Patents

Literature

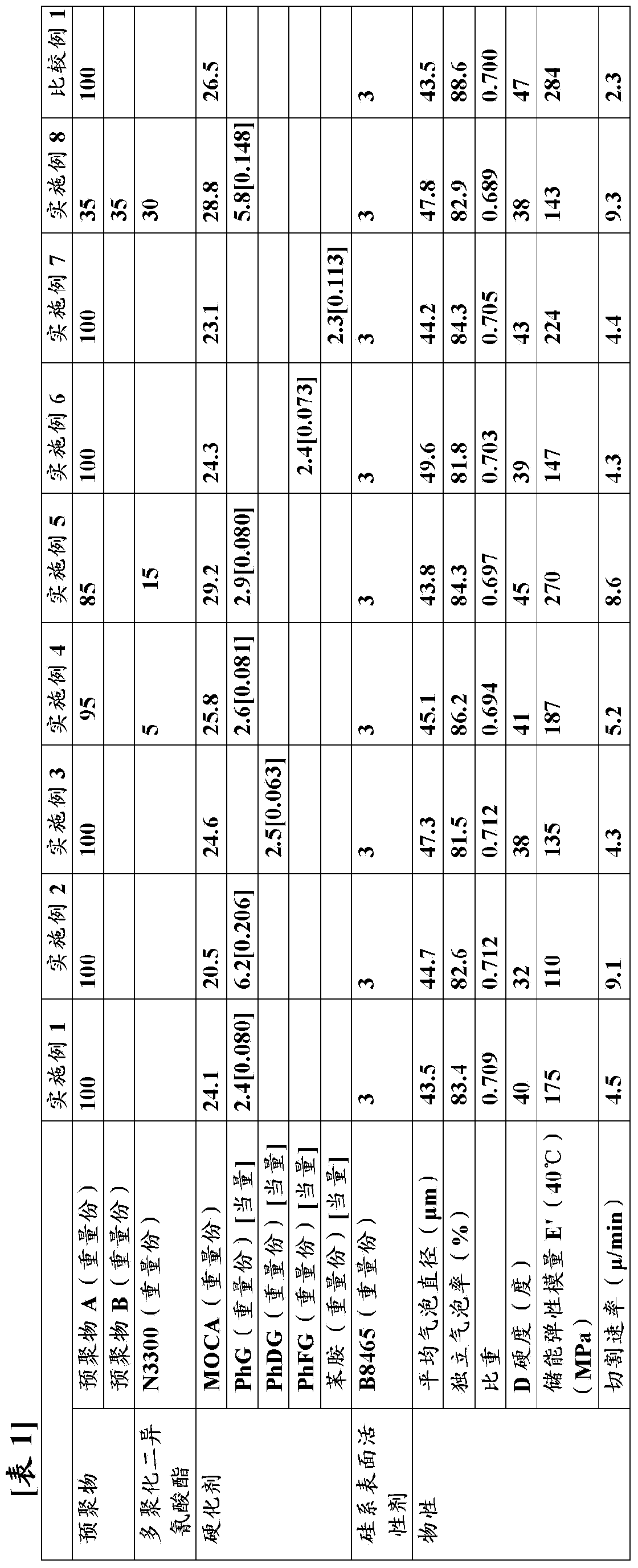

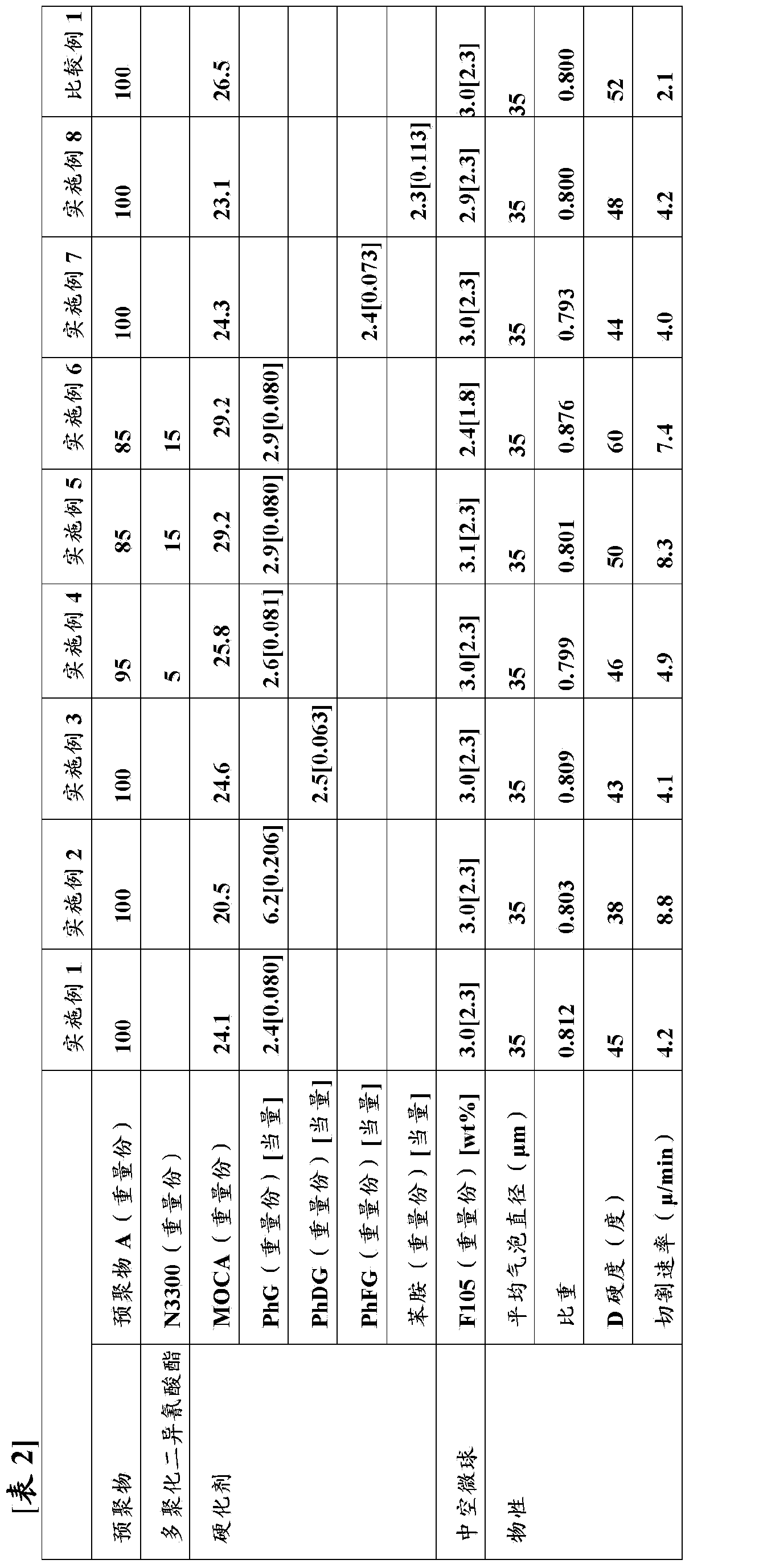

185results about How to "Improve trimming effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

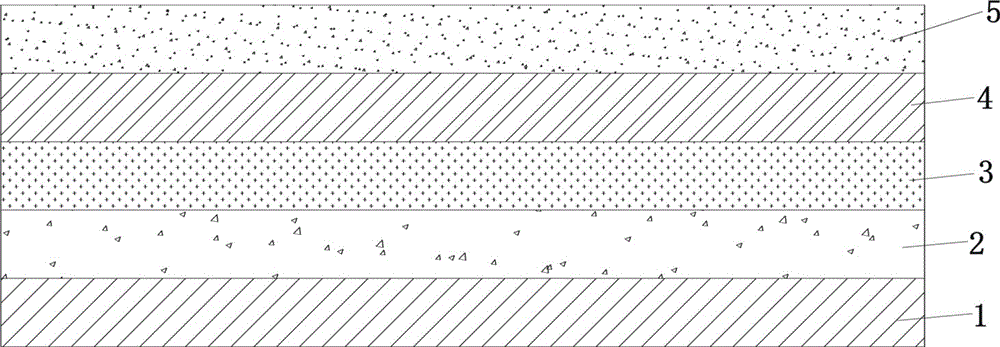

Hot stamping foil applied to overlapping hot stamping on gold stamping layer and preparation method of hot stamping foil

ActiveCN103465668AImprove trimming effectTransfer completelyDuplicating/marking methodsPolyurea/polyurethane coatingsHot stampingCellulose

The invention discloses a hot stamping foil applied to overlapping hot stamping on a gold stamping layer and a preparation method of the hot stamping foil. When overlapping hot stamping is carried out on an existing hot stamping foil, the defects that the transferring is incomplete, the hot stamping is not carried out on some portions due to omission, scumming is caused, powder falls off, and the edge of a hot stamping layer is not clear can happen. The hot stamping foil is composed of a base membrane layer, a release layer, a color coating layer, a vacuum aluminum coated layer and a gumming layer. The gumming layer is prepared by raw materials which comprise, by weight, 1-6 parts of chloroethylene-vinyl acetate resin, 1-10 parts of polyvinyl alcohol, 1-10 parts of acrylic ester, 1-5 parts of nitrocellulose, 1-5 parts of fumed silica, 20-70 parts of ethyl acetate, 10-50 parts of ethyl alcohol and 1-5 parts of propyl acetate. According to the hot stamping foil applied to the overlapping hot stamping on the gold stamping layer, the hot stamping foil has the good stamping performance and the good trimming performance, the overlapping hot stamping layer is complete in transferring, the edge is smooth and free of burrs, the adhesion is firm, the phenomena of dusting, powder falling and the like do not exist, the hot stamping effect is strong in third dimension, and the anti-fake performance is more outstanding.

Owner:云南玉溪东魅包装材料有限公司

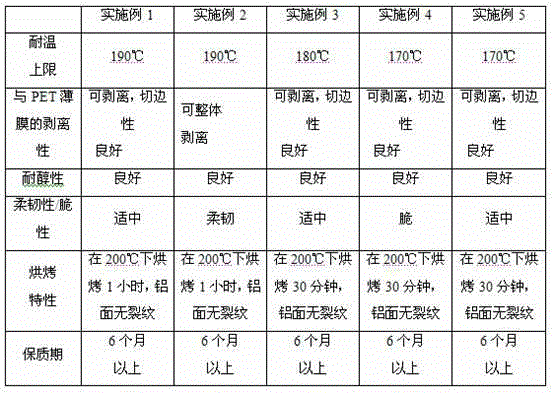

Water-based laser transfer coating for wine bottle glass baking paper, and preparation method thereof

The invention discloses a water-based laser transfer coating for wine bottle glass baking paper, and a preparation method thereof. The coating is prepared by mixing the following components in percentage by mass: 10-30% of water-based acrylic resin, 25-40% of water-based polyurethane resin, 0-8% of cosolvent, 20-45% of deionized water, 0-0.4% of water-based defoaming agent, 0.1-0.4% of base material wetting agent, and 0-0.2% of pH value regulating agent. The water-based laser transfer coating for the wine bottle glass baking paper is an environment-friendly laser transfer coating which meets national VOC detection standard by taking the water-based resin and deionized water as main raw materials. In addition, the composite water-based resin endows a curing film with good temperature resistance, aluminum adherence, strippability, alcohol resistance and the like, thus meeting the index requirement of the wine bottle glass baking paper.

Owner:三友(天津)高分子技术有限公司

Holographic laser cold-turning gold stamping transfer coating composition and preparation method thereof

The invention discloses a holographic laser cold-turning gold stamping transfer coating composition and a preparation method thereof. The coating composition comprises the components in parts by weight: 4-15 parts of polyacrylate resin, 2-8 parts of low molecular weight modified polyacrylate resin, 1-15 parts of cellulose ester resin, 0.1-0.5 part of auxiliary agent and 60-92 parts of solvent. The preparation method comprises the steps of: putting the solvent into a reaction kettle, stirring and evenly mixing; putting the polyacrylate resin, the low molecular weight modified polyacrylate resin and the cellulose ester resin into the reaction kettle, and stirring until the resins are completely dissolved; then, adding the auxiliary agent, and stirring until the mixture is evenly dispersed; and filtering to obtain the coating. Compared with the prior art, in the preparation method disclosed by the invention, the general polymethyl acrylic resin and the low molecular weight functional polyacrylate resin are utilized to be matched so that the cold-turning gold stamping coating with good transfer performance and excellent edge cutting performance can be obtained; the composition is low in production cost and good in printing adaptability, and can realize holographic anti-counterfeiting information transfer; and the product not only has appearance with bright colors, but also has high-end anti-counterfeiting function.

