Patents

Literature

781 results about "Wood machining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

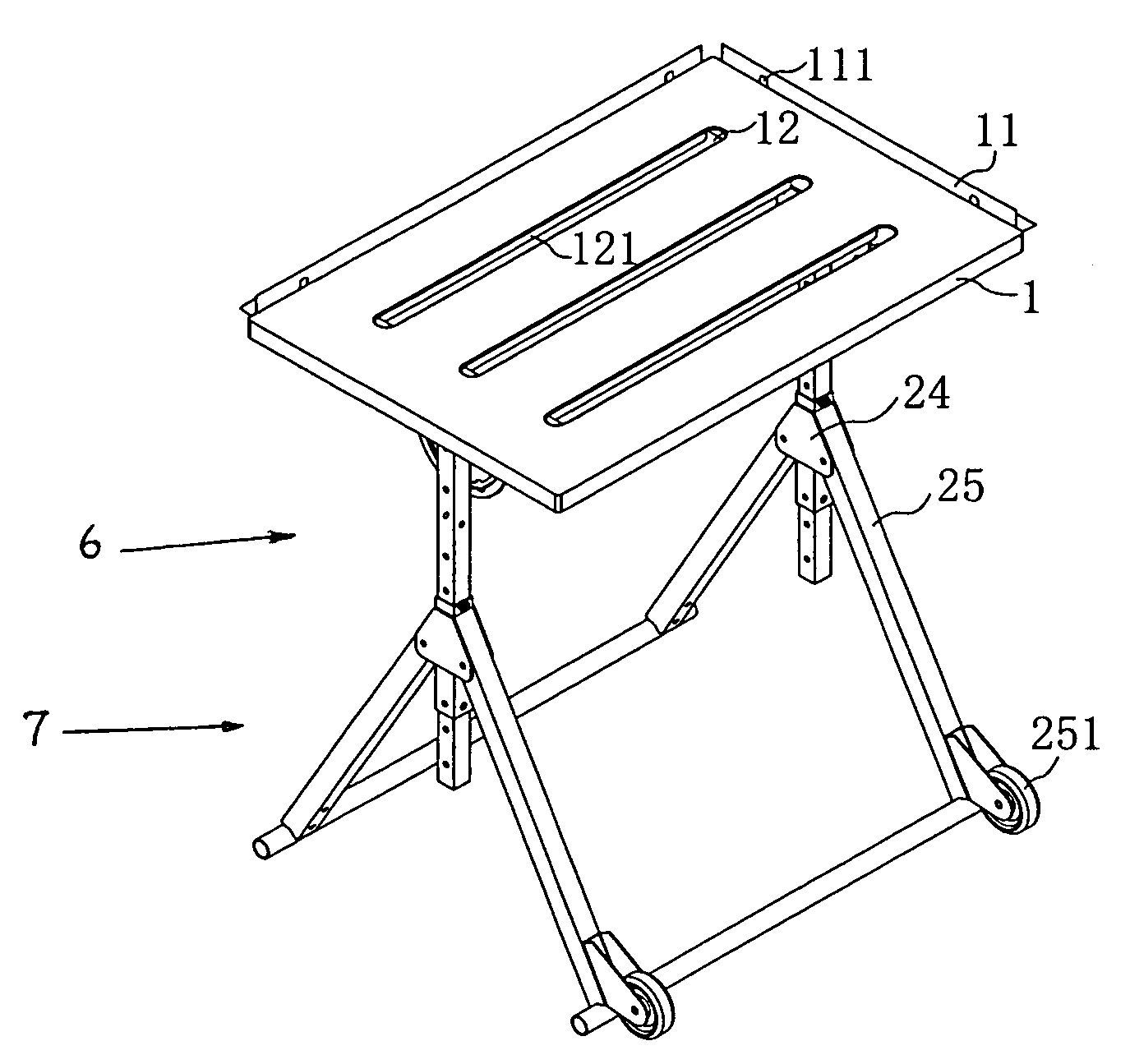

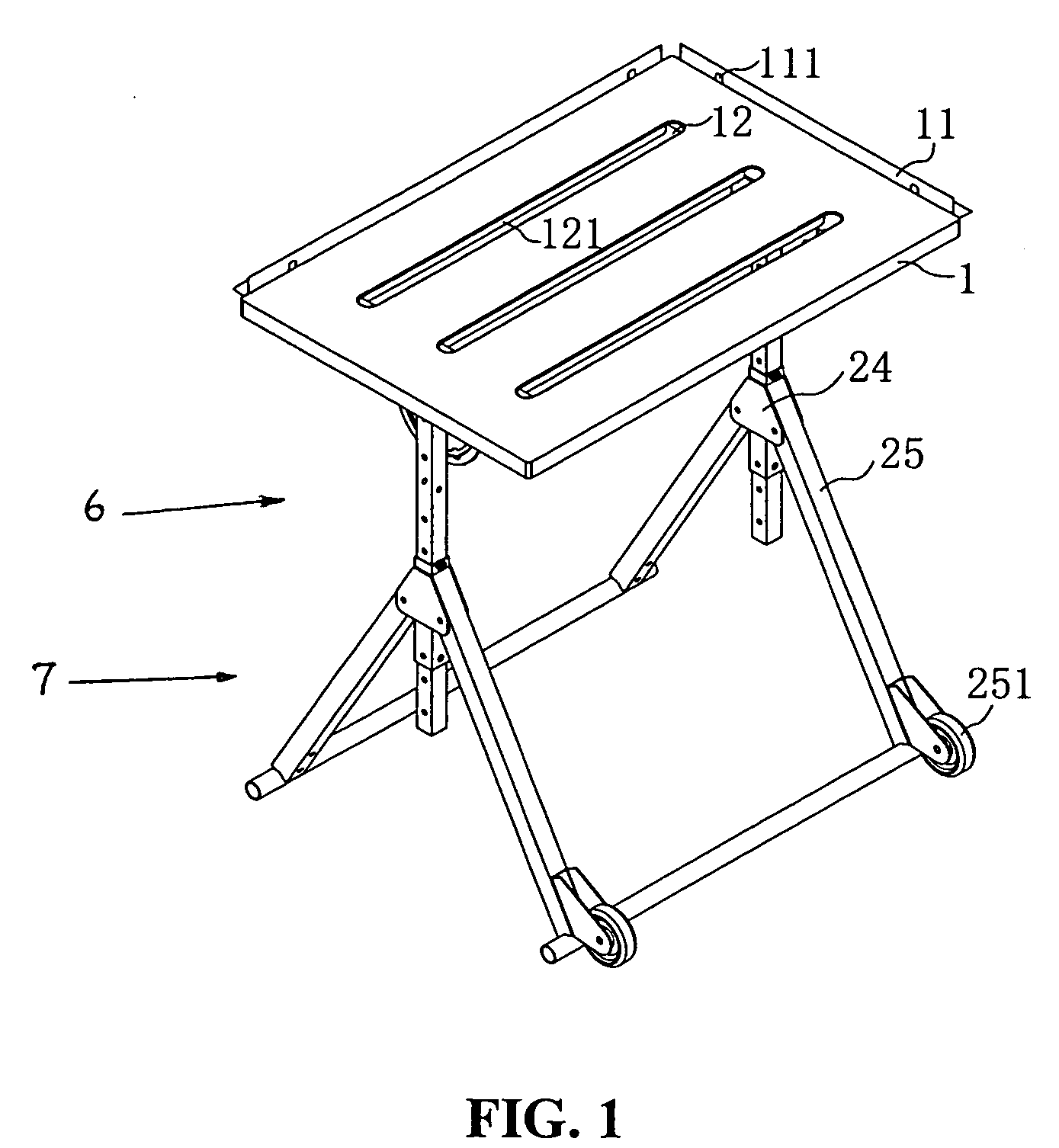

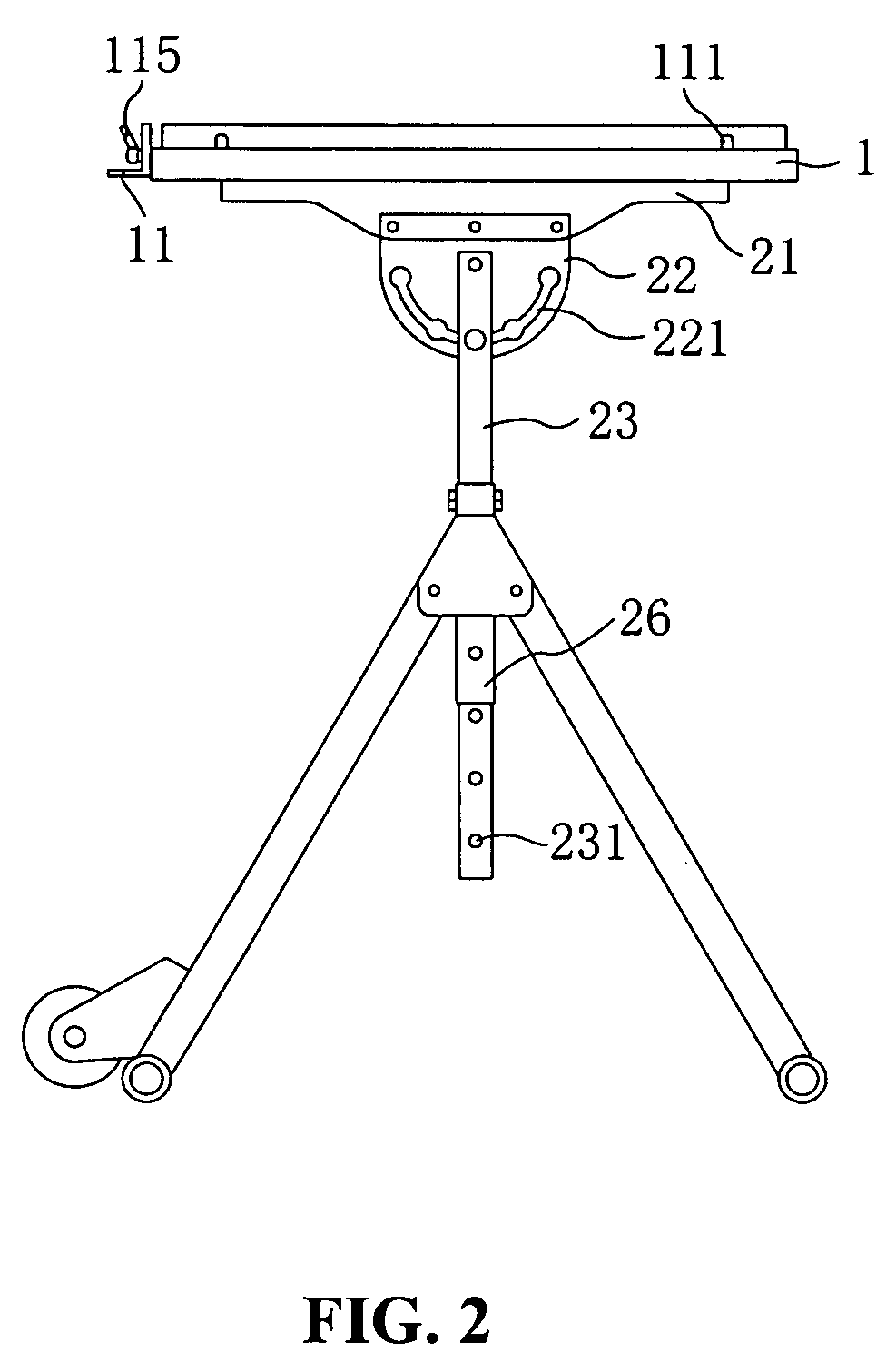

Metal-top welding table

InactiveUS20090283021A1Increase flexibilityImprove convenienceWelding/cutting auxillary devicesFoldable tablesWood machiningEngineering

A welding table used in welding industry and woodworking applications comprises a metal table top with retractable carrying handle and elongated slots for insertion of clamping tools, a protrusion-adjustable angle flange with V-notch mounted to at least one edge of the table top, a support structure having an angle and height adjusting mechanism, and a foldable base frame with casters.

