Patents

Literature

87results about How to "Realize automatic continuous operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparatus and method for reclaiming, purifying and reutilizing boring mud

InactiveCN1803680ARealize automatic continuous operationSimple structureWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningParticulatesMicrowave oven

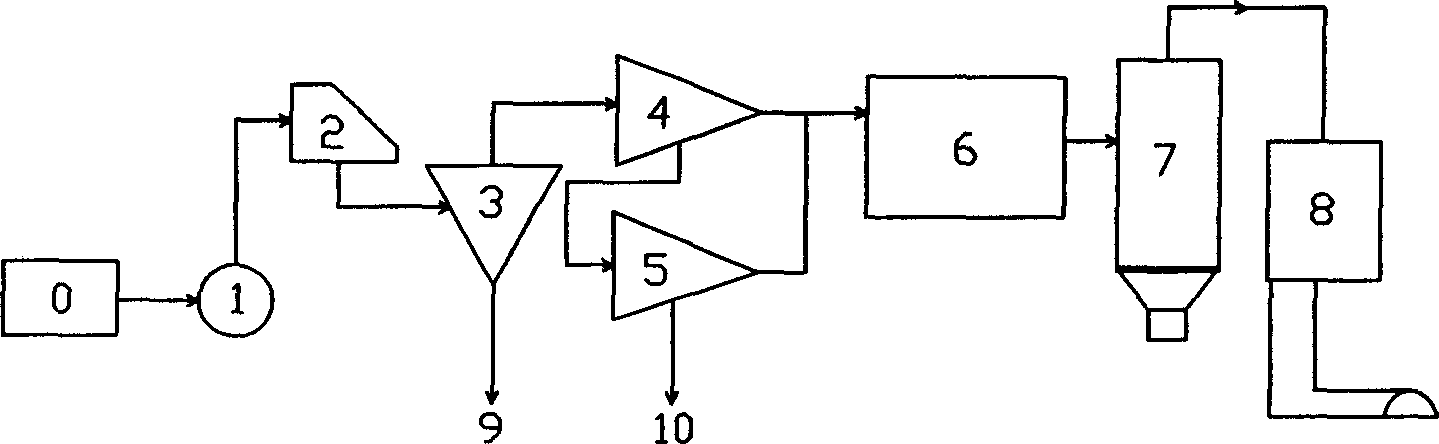

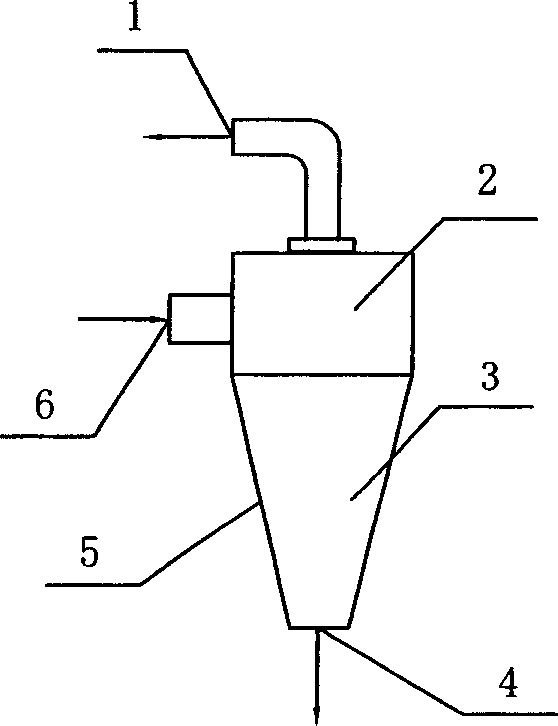

The invention discloses a device system to recover and re-use the drilling mud, which comprises connected by turns: a storage tank to store the waste drilling mud, a vibration screen for coarse purification, a hydrocyclone to separate the mud conveyed by a mud pump and discharge the particulate from its lower end, a first-stage centrifuge for filter and purification, a microwave oven to dry the mud, a crusher to crush the mud again, and an automatic packaging machine to pack and recover the mud. This invention is simple and convenient, has low cost and no pollution danger, and brings hundred millions economic benefits every year.

Owner:王鸿飞 +1

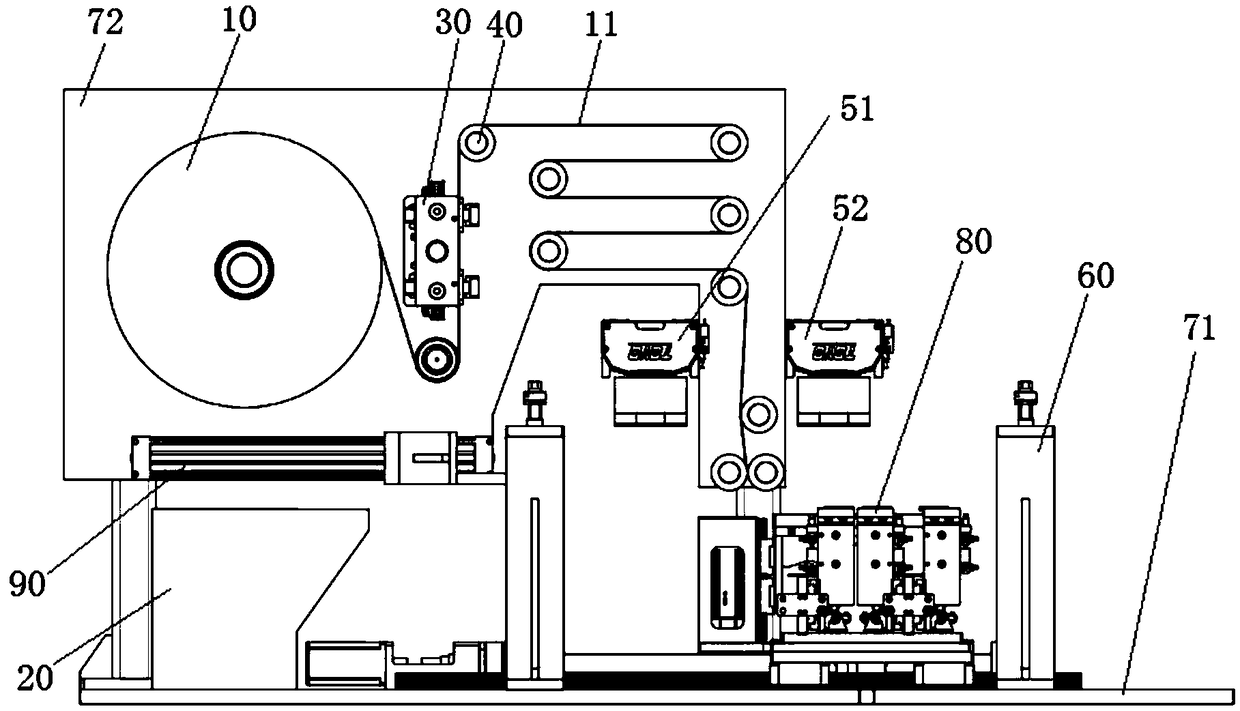

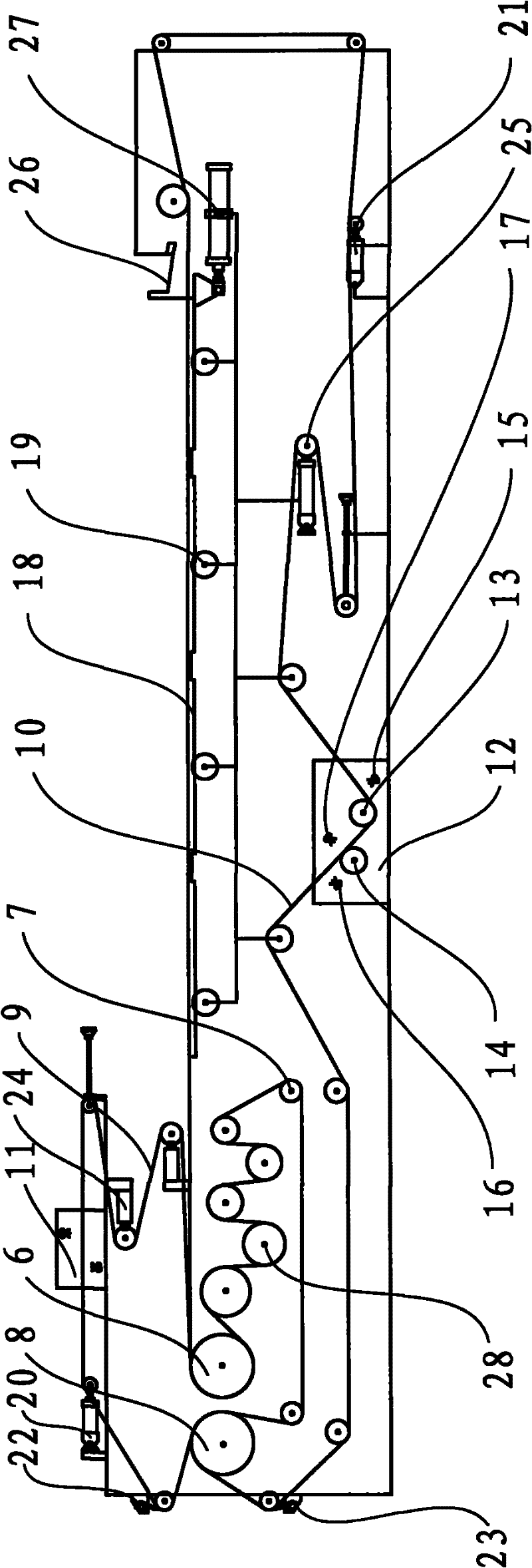

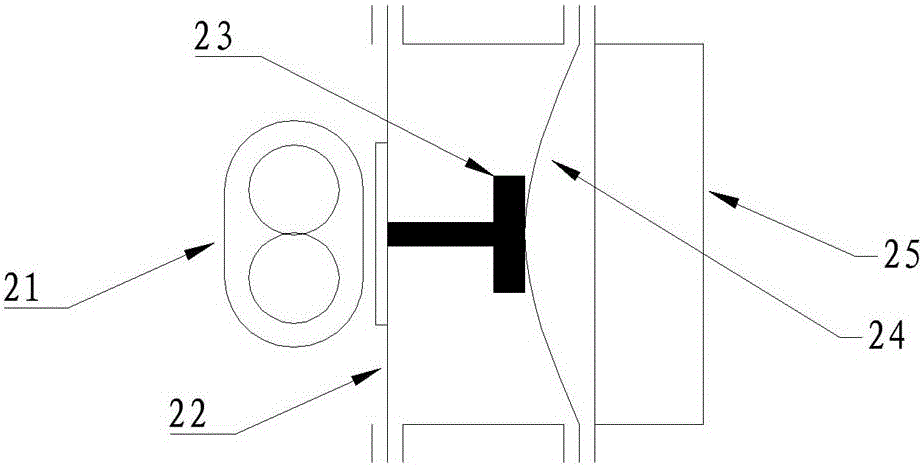

Vacuum belt press filter

InactiveCN101612805AEasy to cleanRealize automatic continuous operationCleaning using liquidsPressesFiltrationPulp and paper industry

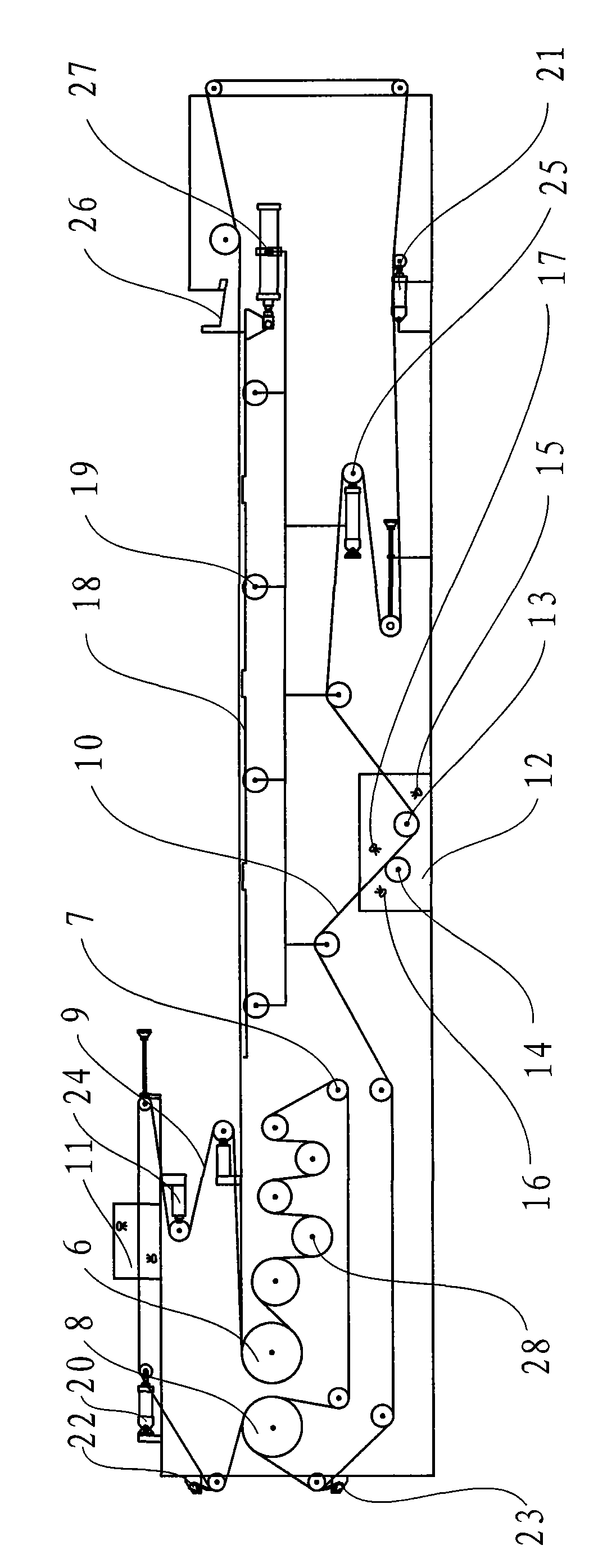

The invention relates to a vacuum belt press filter, comprising a rack, a vacuum filtration assembly, a press assembly and a filtration belt assembly, wherein the filtration belt assembly comprises an upper filtration belt, a lower filtration belt, and a cleaning device A and a cleaning device B which are used for respectively cleaning the upper filtration belt and the lower filtration belt; the cleaning device B comprises a front guide roller and a rear guide roller on the motion direction of the lower filtration belt, the front guide roller is arranged on the upper face the lower filtration belt, closely contacts the lower filtration belt and enables the lower filtration belt to form a V shape, the rear guide roller is arranged on the lower face of the lower filtration belt and is provided with a plurality of pinpricks, the size of each pinprick is matched with the size of a filtration pore of the filtration belt, and the rear guide roller contacts with the lower filtration belt by the pinpricks; and the cleaning device B is provided with a plurality of spray heads, and the spray heads are distributed on the upper face and the lower face of the lower filtration belt. The vacuum belt press filter of the invention has the advantage of favorable cleaning effect of the filtration belts, and belongs to the technical field of press machines.

