Patents

Literature

90results about How to "No pollution hazard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

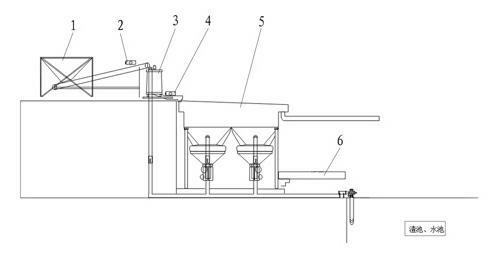

Apparatus and method for reclaiming, purifying and reutilizing boring mud

InactiveCN1803680ARealize automatic continuous operationSimple structureWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningParticulatesMicrowave oven

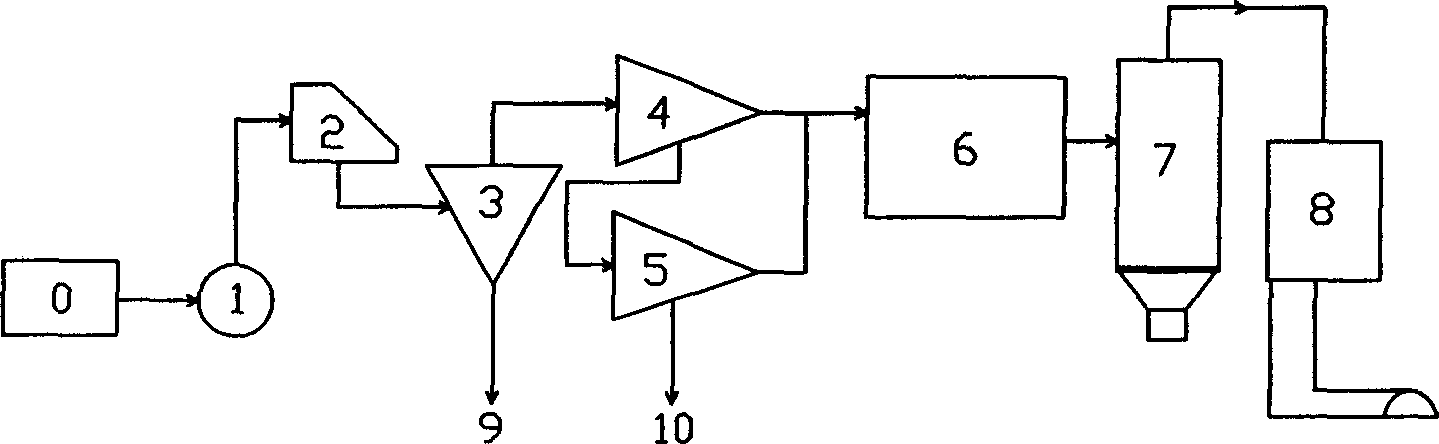

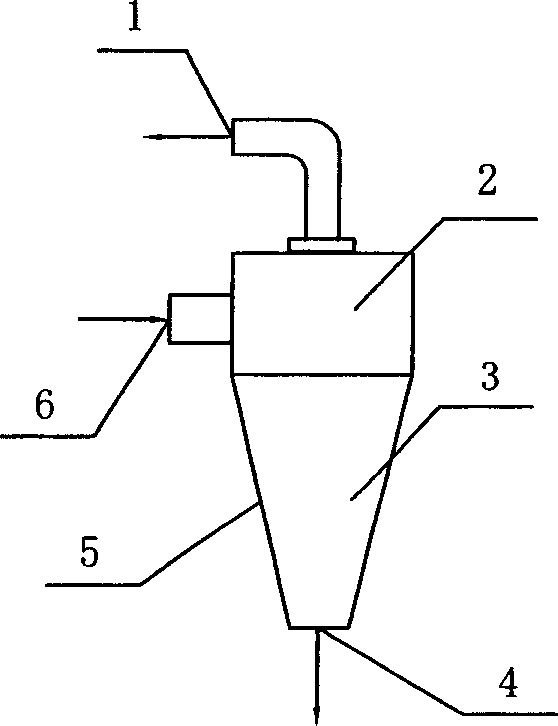

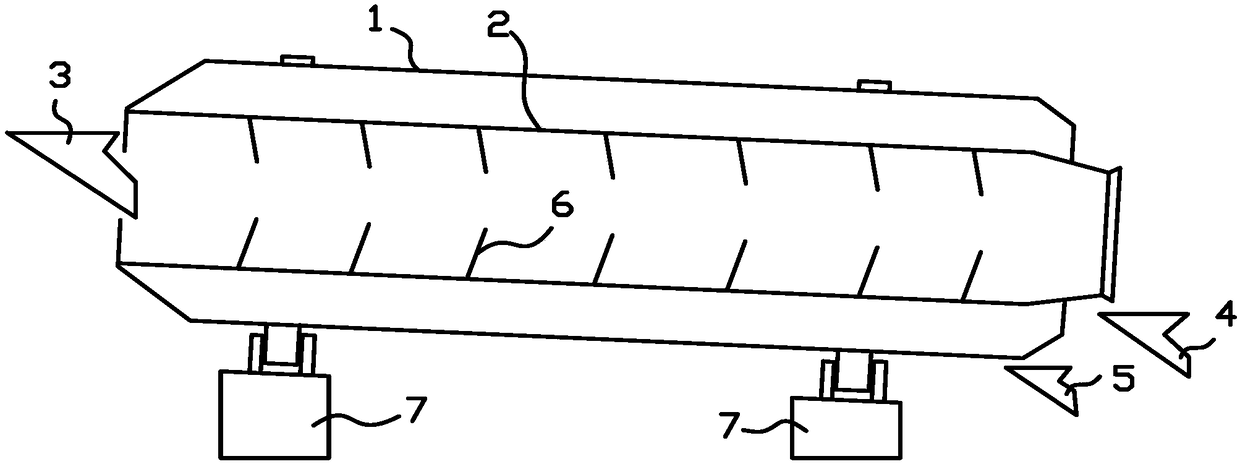

The invention discloses a device system to recover and re-use the drilling mud, which comprises connected by turns: a storage tank to store the waste drilling mud, a vibration screen for coarse purification, a hydrocyclone to separate the mud conveyed by a mud pump and discharge the particulate from its lower end, a first-stage centrifuge for filter and purification, a microwave oven to dry the mud, a crusher to crush the mud again, and an automatic packaging machine to pack and recover the mud. This invention is simple and convenient, has low cost and no pollution danger, and brings hundred millions economic benefits every year.

Owner:王鸿飞 +1

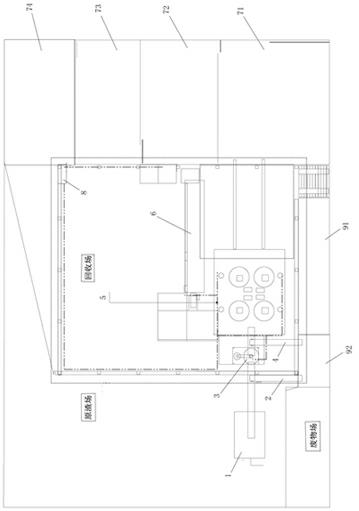

Sorting and separation process for comprehensive utilization of slag

InactiveCN102284350AImprove resource utilizationNo pollution hazardGrain treatmentsWet separationGravity separationHeavy metals

The invention discloses a sorting and separation process for utilizing slag comprehensively. The process comprises the following steps of: crushing pretreated original slag in a wet method, performing magnetic separation to select crushed iron granules, and performing gravity separation on slag charge, so that light products, heavy products and intermediate fine materials are separated out by taking water as a separating medium; and purifying metal subjected to the gravity separation by an ore dressing table concentrator, and sorting the metal. In the process, four kinds of products are sorted by combining crushing equipment and gravity separation equipment under the hydraulic action, and also cay be recycled, wherein like natural gravels, the sorted intermediate fine material sand is a high-quality material for producing high-quality building materials; and in the key point of the process, metal substances in the slag are sorted and separated, so the problems of secondary pollution (including the radiation pollution of heavy metal) during application and the like are solved.

