Patents

Literature

197results about How to "Save glue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

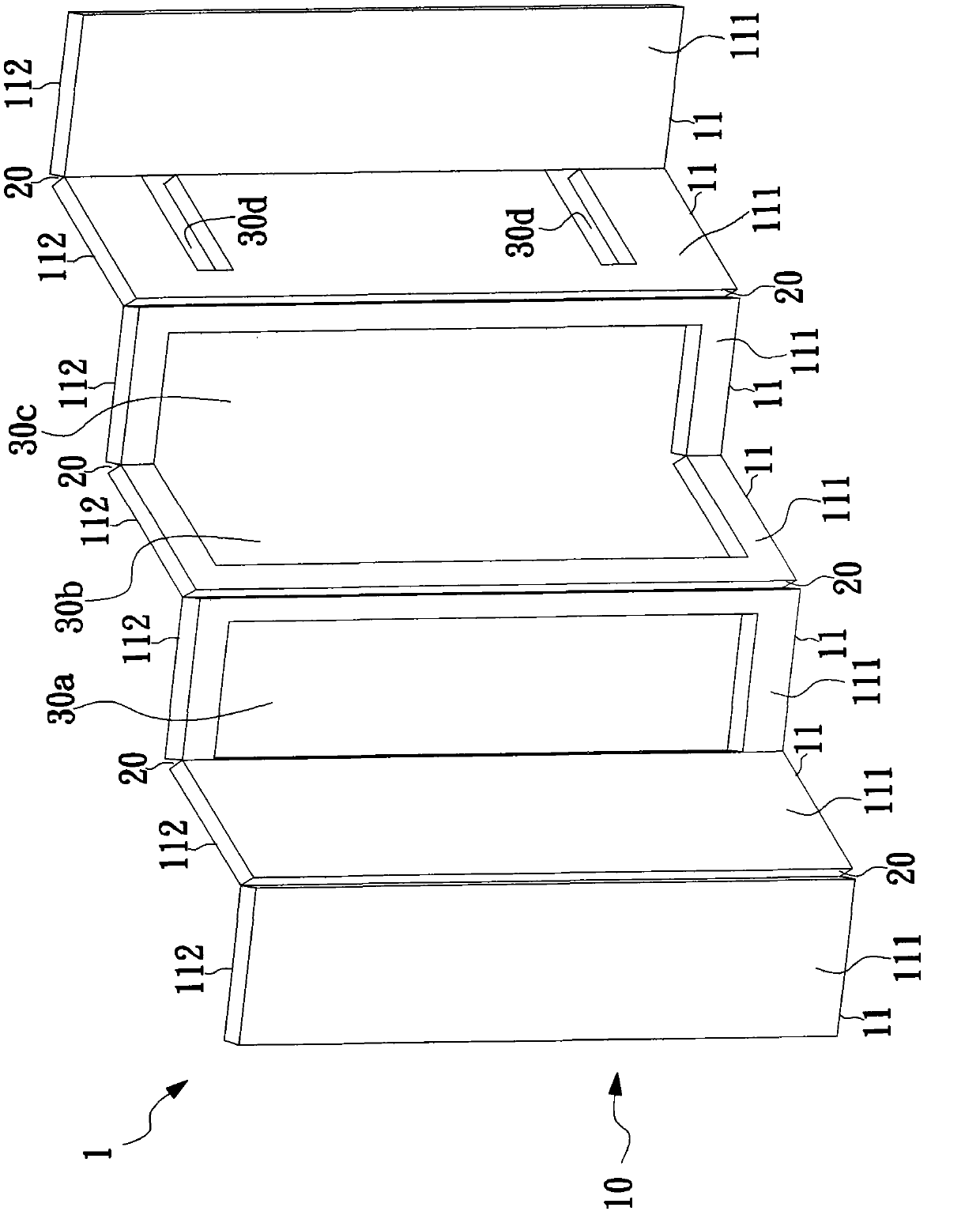

Wood multi-layer floor composed of cut-plate and veneer and method for making same

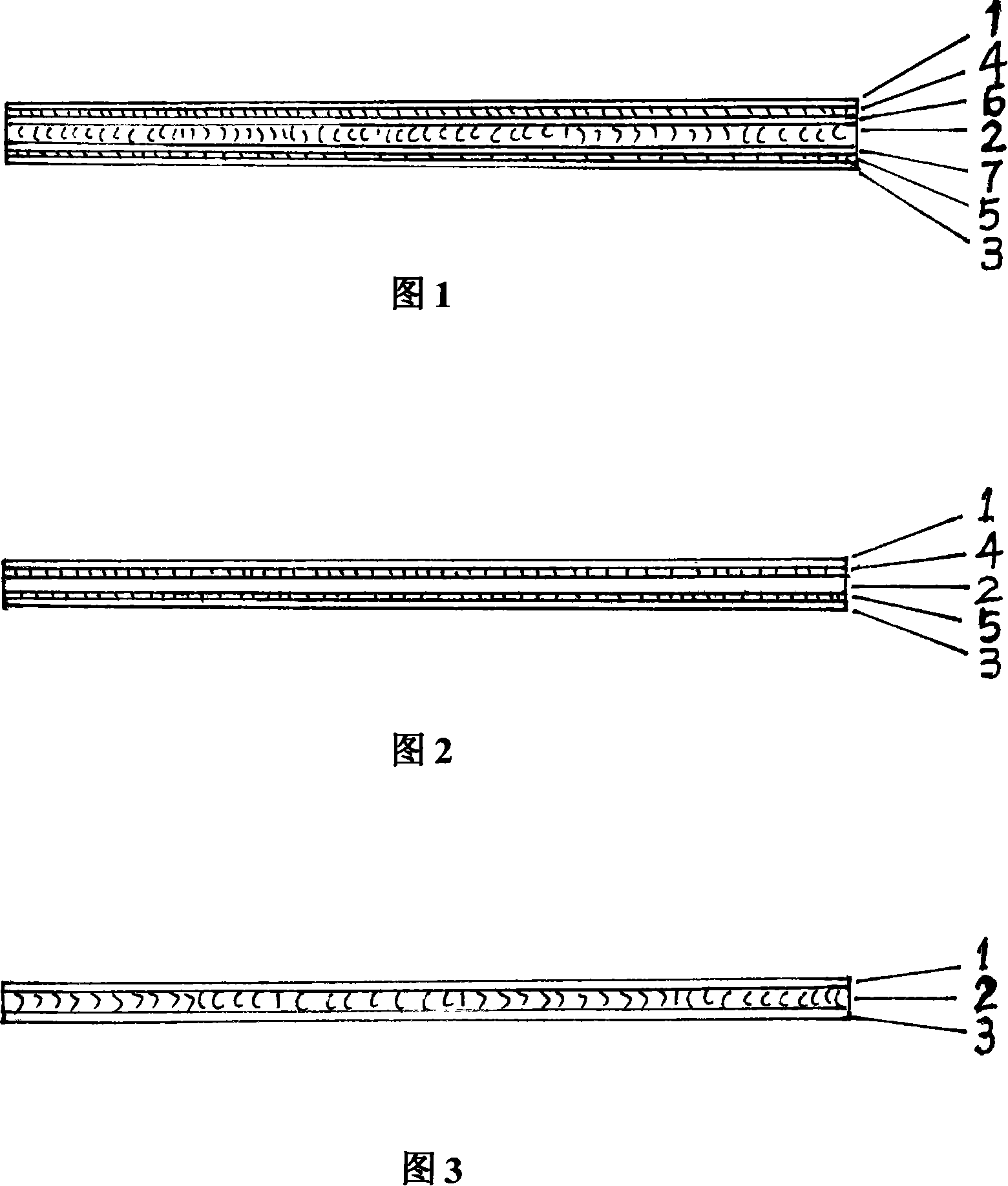

InactiveCN101139864ASave woodImprove product qualityWood working apparatusFlooringSolid woodSurface layer

The invention relates to a real-wood composite floor panel, which adopts a sheet-cut board with a sheet-cutting method as a core layer, a shave-cut single plate with a shave-cutting method as a surface layer, a rotary cut single plate with a rotary cutting method as a base layer, as well as all the other intermediate layers. The invention belongs to a real-wood composite floor panel, which is an artificial board in the industry of wood materials. The invention is characterized in that the core layer of the real-wood composite floor panel is a sheet-cut board that is produced with a sheet-cutting method; the surface layer of the real-wood composite floor panel is a shave-cut single-plate that is processed with a shave-cutting method; the base layer and all the other intermediate layers of the real-wood composite floor panel are rotary-cut single-plates produced with a rotary cutting method. The fabrication method is that the core layer of the real-wood composite floor panel is produced in a one-through mode covering adhesive coating, blank combination and glueing. The invention has advantages of perfect product quality, small deformation, needing no too much investment, saving wood materials, comprehensive utilization of wood materials and low cost. Except for pruducing real-wood composite floor panels, the invention can also be used to make such base material products as fine woodwork boards, real-wood doors and sheet-type furniture.

