Patents

Literature

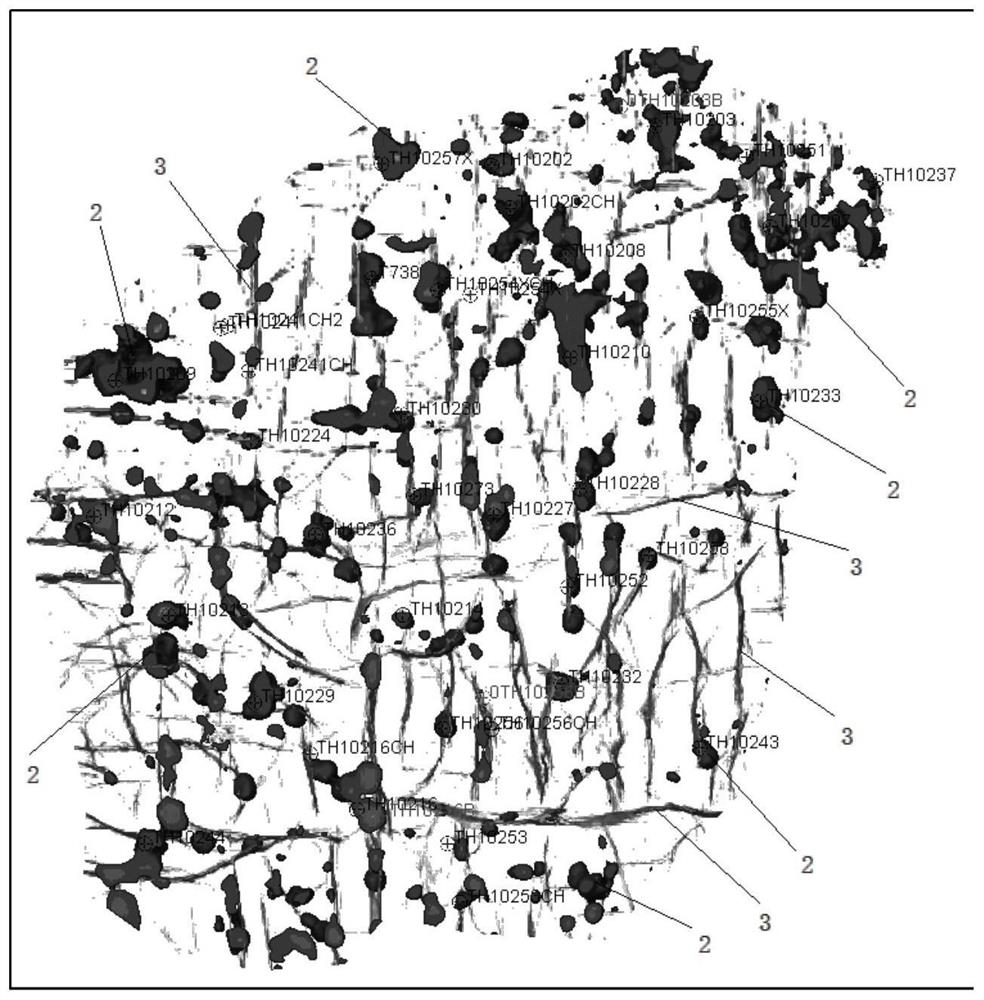

40 results about "Hole Finding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

