Patents

Literature

88results about How to "With tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

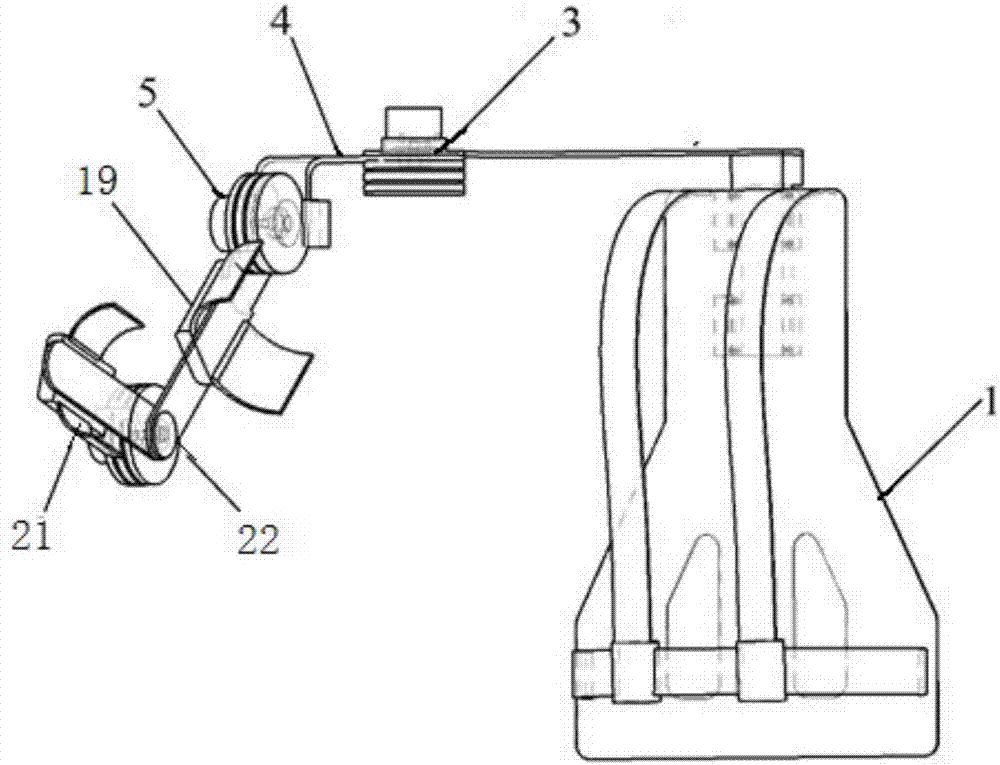

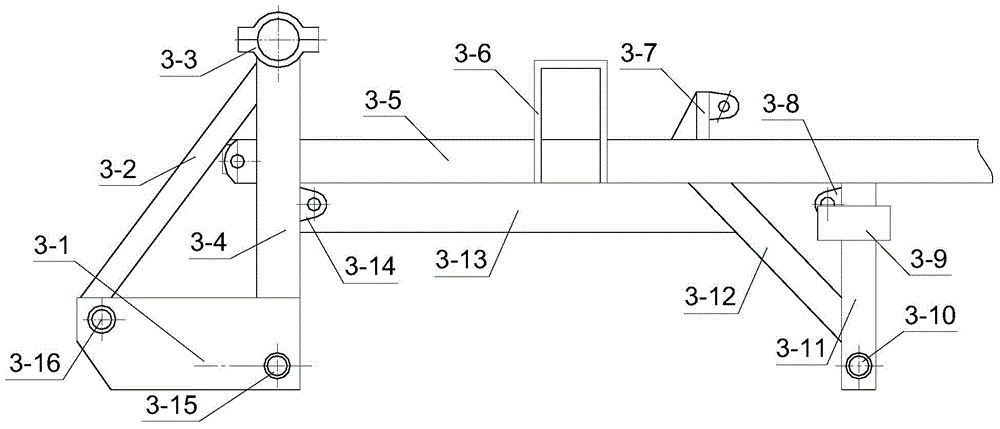

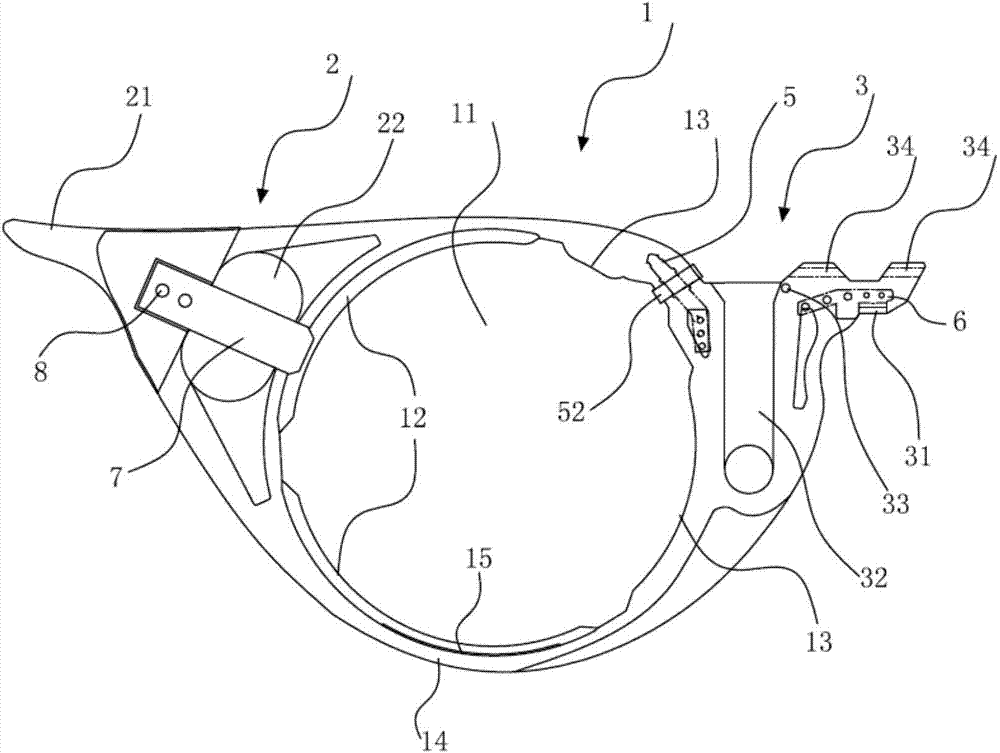

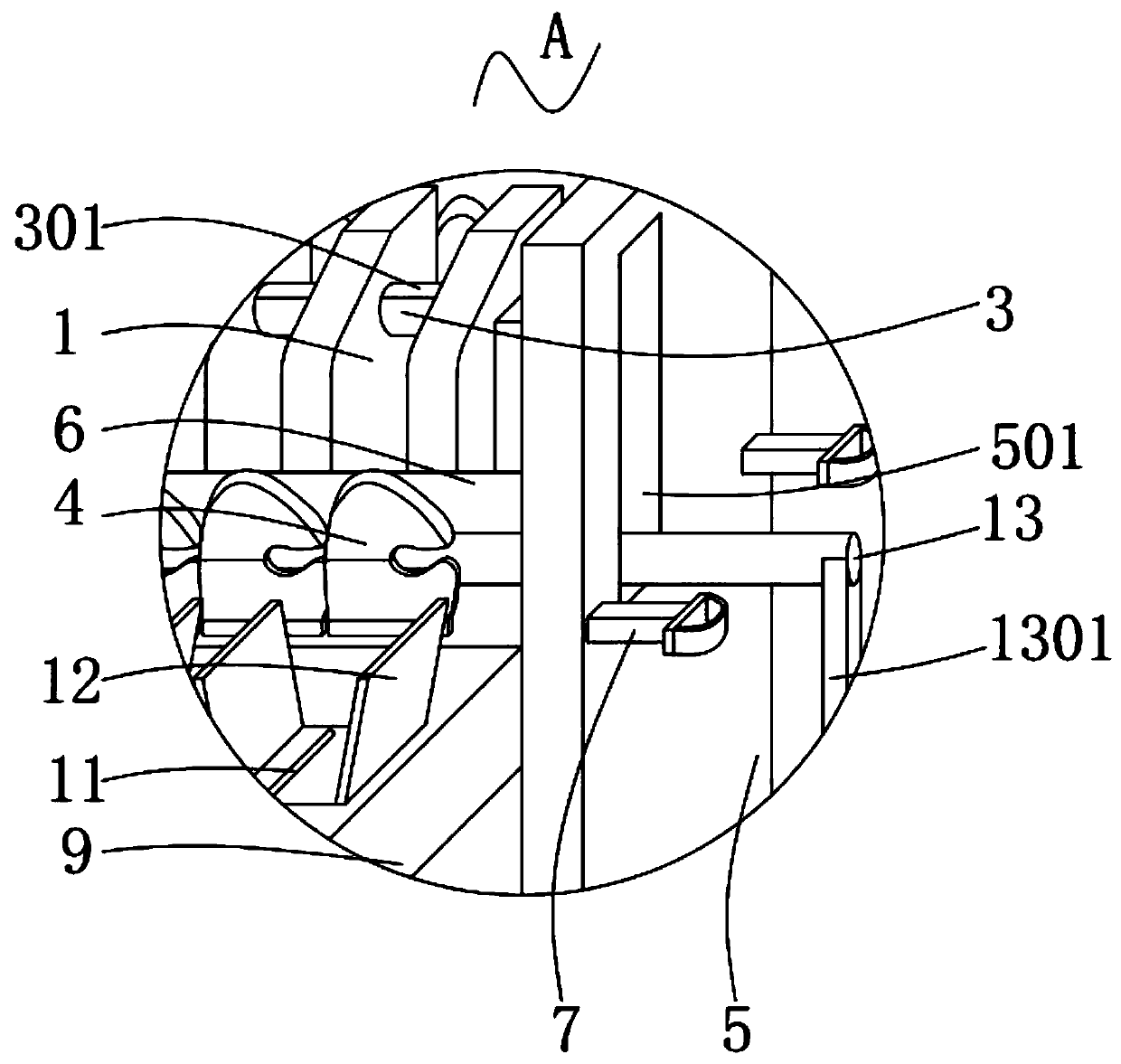

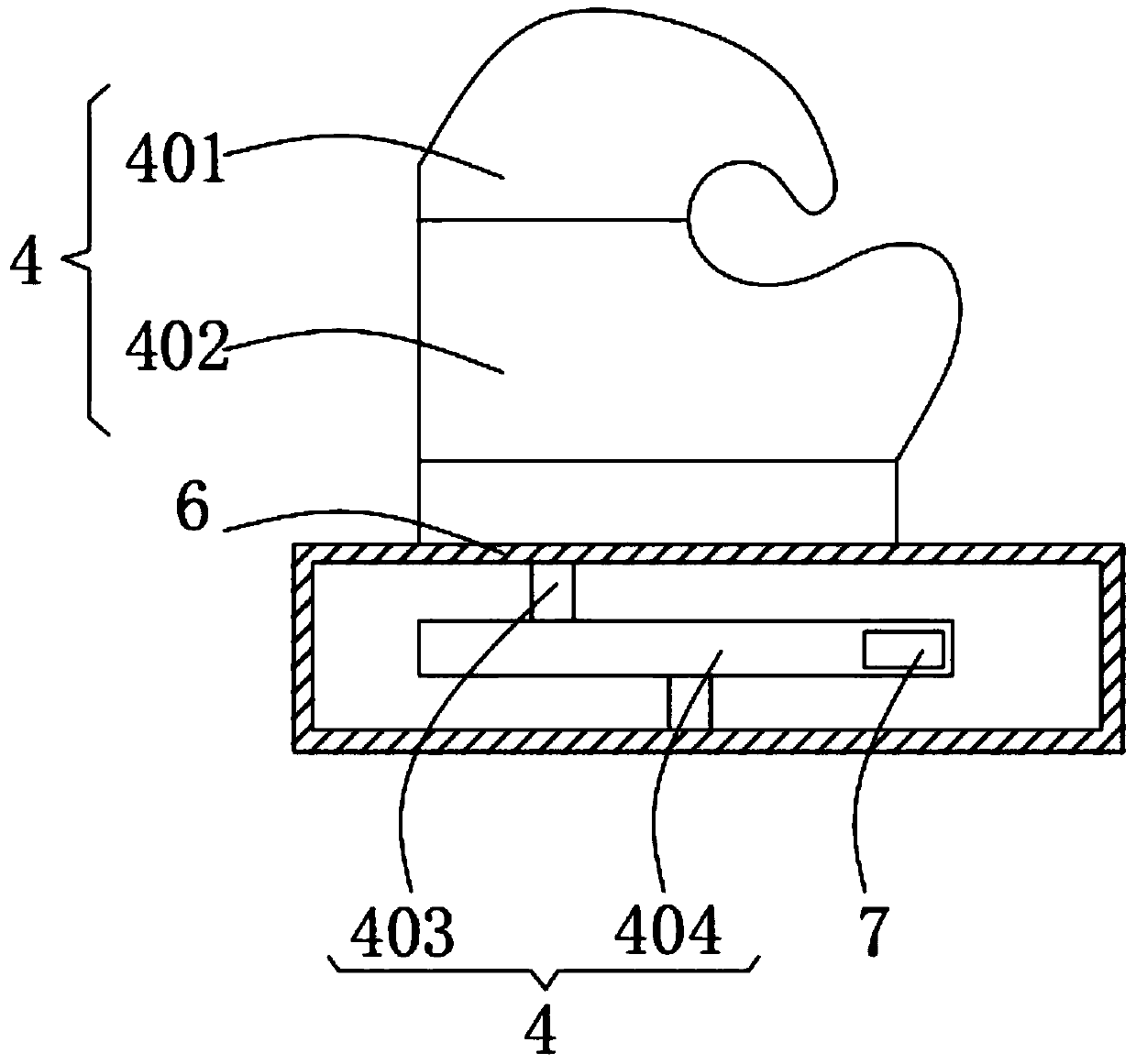

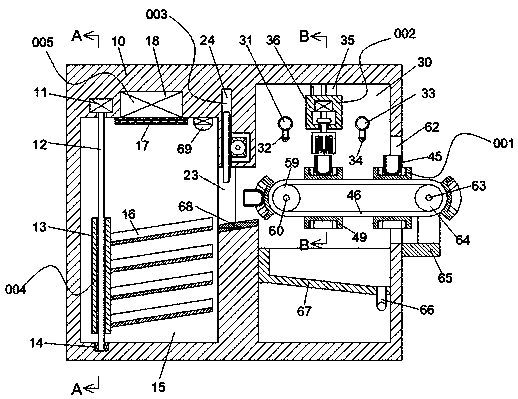

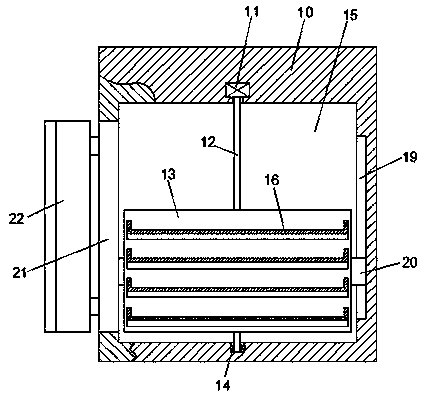

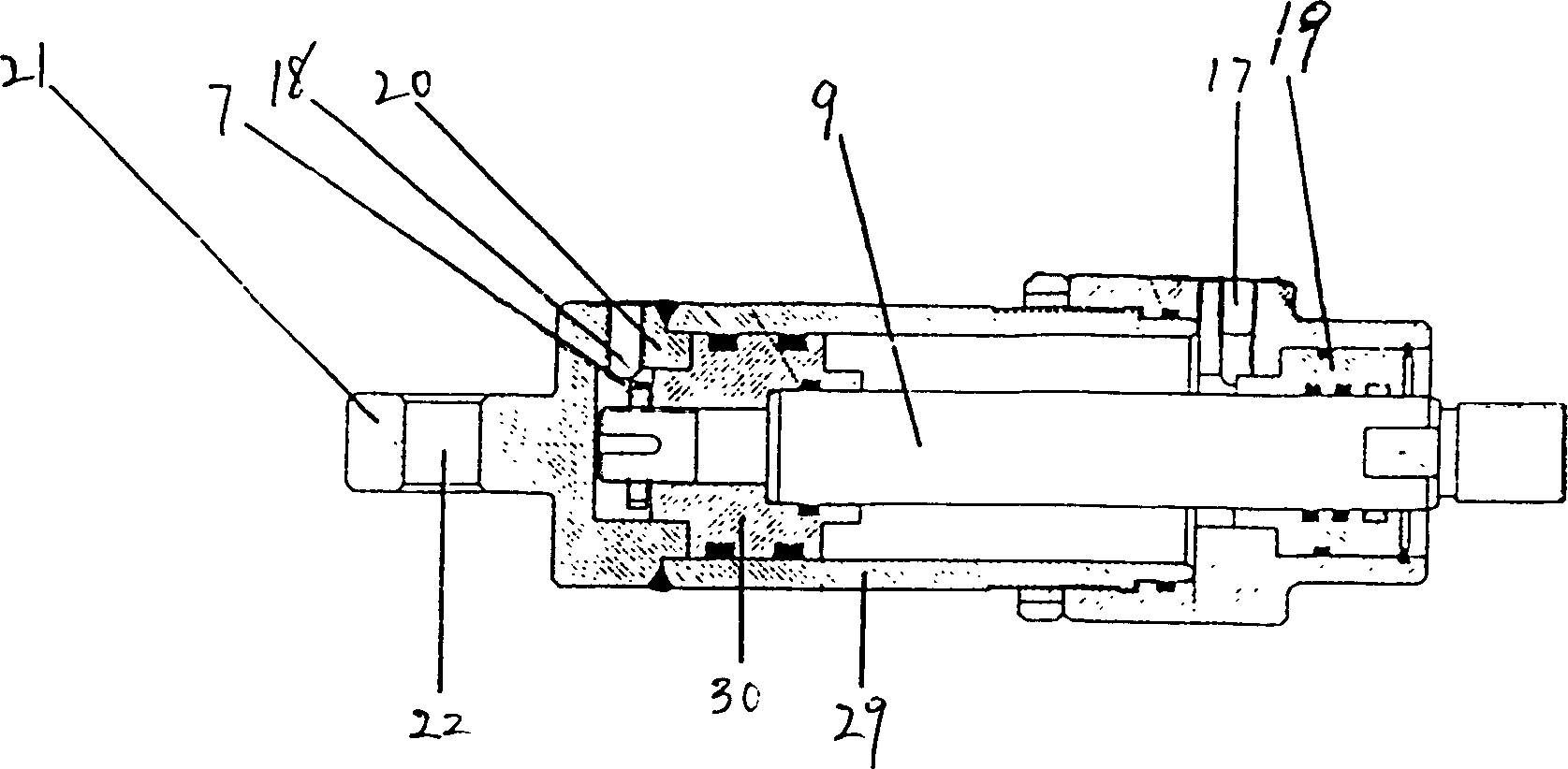

Wearable upper limb exoskeleton rehabilitation device

ActiveCN107374907AWith synergistic rehabilitationIt has the following beneficial effects: the present invention utilizes a wearable structure to realize collaborative rehabilitationChiropractic devicesEngineeringWinch

The invention provides a wearable upper limb exoskeleton rehabilitation device, which includes a fixed backboard served as a base; a driver module can make torque force transfer to each joint by Bowden cable; an exoskeleton module of elbow join is used for coupled rehabilitation movement. rehabilitative training of the elbow, coupled rehabilitation of forearm and exoskeleton of the upper arm and the exoskeleton; a mechanical hard limit device for joint, can achieve mechanical hard limit protection for a forearm connecting rod and a upper arm connecting rod; a three direction adjustable adaptive module, the position of joint winch in the shoulder adduction is adjusted to adopt different somatotype of the patients; a shoulder joint module, the shoulder joint module can achieve rehabilitation training for abduction degree of freedom in the shoulder and rehabilitation training of shoulder flexion and extension degree. The Wearable upper limb exoskeleton rehabilitation device makes use of the wearable structure to realize the free movement of patients during rehabilitation training.

