Patents

Literature

35results about How to "Reduce the amount of rework" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

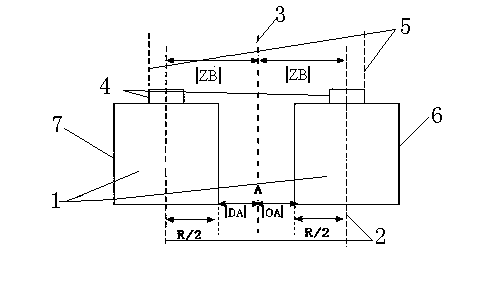

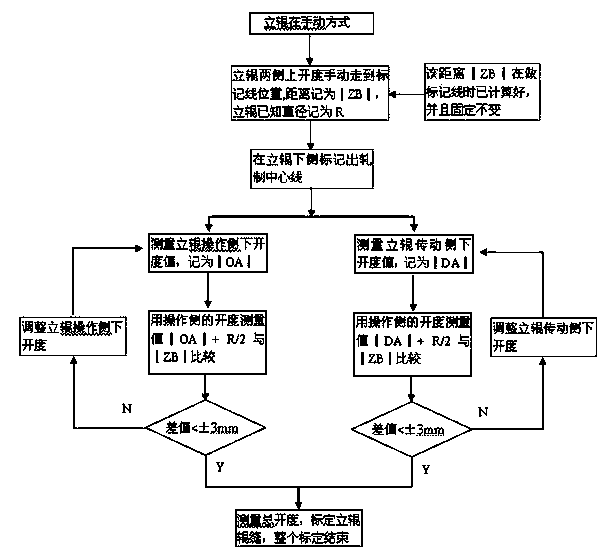

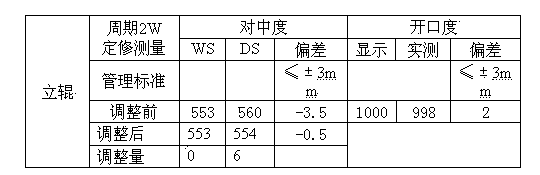

Calibration method for clearance between rolls of hot-rolling vertical rolls

InactiveCN102989792AProtective functionEliminate the problem of abnormal widthMetal rolling stand detailsMeasuring devicesStrip steelEngineering

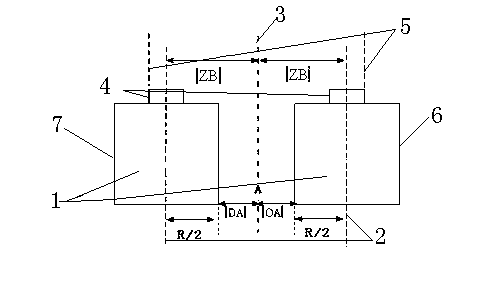

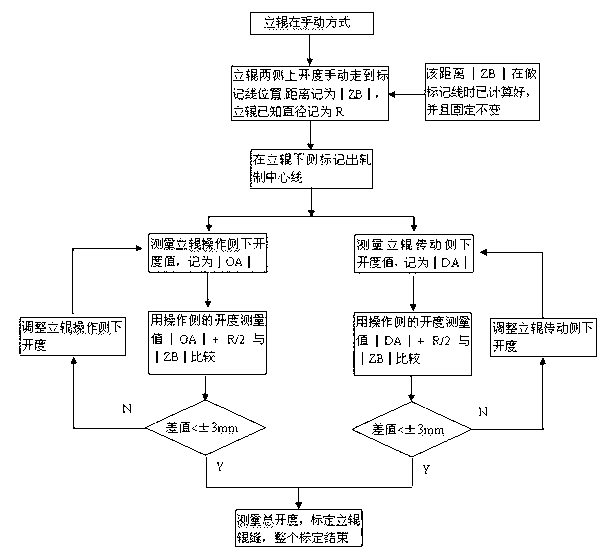

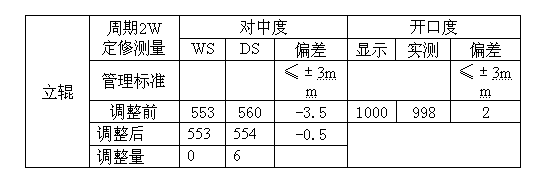

The invention relates to a calibration method for clearance between rolls of hot-rolling vertical rolls, which mainly solves the technical problem that strip steel is deficient in quality because verticality and alignment to calibration of vertical rolls are not considered in current methods. The technical scheme is that the calibration method for clearance between rolls of hot-rolling vertical rolls comprises the steps of: 1, finding a rolling center line and marking; 2, additionally arranging two position marks on a transverse slipway of a hot-rolling vertical roll device, and marking the distance from the marks to the rolling center line as |ZB|; 3, hitting apertures on both sides of the vertical rolls to marked positions, wherein a roll block is inside a marking line and aligned with the marking line; 4, measuring the distance from the lower ends on both sides of the vertical rolls to the rolling center line, and marking the measuring point as a point A, the radius of the rolls as R / 2 and the distances from A to a vertical roll operating side and from A to a transmission side as |OA| and |DA|; 5, comparing the measured value |OA|+R / 2 on the operating side with |ZB|, wherein if the difference is in a precision range, the verticality is good, and if the difference is not in the precision range, the clearance between rolls on the operating side is adjusted so that the difference is in the precision control range; 6, adjusting the clearance between rolls on the transmission side by the adjusting method in the step 5; and 7, measuring the total aperture of the vertical rolls, inputting the measured values and calibrating the clearance between rolls of vertical rolls after adjusting the verticality and alignment.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

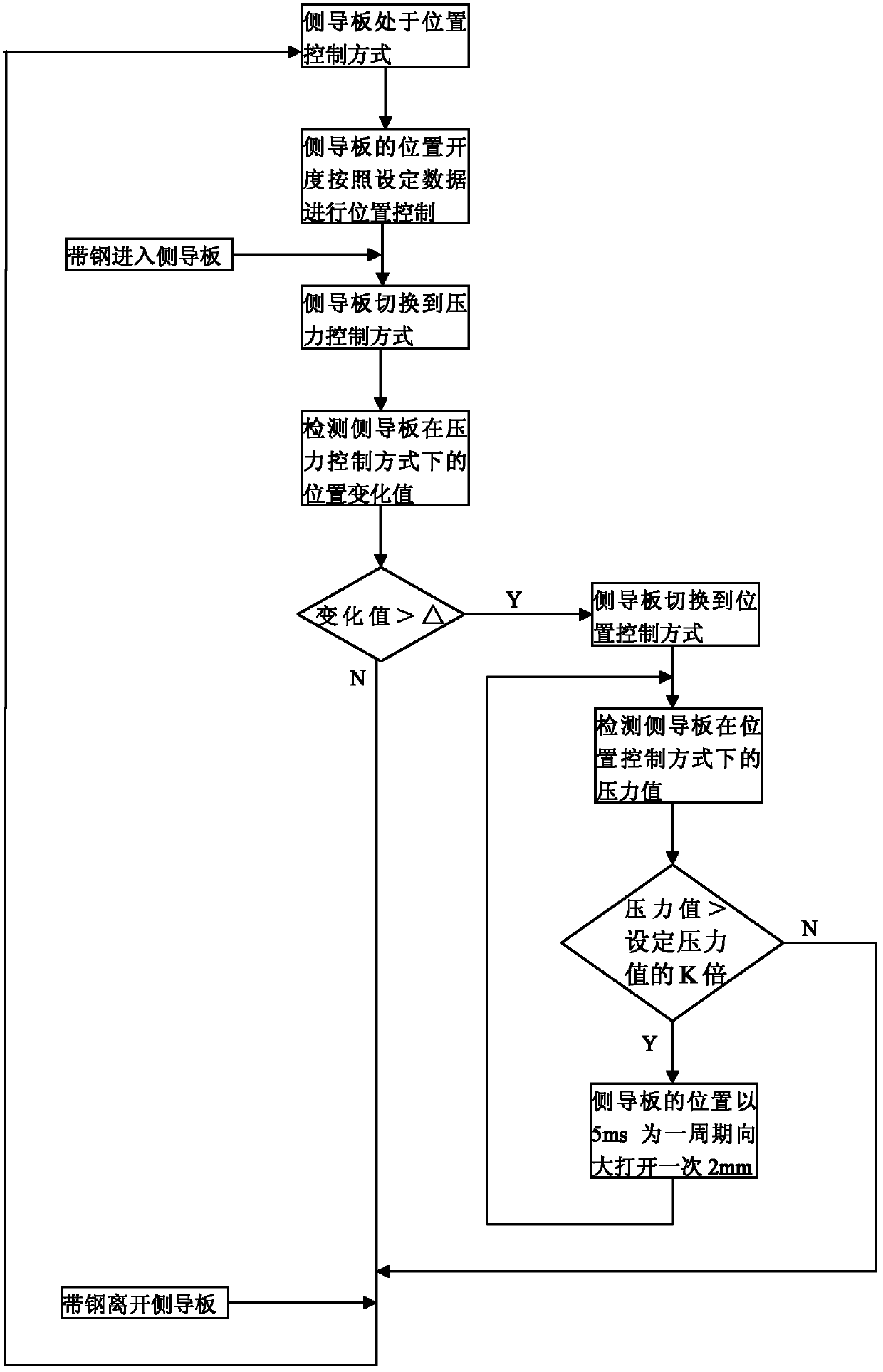

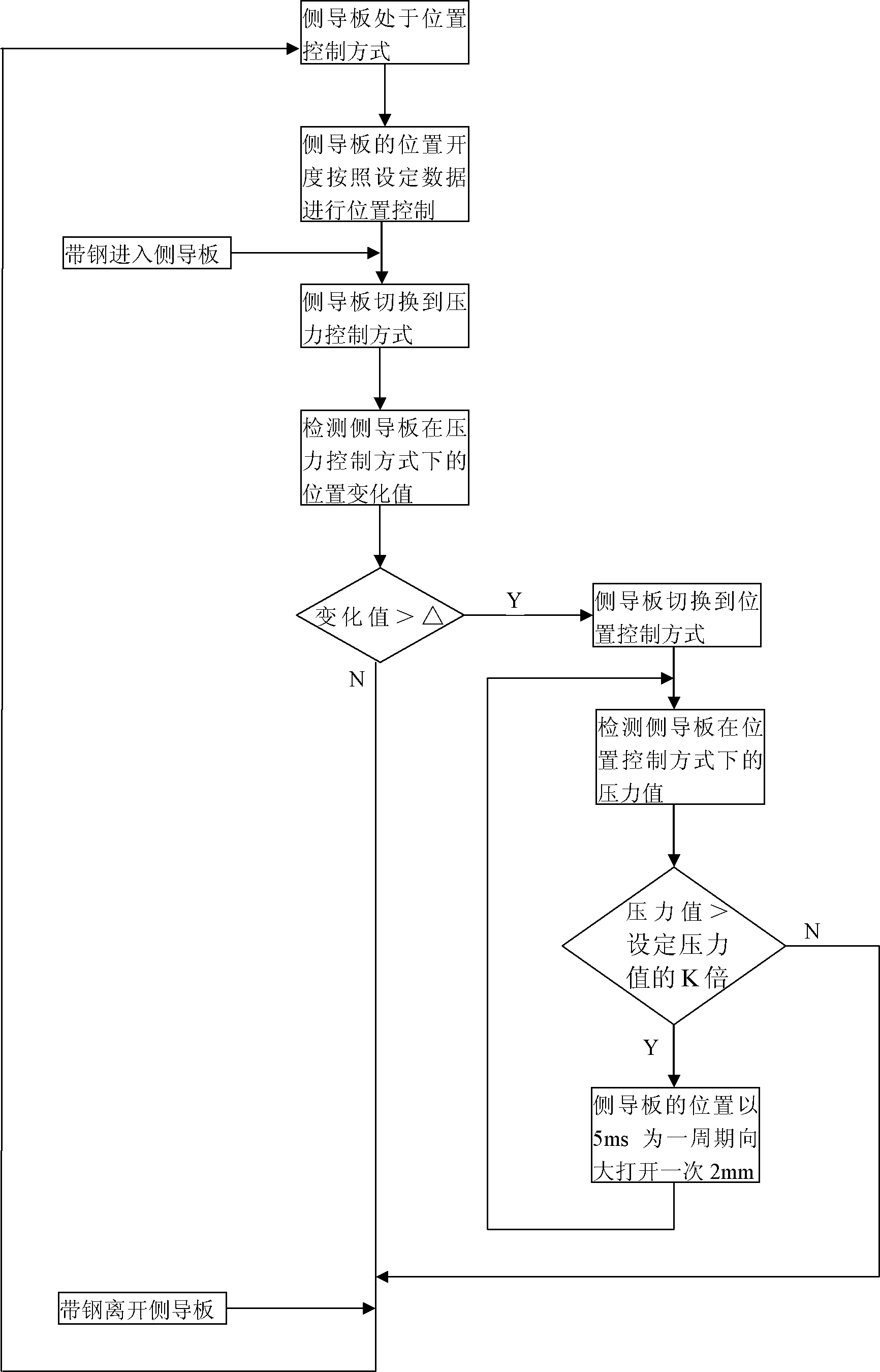

Control method of hot-rolling rolled side guide plate for improving hot-rolling roll shape quality

ActiveCN102896180AReduce the amount of reworkReduce manufacturing costControl mannerPressure feedback

The invention relates to a control method of a hot-rolling side guide plate in the metallurgy field, and relates to a control method of a hot-rolling rolled side guide plate for improving hot-rolling roll shape quality. The side guide plate is in a position ring control mode before the band steel enters into the rolling side guide plate; the control mode of side guide plate is switched to a pressure control mode from the position control mode after the band steel enters into the side guide plate; during the pressure control process, when the detected position change of the side guide plate exceeds [Delta]X mm, the control mode of side guide plate is switched to the position control mode from the pressure control mode; and if the position change does not exceed [Delta]X mm, the side guide plate is at the pressure control mode all the time; after the control mode of side guide plate is switched to the position control mode from the pressure control mode, a pressure feedback value of the side guide plate is detected; if the pressure feedback value exceeds K times of a pressure setting value in the pressure control mode, the position of the side guide plate is opened 2 mm with 5 s as a period, until the pressure feedback value of the side guide plate is lower than K times of a pressure setting value in the pressure control mode; and when the band steel leaves the side guide plate; the side guide plate enters into the position control mode. The method effectively solves the problems of quality defects such as layer offset, edge protrusions and edge cracks of roll shapes when rolling supplied material of the band steel swims or has cambers.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

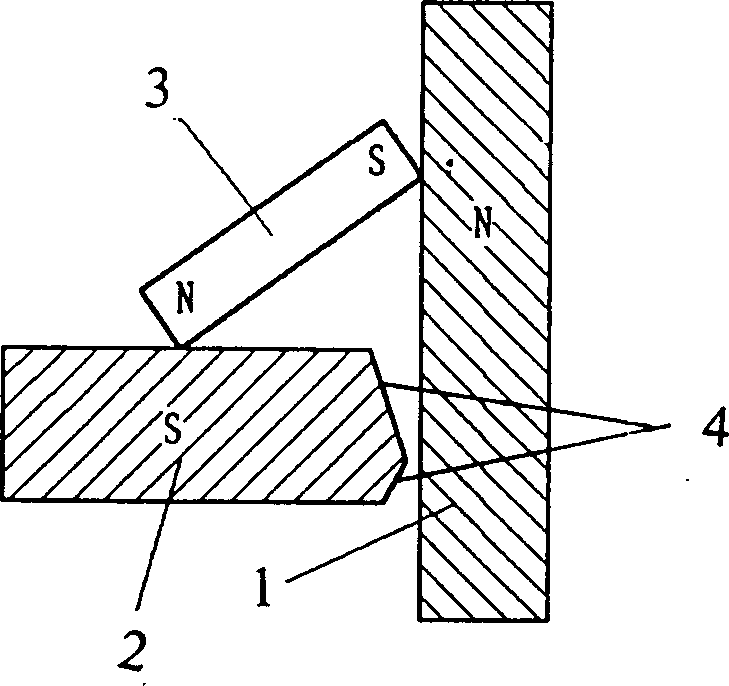

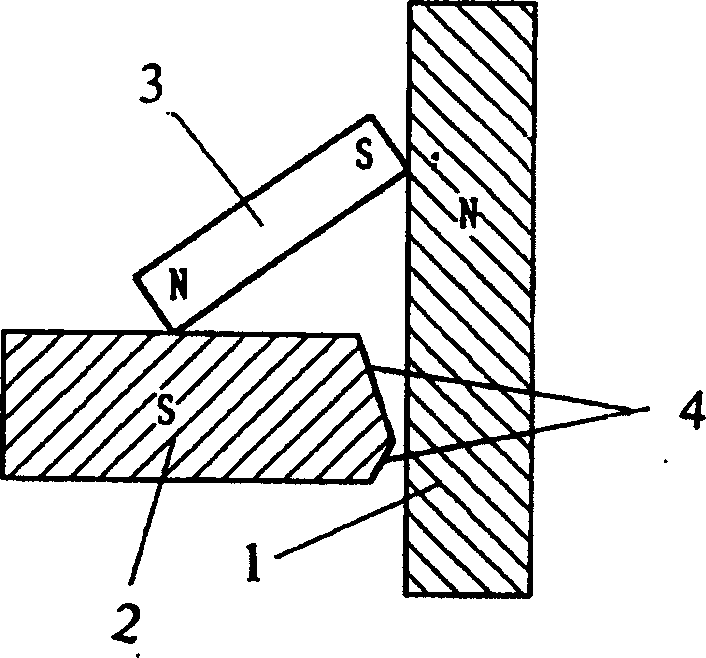

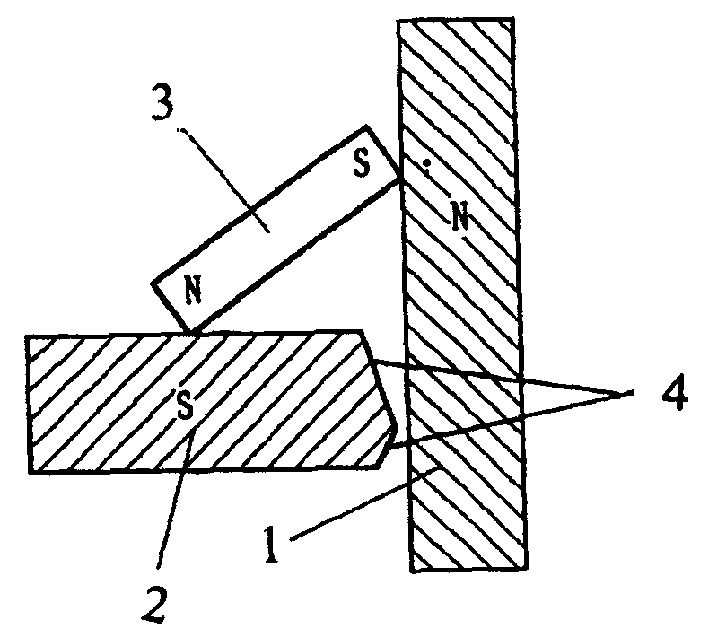

Technique for eliminating magnetic blow of electric arc of austenitic electrode by using permanent magnet

InactiveCN1431079ASolve the problem of magnetic deflection blowing of welding rodGuarantee welding qualityElectrode accessoriesMagnetic polesElectrical polarity

A technique for eliminating the deviation blowing of electric arc of welding austenite electrode by permanent includes measuring magnetic induction intensity and magnetic pole direction of the bevel to be welded, sucking a permaneng magnet to the bevel in such manner that their magnetic polarities are reversed, measuring the magnetic induction intensity less than 2 mT, and welding. Its advantagesare high effect and high welding quality.

