Automatic lamination mechanism of Z-type laminated battery core

A kind of laminated and automatic technology, applied in the direction of circuits, electrical components, secondary batteries, etc., can solve the problems of poor controllability of gravity and airflow, complex structure, poor reliability, etc., achieve continuous and reliable operation, and realize automation Production, the effect of continuous automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in detail below with reference to the accompanying drawings and examples. The examples are preferred implementations of the present invention, and the present invention is not limited to the following implementations and forms.

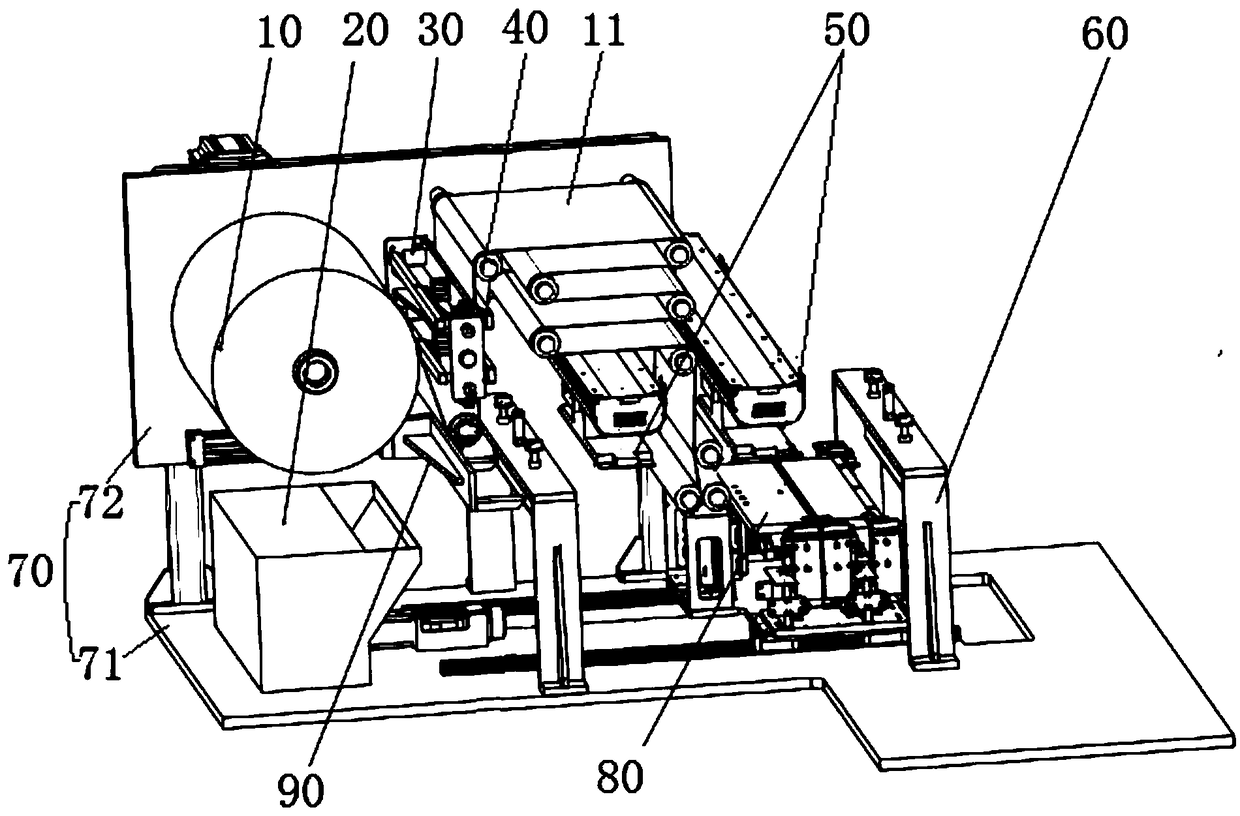

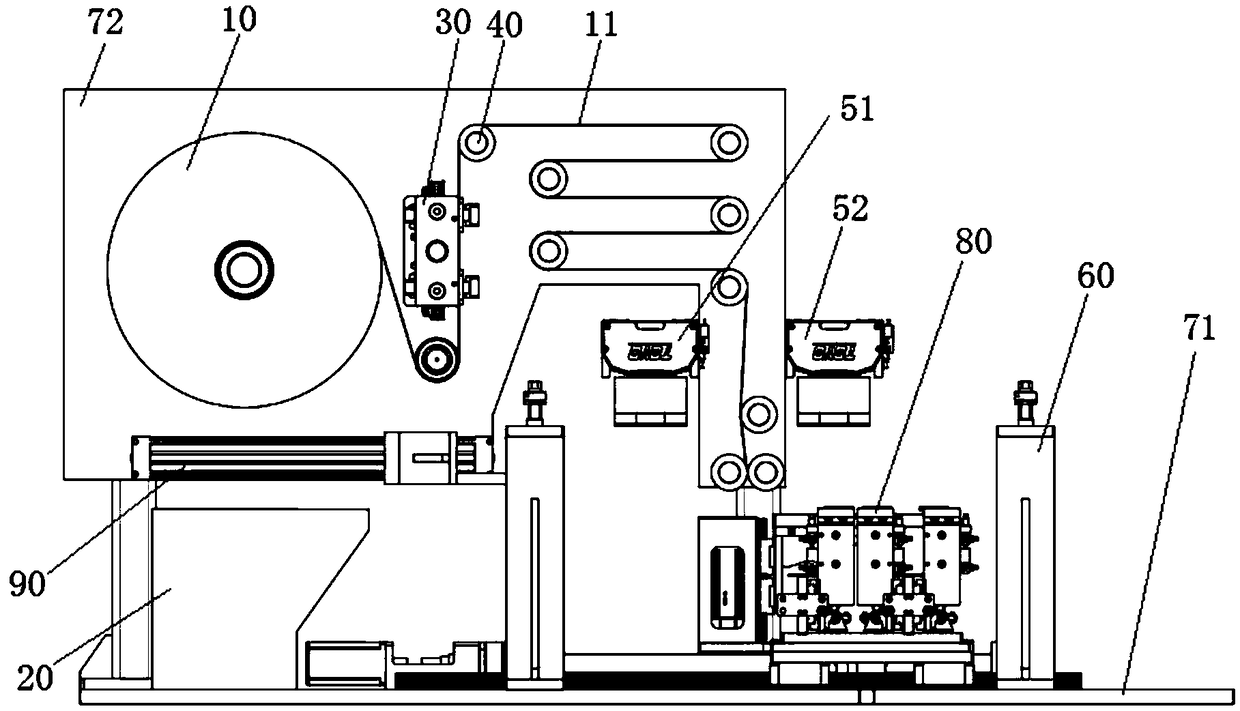