Owner:WONG HARRY

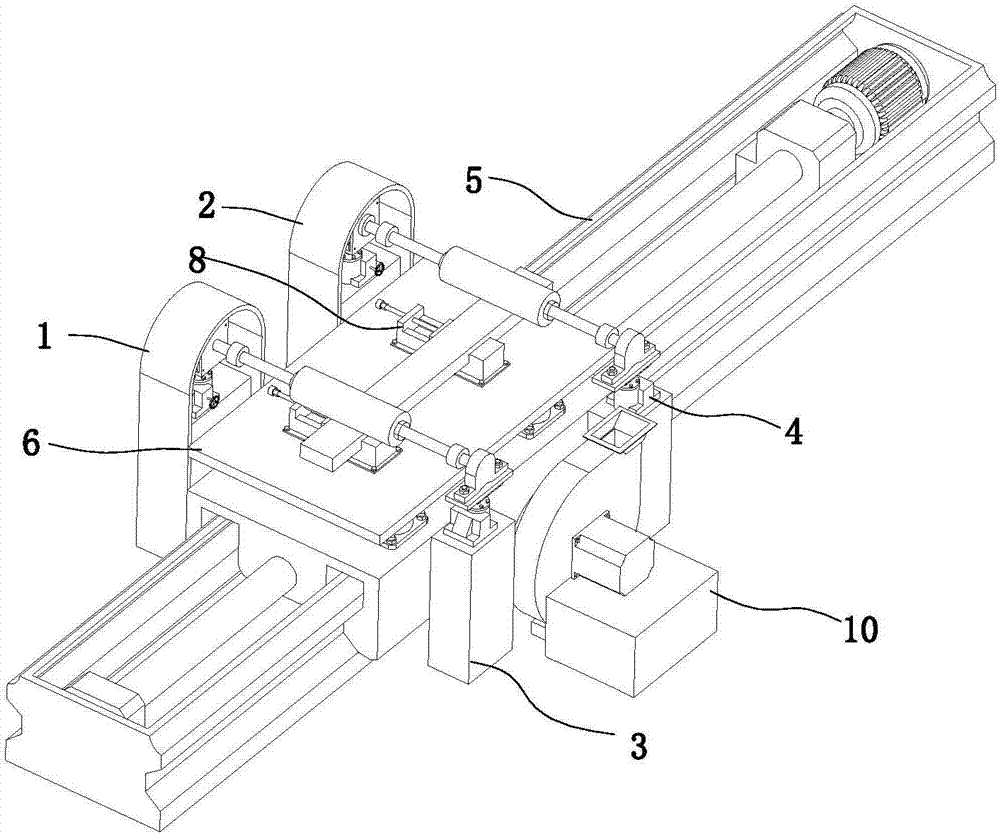

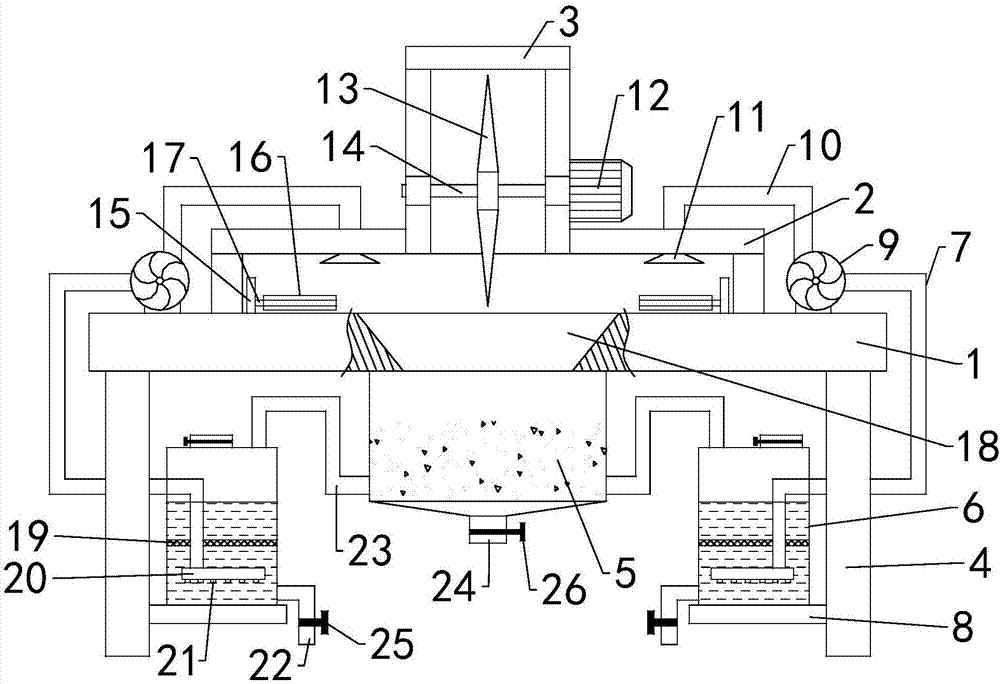

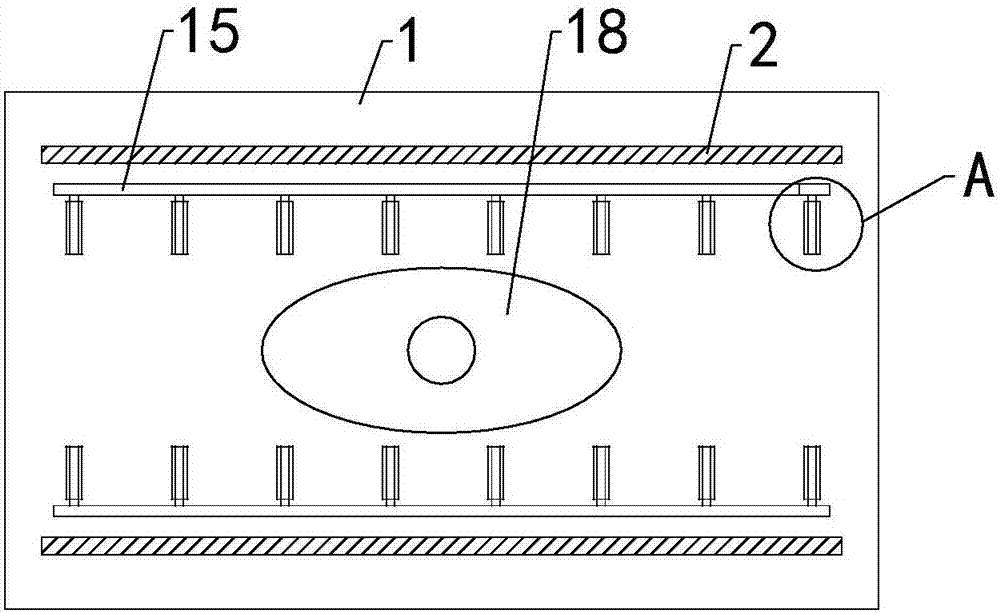

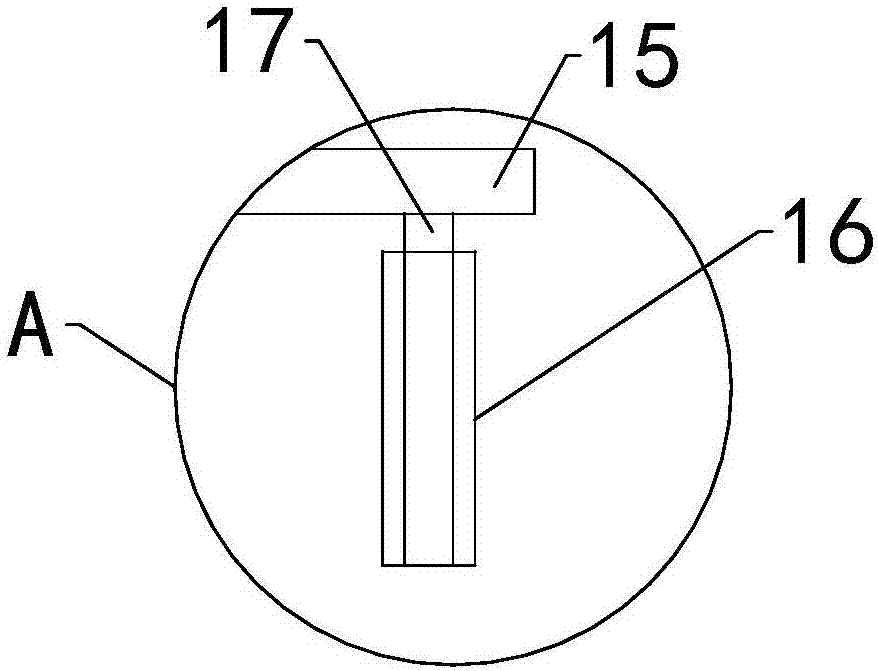

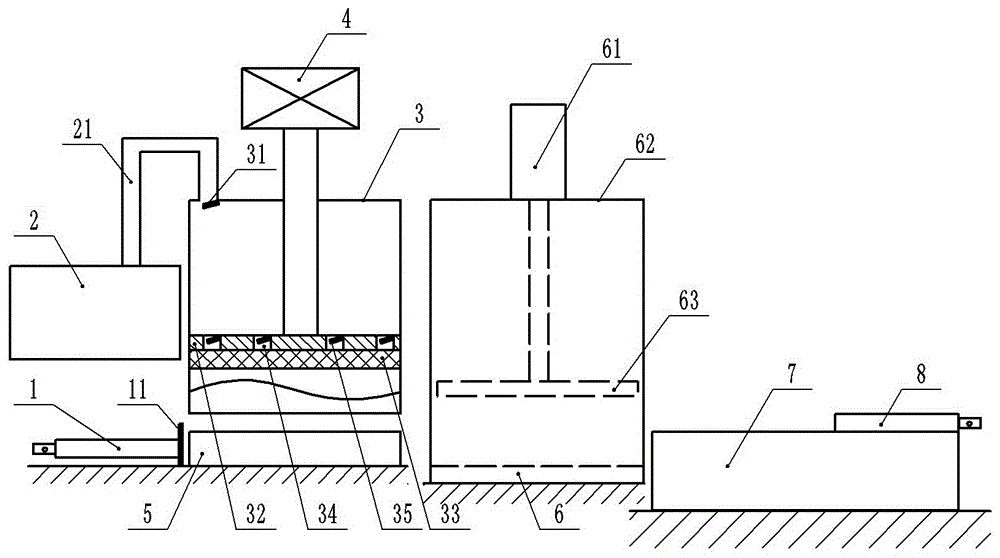

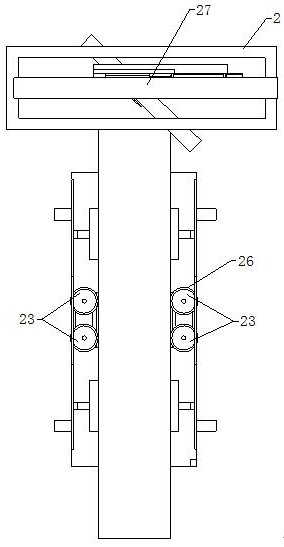

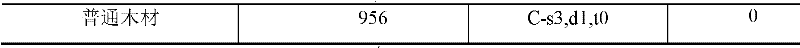

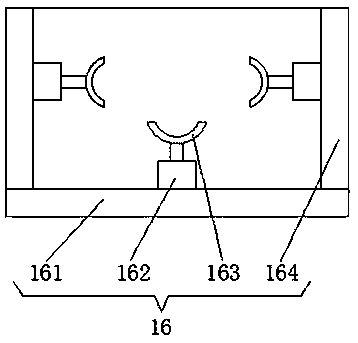

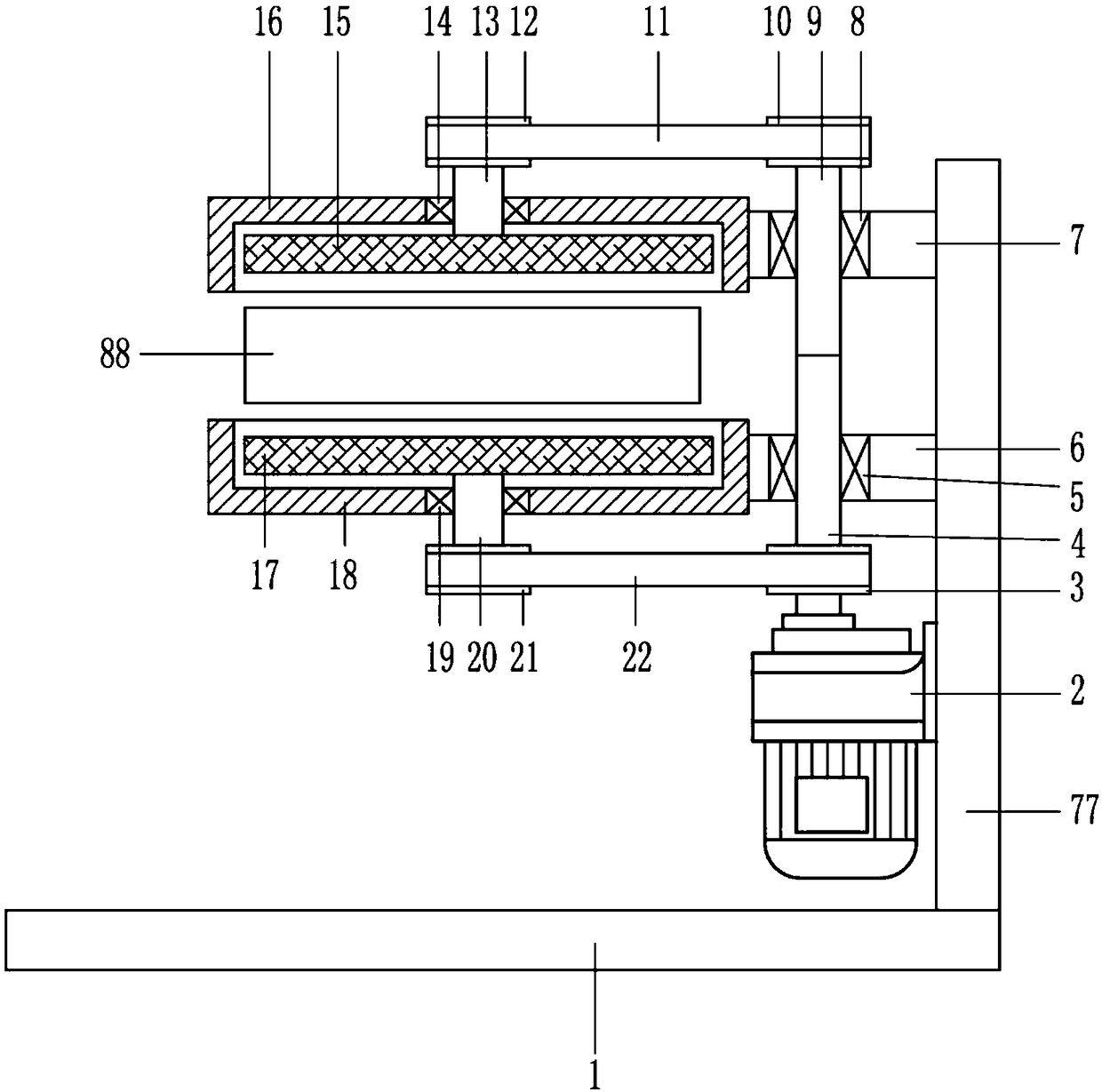

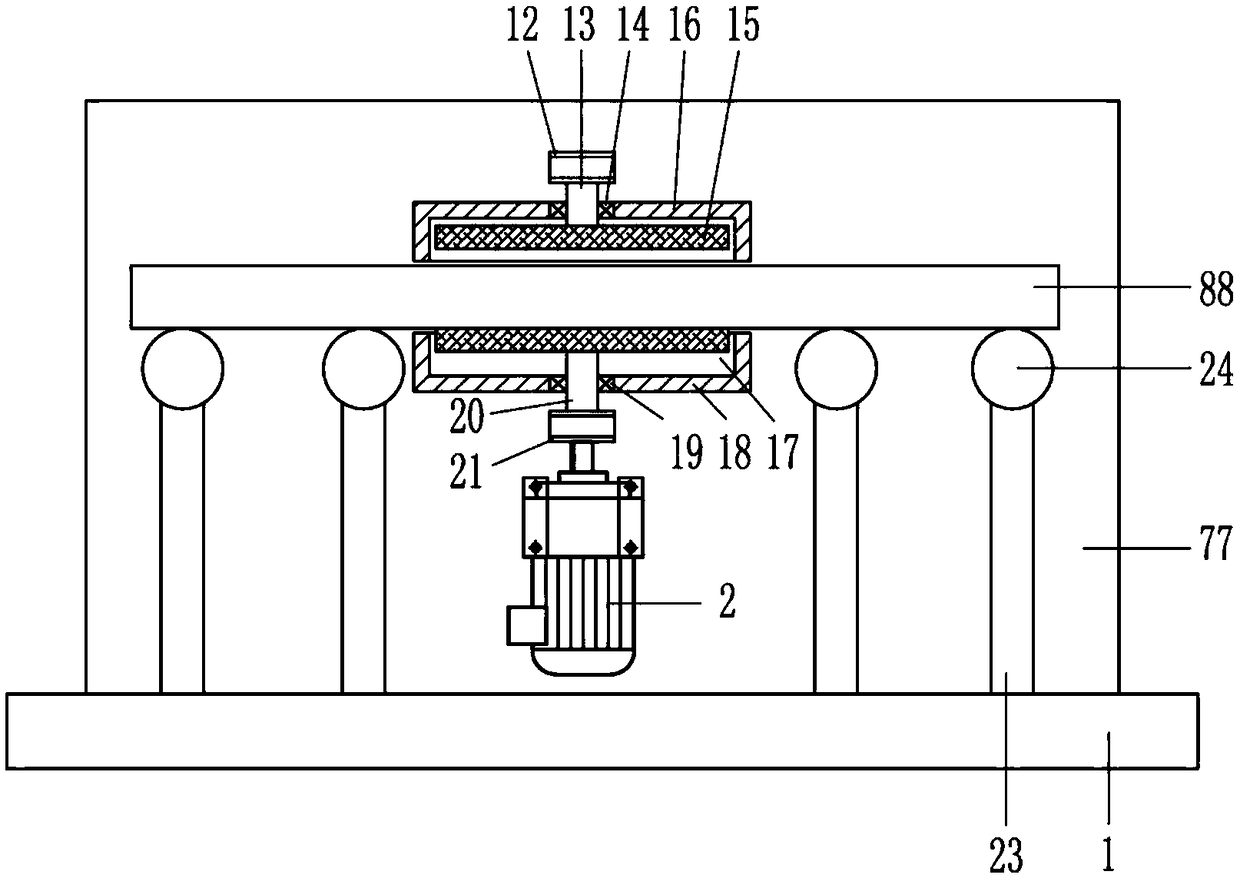

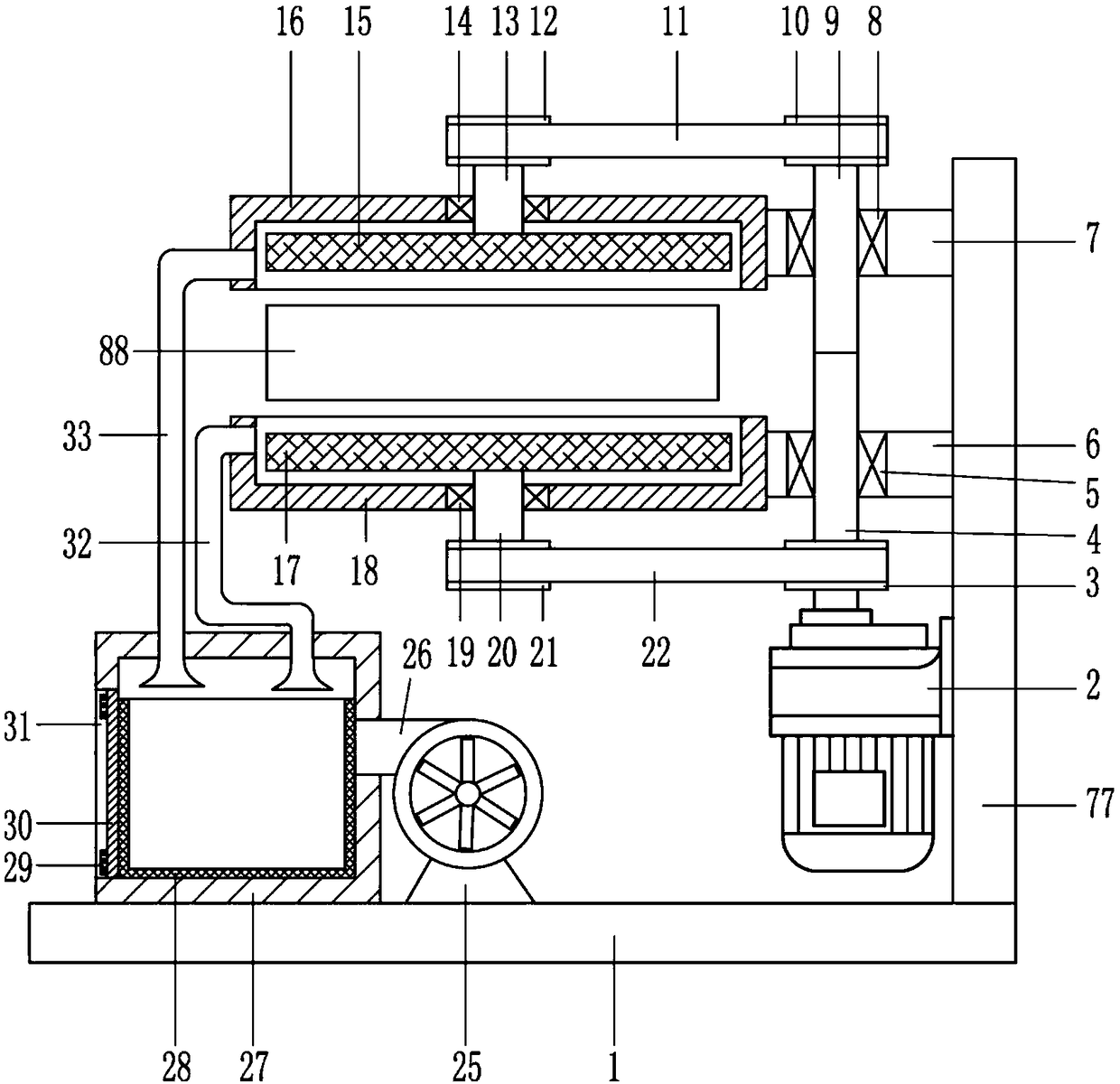

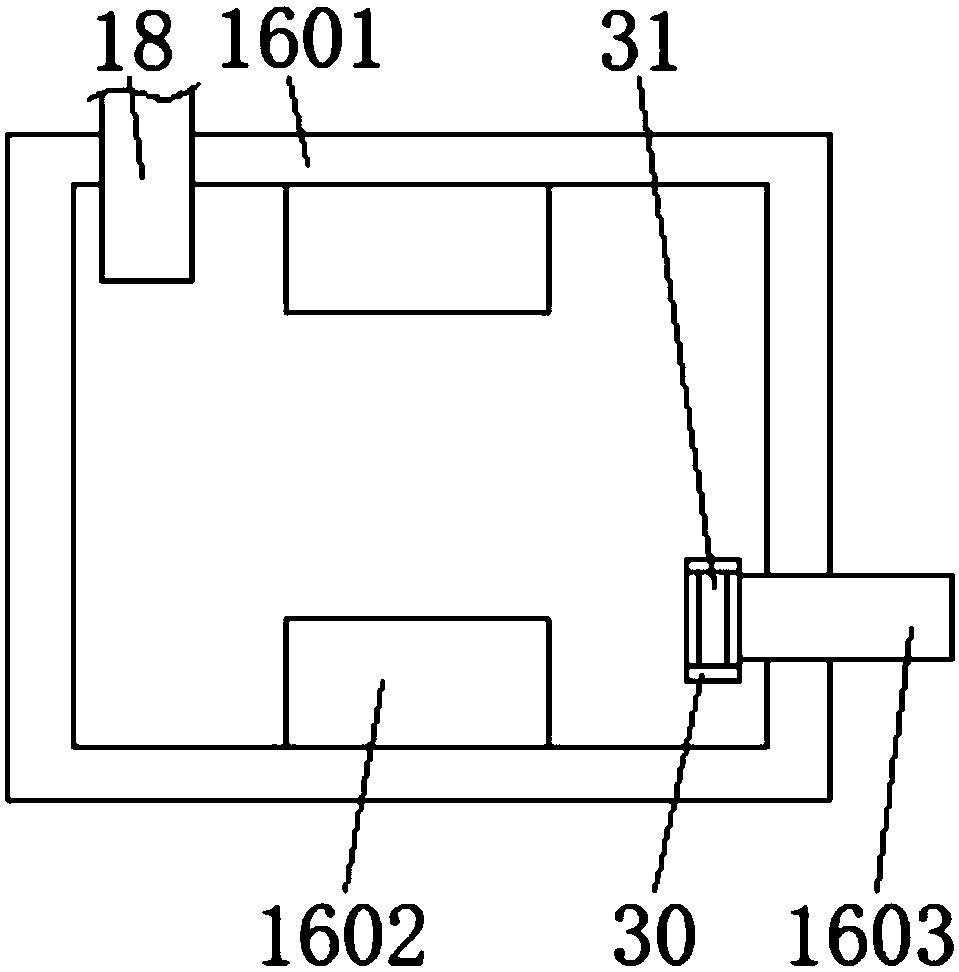

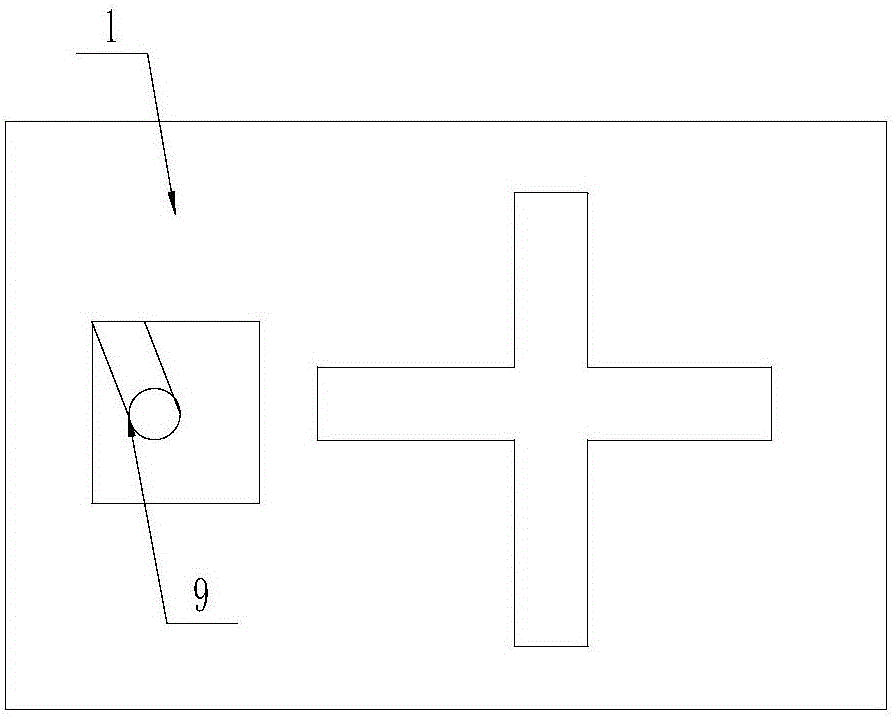

Grinding and polishing device for wood processed surface

InactiveCN107139053ASave human effortReduce work intensityGrinding drivesGrinding work supportsReciprocating motionLocking mechanism

The invention relates to the field of wood processing, in particular to a grinding and polishing device for a wood processed surface. The device comprises a grinding device and a polishing device, wherein the grinding device and the polishing device are spaced. A first lifting mechanism is arranged at the bottom of the grinding device, a second lifting mechanism is arranged at the bottom of the polishing device, a lead screw sliding table is arranged at the bottoms of the grinding device and the polishing device, a workbench is arranged on a sliding block of the lead screw sliding table, and a third lifting mechanism is arranged between the workbench and the sliding block. A locking mechanism is arranged on the top of the workbench, and a dust removal device is arranged beside the workbench. After a workpiece is fastened through a locking assembly, a grinding roller rotates, a first lead screw moves downwards to enable the grinding roller to reach a working region to reciprocate, the grinding roller grinds the workpiece, a first hand wheel is adjusted to adjust the first lead screw to move upwards, a second hand wheel adjusts a second lead screw to move downwards to enable a polishing roller to reach a working region, the lead screw sliding table drives the workbench to the working region of the polishing roller to reciprocate, and the polishing roller polishes the workpiece.