Owner:HUZHOU HEHONG MACHINERY

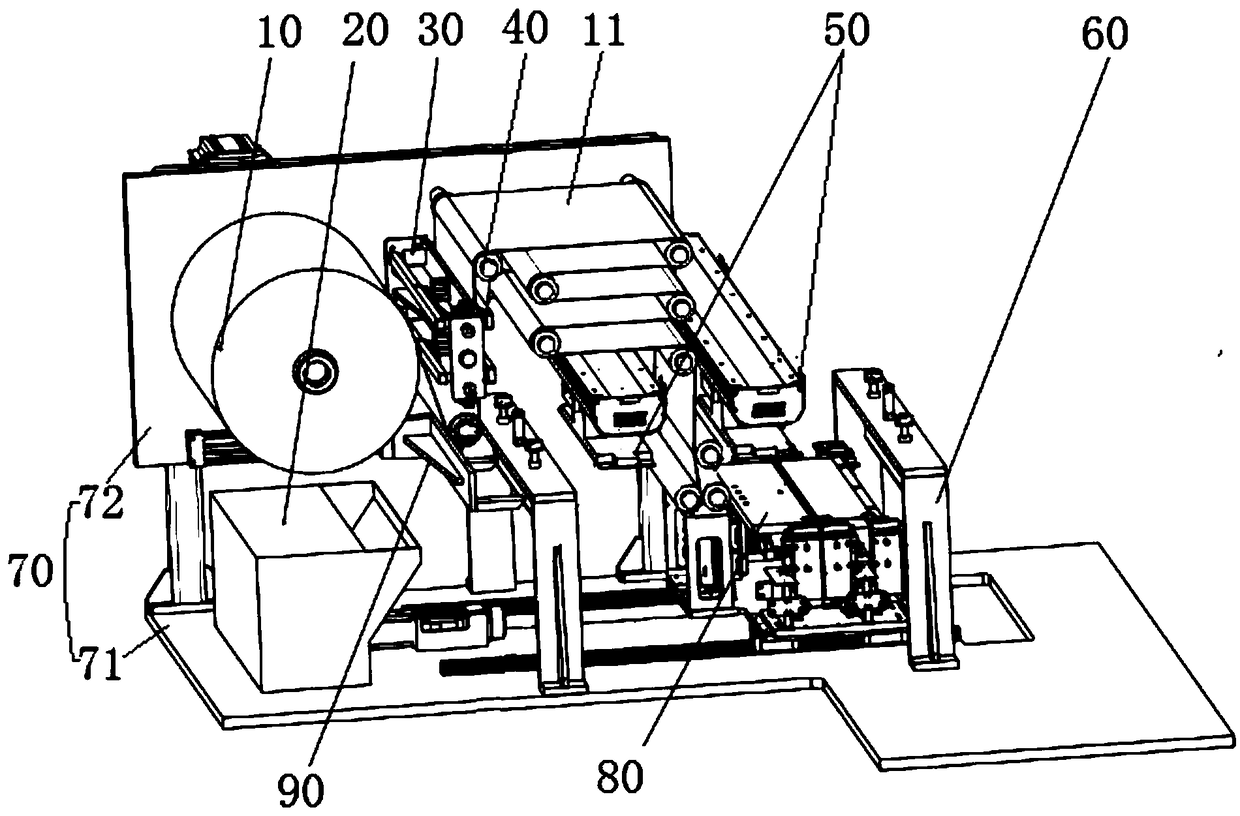

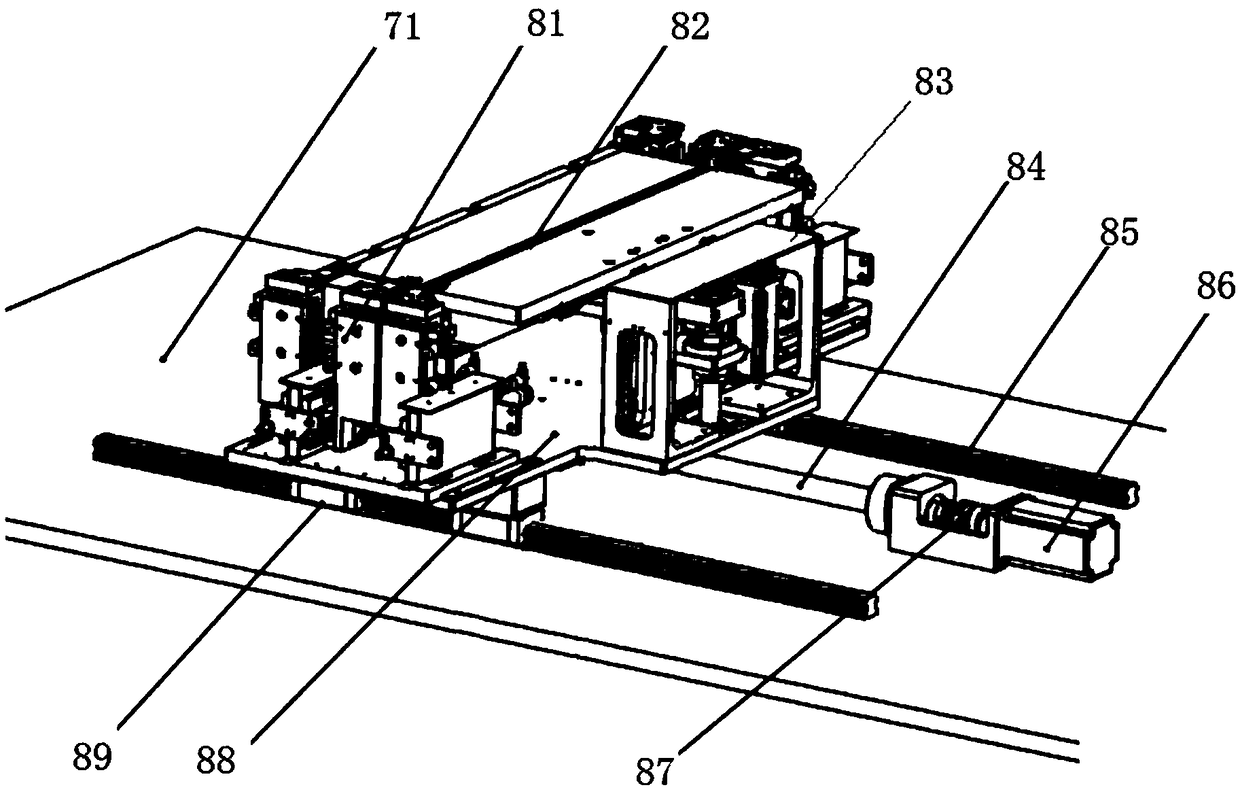

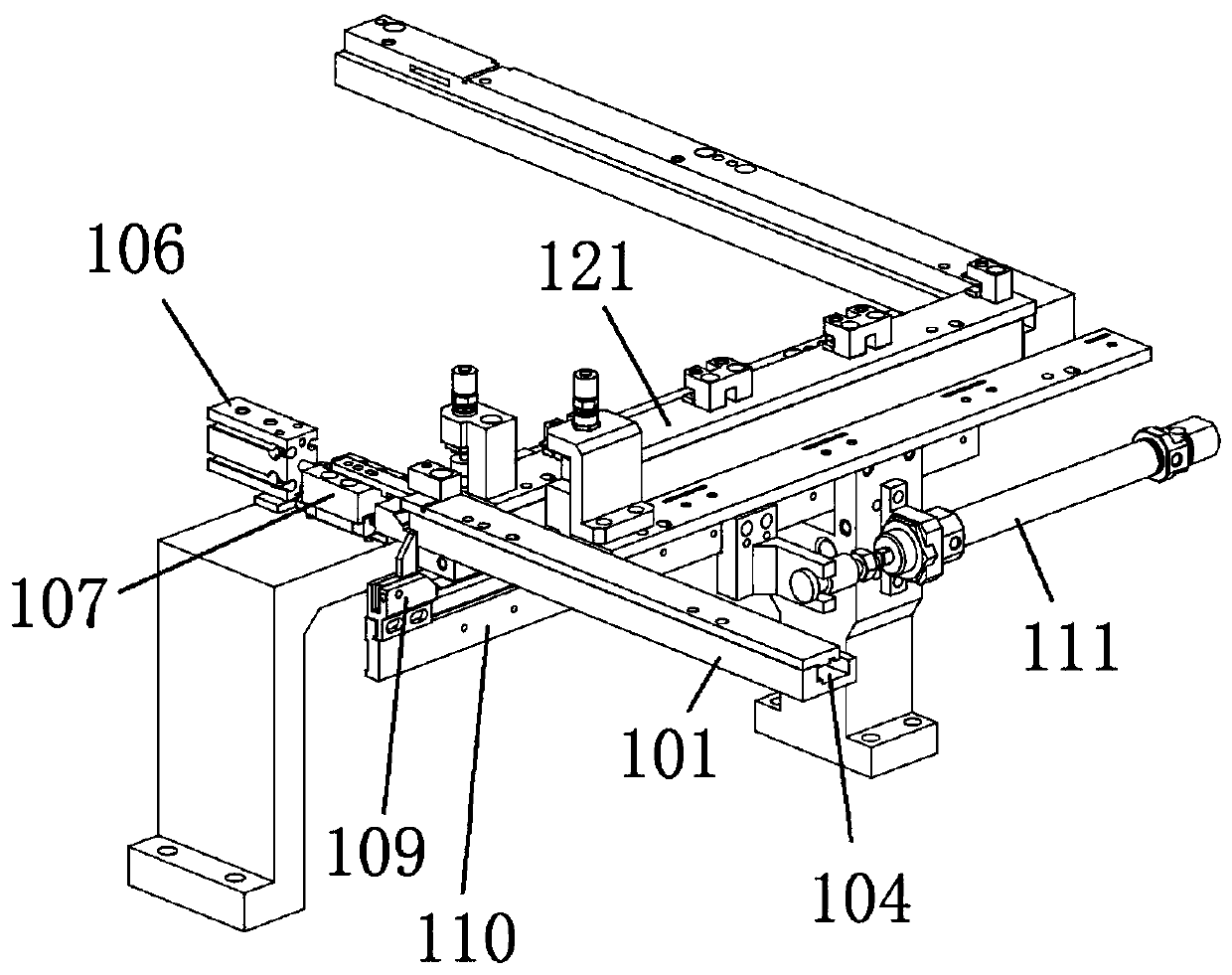

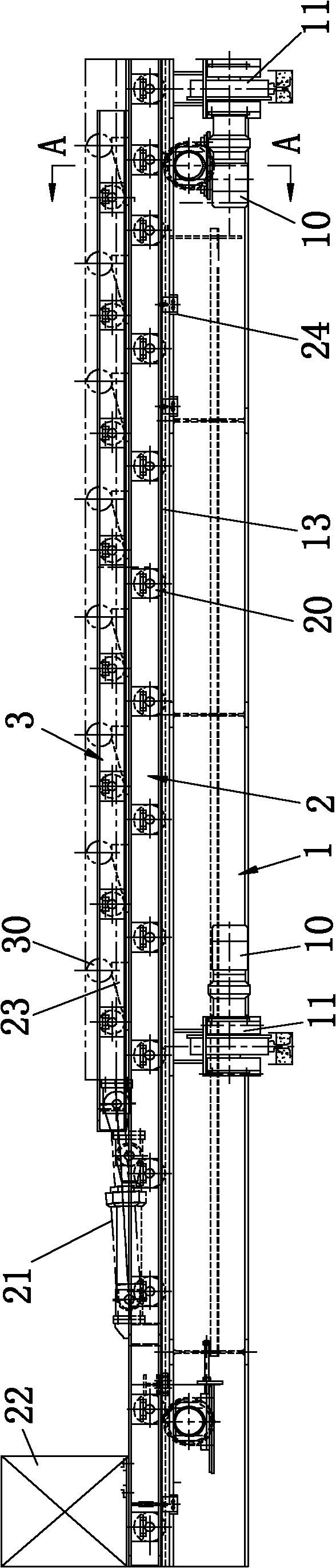

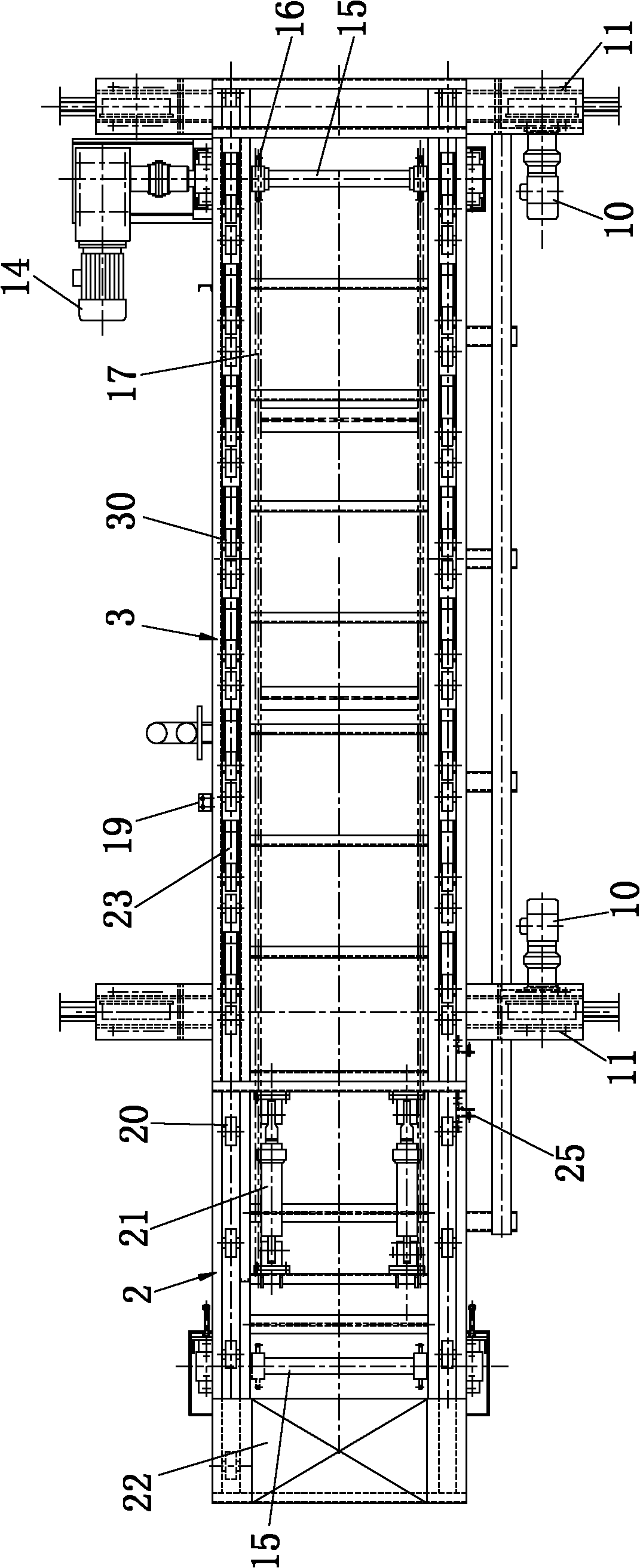

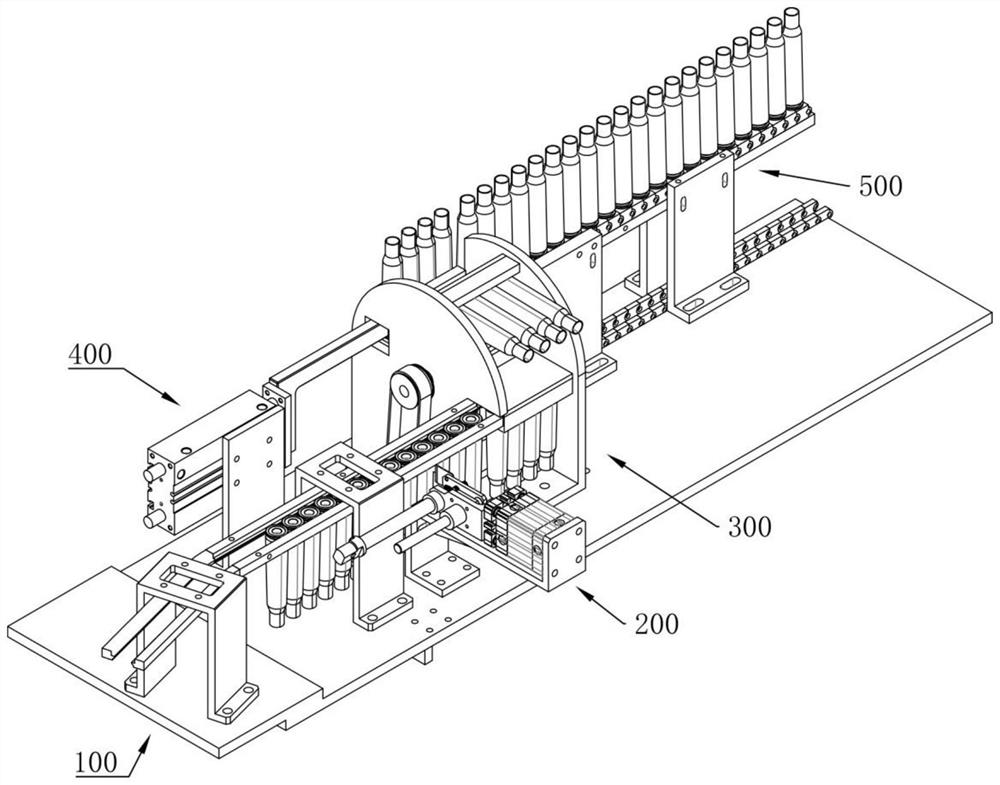

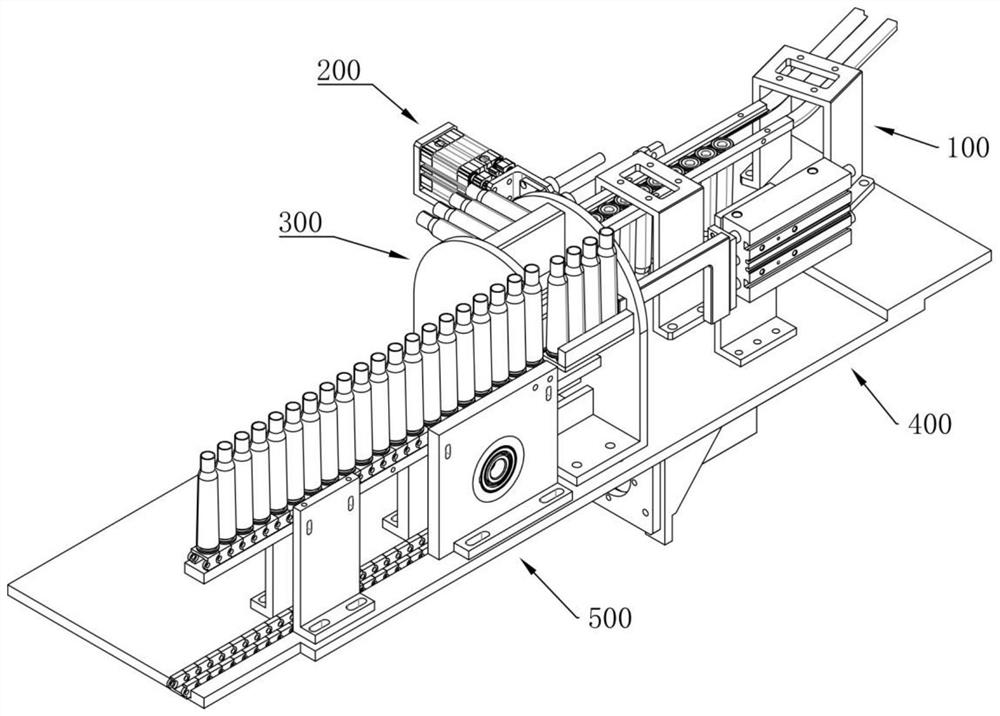

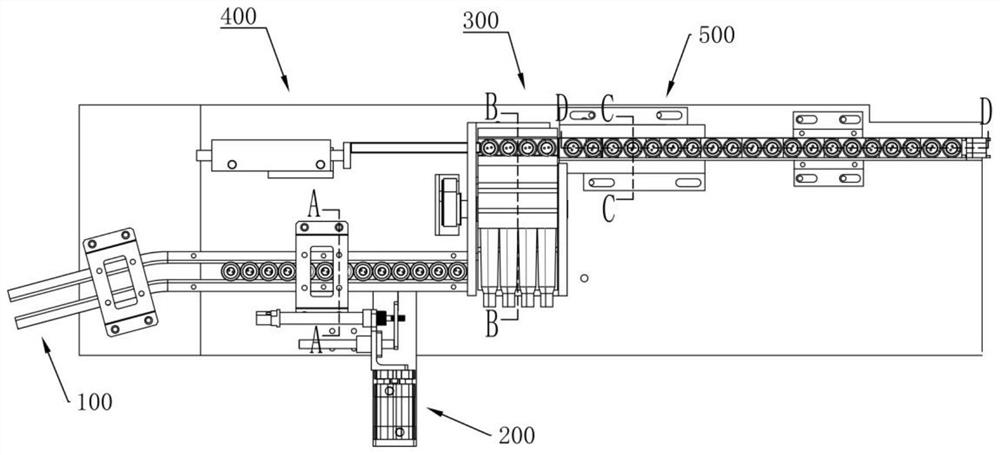

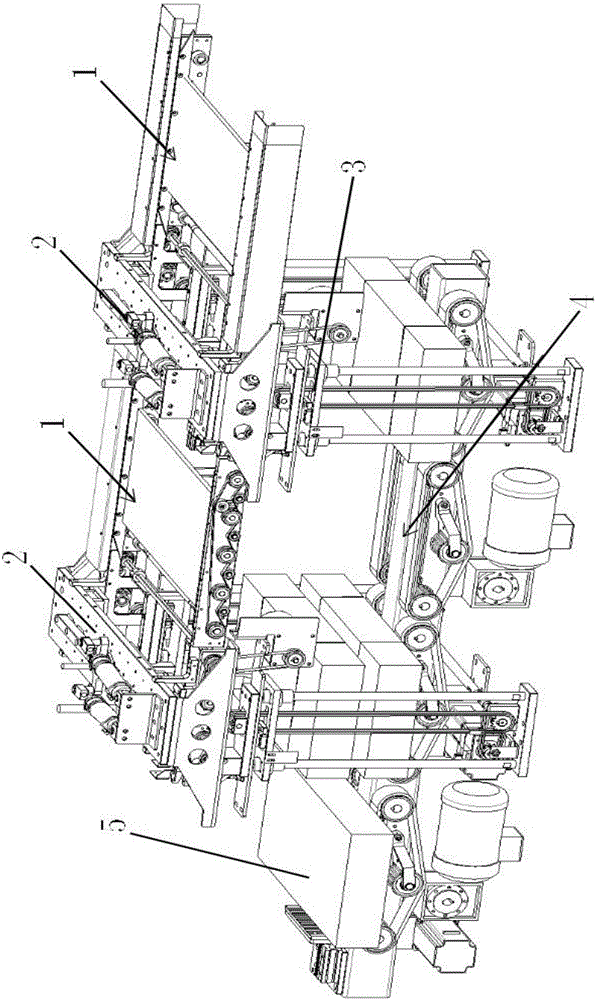

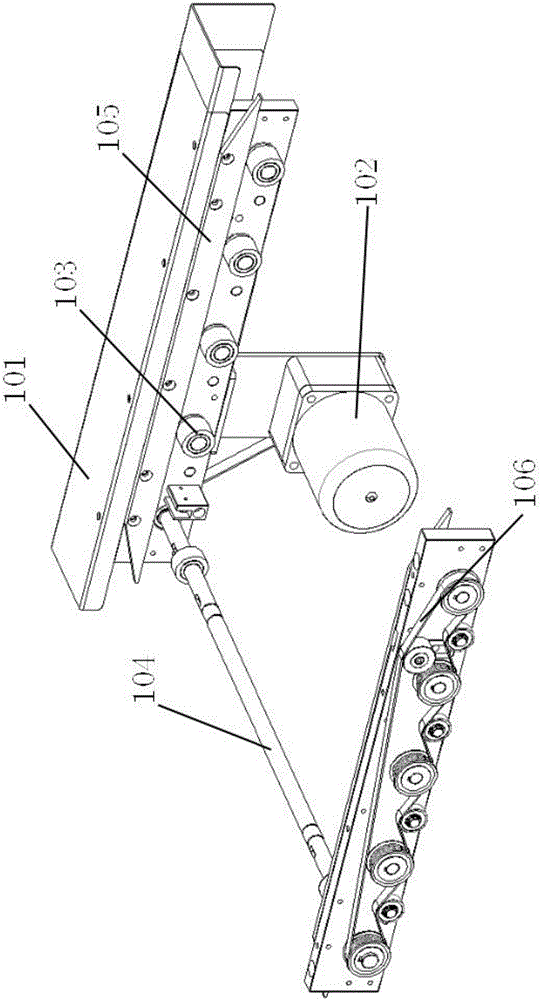

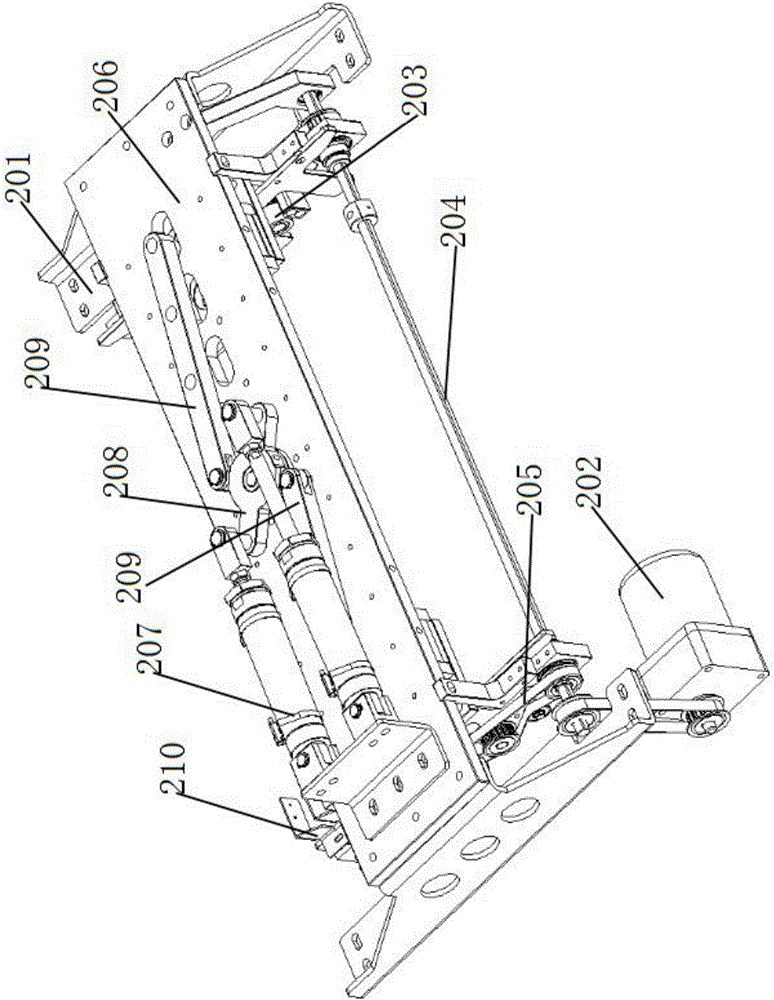

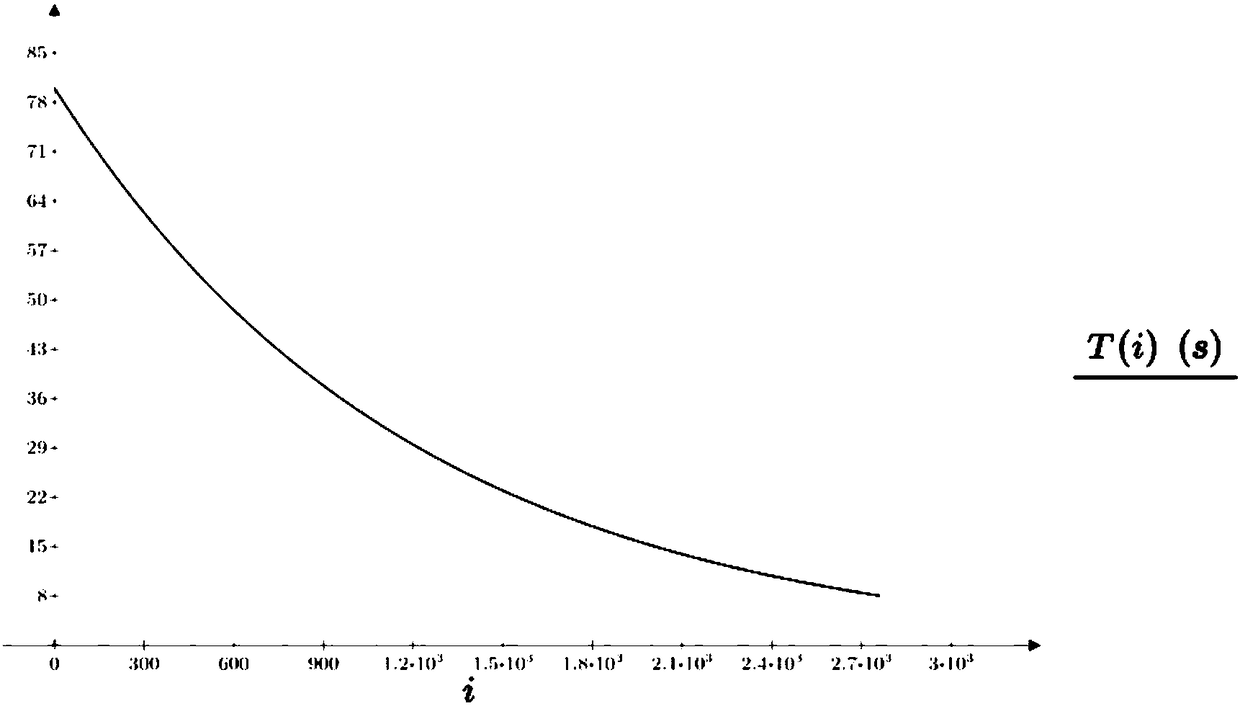

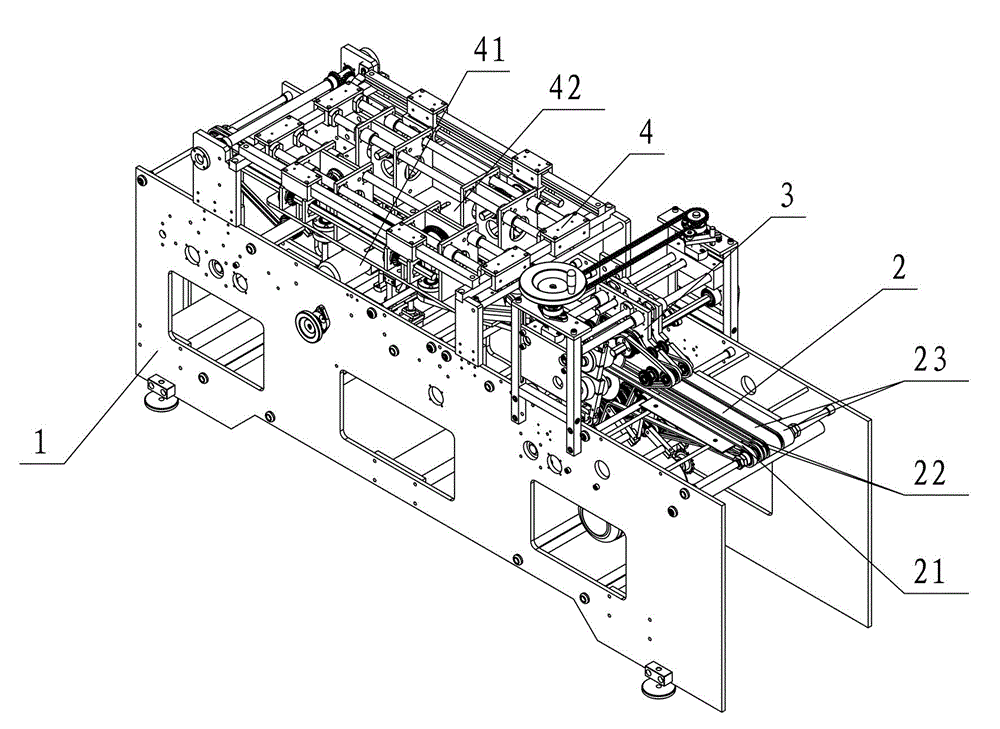

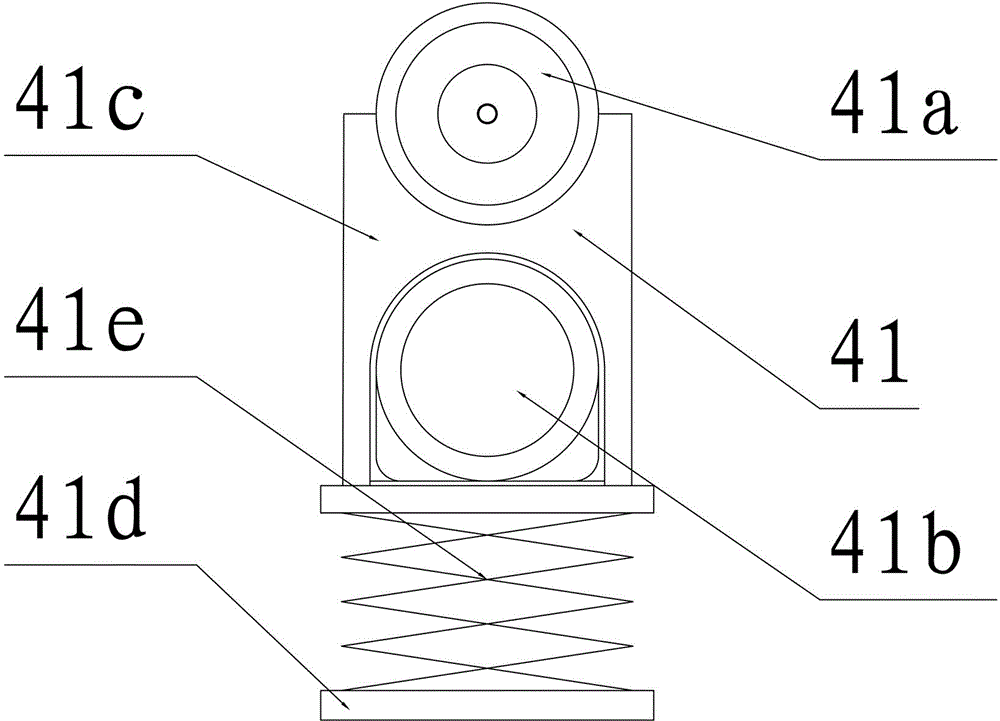

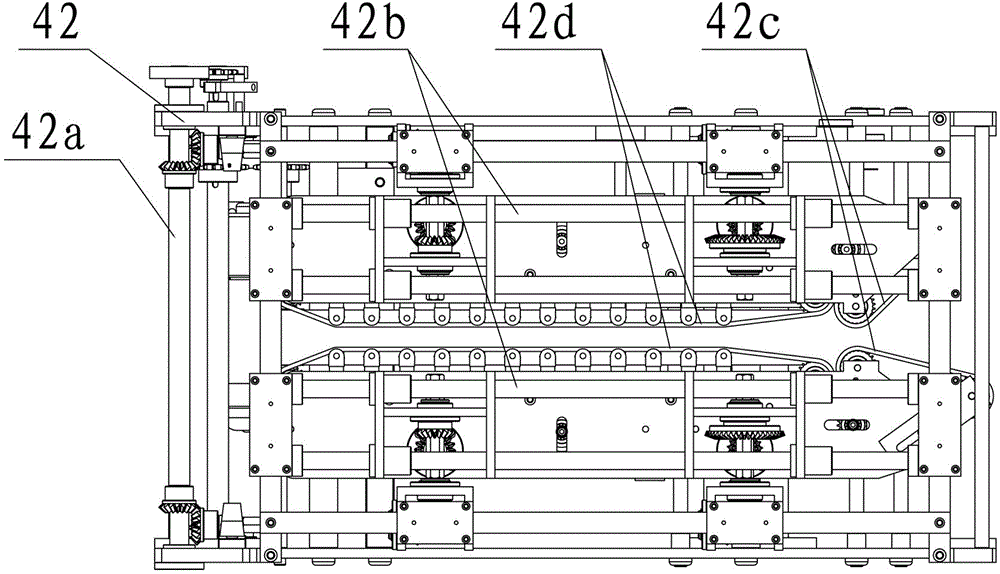

Automatic lamination mechanism of Z-type laminated battery core

ActiveCN109390635AContinuous and reliable operationRealize automated productionFinal product manufactureSecondary cellsScrapContinuous operation

The invention discloses an automatic lamination mechanism of a Z-type laminated battery core, the automatic lamination mechanism comprises a bracket composed of a bottom plate and a side plate, wherein the side plate is fixedly provided with a diaphragm unwinding mechanism, and a traction group used for controlling the tension and the deviation of a diaphragm, the bottom plate is slidably connected with a lamination table, and a cutting mechanism is fixed on the bottom plate; the side plate above the lamination table is fixedly provided with two pole piece manipulators for respectively placingpositive and negative pole pieces; the lamination table includes a work table and pressing holding members which are symmetrically disposed at both ends of the work table and used for pressing and holding of the work table, a lifting mechanism is connected to one side of the work table by a supporting frame, the pressing member, and the pressing holding members and the lifting mechanism are fixedon a moving plate to achieve horizontal movement. The automatic lamination mechanism realizes the automatic continuous operation of automatic cutting, tiling, splicing, automatic discharging and thelike of the diaphragm by a mechanical means, and realizes the cutting and tiling of the diaphragm by the pressing holding members, ensures that the diaphragm is automatically flattened after each electric core is made to achieve continuous automated production.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