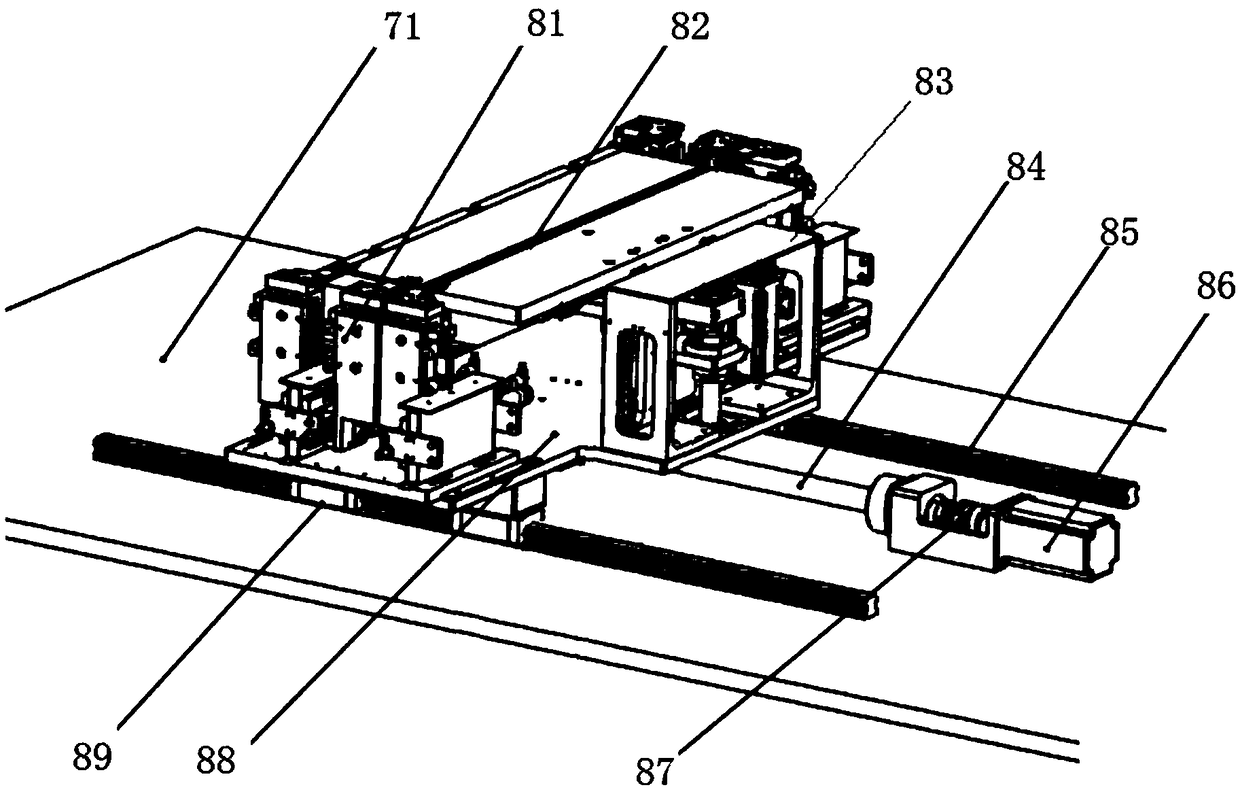

[0052] like figure 1 , 2 As shown, an automatic stacking mechanism for a Z-type laminated battery cell includes a bracket 70 composed of a bottom plate 71 and a side plate 72. The side plate 72 is fixed with a diaphragm unwinding mechanism 10 and is used to align the diaphragm 11 The traction group 40 controlled by tension and deviation correction, the base plate 71 is slidably connected with a lamination table 80, and two cutting mechanisms 60 are symmetrically fixed on the base plate 71 located on both sides of the lamination table 80, which is convenient for lamination The diaphragms at both ends of the platform 80 are moved to be cut off respectively; two pole piece manipulators 50 for placing positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com