Owner:罗厚镇

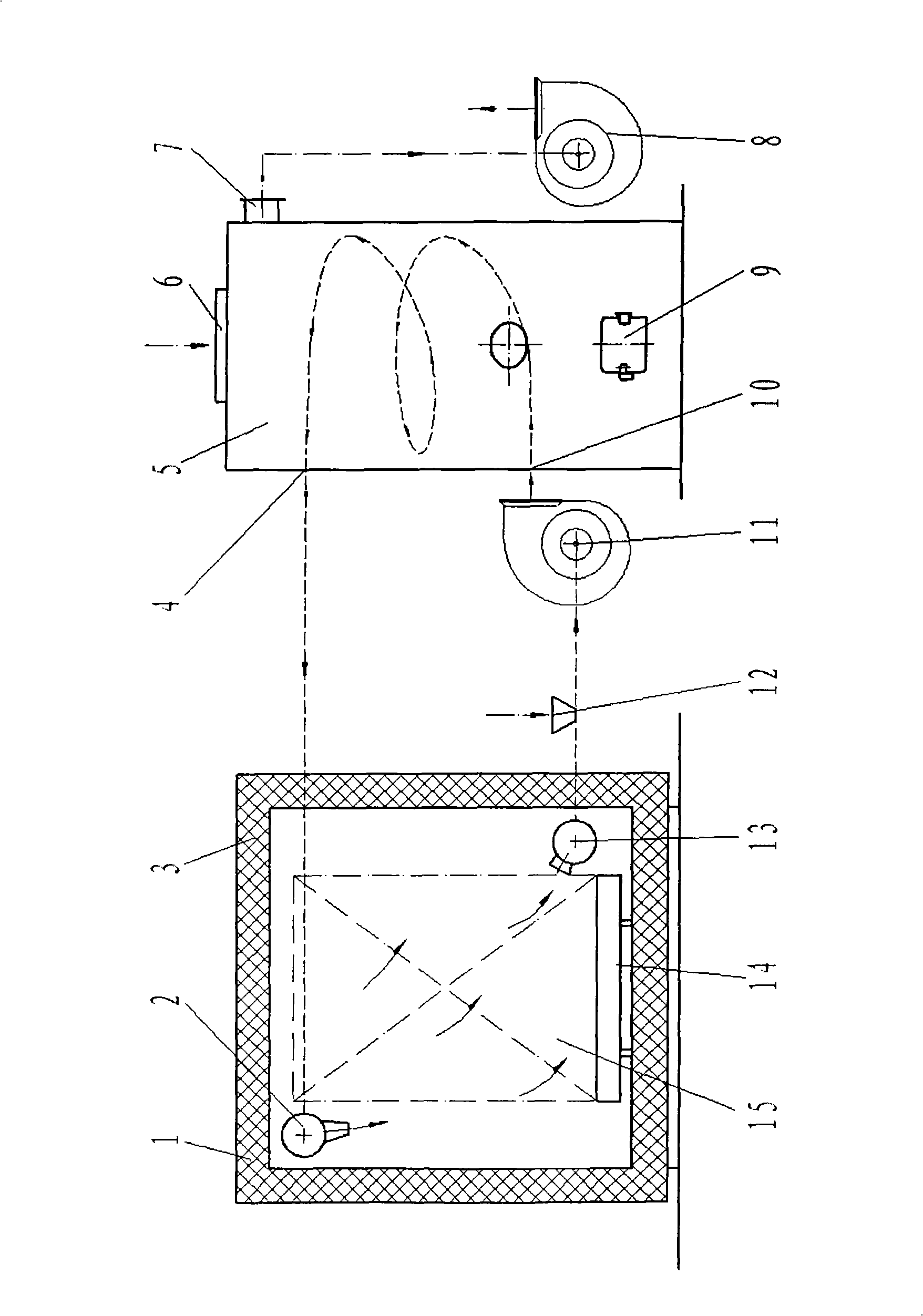

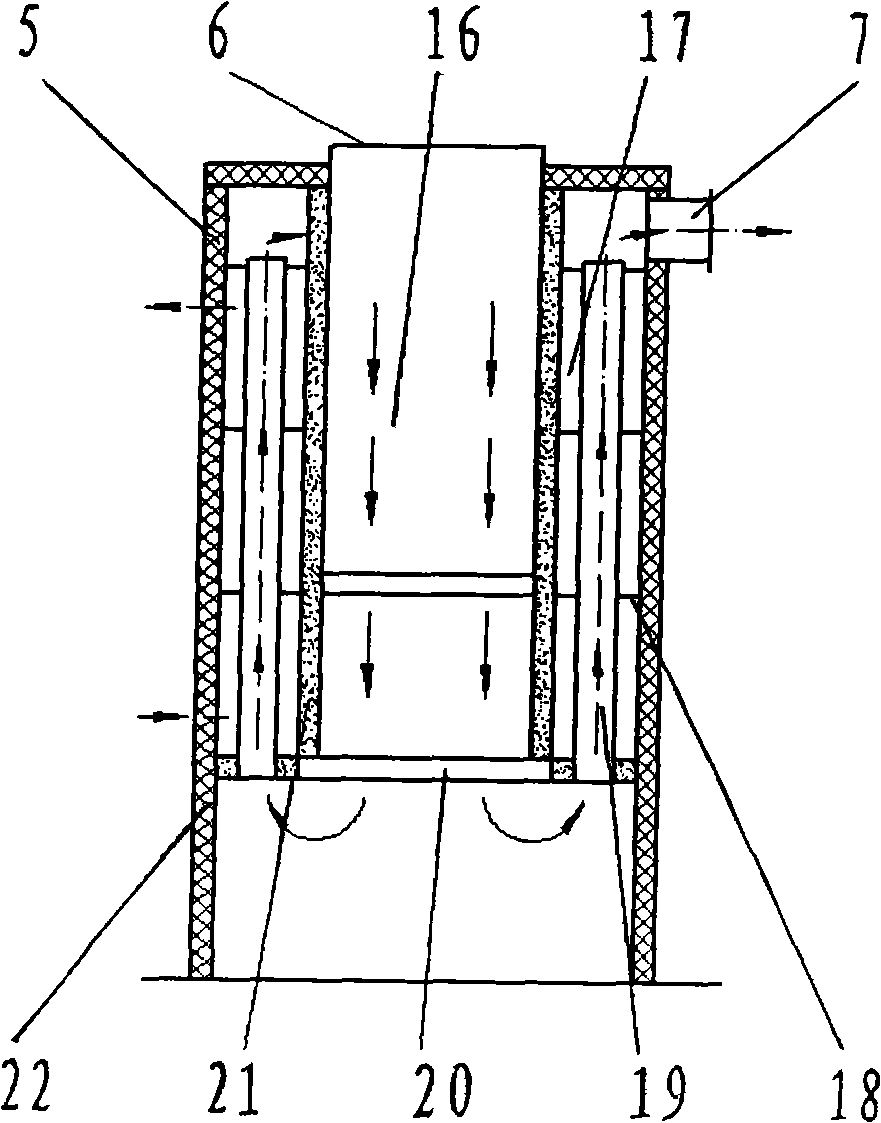

Wood high-heat treatment device and technological process thereof

InactiveCN101491908AImprove thermal efficiencyBurn fullyWood treatment detailsWood dampingCombustionWood machining

The invention relates to a device and a technical method for the high-temperature thermal treatment of timber. The device adopts a structure that: the air outlet of a reverse combustion-type combustion-heat exchange integral hot blast stove is communicated with the air inlet of a gas ejector pipe, the air outlet of the gas ejector pipe is communicated with the air inlet pipe of a return pipe through a log pile in a logging truck, the air outlet pipe of the return pipe is connected with one end of a heat supply fan through a humidifying device, the other end of the heat supply fan is connected with the air inlet of the reverse combustion-type combustion-heat exchange integral hot blast stove, and the smoke outlet of the reverse combustion-type combustion-heat exchange integral hot blast stove is connected with an induced draft fan; and a machine body of the high temperature thermal treatment device is provided with a machine body heat-preservation layer, and the top of the reverse combustion-type combustion-heat exchange integral hot blast stove is provided with a charging hole. The technical method comprises the steps of piling, ignition, process control, conditioning treatment, temperature reduction and discharge and the like. The device and the method have that advantages that: residues of timber processing are used as fuel, the heat exchange of a thermal treatment cyclic medium is carried out through the reverse combustion-type combustion-heat exchange integral hot blast stove at a time, the thermal efficiency is high, the combustion is complete and no pollution is produced.

Owner:NANJING FORESTRY UNIV

Dust sucking type wood processing cutting device

InactiveCN107214777APrevent accidental touchEasy to processProfiling/shaping machinesBark-zones/chip/dust/waste removalWood machiningPulp and paper industry

The invention discloses a vacuum-type wood processing and cutting device, which comprises a working table, a protective box, a protective cover, a sawdust collection box and a water tank. The upper surface of the working table is symmetrically fixed and welded. There are a number of rotating shafts on the inner wall of the plate, each rotating shaft is equipped with a conveying roller, and two fans are symmetrically arranged on the upper surface of both ends of the workbench, and the air inlet of each fan is connected. There is an air intake pipeline, the air intake end of the air intake pipeline is connected with the dust collection hood, the lower part of the inner cavity of the water tank is provided with an annular exhaust pipe, and the annular exhaust pipe is connected with the outlet end of the ventilation pipeline, and the inlet of the ventilation pipeline The gas end is connected with the gas outlet of the blower fan, and the upper part of the inner cavity of the water tank is connected with the lower inner cavity of the sawdust collection box through a connecting pipe. The invention has simple structure, high safety, is convenient for processing and cutting wood boards, can effectively absorb dust and collect sawdust, and is suitable for popularization and use.

Owner:张翔

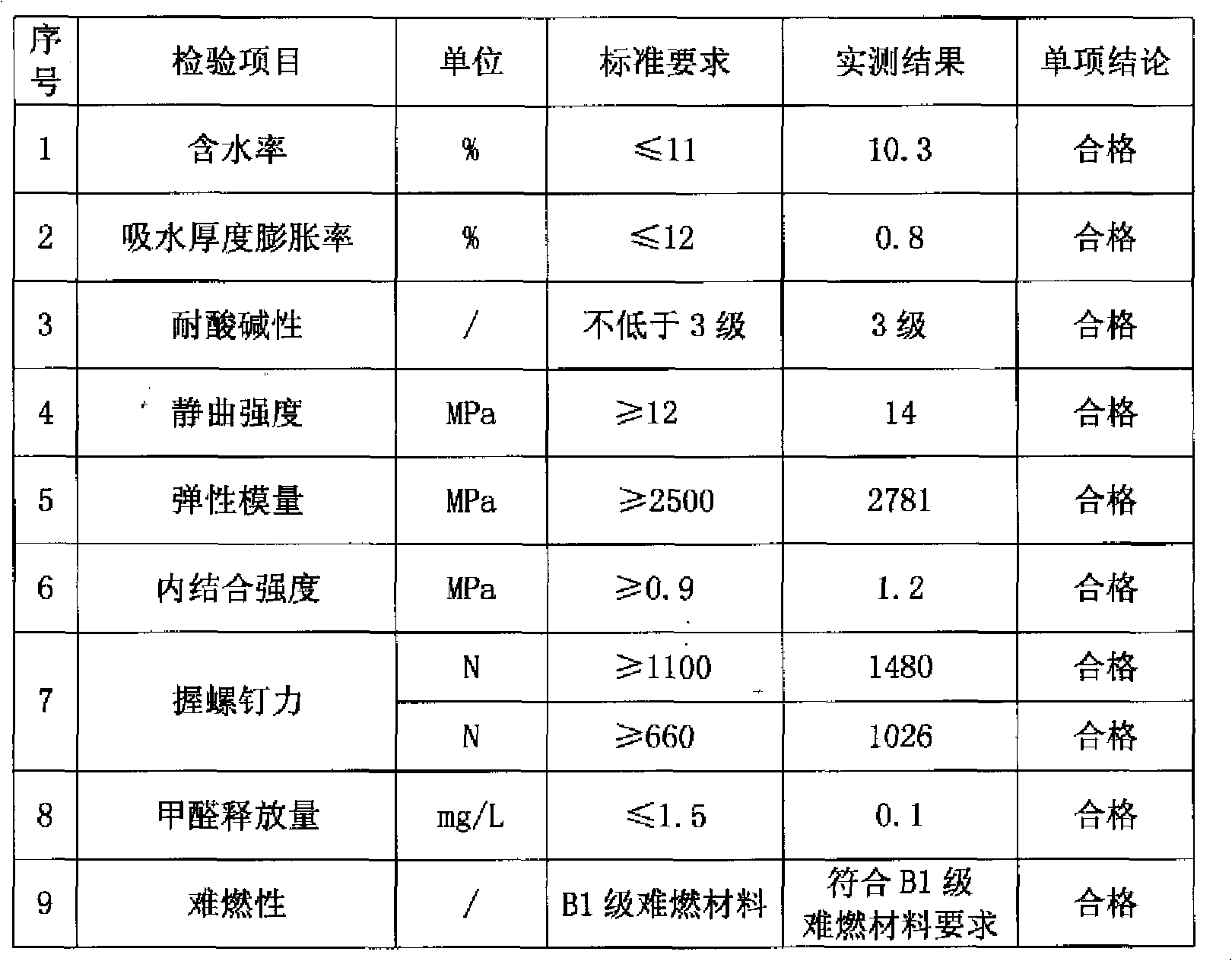

Flame-retardant fiber board and manufacturing method thereof

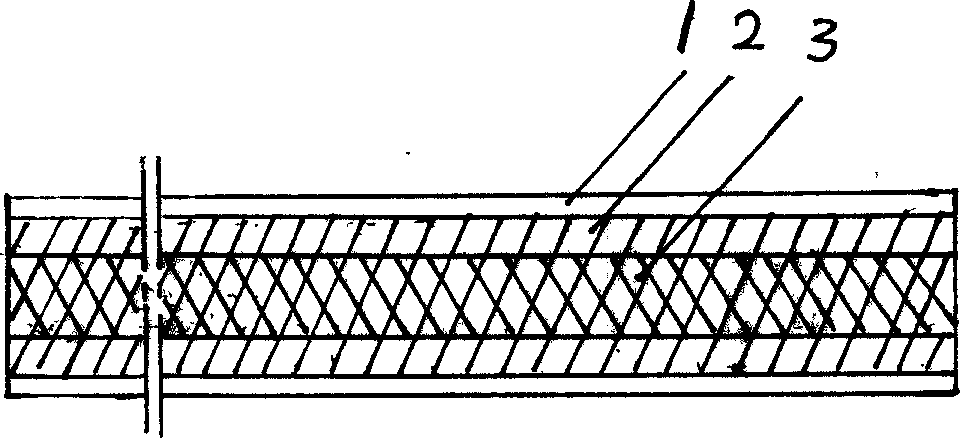

InactiveCN101602224ALow priceMaterials are readily availableDomestic articlesFlat articlesFiberPolymer science

The invention relates to a flame-retardant fiber board and a manufacturing method thereof. The flame-retardant fiber board is prepared from the following raw materials in portion by weight: 80 to 120 portions of fiber, 80 to 120 portions of magnesia, 80 to 200 portions of water solution of magnesium sulfate, 5 to 30 portions of active silica, 0.5 to 2 portions of organosilicon waterproof agent, and 0.5 to 1.5 portions of plasticizer. The manufacturing method comprises the steps: 1) preparing the fiber, namely cleaning and drying crop straws, wood branches or wood processing residual materials, and then obtaining the fiber through the crushing by a crushing machine; 2) preparing an inorganic adhesive, namely mixing the magnesia, the water solution of the magnesium sulfate, the active silica, the organosilicon waterproof agent and the plasticizer, and stirring the mixture to obtain the inorganic adhesive; 3) mixing the fiber and the inorganic adhesive prepared through the step 1 and the step 2, stirring the mixture, and paving the mixture after the screening by a screening machine; 4) paving a reinforcing network on the upper and lower surfaces of a paved slab; and 5) finally performing hot pressing on the board paved with the reinforcing network for 10 to 25 minutes at a temperature of between 100 and 110 DEG C at a pressure of between 12 and 30MPa to obtain the flame-retardant fiber board. The flame-retardant fiber board has broad application field.

Owner:湖南迪普环保建材有限公司

Plate press machine with glue coating function

ActiveCN106738100AAccelerate solidificationLighten the laborPlywood pressesMulti-purpose machinesWood machiningPulp and paper industry

The invention belongs to the technical field of wood working equipment, and particularly discloses a plate press machine with glue coating function. The plate press machine comprises a first horizontal push hydrocylinder, a glue coating device, a plate presser and a feeder from left to right, wherein the glue coating device comprises a bracket, a glue tank, an air cylinder and a glue supply tank; the glue supply tank is a tank body with an opening on the lower end; the glue supply tank is fixed to the bracket; a piston is arranged in the glue supply tank, and driven by the air cylinder; the air cylinder is positioned above the glue supply tank; the side wall of the glue supply tank communicates with a glue suction pipe; one end of the glue suction pipe is positioned in the glue tank; the joint between the glue suction pipe and glue supply tank is provided with a first one-way valve; the piston is provided with a through hole, and the through hole is provided with a one-way valve; the lower surface of the piston is provided with a sponge layer; the feeder comprises an elevating table and a second horizontal push hydrocylinder; and the second horizontal push hydrocylinder is positioned on the elevating table. By adopting the technical scheme, the wood plate can be pressed immediately after finishing glue coating, and the glue coating and pressing processes are continuous, so the production efficiency is high.

