Screening device for chemical raw material processing

A screening device, a technology for chemical raw materials, applied in the direction of filtering, using liquid separating agent, cleaning methods and utensils, etc., can solve the problem of no dust treatment, etc., achieve the effect of reducing dust, improving screening accuracy, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

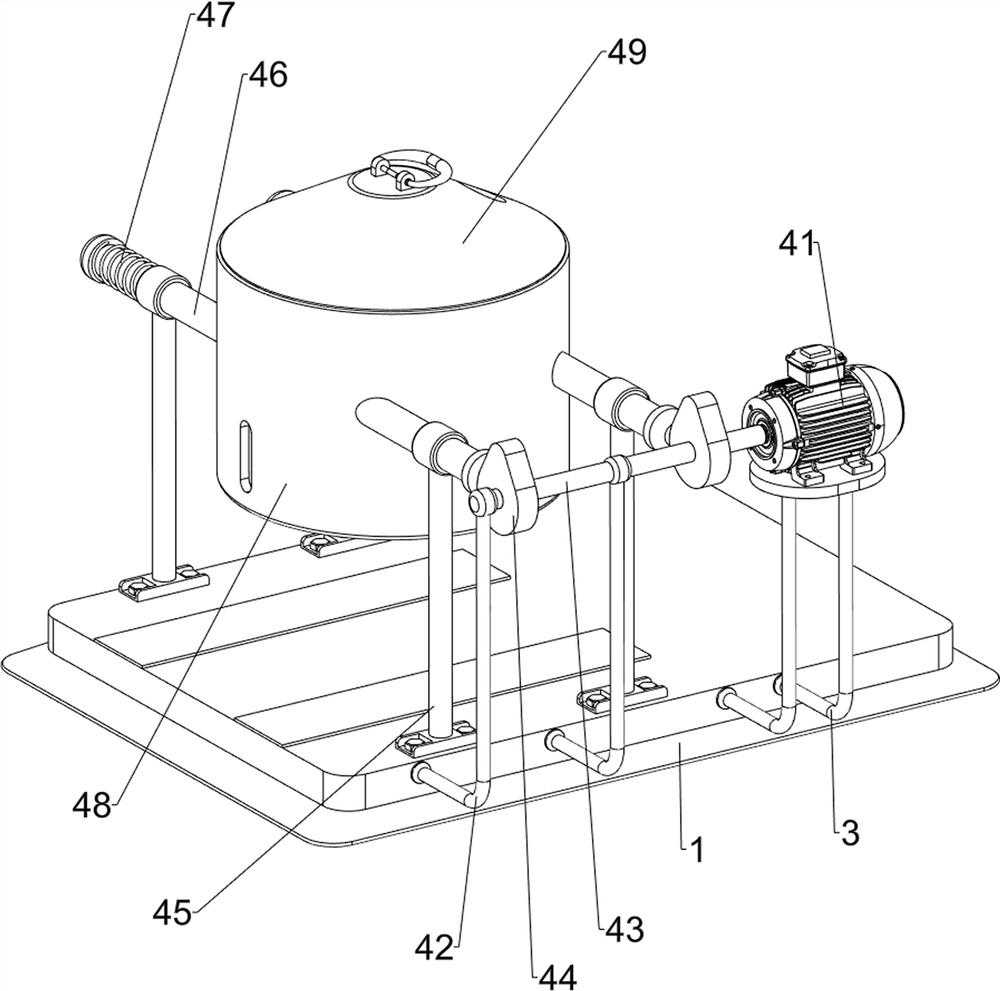

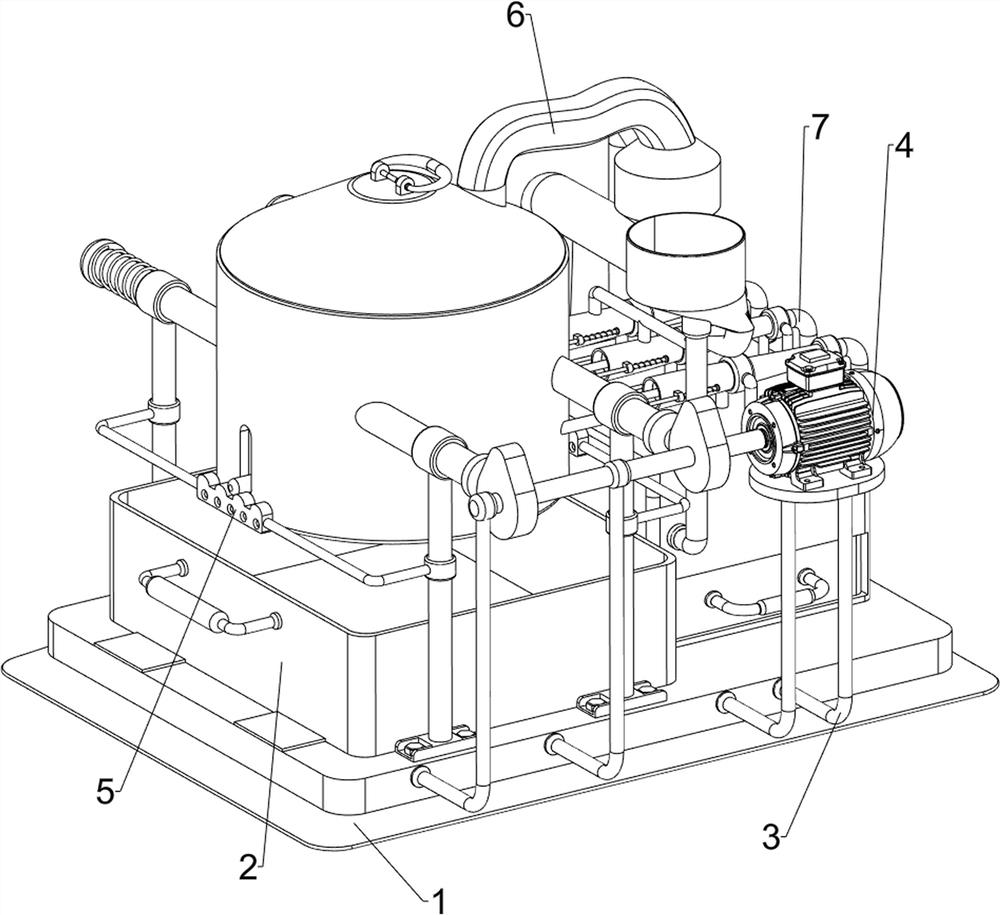

[0027] A screening device for chemical raw material processing, such as figure 1 , figure 2 , image 3 with Figure 4 As shown, it includes a base 1, a collecting frame 2, a first mounting frame 3, a shaking mechanism 4 and a shaking mechanism 5, the collecting frame 2 is on the base 1, the right side of the base 1 is provided with a first mounting frame 3, and the first mounting frame 3 is provided with a shaking mechanism 4, and the base 1 is provided with a shaking mechanism 5.

[0028] First, place the chemical raw materials to be screened in the shaking mechanism 4, then turn on the shaking mechanism 4, the operation of the shaking mechanism 4 will drive the operation of the shaking mechanism 5, and the purpose of screening the raw materials can be realized. After the screening is completed, turn off the shaking Mechanism 4, stopping of shaking mechanism 4 will make shaking mechanism 5 stop working, if need to screen again, repeat above-mentioned steps and get final p...

Embodiment 2

[0030] On the basis of Example 1, such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the shaking mechanism 4 includes a motor 41, a first support 42, a rotating shaft 43, a cam 44, a sliding sleeve rod 45, a slide bar 46, a first spring 47, a discharge frame 48, a cover 49 and a screen cloth 410, the first Motor 41 is installed on the mounting frame 3, and the output shaft of motor 41 is provided with rotating shaft 43, and left and right symmetry is provided with cam 44 on the rotating shaft 43, and base 1 upper front side is provided with first support 42 left and right symmetry, and rotating shaft 43 passes through first. Support 42 is also connected with it in a rotational manner. On the base 1, the front and rear symmetrical sliding sleeve bars 45 are all left and right. The two sliding sleeve bars 45 on the left side are slidingly provided with slide bar 46. On the two sliding sleeve bars 45 on the right side Also slide type is provided with slide bar 46...

