Patents

Literature

821results about How to "Avoid frost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

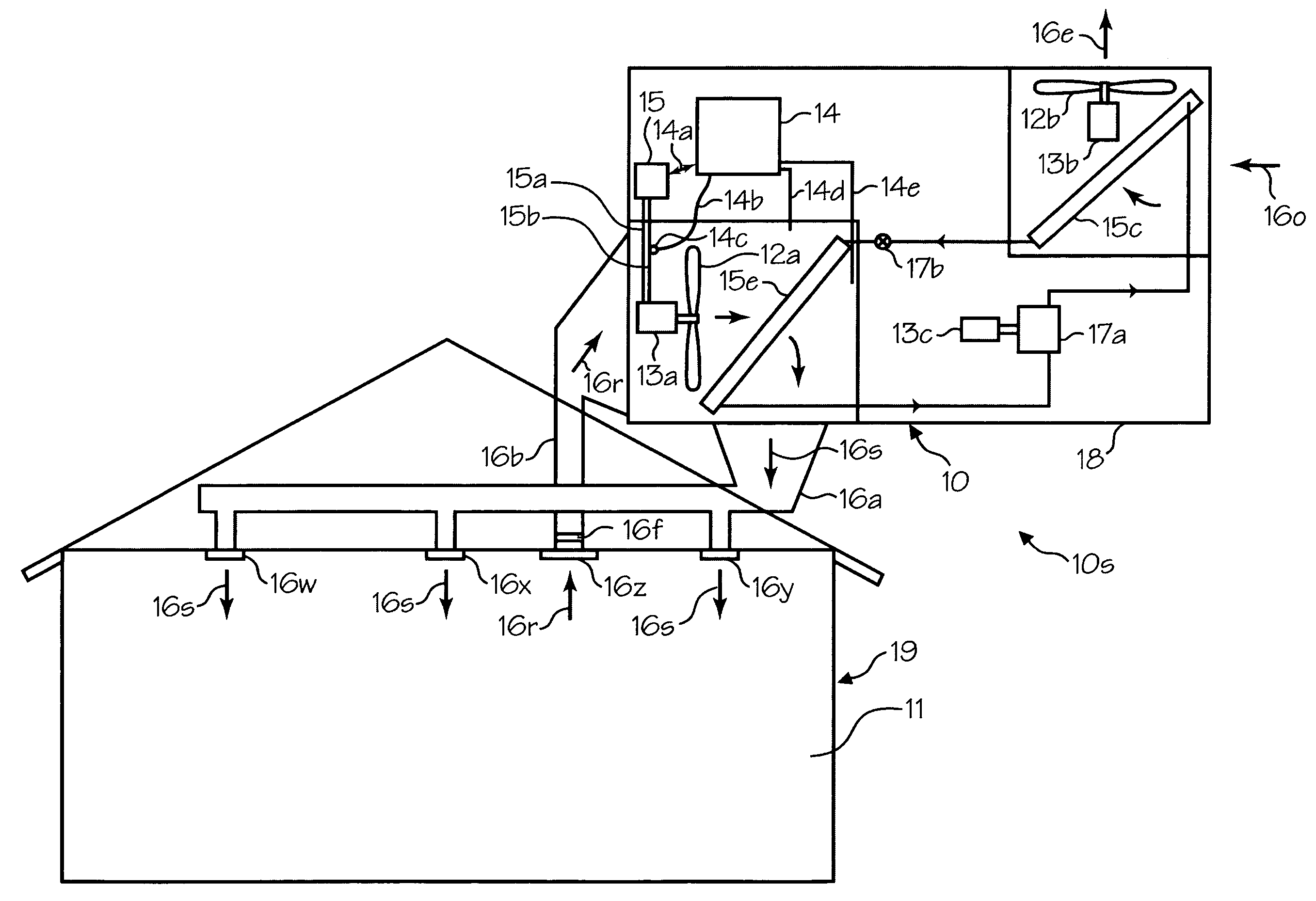

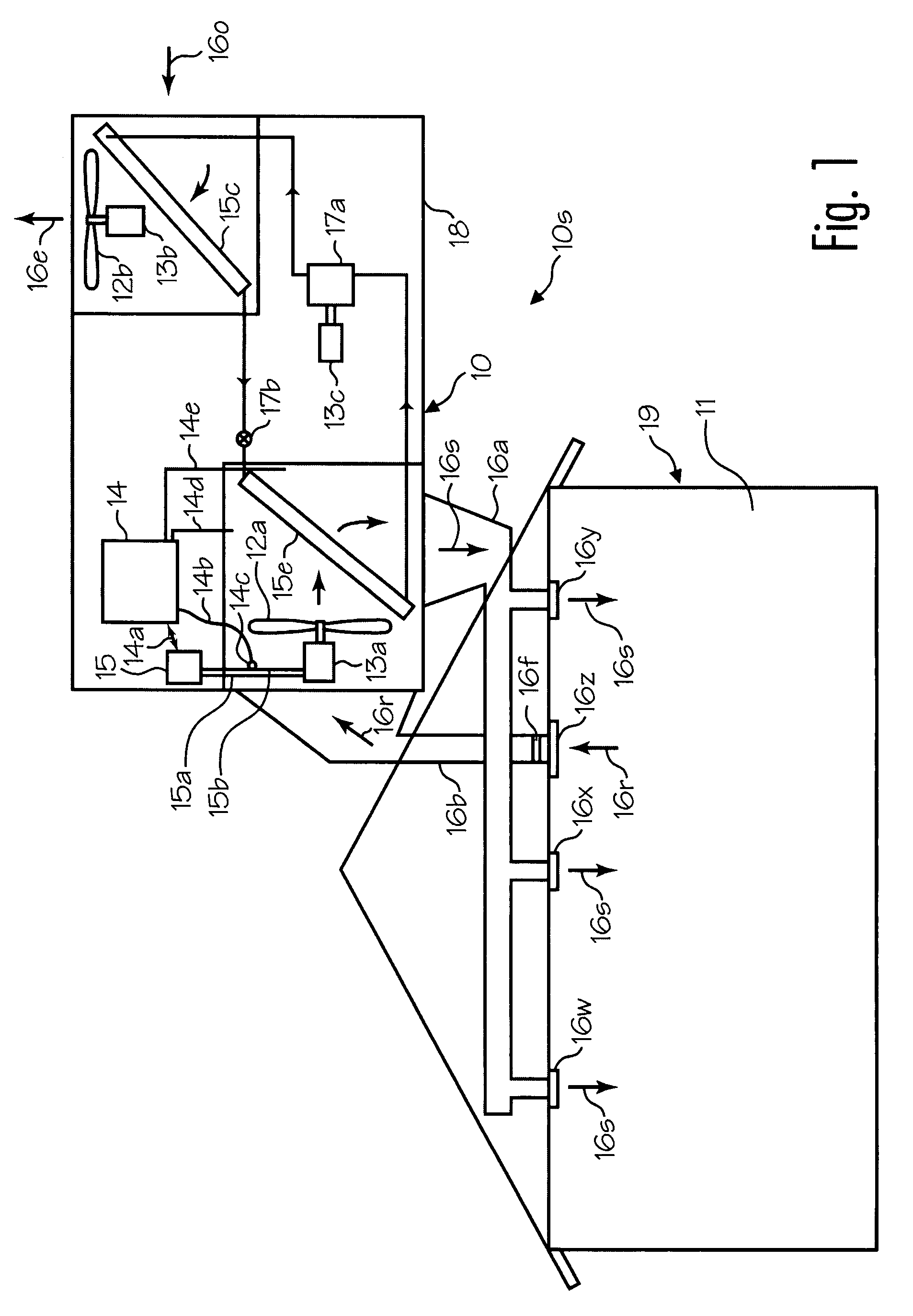

Ventilation airflow rate control

ActiveUS20080188173A1Reduce energy consumptionAvoid insufficientSpace heating and ventilation safety systemsLighting and heating apparatusMotor speedCurrent velocity

Airflow rates within a ventilation system are controlled using motor speed or torque and motor electric current or pressure. Fan speed or torque may be varied to compensate for differing restriction in ductwork, and may provide a constant airflow rate over a range of varying airflow restriction. Air handlers or air conditioning units may be mass produced in common configurations, and installed in different buildings or structures with different ductwork configurations. Methods operate a fan motor at a present speed or torque, sample speed or torque, sample current of the fan motor or pressure within the ventilation system, calculate a present airflow rate within the ventilation system, calculate a new input setting using the present airflow rate and a target airflow rate, change the speed or torque to the new input setting, and repeat these steps to converge on the target airflow rate, often avoiding overshoot.

Owner:NORTEK GLOBAL HVAC

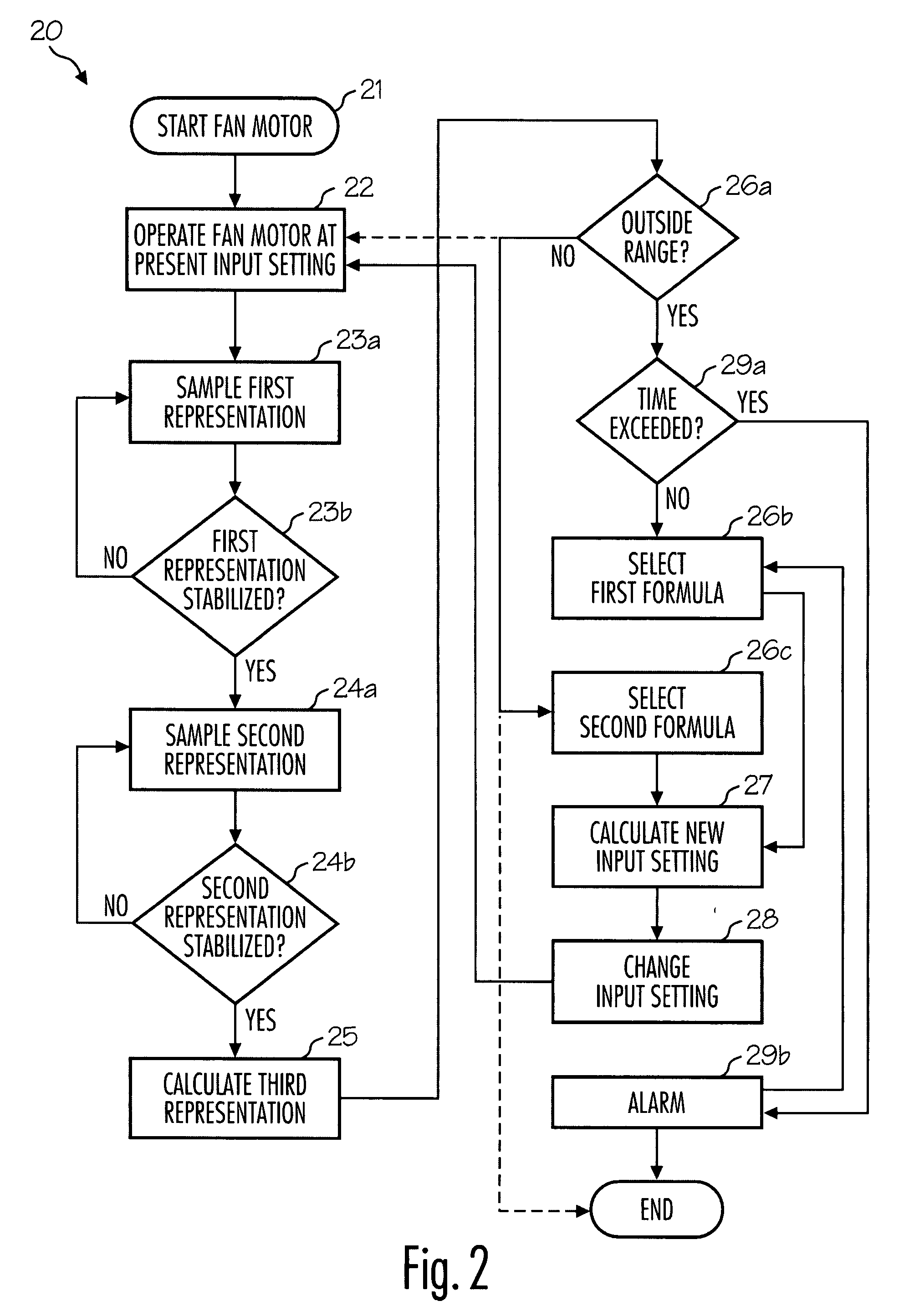

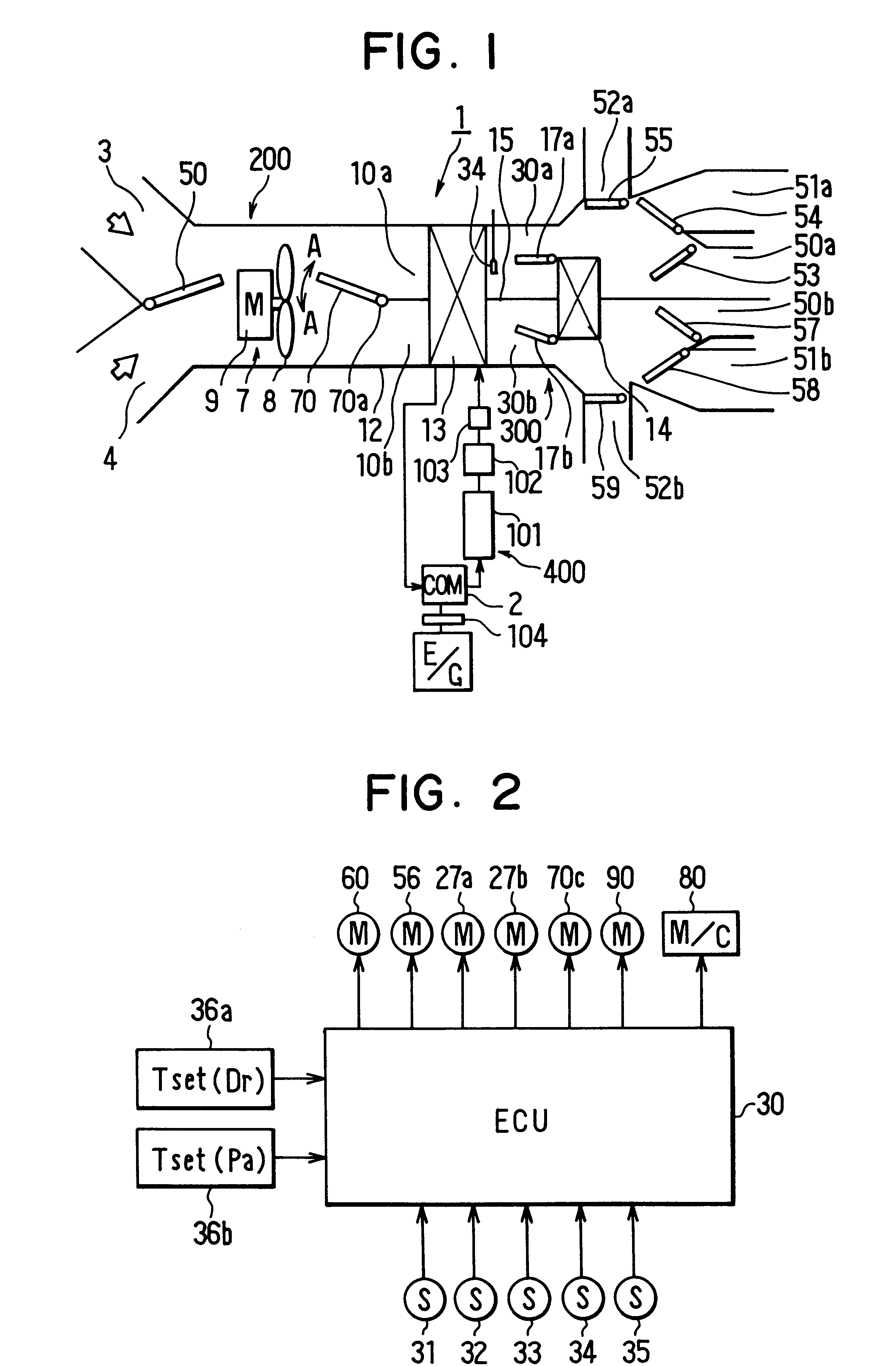

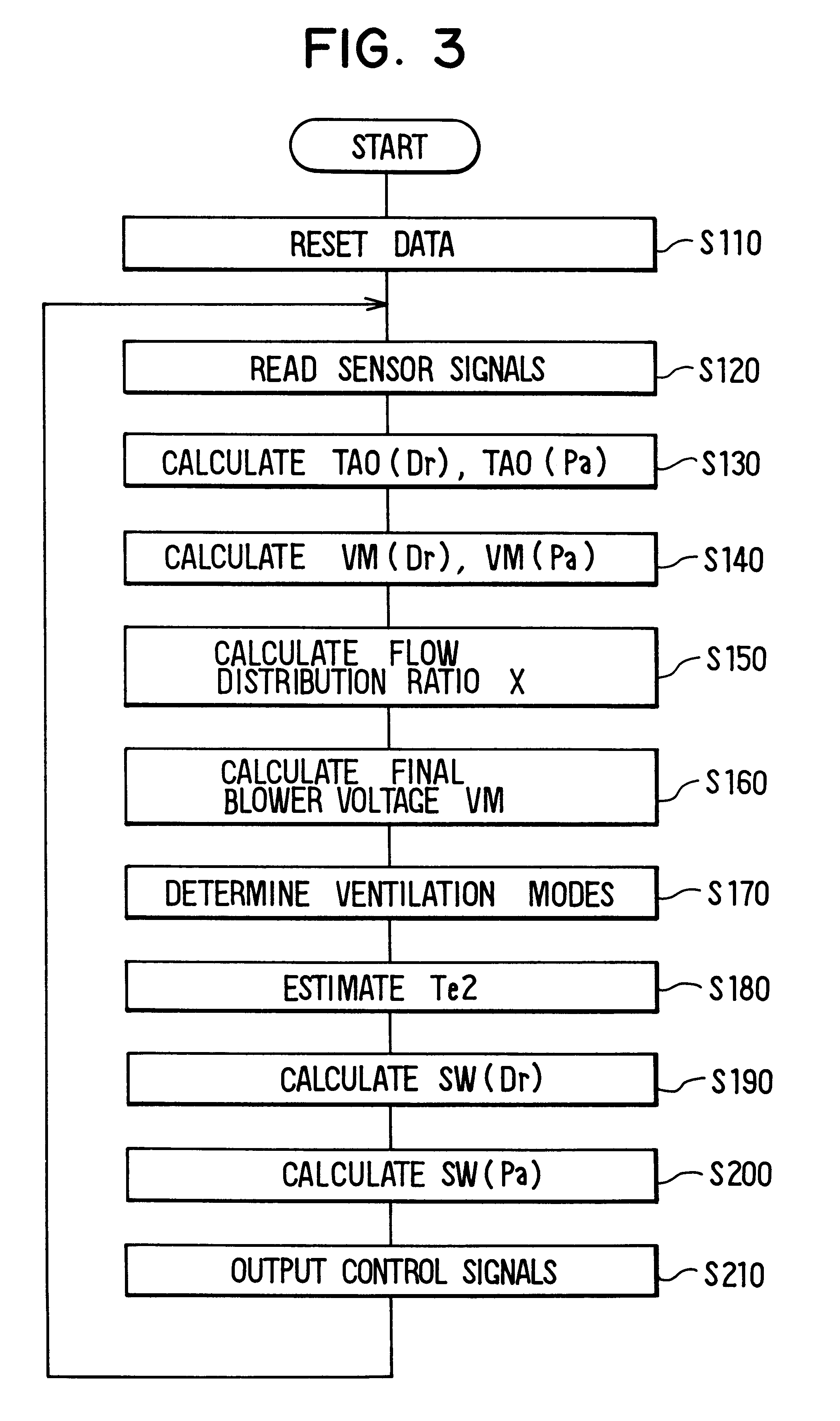

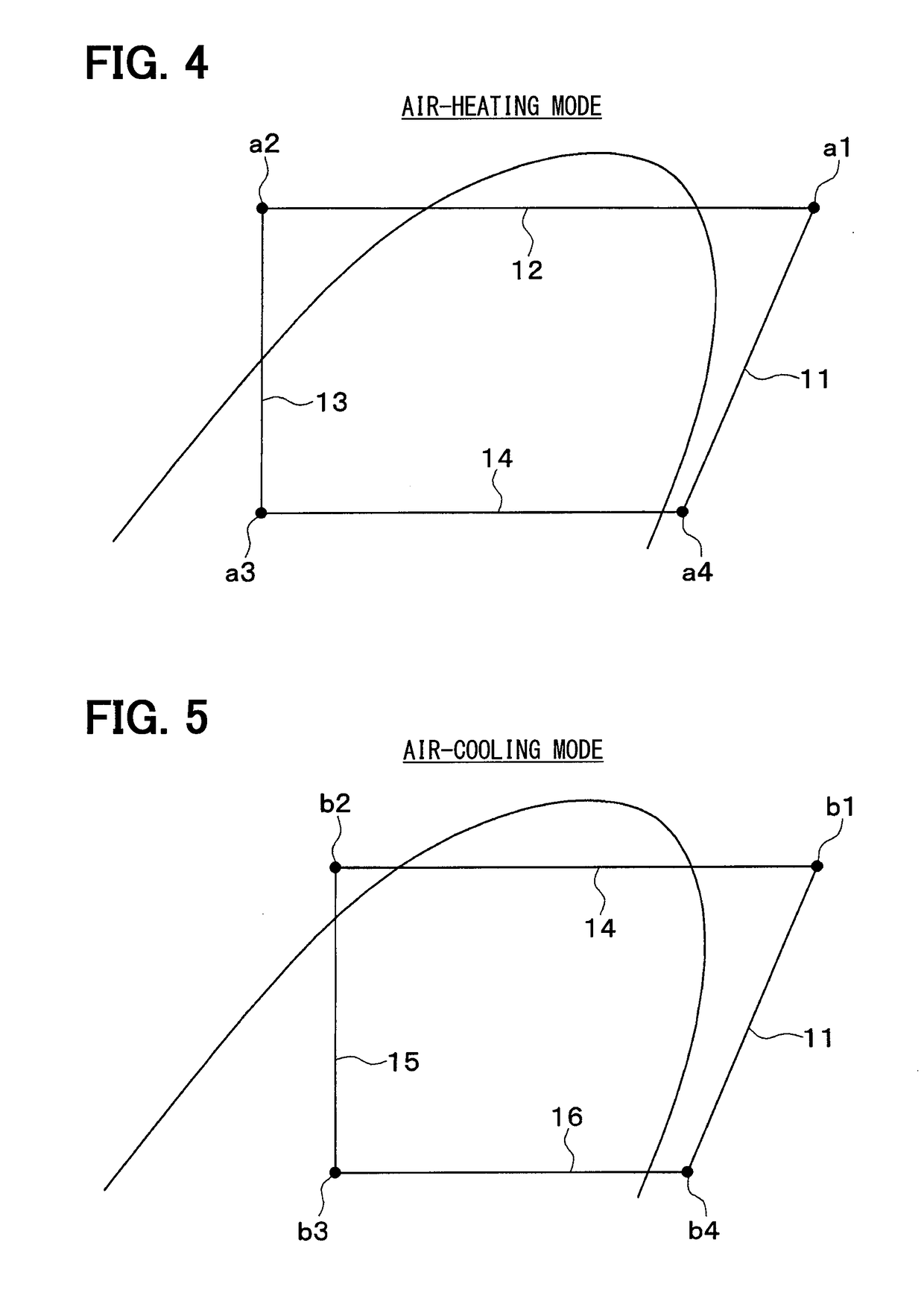

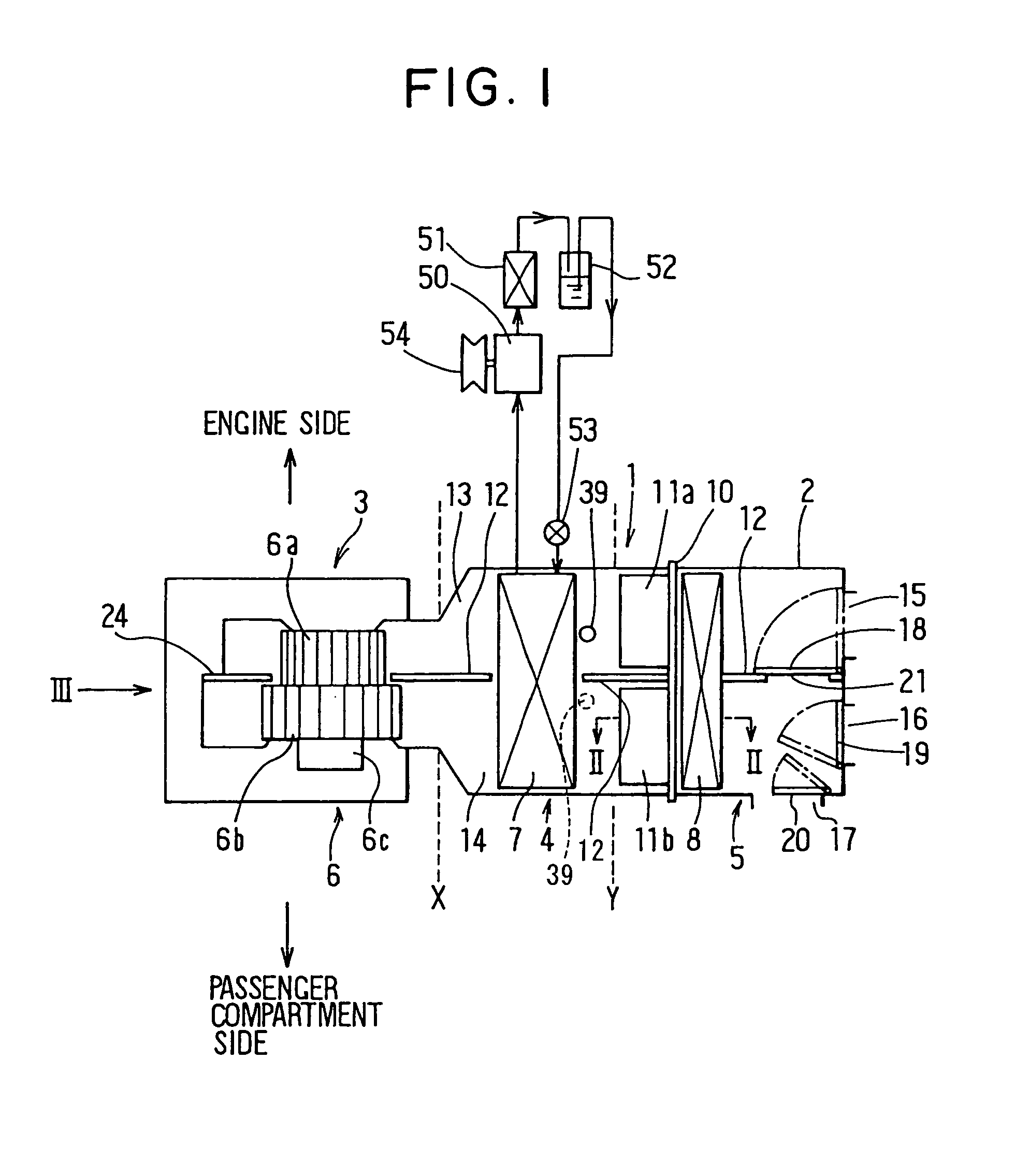

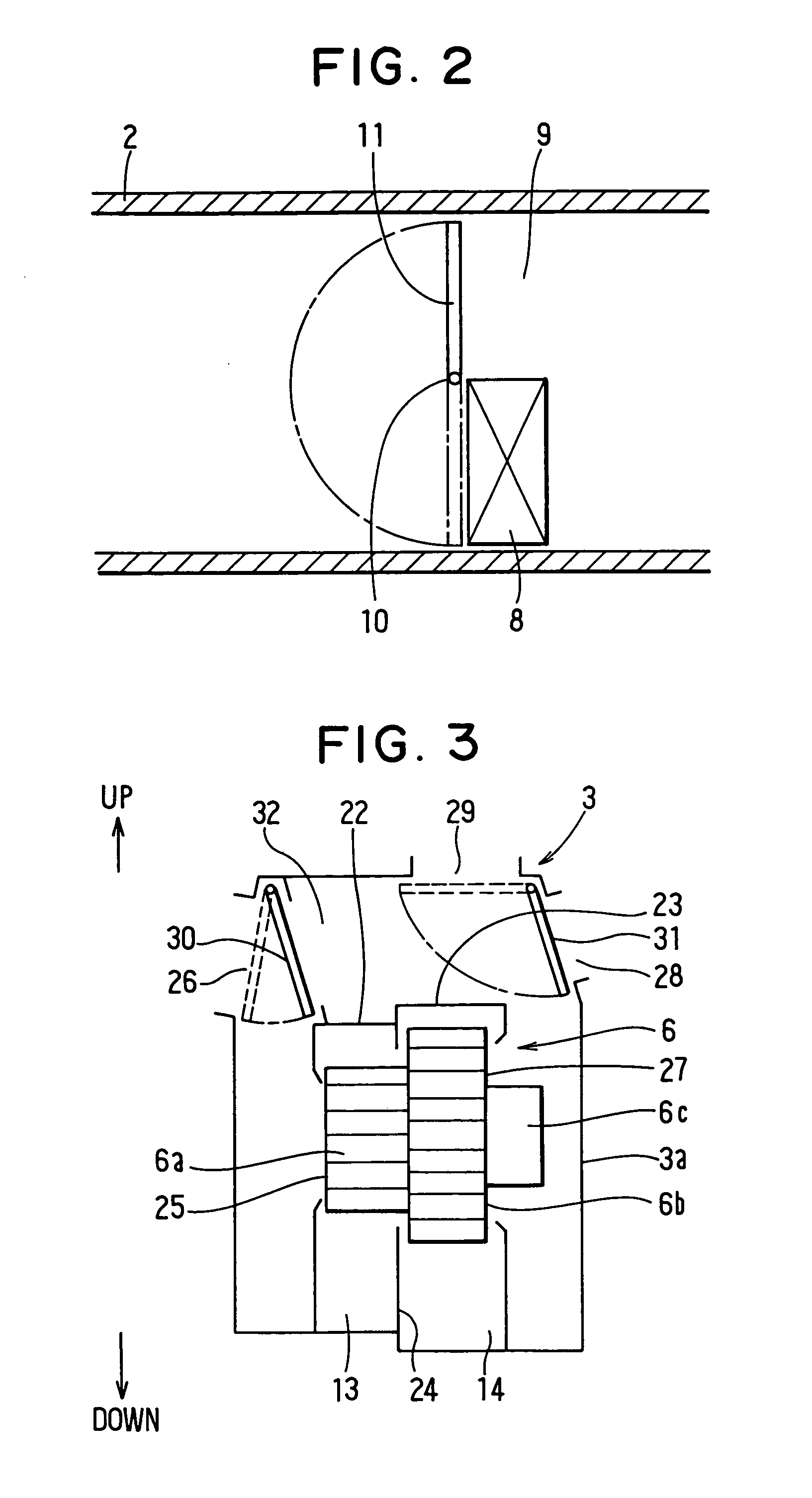

Vehicle-air-conditioning system with cooling degree estimator for left/right temperature control

InactiveUS6192698B1Avoid frostPreventing a windshield from being foggedAir-treating devicesSpace heating and ventilation safety systemsTemperature controlEngineering

In an air-conditioning system having two air-conditioning passages serving two different air-conditioning zones but having a cooling degree detector provided in only one of the passages to reduce cost, with the degree to which air is cooled in the other passage being estimated based on a cooling degree detected by the detector and the difference between flows of air passing through the passages or an intake temperature of air entering the passages. On the other hand, when an evaporator is possible to be frosted in one of the passages, air flow amount in the one of the passages is corrected to be increased. Therefore, it can prevent a windshield from being fogged while preventing the evaporator from being frosted.