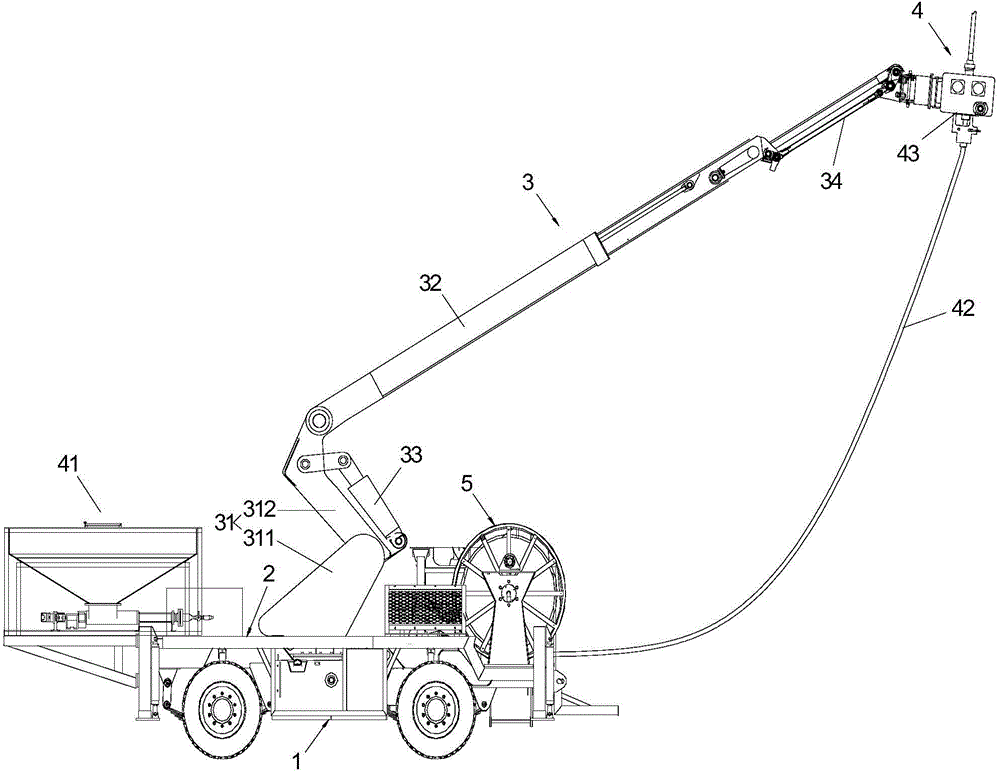

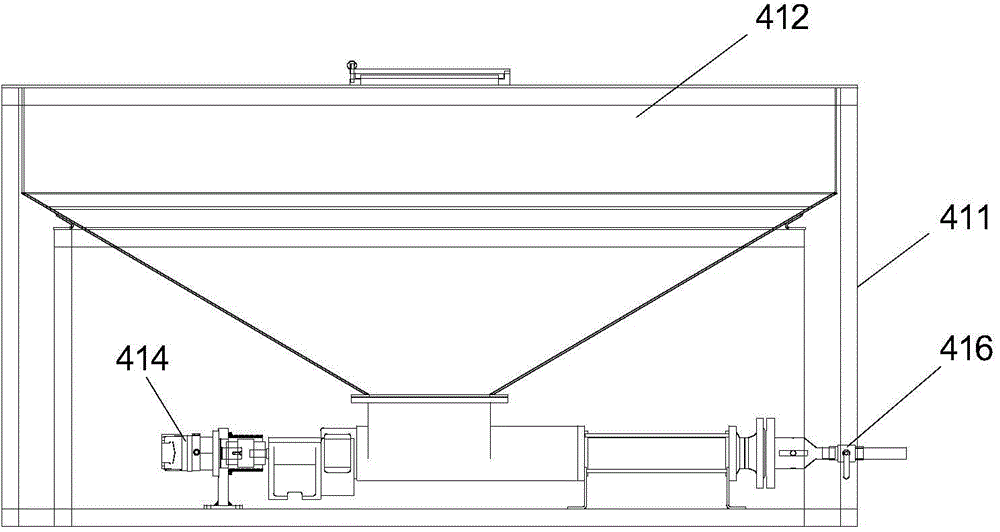

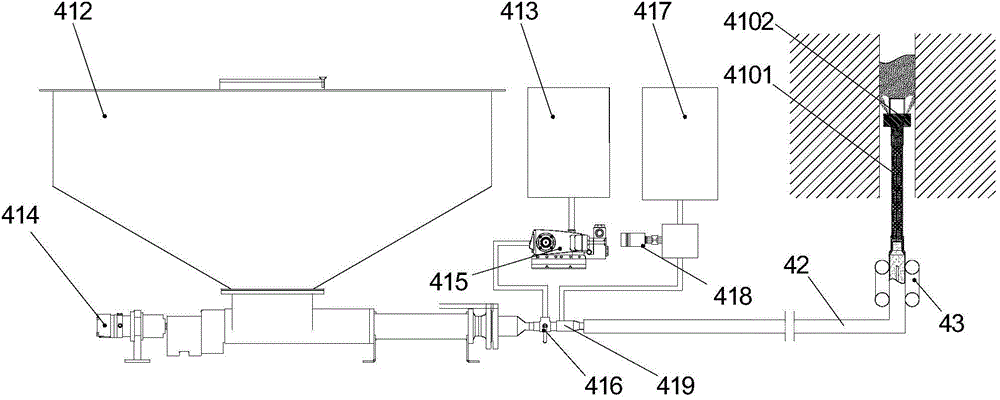

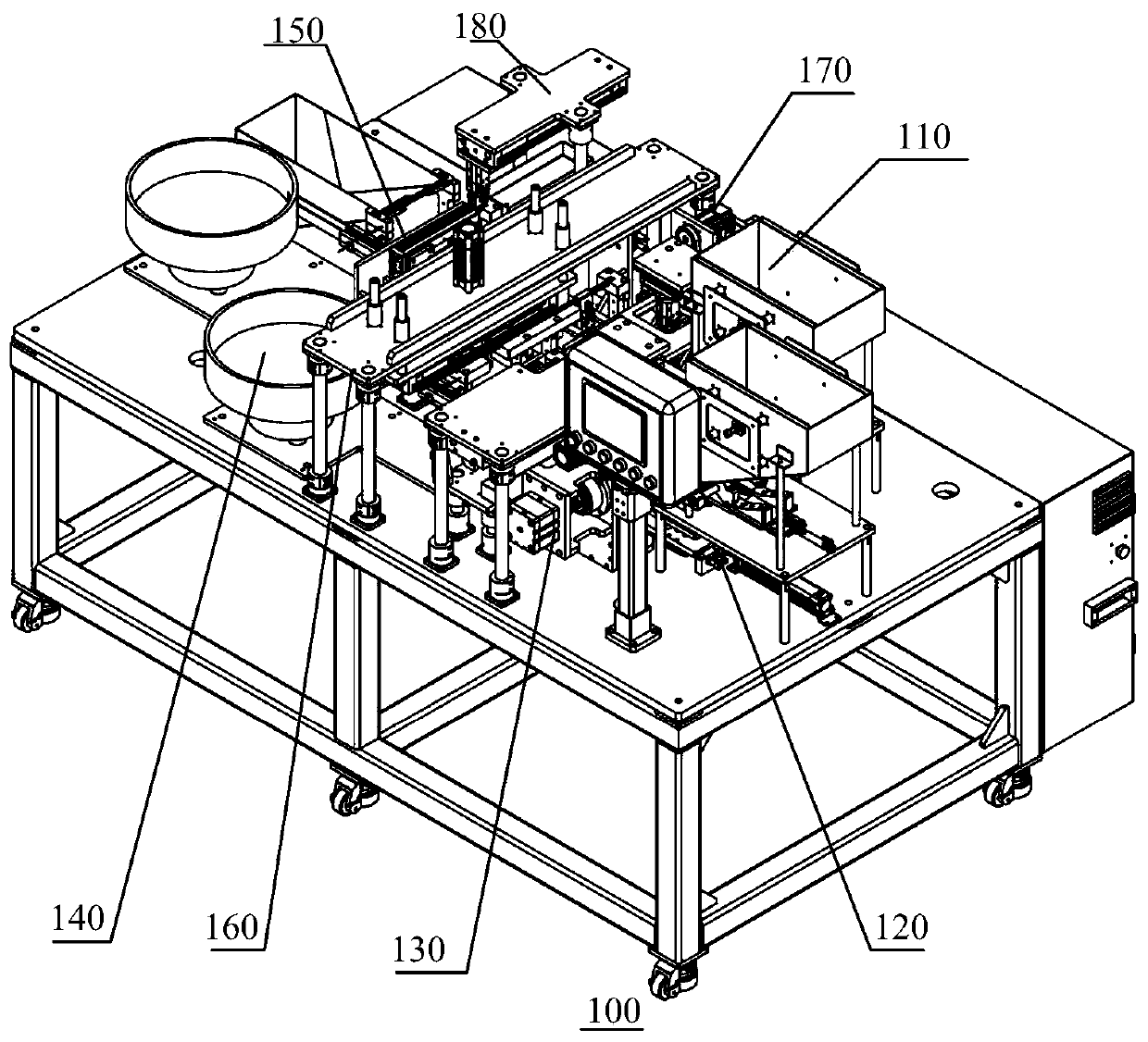

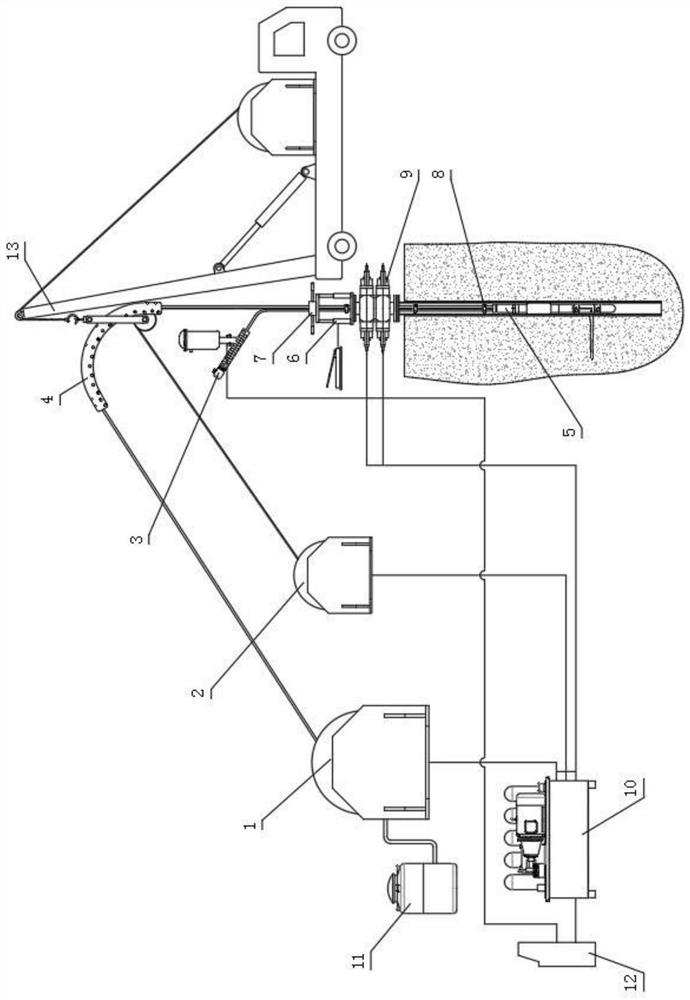

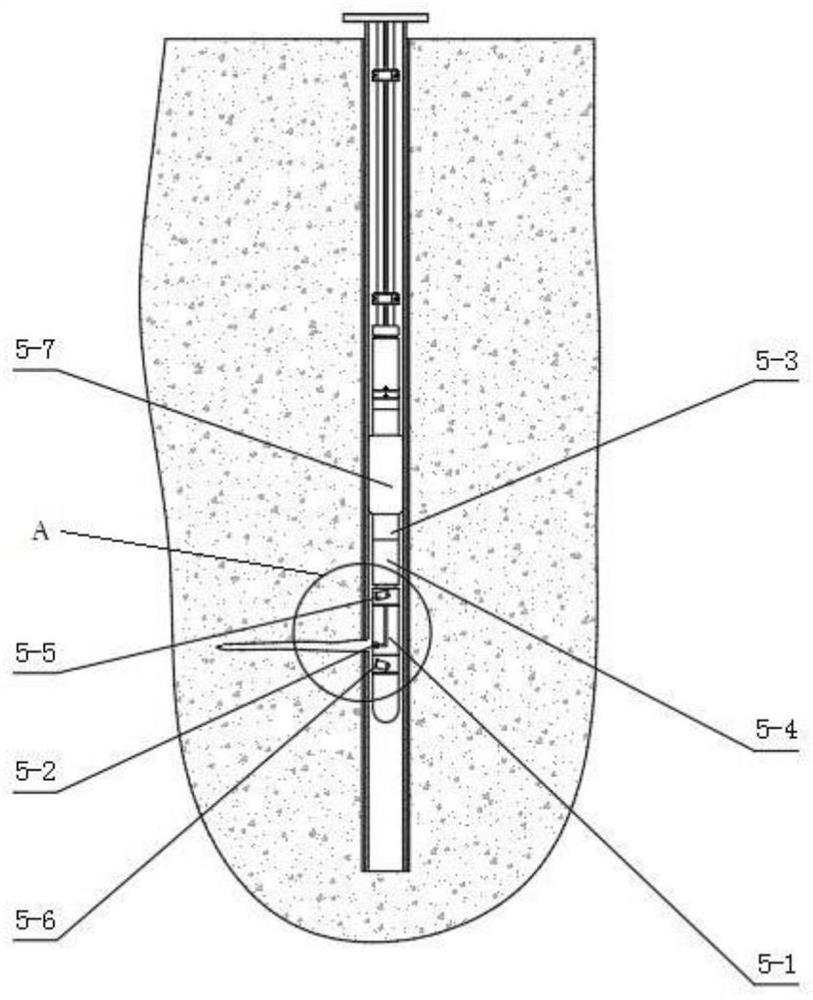

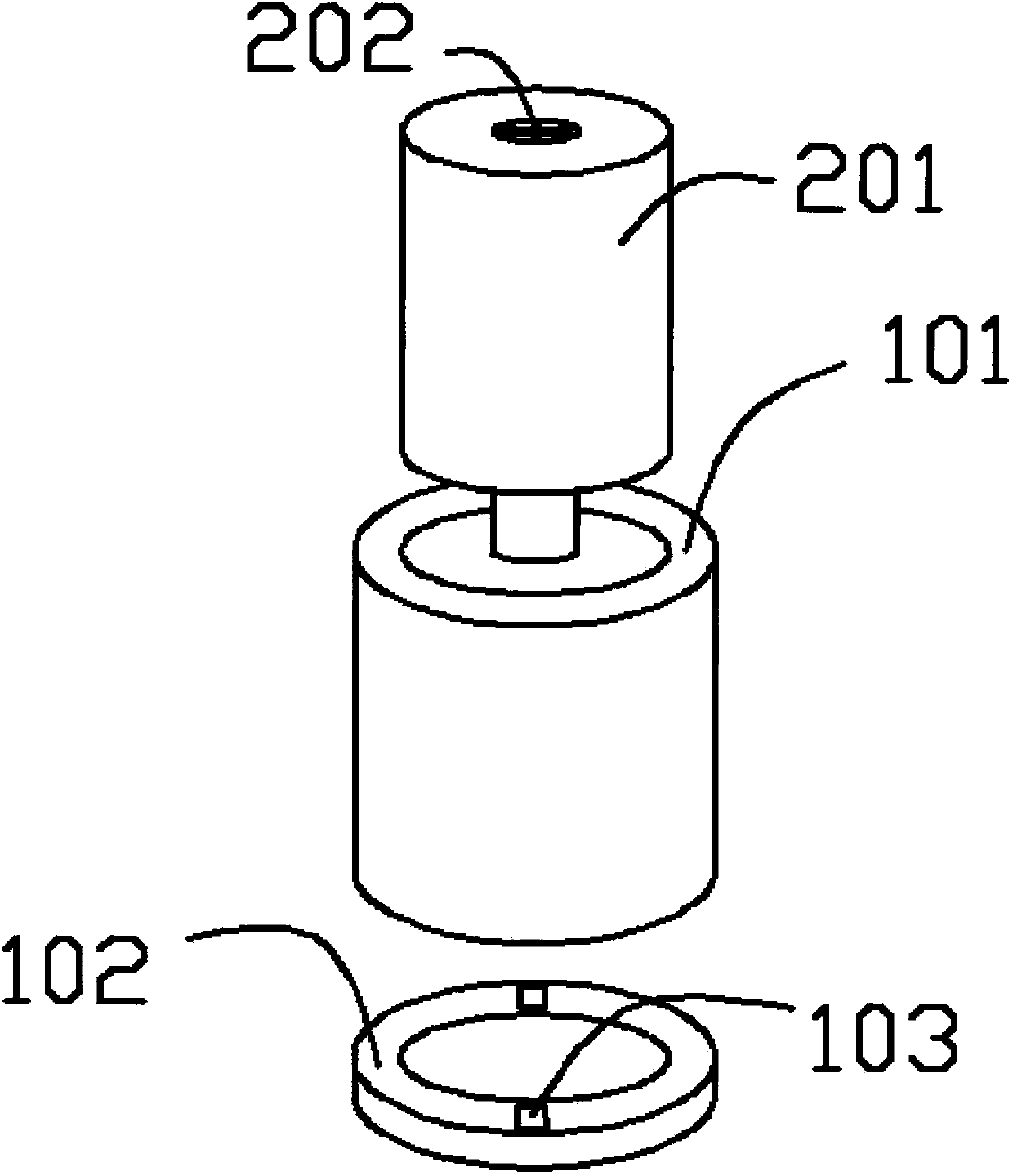

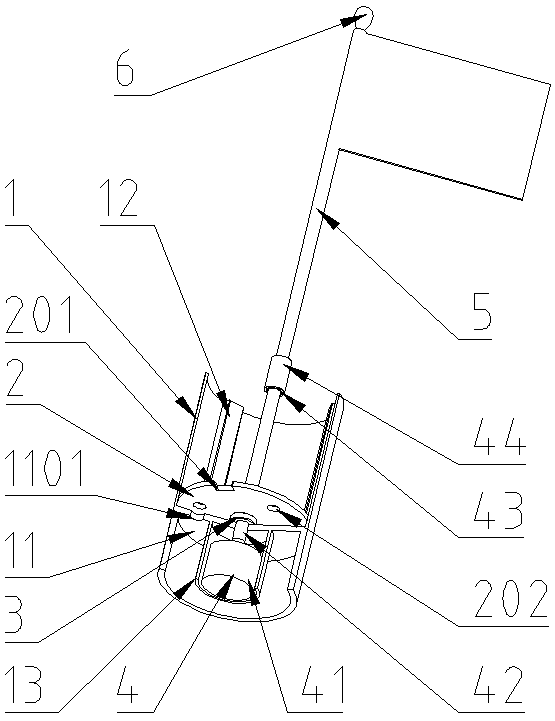

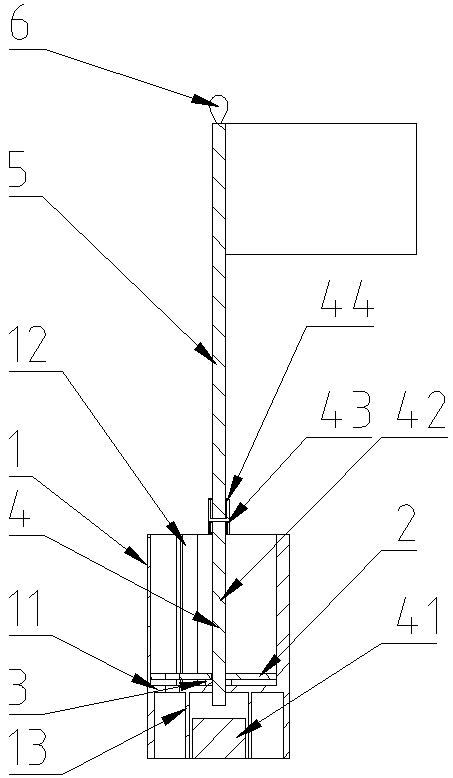

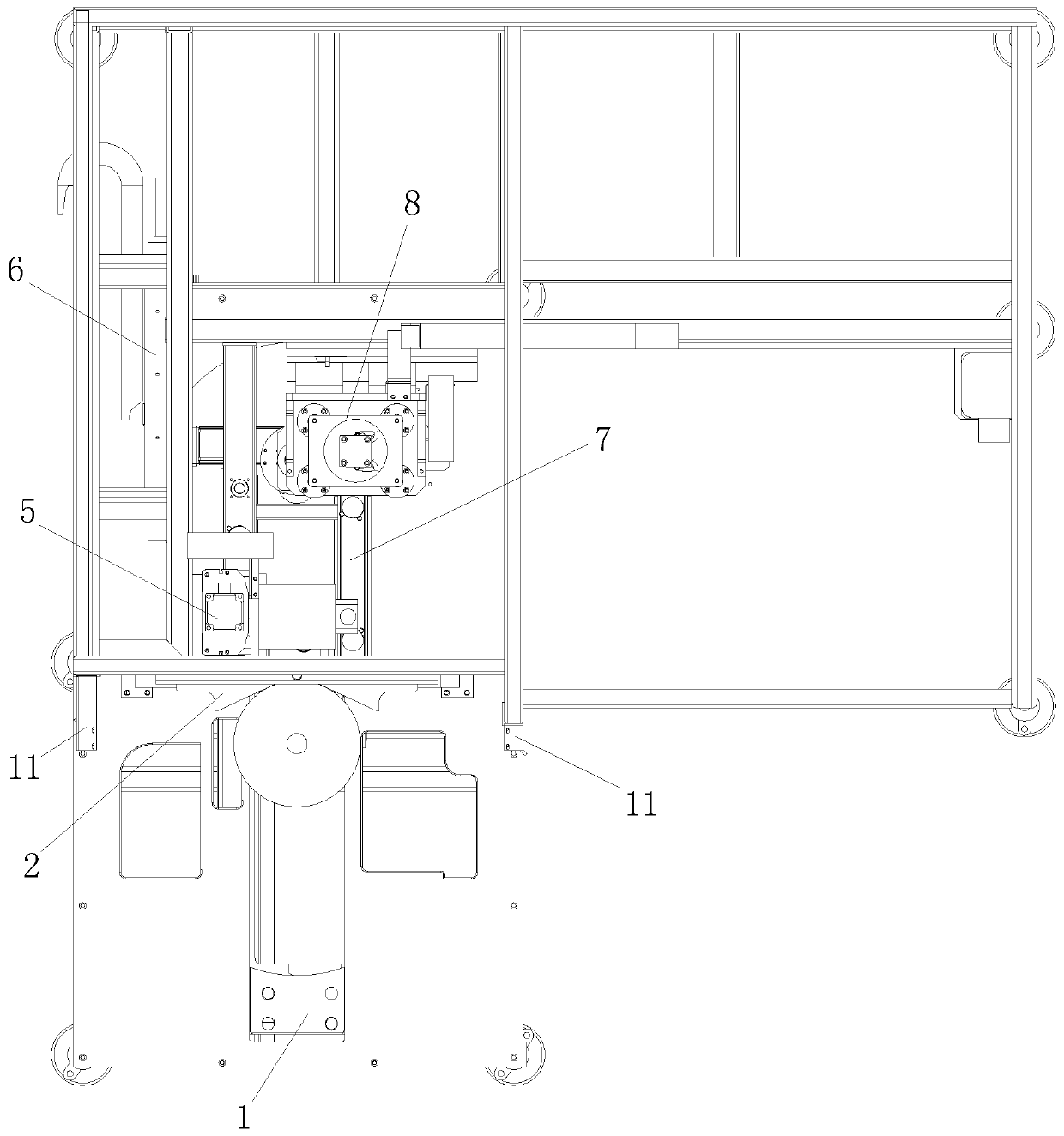

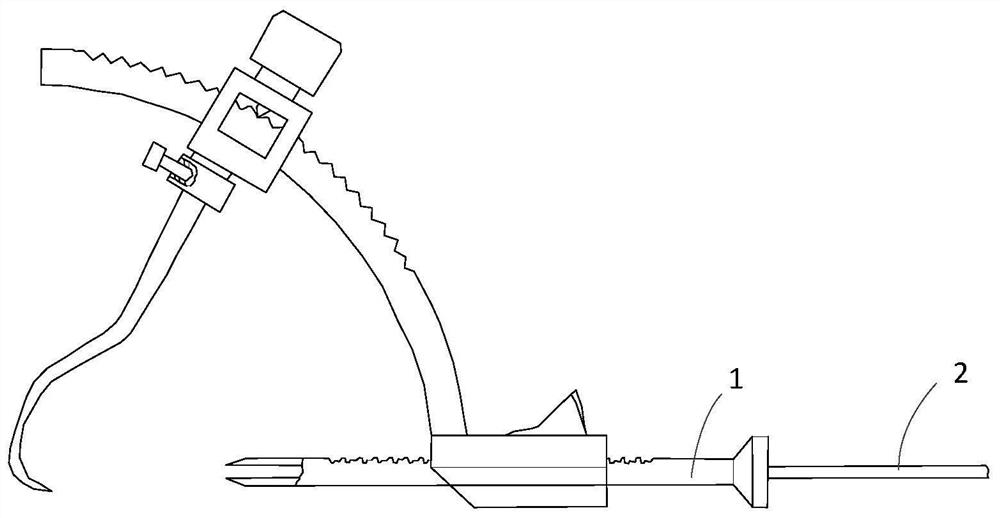

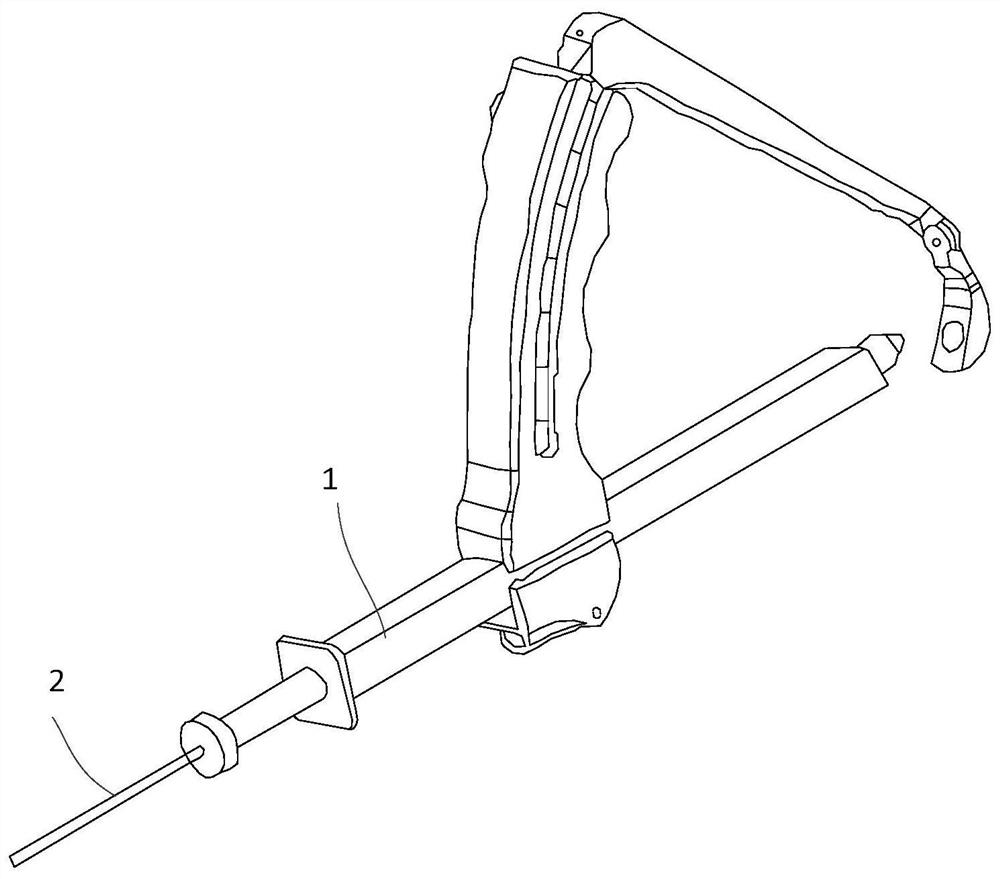

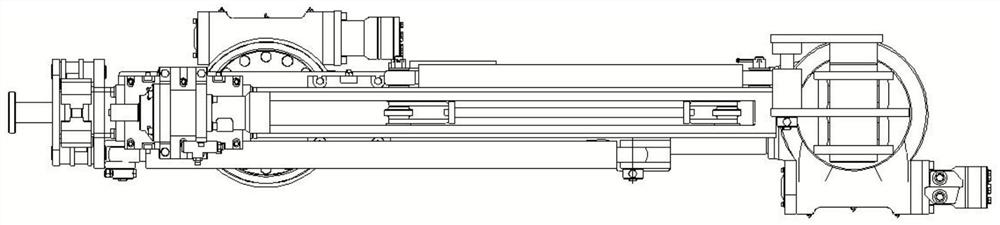

Underground on-site explosive dosing and charging truck

ActiveCN104949593AReduce labor intensityImprove safety conditionsBlastingControl systemEmulsion explosive

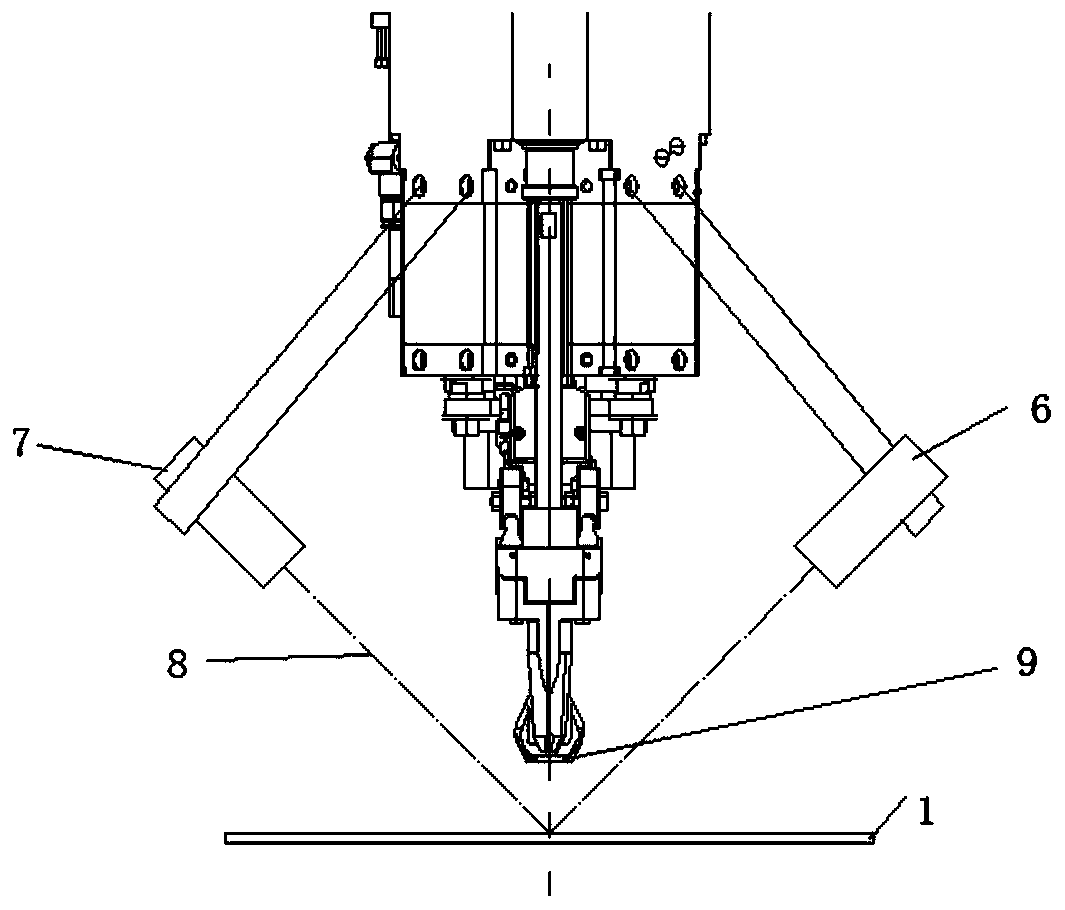

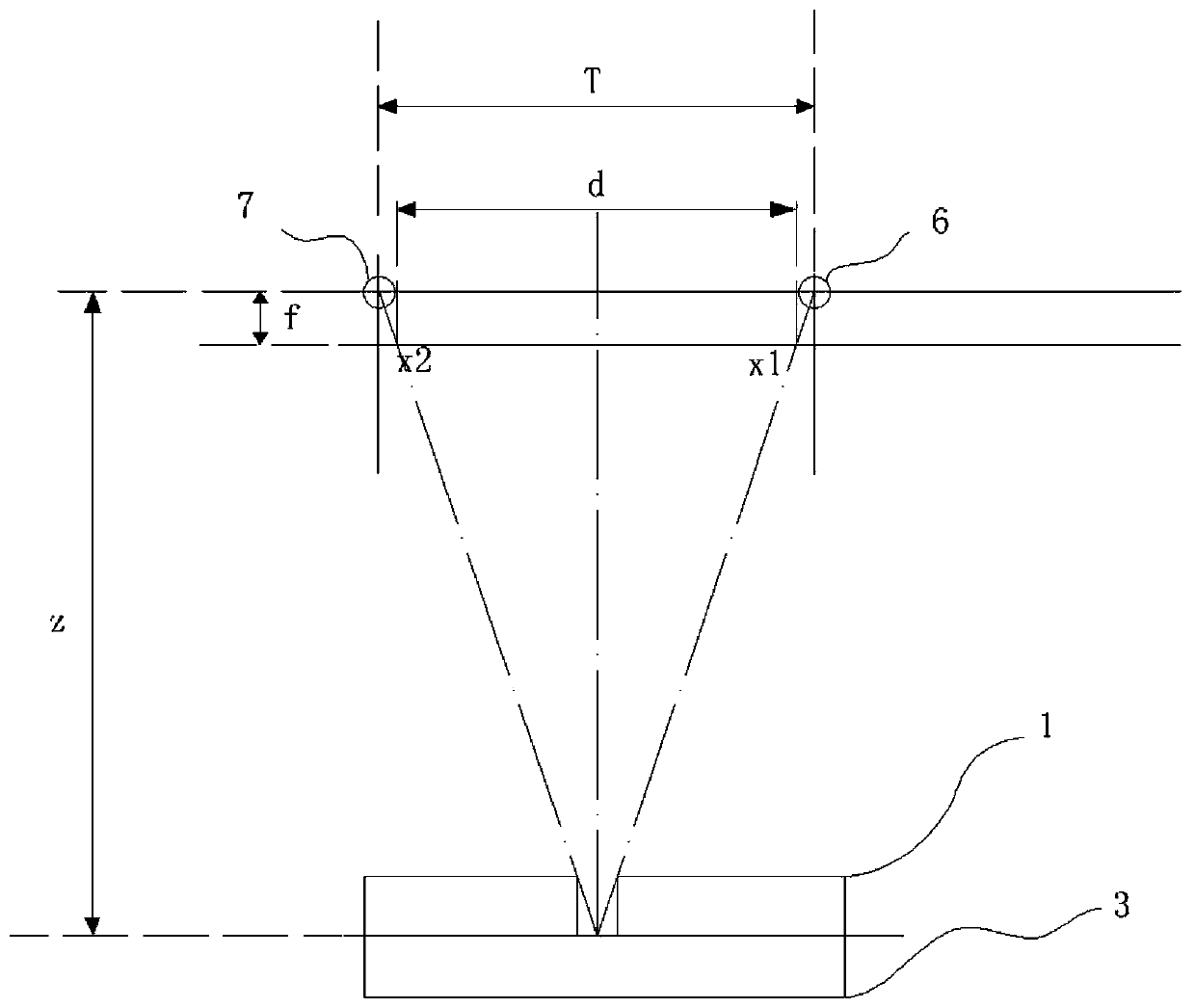

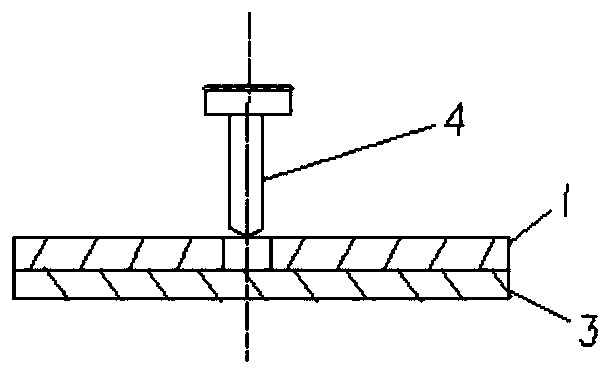

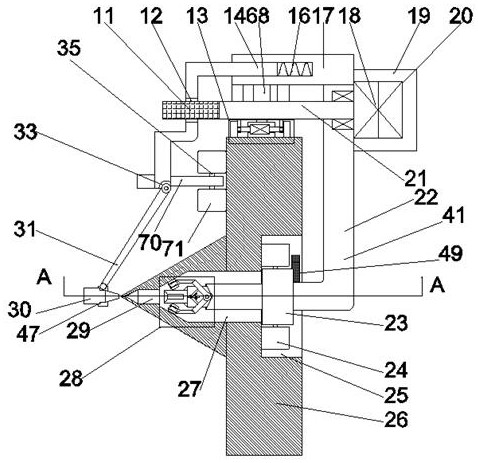

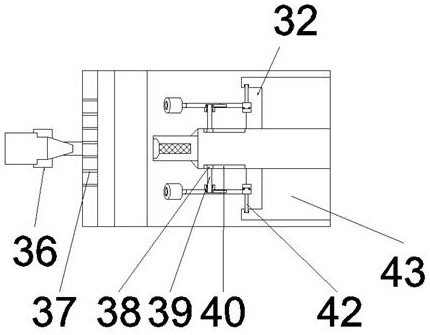

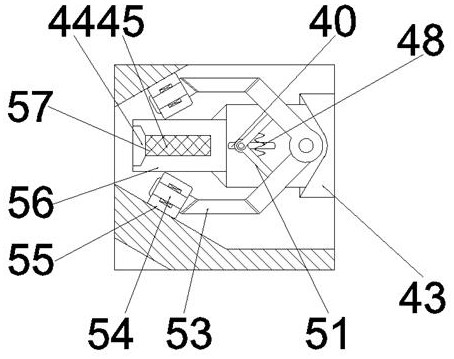

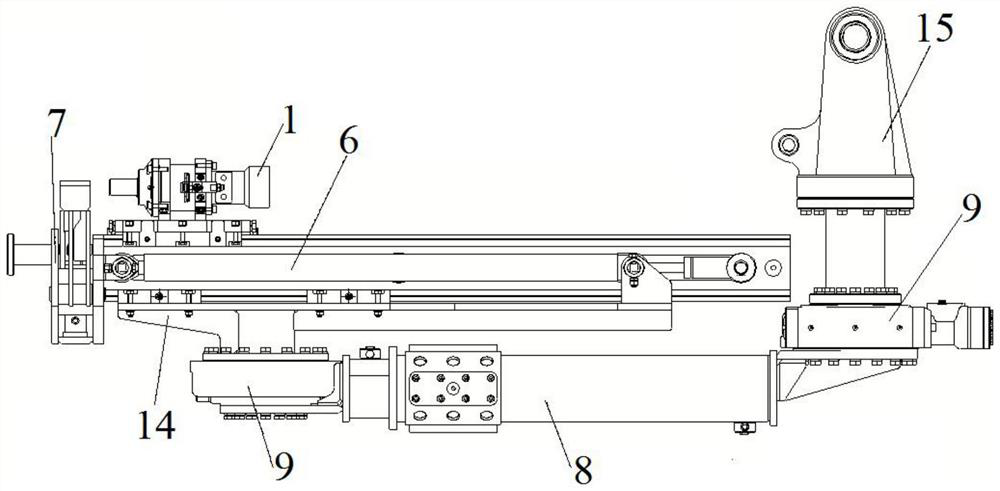

The invention relates to the technical field of underground explosive trucks and discloses an underground on-site explosive dosing and charging truck. The underground on-site explosive dosing and charging truck comprises a truck body, a chassis disposed on the truck body, a mechanical arm automatic hole finding mechanism and a charging conveying mixing mechanism which are disposed on the chassis, and a hydraulic system and an electric control system which are matched with the mechanical arm automatic hole finding mechanism and the charging conveying mixing mechanism, wherein the charging conveying mixing mechanism comprises an automatic charging module used for mixing and charging emulsion matrix to form emulsion explosives, a charging tube which is connected with the automatic charging module and used for conveying the emulsion explosives, and an automatic tube conveyor for automatically conveying the charging tube; the mechanical arm automatic hole finding mechanism is matched with the automatic tube conveyor and used for performing blast hole position alignment on the head end of the charging tube. The underground on-site explosive dosing and charging truck has the advantages that mechanical hole finding, automatic tube collecting and conveying and automatic blast hole filling are achieved, charging efficiency is increased, operator labor intensity is lowered, and operator safety conditions are improved effectively.

Owner:SHENZHEN KING EXPLORER SCI & TECH CORP

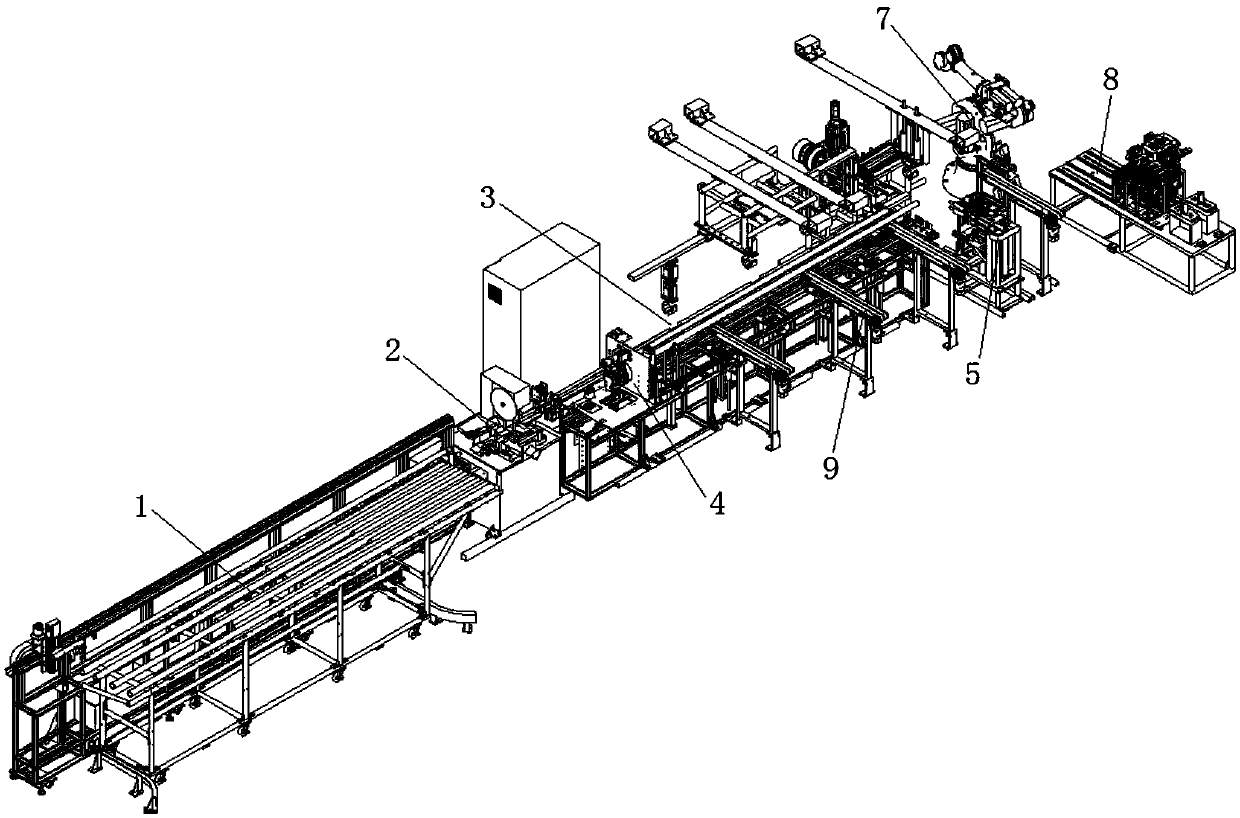

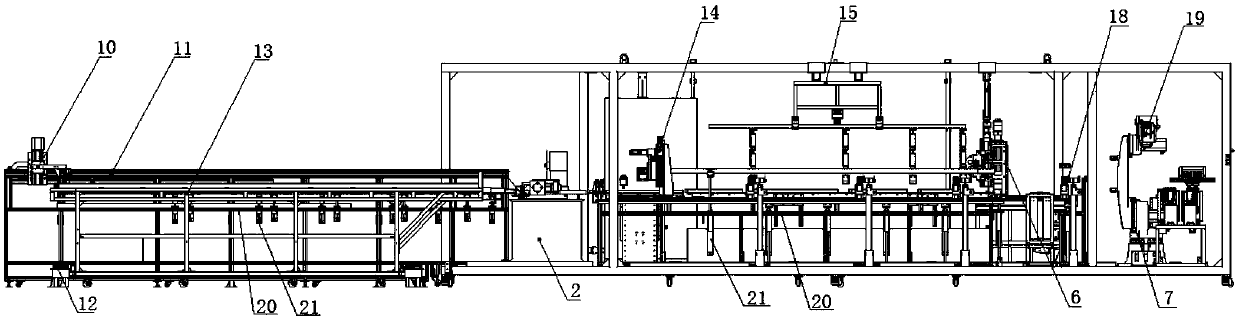

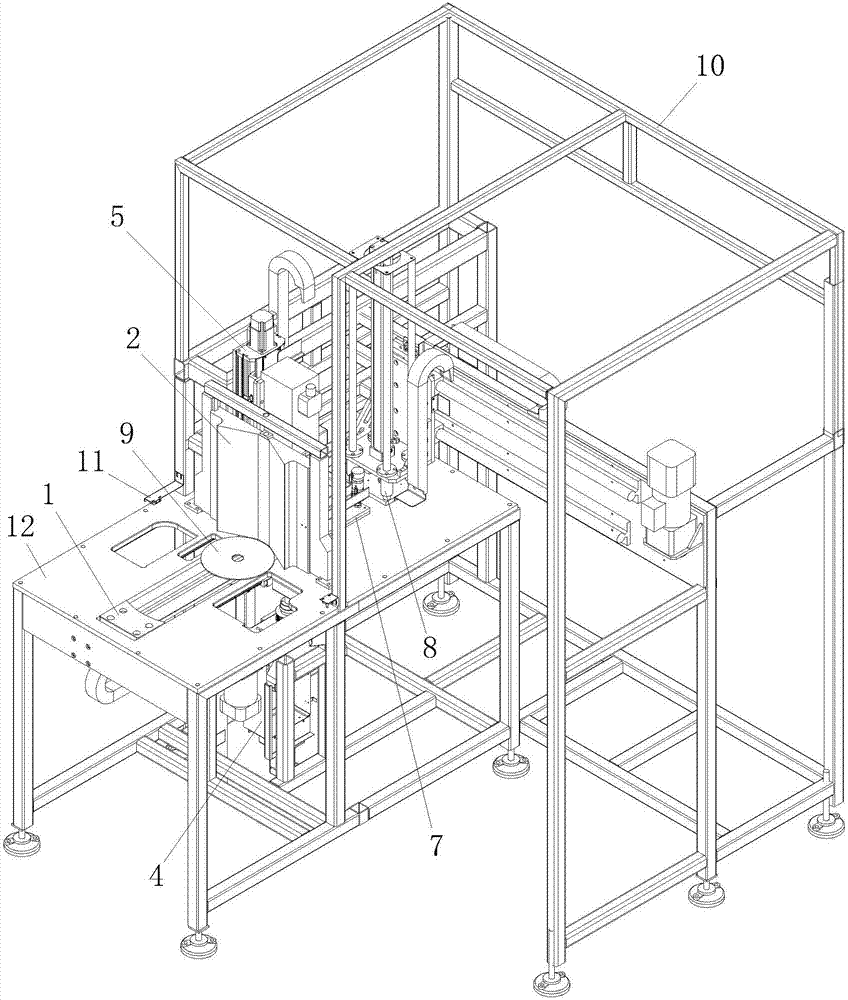

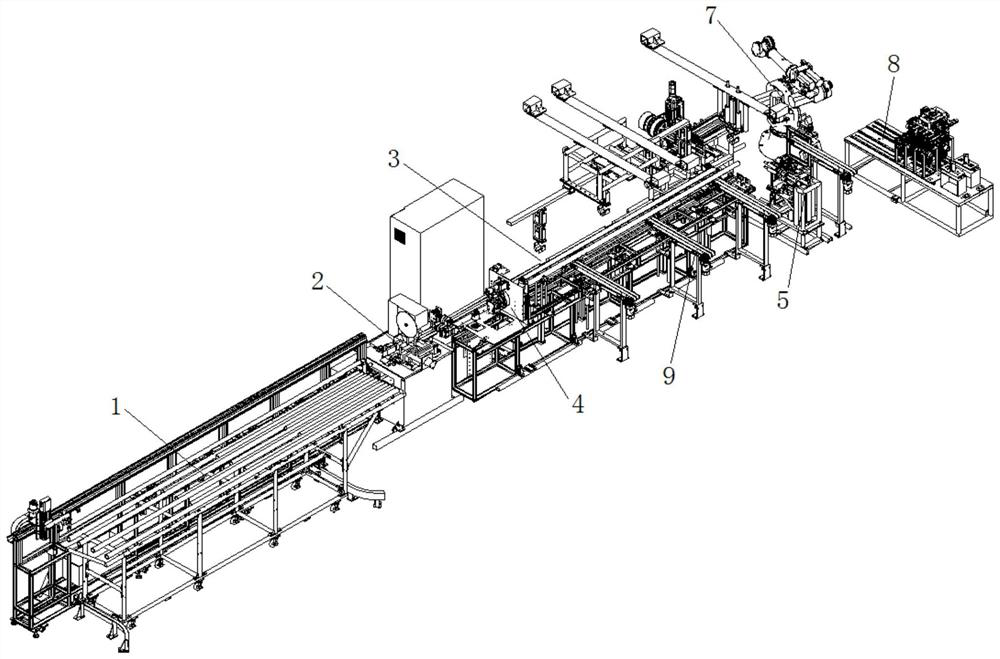

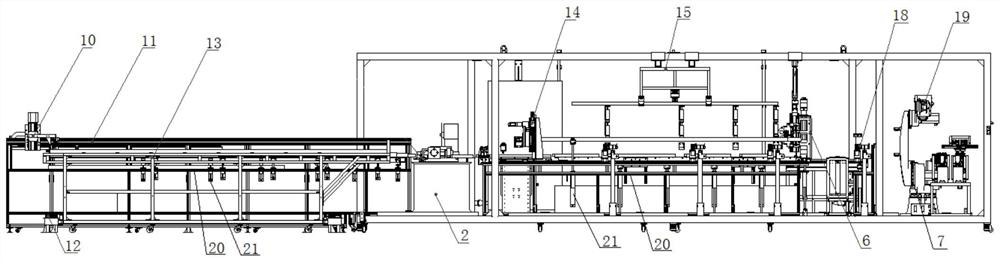

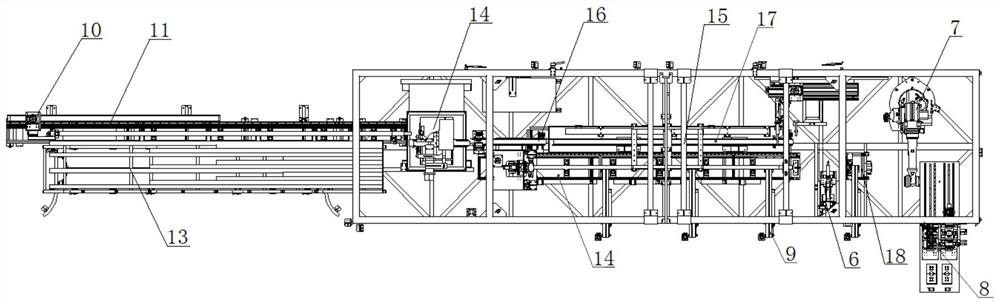

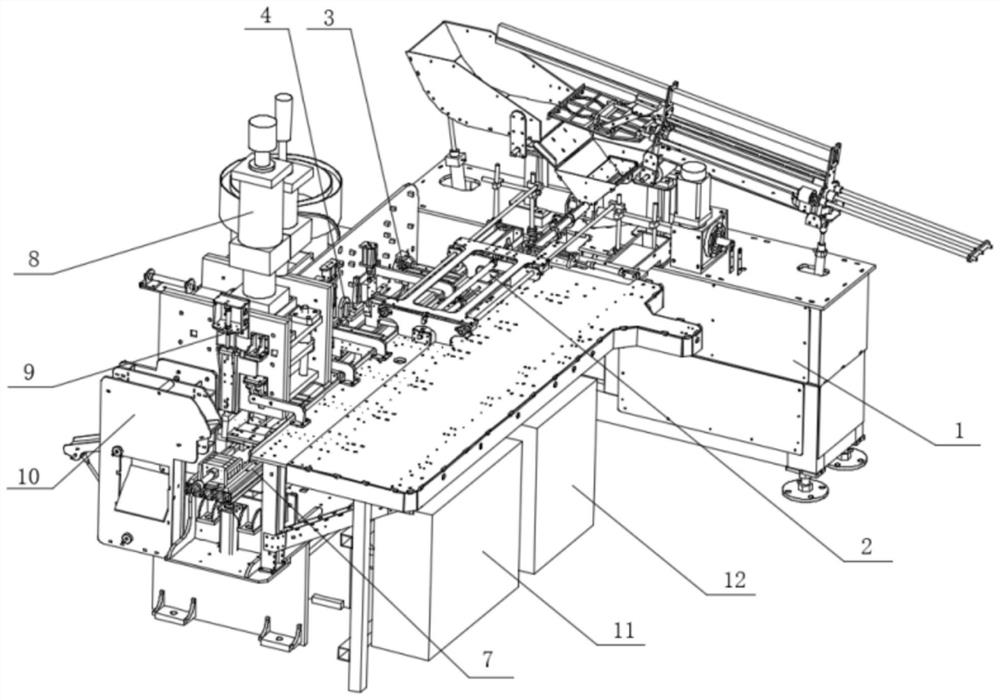

Pipe material assembling platform production line

ActiveCN109648343ARealize continuous automatic feedingImprove continuityOther manufacturing equipments/toolsTube shearing machinesProduction lineContact network

