Patents

Literature

728results about How to "Reduce cooling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

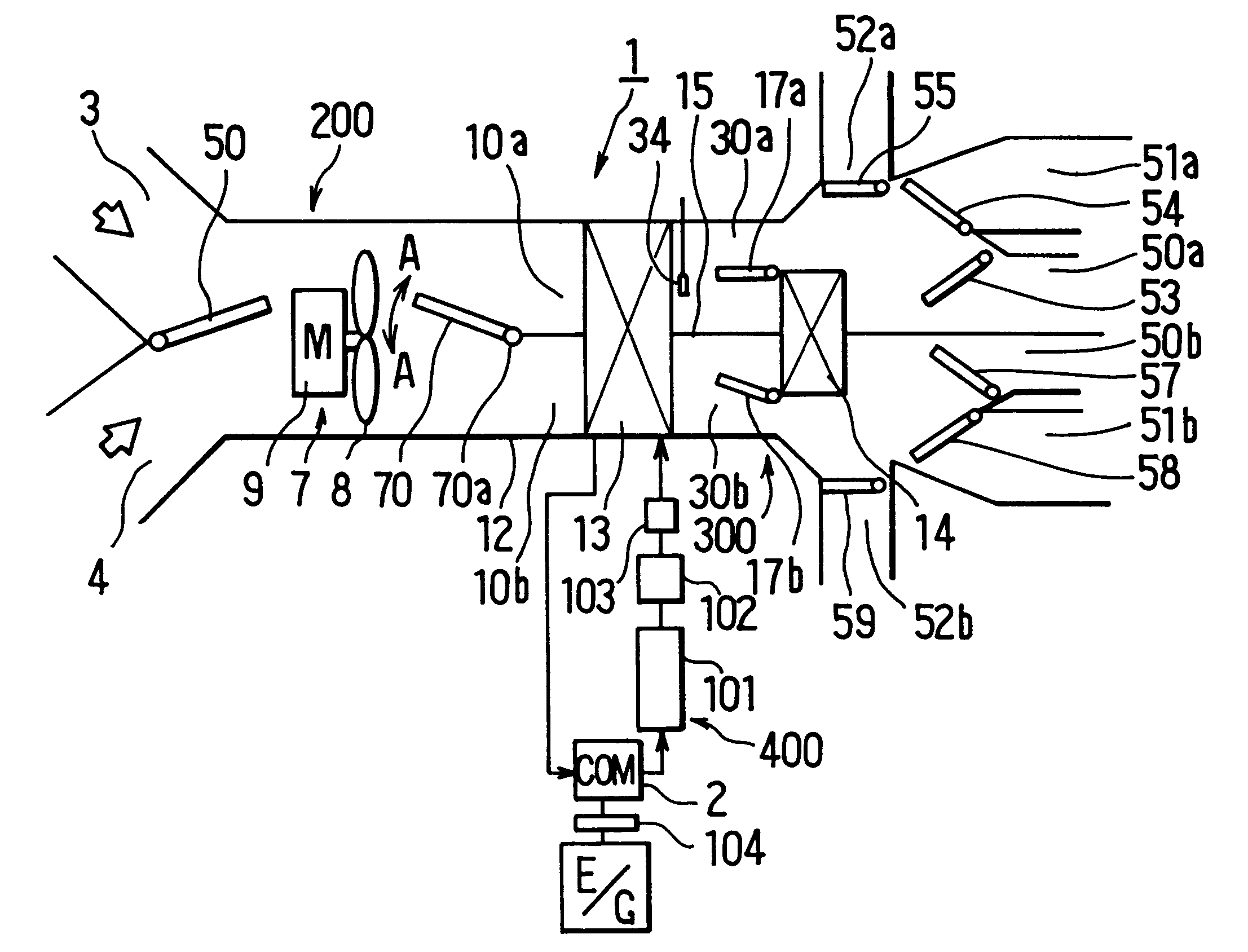

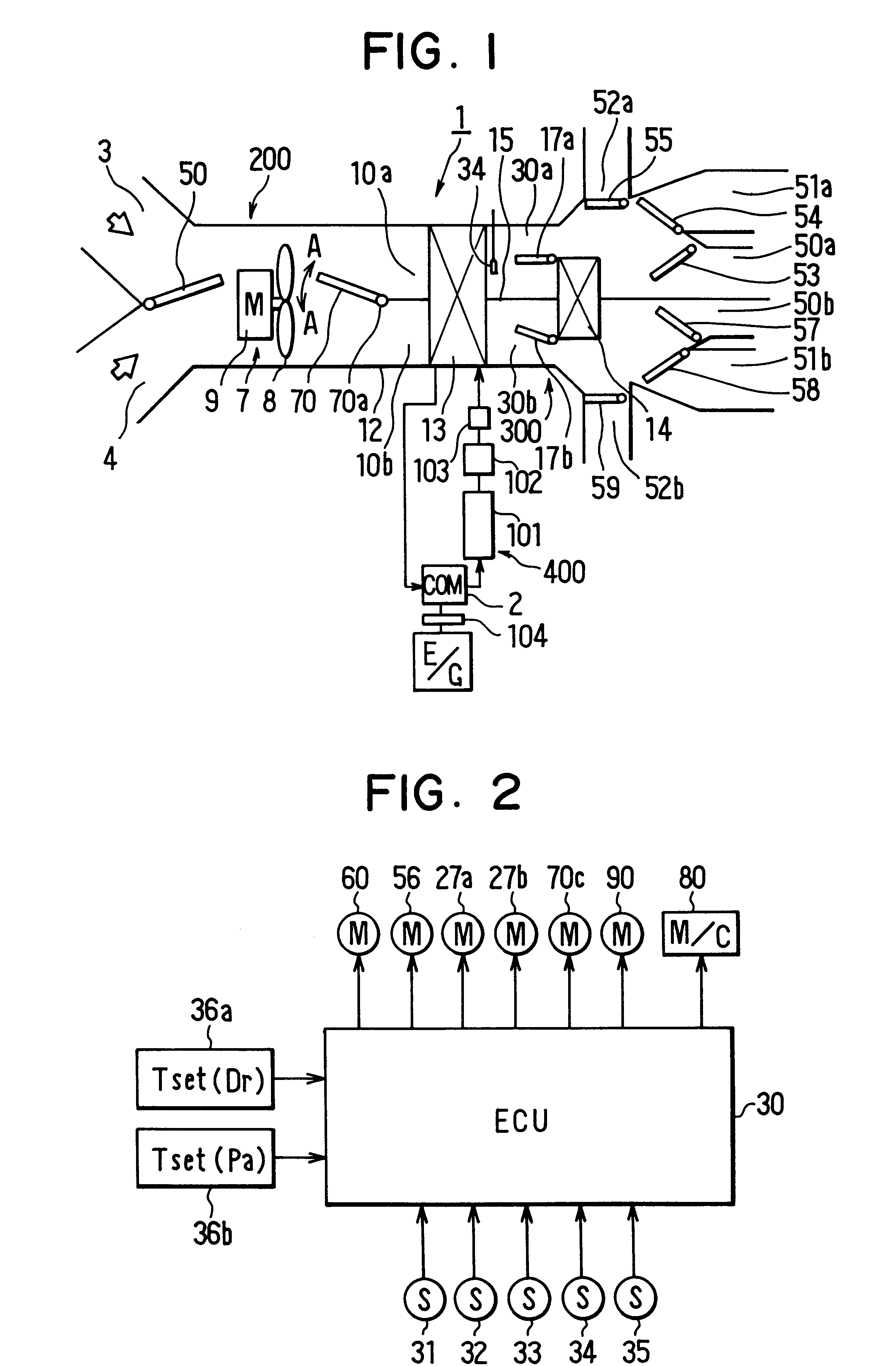

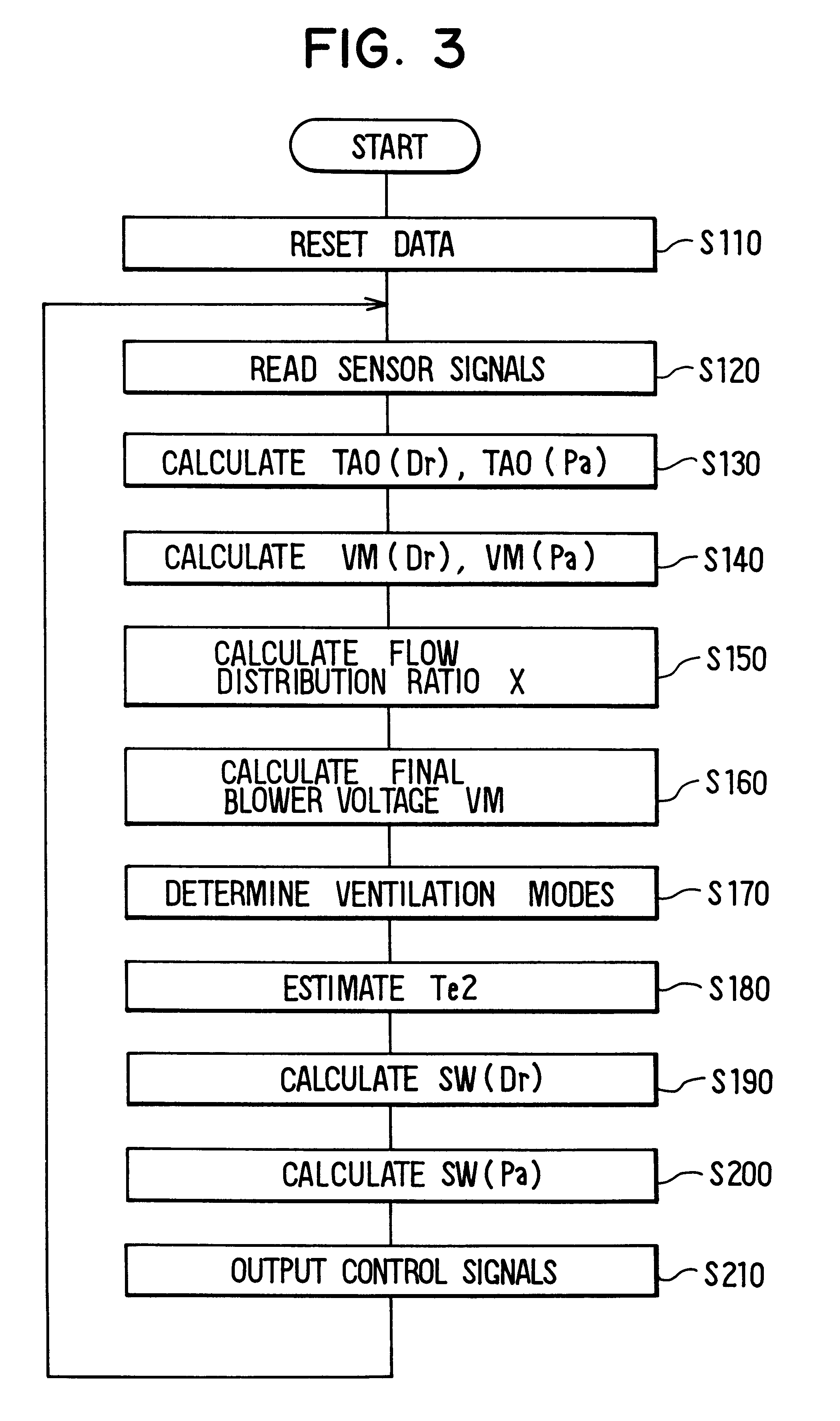

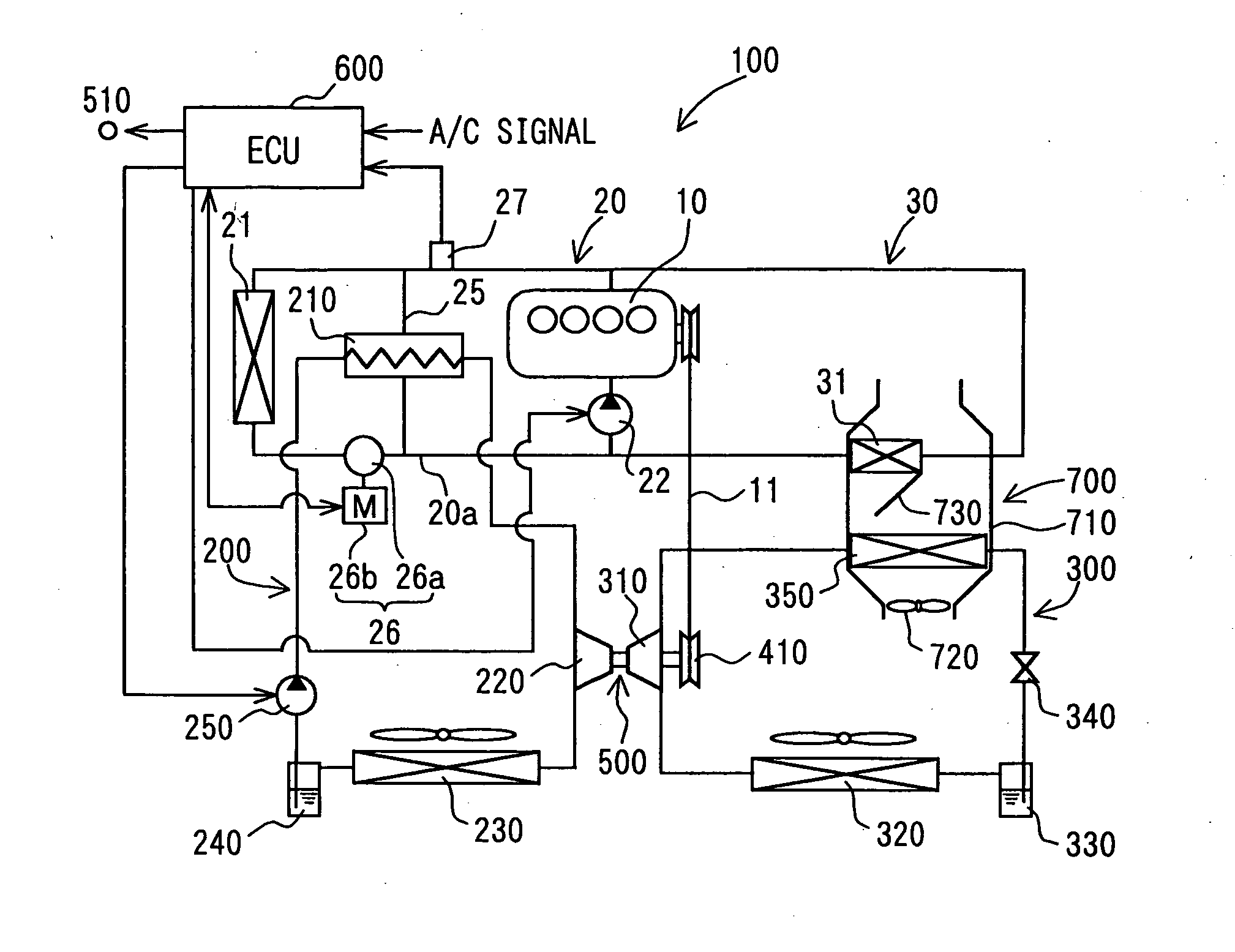

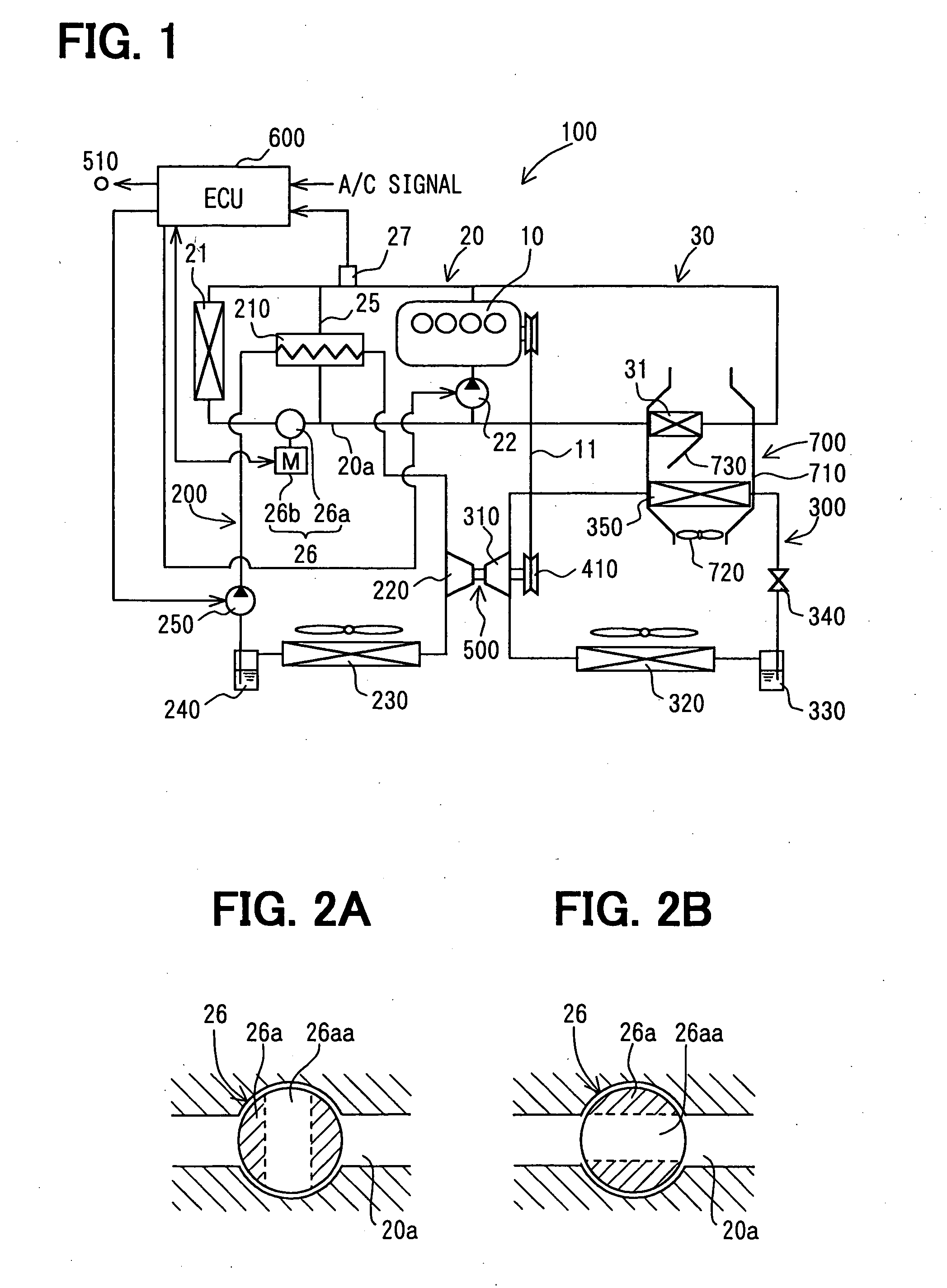

Vehicle-air-conditioning system with cooling degree estimator for left/right temperature control

InactiveUS6192698B1Avoid frostPreventing a windshield from being foggedAir-treating devicesSpace heating and ventilation safety systemsTemperature controlEngineering

In an air-conditioning system having two air-conditioning passages serving two different air-conditioning zones but having a cooling degree detector provided in only one of the passages to reduce cost, with the degree to which air is cooled in the other passage being estimated based on a cooling degree detected by the detector and the difference between flows of air passing through the passages or an intake temperature of air entering the passages. On the other hand, when an evaporator is possible to be frosted in one of the passages, air flow amount in the one of the passages is corrected to be increased. Therefore, it can prevent a windshield from being fogged while preventing the evaporator from being frosted.

Owner:DENSO CORP

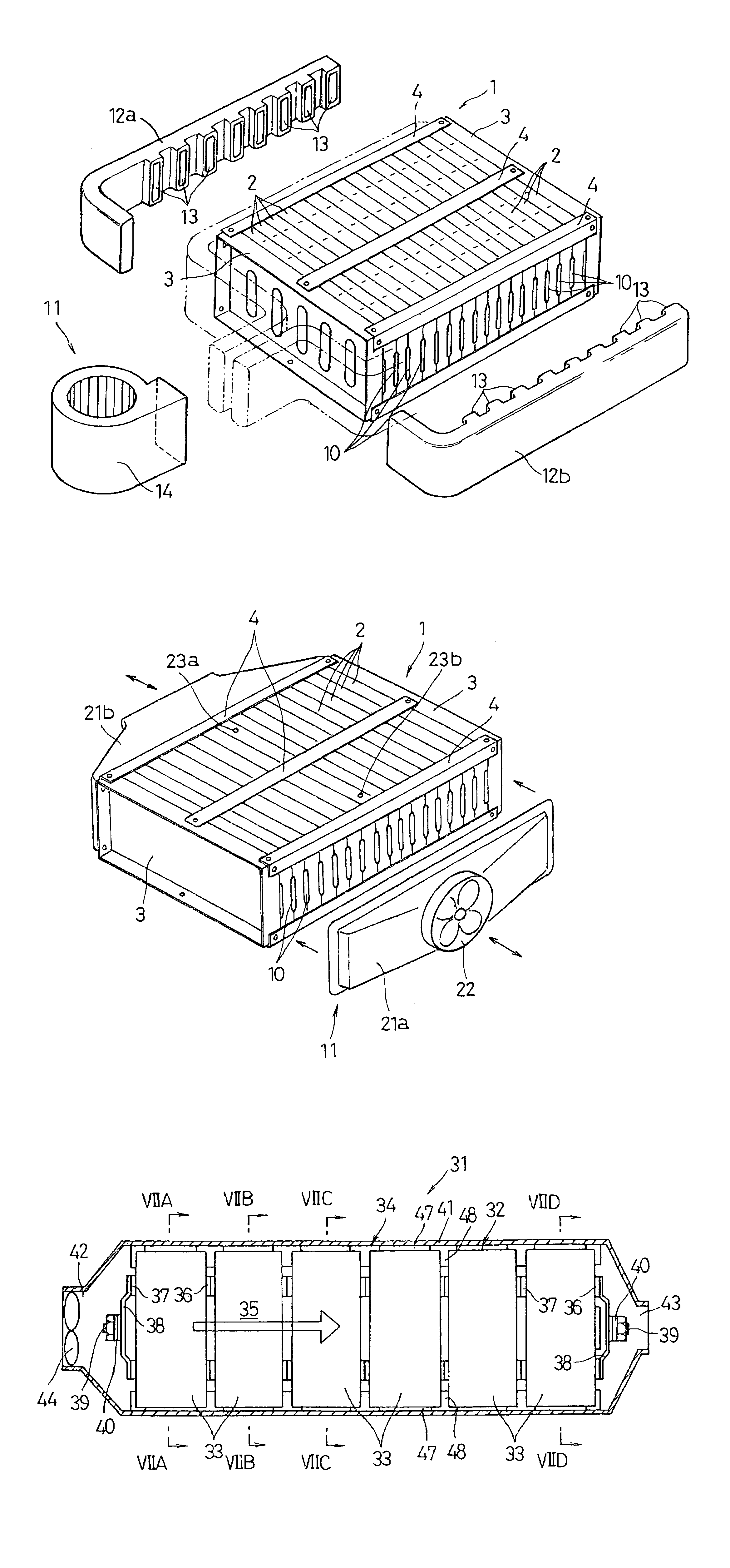

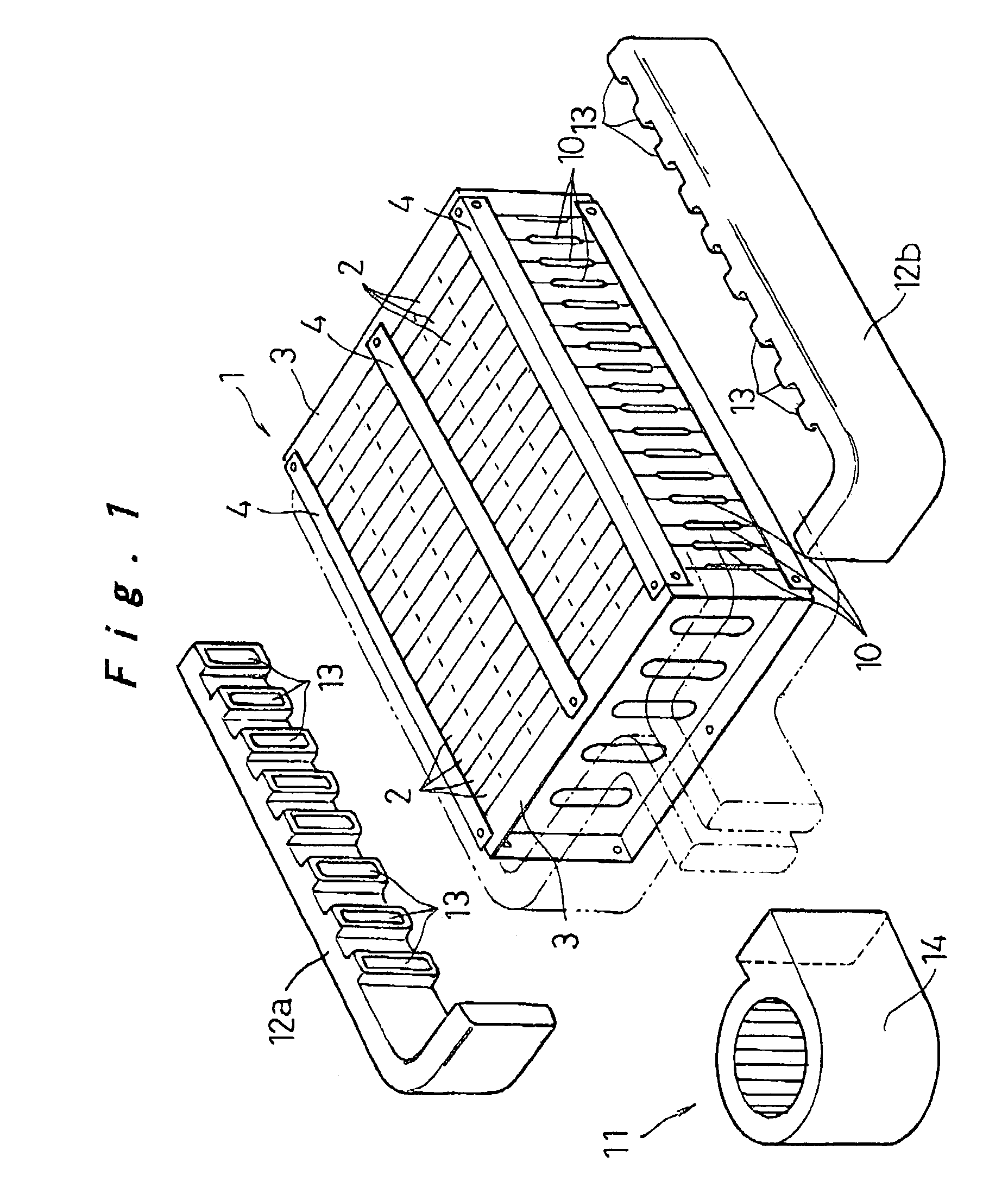

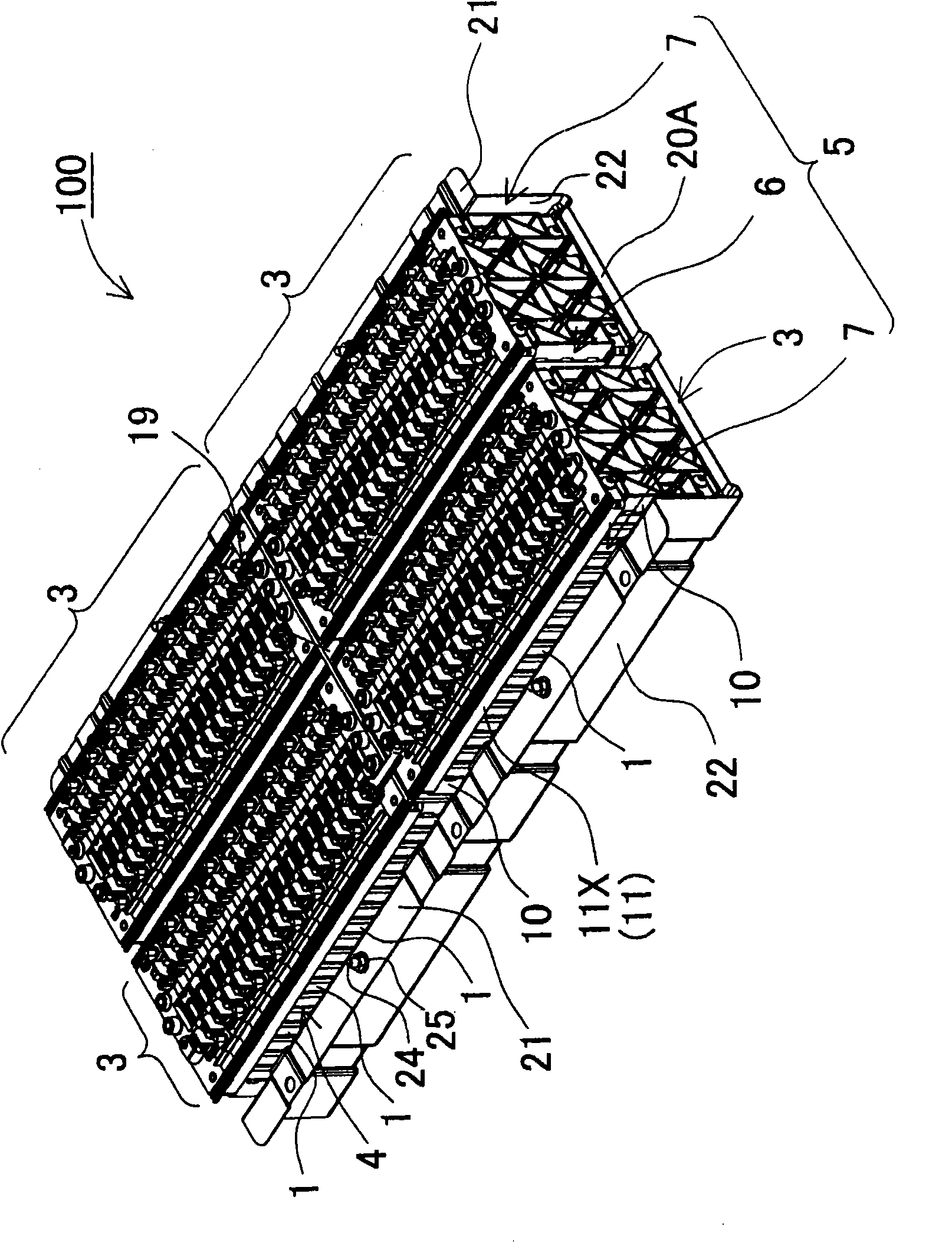

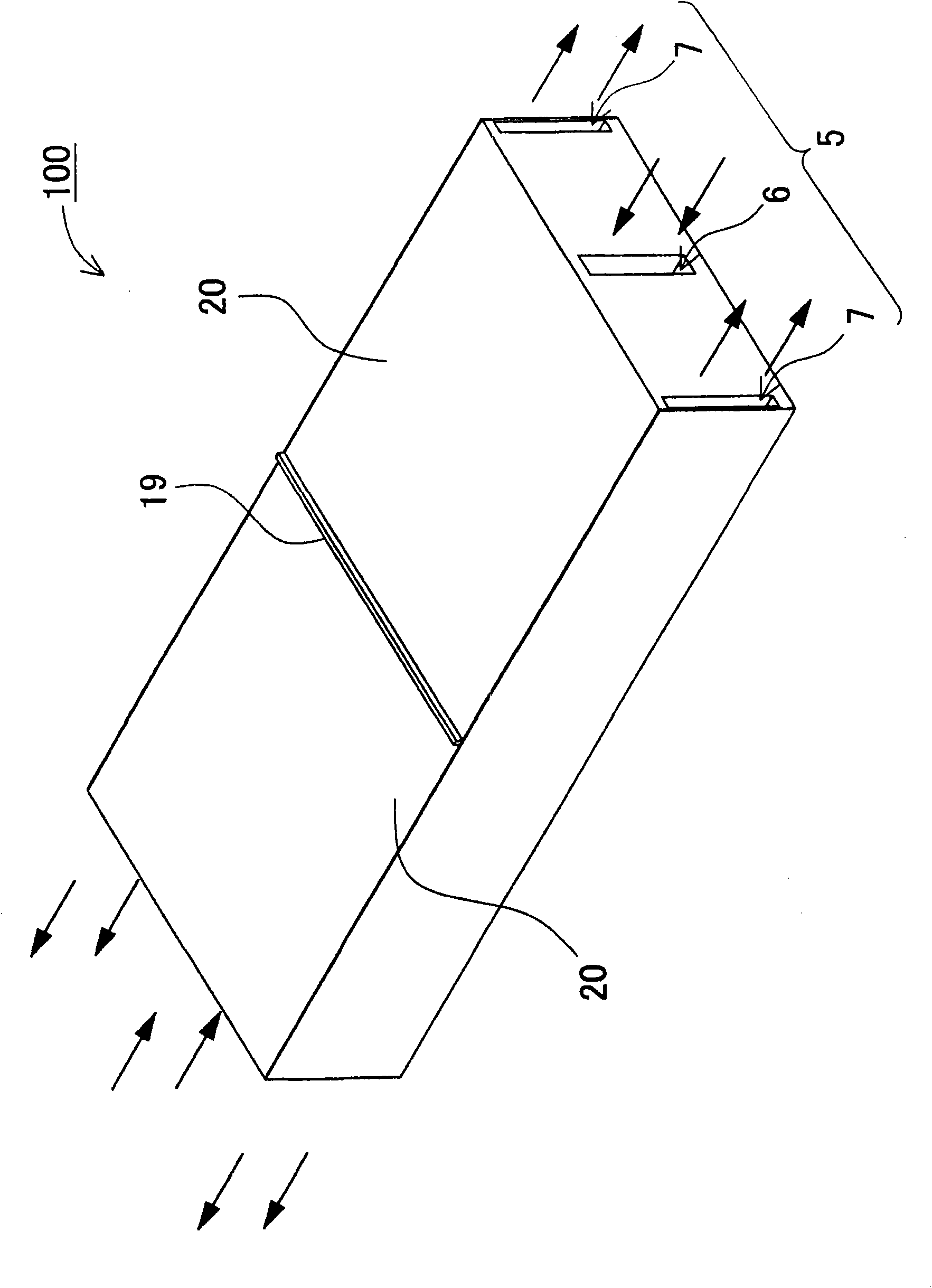

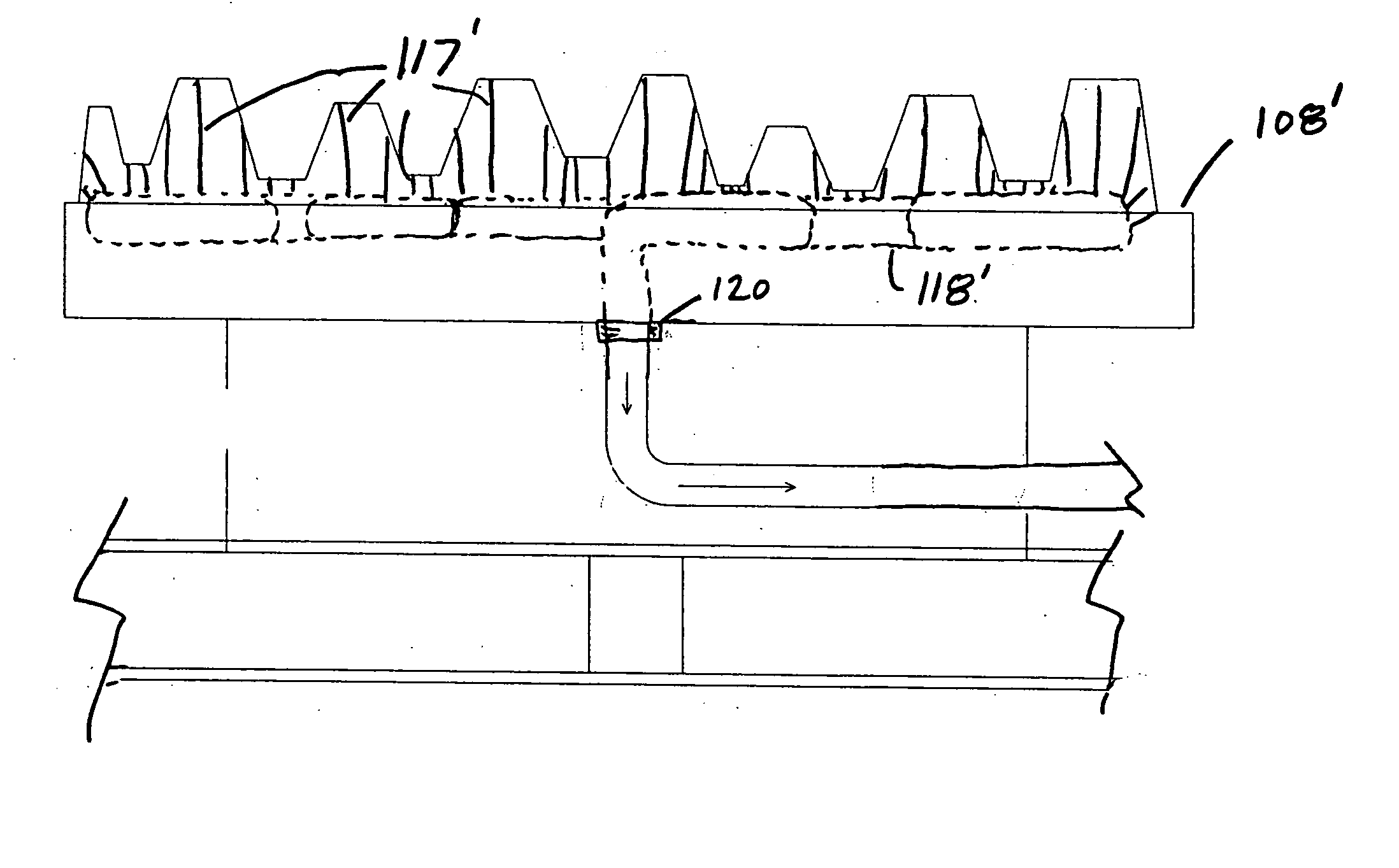

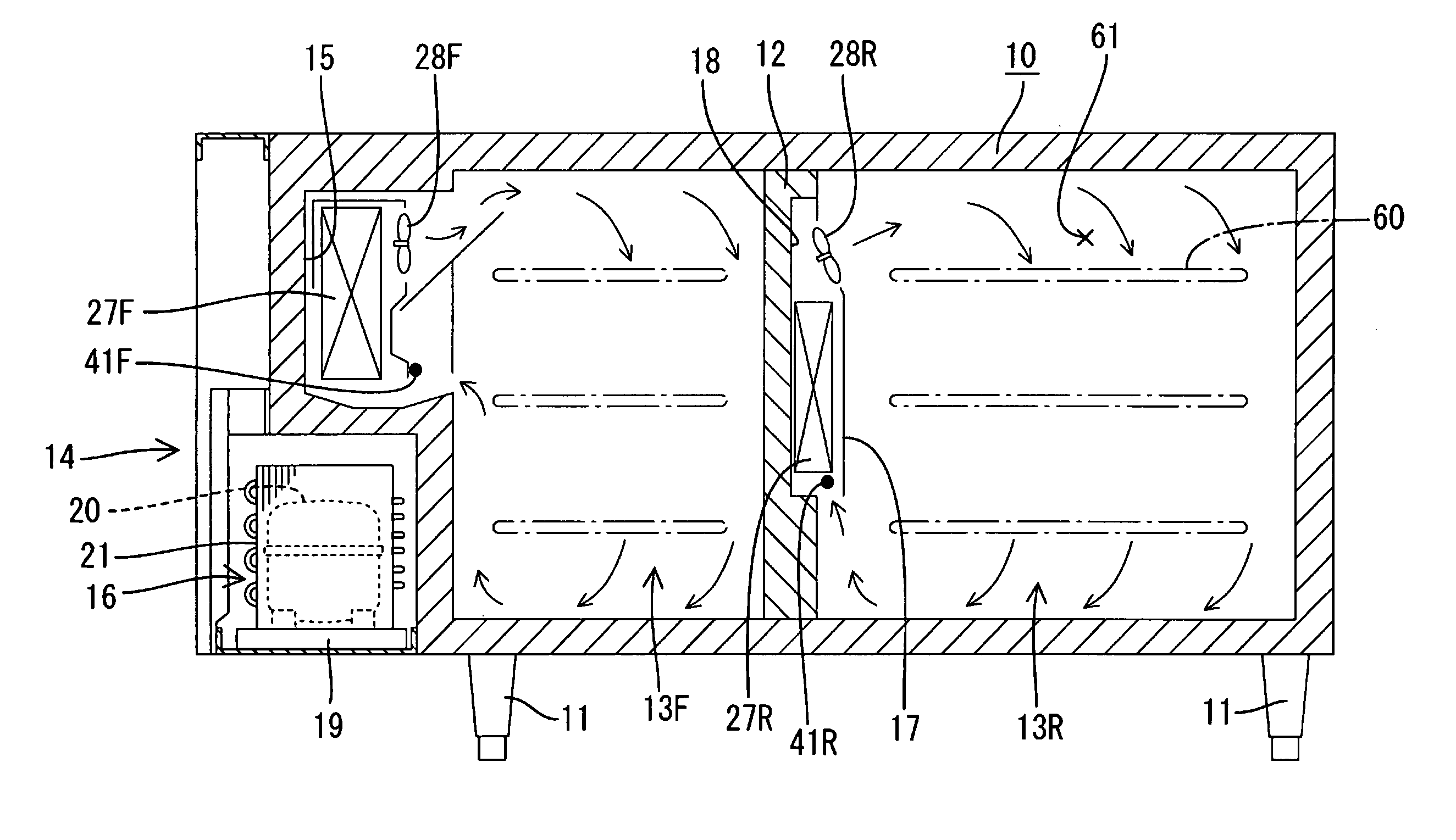

Cooling device for battery pack and rechargeable battery

InactiveUS7150935B2Reduce the overall heightEfficient and uniform coolingPrimary cell to battery groupingCell temperature controlRechargeable cellEngineering

In a battery pack including rechargeable batteries arranged in parallel, a cooling medium path for allowing a cooling medium to horizontally flow be formed between the rechargeable batteries. A cooling medium delivery device for delivering the cooling medium to the cooling medium path is provided so as to reduce a height of the battery pack including a cooling device. The cooling medium delivery device is constituted by a pair of cooling medium introduction ducts provided on both right and left sides of the battery pack, each having delivery ports for delivering the cooling medium alternately in horizontally opposed directions to each of the cooling medium paths, and a cooling medium compression transport device for supplying the cooling medium to both of the cooling medium introduction ducts.