Owner:DENSO CORP

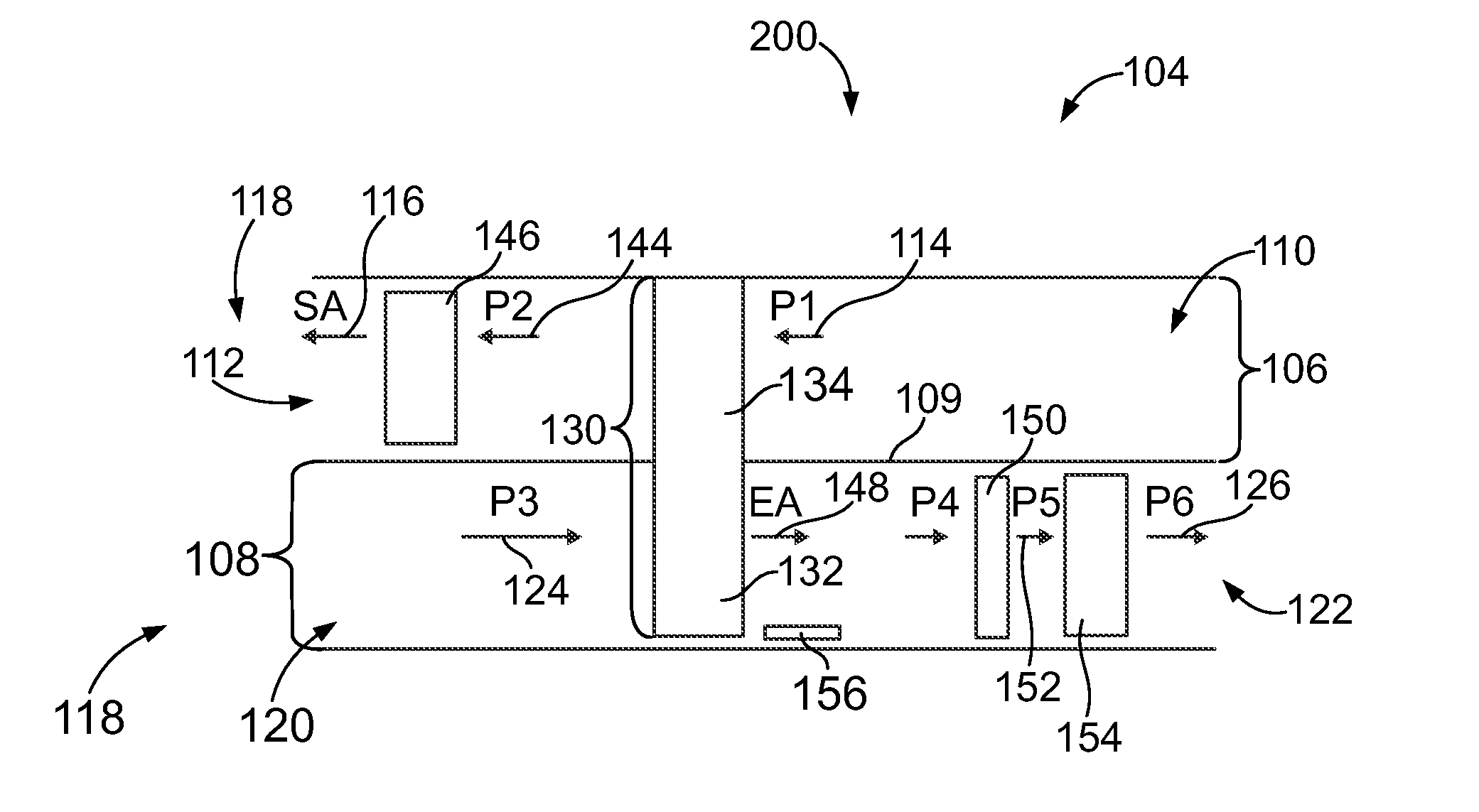

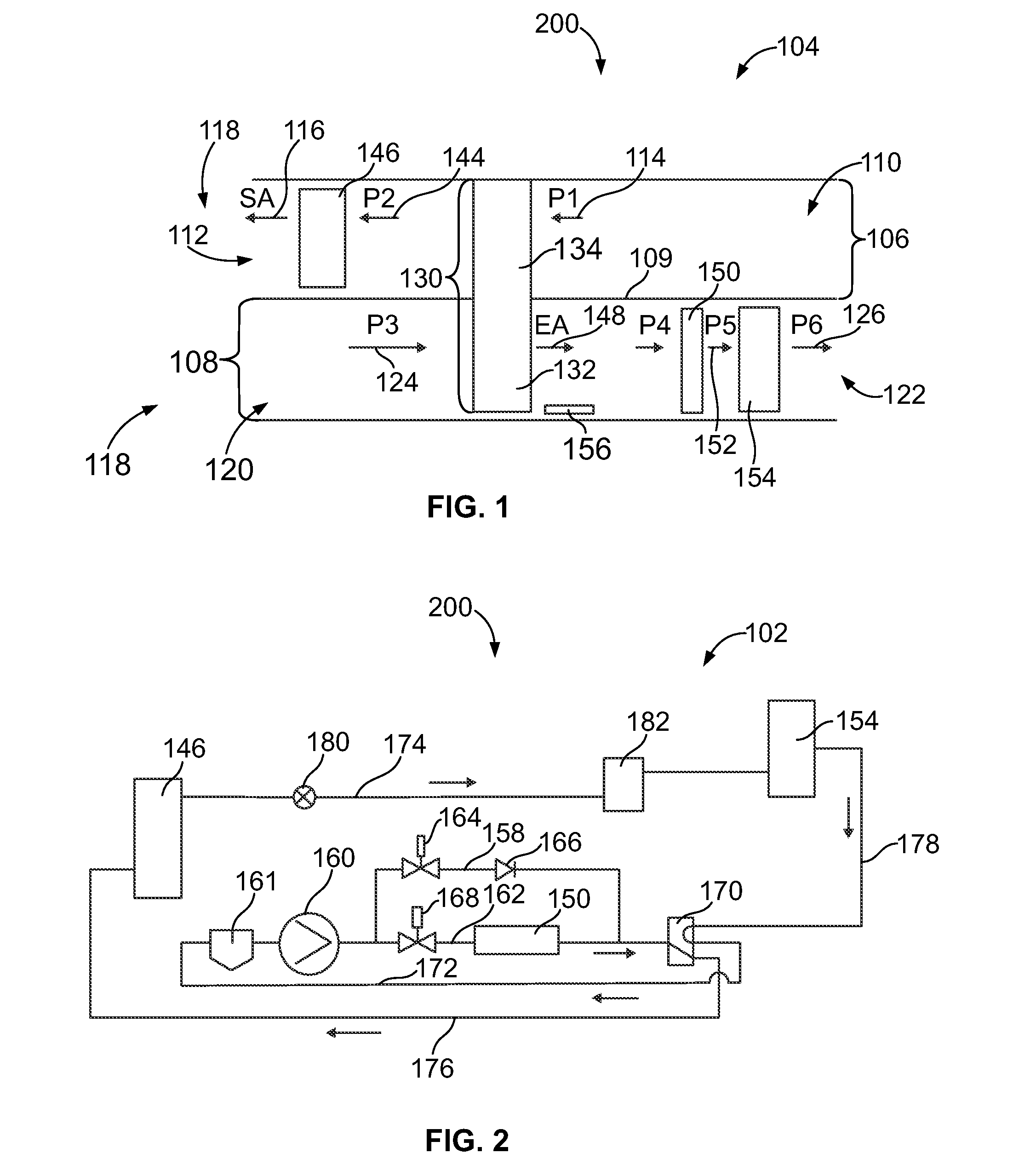

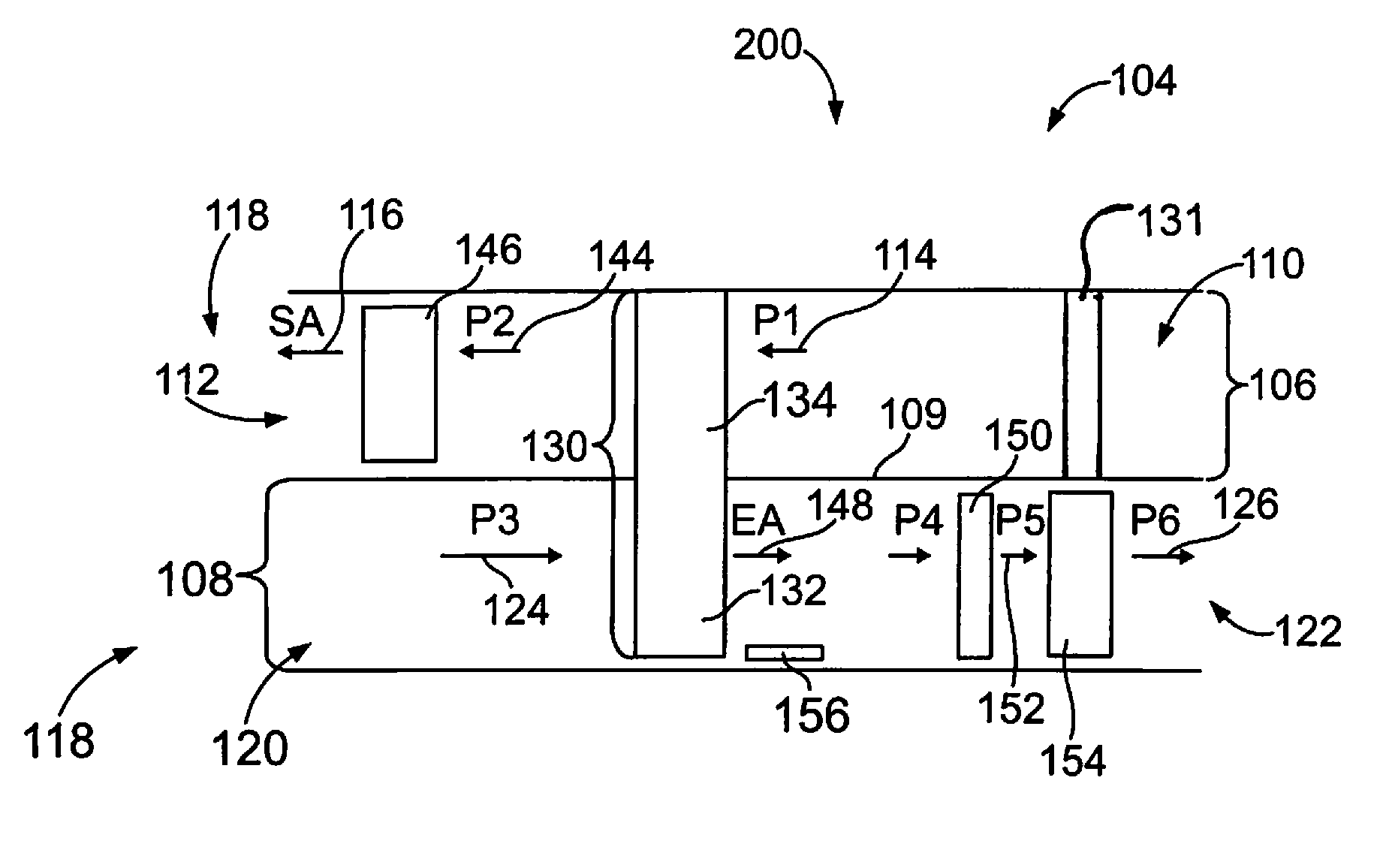

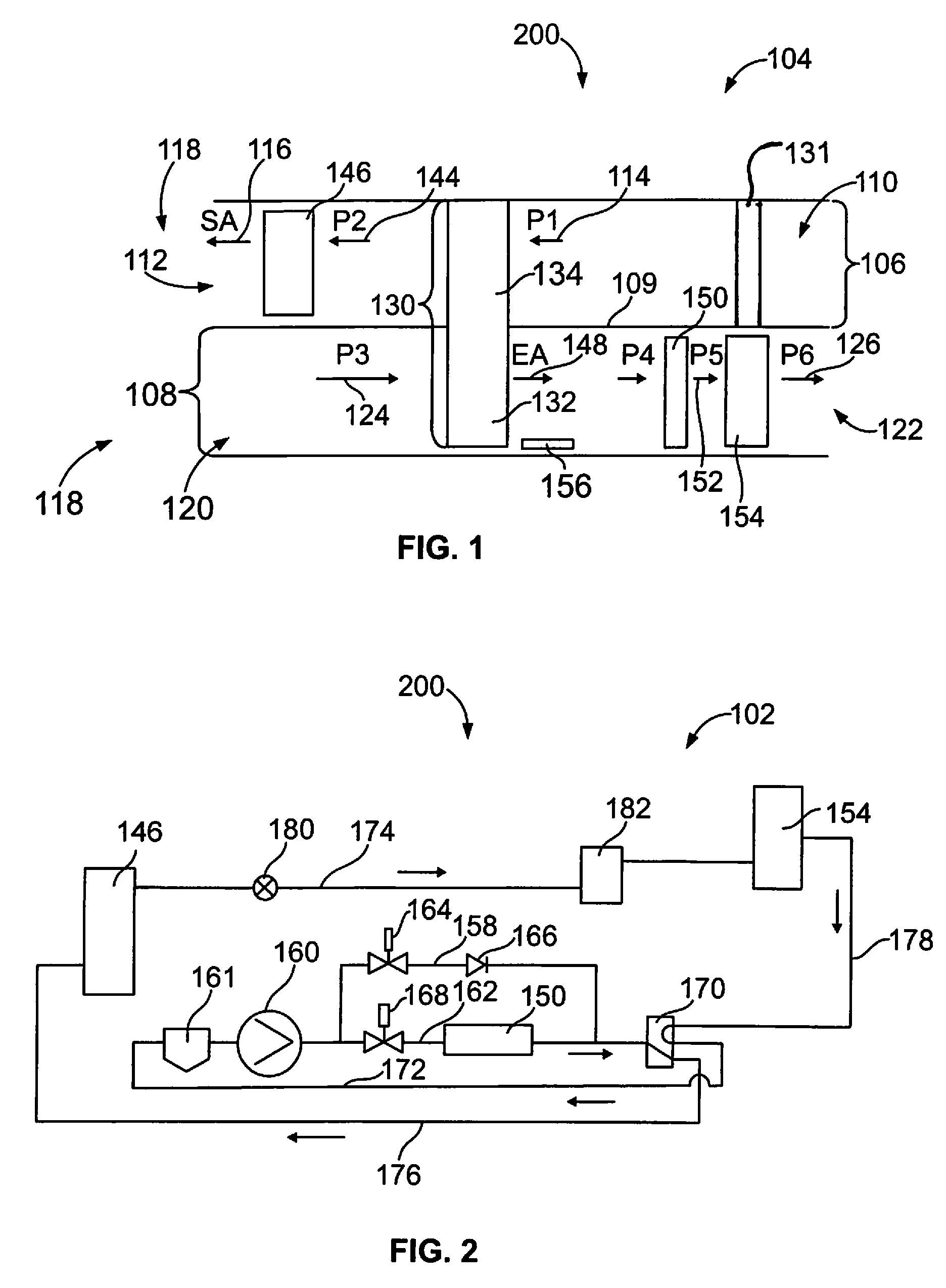

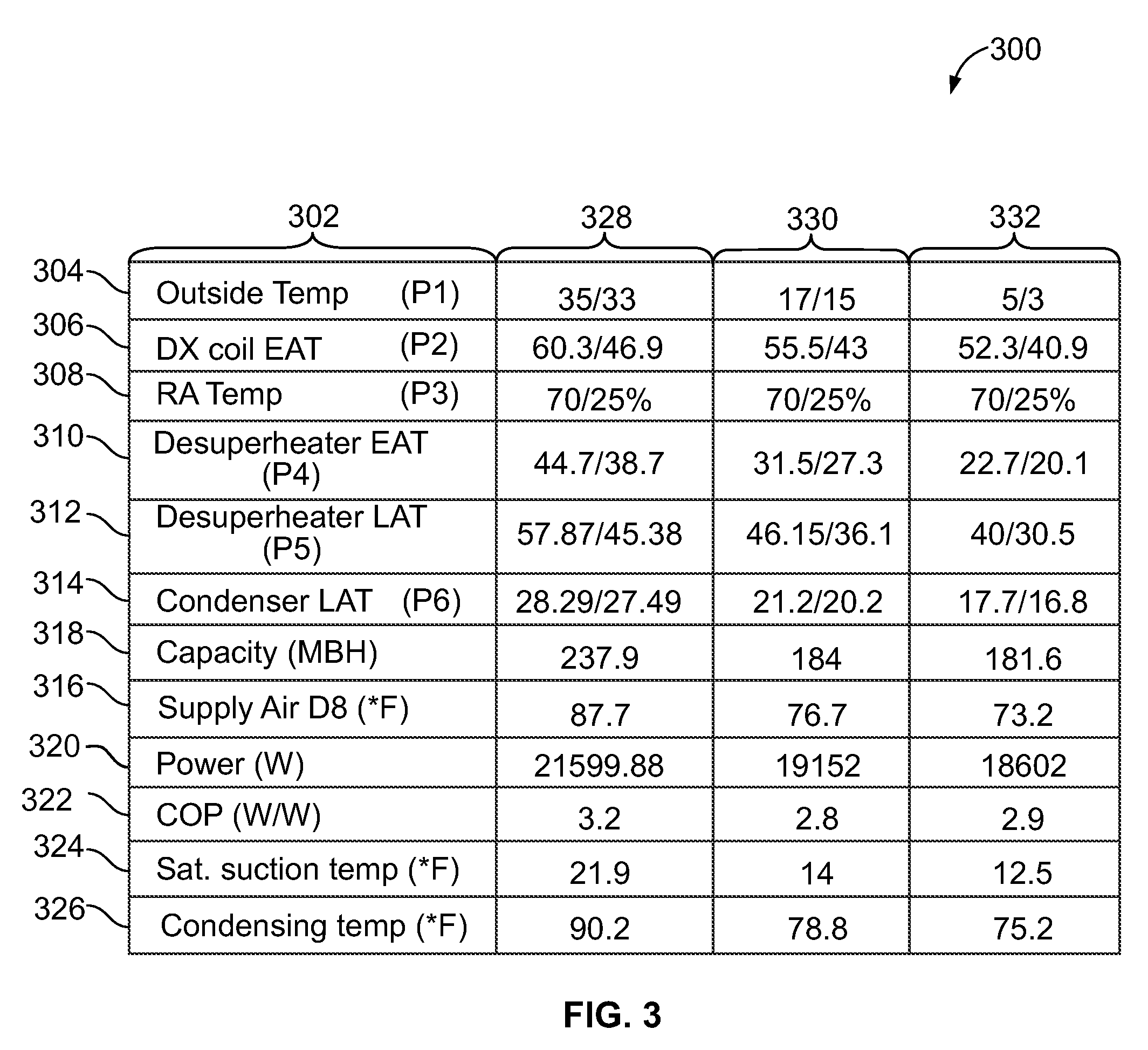

Heat pump system having a pre-processing module

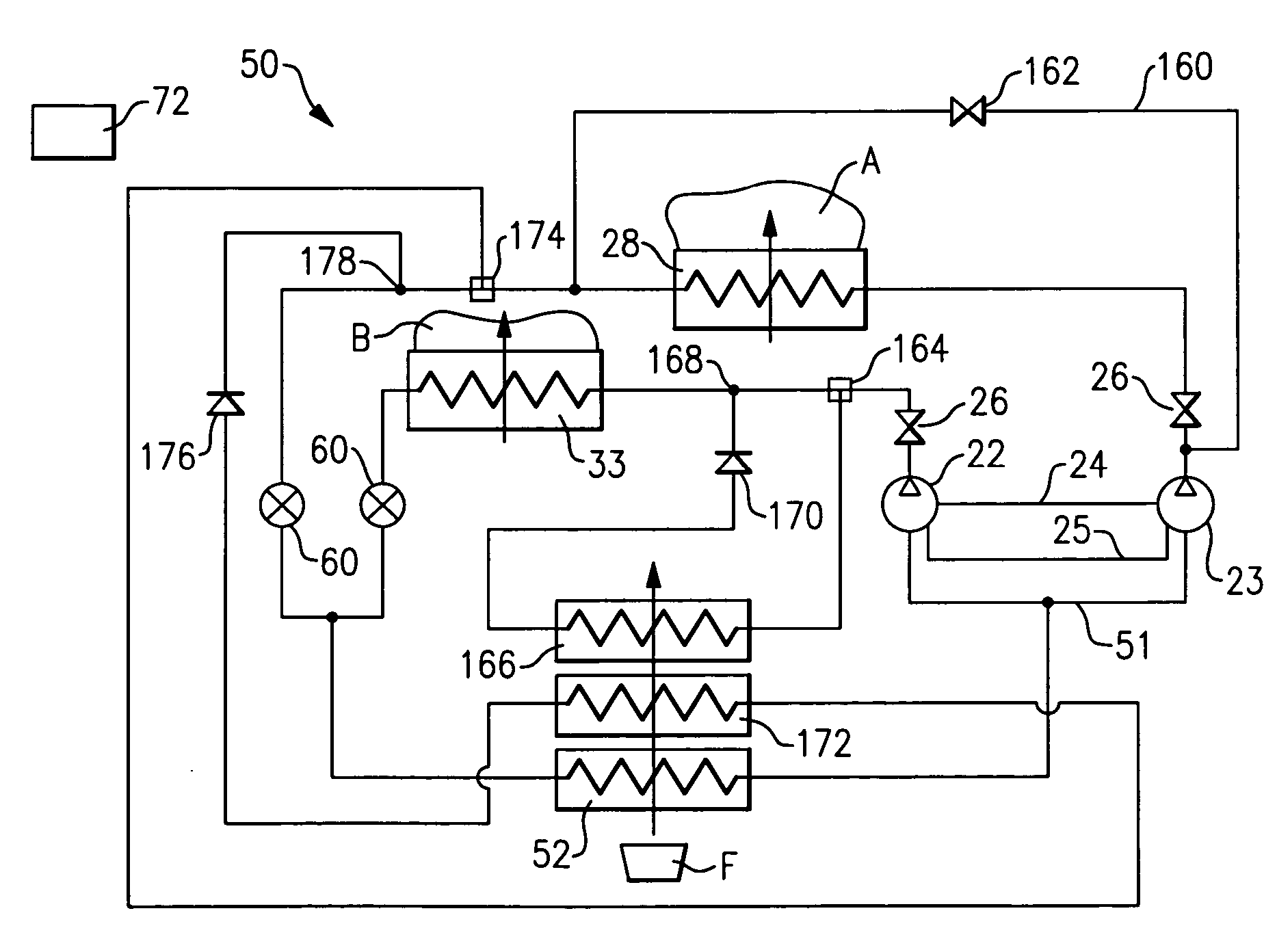

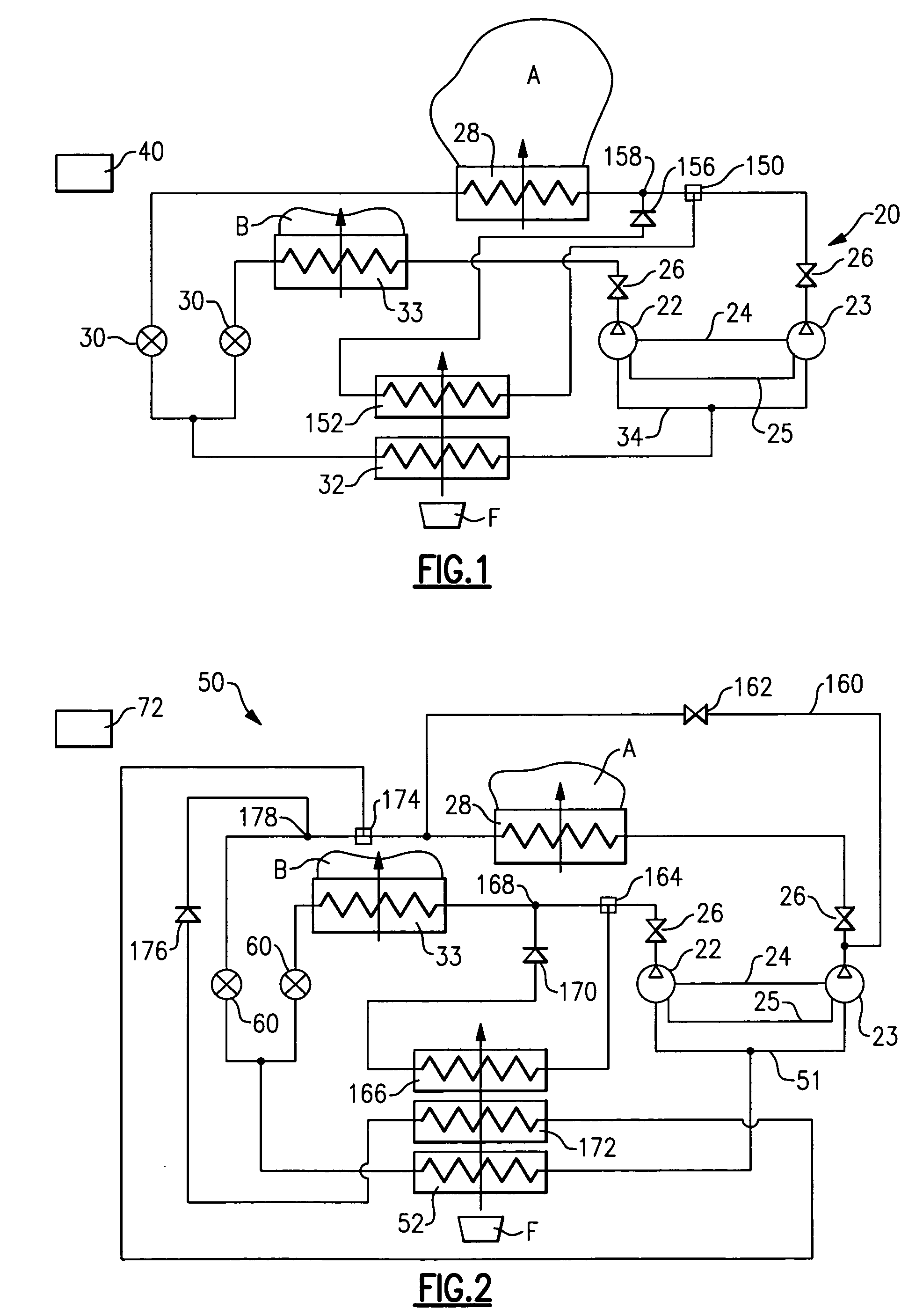

ActiveUS20120180505A1Avoid frostImprove regeneration efficiencyEnergy recovery in ventilation and heatingMechanical apparatusComputer moduleEnergy recovery

A heat pump system is operable in winter mode and / or summer mode, and may be selectively operated in a defrost mode or cycle. The system includes an energy recovery module that receives and conditions air in a regeneration air channel. A pre-processing module is positioned downstream of the energy recovery module. The pre-processing module receives and heats air from the energy recovery module. A regeneration air heat exchanger is positioned downstream of the pre-processing module. The regeneration air heat exchanger receives and conditions air from the pre-processing module. The pre-processing module heats the air from the energy recovery module to increase efficiency of the regeneration air heat exchanger. During the defrost mode, a loop of regeneration air may be recirculated between the supply air channel and the regeneration air channel in order to defrost the regeneration air heat exchanger.

