New technology for producing viscose flat monofilament

A flat monofilament and new process technology, applied in the direction of filament generation, spinneret assembly, filament/thread forming, etc., can solve the problems such as the complicated process of viscose flat monofilament, achieve soft hand feeling, easy dyeing, The effect of uniform thickness of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

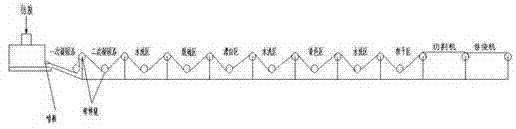

Image

Examples

Embodiment 1

[0029] A new process for the production of viscose flat monofilaments. The spinning solution made from cellulose fiber pulp is sprayed out through the spinneret to form a viscose fiber film with a width of 1.5m, which is drawn into the coagulation bath, In the post-processing area and drying area, after drying, the fiber film is cut into viscose flat monofilaments with a width of 5 mm, and the finished product is wound after cutting.

Embodiment 2

[0031] A new process for the production of viscose flat monofilaments. The spinning solution made from cellulose fiber pulp is sprayed out through the spinneret to produce a 4.5m wide viscose fiber film, which is drawn into the coagulation bath, In the post-processing area and drying area, after drying, the fiber film is cut into viscose flat monofilaments with a width of 60mm, and the finished product is wound after cutting.

[0032] The spinneret is composed of upper and lower spray plates, and the gap between the upper and lower spray plates is 0.05mm.

[0033] The cellulose pulp of the present invention includes cotton pulp, wood pulp and bamboo pulp.

[0034] The viscose flat monofilament made by the new process of viscose flat monofilament production of the present invention has a dry breaking strength of 1.5-2.0CN / dtex, a wet breaking strength of 1.0-1.5CN / dtex, and a dry breaking elongation of 15- 20%.

Embodiment 3

[0036] A new process for the production of viscose flat monofilaments. The spinning solution made from cellulose fiber pulp is sprayed out through the spinneret to form a 2m wide viscose fiber film, which is drawn into the coagulation bath by drafting rollers, and then In the processing area and drying area, after drying, the fiber film is cut into viscose flat monofilaments with a width of 25mm, and the finished product is wound after cutting.

[0037] The spinneret is composed of upper and lower spray plates, the gap between the upper and lower spray plates is 0.5mm, and the upper and lower spray plates are provided with screw holes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com