Patents

Literature

71results about How to "Won't fly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

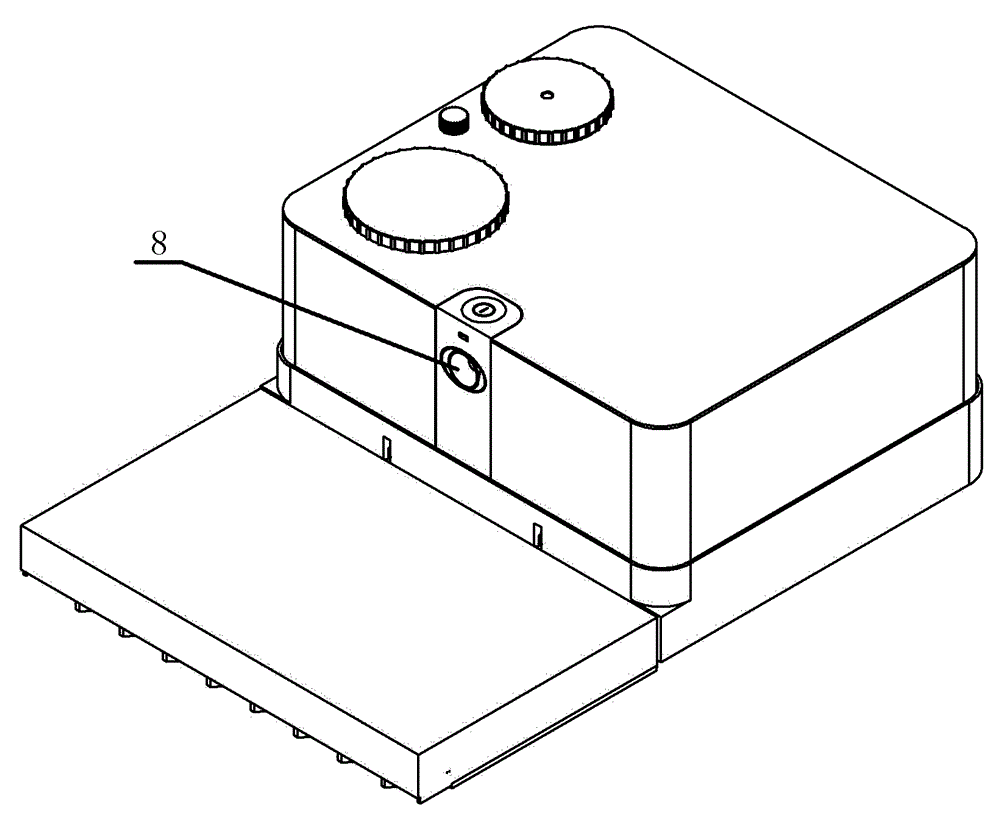

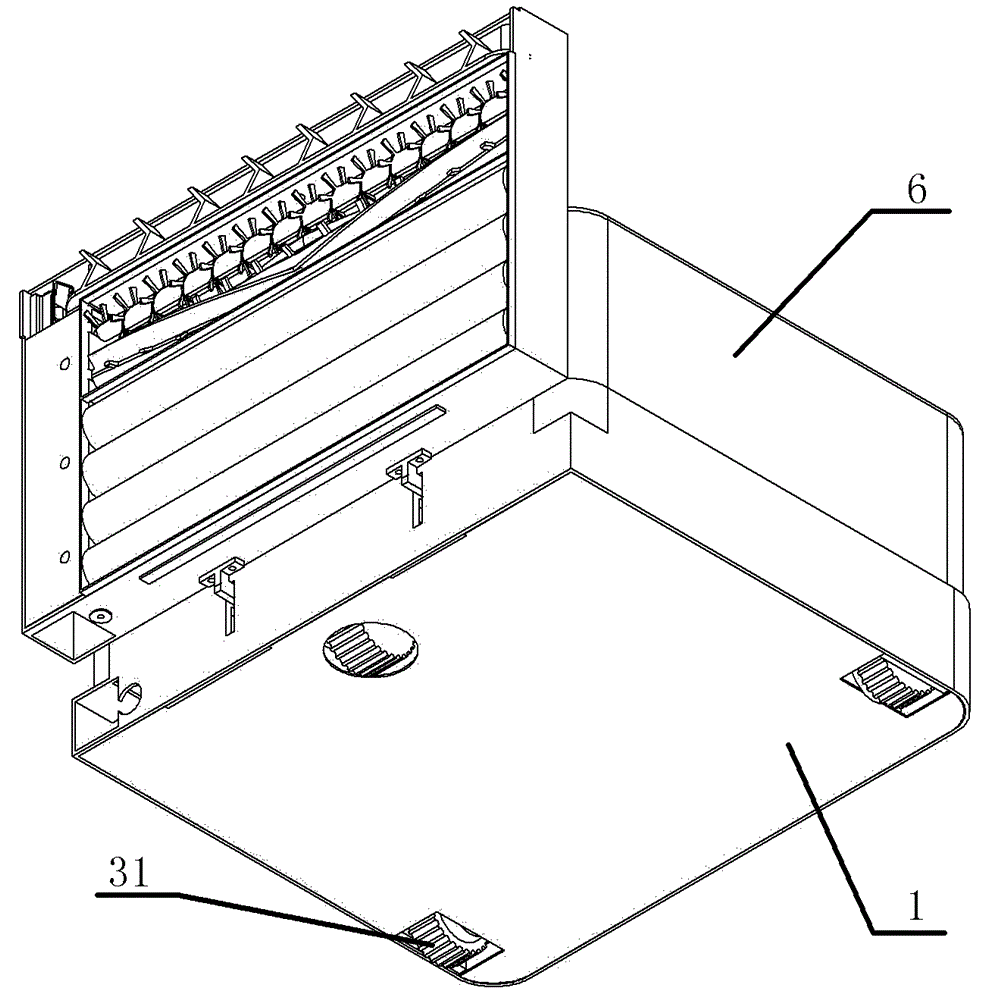

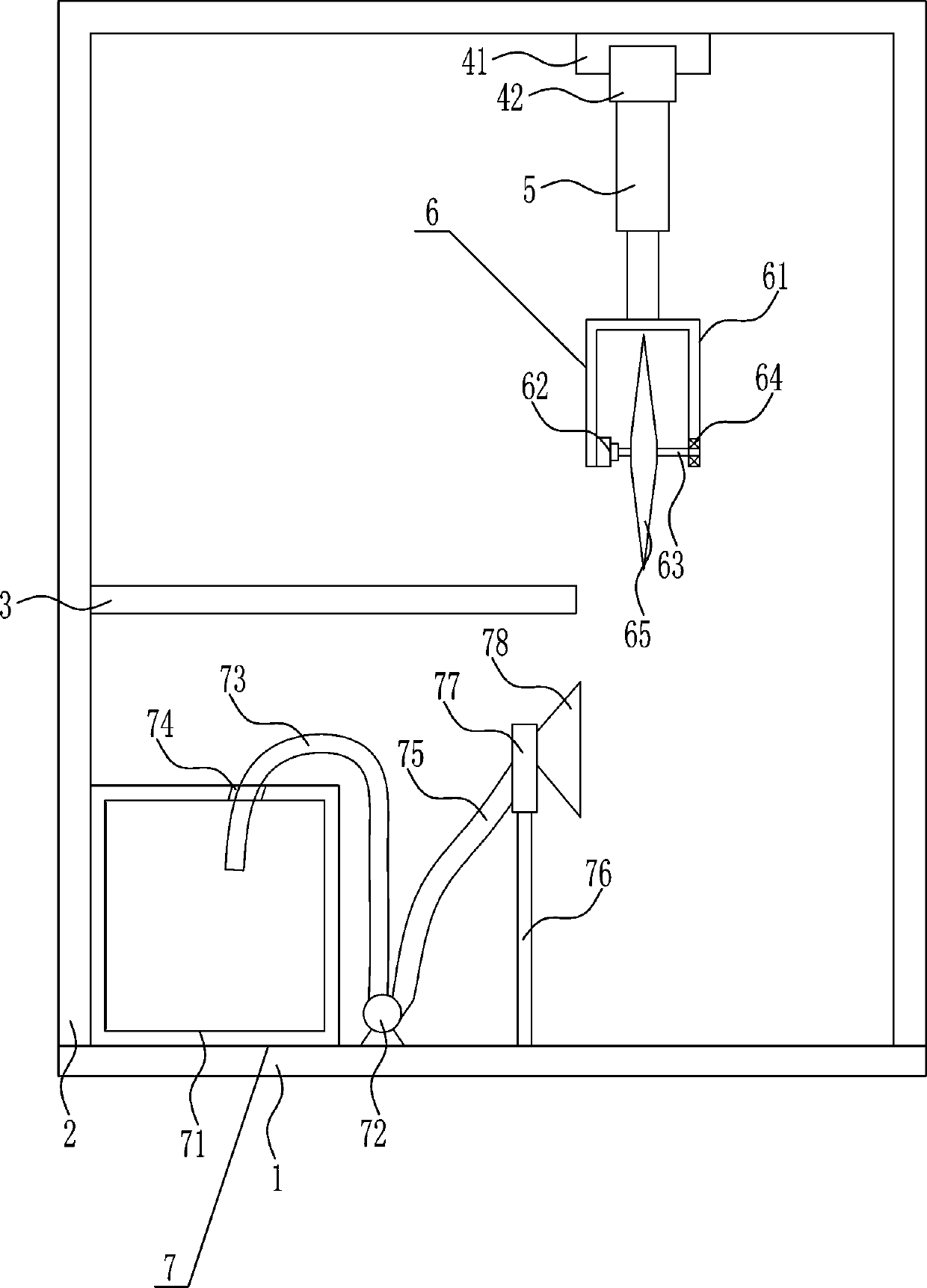

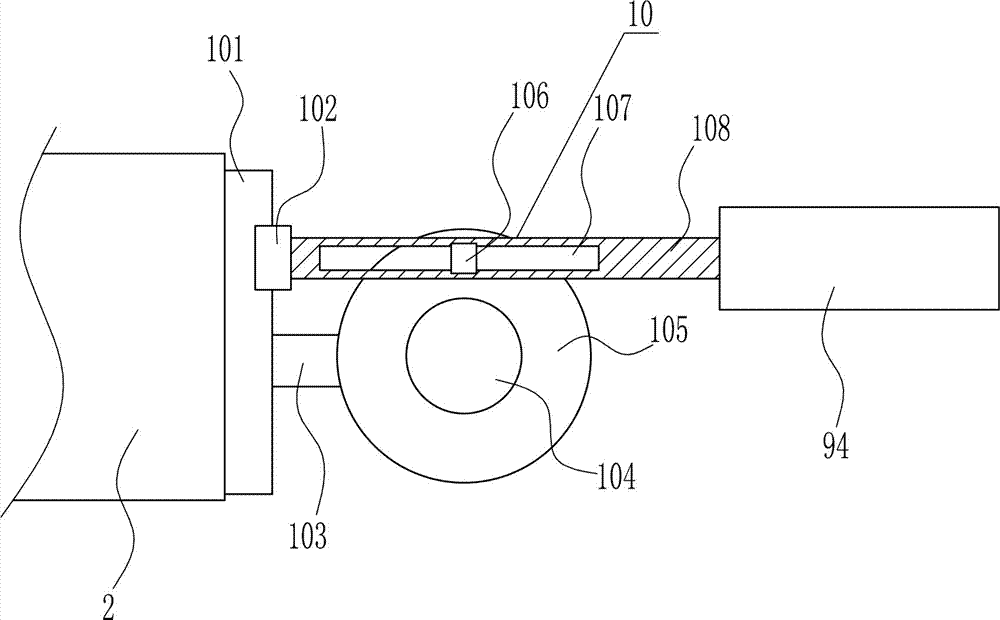

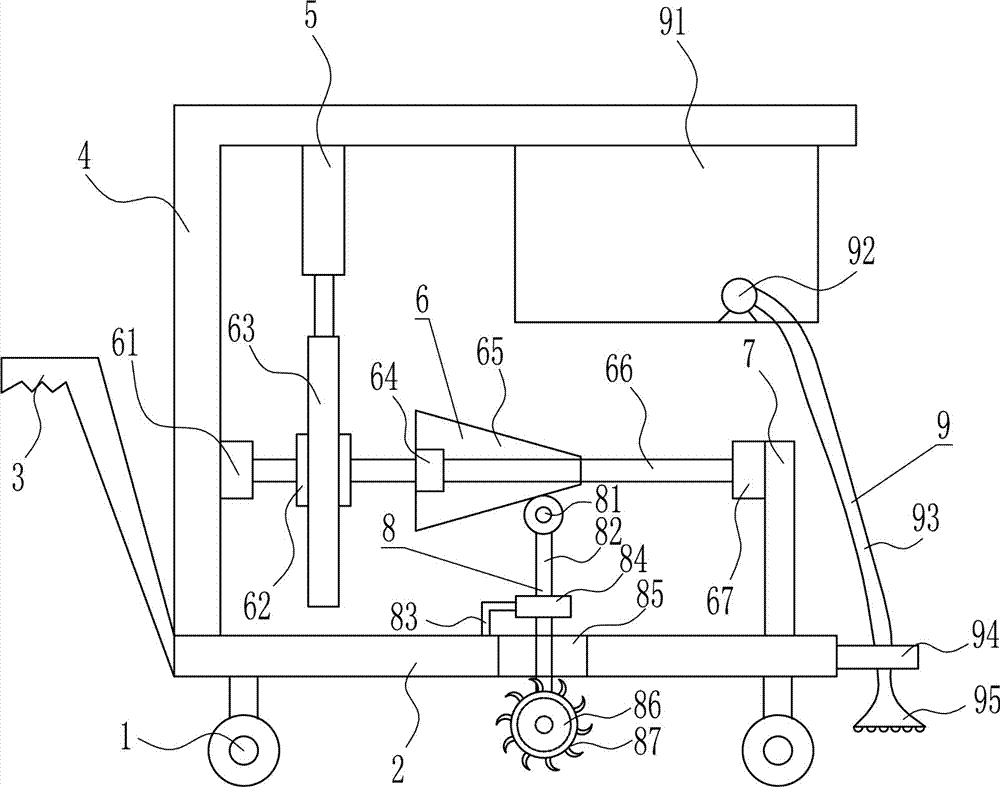

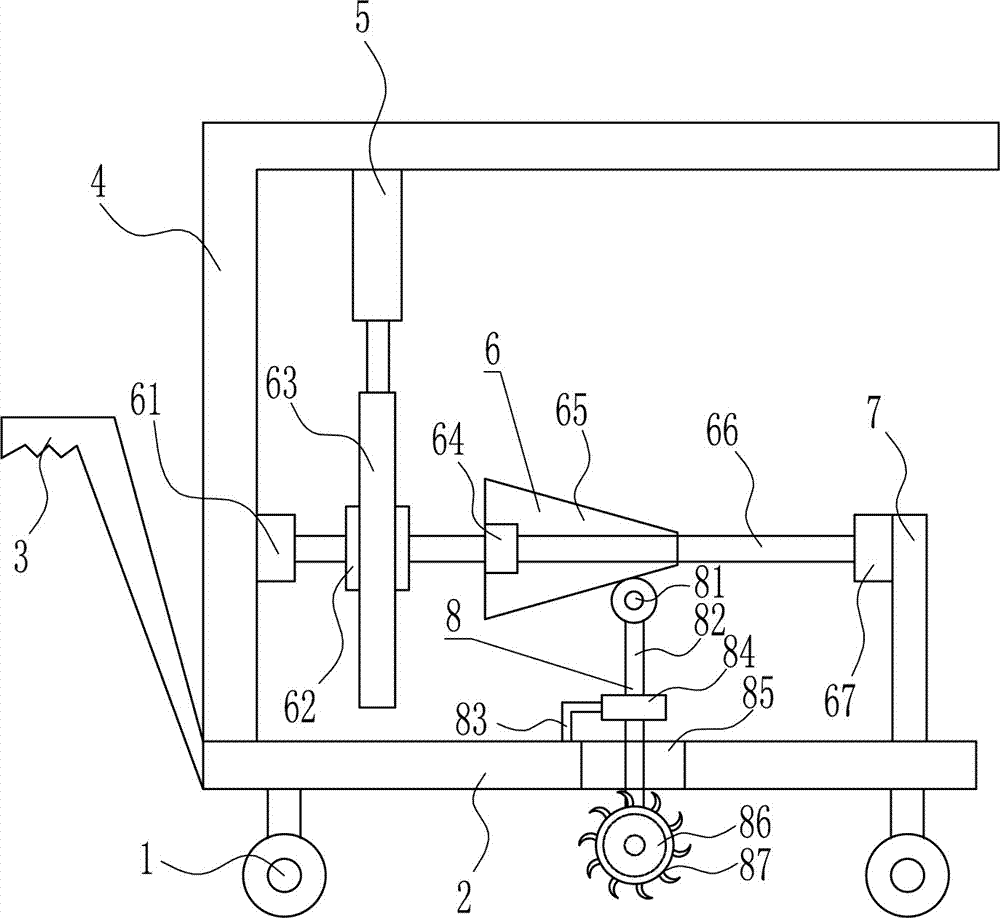

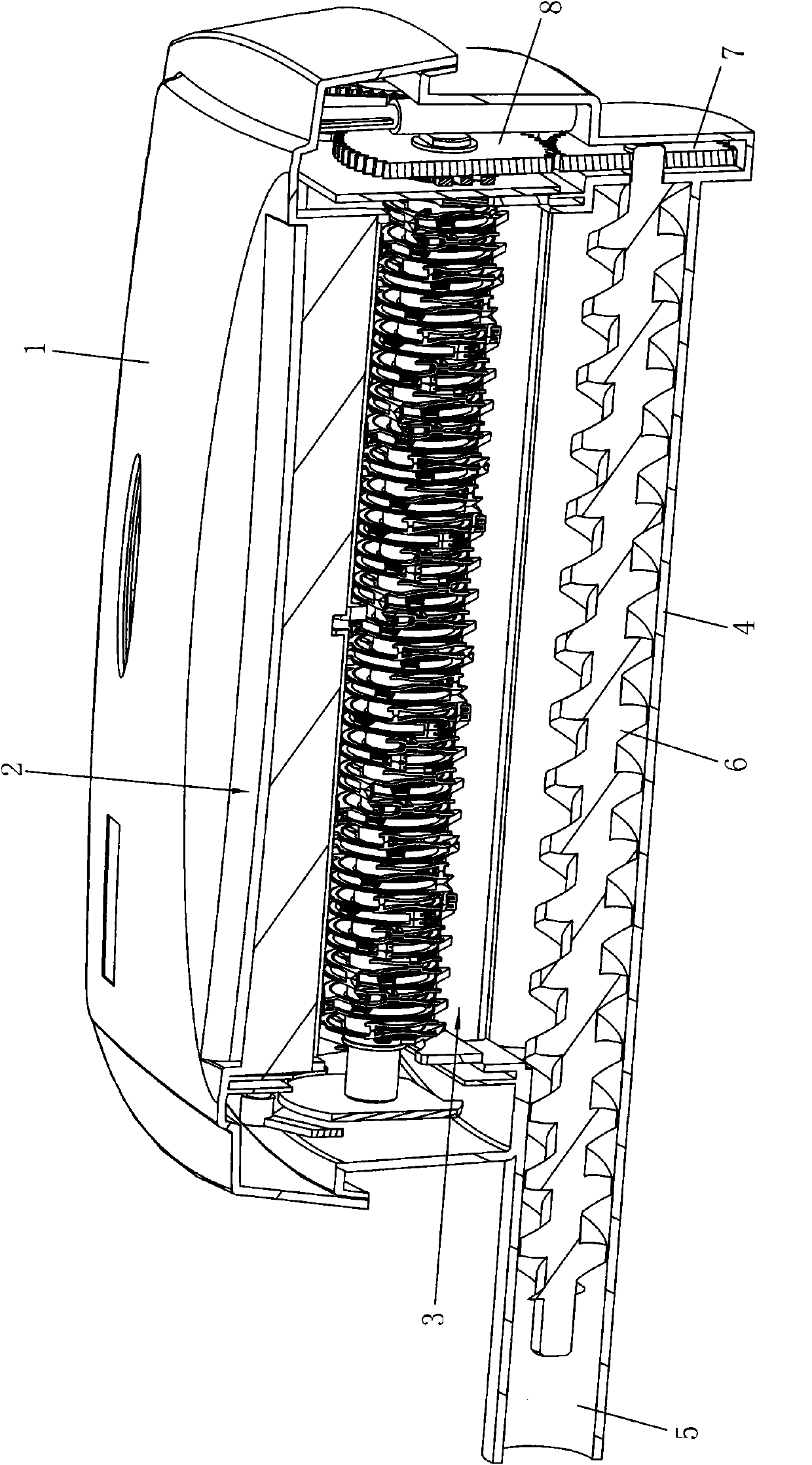

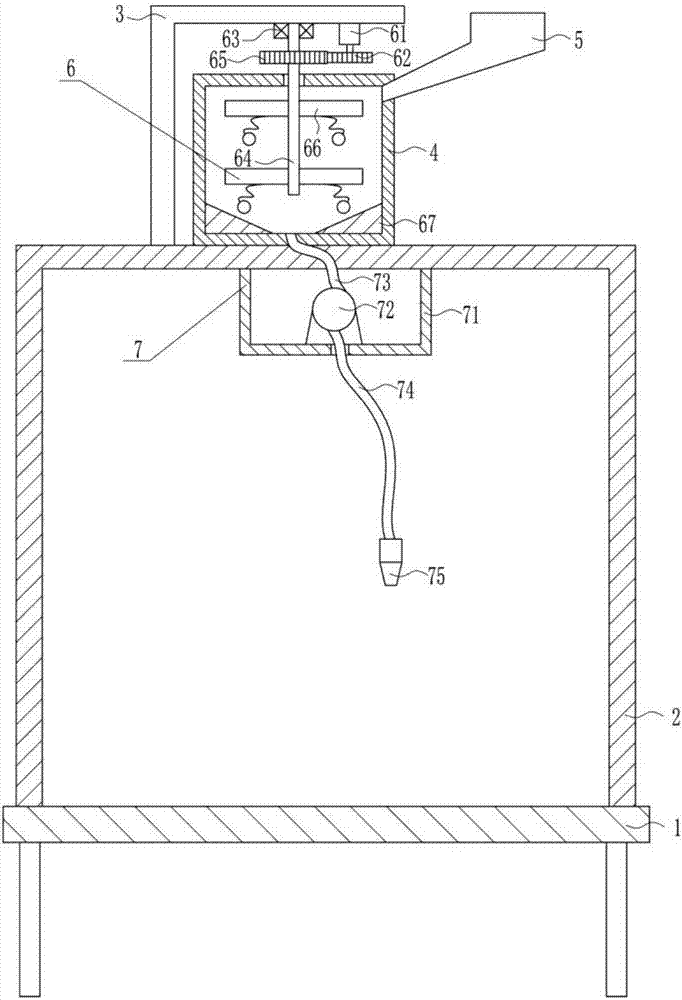

Intelligent cleaning, dust collection and scrubbing integrated machine

ActiveCN105986553AWon't flyReduce use costRoad cleaningFloor-scrubbing machinesMotor driveFiltration