The invention discloses a pipe material assembling platform production line. The pipe material assembling platform production line comprises a feeding conveying part, a cutting machine, a carrying part, a hole finding part and a robot, wherein an output end of the feeding conveying part is in butt joint with an input end of the cutting machine, an output end of the cutting machine is in butt jointwith an input end of the carrying part, the hole finding part is arranged on one side of the carrying part, and the robot is arranged on one side of the hole finding part. continuous automatic feeding, length fixing, cutting and hole finding of a pre-assembled contact network cantilever pipe material and automatic assembling of a workpiece and the pipe material can be realized, field operators can be reduced, the labor intensity can be reduced, and the working efficiency can be improved.

Owner:武汉中安佳通装备技术有限公司

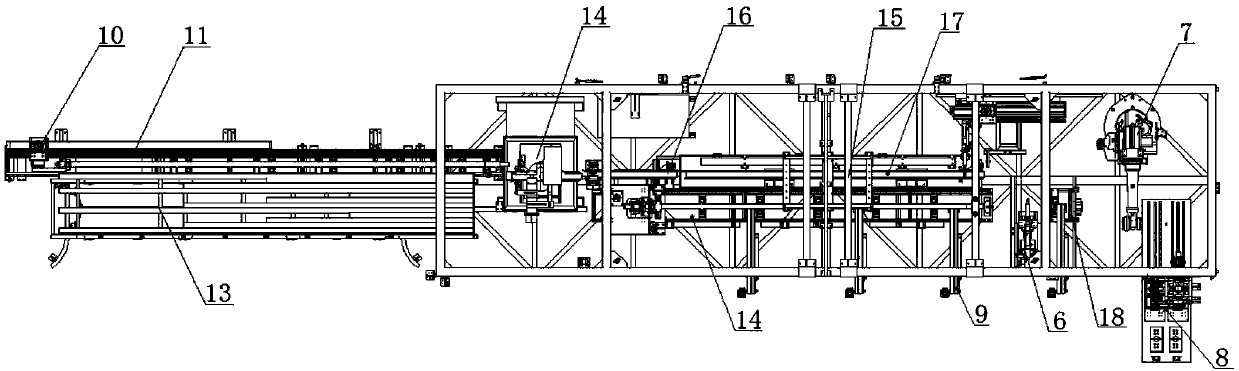

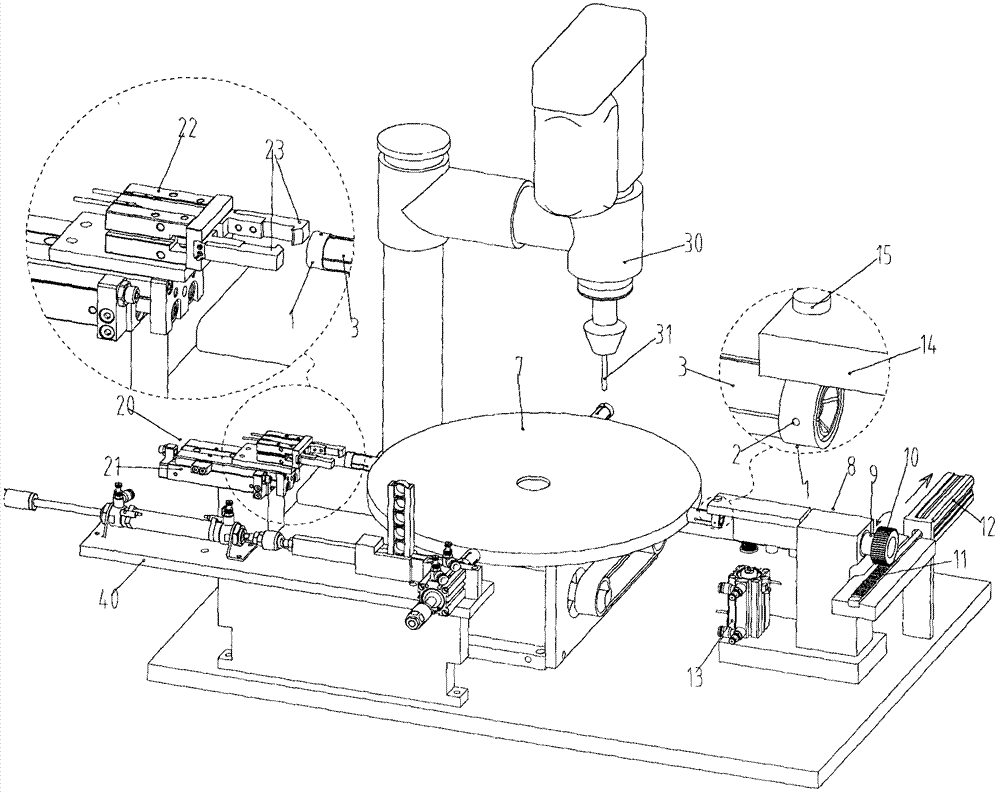

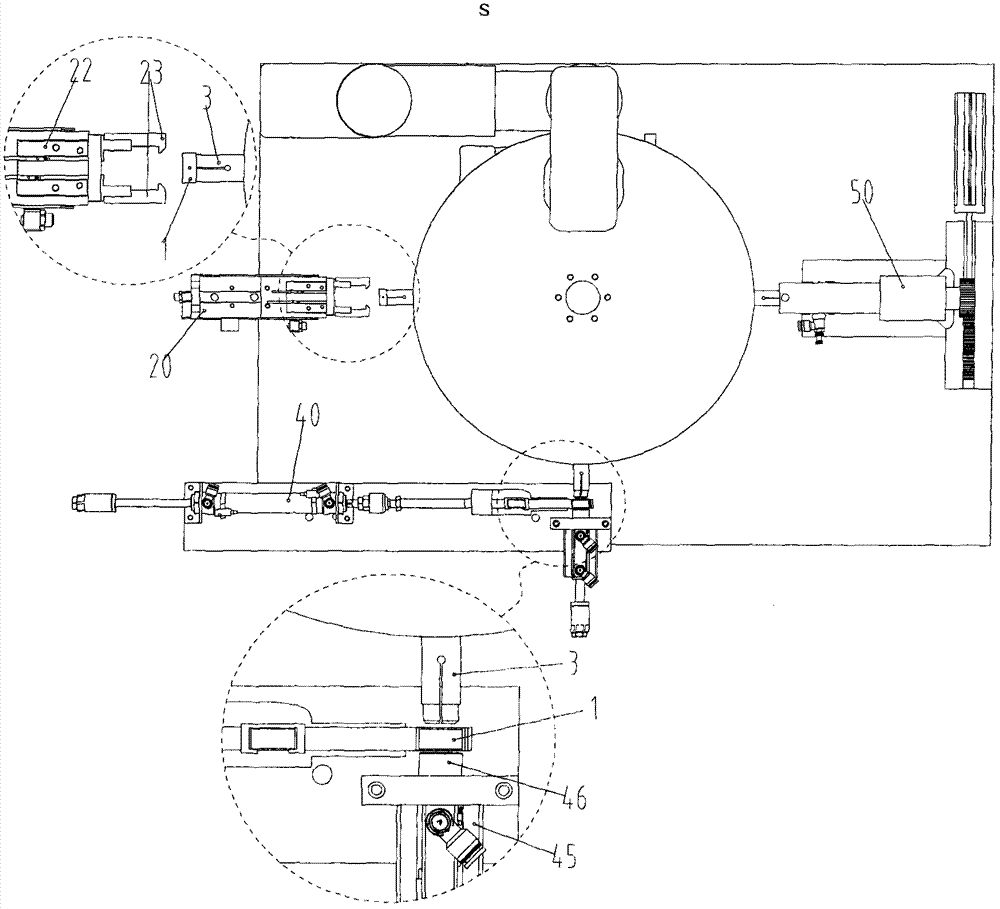

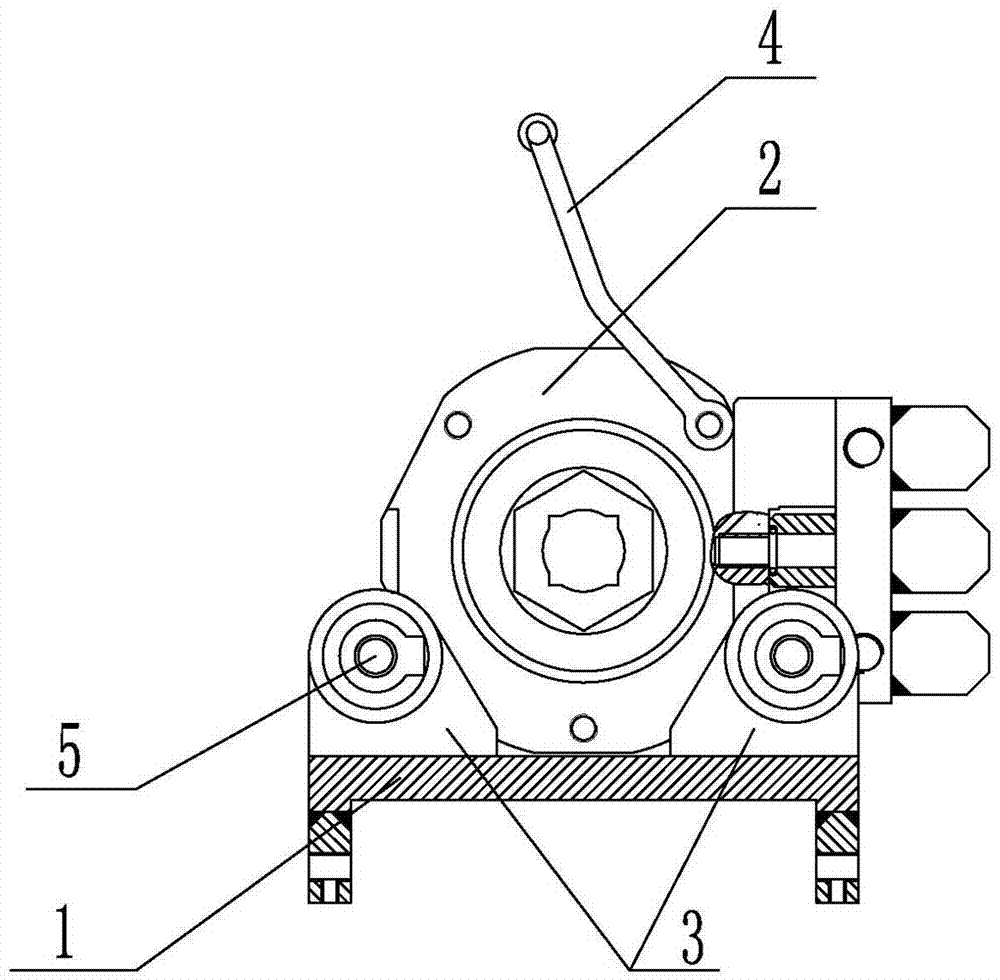

Full-automatic chamfering machine tool of automobile slide bearings

ActiveCN104723160AImprove efficiencySimple actionMeasurement/indication equipmentsChucksEngineeringCam

The invention relates to the field of mechanical manufacturing, in particular to a full-automatic chamfering machine tool. The full-automatic chamfering machine tool of automobile slide bearings comprises a rotary plate, an elastic chuck, a feed mechanism, a position correcting mechanism, a power head and a discharge mechanism. The rotary plate is a quartered rotary disc and placed on a quartered cam divider. The elastic chuck is fixedly connected to the rotary plate and sleeved with the slide bearings. The feed mechanism, the position correcting mechanism, the power head and the discharge mechanism are sequentially arranged on the periphery of the rotary plate. The full-automatic chamfering machine tool is suitable for chamfering including automated sequencing, feeding, clamping, hole finding, chamfering, discharging and the like for the slide bearings, the slide bearings are orderly arrayed through the vibration plate, the disorderly slide bearings are arrayed in sequence one by one and neatly conveyed to machining positions, the slide bearings are clamped and positioned at the machining positions, the positions of small holes are found, and the slide bearings are discharged to be output as finished products after being chamfered.

Owner:QUANJIAO SAIDELI MACHINERY

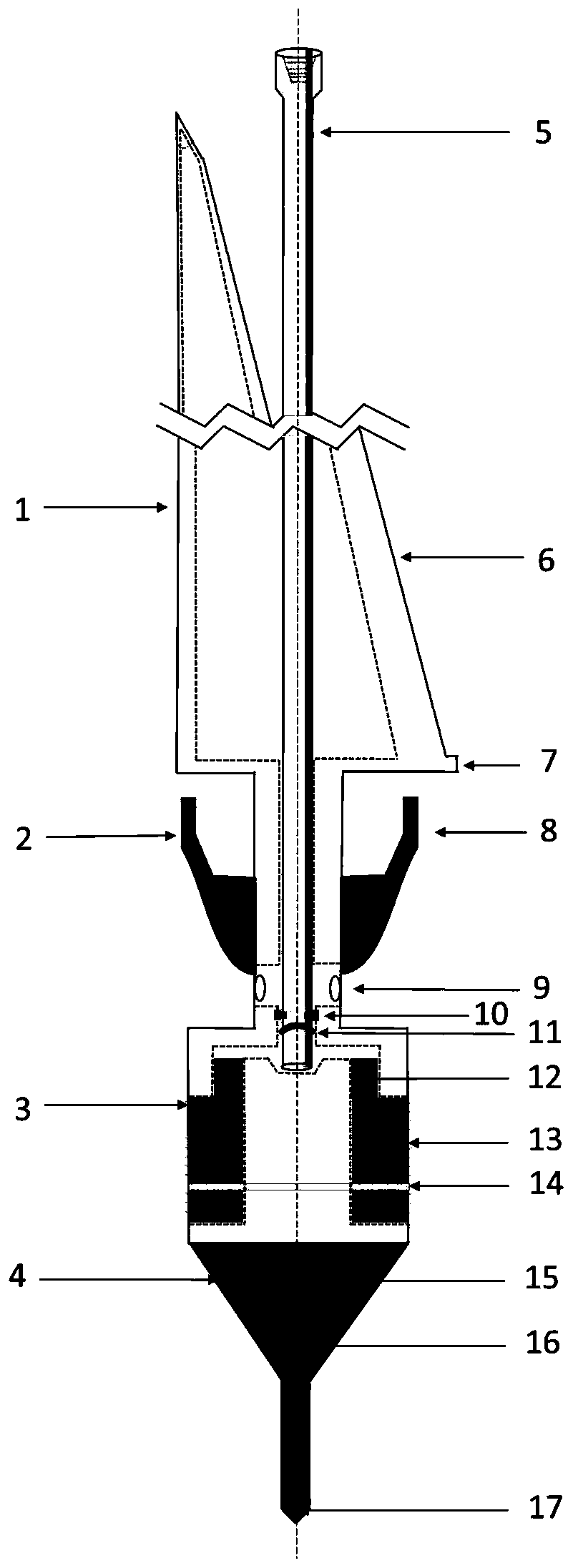

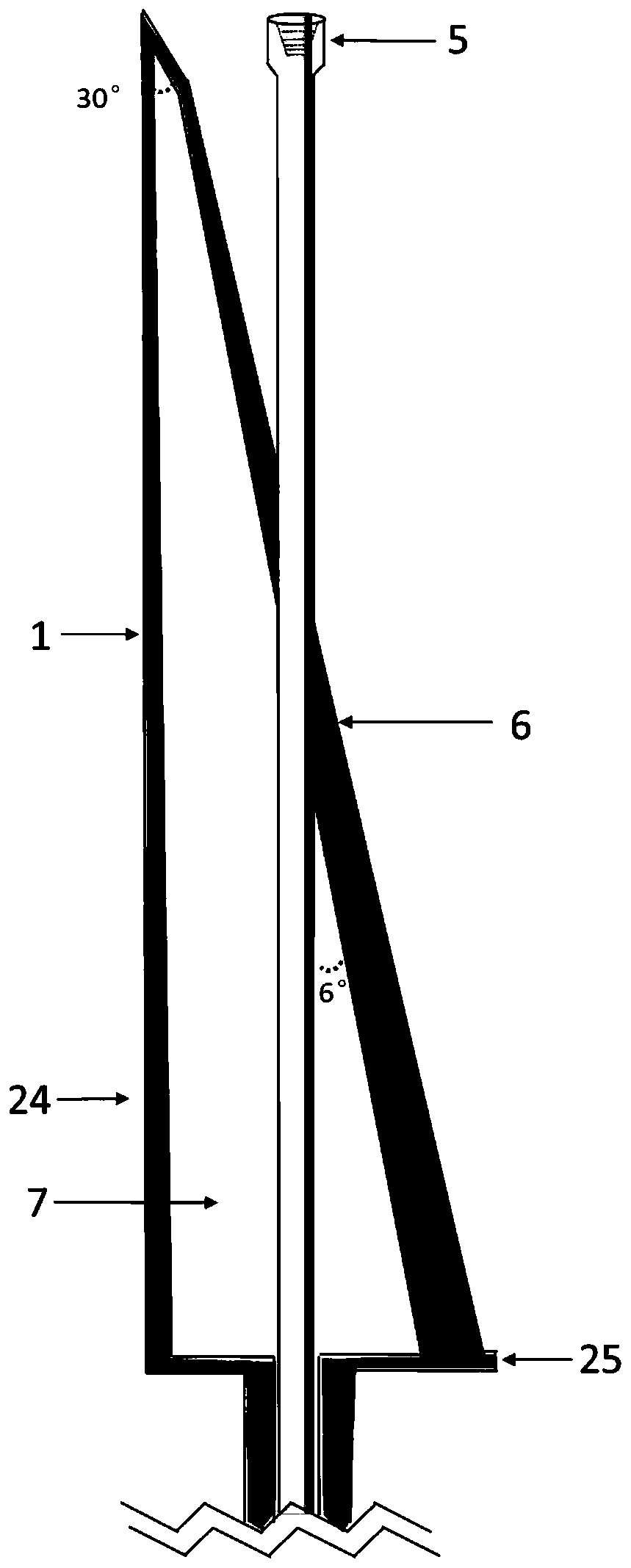

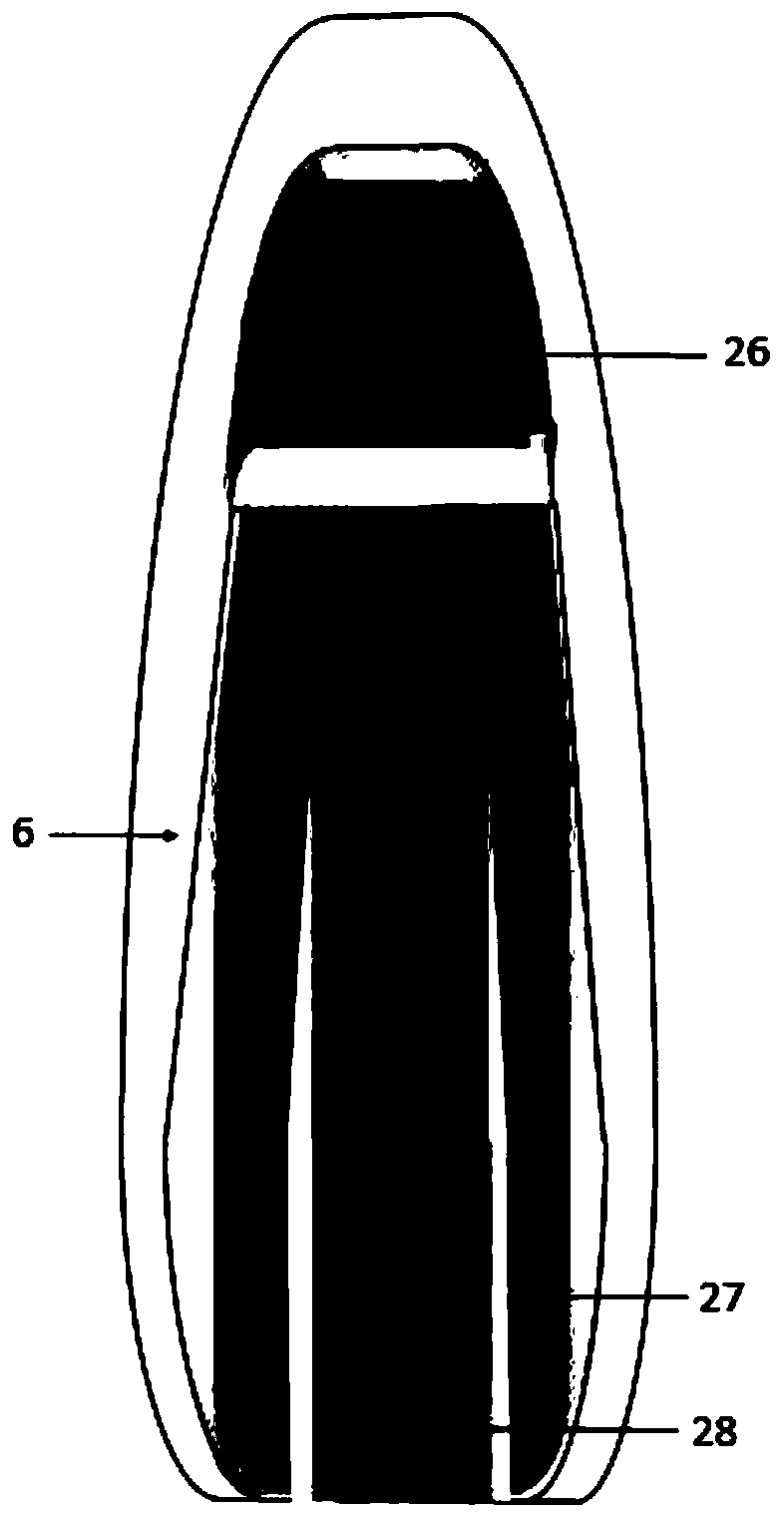

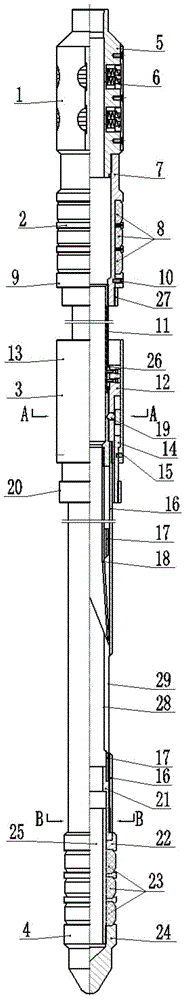

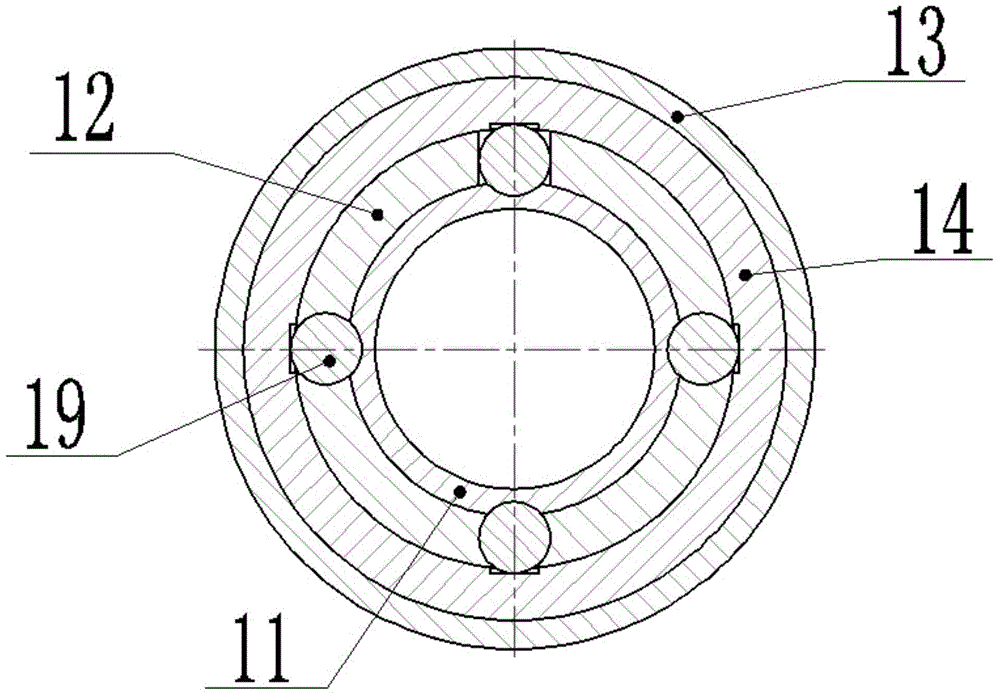

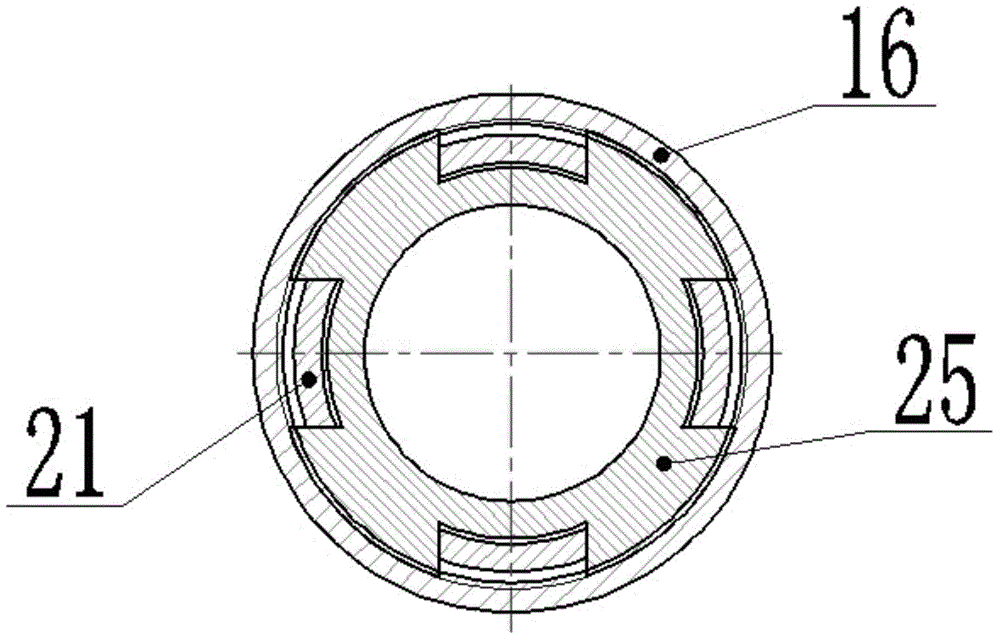

Riser reentry whipstock

ActiveCN110965966ASimple structureEasy to processDrilling rodsFluid removalClassical mechanicsStructural engineering

