Multi-channel spiral feeding device for magnetic buckle plastic

A screw feeding device and multi-channel technology, applied in the direction of conveyors, conveyor objects, vibrating conveyors, etc., can solve the problems of reduced efficiency, low processing efficiency, rework, etc., to improve screening and sorting efficiency, improve production efficiency, large The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

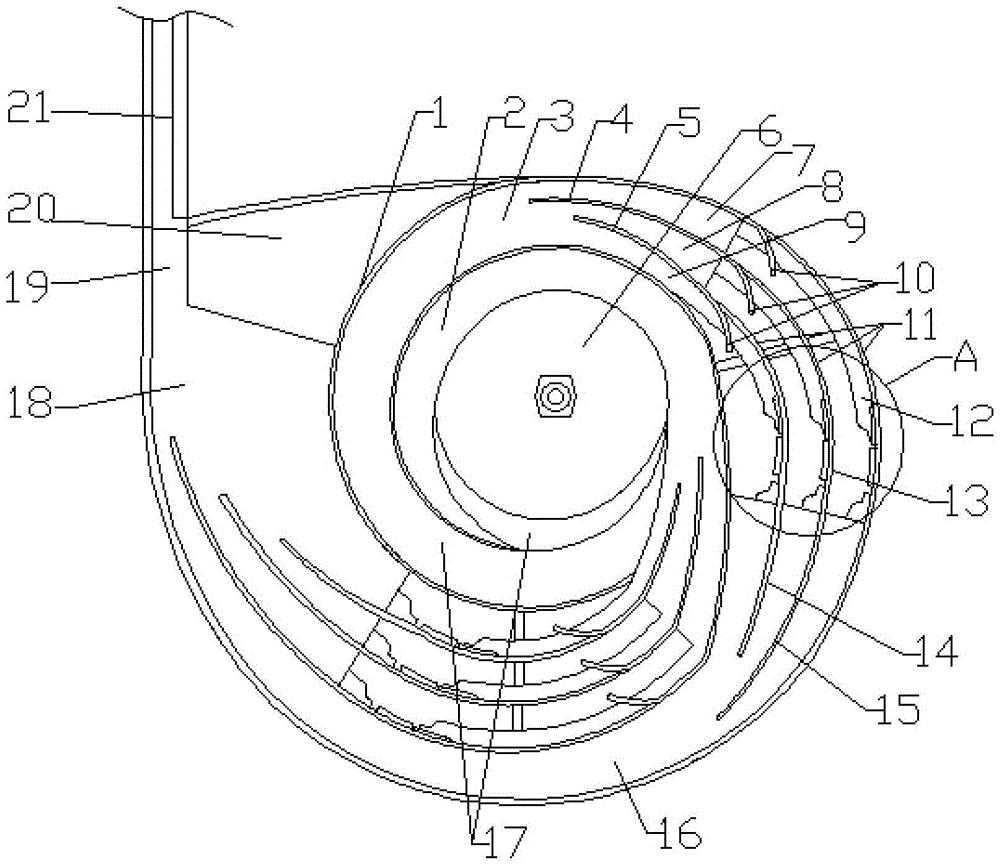

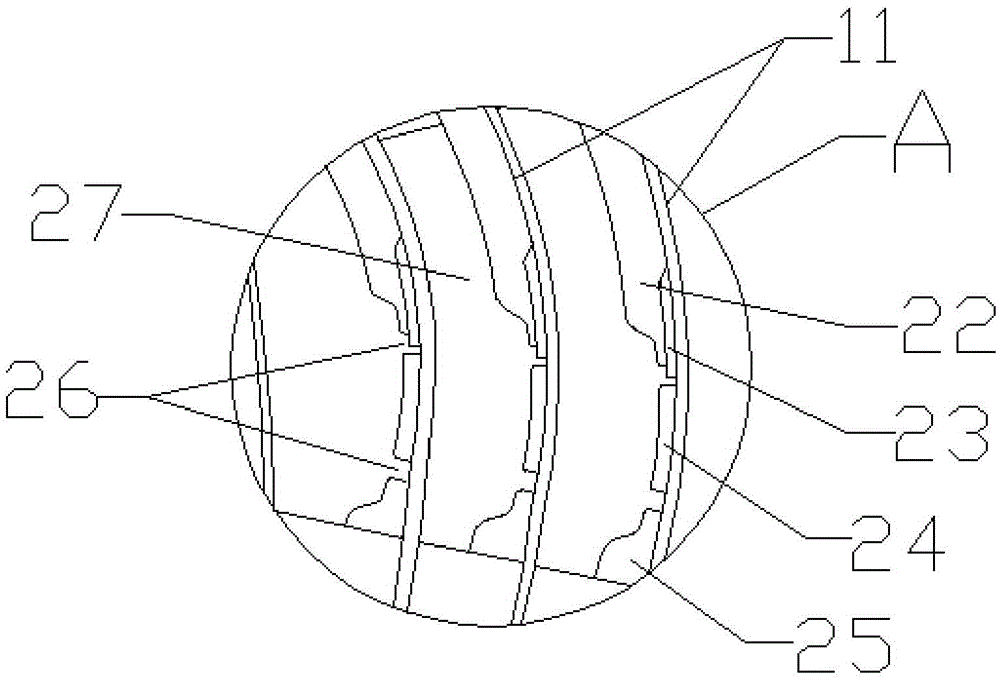

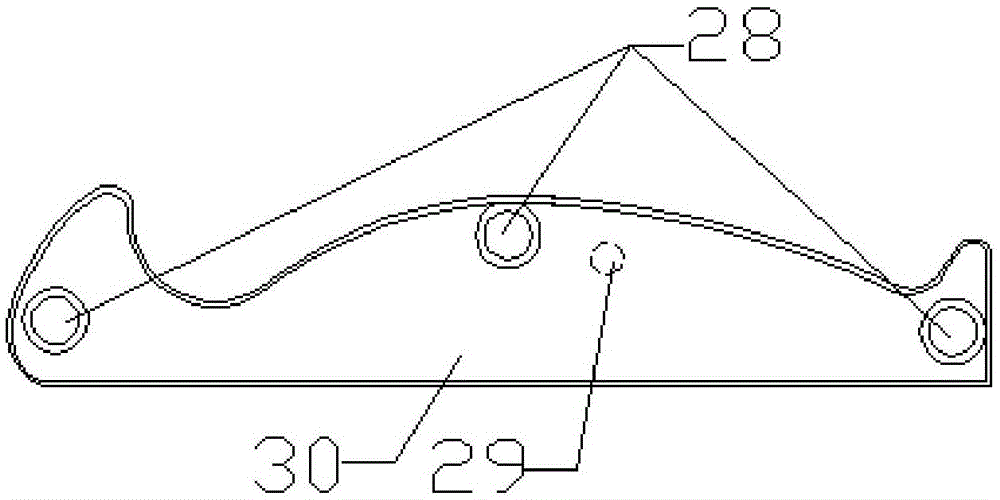

[0026] Such as Figure 1-3As shown, a magnetic buckle plastic multi-channel screw feeding device includes a vibrating plate 1, a hopper 6, a feeding port 16, a feeding track 17, a linear vibrating track 19, a first internal spiral track 2, a second internal spiral track 15 and a spiral The feeding screening and sorting device, the bottom of the vibration plate 1 is provided with a hopper 6, and the hopper 6 is provided with a first internal spiral track 2 and a second internal spiral track 17, and the spiral feeding screening and sorting device has the same two, And respectively connected with the upper ends of the first internal spiral track 2 and the second internal spiral track 17; the spiral feeding screening and sorting device includes a discharge port 3, a first track 7, a second track 8 and a third track 9. The upper end of the first internal spiral track 2 is connected with a discharge port 3, and the discharge port 3 is divided into the first track 7 by the first disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com