Owner:SHANGHAI WEIKAI CHEM +1

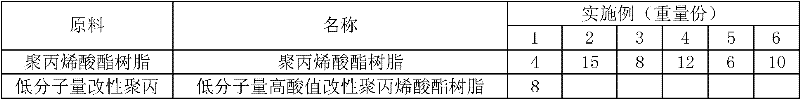

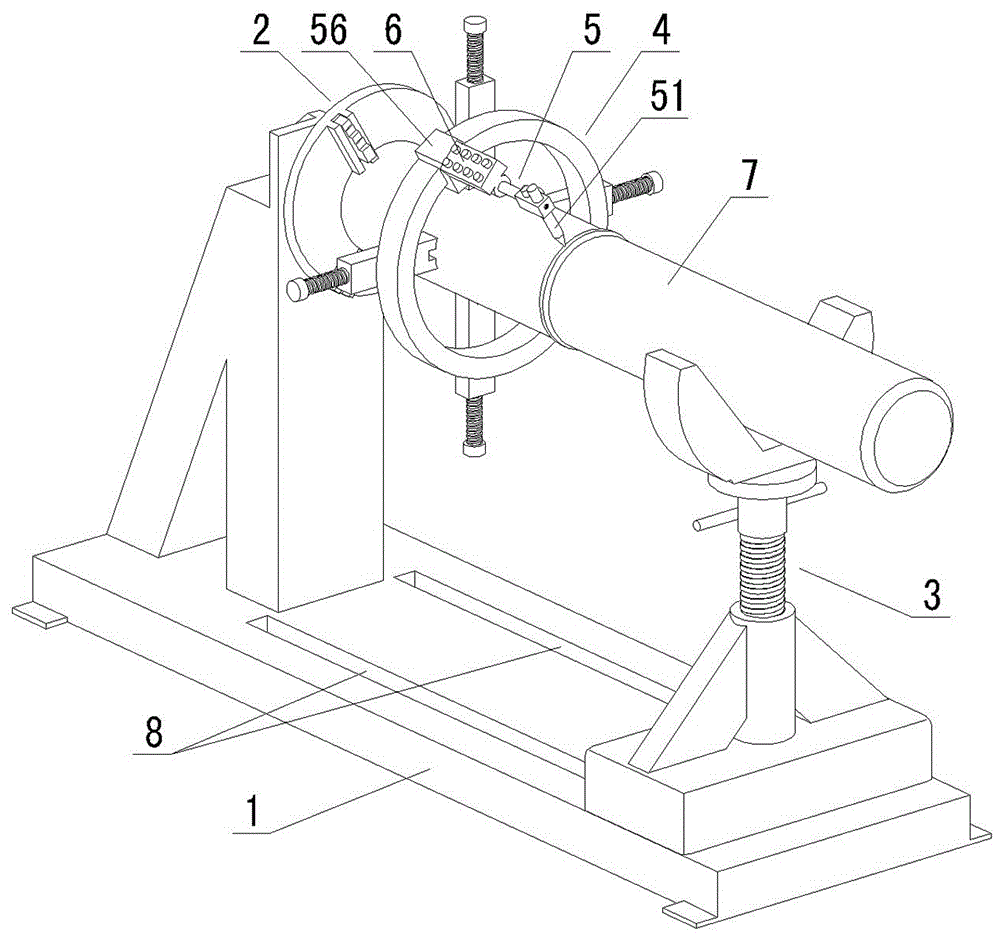

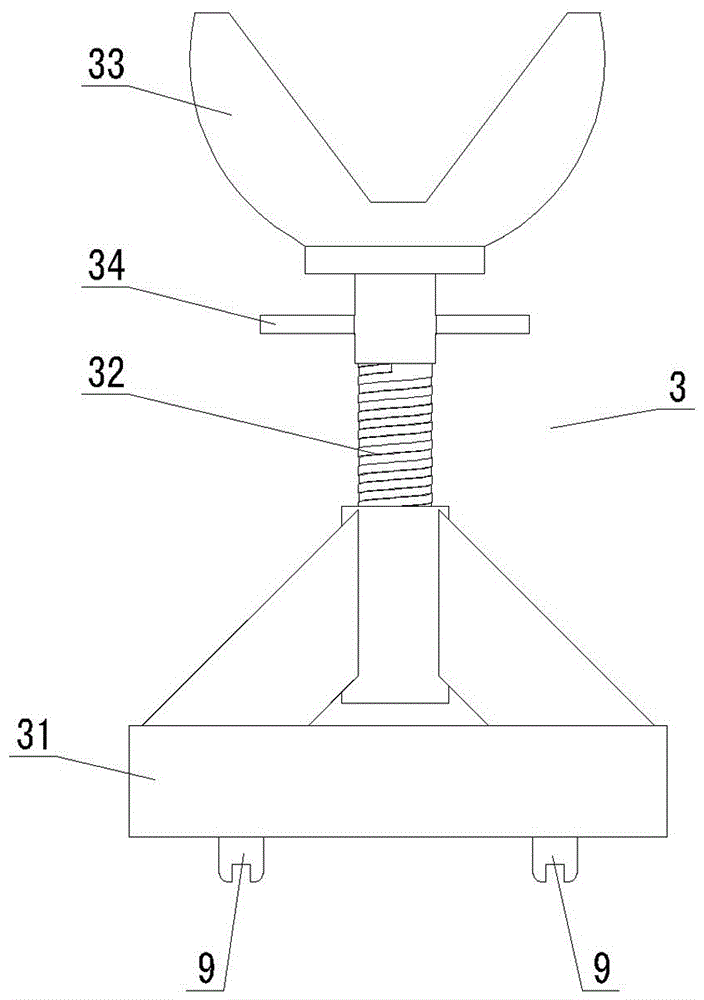

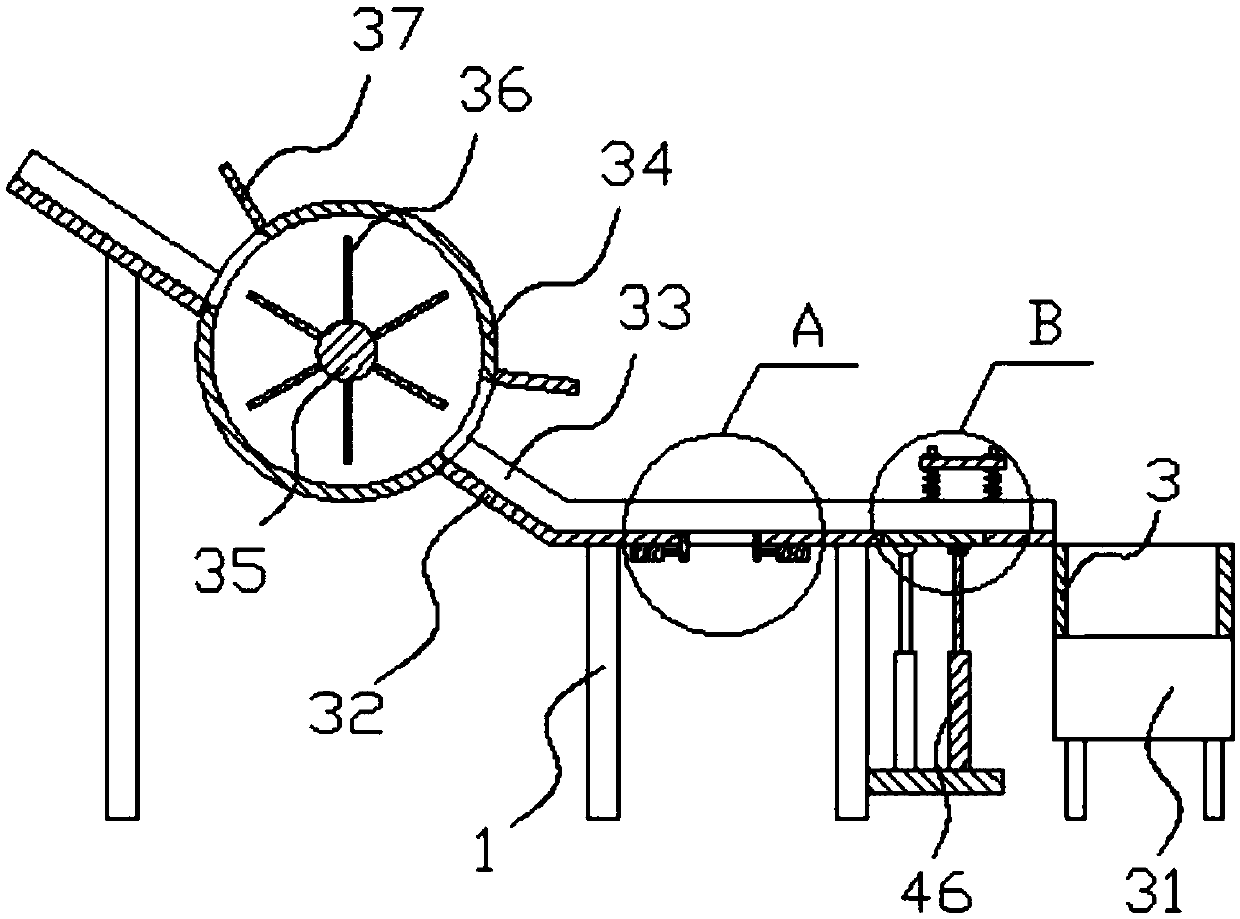

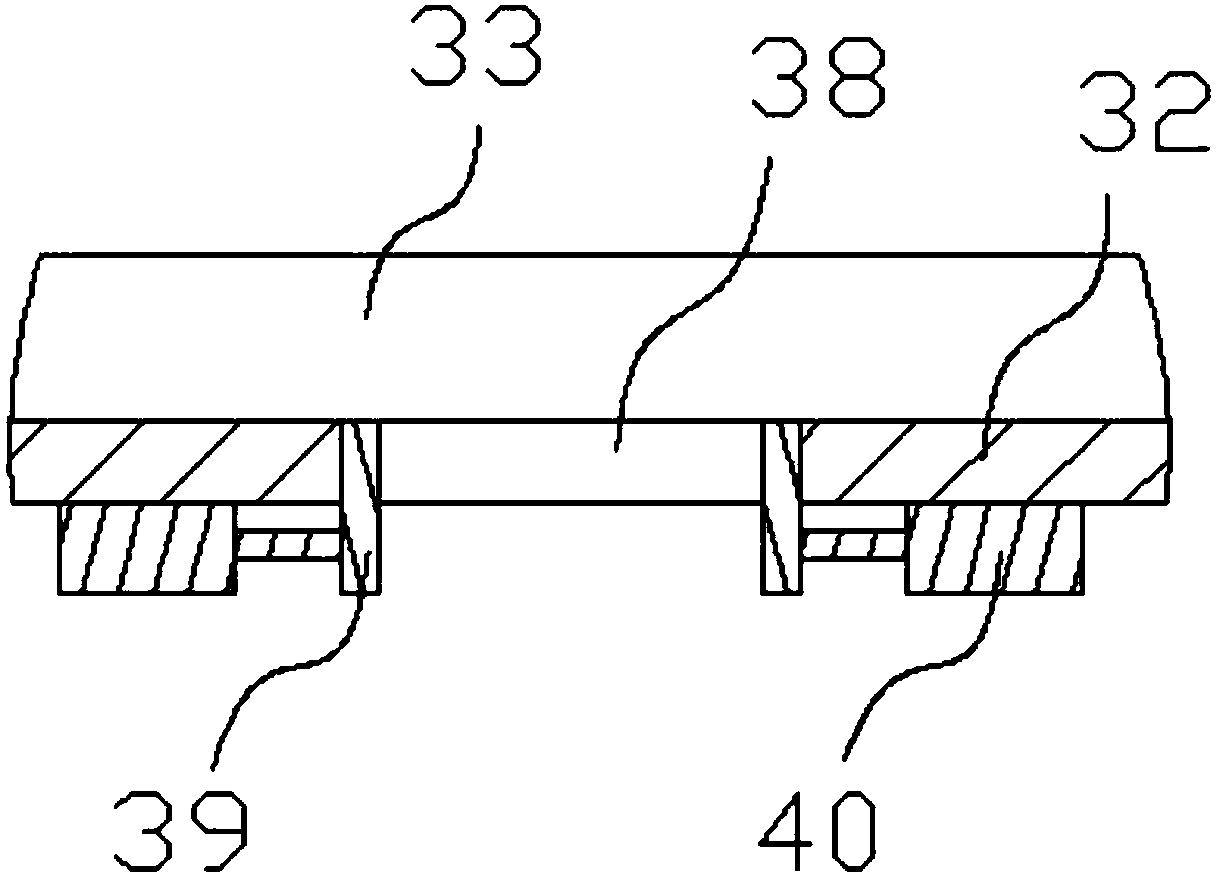

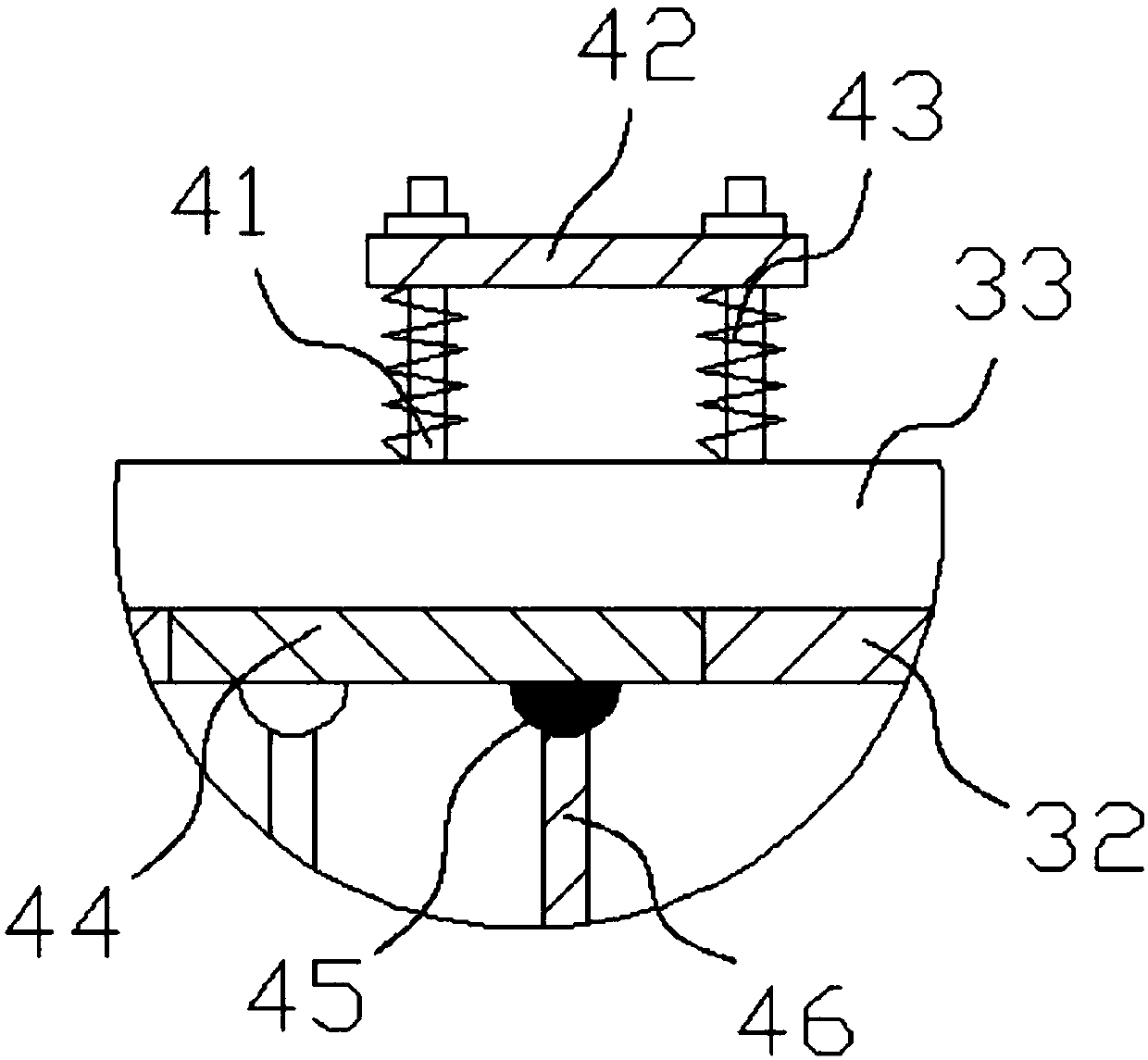

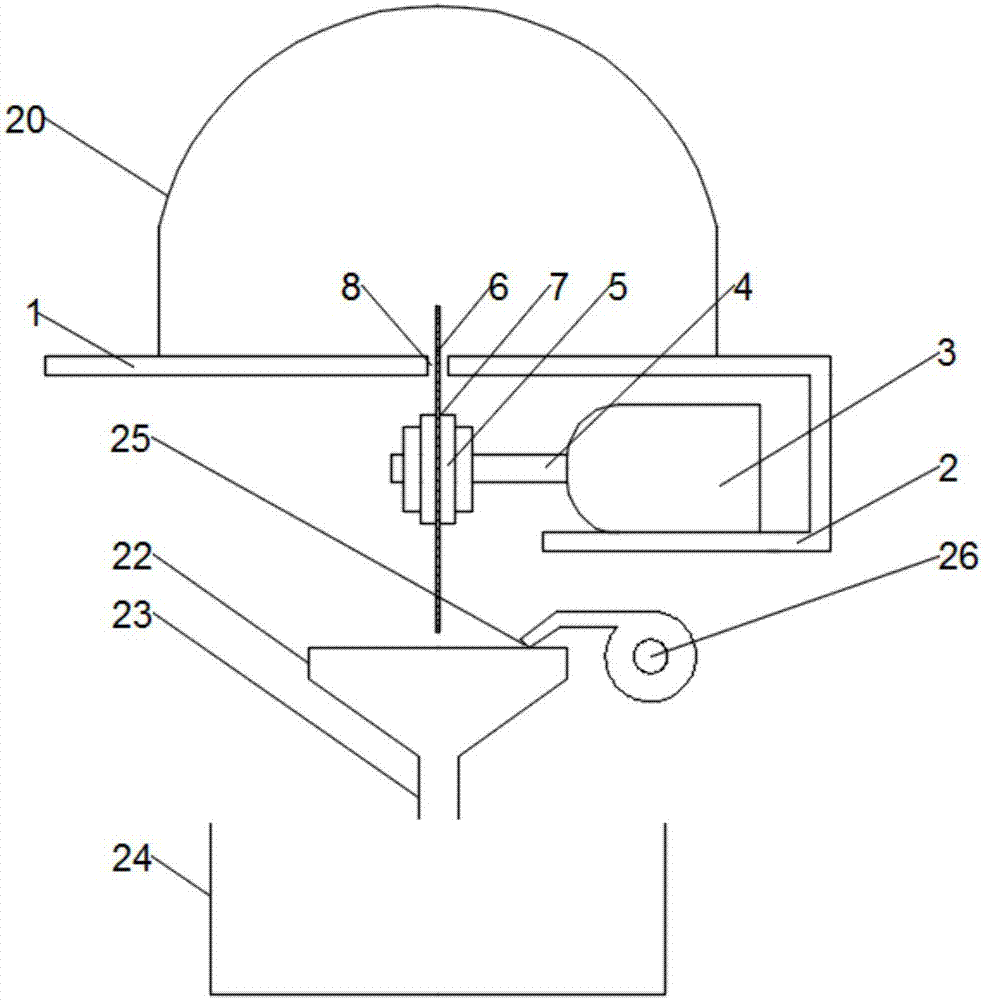

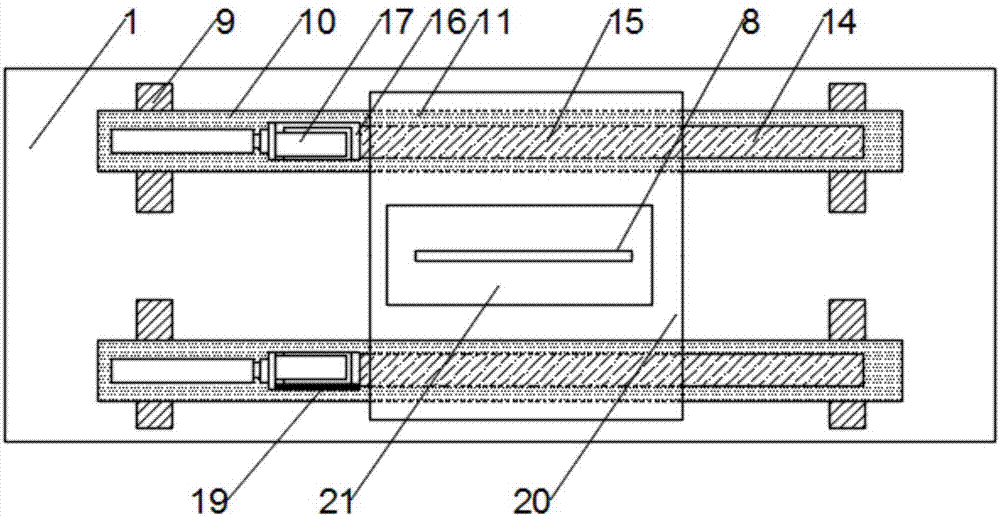

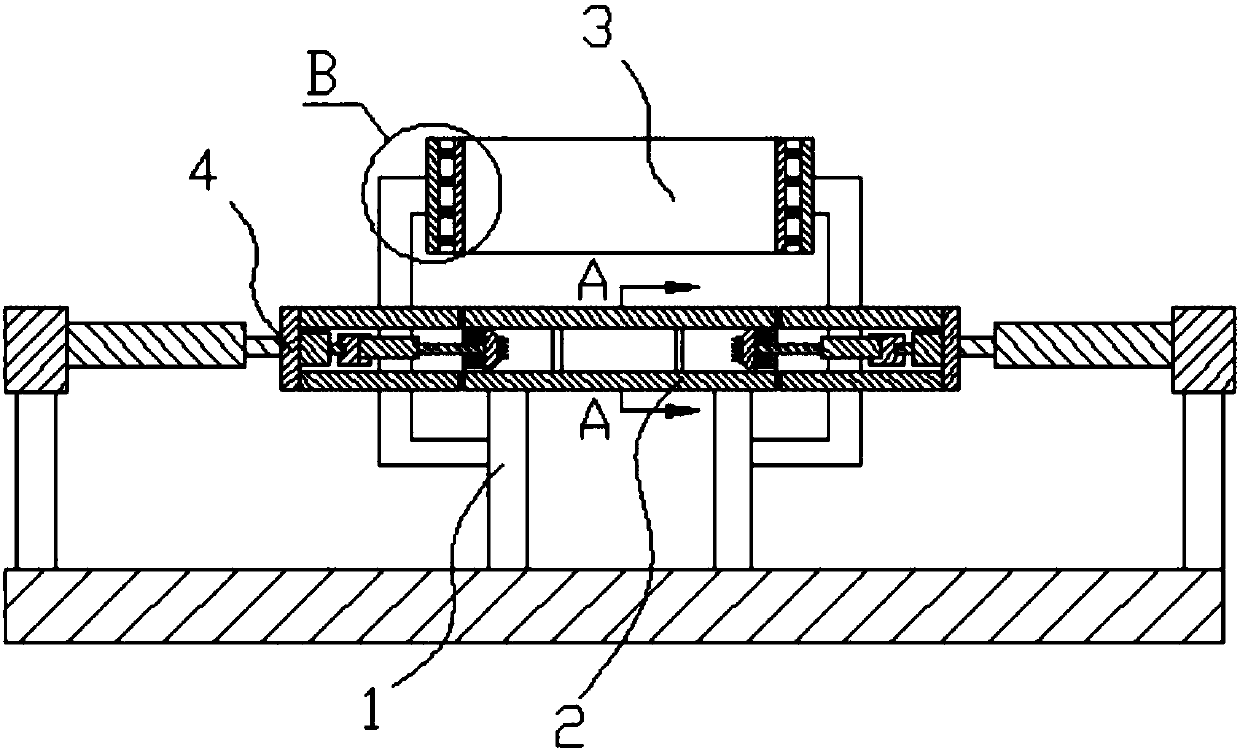

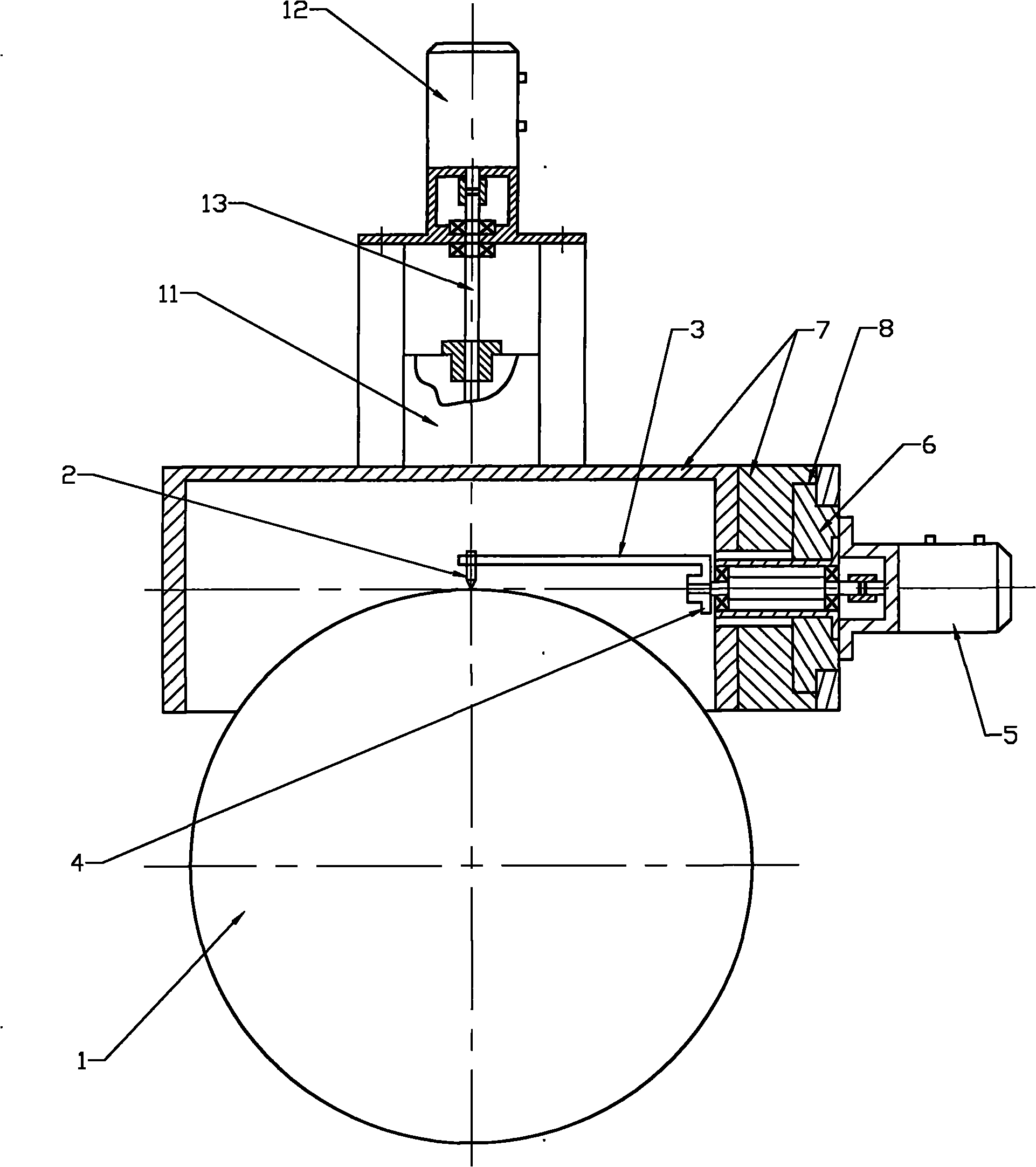

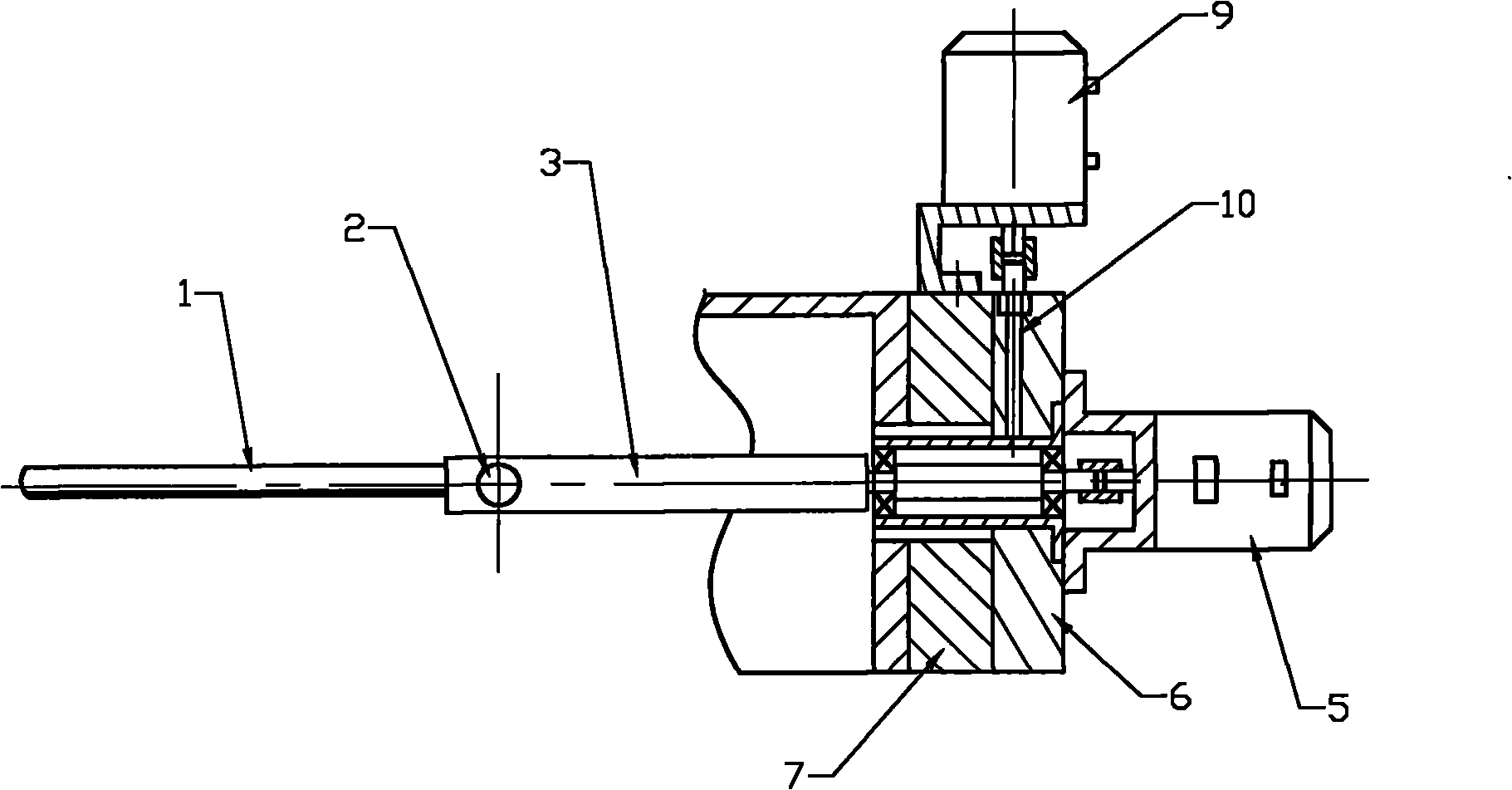

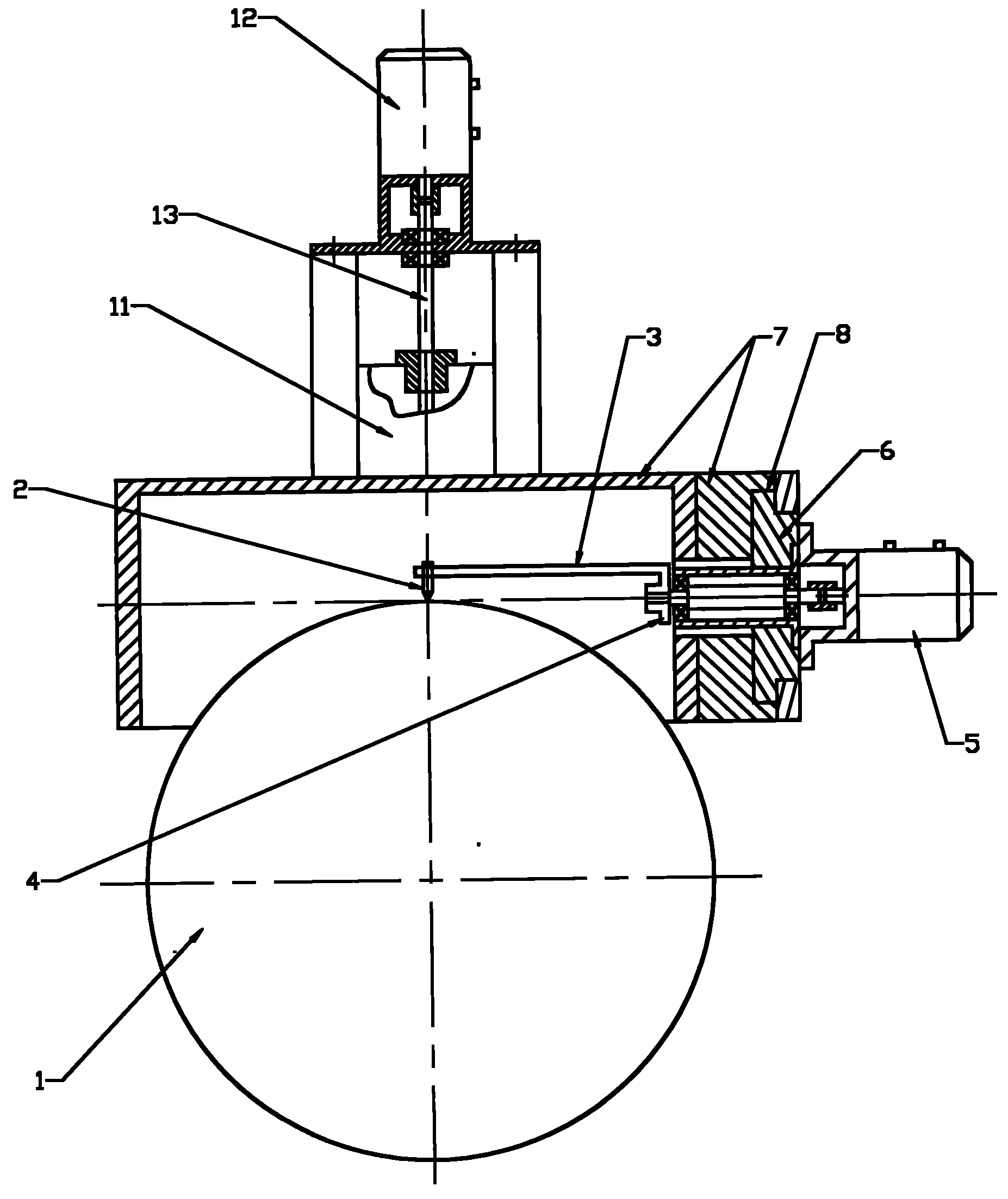

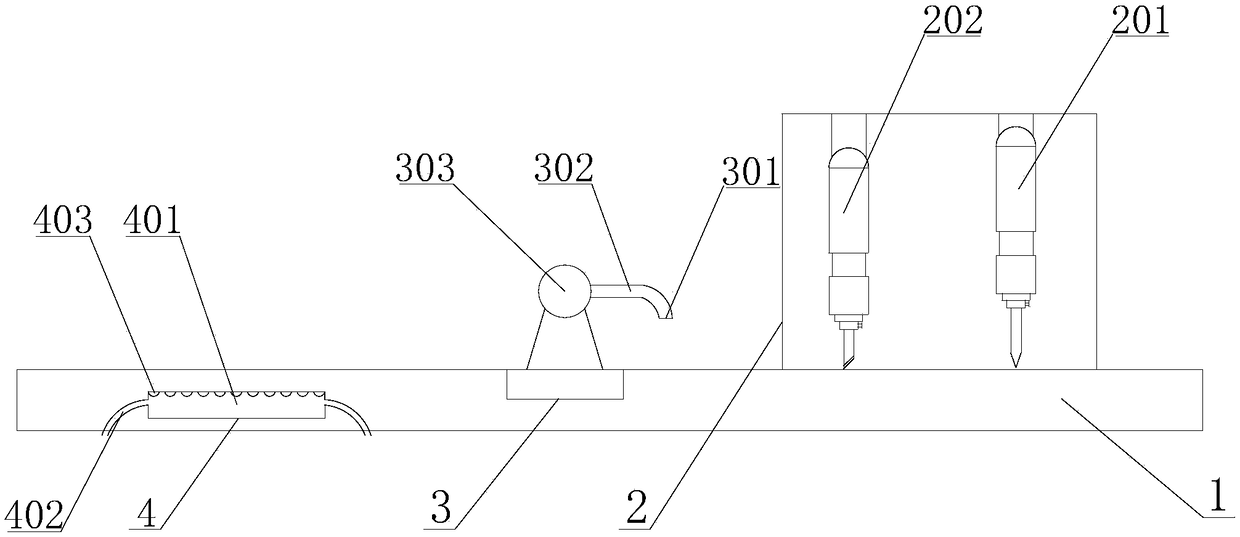

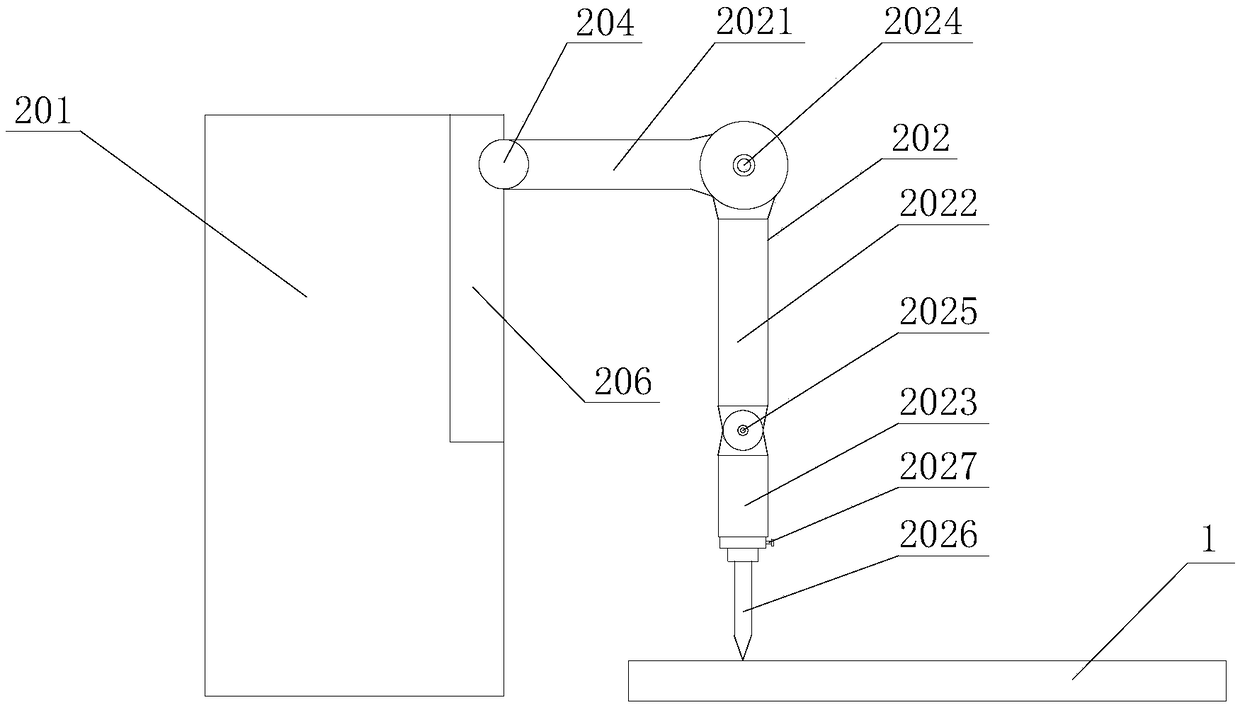

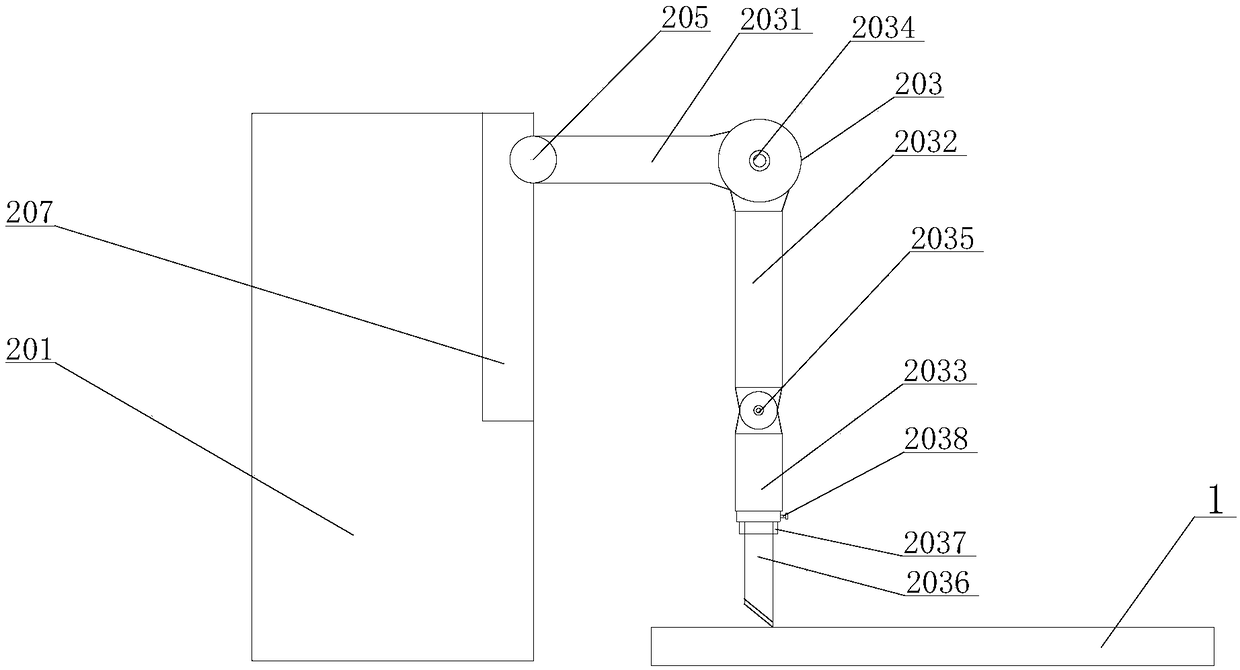

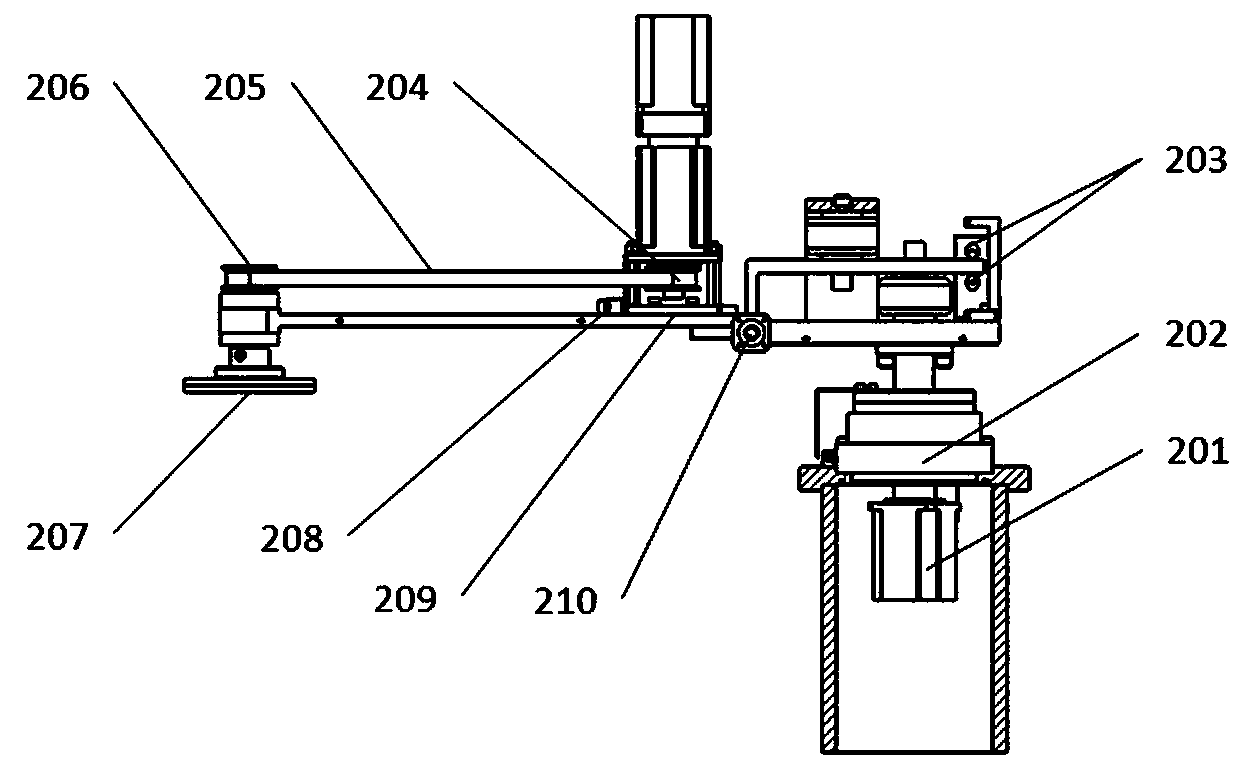

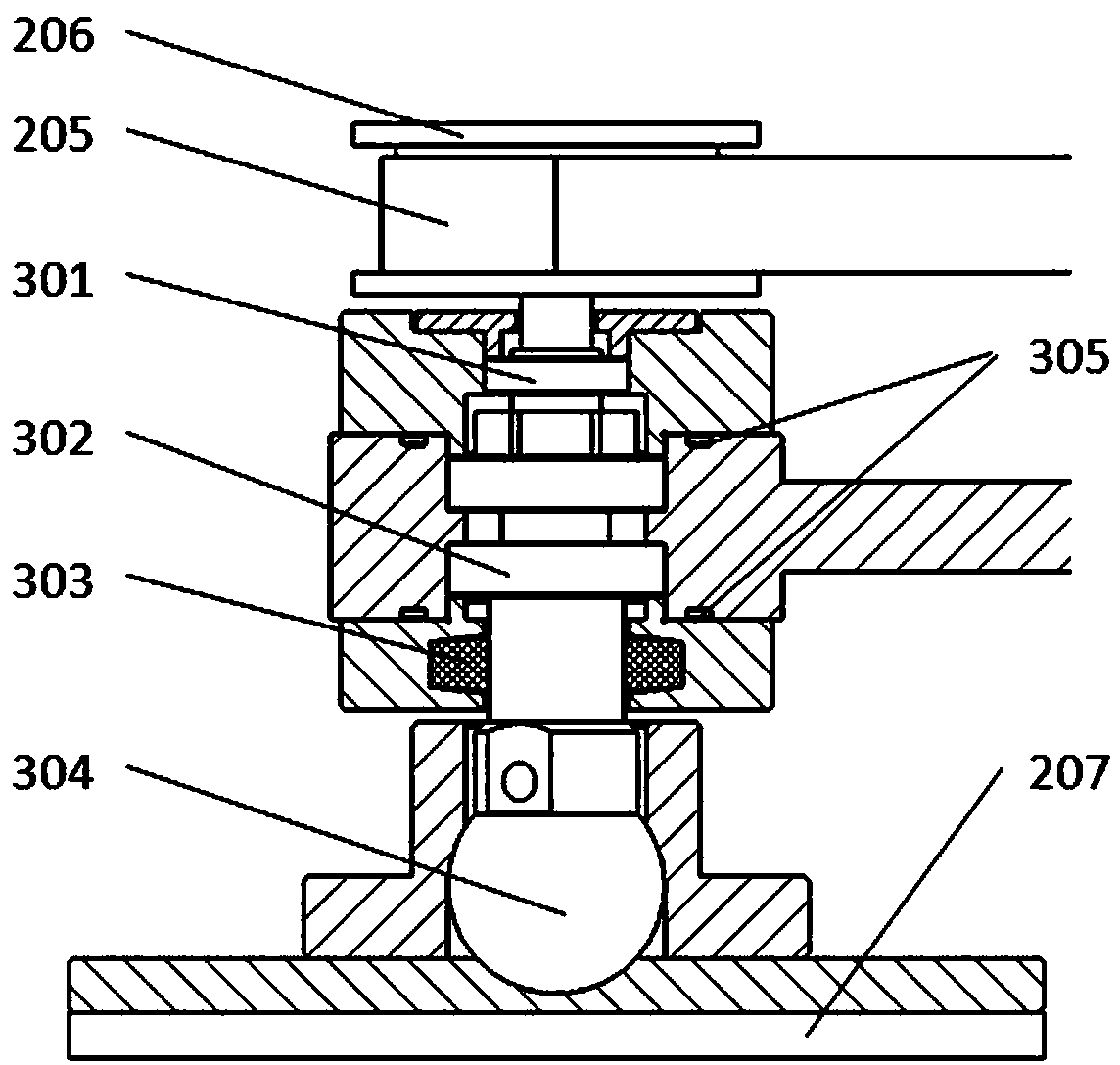

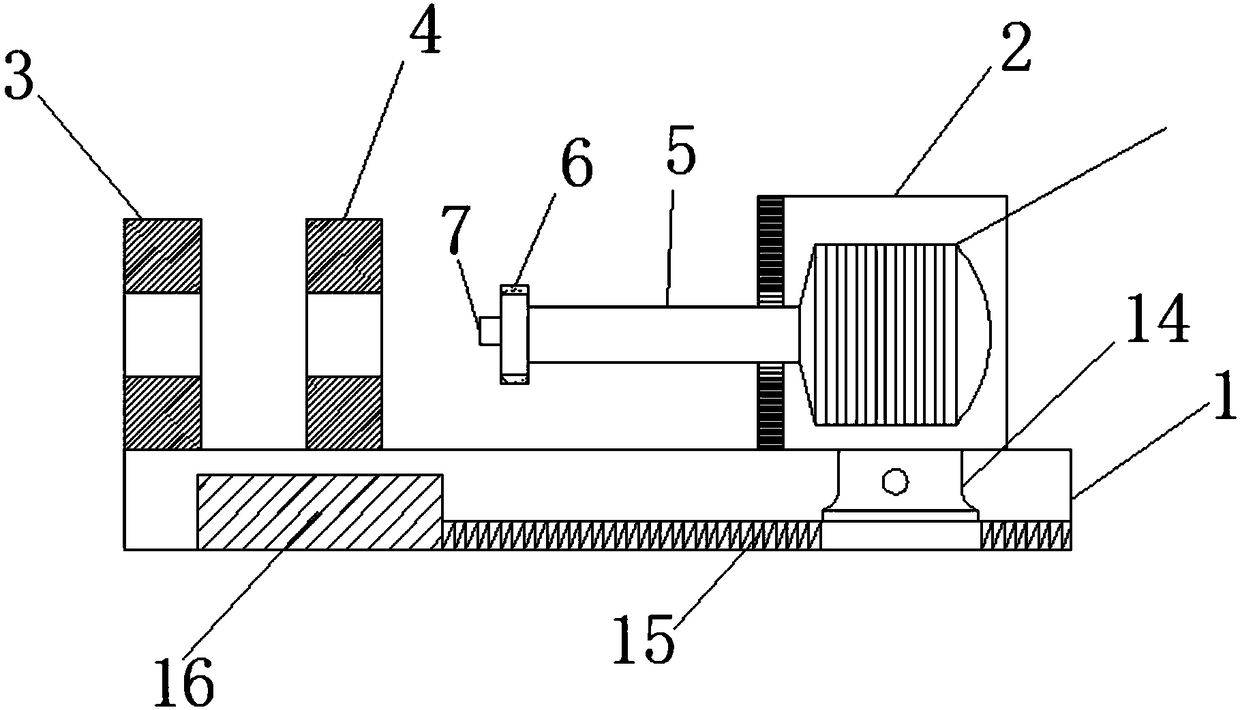

Rotary type plasma removing system for flash butt welding seam burrs outside pipes

InactiveCN105798442AGood equipment flexibilityAdaptableWelding/cutting auxillary devicesAuxillary welding devicesWeld seamPipe support

A rotary type plasma removing system for flash butt welding seam burrs outside pipes comprises a base, a pipe clamping mechanism, a pipe supporting frame, an annular track mechanism, a plasma gouging torch mechanism and a control system. The plasma gouging torch mechanism is connected to the annular track mechanism and can conduct circular motion along the annular track mechanism to be used for plasma removing of welding seam burrs and heat treatment of welding seams. The system is good in flexibility, the same system can be adopted for conducting welding seam burr removing and heat treatment on welding seams outside pipes of different diameters, the welding seam burr removing effect is good, heat treatment can be carried out on welding seams while burrs are removed, the structural constituent and mechanical property of welding seams can be improved remarkably, and the service life of welding seams is prolonged. In addition, the system is compact in structure, can realize overall miniaturization easily, has a wide application range, and can be used for conducting welding seam burr removing and welding seam heat treatment on metal pipes which have the diameters of 200 mm-400 mm and are made from different materials.

Owner:GUANGDONG PROVINCIAL INST OF WELDING TECH GUANGDONG PROVINCIAL ACADEMY OF UKRAINE

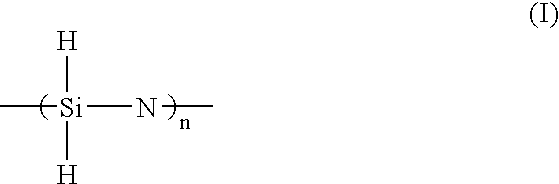

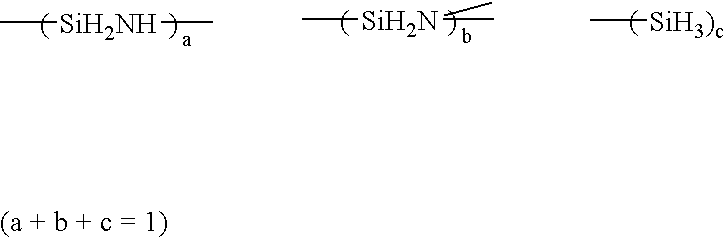

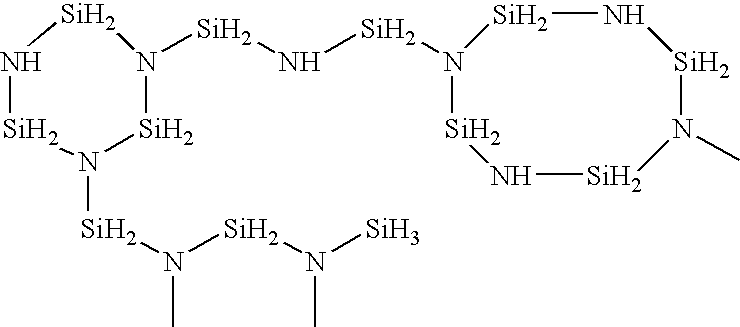

Solvent for treating polysilazane and method of treating polysilazane with the solvent

InactiveUS20050027089A1Excellent propertyImprove trimming effectSemiconductor/solid-state device manufacturingDetergent compounding agentsAlkaneNonane

Polysilazane is treated with a single or mixed solvent comprising one or more members selected from the group consisting of xylene, anisole, decalin, cyclohexane, cyclohexene, methylcyclohexane, ethylcyclohexane, limonene, hexane, octane, nonane, decane, a C8-C11 alkane mixture, a C8-C11 aromatic hydrocarbon mixture, an aliphatic / alicyclic hydrocarbon mixture containing 5 to 25% by weight of C8 or more aromatic hydrocarbons, and dibutyl ether, wherein the number of 0.5 micron or more fine particles contained in 1 ml of the solvent is 50 or less. As the treatment of polysilazane, there are illustrated, for example, edge-rinsing and back rinsing of a polysilazane film formed by spin coating polysilazane on a semiconductor substrate. The water content of the solvent is preferably 100 ppm or less.

