Patents

Literature

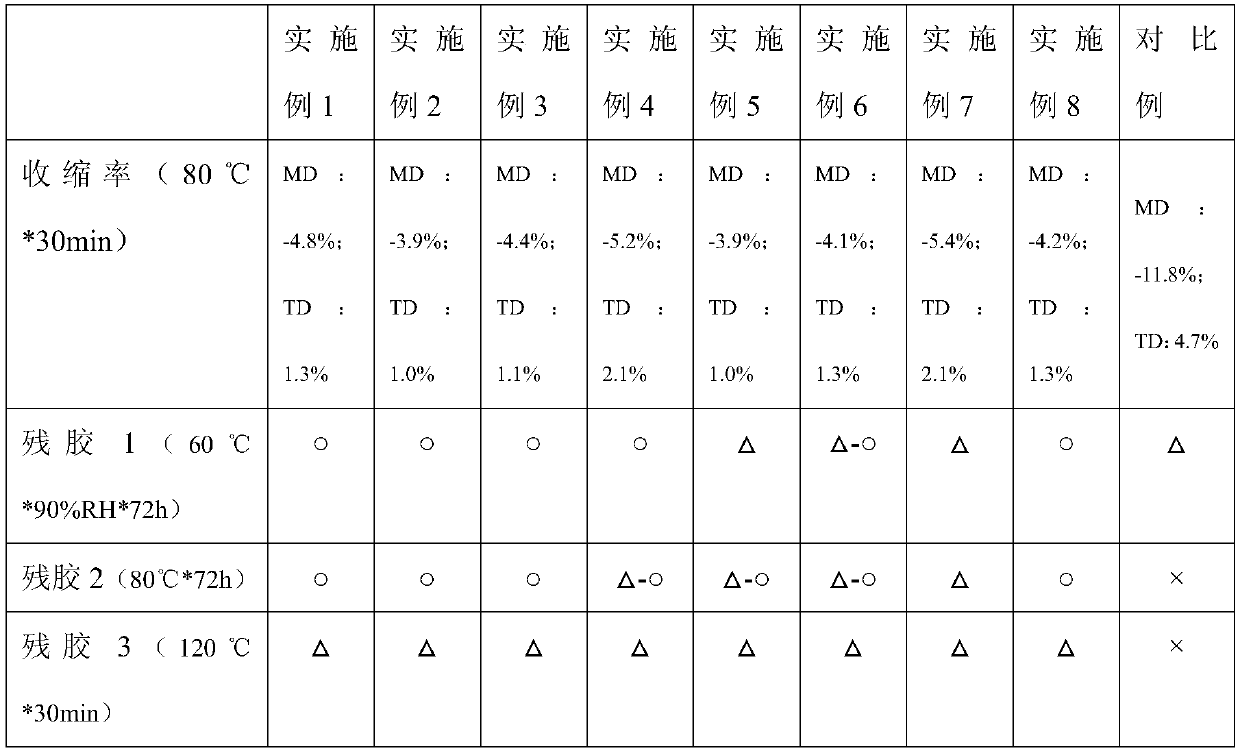

316results about How to "Reduce heating effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

