Embedded handle of doors

An embedded and installation technology, applied in wing handle, door/window accessories, wing components, etc., can solve the problems of high cost, troublesome, troublesome installation, etc., and achieve the effect of simple structure and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Embodiments of the present invention will be described below with reference to the drawings.

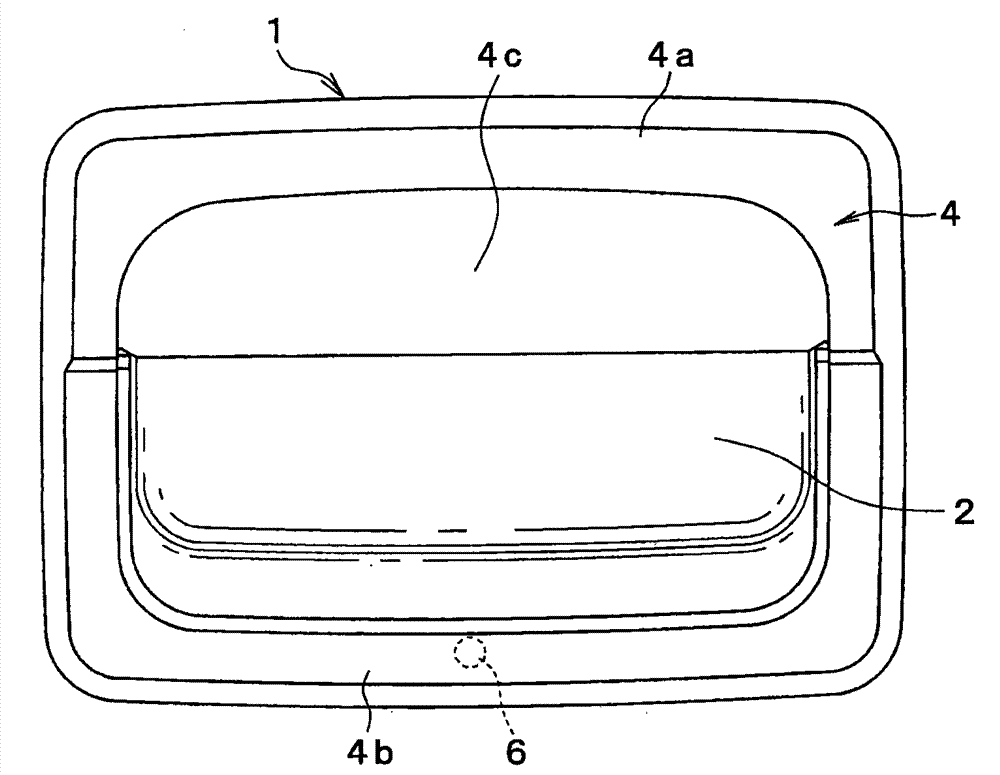

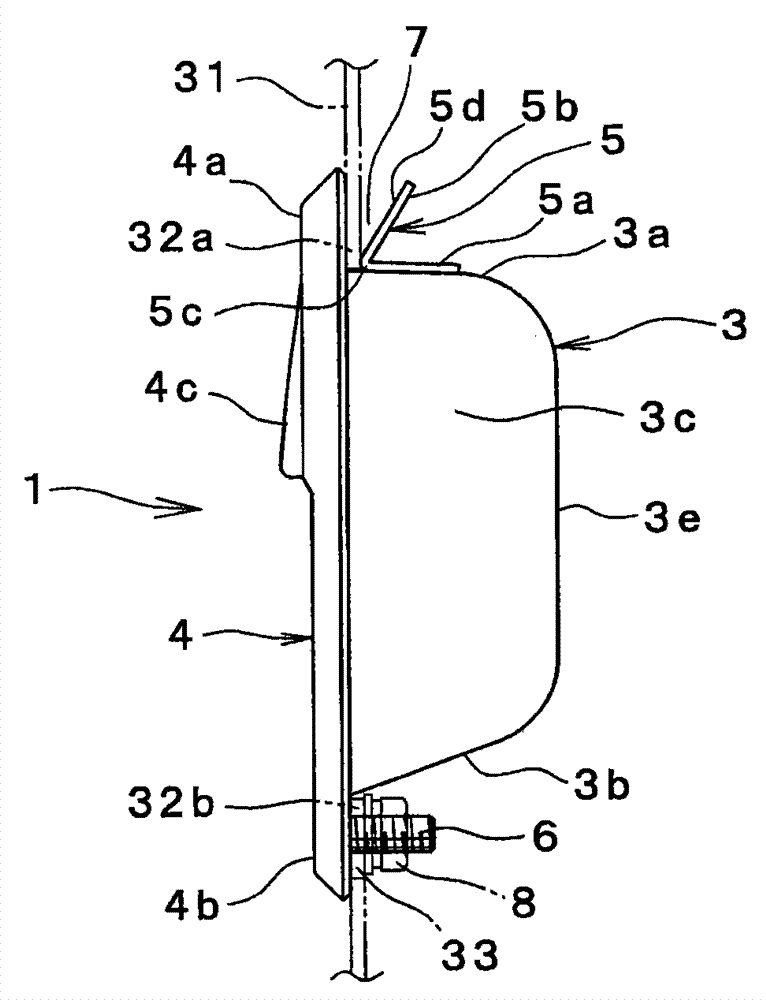

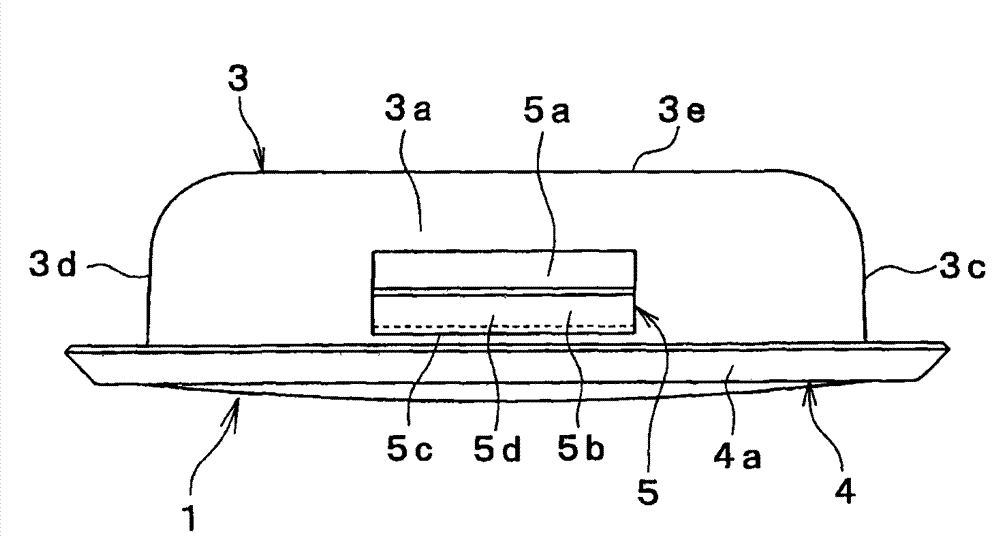

[0049] The built-in handle 1 includes a protruding portion 3 protruding toward the back side in a form in which a hand insertion recess 2 is formed on the front side, and a flange portion 4 extending around the recess 2 . Such as Image 6 As shown, an opening 32 for installation is formed in the front panel 31 of the door. Embedded handle 1 through as Figure 8 Insert the raised part 3 from the front side of the door into the opening 32 for installation as shown Figure 7 As shown, the flange portion 4 is fixed to the front panel 31 by being in close contact with the front surface of the front panel 31 .

[0050] Such as Image 6 As shown, the installation opening 32 formed on the front panel 31 of the door is a roughly rectangular shape similar to and slightly larger than the shape of the base section of the raised portion 3 of the embedded handle 1, including: first side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com