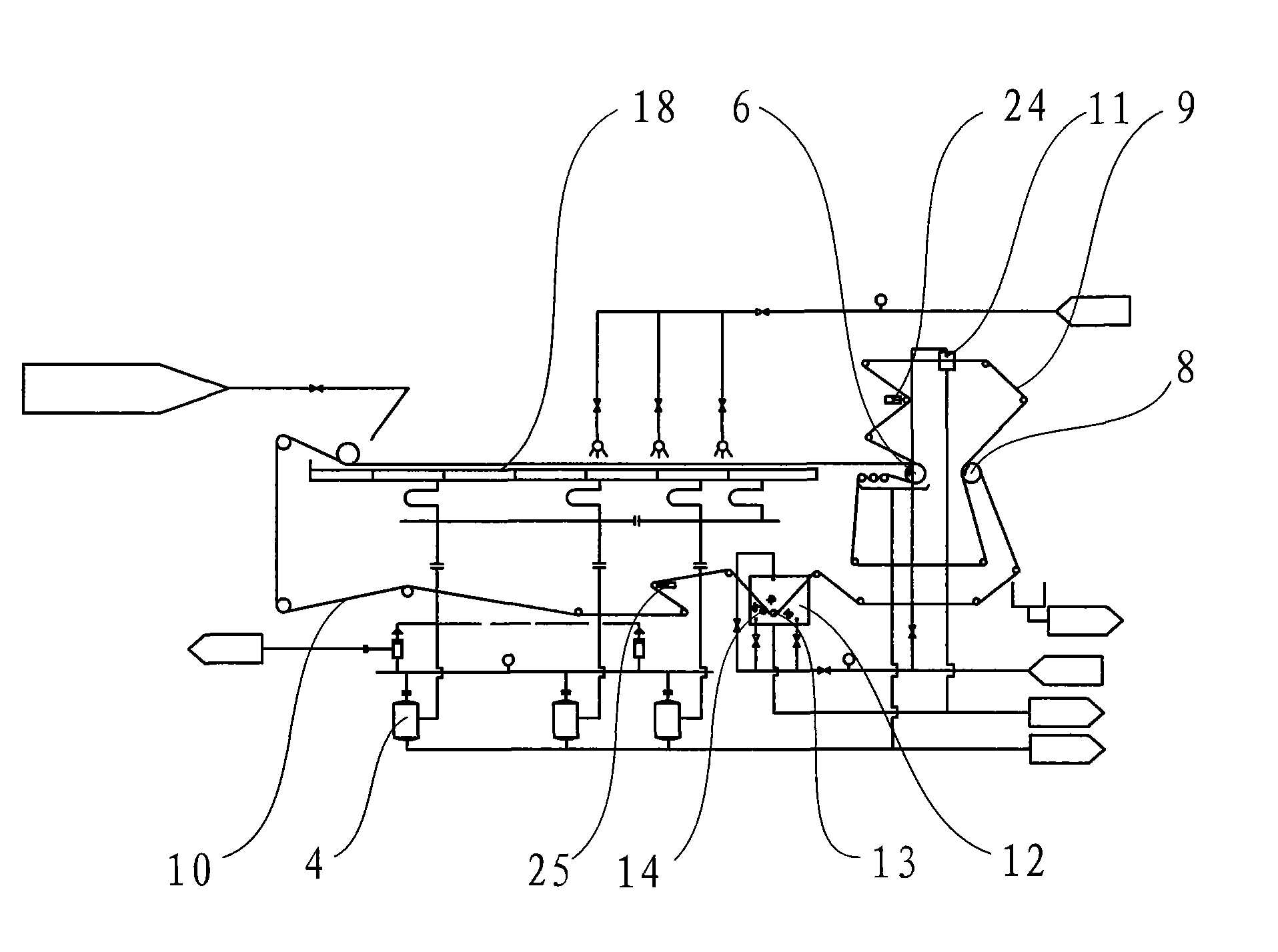

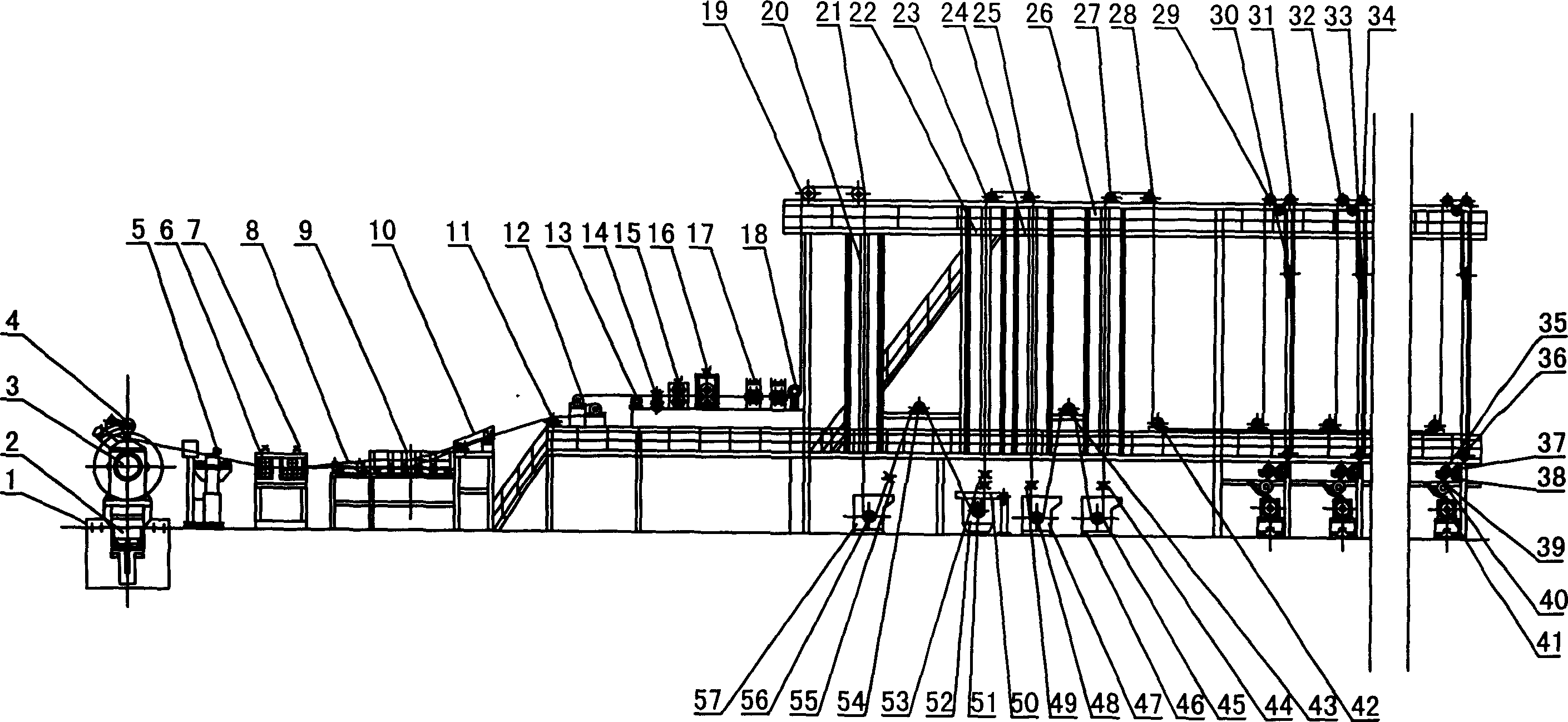

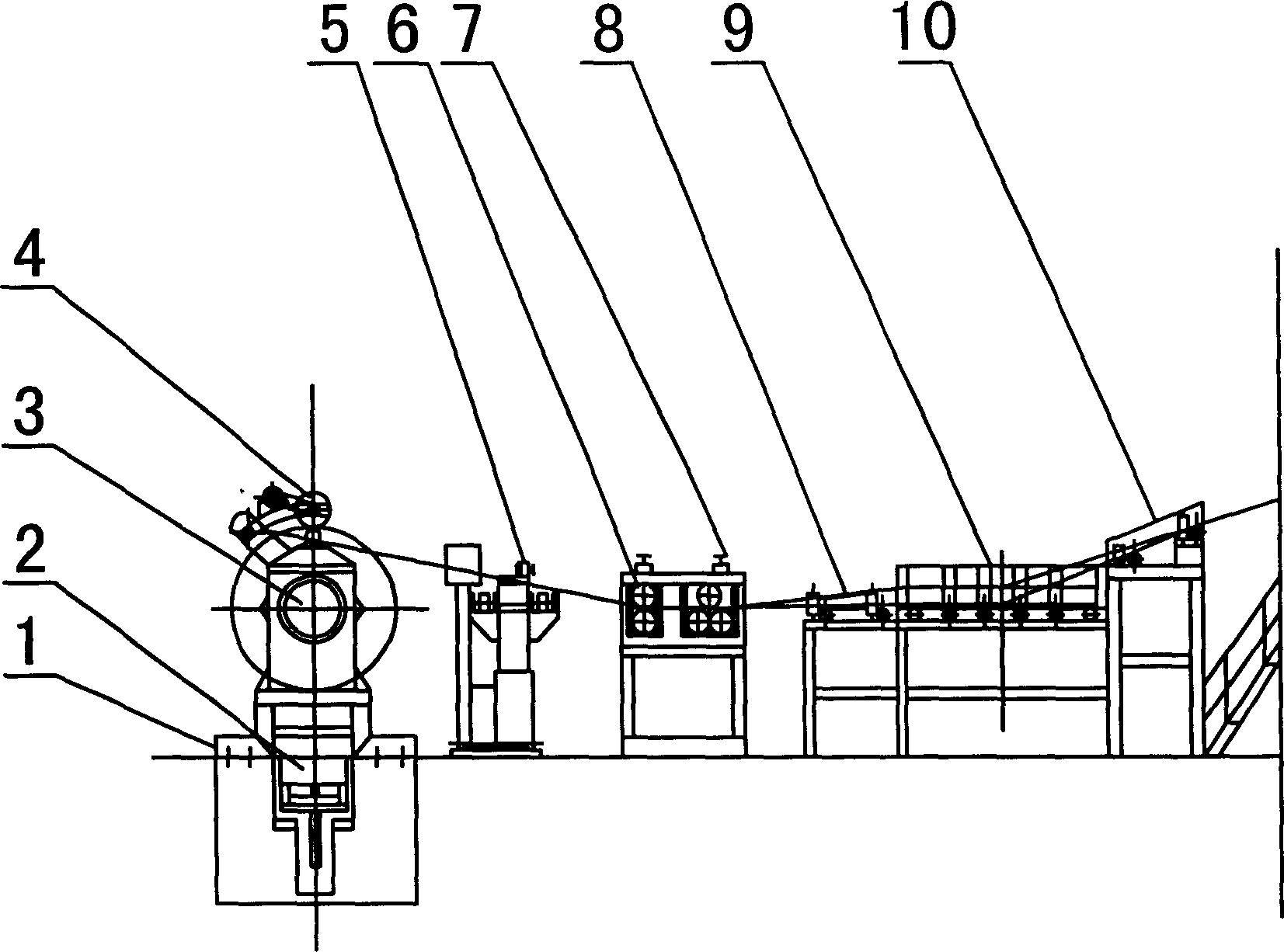

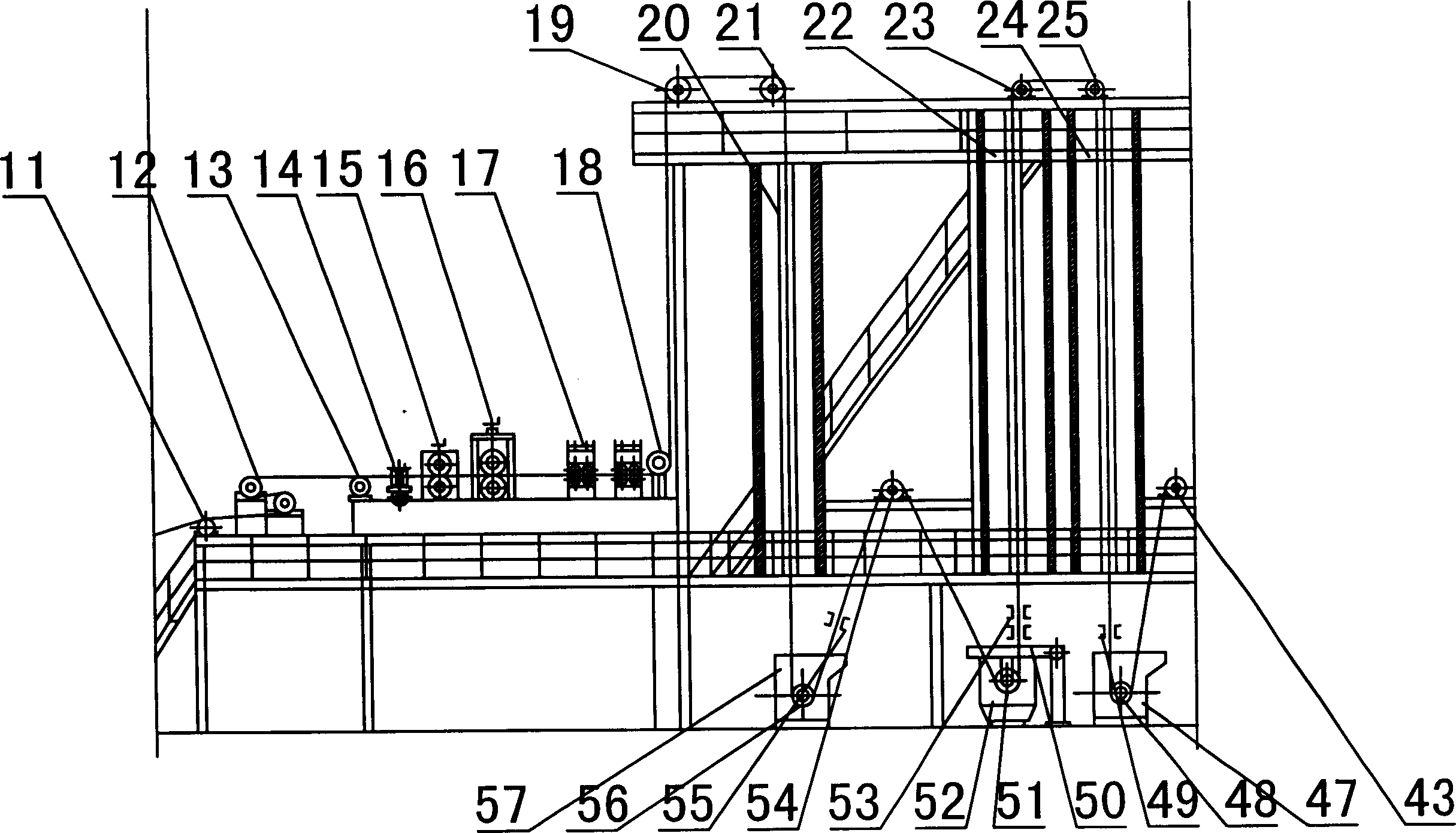

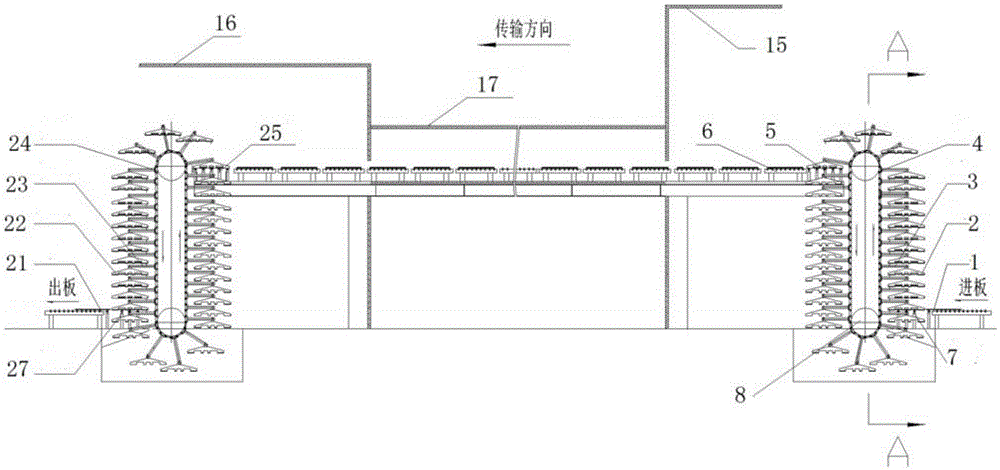

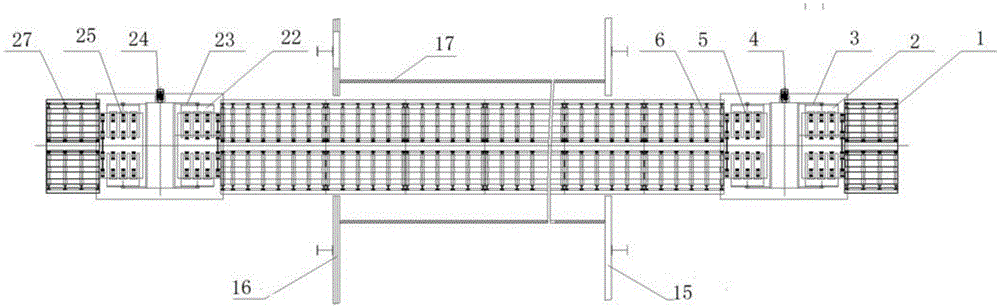

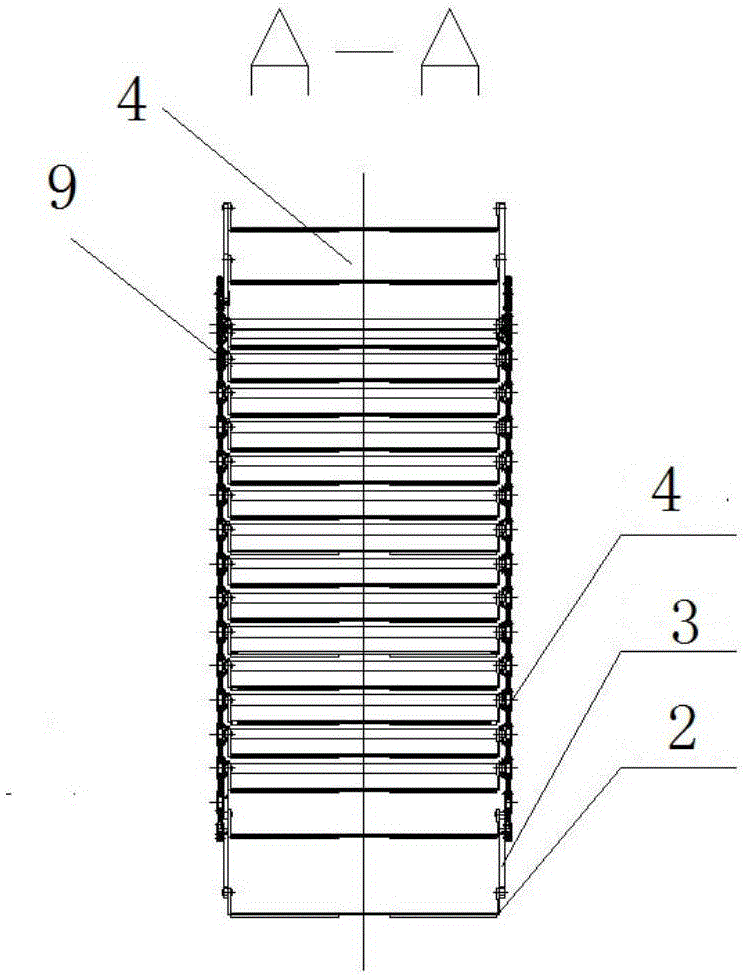

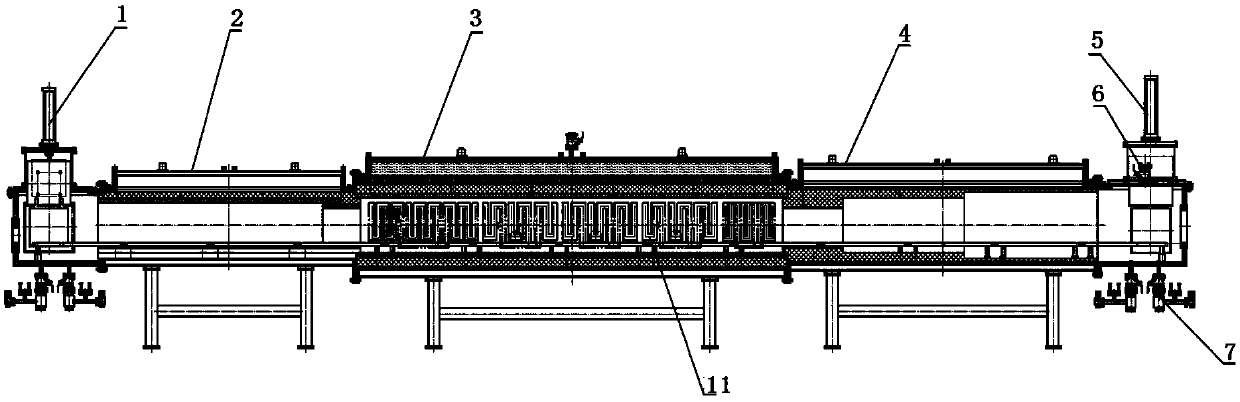

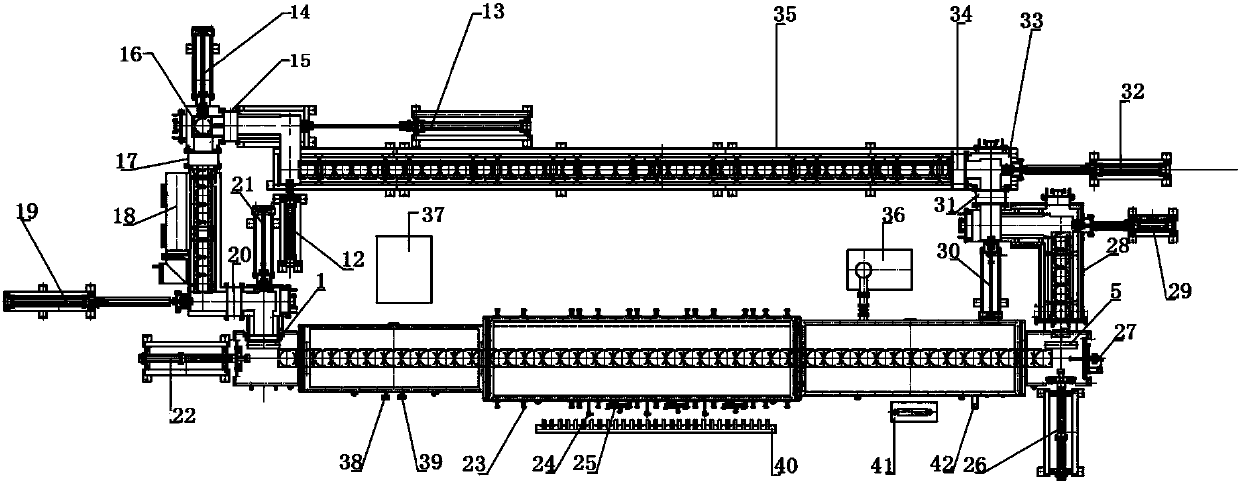

Automatic production line for producing high-strength color coated package steel strip by utilizing non-tempering process

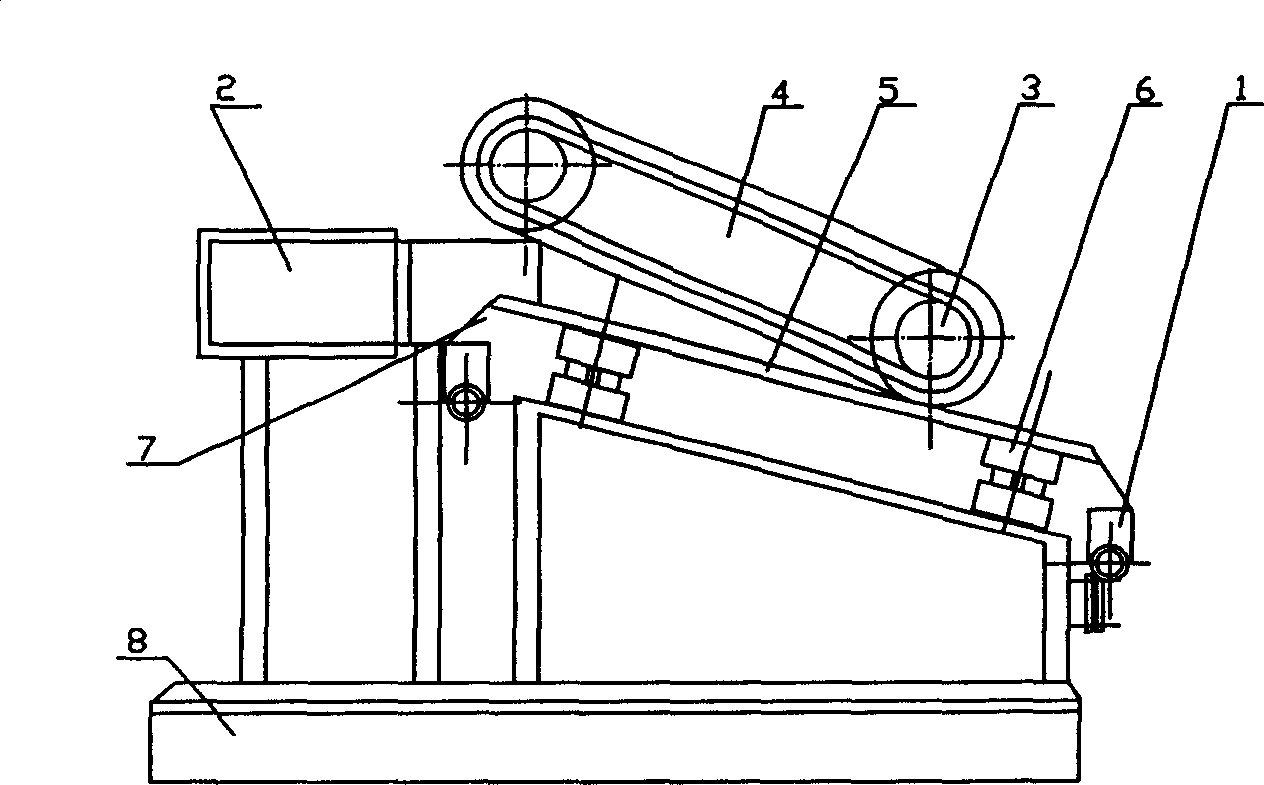

ActiveCN1807003ALess investmentUndiminished strengthLiquid surface applicatorsFurnace typesProduction lineWax

The invention relates the automatic production line producing high-strength colored paint package steel band with non tempering technology, comprising pull-type recoiler, bonding machine, feeding planisher, storage bin, tension speed control S roll units, slitting shears, flat edge trimmer, heating furnace, the first and second cooling trough, coating groove, coating drying furnace, wax or oil groove, drying powder, differential tension speed control S roll units, separate gravity loop units, roll-up units, shipping package units and automatic control system. The roll-up machine comprises adjusting wheel, pressing wheel, nylon wheel, and air-actuated cut, correcting wheel, material received reel and dummy car. The production line makes the whole industrial process on the one production line, and the metallurgical structure of steel band comprises pearlyte and ferrolites. Compared with high-strength package steel band production line at home and abroad, the said production line reduces the cost of manufacture by 40% and equipment investment by 90%.

Owner:ANSHAN FALAN STEEL STRIP CO LTD

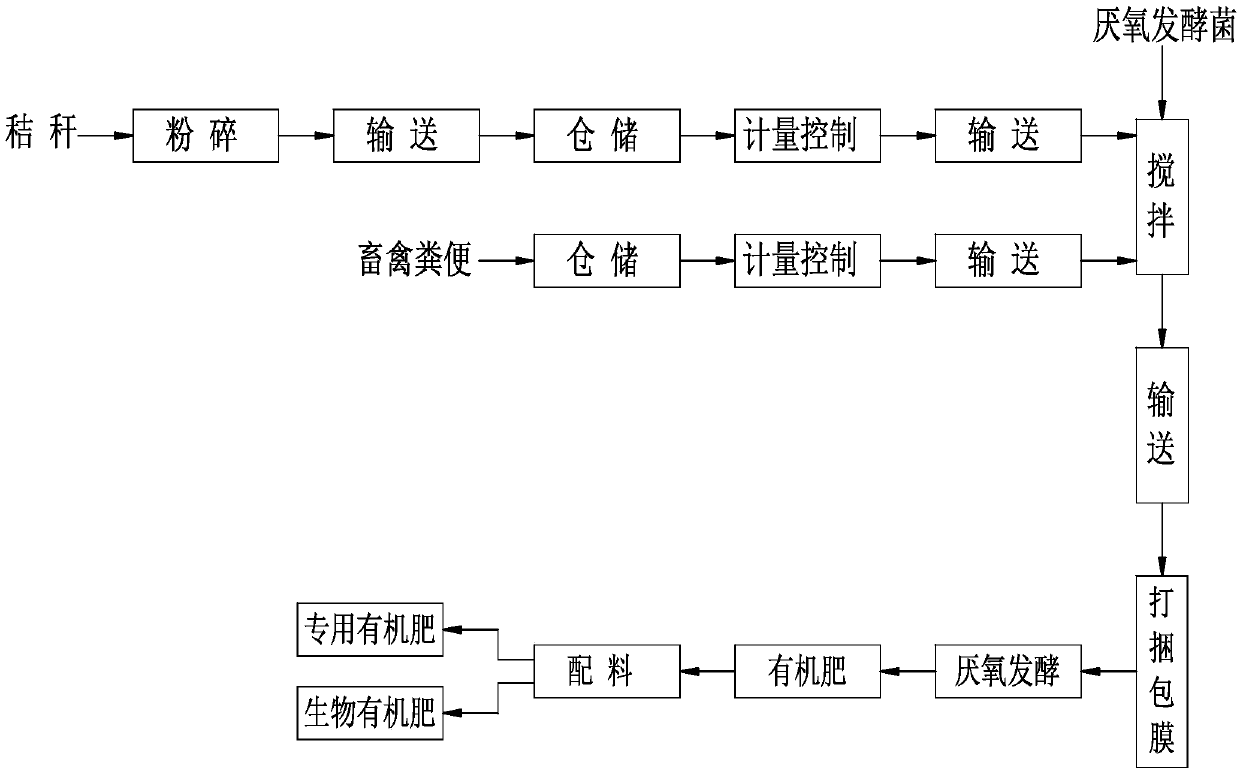

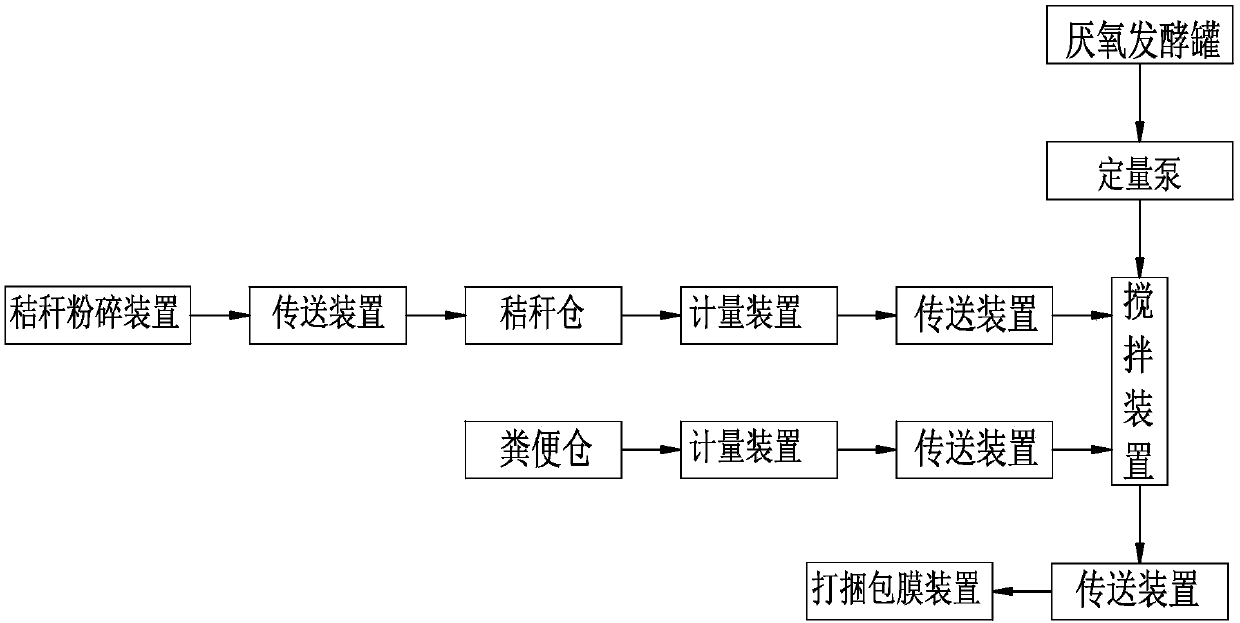

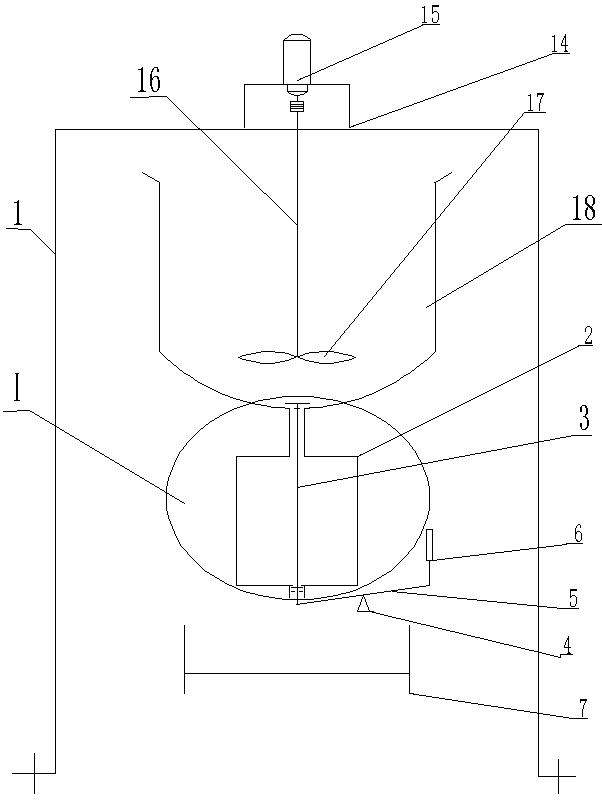

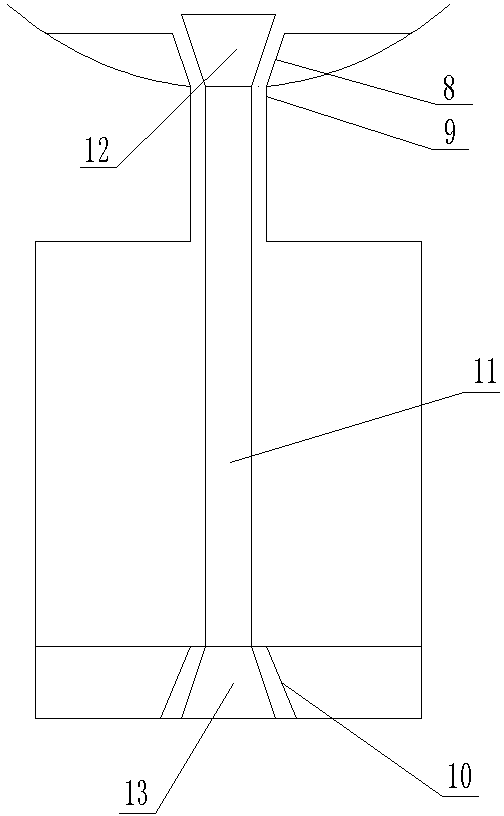

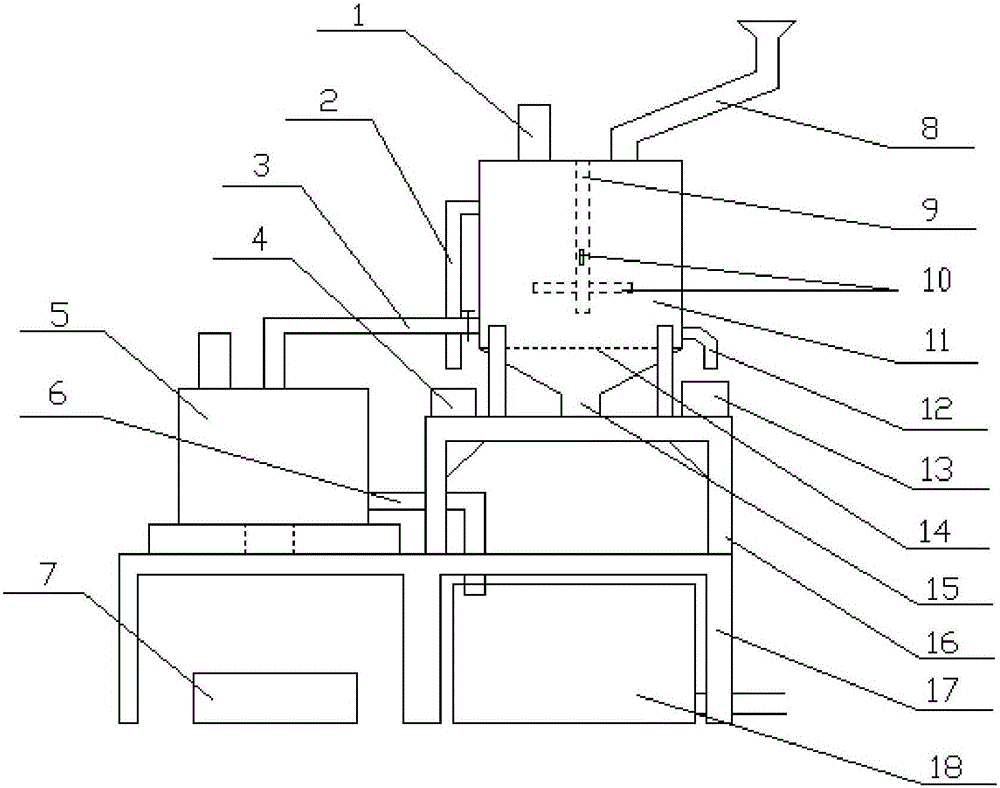

Process and system of producing organic fertilizer by anaerobically fermenting excrement of livestock and poultry

InactiveCN107827490AEasy to useReduce dosageBio-organic fraction processingExcrement fertilisersBiotechnologyAnimal feces

The invention discloses a process and a system of producing organic fertilizer by anaerobically fermenting excrement of livestock and poultry, wherein the process includes the following steps: 1) crushing crop straw into powder via a straw crusher, and feeding the straw powder into a straw bin; 2) collecting the excrement of livestock and poultry in an excrement bin; 3) outputting the straw powderand the excrement of livestock and poultry under metering control and delivering the materials into a stirring apparatus via a delivery device, and stirring the mixture, wherein anaerobic fermentation bacteria are added with uniform mixing; 4) conveying the stirred material into a bundling and coating device to bundle and coat the mixture, and storing the packed material in a natural environmentto perform anaerobic fermentation in a sealing status, so that the organic fertilizer is produced by completely fermenting and composting the excrement of livestock and poultry and straw. In the invention, the organic fertilizer is produced from the excrement of livestock and poultry and crop straw, so that problems of pollution due to livestock and poultry and incineration of straw are solved from the source, and pollution on water body, farmland and atmosphere and environment pollution due to incineration of straw are reduced. The system is reliable in operation and allows the bundling and film-coating operations to be carried out in one step, thus achieving automatic continuous operation. The method is effective for processing the excrement of livestock and poultry and the farmland waste straw.

