Patents

Literature

613results about "Wood splitting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

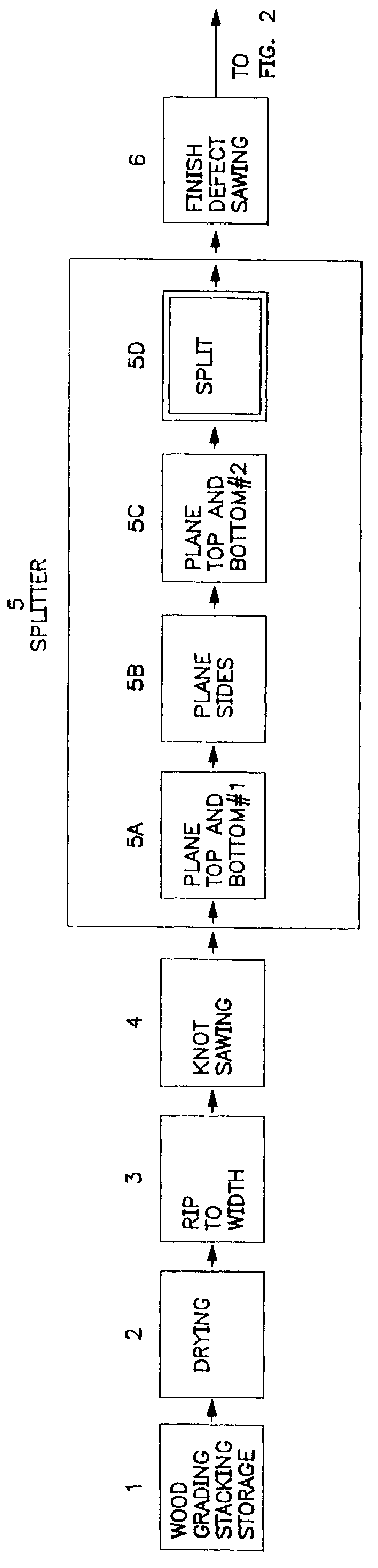

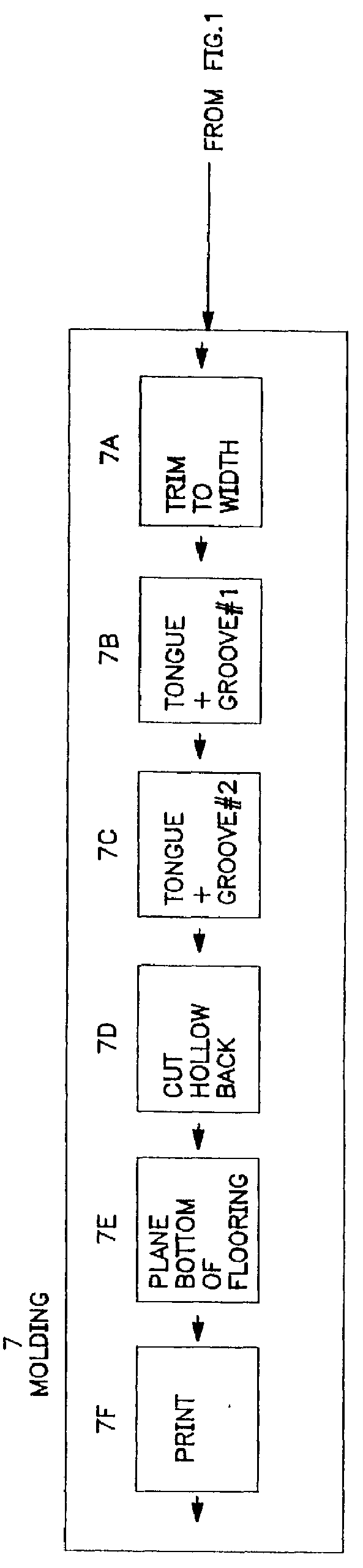

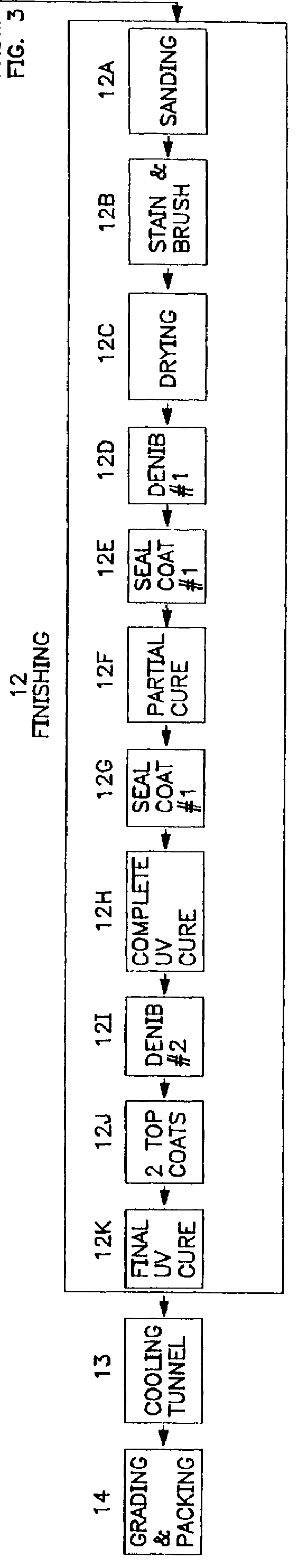

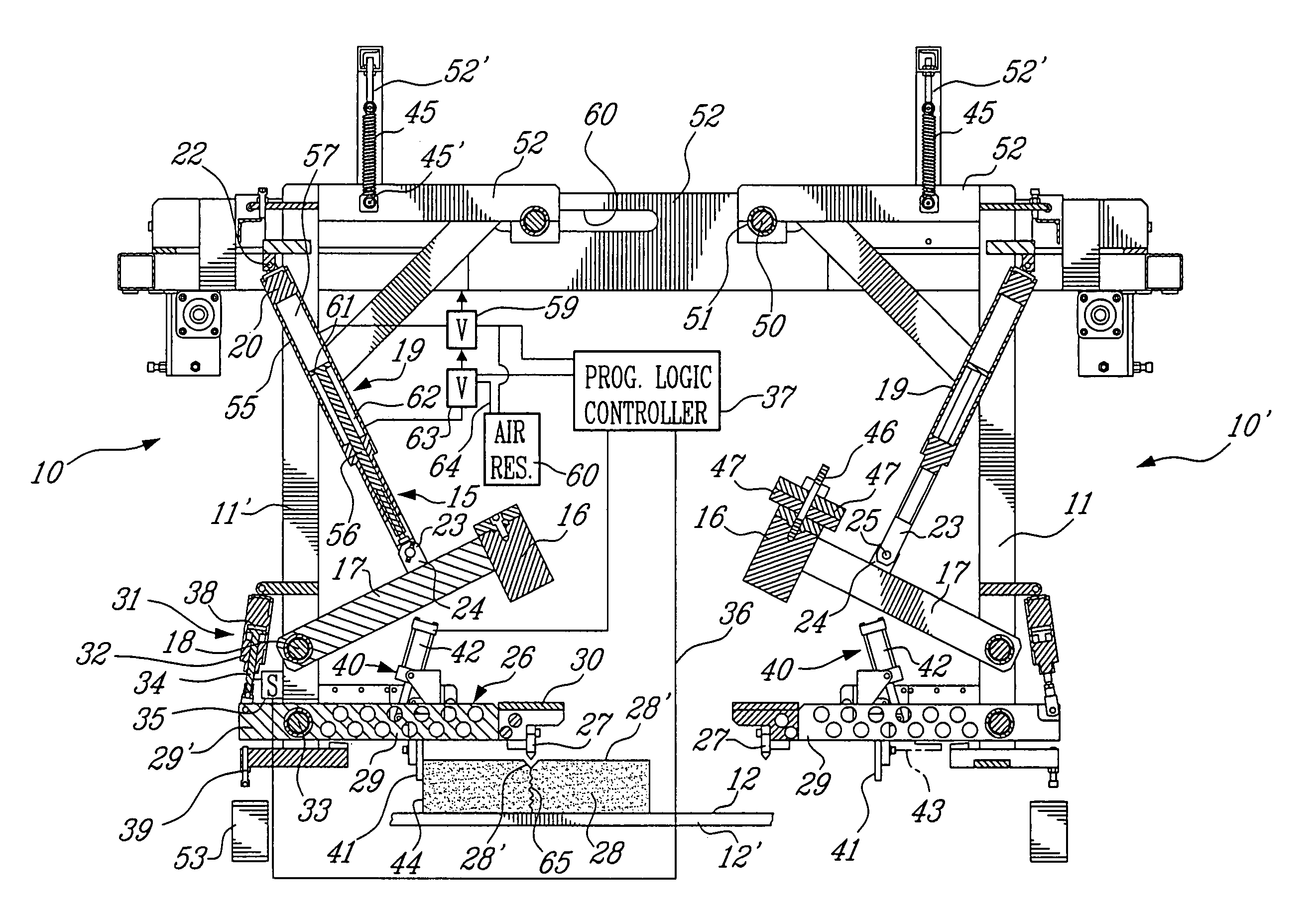

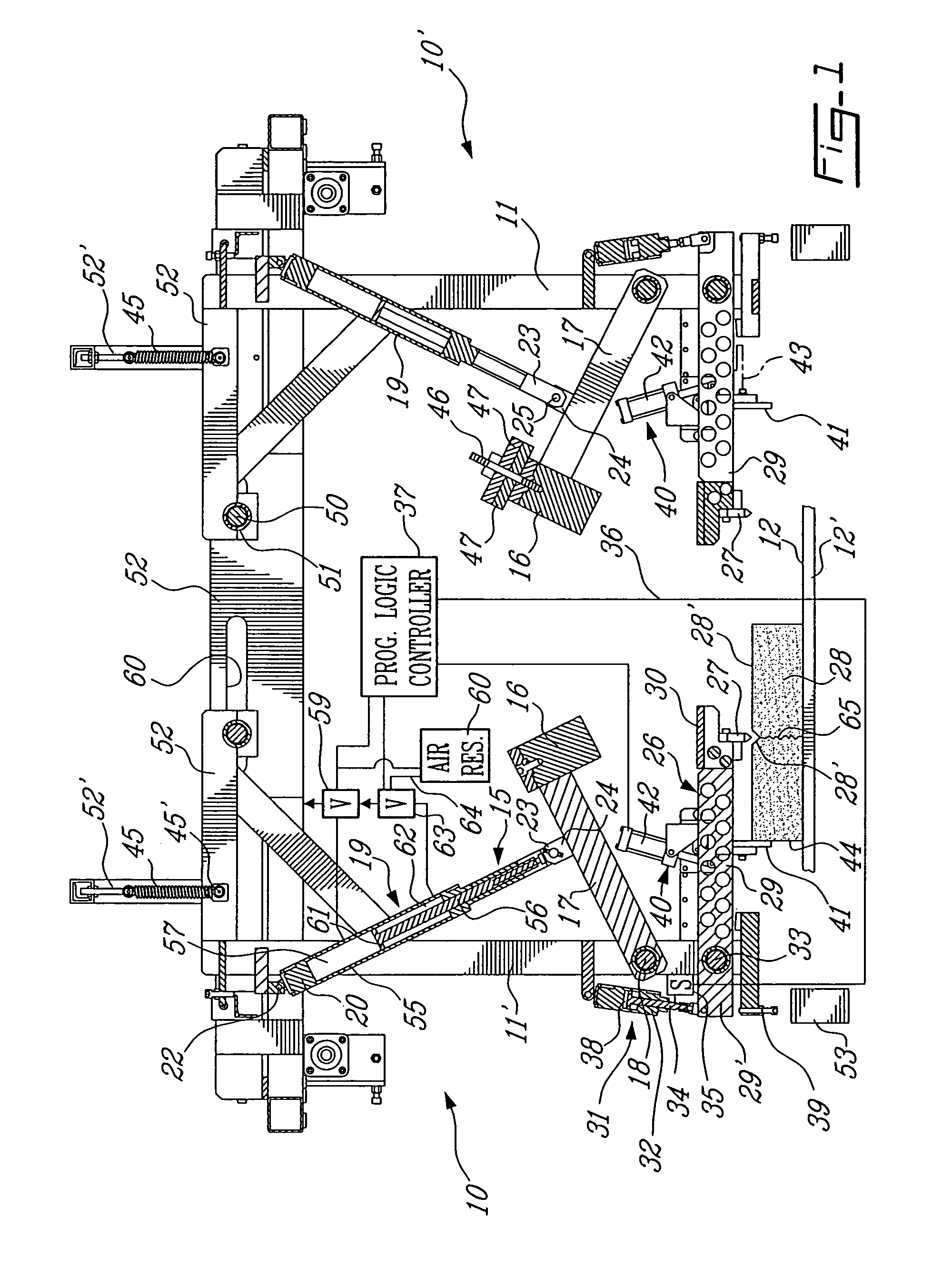

Low profile hardwood flooring strip and method of manufacture

InactiveUS6148884AConsiderable quantityImprove rigidityDovetailed workMulti-purpose machinesCircular sawTongue and groove

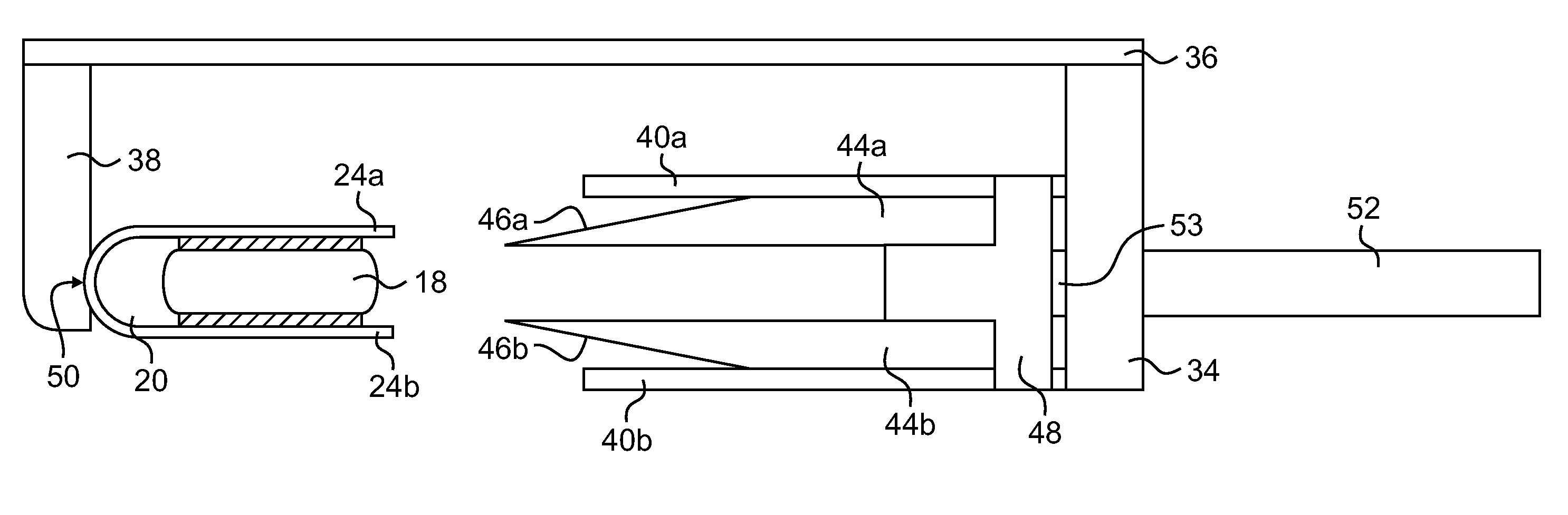

A method of producing a hardwood flooring product, including the steps of processing a strip of raw wood into a blank having a predetermined thickness and width, and top and bottom surfaces defining parallel planes relative to each other, and splitting the blank along the width of the blank from one side to the other to form two low profile flooring strips having the same width as the blank and a thickness less than one-half the thickness of the blank. The splitting step includes the steps of providing first and second circular saw blades mounted on spaced-apart vertical axes for rotation in a single plane intermediate and parallel to the planes of the top and bottom surfaces of the blank and positioning the blank on conveying means upstream from the saw blades with the plane of rotation of the saw blades intermediate and parallel to the planes of the top and bottom surfaces of the blank for movement of the blank from an upstream position to a downstream position relative to the saw blades. The blank is moved downstream into the plane of rotation of the saw blades during rotation of the saw blades thereby horizontally splitting the blank to form first and second low-profile flooring strips. Interlocking members, such as molded, mating tongue and groove members, are molded into first and second longitudinally-extending side edges of the flooring strips for securing together the flooring strips when placed side-to-side to form a floor.

