Patents

Literature

92results about How to "Continuous and reliable operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

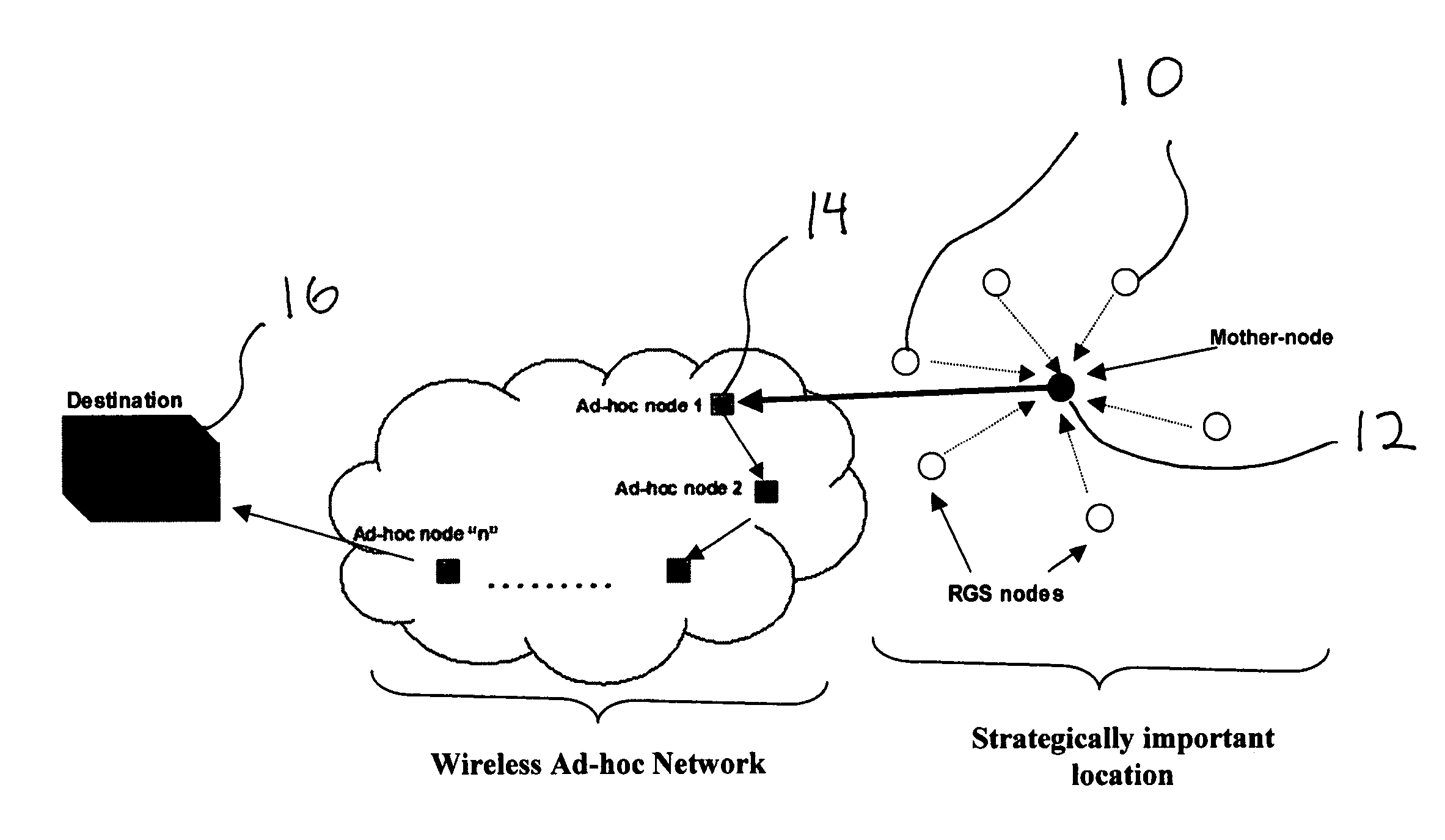

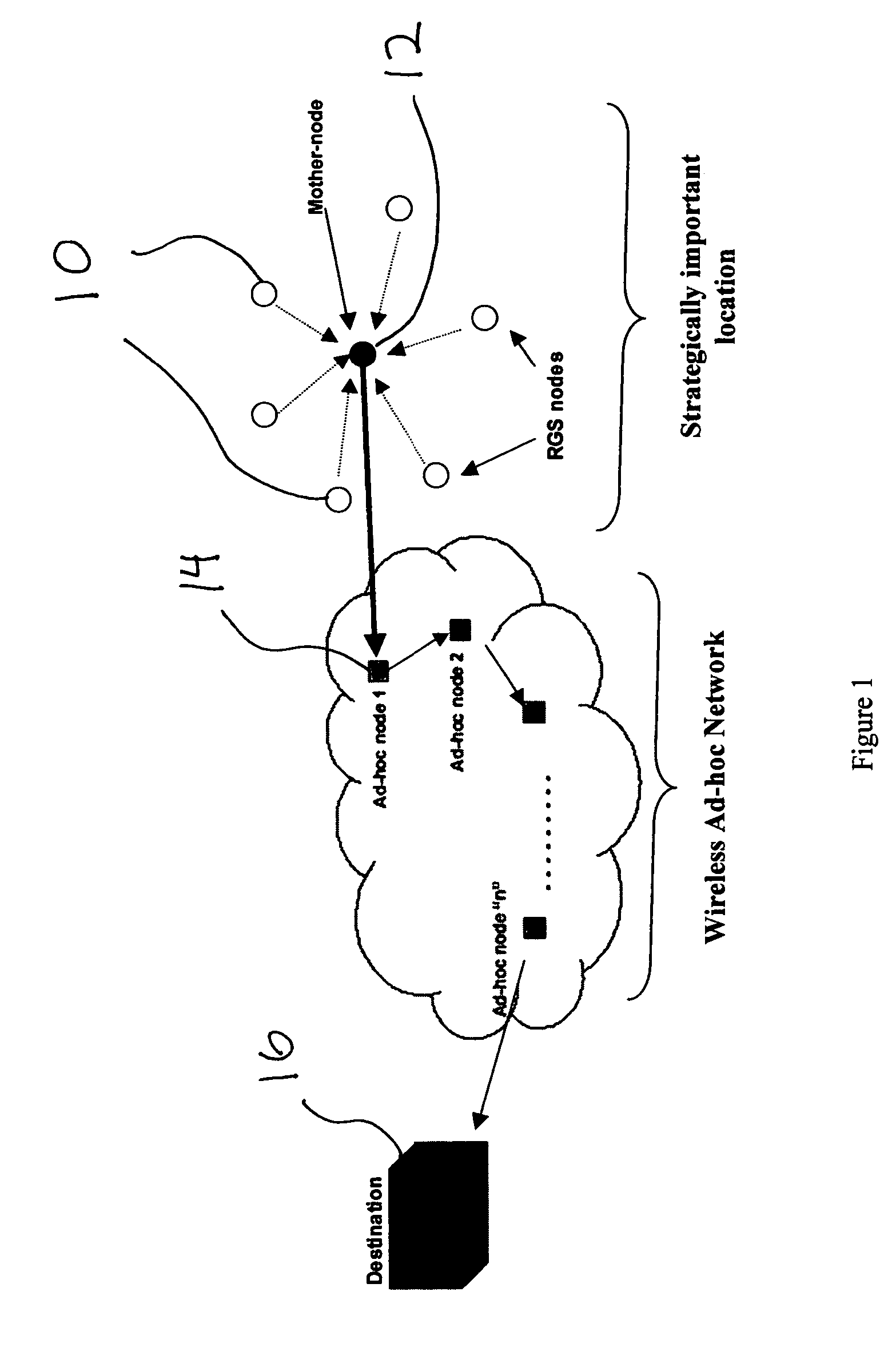

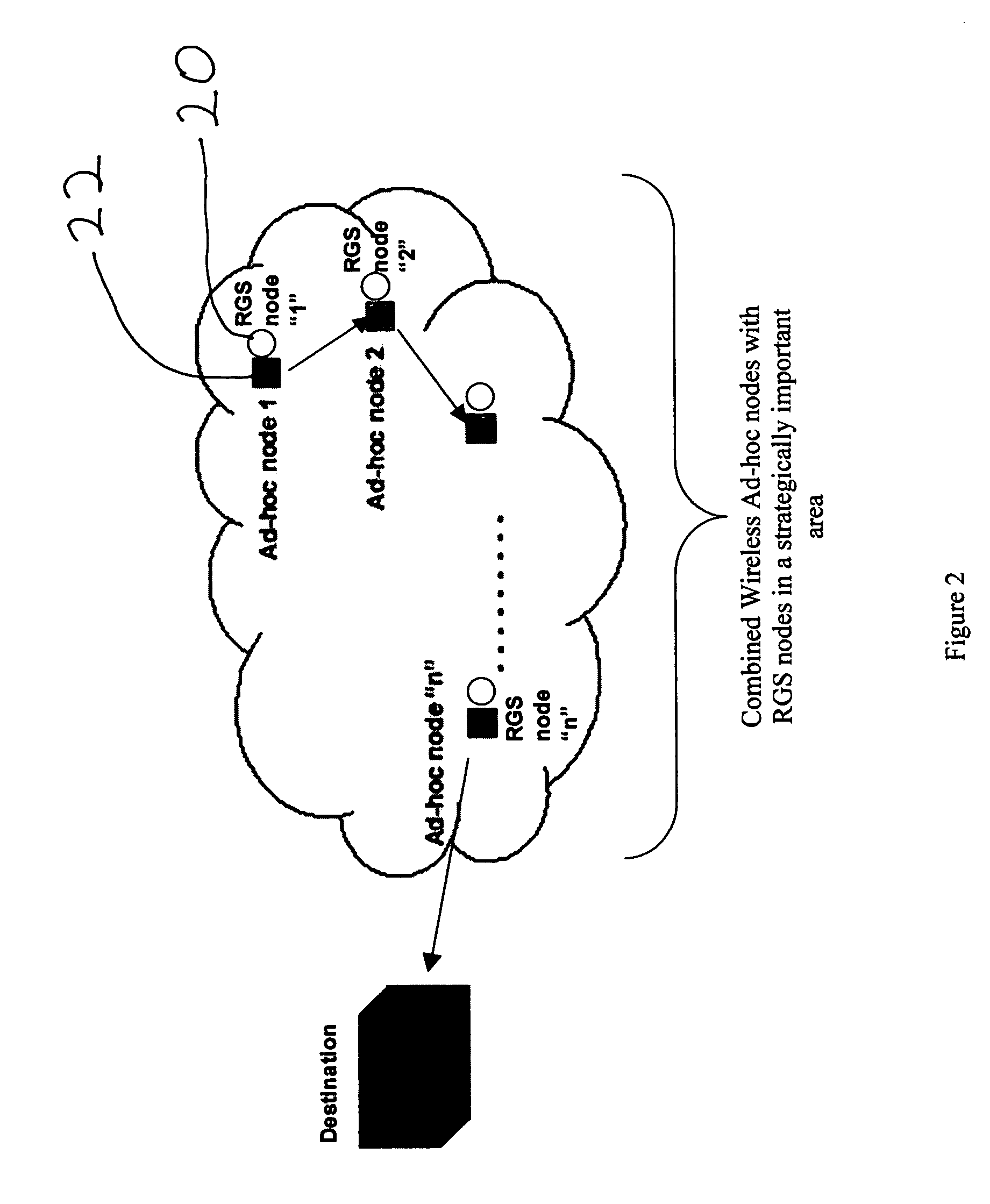

Ultra-wideband radar sensors and networks

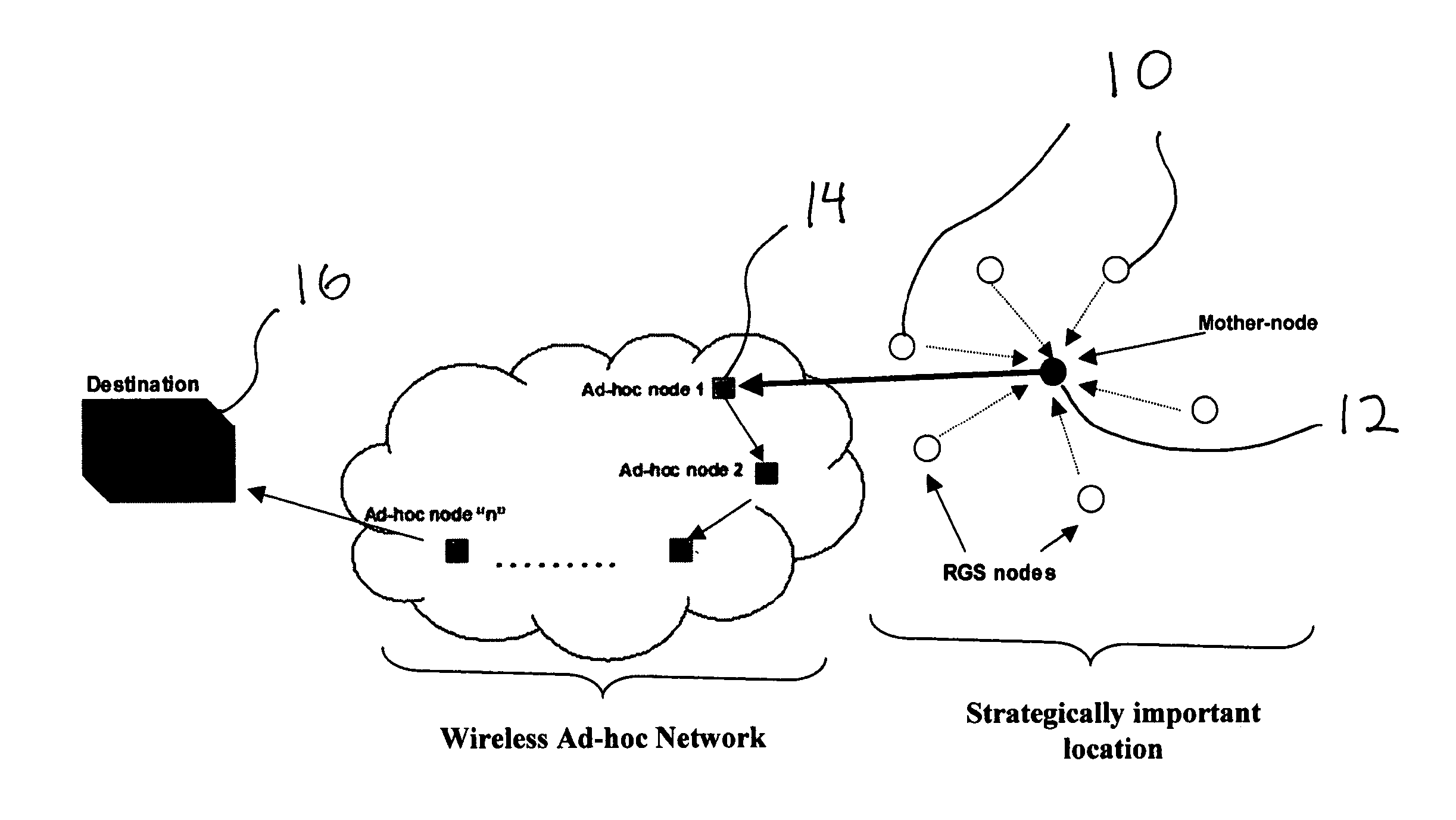

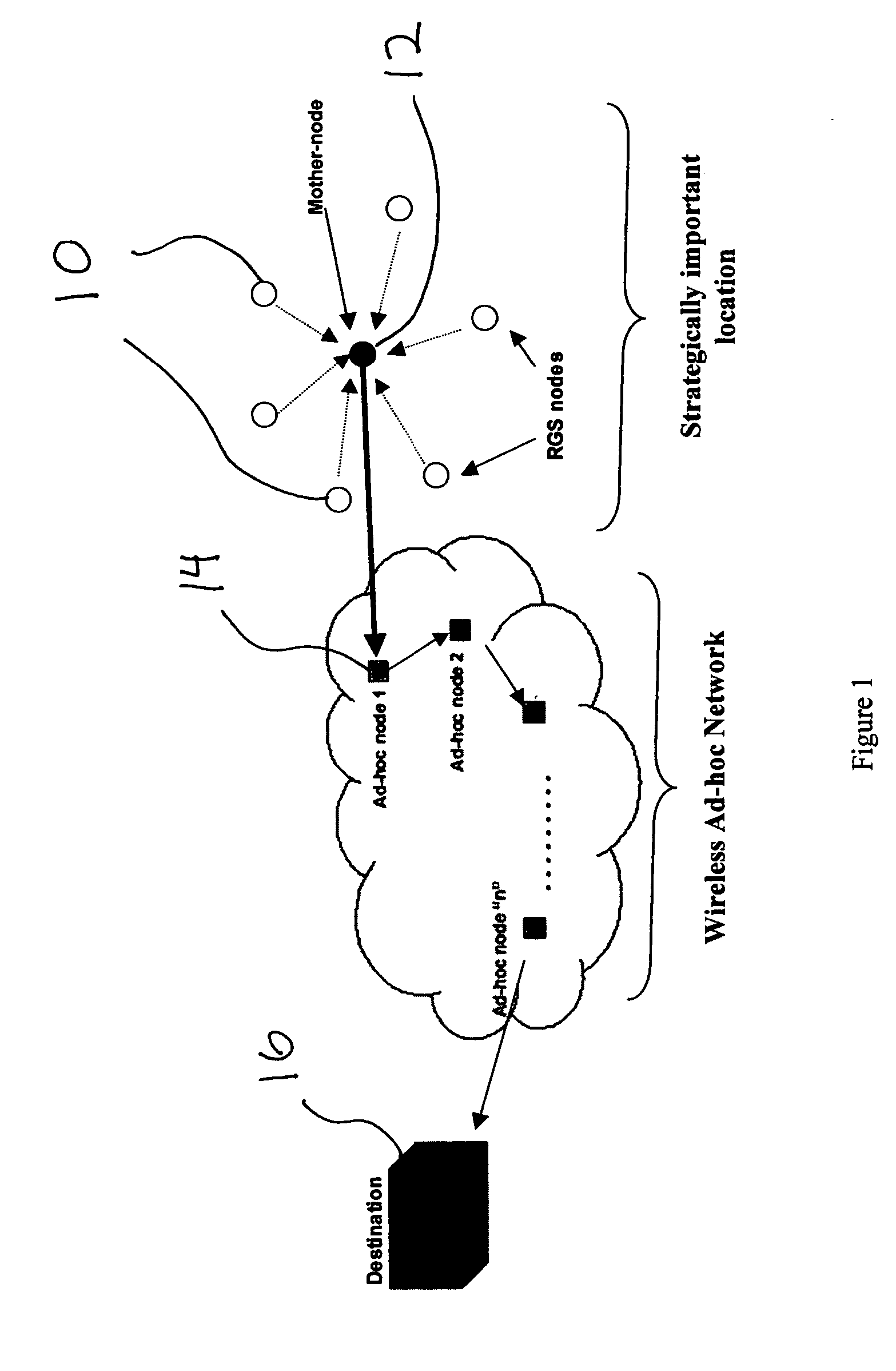

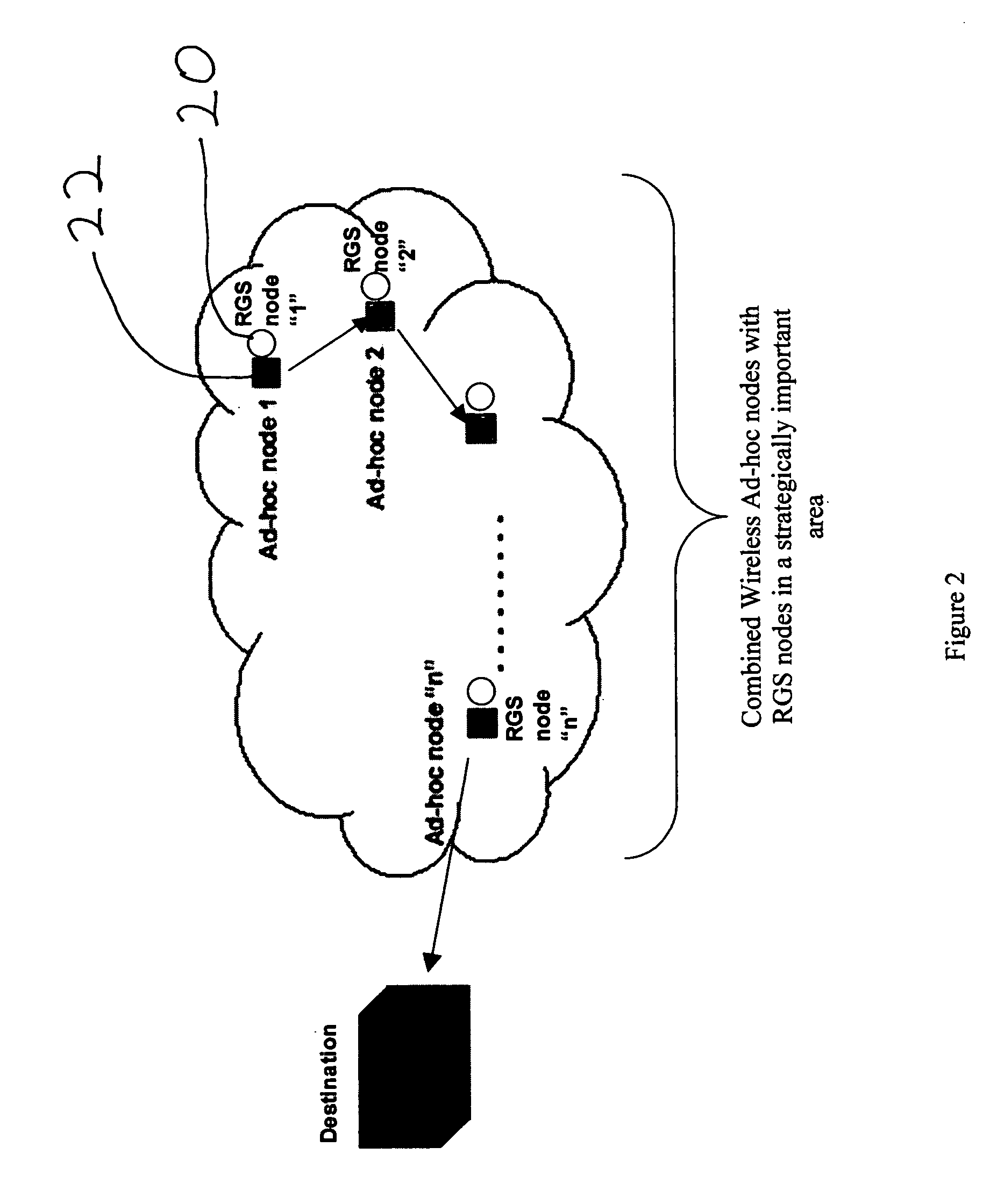

InactiveUS20080007445A1Long monitoring capabilityContinuous and reliable operationLoop antennasRadio wave reradiation/reflectionUltra wideband radarWireless ad hoc network

Ultra wideband radar motion sensors strategically placed in an area of interest communicate with a wireless ad hoc network to provide remote area surveillance. Swept range impulse radar and a heart and respiration monitor combined with the motion sensor further improves discrimination.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