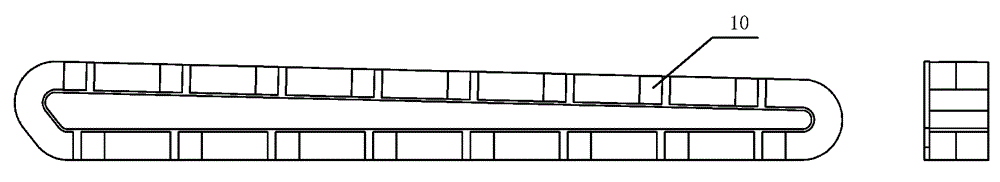

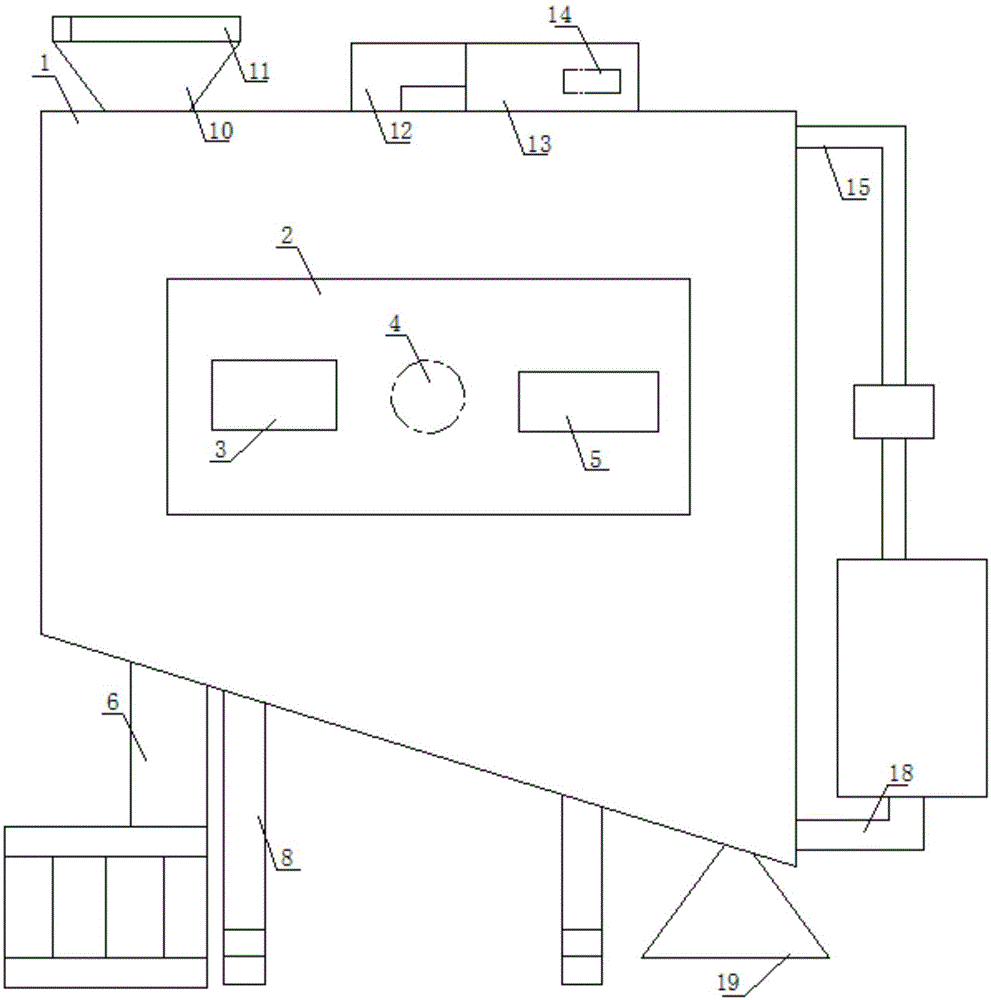

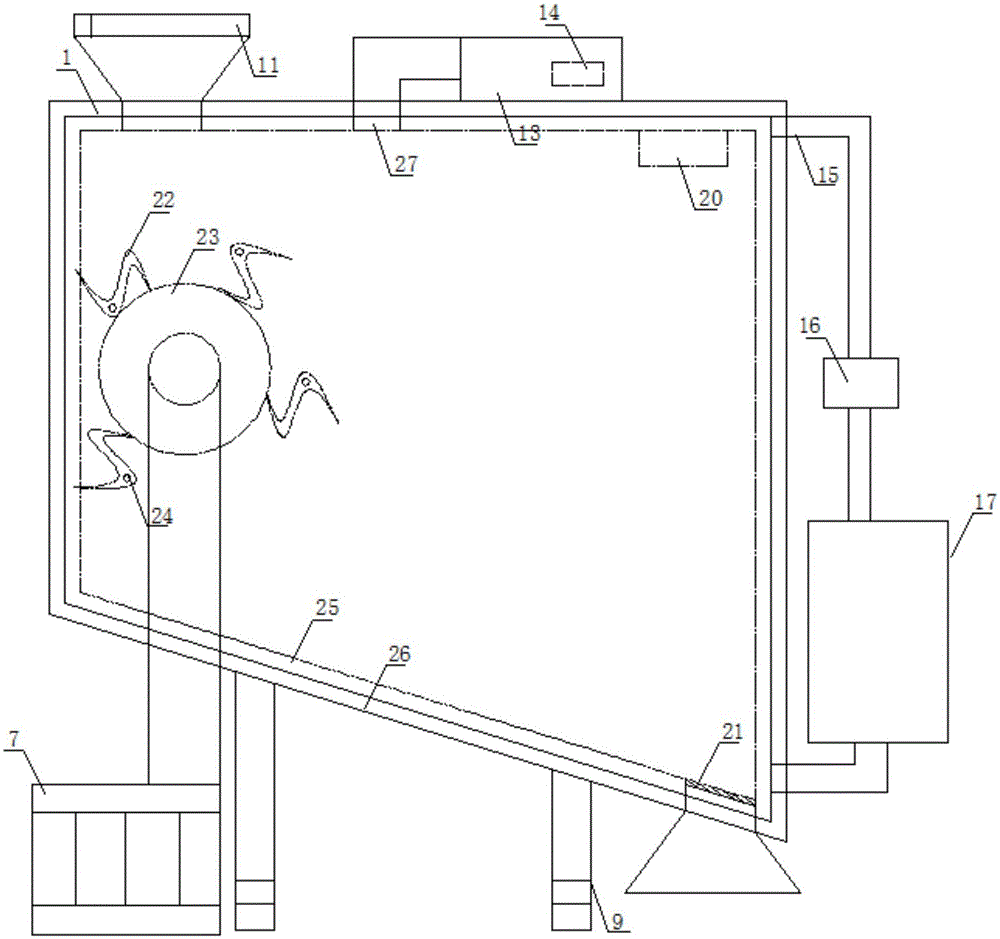

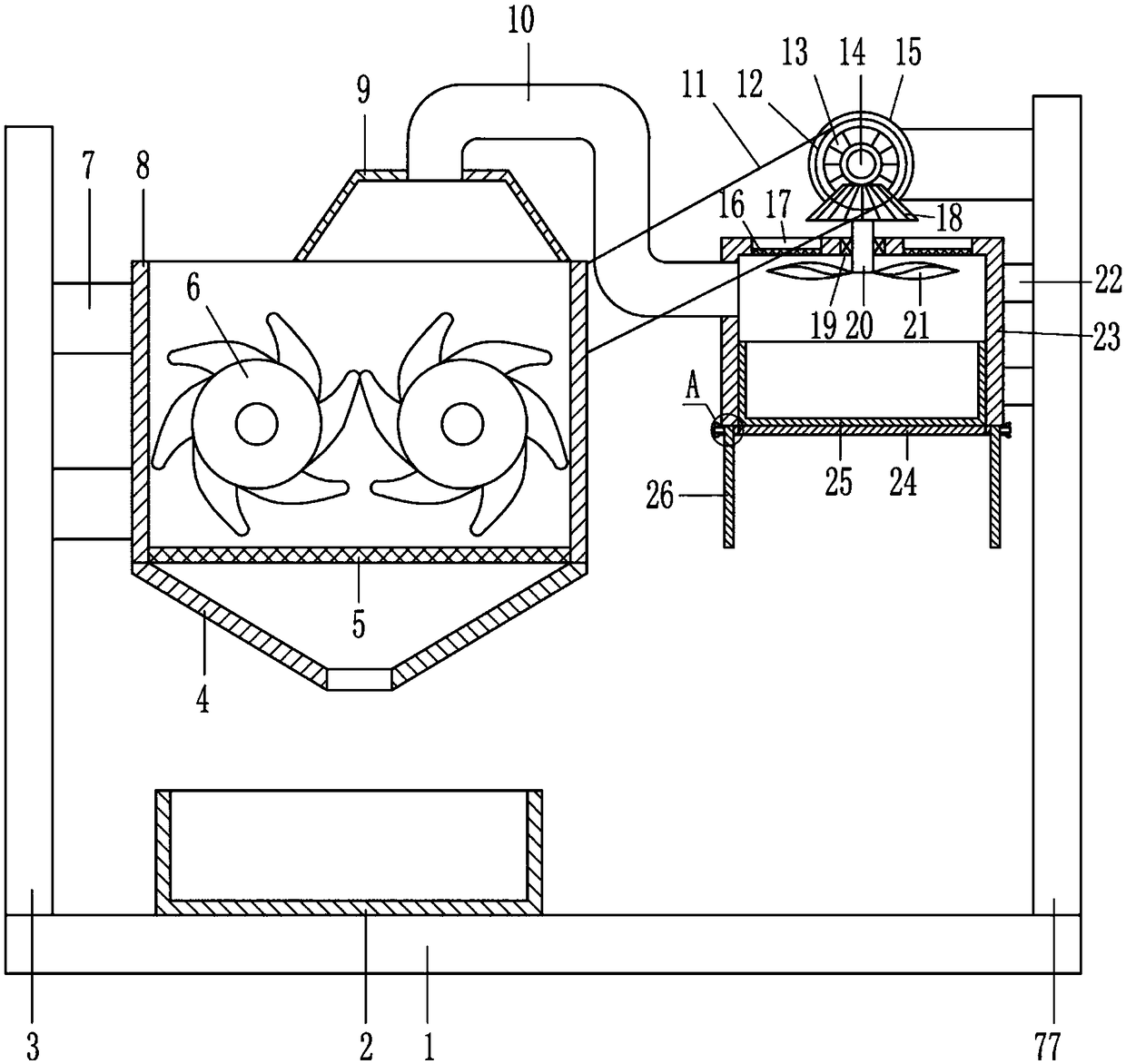

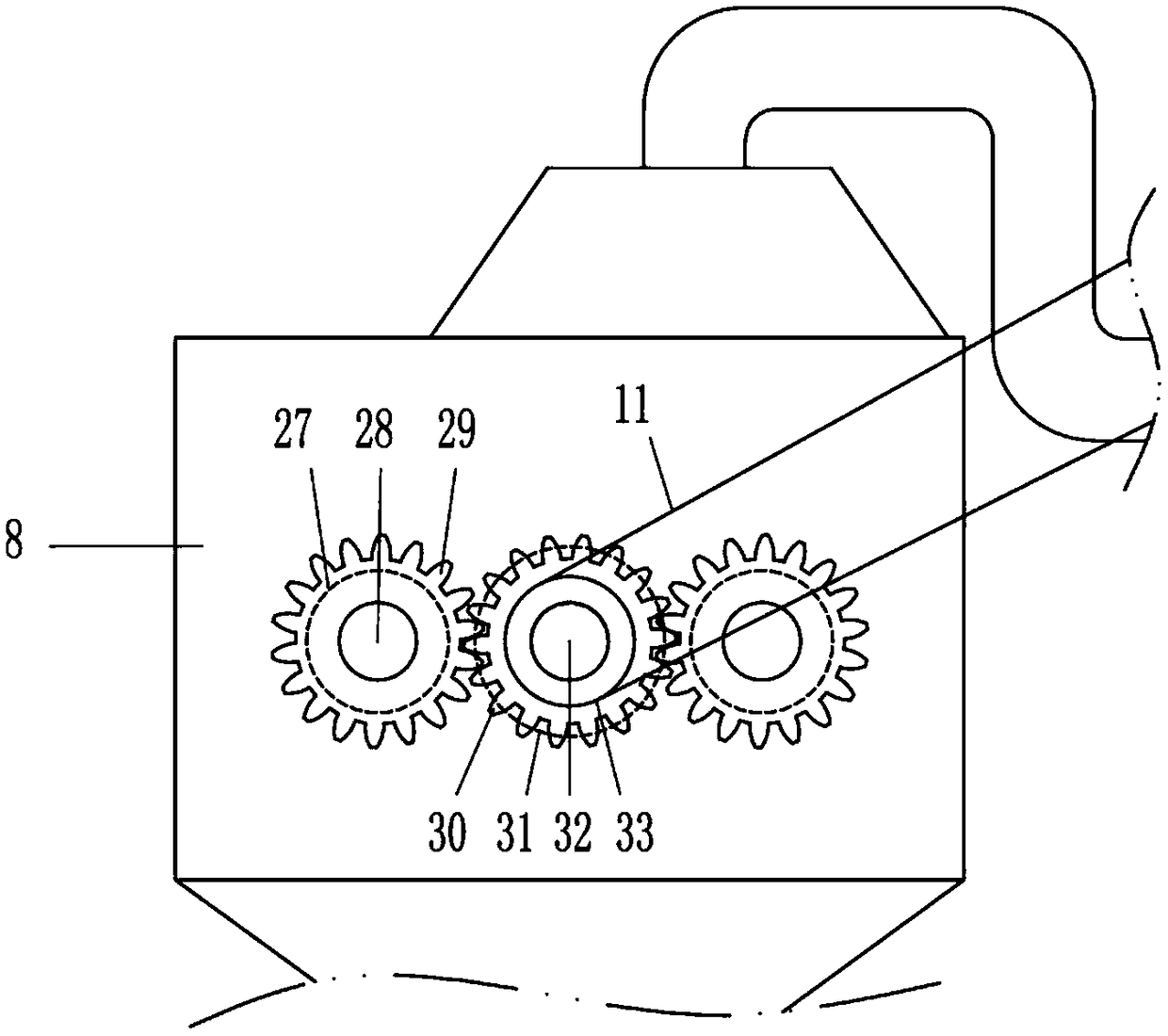

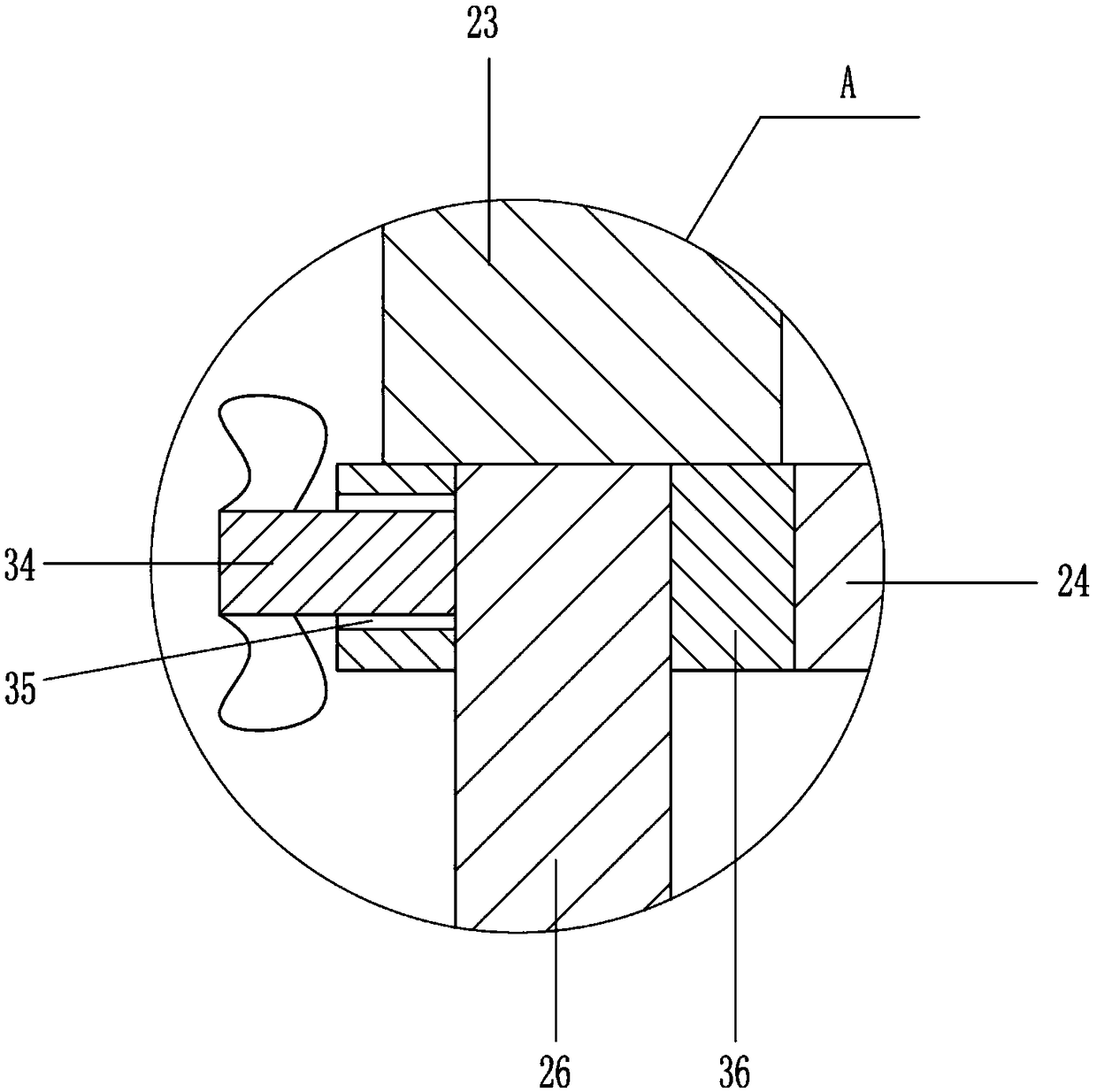

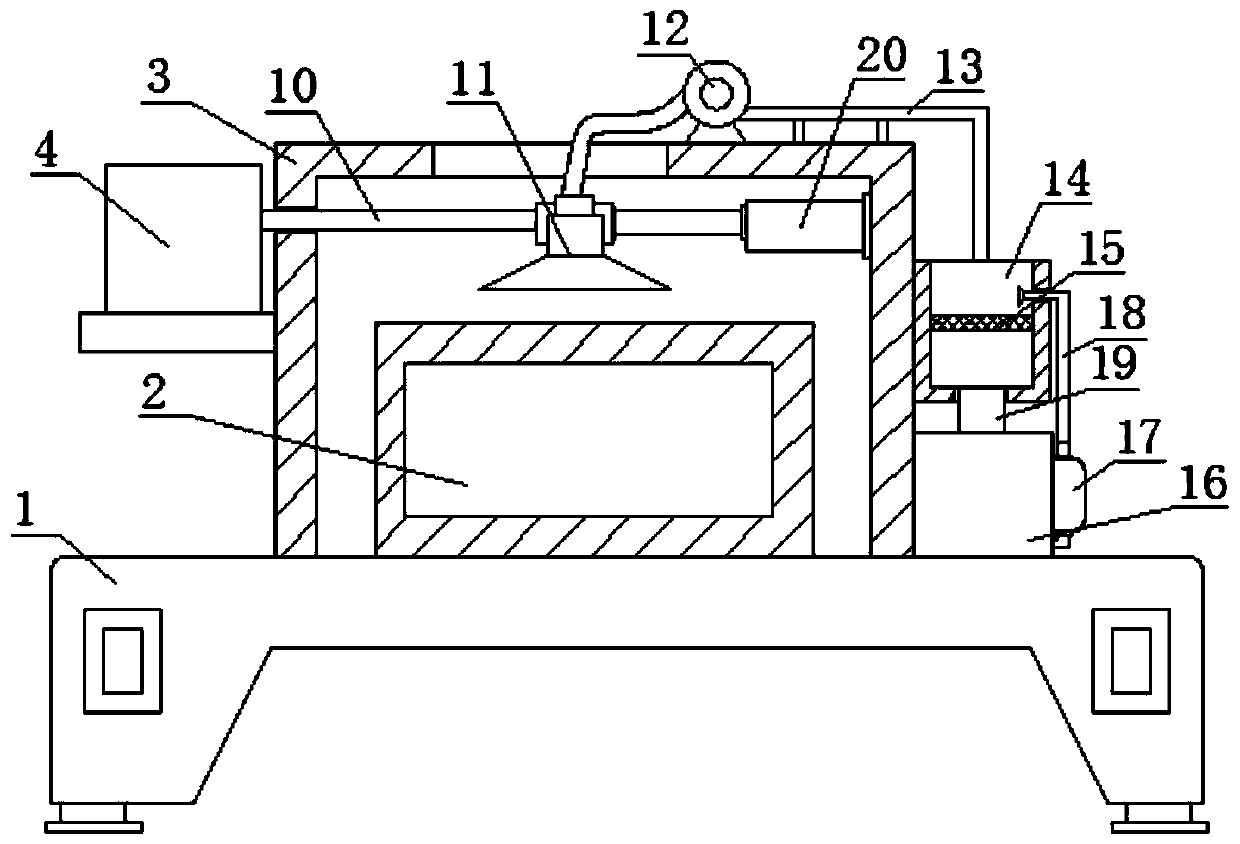

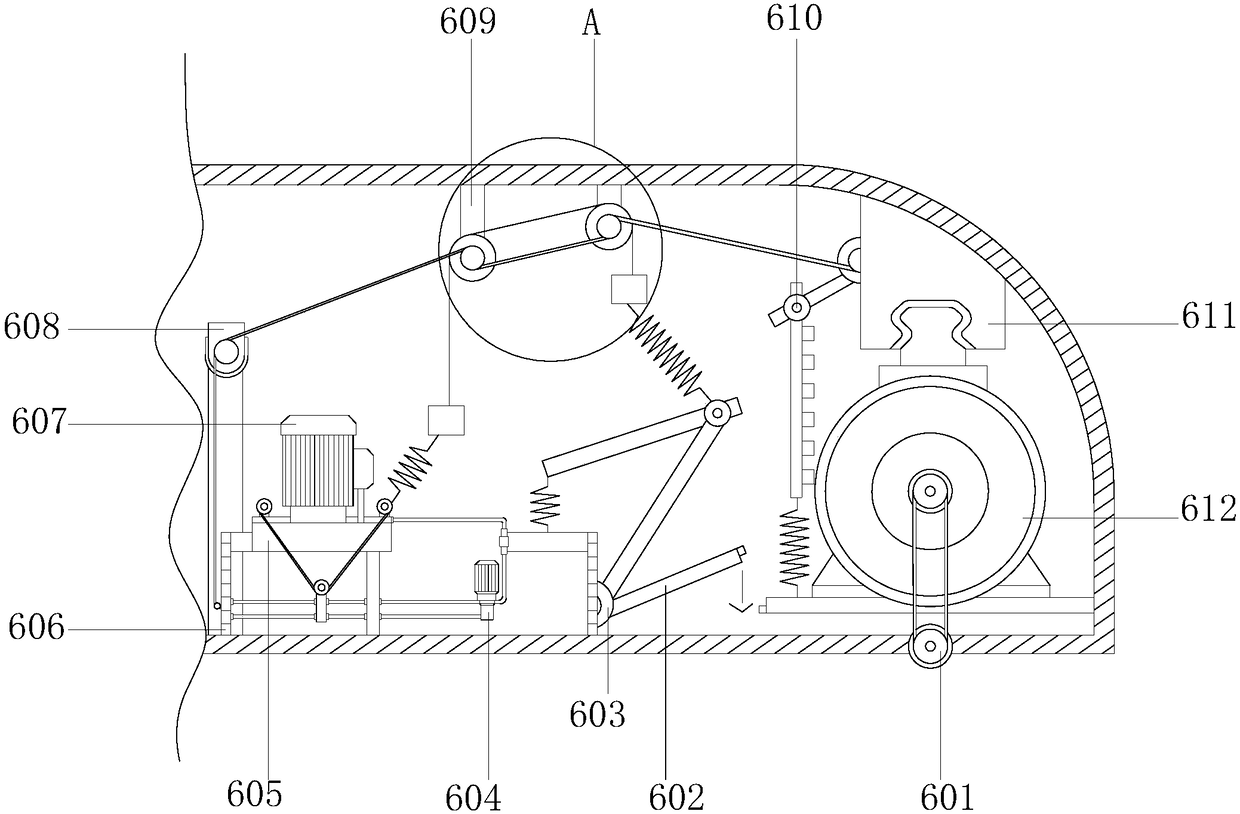

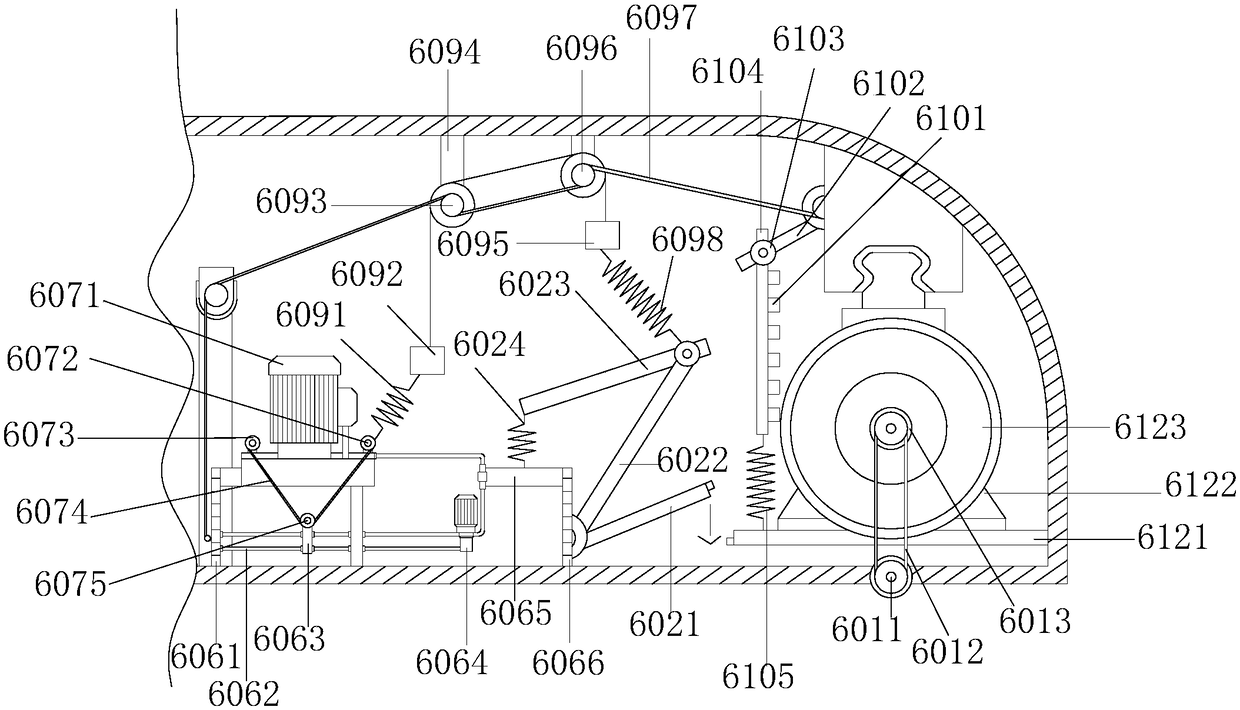

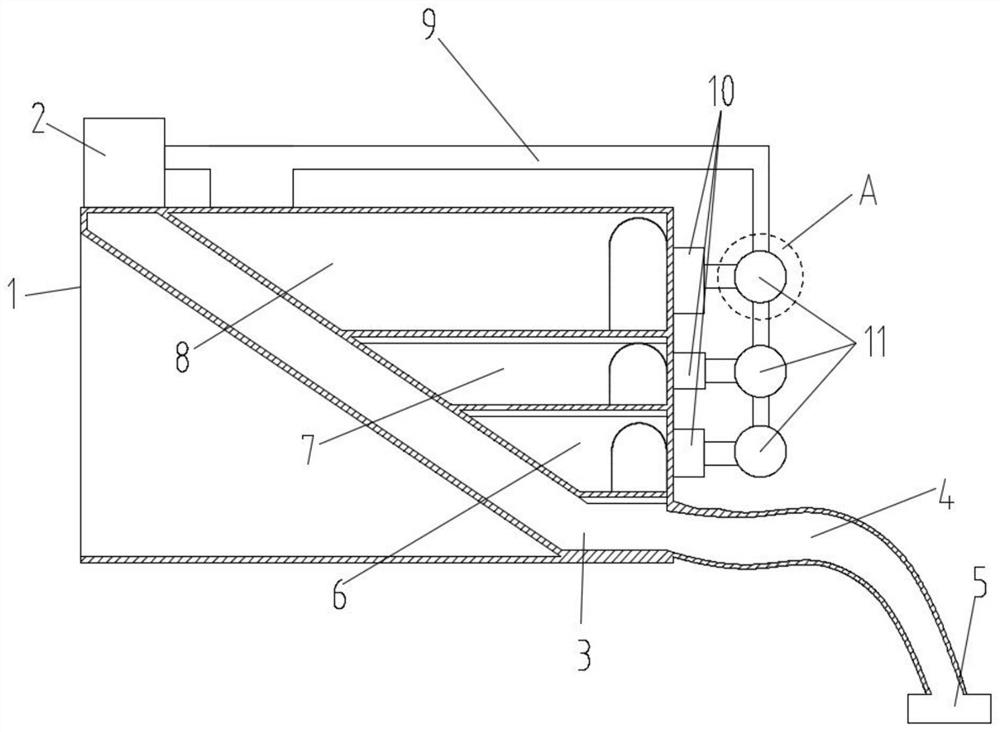

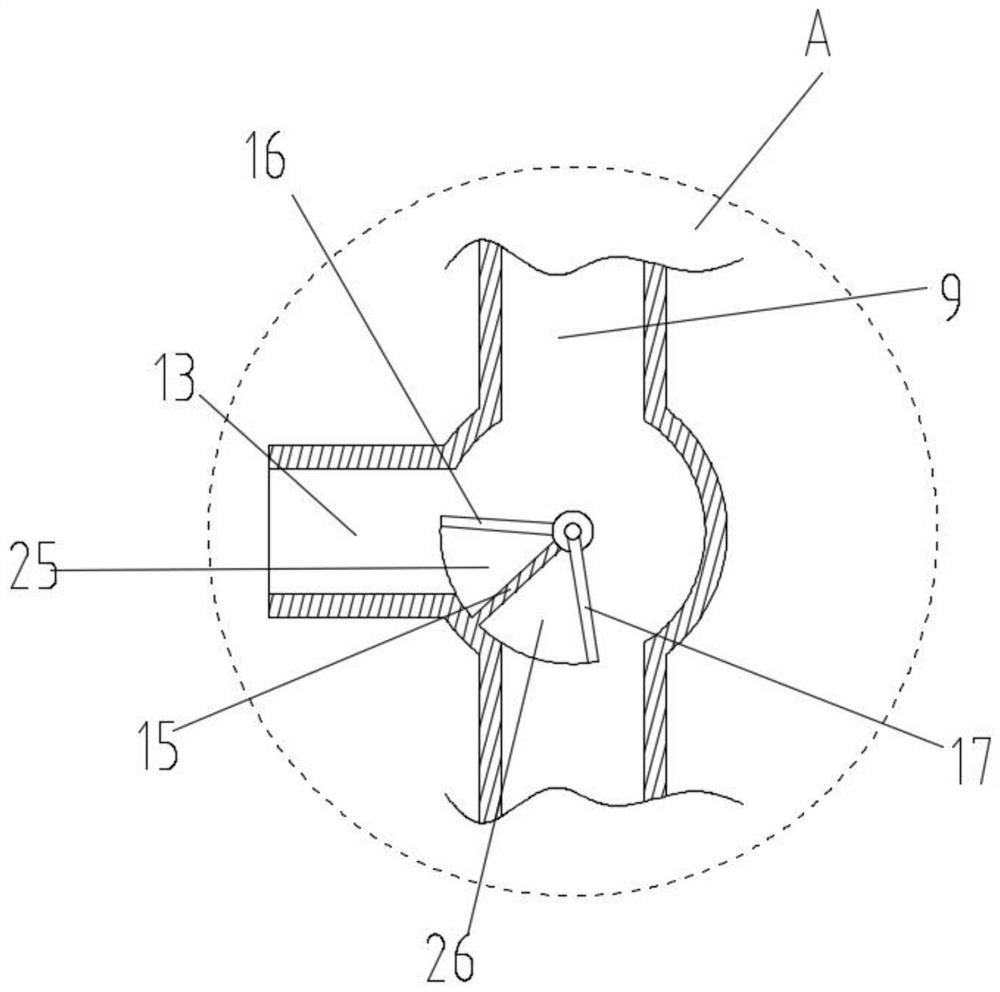

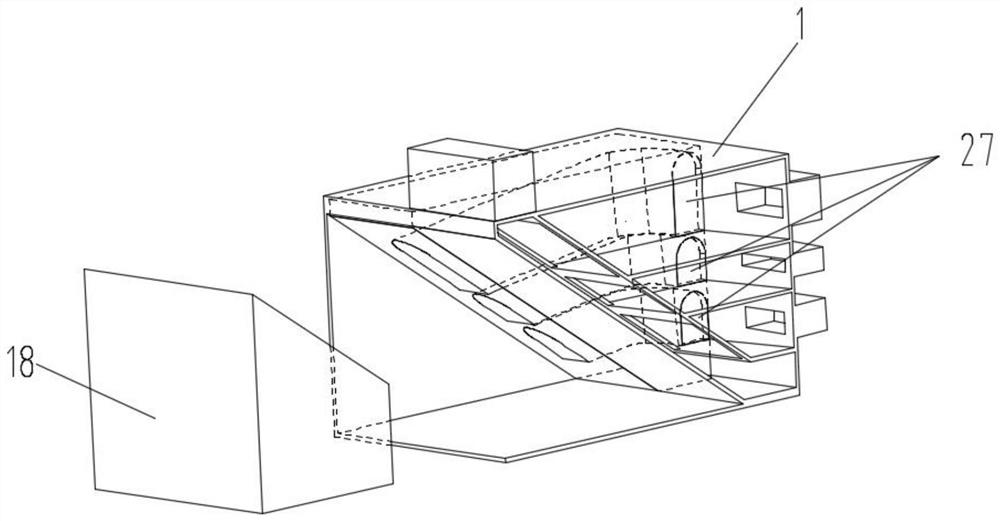

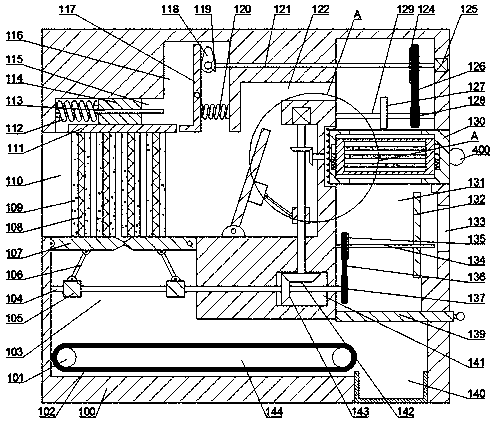

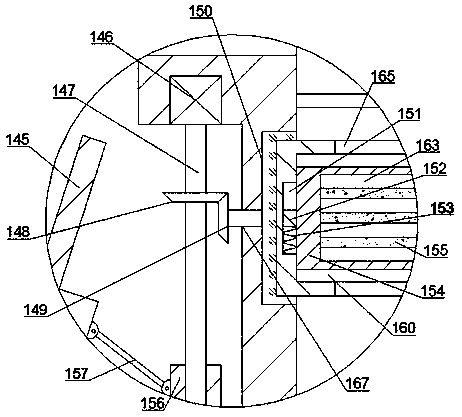

The invention relates to an intelligent cleaning, dust collection and scrubbing integrated machine, belongs to machines for household scrubbing or cleaning, and particularly relates to motor-driven scrubbing machines (sweepers), and scrubbers for street cleaning, rail cleaning and floor cleaning for communal facilities such as markets and airports. The intelligent cleaning, dust collection and floor scrubbing integrated machine comprises a band-type bar brush for horizontal cleaning, a cleaning and wipe-drying brush roll set for scrubbing and wipe-drying, a water collection plate mounted over the cleaning and wipe-drying brush roll set for recycling waste water, a dust removal barrel for water filtration and dust removal, a water tank with a movable partition inside, a rotatable cleaning device, and a camera for collecting images in an environment sensing mode. The problems that cleaning side brushes are easy to twine, duster cloth is used for floor scrubbing leading to inconvenience, disc brushes are large in size, a small amount of waste water is not easy to recycle, filter screens are used for dust filtering, water tanks are not high in space utilization rate, cleaning devices are not easy to maintain, and the whole machines are low in intelligence degree due to poor environmental sensing in existing machines are solved.

