Patents

Literature

318results about How to "Reduce rework costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

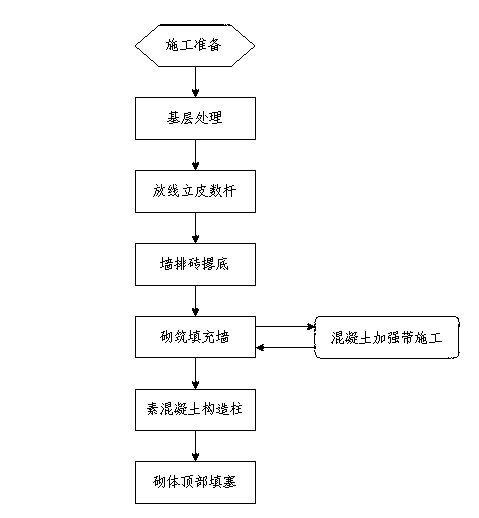

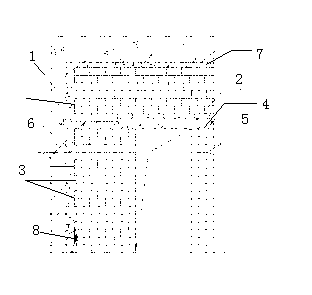

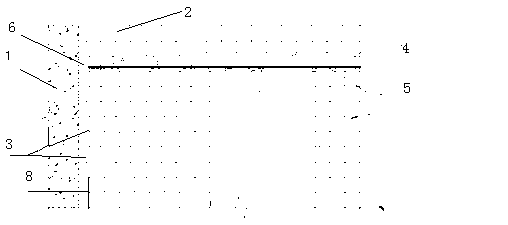

Construction method for preventing and treating cracks between concrete structure and filler wall

The invention discloses a construction method for preventing and treating cracks between a concrete structure and a filler wall. The construction method particularly comprises the following operation steps of step one, preparing construction; step two, treating a basic layer; step three, conducting paying off wire and setting up height pole; step four, conducting brick laying and putting down the bottom row of bricks; step five, masoning the filler wall; step six, constructing plain concrete constructional columns; step seven, filling the top of masonry. The construction method for preventing and treating the cracks between the concrete structure and the filler wall has the advantages of being wide in application range, and applicable to masonry construction of the filler wall with hollow bricks, autoclaved aerated concrete blocks and the like of the industrial and civil construction concrete structure; when the method compared with traditional processes, being capable of saving cost due to the fact that the main difference in procedure is that the plain concrete constructional columns, concrete reinforcing bands, wall crown filled with hard concrete and other portions replace the masonry; fundamentally solving the problem that cracks of a plaster layer and a coating layer caused by the cracks of the contact surface of the concrete structure and the filler wall, improving a project impression level and project quality, eradicating leakage risks of outer wall surfaces, reducing reworking cost and maintenance cost, saving materials, reducing production of construction waste, lowering a complaint rate of users, and being capable of setting up a corporate image in society and considerable in social benefit.

Owner:CHINA AEROSPACE CONSTR GROUP +1

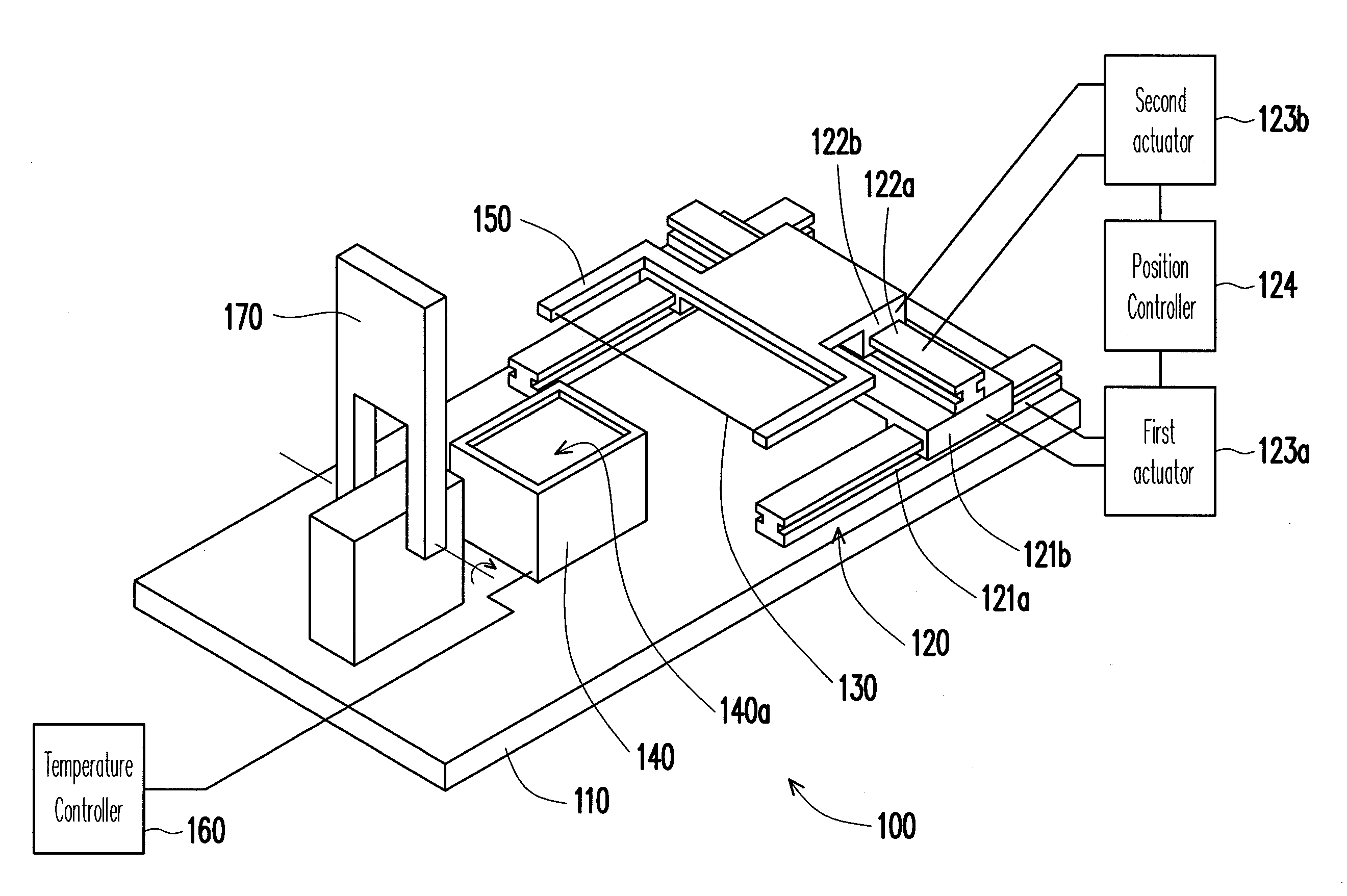

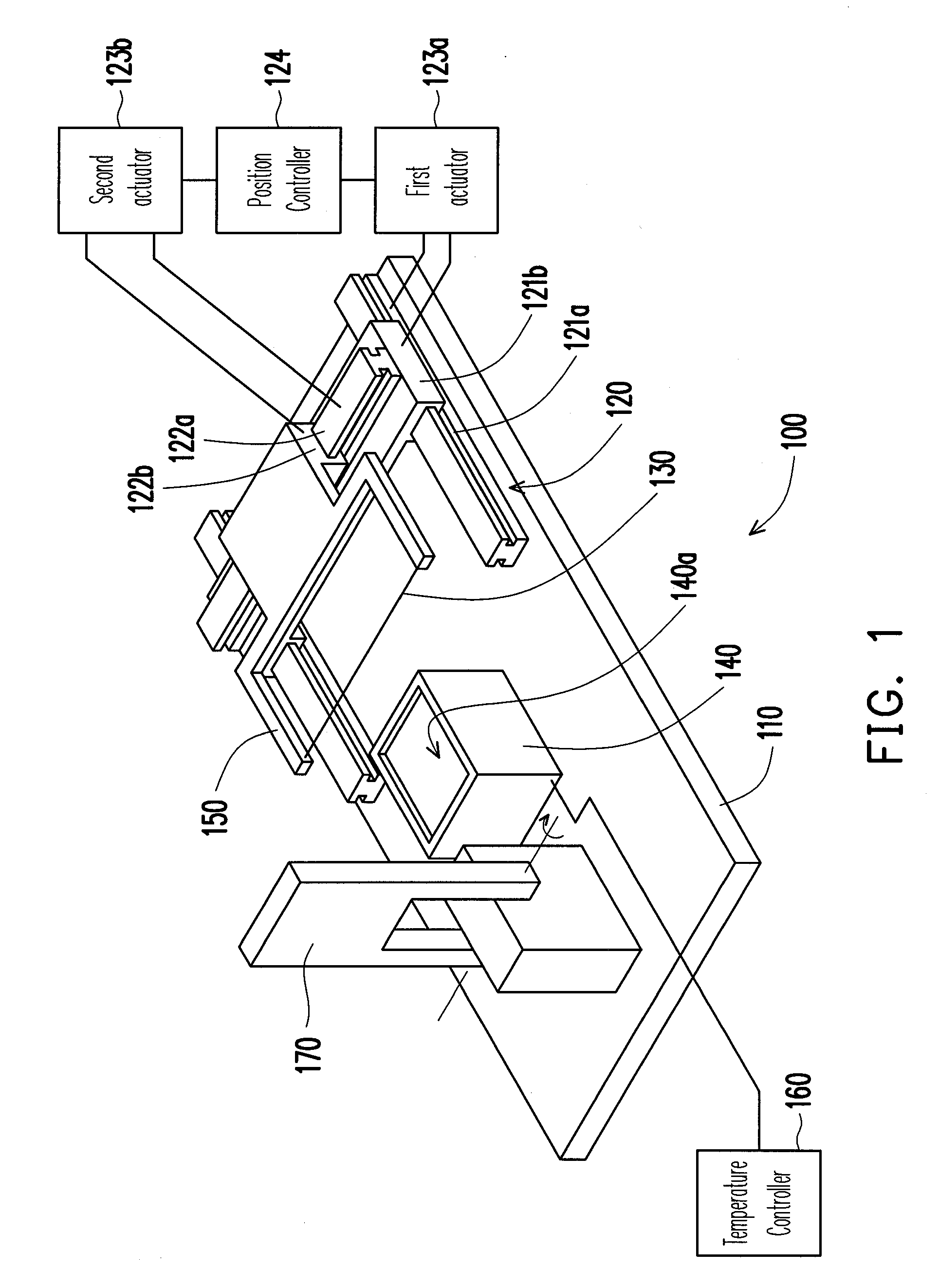

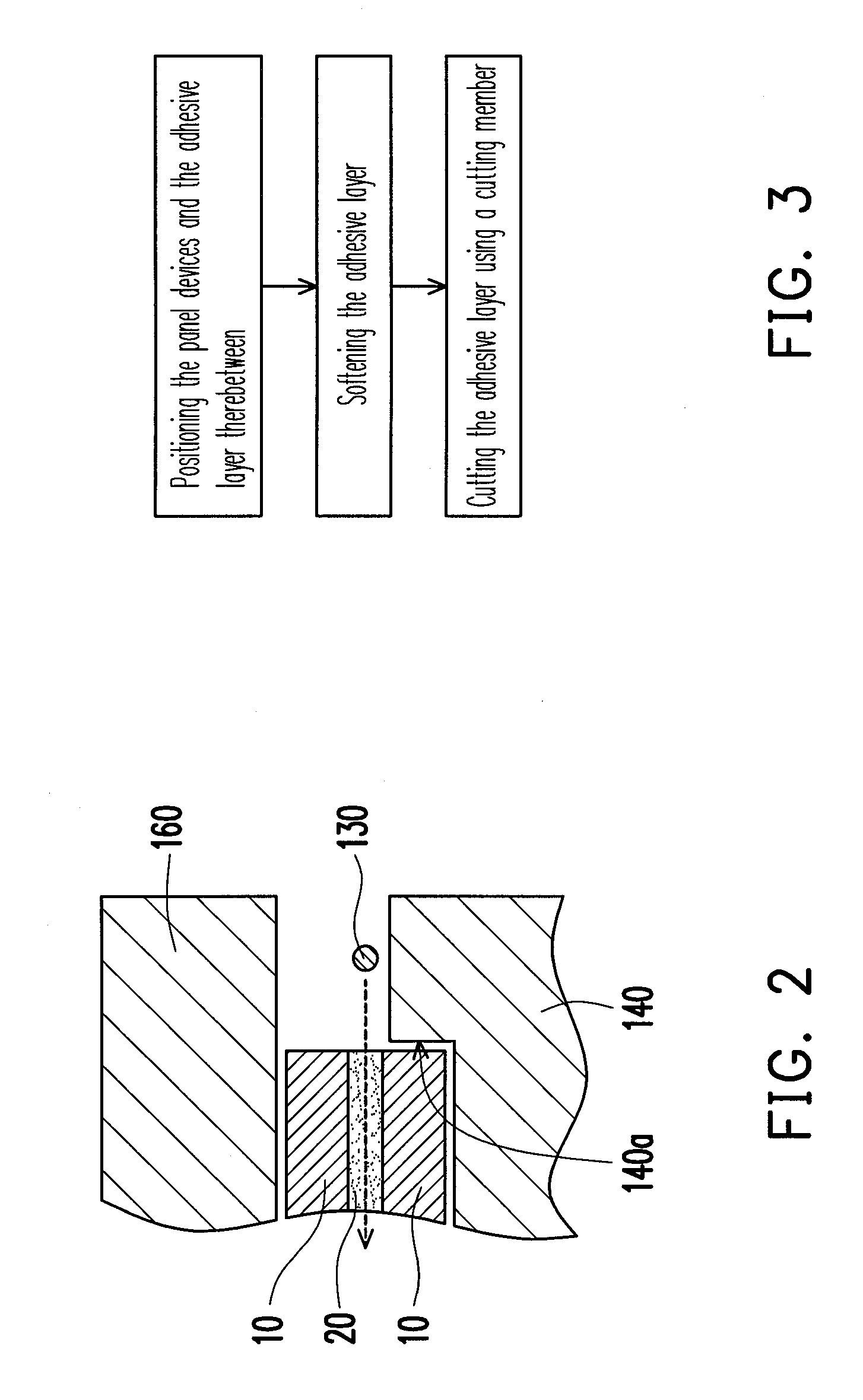

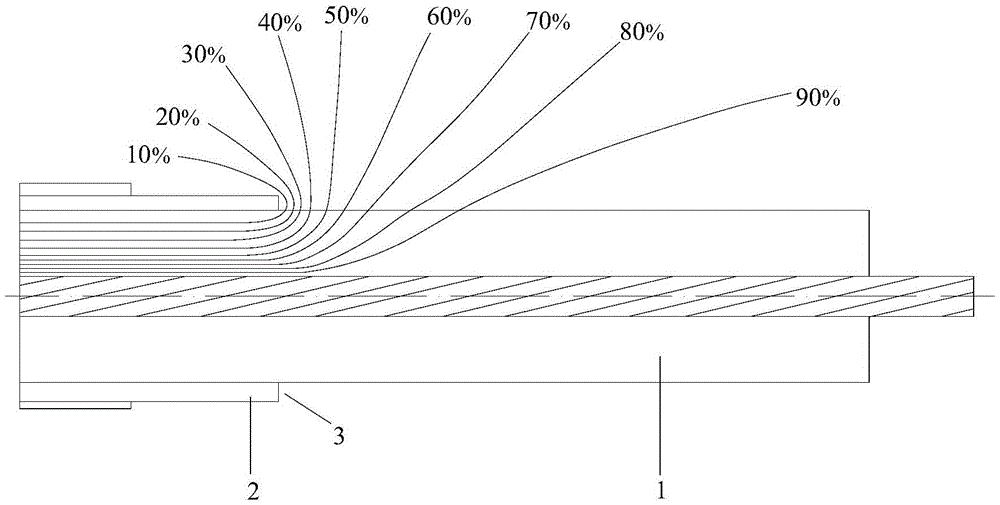

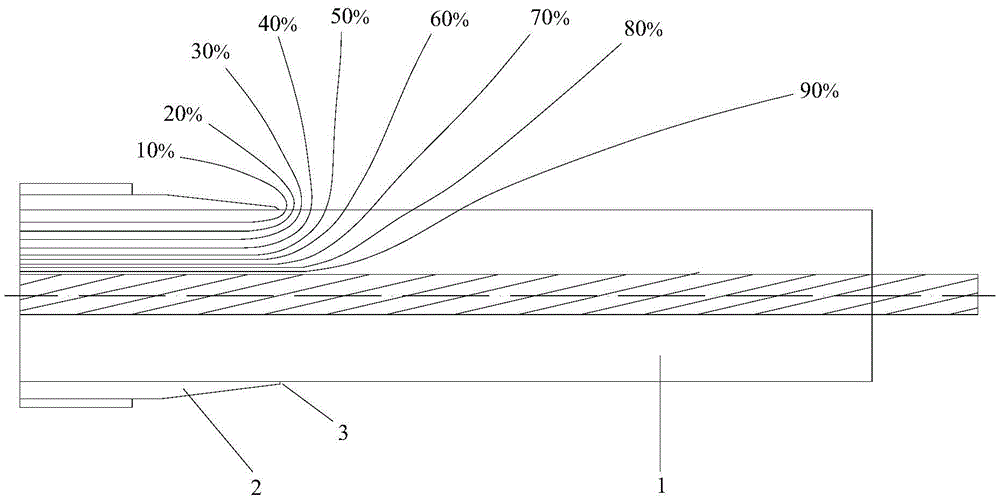

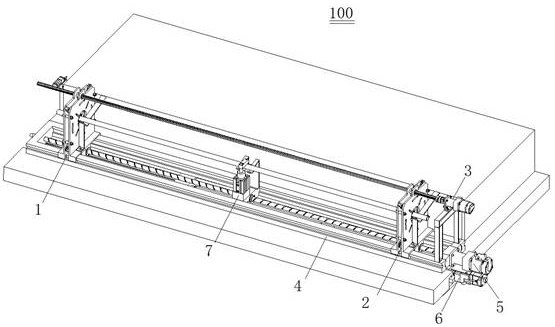

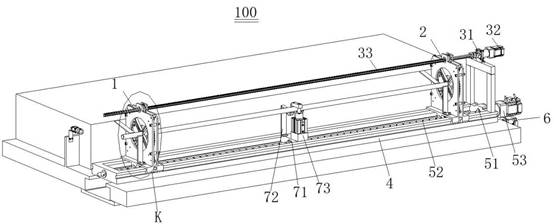

Separation apparatus and separation method

ActiveUS20100107834A1Reduce repair costsReduce rework costsMetal sawing devicesCross-cut reciprocating sawsEngineeringMechanical engineering

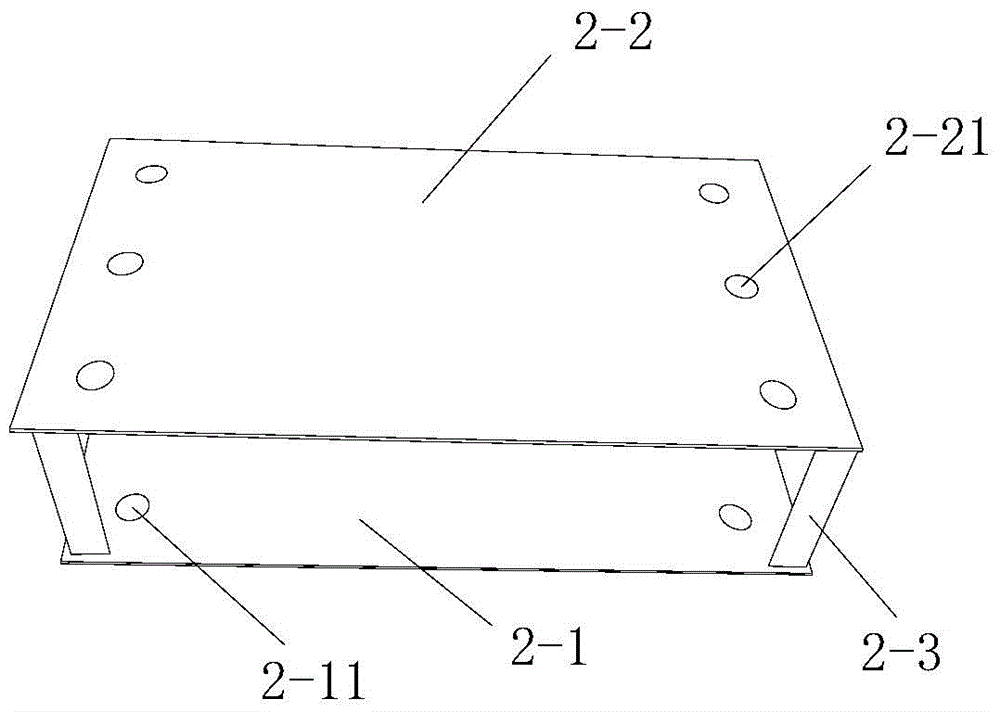

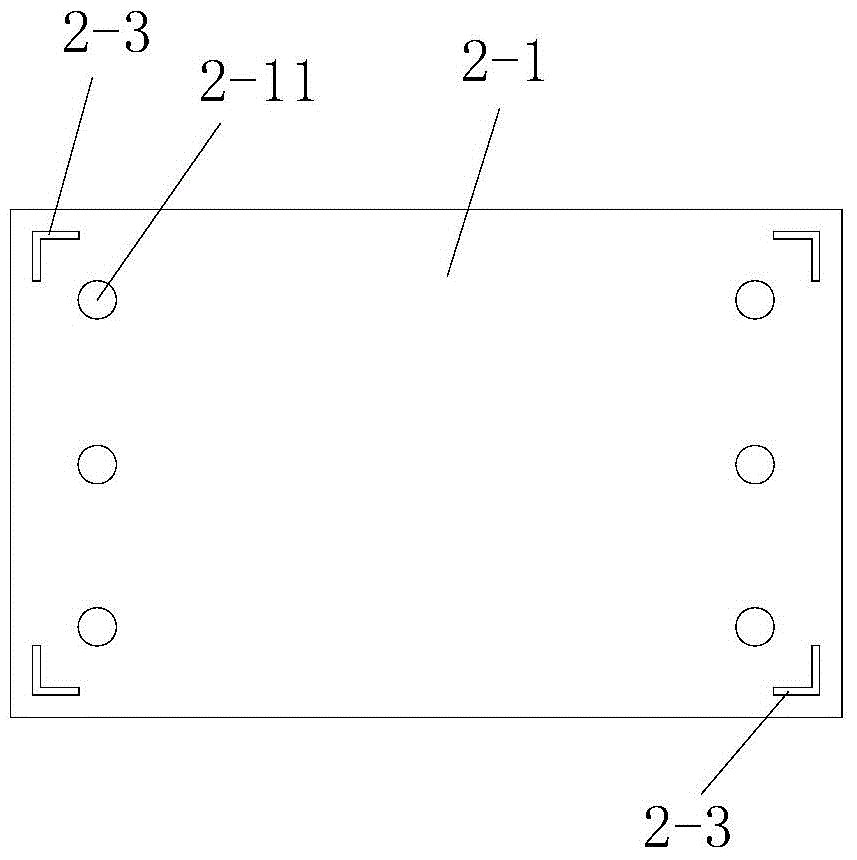

A separation apparatus for separating two planar devices bonded together by an adhesive layer is provided. The separation apparatus includes a base, a sliding module, a cutting member, and a positioning stage. The sliding module is mounted on the base. The cutting member is connected to the sliding module and is moveable in a two-dimensional plane with respect to the base by the sliding module for cutting the adhesive layer. The positioning stage is mounted on the base for positioning the planar devices and the adhesive layer therebetween on the base.