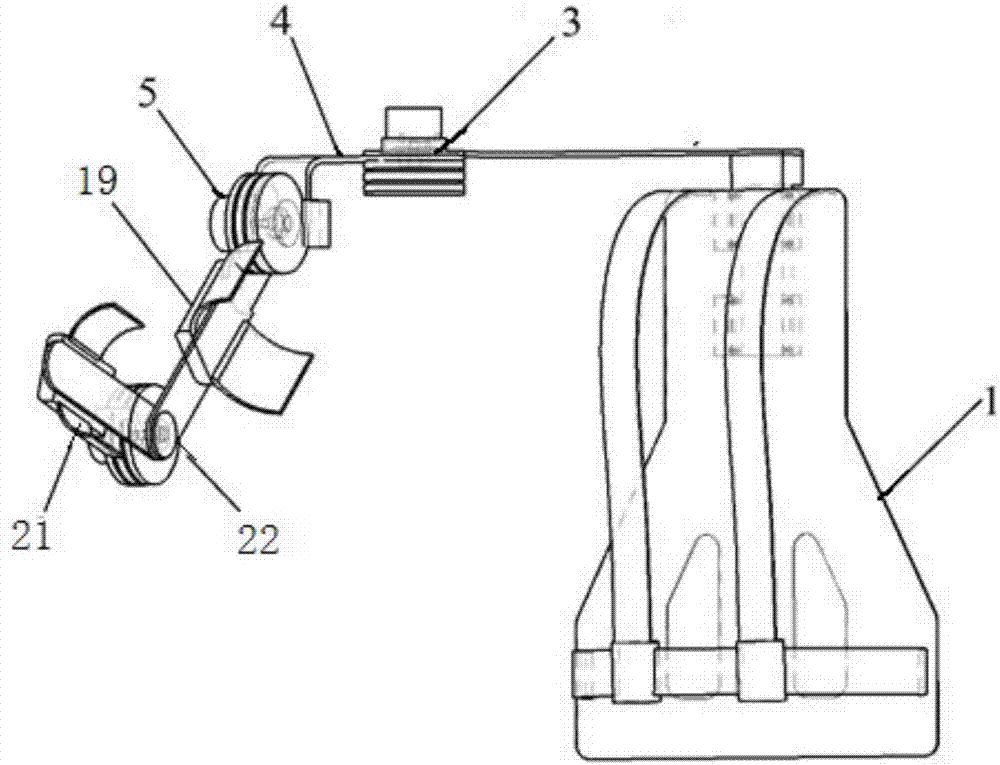

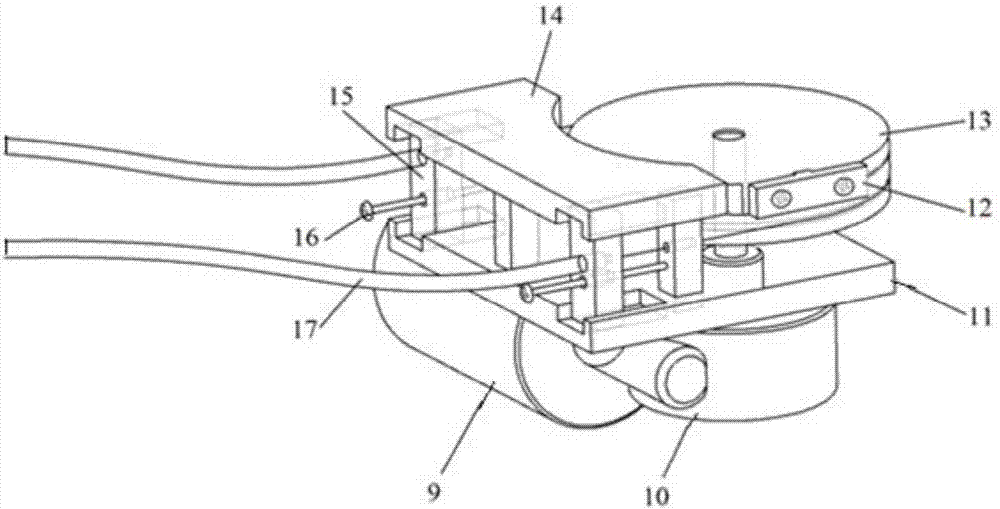

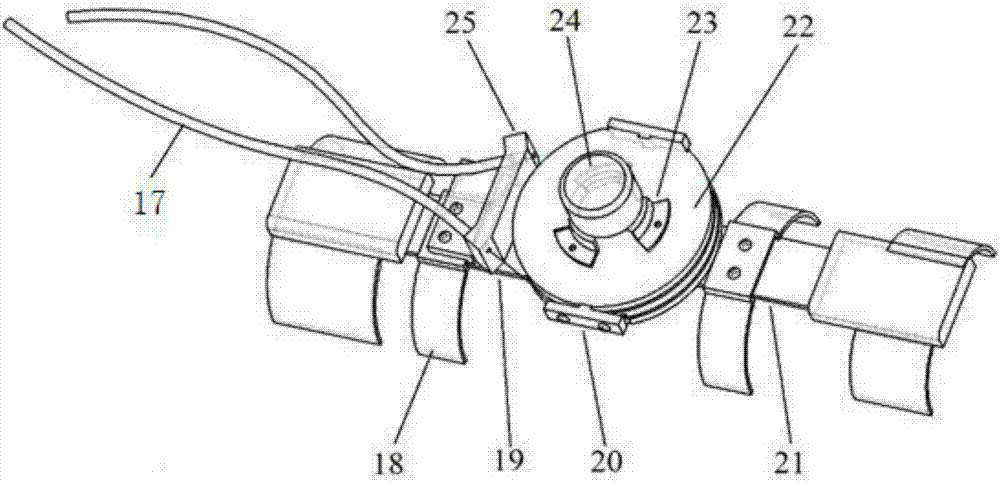

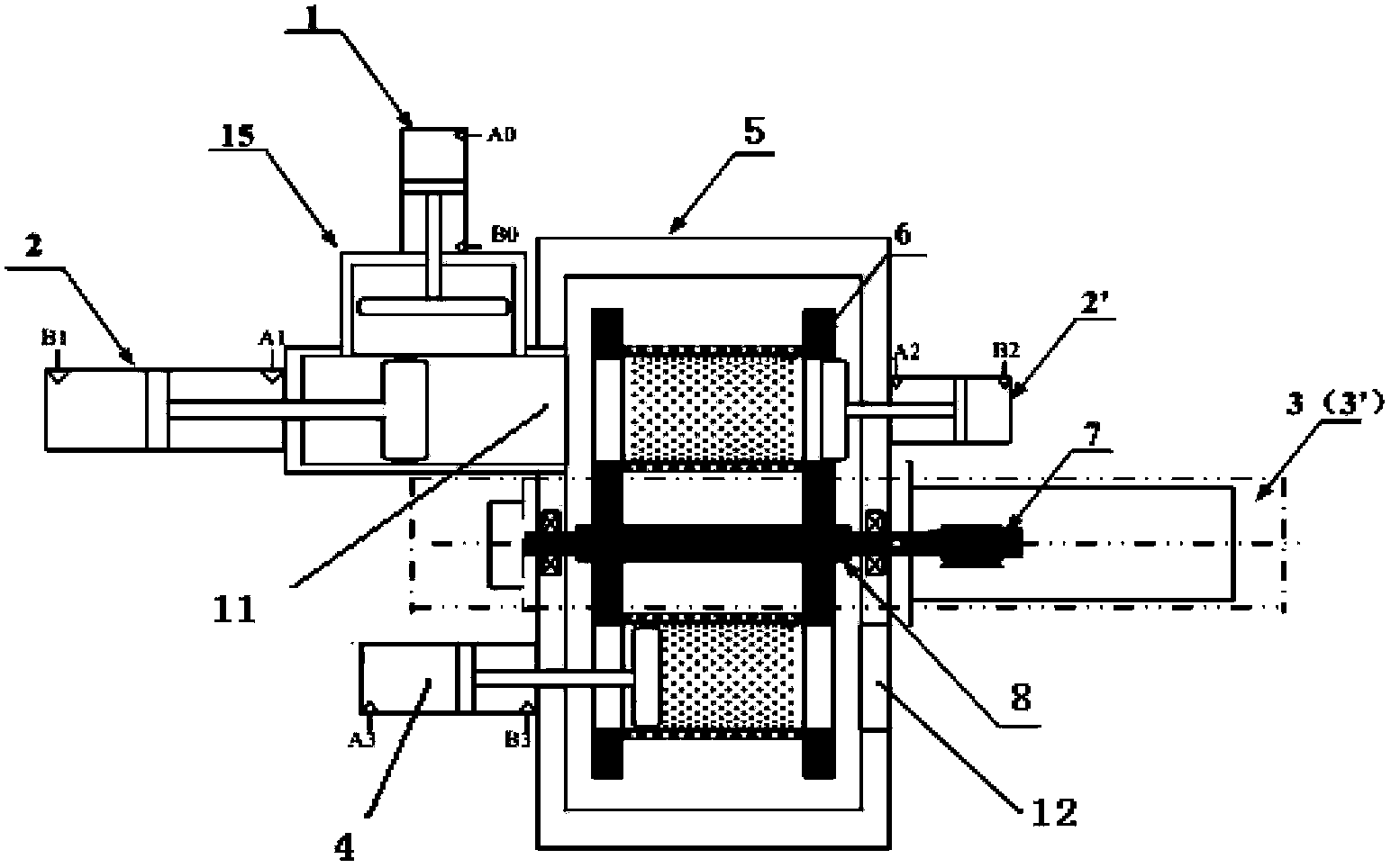

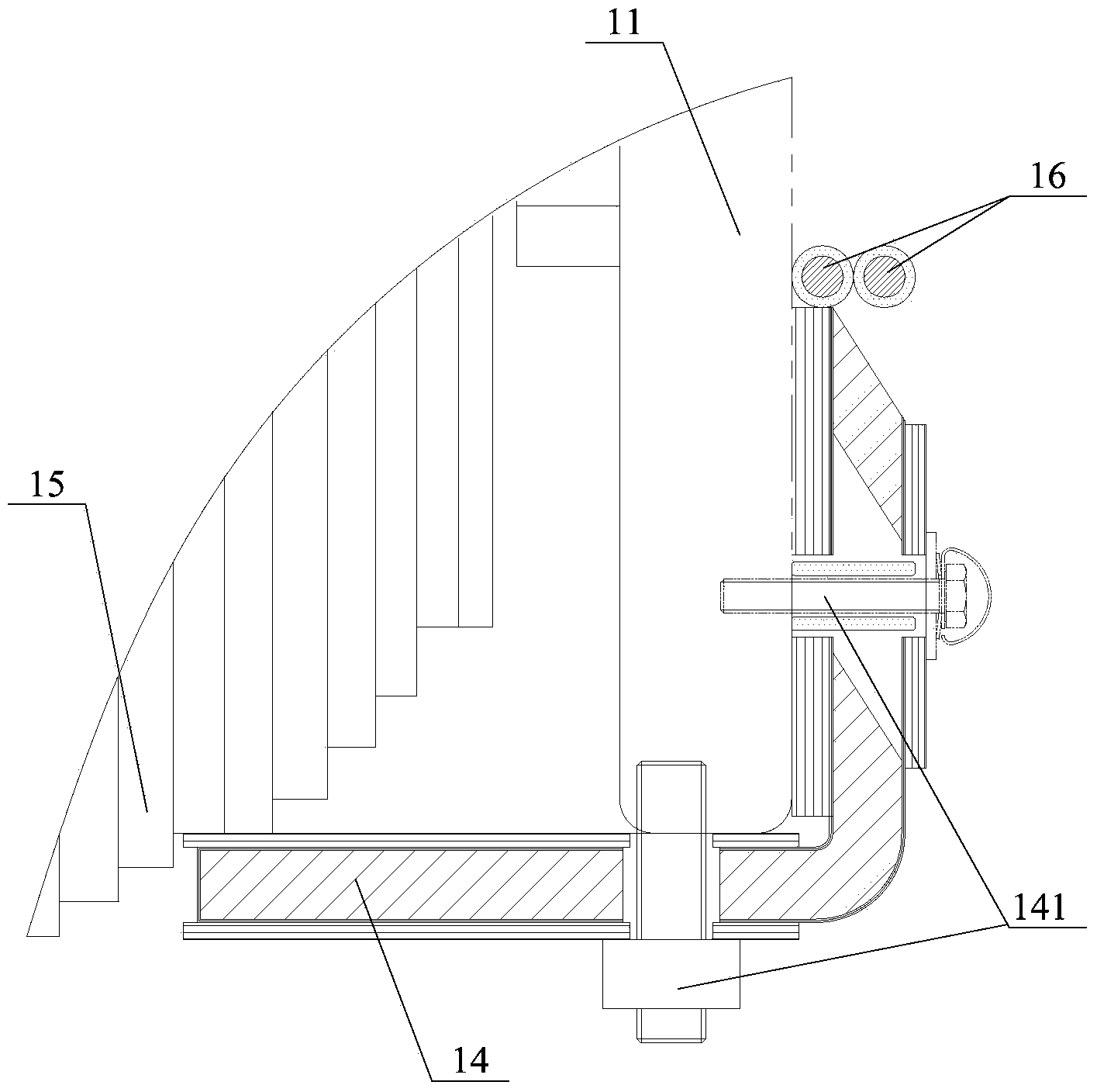

Wearable upper limb exoskeleton rehabilitation device

ActiveCN107374907AWith synergistic rehabilitationIt has the following beneficial effects: the present invention utilizes a wearable structure to realize collaborative rehabilitationChiropractic devicesEngineeringWinch

The invention provides a wearable upper limb exoskeleton rehabilitation device, which includes a fixed backboard served as a base; a driver module can make torque force transfer to each joint by Bowden cable; an exoskeleton module of elbow join is used for coupled rehabilitation movement. rehabilitative training of the elbow, coupled rehabilitation of forearm and exoskeleton of the upper arm and the exoskeleton; a mechanical hard limit device for joint, can achieve mechanical hard limit protection for a forearm connecting rod and a upper arm connecting rod; a three direction adjustable adaptive module, the position of joint winch in the shoulder adduction is adjusted to adopt different somatotype of the patients; a shoulder joint module, the shoulder joint module can achieve rehabilitation training for abduction degree of freedom in the shoulder and rehabilitation training of shoulder flexion and extension degree. The Wearable upper limb exoskeleton rehabilitation device makes use of the wearable structure to realize the free movement of patients during rehabilitation training.

Owner:SHANGHAI JIAO TONG UNIV

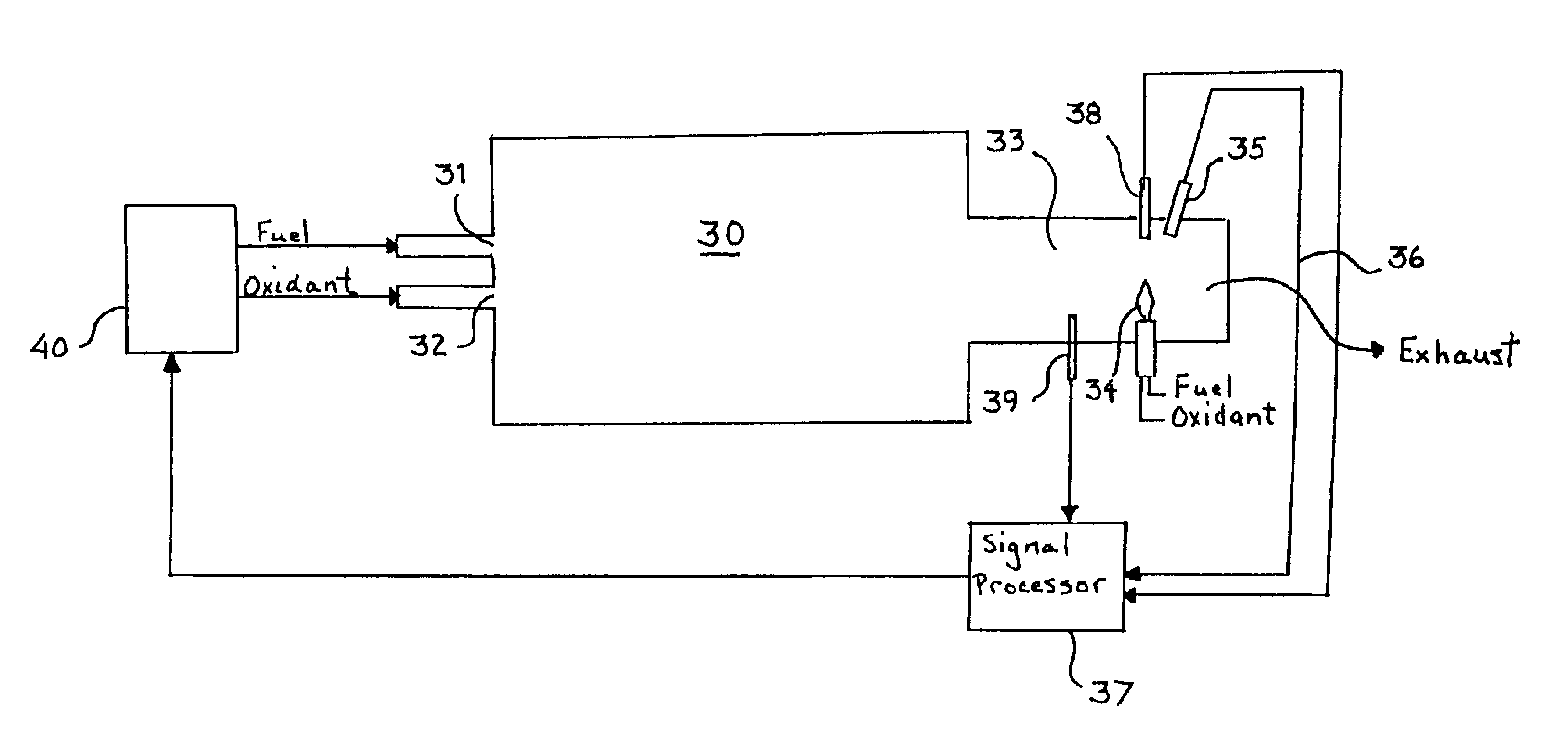

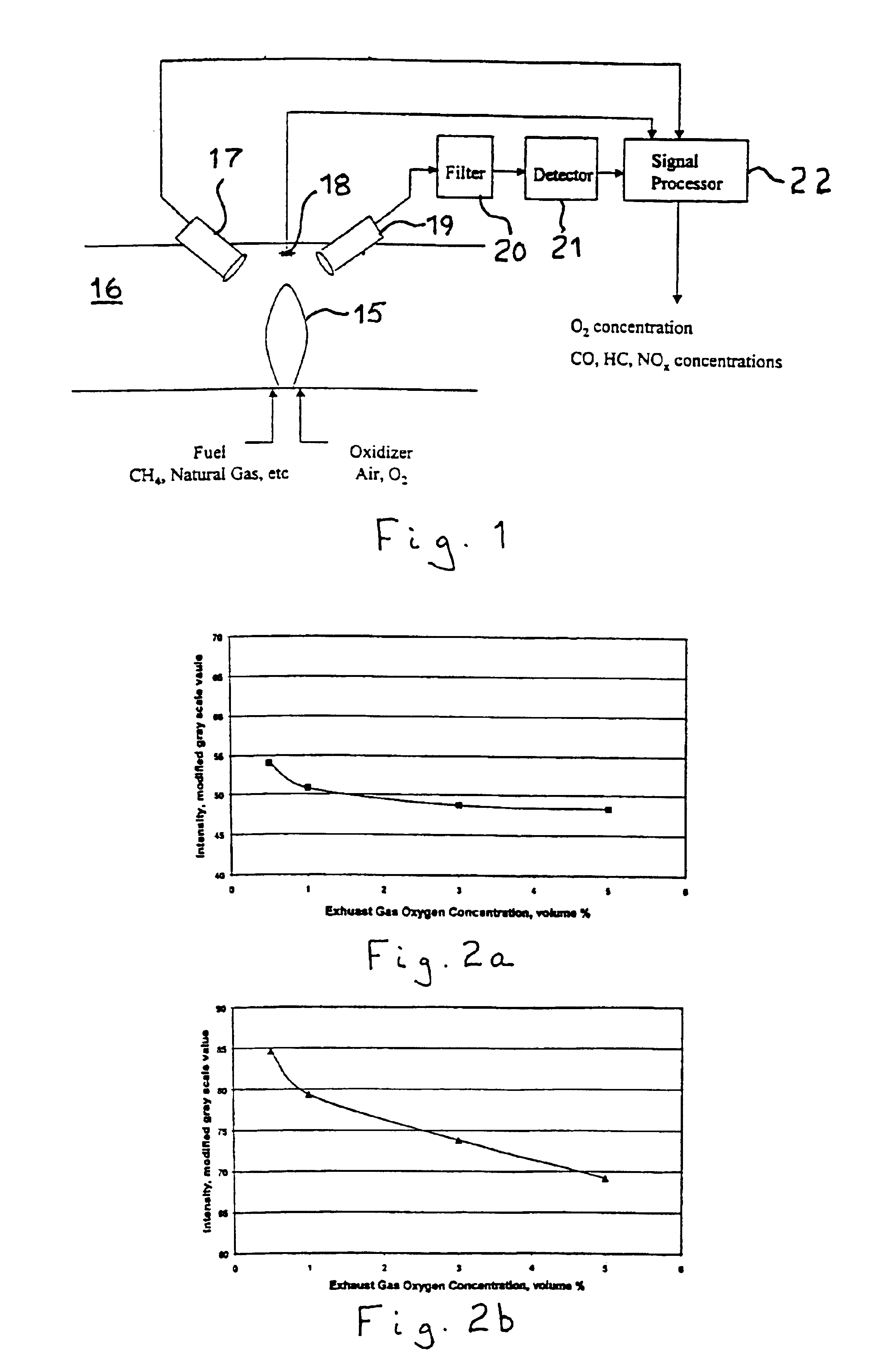

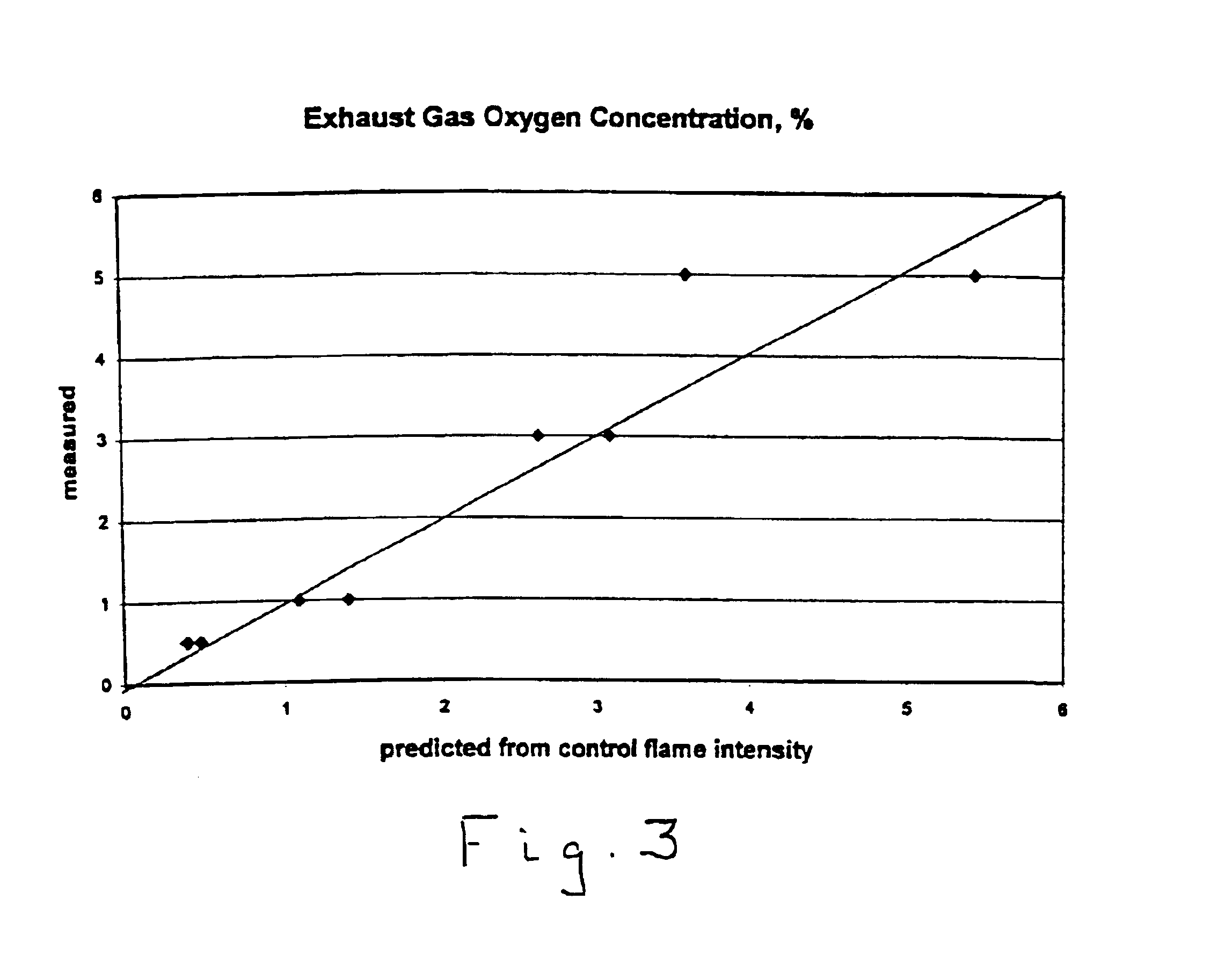

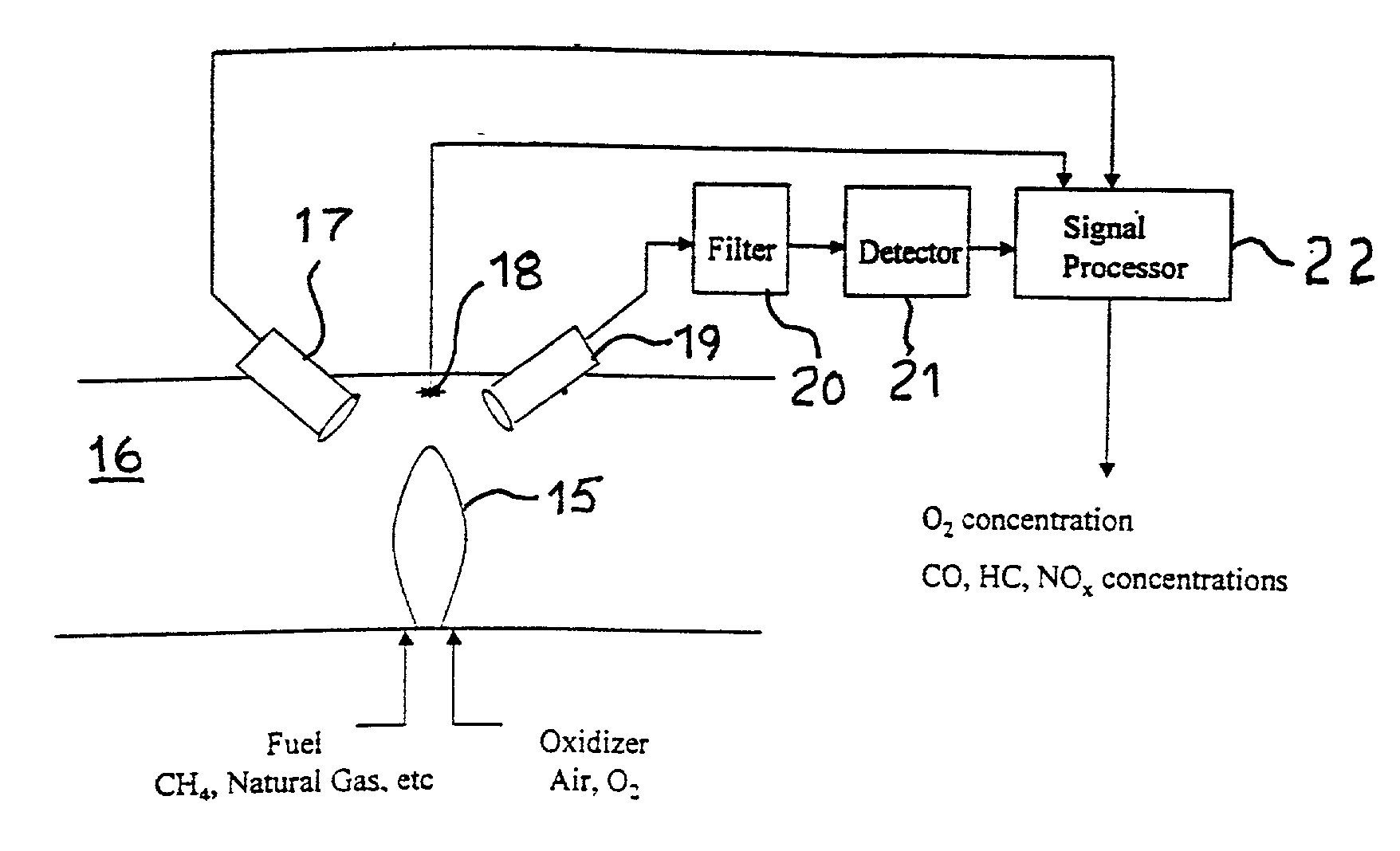

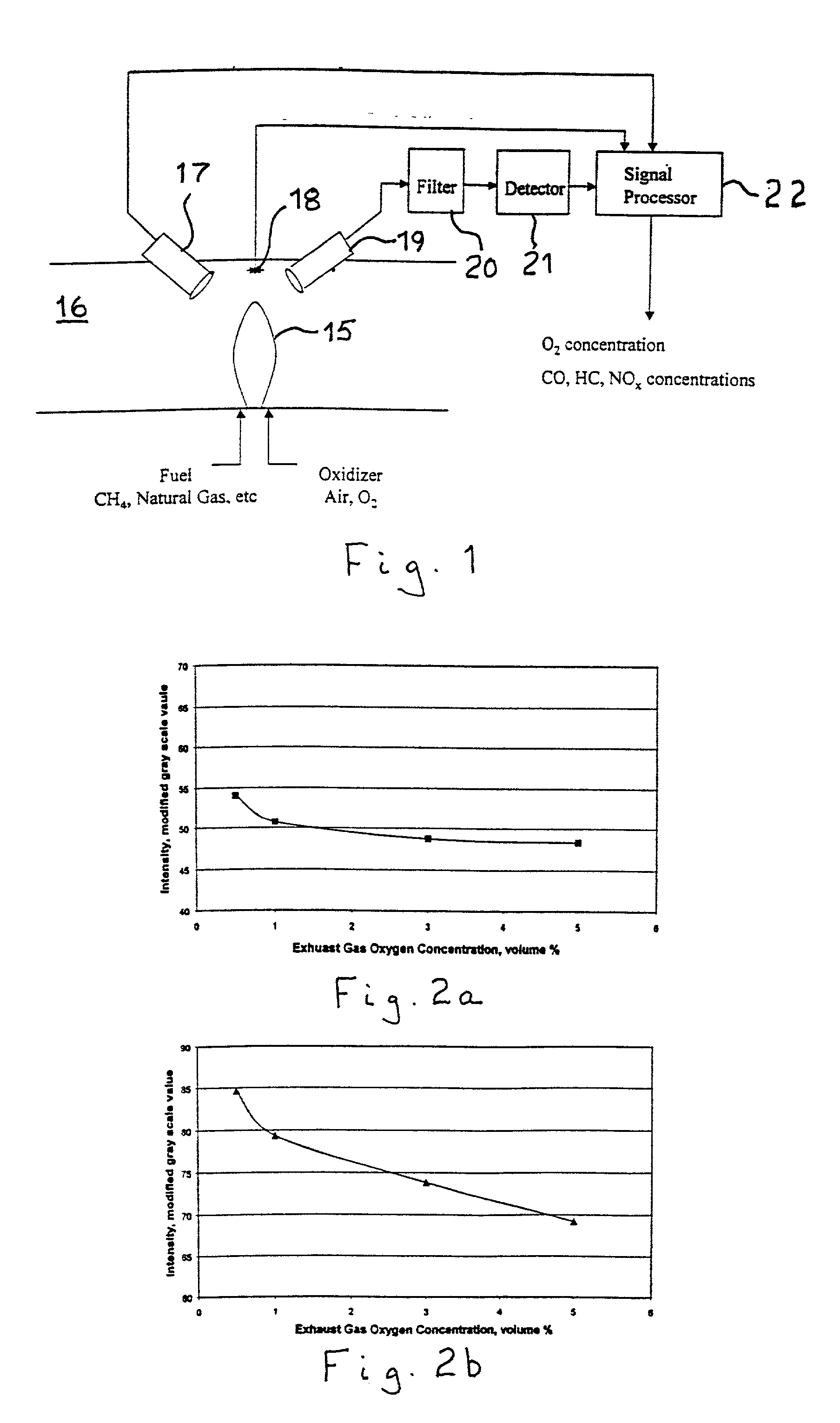

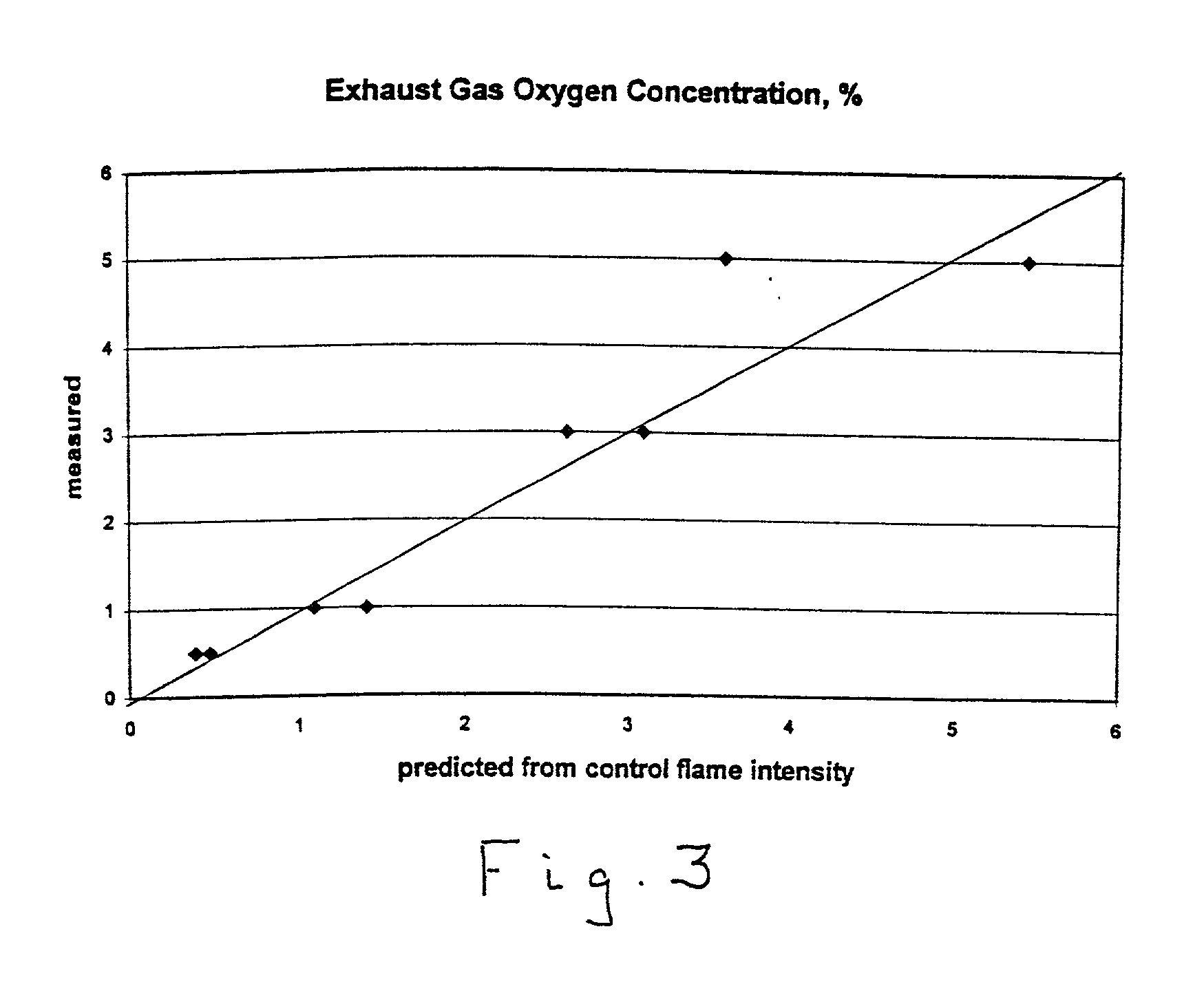

Method for measuring concentrations of gases and vapors using controlled flames

InactiveUS6780378B2Continuous and reliable operationFuel supply regulationRadiation pyrometrySpectral bandsOptical measurements

A method and apparatus for measuring the concentration of at least one gaseous component and / or vaporous component of a gaseous mixture in which a controlled sensor flame is introduced into the gaseous mixture and at least one narrow spectral band in the controlled sensor flame is optically measured. The concentration of the gaseous component using a result obtained from the optical measuring of the at least one narrow spectral band is then calculated. The method of this invention is particularly suitable for substantially real-time control of combustion processes.