Owner:ARMSTRONG HARDWOOD FLOORING CO +2

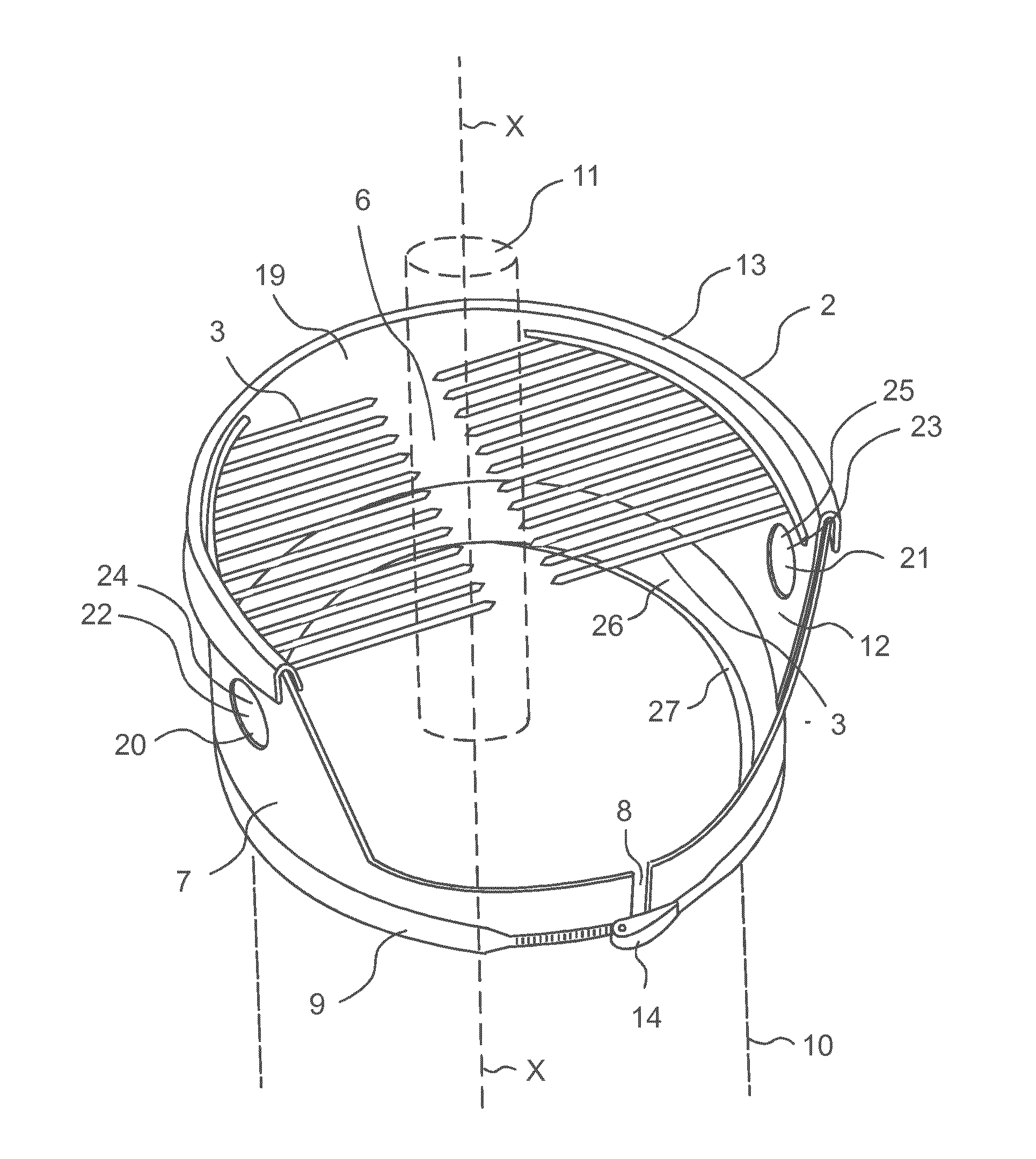

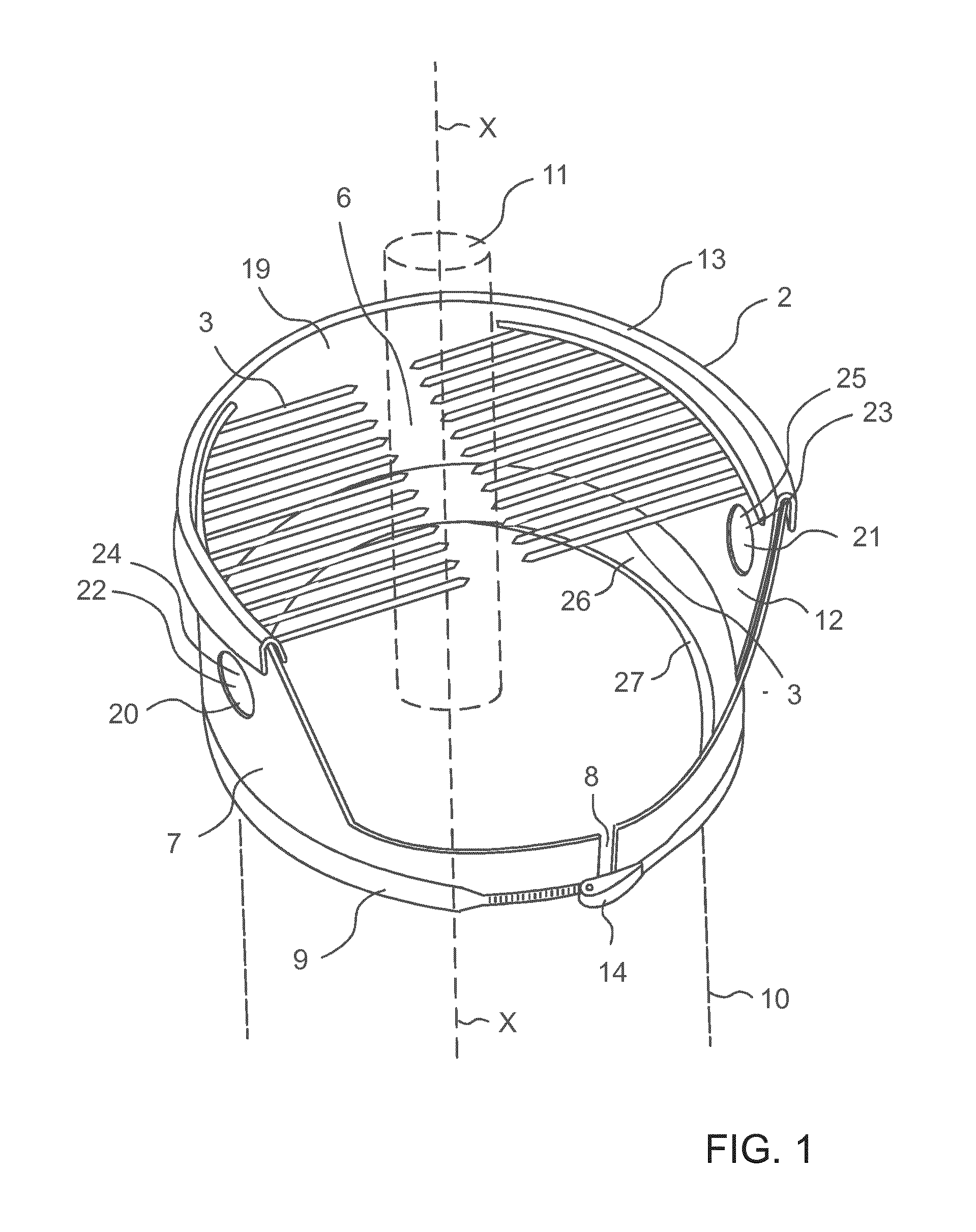

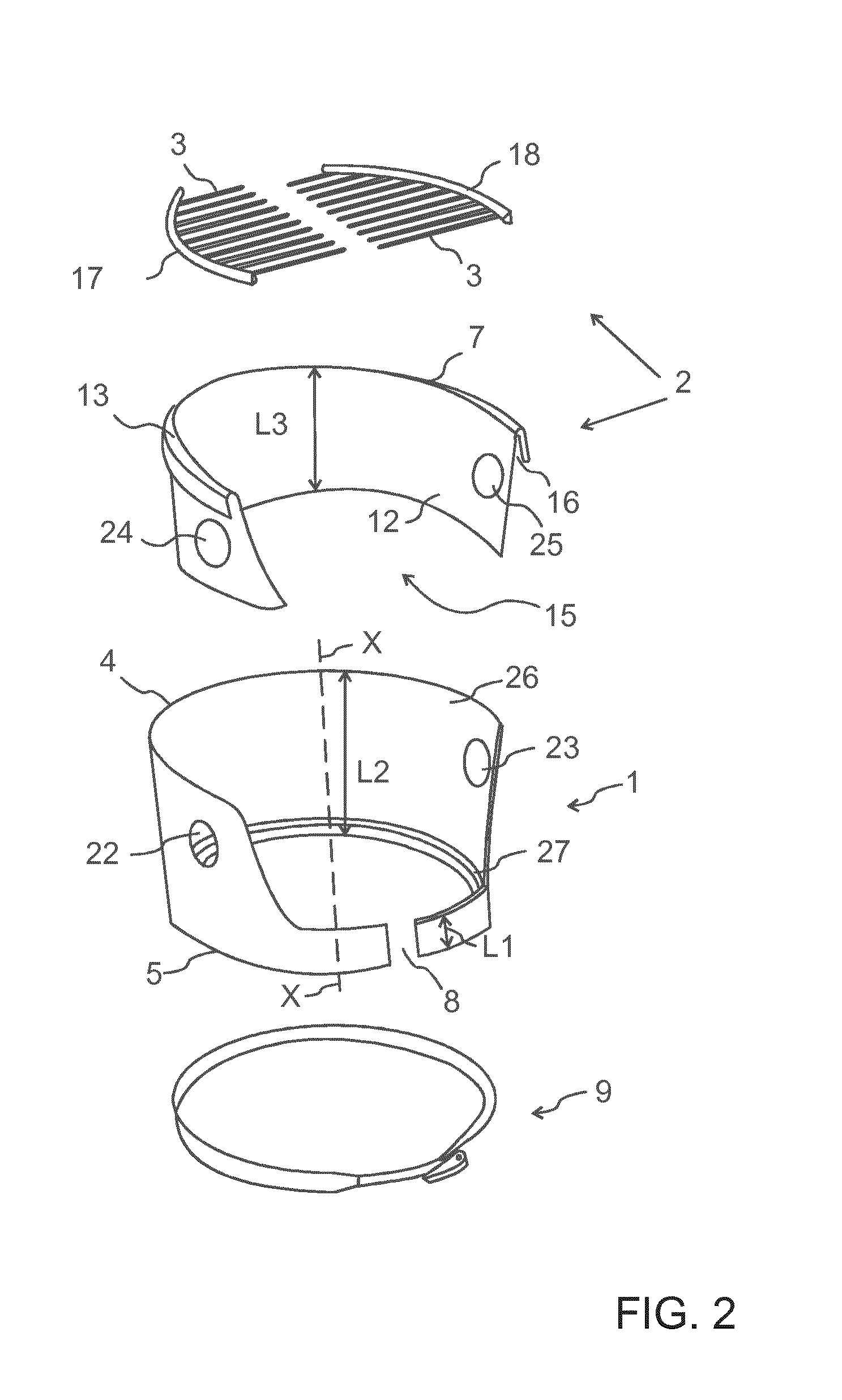

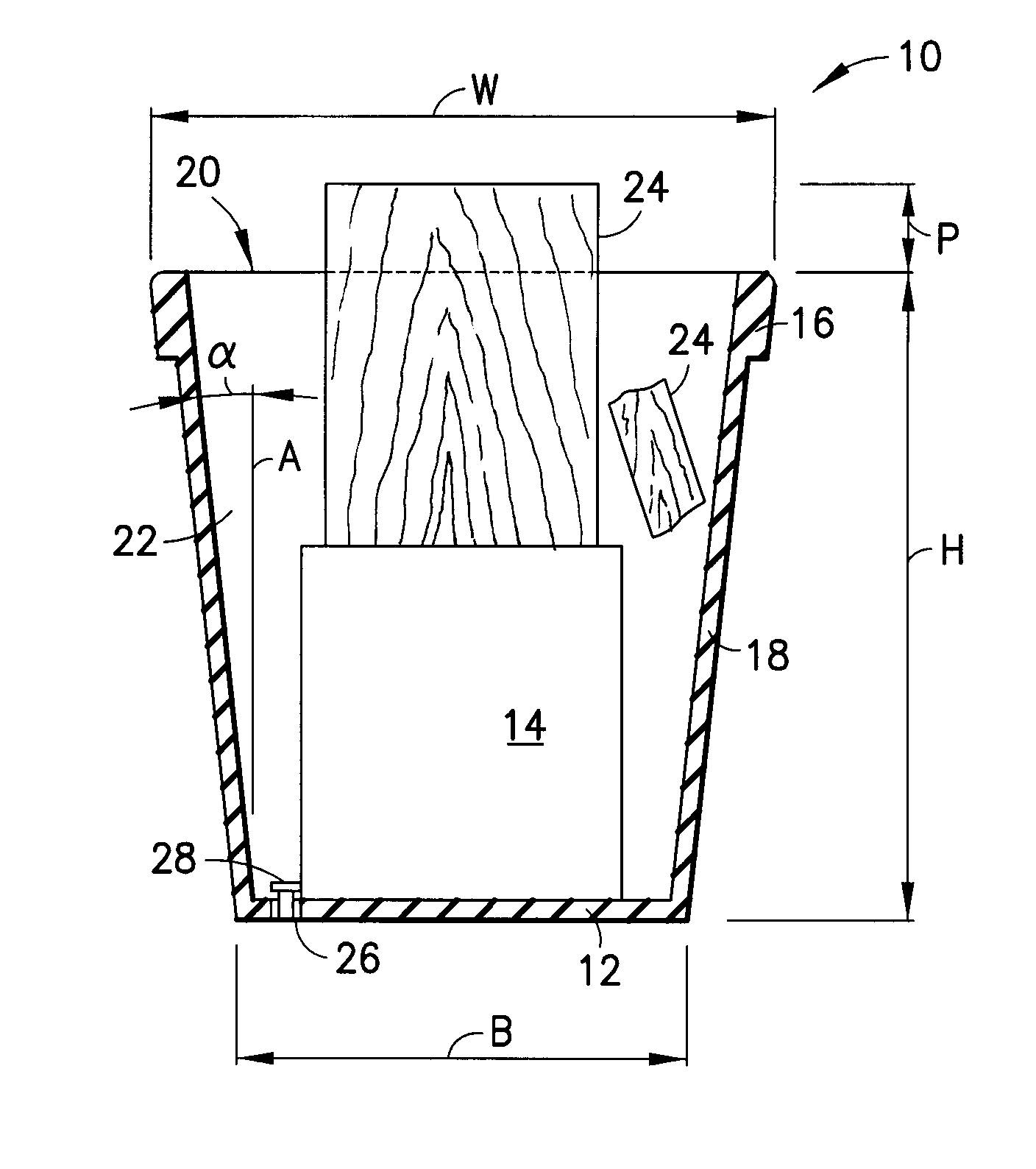

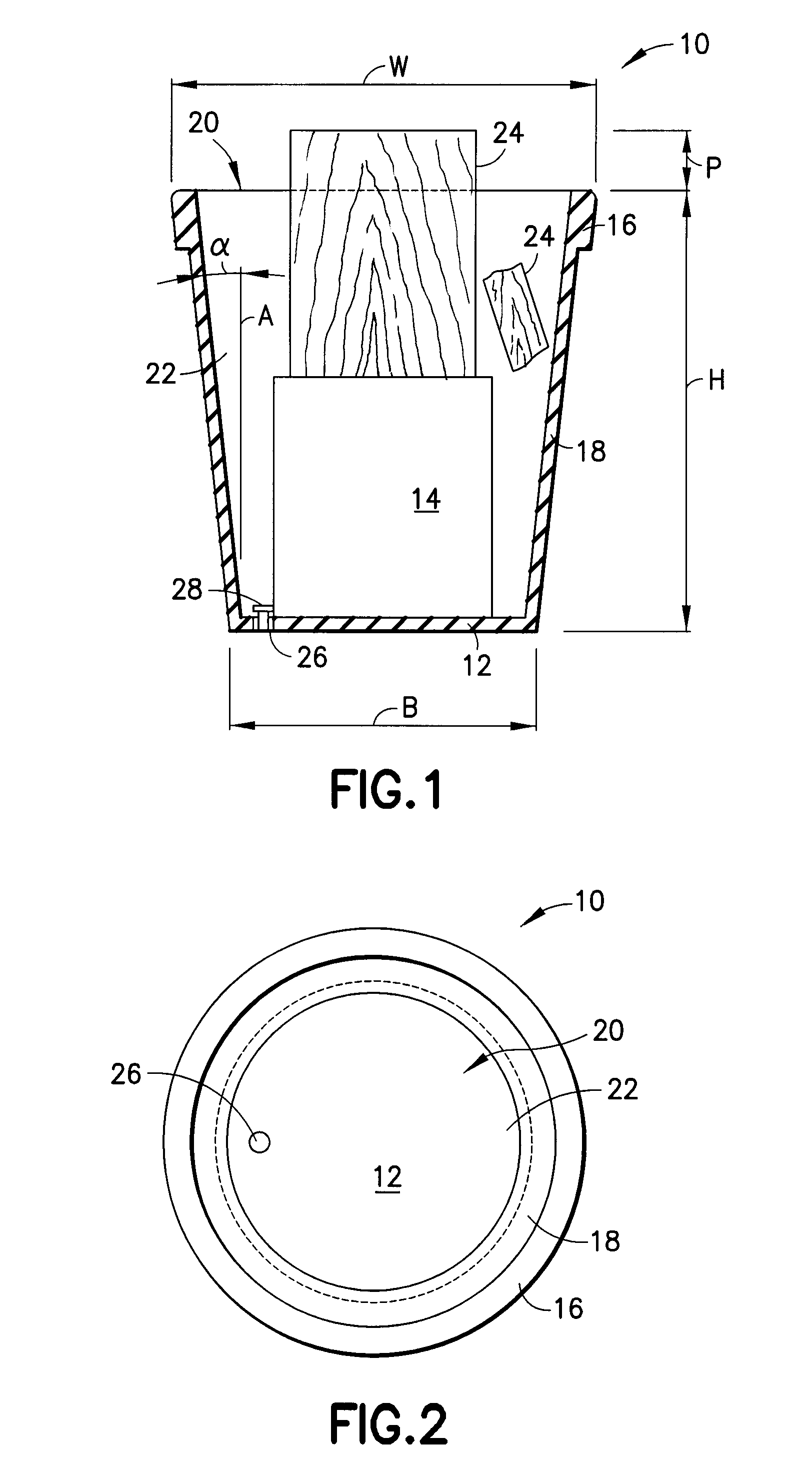

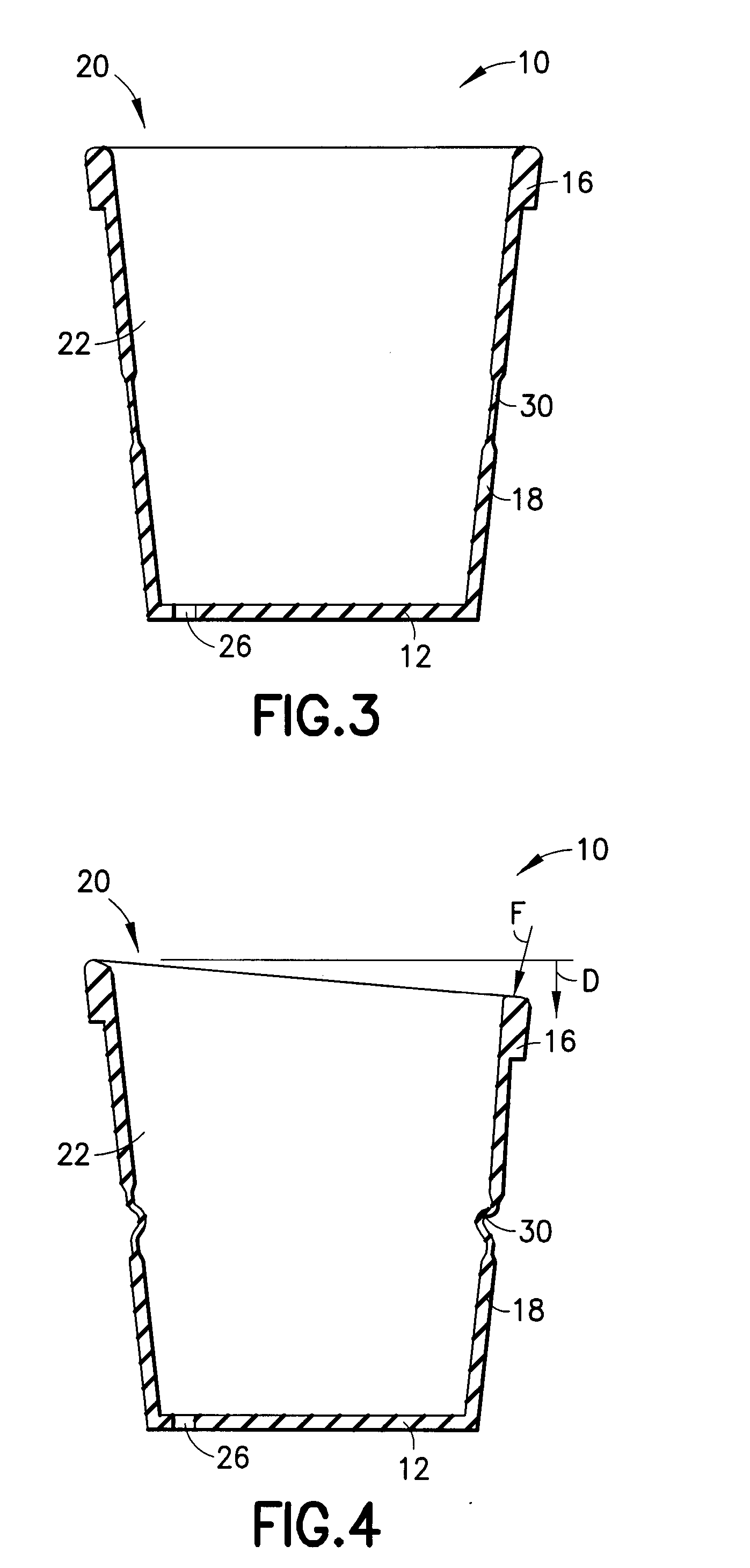

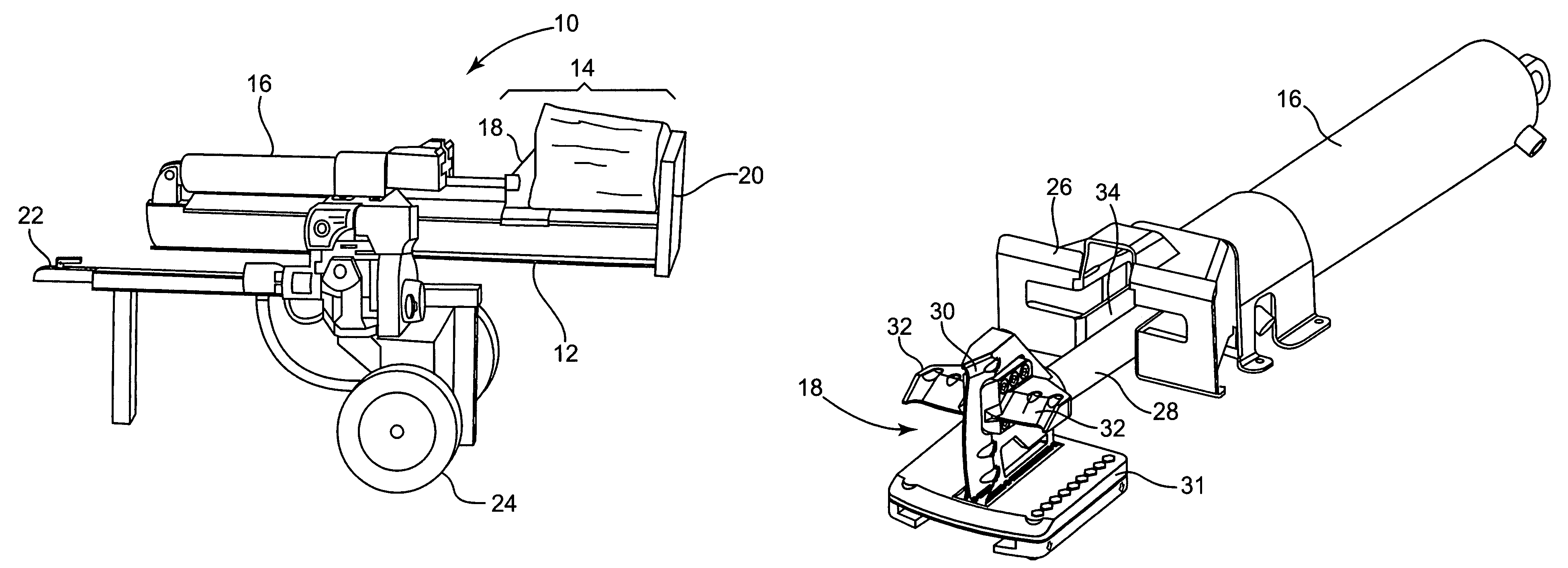

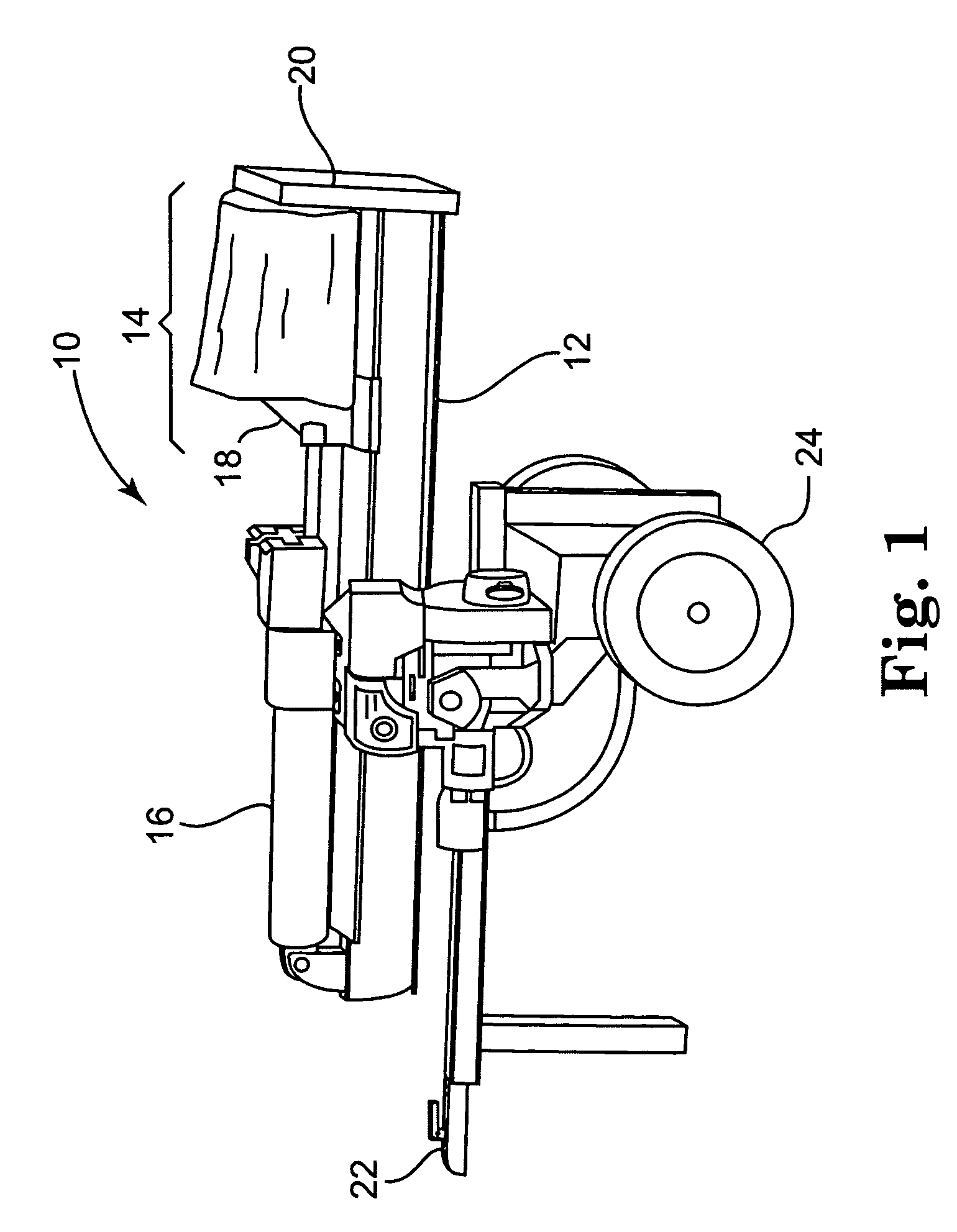

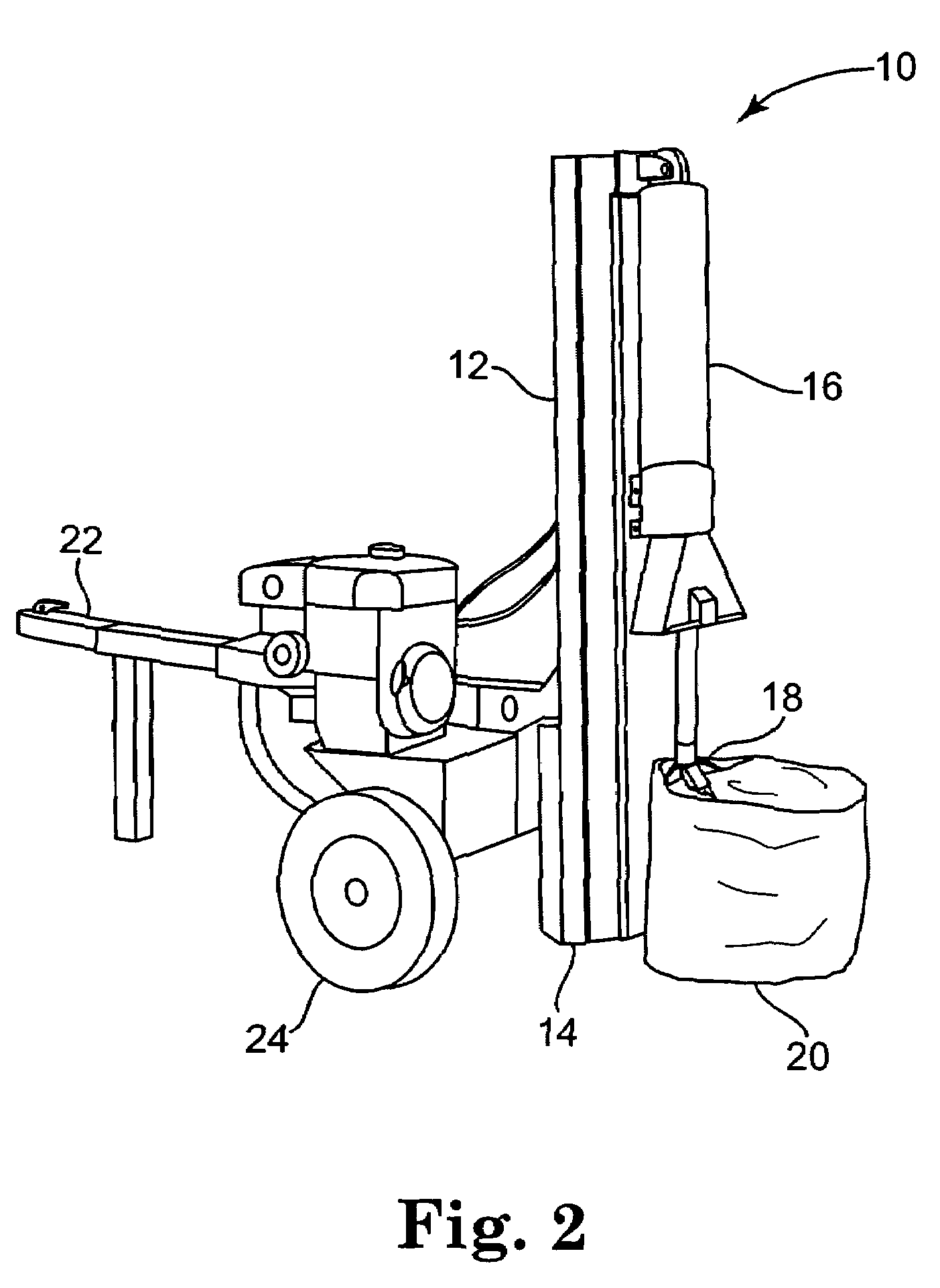

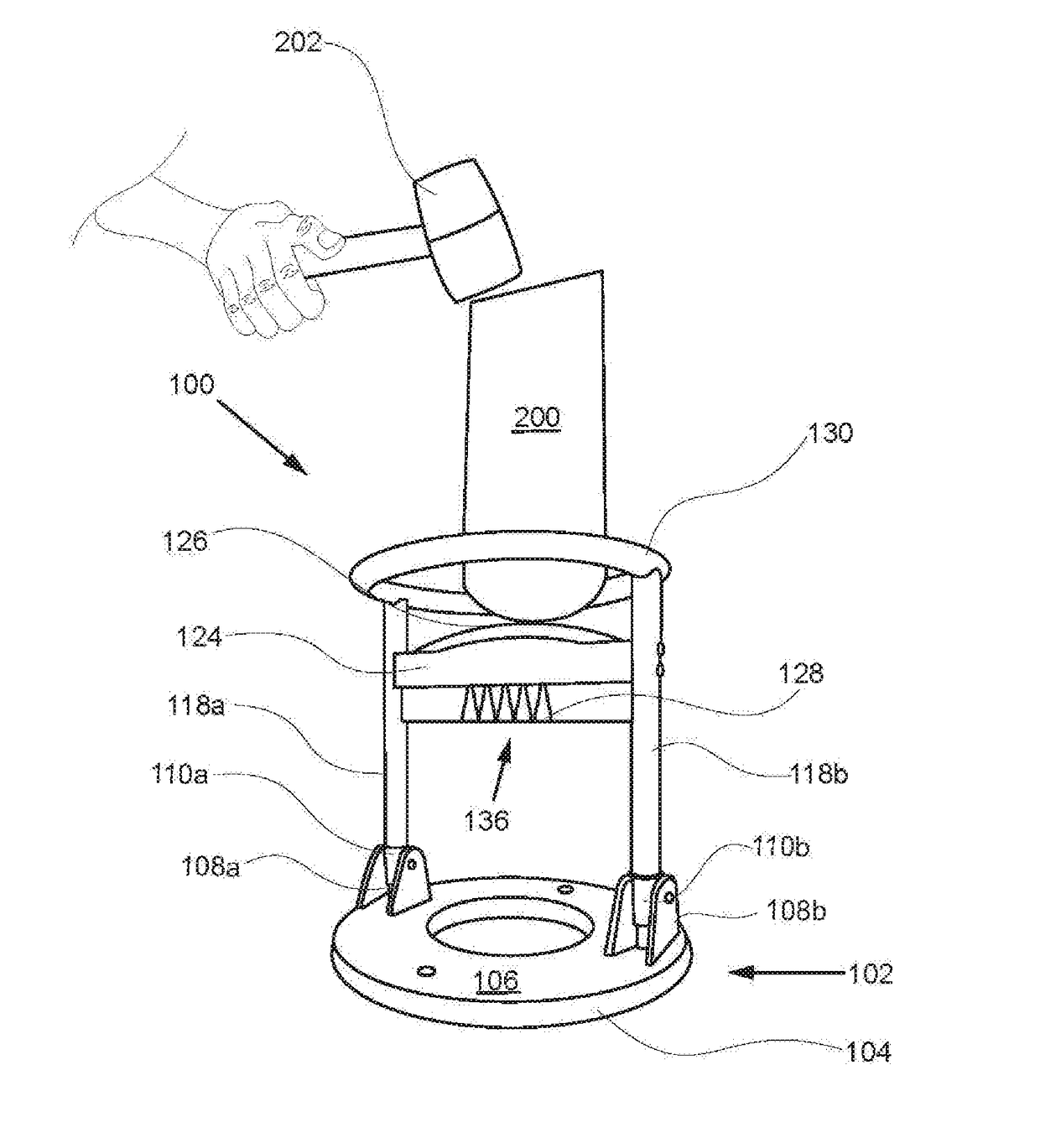

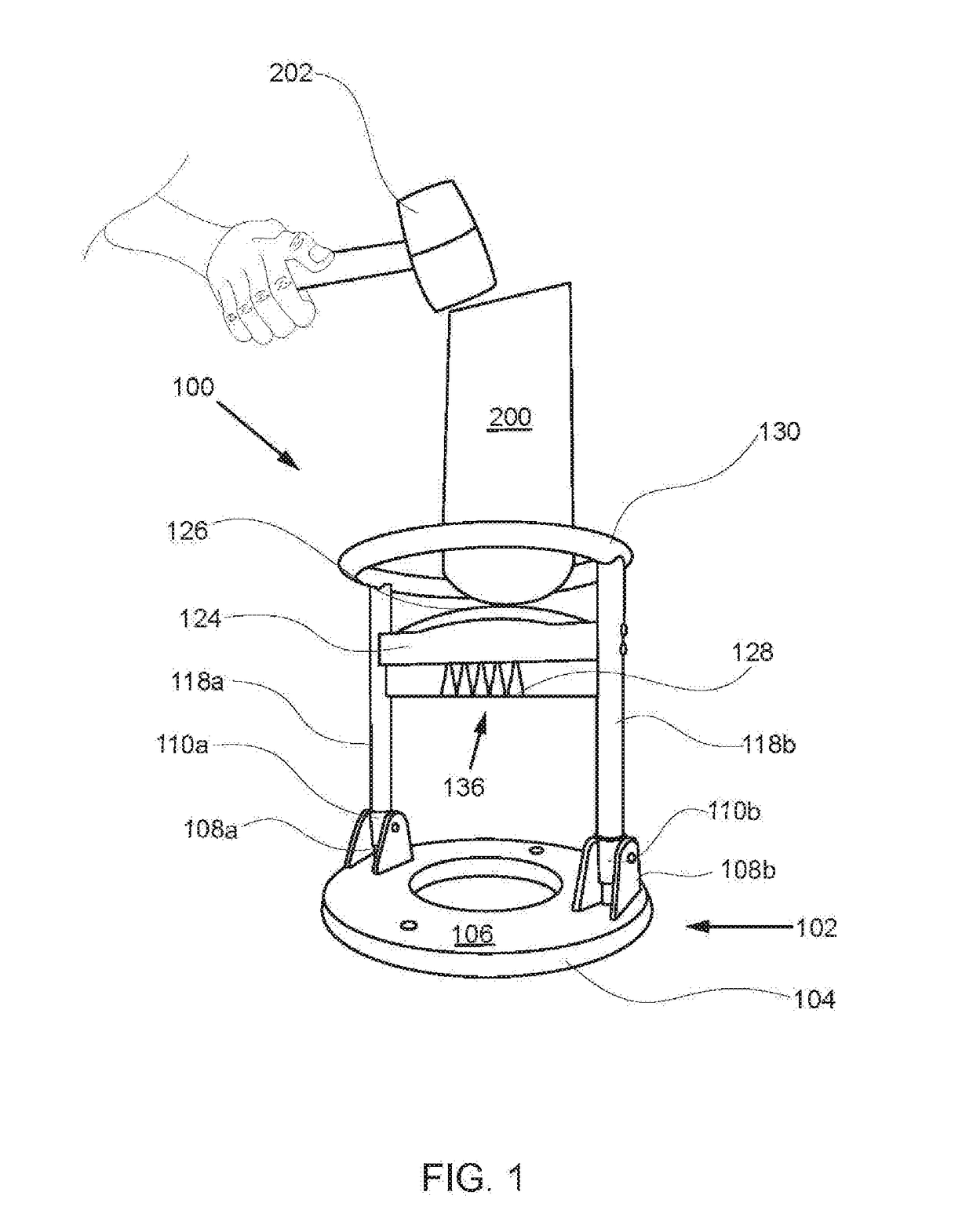

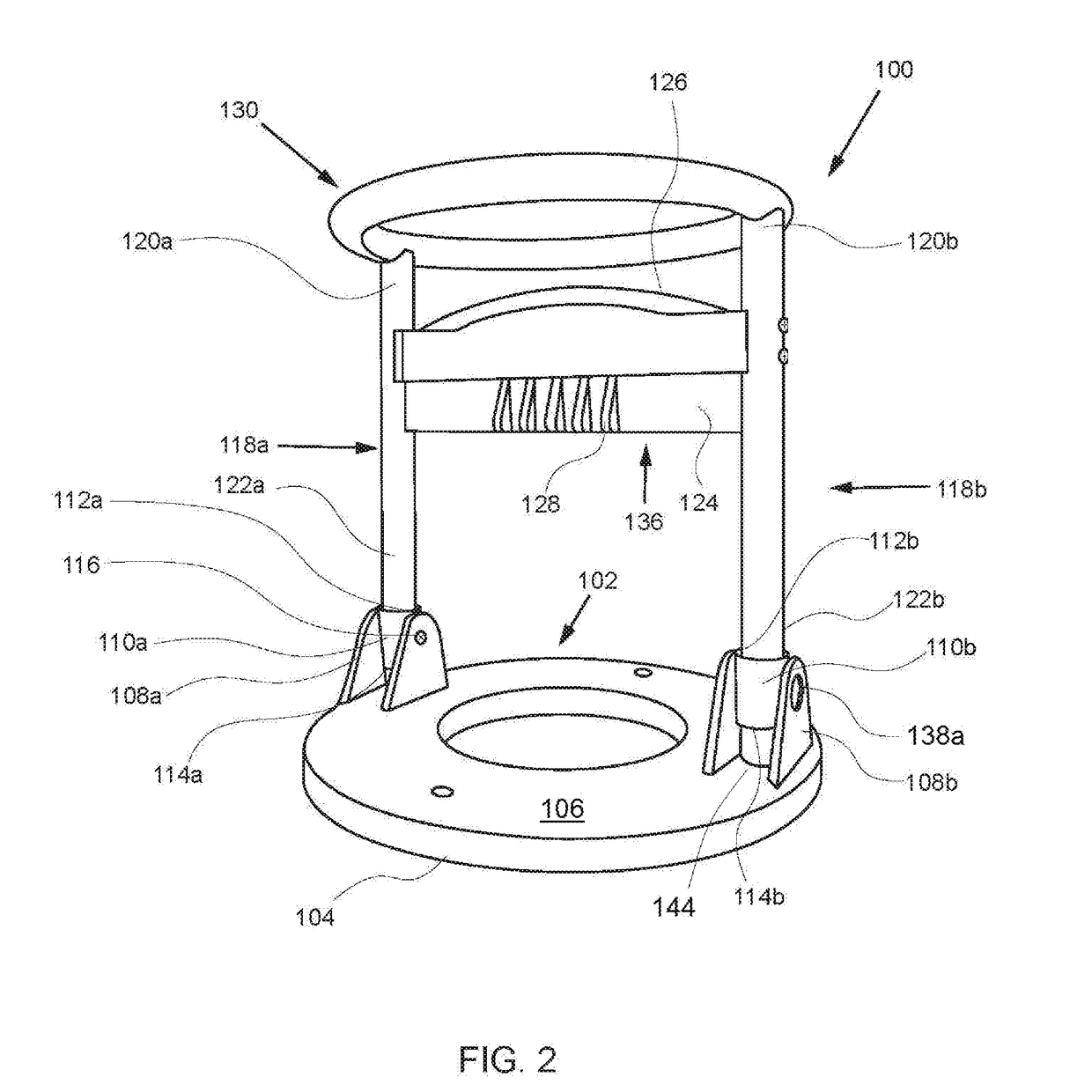

Chopping aid device

ActiveUS20140175724A1Chopping and splitting of logs easier, faster and saferEasy to replaceWood splittingPositioning apparatusFirewoodEngineering

A chopping aid device for use in chopping of firewood includes a frame to pre-vent pieces of wood from spreading into the surroundings outside the chopping aid device during chopping. In order to make chopping of wood easy, fast and safe, the chopping aid device has a support with flexible spikes to keep the firewood in an upright position within the frame.

Owner:FISKARS BRANDS FINLAND

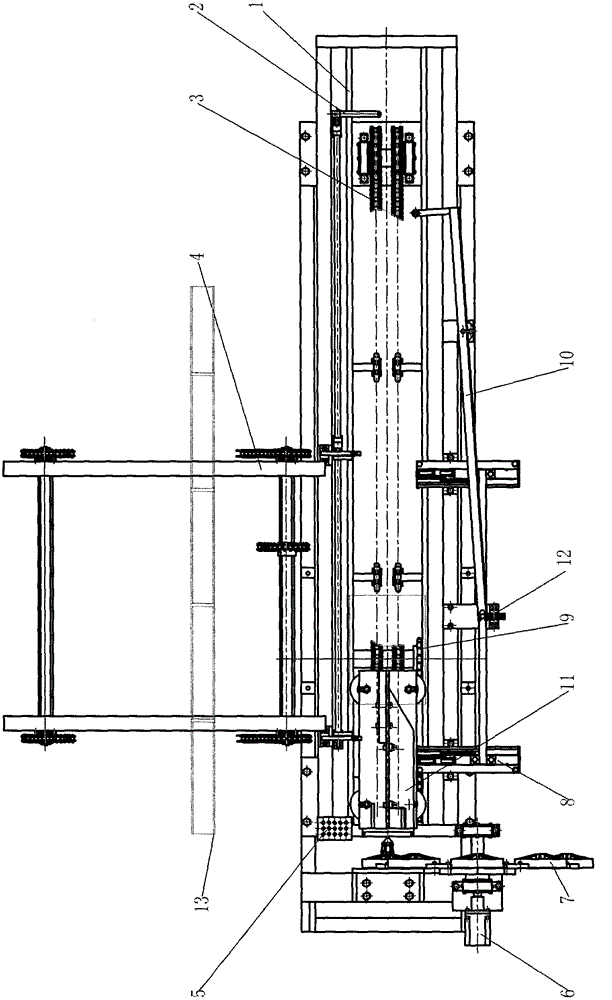

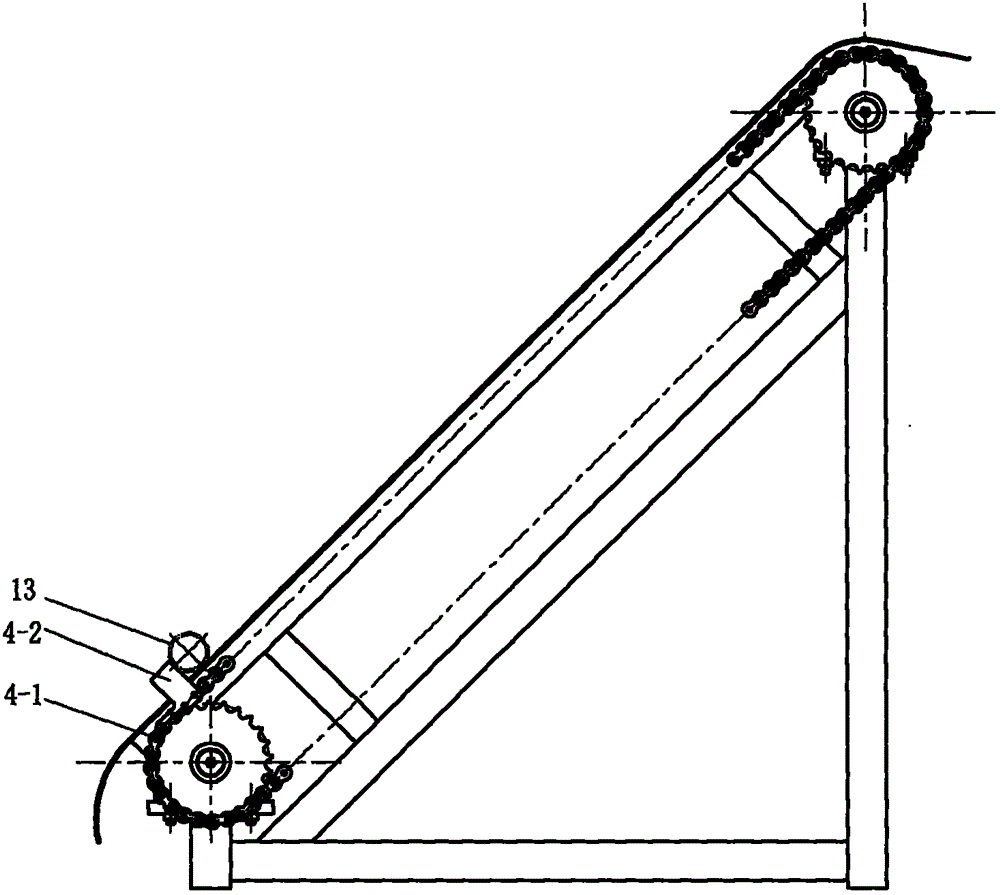

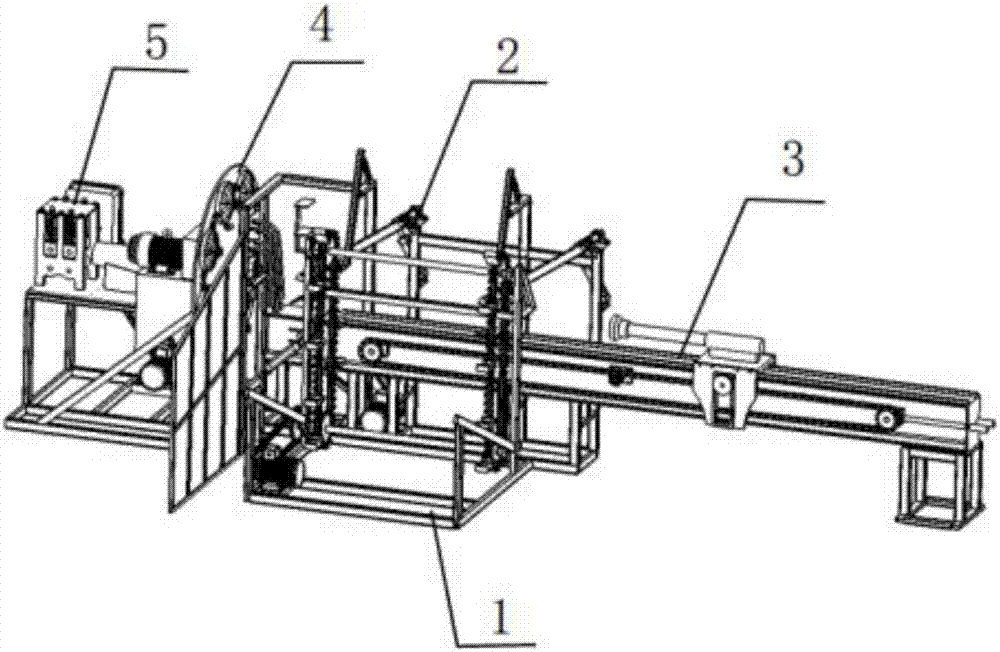

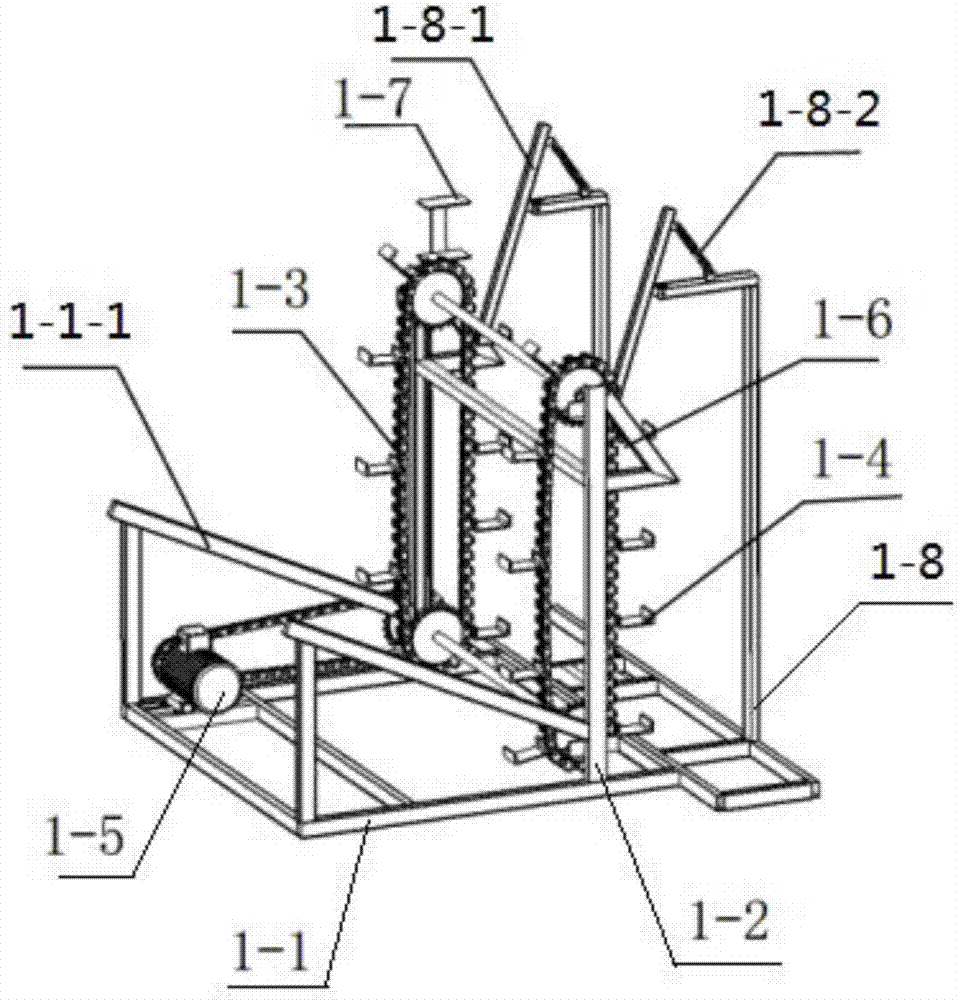

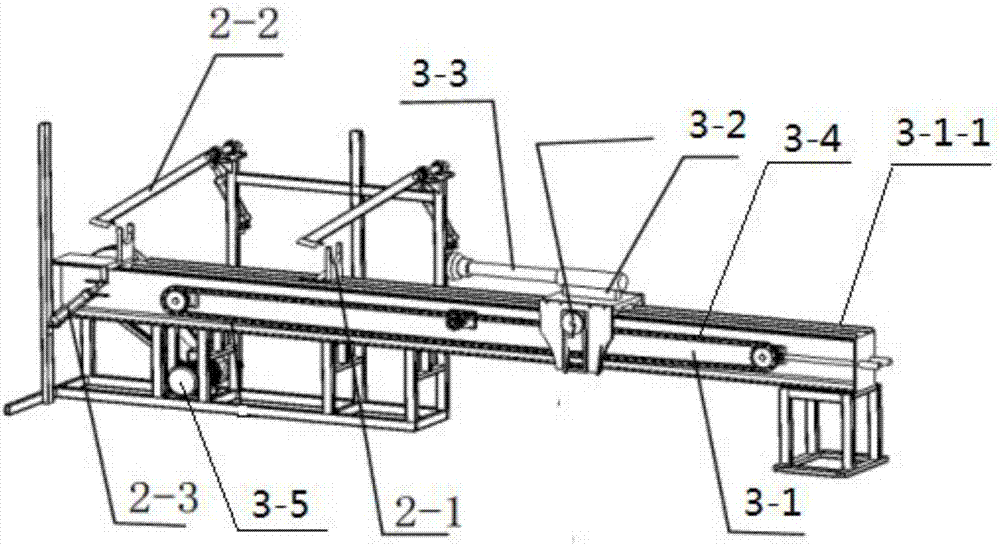

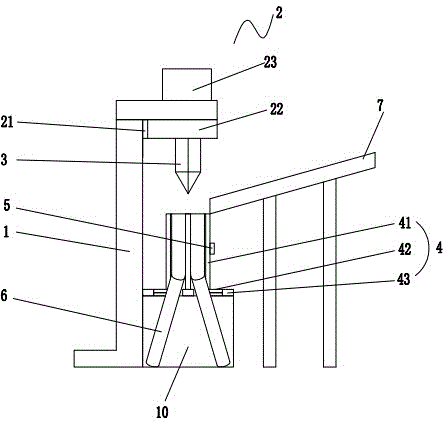

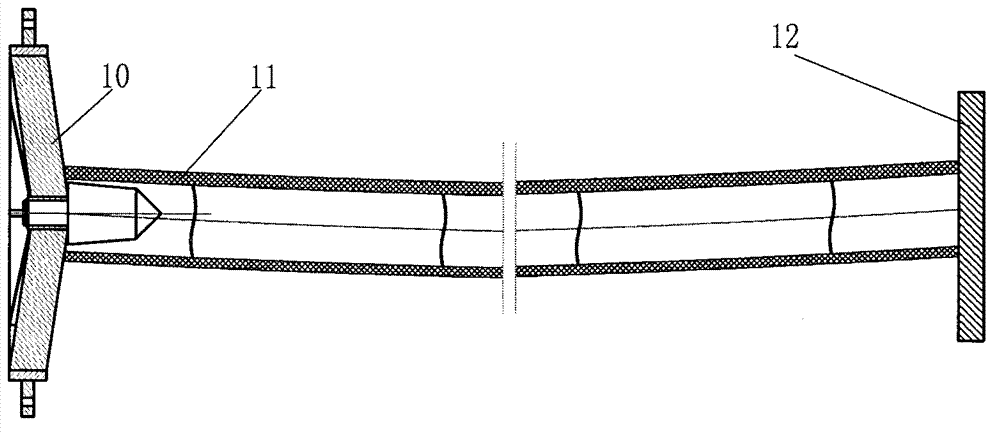

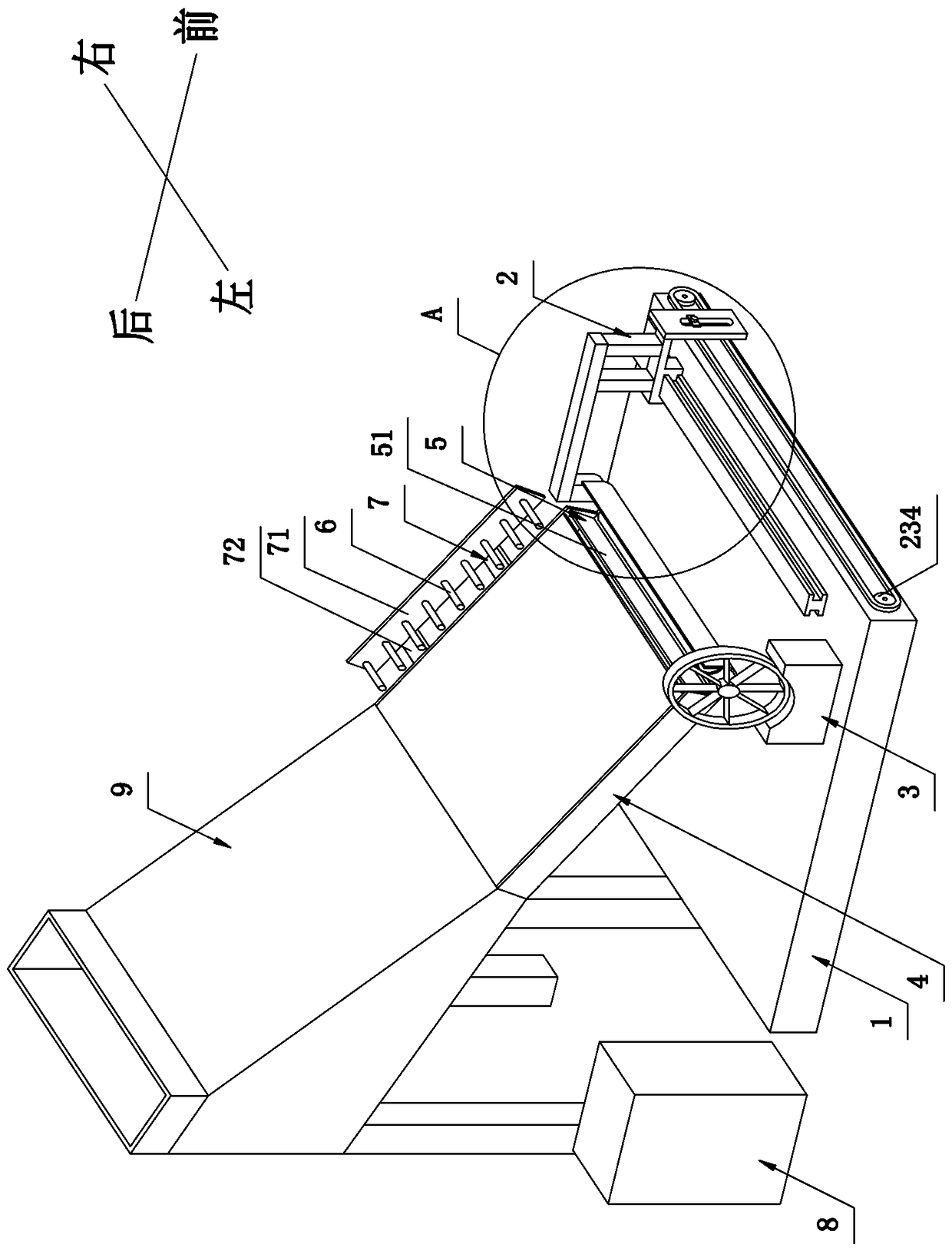

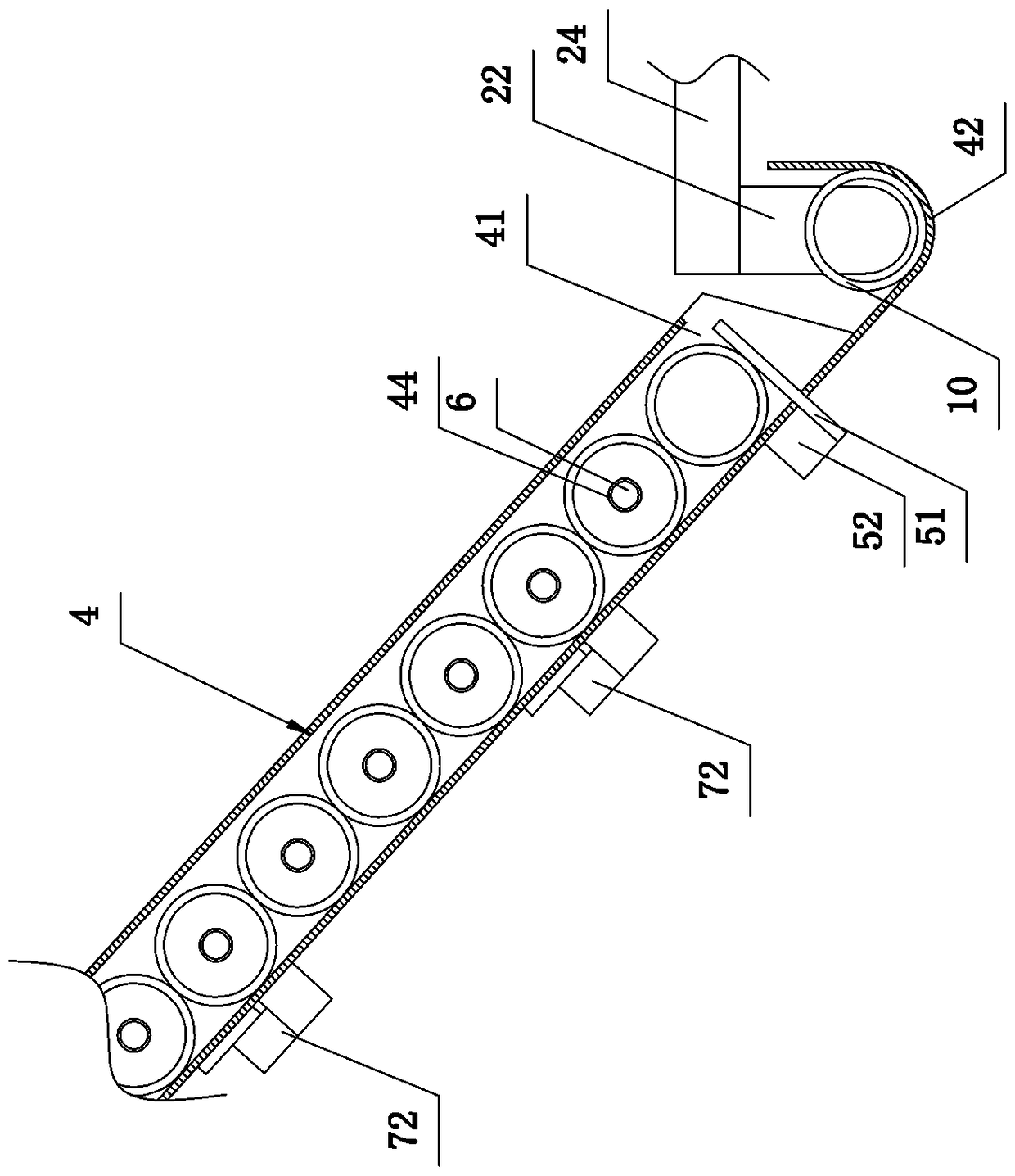

Novel numerical control bamboo splitting machine

ActiveCN102717414AAchieve broken bambooRealize empty back movementWood splittingVeneer manufactureNumerical controlMeasurement device

