Novel numerical control bamboo splitting machine

A new type of bamboo machine technology, applied in the manufacture of veneer, wood processing equipment, wood splitting devices, etc., can solve the problem of drive chain breakage, achieve the effects of preventing chain breakage, reducing operators, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

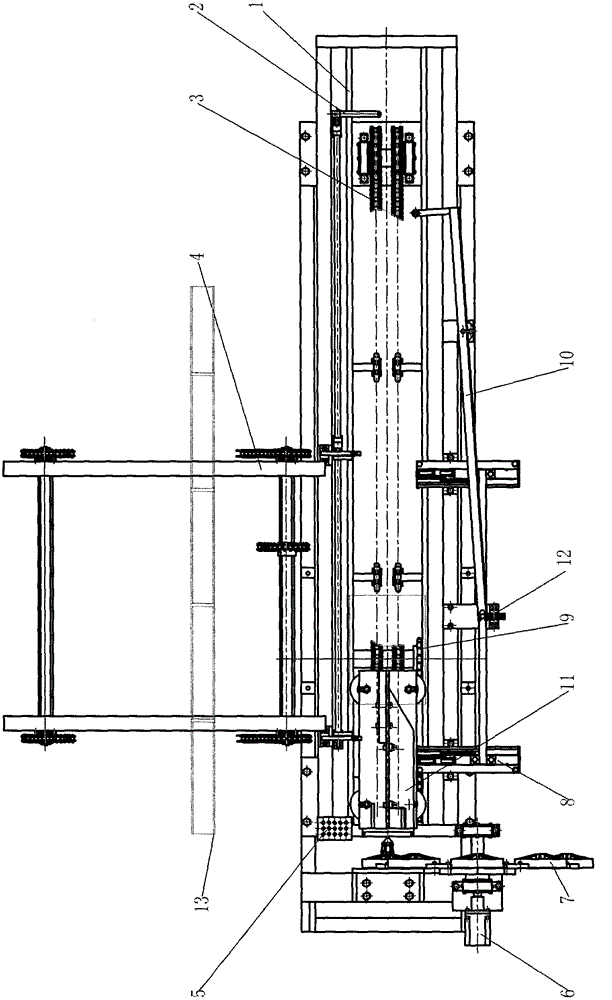

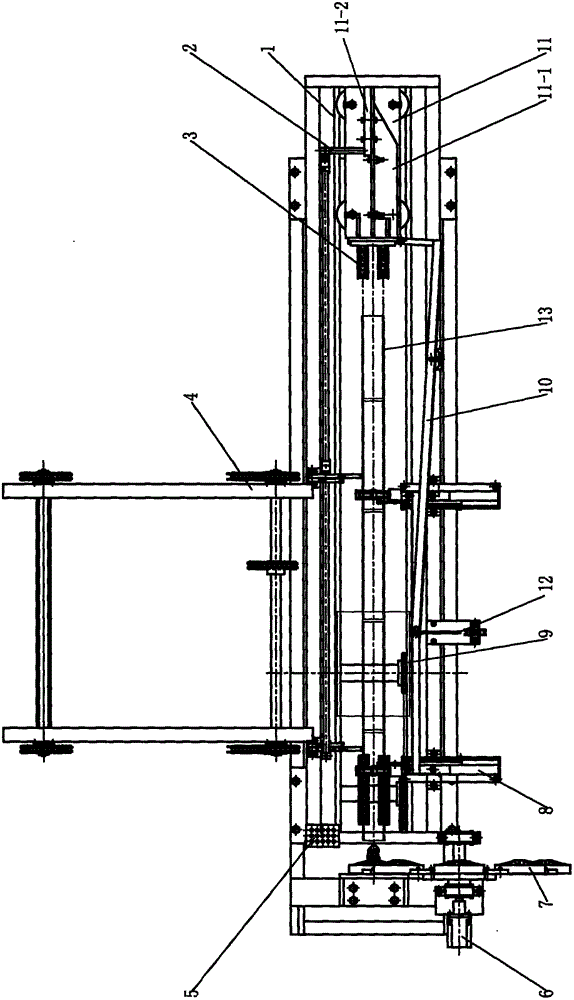

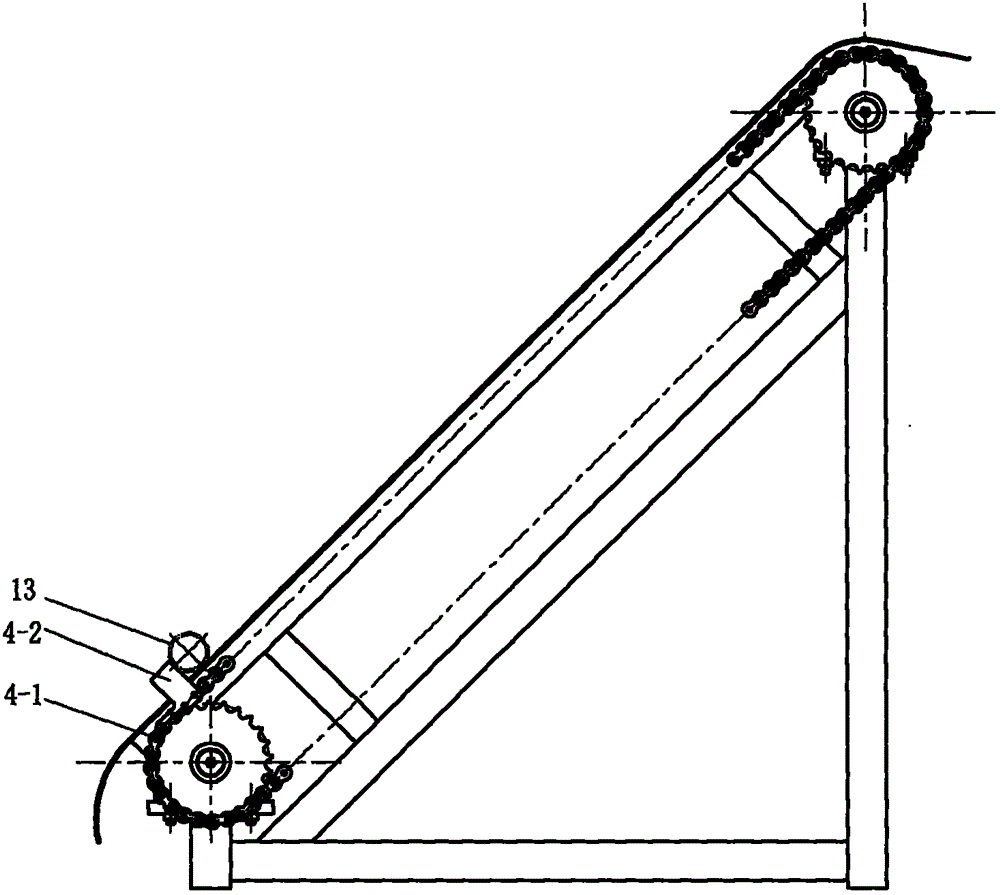

[0024] A new type of CNC bamboo breaking machine consists of a bed guide rail 1, a rotating mechanism 2, a drive chain 3, a bamboo tube feeding mechanism 4, a bamboo tube diameter measuring device 5, a stepping motor 6, a cutter head assembly part 7, a bamboo tube centering assembly part 8, Transmission system 9, swing mechanism 10, push plate combination part 11, pendant hammer 12 form (as figure 1 shown), during installation, the four guide wheels 11-3 in the push plate assembly part 11 are stuck on the bed guide rail 1 (as Figure 6 As shown), the push plate combination part 11 is restricted to move back and forth along the bed guide rail 1, the plane cam I11-1 is installed horizontally on the left side of the push plate combination part 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com