Owner:GAS TECH INST

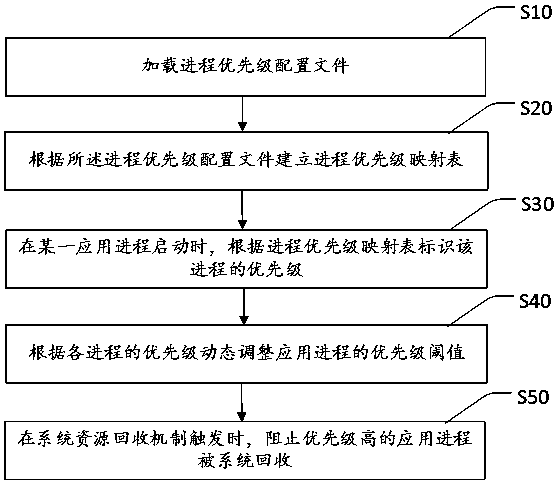

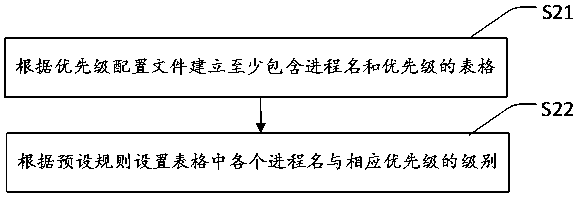

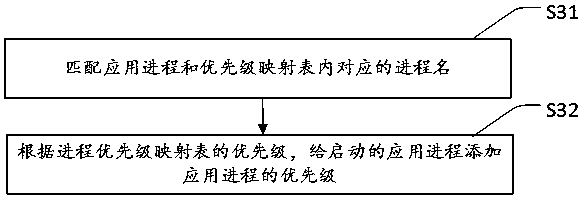

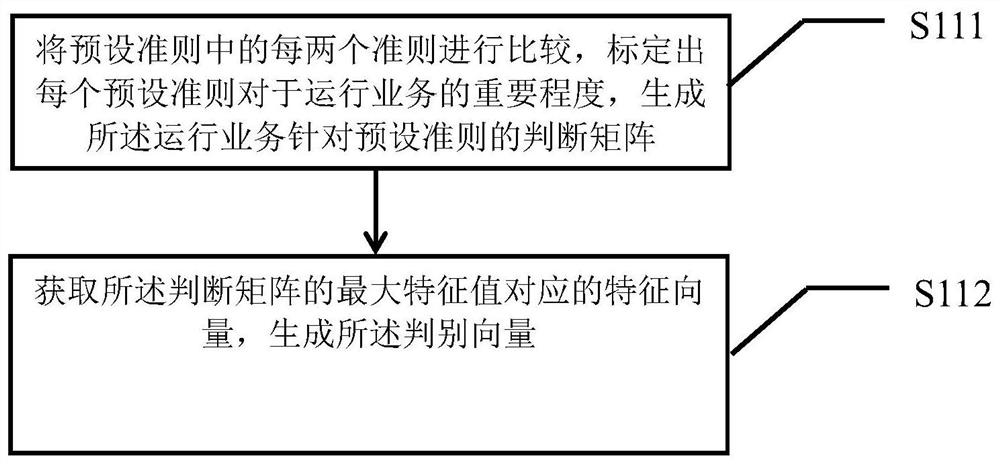

Application priority management method, device and system, and storage medium

ActiveCN107589994AContinuous and runningReliable operationProgram initiation/switchingResource allocationReal-time computingMarine navigation

The invention provides an application priority management method, device and system, and storage medium. The application priority management method comprises the steps of loading a process priority configuration file; according to the process priority configuration file, establishing a process priority mapping table; when an application process is started, marking a priority of the process according to the process priority mapping table; according to the priority of each process, dynamically adjusting a priority threshold of the application process; and when a system resource recycling mechanism is triggered, preventing the application process with the high priority from being recycled by a system. Therefore, the application process of a core function in a vehicle-mounted navigation product can be ensured not to be recycled by the system in a long-time running process; and the core function of the vehicle-mounted navigation product is ensured to continuously and reliably run.

Owner:SHENZHEN APICAL TECH CO LTD

Method for measuring concentrations of gases and vapors using controlled flames

InactiveUS20030003590A1Continuous and reliable operationFuel supply regulationRadiation pyrometryPhysicsOptical measurements

A method and apparatus for measuring the concentration of at least one gaseous component and / or vaporous component of a gaseous mixture in which a controlled sensor flame is introduced into the gaseous mixture and at least one narrow spectral band in the controlled sensor flame is optically measured. The concentration of the gaseous component using a result obtained from the optical measuring of the at least one narrow spectral band is then calculated. The method of this invention is particularly suitable for substantially real-time control of combustion processes.

Owner:GAS TECH INST

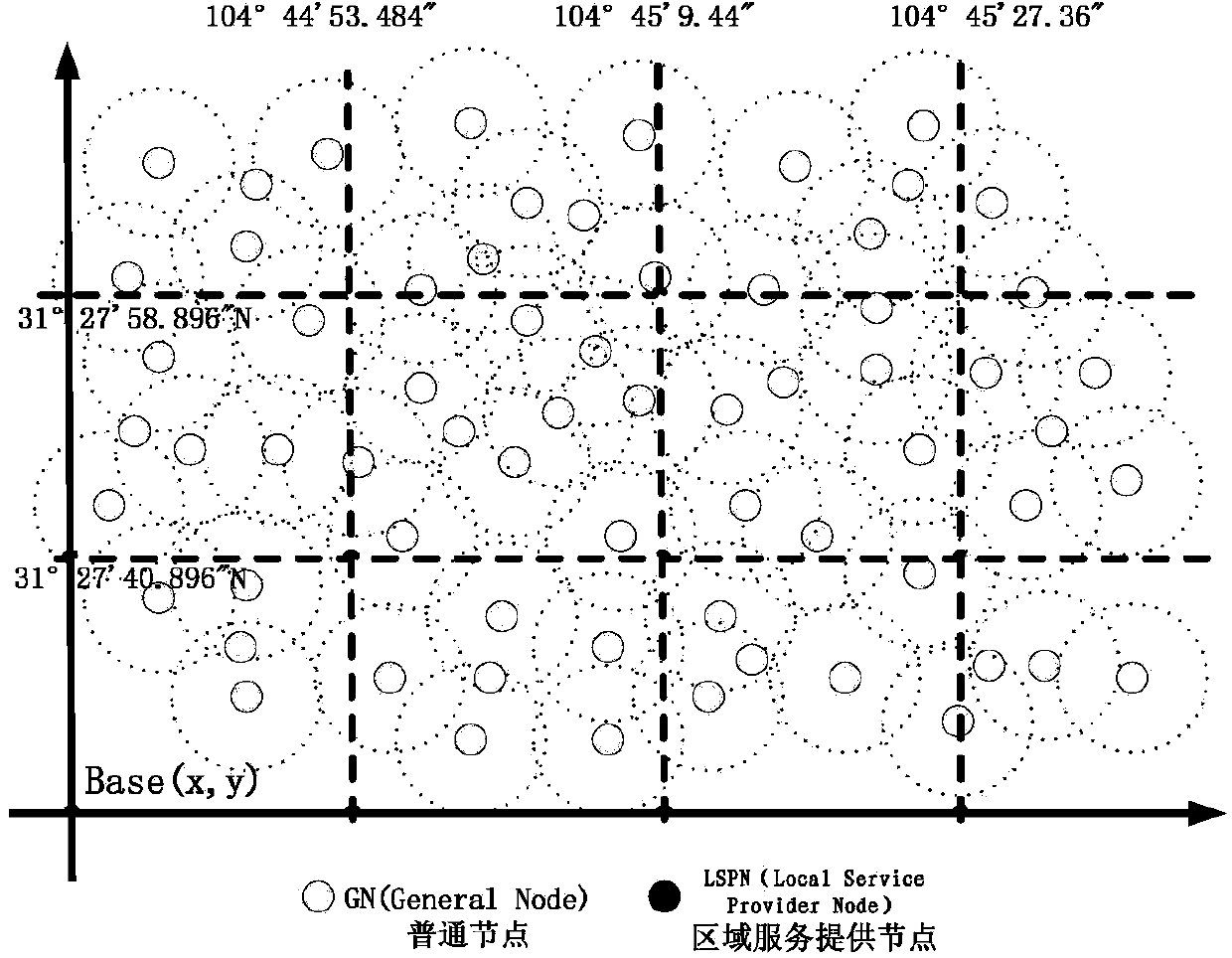

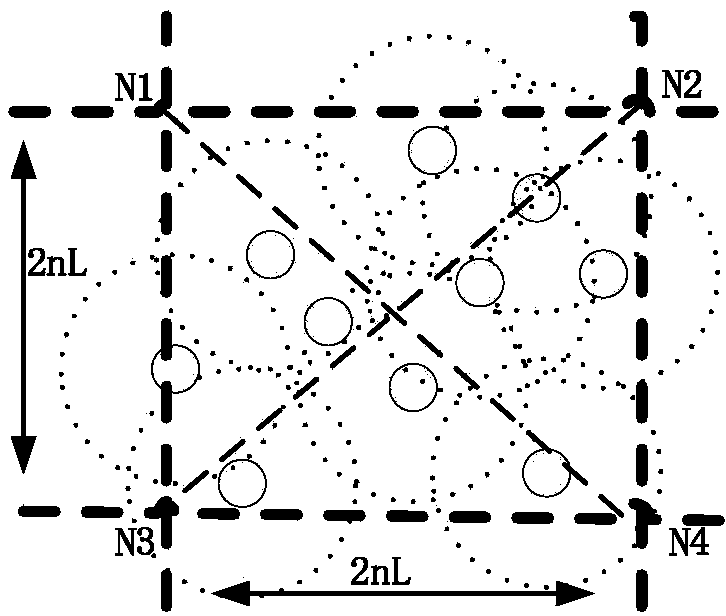

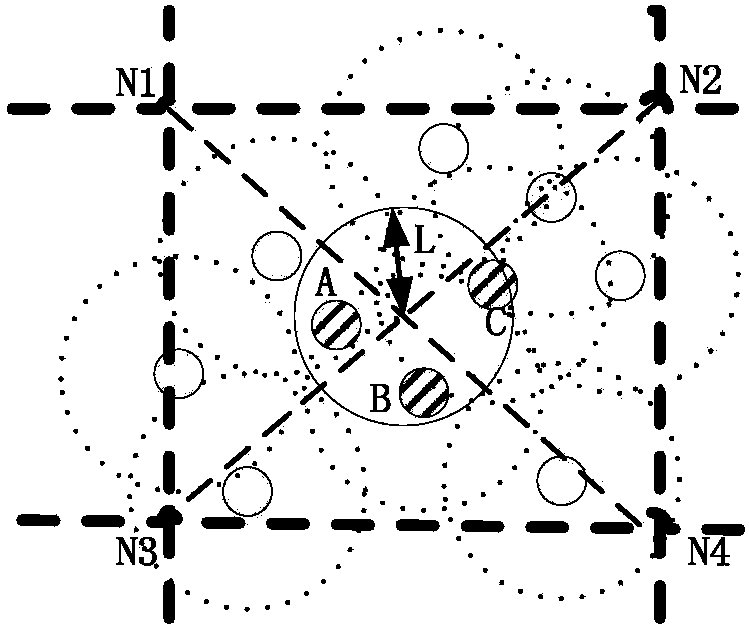

Mobile self-organizing network interrupt data recovery method based on area perception

ActiveCN103813364AReduce overheadReduce latencyNetwork topologiesInformation recoveryNetwork communication

The invention belongs to a network communication data processing method, and particularly relates to a mobile self-organizing network interrupt data recovery method based on area perception. The mobile self-organizing network interrupt data recovery method based on the area perception includes following steps: step 1) initializing a network and performing dynamical initial allocation on area service providing nodes; step 2) dynamically maintaining and routing the area service providing nodes; step 3) performing routing among normal nodes and between each normal node and each area service providing node; step 4) storing and recovering interrupt information of network nodes. The mobile self-organizing network interrupt data recovery method based on the area perception uses global position system (GPS) positioning technology to obtain area distribution of the network nodes and accordingly achieves division of network areas, sets up the area service providing node for each network subsidiary area, and simultaneously uses the area service providing nodes to complete collection, storage and retransmission of transmission interruption data packets in the areas which are respectively corresponding to the area service providing nodes, and accordingly achieves information recovery of the interruption data packets, and furthermore solves the problem that business data among the nodes is lost under a large scale complex mobile wireless self-organizing network environment.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

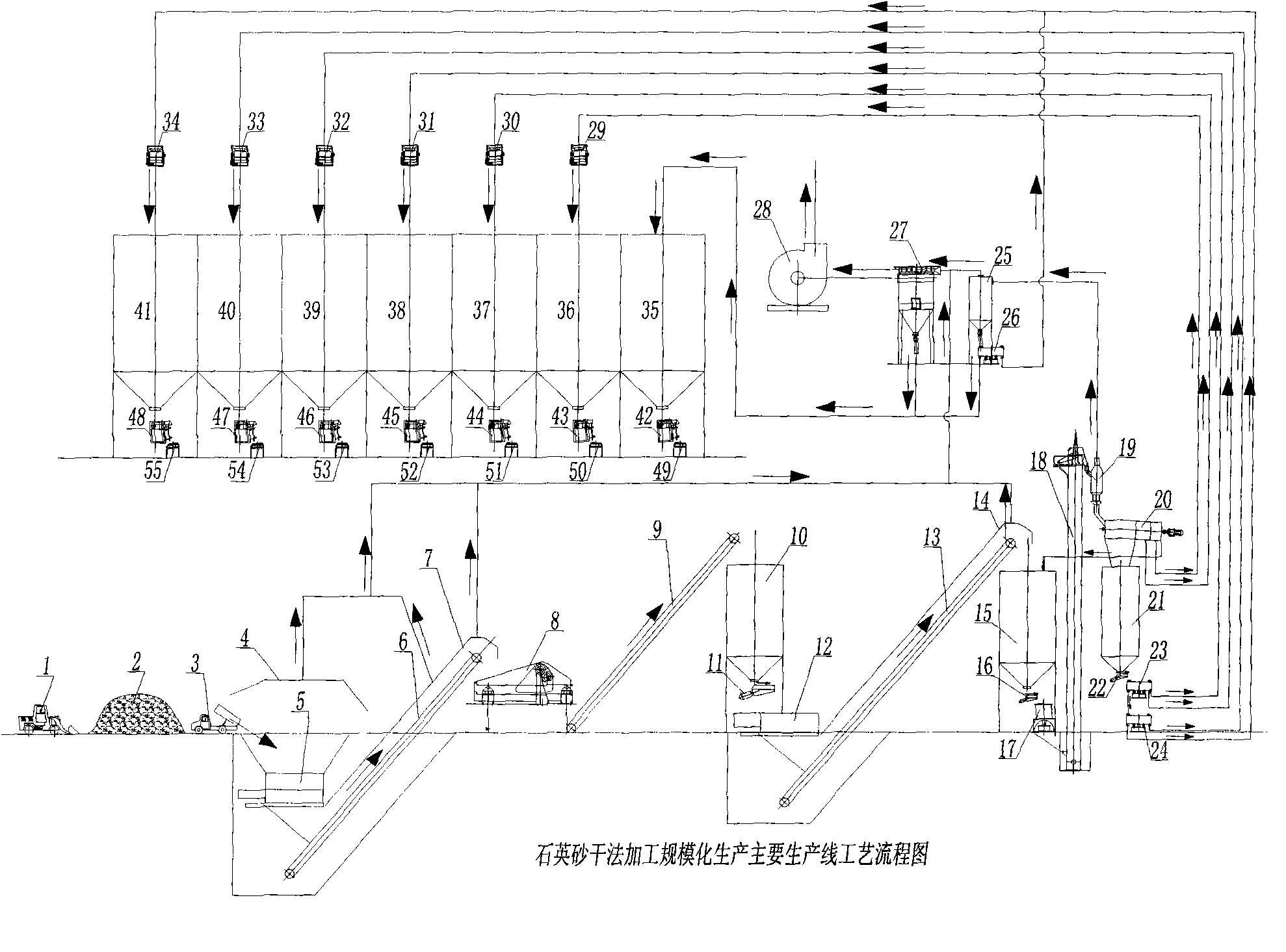

Dry process scale continuous production process of quartz sand

InactiveCN102211854AIncrease productionReduce manual labor intensityGas current separationGlass shaping apparatusProcess scaleProcess engineering

The invention discloses a dry process scale continuous production process of quartz sand, which comprises the process steps of quartz ore breaking and crushing, product grading, packaging and transportation, dust pollution treatment and the like. In the process step of the quartz ore breaking, a two-grade screening type breaker is adopted, and a cleaning dewatering screen and a broken stone drying tower are arranged between two grades of screening and breaking; in the process step of quartz ore crushing, a single-stage HK type sand making machine is adopted, and single-group production or multi-group parallel production can be performed from the HK type sand making machine to the finished product delivery after screening and grading. In the process step of product grading, the mode combining air classification and sieve classification is adopted, namely the process step of single-stage air classification, single-stage drum screen classification and two-stage rotation movable screeningmachine classification is adopted, wherein the air classification adopts negative pressure classification to realize comprehensive functions of separation and dust removal. In the process step of packaging and transportation, a production process in which a plurality of machine sets are connected in parallel is adopted, and the same product is collected and conveyed to a finished product storage bin by the same conveyor to realize the integration of packaging and shipping.

Owner:李立和 +1

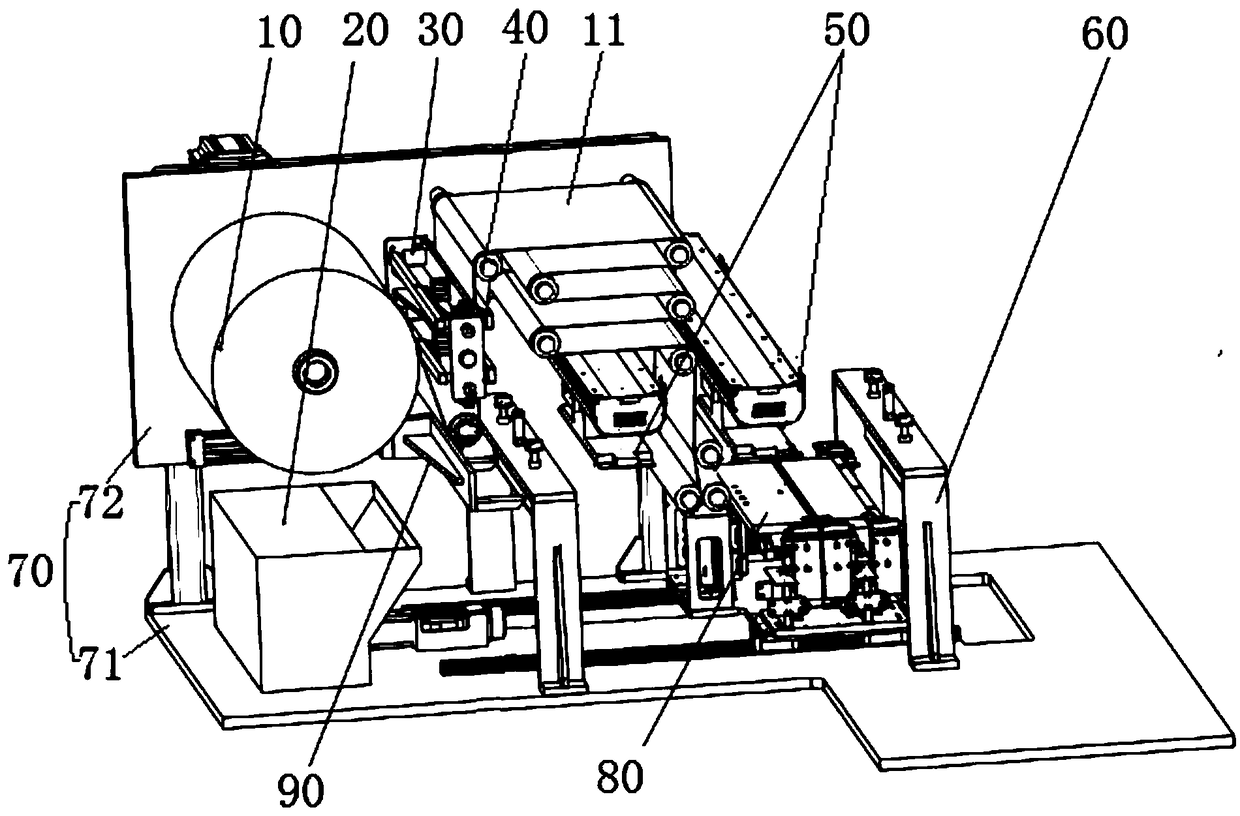

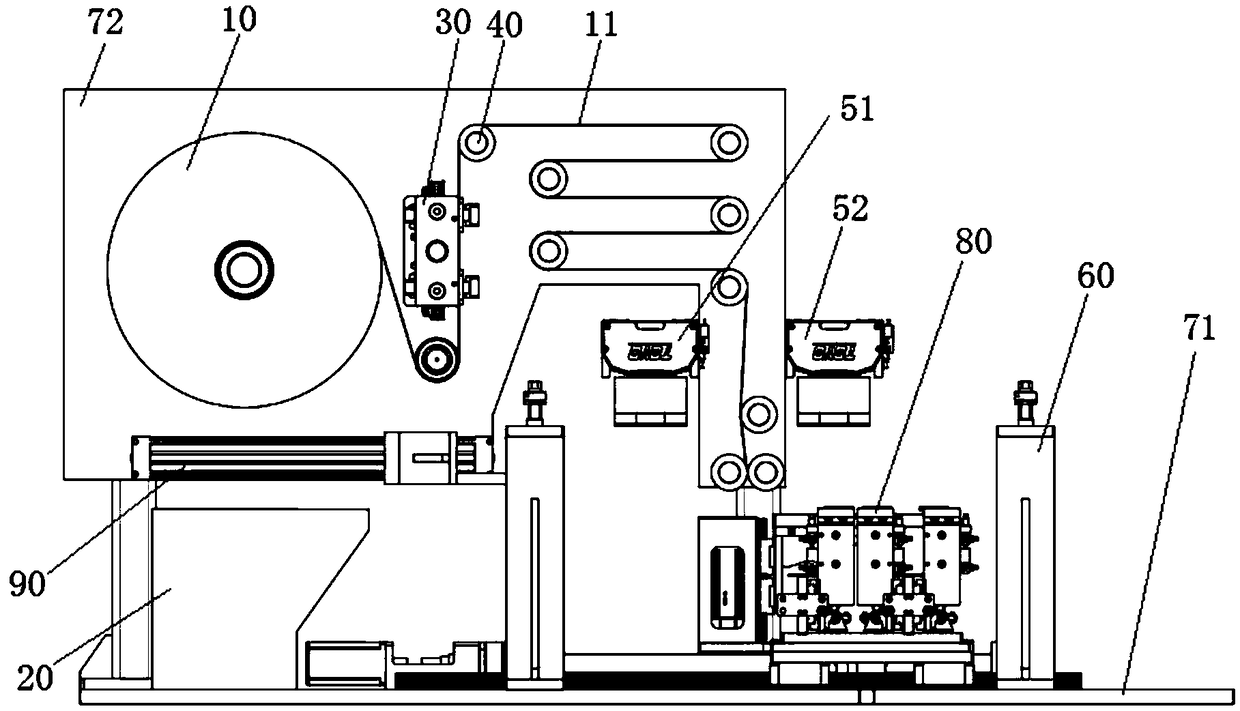

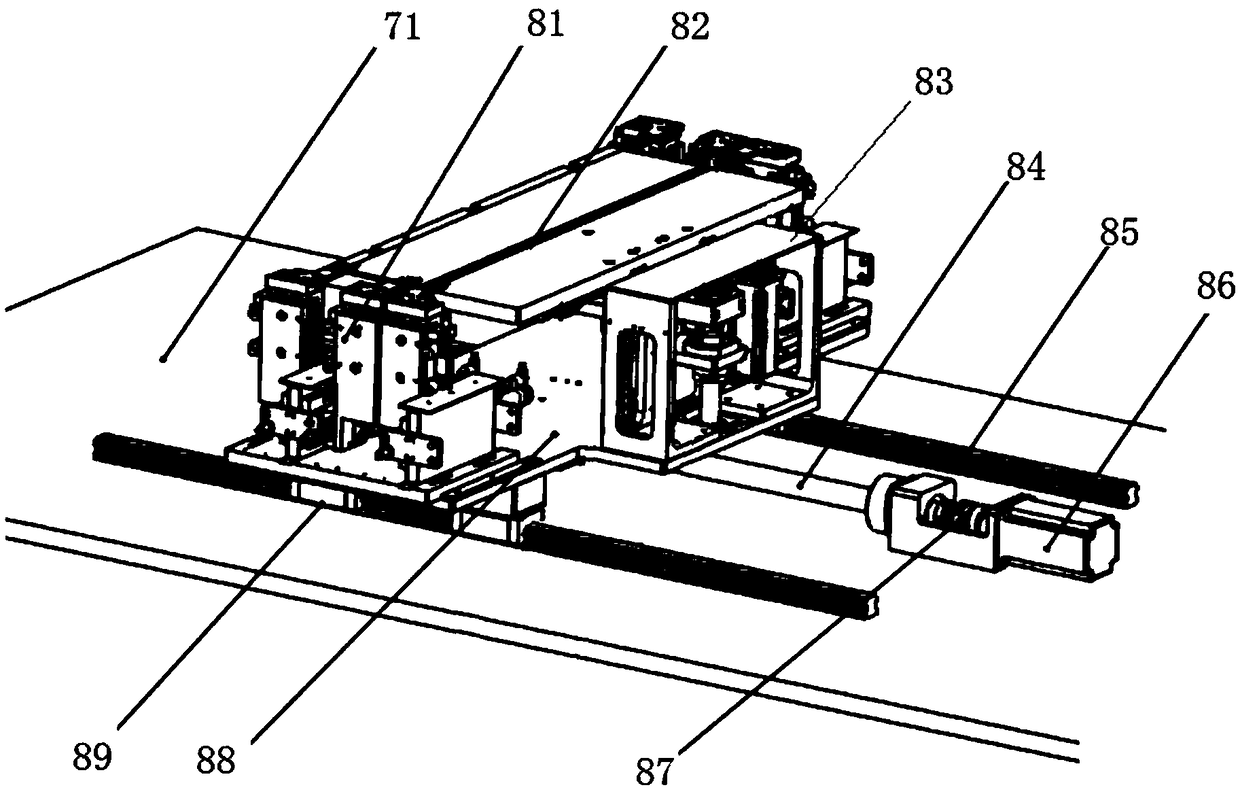

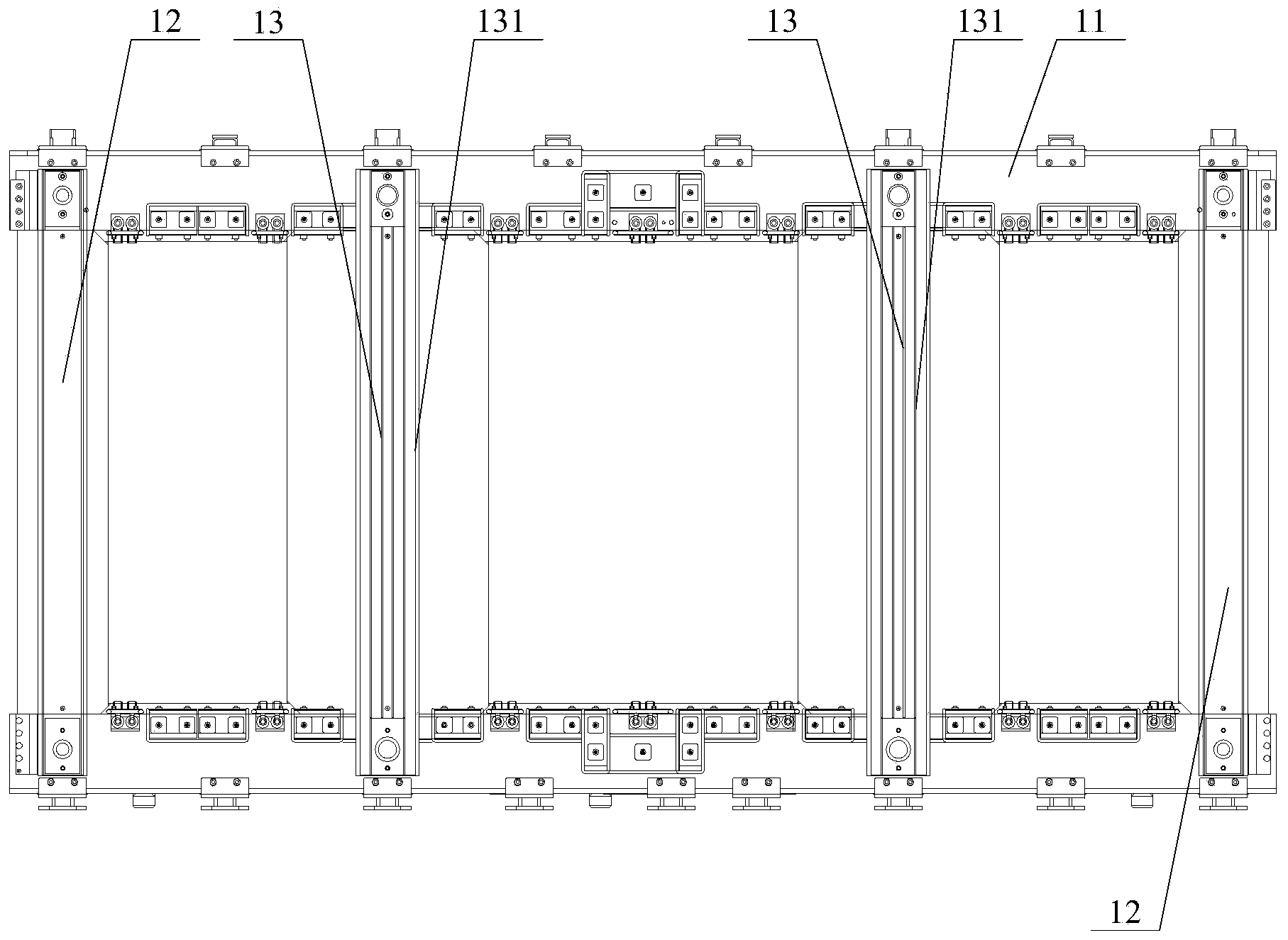

Automatic lamination mechanism of Z-type laminated battery core

ActiveCN109390635AContinuous and reliable operationRealize automated productionFinal product manufactureSecondary cellsScrapContinuous operation

