Position correcting mechanism of automobile slide bearing oil injection holes

A technology of sliding bearings and oil injection holes, which is applied in the direction of automatic control devices, feeding devices, metal processing machinery parts, etc., to achieve the effects of simple actions, increased reliability, and reduced requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

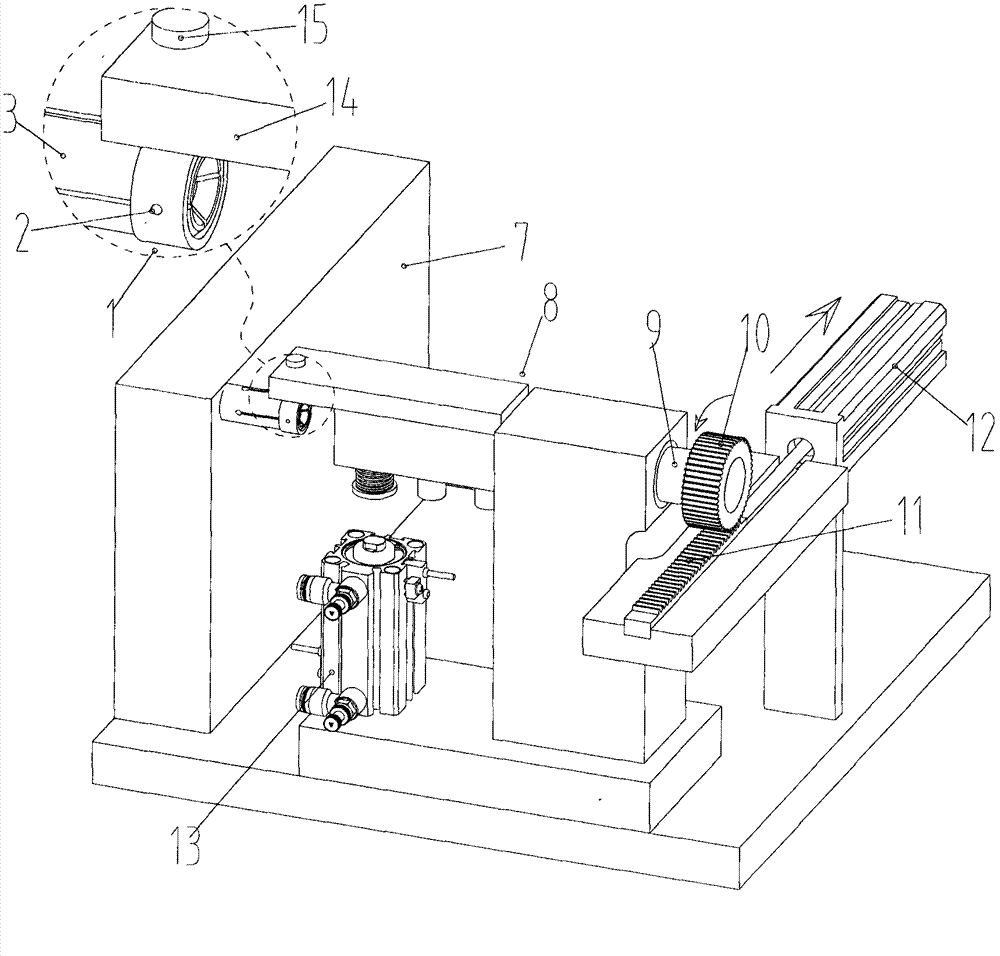

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings, but does not constitute any limitation to the present invention. Similar component numbers in the accompanying drawings represent similar components. As mentioned above, the present invention provides a mechanism for correcting the position of the oil injection hole of the automobile sliding bearing, which has a simple structure and is easy to operate.