Owner:MERCK PATENT GMBH

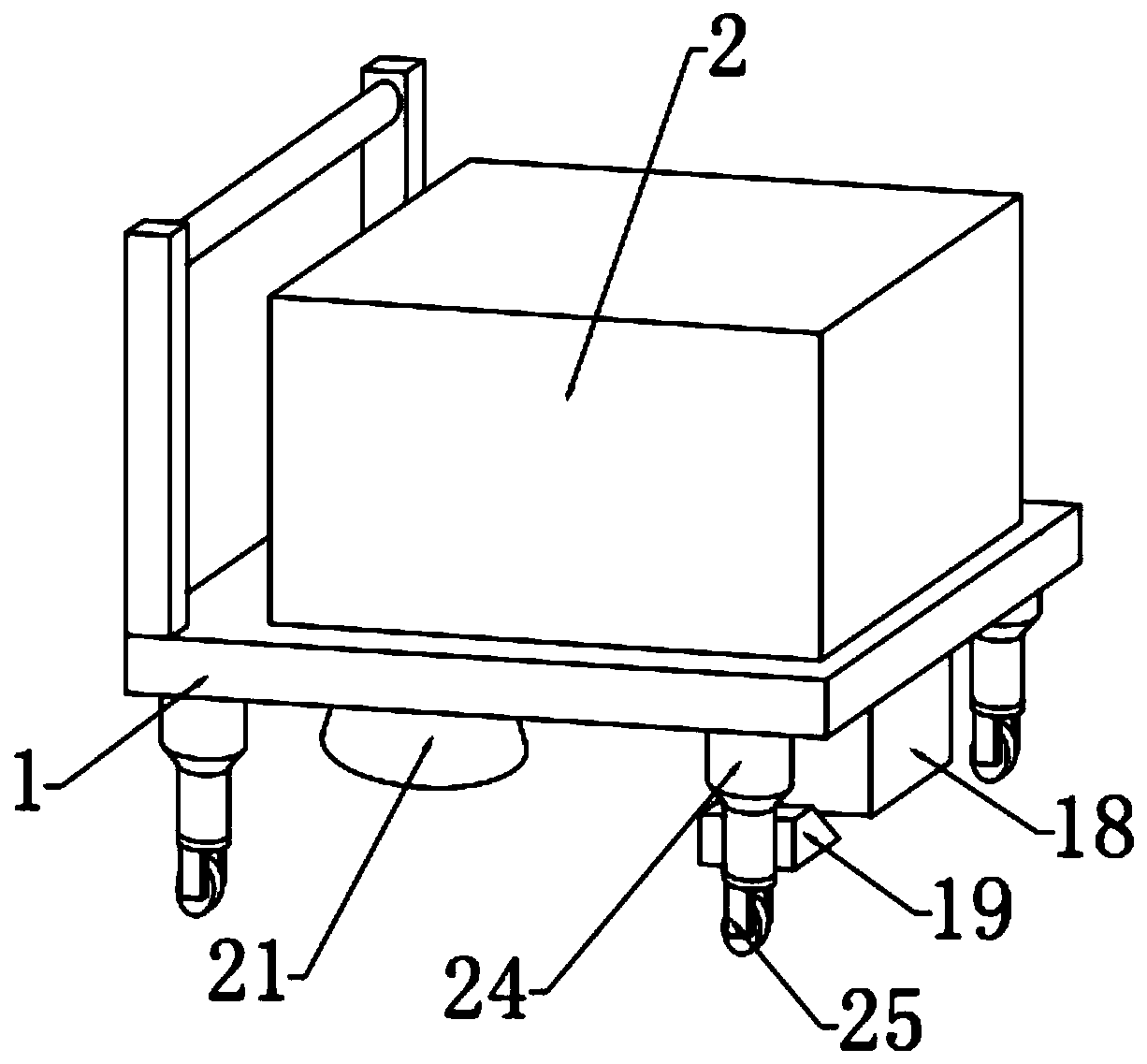

Bamboo splitting machine capable of automatically screening bamboo barrel specification

InactiveCN107803344AGuaranteed accuracyImprove efficiencyWood splittingIrregularity removal devicesHinge angleEngineering

The invention relates to a bamboo breaking machine capable of automatically screening bamboo tube specifications, comprising a frame, a screening device, a bamboo tube blanking device and a bamboo breaking mechanism. The screening device includes a screening conveying plate and a conveying guard plate. The horizontal part of the screening conveying plate is provided with a screening slot and a feeding slot for defective products. The feeding slot for defective products is equipped with a lifting block for feeding defective products. The lower part of the unloading lifting block is provided with a triangular distribution of defective product blanking hinge seats, and the defective product blanking hinge seat is hingedly matched with the cylinder push rod of the defective product blanking lifting cylinder; the present invention adopts a screening groove to match a screening intercepting block Realize a bamboo tube screening with a diameter specification, which can intercept oval and bent bamboo tubes, and set a lowering block for defective products under the screening block to remove the intercepted defective products, ensure the accuracy of screening, and improve the screening and conveying. s efficiency.

Owner:DONGGUAN UNIV OF TECH

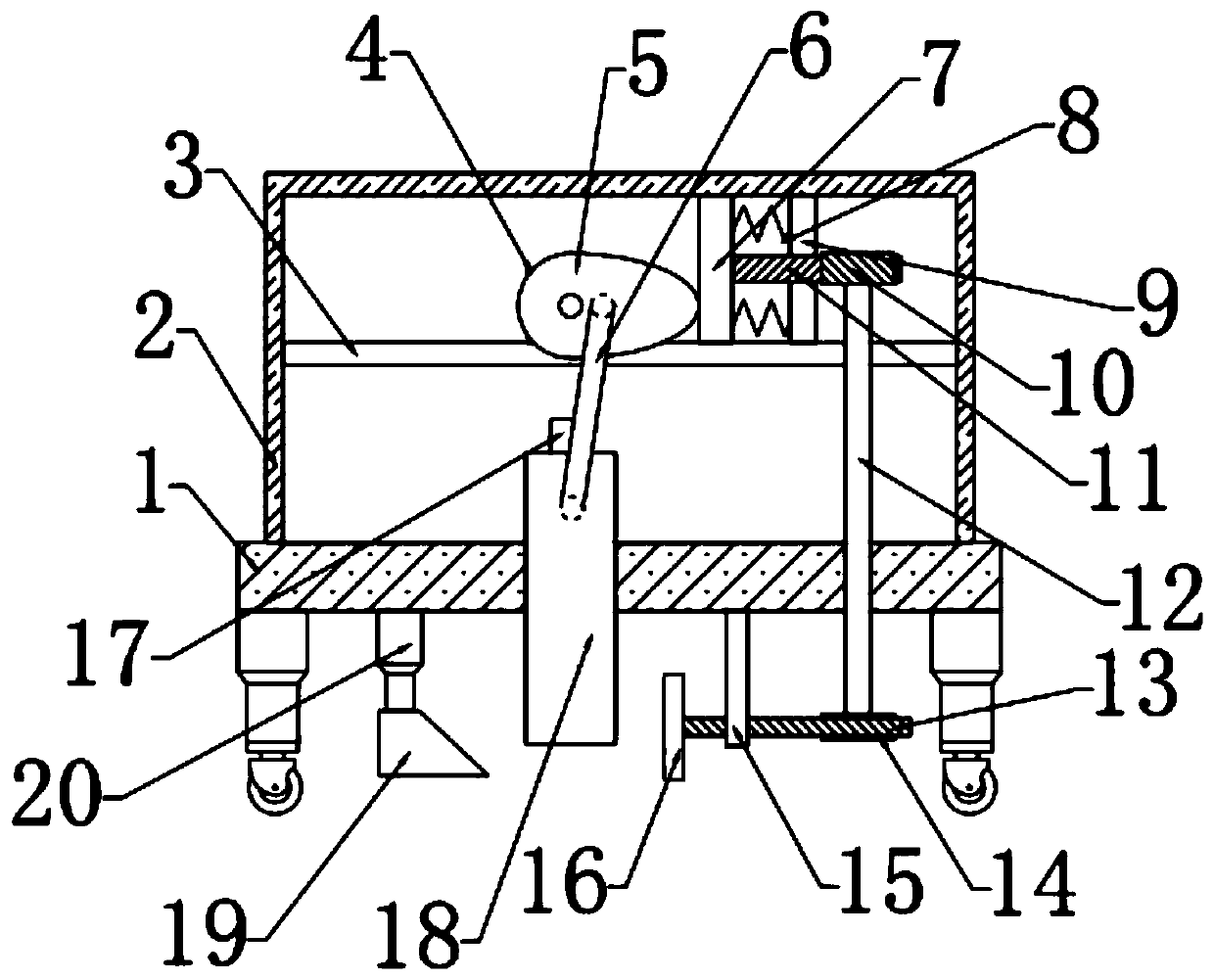

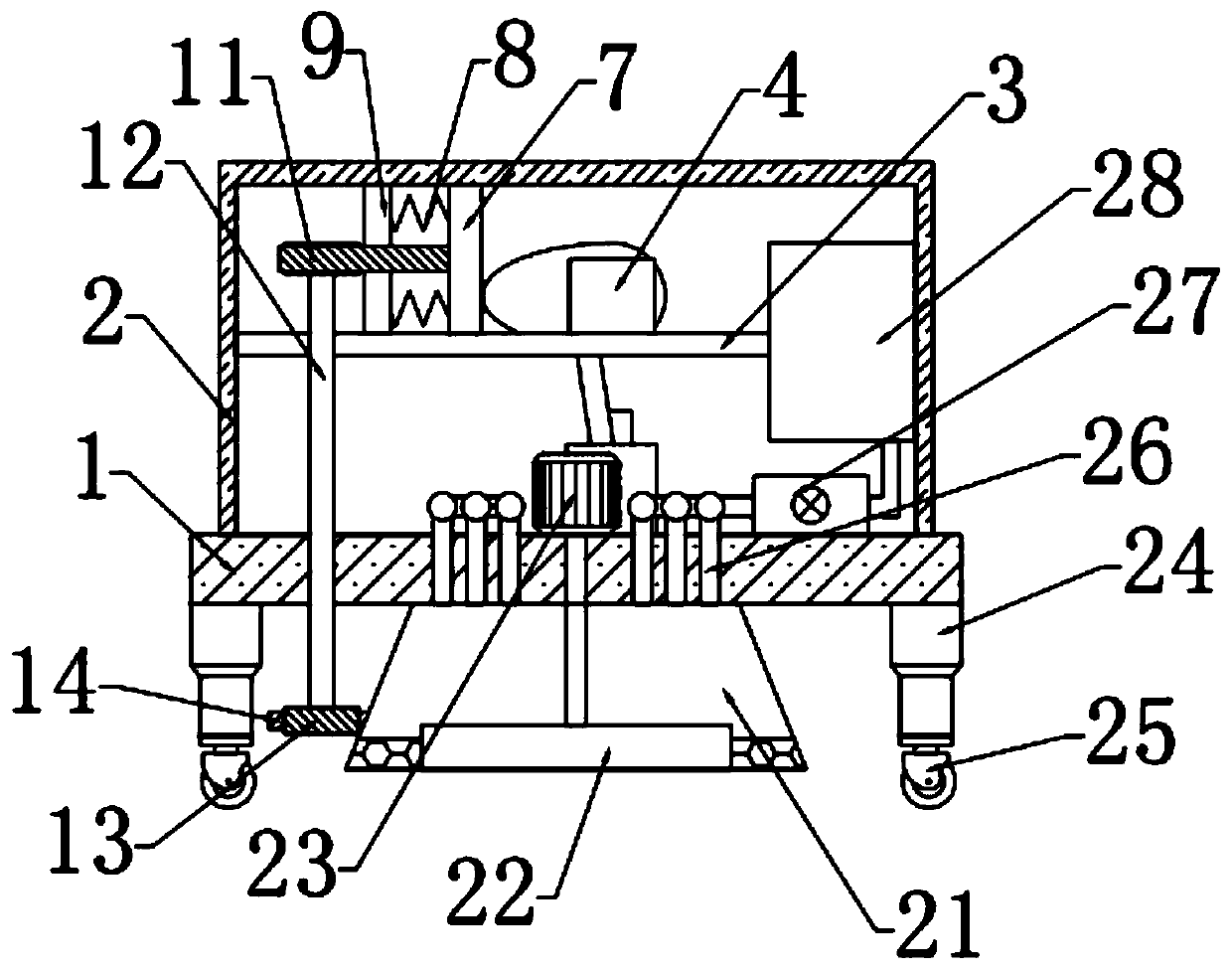

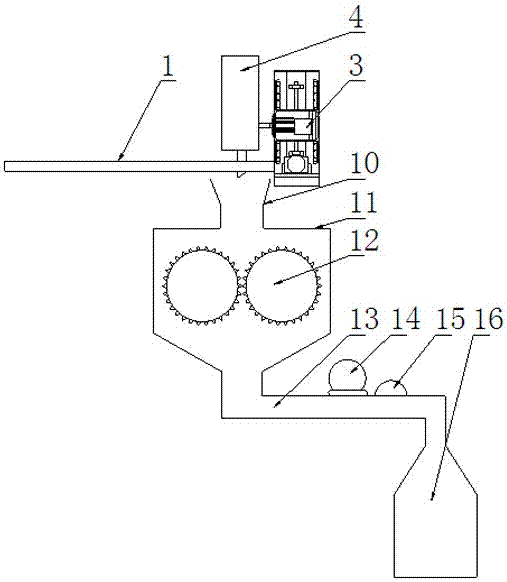

Ground surface dressing device for building construction

ActiveCN110052911ARealize up and down reciprocating motionEasy to polishBuilding repairsPlane surface grinding machinesReciprocating motionArchitectural engineering

The invention relates to the technical field of building construction, in particular to a ground surface dressing device for building construction. The ground surface dressing device for building construction comprises a base. The top of the base is fixedly connected with a shell. A fixing rod is arranged on the right side of the inner portion of the shell. A crushing mechanism is arranged on thefixing rod. A polishing mechanism is arranged on the left side of the crushing mechanism. The left side of the shell is fixedly connected with a push rod. According to the ground surface dressing device for building construction, through arrangement of a first motor, a cam, a connection rod and a crushing press block, the crushing press block can conduct vertical reciprocating motion and impact and crush cement blocks protruding from the cement ground, so that the ground surface is dressed; through arrangement of a transmission device, a scraper blade and a crushed cement collecting box, it can be achieved that when the crushing press block moves upwards, the scraper blade pushes crushed blocky cement into the crushed cement collecting box, and then the polishing wheel can conveniently polish the ground; and through arrangement of a dustproof cover, an exhaust fan and a dust collection box, dust and chips can be removed, and dust pollution to the environment is reduced.