Owner:NORTEK AIR SOLUTIONS CANADA INC

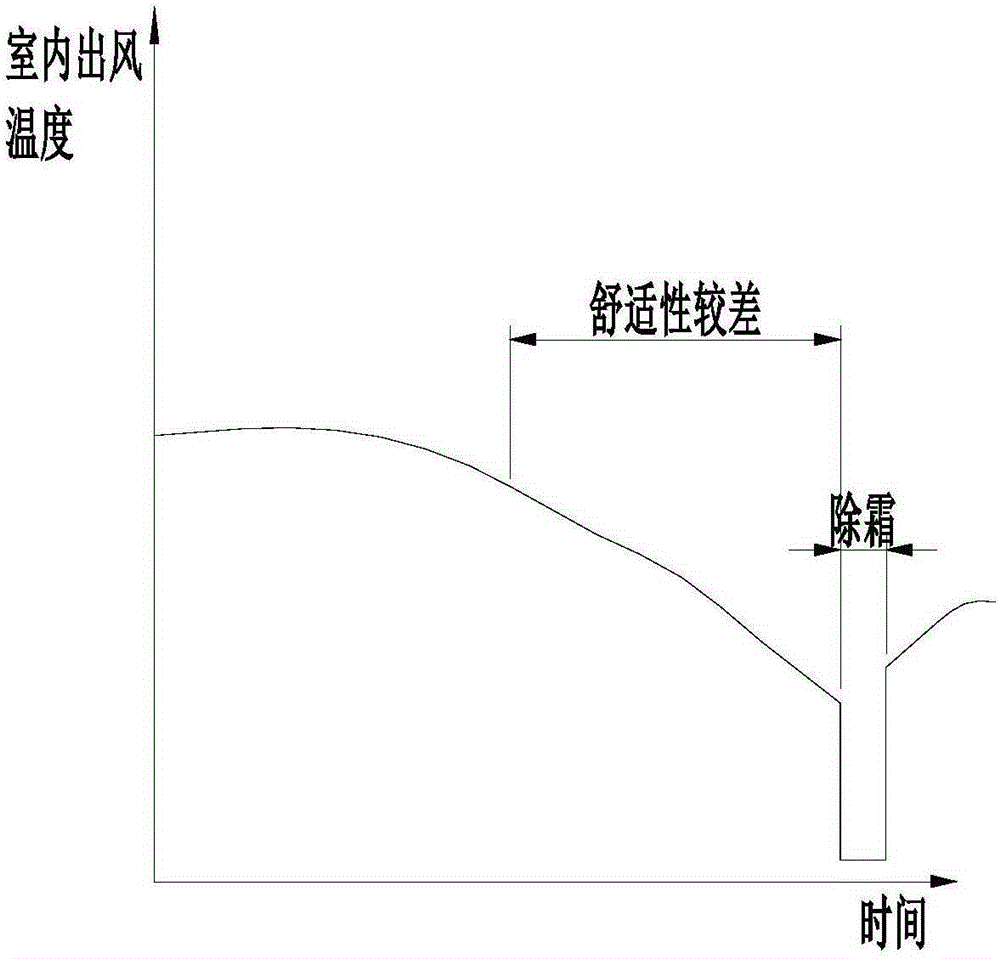

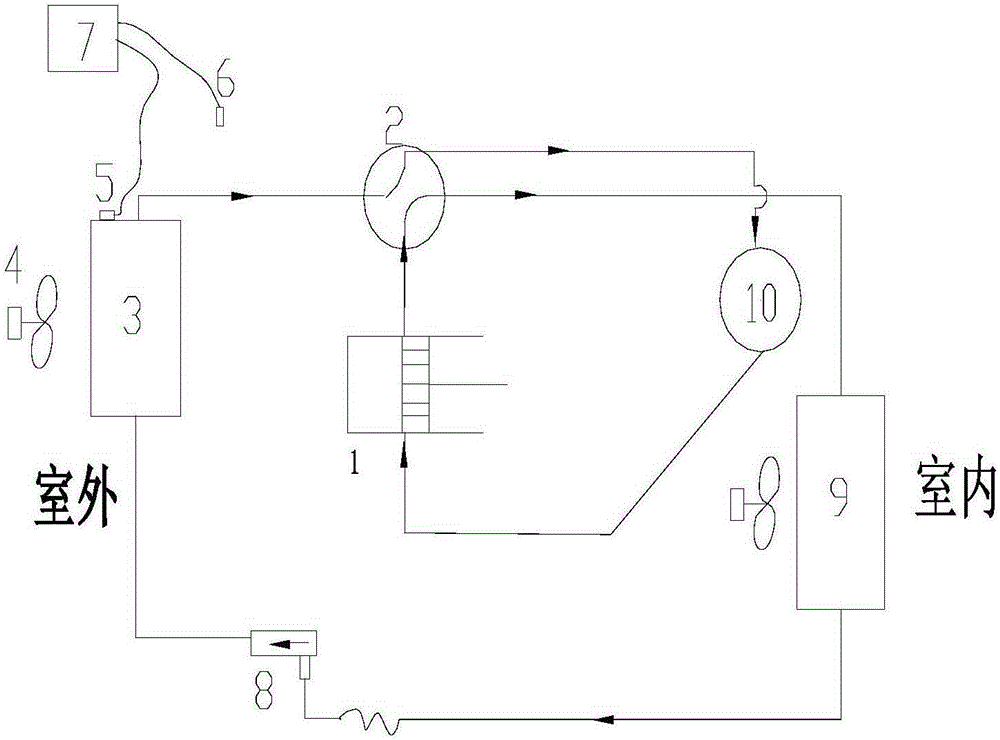

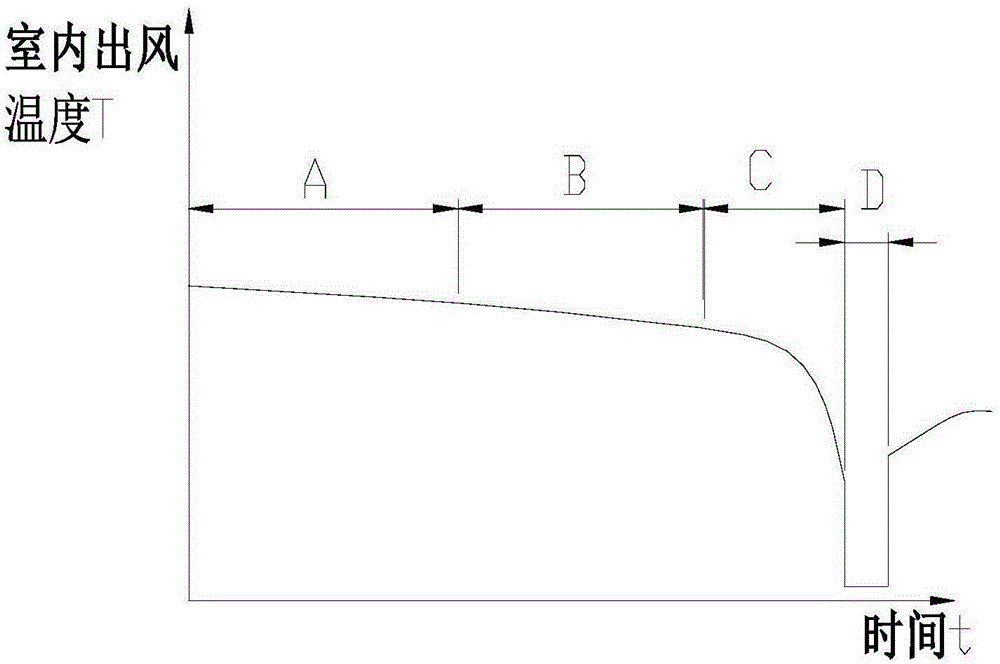

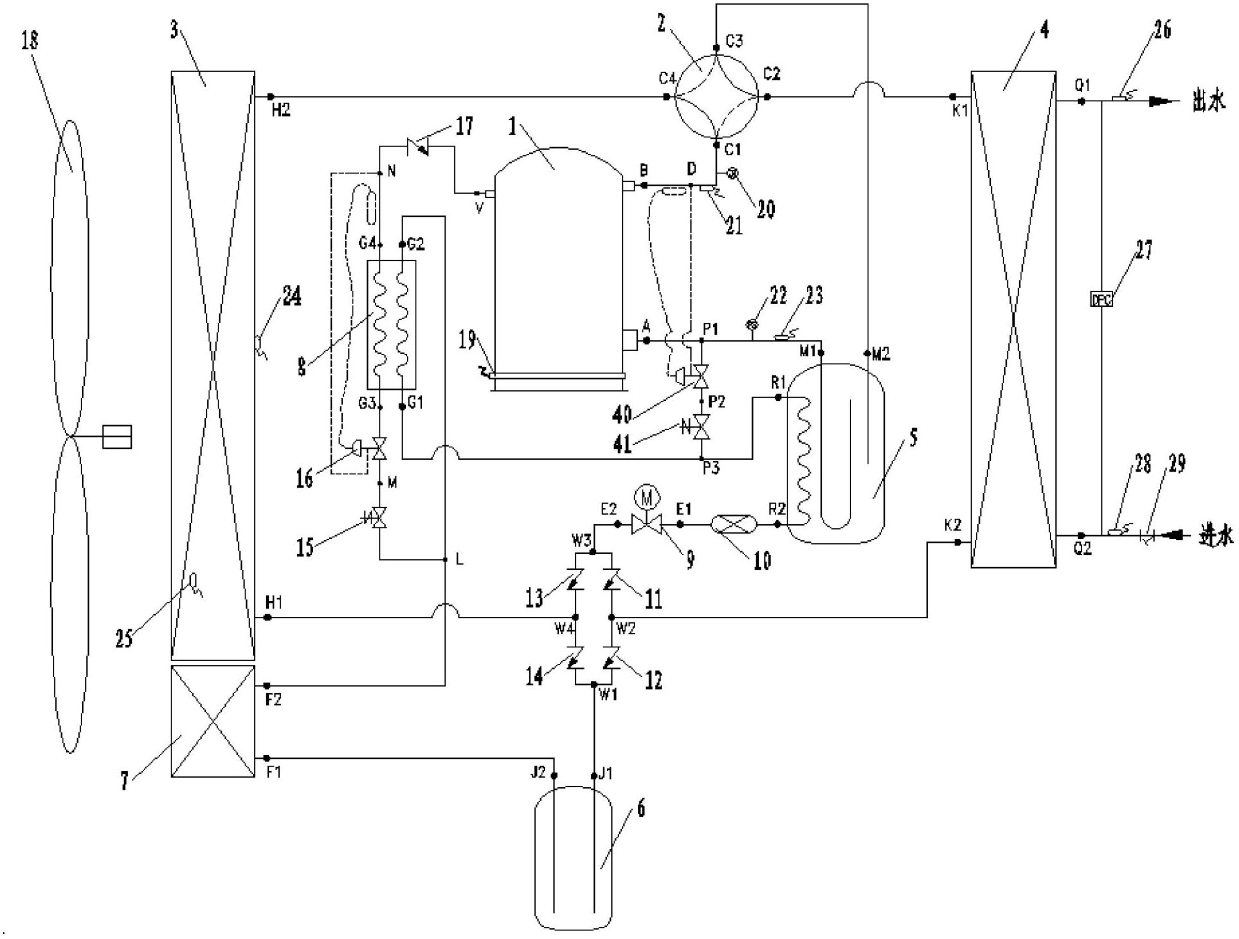

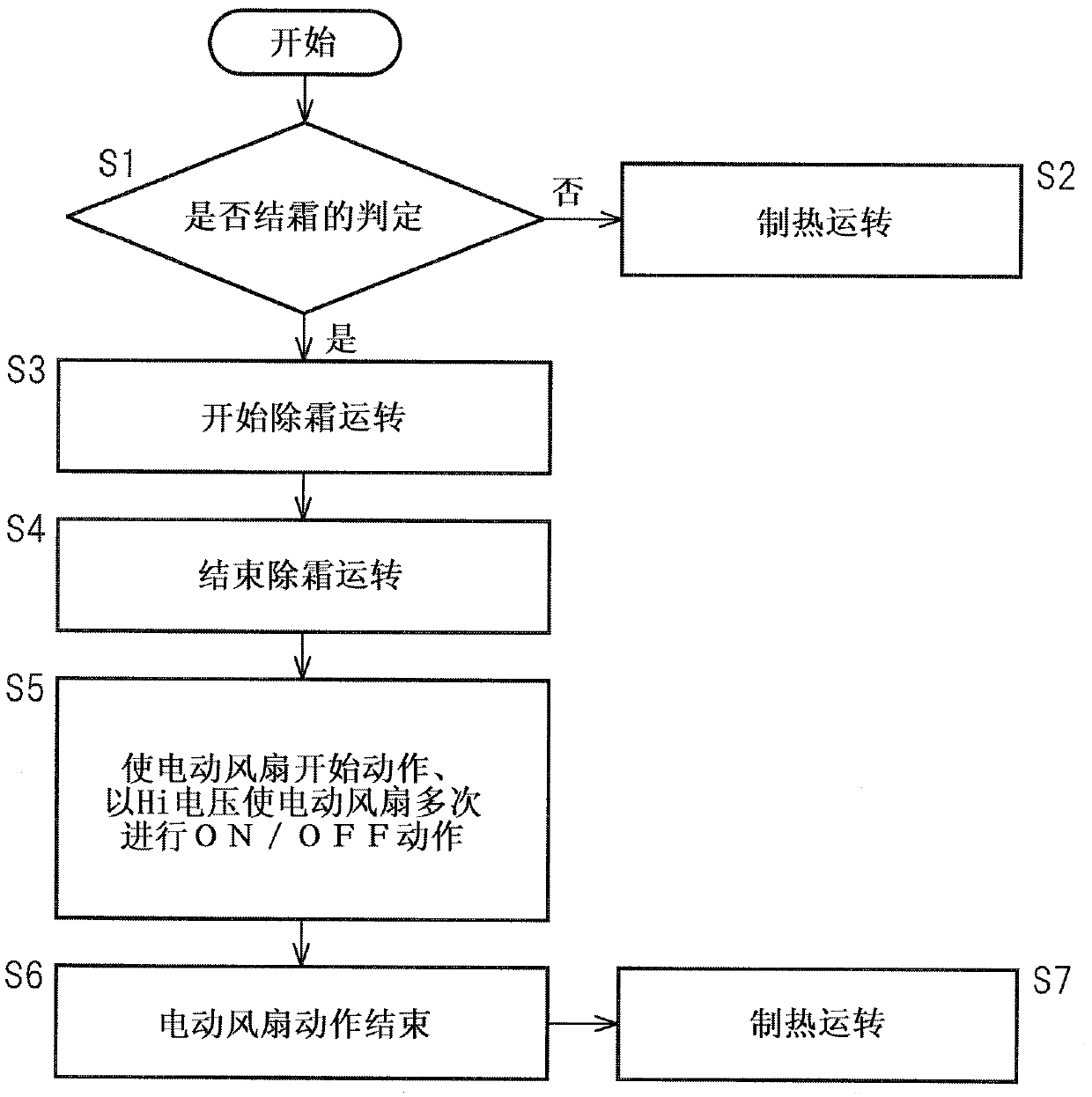

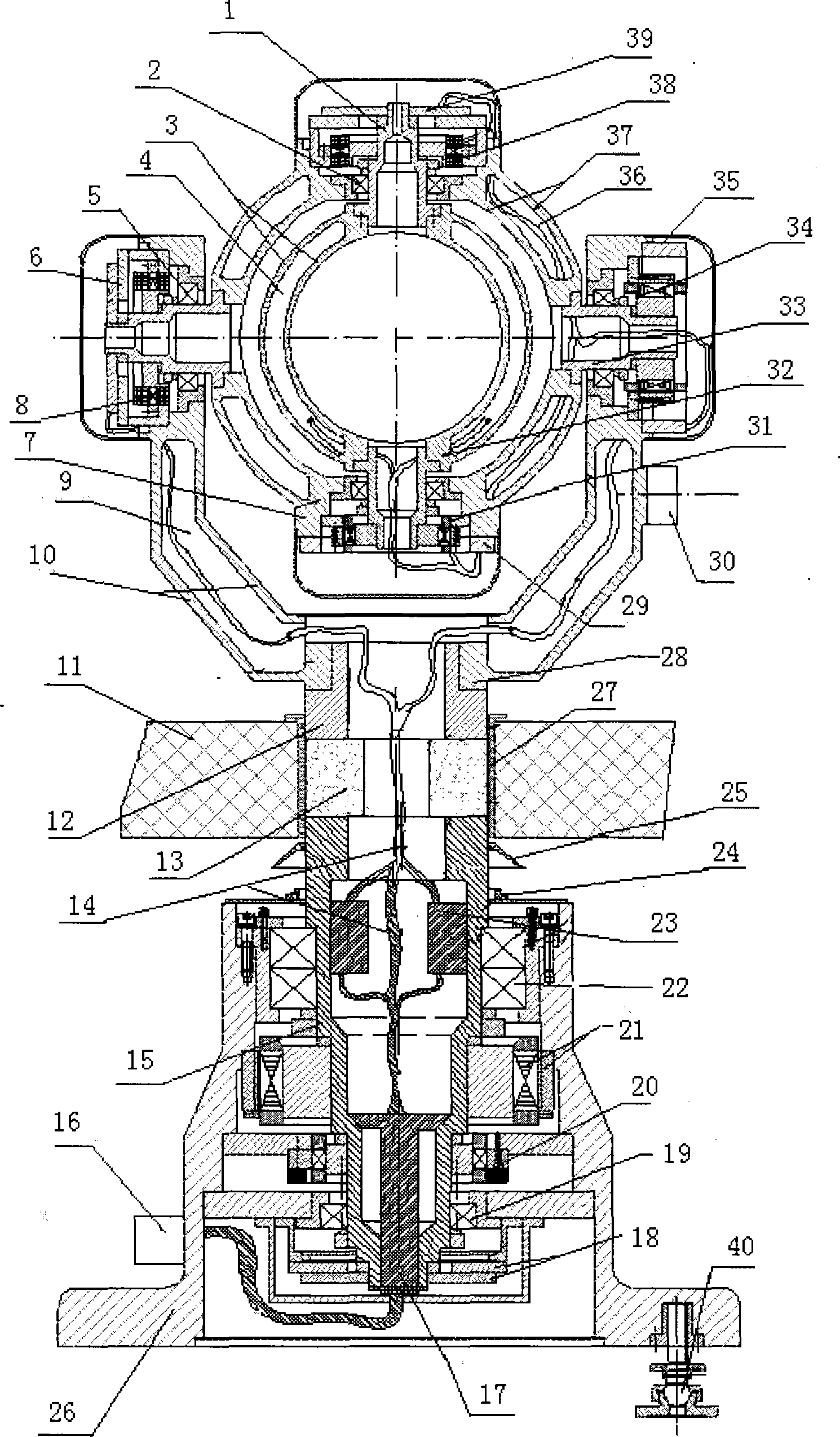

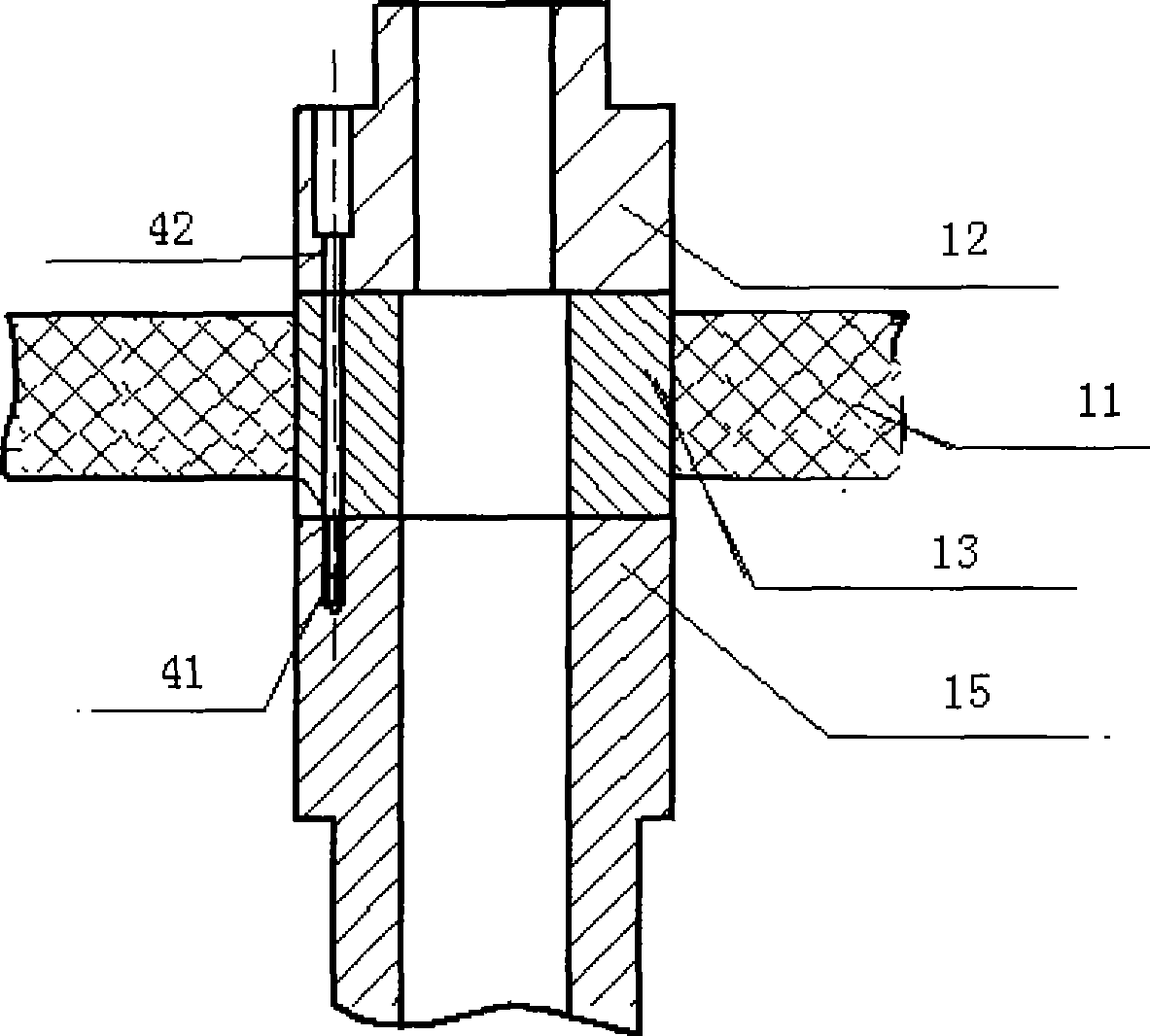

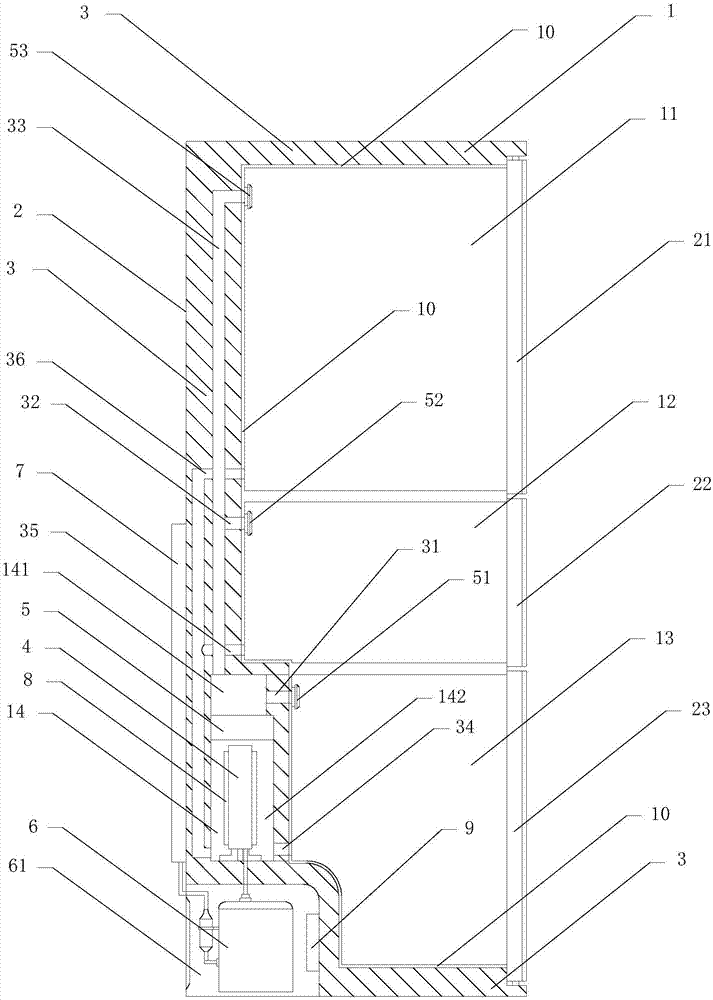

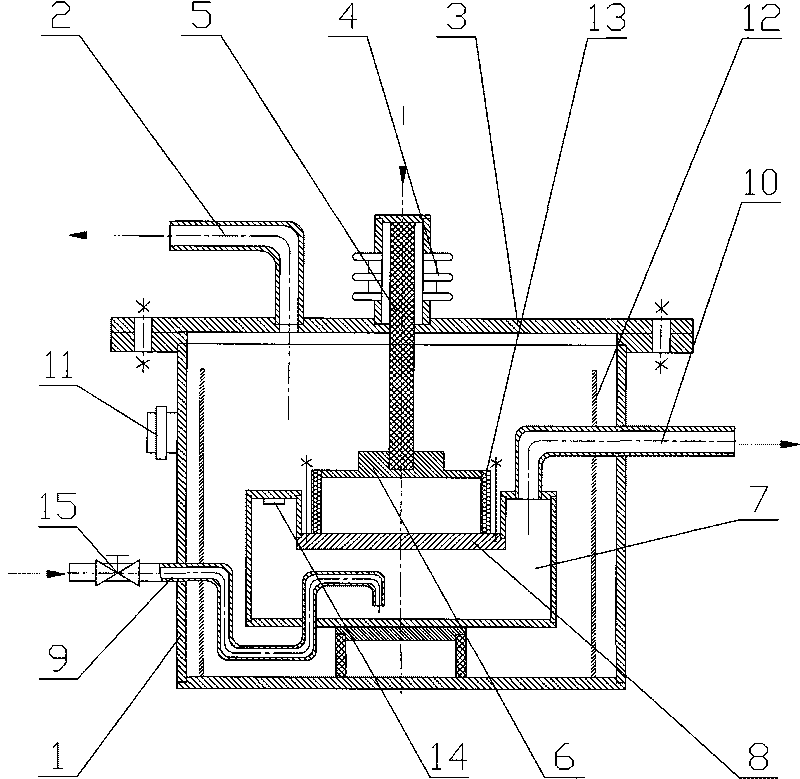

Control system and control method for air-conditioning heating and frosting

ActiveCN105222285AReduce defrosting actionGuaranteed to be uncomfortableMechanical apparatusSpace heating and ventilation safety systemsElectricityControl system

The invention provides a control system for air-conditioning heating and frosting. The control system comprises an air-conditioning system, wherein the air-conditioning system comprises an outdoor unit heat exchanger (3), an electronic expansion valve (8), a compressor (1) and an outdoor motor (4), and further comprises an outer ring temperature detecting element (6) and an outer tube temperature detecting element arranged on the outdoor unit heat exchanger (3) as well as a controller electrically connected with the elements, wherein the controller (7) outputs a control signal to one or more of the electronic expansion valve (8), the compressor (1) and the outdoor motor (4). According to the control system provided by the invention, frostless control can be carried out on a frosting process of an outdoor unit, so that indoor heating comfort is improved; a frosting period is prolonged, so that defrosting action in a using process of a user is reduced; the process is simple and the cost is reduced; and active defrosting is carried out to overcome the defects of passive defrosting. The invention further relates to a control method for carrying out frosting control by utilizing the system.

Owner:GREE ELECTRIC APPLIANCES INC

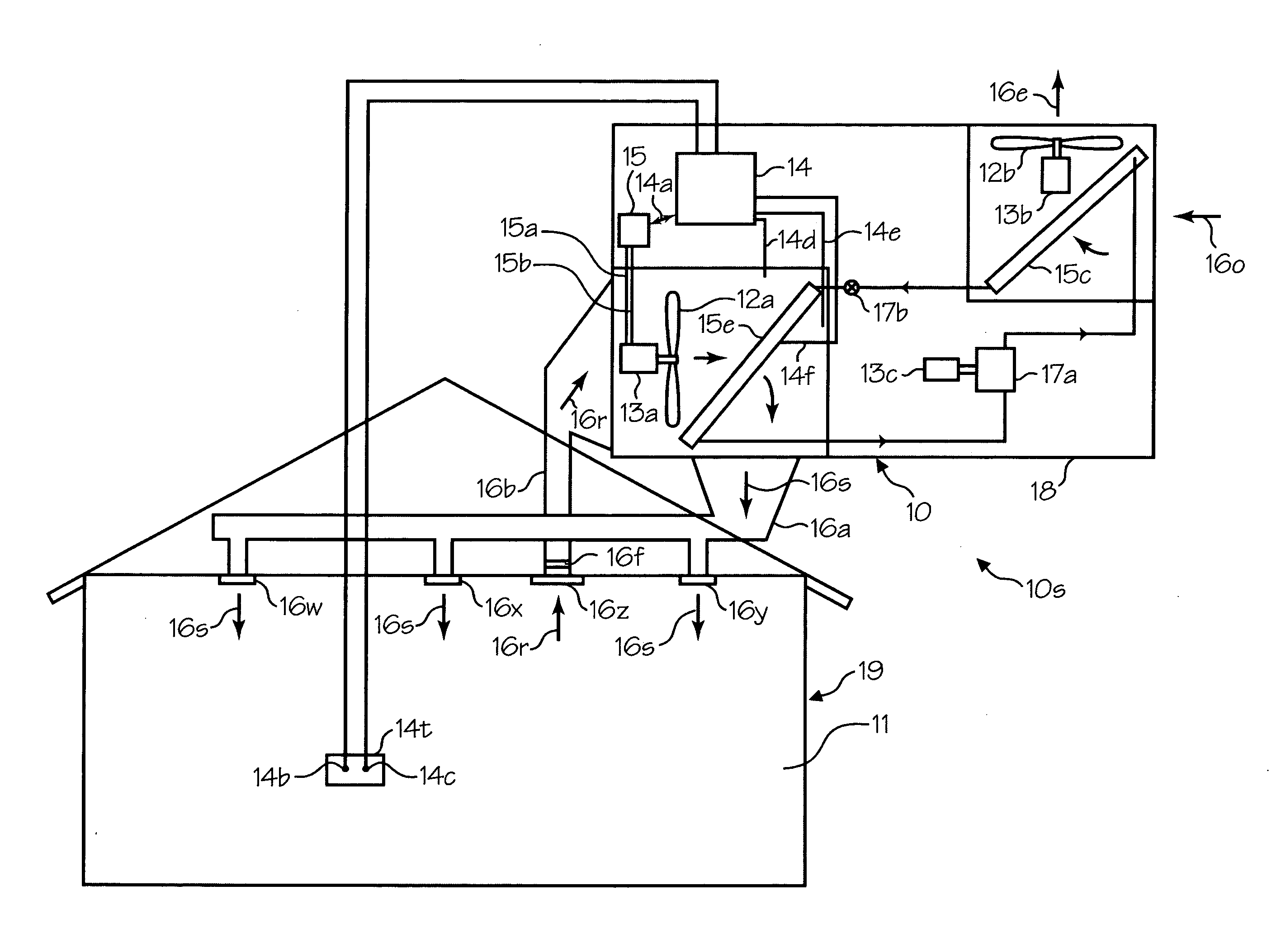

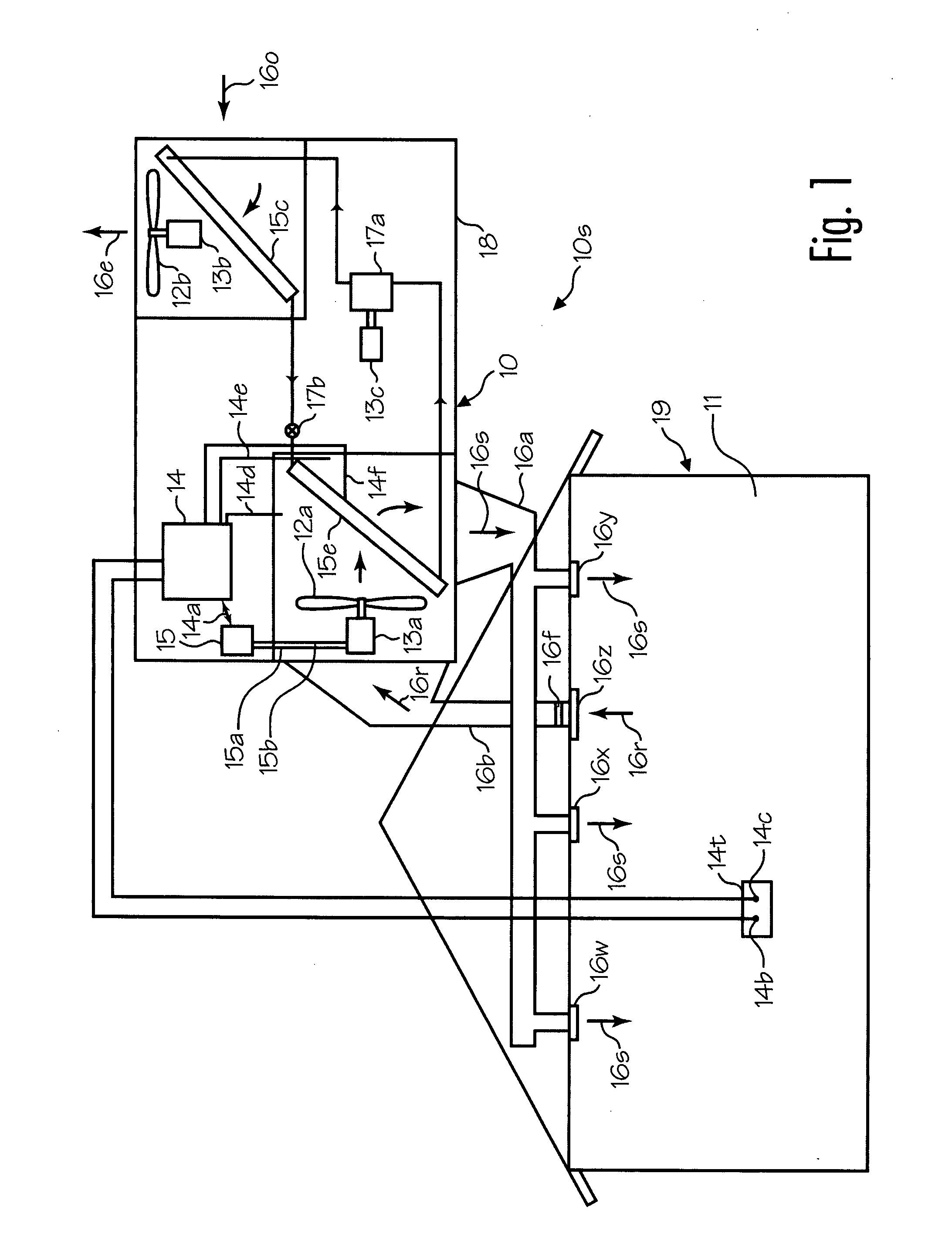

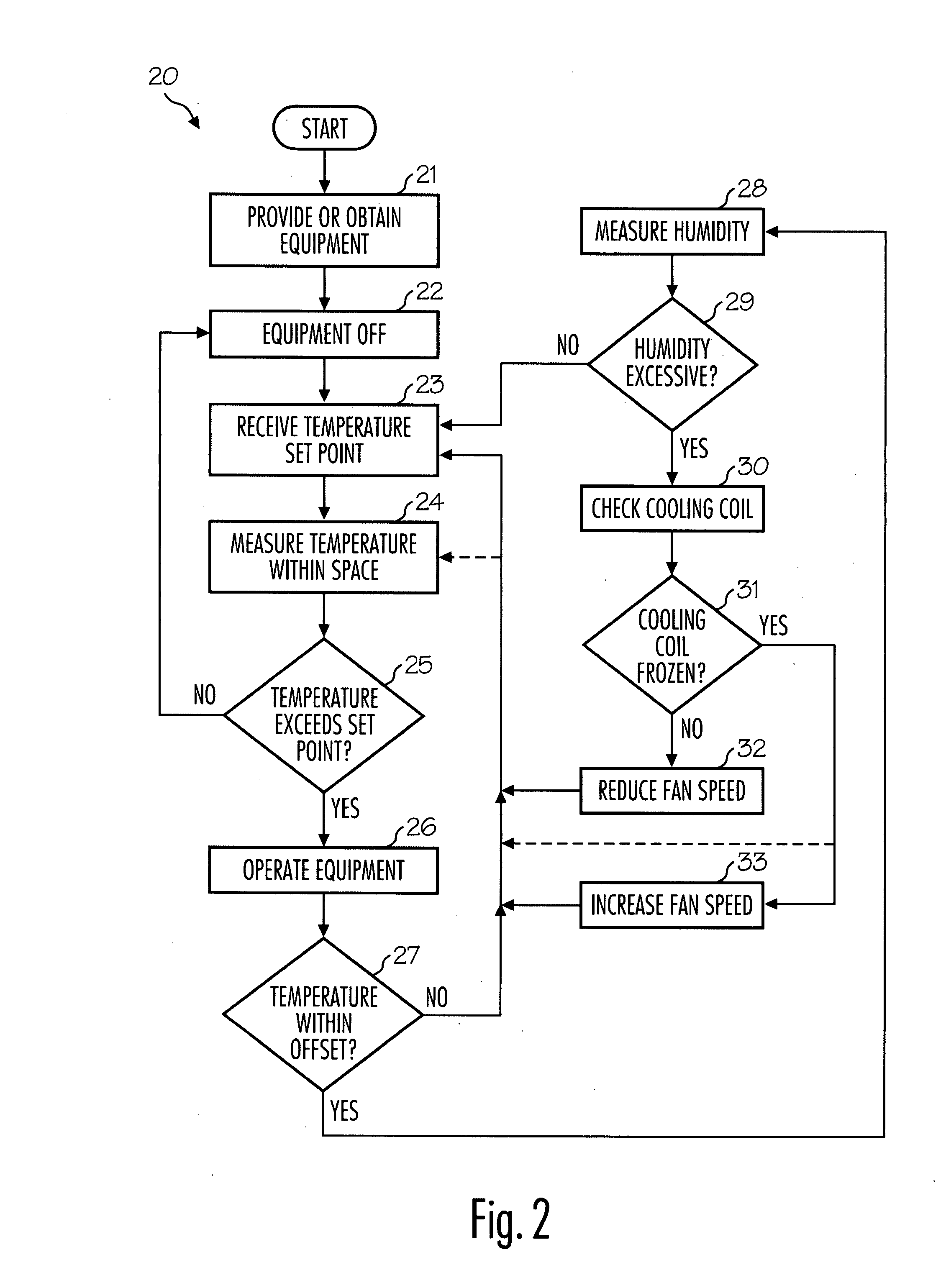

Humidity control and air conditioning

InactiveUS20080307803A1Shorten speedAvoid frostMechanical apparatusCompression machines with non-reversible cycleFrostCooling coil

Air conditioning systems that cool and dehumidify spaces within enclosures, buildings having such systems, and methods of controlling humidity within a space. Embodiments adjust speed of a blower or fan motor based on inputs from sensors within the system, using automated processes, to reduce airflow rates to provide for lower temperatures of the cooling coil and to increase the ratio of latent to sensible heat transfer. Fan speeds may be increased as appropriate to avoid frost formation on the cooling coil, to give priority to cooling when temperatures within the space are high, or periodically to provide for mixing within the space.

Owner:NORDYNE

Air-cooled heat pump air conditioner

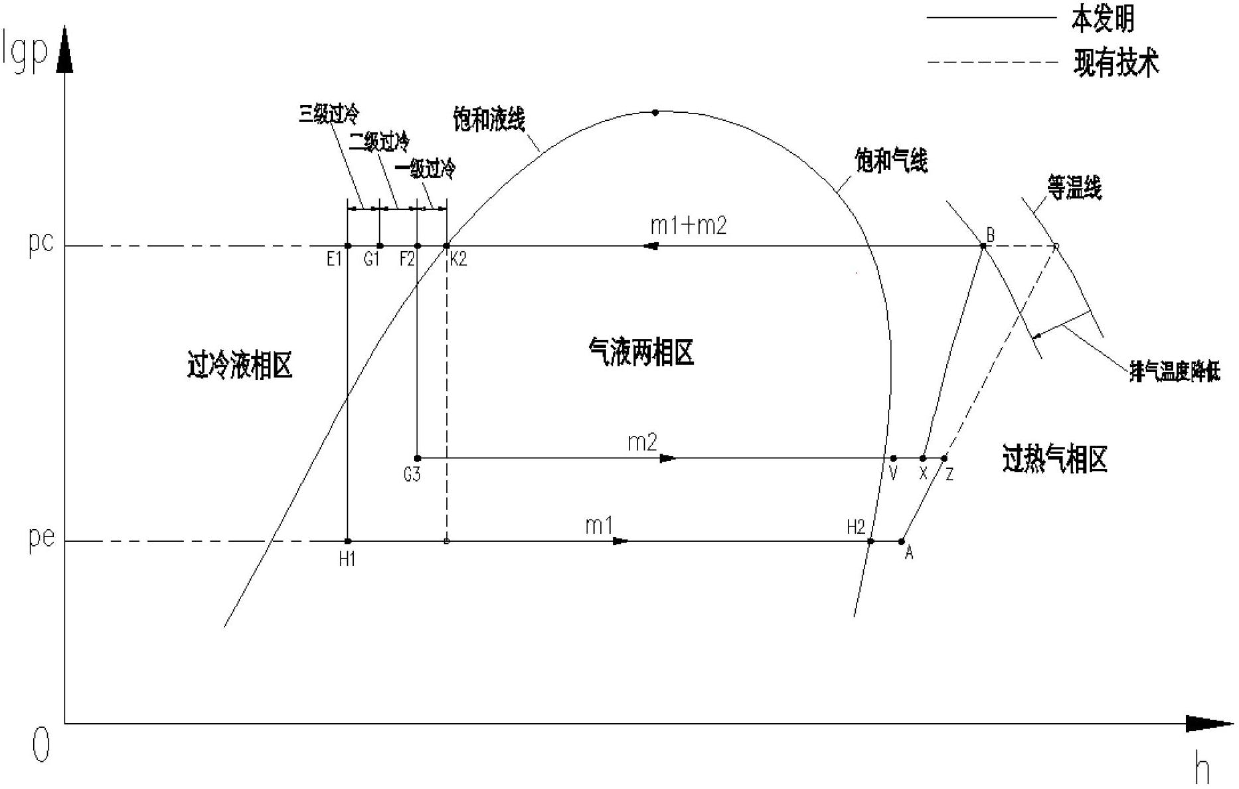

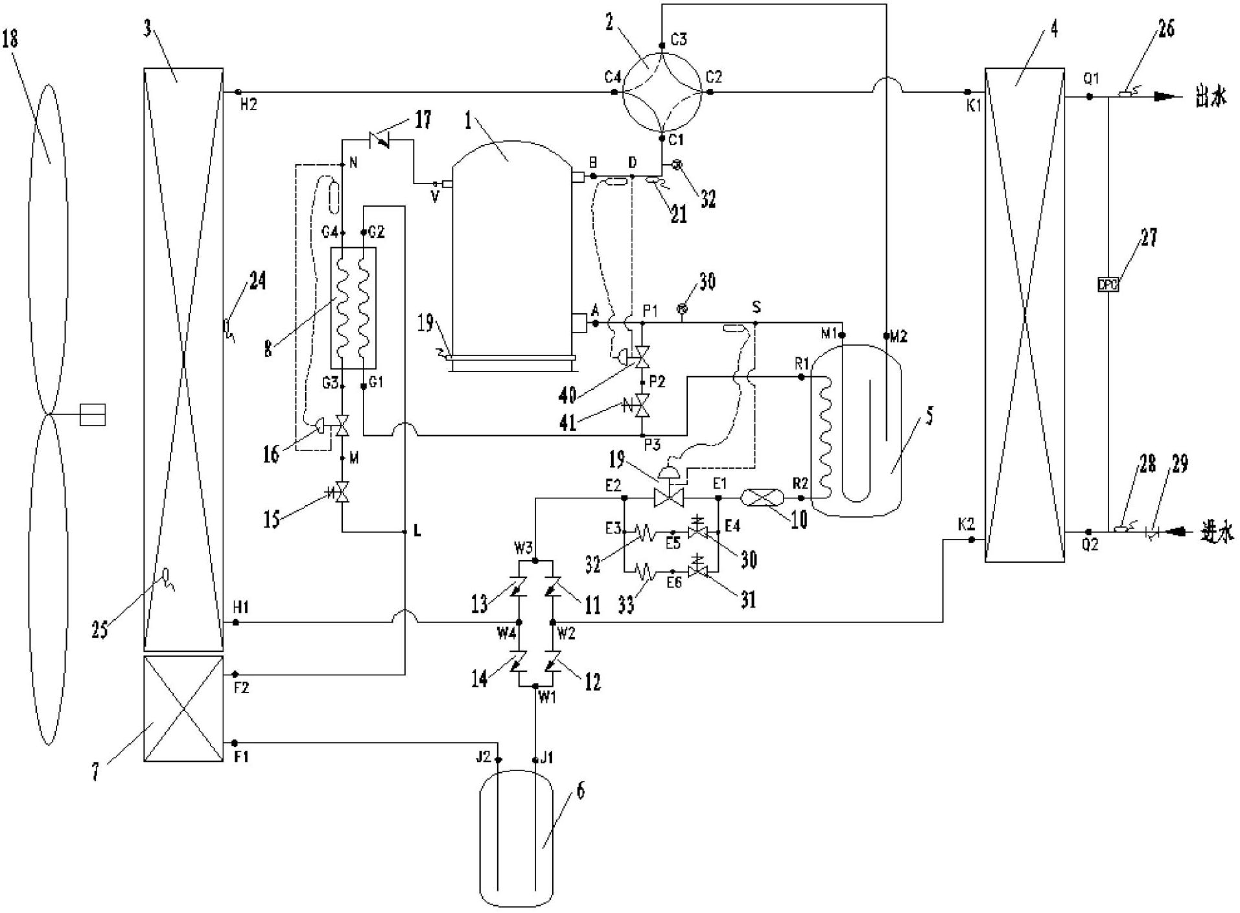

InactiveCN102679609AIncrease subcoolingLow heat recovery functionSubcoolersFluid circulation arrangementLiquid lineVapor–liquid separator

The invention discloses an air-cooled heat pump air conditioner which comprises a compressor, an outdoor coil, a heat exchanger, a main liquid line and supercooling devices, wherein the supercooling devices comprise two or three of a supercooling coil, an economizer and a liquid-vapor separator with a supercooling function, the supercooling devices are arranged on the main liquid line, and liquid state refrigerants which circulate in the main liquid line can achieve repeatedly the supercooling through the supercooling devices. According to the air-cooled heat pump air conditioner, the performance of cooling / heating circulation of the air-cooled heat pump air conditioner is effectively improved, so that the air-cooled heat pump air conditioner is stable and reliable in operation and energy saving in a low-temperature environment.