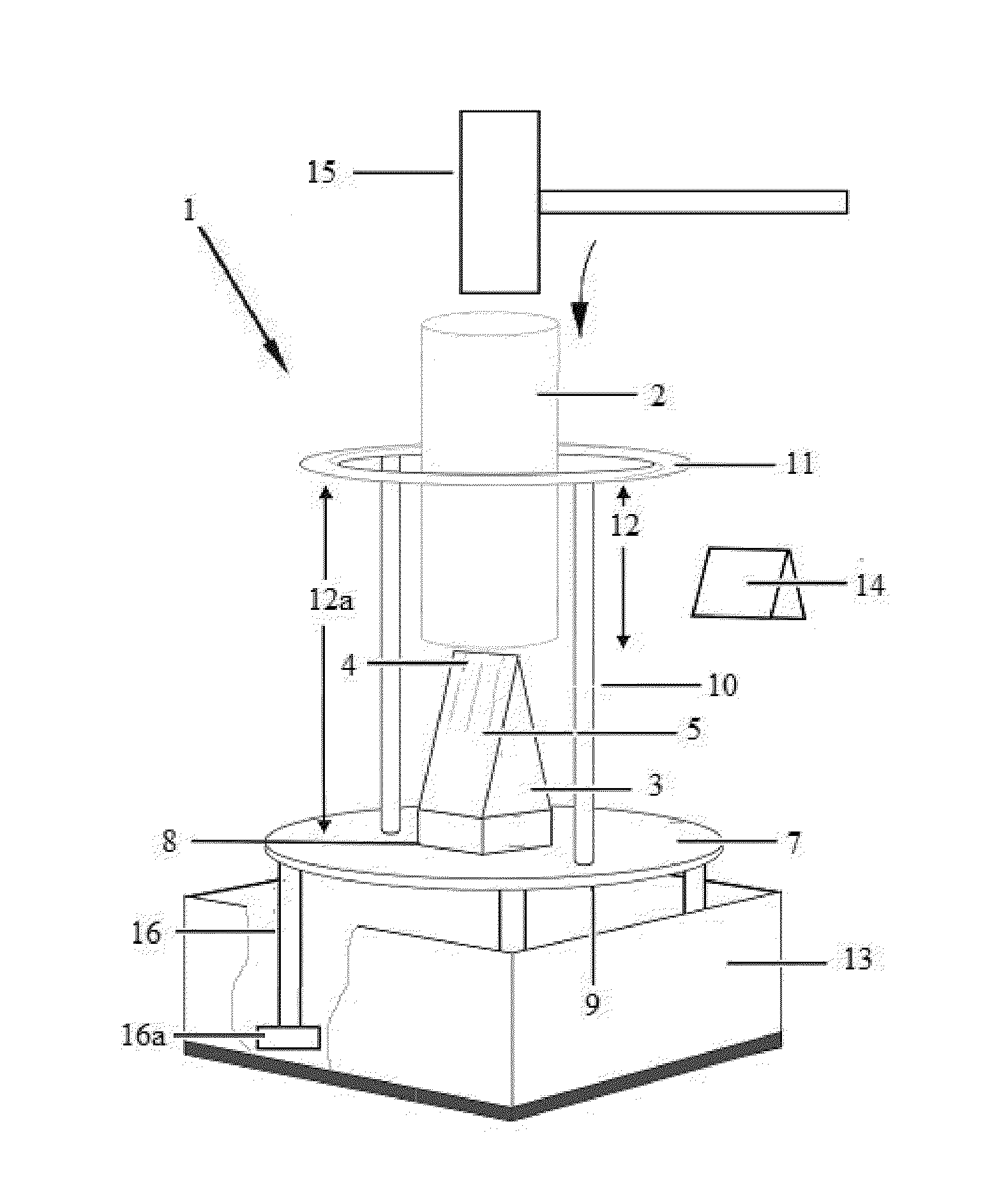

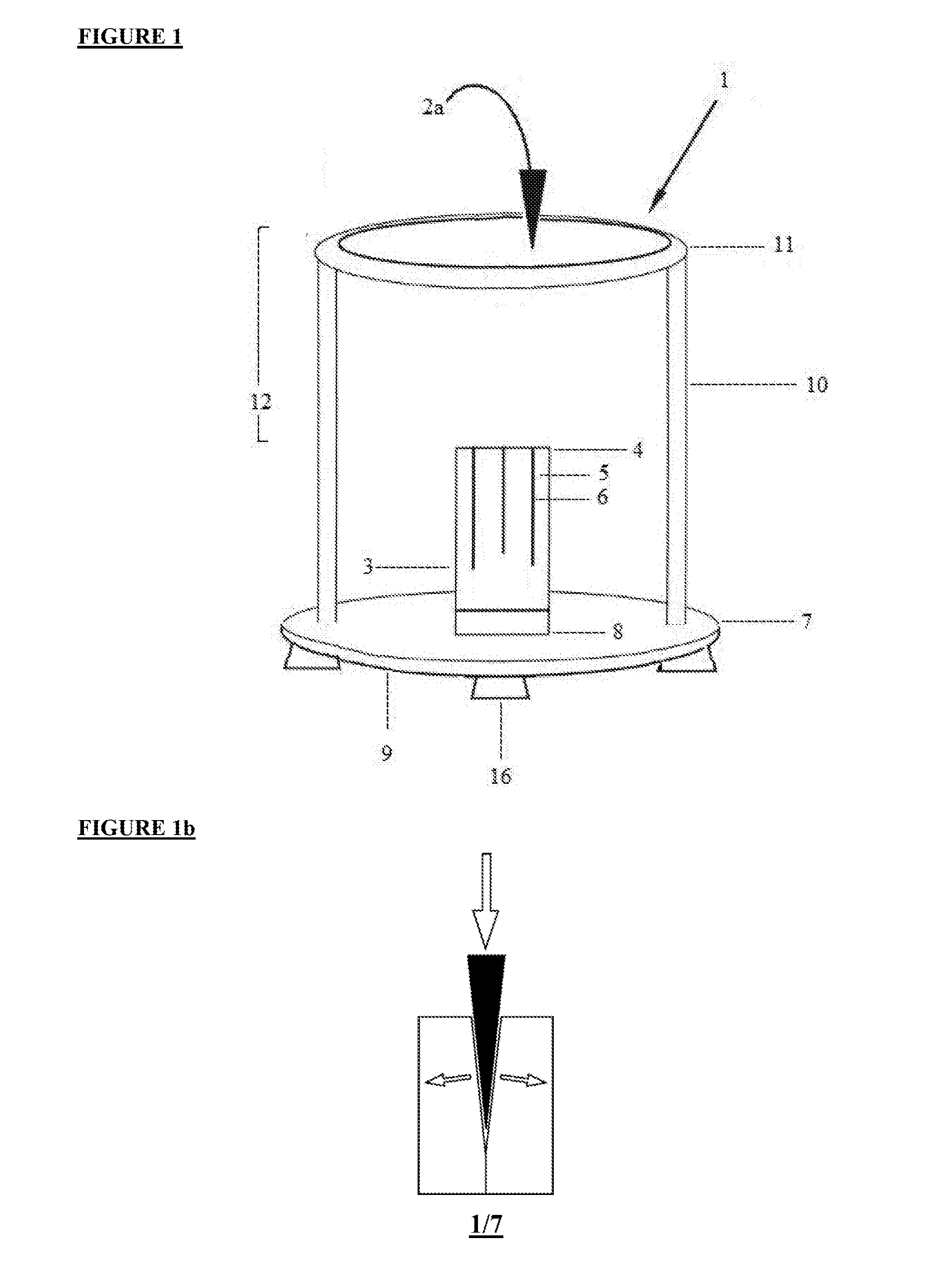

The invention relates to a novel numerical control bamboo splitting machine, which includes a lathe bed guide rail, a rotation mechanism, a driving chain, a bamboo tube loading mechanism, a bamboo tube diameter measurement device, a stepping motor, a cutter combination assembly, a bamboo centring combination assembly, a transmission system, a swinging mechanism, a push plate combination assembly, and a sash weight, and is characterized in that a push plate combination component is arranged on tool body guide rails; a driving chain for driving the push plate combination component to move back and forth is arranged between the two guide rails; a rotational cutter disc combination component is arranged at the front ends of the tool body guide rails; a bamboo tube loading mechanism is arranged on right sides of the tool body guide rails; two movable bamboo tube centering combination components are arranged on the upper left sides of the tool body guide rails; and when the push plate combination component does backlash motion, the bamboo tube loading mechanism conveys a bamboo tube into a measuring device to measure the diameter of a small head of the bamboo tube, the bamboo tube enters two V-shaped bearings, and combination cutters which are matched are rotated to the center of the bamboo tube and aligned; and a transmission system is reversed, and the push plate combination component pushes the bamboo tube to the combination cutters, so that the bamboo tube is split into bamboo chips. Compared with the conventional bamboo splitting machine, the numerical control bamboo splitting machine has the advantages that automatic loading, automatic tool changing and automatic centering of the bamboo tube are realized, one operator is reduced, the labor strength is lowered, the width error of the split bamboo clips is reduced, and the utilization rate of bamboo woods is improved.

Owner:沛县汉腾建设发展有限公司

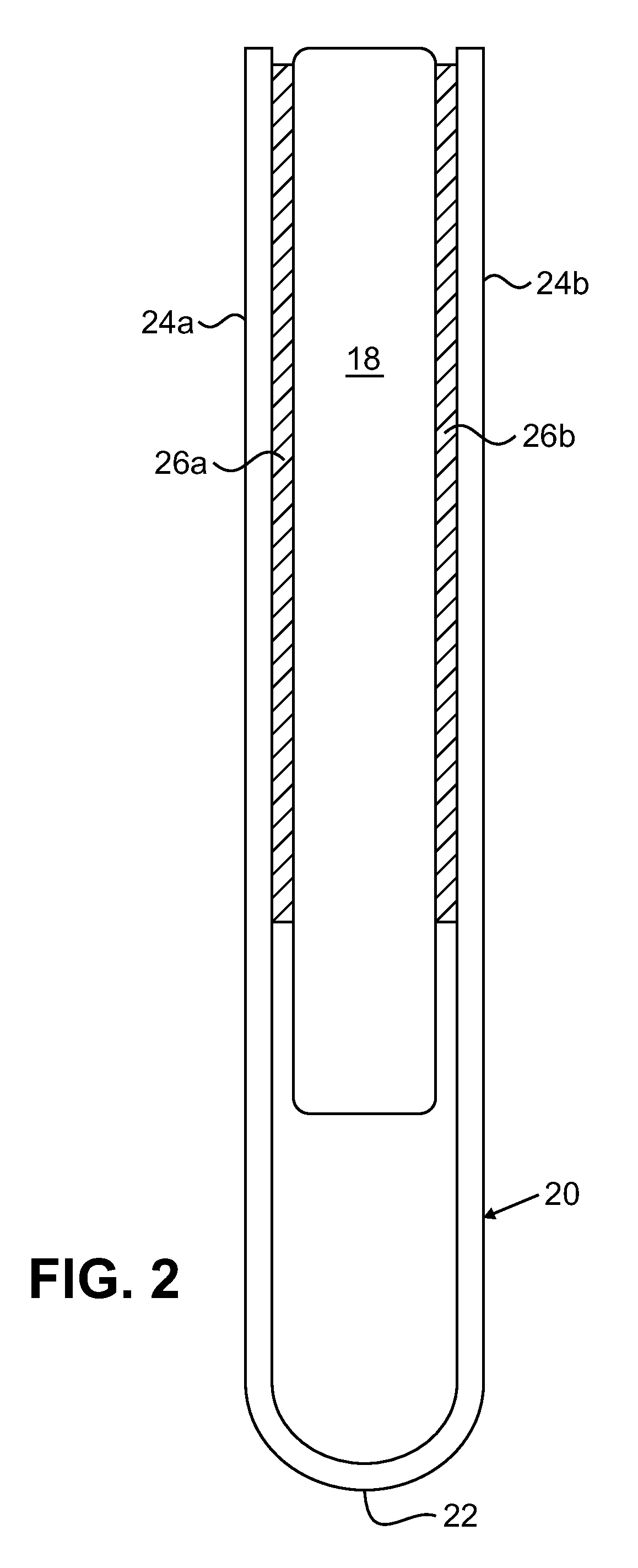

Resilient container

Owner:VETO PRO PAC

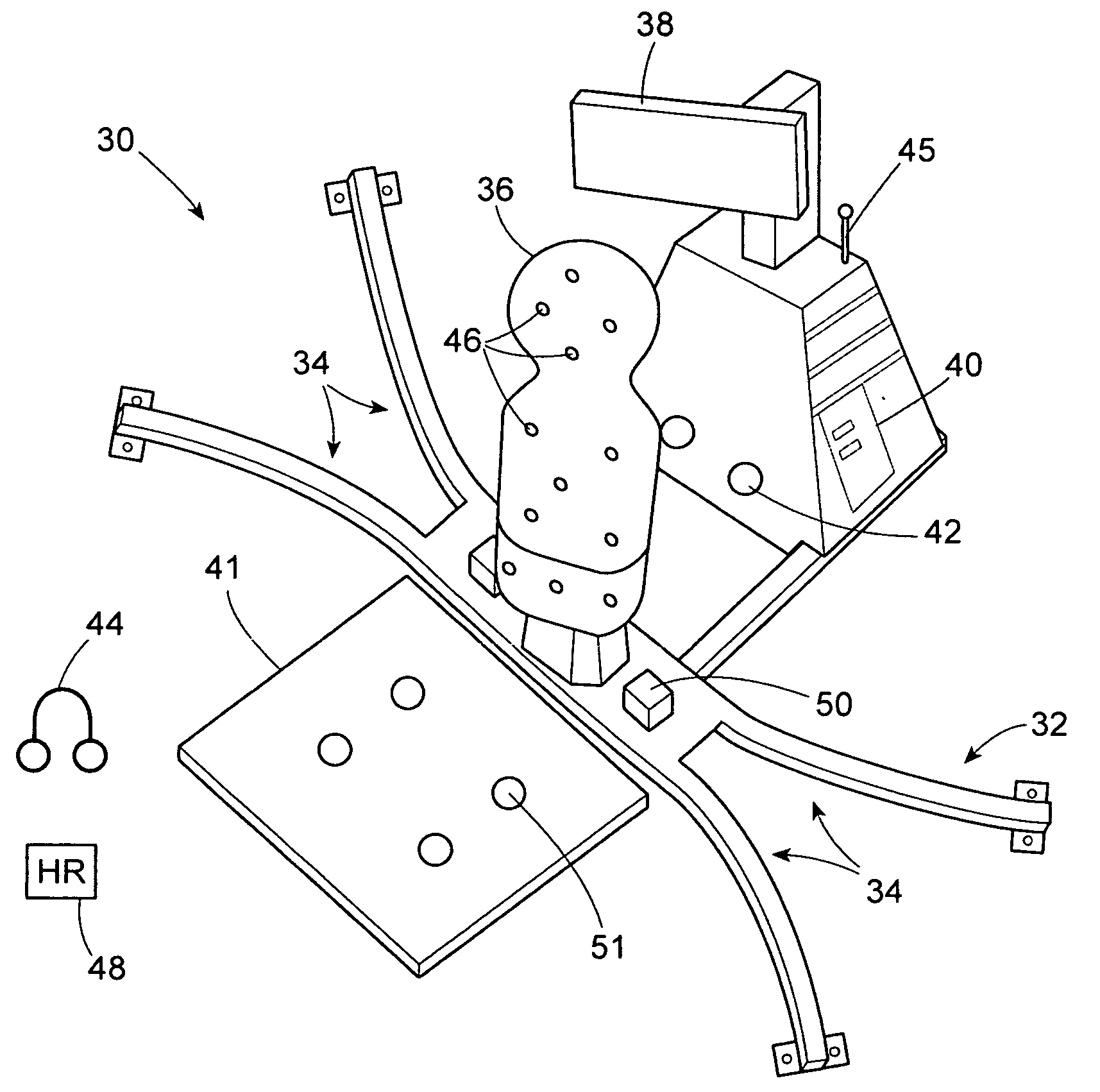

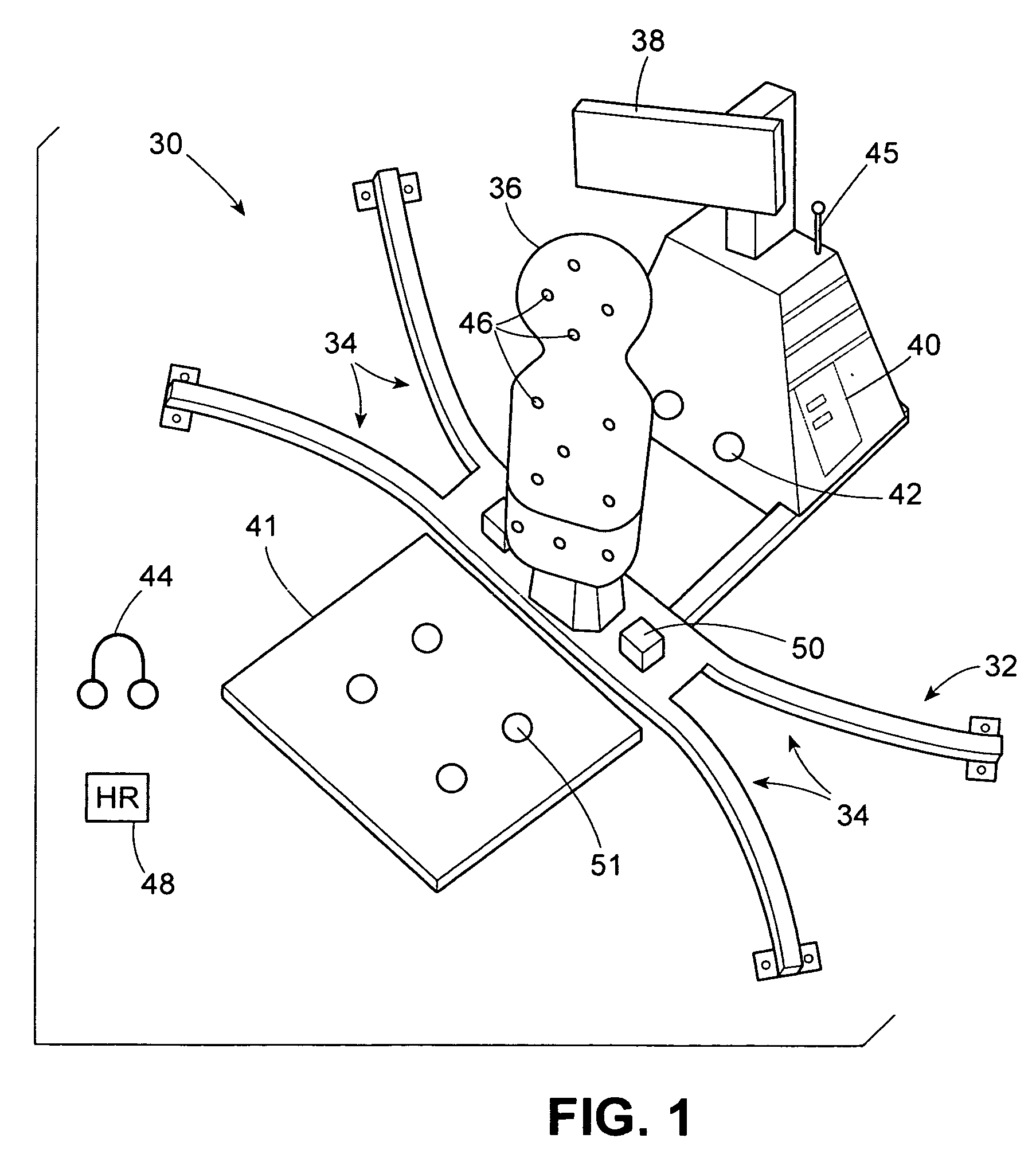

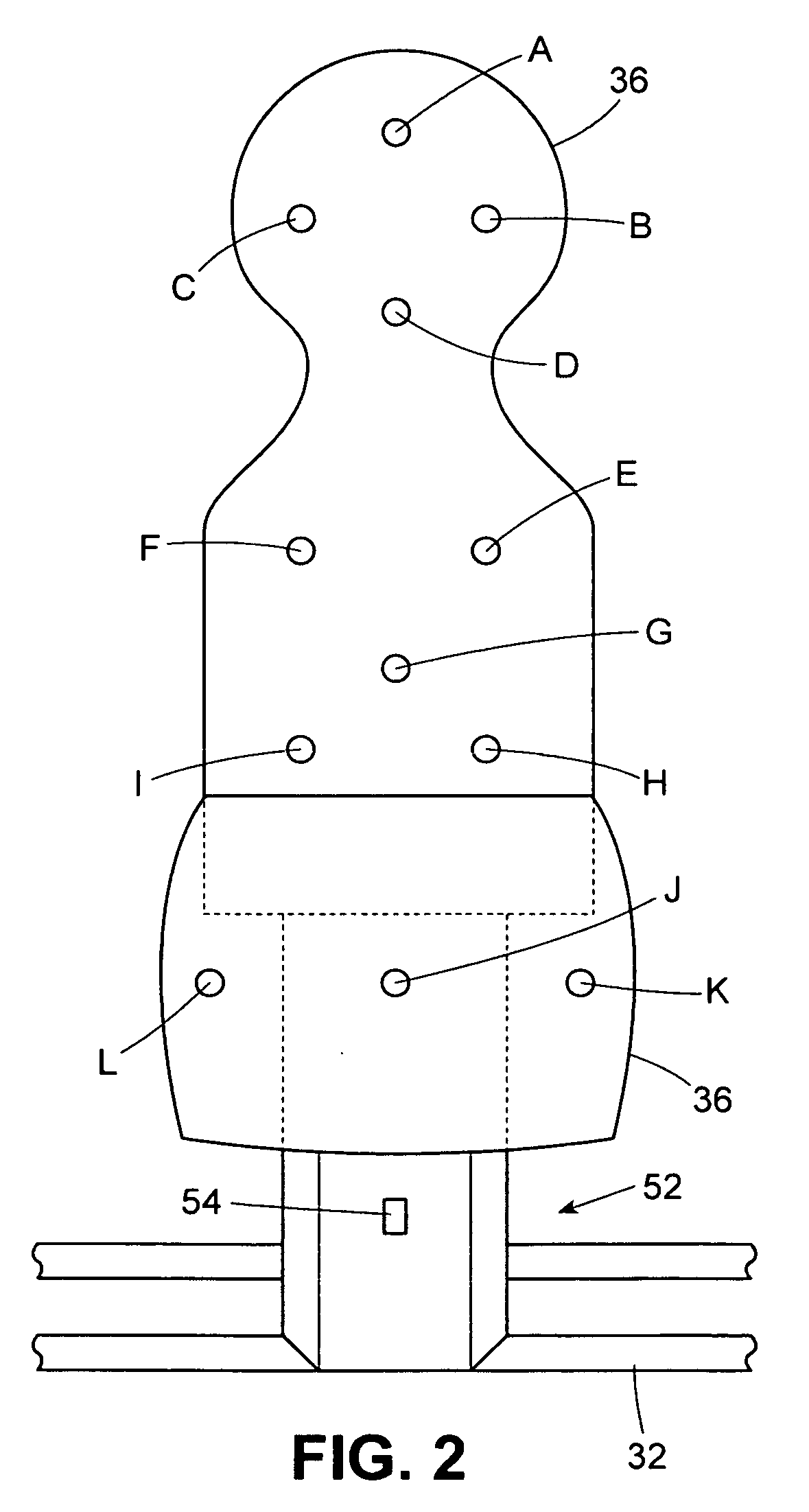

Method for providing a feedback-controlled exercise routine

InactiveUS20060201580A1Facilitate user complianceIncreased complexityWood splittingMulti-purpose machinesSuccessful completionEvaluation data

A method for providing a feedback-controlled exercise routine for a user by providing a predetermined sequence of movements for the user; sensing movements of the user during the sequence; measuring data related to the sensed movements; and evaluating the data to determine whether to repeat or modify the routine. The method can also include storing the user's exercise routine on a user key, displaying exercise instructions to the user from the user key to illustrate the sequence of movements, with the evaluation of the data including modifying the displayed exercise instructions, and storing an updated user exercise routine after successful completion of the routine, wherein the updated routine includes the modified exercise instructions.

Owner:KANG BRIAN J

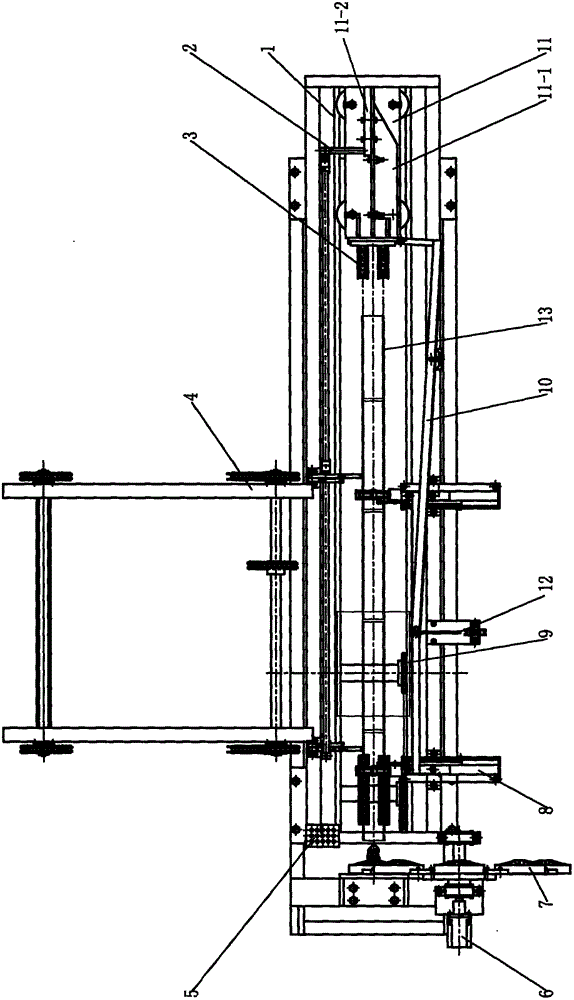

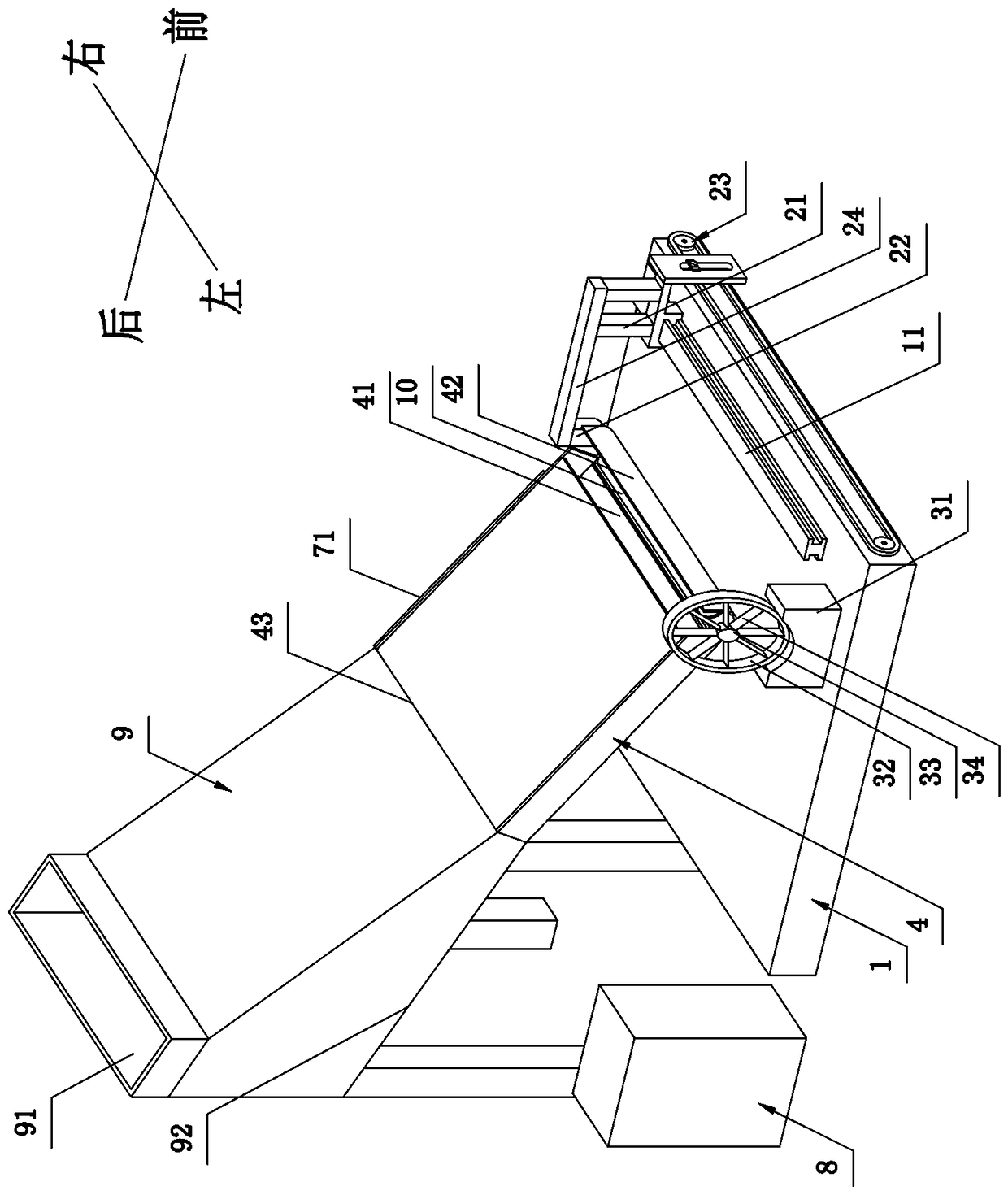

Automatic bamboo breaking machine

ActiveCN107150393APrecise deliveryAccurate control of coordinated operationWood splittingBio-packagingControl systemControl engineering

The invention relates to an automatic bamboo breaking machine. The automatic bamboo breaking machine comprises a feeding device, a clamping and positioning device, a bamboo breaking pushing disk device, a tool rotating disk device, an output device and a control system. The feeding device and the clamping and positioning device are located on the two sides of one end of the bamboo breaking pushing disk device. The tool rotating disk device is located on the front part of the end, close to the feeding device and the clamping and positioning device, of the bamboo breaking pushing disk device, and the output device is located on the tail part of the tool rotating disk device. The control system controls the feeding device, the clamping and positioning device, the bamboo breaking pushing disk device, the tool rotating disk device and the output device to run in a cooperative manner. The automatic bamboo breaking machine has the beneficial effects that the bamboo breaking machine can accurately control cooperative running of the devices, a bamboo tube is conveyed and positioned reliably, the bamboo tube can be accurately cut into bamboo canes, the finally cut bamboo canes can be conveyed out, the automation degree is relatively high, and the production efficiency is improved.