Owner:WUZHENG +1

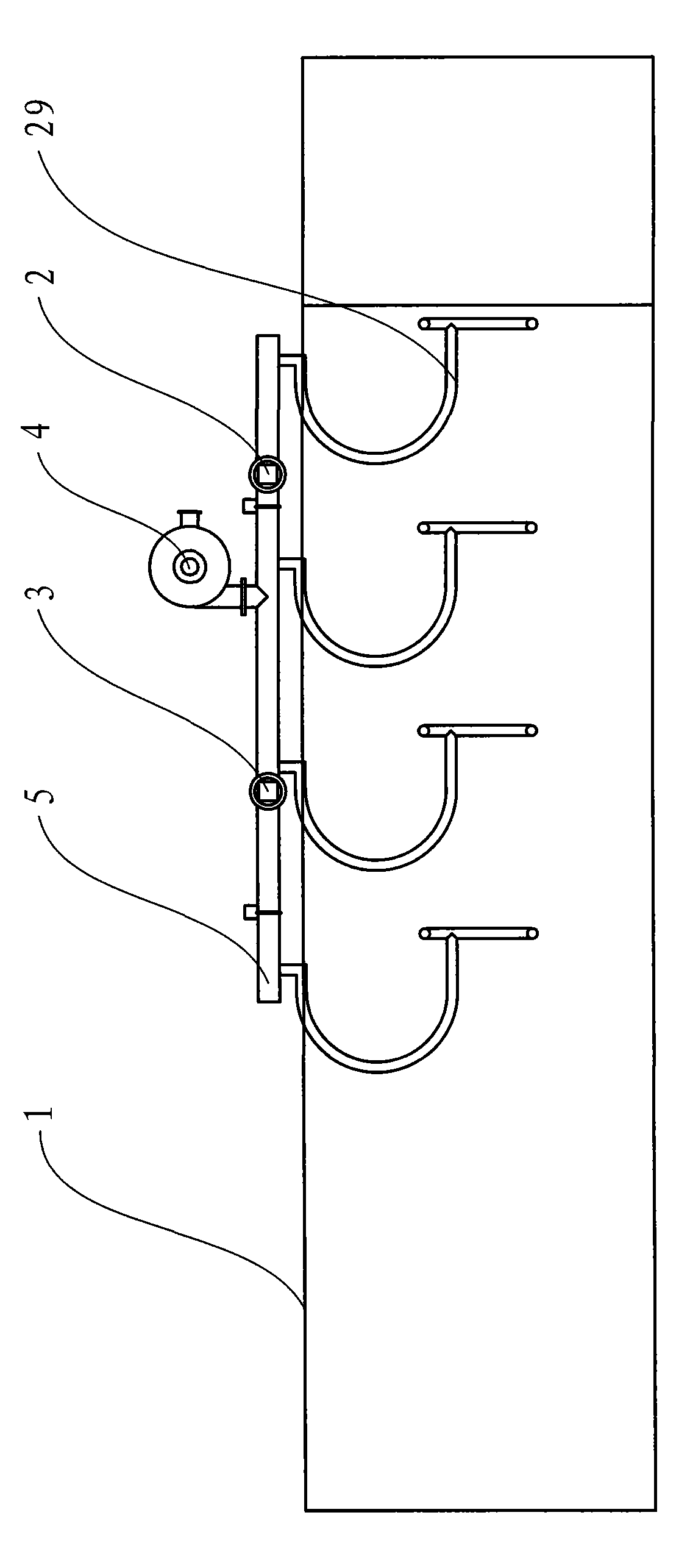

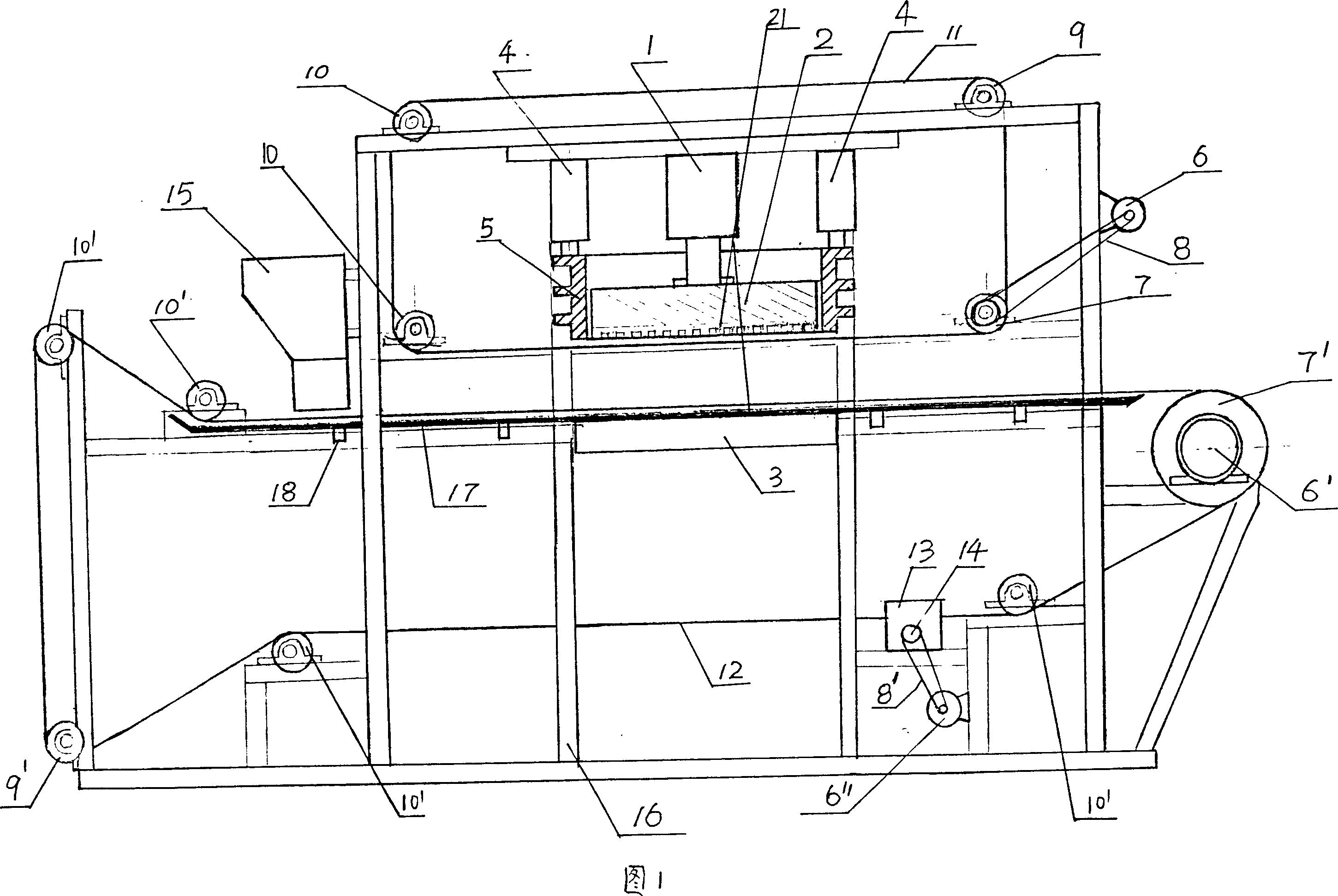

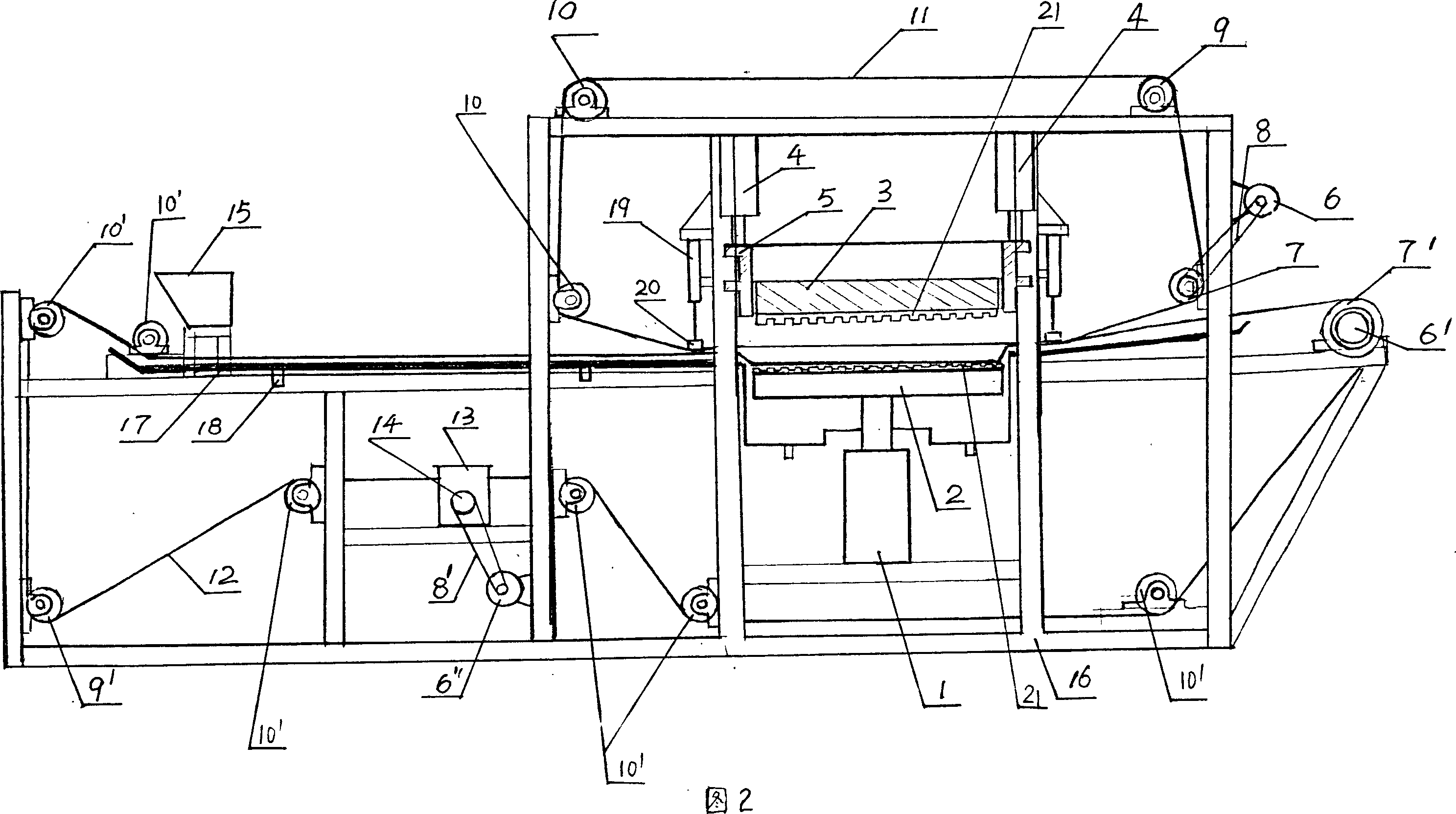

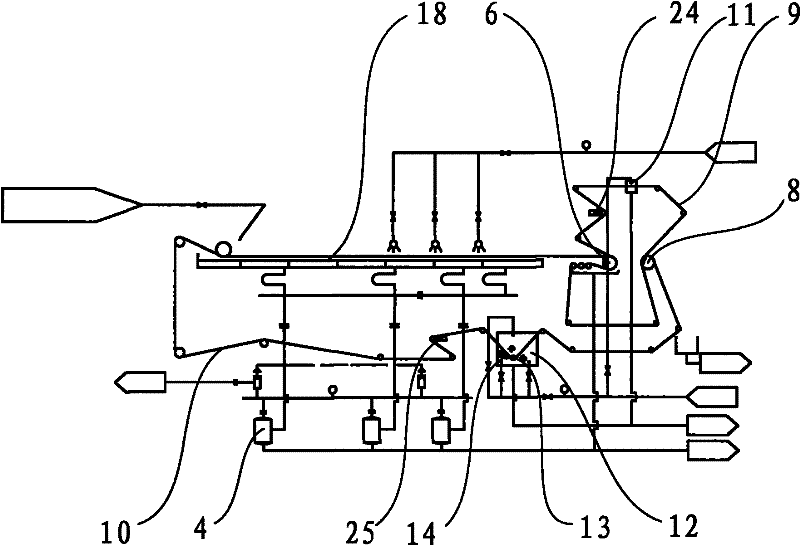

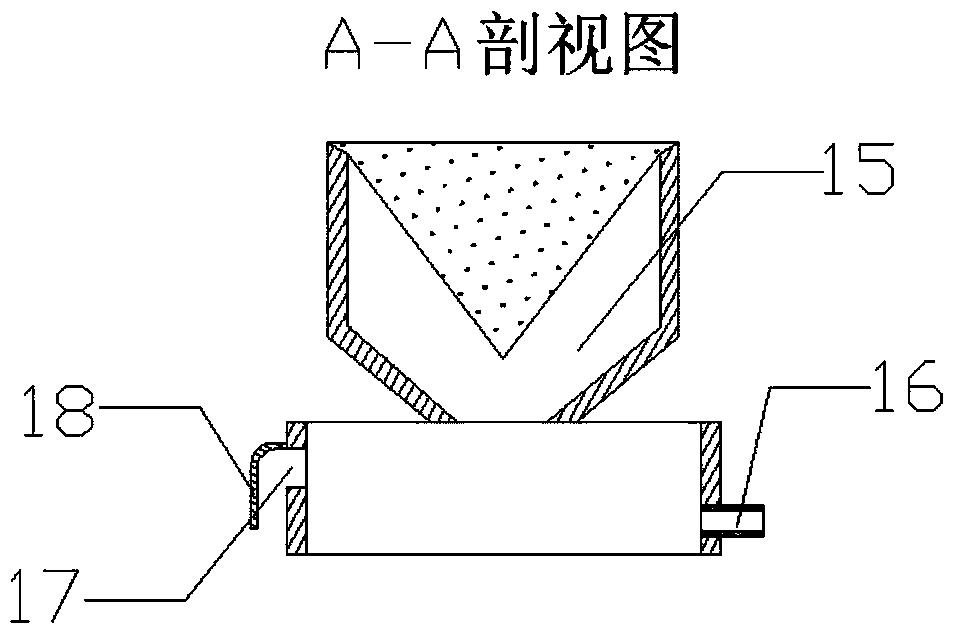

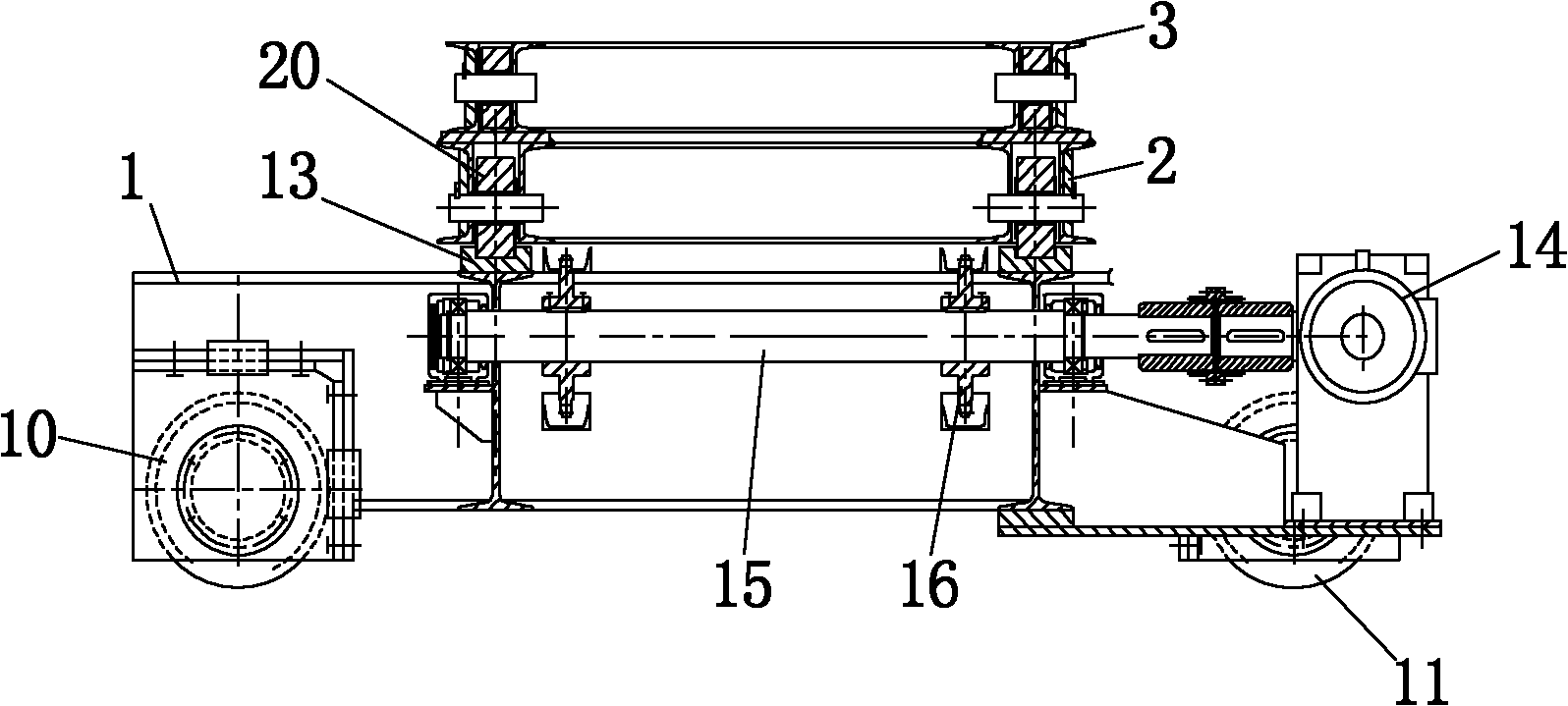

Continuous automatic belt type hydraulic squeezing press

InactiveCN101012997AStrong squeezeImprove applicabilityDrying solid materials without heatDrying machines with progressive movementsContinuous operationDevice form

The invention discloses a continuous automatic band-type hydraulic compressor, comprising a frame (16). The invention is characterized in that the frame (16) is arranged with upper and lower annular filter cloth devices formed by guide roller, expand roller, driving roller and connected upper and lower annular filter cloths and power device. The frame (16) is connected with a material compression sealing device formed by sealing box cylinder (4) and sealing box (5), and a hydraulic compressor formed by a compressing cylinder (1) and a compressing pushing plate (2). The frame (16) is connected with a stop plate (3) relative to the compressing pushing plate (2). The frame (16) is connected with a liquid disc (17) with liquid outlet (18) and a material distributor (15). The invention can realize automatic continuous operation and high compressing speed, with long service life and low cost.

Owner:李连乐

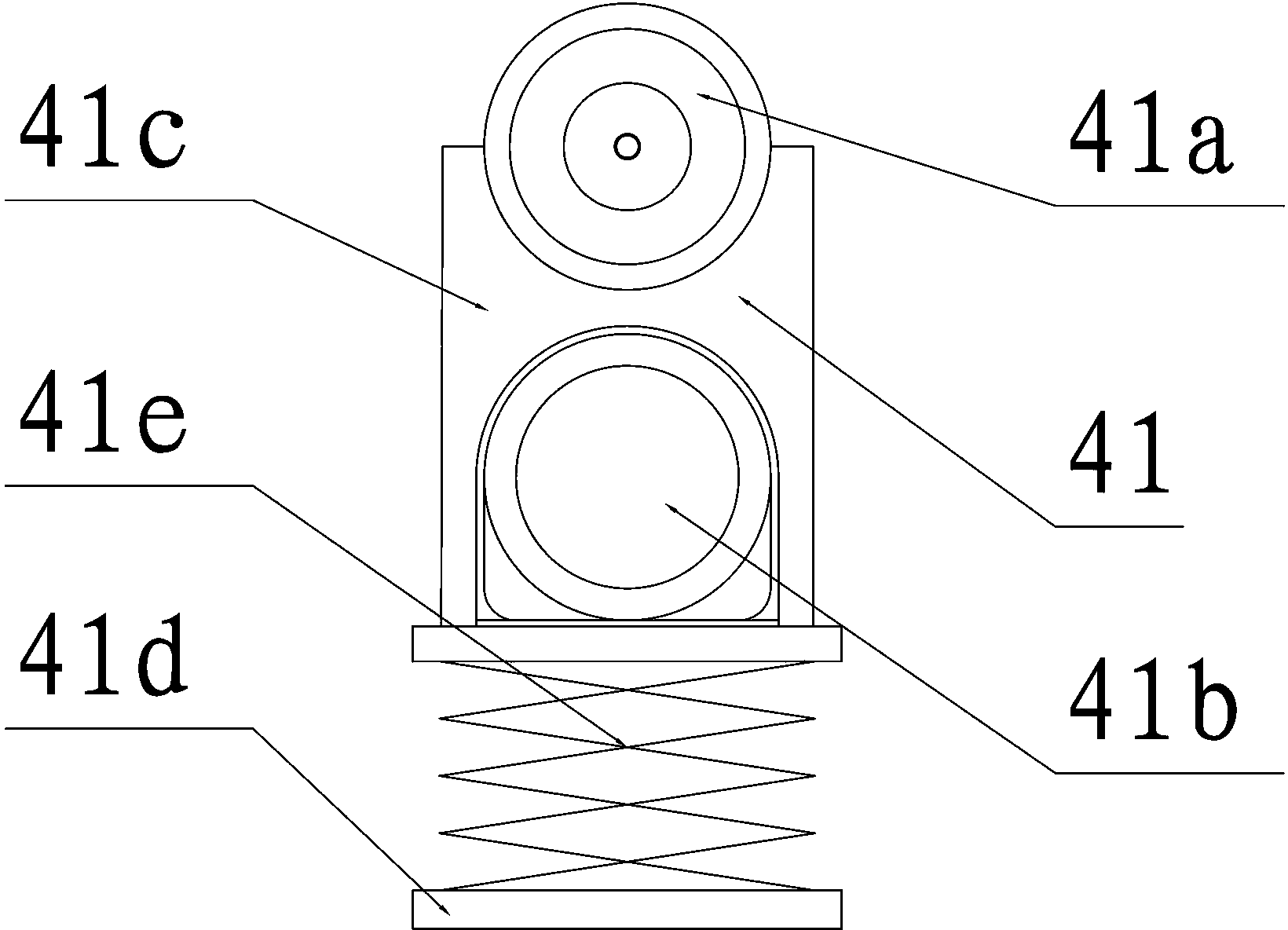

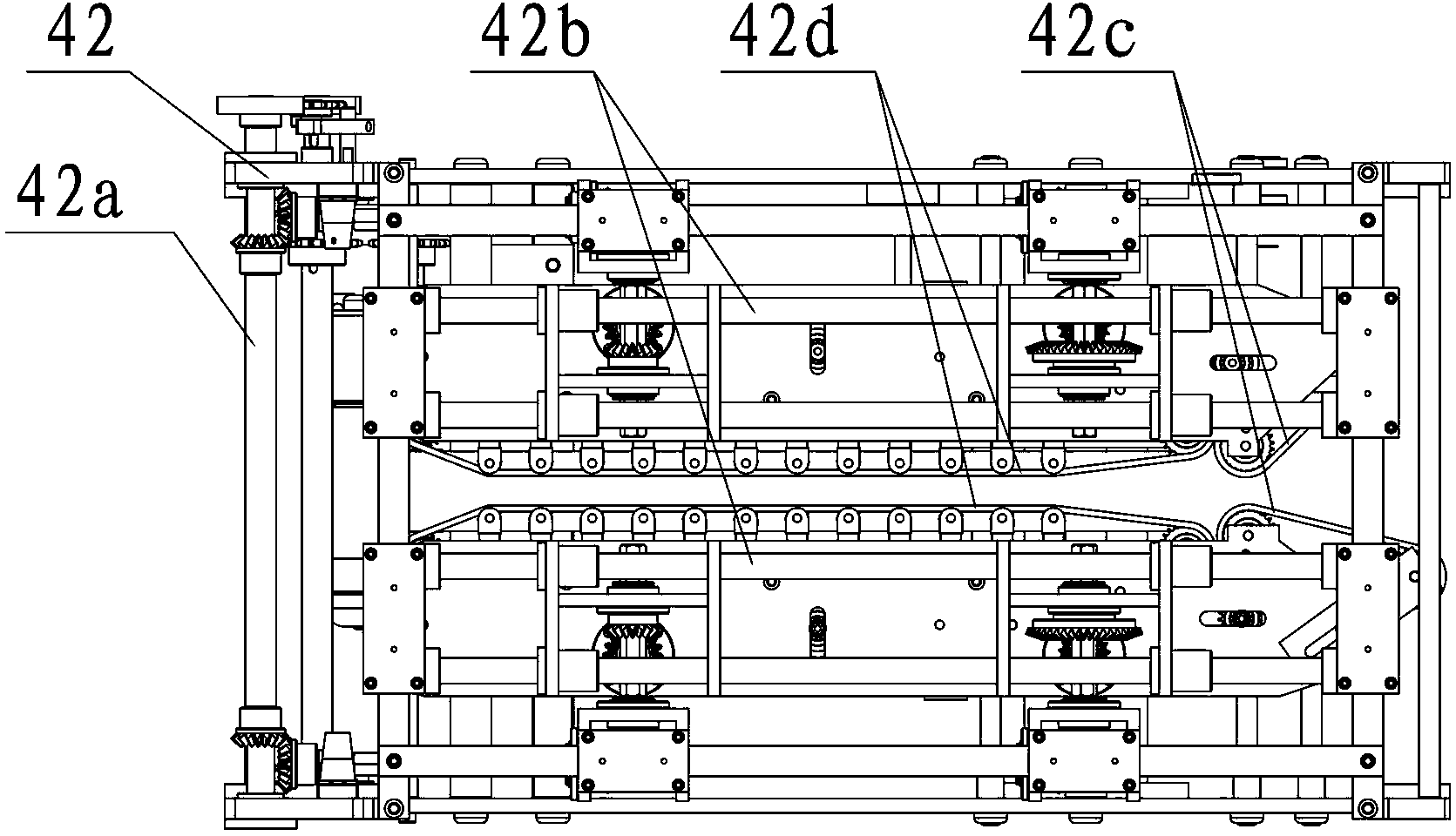

Continuous conveyor capable of automatic lifting

InactiveCN105059861ASave transportation manpower andAvoid pollutionMechanical conveyorsEngineeringEnergy consumption

The invention discloses a continuous conveyor capable of automatic lifting. The continuous conveyor comprises ground transport devices, first automatic lifting devices, overhead transport devices, second automatic lifting devices and ground receiving devices. A plurality of first material loading devices and second material loading devices are arranged. The ground transport devices convey materials into the first material loading devices to be lifted; when the materials enter the overhead transport devices, the overhead transport devices transport the materials into the second material loading devices to downwards transport the materials; when the materials reach the ground receiving devices, the materials are transported to the ground receiving devices to be upwards transported. By means of the continuous conveyor capable of automatic lifting, panels and the like pass through barriers to be continuously transported, the transport manpower and transport cost can be greatly saved, energy consumption in the transfer process is lowered, environmental pollution caused by fuel burning of a transport forklift can be avoided, the continuous automated work degree of a production line is increased, and working efficiency is greatly improved.