Owner:江苏意尔重工有限公司

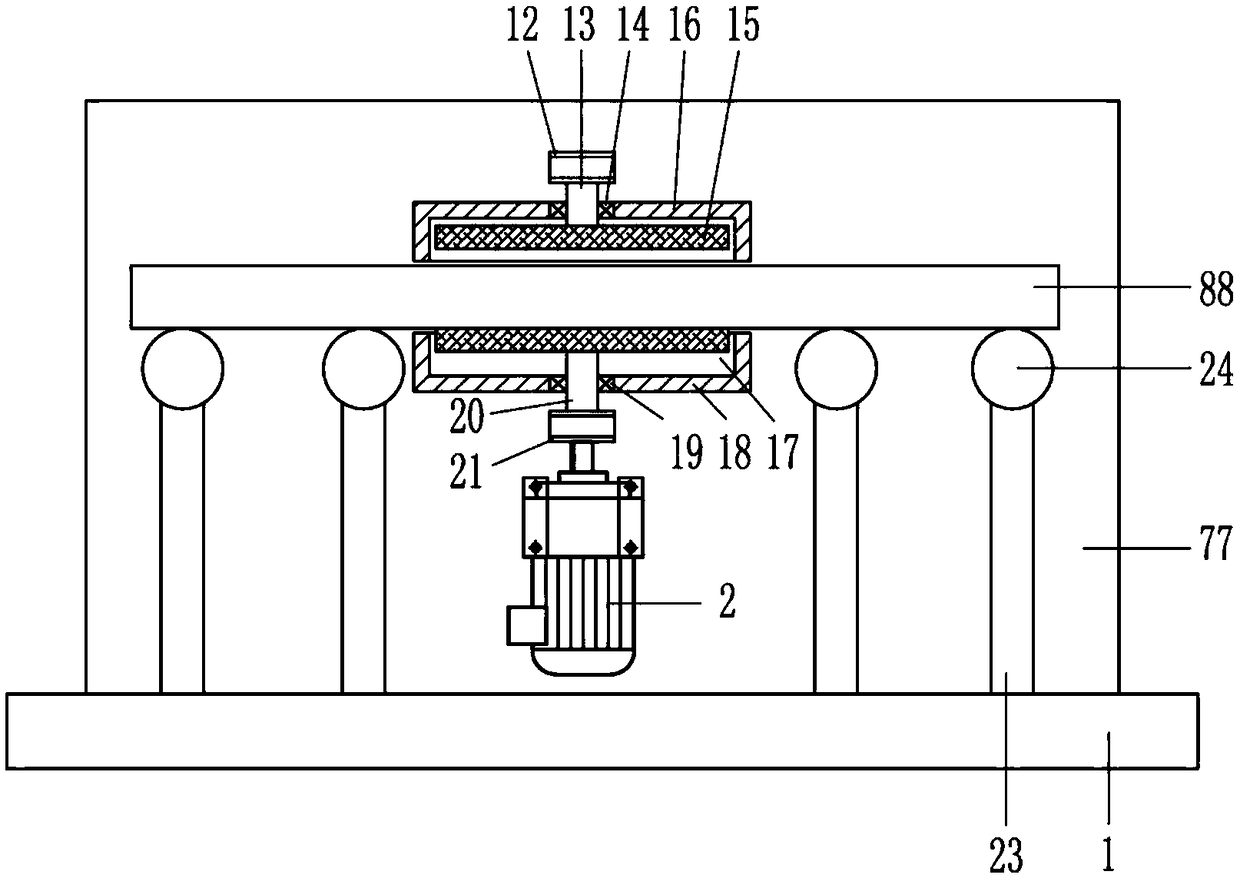

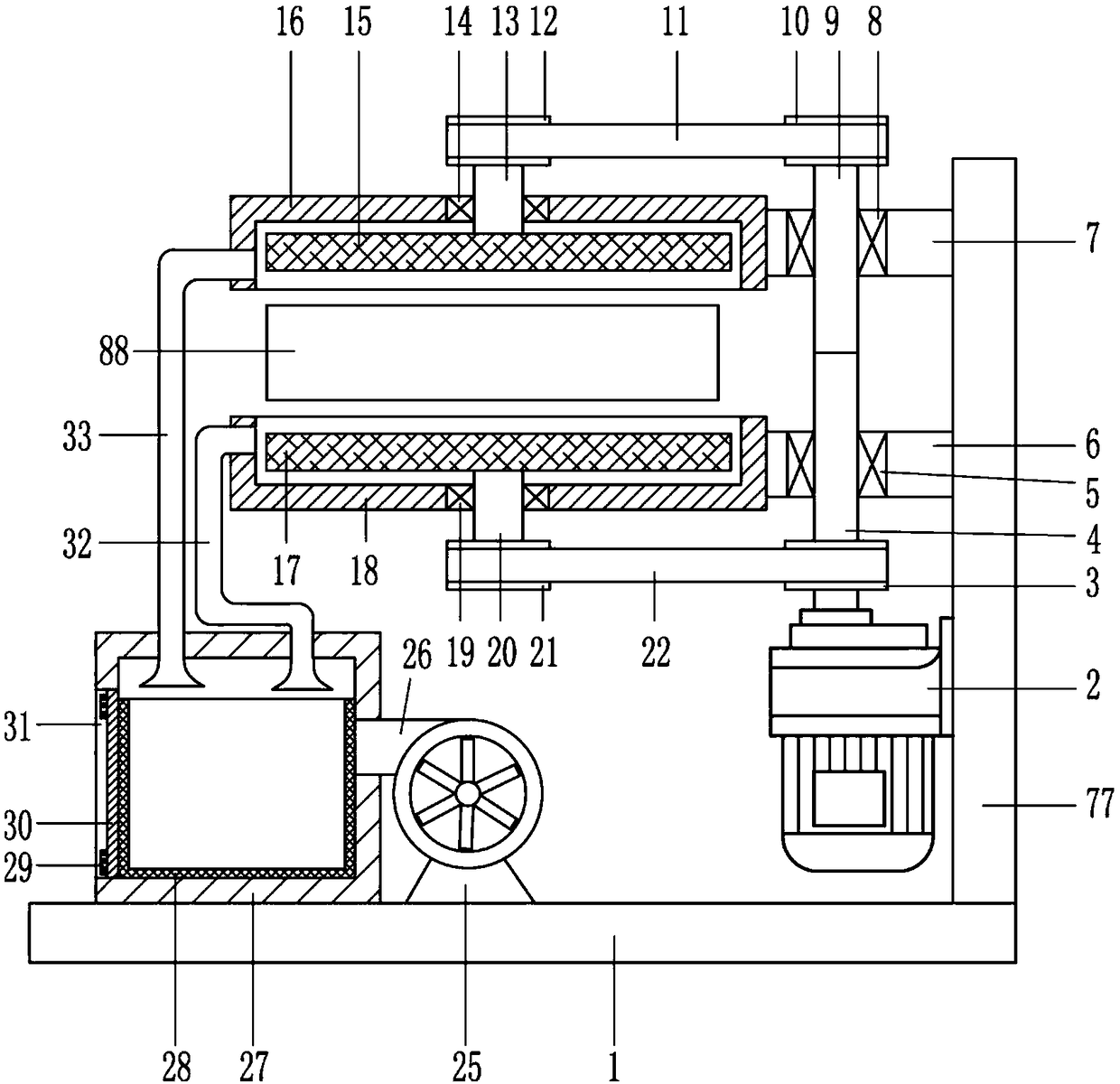

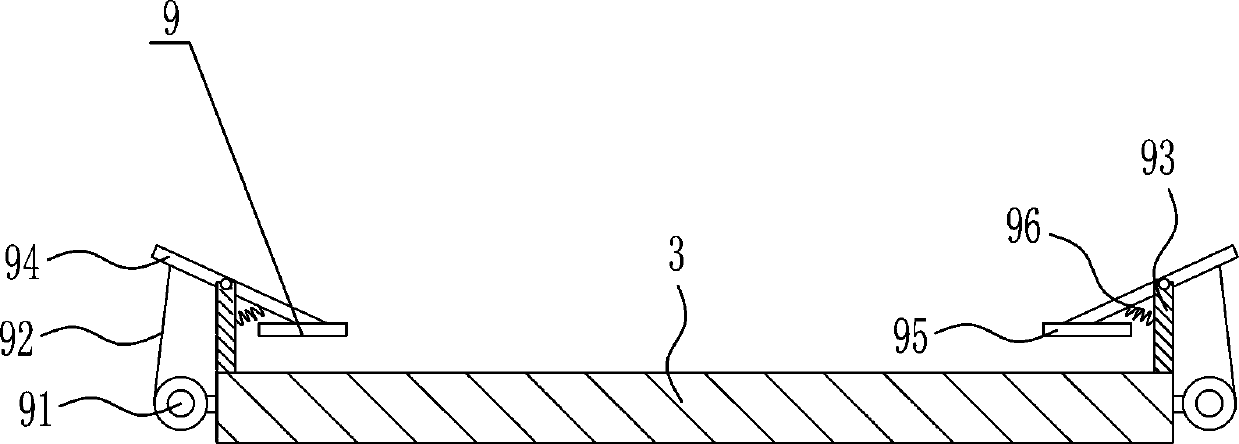

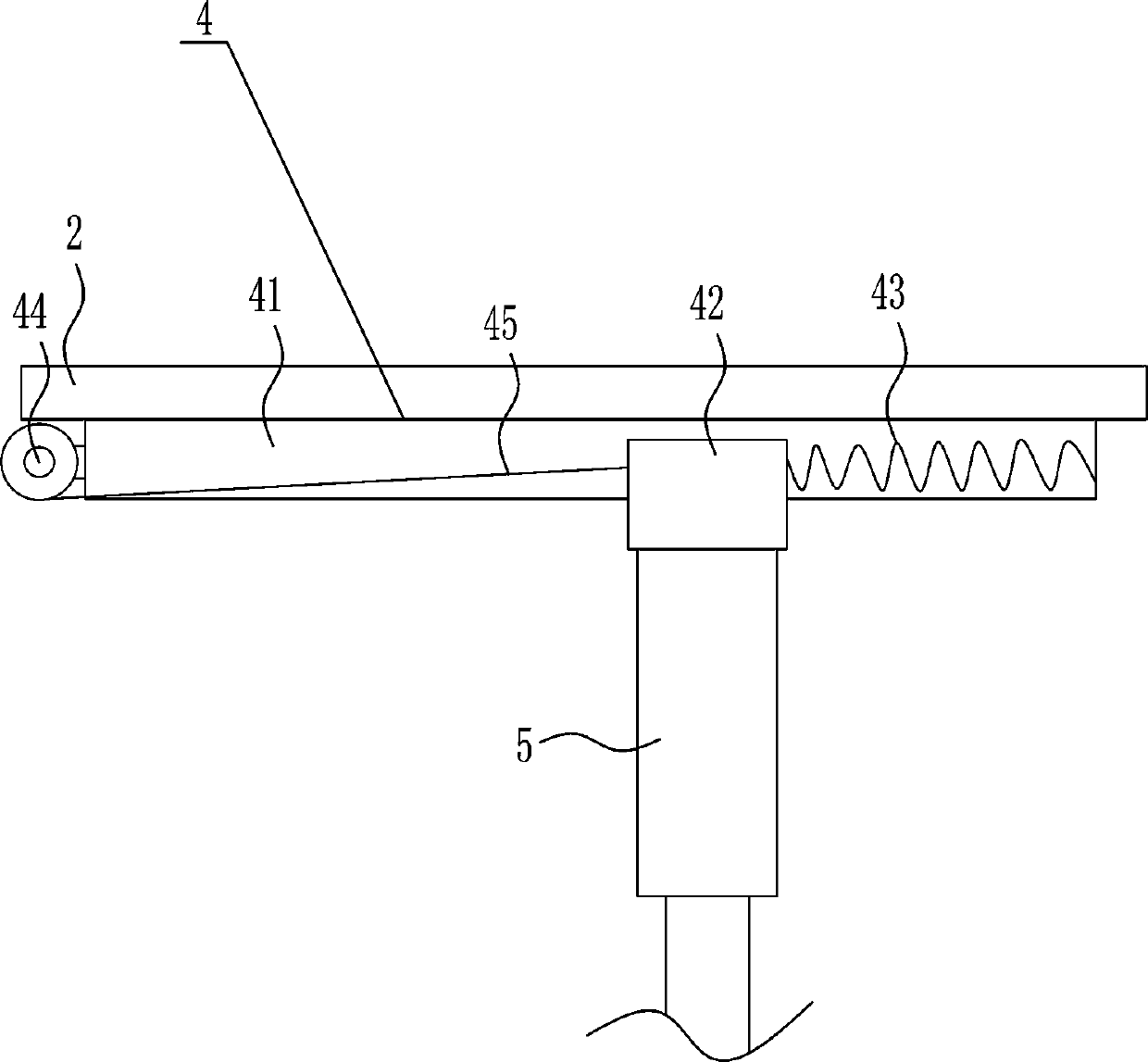

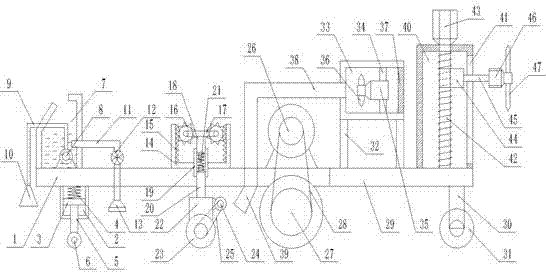

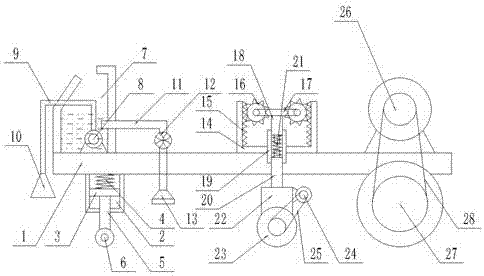

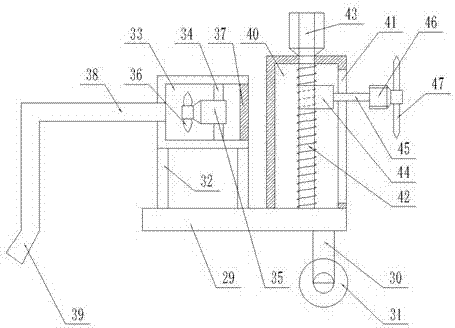

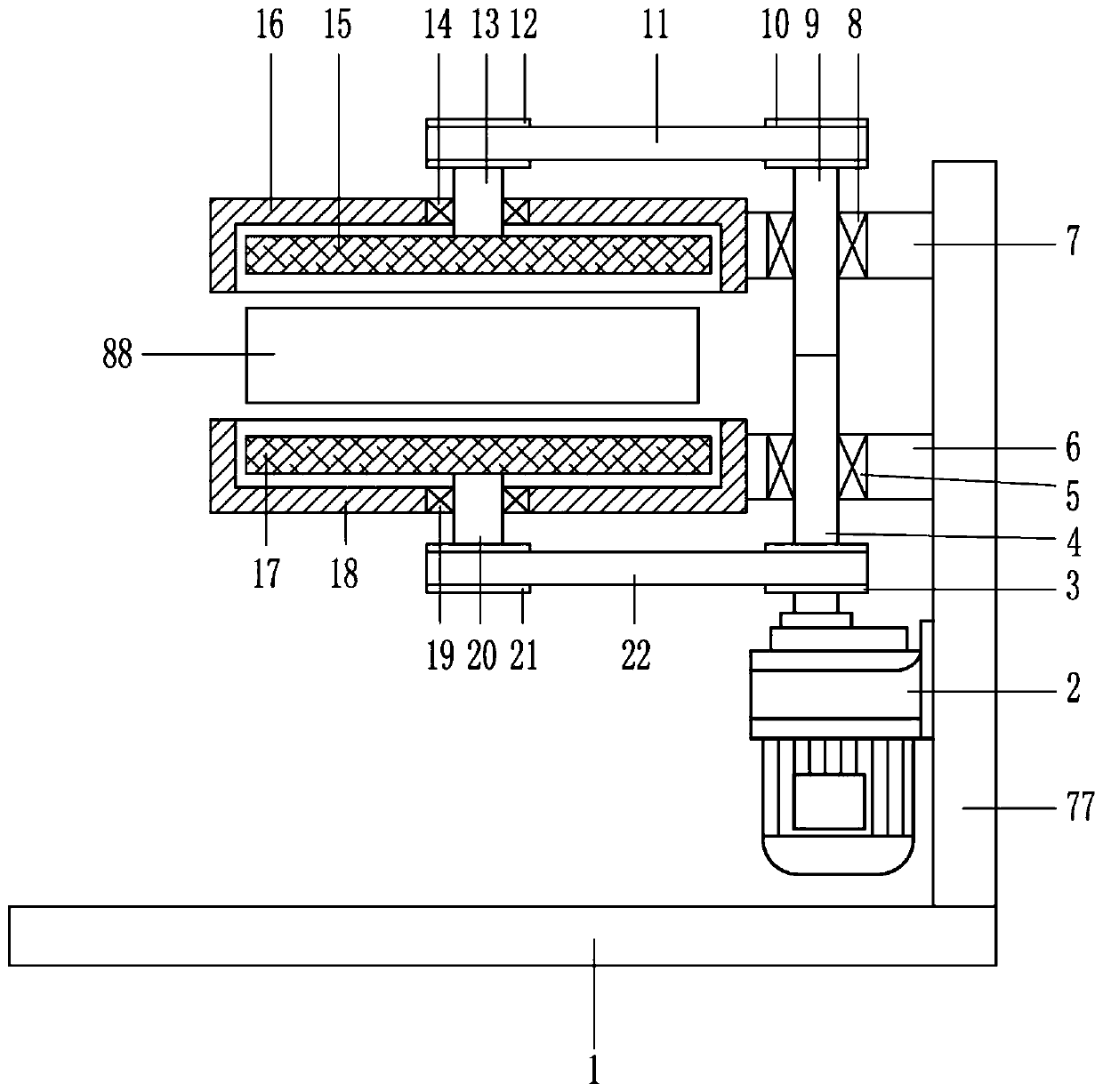

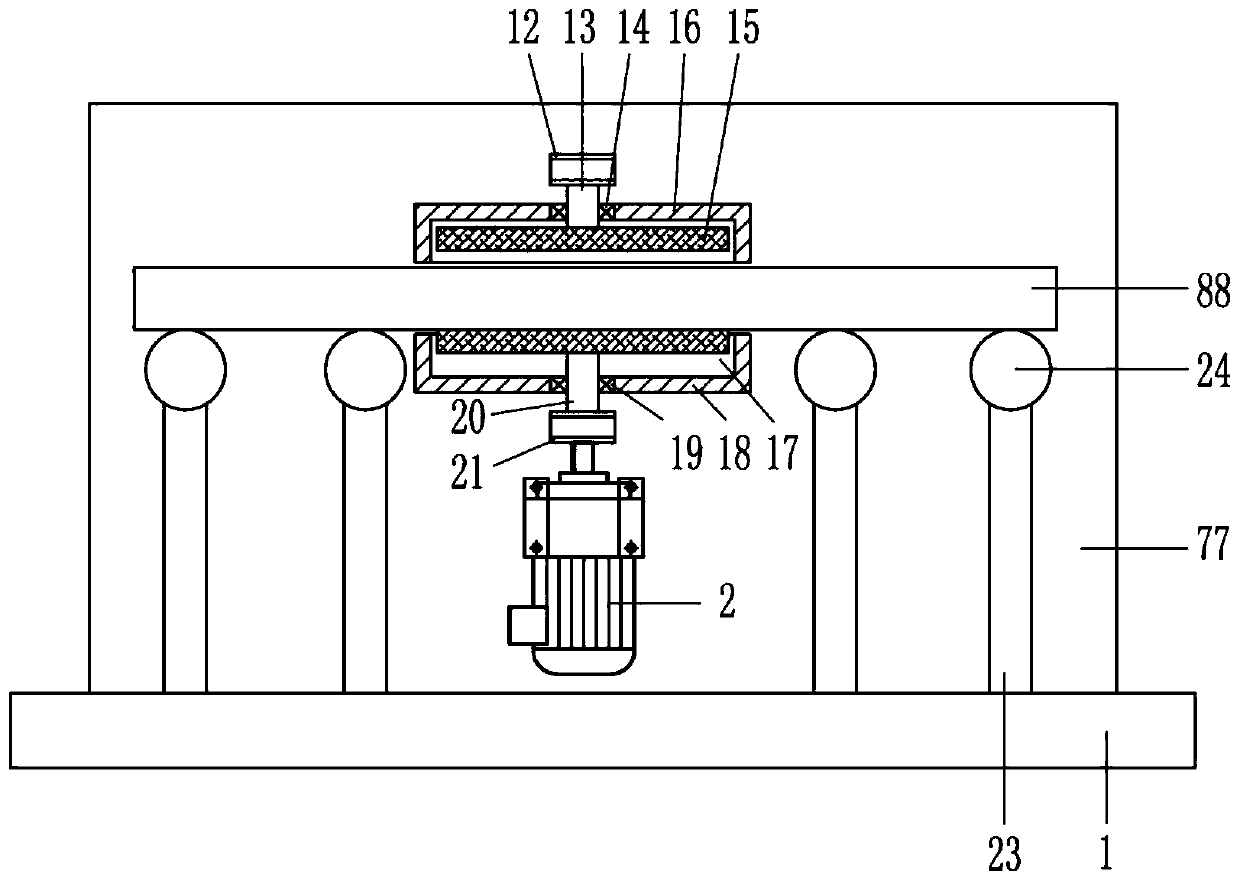

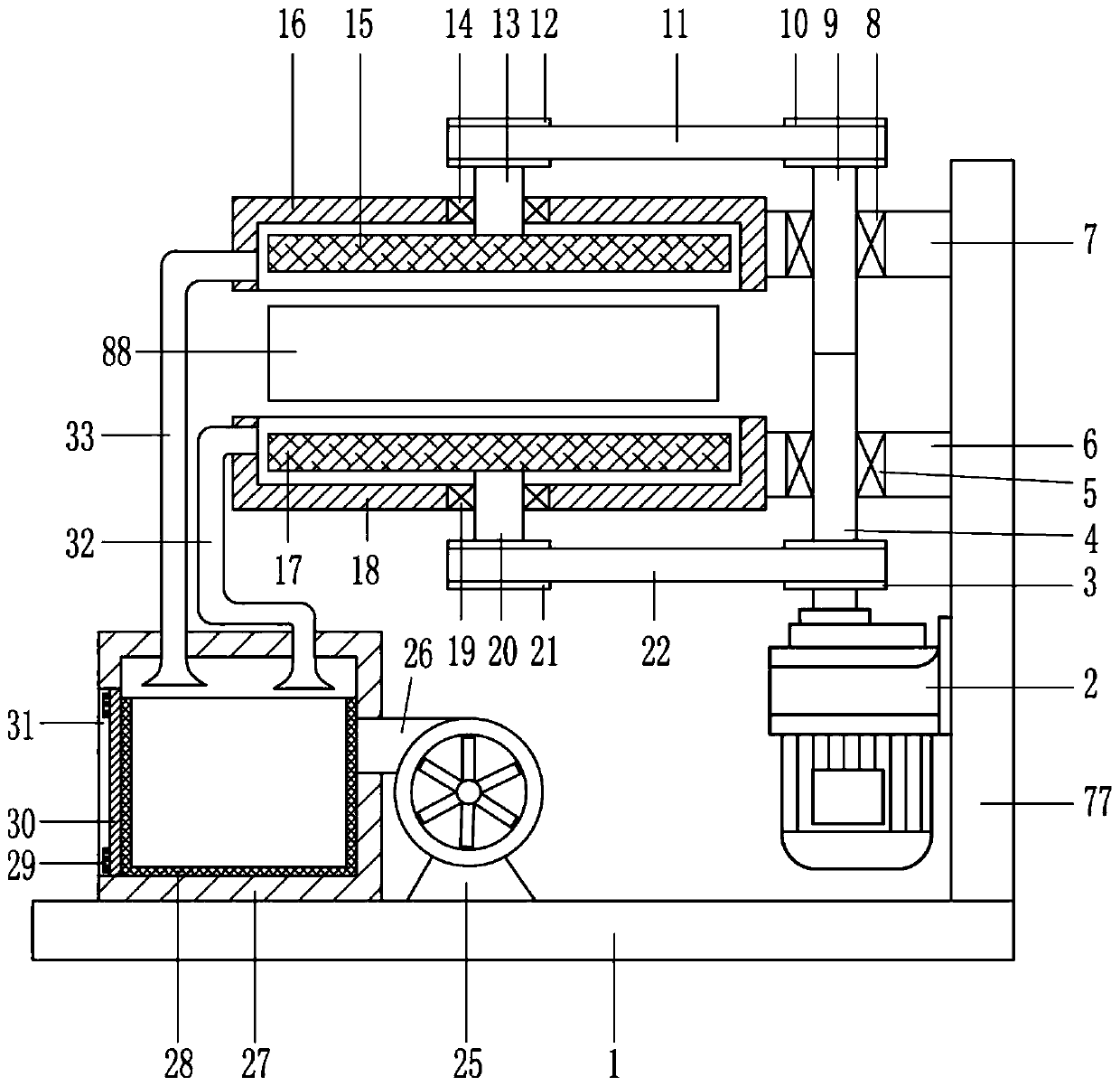

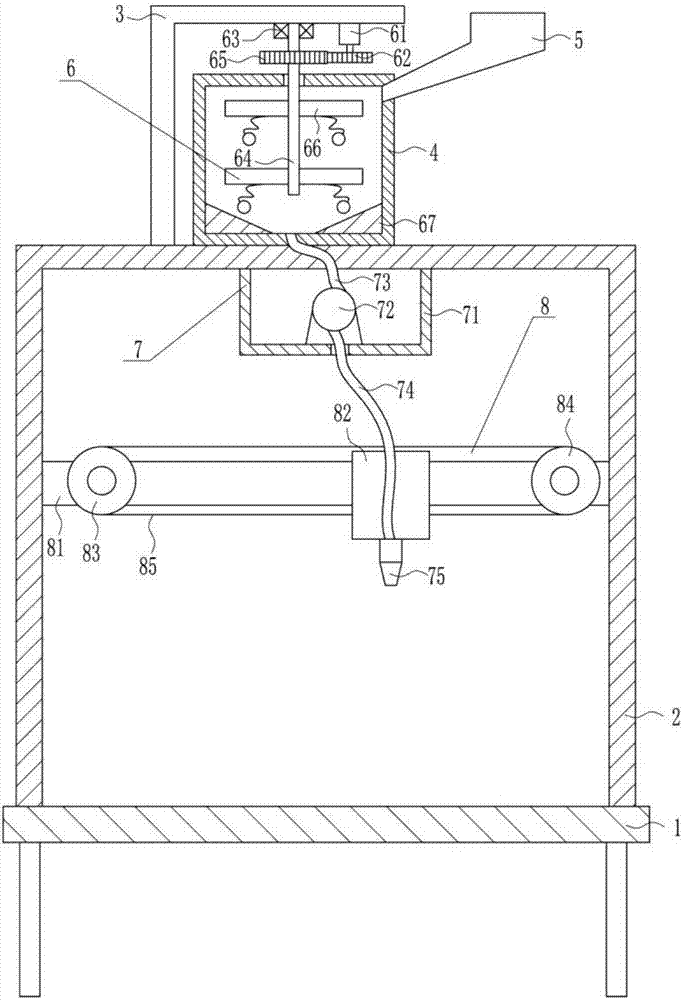

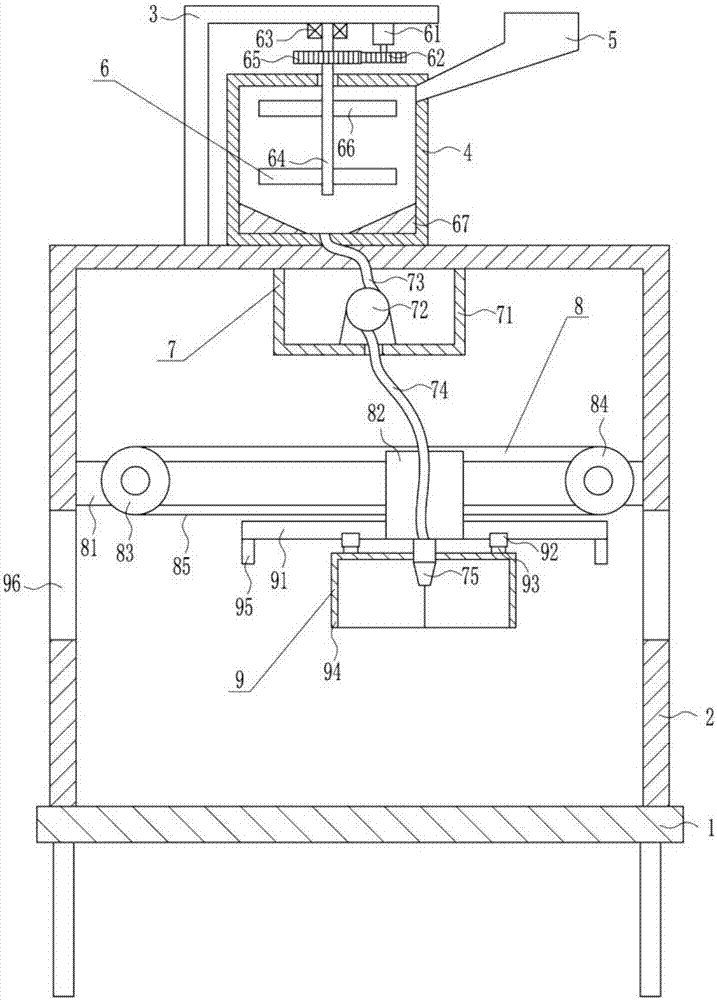

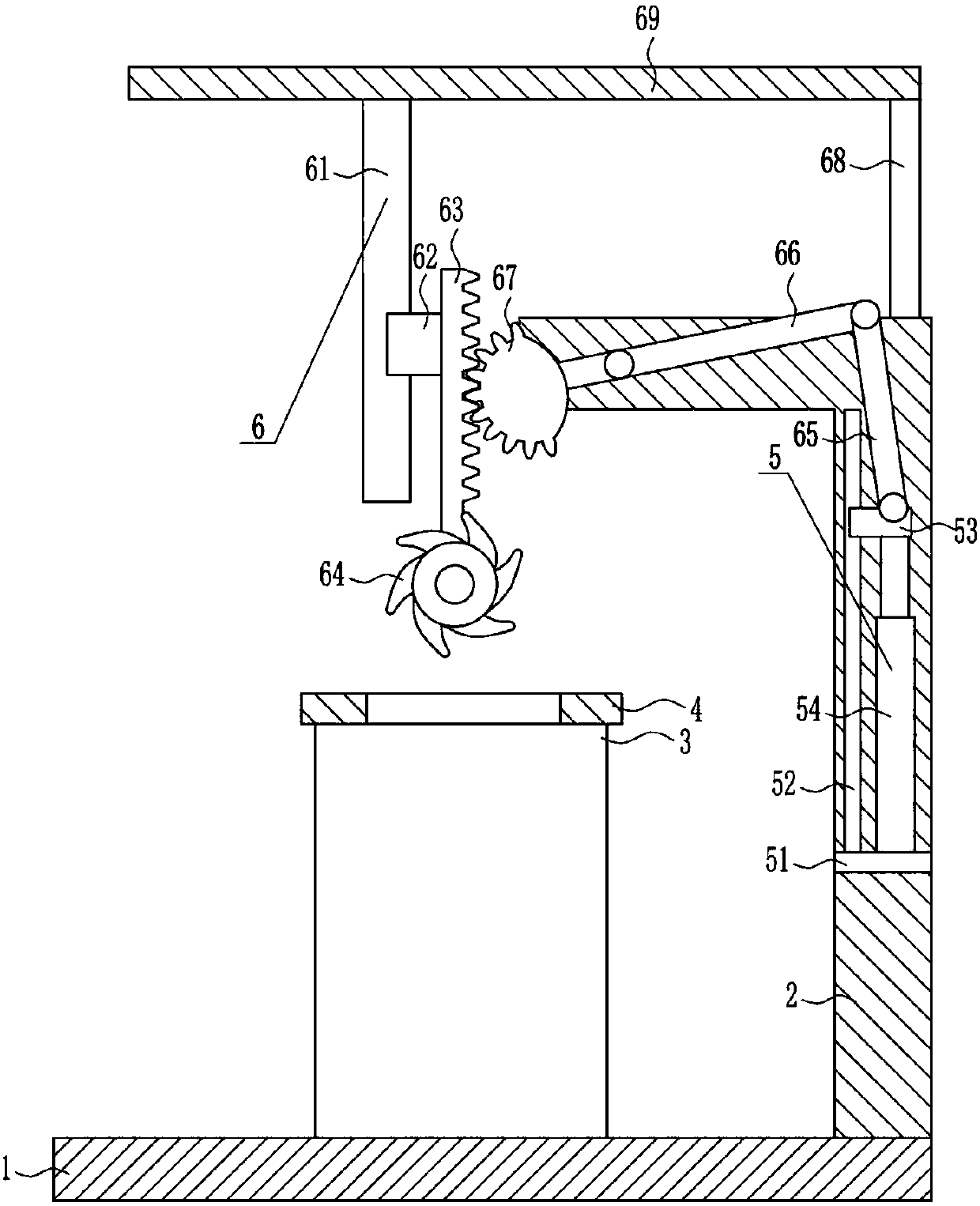

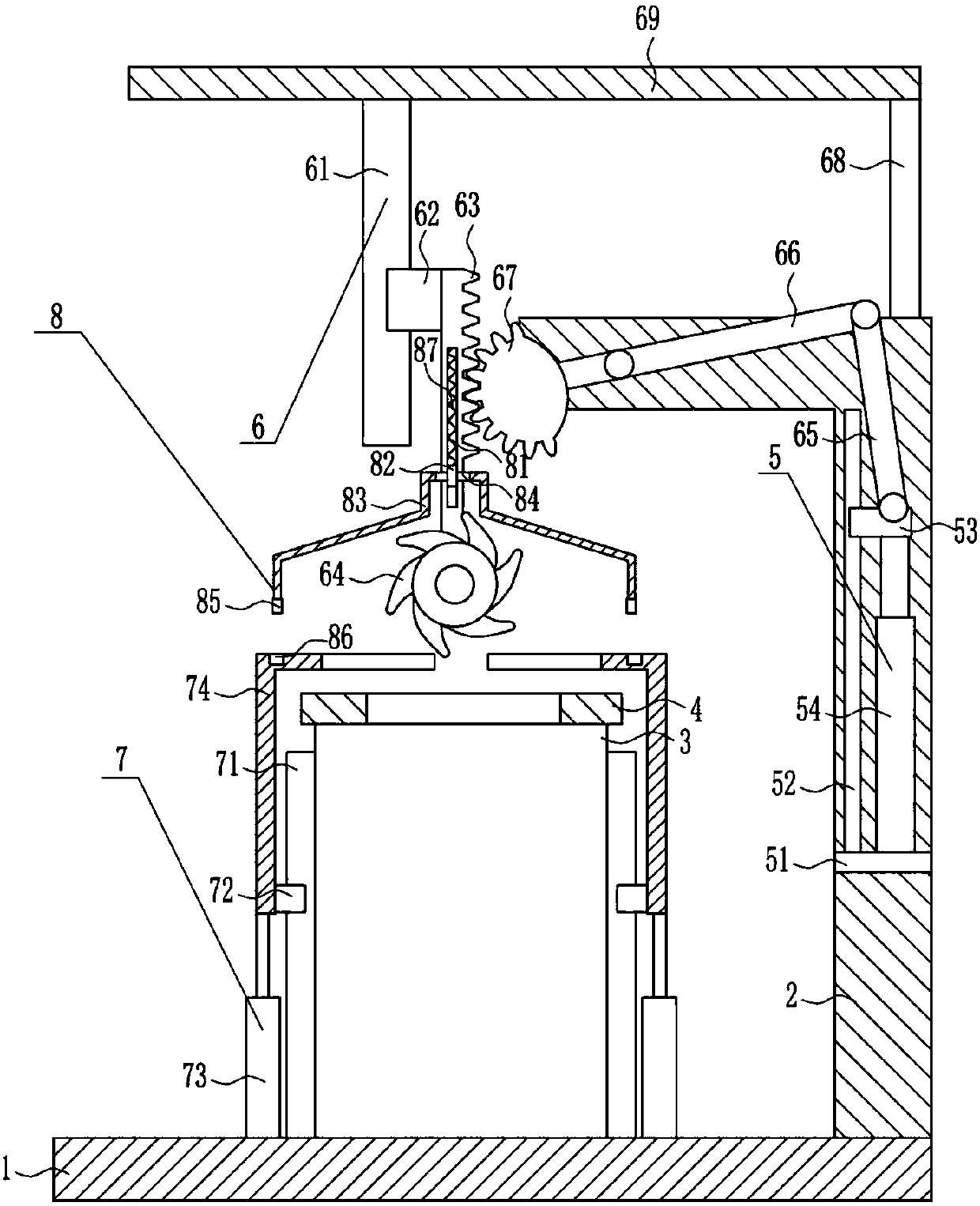

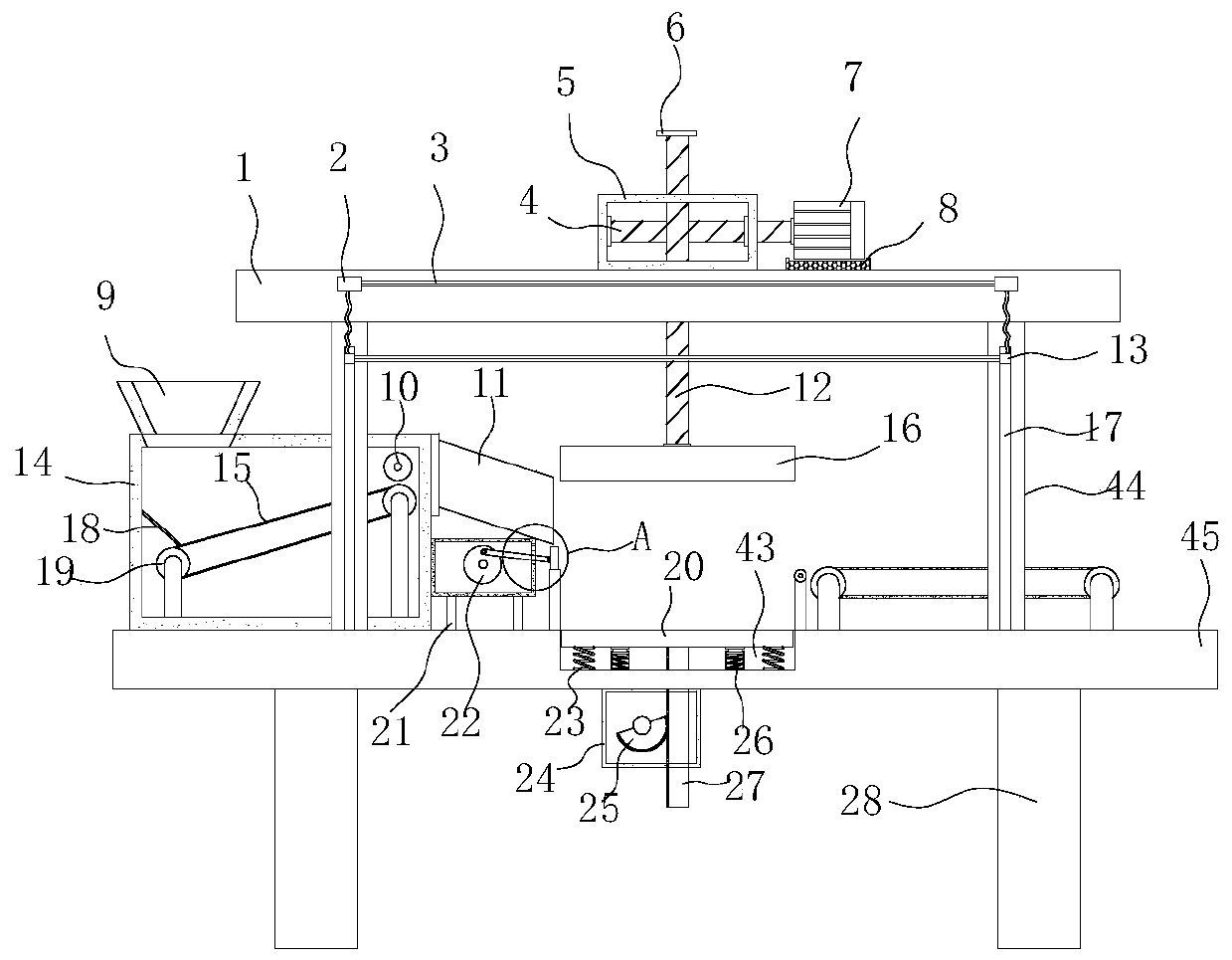

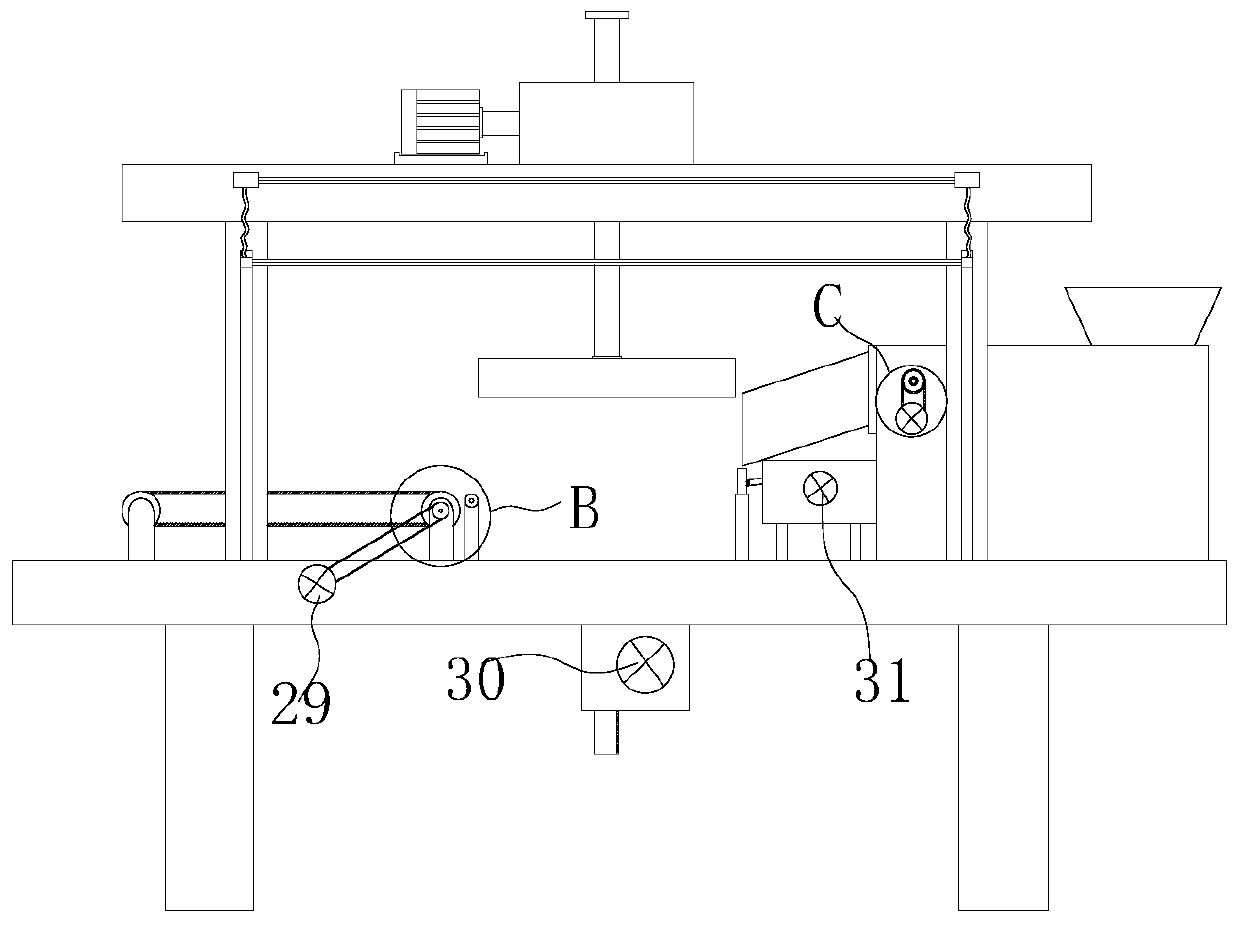

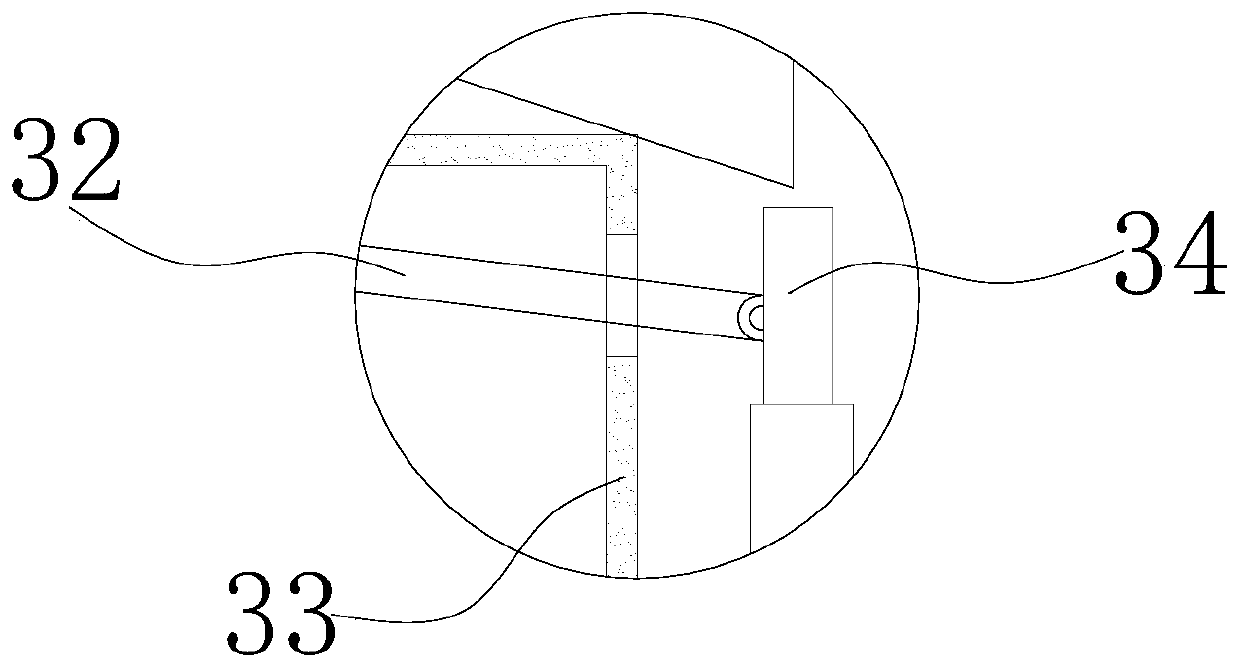

Double-sided polishing machine for wood used for manufacturing furniture

InactiveCN108907936AImprove grinding efficiencyWon't flyGrinding machine componentsPlane surface grinding machinesWood machiningFurniture manufacturing

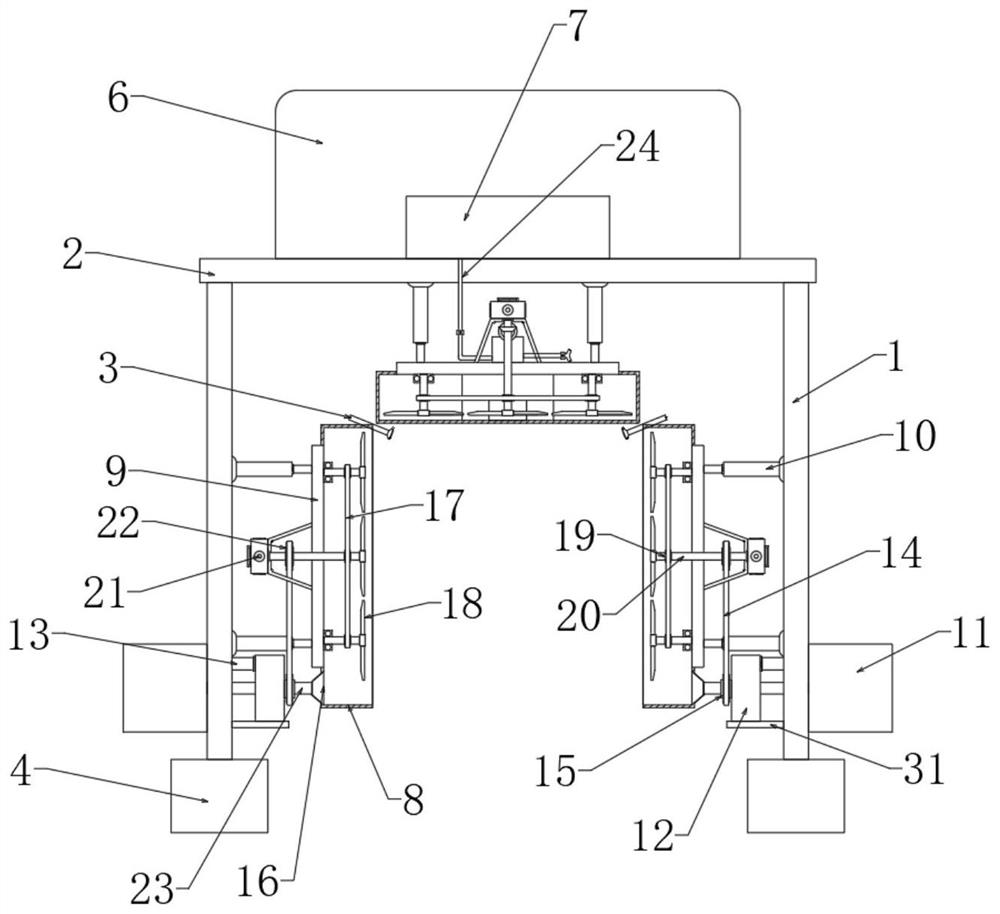

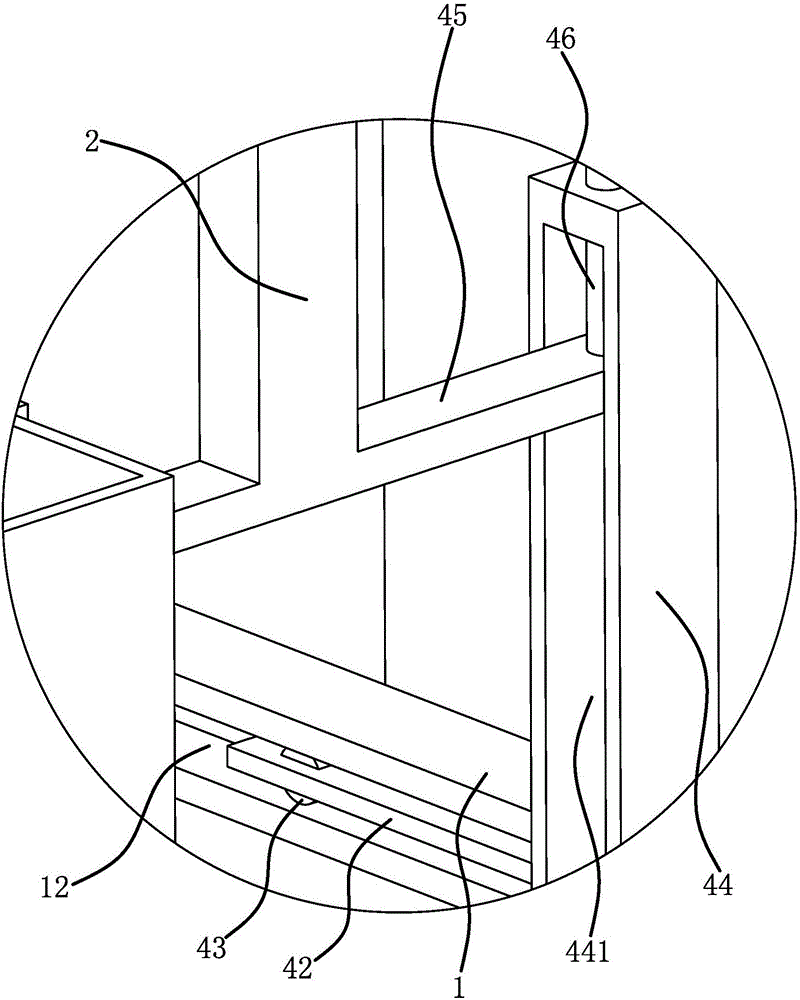

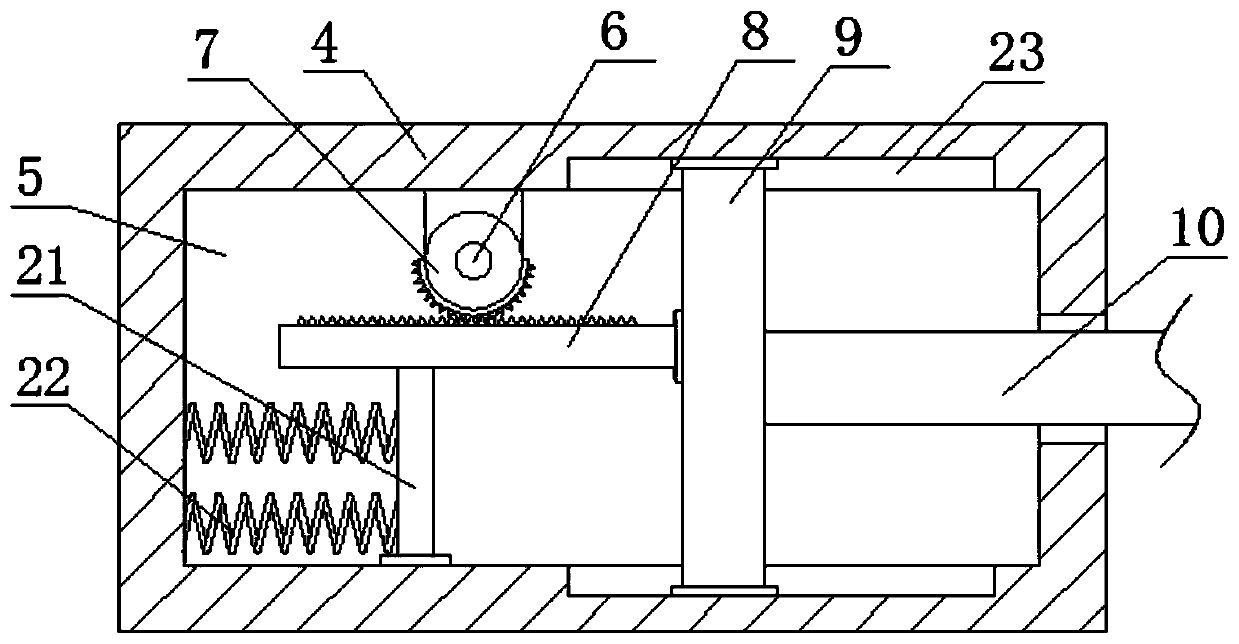

The invention belongs to the field of a wood machining, and particularly relates to a double-sided polishing machine for a wood used for manufacturing furniture. The invention aims to solve a technical problem that polishing efficiency can be improved and a large amount of dust generated in the polishing process can be avoided by providing the double-sided polishing machine for the wood used for manufacturing the furniture and in order to solve the technical problem, the invention provides the double-sided polishing machine for the wood used for manufacturing the furniture. The double-sided polishing machine comprises a mounting plate, a bottom plate, a motor, a first belt wheel, a first rotating shaft, a first bearing seat, a first connecting plate, the second connecting plate, the secondbearing seat, the second rotating shaft, the second belt wheel, a first flat belt, a supporting seat and a guide roller and the like. The mounting plate is fixedly connected with one side part of thebottom plate, a first dustproof frame is fixedly connected with the mounting plate through the second connecting plate, and the second dustproof frame is fixedly connected with the mounting plate through the first connecting plate. According to the double-sided polishing machine, the wood polishing efficiency is improved, and an effect that not too much dust is generated in the polishing processis ensured.

Owner:佛山市新铭思家具有限公司

Cutting device for circuit board production