Owner:S_QBEE SHISHI ENVIRONMENTAL PROTECTIVE BUILDINGMATERIALS

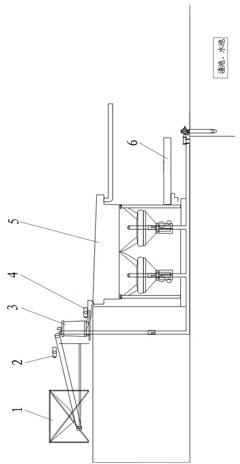

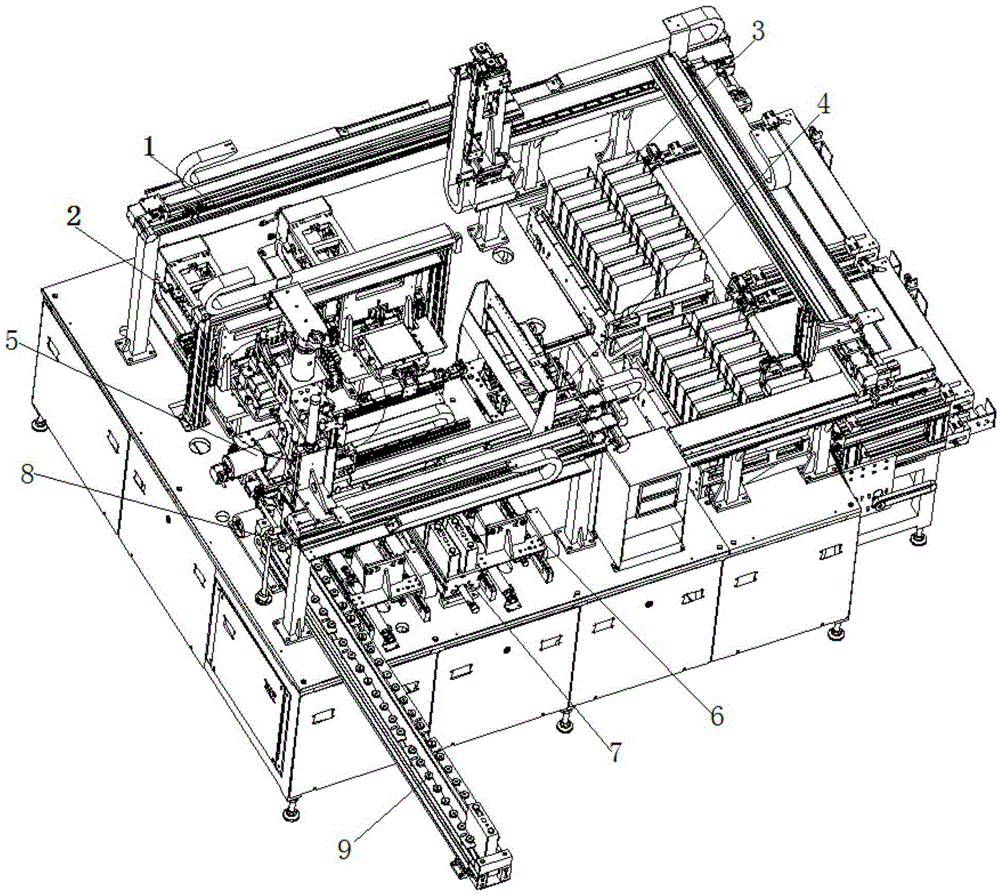

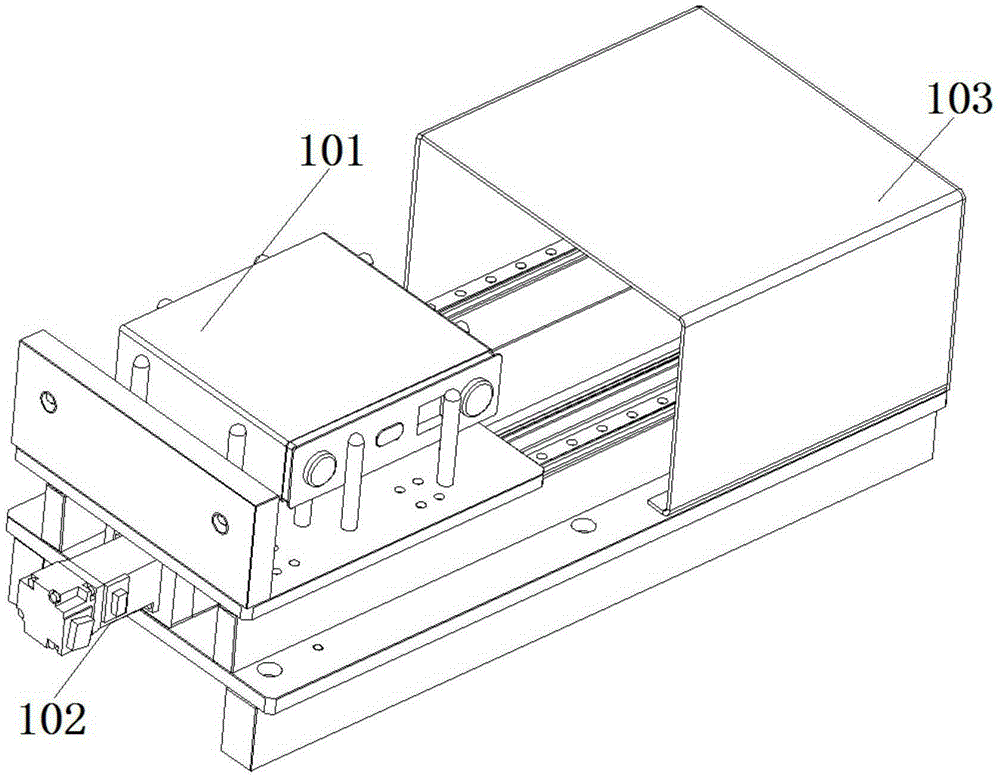

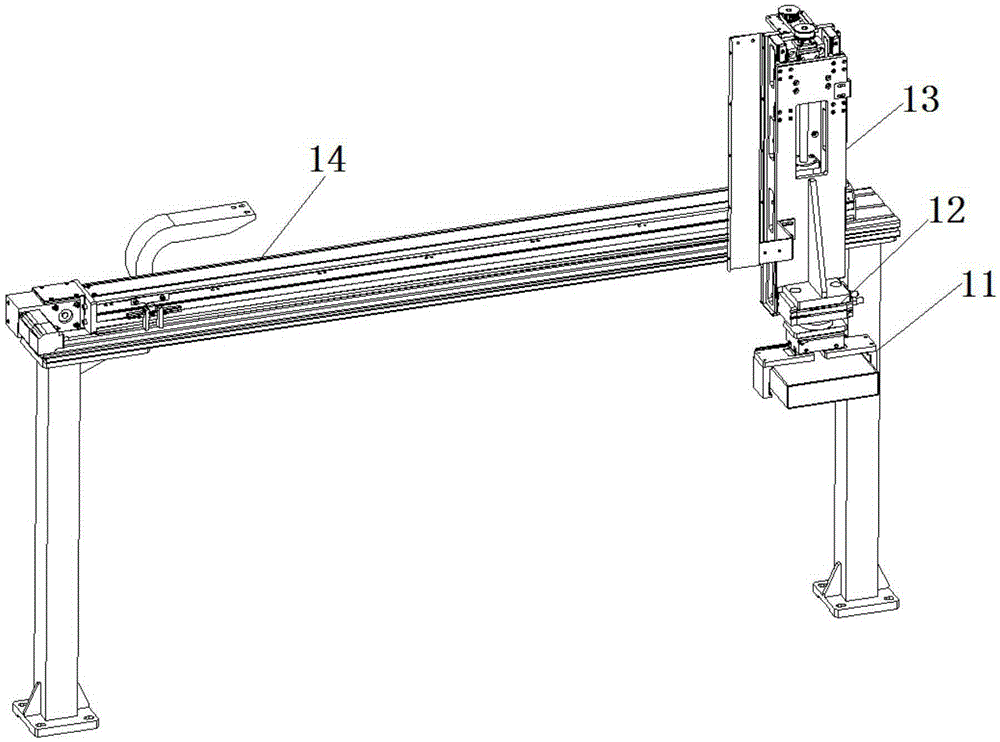

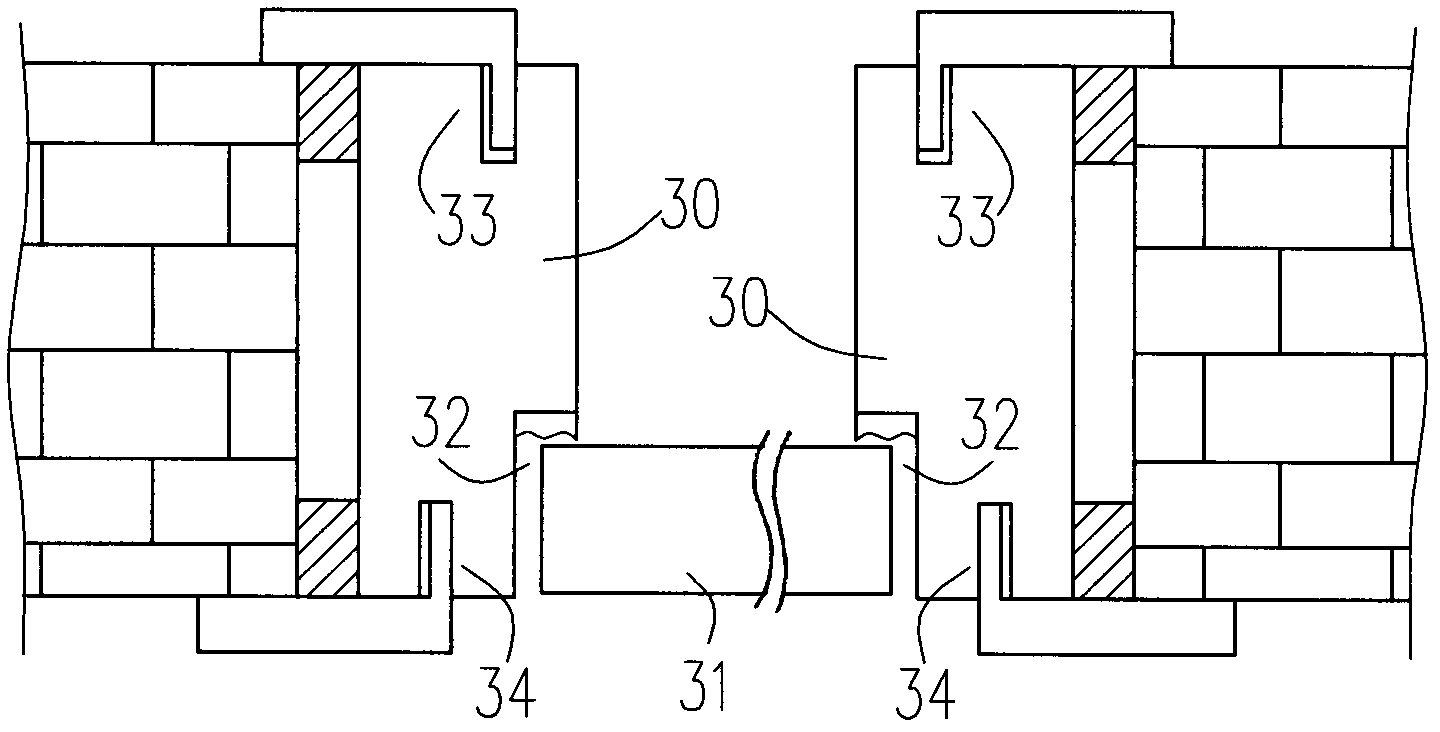

Machine for automatically mounting battery cell of square power battery into shell

PendingCN105390732AQuality assuranceGuaranteed efficiencyAssembling battery machinesFinal product manufacturePower batteryEngineering

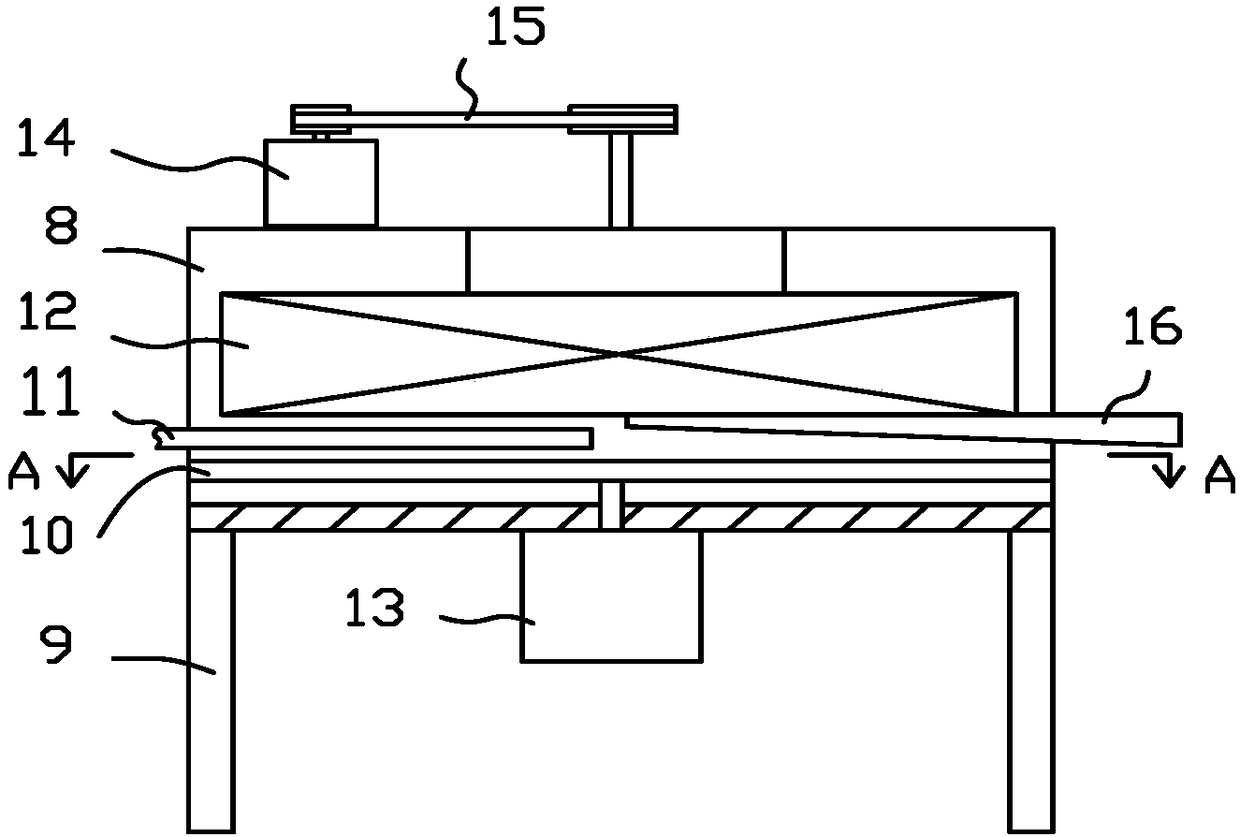

The invention discloses a machine for automatically mounting a battery cell of a square power battery into a shell. The machine comprises a machine frame, wherein a bare battery cell dust removal component used for performing dust removal on a bare battery cell is arranged on the machine frame; an aluminum shell charging component used for conveying an aluminum shell is further arranged on the machine frame; an aluminum shell dust removal component used for performing dust removal on the aluminum shell on the aluminum shell conveying component is further arranged on the machine frame; a tool component used for mounting the bare battery cell into the aluminum shell is further arranged on the machine frame; a bare battery cell charging mechanical hand used for picking the bare battery cell subjected to dust removal on the bare battery cell dust removal component and conveying the bare battery cell subjected to dust removal into a bare battery cell discharging position of the tool component is further arranged on the machine frame; a rotary mechanical hand component used for picking the aluminum shell on the aluminum shell dust removal component and conveying the aluminum shell into an aluminum shell charging position of the tool component is further arranged on the machine frame; an HI-POT test component used for performing an HI-POST test on the battery comprising the bare battery cell and the aluminum shell is further arranged on the machine frame; and a discharging pull line component is further arranged on the machine frame.

Owner:SHENZHEN YUCHEN AUTOMATION EQUIP CO LTD

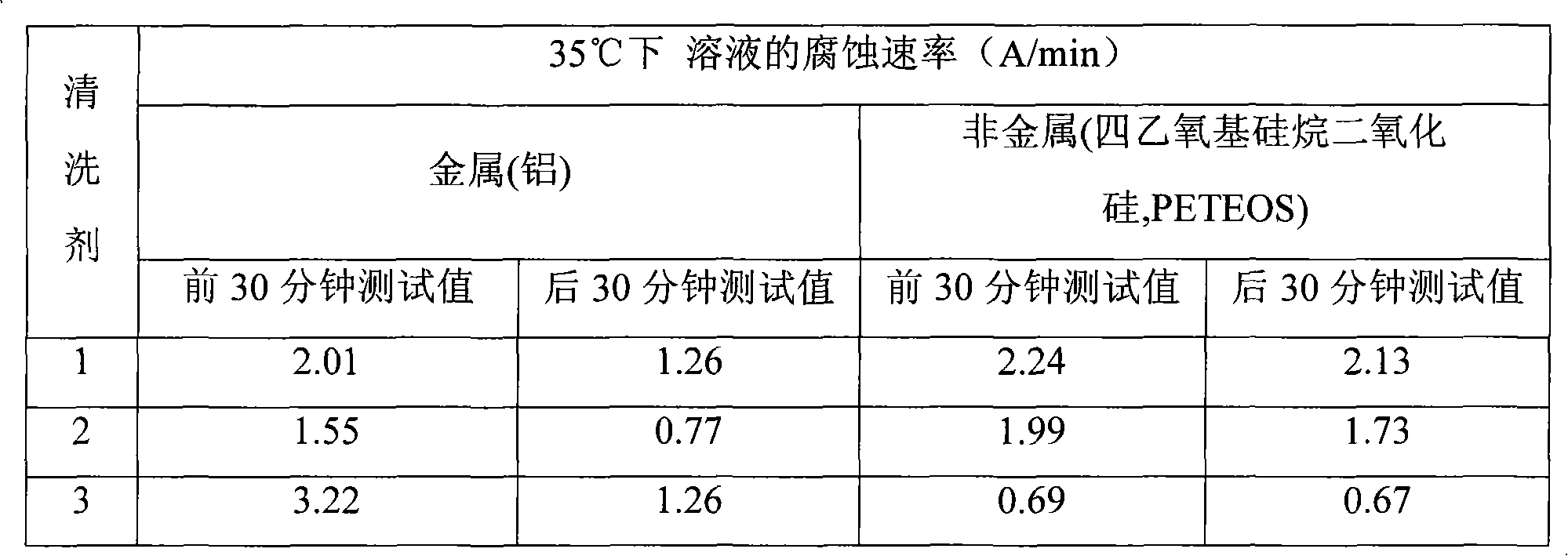

Cleaning fluid for cleaning plasma etching residue

InactiveCN101290482AImprove cleaning efficiencyEfficient and stable cleaning effectNon-surface-active detergent compositionsDetergent mixture composition preparationSilanesSolvent

The invention discloses washing liquid used in the semiconductor industry to wash plasma etching residues. The washing liquid contains citric acid / citrate buffer solution, fluorides, macromoledular corrosion inhibitor, anti-freeze agent and solvent. The washing liquid can effectively wash the plasma etching residues during the process of manufacturing a semiconductor, have low etching velocity on nonmetals and metal substrates such as Si, SiO2, tetraethoxy silane silicon dioxides (PETEOS), low-medium materials, Ti, Al, Cu and so on, is safe and harmless to the environment and the human body, and has good application prospect in the microelectronic field such as washing of semiconductor wafers and so on.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