Owner:四川同达博尔置业有限公司

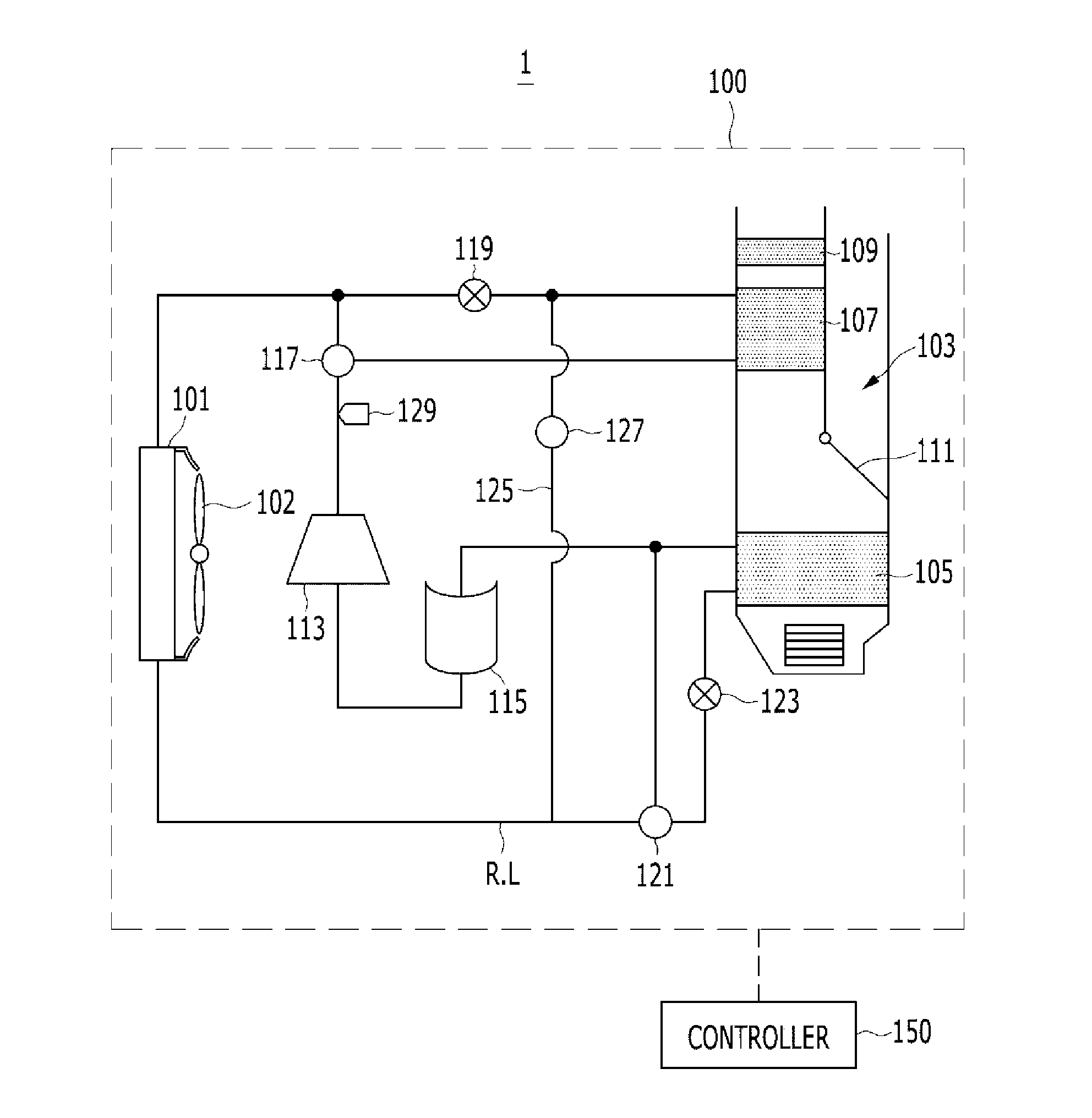

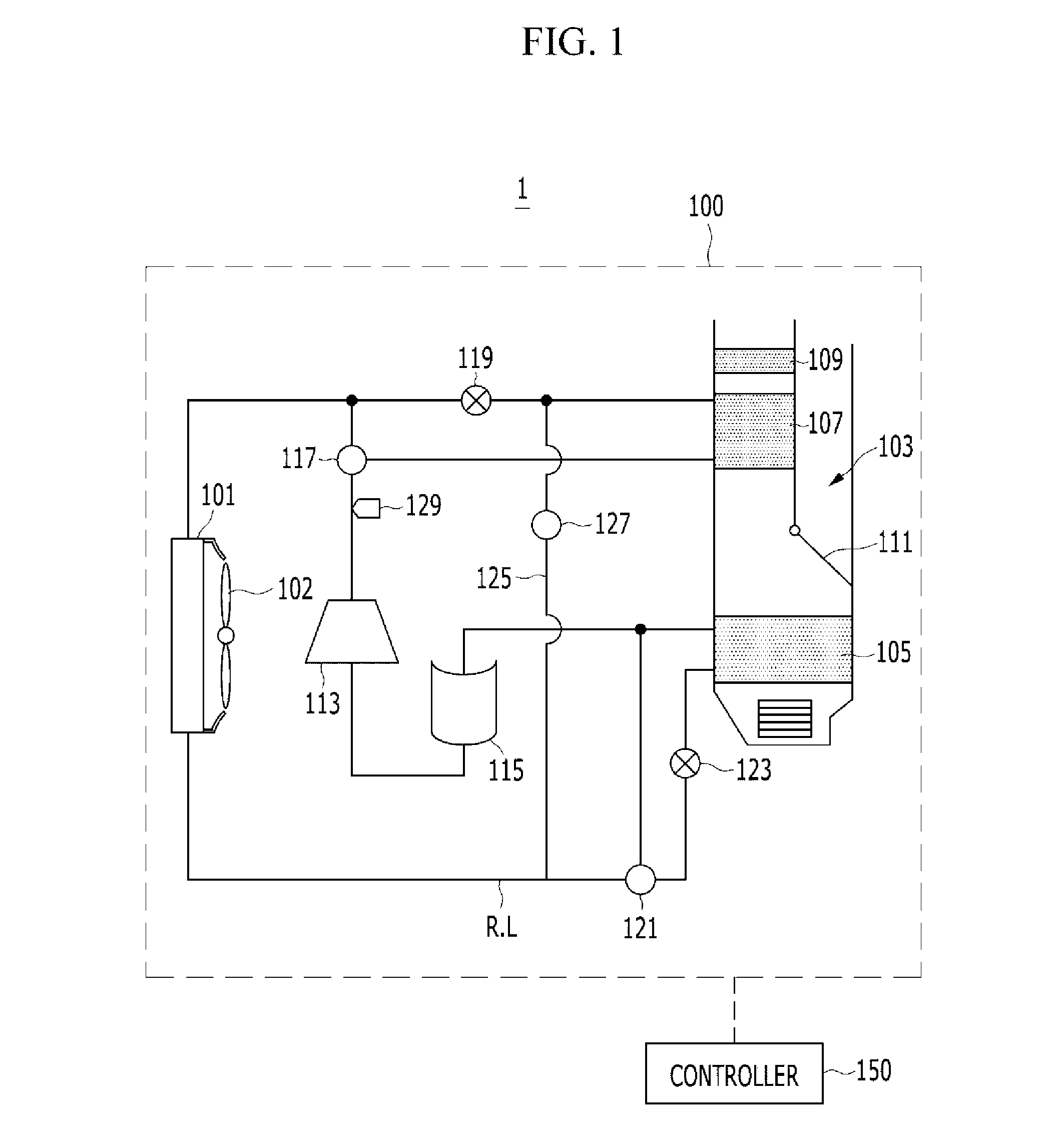

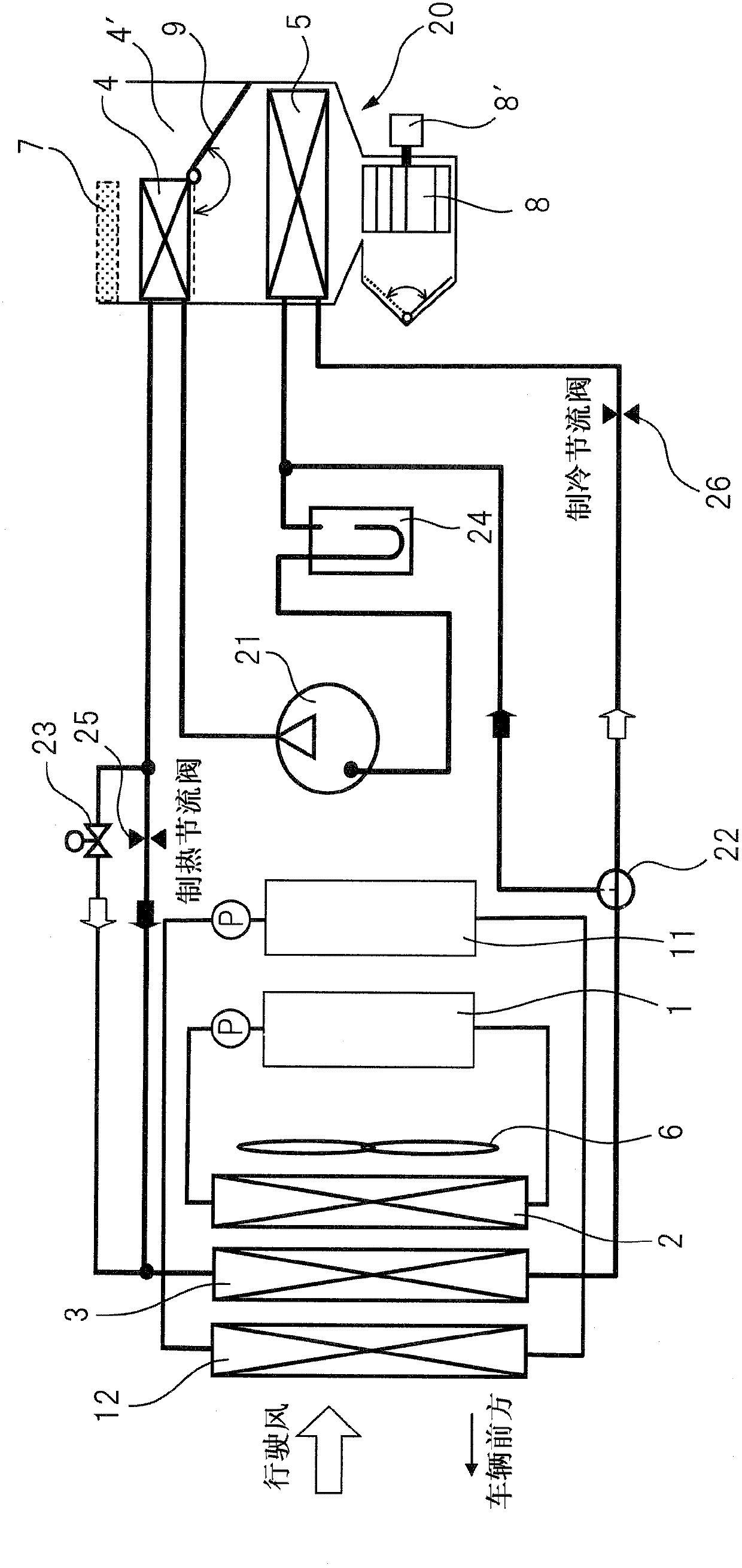

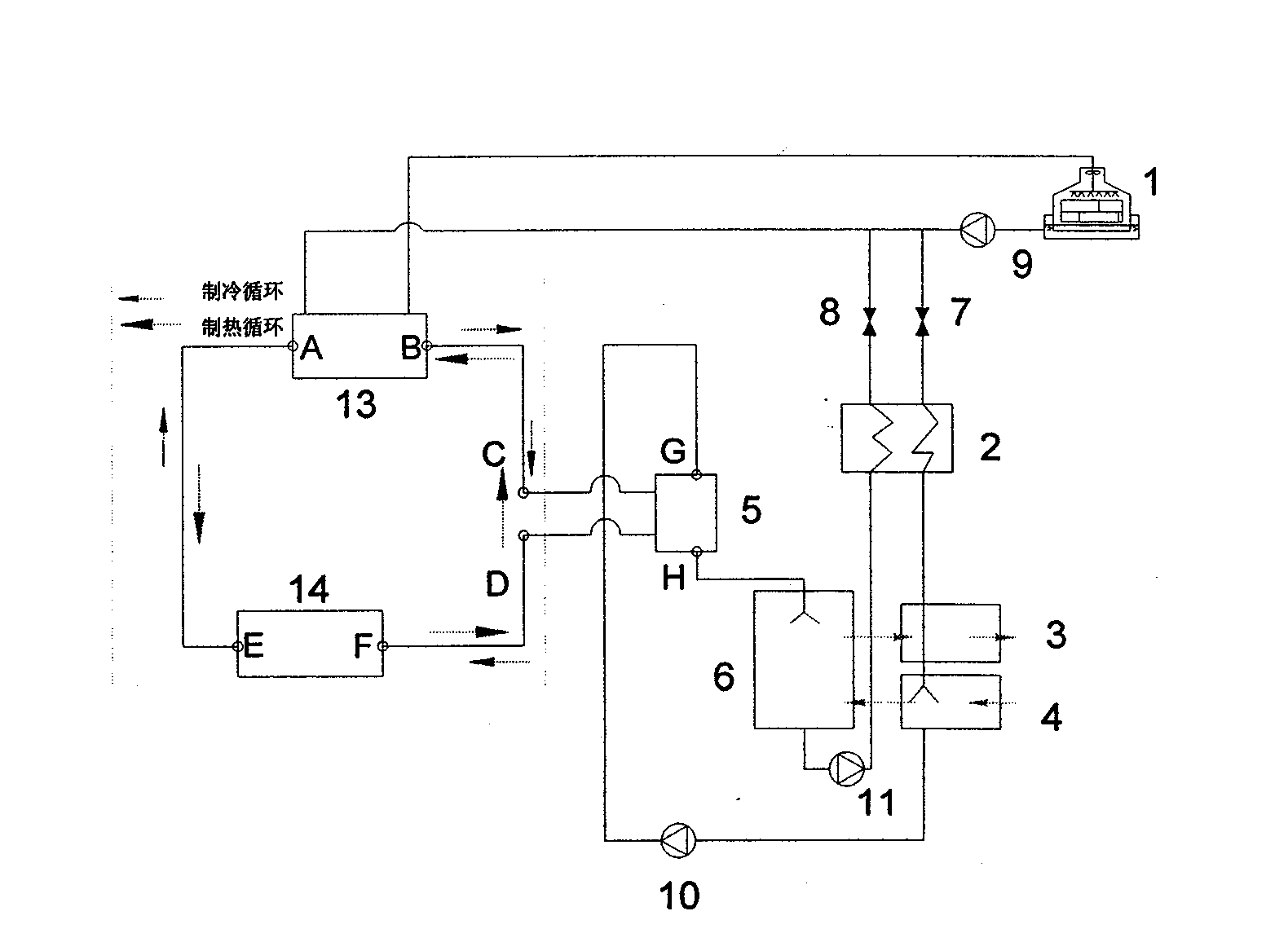

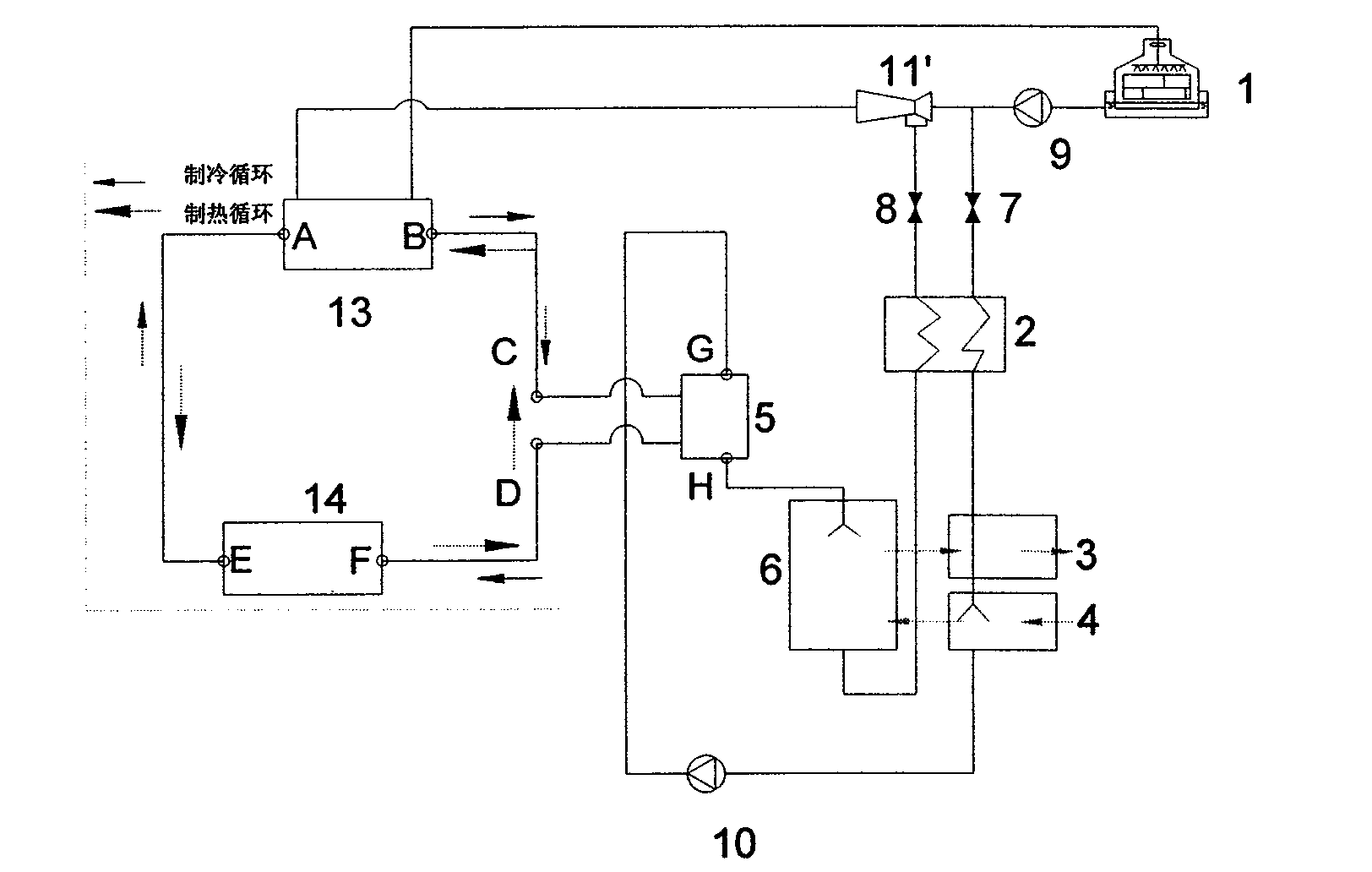

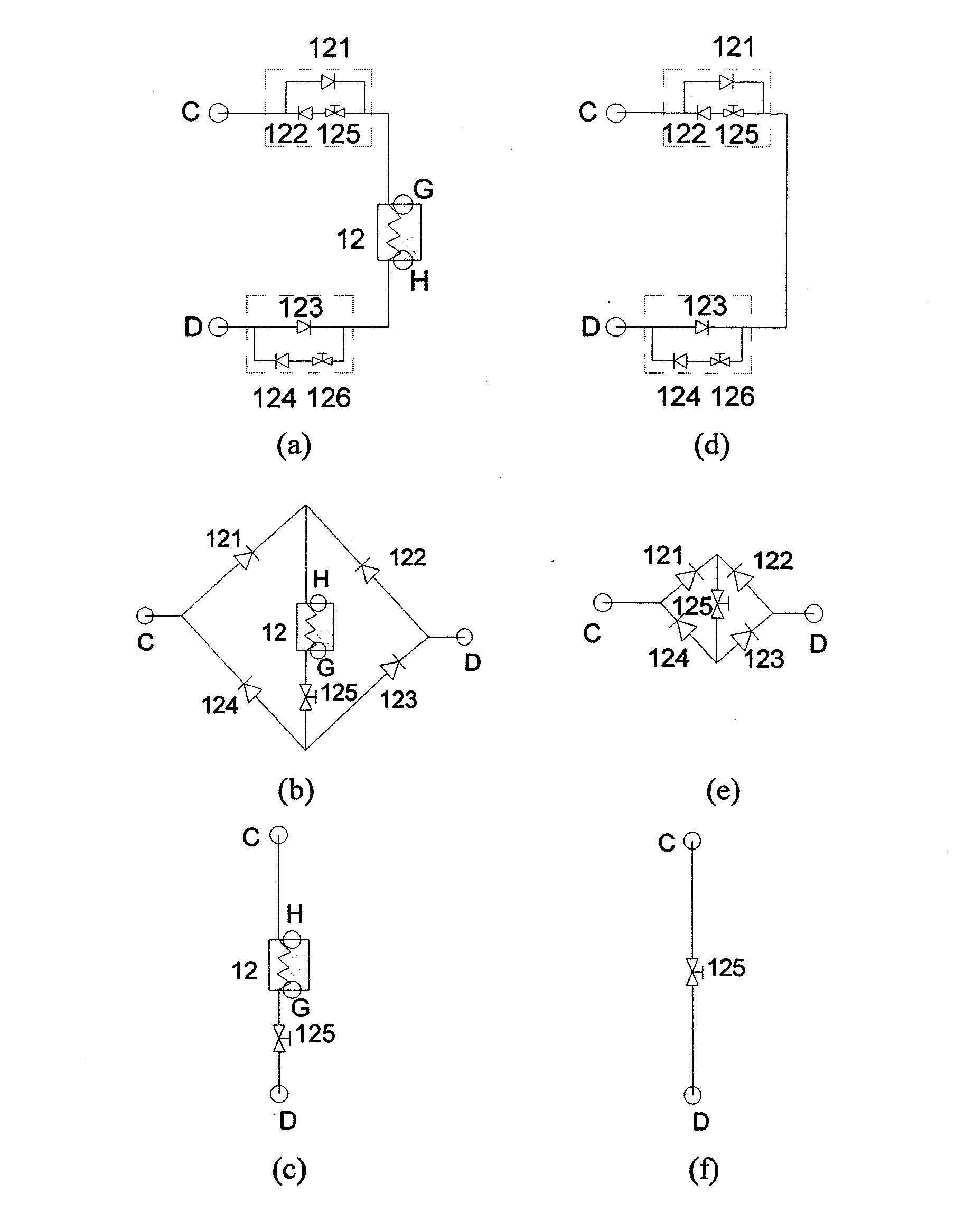

Heat pump system for vehicle and control method thereof

ActiveUS20130019615A1Improve heating performanceImproving performance dehumidificationMechanical apparatusHeat pumpsAir conditioningRefrigerant

A method for controlling a heat pump system is provided with air conditioning means connected to a controller and including a plurality of valves and expansion valves connected to each other through a refrigerant line and a bypass line, a compressor, an accumulator, an evaporator, an exterior condenser, an interior condenser, and an HVAC module having a PTC heater and a door at a warming mode, a cooling mode, a dehumidification mode, a dehumidification / defrosting mode, or an extremely low temperature dehumidification / defrosting mode according to selection of a driver.

Owner:HYUNDAI MOTOR CO LTD +1

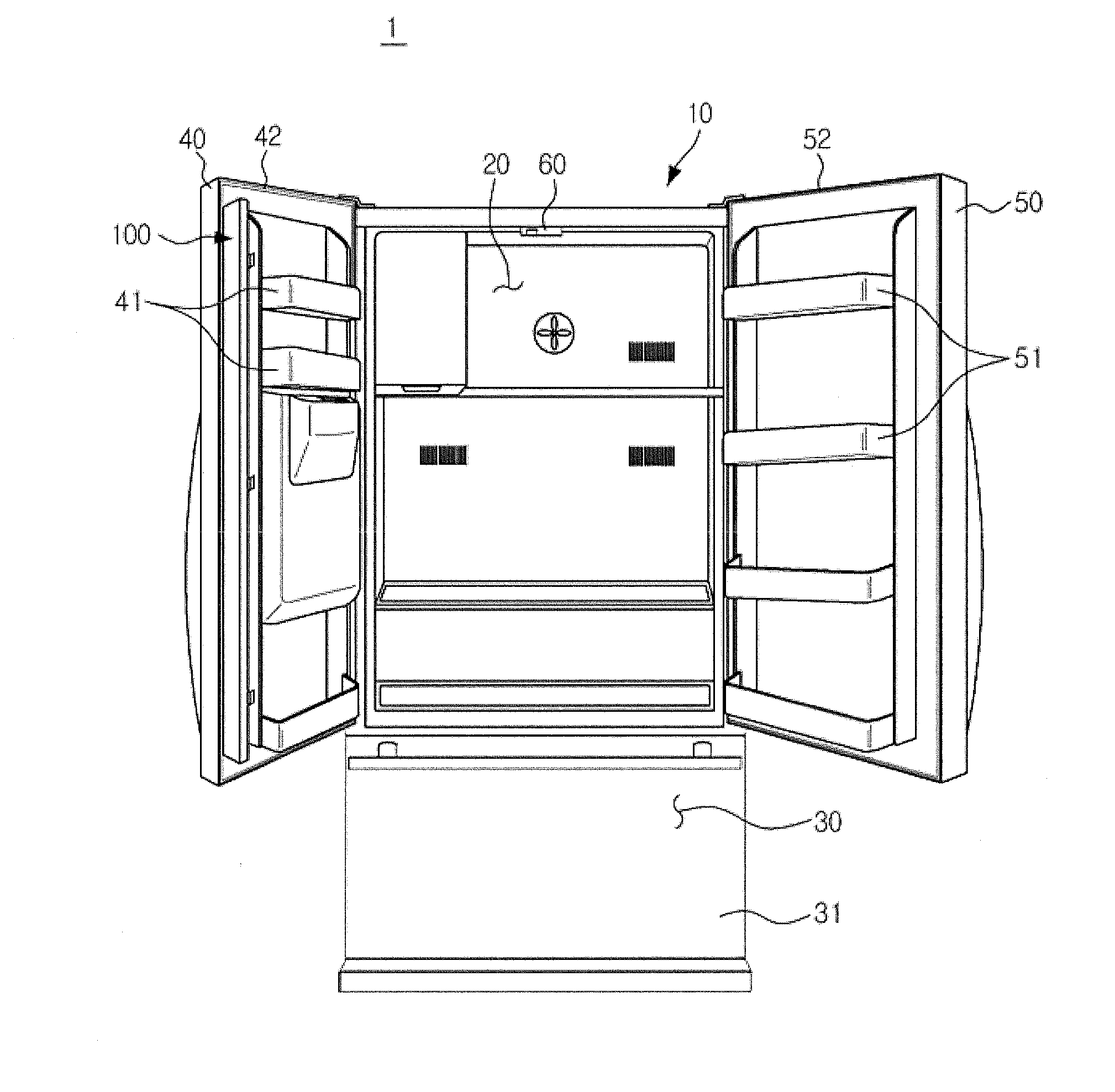

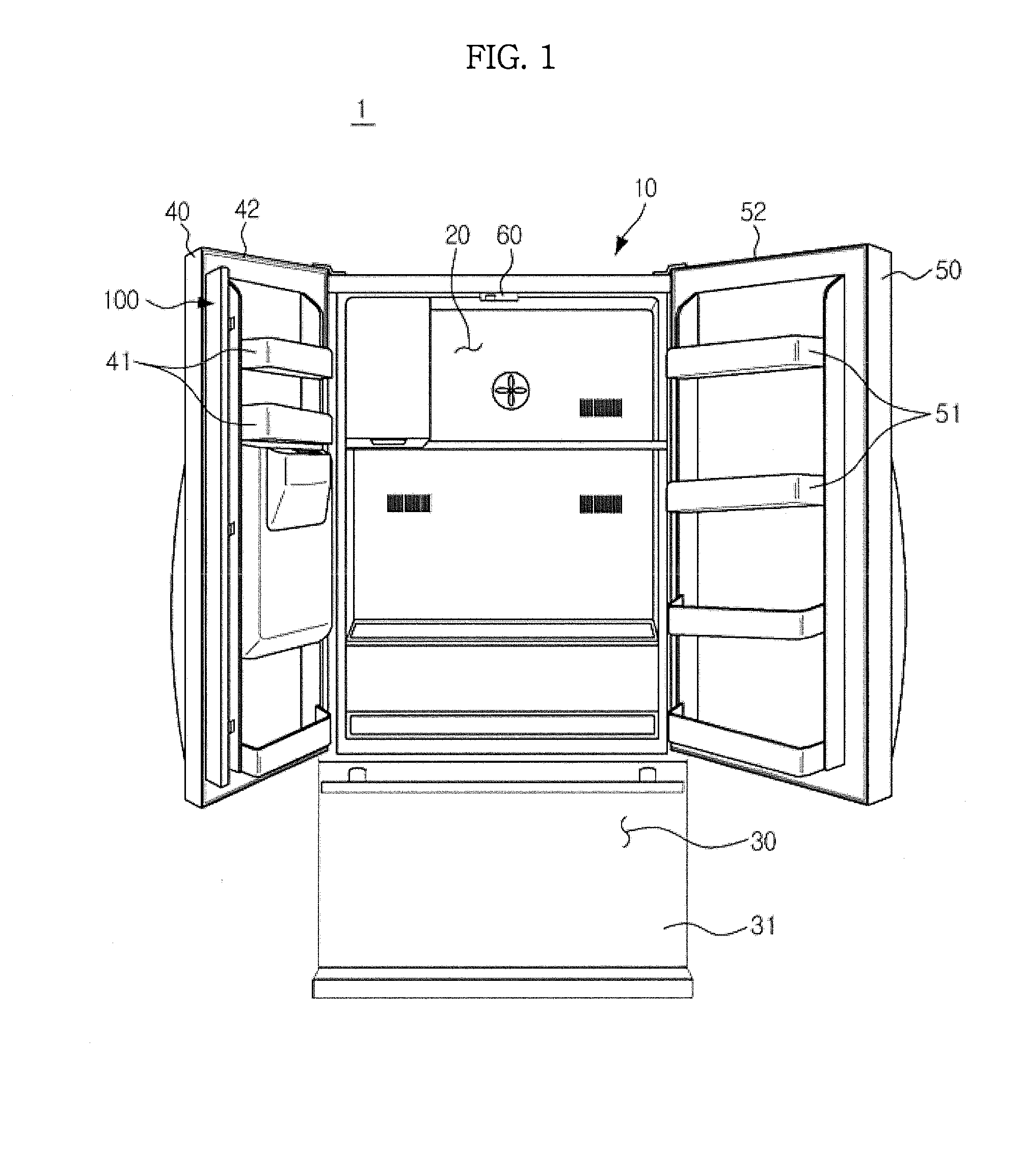

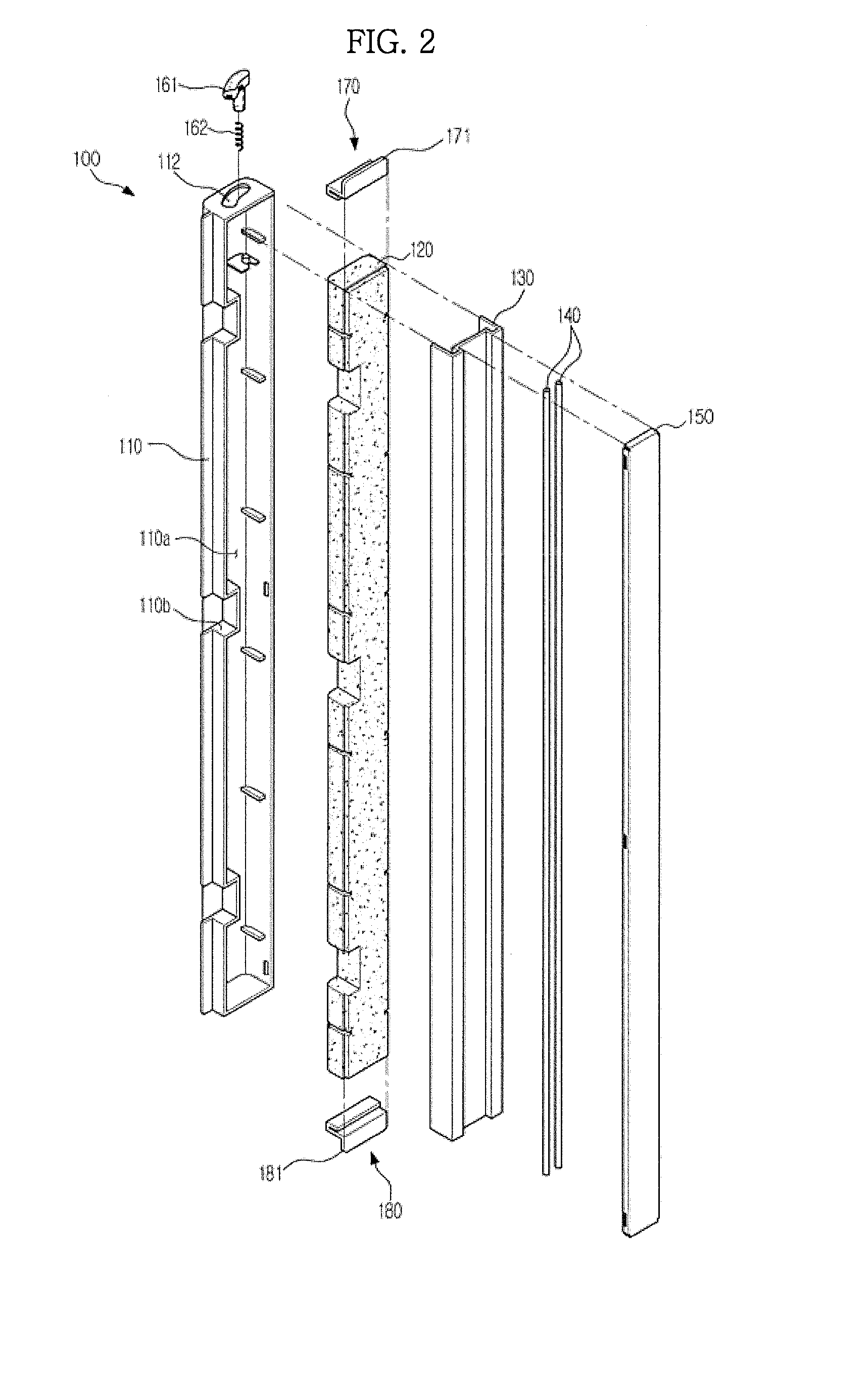

Refrigerator

ActiveUS20130241385A1Improve insulation performanceSealing gapShow cabinetsEngine sealsEngineeringMechanical engineering

A refrigerator provided with a rotating bar configured to seal a gap between one pair of doors, capable of preventing the door from being incompletely closed due to an erroneous operation of the rotating bar, the rotating bar capable of sealing a gap formed between the rotating bar and a body as well as a gap formed between one pair of doors, the rotating bar being elastically supported by an elastic member so as to move by receiving an external force from a guide part provided on the body, the rotating bar including a sealing member protruding from the rotating bar so as to seal a gap between the rotating bar and the body.

Owner:SAMSUNG ELECTRONICS CO LTD

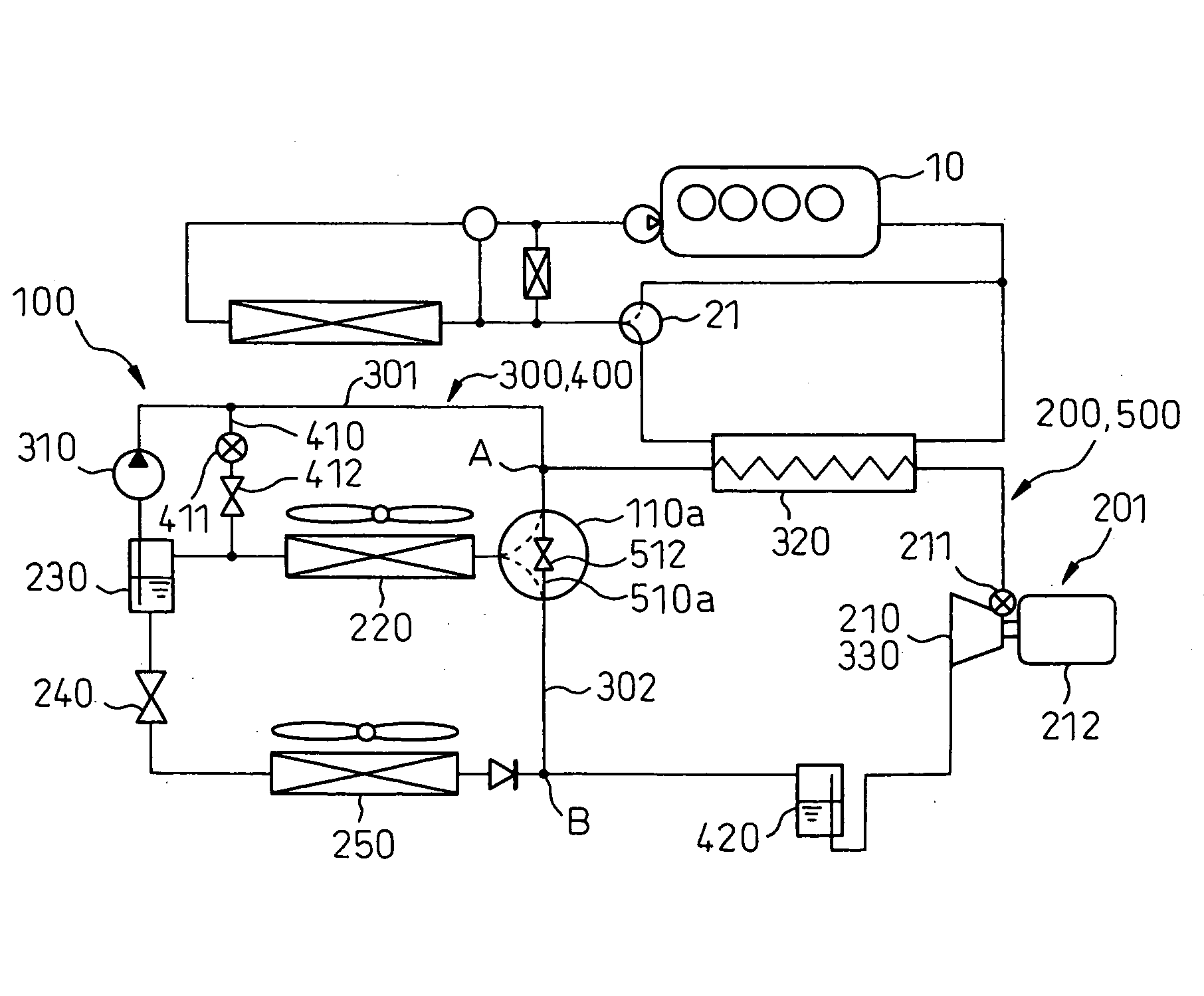

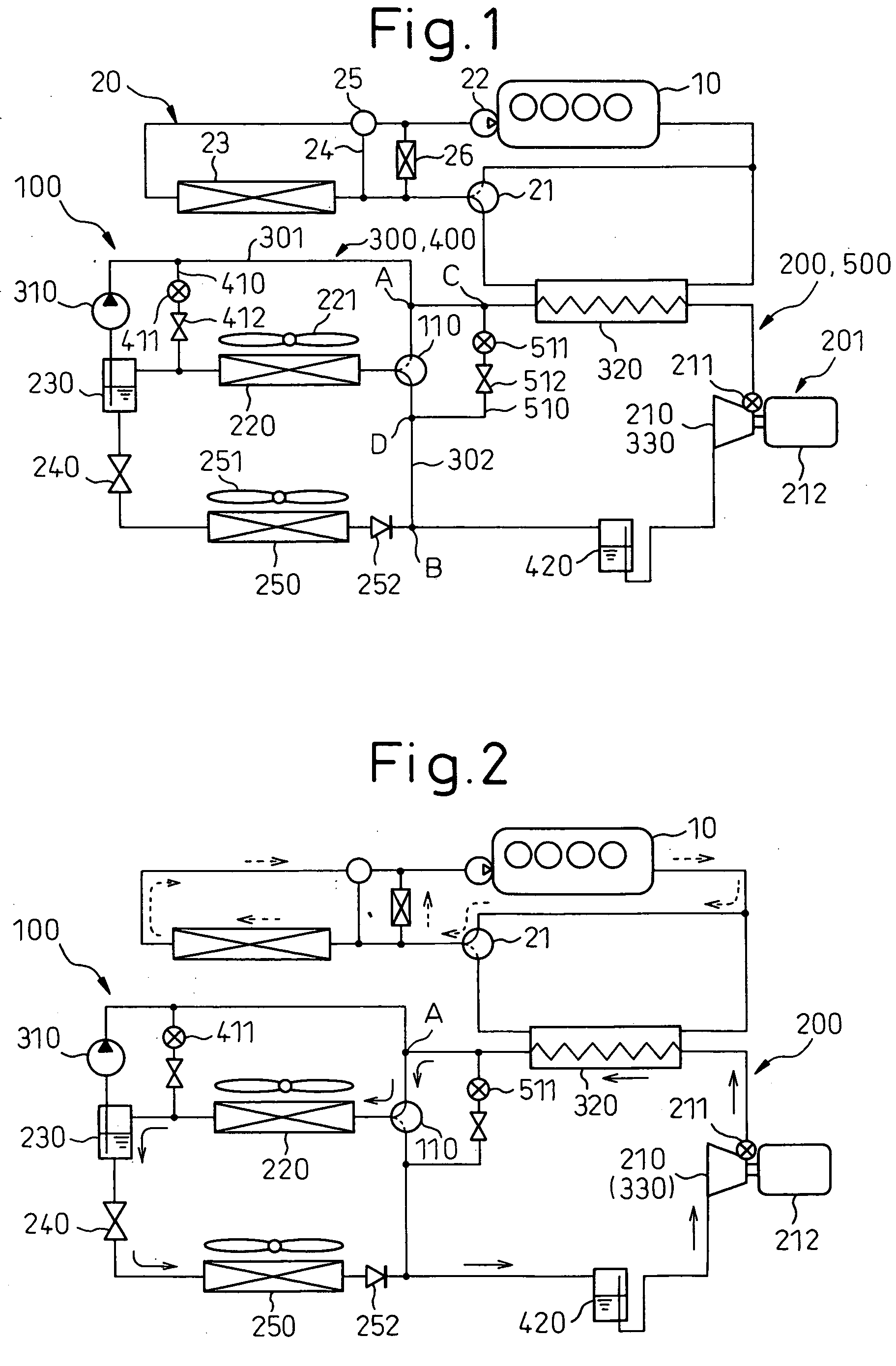

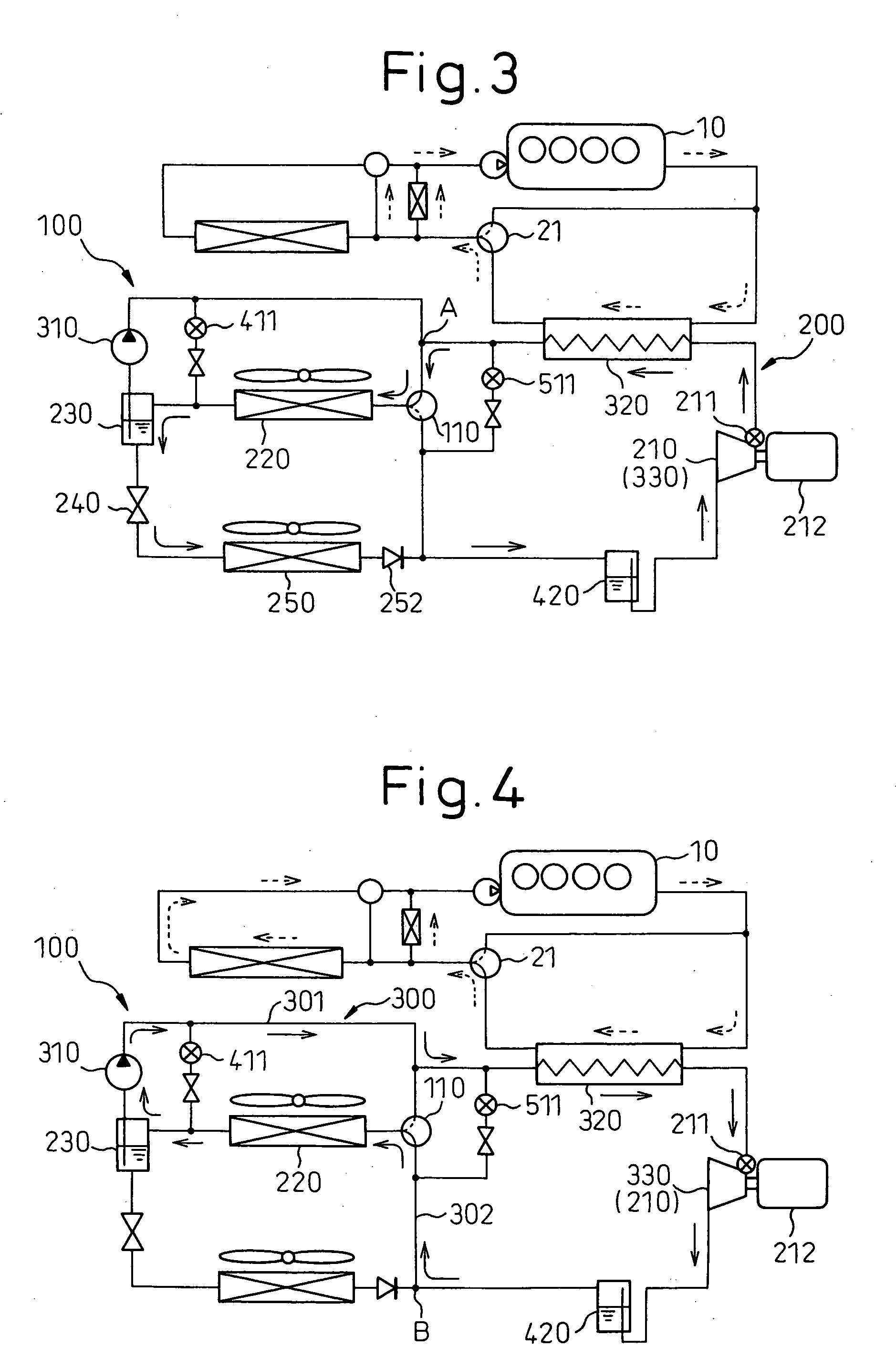

Vapor compression refrigerator

ActiveUS20060005557A1Avoid frostImprove high temperatureAir-treating devicesVehicle heating/cooling devicesEngineeringRefrigerant

A vapor compression refrigerator having a refrigeration cycle (200) is disclosed. In a Rankine cycle (300), a refrigerant is circulated through a pump (310), a heater (320), an expander (330) and a condenser (220) in that order, and power is recovered by the expander 330 due to the expansion of the refrigerant from the heater (320). In a host gas cycle (500), on the other hand, the inlet of the compressor (210) can be connected from a point between the pump (310) and the heater (320) by a switching path (510) having a first restricting portion (510), the refrigerant is circulated by the compressor (210) through the heater (320) and the switching path (510) in that order, and the heater (320) exhibits the function of heating a heat generating device (10).