Owner:ZHUO DA NEW MATERIAL TECH GRP

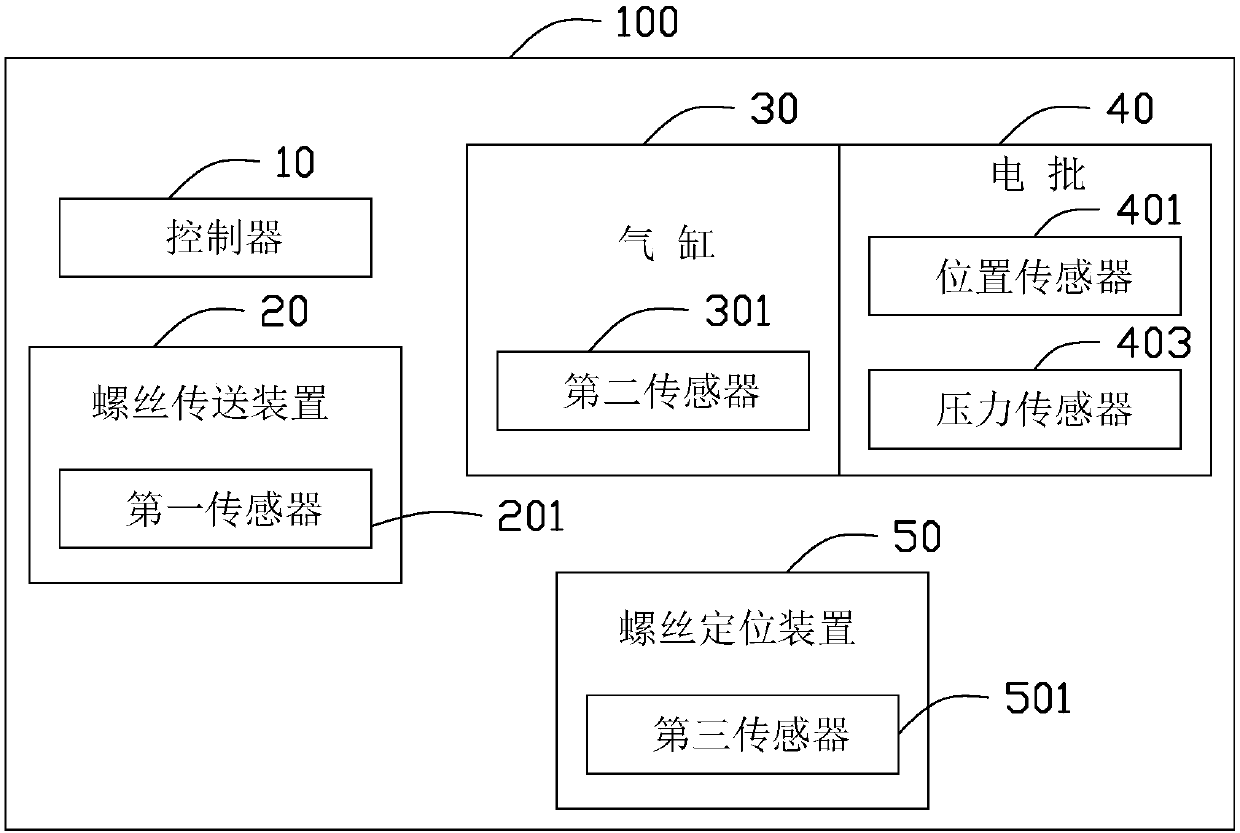

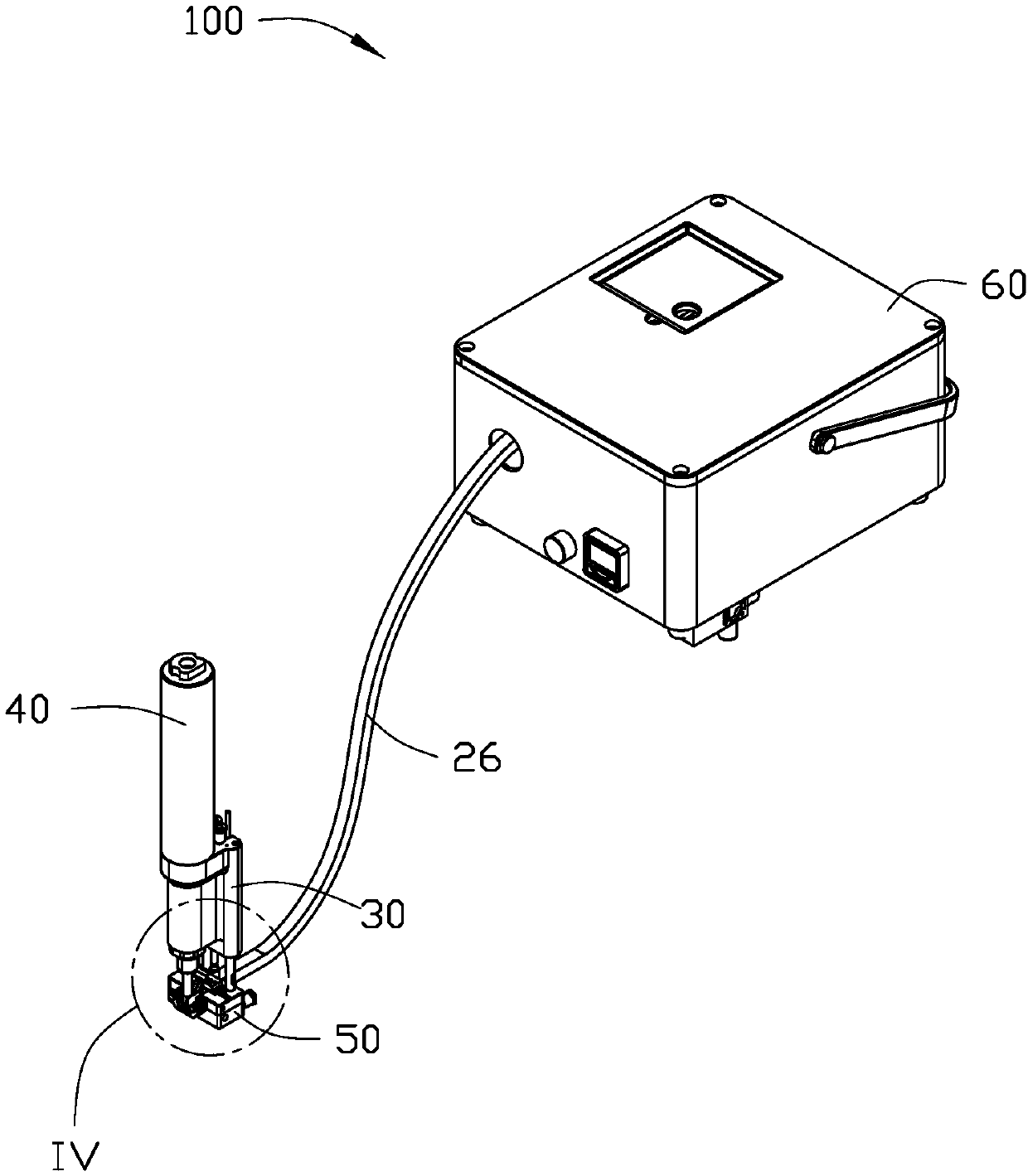

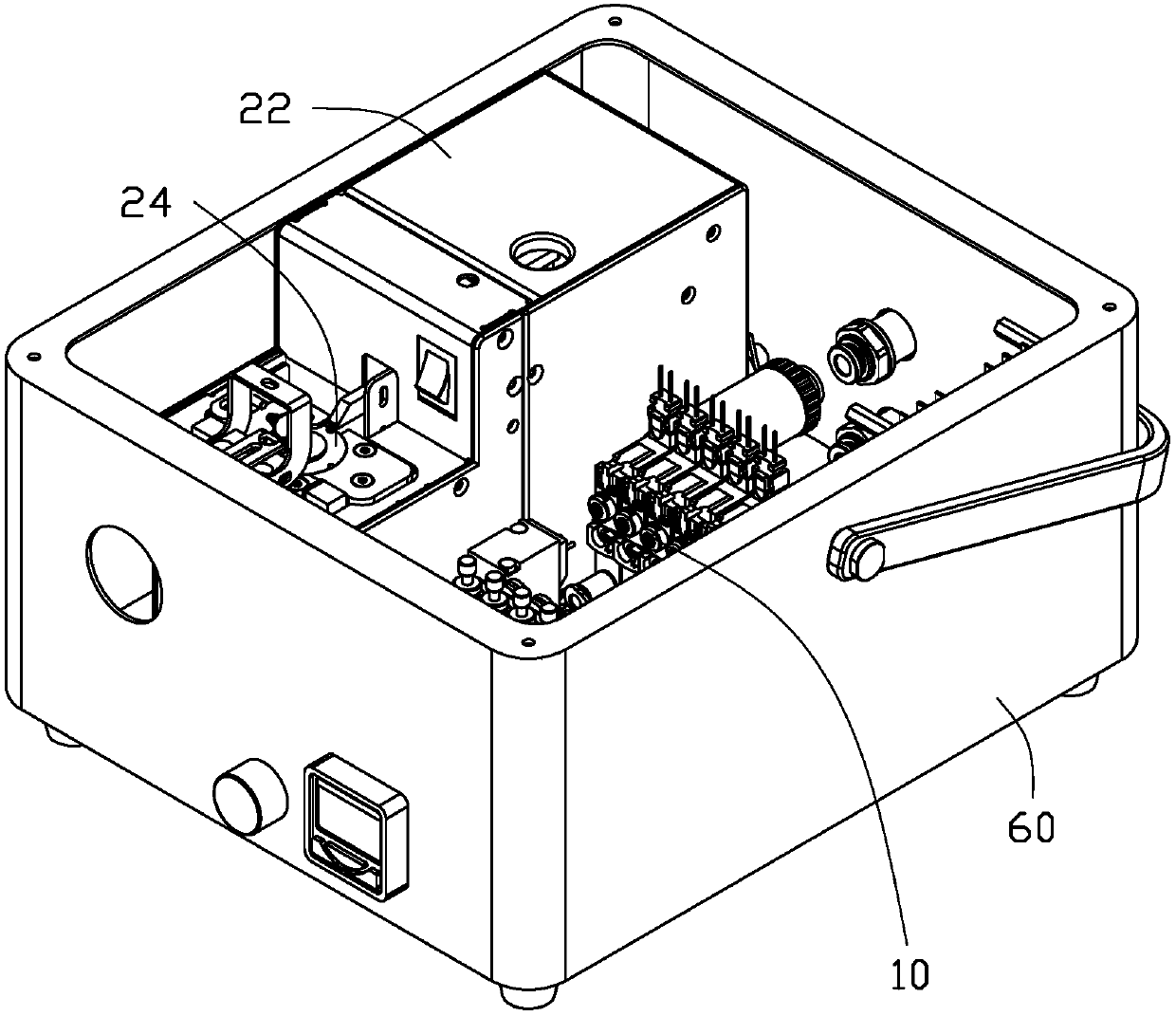

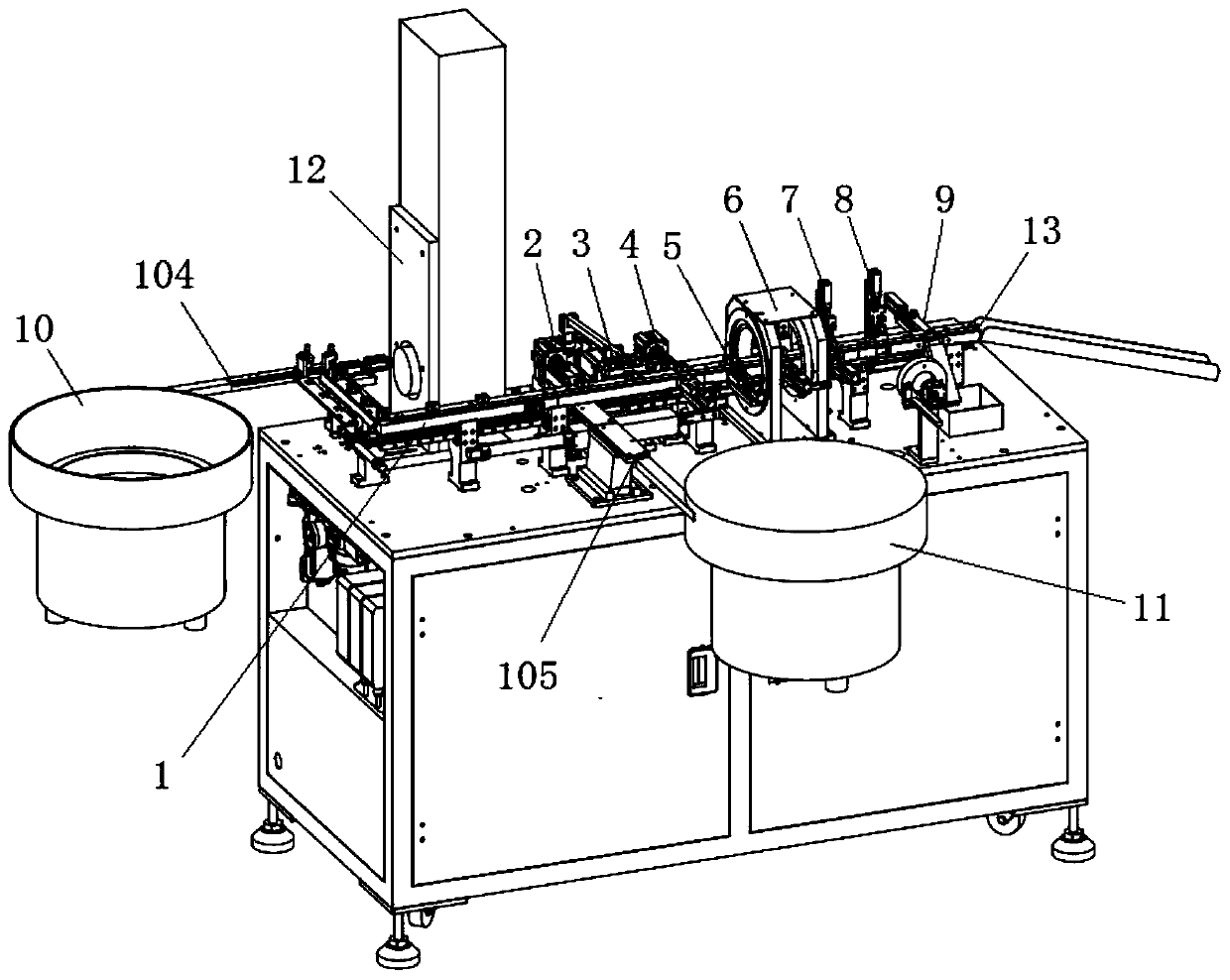

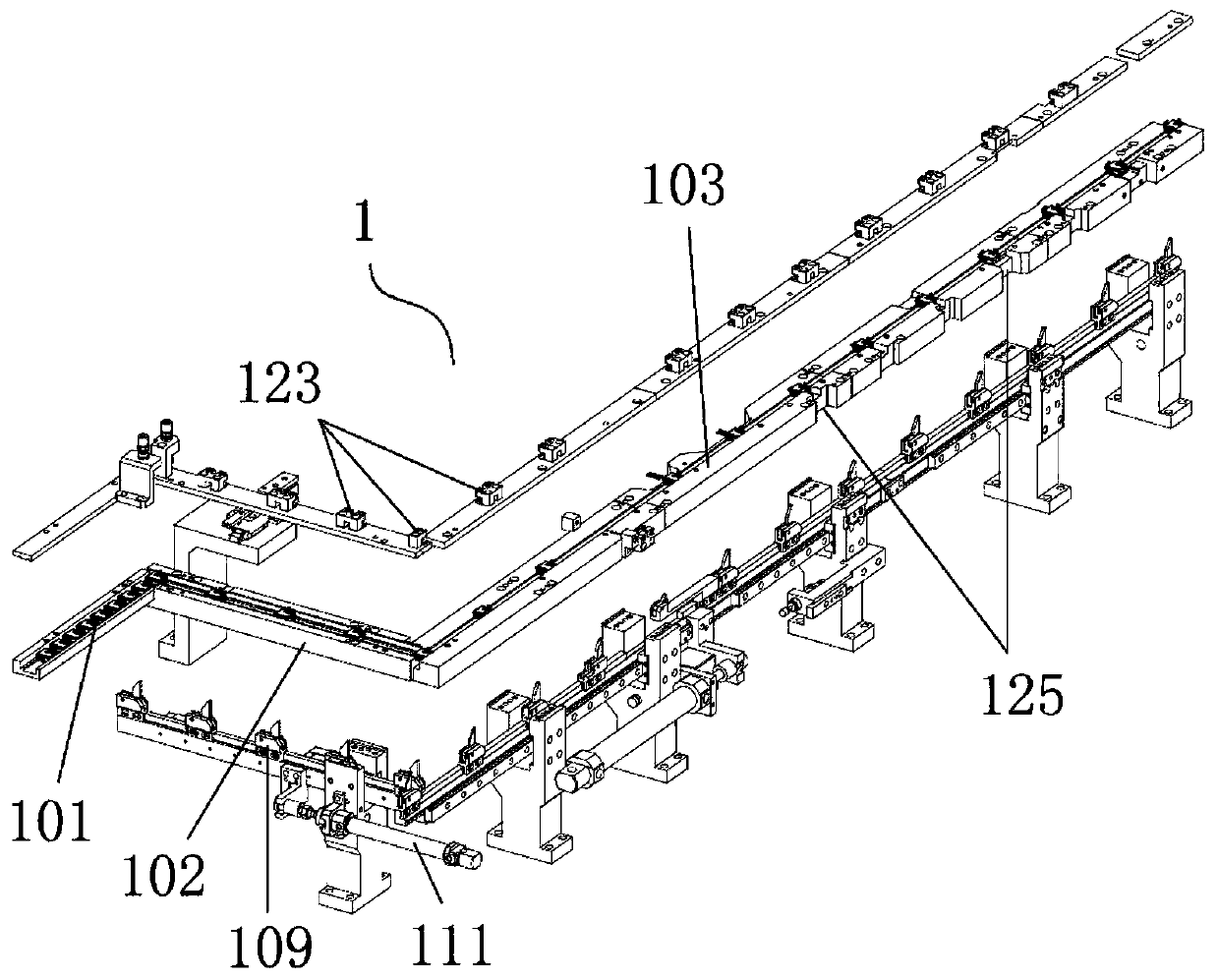

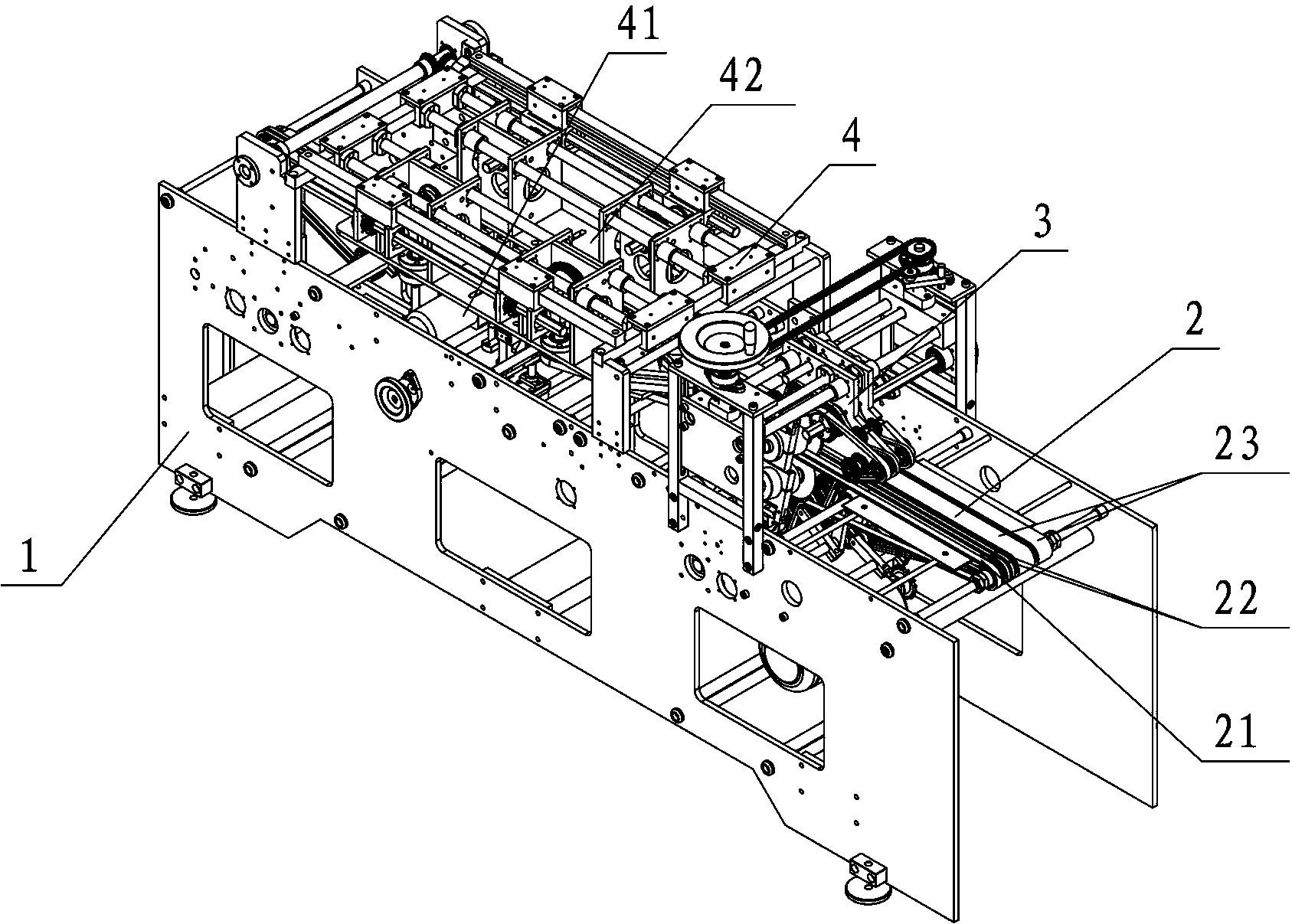

Screw fastening device achieving automatic feeding and control manner thereof

ActiveCN107932053ARealize automatic continuous operationConducive to high-efficiency production and assemblyMetal working apparatusElectricityControl manner

The invention relates to control manner of a screw fastening device achieving automatic feeding. The screw fastening device comprises a controller, a screw conveying device, an air cylinder and an electric screwdriver arranged on the side face of the air cylinder. The control manner comprises the steps that a first sensor is arranged on the screw conveying device and used for sensing whether a screw is conveyed; if the first sensor judged that the screw conveying device conveys the screw, the controller sends out a control signal, and the electric screwdriver is controlled to fetch the screw;a second sensor is arranged on the air cylinder and used for sensing whether the electric screwdriver fetches the screw or not; if the second sensor judges that the electric screwdriver fetches the screw, the controller controls the electric screwdriver to fasten the screw. The invention further provides the screw fastening device achieving automatic feeding and executing the control manner.

Owner:SHENZHEN STRONG TECH

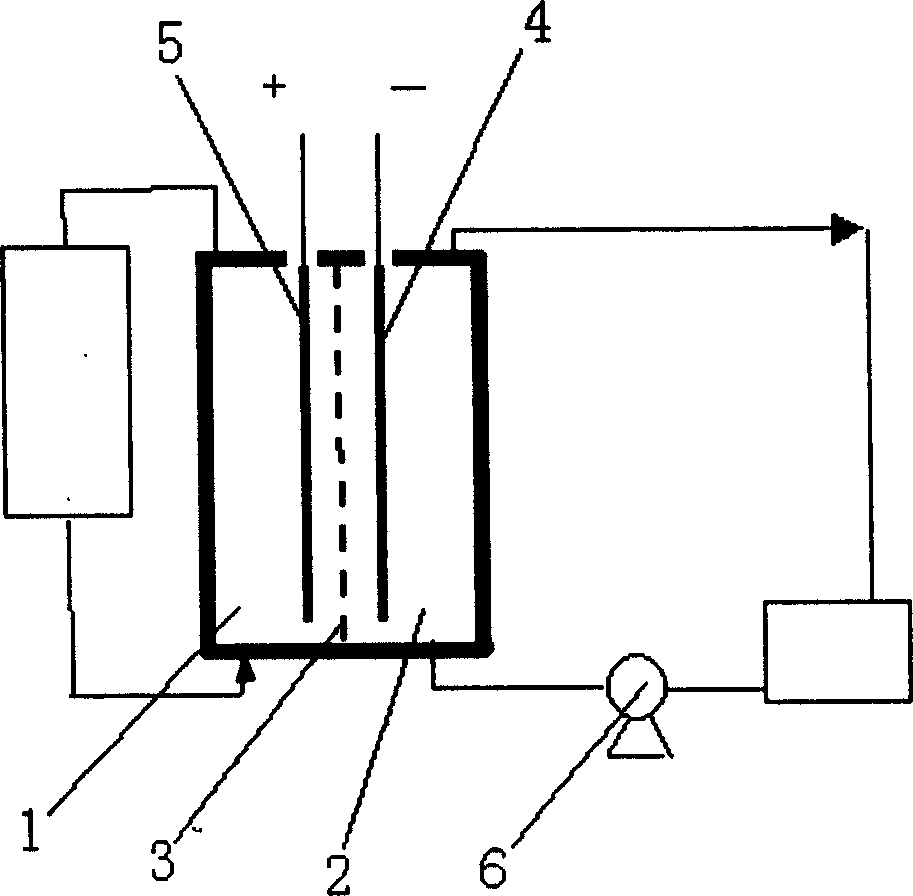

Process for electrolytic reduction preparation of metanilic acid

InactiveCN1605656AMild conditionsGood choiceElectrolysis componentsElectrolytic organic productionElectrolysisHigh selectivity

The electroreduction process of preparing m-aminobenzene sulfonic acid includes the following steps: setting the sulfuric acid water solution of sodium m-aminobenzene sulfonate as electrolyte in the cathode chamber of isolated electrolytic bath; setting sulfuric acid water solution in the anode chamber of isolated electrolytic bath; electrolysis at 0-60 deg.c at current strength of 2-5 A for 2-5 hr; cooling the electrolyte after electrolysis to obtain crystal; and filtering to obtain m-aminobenzene sulfonic acid product. The process of the present invention is clean, needs no addition of oxidant and reductant, has mild condition, high selectivity, yield as high as 96 %, saving in power, easy-to-control reaction speed via current regulation, etc.