The invention relates to the technical field of underwater detection devices, and particularly discloses a riser reentry whipstock. The whipstock comprises an inclined plane body, a straightening unit, a sleeve, an anchoring unit and a lead-in head. The inclined plane body is fixed to a casing cutting opening, the inclined plane body is straightened through the straightening unit, and the inclinedplane body is provided with a longitudinal groove and a transverse groove to play a role in guiding in a riser and a drilling tool. The straightening unit is provided with a straightening cone plate,and performs the preliminary fixing while straightening the inclined plane body; the sleeve is provided with a hollow hole, and cementing sealing can be conducted after the whipstock is disengaged from a hand; the anchoring unit is arranged below the straightening unit and can fix the depth and direction of the inclined plane body; the leading-in head is located below the anchoring unit, and thebottom of the leading-in head is a conical head, so it is guaranteed that the whipstock smoothly descends into a casing cutting opening. The whipstock achieves the reutilization of an abandoned well groove, and effectively solves the problem that an inner-layer casing pipe is not centered; the longitudinal groove and the transverse groove provide guidance for the waterproof guide pipe and a drilling tool, and the risks of well hole finding and orientation deviation are avoided.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Threaded hole alignment mechanism for automatic assembly of vehicle parts

The invention relates to a threaded hole alignment mechanism for automatic assembly of vehicle parts. The mechanism comprises B1 adjusting and positioning frames, wherein the B1 adjusting and positioning frames are respectively and movably arranged along the axial direction and the radial direction of a mounting shaft A, the B1 adjusting and positioning frames are connected with B1 positioning andadjusting parts, B1 hole positioning columns are arranged on the B1 adjusting and positioning frames and are movably arranged on B1 hole finding and mounting parts along the body length directions ofthe B1 hole positioning columns; The B1 hole finding and mounting parts are movably arranged on the B1 adjusting and positioning frames and connected with B1 hole finding and adjusting parts, the B1hole positioning columns are connected with the B1 hole positioning and adjusting parts, the B1 positioning and adjusting parts adjust the postures of the B1 adjusting and positioning frames to enablethe B1 hole positioning columns to be arranged in the radial direction of the mounting shaft A, the B1 hole finding and adjusting parts adjust the B1 hole positioning columns to rotate around the circumferential direction of the mounting shaft A, and the B1 hole positioning and adjusting parts adjust local column bodies of the B1 hole positioning columns to extend into threaded holes A when the B1 hole positioning columns and the threaded holes A are correspondingly arranged. The mechanism is simple and convenient in use and operation, and high in automation level.

Owner:安徽字母表工业设计有限公司

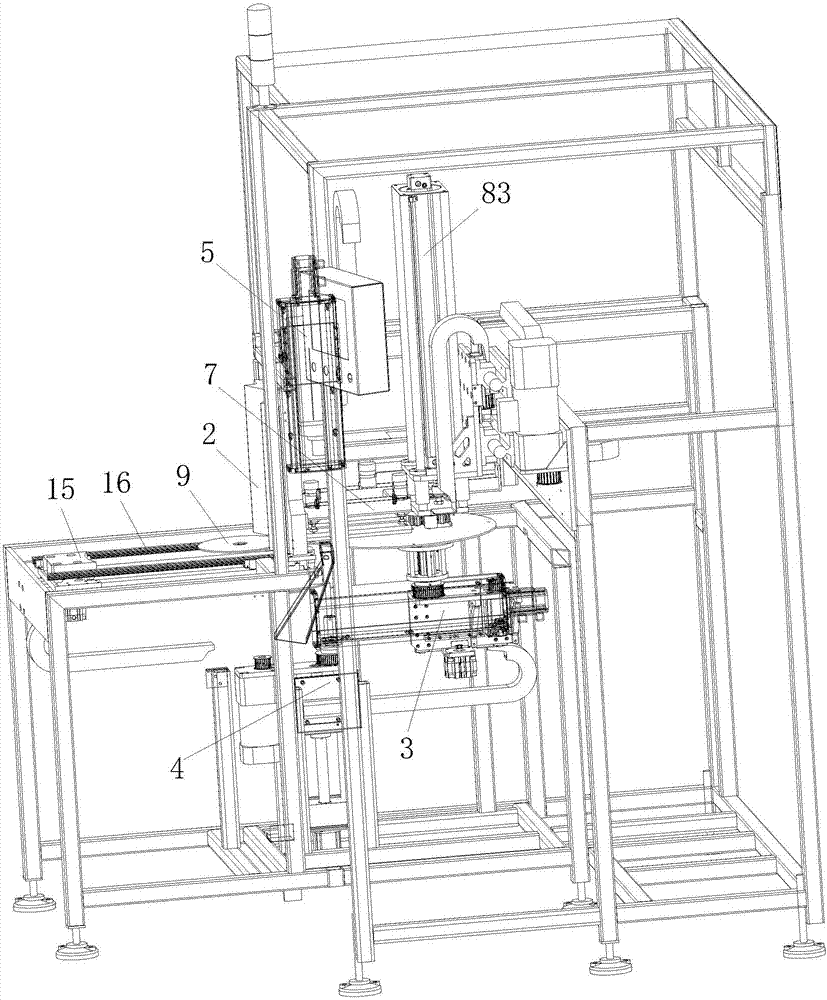

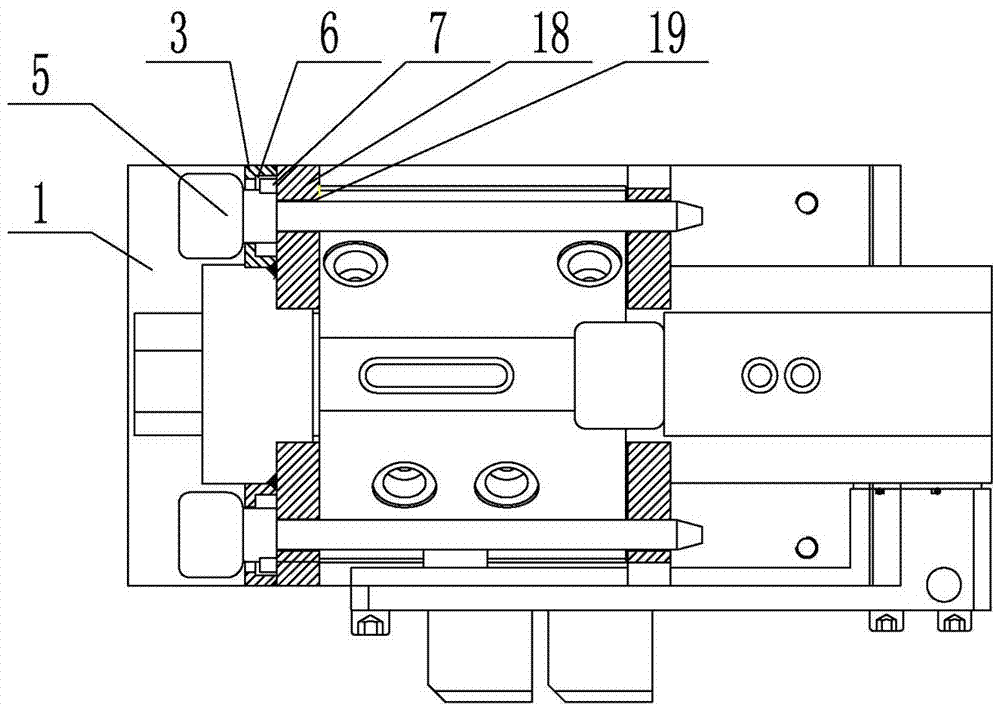

Full-automatic chamfering machine

InactiveCN107971751AGuaranteed work efficiencyImprove processing efficiencyOther manufacturing equipments/toolsReamerManipulator

The invention discloses a full-automatic chamfering machine. The full-automatic chamfering machine comprises a rack, an electronic control mechanism and a chamfering mechanism. The chamfering mechanism is provided with a rose reamer, the chamfering mechanism comprises an upper chamfering mechanism body and a lower chamfering mechanism body which are installed on the upper face and the lower face of a working table used for storing a saw blade correspondingly, and the working table is installed on the rack; and a material pushing mechanism is installed on the working table, a saw blade positioning mechanism is installed below the working table, a hole finding mechanism and a saw blade pressing mechanism are arranged above the working table, and a carrying manipulator is further installed onthe rack. According to the full-automatic chamfering machine, feeding is conducted through the material pushing mechanism, the positioning mechanism conducts positioning, the hole finding mechanism is used for determining the center of a positioning hole, the saw blade pressing mechanism is used for fixing the saw blade, double-faced chamfering is completed by the upper chamfering mechanism bodyand the lower chamfering mechanism body, discharging is completed through the carrying manipulator, and the operation process of each mechanism is conducted in a full automatic mode; and the machiningefficiency is greatly improved, the cost is greatly reduced, meanwhile the chamfering effect is more attractive, the precision is higher, and the centers of a chamfered hole and the original positioning hole coincide with each other.

Owner:GUANGZHOU HENGWEI ELECTROMECHANICAL EQUIP CO LTD

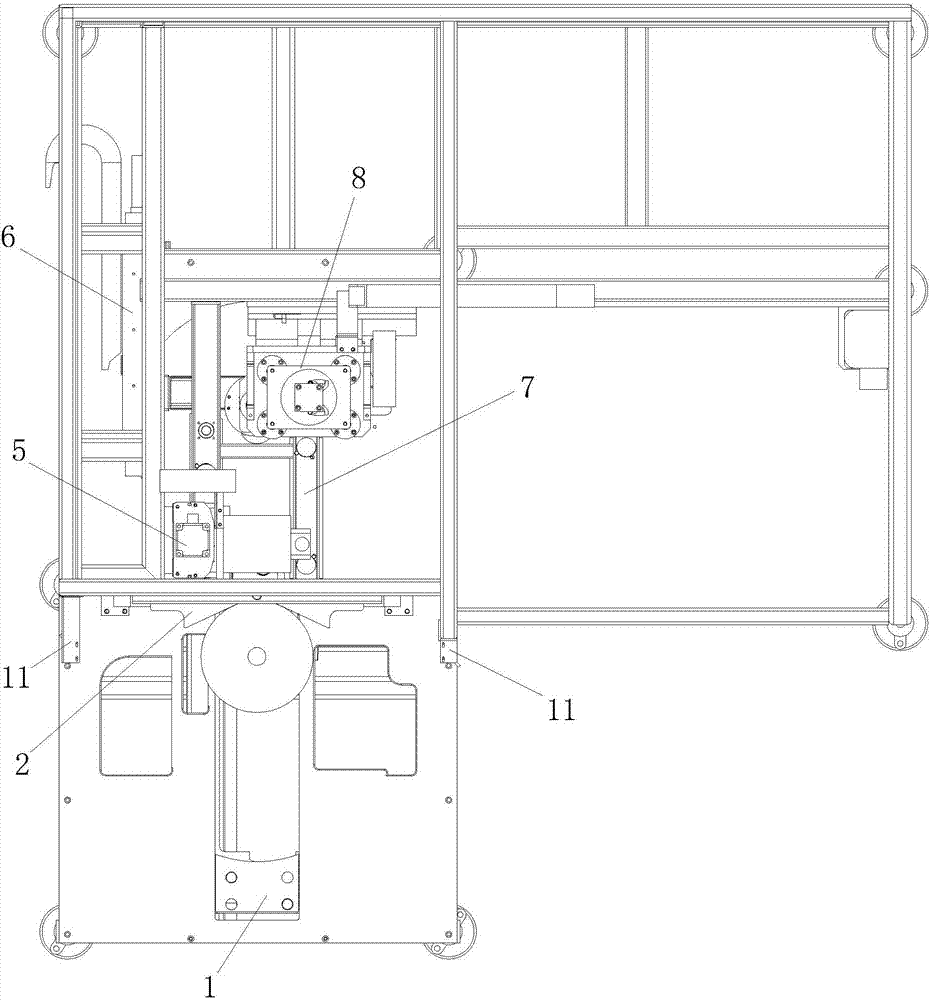

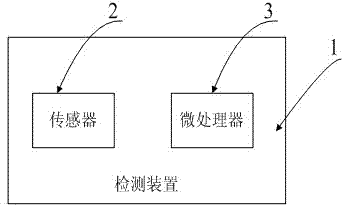

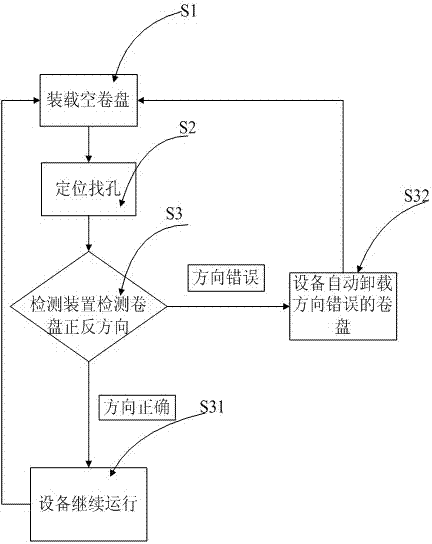

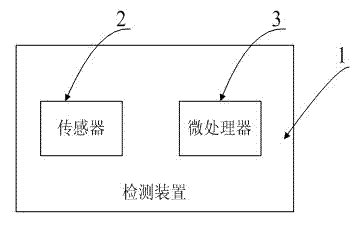

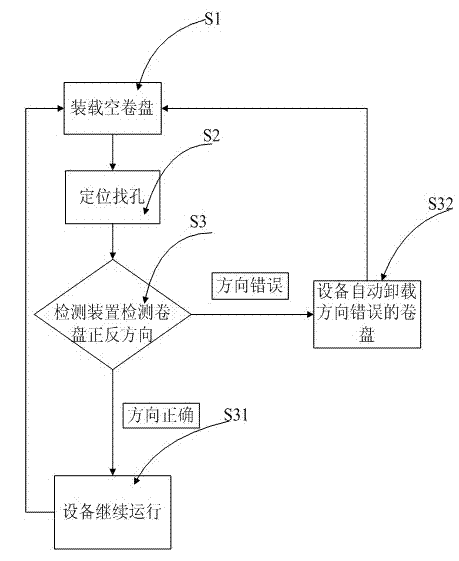

Anti-reverse control method for reels

InactiveCN102343993AAnti-wrappingAnti-circumventionPackaging automatic controlControl signalControl theory

The invention discloses an anti-reverse control method for reels; the method comprises the following steps: in an empty reel loading process, equipment automatically loads an empty reel into a reel motor; in positioning and hole finding processes, an automatic reel replacing mechanism of the equipment automatically finds a carrier tape inserting hole on the reel; a detecting device begins to detect the direction of the reel, if the direction is right, the detecting device transmits a low level control signal output by a sensor to a device control center, the equipment continues to operate; ifthe direction is wrong, the detecting device transmits a high level control signal output by the sensor to the device control center, the equipment automatically removes the reel with the wrong direction and reloads a new empty reel into the reel motor; and the steps of locating and finding holes and detecting the direction of the reel by the detecting device are carried out continuously. According to the anti-reverse control method, a product is prevented from winding reversely relative to the reel after carrying the tape, the unnecessary repetition work is reduced, the control is accurate and the reverse winding of the reel is completely put an end to.

Owner:CHENGDU ADVANCED POWER SEMICON

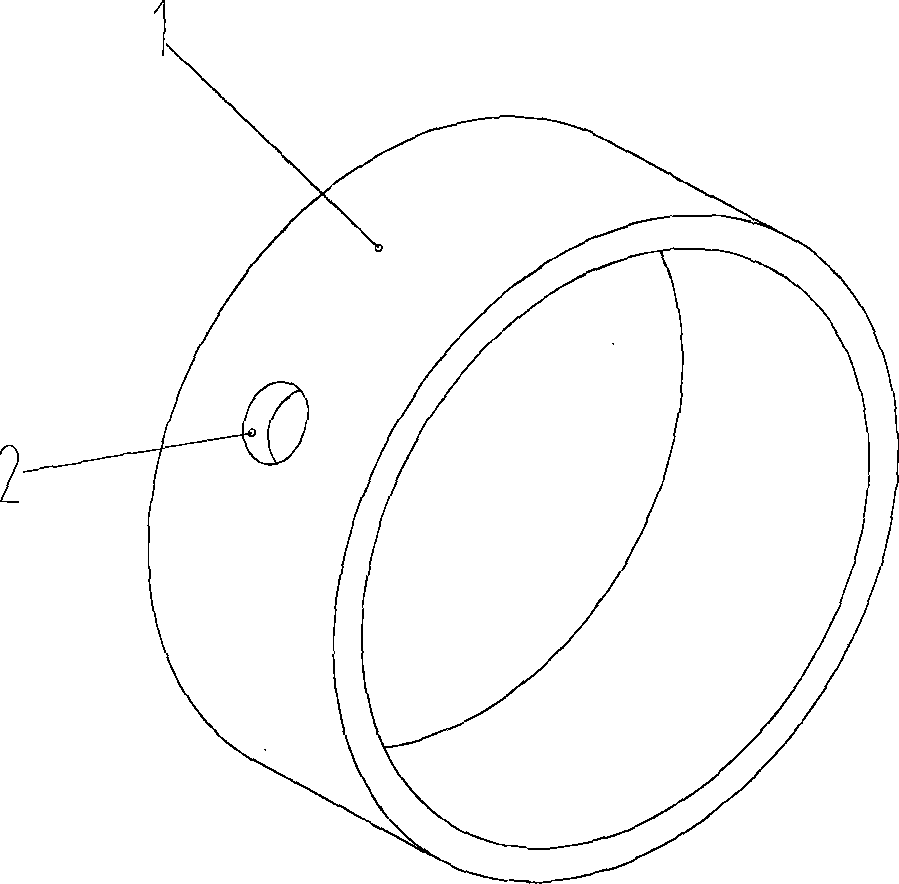

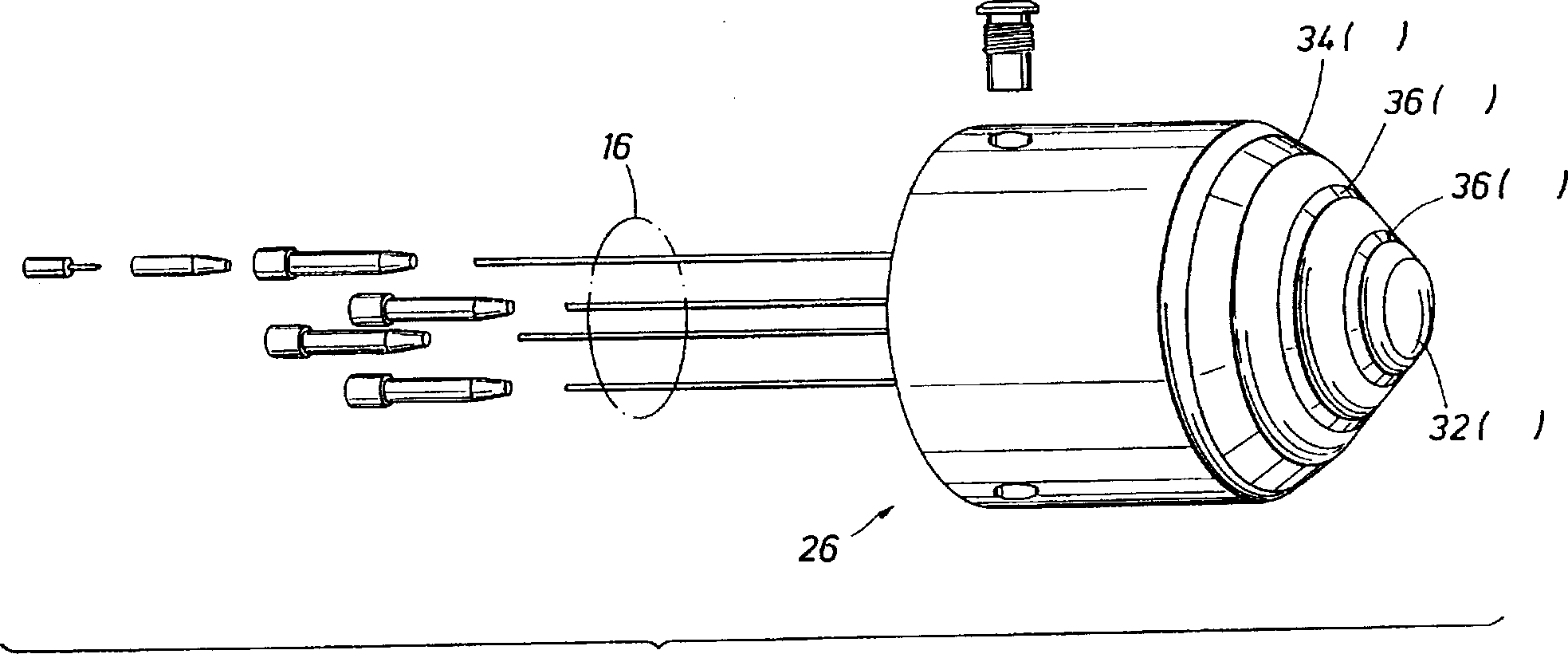

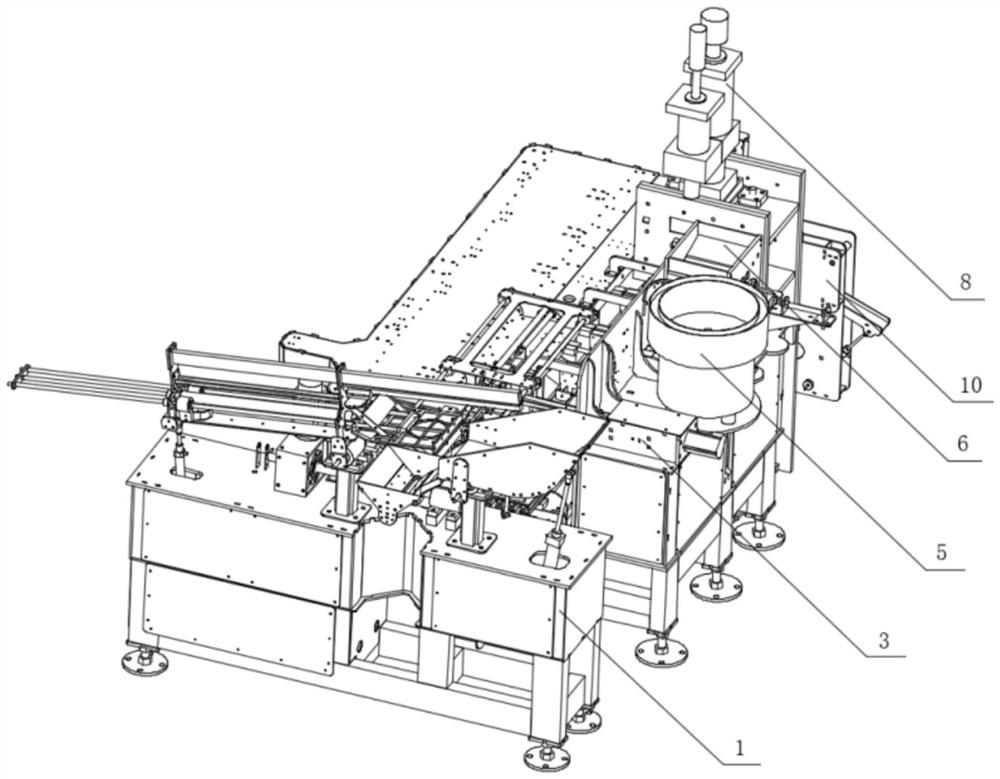

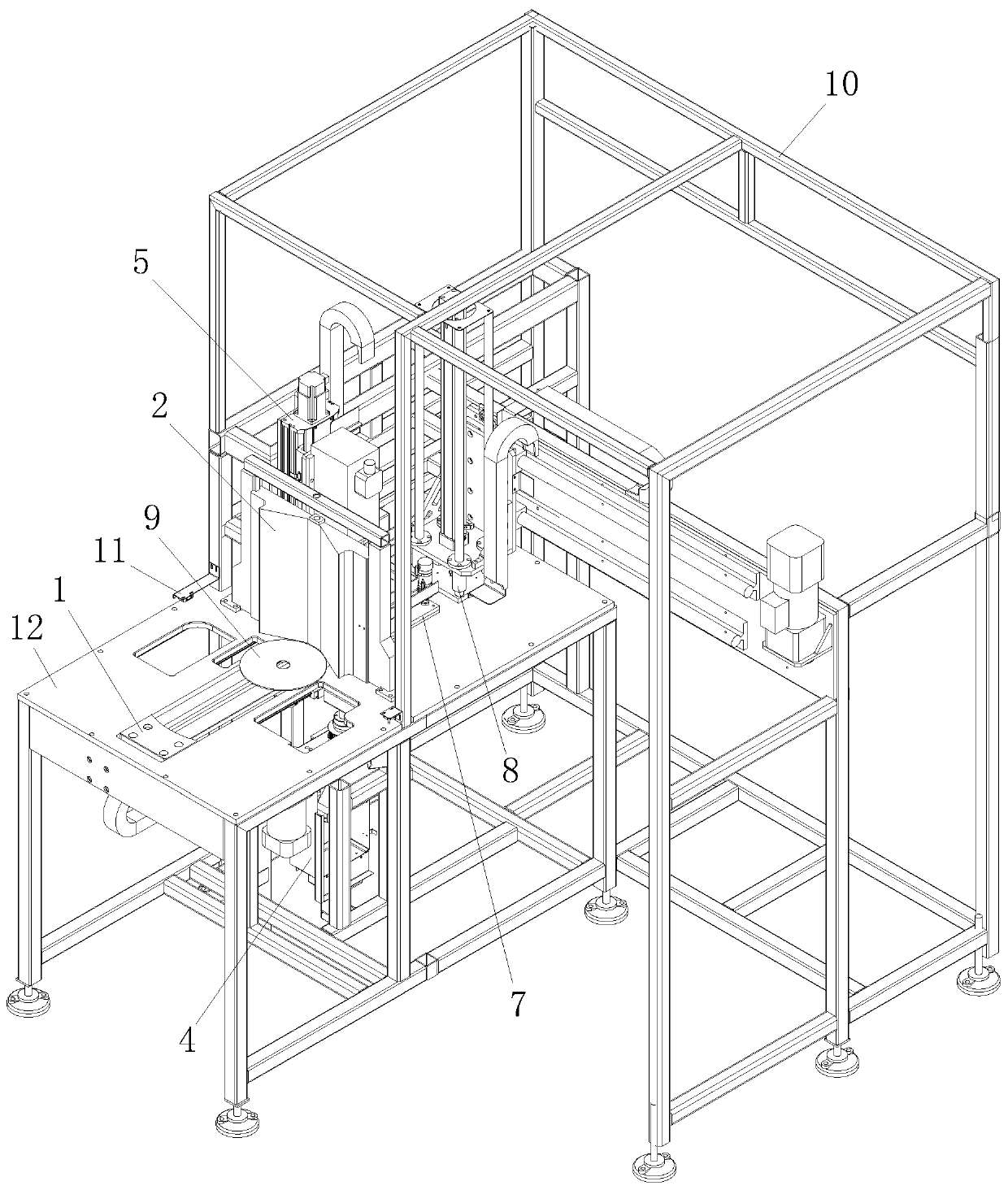

Full-automatic anti-loosening ball assembling machine for outer spherical ball bearing

ActiveCN111590300AReduce labor intensityImprove work efficiencySortingMetal working apparatusBall bearingClassical mechanics

The invention relates to the field of assembling machines, and particularly relates to a full-automatic anti-loosening ball assembling machine for an outer spherical ball bearing. According to the full-automatic anti-loosening ball assembling machine for the outer spherical ball bearing, the bearing is transferred to a corresponding station of a rotary table mechanism through a feeding mechanism,then a bearing outer ring on the station is driven to rotate through a hole finding mechanism, a hole is positioned in a ball assembling station of a ball assembling mechanism, an anti-loosening ballconveyed by a ball discharging mechanism is installed on the hole of the bearing through the ball assembling mechanism, then the ball is pressed into a ball socket of the bearing through a ball pressing mechanism by means of an air cylinder, a ball detecting mechanism detects whether the ball exists in the ball socket of the bearing or not and whether the ball is pressed in place or not in a contact type measuring mode, finally, a kicking mechanism takes out a bearing workpiece which is judged to be unqualified by the ball detecting mechanism, and a discharging mechanism takes out a bearing workpiece which is judged to be qualified by the ball detecting mechanism. The stations are automatically switched through the rotary table mechanism, the anti-loosening steel ball is assembled in a full-automatic mode, the working efficiency and the percent of pass are greatly improved, and the labor intensity of workers is relieved.