Owner:DENSO CORP

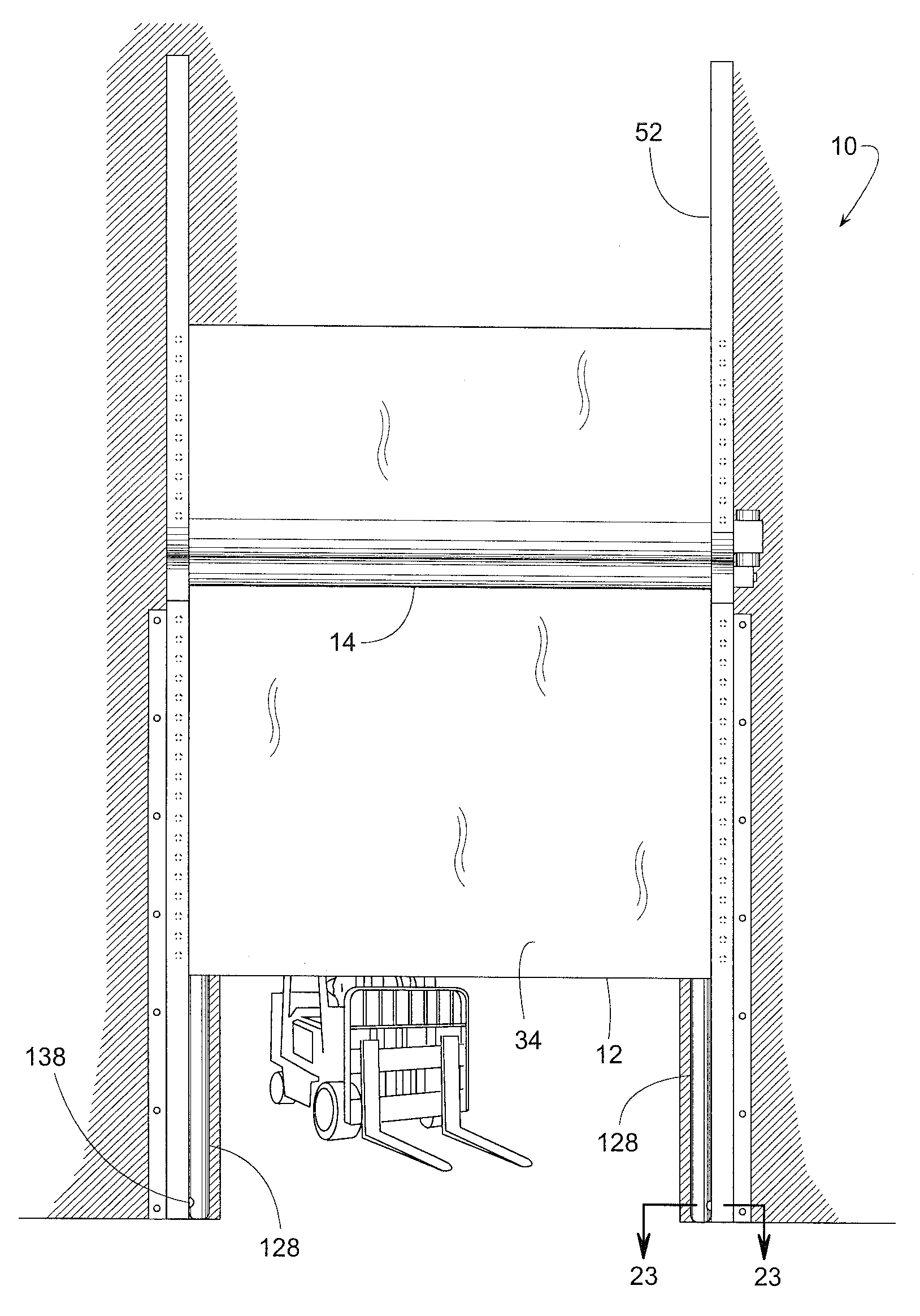

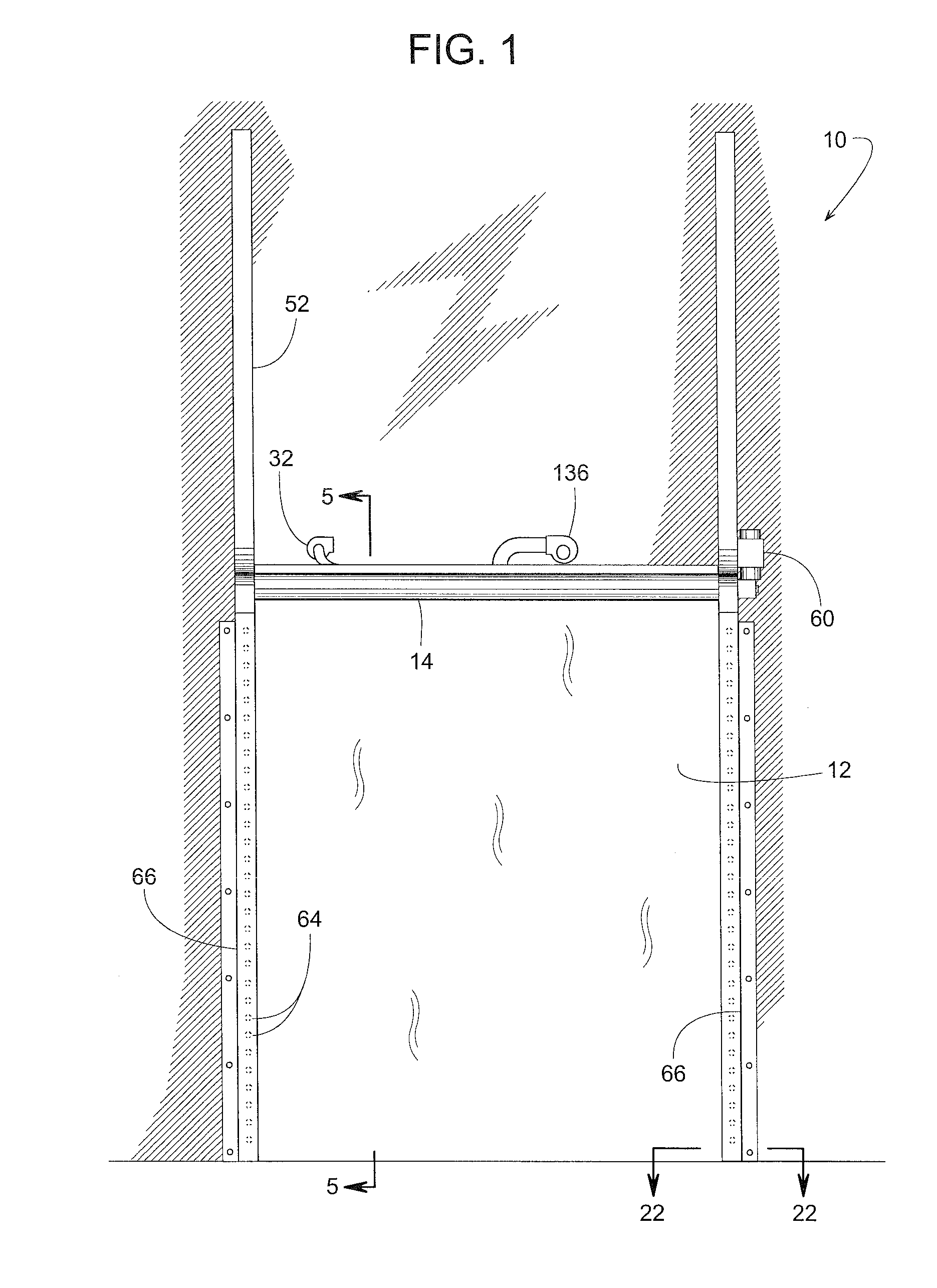

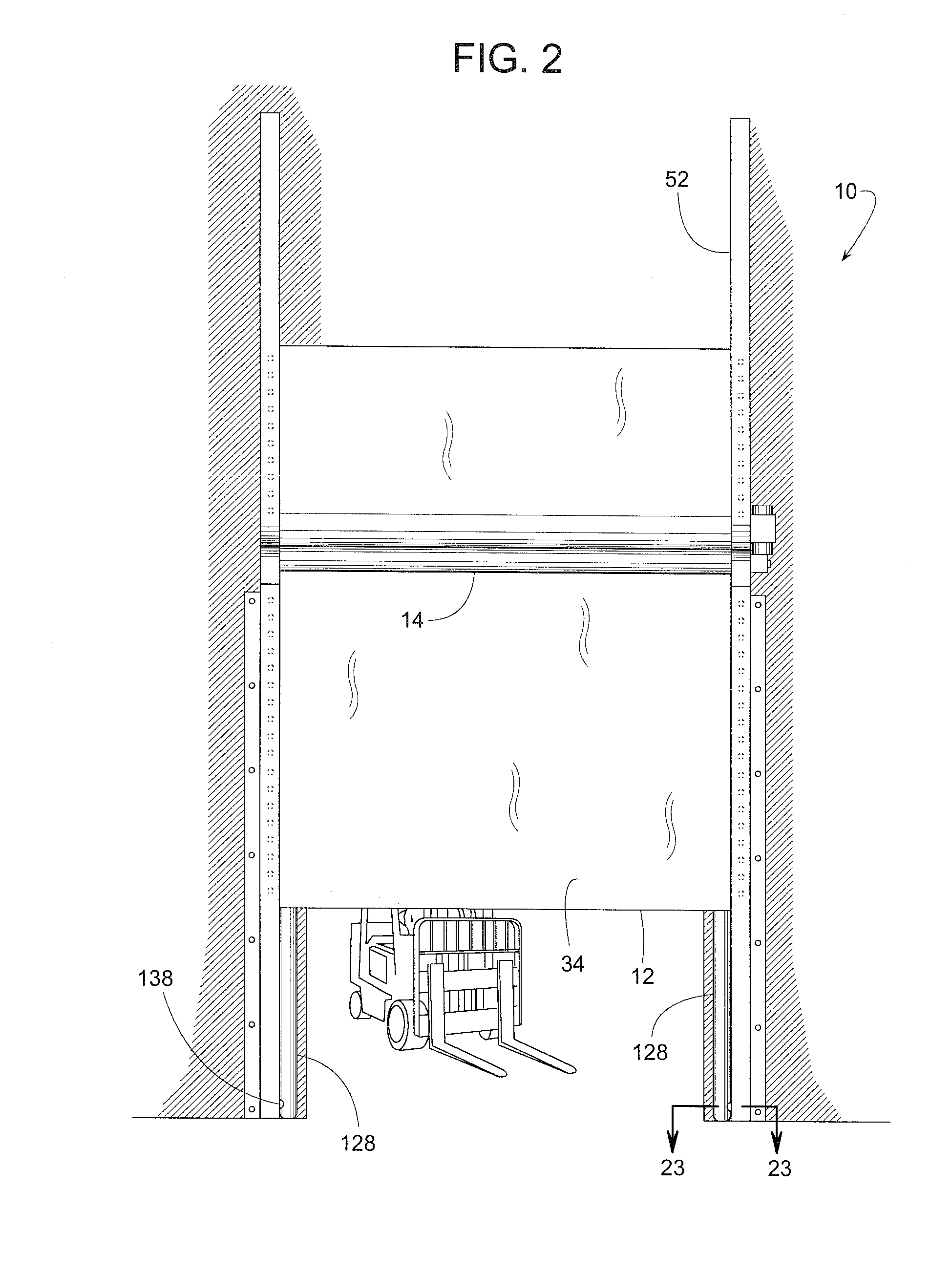

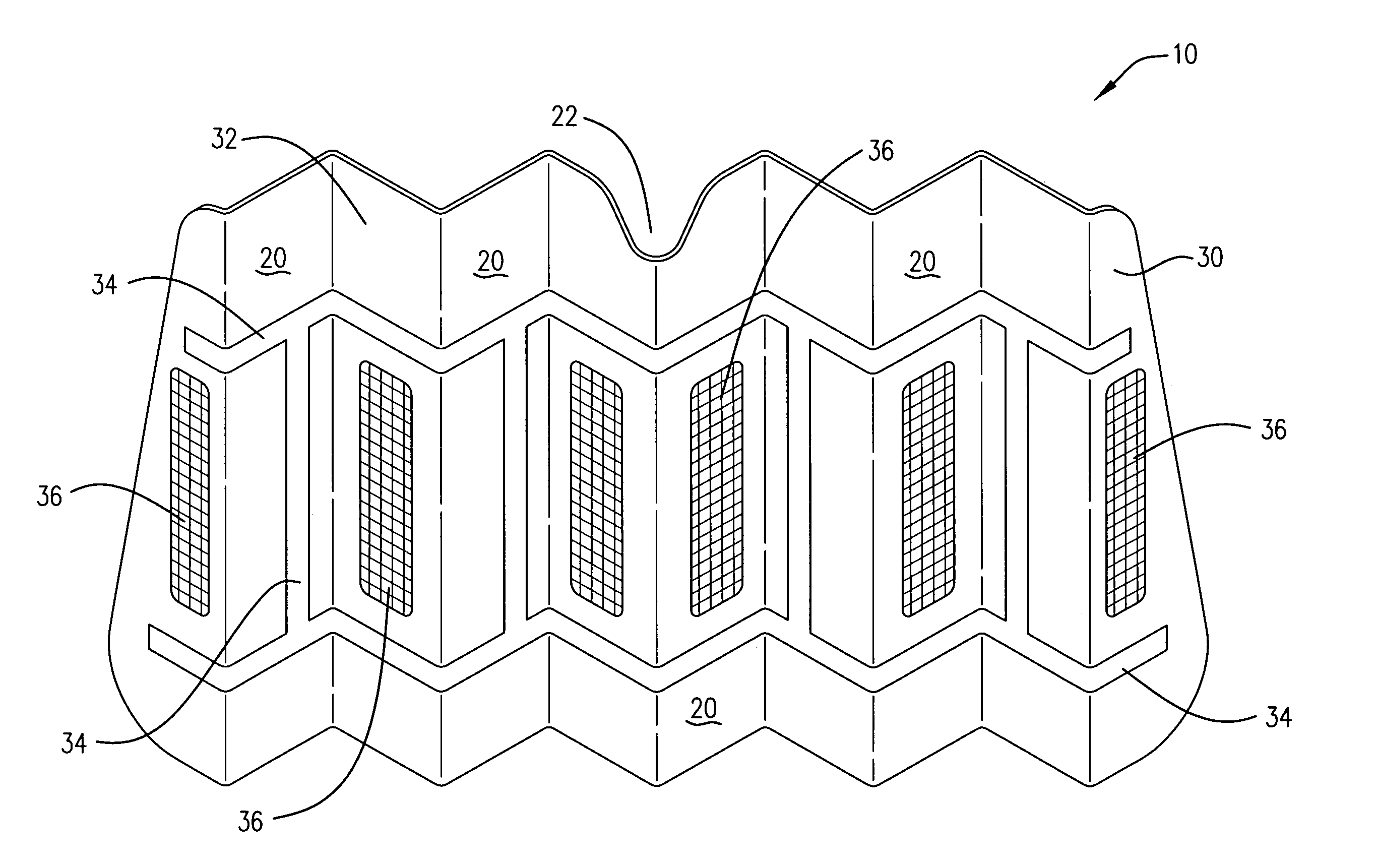

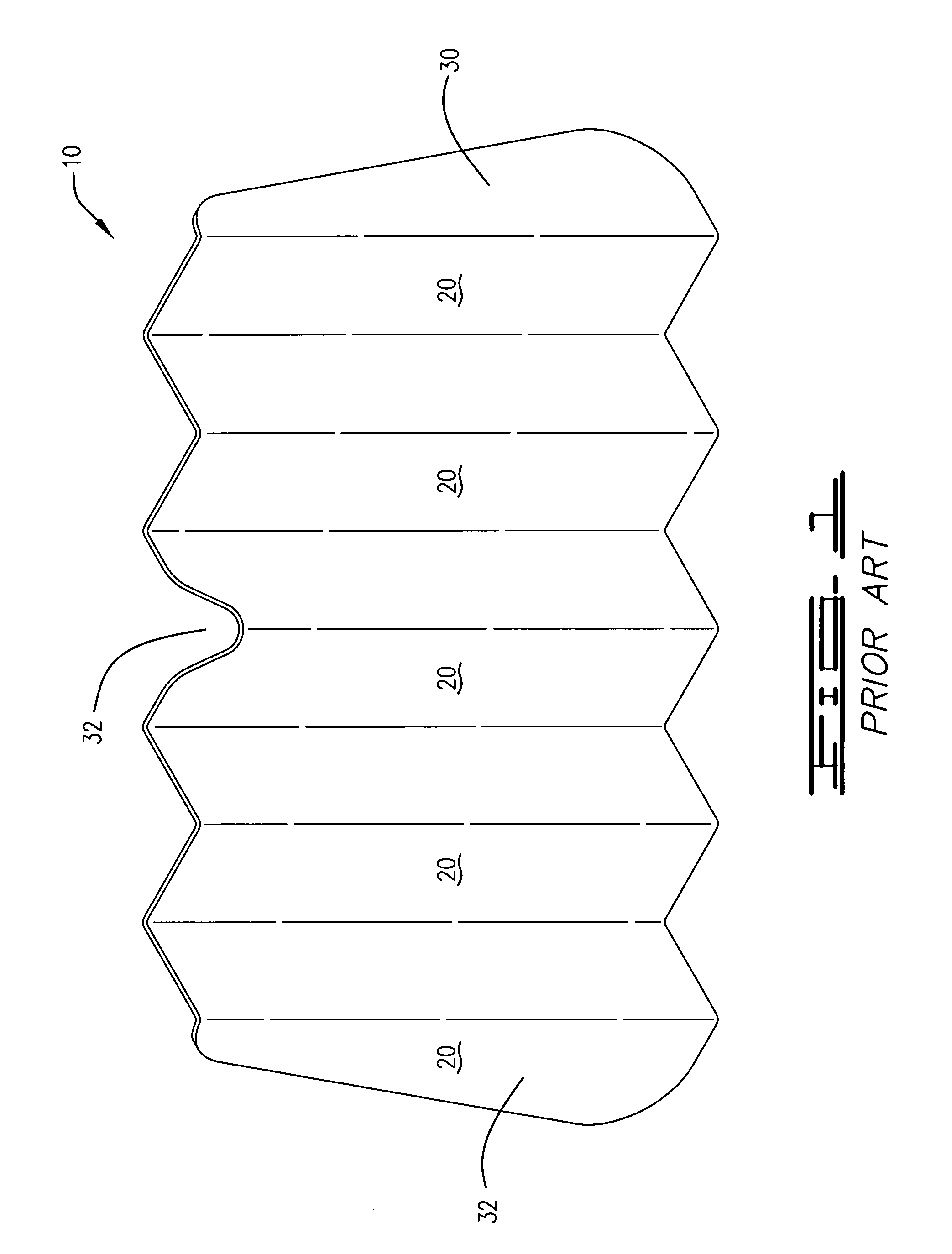

Insulated curtain for a door

InactiveUS20080110580A1Avoid frostShutters/ movable grillesDomestic cooling apparatusFrostThermal insulation

A vertically operating door includes a flexible panel comprising two pliable sheets of material with a layer of thermal insulation between the two. The door includes means for preventing or relieving undesirable air pressure conditions inside the panel. In some cases, a hose from a suction inlet of a blower extends into the space between the two sheets so that when the door is closed with the bottom of the panel resting upon the floor, the blower draws out excess air that happens to leak into the hollow interior of the panel. In other cases, air passageways are created to release or redistribute the excess air inside the panel. The door includes an inflatable seal that helps prevent frost from forming on the door panel's vertical guide tracks, thus the door is particularly suited for refrigerated cold storage rooms.

Owner:RITE HITE HLDG CORP

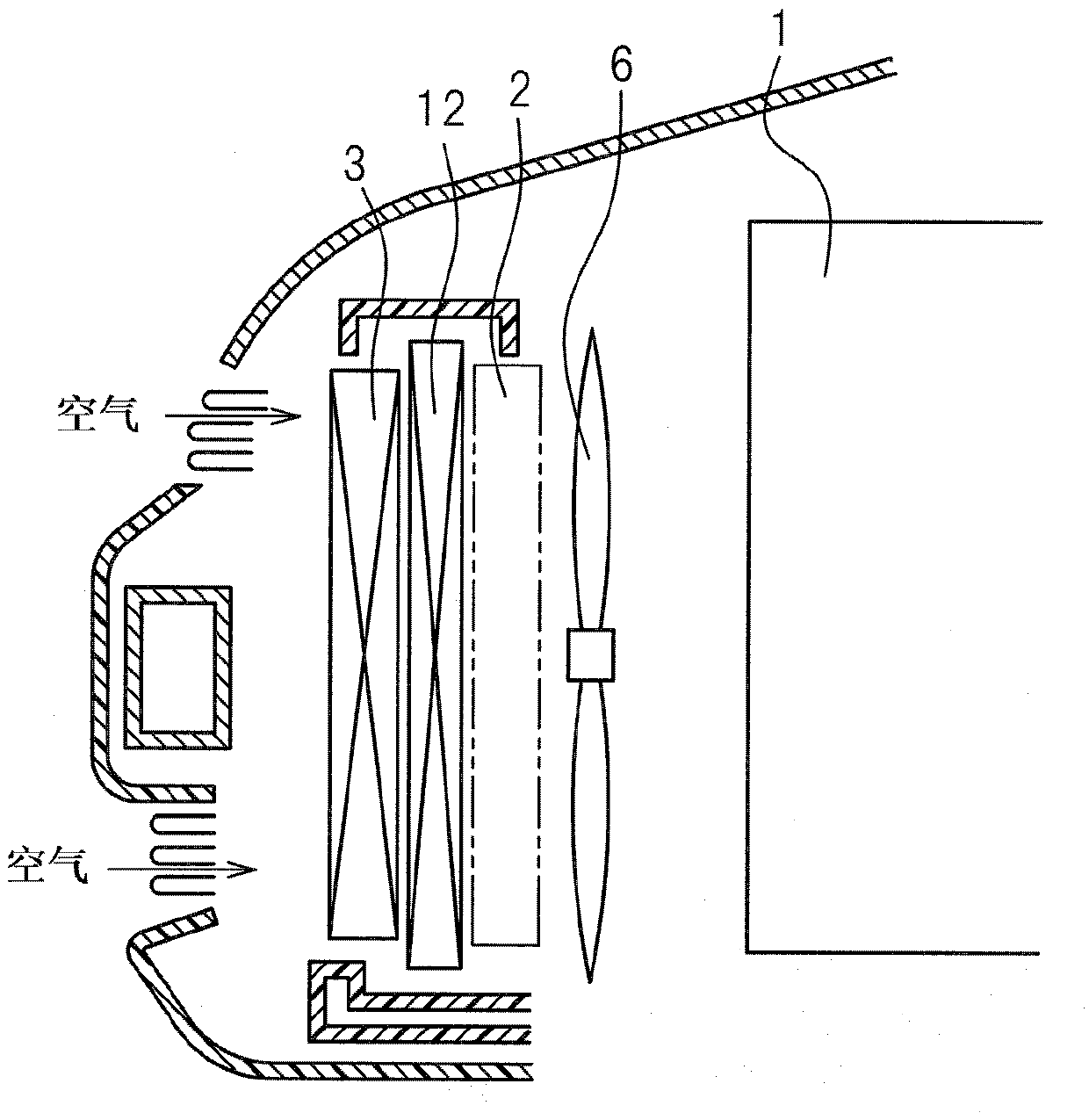

Configuration of vehicle heat exchanger

InactiveCN103121393AImprove abilitiesProtection from frostAir-treating devicesVehicle heating/cooling devicesEngineeringAir conditioning

The present invention provides a configuration of a vehicle heat exchanger. The configuration of the vehicle heat exchanger comprises an outdoor heat exchanger of a heat pump system of a vehicle air conditioning device and a low water temperature radiator used for cooling the low temperature heating elements, including a vehicle driving motor, and is characterized in that relative to the outdoor heat exchanger, the low water temperature radiator is arranged at the upstream side of a cooling airflow direction.

Owner:DENSO CORP

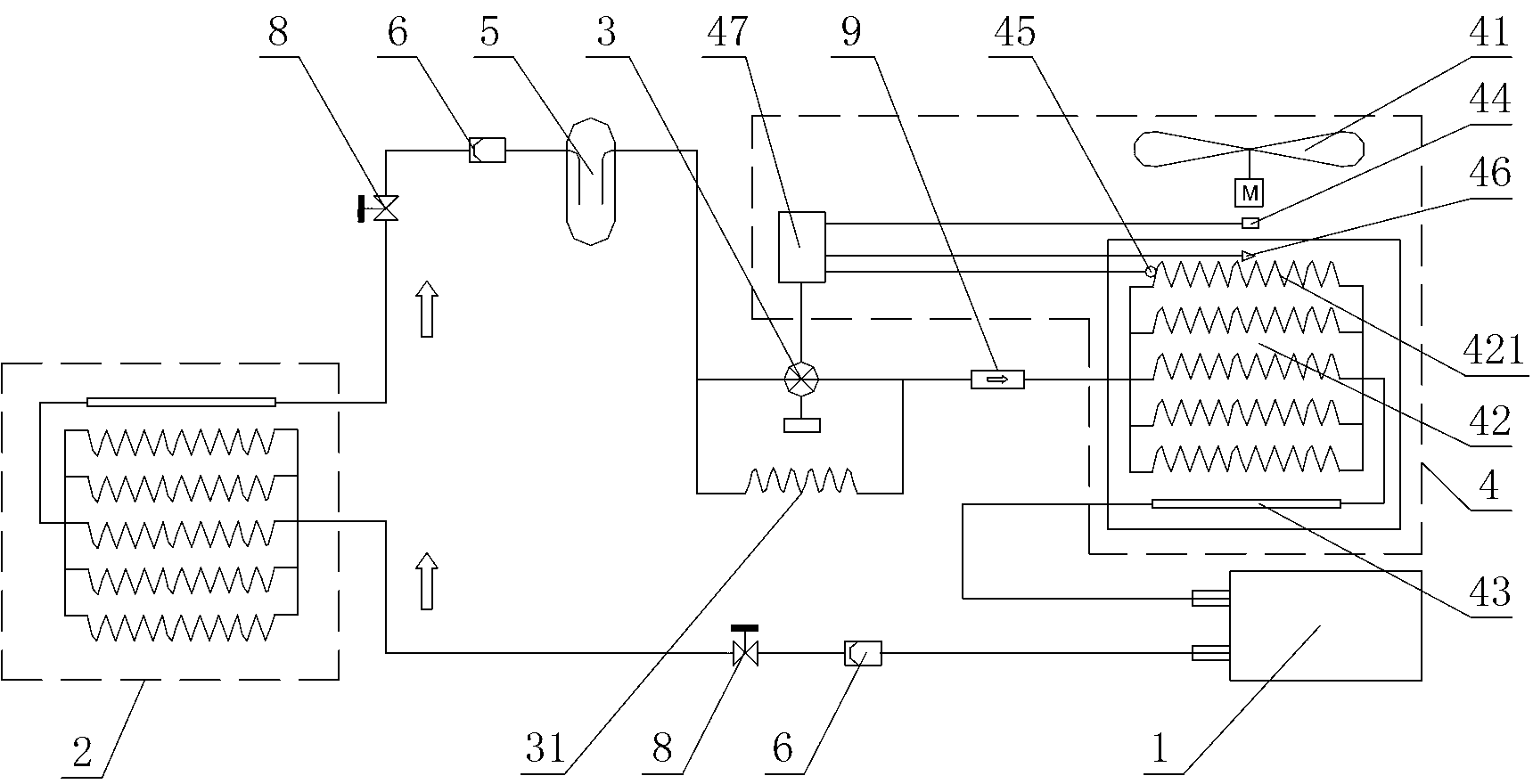

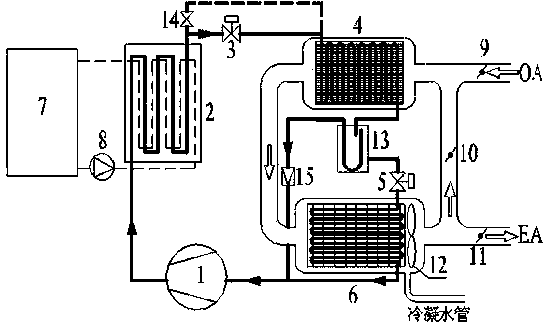

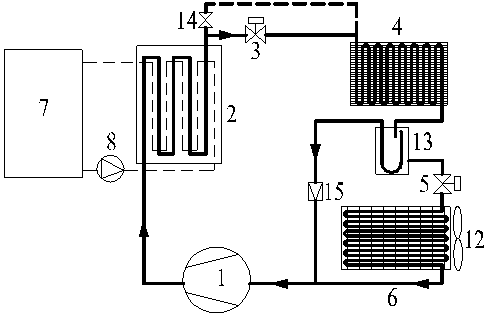

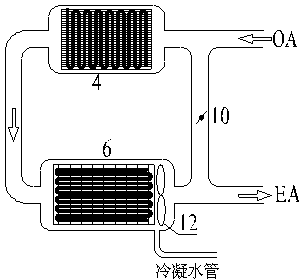

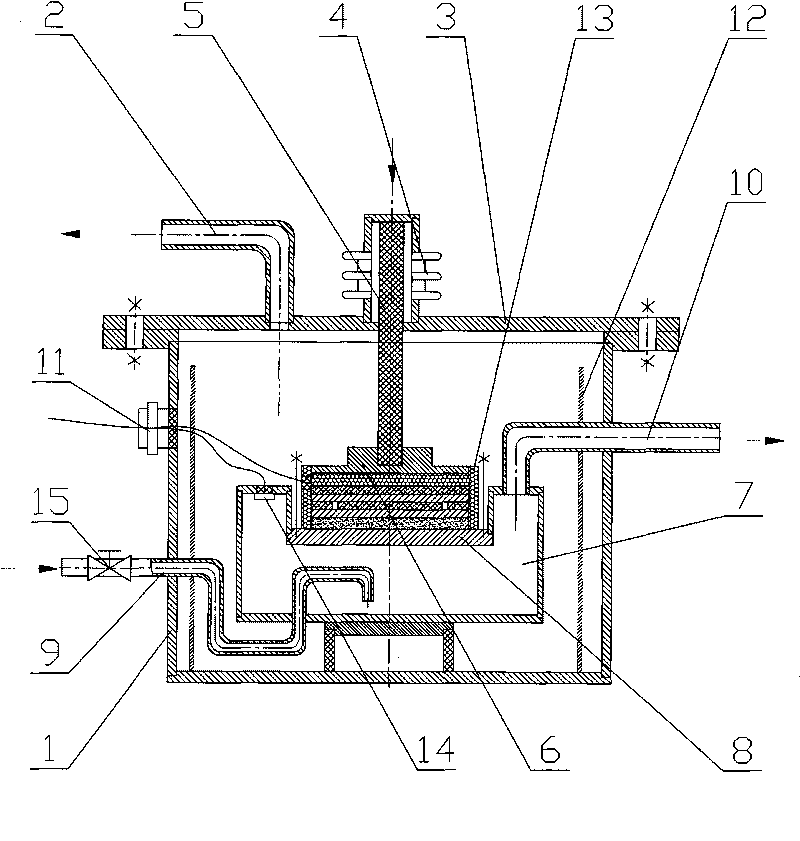

Frost-free type air source heat pump system

The invention discloses a frost-free type air source heat pump system. The system carries out heat pump circulation, can absorb heat from ambient air and can avoid a frosting phenomenon. The system utilizes the characteristic of the absorption / desorption of a similar salt solution, and the heat is absorbed from an ambient environment by a cooling tower. The system comprises a heat pump subcycle part, a solution heat-absorbing subcycle part and a solution regeneration subcycle part. The solution regeneration subcycle part comprises a solution heat regenerator, a solution / air preheater, a first regenerator, a second regenerator and a regenerated heat absorber. After being preheated by the first regenerator, the ambient air enters the second regenerator, and then flows out of the solution / air preheater after water in a regenerated solution is absorbed, and the effluent air is used for preheating part of a low-temperature dilute solution entering the solution / air preheater. The invention avoids the occurrence of the frosting condition of the traditional air source heat pump system; the utilization rate of equipment and energy resources is enhanced.

