Two-time positioning construction process for pre-buried channels of overhead line system of high-speed railway tunnel

A pre-buried channel and tunnel contact technology, which is applied in tunnels, tunnel linings, shaft linings, etc., can solve the problems of pre-buried channels that are difficult to remedy, power outages, and lack of experience, so as to reduce the amount of rework and save rework Cost, the effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

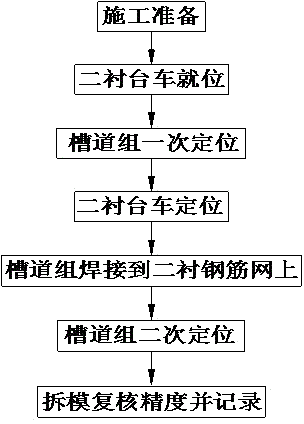

[0024] Embodiment one: if figure 1 As shown, a high-speed railway tunnel catenary pre-buried channel secondary positioning construction process, according to the following steps:

[0025] 1. Construction preparation

[0026] 1. According to the design drawings and on-site construction environment, formulate and implement reinforcement measures for the second lining trolley, and provide sufficient construction lighting environment.

[0027] 2. Equip a professional construction team and construction personnel, provide corresponding skill training and technical disclosure to workers, and provide required mechanical equipment and various materials.

[0028] 3. Determine all types of channels involved in the tunnel according to the design drawings, and accurately cut out "T"-shaped bolt holes on the second lining trolley according to all the dimensions involved in the channels, and pay attention to the process of cutting the trolley The following questions:

[0029] 1) Use a sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com