The invention relates to a circuit board cutting device, in particular to a cutting device for circuit board production. According to the cutting device for circuit board production cutting efficiencyis high, fixing can be conducted during cutting, and dust explosion does not exist during cutting. The cutting device includes a bottom plate and the like. The top of the bottom plate is provided with an n-shaped frame. The right side of the inner top part of the n-shaped frame is provided with a moving mechanism. A moving component of the moving mechanism is connected with an air cylinder. The bottom end of the air cylinder is connected with a cutting mechanism. The lower part of the inner left side of the n-shaped frame is provided with a horizontal plate. The left side of the top of the bottom plate is provided with a dust suction mechanism. According to the cutting device for circuit board production, the effects that cutting efficiency is high, fixing can be conducted during cutting,and dust explosion does not exist during cutting can be achieved; through interaction of the moving mechanism and the cutting mechanism, cutting is conducted to a circuit board; meanwhile, the dust suction mechanism can suck the dust produced during cutting, so that human health cannot be affected.

Owner:南昌安润科技有限公司

Road cutting device for construction of roads and bridges

The invention discloses a road cutting device for construction of roads and bridges. The road cutting device comprises a first base, a mouth-shaped seat, a sliding block, a spring, a support rod, a guide wheel, a water chamber, a water pump, a water pipe, a spray head, a first air duct, an exhaust fan and the like. The road cutting device disclosed by the invention has the advantages of reasonableand simple structure, low production cost, convenience in mounting, no raising of dust during cutting, high cutting speed, time saving and labor saving; a rotating motor drives a driving wheel to move; the water pump pumps water; dust fall is realized by using the spray head; the exhaust fan extracts dust into the water chamber for adsorbing; a fan motor drives a draft fan; the dust enters from asecond exhaust nozzle and is filtered by a filter screen to remove the dust, so that the dust is effectively controlled and raising of the dust is avoided; a gear adjusts the height of a cutting blade; a connecting spring is arranged so as to improve buffer performance; a driving motor drives the cutting blade to cut; a lifting motor drives a lifting seat to adjust the height; a cutting motor drives a rotary cutting blade to cut; high cutting speed, time saving and labor saving are realized.

