Bi-component heat-conducting gel for 5G communication and preparation method thereof

A two-component, gel technology, applied in the field of two-component thermally conductive gel for 5G communication and its preparation, can solve problems such as inconvenient cleaning, easy damage, and failure of electronic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

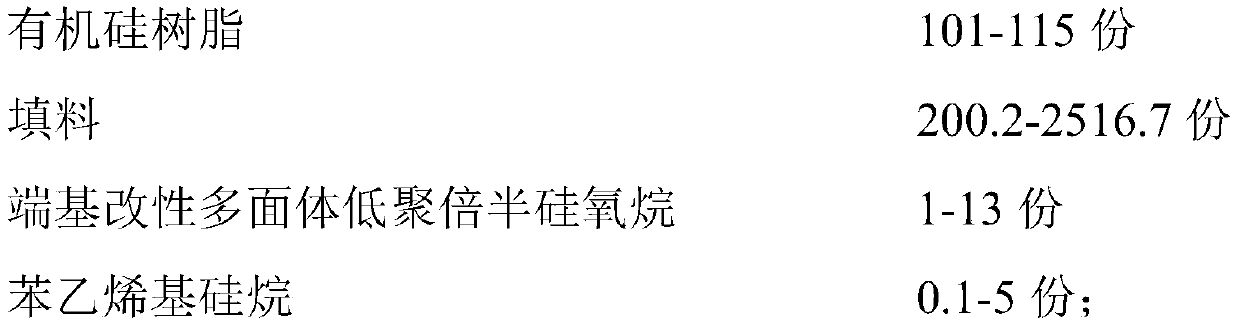

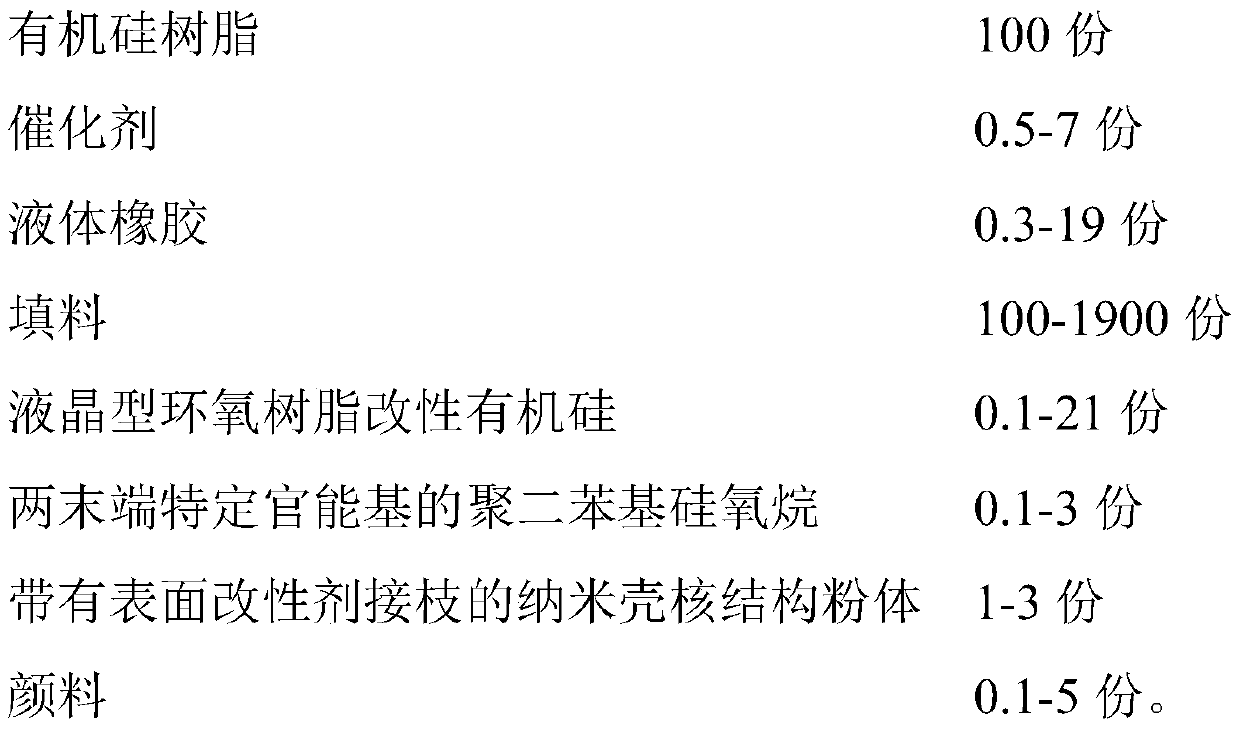

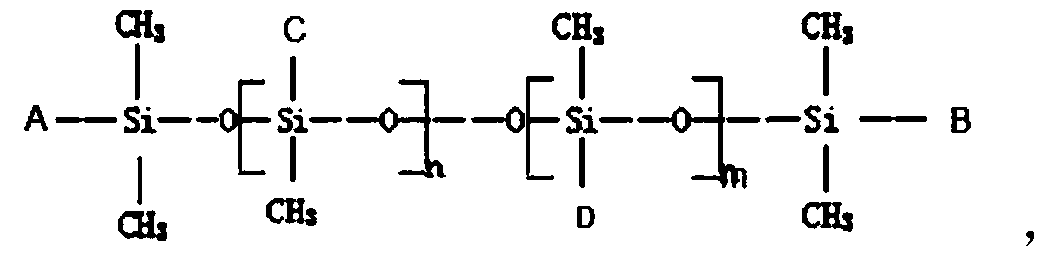

[0057] Preparation of component A:

[0058] Stir the functional polydimethylsiloxane, polymer materials containing reactive silicon-hydrogen bonds, styryl silane, and polyhedral oligomeric silsesquioxane modified by end groups evenly with a high-speed dispersant, and control the raw materials during the stirring process The temperature is 20-30°C, the stirring rate is 1000-2000r / min, and the first mixture is obtained by stirring for 20 minutes; the first mixture is poured into a planetary mixer, and then nano-fillers are added, the temperature of the raw materials is controlled at 20-30°C, and the stirring speed is 20~30r / min, stir for 12min to get the second mixture, then gradually add the inorganic functional filler into the planetary mixer in four parts, the conditions used after each addition are: raw material temperature 20~30℃; stirring speed 20 ~30r / min, stirring for 25min. After the powder is added, carry out vacuum extraction, the vacuum degree is below -0.08MPa, the...

Embodiment 1

[0064]

[0065]