Owner:SHANGHAI JIAO TONG UNIV

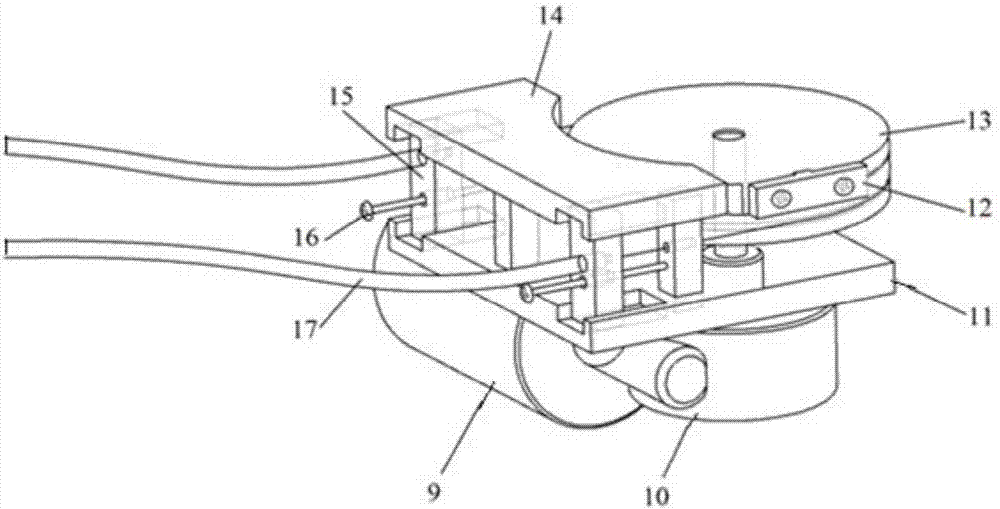

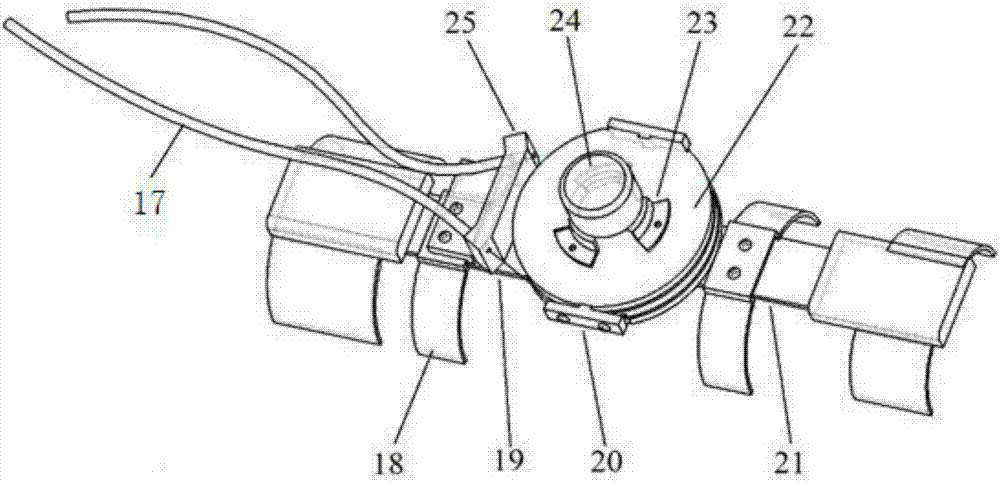

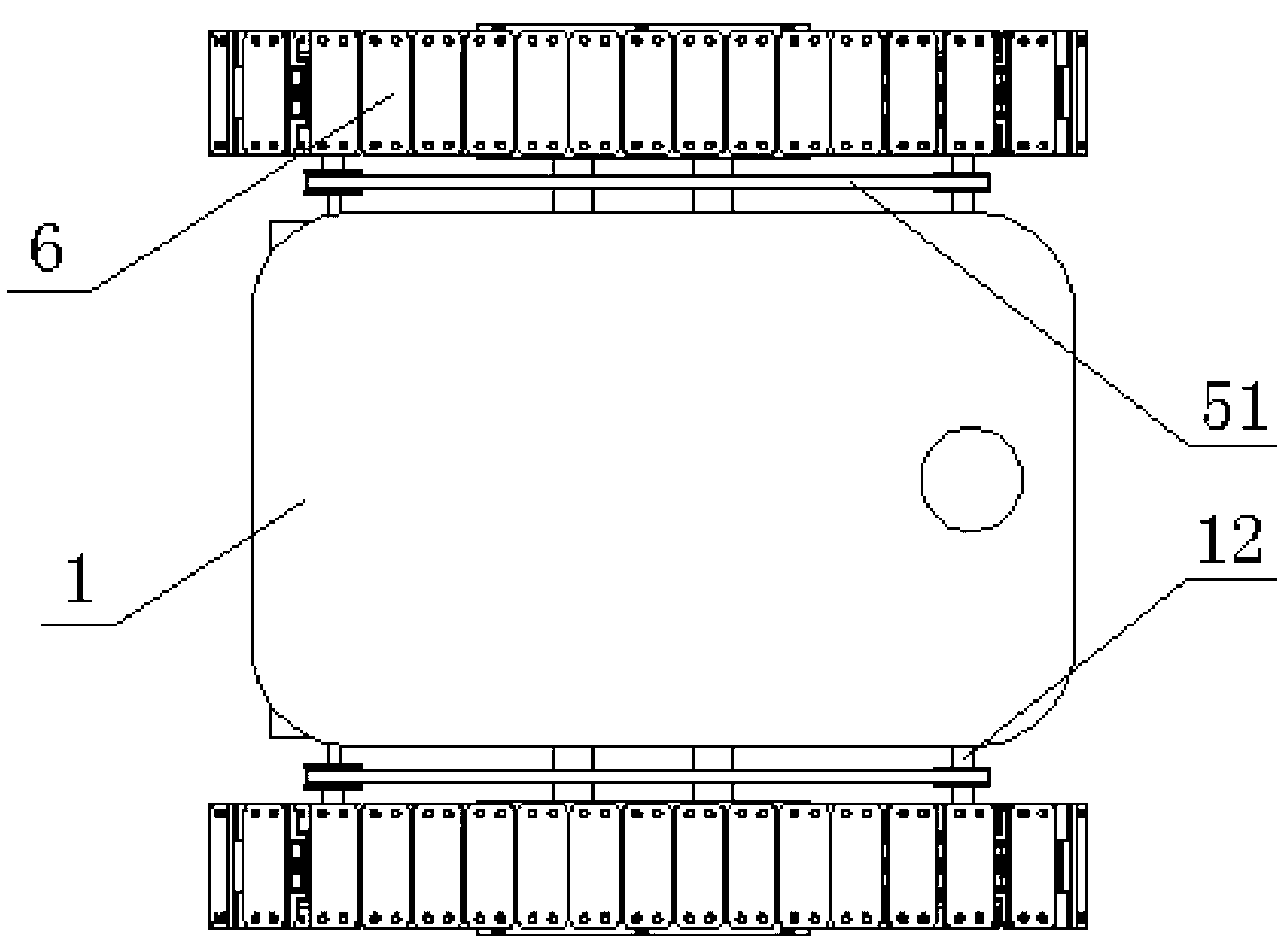

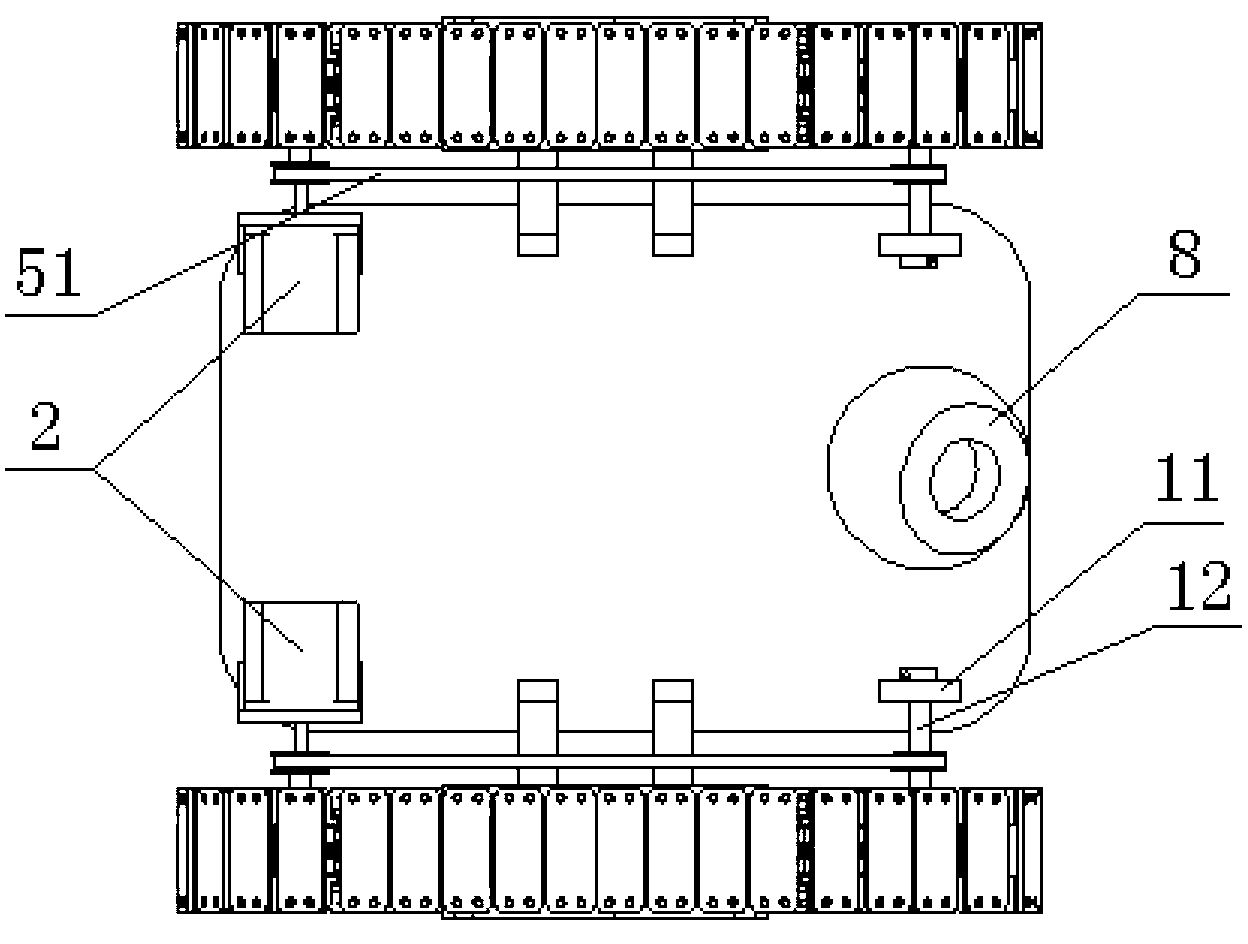

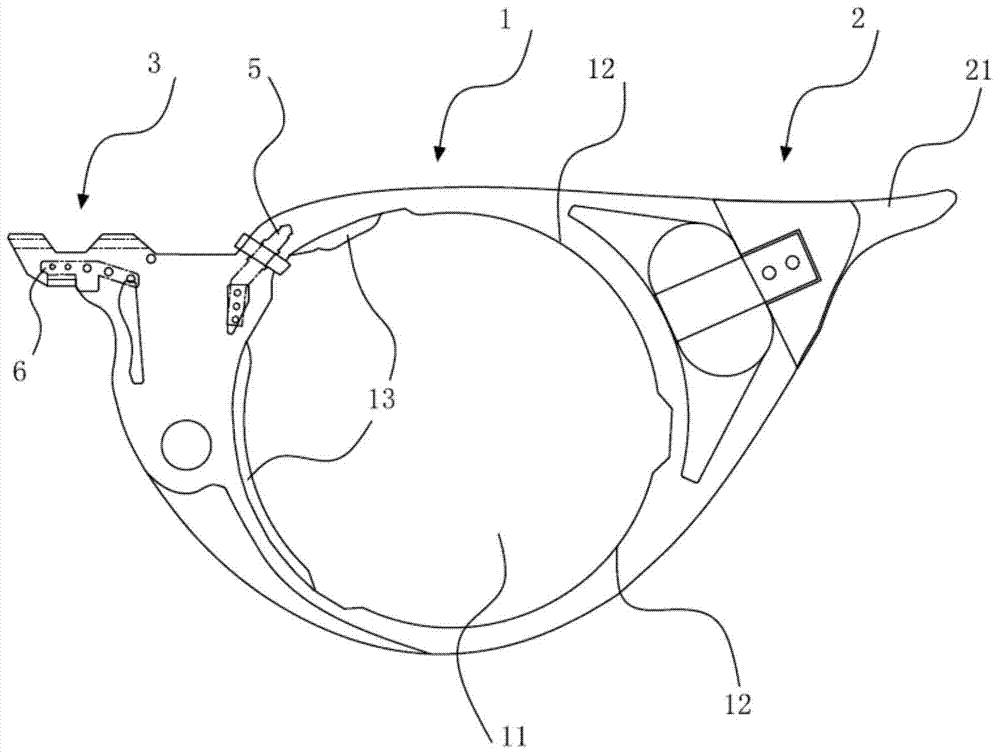

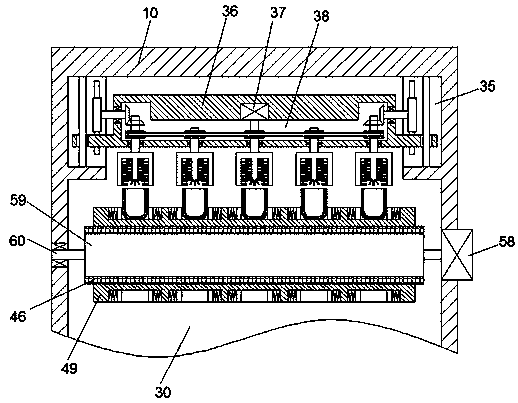

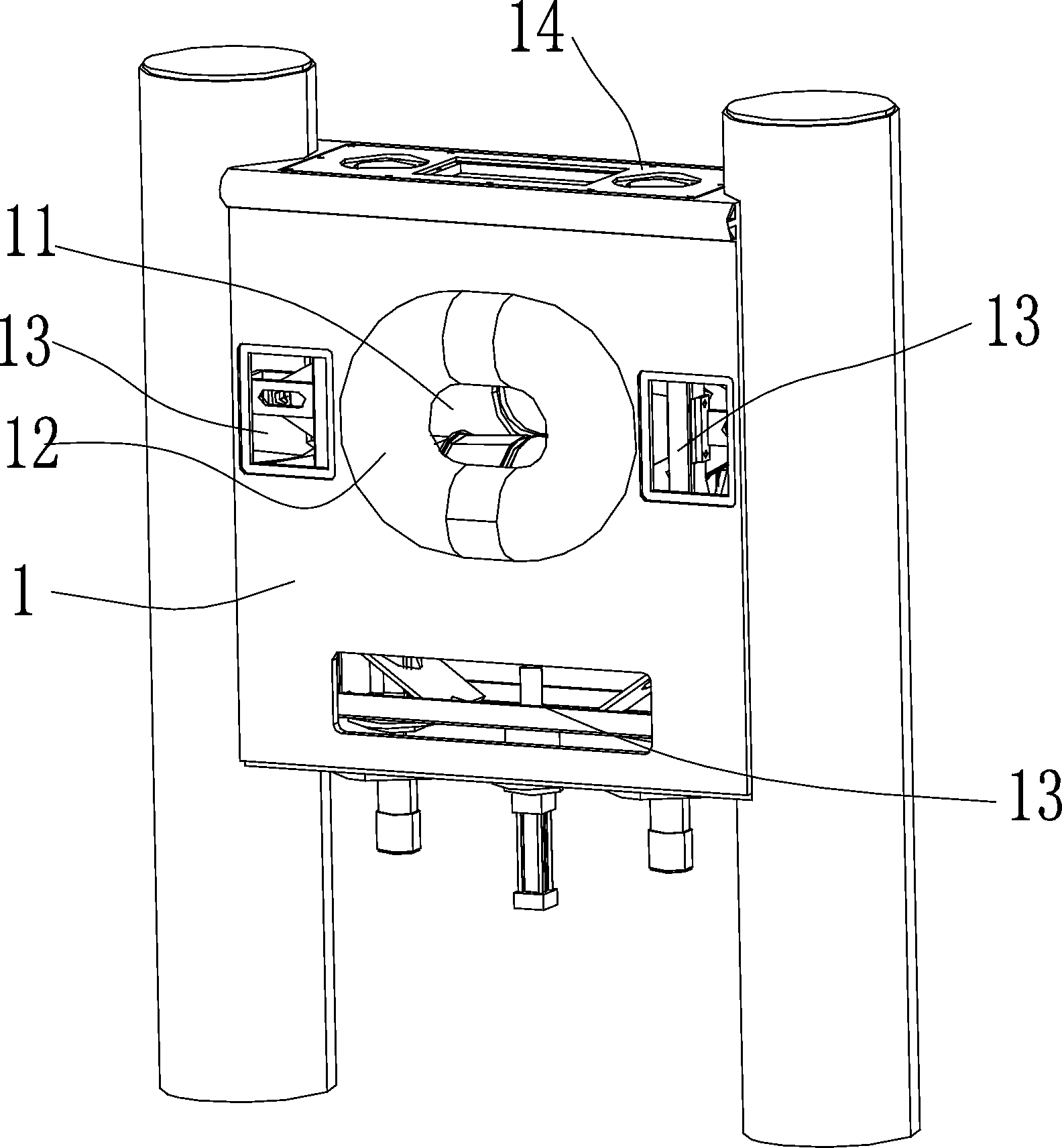

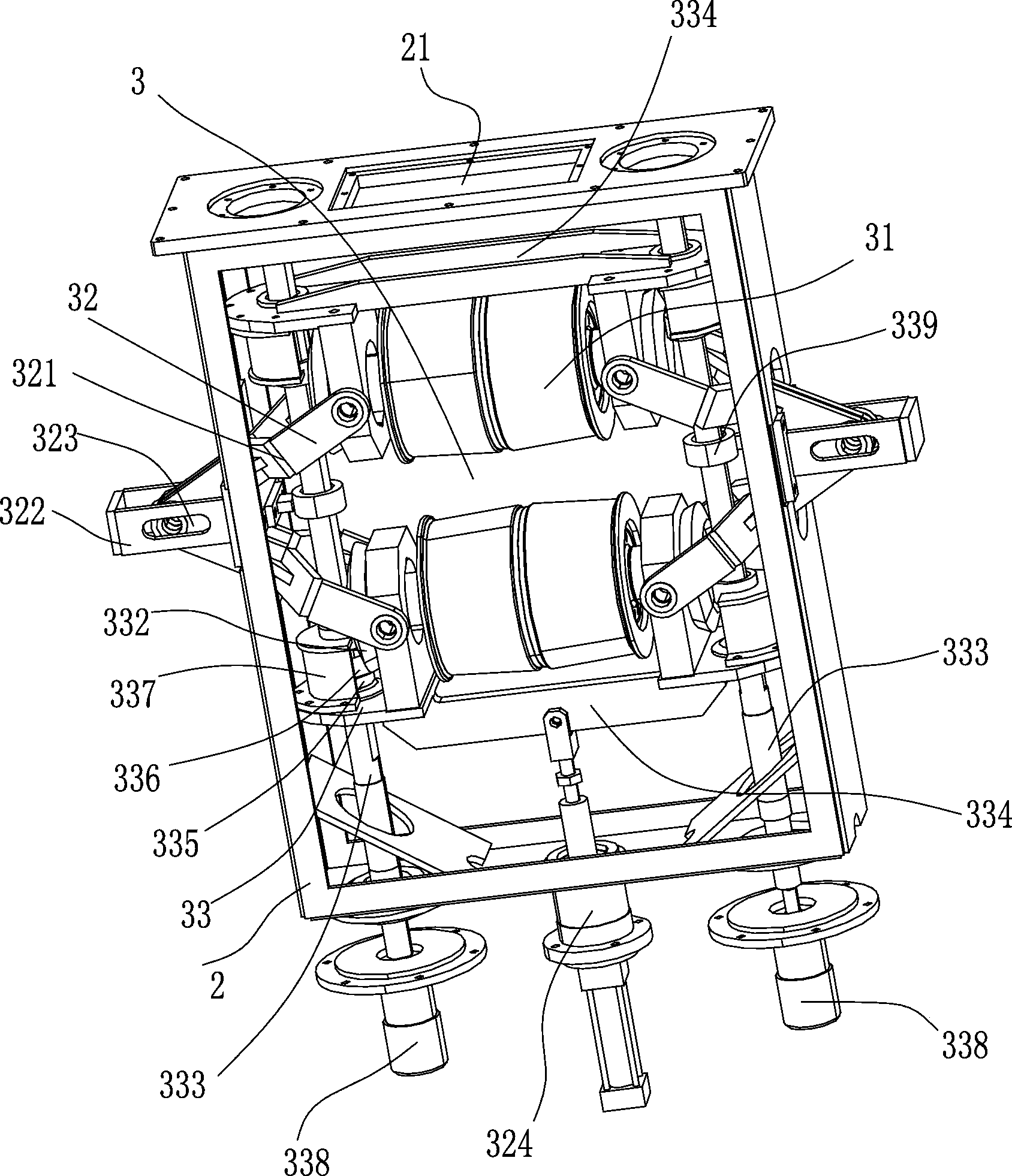

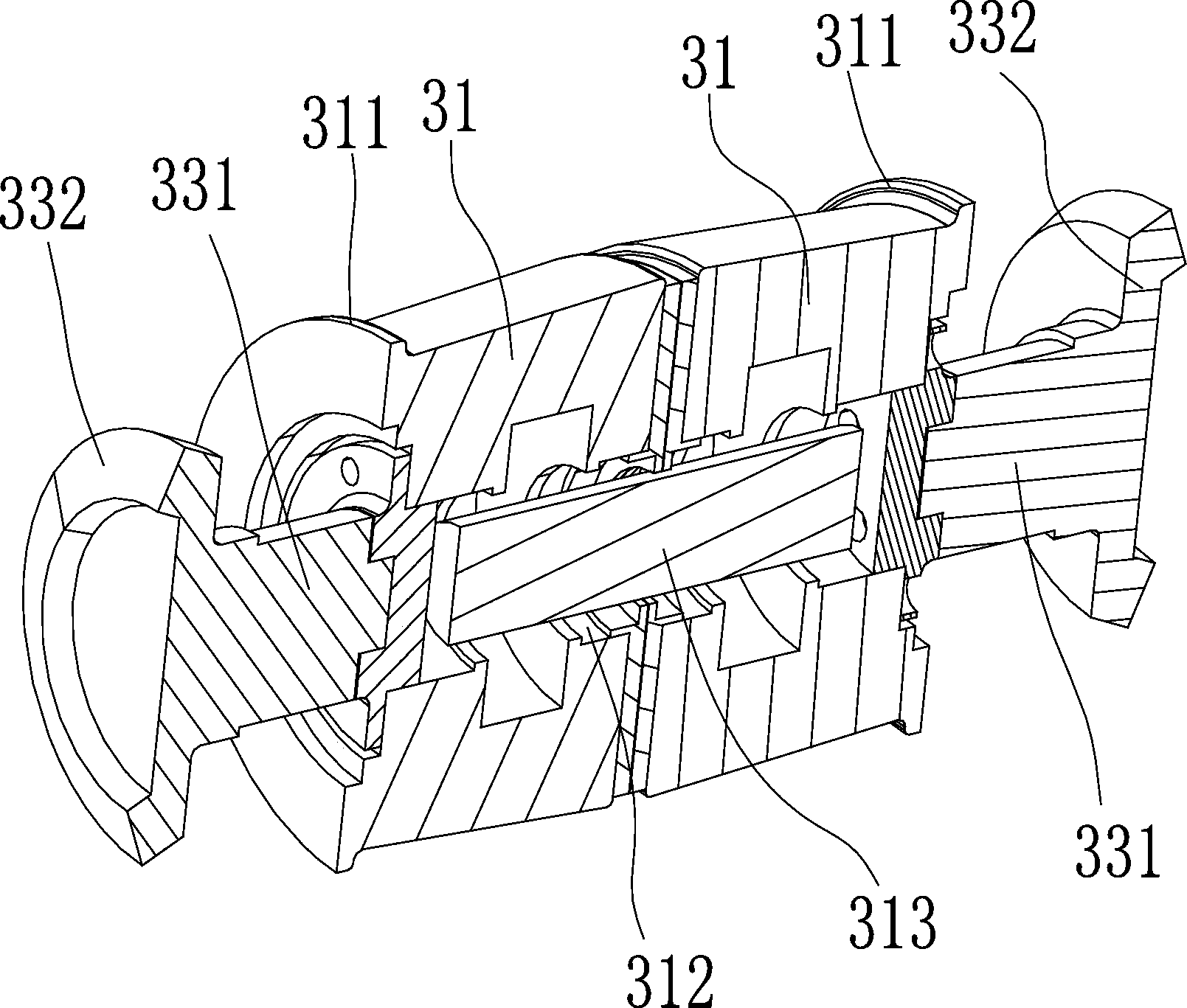

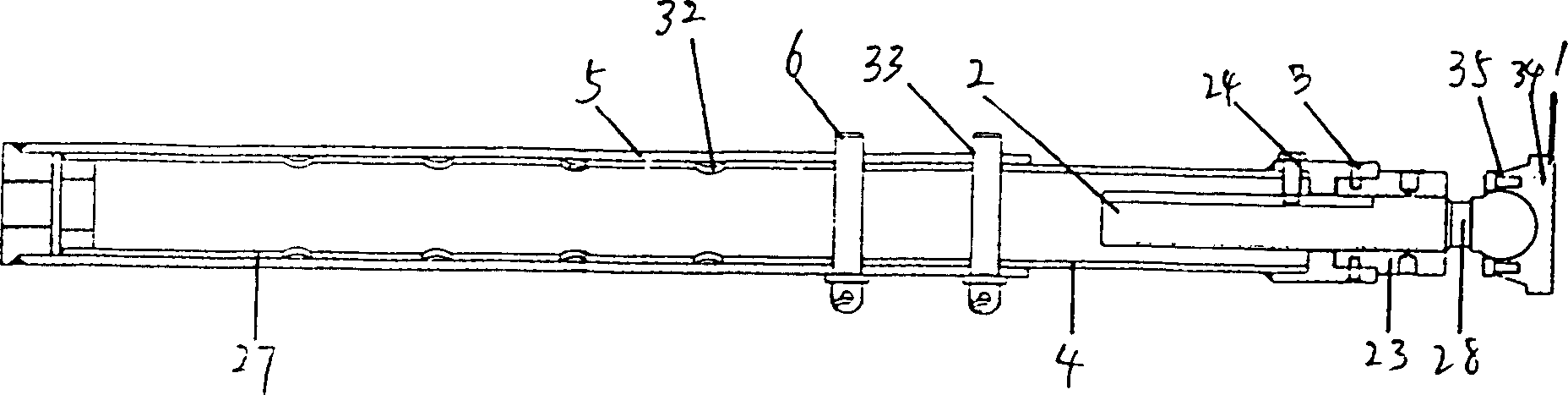

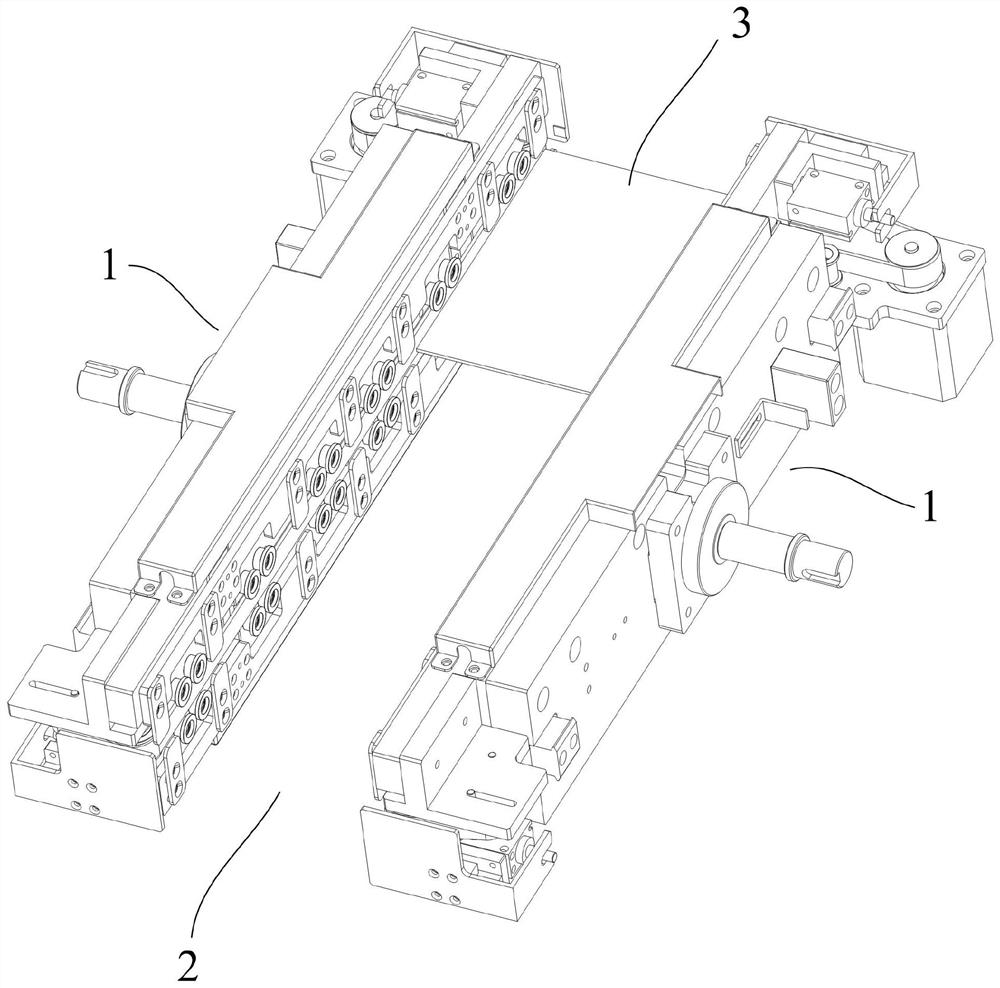

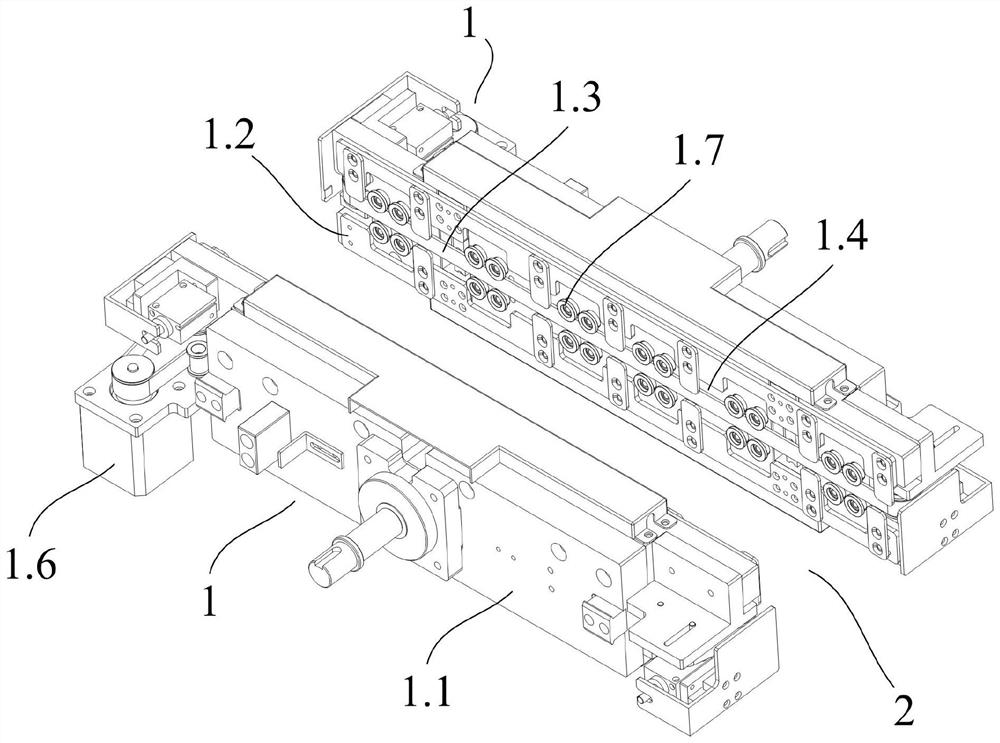

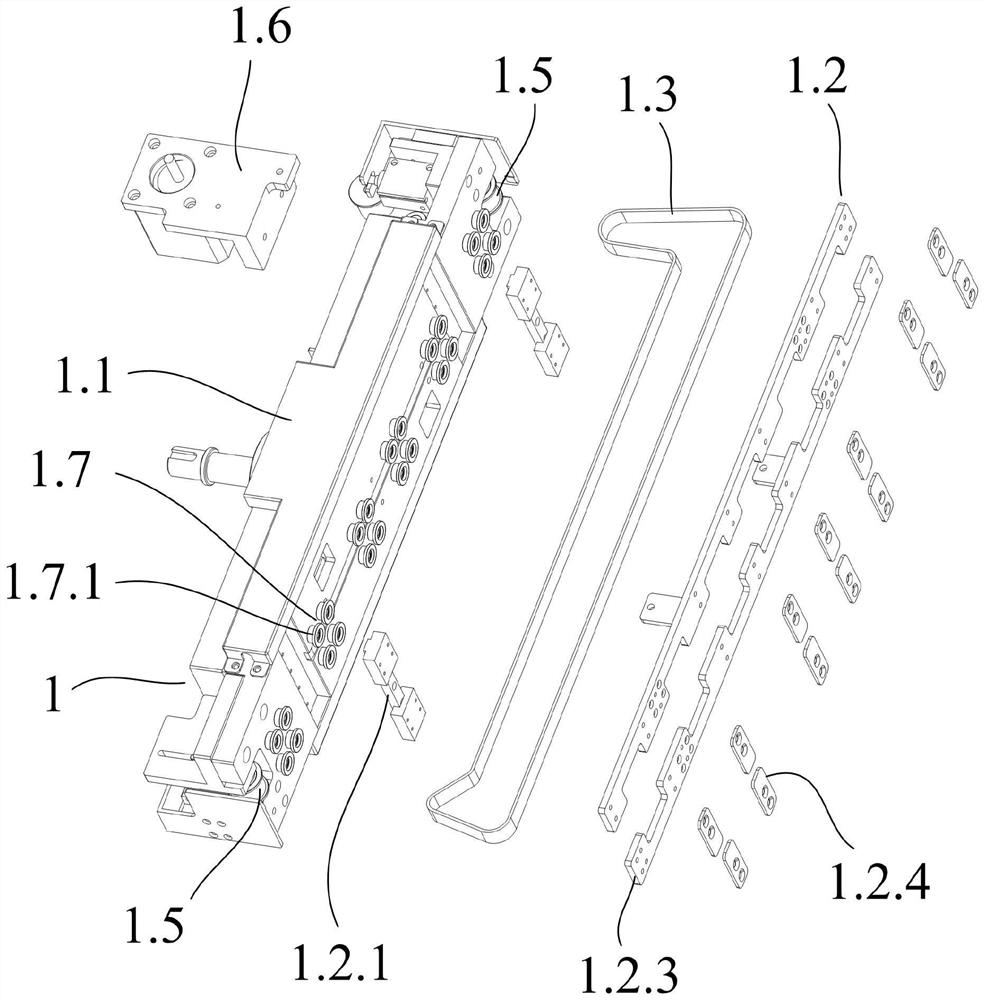

Curved surface self-adaption magnetic adsorption wall-climbing robot

The invention discloses a curved surface self-adaption magnetic adsorption wall-climbing robot, which includes a vehicle body and chain driving assemblies arranged on the two sides of the vehicle body, wherein each chain driving assembly includes a driving motor, a driving chain wheel and a driven chain wheel; each driving motor is fixedly mounted at the bottom of the vehicle body; the driving chain wheels are coaxially and fixedly mounted on driving shafts of the driving motors; and the driven chain wheels are coupled at the bottom of the vehicle body. The curved surface self-adaption magnetic adsorption wall-climbing robot is characterized in that a magnetic chain is arranged between each driving chain wheel and each driven chain wheel; and self-adaption mechanisms are fixedly mounted on the two sides of the vehicle body respectively, and each self-adaption mechanism is positioned on the magnetic chain on the same side where the self-adaption mechanism is arranged. The curved surface self-adaption magnetic adsorption wall-climbing robot has the advantages that the self-adaption mechanisms arranged on the inner sides of the magnetic chains can better clung to and fit with the warped curved surface when the wall-climbing robot walks on a steel curved surface or a warped wall surface, so that the magnetic adsorption area is enlarged, the adsorption efficiency is improved, and the exercise safety performance of the wall-climbing robot is improved, and as lifting wheels arranged on connecting racks can be used for tensioning the magnetic chains, chain slippage and dropping can be prevented during the movement of the wall-climbing robot, and the wall-climbing robot can adapt to and climb the wall with an upright even inverted warped curved surface.

