Method and special fixture for compensating UV gum in Mobile telephone CCD camera assembling process

A mobile phone camera and special fixture technology, which is applied in installation, image communication, color TV parts, etc. It can solve the problems of easy penetration into the gap, less UV glue, and unacceptable curing, so as to prolong the placement time and reduce the amount of glue. The effect of reducing and lowering the jig production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

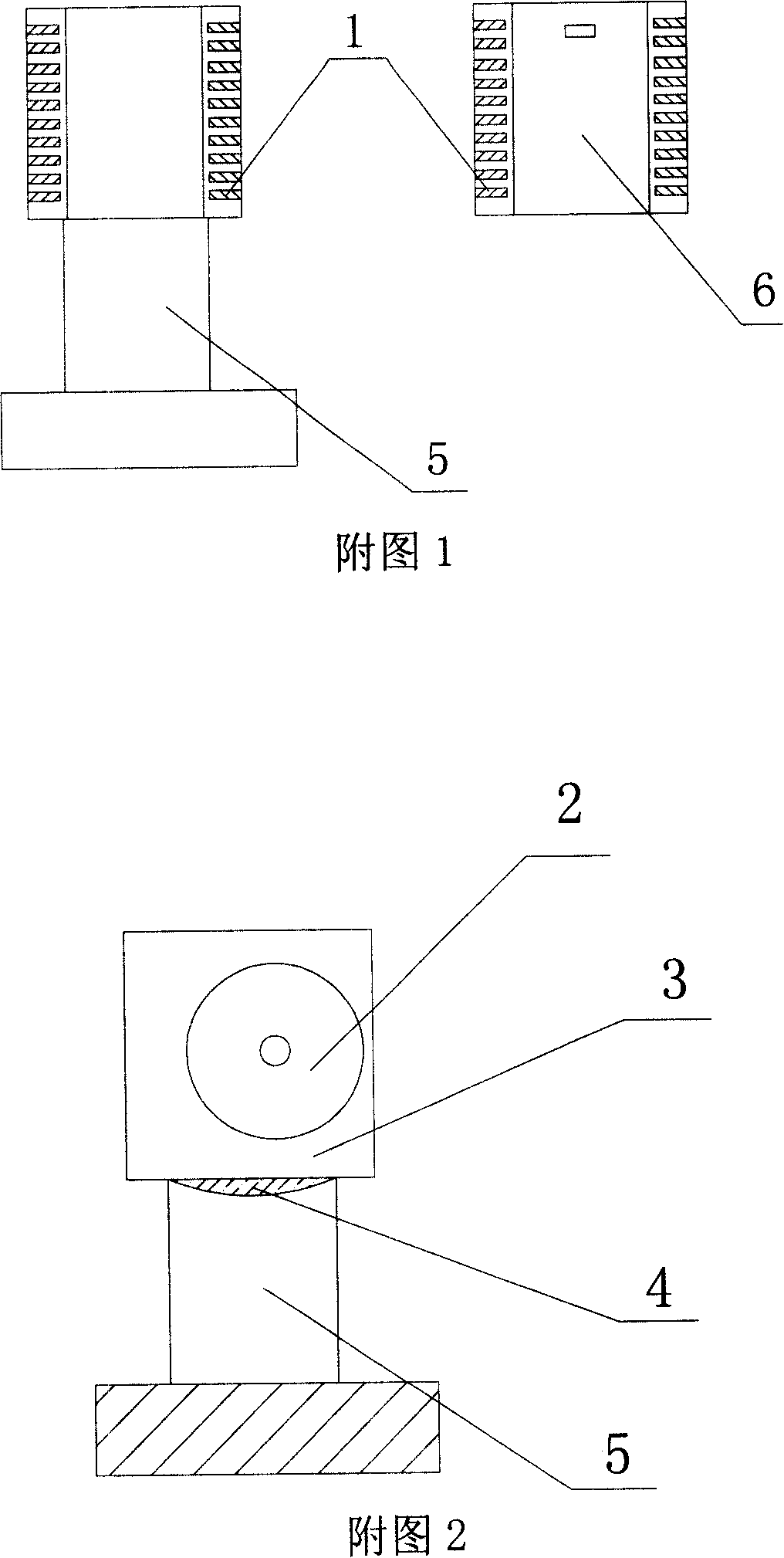

[0024] As shown in Figure 1, Figure 2, and Figure 3: During the COB packaging process of the mobile phone camera, the lens 2 is located on the lens base 3, the printed circuit board PCB6 is located under the lens base 3, and the printed circuit board is located below the printed circuit board PCB6. FPC5, the flexible printed circuit board FPC5 is connected with the printed circuit board PCB6 through heat pressing. Since the range of hot pressing is limited to gold finger 1, there is a space in the middle of FPC5, so in order to increase the connection strength between FPC5 and PCB6, it is necessary to inject UV glue 4 between the lens base Holder3 and FPC5.

