Blockboard automatic edge cutting device

A technology for woodworking boards and cutting devices, which is applied to feeding devices, clamping devices, wood processing appliances, etc., can solve problems such as potential safety hazards, large size errors of woodworking boards, and high labor intensity, and achieve improved safety and stable feeding , Reduce the effect of potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

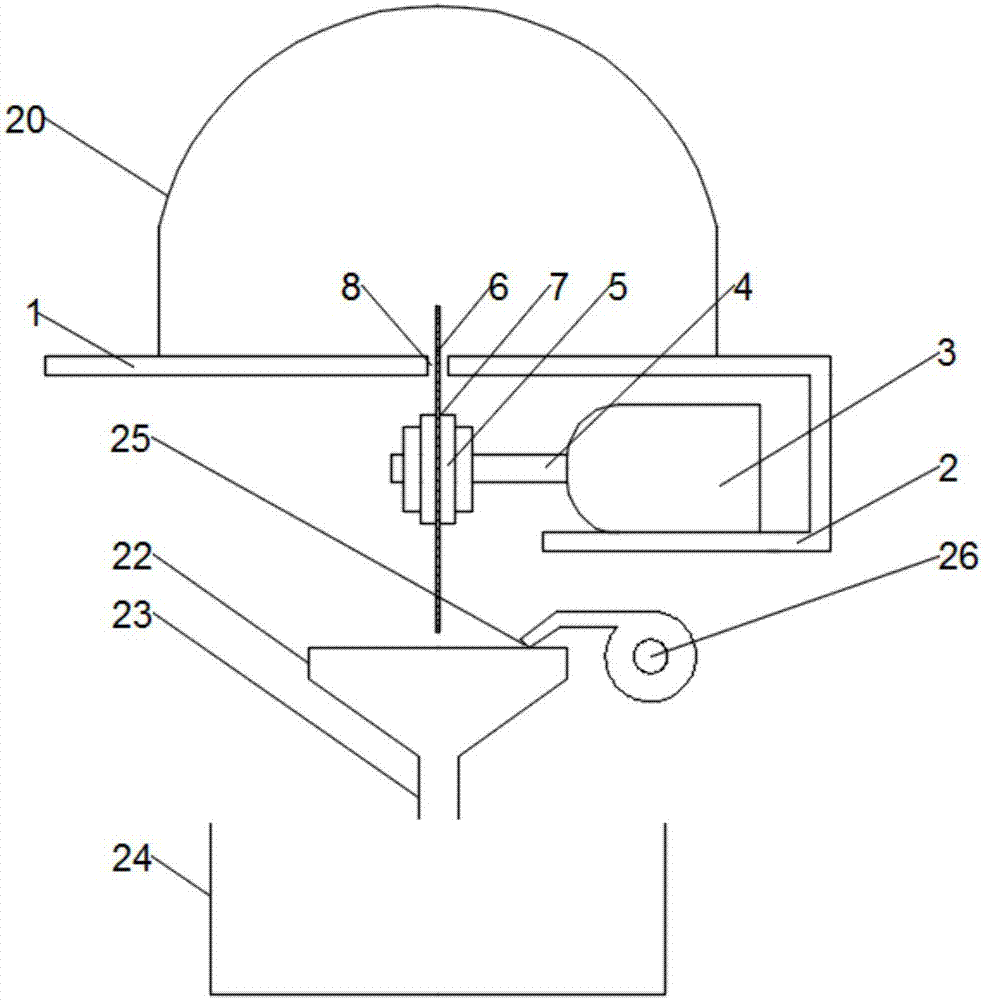

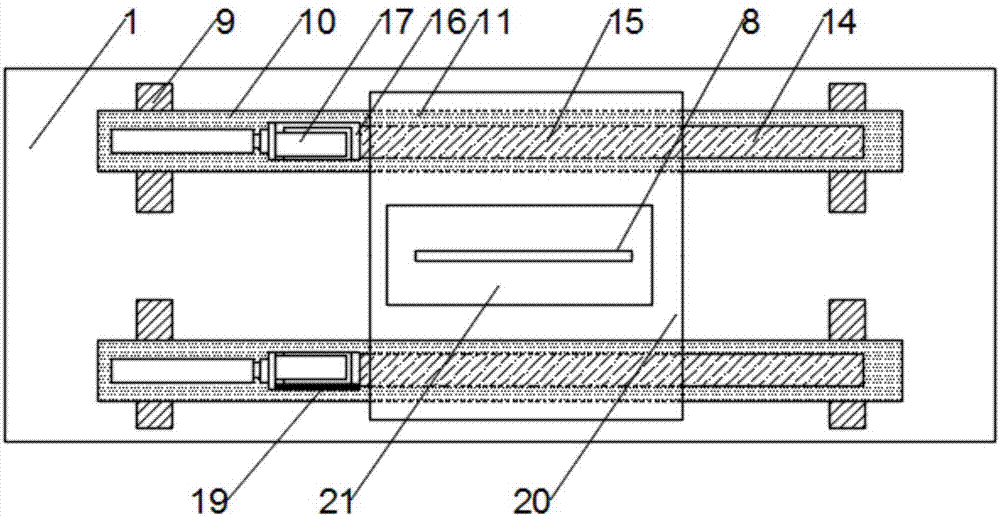

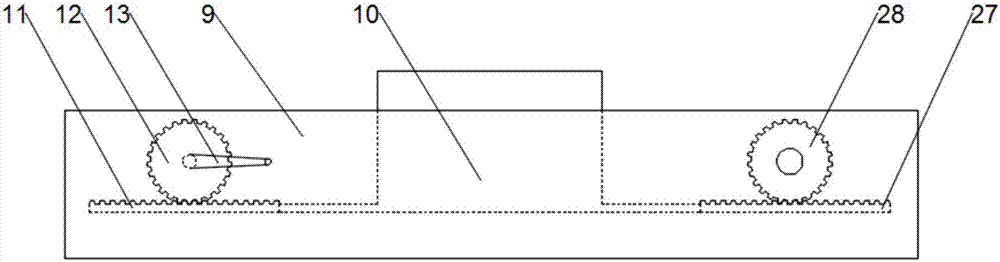

[0021] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a woodworking board automatic trimming device provided by the present invention includes a workbench 1, a receiving platform 2 is provided under the working platform 1, and a cutting device is provided on the receiving platform 2, and the cutting device includes a rotating shaft Motor 3, the rotating shaft motor 3 is fixed on the receiving platform 2, the output shaft of the rotating shaft motor 3 is connected with a rotating shaft 4, a tool seat 5 is installed on the rotating shaft 4, and the tool seat 5 rotates with the rotating shaft 4, so A circular blade 6 is fixedly installed on the cutter seat 5, and the edge of the blade 6 is provided with sawtooth 7, and the upper end surface of the workbench 1 is provided with a slit 8, and the upper end of the blade 6 passes through the slit 8, The distance adjusting device is provided on the workbench 1, and the distance adjusting device includes a distance a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com