Owner:广州顺大智能装备有限公司

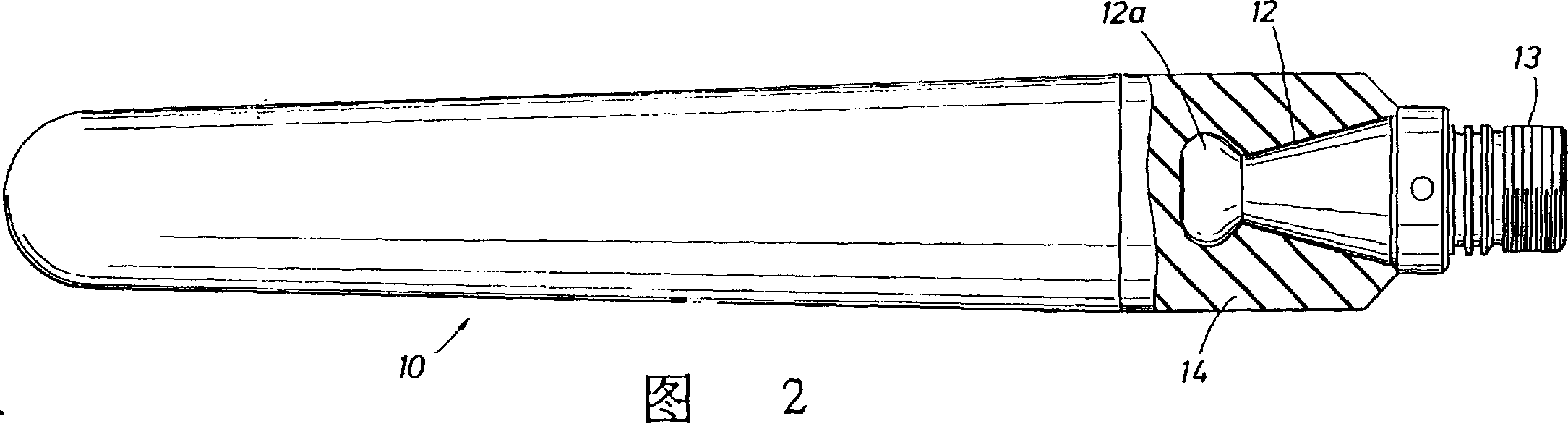

Hole finding apparatus having integrated sensor and its method

InactiveCN1092743CSmall sizeImprove measurement qualityElectric/magnetic detection for well-loggingSurveyWell drillingInstrumentation

Measuring or detecting drilling fluid or formation environment by using electrical, acoustic, mechanical or nuclear devices while conducting borehole detection or during detection. The borehole detection device equipped with an integral sensor of the present invention can effectively combine the measurement or detection capability of the downhole or formation environment either internally (such as by using a nuclear source / sensor) or as part of a borehole detection instrument, so that The device can provide mechanical and detection functions simultaneously or continuously. In the embodiment, a group of electrodes is installed as a probe at the end of the borehole detection device, so that it can measure the drilling fluid resistivity Rm and the natural potential Sp when guiding the equipment through the borehole.