Owner:HTC CORP

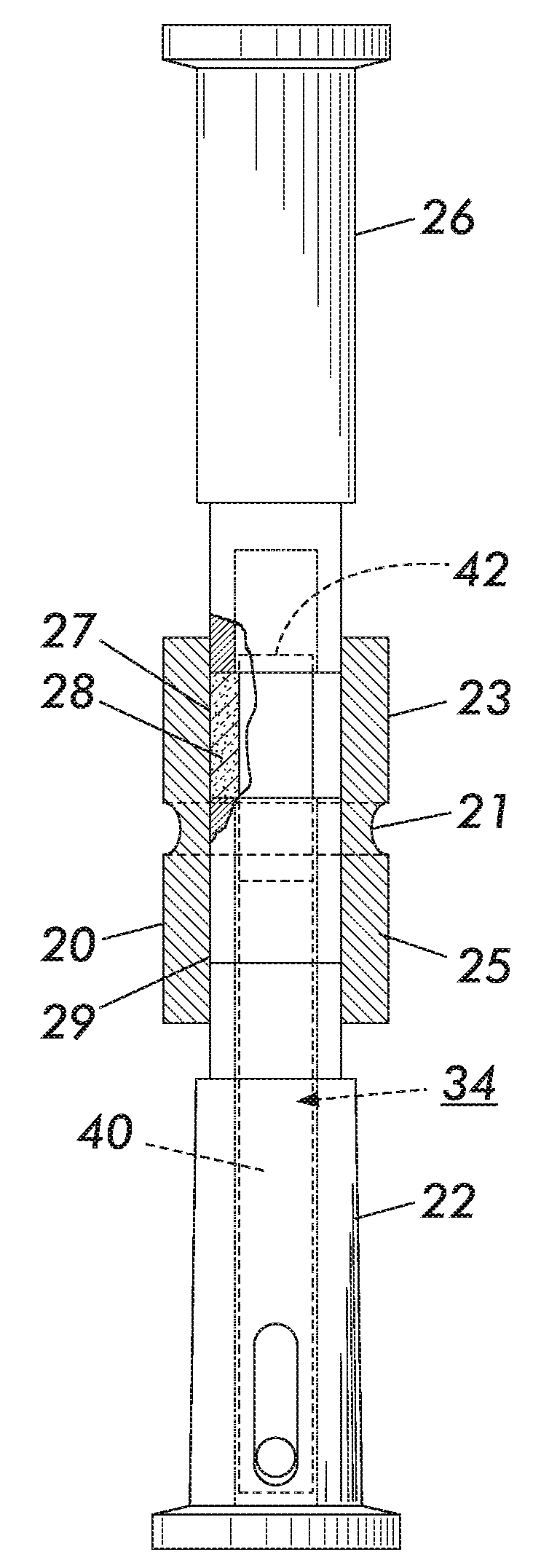

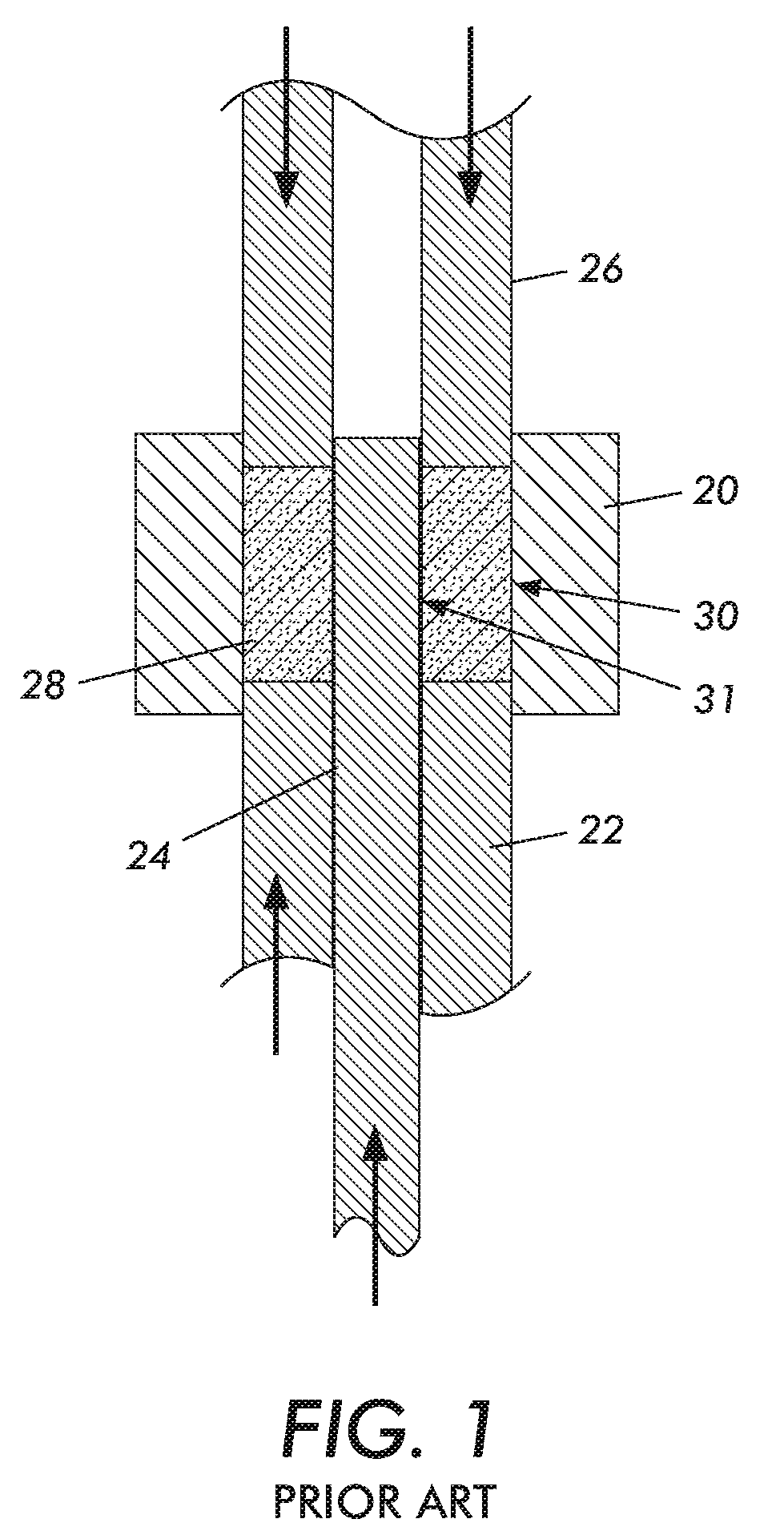

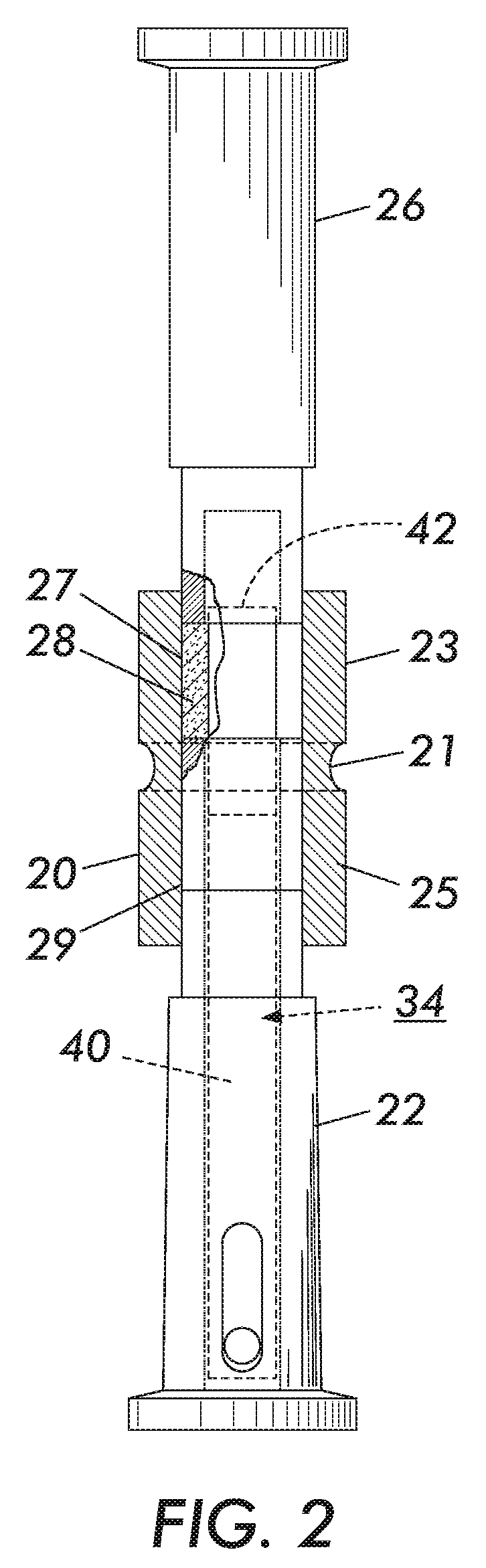

Ceramic center pin for compaction tooling and method for making same

ActiveUS7913369B2Reduce wearSolve the lack of lifeConfectioneryCeramic shaping apparatusMaterials science