The invention discloses an automatic lamination mechanism of a Z-type laminated battery core, the automatic lamination mechanism comprises a bracket composed of a bottom plate and a side plate, wherein the side plate is fixedly provided with a diaphragm unwinding mechanism, and a traction group used for controlling the tension and the deviation of a diaphragm, the bottom plate is slidably connected with a lamination table, and a cutting mechanism is fixed on the bottom plate; the side plate above the lamination table is fixedly provided with two pole piece manipulators for respectively placingpositive and negative pole pieces; the lamination table includes a work table and pressing holding members which are symmetrically disposed at both ends of the work table and used for pressing and holding of the work table, a lifting mechanism is connected to one side of the work table by a supporting frame, the pressing member, and the pressing holding members and the lifting mechanism are fixedon a moving plate to achieve horizontal movement. The automatic lamination mechanism realizes the automatic continuous operation of automatic cutting, tiling, splicing, automatic discharging and thelike of the diaphragm by a mechanical means, and realizes the cutting and tiling of the diaphragm by the pressing holding members, ensures that the diaphragm is automatically flattened after each electric core is made to achieve continuous automated production.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Ultra-wideband radar sensors and networks

InactiveUS8502729B2Long monitoring capabilityContinuous and reliable operationLoop antennasRadio wave reradiation/reflectionUltra wideband radarWireless ad hoc network

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

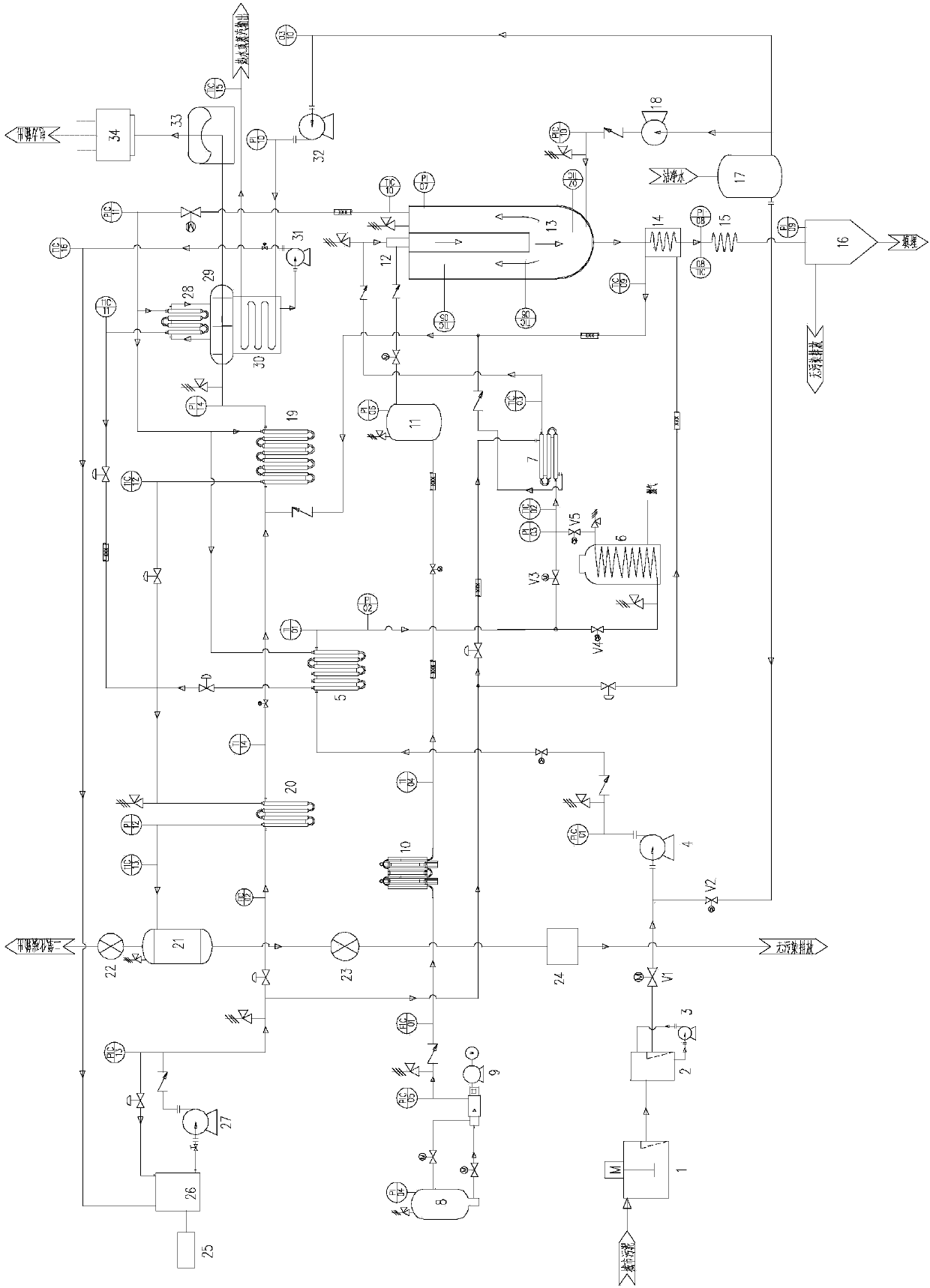

Supercritical water oxidation treatment and generation system of municipal sludge having high-solid content

ActiveCN103626364ALow running costOvercome corrosion and clogging problemsSludge treatment by oxidationSteam engine plantsSaline waterInorganic salts

The invention discloses a supercritical water oxidation treatment and generation system of municipal sludge having high-solid content. The municipal sludge having high-solid content orderly enters a filter basin and a homogenizing basin to carry out pretreatment, and then is transported to the system to carry out supercritical water oxidation treatment by using a high-pressure diaphragm pump; high-temperature fluid after reaction is fully utilized to preheat feedstock when the system runs. Surplus heat generates super-high pressure steam to generate electricity by adopting a low oxidation coefficient; a supercritical zone is arranged at the upper part of a reactor; a subcritical zone is arranged at the lower part of the reactor; an inorganic salt separated out from the supercritical zone at the upper part of the reactor falls into the subcritical zone at the lower part of the reactor to be dissolved again by virtue of inertia and gravity; strong brine containing solid (insoluble salt) orderly enters a cooler and a capillary step-down transformer for cooling and decompression.

Owner:XI AN JIAOTONG UNIV

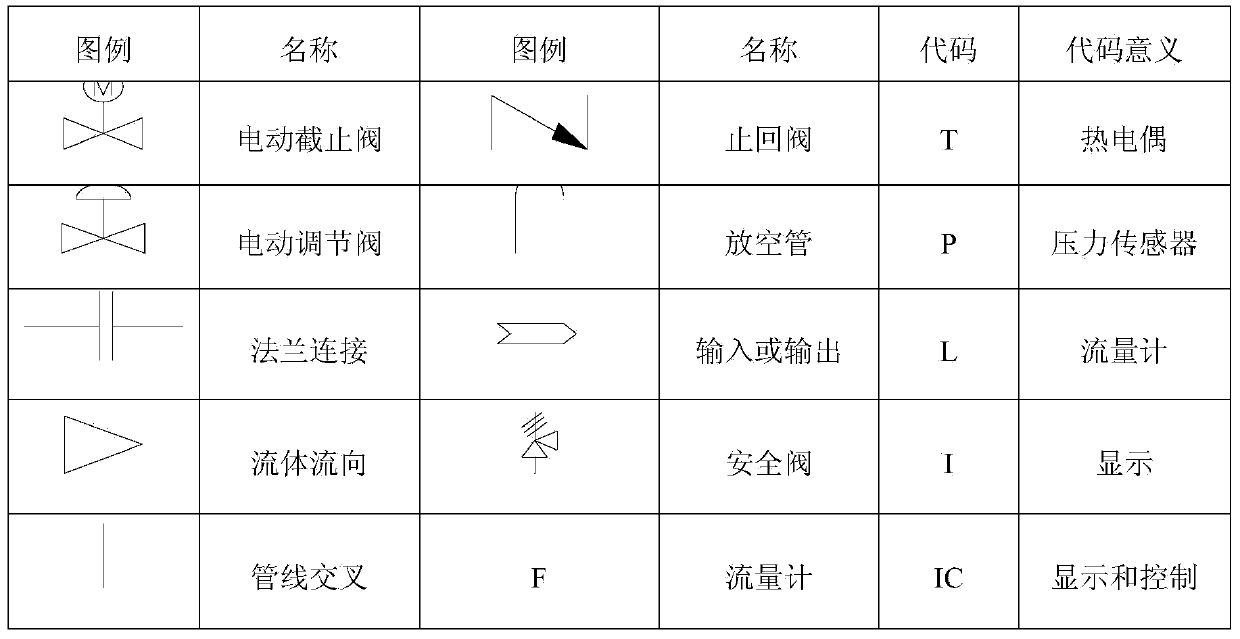

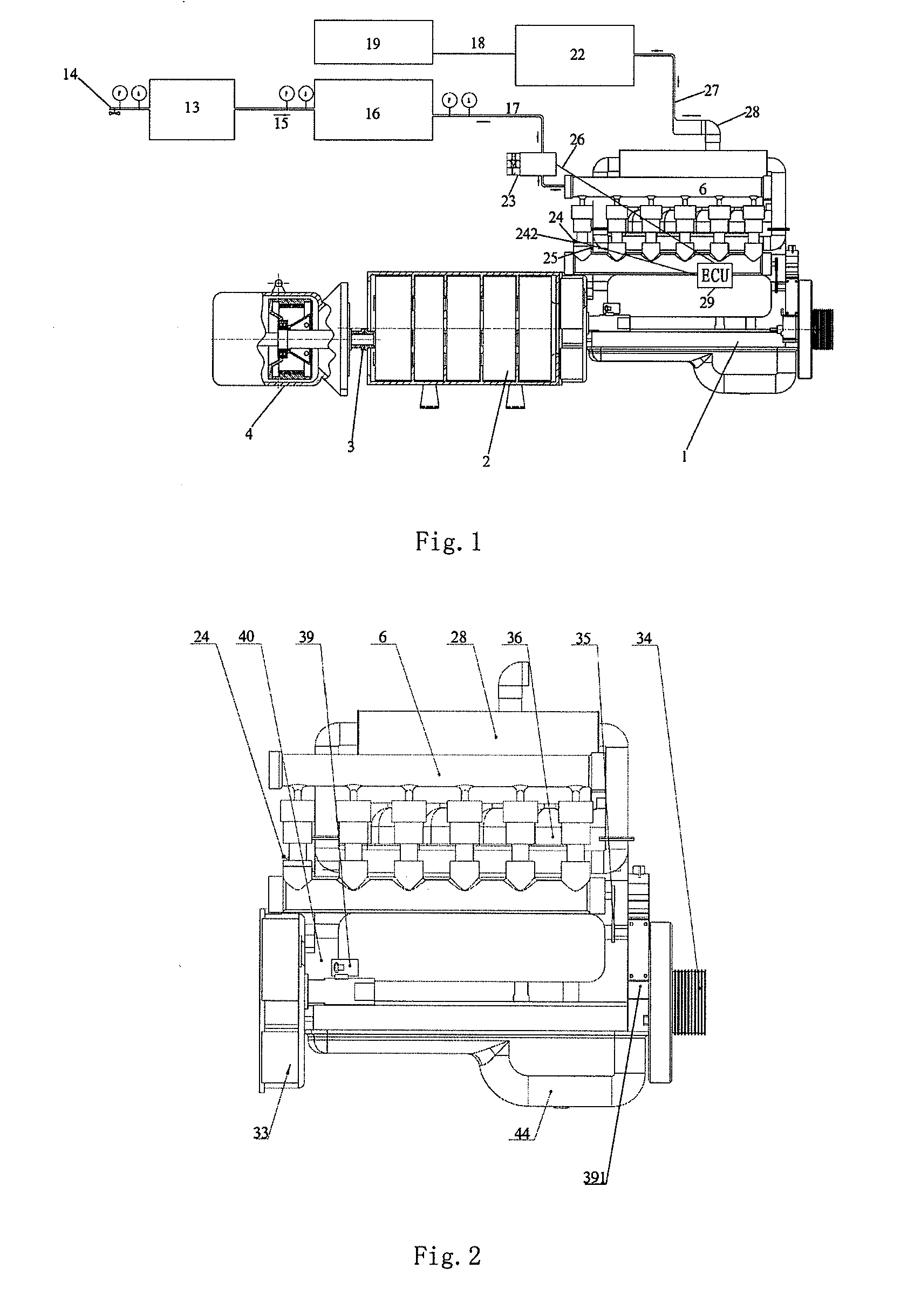

Two-stroke air-powered engine assembly

InactiveUS20140224234A1Continuous and reliable operationEffective distributionCombustion enginesSafety/regulatory devicesElectronic control unitPower equipment

A two-stroke air-powered engine assembly uses compressed air as a power source. The two-stroke air-powered engine includes an engine body (1), a multiple-column power distributor (2), a power equipment (4), a controller system (6), an intake speed control valve (23), a high pressure gas tank set (13), a constant pressure tank (16), and an electronic control unit ECO (29).

Owner:BEIJING XIANGTIAN HUACHUANG AERODYNAMIC FORCE TECH RES INST

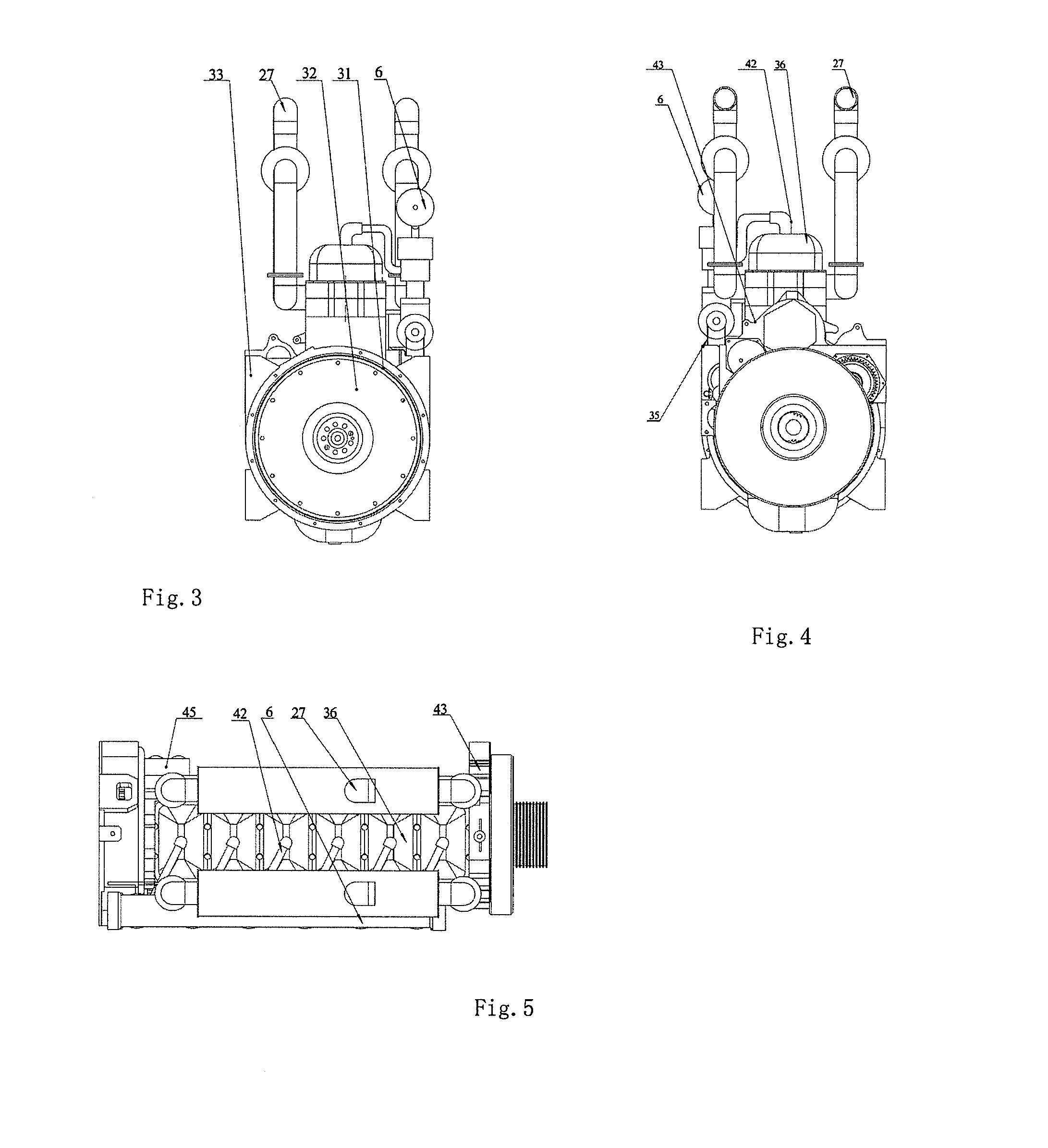

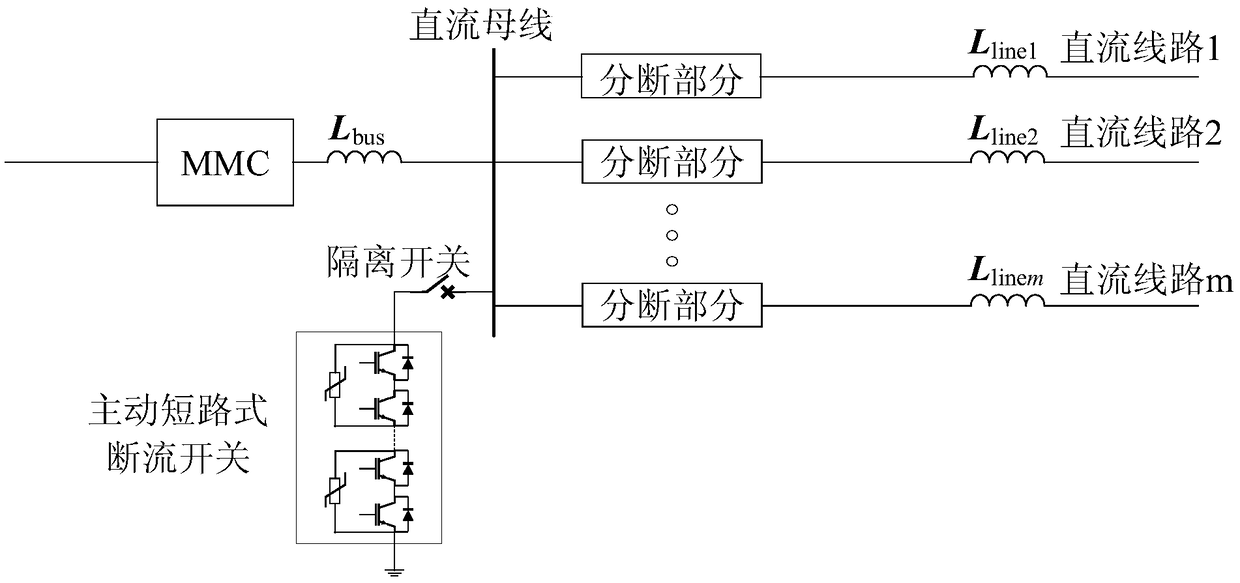

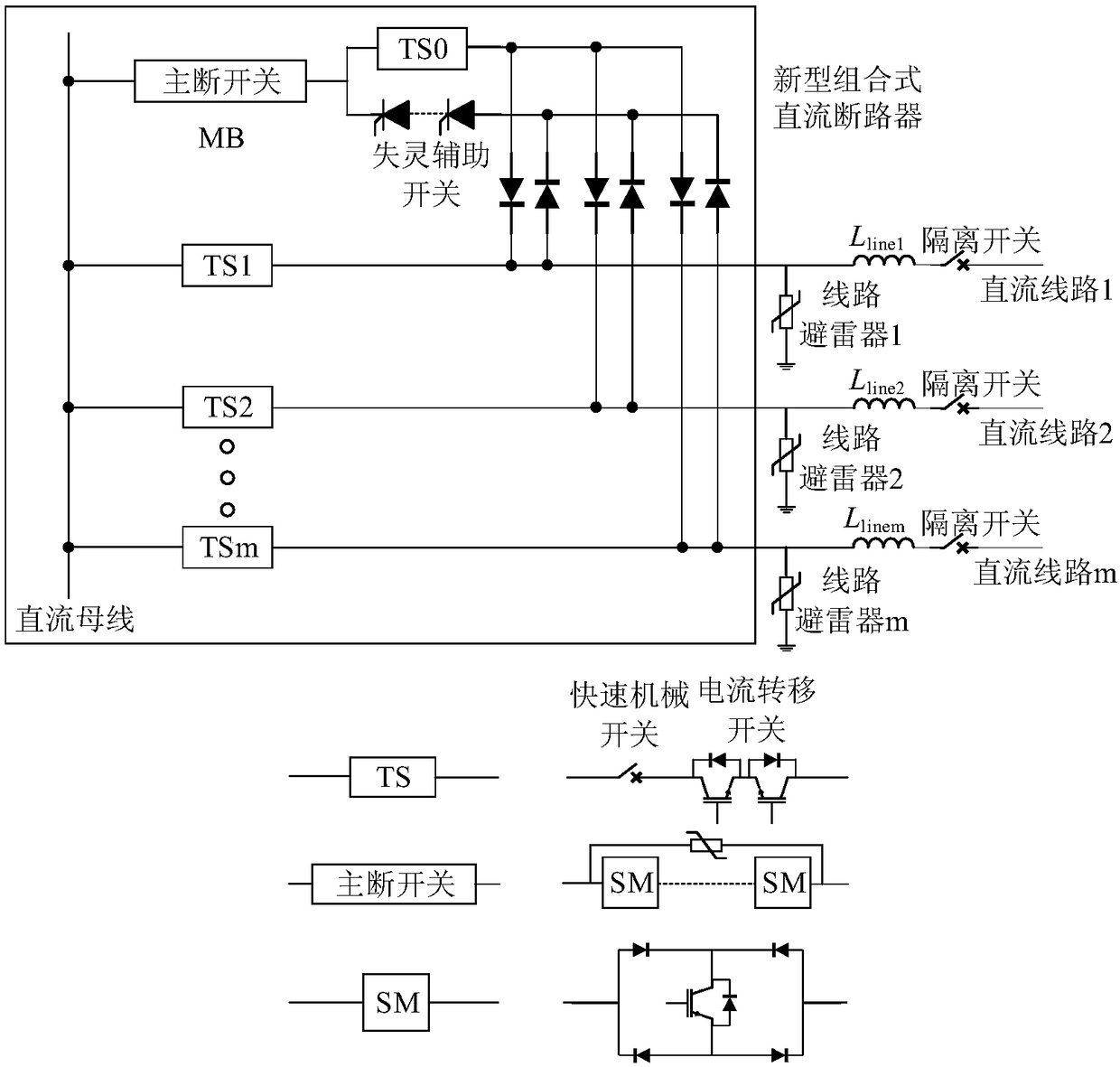

A novel combined DC circuit breaker topology

ActiveCN109193625AImprove economyReduce breakdown rateEmergency protective arrangements for automatic disconnectionEmergency protective arrangements for limiting excess voltage/currentDc circuit breakerTransfer switch

The invention discloses a novel combined DC circuit breaker topology, which adopts only one main breaker switch, one malfunctioning auxiliary switch, one transfer switch TS0 connected in series with the main breaker switch, two groups of diodes in different directions, and a transfer switch TS1 corresponding to m lines on each DC bus bar, wherein, the main breaker switch TS0 is connected with themain breaker switch TS0, and the main breaker switch TS1 is connected with the main breaker switch TS0-TSm. The transfer switch TS0 is connected in parallel with the failed auxiliary switch in serieswith the main disconnect switch, one end of the main disconnect switch is connected with the DC bus bar, the other end is connected with the diode group in the direction of the inflow line through thetransfer switch TS0, and is also connected with the diode group in the direction of the outflow line through the failed auxiliary switch. The transfer switch TS1-TSm is respectively connected to thebus bar and the corresponding line 1-Line m. When the system is in normal operation, the voltage on both ends of the switches of each part of the novel combined DC circuit breaker is zero, which can effectively reduce the breakdown probability of the device, improve the operation reliability of the system as a whole, adopt fewer main devices, and have better economy.