Owner:李雨林

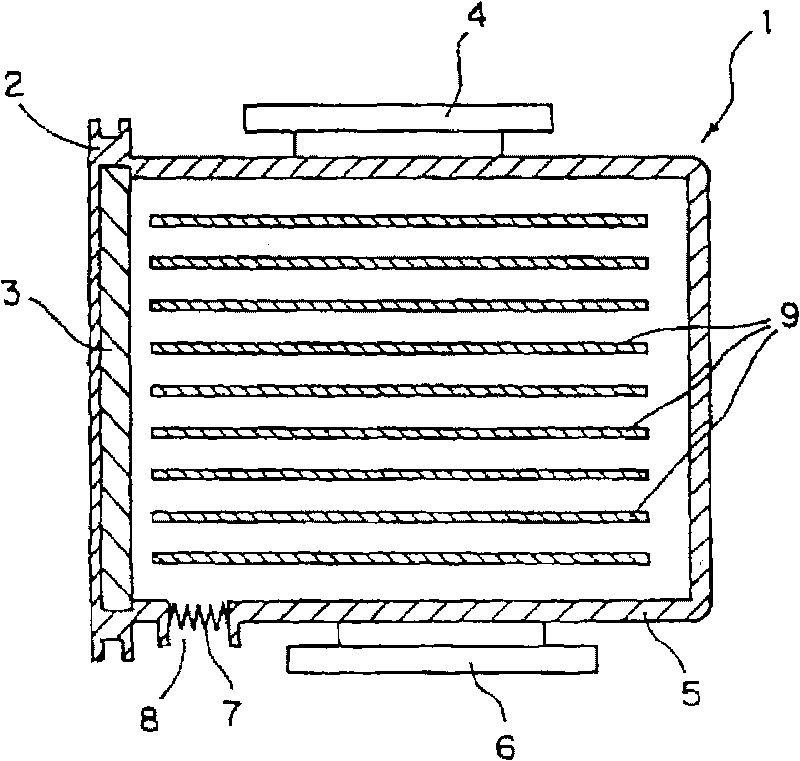

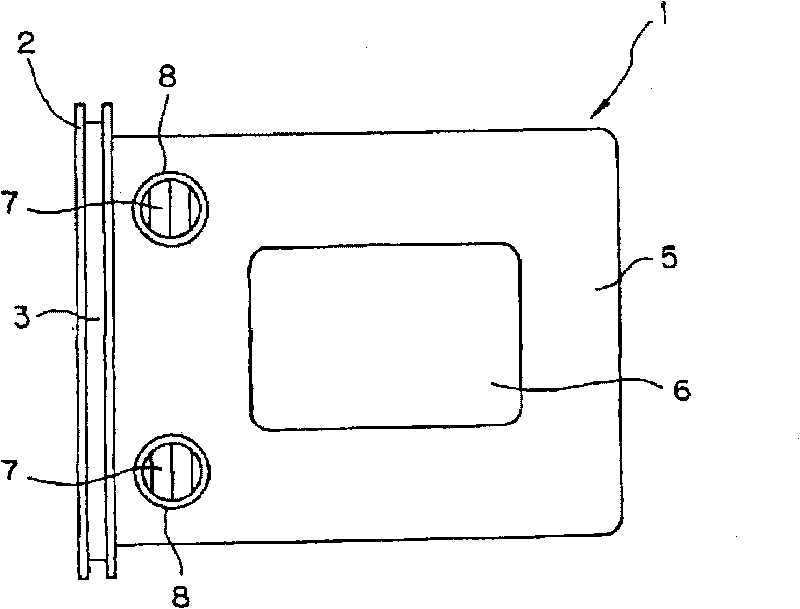

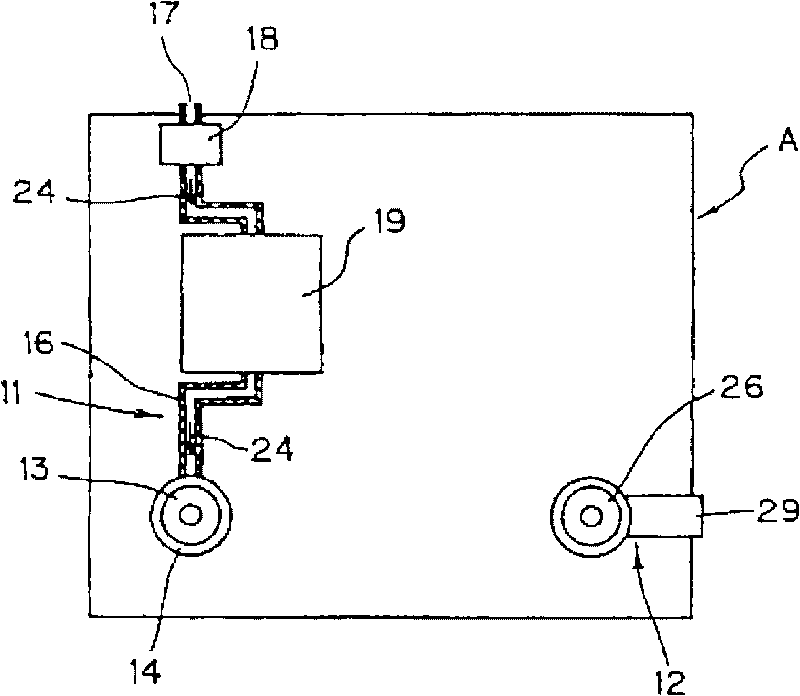

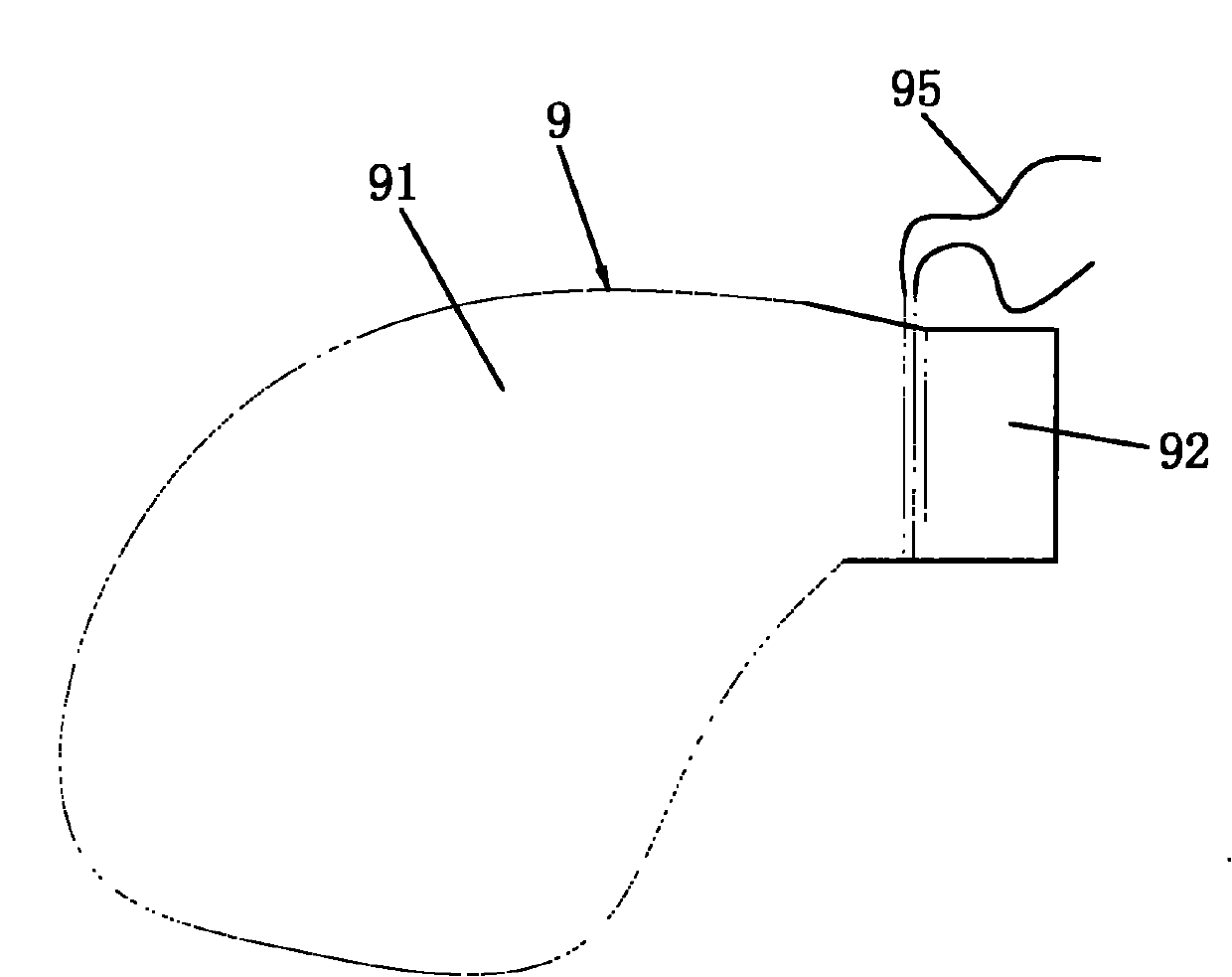

Device for charging dry air or nitrogen gas into semiconductor wafer storage container and wafer static charge removing apparatus utilizing the device

InactiveCN101730933AAvoid corrosionAvoid generatingSemiconductor/solid-state device manufacturingEngineeringProduct gas

Without the need to open the lid of semiconductor wafer storage container, there can be attained removal of any chemical gas present in the semiconductor wafer storage container and inhibition of acid generation therein. There is provided dry air or nitrogen gas charging device (A) connected and fixed to supply-side respiration orifice (8a) and discharge-side respiration orifice (8b) among multiple respiration orifices (8) disposed in bottom board (5) of semiconductor wafer storage container (1) accommodating semiconductor wafers (9), each of the respiration orifices (8a,8b) equipped with PTFE filter (7), which charging device (A) comprisesdry air / nitrogen gas supply part (11) for supplying dry air or nitrogen gas into the semiconductor wafer storage container (1) and used dry air / nitrogen gas discharge part (12) for discharging the dry air or nitrogen gas after, by means of the dry air or nitrogen gas fed into the semiconductor wafer storage container (1), not only removal of chemical gas within the semiconductor wafer storage container (1) but also inhibition of acid generation on the surface of semiconductor wafers by moisture removal.

Owner:KONDO IND +1

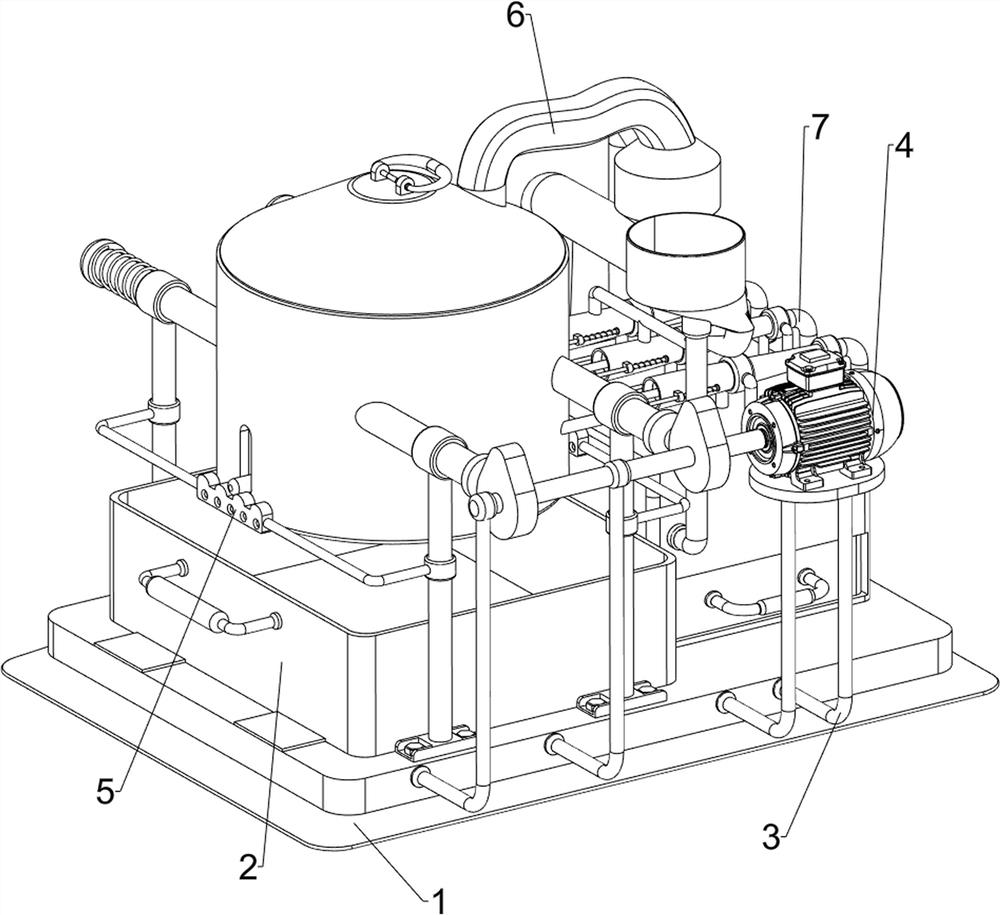

Intelligent smashing machine

ActiveCN105057049AReduce heatGeneration of remissionDirt cleaningGrain treatmentsEngineeringHeat energy

The invention discloses an intelligent smashing machine. The machine comprises a support, the support is provided with a machine body, a feed inlet is formed in the upper end of the machine body, and a discharge opening is formed in the lower end of the machine body. A rotary plate is arranged in the machine body, and a smashing cutter is arranged on the rotary plate. A motor is arranged outside the machine body and is connected with the rotary plate through a rotary shaft. A cooling layer is arranged in the machine body. A water inlet and a water outlet are formed in the cooling layer. A cooling water tank is arranged outside the machine body. The water inlet and the water outlet are connected with the cooling water tank through pipelines respectively. A water pump is arranged in the water inlet. Heat energy generated by the machine body when materials are smashed can be effectively reduced, work efficiency of the smashing machine is improved, and the service life of the smashing machine can be prolonged.

Owner:汕头市合田机械制造有限公司

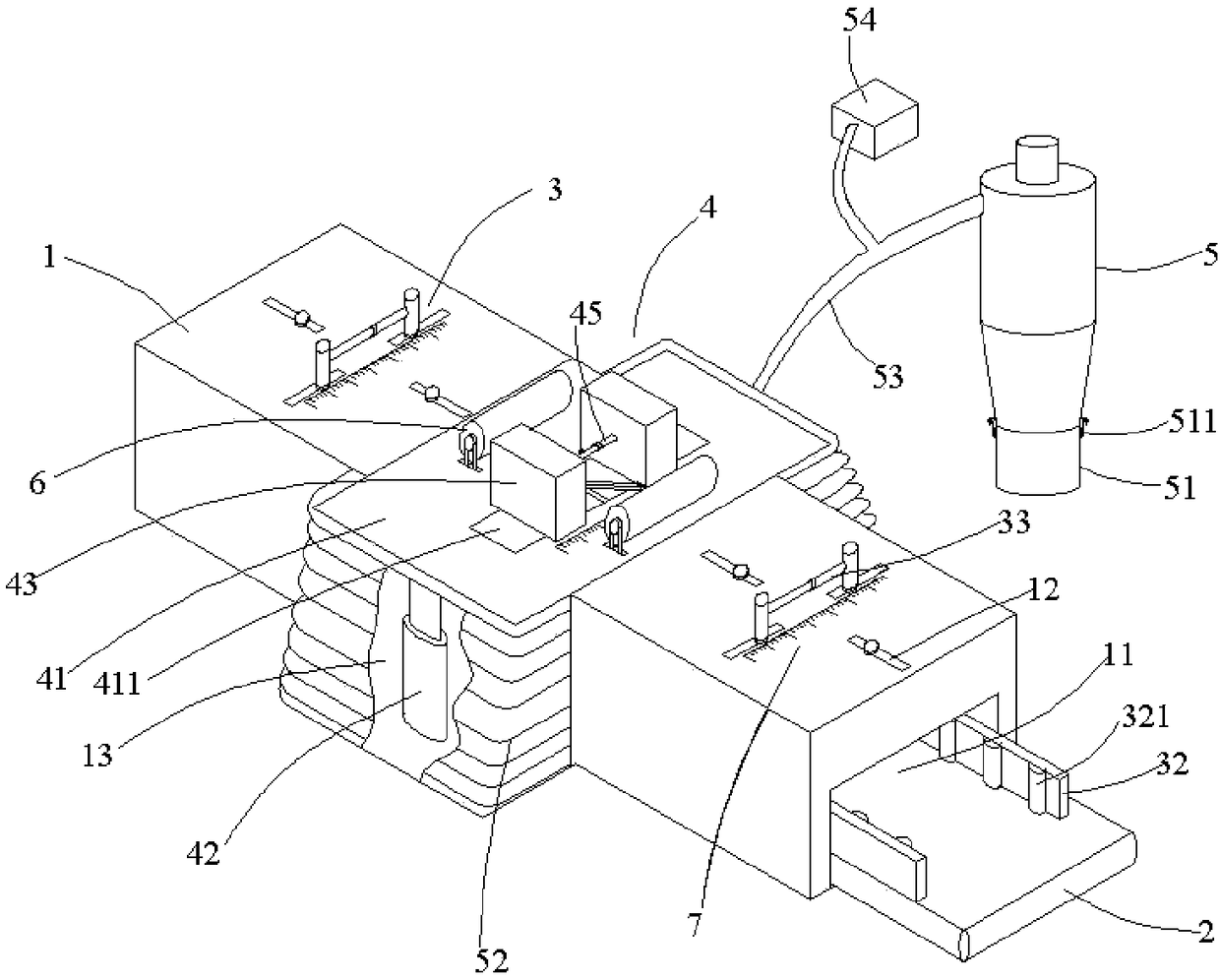

Bush trimming treatment equipment for roads of sponge cities

PendingCN111615945AAchieve pruningReduce laborHedge trimming apparatusCuttersAgricultural engineeringStructural engineering

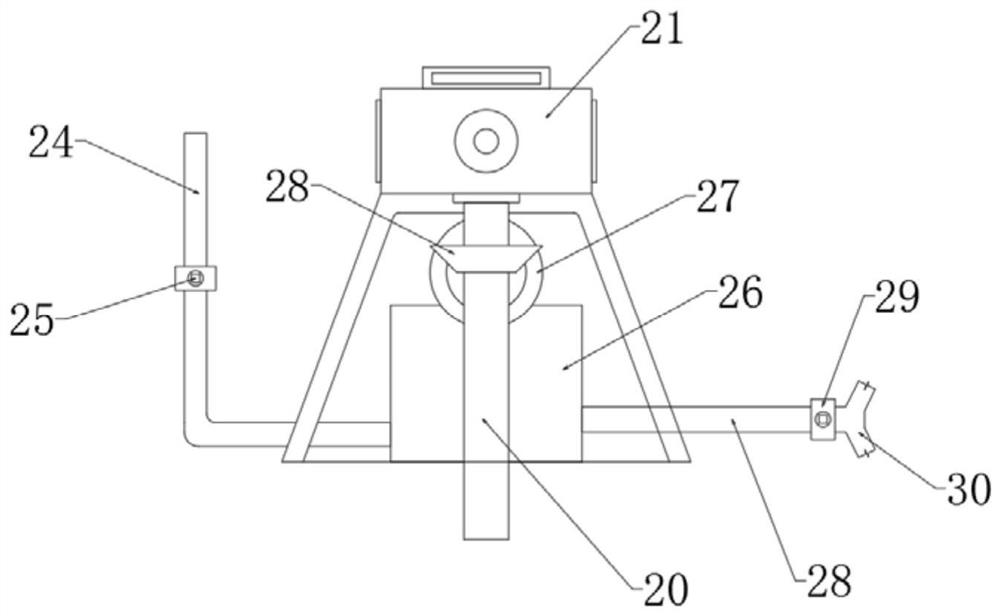

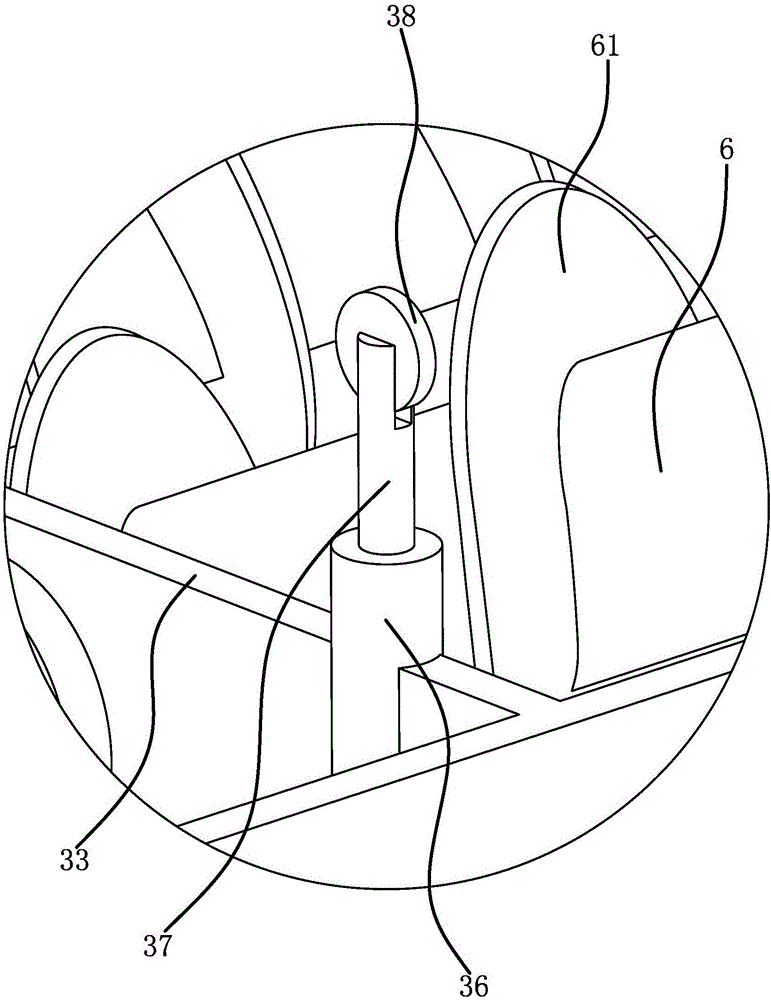

The invention discloses bush trimming treatment equipment for roads of sponge cities. The bush trimming treatment equipment comprises two protection plates, wherein an operation table is fixedly connected to the two protection plates, a cabin is arranged on the operation table, tracks are respectively mounted at the bottoms of the two protecting plates, two air cylinders are arranged at the bottomof the operation table and on two opposite surfaces of the two protection plates, a cutting mechanism located in a shield on the same side is mounted on each of three rotating rods, two support blocks are fixedly connected to one opposite surfaces of the two protection plates, and negative pressure fans are respectively arranged on the rear sides of the shields and on the two support blocks. Thebush trimming treatment equipment is reasonable in structure, can perform effective and efficient trimming on bushes, and can collect leaves obtained by trimming, the labor force of personnel is reduced, the investment of the personnel is reduced, trimmed bushes can be sprayed with water, flying dust during trimming of the bushes can be reduced, and influence on periphery environment is reduced.

Owner:黄汉凡

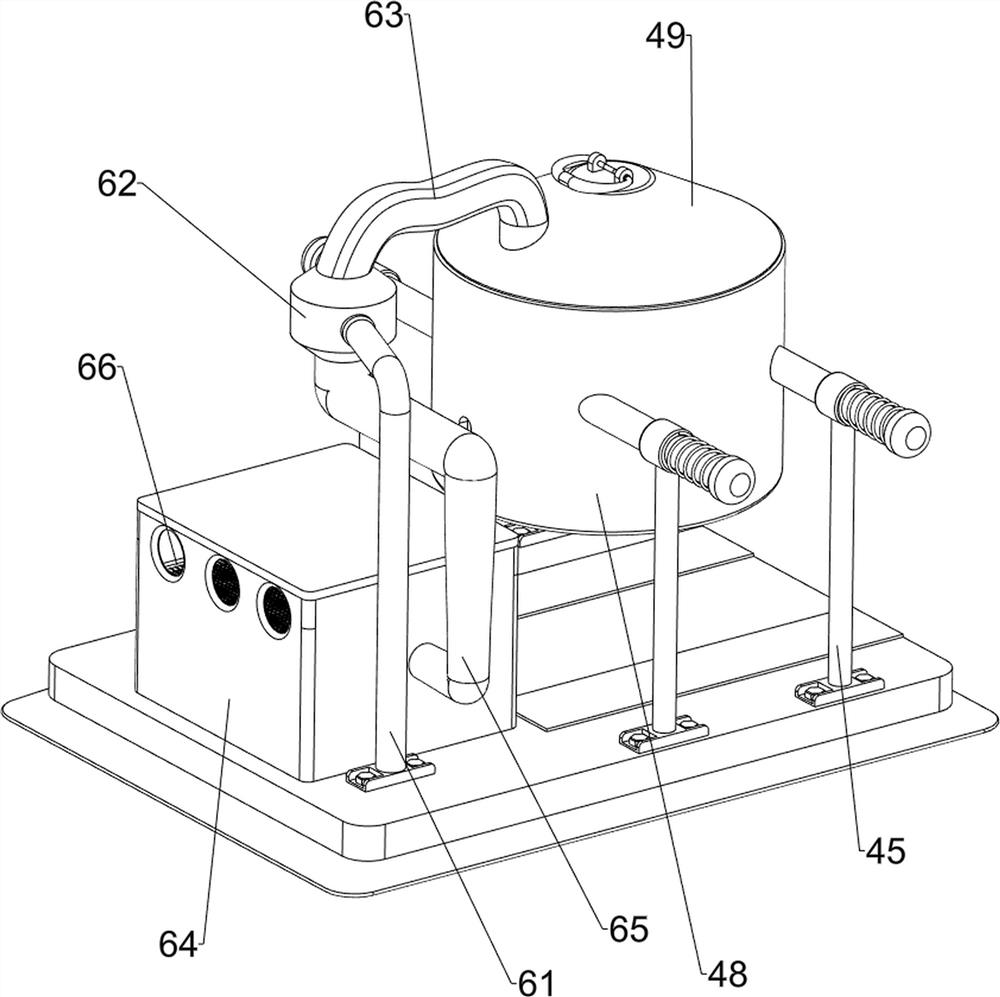

Recycling device for waste silicon rubber material

InactiveCN108819032ACompletely brokenAvoid flyingPlastic recyclingDirt cleaningSilicon rubberWaste management

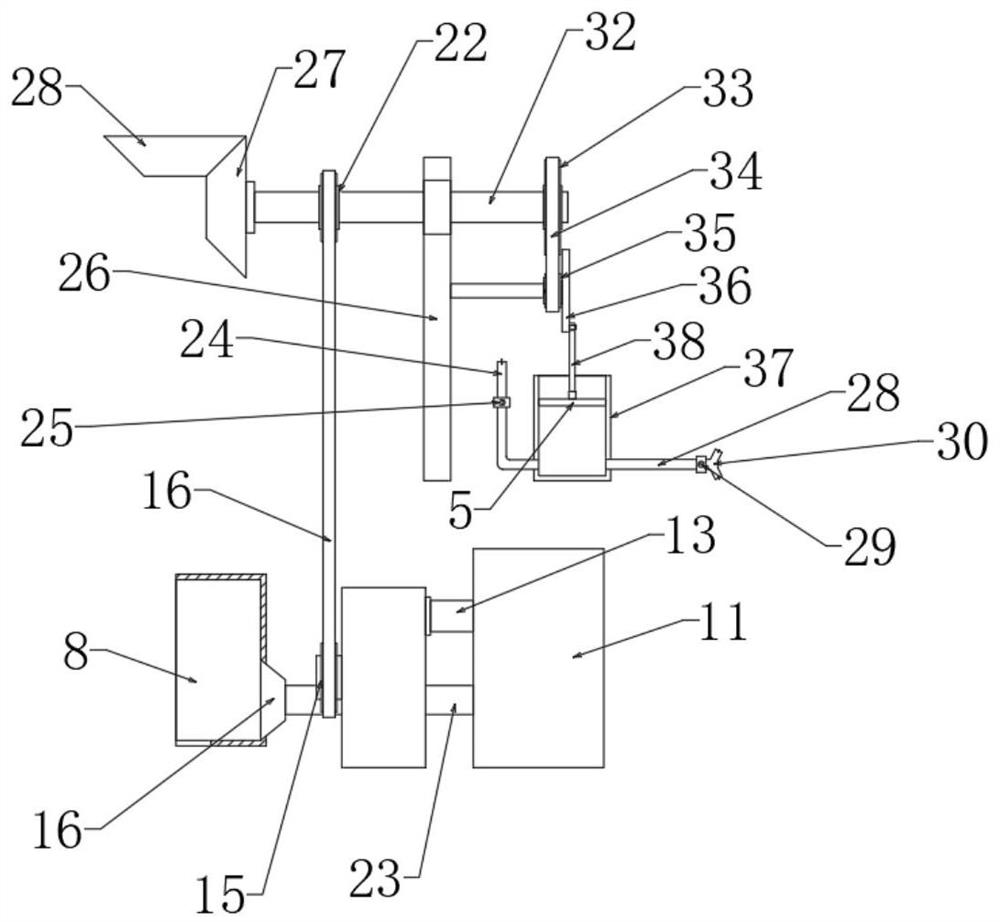

The invention belongs to the field of the silicon rubber regeneration, and particularly relates to a recycling device for a waste silicon rubber material. A technical problem to be solved is to provide the recycling device for the waste silicon rubber material which is capable of treating dust generated by crushing silicon rubber, guaranteeing that the environment is not polluted by the dust, andenabling the silicon rubber to be completely crushed. The recycling device for the waste silicon rubber material comprises a first installing plate, a bottom plate, a first collecting frame, a secondinstalling plate, a discharging funnel, a first screen plate, a crushing wheel, a first gear, a second gear, a motor, a fourth rotation shaft, a second belt pulley, a butterfly bolt and a sliding sleeve and the like. The first installing plate is fixedly connected to one side part of the bottom plate. The second installing plate is fixedly connected to the other side part of the bottom plate. Therecycling device for the waste silicon rubber material is capable of achieving the effects that the waste silicon rubber material is completely crushed, and the dust cannot be generated in a crushingprocess so that the environment cannot be polluted.

Owner:冉朝鹏

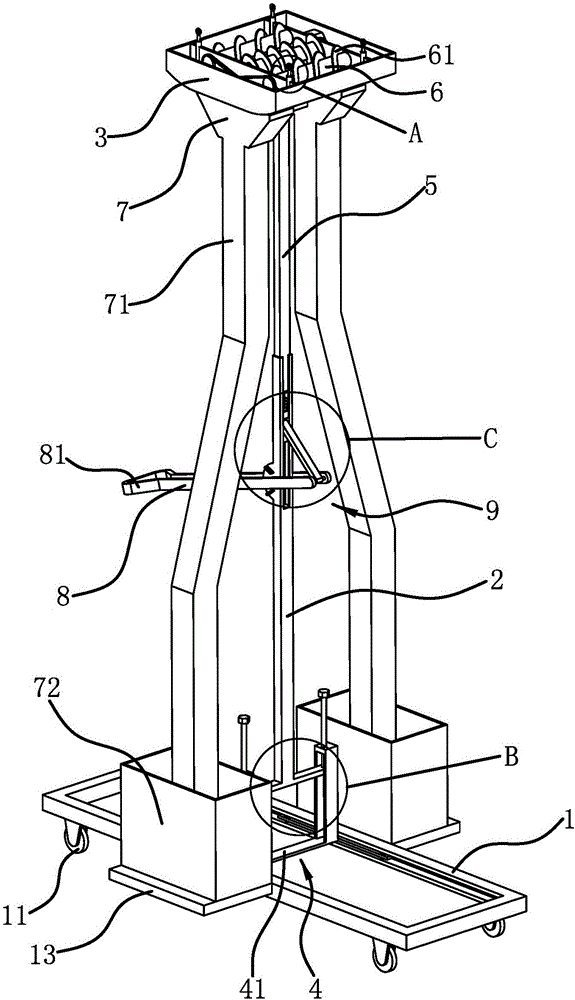

Ash-shoveling device for top surface of house

The invention provides an ash-shoveling device for a top surface of a house, pertaining to the technical field of building construction equipment. Therefore, the problem that ash in the top surface of the house is hard to shovel is solved. The device comprises a bottom frame, a support rod and a shell. The bottom frame is slidably connected with a movable frame. The lower end of the support rod is fixedly connected to the movable frame. The upper end of the support rod is slidably connected with an adjusting rod. The shell is fixedly connected to the upper end of the adjusting rod. Three rotary shafts are rotatably connected in the shell. The outer side walls of the three rotary shafts are provided with blades. The shell is provided with a first motor capable of driving the two rotary shafts on two sides to rotate. The shell is further provided with a second motor capable of driving a rotary shaft in the middle to rotate. Two ash-guiding hoppers are fixedly connected below the shell having ash outlets. The support rod is hinged onto a control push rod. The ash-shoveling device for the top surface of the house is used conveniently and saves force and has good ash-shoveling effect.