Owner:GUANGXI NORMAL UNIV

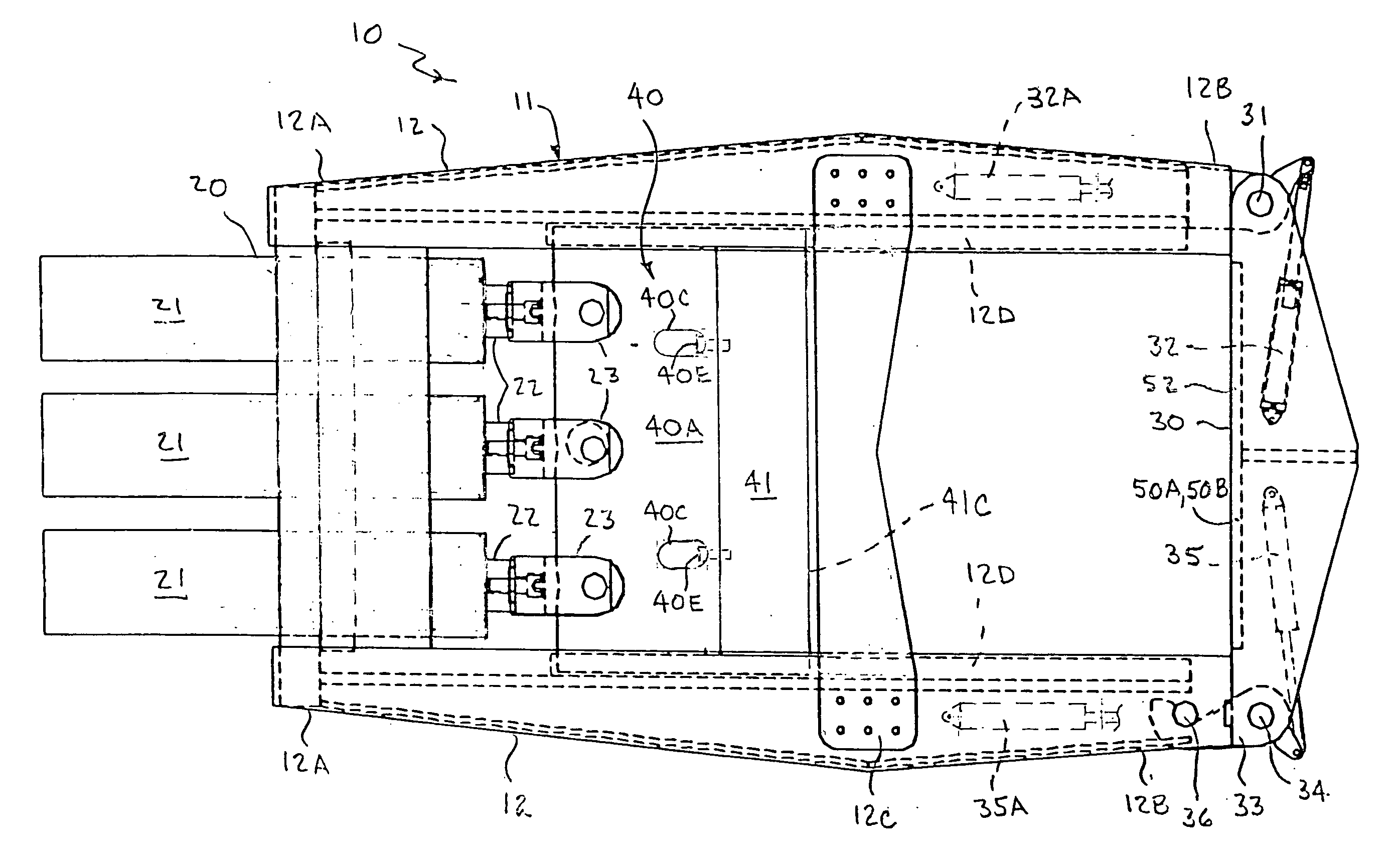

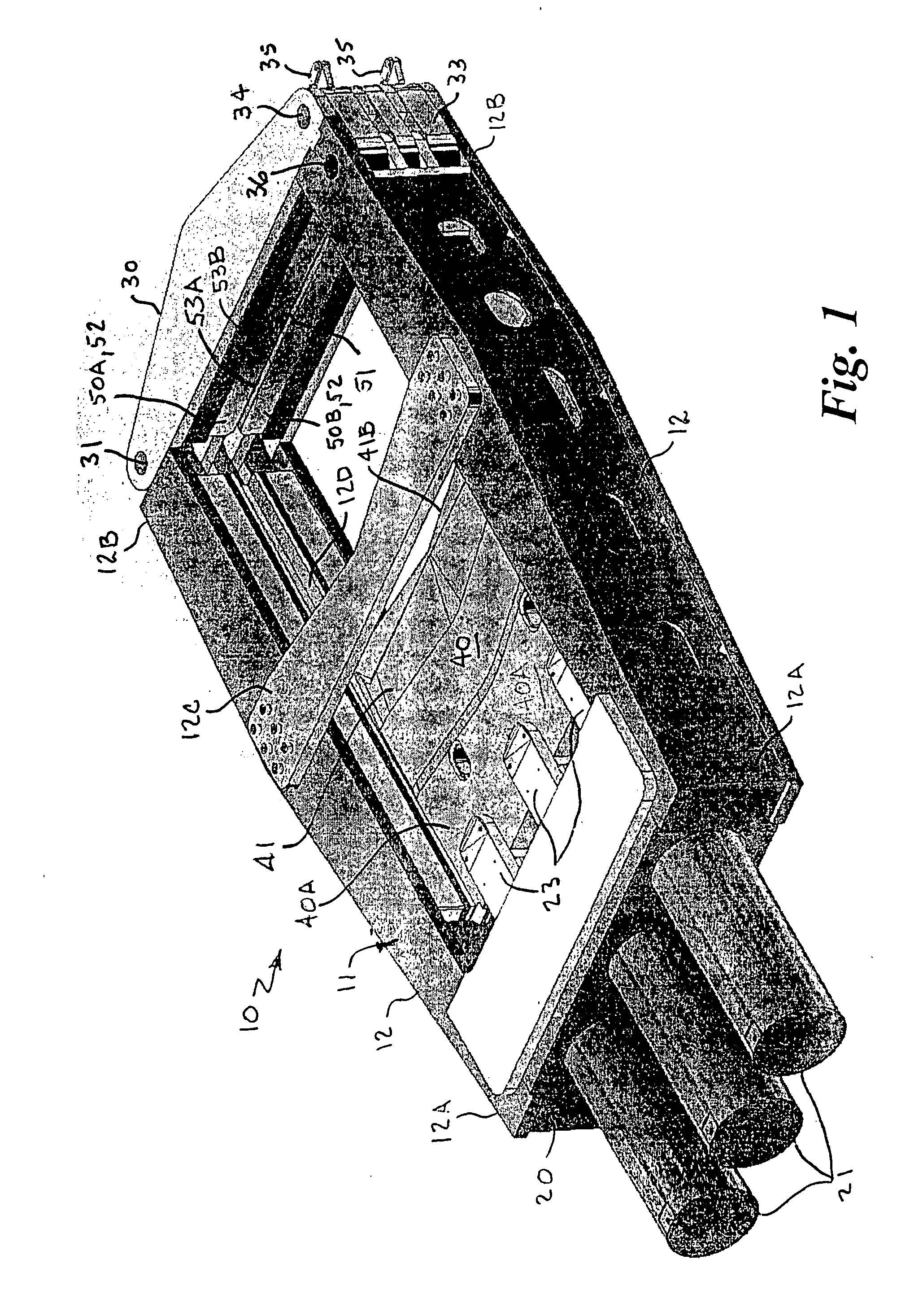

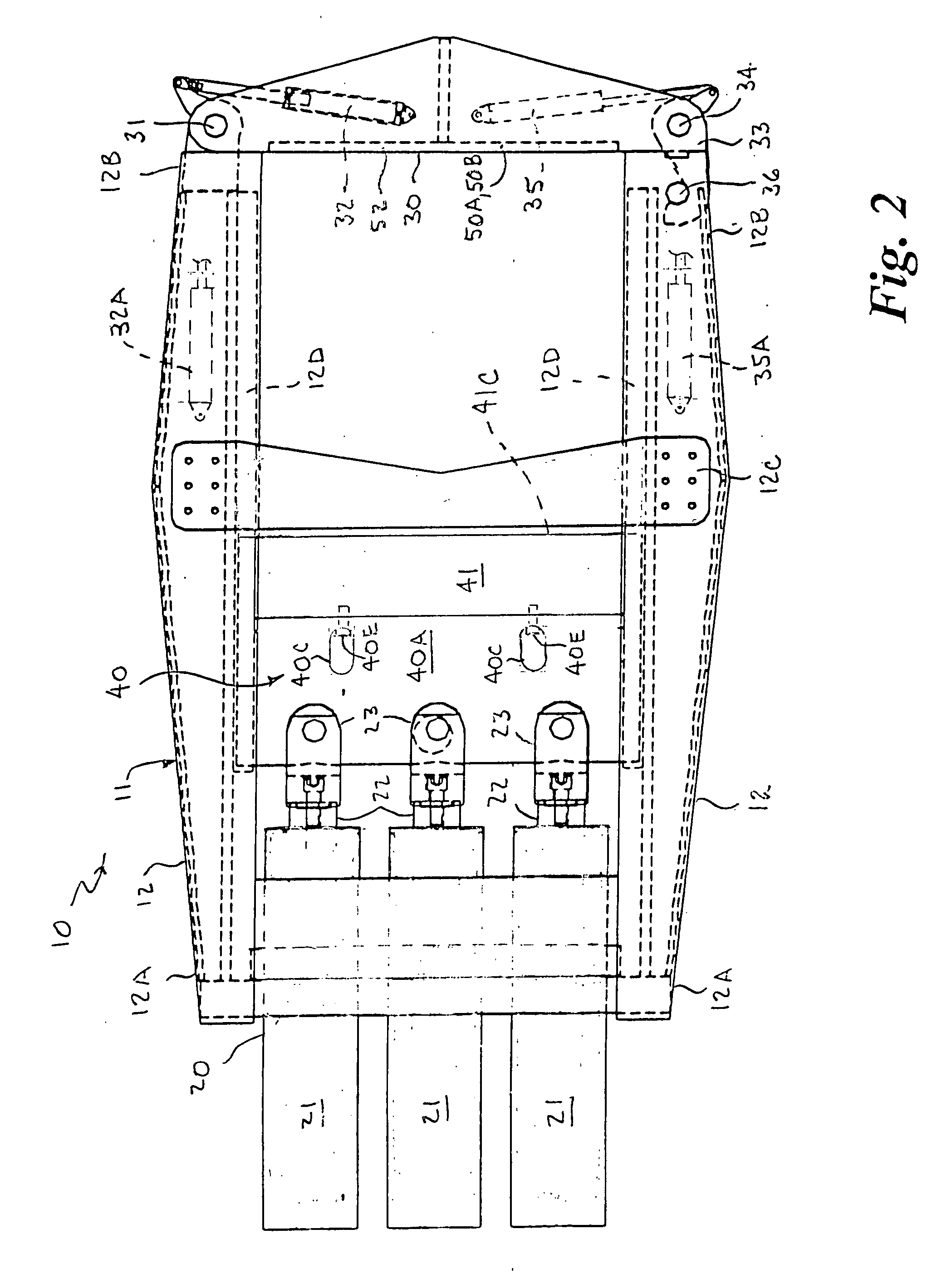

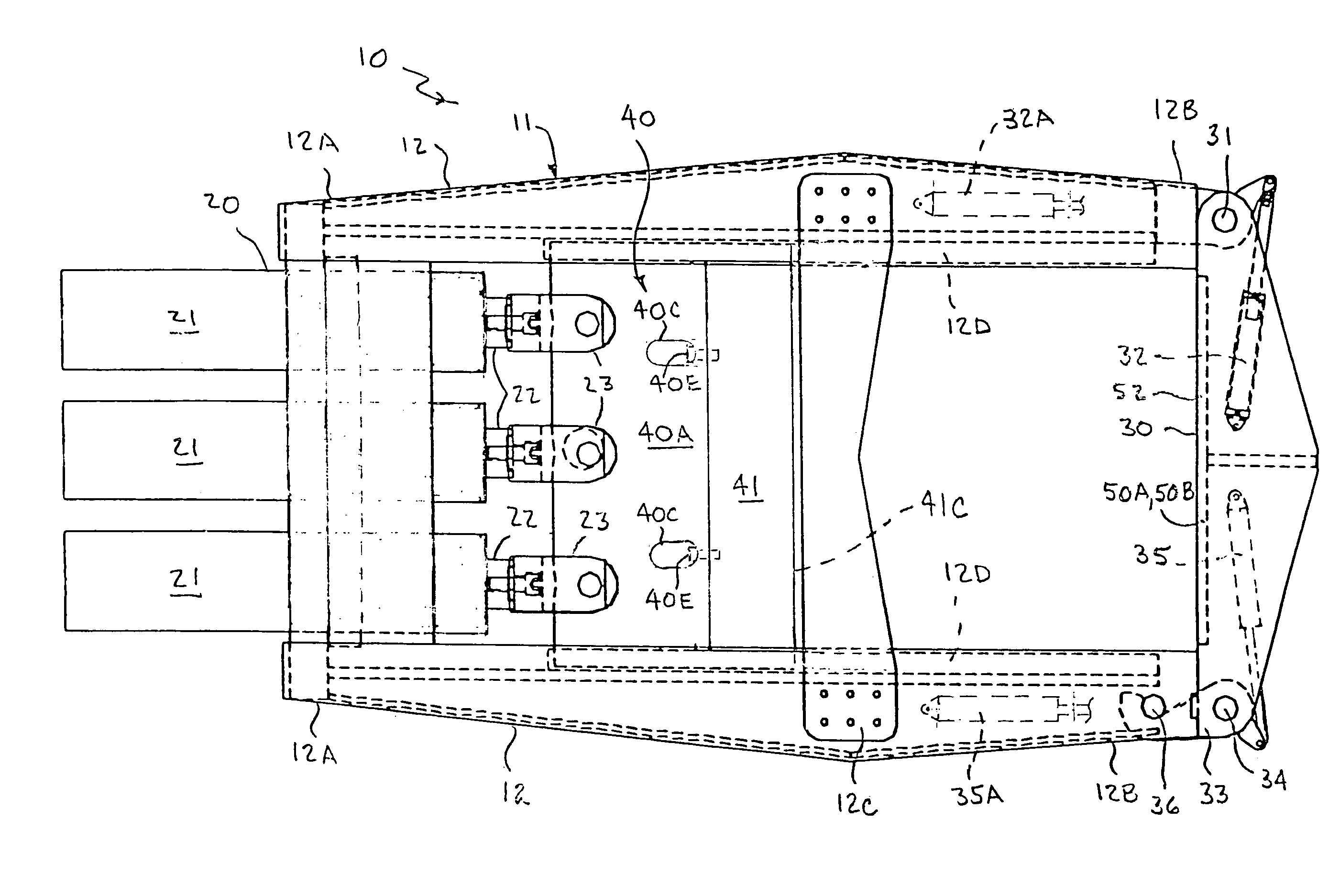

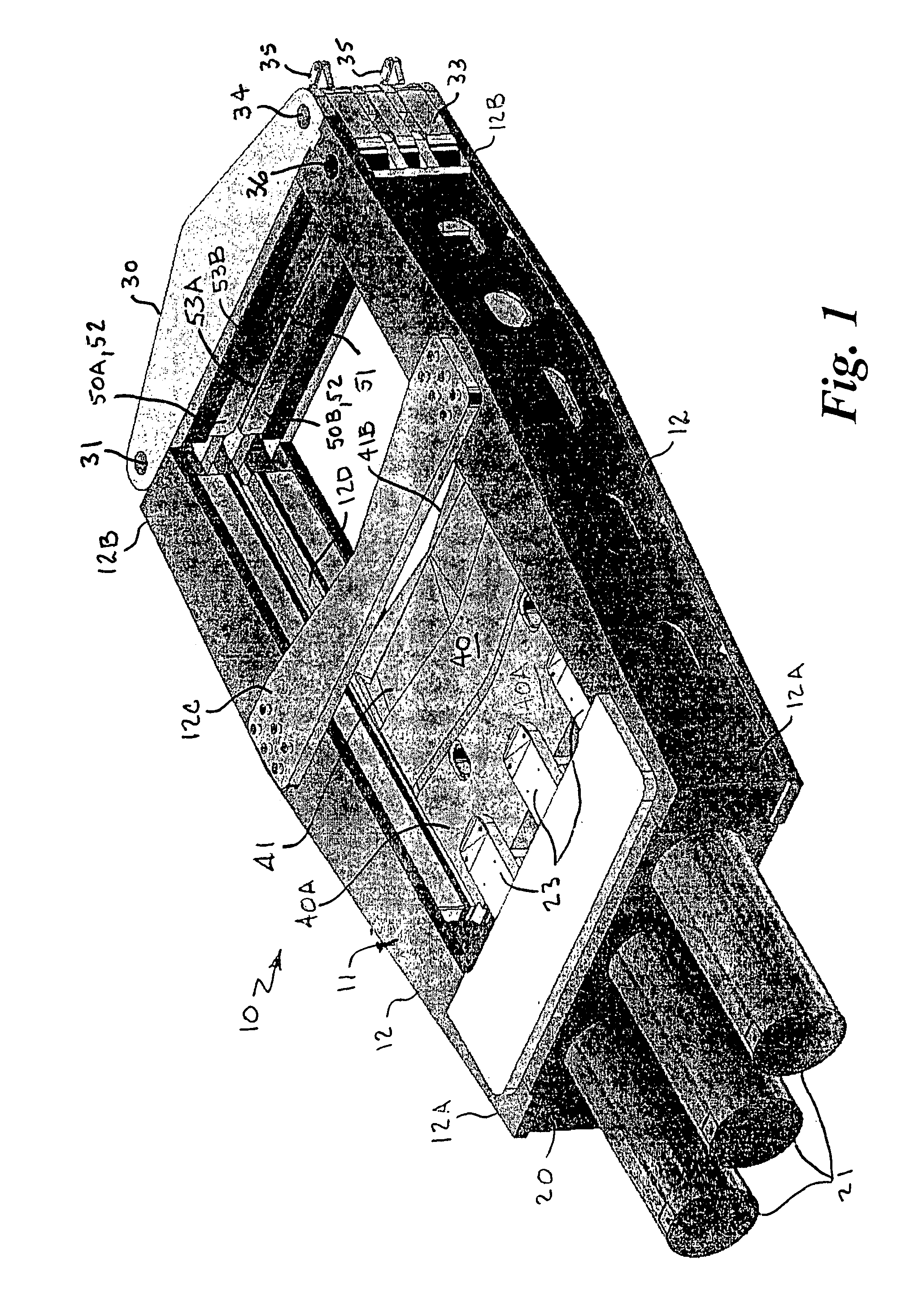

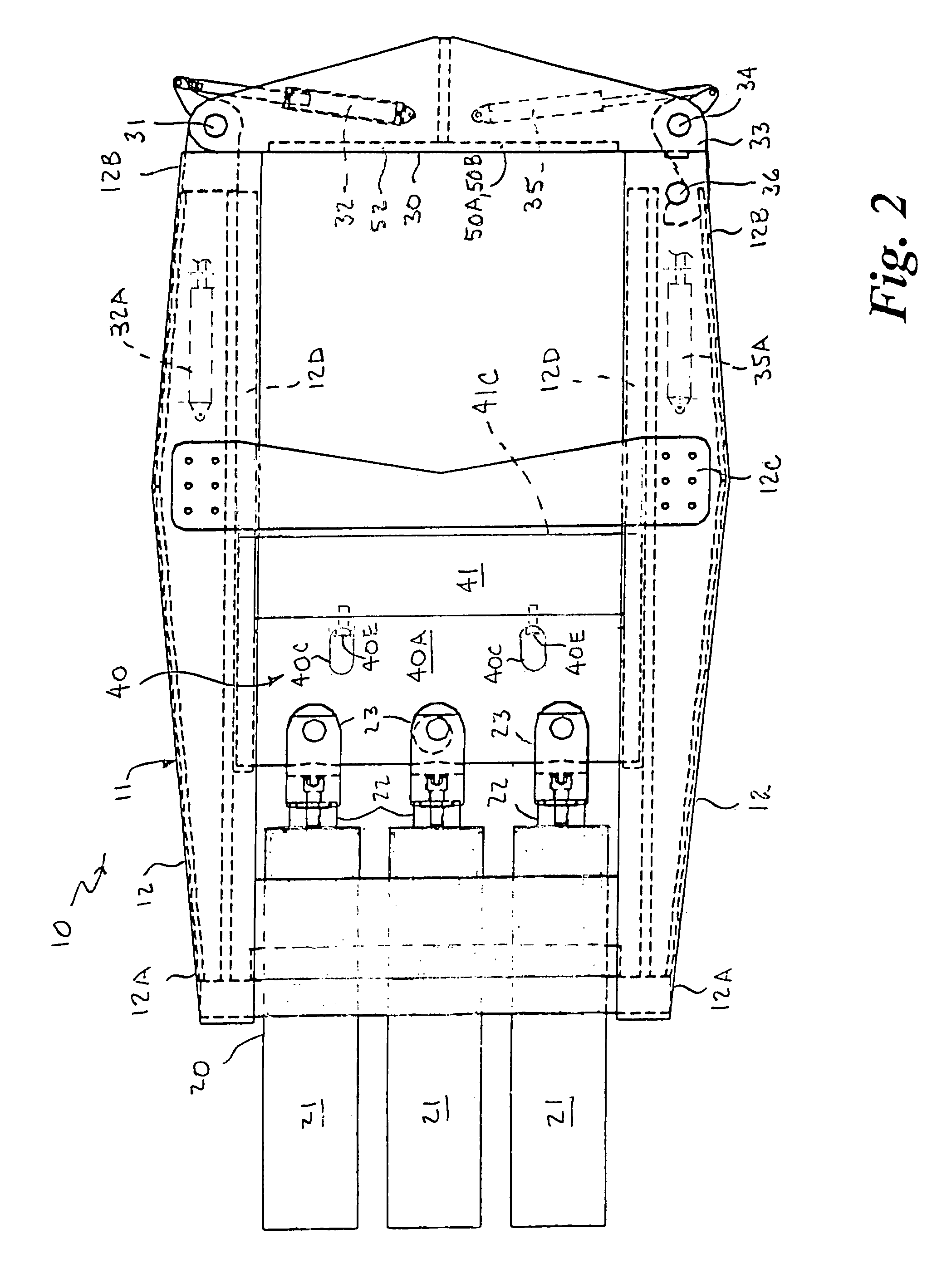

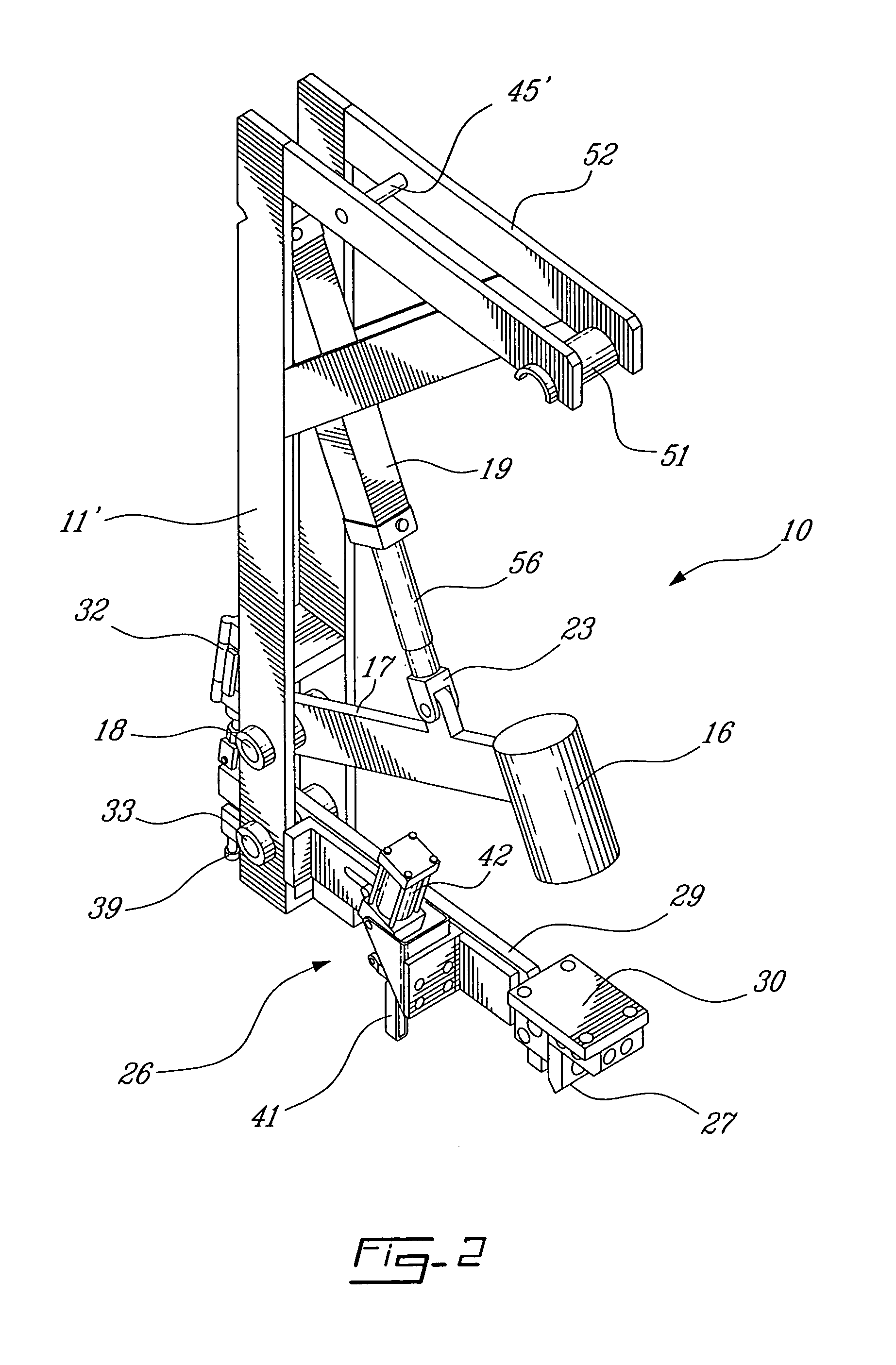

Apparatus and method for shearing reinforced concrete piles and metal piles and crushing reinforced concrete piles

ActiveUS20050194000A1Reduce distortionEngage with obstructionWood splittingMulti-purpose machinesReinforced concreteEngineering

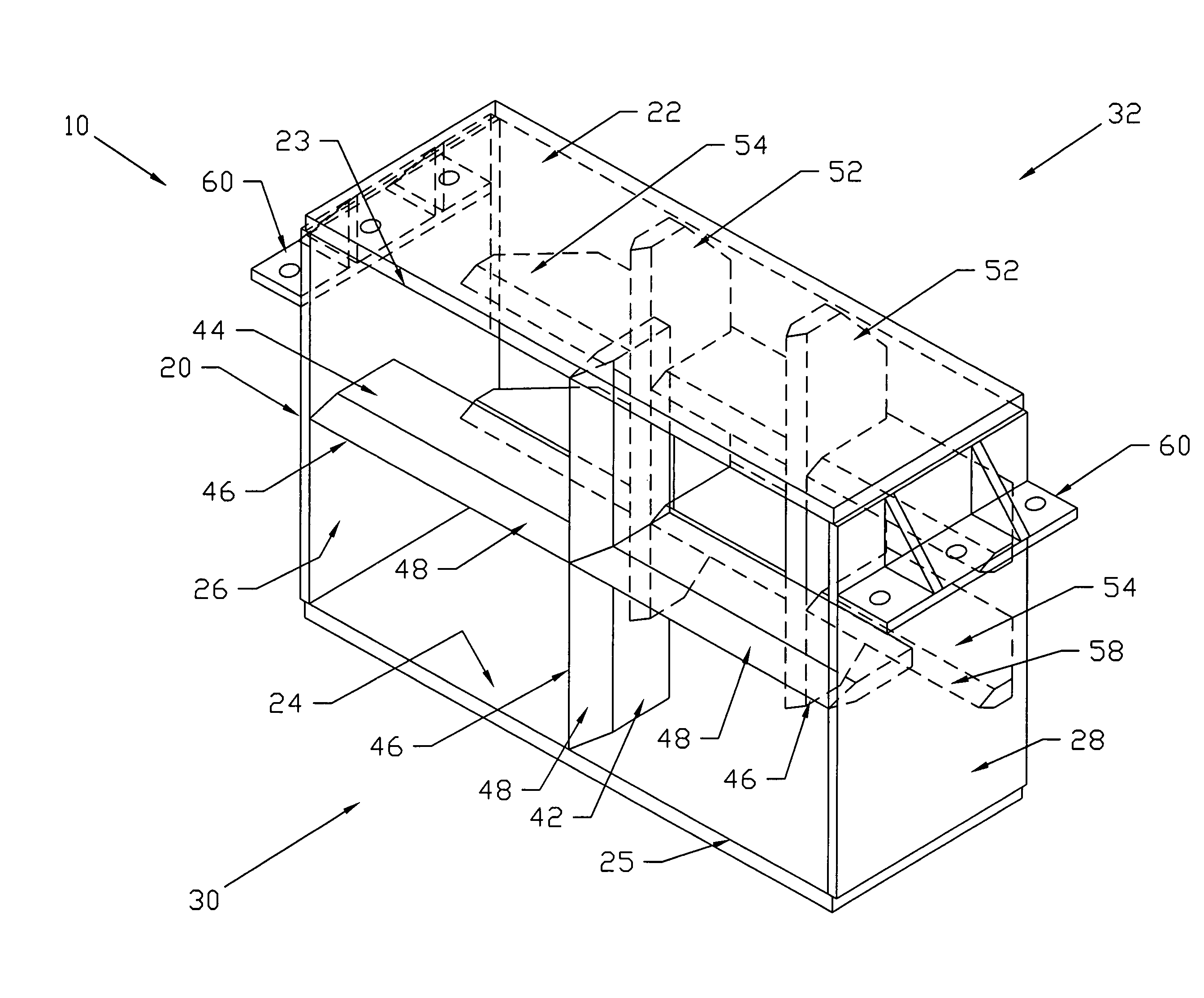

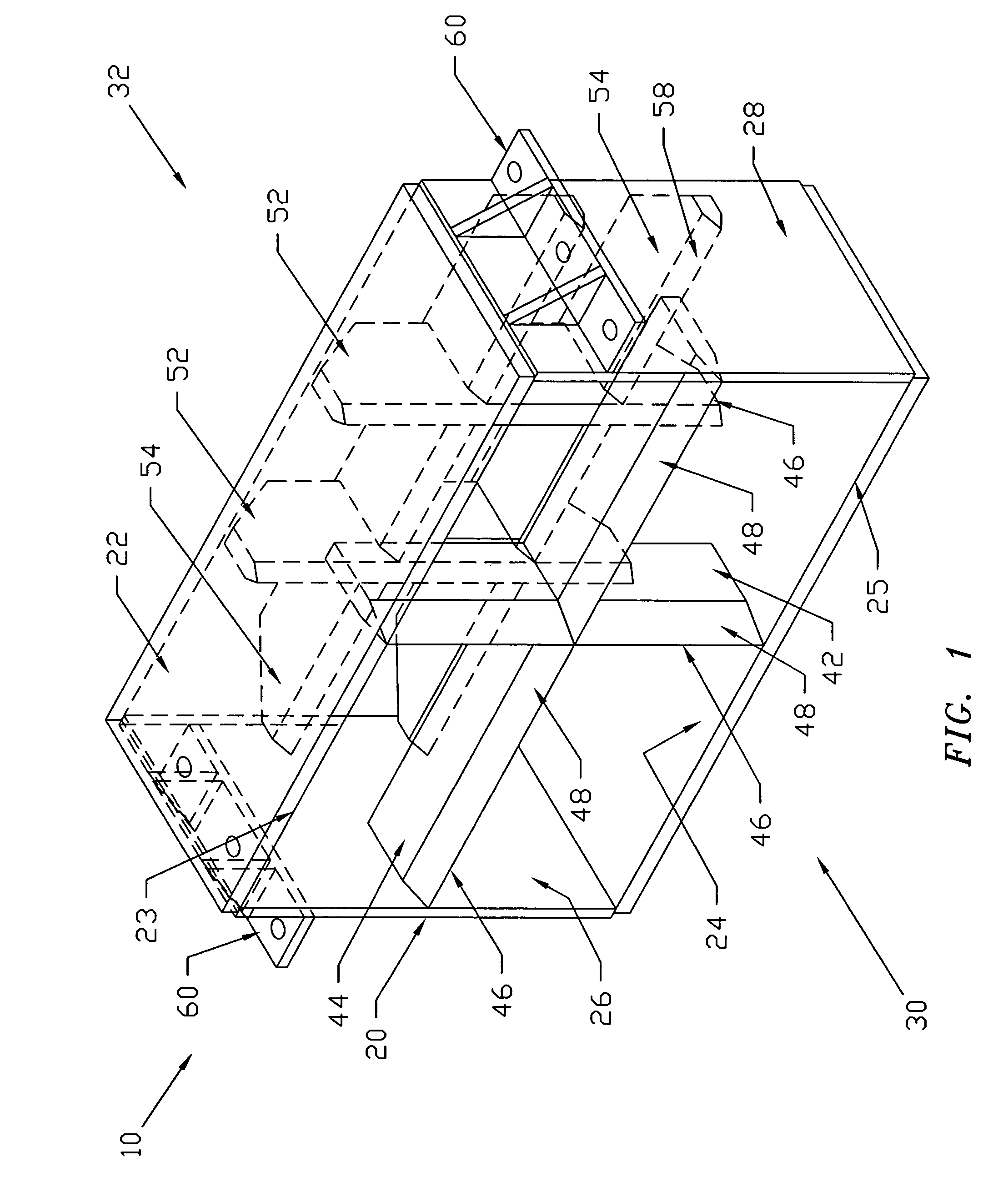

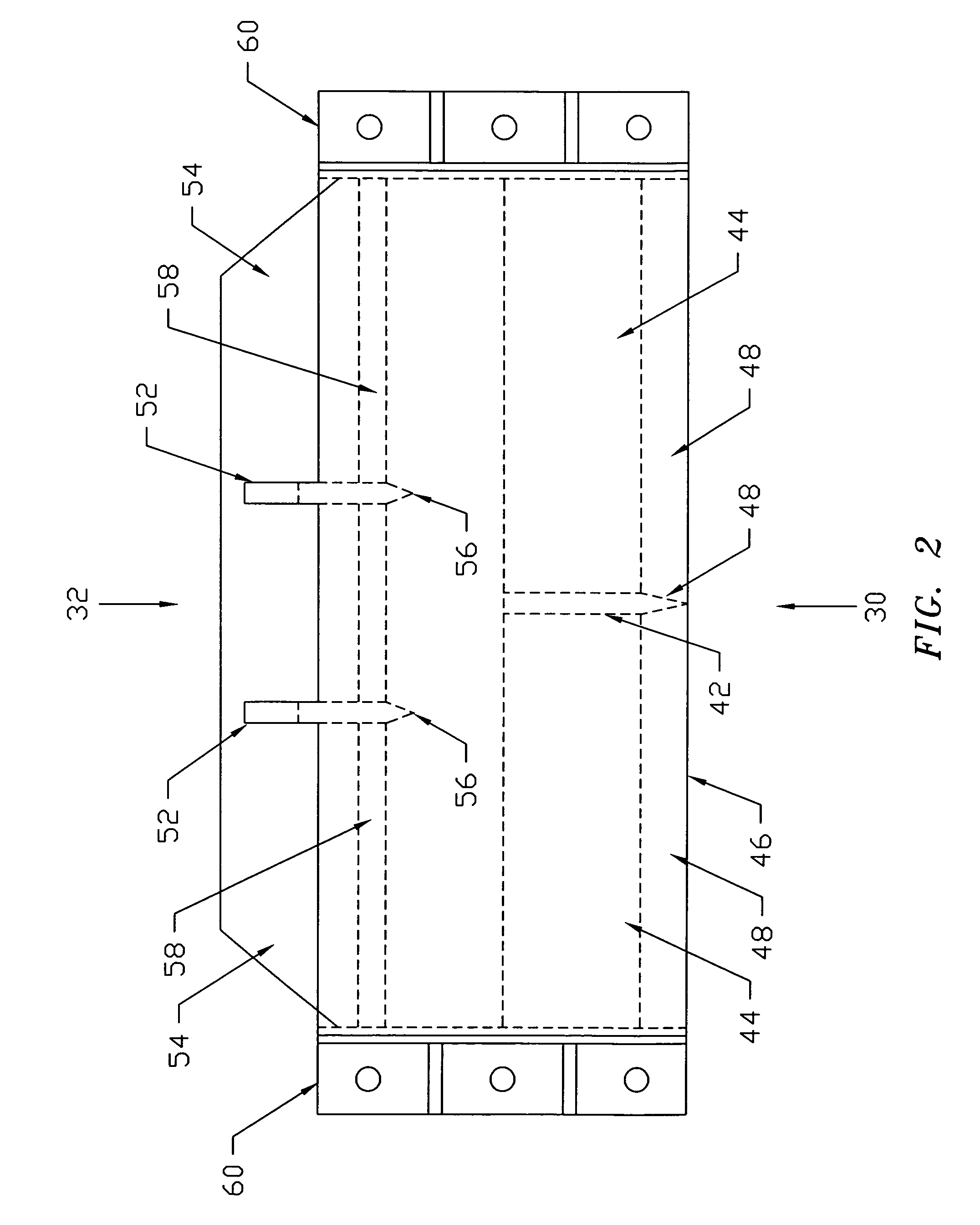

An apparatus (10) for shearing off reinforced concrete piles and metal piles, casing and conductor pipes, and crushing reinforced concrete piles has a frame (11) with first and second ends and a cutter blade (41) movably mounted on the frame driven by hydraulic rams (21) between a retracted position adjacent to the first end and an extended position toward the second end. An abutment gate (30) pivotally mounted and latched at the frame second end has vertically spaced first and second abutment surfaces (52A, 52B) and first and second horizontal shearing surfaces (53A, 53B) disposed in parallel vertically spaced relation defining an opening (51) therebetween through which the cutting edge (41B, 41C) of the blade passes. Removable crushing attachments (60A, 60B) allow crushing of concrete piles, and removable arcuate abutment attachments (54) accommodate cylindrical piles, casing and conductor pipes.