Owner:BLUE SKY VISION PARTNERS

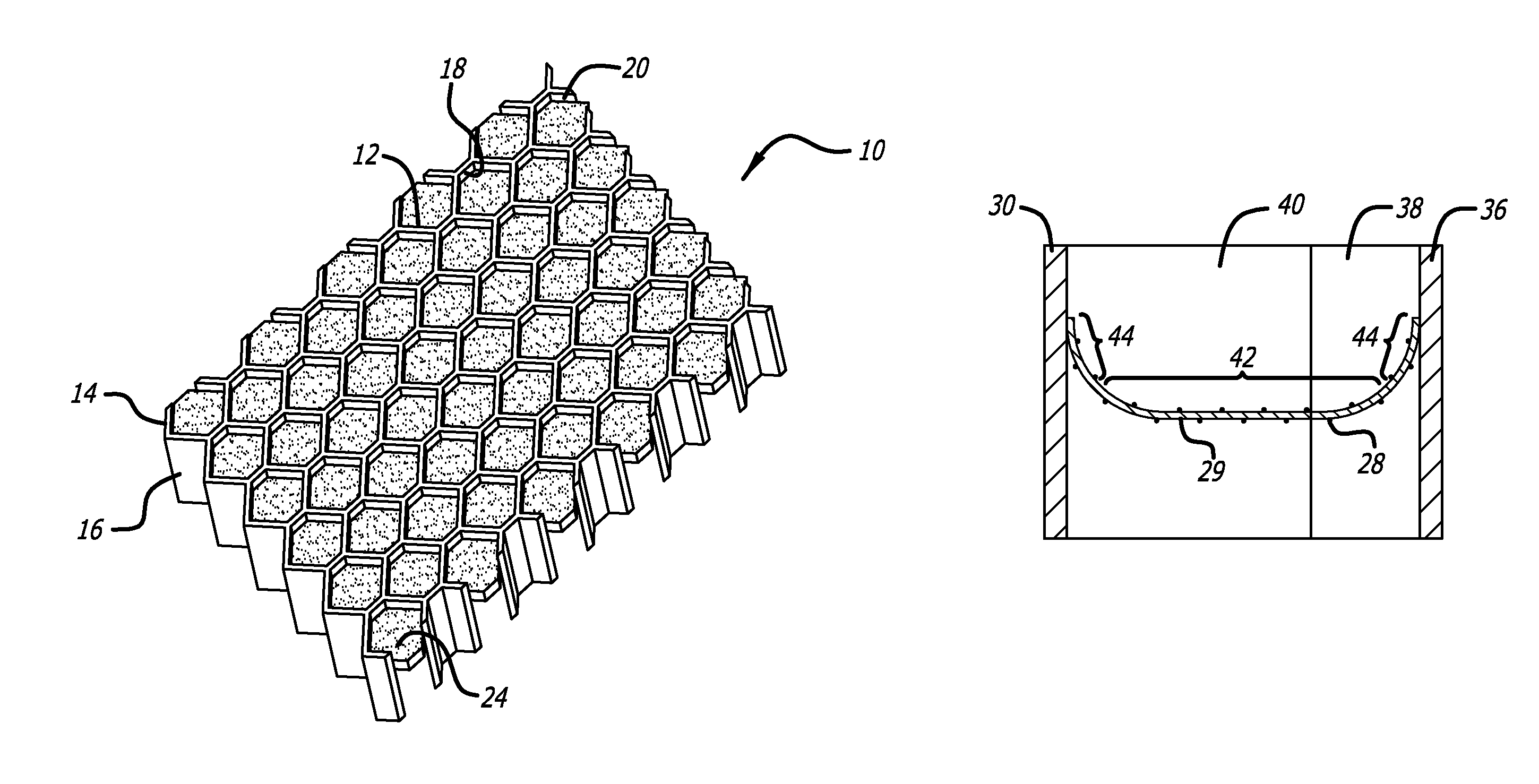

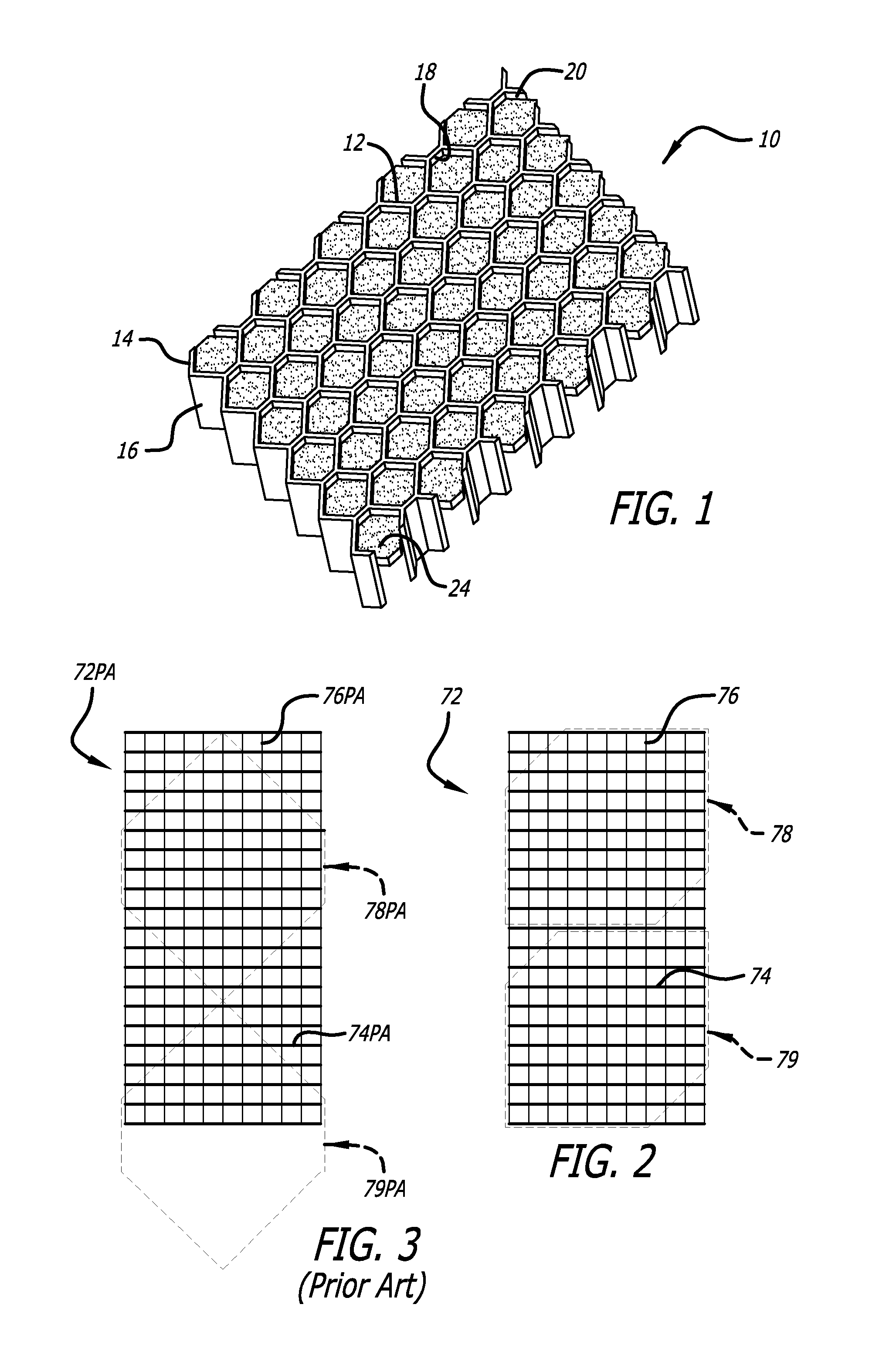

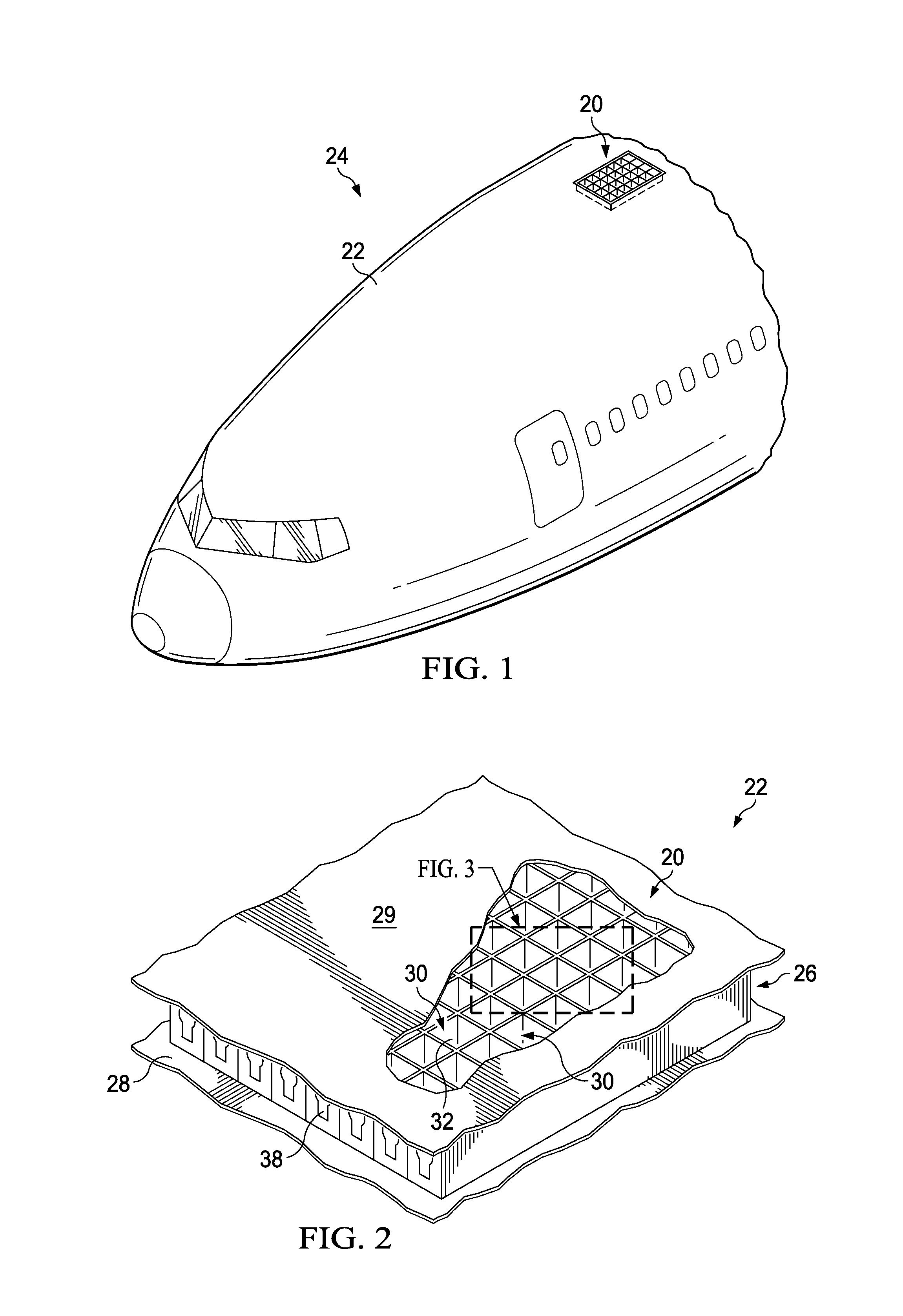

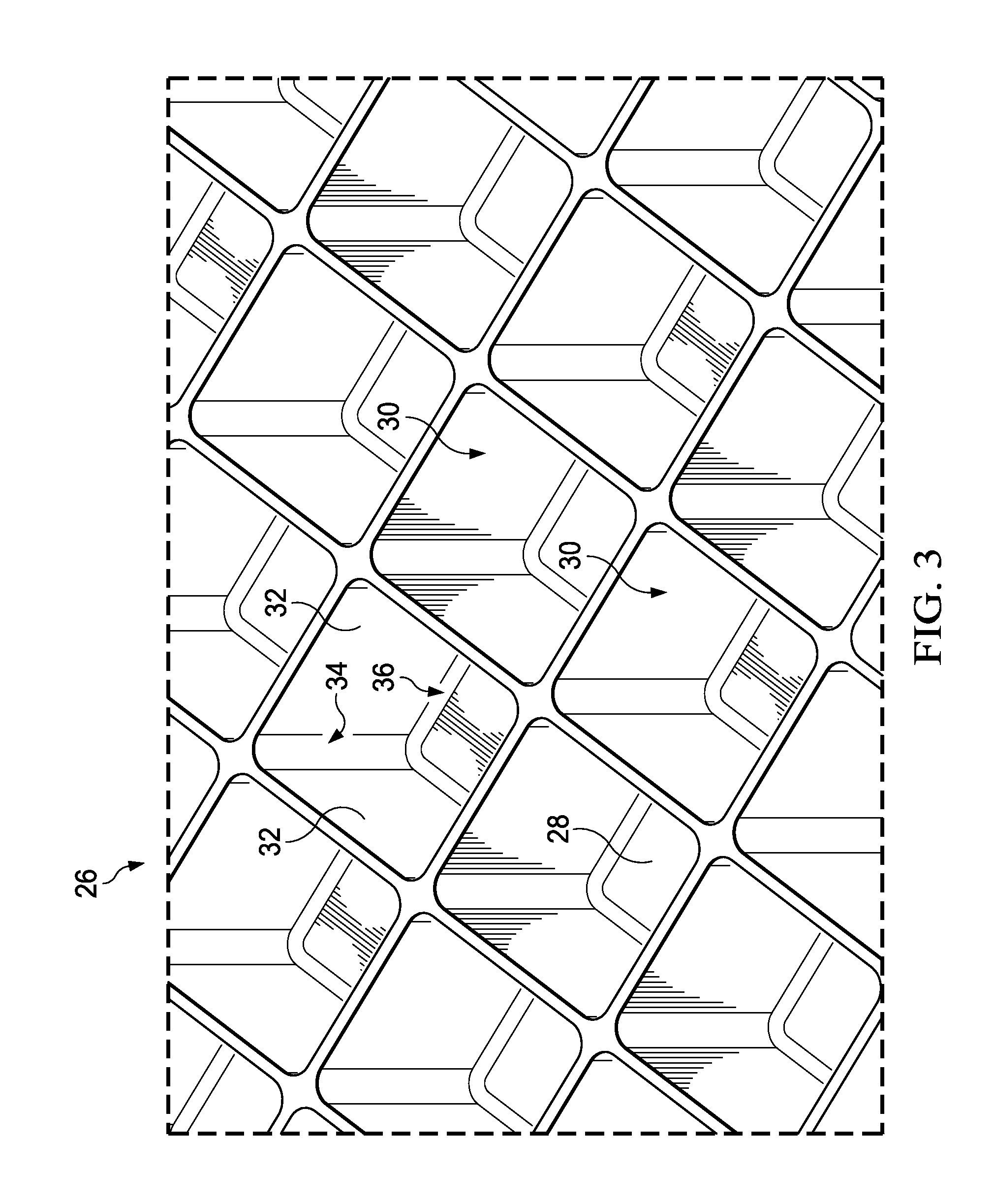

Anchoring of septums in acoustic honeycomb

ActiveUS8607924B2Improves material utilization and friction-lockingReduce rework costsAircraft stabilisationWingsFiberEngineering

A honeycomb structure that includes cells in which septums are located to provide acoustic dampening. The cells are formed by at least four walls wherein at least two of the walls are substantially parallel to each other. The septums include warp fibers and weft fibers that are substantially perpendicular to each other. The septums are oriented in the honeycomb cells such that the weft fibers and / or warp fibers are substantially perpendicular to the parallel walls.

Owner:HEXCEL

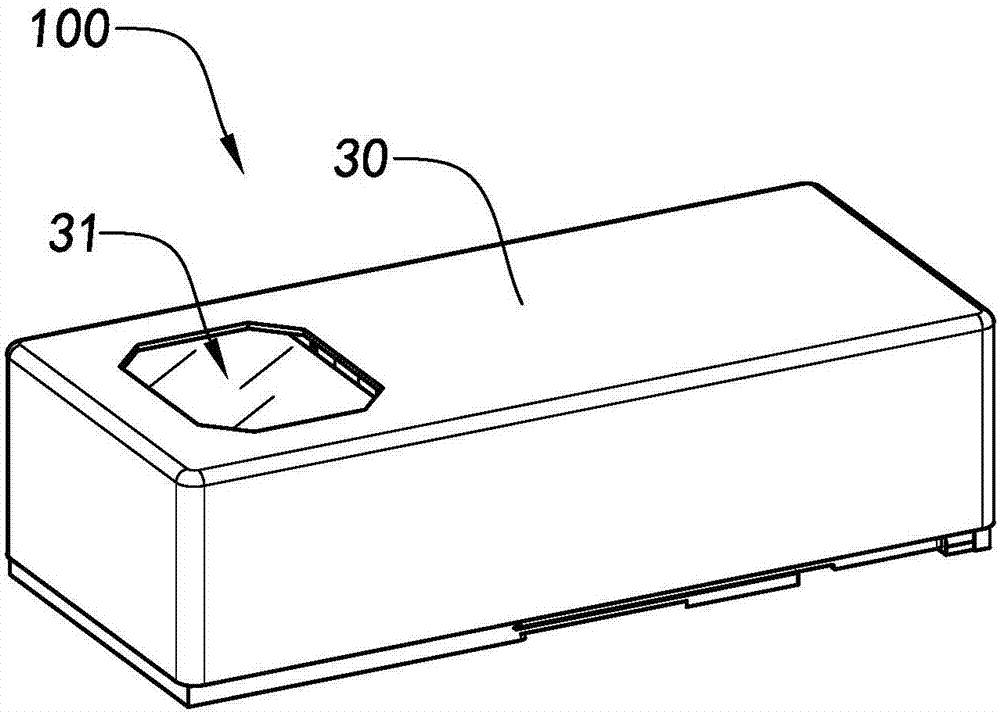

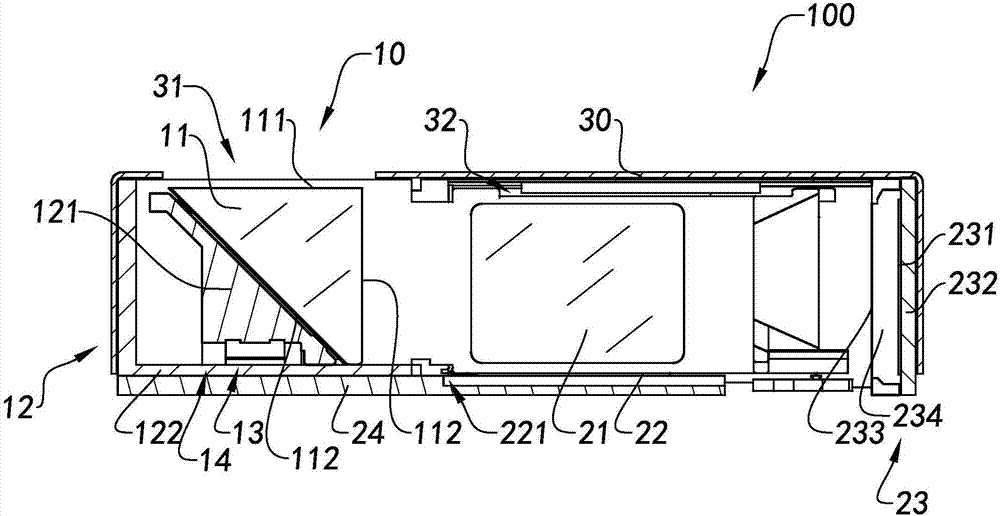

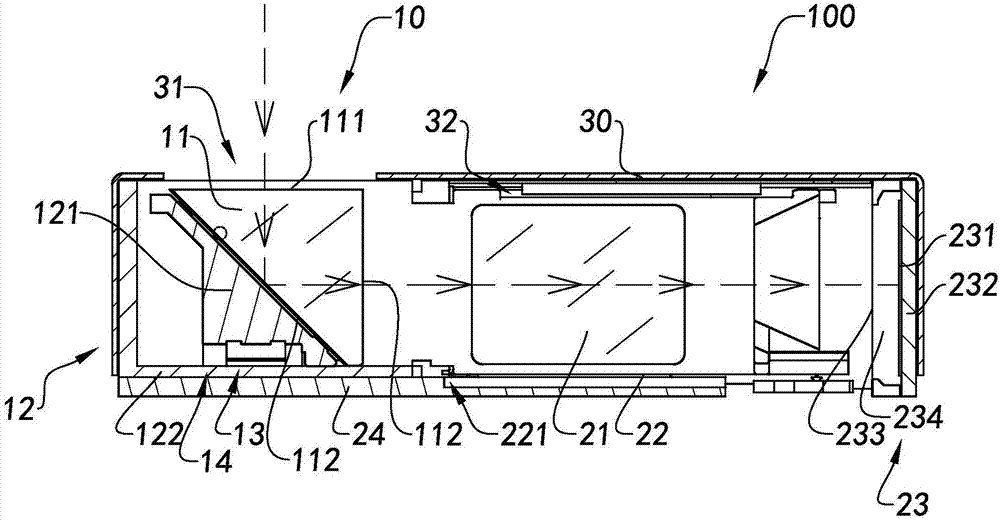

Split type periscope module, and assembly method and application thereof

PendingCN107517285AIncrease profitReduce rework costsTelevision system detailsColor television detailsEngineeringMaterials science

The invention discloses a split type periscope module, and an assembly method and an application thereof. The split type periscope module comprises a light turning component and a module component, wherein the module component comprises a lens and a photosensitive component, and the lens is positioned in a photosensitive path of the photosensitive component; the light running component is assembled into the module component in a split and modularized manner, the lens is positioned in a light ray exiting direction of the light turning component, and thus a light ray turned by the light turning component and exiting from the same reaches the lens.

Owner:NINGBO SUNNY OPOTECH CO LTD

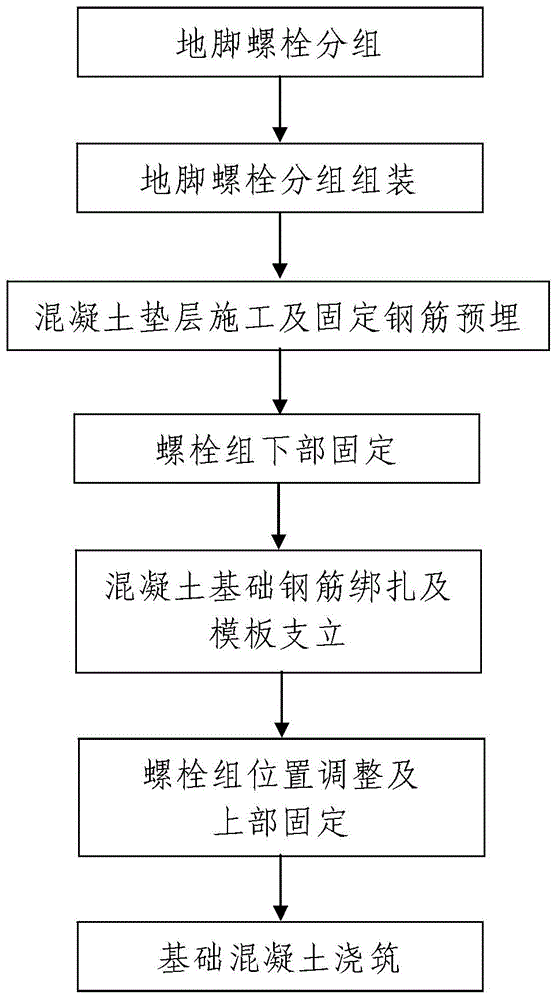

Steel structure building construction method for one-step pre-burying of foundation bolts

The invention discloses a steel structure building construction method for pre-burying of foundation bolts. The steel structure building construction method comprises the following steps: 1. grouping of the foundation bolts: all the foundation bolts to be pre-buried are divided into a plurality of groups, the groups of the foundation bolts are respectively distributed in a plurality of bolt pre-burying areas in a concrete foundation, and the foundation bolts in each group form a bolt group; 2. grouped assembly of the foundation bolts: the bolt groups are respectively assembled, and the assembly procedure comprises manufacturing of a positioning mold, inserting of the foundation bolts, fixing of the foundation bolts, and separating of the bolt groups from positioning mold; 3. concrete cushion construction and pre-burying of fixing steel bars; 4. lower part fixing of the bolt groups; 5. binding of the steel bars and support arrangement of a template erection in the concrete foundation; 6. a position adjustment and upper part fixing of the bolt groups; 7. concrete foundation pouring. The method provided by the invention is simple in procedure, reasonable in design, convenient in implementation, and good in use effects, and has the advantages that the construction process for the high-precision pre-burying of the foundation bolts in the concrete foundation can be simply, conveniently and rapidly completed with high quality.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

Optical film adhesive used for full bonding, preparation method and application of adhesive and optical film based on adhesive

InactiveCN108587484AGood gap filling abilityAvoid high temperature and high humidityFilm/foil adhesivesOrganic non-macromolecular adhesivePolymer scienceOrganic solvent

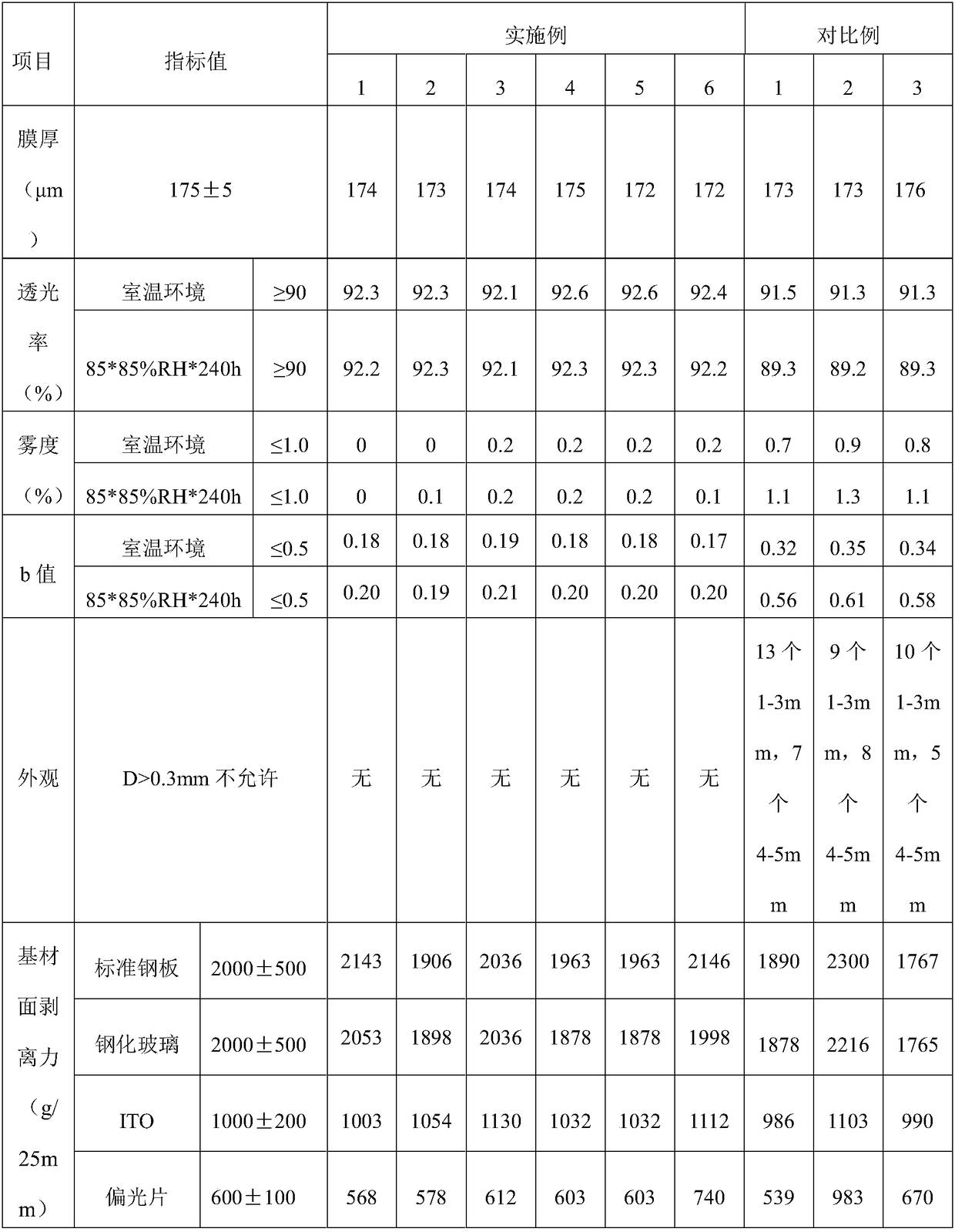

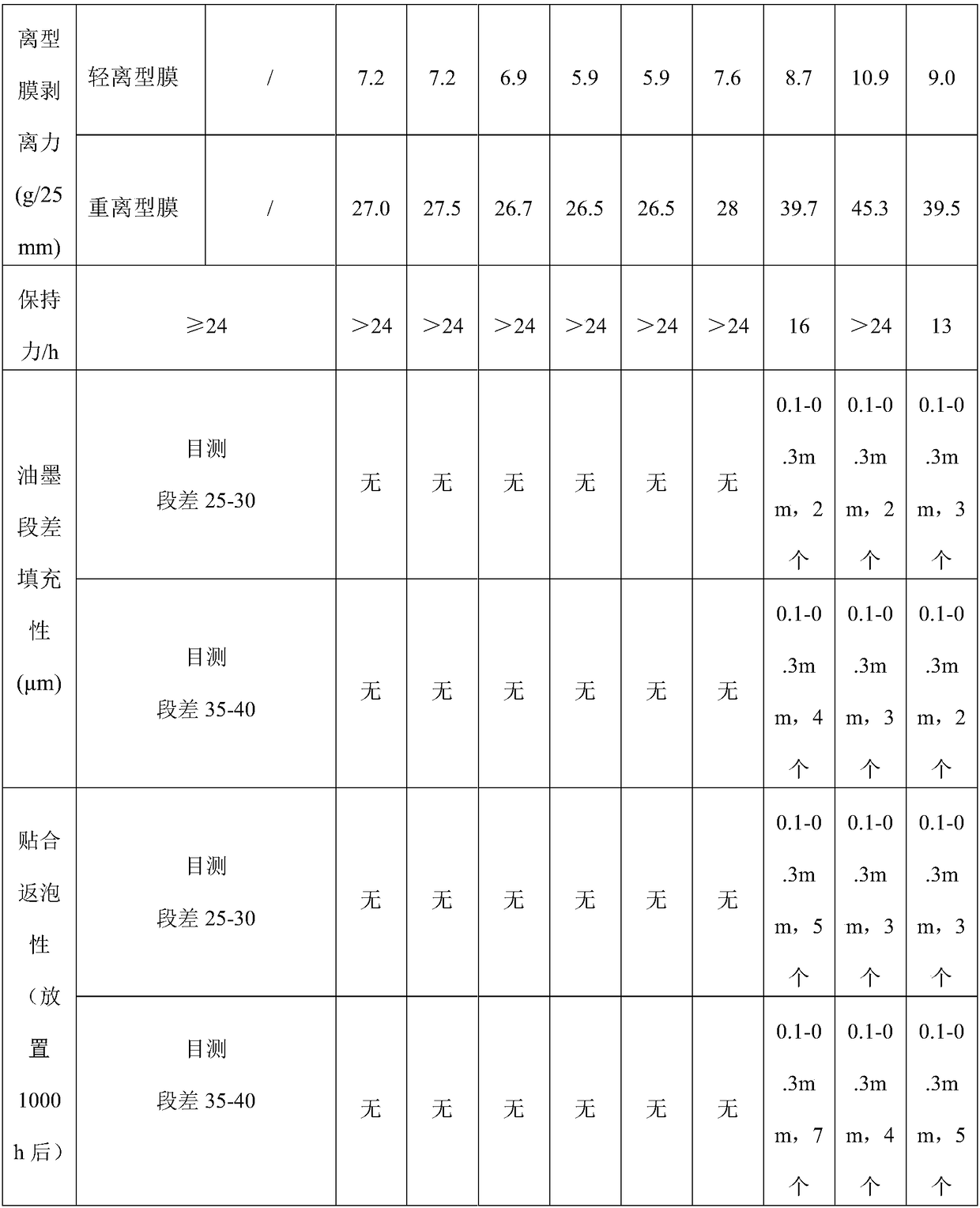

The invention belongs to the technical field of adhesives, and discloses an optical film adhesive used for full bonding, a preparation method and application of the adhesive and an optical film basedon the adhesive. The adhesive composition disclosed by the invention has the characteristics of having excellent segment difference filling performance, having no corrosivity while satisfying the characteristics of preventing high temperature, high humidity and whitening because of water boiling, and being easy to peel off when being reworked. The optical film adhesive comprises the following components in parts by mass: 40-50 parts of an acrylate copolymer, 0.5-5 parts of a crosslinking agent, 0.5-10 parts of an acrylate monomer, 0.02-0.4 part of a photoinitiator, 0.01-1 part of an adhesion modifier, and 20-50 parts of an organic solvent. The optical film adhesive disclosed by the invention improves hydrophilicity of a material by controlling glass transition temperature Tg of the material and introduction of a hydroxyl group, achieves the effect of preventing whitening and fogging in high-temperature high-humidity or water boiling environments, and reacts with the crosslinking agent;and addition of a silane coupling agent is combined, so that the technical effect of easy reworkability is realized.