Owner:吴立忠

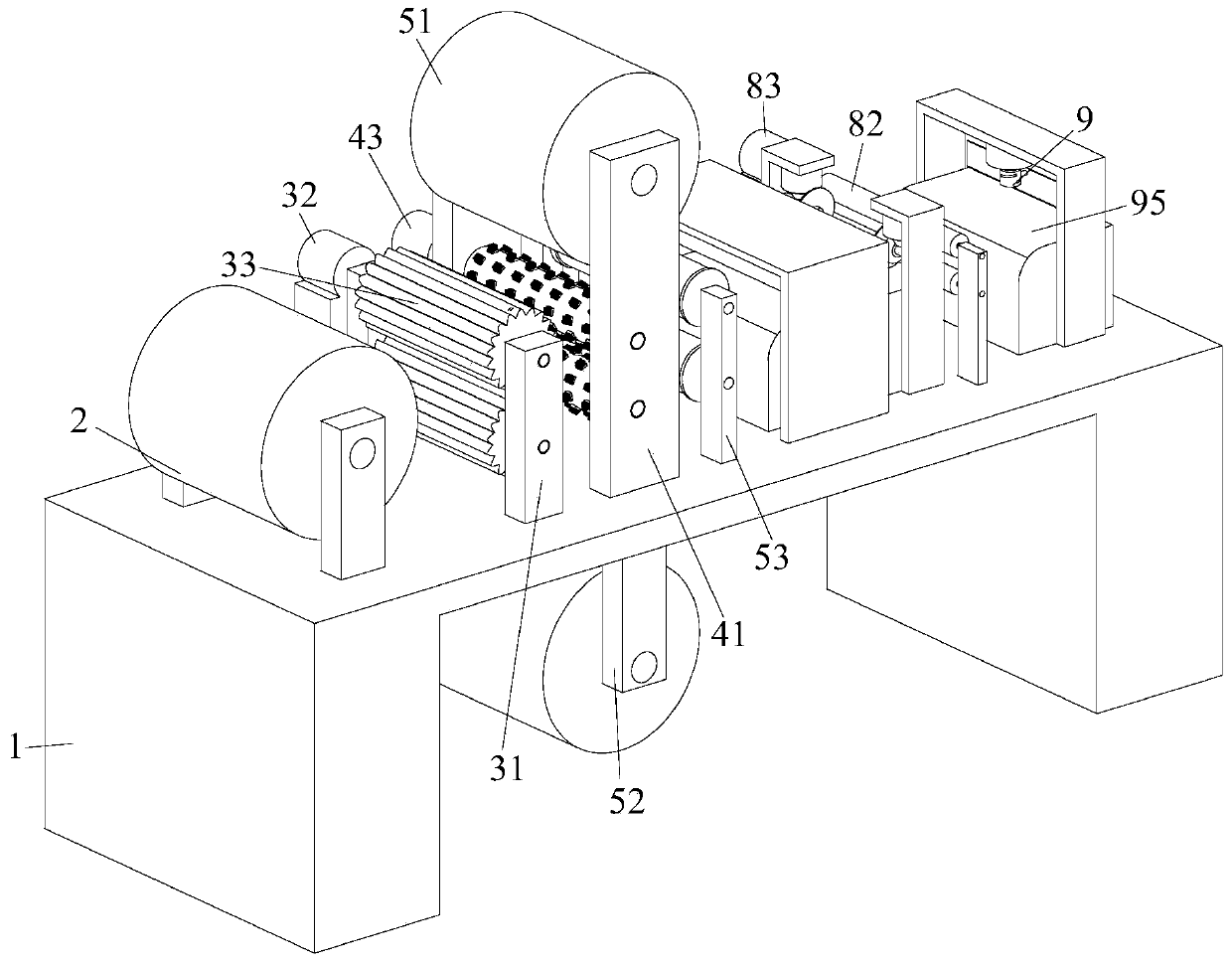

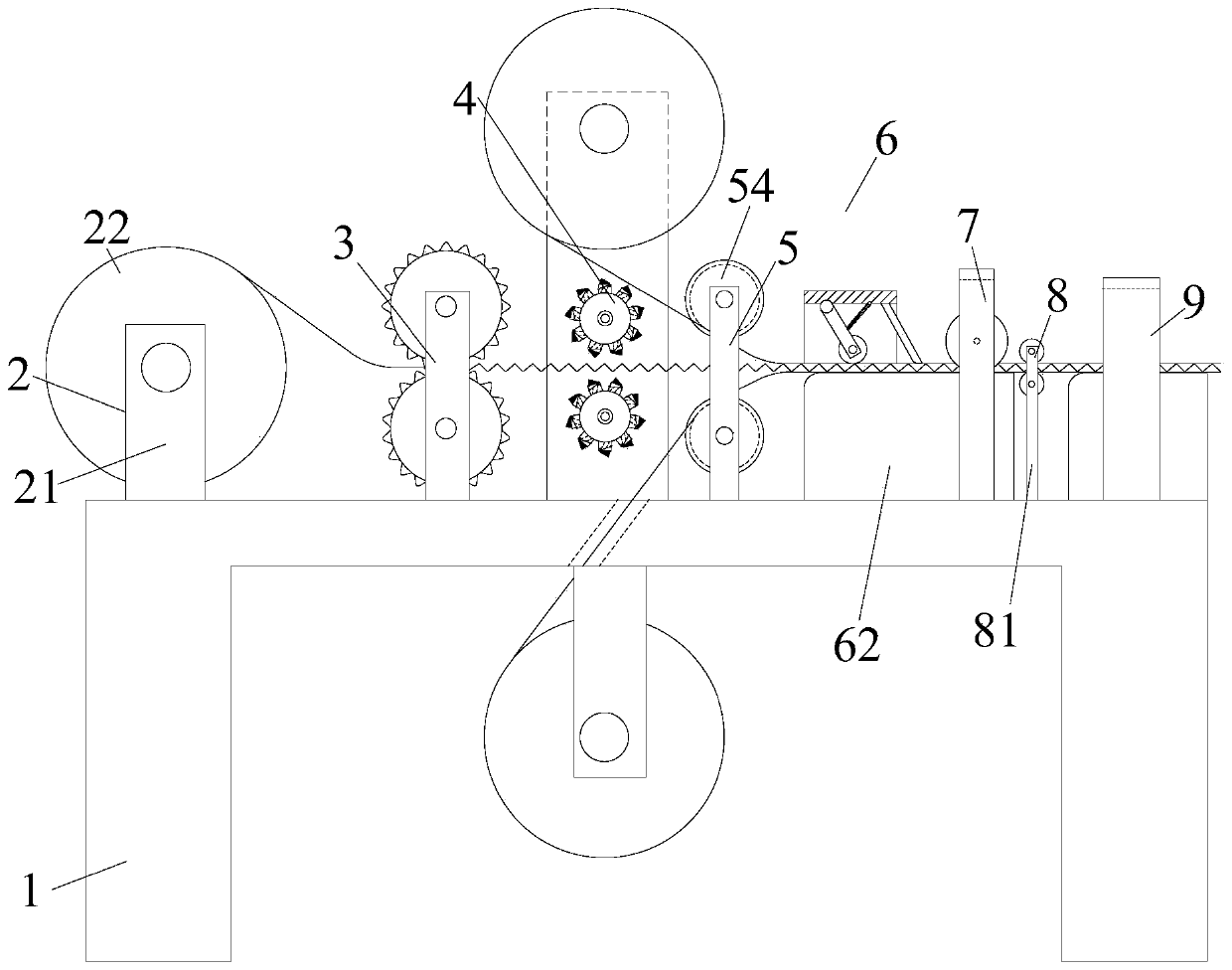

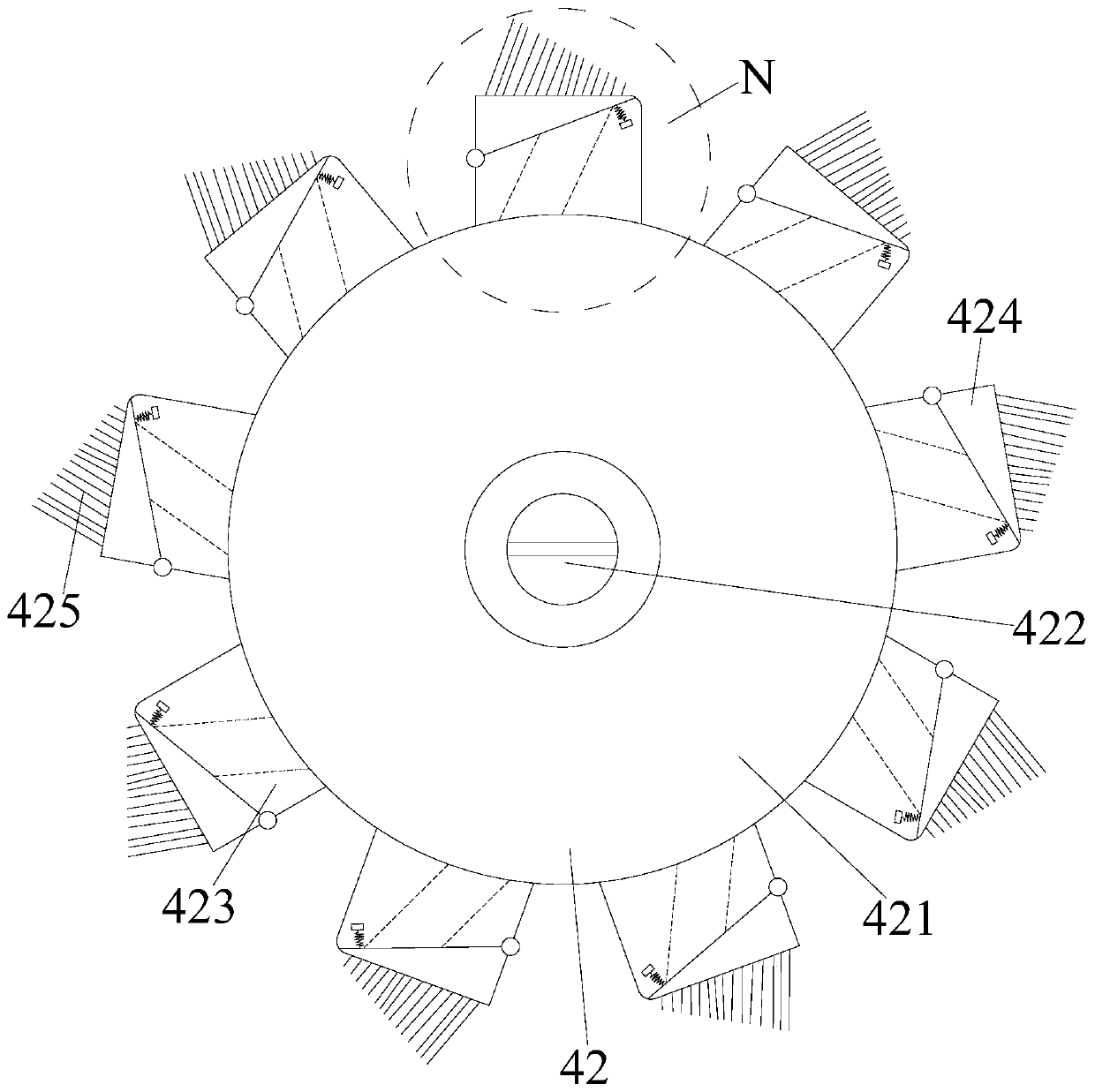

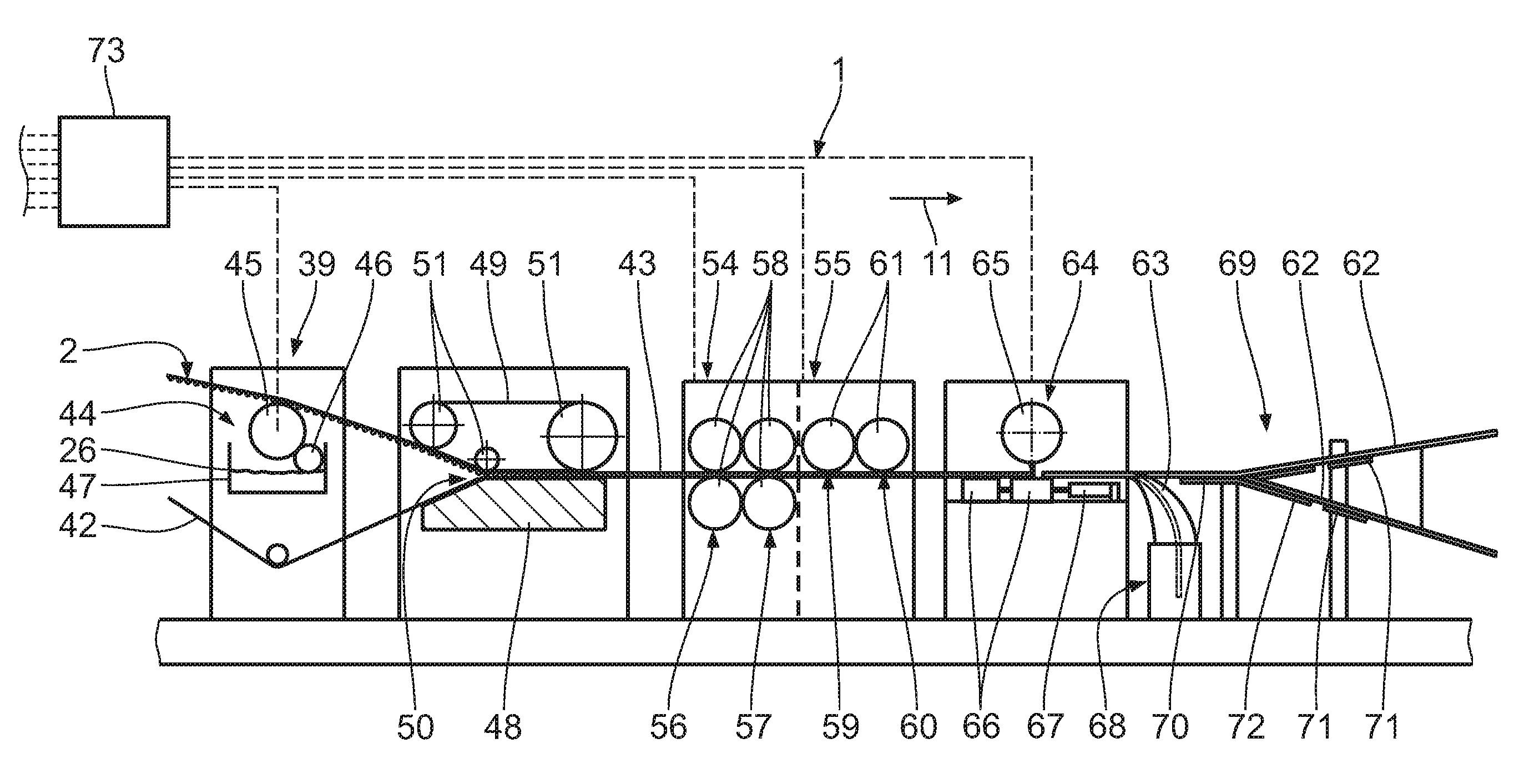

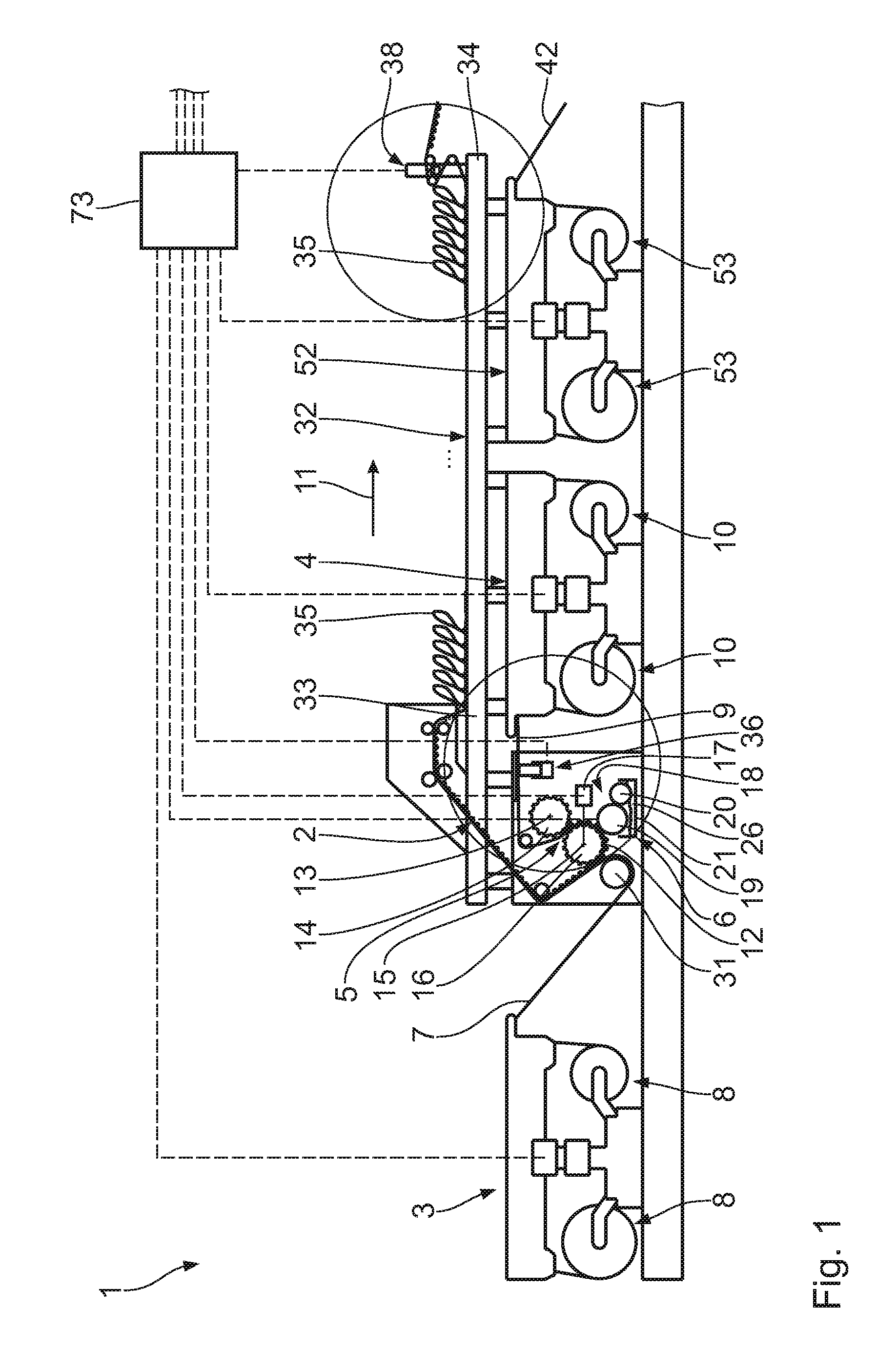

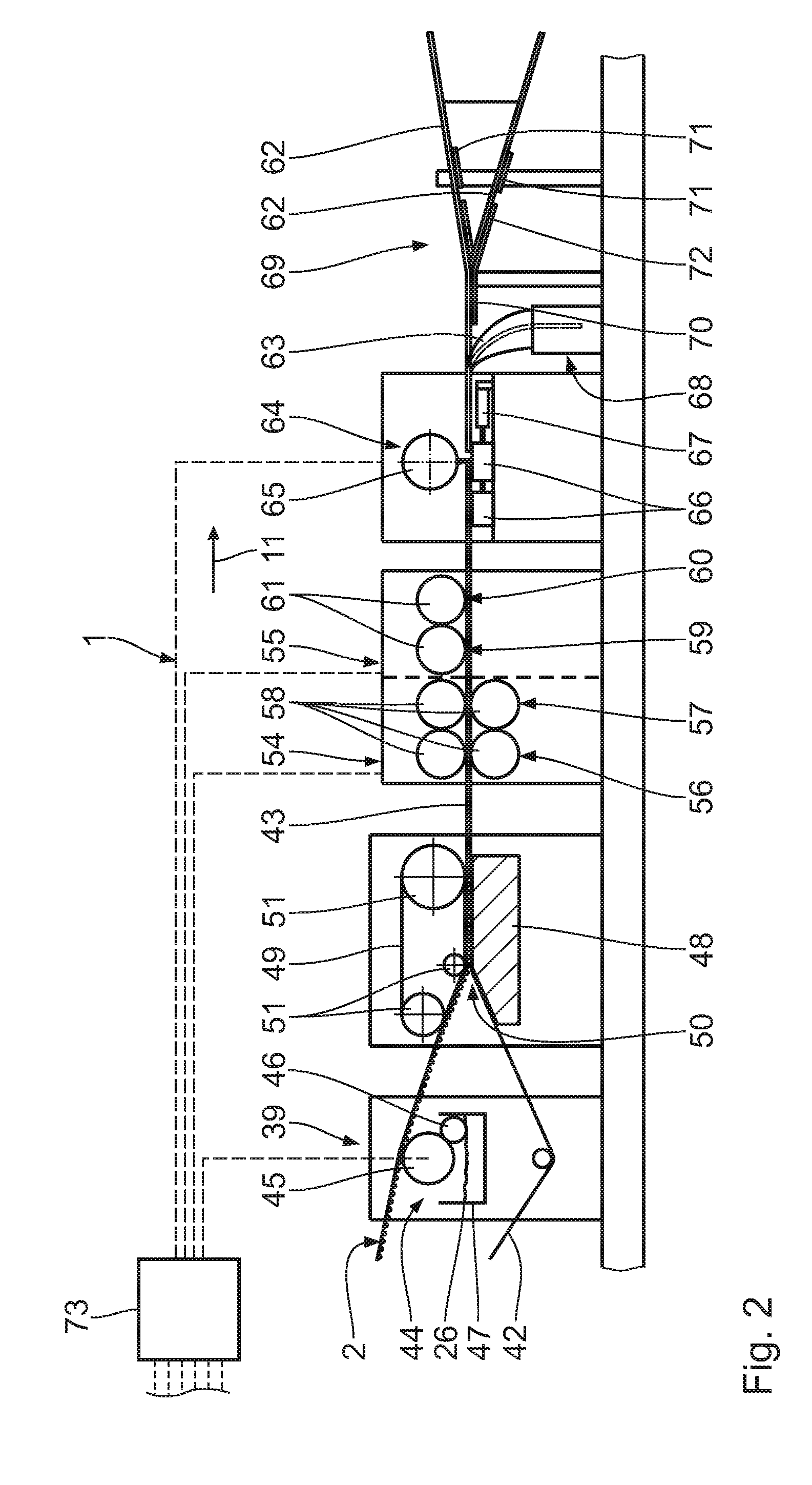

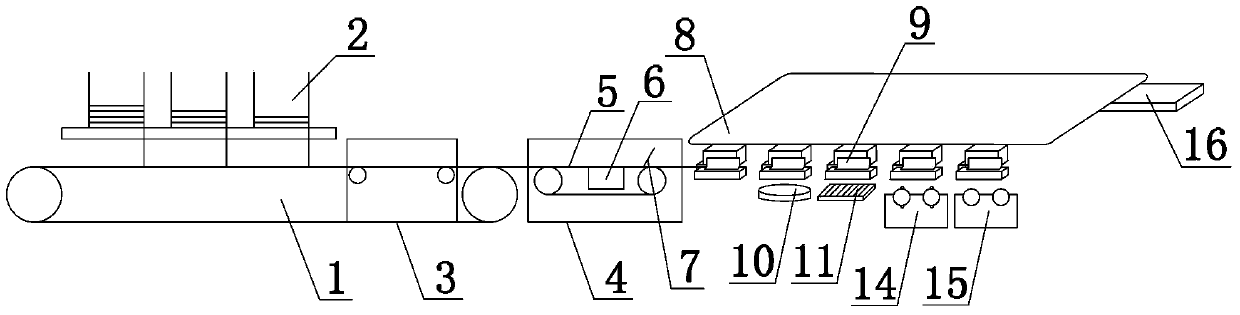

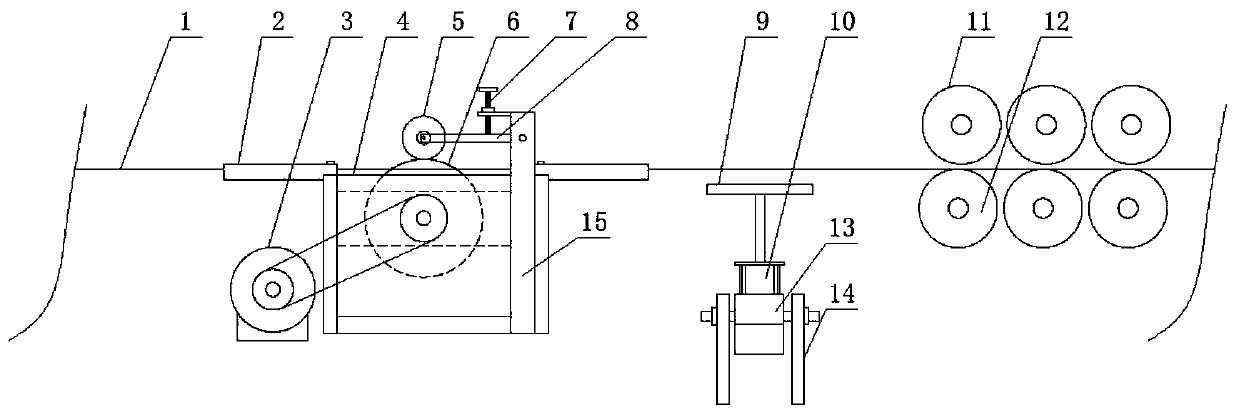

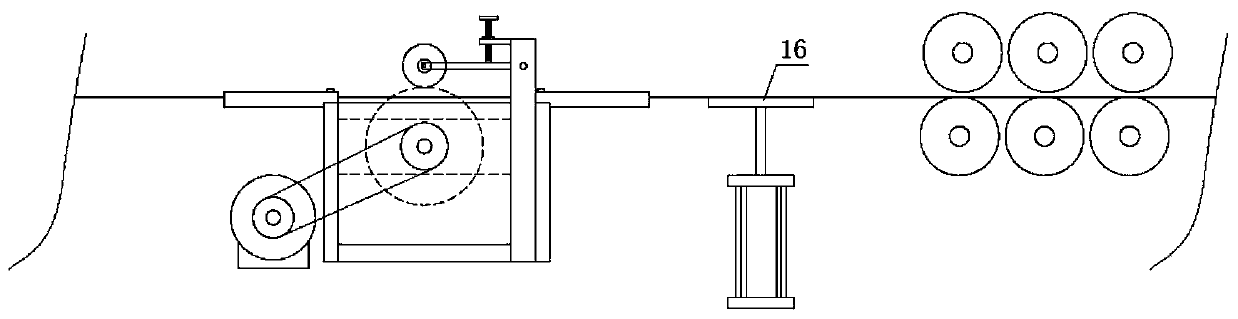

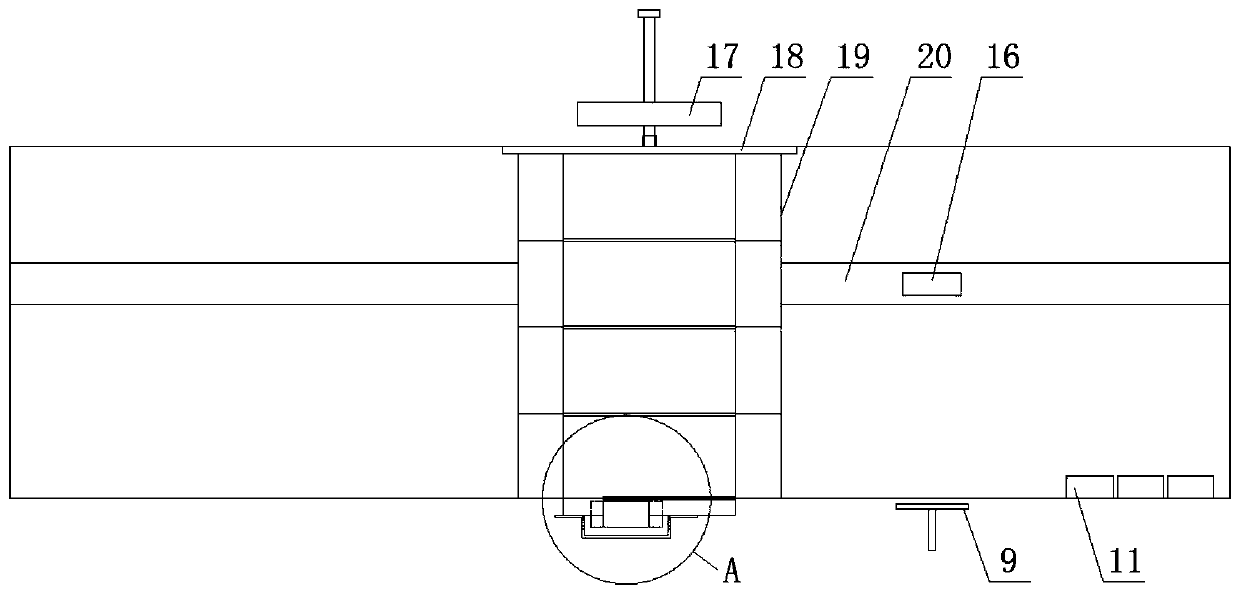

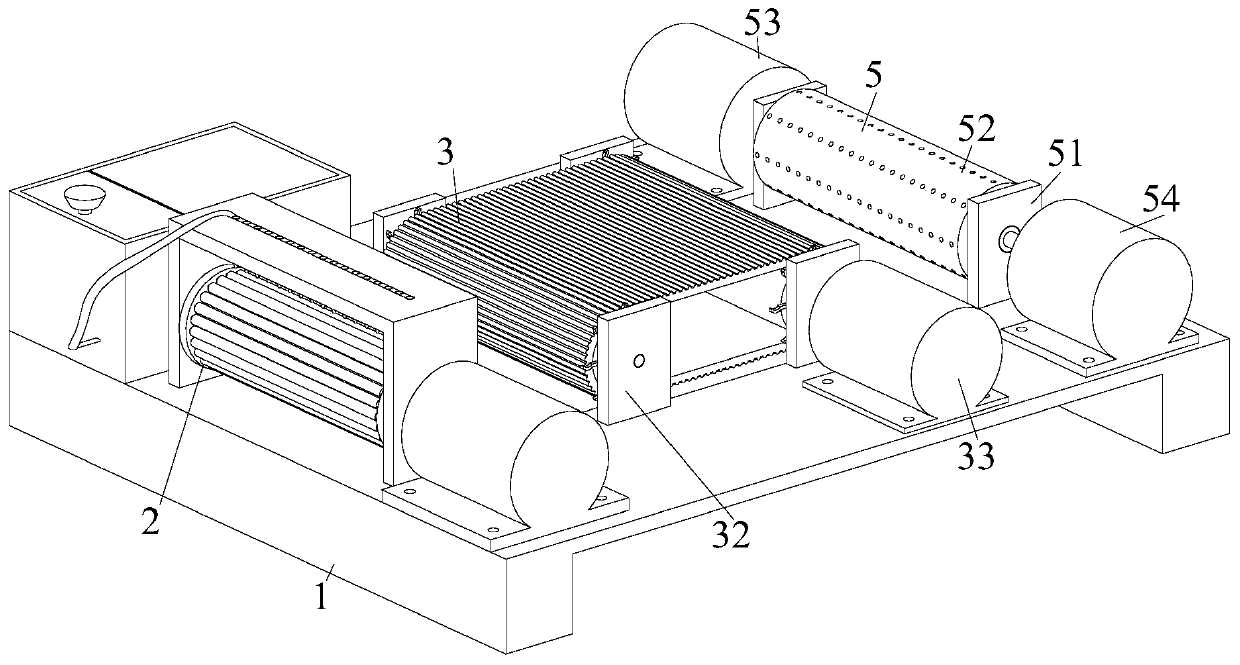

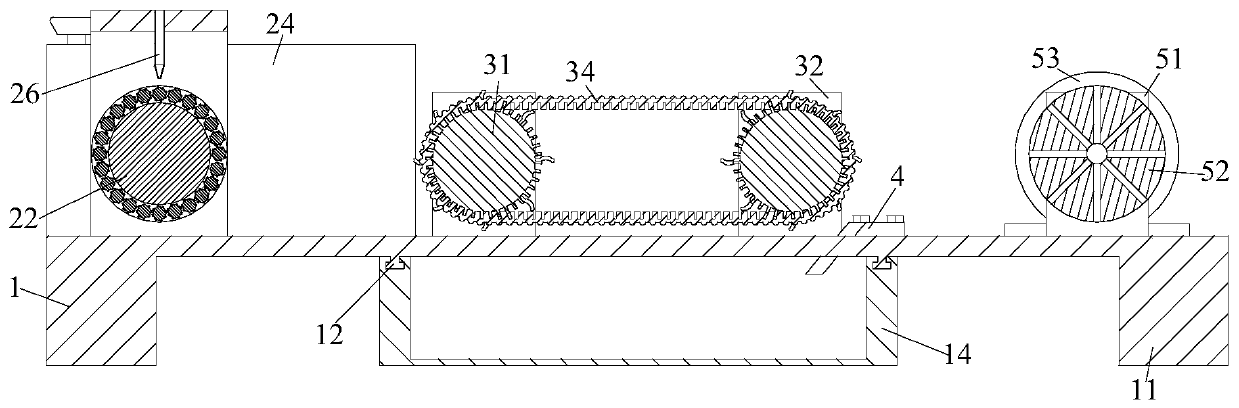

Corrugated paper forming and manufacturing system

ActiveCN110712394ASmooth paperUniform thicknessLiquid surface applicatorsMechanical working/deformationAdhesive glueMechanical engineering

The invention relates to a corrugated paper forming and manufacturing system which comprises a mounting table, a core paper bracket, an indentation device, a gluing device, a surface paper feeding device, a pressing device, two edge cutting devices, a traction device and a cutting device; and the mounting table is sequentially provided with the core paper bracket, the indentation device, the gluing device, the surface paper feeding device, the pressing device, the two edge cutting devices, the traction device and the cutting device from left to right. By adopting the corrugated paper forming and manufacturing system provided by the invention, the problems that the paper surface of corrugated paper processed by existing corrugated paper processing equipment is uneven, is inconsistent in thickness and has phenomena of wrinkles, cracks and holes as well as the problems that the processed corrugated paper is not closely attached to surface paper, a large quantity of glue is wasted, and themanufacturing cost is increased and the like are solved.

Owner:东莞市世昌智能制造科技有限公司

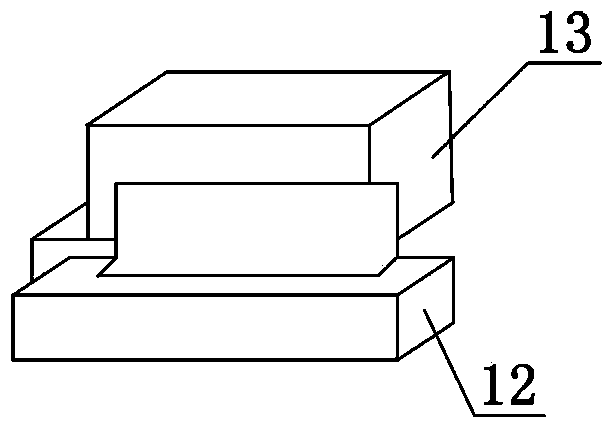

Miniature type surface mounting single-phase full-wave bridge rectifier and manufacturing method of rectifier

ActiveCN102931174ASave glueReduce thermal resistanceSemiconductor/solid-state device detailsSolid-state devicesFull waveSurface mounting

The invention discloses a miniature type surface mounting single-phase full-wave bridge rectifier and a manufacturing method of the rectifier. The miniature type surface mounting single-phase full-wave bridge rectifier is composed of a monolithic frame unit and a lower pin unit, wherein the monolithic frame unit and the lower pin unit comprise 5 components forming a rectification chip of a bridge rectifier circuit, namely, two input terminals as one group, two output terminals as one group, two connection jumpers as one group, four chips as one group and a plastic package body. In comparison with the prior art, the miniature type surface mounting single-phase full-wave bridge rectifier provided by the invention has the following advantages that the total thickness of the mechanism of the rectifier can be halved in comparison with the prior art, and simultaneously, the influence of the material cutting rigidity in the manufacturing procedure on the realized chips is completely eradicated; after the miniature type surface mounting single-phase full-wave bridge rectifier is welded on a PCB (Printed Circuit Board), the vertical distance and the transverse distance from the chips (heat source) to the welding spots on the PCB both are very short, consequentially, the thermal resistance between the chips and the welding spots is very low, so that the heat dissipation efficiency can be improved greatly, and the work of the rectifier can be more steady.

Owner:NANTONG HORNBY ELECTRONICS

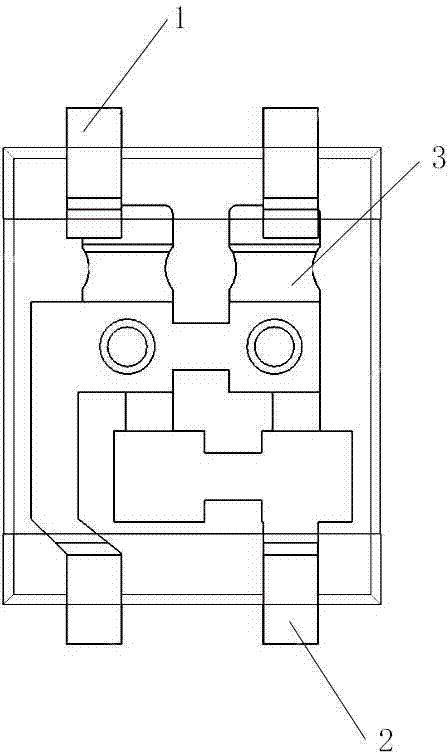

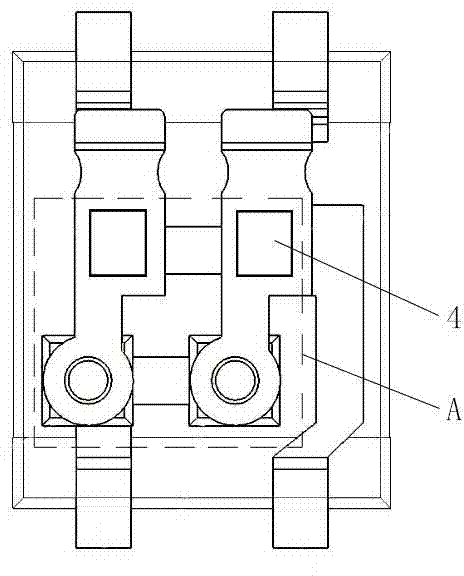

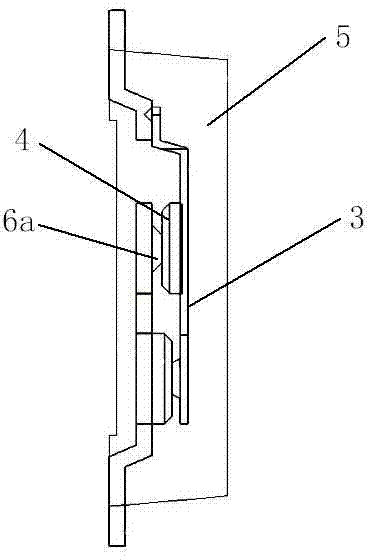

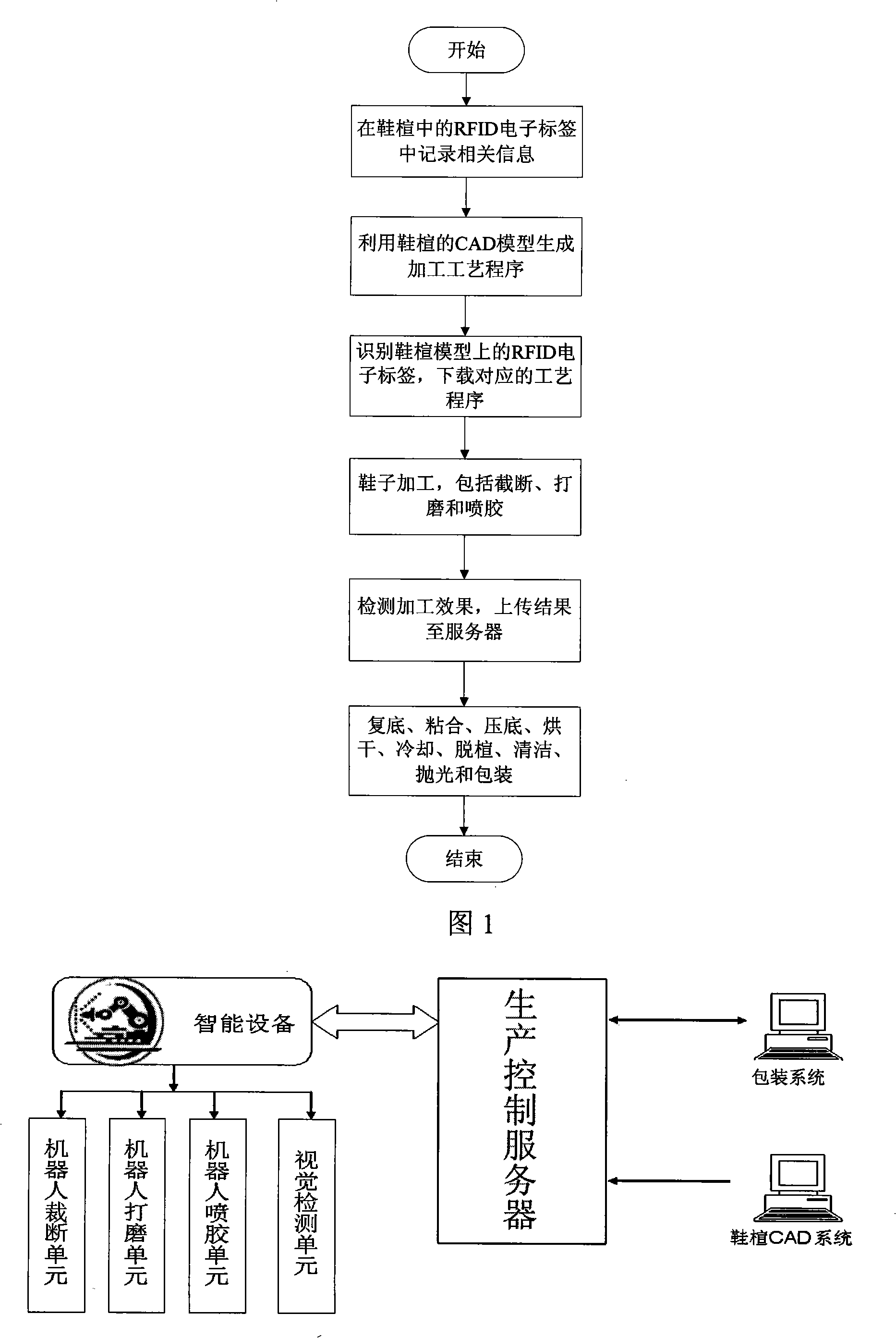

Information driven leather shoe preparation method

InactiveCN101286061AQuality improvementViscose stabilizedShoemaking devicesTotal factory controlProduction lineEngineering

The invention discloses a leather shoe fabrication method driven by information. In the method, an RFID electronic label is embedded in a shoe tree and taken as a sign; furthermore, processing state is recorded; the shoe tree CAD model analysis software is used to extract the required structural geometrical parameters from the shoe tree CAD model; the subsequent processing program is generated; the structural geometrical parameters are then uploaded to a server and shared by various intelligent devices on the production line; when the shoe trees are delivered to various intelligent devices on the production line, after all intelligent devices recognise the RFID electronic labels, the intelligent devices download corresponding processing programs from the server and carry out the processing. The leather shoe fabrication method has the advantages that the processing program is generated by the shoe tree CAD model information, the intelligentization level of the shoe fabrication is improved, the participation of manpower is reduced, and the reliability of the quality is improved.