Owner:NINGBO UNIV

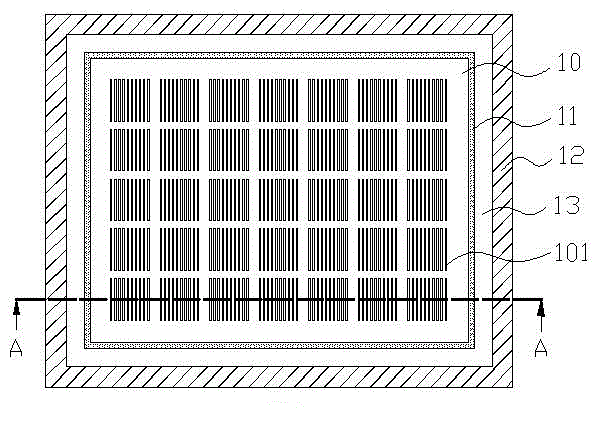

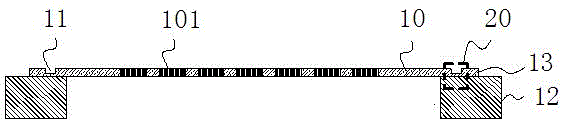

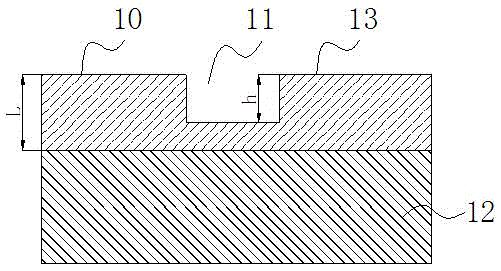

Mask assembly

InactiveCN104372291AWeld firmlyWith tensionElectrical apparatusElectroluminescent light sourcesEngineeringMetal

The present invention discloses a mask assembly, which comprises a mask plate, an outer frame and auxiliary welding strips, wherein the mask plate is provided with a mask pattern and a semi-etching zone, the auxiliary welding strip is placed in the semi-etching zone, and the mask plate and the auxiliary welding strip are fixed on the outer frame through laser welding. With the mask assembly designed by the present invention, when the materials of the mask plate and the outer frame are different metal materials, the mask plate can be firmly welded on the outer frame through the auxiliary welding strip.

Owner:KUN SHAN POWER STENCIL

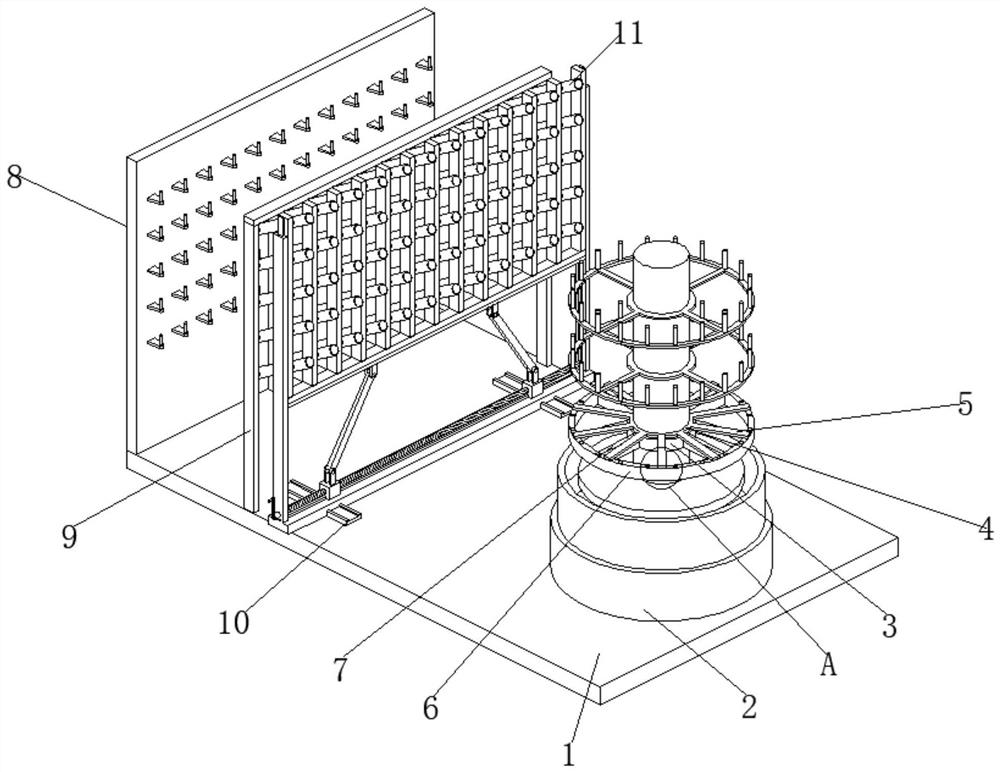

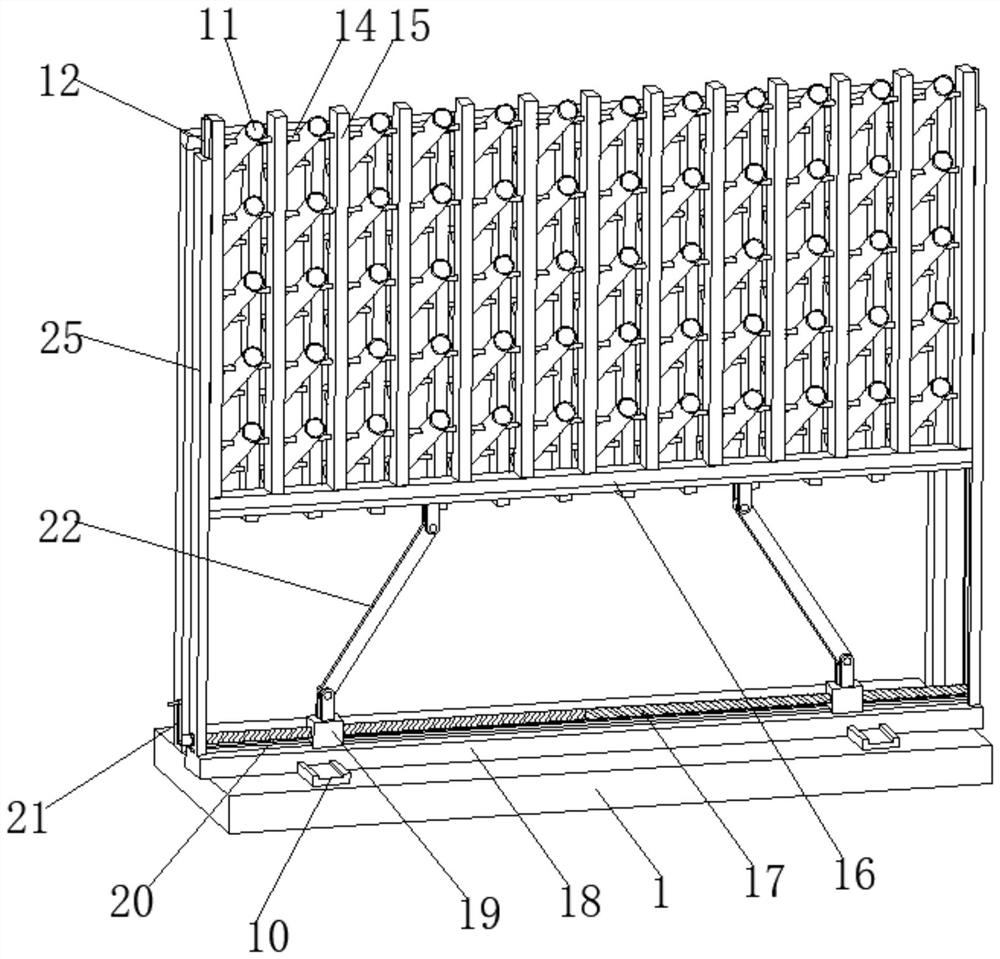

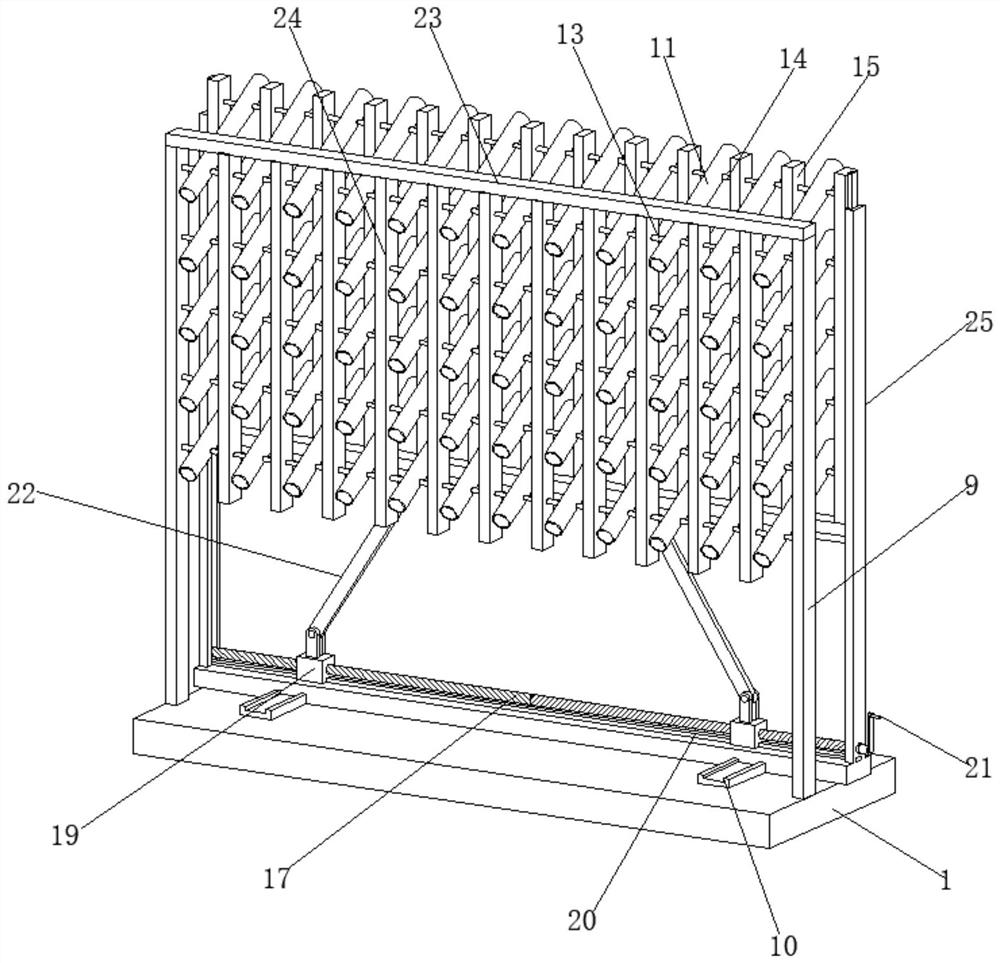

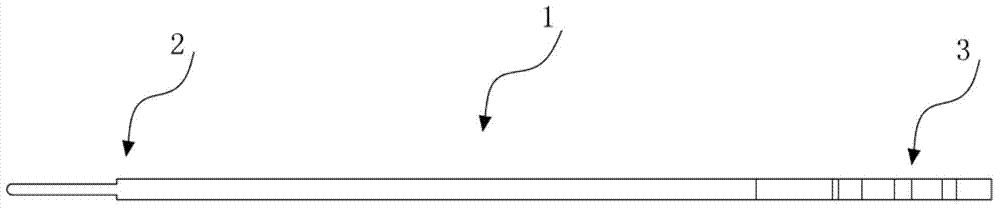

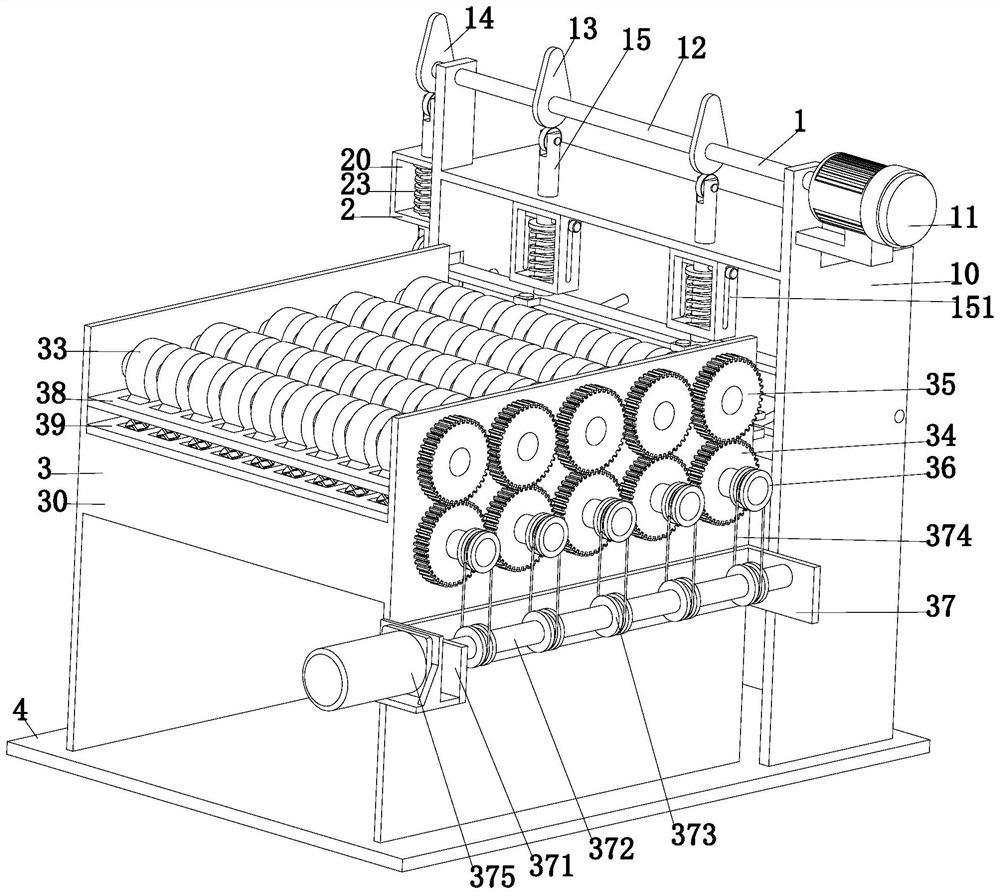

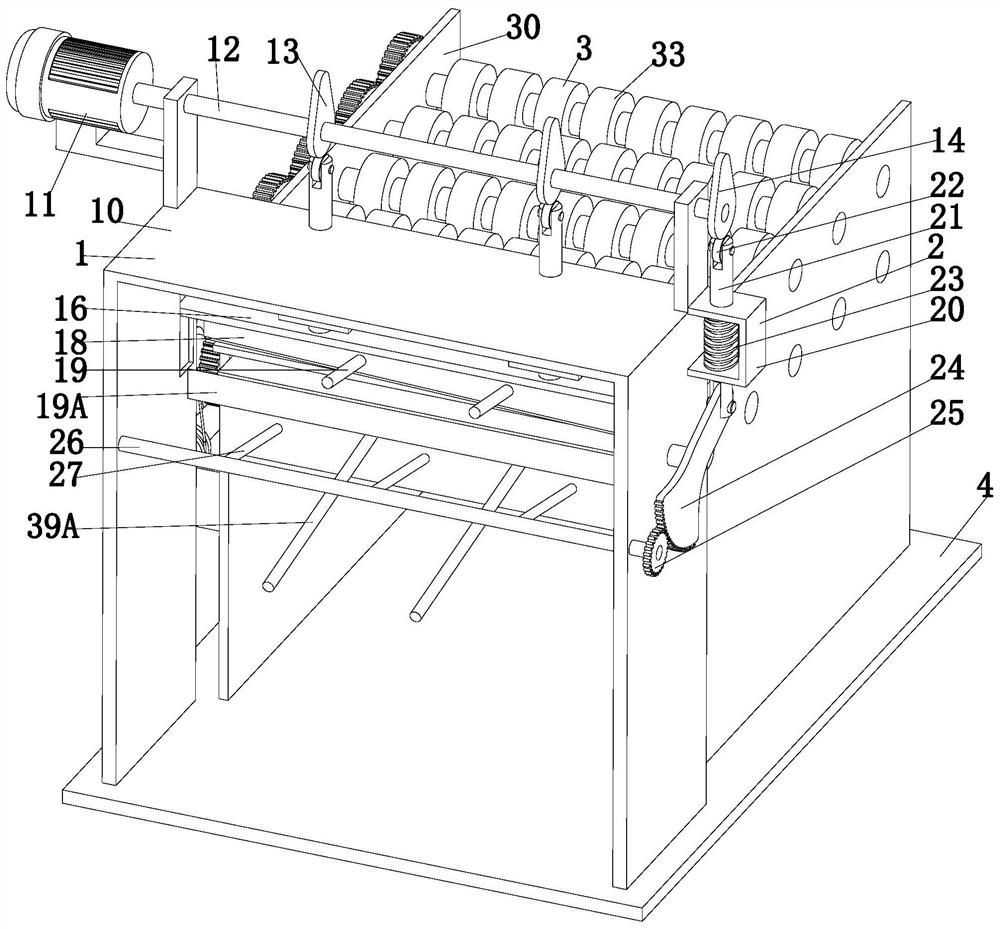

Thread passing device in knitted fabric knitting machine

The invention provides a thread passing device in a knitted fabric knitting machine, and relates to the field of knitting machine parts. The thread passing device in the knitted fabric knitting machine comprises a base. A yarn rack and a knitting machine body are fixedly connected to the top of the base. A fixing ring is fixedly connected to the knitting machine body. A plurality of connecting rods are fixedly connected to the outer side of the fixed ring. The connecting rods are equiangularly distributed with the fixed ring as the center. The end, away from the fixed ring, of the connecting rod is fixedly connected with a wire passing ring in a circular shape. The thread passing device in the knitted fabric knitting machine first draws the yarn on the yarn rack from a yarn cylinder and then passes through a thread passing tube to connect to the body, and then rotate a rotating handle, and the rotating handle drives the screw to rotate, so as to drive a lead screw to corporate with twocopper sleeves on a screw rod to be close to or away from each other. At this time, under the action of a linkage rod, a horizontal plate is driven to move up or down, and because of the first installation board and the second mounting board are hinged to the conduit.

Owner:绍兴柯桥三杰纺织品有限公司

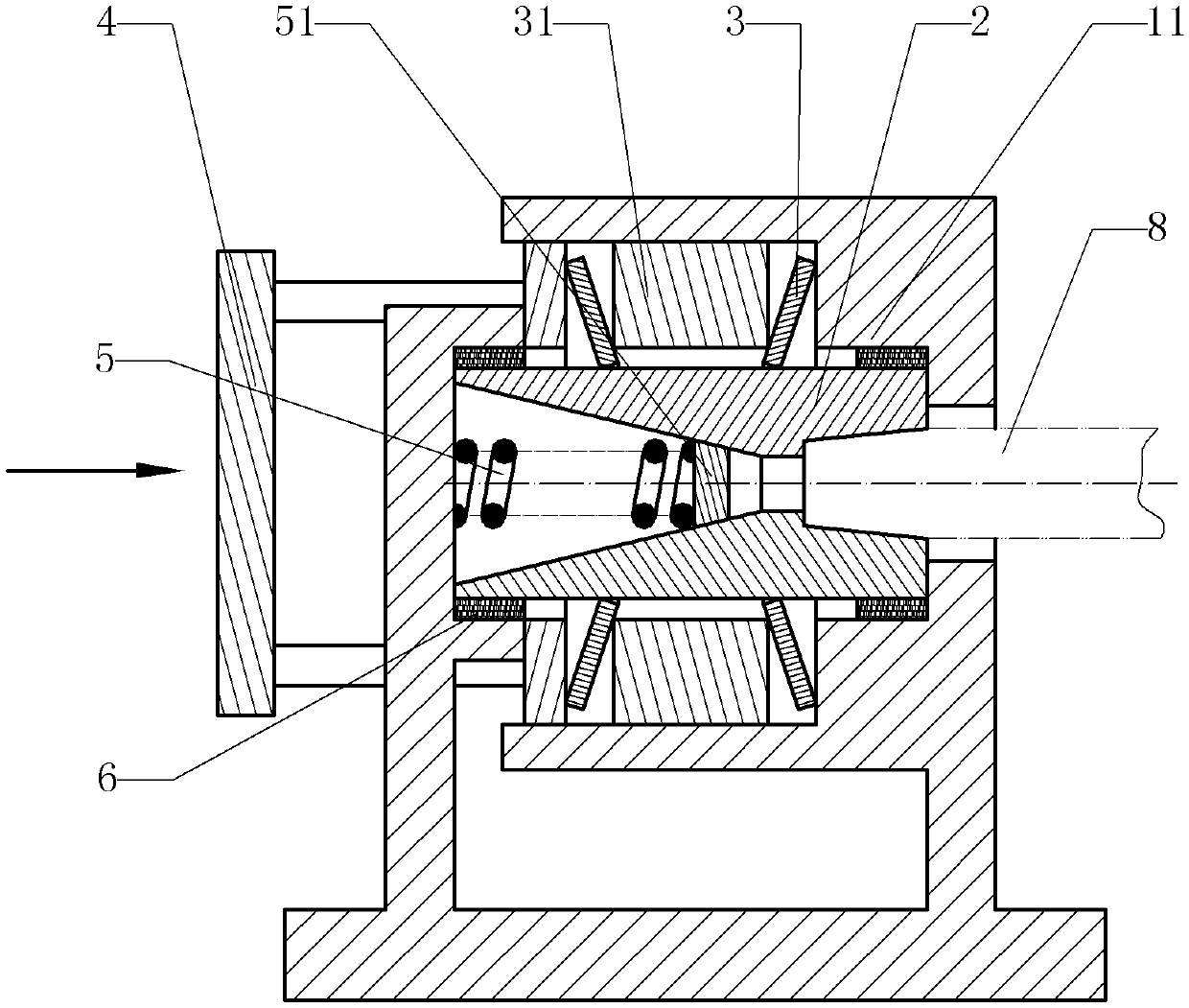

Necking device for metal pipe ends

ActiveCN105499417AWith tensionUniform clamping forceMetal-working feeding devicesPositioning devicesBiomedical engineeringMetal

The invention relates to a necking die and provides a necking device for metal pipe ends. The necking device comprises a machine frame, a clamping head, belleville springs and a pressing sleeve; the clamping head is divided into a plurality of independent blocks, the belleville springs are arranged on the periphery of the clamping head in a sleeving mode, and a tensioning springis arranged in the clamping head; when the belleville springs are compressed, the inner diameter is reduced, the clamping head is extruded and tightened, and the tensioning springs can realize the tensioning effect when the belleville springs are not deformed. According to the invention, the clamping head is tightened and exerts pressure on the pipe ends for pressing the pipe ends and realizing necking, pipes are fixed in the necking process according to the scheme, and no limit for the appearances of the pipes exists.