Owner:江苏复华光电科技有限公司

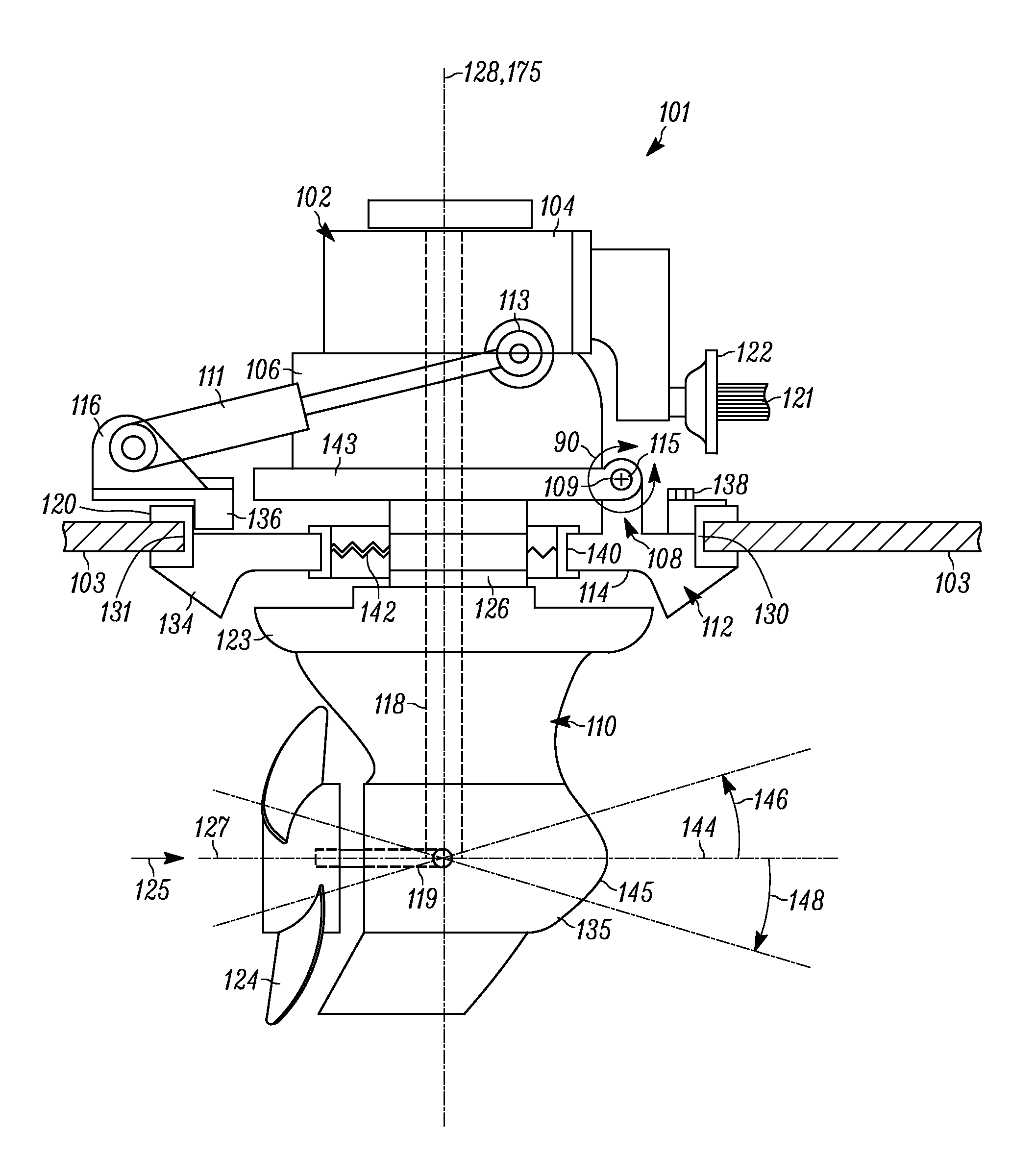

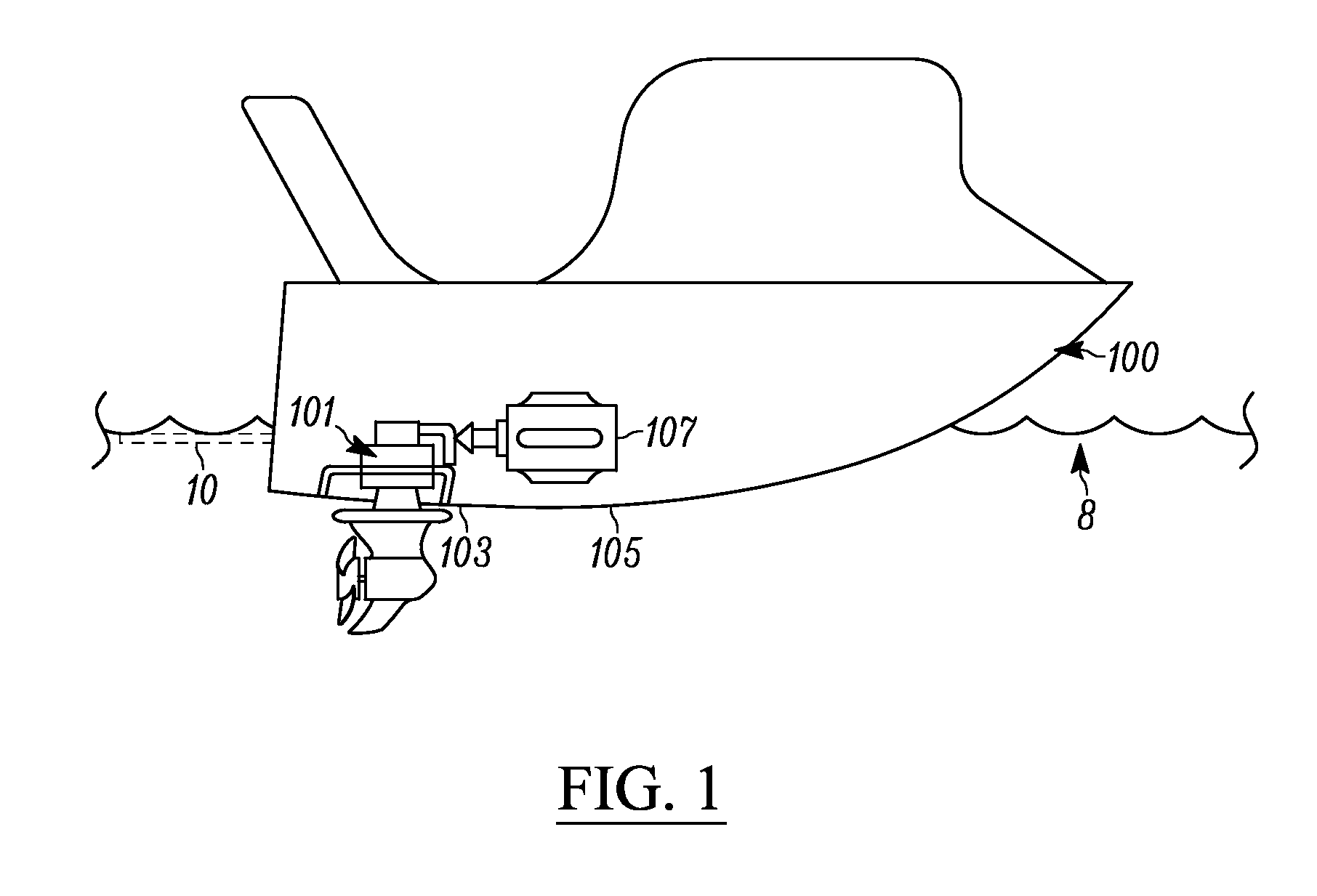

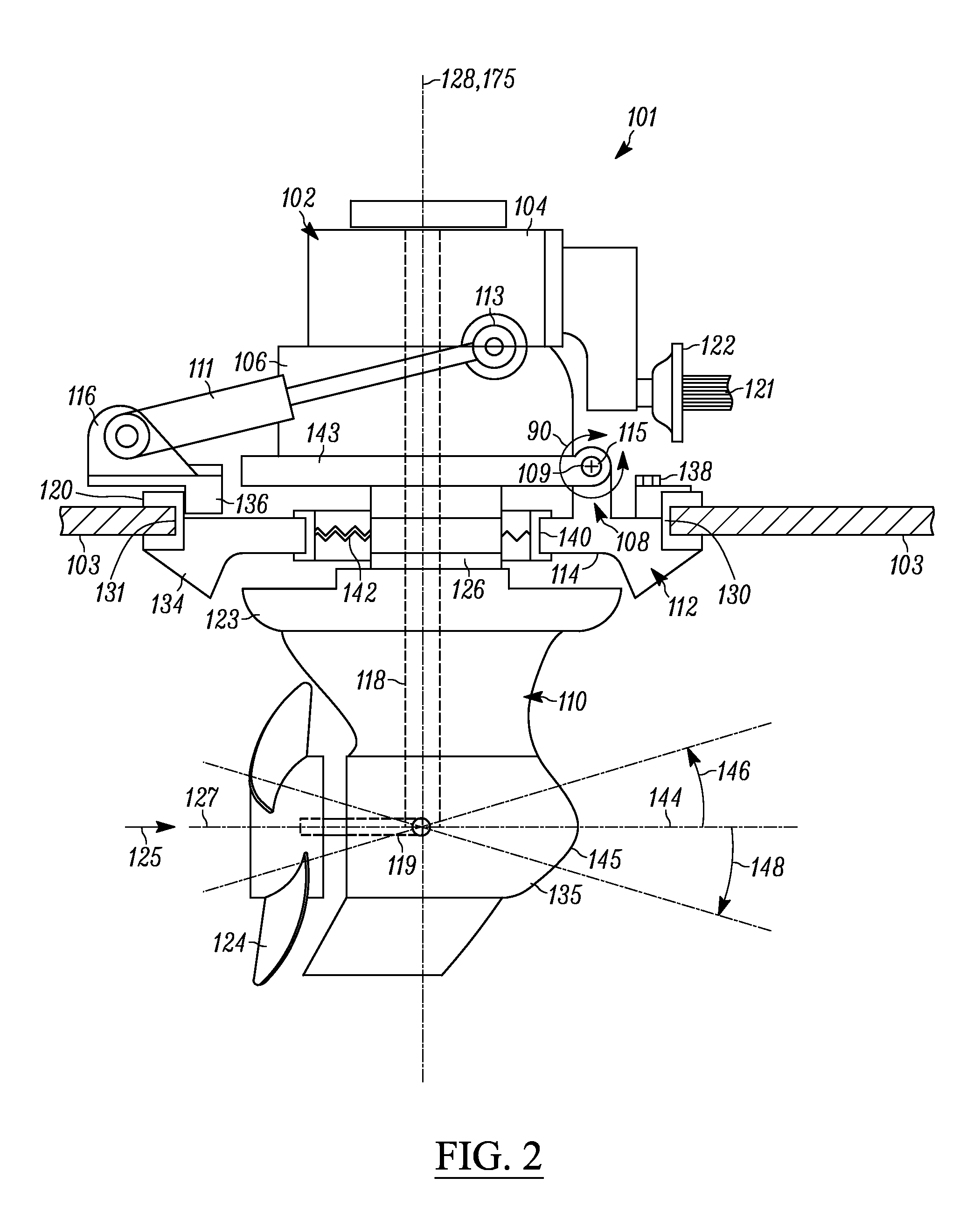

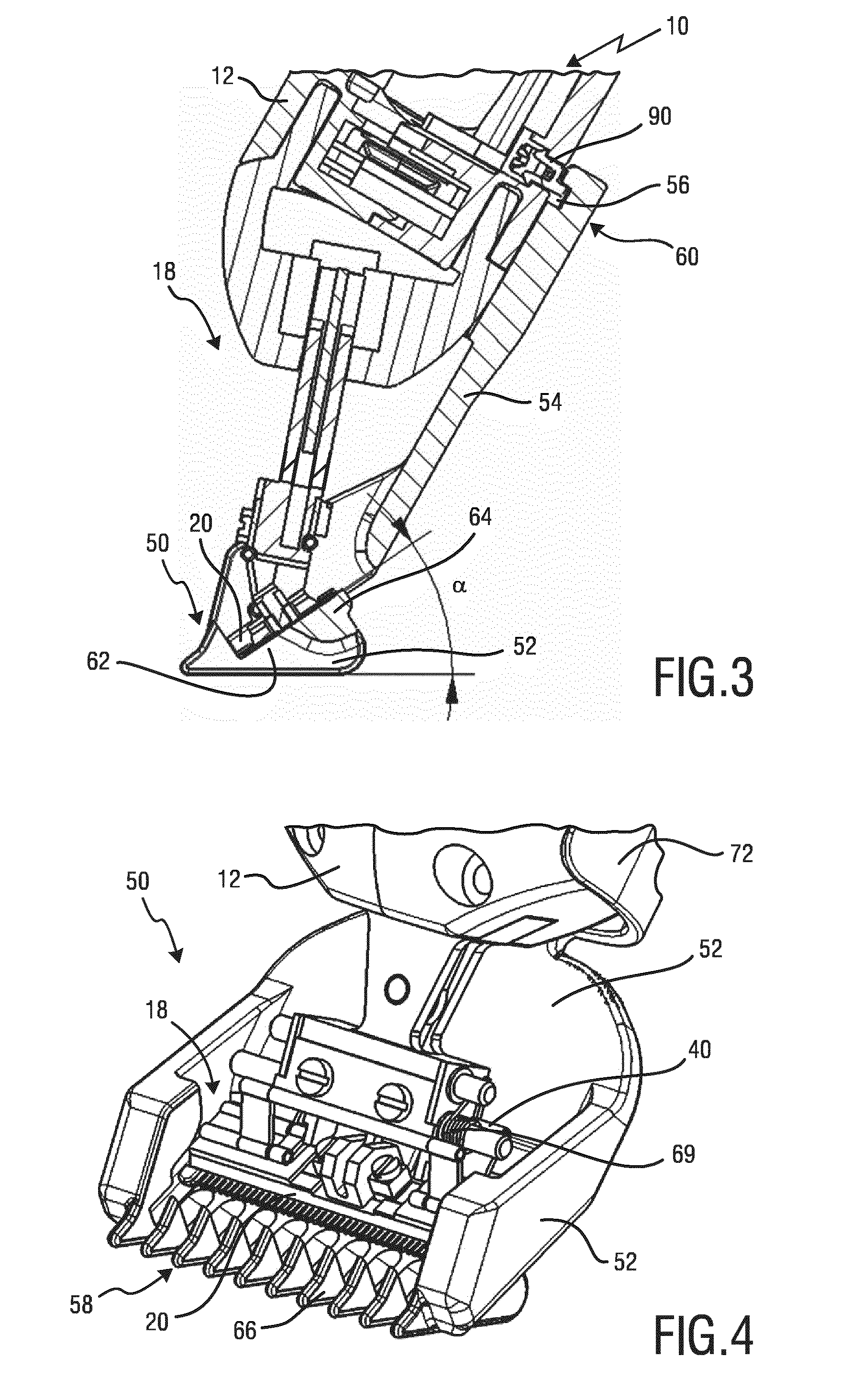

Trimmable pod drive

ActiveUS20110195619A1Improve trimming effectPropulsion power plantsSteering by propulsive elementsPropellerMechanical engineering

Disclosed herein is a trimmable pod drive assembly that includes a pod drive unit having a transmission assembly secured to a steering unit, a gear case assembly coupled to and rotatable by the steering unit about a steering axis, and a propeller rotatable about a propeller driveshaft axis extending through the gear case assembly so as to generate thrust along a thrust vector. The trimmable pod drive assembly further includes a trim assembly secured to the pod drive unit in a manner allowing for rotation of the pod drive unit about a trim axis that is substantially perpendicular to the steering axis, wherein actuation of at least one component of the trim assembly causes movement of the pod drive unit and the thrust vector about the trim axis.

Owner:AXIAL DRIVE SYST LLC

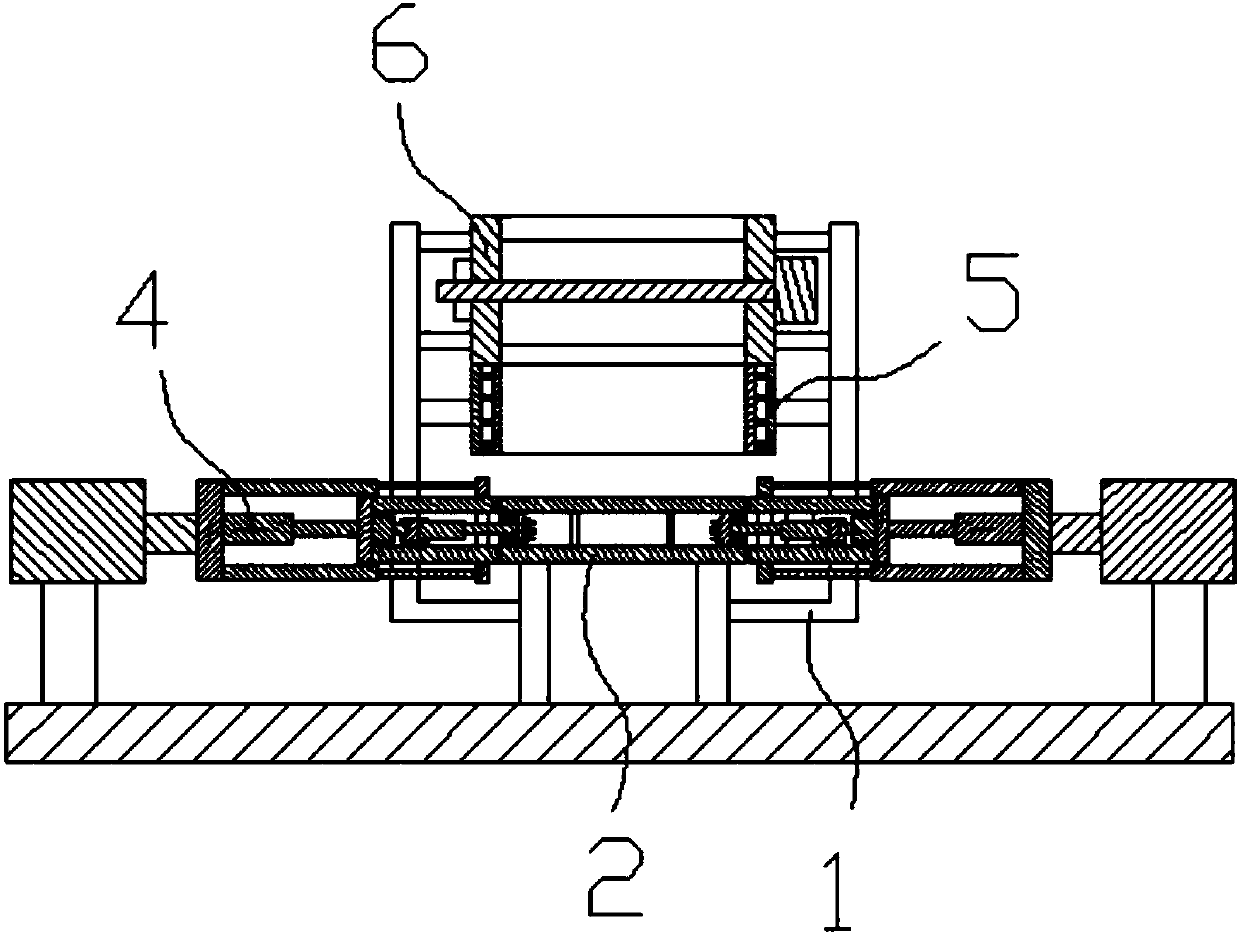

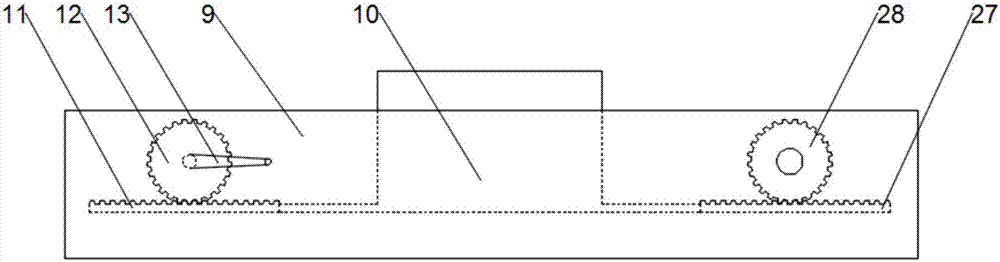

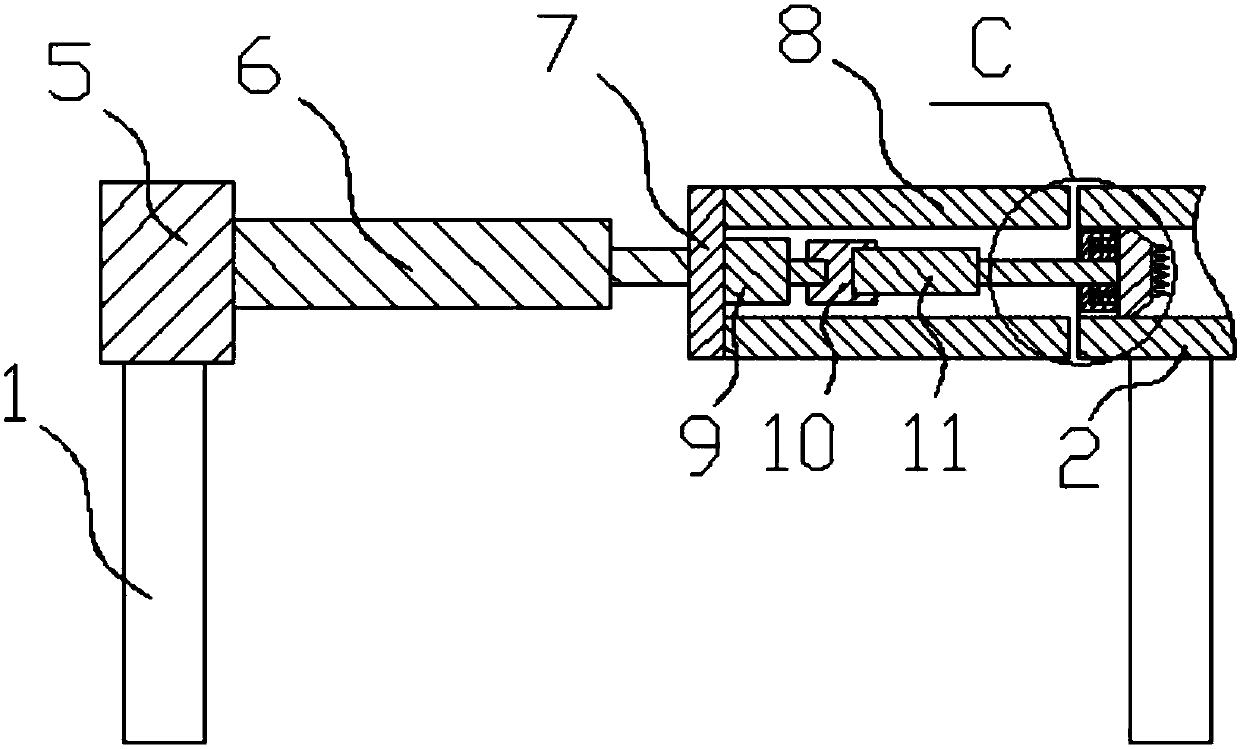

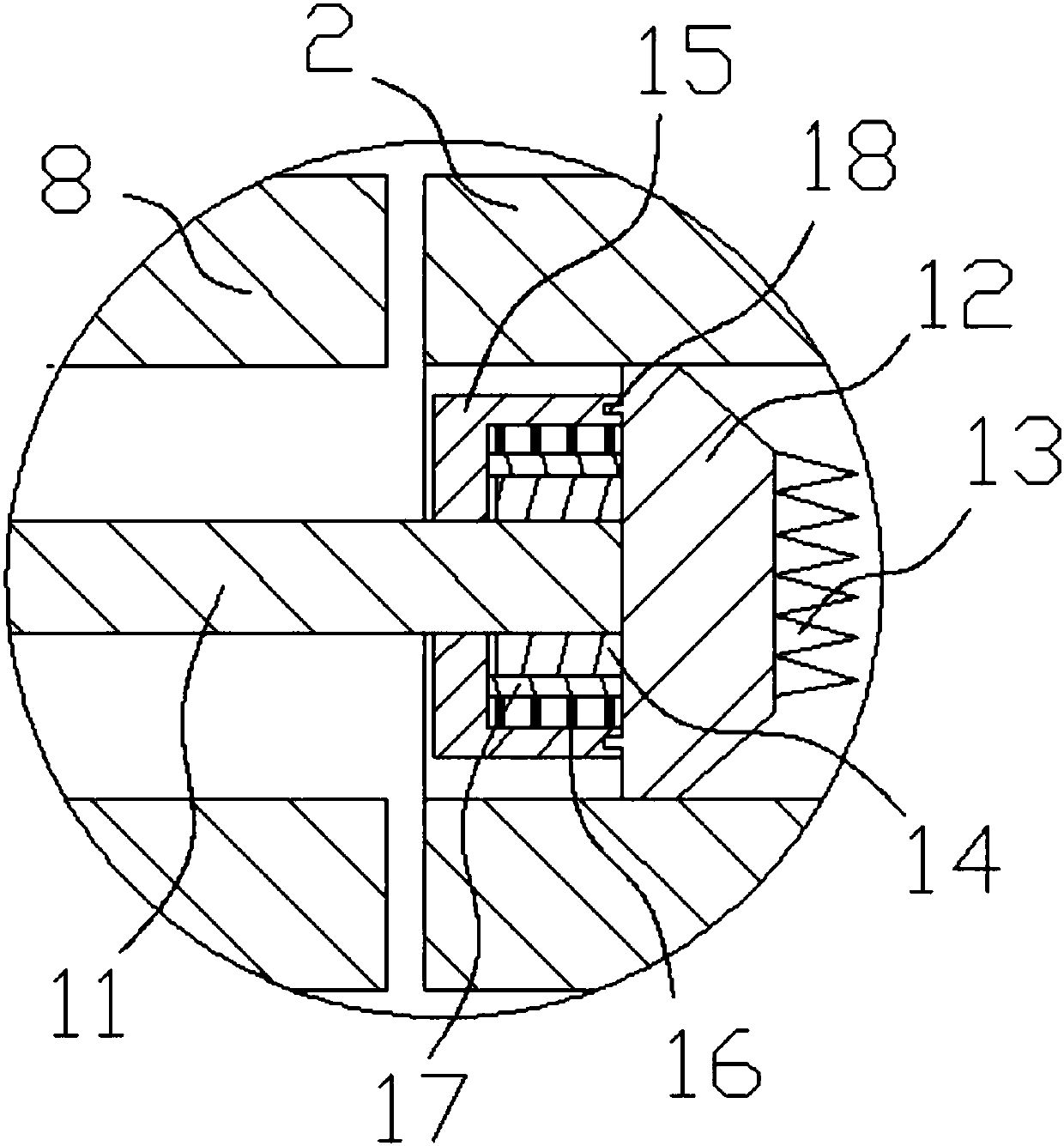

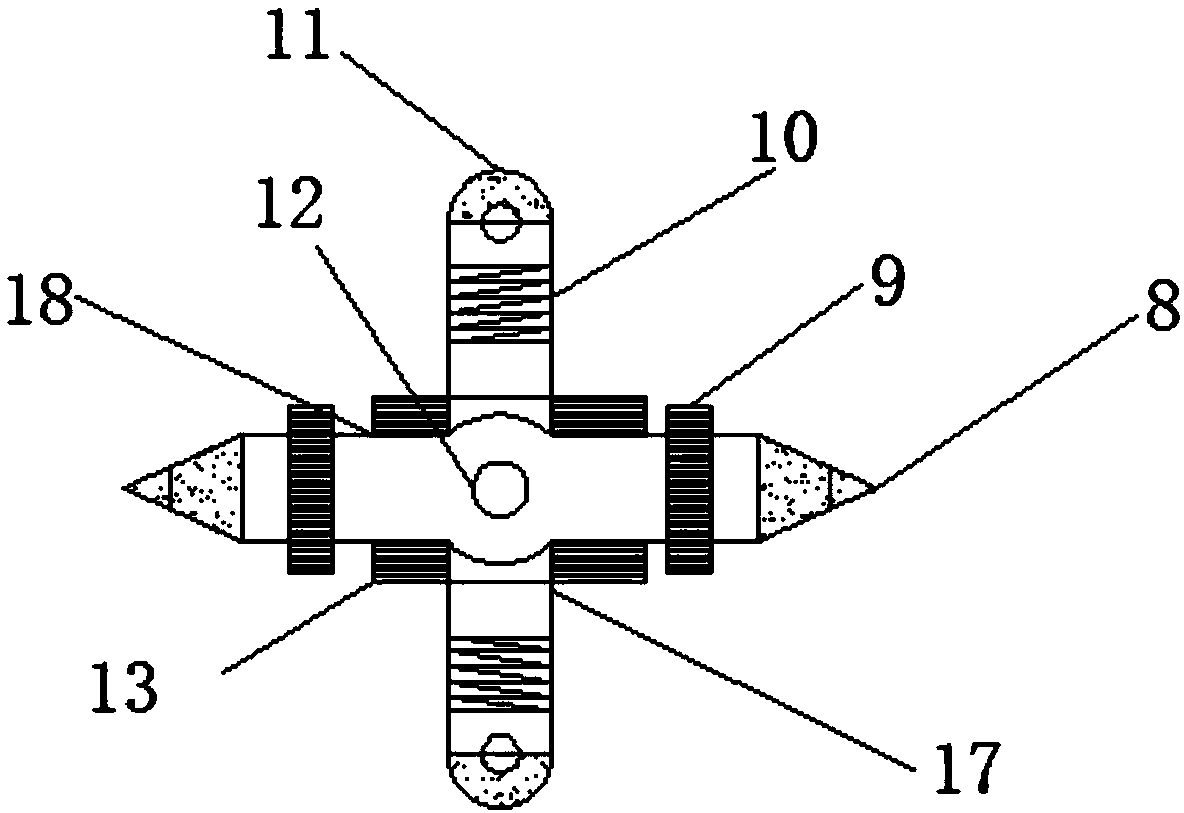

Automatic grinding machine for bamboo joints

InactiveCN107838782ARealize integrated automatic grindingImprove removal efficiencyGrinding drivesCane mechanical workingEngineeringSharpening