Owner:TODACK JAMES J

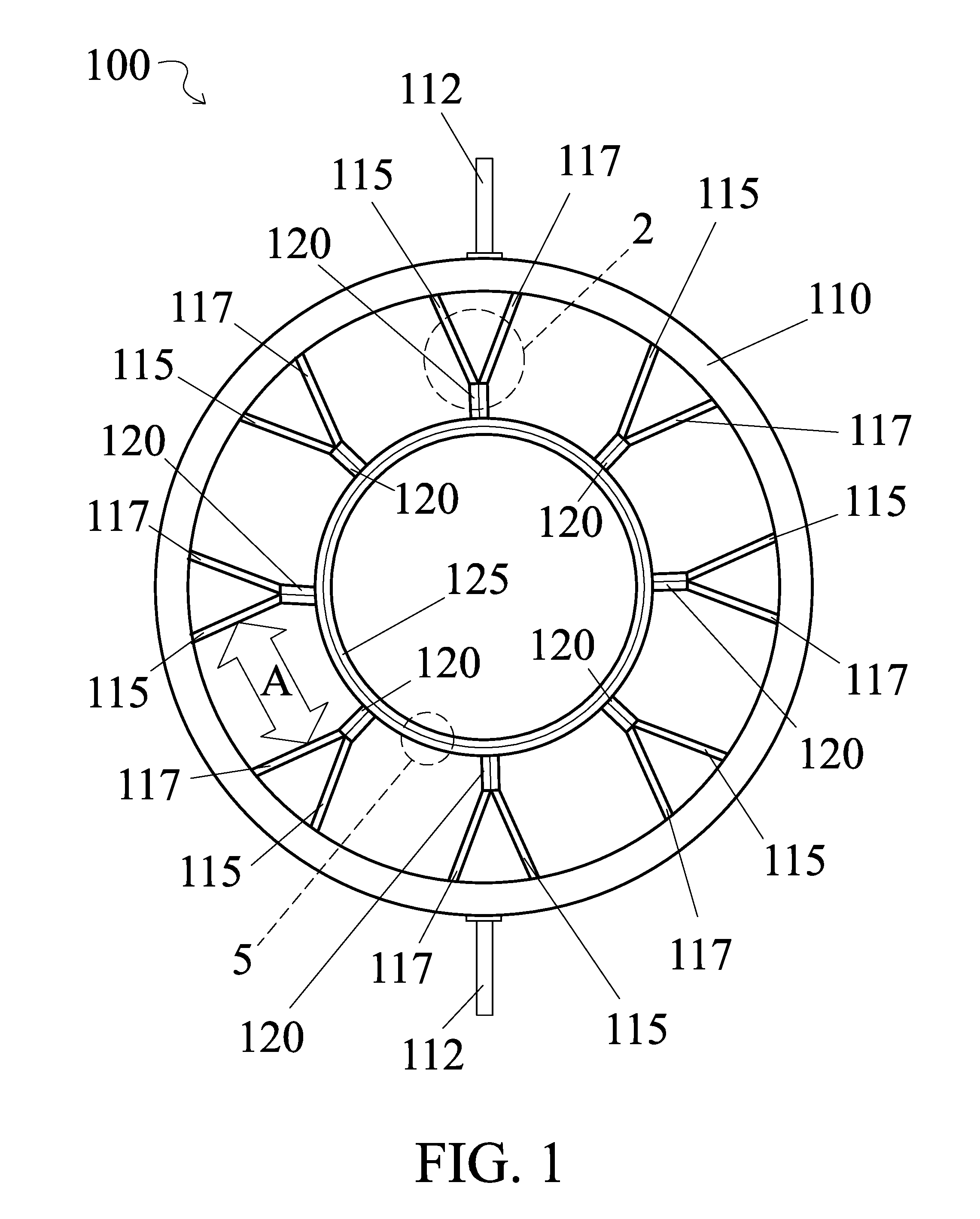

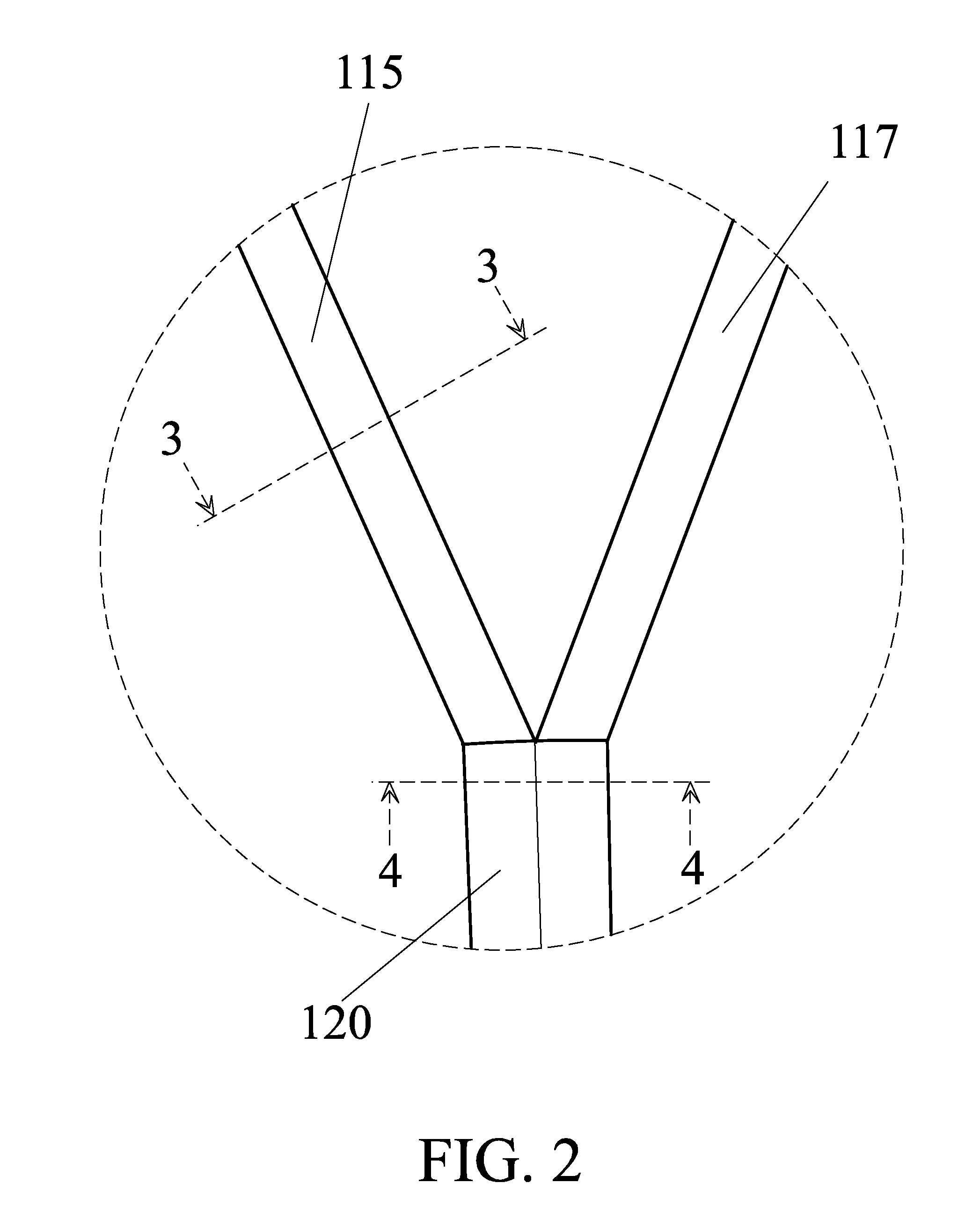

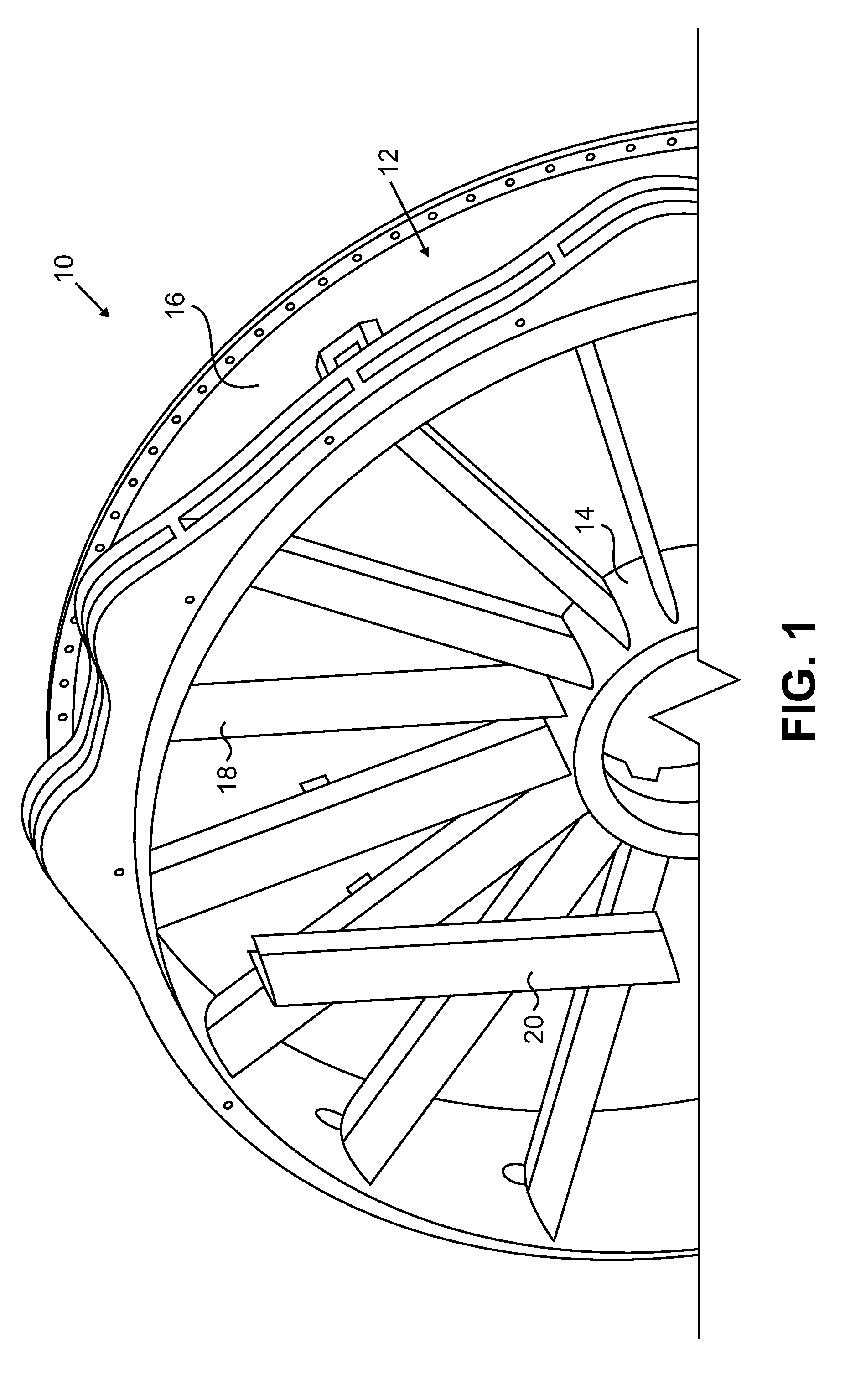

Bamboo splitter

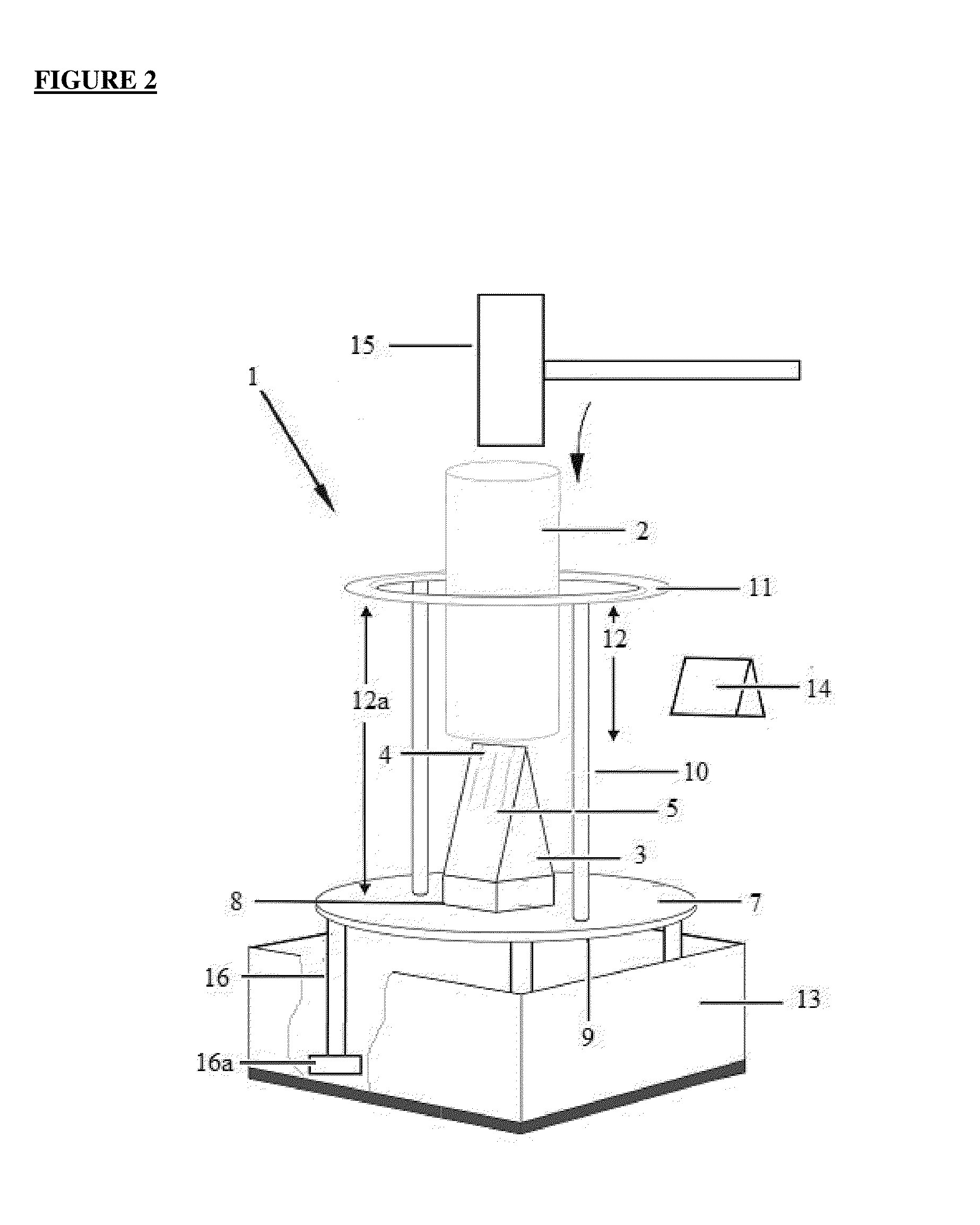

A bamboo splitter has an outer support ring with an interior mounted inner ring blade. A plurality of base blades are radially arranged around the inner ring blade and both the inner ring blade and the base blades have v-shaped cutting surfaces. Attached to each base blade is a pair of slat blades that attach to the base blades at a vertex and have a left and right slat blade. The angle between the vertex and the left and right blades is chosen so that adjacent left slat blades are parallel to adjacent right slat blade forming a parallel cutting space which produces bamboo slats that have orthogonal edges which makes them much more amenable to traditional building methods. A different number of slat blades may be used depending on the size of the bamboo being used and the size and number of the slats being produced.

Owner:BAMBOO TECH

Two-stage two-stroke log splitting system

A log splitting system comprises a splitter box, having top, bottom and sidewalls, and open entrance and discharge ends. A first set of cutting blades secured adjacent to the entrance end divides the entrance end into at least two, first sections. A second set of cutting blades, secured adjacent to the first set of cutting blades and opposite the entrance end, further divides each splitter box's first section into at least two, second sections. A ram assembly with a force applying surface moveable toward the splitter box's entrance end contacts a log with the first set of cutting blades. The ram member's surface has a plurality of surface portions, each sized to fit into one of the splitter box's first section, to further contact the log with the second set of cutting blades, splitting the log into at least four pieces.

Owner:MULTITEK

Component removal tool and method

An apparatus includes a carriage, a first tooth, a second tooth, a feed block and a drive element. The first and second teeth are shaped for breaking bonds and attached to a first side of the carriage. The first and second teeth are spaced apart and generally parallel to each other. The drive element moves the carriage away from the feed block so that the first and second teeth break bonds when they encounter them. A method for removing a bonded component from a structure includes positioning a tool having first and second teeth between the component and the structure. The teeth are positioned between trailing edges of the component and the structure. The method includes driving the teeth from the trailing edges of the structure towards a leading edge of the structure to break bonds between the component and the structure so that the component can be removed.

Owner:UNITED TECH CORP

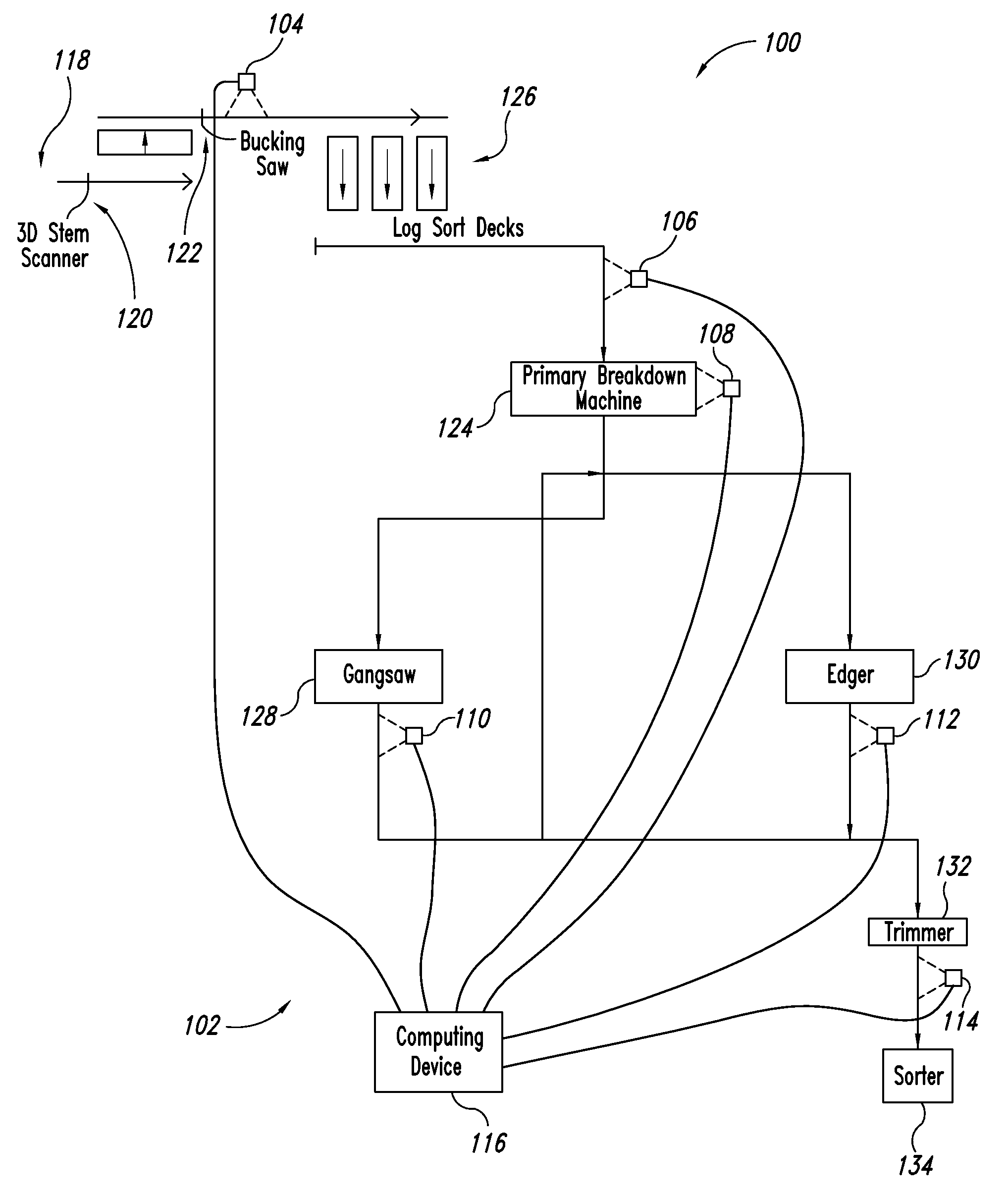

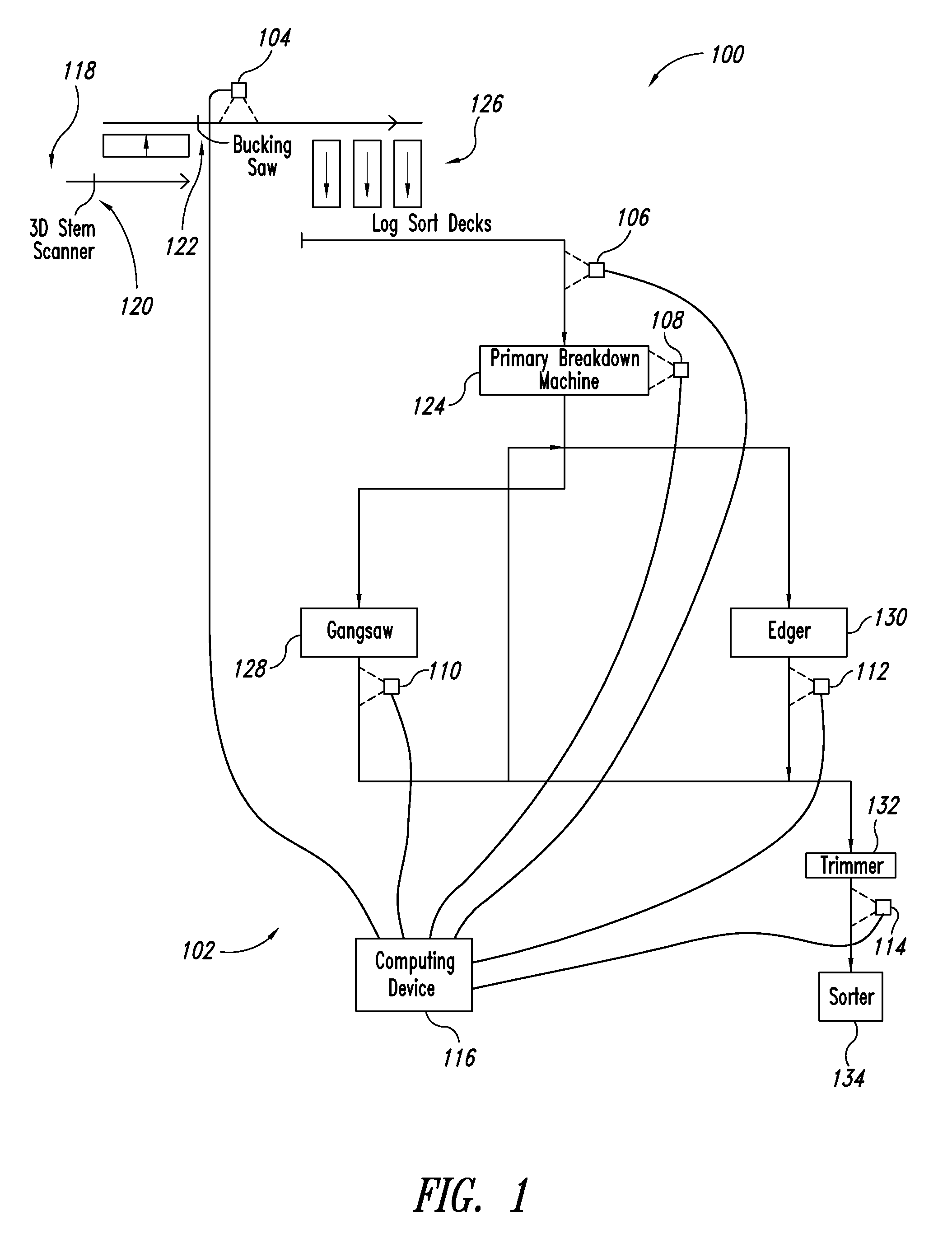

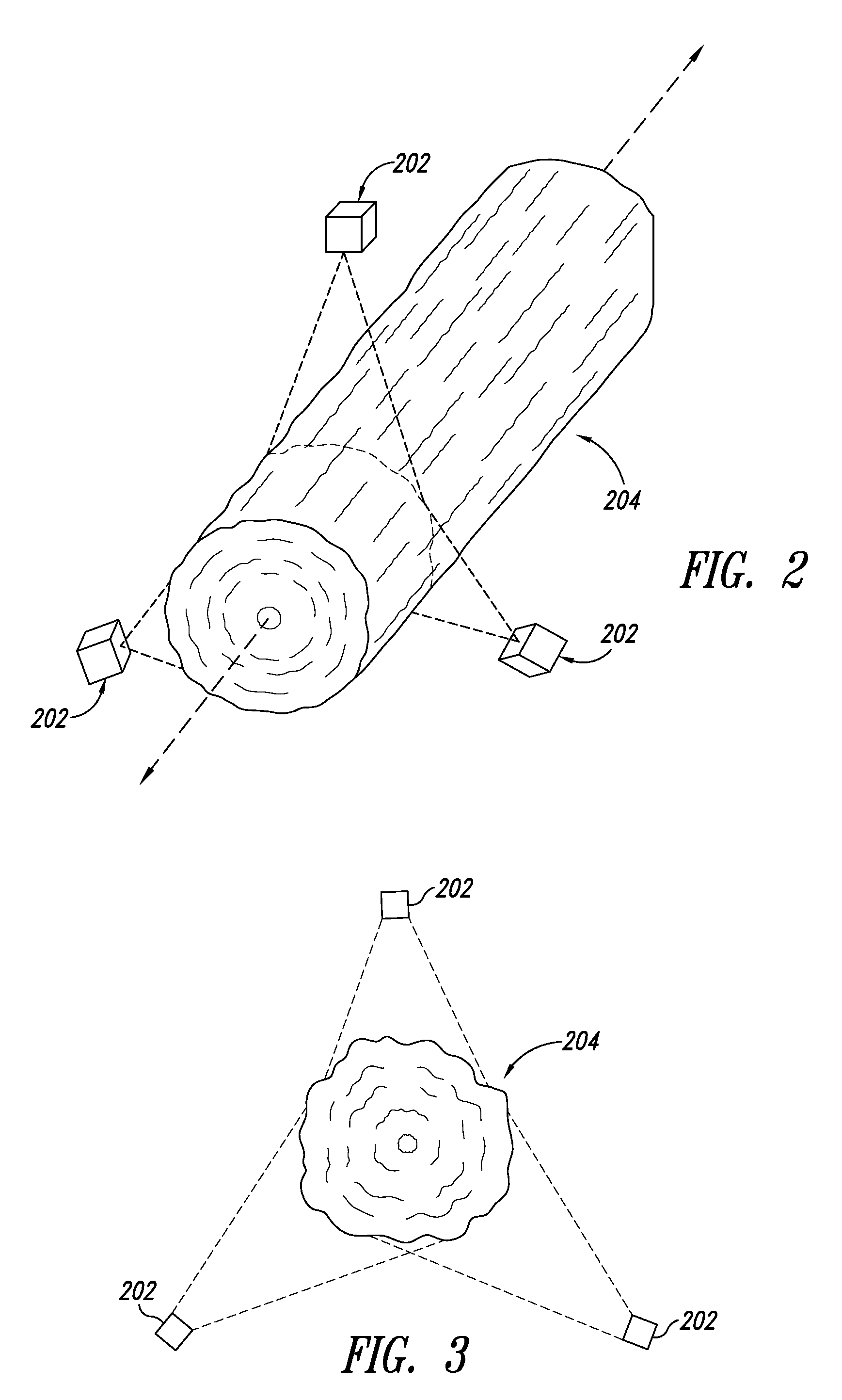

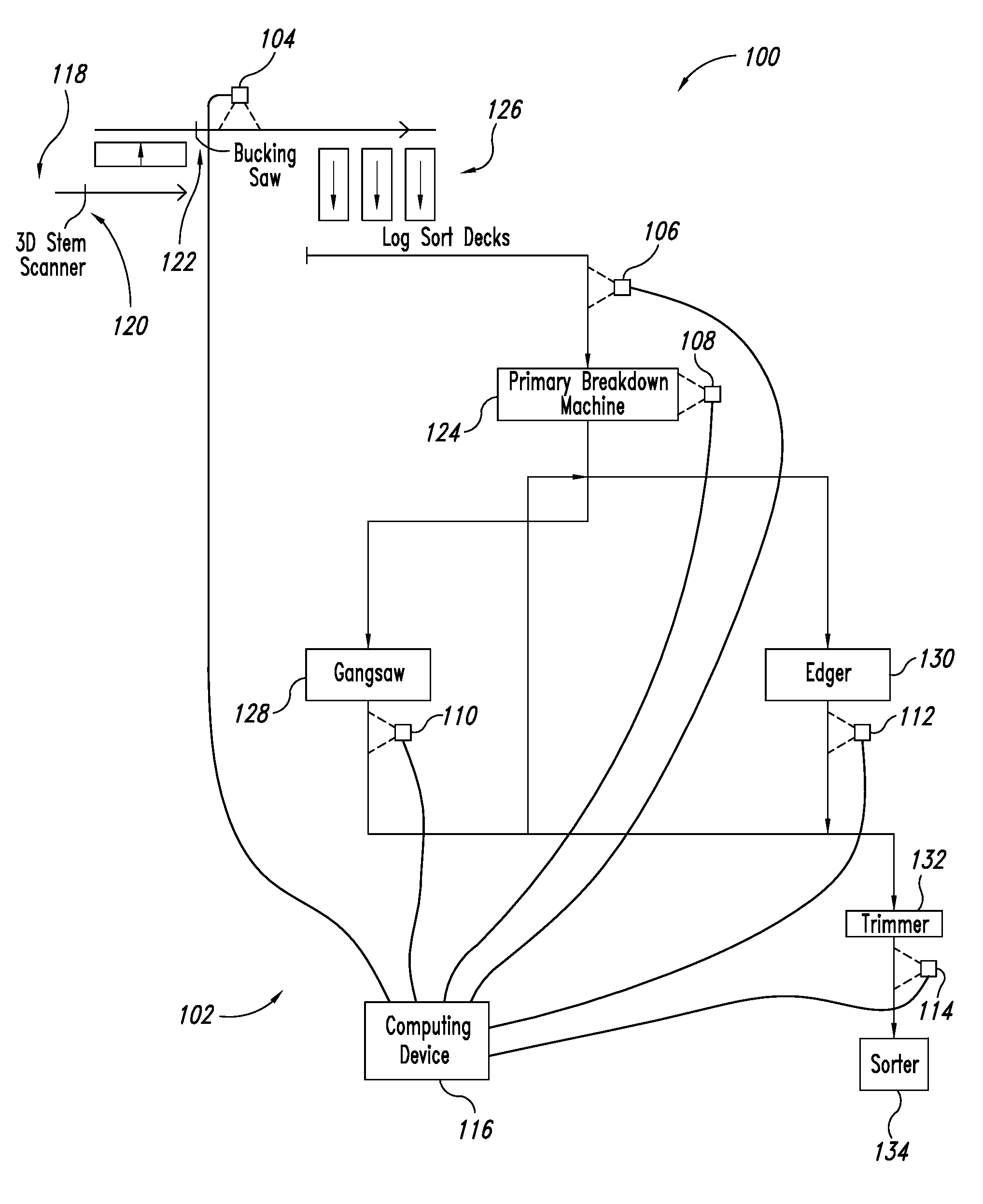

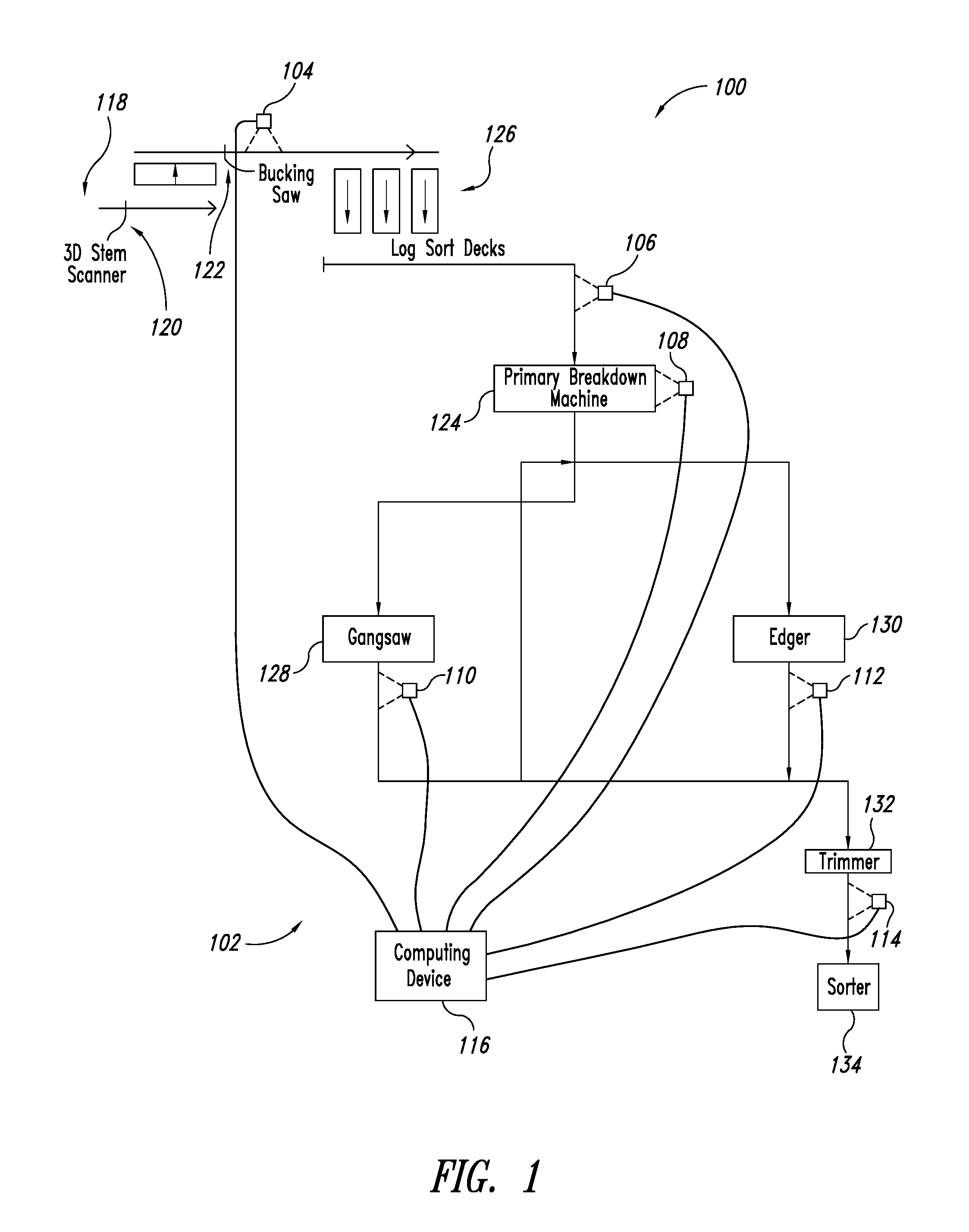

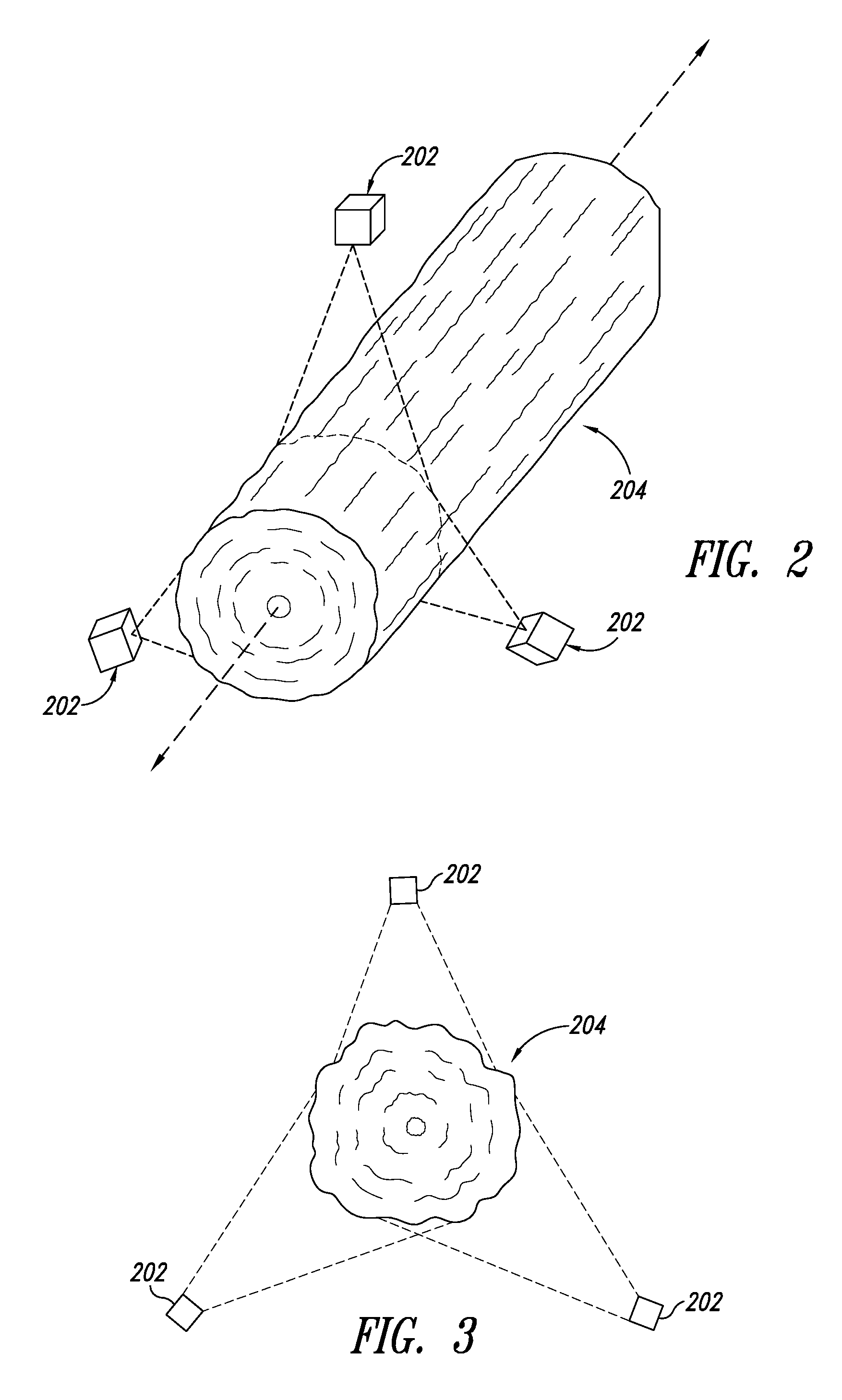

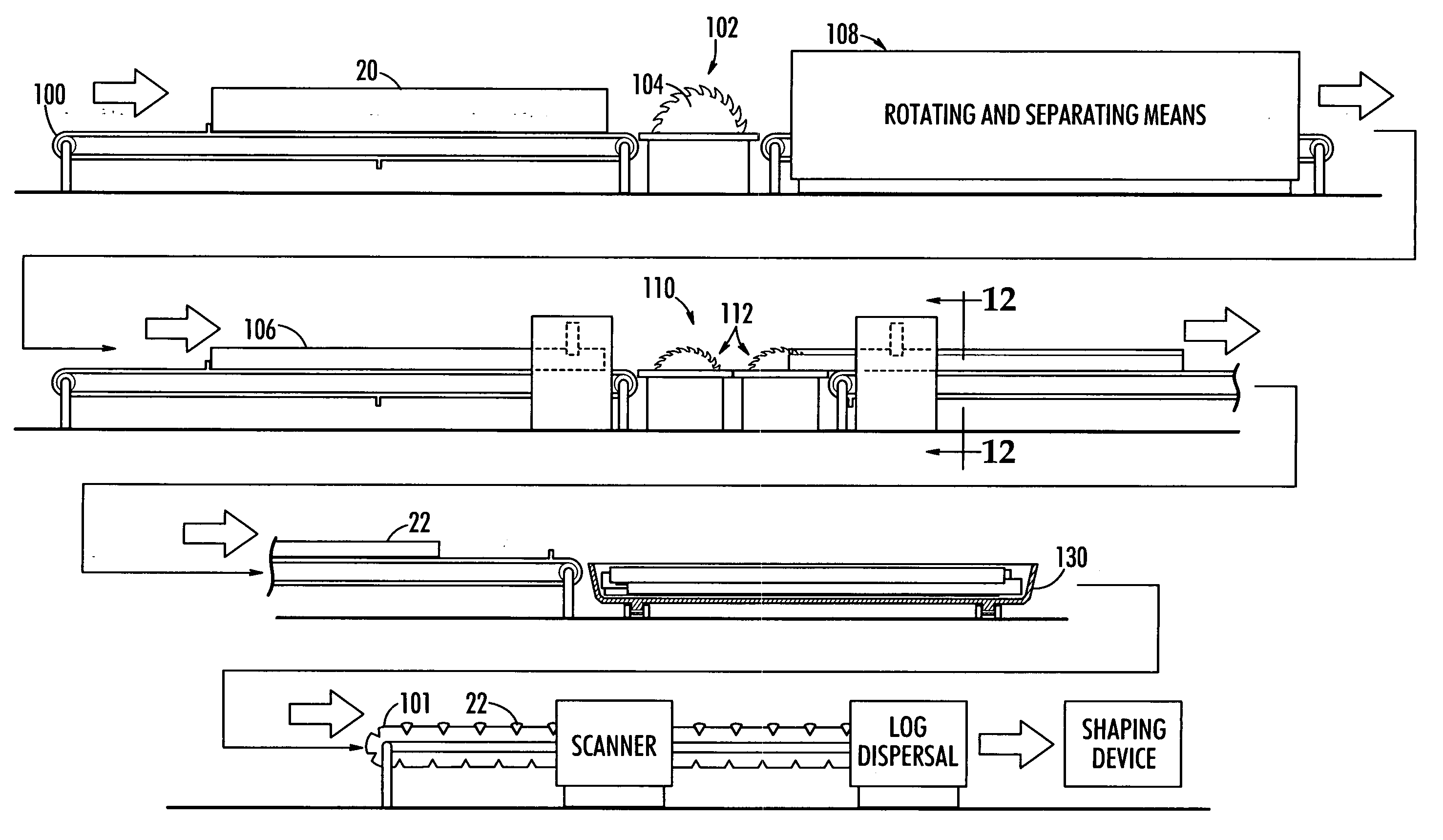

Systems and methods for tracking lumber in a sawmill

ActiveUS20090255607A1Fast and immediate feedbackAutomatic control devicesWood splittingStructural engineeringMechanical engineering

Owner:WEYERHAEUSER NR CO

Apparatus and method for shearing reinforced concrete piles and metal piles and crushing reinforced concrete piles

ActiveUS7243646B2Engage with obstructionWood splittingMulti-purpose machinesReinforced concreteEngineering

An apparatus (10) for shearing off reinforced concrete piles and metal piles, casing and conductor pipes, and crushing reinforced concrete piles has a frame (11) with first and second ends and a cutter blade (41) movably mounted on the frame driven by hydraulic rams (21) between a retracted position adjacent to the first end and an extended position toward the second end. An abutment gate (30) pivotally mounted and latched at the frame second end has vertically spaced first and second abutment surfaces (52A, 52B) and first and second horizontal shearing surfaces (53A, 53B) disposed in parallel vertically spaced relation defining an opening (51) therebetween through which the cutting edge (41B, 41C) of the blade passes. Removable crushing attachments (60A, 60B) allow crushing of concrete piles, and removable arcuate abutment attachments (54) accommodate cylindrical piles, casing and conductor pipes.

Owner:TODACK JAMES J

Quad wedge tip up log splitter

ActiveUS7255143B1Efficient executionProvide flexibilityWood splittingMulti-purpose machinesHydraulic cylinderEngineering

A uniquely configured quad wedge allows for the creation of a tip-up log splitter that is capable of multiple splits in a single stroke of the drive mechanism. The quad wedge is attached to the piston of a hydraulic cylinder, and is slidably mounted to a framework to allow for movement through a splitting zone. The quad wedge further includes a main splitting blade, along with a pair of splitting wings extending outwardly in a perpendicular manner. The blades each have structures on the ends thereof which are configured to help contain a log during splitting operations, thus avoiding undesired movement or wandering. The log splitter further includes a stripper mechanism positioned near the cylinder housing to allow jammed logs to be easily removed, which includes a recess to house the quad wedge when retracted. A jammed log will necessarily contact the stripper mechanism, causing it to be removed from the blade.