Owner:CHONGQING WANSI METAL SPECIAL TYPE FORMING

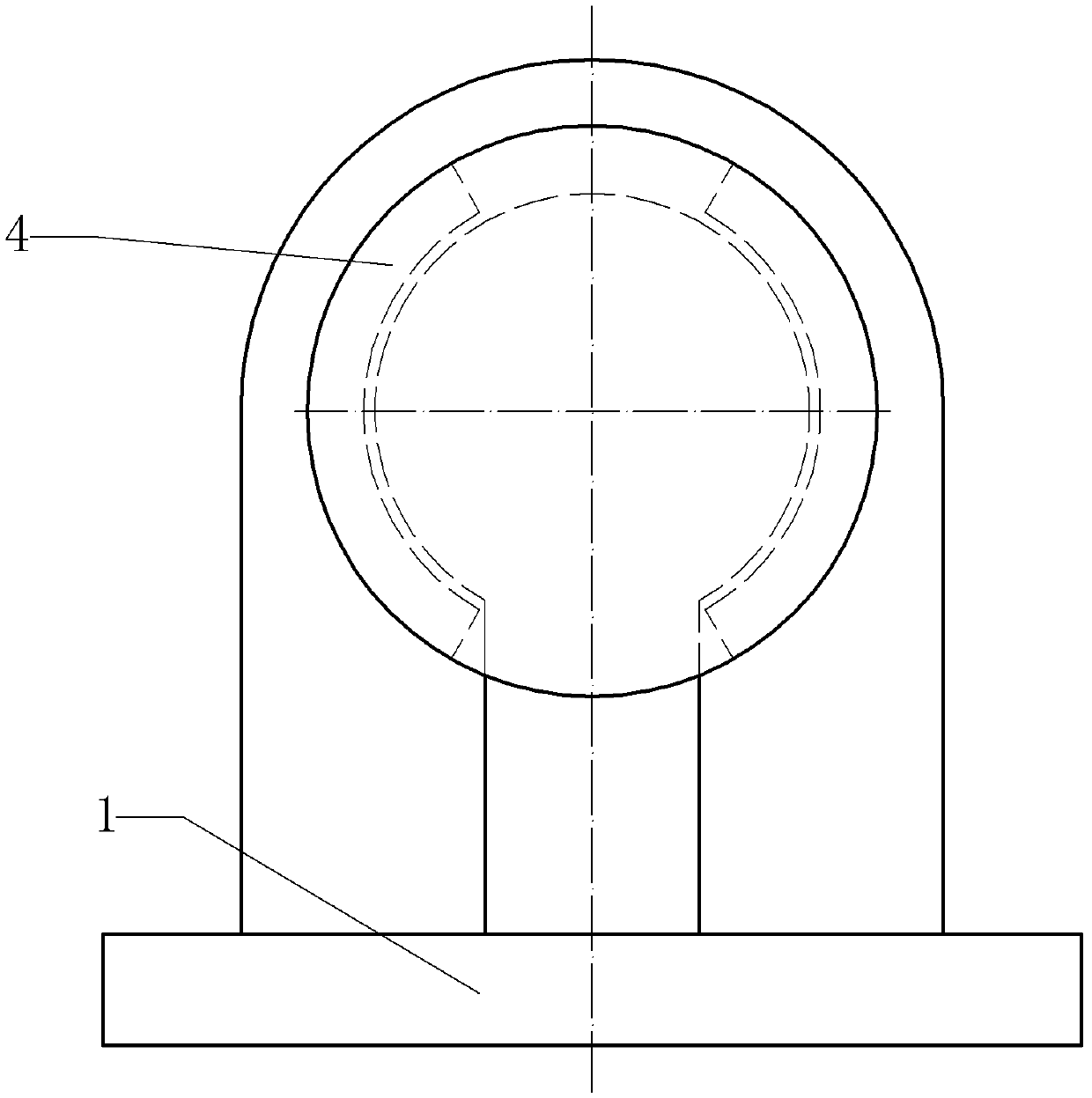

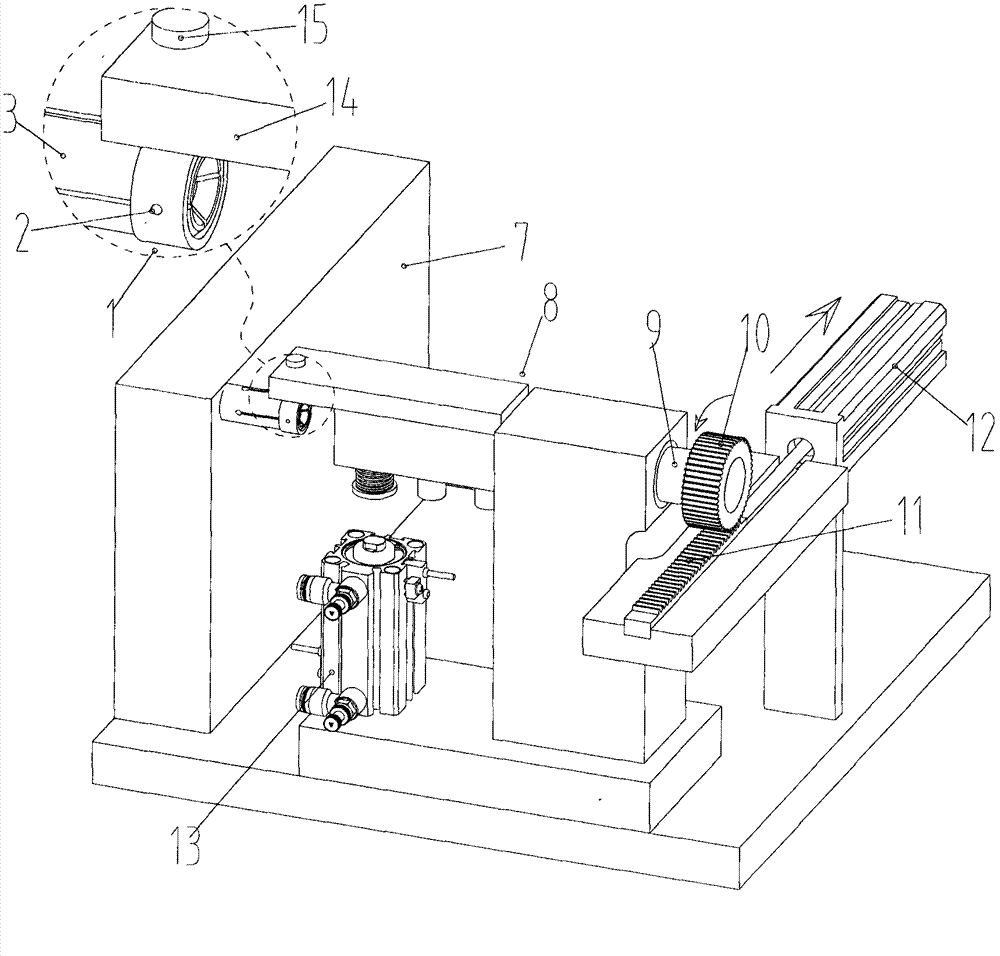

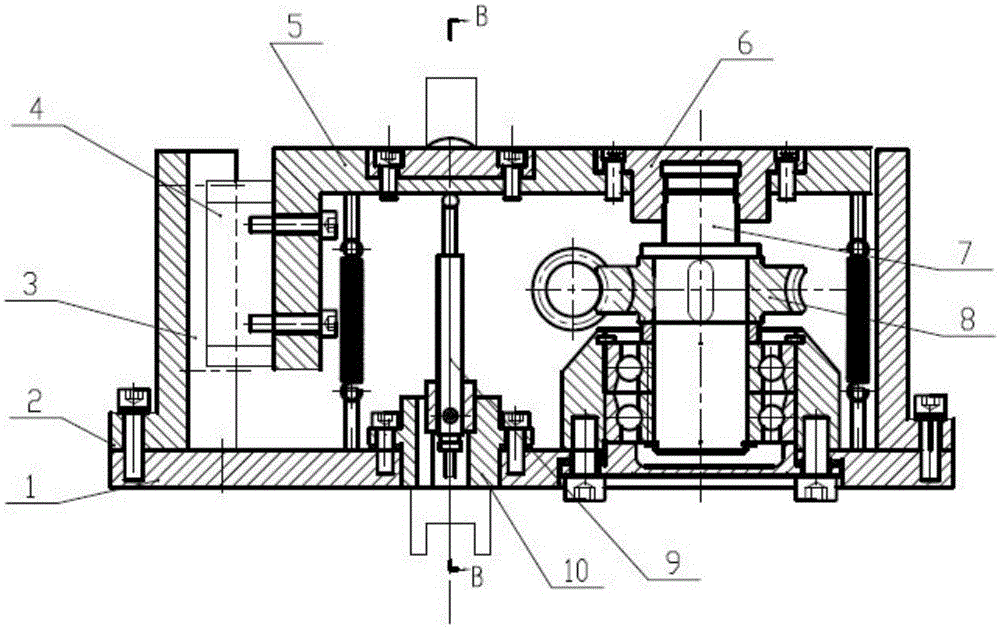

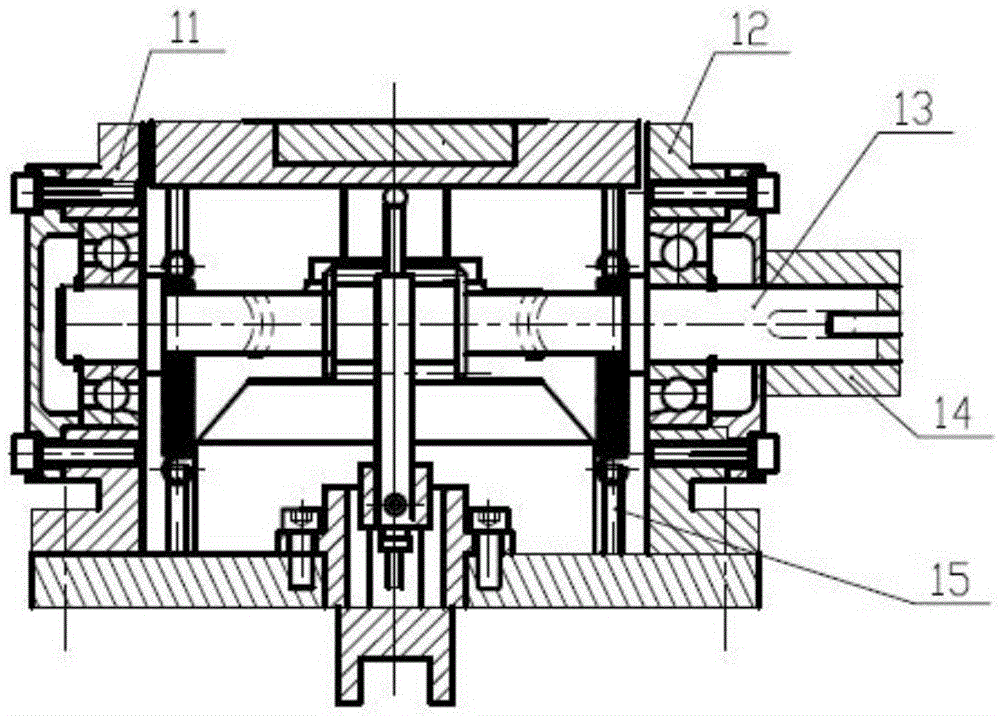

Position correcting mechanism of automobile slide bearing oil injection holes

ActiveCN104723166AIncrease elasticityWith tensionAutomatic control devicesFeeding apparatusFailure rateElectrical control

The invention relates to the field of mechanical manufacturing, in particular to a position correcting mechanism of automobile slide bearing oil injection holes. The position correcting mechanism comprises an elastic chuck, a flexible rotating mechanism and an ejecting cylinder. The elastic chuck is sleeved with slide bearings. The rotating center of the flexible rotating mechanism coincides with the central axes of the slide bearings. The ejecting cylinder is arranged at the lower portion of the flexible rotating mechanism. The position correcting mechanism is used for correcting the positions of the slide bearings, so that the positions of the oil injection holes of the slide bearings face the uppermost portion, and the positions are well prepared for the subsequent chamfering procedure of the oil injection holes. The position correcting mechanism is simple in action and conducts only two actions through a rack cylinder and the ejecting cylinder. The position correcting mechanism is simple in action, the requirement for an electrical control system is lowered, and meanwhile the reliability of a system is improved and the failure rate of the system is decreased.

Owner:高唐融知融智科技服务有限公司

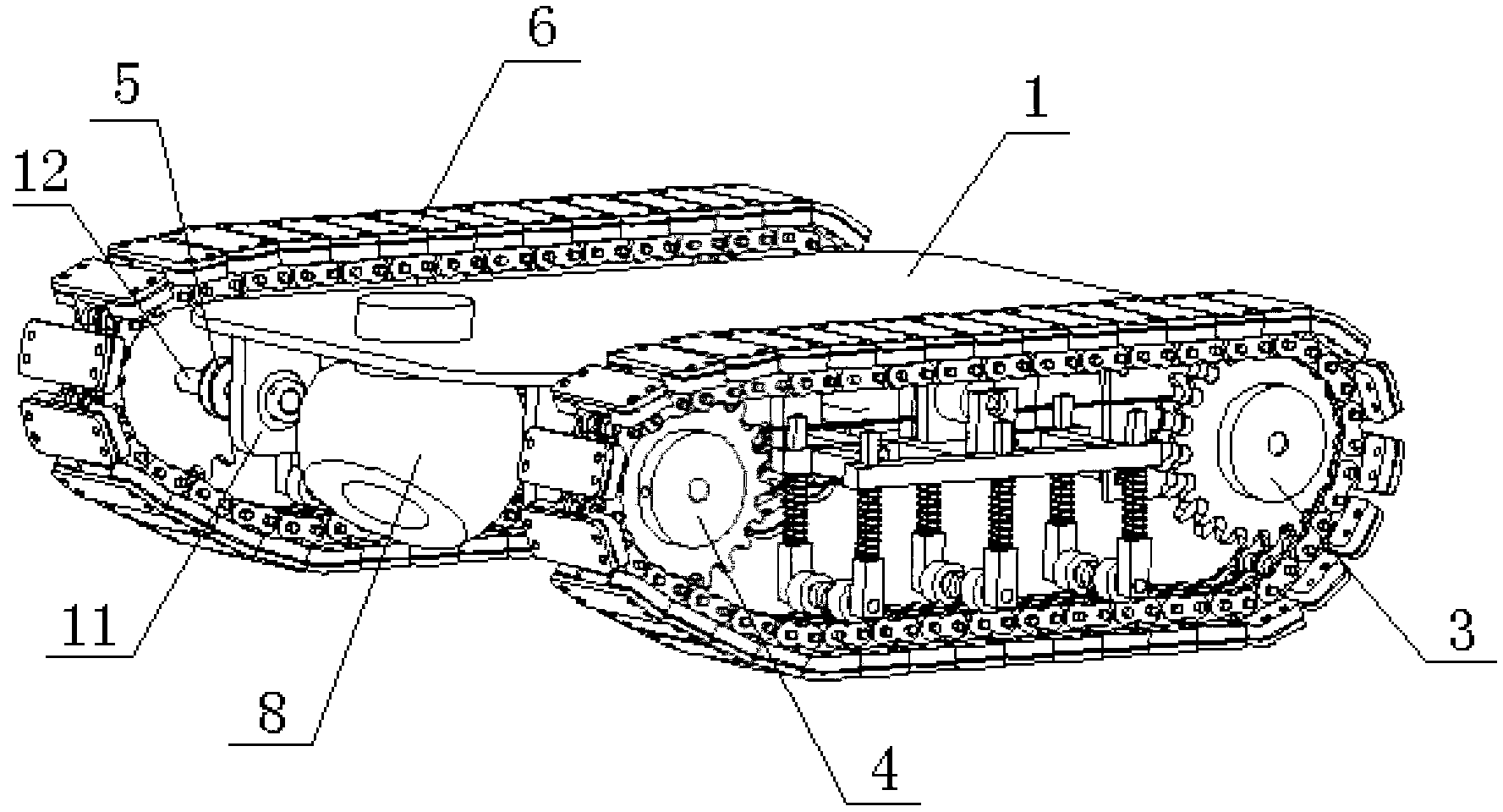

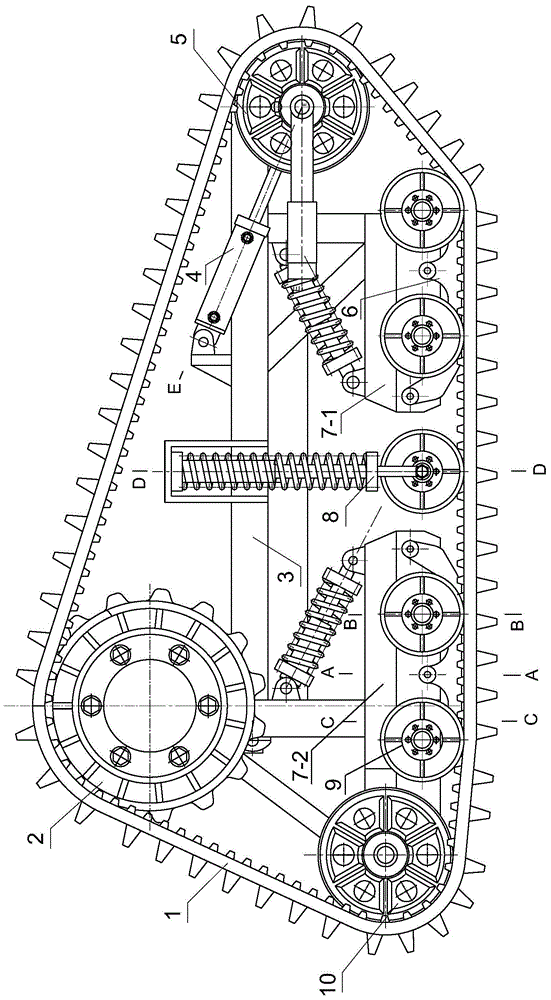

Caterpillar support deformation device for caterpillar farmland operation vehicle

InactiveCN104691633AIncrease stiffnessPrevent slippageEndless track vehiclesGround contactHydraulic cylinder

The invention discloses a caterpillar support deformation device for a caterpillar farmland operation vehicle. The caterpillar support deformation device is characterized in that a driving wheel is mounted above one end of a frame cross member, and a front support wheel is mounted below the other end of the frame cross member and is connected with a hydraulic cylinder mounted on the frame; a rear support frame is welded on the lower side of a certain end of a frame, the certain end of the frame and the driving wheel are positioned on the same side of the caterpillar support deformation device, a rear support wheel is mounted on the rear support frame, a deformation bearing frame supporting seat which is used for mounting a deformation bearing frame is welded in the middle of the frame, a front deformation frame and a rear deformation frame which are respectively connected with the frame and are structurally identical to each other are symmetrically arranged on two sides of the deformation bearing frame, and bearing wheels are mounted on the front deformation frame and the rear deformation frame; telescopic cylinders are arranged in the deformation bearing frame supporting seat, and springs sleeve the telescopic cylinders. The caterpillar support deformation device has the advantages that the hydraulic cylinder can be contracted and extended when the caterpillar farmland operation vehicle crosses a ridge, so that the shape of the middle of a ground-contact caterpillar can be changed, the inclination height of the caterpillar farmland operation vehicle can be lowered, and the operation safety can be improved.

Owner:CHANGSHA XINGJU AGRI MACHINERY

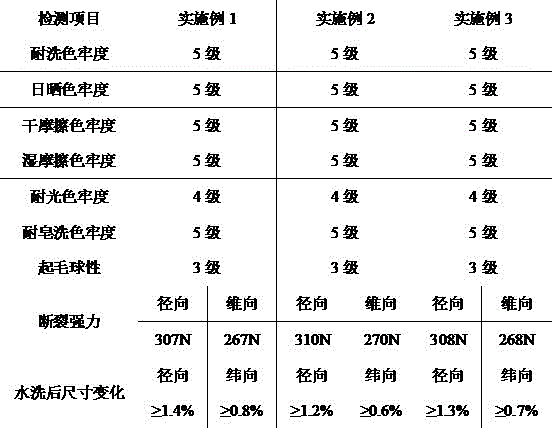

Cloth fabric with holes and preparation method thereof

ActiveCN106367960AIncrease elasticityWith tensionFibre treatmentHeating/cooling textile fabricsFiberPulp and paper industry

The invention relates to a cloth fabric with holes and a preparation method thereof, belonging to the technical field of cloth materials. The grey cloth of the cloth fabric with holes is formed by interweaving T / R fibers, and a plurality of evenly distributed holes are formed in the cloth fabric with holes. The preparation process of the cloth fabric with holes comprises the following steps: cloth batching, continuous desizing and water washing, perforating, dyeing, reduction washing, dewatering and cloth spreading, drying in a drum, in-process inspection and setting. The surface of the cloth fabric with holes disclosed by the invention has regular holes, brings a different visual effect to people, and has excellent elasticity and excellent air permeability.

Owner:JINJIANG LONGXINGLONG DYEING & WEAVING INDALCO

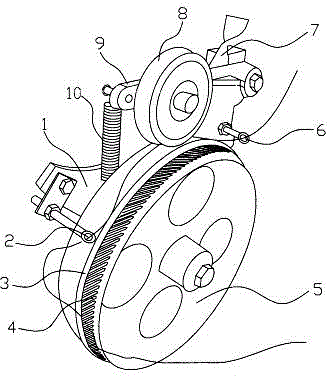

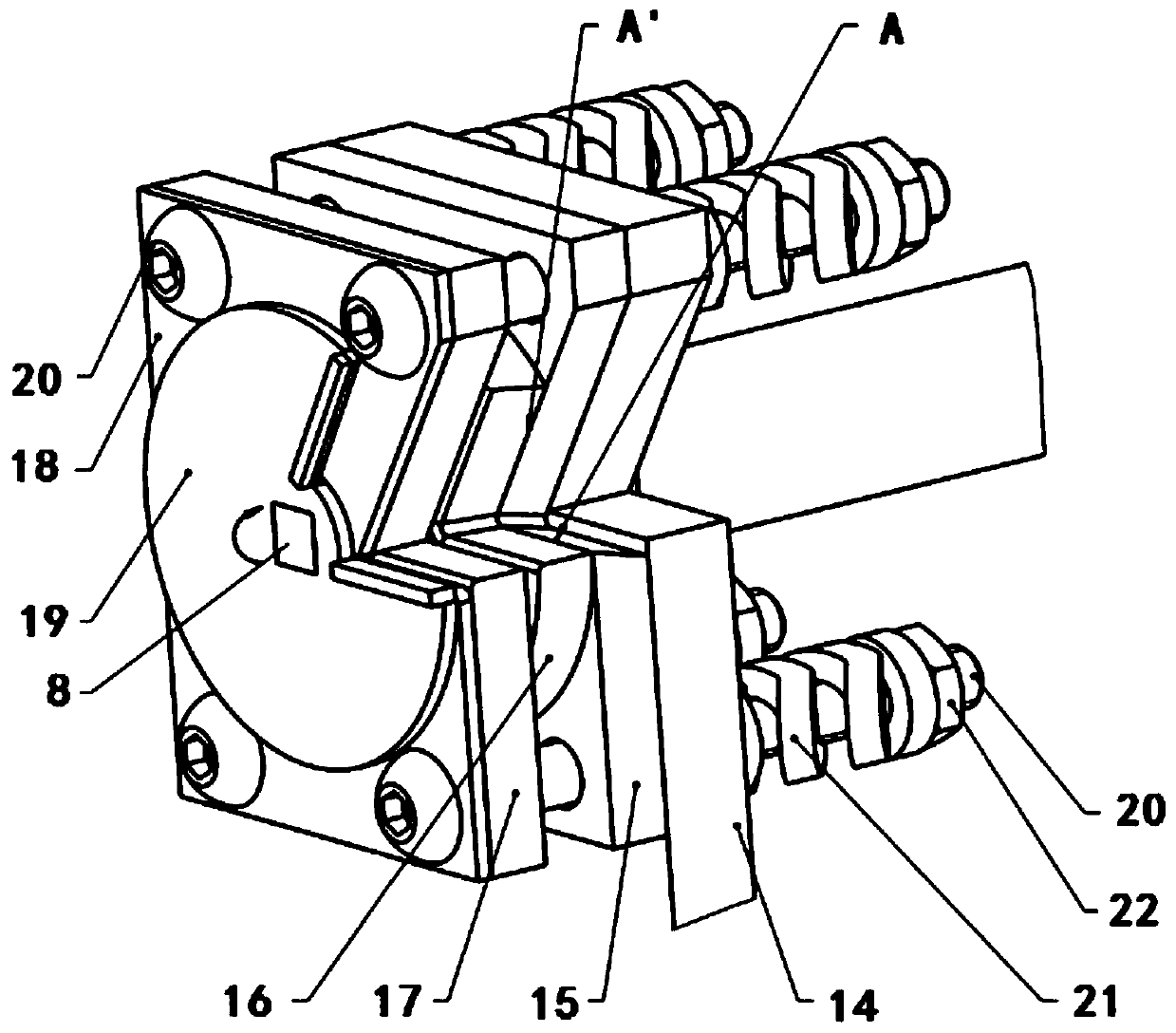

Yarn tension adjusting mechanism

The invention relates to a yarn tension adjusting mechanism. The yarn tension adjusting mechanism is characterized by comprising a body, a yarn outgoing guide hole, a yarn incoming guide hole, a yarn bearing wheel, a ratchet sleeve, an adjusting rod, an adjusting rotary arm, a compression wheel and a spring, wherein the yarn outgoing guide hole is fixedly formed in one side of the body, the yarn incoming guide hole is fixedly formed in the other side of the body, the yarn bearing wheel is rotationally installed on the body, the yarn bearing wheel is sleeved with the ratchet sleeve provided with a plurality of ratchets, the adjusting rod is rotationally installed on the body, the adjusting rotary arm is rotationally installed on the body, the compression wheel is rotationally installed at the free end of the adjusting rotary arm, the spring is tensioned between the body and the adjusting rotary arm, and the yarn breakage detection device is arranged on the yarn bearing wheel. The yarn tension adjusting mechanism is simple in structure and easy and convenient to use, the produced yarn is moderate in tension, the yarn can enter a weaving machine at gentle and stable speed, and the yarn tension adjusting mechanism well meets the requirement for textile industry production, and has the quite positive significance.

Owner:新昌县凯杰机械有限公司

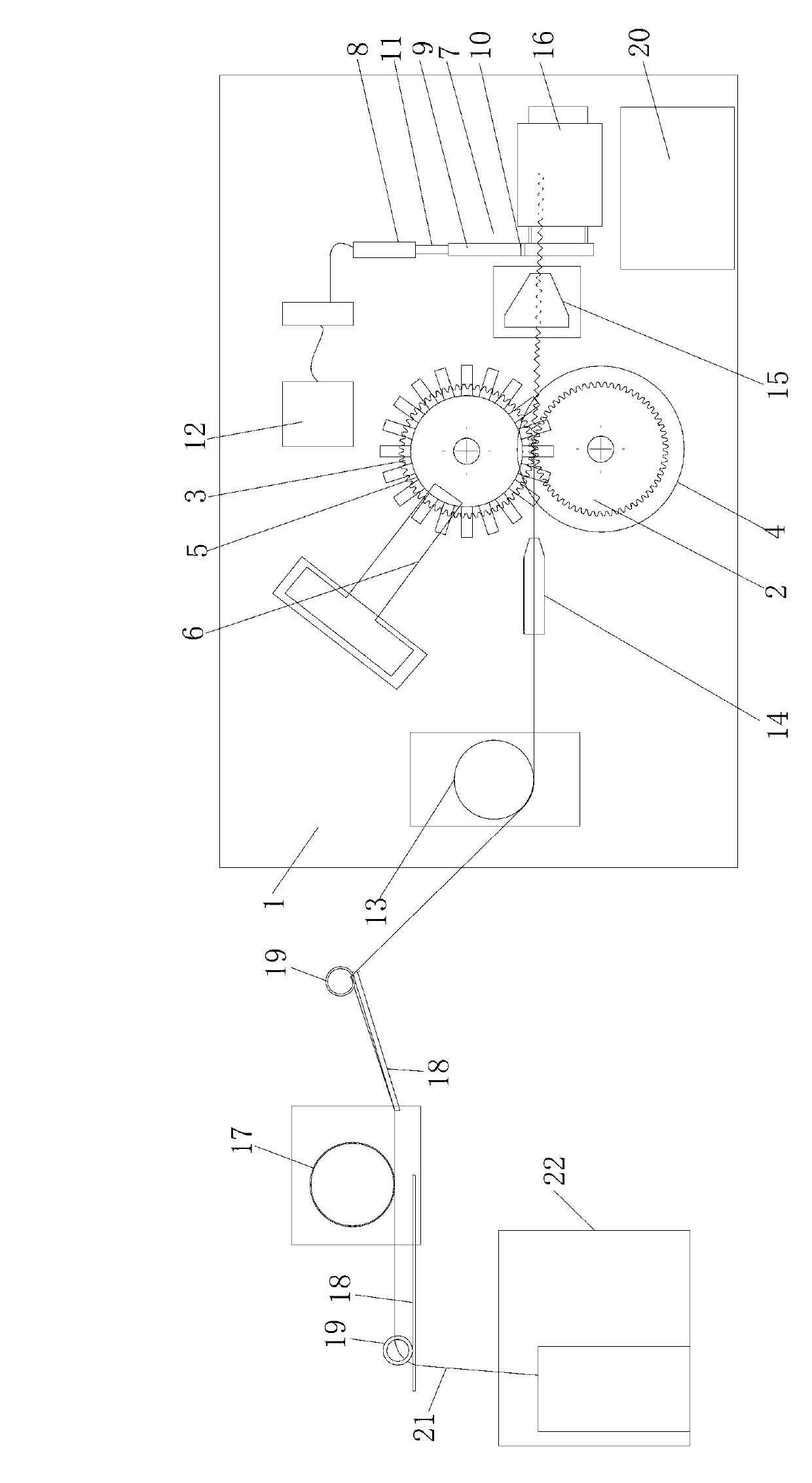

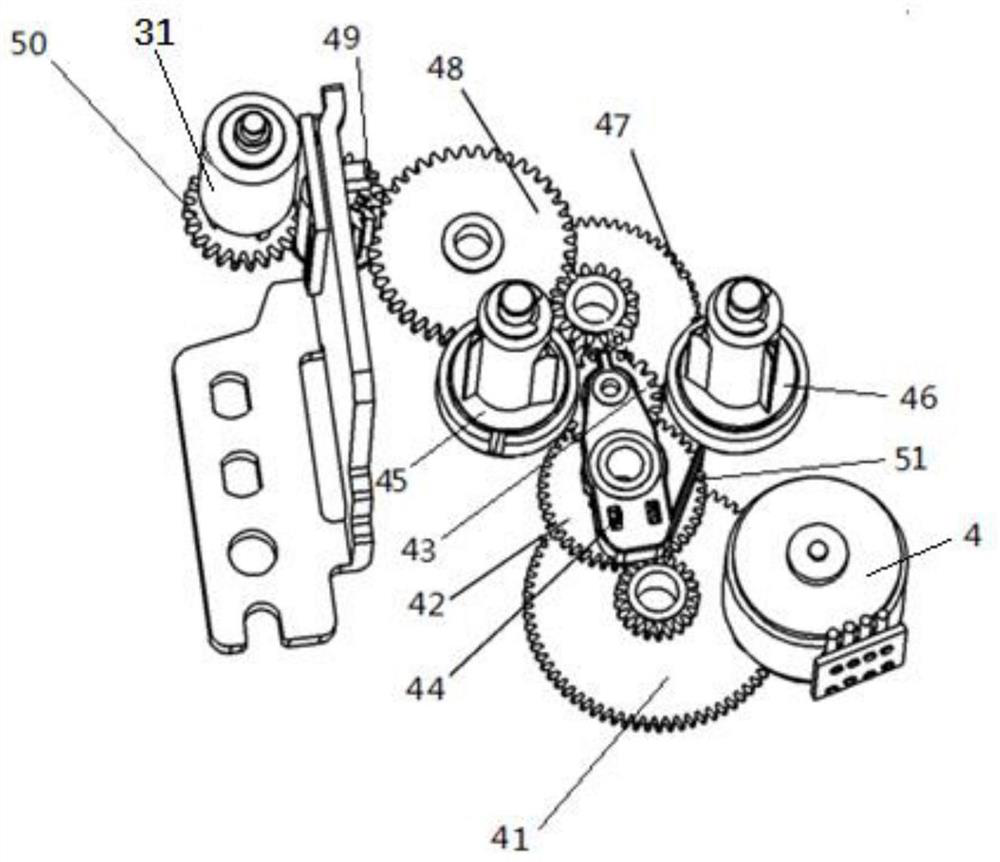

Automatic wire bending and cutting device

ActiveCN102861834AWith tensionImprove work efficiencyMetal working apparatusEngineeringMechanical engineering

The invention relates to an automatic wire bending and cutting device of a wire of a buzzer. The device comprises a support. A wire bending mechanism used for bending the wire is arranged on the support, and a cutting mechanism used for cutting the wire bended by the wire bending mechanism is arranged on one side of the wire bending mechanism. The wire bending mechanism comprises a driving wire bending gear arranged on the support, a driven wire bending gear matched with the driving wire bending gear to conduct wire bending, a measurement disc arranged on the driven wire bending gear and rotating with the driven wire bending gear and a detection sensor located on one side of the measurement disc to detect rotating distance of the measurement disc in real time. The cutting mechanism comprises a cutting knife, a driver arranged on the support and used for driving the cutting knife to cut the bended wire and a controller used for receiving measurement disc rotating distance signals detected by the detection sensor. The controller controls the driver to work according to the received measurement disc rotating distance. The automatic wire bending and cutting device is capable of bending a straight wire into a bended wire automatically and automatically cutting the wire according to required length, thereby being high in working efficiency.