Owner:PANASONIC CORP +1

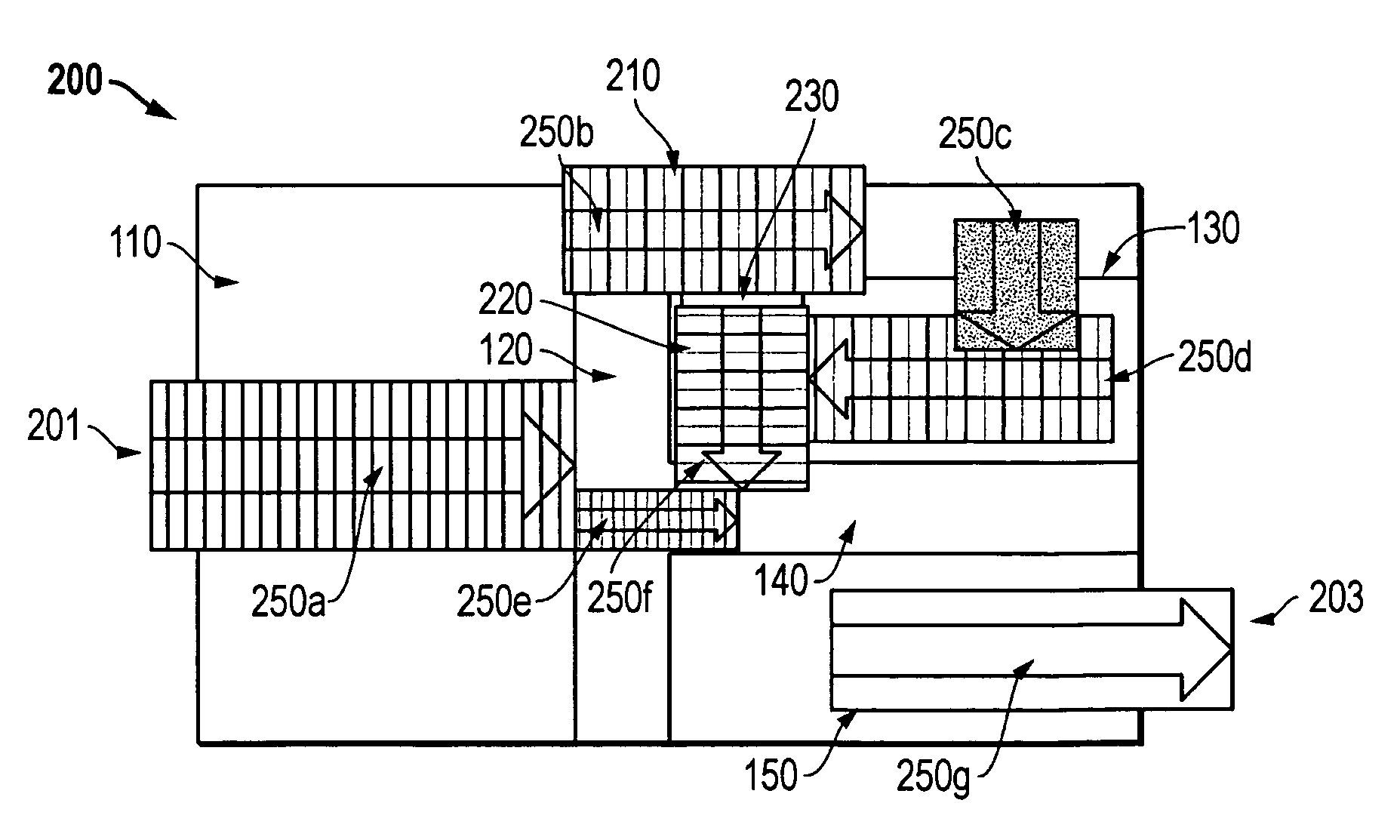

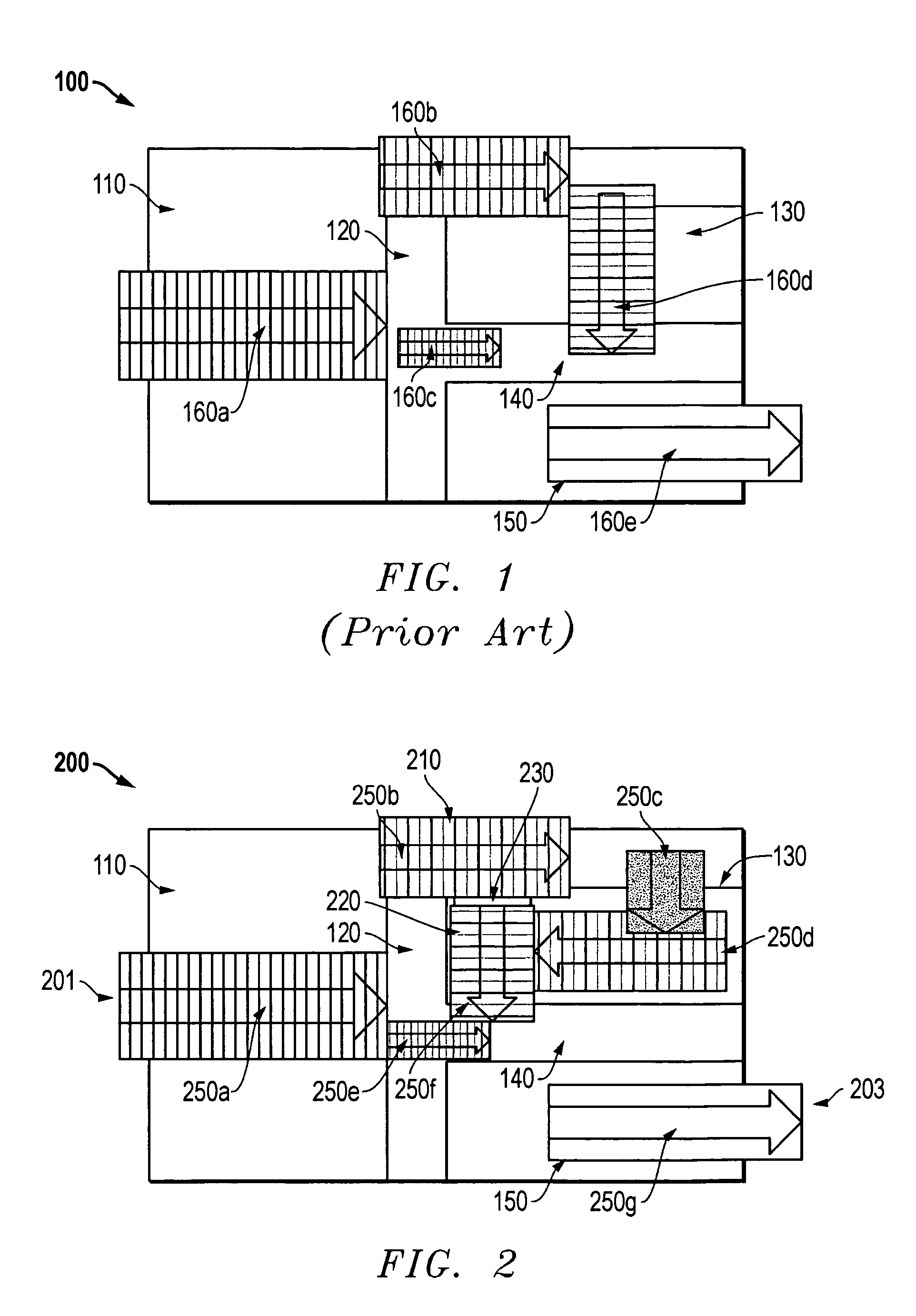

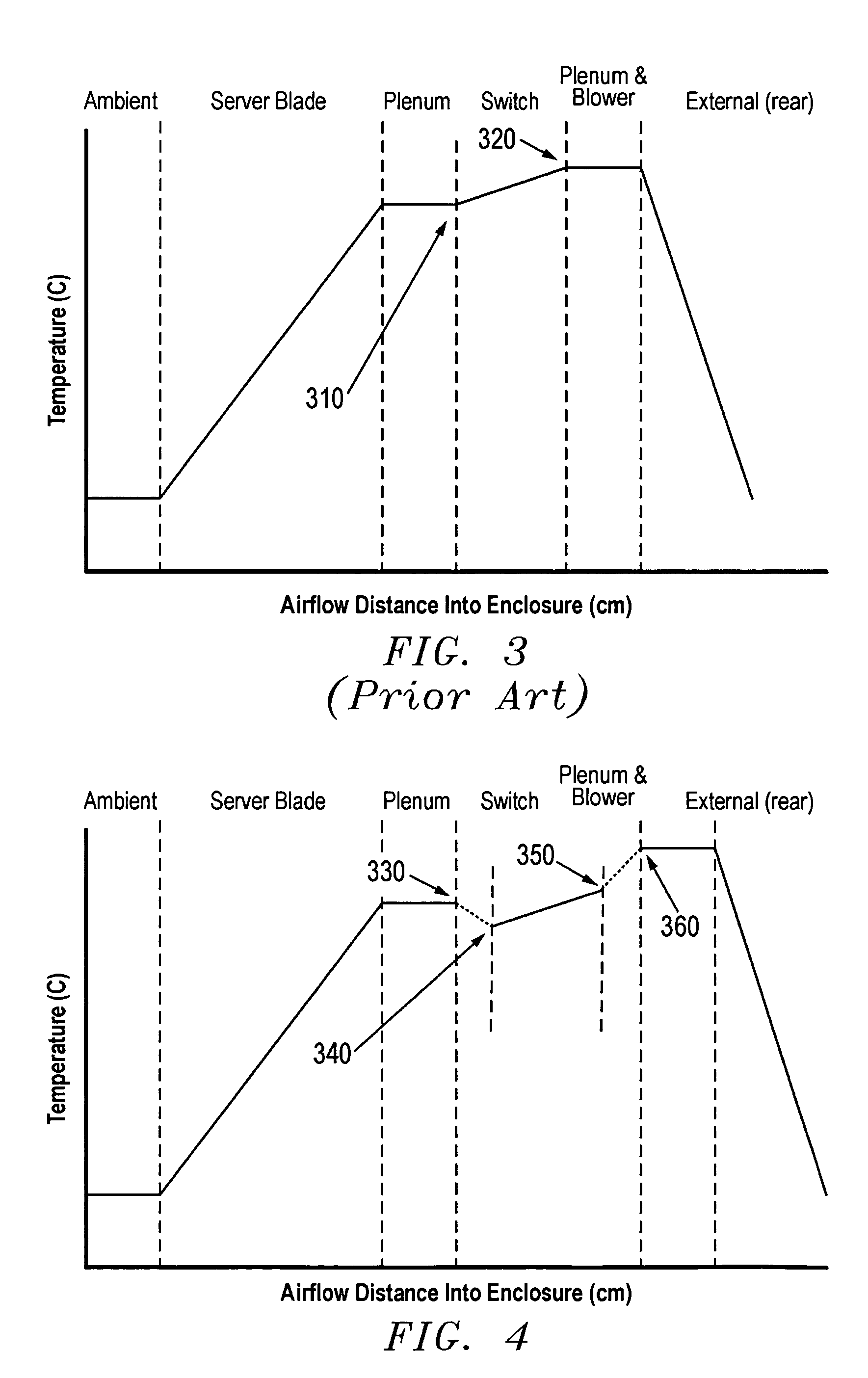

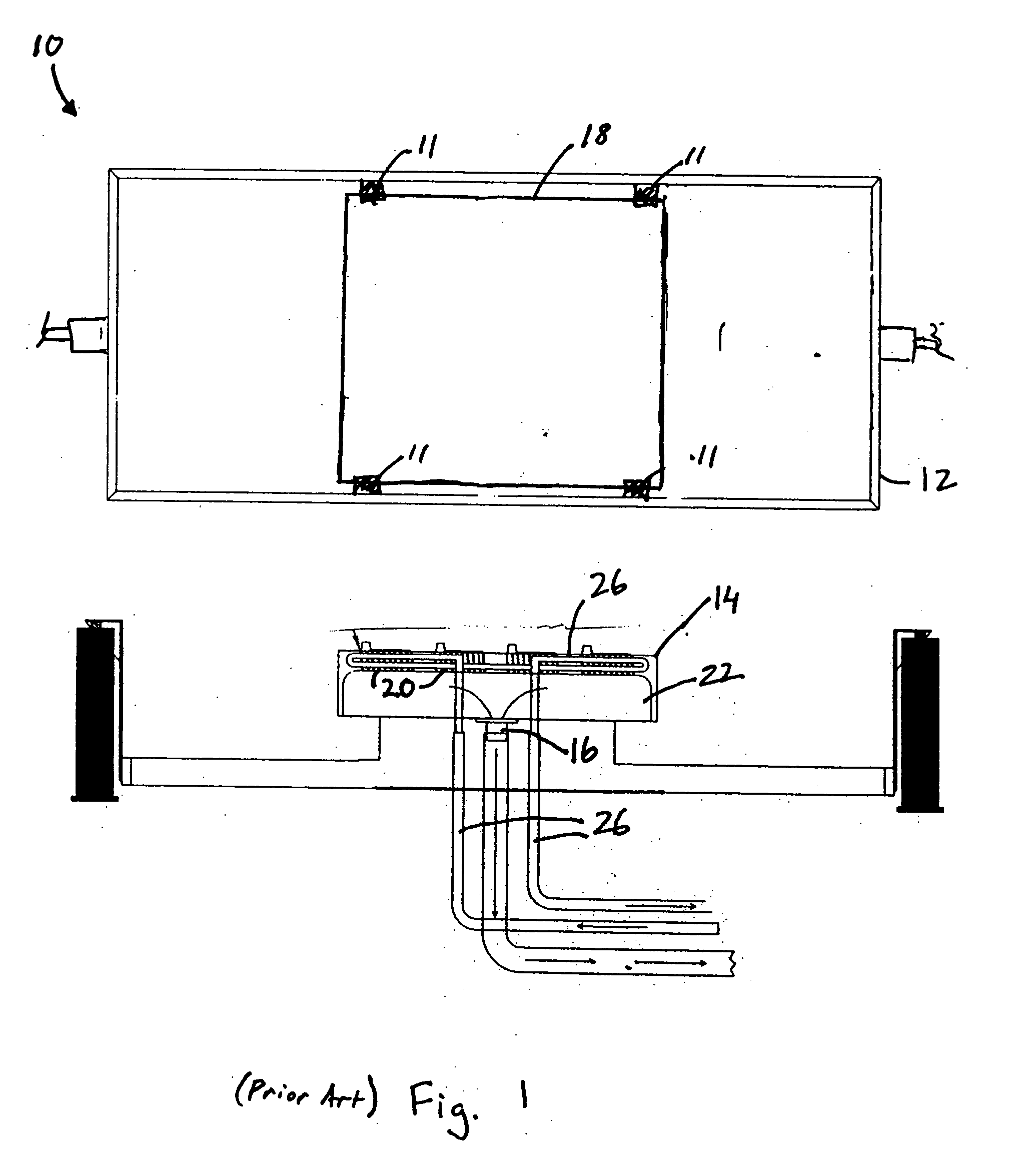

System, method, and apparatus for providing a thermal bypass in electronic equipment

ActiveUS7134288B2Reduce the temperatureReduce cooling effectDomestic cooling apparatusMachines using electric/magnetic effectsCold sideThermoelectric cooling

A system enclosure uses two heat exchangers and a thermoelectric cooling module to manage heat within the system. An airflow enters the system and is heated by server blades. Portions of the airflow split and travel to various portions of the system enclosure. Some heat is removed from the airflow by passing through the first heat exchanger before circulating around downstream subsystems. The first heat exchanger contacts the cold side of a TEC module, to reduce the temperature of that airflow. The air then enters the network switch module or other subsystem where it is further heated. Thereafter, the second heat exchanger ‘bypasses’ those components by reinserting the upstream heat back into the downstream airflow. The second heat exchanger contacts the hot side of the TEC module. The mixture of all heated air is then expelled from the system enclosure.

Owner:INT BUSINESS MASCH CORP

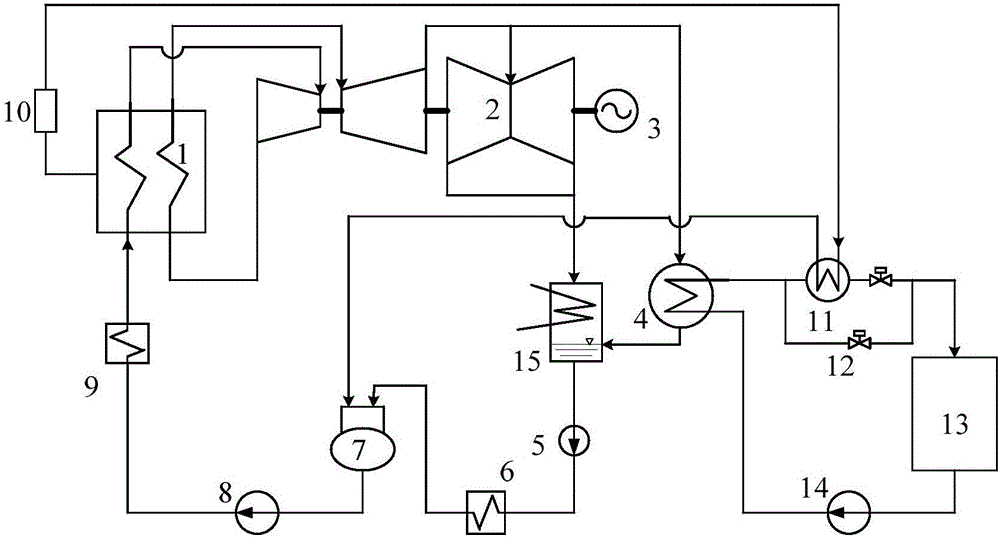

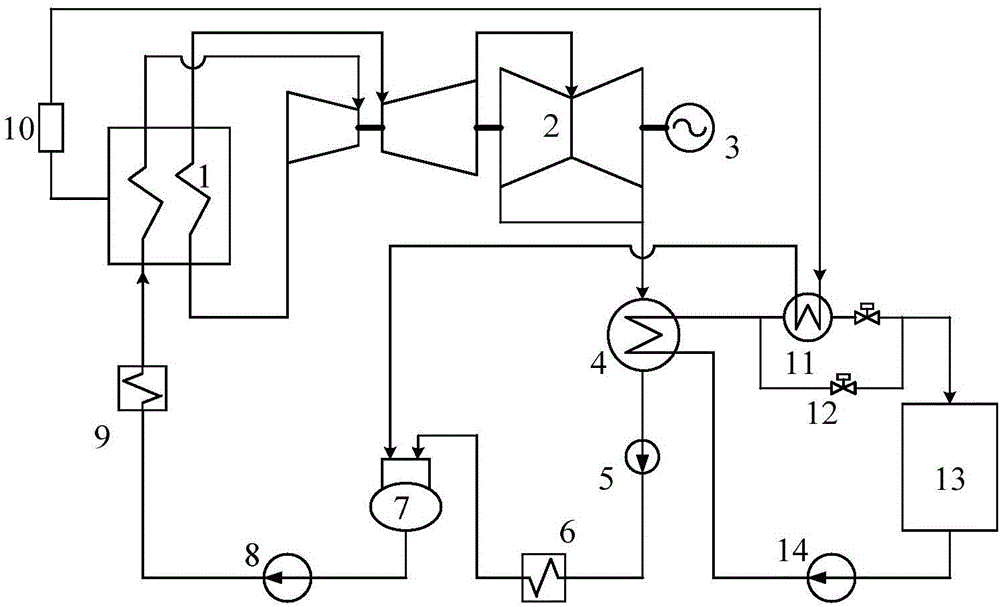

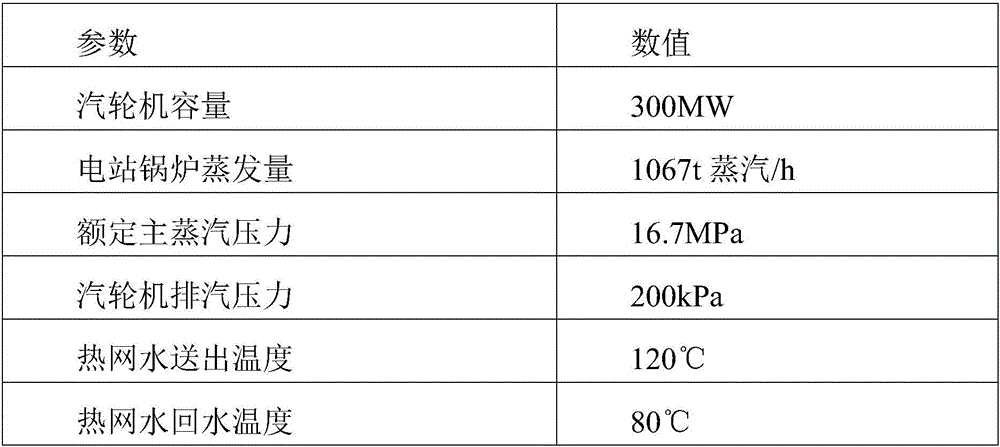

Thermoelectric decoupling heating system extracting steam from utility boiler

InactiveCN106194296AAchieve thermoelectric decouplingCapable of peak regulationSteam engine plantsEngineeringHigh pressure

The invention discloses a thermoelectric decoupling heating system extracting steam from a utility boiler. A steam condensing heat exchanger is mainly adopted for heating return water of a heating network, a steam extraction heater is then additionally arranged behind the steam condensing heat exchanger, and heat source steam of the steam extraction heater is extracted from an overheating section or a reheating section of the utility boiler. When a turbine power generation system is under the high load, exhaust steam of a turbine or steam extracted from a medium-pressure cylinder and low-pressure cylinder communicating pipe of the turbine is completely adopted to be condensed in the steam condensing heat exchanger to release heat to heat the water of the heating network, when the load of the turbine power generation system is reduced and the heating capability of the steam condensing heat exchanger is insufficient, high-pressure steam is extracted from the utility boiler, subjected to pressure reduction and sent to the steam extraction heater, the water of the heating network is further heated, and therefore it is ensured that the heating capability is not reduced under the low power generation load. According to the thermoelectric decoupling heating system extracting the steam from the utility boiler, thermoelectric decoupling of a heating power plant can be achieved, it is ensured that the heating capability under the low power generation load is not reduced, in addition, decreasing of the temperature of tail smoke of the utility boiler under the low load can be relieved, and it is ensured that a boiler denitration system works normally.

Owner:HUANENG POWER INT INC +1

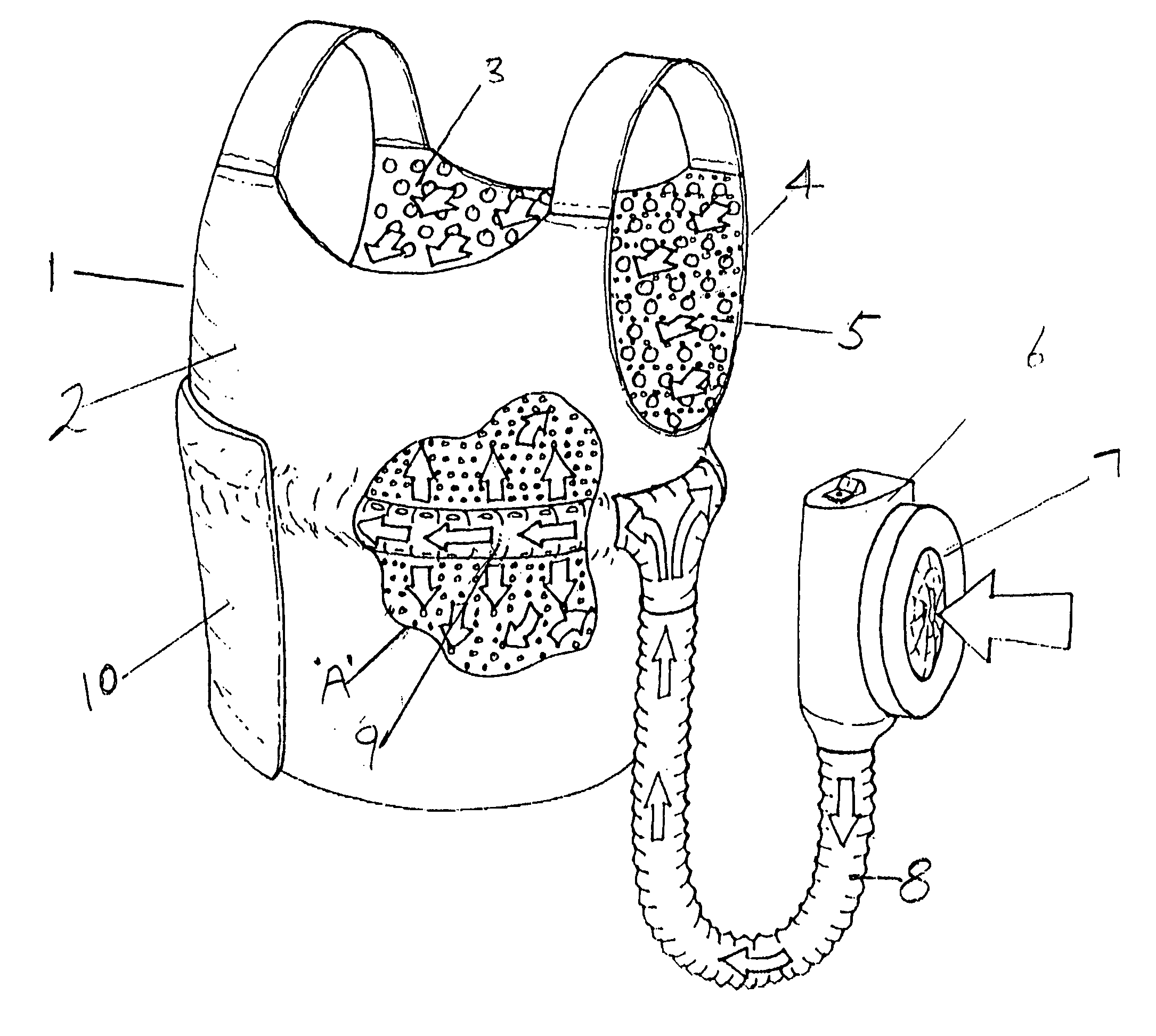

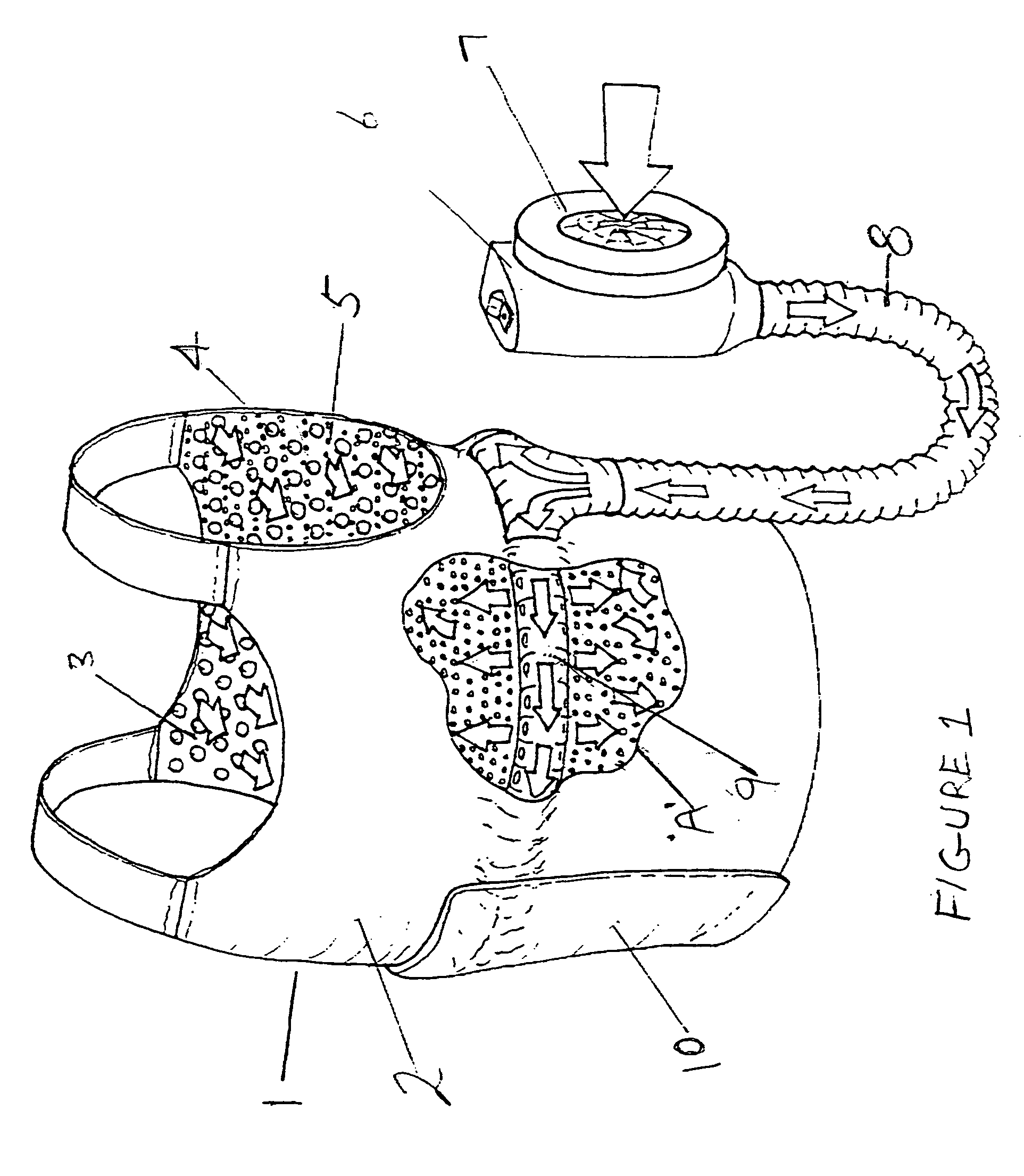

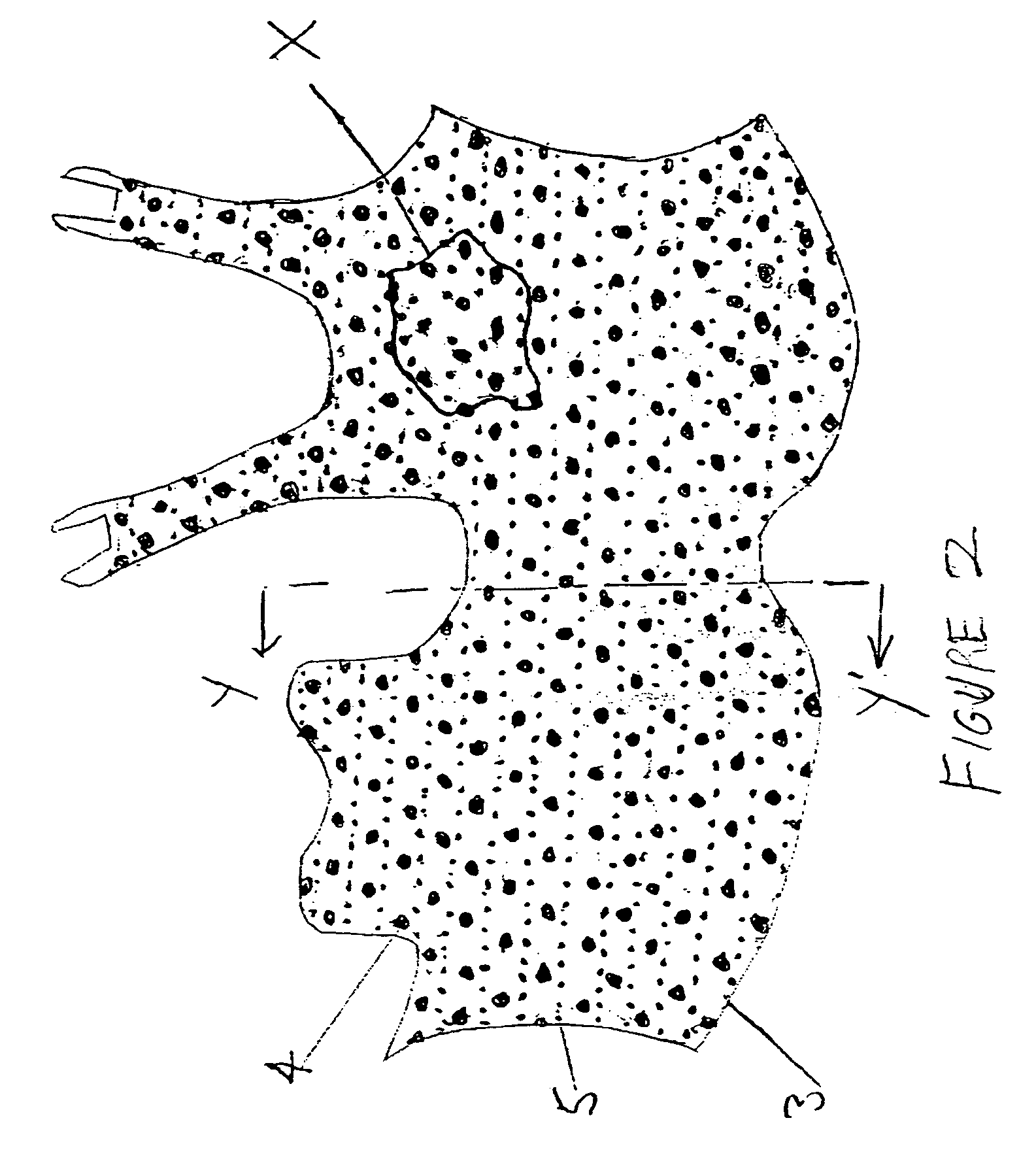

Gas distribution garment

InactiveUS20060026743A1Good cooling efficiencyImprove cooling efficiencyChemical protectionHeat protectionBiomedical engineeringGas supply

A garment for cooling the body of a wearer is described which comprises a substantially gas impermeable first substrate and a gas-permeable second substrate attached to form a cavity. At least one of the first and second substrates comprising a plurality of raised protrusions on a surface within the cavity, and the gas permeable second substrate comprising a plurality of raised protrusions on the surface external to the cavity and proximate to the body of the wearer. The cavity is adapted to be connected to a gas supply such that the gas flows into the cavity and exits the cavity through the gas permeable second substrate. The cooling garment is light weight and conformable, and may be non-tethered for portability.