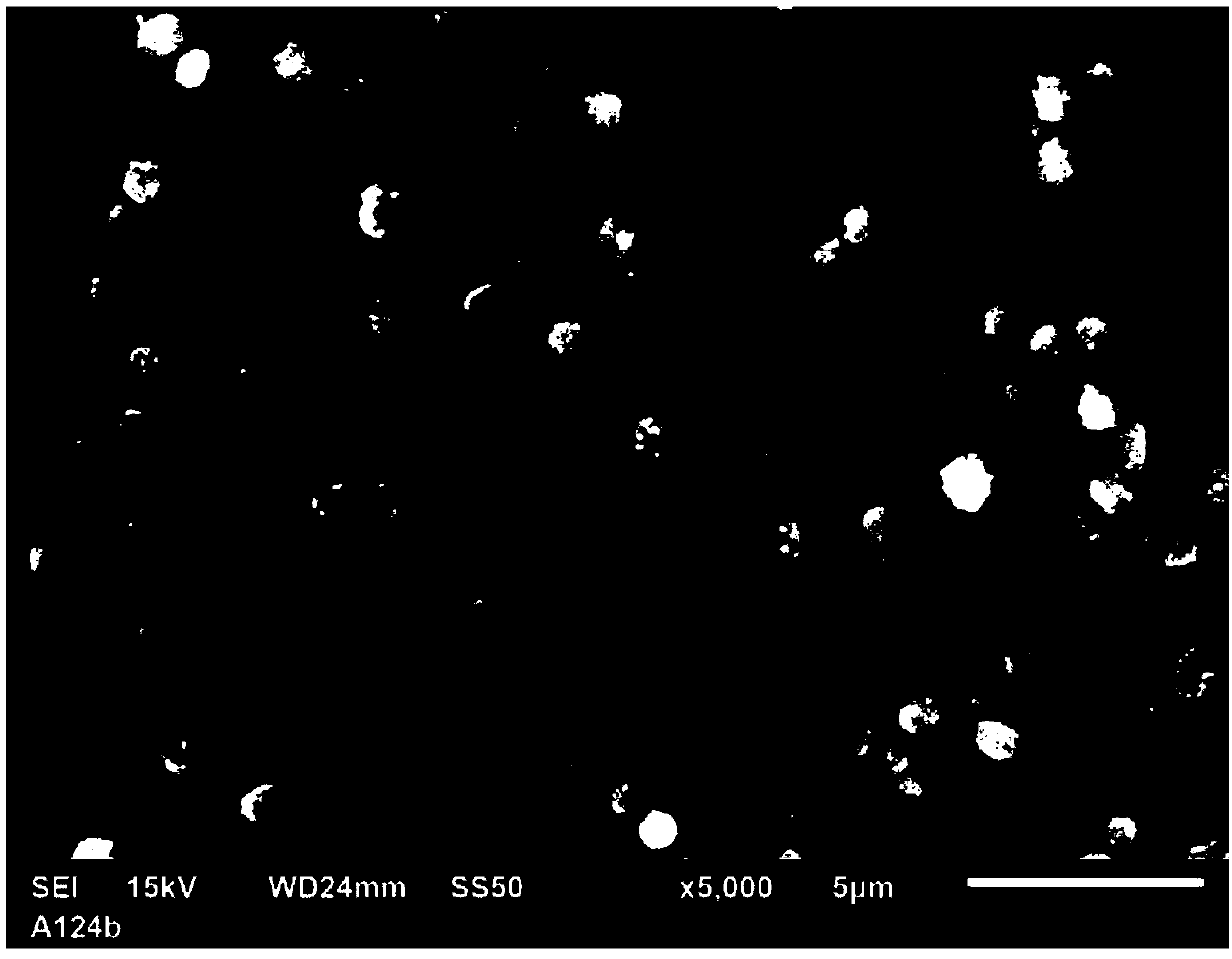

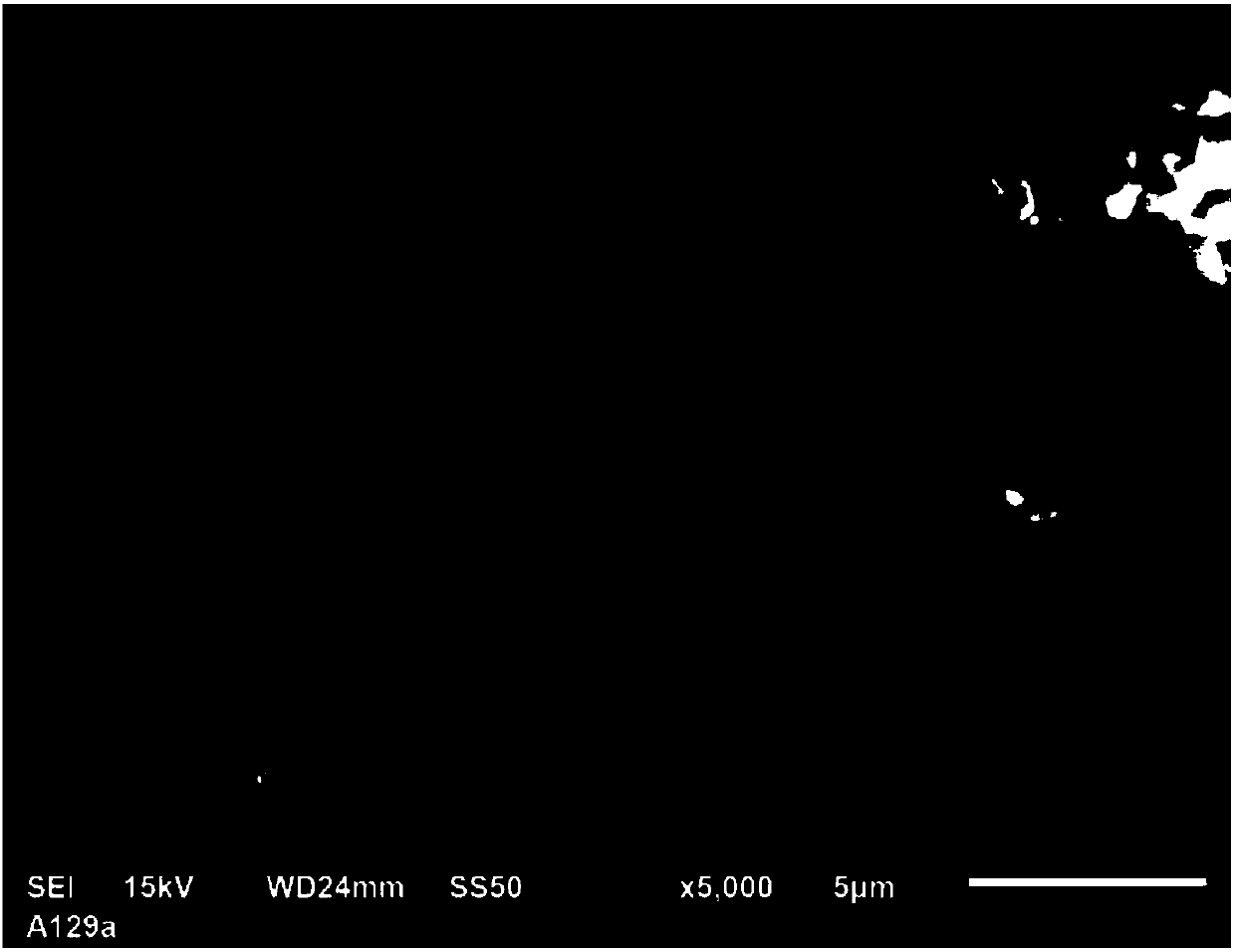

Method for rapid preparation of SiO2 aerogel micro-balloons

The utility model relates to a rapid preparation method of SiO2 aerogel sphere, belonging to a field of inorganic metallic materials, in particular to a method of rapidly preparing SiO2 aerogel sphere. Water glass is used as raw material that performs ion exchange to obtain the silicic acid PH=2-3, after added with alkaline catalyst, the silicic acid is added into the hydrophobic oil, and then is mixed to cut into micro liquid drops that are spherically suspended in the oil under the action of surface tension, the silicic acid is mixed until aerogel sphere is generated, afterwards, the oil and the sphere perform solid-liquid separation, and then are cleaned with water to obtain aerogel sphere, the aerogel sphere is soaked by the ethanol and absolute alcohol in sequence to perform solvent exchange to obtain alcohol gel sphere, after dried, aerogel sphere with micrometer or millimeter grade particles can be otained. The invention has low cost, easy and controllable process, mass production, good product quality and wide application prospect in the heat isolation and catalysis fields.

Owner:UNIV OF SCI & TECH BEIJING

Process for extracting lithium from lithionite by fluorine chemistry

InactiveCN101885496AReduce production energy consumptionNo pollution hazardLithium compoundsReaction temperatureLiquid solid

The invention provides a process for extracting lithium from lithionite by fluorine chemistry, comprising the following steps: throwing raw materials of lithionite powder, an additive and sulfuric acid based on the weight ratio of 1: (0.1-2): (0.5-5) into a pre-reactor, and then stirring to react or simply stirring and then throwing the raw materials into the reactor to react, wherein, the additive is one or more of a fluorine-containing mineral substance, salt or acid; reaction conditions in the pre-reactor are as follows: preheating the raw materials at the temperature of 50-150 DEG C for 0.1-2 hours, and then transferring into the reactor to react at the temperature of 150-350 DEG C for 0.5-4 hours; immediately evacuating the gas generated during the reaction process; leaching the obtained reaction residue with water and then carrying out liquid-solid separation to obtain a sulfate liquor; and adjusting pH into 5.0-10.0 to eliminate ionic impurities such as aluminum, magnesium, calcium, ferrum and the like; and after the liquid-solid separation is carried out, concentrating the sulfate liquor, precipitating lithium ions and then filtering to obtain a crude lithium salt product or the corresponding refined lithium salt product as required. The process of the invention has the advantages of low reaction temperature, small production energy consumption and high lithium extraction efficiency; and various valuable components of the lithionite mineral substance can be comprehensively utilized during the production process of lithium salt.

Owner:江西海汇龙洲锂业有限公司

Selenium-rich agaricus bisporus production method using selenium-rich crop straws

InactiveCN104604519ASolving RecyclingImprove protectionCalcareous fertilisersExcrement fertilisersAgaricusBiotechnology

The present invention discloses a selenium-rich agaricus bisporus production method using selenium-rich crop straws. Selenium-rich crop straws with 50%-70% of the total weight of cultivation dry materials are mixed into the cultivation dry materials. The selenium-rich agaricus bisporus production method uses natural selenium-rich crop straws as raw materials, has a high selenium utilization and no pollution problems, and can solve the crop straw recycling problem, is environmentally friendly, is simple and easy to operate, and improves the selenium content of agaricus bisporus to 0.2-1.5 mg / kg.

Owner:ANHUI YULONG NEW MATERIALS TECH

Method for extracting and separating nickel and molybdenum from nickel-molybdenum-containing coal gangue

InactiveCN102199710AHigh recovery rateNo pollution hazardProcess efficiency improvementSodium bicarbonateSulfur

The invention discloses a method for extracting and separating nickel and molybdenum from nickel-molybdenum-containing coal gangue. The method comprises the steps of: pulverizing raw ores and blending sodium carbonate to prepare pellets, and smelting the coal gangue at high temperature by using carbon contained in the coal gauge per se to extract nickel and obtaining ferro-nickel alloy and molten slag; lixiviating the ferro-nickel alloy with water to obtain molybdenum-containing lixivium; and carbonating the molybdenum-containing lixivium by using CO2-containing furnace gas generated in high-temperature smelting to precipitate sulfur and sodium hydroxide in sequence, and filtering to obtain the sulfur and the sodium hydroxide, wherein the sodium carbonate is recycled for the step of high-temperature smelting, and filtrate is further subjected to a molybdenum wet-process smelting process for molybdenum extraction. Compared with the traditional method, the method disclosed by the invention is an efficient, economic and harmless production method and has the advantages that a carbon reducing agent is unnecessary to add, the nickel and the molybdenum are effectively separated and have high purity and raw materials are utilized comprehensively and favorably.

Owner:CENT SOUTH UNIV +2

Method for modifying carbon porous material

ActiveCN102522569ANo pollution hazardEnsure consistencyCell electrodesActivated carbonElectrical battery

The invention provides a method for modifying a carbon porous material, characterized in that by applying a high pressure pulse voltage on two opposite plate electrodes and inserting an electrolyte plate which has a high dielectric constant and a compact structure and has an area that is slightly larger than the size of the plate electrodes between the two opposite plate electrodes, a uniform discharge plasma reaction zone is formed between the plate electrodes; mixed gasses containing oxygen are uniformly mixed at normal temperatures and pressures, the mixed gasses are subject to ionization activation by the plasma reaction zone to generate a plurality of oxygen-containing plasma gasses, after gas distribution is carried out, the gasses vertically flow through a pre-cleaned carbon porous material in the thickness direction to react to obtain the activated carbon porous material. The method has the advantages of environmental protection, low cost, mild treatment conditions, easy control of function group quantity, and outstanding improvement of the activity of the electrode material, and the method can realize gradient treatment, can reduce the area resistance of the contacting surface of the porous material and the bipolar plate, so as to increase the battery efficiency. The method uses devices, thus the method is easy for industrialized operation.

Owner:DONGFANG TURBINE CO LTD

Method for cultivating pleurotus eryngii uniformly rich in selenium with mixed organic selenium source

InactiveCN102150556AHigh Selenium UtilizationNo hidden danger of selenium pollutionHorticultureFertilizer mixturesPleurotus eryngiiPleurotus

The invention discloses a method for cultivating pleurotus eryngii uniformly rich in selenium with a mixed organic selenium source. The method is characterized in that the method comprises the steps of mixing selenium-rich cultivating material additive accounting for 1-10 percent of the total weight of dried cultivating material into the dried cultivating material, and cultivating pleurotus eryngii according to an ordinary cultivation method to obtain pleurotus eryngii uniformly rich in selenium; the selenium-rich cultivating material additive has a total selenium content of 5-50 mg / kg, and needs to be crushed first and then compressed to form particles of certain grain sizes, the grain sizes of the particles in the selenium-rich cultivating material additive are in the range of 0.005-5.0 mm with multi-grain-size regional distribution, the particles having a grain size of 1.0-5.0 mm account for about 10 weight percent of the total weight of the additive, while the particles having a grain size of 0.005-0.1 mm account for at least 40 weight percent of the total weight of the additive. The method has the advantages that the selenium utilization factor of the cultivating material in pleurotus eryngii is high, the selenium content in different batches of picked pleurotus eryngii is stable, therefore, the method is highly safe, convenient to operate, and easy to promote.

Owner:SUZHOU SETEK

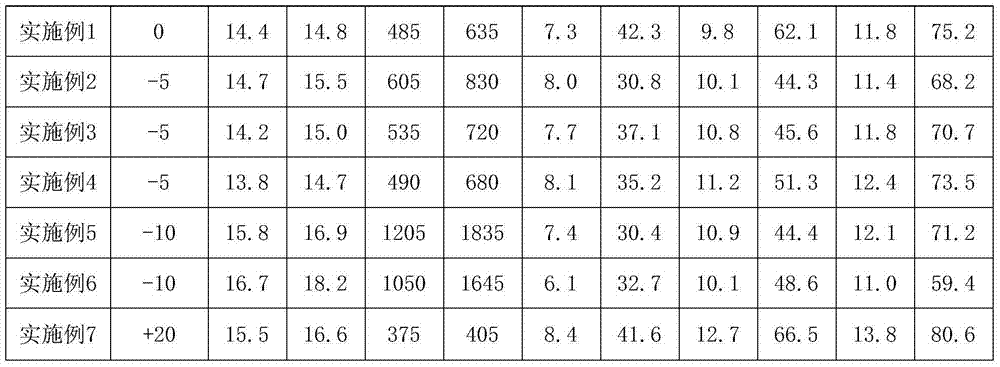

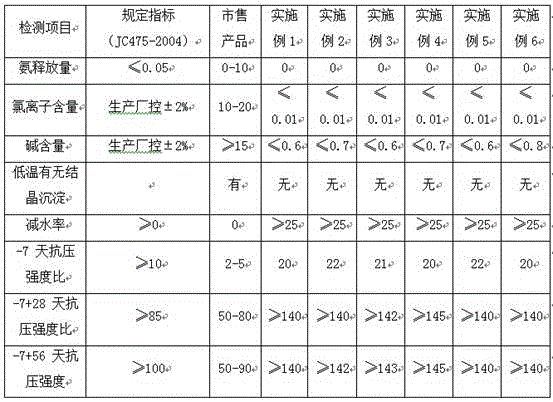

Post-tensioning pre-stress duct grout material for low temperature condition

ActiveCN103922677ARemarkable effect on lowering the freezing pointNormal condensationPre stressingPolyacrylamide

The present invention discloses a post-tensioning pre-stress duct grout material for a low temperature condition, and belongs to the technical field of building materials. The post-tensioning pre-stress duct grout material comprises a coagulation accelerating component, an anti-freezing component, a polycarboxylic acid water reducing agent, an expanding agent, an antifoaming agent, polyacrylamide, a plasticizer and a mineral admixture, wherein the anti-freezing component is a mixture obtained by compounding a nitrite and a sulfate according to a weight ratio of 0.5-2.0:0.5-1.0. The post-tensioning pre-stress duct grout material has characteristics of significant low-temperature resistance effect, controllable setting time, appropriate initial setting time, appropriate final setting time, high compressive strength, high bending strength, zero free bleeding rate, stable performance, and easy and convenient use, and can be widely used in highway bridge and culvert construction.