Owner:中国船舶集团渤海造船有限公司

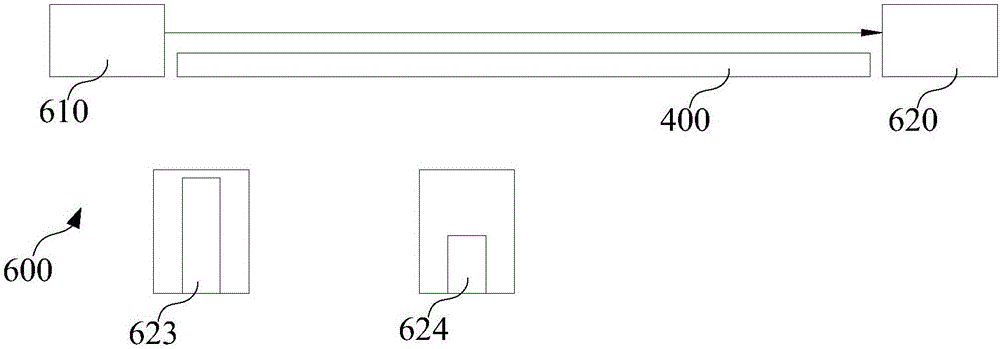

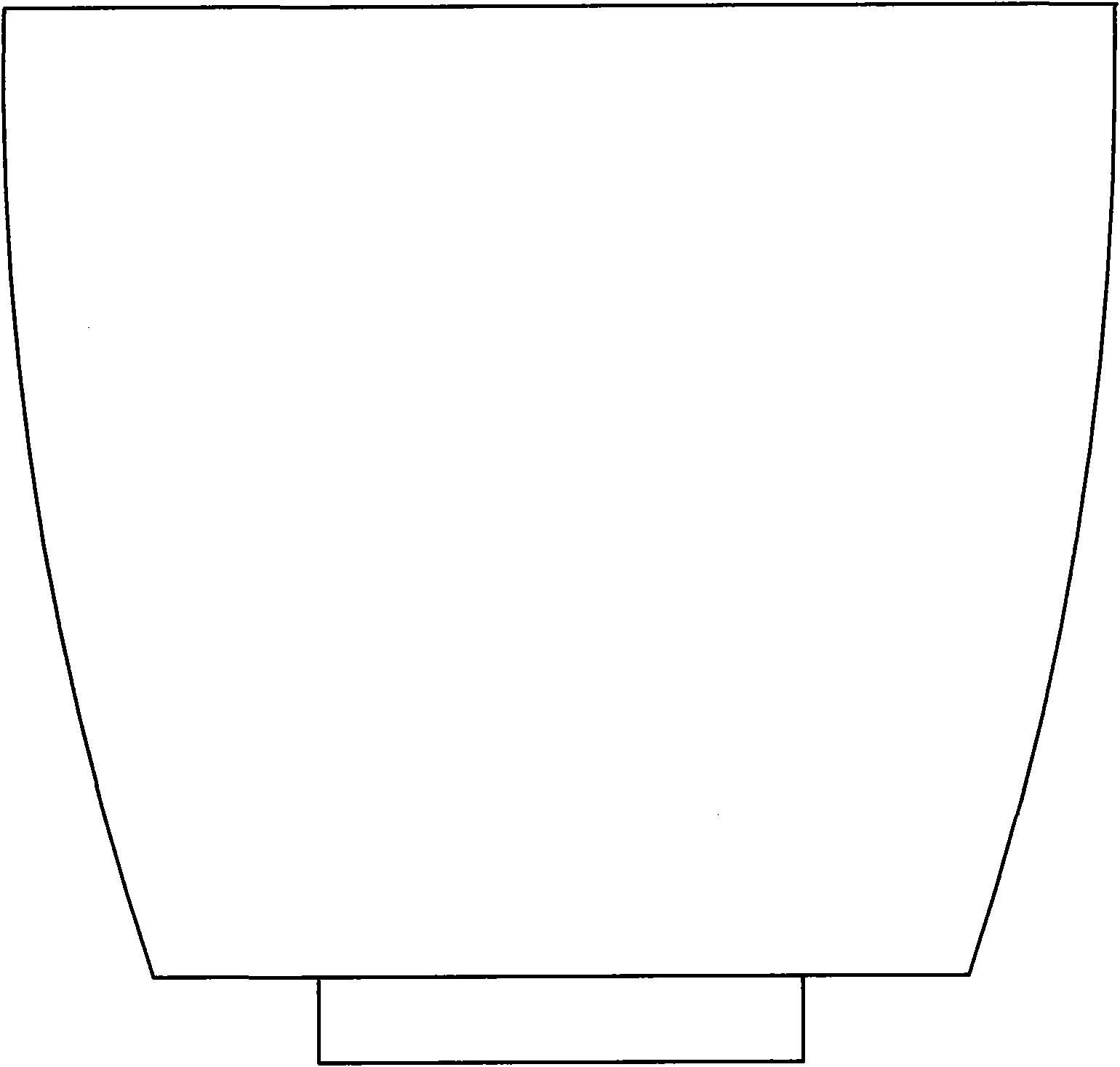

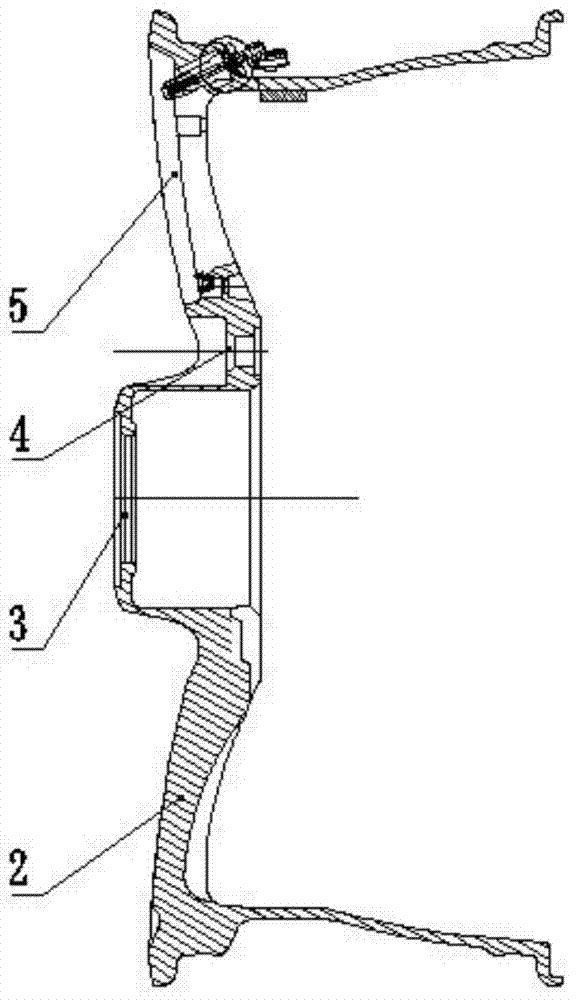

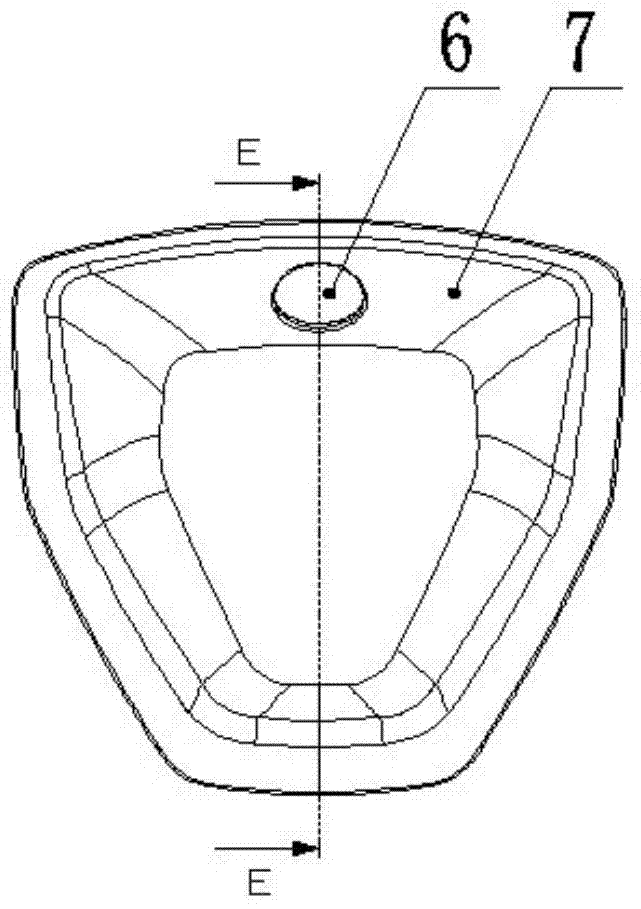

Method and special fixture for compensating UV gum in Mobile telephone CCD camera assembling process

InactiveCN101140345ASave glueReduce the amount of reworkTelevision system detailsColor television detailsCamera lensCcd camera

The present invention discloses a method and a special clamping fixture for UV glue repair in the process of mobile phone camera assembling. Wherein, the method includes steps below: (1) Spreading UV glue between a lens base and a flexible printed circuit board; (2) Vertically arranging products with finished UV glue and keeping the flexible printed circuit board downward; (3) Taking a group of products processed in step (2) into a UV machine for UV solidification. In addition, the clamping fixture comprises a group of arranging boards to conveniently fix and withdraw product fastening pieces. After UV glues are spread between the lens base and the flexible printed circuit board, the method of the present invention vertically arranges products with finished UV glue and keeps the flexible printed circuit board downwards. Thus, gravity of the glue is utilized to balance glue penetration, thus reducing loss due to UV glue penetration and quantity of products returned for reworking.

