Automatic decoration strip and buckle mounting device and method

An automatic installation and buckle technology, applied in transportation and packaging, metal processing, metal processing equipment, etc., can solve the problems of low degree of automation, low assembly efficiency, and poor assembly quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

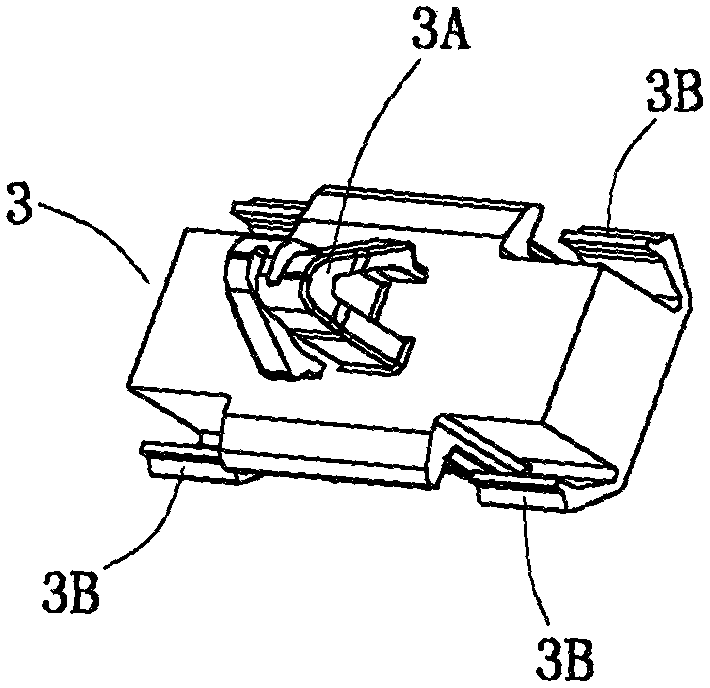

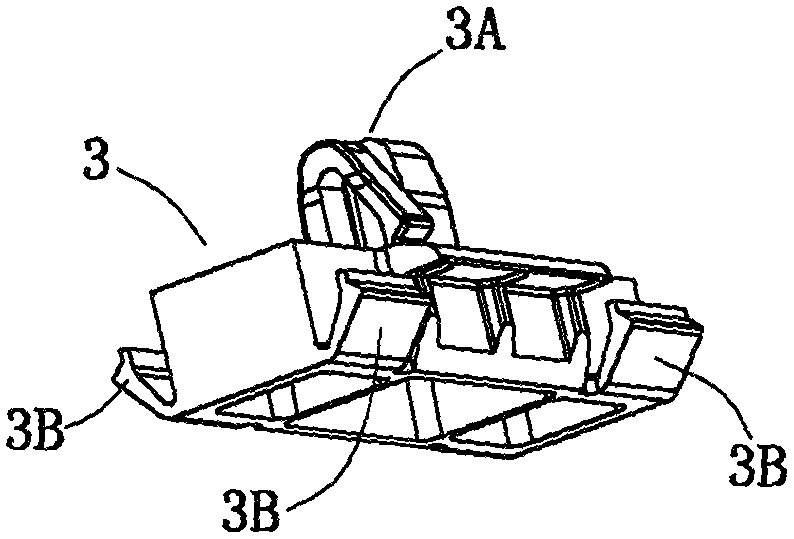

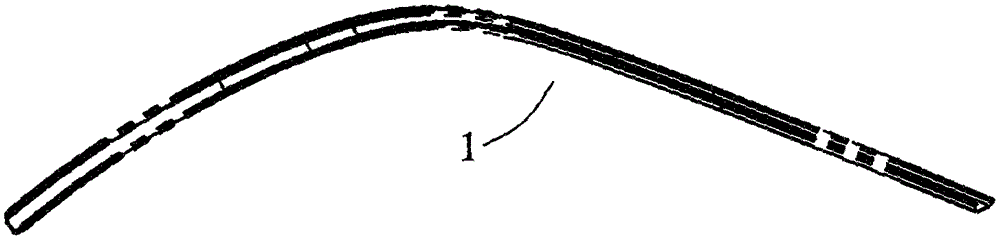

[0033] In this embodiment, the automatic mounting device for trim buckles, such as Figure 5 As shown, it includes a workpiece shelving platform 2 for shelving the decorative strip workpiece 1, a robot 4 for grasping and installing the buckle 3 to the decorative strip workpiece 1, and a buckle vibrating plate 5 for automatically providing the buckle 3, and the workpiece is put on hold. The table 2 includes a platen 6, on which a workpiece resting block 7 is arranged, and a workpiece resting groove 7A whose shape matches the decorative strip workpiece 1 is arranged on the workpiece resting block 7, such as Figure 11 As shown; a plurality of workpiece pressing mechanisms 8 are set at intervals along the stretching direction of the workpiece shelving block 7, and workpiece positioning mechanisms in the direction of stretching are set at both ends of the workpiece shelving block 7; A plurality of buckle holders 10 are evenly arranged in the circumferential direction. The number ...

Embodiment 2

[0040] In this embodiment, the automatic mounting device for trim buckles, such as Figure 10 As shown, it includes two sets of automatic installation devices for decorative strip buckles as described in Embodiment 1, wherein the two sets of workpiece shelving tables 2 are symmetrically arranged front and rear, and are used to place the decorative strip workpieces 1 on the left and right windows of the same car respectively. Two sets of robots 4 with a turntable 9 at the end of the movable arm are symmetrically arranged between the two sets of workpiece resting tables 2, and two sets of buckle vibrating plates 5 with vibrating feeding hoppers 18 are arranged symmetrically between the two sets of workpiece resting tables 2 between the left and right ends.

[0041] When every decorative strip workpiece 1 automatically installs the buckle (3), the following actions are included: the decorative strip workpiece 1 is placed on the workpiece shelving groove 7A of the workpiece shelvi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com