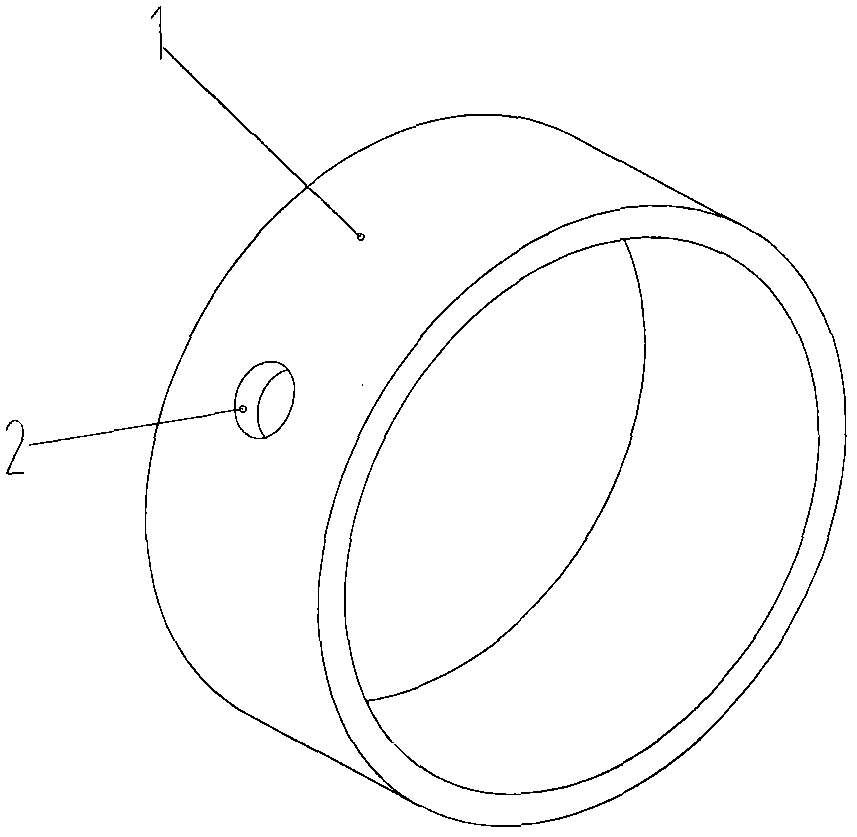

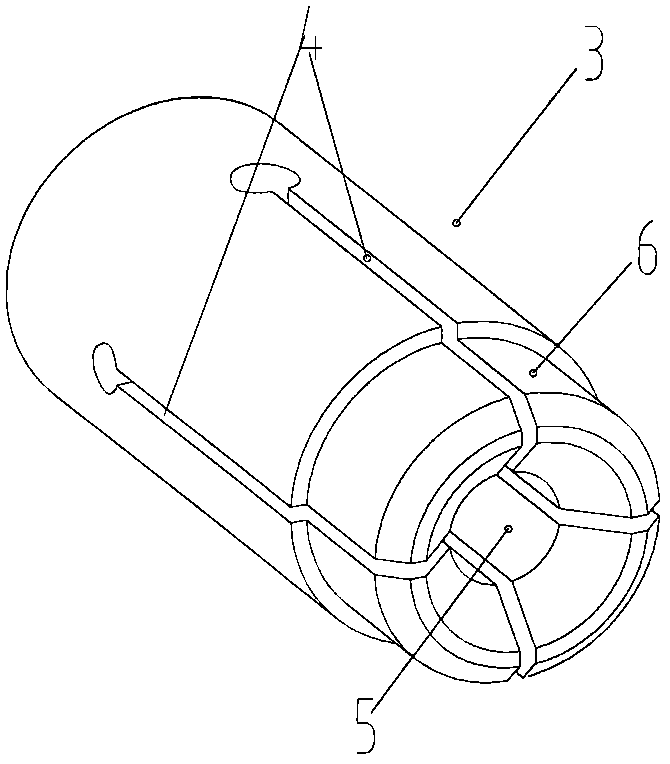

[0029] figure 1 It is a schematic structural diagram of the sliding bearing of the position correction mechanism of the oil filling hole of the automobile sliding bearing of the present invention, figure 2 , 4 , 5, 6 are structural schematic diagrams of the position alignment mechanism of the automobile sliding bearing oil hole of the present invention, image 3 It is a structural schematic diagram of the blanking unit of the position-correcting mechanism of the oil injection hole of the automobile sliding b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com