Owner:SHANGHAI CHLOR ALKALI CHEM

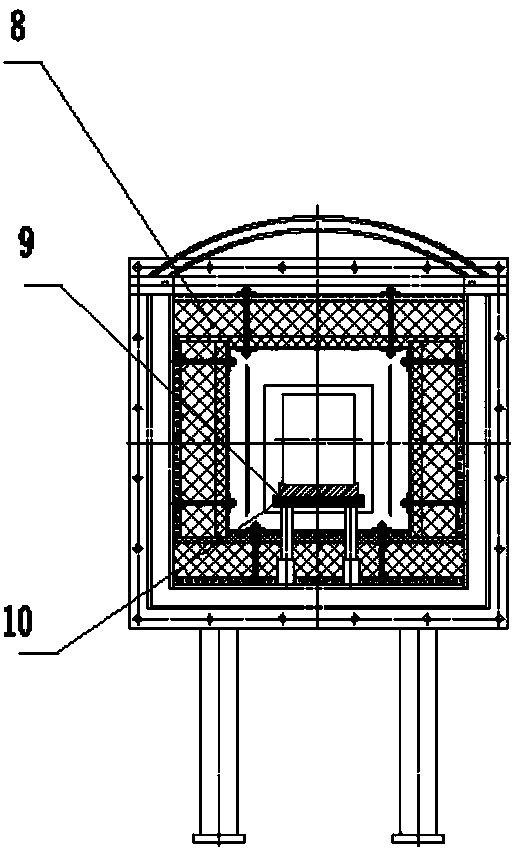

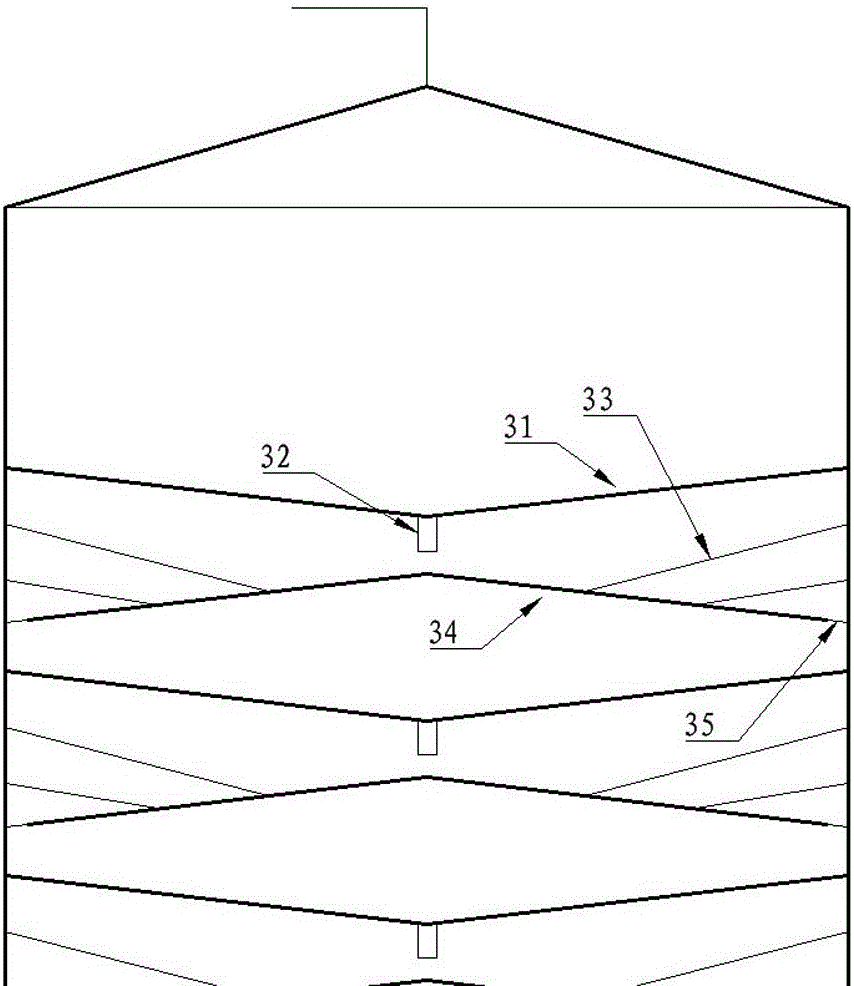

Ultra-high-temperature nitriding continuous tunnel furnace

ActiveCN108020081ASolve the problems of long length, large space occupation and large energy lossRealize fully automatic closed loopFurnace typesEngineeringOxygen

The invention discloses an ultra-high-temperature nitriding continuous tunnel furnace. The furnace comprises an aerobic charging area, a feeding area, a furnace body and a discharging area, wherein the areas are connected in sequence to form a rectangular loop structure, and the areas are independent from one another; the feeding area, the furnace body and the discharging area are of a sealed cavity structure, and the aerobic charging area is of a non-sealing structure; and rails are laid in all the areas, and the materials enter and exit from the areas in a one-way mode. The sintering temperature of the ultra-high-temperature nitriding continuous tunnel furnace can reach 2000 DEG C, and the unique annular structure layout realizes the full-automatic closed circulation of the materials ascompactly as possible, rapid cooling and independent feeding and discharging of the materials in the furnace can be realized, the size is small, and the atmosphere in the furnace is uniform; the circulating production process of discharging the material at one end and feeding the material at the other end can be realized, and the nitriding process of the batch materials is realized; hydraulic propelling is adopted, the whole process is controlled by computers, manual intervention is not needed, and automatic continuous operation is realized; and the furnace is stable and reliable in material running, high in safety performance and low in labor intensity.

Owner:钢研工程设计有限公司

Vacuum belt press filter

InactiveCN101612805BEasy to cleanRealize automatic continuous operationCleaning using liquidsPressesFiltrationPulp and paper industry

The invention relates to a vacuum belt press filter, comprising a rack, a vacuum filtration assembly, a press assembly and a filtration belt assembly, wherein the filtration belt assembly comprises an upper filtration belt, a lower filtration belt, and a cleaning device A and a cleaning device B which are used for respectively cleaning the upper filtration belt and the lower filtration belt; the cleaning device B comprises a front guide roller and a rear guide roller on the motion direction of the lower filtration belt, the front guide roller is arranged on the upper face the lower filtrationbelt, closely contacts the lower filtration belt and enables the lower filtration belt to form a V shape, the rear guide roller is arranged on the lower face of the lower filtration belt and is provided with a plurality of pinpricks, the size of each pinprick is matched with the size of a filtration pore of the filtration belt, and the rear guide roller contacts with the lower filtration belt by the pinpricks; and the cleaning device B is provided with a plurality of spray heads, and the spray heads are distributed on the upper face and the lower face of the lower filtration belt. The vacuum belt press filter of the invention has the advantage of favorable cleaning effect of the filtration belts, and belongs to the technical field of press machines.

Owner:HUZHOU HEHONG MACHINERY

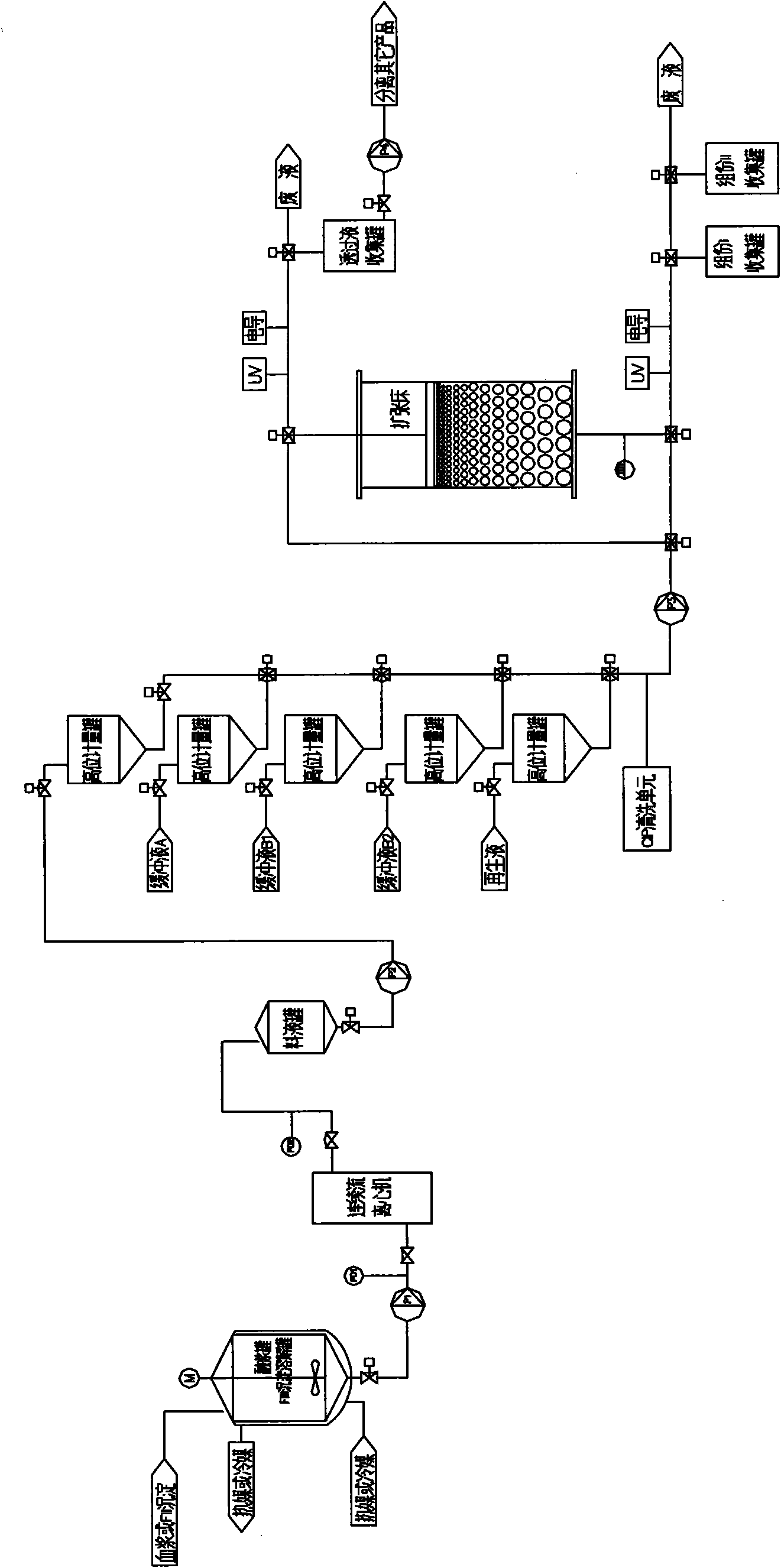

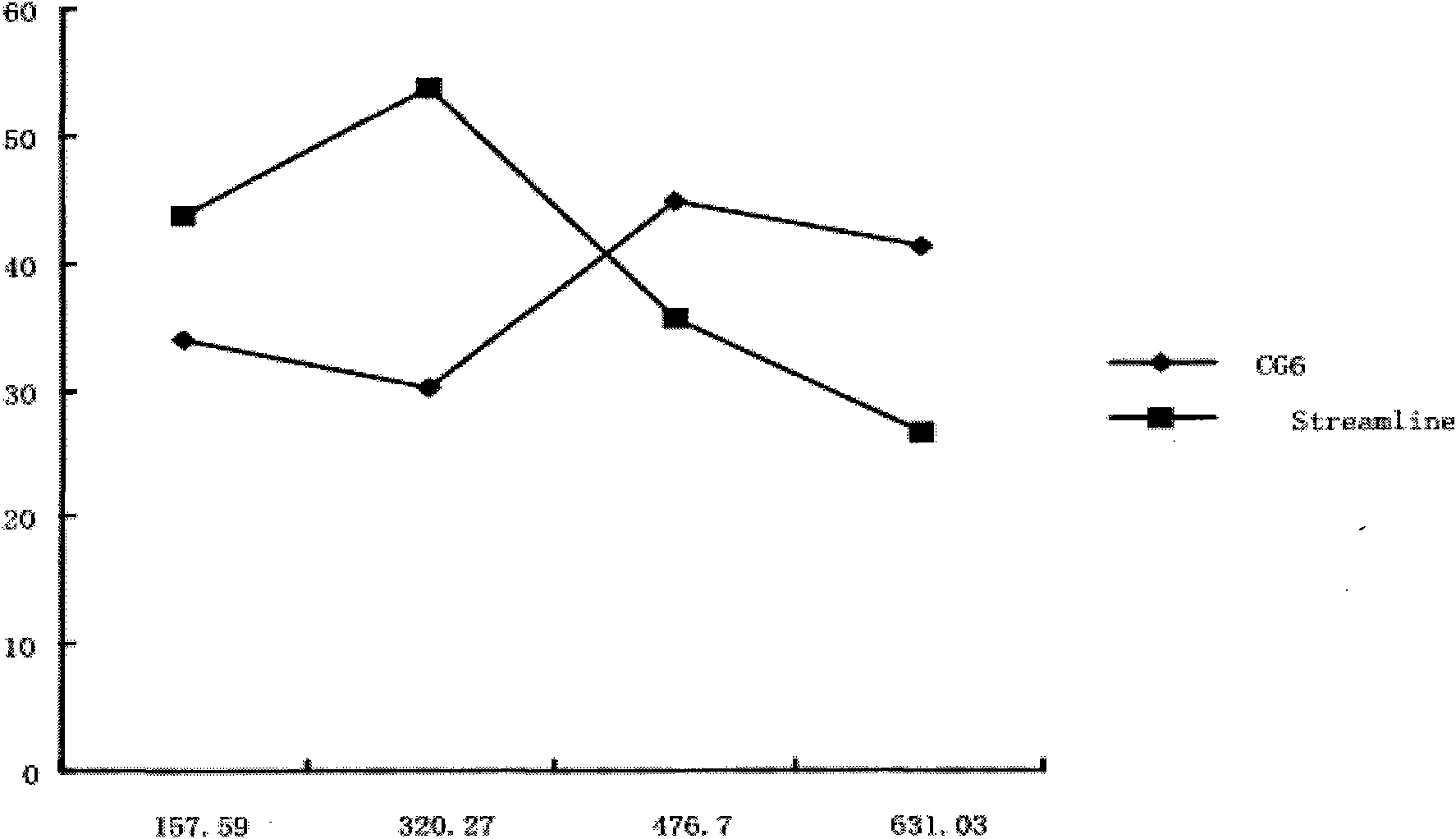

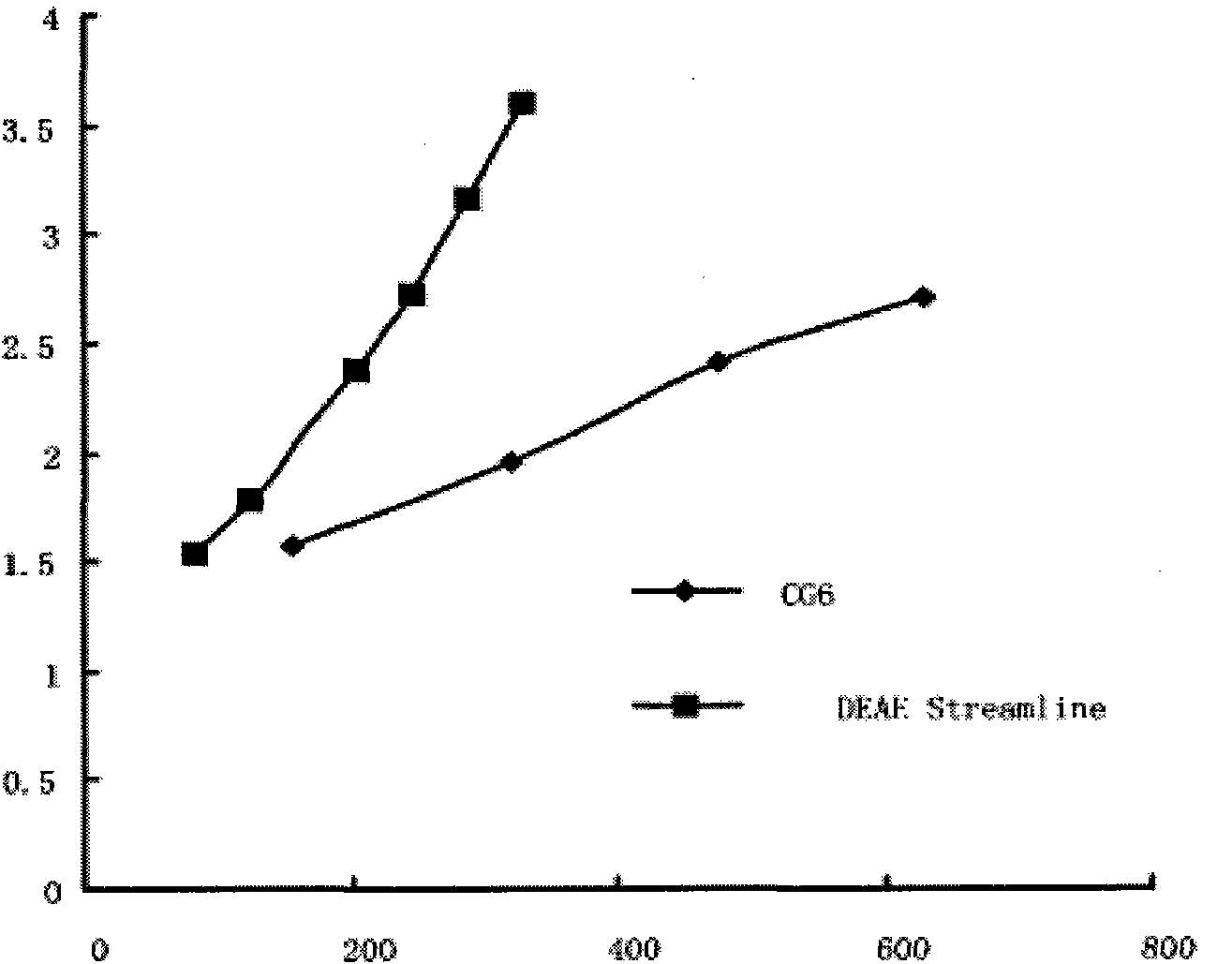

Method for absorbing and separating human prothrombin complex by utilizing expansion bed

InactiveCN101838304AAdsorption separation stabilityEfficient Adsorption SeparationPeptide preparation methodsContinuous flow centrifugationPROTHROMBIN COMPLEX

The invention relates to a method for absorbing and separating a human prothrombin complex by utilizing an expansion bed, comprising the following steps: (a) separating cryoprecitation from melted refrigerated plasma by using a refrigeration type continuous flow centrifuge, and collecting supernate as a raw material; (b) carrying out stable expansion on an expansion bed by using a buffer solution A, wherein the buffer solution A is 0.05mol / L1tris-citric acid with the PH value of 7.0; (c) rapidly switching into a feed solution after the expansion bed is in stable balance, stopping feeding and rapidly switching into the buffer solution A when breakthrough points reaches 5-10%, and washing in an expanded mode; and (d) switching into buffer solutions of 0.4mol / L NaCl and 1.6mol / L NaCl after washing, carrying out gradient elution in a stationary bed mode, and collecting the protein elution peak of the buffer solution of 1.6mol / L NaCl to obtain a prothrombin complex crude product.

Owner:成都英德生物工程有限公司

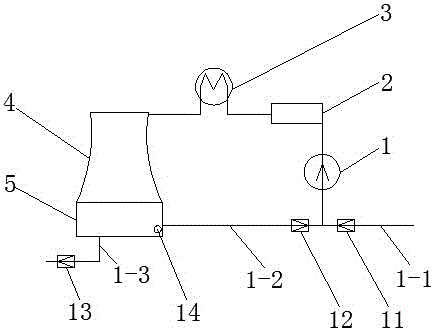

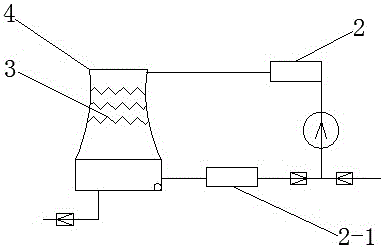

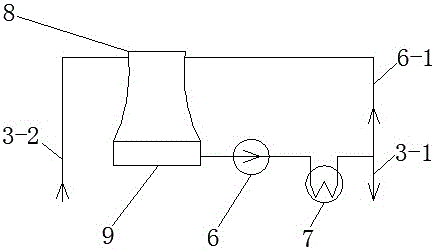

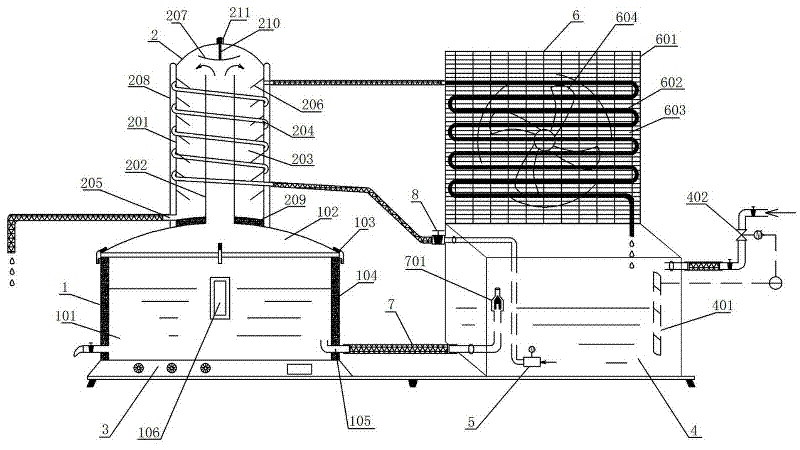

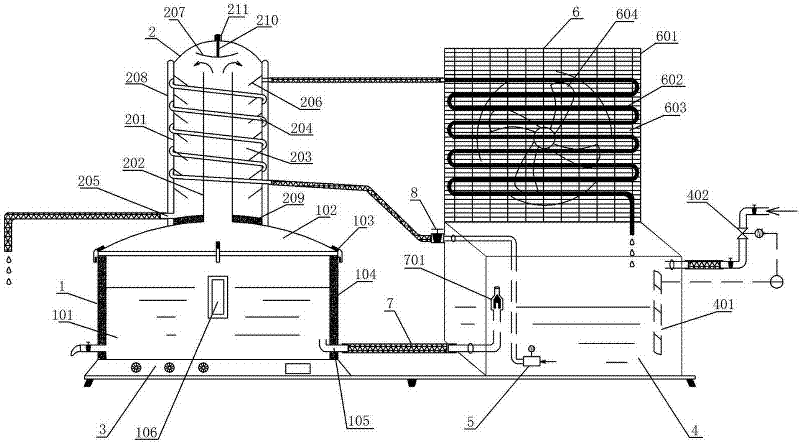

High-salt wastewater evaporation concentration method and device

ActiveCN106006800AImprove cooling efficiencyLow costSpecific water treatment objectivesWater/sewage treatment by heatingCooling towerEnrichment methods

The invention discloses a high-salt wastewater evaporation concentration method and device, belonging to the technical field of high-salt wastewater treatment. The method comprises a process of heating high-salt wastewater for evaporation and concentration. The method is characterized by comprising the following steps: carrying out oriented scale formation before heating the high-salt wastewater, heating the high-salt wastewater by using a surface-type heat exchanger, and evaporating the heated high-salt wastewater by using a mechanical draught cooling tower, wherein the heat medium water adopted in the surface-type heat exchanger is circulating cooling water flowing out of the steam condenser. The circulating cooling water of the condenser is utilized to perform heat exchange and heating on the high-salt wastewater, and the heated high-salt wastewater is sent into the mechanical draught cooling tower for evaporation, thereby lowering the heat loss of the circulating cooling water of the condenser, enhancing the cooling efficiency of the condenser, and lowering the high-salt wastewater treatment cost.

Owner:POWERCHINA HEBEI ELECTRIC POWER SURVEY & DESIGN INST CO LTD

Sesame cleaning machine

InactiveCN103734883ASave human effortReduce labor intensityFood treatmentContinuous operationAgricultural engineering

The invention provides a sesame cleaning machine which comprises a machine frame, a transmission device, a cleaning device, a dewatering device and a filtering tank, wherein the cleaning device is arranged at the upper part of the machine frame, a water tank is arranged in the cleaning device, the upper part of the water tank is provided with a feed port, and both ends of the water tank are respectively provided with a water inlet and a water outlet; the bottom of the water tank is provided with a main shaft, and the main shaft is provided with a tooth-shaped rotating vane and a rotating sieve; the dewatering device is arranged below the water outlet of the cleaning device in a matching mode, the upper part of the dewatering device is provided with the feed port, and the feed port of the dewatering device directly faces the water outlet of the water tank. The sesame cleaning machine adopts the screw-type stainless steel tooth-shaped rotating vane to stir and push sesame seeds in the water tank and adopts the technology of centrifugal dewatering, therefore lots of manpower is saved, the labor intensity is reduced, and the automatic continuous operation of procedures of feeding, adding water, stirring, dewatering and the like is realized; therefore, cleaning standards can be absolutely achieved.

Owner:LUYI COUNTY JINRI EDIBLE OIL

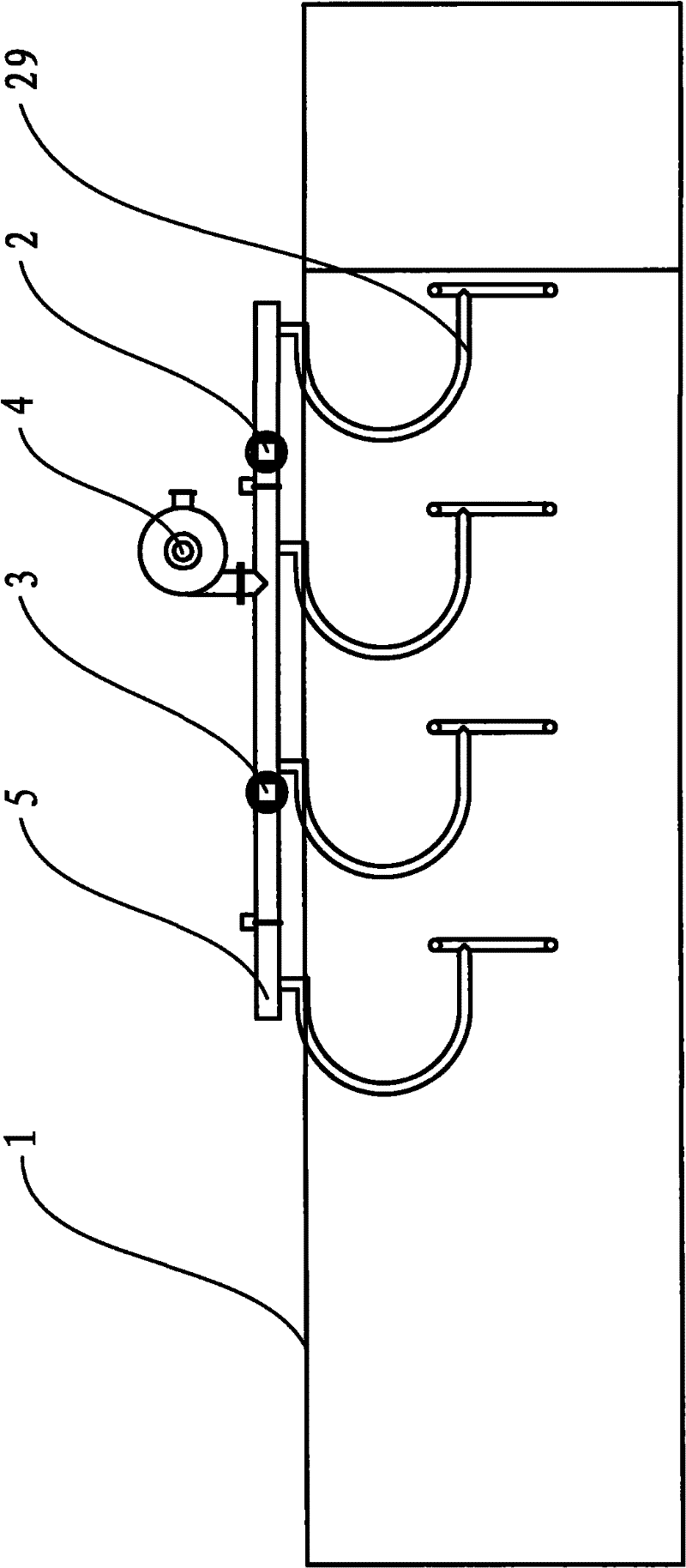

Feed liquid continuous separating, metering and disc distributing device

ActiveCN103738534AAchieve securityAchieving Occupational Health IssuesPackagingEngineeringChemical combination

The invention discloses a feed liquid continuous separating, metering and disc distributing device which aims at providing an accurate disc distributing device for initiating explosive materials. The feed liquid continuous separating, metering and disc distributing device comprises a support and a feed liquid holding device, a metering pot, a conjoined switch, a supporting rod, a connecting rod which can rotate around the supporting rod, a lifting air cylinder and a drug holding disc which are arranged on the support. According to the feed liquid continuous separating, metering and disc distributing device, the disc distributing device is newly designed, the feed liquid pot is arranged between a combination reaction still and the drug holding disc, metering and disc separating of the chemical combination drug feed liquid is achieved, the disc distributing work is achieved, and the production process safety and the production efficiency are improved in combination with the conjoint switches which are arranged at the upper end and the lower end of the metering pot and coordination of the conjoint switches and the lifting air cylinder; meanwhile automatic continuous separation, metering and disc distributing are achieved and the production efficiency and the production safety are greatly improved, and the staff lives and enterprise property safety are guaranteed in combination with a conveying device. The feed liquid continuous separating, metering and disc distributing device is skillful in design, simple in structure, convenient to maintain, accurate in metering and continuous and efficient.