Owner:WL GORE & ASSOC INC

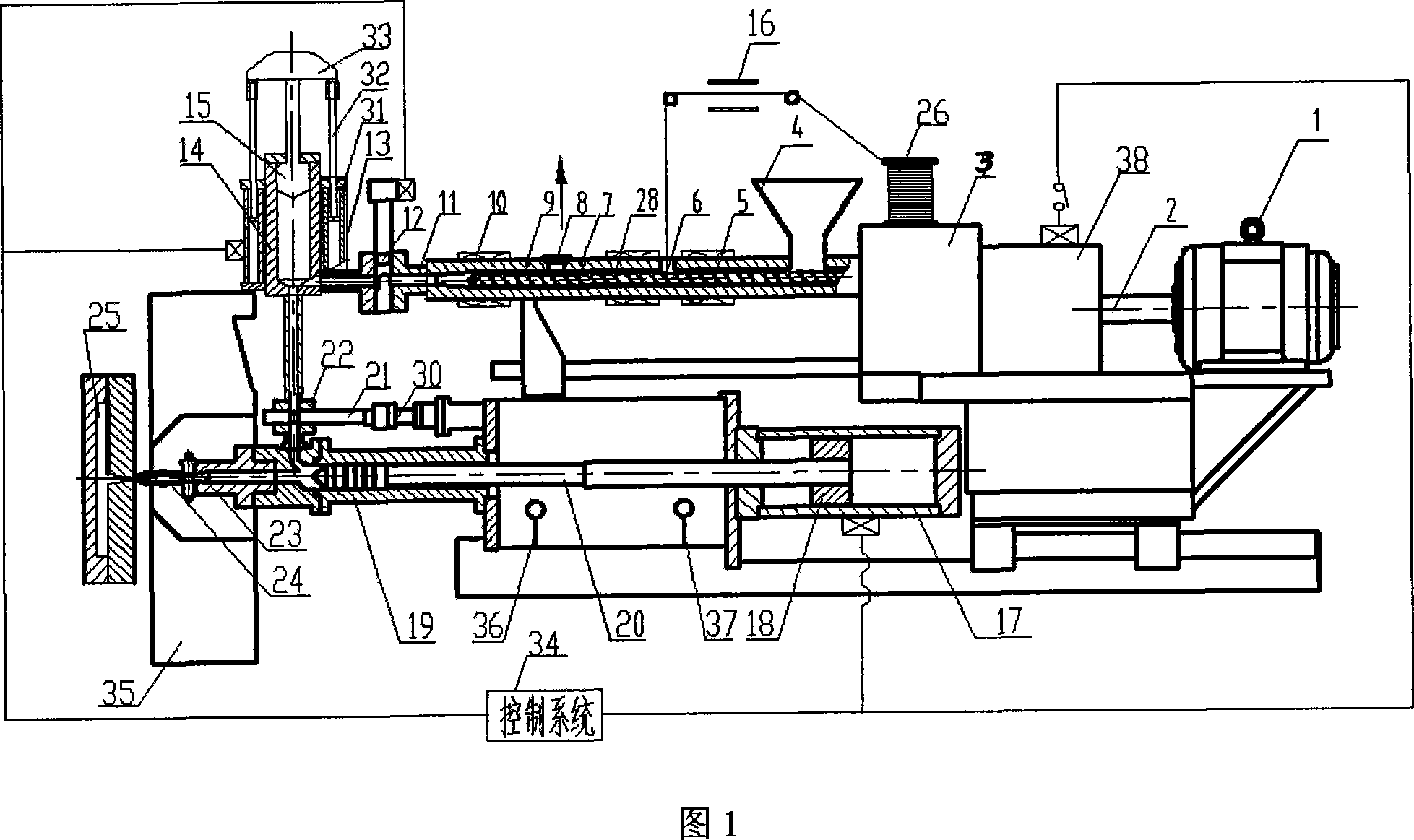

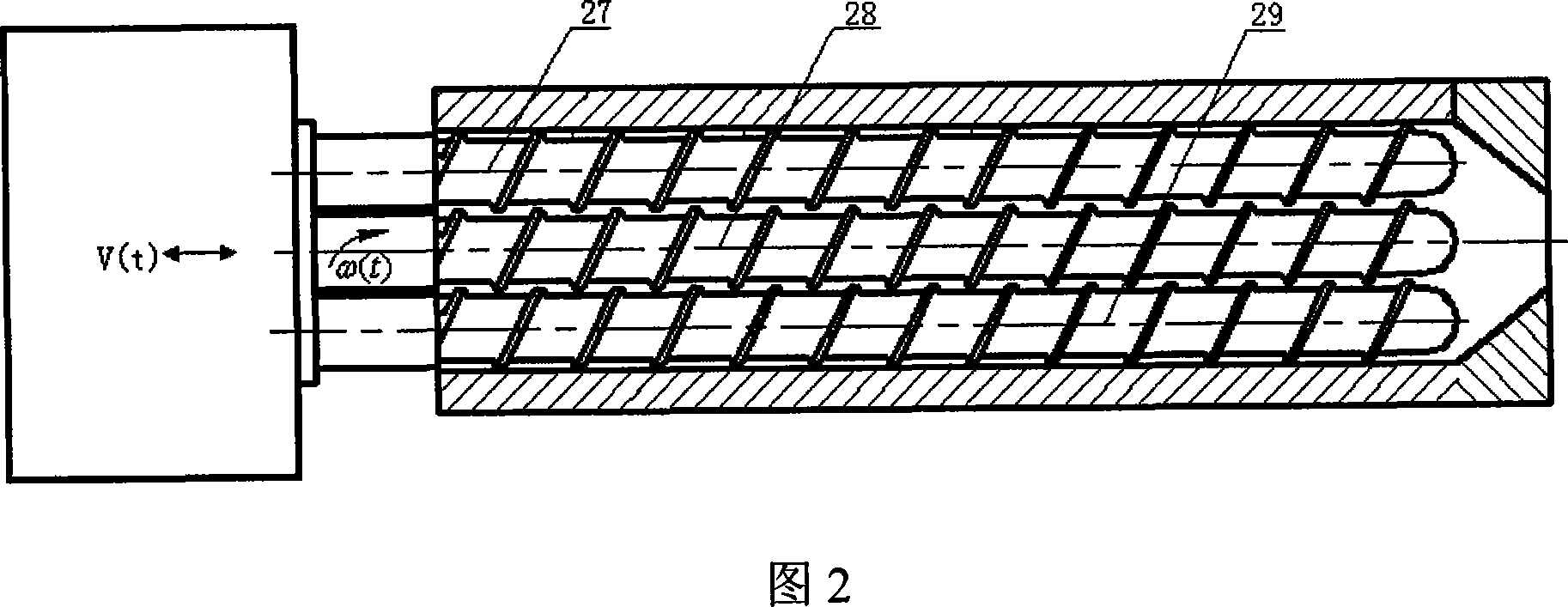

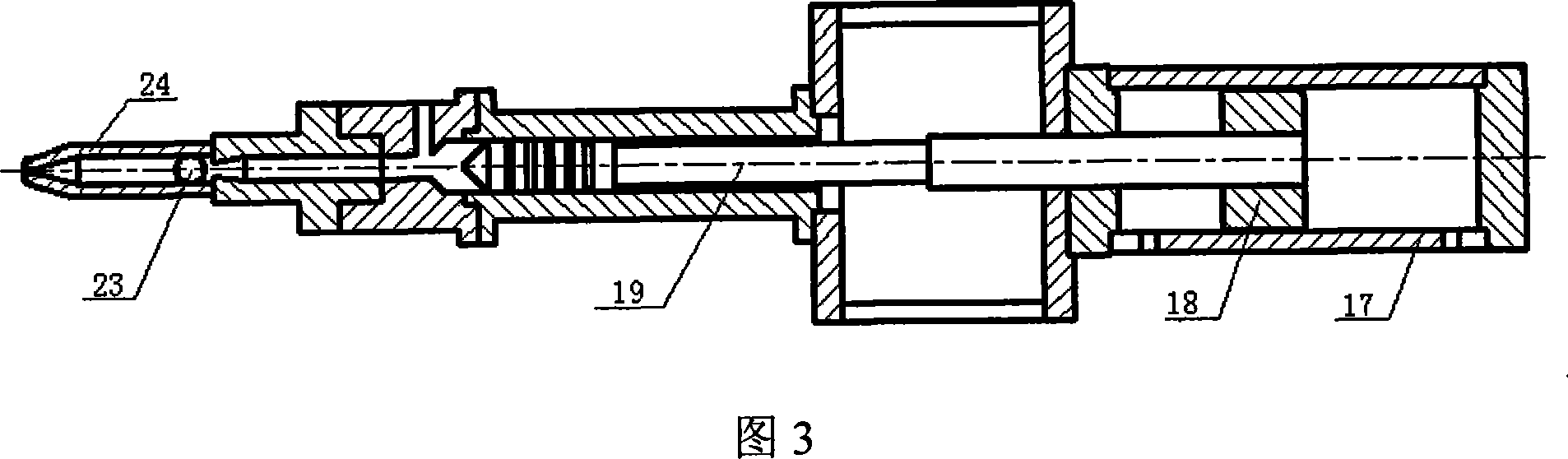

Pulse type shock processing on-line compound injection molding method and its equipment

InactiveCN101077611AIncrease fill ratioImprove interface compatibilityEngineeringFiber-reinforced composite

The present invention discloses pulse type shock reinforced in-line mixing and injecting forming method and apparatus. Pulse type shock is introduced into the whole in-line mixing and injecting forming process of producing fiber reinforced composite polymer material. The apparatus includes one plasticizing extruder with three screws arranged in one line and including one main screw capable of generating periodical axial pulse shock, one buffering storing device, and one pulse type shock pressure reinforcing plunger injecting device. The present invention can lower melt viscosity, raise mixing and homogenizing effect, raise the compatibility between fiber and polymer, lower the processing power consumption and raise product quality.

Owner:SOUTH CHINA UNIV OF TECH

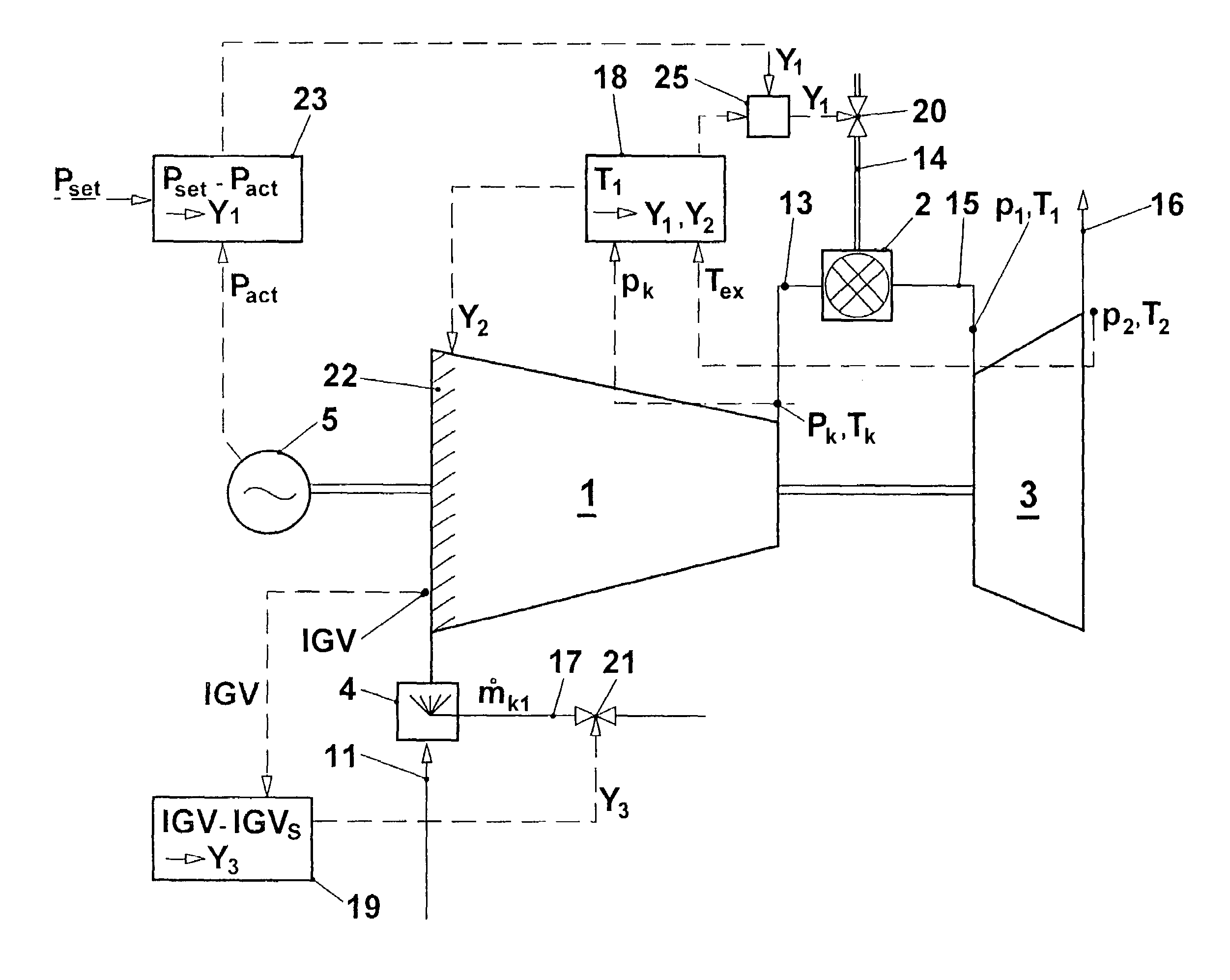

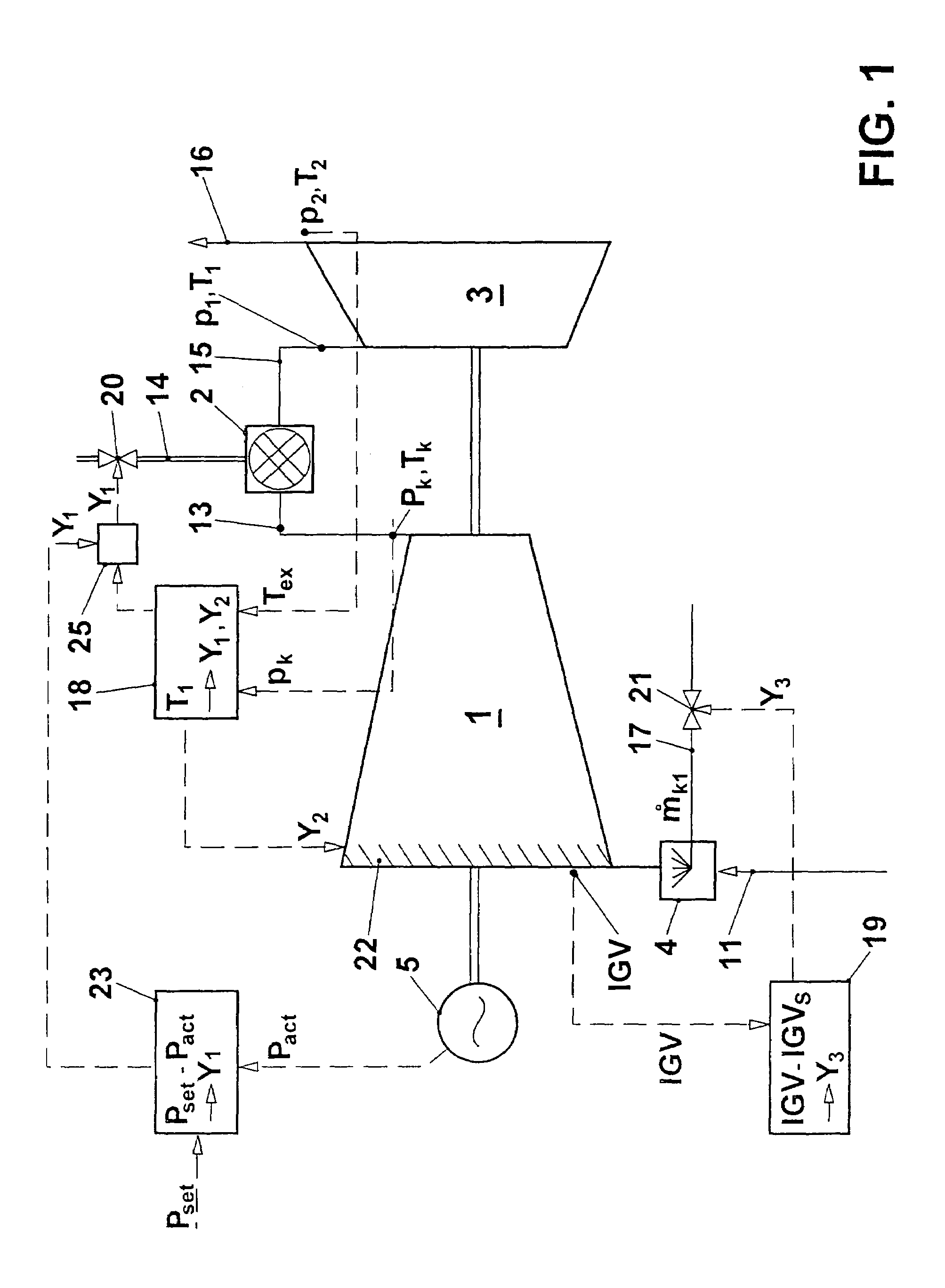

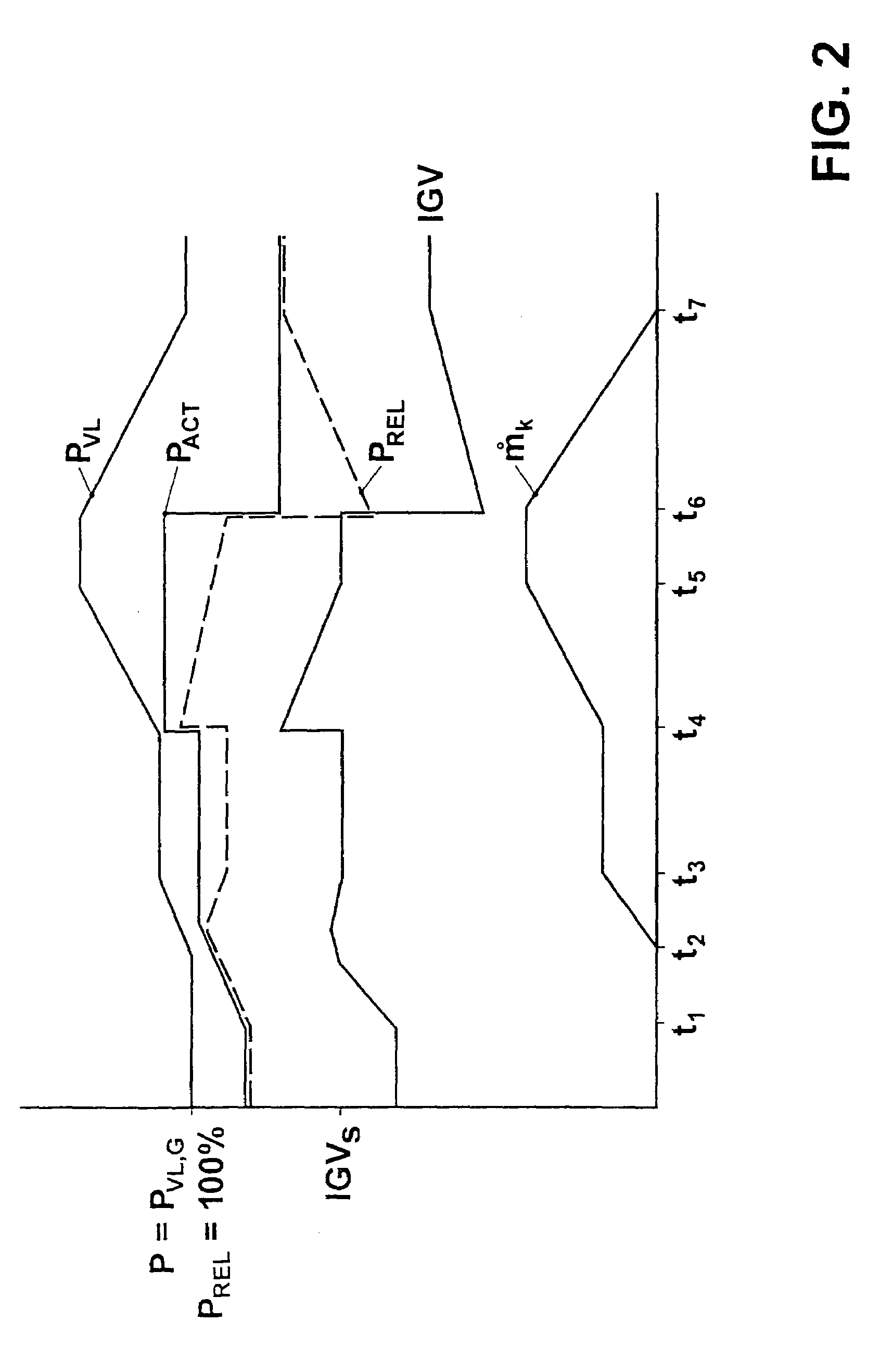

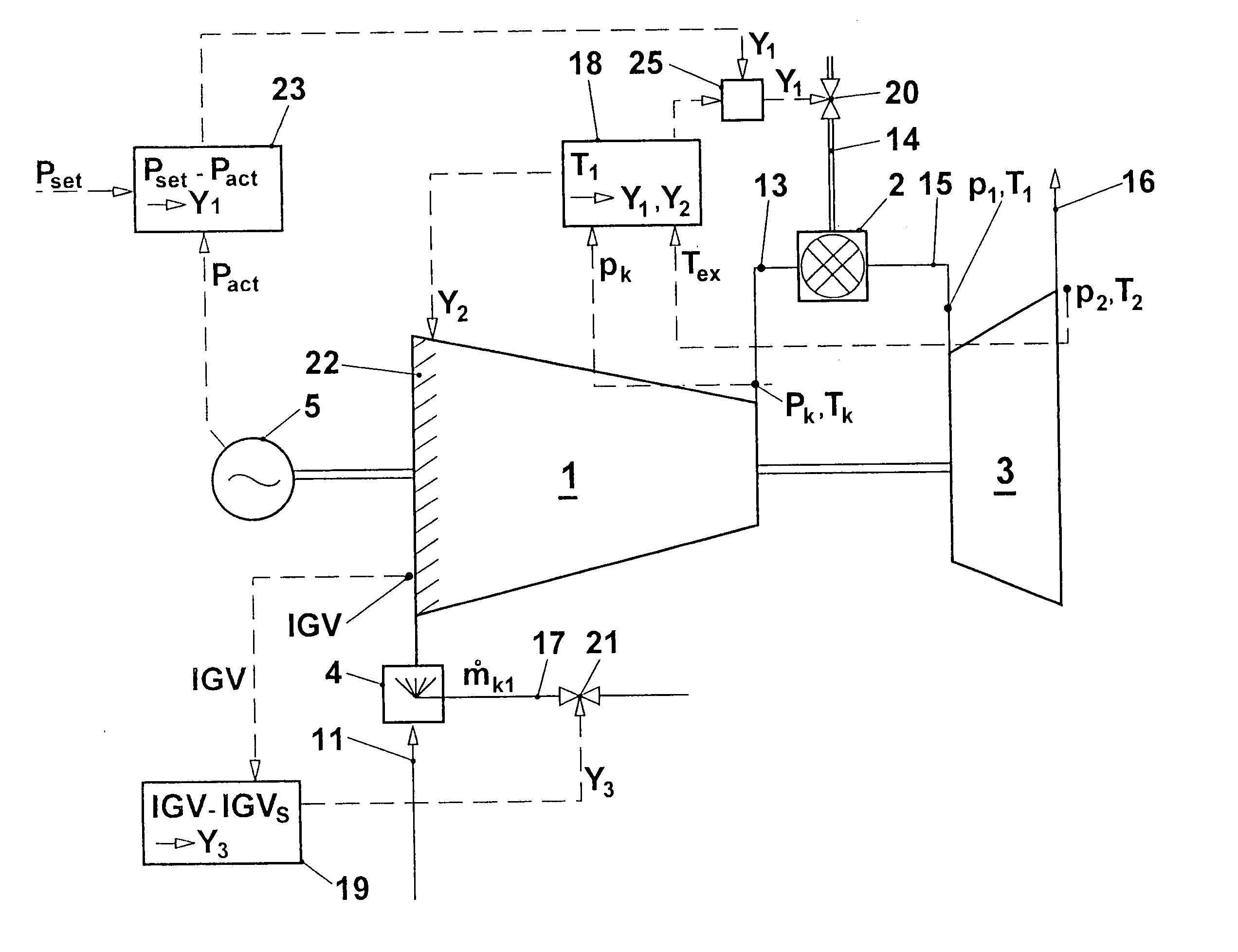

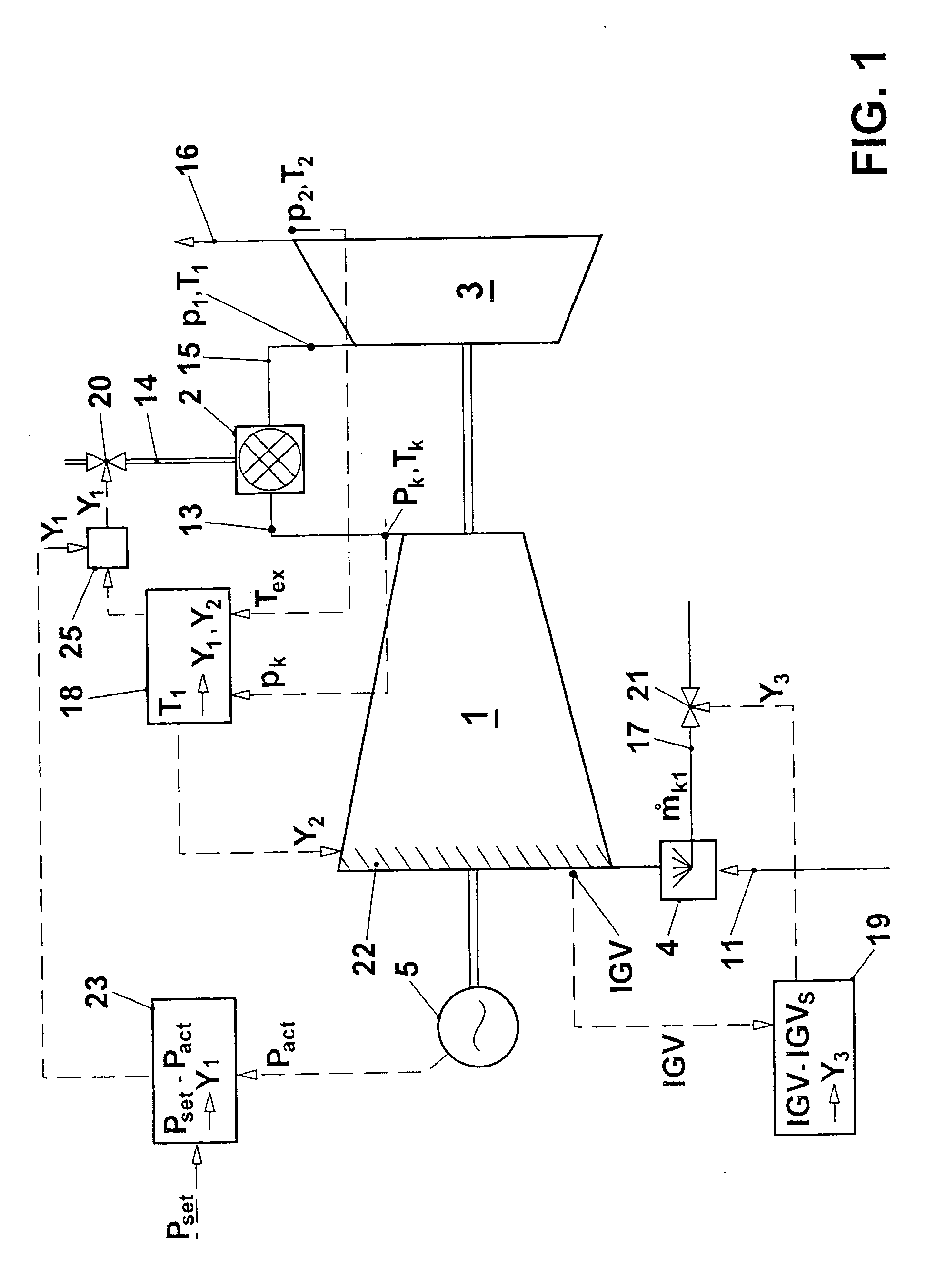

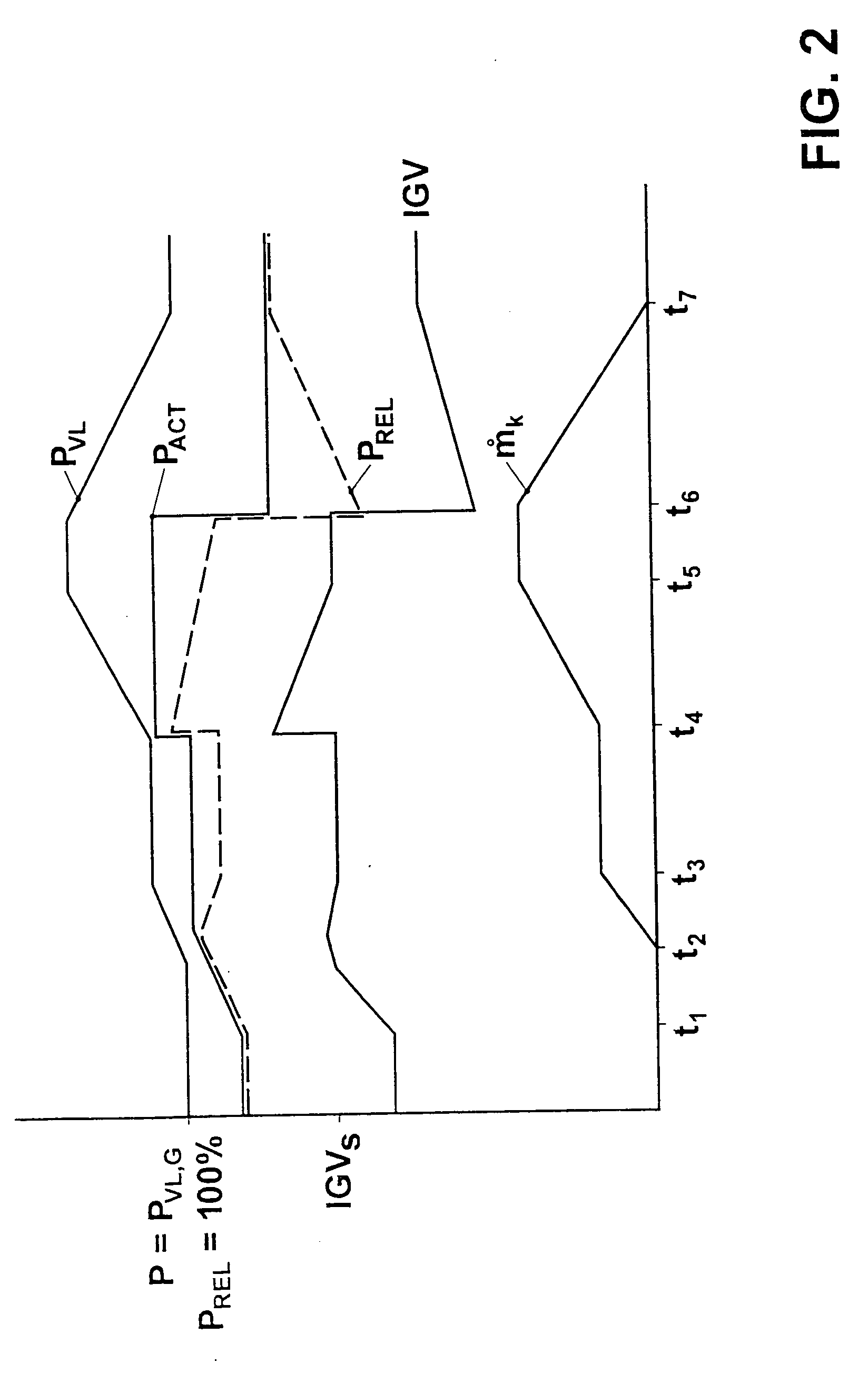

Method of operating a gas turbine group

InactiveUS7293415B2Guaranteed uptimeReduce cooling effectGas turbine plantsTurbine/propulsion fuel controlOperating pointWorking fluid

In a method for operating a gas turbine centre in the vicinity of the group nominal full-load conditions, the cooling of the working fluid before and / or during the compression is set in such a way that the respectively attainable full-load power is above the current power. Rapid power demands can therefore be rapidly satisfied by an increase in the turbine inlet temperature or by opening an adjustable inlet guide vane row, whereas the control of the cooling effect, which has a tendency to be more sluggish, is employed to adjust the full-load operating point.

Owner:ANSALDO ENERGIA IP UK LTD +1

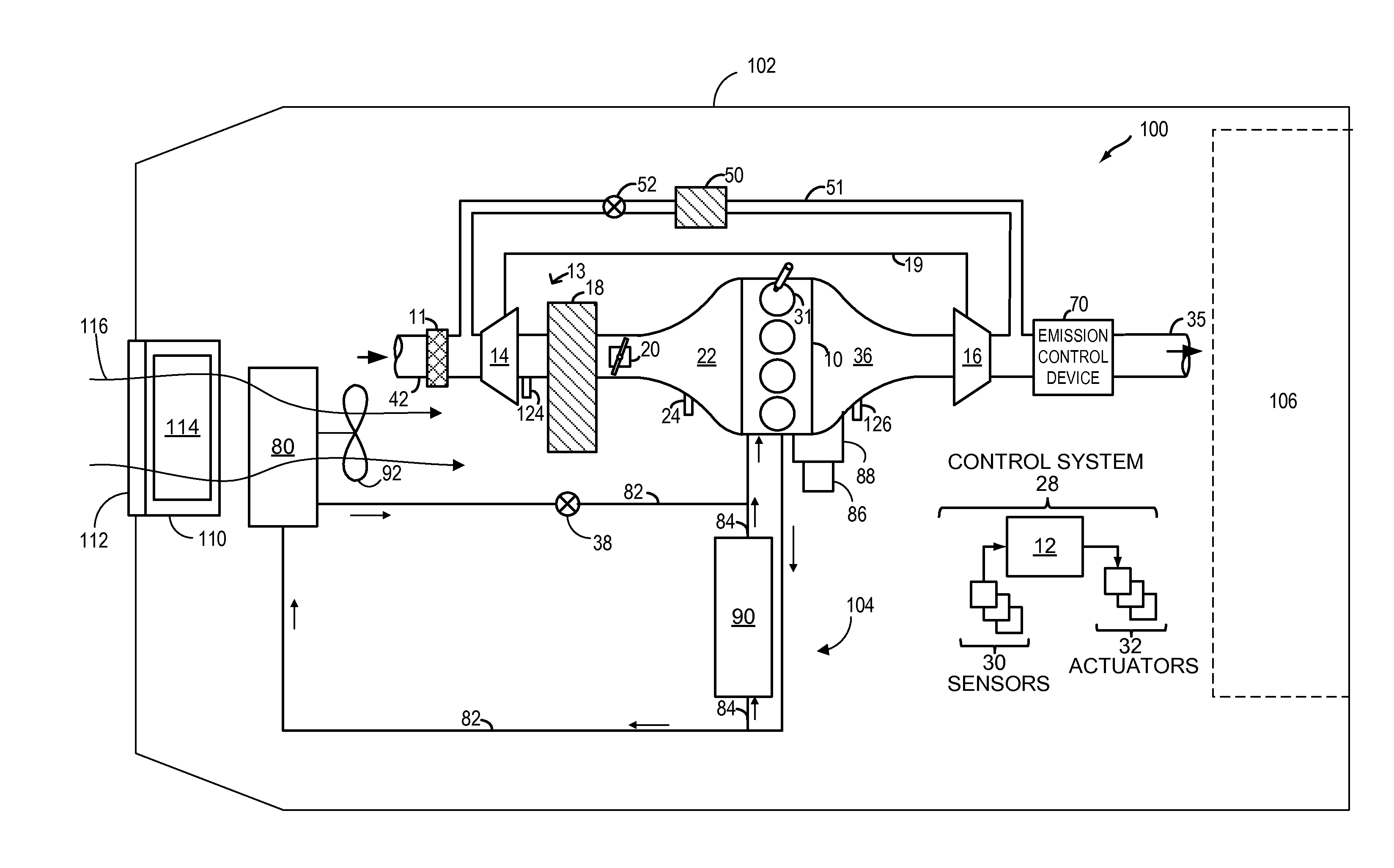

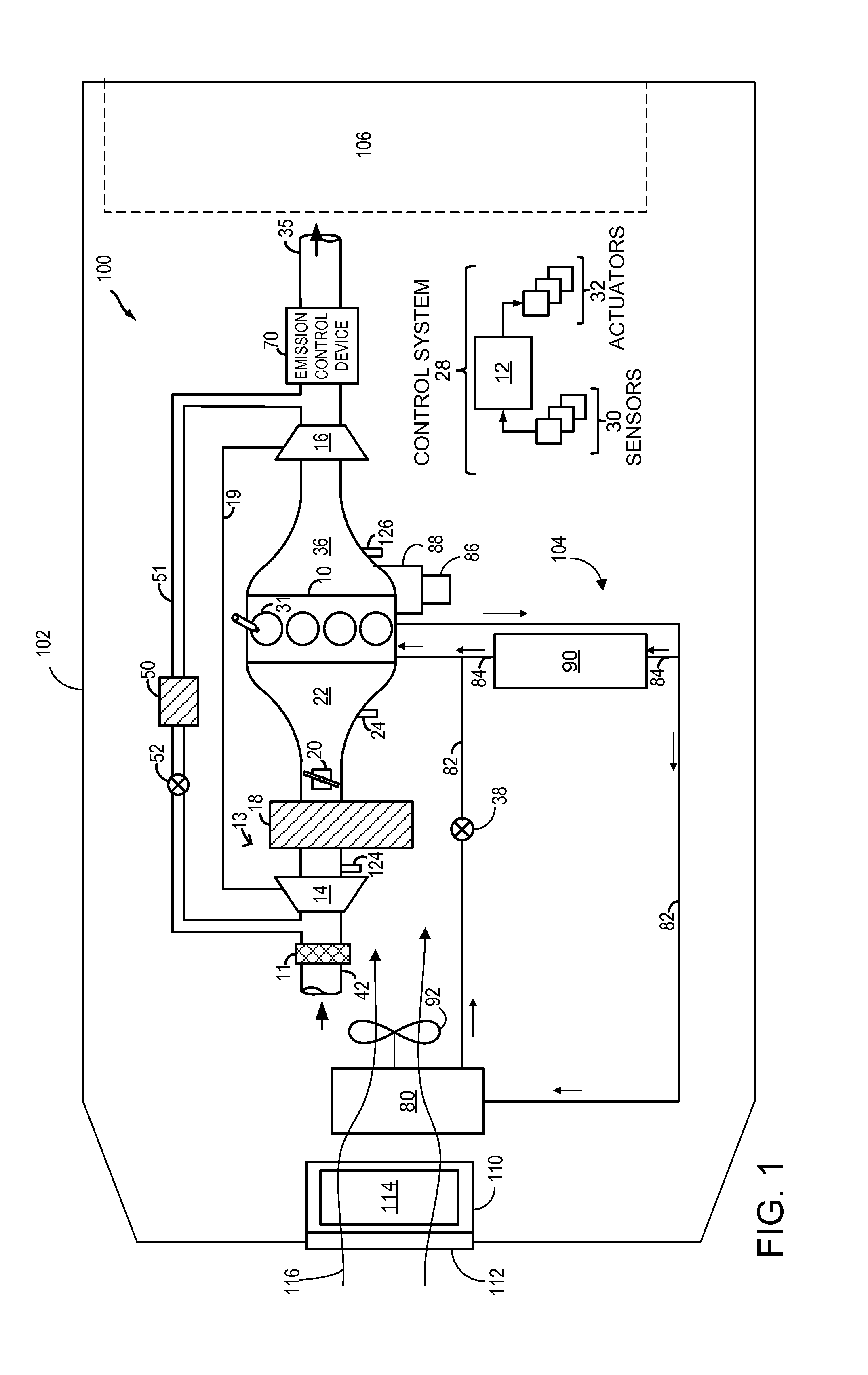

Waste heat recovery system of heat source, with Rankine cycle

InactiveUS7454910B2Easy to useReduce heatInternal combustion piston enginesEngine componentsWaste heat recovery unitWorking fluid

A waste heat recovery system of an engine has a cooling water circuit and a Rankine cycle. Cooling water is circulated between the engine and a radiator in the cooling water circuit. The Rankine cycle has a heater and an expansion device. The heater performs heat exchange between the cooling water heated by the engine and an operation fluid so as to heat the operation fluid in the Rankine cycle. The expansion device expands the heated operation fluid, so as to generate driving power. The heater is arranged in a bypass circuit so as to be in parallel with the radiator with respect to the cooling water flow. Thus, waste heat of the cooling water heated by the engine can be effectively recovered without reducing a cooling capacity of the radiator.