Owner:ZHEJIANG SCI-TECH UNIV

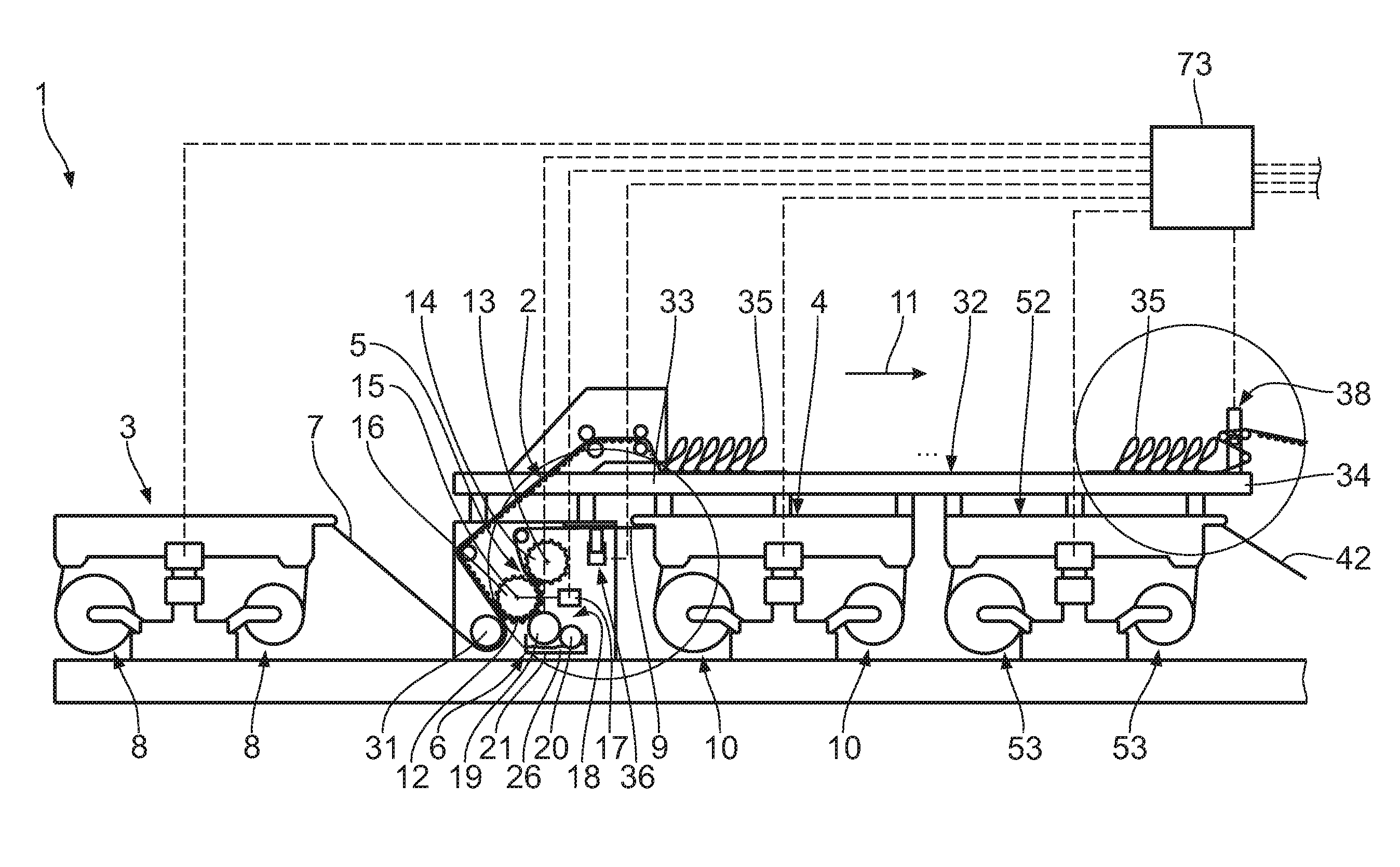

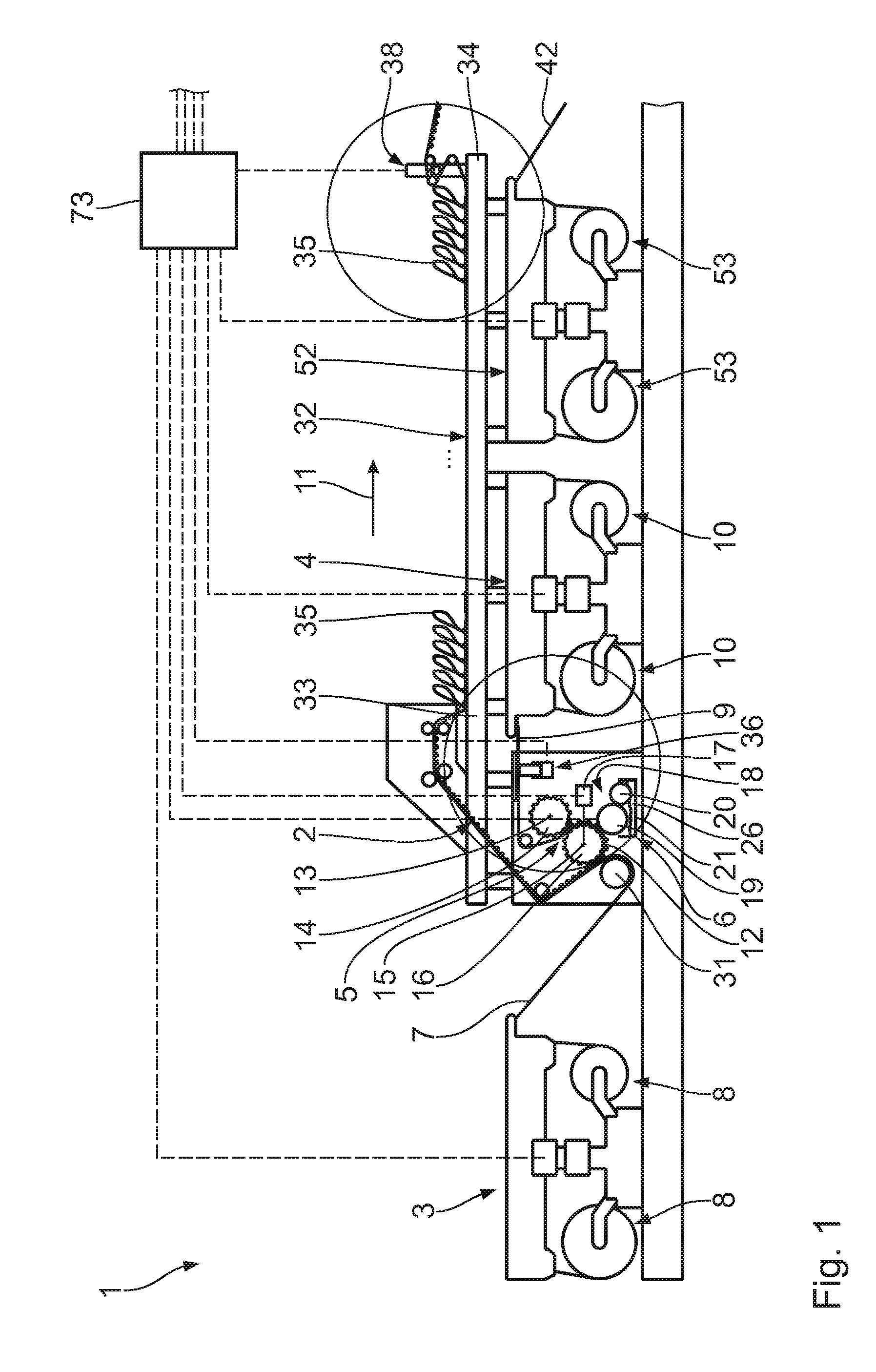

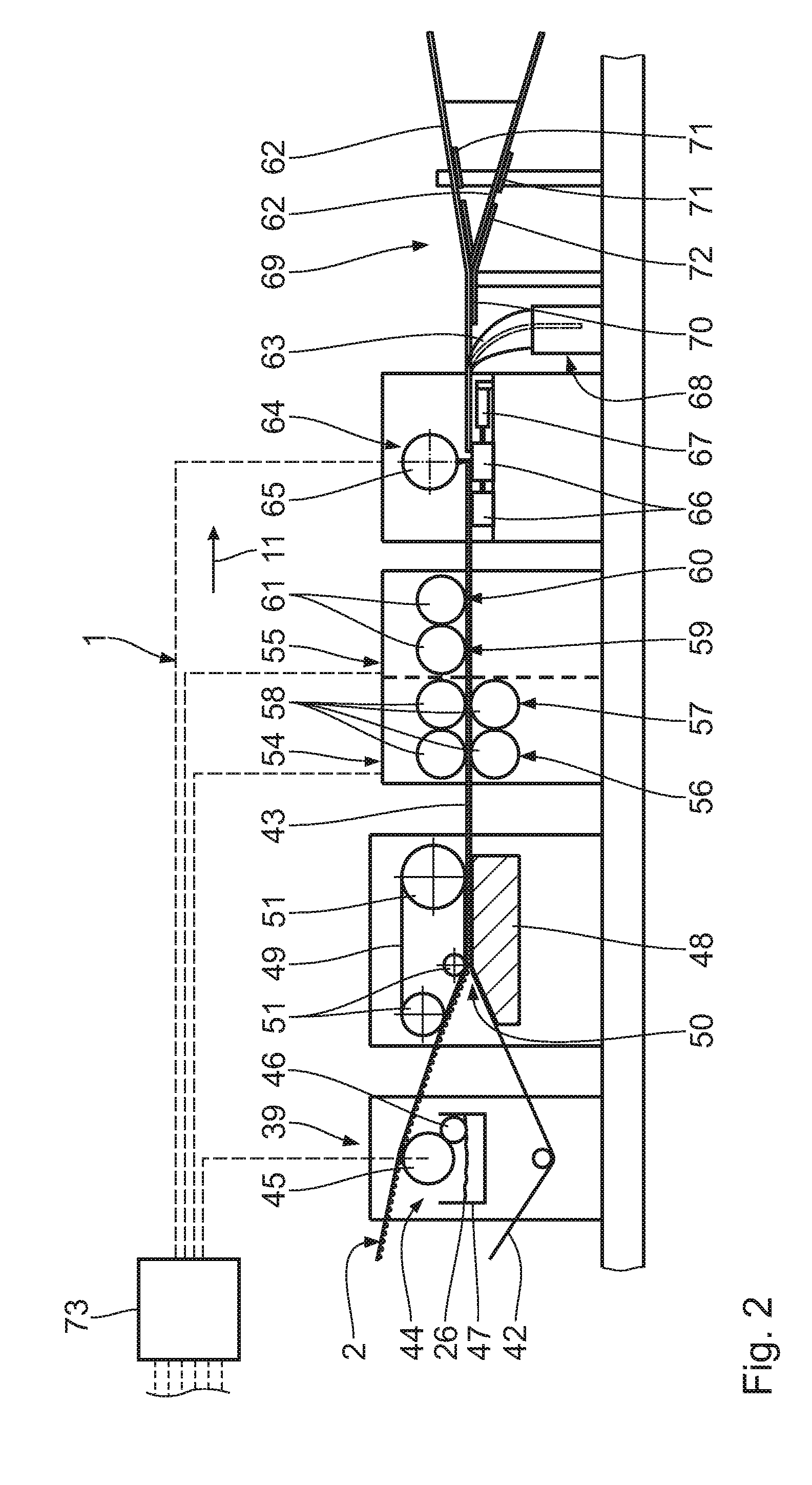

Corrugated cardboard machine and method of producing an endless web of corrugated cardboard

InactiveUS20090120563A1Downtime of the corrugated cardboard machine andReduce consumptionMechanical working/deformationLamination ancillary operationsCardboardEngineering

In a corrugated cardboard machine and in a method of producing a web of corrugated cardboard, an electronic control device is provided in order to avoid downtimes of the corrugated cardboard machine, said control device being designed such that at least one web length of the web of corrugated cardboard between the at least one production device and a longitudinal cutting device is detectable and an application width of the at least one production device is variable in dependence on the at least one web length. Changing the application width prevents an escape of glue from the sides so that there is no need for cleaning.

Owner:BHS CORRUGATED MASCHEN & ANLAGENBAU

Method and production device for preparing graphene micro-plate pre-dispersion master batch

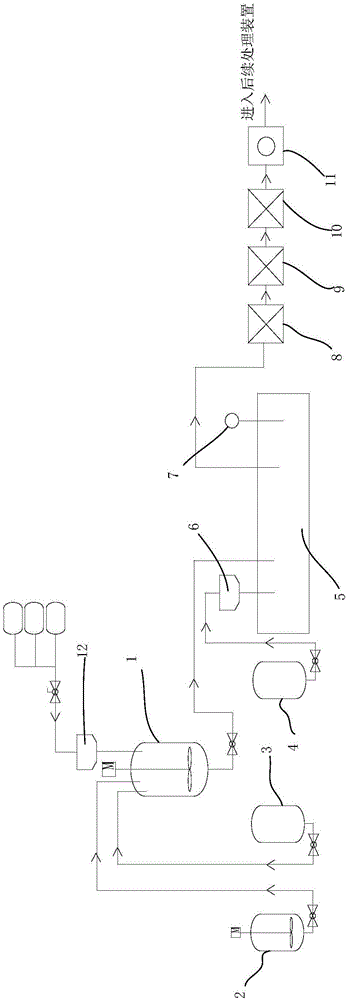

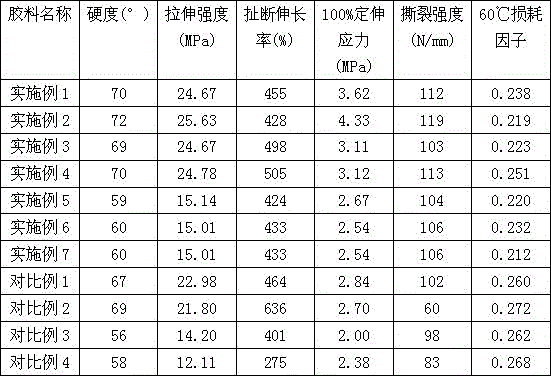

The invention relates to the technical field of technologies for processing rubber, in particular to a method and a production device for preparing graphene micro-plate pre-dispersion master batch. The method includes stirring and mixing graphene micro-plate dispersion liquid and latex with each other by the aid of a high-speed stirring machine to obtain mixed materials, adding flocculating agents into the mixed materials and coagulating the mixed materials to obtain pulp; dehydrating and drying the pulp to obtain the master batch. The method and the production device have the advantages that technologies are simple, the method and the production device are safe in operation, the graphene micro-plate pre-dispersion master batch can be continuously produced on a large scale, and the production efficiency can be improved as compared with original preparation technologies by the aid of batch processes; graphene micro-plates in the master batch prepared by the aid of the method can be highly dispersed as compared with melt processing methods; quick mixing and condensation can be implemented as compared with previous methods, drying and dehydrating phases are combined with squeezing drying and oven-drying modes, accordingly, the drying time can be shortened, rubber materials can be prevented from being aged, and the graphene micro-plate pre-dispersion master batch with excellent performance can be prepared by the aid of the method and the production device.

Owner:青岛蓝湾烯碳材料科技有限责任公司

Controlling method for wrapping surface of tire

InactiveCN101625557AGood smoothnessImprove vulcanization effectProgramme control in sequence/logic controllersLine segmentEngineering

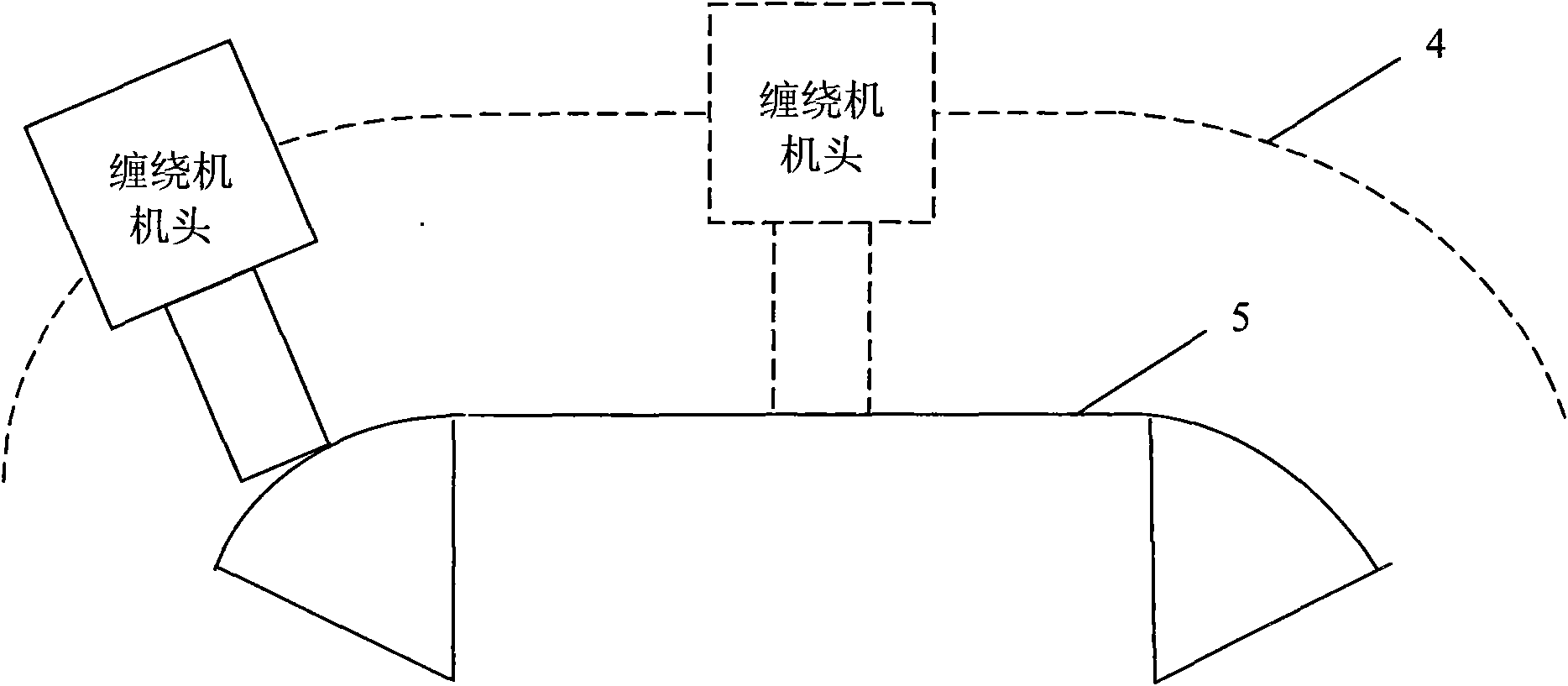

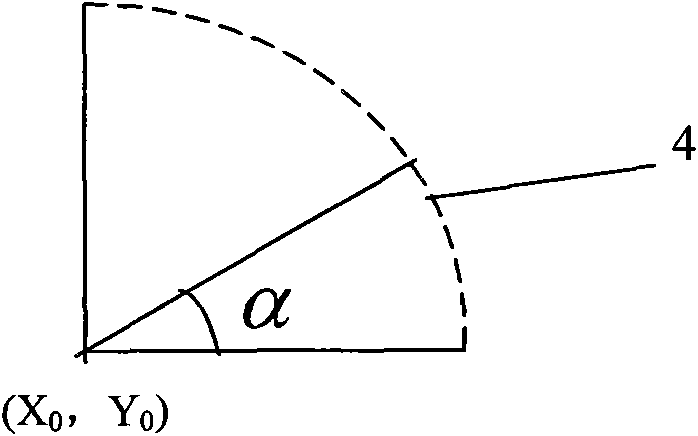

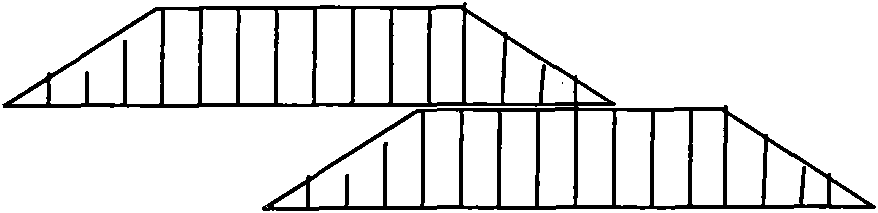

The invention provides a controlling method for wrapping the surface of a tire, comprising the following steps: an industrial personal computer (IPC) analog simulates the deformation of rubber pieces in the process of spire piling and the arrangement distribution situation of the each rubber piece in the surface of the tire to obtain spire pitches among each rubber piece; the IPC computes the virtual circle central coordinate and the radius of a wrapper at each loop of the arc of the surface of the tire, and sends a date to a PLC; the IPC respectively computes the arc of the each loop of the arc section of the surface of the tire, the horizontal coordinate of the each loop of the linear section of the surface of the tire and a corresponding theoretical velocity, to form a data table to be sent to the PLC; the PLC computes the real velocity of the wrapper according to the received data table; and the PLC computes to obtain a track coordinate data of the wrapper corresponding at the each loop and finally controls the wrapper to wrap the surface of the tire. The method realizes analog simulation in the process of wrapping the surface of the tire, adjusts the walk track and the walk velocity of the head of the wrapper immediately, and greatly improves the wrapping quality of the surface of the tire.

Owner:柳州市华工百川橡塑科技有限公司

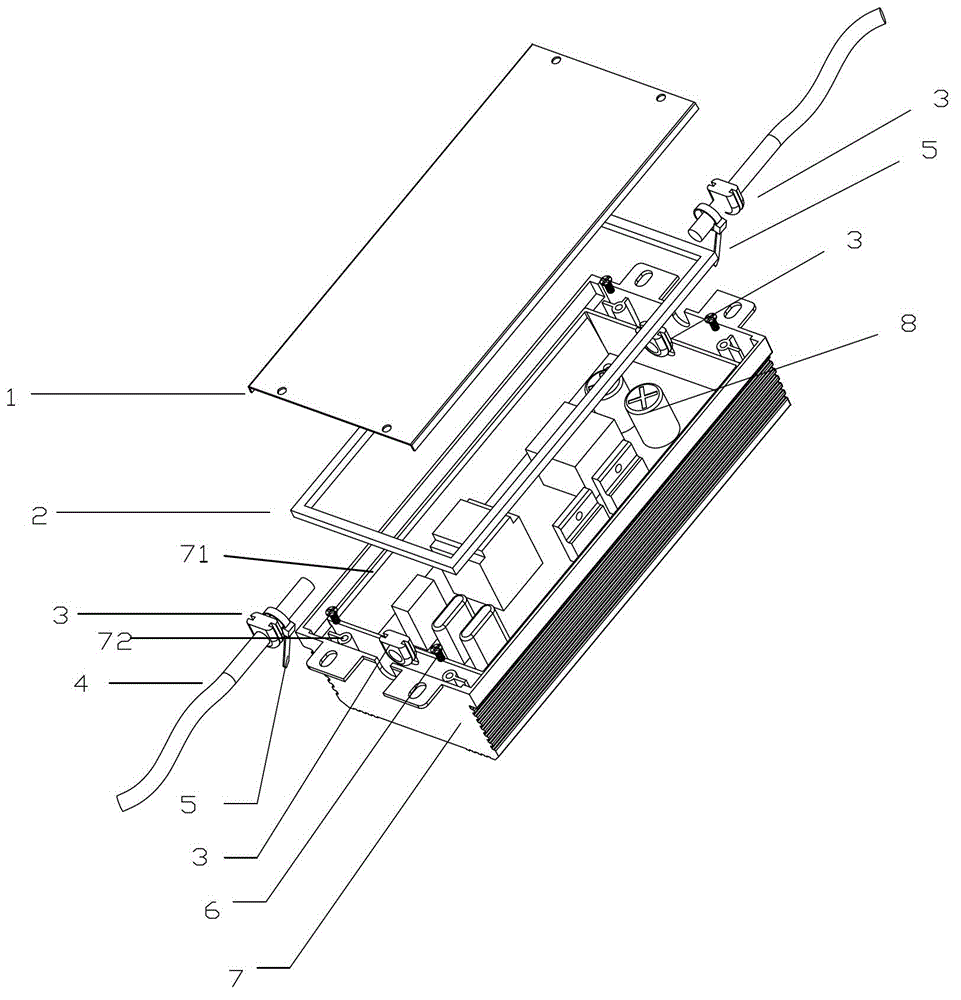

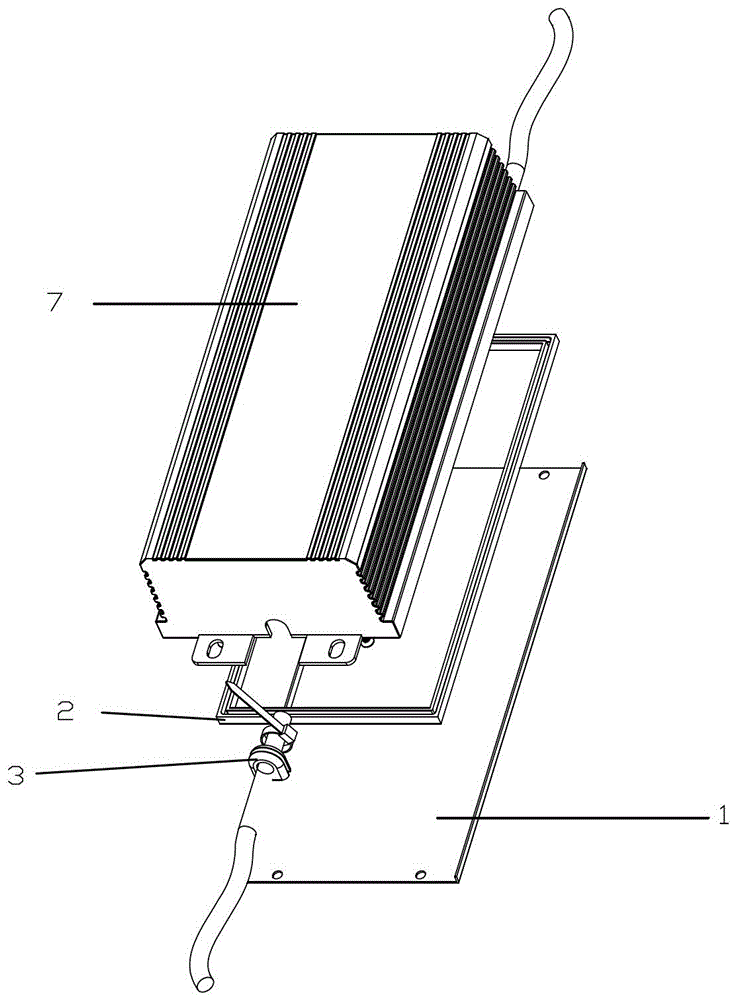

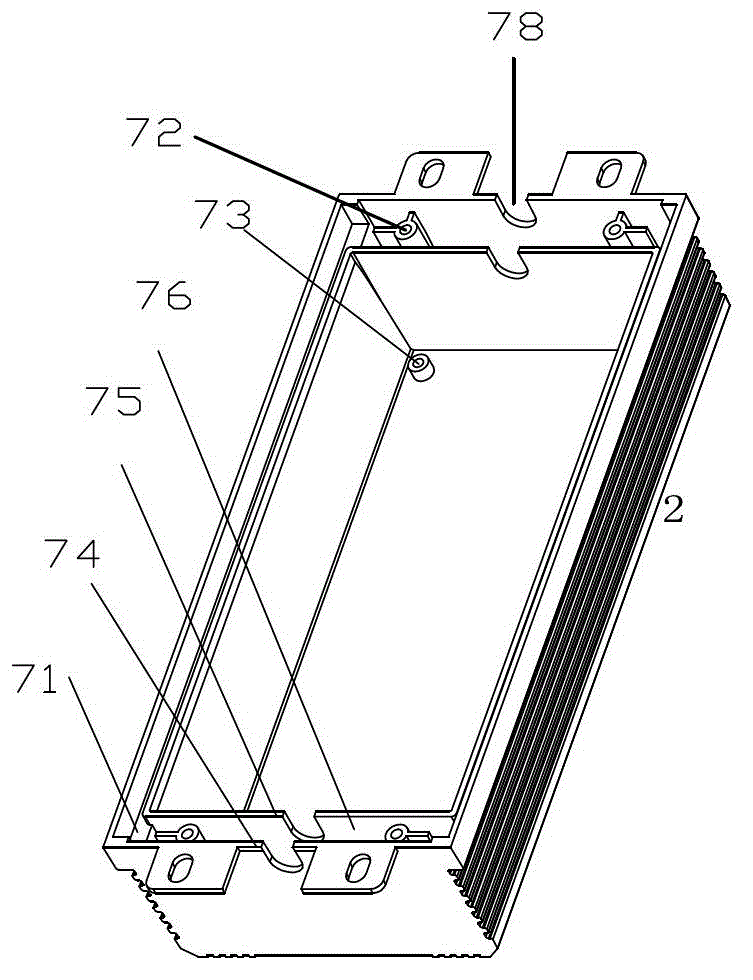

LED sealing power supply and sealing method thereof

InactiveCN102984905AReduce weightEasy maintenancePoint-like light sourceGas-tight/water-tight arrangementsWire rodRubber ring

The invention discloses an LED (Light-Emitting Diode) sealing power supply, which comprises a cover board, a rubber ring, wire protection rings, wire rods, ribbons, cover board screws, a shell and an internal power supply component, wherein the shell adopts a same-bottom double-layer structure, and the double-layer structure comprises an outer layer and an inner layer isolated from the outer layer; wire protection ring necks are formed on the outer layer and the inner layer, and a groove is formed between the inner layer and the outer layer; a boss and a fixed seat are arranged in the groove; the wire protection rings penetrate through the wire rods and are tightened through the ribbons, and the wire robs are welded on a PCB (Printed Circuit Board) positioned on the inner layer; the internal power supply component is also welded on the PCB; the wire protection rings are clamped into the wire protection ring necks on the shell; the rubber ring is installed on the boss of the shell; and the cover board seals the PCB on the inner layer and the internal power supply component through the cover board screws and the fixed seat.