Owner:GUANGZHOU HUMAN ENG MATERIAL

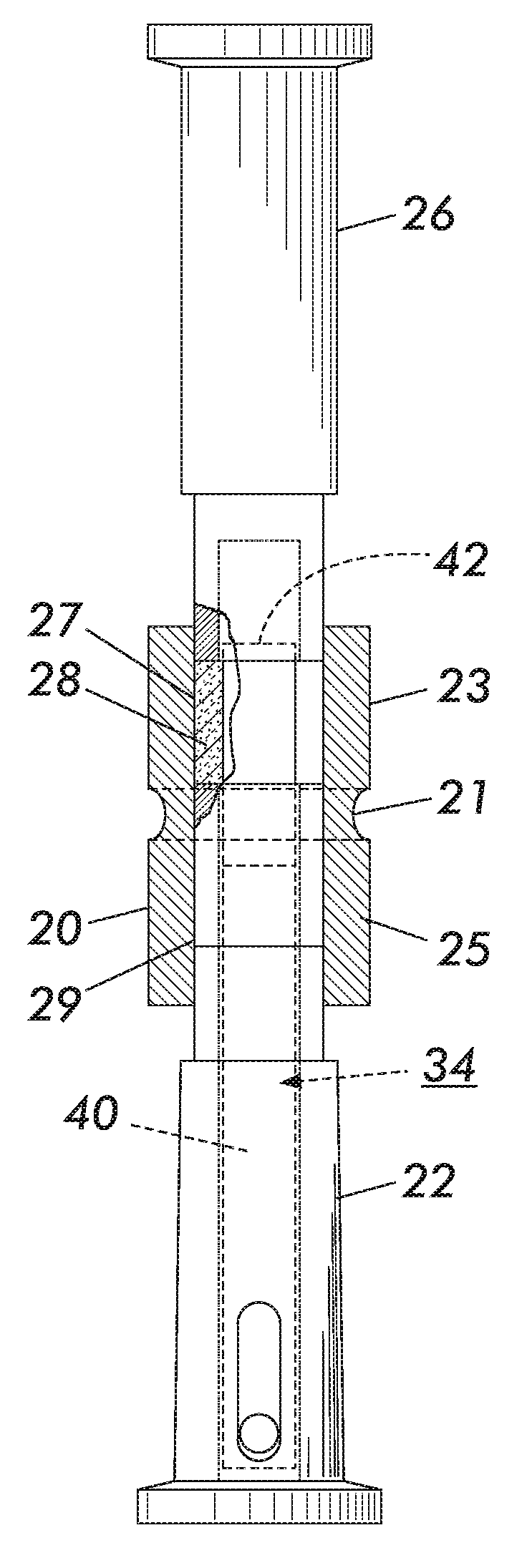

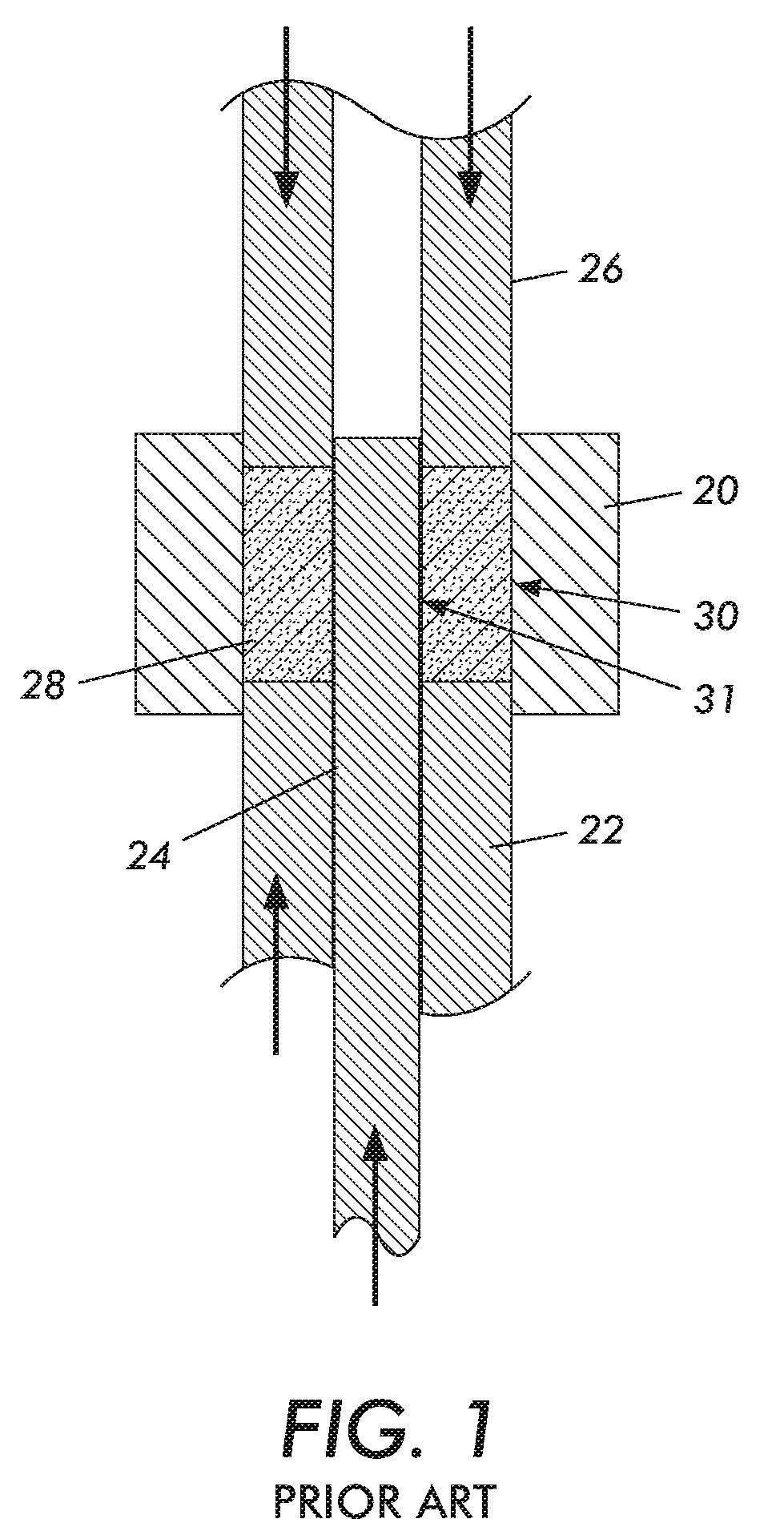

Ceramic center pin for compaction tooling and method for making same

ActiveUS20060193937A1Reduce wearSolve the lack of lifeConfectioneryCeramic shaping apparatusMaterials science

The present invention is a method and apparatus for the production of compacted powder elements. More specifically, the present invention is directed to the improvement of tooling for powder compaction equipment, and the processes for making such tooling. The improvement comprises the use of a ceramic tip or similar component in high wear areas of the tooling, particularly center pins. Moreover, the use of such ceramic components enables reworking and replacement of the worn tool components.

Owner:BLUE SKY VISION PARTNERS

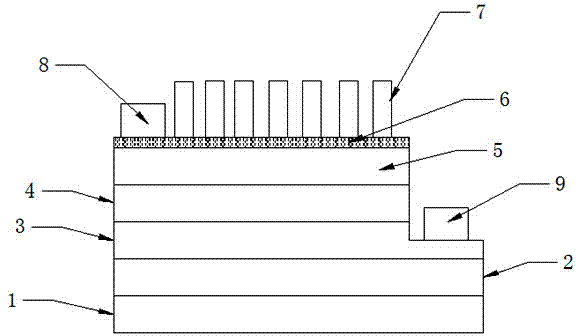

LED (Light Emitting Diode) chip for composite transparent conducting electrode and manufacturing method of LED chip

InactiveCN104505445AImproved ohmic contact characteristicsReduce processing difficultySemiconductor devicesThin membraneGraphite

The invention discloses an LED (Light Emitting Diode) chip for a composite transparent conducting electrode. The LED chip comprises a gallium nitride buffer layer, an N-GaN layer, a quantum well layer, a P-GaN layer and a composite transparent electrode layer which grow on a substrate in sequence. The LED chip is characterized in that an n-type electrode is manufactured on the N-GaN layer; a p-type electrode is manufactured on a graphene layer of the composite transparent electrode layer; the composite transparent electrode layer is formed by compounding a graphene laminar film and ZnO nanorods growing on the graphene laminar film. The invention also discloses a manufacturing method of the chip. The graphene laminar film / ZnO nanorod compounded transparent electrode layer formed by the manufacturing method has the advantages of capability of preventing cracking and good light transmittance performance and is easy to process, so that the contact performance, the current expansion performance and the transmissivity of the chip are greatly improved, and the production cost of the subsequent chip technology can be greatly reduced.

Owner:GUANGDONG DELI PHOTOELECTRIC

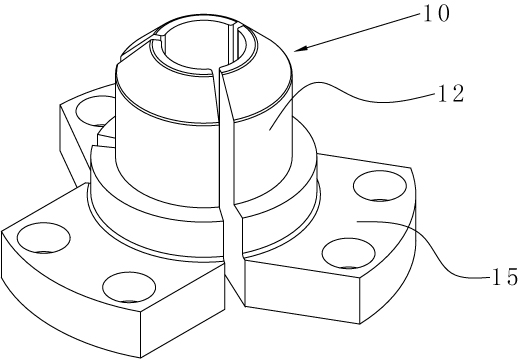

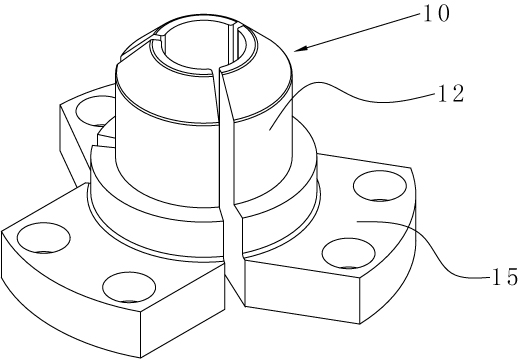

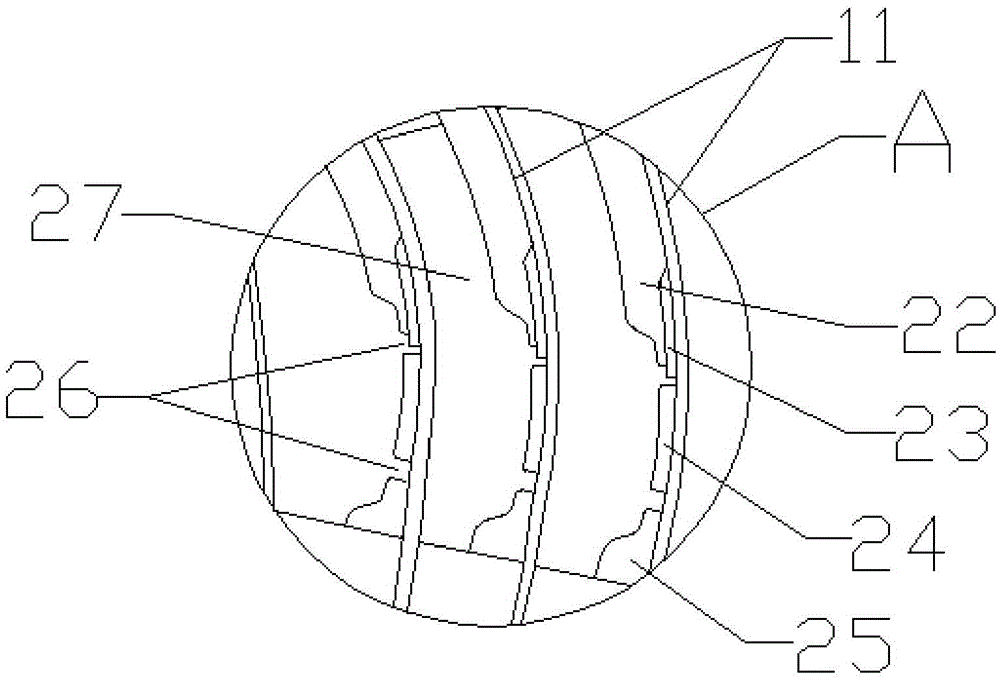

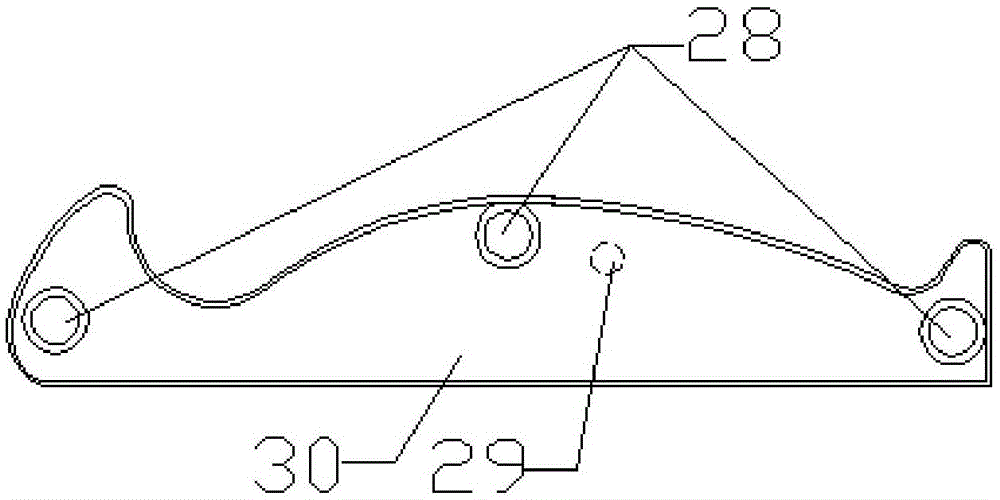

Round pin-inserted positioning device and tensioning and positioning round pin thereof

ActiveCN102121496AGuaranteed positioning accuracyGuaranteed positional stabilityWelding/cutting auxillary devicesBoltsEngineeringCar door

Owner:GUANGQI HONDA

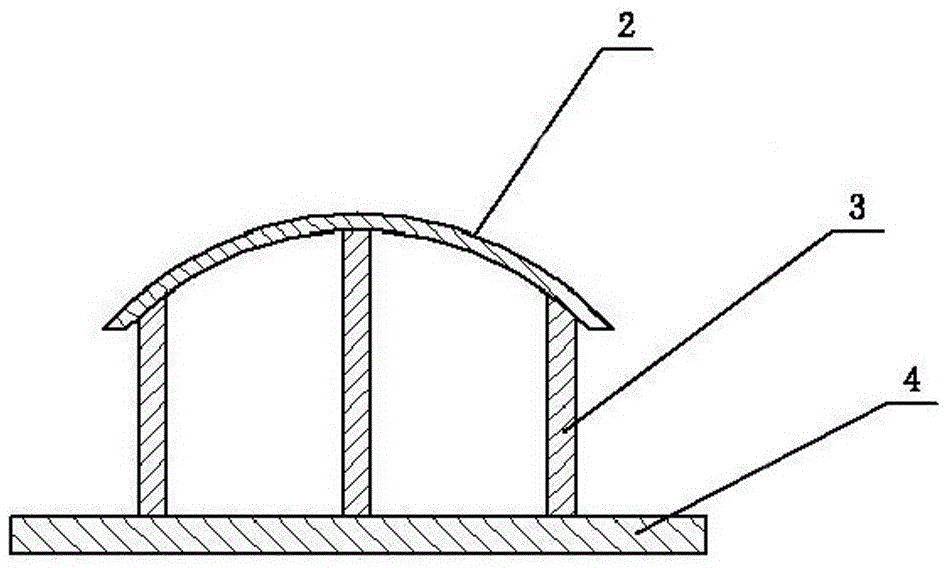

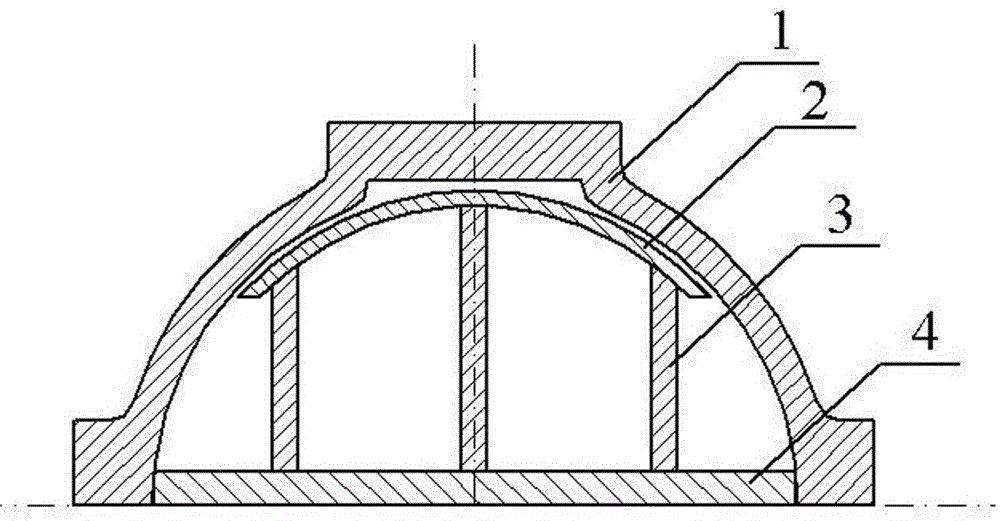

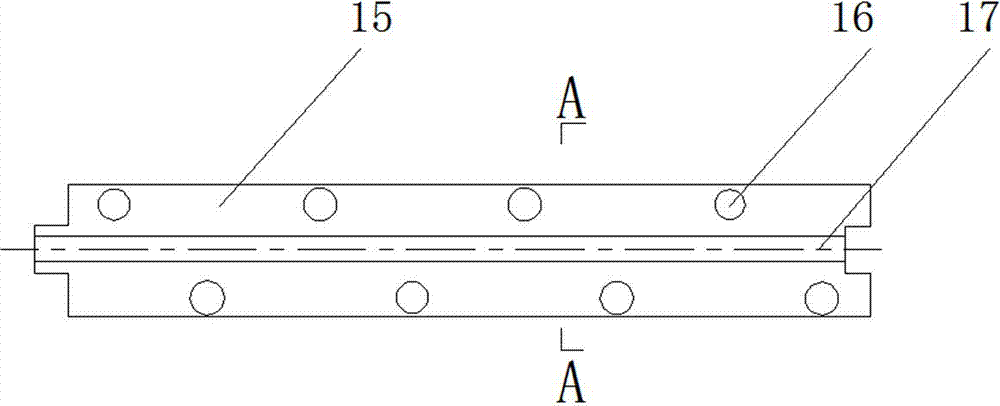

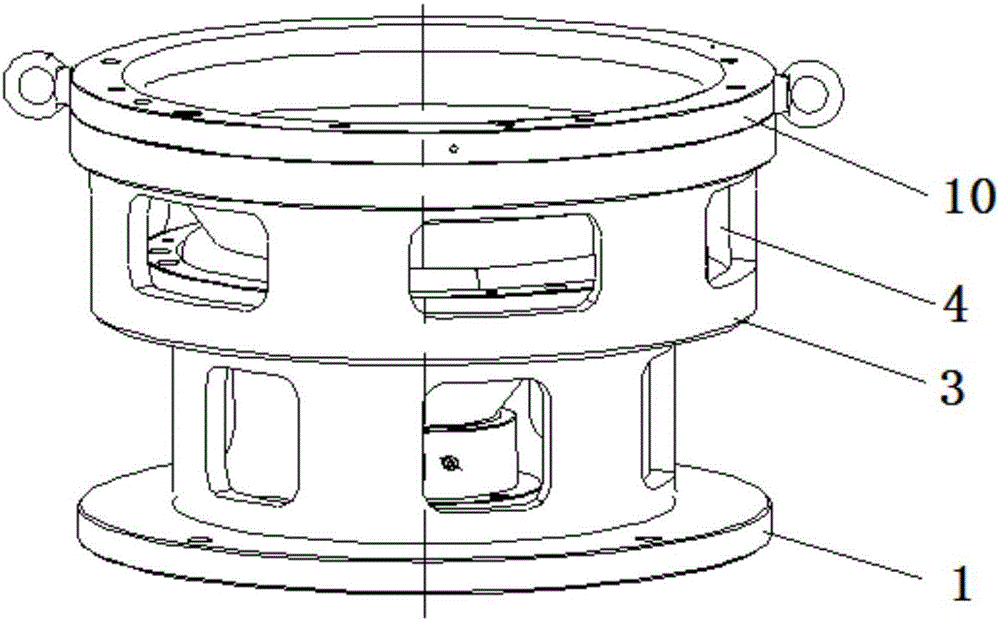

Thermal treatment and deformation prevention tool for thin-wall cylinder body casting and thermal treatment charging method thereof