Owner:HUNAN LIANZHI BRIDGE & TUNNEL TECH

Method for accurately detecting contents of platinum, palladium and rhodium in waste automobile exhaust catalyst

ActiveCN110530850AHigh recovery rateAccurate detectionPreparing sample for investigationAnalysis by thermal excitationProcess optimizationTrapping

The invention, which belongs to the field of platinum group metal analysis and detection, discloses a method for accurately detecting contents of platinum, palladium and rhodium in a waste automobileexhaust catalyst. According to the invention, burdening, smelting trapping, ash blowing separation of metal bismuth and platinum, palladium and rhodium content detection are performed based on bismuthtest gold pyrometallurgy metal enrichment technological process and the process optimization is performed, so that problems of matrix interference and incapability of ash blowing in the traditional method are solved and a defect that platinum, palladium and rhodium in the waste automobile tail gas catalyst are difficult to effectively capture, separate and detect by adopting the existing method is overcome. Therefore, the recovery rate of platinum, palladium and rhodium is increased and the accurate detection of the contents of platinum, palladium and rhodium in the waste automobile tail gascatalyst is ensured.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

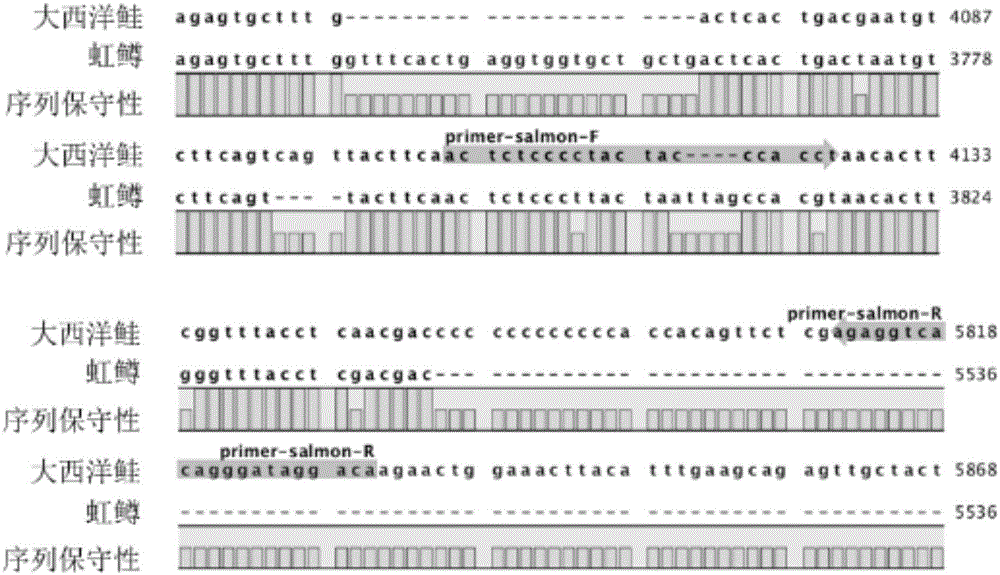

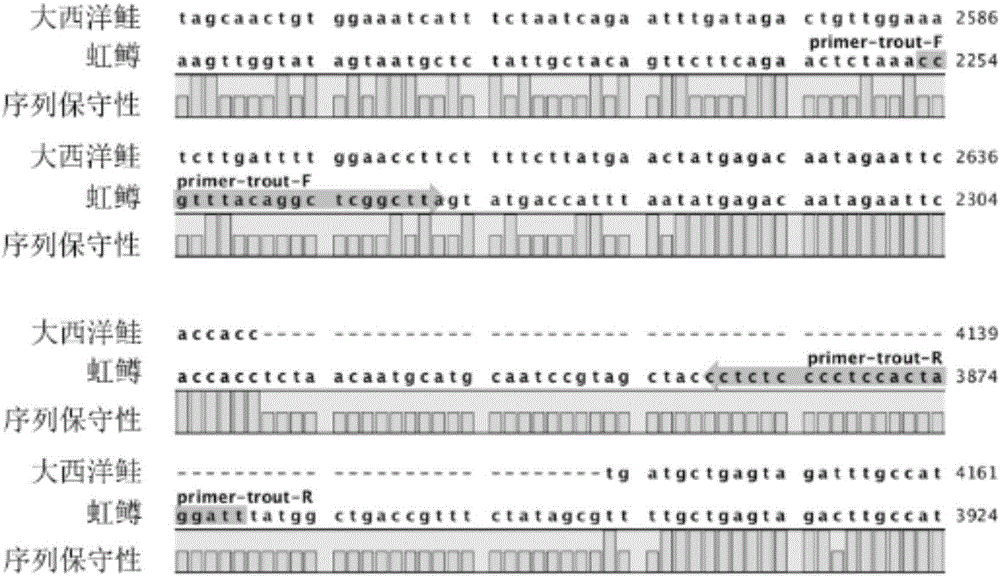

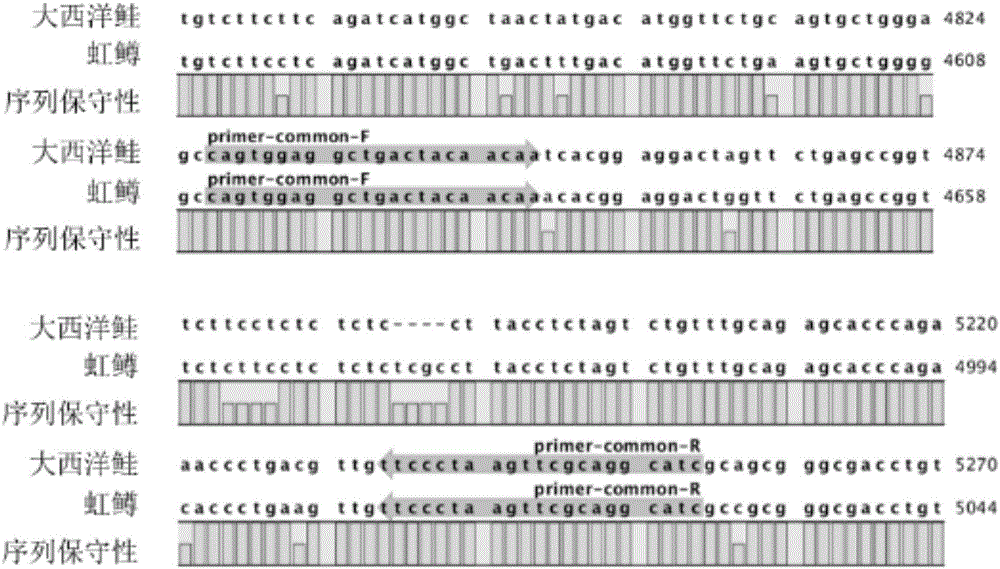

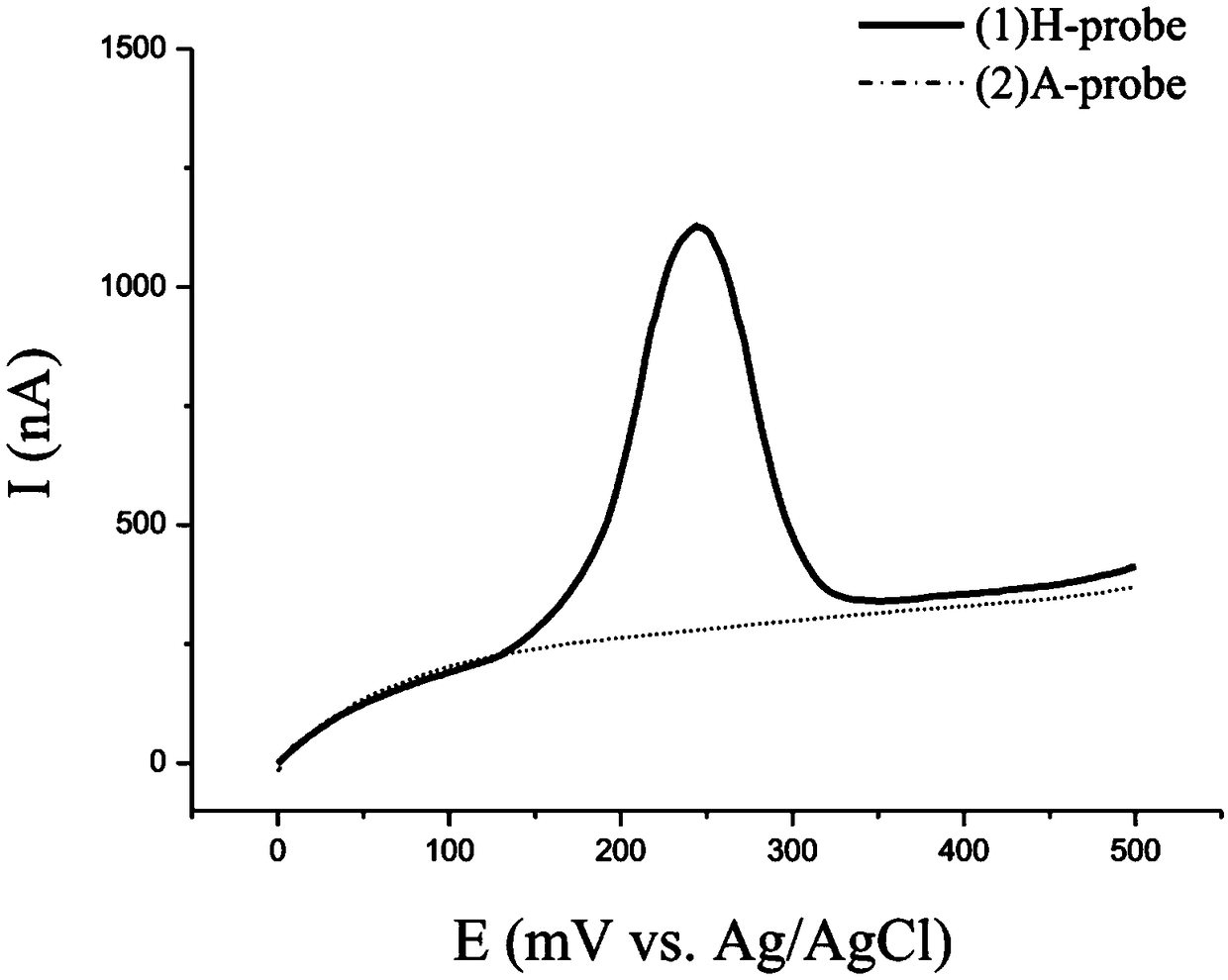

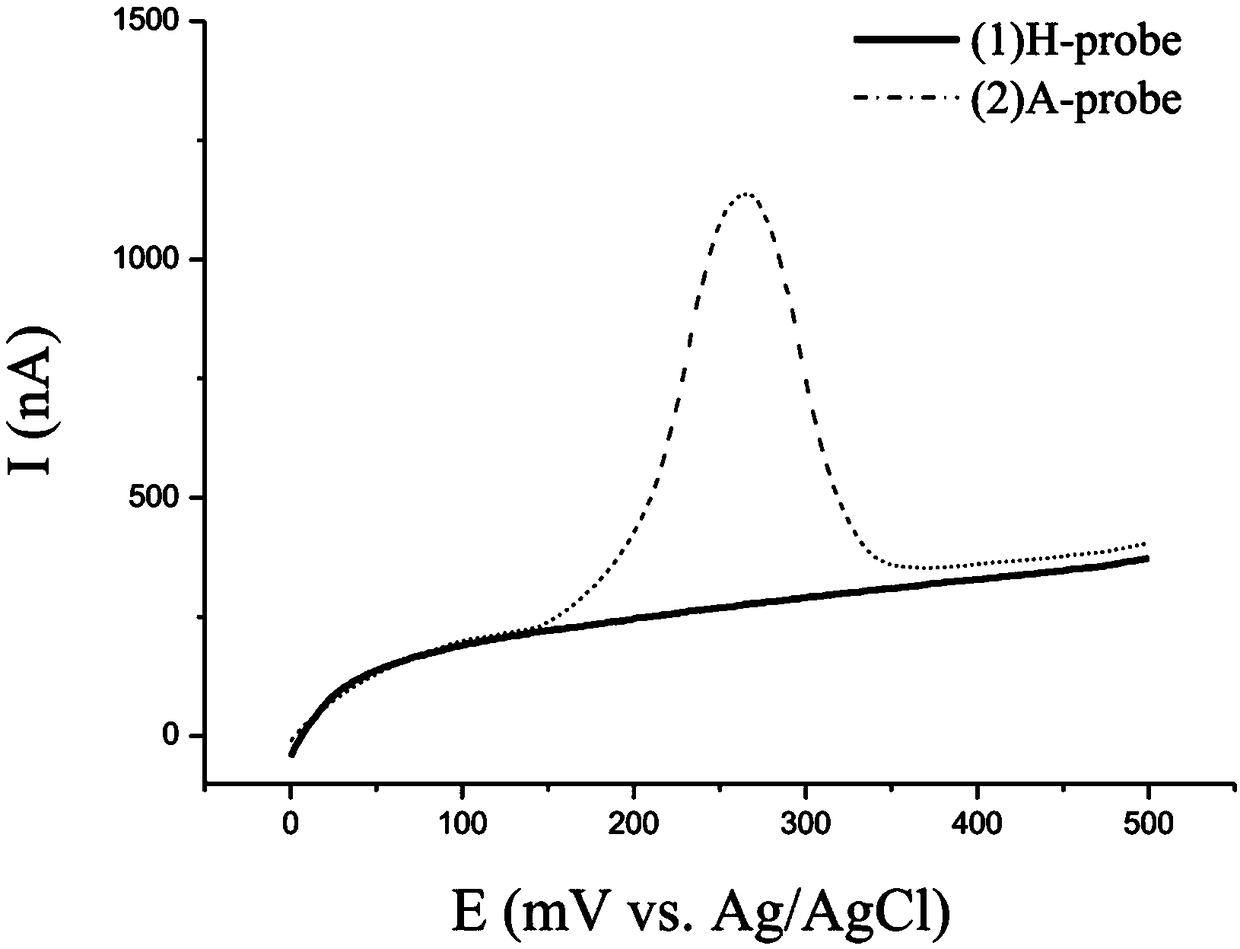

Biosensing detection method used for identifying salmo salar and rainbow trout

ActiveCN106018523AAvoid misleadingEasy to integrateMaterial electrochemical variablesElectrochemistryOrganism

The invention discloses a biosensing detection method used for identifying a salmo salar and a rainbow trout. The biosensing detection method comprises the following steps: the step 1 of extracting genome DNA of a sample to be detected, using a specific primer pair of the salmo salar to carry out PCR reaction with the genome DNA of the sample to be detected as a template and obtaining a PCR amplification product I of the sample to be detected; the step 2 of adding the PCR amplification product I obtained in the step 1 to the surface of an electrode decorated by an anchoring acceptor for reaction; the step 3 of detecting an electrochemistry signal of an electrochemistry activity labeled molecule and deciding that the sample to be detected comes from the salmo salar if the electrochemistry signal of the electrochemistry labeled molecule exists. The specific primer pair of the salmo salar comprises the electrochemistry activity labeled molecule and an anchoring labeled molecule on the upstream of a base sequence respectively, and the anchoring labeled molecule can be captured by the anchoring acceptor to enable the PCR amplification product with the anchoring labeled molecule to be captured by the surface of the electrode. The method is suitable for fish samples of any growth stage and in any shape.

Owner:CHINESE ACAD OF FISHERY SCI

Pressurized acid-leaching potassium extracting technology for potassium feldspar

InactiveCN103193253AReduce the amount of fluosilicic acidReduce production energy consumptionCalcium/strontium/barium sulfatesSulfate/bisulfate preparationAluminium hydroxideReaction temperature

The invention discloses a pressurized acid-leaching potassium extracting technology for potassium feldspar. Products such as potassium sulphate, aluminum hydroxide, quartz and gypsum are obtained from the raw materials such as potassium feldspar powder, fluorosilicic acid, sulfuric acid and cyclic dilute sulphuric acid. The pressurized acid-leaching potassium extracting technology disclosed by the invention is low in sulfuric acid consumption, high in percent conversion, low in reaction temperature, small in energy consumption in production, and low in potassium extraction cost; and various ingredients in potassium feldspar ore are comprehensively utilized.

Owner:FUZHOU UNIV

Concrete antifreezer and preparing method thereof

The invention relates to the technical field of concrete, in particular to concrete antifreezer.The concrete antifreezer is prepared from 15-25 parts of sodium oxide, 8-12 parts of aluminum potassium sulfate, 3-6 parts of triisopropanolamine, 10-12 parts of sodium lignosulphonate, 6-8 parts of sodium carbonate, 12-18 parts of monocalcium aluminate, 3-9 parts of sodium carboxymethylcellulose, 3-5 parts of paraffin, 1-4 parts of pimacol, 2-6 parts of cerous nitrate, 10-15 parts of tea saponin, 12-18 parts of melamine, 1.8-3.8 parts of SAF-I type superplasticizer, 0.8-2.4 parts of sulphonated acetone-formaldehyde resin, 1.2-3.8 parts of modified bentonite, 0.1-0.6 part of air entraining agent and 1.8-4.8 parts of antifoaming agent.The novel antifreezing components are adopted, the alkali content is greatly reduced, concrete alkali aggregate reaction can be avoided, and the antifreezer does not precipitate or crystallize when stored at the subzero temperature; the novel components do not contain ammonia and do not pollute the environment.