Owner:DENSO CORP

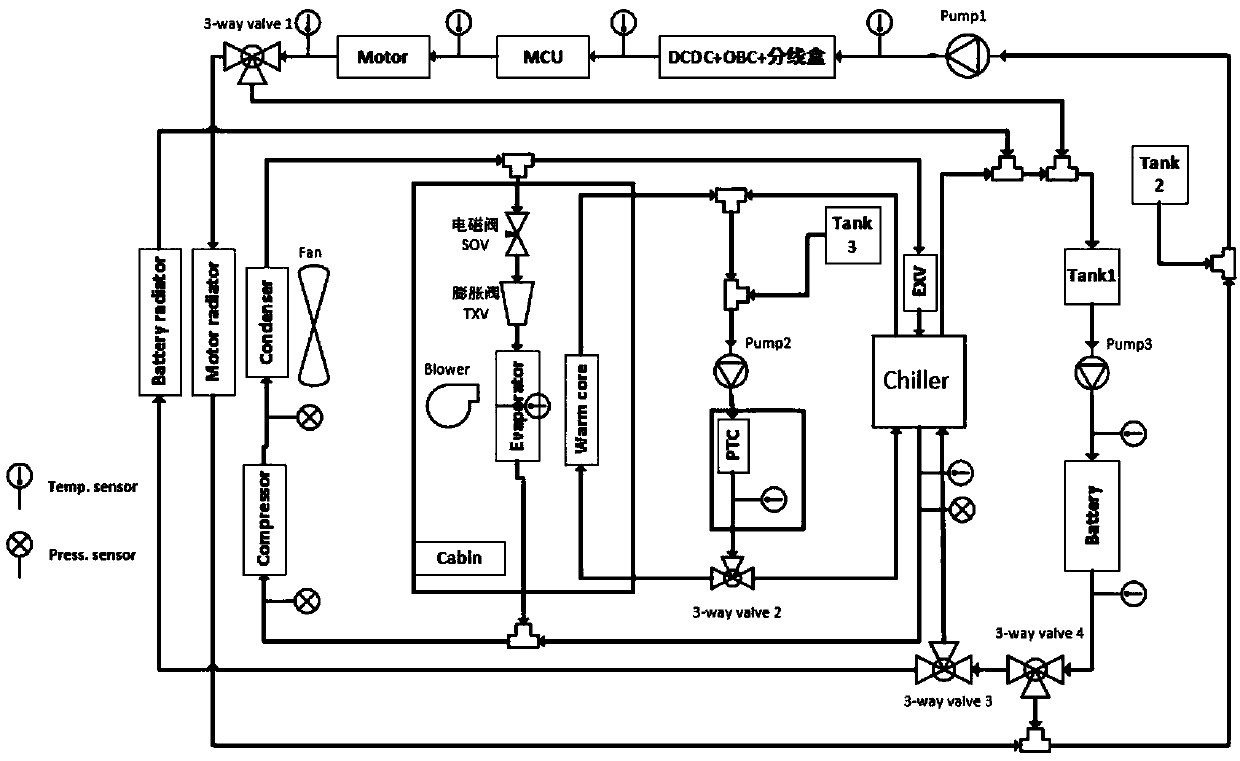

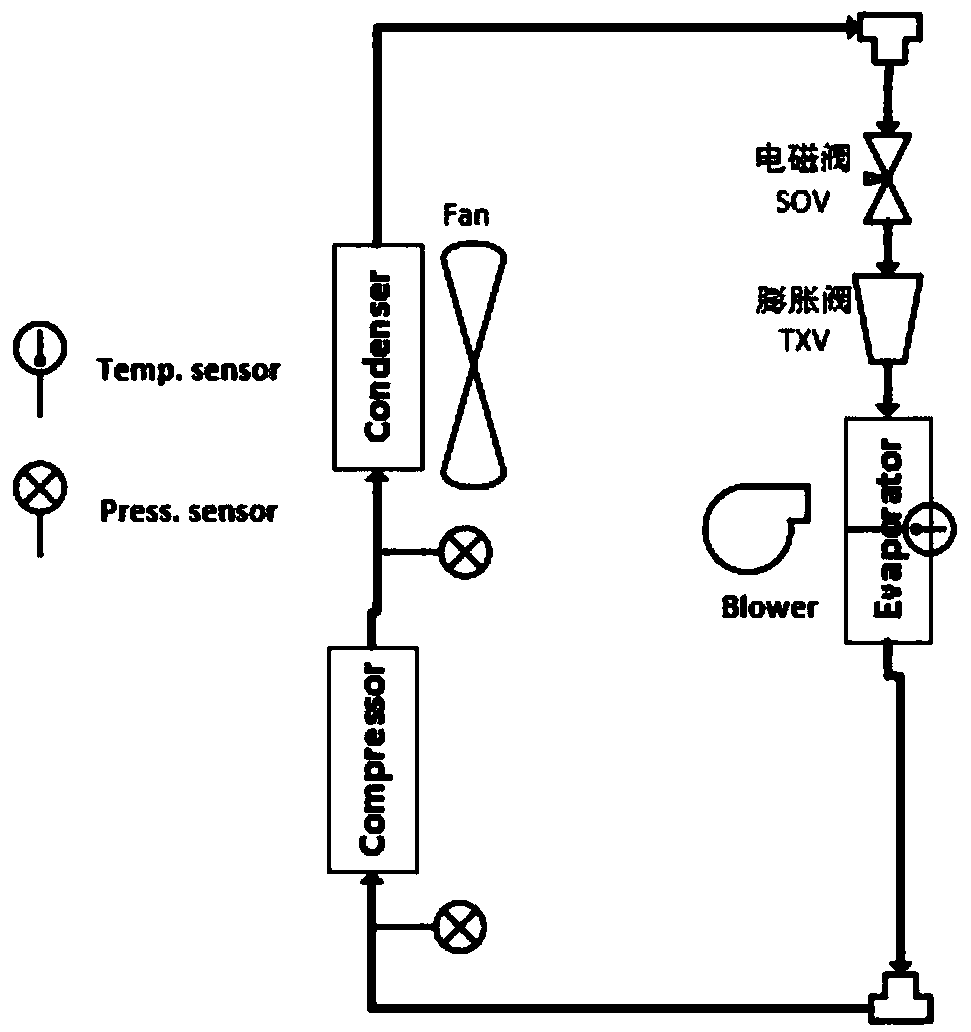

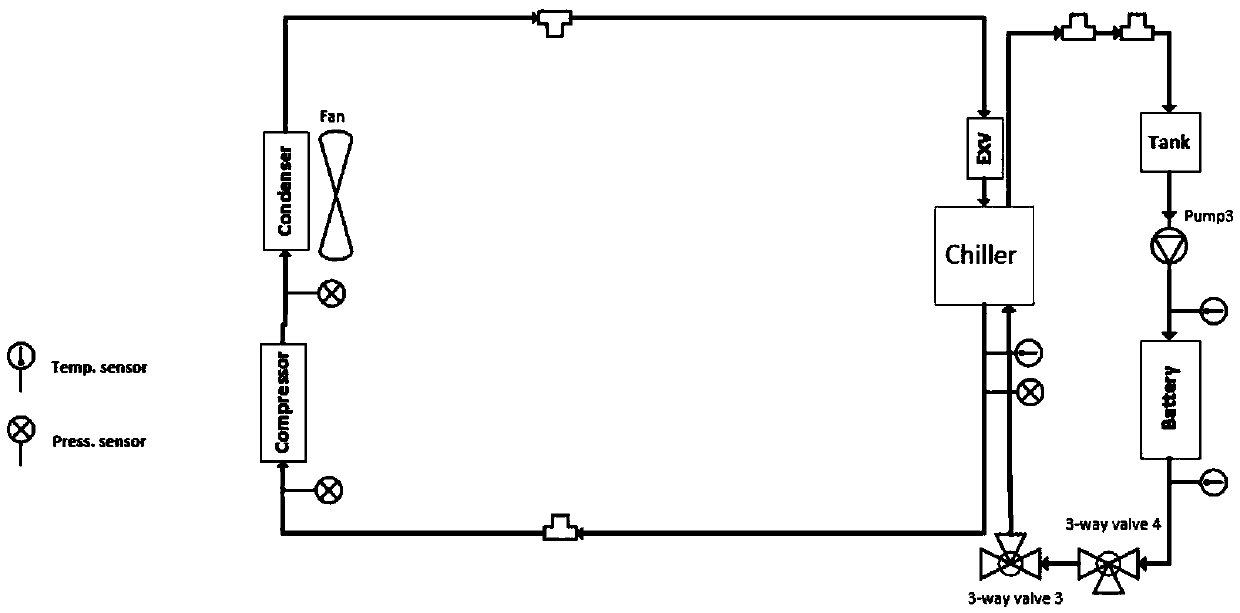

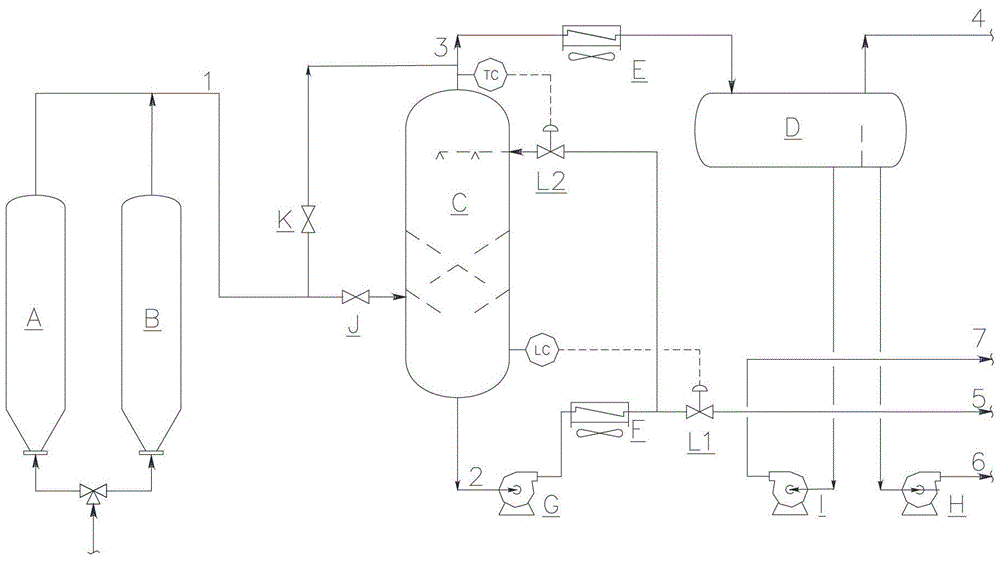

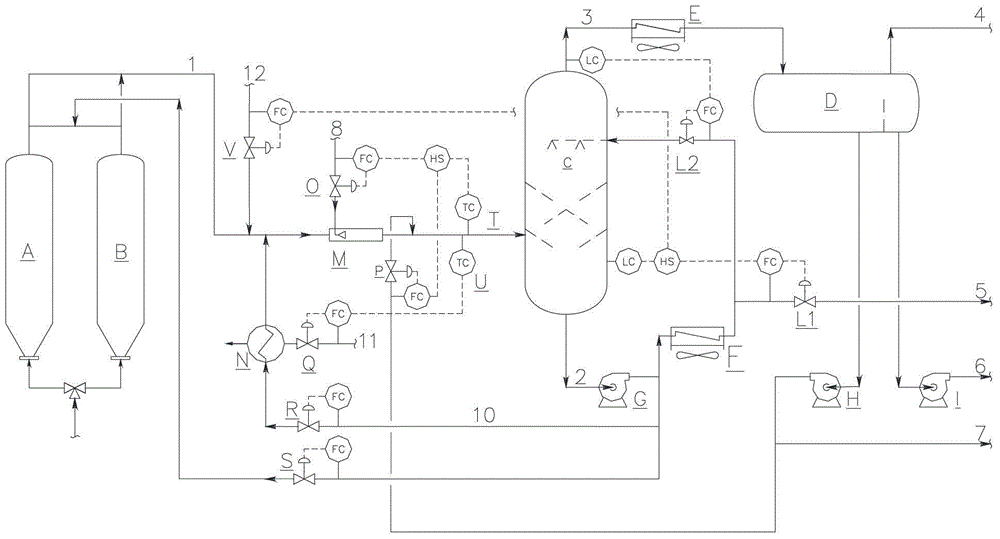

Low-power-consumption heat management system of electric car

InactiveCN109532563AReduce heating effectReduce cooling effectAir-treating devicesSecondary cellsElectrical batterySolenoid valve

The invention relates to an electric car heat management system, in particular to a low-power-consumption heat management system of an electric car. The low-power-consumption heat management system comprises an electric compressor, a condenser, a refrigerant solenoid valve, a thermostatic expansion valve, an HVAC assembly, an electronic expansion valve, a cooler, a first expansion kettle, a thirdelectronic water pump, a fourth three-way valve and a third three-way valve. After the components are combined, a passenger compartment refrigerating cycle loop, a battery forced cooling cycle loop, abattery low-temperature heat radiation cycle loop, a passenger compartment heating cycle loop, a battery forced heating cycle loop, a battery waste heat utilization cycle loop, a battery temperatureequalization cycle loop and a motor cooling cycle loop are formed. According to the low-power-consumption heat management system, the situation that a PTC and the electric compressor are utilized forheating and cooling a battery can be effectively reduced, and therefore the whole car power consumption is reduced, and the driving mileage is increased.

Owner:JIANGSU MINAN AUTOMOTIVE CO LTD

Method of operating a gas turbine group

InactiveUS20060010876A1Guaranteed uptimeReduce cooling effectGas turbine plantsTurbine/propulsion fuel controlWorking fluidOperating point

In a method for operating a gas turbine centre in the vicinity of the group nominal full-load conditions, the cooling of the working fluid before and / or during the compression is set in such a way that the respectively attainable full-load power is above the current power. Rapid power demands can therefore be rapidly satisfied by an increase in the turbine inlet temperature or by opening an adjustable inlet guide vane row, whereas the control of the cooling effect, which has a tendency to be more sluggish, is employed to adjust the full-load operating point.

Owner:ANSALDO ENERGIA IP UK LTD +1

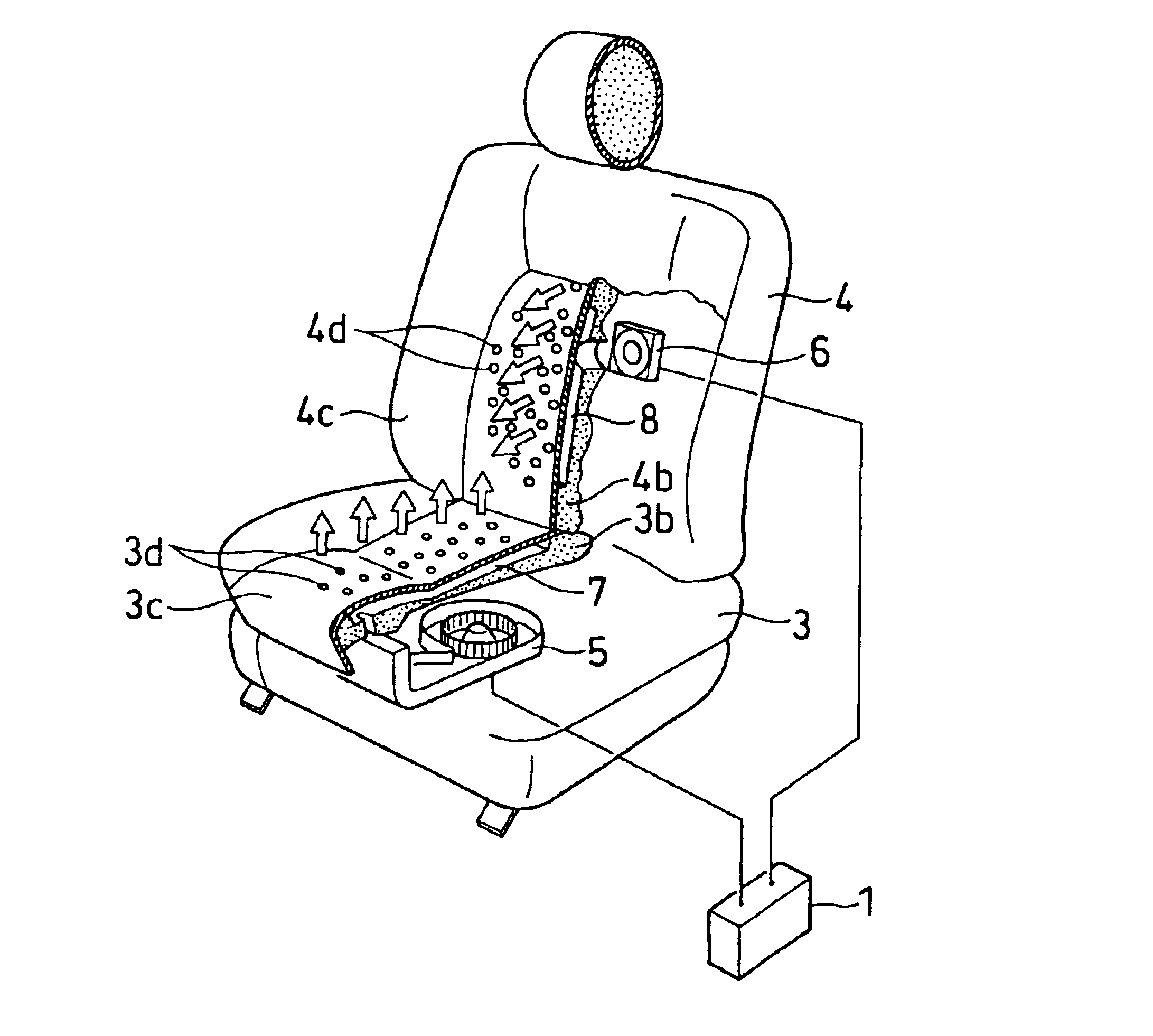

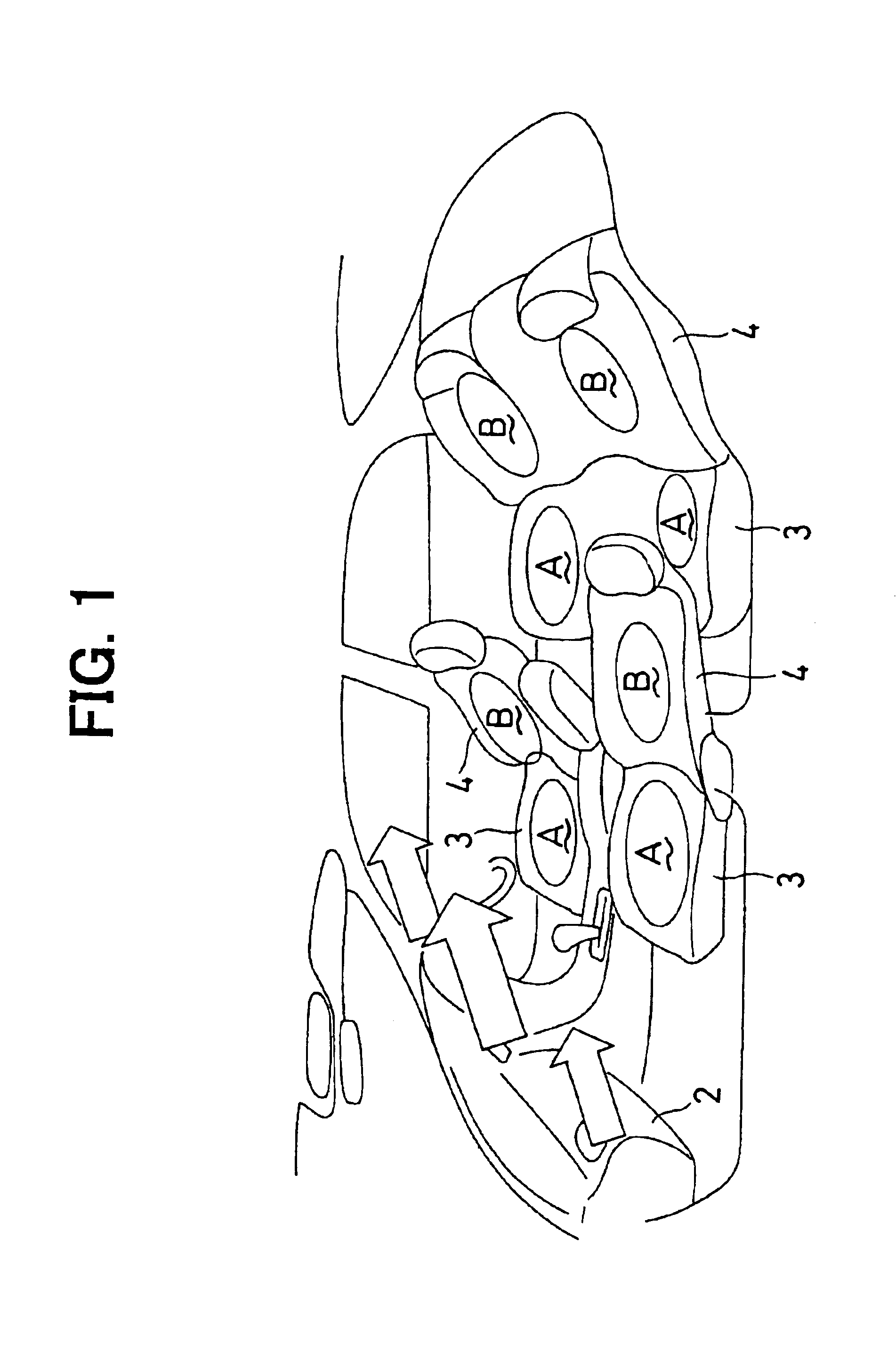

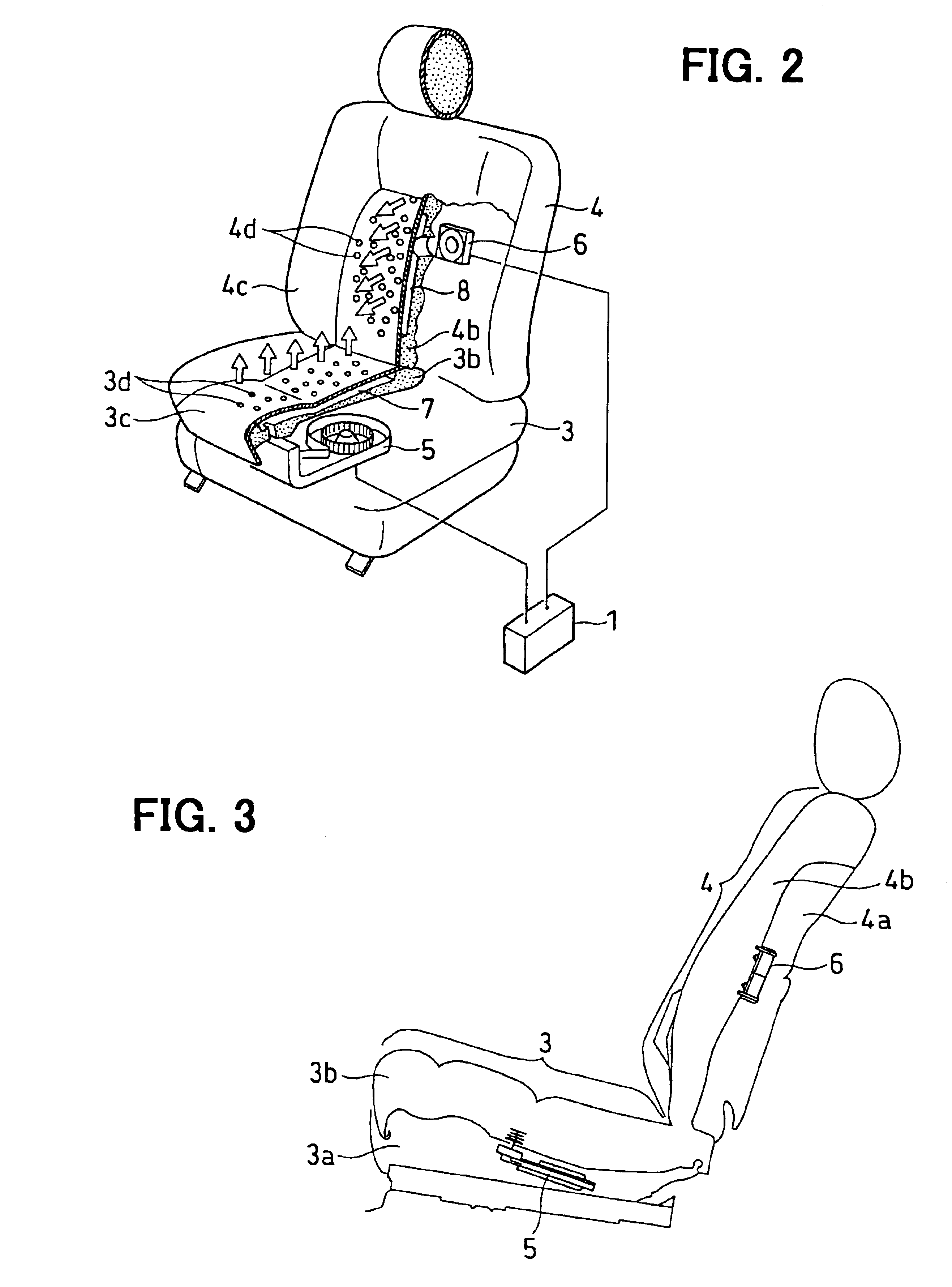

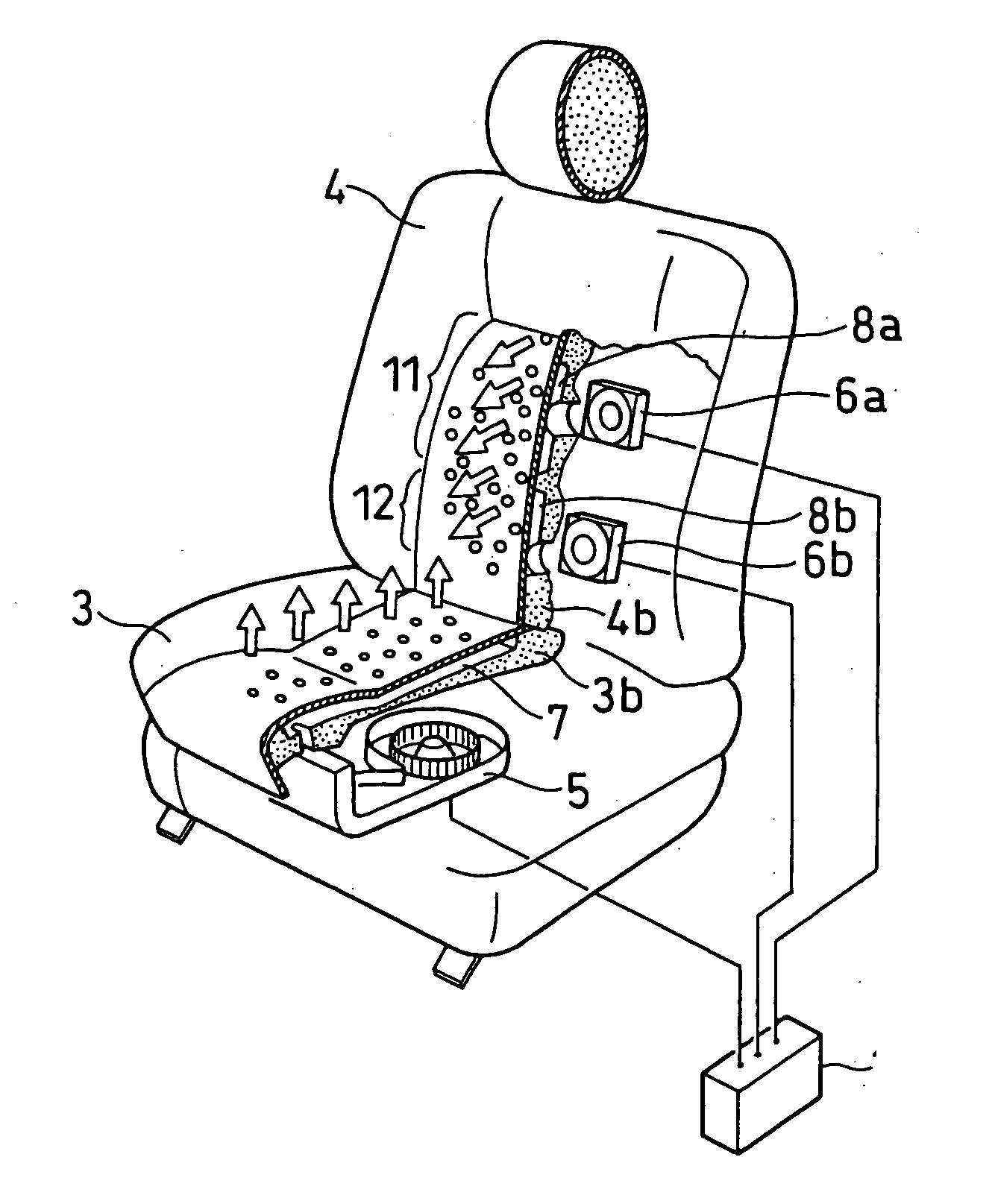

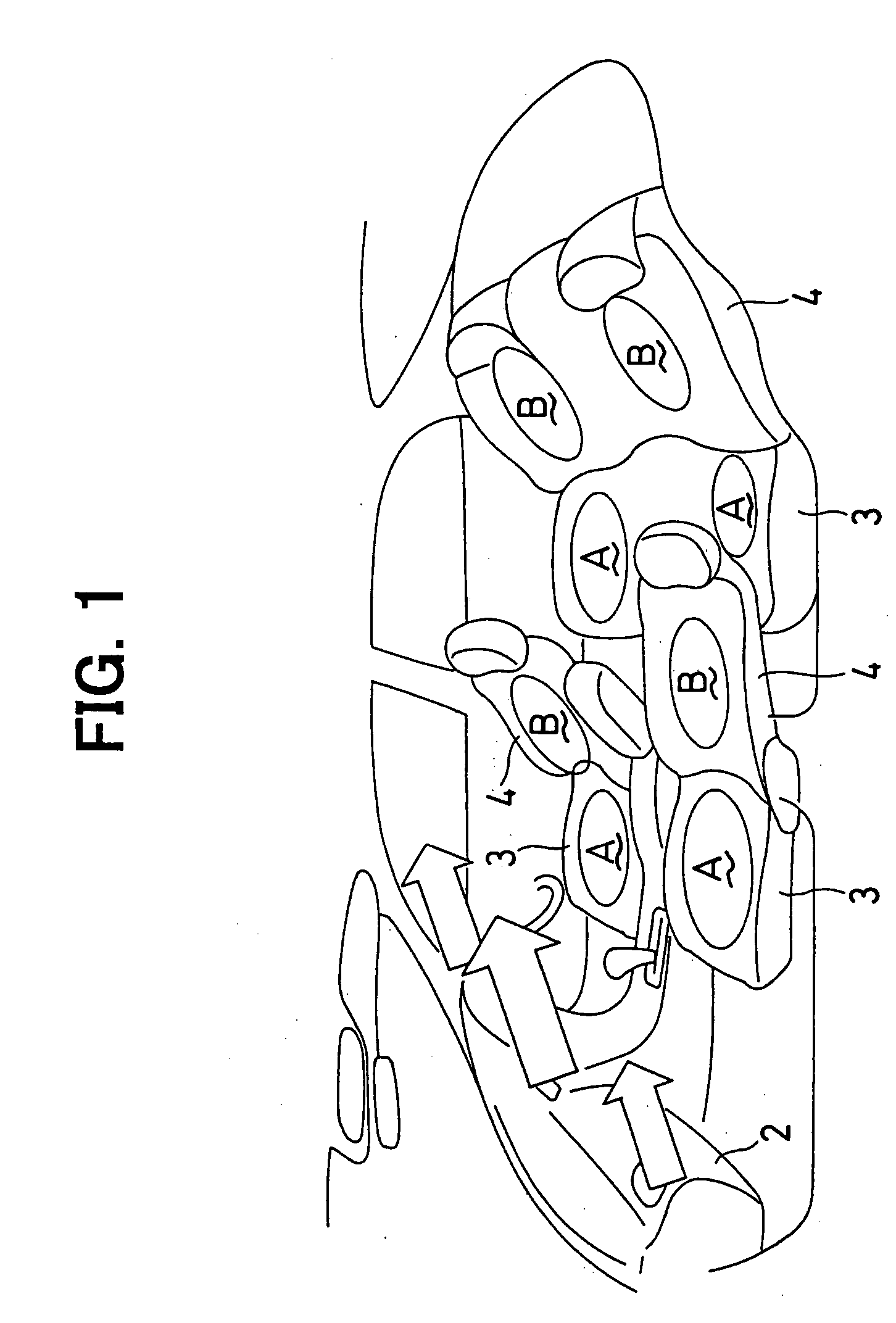

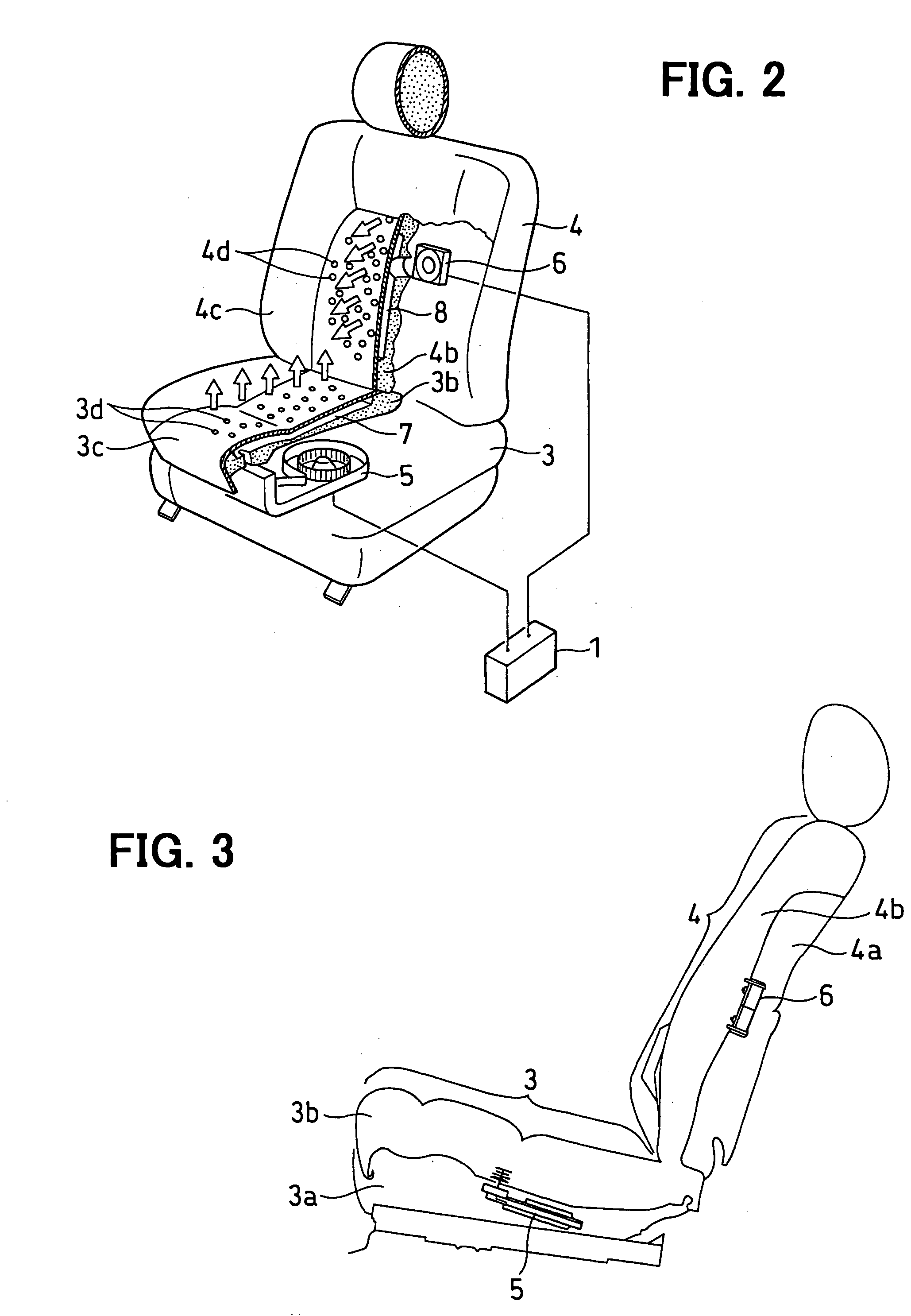

Vehicle air conditioner with seat air conditioning unit

ActiveUS6928829B2Preventing the waist portion of a passenger from being excessively cooledSolve large capacityAir-treating devicesSeat heating/ventillating devicesEngineeringAir conditioning

In a seat air conditioning unit for a vehicle seat constructed with a seat cushion and a seat back, when a seat air conditioning operation is performed in a cooling operation of a passenger compartment, a cooling capacity of cool air blown from the seat back is set smaller than a cooling capacity of cool air blown from these at cushion while a passenger sits on the vehicle seat. Further, the cooling capacity of cool air blown from a lower portion of the seat back can be set smaller than the cooling capacity of an upper portion of the seat back. Accordingly, even when the cooling operation is continued for a long time while the seat air conditioning operation is performed, the waist portion of the passenger can be prevented from being excessively cooled.