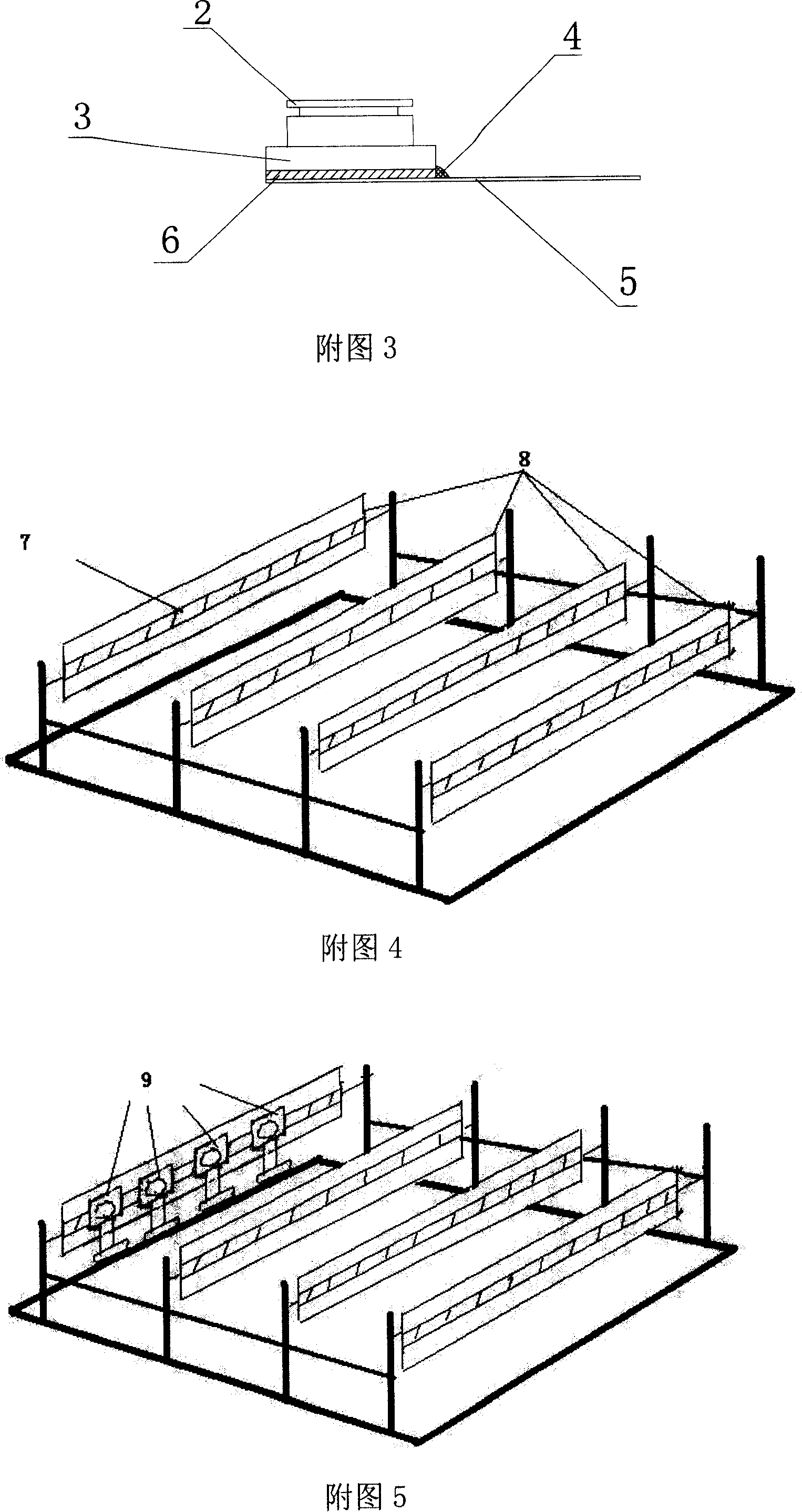

[0025] The fixture in the specific embodiment shown in Fig. 4, Fig. 5 comprises a group of putting plate 8, puts a double-sided adhesive tape 7 on the putting plate 8, and the product 9 that points glue is vertically placed and sticks on the place. Put it on board 8 with FPC5 facing down.

[0026] The following is a brie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com