Midsole prepared from straws and special for moulded shoe and preparation method of midsole

A molding and straw technology, which is applied in the special midsole for molded shoes and its preparation field, can solve the problems of environmental pollution, difficult handling, and increased weight, and achieve the effects of environmental protection, low cost, and less glue brushing personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

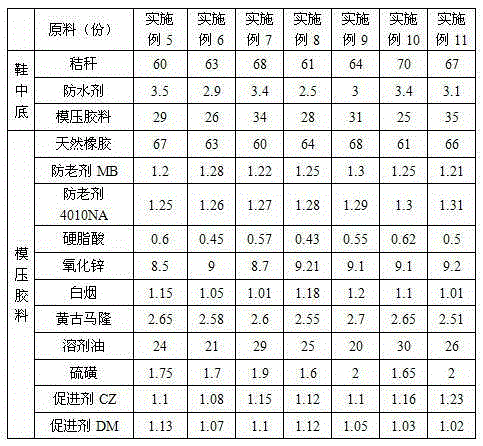

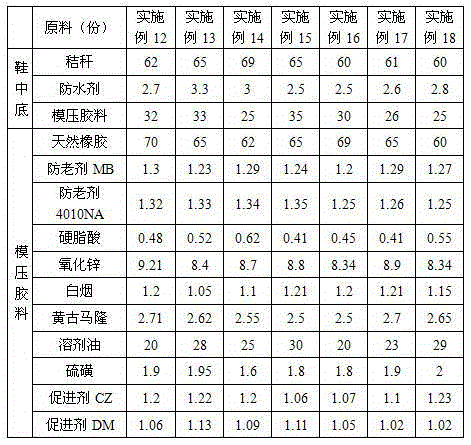

[0024] A special midsole for molded shoes made of straw is prepared from the following raw materials in parts by weight: 60-70 parts of straw, 2.5-3.5 parts of waterproofing agent, and 25-35 parts of molding rubber. The waterproofing agent is preferably an acrylic resin with waterproof function. The molded rubber can be used in the prior art to make molded rubber for the sole of molded shoes. The vulcanizing agent and vulcanization accelerator in the molded rubber preferably have good post-vulcanization properties. performance. Preferably, the molding compound is composed of natural rubber, anti-aging agent, auxiliary agent, solvent oil, vulcanizing agent and vulcanization accelerator. The anti-aging agent is preferably used in combination with anti-aging agent MB and anti-aging agent 4010NA. The auxiliary agent is composed of activator stearic acid, Composed of zinc oxide, reinforcing agent white smoke, tackifier yellow coumarone, solvent oil is preferably No. 120 solvent oil...

Embodiment 2

[0035] A special midsole for molded shoes made of straw is prepared from the following raw materials in parts by weight: 70 parts of straw, 3 parts of acrylic resin waterproofing agent, and 30 parts of molding rubber. The molding compound is composed of the following raw materials in parts by weight: 65 parts of natural rubber, 1.2 parts of anti-aging agent MB, 1.3 parts of anti-aging agent 4010NA, 0.5 parts of stearic acid, 8.5 parts of zinc oxide, 1.1 parts of white smoke, yellow Coumarone 2.6 parts, 25 parts of solvent oil, 2.0 parts of sulfur, 1.1 parts of accelerator CZ, and 1.1 parts of accelerator DM.

[0036] The method for preparing the midsole for molded shoes made of straw includes the following steps:

[0037] (1) Straw treatment: Wash and dry the straw, remove debris and straw branches and leaves, leaving only the wooden poles to be crushed through a 100-mesh sieve;

[0038] (2) Production of masticated rubber material: masticate the natural rubber, then add the ...

Embodiment 3

[0046] A special midsole for molded shoes made of straw is prepared from the following raw materials in parts by weight: 60 parts of straw, 2.5 parts of acrylic resin waterproofing agent, and 25 parts of molding rubber. The molding compound is composed of the following raw materials in parts by weight: 65 parts of natural rubber, 1.25 parts of anti-aging agent MB, 1.3 parts of anti-aging agent 4010NA, 0.41 parts of stearic acid, 8.34 parts of zinc oxide, 1.21 parts of white smoke, Huang Coumarone 2.50 parts, 25 parts of solvent oil, 2.0 parts of sulfur, 1.06 parts of accelerator CZ, and 1.1 parts of accelerator DM.

[0047] The method for preparing the midsole for molded shoes made of straw includes the following steps:

[0048] (1) Straw treatment: Wash and dry the straw, remove debris and straw branches and leaves, leaving only the wooden poles to be crushed through a 100-mesh sieve;

[0049] (2) Production of masticated rubber material: masticate the natural rubber, then a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com