Transformer shell gluing device and gluing method with same

A technology for a transformer casing and a transformer is applied in the field of the casing glue filling device, which can solve the problems of difficult operation, complex structure of the glue filling device, unsuitable for the transformer casing, etc., so as to save costs, improve the filling efficiency, and save the filling. The effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

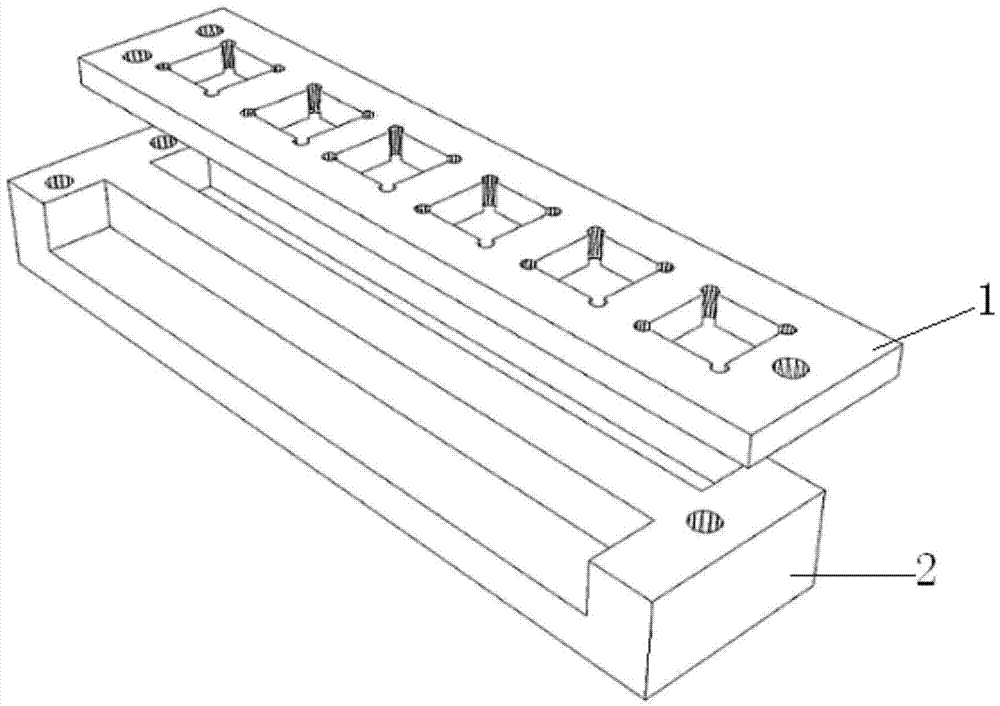

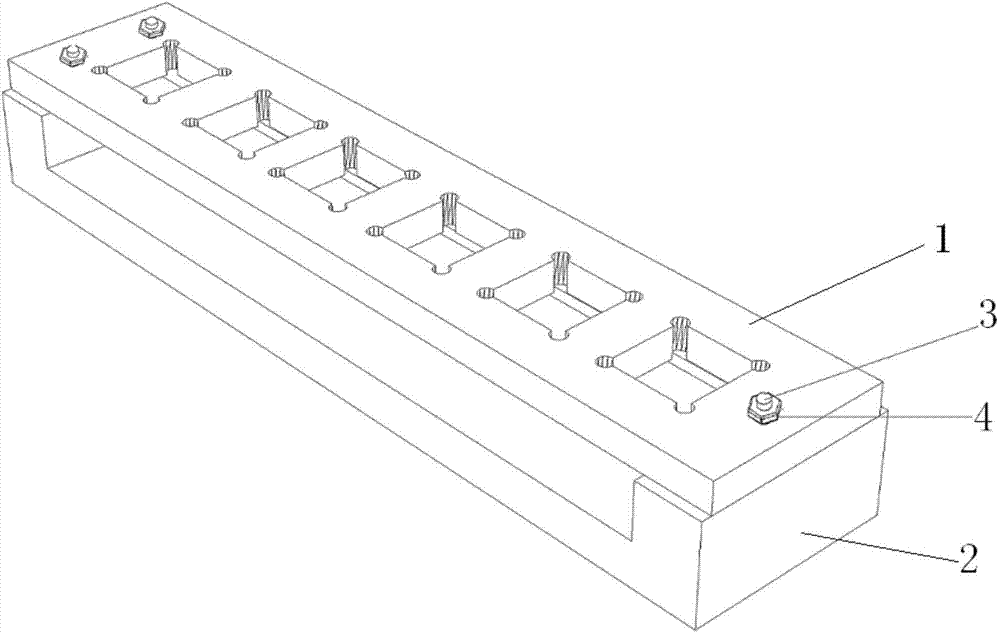

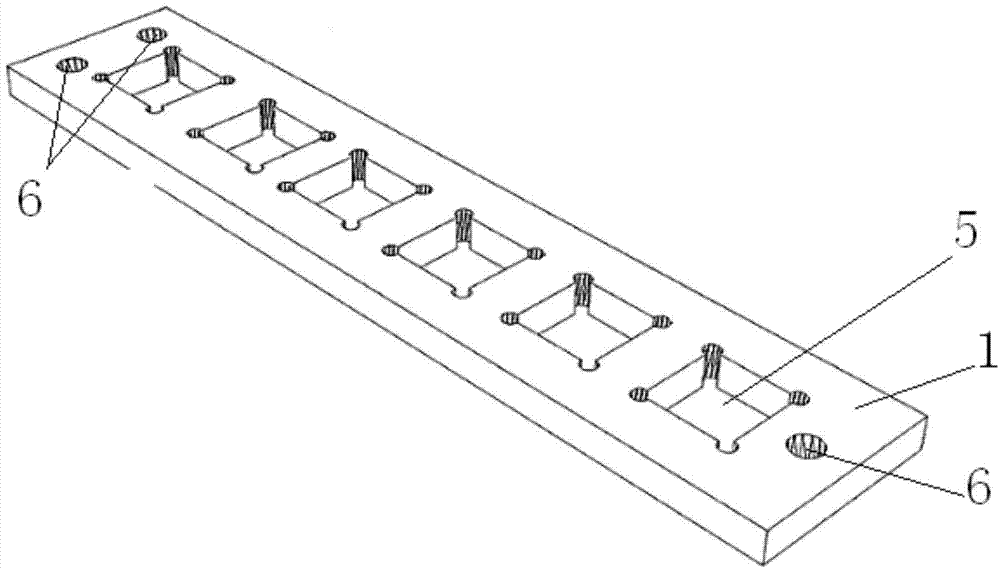

[0026] The transformer shell glue filling device according to the present invention and the glue filling method using the device will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0027] The following is an example of a glue filling device that can simultaneously glue six transformer shells. However, it should be noted that the number of through slots can be selected according to the actual situation, and is not limited to 6.

[0028] Such as Figure 6 Shown is a cross-sectional view of the transformer structure of the transformer casing potting device according to the present invention. The transformer coil 9 (winding 10, magnetic core 11) is wound with raw material tape for one circle, and the outlets on both sides of the raw material tape respectively connect the primary pins 12 on one side, and the secondary pin 13 on the other side, then slowly wrap the raw material tape on the outlet side lightly to seal, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com