Owner:YAHUA GROUP MIANYANG INDAL

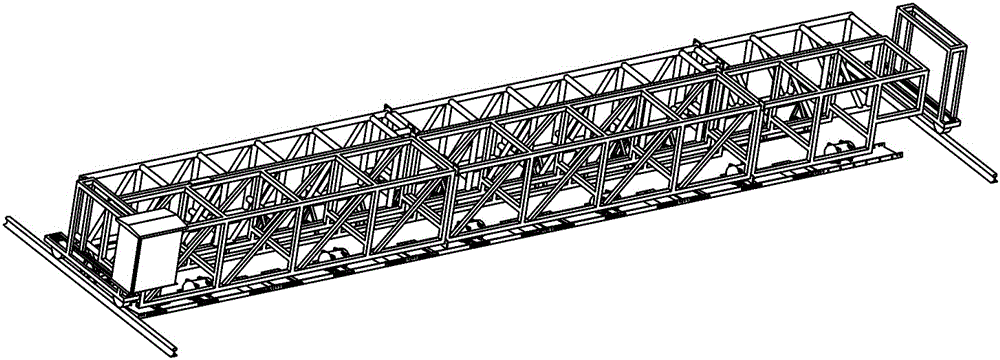

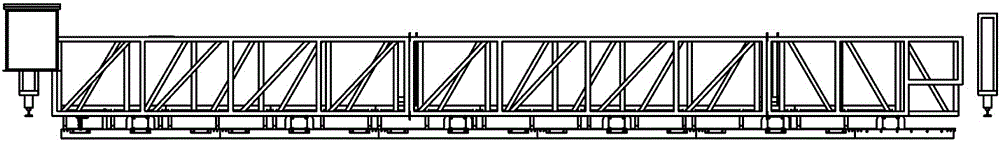

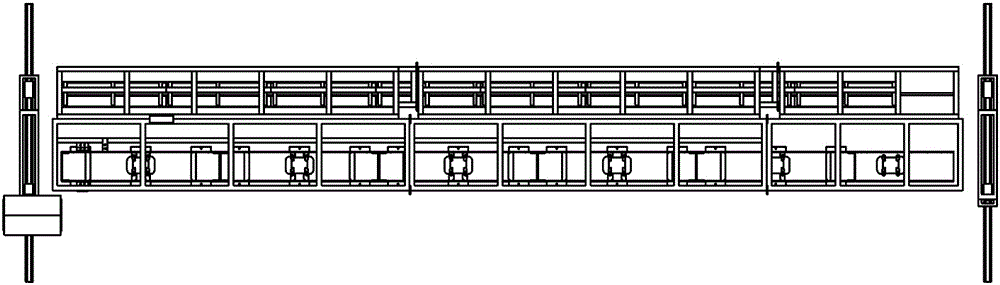

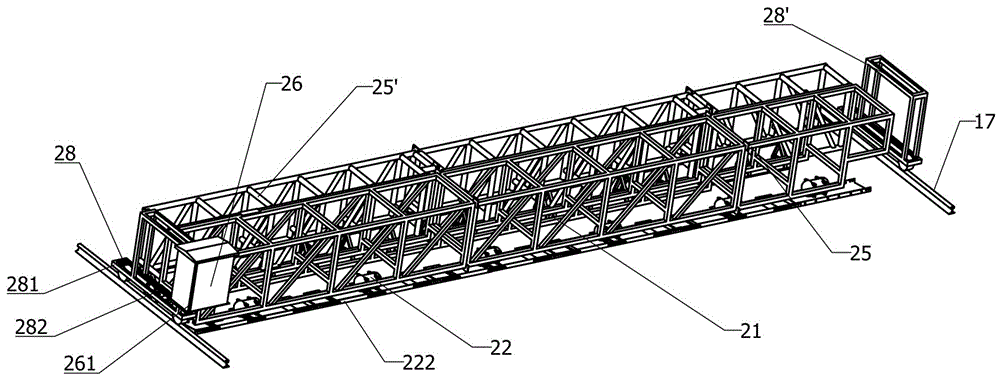

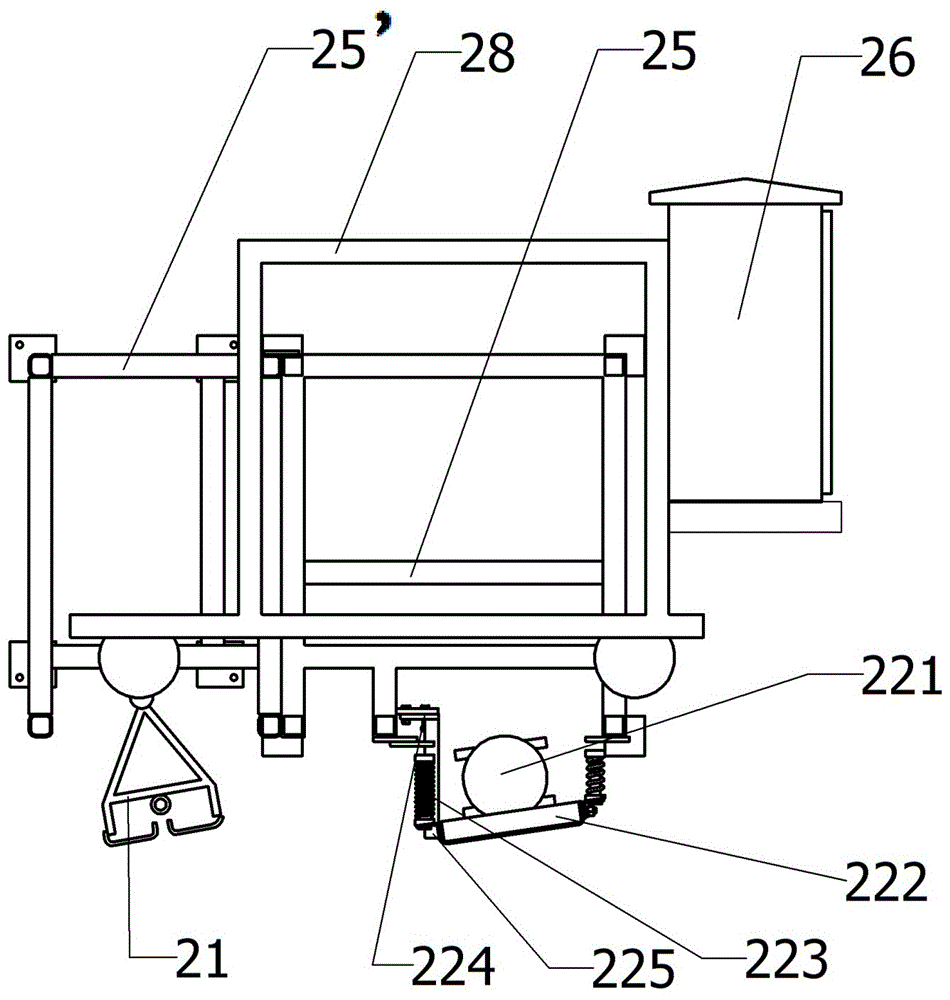

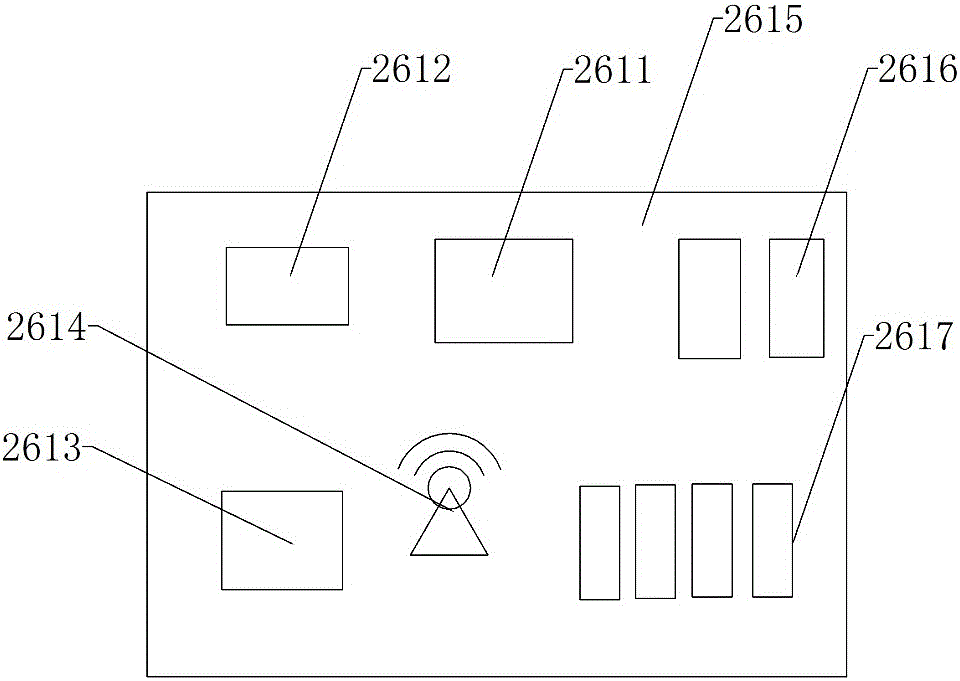

Suspension type high-frequency vibration method and special device

ActiveCN106079029ARealize automatic continuous operationImprove efficiencyClimate change adaptationCeramic shaping apparatusLeveling effectEngineering

The invention provides a suspension type high-frequency vibration method and a special device. The technical problem that reactive powder concrete needs to be vibrated and leveled repeatedly is mainly solved through the suspension type high-frequency vibration method and the special device. According to the technical scheme, the suspension type high-frequency vibration method and the special device are characterized in that vibration leveling walking devices (28) are installed at the two ends of a vibration truss (25) correspondingly; a suspension type high-frequency vibration device body (22) is installed on the lower portion of the vibration truss (25) and comprises two or more vibration flat plates (222); and a vibration flat plate oblique angle adjusting device (224) is installed on each elastic suspension device (223) in a matched mode, so that an 1-70 degree included angle is formed between each vibration flat plate (222) and the horizontal plane. According to the suspension type high-frequency vibration method and the special device, due to the fact that manual operation is not needed, the efficiency is greatly improved, the leveling effect is better, the leveling degree is also greatly improved, and automatic continuous operation is achieved. The suspension type high-frequency vibration method and the special device are mainly used in the field of reactive powder concrete production construction and the like.

Owner:HUNAN ZHONGLU HUACHENG BRIDGE TECH CO LTD

Pin insertion machine

InactiveCN109980479AReduce stepsRealize automatic continuous operationContact member assembly/disassemblySortingContinuous operationBiomedical engineering

The invention provides a pin insertion machine and belongs to the technical field of connector assembly equipment. The pin insertion machine comprises the following steps of a pin insertion mechanismfor inserting a PIN into a plastic part to form connectors; a detecting mechanism disposed at downstream of the pin insertion mechanism for detecting the connectors; and a connector conveying line connected between the pin insertion mechanism and the detecting mechanism for sequentially conveying the connectors from the pin insertion mechanism to the detecting mechanism. The pin insertion machineprovided by the invention connects the pin insertion mechanism and the detecting mechanism through the connector conveying line, and can sequentially send the connectors for completing the pinning operation in the pin insertion mechanism to the detecting mechanism, thereby enabling the automatic detection on the connectors by the detecting mechanism, saving the manual operation between the pin insertion mechanism and the detecting mechanism, realizing the automatic continuous operation of the pin and the detection of the connectors, and improving the automation of the device.

Owner:苏州优瑞信电子科技有限公司

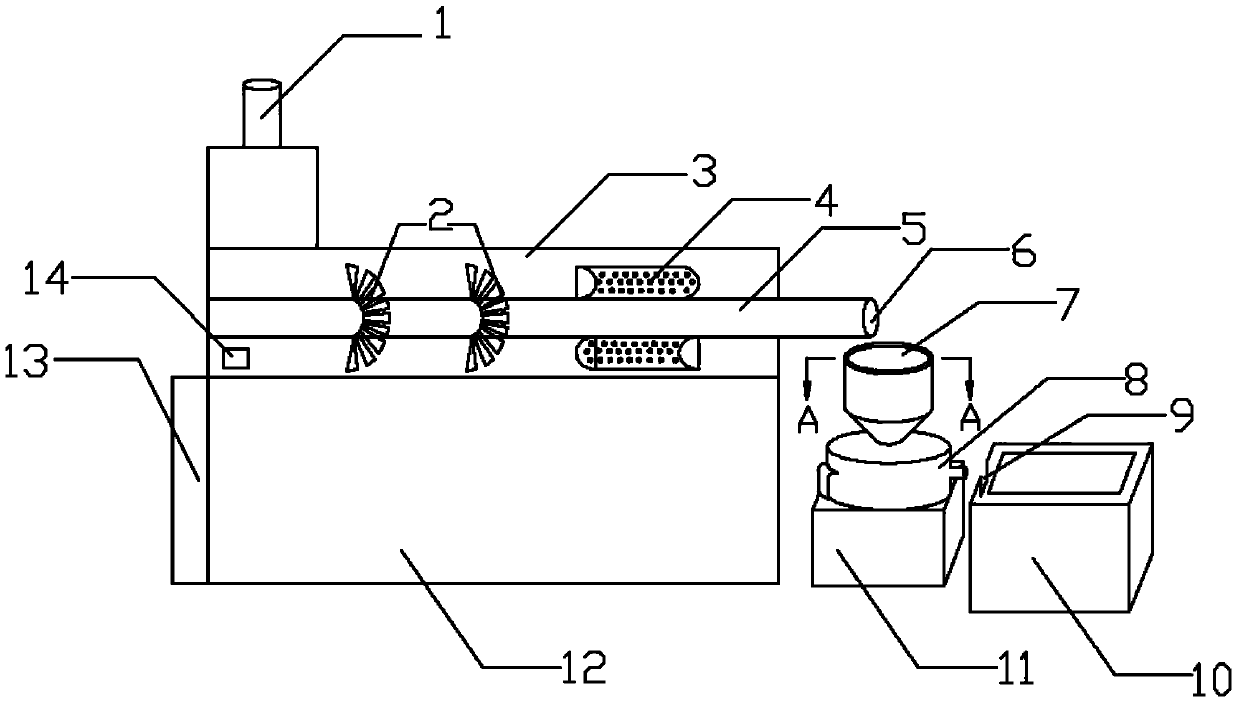

Low-temperature plasma modifying and microscale sizing integrated device for wood thin plates

The invention provides a low-temperature plasma modifying and microscale sizing integrated device for wood thin plates, which ensures that the use level of adhesive for veneer artificial board products is reduced by 30 to 70 percent compared with that in the traditional sizing mode. The device comprises an equipment framework, a wood thin plate conveying component, a power component, a low-temperature plasma processing component, an ultrasonic cyclone glue spraying component and a controller component, wherein the low-temperature plasma processing component comprises at least one pair of dielectric barrier discharge electrodes, a low-temperature plasma generator, a low-temperature plasma power supply and a cooling ozone removal device; the paired electrodes are parallel with a feeding press roll and are fixed on the equipment framework; the ultrasonic cyclone glue spraying component comprises ultrasonic cyclone synergistic nozzles, a nozzle supporting bracket, a glue amount control valve, a pipeline cleaning valve, an adhesive storage device, an adhesive collecting device and a glue sprayed smell removal device; the nozzle supporting bracket is fixed on the equipment framework and is positioned between a discharging press roll and a discharging conveying roll group; the nozzles are adjustably, parallelly and symmetrically arranged on the nozzle supporting bracket.

Owner:NANJING FORESTRY UNIV +1

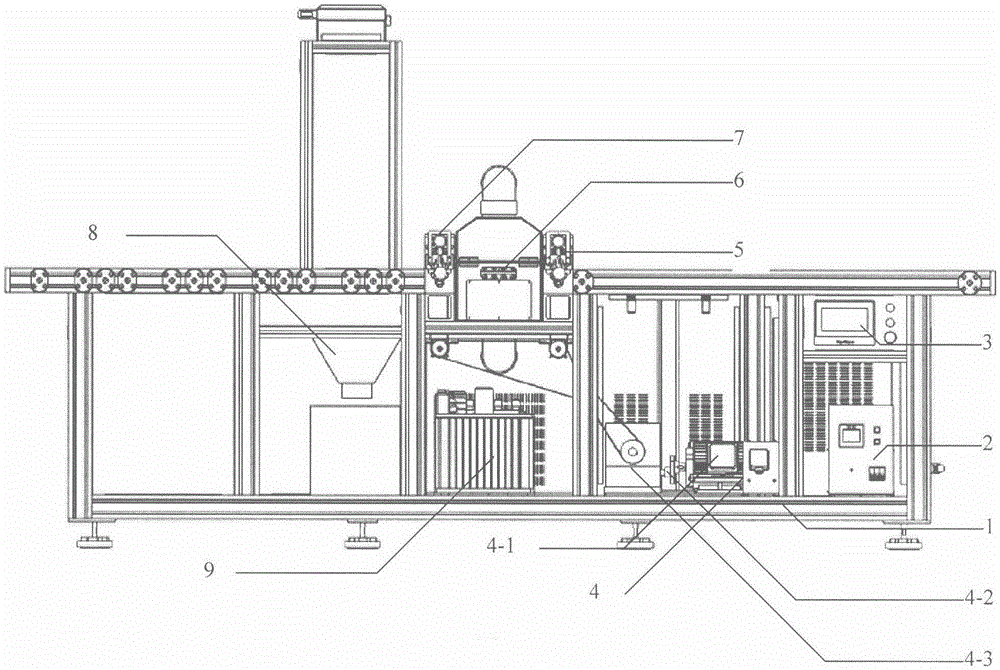

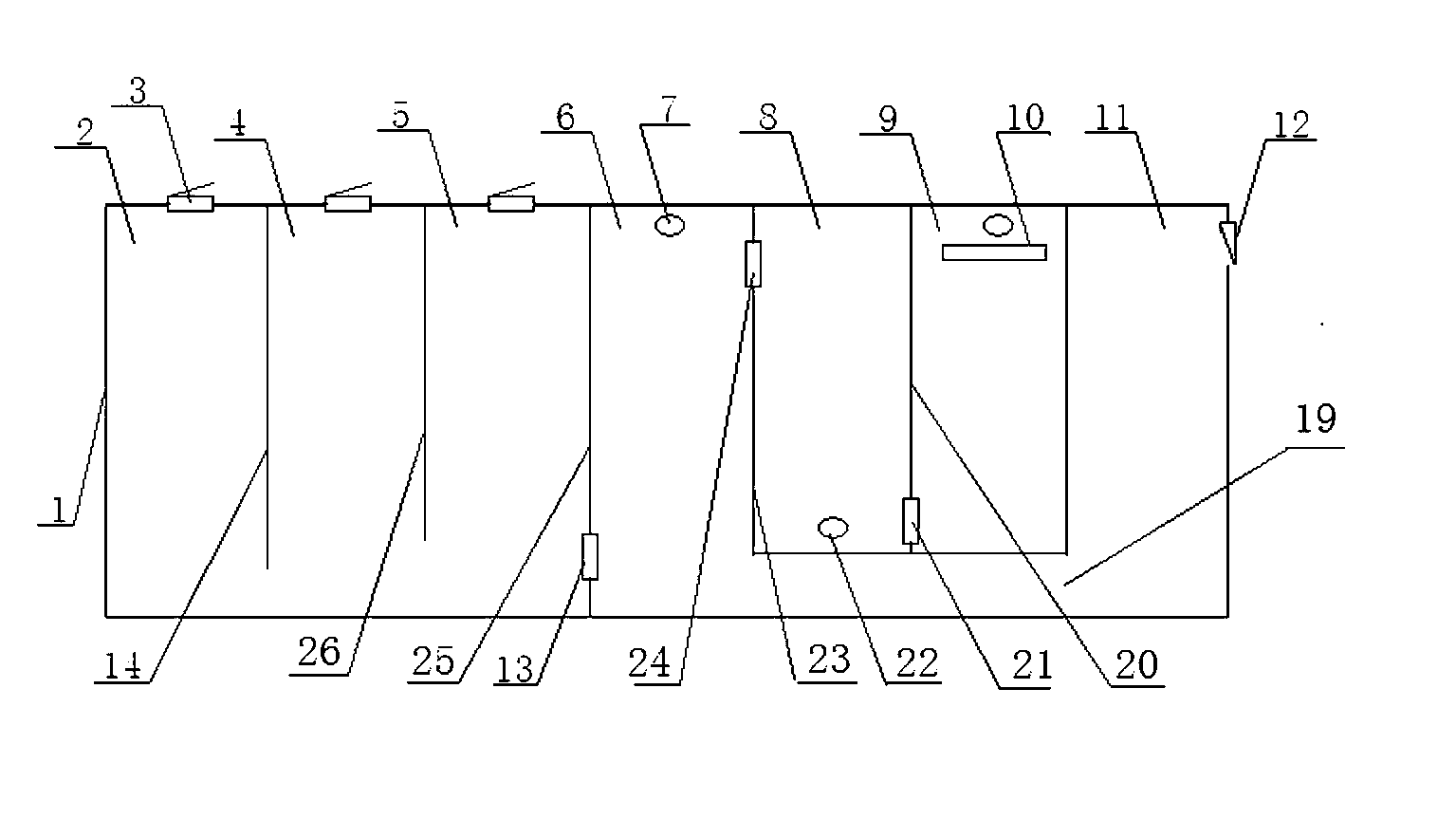

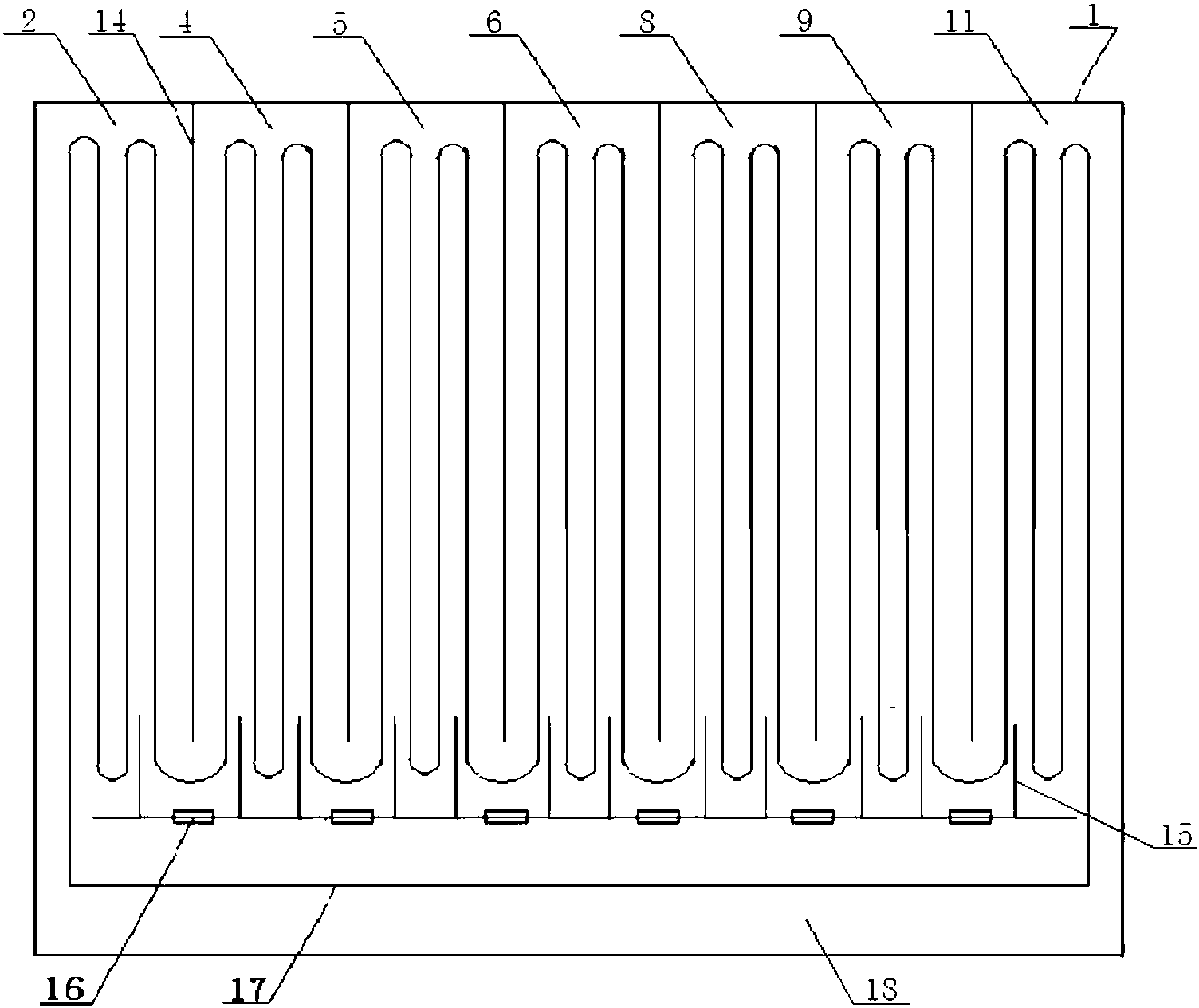

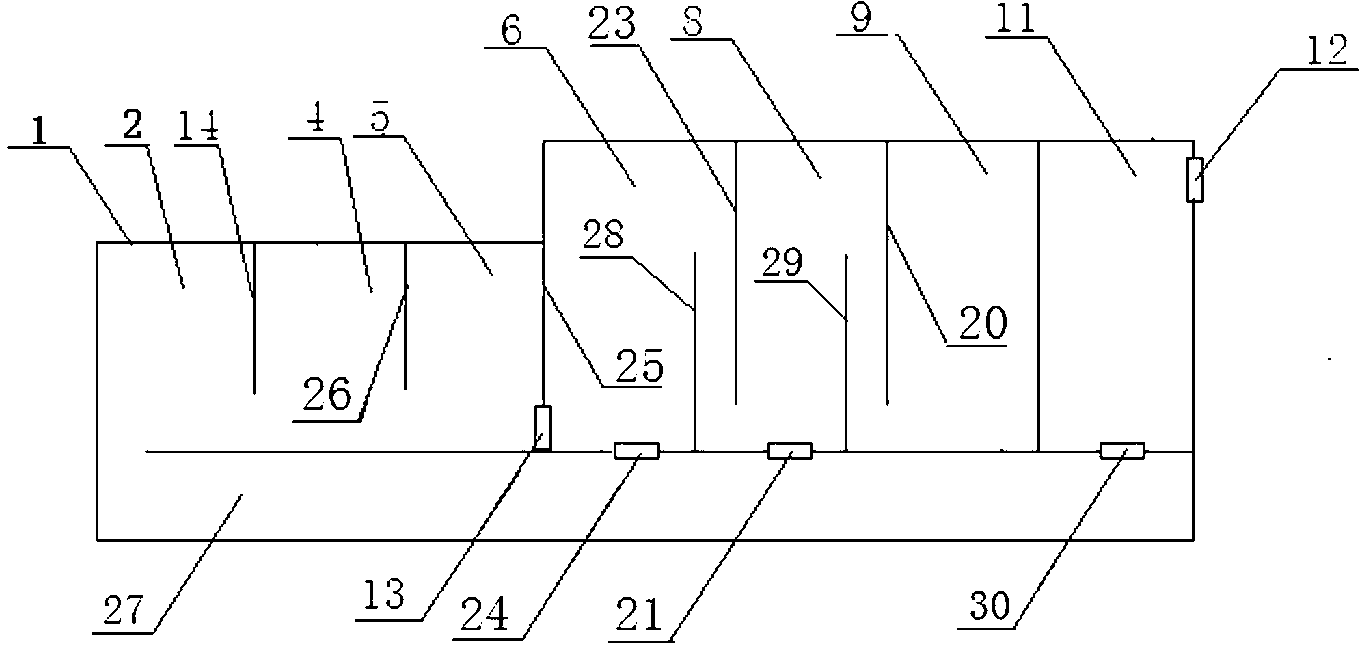

Full-automatic tobacco flue-curing house

InactiveCN103005656AReduce construction costsRealize automatic continuous operationTobacco preparationCooking & bakingControl system

The invention discloses a full-automatic tobacco flue-curing house which belongs to the field of tobacco baking processing and comprises a tobacco flue-curing house body and a chain track, as well as six baking areas, a moisture regain area and chain transmission equipment all for the tobaccos, wherein the six baking areas are sequentially arranged in the tobacco entry direction; a heating device is arranged above the sixth baking area; a fan is arranged above the heating device to blow the hot air downwards; a heated air circulation passage is arranged in the six baking areas; the continuous chain track is rewound in the baking areas and the moisture regain area and is driven by the chain transmission equipment; an exhaust port is formed at the upper part of the moisture regain area; and a control system is used for detecting the temperature of the baking areas and the moisture regain area so as to control the operation of the heating device, the fan and the chain transmission equipment. The tobacco flue-curing house realizes automatic continuous operation of tobacco baking, is convenient to adjust temperature and large in productive output, reduces the labor intensity, improves the production efficiency and reduces the construction cost of the baking room.

Owner:内乡利夫迪尔节能设备有限公司

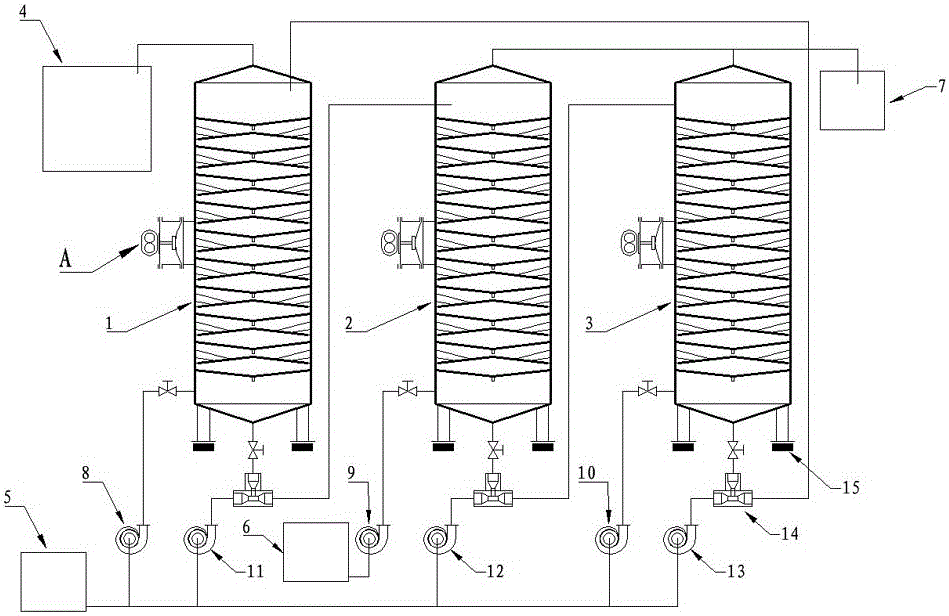

Self-balancing vibration and rubber pad shock absorption fluidized bed type ion exchange water treatment device

ActiveCN105110415AFull cycleImprove liquidityWater/sewage treatment by ion-exchangeFluidized bedIon exchange

Owner:泰州市海通资产管理有限公司

a composite car

InactiveCN102278889AFlexible walkingPrecise positioningCharge manipulationEngineeringUltimate tensile strength

The invention discloses a compound material cart, which comprises a trolley assembly, a middle cart assembly and a cart assembly which are sequentially installed from top to bottom. The bottom of the cart assembly is installed with a first A driving mechanism, a second driving mechanism for driving the longitudinal movement of the middle car assembly is provided between the cart assembly and the middle car assembly, and a third driving mechanism is provided on the middle car assembly to drive the longitudinal movement of the trolley assembly. A roller guiding mechanism is provided between the cart assembly and the trolley assembly to enable the trolley assembly to move vertically while lifting. The annealing furnace, the composite car, and the storage table are arranged in a symmetrical manner, and the compound car can better realize automatic continuous operation, effectively improve production efficiency, and improve the labor intensity of workers.

Owner:ZHEJIANG HAODA IND FURNACE

Thin-layer reactive powder concrete vibrating and levelling method and system

ActiveCN105926947AImprove efficiencyImprove flatnessBuilding material handlingThin layerContinuous operation

The invention relates to a thin-layer reactive powder concrete vibrating and levelling method and system, mainly solving the technical problem that reactive powder concrete needs to be vibrated and levelled for multiple times and the like. According to the technical scheme, the system comprises a vibrating truss (25), suspension type high-frequency vibrating devices (22), suspension type levelling devices (21), a vibrating and levelling travelling device (28) and a smart vibrating and levelling control unit (26), and the suspension type high-frequency vibrating devices (22) and the suspension type levelling devices (21) are hung below the vibrating truss (25); the vibrating truss (25) is mounted on the vibrating and levelling travelling device (28), the smart vibrating and levelling control unit (26) is mounted on the side face of the end of the vibrating truss (25), and the whole vibrating and levelling system is mounted on longitudinal rails (17). Due to the fact that manual operation is not required, efficiency and levelness are improved greatly, and automatic and continuous operation is realized. The method and system is mainly applied to the fields of reactive powder concrete production and construction and the like.