Owner:SCHLUMBERGER OVERSEAS SA

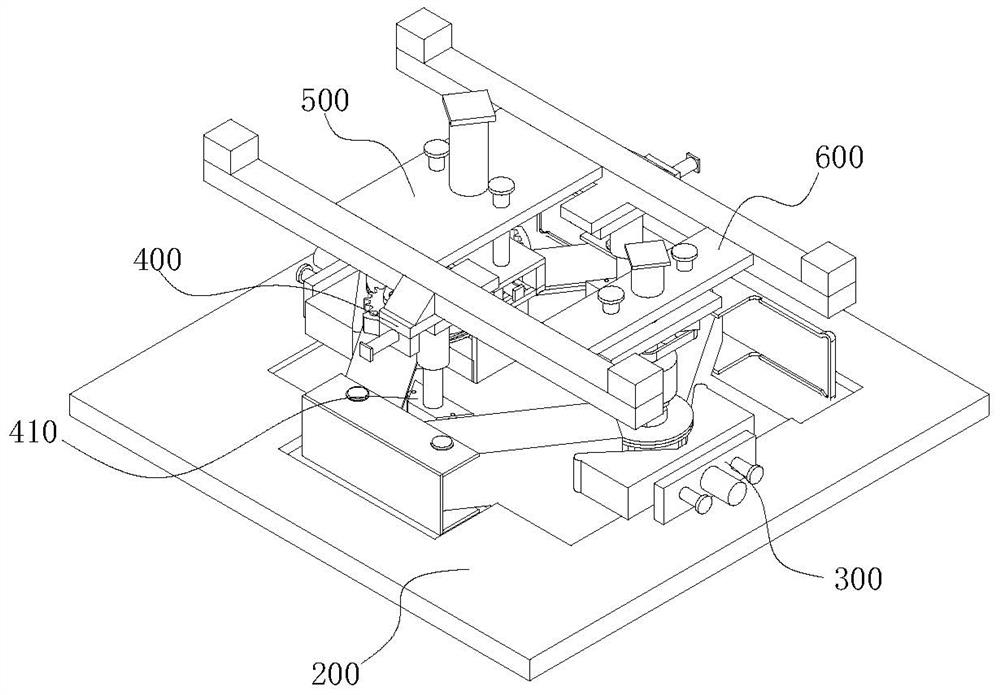

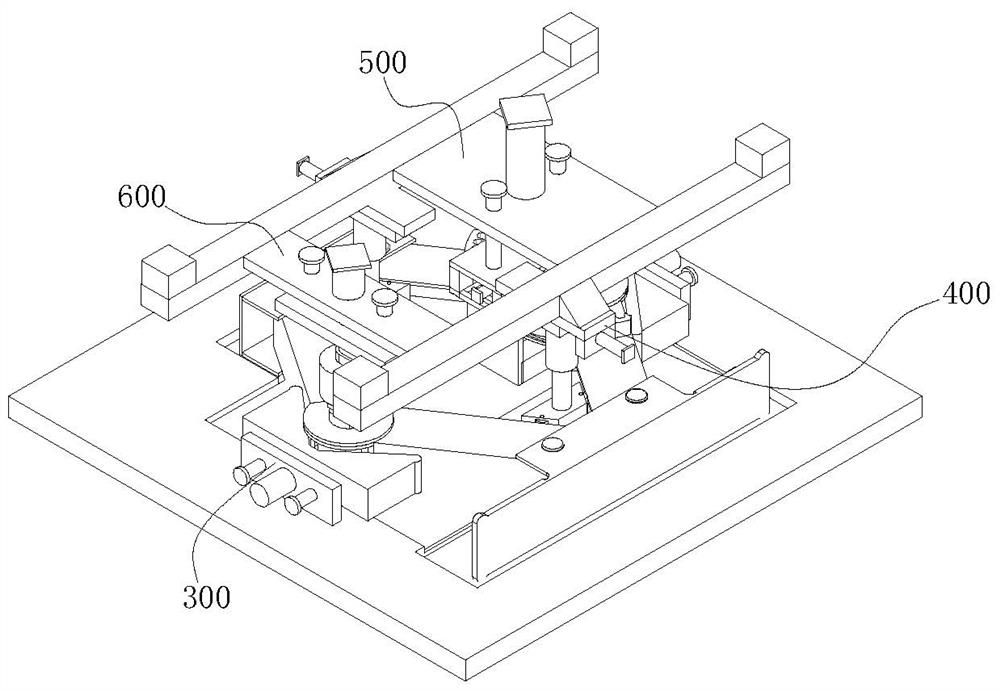

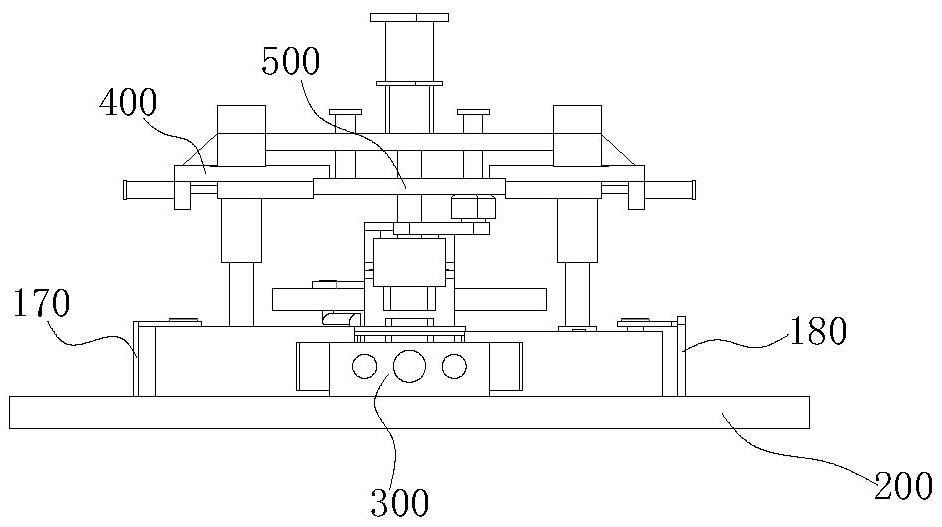

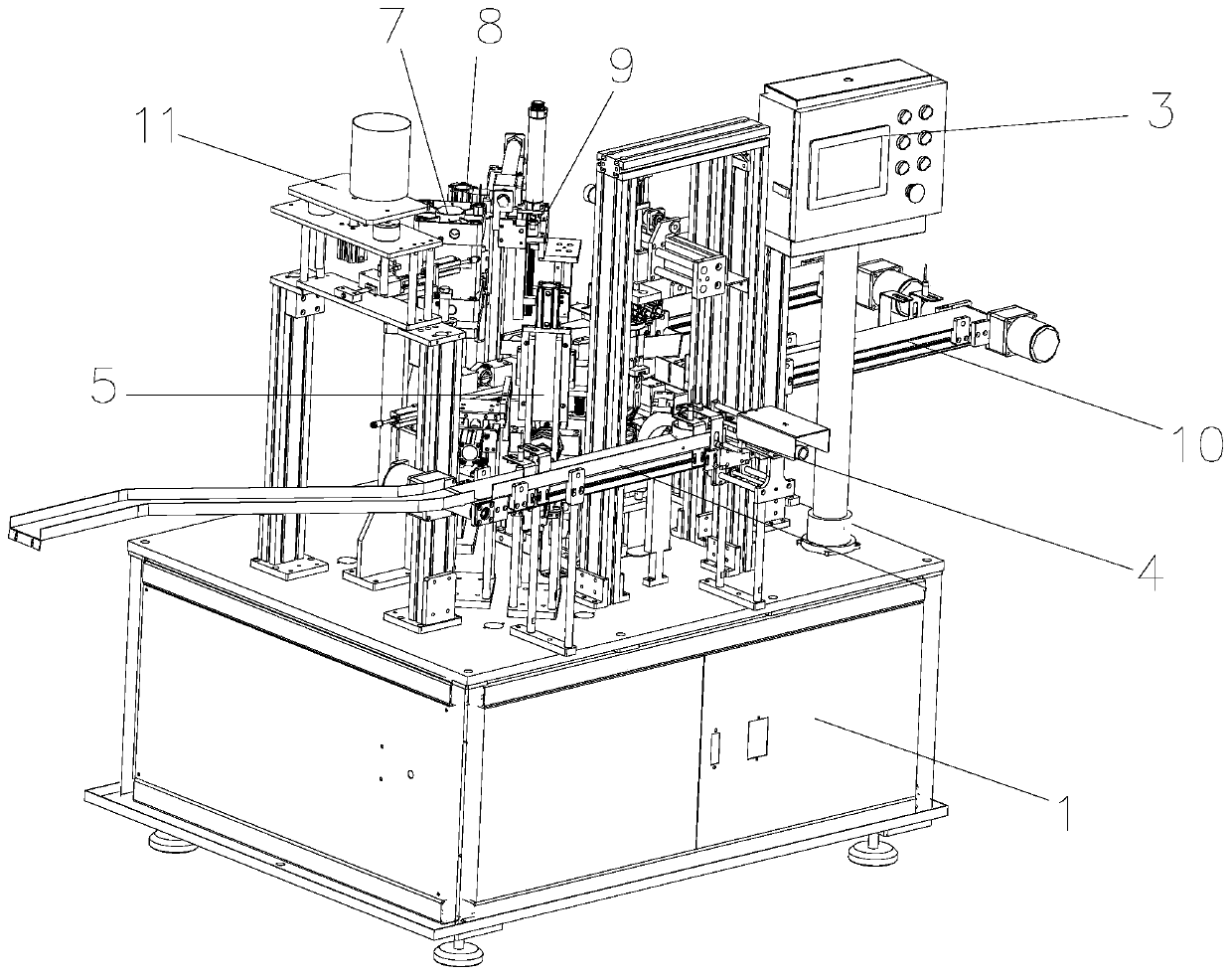

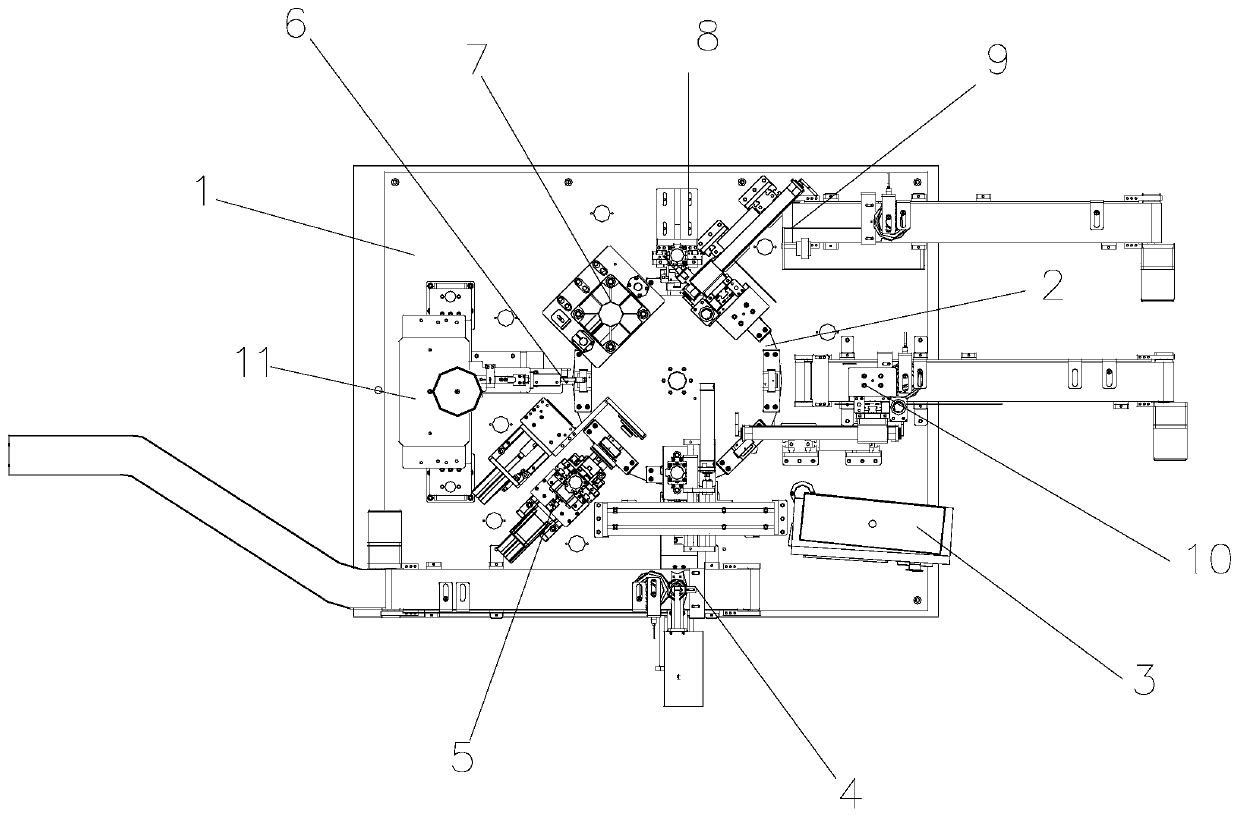

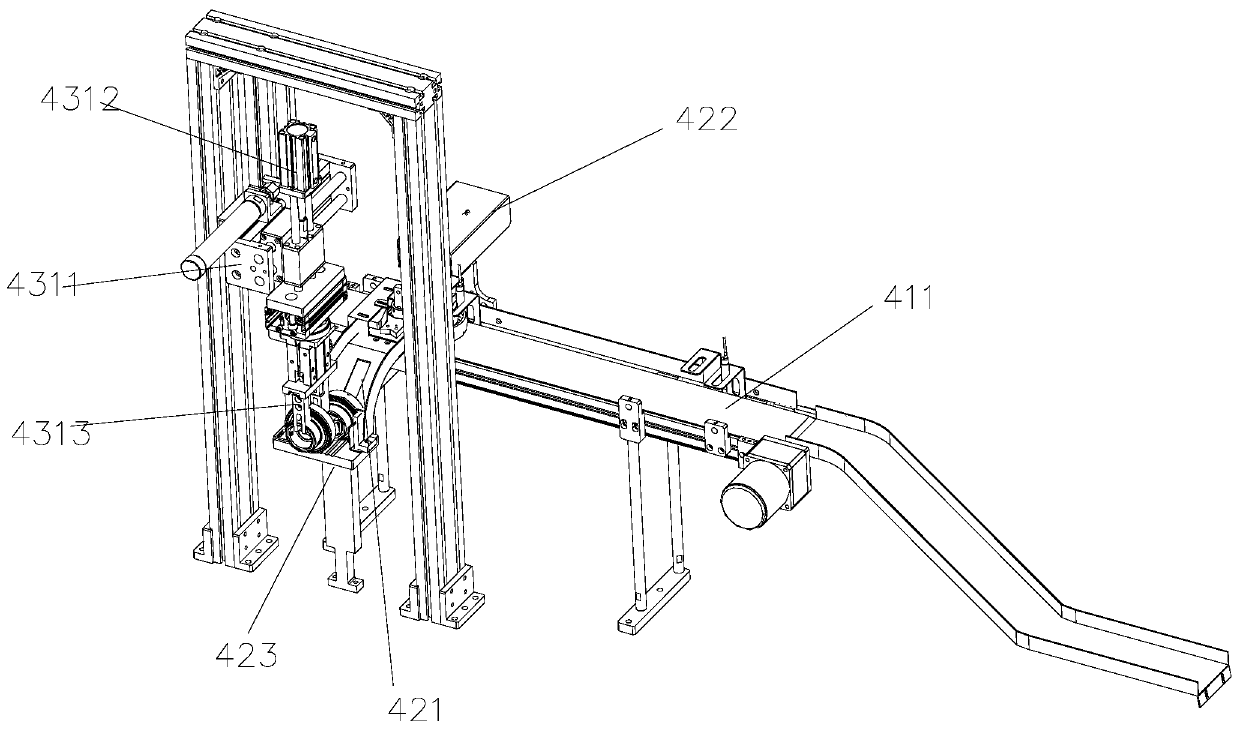

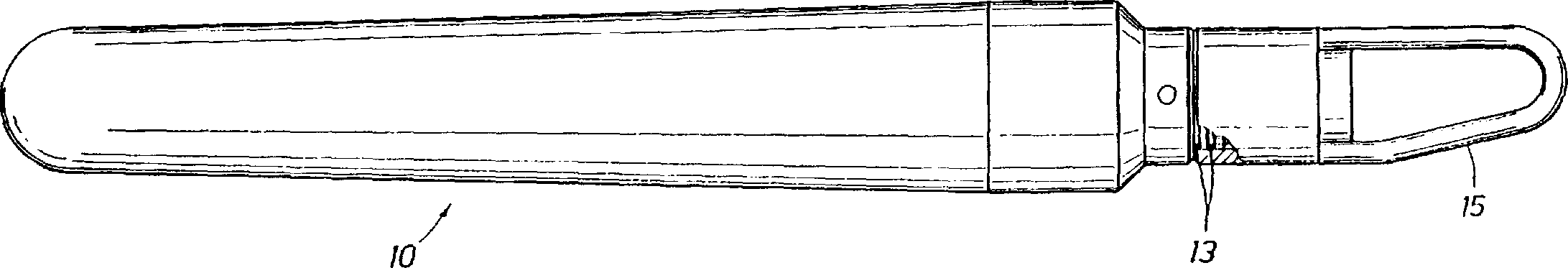

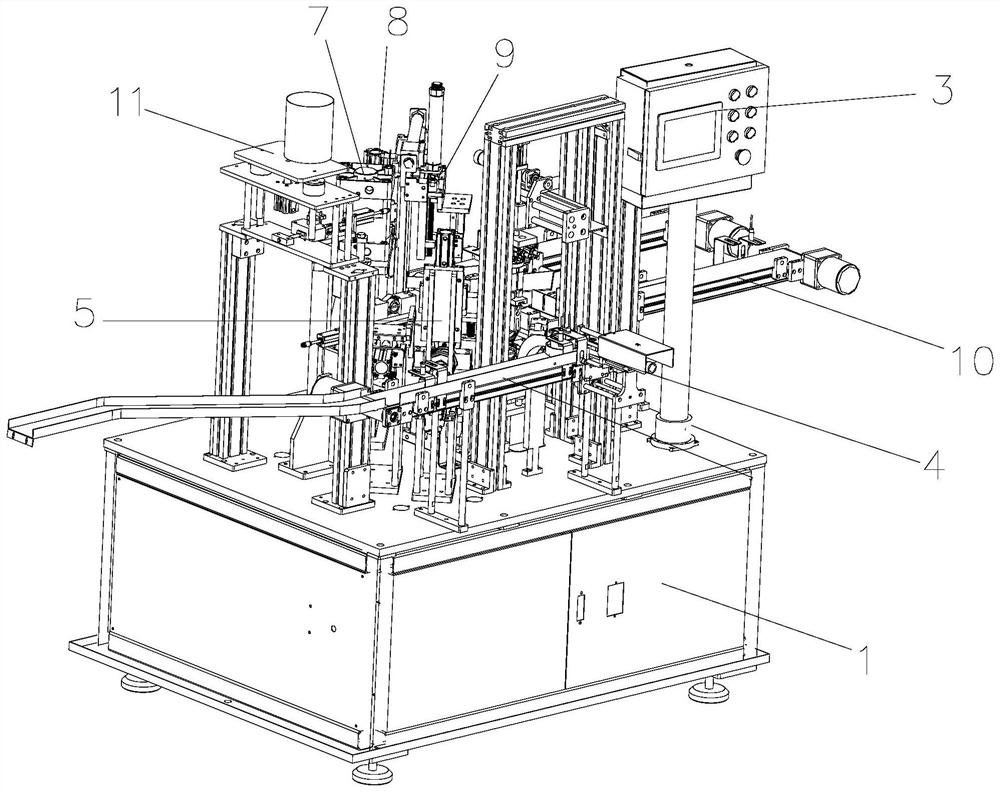

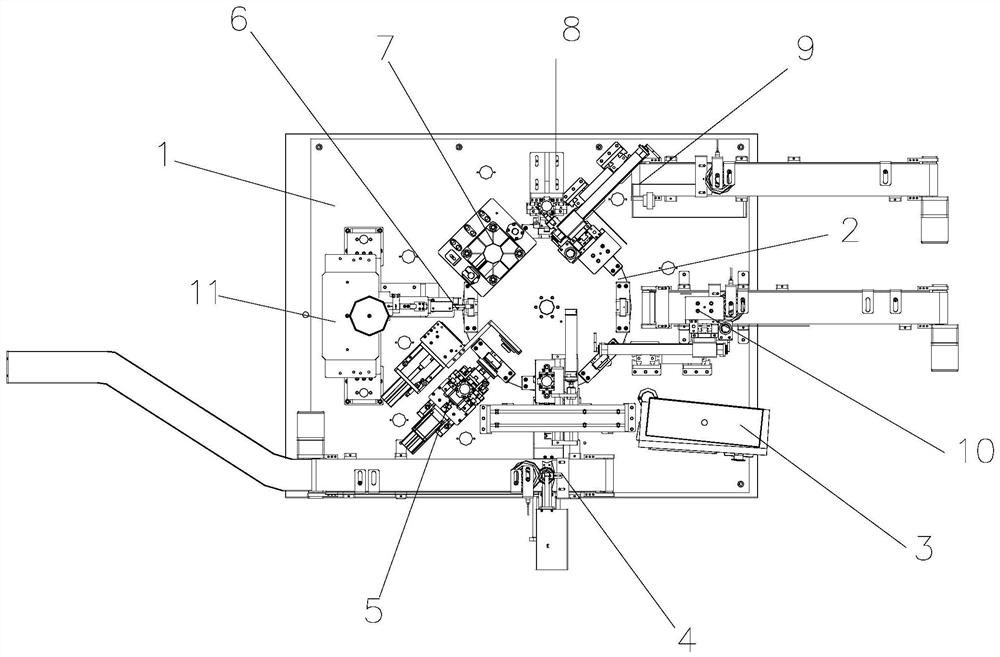

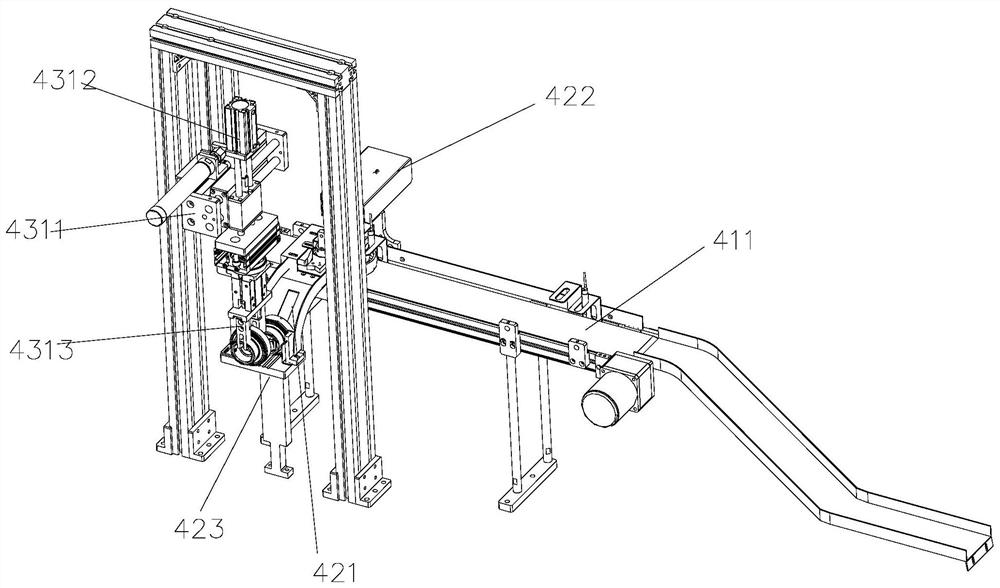

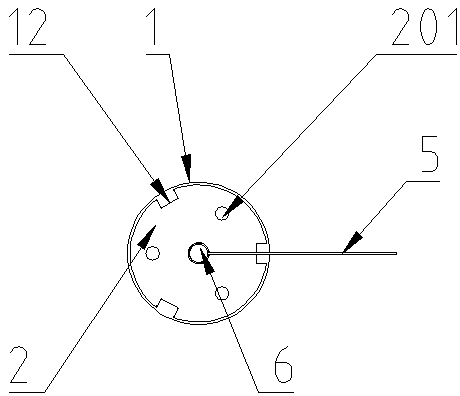

Assembly system for umbrella handle assemblies

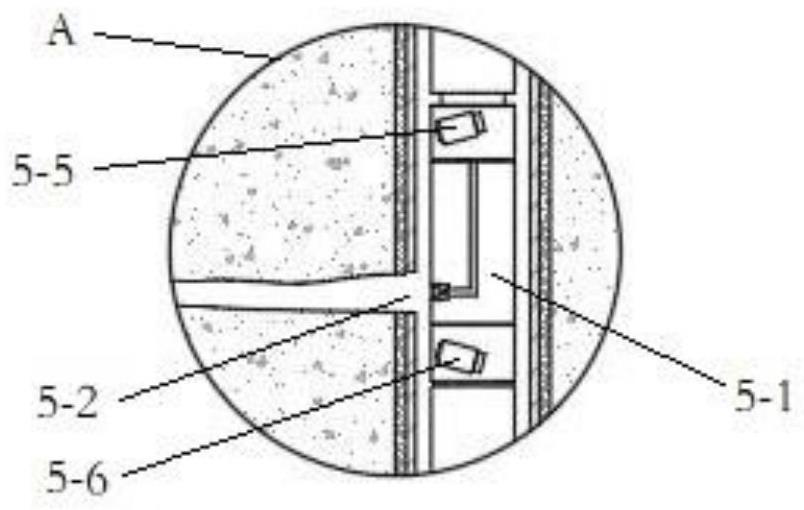

PendingCN110052827ARealize fully automatic assemblyImprove assembly efficiencyAssembly machinesLeaf springHole Finding

The invention provides an assembly system for umbrella handle assemblies. The assembly system for umbrella handle assemblies comprises a feeding mechanism, a conveying mechanism, a rotary hole findingmechanism, a leaf spring feeding mechanism, a leaf spring assembly mechanism, a combined assembly mechanism and a reversing mechanism. The feeding mechanism is used for receiving umbrella handle bodies and conveying the umbrella handle bodies to the conveying mechanism. The rotary hole finding mechanism is used for finding leaf spring installation holes in the umbrella handle bodies. The leaf spring feeding mechanism is used for conveying leaf springs to leaf spring assembly positions corresponding to the leaf spring installation holes. The leaf spring assembly mechanism is used for assembling the leaf springs to the interiors of the umbrella handle bodies at a leaf spring assembly position. The combined assembly mechanism is used for assembling corresponding umbrella handle bodies into one segment of telescopic umbrella handle in a combined manner. The reversing mechanism is used for turning one umbrella handle to be at a preset angle. The conveying mechanism is used for conveying umbrella handles between the rotary hole finding mechanism, the leaf spring assembly mechanism, the combined assembly mechanism and the reversing mechanism according to a preset assembly path. Full-automatic assembly on umbrella handle assemblies can be achieved, the assembly efficiency and the assembly accuracy can be improved, and the human labor intensity can be reduced.

Owner:杭州晟泉智能控制有限公司

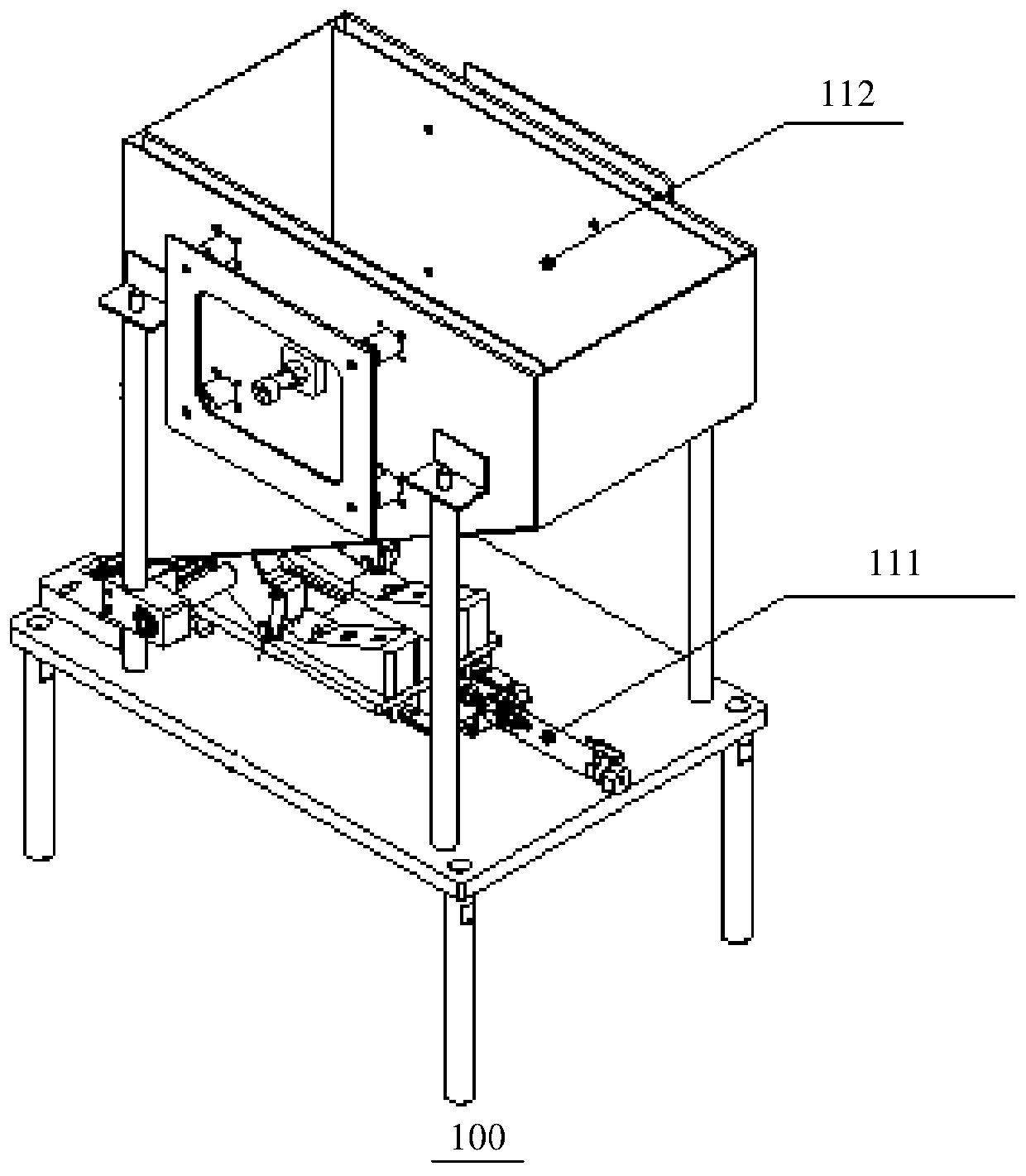

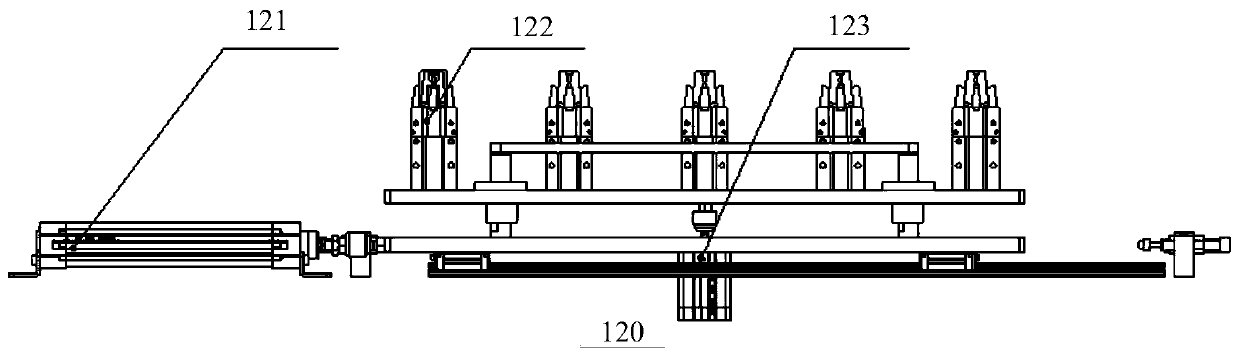

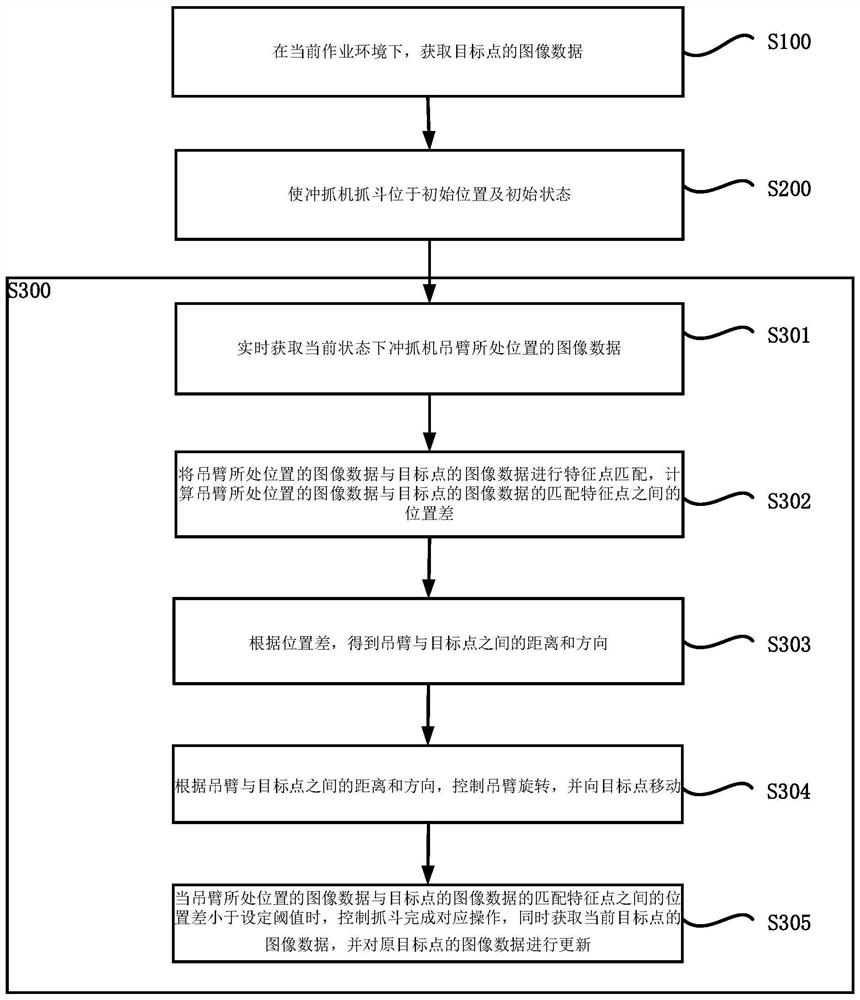

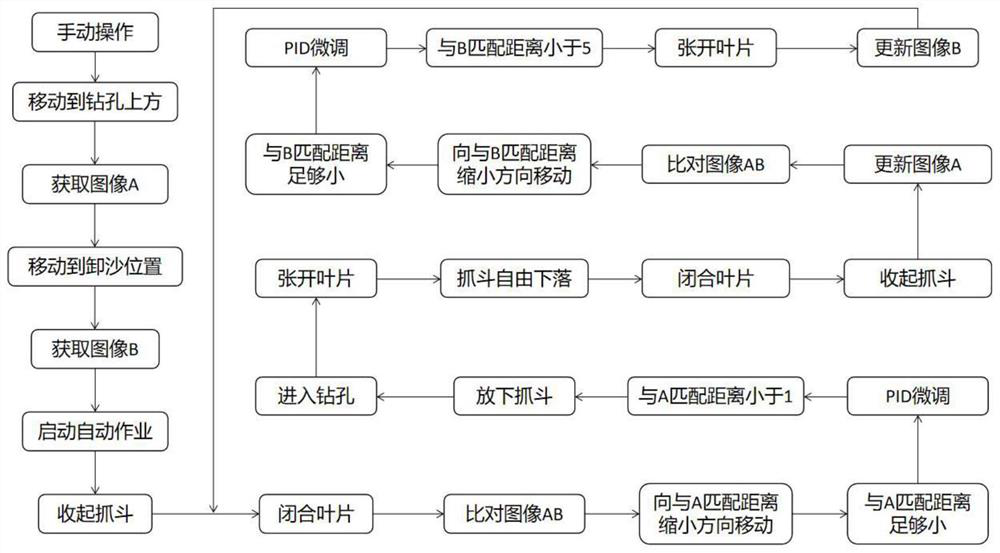

Automatic operation control method and control system of punching and digging machine

PendingCN113805479ARealize fully automatic operationReduce operating costsControllers with particular characteristicsBulkheads/pilesPunchingControl system

Owner:上海亥伯智能科技有限公司

Branch hole positioning guiding tool

ActiveCN105019845ASmooth, accurate and fast importSimple and fast operationBorehole/well accessoriesCoiled tubingEngineering

The invention relates to the technical field of coiled tubing multilateral well repairing work, especially to a branch hole positioning guiding tool which comprises an anchor body and anchor flukes installed on the anchor body. An upper sealing device comprises a central pipe, wherein the lower end of the anchor body is connected to the central pipe, and an upper sealing rubber cylinder sleeves the central pipe. The upper end of the upper sealing rubber cylinder abuts against the end face of the central pipe, a pressure cap is arranged on the lower end of the upper sealing rubber cylinder fixed on the central pipe through a shear pin, and the lower end of the pressure cap is provided with a stopper ring. The branch hole positioning guiding tool can smoothly and rapidly guide a bend pipe, guiding and sealing process can be completed at one time, and operation is simple. The branch hole positioning guiding tool overcomes the defect that hole-finding and guiding for a bend pipe is difficult, labor-consuming, time-consuming and inaccurate in the prior art.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

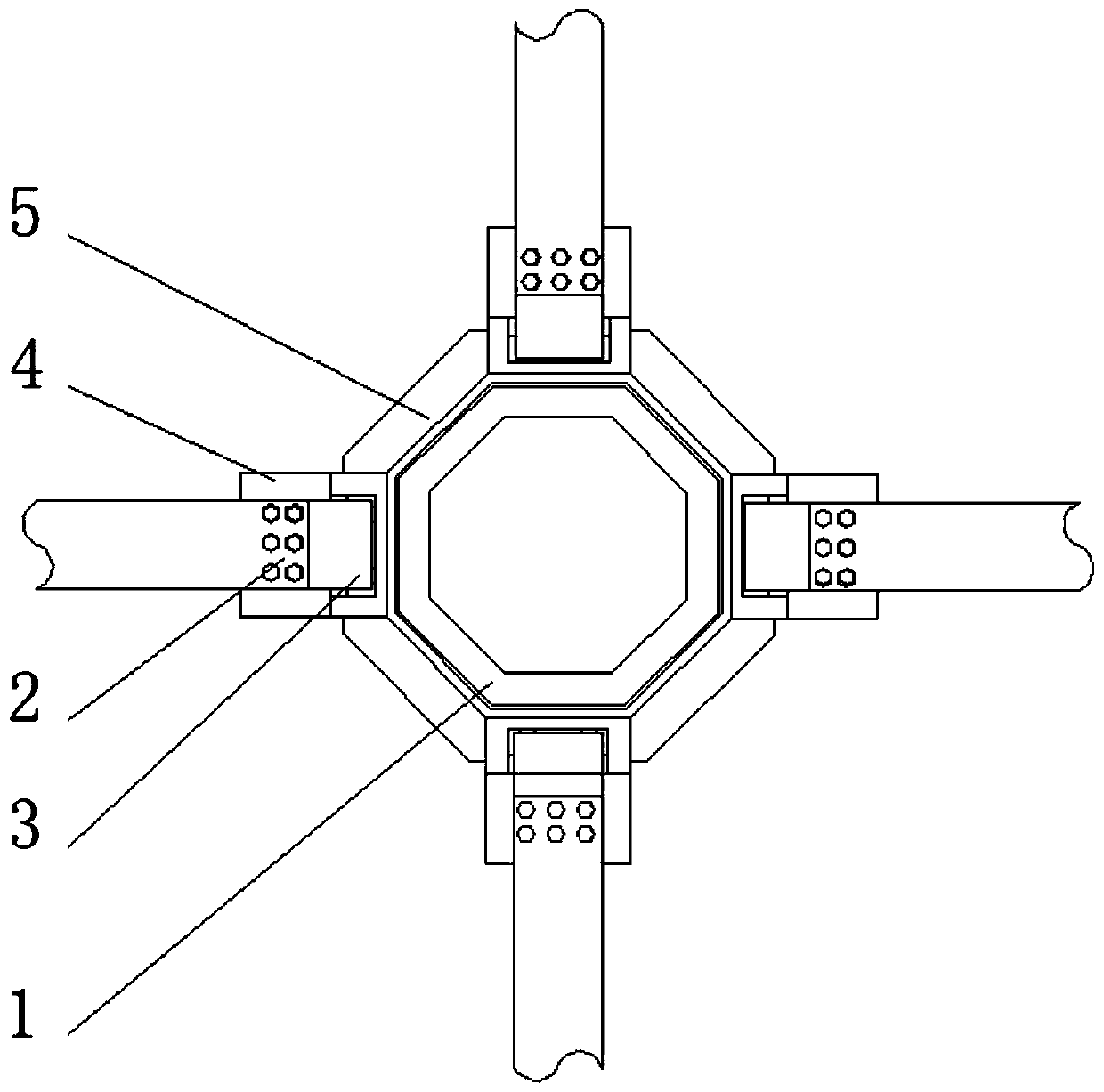

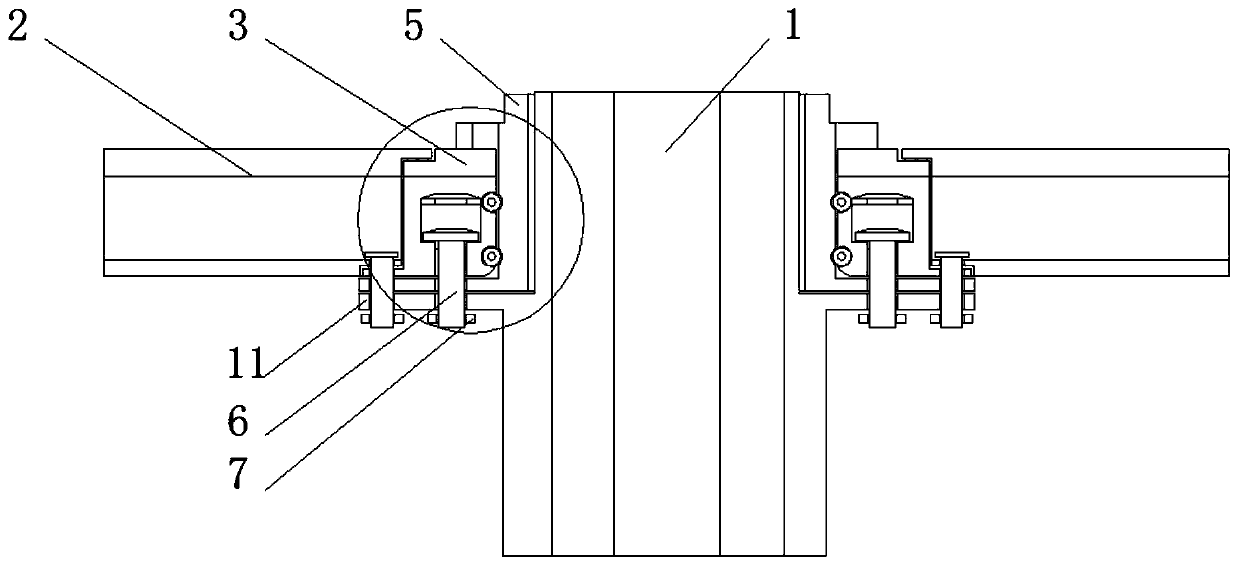

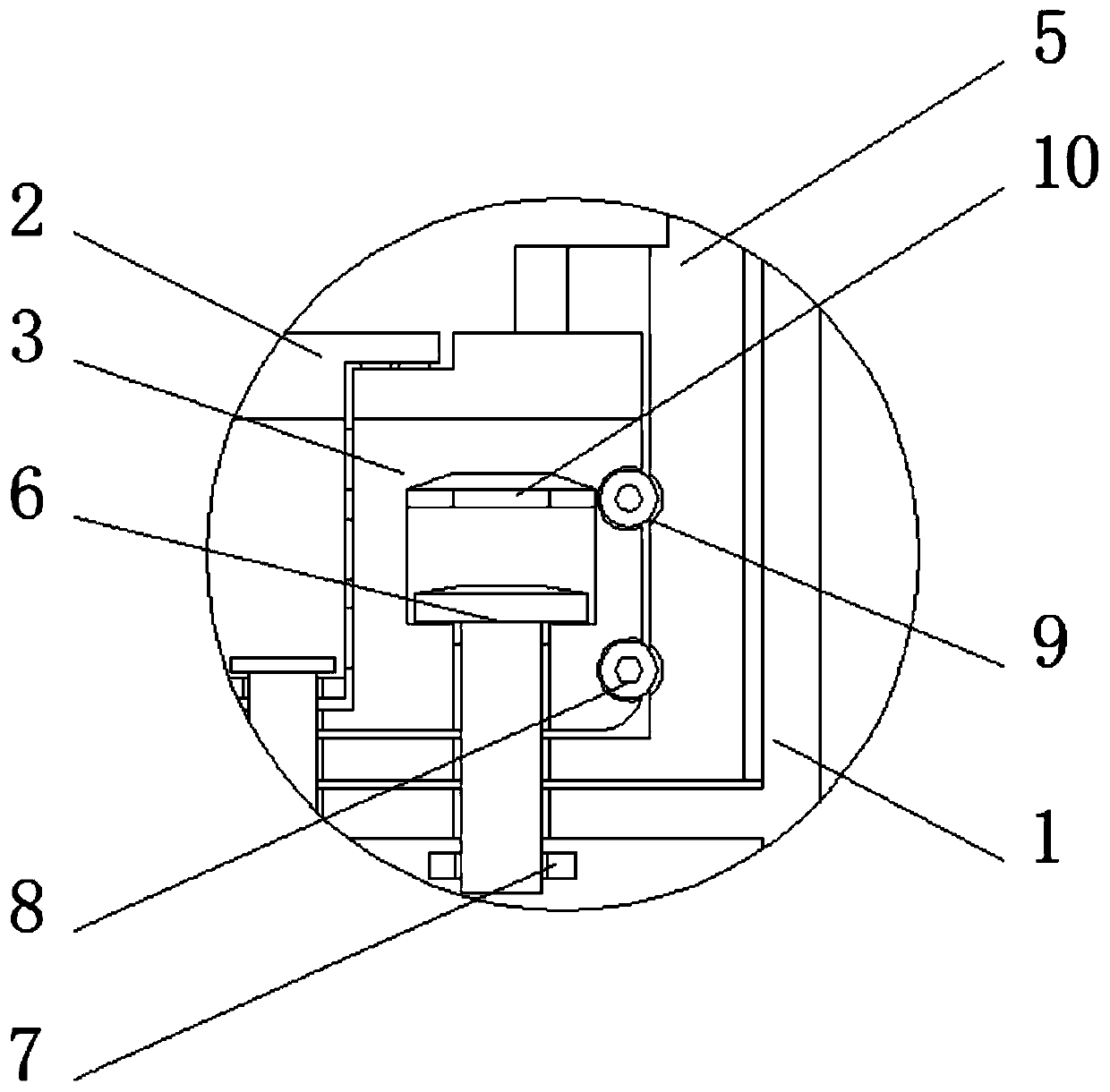

Steel structure beam-column joint

PendingCN109972734AAchieve pre-fixationSolve the problem of inconvenient splitting and recyclingBuilding constructionsMaterials scienceBeam column

The invention discloses a steel structure beam-column joint, which comprises a bearing column, a steel beam, a buffer steel block, a protective steel sleeve, a reinforcing bolt, a reinforcing nut, anda bearing supporting plate. The protective steel sleeve sleeves outside the bearing column; the bearing supporting plate is arranged vertically and horizontally on the outer side of the bearing column and is arranged on the lower edge of the protective steel sleeve; the buffer steel block is arranged between the steel beam and the protective steel sleeve, and is placed above the bearing supporting plate; the buffer steel block is internally provided with a groove; and the upper end of the reinforcing bolt is movably arranged in the groove, the lower end of the reinforcing bolt penetrates through the buffer steel block and the bearing supporting plate successively, and the buffer steel block and the bearing supporting plate are fixedly connected by using the reinforcing nut. According to the steel structure beam-column joint, extension treatment of the connection point between the bearing supporting column and the steel beam is realized, at the same time, it is greatly convenient to disassemble and recycle the bearing column and the steel beam, the reinforcing bolt is mounted movably on the inner side of the buffer steel block, thus prefixing of the steel beam and the bearing supporting plate is realized, hole finding time is shortened, and the assembly efficiency is greatly improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Multi-spliced-board and multi-internal-positioning edge milling structure and machining method thereof

InactiveCN106334823AExtended service lifeReduce difficultyMilling equipment detailsPositioning apparatusEngineeringMachining

The invention discloses a multi-spliced-board and multi-internal-positioning edge milling structure which comprises a multi-spliced-board and multi-internal-positioning edge milling device and can be fixed with a normal added board. A multi-spliced-board and multi-internal-positioning edge milling method comprises the steps that firstly, positioning of a paper wooden base board and an electric wooden board are fixed, and then positioning of a produced product is performed. The multi-spliced-board and multi-internal-positioning edge milling structure has the advantages that 1, positioning hole finding difficulty is greatly reduced, and the device operation efficiency is improved; 2, milling offset caused by positioning pin hole coinciding and scrapping caused by milling damage are avoided; 3, the service life of the electric wooden board is prolonged, and the machining cost is reduced. The multi-spliced-board and multi-internal-positioning edge milling method is wide in market prospect.