Owner:BYD CO LTD

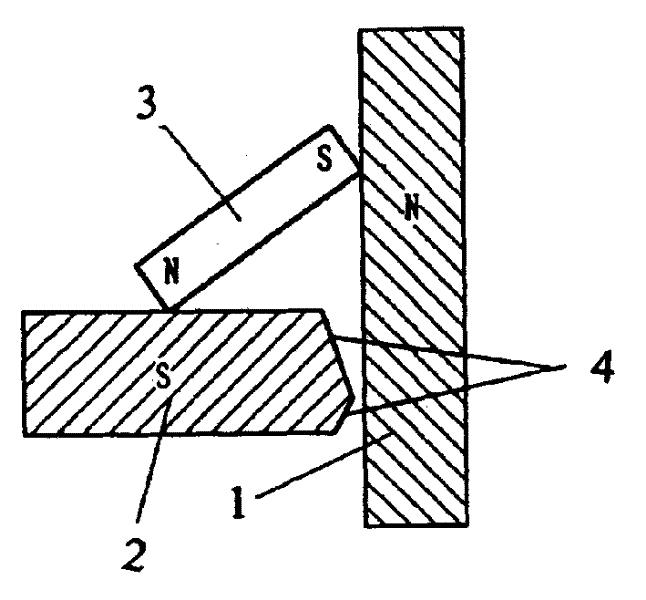

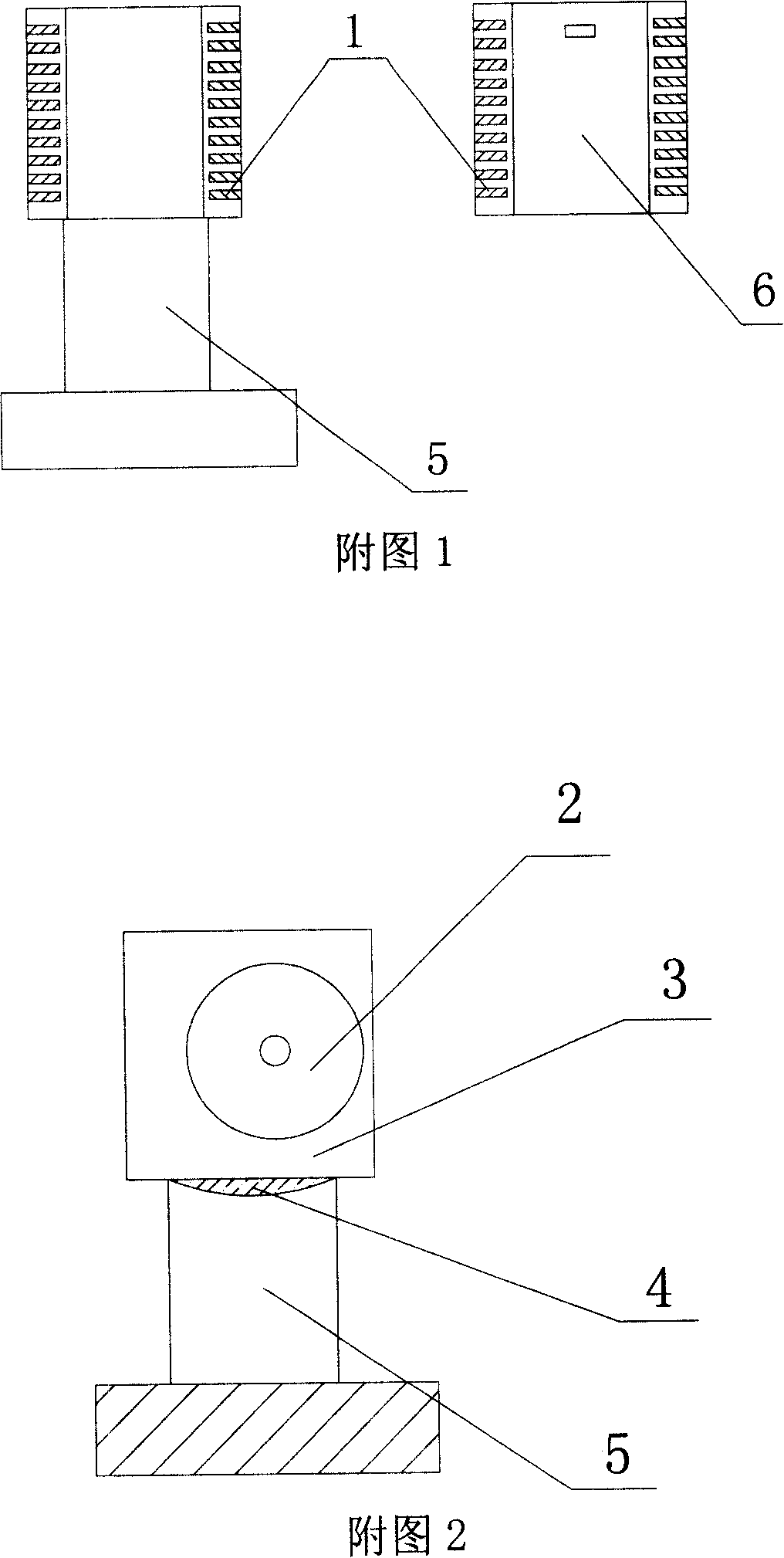

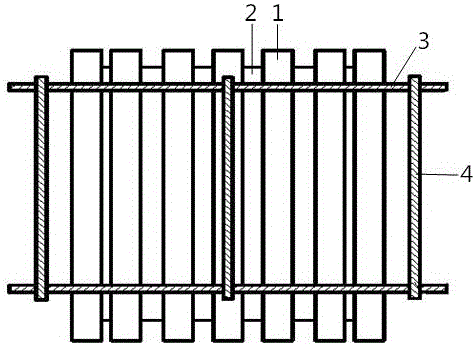

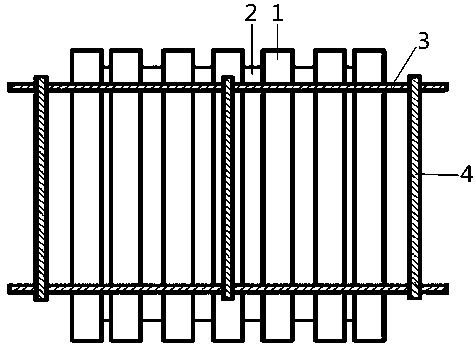

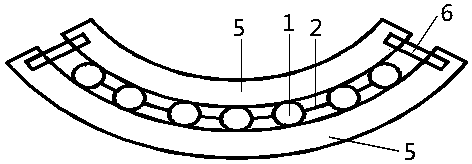

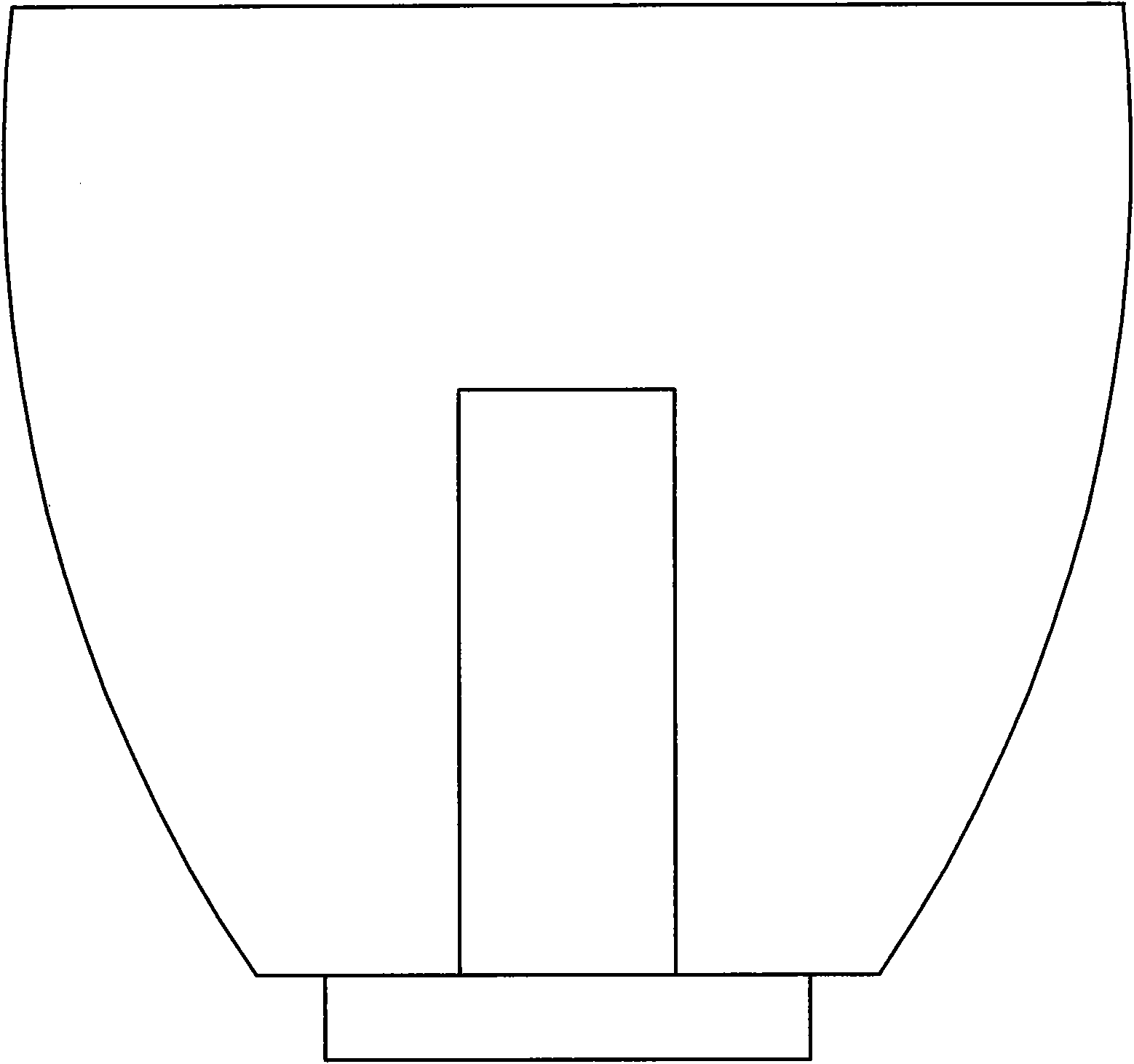

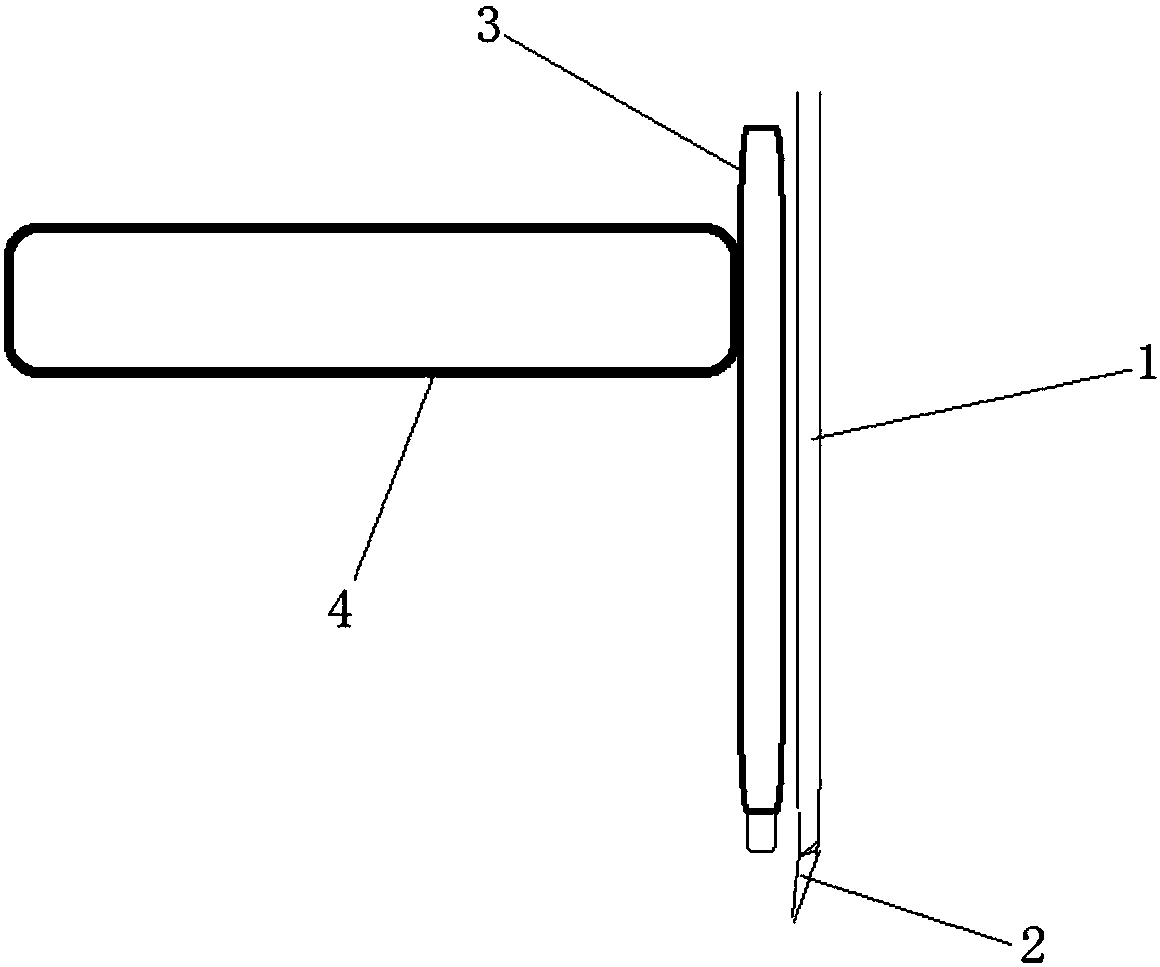

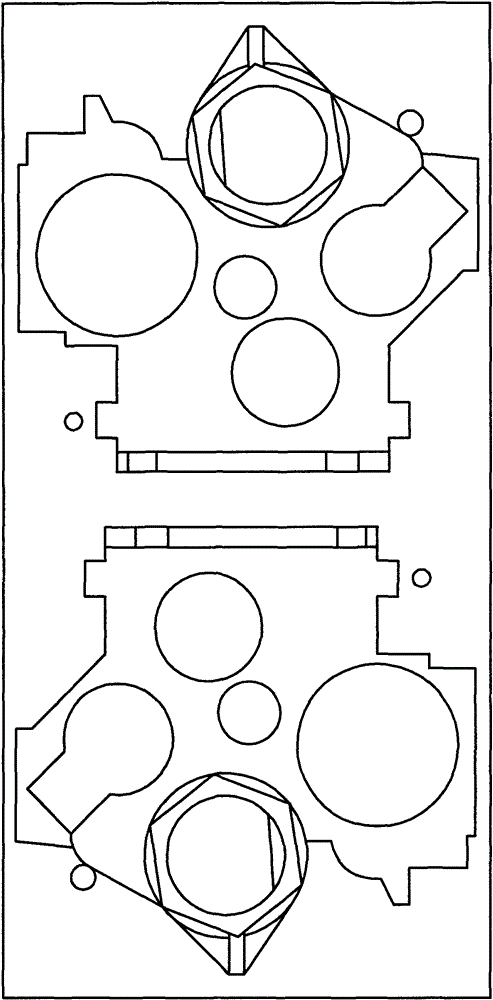

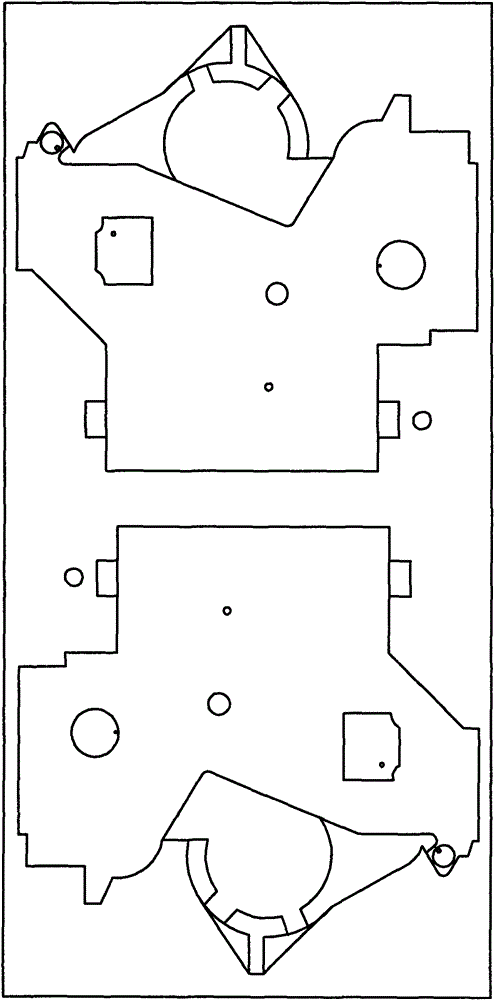

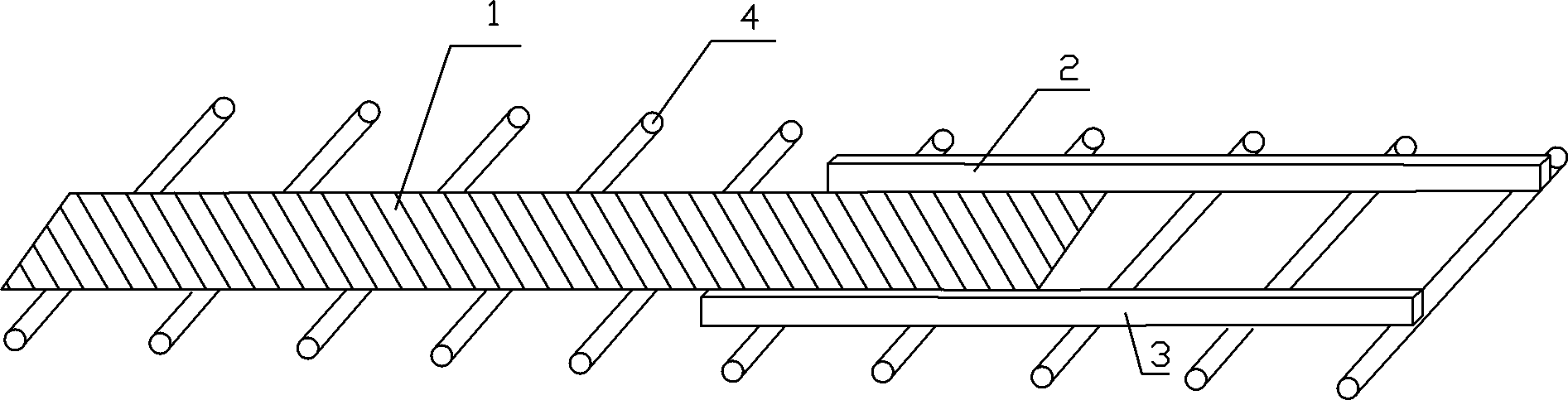

Welding method for nickel-based membrane type wall tube panel

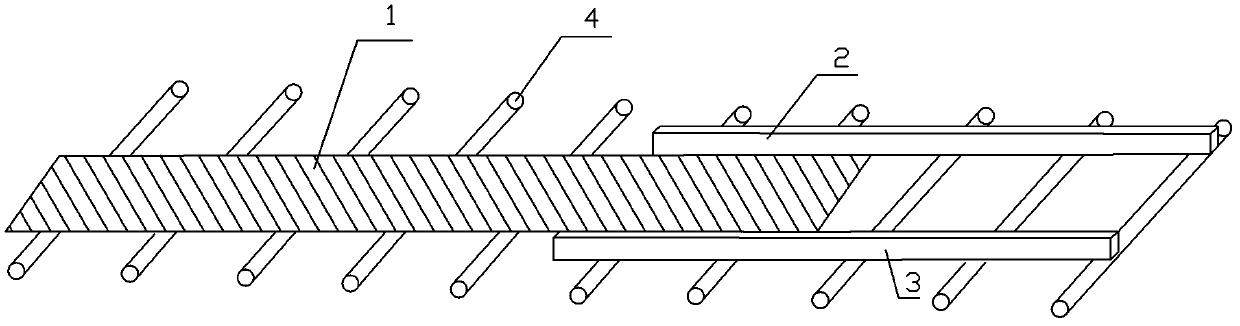

ActiveCN106238866AAvoid deformationGuaranteed dimensional accuracy requirementsCooled electrode holdersEngineeringWeld line

The invention discloses a welding method for a nickel-based membrane type wall tube panel. The welding method includes the following steps that a tube panel is formed by nickel-based tubes (1) and nickel-based flat steel (2), and an anti-deformation tool (3) is arranged at each of the two ends of the tube panel; during welding, a specific welding sequence, a specific welding mode and specific welding line energy are adopted; and it is always kept that flowing cooling water exists in the tube panel in the welding process. The nickel-based tube panel is welded through the welding method, deformation and heat cracks, generated in the welding process, of the nickel-based tube panel can be effectively avoided, therefore, the dimensional precision requirement of the nickel-based tube panel is guaranteed, the repair amount of the nickel-based tube panel is reduced, the production period of the nickel-based tube panel is shortened, and the quality of the nickel-based tube panel is improved.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

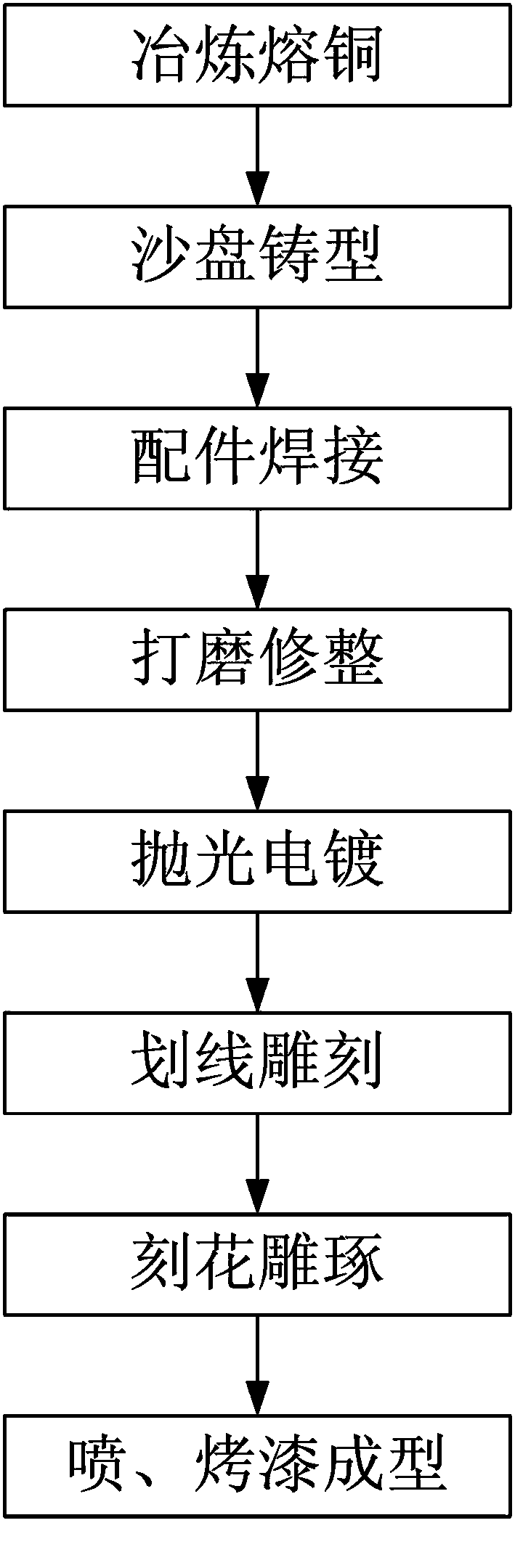

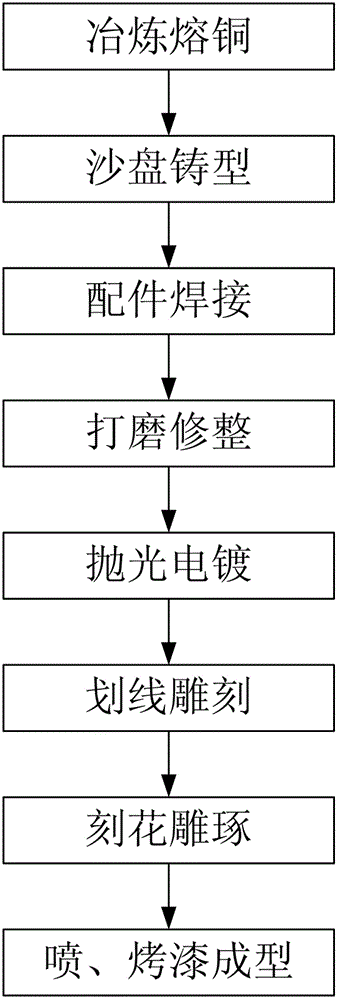

Fabrication method of copper crafts

InactiveCN103738099ANot easy to change colorNot easily oxidizedEdge grinding machinesDecorative surface effectsCopperElectroplating

The invention discloses a fabrication method of copper crafts. The copper crafts are refined by eight procedures of smelting and melting copper; casting a sand table; welding accessories; polishing, trimming, finishing and plating; marking off and engraving; engraving designs, and spraying baking finish and molding. The mass fraction percent of copper and other metals is reasonably set, so that the processed copper crafts do not change in color, and are not easily oxidized at the same time. By adopting the procedures, the problems of size deformation, air shots, air bubbles and the like of the crafts are completely eradicated effectively, the repair amount and the defective index of the crafts are reduced, meanwhile, the quality of the crafts is improved, and the production cost is reduced.

Owner:URUMQI HAMA COPPER HANDICRAFTS

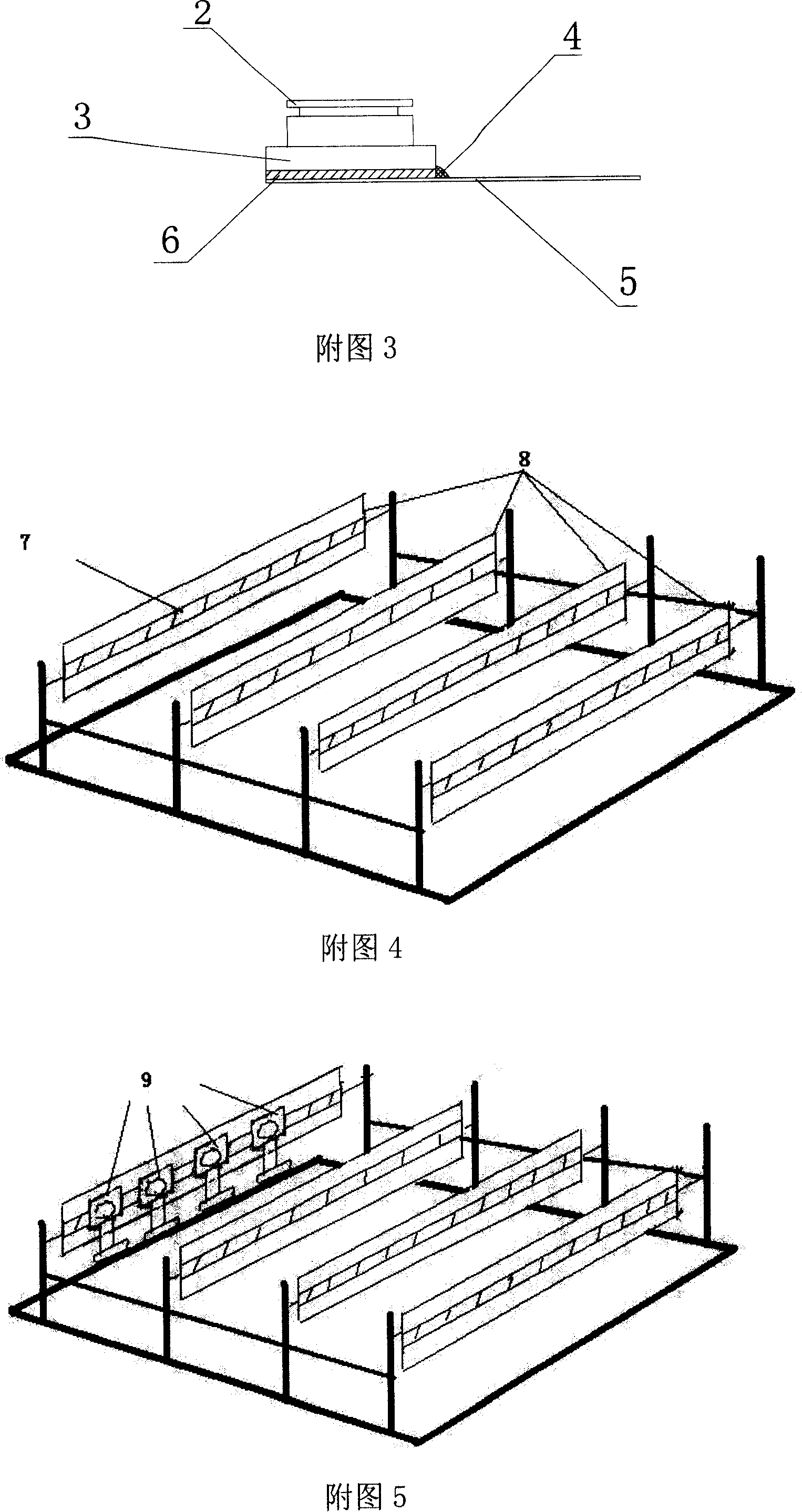

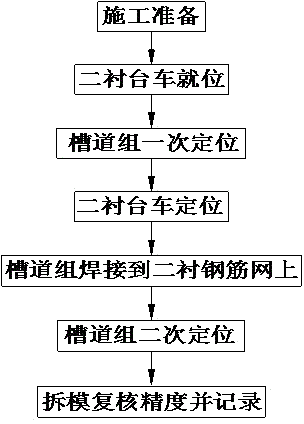

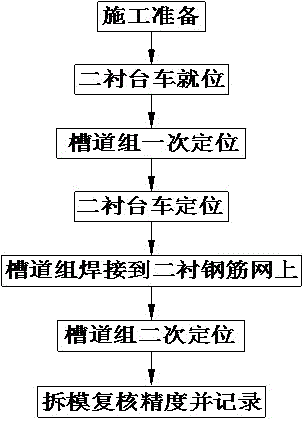

Two-time positioning construction process for pre-buried channels of overhead line system of high-speed railway tunnel

ActiveCN104790969AQuick installationLarge operating spaceUnderground chambersTunnel liningRailway tunnelRebar

The invention relates to a two-time positioning construction process for pre-buried channels of an overhead line system of a high-speed railway tunnel. By adjusting the procedure of installing the pre-buried channels, a larger operation space is provided for construction, and operators can conveniently and rapidly install channel sets on a lining trolley and can rapidly install C type channel sets, D type channel sets and E type channel sets by standing on edges of the lining trolley by means of frames such as ladders. The channels can be positioned in advance while secondary lining reinforcing steel bars are bound, time is used while the space is used sufficiently, multiple steps are executed at the same time and do not affect one another, and the result is gained with half effort.