The invention relates to an automatic grinding machine for bamboo joints. The machine comprises a rack and a clamping and grinding device; the clamping and grinding device comprises two half clampingand grinding device bodies; the half clamping and grinding device bodies are matched with a bamboo tube through arc-shaped clamping blocks; grinding disks are arranged in positions where the arc-shaped clamping blocks are matched with the bamboo tube; bamboo joint grinding devices are matched on the left and right sides of the bamboo tube; each bamboo joint grinding device comprises a bamboo tuberotating motor, the bamboo tube rotating motor is connected with a bamboo tube rotating seat, the bamboo tube rotating seat is connected with a bamboo tube pressing air cylinder and an inner joint removal rotating motor, the bamboo tube pressing air cylinder is connected with bamboo tube pressing blocks matched with the left and right end surfaces of the bamboo tube, the inner joint removal rotating motor is connected with an inner joint removal feeding air cylinder, and an air cylinder push rod of the inner joint removal feeding air cylinder is connected with an inner joint removal grinding column. According to the machine, the clamping and grinding device cooperates with the bamboo joint grinding devices which can rotate and press the bamboo tube to grind outer bamboo joints, and the inner bamboo joints can be ground synchronously by the aid of inner bamboo joint grinding parts arranged in the bamboo joint grinding devices, so that the bamboo joint removal efficiency is improved.

Owner:DONGGUAN UNIV OF TECH

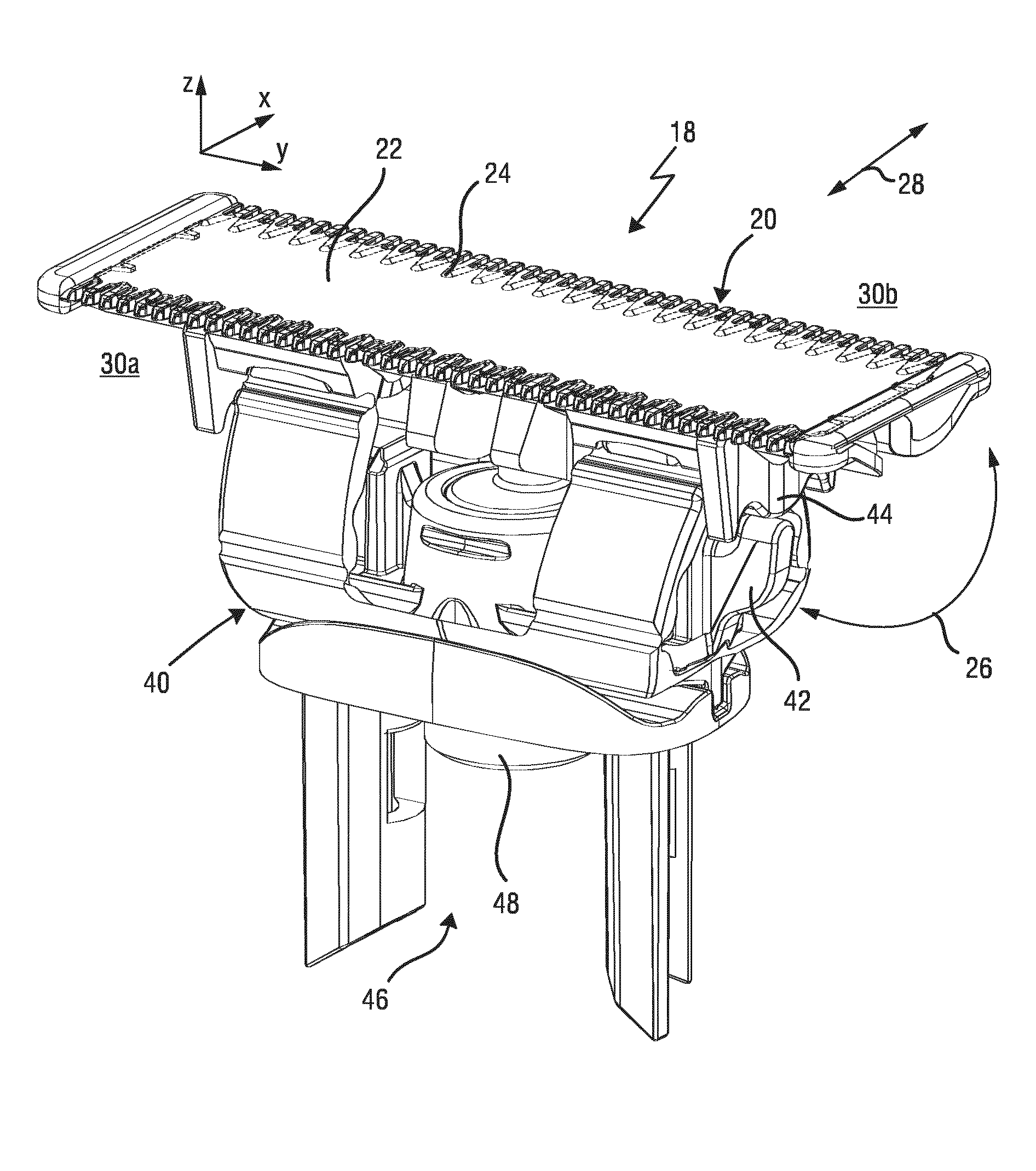

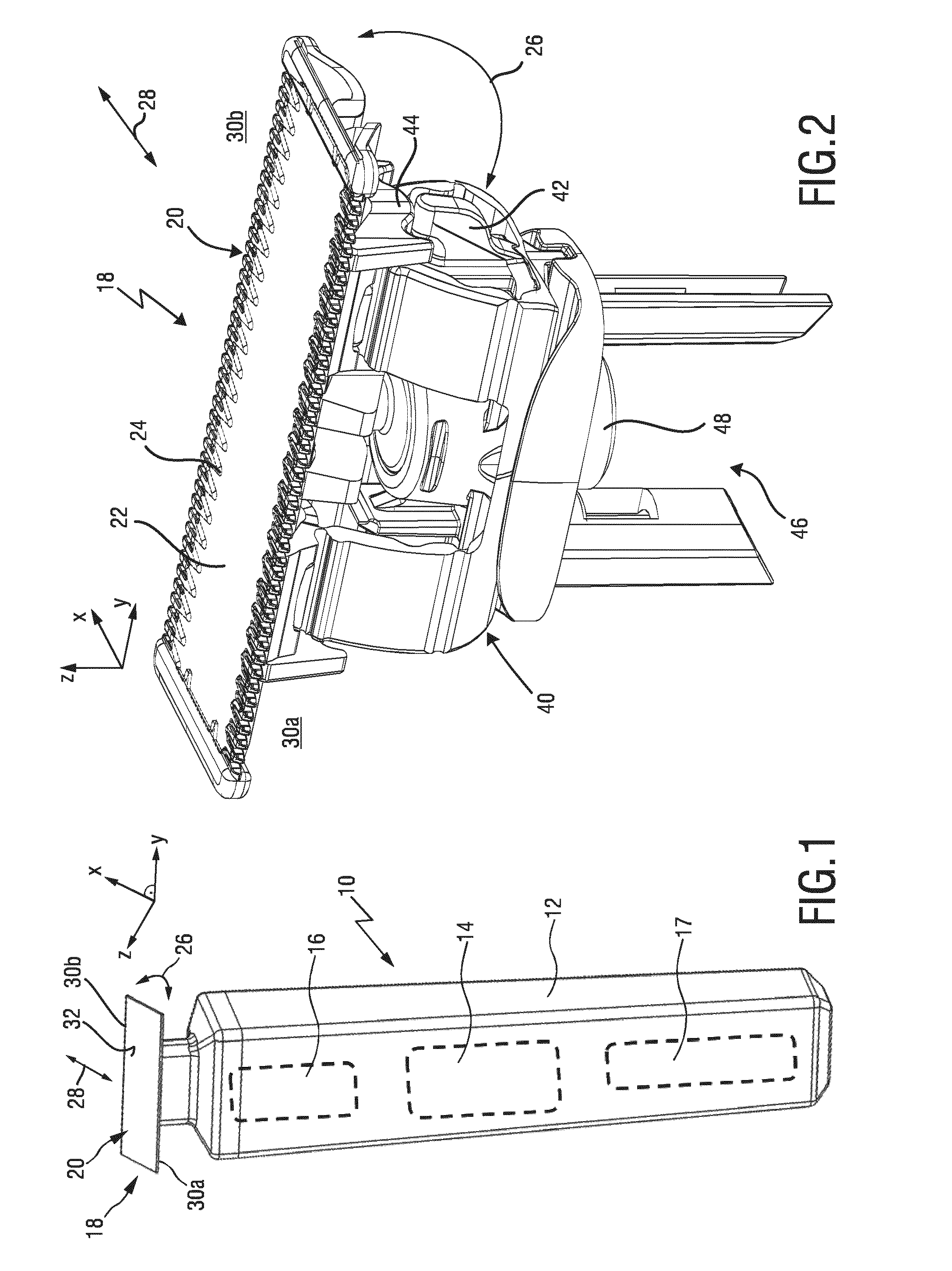

Attachment comb and hair cutting appliance

ActiveUS20170028574A1Good adhesionImprove trimming effectHair combsMetal working apparatusKnife bladesEngineering

The present disclosure relates to a hair cutting appliance (10) arranged to be moved through hair in a moving direction (28) in order to cut hair. The hair cutting appliance (10) having: a housing portion (12), a blade set (20) having a skin-facing top surface (32), and a releasable attachment comb (50). The blade set (20) is arranged pivotably with respect to the housing portion (12). The attachment comb (50) comprises a supporting frame (52), at least one spacing guard element (58) arranged to space the blade set (20) from a working surface when in operation, a mounting portion (60) arranged to be attached to a housing portion (12) of the hair cutting appliance (10), and an orientation determining portion (62) arranged to engage the blade set (20) and to define a locking orientation of the blade set (20) when mounted to the hair cutting appliance (10). The present disclosure further relates to an attachment comb (50) for use with a hair cutting appliance (10).

Owner:KONINKLJIJKE PHILIPS NV

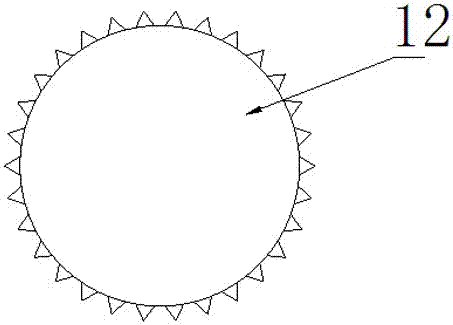

Blockboard automatic edge cutting device

InactiveCN107283533AImprove trimming effectImprove practicalityFeeding devicesGripping devicesEngineeringKnife blades

The invention discloses a blockboard automatic edge cutting device. The blockboard automatic edge cutting device comprises a workbench. A carrying table is arranged below the workbench. A cutting device body is arranged on the carrying table and comprises a rotary shaft motor. The rotary shaft motor is fixed to the carrying table. A rotary shaft is connected with an output shaft of the rotary shaft motor. A tool base is mounted on the rotary shaft and rotates along with the rotary shaft. A circular blade is fixedly mounted on the tool base. Sawteeth are arranged on the edge of the blade. A tool slit is formed in the upper end face of the workbench. The upper end of the blade penetrates through the tool slit. A gap adjustor is arranged on the workbench and comprises gap adjusting sliding grooves and gap adjusting sliding bases. A feeder is arranged on each gap adjusting sliding base and comprises a feeding sliding groove, a feeding sliding base and a feeding air cylinder which are arranged on the upper end face of the gap adjusting sliding base. A clamping unit is arranged on each feeding sliding base. A protection cover is arranged on the workbench. Blockboards in different sizes can be subjected to automatic edge cutting processing, operators can be effectively protected, and potential safety hazards are reduced.

Owner:颍上县亚森木业有限责任公司

Edge cutting waste collection device

InactiveCN106985179AAvoid cloggingStable deliveryGrain treatmentsMetal working apparatusWaste collectionWaste recovery

The invention discloses an edge cutting waste collection device which comprises an edge cutting mechanism, a waste crushing mechanism and a waste recovery mechanism. The edge cutting mechanism comprises an edge cutting plate, an edge cutting knife, an edge cutting motor and an edge cutting cover. A groove opening matched with the edge cutting knife is formed in the edge cutting plate. The edge cutting knife is located in the groove opening and mounted on an output shaft of the edge cutting motor. The edge cutting knife is covered with the edge cutting cover. The edge cutting motor of the edge cutting mechanism is mounted on a cutting knife feed adjusting mechanism. The waste crushing mechanism is arranged below the edge cutting knife and connected with the waste recovery mechanism. According to the edge cutting waste collection device, edge cutting waste is recovered after being crushed through the waste crushing mechanism, a fan and a heater of the waste recovery mechanism further prevent cloth blocking, and conveying is smooth; and the cutting knife feed adjusting mechanism is arranged, a lead screw is driven by a motor to drive a cutting knife mechanism to ascend and descend, the feed amount is controlled, the edge cutting waste collection device is suitable for products of different thicknesses and materials, the edge cutting effect is optimized, and the edge cutting waste collection device is worth of wide popularization.

Owner:JIANGSU HONGHUA SPECIAL EQUIP CO LTD

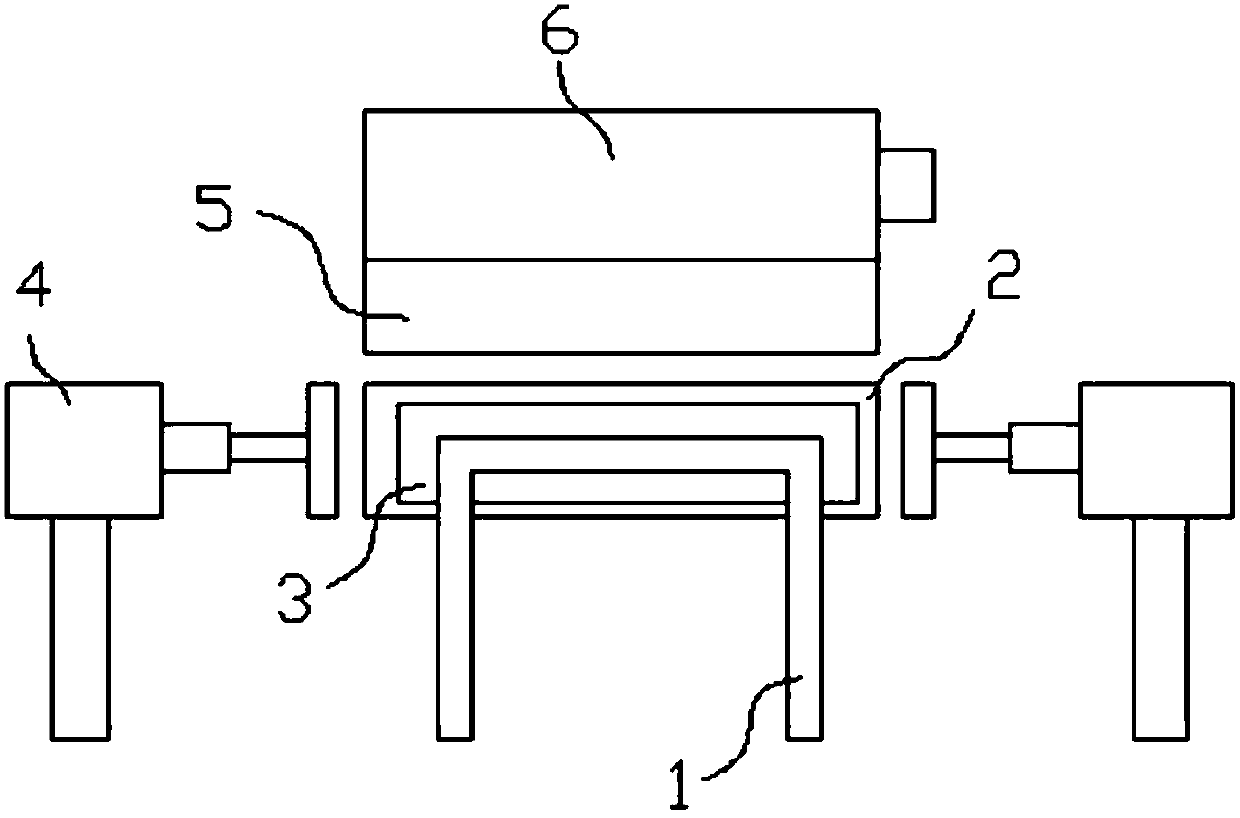

Bamboo splitting and inner joint removing all-in-one machine

InactiveCN107756578AGood sandingPlay a role of position restrictionWood splittingPlant material mechanical workingEngineering

The invention relates to an integrated machine for breaking bamboo and removing internal knots, which includes a frame and a clamping device. The two opening sides of the bamboo tube in the clamping device are equipped with a mechanism for breaking bamboo and removing internal knots. The bamboo-breaking seat is equipped with a bamboo-breaking propulsion cylinder that is consistent with the direction of the bamboo tube, and the bamboo-breaking propulsion cylinder is connected with a bamboo-breaking propulsion seat, and the outside of the bamboo-breaking propulsion seat is uniformly provided with a bamboo-breaking knife that matches the bamboo tube in the clamping device 1. The center is provided with a rotating motor for removing the inner section, and the rotating motor for removing the inner section is connected to the feeding cylinder for removing the inner section. The feed cylinder for inner section removal makes the inner section grinding column located on the feeding side of the bamboo cutter, so that the bamboo cutter penetrating into the bamboo tube plays a role in restricting the position of the bamboo, ensuring good grinding of the inner section grinding column Effect, the effect of breaking bamboo and removing internal joints is improved while realizing integration.

Owner:DONGGUAN UNIV OF TECH

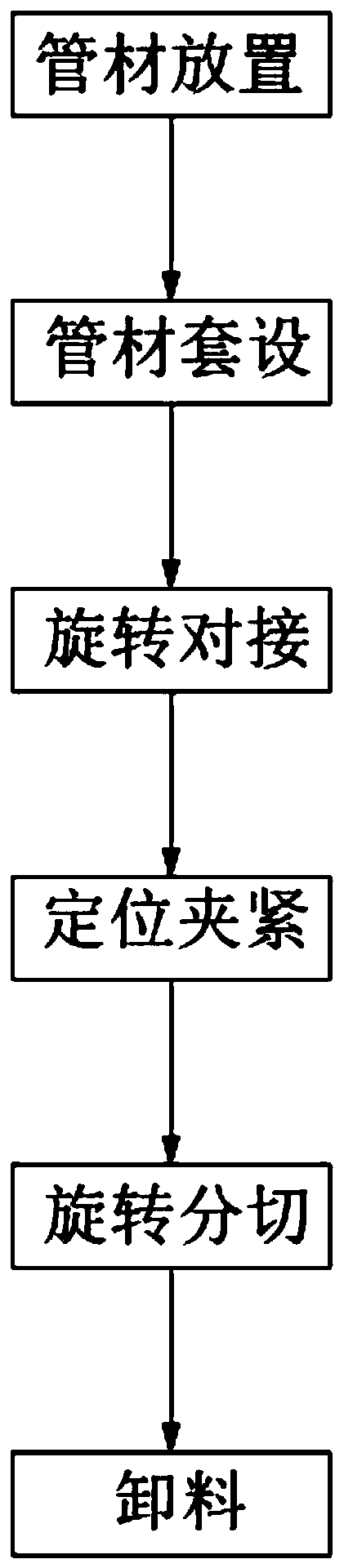

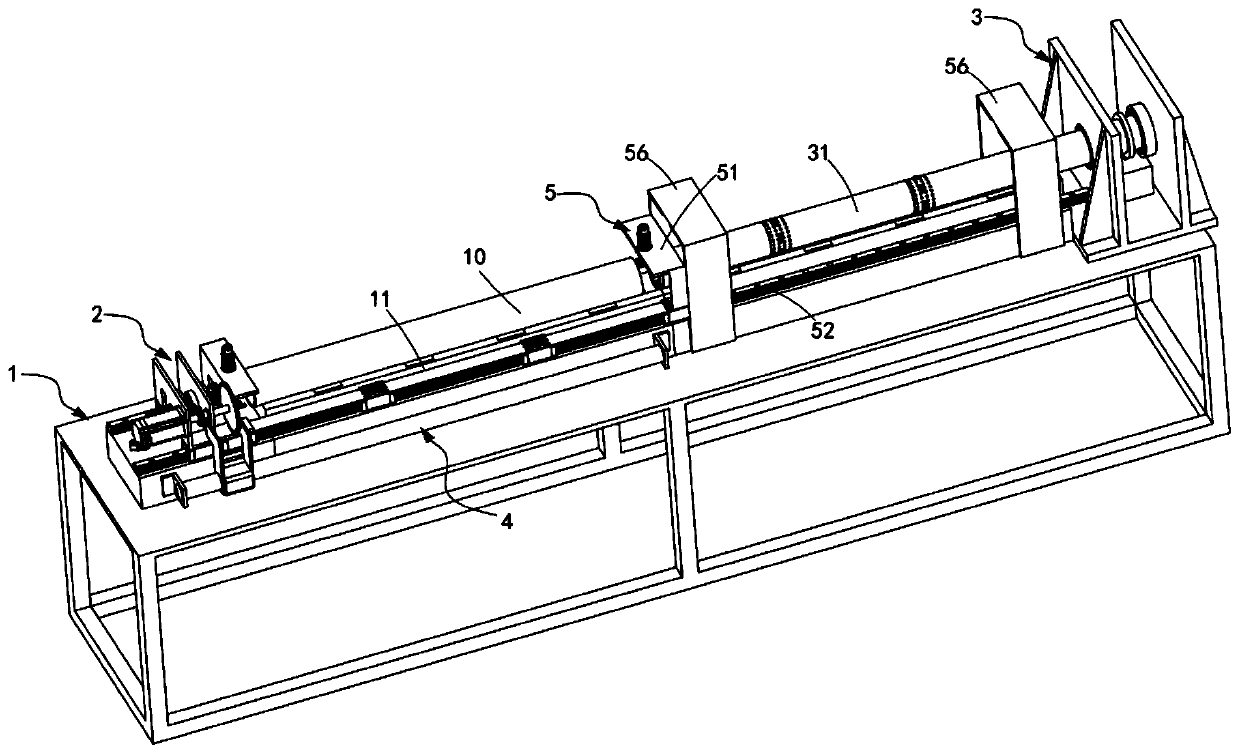

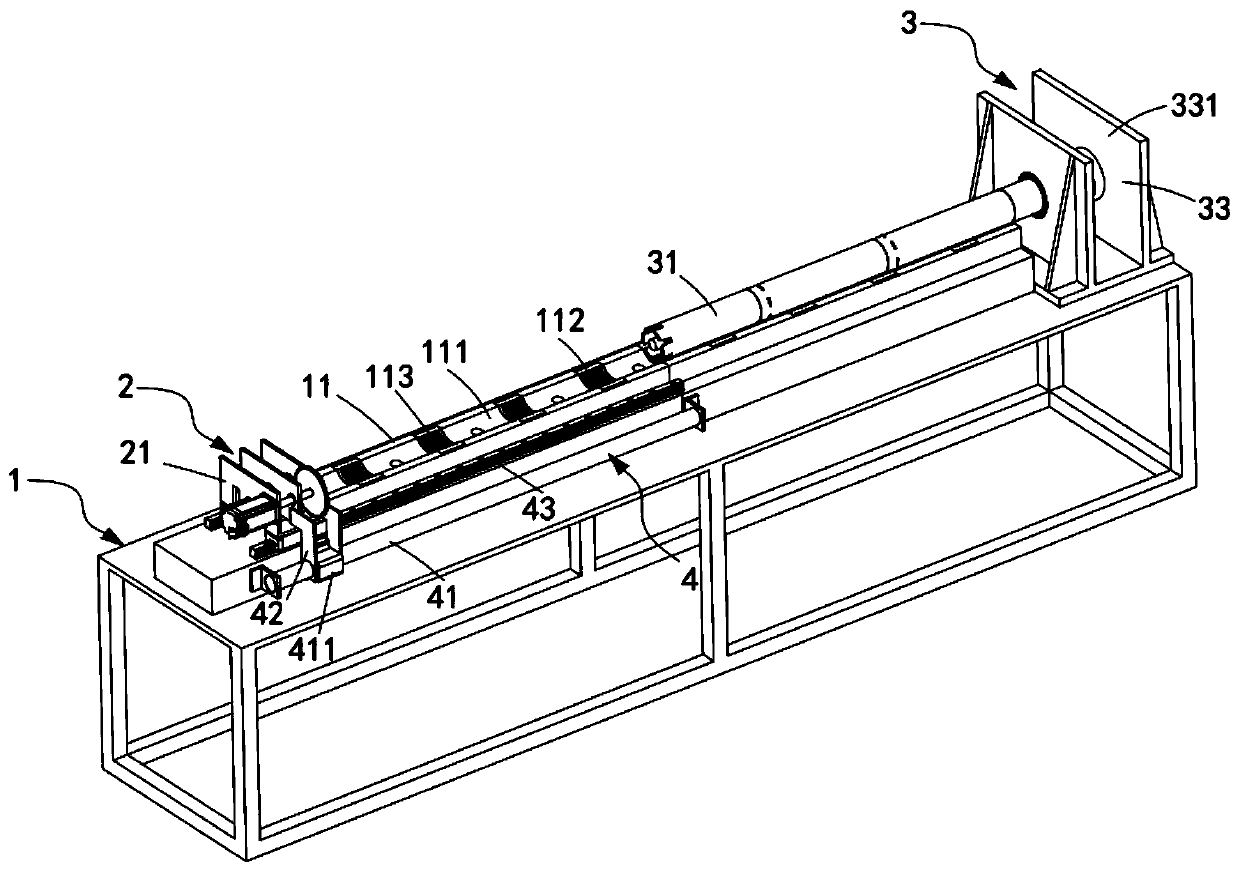

Method for flattening and slitting pipe

InactiveCN111230975AAvoid hard touchAvoid scratchesDispersed particle filtrationMetal working apparatusPhysicsKnife blades

The invention relates to the technical field of pipe production and processing machinery, and particularly discloses a method for flattening and slitting a pipe. The method for flattening and slittingthe pipe comprises the following steps that pipe placement, pipe sleeving, rotary butt joint, positioning and clamping, rotary slitting and discharging are carried out, specifically, in the rotary slitting step, a dust collection step is further carried out synchronously, the pipe is pushed to the sleeve a supporting cylinder group by using a rotating mechanism, the pipe is supported by the supporting cylinder group, the two ends, in the axial direction, of the pipe are clamped and positioned by a clamping mechanism, then the supporting cylinder group is driven to rotate by the rotating mechanism, cutting blades in the supporting cylinder group are further rotated synchronously with the supporting cylinder group, the pipe is divided into equal lengths, and in the cutting process, the cutting blades extend from inside to outside. The technical problem of equal-length slitting of the pipe is solved.