Owner:BESTAR HLDG

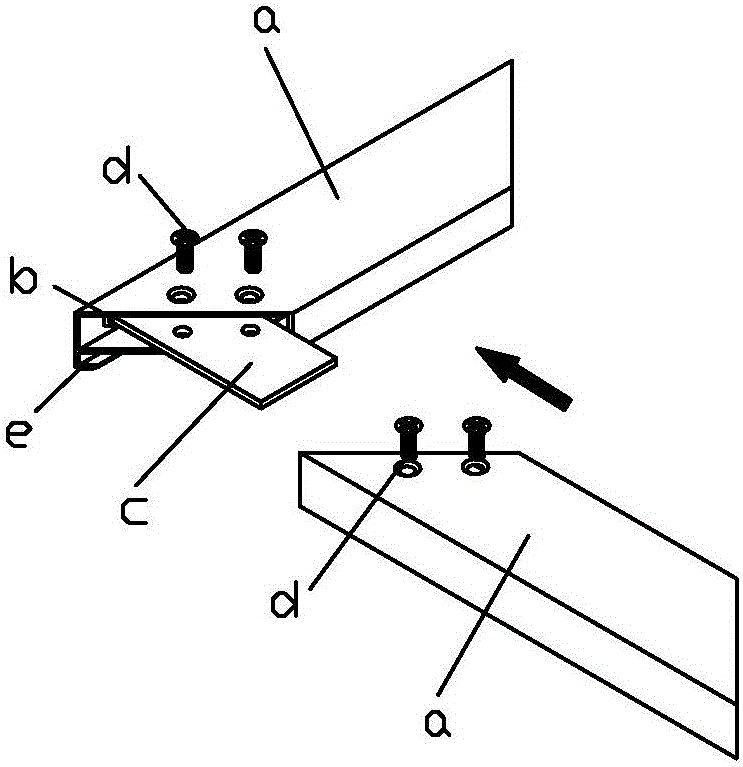

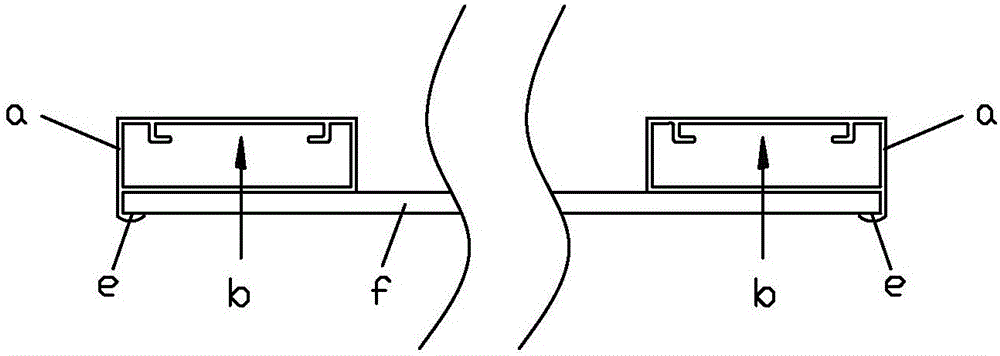

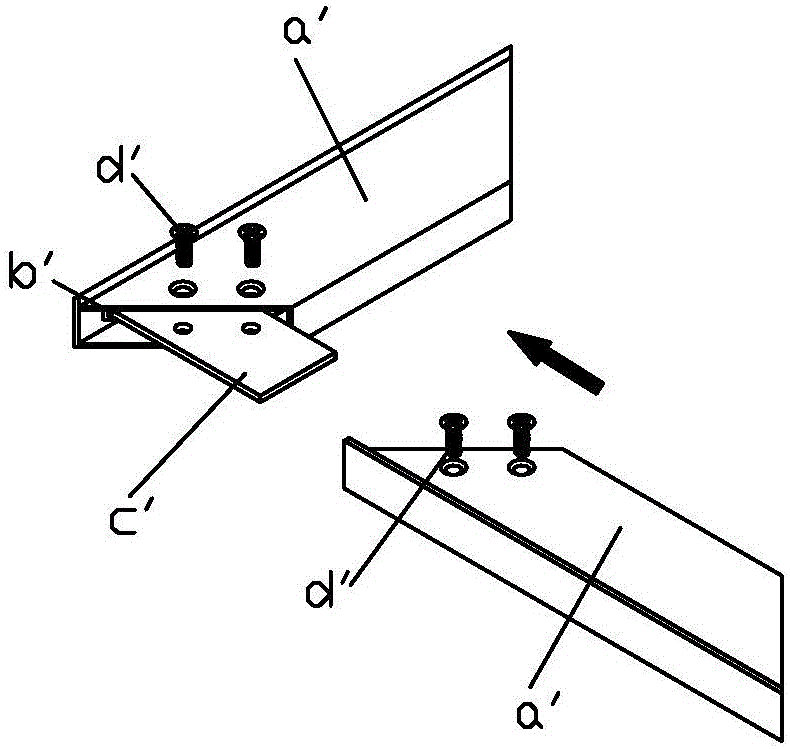

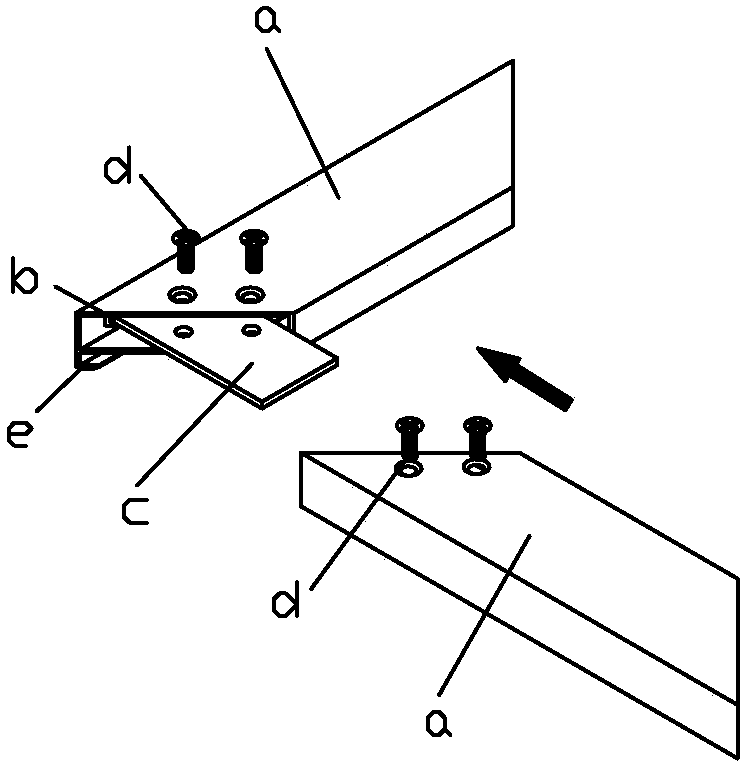

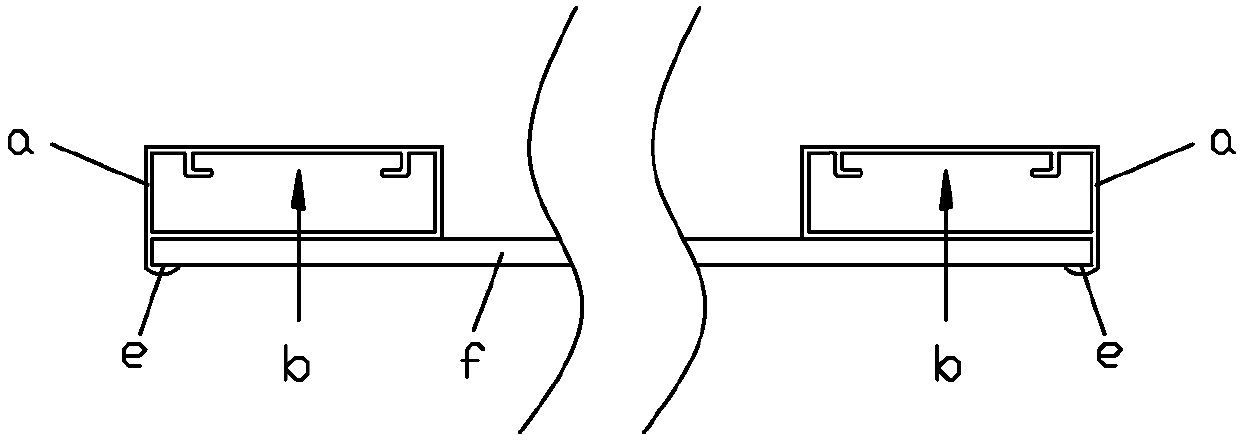

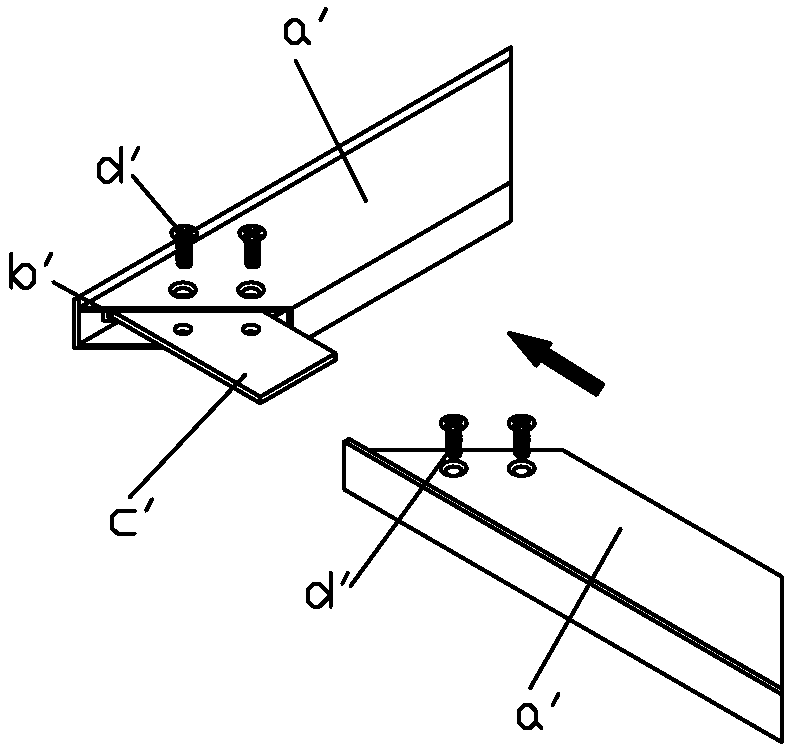

Aluminum alloy door frame, door board with aluminum alloy door frame and use method of aluminum alloy door frame

ActiveCN106014131AEnsuring structural strength and safetyImprove airtightness and stabilityDoor leavesAluminium alloyUltimate tensile strength

The invention discloses an aluminum alloy door frame, a door board with the aluminum alloy door frame and a use method of the aluminum alloy door frame. The manner of plane corner braces and border front face / back face locking screws in the traditional technology is changed into the manner of vertical corner braces and border side face locking screws, pressing strips are matched for shielding the screws and fixing core boards, the screws cannot be seen from the front face and the reverse face of the aluminum alloy door frame, and the whole door frame is attractive and elegant. The pressing strips are designed to be easy to install and difficult to detach, and the structural strength and the safety of a finished product are guaranteed. The pressing strips can be used in cooperation with the core boards with different thicknesses. The aluminum alloy door frame is suitable for a cabinet door board and a common aluminum door and is wide in application range.

Owner:เซี่ยเหมิน โกลเด้นโฮม โค

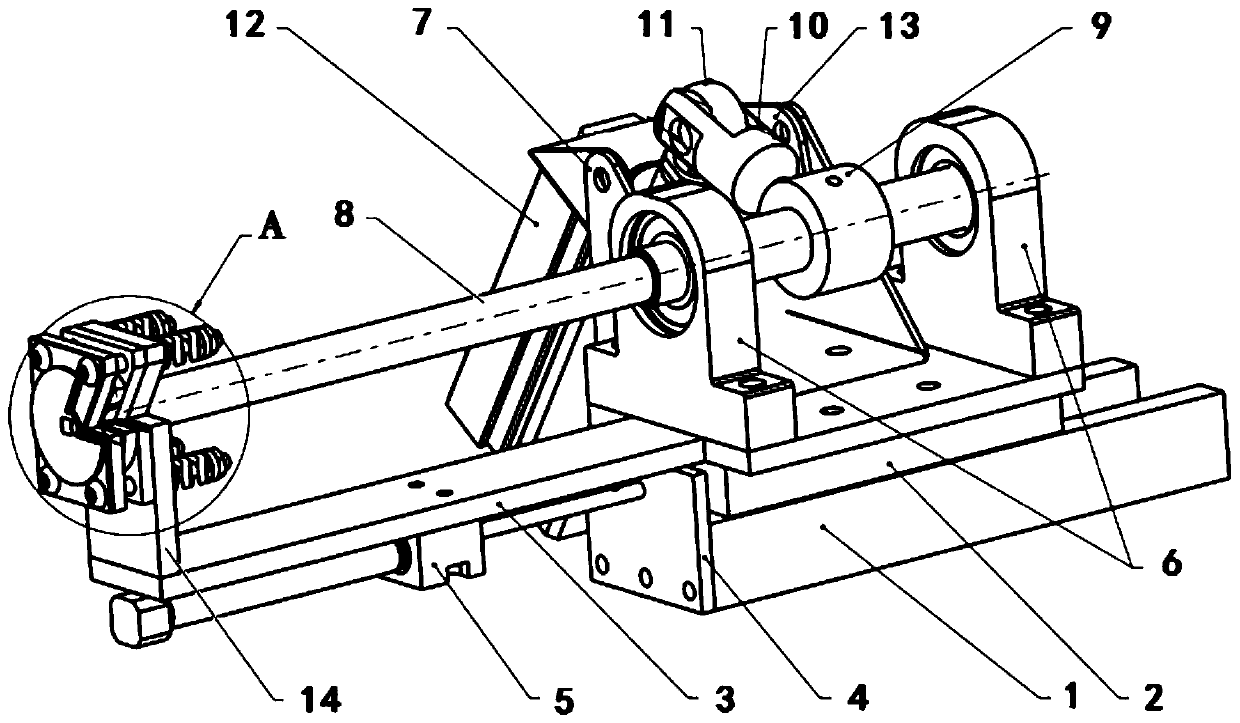

Device for calibration of metal rockwell hardness tester indentation depth measurement systems

A device for calibration of metal rockwell hardness tester indentation depth measurement systems includes a base, one end of the base is vertically provided with a left end plate, the left end plate is provided with a linear guide rail, the linear guide rail is internally provided with a slide block on a mobile plate, the slide block is arranged on the mobile board, and the mobile board is also provided with a drive system for making the mobile plate move up and down; the base is further provided with a displacement sensor, a display value of the metal rockwell hardness tester indentation depth measurement systems is compared, and thus the metal rockwell hardness tester indentation depth measurement systems are calibrated. The device has the advantages of compact structure and smaller specification and dimension, and can be widely applied in calibration of all kinds of the rockwell hardness tester measurement systems with different specifications; the displacement sensor is located on a same axis as the principal shaft of a hardness tester, the working principle of a rockwell hardness tester can be completely simulated, the abbe principle is met, and the synchronicity of the displacement quantity of the displacement sensor and the hardness tester is ensured; and the accuracy of the device is 0.2 [mu]m.

Owner:AECC AVIATION POWER CO LTD

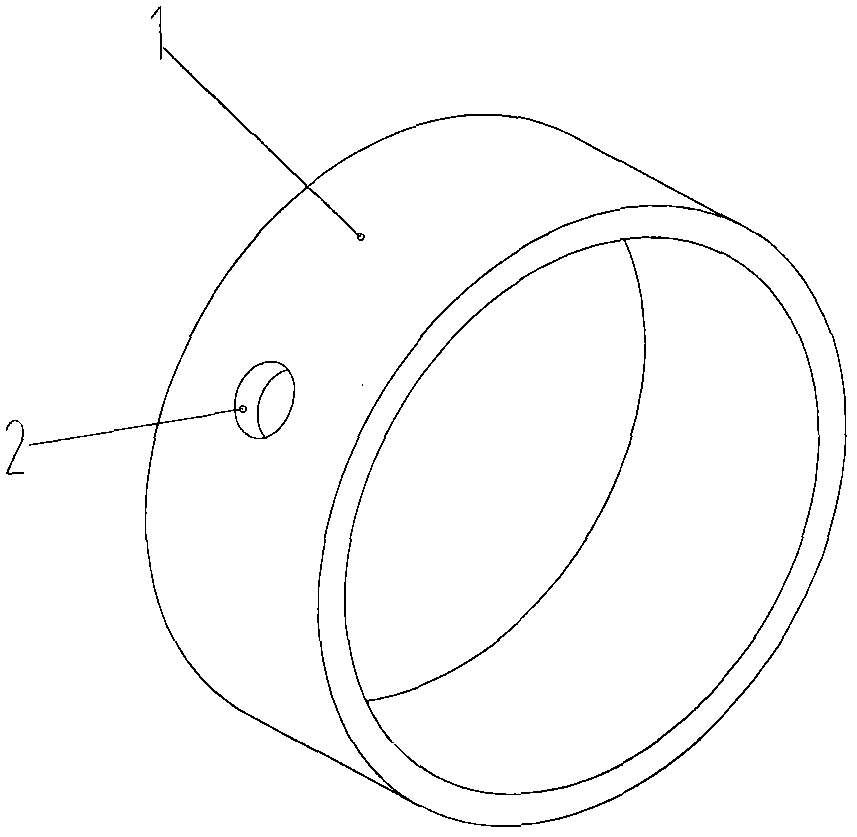

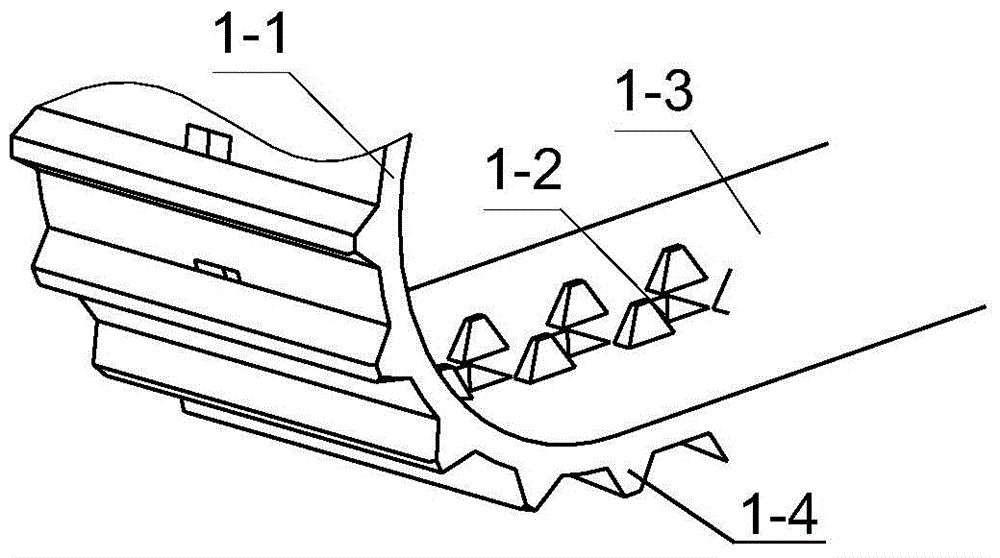

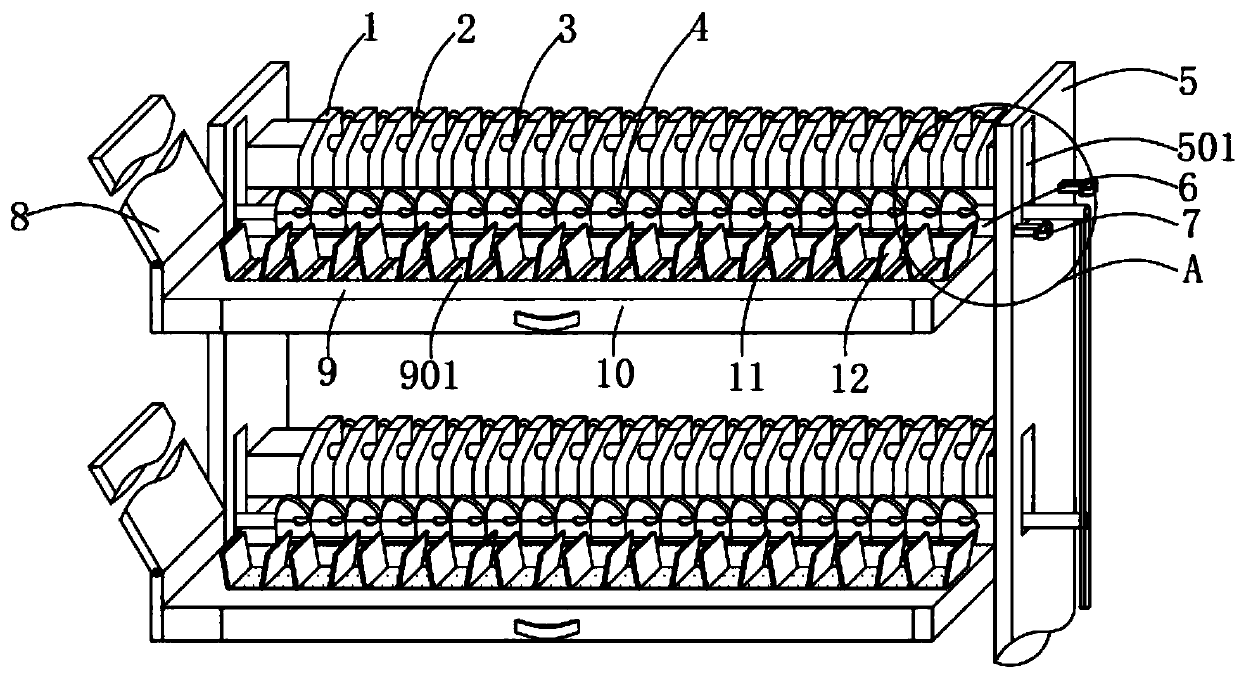

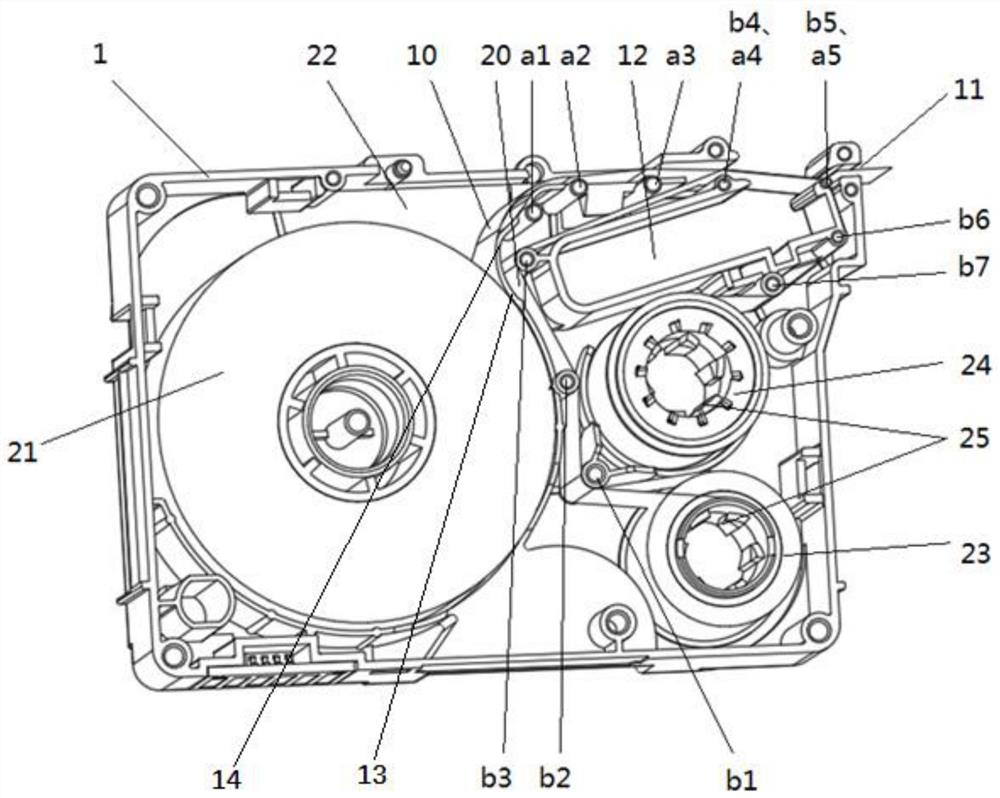

Netting machine plastic shuttle

The invention discloses a netting machine plastic shuttle. The netting machine plastic shuttle comprises an annular body, a head portion and a tail portion, wherein the head portion and the tail portion are located at the two ends of the annular body, a circular opening used for containing a shuttle core is formed in the annular body, the annular body, the head portion and the tail portion are all made of plastic materials, the connecting part of the annular body and the tail portion is provided with a first strengthening rib, and the tail portion is internally provided with a second strengthening rib. The netting machine plastic shuttle has the advantages that since traditional fish-shaped shuttles are all made of copper, the netting machine plastic shuttle adopts the shuttle of which the most part is made of plastic materials, more shuttles can be installed on a netting machine under the condition of the same supporting capacity, and therefore a netting machine with larger width can be fabricated, and finally the efficiency of the netting machine is improved. The service life of the shuttle is improved and is 4-5 times the length of an original copper shuttle. Due to the fact that the copper shuttle is replaced by the plastic shuttle, the mechanical strength of the whole shuttle is weakened, the fracturing problem is prone to occur, but the fracturing problem of the shuttle is not prone to occur any more by the arrangement of the first strengthening rib and the second strengthening rib.