Owner:DENSO CORP

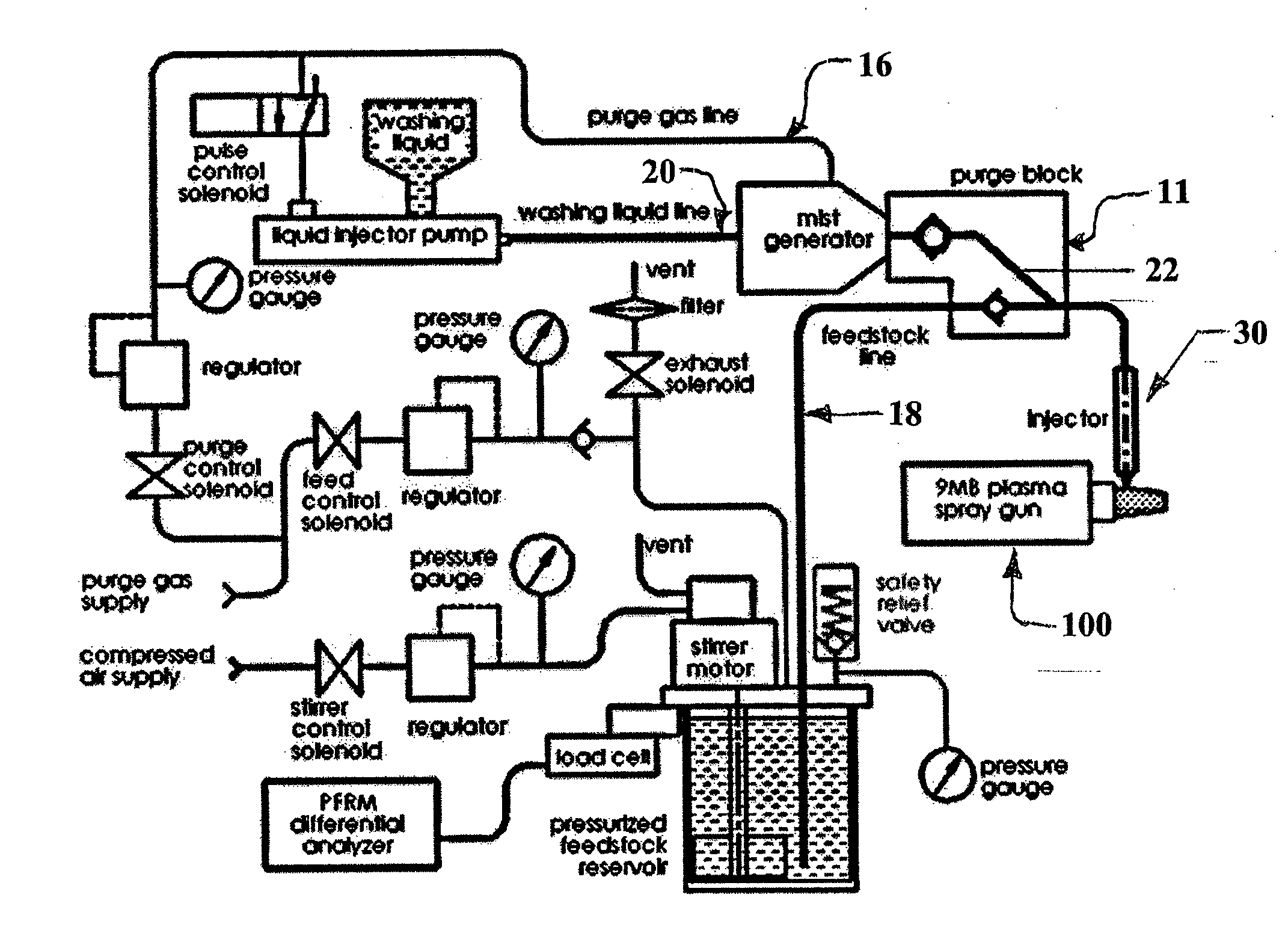

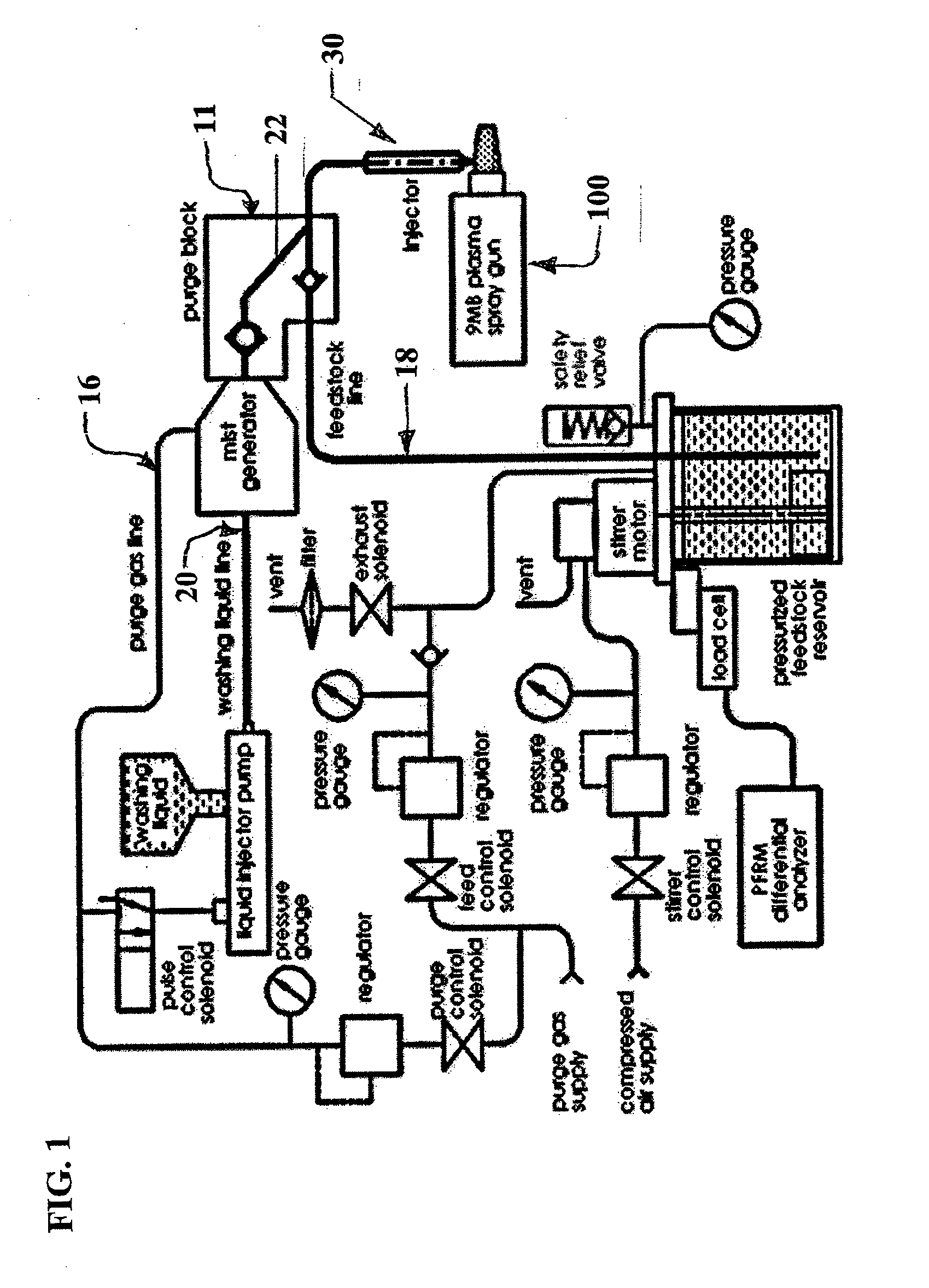

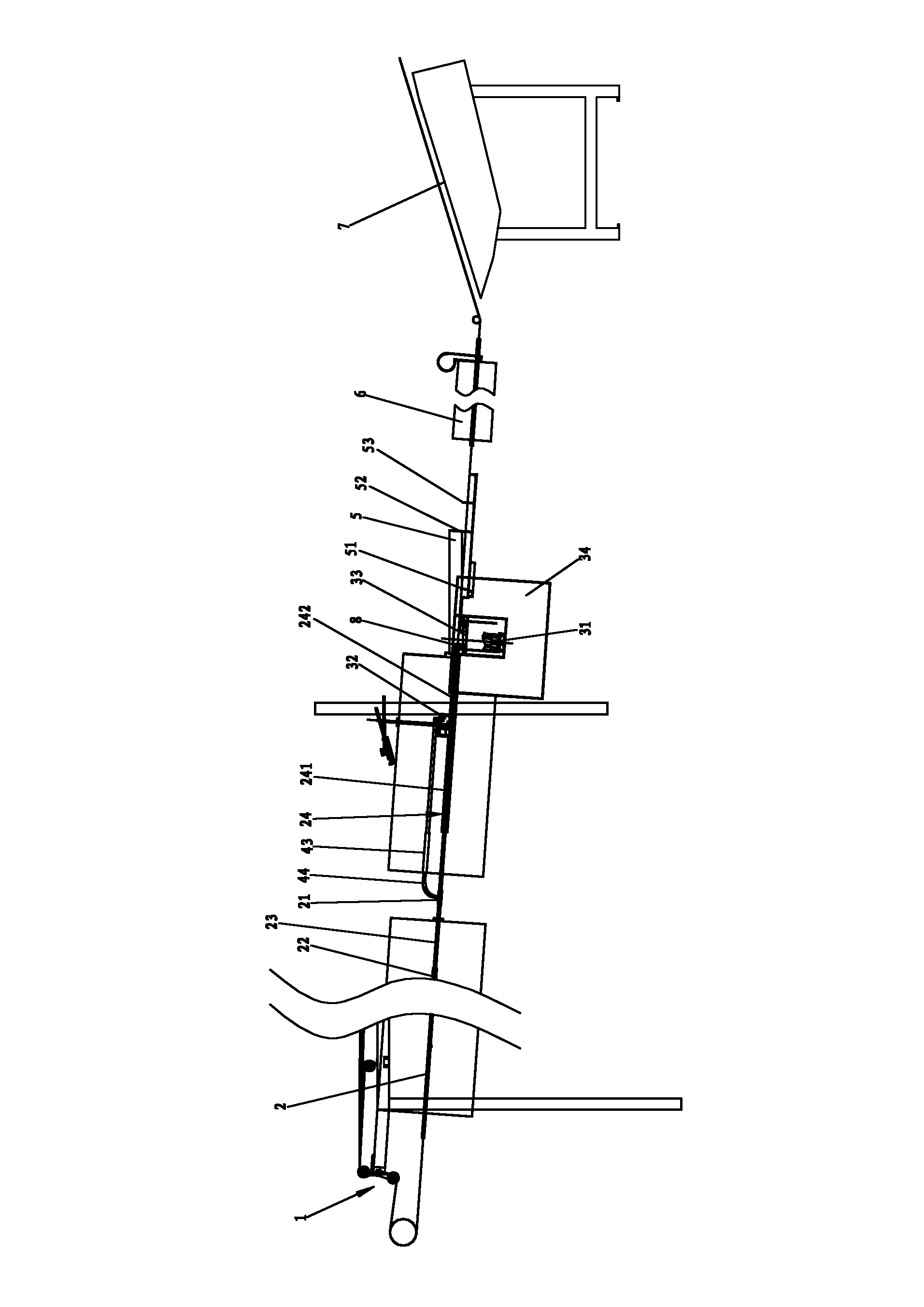

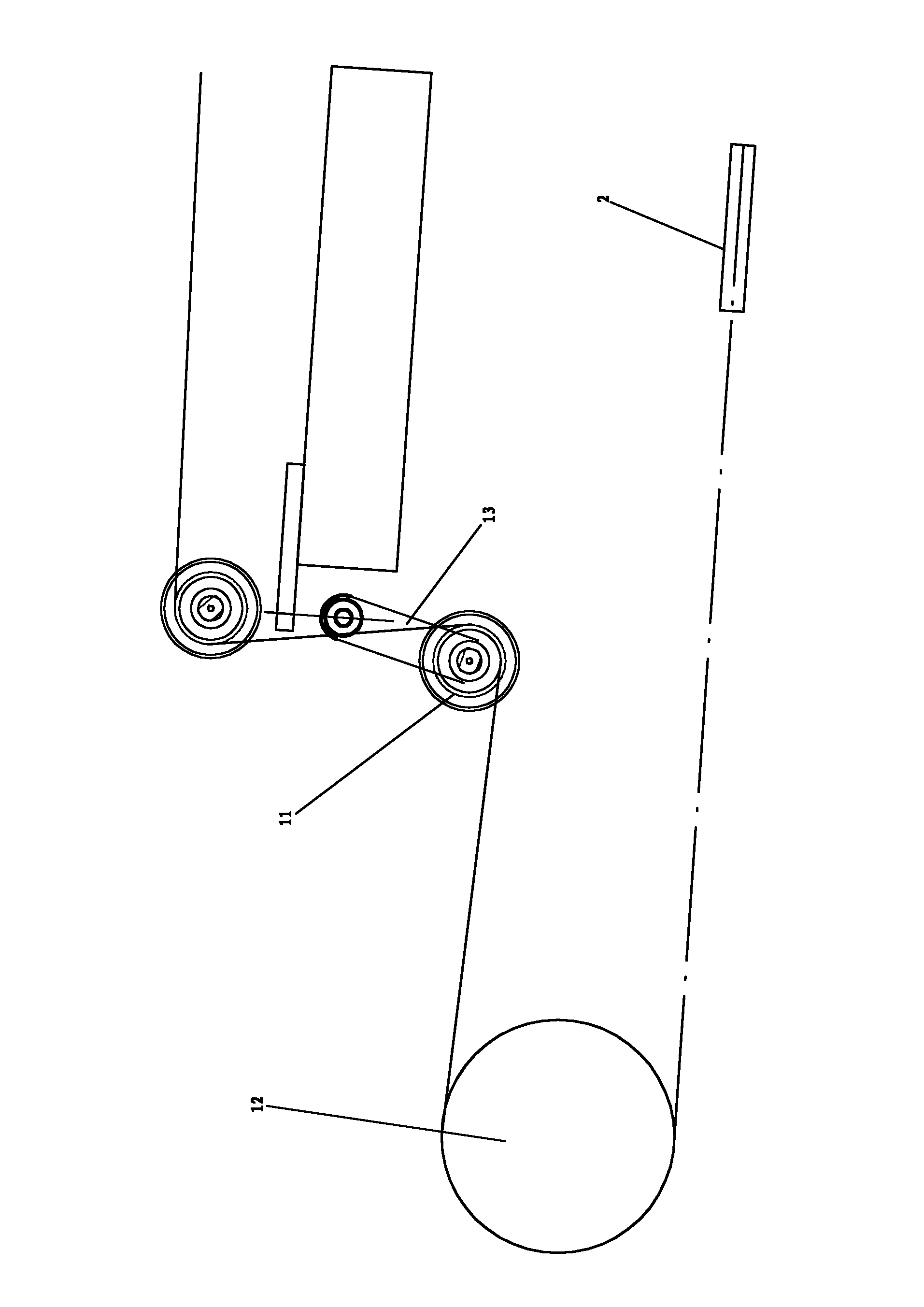

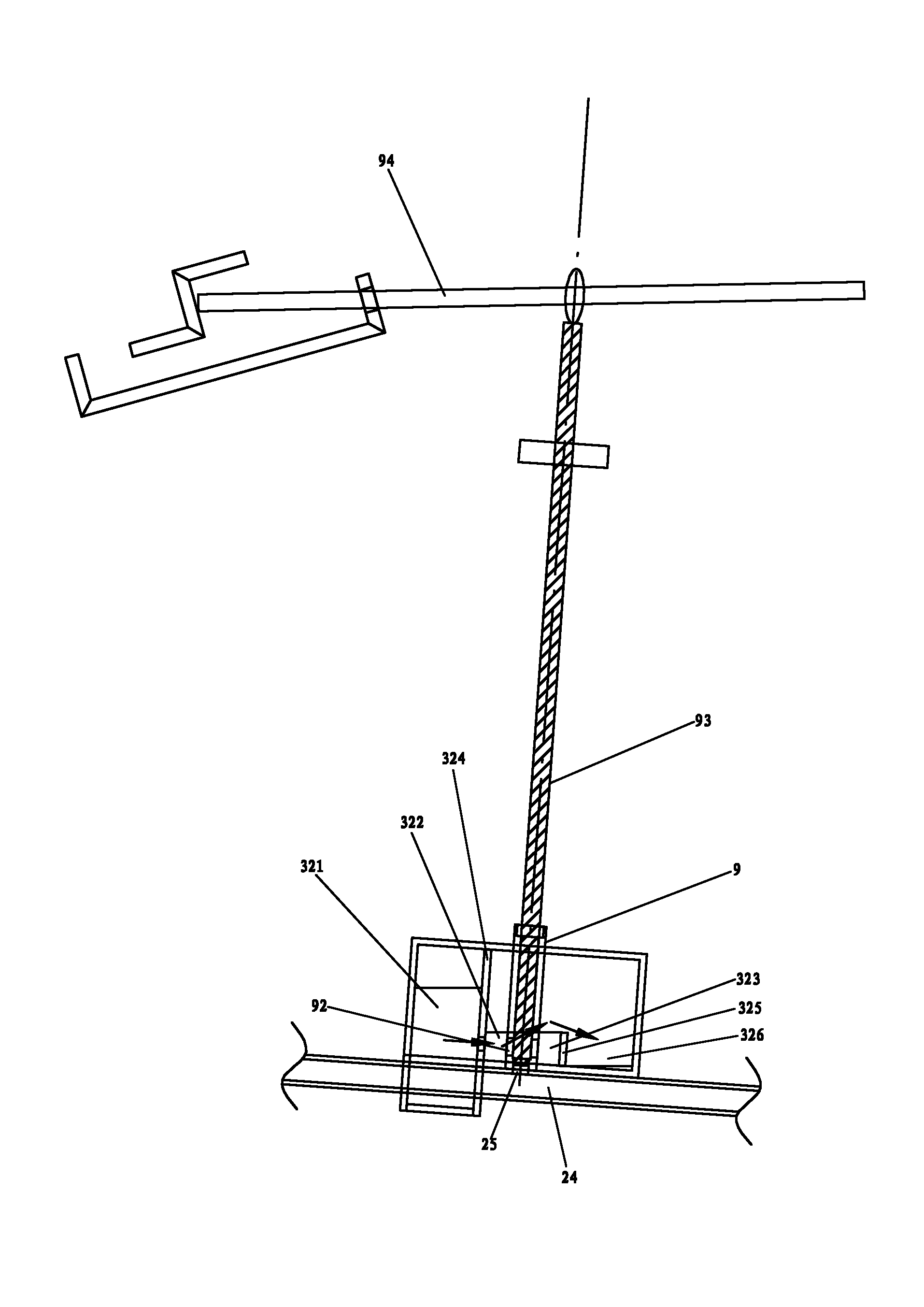

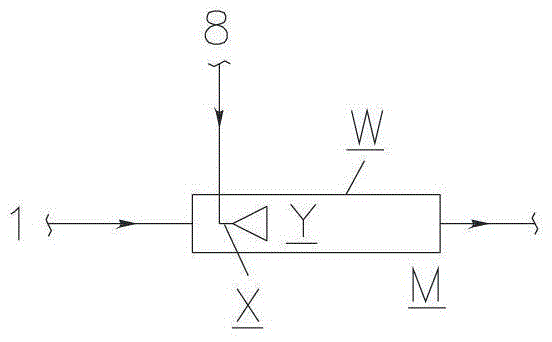

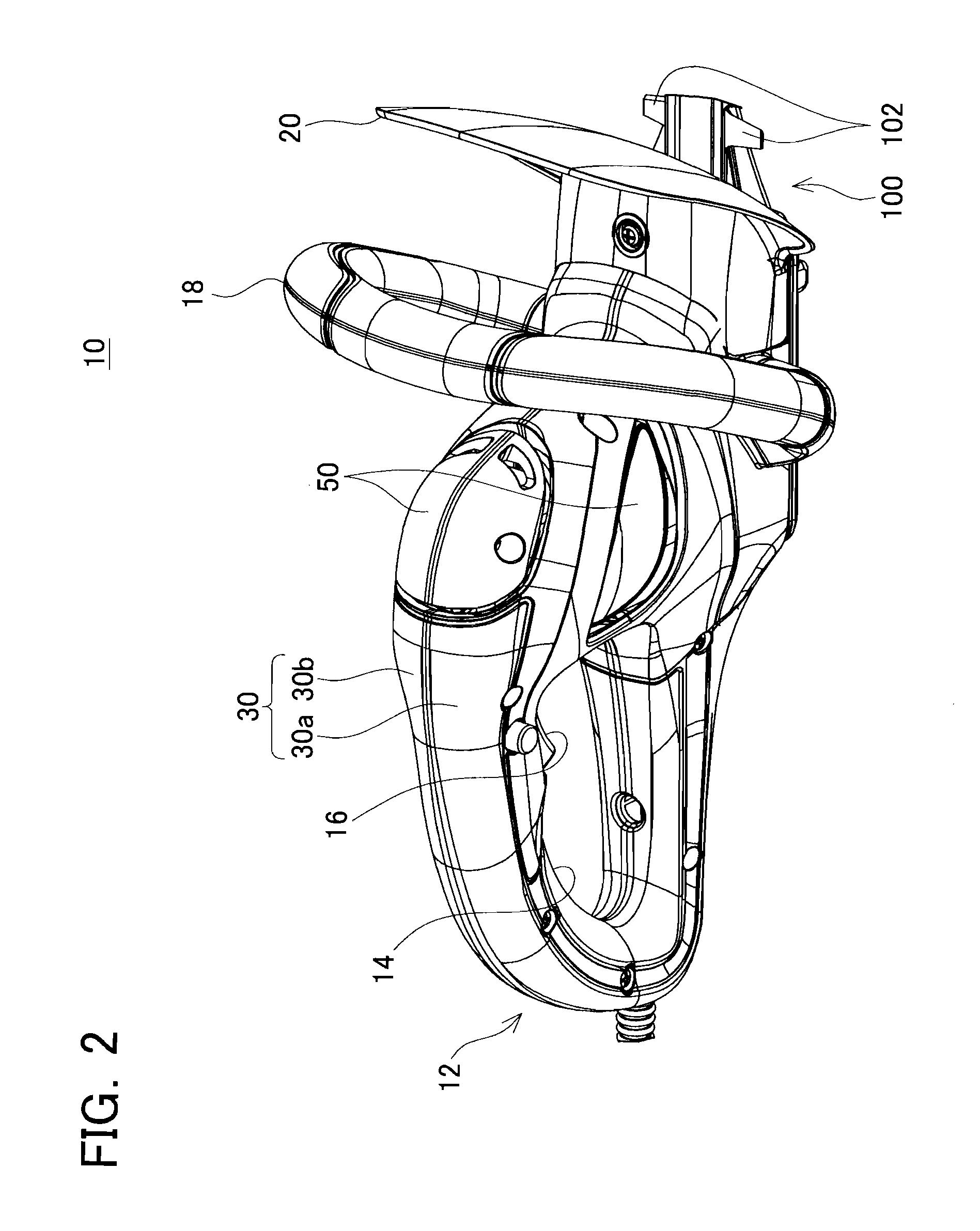

Pressure based liquid feed system for suspension plasma spray coatings

ActiveUS20130270355A1Avoid accumulationReduce cooling effectLiquid surface applicatorsMolten spray coatingLiquid jetLiquid medium

Apparatus (1) for injecting a liquid in an area of a thermal spray gun (100). The apparatus (1) includes an injector cleaning device (10) having an inlet connectable (19) to at least one feedstock supply line (18), an inlet connectable (17) to at least one gas supply line (16), and an inlet connectable (21) to at least one liquid medium supply line (20). An injector (30) orifice is coupled to the injector cleaning device (10) and is adapted to at least one of inject a liquid jet into a hot stream created in the area of the thermal spray gun (100) and receive feedstock, gas and liquid passing into the inlets.