Owner:中铁二十四局集团福建铁路建设有限公司 +1

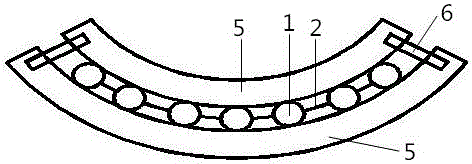

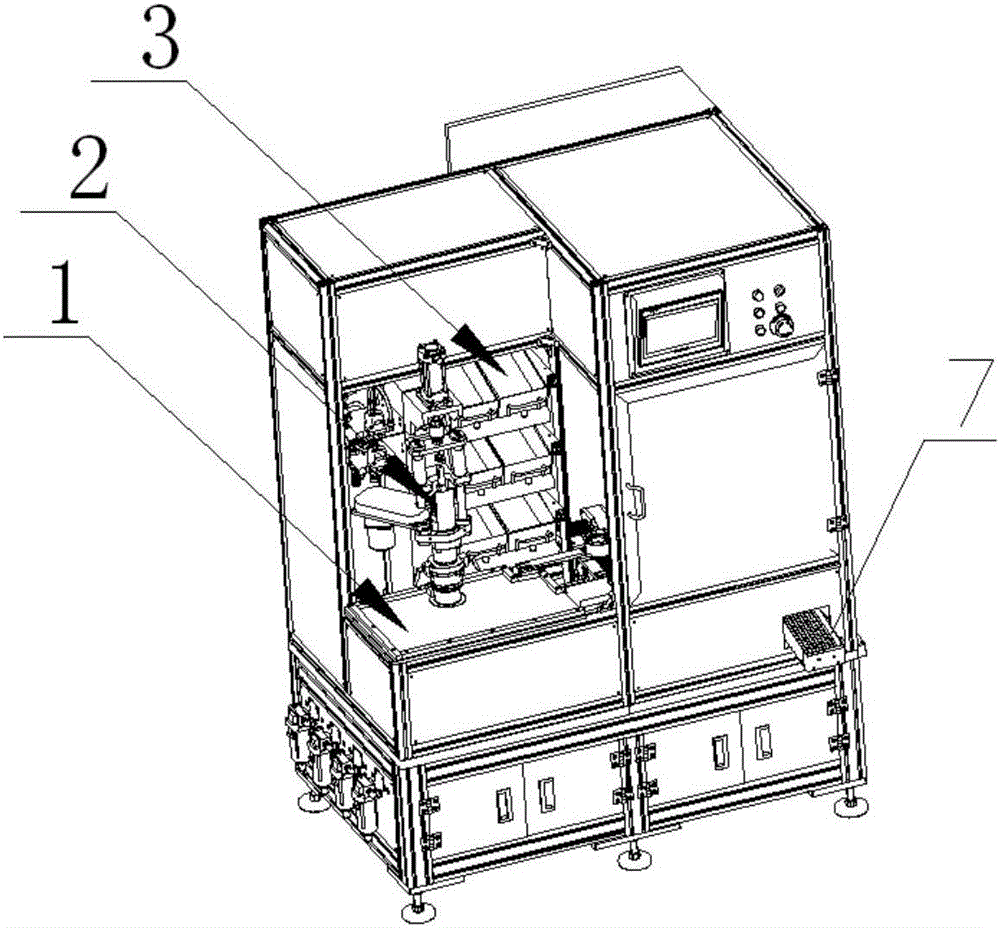

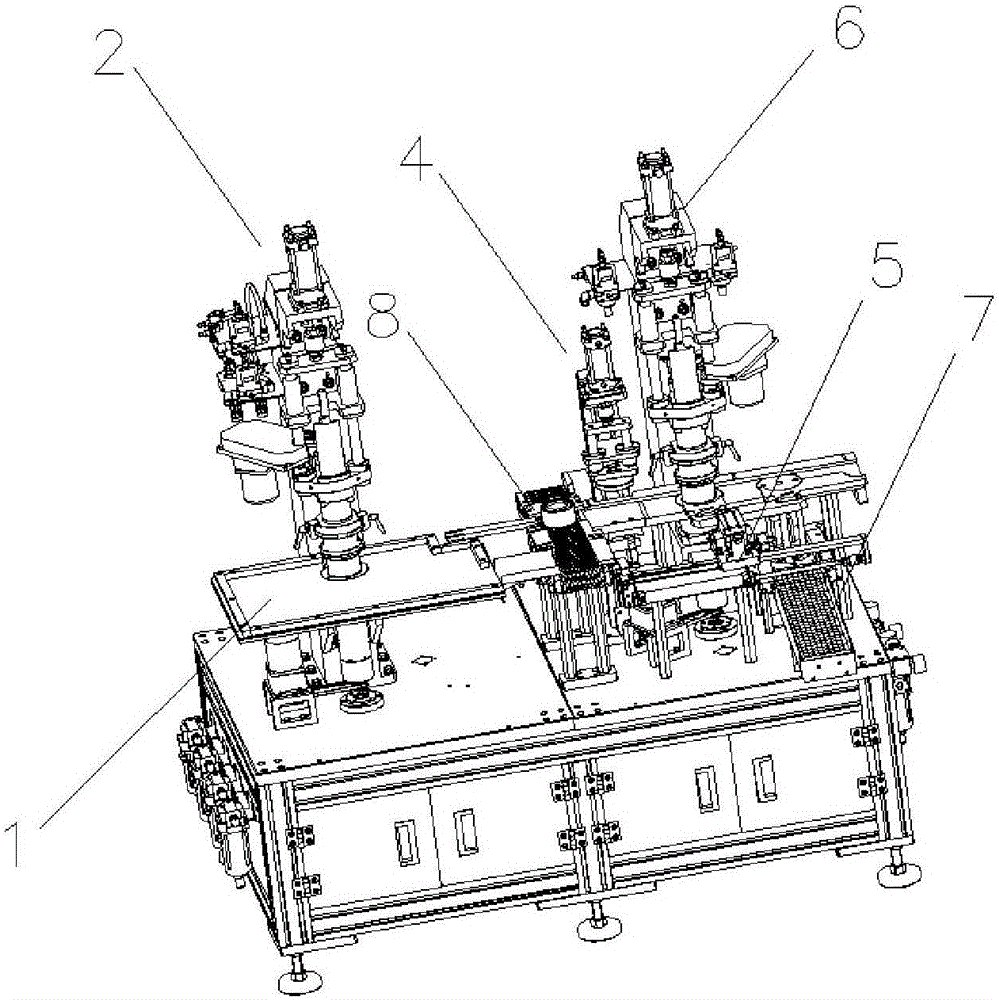

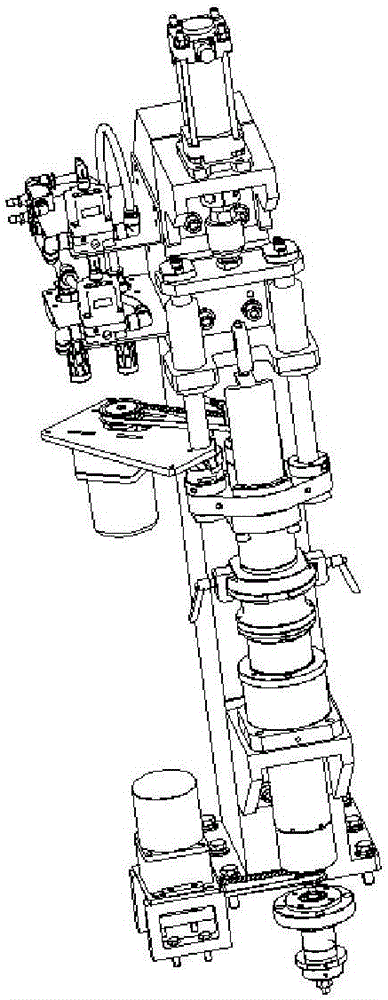

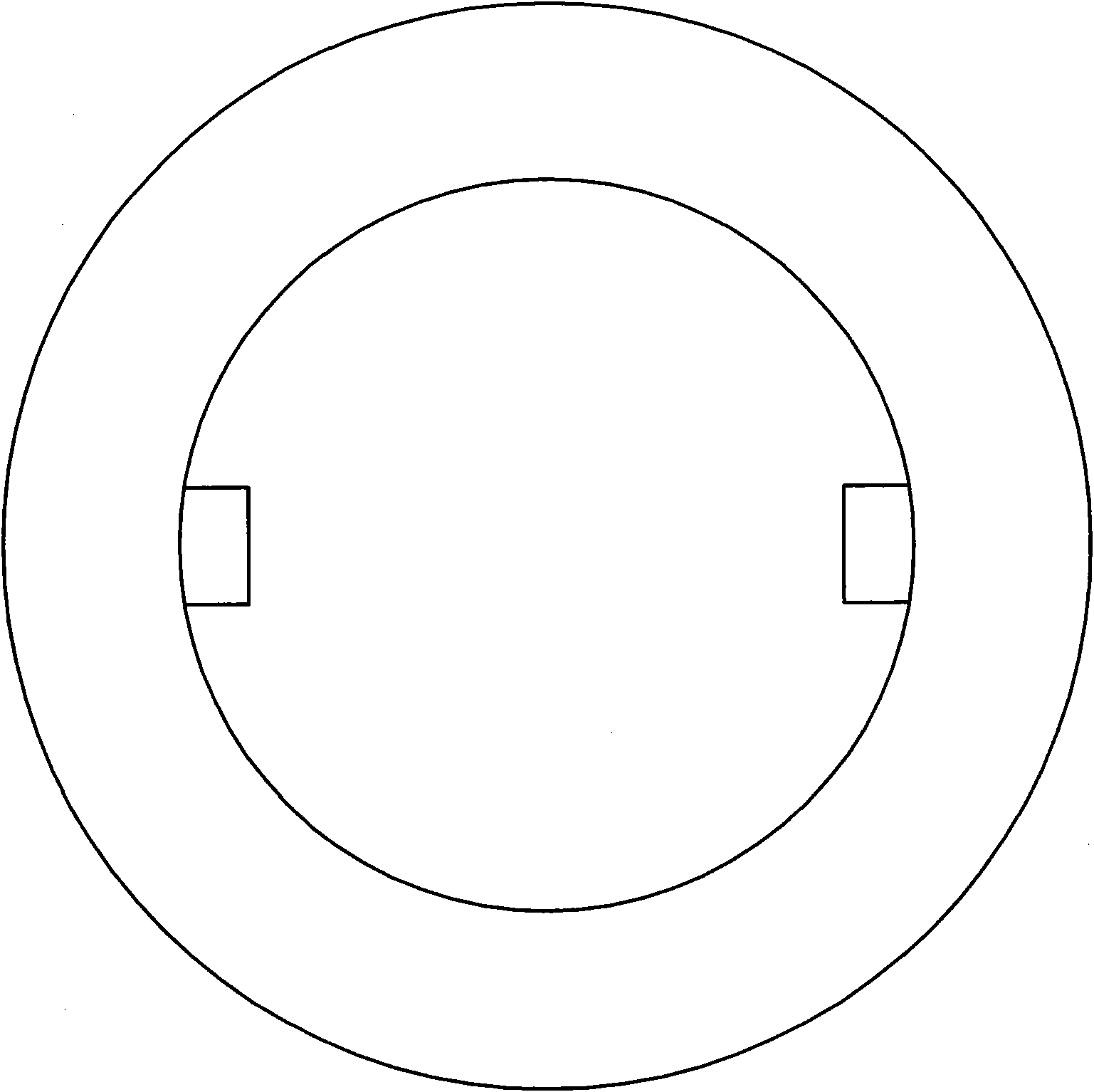

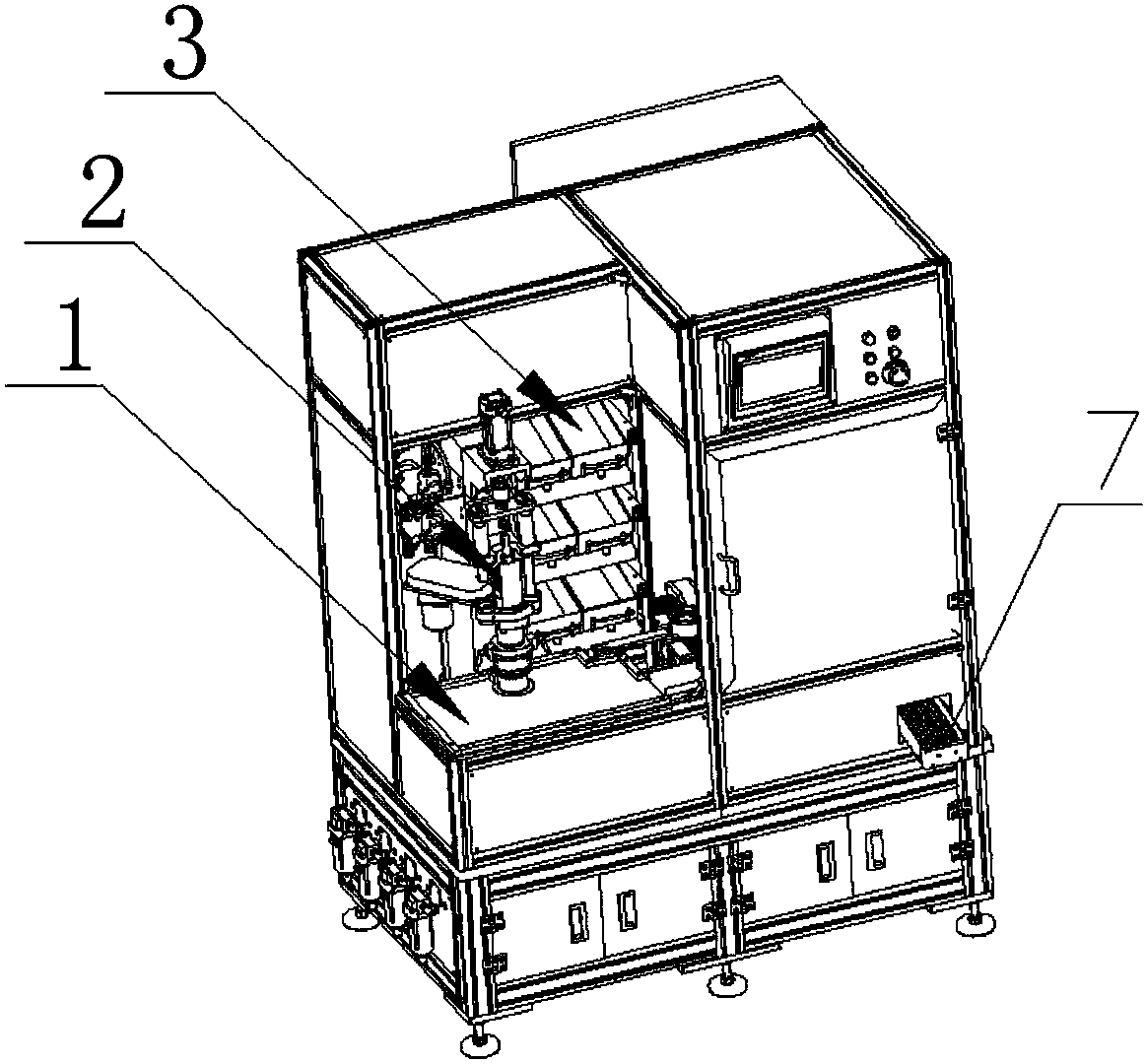

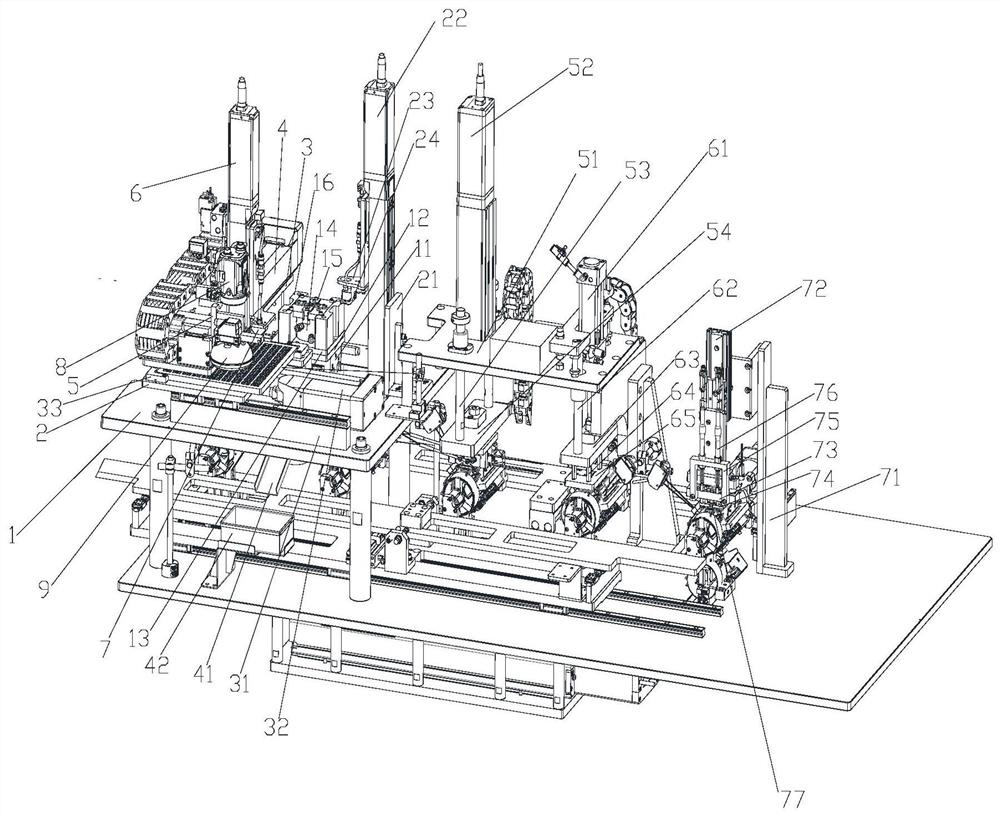

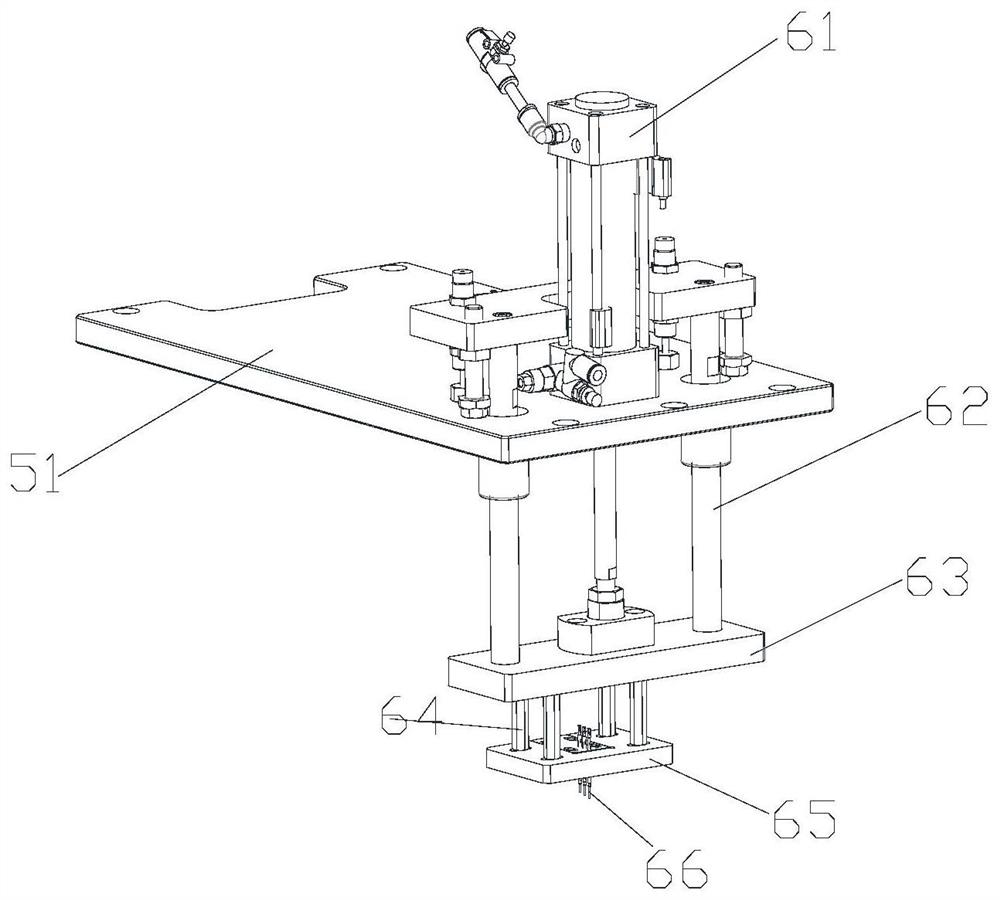

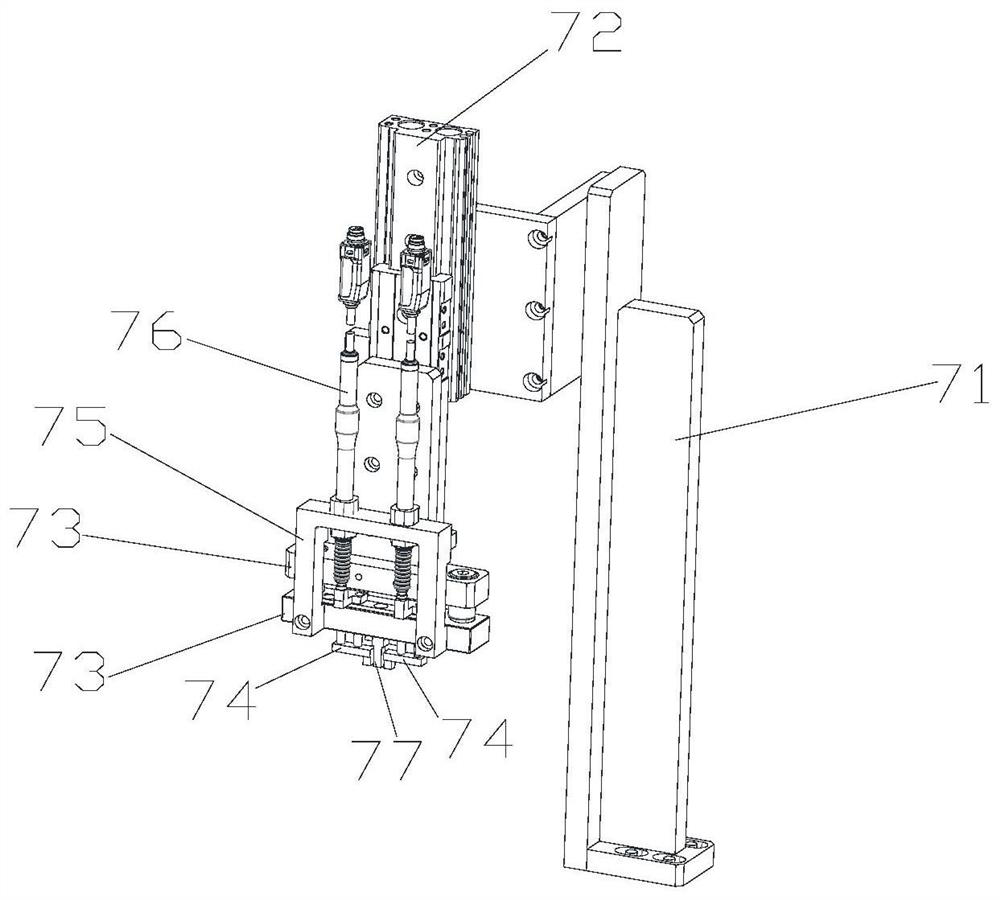

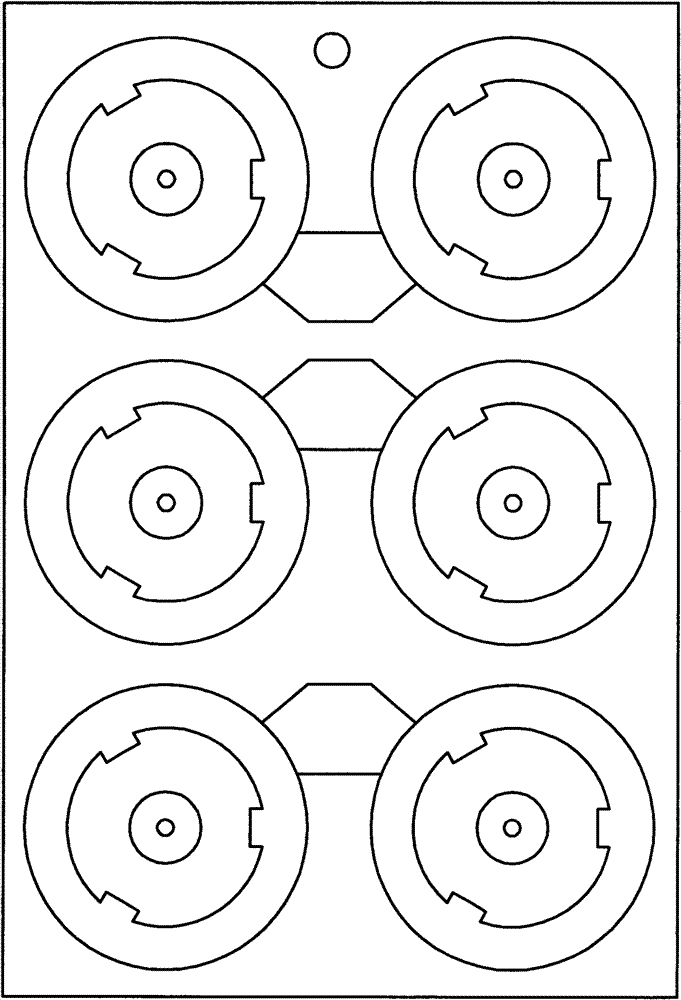

Axial clearance matching machine for hub bearing

ActiveCN106481676ANo stayTimely detection of size deviationsBearing componentsSortingControl systemThrust bearing

The invention discloses an axial clearance matching machine for a hub bearing. A preselecting mechanism can be used for measuring an axial clearance of a bearing formed by assembling a to-be-assembled inner ring, a to-be-assembled outer ring and a standard retainer combination together and transmitting information to a control system; a ball storehouse is used for placing to-be-assembled retainer combinations with different tolerance ranges; a nesting mechanism can be used for pressurizing and nesting a preassembled product formed by the to-be-assembled inner ring, the to-be-assembled outer ring and a set of to-be-assembled retainer combination; a carrying mechanism can be used for conveying the pressurized and nested product into a measuring mechanism, carrying the product in the measuring mechanism to a defective product discharging station and carrying the product on the defective product discharging station to a subsequent output station; the measuring mechanism can be used for measuring the axial clearance of the product and transmitting information to the control system; a defective product discharging mechanism can be used for discharging the product on the defective product discharging station; and the control system is used for controlling the action of each mechanism. By using the axial clearance matching machine, the fit rate is increased, the phenomenon that a great number of intermediate products are detained does not appear, and the production efficiency and yield rate are increased.

Owner:江苏康斯特智能装备有限公司

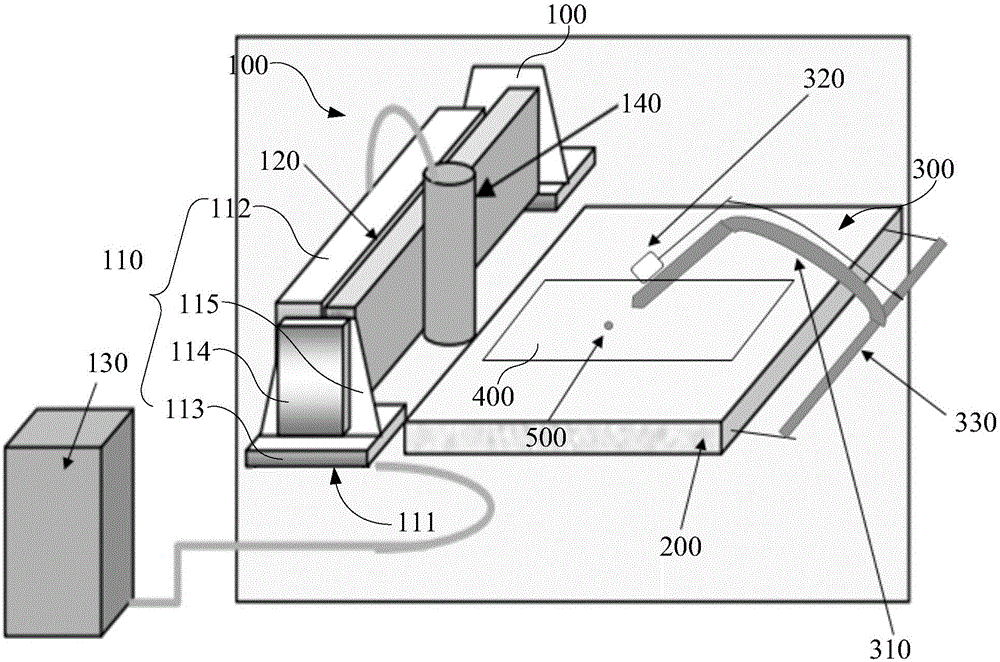

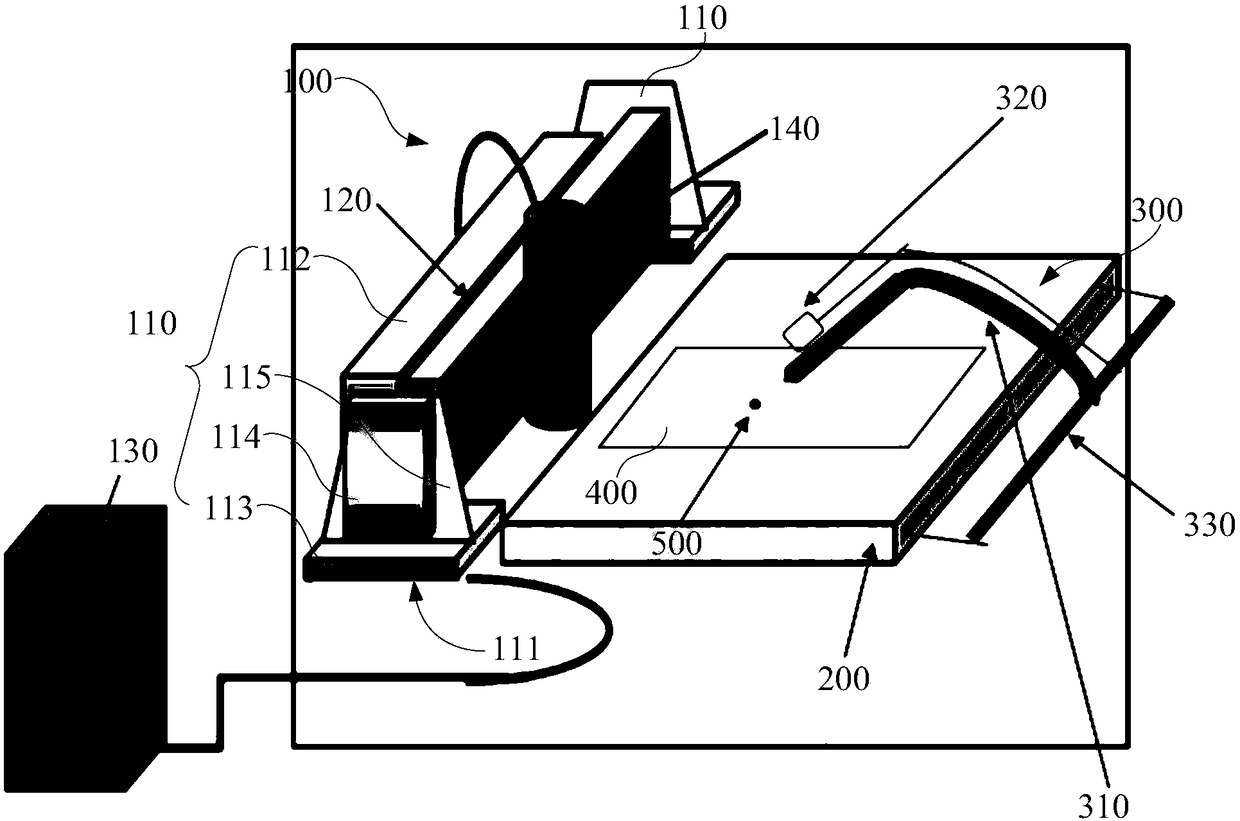

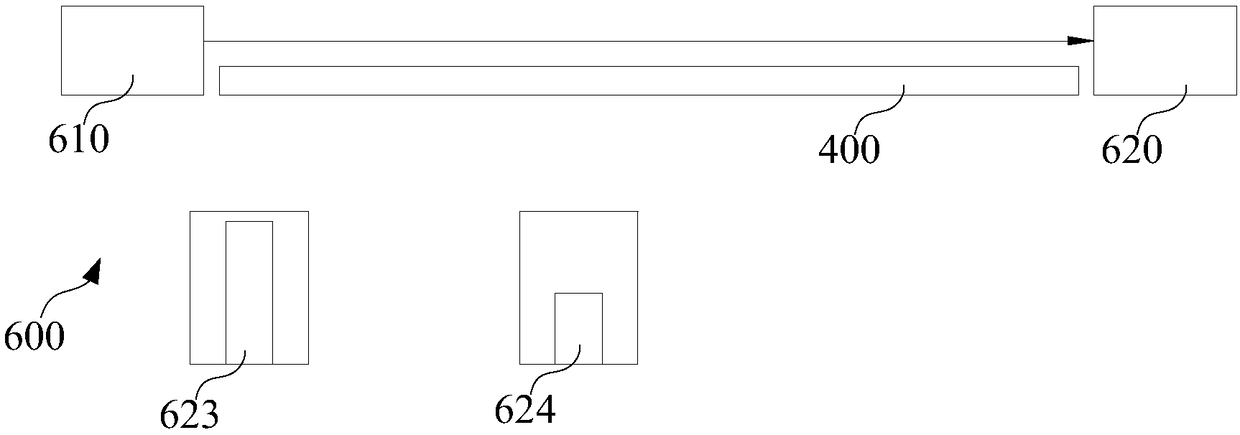

Glass substrate coating device