Owner:珠海杰赛科技有限公司

Pipe material assembly platform production line

ActiveCN109648343BRealize continuous automatic feedingRealize automatic assemblyOther manufacturing equipments/toolsTube shearing machinesMachineCantilever

The invention discloses a pipe material assembling platform production line. The pipe material assembling platform production line comprises a feeding conveying part, a cutting machine, a carrying part, a hole finding part and a robot, wherein an output end of the feeding conveying part is in butt joint with an input end of the cutting machine, an output end of the cutting machine is in butt jointwith an input end of the carrying part, the hole finding part is arranged on one side of the carrying part, and the robot is arranged on one side of the hole finding part. continuous automatic feeding, length fixing, cutting and hole finding of a pre-assembled contact network cantilever pipe material and automatic assembling of a workpiece and the pipe material can be realized, field operators can be reduced, the labor intensity can be reduced, and the working efficiency can be improved.

Owner:武汉中安佳通装备技术有限公司

Anti-reverse control method for reels

InactiveCN102343993BAnti-wrappingAnti-circumventionPackaging automatic controlControl signalControl theory

The invention discloses an anti-reverse control method for reels; the method comprises the following steps: in an empty reel loading process, equipment automatically loads an empty reel into a reel motor; in positioning and hole finding processes, an automatic reel replacing mechanism of the equipment automatically finds a carrier tape inserting hole on the reel; a detecting device begins to detect the direction of the reel, if the direction is right, the detecting device transmits a low level control signal output by a sensor to a device control center, the equipment continues to operate; if the direction is wrong, the detecting device transmits a high level control signal output by the sensor to the device control center, the equipment automatically removes the reel with the wrong direction and reloads a new empty reel into the reel motor; and the steps of locating and finding holes and detecting the direction of the reel by the detecting device are carried out continuously. According to the anti-reverse control method, a product is prevented from winding reversely relative to the reel after carrying the tape, the unnecessary repetition work is reduced, the control is accurate and the reverse winding of the reel is completely put an end to.

Owner:CHENGDU ADVANCED POWER SEMICON

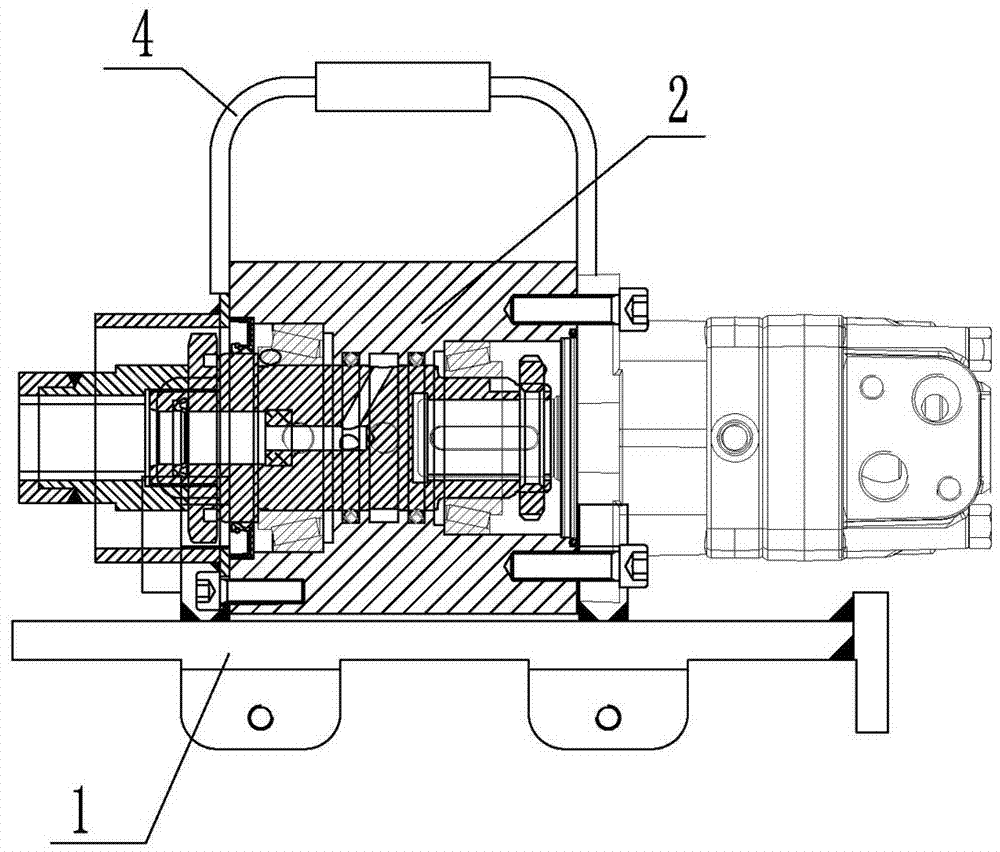

Oilfield injection-production well hole finding ultrahigh-pressure deep-penetrating reaming equipment

InactiveCN114645695AIncreased hydraulic perforation capabilityImprove utilizationFluid removalUltra high pressureLine tubing

The invention relates to the technical field of oilfield injection and production well development, in particular to ultrahigh-pressure deep-penetrating reaming equipment for hole finding of an oilfield injection and production well. Comprising a high-pressure pipeline roller, a bearing steel cable winding and unwinding roller, a high-pressure sand adding device, a leading-in device, an ultrahigh-pressure jet device, a height fine adjustment device, an angle adjustment device, a combined clamp holder, a wellhead blowout preventer, a hydraulic station, a liquid preparation water tank, a control box and a crane. The leading-in device is mounted on the crane, and a high-pressure pipeline of the high-pressure pipeline roller and a high-strength steel cable of the bearing steel cable winding and unwinding roller penetrate through the leading-in device and are connected with the ultrahigh-pressure jet device; a high-pressure sand adding device is connected to the upper portion of the ultrahigh-pressure jet device, and an angle adjusting device, a height fine adjusting device and a combined clamping device are sequentially arranged below the high-pressure sand adding device. A liquid flow channel can be improved, and the oil and gas reservoir utilization degree can be improved; and a borehole pollution area is penetrated, damage to a near-wellbore zone is relieved, and the stratum flow conductivity is improved.

Owner:江苏思源石油科技有限公司

Fully automatic outer spherical ball bearing anti-loosening ball assembly machine

ActiveCN111590300BReduce labor intensityImprove work efficiencySortingMetal working apparatusBall bearingStructural engineering

The invention relates to the field of assembling machines, and particularly relates to a full-automatic anti-loosening ball assembling machine for an outer spherical ball bearing. According to the full-automatic anti-loosening ball assembling machine for the outer spherical ball bearing, the bearing is transferred to a corresponding station of a rotary table mechanism through a feeding mechanism,then a bearing outer ring on the station is driven to rotate through a hole finding mechanism, a hole is positioned in a ball assembling station of a ball assembling mechanism, an anti-loosening ballconveyed by a ball discharging mechanism is installed on the hole of the bearing through the ball assembling mechanism, then the ball is pressed into a ball socket of the bearing through a ball pressing mechanism by means of an air cylinder, a ball detecting mechanism detects whether the ball exists in the ball socket of the bearing or not and whether the ball is pressed in place or not in a contact type measuring mode, finally, a kicking mechanism takes out a bearing workpiece which is judged to be unqualified by the ball detecting mechanism, and a discharging mechanism takes out a bearing workpiece which is judged to be qualified by the ball detecting mechanism. The stations are automatically switched through the rotary table mechanism, the anti-loosening steel ball is assembled in a full-automatic mode, the working efficiency and the percent of pass are greatly improved, and the labor intensity of workers is relieved.

Owner:广州顺大智能装备有限公司

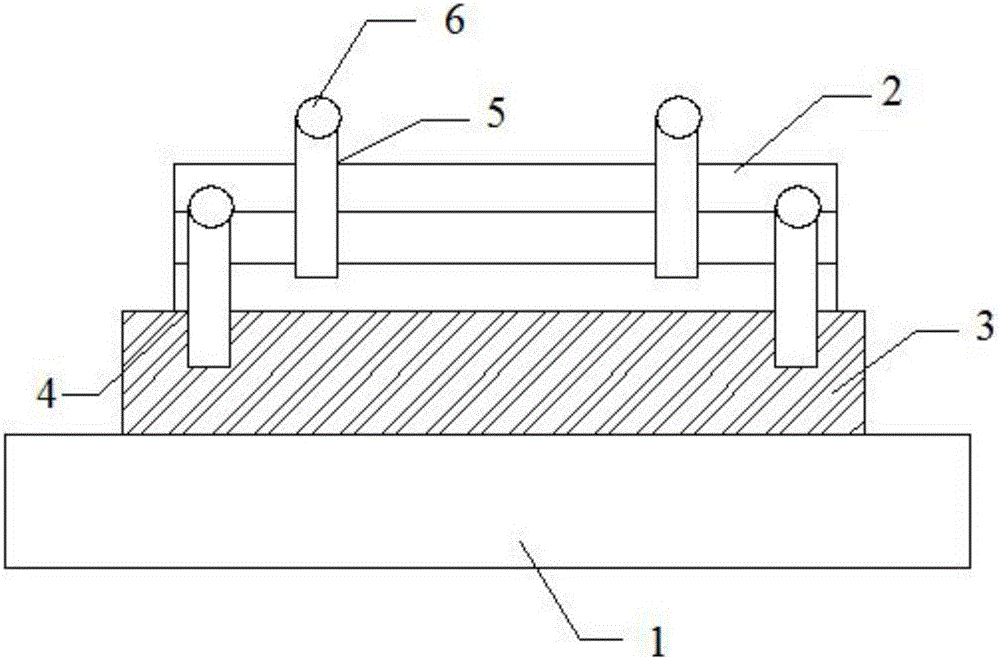

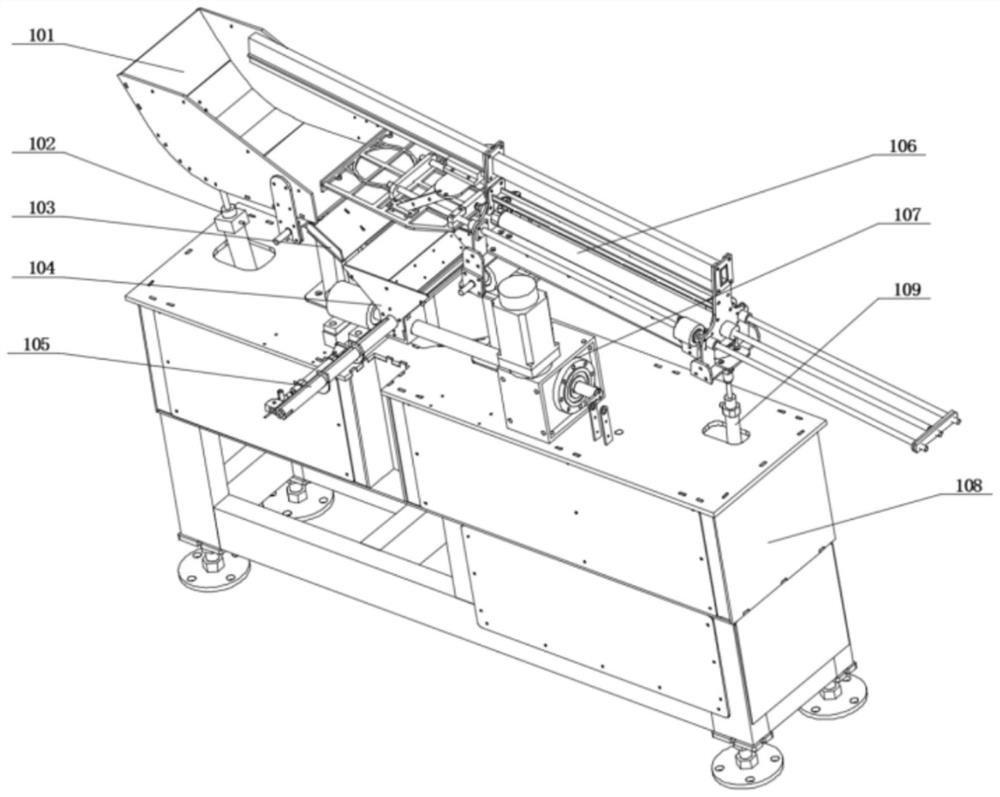

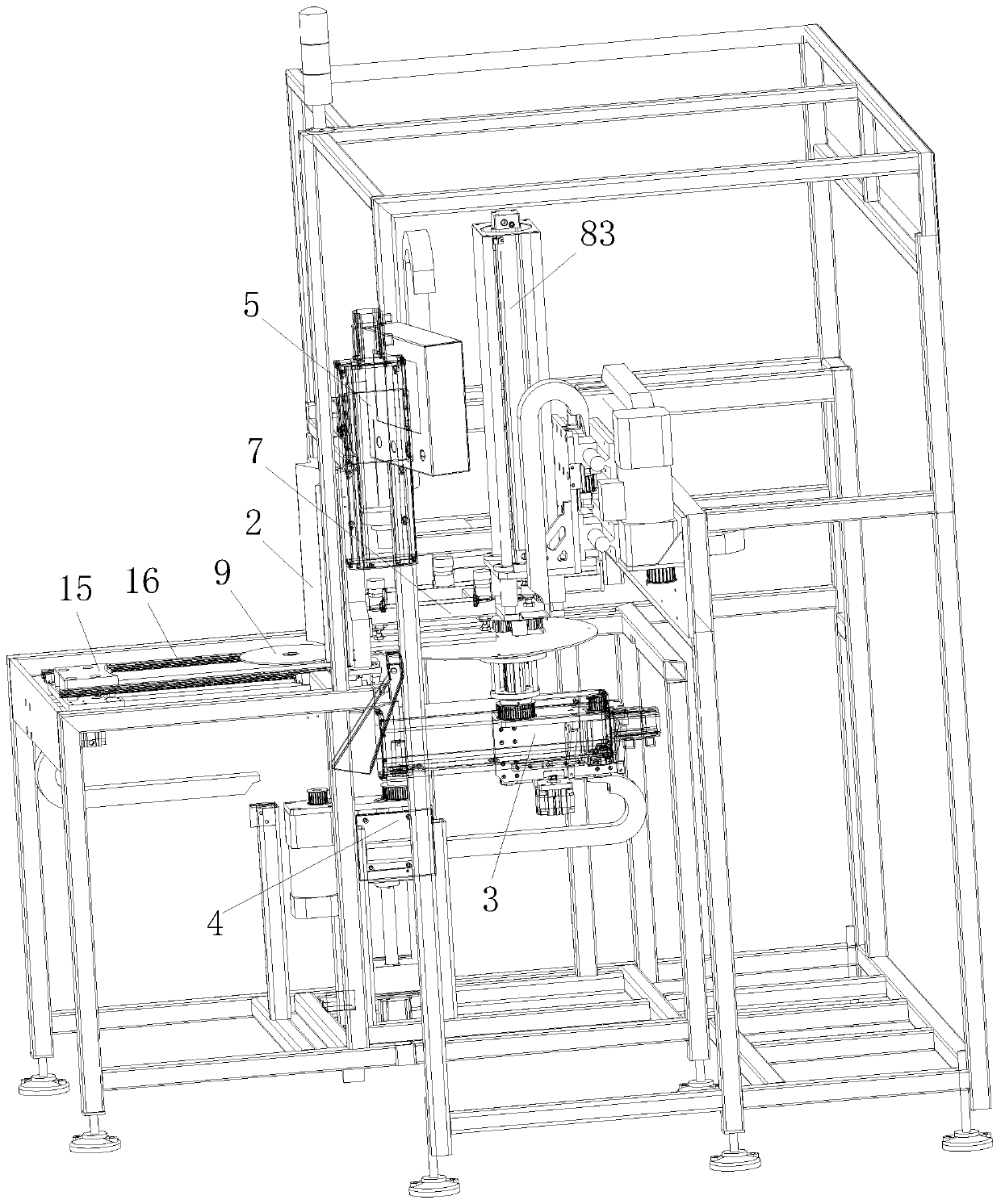

A fully automatic rod production equipment

ActiveCN112008401BEfficient and orderly feedingAssembly machinesMeasurement/indication equipmentsProcess engineeringSteel ball

The invention discloses a fully automatic post production equipment, which belongs to the field of post production. A fully automatic post production equipment includes: a steel handle automatic feeding module, a steel handle placement module, a steel handle hole finding module, a defective Steel handle rejection module, spring automatic feeding and detection module, steel ball automatic feeding and detection module, automatic clamping bottom bracket module, pressing module, finished product quality inspection module and finished product flow direction control module, the steel handle automatic feeding module includes basic The base is provided with a base on the front of the base. In the present invention, through the non-destructive screening of the surface of the steel handle, and the hole position can be identified, the material can be supplied efficiently and orderly; the stable single material supply of the spring can be detected in place and the alarm can be given for lack of material; the stable single material supply of the steel ball can be carried out , can detect in place and can alarm when there is a lack of material; the same model (steel handle diameter) with different lengths can be used for general production; the quality inspection of the product after processing can be carried out, and qualified products and unqualified products can be separated.

Owner:包斌华

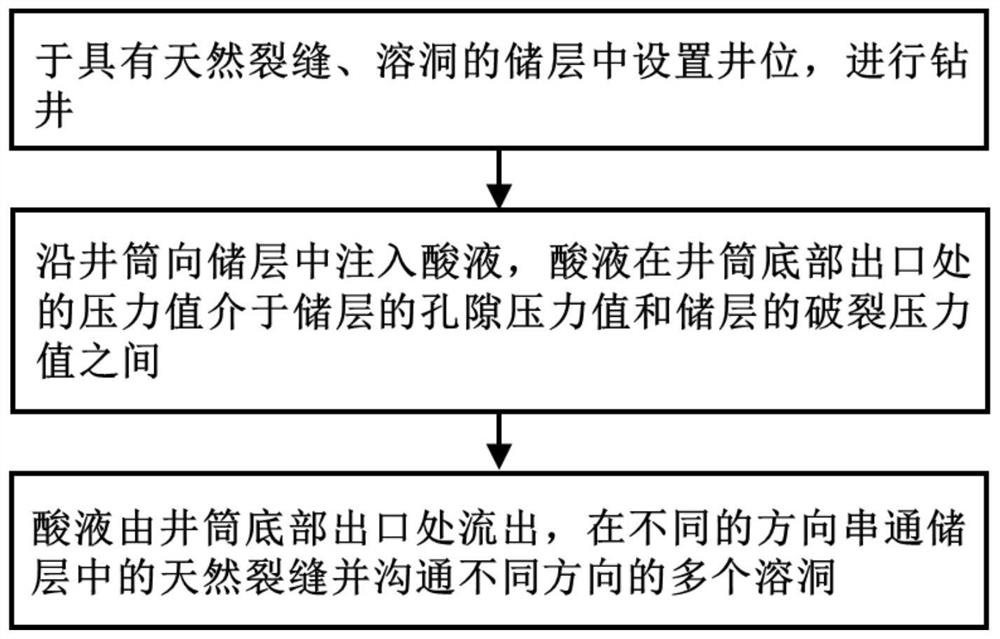

Seam-following hole finding method

The invention discloses a seam following hole finding method which comprises the steps that a well position is arranged in a reservoir, and a shaft is arranged in the well position; injecting acid liquor along the shaft, wherein the pressure value of the acid liquor at the bottom outlet of the shaft is between the formation pore pressure value at the bottom outlet of the shaft and the formation fracture pressure value at the bottom outlet of the shaft; the acid liquid flows out from an outlet in the bottom of the shaft, penetrates through natural cracks with opening degrees in different directions and communicates with a plurality of karst caves which are communicated with the natural cracks in different directions. The inventor puts forward a seam following and hole finding transformation idea for the first time, the pressure value of acid liquor at the bottom outlet of the shaft is limited to be between the formation pore pressure value at the bottom outlet of the shaft and the formation fracture pressure value at the bottom outlet of the shaft, it can be guaranteed that the acid liquor flows in a low-pressure seepage mode, and the natural crack utilization rate can be increased; the capacity of natural fractures for communicating fracture-cavity reservoirs is improved, meanwhile, the construction risk and cost in the deep or ultra-deep carbonate reservoir transformation process are reduced, and the yield of oil and gas fields is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