Owner:NORTHERN TOOL & EQUIP

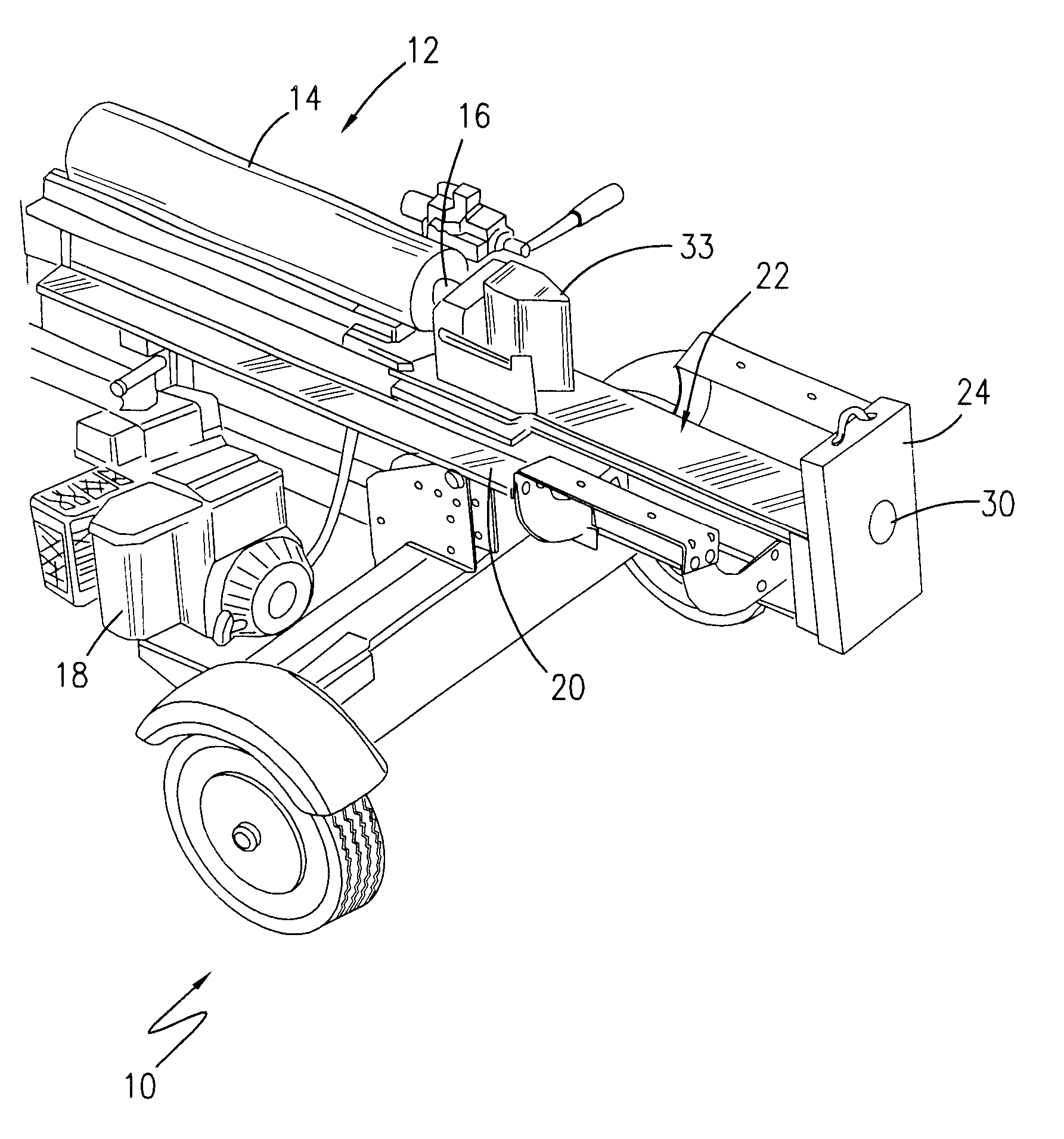

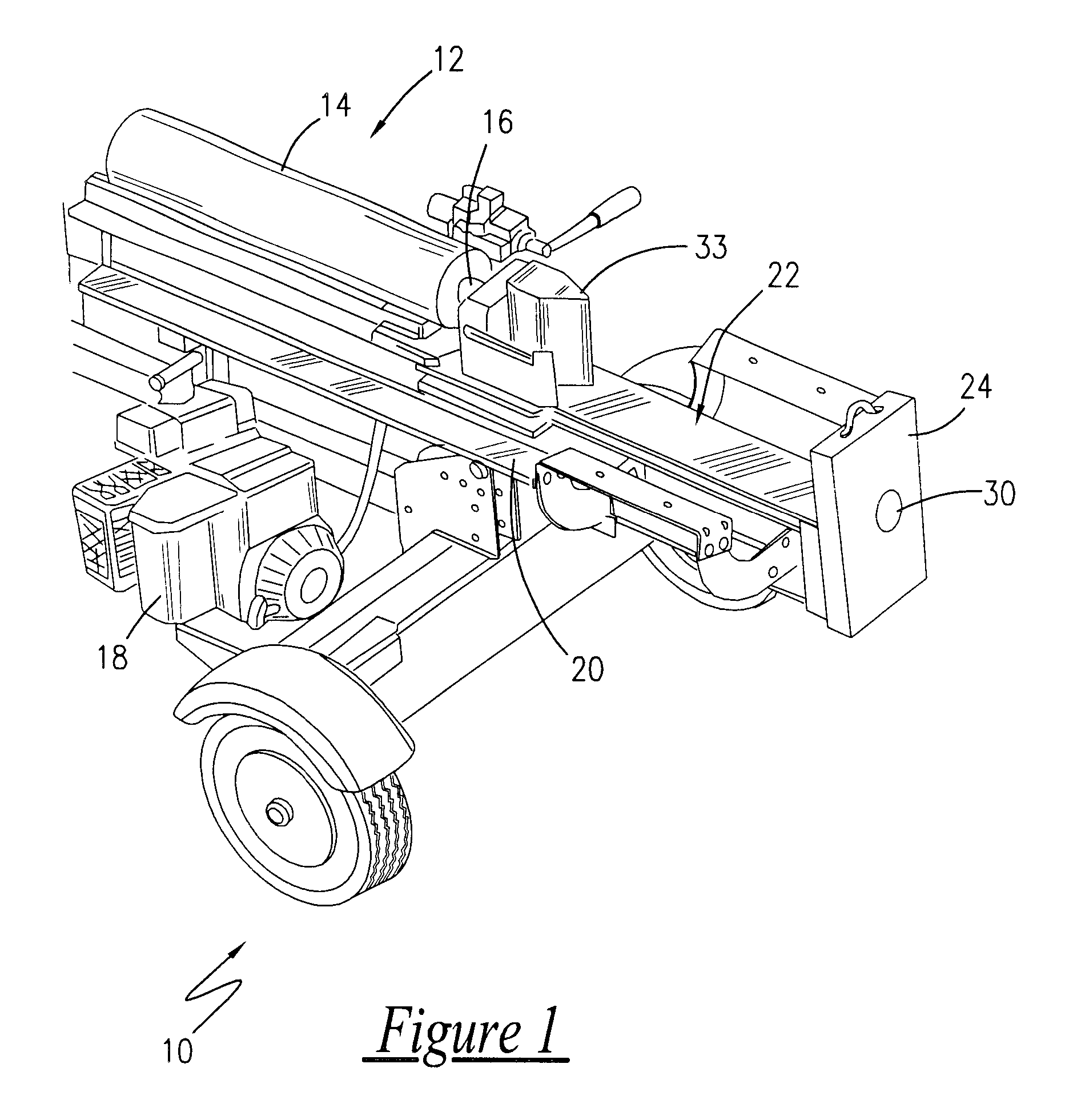

Compact log splitter

Owner:NORTHERN TOOL & EQUIP

Improvements in and relating to splitting apparatus

ActiveUS20160107330A1Reduce weightWood splittingMetal working apparatusEngineeringMechanical engineering

Disclosed is an apparatus for mechanically splitting materials, including a body with a cutting element arranged relative thereto. The cutting element includes at least one cutting surface oriented vertically. The splitting apparatus includes the cutting element applying an upward pressure against the material which is split when a separate downward force is applied to the material. The body of the splitting apparatus also includes a safety element to protect the user from the cutting element; an elongate supporting element to distance the safety element from either or both the cutting element and a surface on which the splitting apparatus is used; a stabilizing element to stabilize the splitting apparatus relative to a surface on which the splitting apparatus is used; and optionally a deflecting element to deflect split materials away from the cutting element and container element to contain therewithin split materials produced during the splitting.

Owner:HUTCHINSON VAUGHAN JOHN

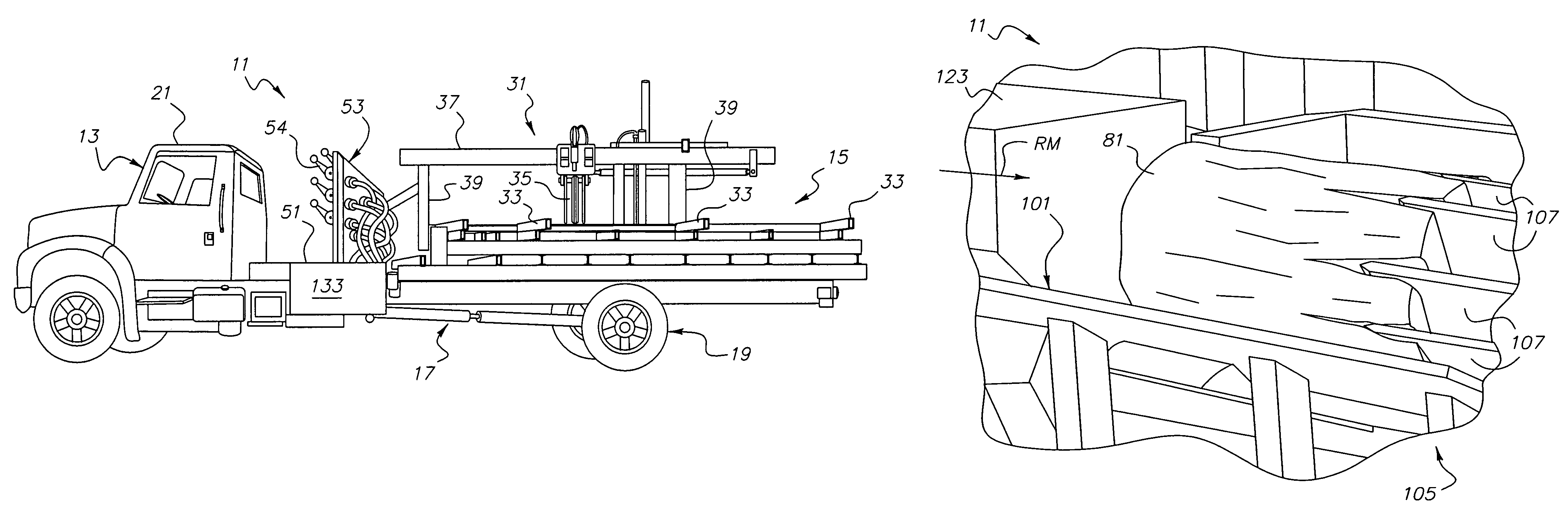

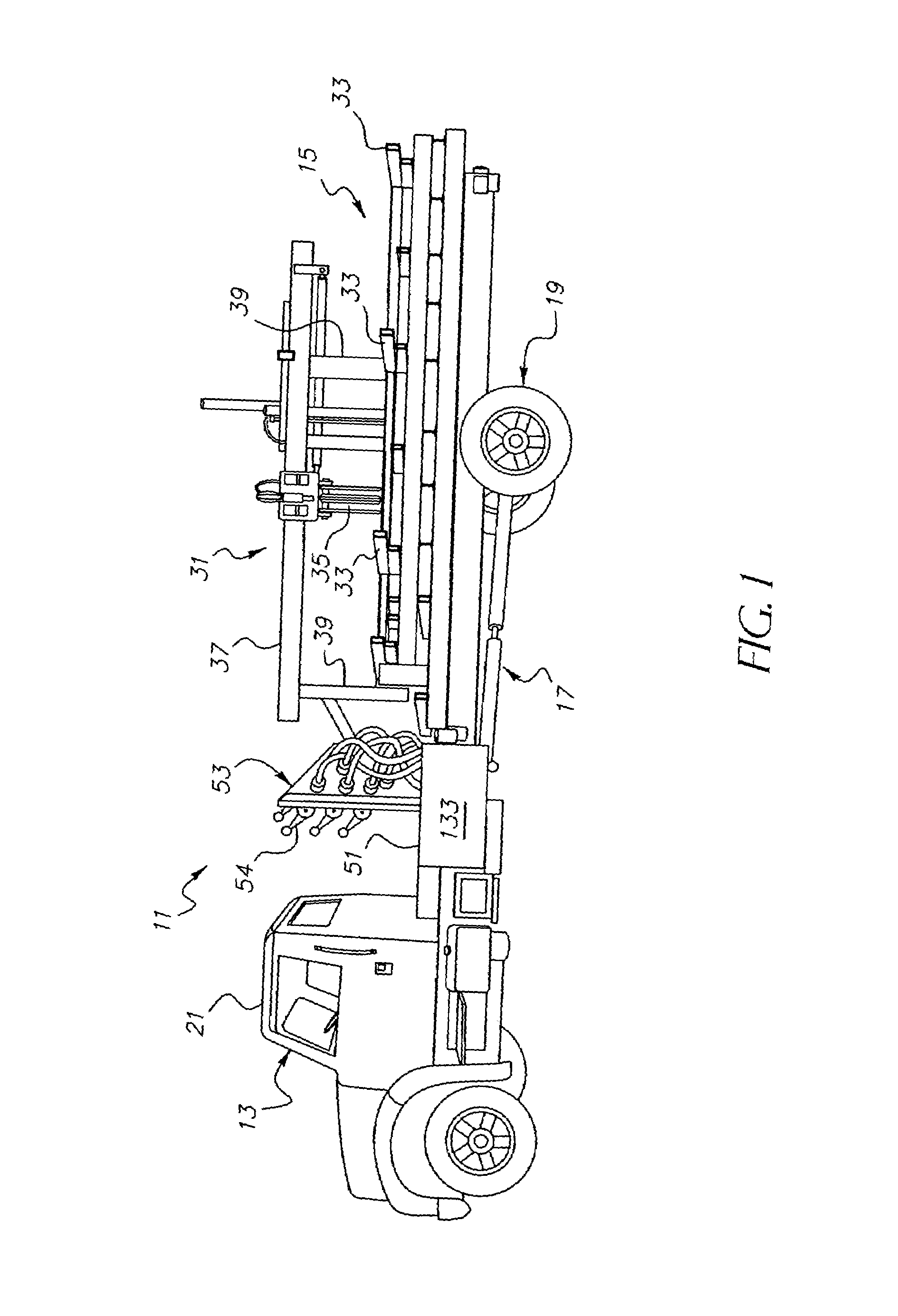

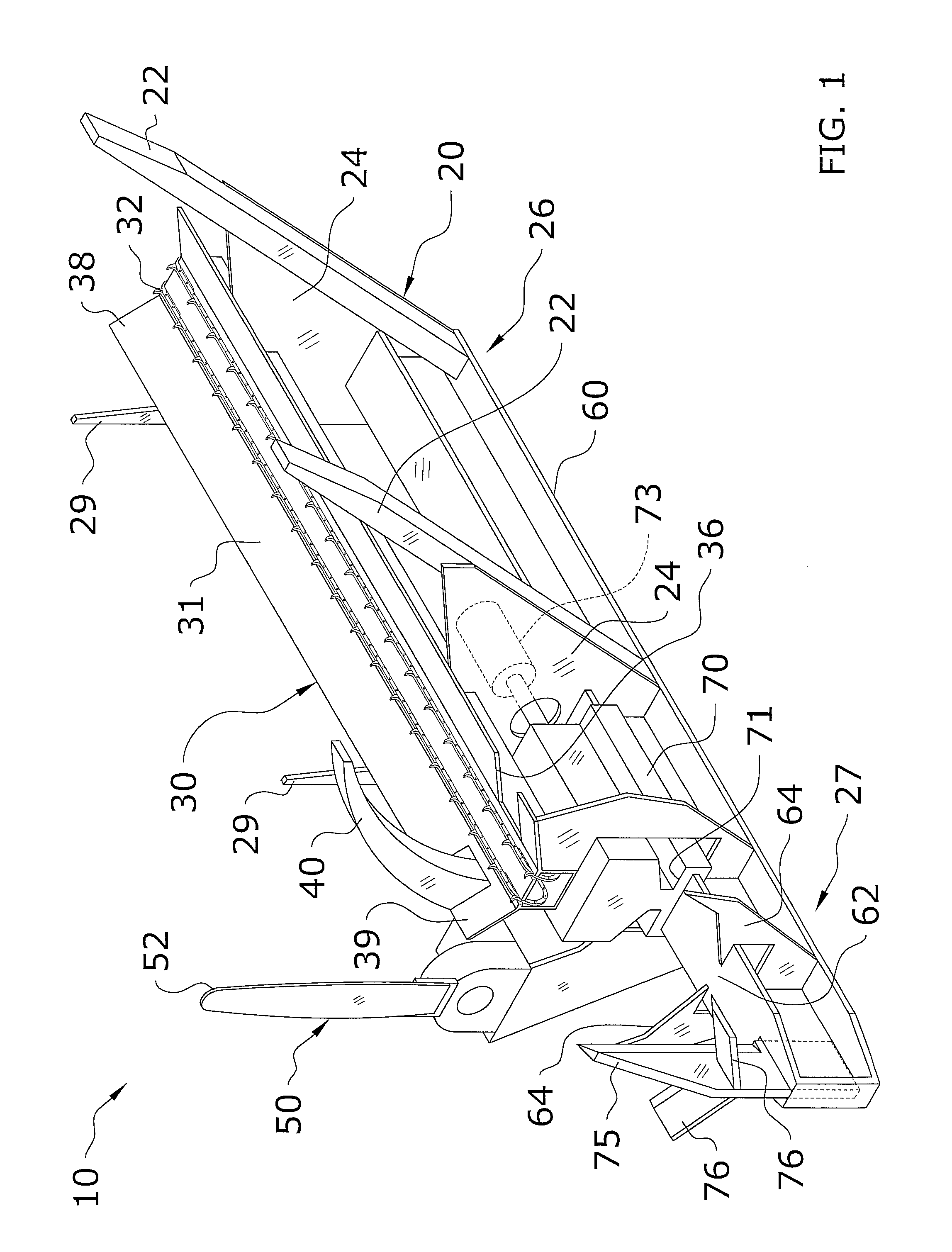

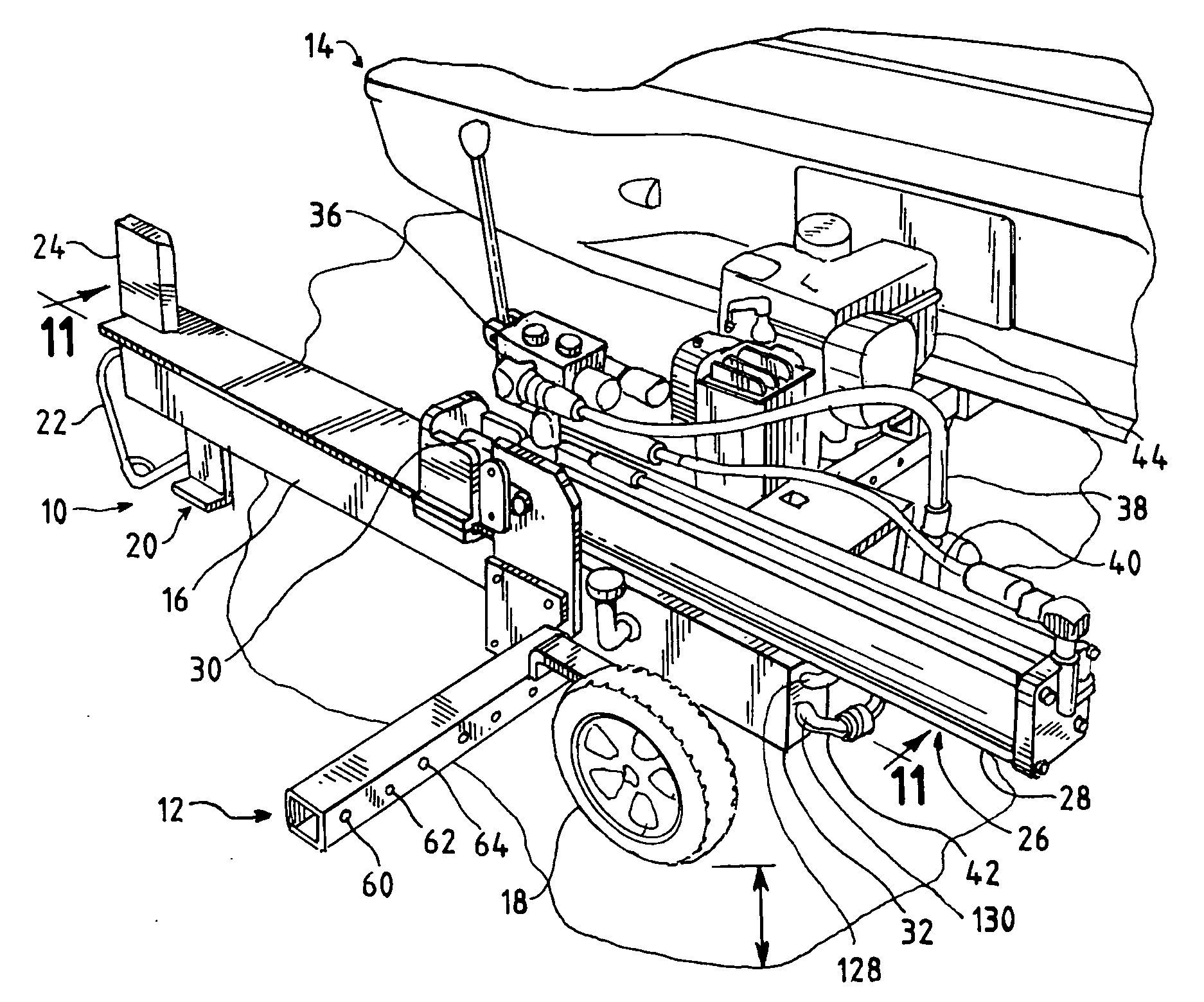

Wood processor

InactiveUS7228881B1Significant processingEasy constructionWood splittingMulti-purpose machinesWood processorWood machining

A wood processor including a motor vehicle having a bed structure, a clamping device on the bed structure for clamping a wood log and positioning it in a first processing position, a power saw for cutting predetermined length members from the wood log, and a splitting device for splitting the wood members into a specified number of pieces.