The invention provides a glass substrate coating device comprising a coating mechanism, a coating stage and a particle removal mechanism. The coating stage is used for carrying a glass substrate to carry out coating via the coating mechanism, the particle removal mechanism is arranged at one end of the coating stage away from the coating mechanism, and the particle removal mechanism removes particles when the particles on the glass substrate are found, personnel enters a machine less frequently, and more particles are avoided being brought in; in the mass production, it is possible to the quantity of glass substrates to be repaired and increase capacity.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Welding method of nickel base membrane wall tube panel

ActiveCN106238866BAvoid deformationGuaranteed dimensional accuracy requirementsCooled electrode holdersEngineeringWeld line

The invention discloses a welding method for a nickel-based membrane type wall tube panel. The welding method includes the following steps that a tube panel is formed by nickel-based tubes (1) and nickel-based flat steel (2), and an anti-deformation tool (3) is arranged at each of the two ends of the tube panel; during welding, a specific welding sequence, a specific welding mode and specific welding line energy are adopted; and it is always kept that flowing cooling water exists in the tube panel in the welding process. The nickel-based tube panel is welded through the welding method, deformation and heat cracks, generated in the welding process, of the nickel-based tube panel can be effectively avoided, therefore, the dimensional precision requirement of the nickel-based tube panel is guaranteed, the repair amount of the nickel-based tube panel is reduced, the production period of the nickel-based tube panel is shortened, and the quality of the nickel-based tube panel is improved.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Method for mine underground deep engineering support

InactiveCN104500091AInhibit deformation and crackingExtended service lifeUnderground chambersTunnel liningCouplingEngineering support

The invention relates to a method for mine underground deep engineering support. The method is characterized in that a double-layered flexible rigid excess limited yielding type relative coupling support mode is adopted in the support process. According to the novel support principle for establishing deep engineering of a mine, namely the double-layer flexible rigid excess limited yielding type relative coupling support theory, a support process and a matched construction method of deep double-layered flexible rigid excess limited yielding type relative coupling of the mine are established. By adopting the method, the purposes that the deep engineering deformation and cracking of the mine are effectively inhibited, the service life of a tunnel is prolonged, the engineering repairing amount is reduced, the cost is reduced, and the normal construction, production and security orders under wells are ensured are achieved.