Owner:山东中粉建材科技有限公司

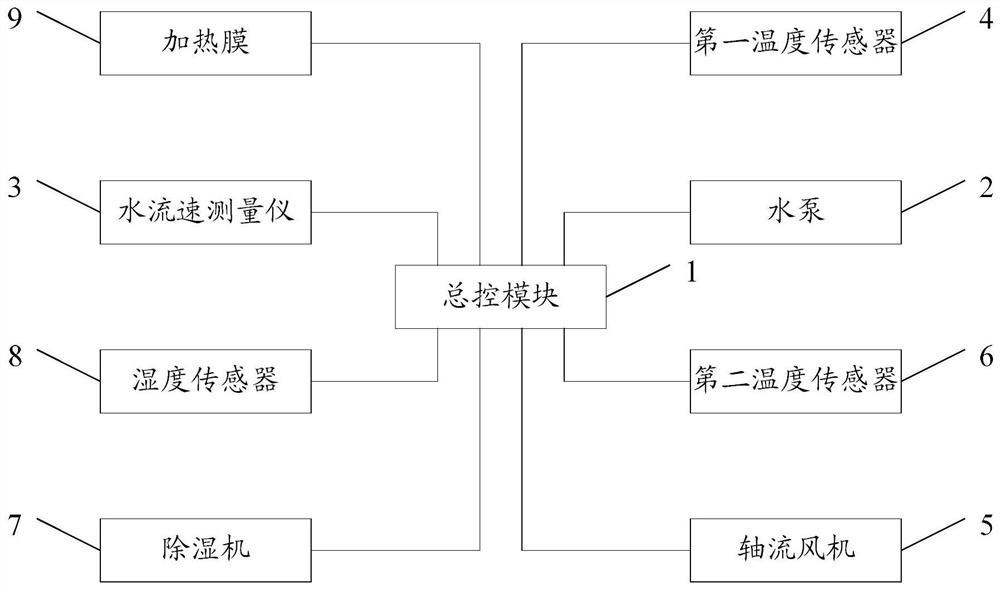

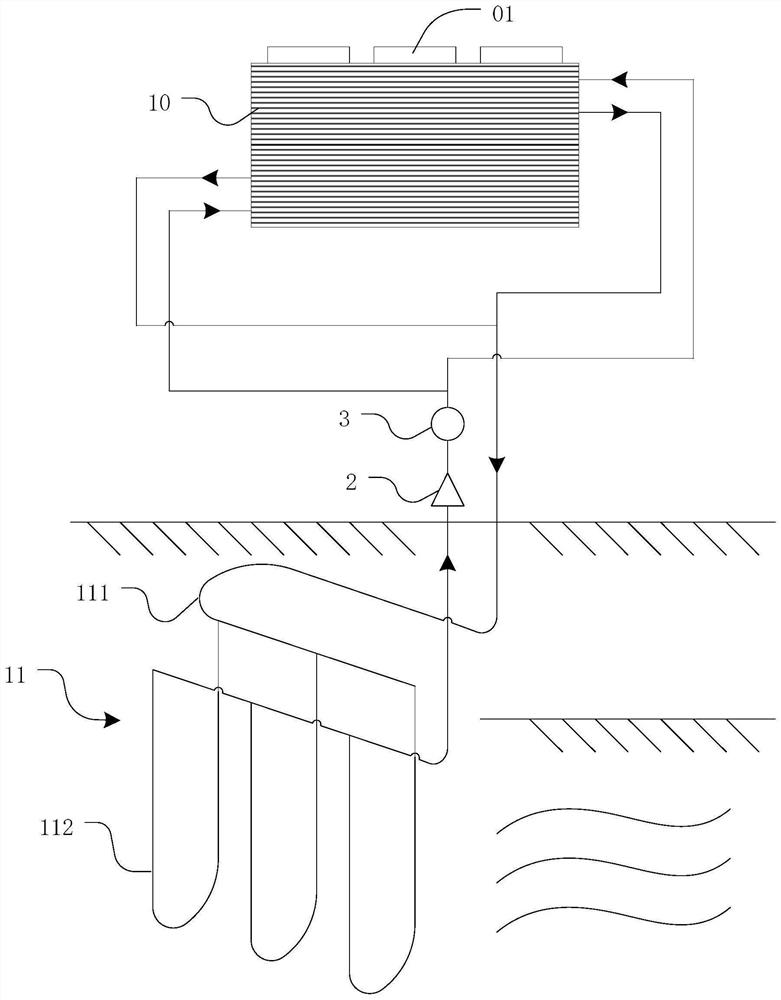

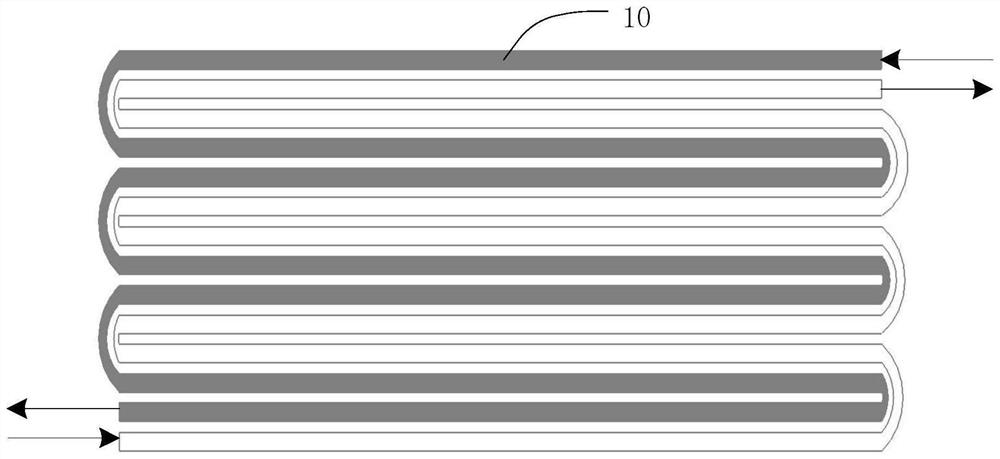

Thermal management system for prefabricated cabin of lithium ion battery energy storage system and control method thereof

ActiveCN112490530AIncrease temperatureNo pollution hazardLighting and heating apparatusGeothermal energy generationAutomatic controlThermal insulation

The invention is applicable to the technical field of heat exchange, and provides a thermal management system for a prefabricated cabin of a lithium ion battery energy storage system and a control method thereof, and the thermal management system comprises an underground water thermal management assembly, an intelligent fresh air assembly, a dehumidification assembly and a master control module. Circulating water is used for adjusting the temperature of the battery module, and the device has the advantages of high adjusting speed and good thermal insulation performance. Circulating water flowsthrough all the modules in the heat exchange plate in a parallel pipeline and cross flow battery module mode, the temperature consistency of all the battery modules in the prefabricated cabin can beimproved, and the service life of the system is prolonged. Circulating water flows in the heat exchange plate and the underground heat exchange pipeline in a closed mode, and potential pollution hazards to soil and underground water do not exist. According to the invention, the relative humidity in the prefabricated cabin can be controlled below 65% through automatic control, and when the ambienttemperature is lower than -30 DEG C, the heating film can be automatically started to assist in heating so as to increase the temperature in the prefabricated cabin, so that the battery module is in aproper humidity and temperature environment.

Owner:常德中科多源电力融合技术研究院

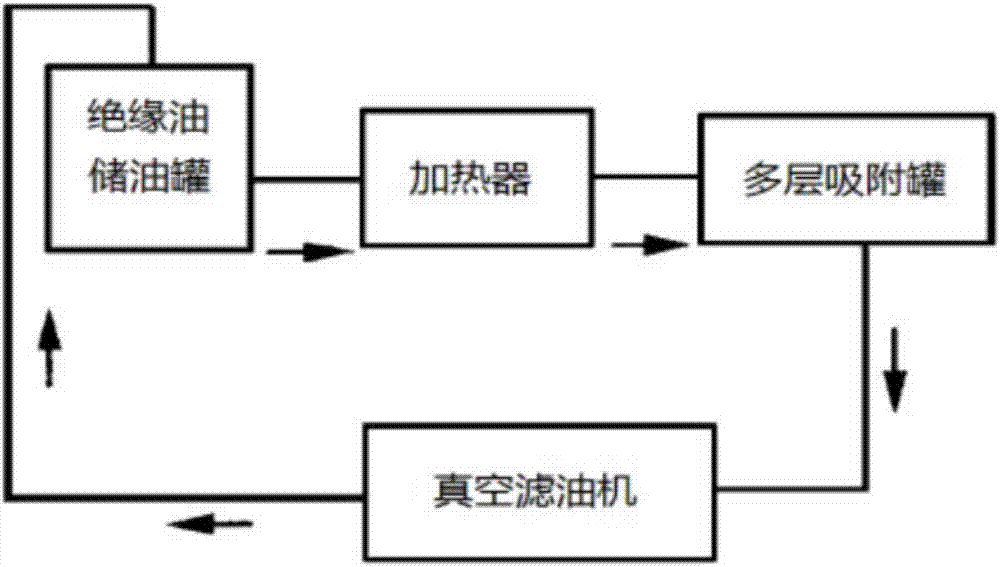

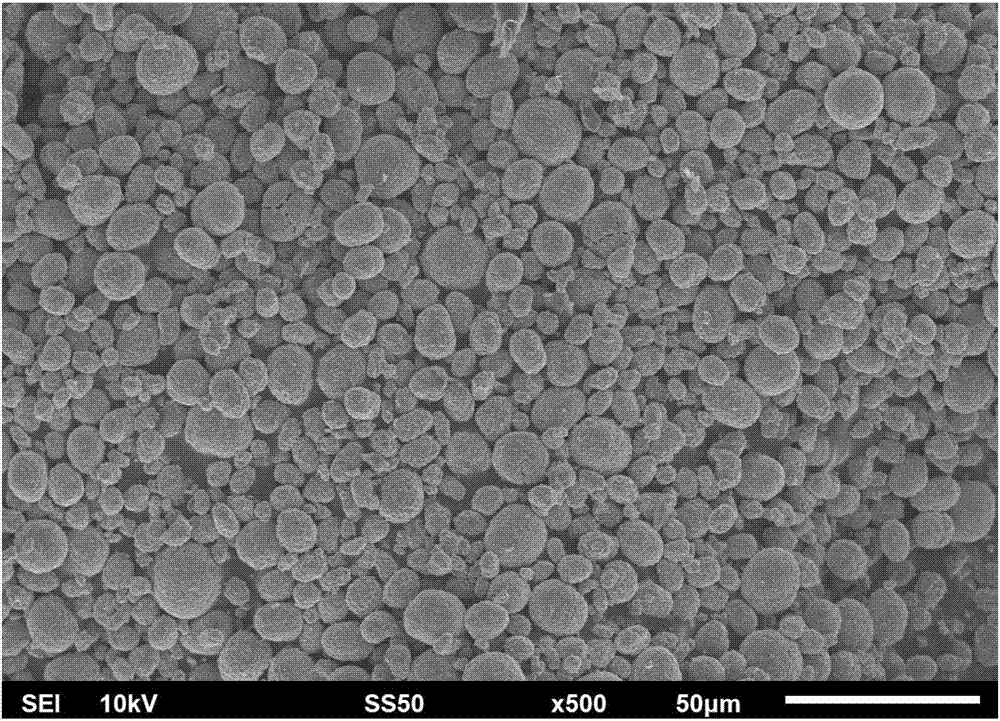

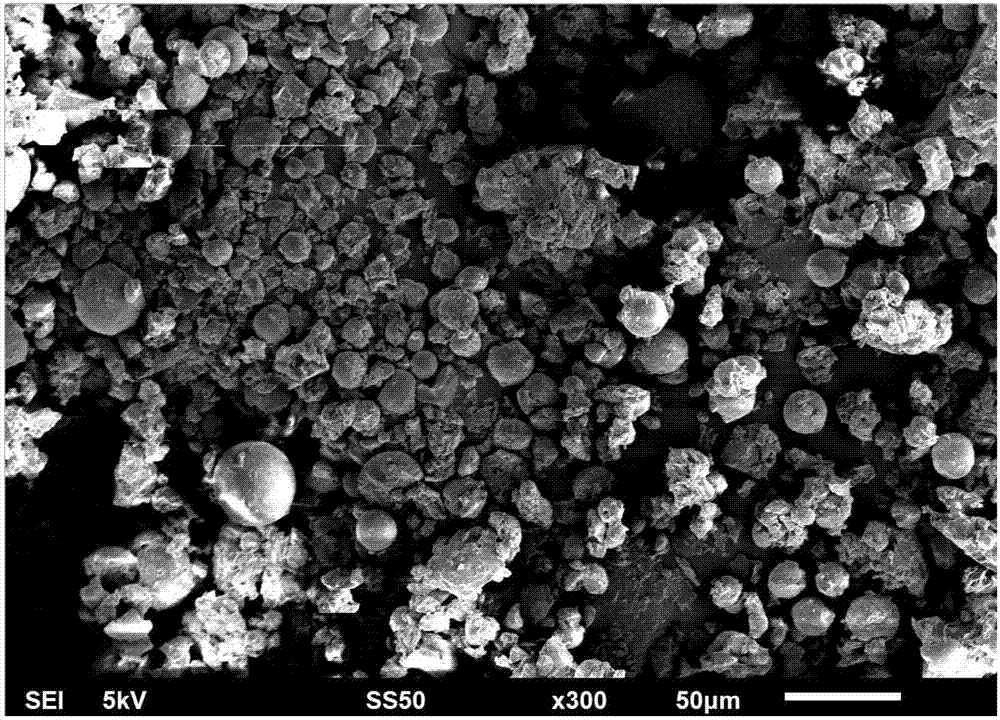

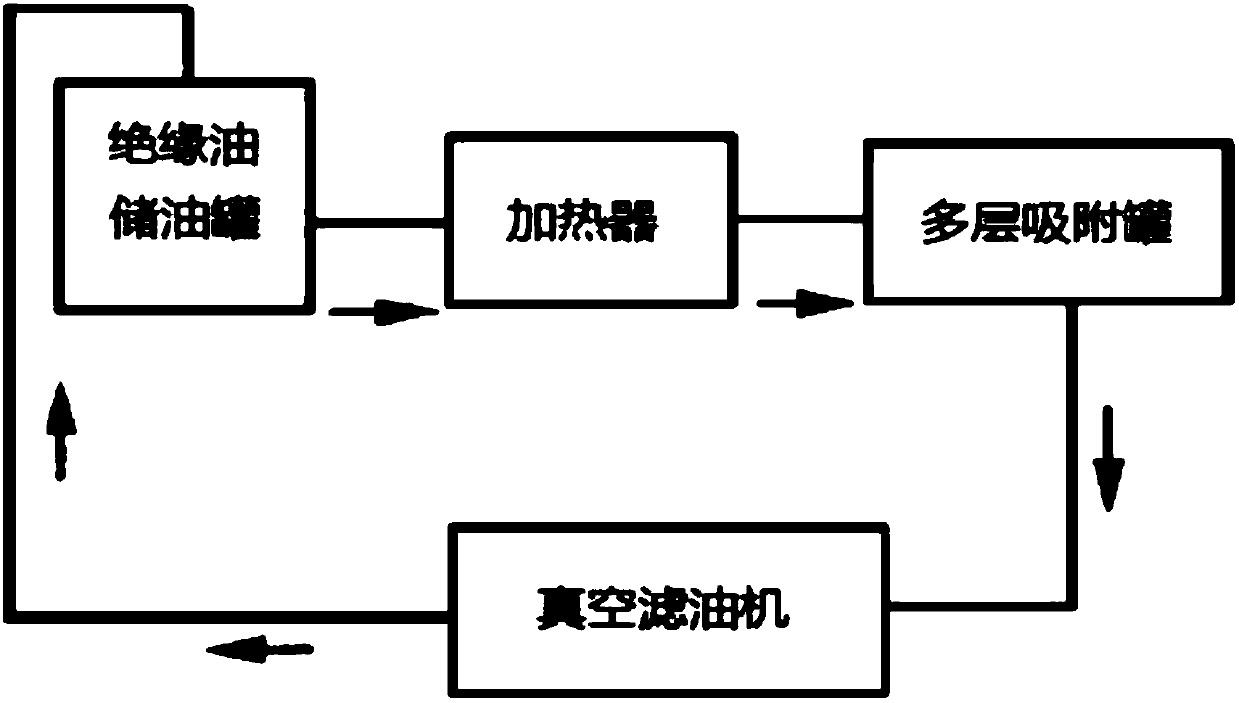

Hydroxypropyl chitosan microsphere, and preparation method and application thereof in reducing dielectric loss of mineral oil

InactiveCN107876025AStable structureLarge specific surface areaOther chemical processesHydrocarbon oils refiningTetramethylammonium hydroxideFiltration

The invention provides a hydroxypropyl chitosan microsphere, and a preparation method and application thereof in reducing the dielectric loss of mineral oil, and belongs to the field of chitosan modification. The preparation method comprises the following steps: mixing chitosan, isopropanol, and a first sodium hydroxide solution; adding tetramethyl ammonium hydroxide, dropwise adding epoxy propaneto carry out reactions; cooling, adjusting the pH to 7 by using hydrochloric acid; dispersing the reaction product in acetone or water, stirring, carrying out suction filtration, washing the reactionproduct by anhydrous ethanol, drying the reaction product in vacuum to obtain hydroxypropyl chitosan; preparing a hydroxypropyl chitosan solution, spraying the solution on sodium polyphosphate to carry out cross-linking reactions, washing the reaction product by water, filtering, adding the reaction product into a sodium hydroxide solution, stirring, adding epoxy chloropropane to carry out reactions to obtain microspheres; washing the microspheres by water, then drip-washing the microspheres by organic solvents with volume percentages of 10-20%, 30-40%, 70-80%, and 90-95% in sequence, and finally performing freeze-drying. The prepared modified chitosan can reduce the dielectric loss of mineral oil.