Owner:HUNAN ZHONGLU HUACHENG BRIDGE TECH CO LTD

Water circulation method used in laboratory circulation-water-type water distiller

InactiveCN102363125AImprove efficiencyReduce lossesLaboratory glasswaresCooling chamberWater circulation

The invention discloses a water circulation method used in a laboratory circulation-water-type water distiller. According to the method, water in a condensed water storing device is delivered to a condensed water pipe; when a condensing cover is cooled by using the condensed water, the water is delivered to a heat dissipating device; after a heat dissipating process, the water is delivered back to the condensed water storing device. Water amount in a distilling tank is supplemented by the water in the condensed water storing device through a water supplying pipe. Water in the distilling tank is heated into steam, and is delivered into a steam guidance sleeve pipe; the steam is pre-cooled during a lifting process, and flows from an upper port of the steam guidance sleeve pipe. With a curved flow guide plate, the steam is diffused into a cooling chamber, and the heat is transferred to cooling water in the condensed water pipe through condensing sheets. The steam is condensed into water, and flows from a distilled water outlet. The water level is detected by using a liquidometer. When the water level is lower than a lower limit, a water level adjusting valve is opened, and water is supplemented to the condensed water storing device. According to the invention, a condensed water circulation and utilization method is adopted, such that water resource is saved; water is supplied to the distilling tank, such that automatic continuous operation is realized; with the curved flow guide plate and the condensing sheets in a condensing device, condensing efficiency is improved, the heat exchange efficiency is high, and a unit time yield is high.

Owner:HENAN UNIV OF SCI & TECH

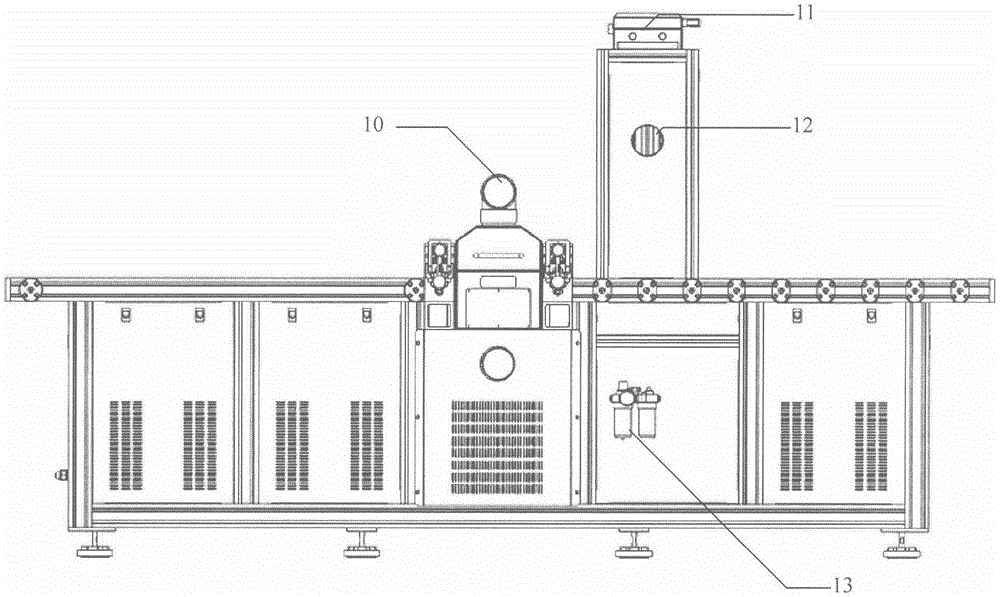

Automatic overturning and conveying device and method for cartridge cases

ActiveCN113335886ARealize automatic continuous operationAvoid pollutionFinal product manufactureAmmunitionProduction lineStructural engineering

The invention belongs to the technical field of bullet assembling, and particularly relates to an automatic overturning and conveying device and method for cartridge cases.The cartridge cases are pushed into an inlet guide hanging plate in an inverted hanging mode after the opening painting procedure is completed on associated equipment, a radial feeding air cylinder stretches out, a front push plate is inserted into the gap between the cartridge cases, and a push-in air cylinder stretches out before overturning. The front push plate pushes the cartridge cases into the overturning hanging plate, a servo motor drives the rotating shaft to turn over through a synchronous belt, the rotating shaft rotates by 90 degrees every beat, the cartridge cases are turned over by 180 degrees after being rotated twice, the push-out air cylinder stretches out after turning over, the rear push plate pushes the cartridge cases onto an outlet guide plate, and the cartridge cases are driven by the conveying chain to enter a drying conveying line. According to the device and method, bullet assembly production equipment is organically connected into an automatic production line, automatic continuous operation of bullet assembly production is achieved, and the production efficiency is effectively improved. Meanwhile, the cartridge cases are hung upside down by utilizing a cartridge case shifting groove, and the opening part of each cartridge case is not in contact with equipment in the overturning process, so that the pollution of paint liquid to the cartridge cases and the equipment is avoided.

Owner:中国兵器装备集团自动化研究所有限公司

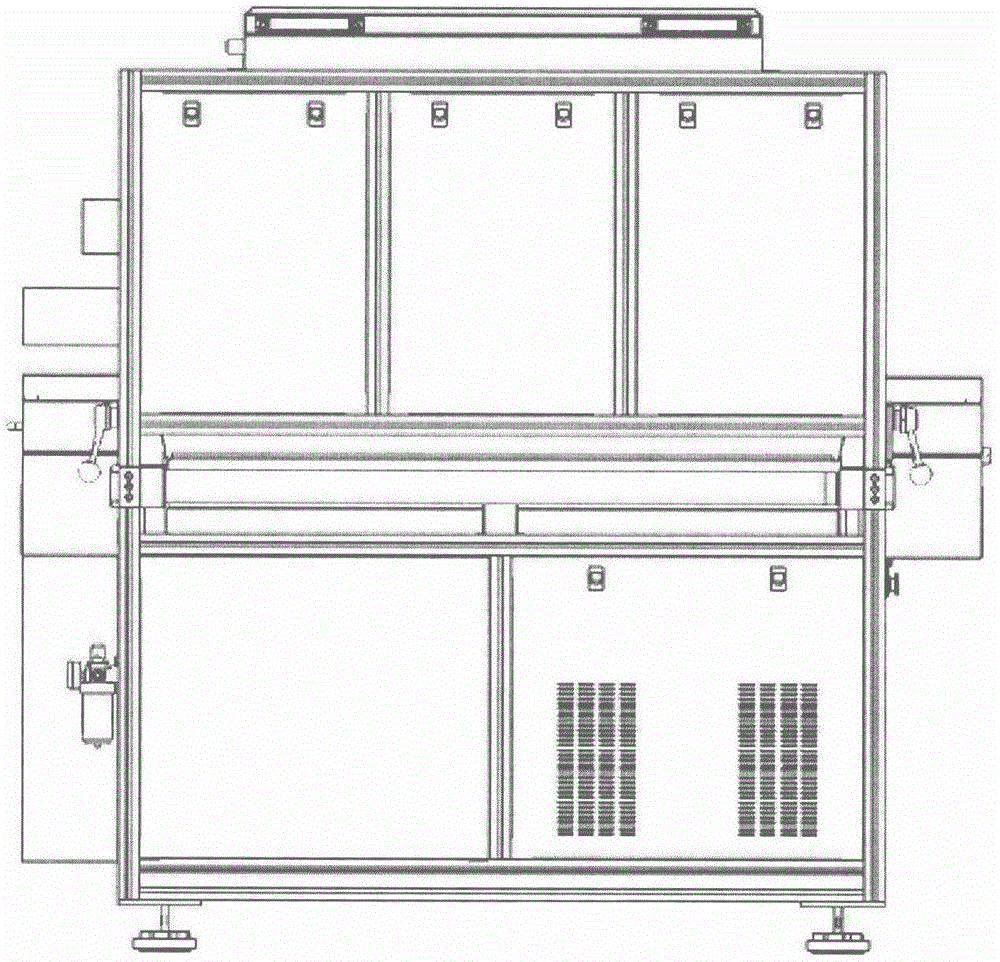

Automatic stacking device and stacking method thereof

ActiveCN105819232AOvercome the defects of packaging intermittent process operationOvercoming operational deficienciesStacking articlesControl systemMaterial resources

The invention relates to an automatic stacking device and a stacking method thereof. The automatic stacking device comprises feeding mechanisms, discharging mechanisms, material collecting mechanisms and a control system. Each discharging mechanism is located at one tail end of the corresponding feeding mechanism. The material collecting mechanisms are located below the discharging mechanisms. By means of the automatic stacking device and the stacking method thereof, automatic and continuous work can be achieved, operation is easy, control is convenient, the automation degree is high, an operator can know and adjust production conditions, labor force and material resources are saved as well, and the production cost is reduced.

Owner:SHENZHEN AMI TECH CO LTD

A sesame cleaning and drying integrated machine

InactiveCN106108068ASave human effortReduce labor intensityClimate change adaptationFood treatmentWater dischargePulp and paper industry

The invention relates to a sesame cleaning and drying integrated machine comprising a rack, a cleaning machine, a drying machine and a circulating water tank. The cleaning machine comprises a drum body, a stirring device, a filter net, a silt discharge pipe, a water outlet and a feeding pipe, wherein the stirring device and the filter net are arranged in the drum body, the filter net is arranged to be close to the water outlet, and the silt discharge pipe is arranged at the edge of the drum body. The upper end of the drying machine communicates with a lower part of the cleaning machine via a material discharge pipe; a material outlet of the drying machine right faces a conveyor belt of an elevator; the drying machine is connected with the circulating water tank via a water discharge pipe. The machine employs stirring cleaning and centrifugal water removal, so that a large amount of manpower is saved, labor intensity is reduced, automatic continuous work is realized and cleaning standards can be completely met. The apparatus is easy to manufacture, simple and convenient to maintain, safe to operate and high in working efficiency and saves water and energy.

Owner:天津市益民金星科技发展有限公司

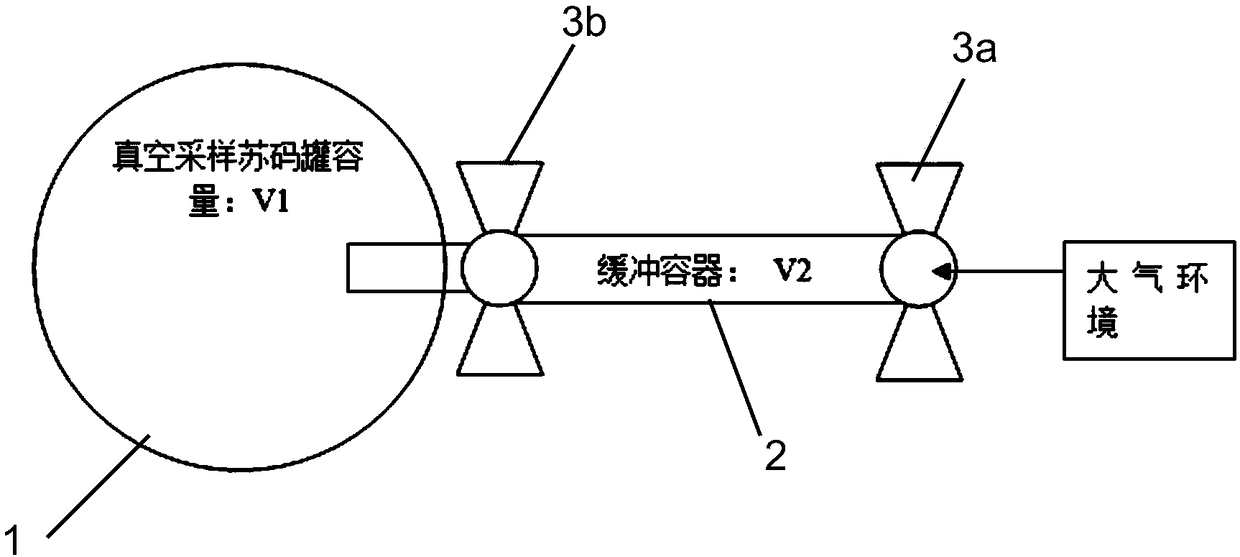

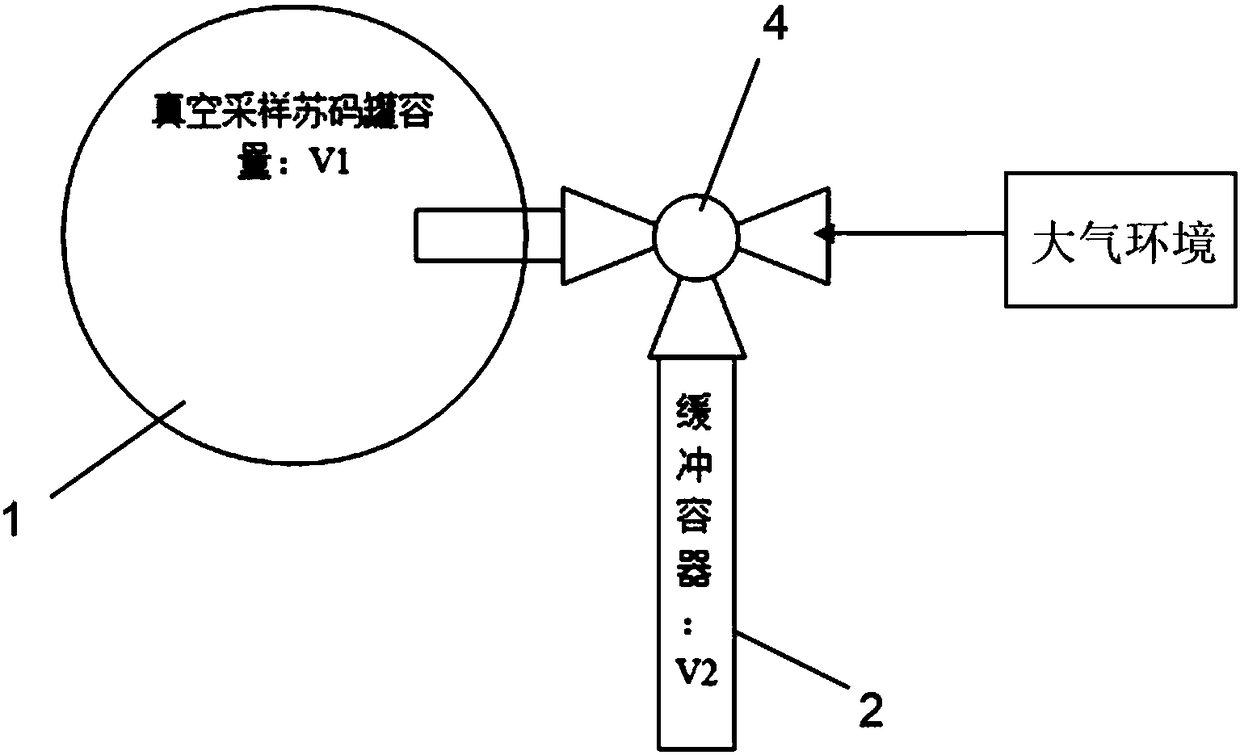

Environment-air constant flow automatic sampling system and sampling method thereof

PendingCN108333001AReduce usageLow costWithdrawing sample devicesFlow control using electric meansAtmospheric airMonitoring and control

The invention discloses an environment-air constant flow automatic sampling system and a sampling method thereof. The system comprises a vacuum sampling tank, a buffer container and a switch valve, wherein the buffer container is respectively communicated with the vacuum sampling tank and the atmospheric environment through the switch valve; through the switching control of the switch valve, the buffer container is alternately communicated with the atmospheric environment and the vacuum sampling tank to reach the air pressure balance of the sample feeding gas. The invention also discloses a constant current environment air sampling method. The technical monopolization in foreign countries on the high-precision atmosphere constant current sampling device is broken; the atmospheric samplingflow rate control precision is controlled; the inertness of the integral gas flow path is ensured; the flexible flow rate control and regulation mode is realized; the common use industrial volume production devices and materials are used; consumable avoidance and easy maintenance are realized; the economic and efficient fully automatic environment air constant flow automatic sampling system is built; the contribution is made for national atmospheric environment monitoring and control.

Owner:SHANGHAI PENGHUAN MEASUREMENT & CONTROL TECH CO LTD

Fish killing device

InactiveCN103380807BRealize automatic continuous operationAchieve fixationFish processingEngineeringSting fish

The invention discloses a fish killing device and relates to a processing device for fishes. The fish killing device comprises a rack, a conveying belt group, a fish head cutting device and a fish belly cutting device, when the fishes are placed with fish bellies facing downwards and placed into an input end of the conveying belt group, a first conveying belt, a second conveying belt and a third conveying belt convey the fishes together, the fishes are turned due to different speeds, fish heads are cut down when the fishes pass through the fish head cutting device, and the fish bellies are cut apart when the fishes pass through the fish belly cutting device. According to the fish killing device, automatic continuous operations of fish head cutting and fish belly cutting are achieved, firstly, the fish head cutting operation is finished through the fish head cutting device, the conveying belt group cooperates with a fish shifting conveying belt to enable the fishes to be turned and enter the fish belly cutting device, a circular knife allowing up-down height adjustment is arranged in the fish belly cutting device and under the conveying belt group, and limiting conveying belts are arranged on two sides of the conveying belt group, so that fish bodies can be fixed, and the fish belly cutting operation can be finished from the lower side.

Owner:WENZHOU UNIVERSITY +1

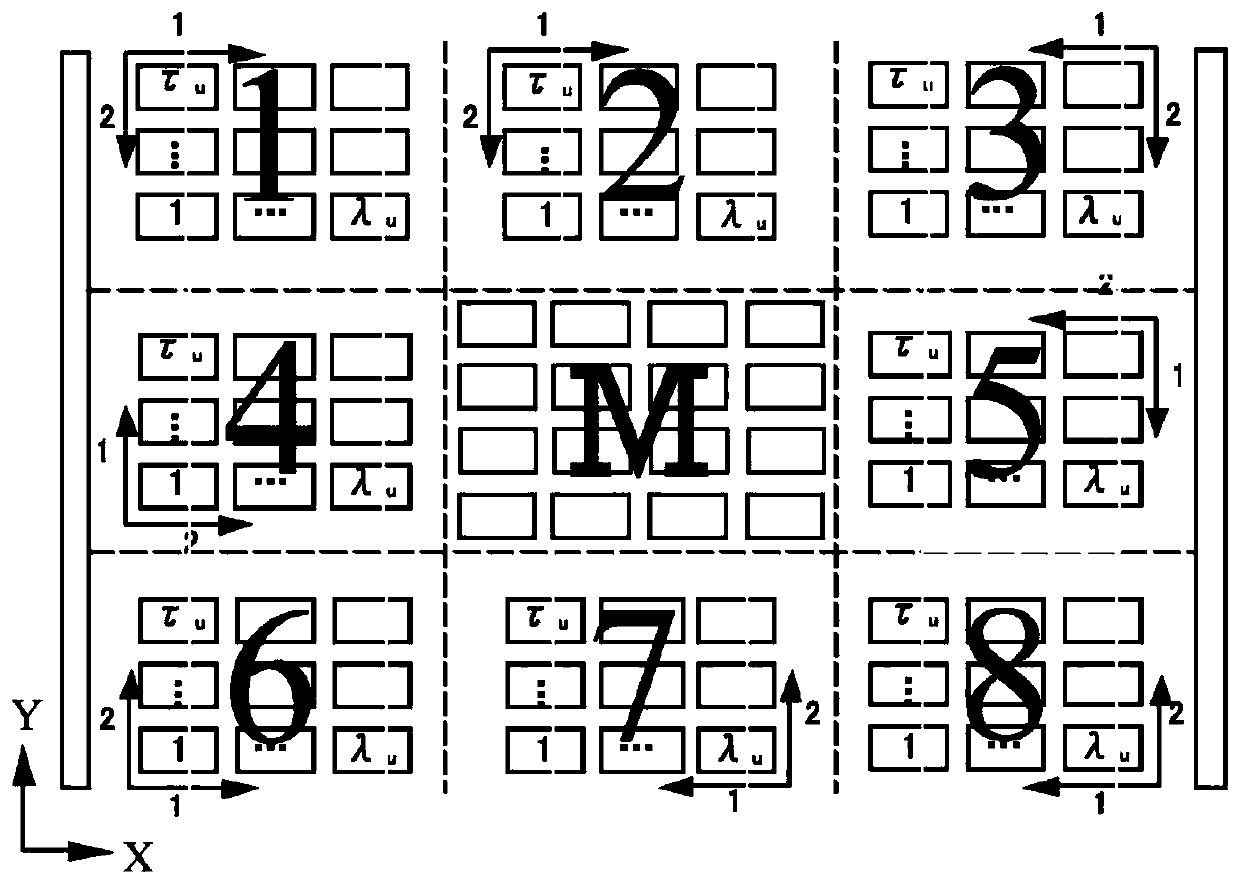

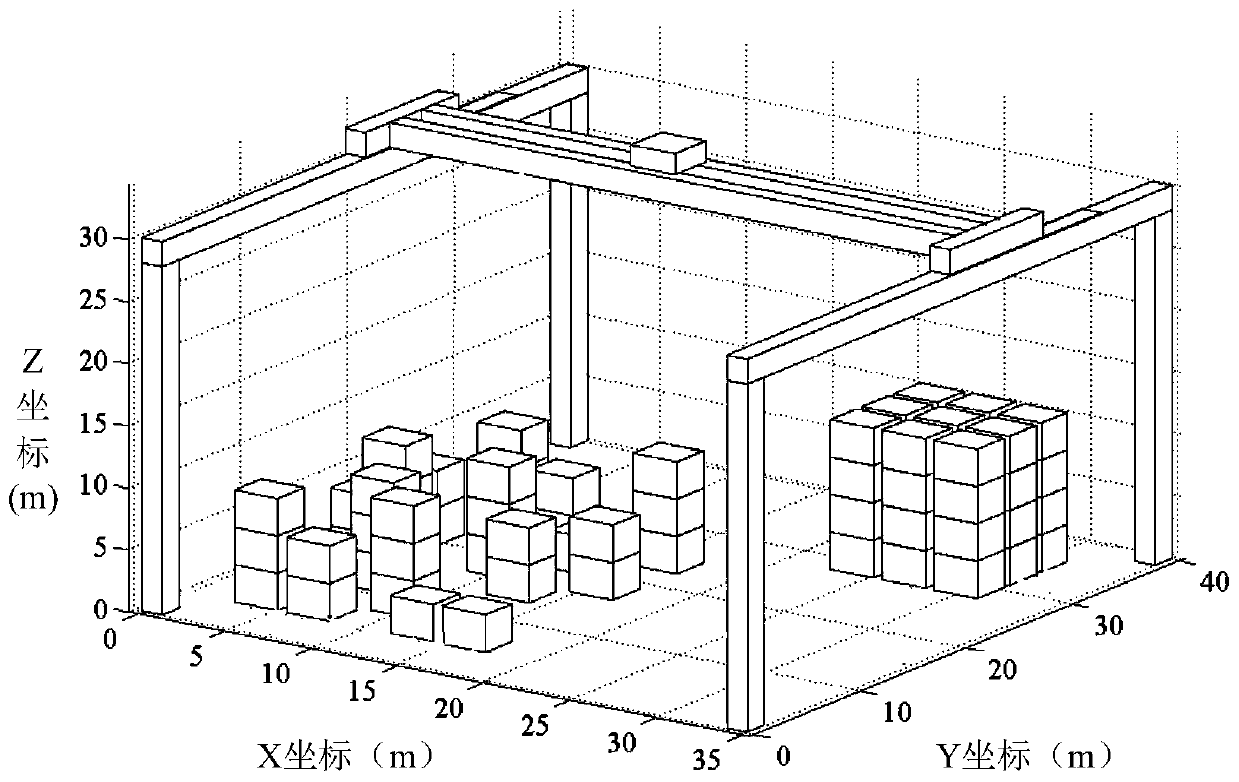

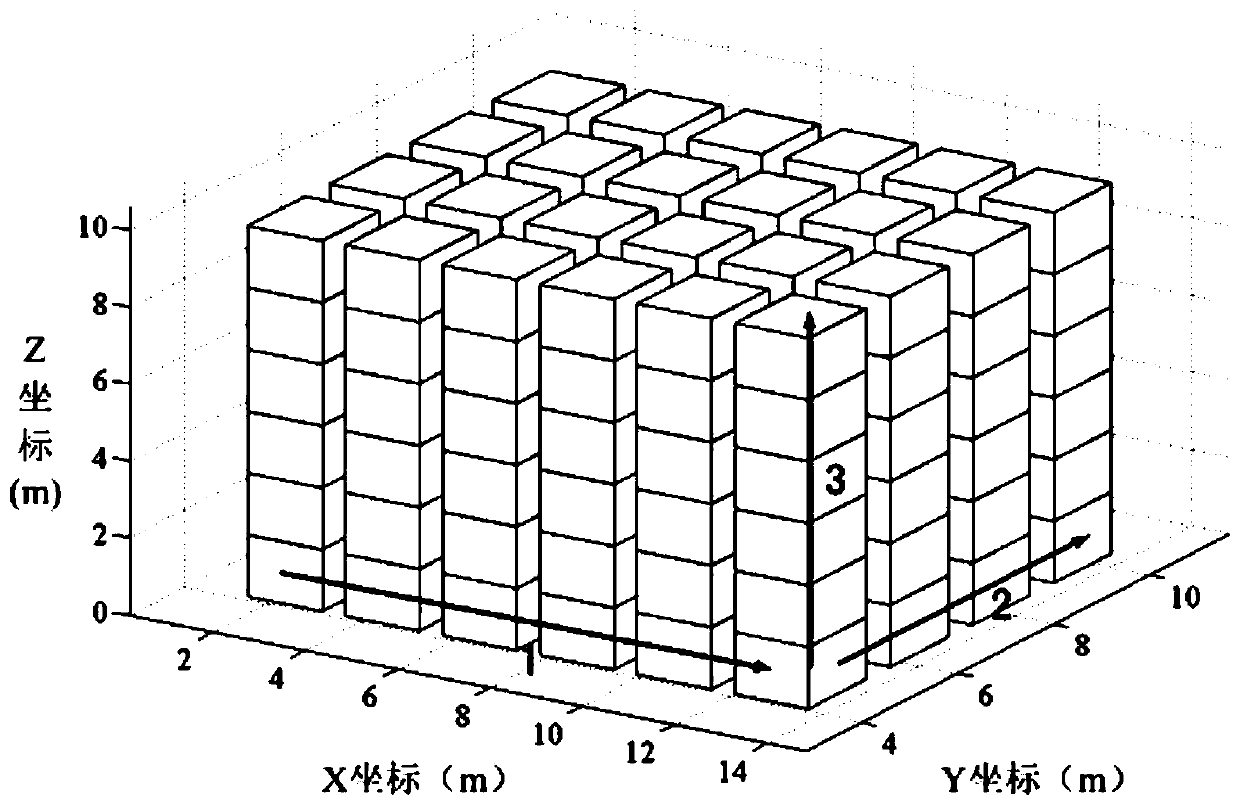

Crane cargo unloading sequence automatic generation method and system

ActiveCN110888905ARealize automatic control operationRealize automatic continuous operationDigital data information retrievalDesign optimisation/simulationThree-dimensional spaceSequence database

The invention provides a crane cargo unloading sequence automatic generation method and system, and the method comprises the steps: defining a plurality of unloading regions at the periphery of an initial position before cargo handling according to the relative position relation of the unloading regions relative to the initial position before cargo handling; establishing a three-dimensional spacecoordinate system by taking limit position points of cargos loaded by the crane in three movement directions of large movement, small movement and vertical descending as original points and taking themovement directions of a small trolley, a large trolley and a hoisting mechanism of the crane as X, Y and Z directions respectively; establishing a corresponding relationship between the unloading position and a three-dimensional space coordinate system to obtain an unloading position information database of each unloading area; and formulating an unloading sequence rule for each unloading area,and rearranging the corresponding unloading position information database according to the unloading sequence rule to obtain an unloading sequence database. According to the method, a theoretical research method is organically combined with actual loading and unloading operation requirements and operation characteristics of the crane, and the cargo unloading sequence of the crane is automaticallygenerated.

Owner:APPLIED TECH COLLEGE OF SOOCHOW UNIV

Fish killing device

InactiveCN103380807ARealize automatic continuous operationAchieve fixationFish processingEngineeringContinuous operation

The invention discloses a fish killing device and relates to a processing device for fishes. The fish killing device comprises a rack, a conveying belt group, a fish head cutting device and a fish belly cutting device, when the fishes are placed with fish bellies facing downwards and placed into an input end of the conveying belt group, a first conveying belt, a second conveying belt and a third conveying belt convey the fishes together, the fishes are turned due to different speeds, fish heads are cut down when the fishes pass through the fish head cutting device, and the fish bellies are cut apart when the fishes pass through the fish belly cutting device. According to the fish killing device, automatic continuous operations of fish head cutting and fish belly cutting are achieved, firstly, the fish head cutting operation is finished through the fish head cutting device, the conveying belt group cooperates with a fish shifting conveying belt to enable the fishes to be turned and enter the fish belly cutting device, a circular knife allowing up-down height adjustment is arranged in the fish belly cutting device and under the conveying belt group, and limiting conveying belts are arranged on two sides of the conveying belt group, so that fish bodies can be fixed, and the fish belly cutting operation can be finished from the lower side.

Owner:WENZHOU UNIVERSITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com