Owner:MOSO POWER SUPPLY TECH

Corrugated cardboard machine and method of producing an endless web of corrugated cardboard

InactiveUS7832441B2Downtime of the corrugated cardboard machine andReduce consumptionMechanical working/deformationLamination ancillary operationsCardboardEngineering

In a corrugated cardboard machine and in a method of producing a web of corrugated cardboard, an electronic control device is provided in order to avoid downtimes of the corrugated cardboard machine, said control device being designed such that at least one web length of the web of corrugated cardboard between the at least one production device and a longitudinal cutting device is detectable and an application width of the at least one production device is variable in dependence on the at least one web length. Changing the application width prevents an escape of glue from the sides so that there is no need for cleaning.

Owner:BHS CORRUGATED MASCHEN & ANLAGENBAU

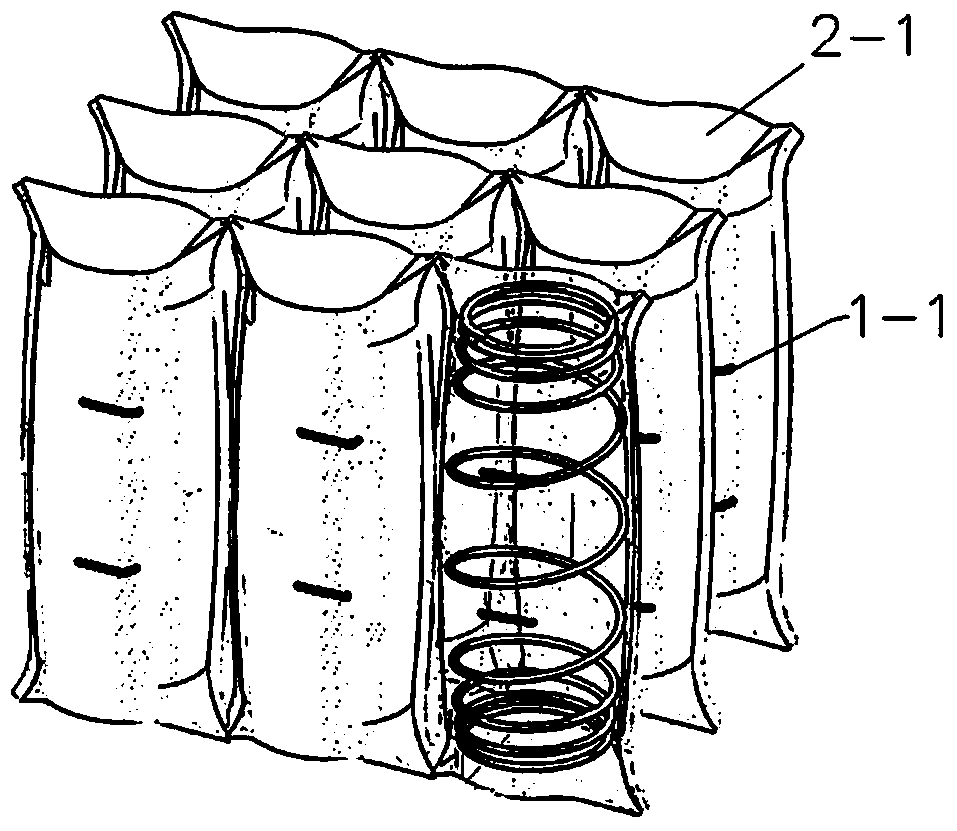

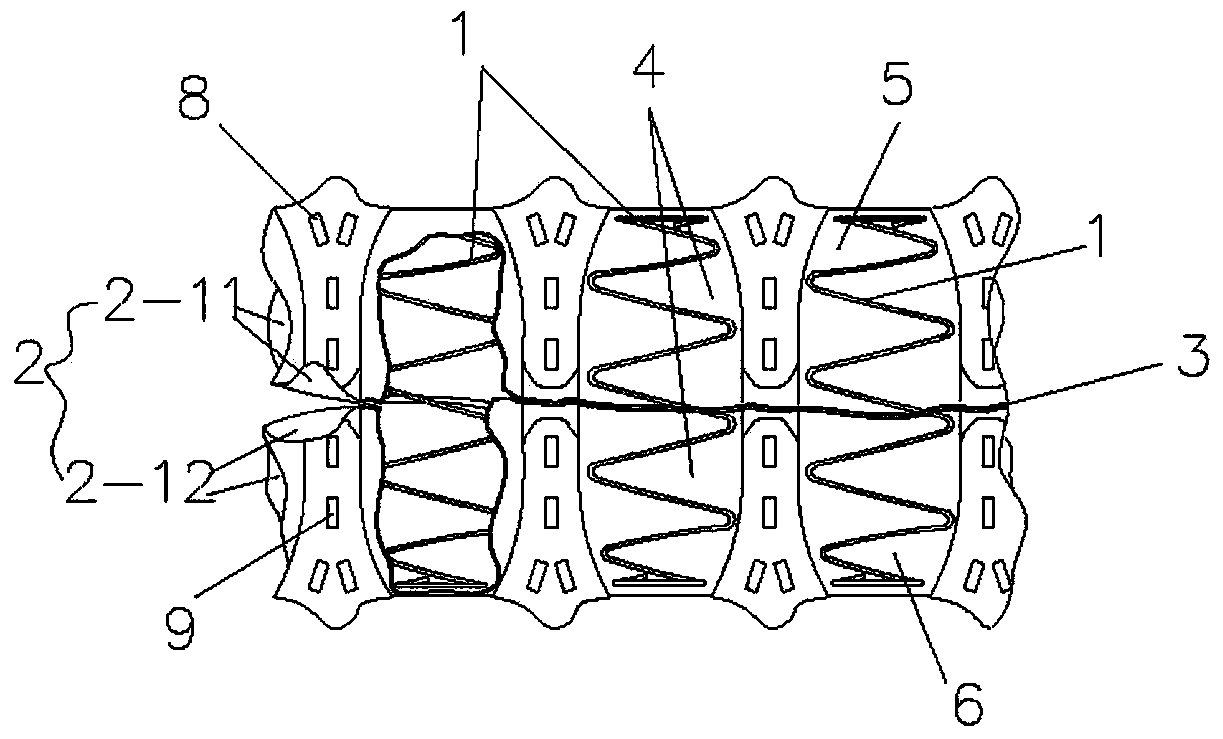

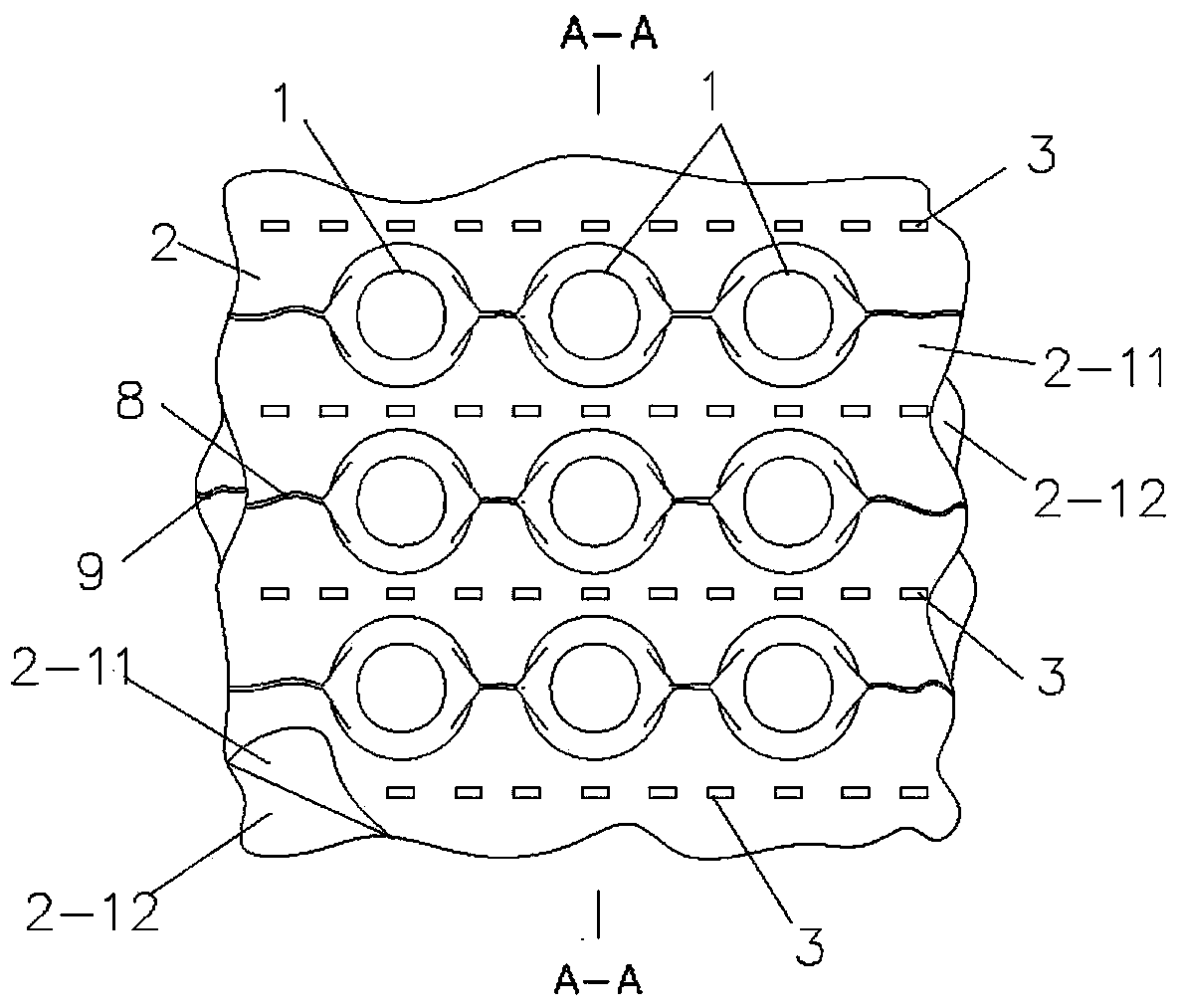

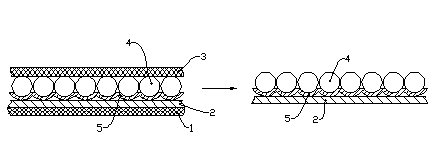

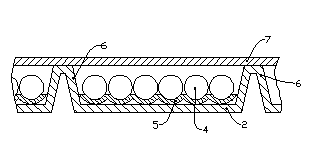

Integral covered bagged spring cushion

InactiveCN103653964ASimple structureNo bonding process requiredStuffed mattressesSpring mattressesCoil spring

The invention belongs to an integral covered bagged spring cushion comprising a plurality of spiral spring rows and two layers of seaming cloth, wherein seams of the two layers of seaming cloth are distributed between every two adjacent spiral spring rows; an upper separating seam of an upper cover body formed by the upper layer of cloth is distributed among individual springs of the spiral spring rows; a lower separating seam of a lower cover body formed by the lower layer of cloth is distributed among the individual springs of the spiral spring rows; and the individual springs of the plurality of spiral spring rows are distributed in a bag body seamed by the upper cover body formed by the upper layer of cloth and the lower cover body formed by the lower layer of cloth. The integral covered bagged spring cushion is simple in structure, low in cost, more environment-friendly, comfortable in use and durable.

Owner:GUANGZHOU LIANROU MACHINERY & EQUIP

Transformer shell gluing device and gluing method with same

Owner:CHINA AEROSPACE TIMES ELECTRONICS CORP

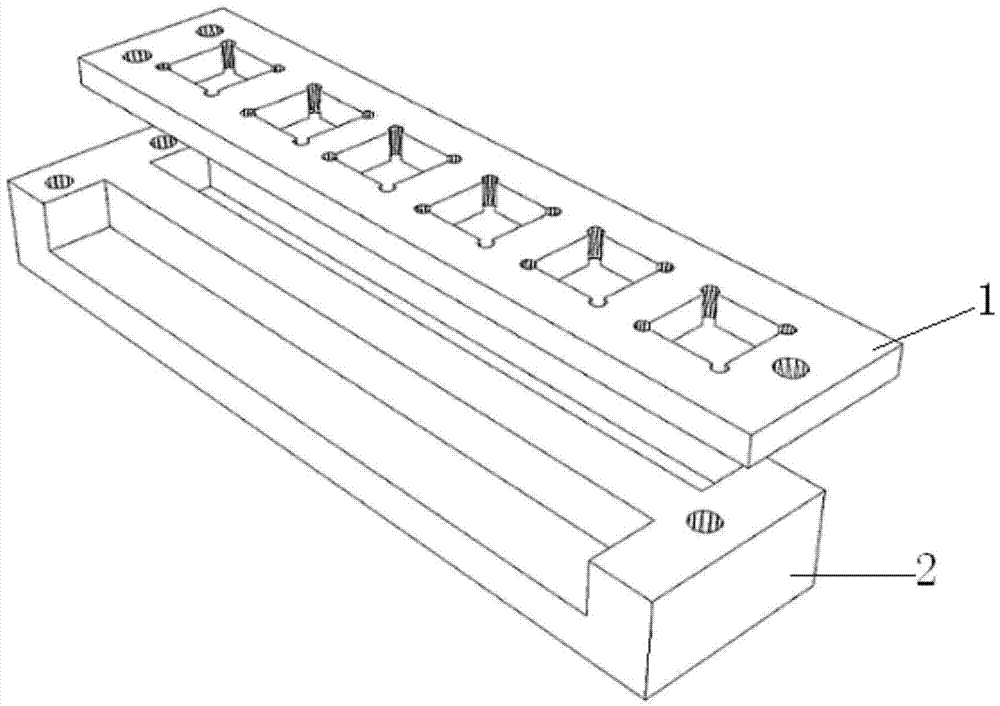

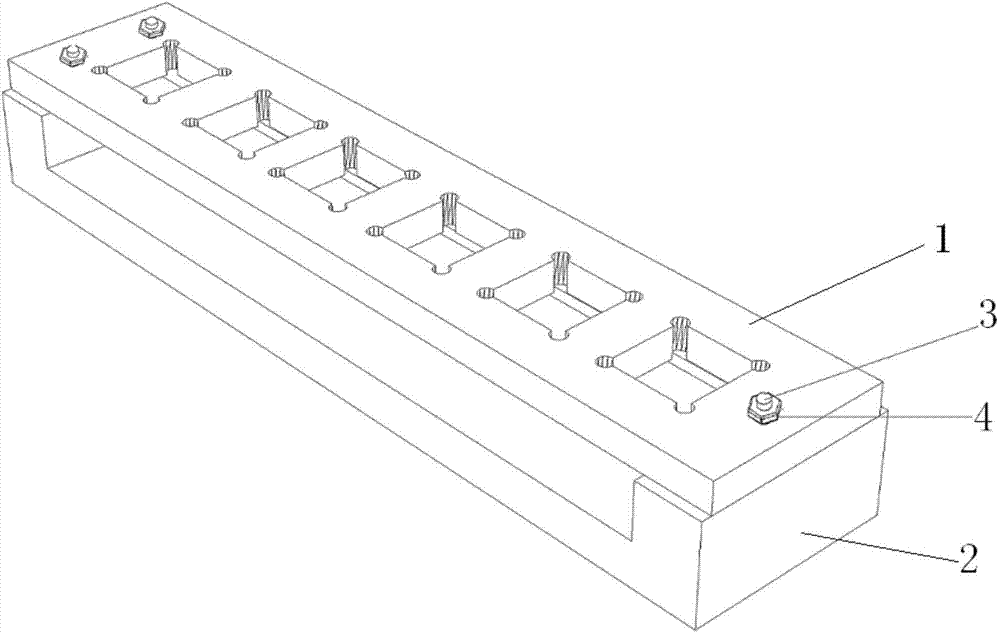

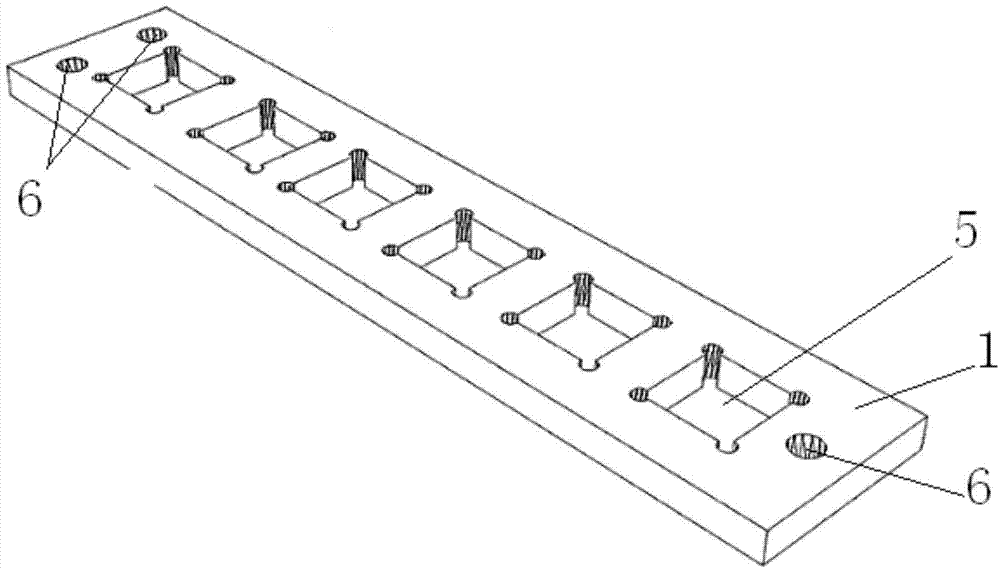

Method and special fixture for compensating UV gum in Mobile telephone CCD camera assembling process

InactiveCN101140345ASave glueReduce the amount of reworkTelevision system detailsColor television detailsCamera lensCcd camera

The present invention discloses a method and a special clamping fixture for UV glue repair in the process of mobile phone camera assembling. Wherein, the method includes steps below: (1) Spreading UV glue between a lens base and a flexible printed circuit board; (2) Vertically arranging products with finished UV glue and keeping the flexible printed circuit board downward; (3) Taking a group of products processed in step (2) into a UV machine for UV solidification. In addition, the clamping fixture comprises a group of arranging boards to conveniently fix and withdraw product fastening pieces. After UV glues are spread between the lens base and the flexible printed circuit board, the method of the present invention vertically arranges products with finished UV glue and keeps the flexible printed circuit board downwards. Thus, gravity of the glue is utilized to balance glue penetration, thus reducing loss due to UV glue penetration and quantity of products returned for reworking.

Owner:BYD CO LTD

Preparation method of nano carboxy styrene-butadiene rubber toughened nylon

The nano-level carboxylic styrene-butadiene latex is uniformly dispersed in polyamide monomer of caprolactam, etc. to form a microemulsion system with thermodynamic stability, isotropy, transparent of semi-transparent appearance and grain size of 1nm-100nm, then they are melt-polymerized so as to obtain organic nano nylon. As compared with general nylon said invented nano-level carboxylic styrene-butadiene latex toughened nylon possesses higher notched impact strength.

Owner:CHINA PETROCHEMICAL CORP +1

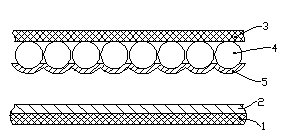

Manufacturing method of high-strength type reflection film

InactiveCN103105637ASimple preparation processFlat coatingLaminationLamination apparatusSizingMaterials science

The invention relates to a manufacturing method of a high-strength type reflection film. The manufacturing method of the high-strength type reflection film includes the following steps: step a, a bonding layer is coated on the surface of a first vase material; step b, a bead establishing layer is formed on the surface of a second base material with pressure-sensitive adhesive, and a reflection layer is plated on the surface of the outer side of glass beads of the bead establishing layer; step c, a light reflecting layer formed by the bonding layer, the reflection layer and the glass beads is formed; step d, embossing is carried out on the back face of the bonding layer through a hot-press embossing roller, and therefore partial of the bonding layer is pressed to form square protruded ribs, and transparent surface material is connected with tops of the protruded ribs; step e, after the bonding layer is embossed, a supporting layer is sprayed on the back of the bonding layer so as to form a plane; and step f, the pressure-sensitive adhesive is evenly coated on the back of the supporting layer, and release materials are covered on the pressure-sensitive adhesive. According to the manufacturing method of the high-strength type reflection film, the smooth supporting layer can be acquired, coating of the pressure-sensitive adhesive can be smooth and uniform, bonding effect is good, and sizing material can be saved.

Owner:JIANGSU TST NEW MATERIALS SCI & TECH

Thick-type paperback perfect binding method

ActiveCN103434296AQuality improvementReduce labor intensityBookbinding adhesiveProduction lineCollation

The invention discloses a thick-type paperback perfect binding method. The method comprises the following steps: step one, overlaying book sections one by one together by a collating machine so as to form a whole book section; then knocking the book sections neatly, positioning, clamping, milling the back, pulling a trough, applying spot glue, thereby preparing the book sections collated for the first time; step two, repeatedly operating the step one until all the book sections are collated; step three, overlaying all the matched book sections together, splicing a book block, gluing through a gluing machine, gluing for the book back of the book block, and applying a seal cover, thereby obtaining the thick-type paperback. According to the method, a spot gluing mode is adopted, not only is the effect of fixing the collated book back each time achieved, but also the effect of saving glue materials is achieved; when in the subsequent book block collation, the glue body is firm after the book back is glued, and the glue disconnection phenomenon can be avoided, and the rejection rate is reduced greatly; the whole production line can be in place by one step, and the production efficiency is improved greatly; the obtained thick-type paperback is firm in binding, and long in service life.

Owner:ZHEJIANG XINHUA DIGITAL PRINTING

Device and method for measuring relationship between lateral vibration displacement and strain of flexible beam

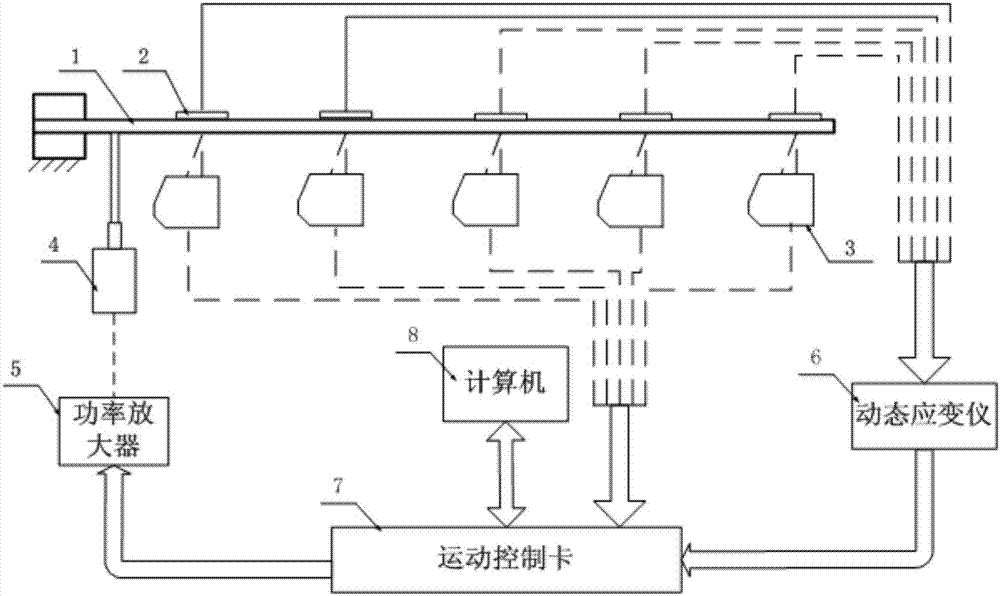

InactiveCN107345786AReduce volumeLight in massSubsonic/sonic/ultrasonic wave measurementUsing electrical meansClassical mechanicsMovement control

The invention discloses a device and a method for measuring the relationship between the lateral vibration displacement and the strain of a flexible beam. The device comprises a flexible cantilever beam. One end of the flexible cantilever beam is fixed by a base, and the other end is a free end. A number of resistance strain gauges are arranged on the front or back of the flexible cantilever beam. A number of laser displacement sensors which are used to measure the vibration lateral displacement at the geometric center the resistance strain gauges are arranged in front of the other side of the flexible cantilever beam. The device further comprises a computer, power amplifier, a motion control card, a vibration exciter and a dynamic strain gauge. According to the device provided by the invention, low-order mode vibration strain distribution and displacement distribution relationship diagram is provided.