Owner:HUBEI ENG UNIV

Insole made of straw

The invention discloses an insole made of straw. The insole comprises an insole material and insole cloth covering the outside of the insole material. The insole material is formed by mixing and pressing raw materials of, by weight part, 88-98 straw and 3-6 adhesives. The insole has the advantages that the straw is used as the raw material, so that raw material costs are saved, and the produced insoles are good in heat retention and breathability. The straw is more prone to rotting into fertilizers than natural leather, synthetic leather and textiles to fade into the soil, so that the insole is free of pollution potential safety hazards and is good for environment protection.

Owner:JIHUA 3515 LEATHER & SHOES

Hydroxypropyl chitosan microspheres as well as preparation method thereof and application thereof in reduction of dielectric loss of vegetable oil

ActiveCN107814953AStable structureLarge specific surface areaTetramethylammonium hydroxideVegetable oil

The invention provides hydroxypropyl chitosan microspheres as well as a preparation method thereof and application thereof in reduction of dielectric loss of vegetable oil, belonging to the field of chitosan modification. The preparation method of the hydroxypropyl chitosan microspheres comprises the following steps: mixing chitosan, having viscosity of 0.25-0.65Pa.s with isopropanol and a first sodium hydroxide solution, adding tetramethyl ammonium hydroxide into the mixture, dropwise adding epoxypropane for carrying out a reaction, cooling and adjusting the pH value to 7, dispersing the product into acetone or water, stirring and carrying out suction filtration, washing with anhydrous ethanol, and carrying out vacuum drying to obtain hydroxypropyl chitosan; preparing the hydroxypropyl chitosan into a solution, spraying the solution onto sodium polyphosphate, carrying out ultrasonic treatment and crosslinking, then washing with water, filtering, adding the product into a sodium hydroxide solution and stirring, and adding glutaraldehyde for carrying out a reaction so as to obtain microspheres; washing the microspheres with water, then leaching the microspheres respectively with organic solvents with volume percentages of 21-29%, 41-49%, 61-69% and 85-89%, and carrying out freeze drying. The modified chitosan prepared by the method can reduce the dielectric loss of the vegetableoil.

Owner:HUBEI ENG UNIV

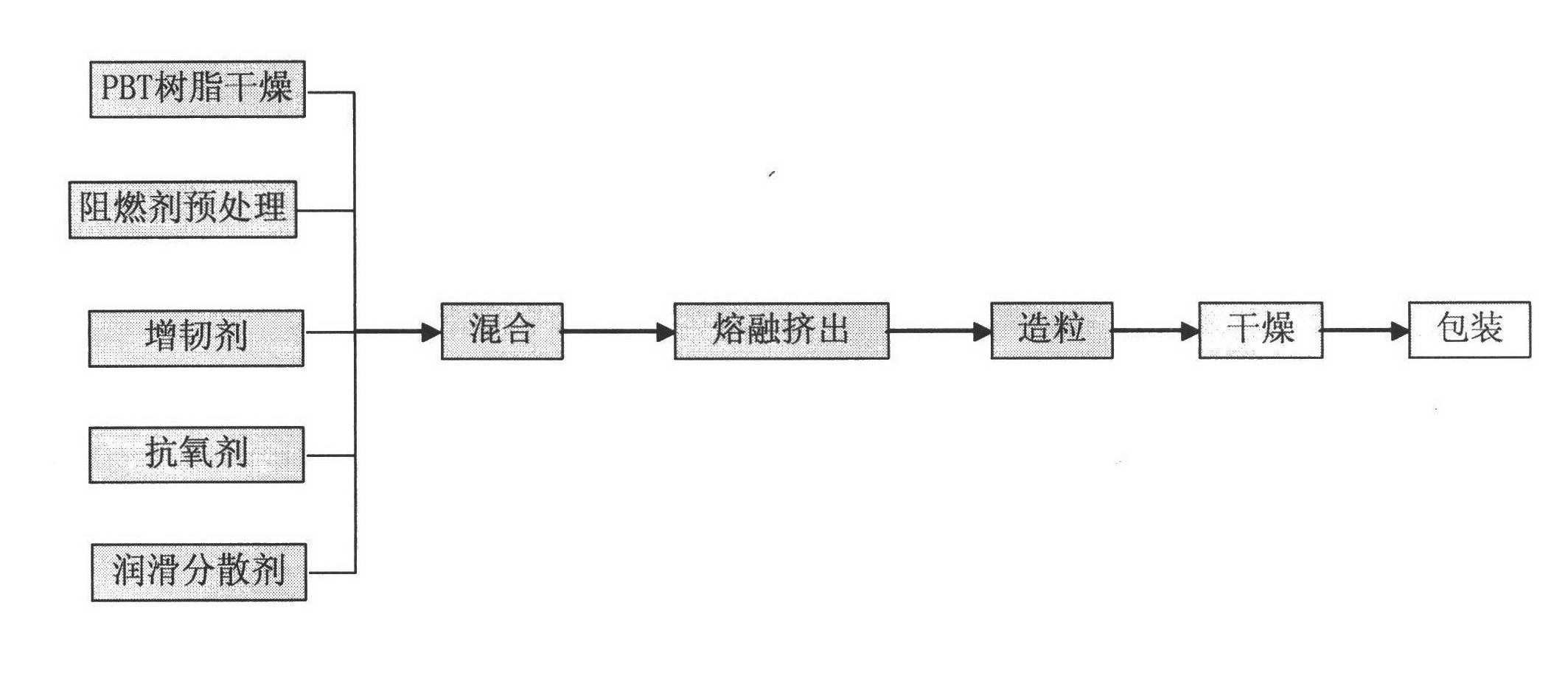

Halogen-free phosphorus-free flame-retarding toughening master batch special for PBT (polybutylene terephthalate) and preparation method thereof

InactiveCN102532830AImprove flame retardant performanceModification of the combustion processPolyethylene terephthalateAntioxidant

The invention provides a halogen-free phosphorus-free flame-retarding toughening master batch special for PBT (polybutylene terephthalate) and a preparation method thereof. The master batch is characterized in that the raw material formulation comprises the following components in percentage by weight: 20-60% of PBT resin, 70-35% of halogen-free phosphorus-free flame retardant, 5-10% of toughening agent, 0.2-0.6% of antioxidant, 1-3% of lubricating and dispersing agent and 0.2-1% of coupling agent. In the preparation method, PBT is used as a carrier, and PDPTP is used as the halogen-free phosphorus-free flame retardant; after surface treatment is carried out, the toughening agent, the dispersing agent and the antioxidant are added, and extrusion and granulation are carried out through two screws so as to prepare the halogen-free phosphorus-free flame-retarding toughening master batch special for PBT. According to the invention, the environment-friendly index of the prepared master batch meets the requirements of European Union RoHS (Restricted of Hazardous Substances), IEC (International Electrotechnical Commission) halogenation-free and Reach laws; and the prepared master batch can be used for modification of PBT, thus the flame-retarding grade of PBT reaches American UL 940.8mm V-0 grade, the CTI (comparative cracking index) value reaches more than 425V, the glowing filament experiment temperature reaches 750 DEG C but firing is not generated, and match color is not influenced.

Owner:SUZHOU CUIZHI NEW TECH DEV

Waterborne weather-resisting anticorrosive coating and preparation method thereof

ActiveCN109762455AAvoid pollutionThe preparation process is easy to operateAnti-corrosive paintsPolyurea/polyurethane coatingsWeather resistanceChemistry

The invention relates to waterborne weather-resisting anticorrosive coating and a preparation method thereof and relates to the field of waterborne anticorrosive coating. The coating is prepared by uniformly mixing and stirring a resin component and an isocyanato curing agent component, wherein the resin component contains fluorocarbon resin, and the ratio of the hydroxyl mol number of the fluorocarbon resin to the isocyanato mol number of the isocyanato curing agent component is 1 to (1.02 to 1.05); the resin component also contains graphene powder which accounts for 0.1 to 5.0 percent of thetotal weight of the coating; the coating can be used for effectively improving the water resistance, acid resistance, alkali resistance, temperature and heat resistance, salt mist resistance and weather resistance of a whole body, so that the safe, green, environment-friendly and pollution-free utilization requirements on the coating in the market can be effectively met.

Owner:赵娜

Waterborne graphene paint and preparation method thereof

InactiveCN108250906AImprove corrosion resistanceSolve the problem of foulingAntifouling/underwater paintsPaints with biocidesGrapheneMaterials science

The invention relates to marine antifouling paint, i.e., waterborne graphene paint and a preparation method thereof. The paint is prepared by evenly mixing a component A with a component B containinggraphene according to a mass percent of (1-2) to (2-4). The paint can effectively solve the problem that marine microorganisms adsorb on the surfaces of ships.

Owner:杨昊龙

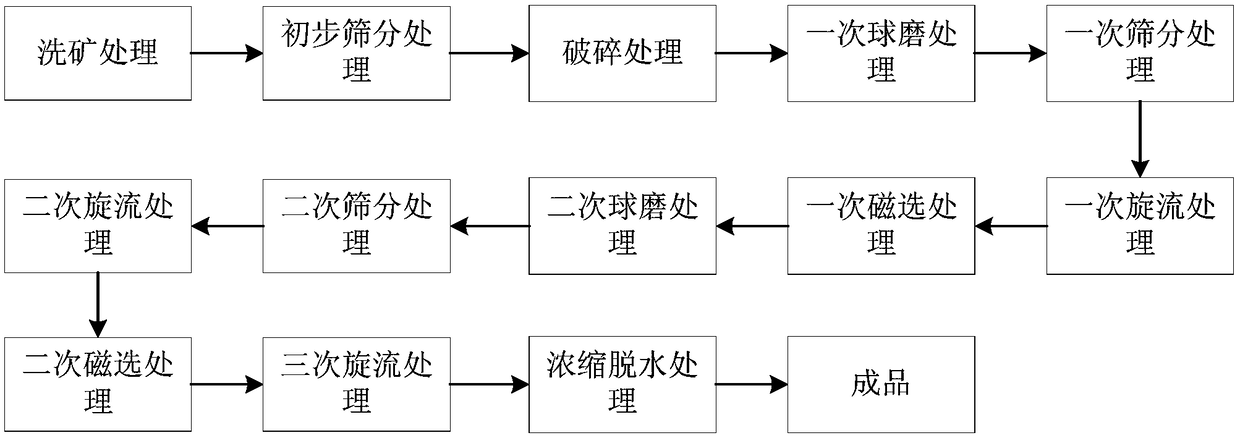

A kind of production preparation method of potassium feldspar powder

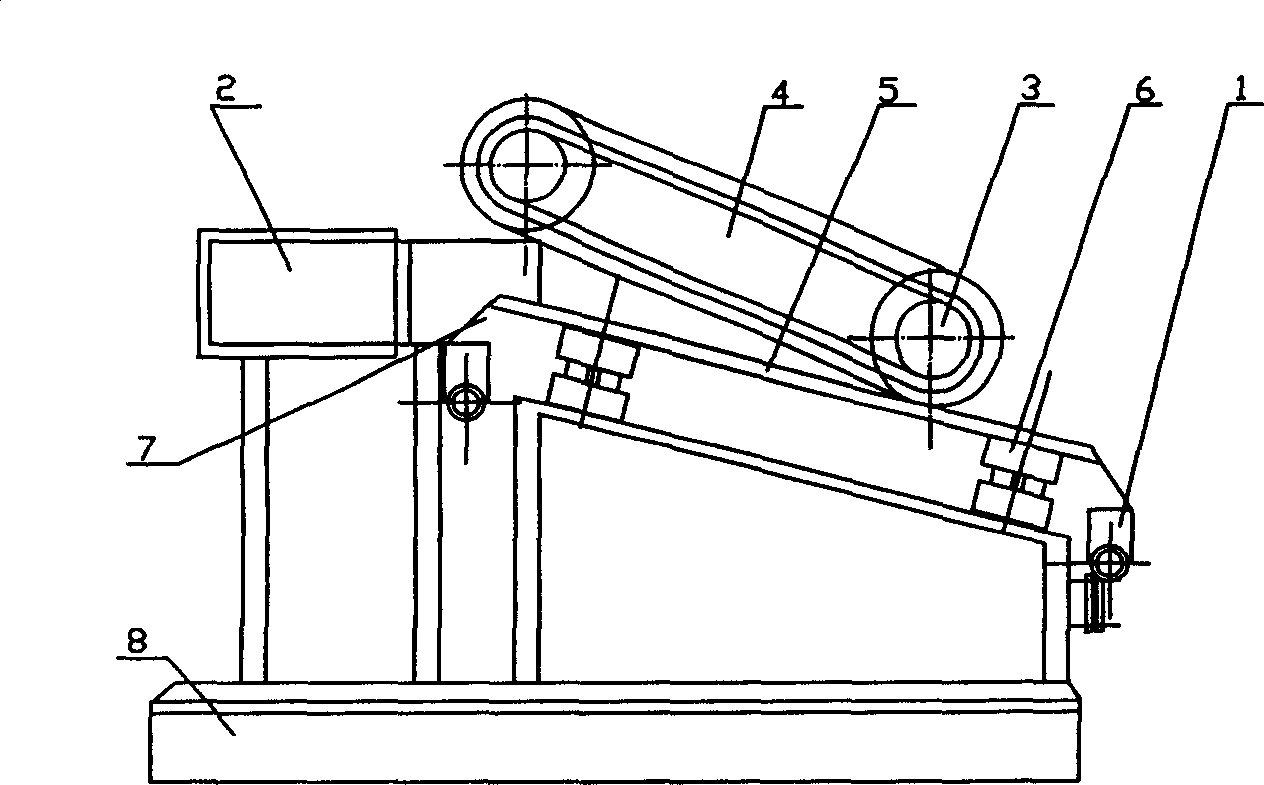

ActiveCN107413518BReduce manufacturing costAvoid damageWet separationPhysical chemistryPotassium feldspar

The invention discloses a potassium feldspar powder production and preparation method, and belongs to machining technologies of potassium feldspar powder. The method comprises the steps of ore washing treatment, preliminary screening treatment, crushing treatment, primary ball milling treatment, primary screening treatment, primary cyclone treatment, primary magnetic separation treatment, secondary ball milling treatment, secondary screening treatment, secondary cyclone treatment, secondary magnetic separation treatment, third cyclone treatment and thickening and dehydration treatment, and potassium feldspar mineral powder with the moisture content being lower than 16% and the brightness being higher than 60% is obtained.