Owner:重庆汇升套装门有限公司

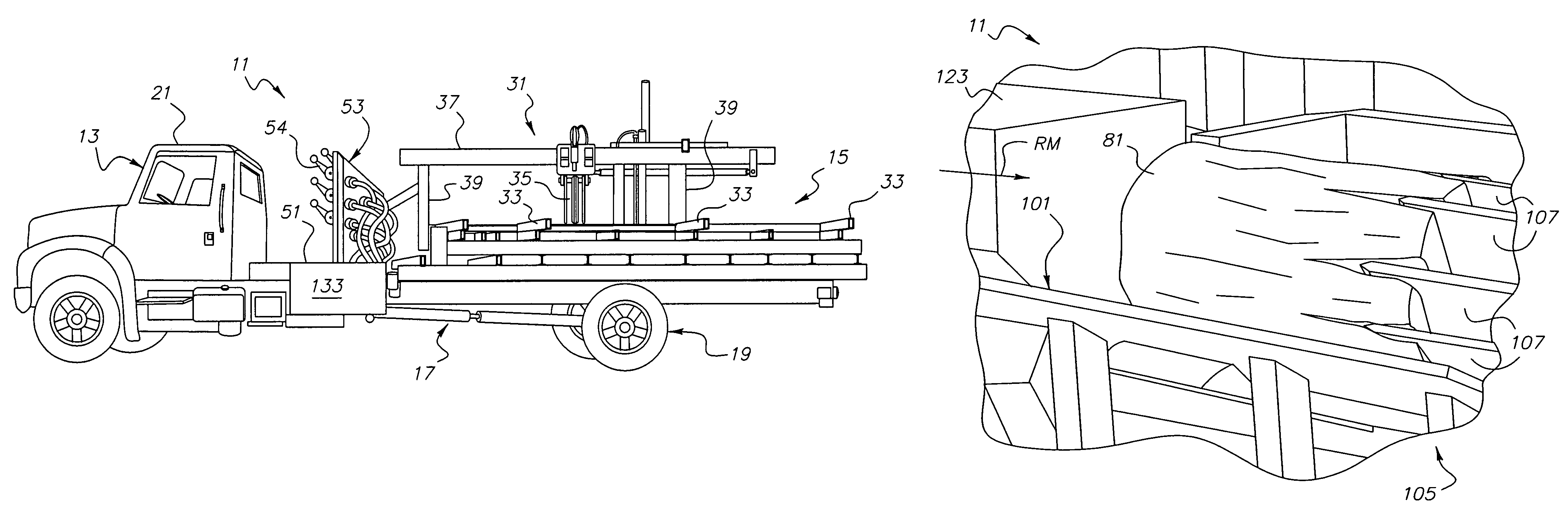

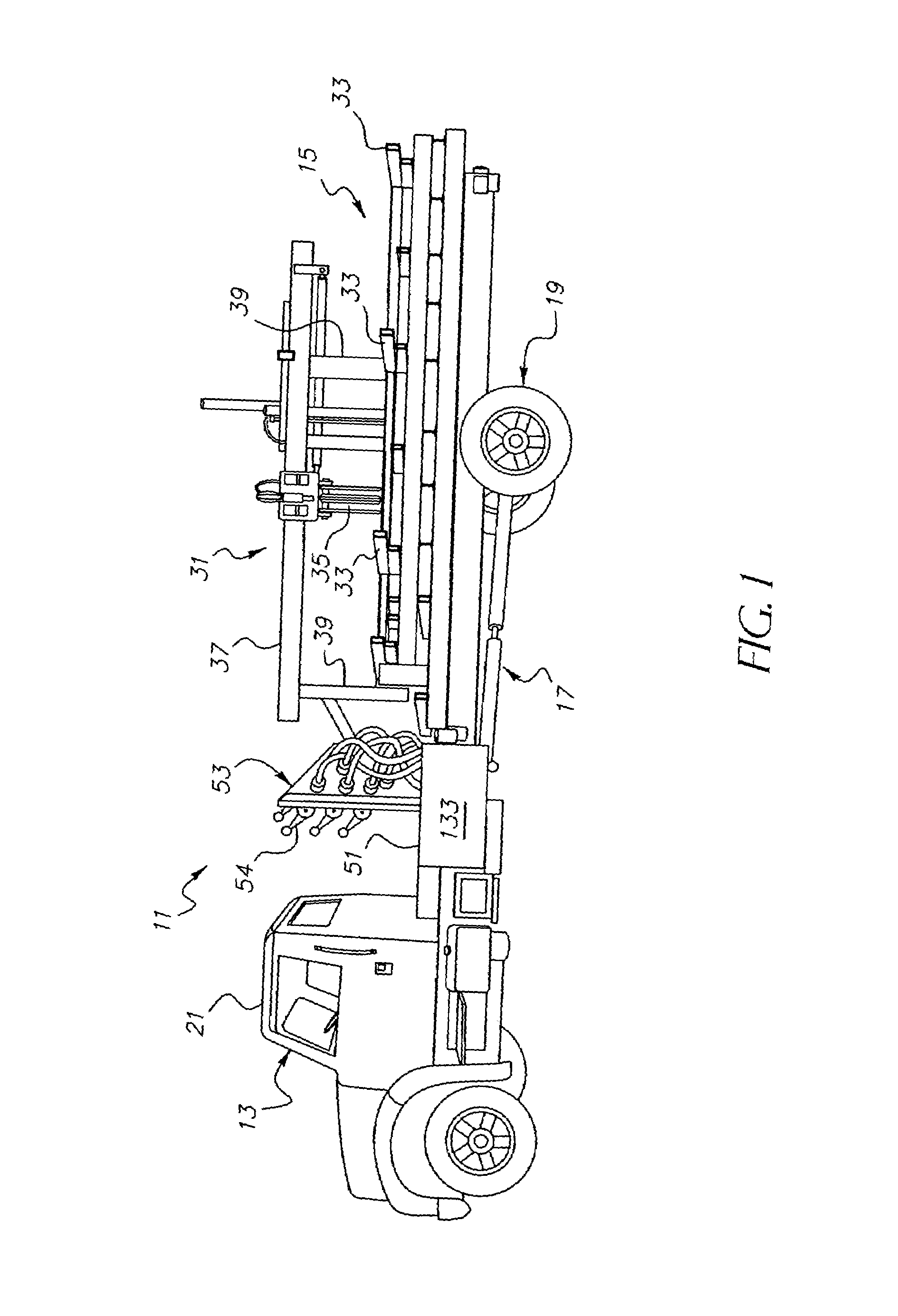

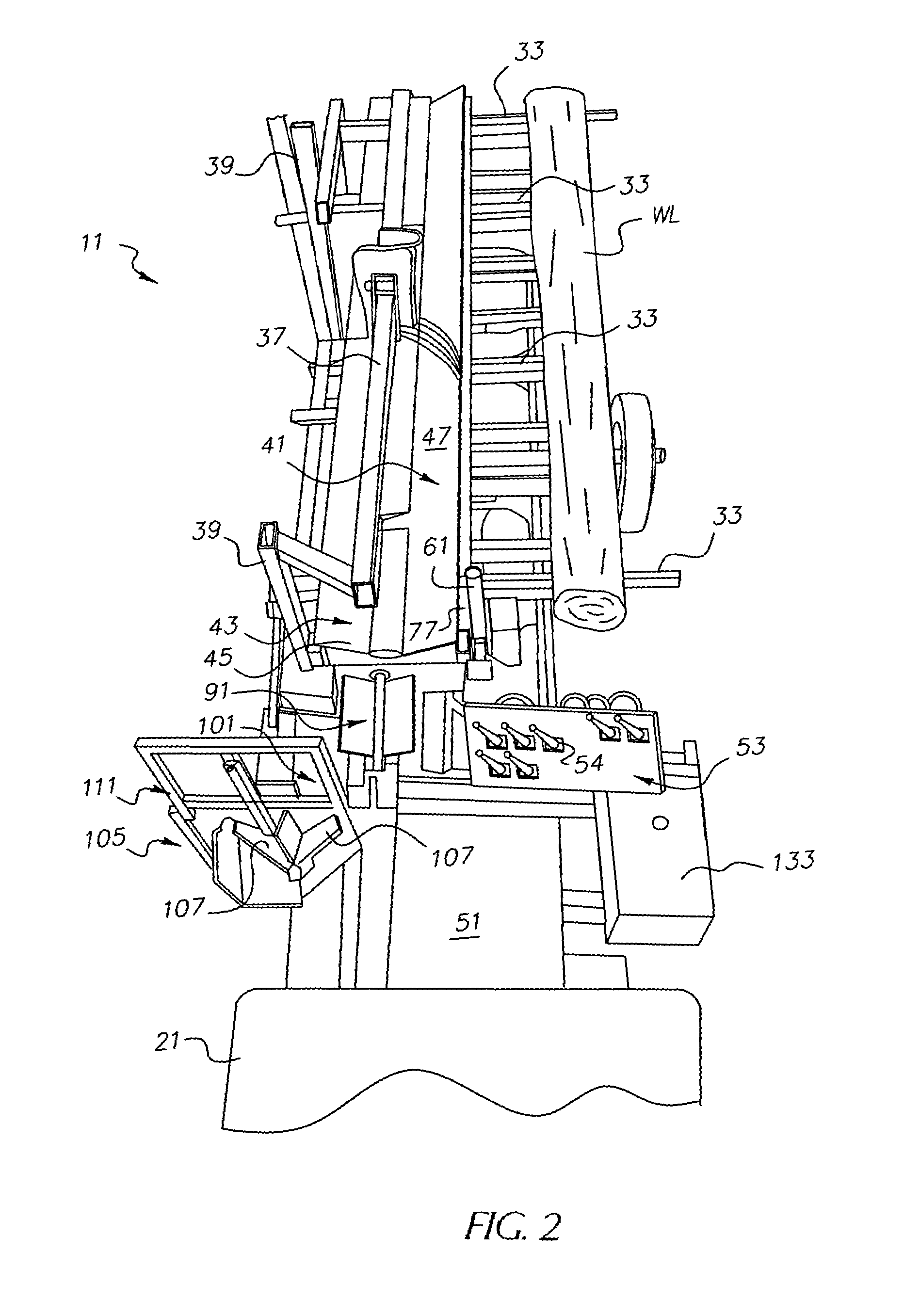

Wood processor

InactiveUS7228881B1Significant processingEasy constructionWood splittingMulti-purpose machinesWood processorWood machining

A wood processor including a motor vehicle having a bed structure, a clamping device on the bed structure for clamping a wood log and positioning it in a first processing position, a power saw for cutting predetermined length members from the wood log, and a splitting device for splitting the wood members into a specified number of pieces.

Owner:SMITH RICHARD H

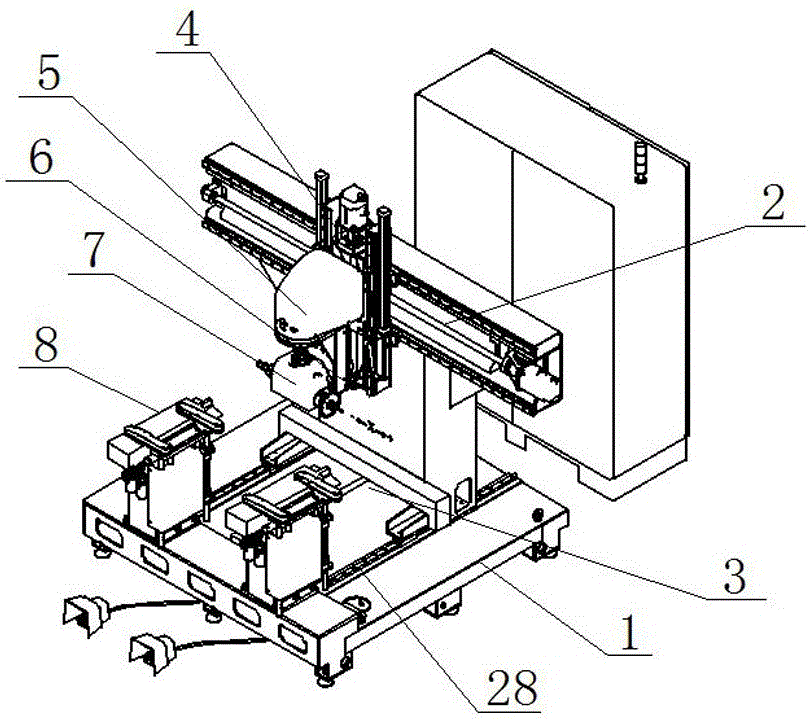

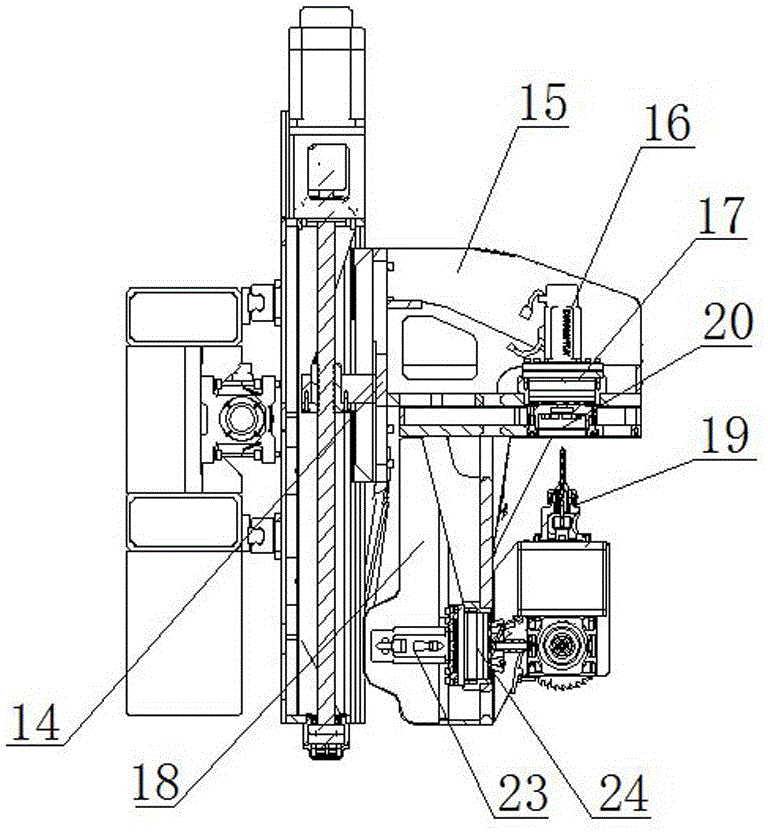

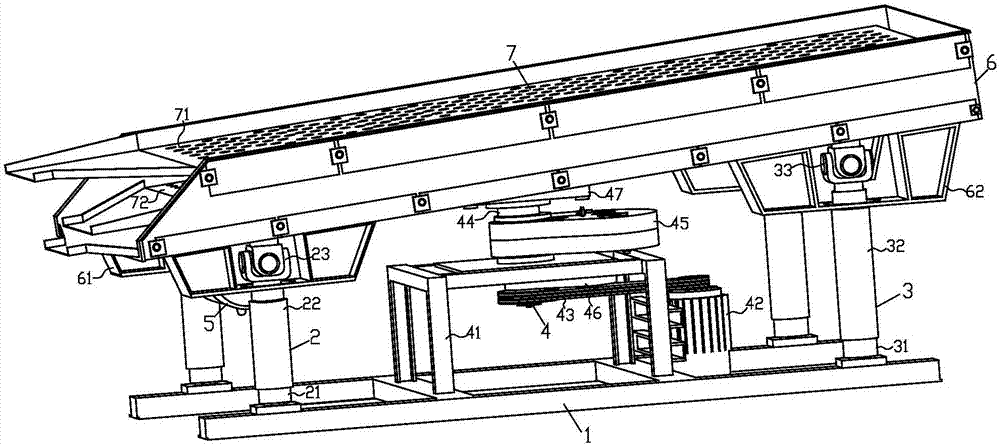

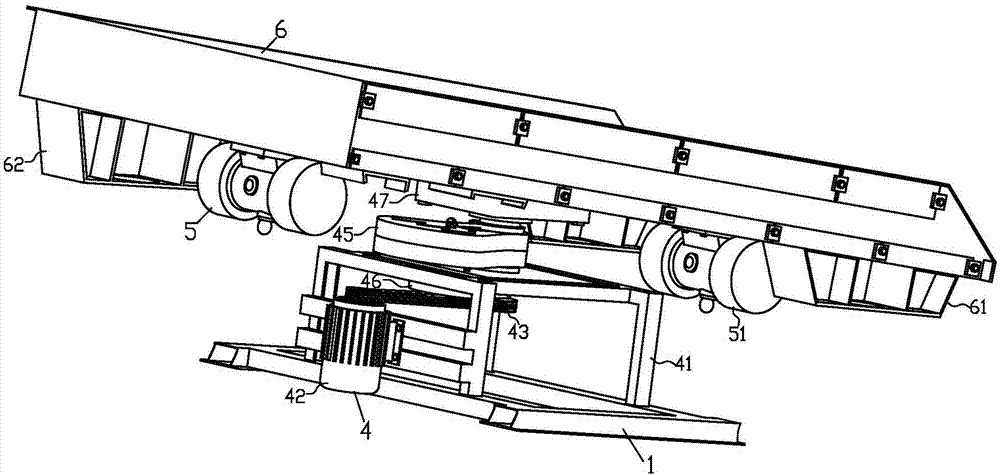

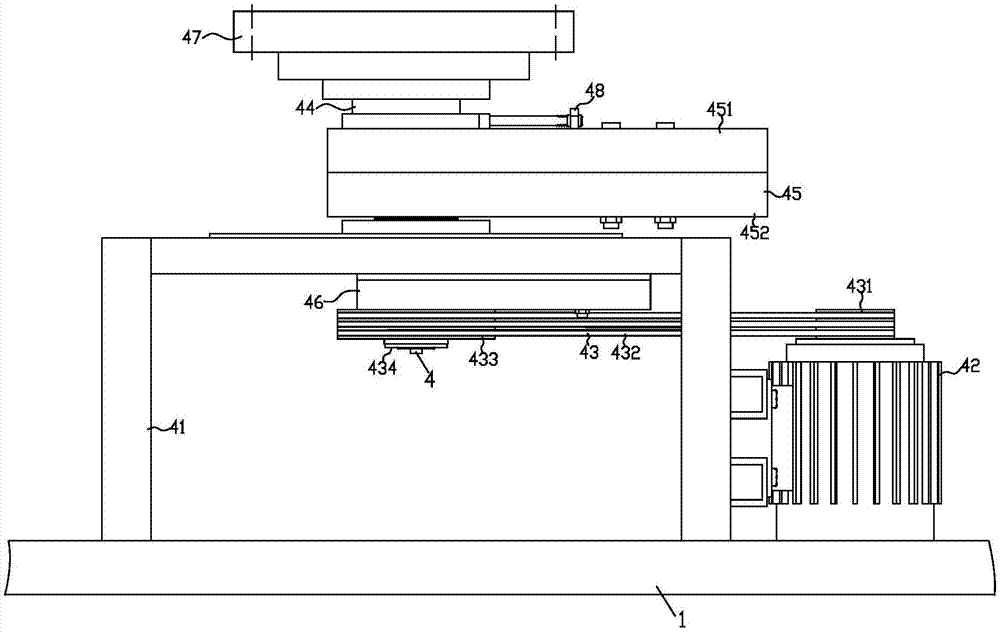

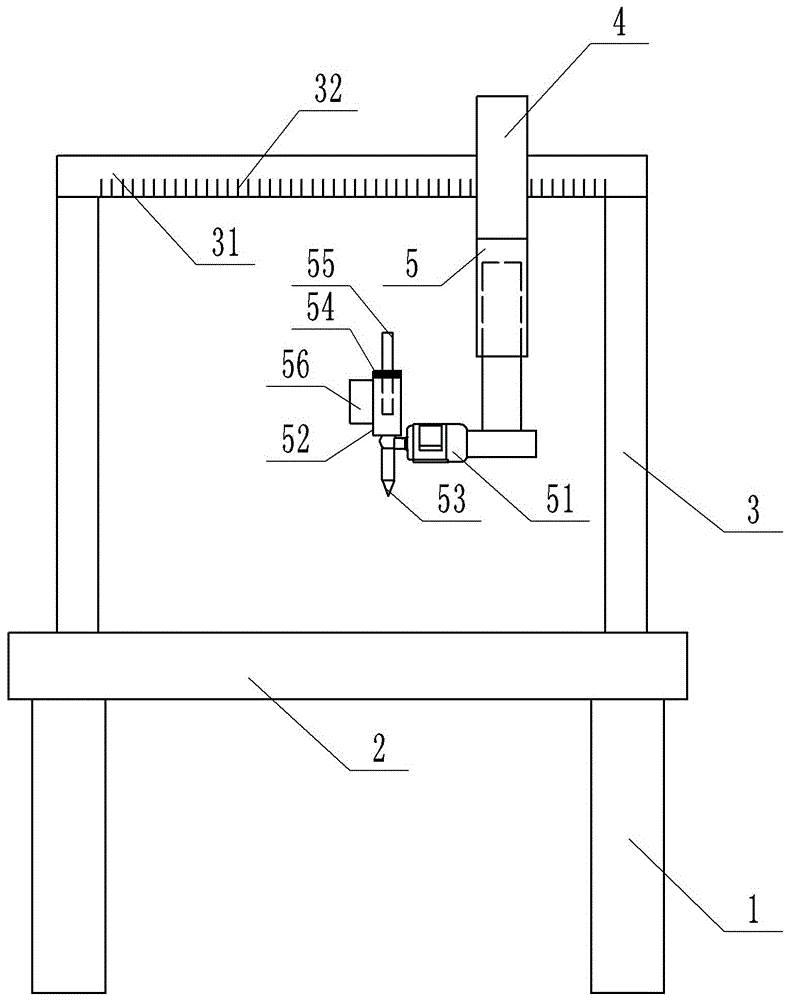

Wood five-axis machining center

ActiveCN106113161AImprove processing efficiencySwitch freelyMulti-purpose machinesWood machiningEngineering

The invention discloses a wood five-axis machining center. The wood five-axis machining center comprises a base, an X-axis moving mechanism, a Y-axis moving mechanism, a Z-axis moving mechanism, a C-axis driving mechanism, an A-axis driving mechanism, a tool and a machining platform; the X-axis moving mechanism drives the tool to move transversely along the base; the Y-axis moving mechanism drives the tool to move longitudinally along the base; the Z-axis moving mechanism drives the tool to move in the vertical direction; the C-axis driving mechanism drives the tool to rotate in the horizontal direction; the A-axis driving mechanism drives the tool to rotate in the vertical direction; and the machining platform is arranged on the base and located on the lower side of the tool. According to the wood five-axis machining center, tool moving in the X-axis, Y-axis and Z-axis directions can be achieved, and meanwhile, tool rotating in the A-axis and C-axis directions can be conducted, so that different-degree inclined plane machining is achieved, and tool switching can be conducted freely; and the multi-functional effect is achieved, and the wood machining efficiency is greatly improved.