Owner:SOUTH CHINA UNIV OF TECH

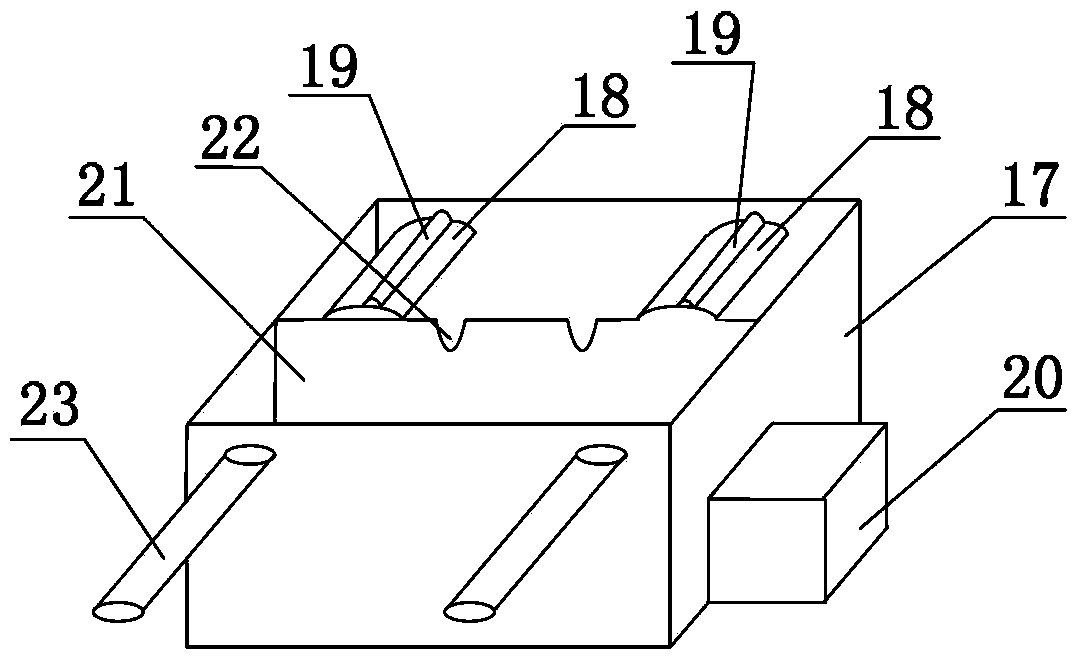

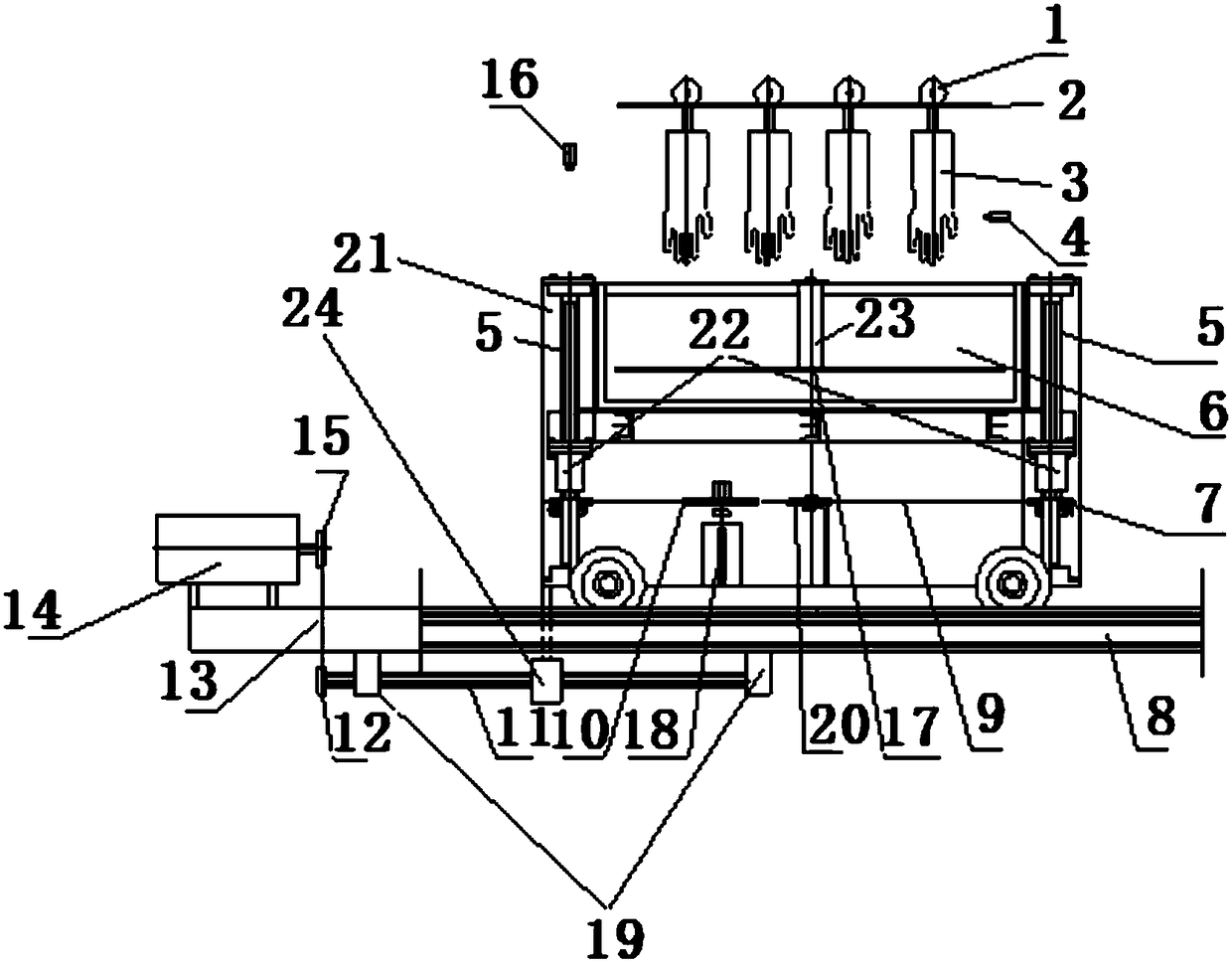

Glue pool system for glue dipping glove production line and glue dipping glove production line

The invention relates to the technical field of glue dipping glove production, in particular to a glue pool system for a glue dipping glove production line and a glue dipping glove production line used for solving the technical problems that due to the fact that the motion track of a hand mold is a curve, the production efficiency is low, the manufacturing cost is high, and remaining glue is muchduring production switching. In the glue pool system, a control unit controls a horizontal moving mechanism to drive a glue pool framework to move in the moving direction of a conveying chain from theinitial position, controls a lifting mechanism to drive a glue pool to move between the initial height and the preset height position in a reciprocating manner according to the preset number of times, and controls the horizontal moving mechanism to drive the glue pool framework to return to the initial position when the glue pool completes reciprocating lifting of the preset number of times. In the glue dipping glove production line, the control unit controls the horizontal moving mechanism to drive the glue pool to move in the moving direction of the conveying chain from the initial positionat the speed the same as the advancing speed of the hand mold below the working area of the horizontal section of the conveying chain.

Owner:SHANDONG XINGYU GLOVES

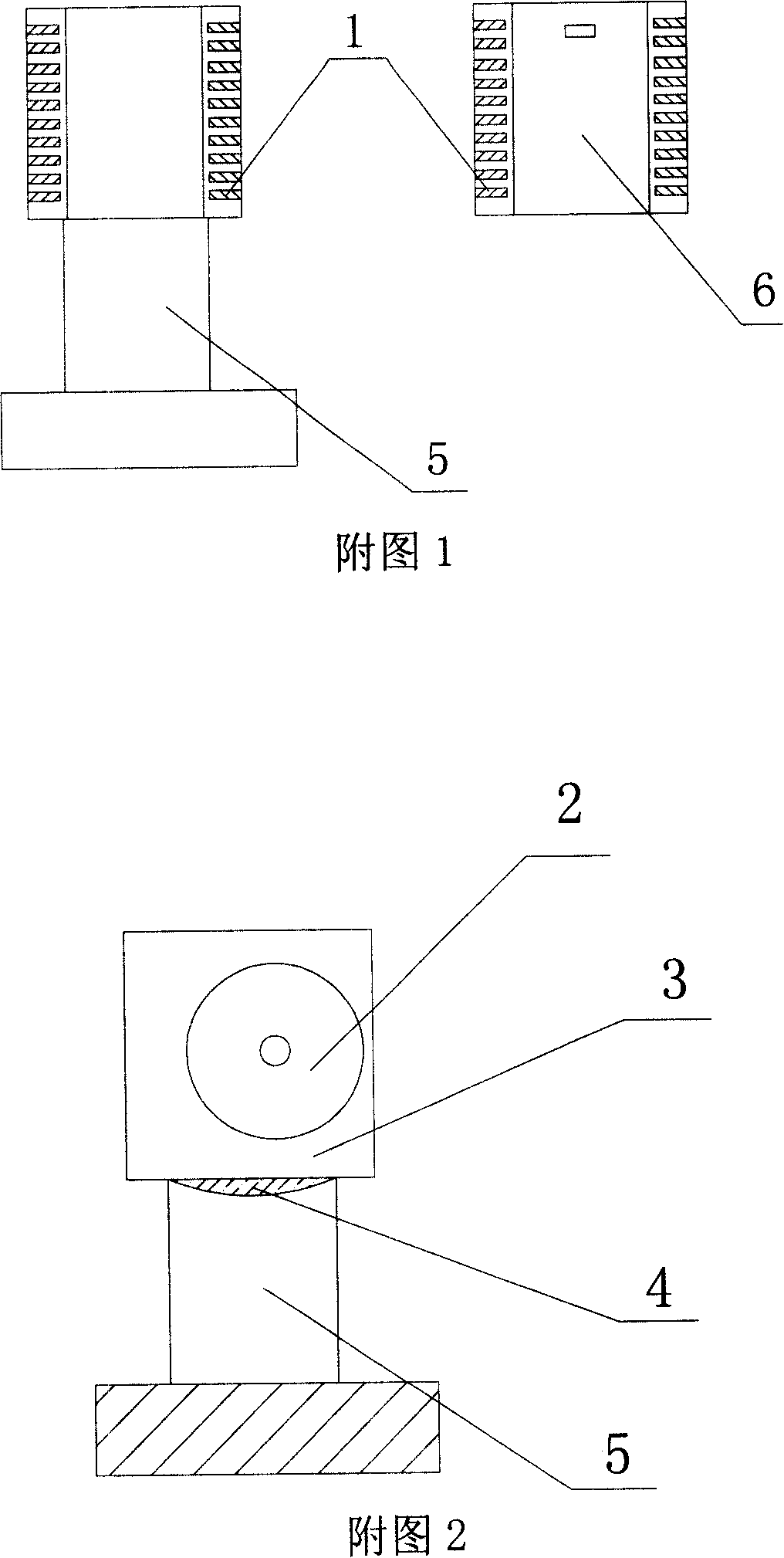

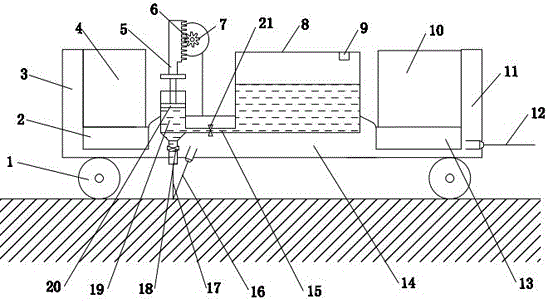

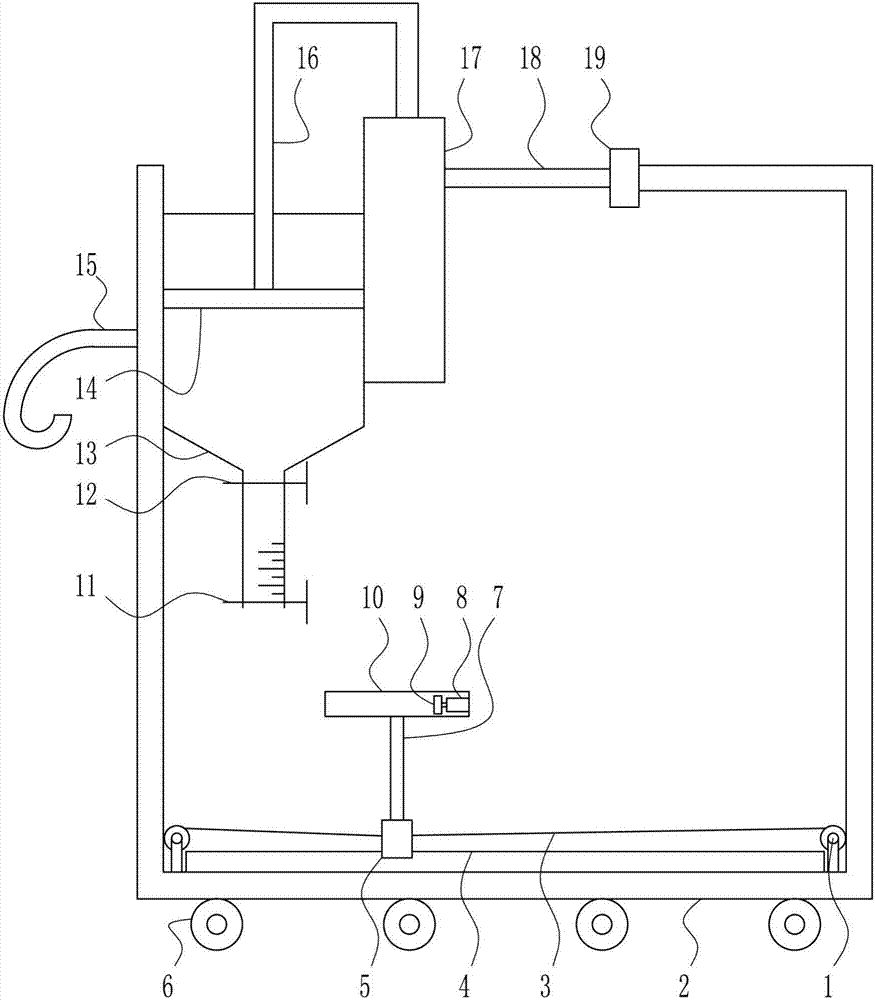

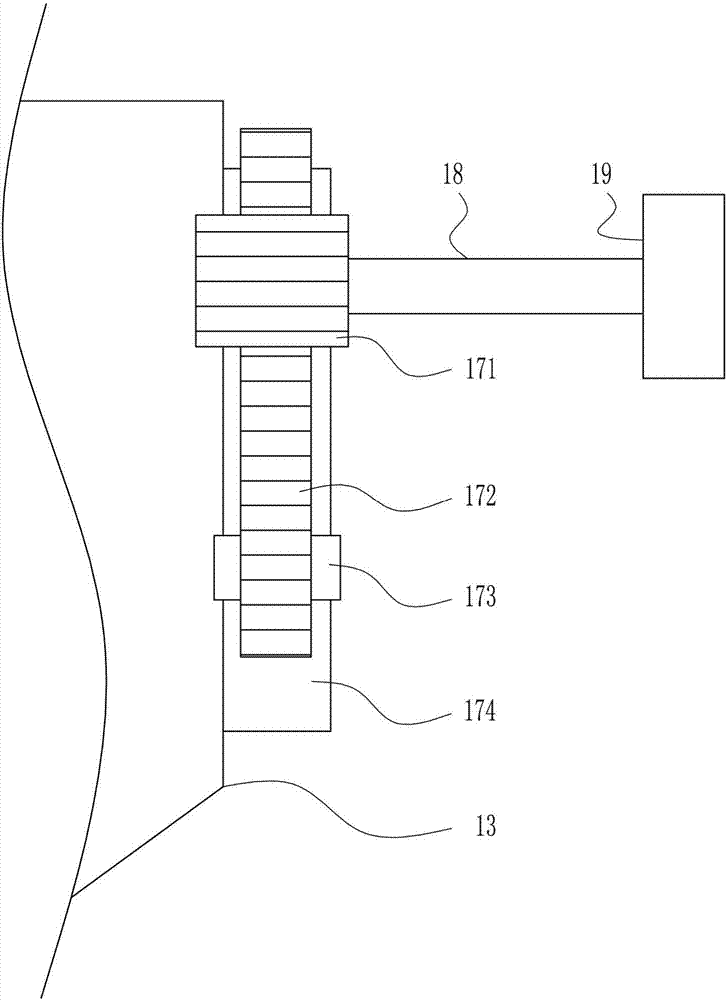

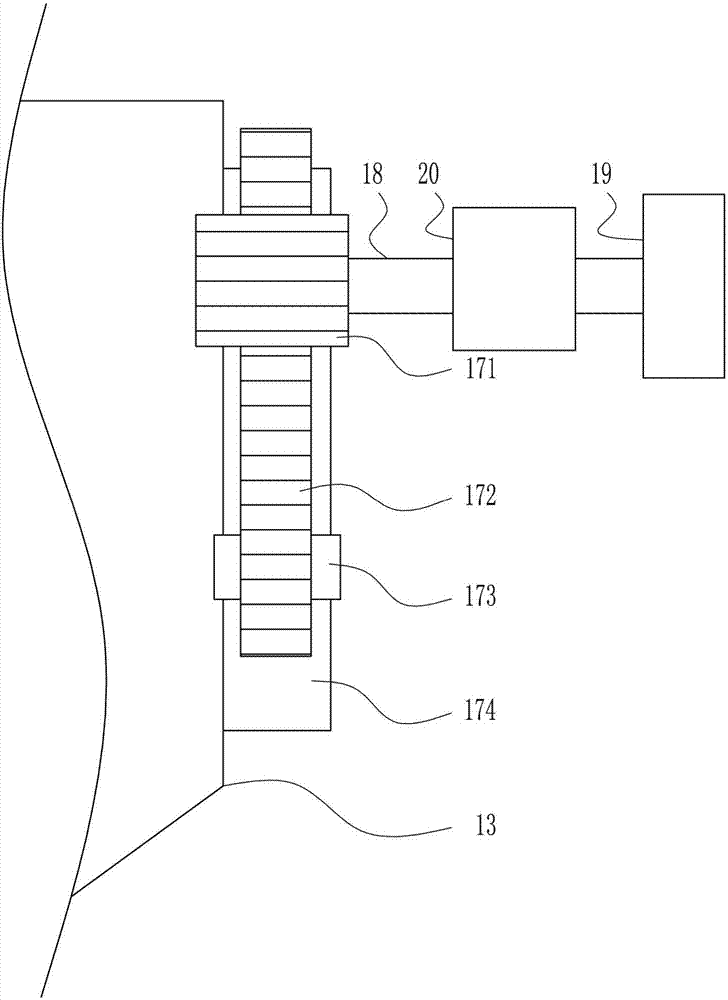

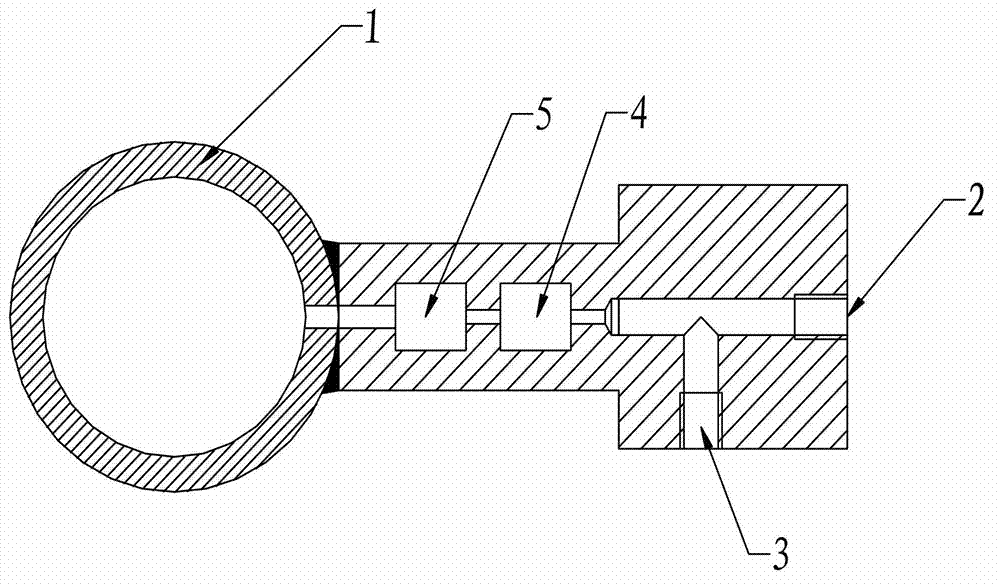

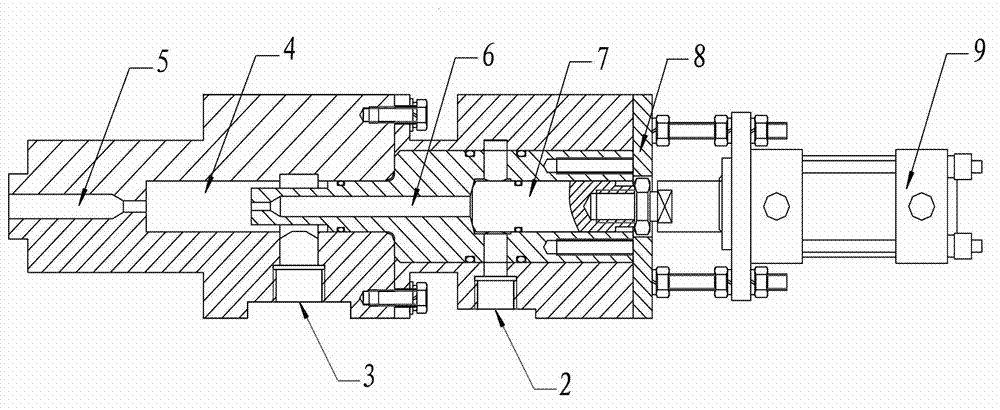

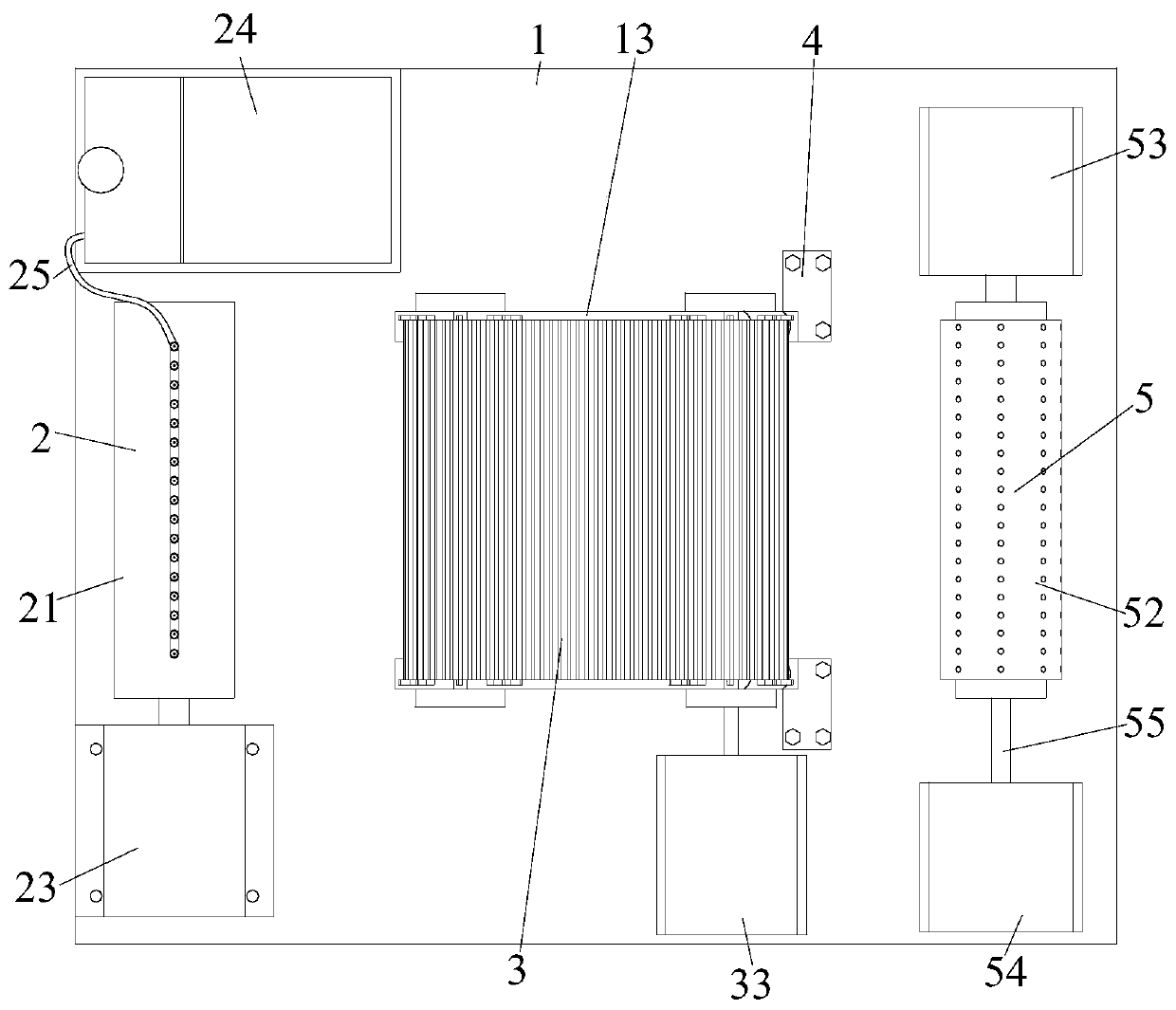

Laser guide type ground glue-injection machine

ActiveCN105484482ASave glueGuarantee product qualityBuilding constructionsLaser transmitterEngineering

The invention relates to a laser guide type ground glue-injection machine which comprises a rack and a rolling wheel. Bases are arranged in the rack and comprise a left base, a middle base and a right base. The left base is adjacent to the left side wall of the rack. The right base is adjacent to the right side wall of the rack. A motor is arranged on the left side wall of the rack. A controller is arranged on the right base. A glue-injection device is arranged in the middle of the middle base in a penetrating mode and comprises a glue storing chamber and a glue-injection device. A laser transmitter is arranged on the right side wall. A depth probing device is arranged at the bottom of the middle base and located at one side of a glue-injection needle head of the bottom of the glue-injection deice. The controller is connected with the motor, the laser transmitter and the depth probing device. The glue-injection machine is simple in structure, glue feeding and injecting are convenient, and controllability is good; after the finite glue-injection device is adopted for injecting glue on the ground, natural stones such as marble and granite can be directly bonded to the glue base plane, industrial production of construction is achieved, construction speed is greatly increased, economic cost is greatly saved, and the construction period is shortened.