Owner:贺州市骏鑫矿产品有限责任公司

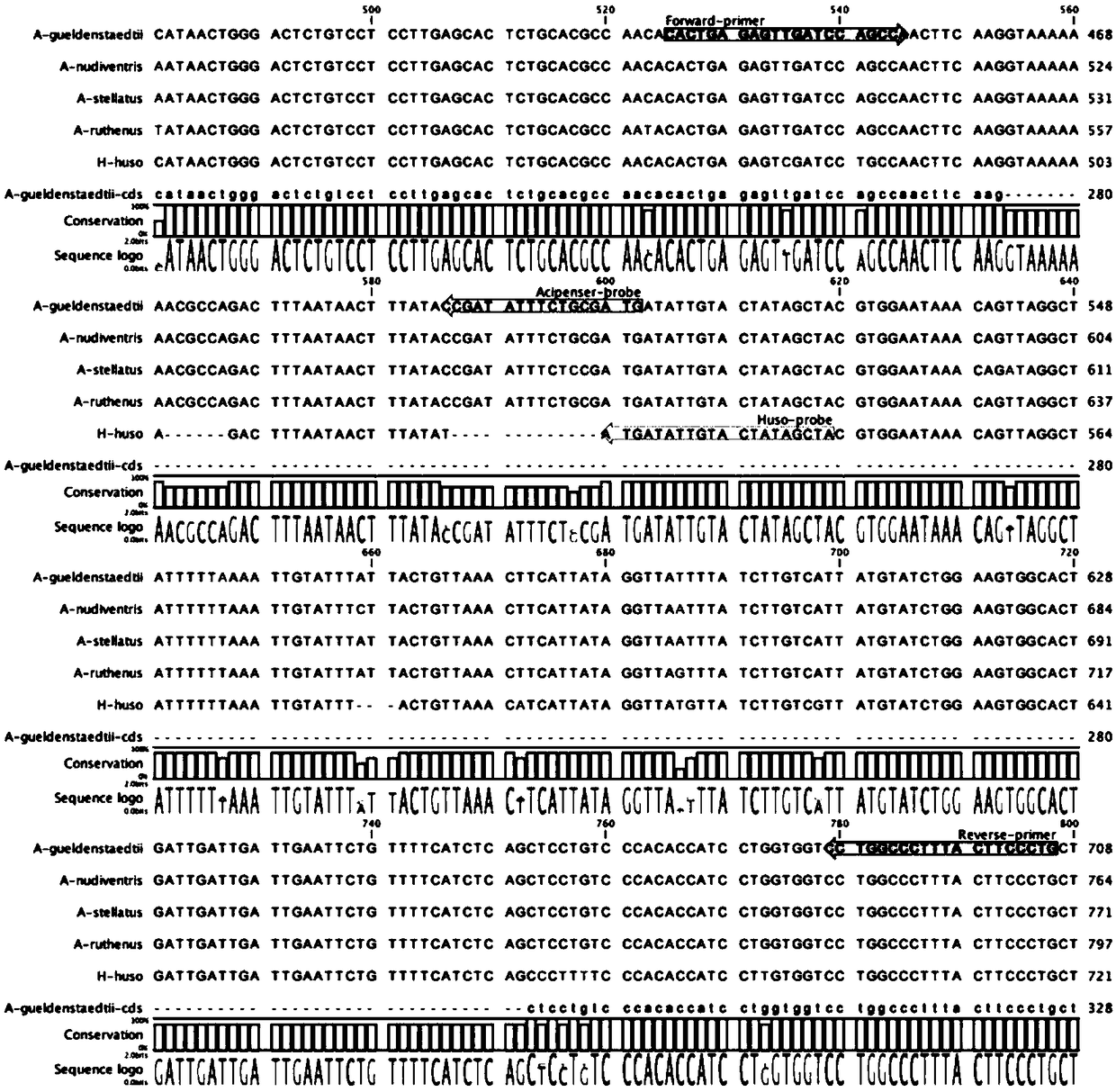

Biological sensing detection method used for Huso huso fry identification

ActiveCN108913778AAvoid misleadingEasy to digitizeMicrobiological testing/measurementSturgeonNucleotide sequencing

The invention discloses a biological sensing detection method used for Huso huso fry identification. According to the biological sensing detection method used for Huso huso fry identification, DNA offry to be measured is taken as a template for probe extension so as to obtain a probe extension product; biological sensing method is adopted to detect that whether the probe extension product can beanchored onto the surface of an electrode modified with an anchored receptor using an anchoring labelled molecule; if the detected results are positive, the dry to be measured is Huso huso fry. The biological sensing detection method comprises following steps: in probe extension, dUTP provided with the anchoring labelled molecule is connected with a probe with a nucleotide sequence represented bySEQ ID NO:3 so as to obtain the probe extension product of the Huso huso fry in the fries to be detected. The biological sensing detection method is capable of identifying specie source in sturgeon fry introduction, and assisting culture organizations to perform cultured objects and processed products grading.

Owner:CHINESE ACAD OF FISHERY SCI

Concrete antifreezing agent

The invention discloses a concrete antifreezing agent. The concrete antifreezing agent comprises the following component in parts by weight: 35 to 45 parts of macrogol ester, 12 to 25 parts of nitrate, 5 to 6 parts of ethanediol perhydrol, 3 to 8 parts of N-sulfoacid, and 25 to 30 parts of para-melamine. The concrete antifreezing agent has the beneficial effects that 1, the concrete antifreezing agent is a composite product which can obviously improve the peaceability of concrete while improving the early strength, and the dosage is 2 to 5% of the total gum quantity; 2, chloride-free antifreezing admixture serving as the concrete antifreezing agent avoids corrosion of a reinforcing steel bar; 3, the novel antifreezing components adopted greatly decrease the alkali content and also avoid the alkali aggregate reaction in concrete, and the antifreezing agent does not settle and crystallize while being stored under a negative temperature; 4, novel components added do not contain ammonia component, so that no pollution and harm are brought to the environment; 5, the concrete doped with the concrete antifreezing agent is high in durability, i.e.,, the loss rate of the intensity of freezing and thawing at 100 times is less than 5%, and the shrinkage rate at 90 days is less than 120%.

Owner:LIUZHOU ZHENGLING GROUP

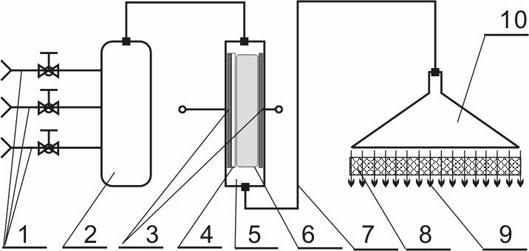

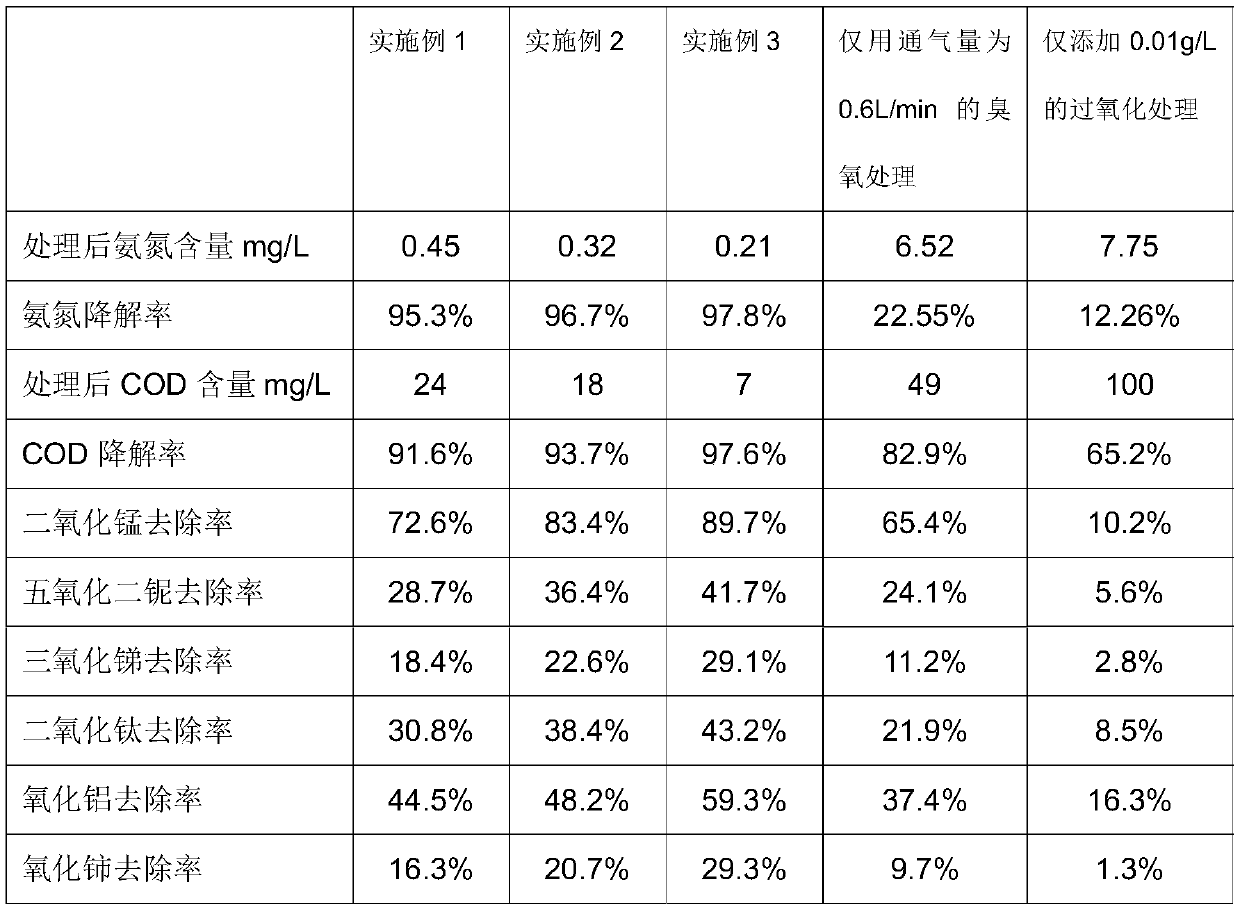

Sewage zero-discharge treatment device and sewage zero-discharge treatment method

InactiveCN110776130AAssistant process is shortNo pollution hazardSludge treatment by de-watering/drying/thickeningTreatment involving filtrationSludge cakeCatalytic oxidation

The invention discloses a sewage zero-discharge treatment device and a sewage zero-discharge treatment method. The device comprises a sewage collection pool, a catalytic oxidation device, a flocculation precipitation pool, a sludge filter pressing device, a sludge crushing device, a drying device, a sewage filtering device, a sewage conveying device and a sludge conveying device, wherein the sewage collection pool is connected to the catalytic oxidation device through the sewage conveying device, the catalytic oxidation device is connected to the flocculation precipitation pool through a pipeline, the sewage outlet in the upper portion of the flocculation precipitation pool is connected to the sewage filtering device, the sludge outlet in the bottom of the flocculation precipitation pool is connected to the sludge filter pressing device through the sludge conveying device, the sewage outlet of the sludge filter pressing device is connected to the sewage collection pool through a pipeline, a sludge cake outlet is connected to the sludge crushing device through a conveying belt, and the sludge crushing device is connected to the drying device. According to the invention, with the method and the device, the sewage assistant process is short, the treated sewage can be recycled as reclaimed water, volume reduction and decrement are achieved after the drying treatment of sludge, resource treatment is achieved after harmless treatment, and pollution hazards are avoided.

Owner:减一污泥处理技术(江苏)有限公司

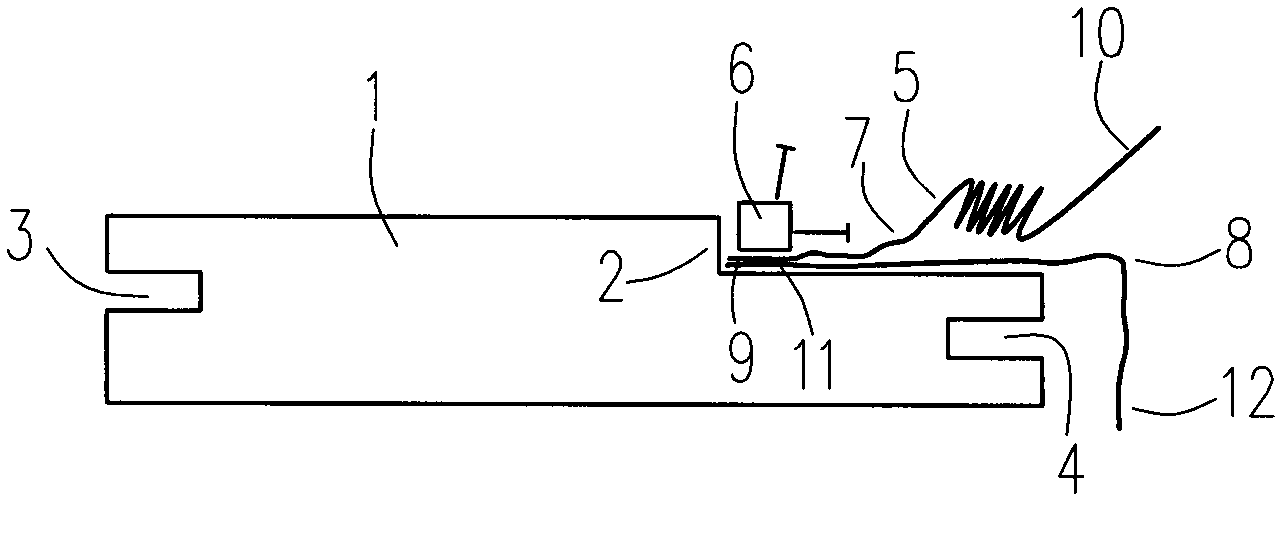

Door frame cover board and processing method thereof

InactiveCN102587789ASimple structureEasy to processWindow/door framesWood working apparatusEngineeringEdge banding

A door frame cover board comprises a cover board body, a leather coat and edge sealing battens. The cover board body is provided with an L-shaped groove and two installation grooves for decorating plates. The leather coat includes a first coat and a second coat, the first coat is provided with a first edge and a third edge, the second coat is provided with a second edge and a fourth edge, the first edge and the third edge are fixed onto the L-shaped groove through the edge sealing battens and fastening nails, and the second edge and the fourth edge are fixed onto the two installation grooves for decorating plates through fastening nails. A door frame cover board processing method includes steps of 1, manufacturing the cover board body and the edge sealing battens and cutting the leather coat; 2, fixing the first coat and the second coat onto the L-shaped groove with the edge sealing battens and coating the cover board body respectively towards two lateral sides. The doorframe cover board is simple in structure and convenient in processing, needs no binding agent, causes no hidden trouble, indoor environment pollution, and accords with the consumption concept of pursuing environment-friendly products.