InactiveCN106282517APrevent concave deformationShorten the production cycleFurnace typesHeat treatment furnacesHeat treatedMaterials science

The invention relates to a thermal treatment and deformation prevention tool for a thin-wall cylinder body casting and a thermal treatment charging method thereof. The thermal treatment and deformation prevention tool for the thin-wall cylinder body casting comprises a plurality of supporting components arranged on the axial inner side of the cylinder body casting in a spacing manner, wherein the supporting components comprise arc-shaped supporting bodies for supporting the inner wall of a cylinder body; the radian of each arc-shaped supporting body is 60 to 90 degrees; the radius of the outer arc surface of each of the arc-shaped supporting bodies is the same as that of the arc surface of the inner wall of the cylinder body; a plurality of supporting rods are perpendicularly arranged on the arc-shaped inner sides of the arc-shaped supporting bodies; the lower ends of the supporting rods are fixedly supported on horizontally arranged supporting plates; the lengths of the supporting plates are less than the inner diameter of the cylinder body casting by 20 to 30 mm; the lower surfaces of the supporting plates and the flange end surfaces of the cylinder body casting to be supported are located on the same horizontal plane. The thermal treatment and deformation prevention tool disclosed by the invention can effectively prevent inwards sunken deformation of the cylinder body casting during high-temperature thermal treatment to prevent two flange ends of the cylinder body casting from being outwards opened.

Owner:KOCEL STEEL

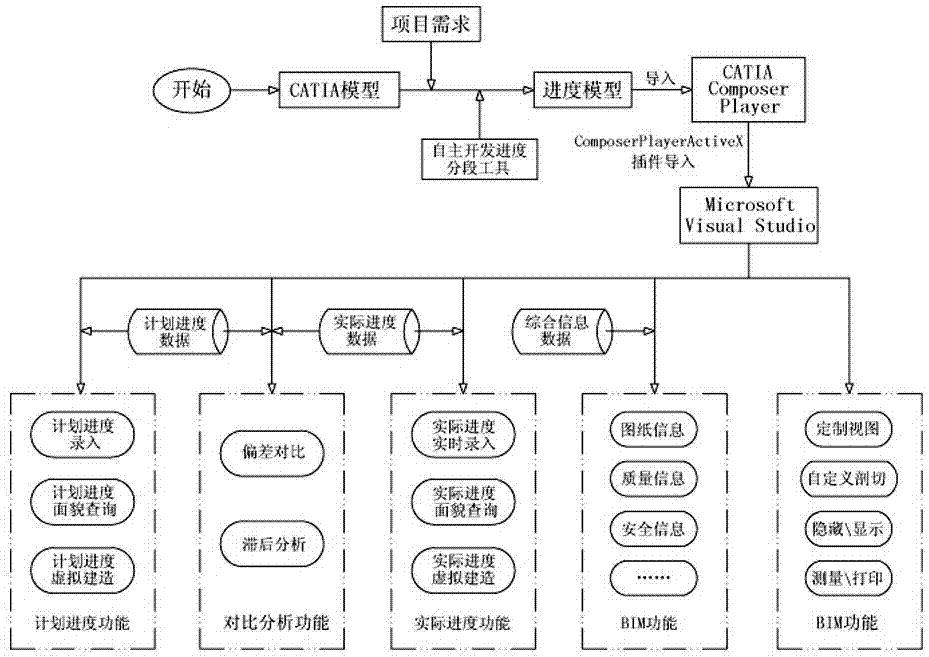

Three-dimensional digital model-based hydraulic and hydropower engineering progress monitoring method

PendingCN107273640AEasy to understandImplement interactive queryGeometric CADData processing applicationsProgram planningDesign software

The invention discloses a three-dimensional digital model-based hydraulic and hydropower engineering progress monitoring method. The method comprises the steps of 1, performing modeling: reading a hydraulic engineering two-dimensional drawing or directly performing hydraulic engineering design, and performing model building by utilizing CATIA three-dimensional design software, wherein a modeling detail requirement is greater than LOD300; 2, performing model division: according to a progress plan, project demands and project characteristics, dividing a design model in the step 1 into progress models, and customizing specific identifiers for names of the progress models, wherein the name of each progress model after division is divided into two parts: the specific identifier and a number; 3, writing the names, as main keys, of all the progress models after division into a database, and then establishing other fields; and 4, performing secondary development on Catia Composer Player. Therefore, the needs of BIM progress input, deviation comparison, lag analysis and virtual construction functions are met.

Owner:YELLOW RIVER ENG CONSULTING

Large area super-flat reinforced concrete floor and colorful diamond sand surface layer one-step forming method

InactiveCN107060171ALow costSolve common quality problemsFloorsFlooringSurface layerReinforced concrete

The invention relates to a large area super-flat reinforced concrete floor and colorful diamond sand surface layer one-step forming method. The one-step forming method comprises the steps of template erection, steel bar binding, expansion reinforcing band arrangement, elevation measurement, steel bar elevation check, laser leveler adjustment, concrete pouring, laser leveler leveling, professional leveling, diamond sand spreading, grinding and flexible compacting, polishing, construction seam cutting, curing, finished product curing and upper structure construction. According to the one-step forming method, a structural floor is used as a base layer, a diamond sand floor surface layer and a structure are subjected to one-step pouring forming, the common quality problem that the floor surface layer is prone to forming hollow protrusions due to secondary pouring is avoided, meanwhile, one concrete base layer is reduced, and cost is greatly reduced. The floor is fully covered with recyclable materials such as plastic films and templates so that an upper main structure can continue to be conveniently constructed.

Owner:SHANGHAI SENXIN CONSTR ENG

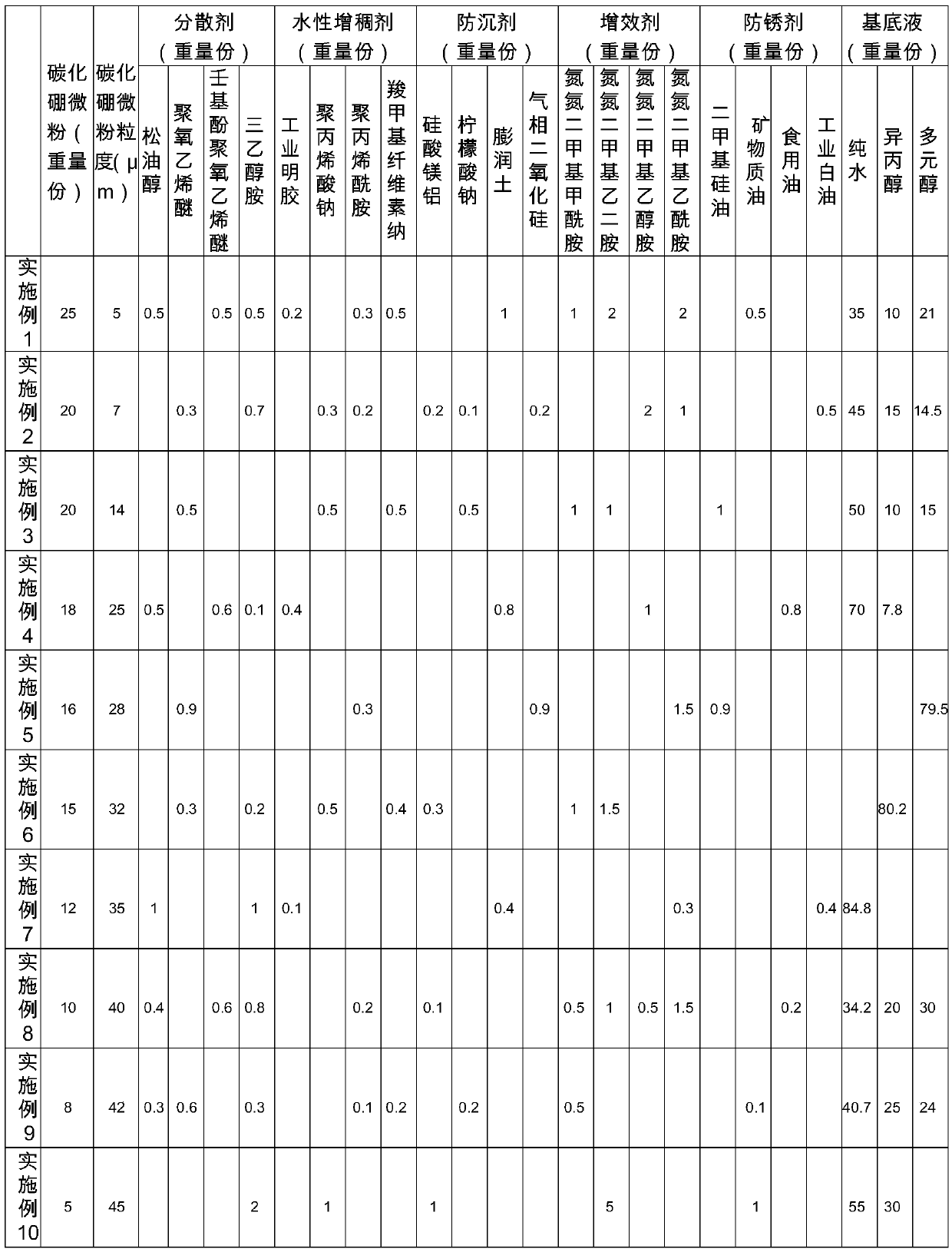

Efficient boron carbide grinding fluid and method for preparing same

InactiveCN105505231AImprove flatnessQuick grindingOther chemical processesPolishing compositions with abrasivesWater basedAlcohol

The invention discloses efficient boron carbide grinding fluid and a method for preparing the same, and relates to the field of technologies for grinding sapphire. The efficient boron carbide grinding fluid comprises, by weight, 5-25 parts of boron carbide micro-powder, 1-2 parts of dispersing agents, 0.5-1 part of water-based thickeners, 0.5-1 part of anti-settling agents, 0.5-5 parts of synergists, 0.5-1 part of antirust agents and 65-92 parts of substrate fluid. The substrate fluid can be one of pure water, isopropyl alcohol and polyhydric alcohol or a mixture of the pure water, the isopropyl alcohol and the polyhydric alcohol, and various components of the substrate fluid have equal weight parts or other proportions when the substrate fluid comprises the mixture of the pure water, the isopropyl alcohol and the polyhydric alcohol. The efficient boron carbide grinding fluid and the method have the advantages that the efficient boron carbide grinding fluid is long in service life, good in stability and applicable to rough grinding for processing sapphire wafers, the A-direction and M-direction sapphire grinding rates can be increased, processed products are good in surface flatness, and the like.

Owner:HUNAN HAOZHI TECH

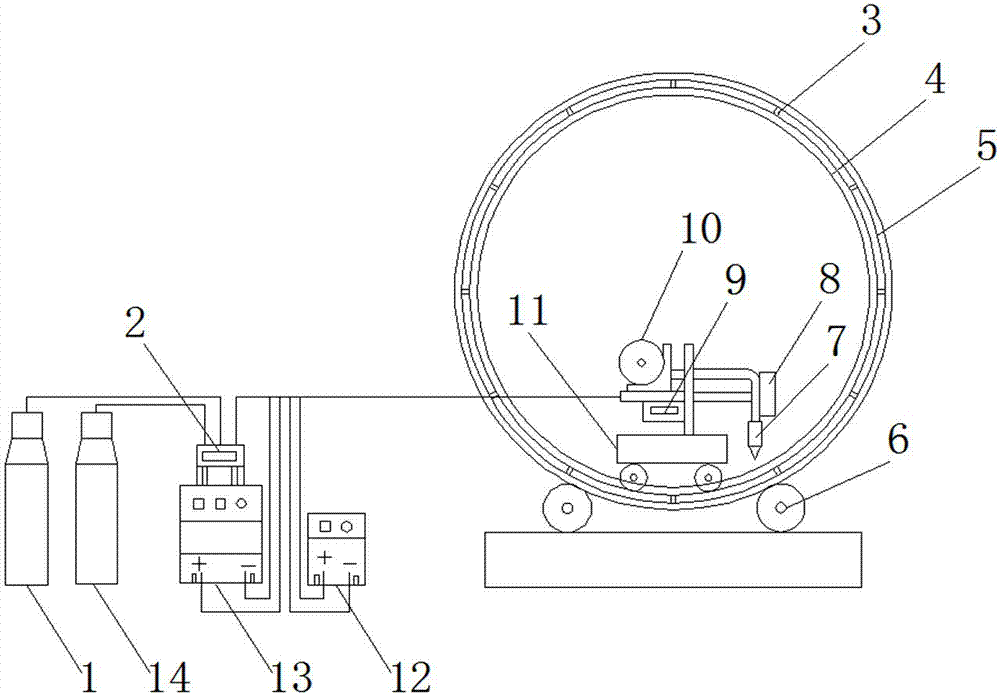

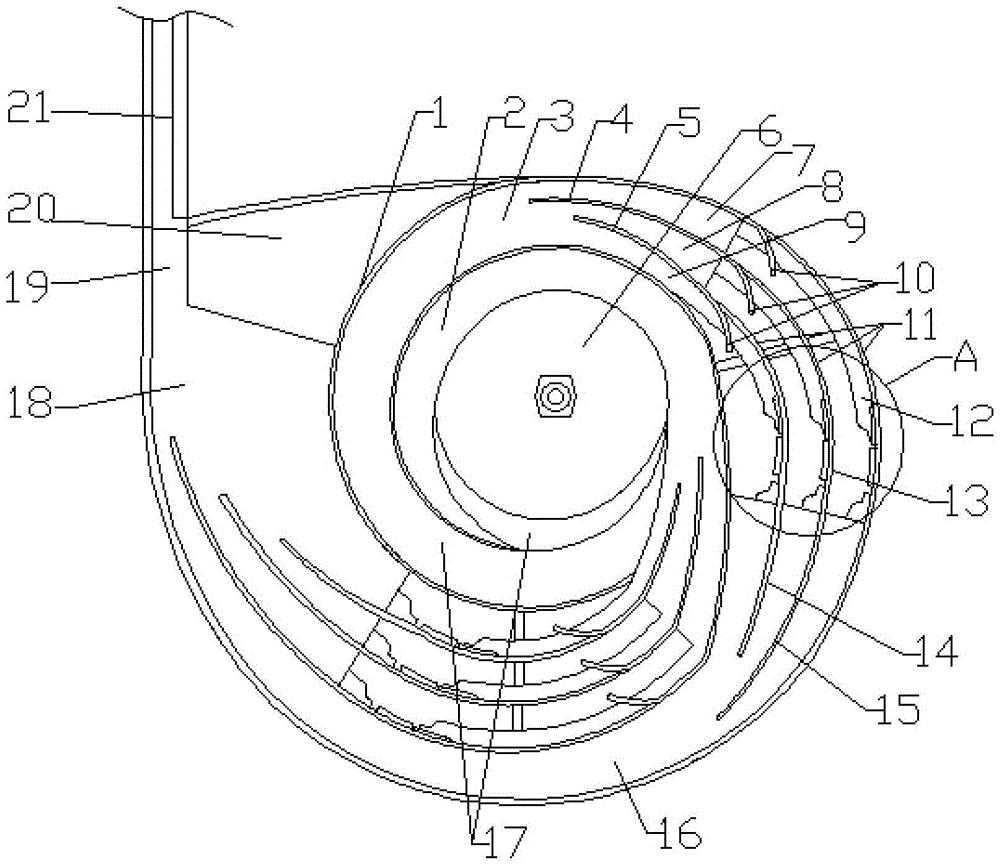

Automatic inner cylindrical circular seam welding machine with flexible rail

InactiveCN104741735AImprove welding qualityReduce rework costsWelding/cutting auxillary devicesCooled electrode holdersWelding power supplySeam welding

The invention discloses an automatic inner cylindrical circular seam welding machine with a flexible rail. The automatic inner cylindrical circular seam welding machine comprises a main welder body, a gas supply mechanism, a cooling mechanism, and a rolling mechanism; the main welder body comprises a weld gun, wherein the weld gun is connected with a wire feeder, and the bottom part of the wire feeder is provided with a welding oscillator; the gas supply mechanism comprises a welding power source connected with the main welder body; the rolling mechanism comprises a speed regulating roller frame, and the cylinder body is located on the speed regulating roller frame; a flexible rail is arranged around the annular seam in the cylinder body, and the flexible rail comprises a rail base layer, and a rail located in the center of the rail base layer; the rail is convexly arranged on the surface of the rail base layer, both sides of the rail are respectively provided with a line of holes, and two lines of holes are aligned at intervals. The automatic inner cylindrical circular seam welding machine is added with a walking trolley, the welding oscillator and a water cold weld gun, and paves rail in the cylinder body, thus the full automatic welding of the circular seam in a pressure container is realized; the automatic inner cylindrical circular seam welding machine can apply welding to multiple circular seams at the same time, and also can eliminate the adverse influence of axial movement of the cylinder in rotating process on welding.