Owner:ZHEJIANG YASHA DECORATION

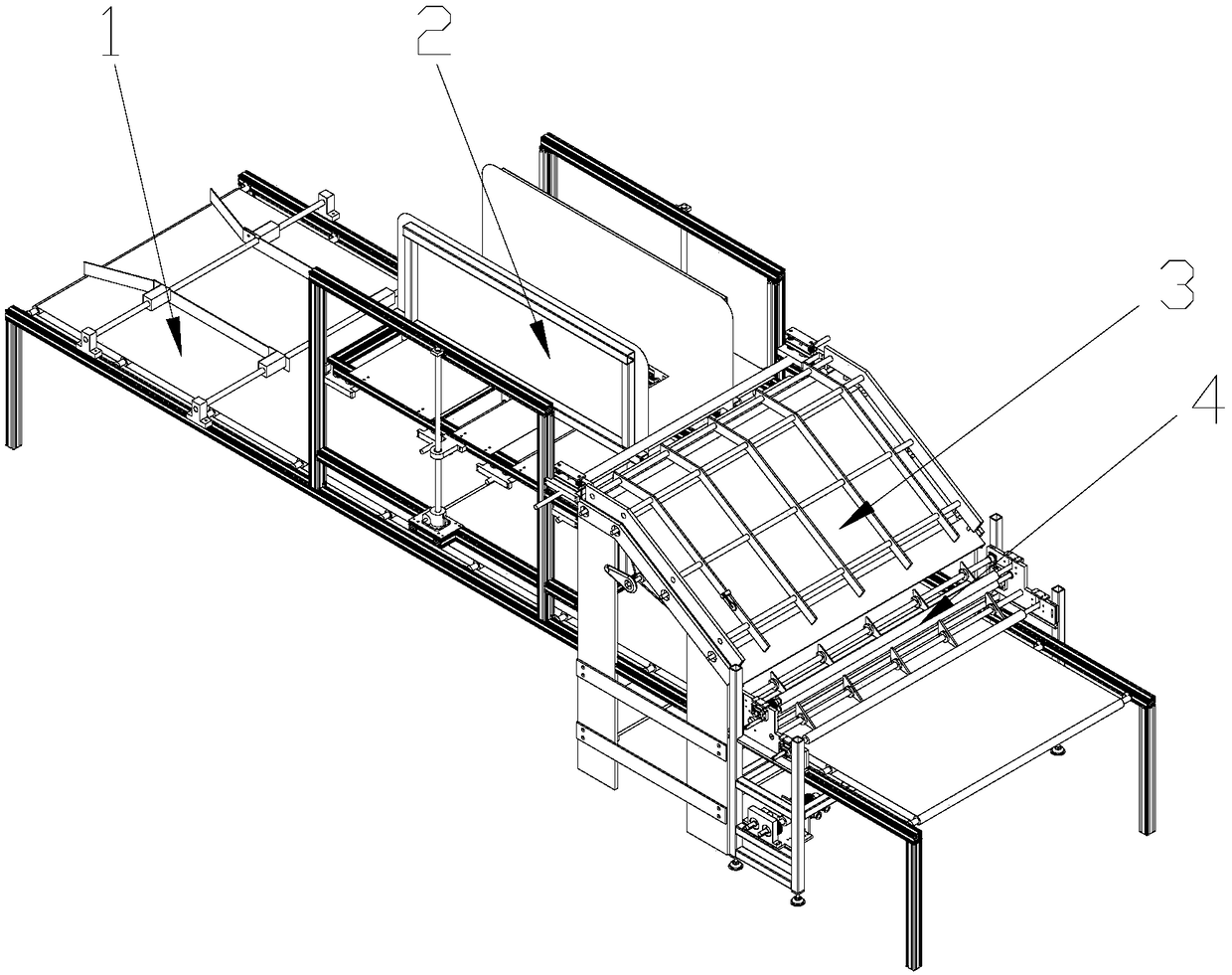

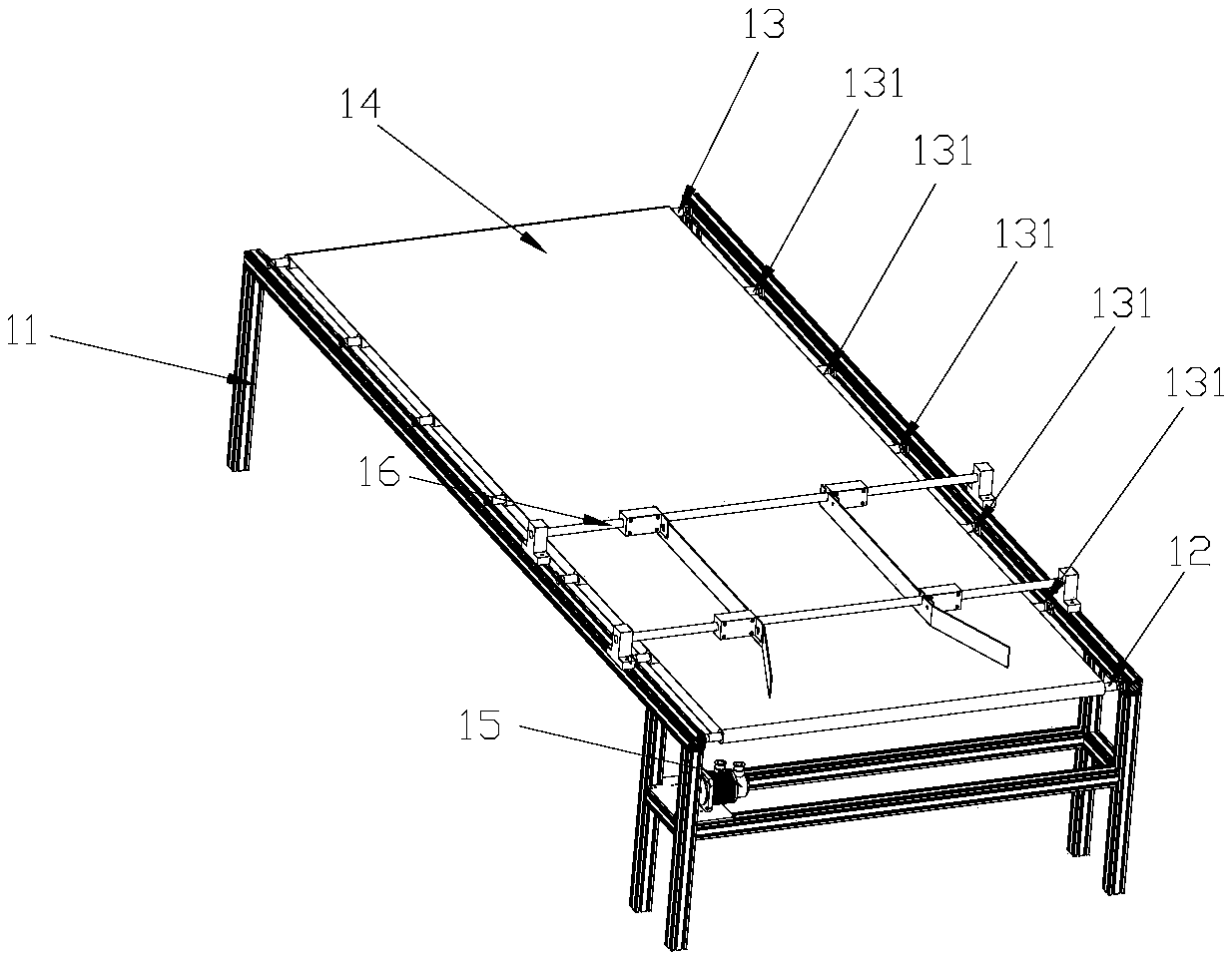

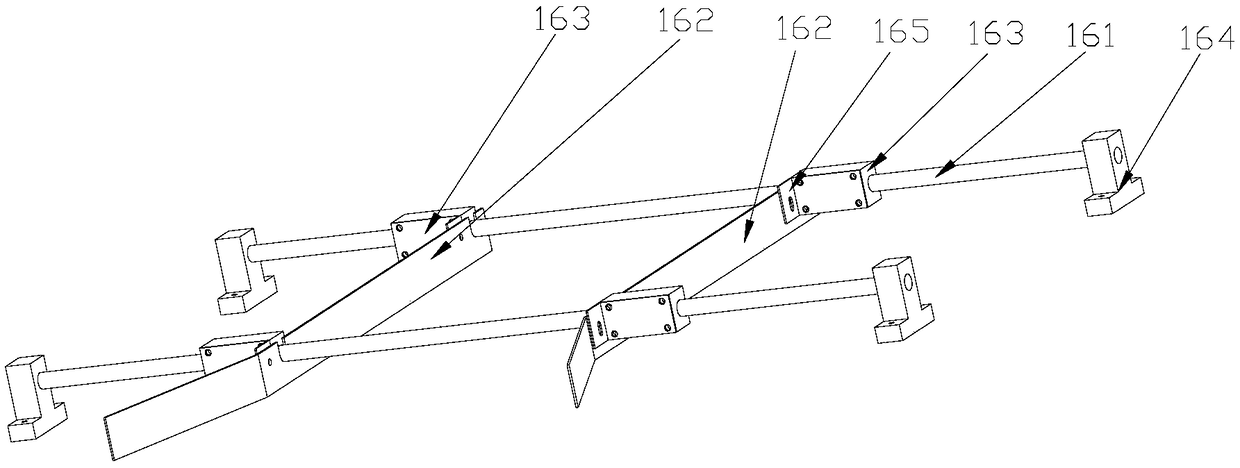

Automatic gluing, edge turning and laminating system for packaging carton

PendingCN109808233AImprove processing efficiencySave human effortBox making operationsPaper-makingElectric machineryWorking environment

The invention relates to an automatic gluing, edge turning and laminating system for a packaging carton. The automatic gluing, edge turning and laminating system is characterized by comprising a rack,conveying belts, a gluing indentation mechanism, an edge turning mechanism, a plate overturning mechanism and a laminating mechanism; the two conveying belts which are arranged in parallel and drivensynchronously through a motor are arranged on the rack; a plate overturning gap is reserved between the two conveying belts; the gluing indentation mechanism and the laminating mechanism are sequentially arranged in the conveying direction of the conveying belts from front to back; the edge turning mechanism located on the outer side of the conveying belts and the plate overturning mechanism located in the rack are arranged between the gluing indentation mechanism and the laminating mechanism; and a plate overturning head of the plate overturning mechanism stretches at the plate overturning gap. The automatic gluing, edge turning and laminating system is scientific and reasonable in structure design and has the beneficial effects that persons and labor are saved, the machining efficiencyis improved, the product quality is ensured, the production cost is reduced, smearing is uniform, glue is saved, and it is ensured that the working environment is neat; and the automatic gluing, edgeturning and laminating system for the packaging carton is high in innovativeness.

Owner:TIANJIN JINGHAI COUNTY LIHUA PRINTING PACKAGING

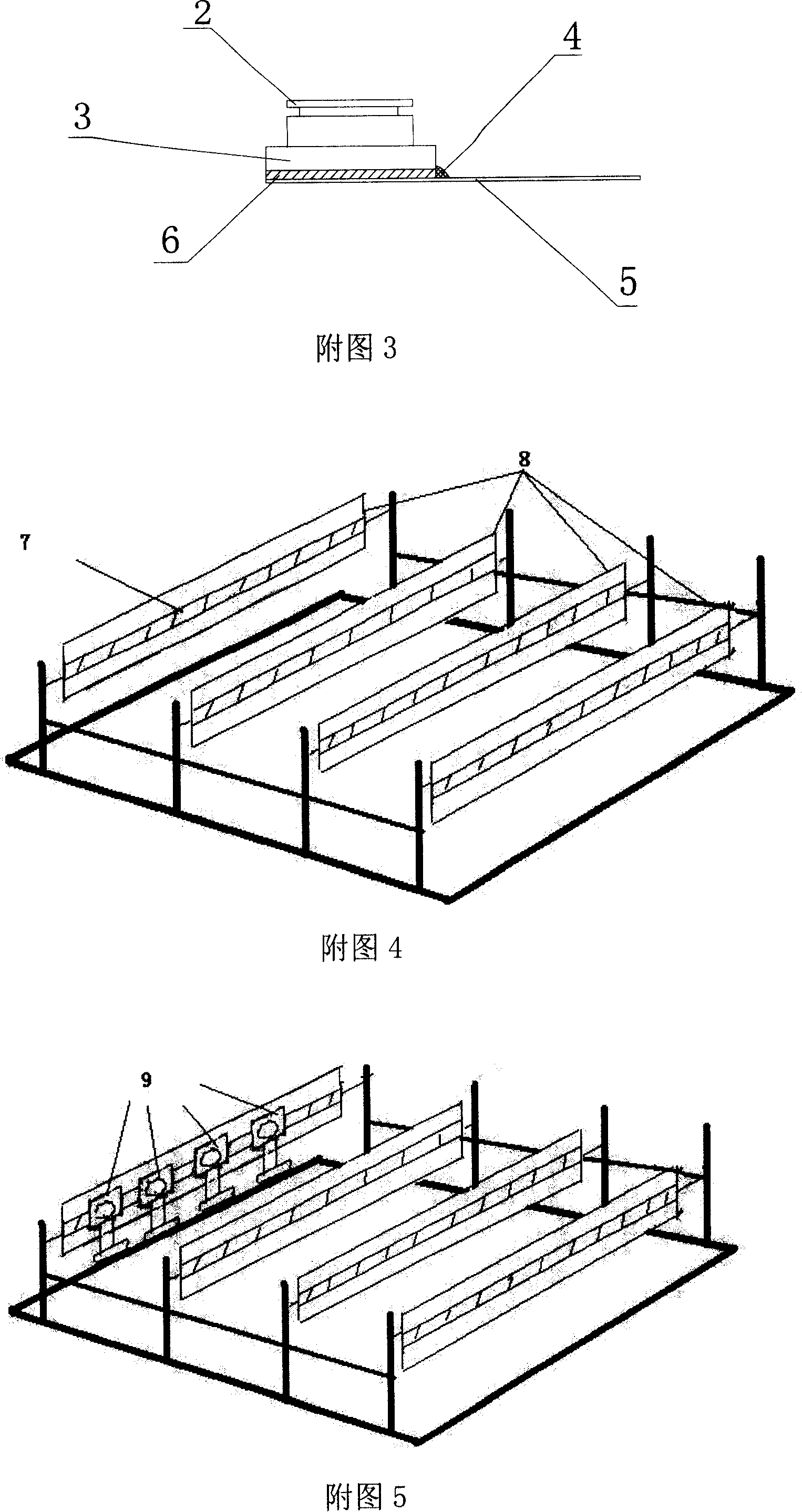

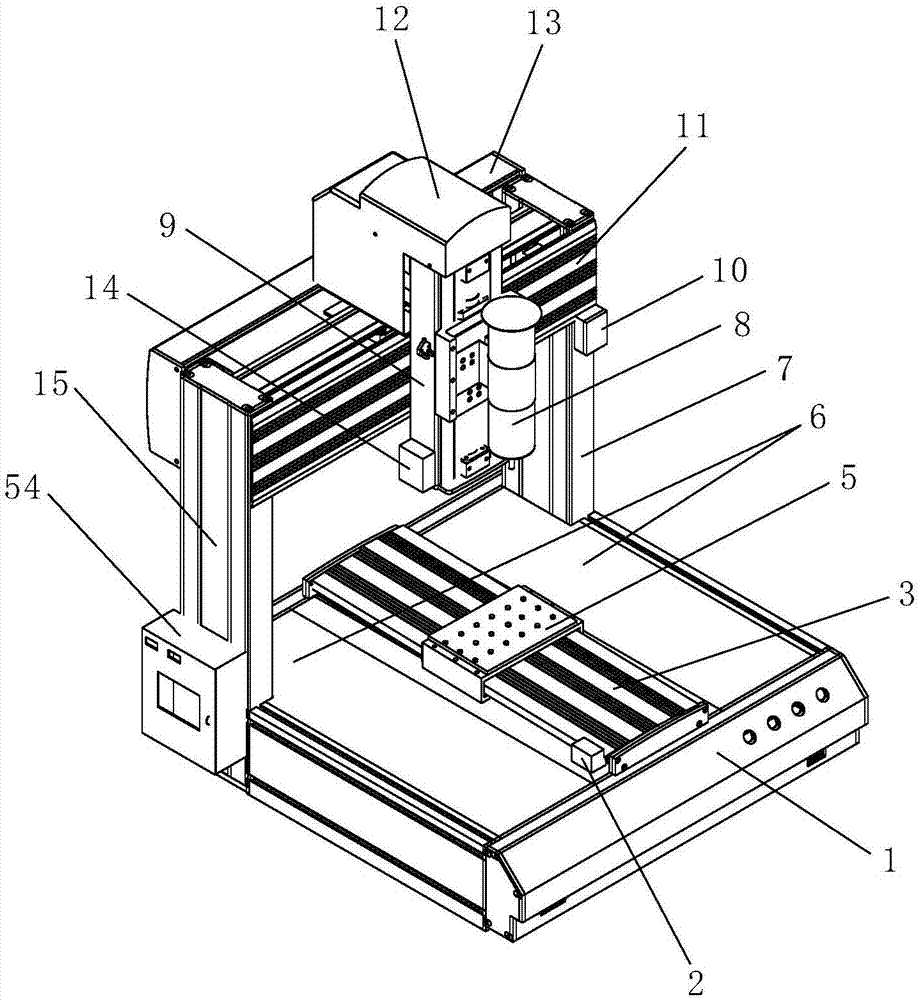

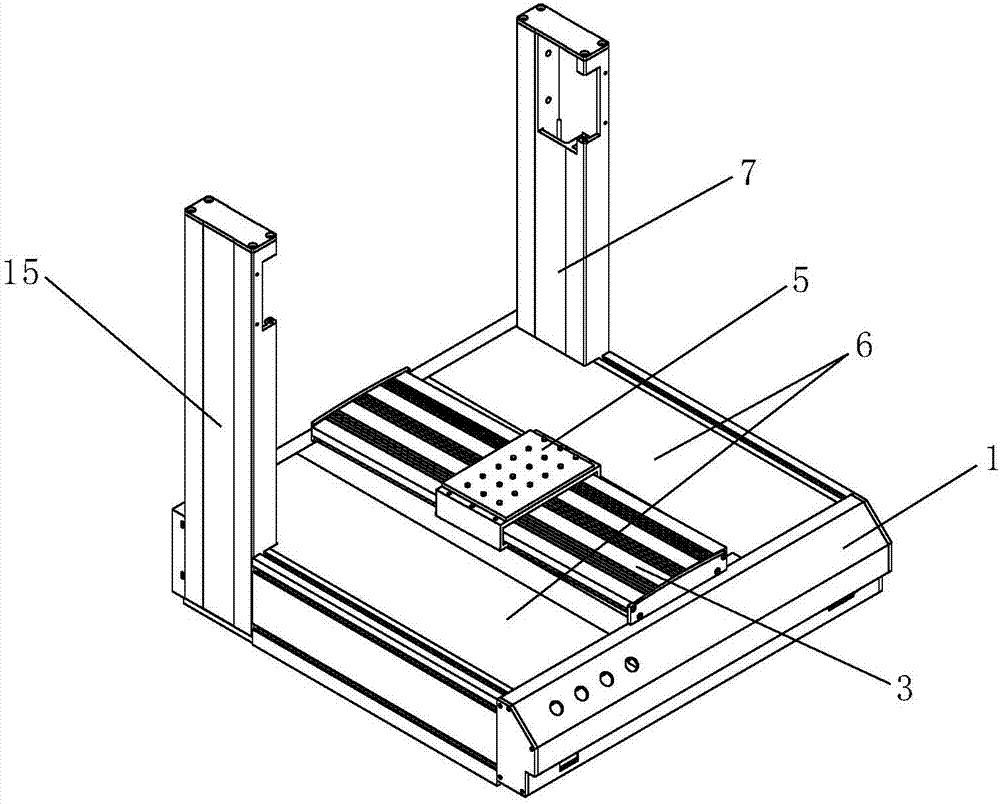

Dispensing machine with accurate positioning performance and consistent dispensing quantity

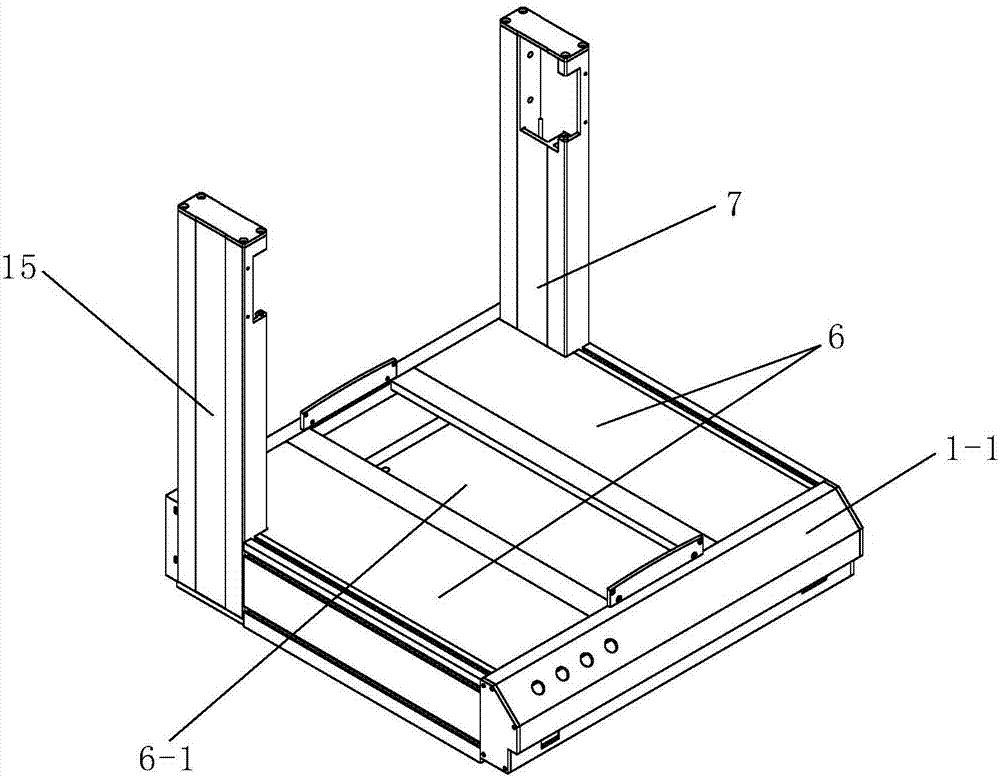

PendingCN107282370ASimple structureReasonable designLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses a dispensing machine with accurate positioning performance and consistent dispensing quantity. The dispensing machine comprises a frame assembly body, an x-axis assembly body, a y-axis assembly body, a z-axis assembly body and a glue outlet assembly body; the frame assembly body comprises a square frame, a left bracket and a right bracket, and the left bracket and the right bracket are mounted on the two sides of the back of the square frame; horizontal operation platforms are mounted on the left and right sides of the square frame, the x-axis assembly body is mounted between the two horizontal operation platforms, the two ends of the y-axis assembly body are connected with the upper end of the left bracket and the upper end of the right bracket respectively, the z-axis assembly body is mounted on the y-axis assembly body, and the glue outlet assembly body is mounted on the front side of the z-axis assembly body; a workpiece platform is mounted on the upper side of the x-axis assembly body, an x-axis displacement sensor is mounted on the left side of the front end of the x-axis assembly body, a y-axis displacement sensor is mounted on the lower side of the right end of the y-axis assembly body, and a z-axis displacement sensor is mounted on the left side of the lower end of the z-axis assembly body. The dispensing machine has the advantages that positioning can be accurate, the dispensing quantity is consistent, the scrap rate of parts is reduced, and the glue is saved.

Owner:XIAN UNIV OF SCI & TECH

Shoe gluing device

The invention relates to a gluing device, and in particular relates to a shoe gluing device. A technical problem to be solved by the invention is to provide the shoe gluing device. In order to solve the technical problem, the invention provides the shoe gluing device comprising electrical reels, a support, pull wires a first sliding rail, a first sliding block, pulleys, a strut, an electrical push rod, an arc-shape stop dog, a shoe-shaped groove and a first valve, wherein the pulleys are uniformly arranged at the bottom outside the support, a handle is arranged on the left side wall outside the support, the first siding rail is arranged at the bottom in the support, the electrical reels are arranged at the bottom in the support on left and right sides of the first sliding rail, the pull wires are wound on the electrical reels, and the tail ends of the pull wires are connected with the first sliding block. It should be noted that abovementioned embodiments with specific and detailed description are only preferred embodiments of the invention, but should not be considered as limiting the scope of the invention.

Owner:林永贵

Glue applying nozzle

InactiveCN102765119AGlue particles are smallProduct quality is stableFlow mixersTransportation and packagingWater particleEngineering

The invention relates to a nozzle, in particular to a glue applying nozzle during production of artificial boards. The glue applying nozzle comprises a glue water inlet and a glue water outlet, wherein the glue water outlet is communicated with a fiber spraying pipe. The glue applying nozzle is characterized in that the side wall of an inlet pipeline communicated with the glue water inlet is also communicated with a compressed air inlet; the diameter of the inlet pipeline is smaller than that of the glue water inlet; a first atomizing chamber is communicated with the inlet pipeline; the diameter of the first atomizing chamber is greater than that of the inlet pipeline; a second atomizing chamber is communicated with the first atomizing chamber; the first atomizing chamber is connected with the second atomizing chamber through a thin pipeline; and the diameter of the second atomizing chamber is greater than that of the thin pipeline and is smaller than that of the first atomizing chamber. According to the glue applying nozzleprovided by the invention, due to the twice atomizing design, the glue water can be fully atomized and dispersed, the obtained glue water particles are smaller and more uniform and can be uniformly coated on the fiber surfaces, the product quality is stable, and the usage amount of the glue water also can be saved.