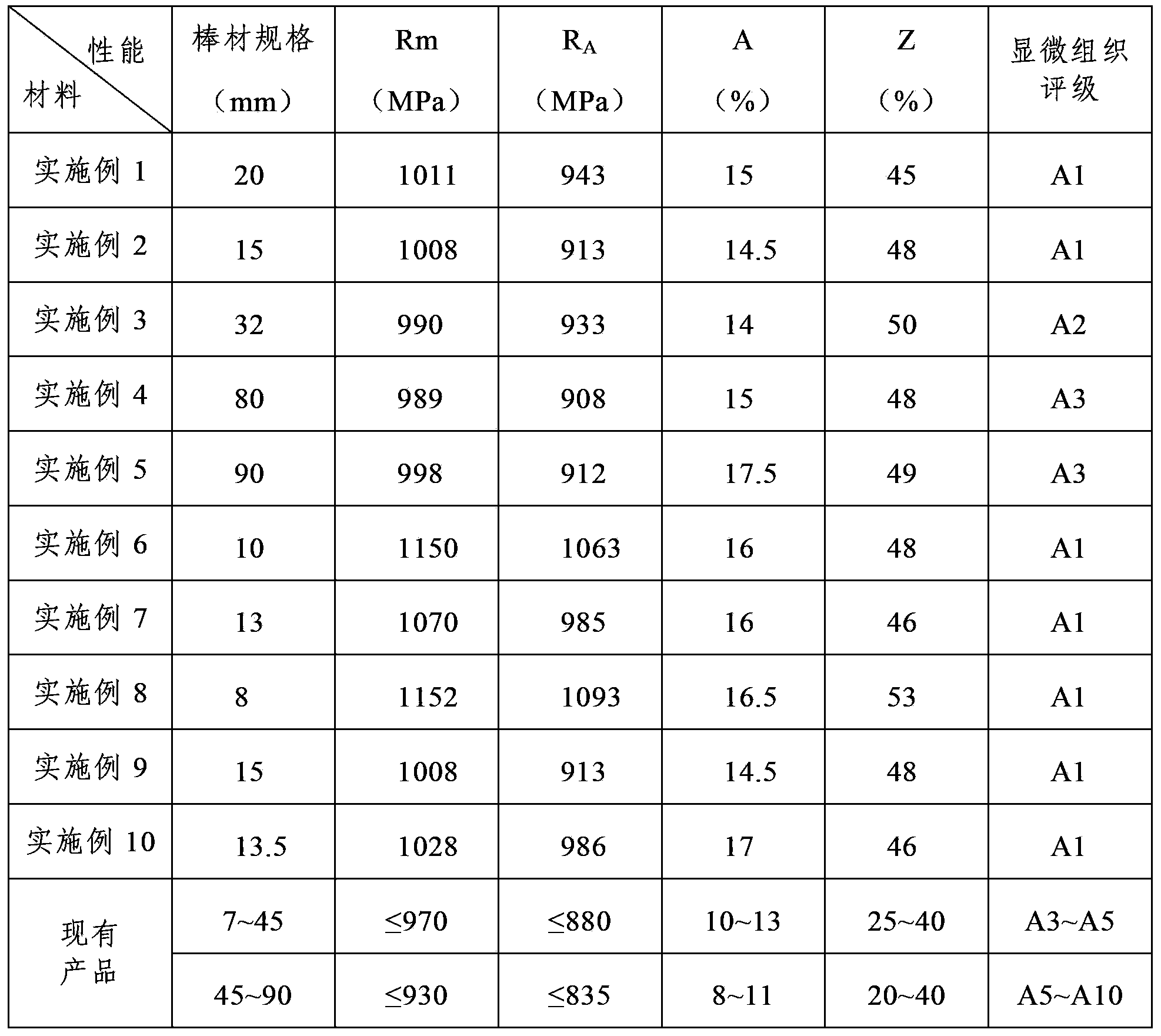

Preparation method of TC4ELI titanium alloy bar

The invention provides a preparation method of a TC4ELI titanium alloy bar. The preparation method comprises the following steps of: (1) carrying out cogging forging; (2) carrying out upsetting forging; (3) carrying out precise forging; (4) carrying out shearing, straightening and annealing treatment in sequence, thereby obtaining the cylindrical TC4ELI titanium alloy bar with the cross-section diameter of 15mm-90mm. The invention also provides a preparation method of the TC4ELI titanium alloy bar. The preparation method comprises the following steps of: (1) carrying out cogging forging; (2) carrying out upsetting forging; (3) carrying out precise forging; (4) rolling; (5) carrying out shearing, straightening and annealing treatment in sequence, thereby obtaining the cylindrical TC4ELI titanium alloy bar with the cross-section diameter of 8mm-15mm. The preparation method is simple in process, strong in repeatability and suitable for large-scale industrial production; the TC4ELI titanium alloy bar prepared by adopting the preparation method is uniform and fine in structure, high in microscopic structure level and excellent in mechanical property.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