Owner:ZHEJIANG UNIV

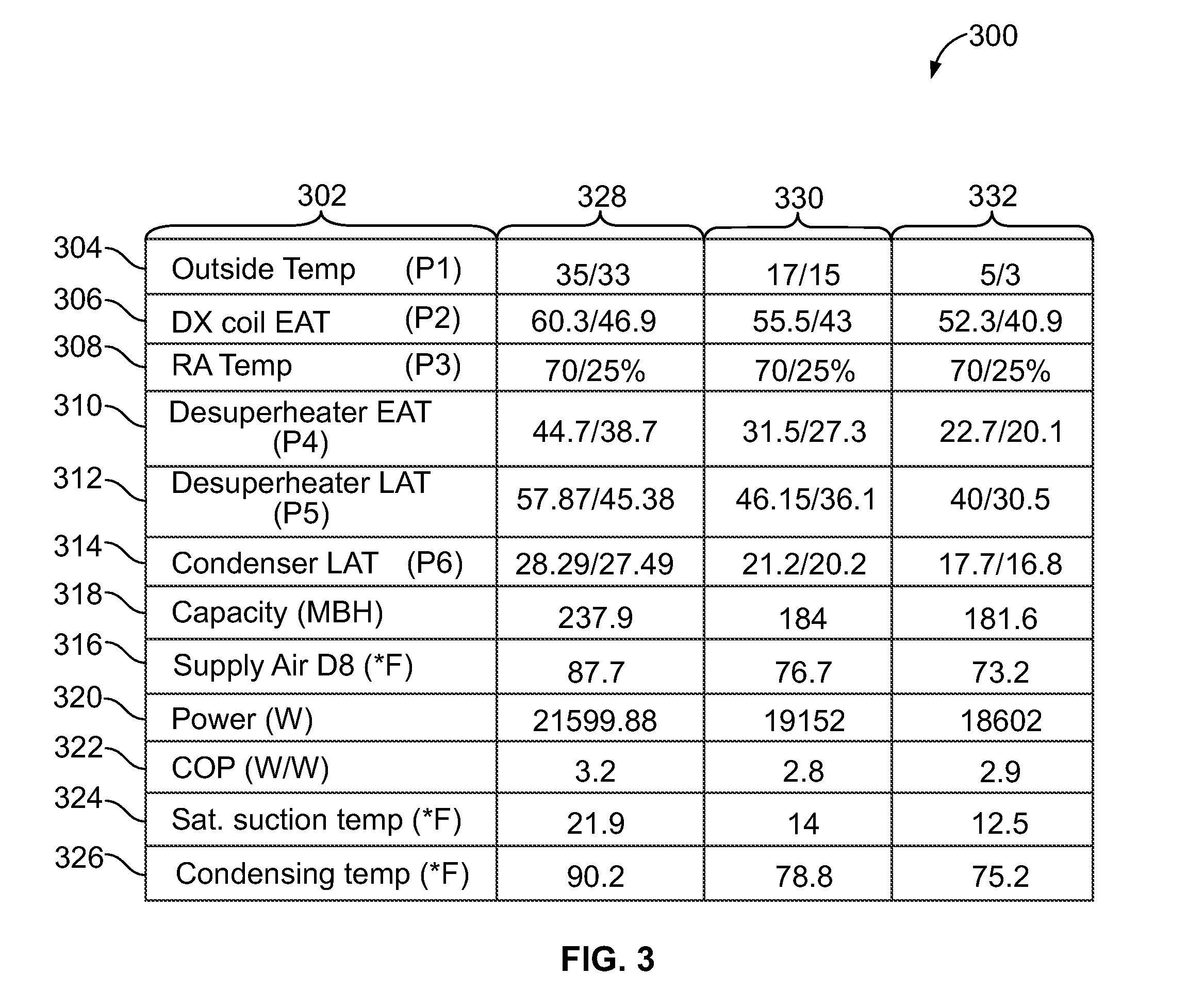

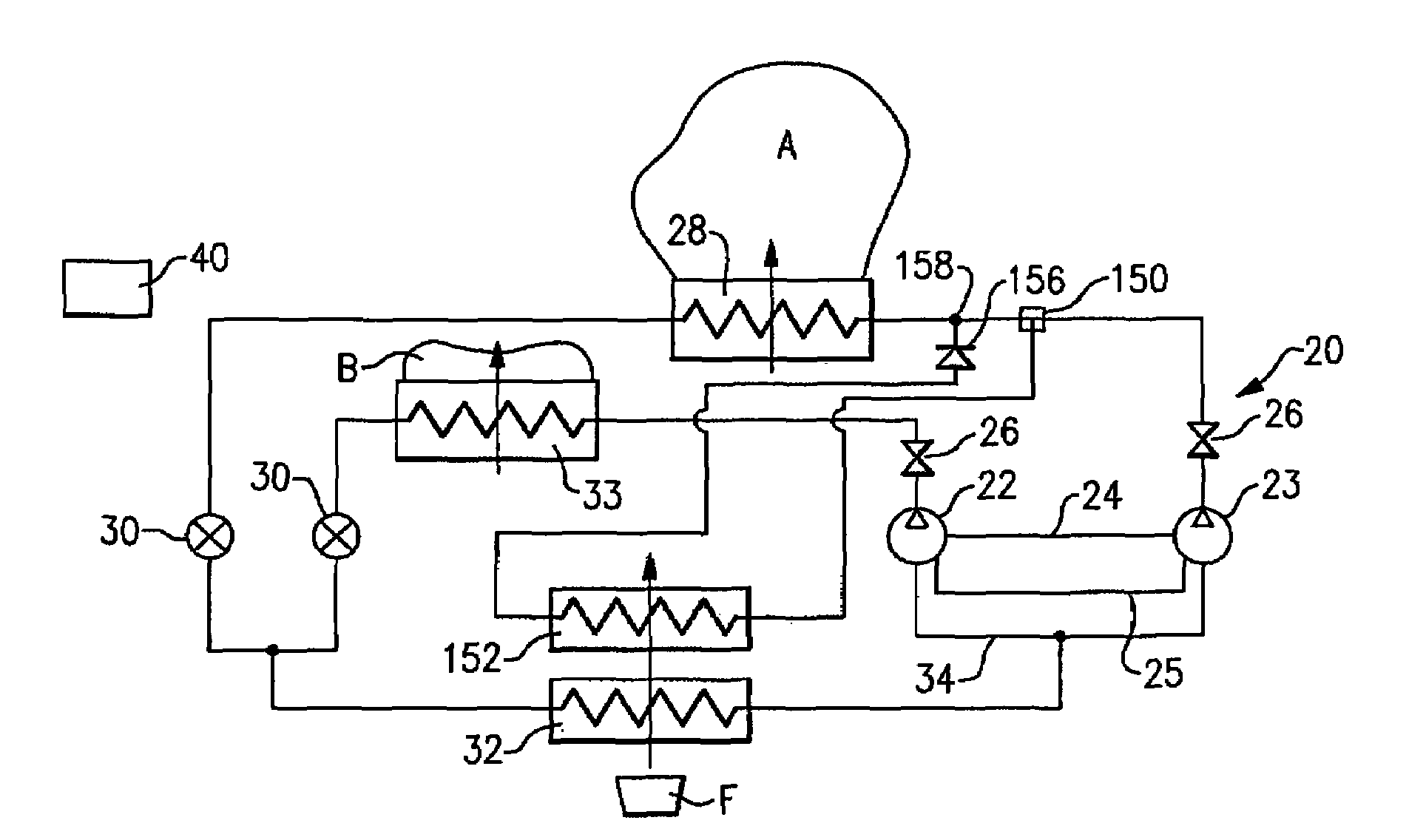

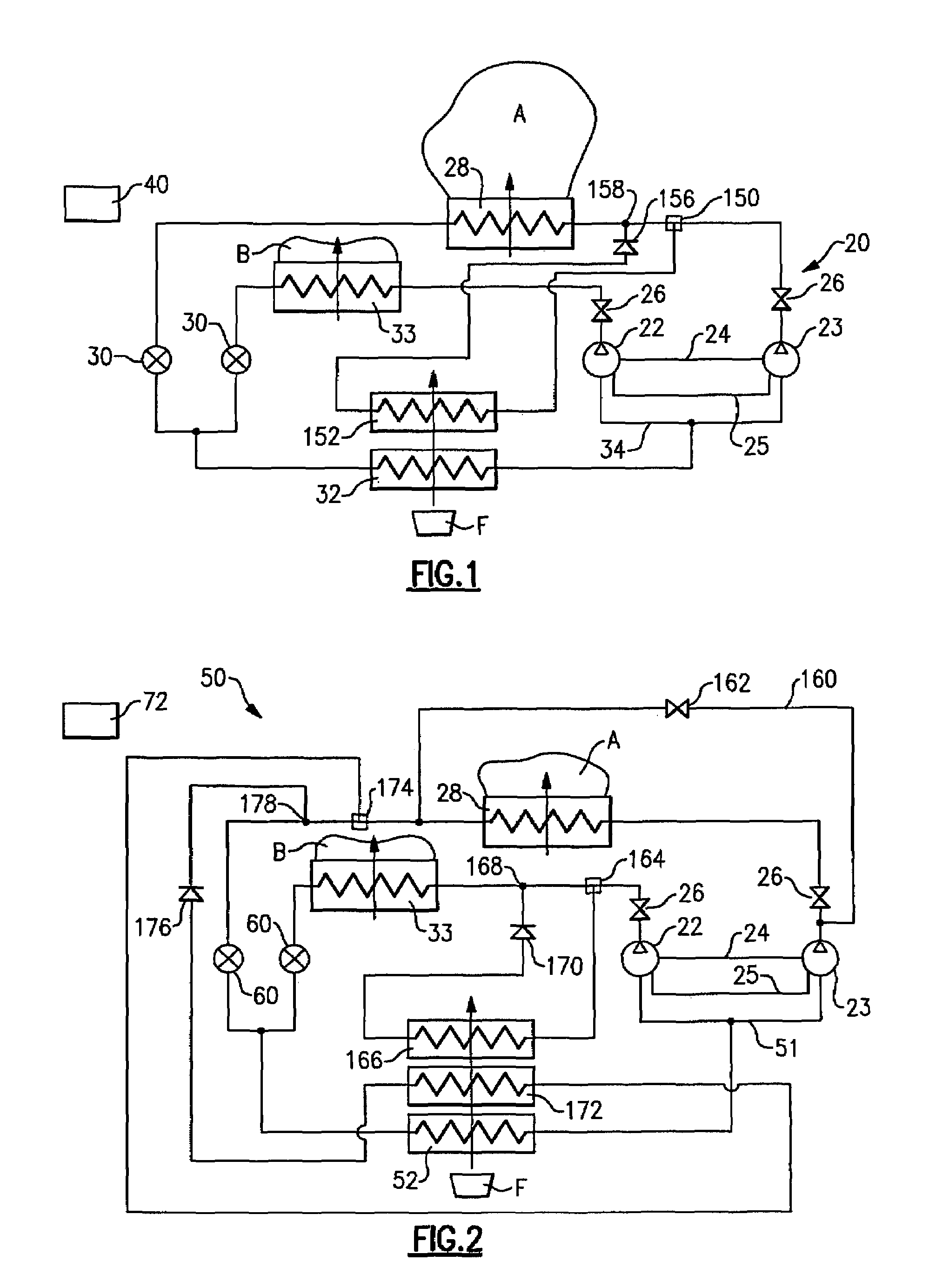

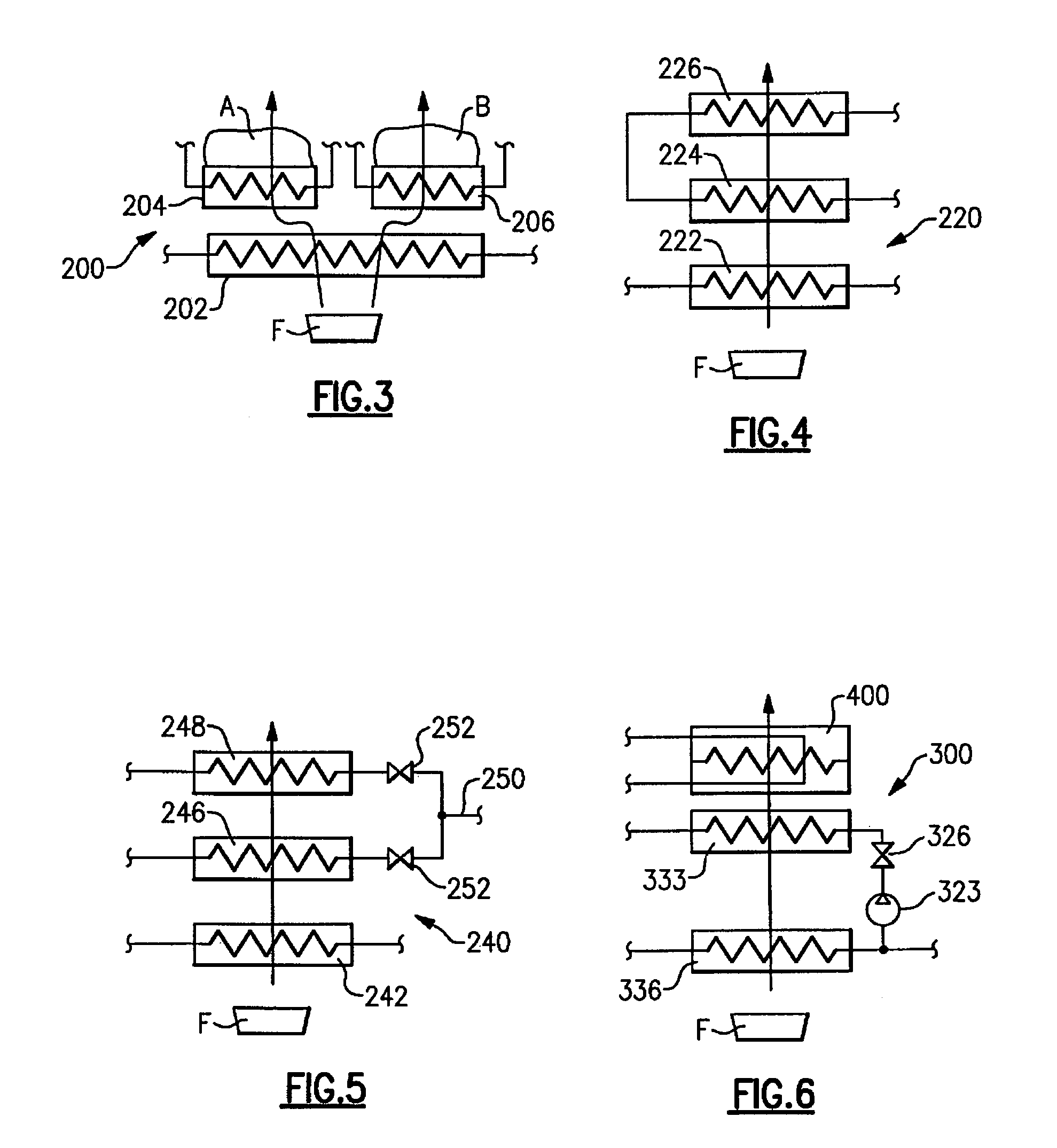

Multiple condenser reheat system with tandem compressors

InactiveUS7469555B2Avoid frostMechanical apparatusCompression machines with non-reversible cycleHeat rejectionEngineering

A tandem compressor system is utilized that receives refrigerant from a common suction manifold, and from a common evaporator. From the compressors, the refrigerant passes to a plurality of condensers, with each of the condensers being associated with a separate zone for heat rejection, preferably at different temperature levels. Each of the condensers is associated with at least one of the plurality of compressors. A reheat coil is associated with the evaporator to improve comfort level in the environment to be conditioned. Multiple reheat circuits associated with separate condensers are employed to provide various stages of reheat or to condition separate environments. By utilizing the common evaporator, a plurality of condensers, and the reheat coils, the ability to independently control temperature, humidity and amount of heat rejection to a number of zones is achieved without the requirement of having dedicated circuits with multiple additional components. Thus, the overall system cost and complexity is significantly reduced and its operational and control flexibility is improved.

Owner:CARRIER CORP

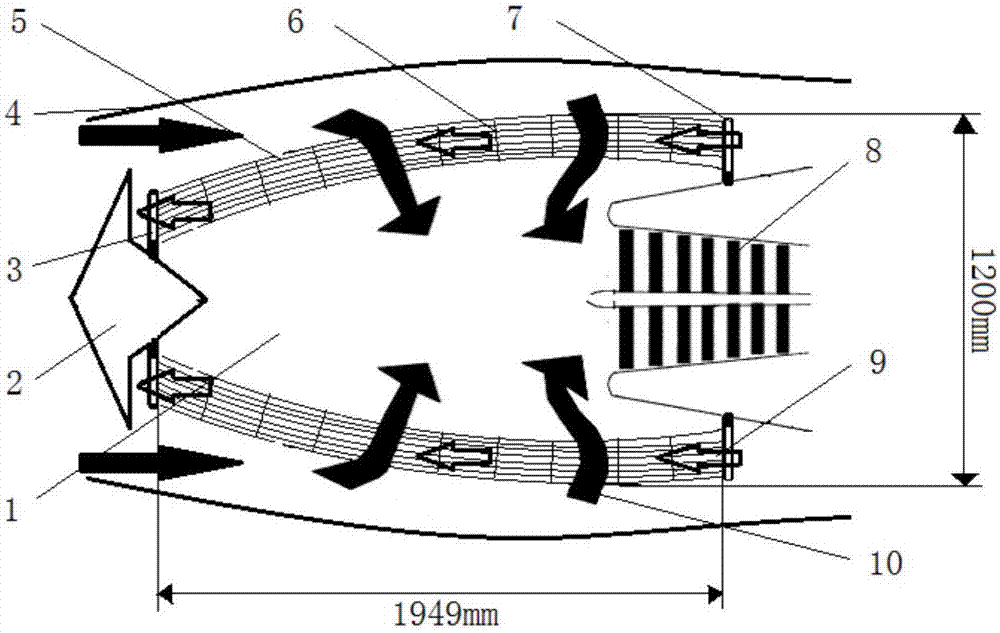

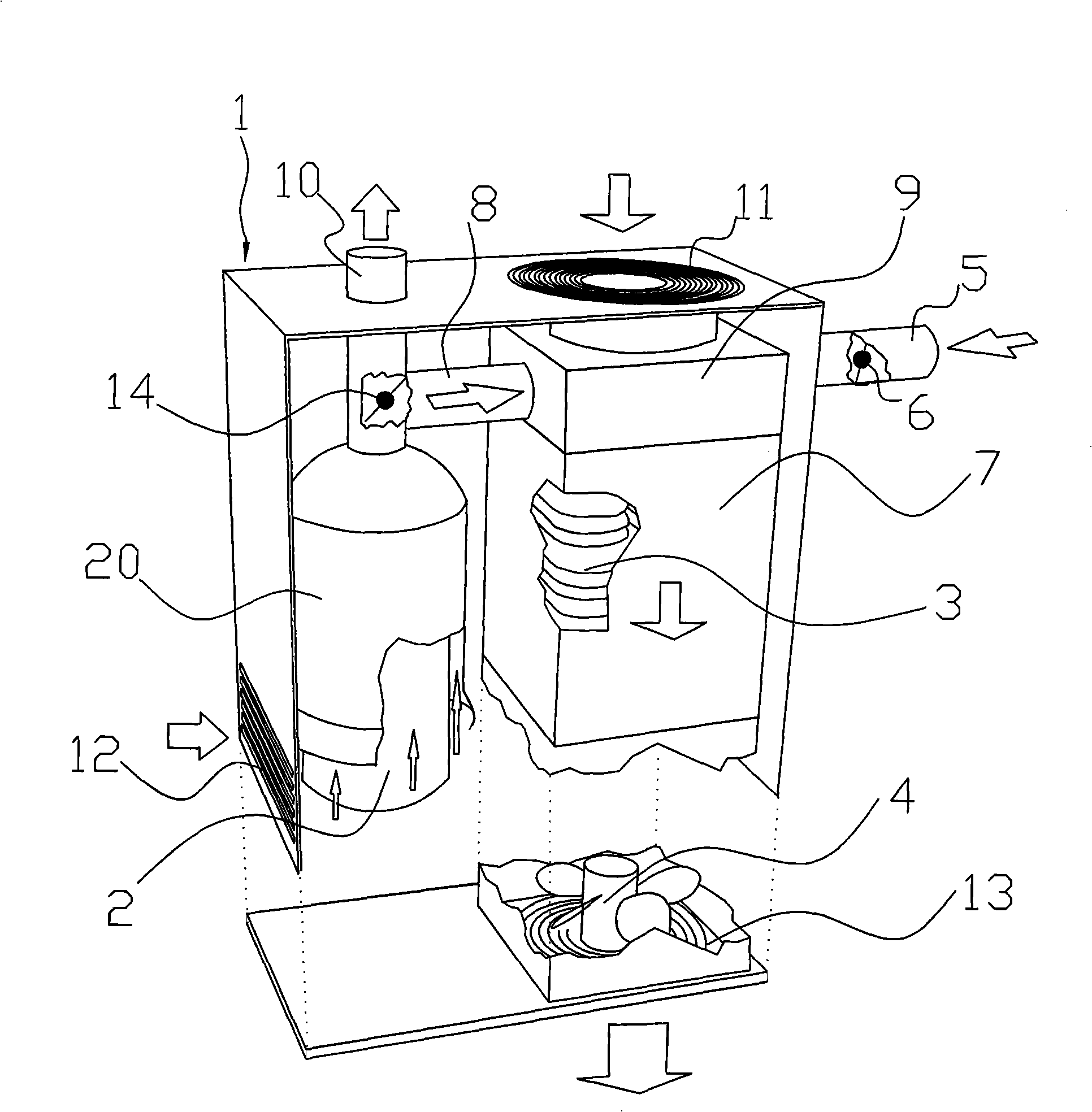

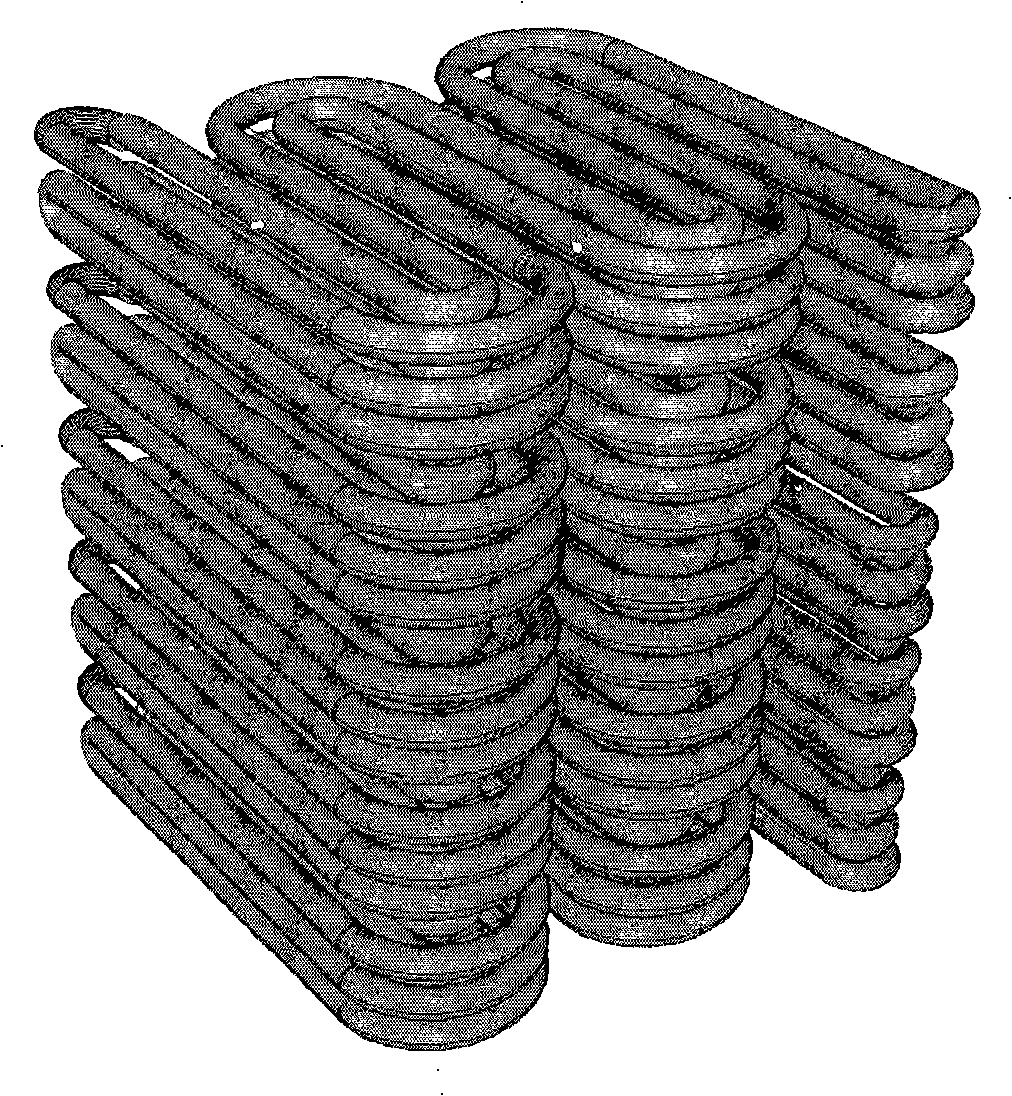

Efficient and compact pre-cooling heat exchanger for pre-cooling gas sucking type engine

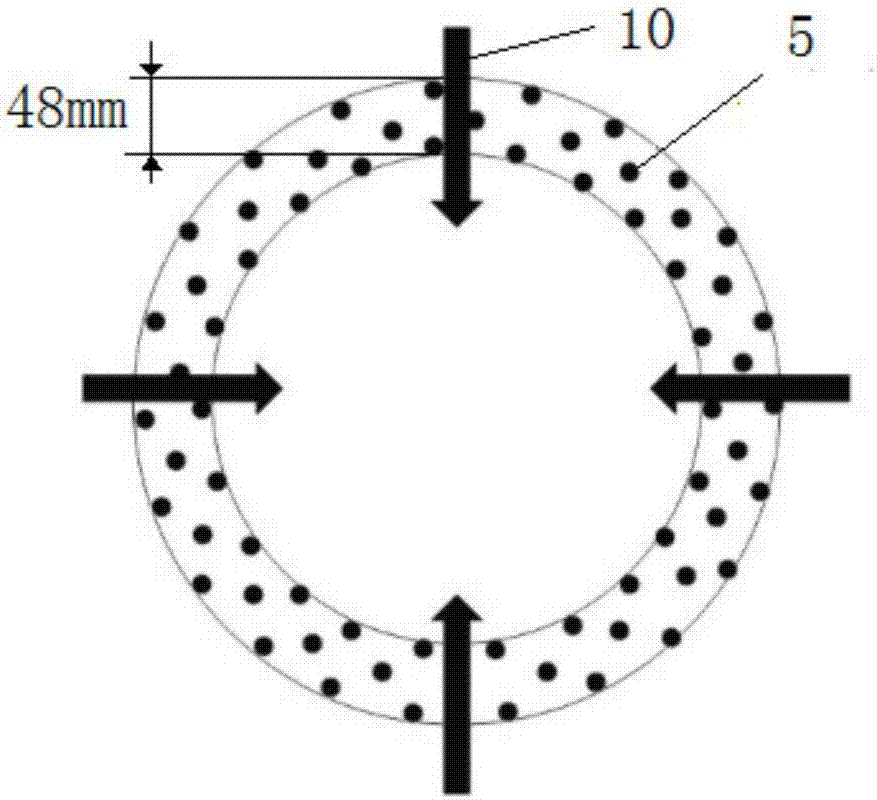

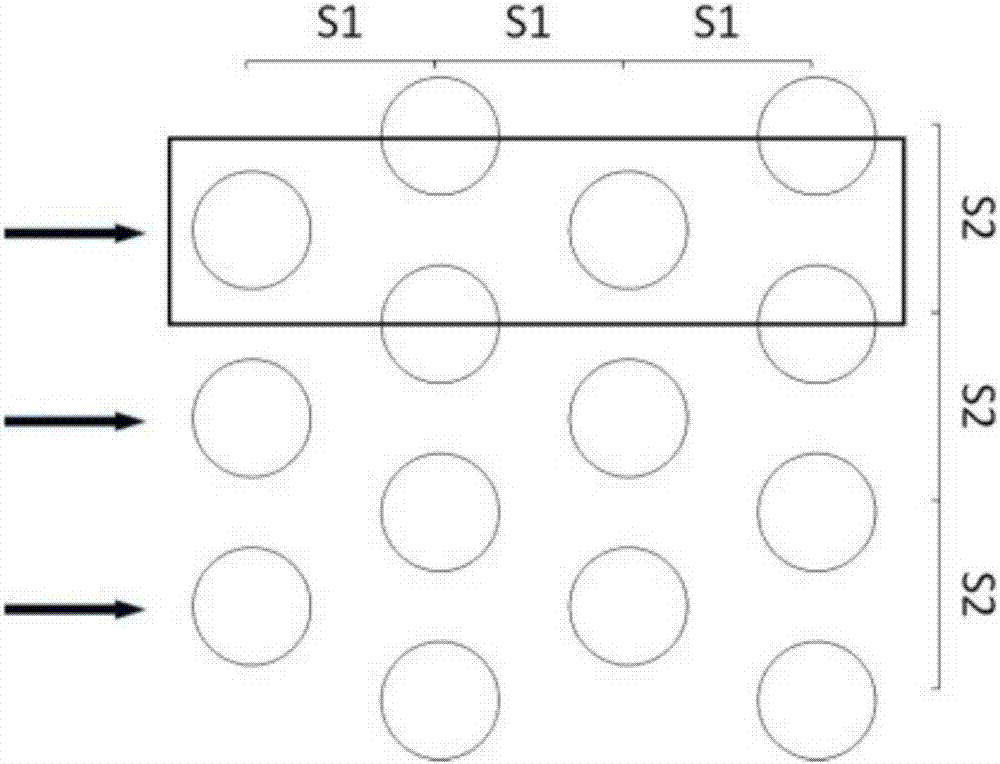

ActiveCN107218133AGuaranteed heat exchange effectReduce welding difficultyTurbine/propulsion engine coolingGas turbine plantsEngineeringCurrent technology

The invention discloses an efficient and compact pre-cooling heat exchanger for a pre-cooling gas sucking type engine. The efficient and compact pre-cooling heat exchanger for the pre-cooling gas sucking type engine comprises a pre-cooling heat exchanger body in the shape of a similar cylinder; the cross section of the similar cylinder is in the shape of a ring different in diameter; the longitudinal section of the similar cylinder is formed by two symmetrically arranged arc segments; the center angle of each arc segment is 45 degrees; the pre-cooling heat exchanger body comprises a cold flow outlet pipe, a cold flow inlet pipe and a plurality of heat exchanging pipes; each heat exchanging pipe is in the shape of an arc; the arc-shaped center angle of each heat exchanging pipe is 45 degrees; and the heat exchanging pipes are distributed into the similar cylinder in a crossed manner. The efficient and compact pre-cooling heat exchanger for the pre-cooling gas sucking type engine can have the engineer realizability on the premise that the heat exchanging effect is guaranteed, so that air incoming flow in front of a gas compressor can be pre-cooled, the high temperature over-running problem of gas compressor blades is solved, the engine thrust is increased, the flight envelop is extended, the welding difficulty is effectively reduced, the frosting blockage problem is effectively solved, the engineer realizability is achieved under the current technology, and after the efficient and compact pre-cooling heat exchanger for the pre-cooling gas sucking type engine is applied to the pre-cooling gas sucking type engine, the engine performance can be substantially improved.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

Refrigeration cycle device

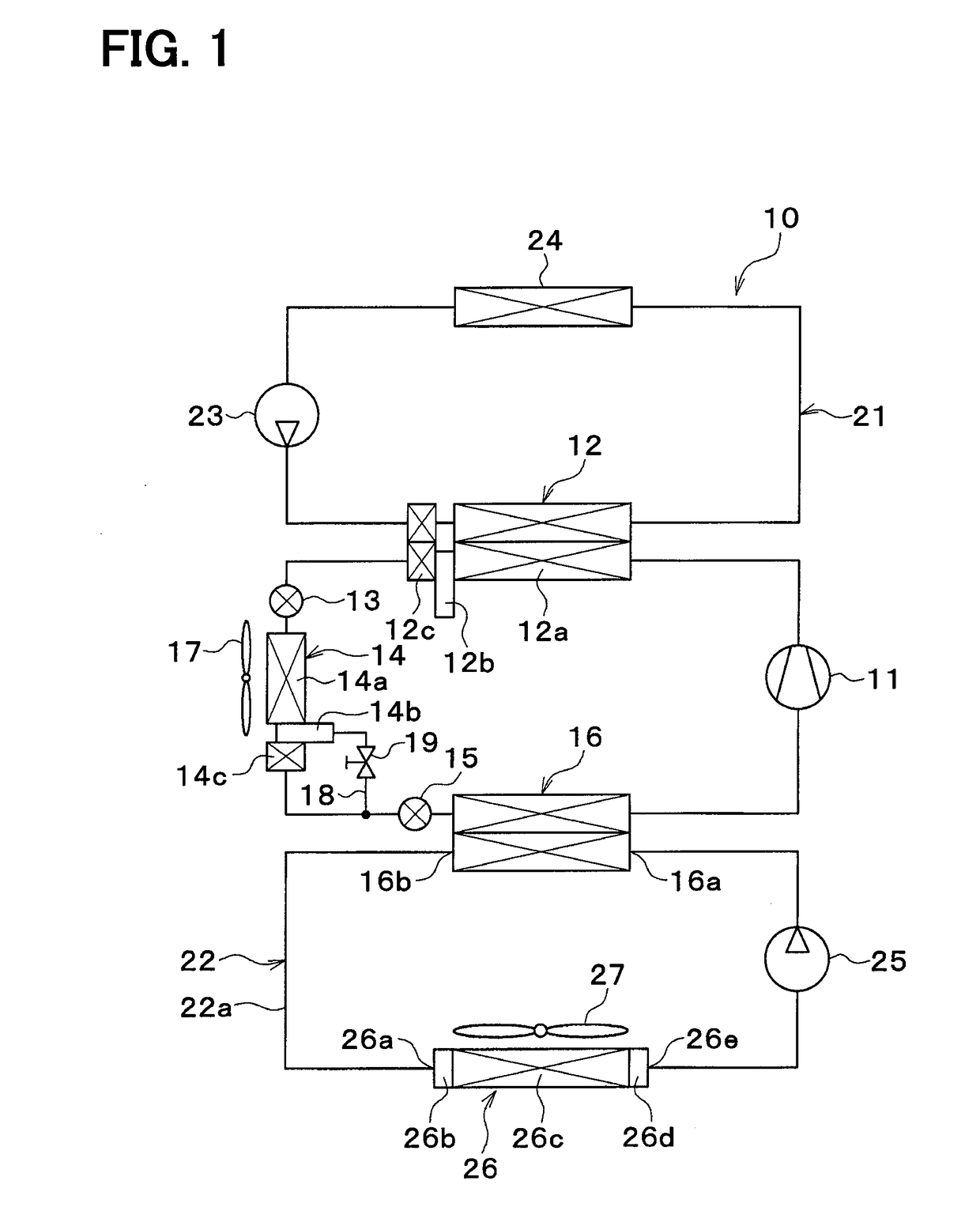

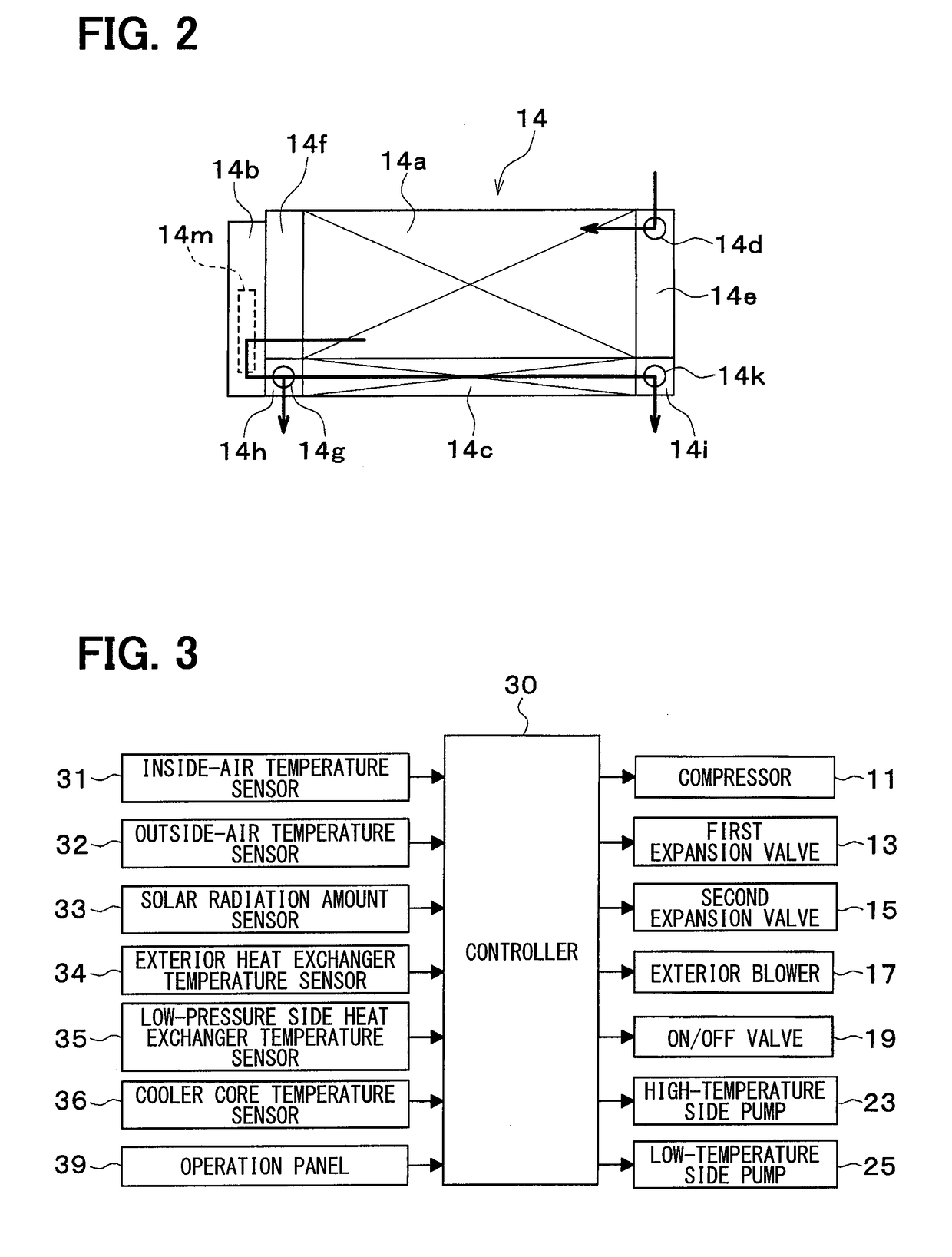

ActiveUS20180361828A1Avoid frostDecrease of heat absorption amountMechanical apparatusAir-treating devicesEngineeringHigh pressure

A refrigeration cycle device includes: a first expansion valve that decompresses a refrigerant flowing out of a high-pressure side heat exchanger; an exterior heat exchanger that exchanges heat between the refrigerant flowing out of the first expansion valve and outside air; a second expansion valve that decompresses the refrigerant flowing out of the exterior heat exchanger; a low-pressure side heat exchanger arranged in series with the exterior heat exchanger; a cooler core that exchanges heat between the heat medium cooled by the low-pressure side heat exchanger and air to be blown into a vehicle interior to cool the air; and a controller configured to switch between a heat absorption mode and a heat dissipation mode by adjusting an amount of decompression in each of the first expansion valve and the second expansion valve.

Owner:DENSO CORP

Defrosting windshield sunshade panel

A sunshade for an automobile placed upon a dashboard in the interior of the vehicle provides a reflective outer surface to deflect heat and sunlight through the windshield into a vehicle during hot weather conditions and also provides the outer surface with heat strip elements when enabled during cold weather to provide a radiant heat to the windshield to prevent ice build-up on the windshield maintaining a clear windshield during freezing temperatures, the heat strip elements drawings a low voltage current from a rechargeable battery supply or a 12 volt DC power from a cigarette lighter plug, or both.