Owner:GLOBE ENVIRONMENTAL SHANGHAI

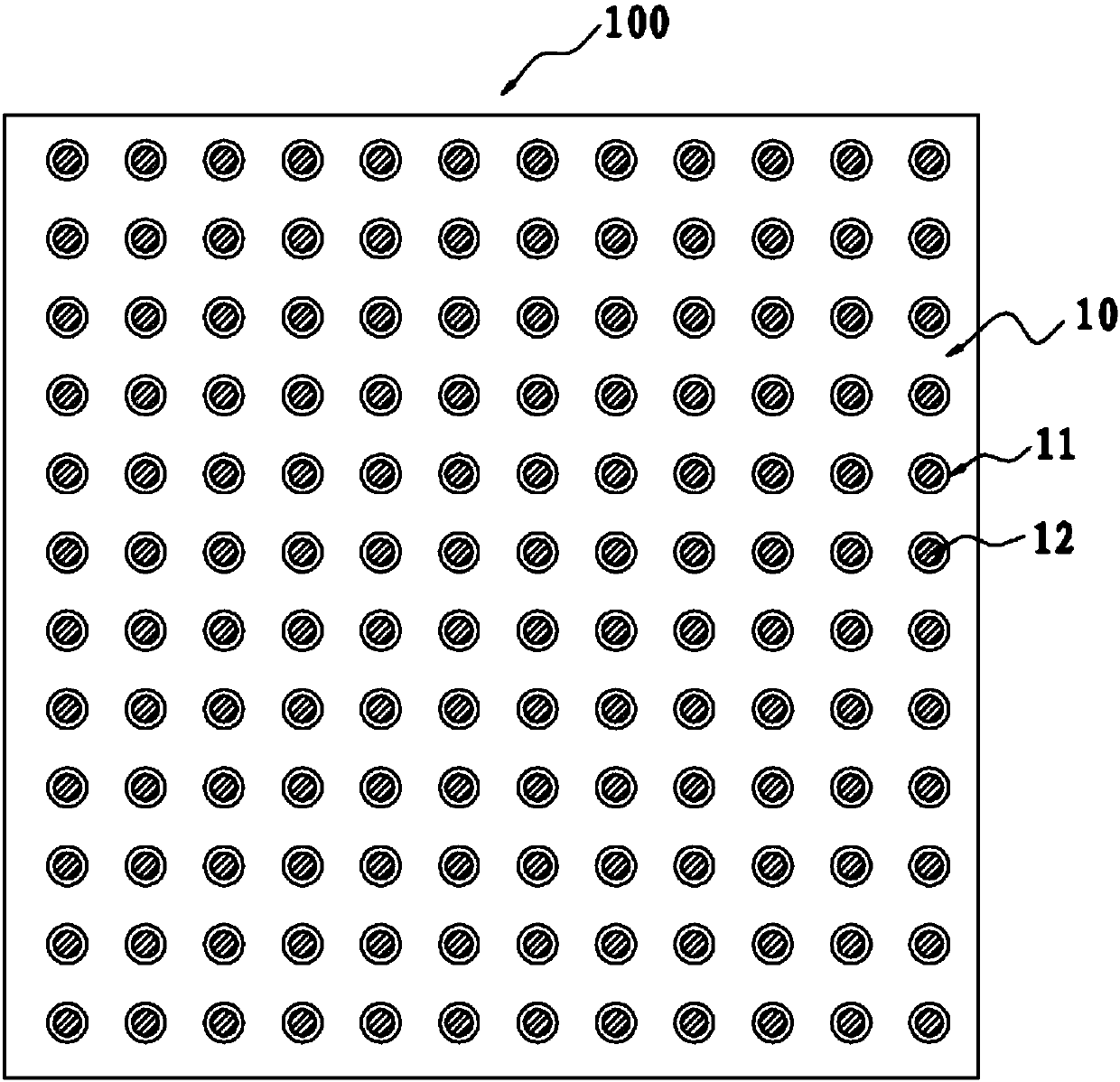

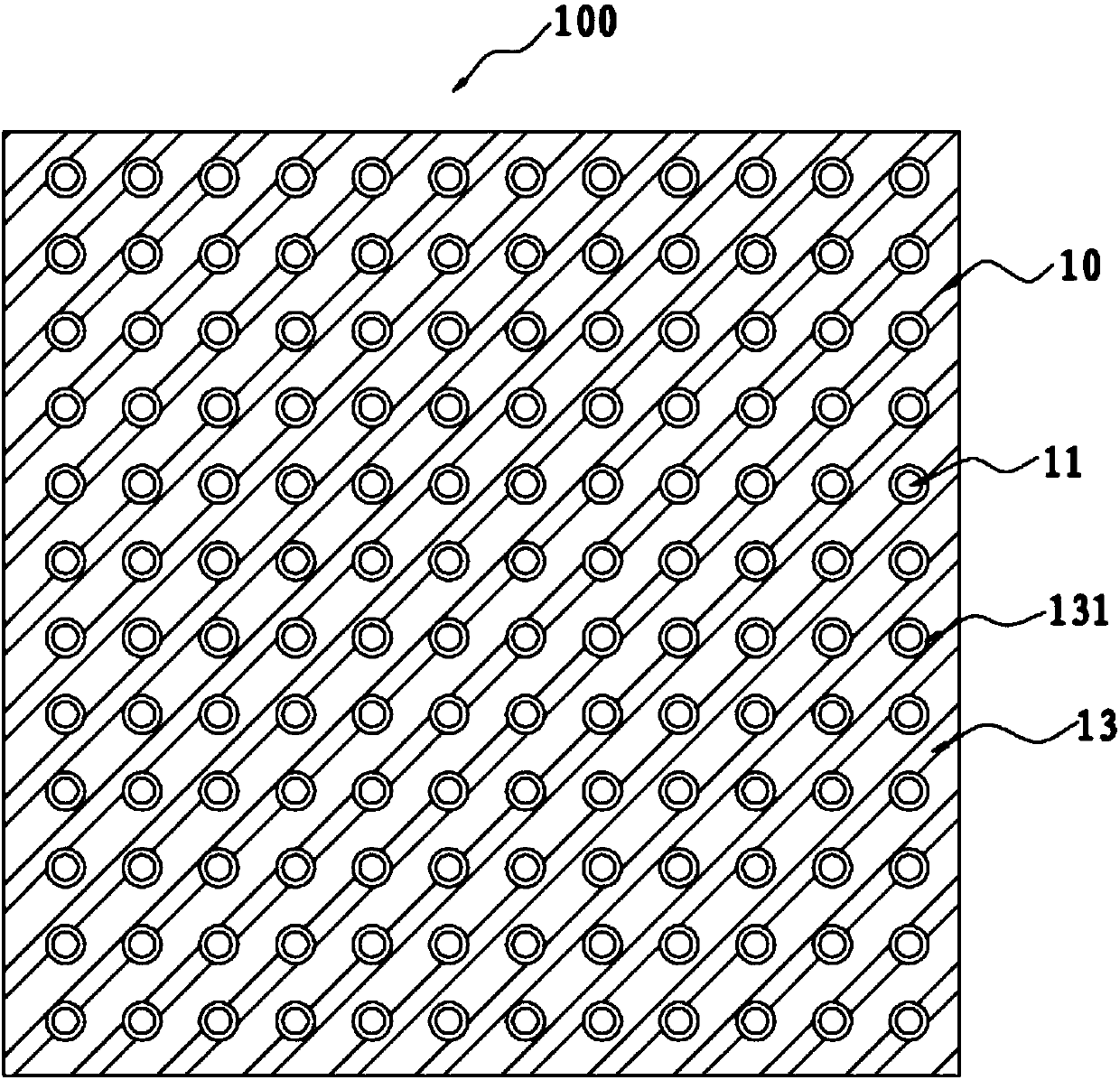

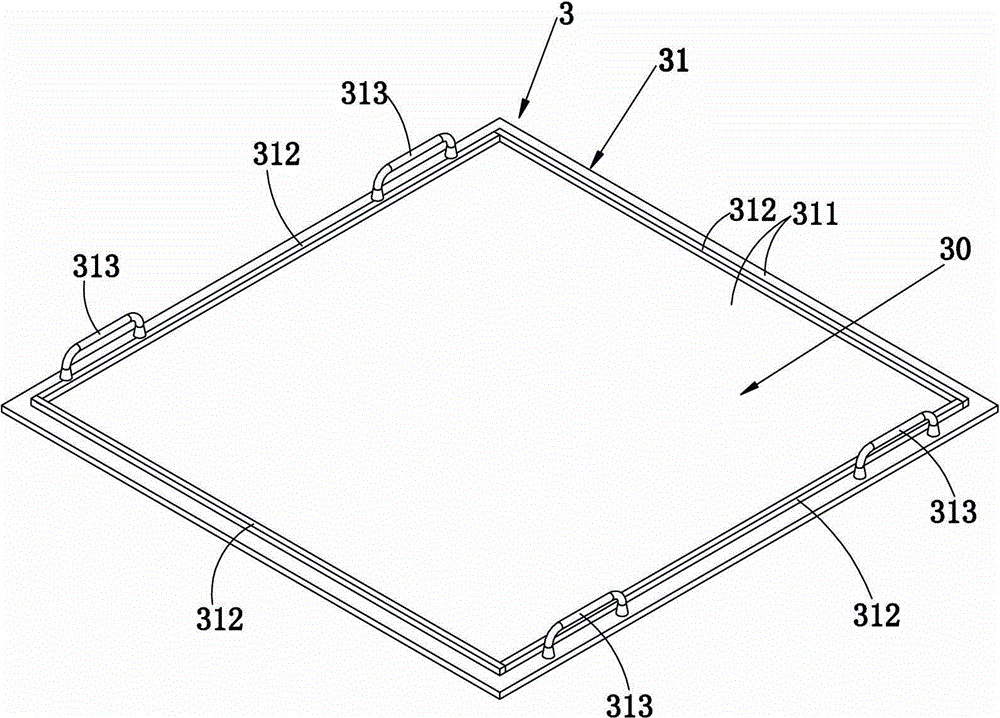

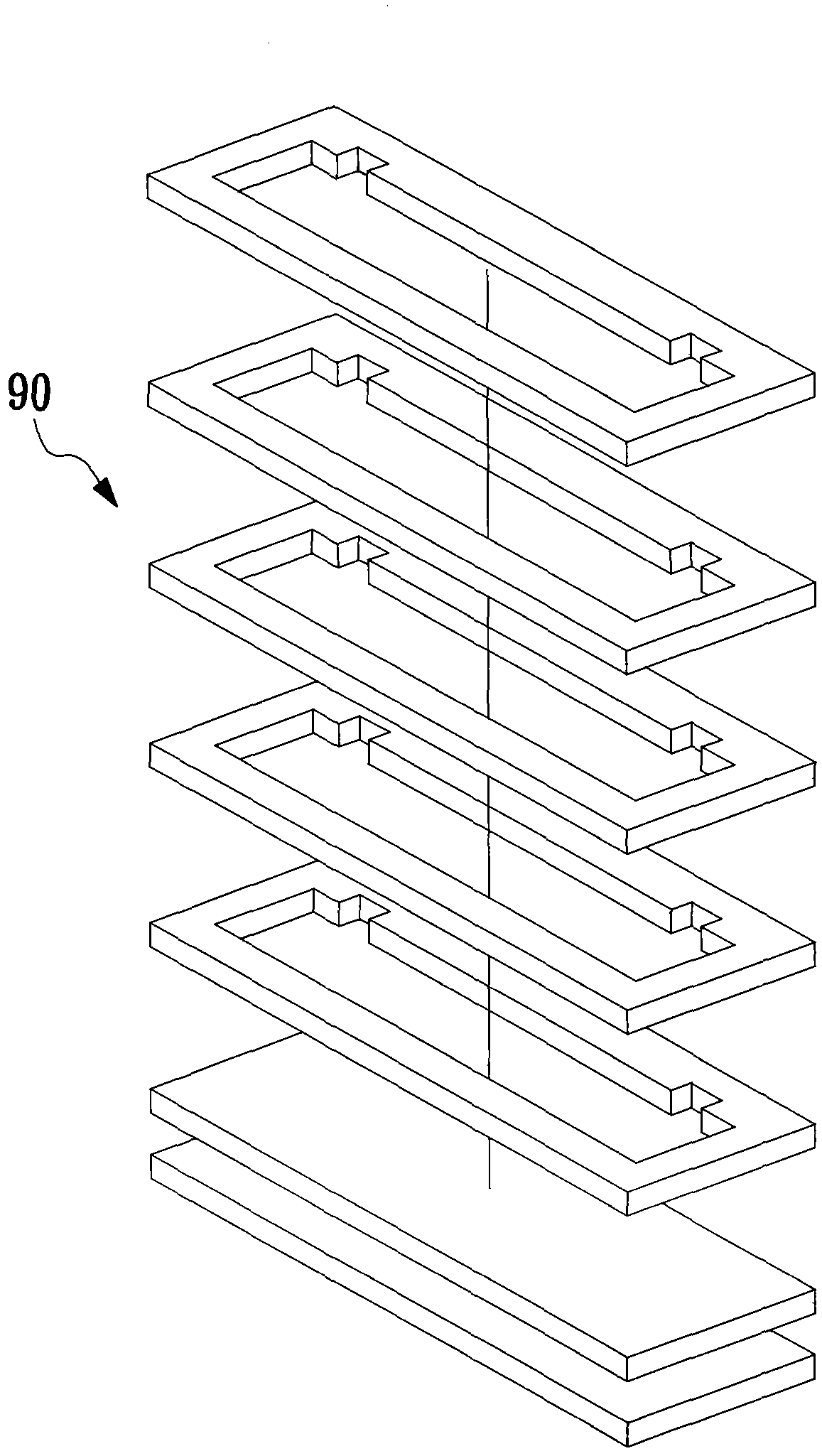

PCB inner layer pattern optimization method, PCB, board splicing structure and laminating structure

InactiveCN107623992AProne to wrinklingEasy to cause lamination voids and other phenomenaElectrical connection printed elementsPrinted circuits structural associationsEngineeringCopper foil

The invention discloses an optimization method for a PCB inner layer pattern, a PCB, a board splicing structure and a laminating structure. The PCB inner layer pattern comprises a coppery region and anon-copper region; the non-copper region comprises a via hole region with at least one via hole; and when a residual copper rate of the coppery region is smaller than a specific value, copper pointsare laid out at via hole positions of the via holes, and the diameter of each copper point is smaller than that of each via hole. Such small-size copper points laid out can improve uniformity of distribution of the pattern and reduce a volume of glue required for glue filling in the non-copper region, so that risks of wrinkling, cavities and the like of a copper foil subjected to lamination processing can be reduced, and meanwhile, the size of each copper point is smaller than that of each via hole, so that in the driving process, the copper points can be drilled off; and in addition, layout of the copper points can further promote PCB drilling quality to a certain degree and particularly has a great improvement effect on drilling haloing, so that CAF performance of the PCB is improved.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

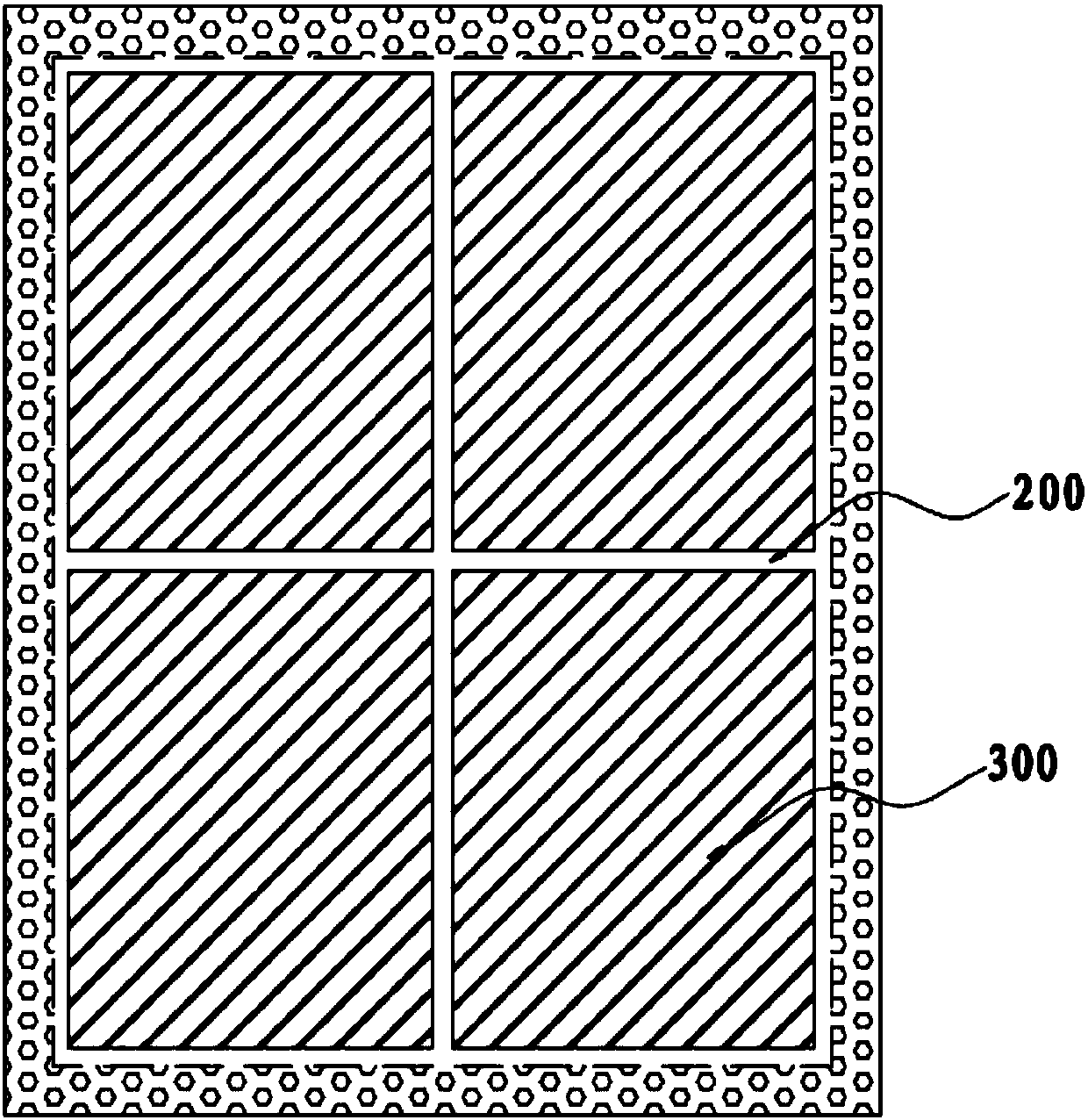

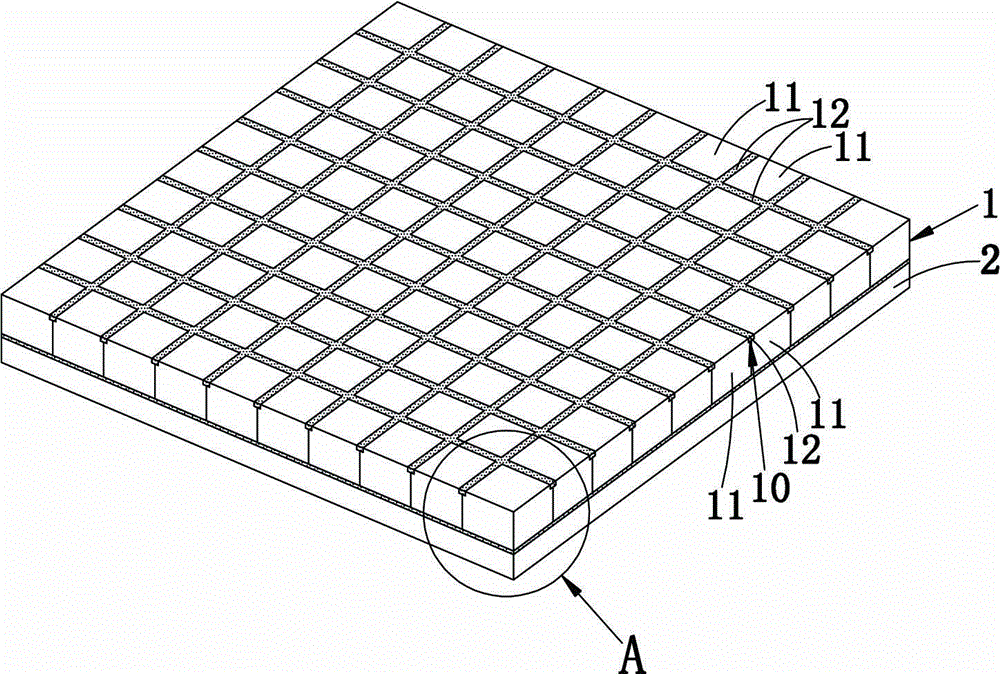

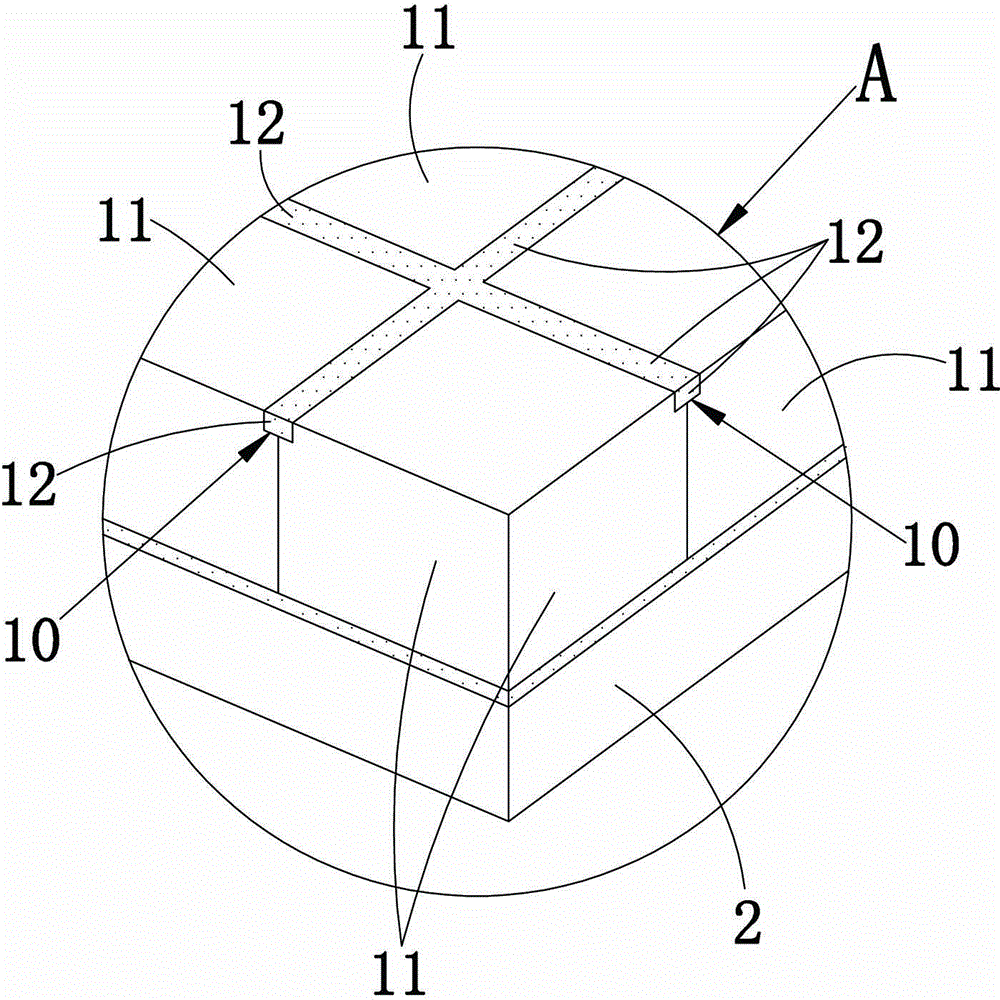

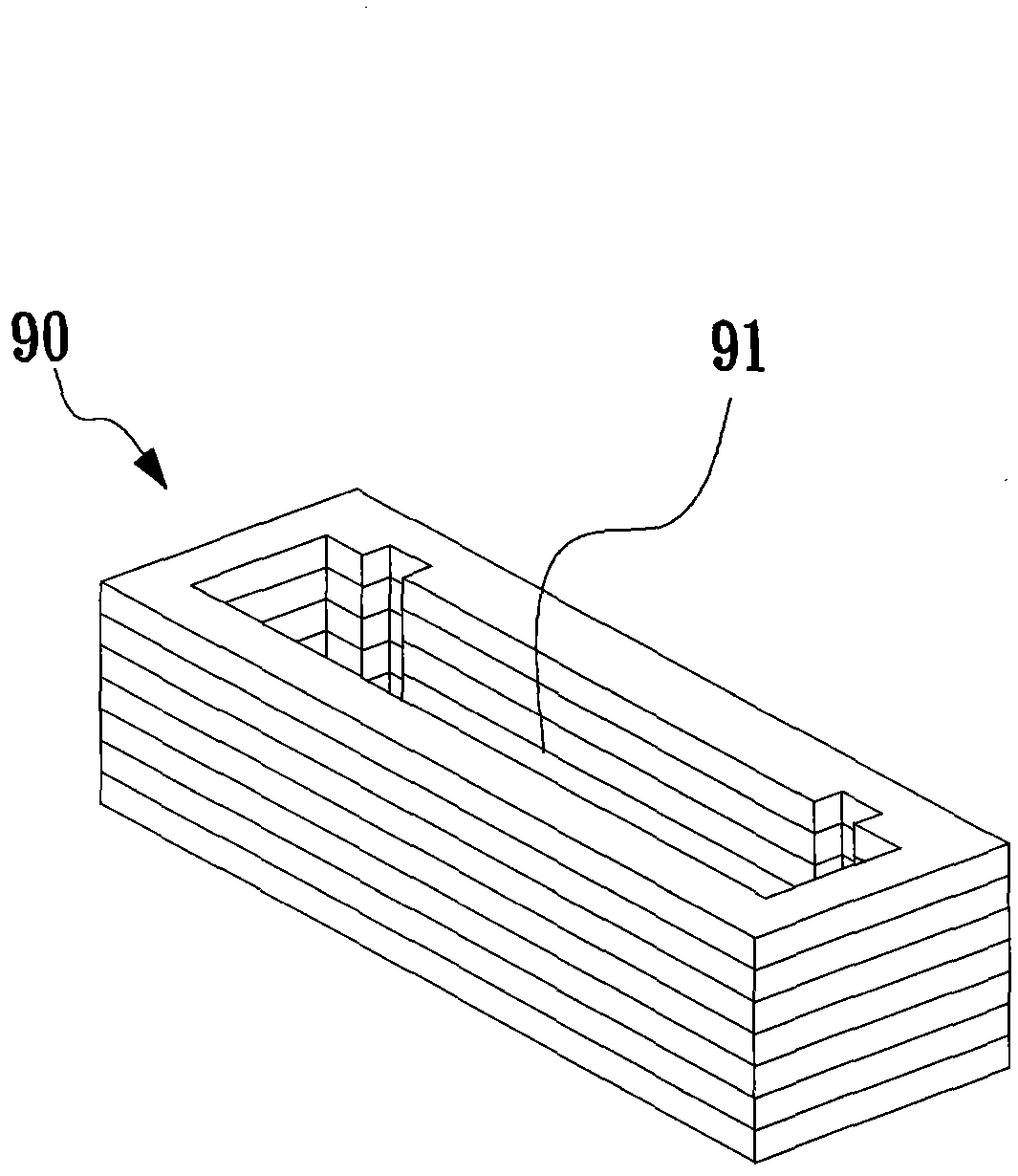

Stone mosaic board and production technology thereof

InactiveCN104947901AGuaranteed structural strengthImprove structural strengthCovering/liningsOrnamental structuresAdhesiveEngineering

The invention relates to a stone mosaic board and a production technology thereof. The stone mosaic board comprises a main board body which is formed by splicing multiple stones. Linear adhesive grooves are distributed in the upper surface of the main board body in a criss-cross mode, every two adjacent stones are seamlessly spliced, and the linear adhesive grooves are formed in the top edges of the splicing surfaces of the stones respectively; the linear adhesive grooves are filled with adhesives used for fixedly connecting every two stones. According to the production technology of the stone mosaic board, splicing, checking, grooving, adhesive applying and grinding and polishing are performed on the stones to obtain the mosaic board. Through the linear adhesive grooves and the adhesives with which the linear adhesive grooves are filled, all the stones of the main board body adhere fixedly into a whole and will not disengage easily; through a base board, the structural strength of the main board body is further improved. The production technology of the stone mosaic board has the advantages that working precision is high, production is easy and convenient, the adhesives used in the whole production process can be saved by at least 90%, production efficiency is effectively improved, product quality is high, the production technology is suitable for batched standard production, and the production cost is low.