Owner:张士全

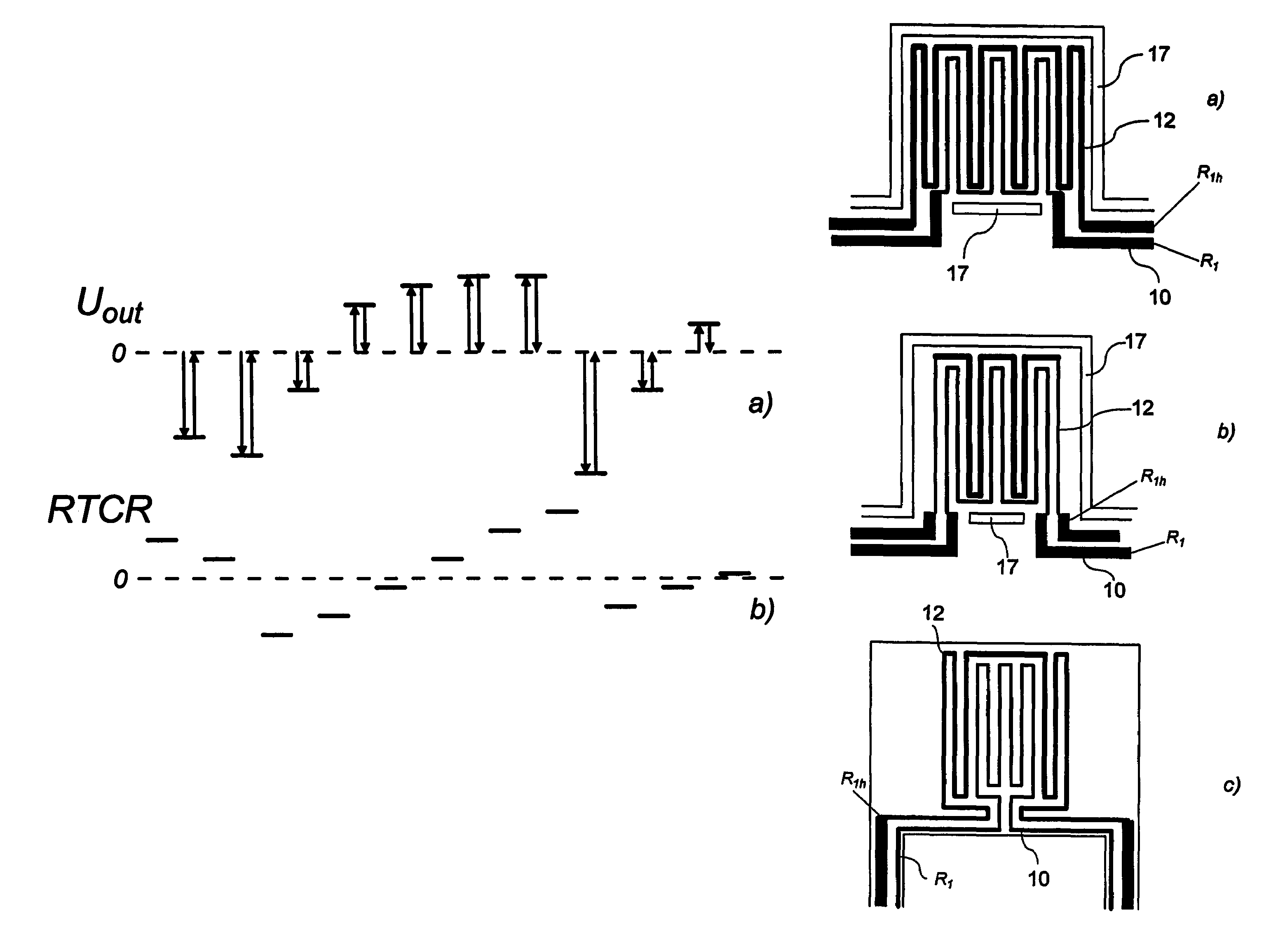

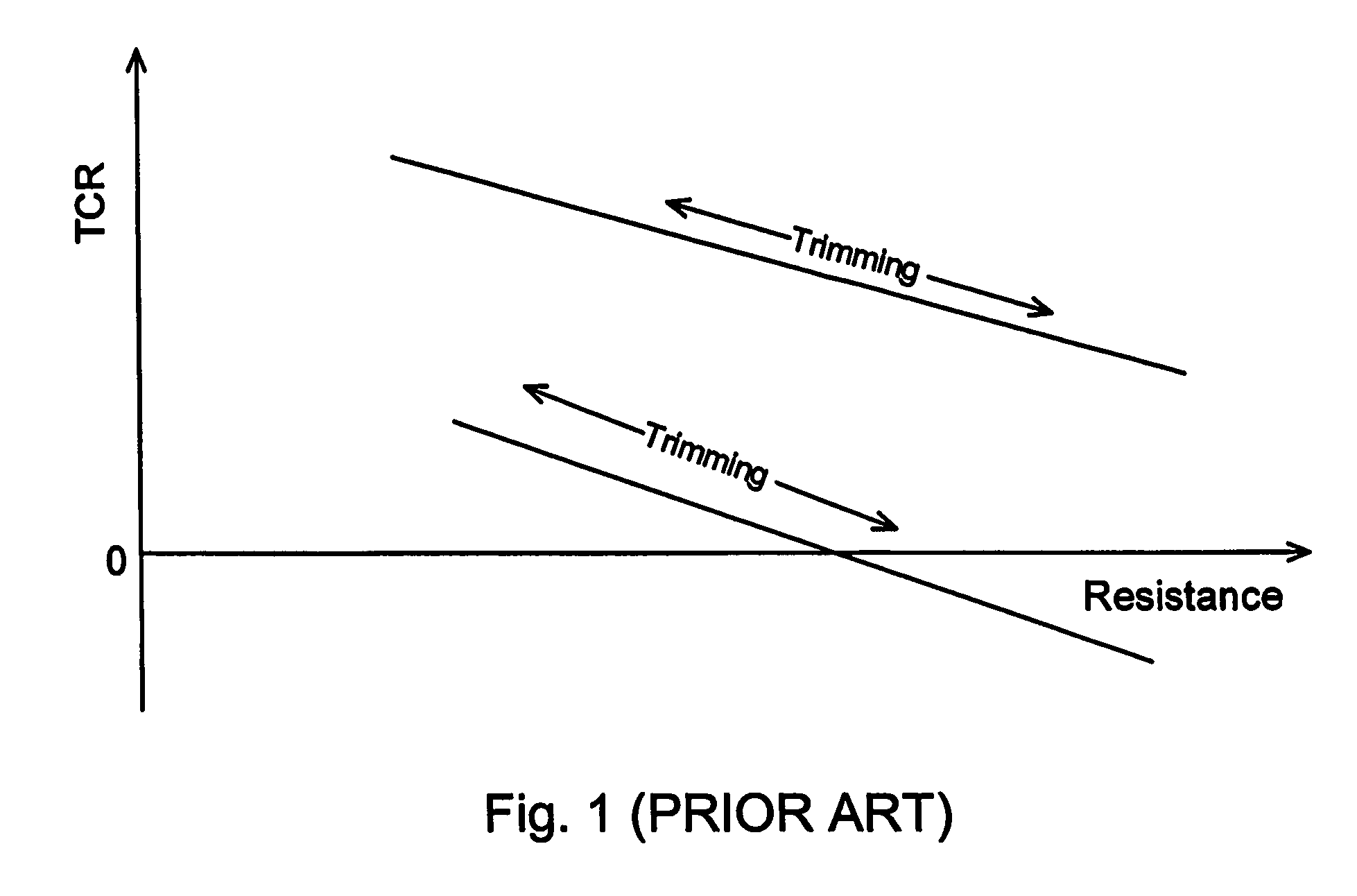

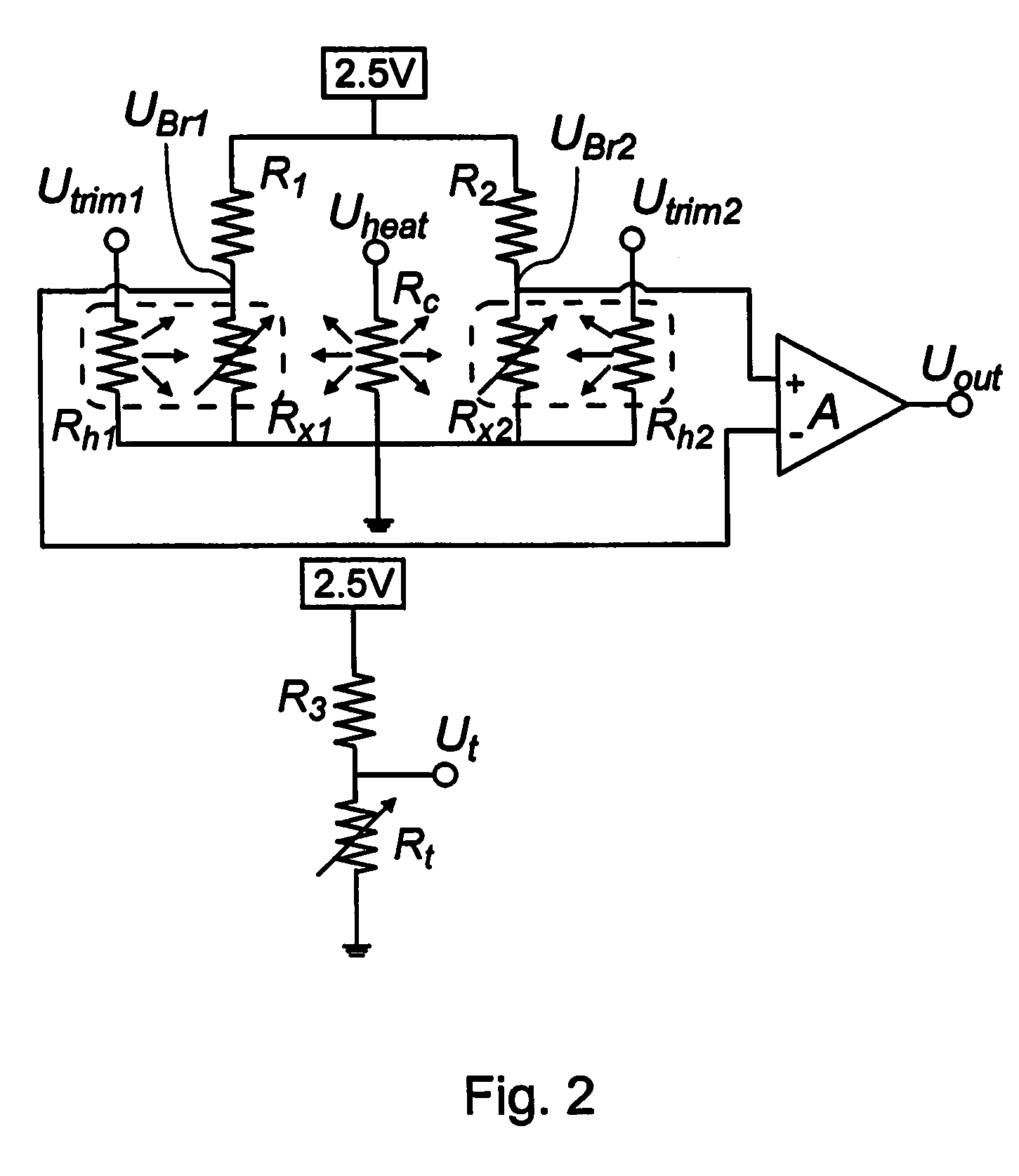

Method for adjusting an output parameter of a circuit

InactiveUS7555829B2Improve trimming effectReduce and eliminate componentLine/current collector detailsWave amplification devicesElectrical resistance and conductanceResistor

Owner:SENSORTECHNICS

Release-color coat two-in-one transfer coating and preparation method and application thereof

The invention discloses a release-color coat two-in-one transfer coating. The release-color coat two-in-one transfer coating is prepared from, by weight, 10-35 parts of polyacrylate resin, 2-10 parts of nitrocellulose, 1-10 parts of petroleum resin and 60-85 parts of solvent. The invention further discloses a preparation method of the coating. The preparation method comprises the steps that petroleum resin is placed into the solvent, and full stirring is performed to enable petroleum resin to be dissolved to obtain a material a; nitrocellulose is placed into the solvent, and full stirring is performed to enable nitrocellulose to be dissolved to obtain a material b; the material a and the material b are mixed to be uniform to obtain a material c; polyacrylate resin and the retaining solvent are placed into the material c, uniform mixing is performed, and then the release-color coat two-in-one transfer coating is obtained. The invention further discloses an application method of the coating. According to the release-color coat two-in-one transfer coating and the preparation method and application thereof, the production cost is lower, the production technology is simpler, the performance of the release-color coat two-in-one transfer coating is more excellent, and the coating not only can be used as a fabric foil release-color coat two-in-one transfer coating, but also can be used as an electrical aluminum transfer coating.

Owner:GUANGDONG BANGGU CHEM TECH

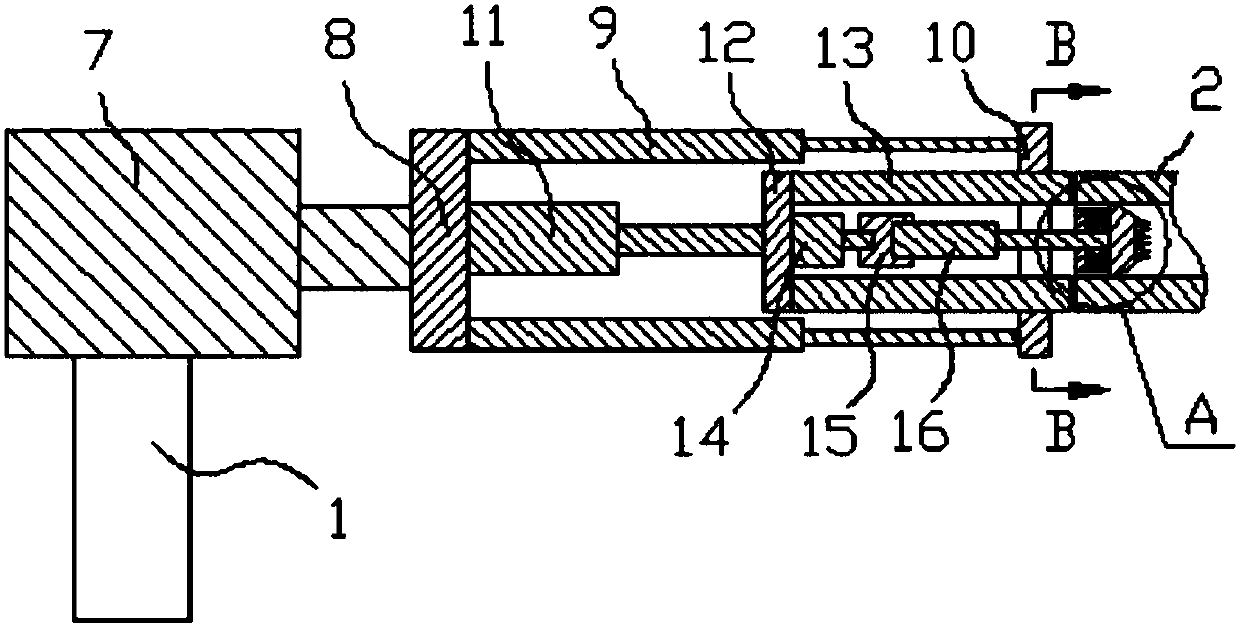

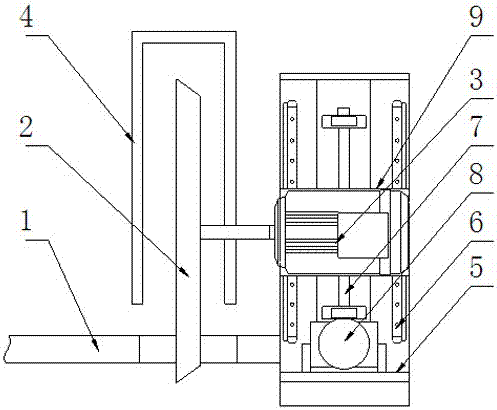

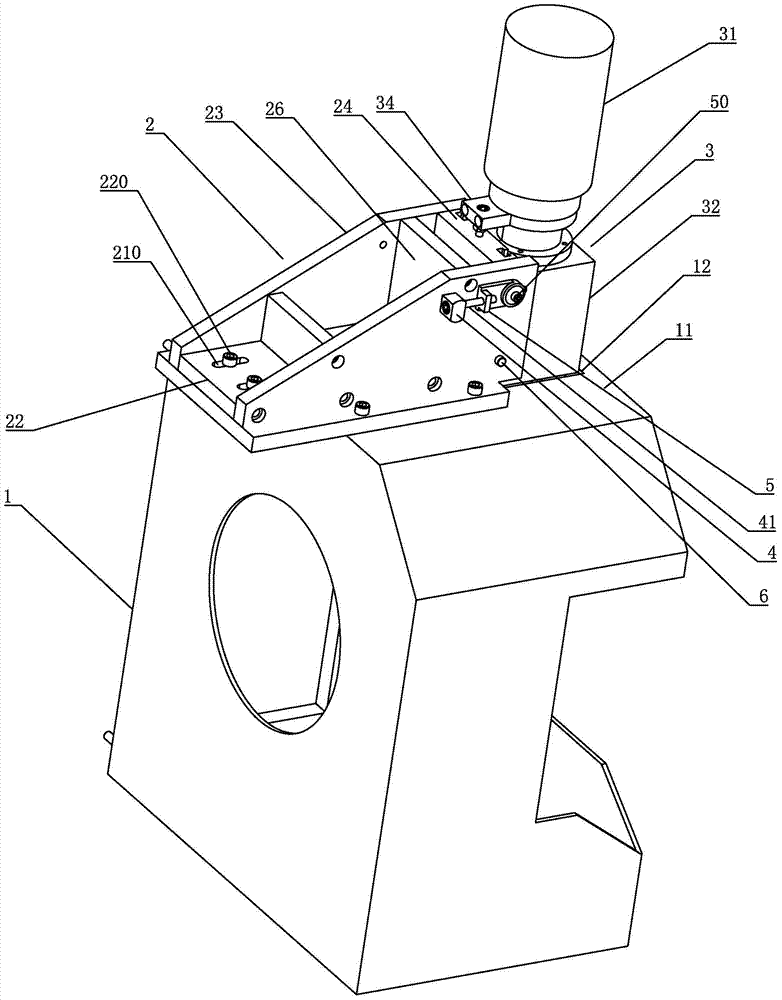

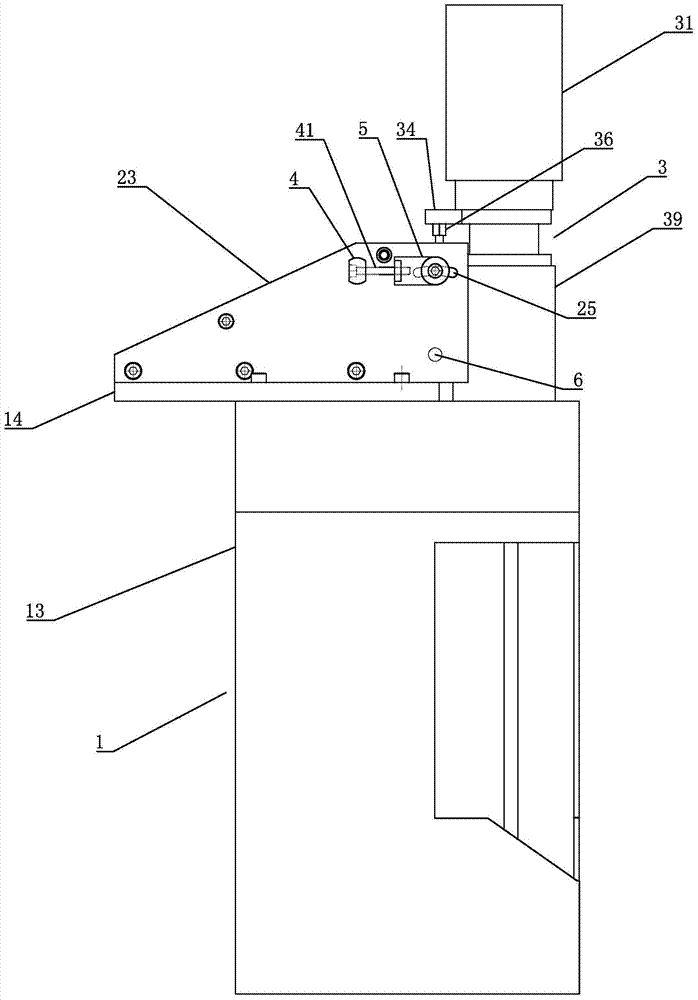

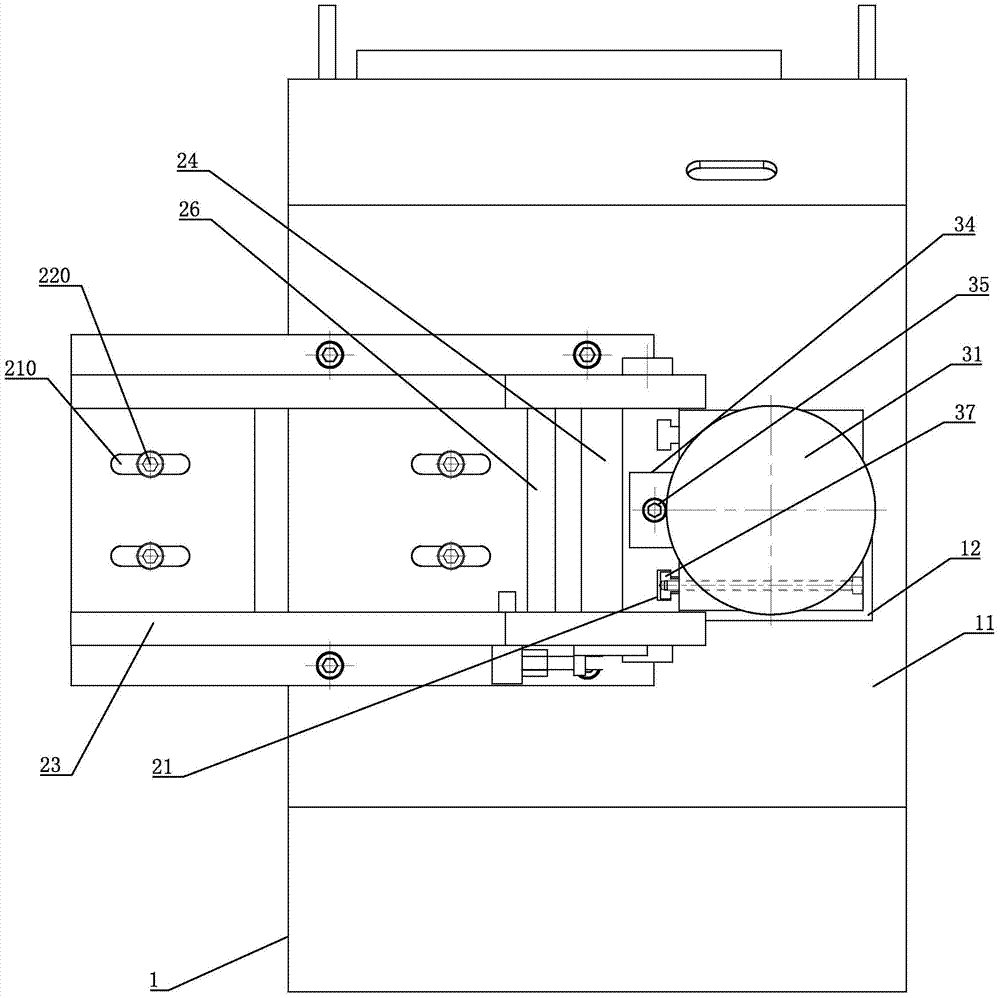

Numerical control groove grinding machine with numerical control grinding wheel trimming device

ActiveCN101844329AGood trimming effectTrim fitAbrasive surface conditioning devicesNumerical controlFixed frame

The invention relates to a numerical control groove grinding machine tool used for grinding grooves of cutting tools, such as drill bits, taps, milling cutters, center drills and the like, in particular to a numerical control groove grinding machine with a grinding wheel trimming device. The trimming part comprises a diamond pen positioned above the top part of a grinding wheel of a grinding head, the diamond pen is mounted at the front end of a rotating arm, the back end of the rotating arm is connected on the edge of a rotating disk, and the rotating disk is driven by a rotating numerical control motor; the rotating numerical control motor is mounted on a horizontal sliding block, the horizontal sliding block is mounted on an encloser part and can move horizontally along a horizontal guide track, the trend of the horizontal guide track is parallel to the axial direction of the grinding wheel of the grinding head, and the horizontal sliding block is driven by a horizontal movement numerical control motor through a horizontal screw rod; and the encloser part is connected on a vertical sliding block, the vertical sliding block is driven by a vertical movement numerical control motor through a vertical screw rod for moving in the vertical direction, and the vertical movement numerical control motor is mounted on a fixed frame of the groove grinding machine. The numerical control groove grinding machine has simple structure and convenient manufacture, and can trim the grinding wheels in various cross section shapes and be easy to realize the digital control.