Owner:SOUTH CHINA UNIV OF TECH

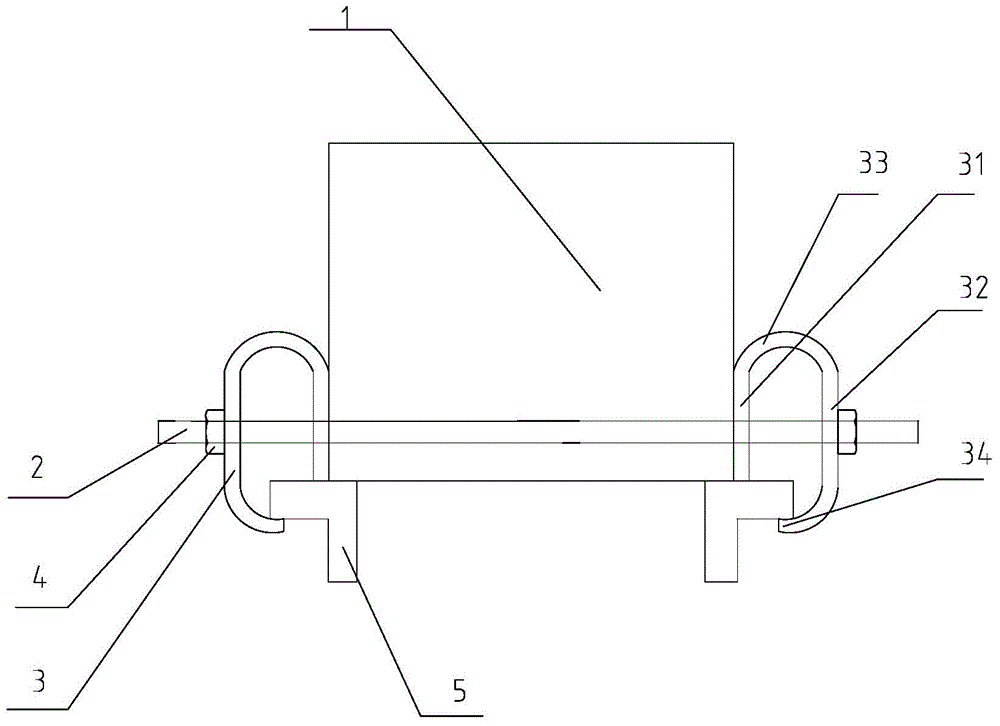

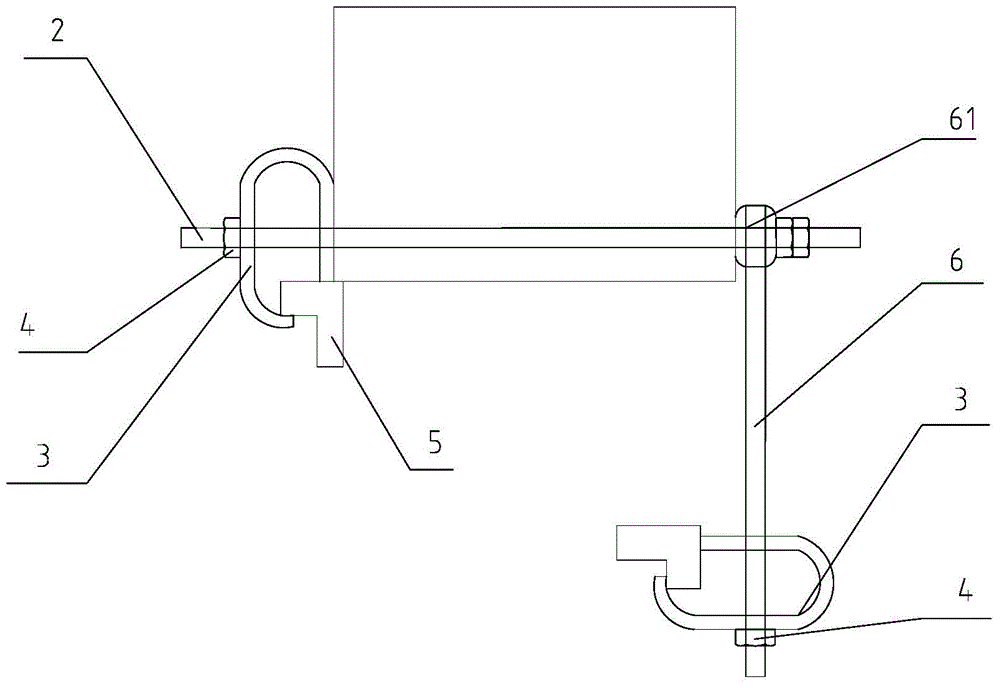

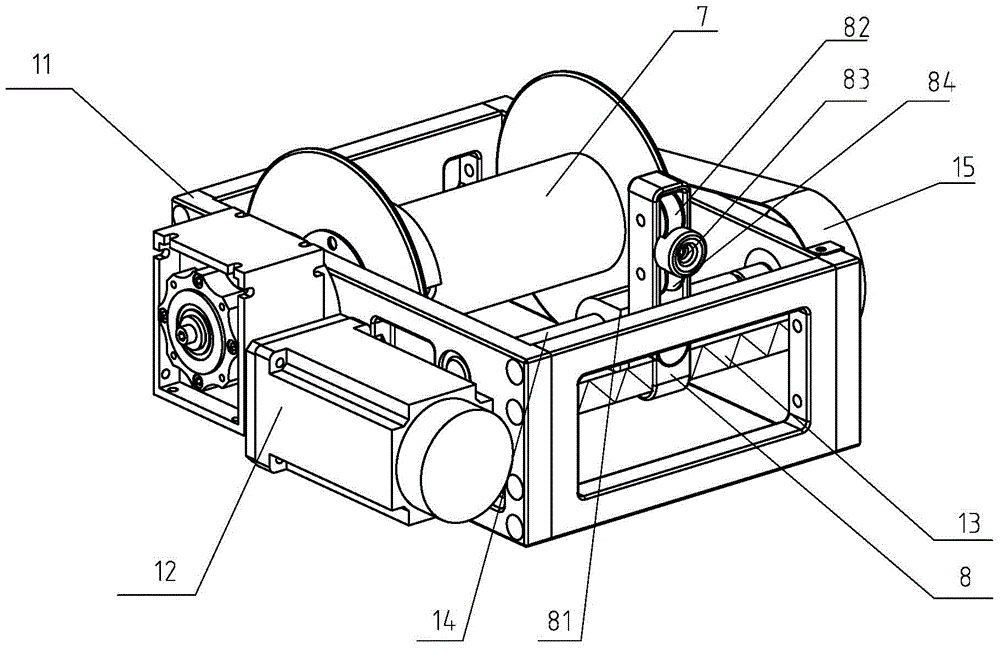

Electric winch for power transmission line

InactiveCN104659708AContinuous and reliable operationRunning state, to ensure reliable and continuous power supply to usersApparatus for overhead lines/cablesPower gridTower

The invention discloses an electric winch for a power transmission line, belongs to the field of power grids and solves the technical problems in the prior art that during maintenance operation of a power transmission line, a hoisting tool is difficult to mount and low in security. The electric winch for the power transmission line comprises a winching machine and a fixture used for fixing the winching machine on a crossarm of a power transmission line, wherein connection holes are formed in the winching machine; the fixture comprises a cross rod and chucks; the cross rod is connected with the connection holes; a mounting hole connected with the cross rod in a sliding manner is formed in each of the chucks; a bent clamping hook is arranged at the bottom of each of the chucks; the clamping hooks correspond to angle iron of the crossarm; locknuts are in threaded connection with the cross rod and compress the chucks on the angle iron. The electric winch is applied to the power field, particularly to maintenance operation of iron tower lines.

Owner:STATE GRID CORP OF CHINA +1

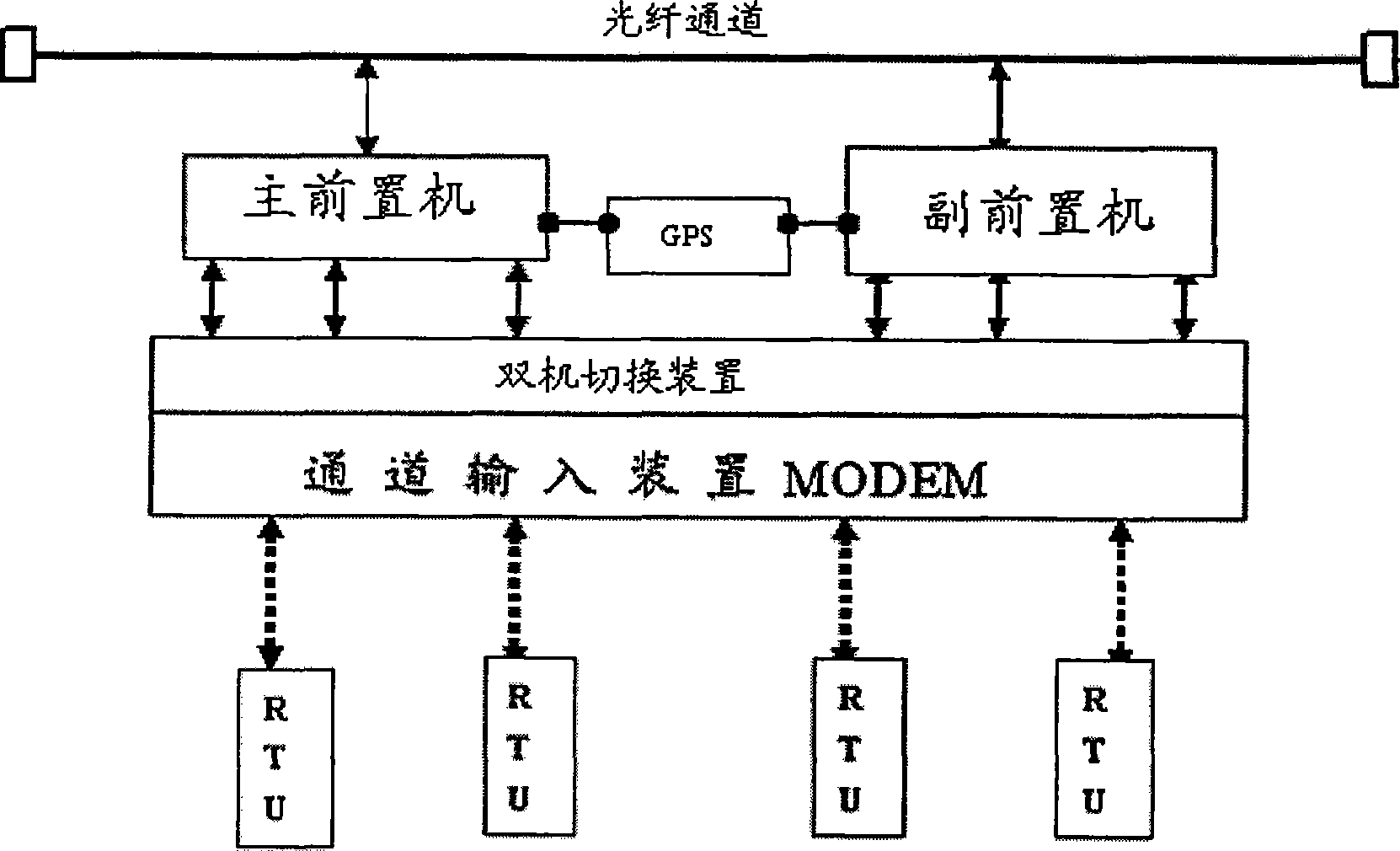

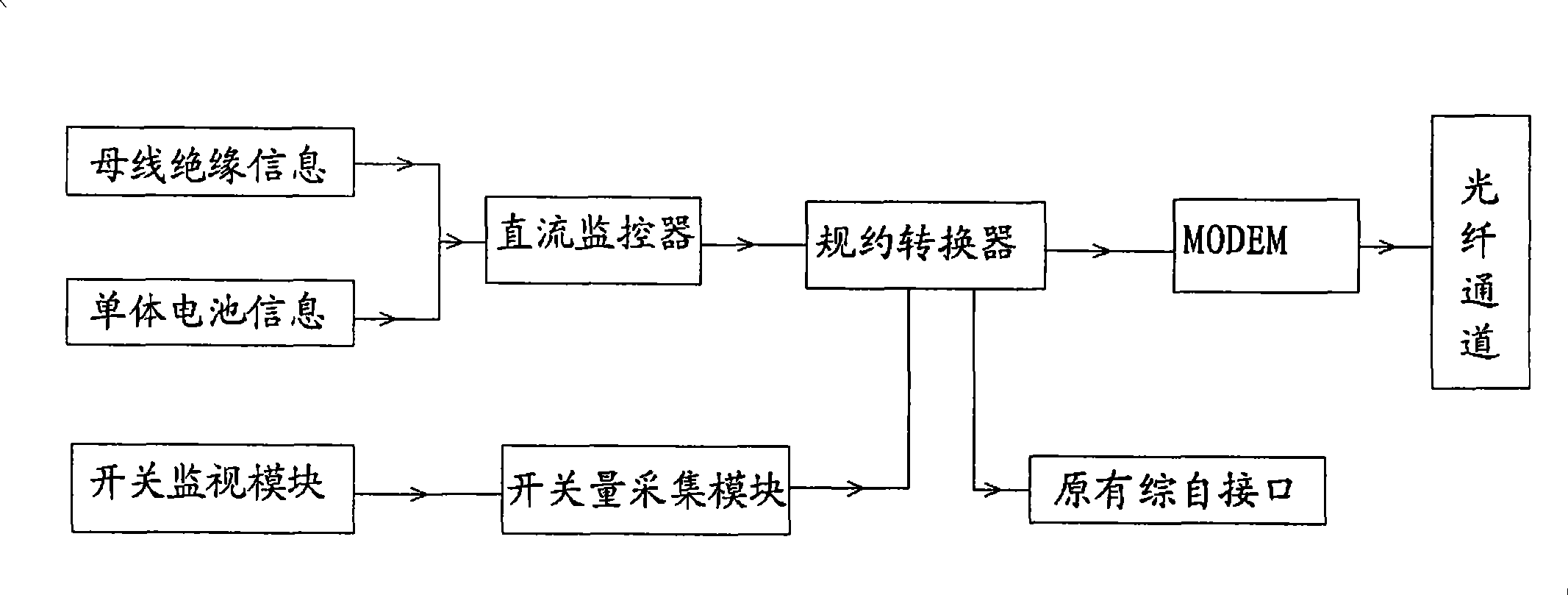

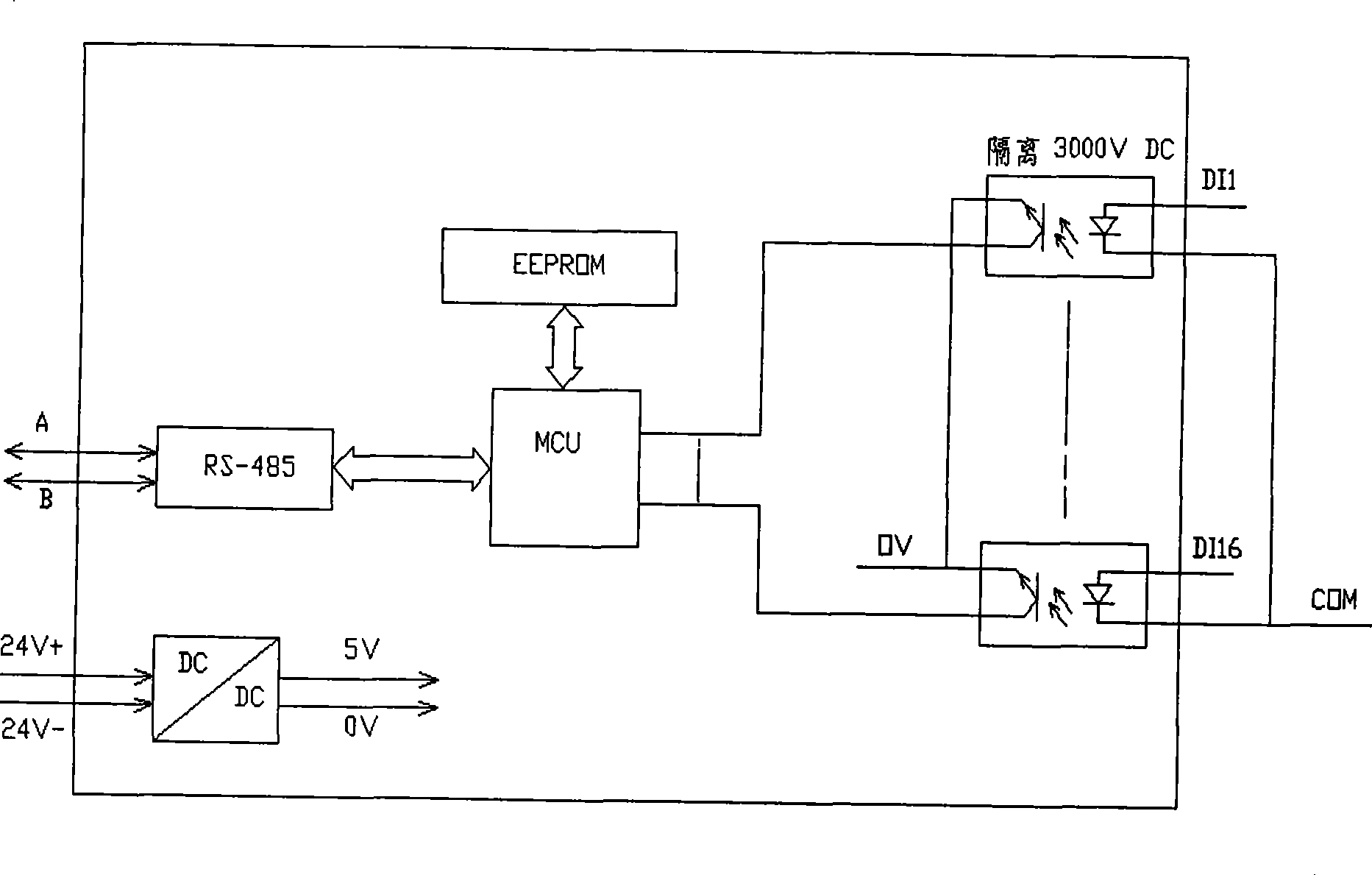

System for monitoring transforming plant DC

InactiveCN101414763AReduce the burden onReduce equipment replacementNon-electrical signal transmission systemsComputer controlData transmissionData simulation

The present invention discloses a transformer DC monitoring system, which consists of a far-end measurement control unit, an optical fiber channel input unit, an optical fiber channel, a server, a workstation and a client. A prepositive computer is arranged between the optical fiber channel input unit and the optical fiber channel; the prepositive computer consists of a main prepositive computer, a deputy prepositive computer and a dual-computer switching device; the dual-computer switching device is connected with the optical fiber channel input unit; the main prepositive computer and the deputy prepositive computer are both connected with the dual-computer switching device; the communication mode between the main prepositive computer and the deputy prepositive computer adopts GPS wireless mode; data monitoring, parameter setting, data analog, data pre-treatment and data transmission computer programs are arranged in the main prepositive computer and the deputy prepositive computer in advance. The transformer DC monitoring system makes full use of existing equipment to establish a long-distance centralized DC monitoring system which is applicable to various substations and improve the comprehensive monitoring level, openness and expandability of the system and the stability and reliability of the monitoring. The transformer DC monitoring system is used for power systems.

Owner:HEBI POWER SUPPLY OF HENAN ELECTRIC POWERCORP

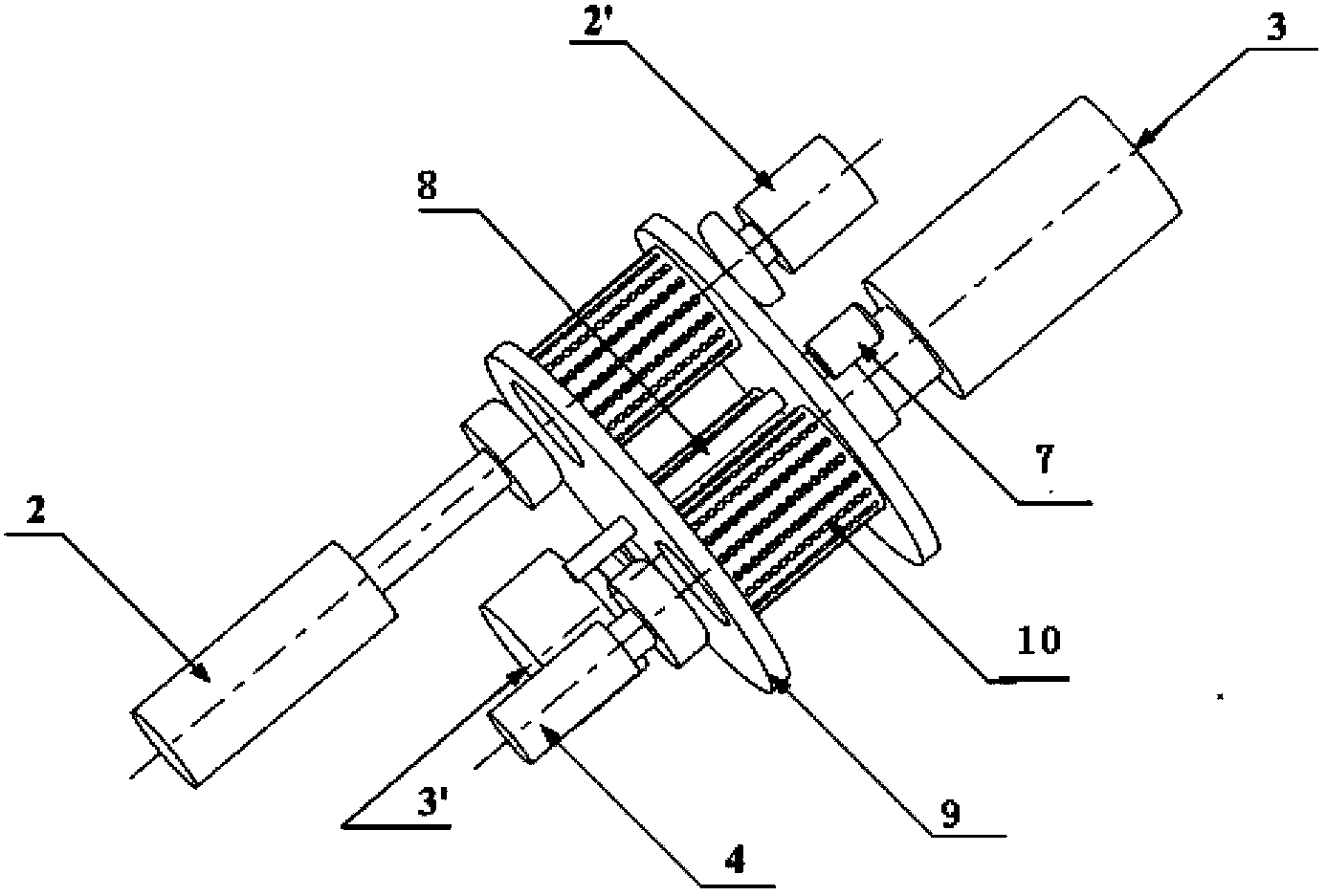

Extruding-separating device for dry and wet separation of municipal solid waste

The invention relates to waste disposal equipment, in particular to an extruding-separating device for dry and wet separation of municipal solid waste. The extruding-separating device solves the problem that dry and wet separation of municipal solid waste in China cannot meet the requirement for recycling resources. A feeding mechanism, a pre-pressing mechanism, an extruding mechanism and a discharging mechanism are arranged on the outer side of a machine body, the feeding mechanism and the pre-pressing mechanism are arranged perpendicular to each other, the pre-pressing mechanism, the extruding mechanism and the discharging mechanism are arranged in parallel, the axis of the pre-pressing mechanism, the axis of the extruding mechanism and the axis of the discharging mechanism are located in the same circumferential line and are arranged at 120-degree intervals, a rotating mechanism is arranged on the central axis in the machine body, the rotating mechanism and a driving mechanism are arranged coaxially or in parallel, and the driving mechanism is arranged on the outer side of the machine body. The extruding-separating device can ensure dry and wet separation of municipal solid waste in China, the water content of the dry municipal solid waste is lower than 30%, and outstanding improvements are made in the respects of waste adaptability, equipment maintainability, equipment reliability, cost reduction and the like.

Owner:BEIJING XINCHANGZHENG TIANGAO INTELLIGENT MACHINE TECH CO LTD

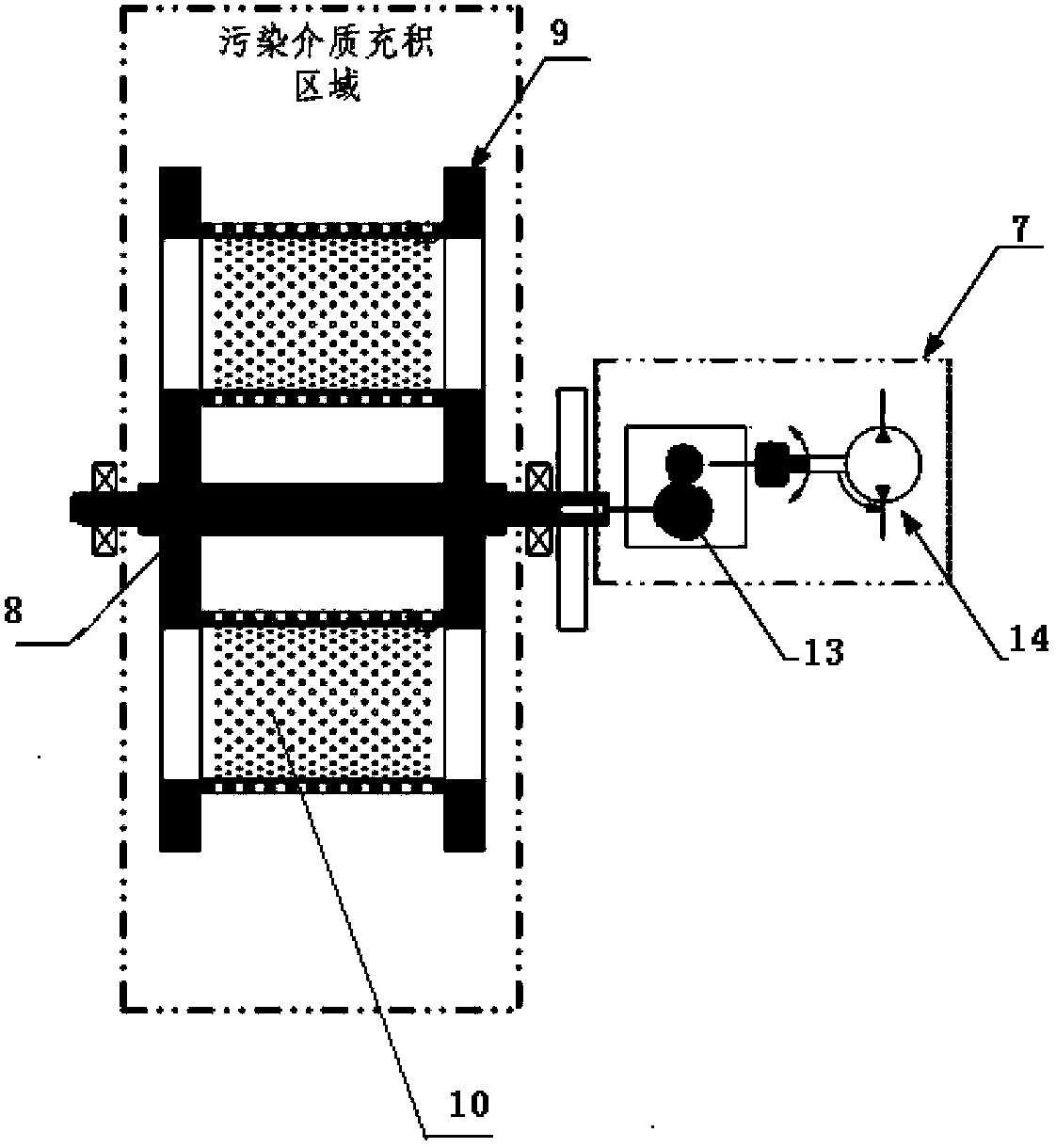

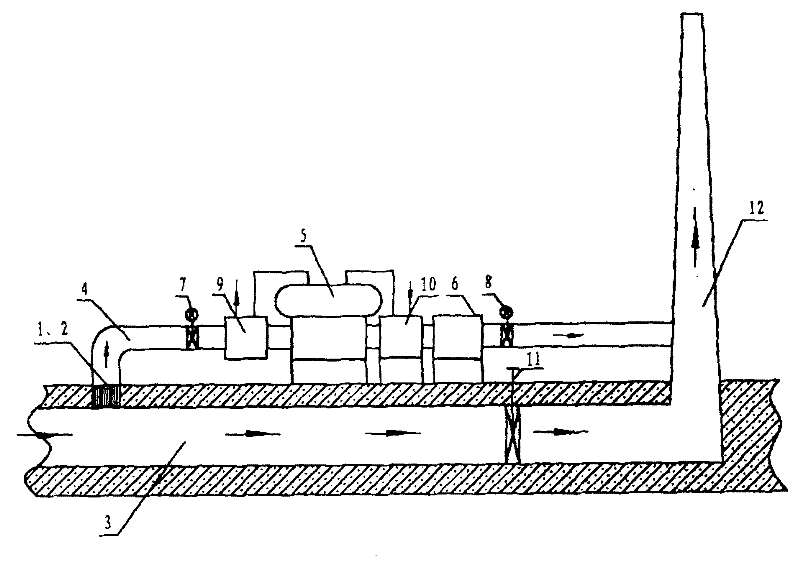

Method for recovering flue gas waste heat of coke oven

InactiveCN102338366AEfficient Waste Heat RecoveryContinuous and reliable operationIncreasing energy efficiencySteam generation using hot heat carriersFlueProcess engineering

The invention relates to a method for recovering flue gas waste heat of a coke oven. The method comprises the following steps of: machining a flue gas acquisition conveying channel and a flue gas output channel on an output flue of the coke oven; constructing a coke oven flue gas waste heat recovery pipeline which is communicated with the flue gas acquisition conveying channel and the flue gas output channel and is positioned between the flue gas acquisition conveying channel and the flue gas output channel, and installing a waste heat recovery system in the waste heat recovery pipeline; and regulating pressure in the waste heat recovery pipeline, performing heat energy conversion by using the waste heat recovery system, outputting heat energy and discharging coke oven flue gas from which the waste heat is recovered along the flue gas output channel. The method is mainly applied to the waste heat recovery of the flue gas of a newly-built or rebuilt coke oven system, and can be matched with the coke oven systems with various structures; and the method is a set of integral independent waste heat recovery system, an integral structure of the coke oven system is not changed, the flue gas waste heat of the coke oven system can be recovered efficiently, and the coke oven system can run stably, reliably and continuously. The method is small in investment and flexibly and conveniently applied, and meets the requirements of the waste heat recovery of the coke oven systems with the various structures, maintenance cost is low, and the integral structure is simple.