Owner:NANTONG UNION MACHINERY ELECTRONTCS TECH CO LTD

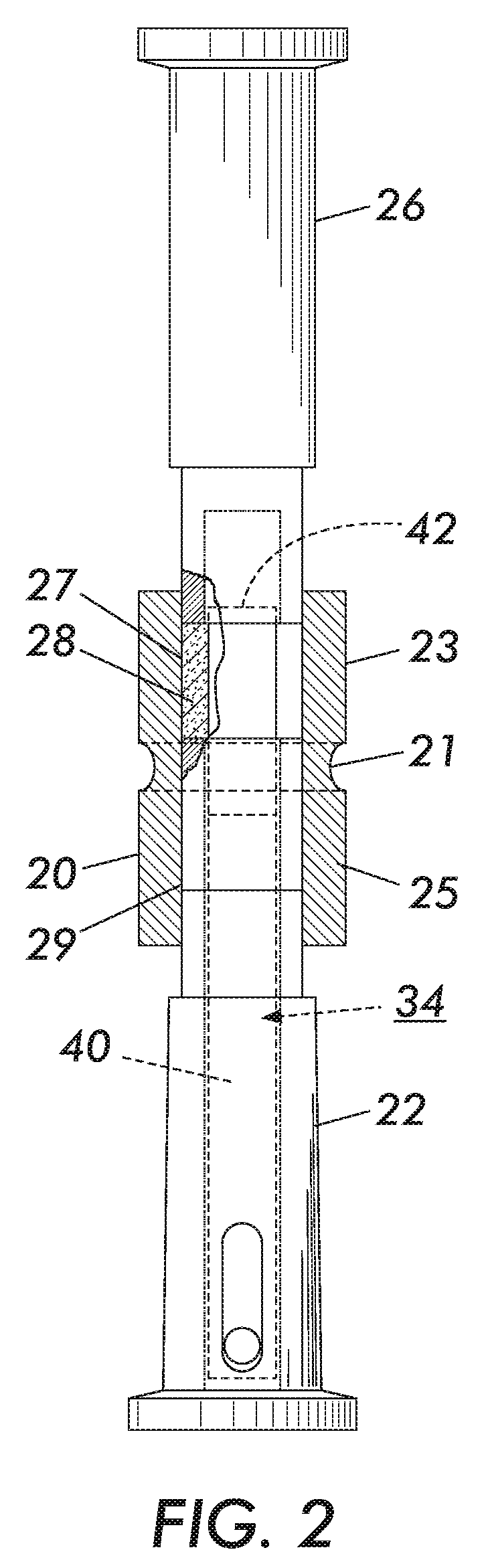

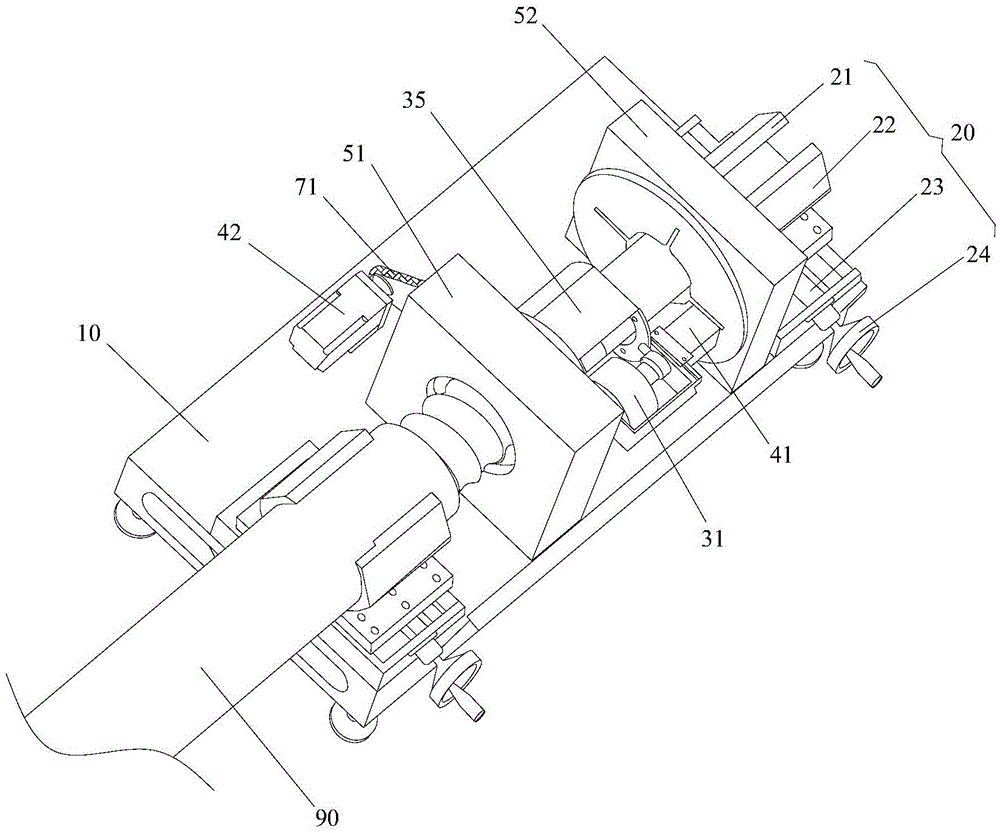

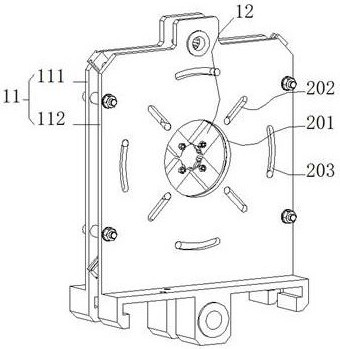

Cable insulation shielding layer processing device

ActiveCN105538089AQuality assuranceSolve the problem that it is not easy to automatically handle smooth transitionsGrinding machinesGrinding work supportsEngineeringMechanical engineering

The invention provides a cable insulation shielding layer processing device which comprises a bracket (10), a clamping mechanism (20), a grinding mechanism and a drive mechanism, wherein the clamping mechanism (20) is arranged on the bracket (10); the clamping mechanism (20) is provided with a clamping opening for clamping a cable (90); the grinding mechanism can be rotatably arranged on the cable (90) and is positioned at the insulation shielding layer of the cable (90); and the drive mechanism is in driving connection with the grinding mechanism for driving the grinding mechanism to grind the insulation shielding layer. According to the technical scheme adopted by the invention, the cable insulation shielding layer effectively solves the problem that an insulation shielding fracture cannot be manually processed easily to realize smooth transition in the prior art.

Owner:STATE GRID BEIJING ELECTRIC POWER +2

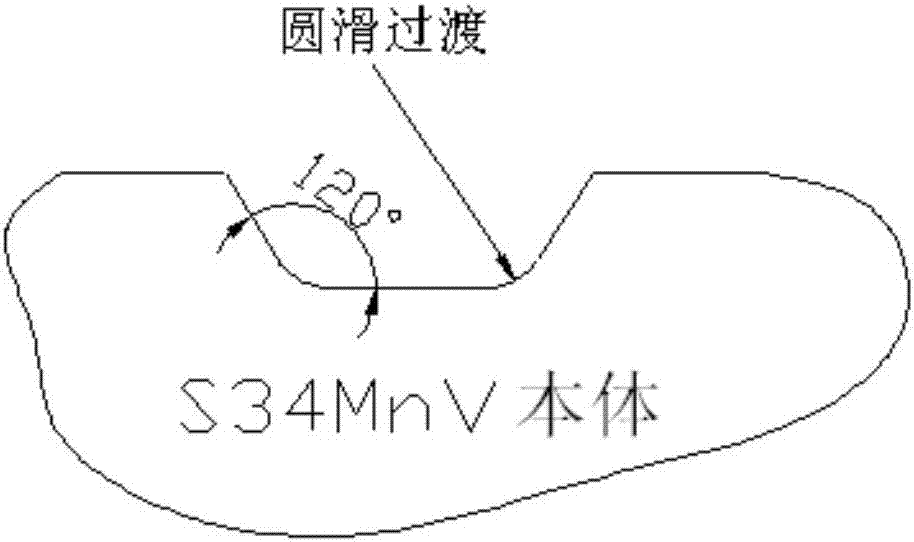

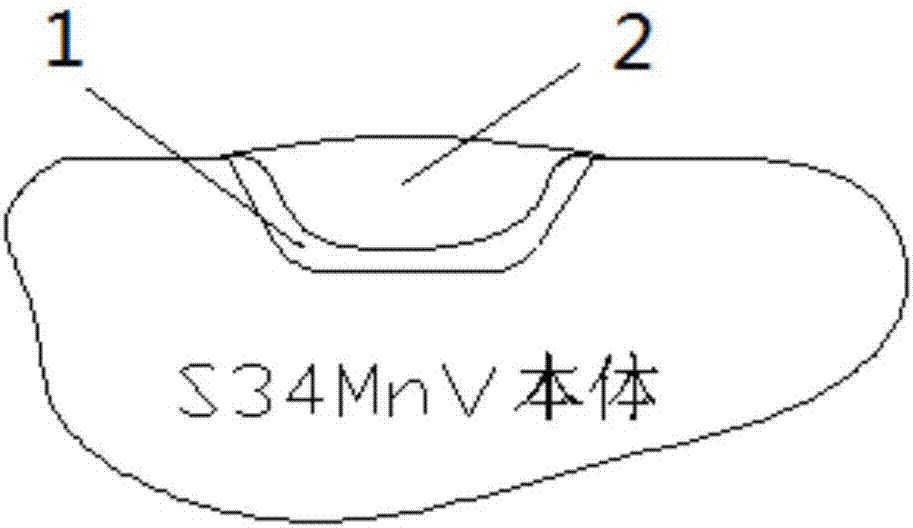

Welding repair method for local defect of crankshaft for ship

Disclosed is a welding repair method for a local defect of a crankshaft for a ship. The crankshaft is made of S34MnV. The welding repair method is characterized in that preheating before welding is not conducted, and the local defect on the surface of the crankshaft is repaired through a cold welding method; and the welding repair method comprises the steps that polishing treatment is conducted on the defect on the surface of the crankshaft before welding, then a priming coat is formed through argon arc welding, then CO2 gas shielded welding is adopted for welding of a filling covering layer, and finally grinding and polishing are conducted on the repaired surface. According to the welding repair method, the tedious processes of preheating before welding, and heat preservation and slow cooling after welding are avoided, repair cost is reduced, meanwhile, the welding repair method has the advantages that the processes are simple, operability is high, and work efficiency is high and can be used for repair and maintenance of the local defect of the crankshaft for the ship, and very high practicability is achieved.

Owner:HUDONG HEAVY MACHINERY +1

Multi-channel spiral feeding device for magnetic buckle plastic

InactiveCN105984694AGuarantee sufficiencySolve the speed problemJigging conveyorsConveyor partsEngineeringLinear vibration

The invention discloses a multi-channel spiral feeding device for magnetic buckle plastic. The multi-channel spiral feeding device comprises a vibration disc, a hopper, a feeding port, a feeding track and a linear vibration track. The multi-channel spiral feeding device is characterized by further comprising a first inner spiral track, a second inner spiral track and spiral feeding screening and sorting devices; the hopper is arranged at the bottom of the vibration disc and provided with the first inner spiral track and the second inner spiral track, and the two same spiral feeding screening and sorting devices are arranged and connected with the tail end of the upper portion of the first inner spiral track and the tail end of the upper portion of the second inner spiral track correspondingly; and each of the spiral feeding screening and sorting device comprises a discharging port, a first track, a second track and a third track. The multi-channel spiral feeding device has the beneficial effects of being simple in structure, high in automation degree and high in precision of screening of plastic buckles.

Owner:LIXIN FUYA GAUZE CO LTD

Paint baking device for electronic product processing

InactiveCN108838043AImprove continuityImprove work efficiencyPretreated surfacesCoatingsCooking & bakingEngineering

The invention discloses a paint baking device for electronic product processing. A base is arranged at the bottom of a device body, an Y355 motor is installed at the bottom in the base, and a belt isinstalled at one end of the Y355 motor. Conveyor rollers are installed at one end of the belt, a conveyor belt is laid on the outer side of the conveyor rollers, a baking box is installed at the top of the base, and a fan is installed on the middle portion of the top of the baking box. Wind supply pipes are installed on two sides of the fan, telescopic pipes are fixedly connected to the bottom ends of the wind supply pipes, wind distributing plates are installed at the bottoms of the telescopic pipes, and a roaster is installed at the top end of the middle portion in the baking box. Electric heating pipes are installed on middle portions of two sides in the baking box, wind outlets are formed in bottom ends of two sides in the baking box, and wind exhaust boxes are installed on the outer sides of the wind outlets. The wind supply pipes are connected with the wind distributing plates through the telescopic pipes, the telescopic pipes can drive the wind distributing plates to stretch andretract back and forth when wind blows, the paint baking device is flexible and fast, the blowing range of draught of the wind distributing plates is expanded, and the work efficiency of the device body is improved.