Owner:SMITH RICHARD H

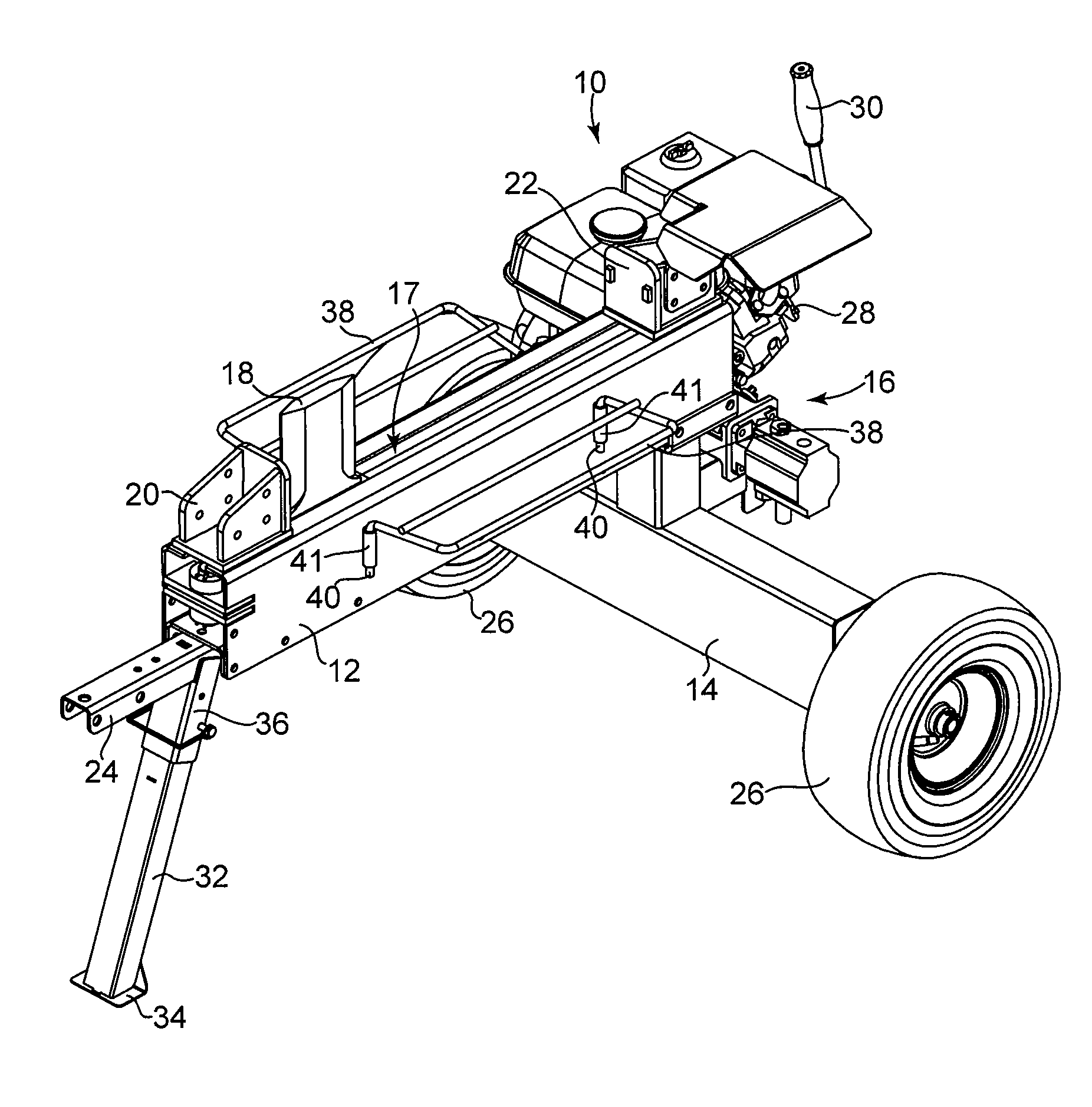

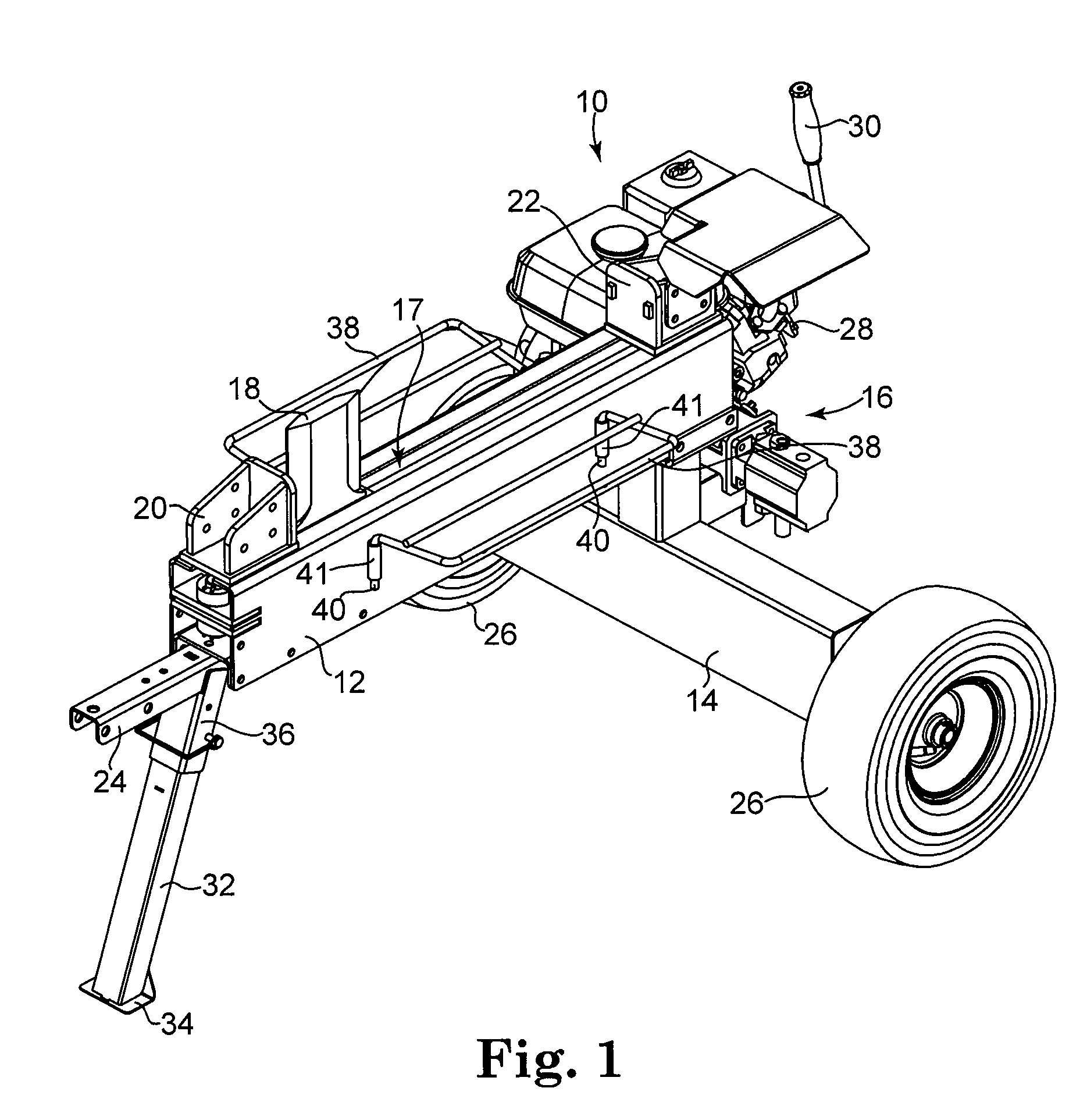

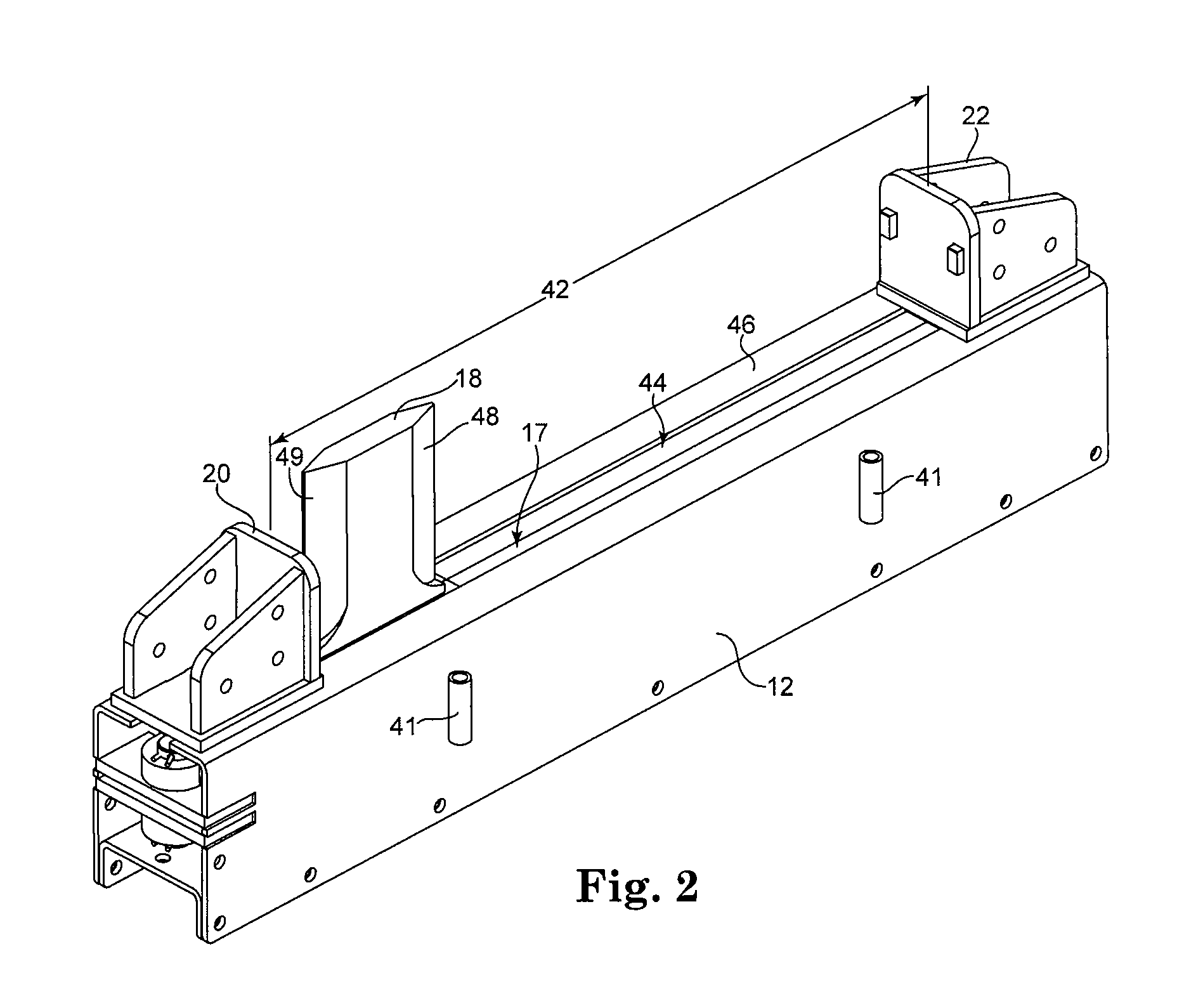

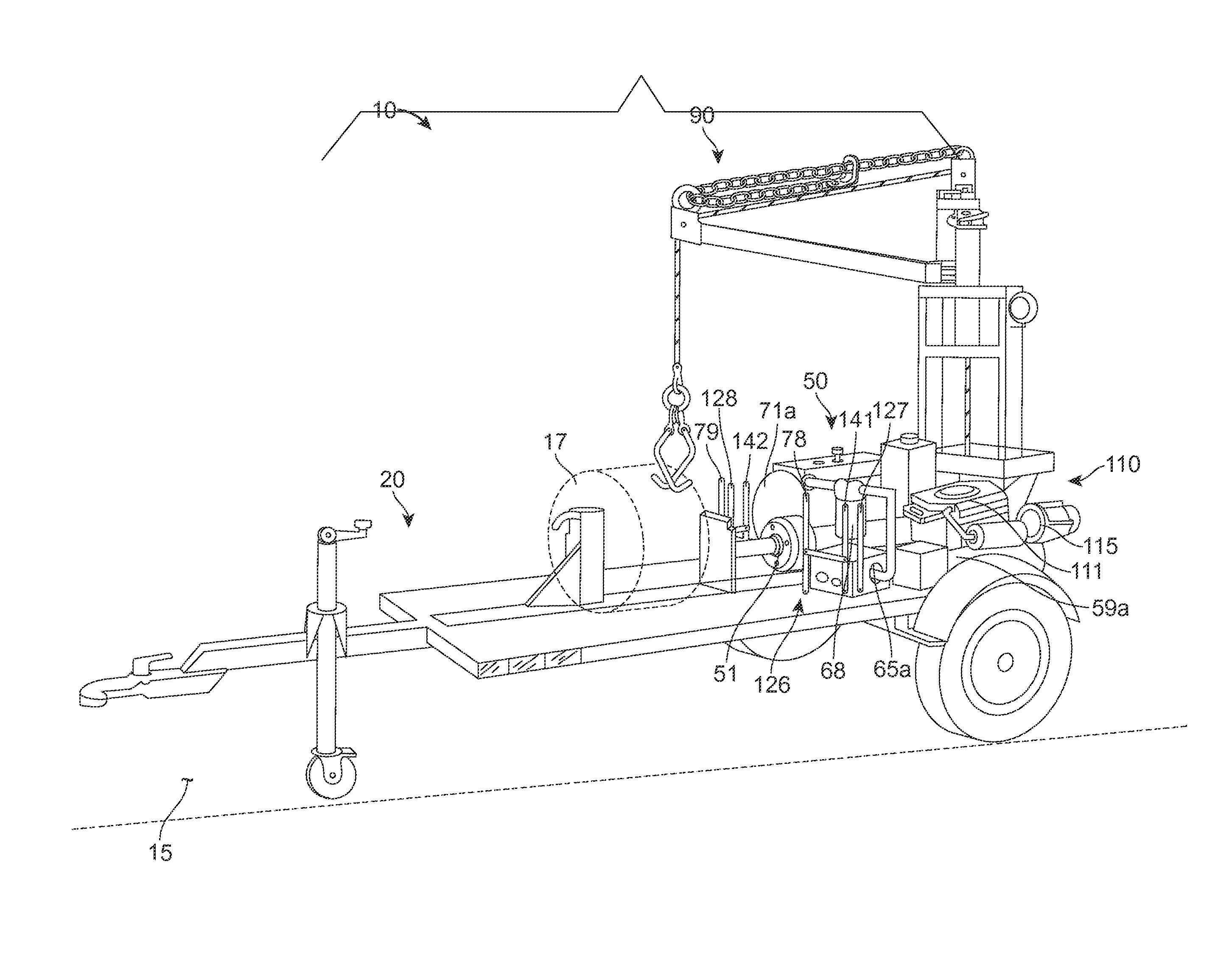

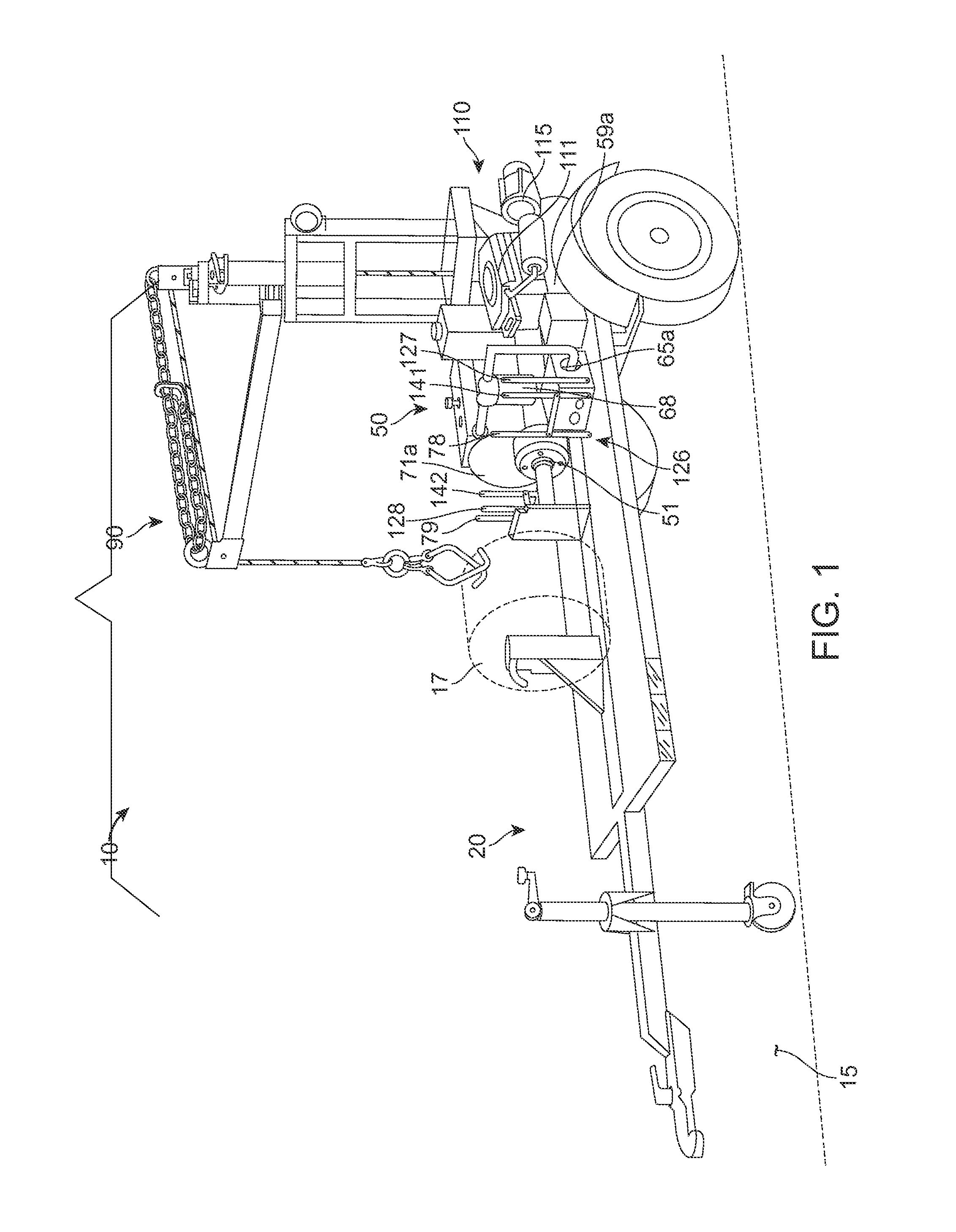

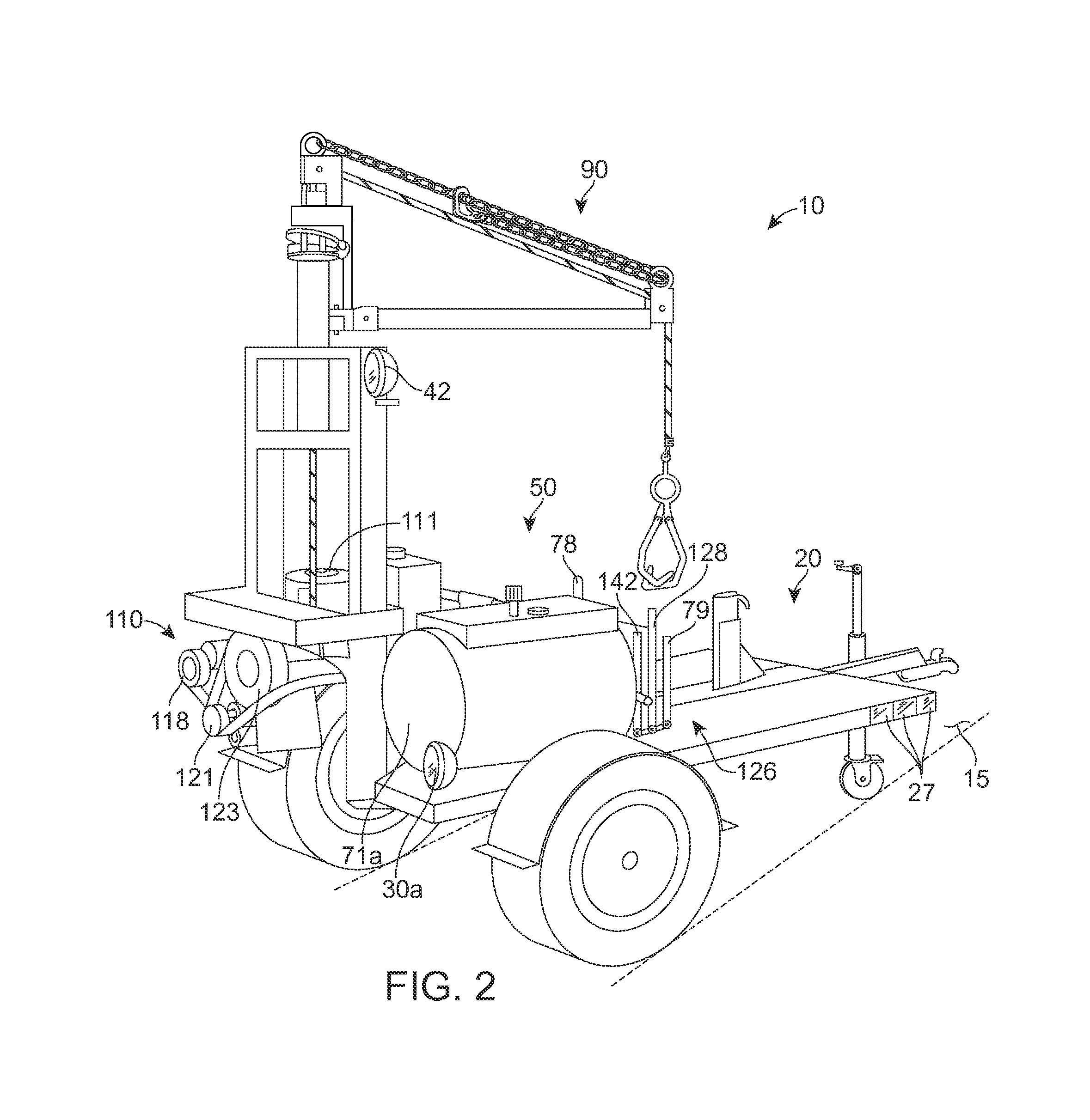

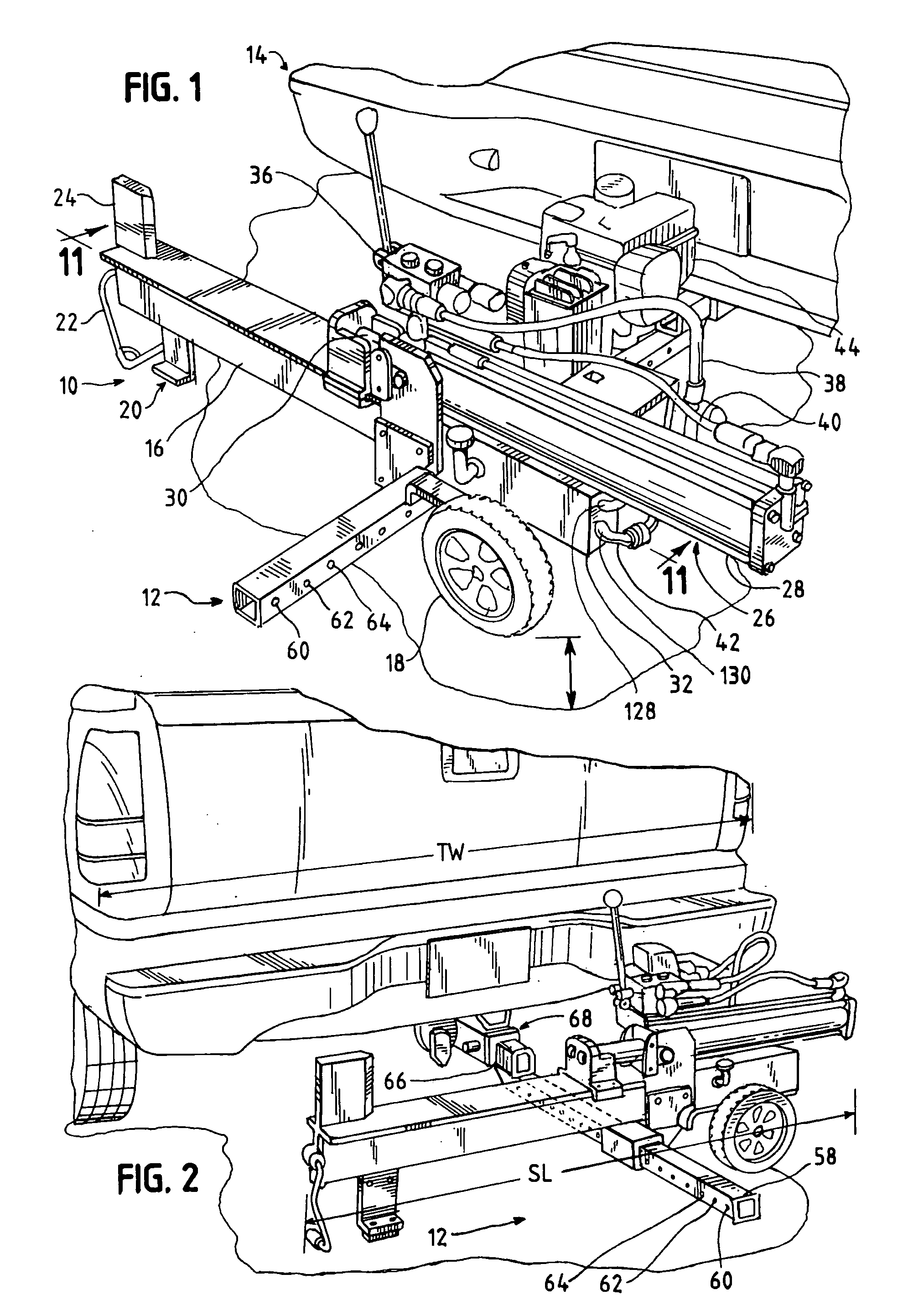

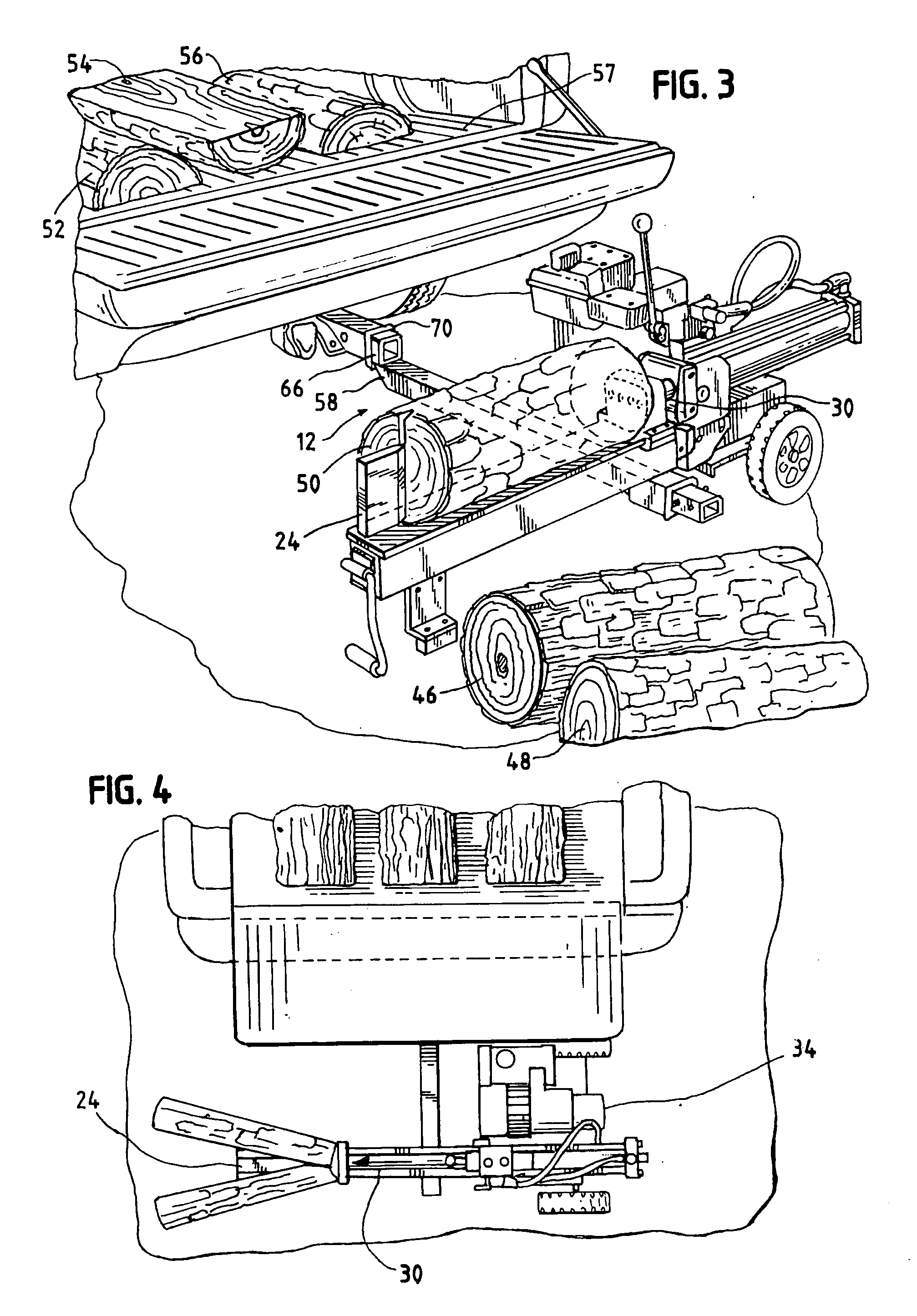

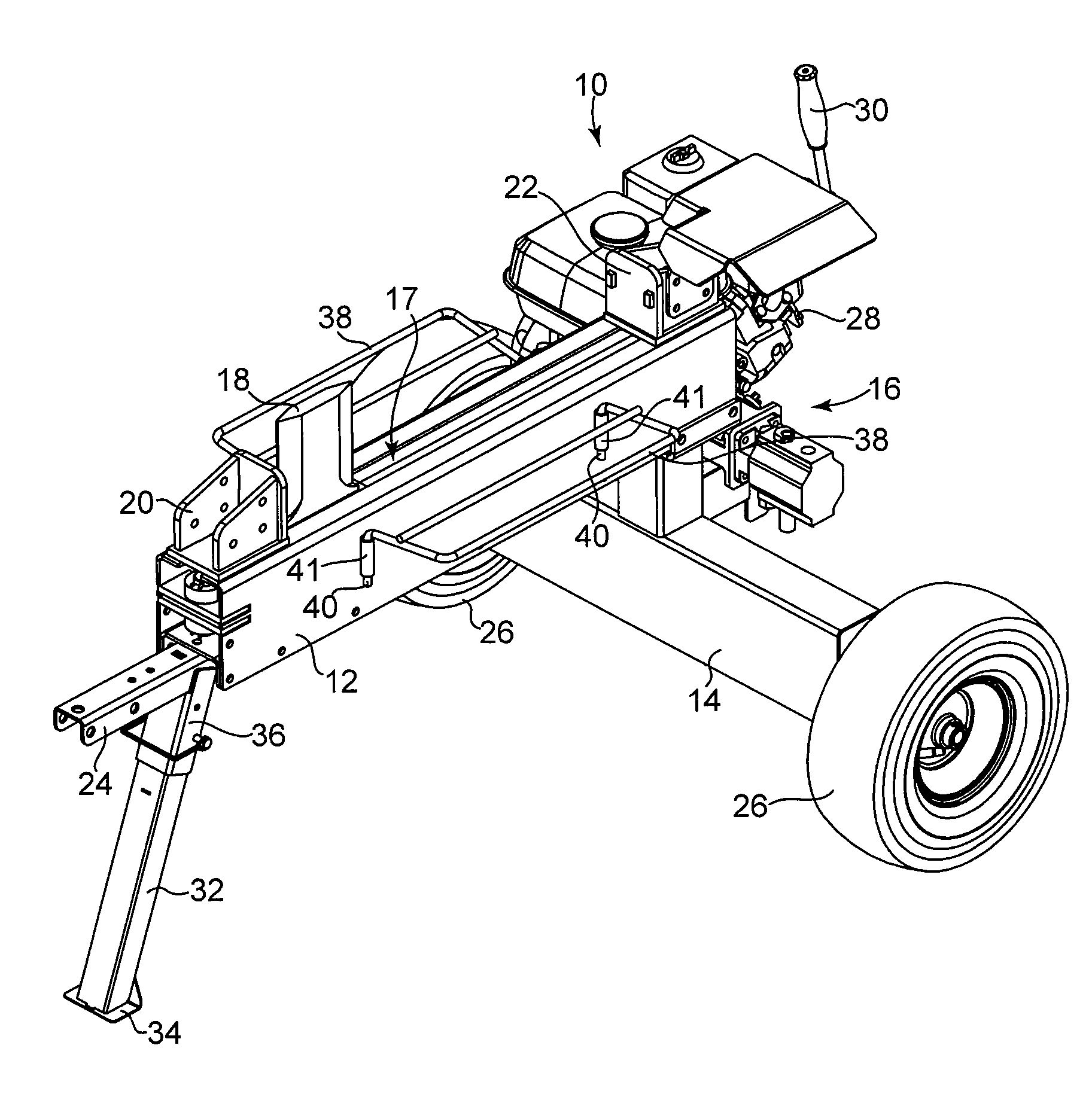

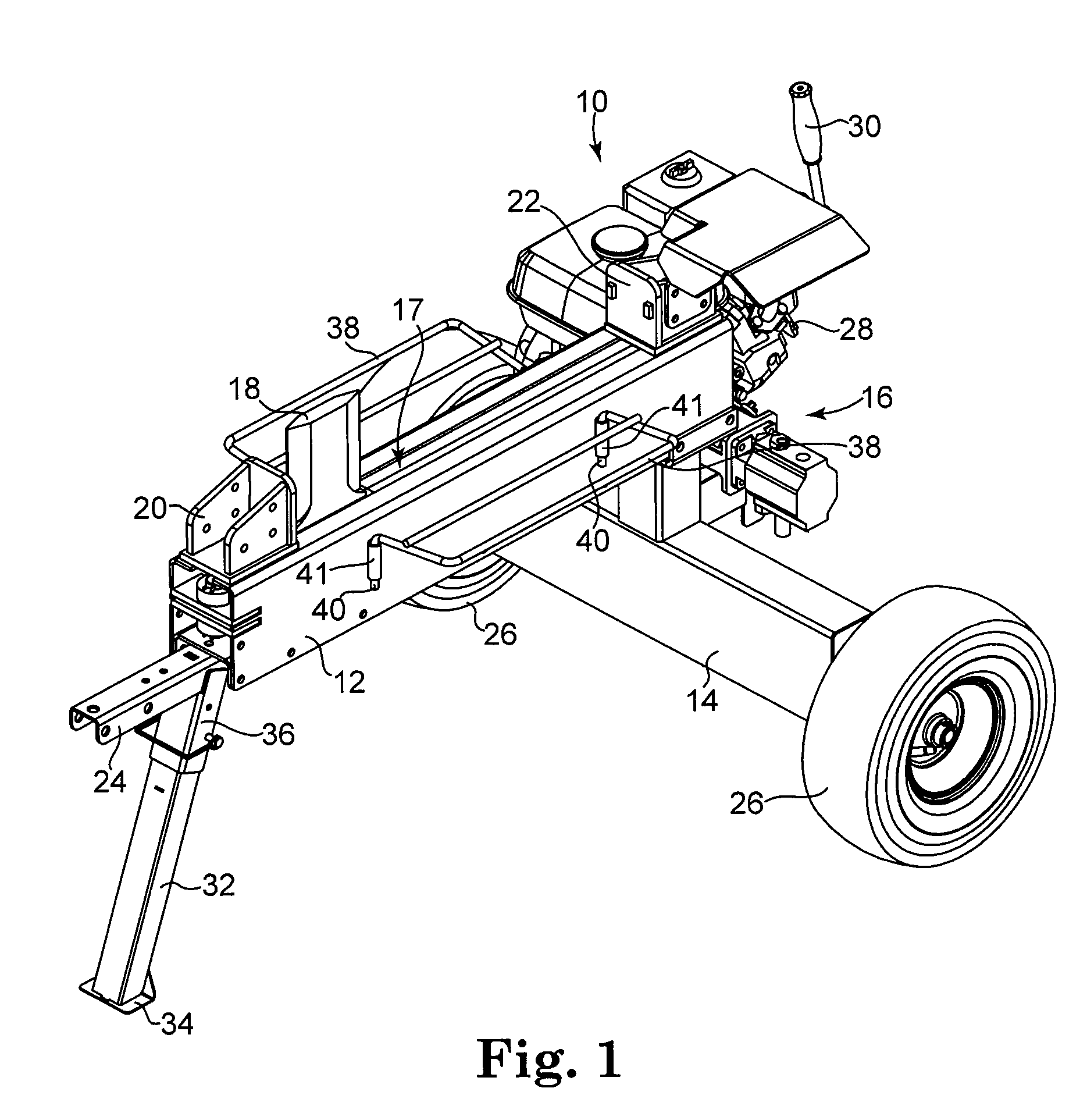

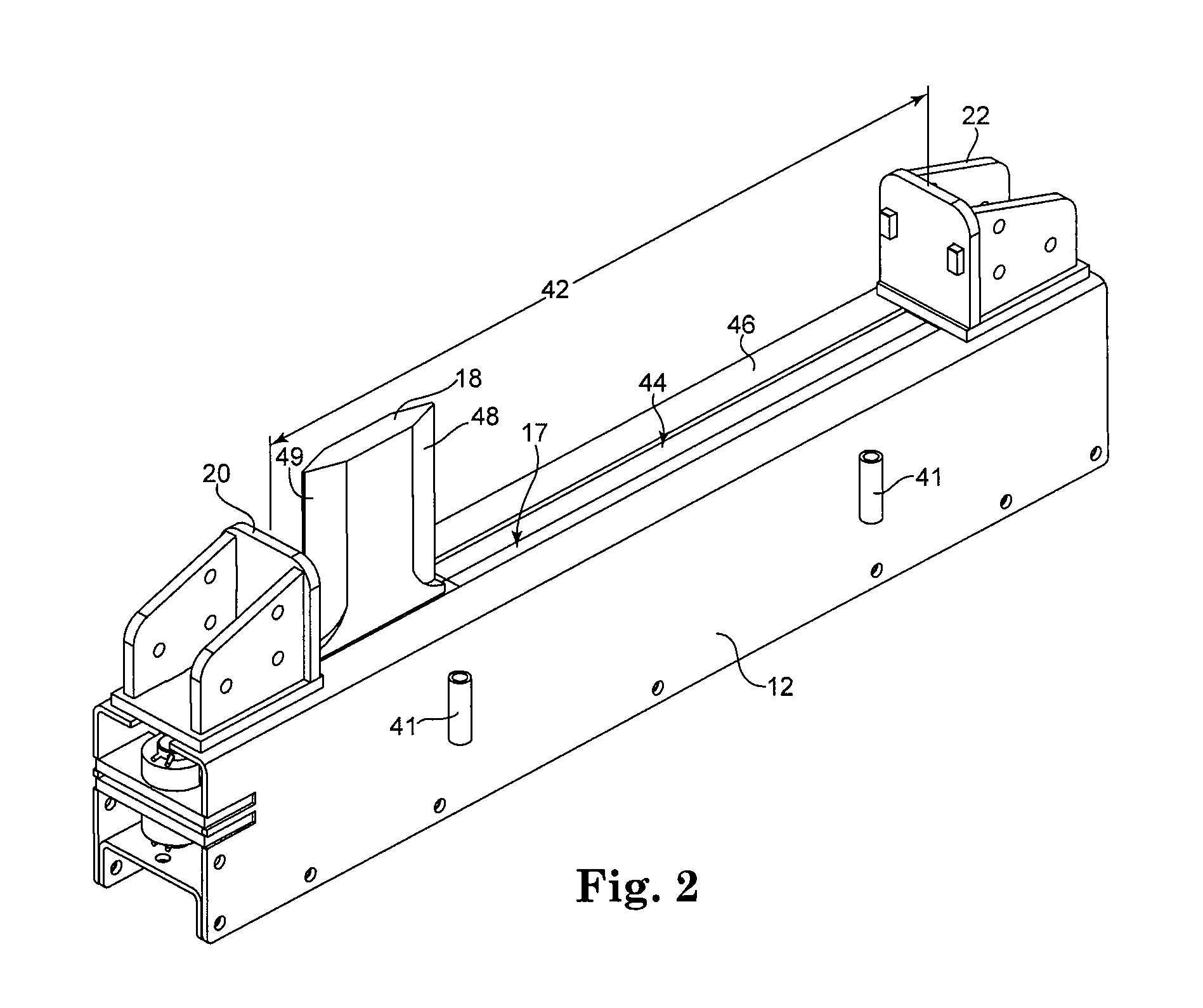

Trailer-mounted table wood splitter

A trailer-mounted wood splitter with an integral platform, log boom and grappler provides an extended table area to facilitate the splitting of wood. The apparatus comprises a hydraulic-powered wood splitting assembly operated by an internal combustion engine mounted to a trailer. A horizontal surface worktable is provided all around the upper surface of the wood splitting plane. In such a manner, any wood that is placed upon the platform for splitting does not fall off after splitting is complete. This allows the user to reposition any remaining sections of wood for additional splitting without having to pick them up off the ground. Once completely split, the wood can be directed to the side of the table or platform for stacking or transportation. The apparatus further comprises a log boom with a grappler attached to a far end for moving and manipulating felled logs.

Owner:HONNELL JAMES W

Automatic firewood chopping equipment

The invention relates to automatic firewood chopping equipment. The automatic firewood chopping equipment comprises a frame, a driving mechanism arranged on the frame, and a chopper mounted on the driving mechanism, wherein a positioning device for positioning logs is arranged rightly below the chopper, and comprises four vertical stoppers; each of the stoppers is connected with a horizontal slide rail; the horizontal slide rails are respectively connected with push cylinders; and inductors for inducing the existence of the logs in the stoppers are arranged at the outer sides of the stoppers. The automatic firewood chopping equipment is reasonable in structural design, realizes the positioning of the logs and automatic firewood chopping, largely improves the firewood chopping efficiency, largely saves the labor cost, and reduces the labor intensity.