Owner:HANSEN SCOTT P +1

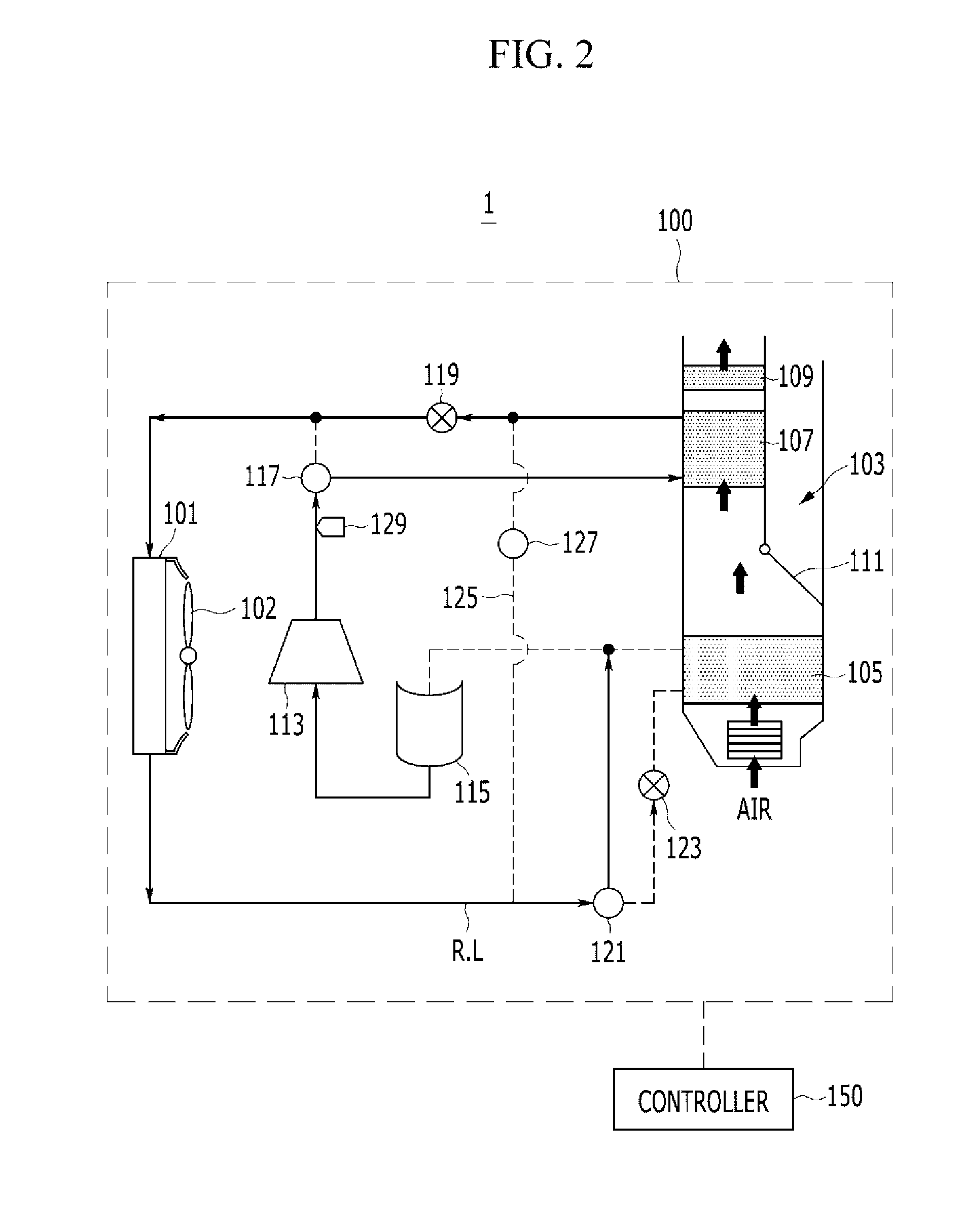

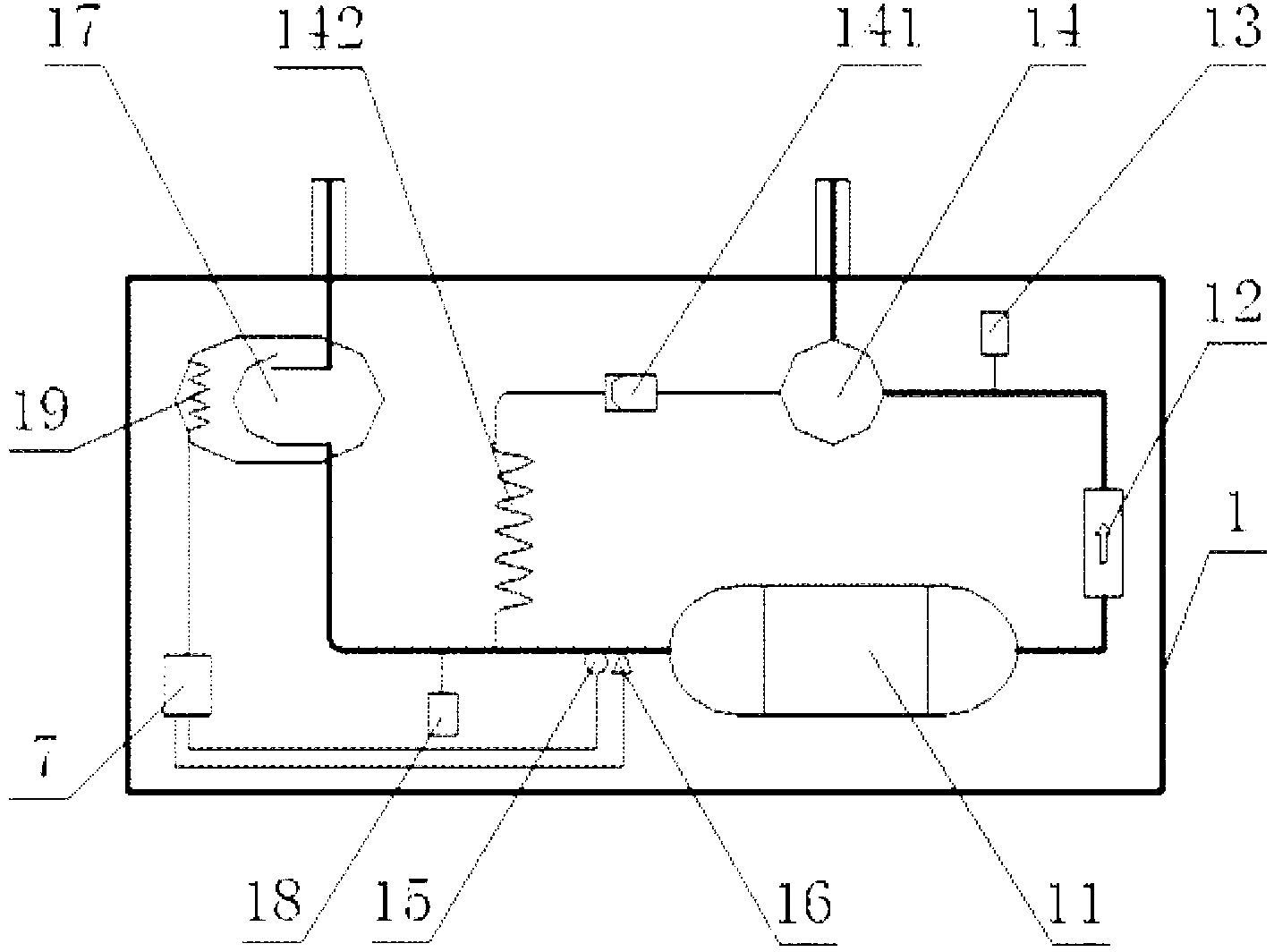

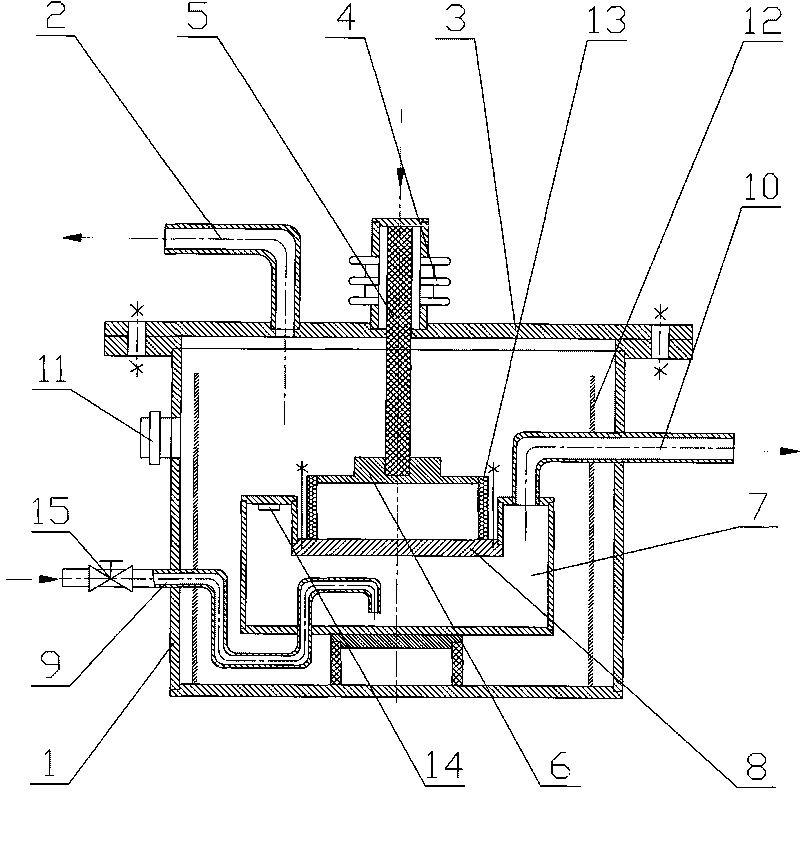

Frostless air handling unit and proportion-integration-differential control method thereof

InactiveCN103216981AWell mixedImprove performanceCorrosion preventionRefrigeration safety arrangementElectricityEngineering

The invention discloses a frostless air handling unit and a proportion-integration-differential control method of the frostless air handling unit. The frostless air handling unit comprises a circulating working return circuit and a controllable silicon power adjuster, wherein the circulating working return circuit is composed of a compressor assembly, a condenser, an electronic expansion valve and an evaporator assembly, the compressor assembly, the condenser, the electronic expansion valve and the evaporator assembly are sequentially connected along the refrigerating fluid flowing direction. When a calculation controller receives an outdoor temperature parameter transmitted by a temperature-humidity sensor and the temperature parameter is lower than 0 DEG C, the calculation controller carries out calculation according to received air temperature and humidity parameters, an air pressure parameter and an evaporator surface temperature parameter, controls the opening degree of the electronic expansion valve according to the calculation results, and adjusts evaporator surface temperature through increase or reduction of the opening degree of the electronic expansion valve. Meanwhile, the controllable silicon power adjuster judges an air suction superheat degree of a compressor through received compressor air suction temperature and air suction pressure, adjusts increase or reduction of electric heater power, and maintains the air suction superheat degree of the compressor to be kept in a preset value range. According to the frostless air handling unit and the proportion-integration- differential control method of the frostless air handling unit, the aim of maintaining safe and high-efficiency operation of the system is achieved.

Owner:宁波沃弗圣龙环境技术有限公司 +1

Three-shaft high-low temperature speed turntable

The invention belongs to a gyro calibrator and discloses a three-shaft high-low temperature speed turntable adaptable to high and low temperature ranges. The turntable comprises a turntable base, an outer frame, a middle frame, an inner frame, driving shafts of the outer frame, the middle frame and the inner frame, and a driving motor, wherein the outer frame has a U-shaped structure, the driving shaft of the outer frame is arranged in the turntable base; the turntable also comprises a temperature box, the outer frame, the middle frame and the inner frame are arranged in the temperature box, and a base plate of the temperature box is provided with a shaft hole which allows the driving shaft of the outer frame to pass through; the middle frame and the inner frame are standard positive circular ring shaped; and the wall of the temperature box is provided with a glass window. The three-shaft high-low temperature speed turntable has the advantages that tests on a gyro in three directions in a high temperature environment and a low temperature environment can be performed simultaneously, and the turntable has low requirement on the motor moment and has high test efficiency.

Owner:BEIJING AEROSPACE INST FOR METROLOGY & MEASUREMENT TECH

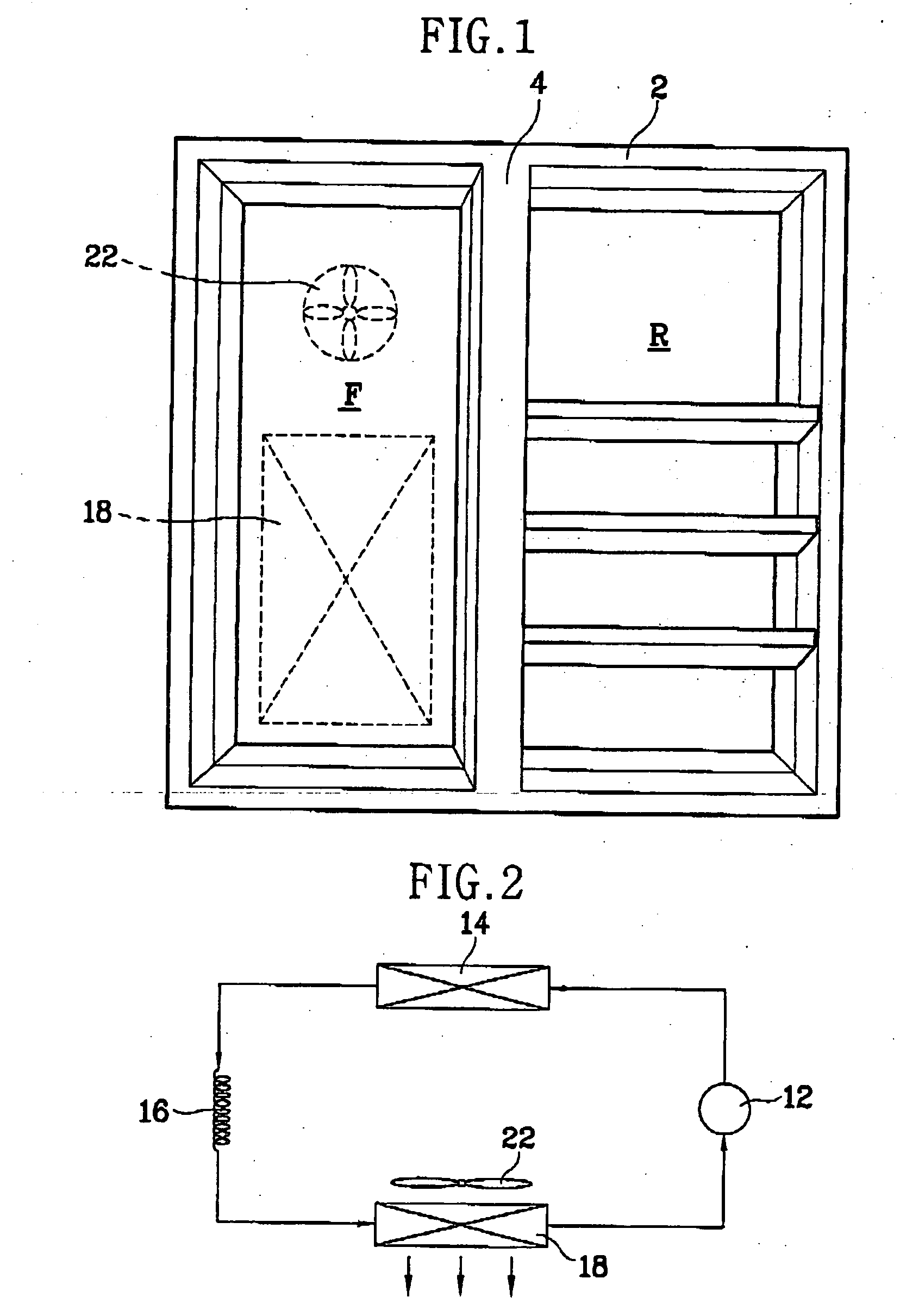

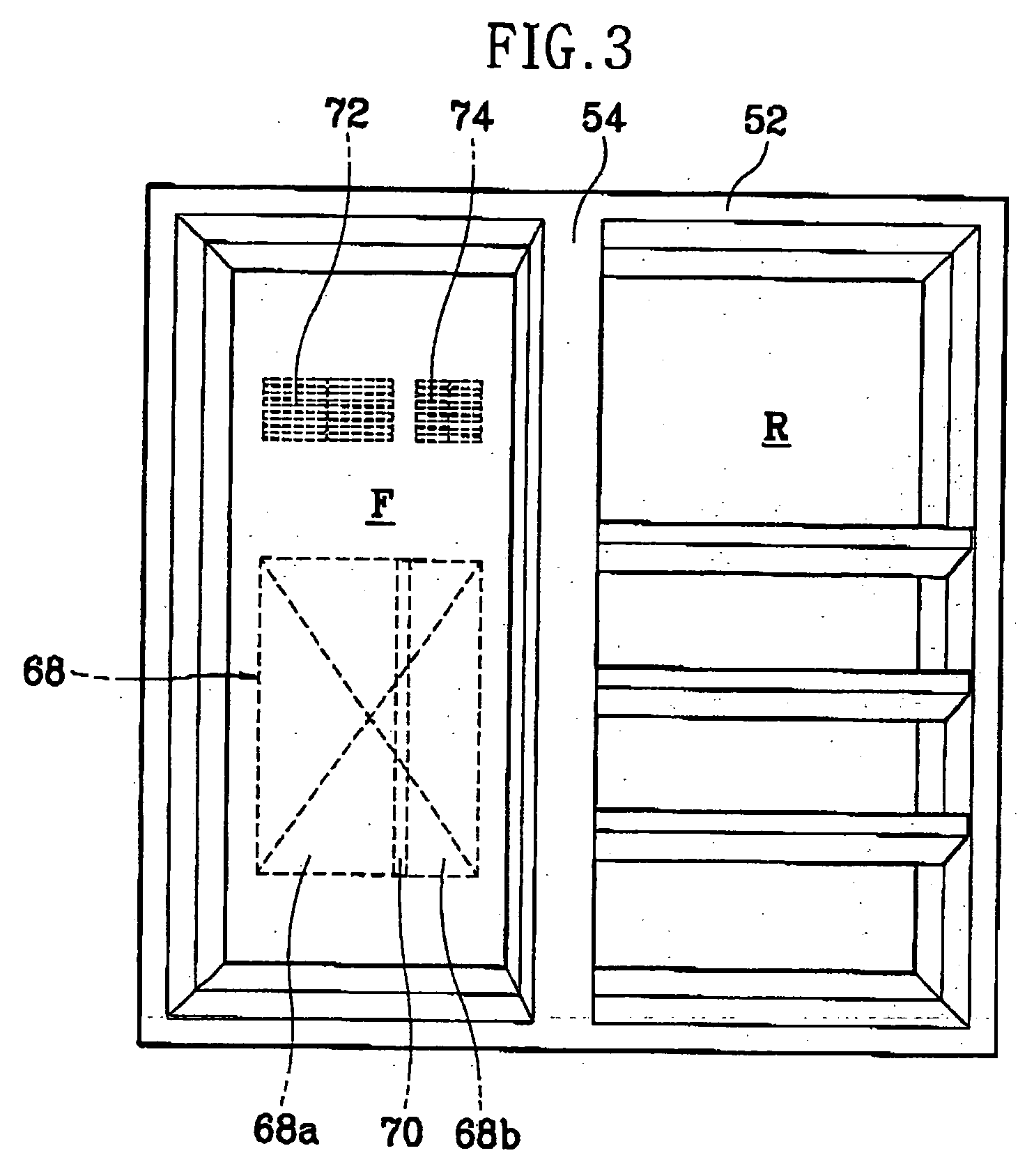

Air-cooled refrigerator and humidifying and freshness keeping method

PendingCN107328154AAvoid enteringAvoid dischargeLighting and heating apparatusDomestic refrigeratorsCold airThermodynamics

The invention discloses an air-cooled refrigerator. The air-cooled refrigerator is provided with a box which comprises a shell and a liner; the liner is arranged in the shell, and the space between the liner and the shell is filled with a heat preserving layer; and the liner is sequentially provided with a cold storage chamber, a temperature changing chamber and a freezing chamber from top to bottom. On the interior of the rear side of the freezing chamber, the heat preserving layer is provided with a cold air cavity for containing an evaporator and a draught fan. The cold air cavity is communicated with the freezing chamber through a first air feeding air duct which is located on an air outlet of the inner wall of the freezing chamber, and a freezing air door is arranged. The cold air cavity is communicated with the temperature changing chamber through a second air feeding air duct which is located on an air outlet of the inner wall of the temperature changing chamber, and a temperature changing air door is arranged. The cold air cavity is communicated with the cold storage chamber through a third air feeding air duct which is located on an air outlet of the inner wall of the cold storage chamber, and a cold storage air door is arranged. The invention further discloses a humidifying and freshness keeping method. The air-cooled refrigerator is reasonable in structure, accurate in humidity control and high in practicability, water in the air-cooled refrigerator is kept conserved, and frosting is effectively prevented.

Owner:AUCMA

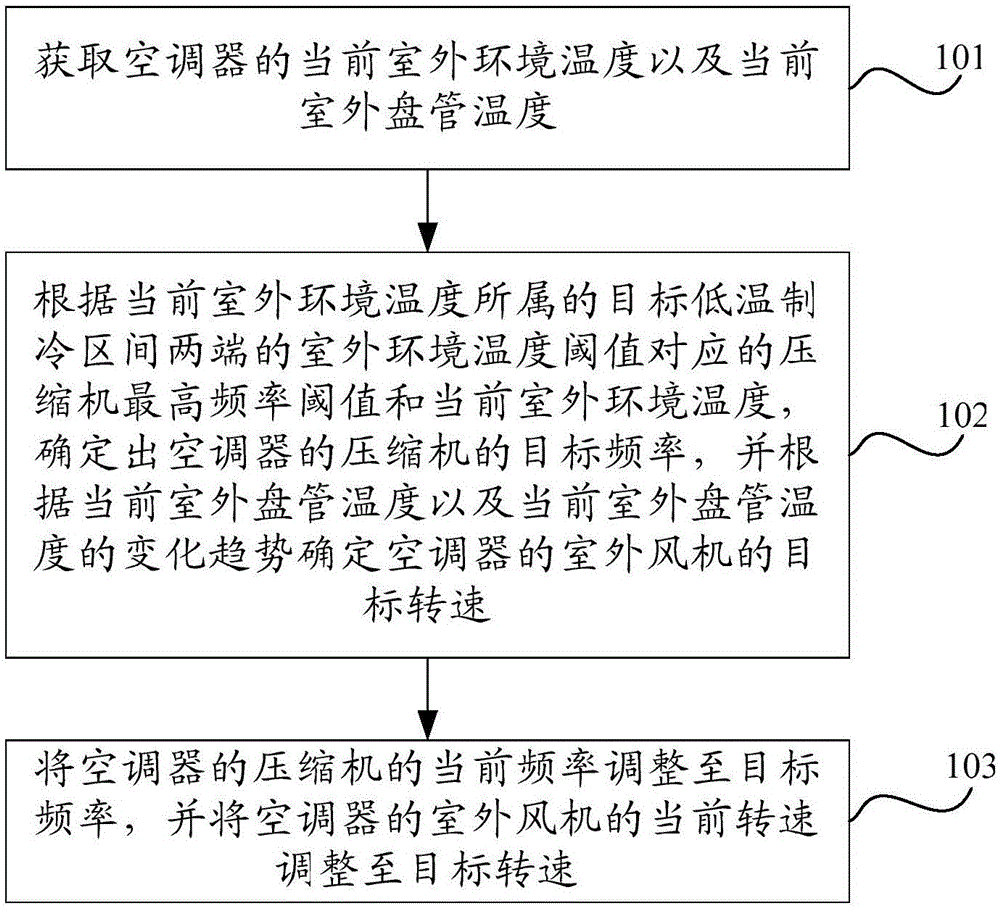

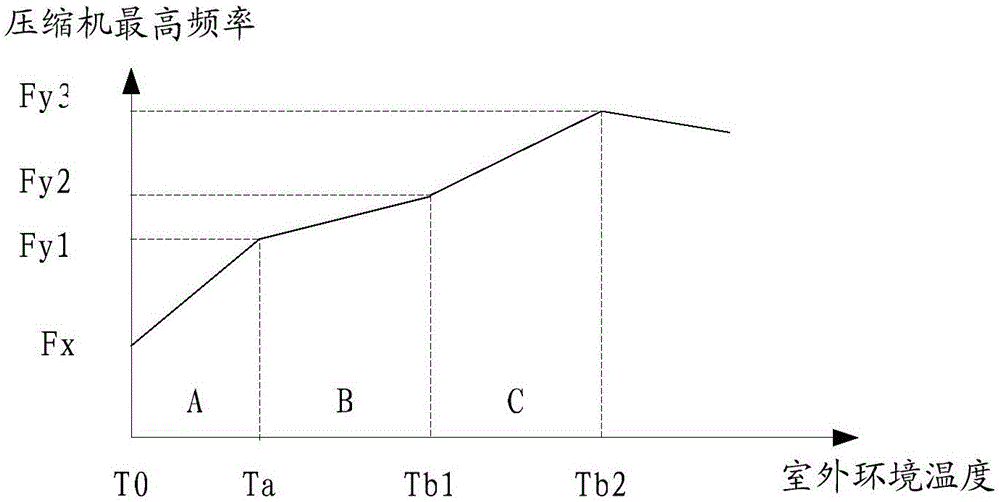

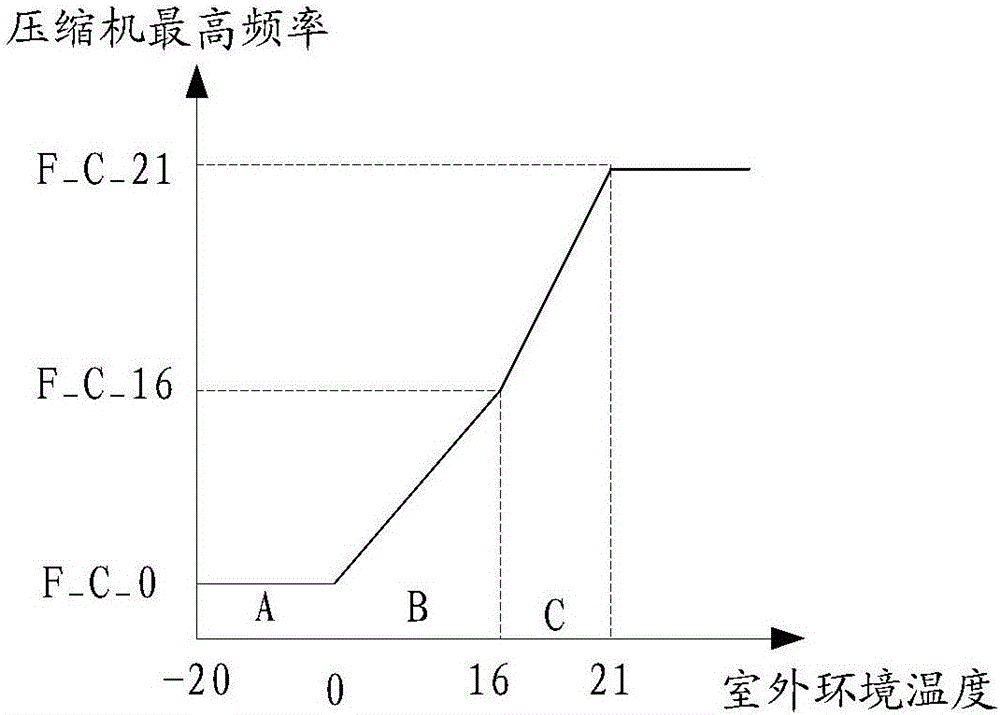

An air conditioner cooling control method and air conditioner

InactiveCN106440587AIncrease the temperature of the refrigerantAvoid frostingCorrosion preventionRefrigeration safety arrangementEvaporatorEngineering

The embodiment of the invention provides an air conditioner cooling control method and an air conditioner and relates to the field of air conditioners. The air conditioner cooling control method and the air conditioner aim at solving the problems that when the outdoor temperature is low, an existing air conditioner still cools the interior of a room, and consequently an indoor evaporator frosts and the indoor static electricity is high. The method comprises the steps that the current outdoor environment temperature and the current outdoor coil temperature of the air conditioner are obtained, according to the compressor maximum frequency threshold value and the current outdoor environment temperature corresponding to the outdoor environment temperature threshold values of the two ends of the target low-temperature cooling interval to which the current outdoor environment temperature belongs, the target frequency of a compressor of the air conditioner is determined, the target rotating speed of an outdoor fan of the air conditioner is determined according to the current outdoor coil temperature and the change trend of the current outdoor coil temperature, the current frequency of the compressor of the air conditioner is adjusted to the target frequency, and the current rotating speed of the outdoor fan of the air conditioner is adjusted to the target rotating speed.

Owner:HISENSE (GUANGDONG) AIR CONDITIONER

Heat pump system having a pre-processing module

ActiveUS8915092B2Avoid frostImprove regeneration efficiencyMechanical apparatusDesuperheatersComputer moduleEnergy recovery

Owner:NORTEK AIR SOLUTIONS CANADA INC

Multiple condenser reheat system with tandem compressors

InactiveUS20060090507A1Prevent excessive frost formationAvoid frostMechanical apparatusCompression machines with non-reversible cycleHeat rejectionRefrigerant

A tandem compressor system is utilized that receives refrigerant from a common suction manifold, and from a common evaporator. From the compressors, the refrigerant passes to a plurality of condensers, with each of the condensers being associated with a separate zone for heat rejection, preferably at different temperature levels. Each of the condensers is associated with at least one of the plurality of compressors. A reheat coil is associated with the evaporator to improve comfort level in the environment to be conditioned. Multiple reheat circuits associated with separate condensers are employed to provide various stages of reheat or to condition separate environments. By utilizing the common evaporator, a plurality of condensers, and the reheat coils, the ability to independently control temperature, humidity and amount of heat rejection to a number of zones is achieved without the requirement of having dedicated circuits with multiple additional components. Thus, the overall system cost and complexity is significantly reduced and its operational and control flexibility is improved.

Owner:CARRIER CORP

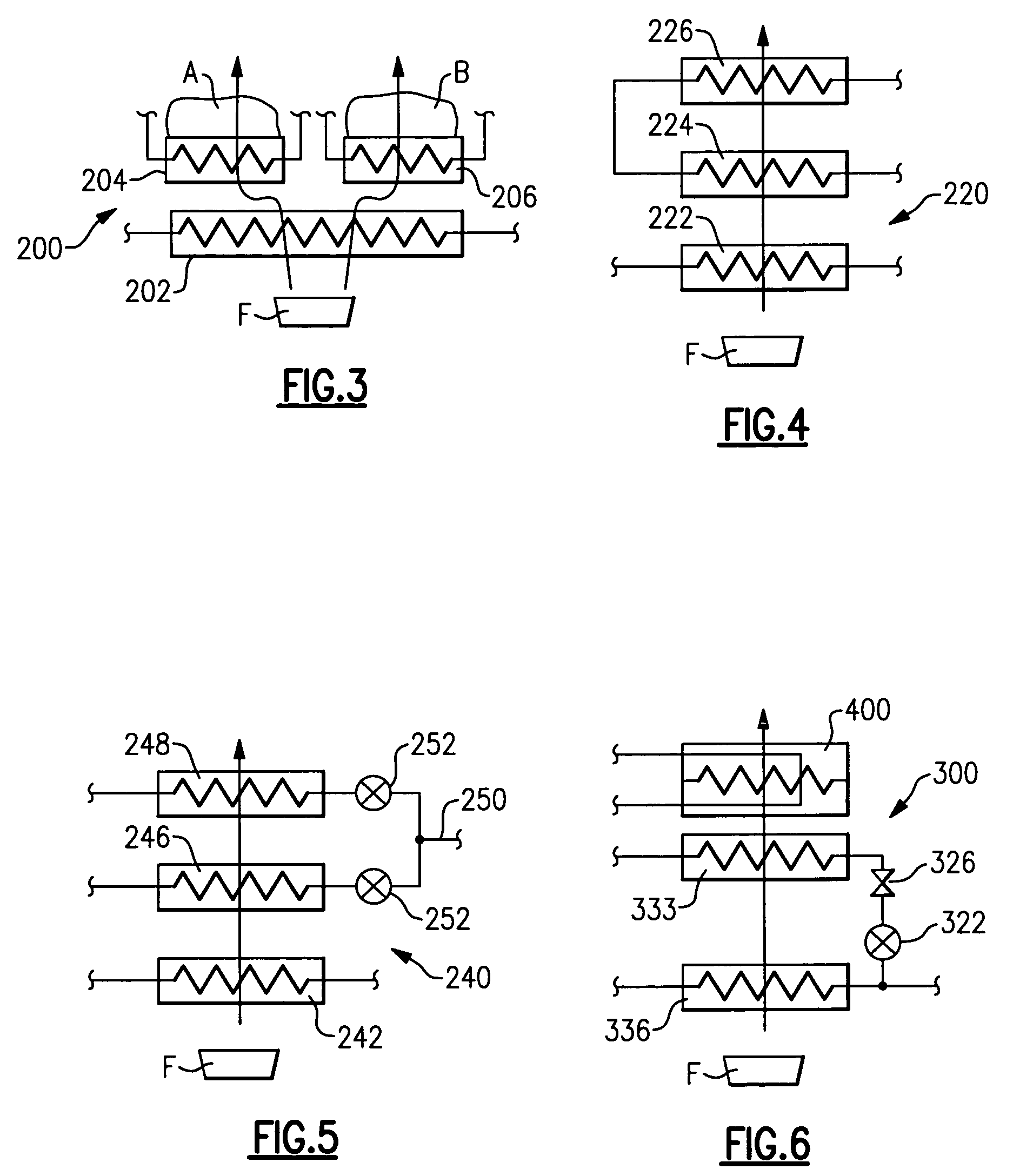

Air conditioning apparatus for vehicle

InactiveUS7082990B1Avoid frostAvoid partialAir-treating devicesRailway heating/coolingWinter seasonEvaporator

An interior of an air conditioning case is partitioned into a first air passage extending from an inside air suction port to a foot opening portion and a second air passage extending from an outside air suction port is disposed at a side of the first air passage to detect a temperature of air blown out from the evaporator disposed in the first air passage and the second air passage. An operation of the compressor for supplying the refrigerant to the evaporator is intermitted by comparing the temperature detected by the temperature sensor and the set temperature set in advance, and the set temperature is changed to be higher according to an increase in the temperature of outside air. In this way, it is possible to prevent the frosting of the evaporator in winter season, when the inside air is introduced into the first air passage and the outside air is introduced into the second air passage.

