Strip steel reeling temperature controlling method and device

A technology of coiling temperature and control method, which is applied to the coiling temperature control of hot-rolled strip steel and the device field of strip steel coiling temperature control. It can solve the problems of increasing operation and control costs and increasing control difficulty, and achieves temperature control. The method is simple and accurate, the effect of reducing the number of samples and shortening the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

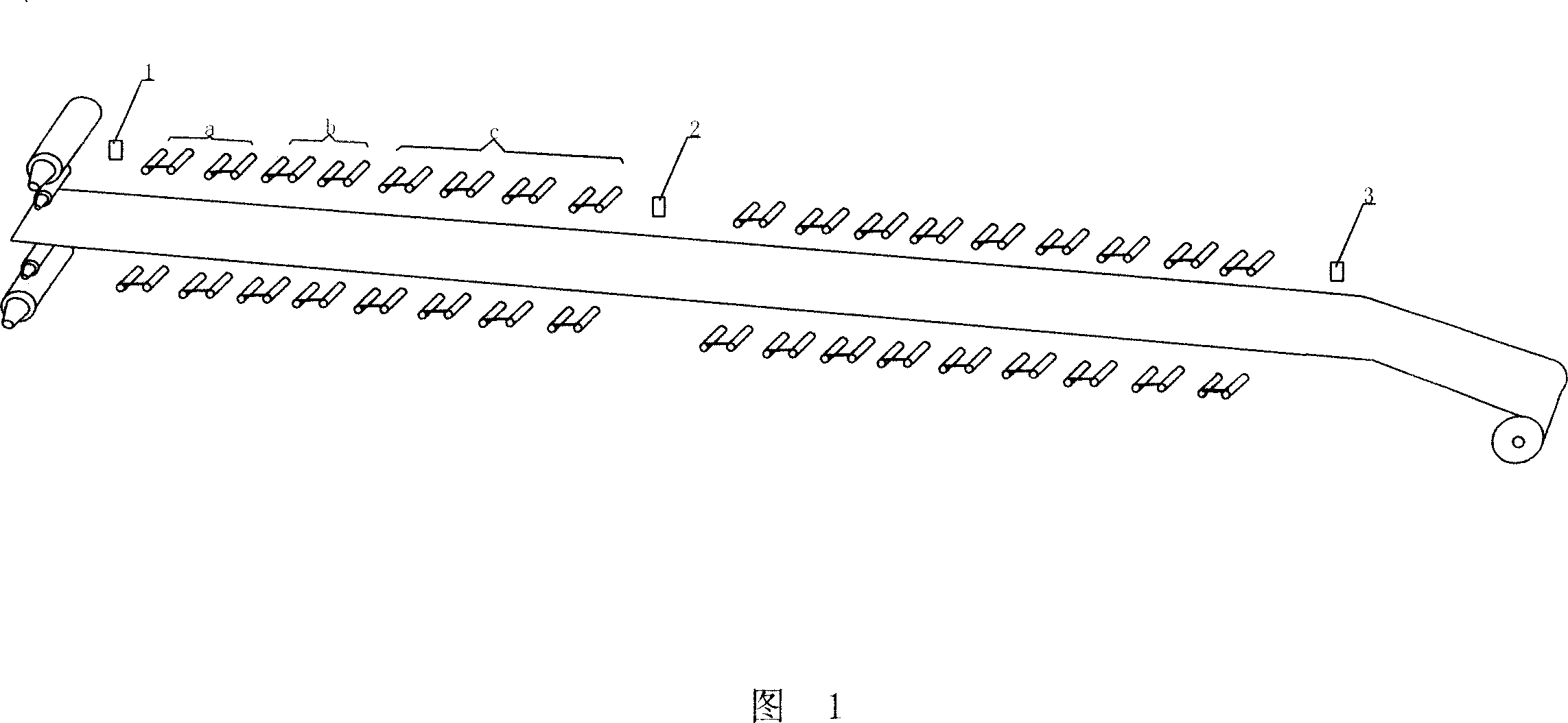

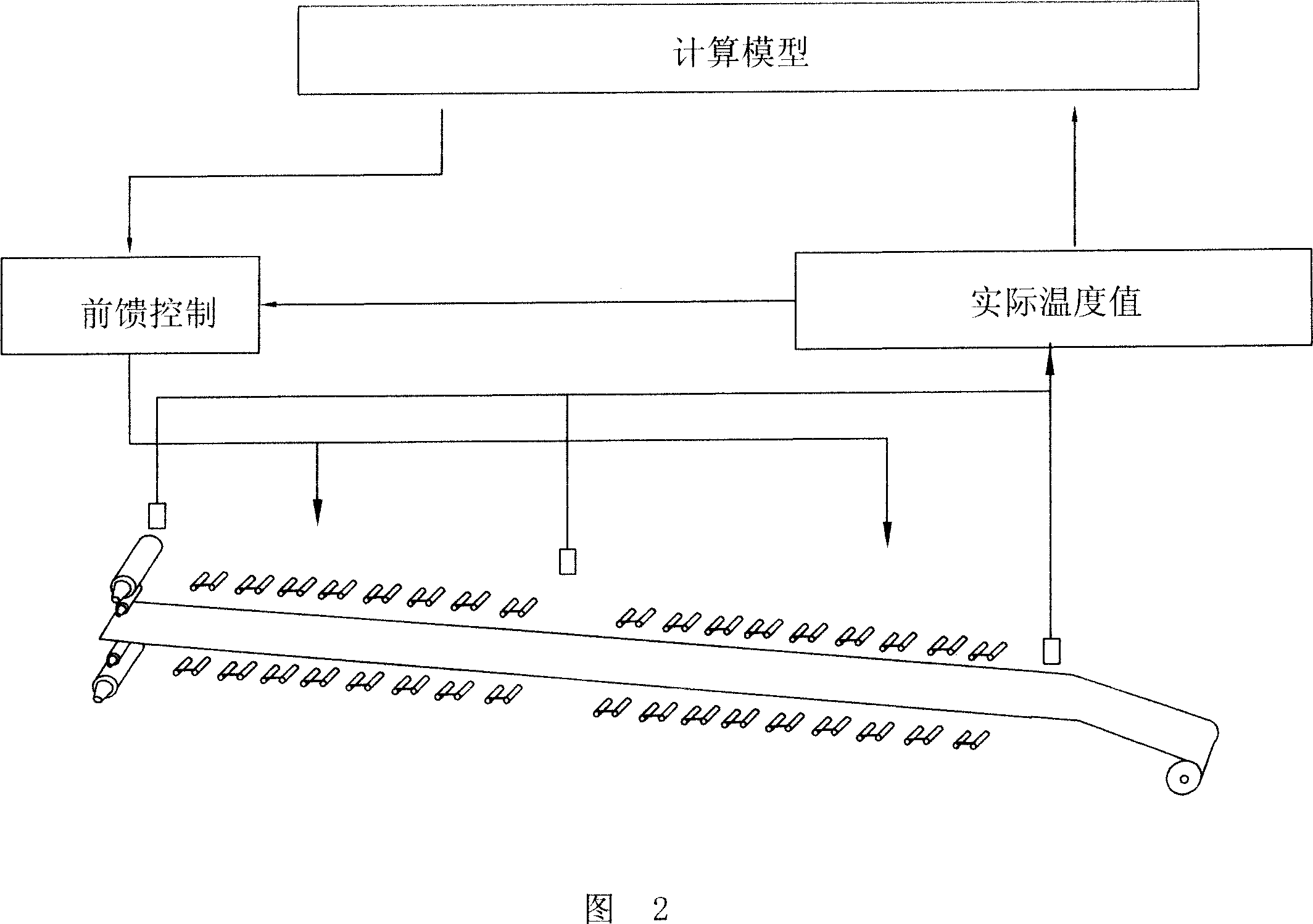

[0022] The strip coiling temperature control method is to set a cooling zone along the running direction of the strip, distribute two cooling sections, the main cooling section and the finishing cooling section in turn, and set up three temperature measuring devices in the water spray cooling area to detect the temperature of the strip. Steel temperature, and as the feed-forward parameter of the computer control system, the computer control system compares the feed-forward parameter with the set value and compensates, thereby adjusting the water spraying amount of the water spray header and the coiling speed of the strip to control the coiling of the strip. Coiling temperature.

[0023] As shown in the figure, the cooling zone of the strip coiling temperature control device using this temperature control method is mainly composed of seventeen groups of upper laminar flow headers and a corresponding number of lower spray headers. The cooling zone is composed of the main cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com