Owner:张家港市新盈模具塑化有限公司

Adjustable yarn guiding frame for polyester monofilaments

The invention relates to the field of yarn guiding devices for doubling threads, in particular to an adjustable yarn guiding frame for polyester monofilaments. The adjustable yarn guiding frame comprises side baffles, a base is fixed between the two side baffles, and the top of the base is provided with limiting plates; the limiting plates are connected through yarn guiding wheels, and a first limiting frame is arranged on one sides of every two limiting plates; a second limiting frame is arranged on the other sides of every two limiting plates; each second limiting frame comprises a rotatingrod, a pull rod, a rotating shaft, a fixing portion and a movable portion; the sides of the base are fixedly provided with dust collecting boxes, and the tops of the dust collecting boxes are provideddust collecting plates; and the bottoms of the two dust collecting plates are provided with discharge electrodes, and first filter meshes are mounted on the dust collecting boxes. The adjustable yarnguiding frame can prevent yarns from segregating out, meanwhile, the yarns have certain tension, stability during conveying is ensured, and knotting phenomena are avoided; the yarns can be taken out,operation is sensitive, and damage to yarn taking and placing is small; and meanwhile, the electrostatic dust removal manner can be utilized for removing and collecting dust in the yarn conveying process.

Owner:安徽省兰飞化纤织造有限公司

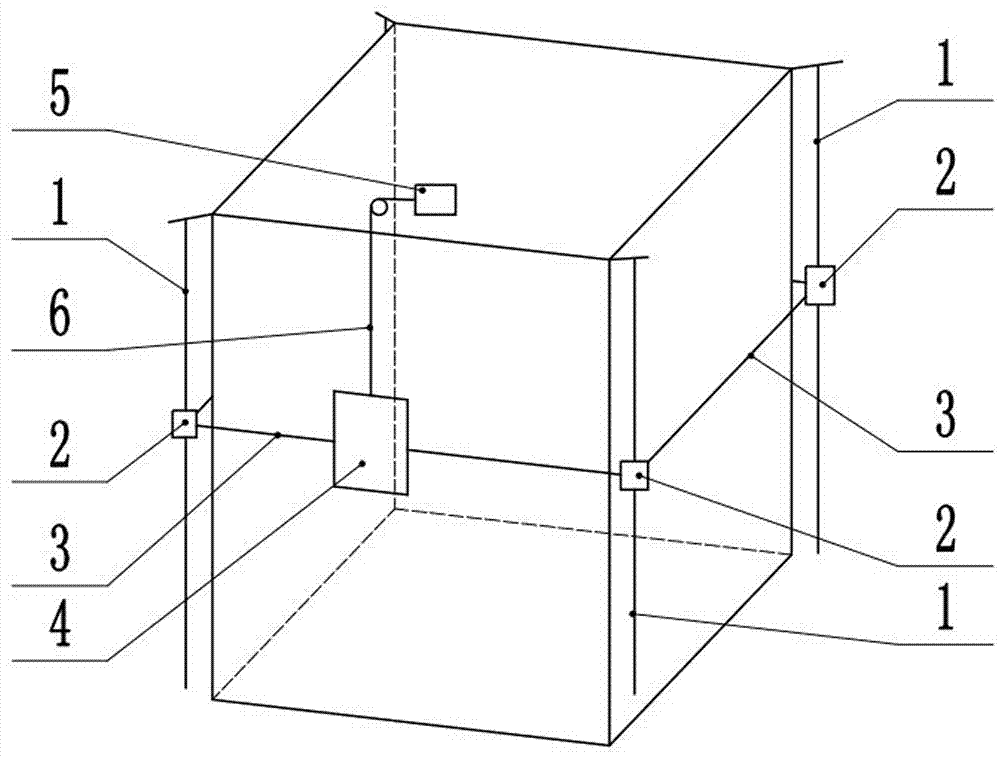

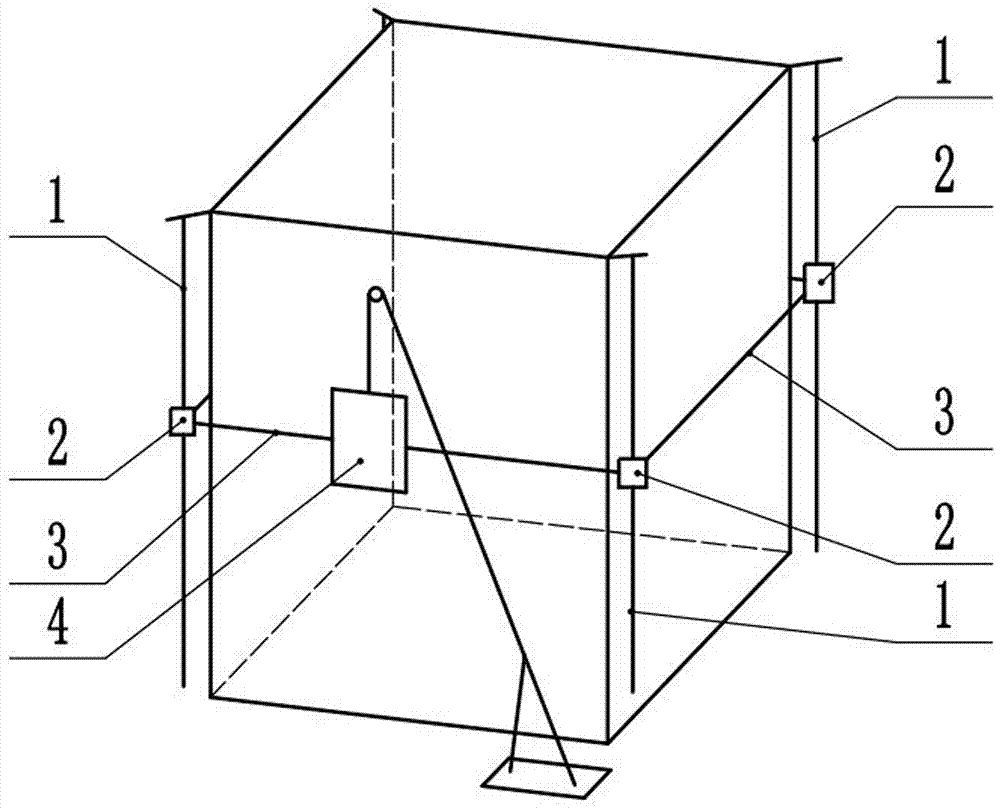

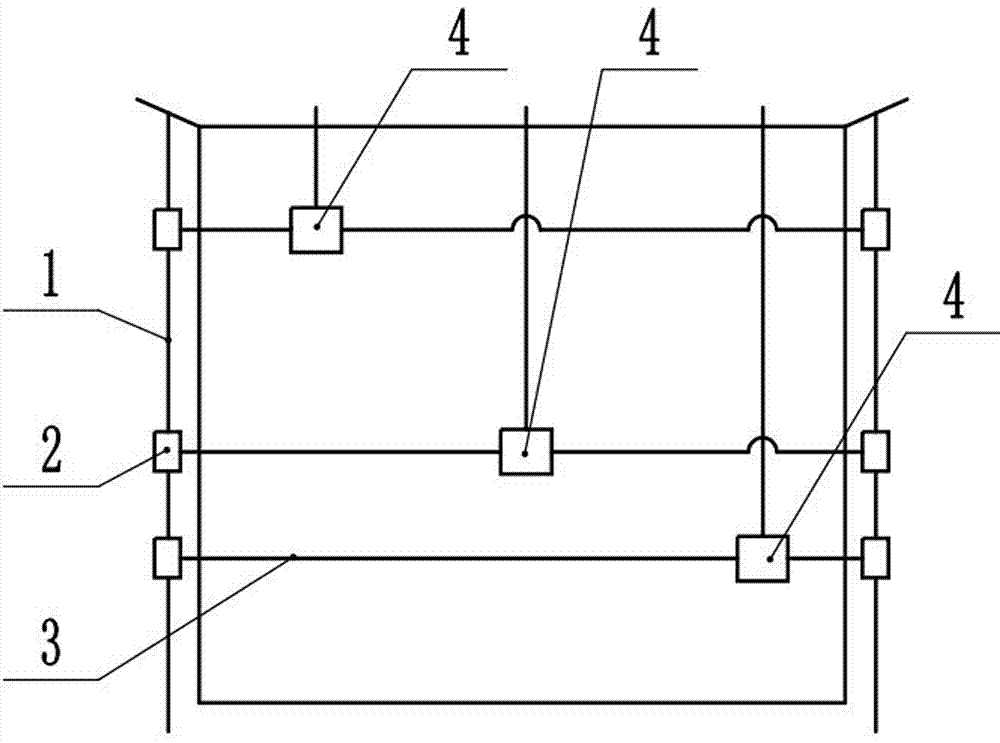

Building cleaning system and cleaning method

The invention discloses a building cleaning system and cleaning method. The cleaning system comprises lifting devices and cleaning modules (4) connected with the lifting devices, and the cleaning modules (4) are driven by the lifting devices to move up and down; and the cleaning system further comprises annular ropes (3) arranged on the outer wall of a building in a sleeving mode, and the annular ropes (3) are connected with the cleaning modules (4). According to the cleaning method, the cleaning modules (4) are adopted to conduct cleaning simultaneously, and a computer device is used for coordinated controlling to avoid interference. According to the building cleaning system and cleaning method, the annular ropes (3) and the cleaning modules (4) are subjected to the reverse force from the building, so that the cleaning modules (4) always maintain sufficient contact force with the building, and the desired cleaning effect can be achieved; and meanwhile, the cleaning efficiency is improved greatly through multi-module coordinated cleaning.

Owner:盛富春

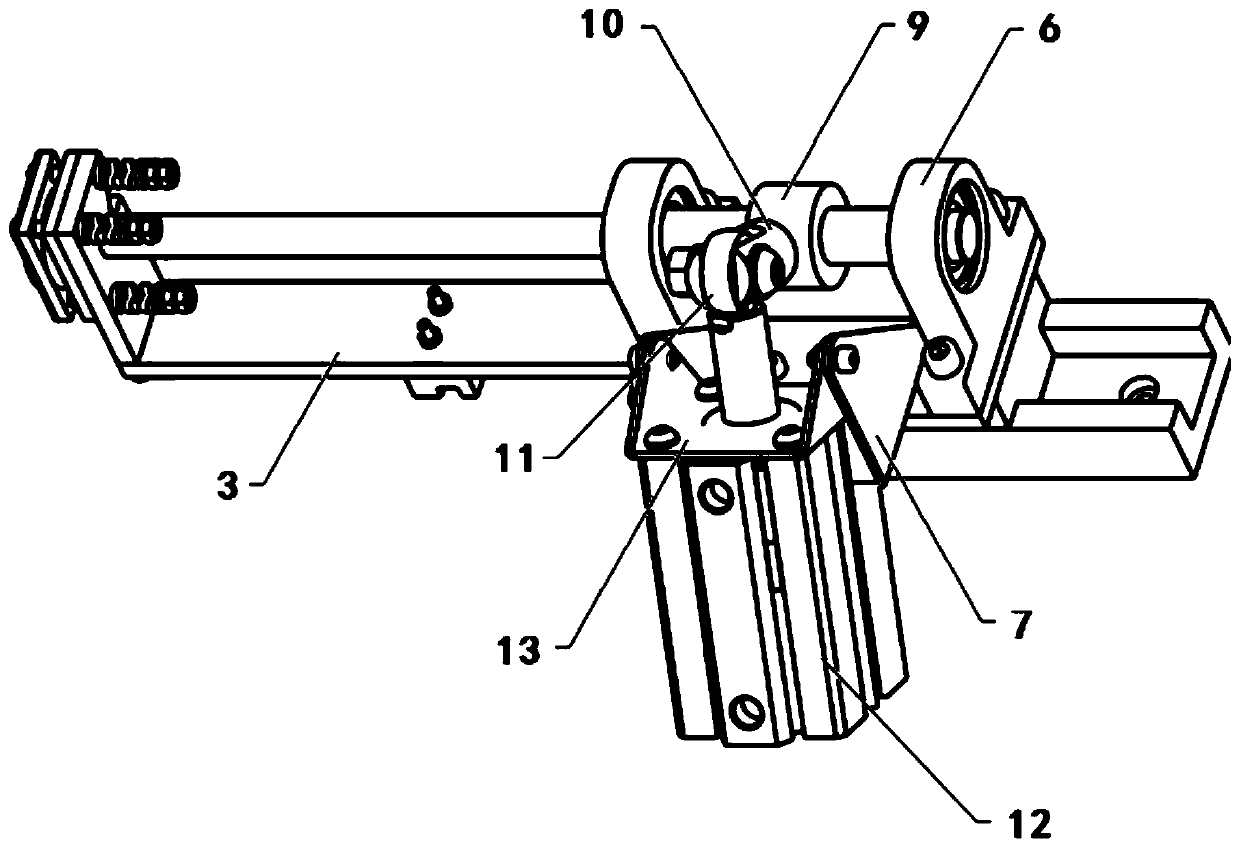

Steel wire rope cutting-off, clamping, correcting and tensioning combined device and using method

ActiveCN111451420AGood structural compositionWith tensionWire networkRotational axisManufacturing engineering

The invention discloses a steel wire rope cutting-off, clamping, correcting and tensioning combined device and a using method. According to the combined device and the using method, a steel wire ropeis placed in a device notch, along with rotation of a rotating shaft, the steel wire rope is cut off through a cutting-off clamping plate, rotation is continued, the steel wire rope is clamped betweena clamping plate and the cutting-off clamping plate through the cutting-off clamping plate, then the rotation is continued, a correcting plate corrects the stainless steel wire rope, and a mounting plate moving assembly moves for a certain distance to tension the steel wire rope. And therefore, cutting-off, clamping, correcting and tensioning type automatic production of the steel wire rope in the weaving process is achieved.

Owner:SHANDONG JIAOTONG UNIV

Medical medicine cup cleaning and disinfecting machine

InactiveCN111589823AEasy to cleanAutomatic fall offHollow article cleaningRadiationSurgeryBiomedical engineering

The invention discloses a medical medicine cup cleaning and disinfecting machine. The medical medicine cup cleaning and disinfecting machine comprises a device body with a cleaning cavity in the rightside end face, wherein the right side wall of the cleaning cavity communicates with the right side end face of the device body and is provided with a cleaning inlet; supporting bases are fixedly arranged at the positions, positioned below the cleaning inlet, of the right side end face of the device body in a front-back corresponding manner; and a first belt wheel is rotationally arranged betweenthe supporting bases in front-back corresponding manner through a first rotation shaft. According to the cleaning device, a cleaning liquid mixed with water is used for flushing a medical medicine cupfirstly, then a cleaning brush is used for brushing, residual dirt is flushed through purified water, and through the combined cleaning manner, the medical medicine cup can be efficiently cleaned.

Owner:牛俊静

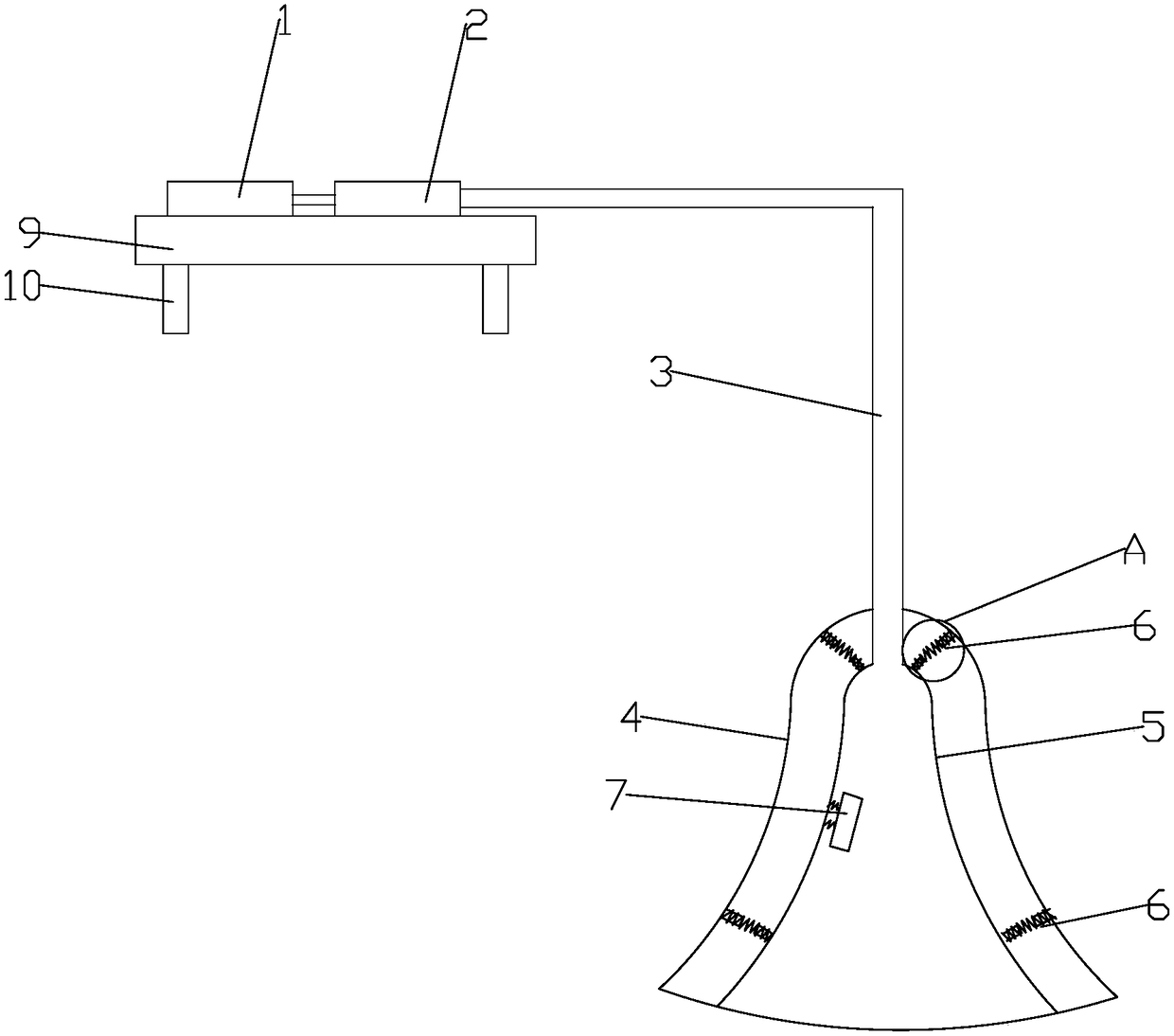

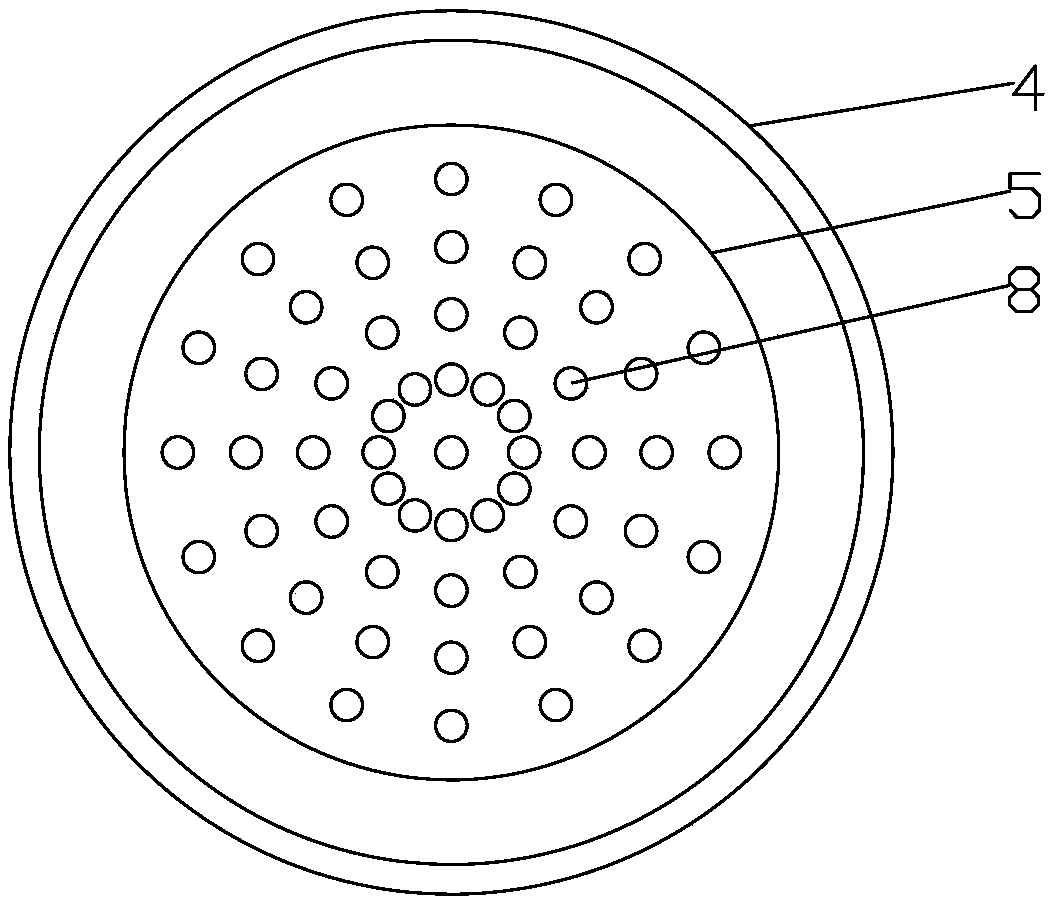

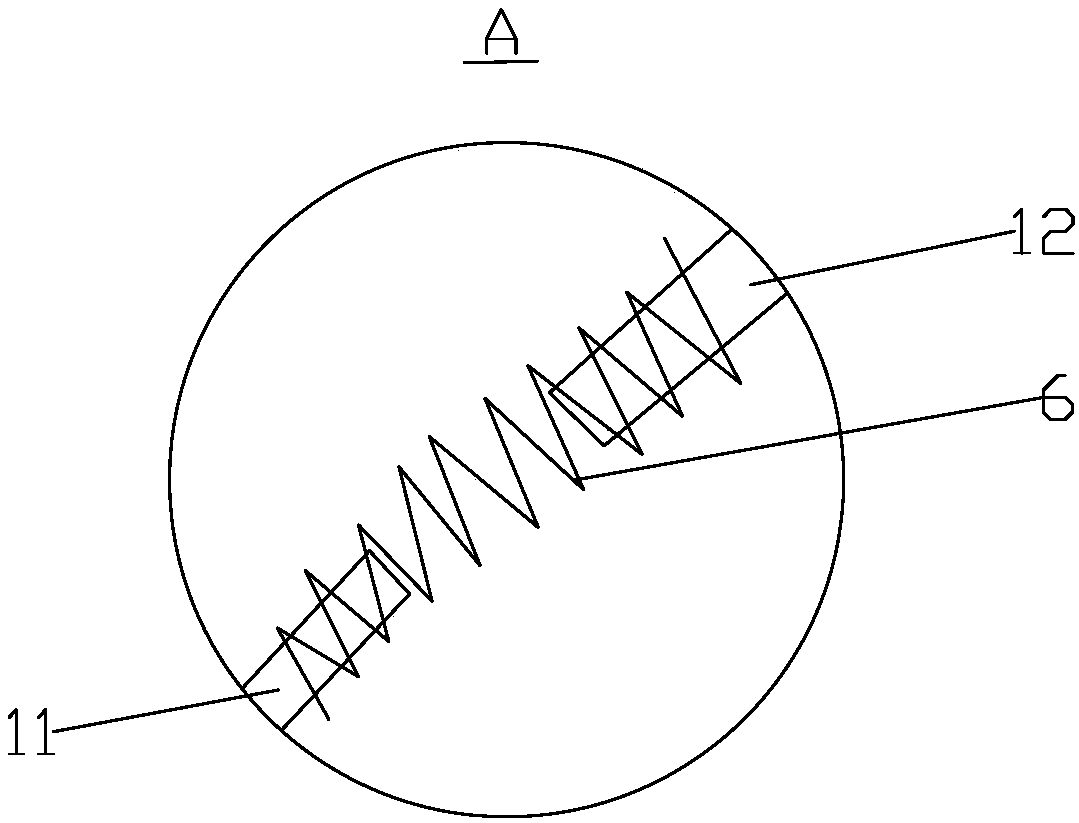

Negative-pressure vibration scar treatment device

PendingCN108498295ASimple structureWork reliablyPneumatic massageVibration massageDuctilityEngineering

The invention relates to a scar treatment device, in particular to a negative-pressure vibration scar treatment device and belongs to the technical field of medical instruments. The device comprises avacuum generation device, a vibrator, an outer suction cover and an inner suction cover, wherein the inner suction cover is located in an inner cavity of the outer suction cover and integrally connected with the outer suction cover through multiple of elastic members; an inner cavity of the inner suction cover is connected with the vacuum generation device through a vacuum pipe, and the vacuum generation device causes vacuumizing in the inner cavity of the inner suction cover to generate negative pressure; the vibrator is arranged on the inner side wall of the inner suction cover and can drive the inner suction cover to move up and down and move laterally within a certain range. The front end face of the inner suction cover is provided with a plurality of suction holes, and the suction holes are uniformly distributed on the front end face of the inner suction cover. Local scars are fixed by negative pressure, so that the skin has a certain tension degree; local scar tissue is lifted and shaken, so that the tissue ductility is improved, the scars are softened, local adhesion is loosened, and therefore scar contracture is prevented and treated.