Owner:DENSO CORP

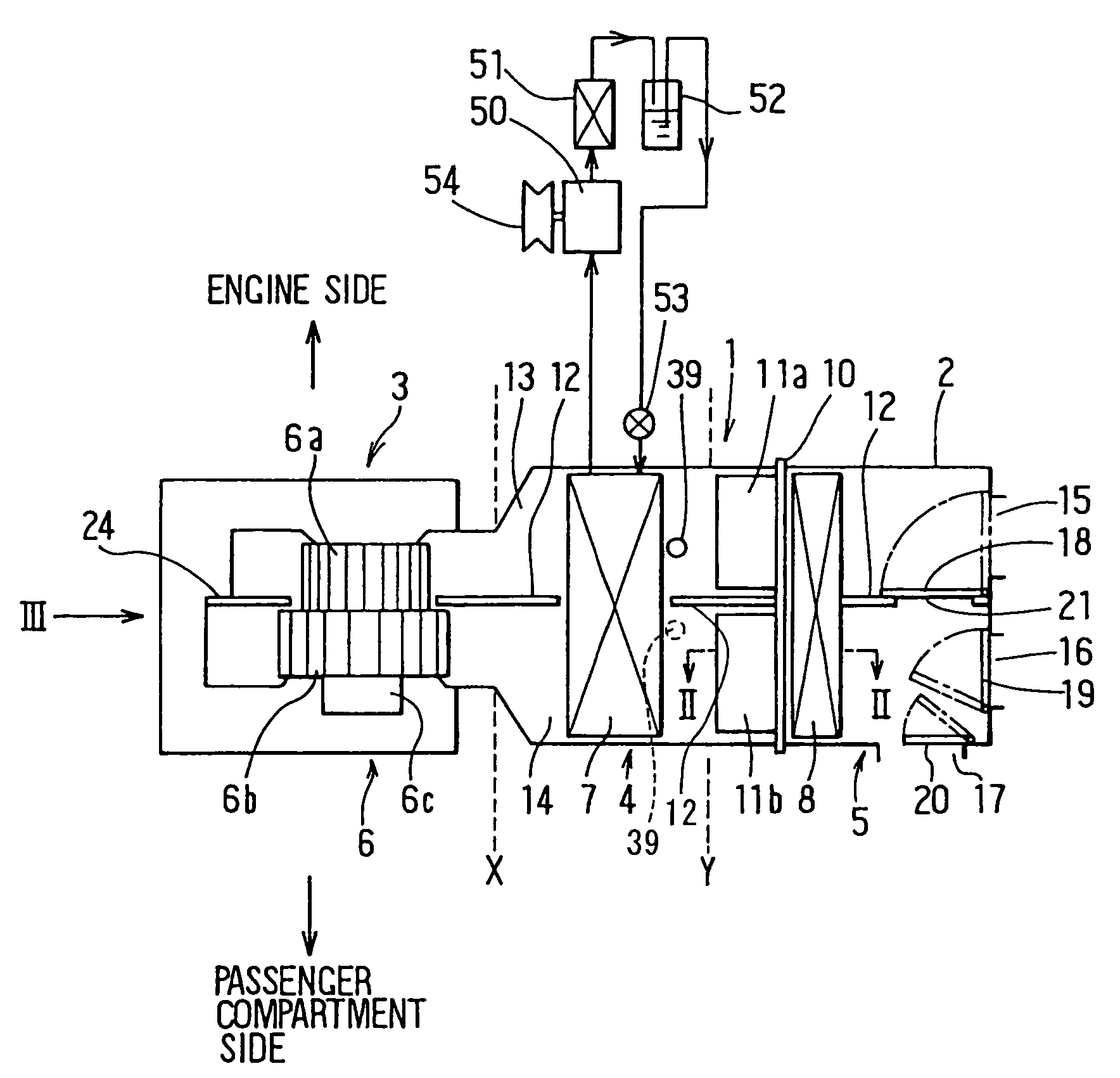

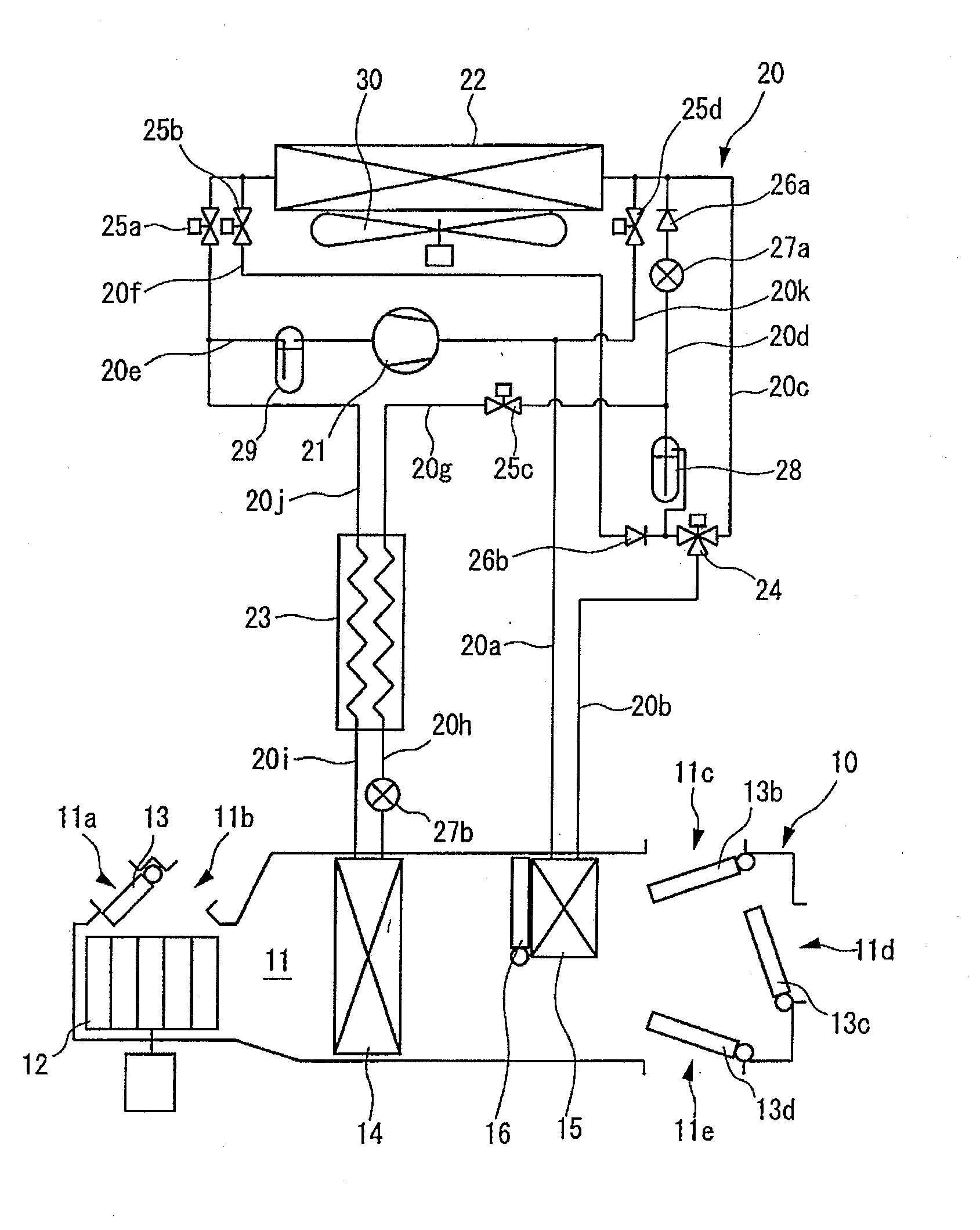

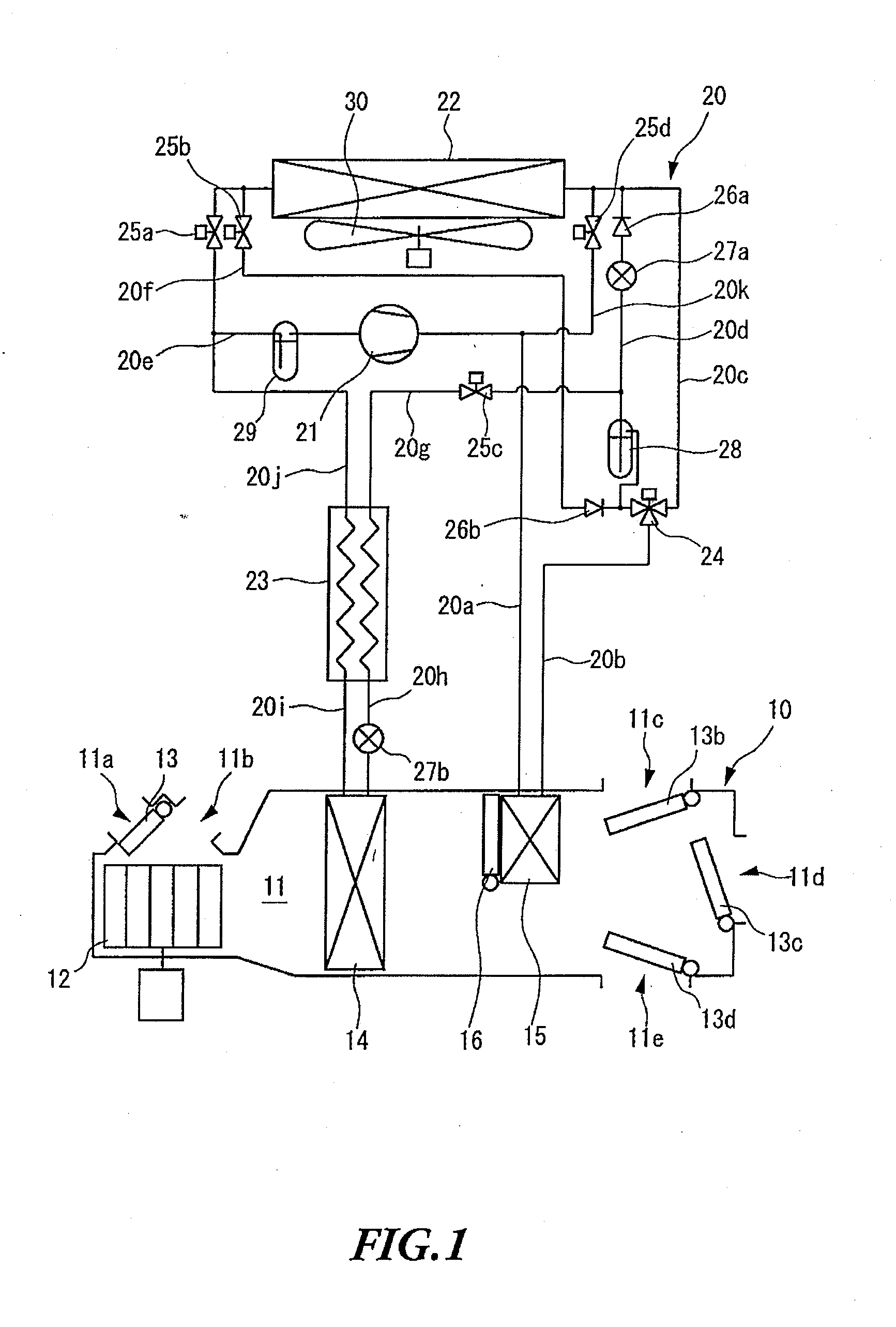

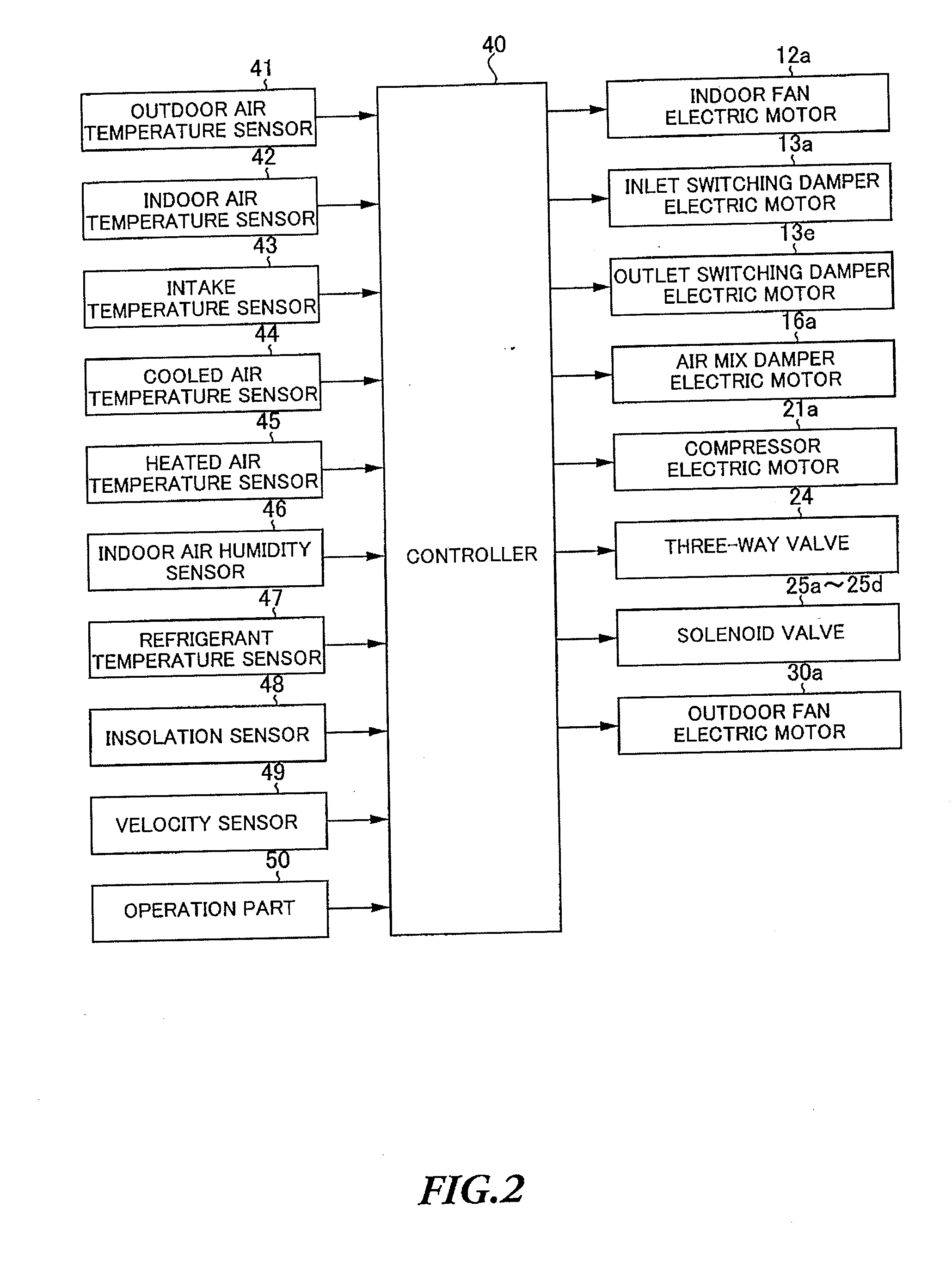

Air conditioning device for vehicle

ActiveUS20130312442A1Maintain dehumidification performanceAvoid frostMechanical apparatusAir-treating devicesFrostSolenoid valve

A vehicle air conditioning apparatus is provided to prevent a frost from being formed on a heat exchanger under the condition that the outdoor temperature is low. During a heating and dehumidifying operation, the third solenoid valve 25c is closed when outdoor temperature Tam is predetermined temperature T1 or lower, or when temperature Thex of the refrigerant flowing out of the outdoor heat exchanger 22 is a predetermined temperature T2 or lower and temperature Te detected by the cooled air temperature sensor 44 is temperature Tet-β or lower. By this means, during the heating and dehumidifying operation, when a frost is likely to be formed on the heat exchanger 14, it is possible to prevent the refrigerant from flowing into the heat exchanger 14, and to prevent a frost from being formed on the heat exchanger 14.

Owner:SANDEN CORP

System and method for preventing air source heat pump water heater from frosting by using solid dehumidification

InactiveCN103900289AReduce humidityAvoid frostHeat pumpsDispersed particle separationPre conditioningEngineering

The invention provides a system and method for preventing an air source heat pump water heater from frosting by using solid dehumidification. In the method, a heat exchanger with a solid drying agent coating is used for preprocessing water in moist air, and therefore the water in the moist air is prevented from frosting on the surface of an evaporator. According to the system and method, the air of an inlet of the evaporator is dehumidified by means of the solid drying agent coating, so that the frosting problem of the heat pump water heater is resolved, and heating performance of the heat pump water heater is enhanced. When the water absorbed by solid adsorbing agents reaches a limitation, water in the solid adsorbing agents is desorbed by means of heat released by condensation of heat pump work media, at this time, circulation air with desorbed high-temperature moisture has heat exchange and congeals on the surface of the evaporator, the evaporator recycles the heat released in a condenser, and regeneration efficiency of a heat pump is improved.

Owner:SOUTHEAST UNIV

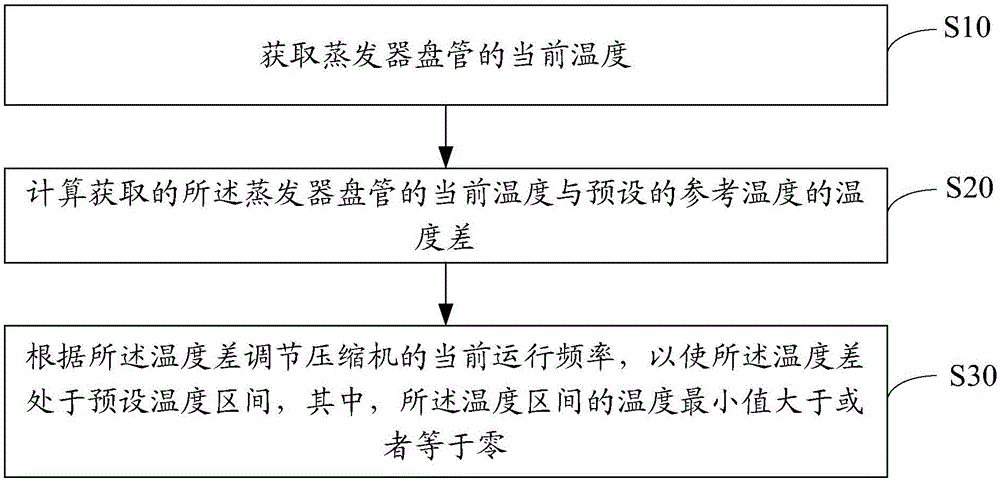

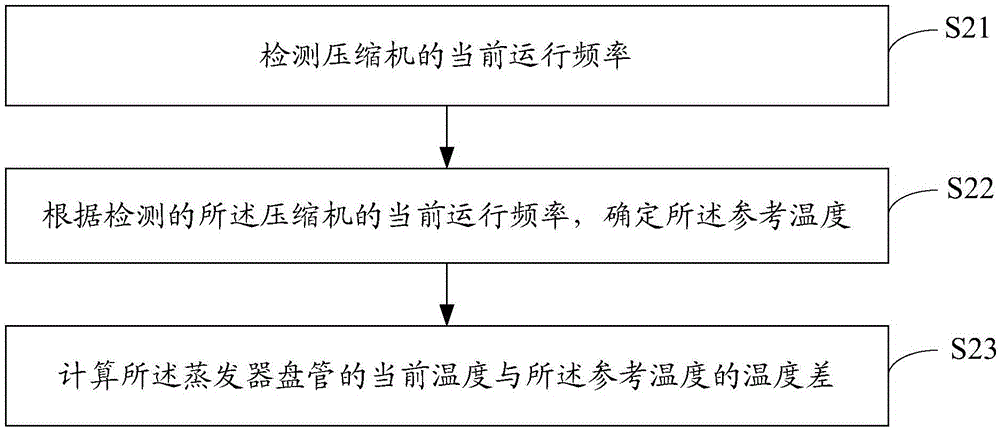

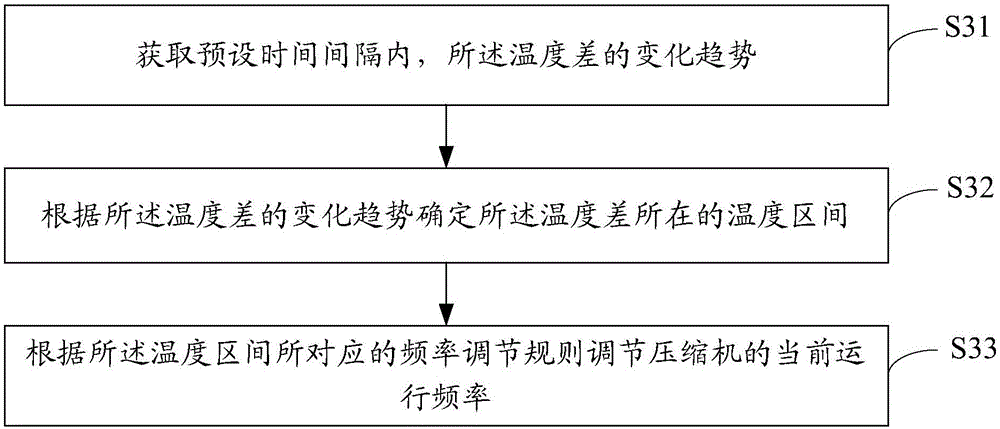

Method and device for controlling air conditioner

ActiveCN105157172AAvoid frostImprove cooling effectSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringTemperature difference

The invention discloses a method for controlling an air conditioner. The method for controlling the air conditioner comprises the steps of obtaining the current temperature of an evaporator coil pipe, calculating the temperature difference between the obtained current temperature of the evaporator coil pipe and a preset reference temperature, and adjusting the current operation frequency of a compressor according to the temperature difference to enable the temperature difference to be within a preset temperature interval with the minimum temperature being larger than or equal to zero. The invention further discloses a device for controlling the air conditioner. By means of the method and device, the refrigeration effect of the air conditioner is improved.

Owner:TCL AIR CONDITIONER ZHONGSHAN CO LTD

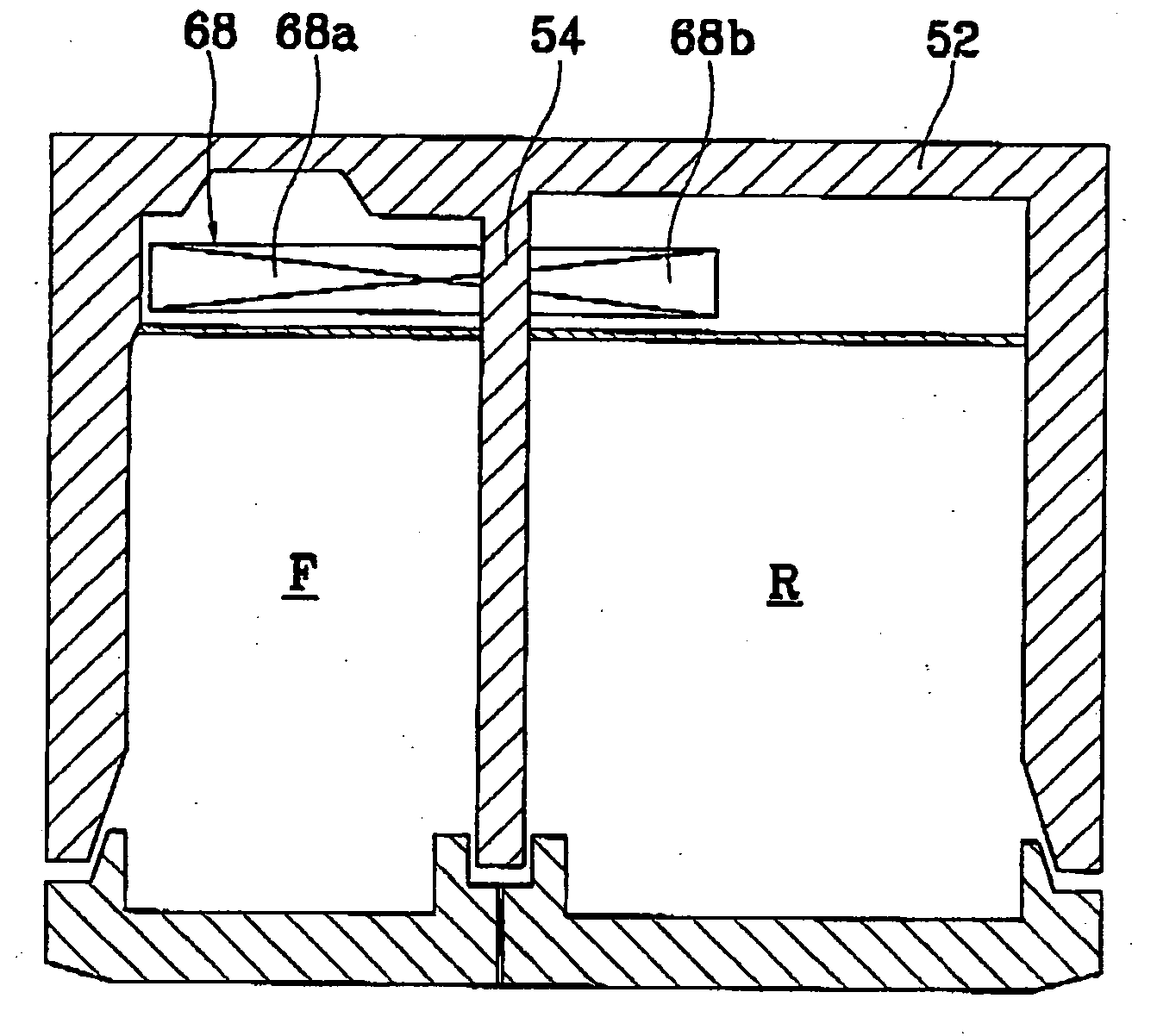

Refrigerator, and method for controlling operation of the same

InactiveUS20050279119A1Improve cooling efficiencyReduce power consumptionMechanical apparatusEvaporators/condensersEngineeringRefrigerated temperature

The present invention discloses a refrigerator which can individually cool a freezing chamber and a refrigerating chamber by dividing a heat exchange region of an evaporator into a freezing chamber side region and a refrigerating chamber side region, forming individual circulation passages for supplying cool air from each region to the freezing chamber and the refrigerating chamber, and forming a freezing chamber fan and a refrigerating chamber fan on each circulation passage, and method for controlling operation of the same which can efficiently perform a cooling operation and reduce power consumption by effectively controlling the operations of each component.

Owner:LG ELECTRONICS INC

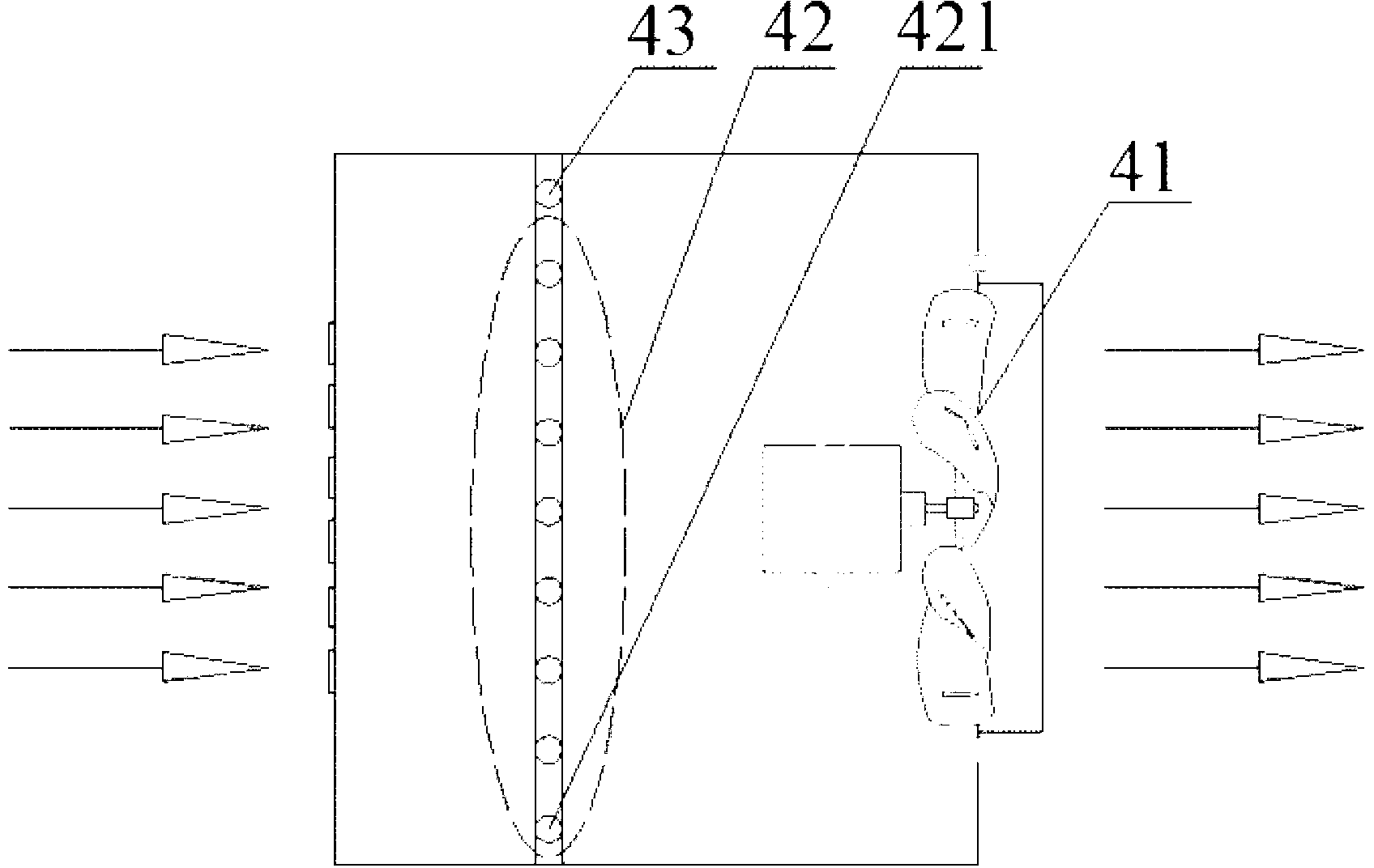

Heat pump type air conditioner outdoor machine

InactiveCN101285605AAvoid frostIncrease temperatureHeat pumpsAir conditioning systemsEngineeringHeating effect

The invention relates to an outdoor unit of a heat pump type air conditioner. The outdoor unit comprises a shell and a compressor, a heat exchanger and a fan system arranged in the shell. The shell is provided with a first air inlet and an air outlet, the air outlet is corresponding to the fan system, the first air inlet is corresponding to the heat exchanger. The invention is characterized in that: the outdoor unit also comprises a compressor waste heat collection device, the shell is also provided with a second air inlet on the position corresponding to the waste heat collection device; when the outdoor unit works, the waste heat collection device preheats the air which enters through the second air inlet and conveys the preheated air to a plenum box which covers outside the heat exchanger through a heating pipeline, so that the mixed air of the outside air from the first air inlet and the preheated air from the heating pipeline enters into an inner cavity of the plenum box. Compared with the prior art, the outdoor unit improves the air temperature of the heat exchanger so as to avoid frosting of the heat exchanger and overcome the defect that the prior air conditioner needs to close down twice to defrost the heat exchanger to affect the heating effect.

Owner:闫成文

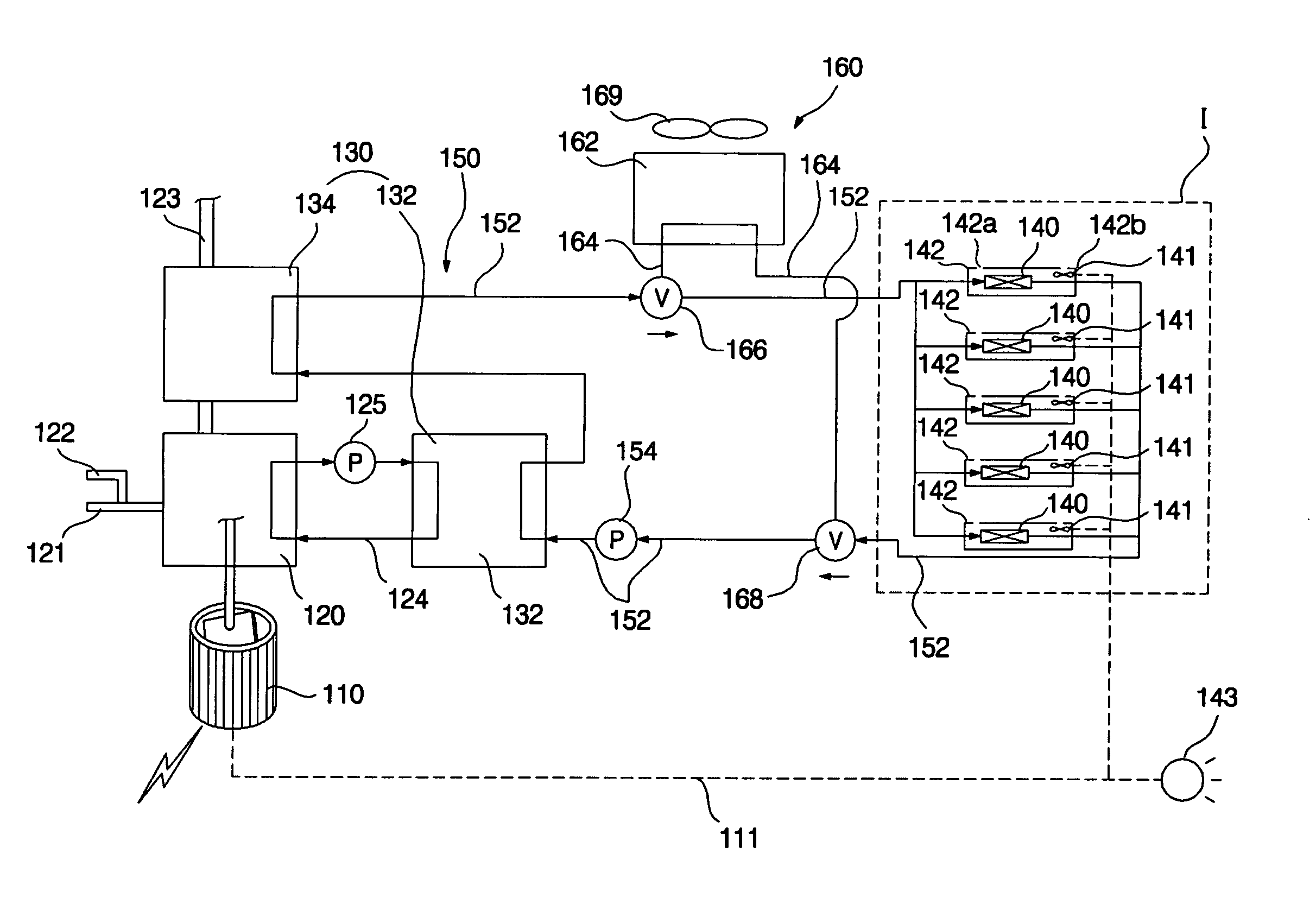

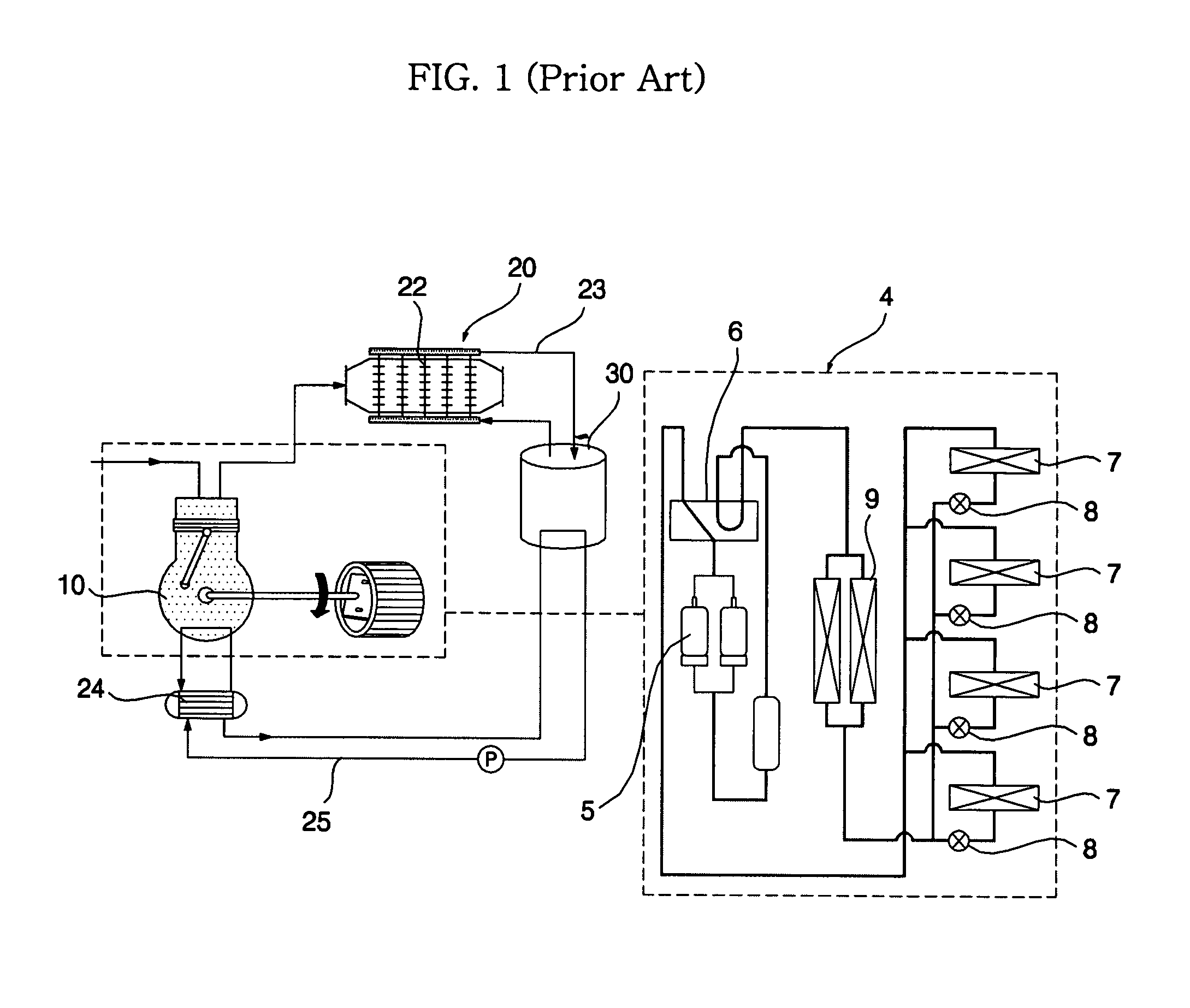

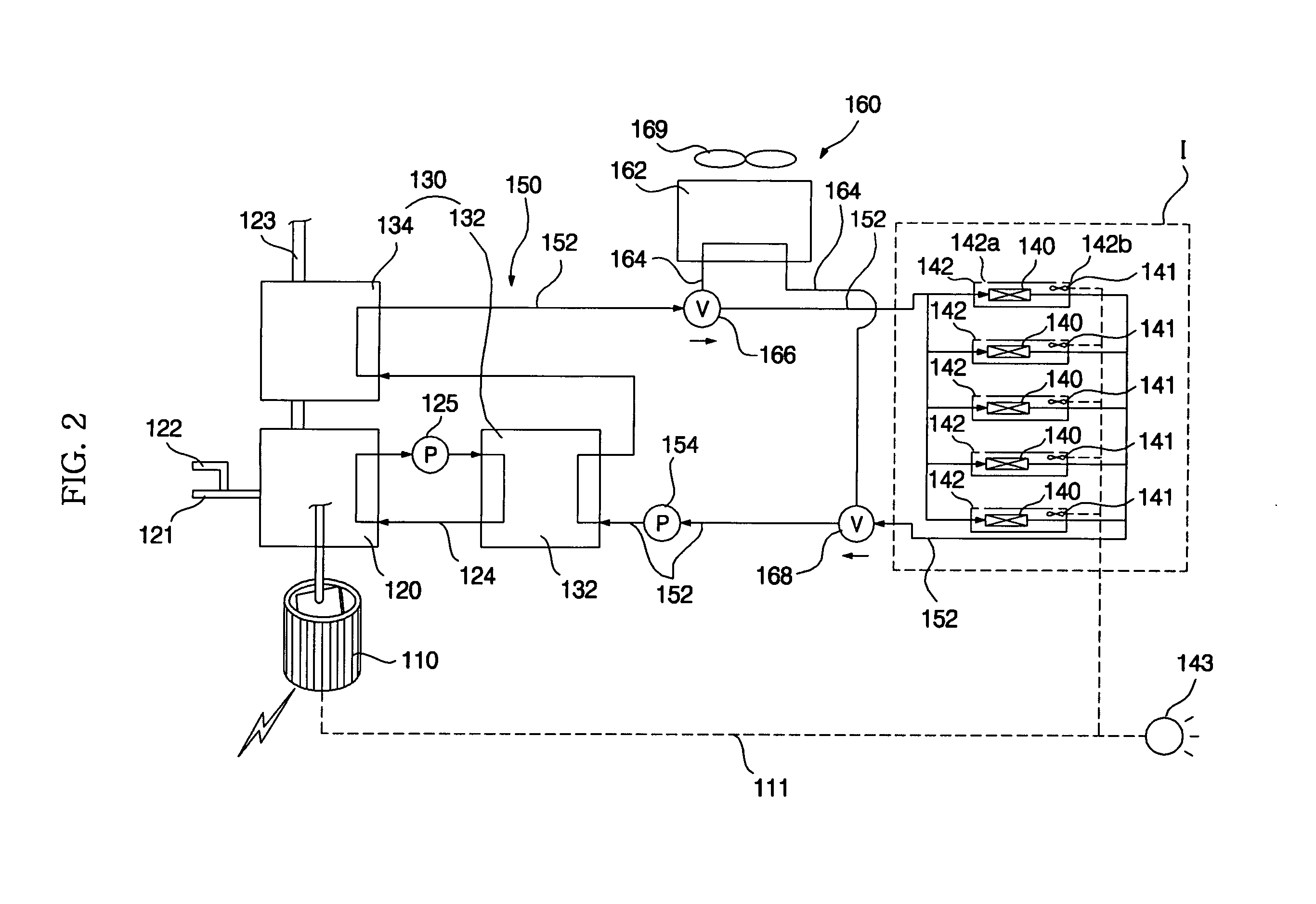

Cogeneration system

InactiveUS20060123823A1Maximize efficiencyAvoid frostInternal combustion piston enginesHeat storage plantsCogenerationEngineering

A cogeneration system is disclosed which includes a waste heat recovering heat exchanger for recovering waste heat generated from a drive source when the drive source operates to drive a generator, heating heat exchangers for heating indoor air, and a heat transfer unit for transferring heat from the waste heat recovering heat exchanger to the heating heat exchangers. The waste heat of the drive source can be used to heat indoor air present in an indoor space. Accordingly, it is possible to maximize the efficiency of the cogeneration system, and to heat indoor heat without driving a compressor.

Owner:LG ELECTRONICS INC

Device for testing low-temperature heat conduction rate of foam heat insulation material in loaded state

The invention discloses a device for testing the low-temperature heat conduction rate of a foam heat insulation material in a loaded state, which is simple in structure, low in cost, convenient in operation and accurate in test result, and is provided with a sealed vacuum cavity communicated with a vacuumizing pipe, wherein a sealing cover on the vacuum cavity is fixed with a corrugated pipe; a heat insulating pressure bar is arranged in the corrugated pipe; the upper end of the heat insulating pressure bar is connected with the corrugated pipe and the lower end of the heat insulating pressure bar passes through the sealing cover to enter the vacuum cavity to be connected with a pressing plate; a cold cavity is arranged below the pressing plate; a cold plate is arranged on the top of the cold cavity; the lower end of the cold cavity is communicated with a low-temperature liquid input pipe and the upper end of the cold cavity is communicated with an air exhaust pipe; the end of the airexhaust pipe comes out of the vacuum cavity; and a wire hole is formed on the vacuum cavity.

Owner:DALIAN FISHERIES UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com