Owner:达濠市政建设有限公司

Grinding machine with efficient dust removing function

PendingCN111546201AImprove adsorption capacityWill not affect healthUsing liquid separation agentDirt cleaningPhysical healthReciprocating motion

The invention belongs to the field of grinding machines, and particularly relates to a grinding machine with an efficient dust removing function. The grinding machine aims at the problems that in theprocess that raw materials are machined by an existing grinding machine, dust is generated, serious pollution is caused, and therefore the physical health of operators is influenced; and meanwhile thedust falls onto mechanical equipment to be accumulated, and the mechanical equipment is likely to be damaged. According to the following scheme, the grinding machine comprises an operation table, thetop of the operation table is fixedly connected with a grinding machine body, and the top of the operation table is fixedly connected with a dustproof frame; and the grinding machine body is locatedin the dustproof frame, and one side of the dustproof frame is fixedly connected with a supporting plate. The grinding machine is reasonable in structure and easy to operate, a driving motor can drivea dust suction cover to do transverse reciprocating motion, and therefore the dust suction area is increased, dust removal is more efficient, then the physical health of the operators cannot be influenced, and harm of the dust to the mechanical equipment can be avoided.

Owner:YANCHENG INST OF IND TECH

Pavement cutting apparatus used for road and bridge construction

The invention relates to a pavement cutting apparatus, and especially relates to a pavement cutting apparatus used for road and bridge construction. A technical problem to be solved in the present invention is to provide the pavement cutting apparatus used for road and bridge construction, having the advantages of no dust flying during cutting, high cutting rate, and time and labor saving. The pavement cutting apparatus used for road and bridge construction comprises universal wheels, a baseboard, a pusher, a left support, a cylinder and a driving device; and the bottom of the baseboard is provided with the universal wheels, the pusher is arranged at the left end of the baseboard, the left support is arranged at the left side of the top of the baseboard, the cylinder is arranged at the left side of the top in the left support, the driving mechanism is arranged at the middle portion of the right side of the left support, a right support is arranged at the right side of the top of the baseboard, and a cutting device is arranged at the middle portion of the baseboard. The pavement cutting apparatus used for road and bridge construction has the advantages of no dust flying during cutting, high cutting rate, and time and labor saving.

Owner:李建云

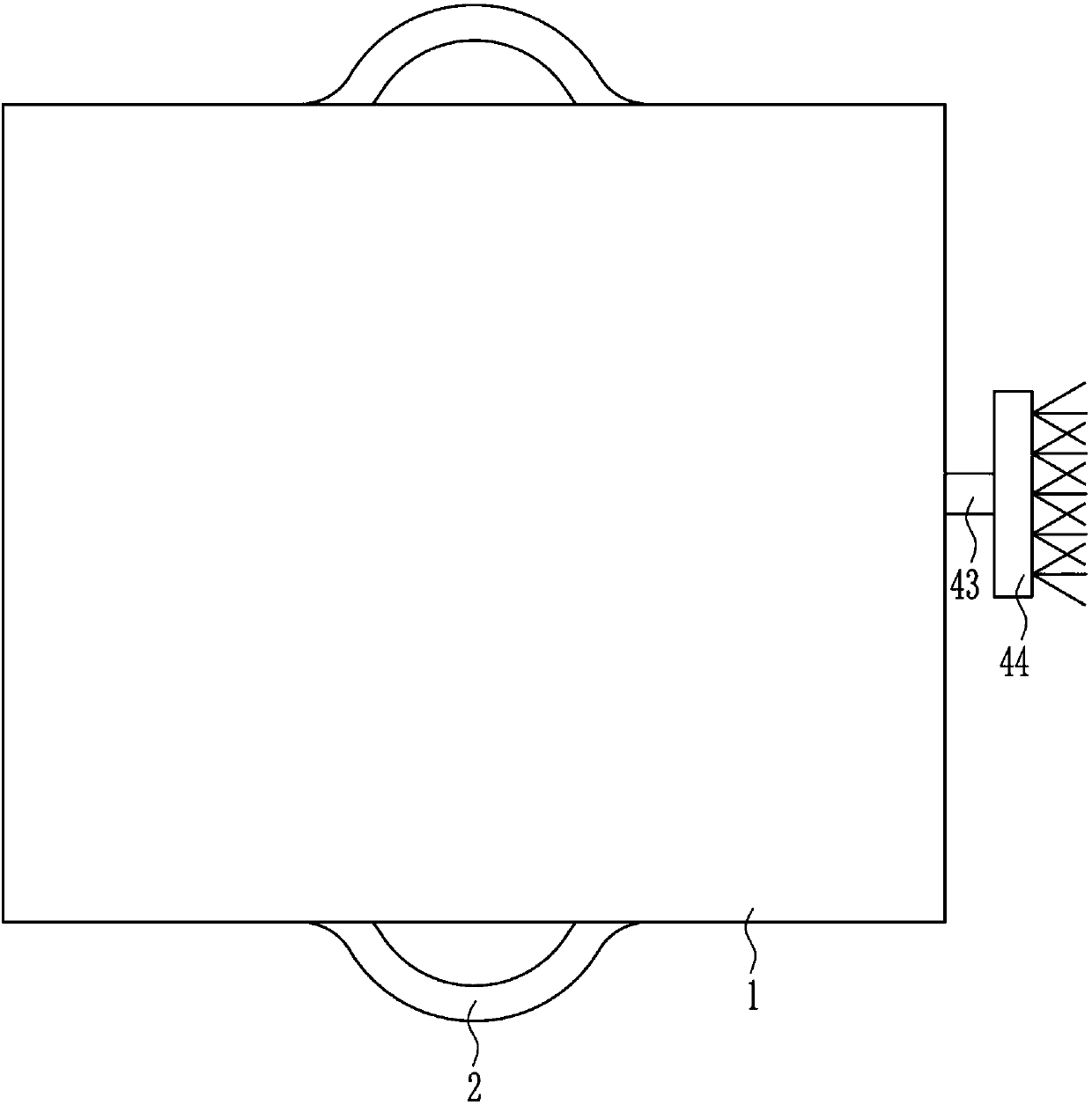

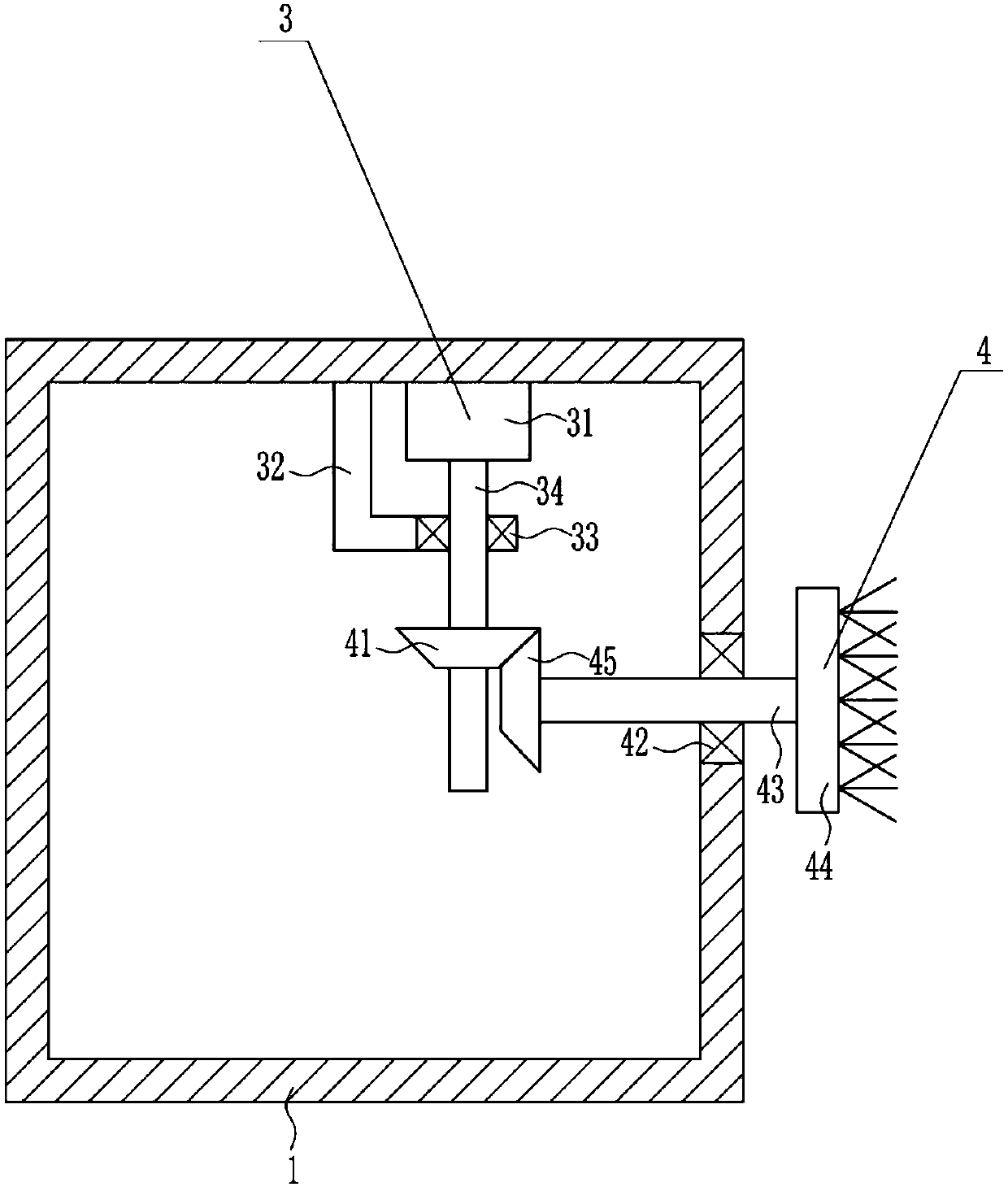

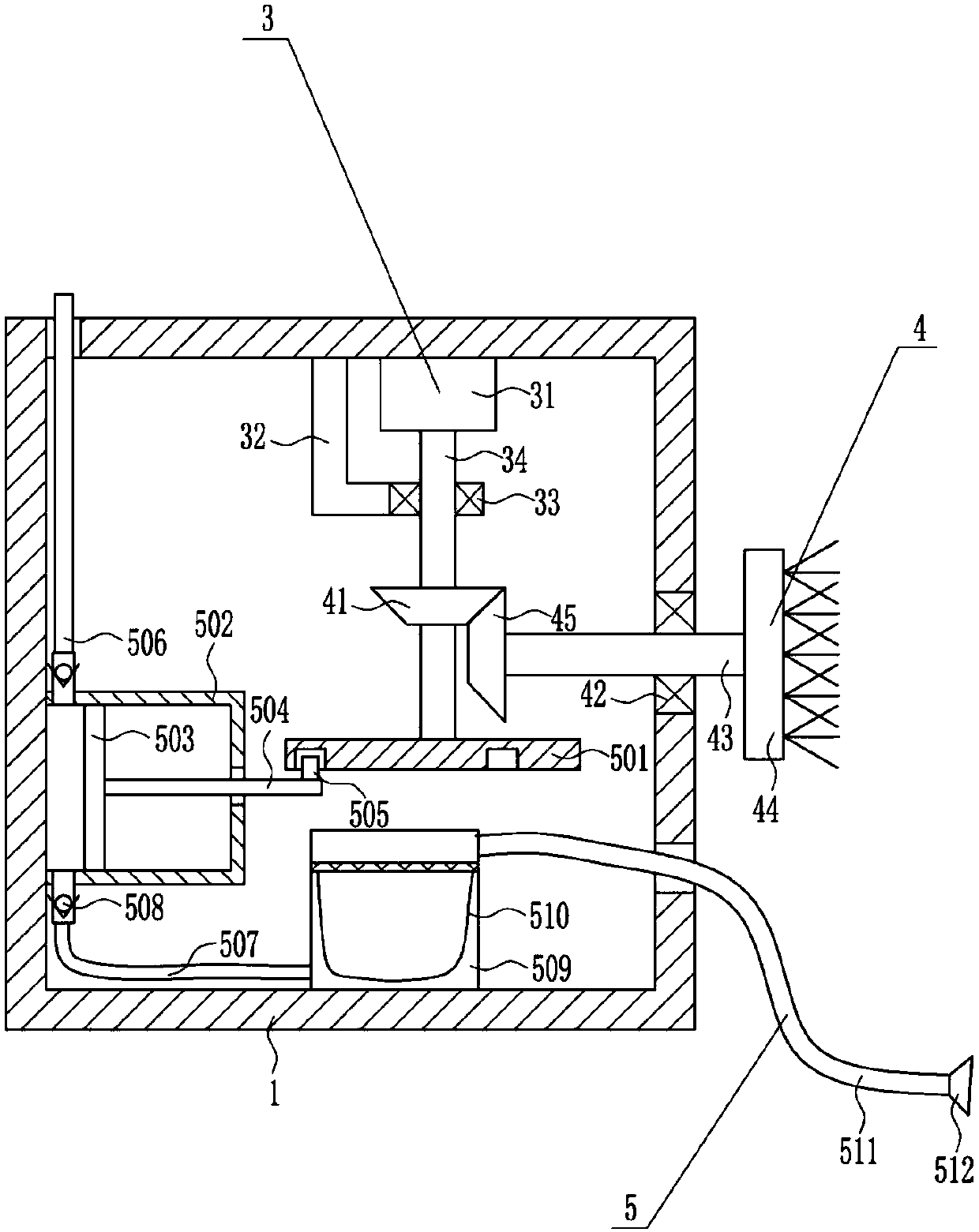

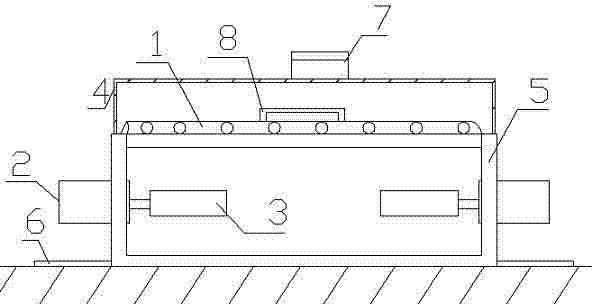

Dust removal device for automobile audio loudspeaker

InactiveCN107899990AWon't flyShorten the timeCleaning using toolsCleaning using gasesEngineeringLoudspeaker

The invention relates to a dust removal device, in particular to the dust removal device for an automobile sound equipment loudspeaker. The dust removal device for the automobile sound equipment loudspeaker is capable of being saved in time, dust is prevented from flying in the dust removal process, and the dust removal effect is good. The dust removal device for the automobile sound equipment loudspeaker comprises a box body and the like, wherein handles are symmetrically arranged in the middle of inner top of the box body in a front-back mode, a driving device is arranged in the middle partof the inner top of the box body, a dust sweeping device is arranged on the right side in the box body, the dust sweeping device is matched with the driving device, and a dust sweeping component of the dust sweeping device is located on the right side outside the box body. According to the dust removal device, the dust sweeping part of the dust sweeping device is driven by the driving device to perform dust removal on the loudspeaker, dust is sucked into a dust suction device, so that the dust is prevented from flying, and therefore time is saved, the dust is prevented from flying in the dustremoval process, and the dust removal effect is good.

Owner:李镜萍

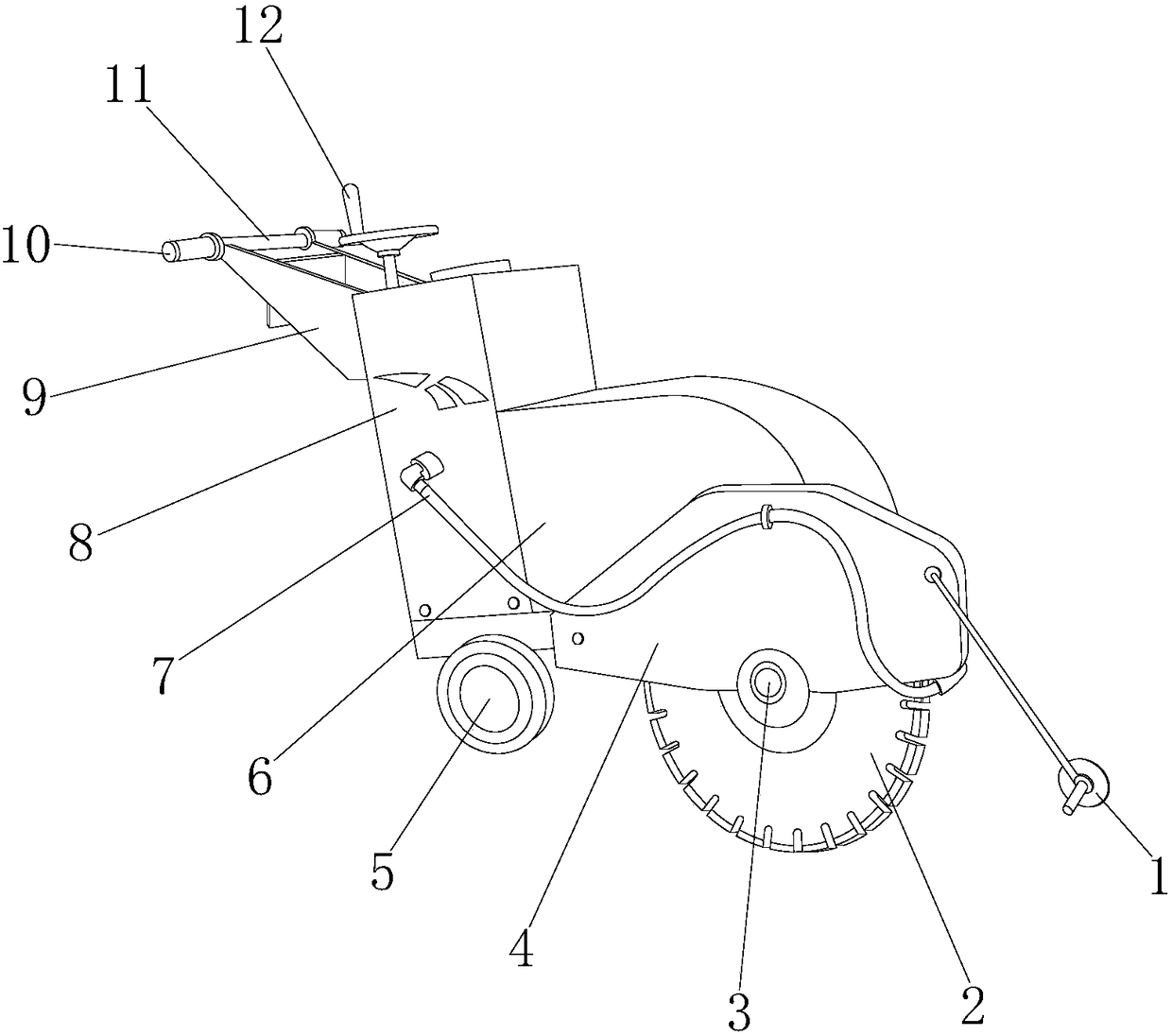

Automatic cutting equipment for asphalt concrete road construction

PendingCN108560382AEasy to useGood for physical and mental healthRoad cleaningRoads maintainenceArchitectural engineeringRoad surface

The invention discloses automatic cutting equipment for asphalt concrete road construction. The structure of the automatic cutting equipment for the asphalt concrete road construction comprises a linear cutting marker, a cutting blade, a mounting shaft, a protective cover, wheels, a starting mechanism, a water spraying pipe, a dustproof water tank, a triangular fixing plate, an accelerator handle,a supporting rod and a cutting depth adjuster; the linear cutting marker is horizontally fixed at the side end of the protective cover and matched with the cutting blade; the section of the cutting blade is of a circular structure; and the cutting blade is horizontally embedded in the outer ring of the mounting shaft and connected with the mounting shaft by using threads. According to the automatic cutting equipment for the asphalt concrete road construction, by using the starting mechanism, the automatic cutting equipment for the asphalt concrete road construction is safe and convenient forworking personnel to use; by using the water spraying pipe to spray water to a pavement to be cut, flying dusts can be prevented from flying during cutting the pavement to be beneficial for physical and psychological health of the working personnel; by using an infrared receiving device and an infrared transmitting device in the structure of the linear cutting marker to locate the cutting distance, the cutting operation is made more convenient, and the distance between two cutting joints is made more accurate.

Owner:沈志成

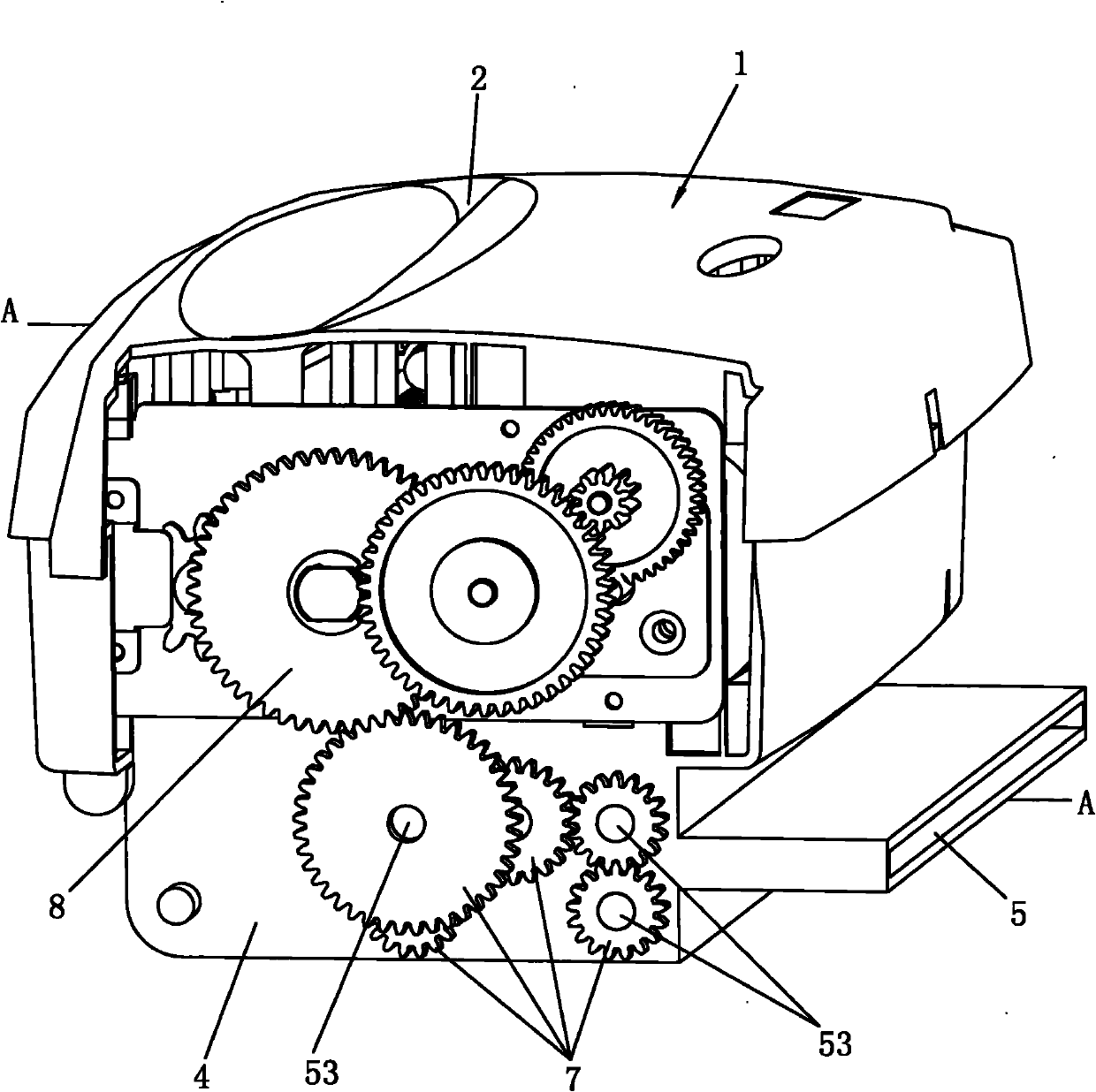

Method for discharging and collecting paper for paper shredder and paper shredder with function of discharging paper

InactiveCN101829622AReduce volumeEasy to handleGrain treatmentsPressesPaper dustPulp and paper industry

The invention relates to the technical field of paper shredders, in particular to a method for discharging and collecting paper for a paper shredder and the paper shredder with the function of discharging paper. In the method for discharging and collecting the paper, a paper-discharging device is arranged at the bottom of a paper shredder head; the paper-discharging device adopts the structure of a push plate, a screw or a conveyer belt; the paper scrap which falls off from a paper outlet is received through the paper-discharging device; and the paper-discharging device conveys the paper scrap into a paper scrap collecting bag through a paper scrap output interface, so that a user directly handle the paper scrap collecting bag. Due to the adoption of the method for discharging and collecting the paper, a garbage can is not needed, and the volume of the paper shredder is greatly reduced. The user does not need to clean the paper shredder either, and in the process of handling the paper scrap collecting bag, the paper scrap cannot fly everywhere or pollute the environment; and more convenience for handling the paper scrap is provided for the user.

Owner:DONGGUAN BONSEN ELECTRONICS

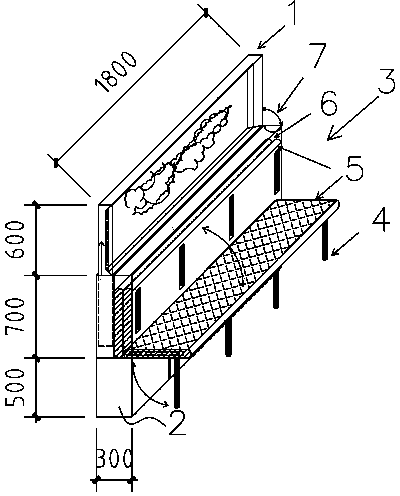

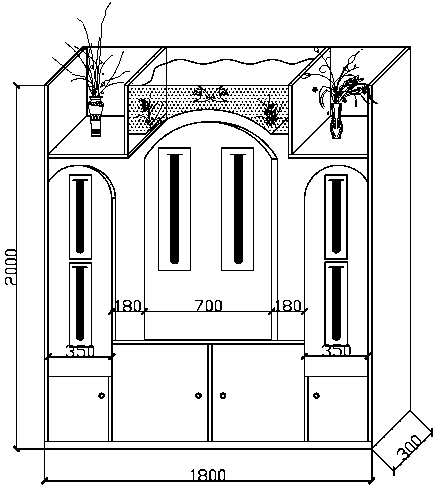

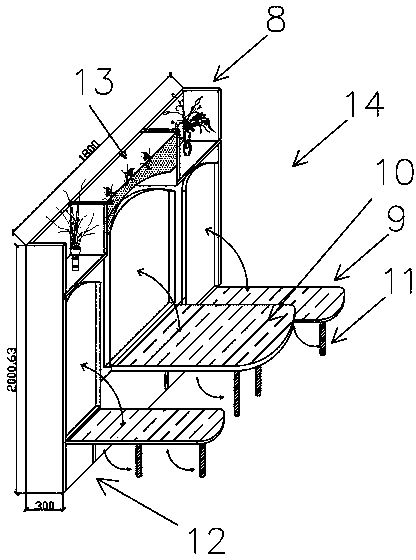

Interior decoration method achieved through home, furniture and decoration unitary combination three-dimensional modules

InactiveCN104131664AWon't flyAvoid wastingCovering/liningsSectional furnitureConstruction engineeringBuilding renovation

The invention discloses an interior decoration method achieved through home, furniture and decoration unitary combination three-dimensional modules. According to the interior decoration method, home, furniture and decoration are melted in various three-dimensional modules with proper models, sizes and weights, the three-dimensional modules can be carried by people and are fixedly installed on walls, floors or ceilings in a combination mode, interior decoration and furniture arrangement can be finished simultaneously, no cutting noise, no building rubbish and no rising dust exist on a construction site, onsite assembling time can be shortened to one day due to integration, the modules can be separately arranged or combined, the various arrangement modes of the modules can meet various requirements of men and women and people at different ages, of different heights and with different kinds of work and hobbies, interior decoration is customized and personalized, home life is intelligent and high-end, furniture is foldable, space utilization is optimized to the largest extent, the combined modules are convenient to assemble and disassemble and are recyclable, waste of building materials, panels and the furniture is prevented, more available space is created, occupied space is reduced, expenses of building decoration and the furniture are reduced, and the interior decoration method accords with the principles of green ecology, low carbon, energy conservation and environment protection.