Owner:李飞

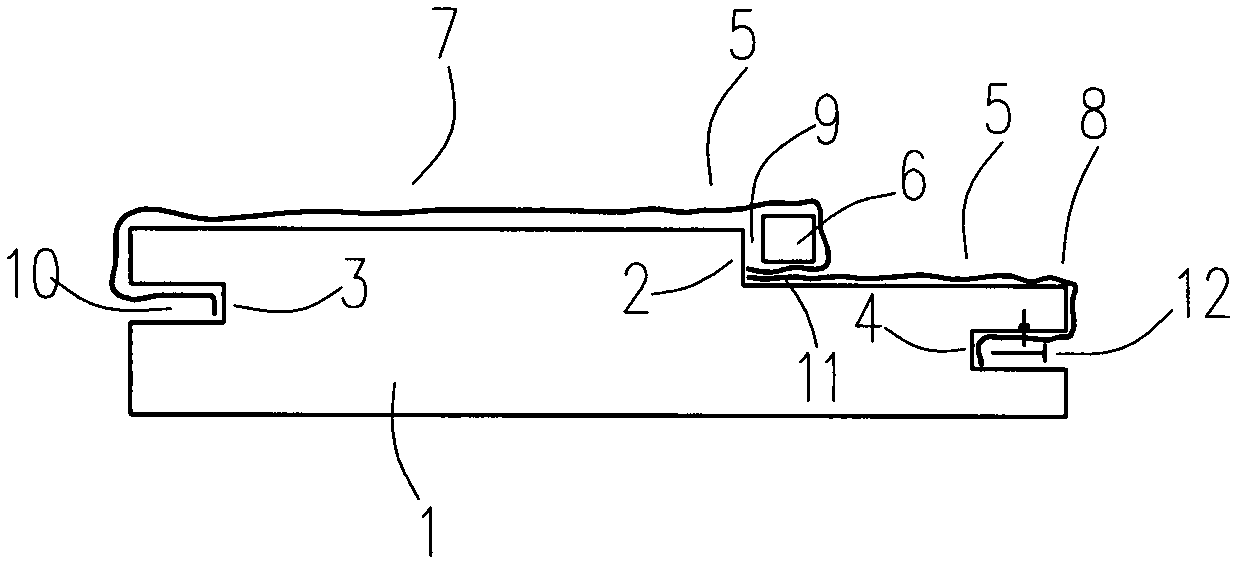

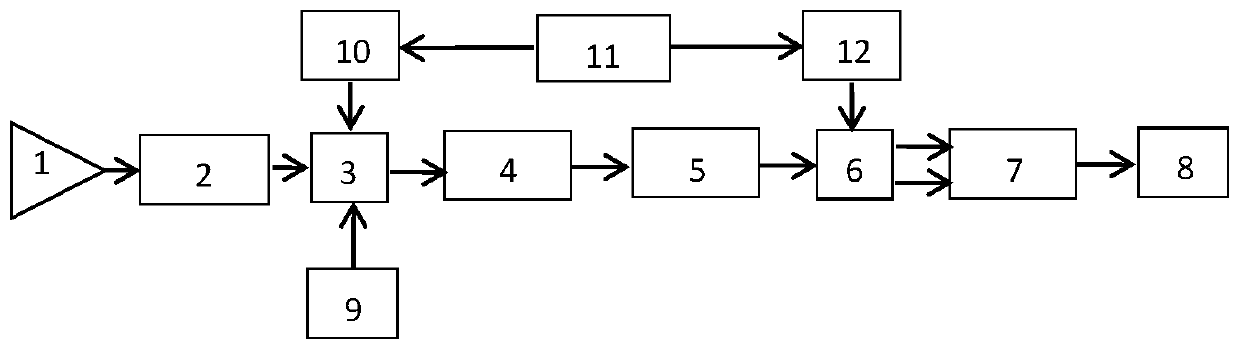

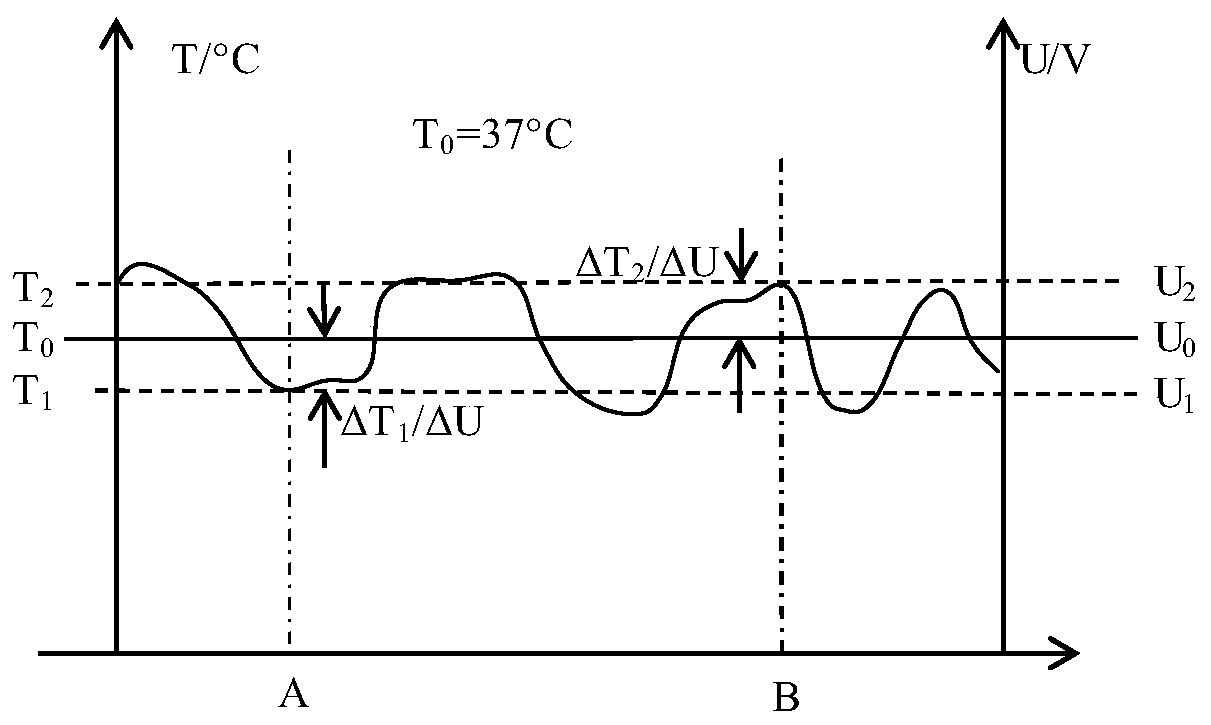

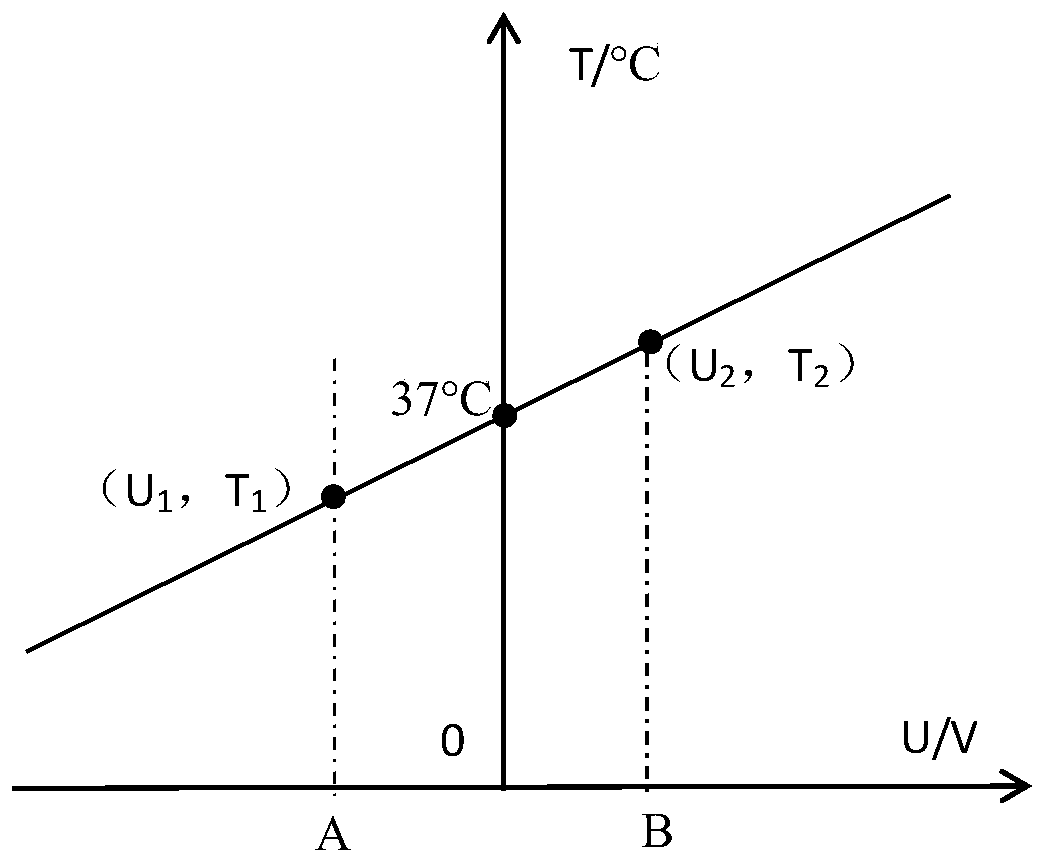

Millimeter-wave human body temperature measuring device

InactiveCN111579079ANo pollution hazardQuick measurementSensing radiation from moving bodiesHuman bodyBody temperature measurement

The invention relates to application of a millimeter wave technology and particularly relates to a millimeter wave human body temperature measuring device. The device comprises a millimeter wave antenna, a first millimeter wave amplifier, a first single-pole double-throw switch, a second millimeter wave amplifier, a millimeter wave detector, a second single-pole double-throw switch, a comparison amplifier and a reference load, wherein the millimeter wave antenna, the first millimeter wave amplifier, the first single-pole double-throw switch, the second millimeter wave amplifier, the millimeterwave detector, the second single-pole double-throw switch and the comparison amplifier are connected in sequence, and the reference load is further connected with the first single-pole double-throw switch. The device is advantaged in that the device does not need to be aligned with exposed skin, can penetrate through clothes of a human body, carries out non-contact body temperature measurement ona human body, has no mercury pollution hidden danger, and is rapid in measurement and simple and convenient in reading.

Owner:CHANGZHOU INST OF TECH

Cleaning method of graphite boat for manufacturing solar cells

InactiveCN111229736AEasy to cleanReduce pressure on environmental protectionChemical vapor deposition coatingCleaning processes and apparatusForeign matterEngineering

The invention provides a cleaning method of a graphite boat for manufacturing solar cells. The cleaning method of the graphite boat for manufacturing the solar cells comprises the steps that the graphite boat with impurities is put into a vacuum sintering furnace to be subjected to vacuum high-temperature sintering, the impurities attached to the graphite boat are changed into gas to be separatedfrom the graphite boat in the vacuum high-temperature sintering process, the gas converted from the impurities is pumped away by a vacuum pump and conveyed to a tail gas treatment system to be subjected to tail gas purifying treatment, and then the impurities such as foreign matter film on the surface of the graphite boat are burnt off. According to the cleaning method of the graphite boat for manufacturing the solar cells, the graphite boat can be cleaned up in a short time, no chemical agent such as HF acid is used in the whole process, no environmental pollution hidden danger exists, the environmental protection pressure for factories is reduced, no harm is generated to operating personnel, and the cleaning efficiency and the cleaning effect are improved; the graphite boat does not needto be disassembled, and damage to the graphite boat in the disassembling process is avoided; and in addition, few treatment link is needed, the cleaning time is short, and the production efficiency is higher.

Owner:山东伟基炭科技有限公司

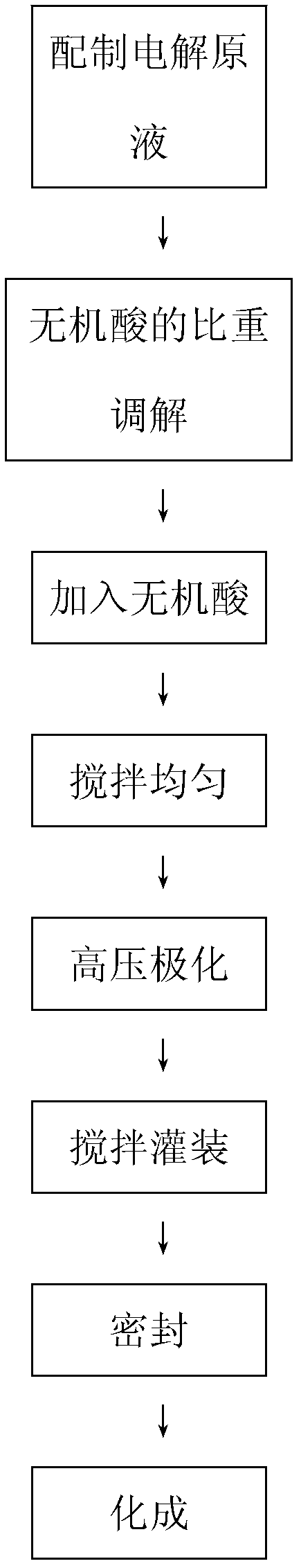

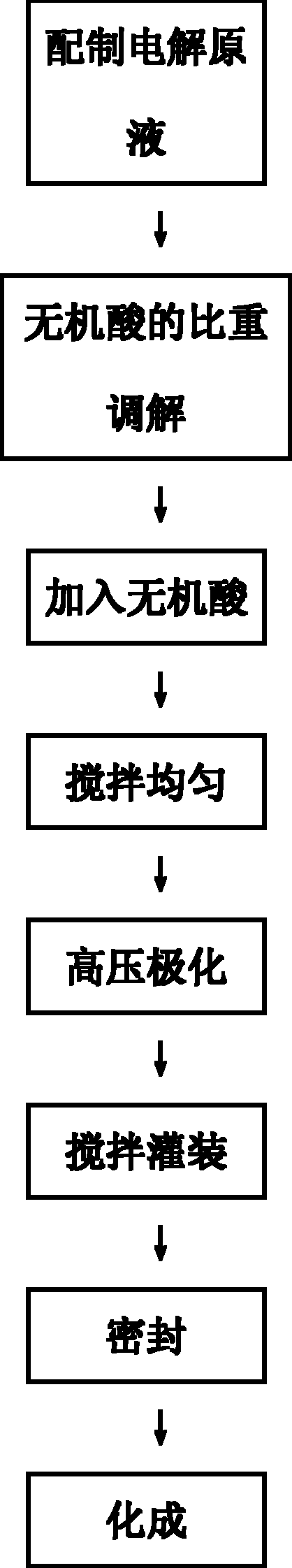

Preparation method of environmentally-friendly storage battery

InactiveCN102664288AOvercoming the drawbacks of severe pollutionNo pollution hazardFinal product manufactureSecondary cellsAminosilochromeHigh pressure

The invention provides an electrolyte used for manufacturing a sodium silicate storage battery. The electrolyte comprises 12-15% of sodium silicate (Na2OSiO2), 11-16% of sodium sulfate, 9-10% of sodium carbonate, 0.014-0.028% of poly(3-chlorobutene), 0.38-1.18% of polyaminosiloxane, and the balance water, wherein the sodium silicate contains 31-37.9% of silica (SiO2) particles, and above percentages are volume percents. The invention also provides a preparation method of the electrolyte of the sodium silicate storage battery. The preparation method comprises the following steps: weighing above materials according to above formula, putting the materials into a high pressure container, heating the container to the temperature in the high pressure container of 100-400DEG C and the pressure in the high pressure container of 2.85-6.17MPa, maintaining the temperature and the pressure for 21-31h, and cooling to room temperature to obtain the clarified liquid electrolyte containing granulated nano-scale SiO2. According to the preparation method, severe acid mist pollution in the making of traditional electrolytes is overcome, so there are no pollution damages to humans and the environment, and problems of hydrogen evolution flash-explosion, acid mist corrosion and the like are solved; and used electrolytes are acidic composite fertilizers, have no pollution and are extremely easy to process, and battery plates can also be recycled.

Owner:ZHEJIANG GOOD LUCK GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com