Owner:BAODING RUNLI ENERGY SAVING & ENVIRONMENTAL PROTECTION

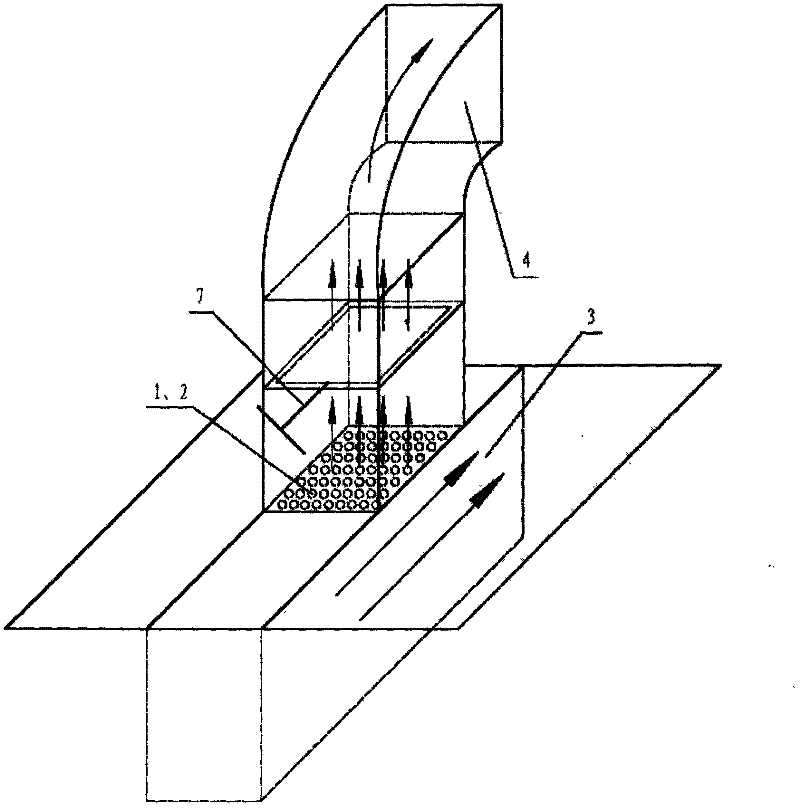

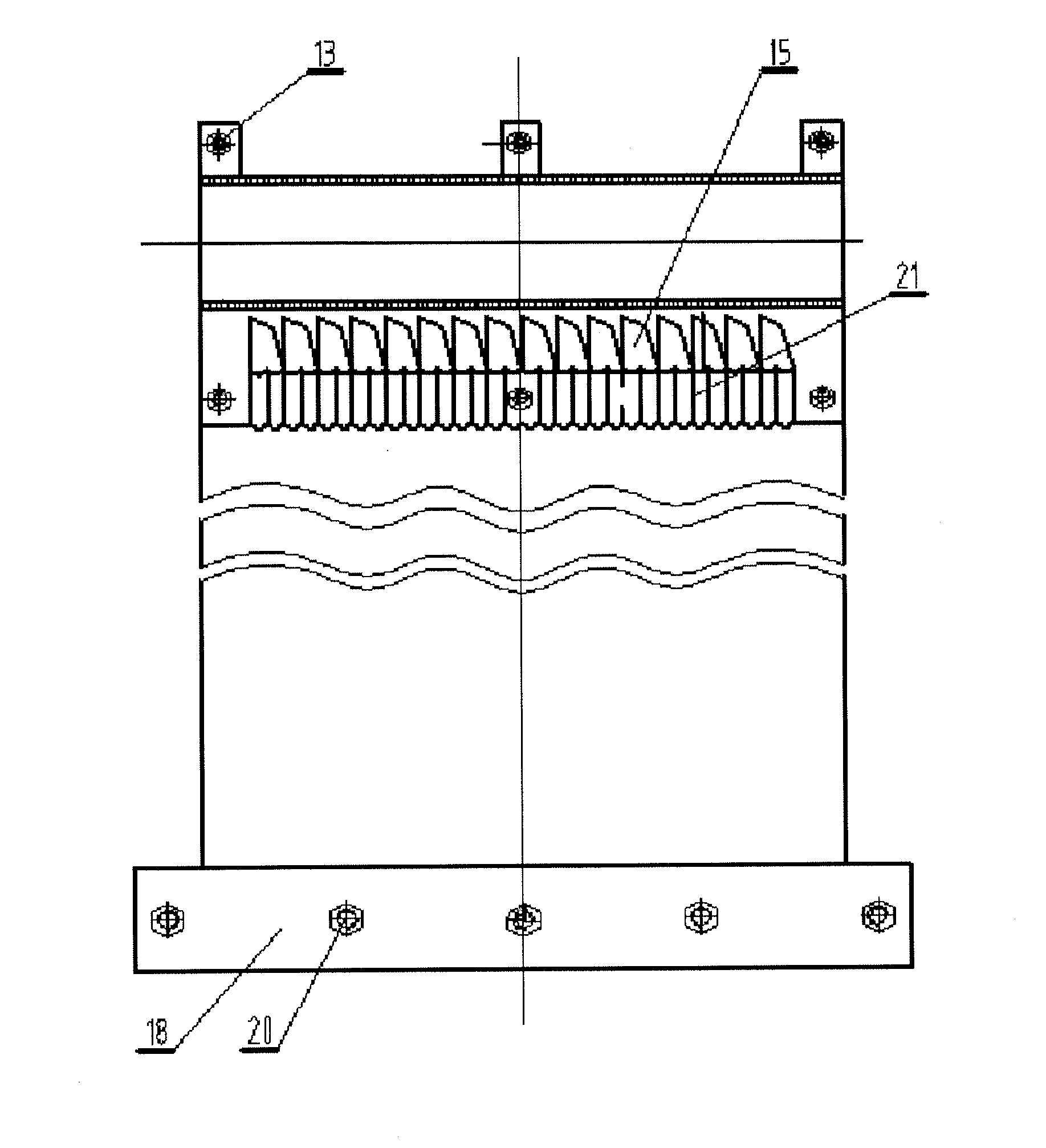

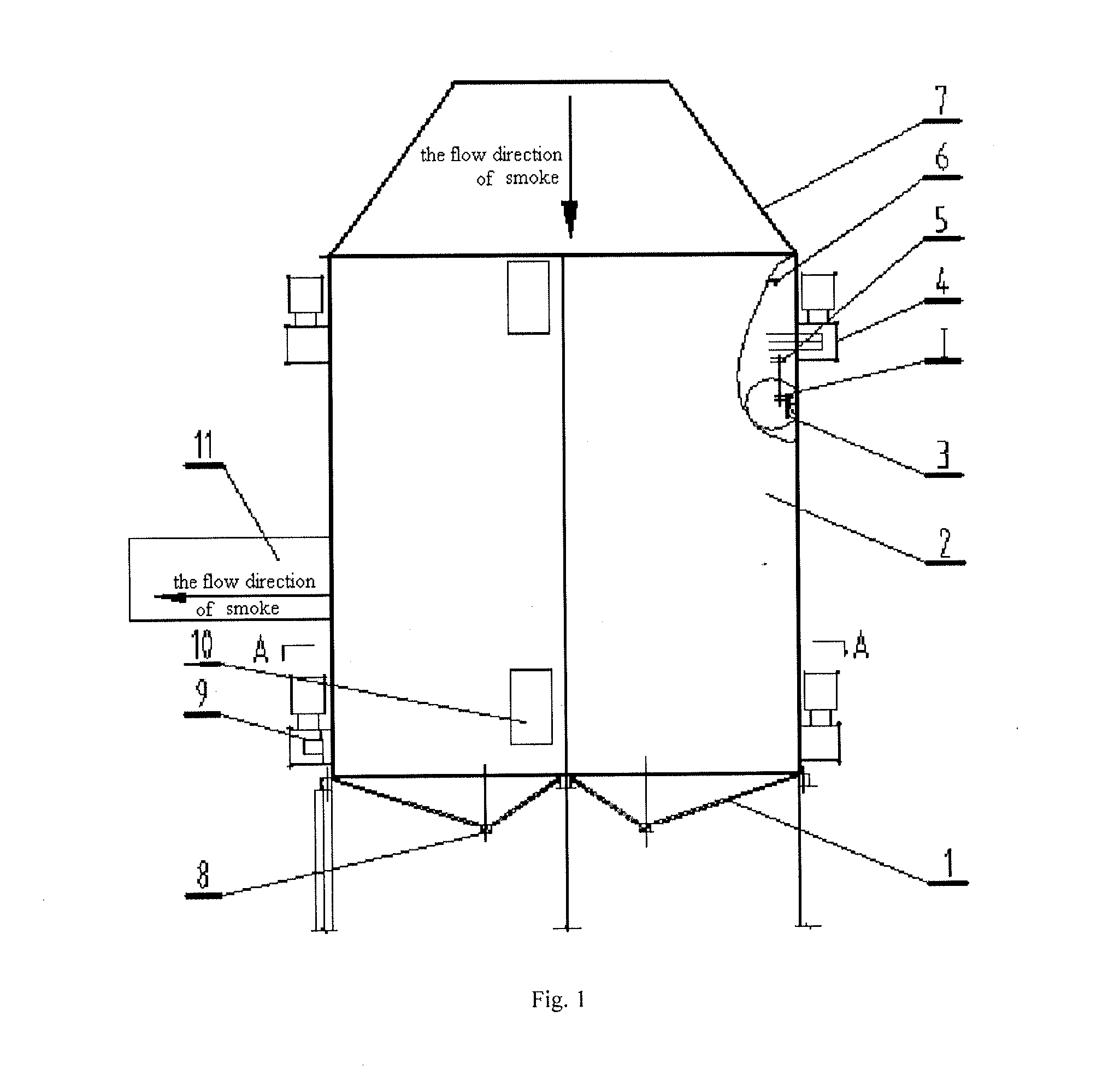

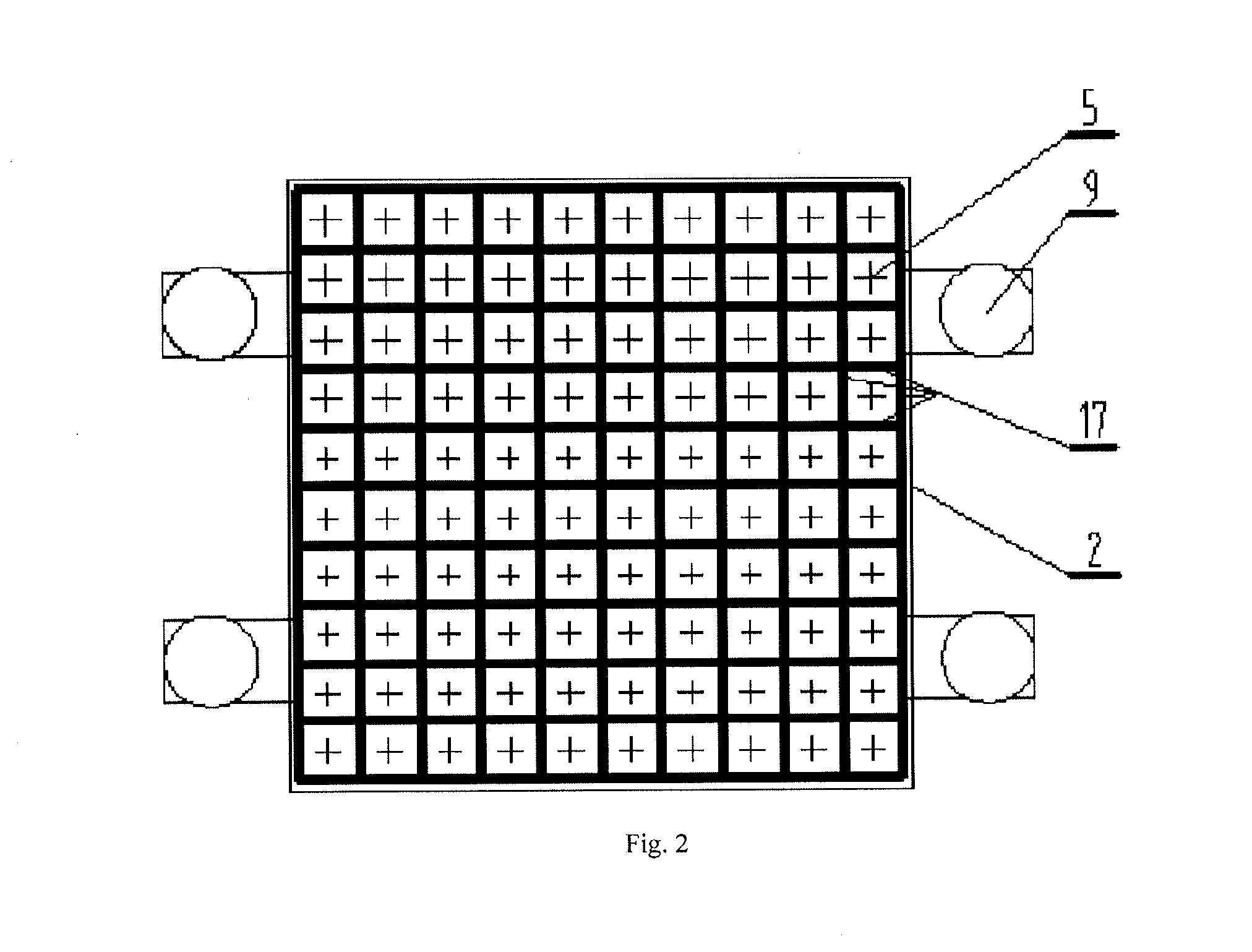

Technology and device for uniform distribution of water film on solid collecting plate

ActiveUS20140150718A1High strengthIncrease in film speedLiquid surface applicatorsDispersed particle separationEnvironmental engineeringPre treatment

Disclosed is technology and device for uniform distribution of water film on solid collecting plate used on a wet electrostatic precipitator (ESP). The device includes clamping plate fastening bolts, suspended clamping plates, a water distribution pipe, guide vanes, collecting plate, a limiter, a two-way limited fixed axis and a double arming bolt. The surfaces of the solid collecting plate are subjected to coating pretreatment, the upper parts of the collector are connected with the water distribution pipe, and the 45° guide vanes are twisted; a corrugated diversion with the width of 5 to 8 mm is adopted; stainless steel pipes are crosswise welded, water distribution holes are formed at the water distribution pipe, the distribution pipe is connected with an external water tank, and the inlet quantity of the water is controlled by a PLC; the collectors are placed vertically, and the ESP contains a set of sharp discharge electrodes.

Owner:GUONENG (SHANDONG) ENERGY & ENVIRONMENT CO LTD +1

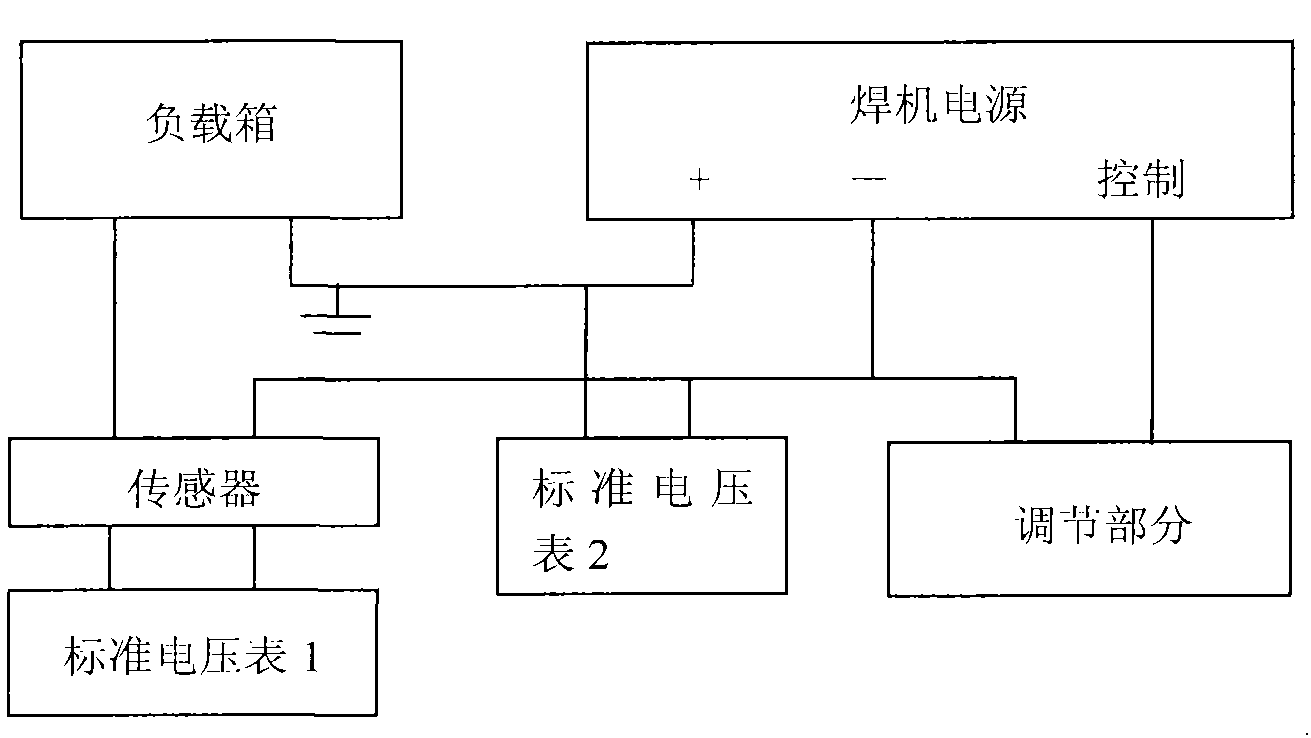

Large-current intelligent digital welding system verification and calibration method

ActiveCN103913660ARun accuratelyContinuous and reliable operationElectrical testingSystem verificationWelding power supply

The invention relates to a large-current intelligent digital welding system verification and calibration method which solves the problem that measurement is not accurate by means of an existing method. A load box, the current end of a sensor and the welding power output end of a welding system are sequentially connected in series in an end-to-end mode to form a circuit. A standard digital multifunctional meter is connected with the two voltage ends of the sensor, another standard digital multifunctional meter is in parallel connection with the two output ends of a welding power source, the welding power source is connected with an adjusting part through a special line to form a control circuit, and the load box is set to be a rated current value of the welding system to be measured; through power-on detection, verification and calibration, if the current error delta 1 of the welding system is larger than a current error limit value or the voltage error delta 2 of the welding system is larger than a voltage error limit value, the welding system is unqualified; if the current error delta 1 is smaller than or equal to the current error limit value and the voltage error delta 2 is smaller than or equal to the voltage error limit value, the welding system is qualified. The large-current intelligent digital welding system verification and calibration method provides technical guarantee and scientific bases for accurate, continuous and reliable operation of the welding system.

Owner:内蒙古第一机械集团股份有限公司

Extra-high voltage transformer and iron core assembly thereof

InactiveCN103824682AEffective control of main flux distributionImprove continuityTransformers/inductances coolingTransformers/inductances magnetic coresMagnetic fluxEngineering

The invention discloses an iron core assembly. The iron core assembly comprises an iron core clamping piece which is horizontally arranged, and two lateral columns which are arranged in parallel, wherein the extension directions of the axes of the lateral columns are vertical to the extension direction of the iron core clamping piece, two core columns are arranged in parallel between the two lateral columns, the axes of the core columns are parallel to the axes of the lateral columns, a cooling oil duct is arranged at the side part of each core column, and the extension directions of the cooling oil ducts are consistent with the extension directions of the core columns. In the work process, the cooling oil duct can isolate a frame formed between adjacent lateral columns or core columns and iron core clamping pieces into a solo magnetic circuit system, thereby effectively controlling the main magnetic flux distribution of a transformer, avoiding a local superheating phenomenon caused by superhigh local magnetic flux density of an iron core, and effectively increasing the whole operating continuity and reliability of the transformer. The invention also discloses an extra-high voltage transformer which applies the iron core assembly.

Owner:STATE GRID CORP OF CHINA +1

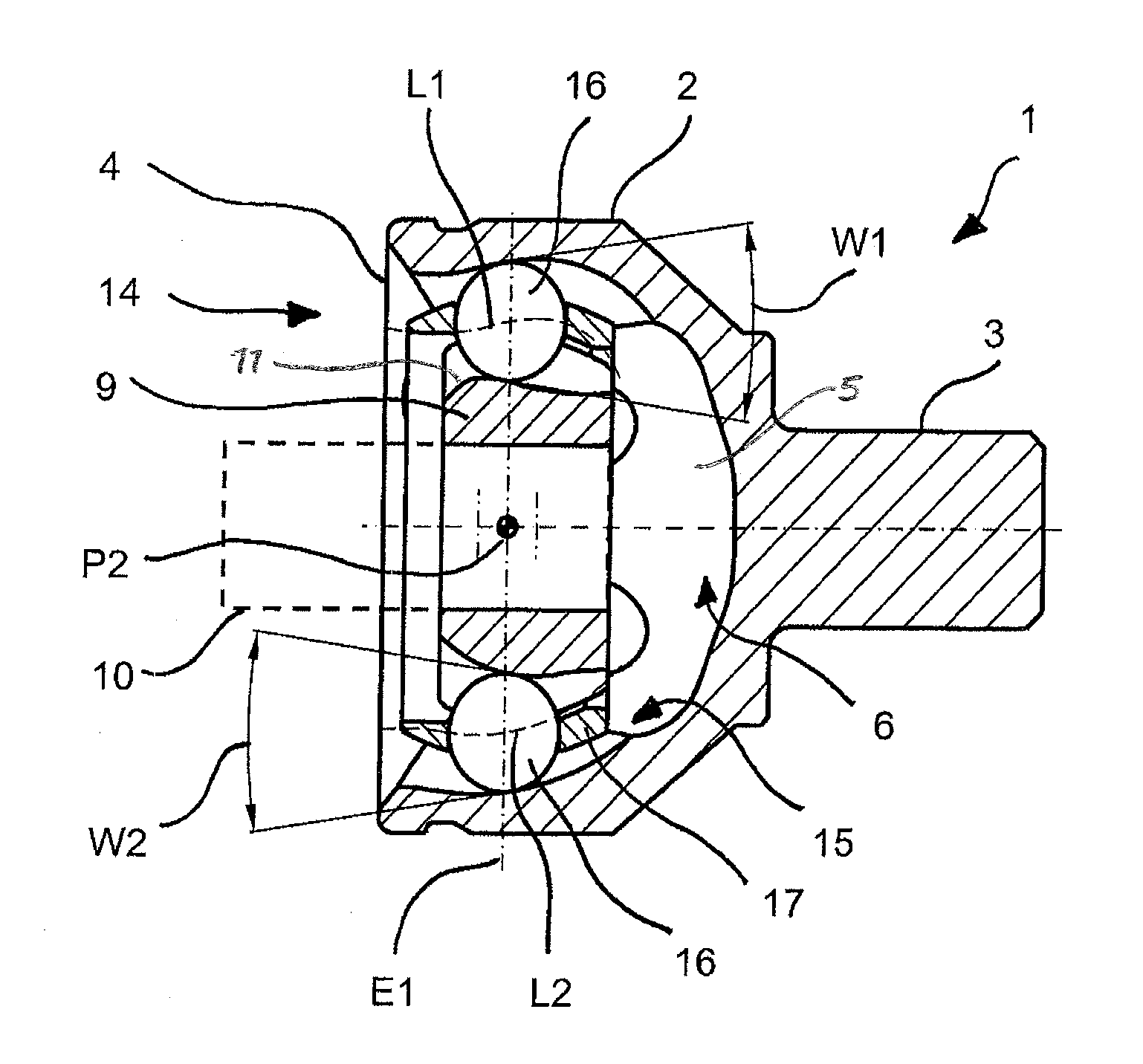

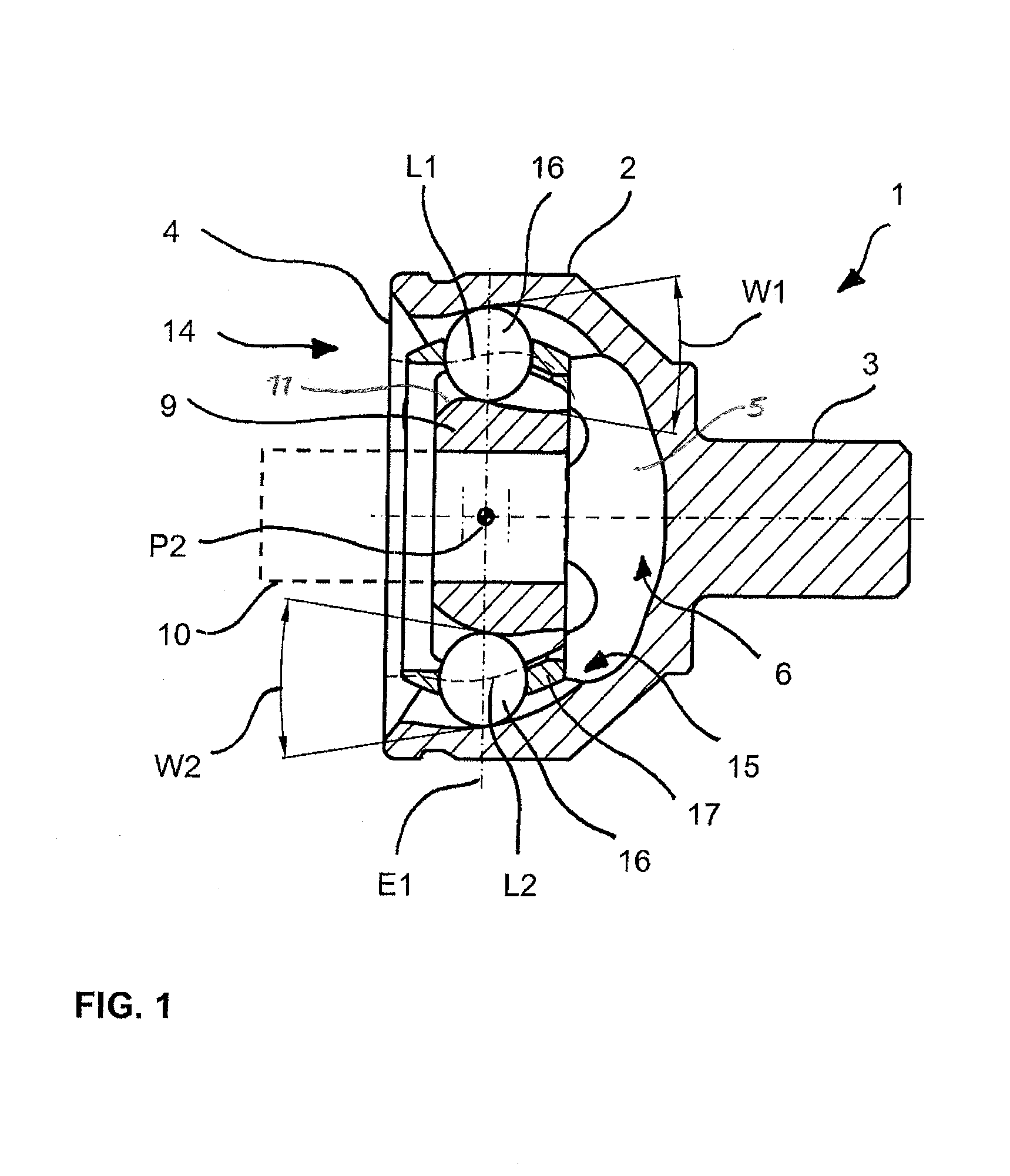

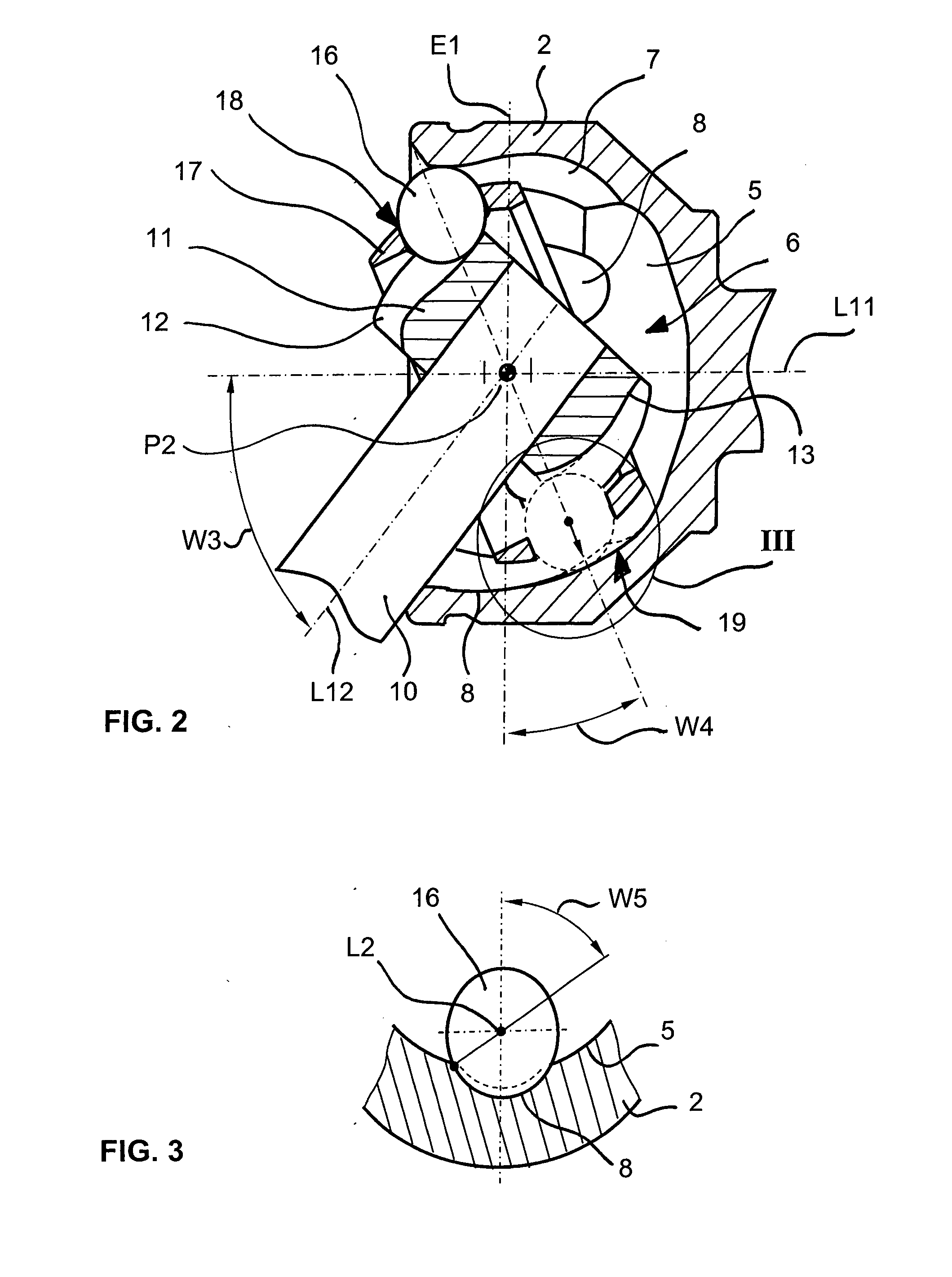

Constant velocity ball joint in the form of a counter track joint

ActiveUS20100113167A1Large articulation angleIncreased noise developmentYielding couplingOrbitControl theory

An exemplary constant velocity ball joint in the nature of a counter track joint, includes first and second track pairs that form an opposite opening angle (W1, W2), wherein the first track pairs are provided with a track inflection point (P1) and the second track pairs each form a second track centerline (L2) that has a path other than a singular circular path in a section between the central joint plane (E1) and the connection side.