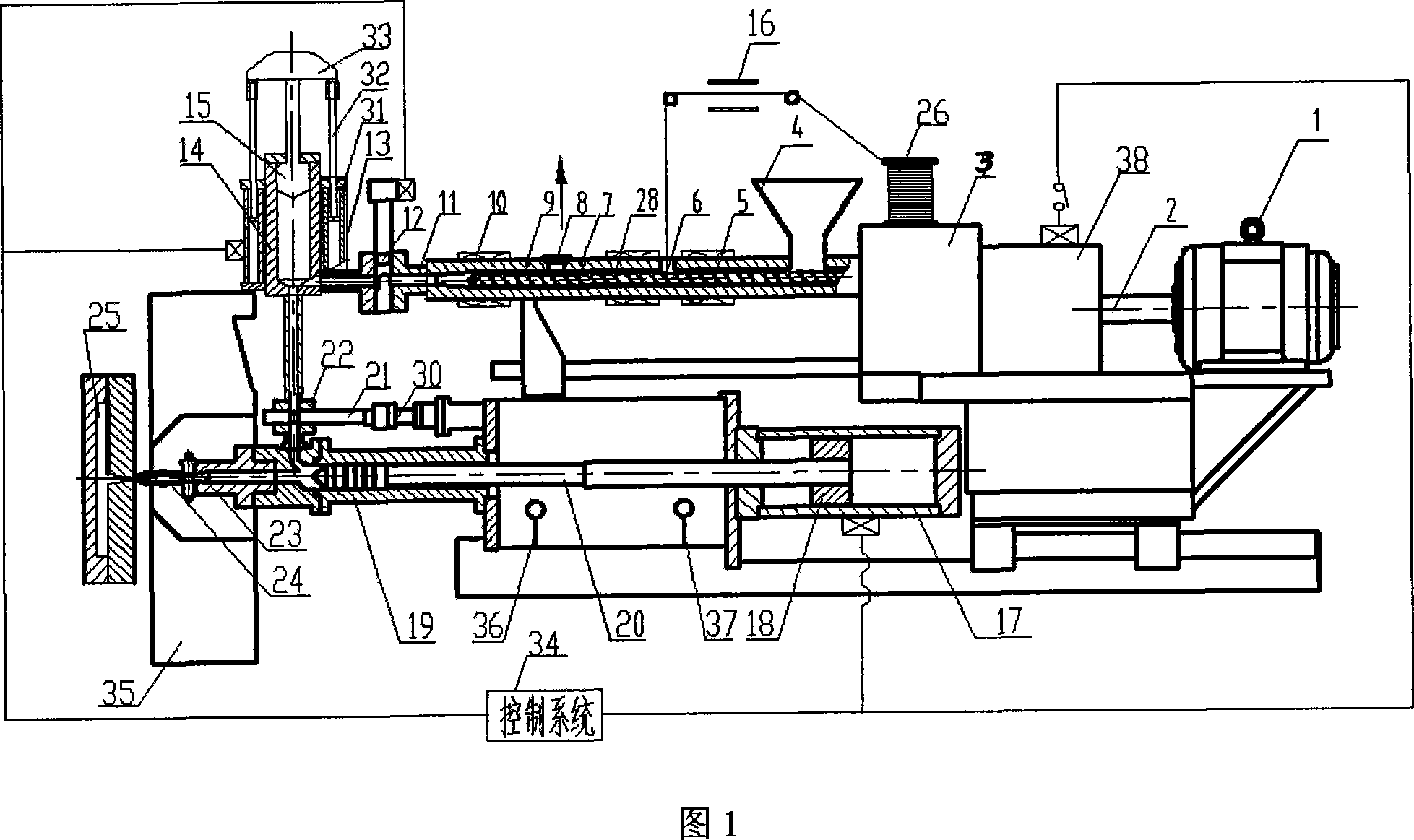

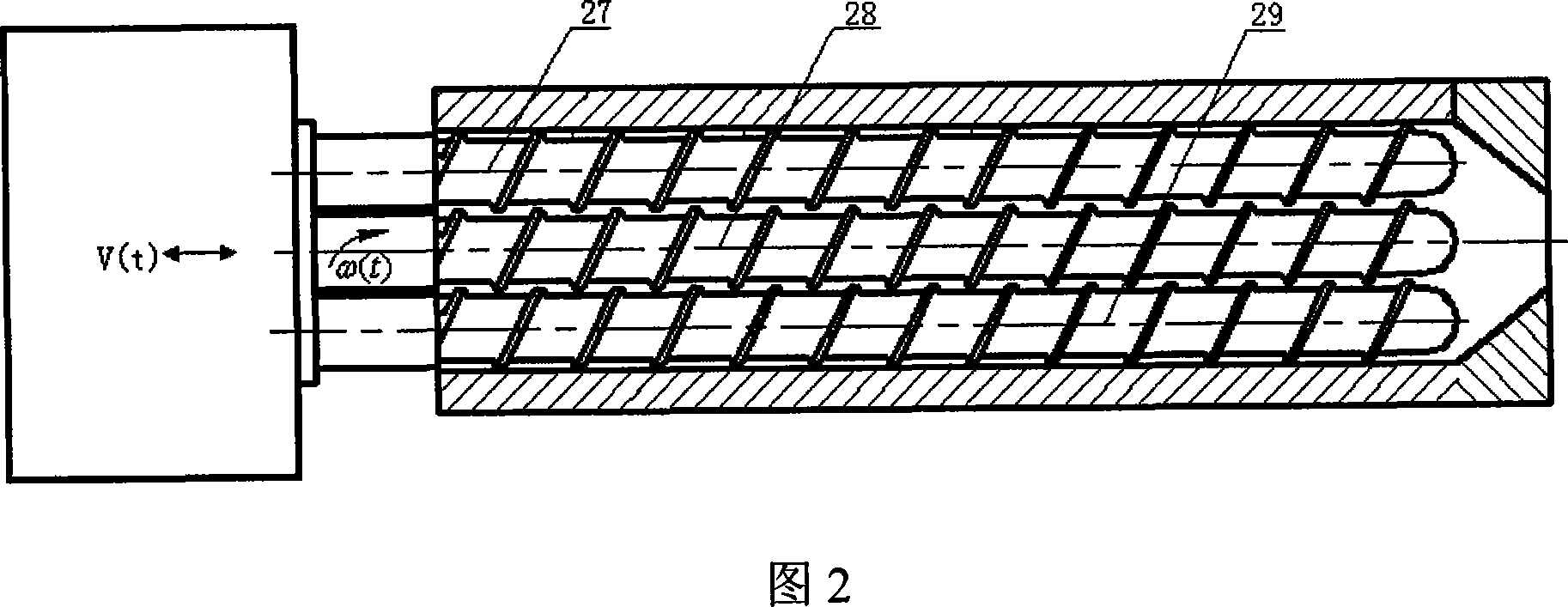

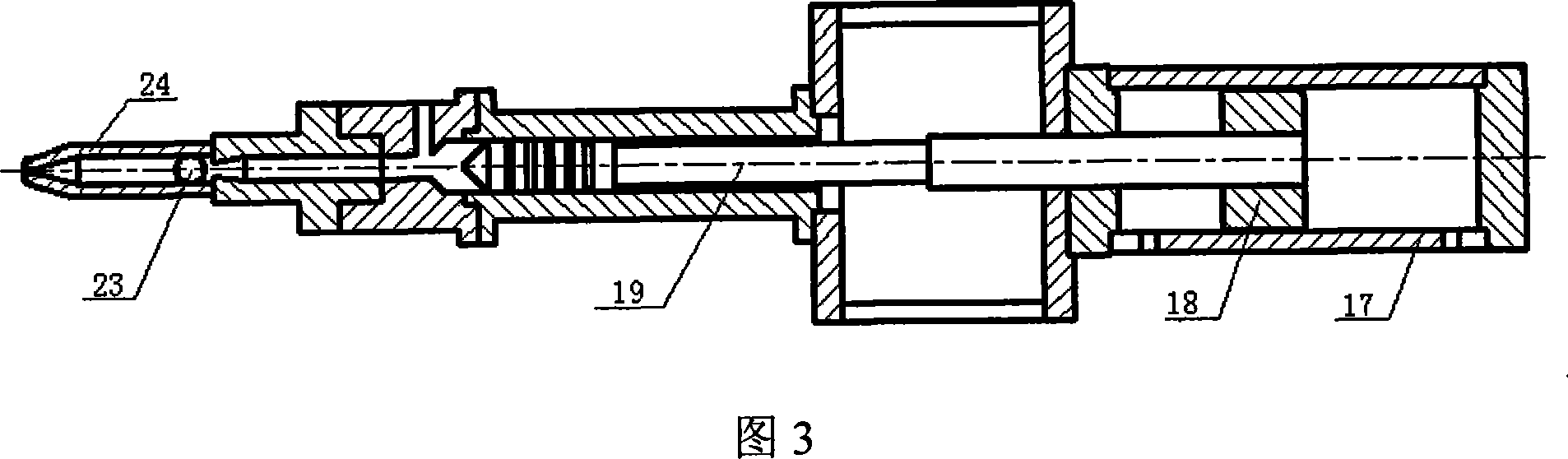

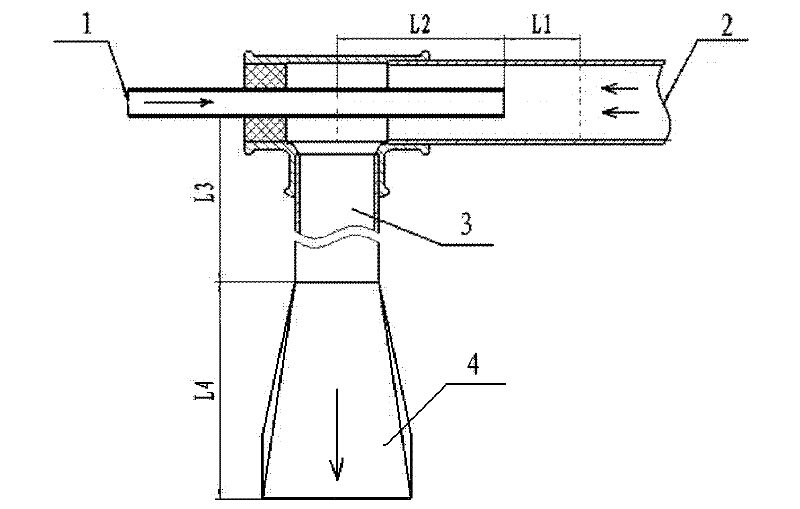

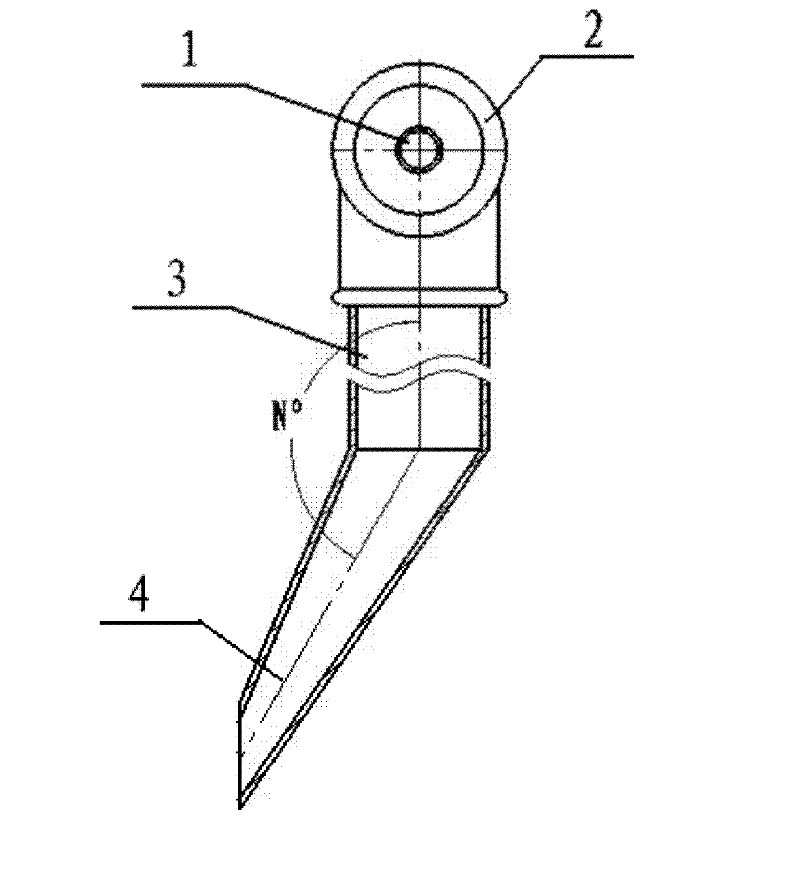

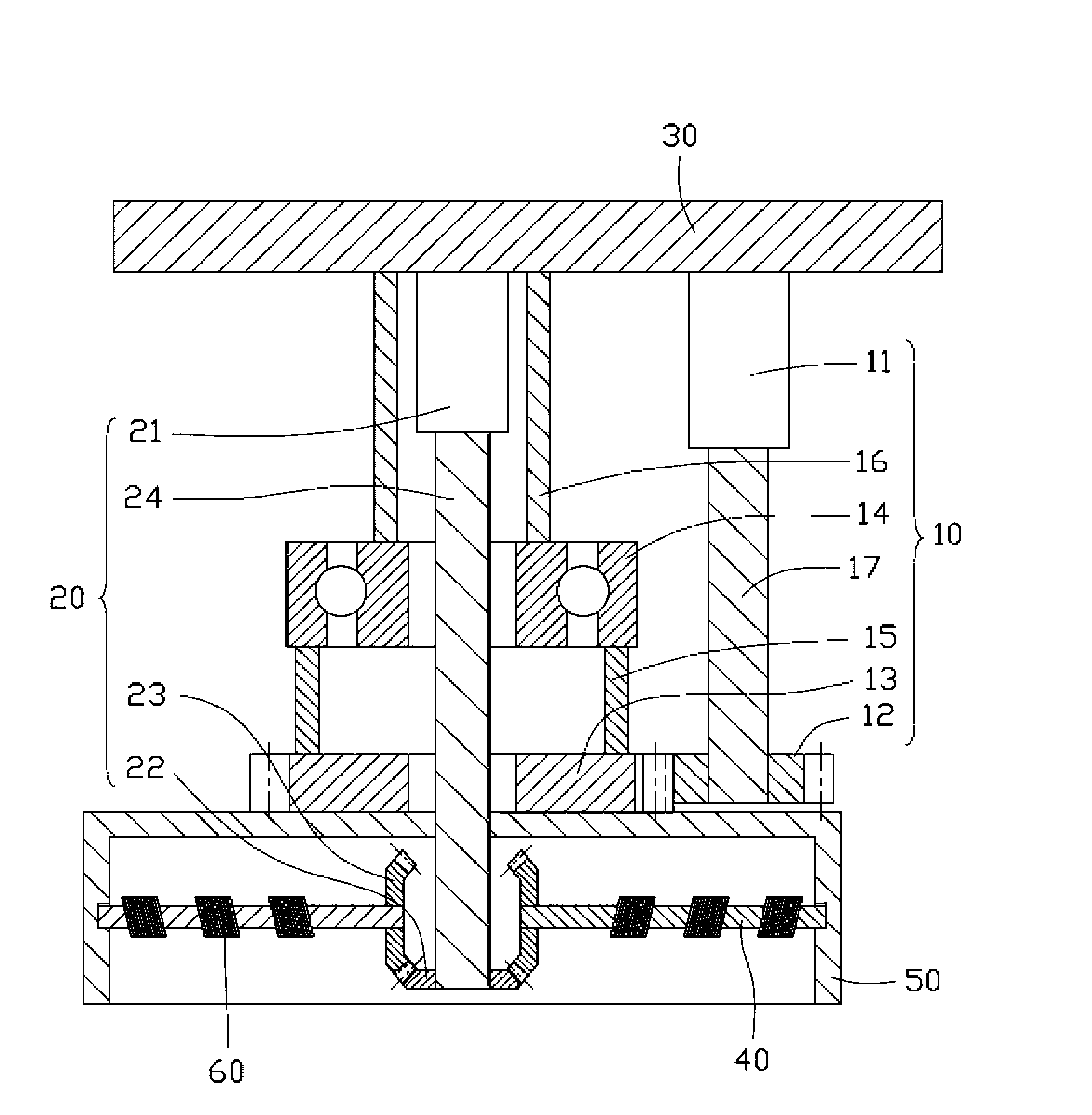

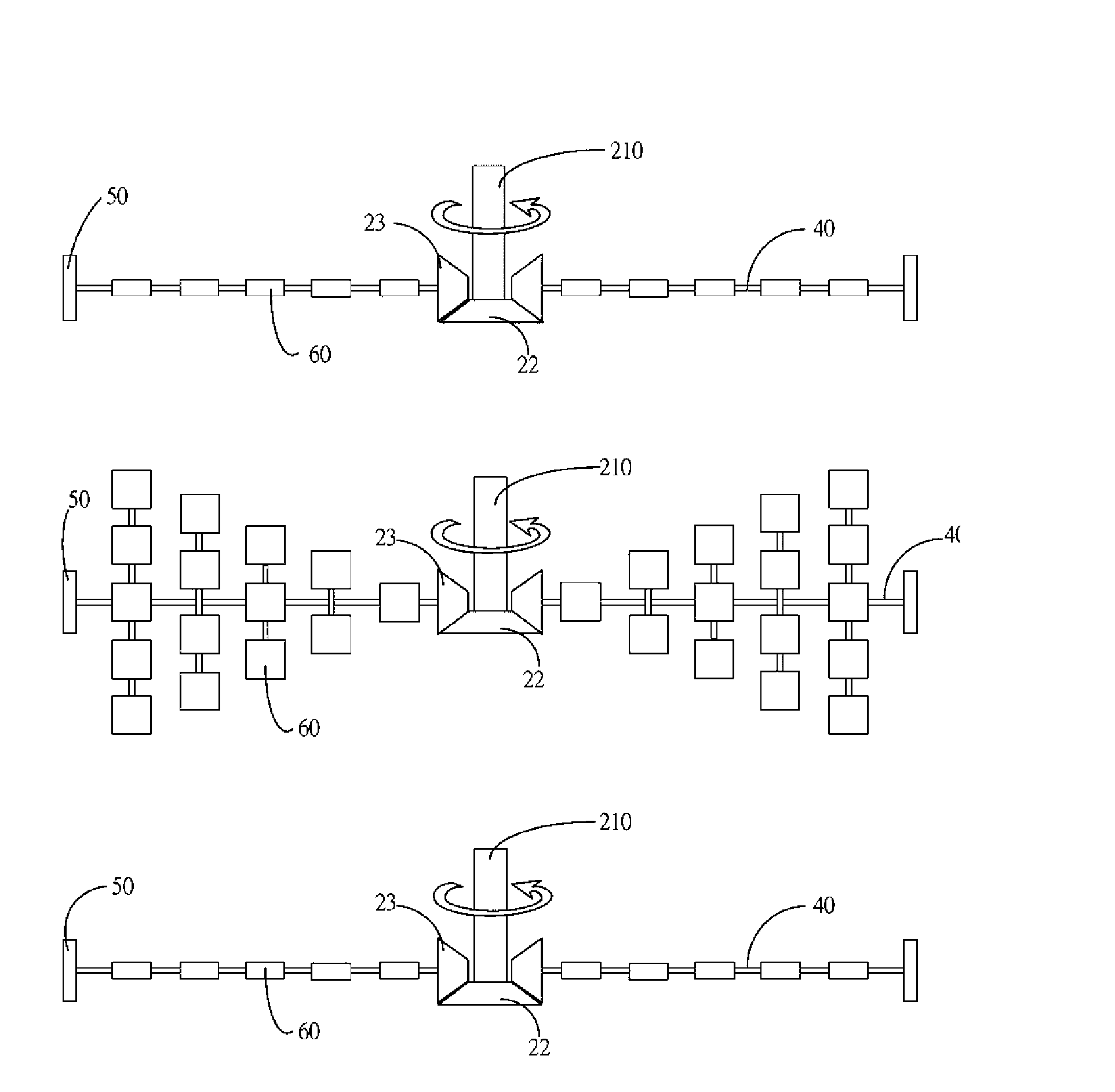

Pulse type shock processing on-line compound injection molding method and its equipment

InactiveCN101077611AIncrease fill ratioImprove interface compatibilityEngineeringFiber-reinforced composite

The present invention discloses pulse type shock reinforced in-line mixing and injecting forming method and apparatus. Pulse type shock is introduced into the whole in-line