Owner:JINCHUAN GROUP LIMITED

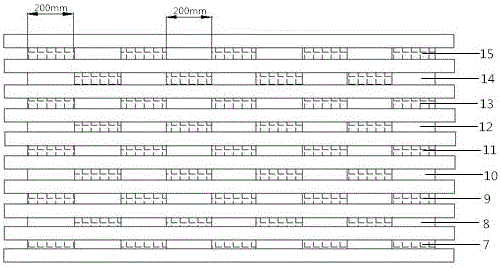

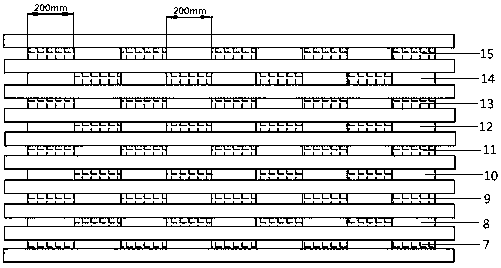

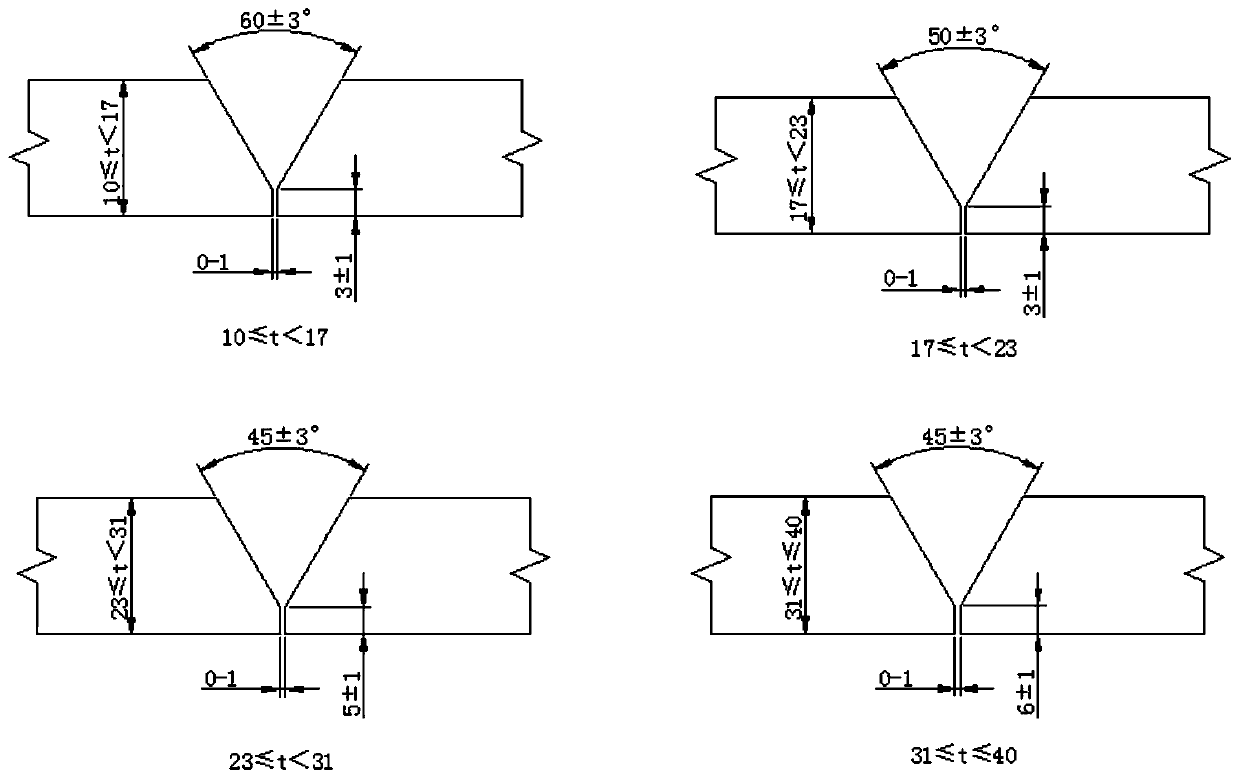

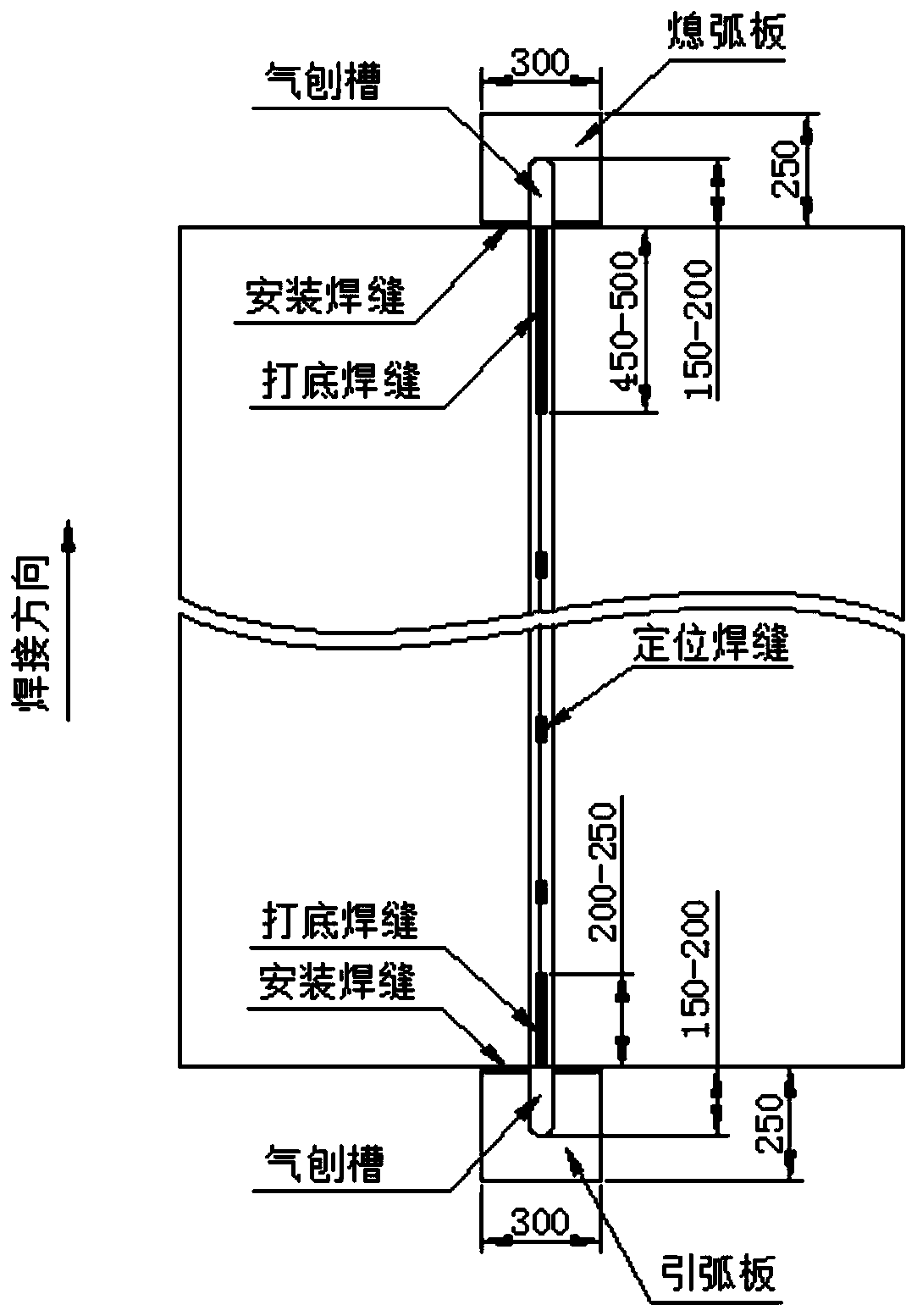

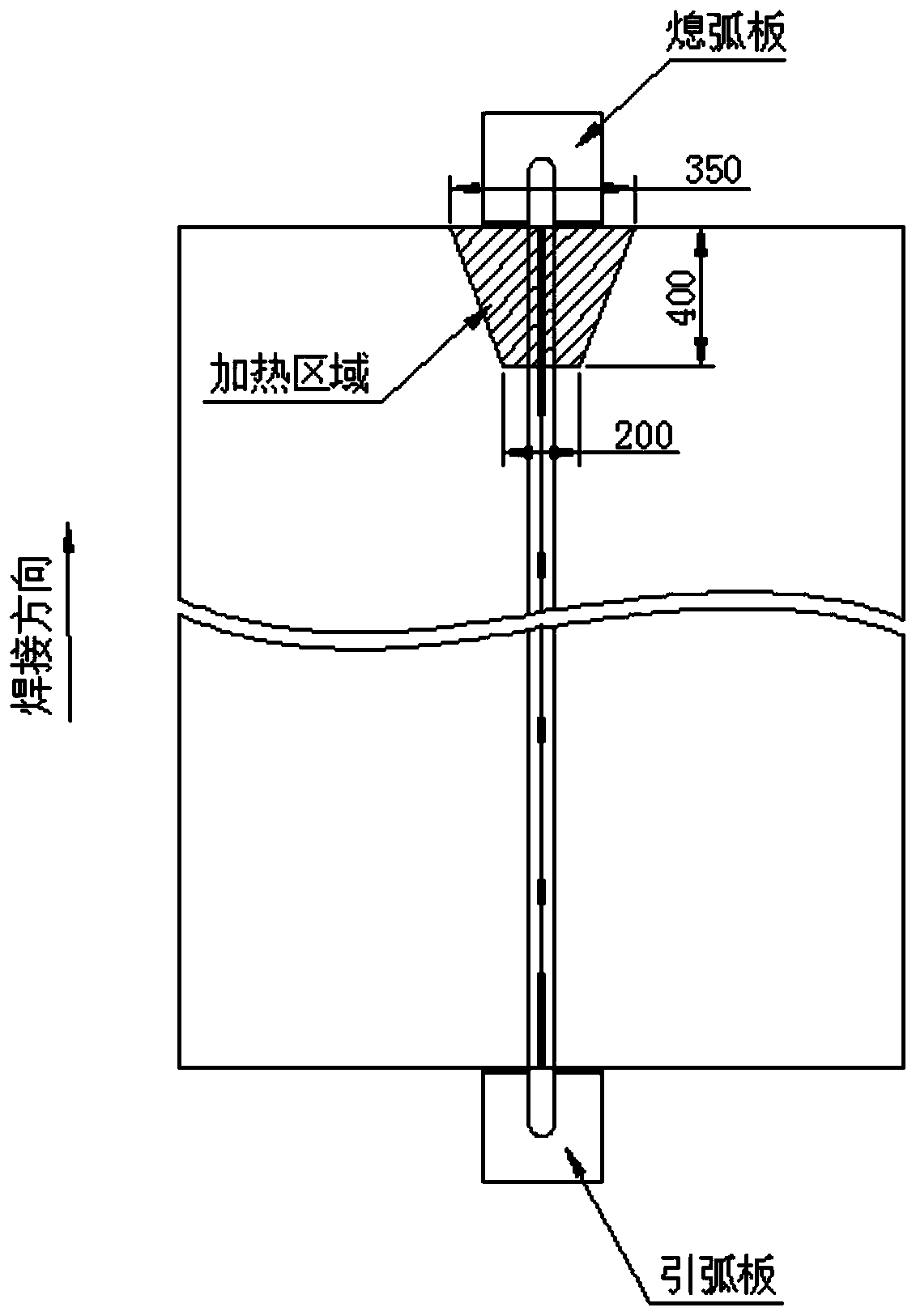

Terminal crack prevention process of Q420 high-strength steel flux copper backing submerged-arc welding

ActiveCN110640278AReduce rotation deformationAvoid crackingArc welding apparatusWelding/soldering/cutting articlesEngineeringSolder material

The invention provides a terminal crack prevention process of Q420 high-strength steel flux copper backing (FCB) submerged-arc welding. The terminal crack prevention process comprises the following steps of processing Y-shaped welding grooves at welding portions of steel plates, and after processing is finished, cleaning away oxidation layers and impurities on the faces of the Y-shaped welding grooves and the portions within the range of 20 mm away from the peripheries of the Y-shaped welding grooves; conducting assembling and positioned welding on the to-be-welded grooves of the steel plates;preparing arc striking plates and arc quenching plates; installing each arc striking plate and each arc quenching plate at the two ends of the corresponding welding groove; conducting backing weldingon the portion 200-250 mm away from the top of each Y-shaped welding groove and on the portion 450-500 mm away from the terminal of each Y-shaped welding groove; selecting a welding material which meets the requirement for conducting FCB submerged-arc welding; heating and welding a terminal trapezoid area; after welding is finished and weld joints are cooled, cutting off the arc striking plate and the arc quenching plate at the two ends of each weld joint. By means of the terminal crack prevention process, the terminal welding crack problem of Q420 high-strength steel flux copper backing submerged-arc welding can be effectively solved, and the repair workload for post-welding weld joint terminal cracks is reduced.