Owner:JIANGNAN UNIV

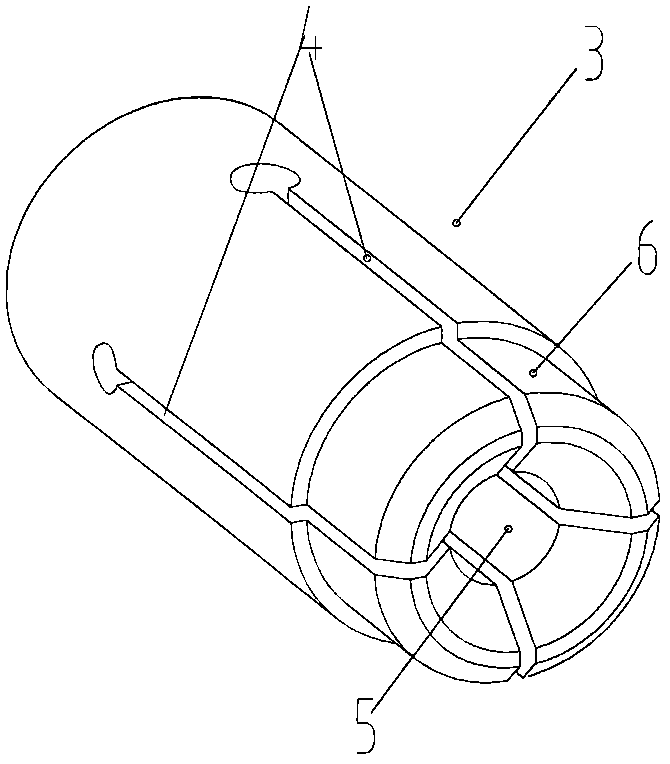

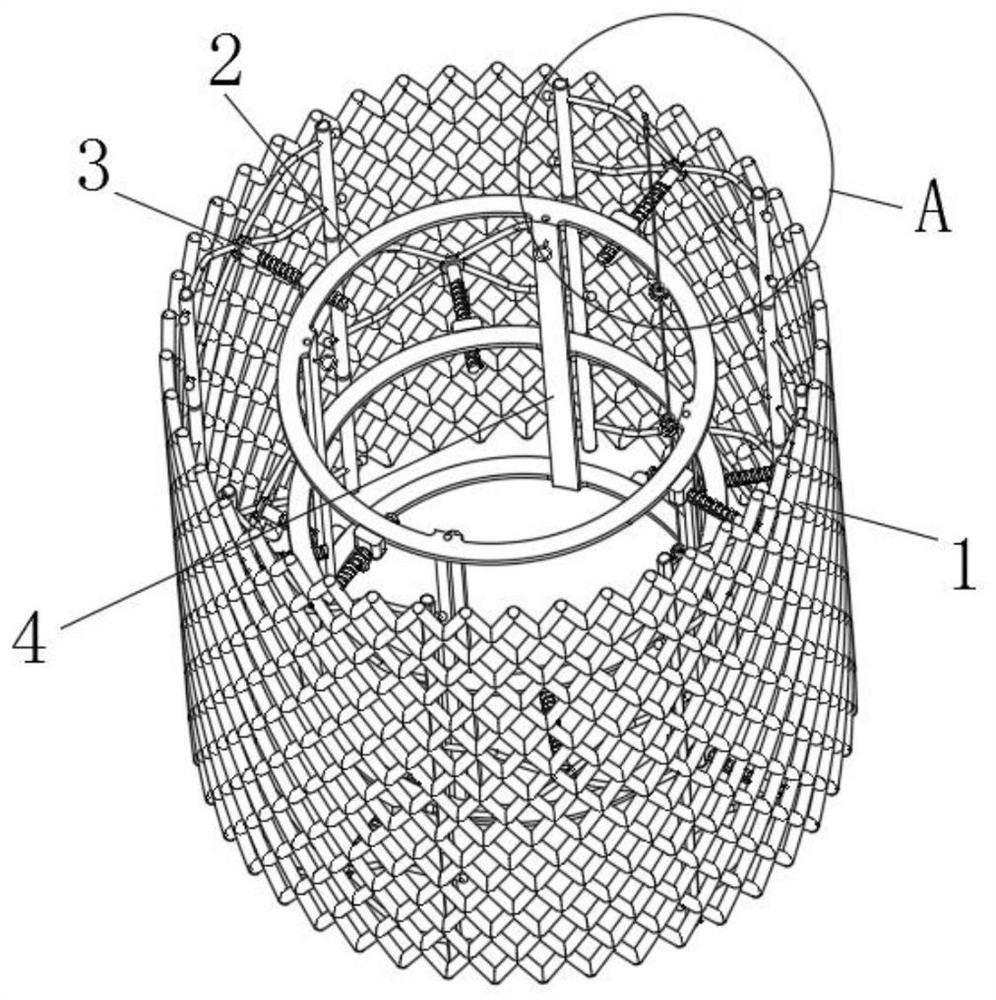

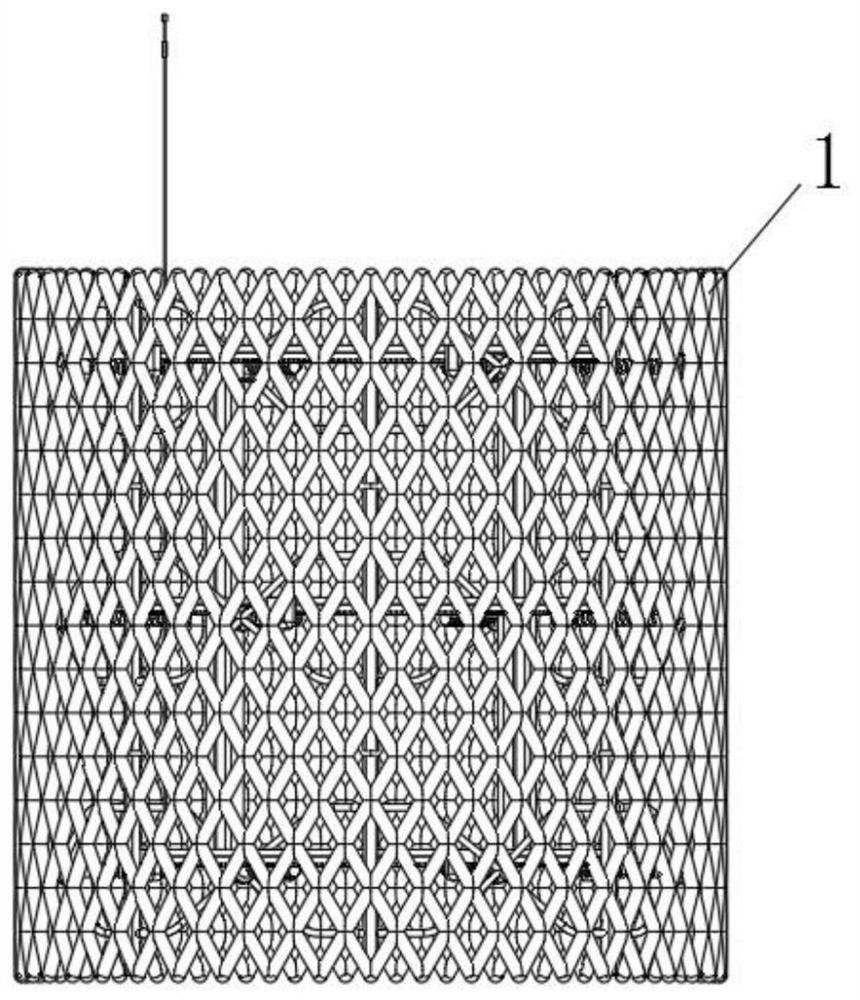

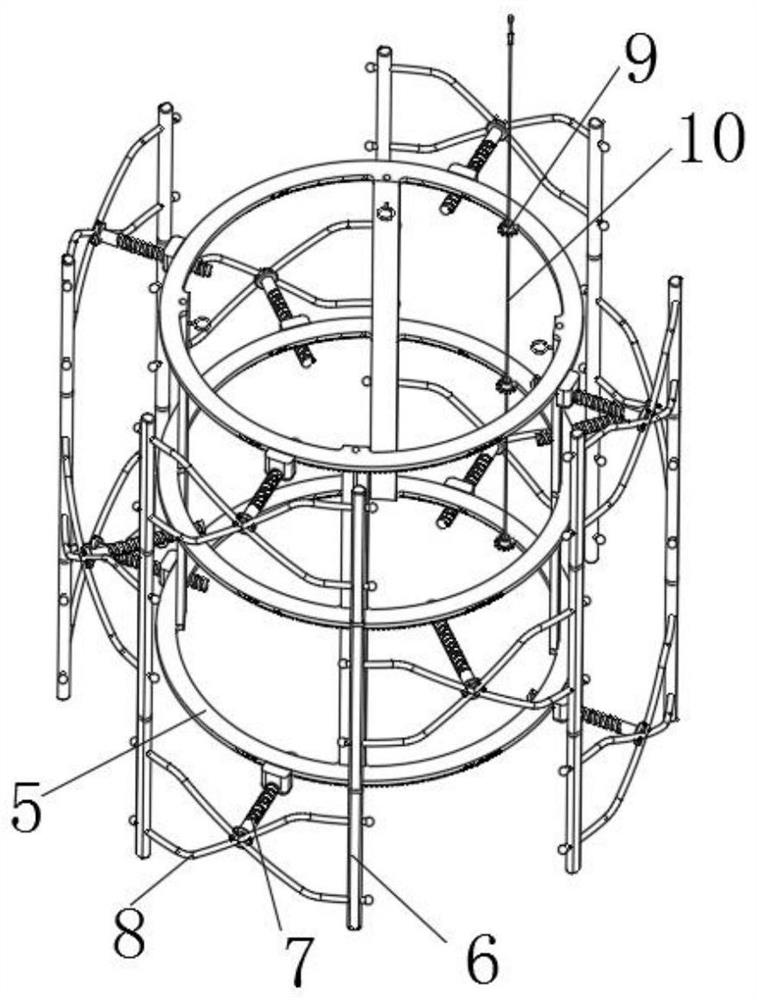

Respiratory tract stent capable of being taken out

PendingCN113616375AReasonable structureReduce the inner diameterStentsTracheaeEngineeringReoperative surgery

The invention discloses a respiratory tract stent capable of being taken out, and relates to the technical field of medical instruments. The stent comprises a supporting net, a supporting skeleton is arranged in the supporting net, the supporting skeleton comprises a plurality of telescopic supporting parts which are coaxially and vertically arranged, the plurality of telescopic supporting parts are fixedly connected through a plurality of connecting rods, and the plurality of telescopic supporting parts are used for supporting different positions of the supporting net; and the telescopic supporting parts comprise holders, the bottoms of the holders are rotationally connected with turbines, and the turbines mesh with a plurality of worms evenly distributed on the peripheral sides. The stent is reasonable in structure, in the operative treatment of benign airway stenosis and airway-esophageal fistula plugging and the post-period rehabilitation process, sliding displacement of the respiratory tract stent is avoided, granulation hyperplasia is relieved, the respiratory tract stent is convenient to take out, the pain of a patient in the later taking-out operation is greatly reduced, and secondary injury caused by the operation is avoided.

Owner:SUZHOU FRANKENMAN MEDICAL EQUIP

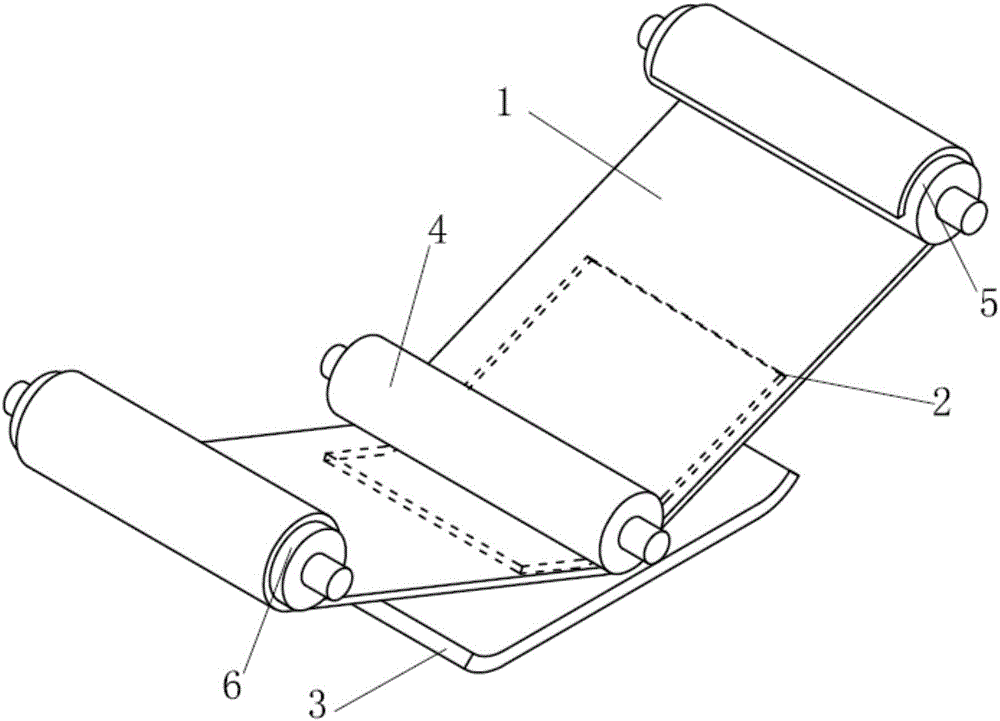

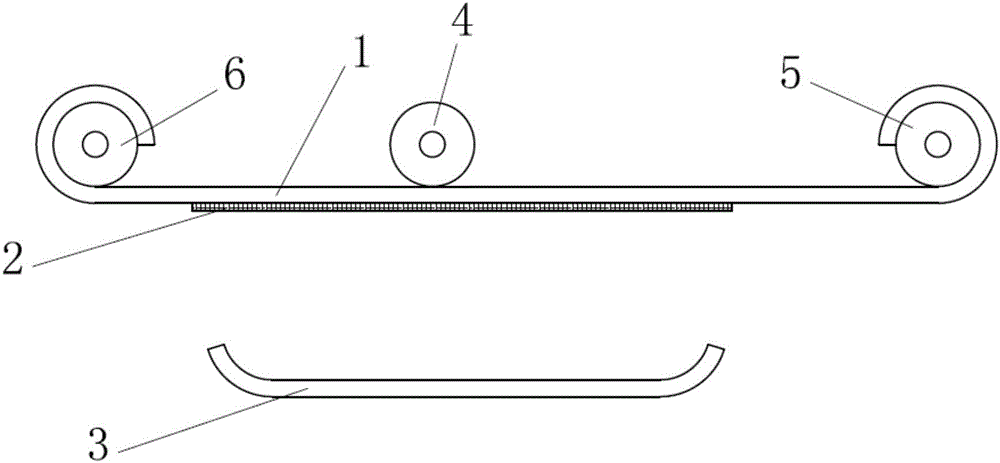

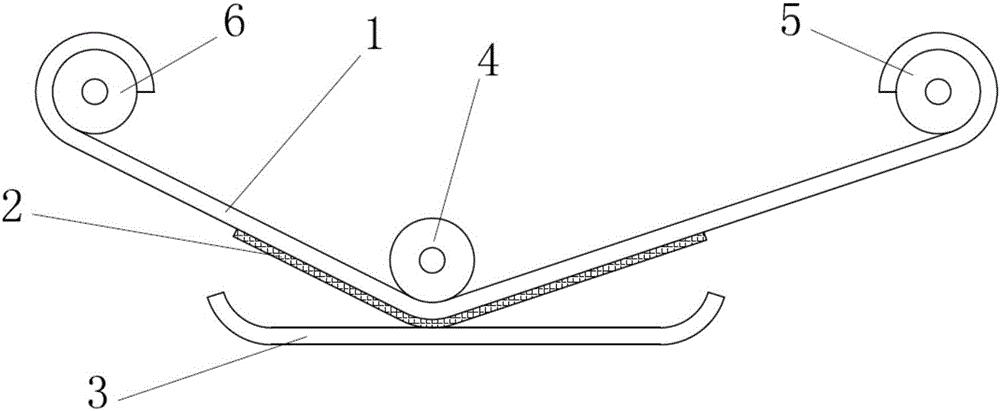

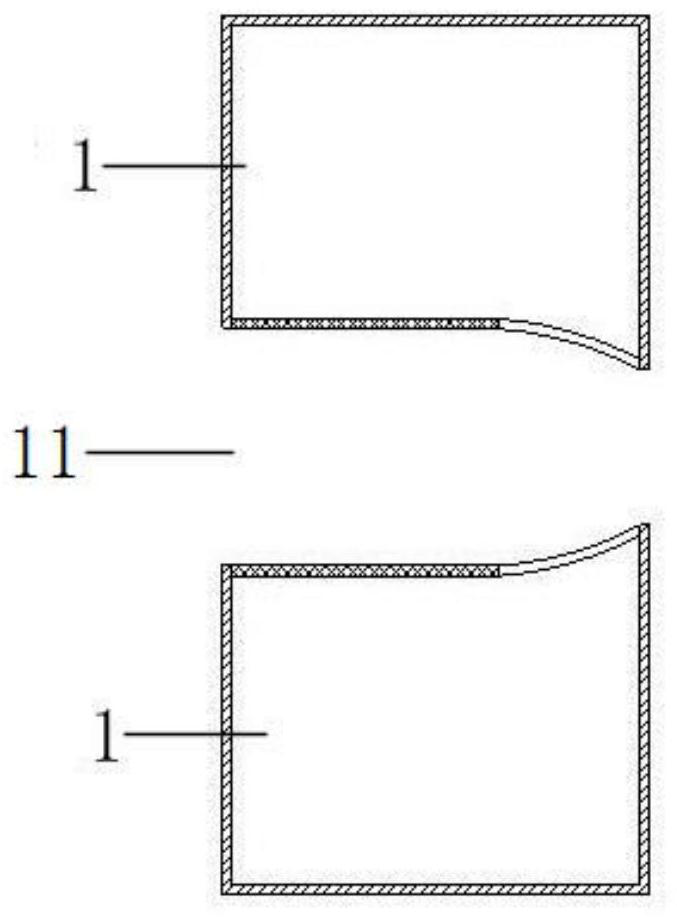

Method for attaching carbon-coated copper foil in organic electroluminesence display

ActiveCN106808780AWith tensionWith exhaust functionLaminationLamination apparatusCopper foilViscosity

The invention discloses a method for attaching a carbon-coated copper foil in an organic electroluminesence display. The method comprises the following steps: attaching the upper surface of a carbon-coated copper foil to the lower surface of a middle strip; pressing a position corresponding to the carbon-coated copper foil, of the middle strip; enabling the lower surface of the carbon-coated copper foil to be in contact with the upper surface of an attaching plate, and rolling the middle strip; transferring and attaching the carbon-coated copper foil to the upper surface of the attaching plate from the lower surface of the middle strip. The lower surface of the middle strip has viscosity, and the viscosity is less than those of the lower surface of the carbon-coated copper foil and the upper surface of the attaching plate, so that the carbon-coated copper foil can be transferred to the attaching plate. The middle strip has ductility, the surface of the middle strip can be prolonged when the pressing rollers presses down, the carbon-coated copper foil attached to the surface of the middle strip is tightened and flattened because of certain tensile force, then the attaching flatness can be improved, the middle strip has elastic and capillary pores perpendicular to the direction of the surface of the middle strip, soft force is needed when the carbon-coated copper foil is attached, bubbles can be avoided, the attaching flatness of the carbon-coated copper foil can be improved, the attaching efficiency can be improved, and the method can be applied to the field of curved surface attachment.

Owner:SUZHOU JIERUISI INTELLIGENT TECH CO LTD

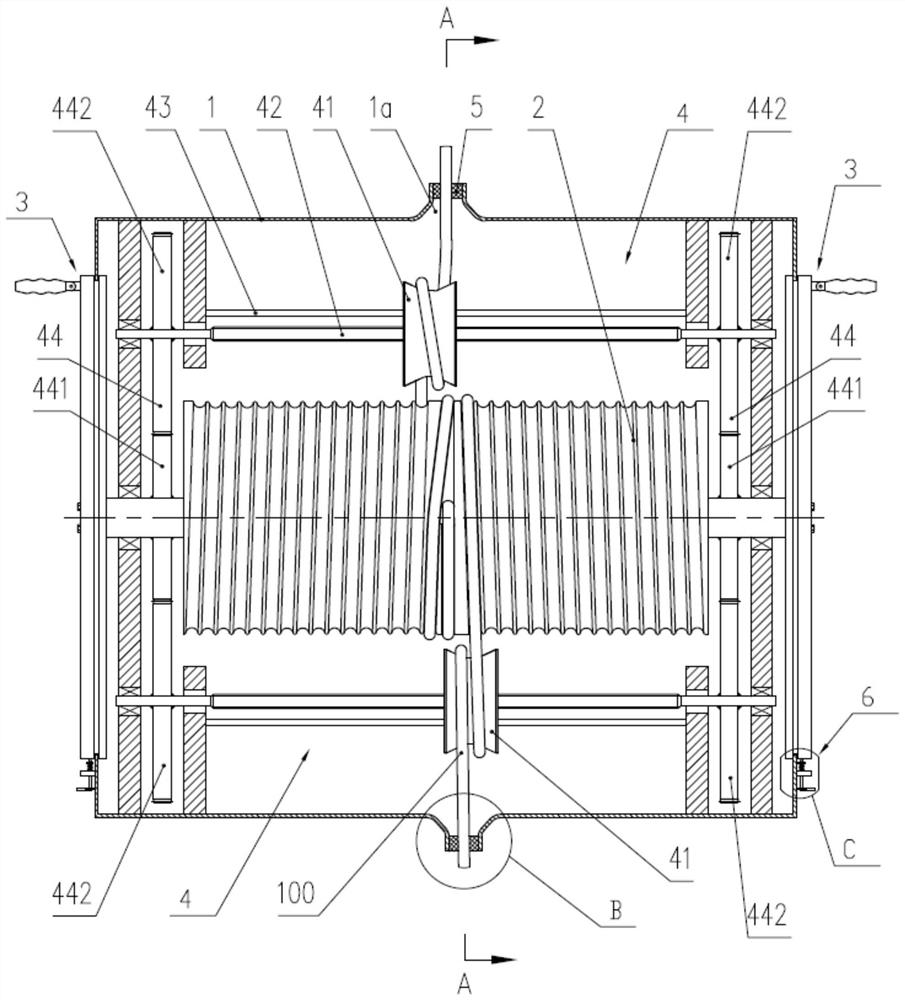

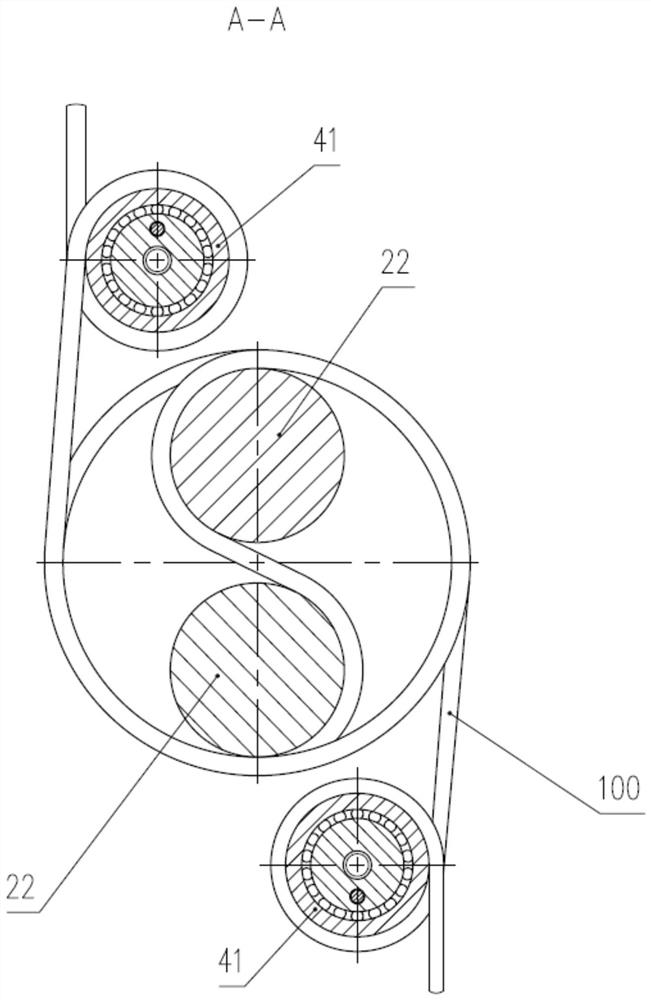

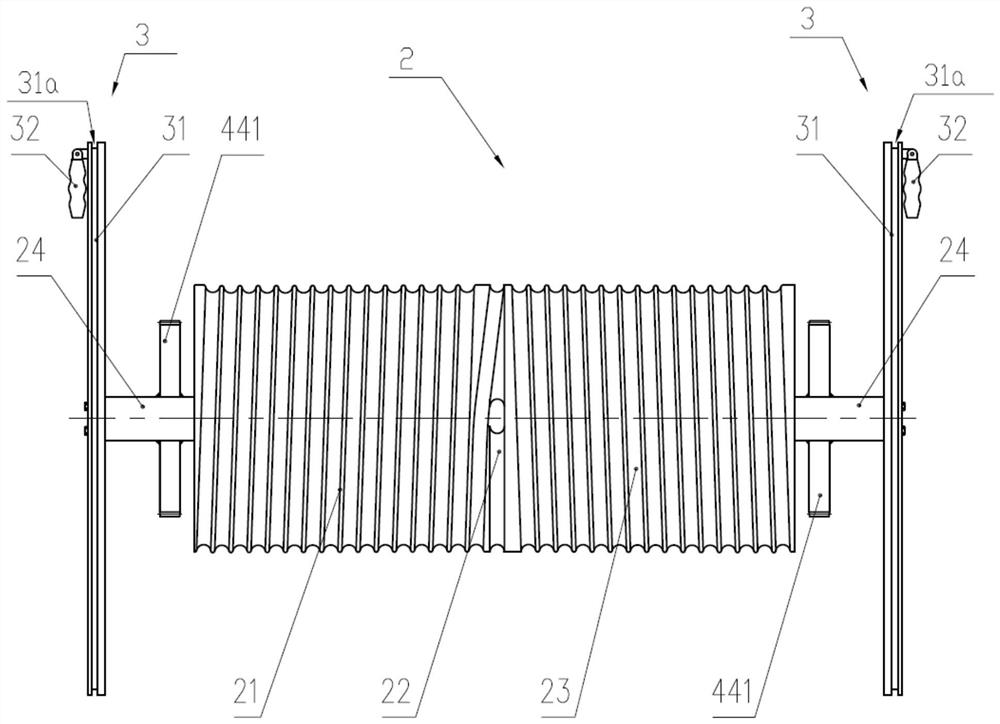

Rope feeding device

The invention discloses a rope feeding device, which comprises a shell. The shell is provided with a rope through hole; a support is arranged in the shell; a rope pressing device is arranged in the rope through hole. A certain force is applied to a mooring rope by arranging the rope pressing device, and therefore, the mooring rope between the rope feeding device and a winch is prevented from being too loose when takeup is performed by the winch.

Owner:捷胜海洋工程装备有限公司 +1

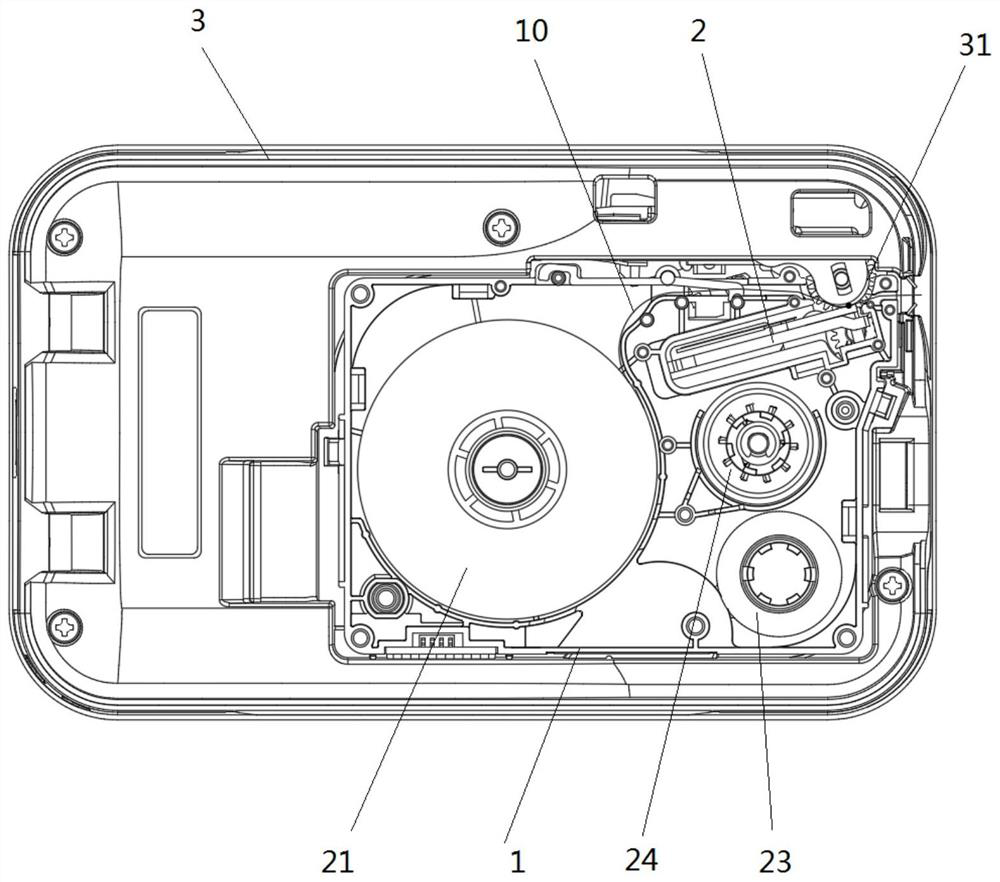

Label printer and label accurate positioning printing method thereof

PendingCN113978137ACompact structureClose pathInking apparatusTypewritersGear driveComputer printing

The invention discloses a label printer and a label accurate positioning printing method thereof. The label printer comprises an outer shell, a label box installed in the outer shell, a power mechanism and a control mechanism which are used for controlling paper outlet of the label box and take-up and pay-off of thermal transfer ribbons, and a printing head used for achieving label printing. According to the invention, internal spaces of the label box are reasonably planned, and a linear label paper outlet channel and a label rollback release space are arranged, so that smooth paper feeding and discharging are guaranteed, and label paper is prevented from wrinkling in a rollback process; through improvement of a gear transmission system, forward and reverse rotation of a gear can be realized through the same motor, so that normal printing of the label paper and the thermal transfer ribbons can be realized, rollback of the label paper and the thermal transfer ribbons can also be realized, waste of the label paper and the thermal transfer ribbons is avoided, and the material utilization rate is improved; and through arrangement of a photoelectric sensor with a reflecting prism, an occupied space of the label box is reduced, and favorable conditions are provided for realizing a miniaturized label box. The invention is compact in structure, high in space utilization rate, accurate and reliable in printing and wide in application range.

