Hole exploring method for flow drilling tightening equipment

A kind of equipment, flow drilling technology, applied in the direction of metal processing equipment, measuring/indicating equipment, metal processing machinery parts, etc., can solve the problems that riveting equipment cannot be automatically adapted, increase production time and cost, and accuracy cannot be guaranteed, etc., to achieve Eliminate hole depth measurement errors, reduce labor costs, and minimize ambient light interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

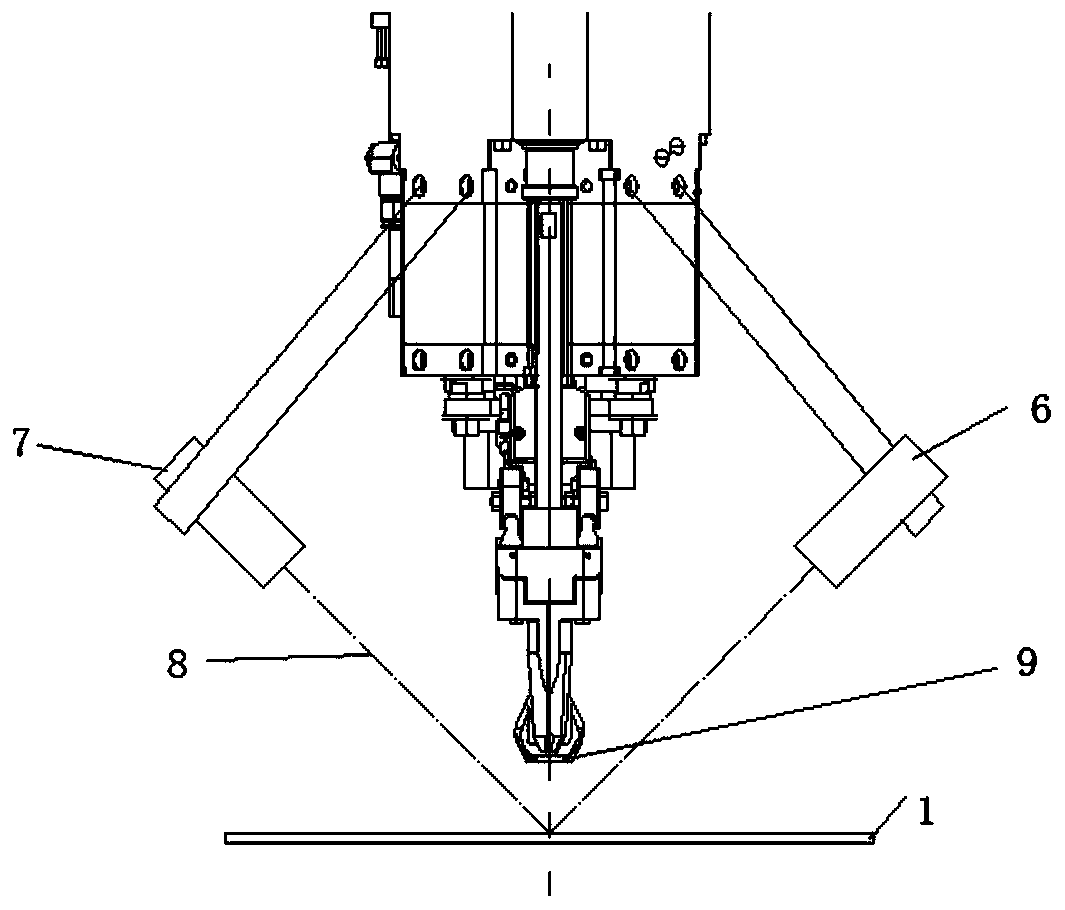

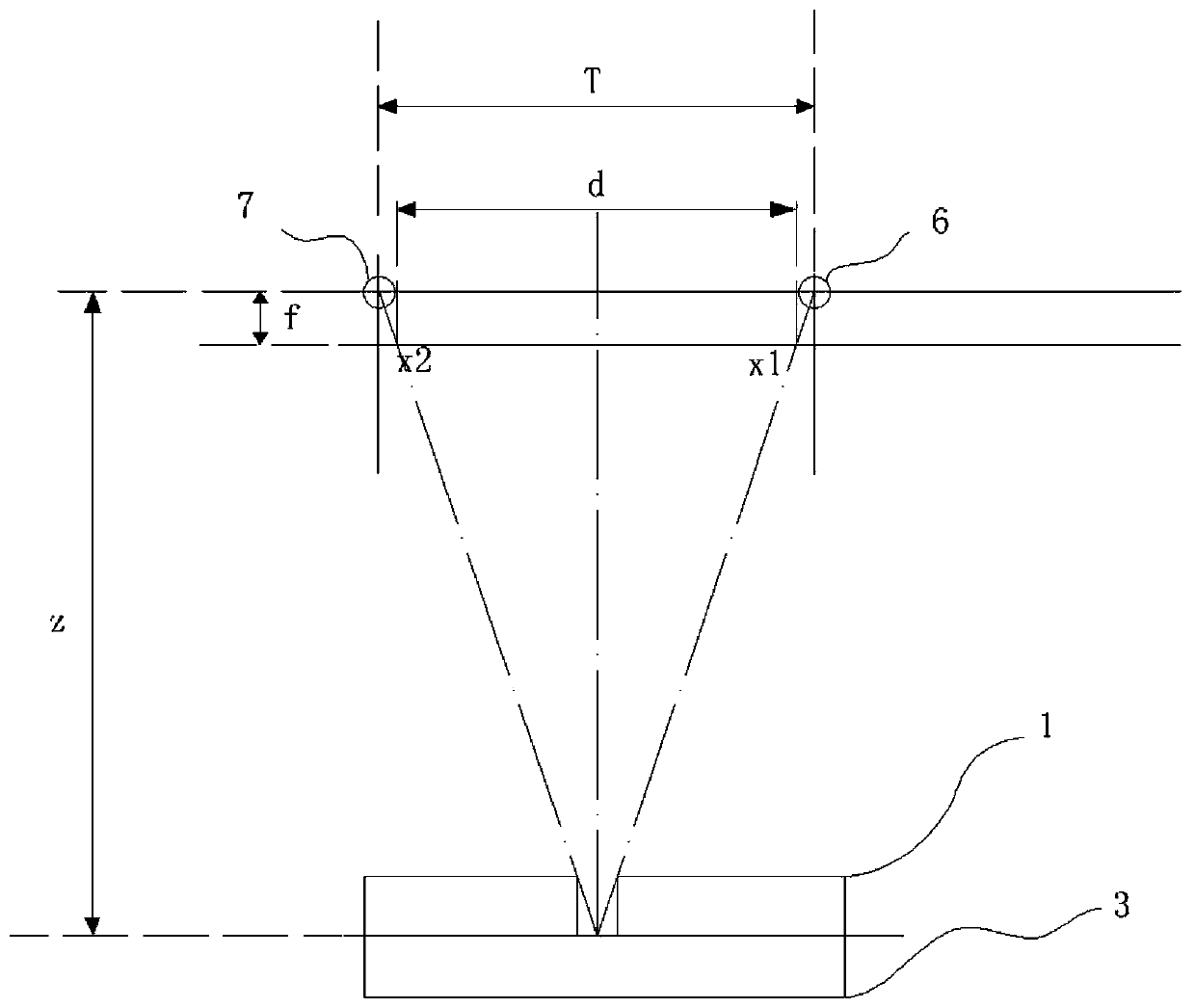

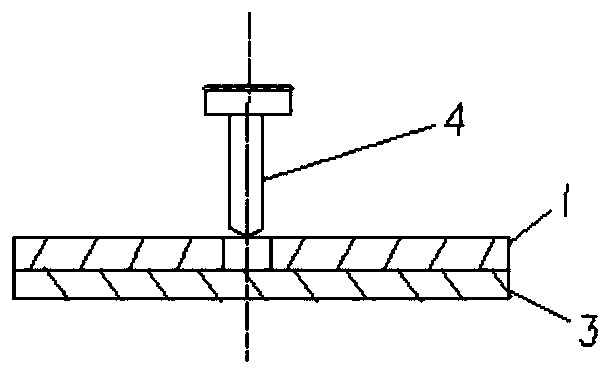

[0035] see figure 1 , figure 2 and image 3 , the present embodiment is a flow drilling and tightening equipment probing method, and its probing refers to the pre-opening in the upper layer plate 1 with pre-opening holes in the riveting parts when using the flow drilling and tightening equipment to rive the parts to be riveted. The position and depth of the hole are detected.

[0036] In the present embodiment, the drilling method of the flow drilling and tightening equipment is carried out as follows:

[0037] Step 1. Fixedly install the main camera 6 on the gun head side of the flow drill tightening equipment gun 2, and use the main camera 6 to take pictures to obtain photographed images of the relative positions of the flow drill tightening equipment gun 2 and the pre-opened holes in the upper plate 1 ; The captured image contains at least position information of reference points at three different positions, and the reference points are fixed points with known spatial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com