Owner:SULZER METCO (US) INC

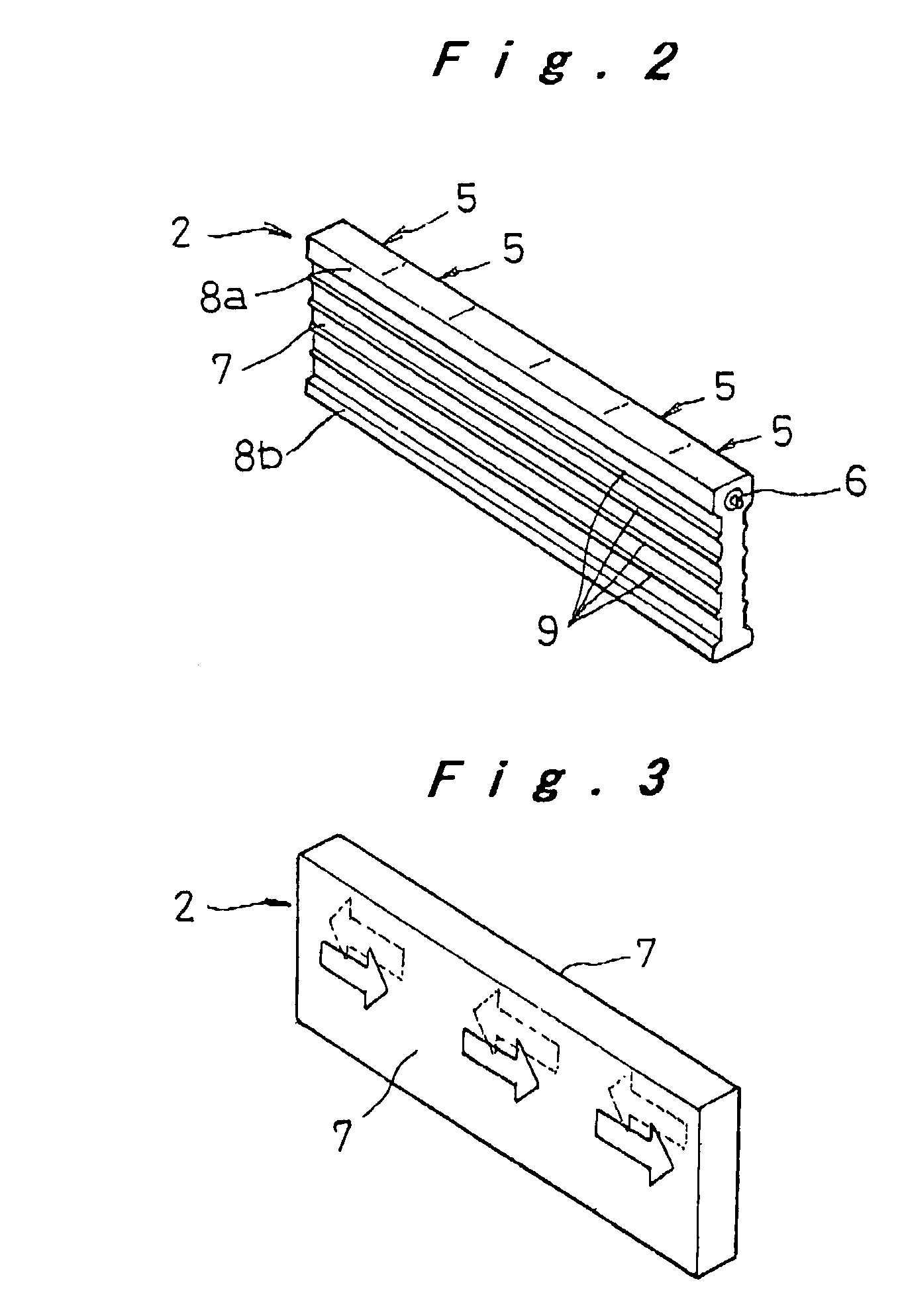

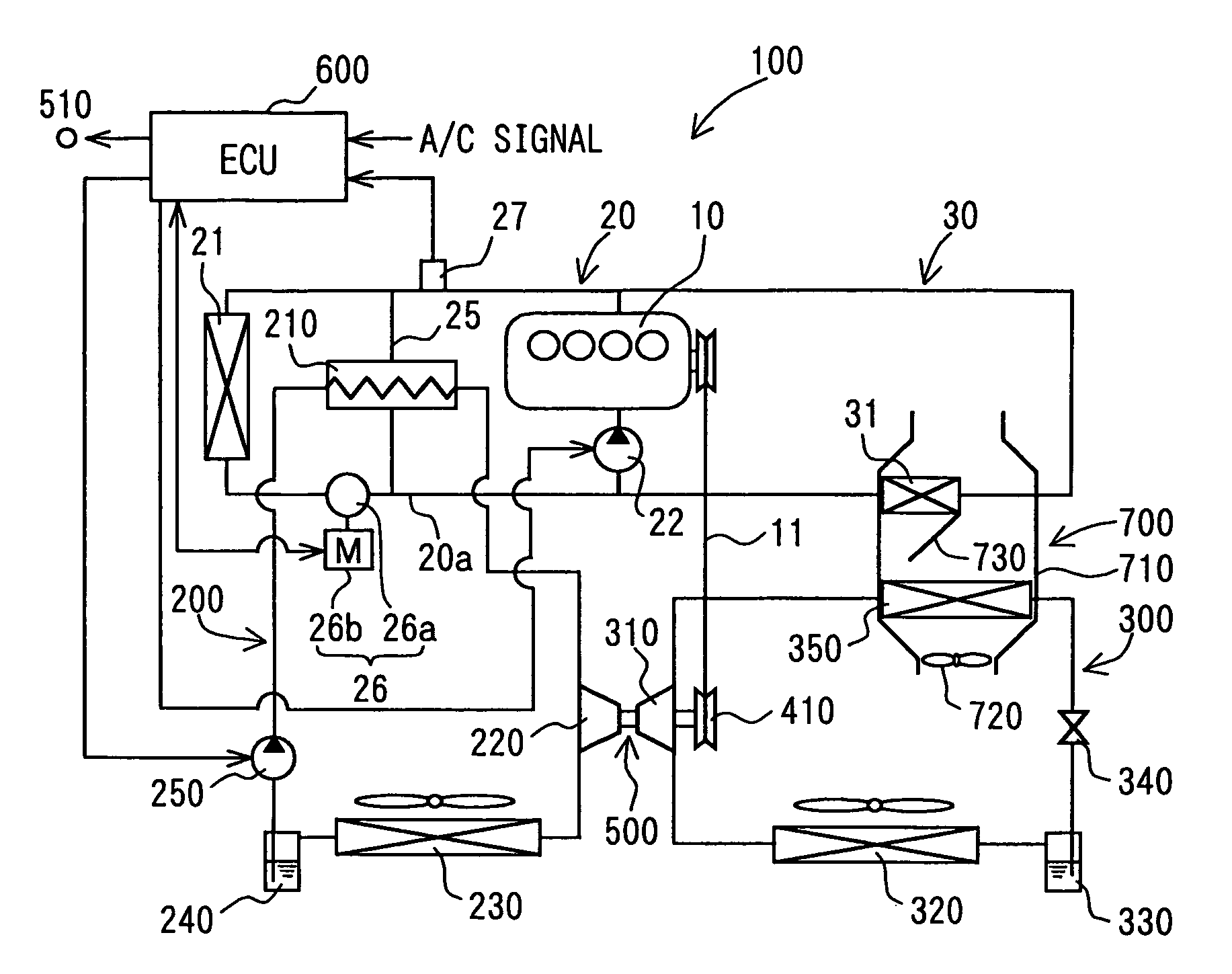

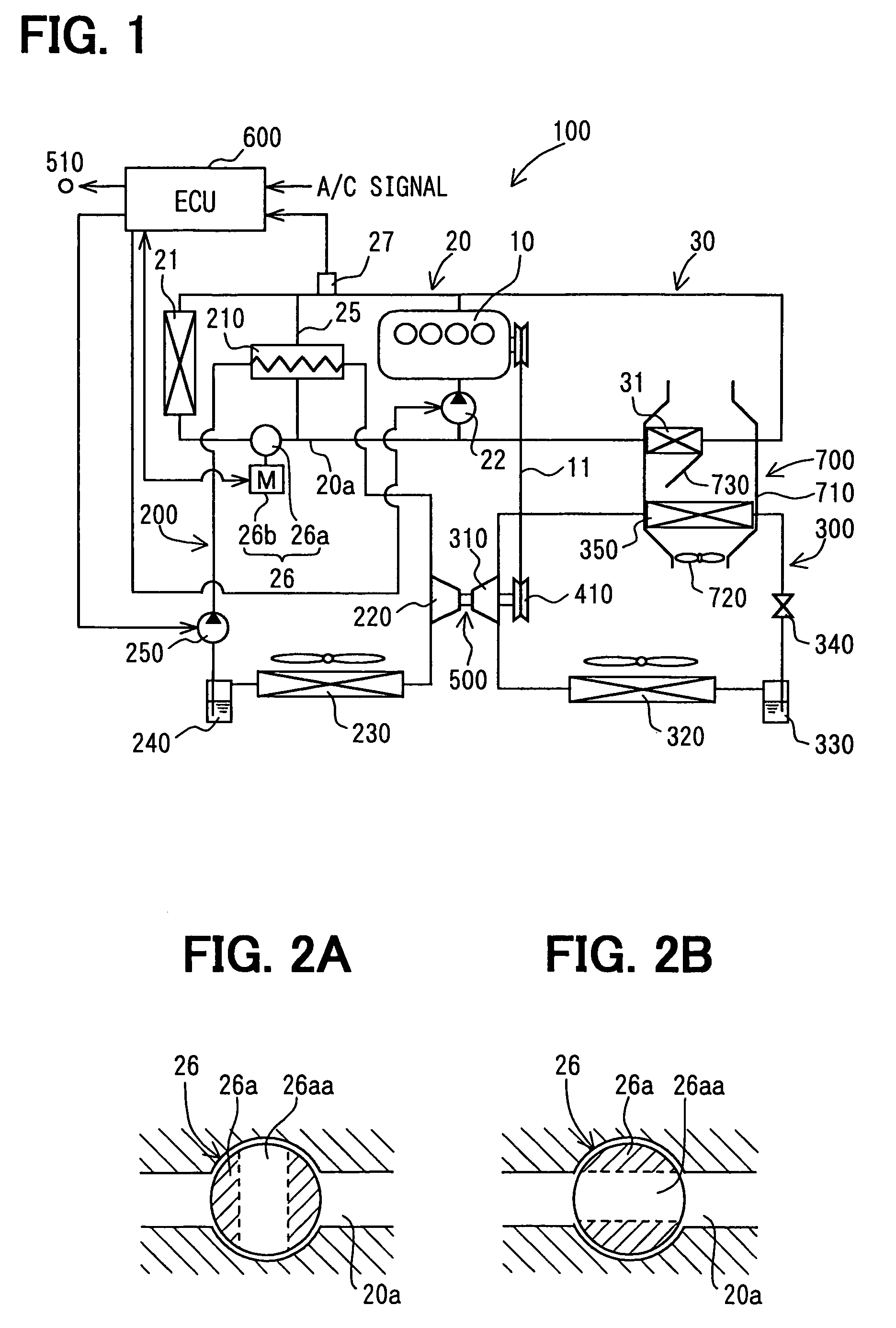

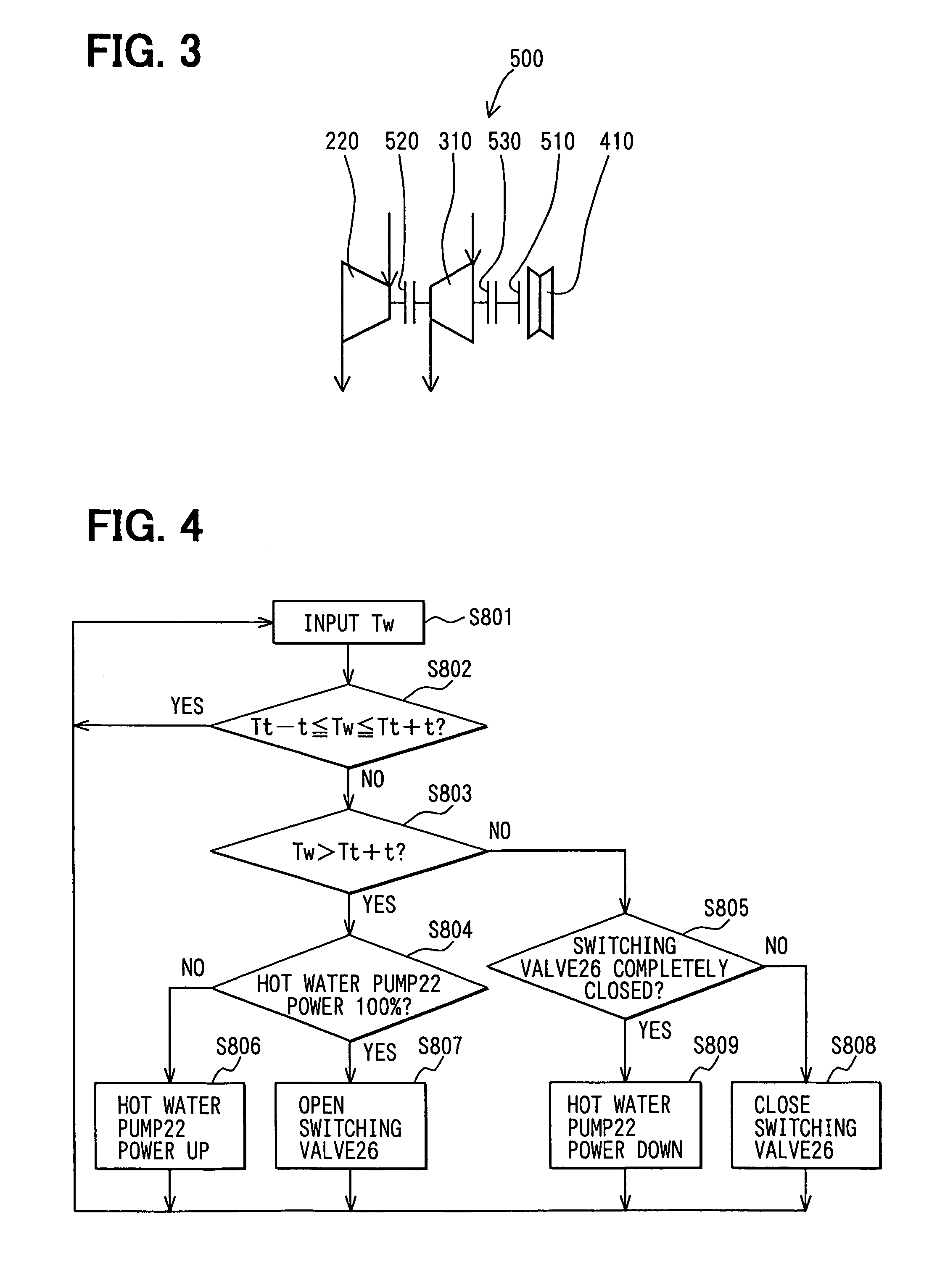

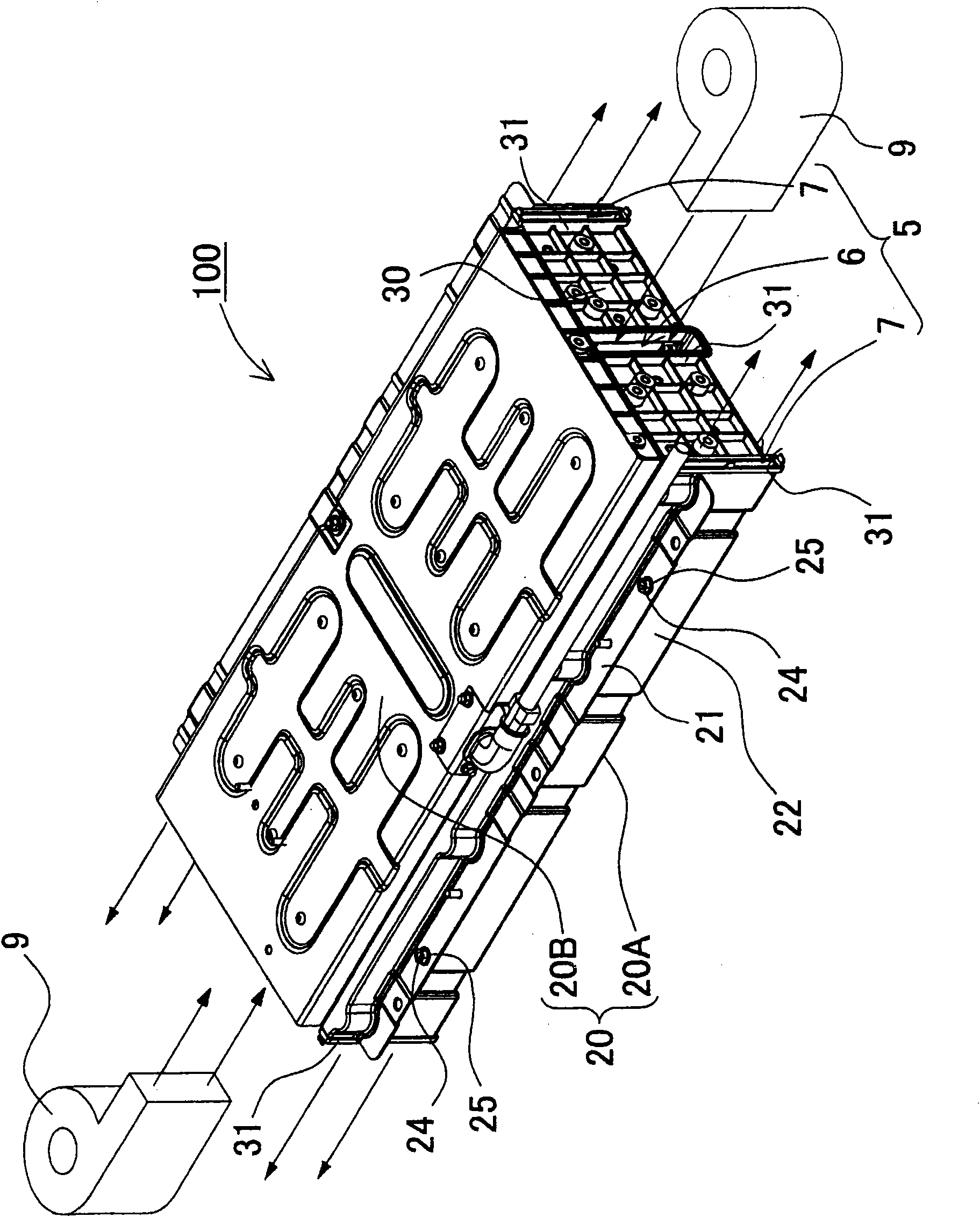

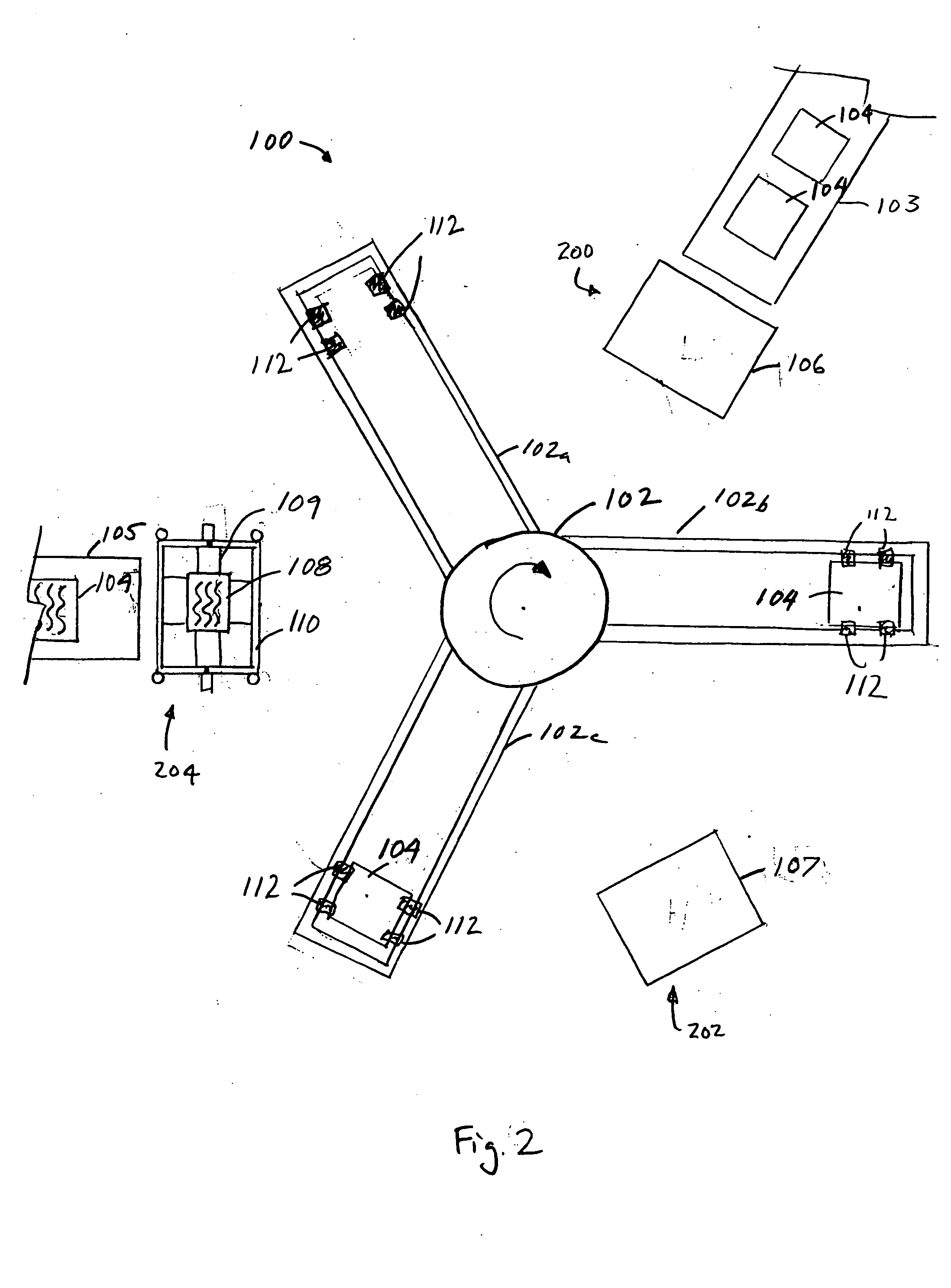

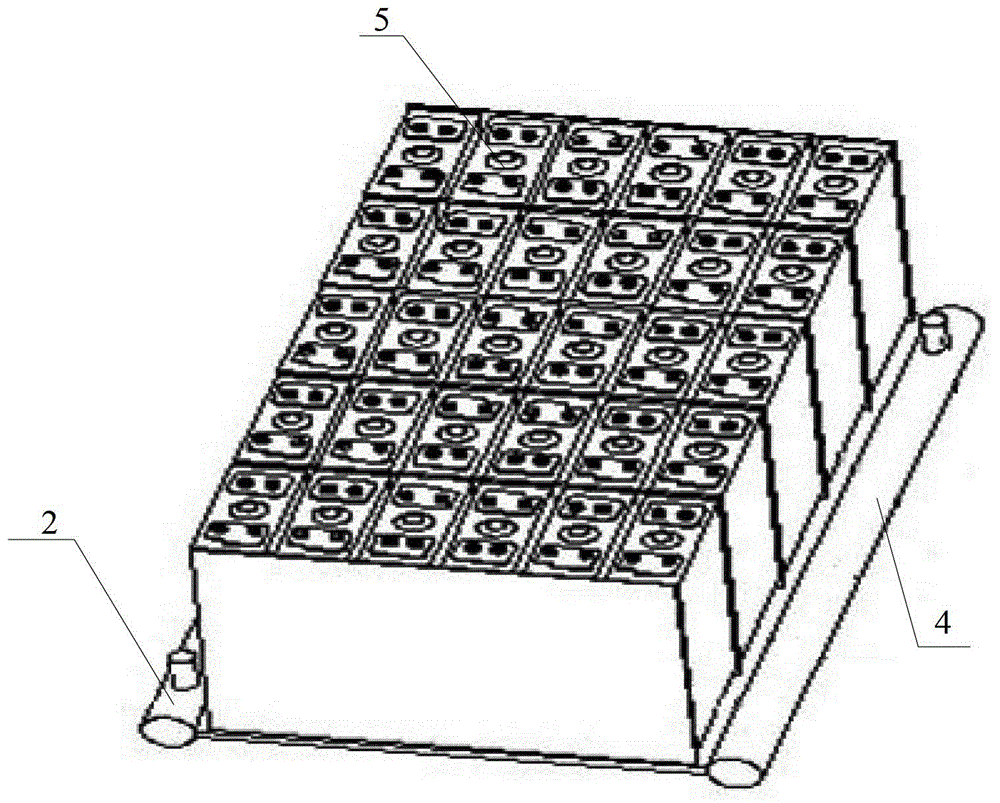

Power supply device and vehicle having the same

ActiveCN102054948AReduce manufacturing costEasy to set upPrimary cell to battery groupingLarge-sized flat cells/batteriesClosed chamberBinding state

The invention provides a power supply device capable of making the temperatures of the battery cells almost consistency at any position by reducing the temperature differences, and a vehicle having the same.A power supply device includes rectangular battery cells 1, resin separators 2, end spacers, thick metal end plates, and coupling members. The separator 2 is inserted between the cells 1 to insulate adjacent cells 1 from each other, and in thermal contact with the cells 1. The end spacers cover end battery cells on the opposed end surfaces of a battery block composed of the cells and the separators alternately arranged. The end plates cover the surfaces of the end spacers. The coupling members couple the end plates to each other. The separators form gaps for flowing air along the surfaces of the cells in contact with the separators. The end spacers have hollow layers on their surfaces in contact with the cells, and define closed chambers.

Owner:SANYO ELECTRIC CO LTD

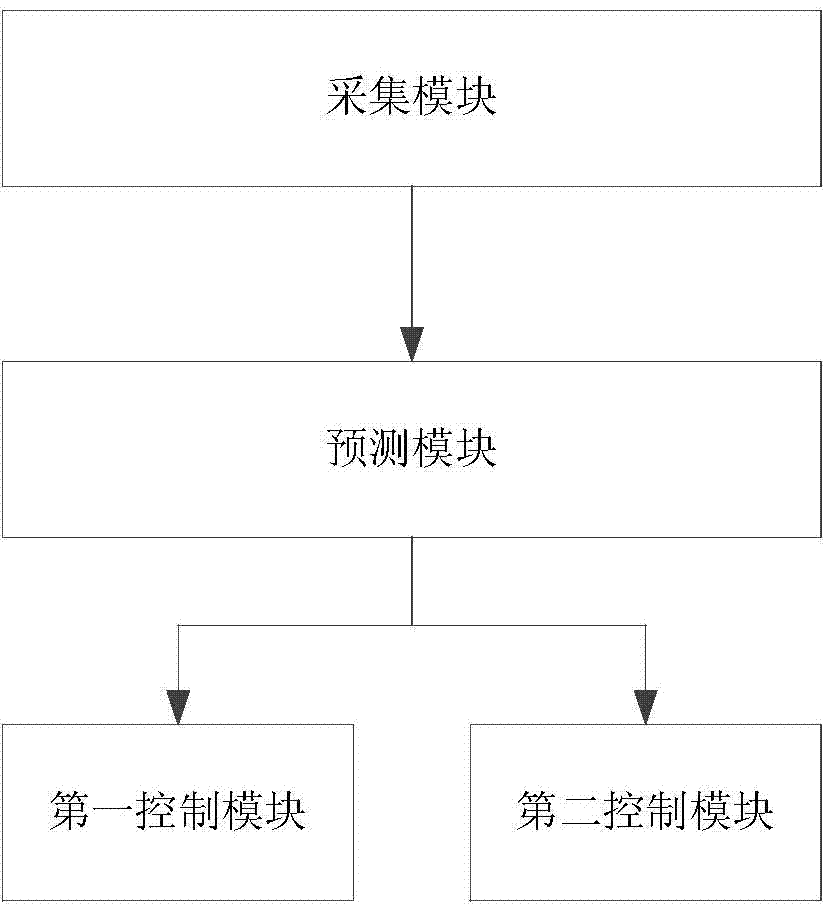

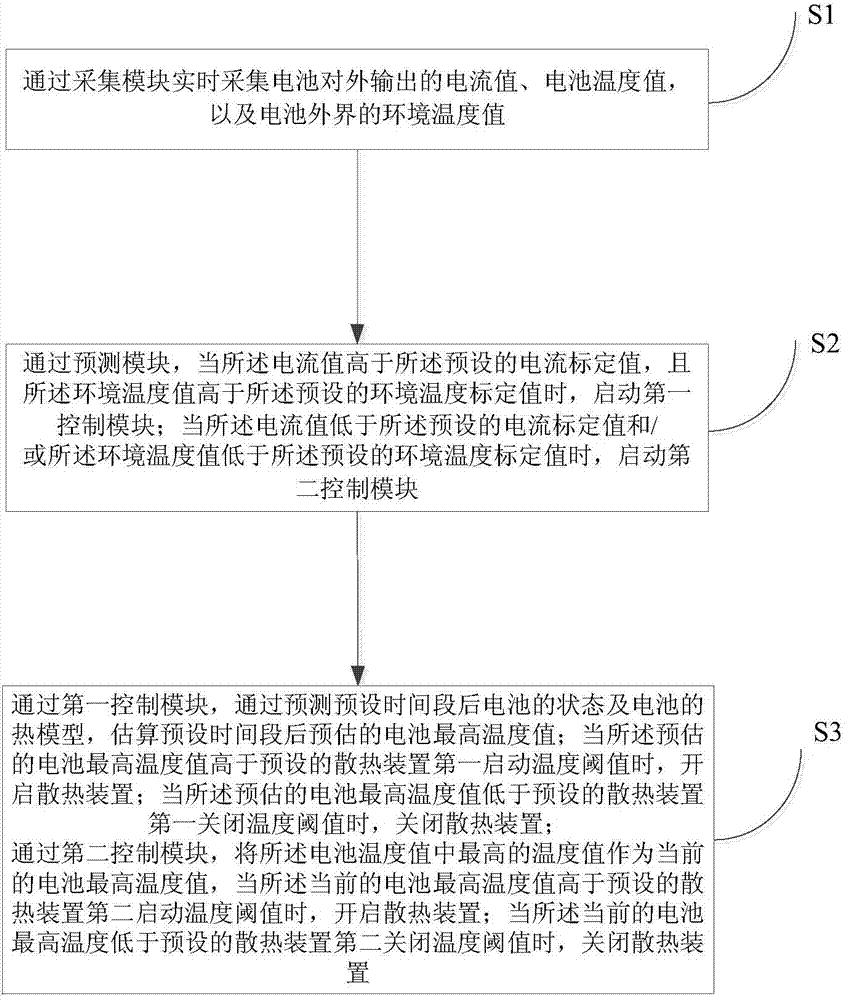

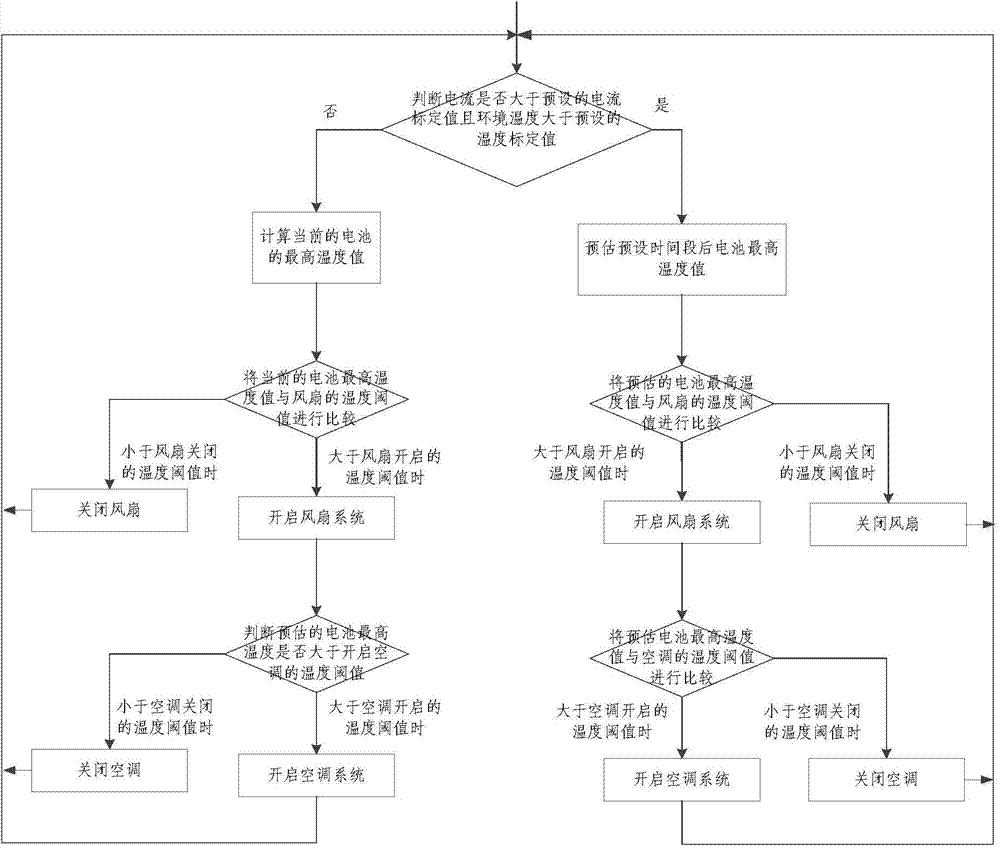

Power cell heat management device and method

InactiveCN104733801AImprove cooling effectWithin a reasonable temperatureSecondary cellsHysteresisHeat management

The invention provides a power cell heat management system and method and relates to the technical field of automobile power cells. The power cell heat management system comprises an acquisition module for real time acquisition of a current value and a cell temperature value output by the cell, a prediction module for predicting a cell heating state and determining if a heat radiation mode is started in advance according to the cell heating state, and first and second control modules respectively for controlling a cell heat radiation device. Through prediction of a cell state after preset time, the highest temperature after the predicted time can be predicted so that a cooling treatment process is carried out before cell heating and the cell temperature is in a reasonable temperature range. The power cell heat management system and method solves the problem that because of temperature hysteresis quality, the cell is cooled only after heating. The power cell heat management system and method realize effective cell heat management and guarantee high efficiency and long life operation of the cell.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

Waste heat recovery system of heat source, with rankine cycle

InactiveUS20050144949A1Easy to useReduce cooling capacityInternal combustion piston enginesSteam accumulatorsWorking fluidWater flow

A waste heat recovery system of an engine has a cooling water circuit and a Rankine cycle. Cooling water is circulated between the engine and a radiator in the cooling water circuit. The Rankine cycle has a heater and an expansion device. The heater performs heat exchange between the cooling water heated by the engine and an operation fluid so as to heat the operation fluid in the Rankine cycle. The expansion device expands the heated operation fluid, so as to generate driving power. The heater is arranged in a bypass circuit so as to be in parallel with the radiator with respect to the cooling water flow. Thus, waste heat of the cooling water heated by the engine can be effectively recovered without reducing a cooling capacity of the radiator.

Owner:DENSO CORP

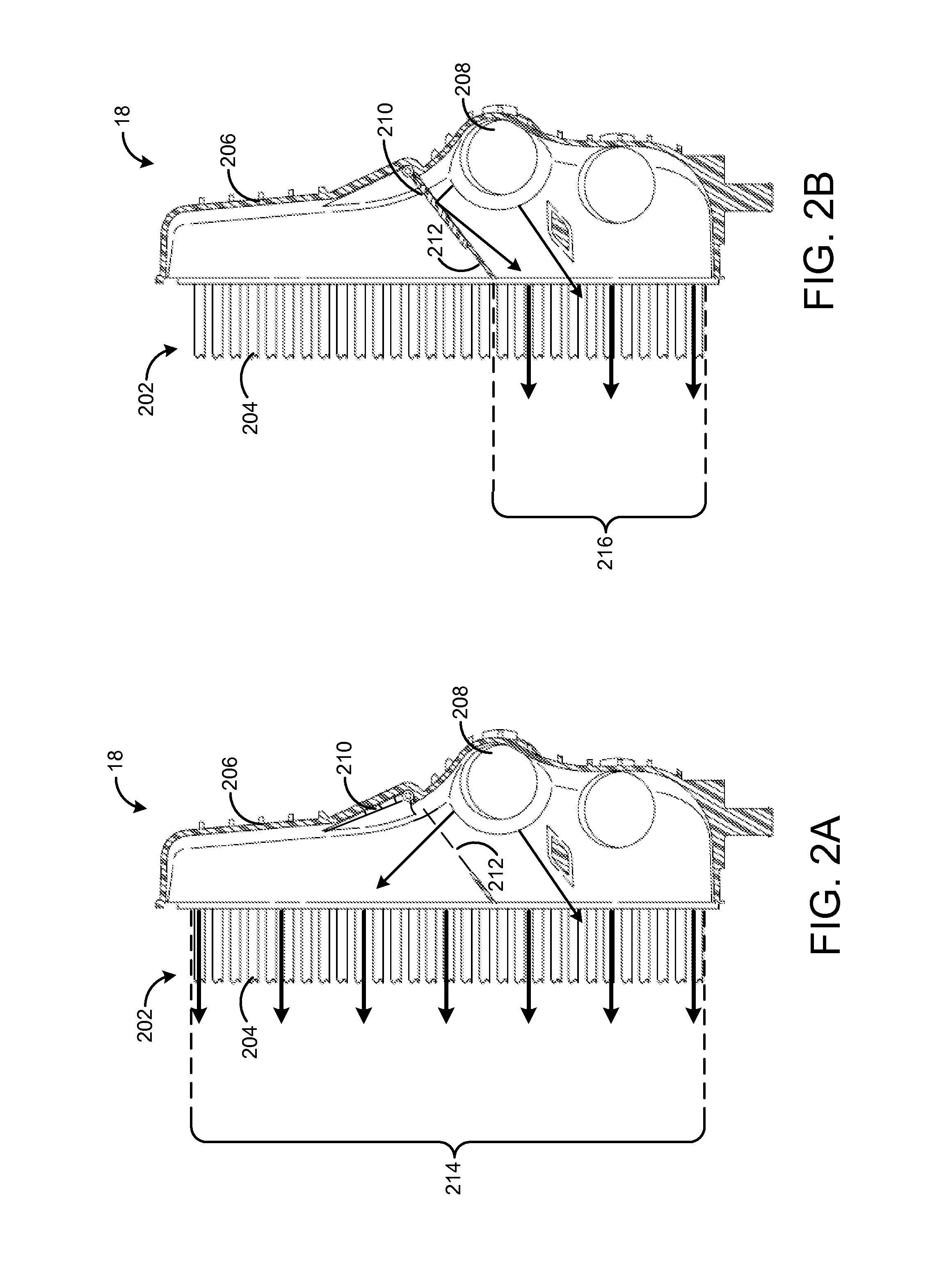

Charge air cooler component diagnostics

ActiveUS20140150756A1Increase powerHigh densityInternal combustion piston enginesExhaust gas recirculationTemperature differenceEngineering

Embodiments for a charge air cooler are provided. In one example, a method comprises adjusting an operating parameter in response to a degraded grille shutter, the degraded grille shutter determined based on a temperature difference across a charge air cooler. In this way, degradation of the charge air cooler or engine may be reduced.

Owner:FORD GLOBAL TECH LLC

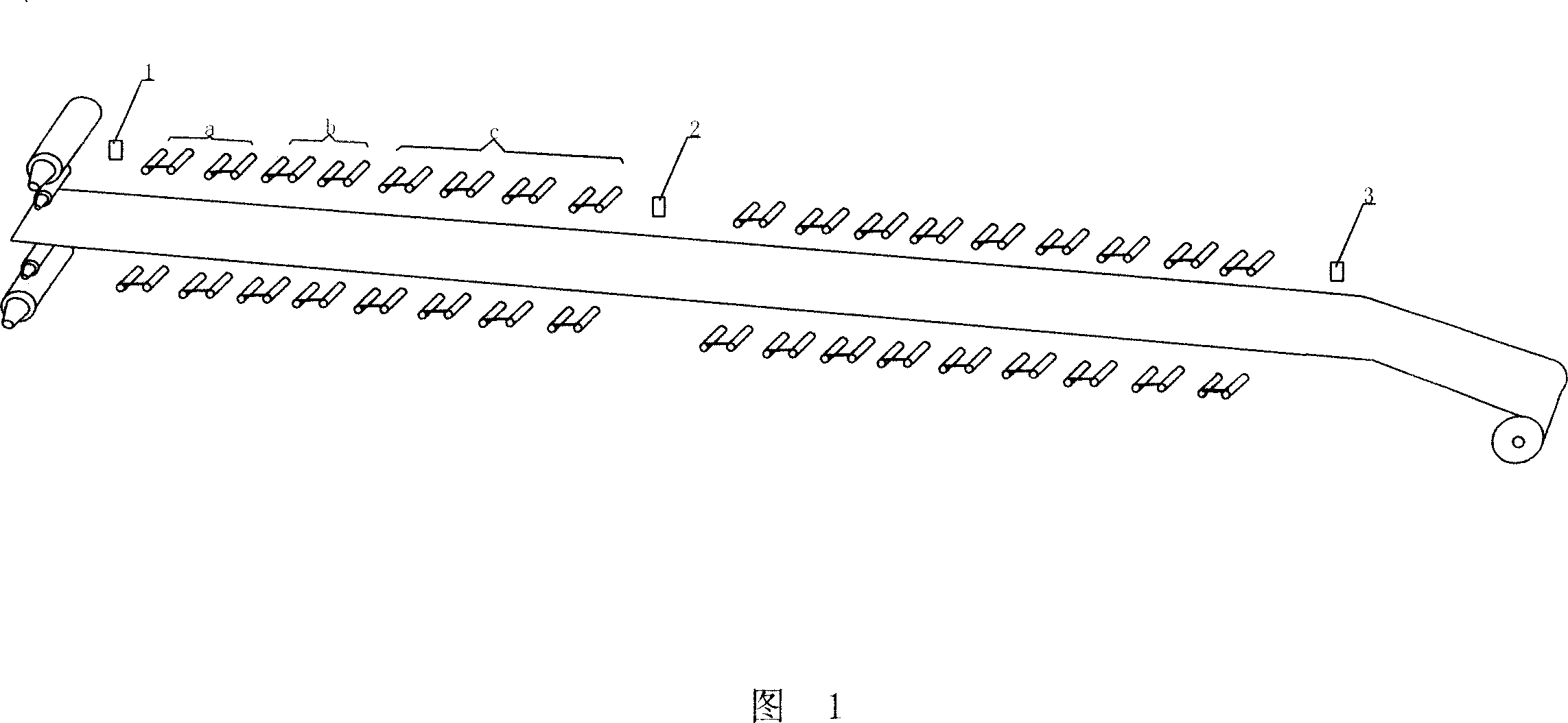

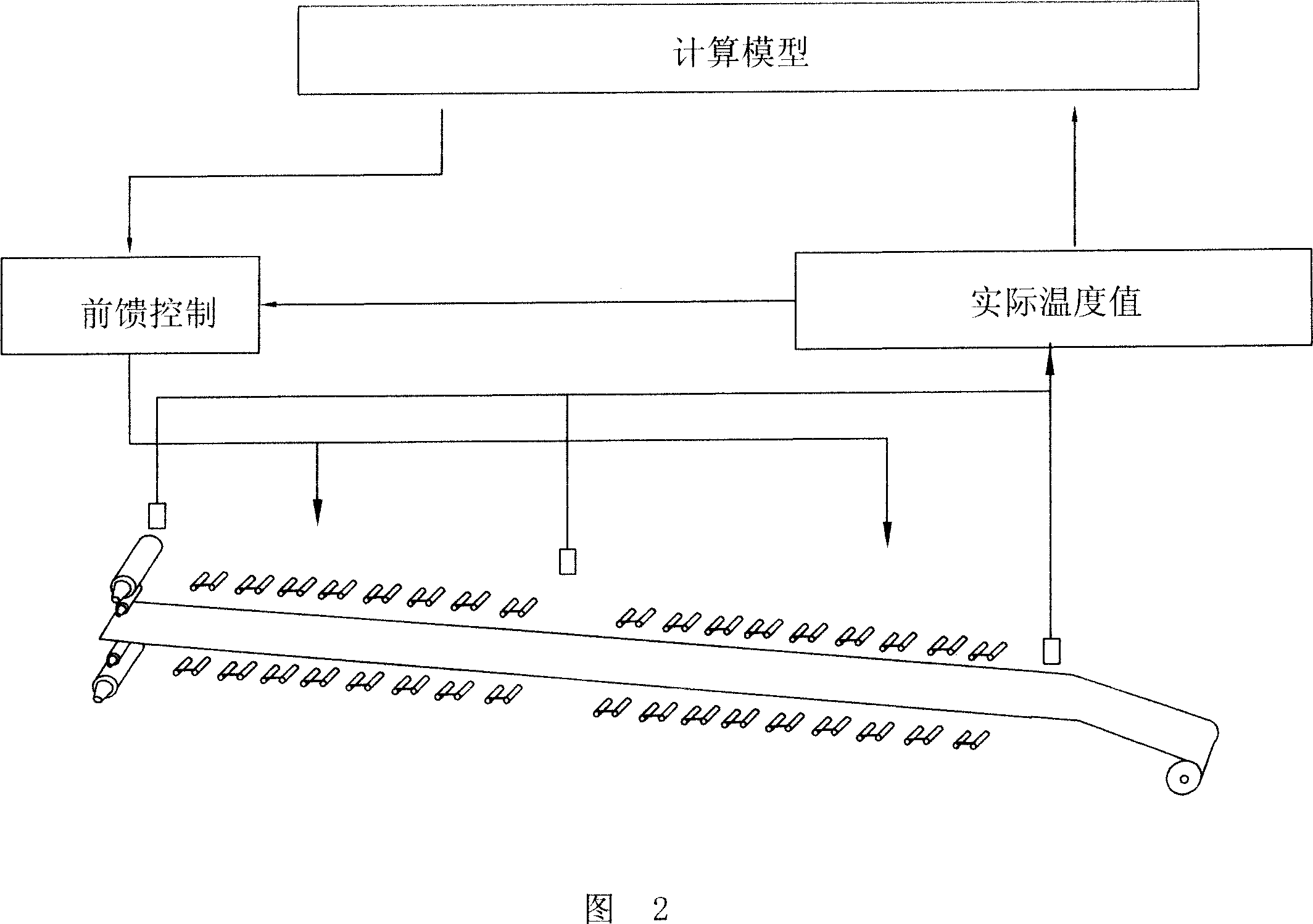

Strip steel reeling temperature controlling method and device

InactiveCN1974041AReduce cooling effectHigh control precisionTemperature control with auxillary non-electric powerTemperature control deviceTemperature controlControl system

The strip steel reeling temperature controlling method and device belongs to the field of strip steel reeling temperature controlling technology. The strip steel reeling temperature controlling device includes one cooling area comprising water spraying header pipe and one computerized control system, and features that three temperature measuring units are set along the strip steel moving direction in the cooling area to obtain the feed forward parameters for computerized control and the computerized control system compares the feed forward parameters with the set values for compensating and regulating the water spraying amount and the reeling speed so as to control the reeling temperature. The present invention can raise the reeling temperature controlling precision and raise the mechanical performance of the strip steel product.

Owner:SHAGANG GROUP

Method for preparing polymer modified asphalt by one-step method

ActiveCN101457023ASimple processEasy to operateBuilding insulationsPolymer modifiedStabilizing Agents

The invention relates to a method of preparing polymer asphalt with one step to modify the asphalt by adopting the polymer as a modifying agent. In a peptizator of 80 to 160 DEG C which account for 5 to 27 percent of the total weight of the raw materials, the polymer modifying agent and 0.1 to 2 percent of stabilizer which account for 2 to 9 percent of the total weight of the raw materials are added, and then is poured into a plastic extruder where the rotating speed is 300 to 800 rotations per second to be extruded; the extruding temperature is controlled to be 130 to 210 DEG C; the extruded polymer is directly and mixingly stirred for 0.5 to 6 hours together with the asphalt which accounts for 62 to 89.9 percent of the total weight of the raw materials, then the polymer modified asphalt is gained, which is provided with good heat preservation function, good low temperature expanding performance, anti-fatigue and anti-tearing function and relatively good weatherproof function. After being mixed with the stones, the mixed materials perform good water stability and high and low temperature stability, which can effectively improve the using performance of the asphalt pavement and prolong the service life.

