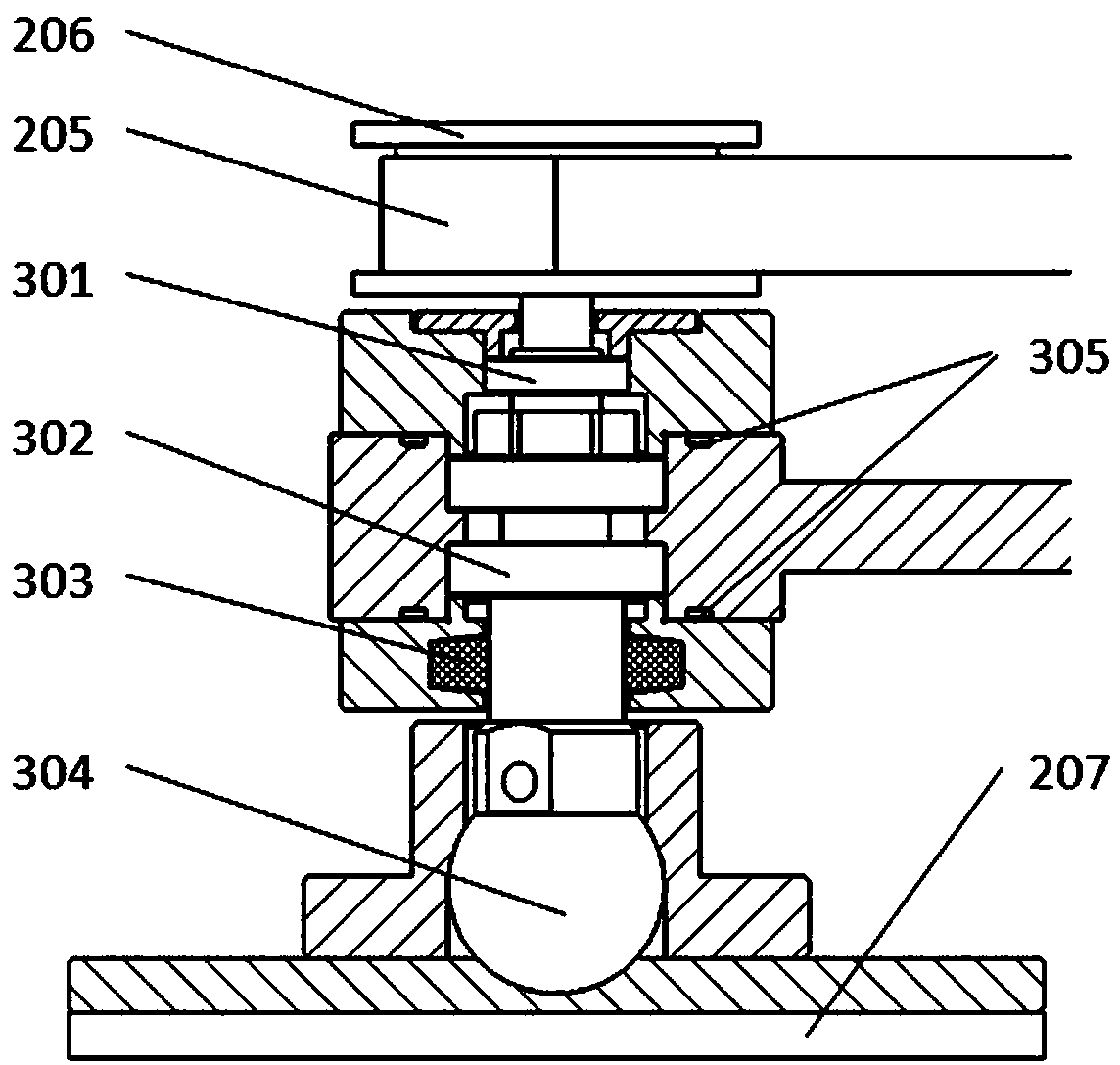

[0027] The structure and application method of the present invention will be described below in conjunction with the accompanying drawings. First, the upper end air bag 104 is inflated slowly, and the swing arm 108 is raised to a certain height through the lever mechanism, and under the action of the swing servo motor 201 and the swing reducer 202, the trimming head (ball head universal structure 107) is rotated from the edge of the polishing table to the center of the polishing table At this time, the rotary servo motor 106 and the rotary reducer 105 drive the dressing wheel (diamond wheel) 207 to rotate through the synchronous pulleys (204 and 206) and the synchronous belt (205), after which the upper airbag 104 is slowly deflated, and the lower airbag 104 is slowly inflated , so that the dressing diamond wheel 207 is pressed tightly on the polishing table (polishing pad) under the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com