Apparatus and method for reclaiming, purifying and reutilizing boring mud

A drilling mud and mud technology, which is applied in dehydration/drying/concentrated sludge treatment, mining wastewater treatment, etc., can solve the problems of hidden dangers of pollution, time-consuming and labor-intensive, and large limitations, and achieve significant economic benefits, convenient use, and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

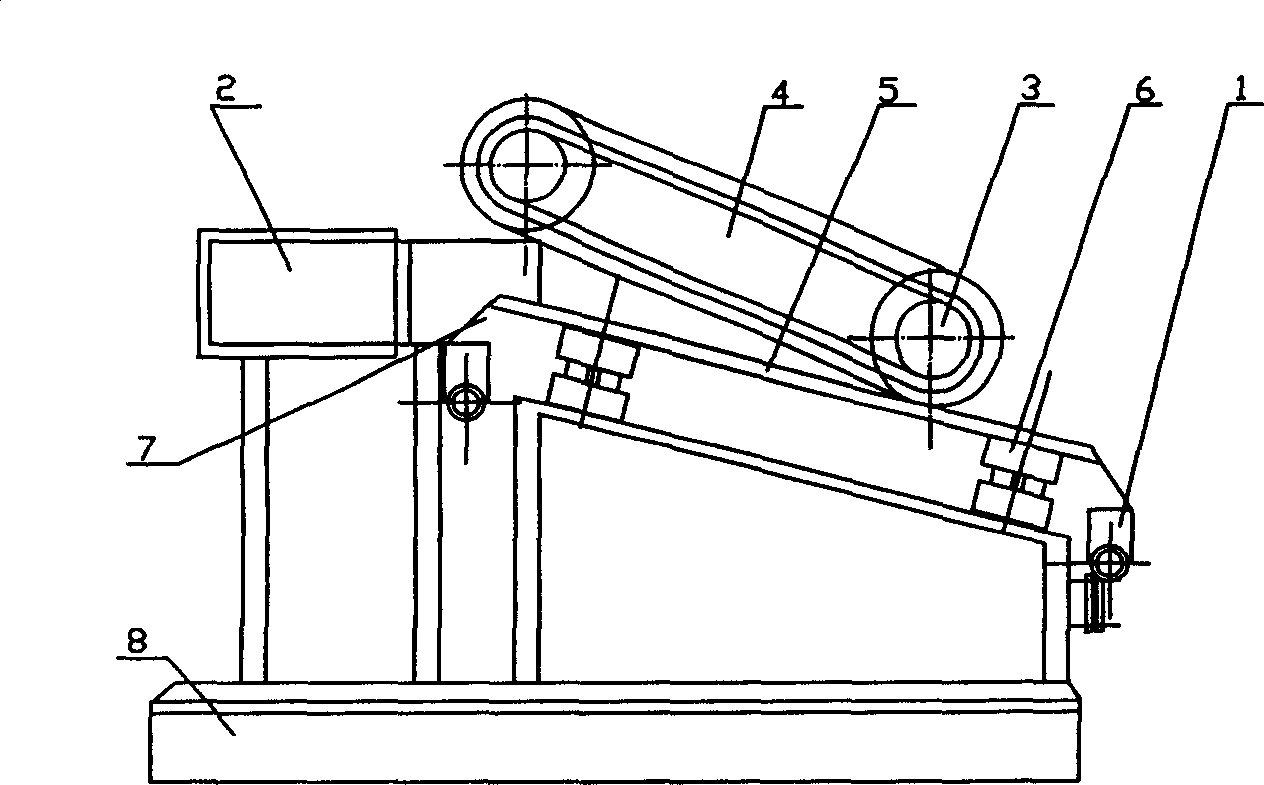

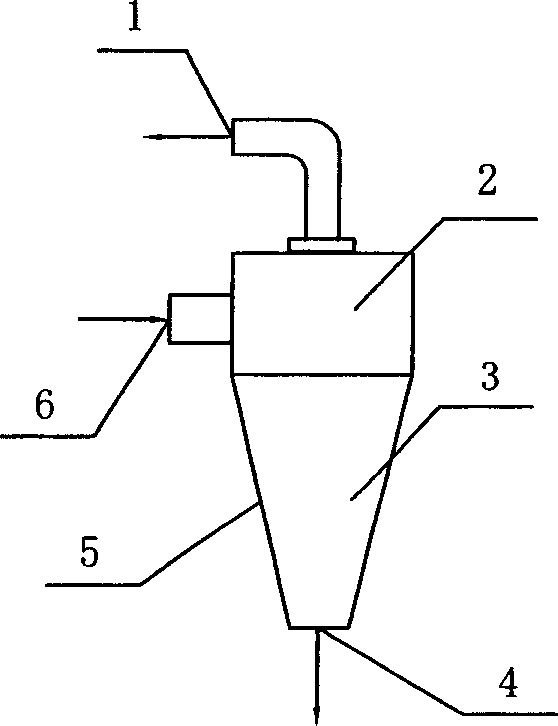

[0049] Accompanying drawing is embodiment of the present invention.

[0050] Below in conjunction with accompanying drawing, content of the present invention will be further described:

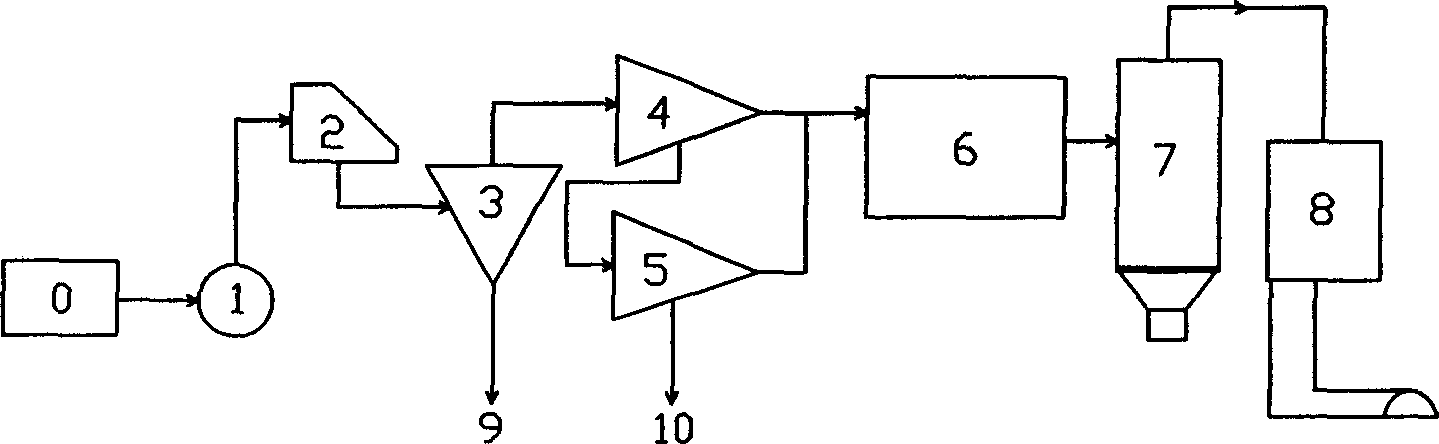

[0051] a. Systematic process flow

[0052] refer tofigure 1 As shown, the drilling mud recovery, purification and reuse device system consists of a storage tank 1 connected with a vibrating screen 2, a vibrating screen 2 connected with a hydrocyclone 3, and a hydrocyclone 3 connected with a first-stage centrifuge 4 , the first-stage centrifuge 4 is connected with the second-stage centrifuge 5, the second-stage centrifuge 5 is connected with an improved microwave oven 6, the microwave oven 6 is connected with the pulverizer 7, and the pulverizer 7 is connected with the automatic packaging machine 8 are connected together to form a device system. The separated impurity particles are discharged from the discharge port 9 of the hydrocyclone, and the detached water after deep purification is disc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com