Extruding-separating device for dry and wet separation of municipal solid waste

A technology for separation of municipal solid waste from wet and dry, applied in the field of waste treatment equipment, can solve problems such as imperfection, complex composition of waste, corrosive substances, hard objects mixed in it, and meet the requirements of reducing energy and meeting the index requirements of moisture content , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

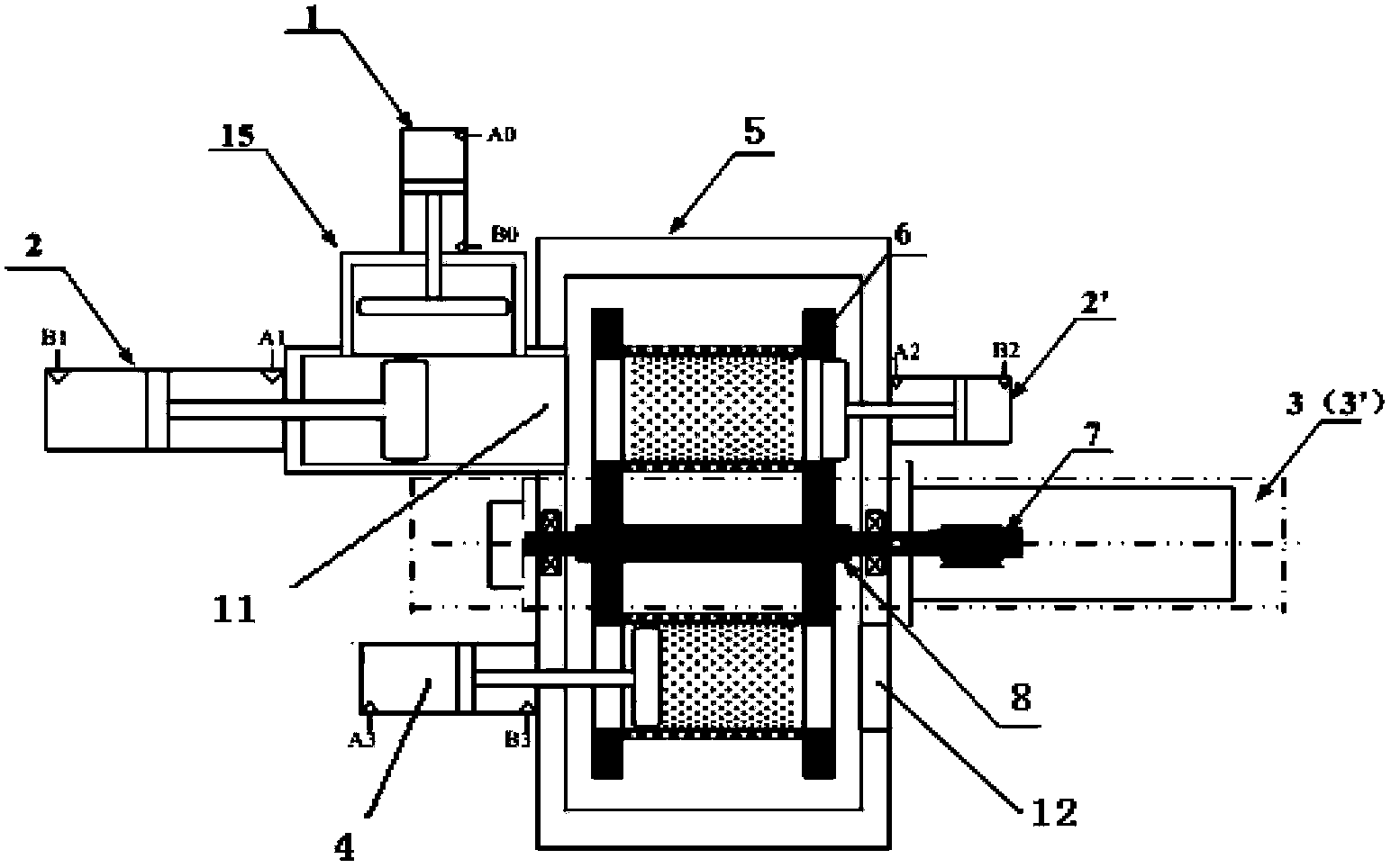

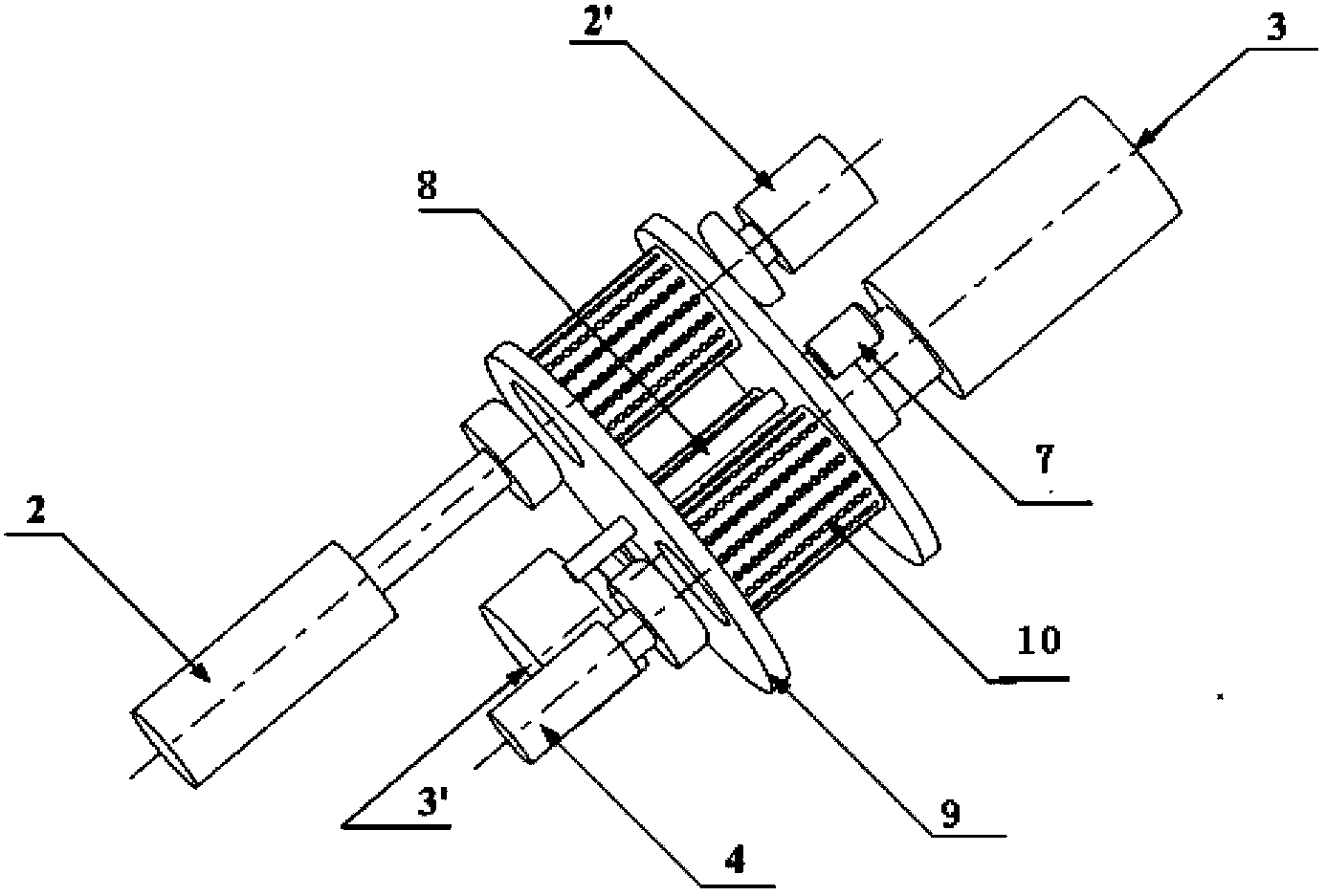

[0025] Such as figure 1 , 2 , 3 and 4, an extrusion separation device for dry-wet separation of municipal solid waste, including feeding mechanism 1, pre-pressing mechanism 2 and 2', extrusion mechanism 3 and 3', discharge mechanism 4, body 5. The rotating mechanism 6 and the driving mechanism 7.

[0026] The feeding mechanism 1 is a hydraulic cylinder propulsion structure; the pre-pressing mechanism 2 and 2' is a pair of 10Mpa-50Mpa hydraulic cylinder structure distributed on top; the extrusion mechanism 3 and 3' is a 50Mpa-100Mpa hydraulic cylinder distributed on top structure, that is, a pressurized hydraulic cylinder, and a hydraulic cylinder structure that can withstand high pressure on the top; the discharge mechanism 4 is a hydraulic cylinder structure. The rotating mechanism 6 is arranged on the central axis inside the machine body 5 . A feeding mechanism 1, a pre-pressing mechanism 2 and 2', an extruding mechanism 3 and 3', a discharge mechanism 4 and a driving mec...