Owner:JIANGSU GUOQUAN AUTOMATION TECH CO LTD

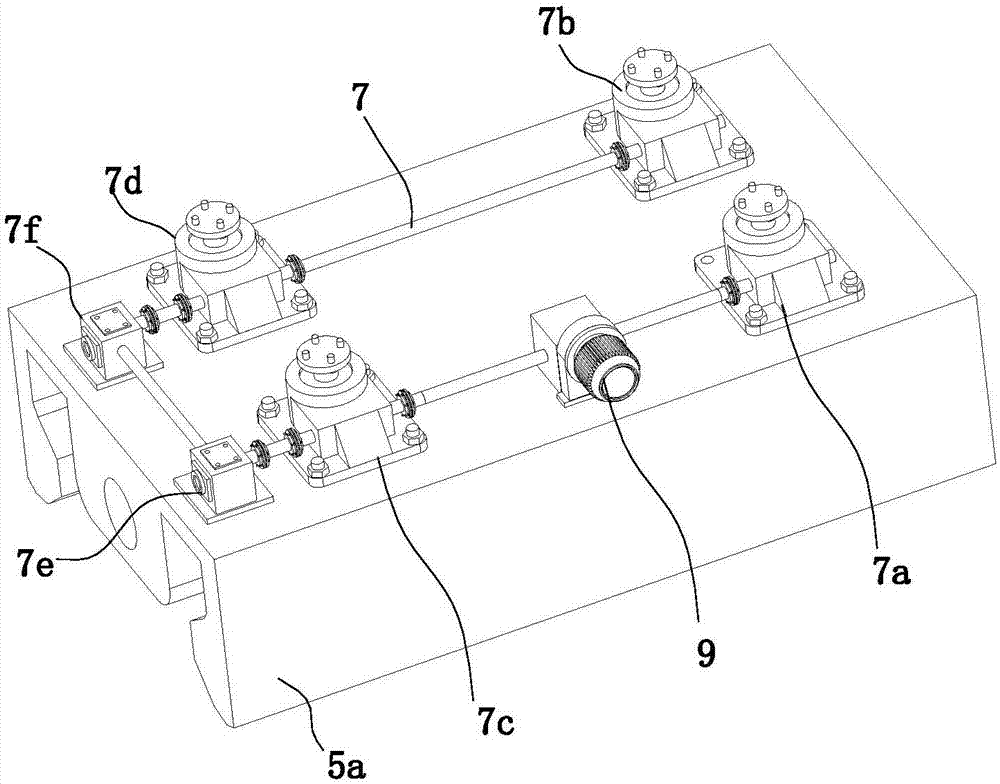

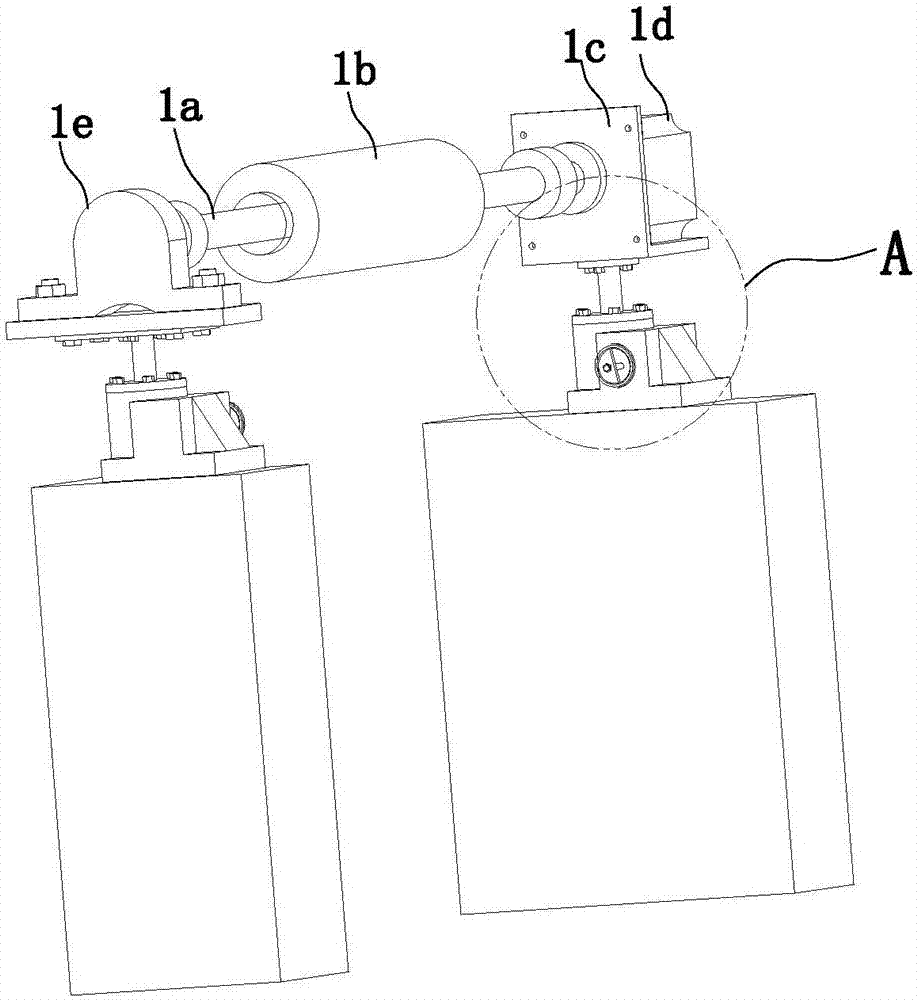

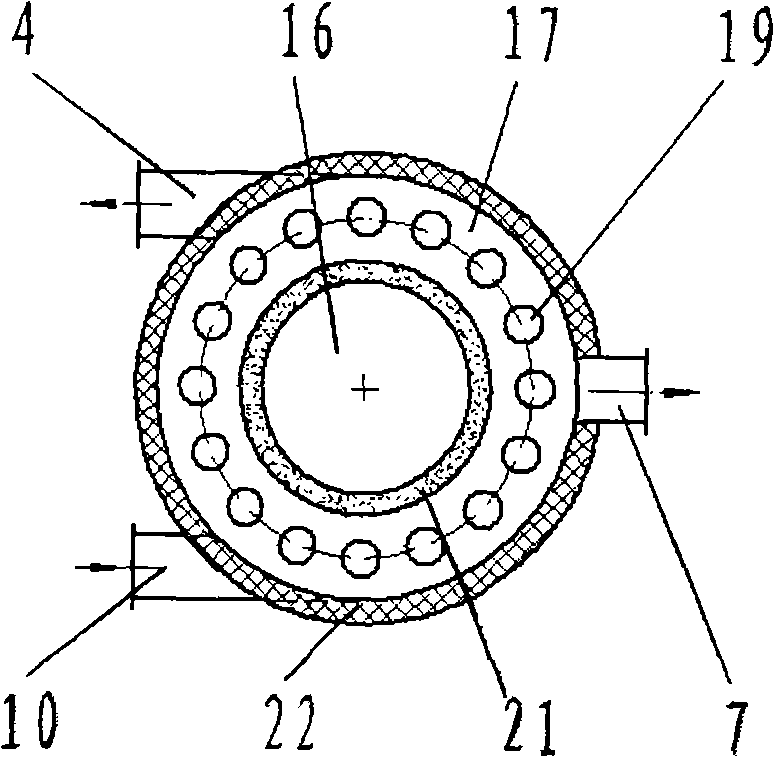

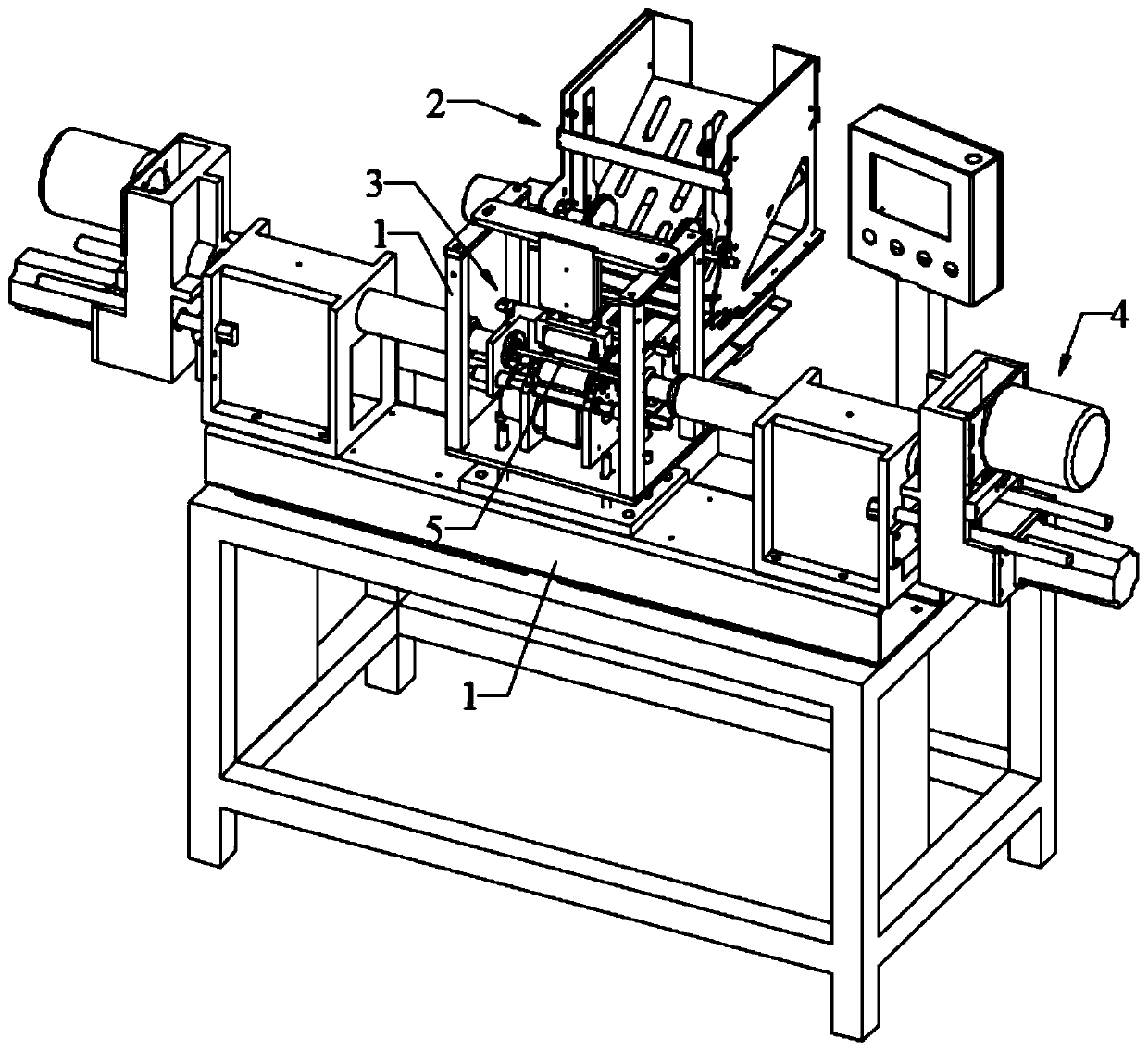

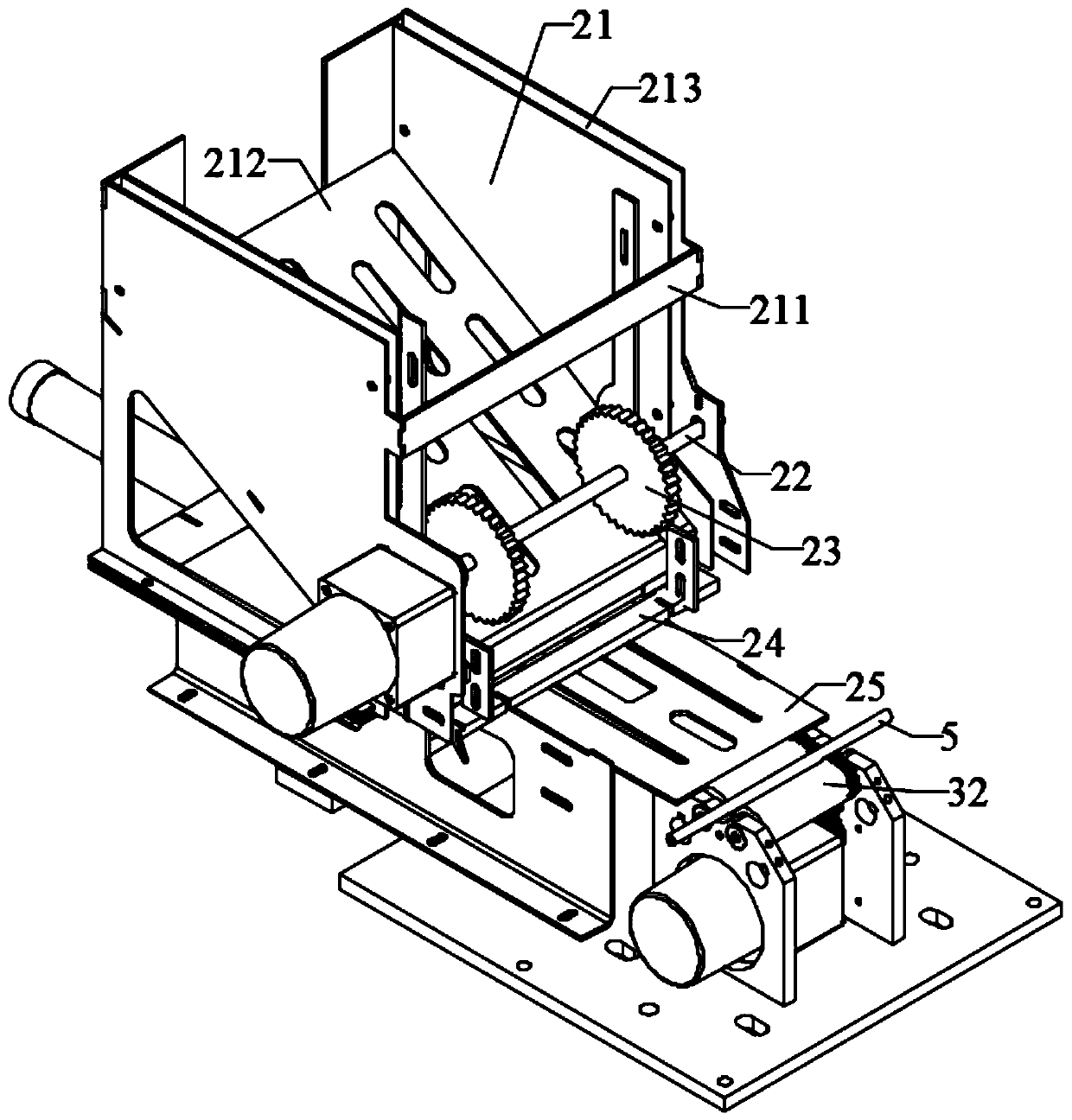

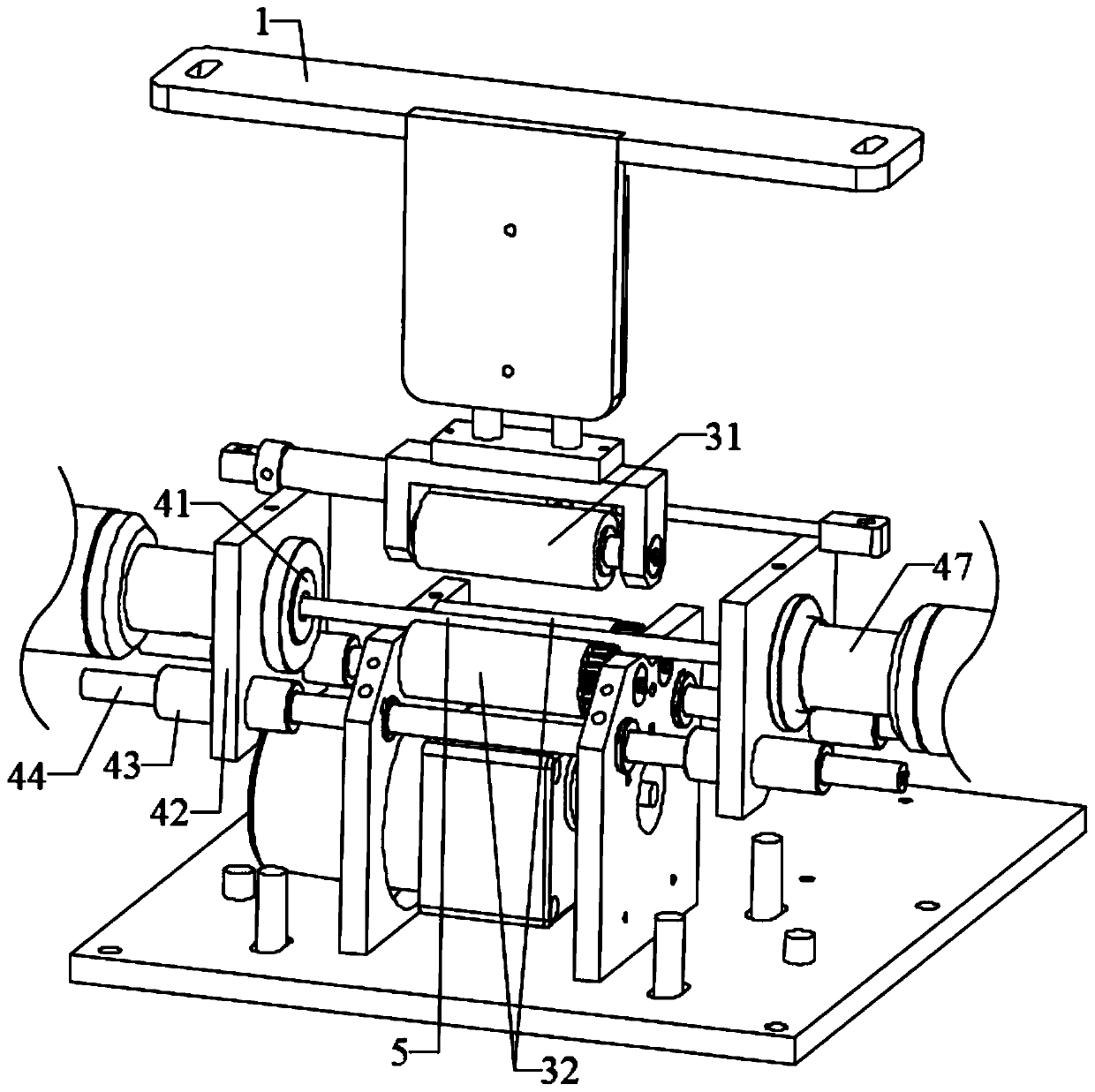

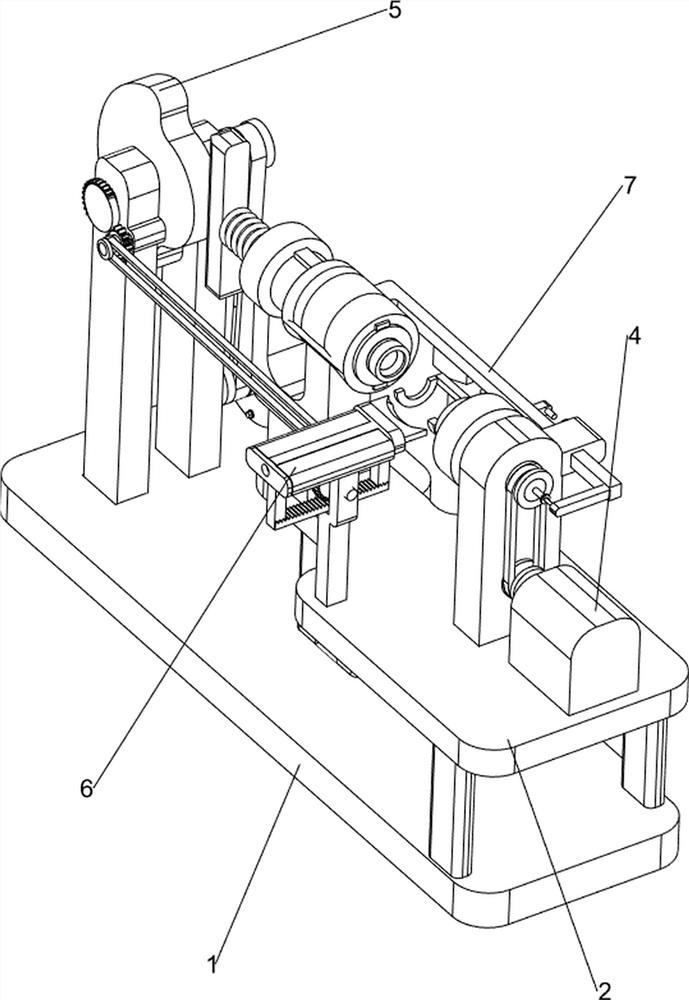

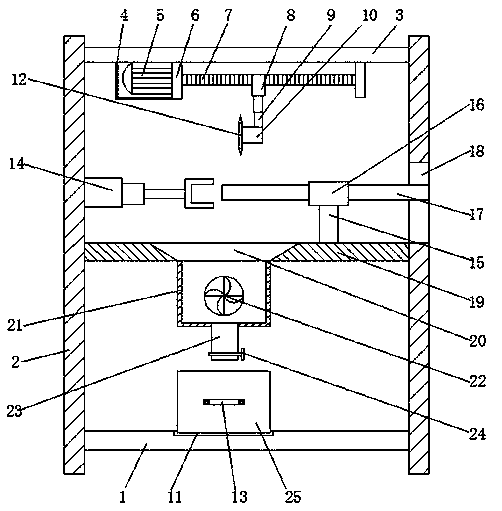

Bamboo stick clamping and drilling equipment for bamboo straw manufacturing

InactiveCN111168790AImprove processing efficiencyImprove yieldStationary drilling machinesCane mechanical workingWood machiningProcess engineering

The invention relates to the technical field of bamboo and wood machining, in particular to bamboo stick clamping and drilling equipment for bamboo straw manufacturing. The equipment comprises a conveying device, a clamping device and a drilling device which are arranged on a rack, wherein the conveying device is arranged on one side of the clamping device and used for conveying a bamboo stick tothe clamping device, and the drilling device is used for drilling the bamboo stick clamped by the clamping device. According to the bamboo stick clamping and drilling equipment for bamboo straw manufacturing, the machining efficiency of the bamboo straw is greatly improved, and the equipment is simple in mechanism and easy to disassemble and maintain; the formed bamboo stick can be directly drilled, and compared with a traditional bamboo straw manufacturing mode, the efficiency is higher; and through the straightening and fixing effect of a taper sleeve and a clamping roller on the bamboo stick, the bamboo stick is always in a rotating state in the drilling process, it is guaranteed that a drill bit advances straightly in the bamboo stick, the problem that the drill bit drills through thebamboo stick due to the insufficient straightness of the bamboo stick or the structure of a sunny side and a nightside is avoided, and the yield of bamboo straw machining is greatly increased.