Owner:GKN DRIVELINE INT GMBH

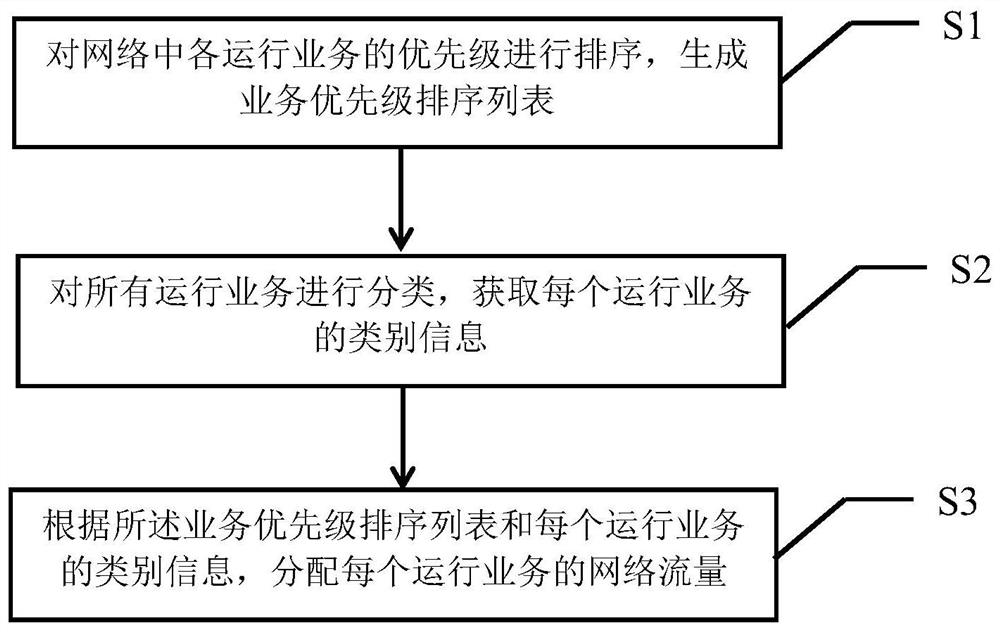

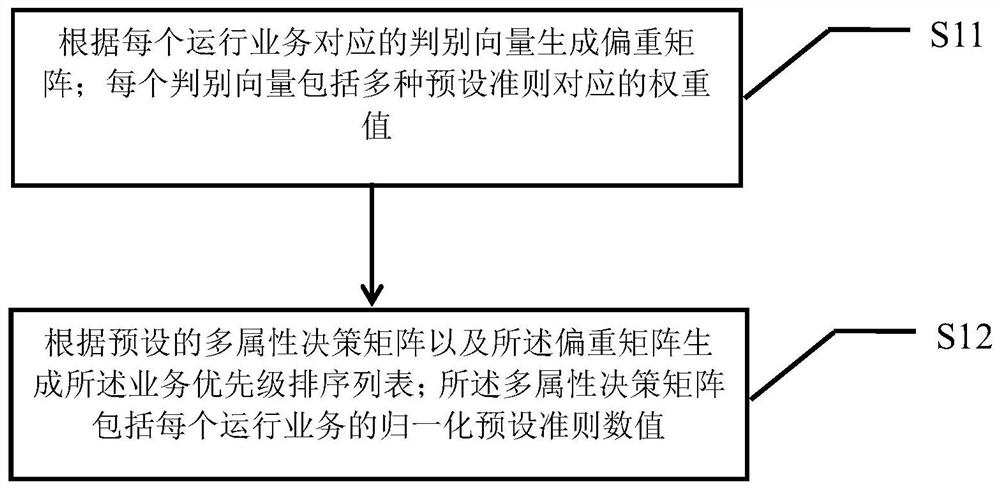

Network flow distribution method and device

ActiveCN113055307APriority forwardingImprove experience comfortData switching networksService flowBanking industry

The embodiment of the invention provides a network flow distribution method and device which can be used in the technical field of information safety. The method comprises the steps: sorting the priorities of all operation services in a network, and generating a service priority sorting list; classifying all the running servicees, and obtaining category information of each running service; and distributing the network flow of each operation service according to the service priority ranking list and the category information of each operation service. According to the method and the device, the key banking service flow or the flow which relatively affects the customer experience can be preferentially forwarded, so that the continuous and reliable operation of the network is ensured, and the customer experience comfort is improved.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

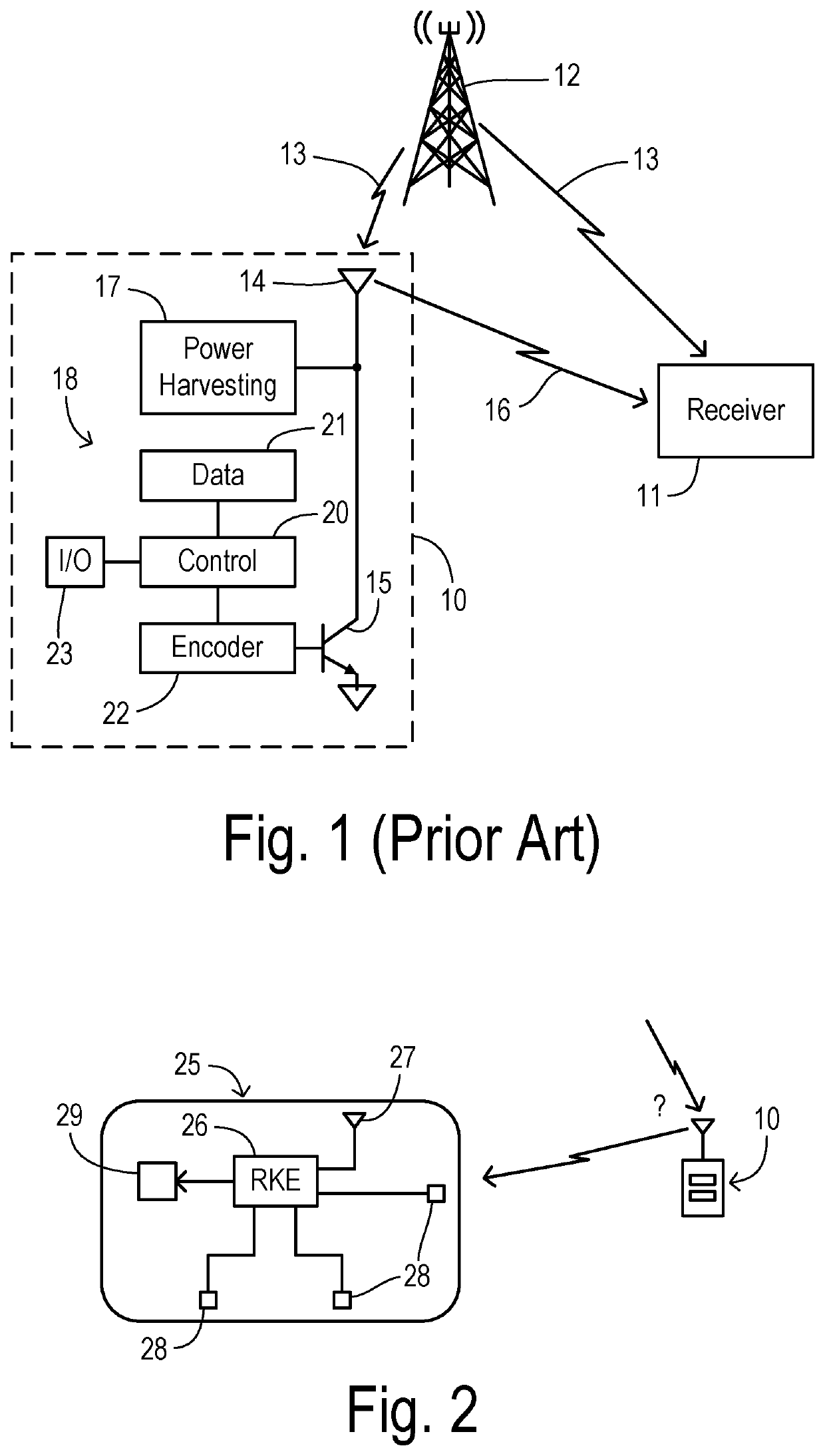

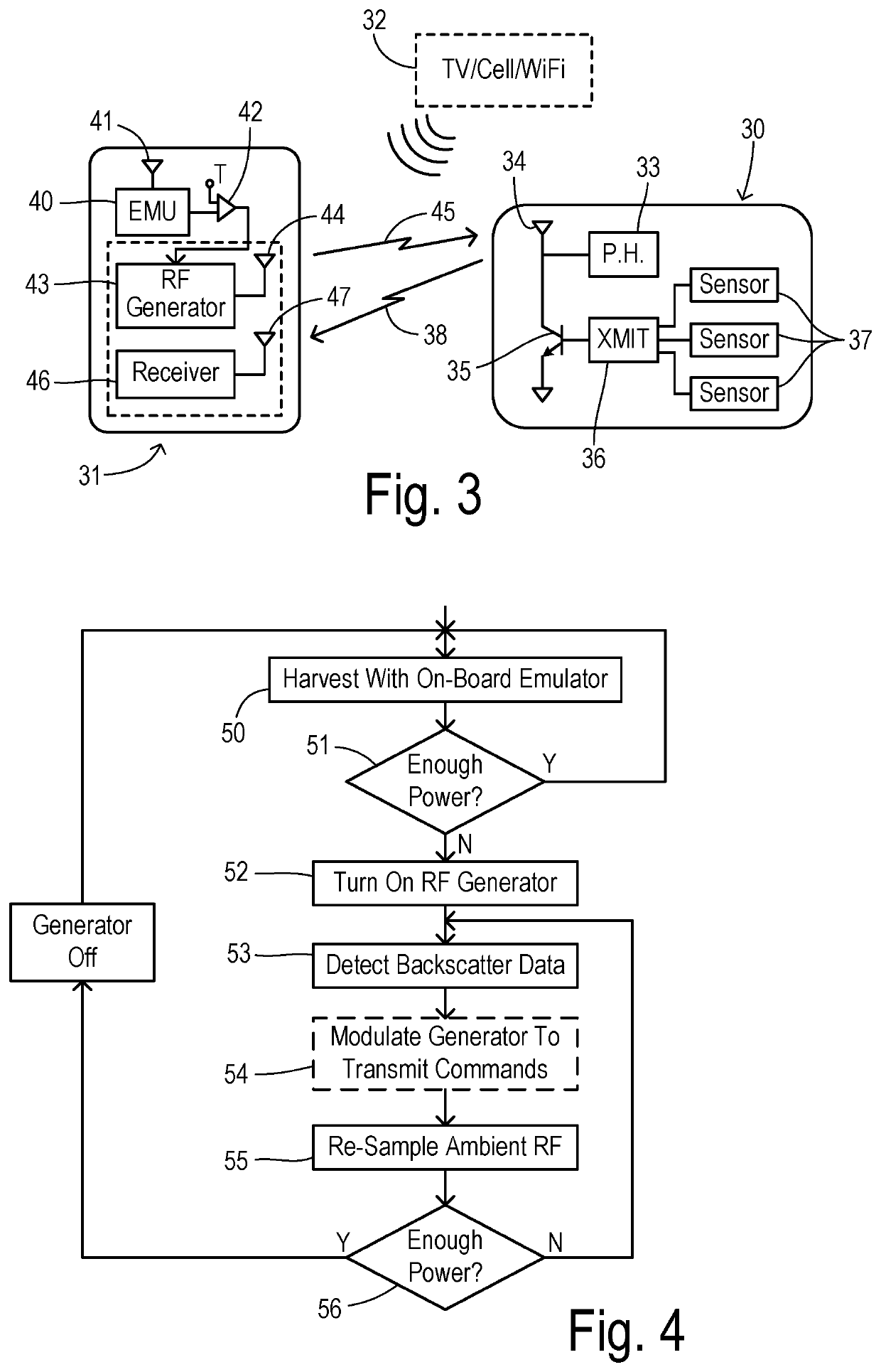

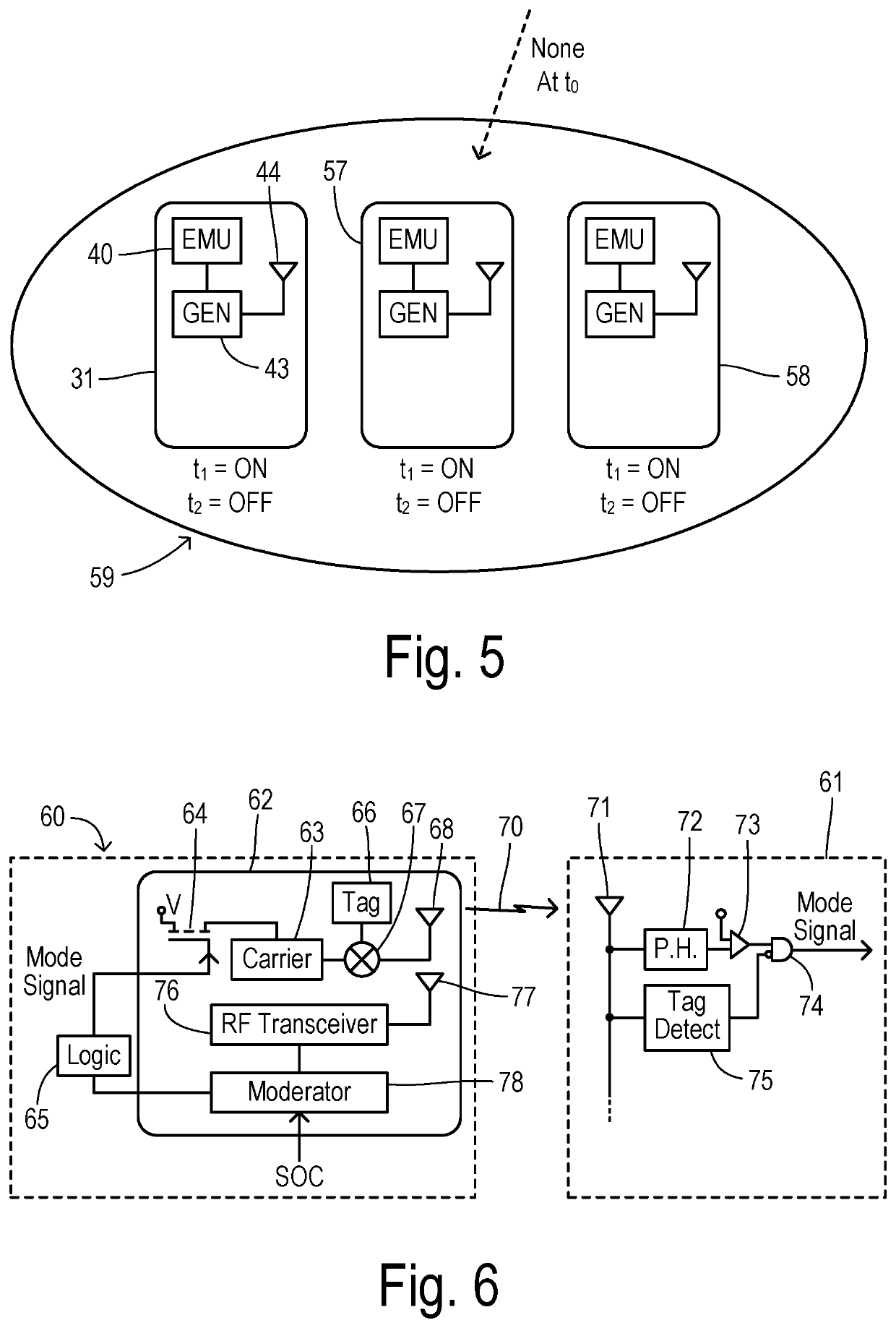

Ambient RF backscatter communication for vehicle remote control

ActiveUS10587150B1Continuous and reliable operationSufficient powerCircuit arrangementsAnti-theft devicesAutomotive engineeringReceiver

A vehicle communicates with a remote key fob while ensuring an RF environment is sufficient to maintain adequate power from an RF-harvesting power supply that allows the fob to operate without a battery. The vehicle has a receiver adapted to detect a backscatter communication signal from the fob. A harvesting emulator in the vehicle is responsive to ambient RF around the vehicle to duplicate a concurrent response of the fob power supply. A vehicle-powered RF transmitter is activated to broadcast energizing RF radiation around the vehicle when the duplicated response is below a threshold.

Owner:FORD GLOBAL TECH LLC

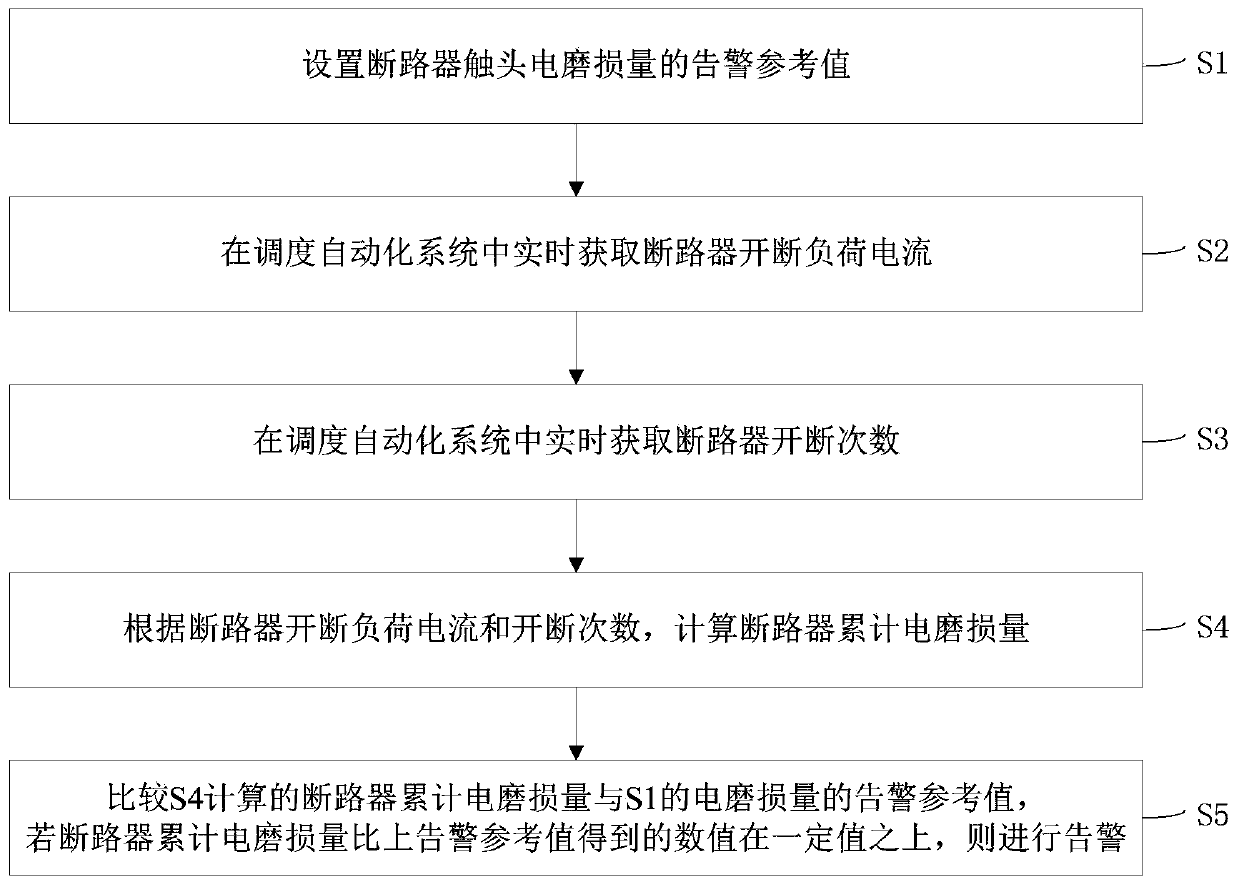

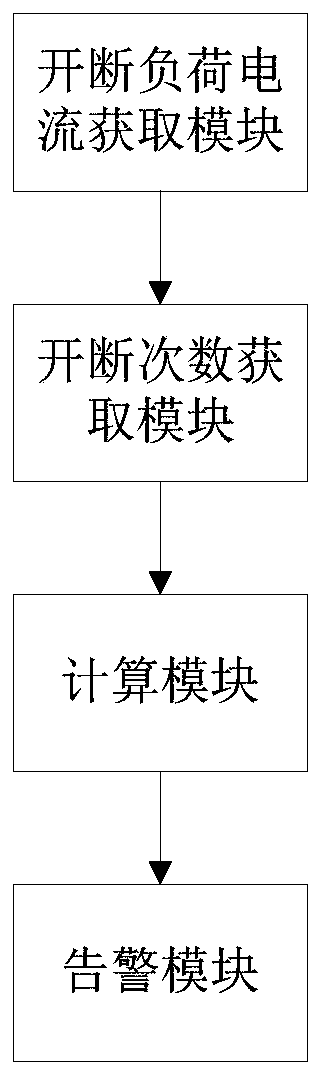

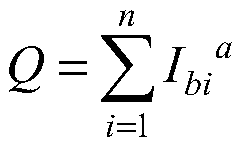

Breaker electrical life diagnosis method and system based on dispatching automation data

ActiveCN110954812AContinuous and reliable operationCalculation of electrical wearCircuit interrupters testingPower gridCapacitor

The invention discloses a breaker electrical life diagnosis method based on dispatching automation data. The method comprises the following steps: S1, setting an alarm reference value Qm of the electrical wear amount of a breaker contact; S2, acquiring the on-off load current of the circuit breaker in real time in the dispatching automation system; S3, acquiring the on-off times of the circuit breaker in real time in the dispatching automation system; S4, calculating the accumulated electric wear amount Q of the circuit breaker according to the on-off load current and the on-off frequency of the circuit breaker; and S5, comparing the accumulated electric wear amount of the circuit breaker calculated in the step S4 with the alarm reference value of the electric wear amount in the step S1, and if the numerical value obtained by comparing the accumulated electric wear amount of the circuit breaker with the alarm reference value is greater than a certain value, giving an alarm.By scheduling the power grid operation data of the automation system, the load during the breaking action of the compensation capacitor or the reactor can be obtained in real time without installing any sensor, the electrical wear amount of the circuit breaker can be calculated in real time, the electrical wear amount can be monitored in real time, and the degradation degree of the contact of the circuit breaker can be alarmed.

Owner:GUANGDONG POWER GRID CO LTD +1

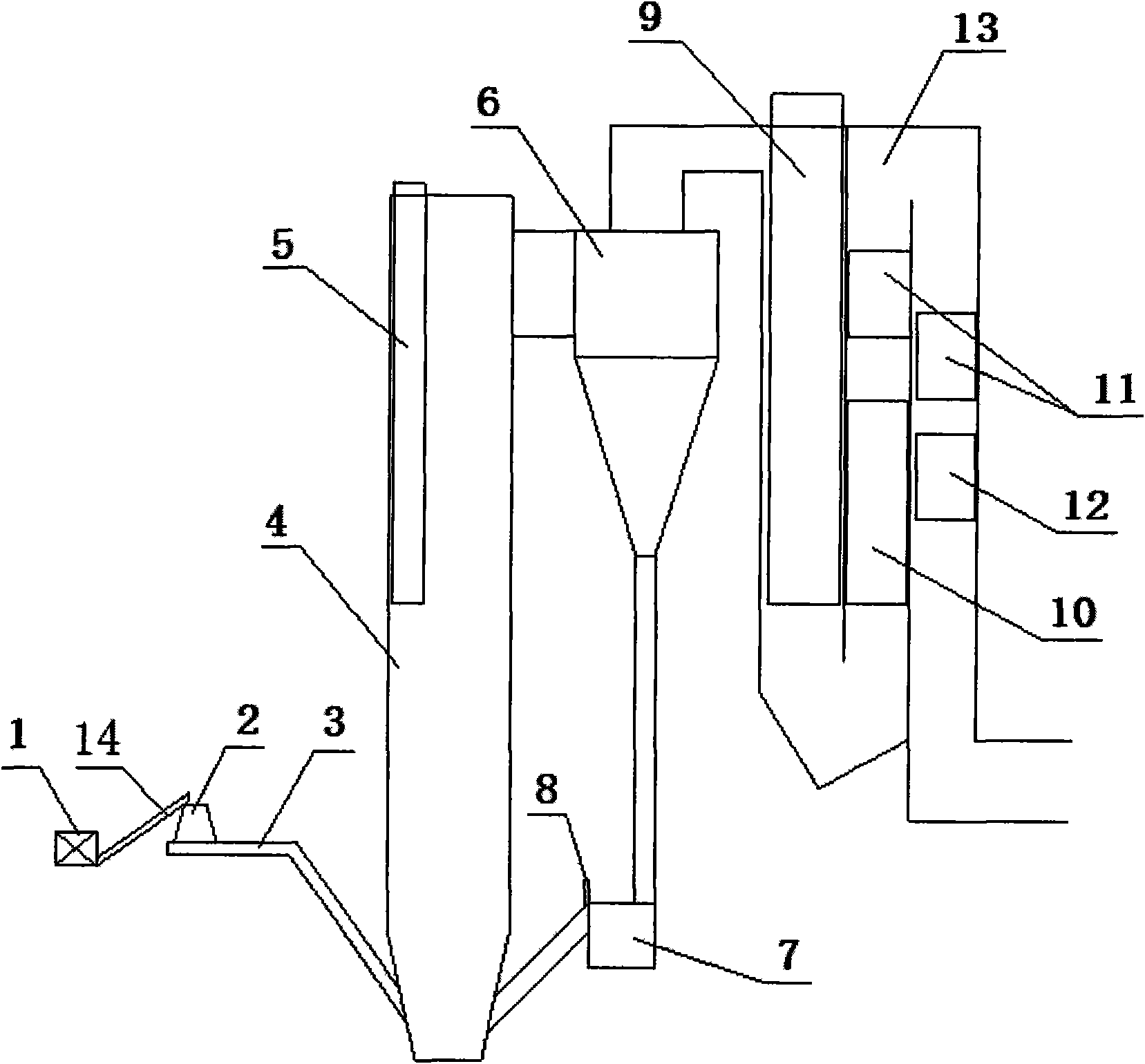

Circulating fluidized bed boiler burning straw-like biomass and feeding method

ActiveCN101614392AReduce volumeSimple compositionFluidized bed combustionIndirect carbon-dioxide mitigationBiomassCirculating fluidized bed boiler

The invention discloses a circulating fluidized bed boiler burning straw-like biomass and a feeding method. The feeding method comprises the following steps that: before being delivered into a furnace, the straw-like biomass serving as a fuel is crushed and compressed by compression molding equipment so as to be solidified; and the solidified straw-like biomass is conveyed to a furnace by a conveying belt so as to be burnt. By compressing the light and large-volume straw-like biomass before conveying the light and large-volume straw-like biomass to the furnace, the method reduces the volume of the straw-like biomass, has the advantages of simple structure and low cost, keeps the straw-like biomass away from bridging and block which frequently occur in a conveying process, ensures smooth feeding and the safe operation of the boiler, and effectively guarantees the continuous, reliable and safe operation of biomass power plants.