Owner:广州黄船海洋工程有限公司

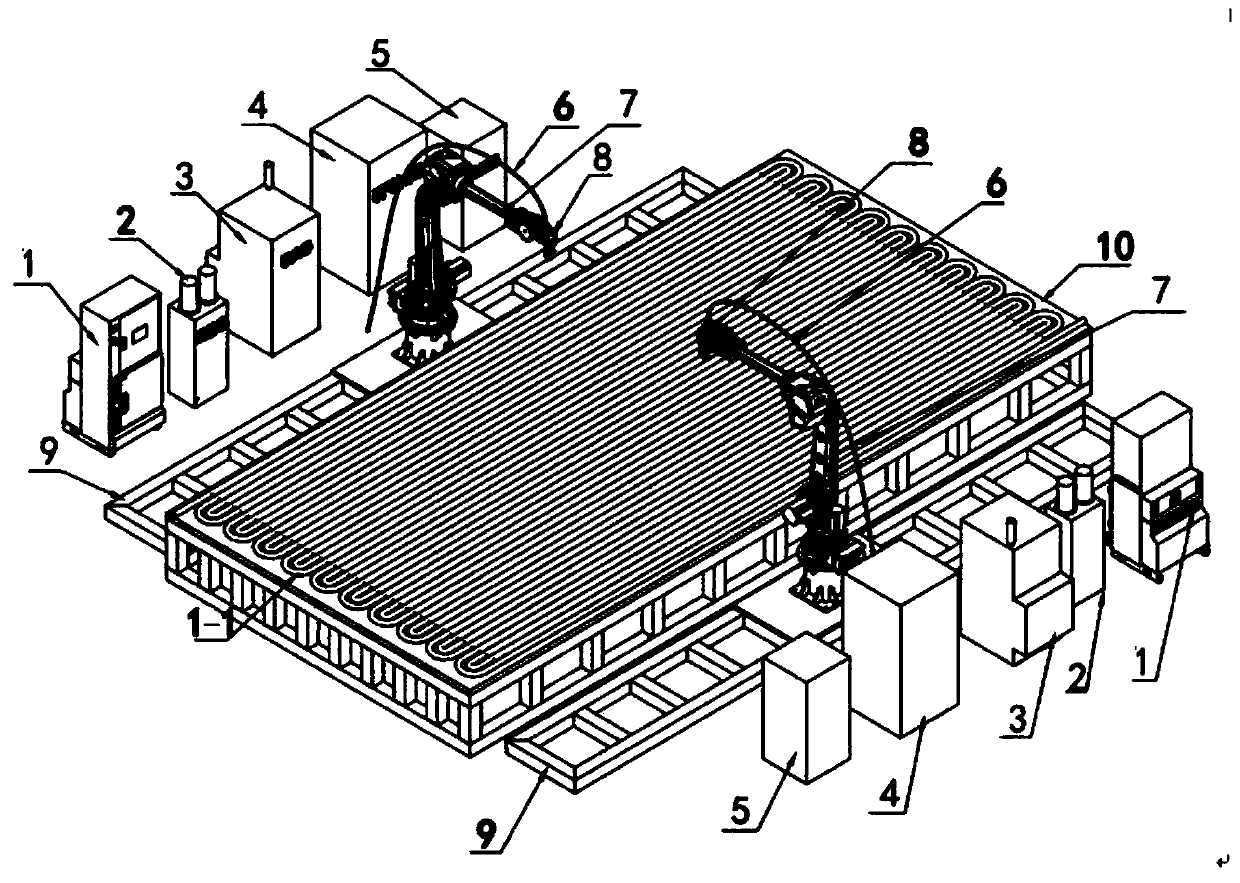

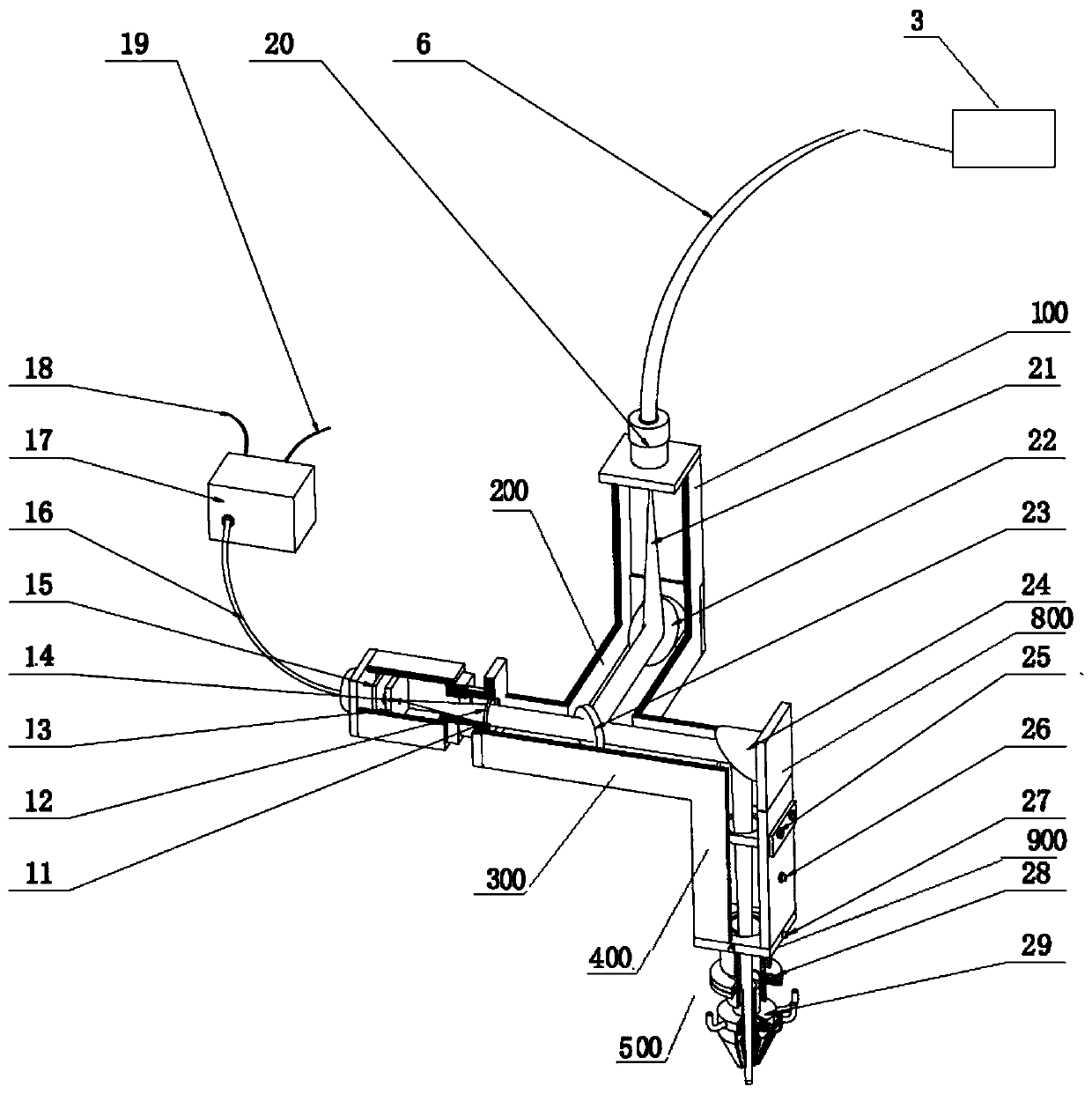

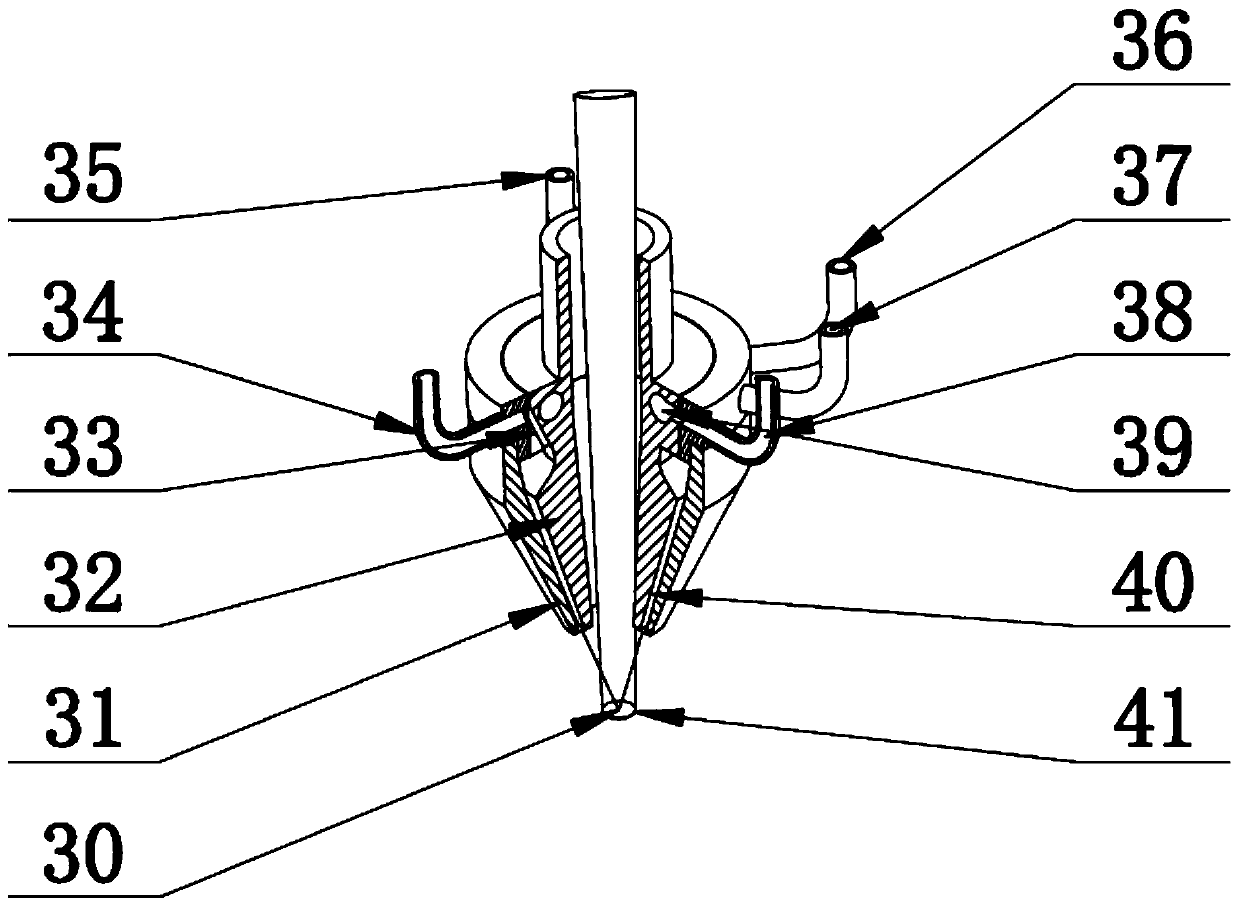

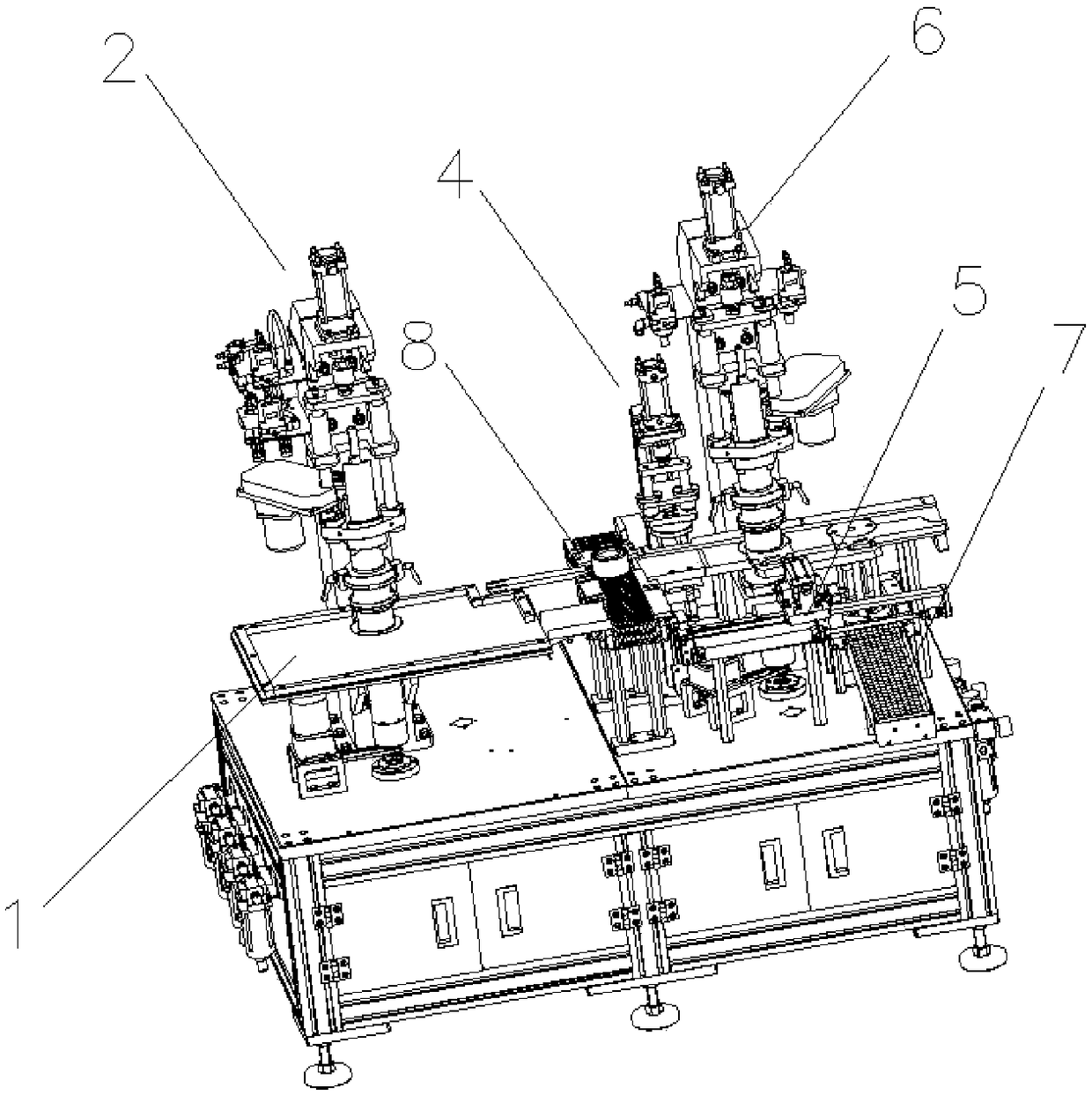

Optical fiber laser double-rail cladding equipment for membrane water wall of high-parameter waste incineration boiler

ActiveCN111560609ASave resourcesLow input costMetallic material coating processesLoop controlLaser light

The invention provides optical fiber laser double-rail cladding equipment for a membrane water wall of a high-parameter waste incineration boiler. The optical fiber laser double-rail cladding equipment comprises a machine tool platform, sliding rails, robots, laser cladding heads and optical fibers; the machine tool platform is fixedly arranged on the horizontal plane, and one sliding rail is independently arranged along each of the side edges parallel to the two sides of the machine tool platform; the robots are fixedly arranged on the sliding rails, and after arms of the two robots stretch out to work, the cladding width between the robots is not smaller than 6 m; and laser cladding units are fixedly arranged at the tops of the robots, one ends inside the laser cladding units are connected with the optical fibers, and the laser cladding units comprise the optical fibers, laser light path adjusting modules and molten pool light path detecting modules. According to the equipment, a closed-loop control system is arranged, under the ultra-low heat input amount, the cladding layer thickness can reach 0.8 - 1.5 mm, the height is consistent, uniform and attractive, the powder utilization rate of laser cladding and the stable state of a molten pool are scientifically and reasonably controlled through adjustment, and a solid foundation is laid for large-scale and long-time unmanned operation.

Owner:熔创金属表面科技(常州)有限公司

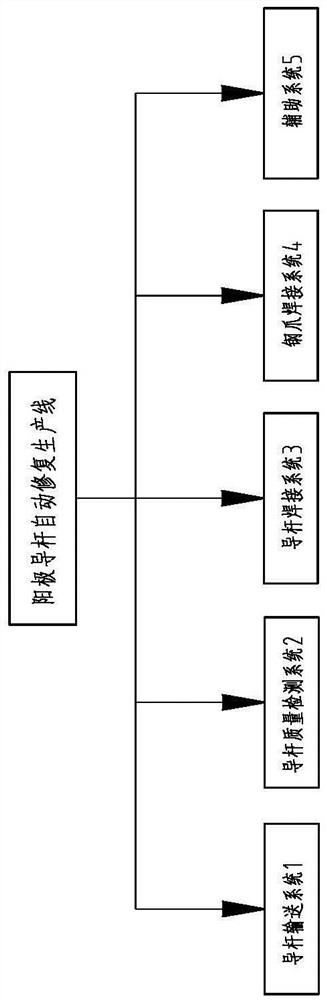

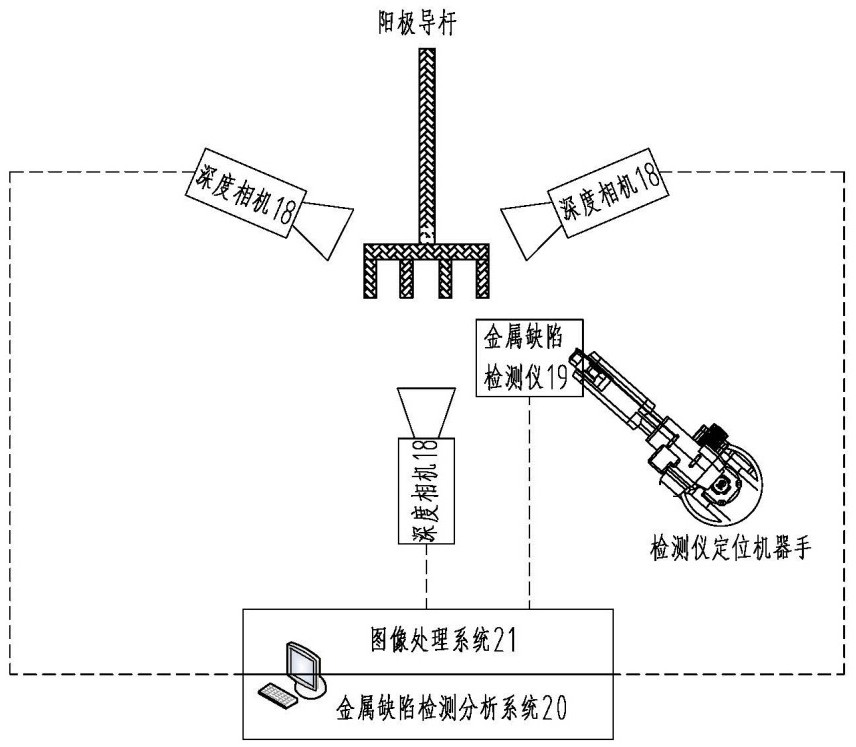

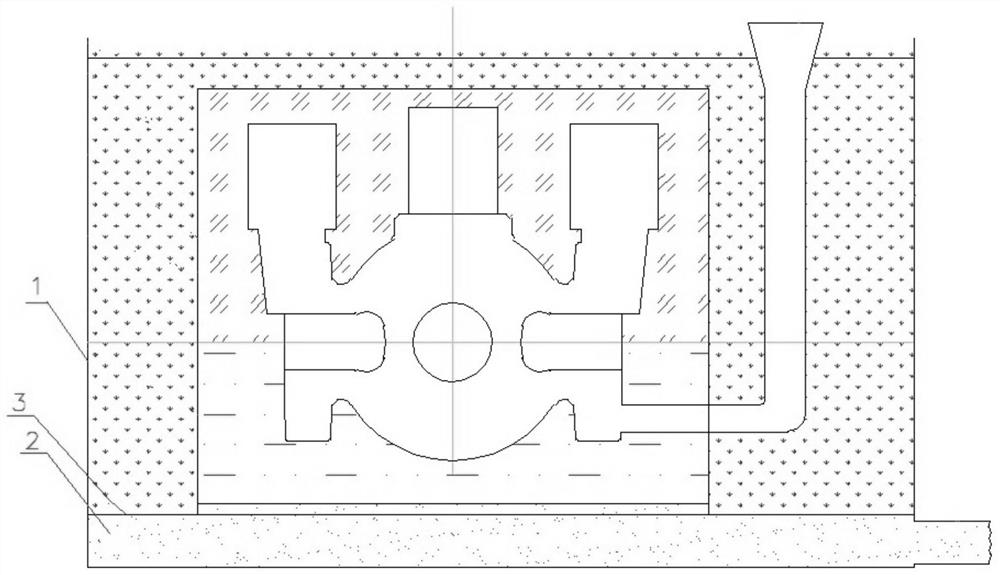

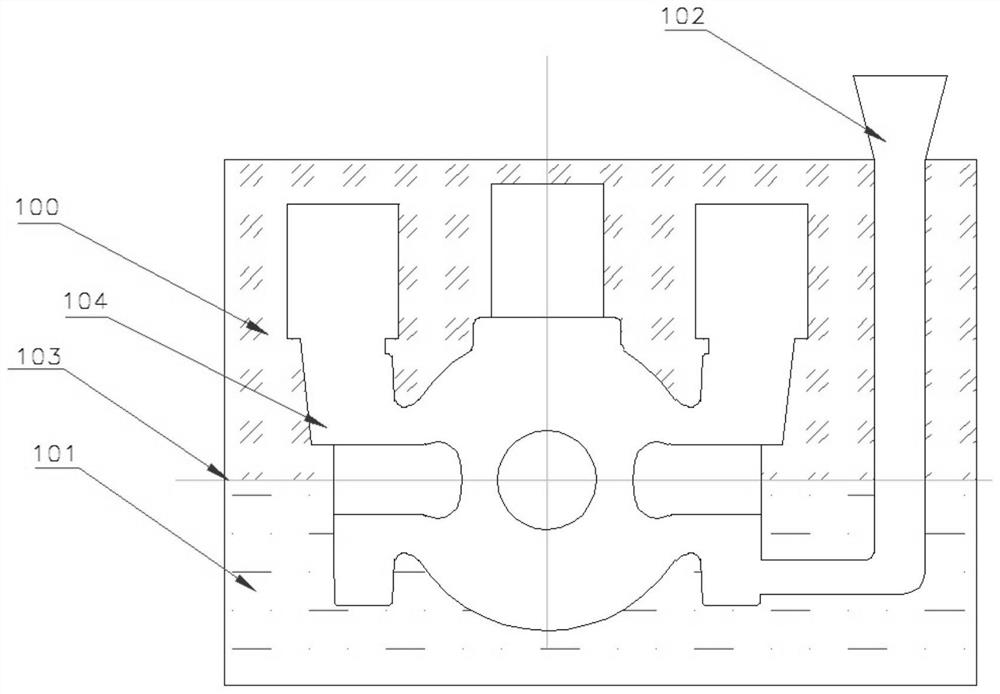

Aluminum electrolysis anode guide rod automatic repair method and production line

InactiveCN111843484AReduce wasteAvoid wastingOther manufacturing equipments/toolsProduction lineTemperature control

The invention discloses an aluminum electrolysis anode guide rod automatic repair method and a production line. The production line comprises an aluminum rod welding system, a steel claw welding system, a guide rod quality detection system, a guide rod conveying system and an auxiliary system. The guide rod quality detection system is used for conducting surface damage analysis and / or internal flaw detection on anode guide rods. The guide rod conveying system transfers the anode guide rods to the aluminum rod welding system and / or the steel claw welding system according to information of the guide rod quality detection system and transfers the anode guide rods within the range of the production line. The auxiliary system provides material support, temperature control and dust recycling forthe aluminum rod welding system and the steel claw welding system. All subsystems cooperate closely for distinguished repair work procedures of all the anode guide rods, flexibility is high, the labor intensity of workers is remarkably lowered, the connector strength is improved by 50% or above, the reworking amount is decreased by 50%, and the aluminum electrolysis anode guide rod automatic repair method and the production line have the advantages of being good in guide rod repair quality, low in use pressure drop, low in repair labor cost, long in service life, high in automation degree, capable of saving energy and environment-friendly.

Owner:CHINALCO INTELLIGENT TECH DEV CO LTD +1

Negative-pressure vacuumizing pouring method for high-pressure regulating valve casting

InactiveCN112276044AImprove casting qualityOvercoming organizational segregationPumping vacuumDry sand

The invention discloses a negative-pressure vacuumizing pouring method for a high-pressure regulating valve casting. The method includes the following steps that S1, a sand mold is closed and put intoa tool which is a box body with an opening formed in the upper end, an air suction cavity is formed in the lower end of the box body, and the air suction cavity is separated from the box body througha filter screen; S2, the space between the box body and the sand mold is filled with dry sand; S3, after the spaced is full of the dry sand, plastic is laid at the upper end of the box body, and thedry sand is laid on the plastic; S4, a vacuum pump is started, and the air suction cavity is vacuumized; S5, pouring is conducted in the sand mold, and the vacuum pump is kept to be started; and S6, after pouring is completed, the vacuum pump is stopped. According to the method, the pouring speed is increased, the mold filling time of the high-pressure thick-wall casting is shortened, the qualityof the casting is further improved, particularly, the shrinkage crack defects of the chromium-molybdenum steel shot casting of the high-pressure regulating valve are overcome, and the problem of structure segregation of the high-pressure thick-wall valve body casting is effectively solved.

Owner:NINGXIA LANGSHENG PRECISION MFG TECH CO LTD

Pump head production method

InactiveCN101671791AFlat surfaceFine surfacePositive displacement pump componentsFoundry mouldsFoundryRetention time

The invention relates to a pump head production method, comprising the following steps: adding ferrous raw material into a medium-frequency electric furnace; heating the ferrous raw material to be molten into molten iron; carrying out reaction of the molten iron with a nodularizer and an alloy raw material to obtain alloy melt; making an iron mould sand lined die by using cast iron; and injectingthe alloy melt into the iron mould sand lined die. Through long-term study, the inventor makes strict control on the working temperature of the product, alloy pouring temperature and alloy pouring speed as well as retention time of cast parts in casting molds, and makes a breakthrough by adopting the iron mould sand lined die for foundry, thereby solving the technical problems of poor dimensionalprecision and low yield by using wet mould sand manually-made dies for a long term in the field.

Owner:湖州鼎盛机械科技股份有限公司

Flame cutting machine nitrogen accompanying purging system and method

The invention relates to a flame cutting machine nitrogen accompanying purging system and method. The system comprises a metal hose, a high-pressure nitrogen hard pipe, spray nozzles and a fixing device; the high-pressure nitrogen hard pipe is fixed to the front / back position of a flame cutting machine cutting torch in the casting direction of a cast blank through connection of the metal hose; andthe spray nozzles at the tail end of the high-pressure nitrogen hard pipe act on the position of oxides, in a molten state, on the cast blank at the specified heights, intervals and included angles.The method includes the steps that the flame cutting machine nitrogen accompanying purging system is assembled; and an nitrogen source is opened, the spray nozzles of the flame cutting machine nitrogen accompanying purging system rapidly cool oxidative products which are in a molten state and are generated through flame cutting through a continuous high-pressure high-speed nitrogen stream, and thetwo ends of slits are stripped under impact and purging of the nitrogen stream. By means of the flame cutting machine nitrogen accompanying purging system and method, the cut end faces are more smooth and flatter, information is fed back simultaneously according to continuous rolling, and the amount of repair caused by hot rolling roll head and tail scab defects is decreased substantially.

Owner:BENGANG STEEL PLATES

Hub bearing axial clearance matching machine

ActiveCN106481676BNo stayTimely detection of size deviationsBearing componentsSortingControl systemEngineering

The invention discloses an axial clearance matching machine for a hub bearing. A preselecting mechanism can be used for measuring an axial clearance of a bearing formed by assembling a to-be-assembled inner ring, a to-be-assembled outer ring and a standard retainer combination together and transmitting information to a control system; a ball storehouse is used for placing to-be-assembled retainer combinations with different tolerance ranges; a nesting mechanism can be used for pressurizing and nesting a preassembled product formed by the to-be-assembled inner ring, the to-be-assembled outer ring and a set of to-be-assembled retainer combination; a carrying mechanism can be used for conveying the pressurized and nested product into a measuring mechanism, carrying the product in the measuring mechanism to a defective product discharging station and carrying the product on the defective product discharging station to a subsequent output station; the measuring mechanism can be used for measuring the axial clearance of the product and transmitting information to the control system; a defective product discharging mechanism can be used for discharging the product on the defective product discharging station; and the control system is used for controlling the action of each mechanism. By using the axial clearance matching machine, the fit rate is increased, the phenomenon that a great number of intermediate products are detained does not appear, and the production efficiency and yield rate are increased.