Owner:PETROCHINA CO LTD +1

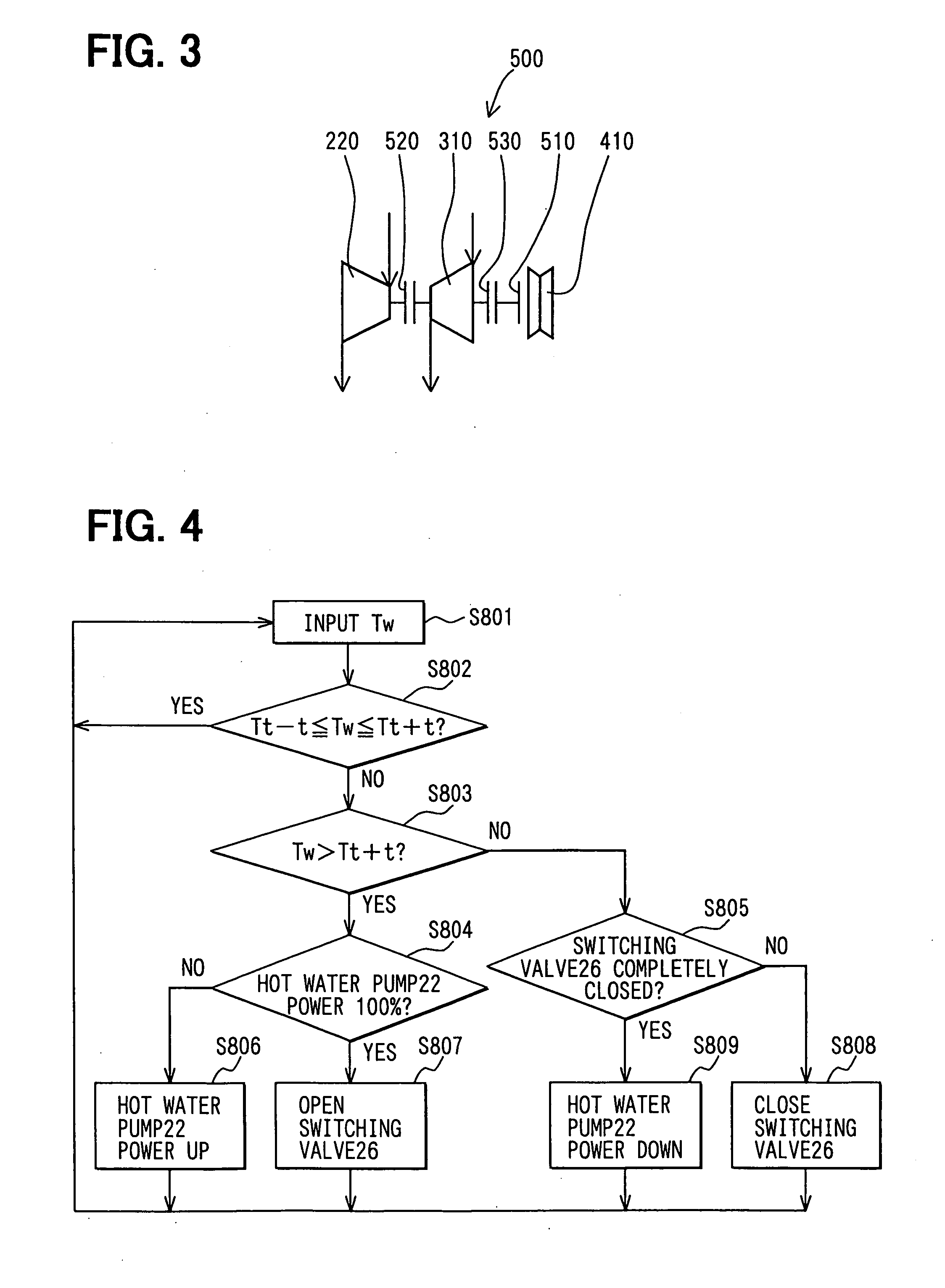

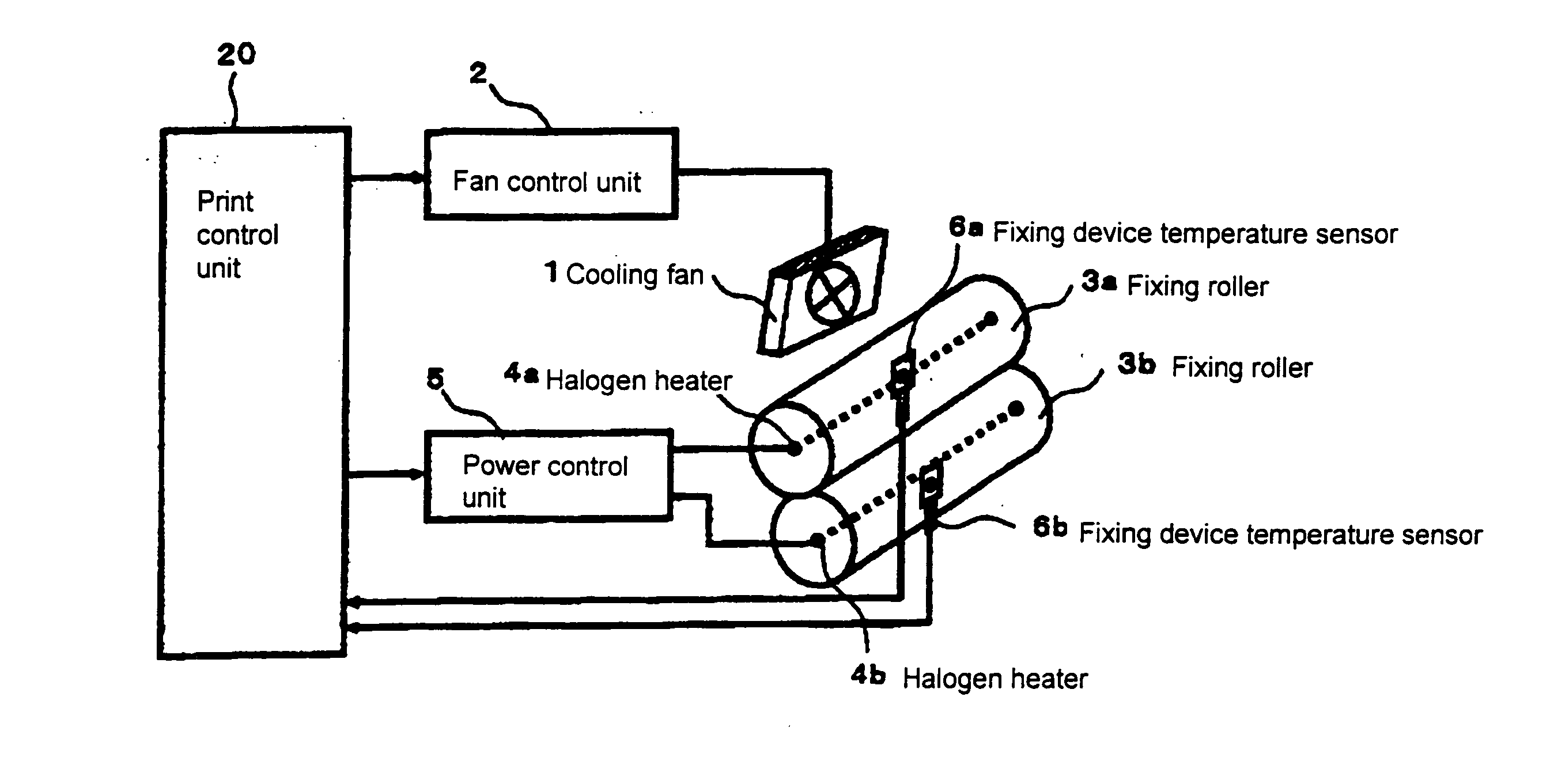

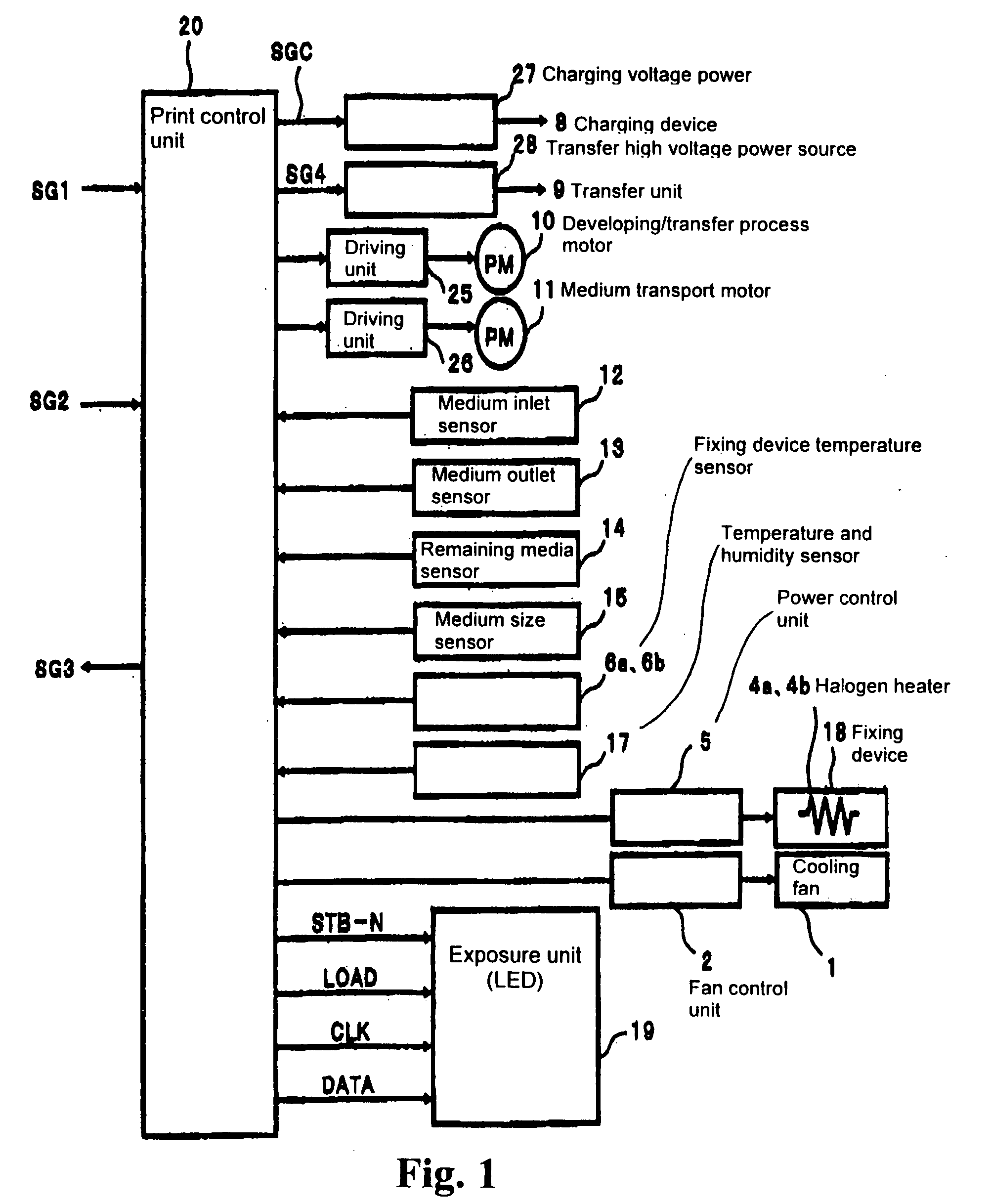

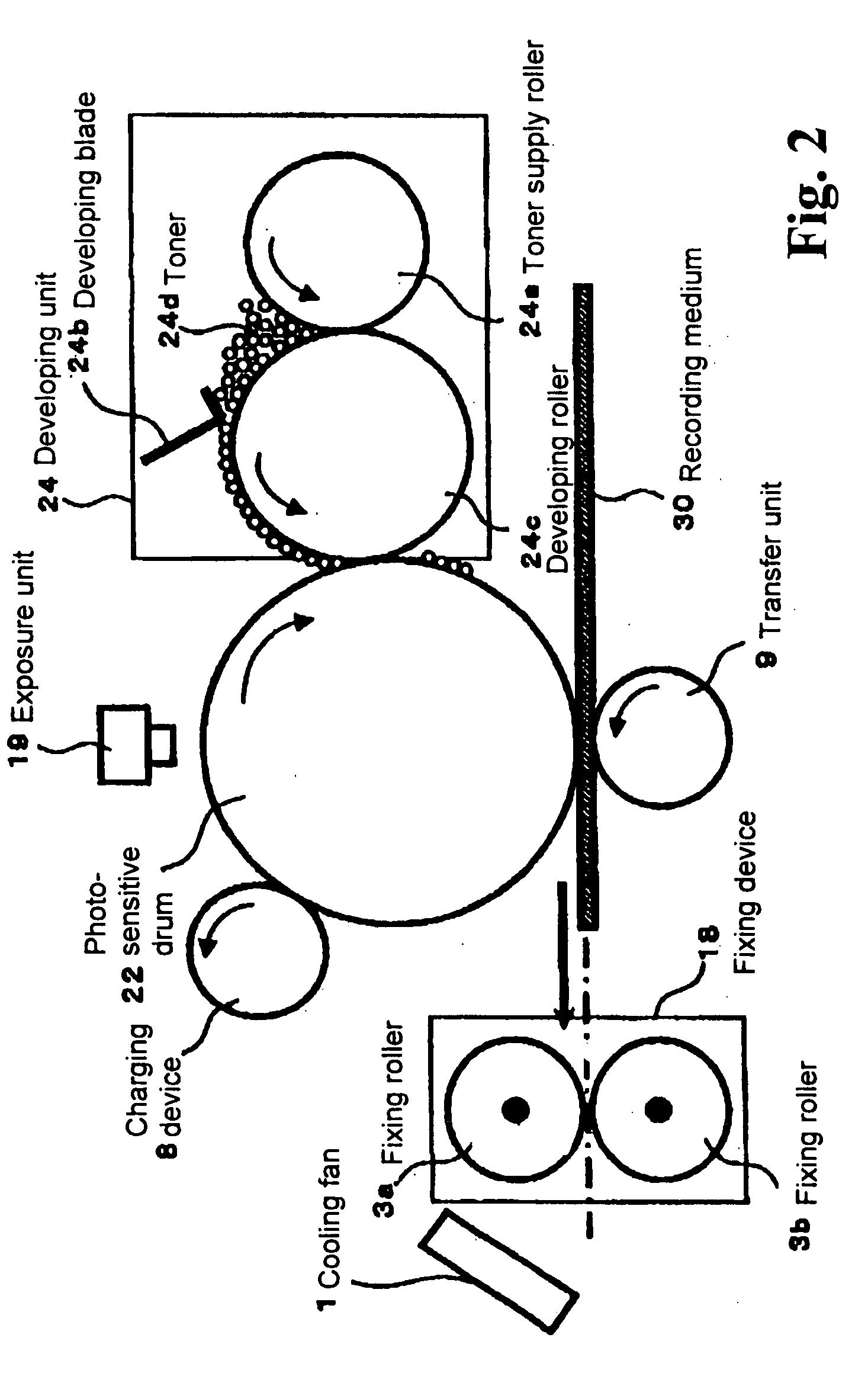

Image forming apparatus

ActiveUS20060127119A1Reduce cooling effectReduce waiting timeElectrographic process apparatusImage formationCooling effect

An image forming apparatus includes a fixing device for fixing developer on a recording medium; a heating device for heating the fixing device; a cooling device for cooling the fixing device; a temperature detecting device for detecting a temperature of the fixing device; a heating device control unit for controlling drive of the heating device; and a cooling device control unit for controlling drive of the cooling device. After the fixing device fixes the developer on the recording medium, when the temperature detecting device detects the temperature of the fixing device below a first temperature, the cooling device control unit reduces cooling effect of the cooling device.

Owner:OKI ELECTRIC IND CO LTD

Circulating tin plating process and device

The invention relates to the technical field of tin plating of copper wires, in particular to a circulating tin plating process and device. The circulating tin plating process comprises the following steps of: setting speed and stabilizing speed and tension in a tension buffer area; annealing in a high-temperature annealing area at high temperature; initially cooling in an annealing and cooling area; pre-plating tin in an inlet tin heating area; finally plating tin in an outlet tin heating area; scraping residual tin by using a tin plating mold for sizing; protecting reducing gas to deoxidize liquid tin and protecting a wire rod from being oxidized; cooling a hot plated tin wire with water; scraping water on the tin-plated wire with rubber; scraping water and possible tin beads by using a mold; drying residual water by using a drier; cooling the tin-plated wire to room temperature by using a cooling wind scoop; and rolling into a finished product, and the like. By adopting the circulating tin plating process, the product quality of the tin-plated wire is ensured, use of a soldering flux causing pollution can be avoided, noble rare earth metals are avoided or reduced, a large amount of electric energy is saved, waste of tin dross is reduced, operation is simplified and concealed danger of quality is reduced.

Owner:周开勇

Thermoforming method and apparatus

InactiveUS20050040569A1Shorten cycle timeEasy to manufactureConfectioneryFilament/thread formingQuenchingVacuum chamber

A thermoforming apparatus having a mold with an internal vacuum chamber and a quench for cooling a thermoplastic sheet while it remains on the mold. Because the quench cools the sheet, conventional cooling lines are eliminated from the mold. One method of using the thermoforming apparatus includes pushing a heated sheet towards the mold with a plug assist, drawing the heated sheet over the mold, creating a partial vacuum in the vacuum chamber of the mold to maintain the sheet on the mold and quenching the sheet on the mold in a quenching tank by moving the quenching tank to the mold.

Owner:CORVAC COMPOSITES

Special water-based cutting fluid for diamond wire saw

The invention relates to a special water-based cutting fluid for diamond wire saw comprising the following components in percentage by weight: 0.01% of dispersing agent, 0.01-3% of wetting agent, 0.05% of defoaming agent, 0.01% of corrosion inhibitor, 0.01% of chelating agent, 0.01% of bactericide, 0.01% of penetrating agent and the balance of water. The invention has the advantages of extremely lower viscosity, good cooling property and good chip suspension and diffusivity; in addition, silicon grains of chip grains can be greatly wetted, the diamond wire saw is cleaned clearly, has low foaminess, is not sensitive to metal ions and can not be combusted. The special water-based cutting fluid disclosed by the invention is stable during use at high temperature and has longer service life and higher cutting efficiency; and in addition, the cutting fluid left on the silicon chips is easy to be removed, and the recovery of silicon powder turns to be very easy.

Owner:JIANGSU KAIXING PLASTICS

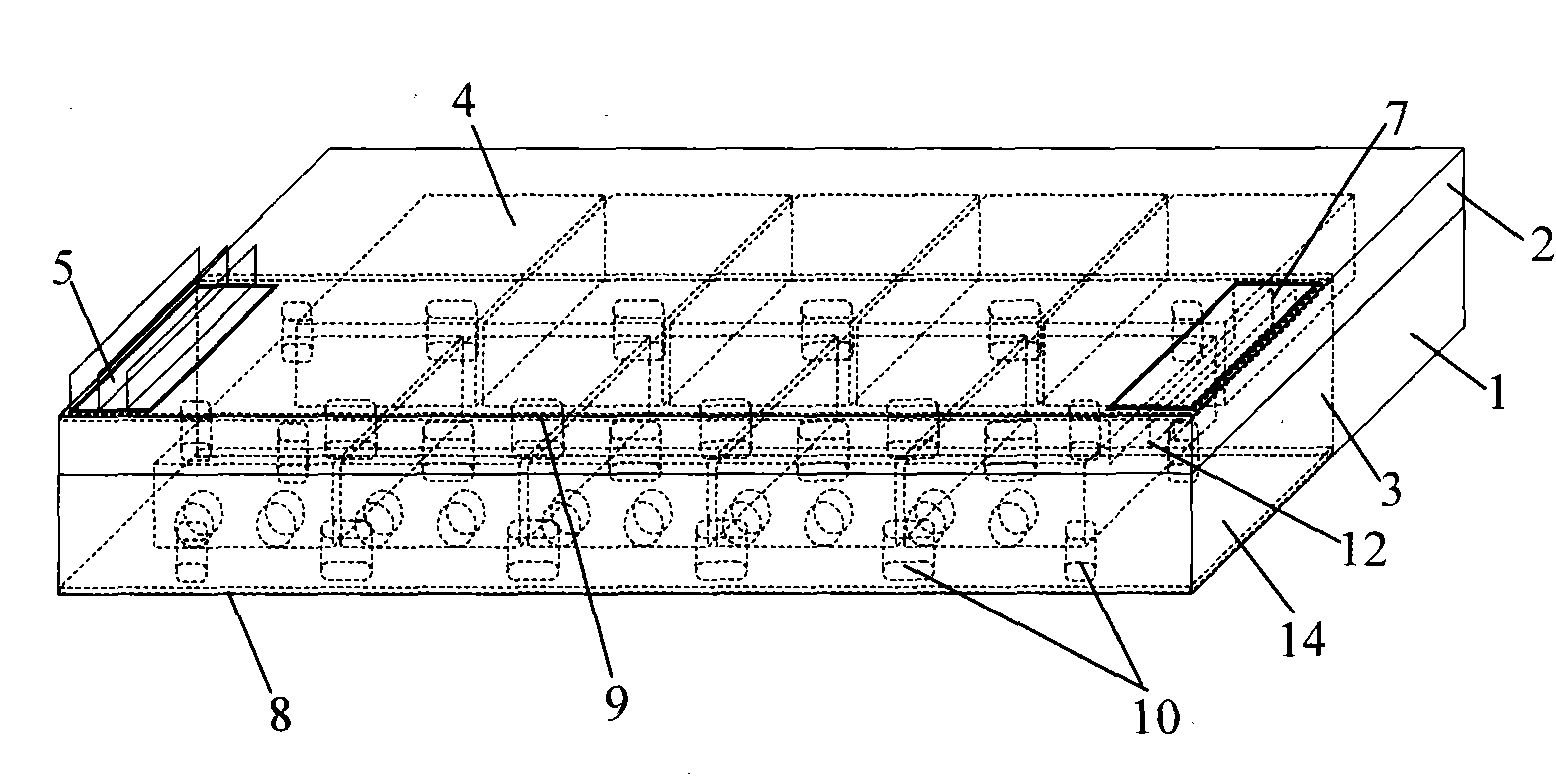

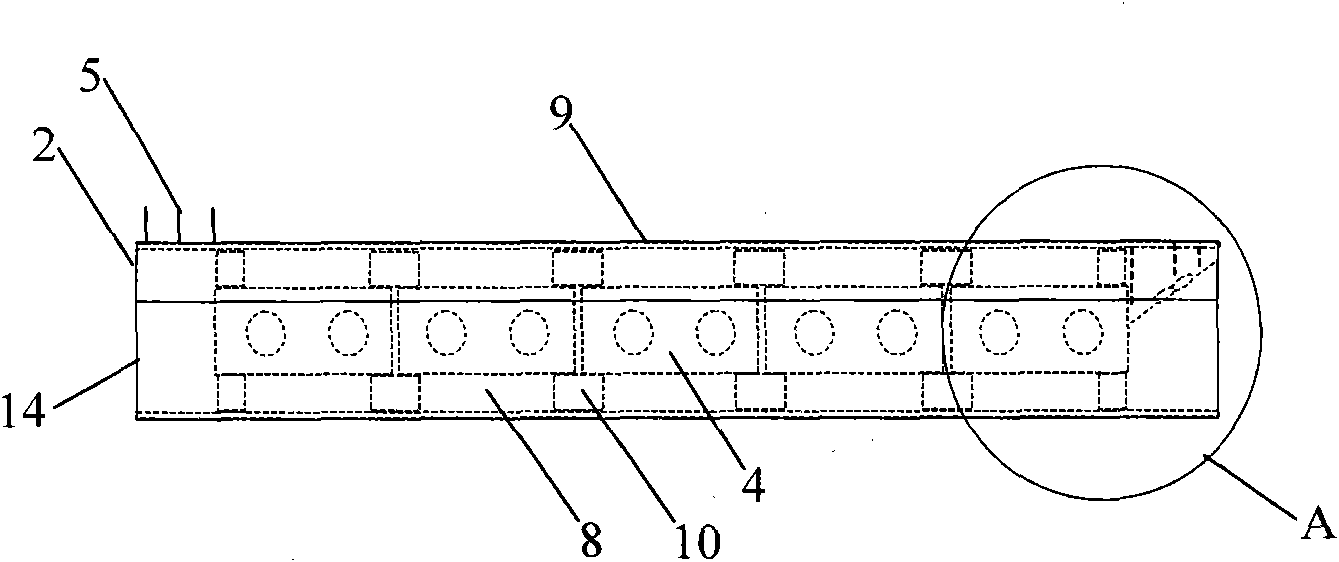

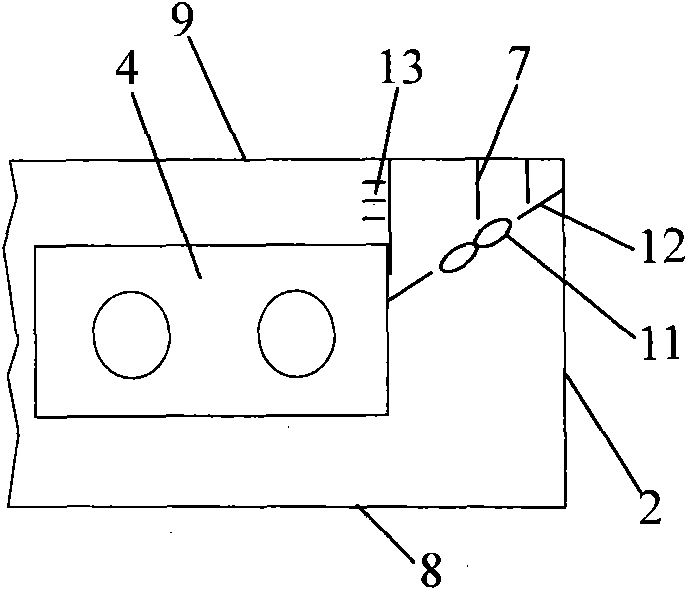

Heat exchange structure of power battery box

InactiveCN101789518AMeet the demanding requirements of operating temperatureImprove performanceCell temperature controlAcute angleWorking temperature

The invention relates to a heat exchange structure of a power battery box, wherein a temperature monitoring element is arranged in a battery module of a battery pack; the battery pack is erected in the middle of a battery box; a top space, a bottom space and a side surface space are respectively positioned between the upper surface, the lower surface and the side surface of the battery pack and the top, the bottom and the side surface of the battery box; a heating element is arranged in the battery box; a first air door and a second air door are arranged on the battery box; an air driving element is arranged in the battery box towards the second air door and at an acute angle with the second air door; and a control unit is electrically connected with the first air door, the second air door, the air driving element, the heating element and the temperature monitoring element. The invention has ingenious design, simple structure, low cost, convenient operation and both cooling and heating, thereby solving the problem of heat management of the battery box of an all-electric hybrid power vehicle, meeting the strict requirements of a battery on working temperature, enhancing the property of the battery and being suitable for large-scaled popularization and application.

Owner:SHANGHAI ZHONGKE SHENJIANG ELECTRIC VEHICLE

Method for recycling water-containing sump oil by utilizing delayed coking device

ActiveCN104419444AReduce cooling effectReduce energy consumptionThermal non-catalytic crackingEconomic benefitsSewage

The invention discloses a method for recycling water-containing sump oil by utilizing a delayed coking device. The method comprises the following steps: (1) injecting water-containing sump oil into a steam blowing exhausting pipeline of a coke chamber when the coke chamber of the delayed coking device is subjected to large steam blowing and coke cooling process, wherein the water-containing sump oil is heated by high-temperature oil gas from the coke chamber; (2) gasifying water and light oil fractions in the water-containing sump oil, mixing the gasified water and light oil fractions with cooled oil, oil gas and steam from the coke chamber, and allowing the mixed oil gas to enter an emptying tower; and (3) distilling off the steam and light oil fractions from the top of the emptying tower, condensing, cooling, allowing the steam and light oil fractions to enter a liquid separation tank on the top of the emptying tower, and separating non-condensable gas, light sump oil and sulfur-containing sewage from the liquid separation tank, wherein heavy oil fractions are extracted from the bottom of the emptying tower. According to the method disclosed by the invention, the water-containing sump oil which is difficultly treated in an oil refinery is treated, the cooling load and energy consumption of the coking device are reduced, and the method is not influenced by the properties of the water-containing sump oil. The energy conservation and emission reduction in a refinery plant are promoted, and a certain economic benefits are created for the refinery plant.

Owner:SINOPEC ENG +1

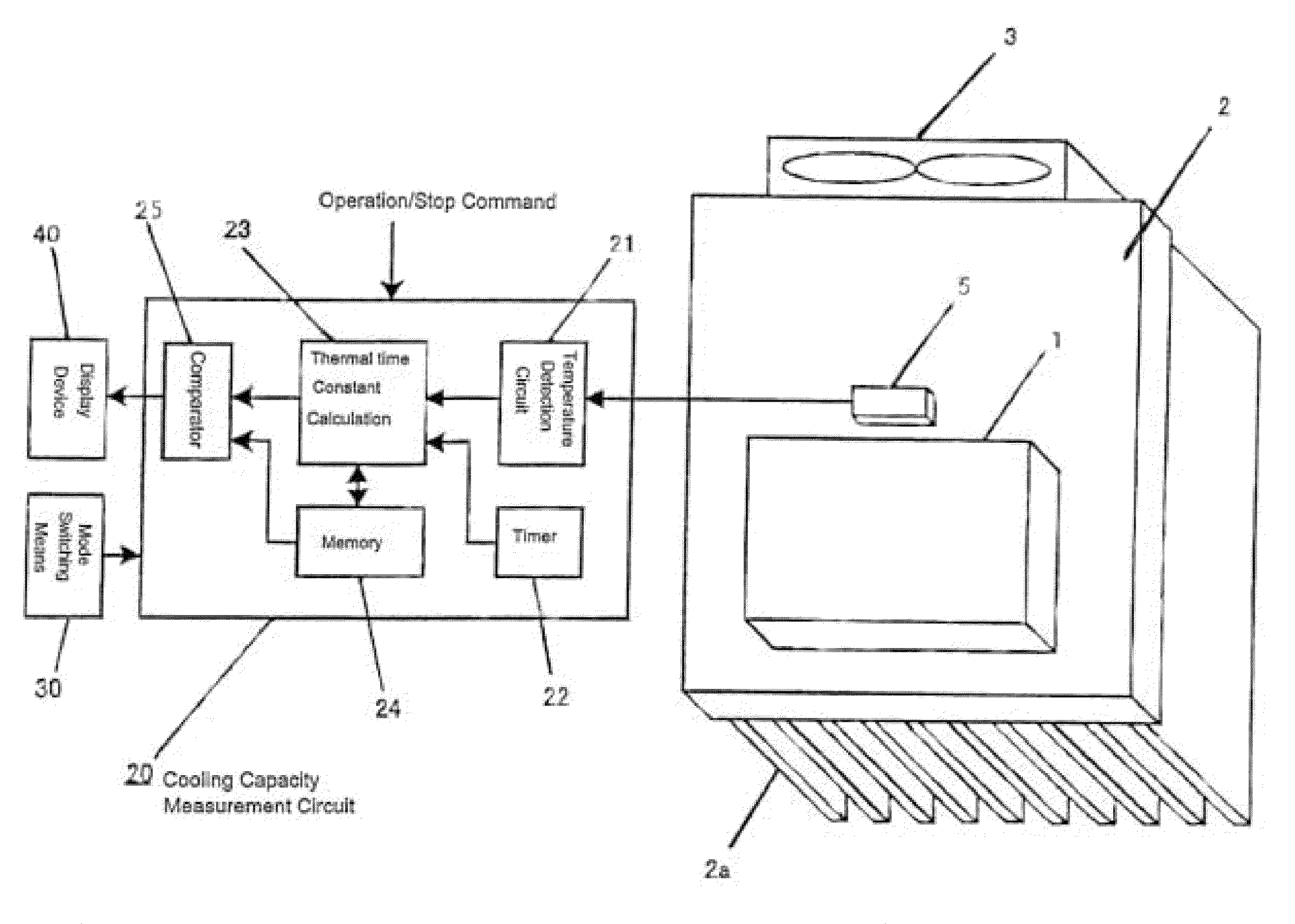

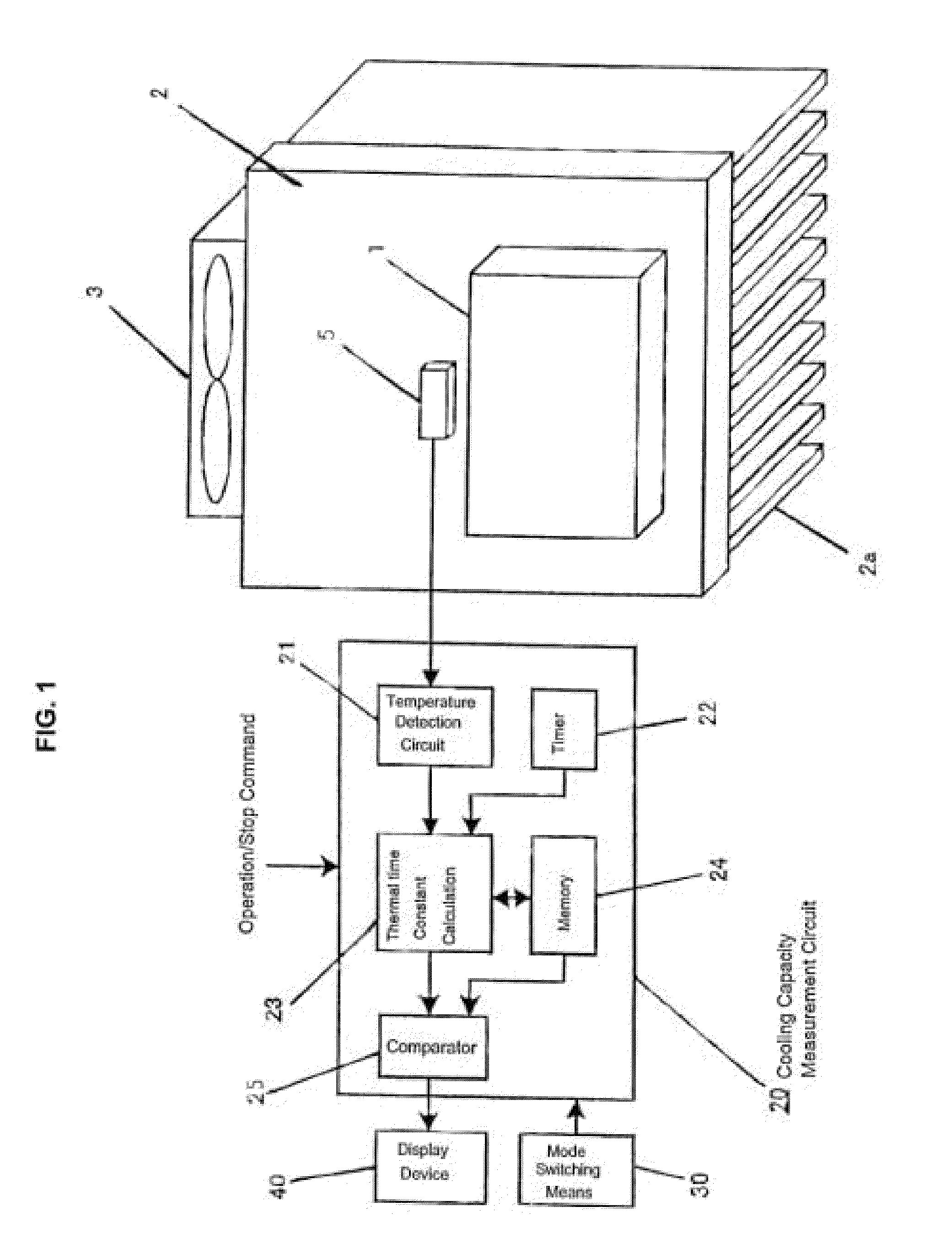

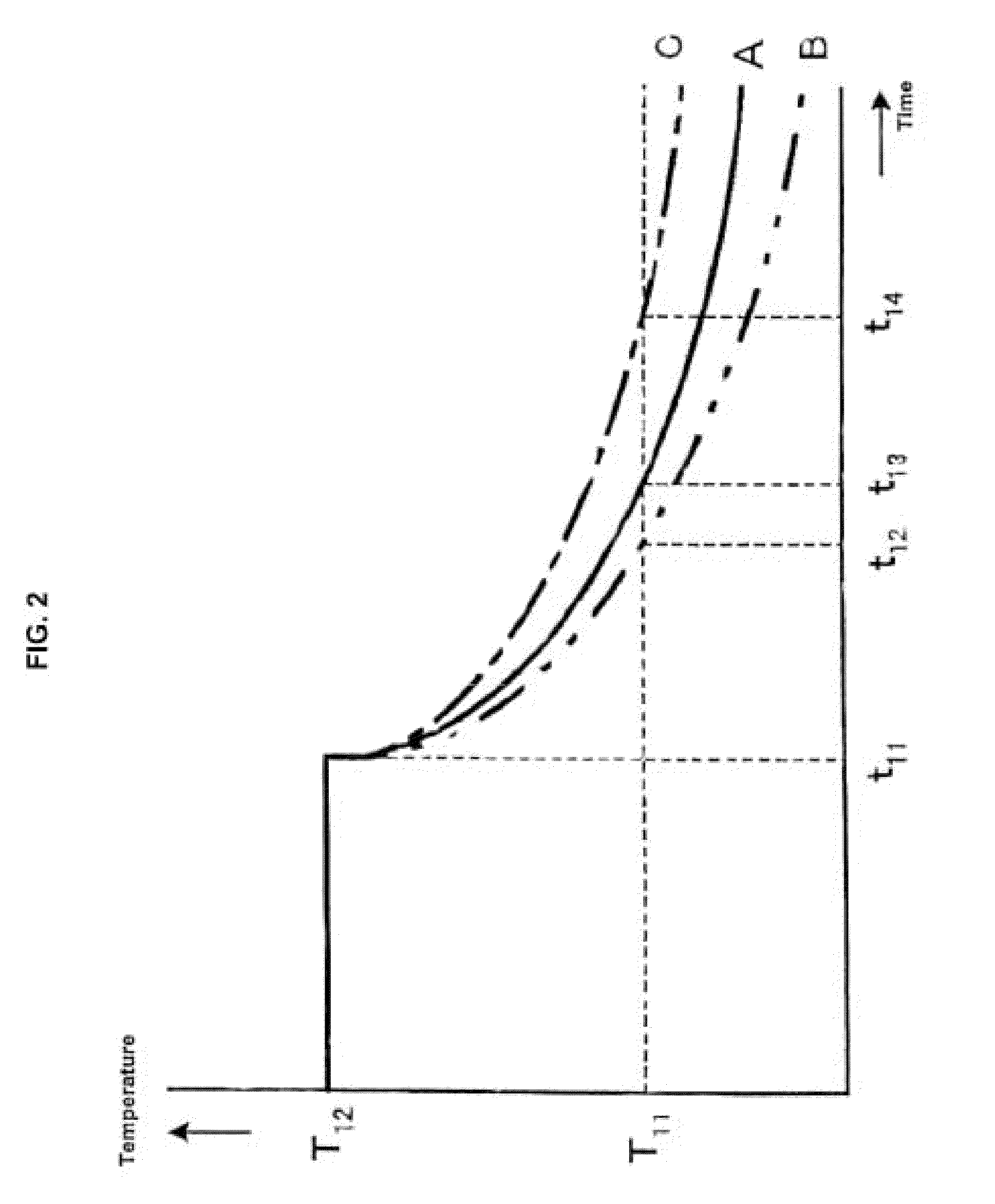

Cooling capacity measurement method for inverter device

ActiveUS20100111134A1Cool capacity decreaseReduce cooling effectMaterial heat developmentThermometers using electric/magnetic elementsEngineeringTime constant

An inverter device is provided that can measure a decrease in cooling capacity caused by a finite service life of a cooling fan or clogging of a cooling fin, without being affected by an ambient temperature or a load state. A thermal time constant is calculated in a thermal time constant calculation circuit from a temperature detection value from a temperature detection circuit and a time signal from a timer on the basis of an operation / stop command for the inverter device. The calculated value of the thermal time constant calculated in the thermal time constant calculation circuit is compared by a comparator with a reference value of the thermal time constant that is stored in advance in a memory. Whether the cooling capacity has decreased is determined based on the comparison results.

