Production and preparation process of adhesive tapes

A preparation process and adhesive tape technology, applied in the direction of pretreatment surface, coating, surface coating liquid device, etc., can solve the problems of excessive glue, glue coating too much, high glue temperature, etc., to reduce manufacturing costs and avoid Waste glue, evenly coated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

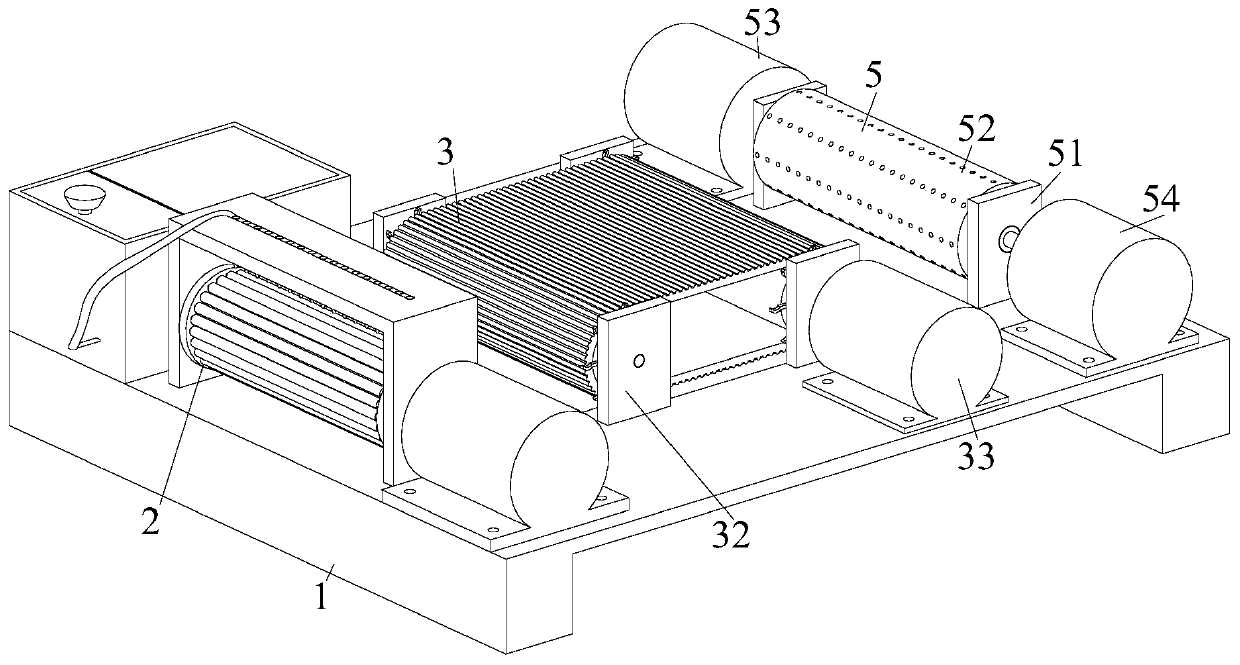

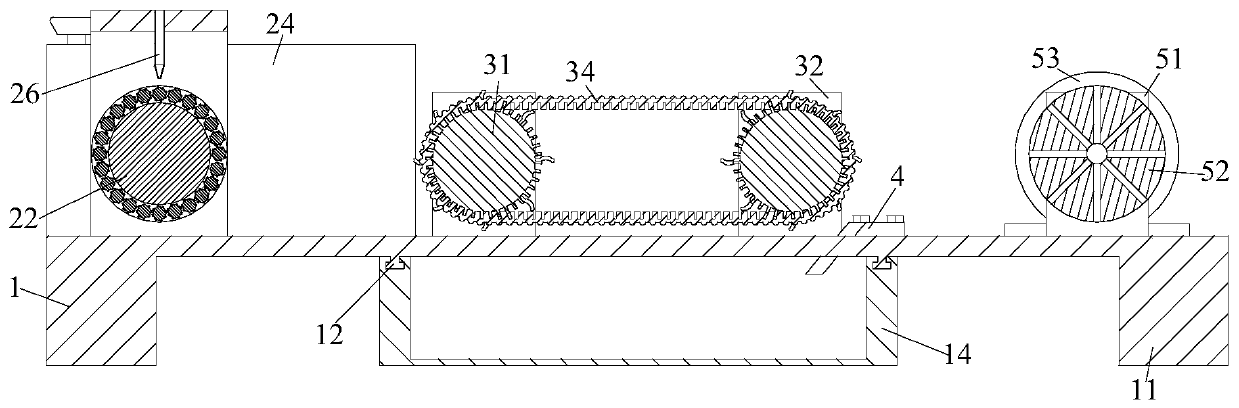

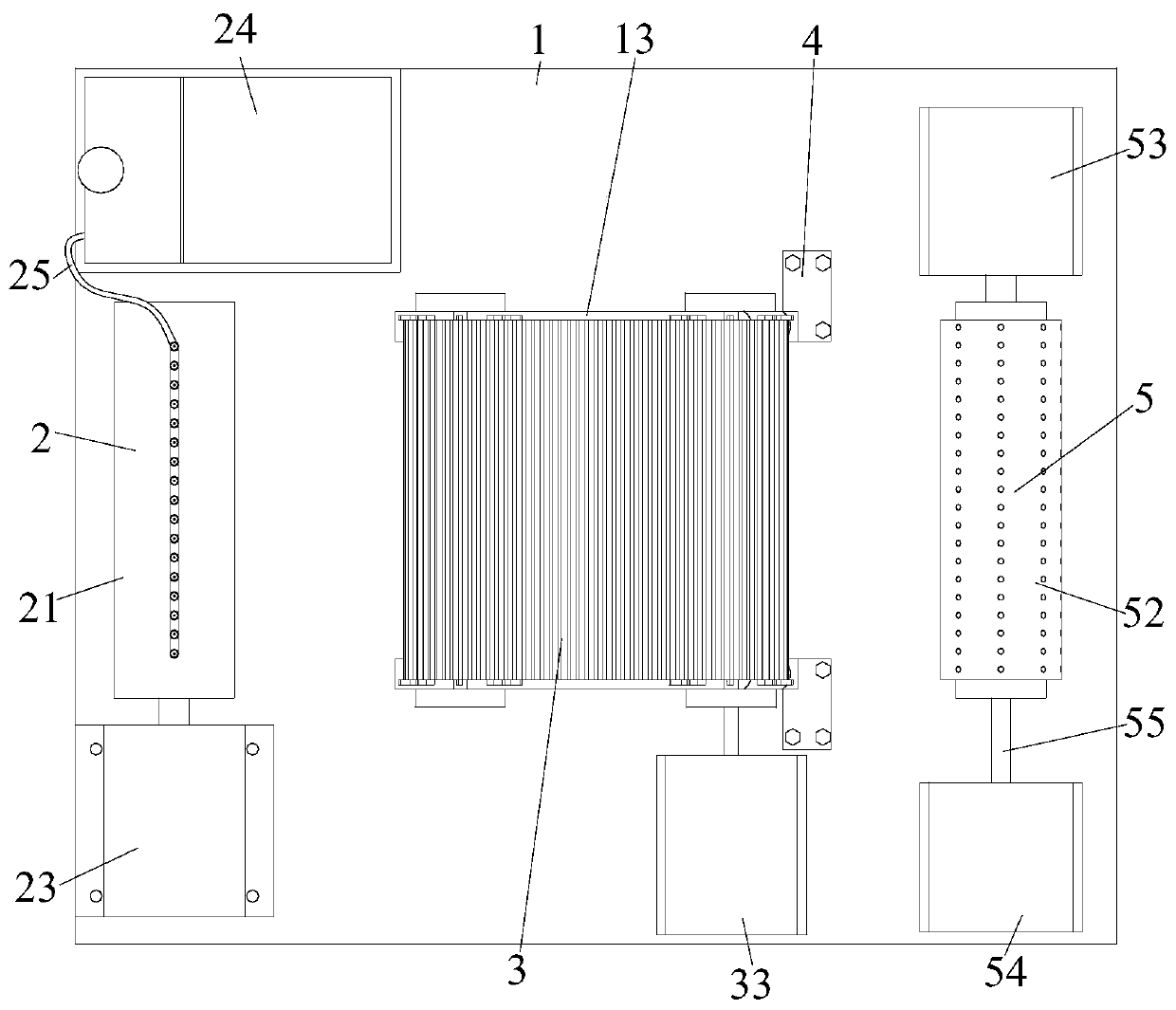

[0042] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 10 , to further elaborate the present invention.

[0043] A production and preparation process for adhesive tape is characterized in that: the specific production and preparation process is as follows:

[0044] S1. Film blowing: According to the purpose of the tape, select different plastic particles and special additives, and then blow the plastic particle raw materials into a plastic film of the tape;

[0045] S2. Glue coating: through the unique gluing device 2, gluing device 3, squeegee device 4 and cooling device 5, the blown plastic film is glued, and the specific steps are as follows:

[0046] a. Gluing: After manually opening the upper cover of the glue tank 24, manually add glue to the glue tank 24. After the glue is added, the glue motor 23 rotates, thereby driving the glue roller 22 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com