Multi-cycle cooling phase change material cold storage system

A technology of phase change materials and cooling methods, which is applied in heating/cooling equipment, cooling fluid circulation devices, heat storage equipment, etc., and can solve the problems of reduced quality of damaged goods, heat energy loss, and performance degradation of phase change materials for vehicle-mounted cold storage plates. , to reduce heat loss and prevent frosting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0029] Below, the embodiment of the present invention is described in detail as follows by accompanying drawing:

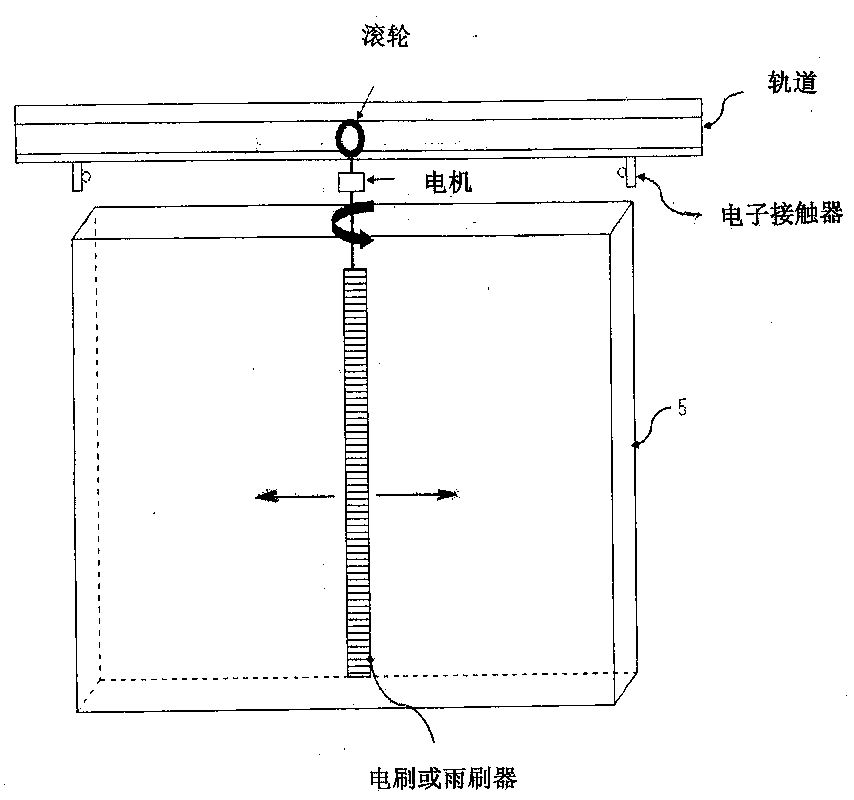

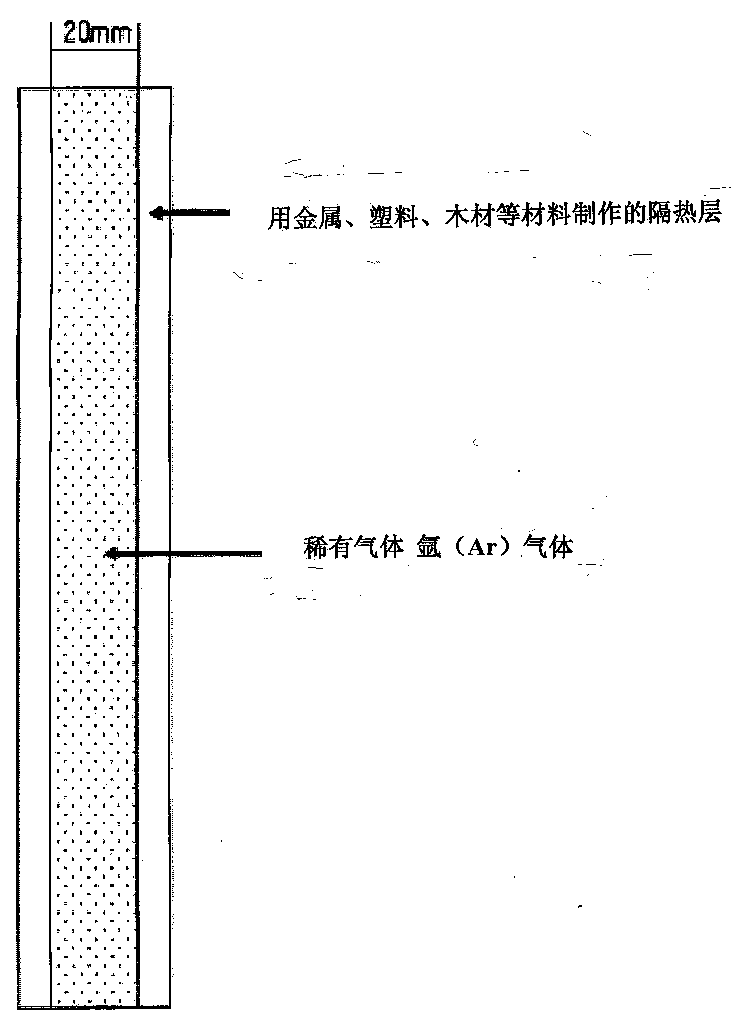

[0030] See Figure 1-6 , the present invention does not use fuel oil or daytime electricity, but uses low-cost AC220V power on the ground at night to start the AC refrigerator 1 installed in the front of the refrigerator, refrigerated van truck, low-temperature warehouse, and low-temperature showcase. Connect the cold storage tank 6 that stores the low-temperature latent heat P.C.M phase change material (Phase Change Material) 11, and install the gas heat exchanger 3 and the double-pipe refrigerant distributor 4 in the cold storage tank 6, and pass through the expansion valve 2 in the AC refrigerator 1 The discharged refrigerant gas (Gas) circulates in a direct expansion type, and the low-temperature latent heat P.C.M phase change material in the cold storage tank 6 changes from a liquid phase to a solid state under a certain temperature condition, is frozen and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com