Owner:FUJIAN NANAN XINDONGYUAN STONE

Labelling machine

The invention relates to the field of product packing equipment, and particularly relates to a labelling machine for adhering labels to corrugated paper. The labelling machine comprises a corrugated paper conveying device for horizontally conveying the corrugated paper, a label conveying device which is erected at the upper part of the corrugated paper conveying device and is capable of synchronously conveying the labels in the same direction with the corrugated paper conveying device, and an adhering device which is erected at the upper part of the corrugated paper conveying device and is used for adhering the corrugated paper conveyed by the corrugated paper conveying device to the labels conveyed by the label conveying device. The labelling machine is capable of labelling the corrugatedpaper; the labelling process is simple; the automation degree is high; the labels can be uniformly coated with glue; the labels can be firmly and reliably adhered to the corrugated paper on the premise that the glue is saved, and the labels are smoothly adhered without any bubbles; in addition, the labelling process is basically not limited by the labelling range; the labelling machine is applicable to adhering of labels with various sizes, so that the industrial applicability is high.

Owner:ZHEJIANG GREAT SHENGDA PACKING CO LTD

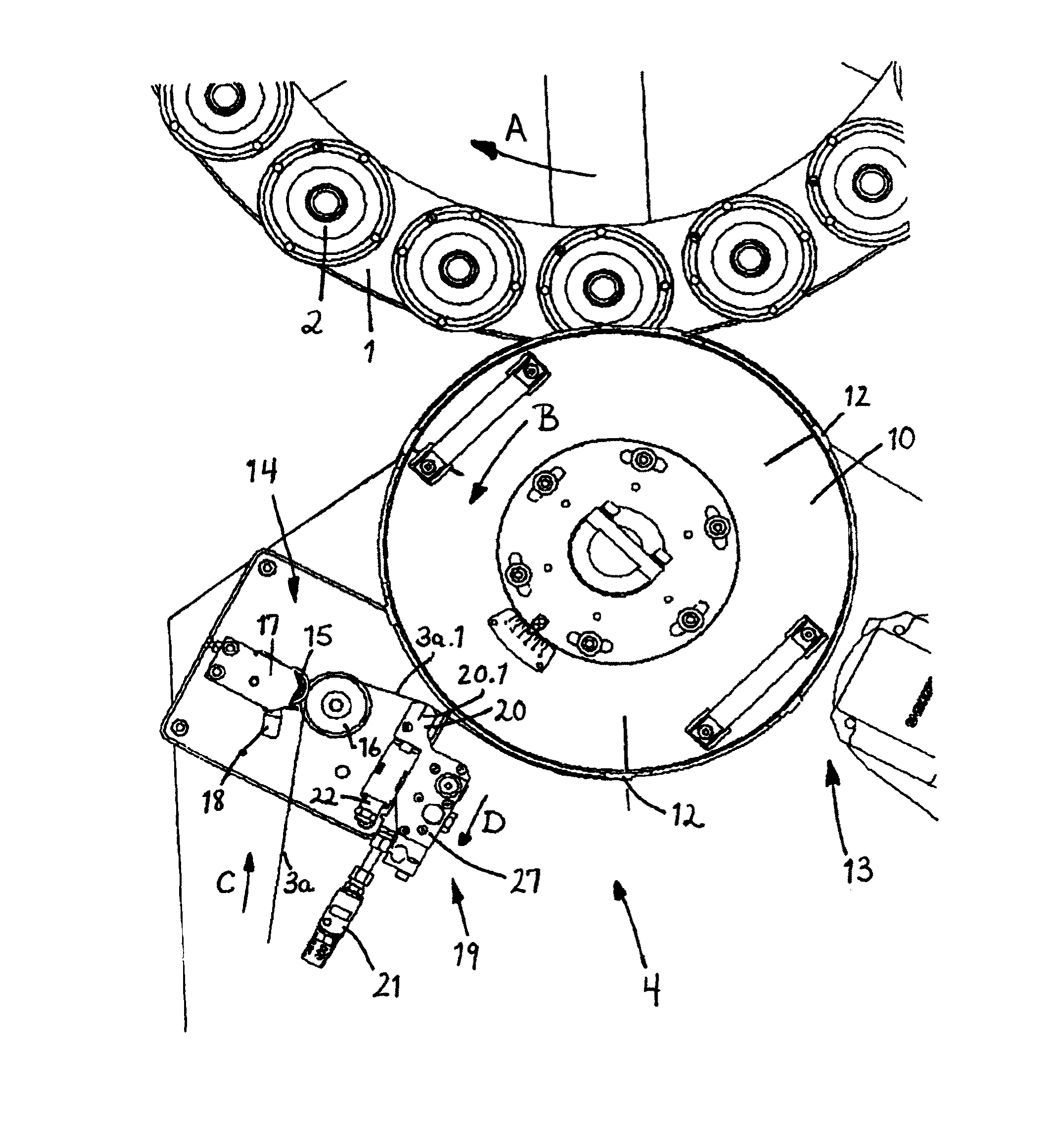

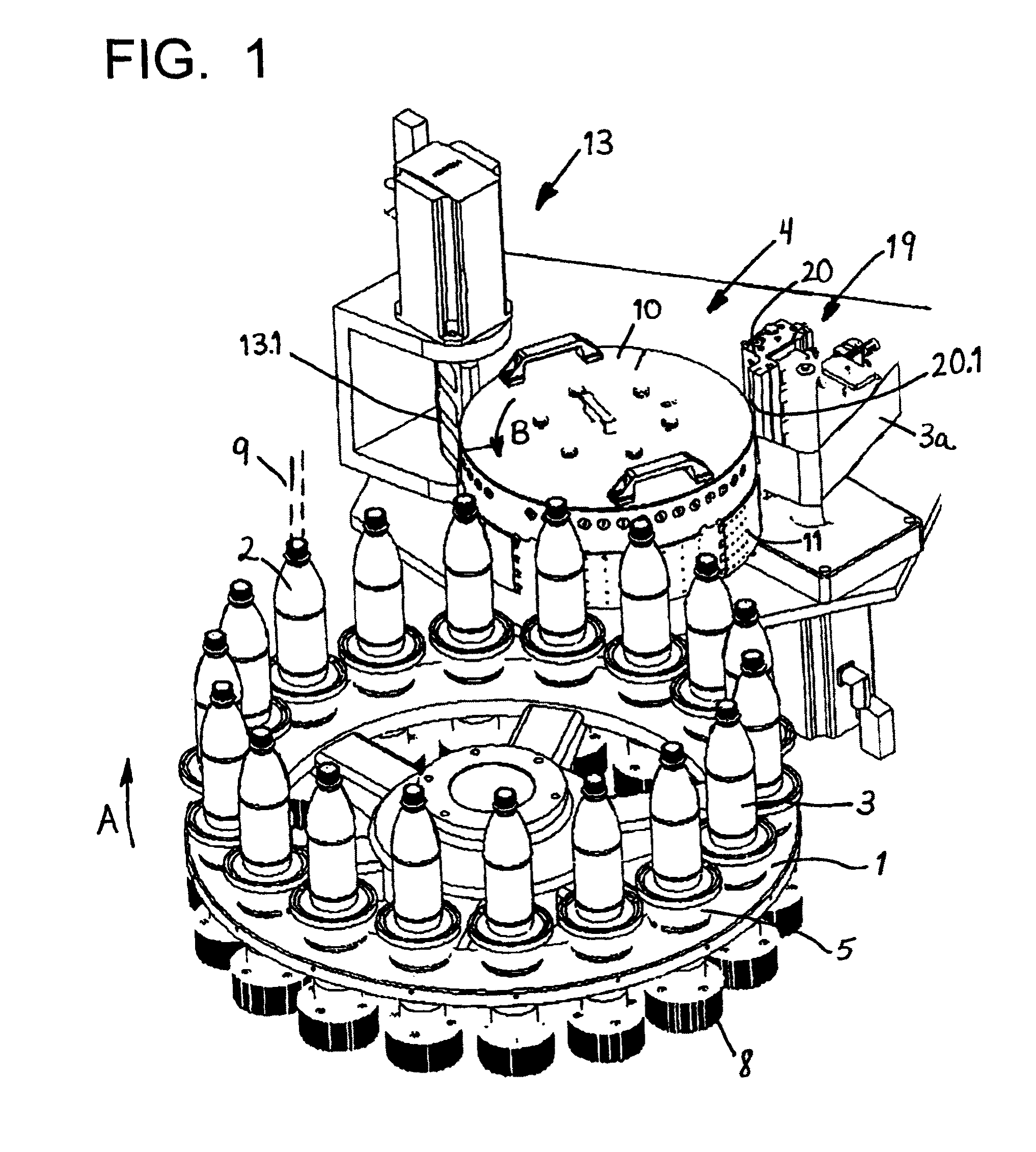

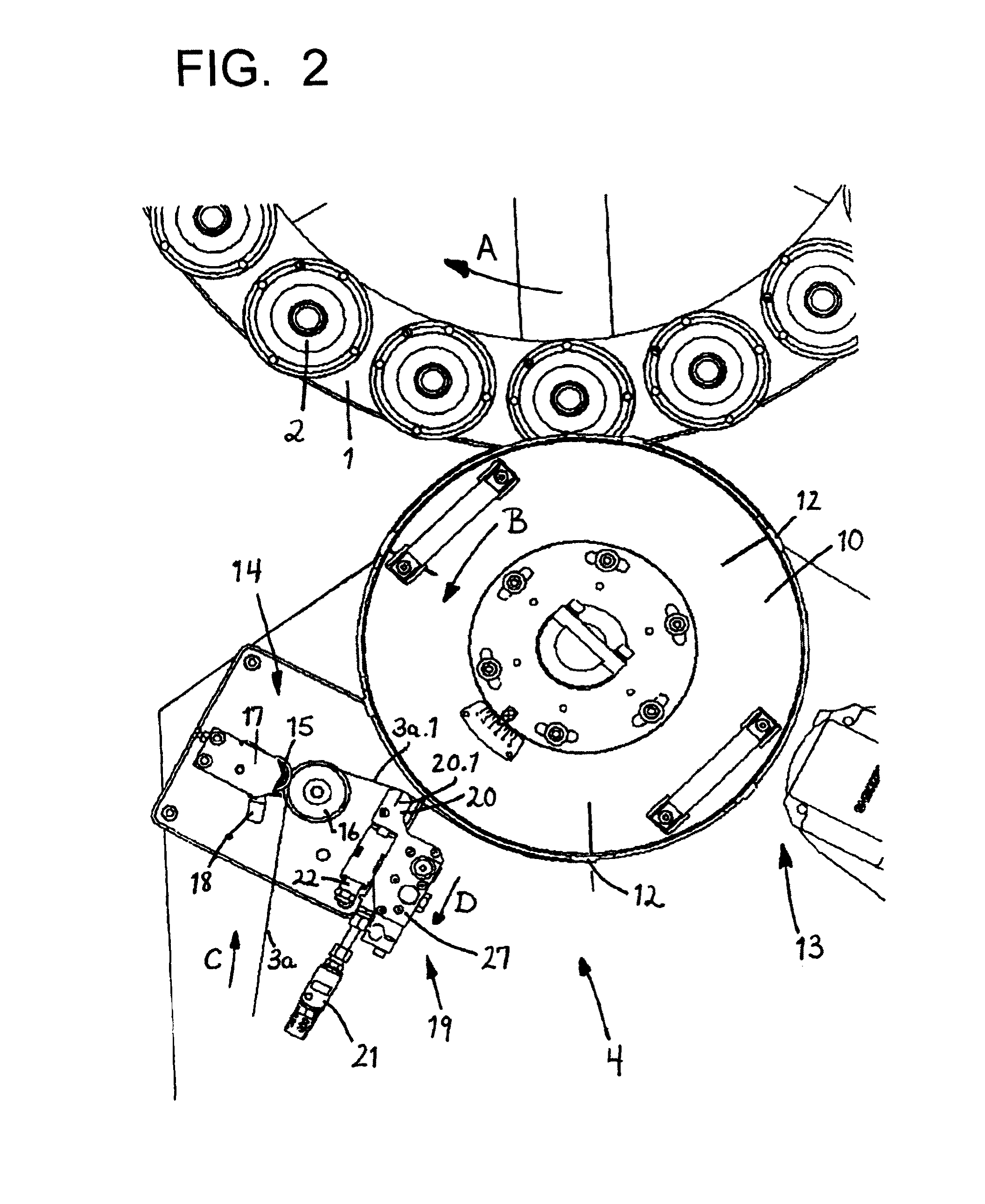

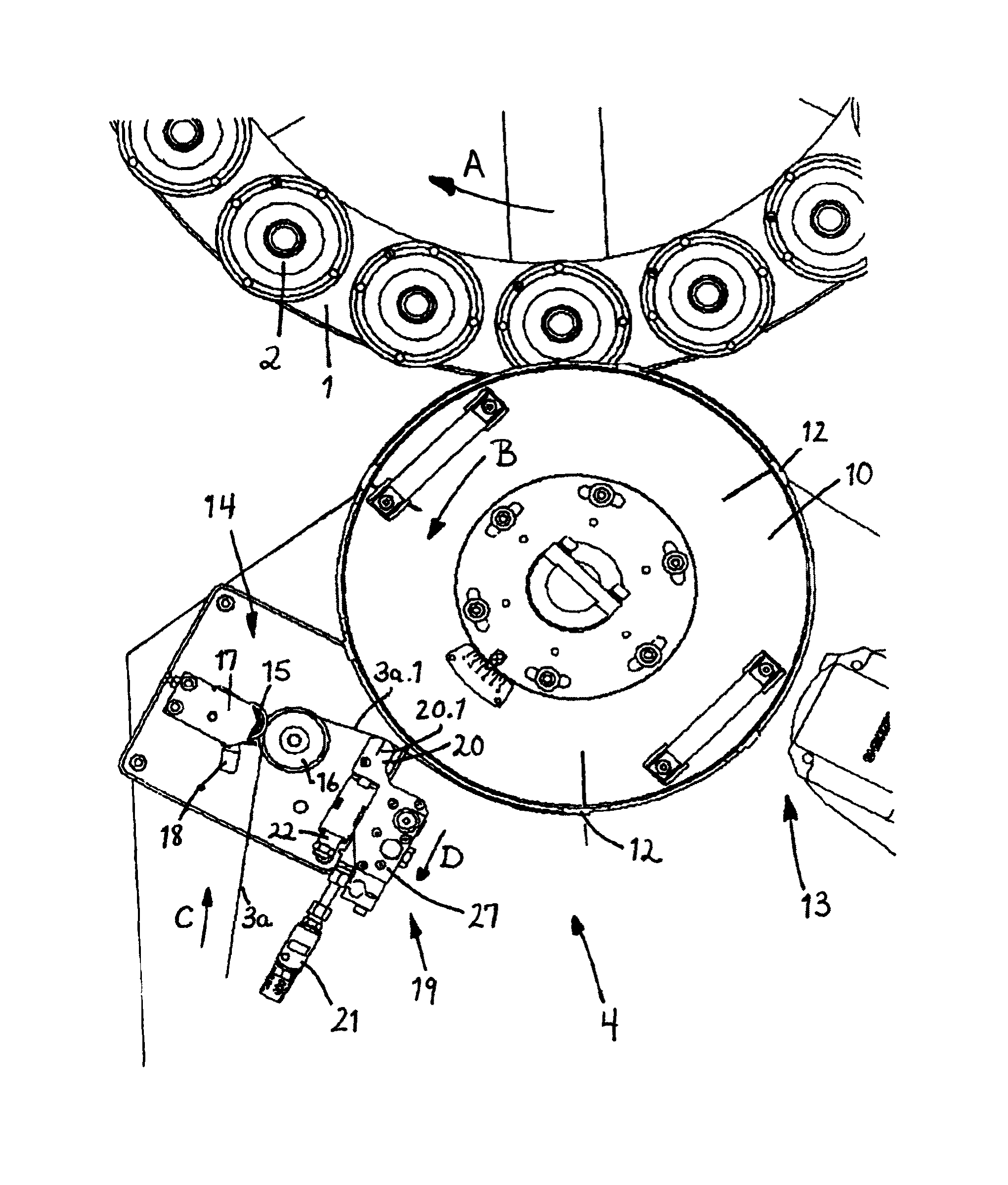

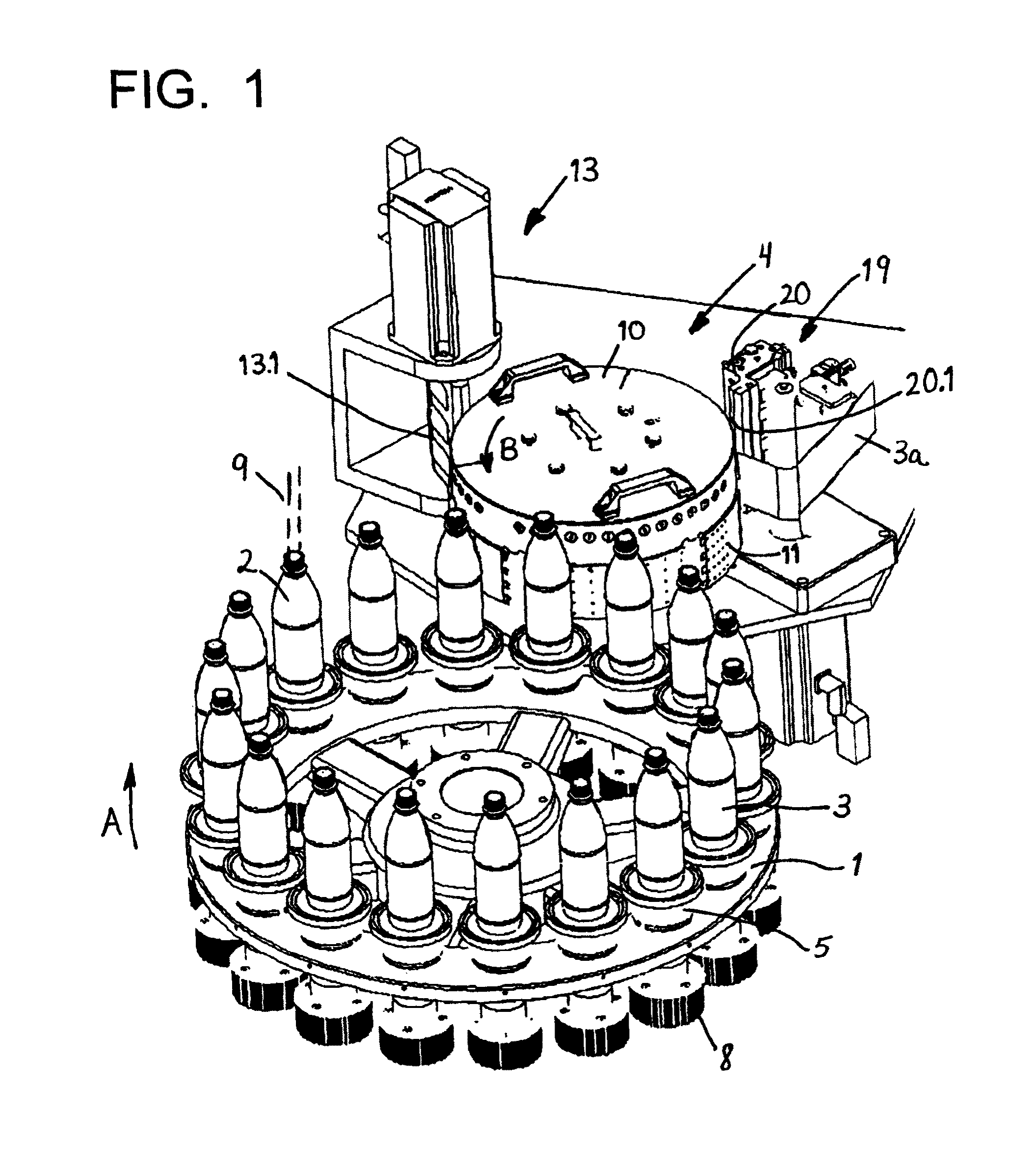

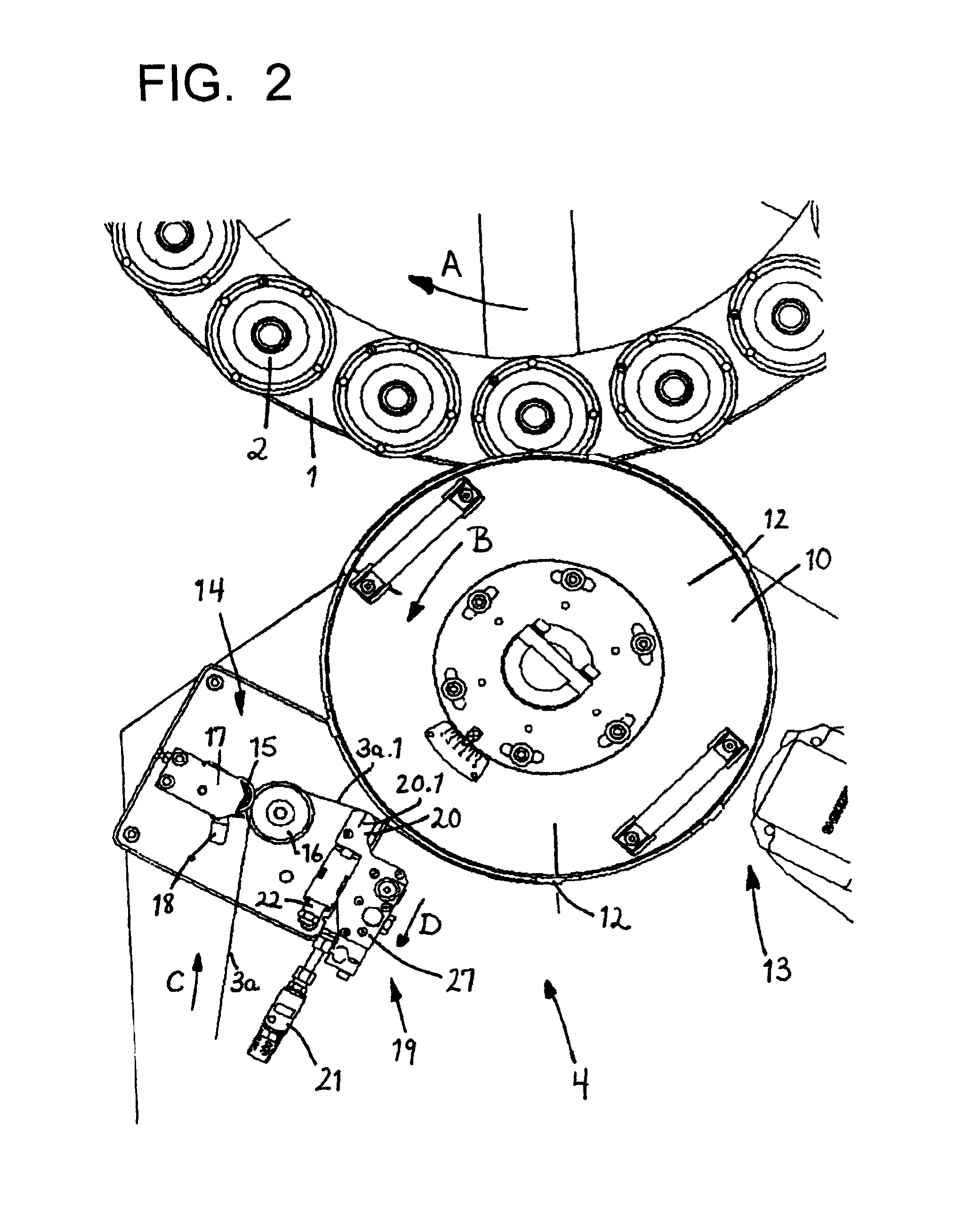

Method for labeling containers in a beverage bottling plant and a labeling station for a labeling machine in a beverage bottle labeling plant

ActiveUS20100300614A1Save glueMaximize accuracyLamination ancillary operationsLaminationTrademarkEngineering

A method for labeling containers in a beverage bottling plant and a labeling station for a labeling machine in a beverage bottle labeling plant. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

New technology for producing viscose flat monofilament

InactiveCN103614793AShort processEasy to operateSpinnerette packsFilament manufactureViscose fiberPolymer science

In order to solve the problem that the processes of viscose flat monofilaments are complex, the invention provides a new technology for producing the viscose flat monofilaments. The new technology for producing the viscose flat monofilaments is characterized in that cellulosic fiber pulp is used as the raw material to manufacture a spinning solution, a viscose fiber membrane with the width of 1.5-4.5m is ejected through a spinneret plate, the viscose fiber membrane enters coagulating bath, a postprocessing area and a drying area through a drafting roller, and after the viscose fiber membrane is dried, the viscose fiber membrane is cut into the viscose flat monofilaments with the thickness of 5-60mm. After cutting is finished, the finished viscose flat monofilaments are obtained by winding. The new technology is short in process, operation is convenient, the yield is high, and the quality of products is easy to control.

Owner:YIBIN GRACE +2

Production and preparation process of adhesive tapes

The invention relates to a production and preparation process of adhesive tapes. An installation table, an adhesive application device, an adhesive leveling device, an adhesive scraping device and a cooling device are included. The adhesive application device is installed on the left side of the upper end of the installation table, the adhesive leveling device is arranged on the right side of theadhesive application device, the adhesive scraping device is installed on the right side of the upper end of the installation table, and the cooling device is installed on the right side of the upperend of the installation table. The production and preparation process of the adhesive tapes can solve the problems that some areas are prone to adhesive leakage or excessive adhesive coating when plastic films are coated with the adhesives by rollers during adhesive application to the adhesive tapes by existing adhesive tape production equipment; too many adhesives are wasted due to the fact thatthe adhesives are applied unevenly and the temperature of the adhesives is too high as the adhesives are applied only once, and are naturally cooled normally after being applied.

Owner:江门市宝冠胶粘材料有限公司

Package cushion pad

InactiveCN103318542ASave storage spaceSave stickersContainers to prevent mechanical damageCushionEngineering

A package cushion pad can be used for accommodating an article object after being folded, and is characterized by being made of foaming material and including a plane body, a plurality of bending parts and a plurality of holes, wherein the bending parts are positioned on the plane body to fold the plane body, and divide the plane body into at least three connected sub bodies. According to the invention, the openings are formed in the at least three sub bodies, when the plane body is bended and folded along the bending parts, any two adjacent sub bodies are mutually and tightly clung, so that the holes form an embedded groove to accommodate the article object.

Owner:ELITEGROUP COMPUTER SYSTEMS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com