Owner:邵武市意创机械有限公司

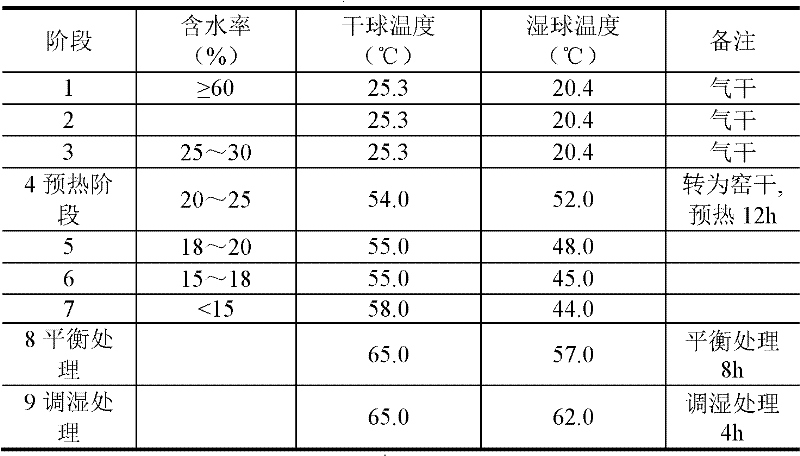

Pine drying method

ActiveCN104511953AUniform moisture contentAvoid deformationWood treatment detailsDrying gas arrangementsWood machiningEngineering

The invention discloses a pine drying method, and belongs to the field of timber processing. The method comprises the following steps: selecting pine sheets with the thickness of 25-35mm and the water content of 40-45% before drying, putting the pine sheets in a kiln, stacking, using division bars between layers of the pine sheets, making a pine water content drying reference according to the dimension of the stack of the pine sheets, the flow velocity of a drying medium and the water content of the sheets, setting a wet and dry bulb temperature according to the water content drying standard, starting a system in the drying kiln to carry out automatic heating and steam injection to a preset required range, cooling the pine sheets, and discharging the cooled pine sheets from the kiln to obtain a finished product. The method allows the water content of the timber to be balanced in the drying process by adopting the pine drying reference and using automatic steam injection, prevents the deformation, cracking and bending of the sheets in the drying process, and realizes an optimal drying state through multi-time automatic steam injection, humidity elimination and adjustment.

Owner:柳州林道轻型木结构制造有限公司

Straw particle board employing bark powder modified phenolic resins as adhesives

ActiveCN101693380ALow costImprove performanceFlat articlesDomestic articlesWood shavingsWood machining

A straw particle board employing bark powder modified phenolic resins as adhesives adopts straws as main raw materials and woodworking fragment wood shavings as secondary materials. The particle board is characterized in that the adhesives of the pressed straw particle board employ the bark powder modified phenolic resins, a large amount of renewable wood processing remained bark powders are adopted to replace parts of petrochemical phenols, the phenols are employed to directly activate the bark powders, the bark powders are applied to preparation of phenolic resin adhesives, and operation is simple. In a gluing process, CH3Si (OH) 3 organic silicon liquor with low cost is adopted to modify the adhesives so as to enable the adhesives to easily moisten, penetrate and diffuse on the surfaces of the straws, thereby being favorable for glue joint of the straws. Simultaneously, interfaces of the straws are modified so as to enable the bark powder adhesives to be applied to production of the straw particle board. The straw particle board produced by adopting the adhesives has the advantages of attaching importance to effective usage of biological materials, having low product manufacturing cost, fine performance, strong operability and bringing remarkable ecological benefits and environmental benefits after being popularized.

Owner:BEIHUA UNIV

Type of wood section material and its manufacturing method

ActiveUS20110262727A1Easy to useLow densityThermal wood treatmentWood layered productsWood machiningCarbonization

The present invention relates to a type of wood section material manufacturing method, especially with respect to soft wood section material and its manufacturing method. It belongs to wood processing field. This invention is achieved by the following technical plans: a type of wood section material manufacturing method includes the following steps: (1) wood preparation; (2) drying; (3) Polishing; (4) Hot pressing, which is to use two hot pressing boards with 140-200° C. to firmly press two surfaces of panel blank material; (5) Pre-carbonization, which pre-carbonize the panel blank material under 160° C. and 200° C.; (6) Carbonization, which carbonize the panel blank material between 200° C. and 225° C.; (7) Cooling; and (8) Moisture content control. This invention is particularly suitable to make wooden floor boards and office furniture.

Owner:TU DENGYUN +1

Wood strip grinding machine for wood processing

InactiveCN111922858ANo manual controlImprove work efficiencyGrinding carriagesGrinding drivesWood machiningElectric machinery

Owner:陈卓文

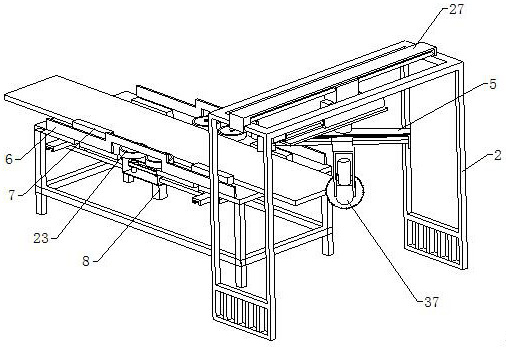

Construction wood-cutting machine with adjustable angle

InactiveCN112140241AReduce labor costsImprove cutting efficiencyFeeding devicesGripping devicesAgricultural engineeringWood machining

The invention relates to the technical field of construction wood cutting, in particular to a construction wood-cutting machine with an adjustable angle. The construction wood-cutting machine with theadjustable angle comprises a conveying table, a portal frame vertically erected at one end of the conveying table, a conveying and positioning mechanism which is arranged on the conveying table and used for transferring wood to a processing portion of the portal frame and conducting positioning, and a rotary adjusting and cutting mechanism which is arranged on the portal frame and used for conducting angle cutting on processing ends of the wood conveyed by the conveying and positioning mechanism, and the construction wood-cutting machine with the adjustable angle is characterized in that therotary adjusting and cutting mechanism comprises a horizontal overturning board which is horizontally arranged at the upper end of the interior of the portal frame and can horizontally rotate. By means of the construction wood-cutting machine with the adjustable angle, the wood can be automatically conveyed and positioned, and cutting is conducted with the angle of a cutting machine body automatically adjusted according to angles needed for wood cutting, so that the labor cost is reduced, and the cutting efficiency is improved.

Owner:潘长艳

Novel shaving board and production method thereof

This invention discloses a new shaving plate and its product method, belonging to building and decorating material realm, characterized in adopting saw powder and abatement in course of processing deserted wood or timber to be crashed into wood powder with different diameters, and mixing them with adhesive made from mineral powder including magnesia and magnevit, and one-shot cold-pressing forming under effect of trigger squeezer, wherein, the two surface of plate are layers made through mixing 60-100 order thin powder with its thickness being 0.1-0.3mm and adhesive, the middle of it is high-intensive layer made through mixing coarse wood powder with 1-30mm length and 0.5-3mm width and adhesive, between surface and intensive layer is equipped with natural vine fabric or chemical glasses or plastic fabric, which forms reinforcement. The plate without other additive is a environment-friendly type plate with fireproof, damp-proof, and non-poison functions, suitable for building, furniture and decoration industries.

Owner:河北金赛博板业有限公司

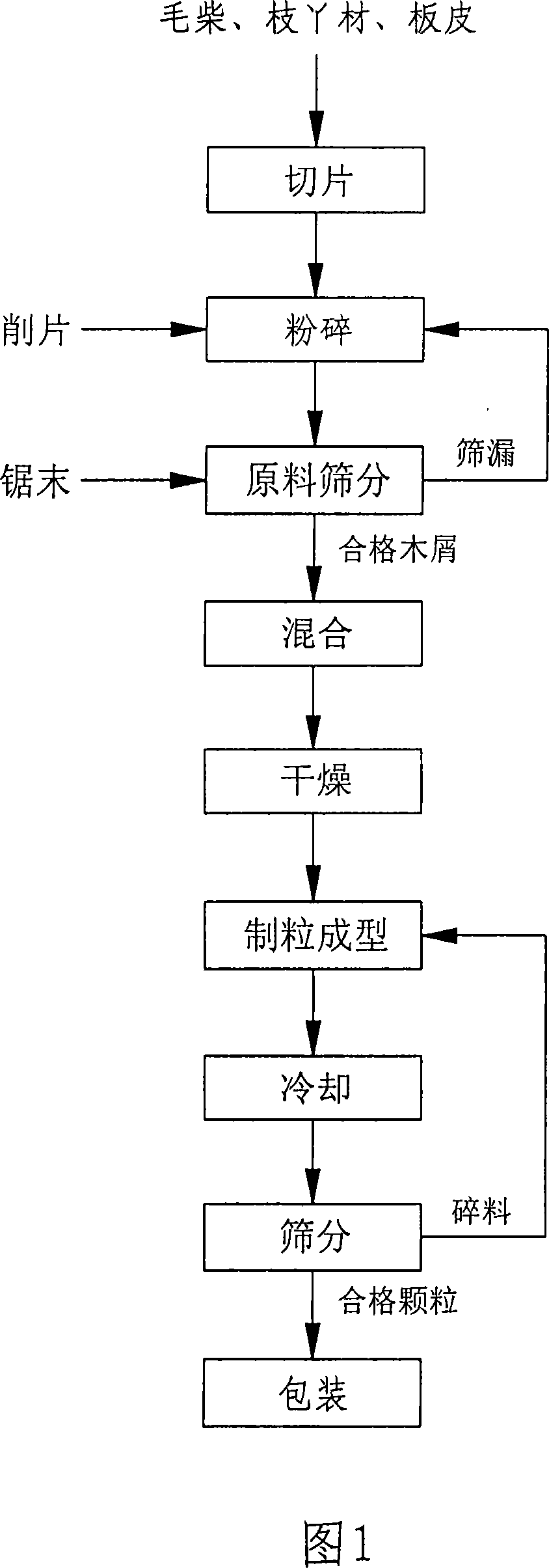

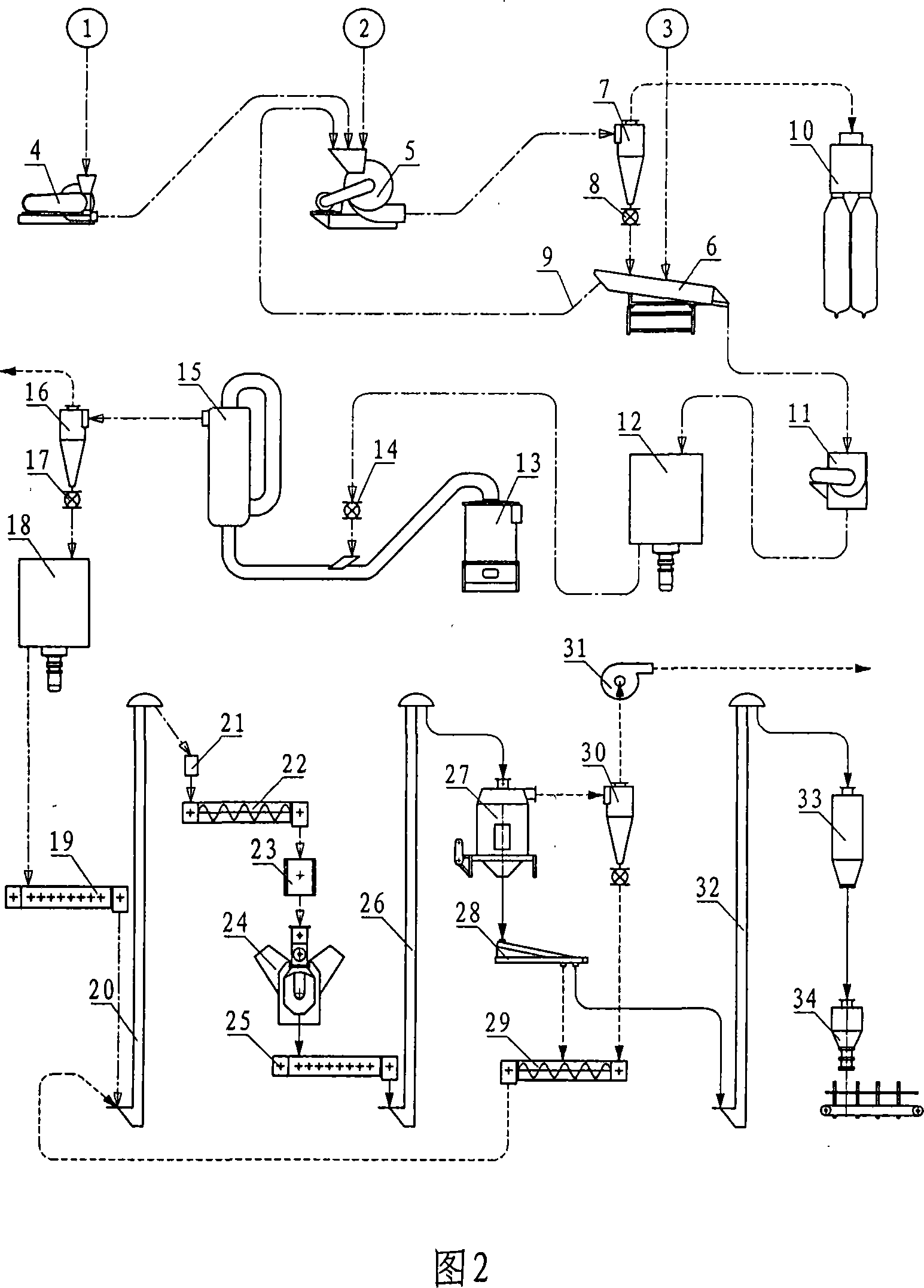

General wood substance grain processing technique and system

ActiveCN101195234AReduce total powerReduce energy consumptionDrying solid materials with heatDomestic articlesGeneral purposeWood machining

The invention discloses a process of general-purpose wood particles, which employs remains of tending and cutting of forest and wood-curing waste as materials which are processed into wood chippings and crashed into wood particles. Crashed wood particles are screened, and wood particles with qualified size are passed to next process and wood particles with unqualified size are crashed again. Heat produced in forming process is used to vaporize contained water to soften the powder materials, and then the powder materials are compressed into particles under the effect of extrusion force. The formed particles which have high temperature and include a small amount of crushed aggregates must be cooled and screened. Screened crushed aggregates returns to the particle processing and forming process and the finished products of particles enters the final package process. Compared with prior art, the energetic consumption of specific yield of the invention can be remarkably reduced, and gross investment can be greatly decreased. The invention discloses a process for producing wood particles, which is on the premise that products quality is met, changes the order of processing technique, reduces gross investment of device, decreases energetic consumption of specific yield, and has low manufacture cost and simple process.

Owner:吉林宏日新能源股份有限公司 +1

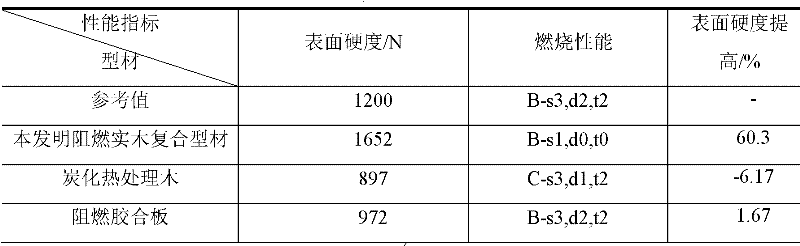

Flame-retardant solid wood composite section and manufacturing method thereof

InactiveCN102248559AOvercoming the problem of not being flame retardantGood dimensional stabilityVeneer manufactureWood veneer joiningSolid woodWeather resistance

The invention relates to a method for improving functionality of wood, in particular to a flame-retardant solid wood composite section improved through processes of wood heat treatment and flame retardant treatment and a manufacturing method thereof, belonging to the technical fields of wood functionality improvement and wood processing. The manufacturing method of the flame-retardant solid wood composite section comprises the steps of: (1) wood chip manufacturing; (2) first stacking and drying; (3) heat treatment improvement; (4) normal-pressure impregnation flame retardant treatment on wood chips; (5) second stacking and drying; and (6) gluing and fixing. By means of the method, the advantages of the wood subjected to the carbonization heat treatment and the flame retardant treatment are combined together and the respective disadvantages are overcome to ensure that the obtained solid wood composite section has the advantages of high dimensional stability, strong decay and weather resistance, good flame retardant effect because of a uniformly permeated flame retardant, simple production facility, low production cost and high wood outturn percentage. The obtained solid wood composite section is a good material applied to indoor structure beams, furniture and flame retardant wood doors.

Owner:东莞市华富立装饰建材有限公司

Enhanced polyurethane wood-imitation material and manufacturing method thereof

The invention relates to a manufacturing method of an enhanced polyurethane wood-imitation material. The material comprises components of nano cellulose, polyisocyanate, polyether polyol and additives. The components are mixed according to a certain proportion and synthesized into the enhanced polyurethane wood-imitation material through a one-step forming method. The invention adopts the nano cellulose prepared from wood machining residues to mix with polyisocyanate, polyether polyol and additives, and the mixture is synthesized into the enhanced polyurethane wood-imitation material through a one-step forming method; so the polyurethane wood-imitation material has high strength, good heat resistance, good molding ability and high strength-to-weight ratio, and is a novel engineering material. Compared with an existing polyurethane wood-imitation material, the polyurethane wood-imitation material of the invention has advantages of greatly enhanced mechanical properties and heat resistance, good size stability, high hardness, good aging resistance, effectively expanded application range, simple manufacturing process, easiness for application and low comprehensive cost.

Owner:GUANGDONG YIHUA TIMBER IND +1

Wood cutting device for furniture manufacturing

InactiveCN108789658AEasy to operateImprove working environmentProfiling/shaping machinesBark-zones/chip/dust/waste removalWood machiningWorking environment

The invention provides a wood cutting device for furniture manufacturing. The device comprises a base plate; support plates are fixedly mounted at the two ends of the base plate; a cover plate is fixedly mounted on the upper sides of the support plates; a motor box is fixedly mounted on the left side of the cover plate; a first servo motor is arranged in the motor box; two bearing bases are arranged on the right side of the first servo motor; a lead screw is arranged between the two bearing bases, and is slidingly connected with a slide block; a first electric extension rod is fixedly mountedat the top of the slide block; a second servo motor is fixedly mounted at the end, far from the slide block, of the first electric extension rod; and the invention relates to the field of wood machining. The wood cutting device for furniture manufacturing is provided with a wood chip collecting box and a wood chip storage box, so that wood chips and dust are sucked into the wood chip collecting box through an electric blower and fall into the wood chip storage box through a discharge pipe, the wood chips are convenient to collect, both time and manpower are saved, and the improvement of the working environment is facilitated.

Owner:刘闪闪

Wood working process

InactiveCN101913181AImprove carrying capacityHigh densityWood impregnation detailsHigh densityMass ratio

The invention provides a wood working process, which comprises the following steps of: the preparation of first mixed solution; the preparation of second mixed solution; square stock impregnation, namely, impregnating a square stock into the first mixed solution to make the square stock absorb the first mixed solution until reaching a completely saturated state, and placing the square stock impregnated in the first mixed solution into the second mixed solution for impregnation to make spaces among wood cells of the square stock absorb the mixed solution until the mass ratio of furfural to the wood is 0.3-0.5:1; hot-pressing, namely, performing hot-pressing on the impregnated square stock; cutting, namely, cutting the square stock into required wood boards; and sanding and notching, namely, sanding and notching the wood boards. The wood boards obtained by the wood working process provided by the invention have the characteristics of high load-bearing properties, high density, high durability, strong bending strength, low water absorption and low expansion ratio.