Embodiment 3

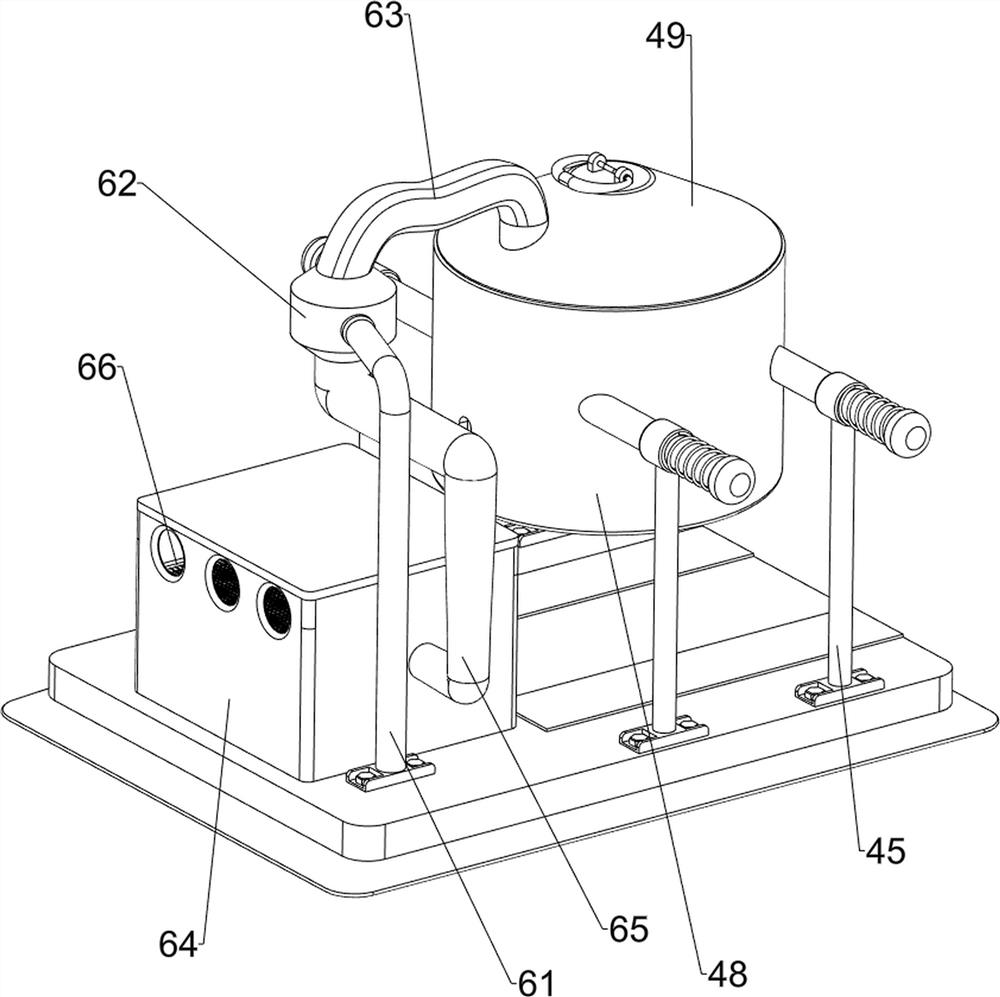

[0035] On the basis of Example 2, such as Figure 5 , Image 6 with Figure 7 As shown, a filter mechanism 6 is also included, and the base 1 is provided with a filter mechanism 6. The filter mechanism 6 includes a second support 61, an exhaust fan 62, a hose 63, a filter frame 64, a connecting pipe 65, a filter plate 66 and a collection Waste frame 67, the base 1 is provided with a second support 61 on the rear side, the second support 61 is provided with an exhaust fan 62, the exhaust fan 62 is provided with a hose 63, the hose 63 is connected to the cover 49, and the base 1 is on the right side A filter frame 64 is provided, and a connecting pipe 65 is provided on the upper and rear sides of the filter frame 64. The connecting pipe 65 is connected to the exhaust fan 62, and a filter plate 66 is arranged inside the filter frame 64, and a waste collection frame is provided slidingly on the front side of the filter frame 64. 67.

[0036]After placing the raw materials, turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com