Owner:芜湖通全电子电器科技创业有限公司

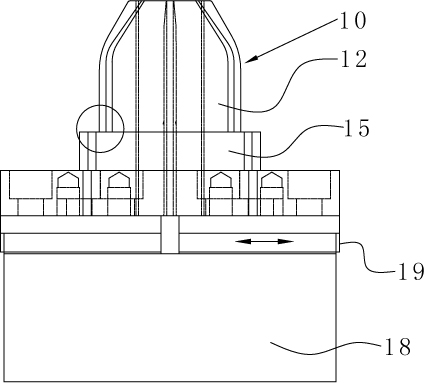

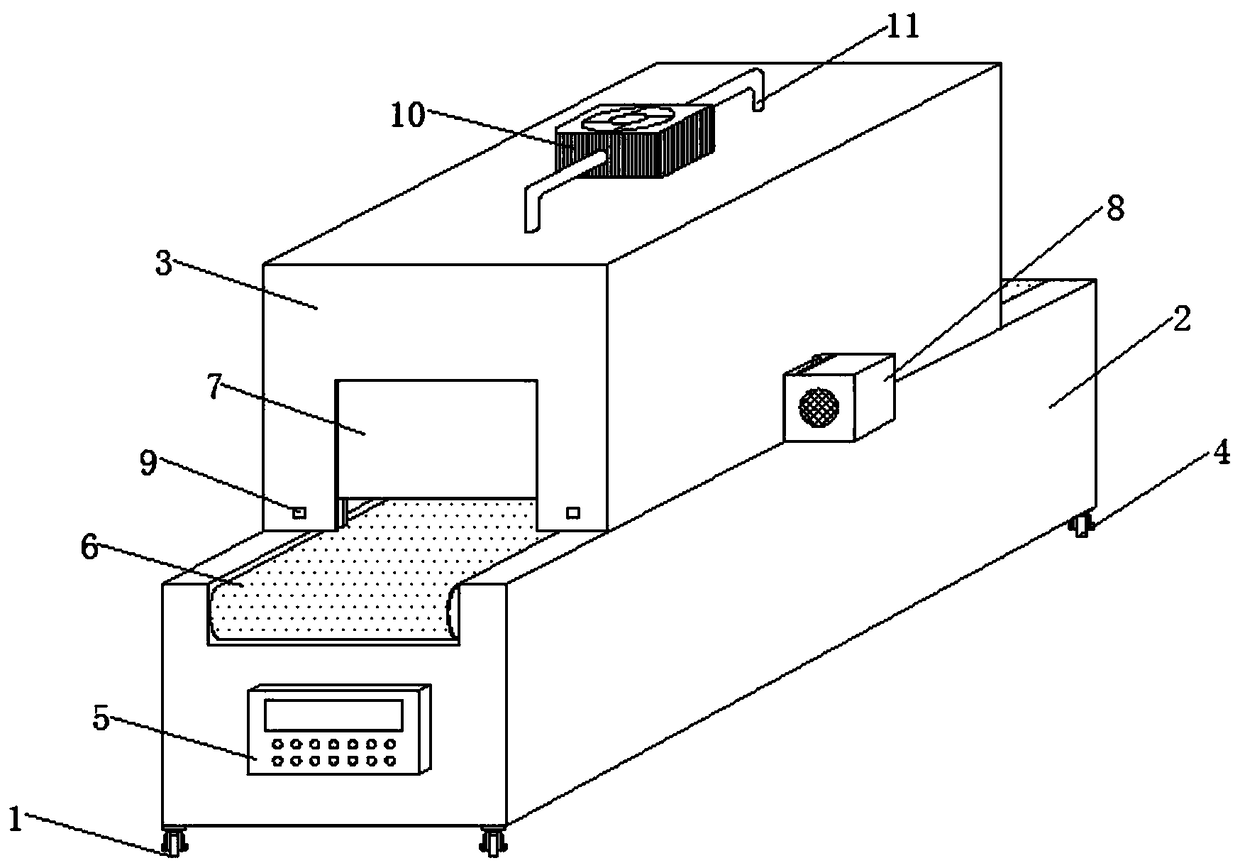

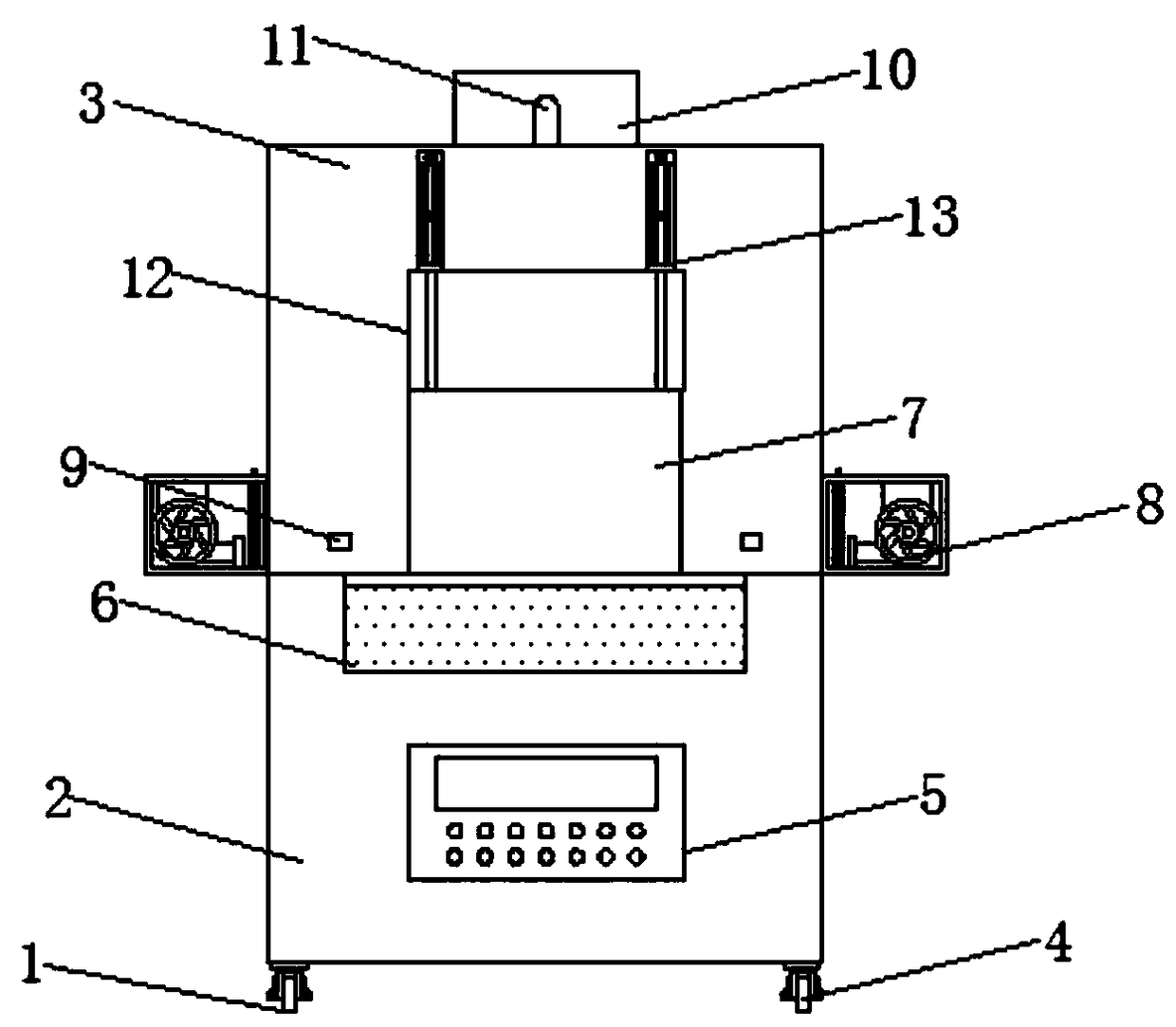

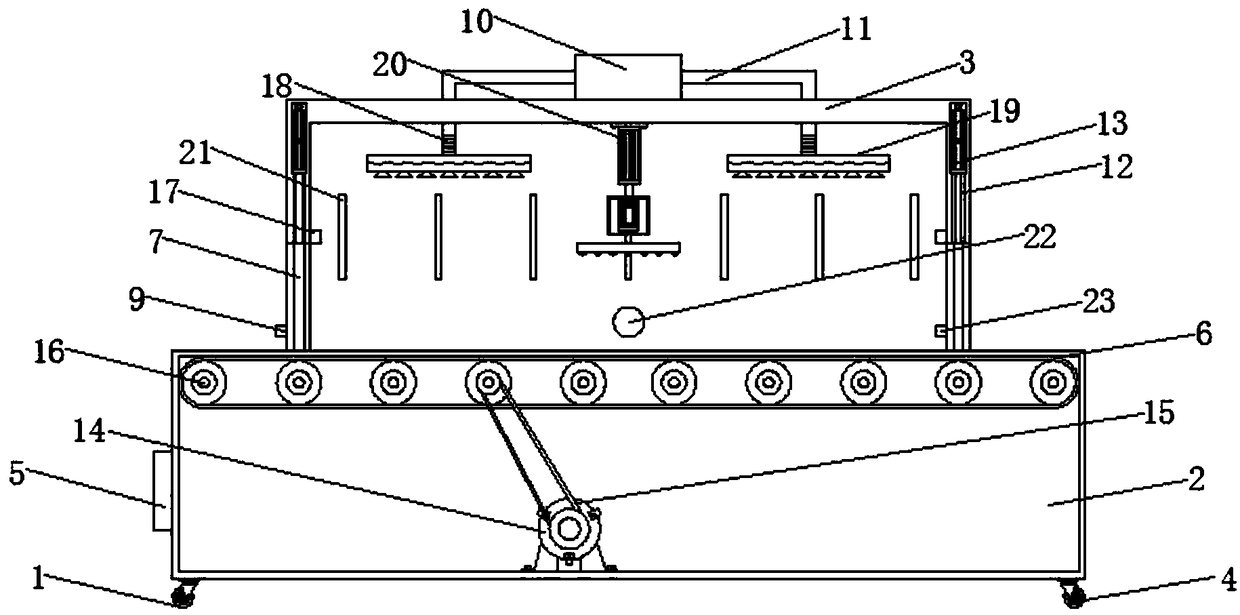

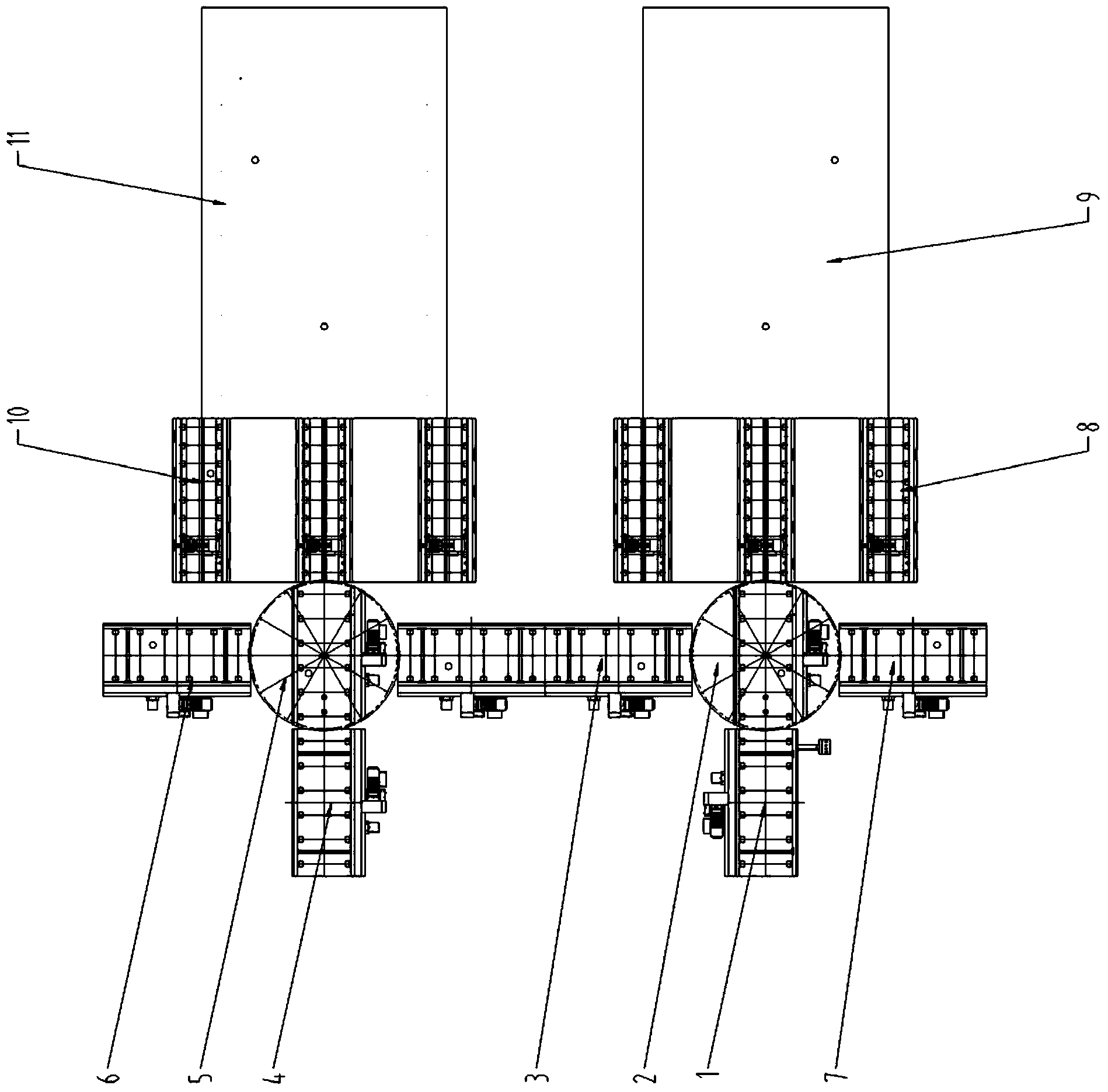

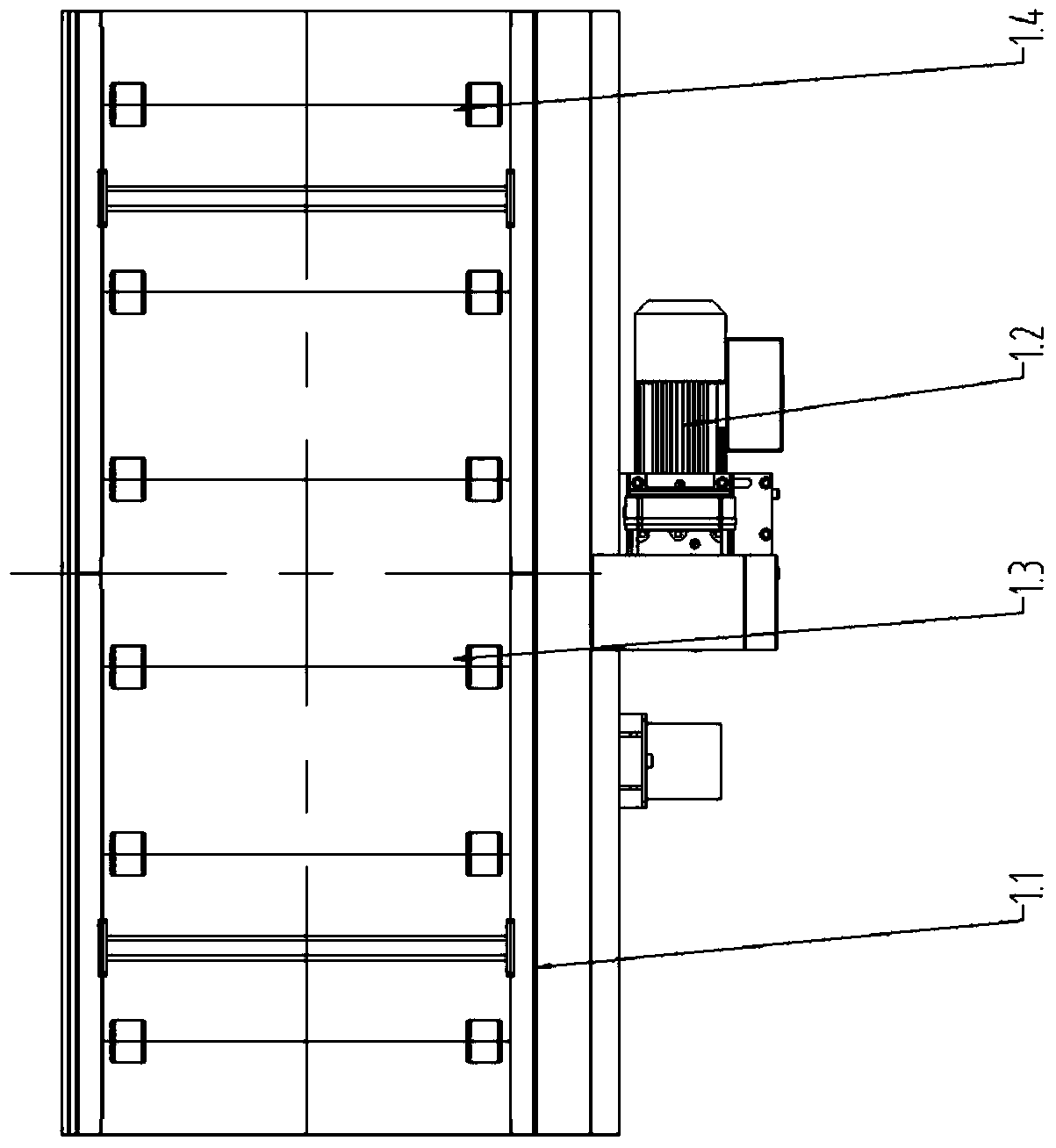

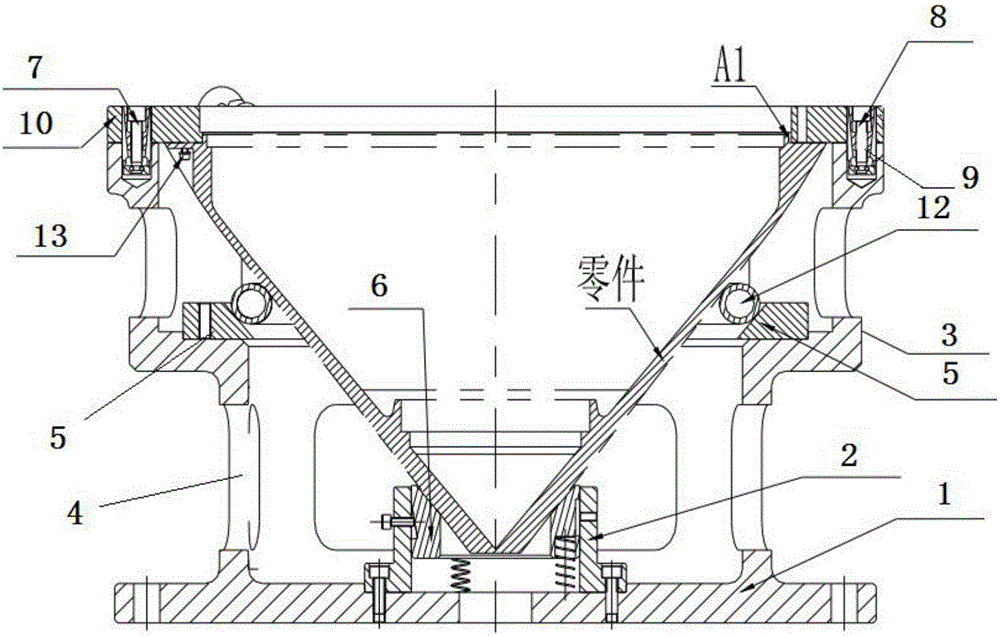

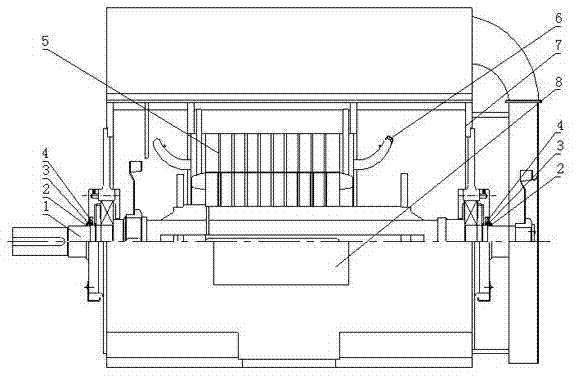

Production line for cold test of diesel engine

ActiveCN103934683AReduce rework costsImprove rework efficiencyInternal-combustion engine testingAssembly machinesCold testDiesel engine

The invention relates to a production line for a diesel engine, in particular to the production line for cold test of the diesel engine and belongs to the field of the diesel engine production technology. The production line comprises a first rotary table and a second rotary table, wherein a cold test conveying line body is arranged between the first rotary table and the second rotary table, a first repair section line body is arranged on other side of the first rotary table and opposite to the side where the cold test conveying line body is positioned, and a second repair section line body is arranged on other side of the second rotary table and opposite to the side where the cold test conveying line body is positioned. A last process conveying line body is arranged on one side of the first rotary table, and a first front transitional machine and a first cold test rack are arranged on the other side of the first rotary table. A next process conveying line body is arranged on one side of the second rotary table, and a second front transitional machine and a second cold test rack are arranged on the other side of the second rotary table. By means of the production line, online cold test can be performed during assembly of the diesel engine, repair is facilitated, and the production line is reasonable in integral layout, attractive and capable of facilitating production organization and logistics arrangement.

Owner:CHINA FIRST AUTOMOBILE

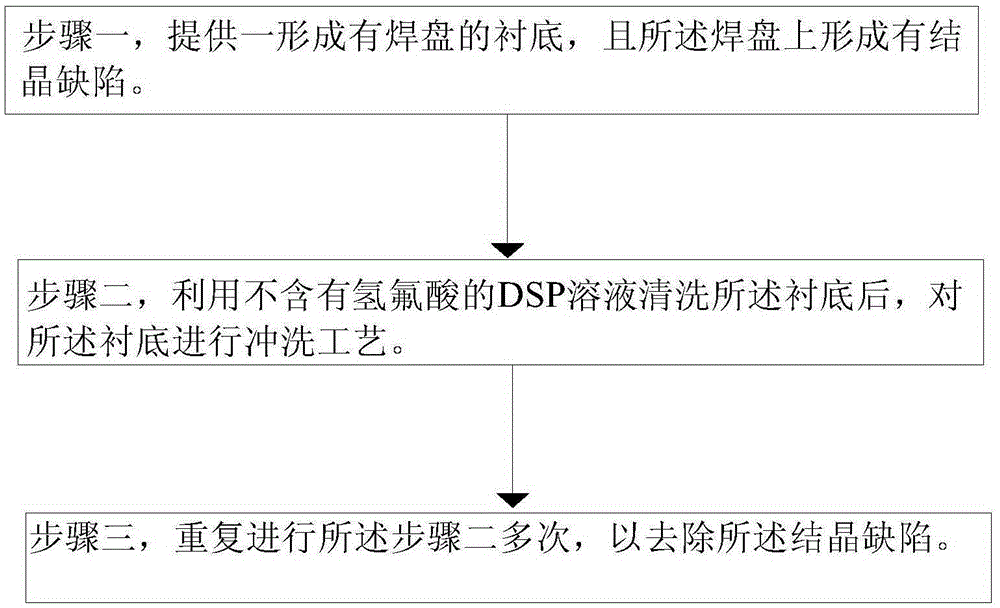

Method for removing pad defect

InactiveCN105428211AAvoid damageEfficient removalSemiconductor/solid-state device manufacturingHydrofluoric acidEngineering

The present invention relates to the technical field of semiconductor manufacturing and particularly relates to a method for removing a pad defect. After a DSP solution without hydrofluoric acid is used to clean a pad, the pad is subjected to washing process, the cleaning and washing processes are repeated for many times to remove the pad defect, since the DSP solution does not contain the hydrofluoric acid, the pad damage in the process of removing the pad defect can be reduced, and pit defects are reduced. Since the DSP high and low speed matching is used, the streaming can be increased to increase chemical cleaning ability, the mode of repeated cleaning and washing is employed, the effect of the sulfuric acid and hydrogen peroxide in the solution can be improved, thus the pad defect can be effectively removed, scrap can be reduced, the yield is improved, and the cost os rework is saved.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

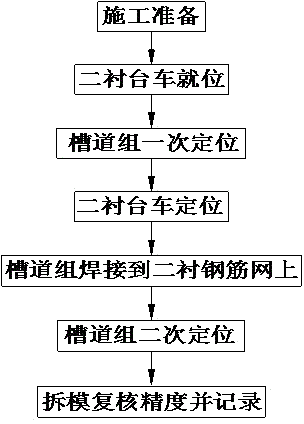

Two-time positioning construction process for pre-buried channels of overhead line system of high-speed railway tunnel

ActiveCN104790969AQuick installationLarge operating spaceUnderground chambersTunnel liningRailway tunnelRebar

The invention relates to a two-time positioning construction process for pre-buried channels of an overhead line system of a high-speed railway tunnel. By adjusting the procedure of installing the pre-buried channels, a larger operation space is provided for construction, and operators can conveniently and rapidly install channel sets on a lining trolley and can rapidly install C type channel sets, D type channel sets and E type channel sets by standing on edges of the lining trolley by means of frames such as ladders. The channels can be positioned in advance while secondary lining reinforcing steel bars are bound, time is used while the space is used sufficiently, multiple steps are executed at the same time and do not affect one another, and the result is gained with half effort.

Owner:中铁二十四局集团福建铁路建设有限公司 +1

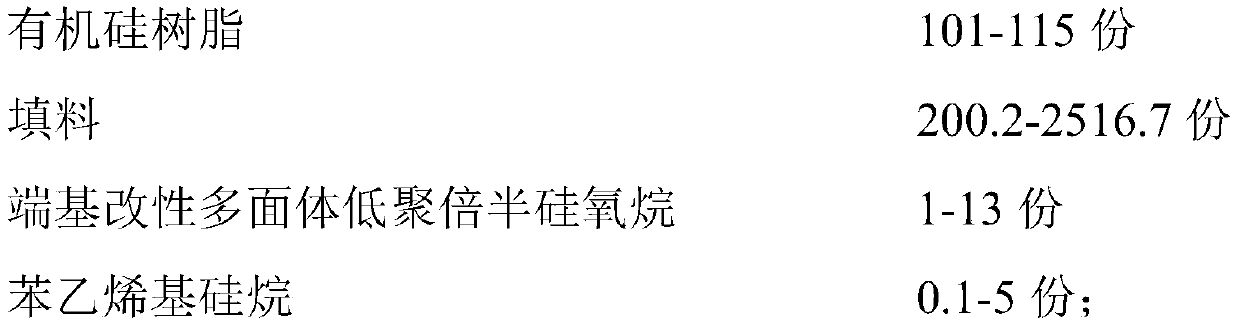

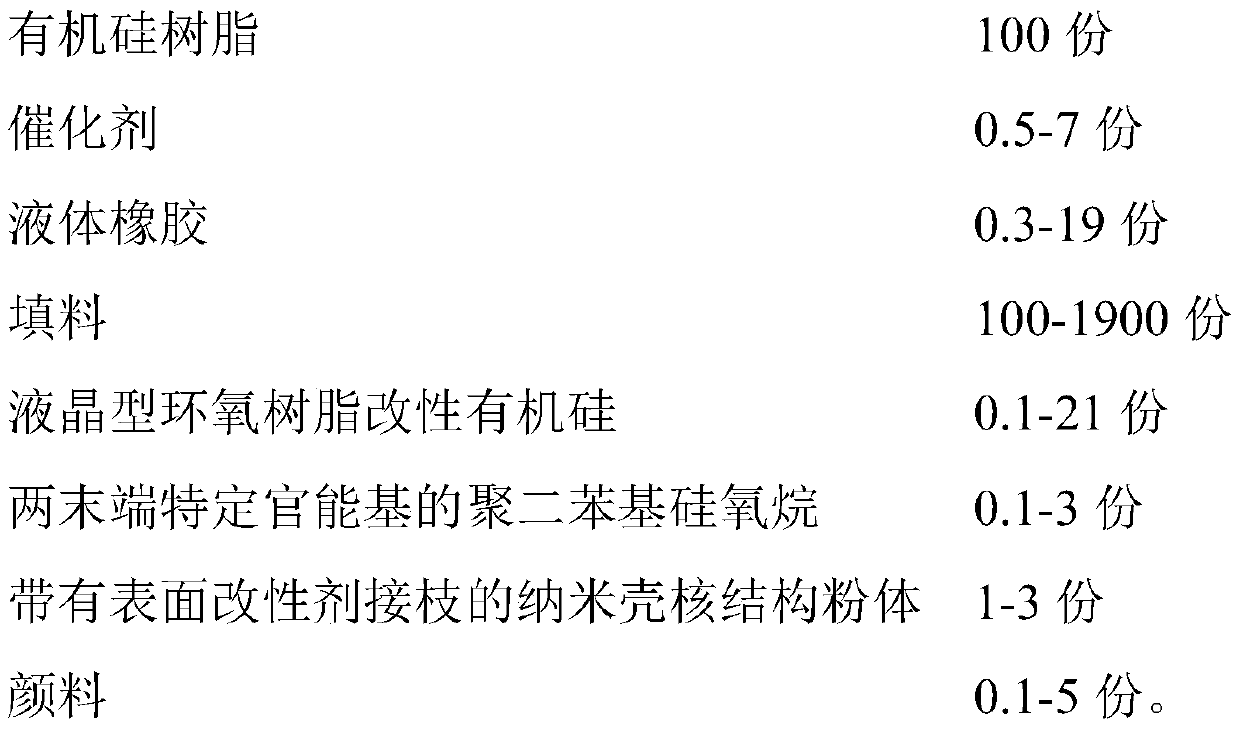

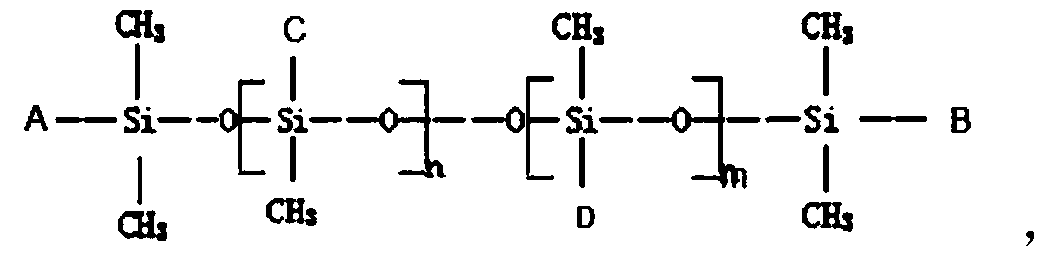

Bi-component heat-conducting gel for 5G communication and preparation method thereof

ActiveCN111410459AImprove thermal conductivityWeak surface adhesionHeat-exchange elementsEpoxyPolymer science

A bi-component heat-conducting gel for 5G communication comprises a component A and a component B, wherein the component A is prepared from organic silicon resin, filler, terminal group modified polyhedral oligomeric silsesquioxane and styryl silane; the component B is prepared from organic silicon resin, a catalyst, liquid rubber, filler, liquid crystal type epoxy resin modified organic silicon,polydiphenyl siloxane with specific functional groups at the two tail ends, nano shell-core structure powder grafted with a surface modifier and pigment. The invention further discloses a preparationmethod of the bi-component heat-conducting gel for 5G communication. The bi-component heat-conducting gel is packaged by double tubes, and the component A and the component B are mixed when the bi-component heat-conducting gel is used. The bi-component heat-conducting gel has good heat conduction performance, is convenient to repair, can be repeatedly used after repair, improves the repair efficiency and reduces the repair cost.