Owner:CHINA HUADIAN ENG +1

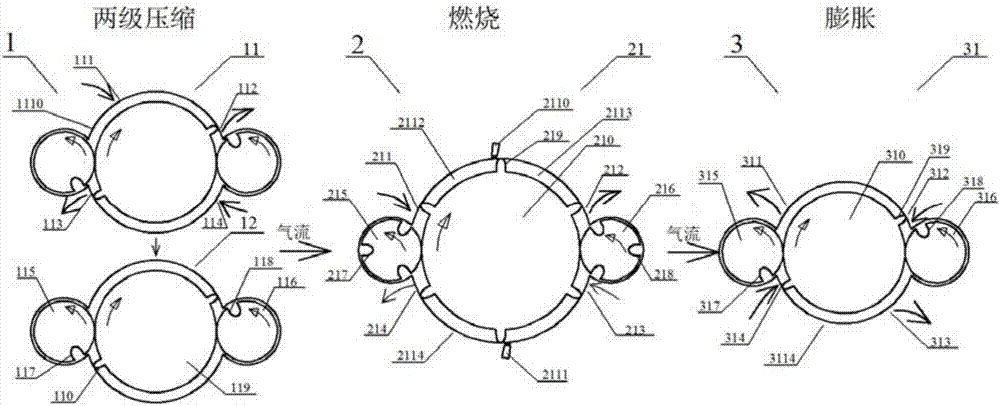

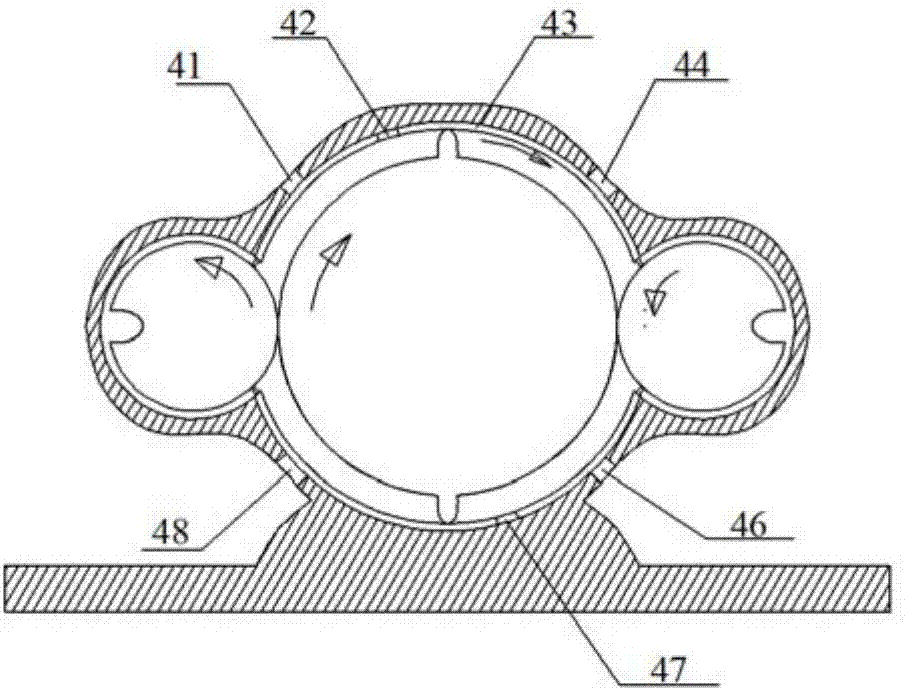

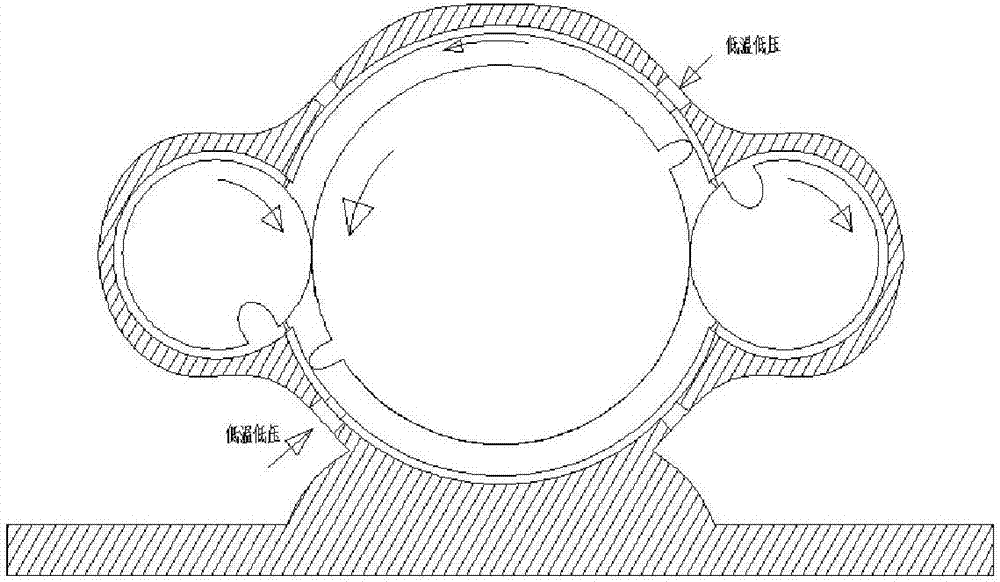

Rotor type engine

ActiveCN106948936ALow lubrication requirementsCycle simpleInternal combustion piston enginesRotary piston pumpsCombustorCore component

The invention provides a rotor type engine and relates to the technical field of engines. The rotor type engine comprises three functional levels including a compression level, a combustion level and an expansion level. The rotor type engine is characterized in that all levels are independent to one another and are connected in series into a whole through a main shaft, and each level is composed of one or more heating power conversion units. The heating power conversion units comprise compressors, combustors and expansion machines at different functional levels. The engine is mainly composed of a main rotor, an auxiliary rotor, a shell and a timing device; main components are all subjected to revolved body machining, the outer diameter of the main rotor is tangent to that of the auxiliary rotor and is two times that of the auxiliary rotor, and the angular speed of the auxiliary rotor is two times that of the main rotor; and the shell contains fixed air feeding openings and exhausting openings, the timing device is a cylindrical piece containing a circumferential air opening, and the timing device and the shell are subjected to sealed treatment through comb teeth. Core components of the compressors, the combustors and the expansion machines are all served as the timing device.

Owner:HUNAN UNIV

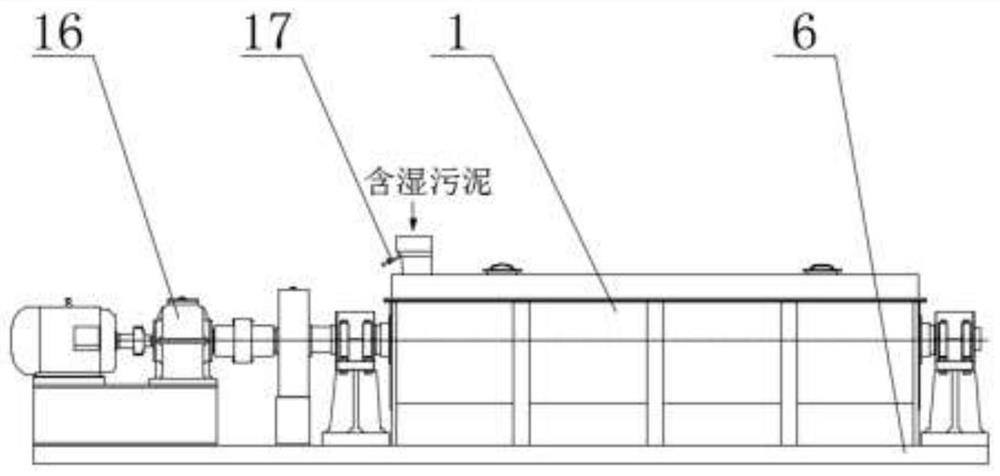

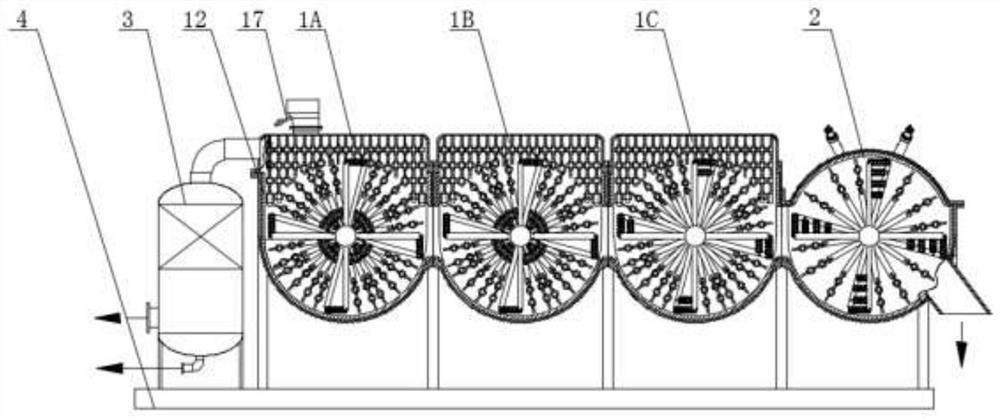

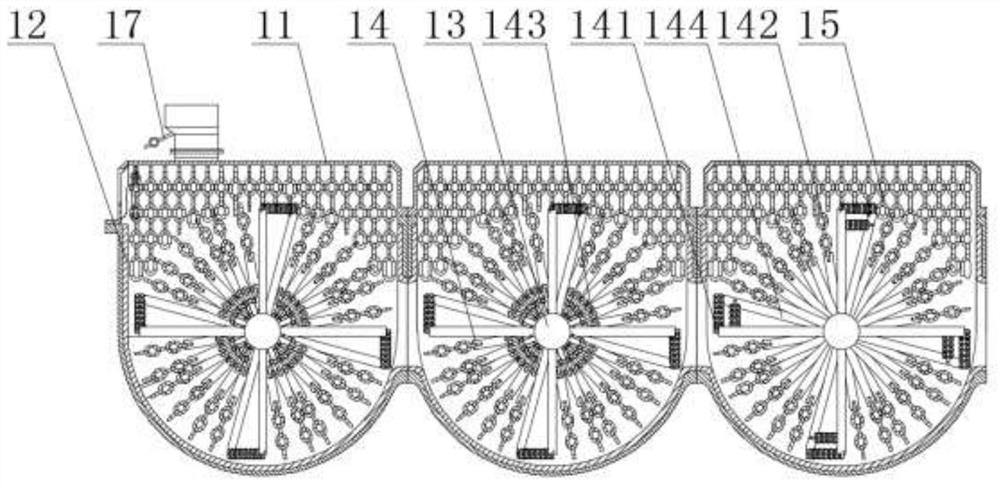

Municipal sludge chain rolling suspension drying clean incineration equipment and incineration method

PendingCN112777903ALarge amount of disposalSimple processSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesExhaust fumesDry heat

The invention discloses municipal sludge chain rolling suspension drying clean incineration equipment and an incineration method, and the municipal sludge chain rolling suspension drying clean incineration equipment comprises more than two stages of horizontal sludge rod chain rolling suspension drying devices, plasma flame suspension incineration devices and waste gas purification devices which are communicated in sequence.Municipal sludge chain rolling suspension drying clean incineration can be integrated, the treatment process is simple, the heat utilization efficiency is high, the energy consumption is low, operation is continuous and reliable, the sludge treatment amount is large, the occupied area is small, and the operation cost is lower. The invention further provides the incineration method, the technology that wet sludge and hot air are rolled, hung, suspended and dried in a relatively closed space through a multi-stage rod chain is utilized, moisture in the sludge can be rapidly removed, the retention time of a sludge viscous area is effectively shortened, the sludge dewatering and drying efficiency is effectively improved, and the drying heat consumption is reduced.

Owner:长沙紫宸科技开发有限公司

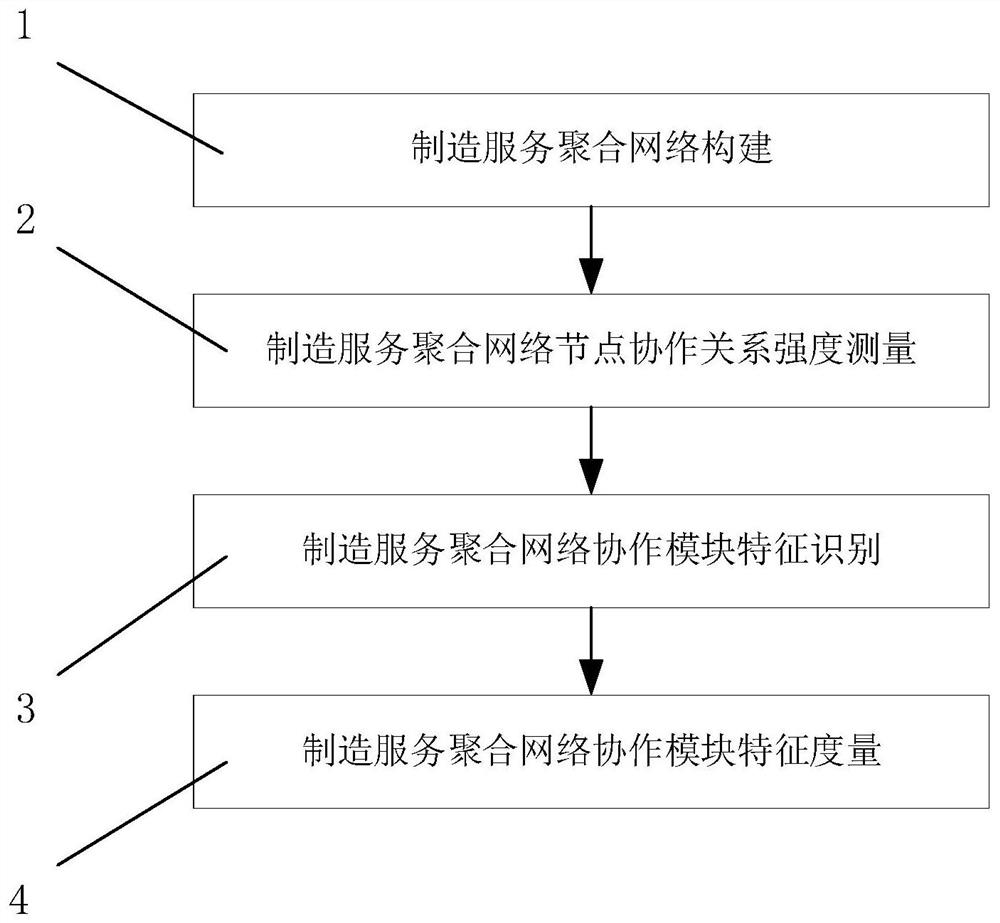

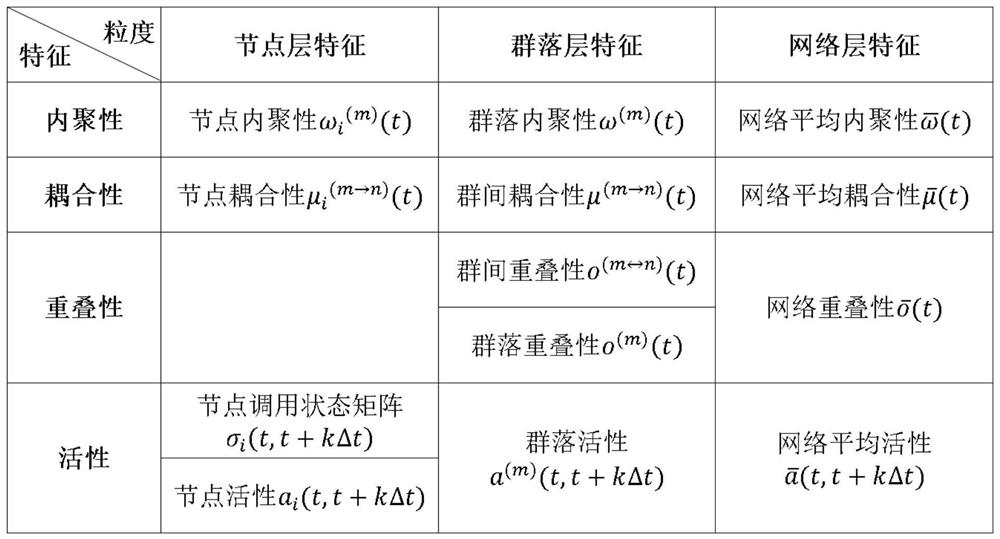

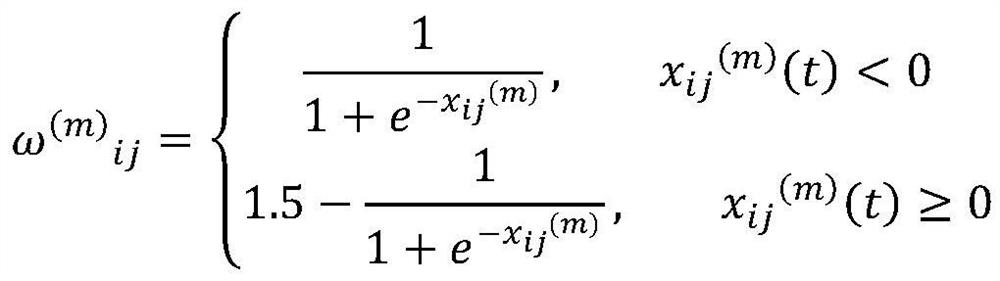

Network manufacturing service aggregation cooperation characteristic dynamic measurement method

ActiveCN112381134ACharacterize the strength of the portfolio collaboration relationshipSolve the problem that the characteristics of collaboration are difficult to measureData processing applicationsCharacter and pattern recognitionThe InternetNetwork measurement

The invention relates to a network manufacturing service aggregation cooperation characteristic dynamic measurement method. The method comprises the following steps of 1, judging a cooperation relationship between manufacturing service nodes, and constructing a manufacturing service aggregation network; 2, measuring clustering and combination cooperation relationship strength among nodes in the manufacturing service aggregation network; 3, identifying cooperation module characteristics of the manufacturing service aggregation network; and 4, measuring cooperation module characteristics of themanufacturing service aggregation network. The method can effectively evaluate the manufacturing service aggregation cooperation characteristics based on the industrial Internet / industrial cloud platform, provides a measurement basis for the dynamic evolution of the manufacturing service aggregation network and the dynamic cooperation of the manufacturing service as required, and facilitates improvement of the operation regulation and control capability and reliability of the industrial Internet / industrial cloud platform.

Owner:BEIHANG UNIV

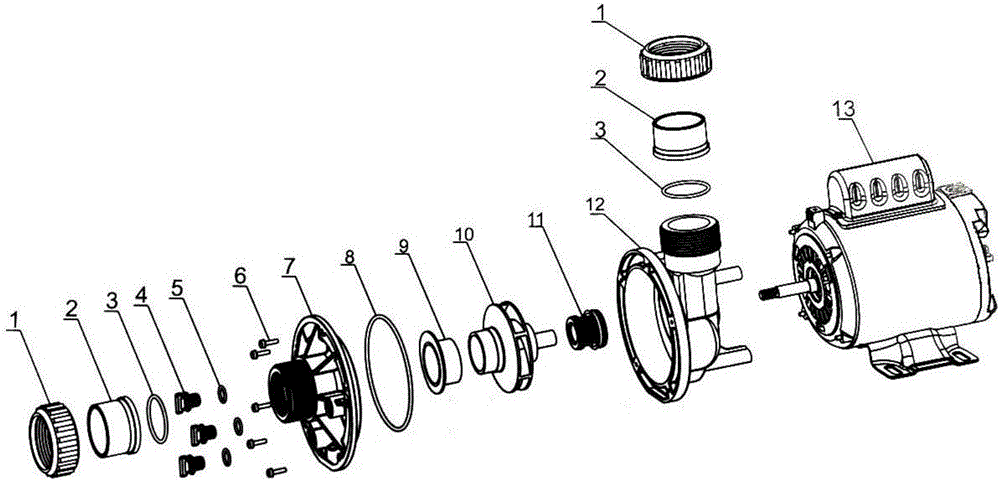

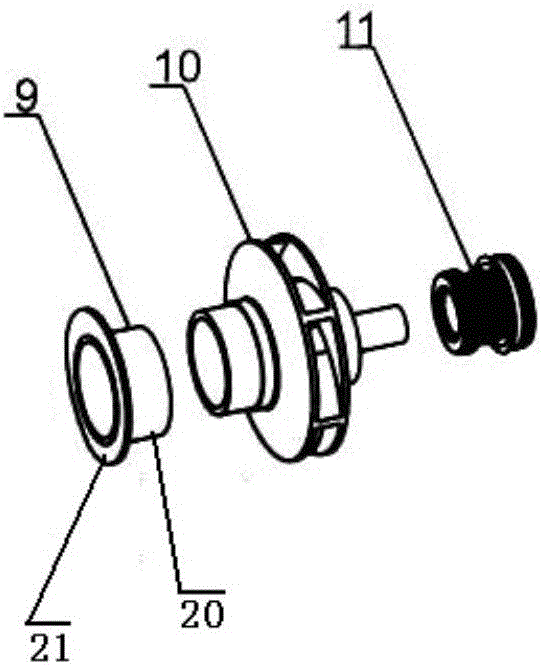

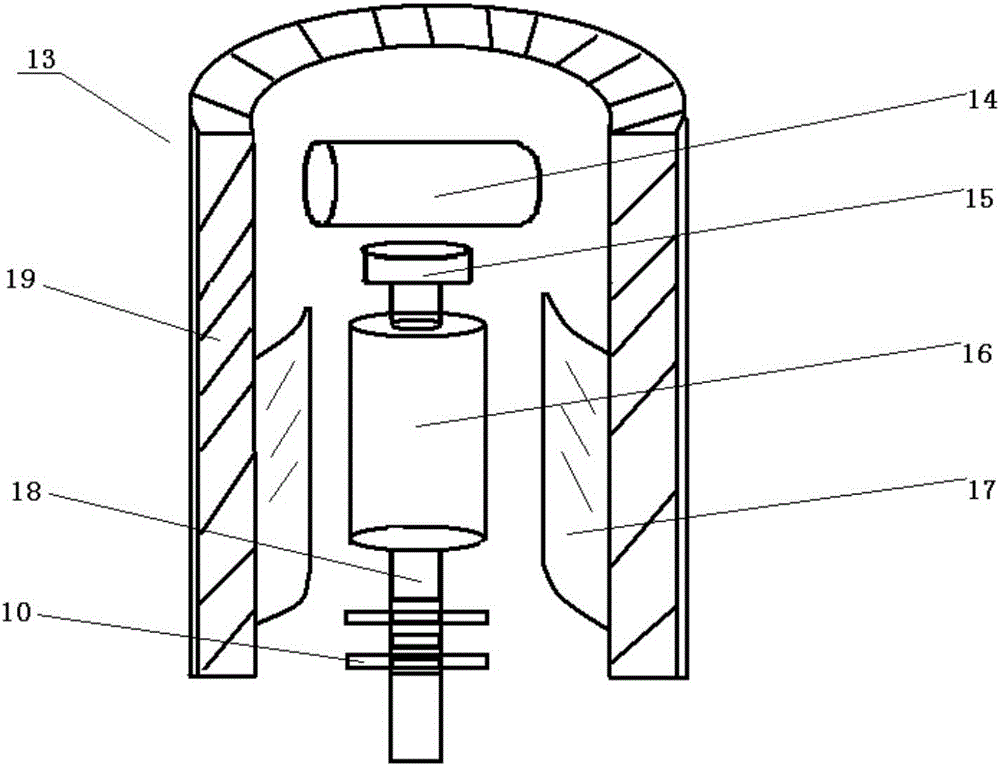

Special SPA circulating pump

ActiveCN105673520AAchieve separationAchieving Zero LeakagePump componentsMagnetic circuit stationary partsInterference fitImpeller

The invention provides a special SPA circulating pump which comprises a pump case assembly (12), an impeller (10), bearings (18), a pump cover (7) and a motor (13). The impeller (10) is connected to the corresponding bearing (18) through a shaft sleeve in a sleeving mode. The impeller (10) makes contact with the pump cover (7) through a movable impeller opening cup (9) and a big O-shaped ring (8). The movable impeller opening cup (9) comprises a sleeve (20) and an end ring (21). The outer diameter of the end ring (21) is two to three times that of the sleeve (20). The outer wall of the shaft sleeve is sleeved with the sleeve (20). The end ring (21) is in interference fit with an inner hole of the pump cover (7). The motor (13) comprises a stator (17) with a winding and a rotor (16), wherein the stator (17) and the rotor (16) are located in a motor shell (19). The two ends of the rotor (16) are connected in series with a deep groove ball bearing head (15) and the impeller (10) through the bearings (18) correspondingly. The deep groove ball bearing head (15) is matched with a capacitor (14). The special SPA circulating pump is low in ventilation noise and capable of continuously and reliably operating in a moisture environment, and the problem that water leakage of a mechanical seal is caused by the quality or service life of the mechanical seal of a traditional circulating pump is solved.

Owner:GUANGDONG LINGXIAO PUMP IND

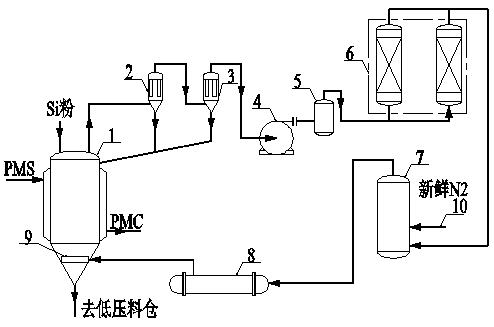

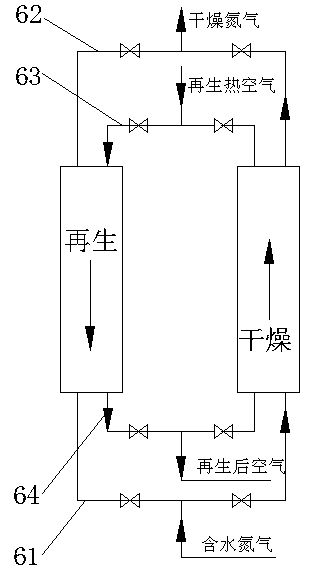

Silica powder drying and nitrogen recycling device

The invention discloses a silica powder drying and nitrogen recycling device which comprises a silica powder dryer, wherein an air inlet, an air outlet, a feed port and a discharge port are formed inthe silica powder dryer, the recycling device further comprises a filter, a gas-liquid separator, a dehydration prying block and a nitrogen heater, the filter is connected with the silica powder dryer, the gas-liquid separator is connected with the filter, the dehydration prying block is connected with the gas-liquid separator, the nitrogen heater is connected with the dehydration prying block which comprises two towers filled with adsorbents, the two towers perform drying and recycling alternatively, an air inlet, an air outlet, a feed port and a discharge port are formed in the filter, the air outlet of the silica powder dryer is connected with the air inlet of the filter, the discharge port of the filter is connected with the silica powder dryer, the air exhausted by the air outlet of the filter is fed into the gas-liquid separator, the air exhausted from the gas-liquid separator is fed into the dehydration prying block, the dried air dried by the dehydration prying block is fed into the nitrogen heater, and nitrogen heated by the nitrogen heater is fed into the air inlet of the silica powder dryer.

Owner:SINOPEC NANJING ENG & CONSTR +1

FPGA-based information security maintenance method

ActiveCN110795754AContinuous and reliable uptimeUndamagedDigital data protectionData securityIndustrial control system

The invention belongs to the technical field of industrial control systems, and particularly relates to an FPGA-based maintenance information security method. According to the technical scheme, the FPGA-based maintenance information security method can strengthen data security of a distributed control system (DCS) and an engineer station, encrypt and sign communication, and ensure that the controlsystem can still normally and reliably operate when receiving malicious attacks.

Owner:CHINA NUCLEAR CONTROL SYST ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com