Owner:BEIJING SUPVAN ELECTRONIC TECH CO LTD

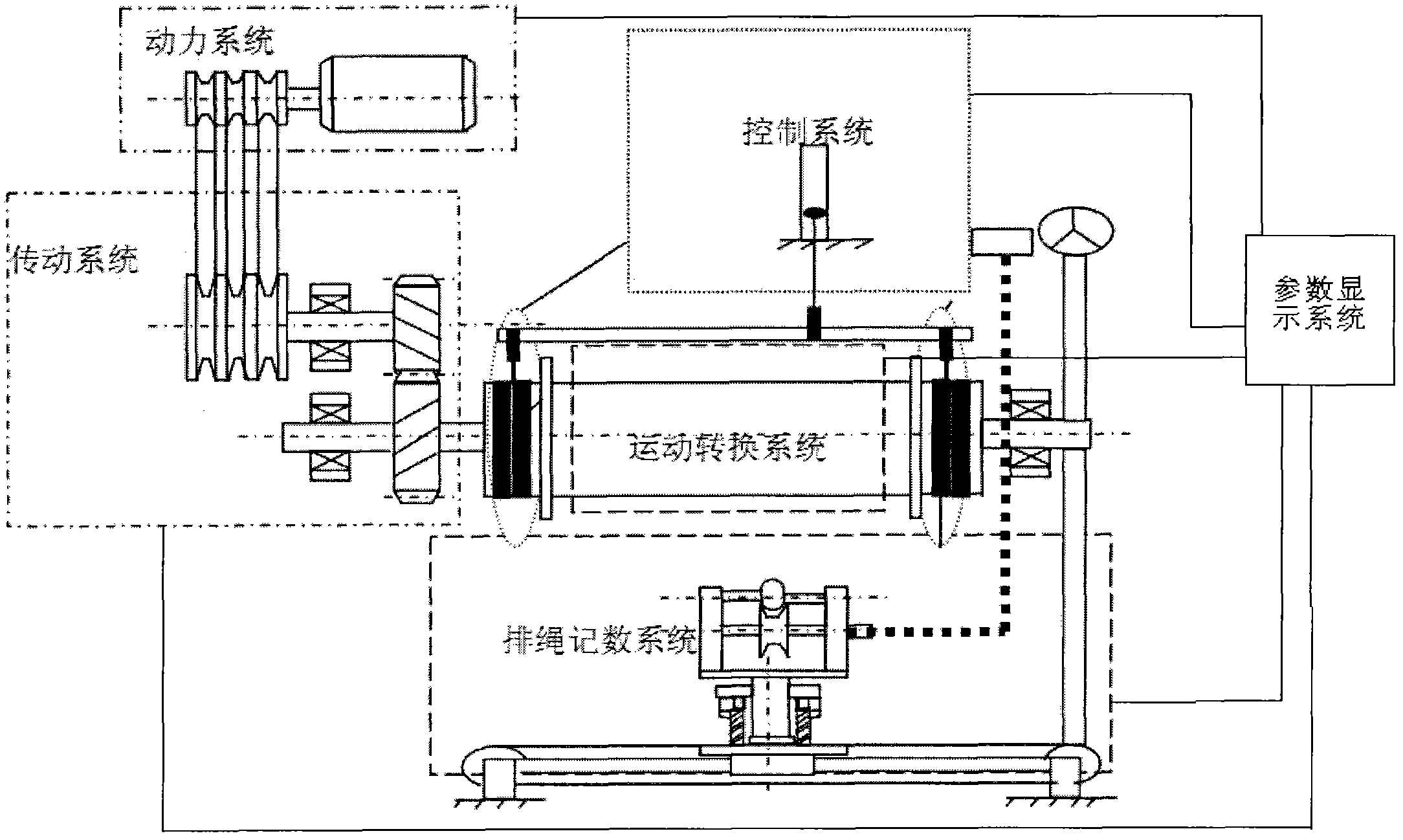

Novel mechanical paraffin cleaning hoist applied to petroleum field

The invention discloses a novel mechanical paraffin cleaning hoist applied to the petroleum field. The novel mechanical paraffin cleaning hoist is mainly formed by a power system, a transmission system, a motion conversion system and a rope arrangement notation system which are sequentially connected. A control system is connected onto the motion conversion system. The power system, the transmission system, the motion conversion system, the rope arrangement notation system and the control system are connected with the same parameter display system. The novel mechanical paraffin cleaning hoist is small in volume, compact in structure, stable in transmission and reliable in braking, and has the function of tension, depth and speed display.

Owner:陈红兵

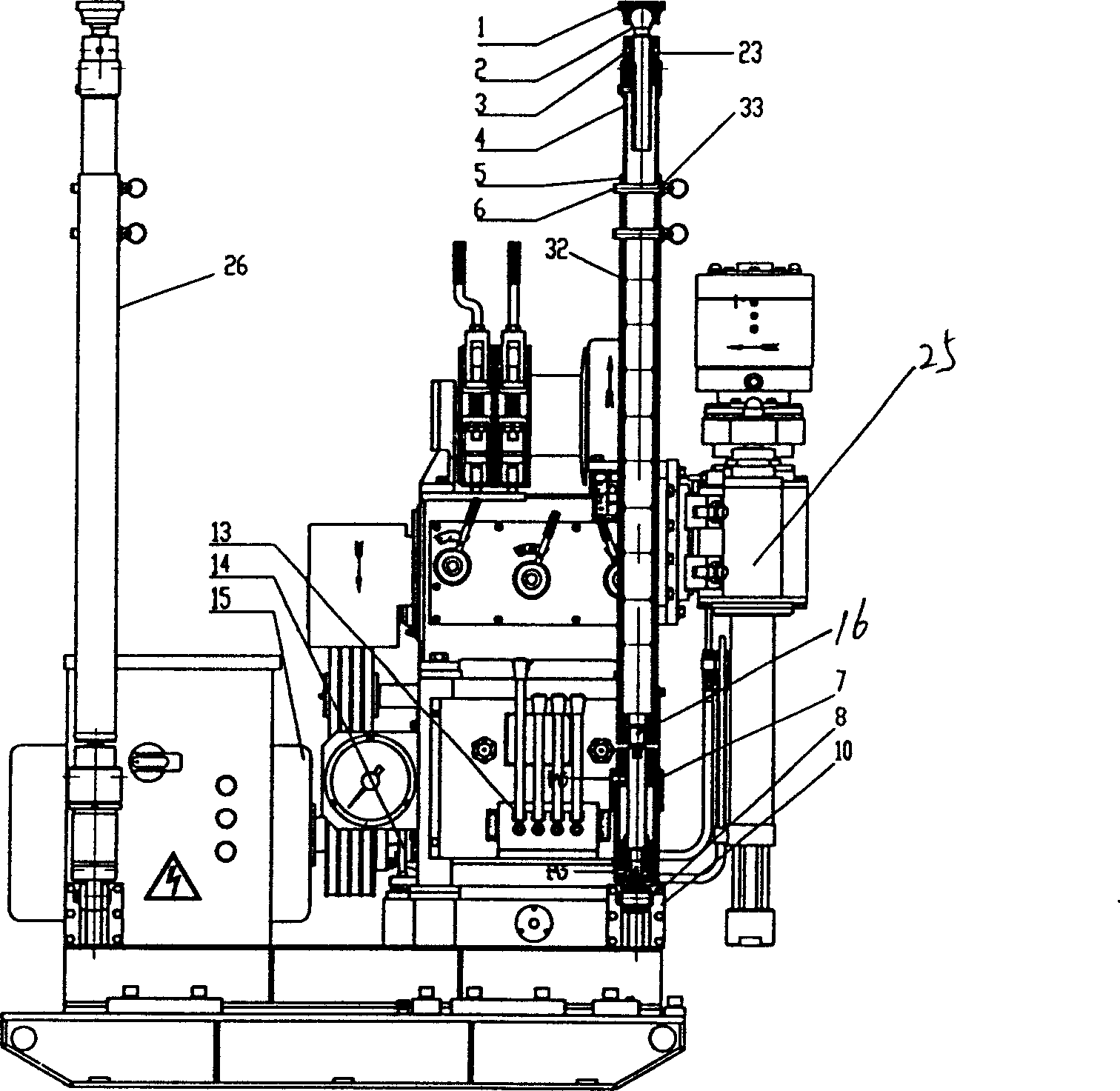

Drilling machine with supporting frame

InactiveCN1888371AEasy to fixImprove work efficiencyConstructionsDerricks/mastsEngineeringControl valves

The present invention relates to a drilling machine with supporting frame. It is composed of machine body, motor, oil pump and control valve. Its structure is characterized by that on the machine body a supporting frame is set, said supporting frame is composed of hinged support, supporting oil cylinder, supporting bar and fine tuning device. Said invention also provides the connection mode of all the above-mentioned portion and working principle and operation method of said drilling machine with supporting frame.

Owner:HANGZHOU XIANGLONG DRILLING EQUIP TECH CO LTD

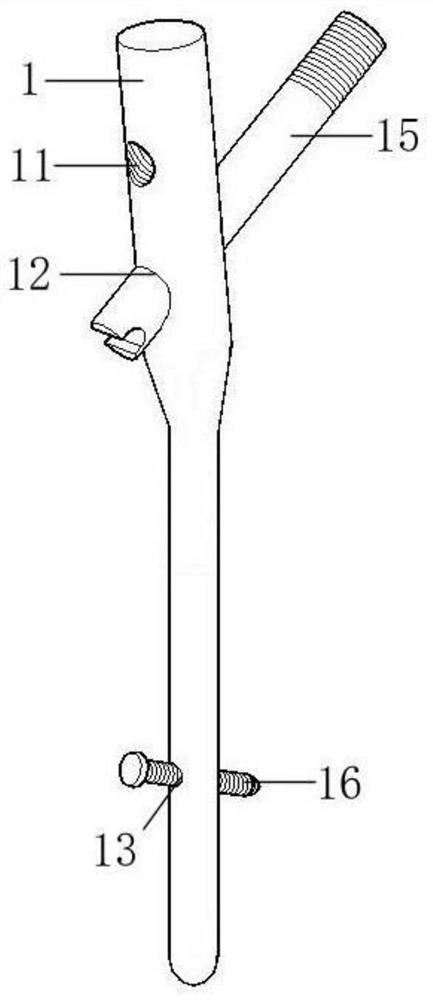

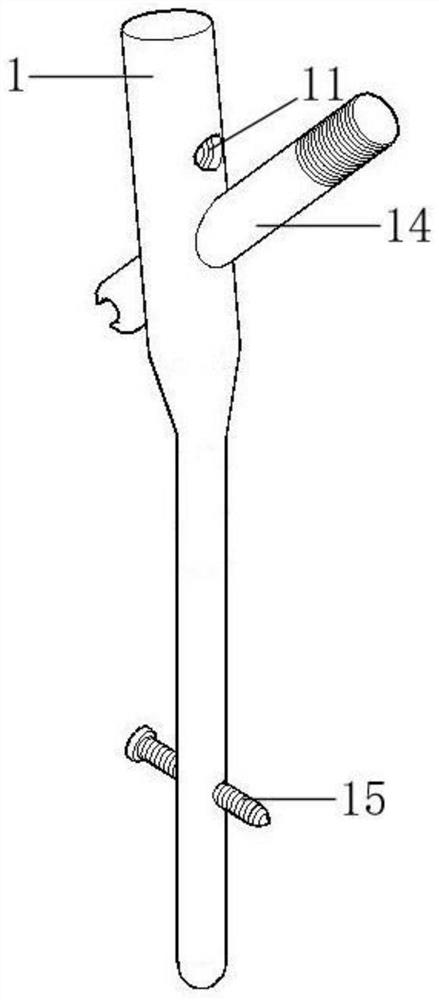

Improved tension bone trabecula reconstruction type proximal femur intramedullary nail

PendingCN112656500AImprove stabilityIncreased resistance to varus stressInternal osteosythesisFemoral neckBiomedical engineering

The invention relates to an improved tension bone trabecula reconstruction type proximal femur intramedullary nail. The improved tension bone trabecula reconstruction type proximal femur intramedullary nail comprises a main nail body, a reconstruction device and a locking device, a reconstruction device through hole is transversely formed in the near section of the main nail body; and the reconstruction device comprises an anchor and a titanium cable. The titanium cable is fixedly connected with the tail end of the anchor; the locking device comprises a locking head and a connecting part; and the two ends of the locking head are of a conical opening structure. The surface of the front end of the connecting part is provided with an external thread structure, and the tail end is of a hollow inner hexagonal structure. A conical hole structure matched with the tail end of the locking head is further arranged in the center of the connecting part. The improved tension bone trabecula reconstruction type proximal femur intramedullary nail has the advantages that the tension bone trabecula of the neck of the femur is reconstructed, and the elastic fixing effect is achieved; meanwhile, the anti-rotation and anti-introversion stress of the femoral head and neck bone block can be enhanced, and good stability can be achieved; and the driving direction of the anchor can be freely adjusted according to different femoral neck diameters of a patient.

Owner:SHANGHAI TONGJI HOSPITAL

Turning mechanism

PendingCN111747074ASimple structureHigh clamping accuracyConveyorsConveyor partsTransmission beltElectric machinery

The invention relates to a turning mechanism. The turning mechanism comprises two turning devices. The two turning devices are arranged side by side at intervals, and a conveying channel for conveyingPCBs is arranged between the two turning devices. Each turning device comprises a turning body, a clamping plate device and a conveyor belt. The clamping plate devices are fixedly placed on the sidewalls of the turning bodies. A clamping channel is arranged in the middle of the clamping plate devices. Both ends of each turning body are provided with pulleys. The two pulleys are connected with each turning body. One end of each turning body is fixedly provided with a motor. The conveyor belt extends along the clamping channel, extends into each turning body through the pulley and an output end of the motor, and then extends to the clamping channel end to end through another pulley. A plurality of pulley sets are arranged on the side walls, close to the conveying channel, of the turning bodies, and the pulley sets are arranged at intervals along the conveyor belts. Compared with the prior art, the turning mechanism can not only reverse and transport the PCBs, but also facilitate laserengraving and coding on the edge of the PCBs.

Owner:深圳市青马技术有限公司

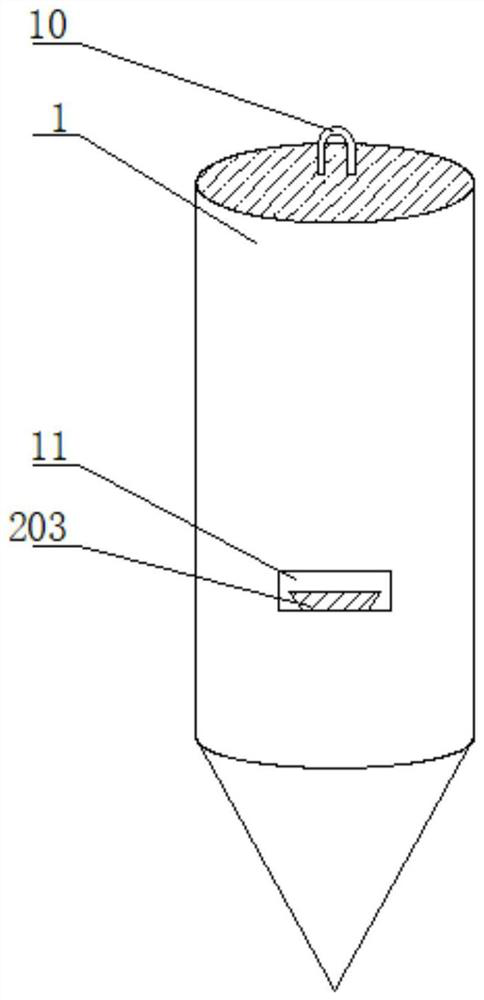

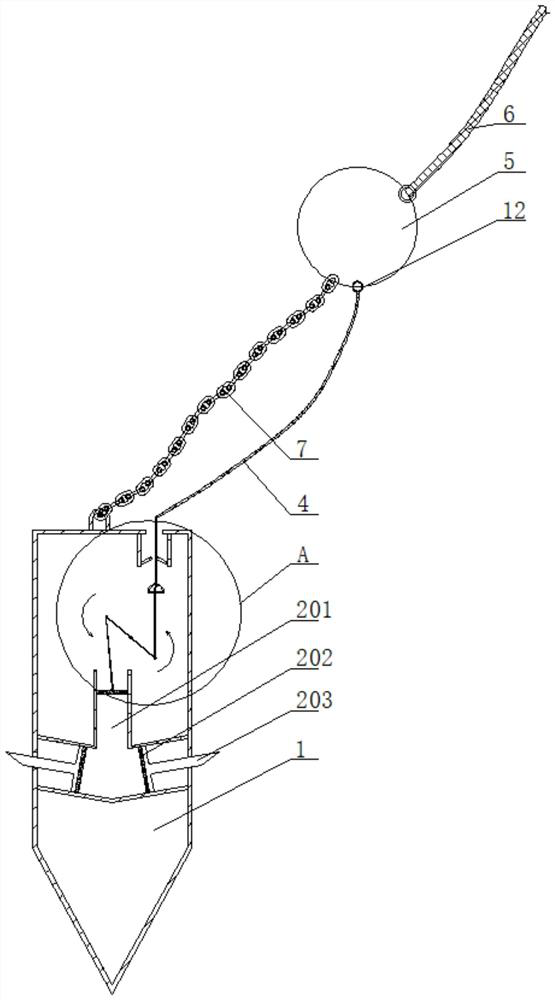

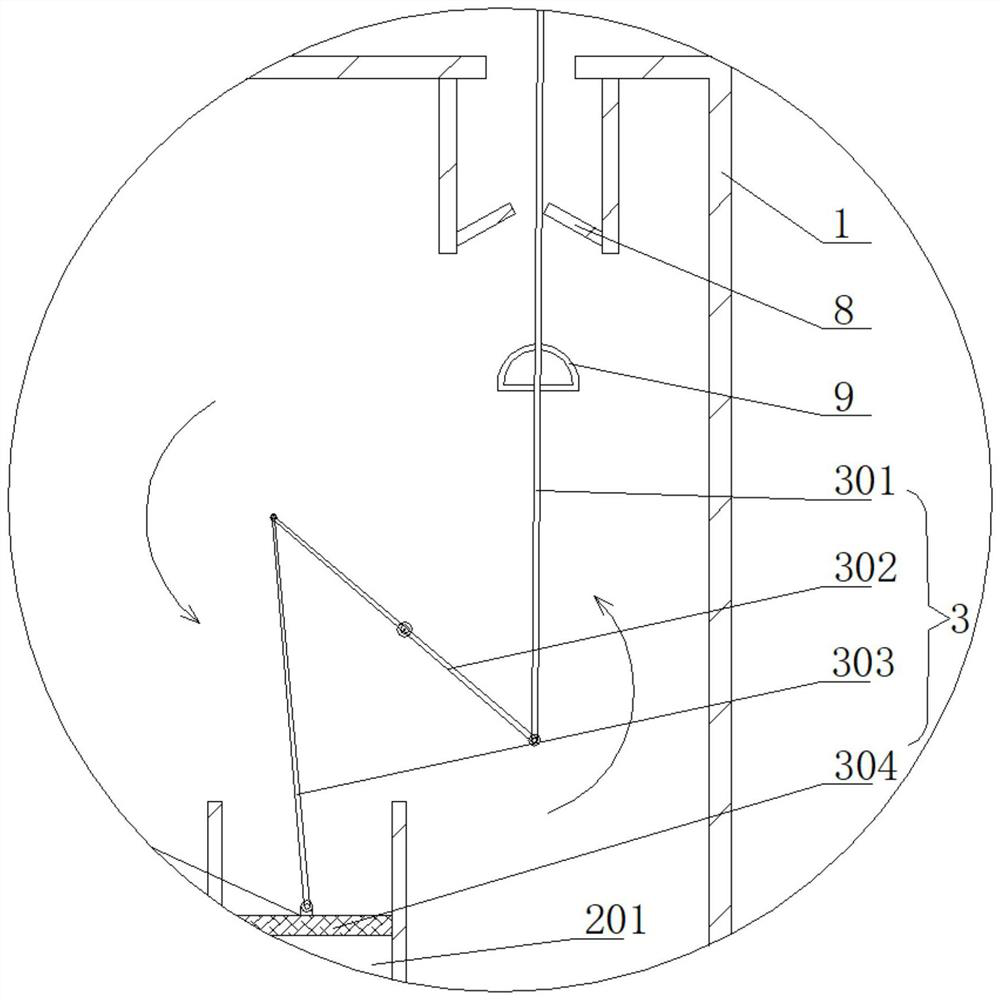

Rapid laying and anchoring system and use method

ActiveCN113978620ACompact structureEasy to operateClimate change adaptationAnchorsPistonClassical mechanics

The invention relates to a rapid laying and anchoring system and a use method. The rapid laying and anchoring system comprises an anchor body shell, a hydraulic assembly and a connecting rod assembly, wherein the hydraulic assembly comprises a hydraulic cavity and a piston plate, the piston plate is connected with a damping plate, the connecting rod assembly comprises a driving rod penetrating through the anchor body shell, a transmission rod hinged to one end of the driving rod and a driven rod hinged to the end, away from the driving rod, of the transmission rod; the middle point of the transmission rod is hinged to the inner wall of the anchor body shell, a movable sealing cover is hinged to the end, away from the transmission rod, of the driven rod and moves in the hydraulic cavity, a safety rope is connected to the end, extending out of the anchor body shell, of the driving rod, a shackle is connected to the end, away from the anchor body shell, of the safety rope, and an upper mooring rope is further connected to the shackle; and a lower mooring rope connected with the anchor body shell extends from the shackle. Due to the integrated design of a safety pin, the safety rope, a connecting rod device and a hydraulic system, the anchor body has certain tension.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

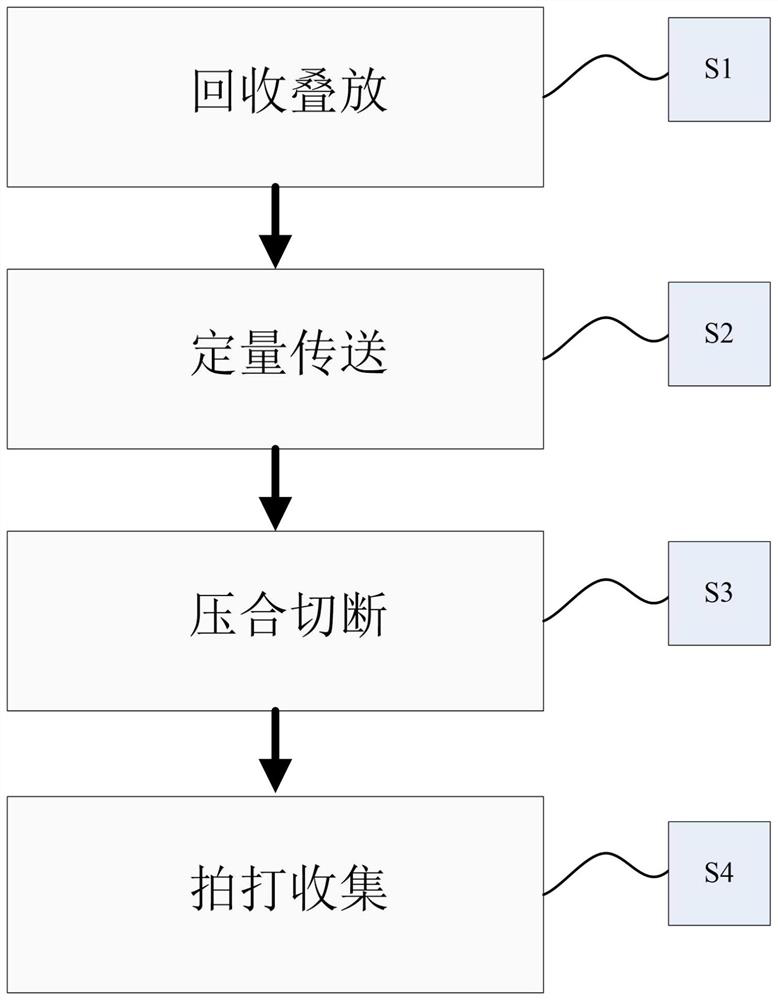

Plastic woven bag recycling and reusing processing process

InactiveCN113306046AReduce resistanceReduce noisePlastic recyclingMechanical engineeringCement Material

The invention provides a plastic woven bag recycling and reusing processing process. The process comprises a pressing and cutting mechanism, a beating mechanism, a conveying mechanism and a bottom plate. The problems that in the existing processing process of cutting cement plastic woven bags into strips, due to the particularity of cement plastic woven bag materials, the slipping phenomenon is likely to occur in the conveying process, the cement plastic woven bags cannot be quantitatively and stably conveyed, conveying errors can be caused, the size required by cutting cannot be met, the cement woven bags and cement dust are prone to being compacted and adhering in the conveying process, the follow-up cleaning difficulty is increased, and follow-up work after recycling is affected are solved; and the problems that due to the fact that the cement woven bags have the characteristics of high strength and good toughness, the cutting and shearing difficulty is increased, resistance is large and noise is high in the cutting process, the cement woven bags cannot be continuously and rapidly sheared into strips, and negative influences are caused to the recycling efficiency are also solved.

Owner:王兆春

An aluminum alloy door frame, a door panel using the aluminum alloy door frame, and a method of use thereof

ActiveCN106014131BInhibit sheddingGuaranteed structural strengthDoor leavesUltimate tensile strengthAluminium alloy

The invention discloses an aluminum alloy door frame, a door board with the aluminum alloy door frame and a use method of the aluminum alloy door frame. The manner of plane corner braces and border front face / back face locking screws in the traditional technology is changed into the manner of vertical corner braces and border side face locking screws, pressing strips are matched for shielding the screws and fixing core boards, the screws cannot be seen from the front face and the reverse face of the aluminum alloy door frame, and the whole door frame is attractive and elegant. The pressing strips are designed to be easy to install and difficult to detach, and the structural strength and the safety of a finished product are guaranteed. The pressing strips can be used in cooperation with the core boards with different thicknesses. The aluminum alloy door frame is suitable for a cabinet door board and a common aluminum door and is wide in application range.

Owner:เซี่ยเหมิน โกลเด้นโฮม โค

Hose storage fixer

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com