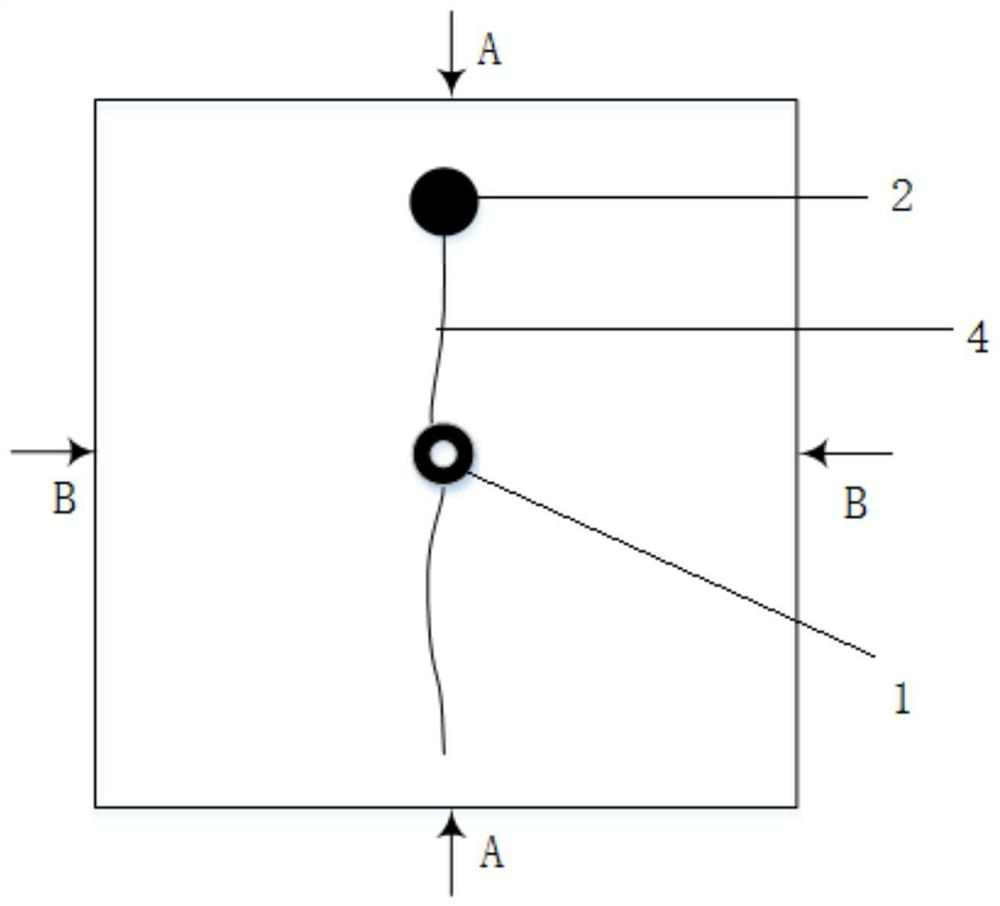

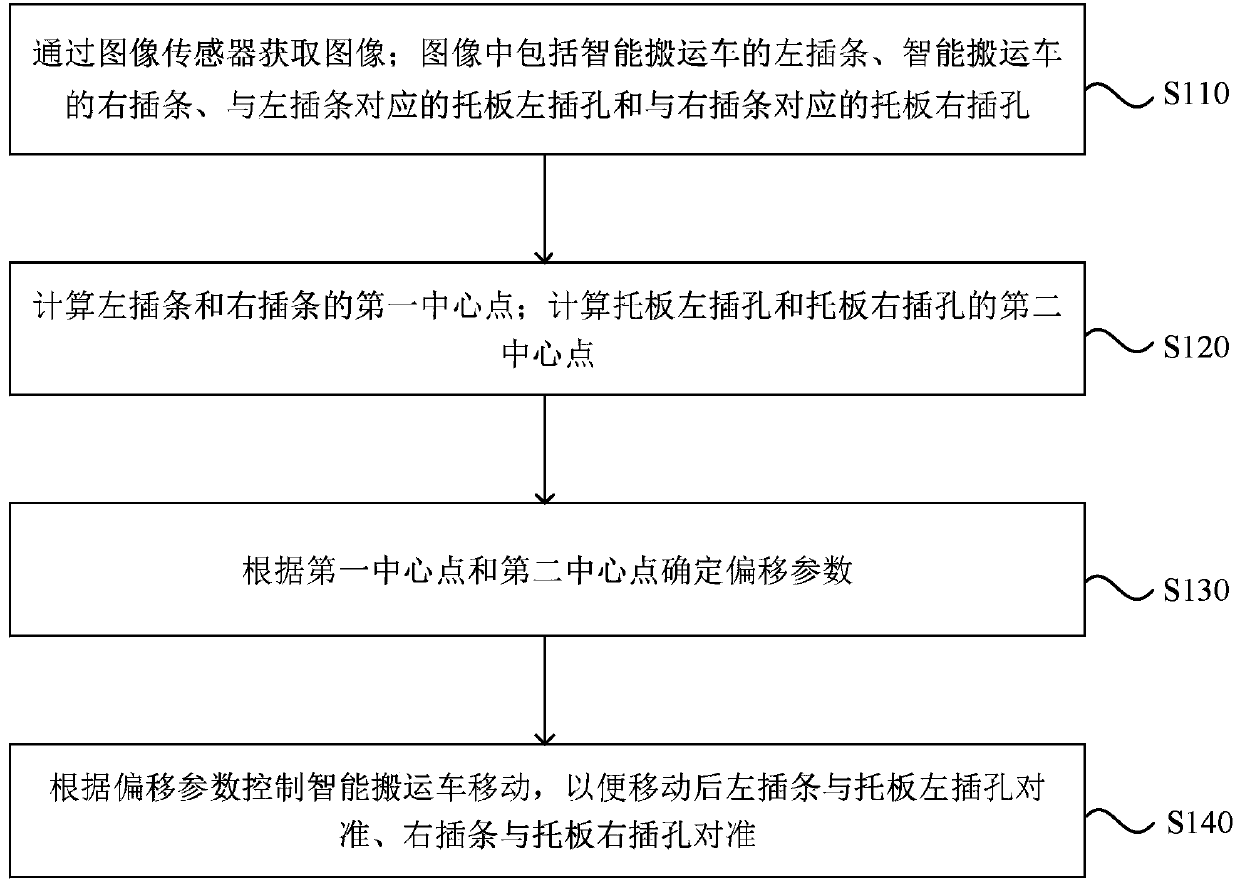

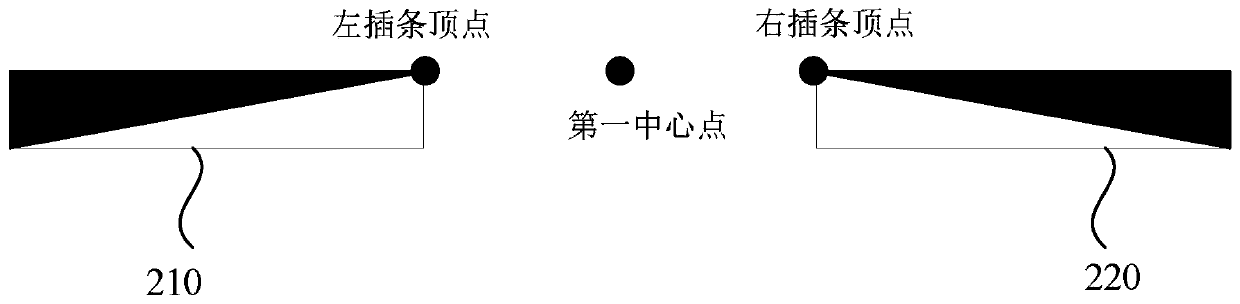

Visual hole finding method and device, equipment and storage medium

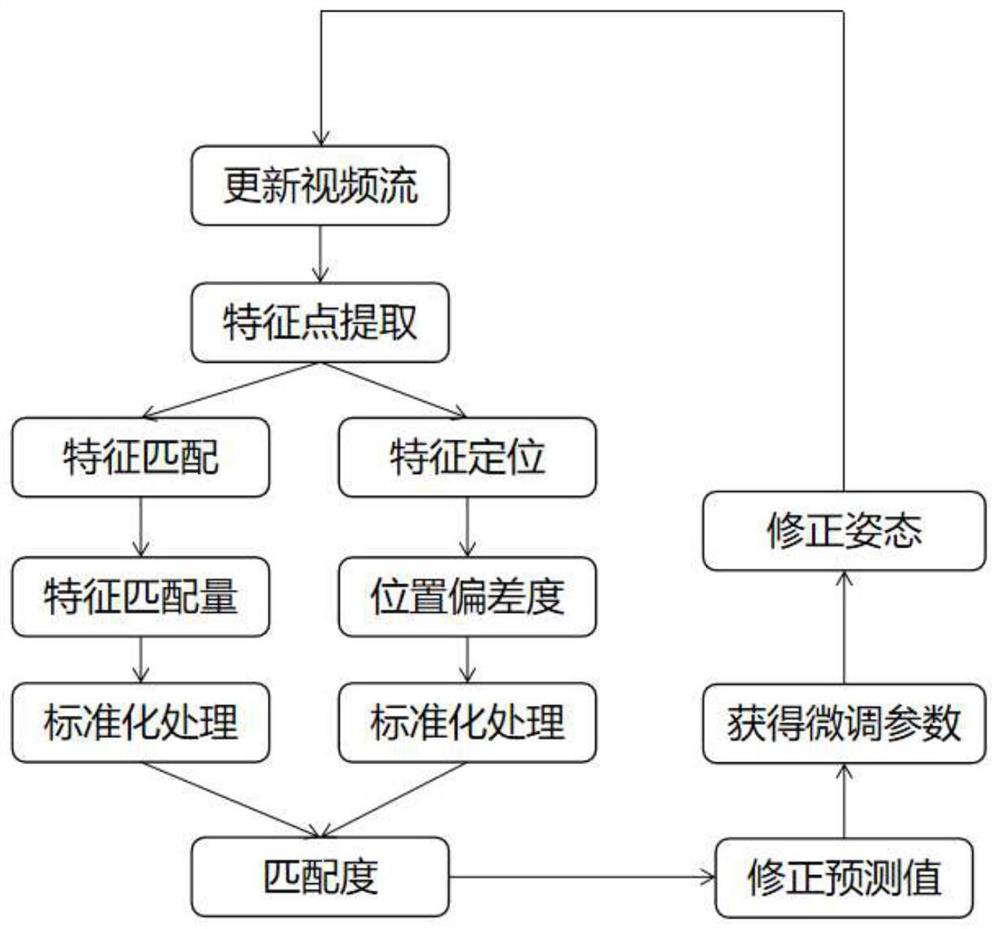

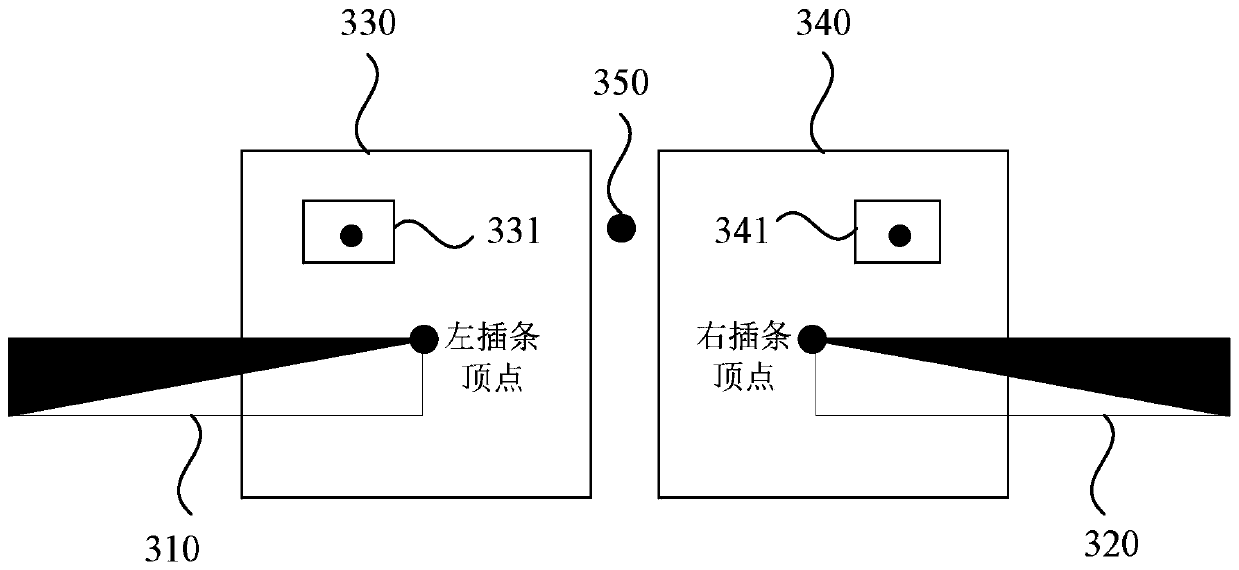

ActiveCN110488832APrecisely hold upImage analysisPosition/course control in two dimensionsTruckParameter control

An embodiment of the invention discloses a visual hole finding method and device, equipment and a storage medium which can be applied to an intelligent truck. The visual hole finding method comprisesa step of acquiring an image through an image sensor, wherein the image includes a left insertion strip of the intelligent truck, a right insertion strip of the intelligent truck, a pallet left insertion hole corresponding to the left insertion strip, and a pallet right insertion hole corresponding to the right insertion strip, a step of calculating first center points of the left insertion stripand the right insertion strip, a step of calculating second center points of the pallet left insertion hole and the pallet right insertion hole, a step of determining an offset parameter according tothe first center point and the second center point, a step of controlling the intelligent truck to move according to the offset parameter such that the left insertion strip is aligned with the palletleft insertion hole and the right insertion strip is aligned with the pallet right insertion hole. According to the embodiment of the invention, the precise insertion of the insertion strips into thepallet insertion holes is achieved, and the intelligent truck can lift goods.

Owner:国以贤智能科技(上海)股份有限公司

Hole exploring method for flow drilling tightening equipment

ActiveCN110587379ANo manual operationReduce labor costsMeasurement/indication equipmentsInformation processingCamera image

The invention discloses a hole exploring method for flow drilling tightening equipment. The hole exploring method comprises the following steps of obtaining a shooting image of a relative position ofa flow drilling tightening equipment gun to a pre-drilled hole of an upper-layer plate by using a one-sided main camera, wherein the shooting image at least contains position information of referencepoints on three different positions; performing information processing to obtain predrilling boundary information in the shooting image, and further realizing hole site detection for predrilling; respectively shooting the same position of a lower-layer plate in the pre-drilled hole of the flow drilling tightening equipment at the pre-determined pressure by using cameras which are symmetrically arranged on two sides of a gun head to obtain a main camera image and an auxiliary camera image at the pre-determined pressure; and realizing the site detection for predrilling by calculating. Accordingto the method, automatic hole finding and hole depth measurement of the flow drilling tightening equipment can be realized under the control of a computer system, and thus successful riveting is ensured and the working efficiency is improved.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

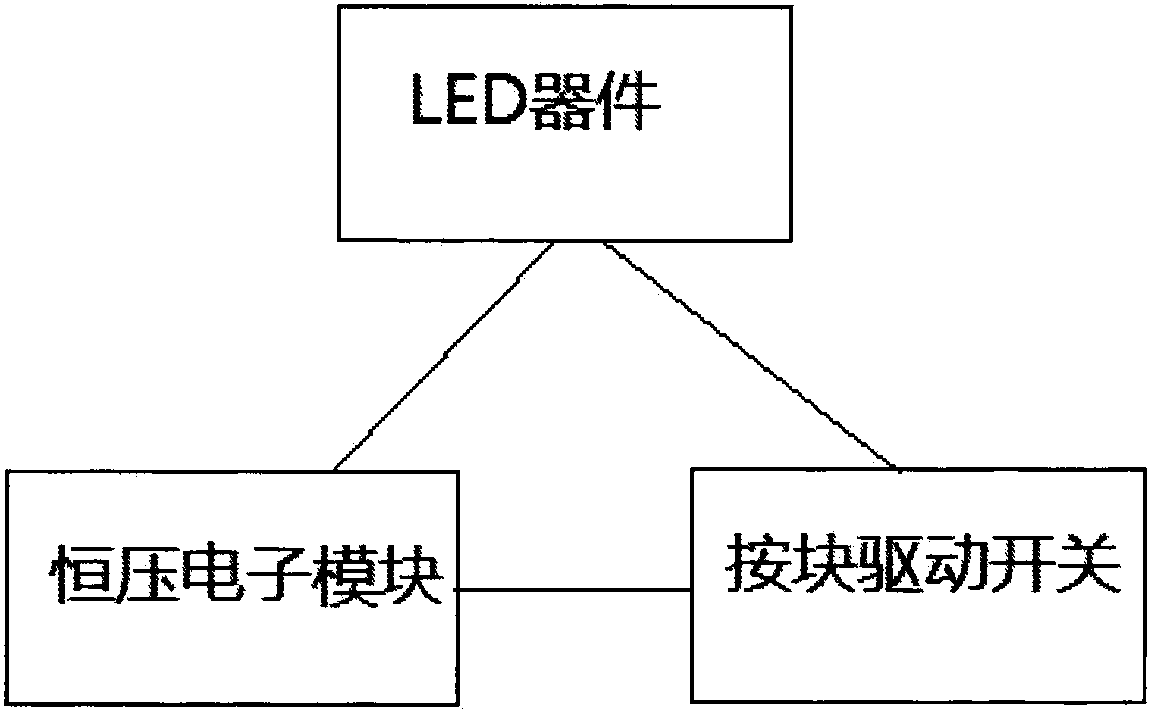

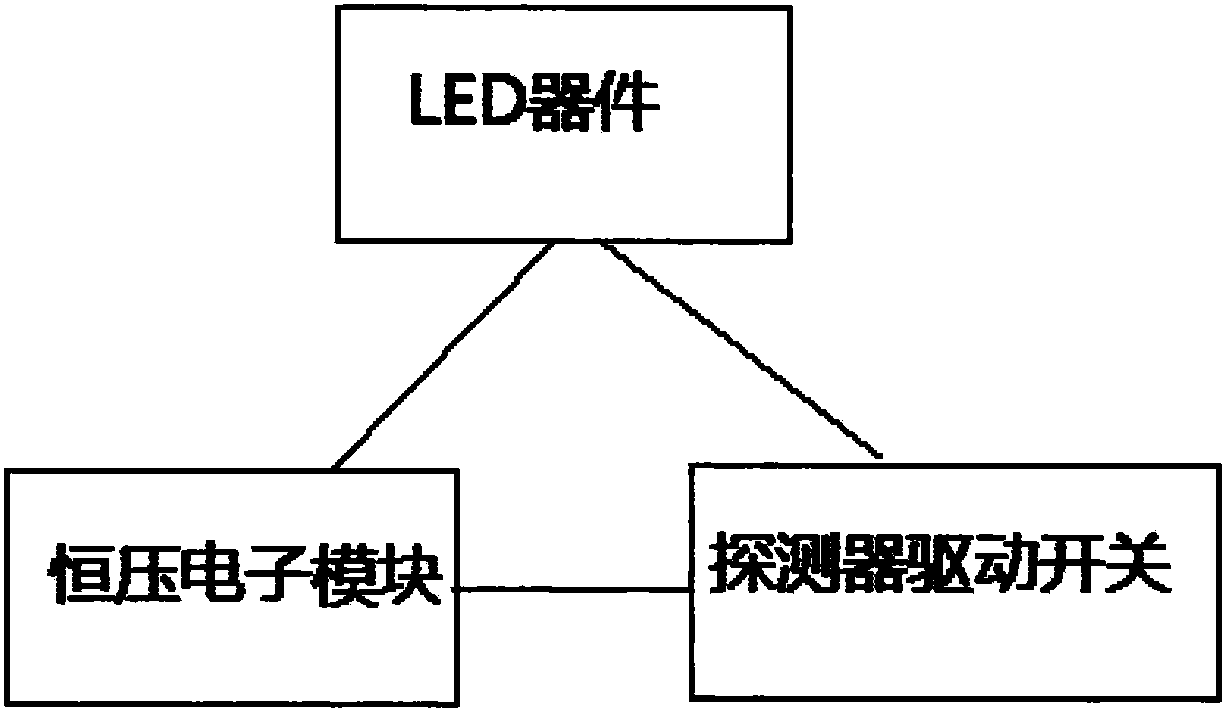

LED indicator

InactiveCN103867929AOpen the door fastImprove conveniencePoint-like light sourceElectric circuit arrangementsEngineeringAluminum substrate

The invention provides an LED indicator. The LED indicator comprises a plurality of LED devices, wherein the LED devices are arranged on a circular-arc-shaped aluminum substrate, the aluminum substrate is sleeved by a lock cylinder and embedded into a lock hole of a door, one side of the aluminum substrate provided with the LED devices is outward, a semi-transparent hollow columnar tube sleeves the lock cylinder, one end face of the columnar tube is in contact with the aluminum substrate, the other end face of the columnar tube is located on the same plane with the door outer side, and the LED devices are connected with a constant-current electronic module and a driving switch in series. When the door is required to be opened at night, the driving switch is automatically or manually, the indicator gives out light, the position of the lock cylinder is clearly indicated, accordingly lock hole finding trouble is avoided, and the door opening speed and convenience degree are greatly improved.

Owner:XIAN JUNXIE OPTOELECTRONICS TECH

Golf hole cup

InactiveCN108704283AWon't rotateAvoid the hassle of difficult ball fetchesGolfing accessoriesBall screwEngineering

The invention discloses a golf hole cup. The cup comprises a cup body, a movable plate and a flag, the inner middle portion of the cup body is provided with a partition plate, the lower portion of thepartition plate is provided with an inner fixing ring, the inner portion of the cup body is provided with a movable plate, the center of the lower portion of the movable plate is fixedly provided with a sensor, the center of the movable plate is provided with a transmission mechanism, the transmission mechanism includes an electric motor, a ball screw, a quill roller bearing and a flag fixing seat, the motor is fixedly arranged on the inner fixing ring of the cup body, the motor is connected to the movable plate through the ball screw, the top of the ball screw is provided with the flag fixing seat through the quill roller bearing, the upper portion of the flag fixing seat is provided with a flag, and the upper portion of the flag is provided with an LED lamp; when a golf ball enters a hole, the sensor is triggered, the ball is taken out by using the motor to drive the quill roller bearing to move the movable plate upward, and when light is not good, through the arranged LED lamp, convenience is provided for a player to find the hole; the cup has the advantages of convenient use and convenient hole finding.

Owner:襄城县实验学校

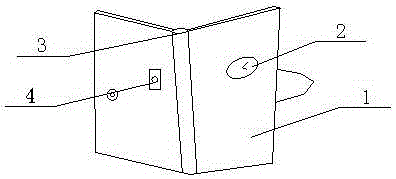

Mechanical part storage device

InactiveCN106539263ADo not affect operationDon't worry about affecting the operationPursesLuggageButton batteryLED lamp

The invention discloses a mechanical part storage device, and belongs to the field of cases. The mechanical part storage device comprises a symmetric folded body, the folding position is a cylinder, the end surface of the folding position of the body is provided with an LED lamp and a button battery power supply, a switch is arranged at one side of the external surface of the body, and the switch is serially connected with the LED lamp and the power supply; and a clock is arranged at the other side of the external surface of the body, a handle is arranged at the outer side of the body, and a zipper is connected with the edge of the body. Compared with present storage devices, the mechanical part storage device disclosed in the invention has the following advantages: the device can be used for storing a part, also can be used for illumination for object counting at night or door opening lock hole finding; and the external surface is provided with the clock, so the time can be accurately known, and influence of watch wearing of a hand on operation is prevented.

Owner:梁勇彬

Turnable power head for drilling box and drilling machine

PendingCN107989542AAvoid breaking accidentsPrecisely find holesConstructionsRotary drillingEngineeringDrilling machines

Owner:ZOUCHENG TIANHE SCI & TECH

Automatic chamfering machine

InactiveCN107971751BImprove processing efficiencyHigh precisionOther manufacturing equipments/toolsEngineeringElectric control

The invention discloses a full-automatic chamfering machine. The full-automatic chamfering machine comprises a rack, an electronic control mechanism and a chamfering mechanism. The chamfering mechanism is provided with a rose reamer, the chamfering mechanism comprises an upper chamfering mechanism body and a lower chamfering mechanism body which are installed on the upper face and the lower face of a working table used for storing a saw blade correspondingly, and the working table is installed on the rack; and a material pushing mechanism is installed on the working table, a saw blade positioning mechanism is installed below the working table, a hole finding mechanism and a saw blade pressing mechanism are arranged above the working table, and a carrying manipulator is further installed onthe rack. According to the full-automatic chamfering machine, feeding is conducted through the material pushing mechanism, the positioning mechanism conducts positioning, the hole finding mechanism is used for determining the center of a positioning hole, the saw blade pressing mechanism is used for fixing the saw blade, double-faced chamfering is completed by the upper chamfering mechanism bodyand the lower chamfering mechanism body, discharging is completed through the carrying manipulator, and the operation process of each mechanism is conducted in a full automatic mode; and the machiningefficiency is greatly improved, the cost is greatly reduced, meanwhile the chamfering effect is more attractive, the precision is higher, and the centers of a chamfered hole and the original positioning hole coincide with each other.

Owner:GUANGZHOU HENGWEI ELECTROMECHANICAL EQUIP CO LTD

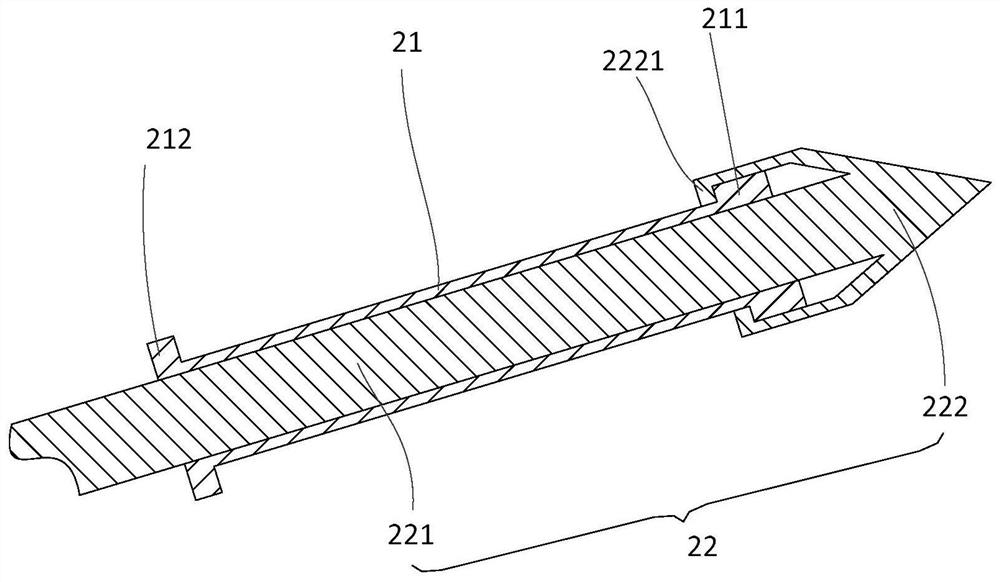

Drilling assembly and positioner for tibial plateau ankle intertrochanteric avulsion fracture

The invention discloses a drilling assembly and positioner for tibial plateau ankle intertrochanteric avulsion fracture. The drilling assembly is applied to the positioner for tibial plateau ankle intertrochanteric avulsion fracture. The positioner comprises a positioning sleeve. The drilling assembly comprises a sleeve and a drilling needle. The drilling assembly can movably penetrate through the positioning sleeve; the drilling needle comprises a long shaft section and a conical structure; the long shaft section is arranged in the sleeve; the large end of the conical structure is in buckled shaft connection with the sleeve; and the two ends, away from the conical structure and clamped to the conical structure, of the sleeve are each provided with a clamping protrusion structure capable of clamping the sleeve into the bone. The drilling assembly can conveniently and accurately carry out hole finding and threading actions, and an operation can be conveniently and smoothly carried out.

Owner:SHENZHEN HOSPITAL OF SOUTHERN MEDICAL UNIV

Hole blocking detection device for spinneret plate

InactiveCN112068215AImprove production efficiencySave manpower and material resourcesOptical detectionLaser transmitterEngineering

A hole blocking detection device for a spinneret plate comprises a detection mechanism, an auxiliary device and a power mechanism. The detection mechanism is placed in a second cavity of a spinneret plate, a detection device box is arranged at the left end of the detection mechanism, and a light receiving cavity with a leftward opening is formed in the left end of the detection device box. A detection device cavity which is communicated with the light receiving cavity and is provided with leftward opening is formed at the right end of the light receiving cavity, and a detection device is fixedly installed in the detection device cavity. According to the invention, a laser transmitter and a laser sensor are adopted, a blocked hole can be easily found through modeling of a spinneret plate hole, a full-automatic design is adopted, a large amount of manpower and material resources consumed for hole finding of the spinneret plate are reduced, the efficiency is greatly improved, the manufacturing efficiency of the spinneret plate is greatly improved, and the manufacturing cost is reduced.

Owner:ZIBO YIFAN KNITTING CO LTD

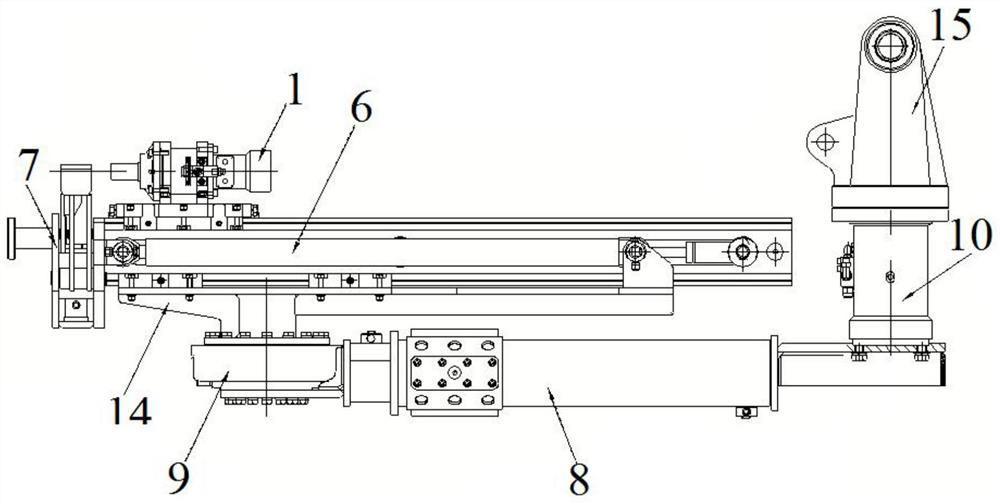

Hole-finding angle adjusting mechanism for jumbolter

PendingCN112211655ASolve the problem of finding the hole positionEasy to find holesDerricks/mastsAnchoring boltsHydraulic motorReduction drive

The invention discloses a hole-finding angle adjusting mechanism for a jumbolter. The hole-finding angle adjusting mechanism comprises a sliding frame assembly, a power assembly, a drill boom and twoswing mechanisms, wherein the power assembly comprises a hydraulic motor, a speed reducer, a propelling oil cylinder, a drill rod and a drill bit, the propelling oil cylinder is arranged on the rear portion of the sliding frame assembly, the hydraulic motor is connected with the speed reducer and connected to the propelling oil cylinder through a supporting base, the supporting base is slidably arranged on the rear portion of the sliding frame assembly, the speed reducer is sequentially connected with the drill rod and the drill bit, the drill rod penetrates through a front base of the slidingframe assembly, the front end of the drill arm is connected with the rear portion of the sliding frame assembly through one swing mechanism, the rear end of the drill arm is connected with a connecting base through one swing mechanism, and the connecting base is used for connecting with a main chine. According to the hole-finding angle adjusting mechanism for the jumbolter, the problem that whenan existing jumbolter drills a hole, hole position finding is difficult is solved, the power assembly of the jumbolter can be operated to drill an anchor rod hole or an anchor cable hole after preliminary rough and accurate hole finding, hole finding operation is easy, time is short, and precision and efficiency are high.

Owner:JIANGXI LANXIANG HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com