mixing and injecting forming process of producing fiber reinforced composite polymer material. The apparatus includes one plasticizing extruder with three screws arranged in one line and including one main screw capable of generating periodical axial pulse shock, one buffering storing device, and one pulse type shock pressure reinforcing plunger injecting device. The present invention can lower melt viscosity, raise mixing and homogenizing effect, raise the compatibility between fiber and polymer, lower the processing power consumption and raise product quality.

Owner:SOUTH CHINA UNIV OF TECH

Super plastic forming method for plate type heat converter special titanium plate

InactiveCN101121178AHigh yield strengthEasy to processRoll mill control devicesFurnace typesPlate heat exchangerTitanium

The present invention relates to a superplastic forming method for the titanium plate specially used for the plate type heat exchanger, which belongs to the field of mechanical processing technology. The present invention comprises the following steps that spongy titanium is chosen to be the melted raw material; the spongy titanium is placed in a vacuum plasma smelting furnace to be directly cast into plate base; the plate base forms a plate of a thickness of 2.0 to 2.4 mm after the process of heating, hot rolling, acid and alkali washing; second heating, hot rolling and acid and alkali washing and annealing; the plate of a thickness of 2.0 to 2.4 mm after the annealing in the vacuum smelting furnace forms a titanium plate of a thickness of 0.5 to 0.6 mm after the process of cold rolling, cleaning, second annealing and cold rolling, acid and alkali washing and third annealing. The present invention adopts the process that the spongy titanium which contains oxygen, iron and nitrogen of comparatively high content is directly processed into the titanium plate base in the plasma smelting furnace and directly rolled into the plate without forging and pressing.