Owner:JIANGSU WANLI MACHINERY

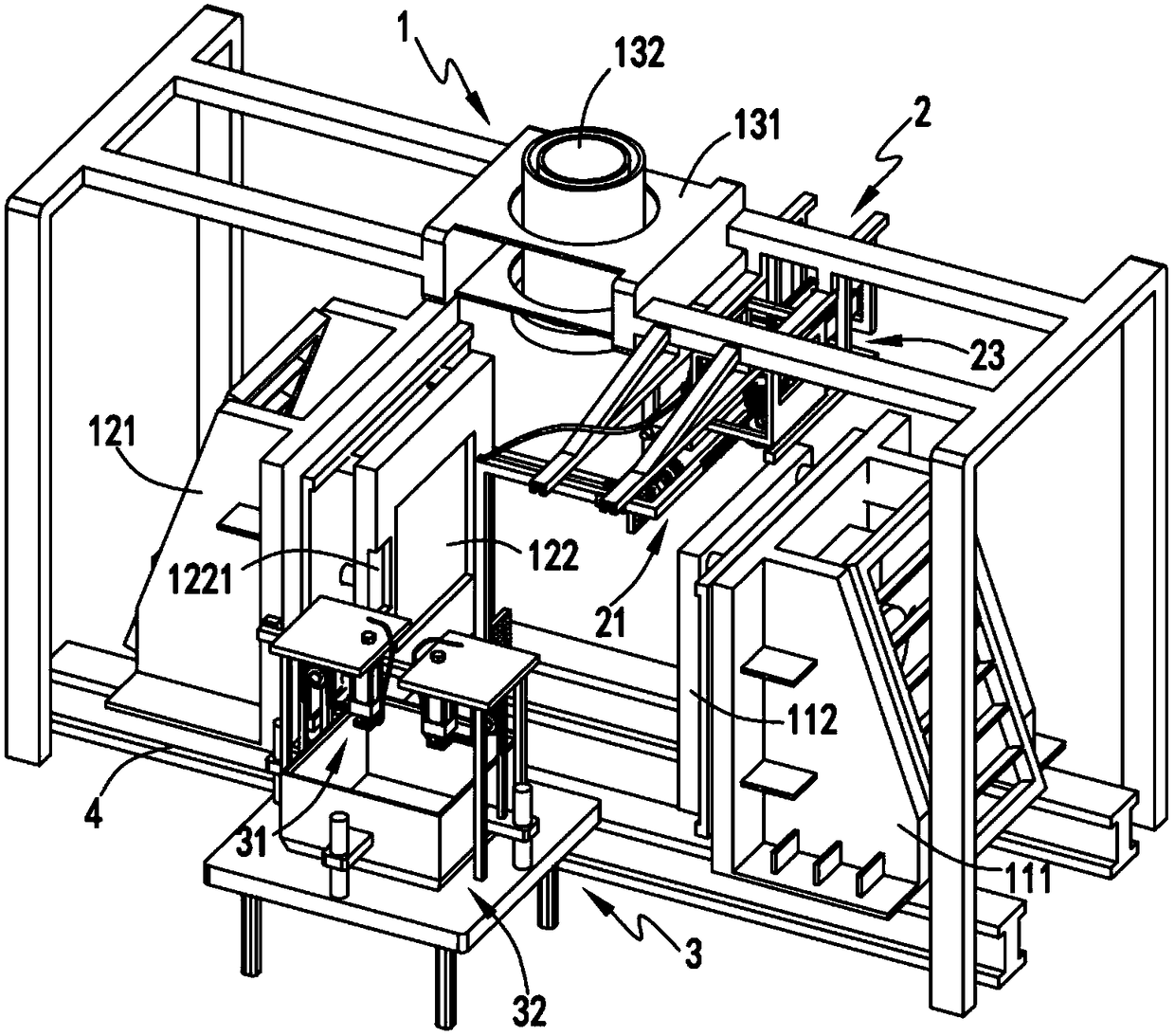

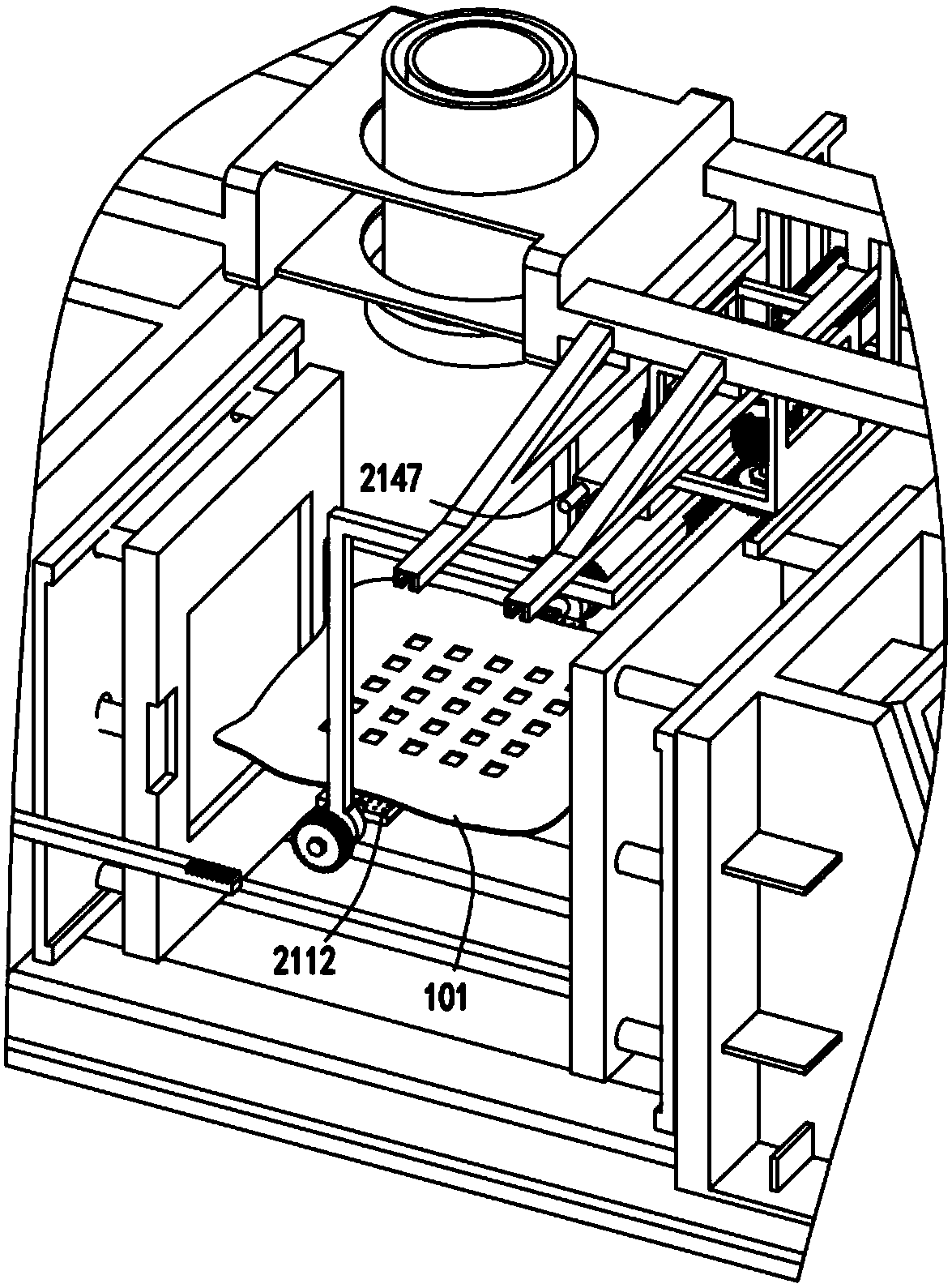

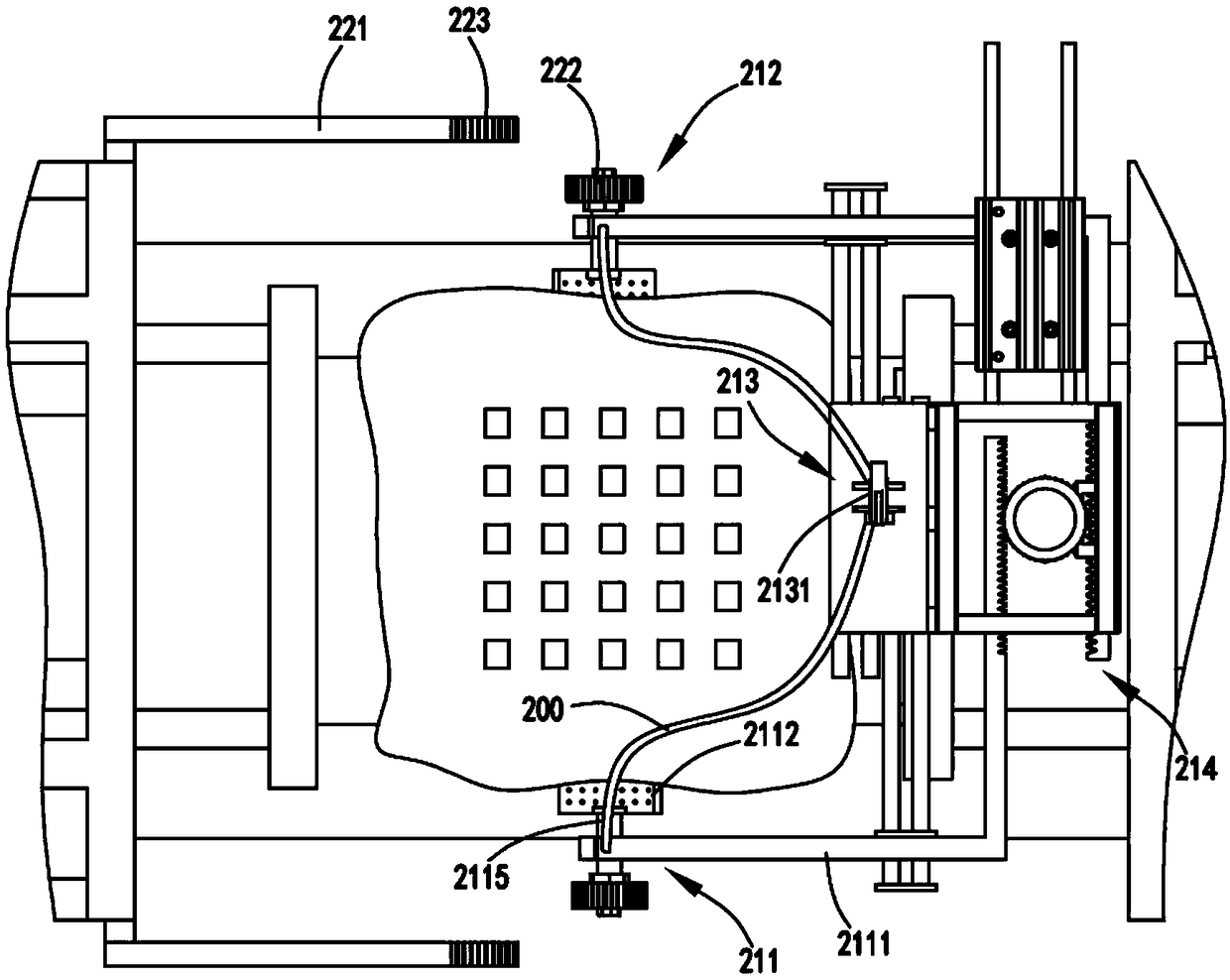

Automatic demolding and trimming PP plastic part forming equipment and process

The invention relates to automatic demolding and trimming PP plastic part forming equipment and a process. The equipment comprises a forming device which comprises a convex mold mechanism, a concave mold mechanism and a material injection mechanism arranged above the position between the convex mold mechanism and the concave mold mechanism. The equipment also comprises a discharging device arranged on one side of the material injection mechanism and a trimming device arranged on the same side of the convex mold mechanism and the concave mold mechanism. The discharging device comprises a fixingmechanism which adsorbs and fixes leftover materials of a desk plate, an overturning mechanism which drives the fixing mechanism to overturn to be in a flatwise state together with the desk plate anda moving-out mechanism which drives the fixing mechanism to be moved out to reach the trimming device together with the desk plate; the trimming device comprises a push-down mechanism which pushes the desk plate to move downwards vertically and settles the material flash wastes of the desk plate and a cropping mechanism which crops the leftover materials in the reset process of the push-down mechanism. The equipment provided by the invention solves the problems that a plastic desk plate is low in forming and demolding efficiency, the equipment is low in efficiency and wastes labor as a resultof manual operation needed by discharge, the surface of the desk plate is easily damaged and the leftover materials of the desk plate are inconveniently cropped in the discharging process, and the cropping effect is poor and the efficiency is low.

Owner:ZHEJIANG LIFAN FURNITURE

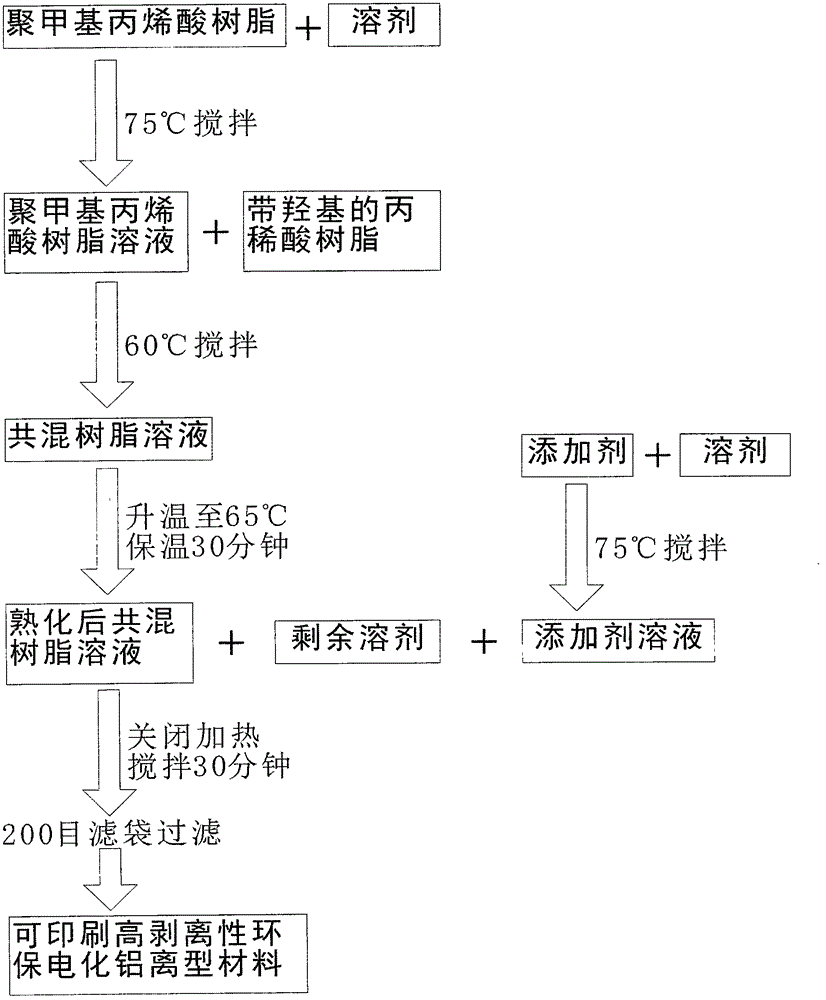

Printable environment-friendly electric aluminium release type material with high strippability

InactiveCN105885506AExcellent peelabilityIncrease surface tensionCoatingsHot stampingPolymer science

The invention discloses a printable environment-friendly electric aluminium release type material with high strippability. The material has the advantages of good strippability, excellent trimming performance, few influence on environments during production and usage processes, short production period, and wide application to cold stamping films and hot stamping films. The material is prepared by the following steps: 1. polymethacrylic resin is added into a solvent with stirring, after dissolving, acrylic resin with hydroxyl is added with stirring, and a blended resin solution is obtained; 2. an additive is added into the solvent with stirring in order to obtain an additive solution; 3. the stirred blended resin solution and the additive solution are blended, a solvent is added with stirring, after stirring, a 200 mesh filter bag is used for filtering, and the printable environment-friendly electric aluminium release type material with high strippability is prepared.

Owner:GUANGDONG LASER OPTRONICS TECH

UV (ultraviolet) cold stamping glue

ActiveCN104263311ASimple production processImprove trimming effectNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterAryl

The invention discloses UV (ultraviolet) cold stamping glue. The UV cold stamping glue contains urethane acrylate oligomer, polyester acrylate oligomer, epoxy acrylate oligomer, phosphate adhesion promoters, acrylate monomer and auxiliaries, wherein the glue further contains ester-soluble vinyl chloride-vinyl acetate resin and aryl (methyl) semi-acrylate. The UV cold stamping glue disclosed by the invention has excellent adhesion on a vacuum coating, especially an aluminum-coated layer. The UV cold stamping glue can be used for solving the technical state that a connecting layer is needed to be additionally arranged outside a vacuum coating for an existing cold stamping film, thereby simplifying the production process of the cold stamping film, lowering the manufacturing cost of the cod stamping film and reducing the emission of VOC (volatile organic compounds).

Owner:WUHAN HUAGONG IMAGE TECH & DEV

Grinding wheel dressing mechanism with position-adjustable dresser

ActiveCN103537984ALarge adjustment rangeMany modelsAbrasive surface conditioning devicesElectric machineryDrive motor

The invention discloses a grinding wheel dressing mechanism with a position-adjustable dresser. The grinding wheel dressing mechanism comprises a dresser mounting seat. The dresser mounting seat comprises a top plate. A dresser regulating seat is supported on the dresser mounting seat and provided with strip-shaped holes, each strip-shaped hole is penetratingly connected with a first bolt, a dresser regulator is fixed on the dresser mounting seat through the first bolts, an opening is formed in the top plate of the dresser mounting seat, and the dresser capable of moving or swinging in a position where the opening is formed is arranged in the position of the opening of the top plate. The dresser comprises a vertically-arranged driving motor which is supported by the dresser regulating seat and connected with a dressing-wheel main shaft device, and the other end of the dressing-wheel main shaft device penetrates the top plate from a position of the opening to be connected with the dressing wheel. The grinding wheel dressing mechanism is reasonable in structural design, large in regulation range of the dresser, large in the amount of types of grinding wheels capable of being dressed, high in regulating precision, large in machinable range and good in dressing effect.