Owner:SHENZHEN BORNSUN INDAL

Method for solving cold-batch pretreatment uneven dying

ActiveCN106012380ARemove completelyPromote moisture penetrationTwo or more solvent application treatmentDry-cleaning apparatus for textilesAcetic acidWater temperature

The invention discloses a method for solving cold-batch pretreatment uneven dying. Before the dyeing process, dyeing pretreatment is carried out on cloth and includes the steps of padding, batching and neutral washing. In the step of neutral washing, the batched cloth is put into a dye vat, water is fed, the batched cloth is operated for 10+ / -2 min in water at the temperature of 40-60 DEG C, and the water is drained; water is fed, the water temperature in the dye vat is made to be 88-98 DEG C, the cloth is operated for 10+ / -2 min and then cooled to 40-60 DEG C, and the water is drained; water is fed, the water temperature in the dye vat is made to be 40-60 DEG C, acetic acid is added, the cloth is operated for 5-10 min, then ferment is added, the cloth is operated for 5-10 min, and the water is drained. By adopting the method, the rate of additive color uneven dyeing can be reduced by 70%, and the ratio of uneven dying chromatic aberration is greatly reduced.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Method and device for detecting clearance between rotor and stator of compressor

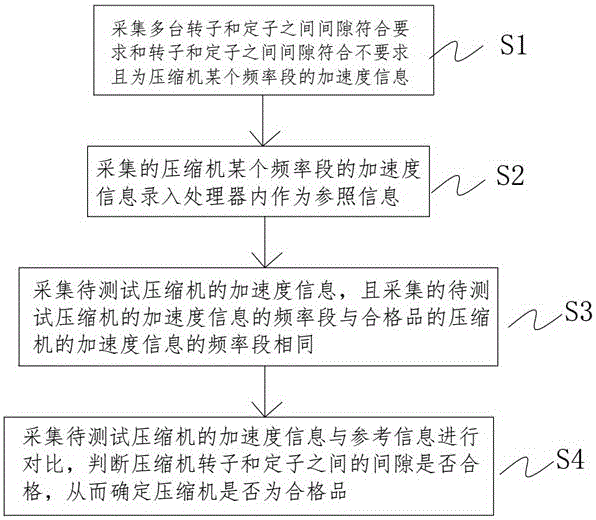

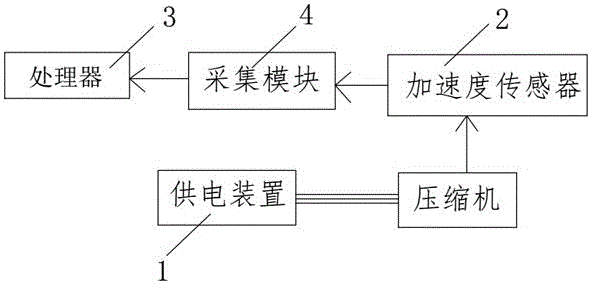

ActiveCN106403880AImprove judgment efficiencyWon't breakMeasurement devicesMachines/enginesTest efficiencyEngineering

The invention discloses a method for detecting a clearance between a rotor and a stator of a compressor. The method comprises the steps of: S1, acquiring acceleration information of compressors which are qualified products and have clearances between rotors and stators conforming to requirements; S2, inputting the acquired acceleration information of the compressors into a processor to serve as reference information; S3, and acquiring acceleration information of a compressor to be tested, comparing the acceleration information with the reference information, and judging whether a clearance between a rotor and a stator of the compressor is qualified, so as to determine whether the compressor is a qualified product. The invention further discloses a device for detecting the clearance between the rotor and the stator of the compressor. According to the method and the device, a top cover of the compressor does not need to be turned off from a compressor shell body, the efficiency of judging whether the clearance between the rotor and the stator in the compressor shell body conforms to the requirement is improved, the production cost is saved, the rework cost is decreased, the testing efficiency is improved, the method and the device are suitable for batched compressor detection, and the product quality is improved.

Owner:TCL RUIZHI (HUIZHOU) REFRIGERATION EQUIP CO LTD

Tubular workpiece synchronous rotating and clamping mechanism and welding system based on visual inspection

ActiveCN114161075AEasy to holdClamping is easy to implementWelding/cutting auxillary devicesAuxillary welding devicesSynchronous controlVisual inspection

The invention provides a tubular workpiece synchronous rotating and clamping mechanism and a welding system based on visual inspection. The tubular workpiece synchronous rotating and clamping mechanism comprises a first clamp, a second clamp, a driving mechanism and a sliding rail base. The first clamp and the second clamp are movably arranged on the sliding rail seat, the sliding rail seat extends in the axial direction of the tubular workpiece, and a clamping opening of the first clamp is opposite to a clamping opening of the second clamp in the axial direction of the tubular workpiece; the first clamp and the second clamp are connected with the driving mechanism, and the driving mechanism is used for synchronously controlling the clamping opening of the first clamp and the clamping opening of the second clamp to be switched between the first state and the second state. According to the device, tubular workpieces with different lengths and different pipe diameters can be conveniently clamped, it is ensured that the tubular workpieces synchronously rotate along with an automatic girth welding machine in a horizontal posture, and the girth welding quality is conveniently ensured by conducting visual inspection on the to-be-welded ends of the tubular workpieces before girth welding and recognizing the diameter and pipe wall defects.

Owner:北京东方国信科技股份有限公司

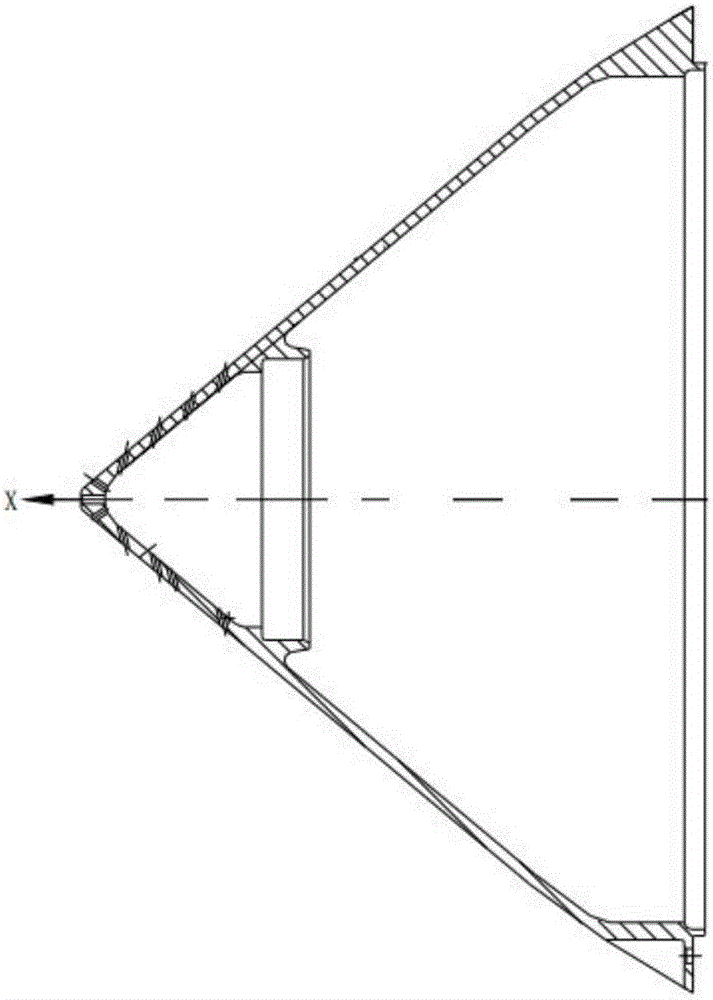

Process method of improving wall thickness uniformity of closed thin-walled rotary part

The invention discloses a process method of improving wall thickness uniformity of a closed thin-walled rotary part. The process method comprises the steps: (1) designing a finish turning clamp of a novel structure; (2) designing a following process route according to the finish turning clamp; and (3) adjusting the working allowance of a finish turning procedure. As the performance and reliability of a new generation engine are improved, a higher requirement is posed to the processing precision of a part; a designer requires the amount of unbalance of the rotary part more and more strictly. Therefore, reduction of the amount of unbalance of a cover hood part which is relatively great in processing difficulty will be widely applied by using the method. Meanwhile, the technology is suitable for both processing closed rotary parts which are different in structure and size and improving the processing precision of the part, and the process method has a wide application prospect.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Assembling method of large box type high-voltage asynchronous motor

InactiveCN102790477AAvoid reworkStable deliveryManufacturing stator/rotor bodiesControl theoryHigh voltage

The invention relates to an assembling method of a large box type high-voltage asynchronous motor, in particular to a motor assembling method for performing processing when partial processing procedures of a motor rotating shaft are transferred to motor assembling. The assembling method mainly solves problems of large reworking amount and cost increasing caused by faults in partial motor part matching due to dimensional tolerance accumulation of all parts in the production process of the large box type high-voltage asynchronous motor. The assembling procedures of a rotor and a stator of the motor are as follows: the rotor is hoisted into the stator, an outer cover of a bearing at the non-shaft-extension end of the motor rotor is assembled, fixing holes of water throwing rings at two ends of a shaft of the motor rotor are punched, oil seals at two ends of the shaft of the motor rotor are assembled, the water throwing rings at the two ends of the shaft of the motor rotor are assembled, a motor end cover is assembled, a motor outer fan is assembled, an air cooler is assembled, and a finished product is tested. The assembling method avoids motor reworking, reduces reworking expanse, and simultaneously can reduce cable waste and production cost due to the fact that a motor lead-out wire is welded during whole motor assembling.

Owner:襄阳中车电机技术有限公司

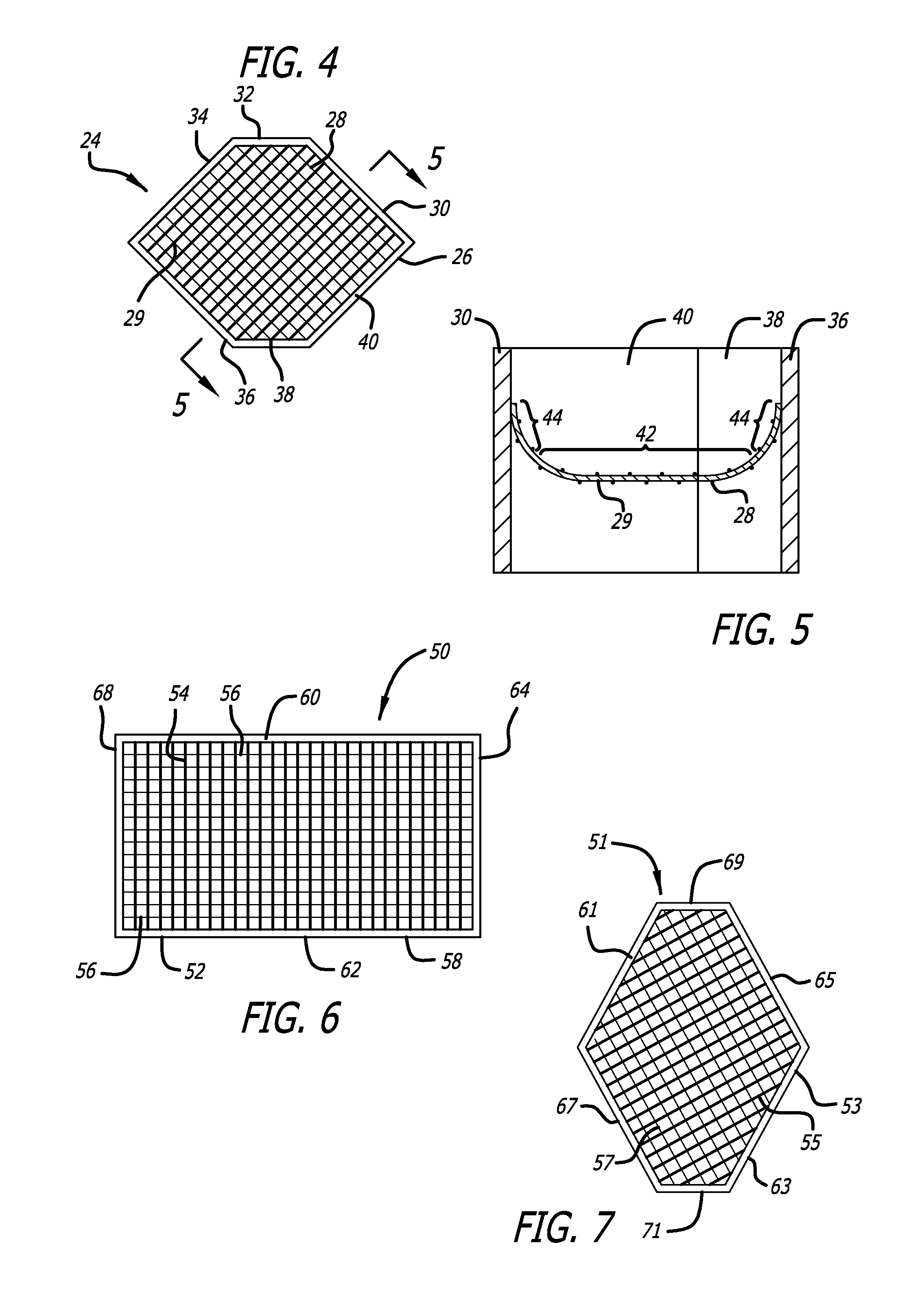

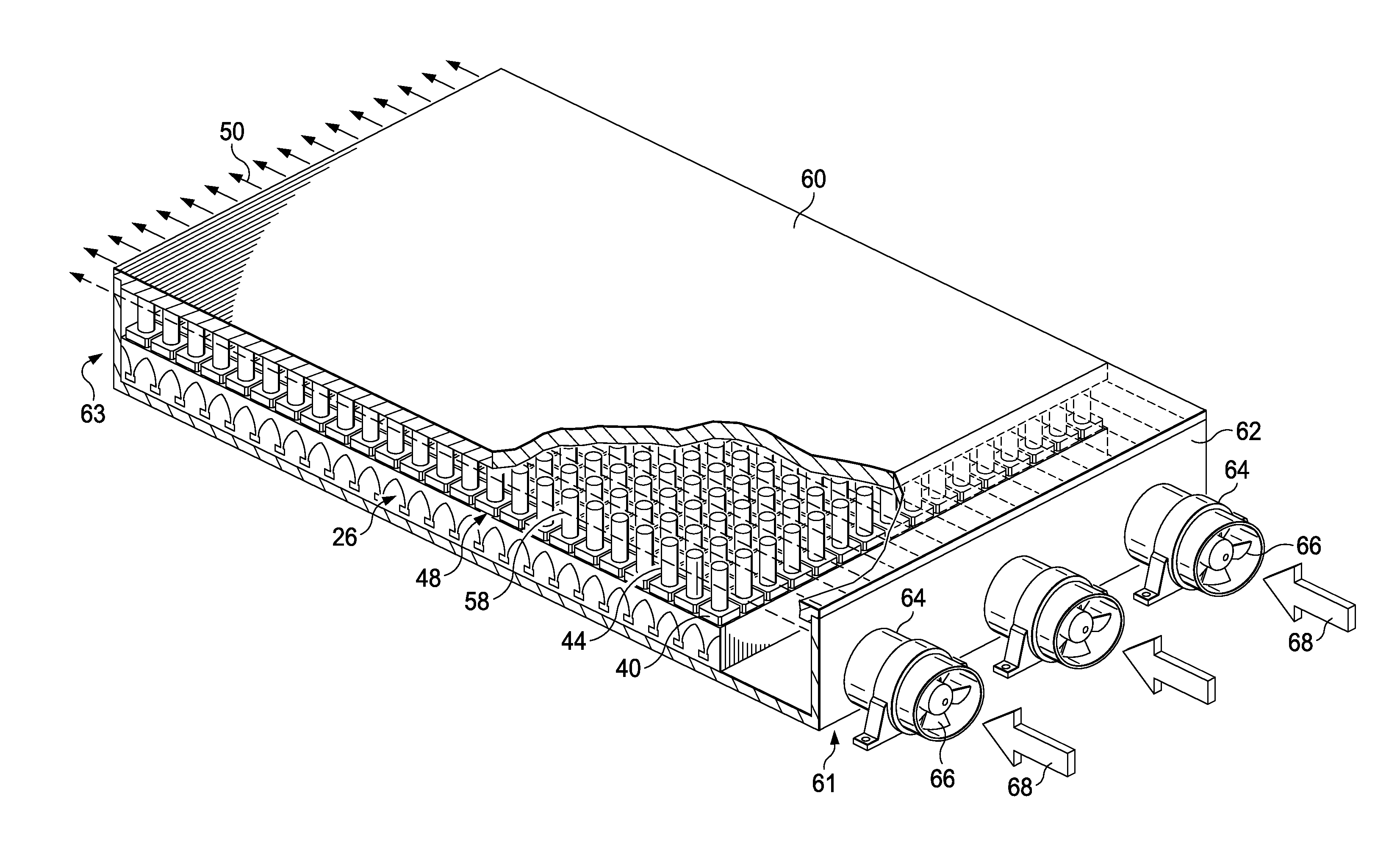

Thermal Curing of Cell-Based Structural Arrays

ActiveUS20140338812A1High yieldReduce fabricationLaminationLamination apparatusCell basedMaterials science

Cells of a composite cell array are cured by placing tool blocks in the cells and inserting thermally conductive elements in each of the tool blocks. The thermally conductive elements are convectively heated by a flow of hot air. The heated conductive elements conduct heat to the tooling blocks, which then conduct heat to the cells to cure the composite and adhesive.

Owner:THE BOEING CO

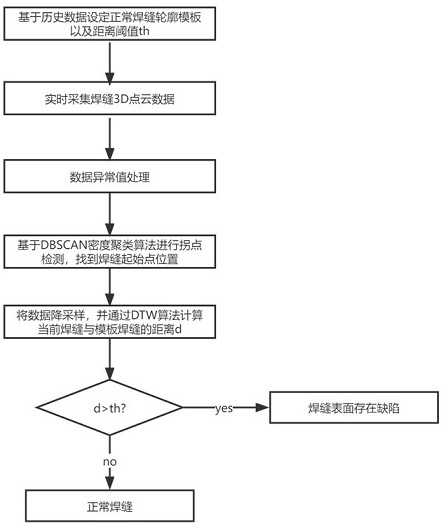

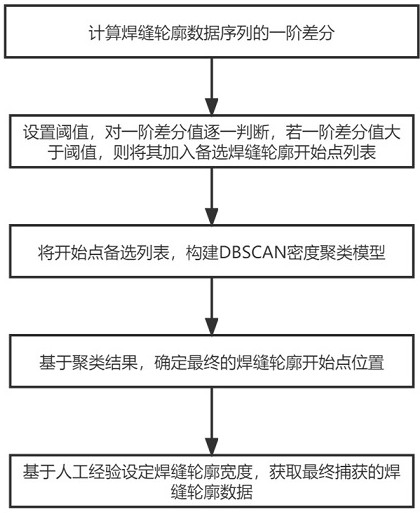

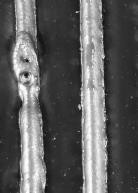

Weld defect real-time detection method and system based on 3D point cloud

ActiveCN114354639AAvoid judgmental logicImprove accuracyImage analysisCharacter and pattern recognitionAlgorithmDensity based

The invention discloses a weld defect real-time detection method and system based on 3D point cloud. The method comprises the following steps: setting a normal weld contour template based on historical data; scanning the cross section of the welding seam through line laser, collecting 3D point cloud data of the welding seam in real time, and recording initial contour data obtained through real-time scanning of the line laser as data; carrying out inflection point detection based on a DBSCAN density clustering algorithm, and determining current weld contour data; and calculating the distance d between the current welding seam contour data and the normal welding seam contour template through a DTW algorithm so as to judge whether defects exist on the surface of the welding seam. According to the method, whether the defects exist on the surface of the weld joint can be effectively distinguished without constructing a complex machine learning or neural network model, calculation resources are greatly saved, meanwhile, rapid and accurate real-time detection is achieved, therefore, the defects are found as early as possible in actual production, losses are reduced, weld joint scrapping is avoided, the repair cost is reduced, and high production value is achieved.

Owner:苏芯物联技术(南京)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com