Owner:聂小勤

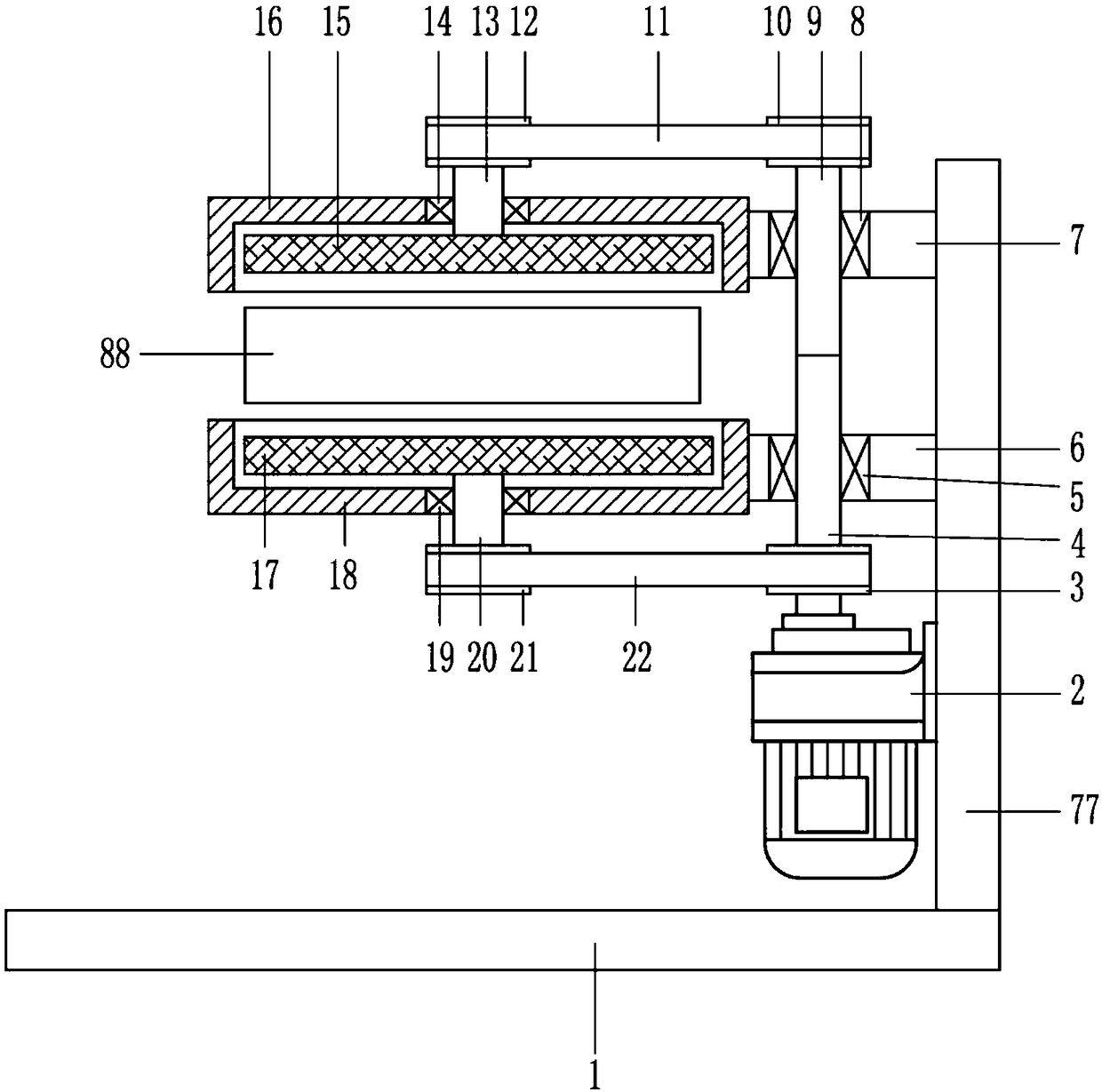

Wood double-sided grinding machine for furniture manufacturing

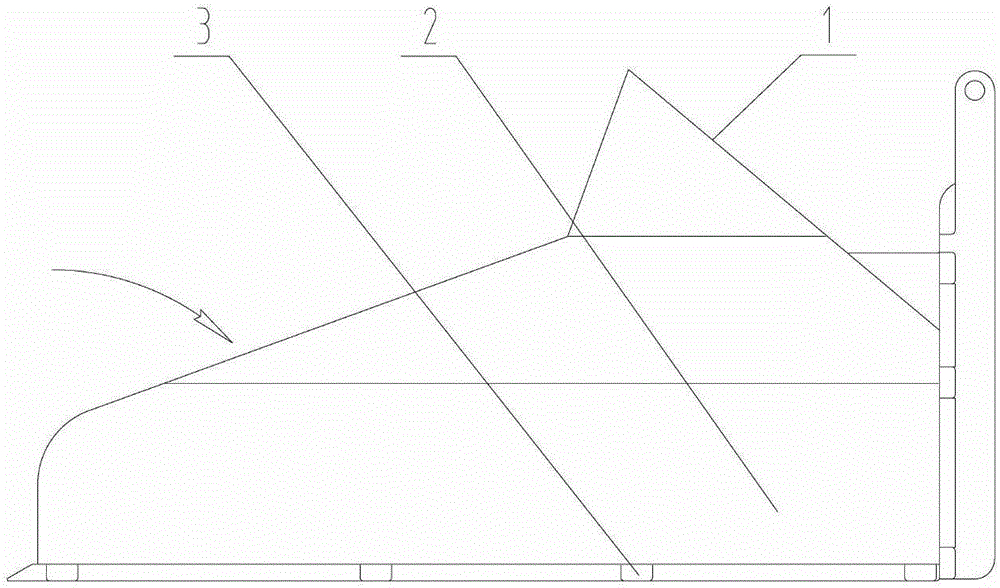

InactiveCN108907936BImprove grinding efficiencyWon't flyGrinding machine componentsPlane surface grinding machinesSanderPolishing

The invention belongs to the field of a wood machining, and particularly relates to a double-sided polishing machine for a wood used for manufacturing furniture. The invention aims to solve a technical problem that polishing efficiency can be improved and a large amount of dust generated in the polishing process can be avoided by providing the double-sided polishing machine for the wood used for manufacturing the furniture and in order to solve the technical problem, the invention provides the double-sided polishing machine for the wood used for manufacturing the furniture. The double-sided polishing machine comprises a mounting plate, a bottom plate, a motor, a first belt wheel, a first rotating shaft, a first bearing seat, a first connecting plate, the second connecting plate, the secondbearing seat, the second rotating shaft, the second belt wheel, a first flat belt, a supporting seat and a guide roller and the like. The mounting plate is fixedly connected with one side part of thebottom plate, a first dustproof frame is fixedly connected with the mounting plate through the second connecting plate, and the second dustproof frame is fixedly connected with the mounting plate through the first connecting plate. According to the double-sided polishing machine, the wood polishing efficiency is improved, and an effect that not too much dust is generated in the polishing processis ensured.

Owner:佛山市新铭思家具有限公司

Clamping type coat hanger edge grinding machine with dust collection device

InactiveCN108637834AConsistent sandingDistance balanceEdge grinding machinesGrinding work supportsEngineeringWood processing

The invention relates to the technical field of wood processing equipment, in particular to a clamping type coat hanger edge grinding machine with a dust collection device. The clamping type coat hanger edge grinding machine with the dust collection device comprises a box, a conveyor belt, deviation prevention devices, an edge grinding device and the dust collection device. The conveyor belt penetrates the box, and the two ends of the conveyor belt extend out of feed ports correspondingly. The two deviation prevention devices are located at the two ends in the box. Each deviation prevention device comprises a rhombus movable frame, limiting plates and a first adjusting rod. The deviation prevention devices can accurately feed materials to the edge grinding device or discharge the materialsout of the edge grinding device. The edge grinding device is located between the two deviation prevention devices, can polish the edges of the materials and can be suitable for the materials with different thicknesses. The dust collection device is used for collecting the dust generated by the edge grinding device. The clamping type coat hanger edge grinding machine with the dust collection device can polish the edges of rapid clamping type coat hangers and can be suitable for polishing the clamping wood coat hangers with various specifications.

Owner:广西荔浦安吉利木业有限公司

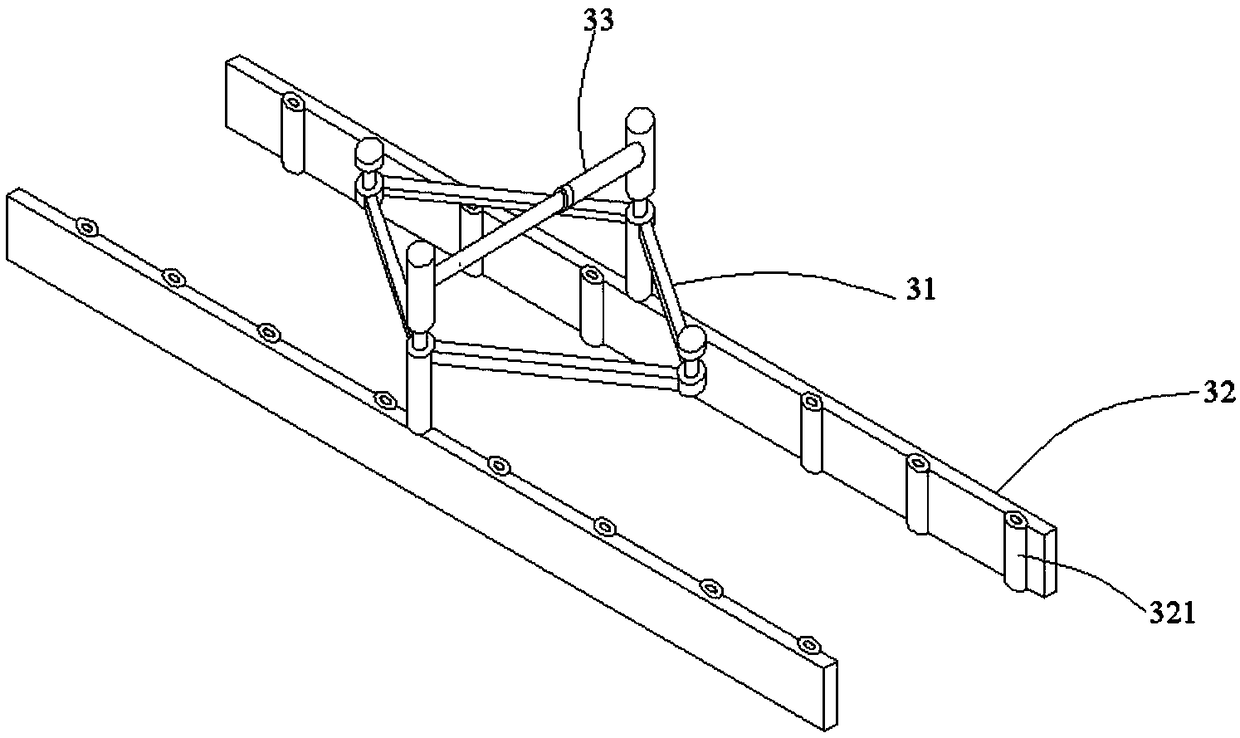

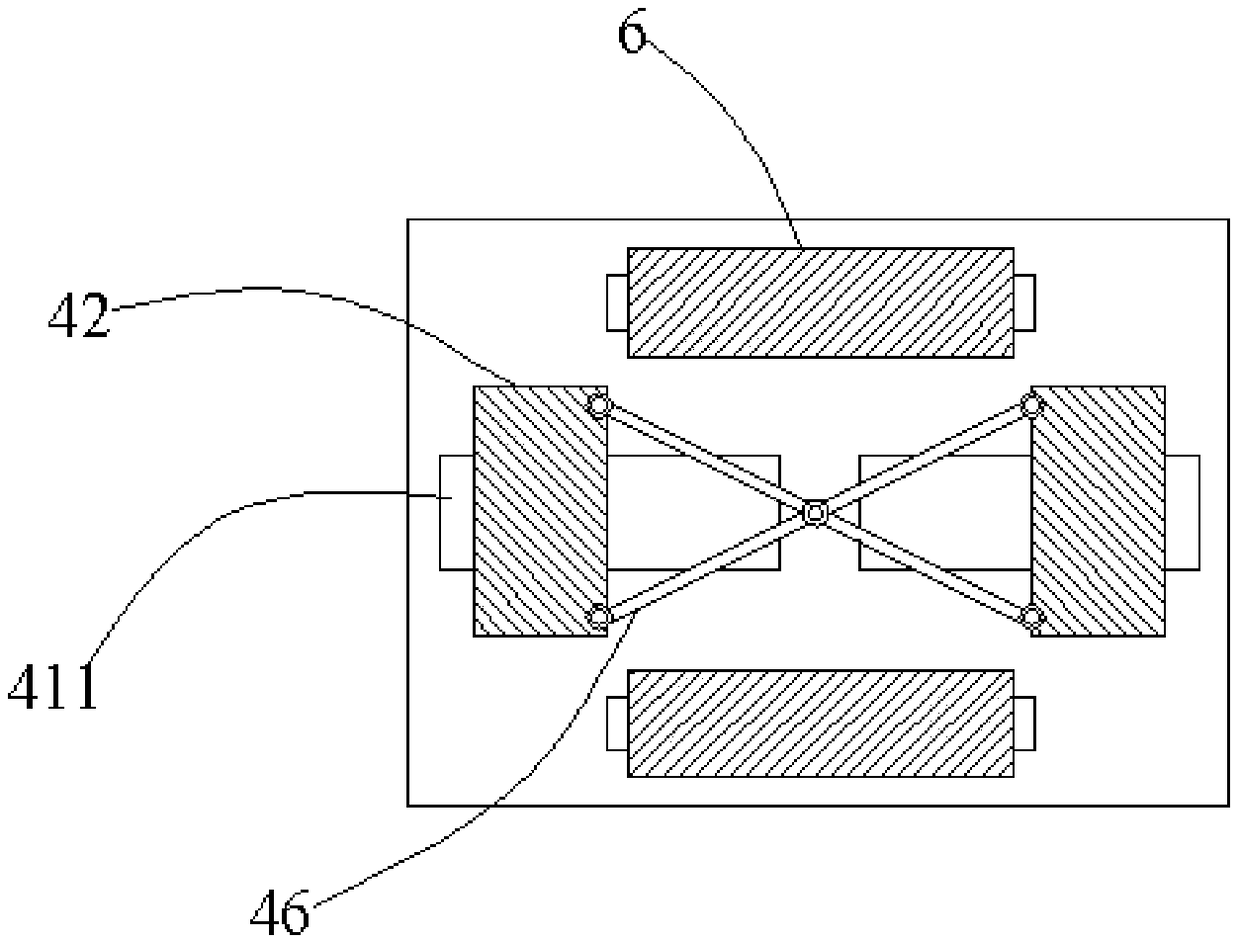

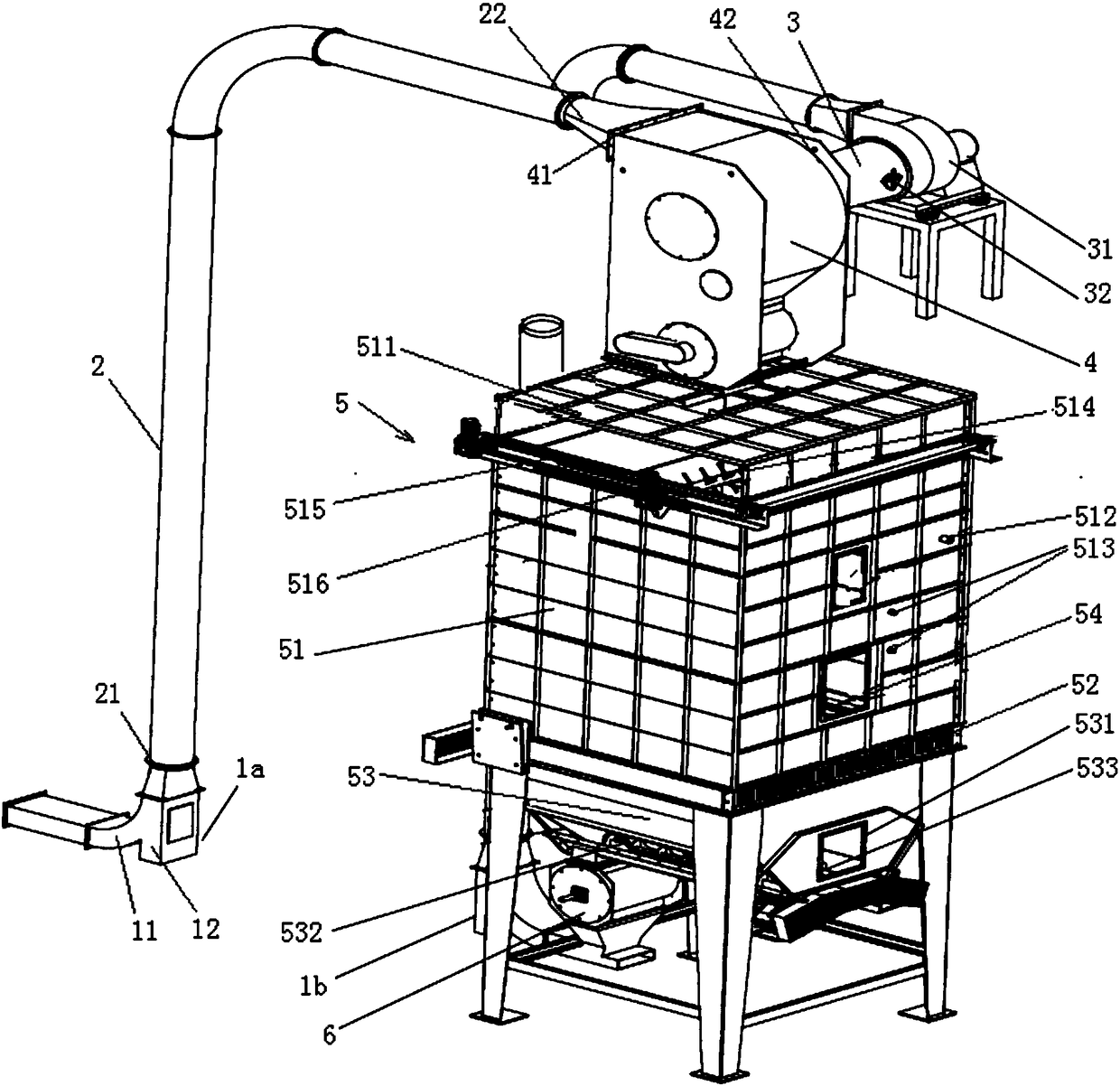

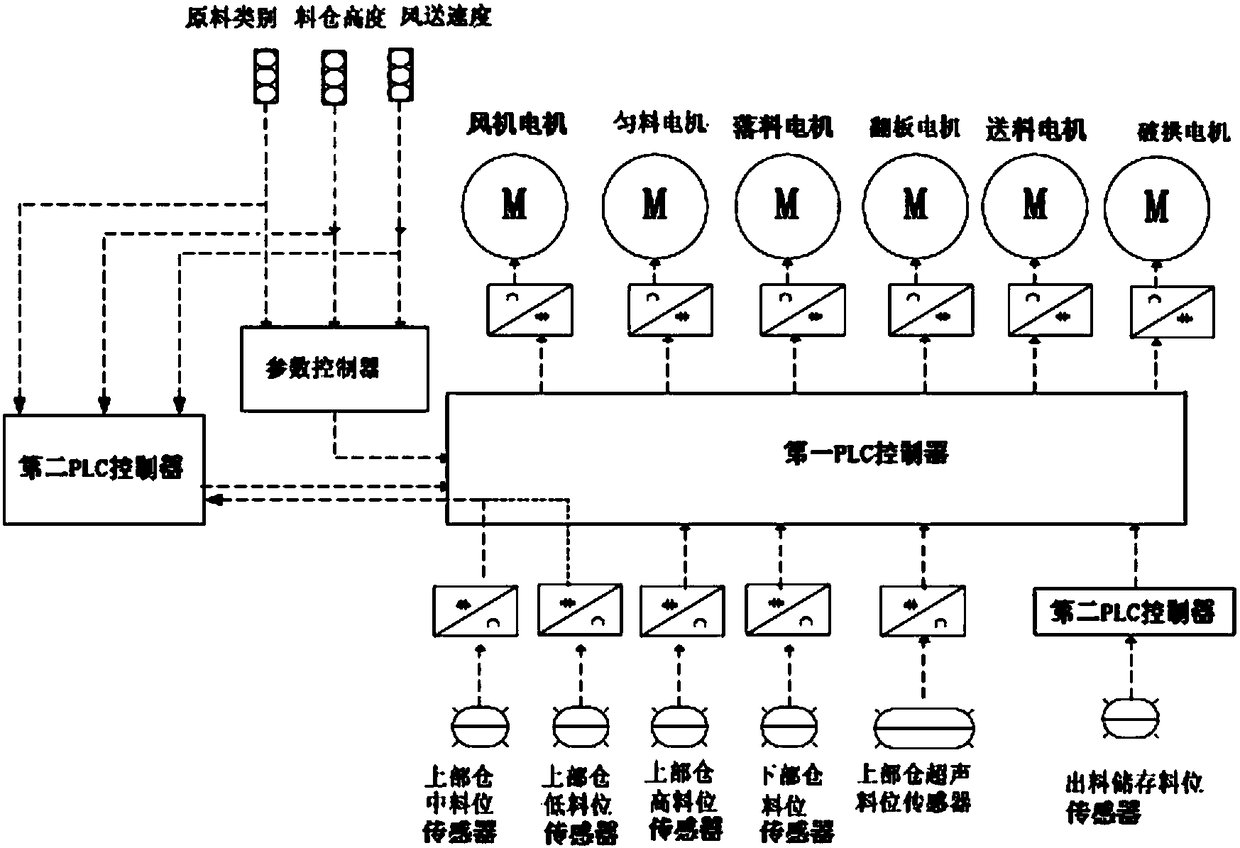

Vertical device for removing impurities and storing tobacco chips

The invention relates to a vertical device for purifying and storing tobacco fragments. The vertical device comprises a feeding air duct, a storage cabinet, a first blanking box and an air suction duct, wherein the first blanking box is arranged above the storage cabinet, and is communicated with the bottom of the first blanking box and the top of the storage cabinet; the feeding air duct is provided with a suction port and a feeding port; the side face of the first blanking box is provided with a feeding hole; the feeding hole is hermetically connected with the feeding port of the feeding air duct; the air suction duct is communicated with the first blanking box, and can generate a negative pressure lower than an air pressure at the suction port of the feeding air duct on the feeding hole of the first blanking box to absorb the tobacco fragments into the first blanking box through the feeding air duct; then, the tobacco fragments fall into the storage cabinet through the first blanking box; a heavy separator is connected to the suction port of the feeding air duct, and can be used for removing heavy purities in the tobacco fragments. By adopting the vertical device, the tobacco fragments are absorbed into the enclosed storage cabinet, and powder in the tobacco fragments is prevented from flying.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

Differential pressure type multi-effect control dust collector

The invention discloses a differential pressure type multi-effect control dust collector, which comprises a garbage classification assembly, wherein the garbage classification assembly is located on one side of a dust collection channel assembly, the garbage classification assembly is connected with the dust collection channel assembly through a pipeline, a garbage treatment assembly is arranged on one side of the garbage classification assembly, and the garbage treatment assembly is connected with the garbage classification assembly in a sliding manner; and the self-cleaning mechanism comprises a self-cleaning pipeline assembly, and the self-cleaning pipeline assembly is in pipeline connection with a garbage distribution assembly and the dust collection channel assembly. By arranging themain dust collection channel, garbage dust can be adsorbed into the main dust collection channel through suction force of an air suction pump, then garbage of different masses can be classified and recycled through air suction ports in the rear portions of the dust collection cavities, and thus the treatment is more convenient; and by arranging a differential pressure control valve, the differential pressure control valve can be more stable in the using process due to the fact that the flowability of the non-Newtonian fluid is small.