Owner:江门杰能刀剪装备科技有限公司

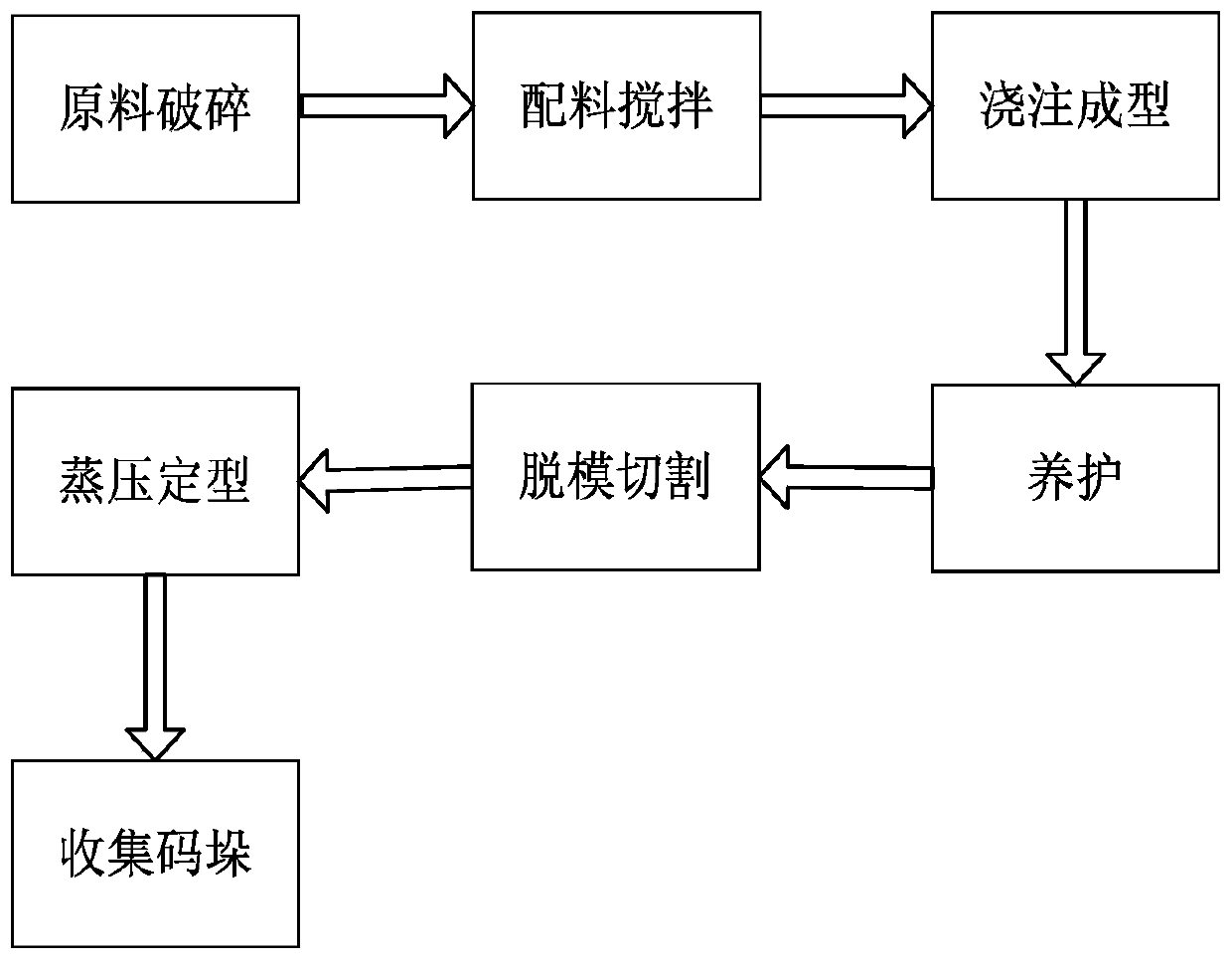

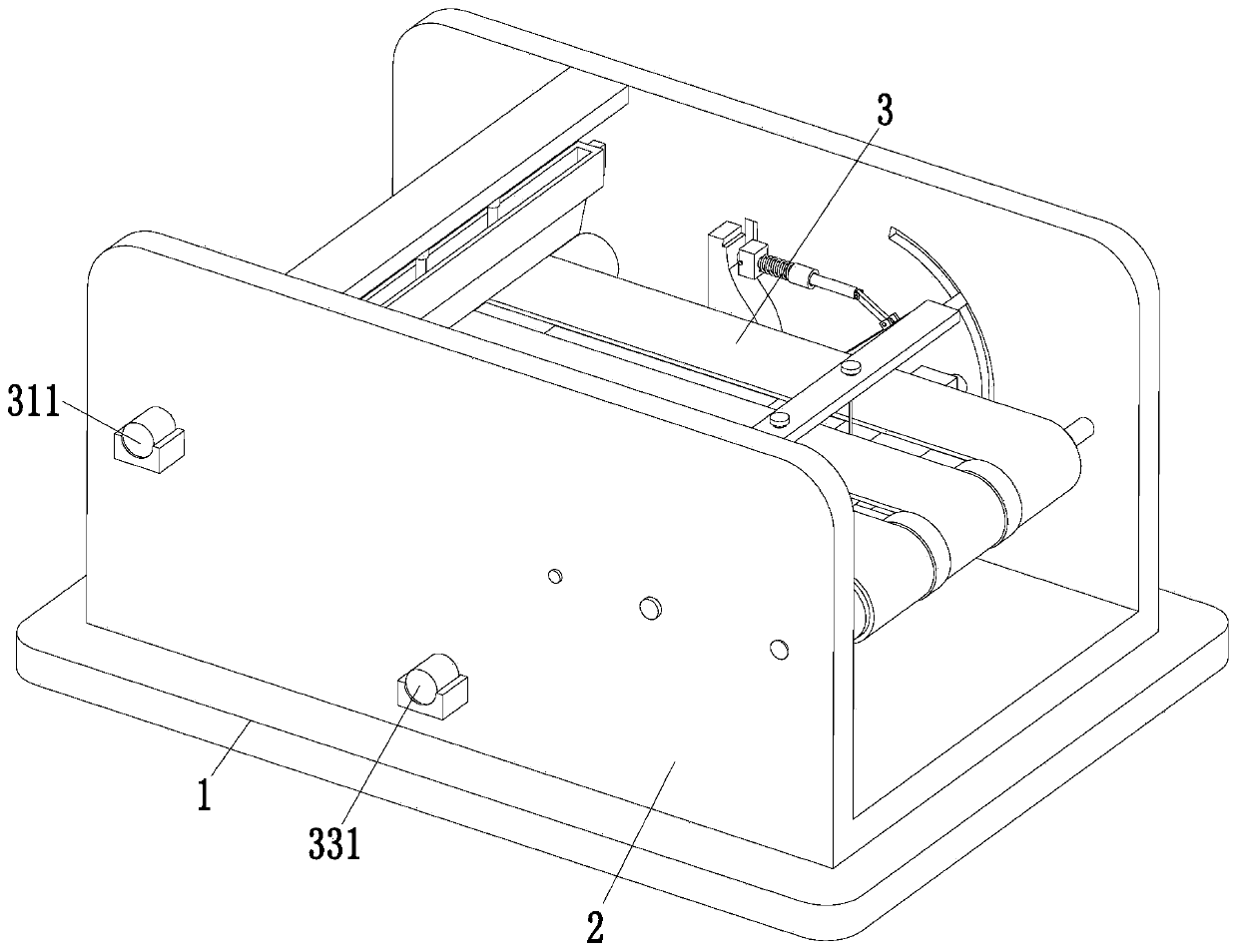

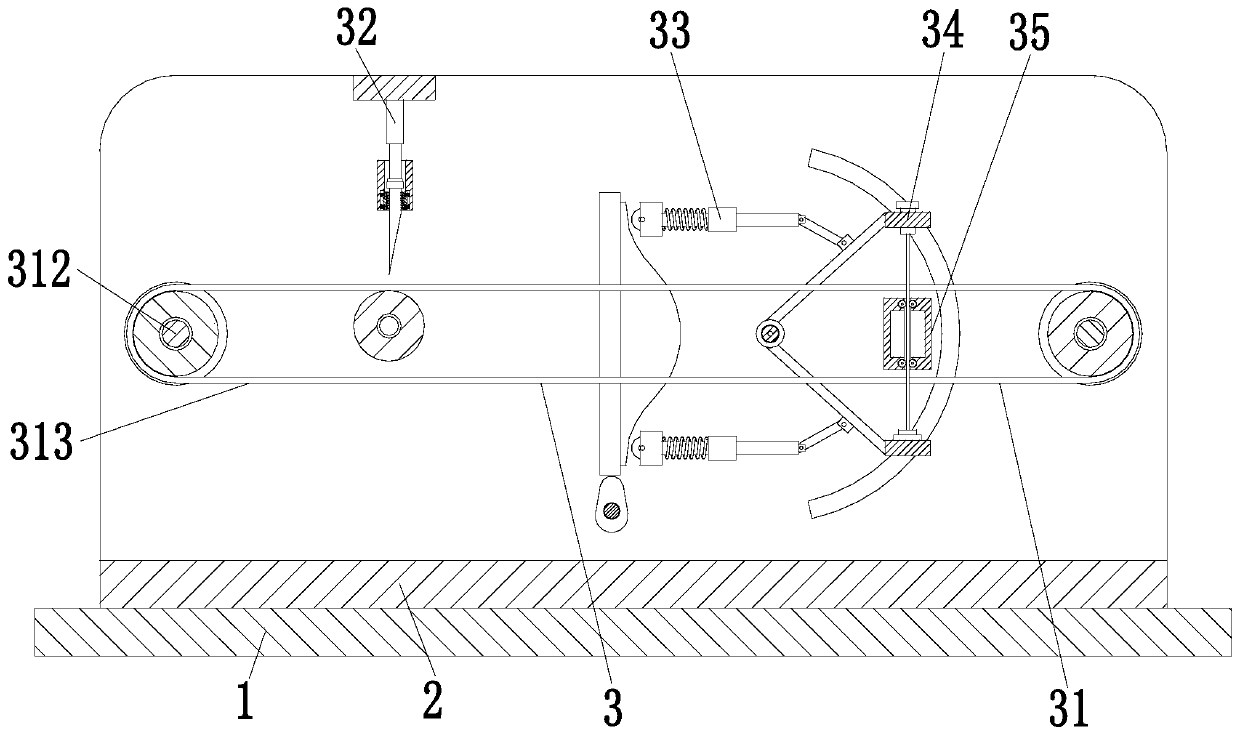

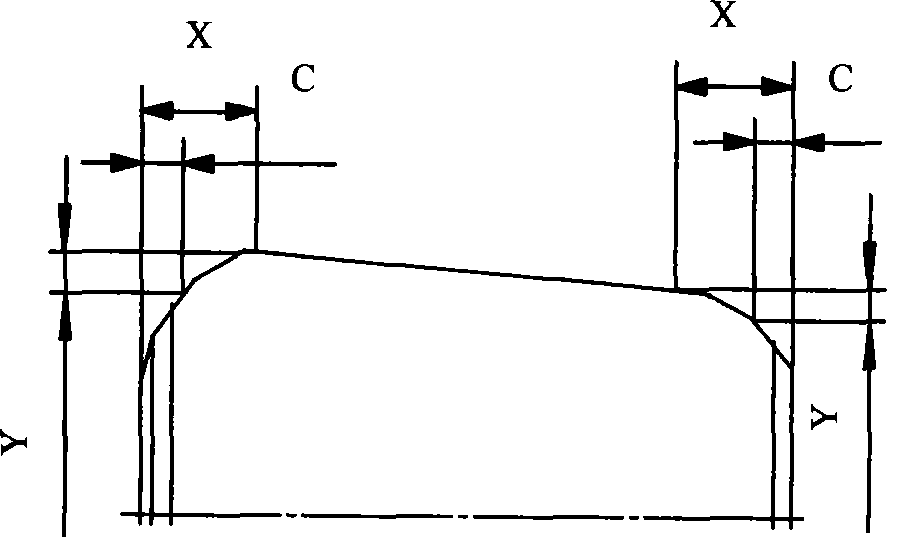

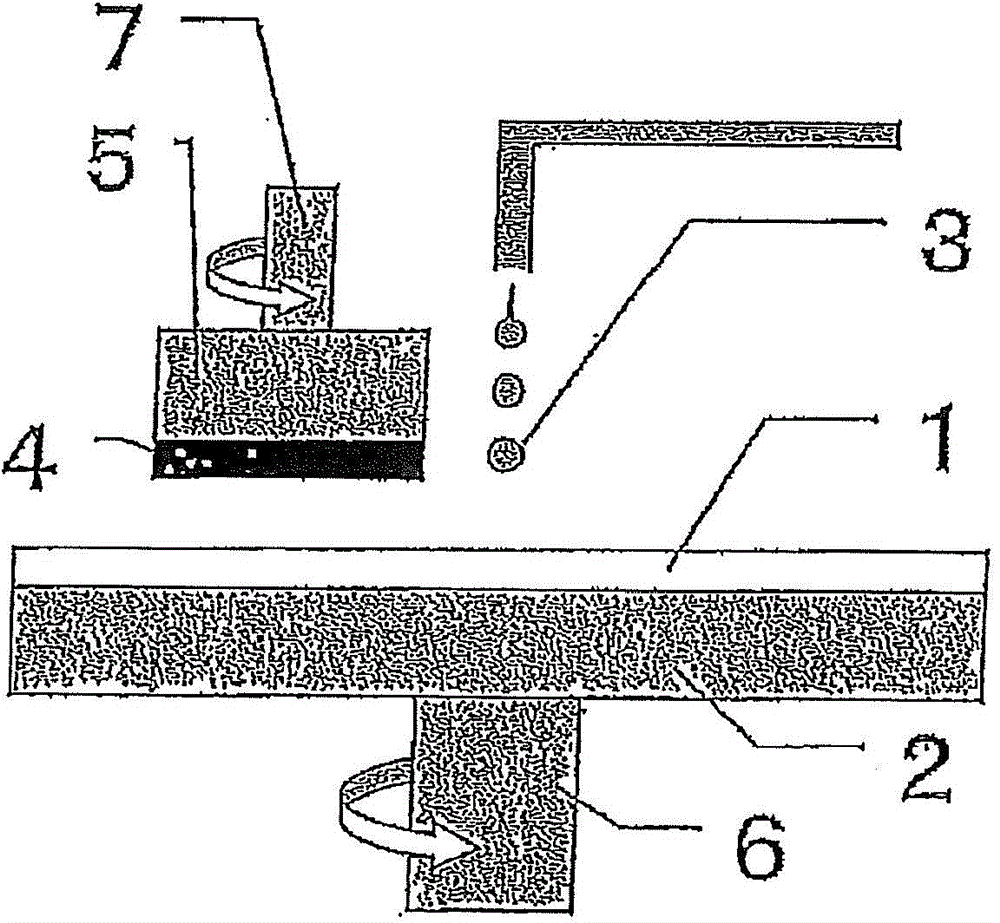

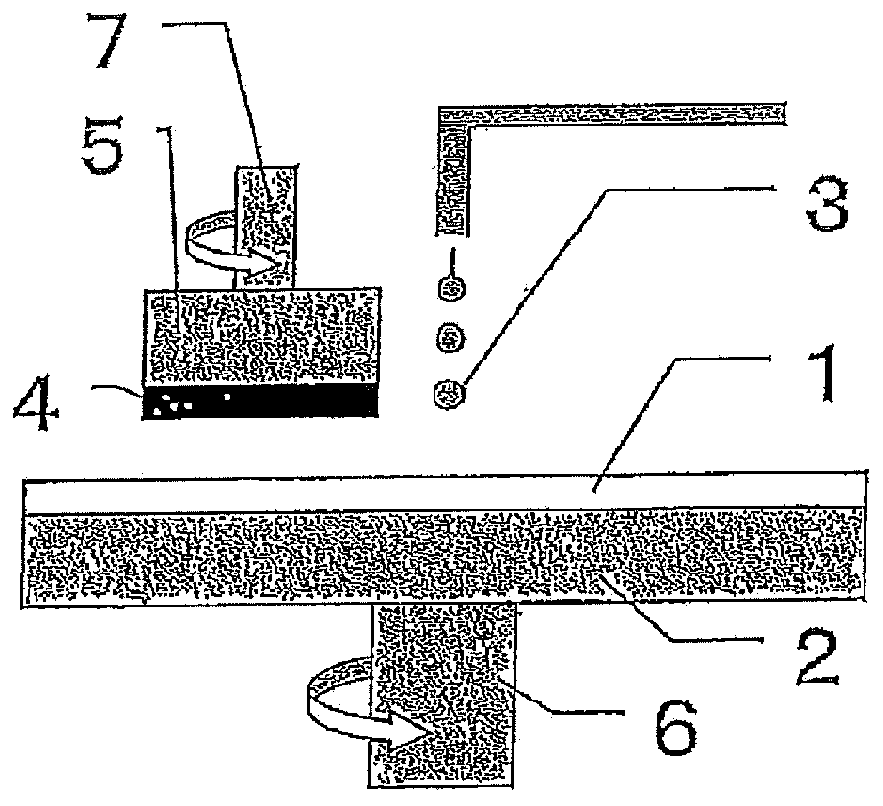

Technology for preparing, forming and processing aerated concrete blocks

ActiveCN111438809AAffect the use effectSo as not to damageDischarging arrangementFeeding arrangmentsArchitectural engineeringWire cutting

The invention relates to a technology for preparing, forming and processing aerated concrete blocks. A bottom plate, a supporting frame and a cutting device are included, the supporting frame is installed in the middle of the upper end of the bottom plate, the section of the supporting frame is of a U-shaped structure, and the cutting device is installed in the supporting frame. The technology cansolve the problems that when existing equipment cuts a concrete green body, the cutting effect is poor, edge cutting is uneven, during cutting, the concrete green body is prone to damage, the subsequent using effect of the concrete green body is affected, and when the existing equipment conducts linear cutting on the concrete green body, impurities adhering to the surface of a cutting steel wirecannot be effectively and rapidly removed, consequently, the section of the cut green body is uneven, and the surface quality of the block is affected.

Owner:安徽阜阳富龙建筑材料有限责任公司

Method for grinding conical bearing large cone angle roller for wind power generation

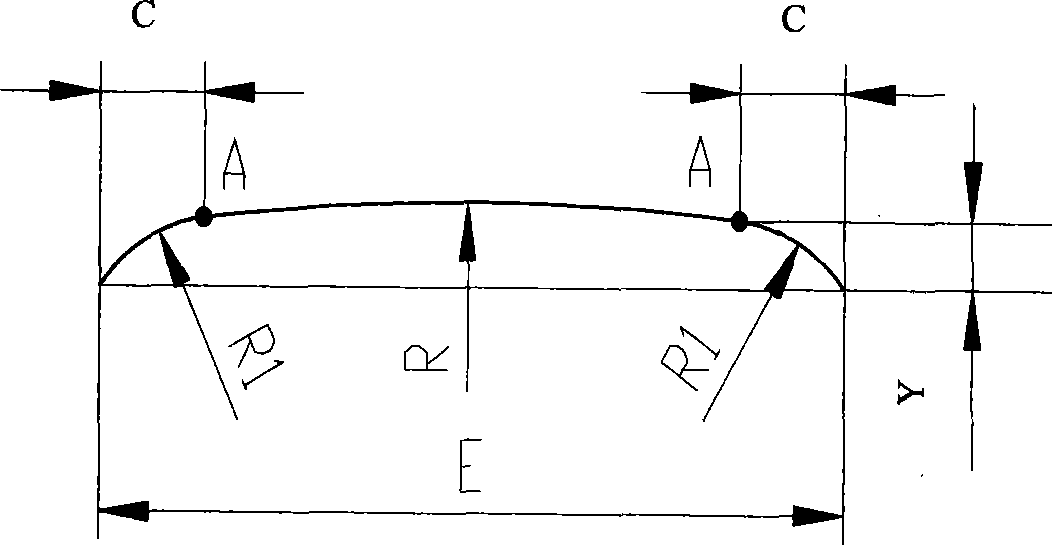

ActiveCN101462245AGood self-sharpeningSelf-sharpening moderately bluntRevolution surface grinding machinesGraphicsPosition tolerance

The invention relates to a processing method for grinding a large cone-angle roller of a wind power generation conical bearing, which comprises the following steps: 1, performing plunge grinding for multiple times through fine grinding and accurate grinding on the same machine tool of a novel grinding machine MG1080B; 2, performing plunge grinding on the outside diameter of a taper roller, and using a grinding wheel master plate with the diameter R of 100 meters to perform processing and using a manual oilstone to perform reciprocating grinding, wherein the outside diameter allowances of the roller are different and are divided into three parts, the size of the outside diameter of the roller after the final grinding is 1.5mu m, and the convexity of the outside diameter of the roller is 1.5mu m; and 3, adopting a grinding wheel master plate with the diameter R of 40 meters to process grinding slopes on two ends of the roller, and adopting a rubber grinding wheel of No. 100 to process radial graphics singly through an anti-thrust method, wherein when the slope depth, the slope length and the surface roughness reach between 13 and 21mu m and Ra is 0.08mu m, two bearing inner races are combined into a whole. With the method, the outside diameter form and position tolerance of the taper roller always reaches the technological requirements, and the difficulties in the process of grinding the outside diameter of the large cone-angle taper roller are overcome.

Owner:WAFANGDIAN BEARING GRP CO LTD

ABS seal composite material

InactiveCN103232670AImprove heat resistanceImprove trimming effectPolypropyleneEnvironmental resistance

The invention discloses an ABS seal composite material, which comprises the following materials by weight: 50-80 parts of ABS resin, 10-15 parts of calcium stearate, 10-14 parts of stearic acid, 1-9 parts of polyacrylate, 10-30 parts of calcium carbonate, 10-20 parts of polypropylene ester, 4-15 parts of oxidized polyethylene, 10-16 parts of an ultraviolet absorbent, 10-15 parts of an antistatic agent, 5-9 parts of plasticized starch, 5-12 parts of a degradation promoting agent, 10-12 parts of a dispersant, 10-12 parts of antimony trioxide, 10-15 parts of a glass fiber, and 10 parts of a compatilizer. With the ABS seal composite material disclosed in the invention, the heat resisting ability and trimming effect of furniture edge seals are improved, so that the heat resistance and service life of furniture can be enhanced. At the same time, the ABS resin contains no oxygen element, and its degradation has no adverse effect on the environment, so that the composite material has safety and environmental protection properties.

Owner:青岛永卓真塑料制品有限公司

Full-automatic cloth edge cutting device

ActiveCN108149465AReduce labor intensityImprove trimming effectMarking textilesSevering textilesWorking environmentEngineering

The invention provides a full-automatic cloth edge cutting device which comprises a working table. An edge cutting device body, a dust suction device and a heating device are sequentially arranged onthe working table from the cloth inlet end. The edge cutting device body comprises a control mechanism and two mechanical hands. The first mechanical hand can drive a fluorescent ink pen to draw lineson cloth, and the second mechanical hand can drive a blade to edge edges of cloth. Cloth of different widths can be automatically and continuously cut by means of the control mechanism of the edge cutting device body, labor intensity is reduced, work efficiency is improved, and the edge cutting effect is high; cut-off cloth is collected through the dust suction device, and therefore the working environment is improved, and work efficiency is improved; a fluorescent agent left when cloth is subjected to line drawing and cutting is removed through high-temperature wastewater, and environment protection and energy conservation are achieved.

Owner:佛山市格元科技服务有限公司 +1

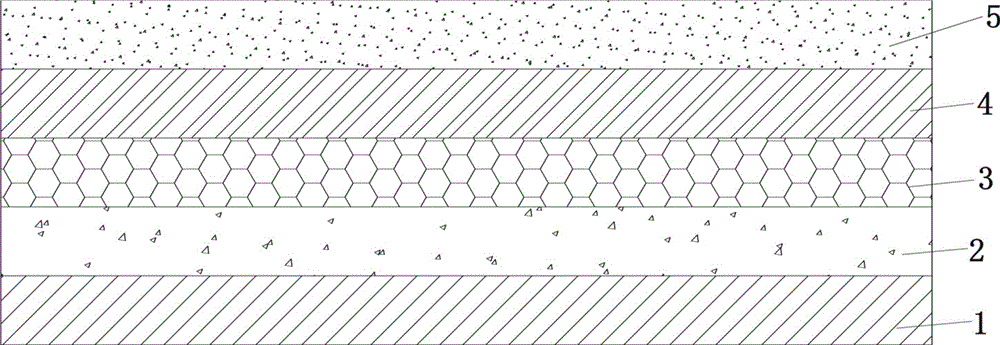

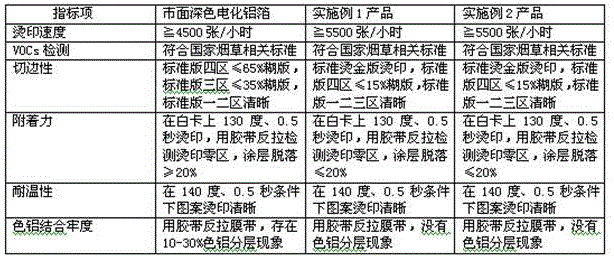

Dark electrochemical aluminium foil with applicable thermoprinting scope

ActiveCN107433814AImprove trimming effectSmall molecular weightNon-macromolecular adhesive additivesDecorative surface effectsFine lineLeveling effect

The invention provides a dark electrochemical aluminium foil with an applicable thermoprinting scope. The electrochemical aluminium foil comprises a carrier membrane, a release layer, an imaging layer, an aluminum plating layer and a glue layer, the imaging layer comprises the following components by weight percentage: 14.5-16% of amino-acrylic resin, 13-14% of methyl hydroxy modified acrylic resin, 5-7% of nitrocellulose, 37-40%of butanone, 24-26% of butyiate, and 4.5-5.5% of color powder; the imaging layer employs template roller printing with 180 meshes, and the dry coating amount is 1.26+ / -0.05 g / m<2>. According to the dark electrochemical aluminium foil, the coating apparent leveling effect of the imaging layer is good, the moulding effect is good, the moulding effect is good, the color aluminium combination fastness is high, moulding is carried out without coating the imaging layer with a layer of protective layer, the dark electrochemical aluminium foil is suitable for thermoprinting the patterns with small area or fine line patterns, the cost is saved, and the applicable thermoprinting scope is widened.

Owner:GUANGDONG XINRUI NEW MATERIAL TECH

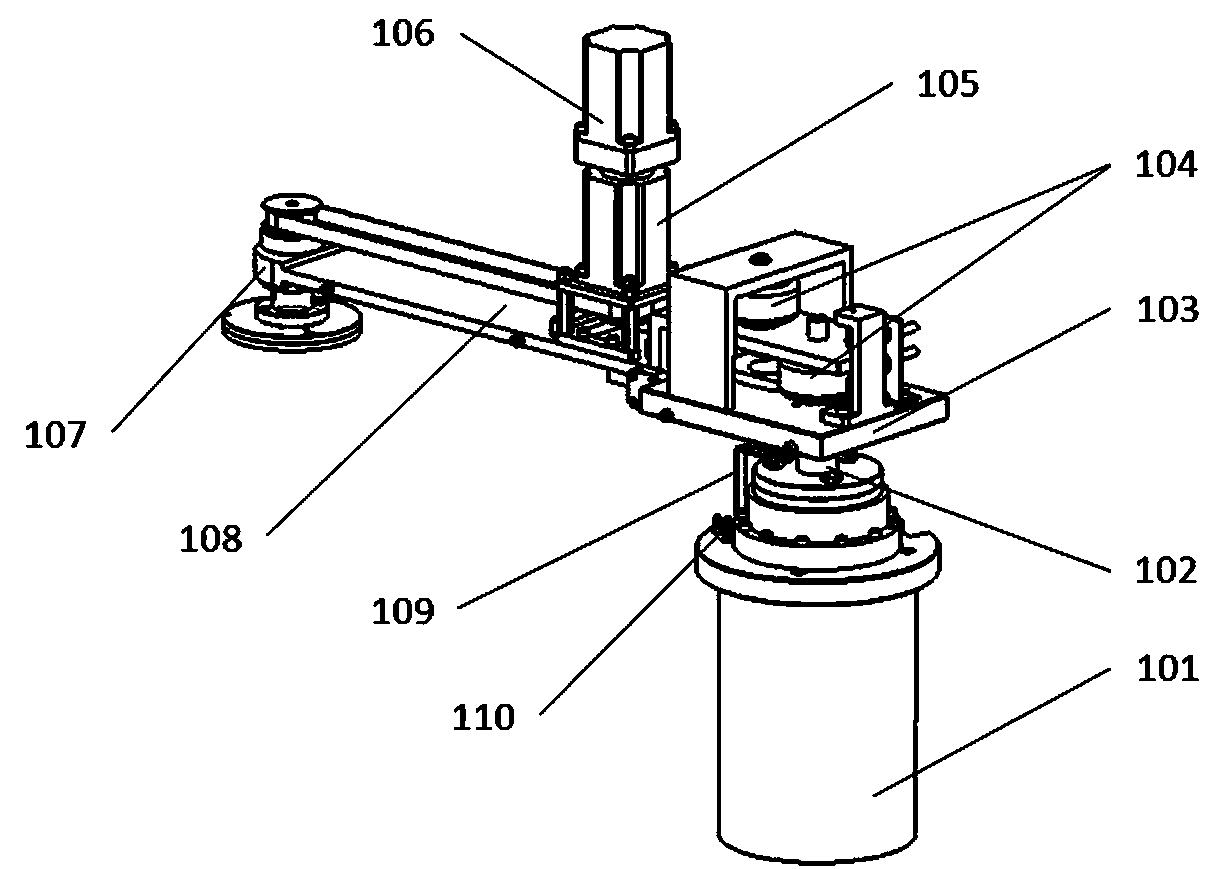

Polishing pad finisher used for wafer chemical-mechanical planarization equipment

ActiveCN103506956ASimple structure and controlNo cross contaminationAbrasive surface conditioning devicesChemical-mechanical planarizationControl mode

The invention discloses a polishing pad finisher used for wafer chemical-mechanical planarization equipment. The polishing pad finisher is mainly composed of a rack, a motor, a speed reducer, an air bag, a synchronous belt, belt wheels, a swing arm, a supporting shaft, a supporting bottom plate, a ball universal structure, a detecting sensor and other components. A lever mechanism inflates the air bag to drive the swing arm to rise, fall and exert finishing force on a polishing bench. By the adoption of the belt wheel transmission mode, the motor and the speed reducer are placed away from a polishing area, and meanwhile a stainless steel protective cover is installed outside the whole finisher to prevent internal electronic components from being corroded. The ball universal structure is arranged at the finishing end to solve the contact problem of a finishing wheel and the polishing bench surface. The polishing pad finisher is simple in structure and control mode, free of cross pollution and good in finishing effect and meanwhile remarkably prolongs service life of a polishing pad.

Owner:THE 45TH RES INST OF CETC

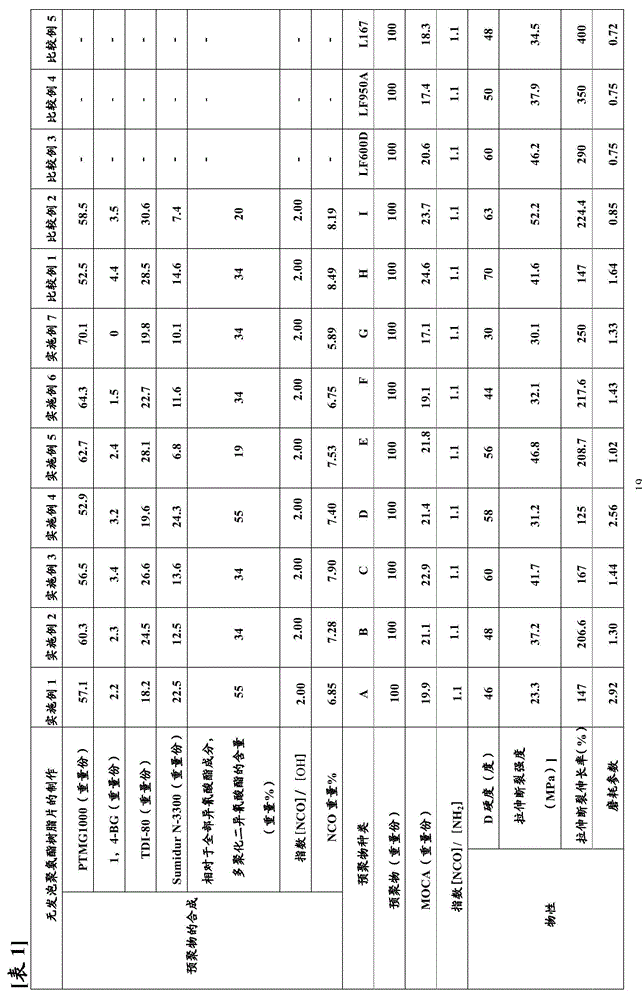

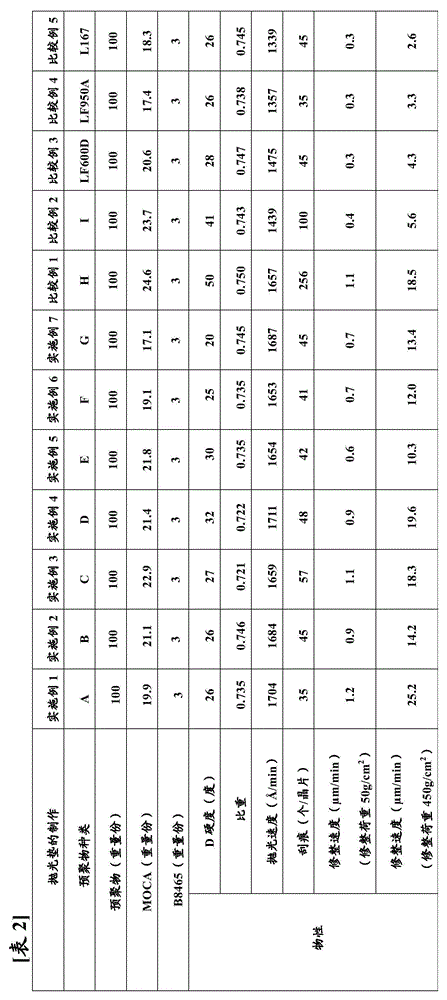

Polishing pad

InactiveCN103958125ALow hardness and softLarge wear parametersAbrasion apparatusSemiconductor/solid-state device manufacturingBreaking strengthHardness

An aim of the present invention is to provide a polishing pad which generates almost no scratches on the surface of an object to be polished, and has improved dressability. Another aim of the present invention is to provide a semiconductor device manufacturing method using the polishing pad. The polishing pad according to the present invention comprises a polishing layer formed of a microbubble-containing polyurethane resin foam. The polyurethane resin foam contains a polyurethane resin whose asker D hardness is between 20 degrees and 60 degrees, and whose wear parameter, which is expressed by the following formula, is between 1 and 3. Wear parameter = {1 / (tensile breaking strength [MPa] tensile breaking elongation [%] / 100)} 100

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Inner wall trimming device for composite steel pipe

InactiveCN108067956AHigh glossEffective protectionRevolution surface grinding machinesGrinding drivesSpray nozzleMechanical engineering

The invention discloses an inner wall trimming device for a composite steel pipe. The inner wall trimming device comprises a workbench and a polishing device. A first clamp is fixedly installed at oneside of the workbench, and a second clamp is fixedly installed at one side of the first clamp. A driving device is fixedly installed at the other side of the workbench. A motor is arranged in an inner cavity of the driving device. A spindle of the motor is connected with a rotating shaft in a rotating mode. The polishing device is connected with the rotating shaft in a rotating mode and is further composed of a polishing rod and a liquid spraying pipe. The polishing rod and the liquid spraying pipe are fixedly connected through a fixing shaft. Polishing wheels are installed at the two ends ofthe polishing rod in a rotating mode, and one side of each polishing wheel is provided with a spring piece. Spraying nozzles are arranged at the two ends of the liquid spraying pipe, and one end of each spraying nozzle is provided with a valve. A connecting piece is fixedly installed at the lower end of the driving device. A ball screw is arranged on the workbench. A servo motor is arranged at one end of the ball screw. The inner wall trimming device for the composite steel pipe is simple in structure, convenient to use and practical.

Owner:TIANJIN HAOHANG COMPOSITE PIPE

Polishing pad

InactiveCN103764346AImprove trimming effectImprove production efficiencySemiconductor/solid-state device manufacturingLapping machinesPolyolHardness

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com