Road cutting device for construction of roads and bridges

A technology of bridge construction and cutting device, applied in the direction of roads, roads, road repair, etc., can solve the problems of flying dust, time-consuming and laborious, low cutting rate, etc., and achieve the effect of high cutting rate, reasonable and simple structure, and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

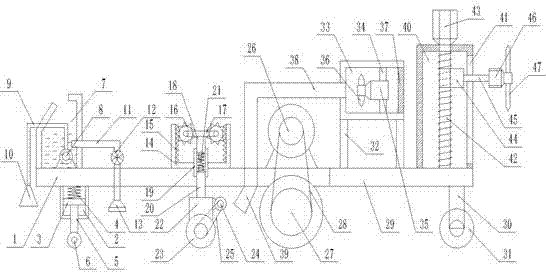

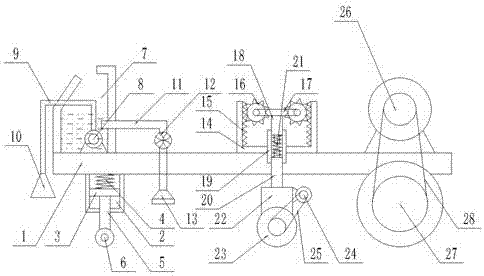

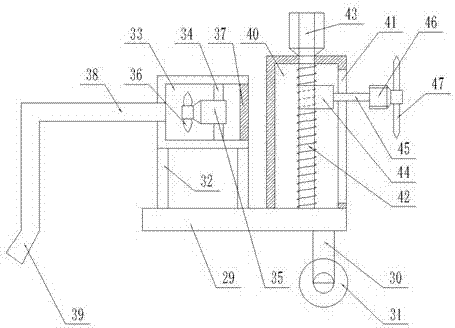

[0023] like figure 2 As shown, this specific embodiment adopts the following technical solutions: a road surface cutting device for road and bridge construction, including a first base 1, a mouthpiece seat 2, a slider 3, a spring 4, a pole 5, a guide wheel 6, and a water chamber 7. Water pump 8, water pipe 9, nozzle 10, first air pipe 11, exhaust fan 12, first air nozzle 13, recessed seat 14, rack 15, gear 16, connecting rod 17, upper pin 18, bushing 19. Lower pin shaft 20, connecting spring 21, cutting piece mounting seat 22, cutting piece 23, driving motor 24, first belt 25, rotating motor 26, driving wheel 27 and second belt 28; the first base 1 There is a mouthpiece 2 fixedly connected to the left side of the surface; a slider 3 is slidably connected to the mouthpiece 2; a spring 4 is fixedly connected to the top of the slider 3; the bottom of the slider 3 A pole 5 is fixedly connected to the top; a guide wheel 6 is movably connected to the end of the pole 5; a water cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com