Embodiment 2

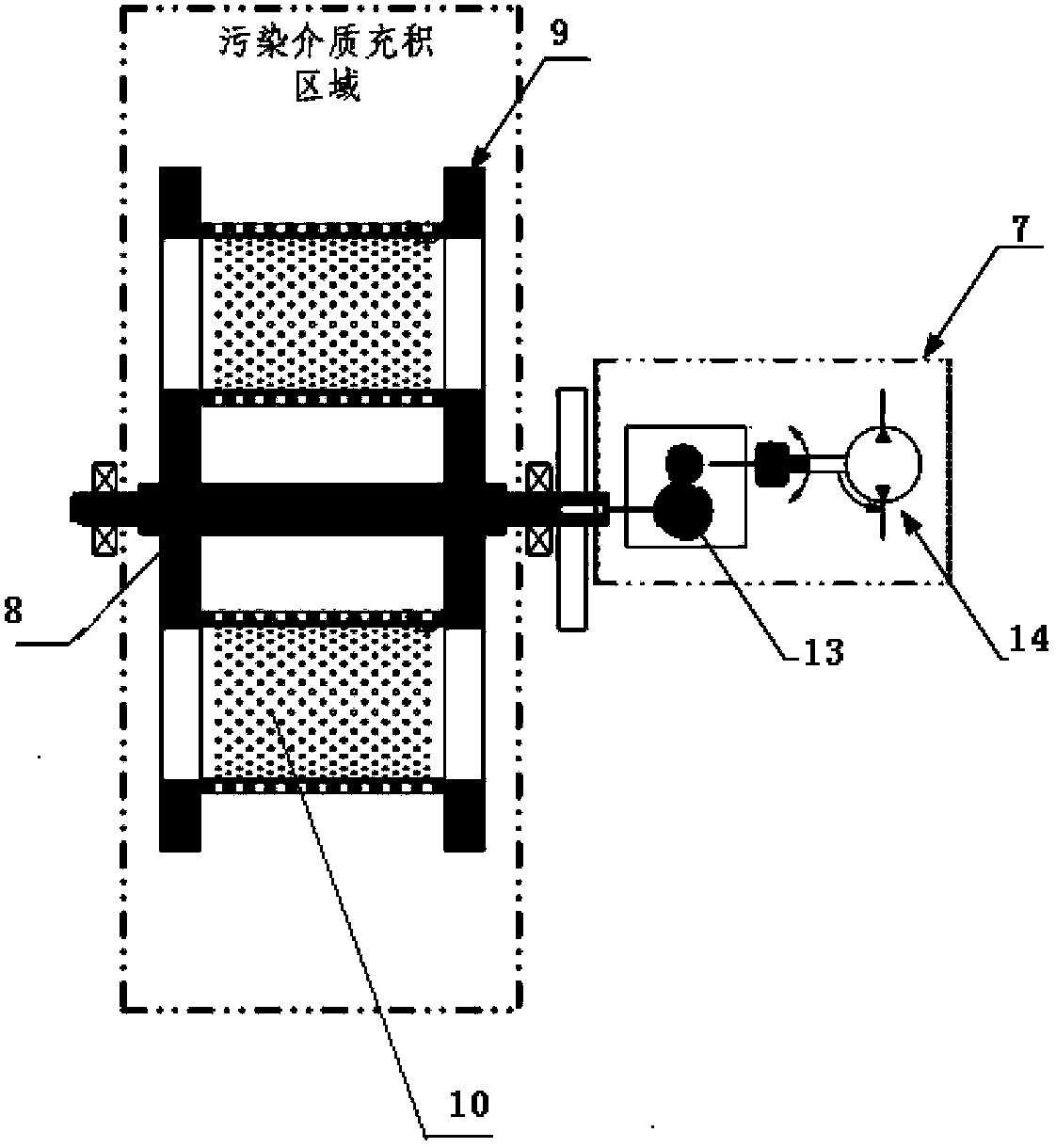

[0030] Such as Image 6 , 7 As shown, another extrusion separation device for dry-wet separation of MSW is different from Embodiment 1 in that: the outer circumference of the turntable 9 is provided with teeth, and the rotation mechanism 6 and the drive mechanism 7 are arranged in parallel.

[0031] The driving mechanism 7 includes a reducer 13 and a hydraulic motor 14. The reducer 13 is arranged inside the body 5, and the hydraulic motor 14 is arranged outside the body 5. The output shaft of the hydraulic motor 14 is connected to the shaft of the reducer 13, and the reducer 13 adopts a gear Box, the rotation of the turntable 9 is realized by means of the gear of the gear box meshing with the teeth on the turntable 9, and the parallel arrangement of the rotation mechanism 6 and the drive mechanism 7 is realized.

[0032] The working process of the present invention: the feeding mechanism 1 transfers the garbage into the device and sends it to the working surfaces of the pre-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com