Owner:江苏康斯特智能装备有限公司

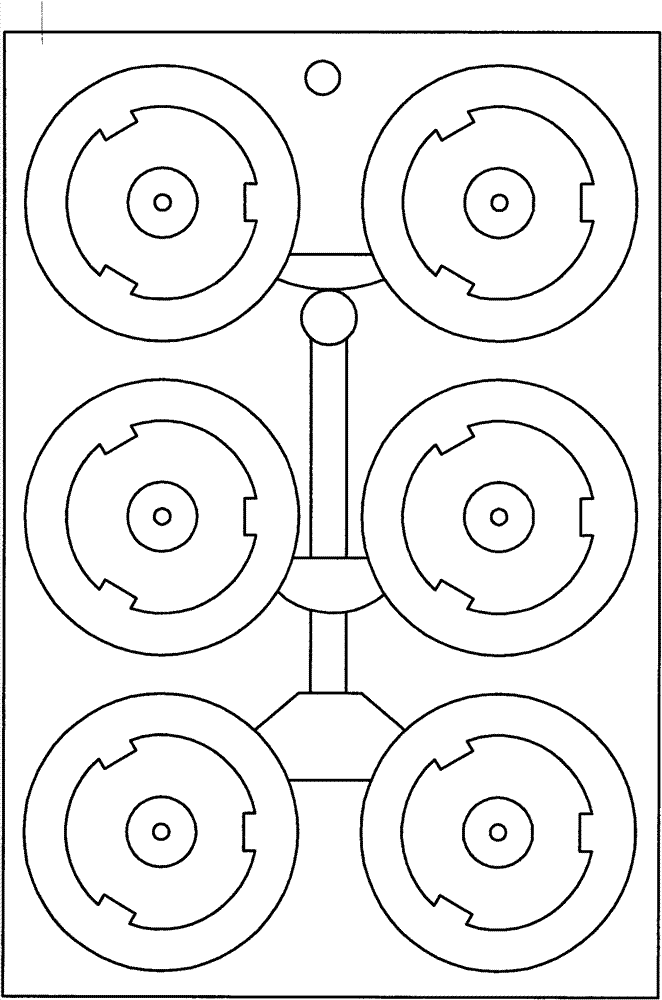

Ink cartridge head board arranging device

InactiveCN111660674AReduce in quantitySave human effortElectric connection testingMaterial analysis by optical meansFully automatedElectrical and Electronics engineering

The invention discloses an ink cartridge head board arranging device. The ink cartridge head board arranging device comprises a supporting frame body, a material containing plate, a first detection mechanism, a second detection mechanism and a board arranging mechanism, wherein the material containing plate, the first detection mechanism, the second detection mechanism and the board arranging mechanism are arranged on the supporting frame body correspondingly; and a through hole is formed in the supporting frame body, and a to-be-board arranged part is arranged below the through hole, so thatthe board arranging mechanism can penetrate through the through hole to arranged PCBs on the to-be-board arranged part. According to the ink cartridge head board arranging device, full-automatic operation is achieved in the process from PCB detection to arrangement, so that manpower is saved, the number of defective products generated after arrangement due to the quality problem of the PCBs is reduced, and the follow-up repair amount of arrangement is reduced.

Owner:蔡怀峰

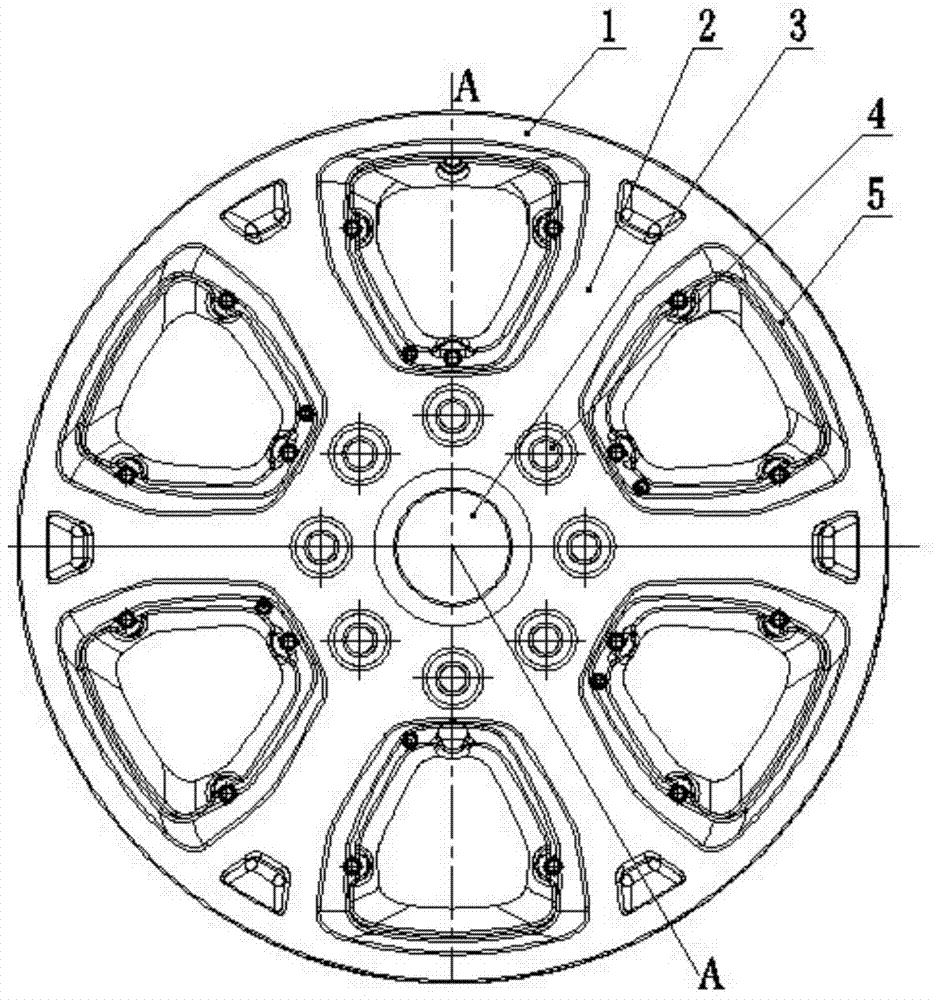

Automobile wheel with inserts and installation method of inserts

ActiveCN103660777ADesign scienceGuaranteed mechanical propertiesWheel protectionEngineeringUltimate tensile strength

The invention relates to an automobile wheel with inserts and an installation method of the inserts. The automobile wheel comprises a disc face, a center hole, bolt installation holes and spokes. The center hole is formed in the middle of the disc face, the bolt installation holes are evenly formed in the central disc face on the periphery of the center hole in the radial direction, and the center hole is used for containing an automobile axle coaxially. A plurality of spoke through holes are evenly formed in the portion, on the peripheries of the bolt installation holes, of the disc face at intervals, and a connecting structure between every two adjacent spoke through holes is a spoke. A rim is manufactured outside the disc face in the axial direction. A structural groove is formed in the portion, on the periphery of each spoke through hole, of the disc face. One insert used for wrapping the edge of the inner ring of each spoke through hole is installed in the structural groove of the corresponding spoke through hole. A plurality of installation holes are evenly formed in the lower ends of the inserts. The modeling of the inserts of the structure are consistent with the modeling of a window, the surfaces of the inserts are smooth and bright, the appearance can be more attractive, in addition, the inserts can improve the strength of the window, a window coating is protected, the wheel is protected, the spokes are prevented from being damaged, the overall performance of the wheel is improved, and the service life of the wheel is prolonged.

Owner:TIANJIN LIZHONG GRP CO LTD

Method for producing engine gear case

ActiveCN101695742BFlat surfaceFine surfaceFoundry mouldsFoundry coresIntermediate frequencyWorking temperature

Owner:湖州鼎盛机械科技股份有限公司

A kind of manufacturing method of copper handicraft

InactiveCN103738099BNot easy to change colorNot easily oxidizedEdge grinding machinesDecorative surface effectsCopperMetal

The invention discloses a fabrication method of copper crafts. The copper crafts are refined by eight procedures of smelting and melting copper; casting a sand table; welding accessories; polishing, trimming, finishing and plating; marking off and engraving; engraving designs, and spraying baking finish and molding. The mass fraction percent of copper and other metals is reasonably set, so that the processed copper crafts do not change in color, and are not easily oxidized at the same time. By adopting the procedures, the problems of size deformation, air shots, air bubbles and the like of the crafts are completely eradicated effectively, the repair amount and the defective index of the crafts are reduced, meanwhile, the quality of the crafts is improved, and the production cost is reduced.

Owner:URUMQI HAMA COPPER HANDICRAFTS

Control method of hot-rolling rolled side guide plate for improving hot-rolling roll shape quality

The invention relates to a method for controlling a hot-rolled side guide plate in the field of metallurgy, and is a method for controlling a hot-rolled coiling side guide plate to improve the quality of a hot-rolled coil. After the strip steel enters the side guide plate, the side guide plate switches from position control to pressure control; during the pressure control process of the side guide plate, it detects that the position of the side guide plate changes by more than △Xmm, then the side guide plate switches from pressure control to position control, if the position changes If it does not exceed △Xmm, the side guide plate is always under pressure control; after the side guide plate switches from pressure control to position control, detect the pressure feedback value of the side guide plate, if the pressure feedback value exceeds K times the pressure setting value under pressure control mode , the position of the side guide plate is opened once every 5s by 2mm until the pressure feedback value of the side guide plate is less than K times the pressure setting value in the pressure control mode; when the strip leaves the side guide plate, the side guide plate enters position control . The invention effectively solves the problems of misalignment, edge-out, and side-cut quality defects in the shape of the coil when there is swimming and sickle bending in the incoming strip steel.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Calibration method for clearance between rolls of hot-rolling vertical rolls

InactiveCN102989792BProtective functionEliminate the problem of abnormal widthMetal rolling stand detailsMeasuring devicesStrip steelHot rolled

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Secondary positioning construction technology of catenary pre-buried channel in high-speed railway tunnel

ActiveCN104790969BQuick installationLarge operating spaceUnderground chambersTunnel liningRailway tunnelRebar

Owner:中铁二十四局集团福建铁路建设有限公司 +1

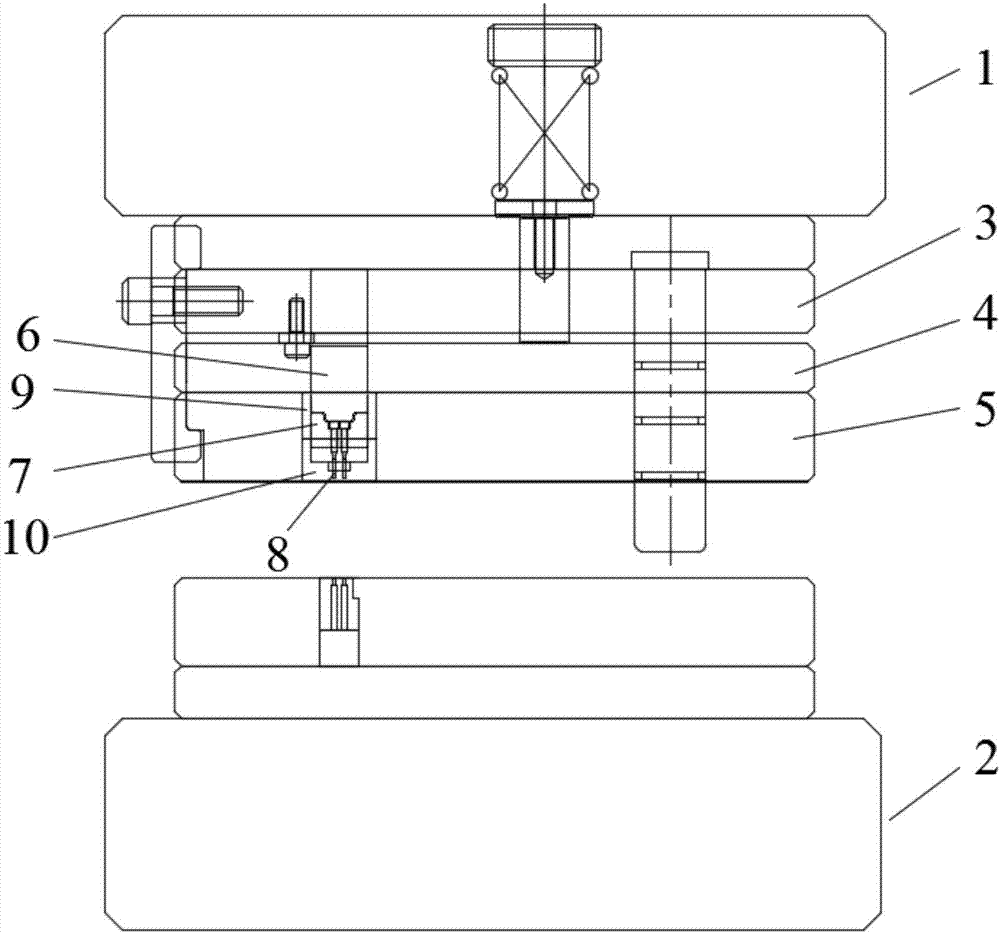

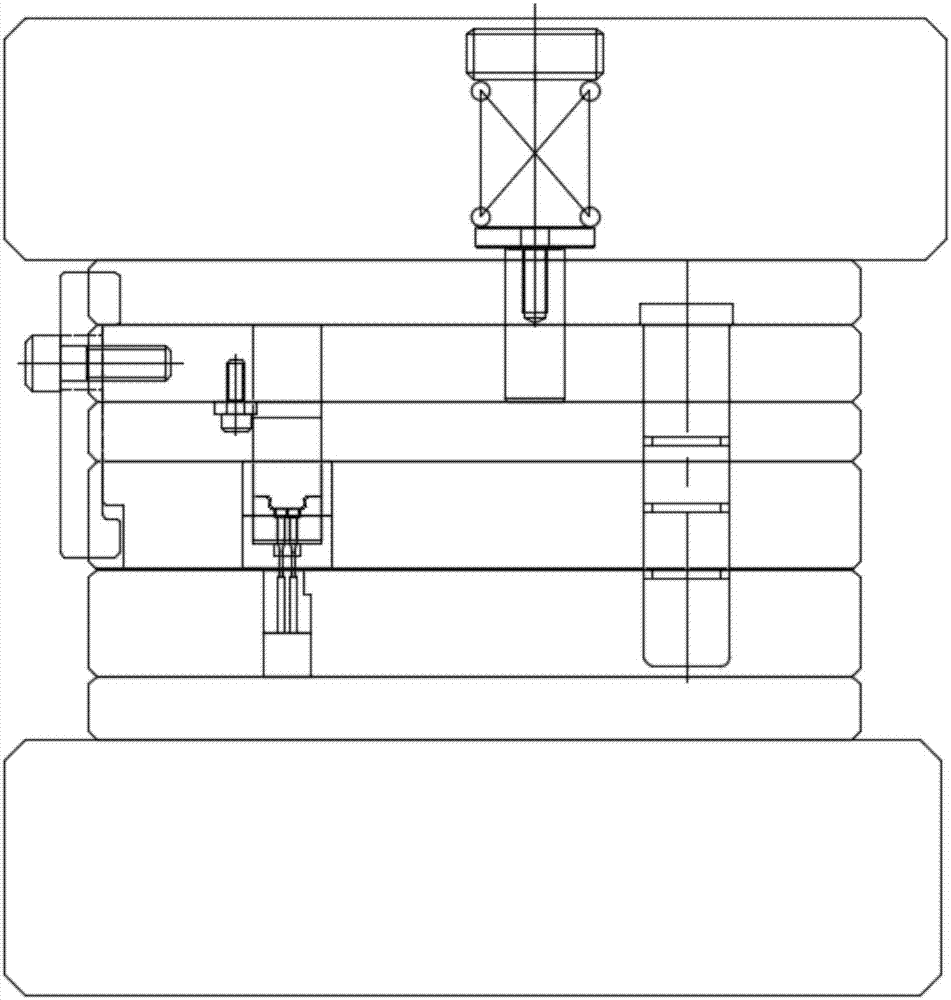

Small hole punching mechanism

The invention relates to a small hole punching mechanism which comprises an upper die and a lower die, wherein the upper die comprises an upper clamping plate, a stopping plate, a stripping plate anda punching device; and the punching device comprises a first punching head clamping block, a second punching head clamping block, a punching head, a first stripping plate insert and a second strippingplate insert. The small hole punching mechanism provided by the invention has the beneficial effects that by adoption of the first punching head clamping block, the second punching head clamping block, the first stripping plate insert and the second stripping plate insert, the length of the punching head can be effectively shortened, the strength of the punching head can be improved, and the punching head breakage frequency can be reduced; the machining efficiency is high, the punching head can be directly replaced on a punching machine, the replacement time is short, the punching head need not be frequently replaced, the service life of the punching head is long, the waste of resources can be avoided, and the machining cost can be reduced; and the phenomenon that the punching of severalproducts is omitted can be avoided, the quantity of the products which are scrapped and need to rework can be reduced, the raw material utilization ratio can be improved, and the production cost can be reduced.

Owner:SUZHOU XINJIESHUN HARDWARE ELECTROMECHANICAL

Technique for eliminating magnetic blow of electric arc of austenitic electrode by using permanent magnet

InactiveCN1189281CSolve the problem of magnetic deflection blowing of welding rodGuarantee welding qualityElectrode accessoriesElectrical polarityMagnetic poles

A technique for eliminating the deviation blowing of electric arc of welding austenite electrode by permanent includes measuring magnetic induction intensity and magnetic pole direction of the bevel to be welded, sucking a permaneng magnet to the bevel in such manner that their magnetic polarities are reversed, measuring the magnetic induction intensity less than 2 mT, and welding. Its advantages are high effect and high welding quality.

Owner:中国船舶集团渤海造船有限公司

A Method of Avoiding Burr Defects on the Edge of Ultra-low Carbon Steel

ActiveCN109226260BImprove edge qualityFulfil requirementsRoll force/gap control deviceTemperature control deviceStrip steelWater cut

The invention relates to a method for avoiding the burr defect of the ultra-low carbon steel edge. The weight percentage of C in ultra-low carbon steel is less than 0.0035%. The method specifically includes the following steps that the installation accuracy of a water cutting board and a guide device on rough rolling R1 and R2 mills are improved; the cooling water pressure of each rack in a roughrolling area, the diameter of vertical roll body water nozzle, the spray angle and the forward slip value are controlled; at the times of rough rolling, the heating tapping temperature, the rough rolling outlet temperature, the intermediate billet thickness, the reduction rate of each rack in finish rolling, the side pressure amount and the vertical roll rolling force are controlled. The method can effectively improve the edge quality of ultra-low carbon hot rolled strip steel, the subsequent cold rolling process production is prevented from being affected by the burr defect, the user requirement is met, meanwhile, the cold rolling repair is reduced, and the production cost of enterprises is reduced.

Owner:ANGANG STEEL CO LTD

Method for producing traveling wheel

ActiveCN101695743BFlat surfaceFine surfaceFoundry mouldsFoundry coresMiddle frequencyWorking temperature

The invention discloses a method for producing a traveling wheel, which comprises the following steps: putting an iron-containing raw material into a middle frequency furnace and heating the iron-containing raw material; melting the iron-containing raw material into molten iron; reacting the molten iron with a nodulizer and an alloy raw material to obtain a molten alloy; making a sand-lined metalmould with cast iron; and injecting the molten alloy to the sand-lined metal mould. The inventor controls the working temperature of a product, the casting temperature and the casting speed of the alloy, the standing time of a cast product in the mould strictly after long term grope and adopts the breakthrough sand-lined metal mould for casting so as to solve the technical problems of poor dimensional precision and low finished product ratio of a long-term used green sand hand-made mould in the field.

Owner:湖州鼎盛机械科技股份有限公司

Glass substrate coating device

The invention provides a glass substrate coating device comprising a coating mechanism, a coating stage and a particle removal mechanism. The coating stage is used for carrying a glass substrate to carry out coating via the coating mechanism, the particle removal mechanism is arranged at one end of the coating stage away from the coating mechanism, and the particle removal mechanism removes particles when the particles on the glass substrate are found, personnel enters a machine less frequently, and more particles are avoided being brought in; in the mass production, it is possible to the quantity of glass substrates to be repaired and increase capacity.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com