Owner:FUJI ELECTRIC CO LTD

Vehicle air conditioner with seat air conditioning unit

ActiveUS20040139754A1Solve large capacityComfortable seat coolingAir-treating devicesSeat heating/ventillating devicesAir conditioningCooling capacity

In a seat air conditioning unit for a vehicle seat constructed with a seat cushion and a seat back, when a seat air conditioning operation is performed in a cooling operation of a passenger compartment, a cooling capacity of cool air blown from the seat back is set smaller than a cooling capacity of cool air blown from these at cushion while a passenger sits on the vehicle seat. Further, the cooling capacity of cool air blown from a lower portion of the seat back can be set smaller than the cooling capacity of an upper portion of the seat back. Accordingly, even when the cooling operation is continued for a long time while the seat air conditioning operation is performed, the waist portion of the passenger can be prevented from being excessively cooled.

Owner:DENSO CORP

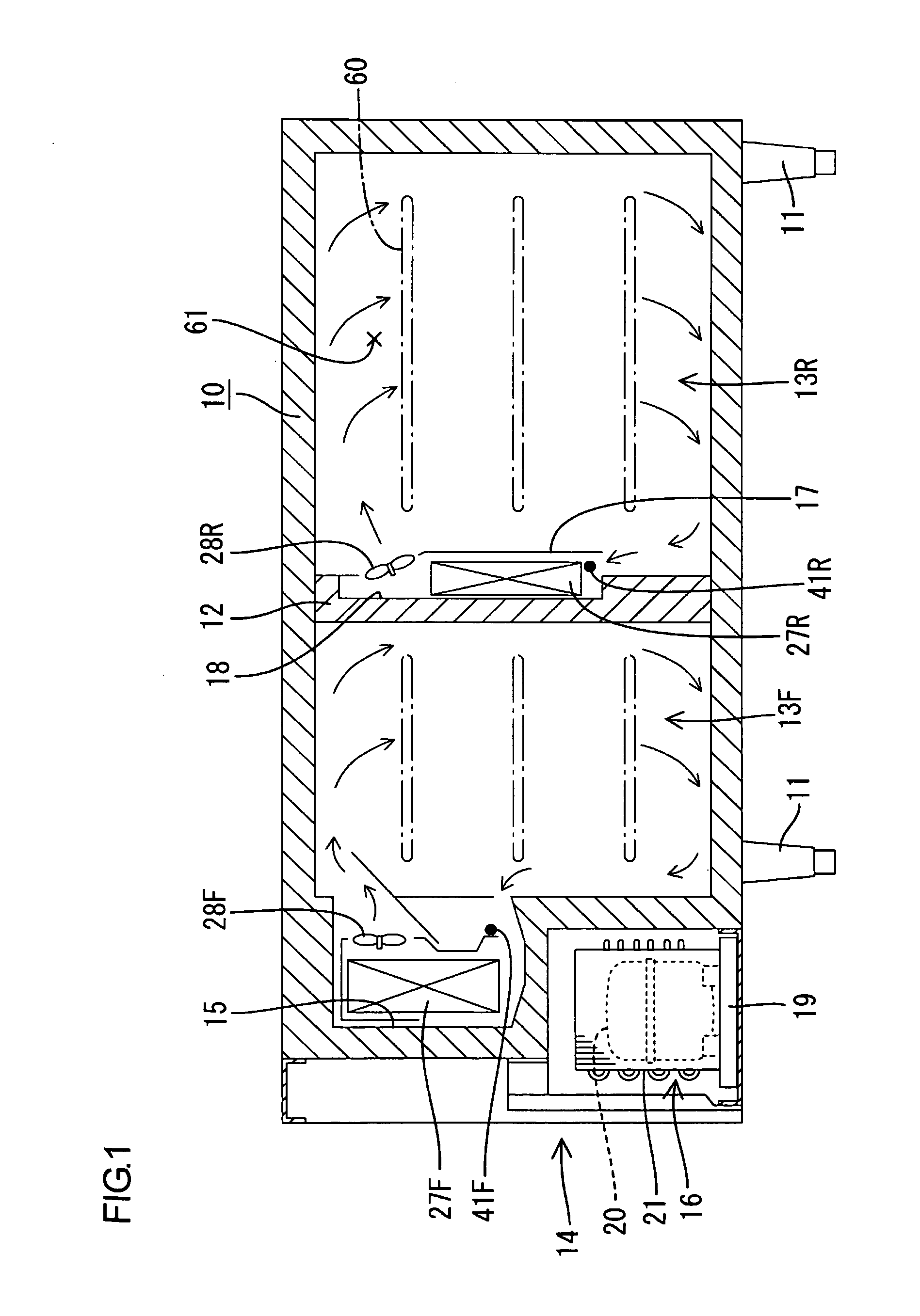

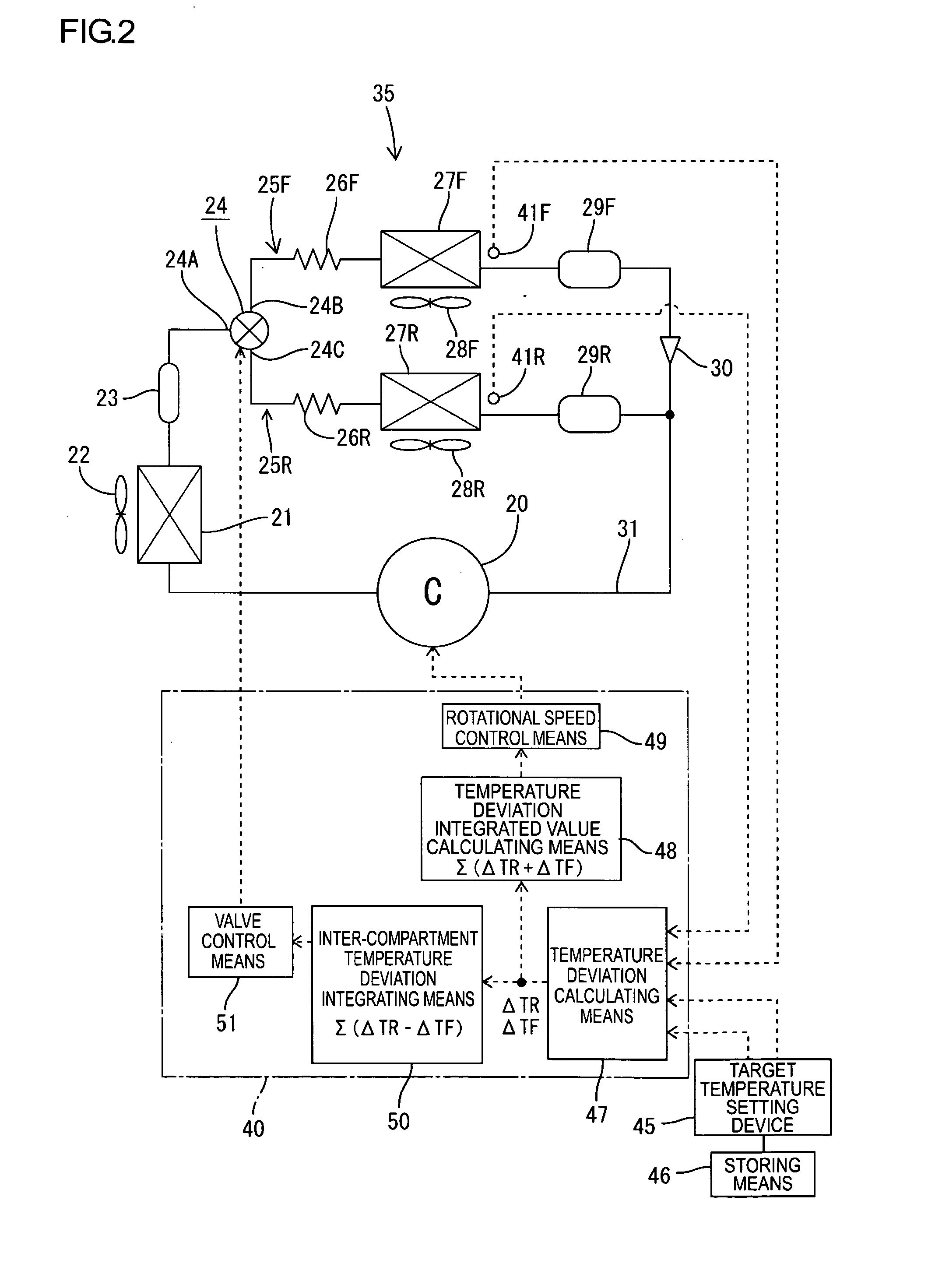

Cooling Storage Cabinet and Method of Operating Thereof

InactiveUS20090235677A1Preventing local overcoolingReduce speedSampled-variable control systemsComputer controlLower limitCool storage

When an internal temperature of a freezing compartment becomes lower than a lower limit temperature TF(OFF) during R-compartment F-compartment alternate cooling, a request for start of R-individual overcool preventing control is made. Then, the rotational speed of the compressor is decreased by one stage and, subsequently, a three-way valve comes to a “R-side open state”, and thus individual cooling of the refrigerating compartment is executed. Thereafter, after a set time, the rotational speed of the compressor is decreased by one stages. When the refrigerating compartment becomes lower than a lower limit temperature TR(OFF), a request for stop of the R-individual overcool preventing control is made. Then, the process shifts to individual cooling of the freezing compartment and then, after waiting for the freezing compartment to again become lower than the lower limit temperature, the compressor is stopped. When shifted to the individual cooling of the refrigerating compartment, the rotational speed of the compressor is drastically decreased in a short time, i.e. the cooling capacity is drastically decreased.

Owner:HOSHIZAKI ELECTRIC CO LTD

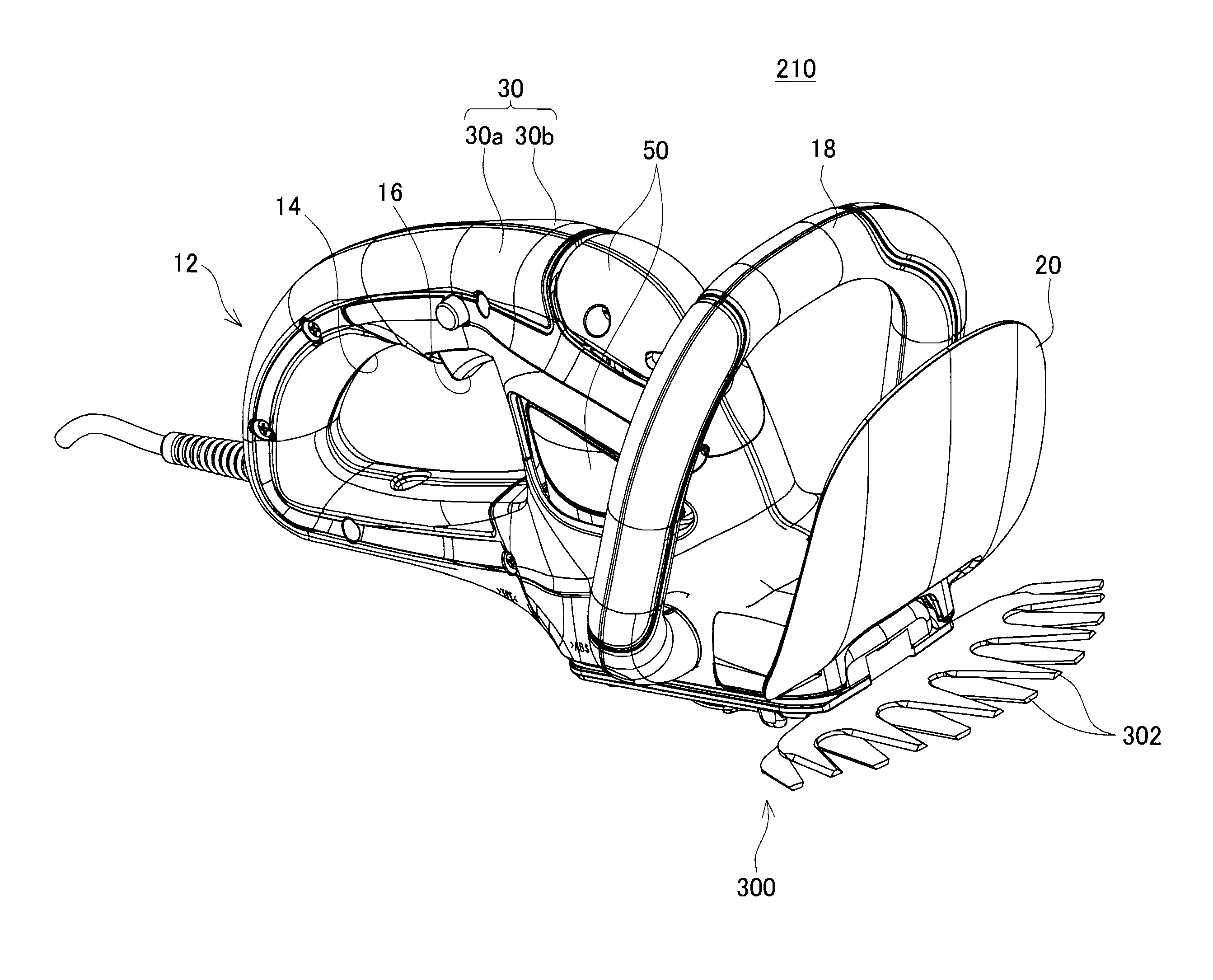

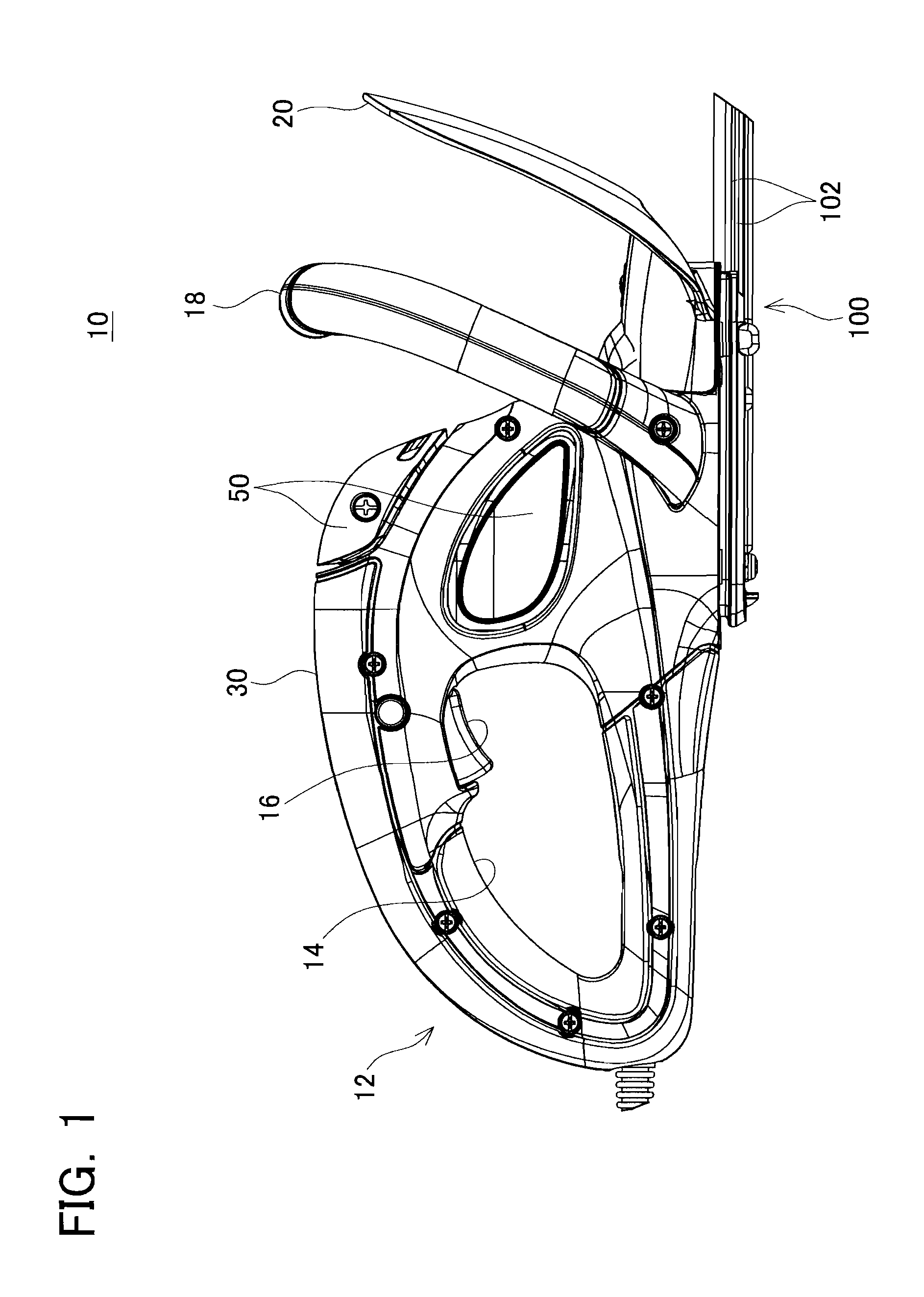

Power tool

ActiveUS20100095533A1Prevent and reduce vibrationExtended service lifeSpringsNon-rotating vibration suppressionEngineeringPower tool

A power tool includes an inner housing (50) at least partially housed within and spaced from an outer housing (30). The inner housing supports a tool (102, 302), such as a pair of shear blades, and houses a motor (80) that drives the tool. The outer housing includes a grip (14, 18) to be grasped by a user. At least one vibration insulator (71-75) can be disposed between the inner housing and the outer housing and in a manner such that the vibration insulator(s) is(are) protected by the outer housing. An intake opening (60a, 60b) and exhaust opening (64a, 64b) can be formed in the inner housing and can be shielded by respective portions of an inner surface of the outer housing.

Owner:MAKITA CORP

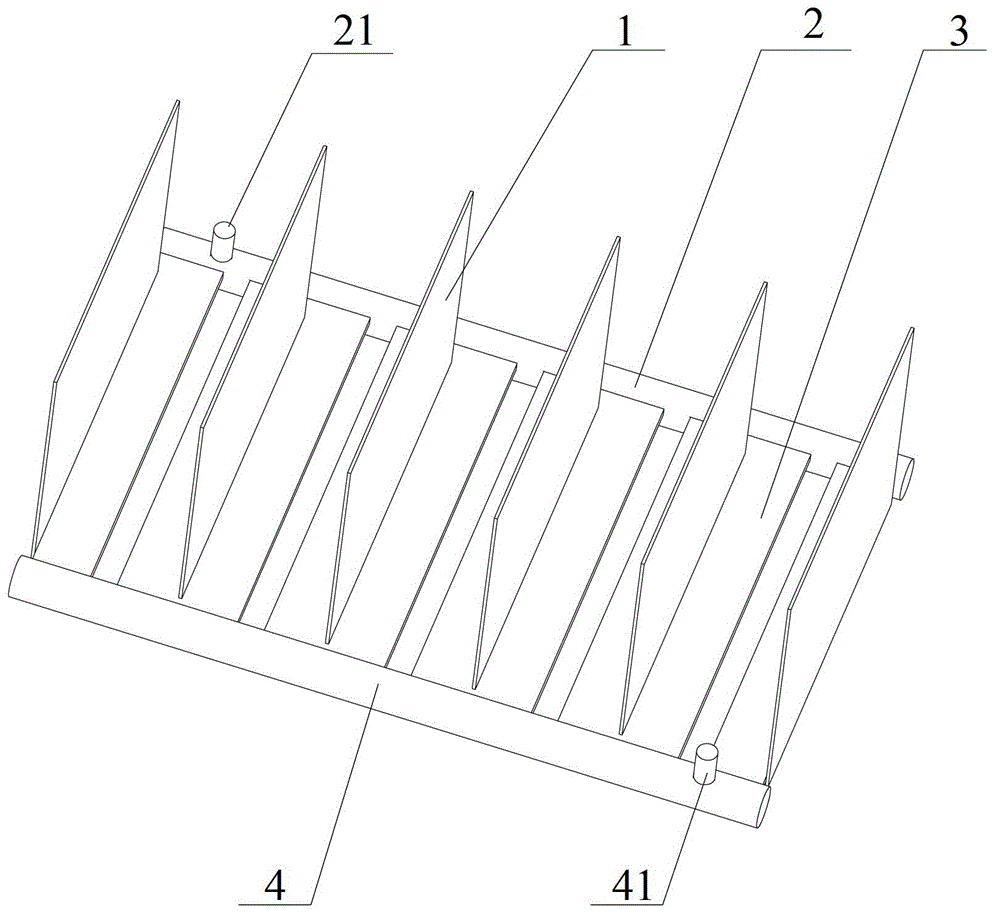

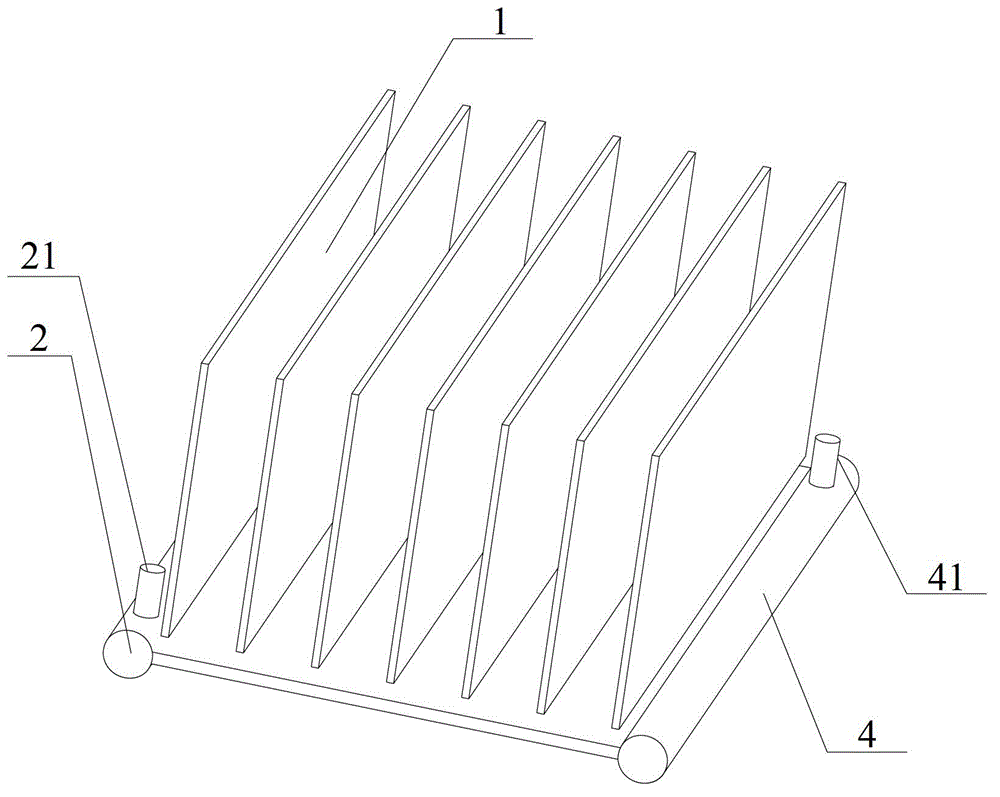

Automobile and battery radiating structure thereof

InactiveCN102717700ASolve the problem of large difference in cooling effect, resulting in large temperature differenceSmall temperature differenceSecondary cellsPropulsion coolingElectrical batteryHeat conducting

The invention discloses a battery radiating structure which comprises a liquid inlet pipe (2) with a liquid inlet (21) and a liquid outlet pipe (4) with a liquid outlet (41), a cooling pipe (3) for being arranged at the bottom of a battery pack (5) and a heat conducting plate (1). The cooling pipe (3) is communicated with the liquid inlet pipe (2) and the liquid outlet pipe (4), the heat conducting plate (1) is fixedly connected with the cooling pipe (3) and can be placed at a gap between adjacent batteries. According to the battery radiating structure, the heat conducting plate fixedly connected with the cooling pipe is arranged in the gap between the adjacent batteries, the heat conducting plate can take away heat on the side faces of the batteries and transfer the heat to the cooling pipe fixedly connected with the heat conducting plate, and side faces of the batteries are cooled simultaneously so as to enable difference of cooling effects of the top and the bottom of the battery pack to be small and reduce temperature difference between the top and the bottom of the battery pack. The invention further discloses an automobile with the battery radiating structure.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD +1

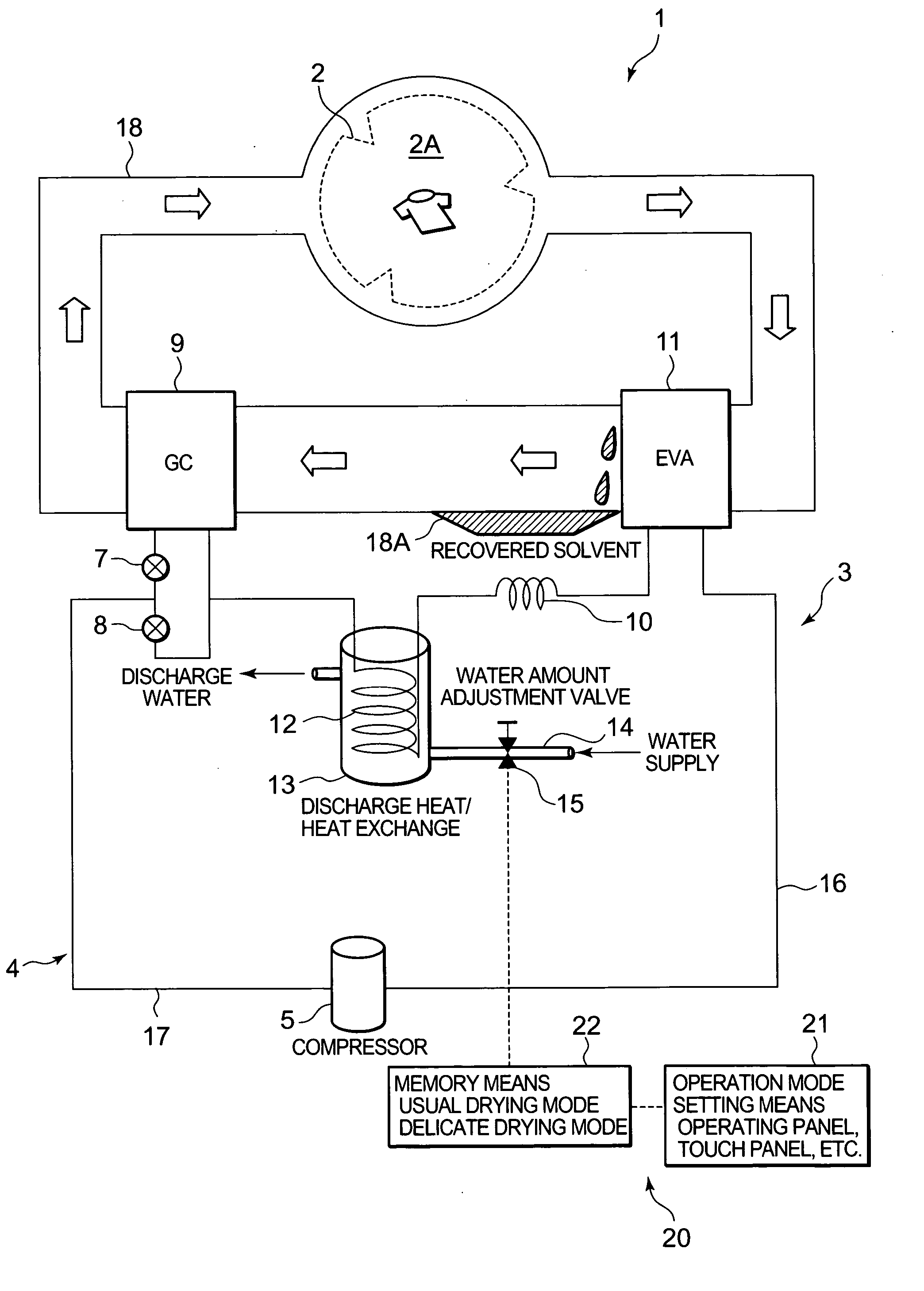

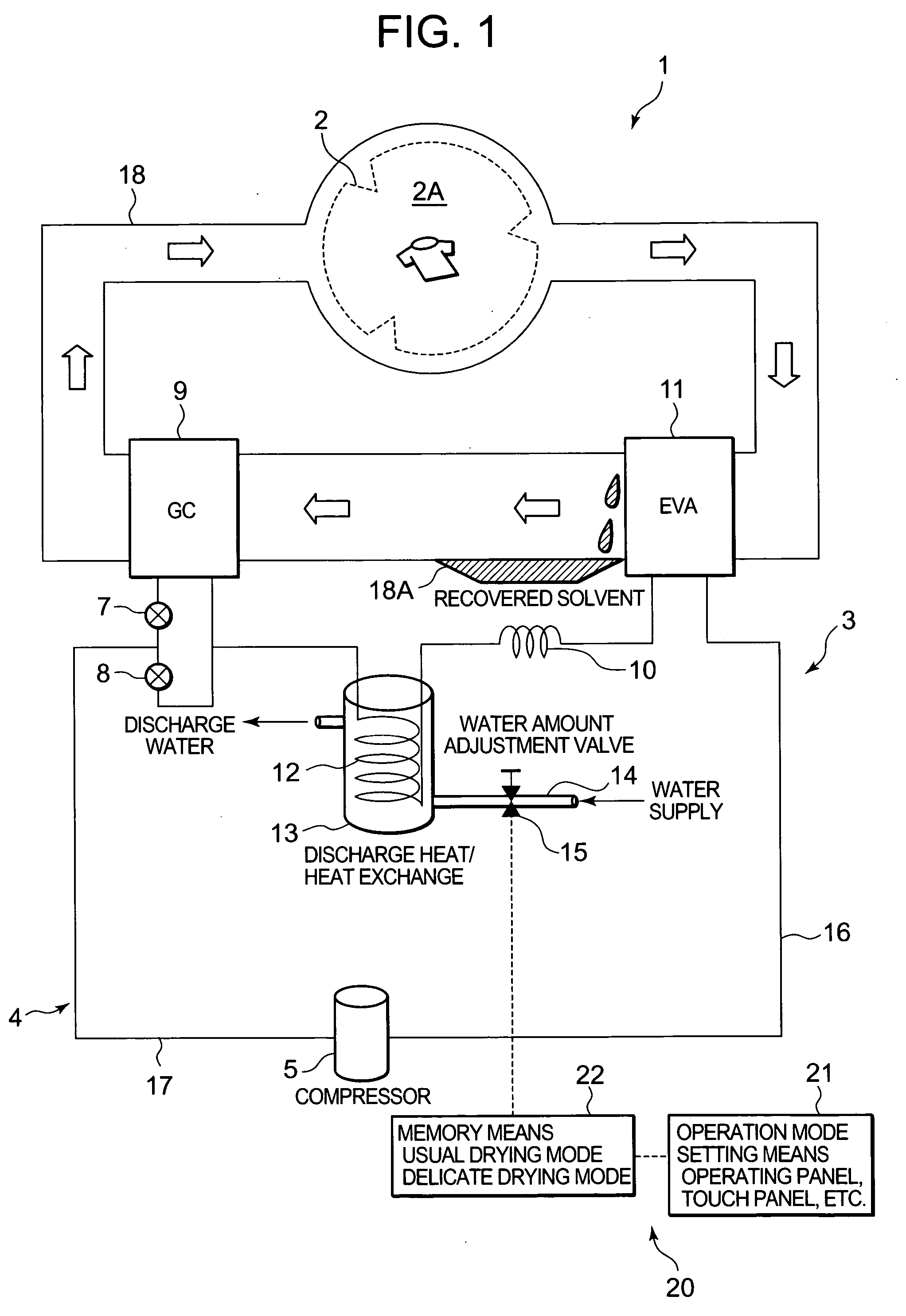

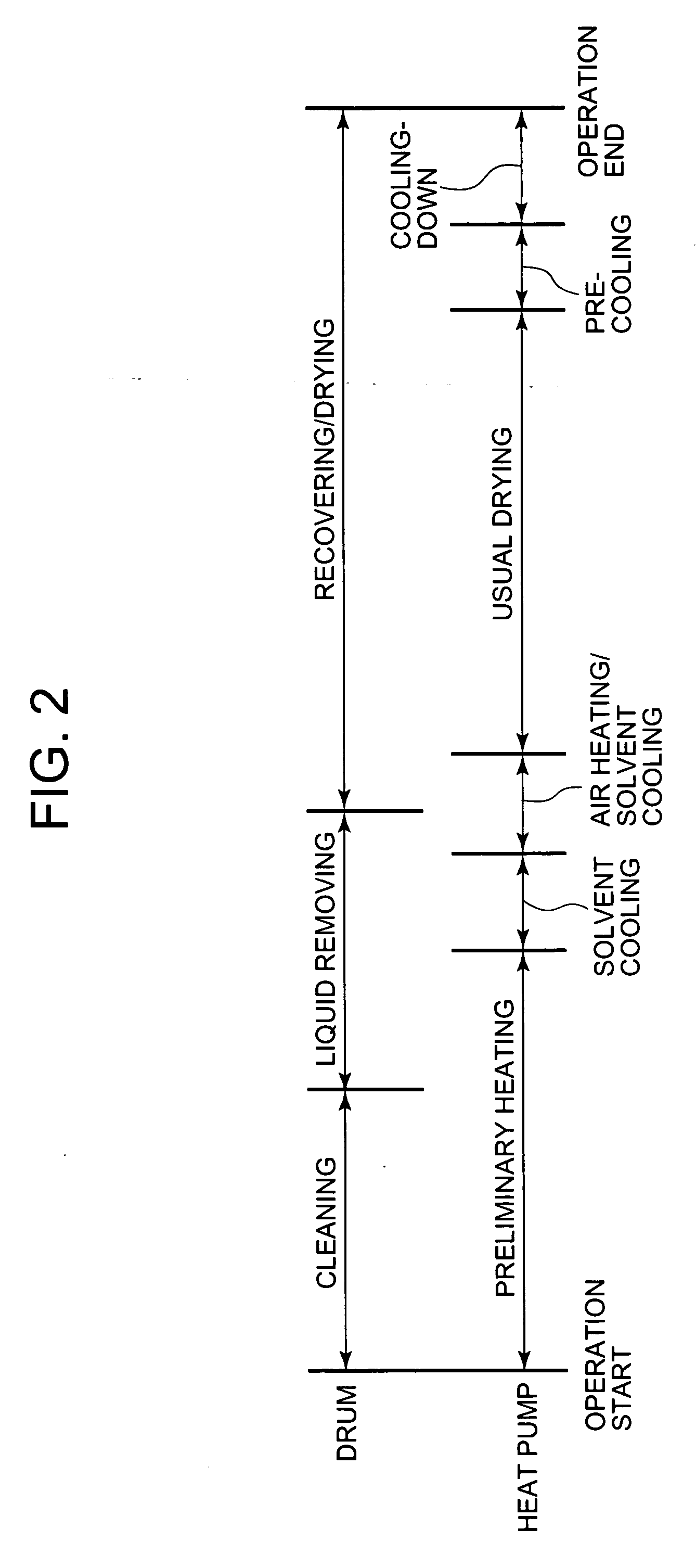

Drying machine

InactiveUS20060053651A1Reduce cooling effectReduce the temperatureDrying solid materials with heatDry-cleaning apparatusPlate heat exchangerProcess engineering

An object is to provide a drying machine which can accomplish delicate drying and reduce burdens on a matter to be dried during drying while securing a predetermined evaporation temperature in an evaporator. In summary, a dry cleaner equipped with a heat pump device comprises a water-cooling heat exchanger which removes heat from a refrigerant entering a capillary tube; and a control device which variably controls a discharged heat amount in the water-cooling heat exchanger and capacity of the compressor, wherein the control device has at least two kinds of drying modes including a usual drying mode and a delicate drying mode, and in the delicate drying mode, a temperature of air discharged into a storage chamber is set lower than in the usual drying mode to control the capacity of the compressor and to increase the discharged heat amount in the water-cooling heat exchanger.

Owner:SANYO ELECTRIC CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com