[0066] Prepare component A and component B respectively according to the dosage of each raw material in the above table;

[0067] Preparation of component A:

[0068] Monovinylmethoxypolydimethylsiloxane with a molecular weight of 10000, bisvinylpolydimethylsiloxane with a molecular weight of 5000, polyacrylpolyethoxysiloxane with a molecular weight of 5000, and dihydrogen with a molecular weight of 2000 Bonded polydimethylsiloxane, molecular weight 2000 multi-hydrogen bond methoxy polydimethylsiloxane, methoxy polyhedral oligomeric silsesquioxane and styryl silane are stirred evenly with a high-speed dispersant, and the stirring process Control the temperature of the raw material at 20-30°C, stir at a rate of 1000-2000r / min, and stir for 20 minutes to obtain the first mixture; pour the first mixture into a planetary mixer, then add nano-graphene, and control the temperature of the raw material at 20-30°C , the stirring speed is 20-30r / min, and the sec...

Embodiment 2

[0073]

[0074]

[0075] According to the preparation method of Example 1, use the raw material ratio in this example to prepare component A and component B, put the prepared component A and component B into the mixing tube respectively, and use a 3D printer through a static mixer Mix the product at a certain speed according to the ratio of 1:1 and dispense glue on the aluminum plate to prepare a thermally conductive gel material. The thermally conductive gel material is tested for thermal conductivity, surface viscosity and tensile strength. The test results As shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com