Owner:尹侃

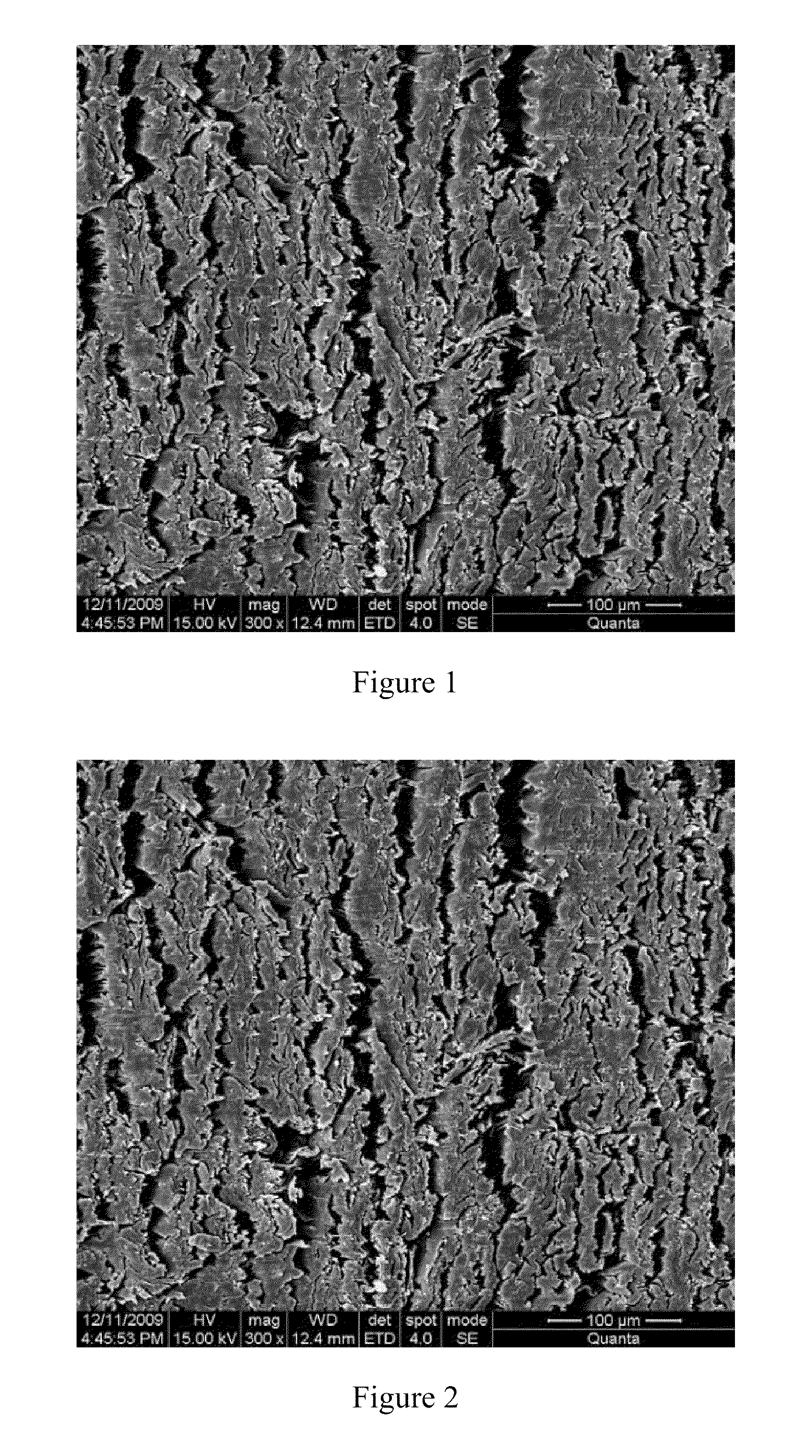

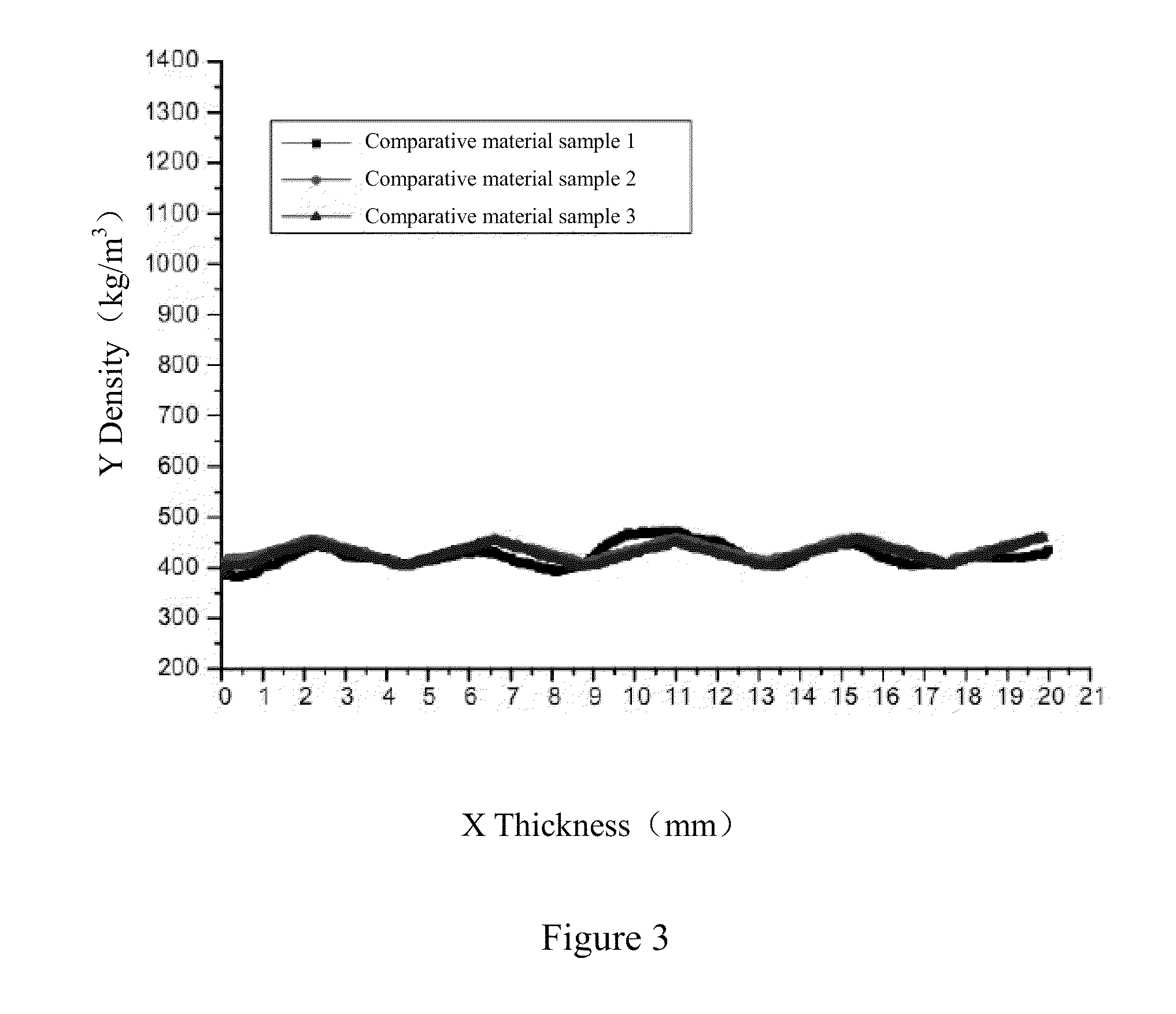

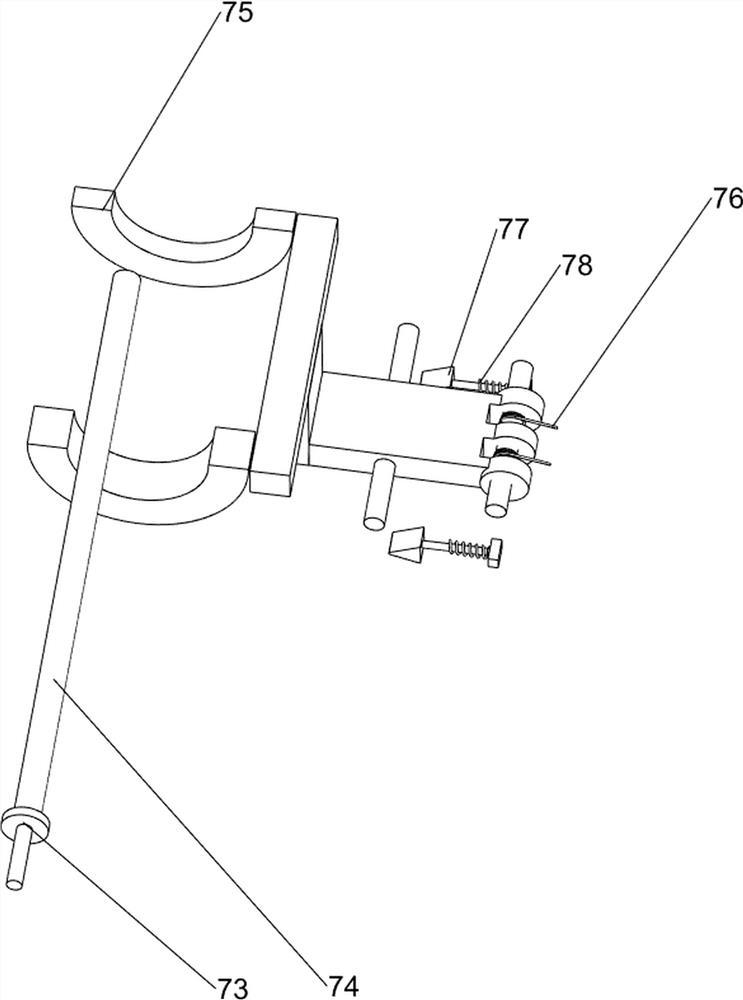

Integral reinforced solid wood section bar and manufacturing method thereof

ActiveCN103481348ASmall volume lossHigh strengthWood working apparatusDomestic articlesSolid woodThermal insulation

The invention belongs to the technical field of function improving and machining of wood and particularly discloses an integral reinforced solid wood section bar and a manufacturing method thereof. The method comprises the steps of under the condition of lower water content (1-3%), adopting a single heating softening molding technology to perform low-compression rate integral compressing treatment on the wood to obtain an integral staypak with the section being uniform in density. According to the method, bursting and bubbling phenomena generated by overhigh steam pressure in the wood can be effectively reduced, the thermal insulation time can be greatly shortened, and the work efficiency is improved. The integral compression wood section bar generated by the method is good in size stability, environment-friendly and healthy, and can be used for manufacturing solid wood floors and solid wood furniture and as indoor decoration materials.

Owner:江门健威家具装饰有限公司

Manufacturing method for gum wood finger-joined floors

ActiveCN103753661AReduce wasteSolve roughnessWood veneer joiningWood dampingAdhesive glueWood machining

The invention belongs to the technical field of wood processing, and particularly discloses a manufacturing method for gum wood finger-joined floors. The manufacturing method comprises the following steps of drying, selecting, improvement of machining properties, humidifying, connection and combination, treatment of grooves and tongues, sanding, painting and the like. By using the manufacturing method for the gum wood finger-joined floors, the problems that in production of fast-growing gum wood finger-joined floors, sanding cost is high, loss of materials is high, the using amount of glue is high, tree laces crack, the moisture content of a portion between each two gum wood finger-joint floors is not uniform, finger joining is difficult, and the like are solved. The manufacturing method for the gum wood finger-joined floors has the advantages of low production cost, high product quality and the like.

Owner:丰胜(广州)建材有限公司

Double-sided polishing machine for wood used for manufacturing furniture

InactiveCN108907936AImprove grinding efficiencyWon't flyGrinding machine componentsPlane surface grinding machinesWood machiningFurniture manufacturing

The invention belongs to the field of a wood machining, and particularly relates to a double-sided polishing machine for a wood used for manufacturing furniture. The invention aims to solve a technical problem that polishing efficiency can be improved and a large amount of dust generated in the polishing process can be avoided by providing the double-sided polishing machine for the wood used for manufacturing the furniture and in order to solve the technical problem, the invention provides the double-sided polishing machine for the wood used for manufacturing the furniture. The double-sided polishing machine comprises a mounting plate, a bottom plate, a motor, a first belt wheel, a first rotating shaft, a first bearing seat, a first connecting plate, the second connecting plate, the secondbearing seat, the second rotating shaft, the second belt wheel, a first flat belt, a supporting seat and a guide roller and the like. The mounting plate is fixedly connected with one side part of thebottom plate, a first dustproof frame is fixedly connected with the mounting plate through the second connecting plate, and the second dustproof frame is fixedly connected with the mounting plate through the first connecting plate. According to the double-sided polishing machine, the wood polishing efficiency is improved, and an effect that not too much dust is generated in the polishing processis ensured.

Owner:佛山市新铭思家具有限公司

Application of waterproof type emulsified olefin in use for production of fiberboard

A method to apply waterproof emulsified paraffin wax in fibreboard production includes emulsifying paraffin wax in water with emulsification additive to let paraffin wax solid content up to 40-50 % of being used as waterproofing agent, applying it in fibreboard production and drying all hydrophilic contents in emulsification agent off at drying process of 100-180 deg.C for achieving purpose of waterproof for fibre.

Owner:曾宪平

Surface spraying equipment for wood processing

InactiveCN107824359ALow costAvoid artificial spraying unevennessSpray boothsMotor driveWood machining

The invention discloses a surface spraying equipment for wood processing, which comprises a device body, the top of the device body is provided with a feed port, the middle part of the left side of the device body is opened with an opening, and the top of the feed port is Hinged with cap through fire hydrant. The surface spraying equipment for wood processing can spray the paint inside the paint box through the nozzle through the installed paint box under the action of the water pump, and under the action of the first motor, cooperate with the slider to drive the nozzle to move up and down , spraying the wood evenly, avoiding the unevenness of artificial spraying, saving the extra spraying paint and saving the cost, through the set rotating shaft, under the action of the second motor, the clamping device can be driven to rotate, effectively Rotate the wood at 360 degrees and spray it comprehensively to ensure that the wood is sprayed more evenly and the wood after spraying is more beautiful, which is convenient for later sales.

Owner:新昌县城关升华机械厂

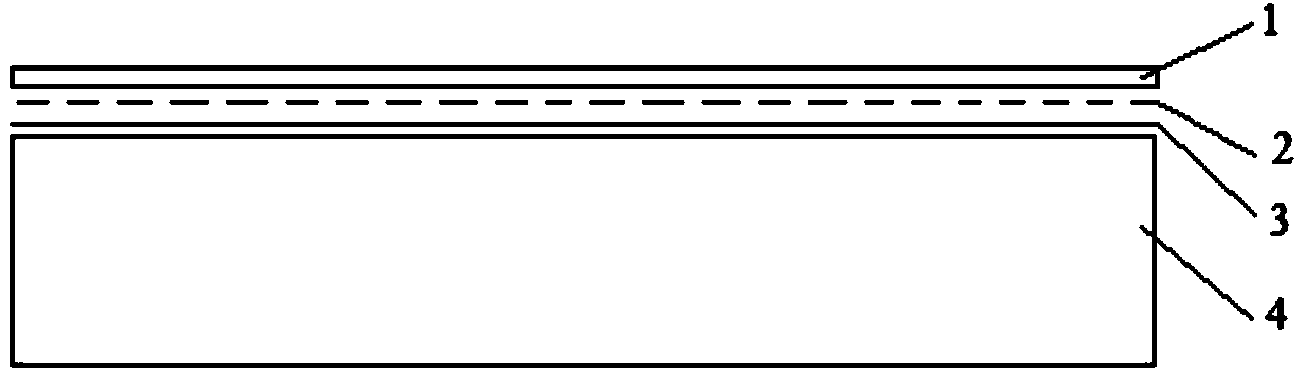

Wood-plastic composite of wood decorative sheet attaching veneer and preparation method thereof

ActiveCN103831885AUniform and beautiful texturePleasant colorLaminationWood working apparatusSurface layerAdhesive

The invention relates to a wood-plastic composite of wood decorative sheet attaching veneer and a preparation method thereof and aims at solving the problems that an existing wood-plastic composite lacks the natural texture of wood, and it is hard to enable a wood decorative sheet to be adhered to a wood-plastic composite sheet through traditional wood adhesive. The wood-plastic composite is mainly made of a wood-plastic composite sheet, non-woven cloth, a wood decorative sheet and wood adhesive or is made of the wood-plastic composite sheet, the non-woven cloth and the wood decorative sheet. According to the two technical schemes of the wood-plastic composite, the special structure of the non-woven cloth is utilized, wood adhesive is used, and the wood decorative sheet and the wood-plastic composite sheet are finalized in design through a hot-press means, so that preparation is finished. In the other technical scheme, on the condition that no wood adhesive is used, the consistency of the non-woven and the surface of the wood-plastic composite sheet and the penetrating function of the non-woven cloth on surface layer materials at melting time are utilized, and the wood decorative sheet and the wood-plastic composite sheet are finalized in design through hot press and cooling. The wood-plastic composite of the wood decorative sheet attaching veneer and the preparation method are applied in the wood processing field.

Owner:NORTHEAST FORESTRY UNIVERSITY

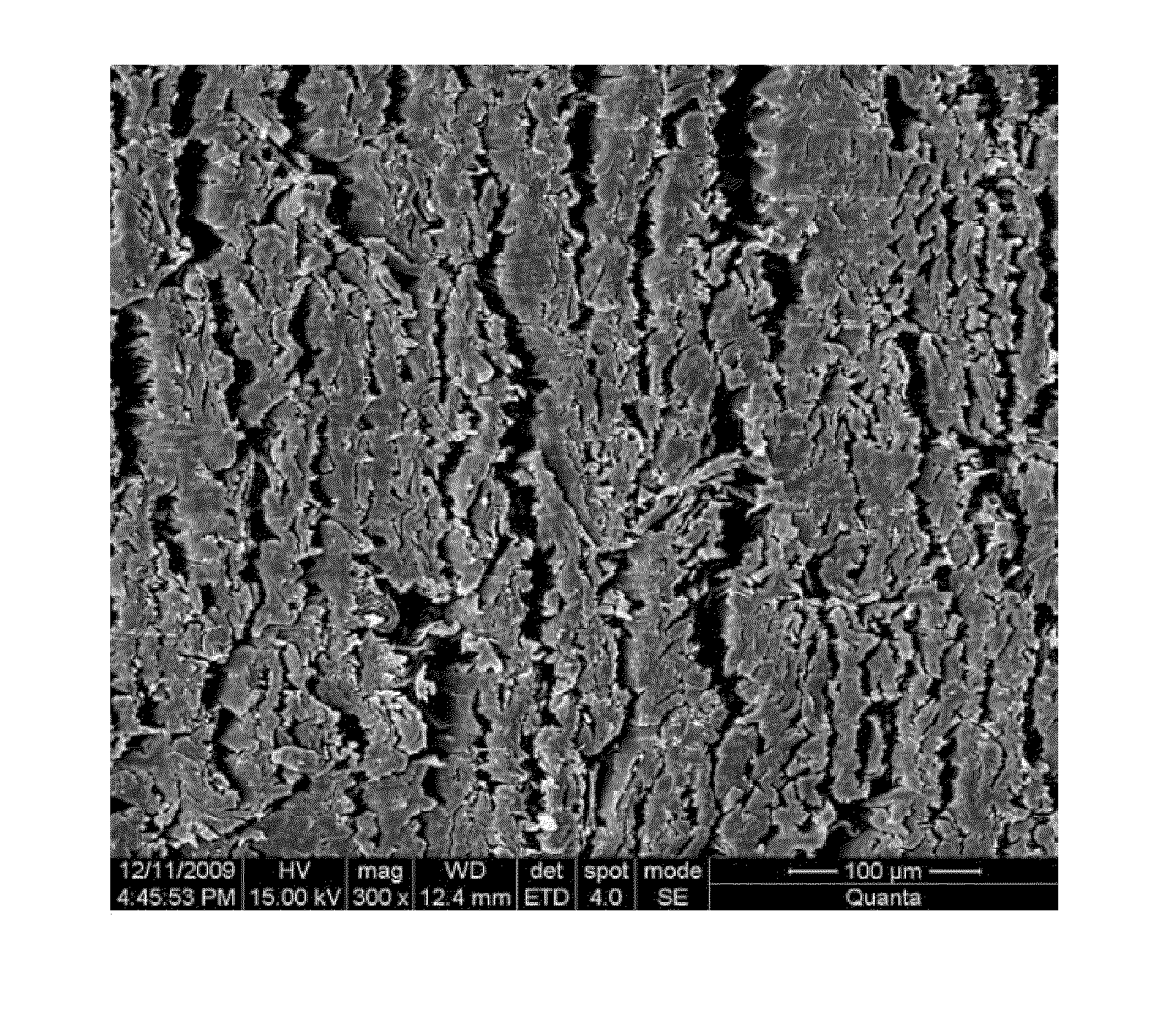

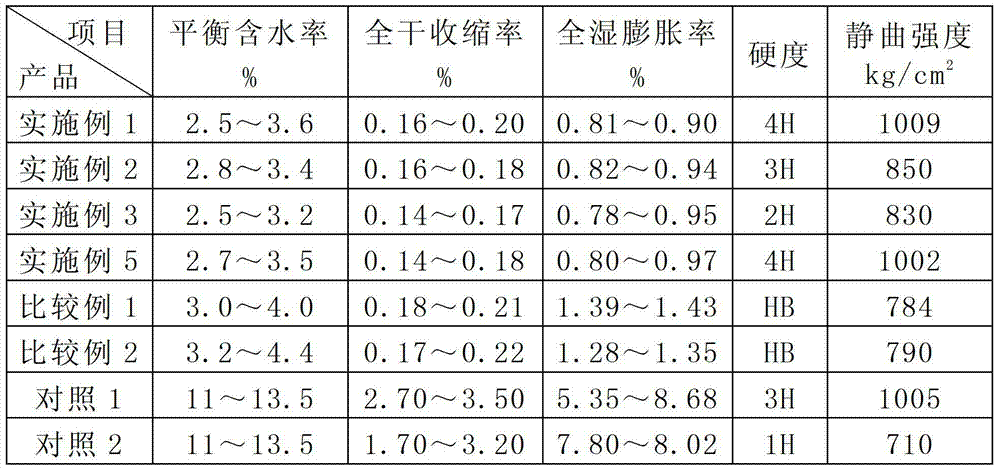

Nanometer inorganic carbonized wood preparation method, nanometer inorganic carbonized wood products and application of nanometer inorganic carbonized wood

ActiveCN103240782ASolve the strength problemSolve the hardnessWood charring/burningFiber saturation pointWood machining

The invention relates to a nanometer inorganic carbonized wood preparation method, nanometer inorganic carbonized wood products and application of nanometer inorganic carbonized wood, belongs to the technical field of wood processing, and aims to solve technical problems of low strength and hardness of the existing carbonized wood. The nanometer inorganic carbonized wood preparation method includes performing deep carbonizing treatment on absolute dry wood panels at the temperature of 195 DEG C to 220 DEG C, and cooling to perform humidifying and heat insulating treatment to enable moisture content of the carbonized wood to reach a fiber saturation point; and then placing the humid carbonized wood into inorganic nanometer additive to be inorganically nanocrystallized so as to acquire the nanometer inorganic carbonized wood. The nanometer inorganic carbonized wood preparation method has the advantages that the method is simple in technique conditions and easy to operate, the strength and hardness of the acquired products are high, the carbonized wood performance is acquired, and adsorbability, fire resistance, non corrosibility and dewatering performance to harmful gas are better and air shrinkage bulking factor is low. The nanometer inorganic carbonized wood can be further used for wood components like floors.