Owner:张丽花

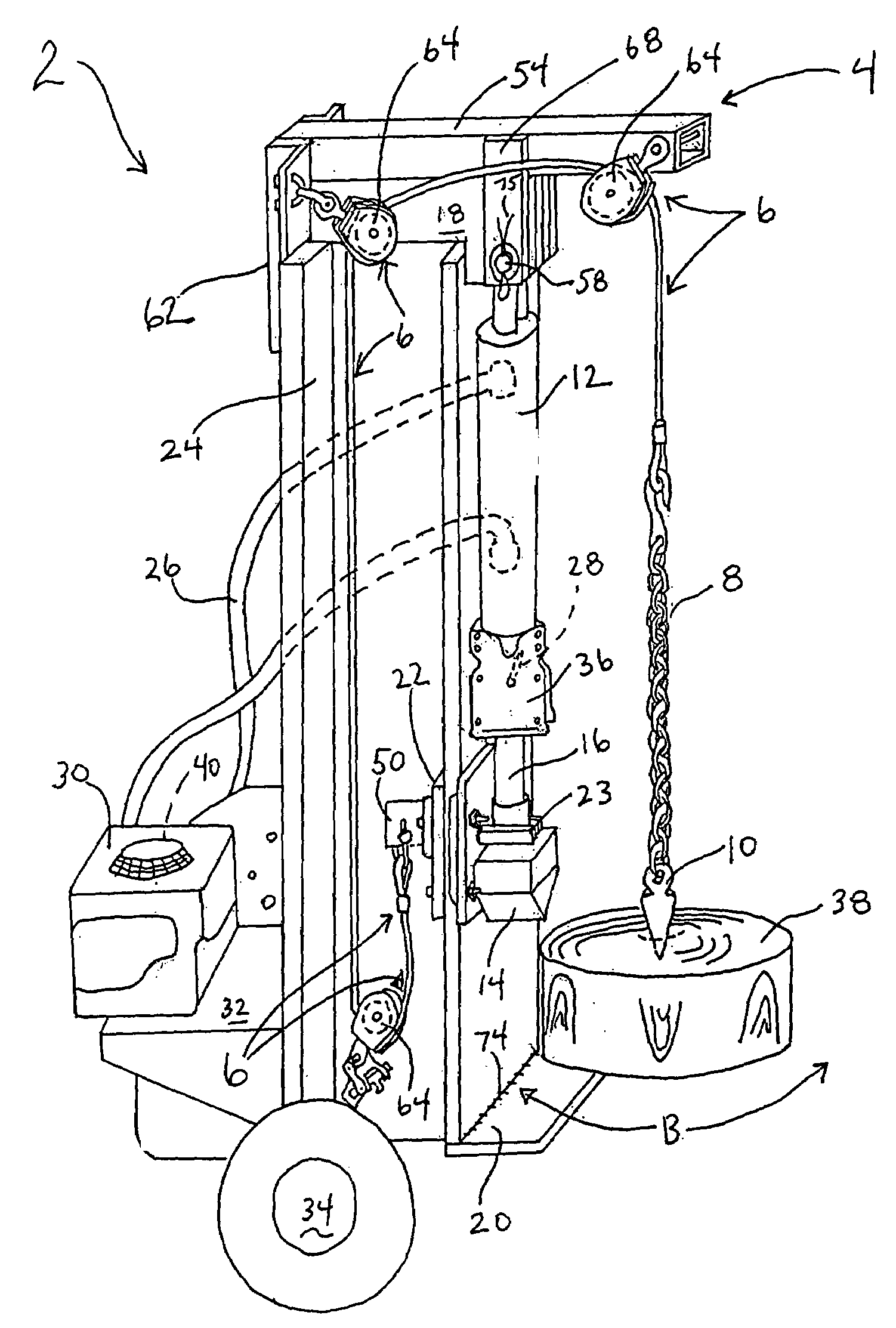

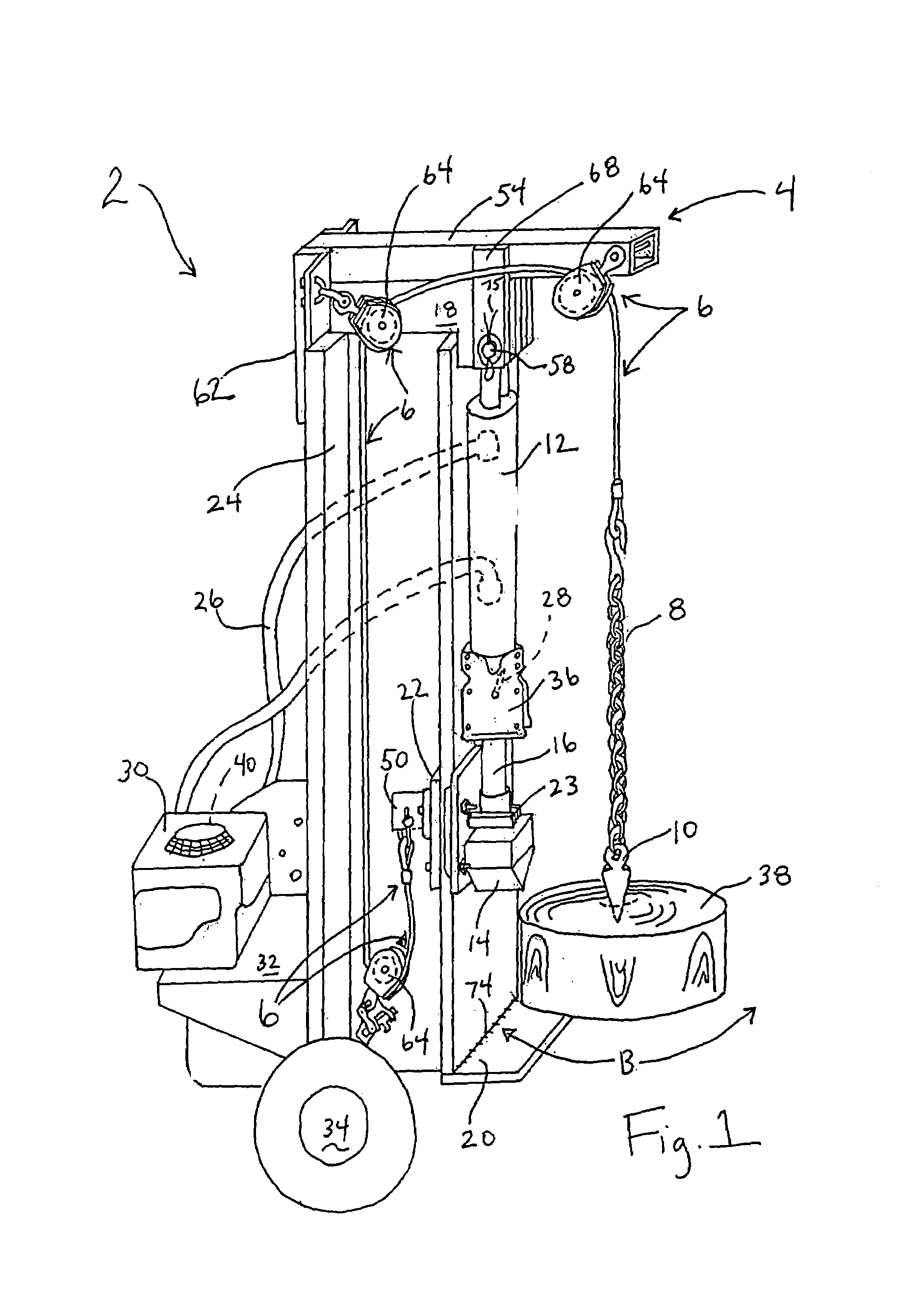

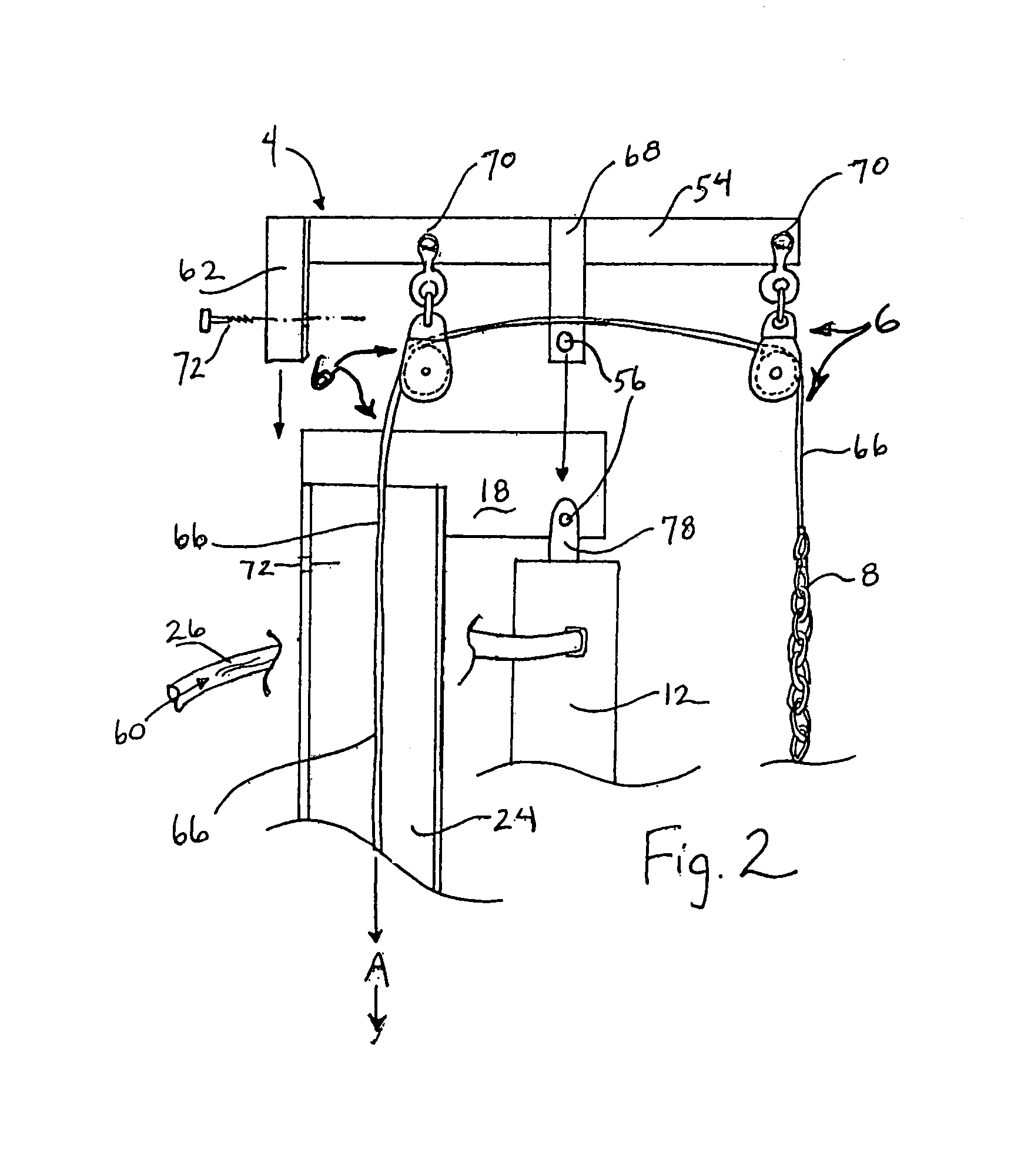

Block hoist

Owner:PETERSON BYRON

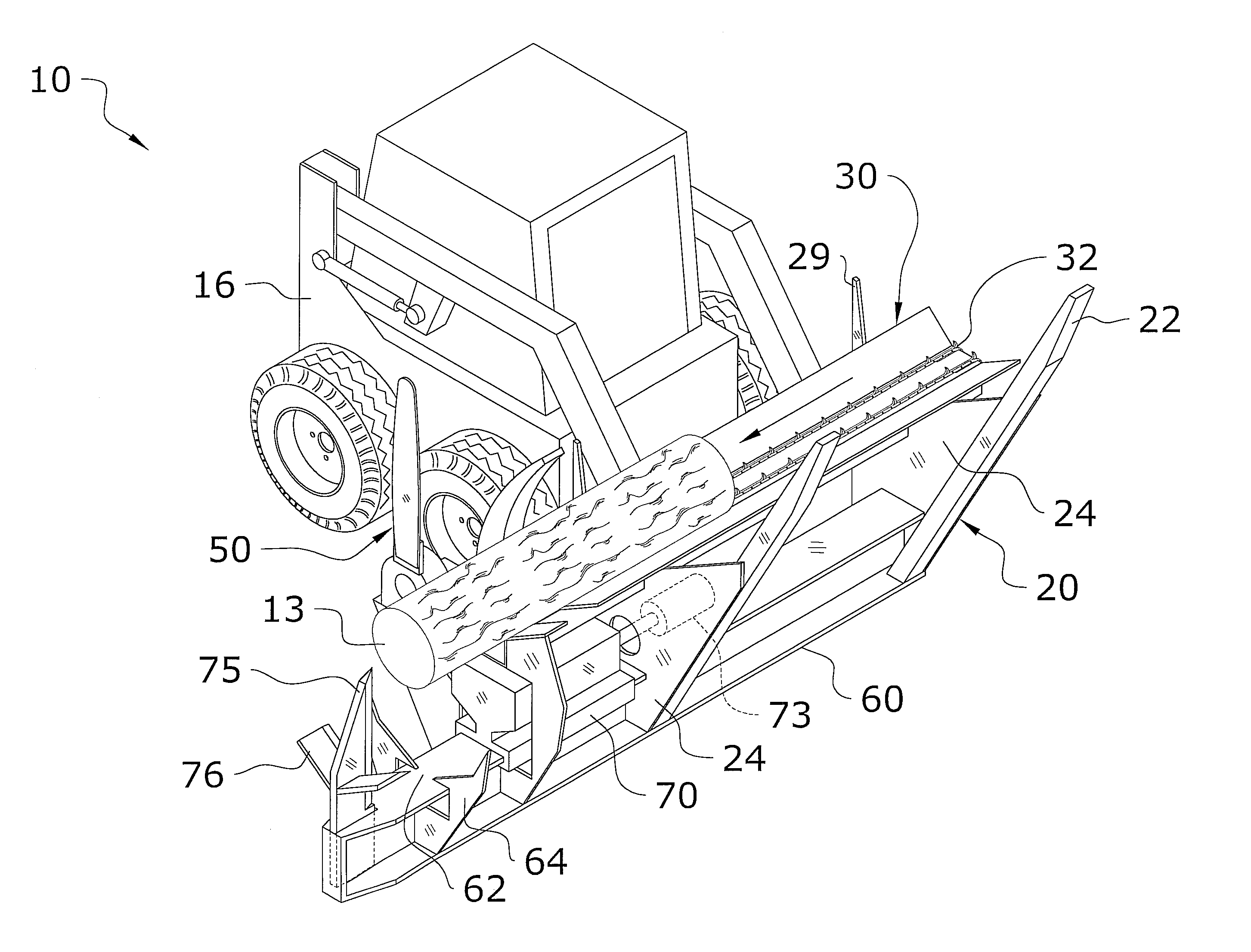

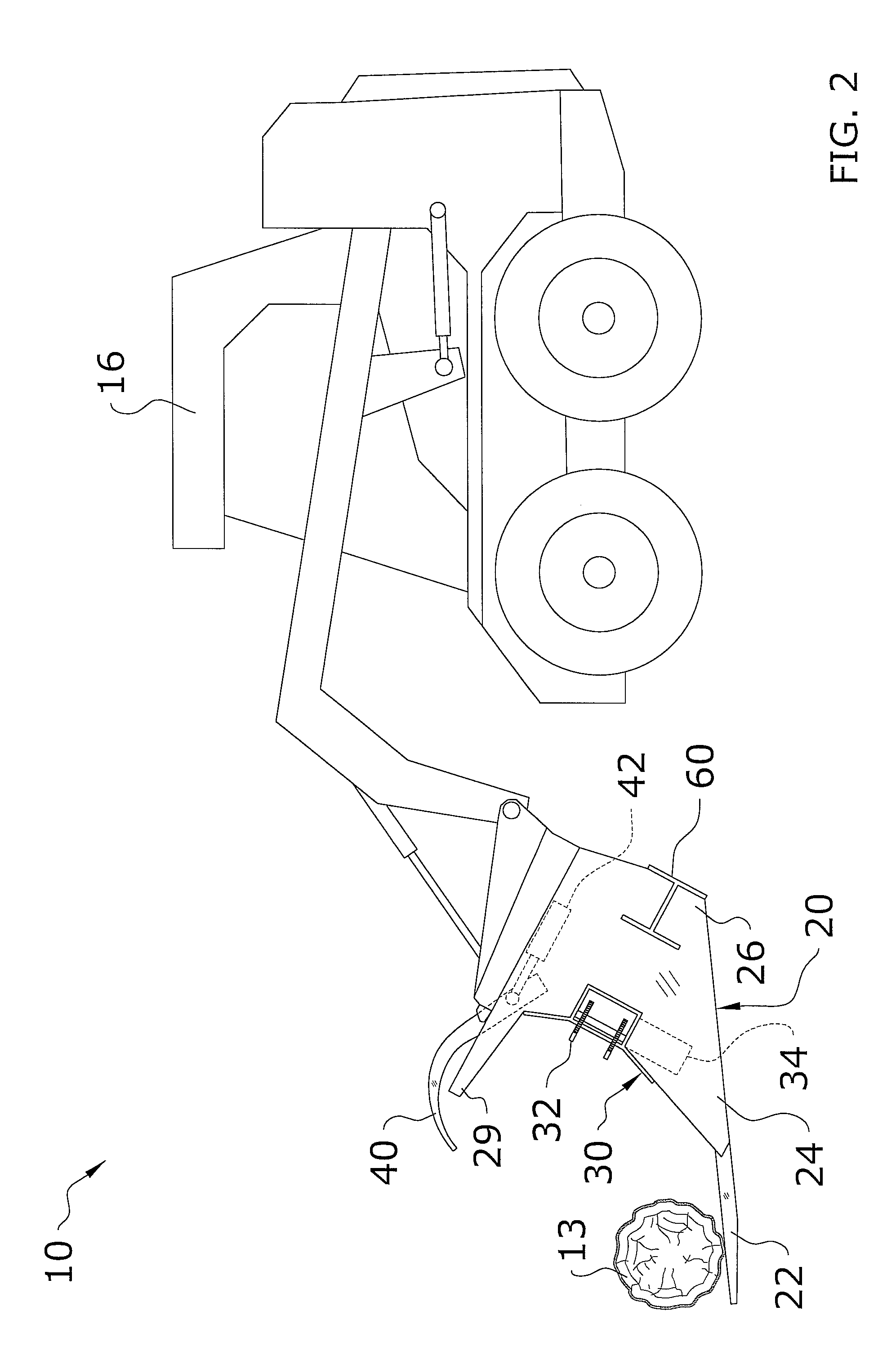

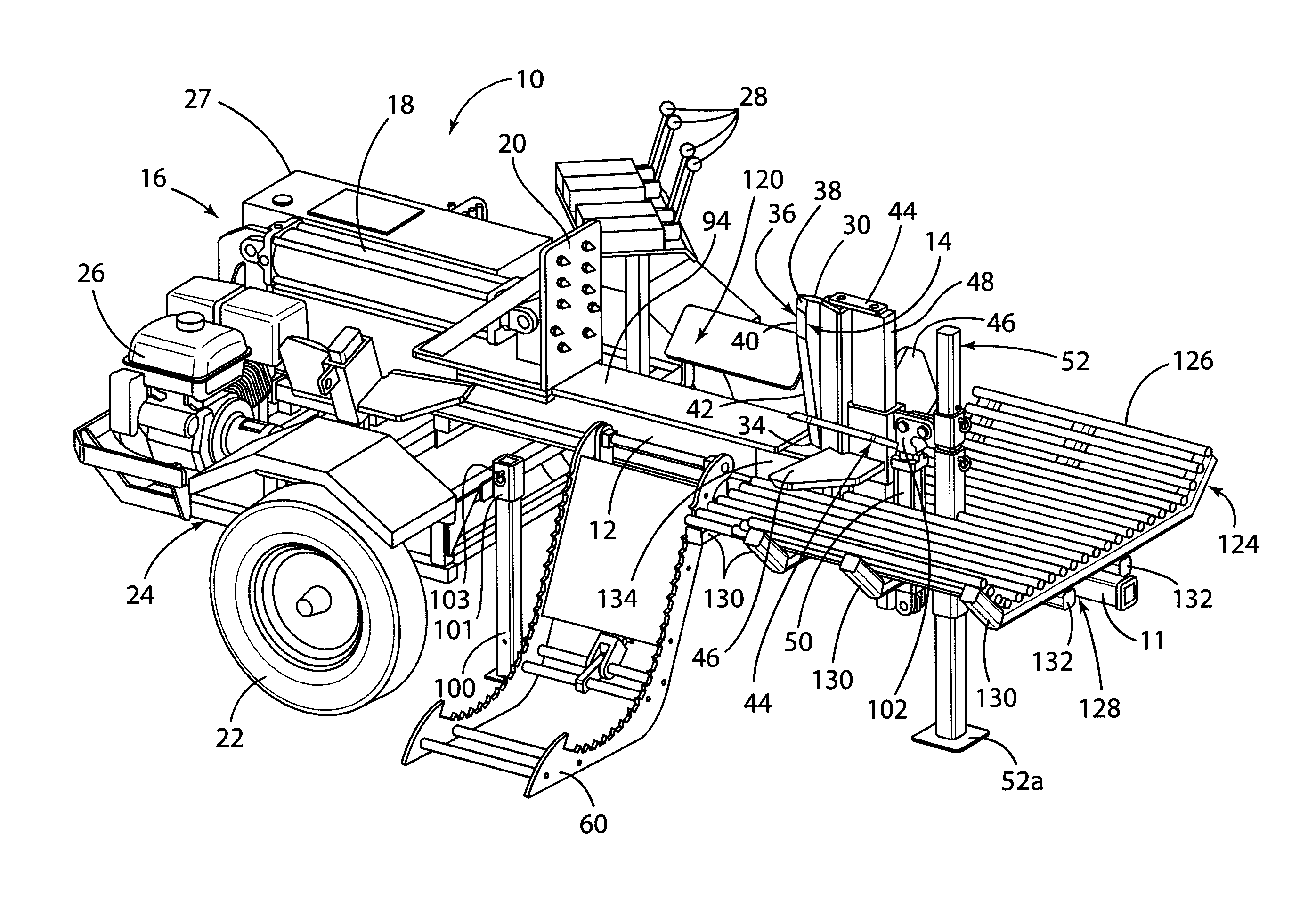

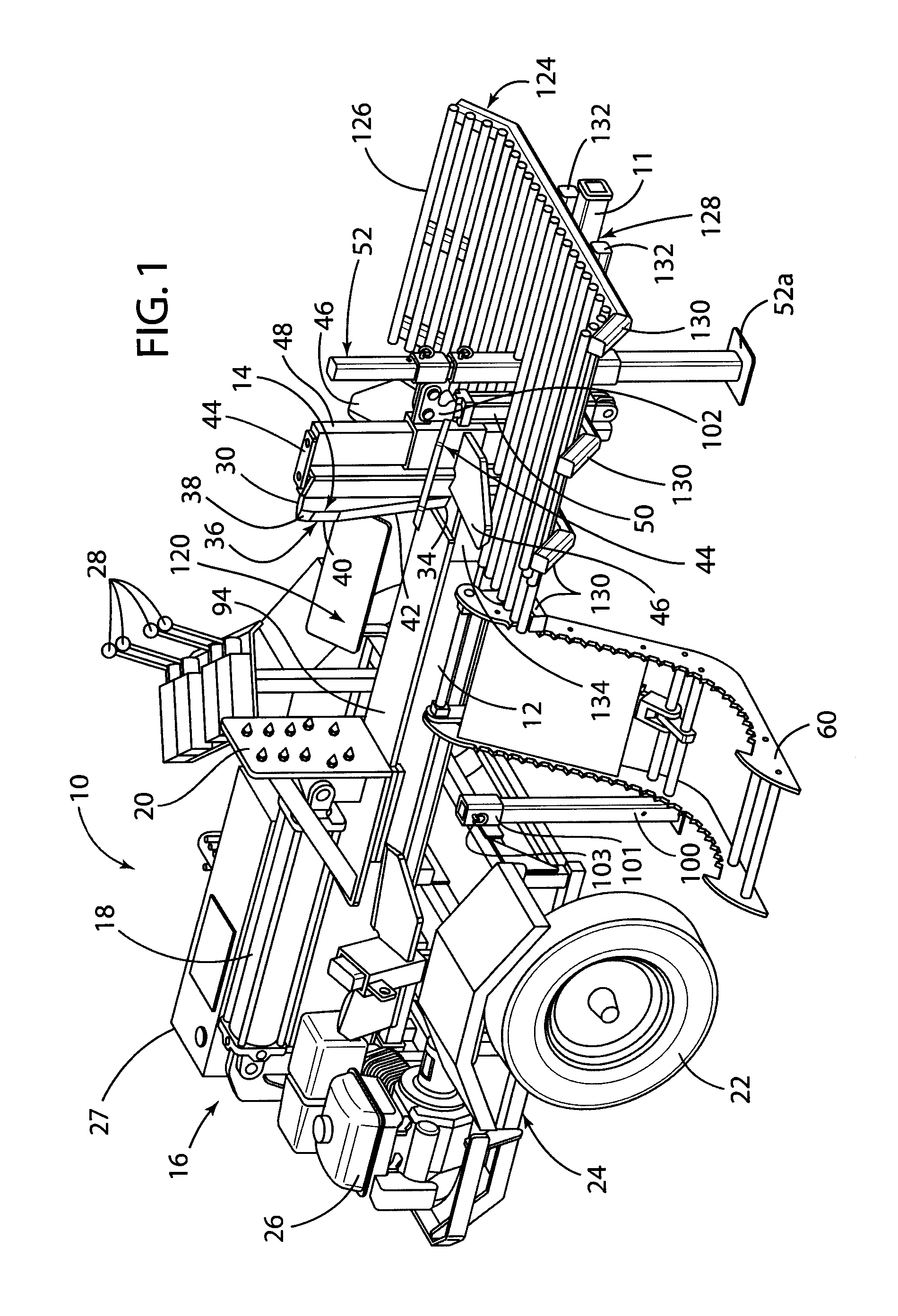

Wood processor attachment for skid steer loader

ActiveUS7669618B1Efficient cuttingEfficient splitWood splittingMulti-purpose machinesWood processorTractor

A wood processor attachment for skid steer loader for efficiently cutting and splitting logs. The wood processor attachment for skid steer loader generally includes a pivotally mounted support structure including a receiving end, a working end opposite the receiving end and a loading apparatus. A conveying member, a cutting unit, a ram and a wedge are attached to the support structure. The loading apparatus extends from the receiving end, wherein the loading apparatus transfers a log to the conveying member. The conveying member travels between the receiving end and the working end, wherein the cutting unit, the ram and the wedge are adjacent the working end to selectively cut and split the log. The support structure may be pivotally mounted upon various objects, such as but not limited to a skid steer loader or a tractor.

Owner:HALVERSON WOOD PROD INC

Systems and methods for tracking lumber in a sawmill

ActiveUS20090095377A1Fast and immediate feedbackAutomatic control devicesWood splittingStructural engineeringMechanical engineering

Owner:WEYERHAEUSER NR CO

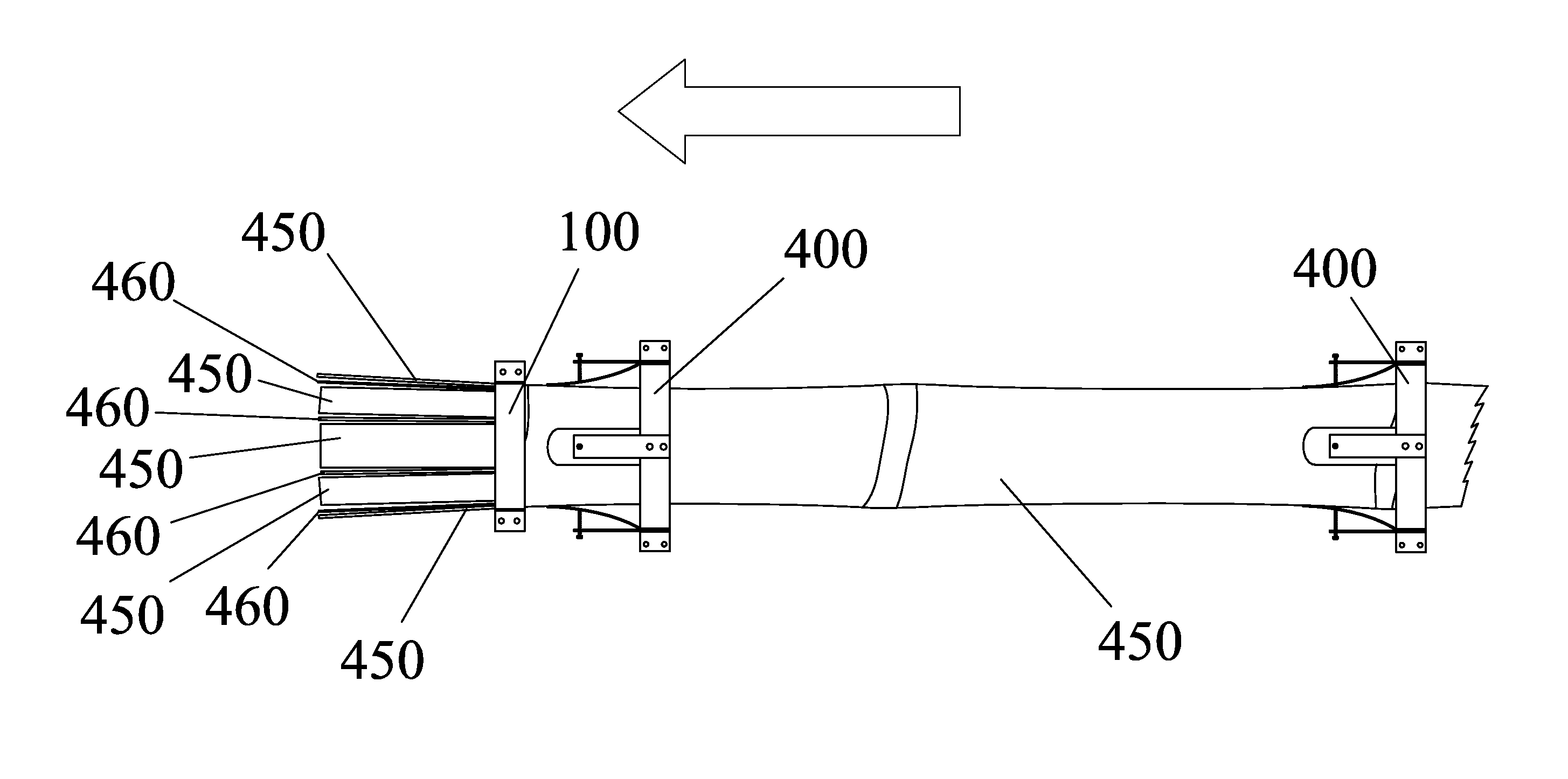

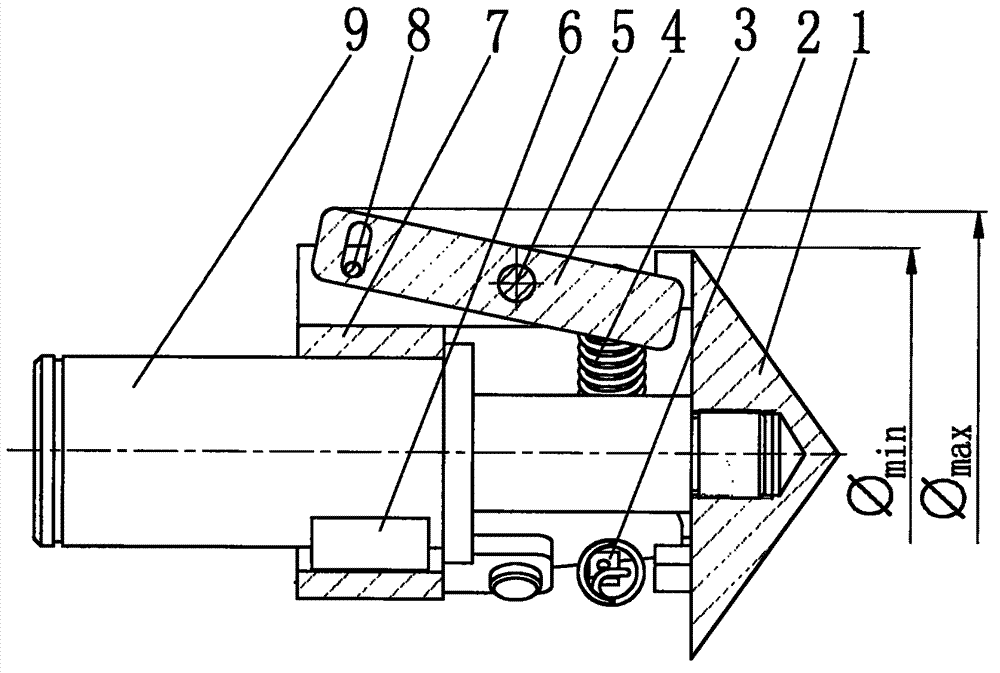

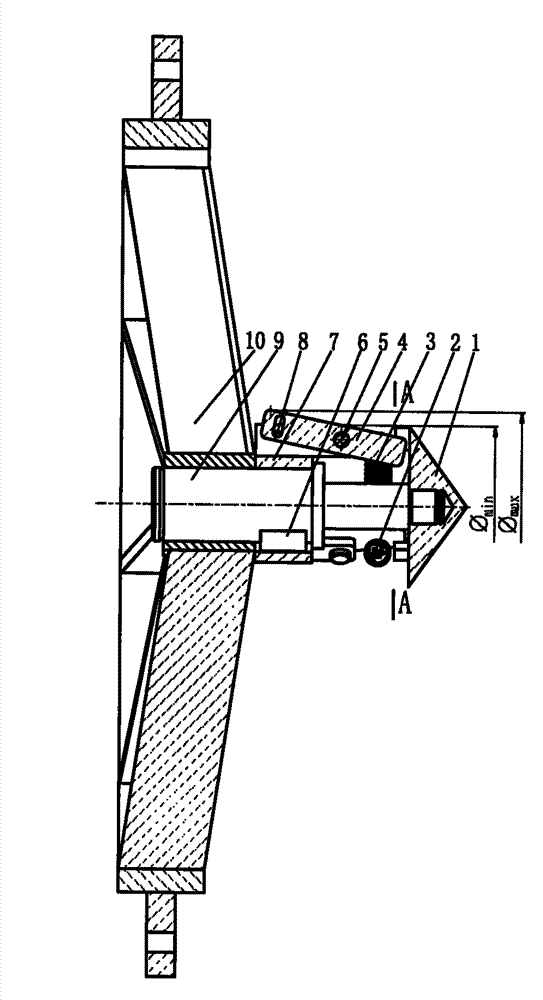

Baboon drum-centering mechanism for bamboo breaking machine

The invention provides a baboon drum-centering mechanism for a bamboo breaking machine. A front cone in the baboon drum centering mechanism is in threaded connection with a mandrel, a support rod support piece is sleeved in the middle of the mandrel, the peripheral fixation between the support rod support piece and the mandrel can be realized by a flat key, three support rods are respectively hinged in three grooves of the support rod support piece by pin shafts, two edges at the front ends of the three support rods are respectively provided with a tension spring base, and two heads of the three tension springs are respectively hooked on the tension spring bases, so that the three support rods form into a cone body which is front in the front part and large in the back part; after the baboon drum centering mechanism on a baboon drum small head is pushed away from the cross section at which the centers of the three pin shafts are placed by a section of distance, the inner wall of the baboon drum small head is contacted with the support rods; and the baboon drum continuously moves forwards, the inner wall of the baboon drum small head can lead the thee support rods to synchronously swing around the pin shafts, till the three support rods enter the baboon drum and the baboon drum is supported by the tail parts of the three support rods in the baboon drum, the three support rods stop swinging, and the baboon drum and a baboon breaking knife can be centered with each other.

Owner:沛县汉腾建设发展有限公司

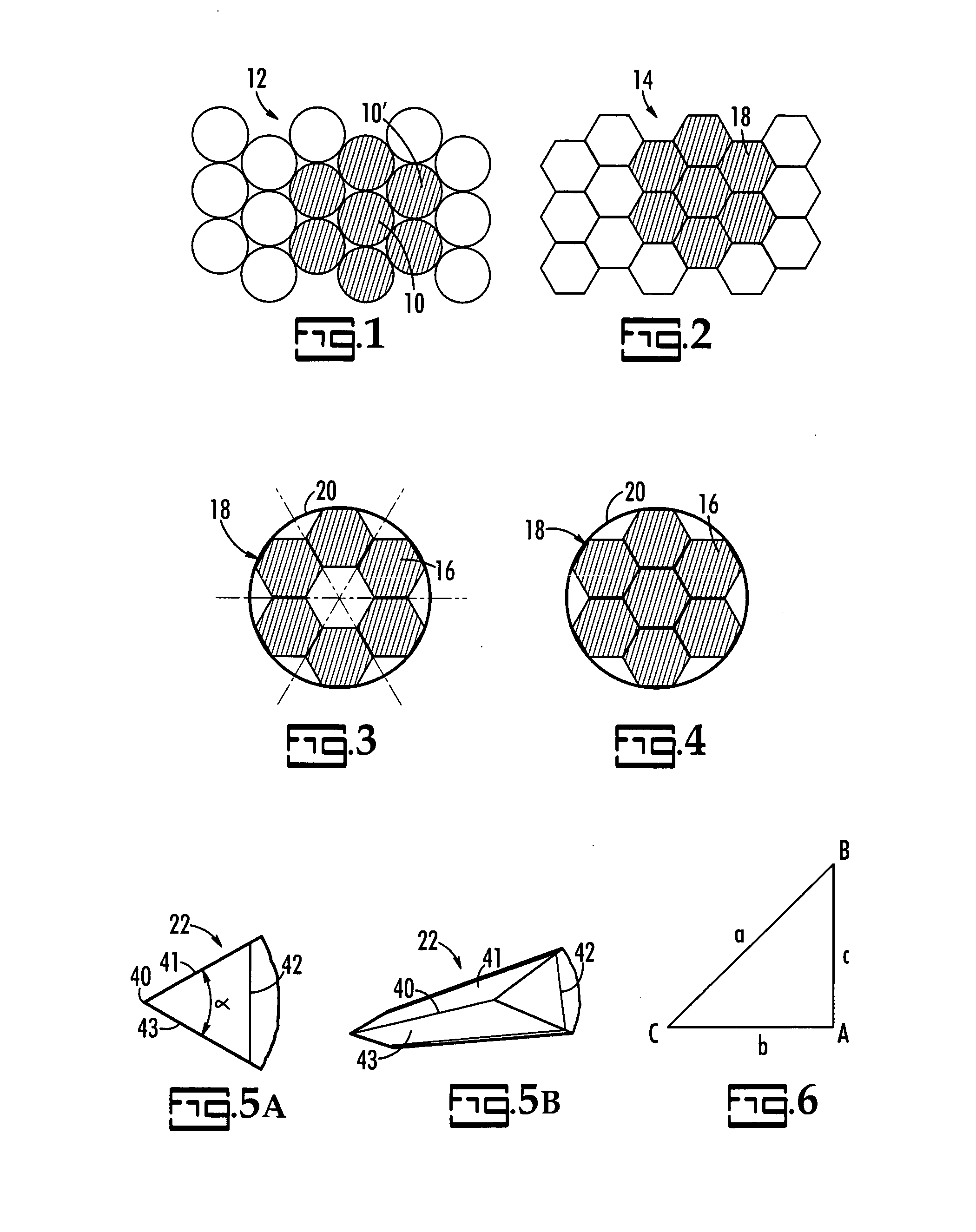

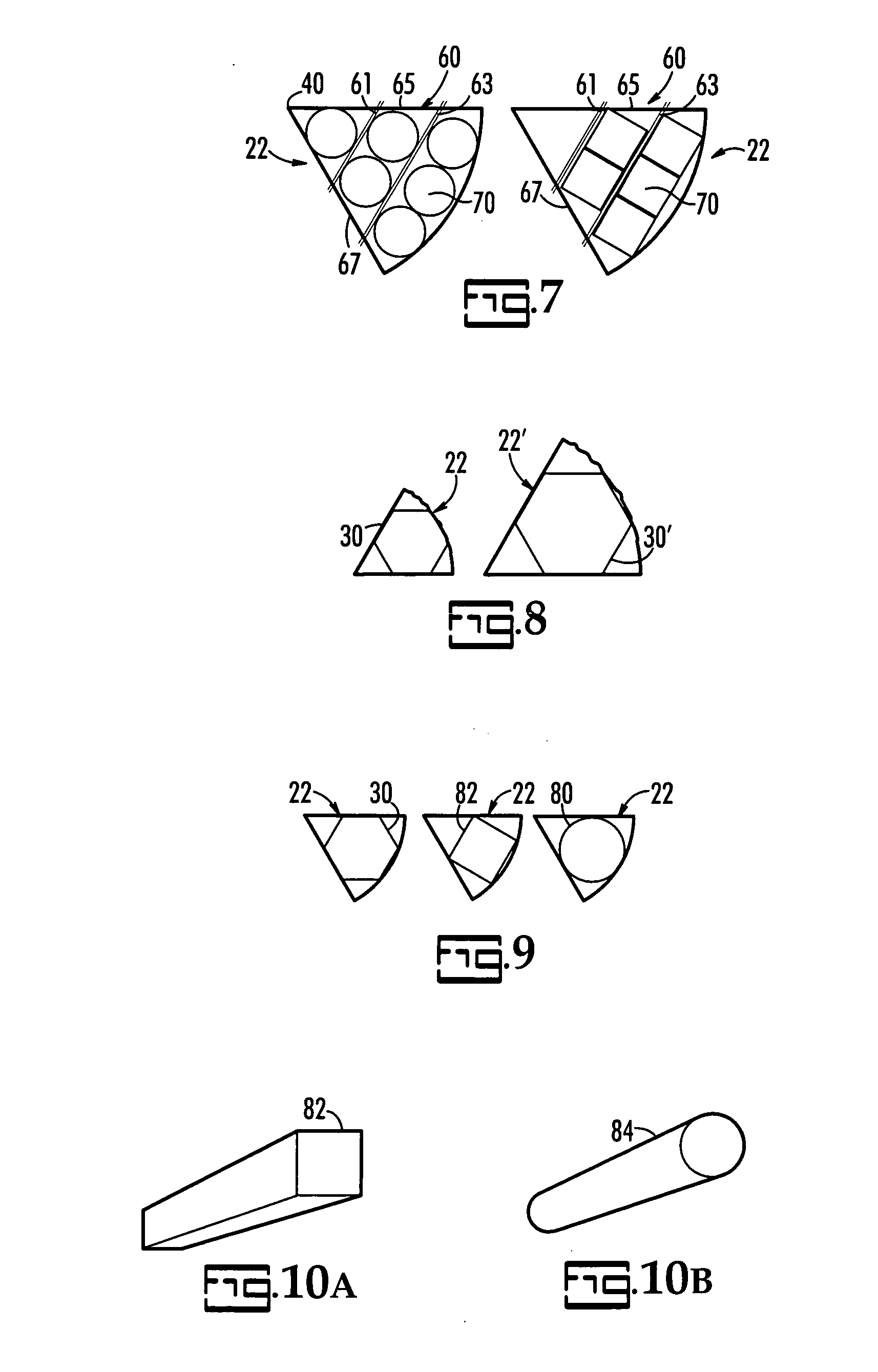

Radial sawing method

InactiveUS20050034786A1Efficient configurationReduce quality problemsWood splittingMulti-purpose machinesIsoetes triquetraEngineering

A radial sawing method for cutting a log into six sections. Each resulting section has a triangular wedge shape, such that in cross-section, an angle of approximately sixty-degrees (60°) at the interior edge of the log section is formed. The approximately 60° angle can be the point of an equilateral triangle. After the log has been formed into six pieces that are relatively equivalent in size and shape, each respective piece can then be fed into additional sawing machines for additional processing, such as to form symmetrically shaped pieces, include a circle, a square, a hexagon, an octagon, or other polygon pieces.

Owner:DARGAN SAMUEL G

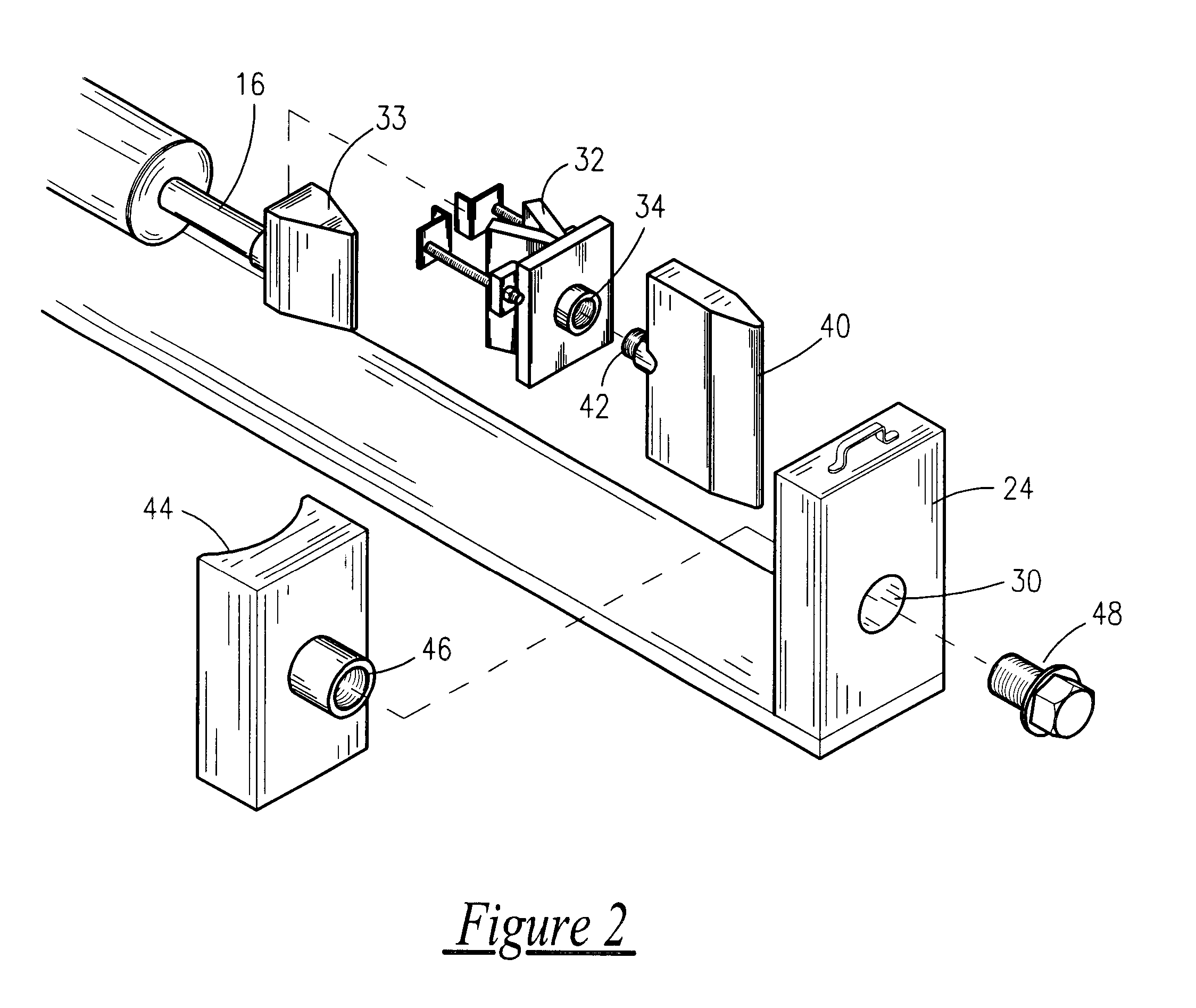

Log splitter

InactiveUS20050284541A1Maximize mixingMinimizes direct flow of fluidWood splittingMulti-purpose machinesHydraulic cylinderSet screw

A log splitter which includes an elongated frame which defines a reservoir for hydraulic fluid. A log splitting wedge secured to one end of the frame and a hydraulic cylinder and ram / piston secured to the other end of the frame. The ram / piston being movable toward and away from the wedge. The reservoir includes an inlet and outlet and a discharge tube associated with the inlet having a length effective to discharge incoming fluid into the reservoir at a position remote from the inlet. The elongated tube may be associated with the reservoir outlet so as to draw fluid from the reservoir and thus maximize flow from the reservoir even if the reservoir, or log splitter is in a tipped position. A log splitter and arm for mounting the splitter to a vehicle having a hitch style receiver secured to the rear of the vehicle. The splitter has a substantially linear working action. The mounting system includes an elongated arm for securement to the receiver in a cantilever fashion. The splitter is adapted to be secured, by a pin or a set screw mechanism, to the arm and be supported above the ground. The splitter's linear working action is substantially normal to the vehicle's direction of movement and the support arm. This system permits the vehicle to travel at normal highway speeds and carry the splitter.

Owner:BRAVE PRODS

Block impact splitter

A block impact splitter is comprised of a support frame connected on a swivel to a stationary frame. A hammer is provided with a hammer head and secured to a pivotal arm pivotally connected to the support frame at a pivot connection. An actuating piston has a cylinder end thereof pivotally connected to the support frame and a piston rod end pivotally connected to the pivotal arm. The actuating piston displaces the hammer head to impact against a pitching blade assembly and to retract it therefrom. The pitching blade assembly has a pivotal support arm to which is secured a pitching blade. An adjusting mechanism positions the pitching blade relative to a block to be split along a parting slot of the block.

Owner:TECHO BLOC

Compact log splitter

A log splitter comprises a support structure having a first end, a second end, and an open center portion defined therebetweeen, a splitting device slidably coupled to the support structure, and a drive mechanism for driving movement of the splitting device through a splitting zone. The splitting device comprises an elongate beam having an outer surface, a first end, a second end, and an open center portion between the first end and the second end, and a splitting wedge coupled to the outer surface of the elongate beam and having at least one splitting surface formed thereon. The elongate beam is disposed within the open center portion of the support structure. The drive mechanism is disposed within the open center portion of the elongate beam, and is coupled on a first end to the first end of the support structure and on a second end to the second end of the elongate beam.

Owner:NORTHERN TOOL & EQUIP

Multi-purpose hydraulic press, metal bending, and log splitting apparatus

InactiveUS6318424B1Provide functionalityWood splittingMulti-purpose machinesHydraulic ramEngineering

A multi-purpose hydraulic press, metal bending, and log splitting apparatus is disclosed. An hydraulic ram, having a piston cylinder for extending and retracting a piston rod driven by an hydraulic power means, is rigidly affixed to an elongated I-beam frame member, the central portion of which spans a throat area bounded on one side by the hydraulic ram and on the opposite side by a rigidly attached foot plate. The foot plate is formed of a planar steel member affixed perpendicularly to the frame member, and forms a ram extension penetration orifice within the plane of the plate in a position aligned with the piston rod. A series of functional inserts are included for placement against the foot plate or piston rod. A series of functional extension elements are also included for placement against the piston rod for extension through the ram extension penetration orifice. These functional extensions thereby allow the apparatus to be adapted to transmit its hydraulic ram capacity outward, in a controllable fashion, past the working throat of the apparatus.

Owner:ELFRINK HERMAN F

Bamboo breaking equipment easy to operate

ActiveCN109454734ASimple structurePracticalWood splittingCane mechanical workingLoss of resistanceEngineering

The present invention discloses bamboo breaking equipment easy to operate, and the equipment comprises a rack, a bamboo pushing mechanism, a slicing mechanism, a bamboo rolling chamber, an electric limiting mechanism, a plurality of bamboo limiting rods, a transverse moving mechanism and a control console. In the bamboo breaking equipment of the present invention, after the electric limiting mechanism moves away from the bamboo rolling chamber, bamboo originally colliding with the electric limiting mechanism is able to automatically tumble into bamboo accommodating grooves upon loss of resistance, while other bamboo is able to be always kept in the bamboo rolling chamber under the action of the bamboo limiting rods; after the electric limiting mechanism returns to the bamboo rolling chamber, the bamboo limiting rods are separated from the bamboo in the bamboo rolling chamber, so that the bamboo in the bamboo rolling chamber is able to continue to tumble so as to collide with the electric limiting mechanism, and the bamboo limiting rods are inserted into each bamboo (excluding a piece of bamboo colliding with the electric limiting mechanism) in the bamboo rolling chamber again for asubsequent action, thereby achieving transmission of single piece of bamboo; besides the bamboo breaking equipment is stable and reliable in structure, reduced in labour cost, and improved in workingefficiency.

Owner:大田县源生竹业有限公司

Collapsible log splitting assembly with safety perimeter

A collapsible log splitting assembly with safety perimeter splits a log with a parabolic-shaped blade, a blade housing having a plurality of ridges for separating the split log further, and a perimeter barrier for retaining the log upright while splitting, and protecting an operator from contact with blade. The assembly has an upright disposition that is pivotally collapsible into a planar configuration when not in use. The assembly has a base that is for support on a surface. The base includes a pair of brackets. A pair of sleeves pivotally join with the brackets, pivoting about the brackets. A pair of shafts slide within sleeves, sliding between operational and collapsed positions. A cutting apparatus comprises a blade housing that houses a parabolic blade, and extends between the shafts. Ridges along the base housing separate the log into smaller components. The perimeter barrier detachably attaches to top end of the shafts.

Owner:ZAKE IP HLDG LLC

Wood Splitting Apparatus

A wood splitting apparatus having a splitting wedge mounted to a frame. The wedge configured to have multiple cutting edges that engage the workpiece. The apparatus further including a lift mechanism for transferring a workpiece to a workpiece carriage area adjacent the splitting wedge. The lift mechanism is pivotally connected to the frame whereby actuation of a power cylinder moves the lift mechanism from an initial position where a workpiece is loaded onto the lift mechanism and a second position wherein the workpiece is deposited from the lift mechanism into the workpiece carriage area.

Owner:GREEN KEVIN J

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com