Owner:钱才英

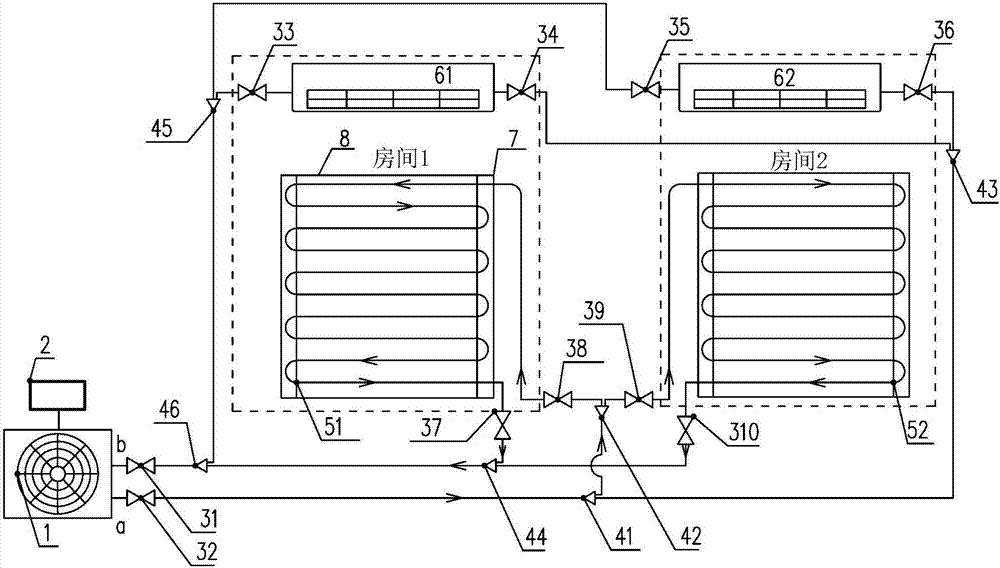

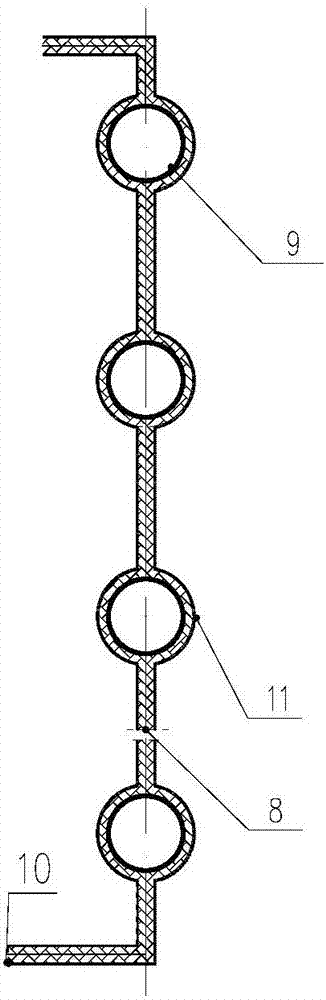

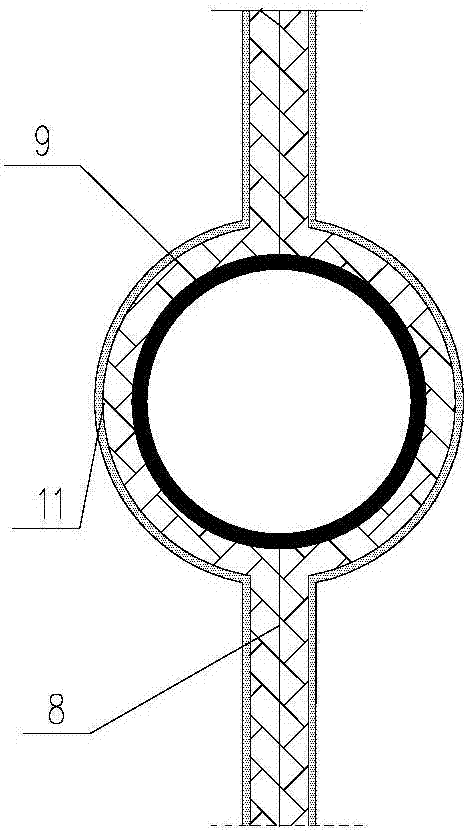

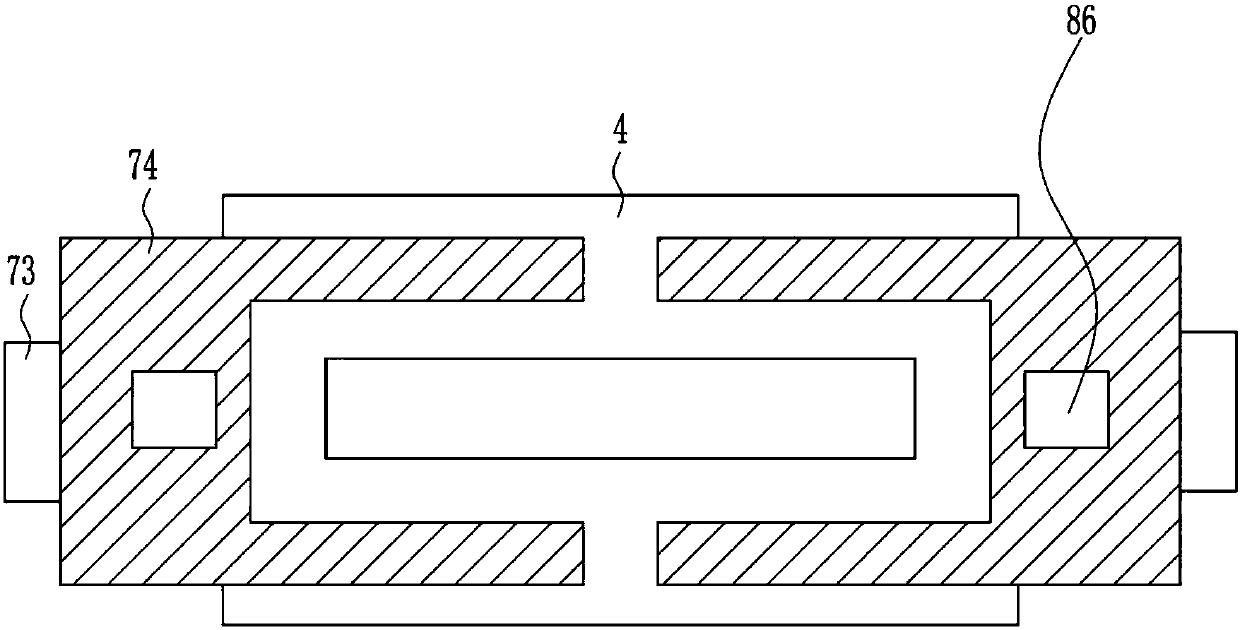

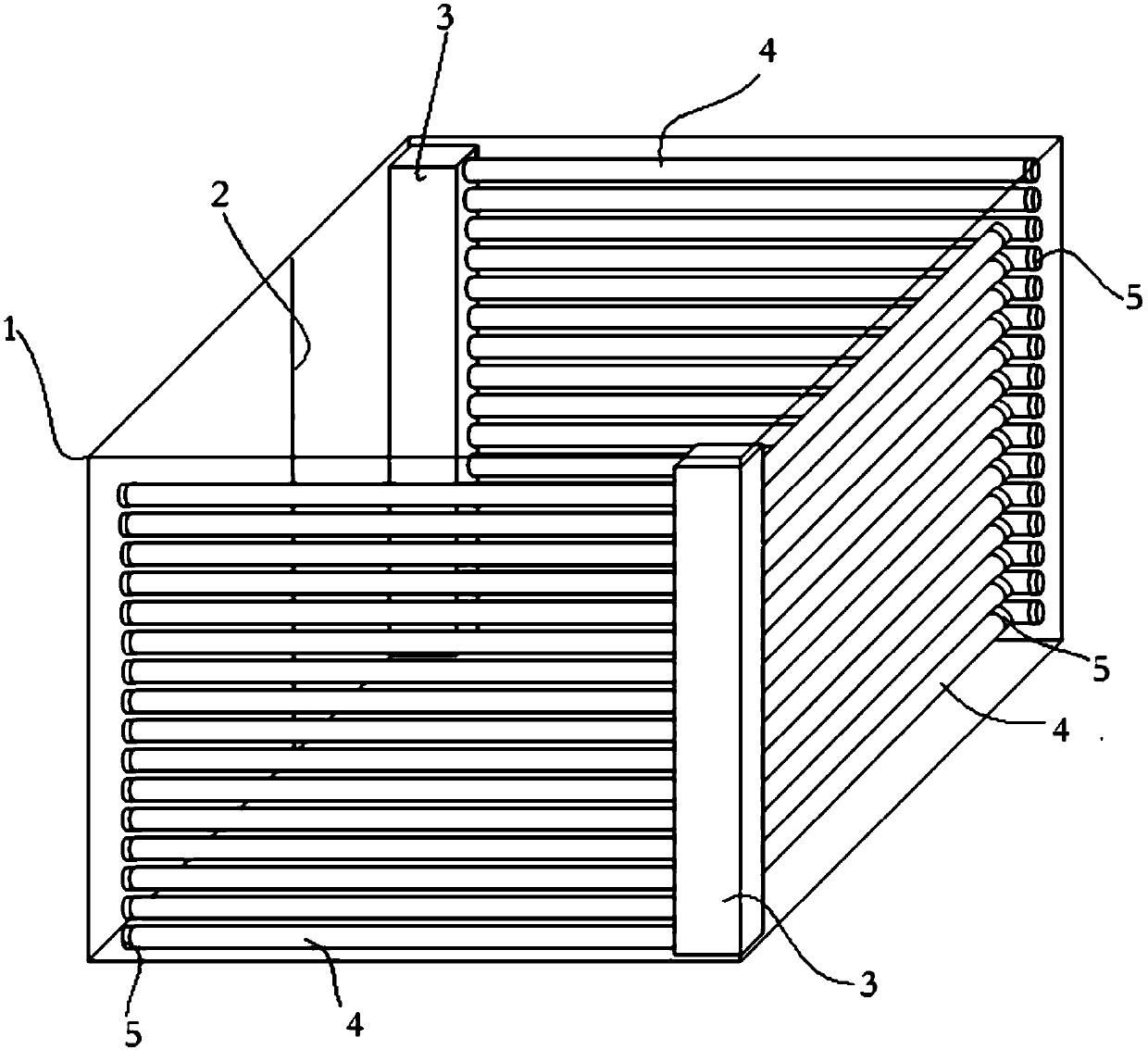

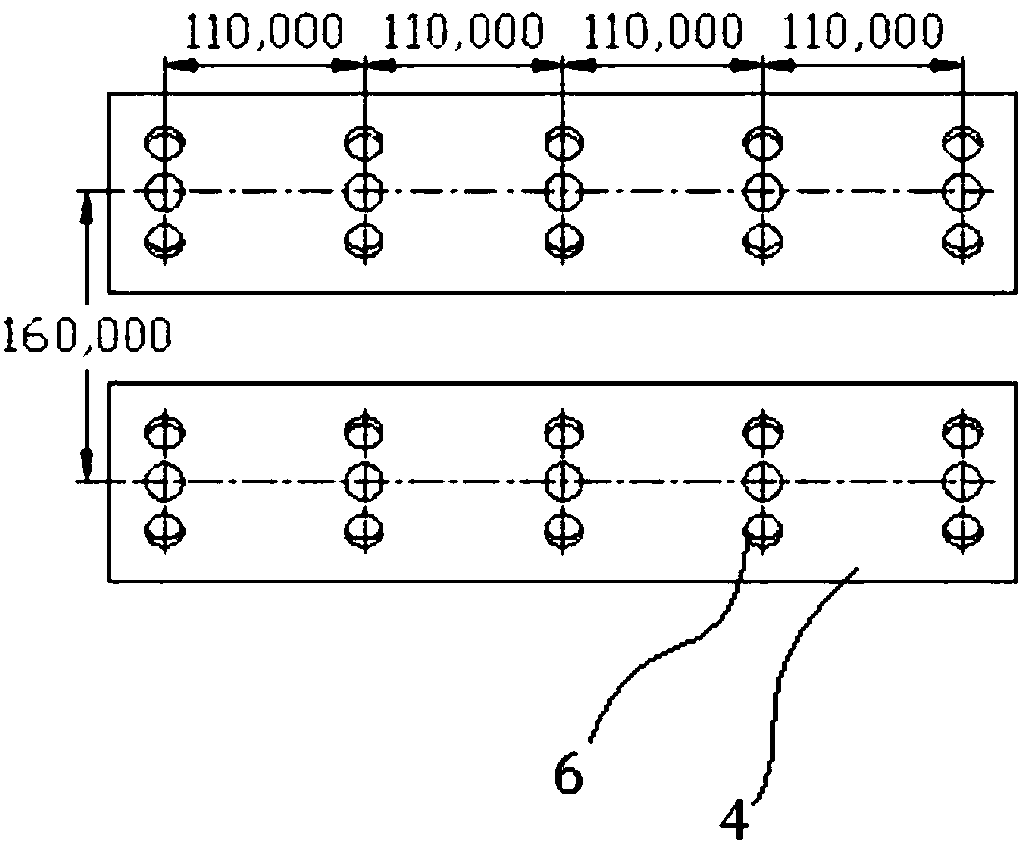

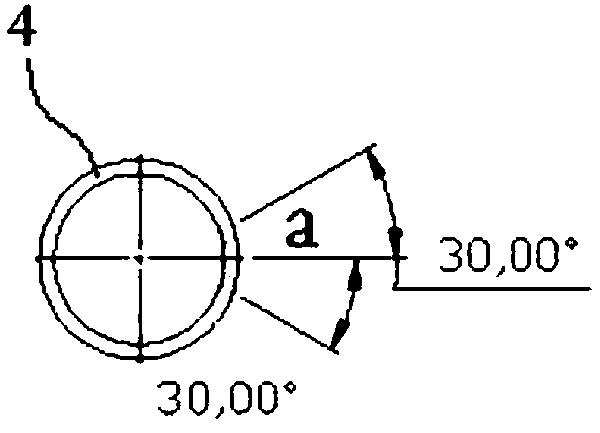

Multi-split air source double-tail-end system of wall-mounting type duplex metal radiant panels

ActiveCN107228427ATaking into account the air conditioning and cooling in summerTaking into account the needsLighting and heating apparatusSpace heating and ventilation detailsCeramic coatingEngineering

The invention discloses a multi-split air source double-tail-end system of wall-mounting type duplex metal radiant panels. The multi-split air source double-tail-end system comprises a controller connected with a heat pump outdoor unit and multiple air conditioner indoor units arranged in multiple rooms, and each room is internally provided with one wall-mounting type duplex metal radiant panel; each wall-mounting type duplex metal radiant panel comprises a duplex metal radiant panel body directly wrapping a refrigerating fluid heating pipe, the outer surface of the wall-mounting type duplex metal radiant panel is coated with an infrared radiation ceramic coating, the heat transferring effect of a condenser pipe is improved, and the effect of protecting the pipe is achieved; and the wall-mounting type duplex metal radiant panels and the air conditioner indoor units are connected in parallel through adjusting control valves and splitters, the switching states of the adjusting control valves and the splitters are controlled, and refrigeration in summer and heating and defrosting in winter can be achieved. When the multi-split air source double-tail-end system is used for heating, the indoor temperature field is evenly distributed, the heat pump condensing temperature is further reduced, the COP of the air source heat pump is improved, and energy saving and emission reduction are achieved.

Owner:TIANJIN UNIV

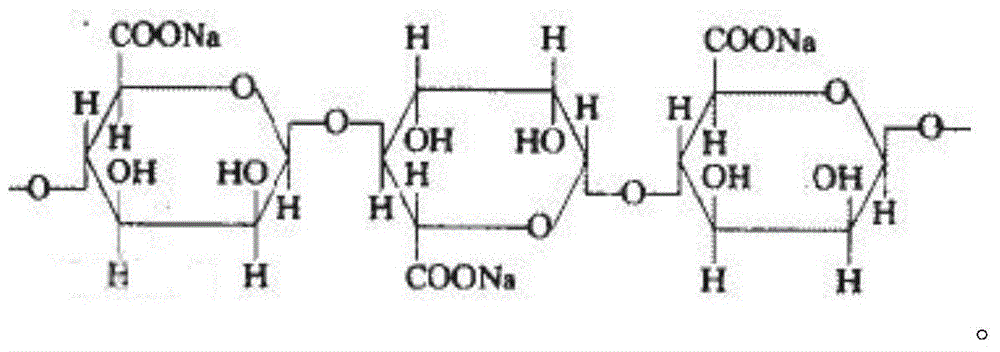

Hemostasis dressing and preparation method thereof

InactiveCN104784742AHas good water absorptionImprove water absorptionAbsorbent padsBandagesPolyethylene glycolWound surface

The invention discloses a hemostasis dressing which comprises zeolite and a medicinal auxiliary material, wherein the ratio of zeolite to the medicinal auxiliary material is (1-20):1; the particle size of zeolite is 0.1-0.6 mm; the medicinal auxiliary material is at least one of povidone K30, povidone K90, starch, dextrin, polyethylene glycol, pregelatinized starch, arabic gum, carbomer 974P and sodium alginate. The medicinal auxiliary material used in the hemostasis dressing is relatively good in water absorbing function and can cooperate with zeolite for stop bleeding, and gel can be generated after the auxiliary material absorbs water and can be adhered to zeolite powder, so that a protecting layer can be formed on a wound surface; the auxiliary material can be absorbed by a user, and healing of wound can be promoted.

Owner:ZHEJIANG UNIV +1

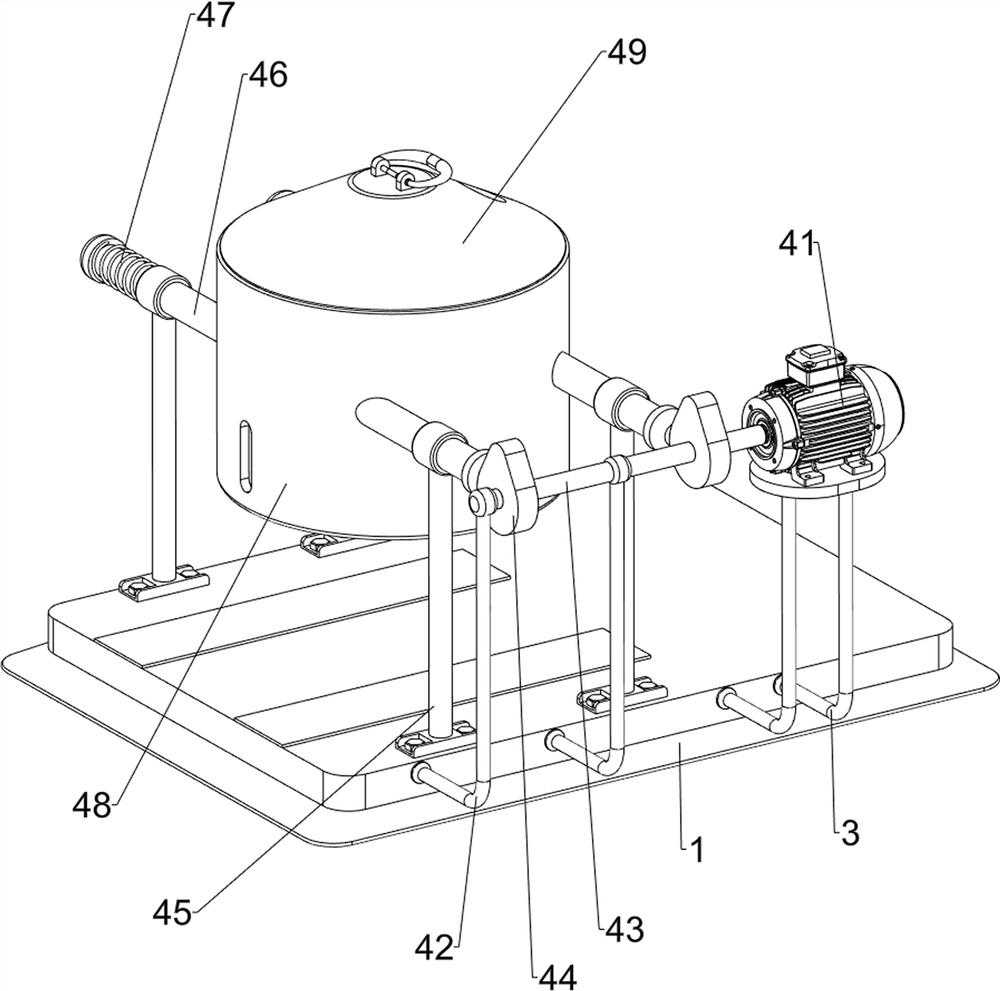

Paint spraying equipment for wood production

The invention relates to paint spraying equipment, in particular to paint spraying equipment for wood production, and aims to solve technical problems in the prior art. In order to solve the above technical problems, the paint spraying equipment which has the effects that time is saved, the paint spraying effect is good, paint is not easy to splash during the paint spraying process, and the surrounding environment is not influenced is provided. The paint spraying equipment comprises a workbench and the like, wherein an n-shaped frame is mounted at the top of the workbench; a 7-shaped plate ismounted at the top of the n-shaped framer; a tank body is mounted at the middle of the top of the n-shaped frame; an unloading hopper is mounted at the upper part of the right side surface of the tankbody and communicates with the tank body; a stirring device is arranged at the middle of the inner top of the 7-shaped plate; and a stirring part of the stirring device is positioned in the tank body. According to the paint spraying equipment provided by the invention, the paint and a diluent are stirred through the stirring device; the paint is sprayed onto wood through a paint spraying device;furthermore, a shielding device is arranged, so that the paint is prevented from splashing when being sprayed through a spray head; and the paint spraying equipment achieves the effects that time is saved and the paint spraying effect is good.

Owner:曹鹏飞

Cutting equipment for producing wooden calibrated scale

The invention relates to cutting equipment, in particular to the cutting equipment for producing a wooden calibrated scale. The invention aims to achieve the technical effect of providing the cuttingequipment for producing the wooden calibrated scale, wherein the cutting equipment is good in cutting effect when cutting wood, the operating staff are not prone to be injured, and bits of wood are not prone to fly around when cutting is performed. To achieve the technical effect, the cutting equipment for producing the wooden calibrated scale comprises a bottom plate and the like. The middle of the right portion of the top of the bottom plate is provided with a 7-shaped plate, the front of the 7-shaped plate is provided with a vertical movement device, the middle of the top of the bottom plate is provided with an installation block, the top of the installation block is provided with a cutting table, and a cutting slot is formed in the middle of the top of the cutting table; and the 7-shaped plate is provided with a cutting device, and the cutting device is matched with the vertical movement device. The vertical movement device drives the cutting device to move up and down, a fixing device is arranged so that the cutting equipment can be more convenient to use, and the effects that the cutting effect is good, the operating staff are not prone to be injured, and the bits of wood arenot prone to fly around in the cutting process are achieved.

Owner:国科科技创新中心(九江)有限公司

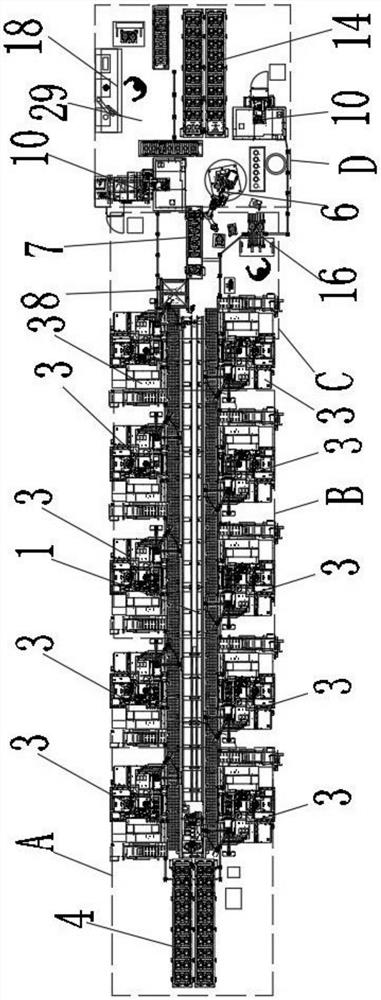

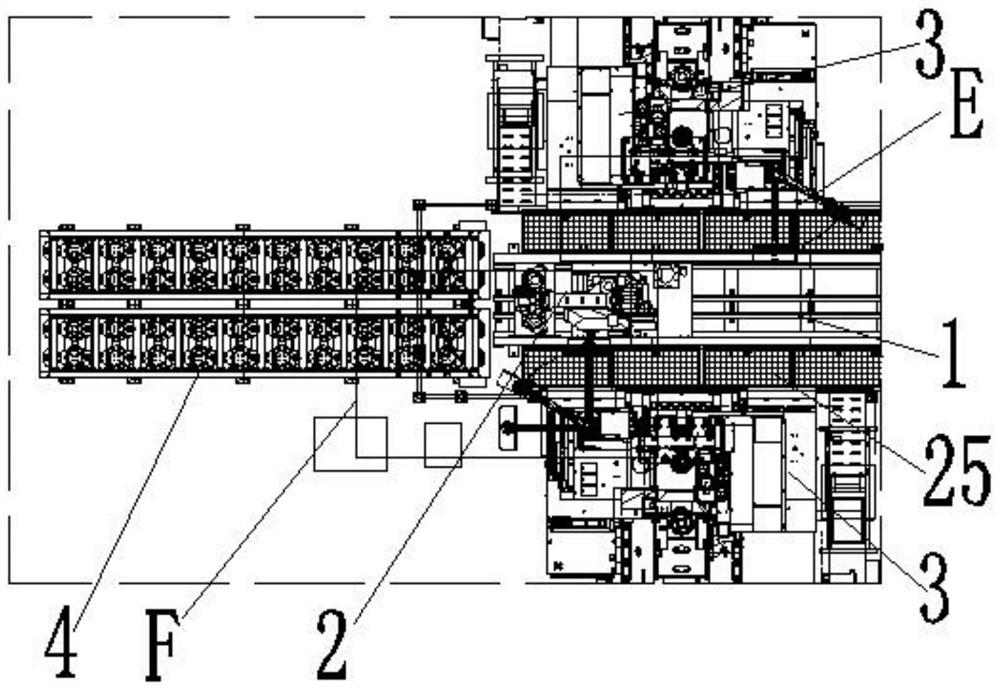

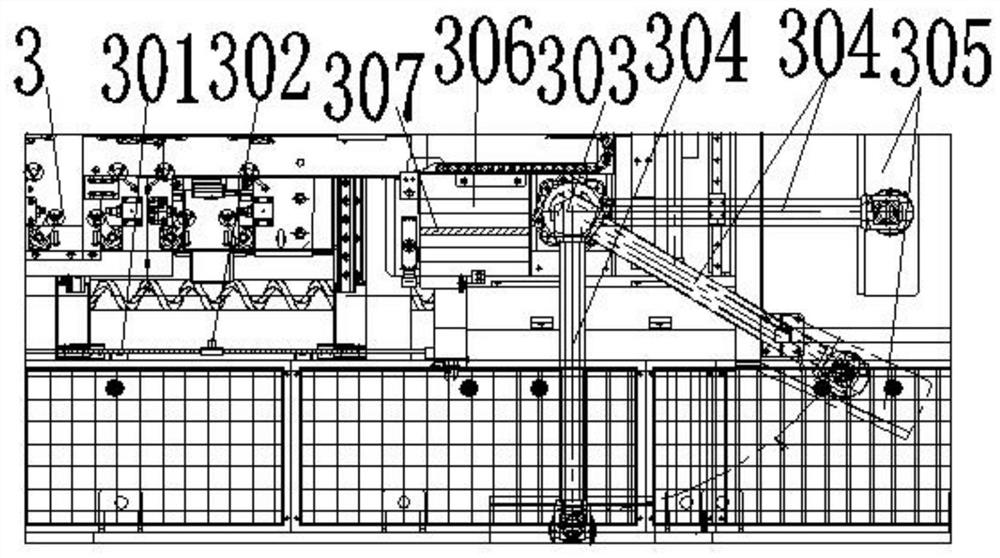

Automatic machining production device for automobile brake component and working method thereof

ActiveCN112719931AAvoid running back and forthWon't flyOther manufacturing equipments/toolsNumerical controlBrake

The invention discloses an automatic machining production device for an automobile brake component and a working method thereof. The production device comprises a transversely-arranged robot travelling ground rail, a first grabbing mechanism, a plurality of numerical control grinding machine tools, a feeding conveying belt, an automobile brake component overturning table, a second grabbing mechanism, a transfer conveying belt, a pneumatic scrap clearing table, a control center, two drilling and tapping numerical control machine tools, a cutting fluid filtering disc, a weighing disc, a coding machine, a first qualified product discharging conveying belt, an unqualified product discharging conveying belt, a sampling inspection circulating table, a detection analysis table, a manual processing device and a second qualified product discharging conveying belt. The first grabbing mechanism grabs the automobile brake component to be ground in the numerical control grinding machine tools, and the second grabbing mechanism grabs the automobile brake component to be subjected to drilling, tapping and other operations, so that the technical problems that in the prior art, the automobile brake component machining efficiency is low, the labor intensity of workers is too large, industrial accidents frequently happen, and the product percent of pass is low are solved.

Owner:山东时风(集团)有限责任公司

Mineral resource mining occupational disease protective equipment

InactiveCN109893922ARealize adsorption filtrationGuaranteed Quality CleaningDispersed particle filtrationMineral SourcesAir filter

The invention discloses mineral resource mining occupational disease protective equipment, which comprises a mainframe. The mainframe is internally provided with a left filter cavity, the left side ofthe left filter cavity is communicated with an exhaust fan, a primary filter mechanism is arranged in the left filter cavity, the top wall of the left filter cavity is provided with a slide groove, and the right wall of the slide groove is provided with a strike plate cavity. Air with dust can be filtered through the primary filter mechanism and a secondary filter mechanism to achieve clean air,and the secondary filter mechanism can be drawn out for replacement to guarantee cleanness of air filtered by the secondary filter mechanism. By a retaining plate mechanism, a passage can be closed invibratory dedusting with a filter screen, dust flying is avoided, and air pollution caused by dust entering the air is prevented.

Owner:杭州君笑文化传播有限公司

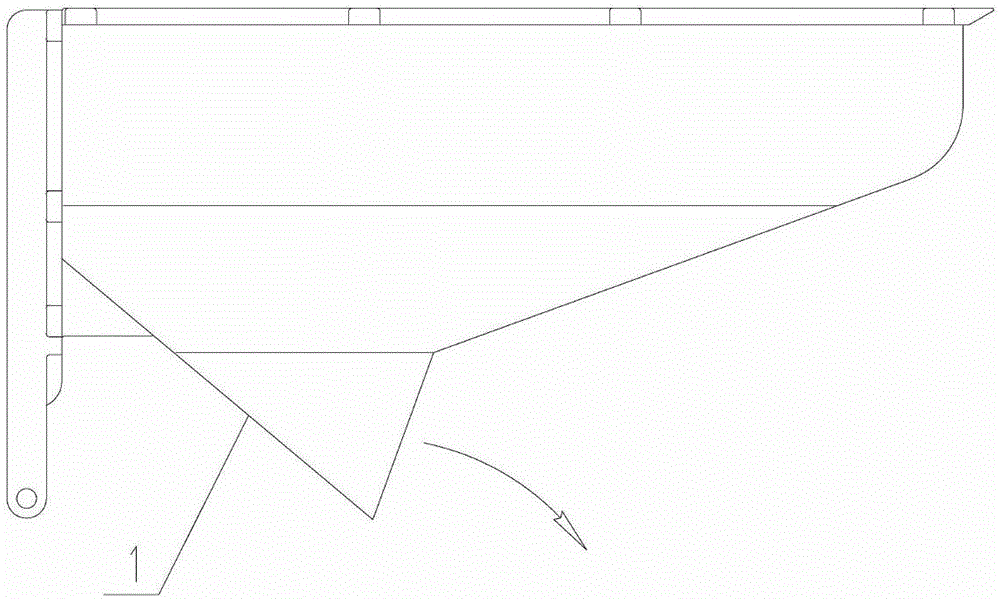

Garbage compacting box garbage scattering-free hopper

The invention relates to a garbage compacting box garbage scattering-free hopper. The hopper is made of steel plates of 3mm and is light in weight. Flanging steel channels are welded to the back surface of the hopper to enhance the stiffness. Each flanging steel channel is one side less than a rectangular tube, and the weight of each flanging steel channel is less than that of the rectangular tube. The whole hopper is light in weight. The use amount of steel plates is reduced. The overturning force for the hopper is small. Energy is saved. When the hopper is overturned by 180 degrees upside down to dump garbage, the whole hopper is embedded among three baffles of a compacting box without outward open surfaces. Garbage slides down along an inclined guide plate and inclined baffles on the two sides without dust generation and garbage flying, so that the working environment is clean and free of secondary pollution. The hopper is provided with a trigger control circuit for intelligently adjusting the inclination angle of the inclined guide plate, and the adjusted angle can be displayed in real time.

Owner:上海赫得环境科技股份有限公司

Iron screen primary filter device for warehousing paddy rice

The invention discloses an iron screen primary filter device for warehousing paddy rice. The iron screen primary filter device comprises an iron screen filter plate, air cylinders, a baffle plate and a supporting frame, wherein the supporting frame is fixed above a feeding port, one end of the iron screen filter plate is fixed on the top of the supporting frame in a rotating manner, two ends of the inner side of the supporting frame are respectively fixedly provided with the air cylinder, and an air cylinder shaft of each air cylinder is fixedly connected with the baffle plate; a transparent cover is fixedly arranged on the supporting frame, and a sealing plate is fixed on a top feeding port of the transparent cover in a sliding manner. The iron screen primary filter device has the beneficial effects that reasonability in design and simplicity in production can be realized, convenience in clearing is realized while the impurity removal is successfully carried out, and the working efficiency is improved.

Owner:张永清

Screening device for chemical raw material processing

PendingCN112246603AImprove screening accuracyReduce pollutionSievingScreeningProcess engineeringManufacturing engineering

The invention relates to a screening device, and particularly relates to the screening device for chemical raw material processing. The invention provides the screening device for chemical raw material processing, and the screening device for chemical raw material processing can automatically screen chemical raw materials and treat impurities such as dust. The screening device for chemical raw material processing comprises a base, a collecting frame, a first mounting frame, a rocking mechanism and a shaking mechanism, wherein the collecting frame is arranged on the base; the first mounting frame is arranged on the base; the rocking mechanism is arranged on the first mounting frame; and the shaking mechanism is arranged on the base. According to the screening device for the chemical raw material processing, through the design of the rocking mechanism, a material placement frame and a screen can be driven to move front and back, screening of the raw materials is facilitated, and the rawmaterials which do not meet the size requirement are left on the screen; through the design of the shaking mechanism, the raw materials on the screen can be shaken, and the screening precision of theraw materials is improved; and through the design of a filtering mechanism, the dust generated in the raw material screening process can be treated, and pollution to the surrounding environment is reduced.

Owner:王亨康

Cotton wool flattening device for efficiently producing clothes

ActiveCN111074467AReduce labor intensityIncrease production speedTextile shapingGear wheelElectric machinery

The invention discloses a cotton wool flattening device for efficiently producing clothes and relates to the technical field of clothes production. The cotton wool flattening device for efficiently producing the clothes comprises a workbench; supporting legs and a first mounting box are welded to and mounted at the bottom of the workbench; the supporting legs are provided with four sets and are arranged at the bottom of the workbench in a rectangular array; rubber patches are arranged at the bottoms of the supporting legs; a half gear is rotationally mounted on the front and rear inner walls of the first mounting box and the first mounting box is located at the middle of the bottom of the workbench; a third motor is welded to and mounted on the rear wall of the first mounting box; and an output end of the third motor transversely runs through the first mounting box through a coupler and is arranged in a manner of being welded to and connected with a rotating shaft of the half gear. According to the cotton wool flattening device for efficiently producing the clothes, machinery is adopted to replace manual work to perform compaction and flattening work on the cotton wool, so that thelabor intensity of workers is reduced to a certain extent, and meanwhile, substitution of the manual work by the machinery accelerates the production speed and improves the production efficiency to acertain extent.

Owner:曲阜东方服装有限公司

Drying room with hot air distributed uniformly

InactiveCN107806745AWon't flyWon't cause flappingDrying gas arrangementsDrying chambers/containersAir velocityEngineering

The invention discloses a drying room with hot air distributed uniformly. The drying room comprises a drying room body with drying hot air supplied by a heat source, and further comprises multiple airguide pipes evenly distributed in the drying room body. The air guide pipes are arranged on side faces close to the drying room body. Multiple exhaust holes are evenly distributed in the air guide pipes. The drying hot air supplied by the heat source is dispersed in the drying room body through the exhaust holes of the air guide pipes. The drying hot air is uniformly distributed in the three-dimensional space of the whole drying room body through the evenly-distributed air guide pipes and the exhaust holes of the air guide pipes, and balance and uniformity of temperature and temperature riseof all sections of the drying room body are achieved. The wind power and the wind speed are gentle, flying of dust cannot be caused, and safety of the system can be effectively improved for drying ofpyrotechnic powder materials. Better empirical effects can be achieved for the drying efficiency, the drying quality and safety.

Owner:湖南省驰安新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com