Owner:ZHEJIANG GUOZHEN FURNITURE

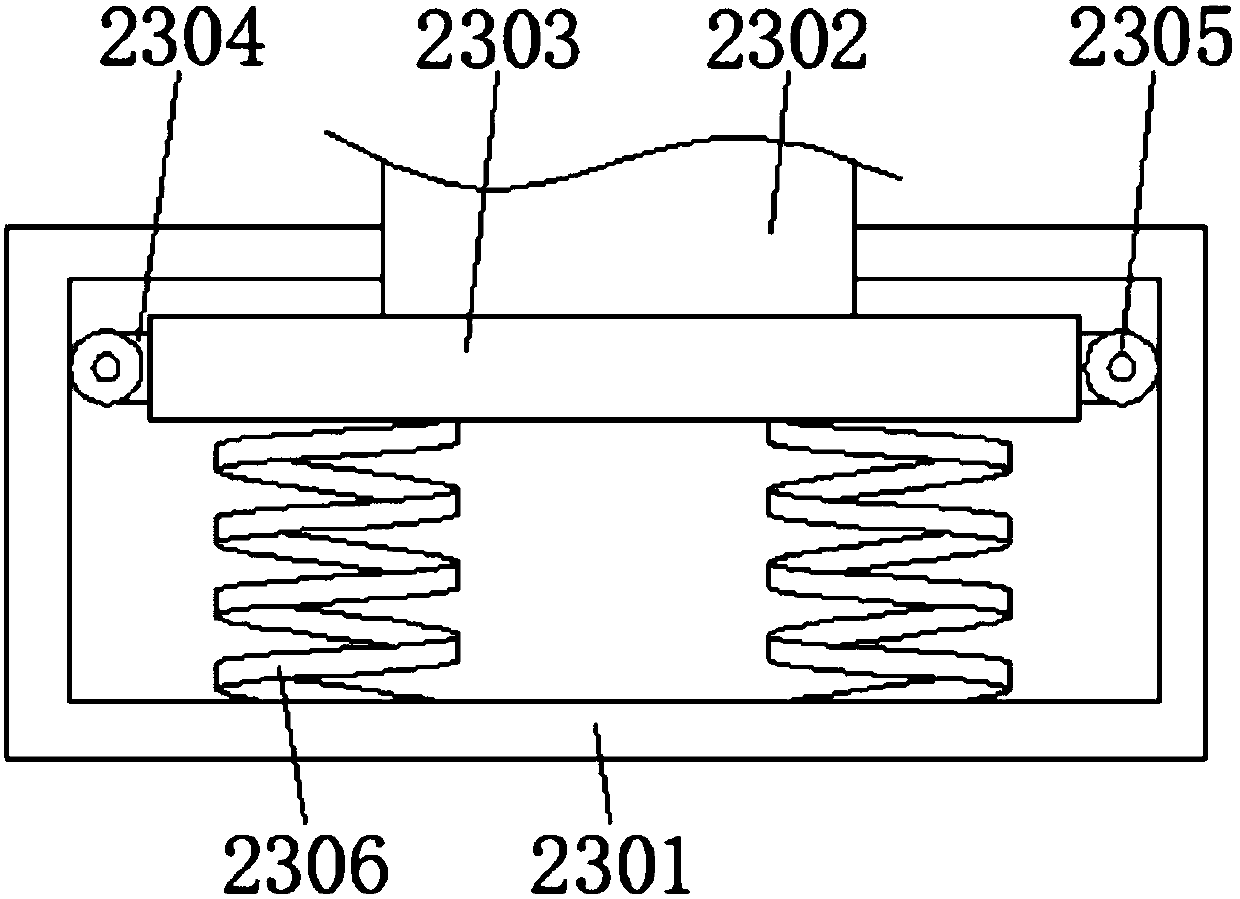

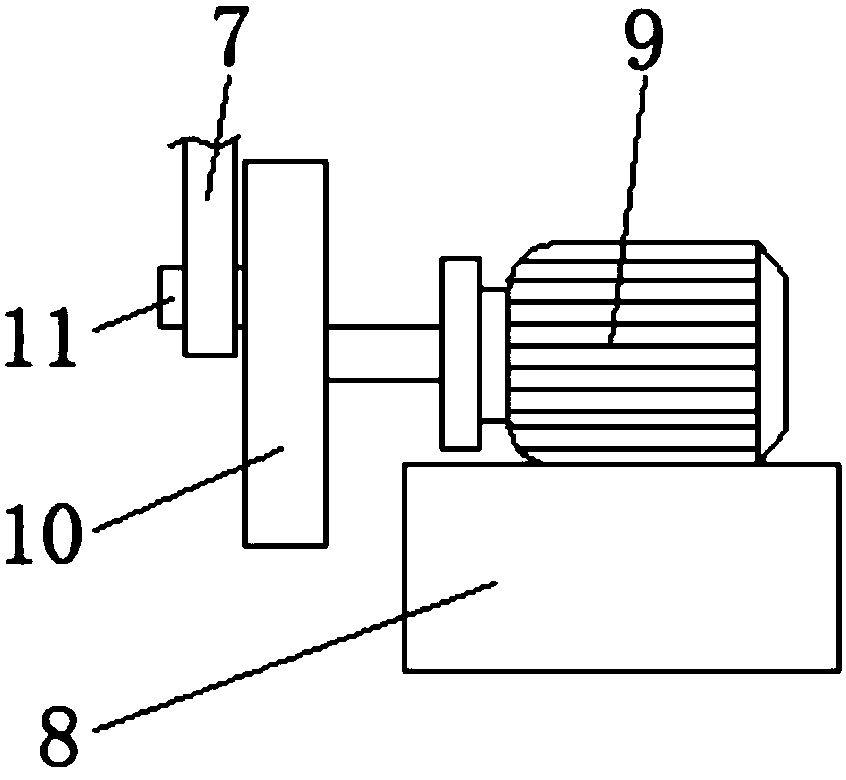

Two-degree-of-freedom oscillating screen

PendingCN107537767ALarge amount of processingImprove screening efficiencySievingScreeningChemical industryEnvironmental resistance

The invention discloses a two-degree-of-freedom oscillating screen. The two-degree-of-freedom oscillating screen comprises a base, front supporting rods, rear supporting rods, an oscillating driving device, a vertical shock excitation device, a screen frame and a screen mesh. The front end and the rear end of the screen frame are connected with the base through the front supporting rods and the rear supporting rods. The two-degree-of-freedom oscillating screen can generate shock excitation of two degrees of freedom. The oscillating driving device located in the middle portion of the base provides power for rotating and oscillating of the screen frame. The vertical shock excitation device mounted at the bottom of the screen frame provides power for vertical reciprocating vibration of the screen frame and the screen mesh. Materials on the screen surface can do front-back, left-right and vertical motion to realize screen passing. Under the condition of not changing the occupied area and the screen body structure, the processing capacity can be substantially increased, the production efficiency can be greatly improved, and the production cost can be reduced. The two-degree-of-freedom oscillating screen has the advantages of being simple in structure, high in overall machine reliability, good in comprehensive performance, stable in motion, convenient to maintain and the like and isapplicable to the fields of wood processing, coal, metallurgy, chemical engineering, food and environmental protection.

Owner:ANHUI UNIV OF SCI & TECH

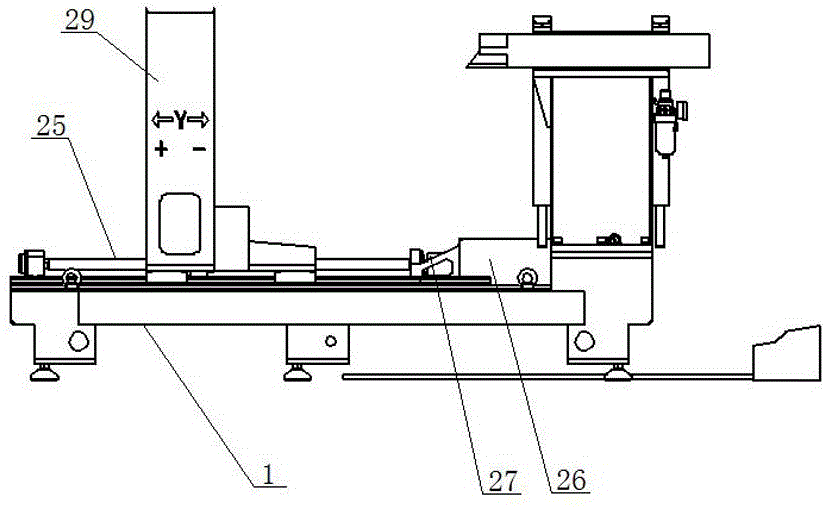

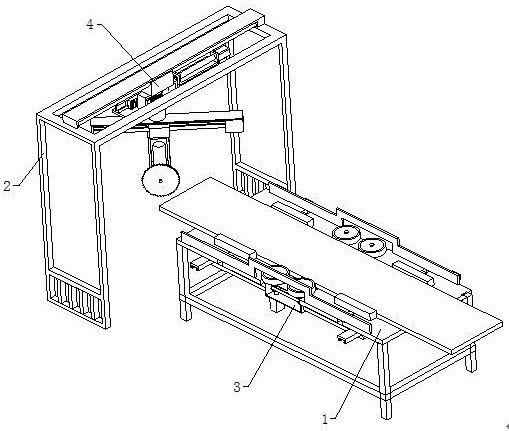

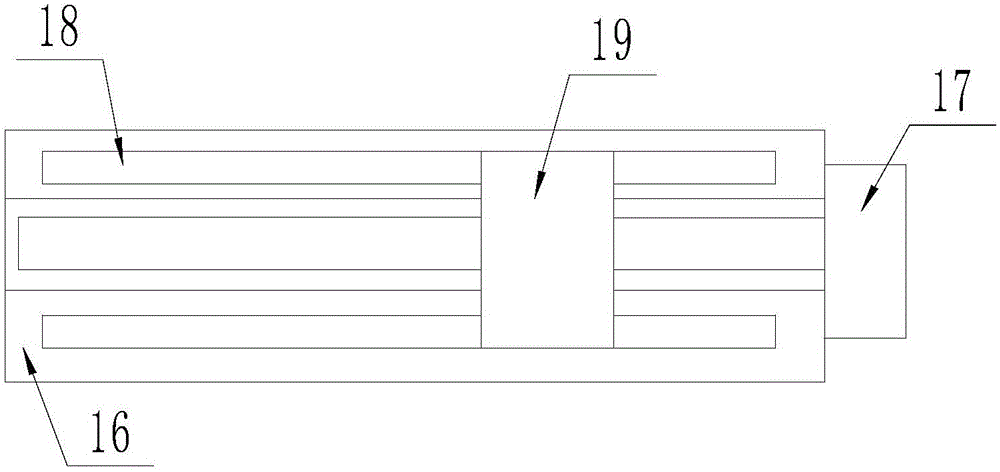

Wooden door scribing and cutting integrated machine

ActiveCN106671210AReduce space areaImprove space utilizationProfiling/shaping machinesOther workshop equipmentWood machiningEngineering

The invention belongs to the technical field of wood machining equipment, and particularly discloses a wooden door scribing and cutting integrated machine. The wooden door scribing and cutting integrated machine comprises a supporting frame, a workbench and a movable bracket; the workbench is provided with a guide rail allowing the movable bracket to slide longitudinally; the upper end of the movable bracket is provided with a guide column; a movable rod is arranged on the guide column; the lower end of the movable rod is provided with an air cylinder; a servo motor is connected to a piston rod of the air cylinder and provided with a scribing and cutting device; the scribing and cutting device comprises a scribing pen, a rotary shaft, a motor body and a cutting knife located in the vertical direction same as the direction of the scribing pen; the cutting knife is fixed to the rotary shaft; the rotary shaft is provided with a shell covering the lower end of the cutting knife; the scribing pen is fixed to the shell; and an output shaft of the servo motor is fixed to the joint of the shell and the scribing pen. According to the wooden door scribing and cutting integrated machine, only one set of equipment is used, the functions of scribing and cutting are integrated into a whole, the occupied plant space area is small, a wooden door is cut after scribing is completed, and the convenient and rapid effects are achieved.

Owner:重庆汇升套装门有限公司

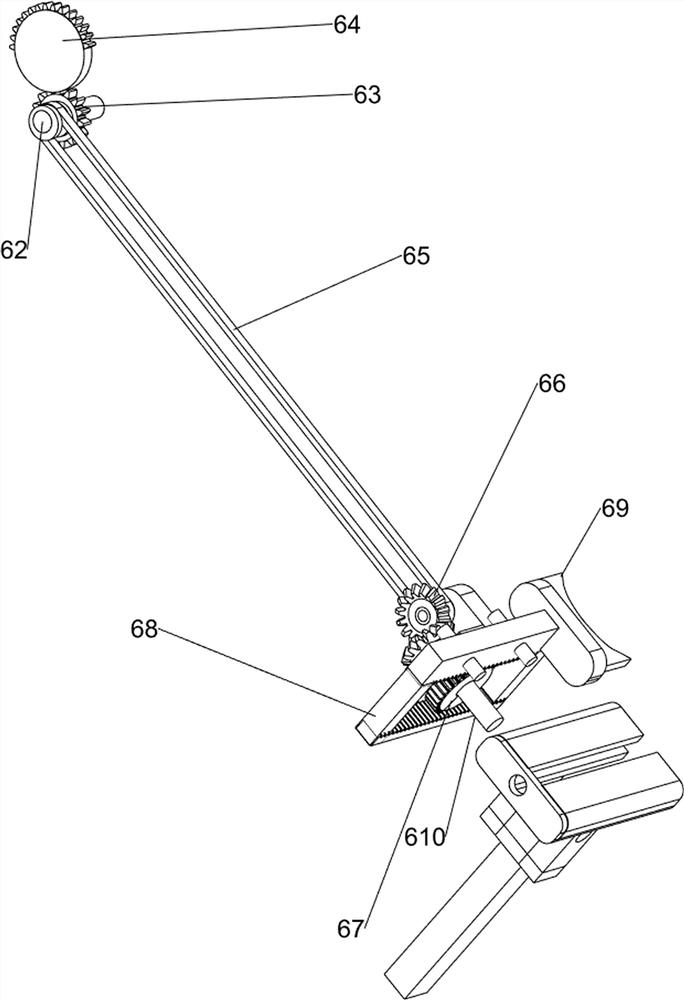

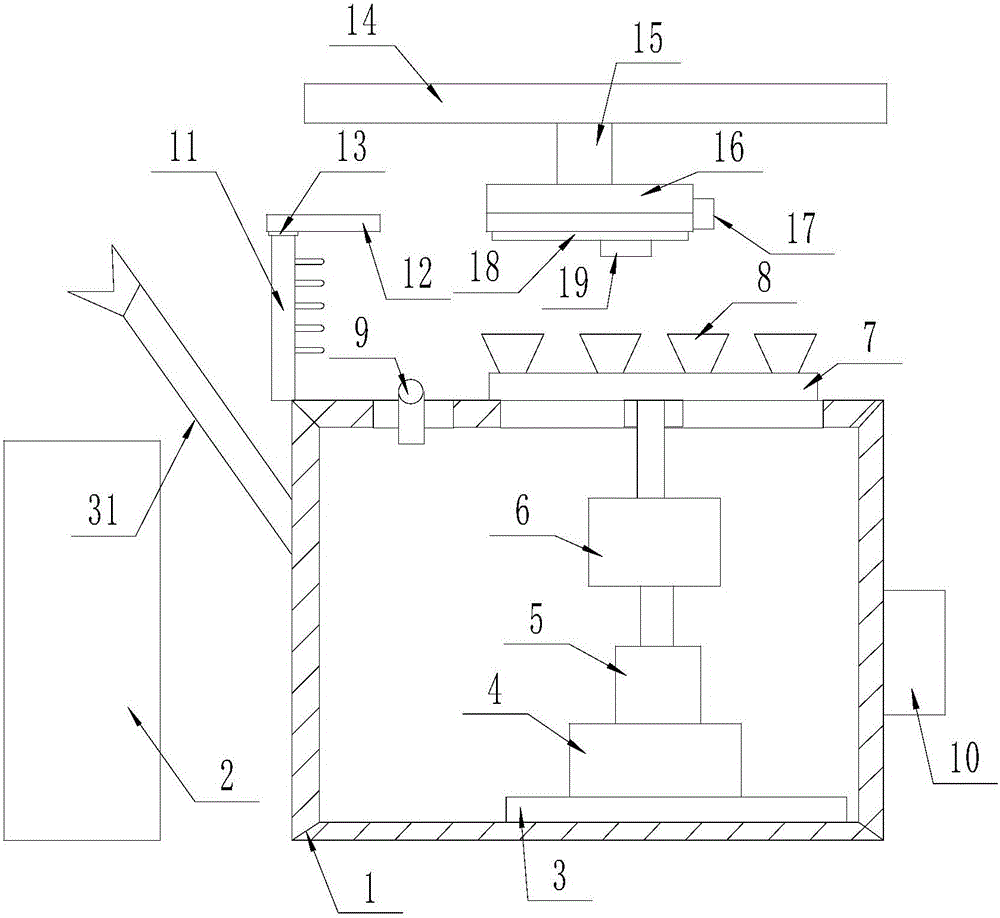

Long-span position adjusting wood processing device

InactiveCN105856341ALarge adjustment rangeShorten the timeMulti-purpose machinesWood machiningEngineering

The invention discloses a long-span position adjusting wood processing device. The device comprises a worktable, wherein the inner part of the worktable is a cavity structure; a conveyor belt is arranged on one side of the worktable; a No.1 mechanical arm is arranged on the side surface, close to the conveyor belt, of the worktable; an opening communicating with the inner cavity structure of the worktable is formed at one end, close to the conveyor belt, of the worktable; a cross opening communicating with the inner cavity structure of the worktable is formed on the upper surface of the worktable; a control box is arranged on the side surface of the worktable; the control box is electrically connected to the conveyor belt, an electric trolley, a No.1 air cylinder, a No.1 rotating motor, a plurality of vacuum sucking discs, a clamping mechanism, a wood position fine adjustment unit, a wood drilling unit and a wood plug implanting perpendicularity detection unit. The device disclosed by the invention has the beneficial effects that the device is simple in structure and high in practicality.

Owner:黄斌

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com