Owner:上海桦厦实业有限公司

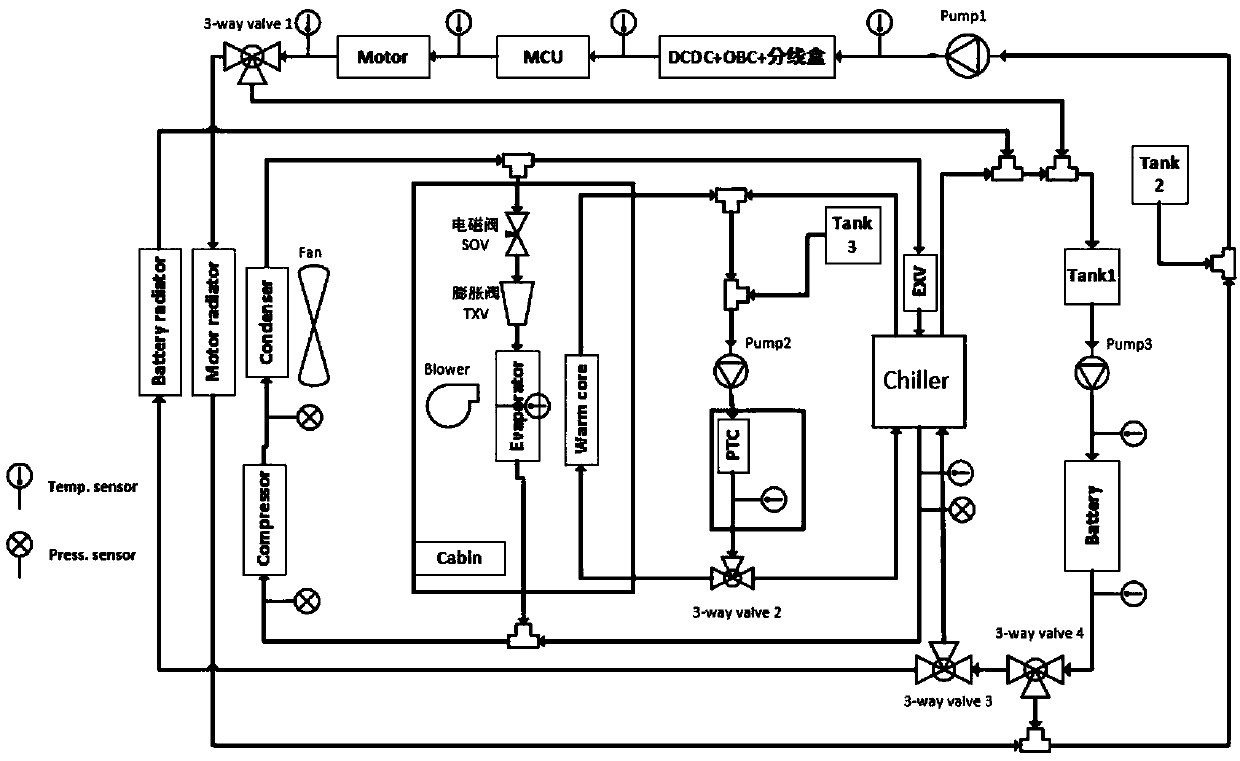

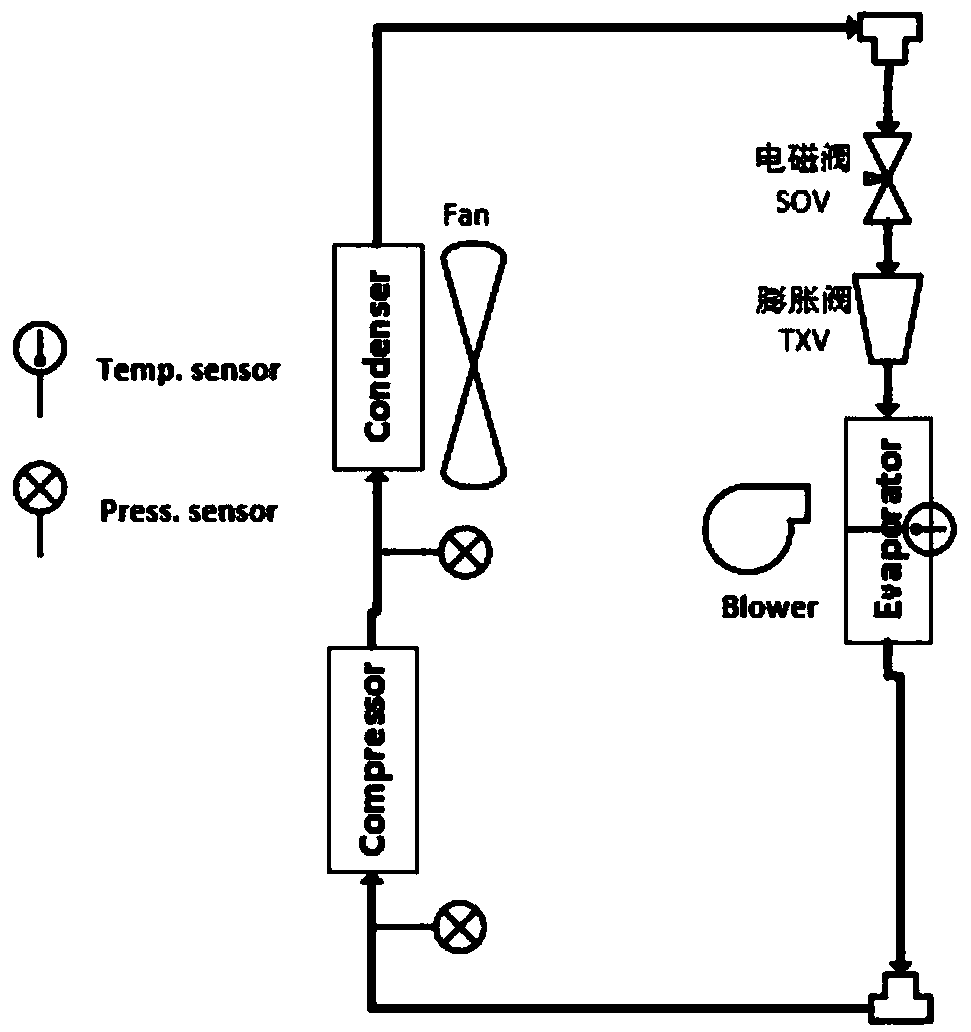

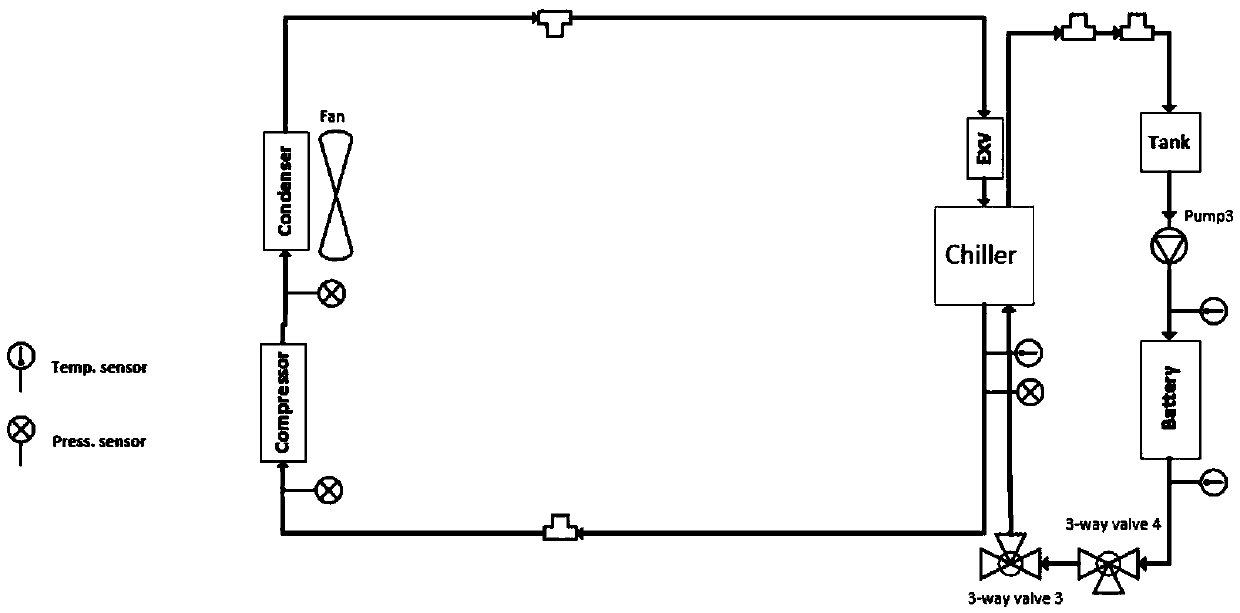

Low-power-consumption heat management system of electric car

InactiveCN109532563AReduce heating effectReduce cooling effectAir-treating devicesSecondary cellsElectrical batterySolenoid valve

The invention relates to an electric car heat management system, in particular to a low-power-consumption heat management system of an electric car. The low-power-consumption heat management system comprises an electric compressor, a condenser, a refrigerant solenoid valve, a thermostatic expansion valve, an HVAC assembly, an electronic expansion valve, a cooler, a first expansion kettle, a thirdelectronic water pump, a fourth three-way valve and a third three-way valve. After the components are combined, a passenger compartment refrigerating cycle loop, a battery forced cooling cycle loop, abattery low-temperature heat radiation cycle loop, a passenger compartment heating cycle loop, a battery forced heating cycle loop, a battery waste heat utilization cycle loop, a battery temperatureequalization cycle loop and a motor cooling cycle loop are formed. According to the low-power-consumption heat management system, the situation that a PTC and the electric compressor are utilized forheating and cooling a battery can be effectively reduced, and therefore the whole car power consumption is reduced, and the driving mileage is increased.

Owner:JIANGSU MINAN AUTOMOTIVE CO LTD

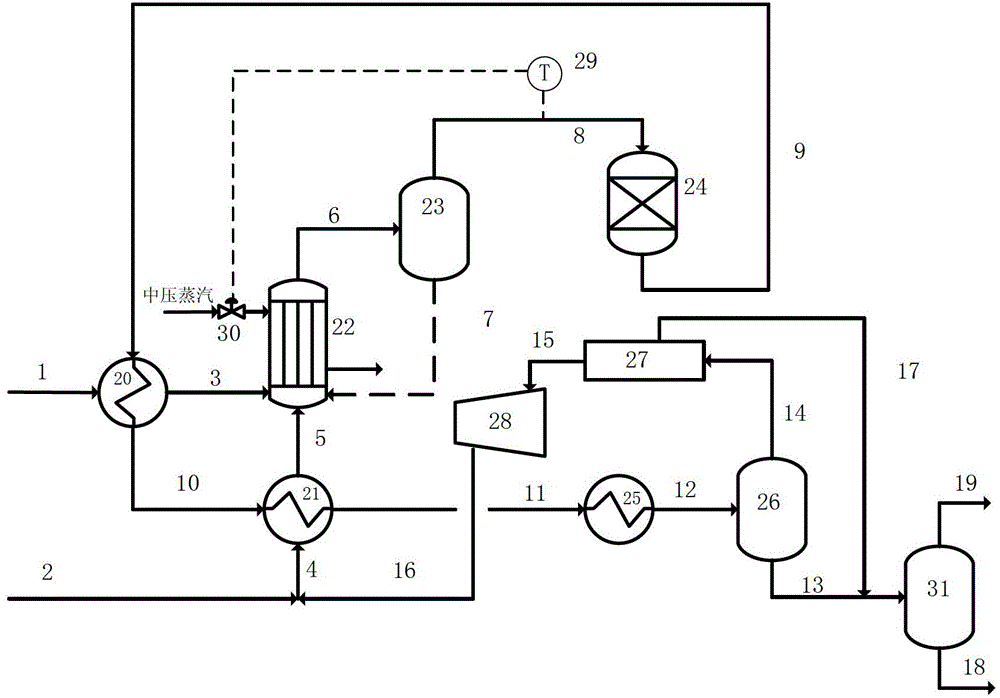

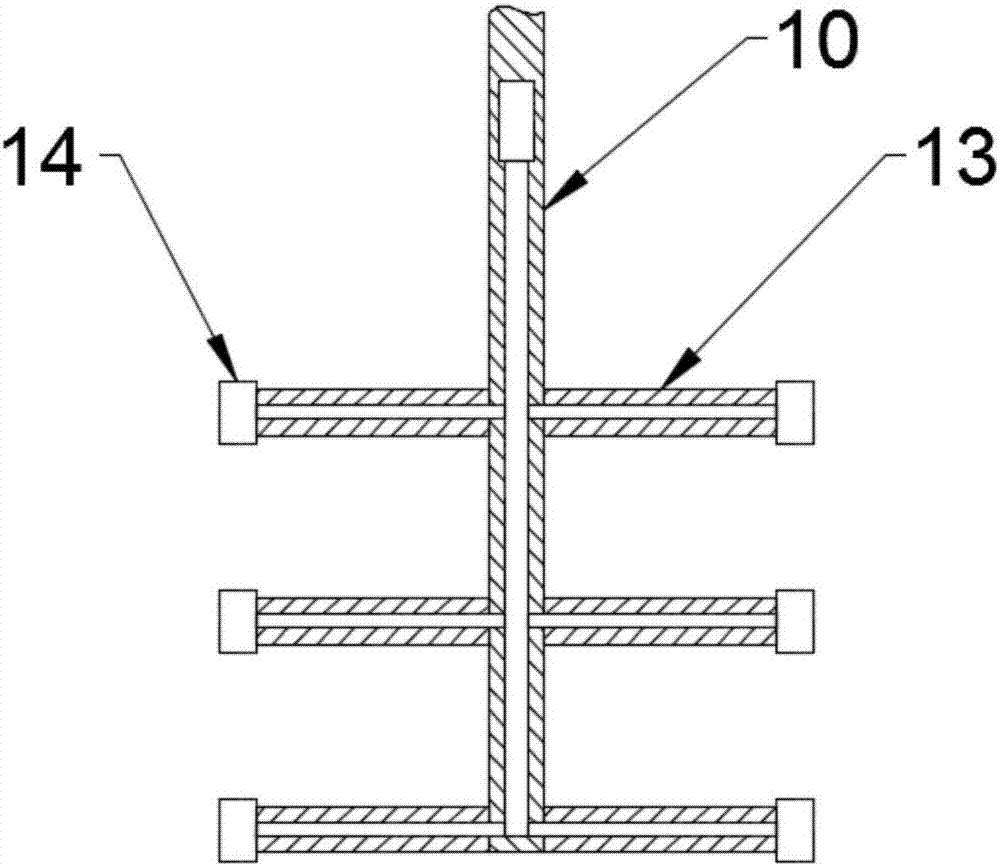

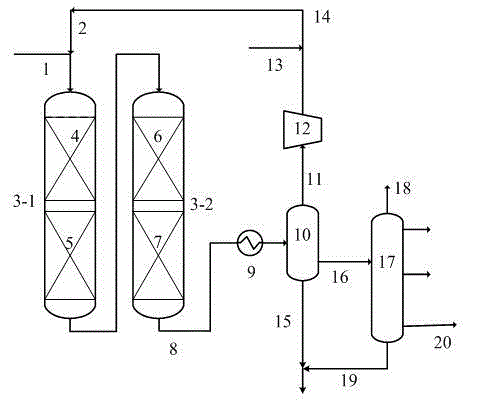

Method for preparing ethanol via hydrogenation of acetic ester based on recirculating of recovered hydrogen

ActiveCN102942446ALow costReduce heating effectOrganic compound preparationEnergy inputGas phaseProduct gas

The invention relates to a method for preparing ethanol via hydrogenation of acetic ester based on recirculating of recovered hydrogen. The method comprises the steps of: recycling hydrogen in the gas phase of a product by using a pressure swing adsorption (PSA) device and then increasing the pressure for recirculating; heating the mixed gas of acetic ester, circulated hydrogen and fresh hydrogen by using reaction heat; heating the preheated raw material gas by medium-pressure steam and then importing into a reactor so as to realize high acetic ester conversion rate and high ethanol selectivity in the presence of a catalyst; and carrying out gas-liquid separation on the product gas obtained via the reaction, and liquefying and separating the reaction principal product ethanol, a small amount of byproducts and unreacted acetic ester to obtain an initial product. According to the method, hydrogen is recycled and recirculated via PSA so that the use of the raw material hydrogen can be greatly reduced, the reaction raw materials are preheated by fully utilizing the reaction heat so that the energy consumption of the heating and the cooling is decreased, the flow is simple and the control is simple and convenient.

Owner:DATANG INT CHEM TECH RESINST

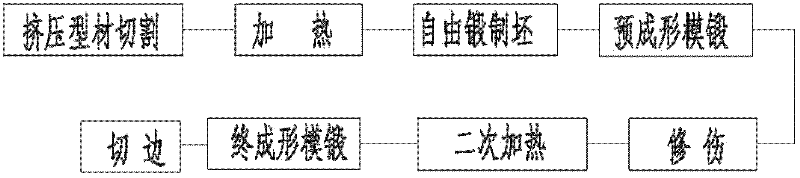

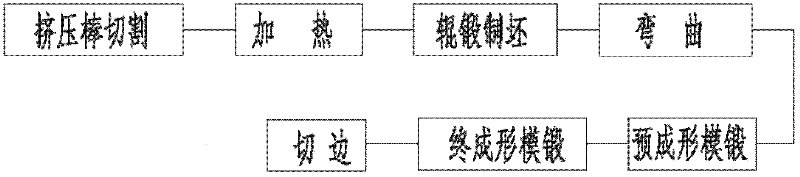

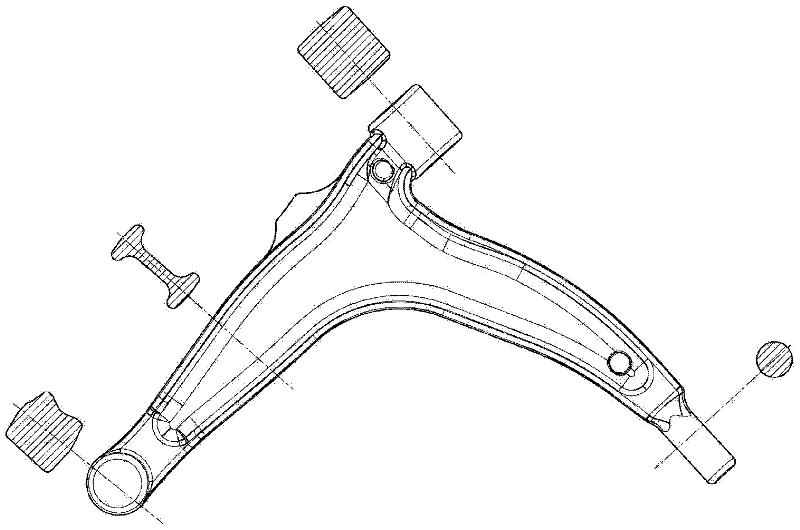

Manufacturing process for lambdoidal control arm

InactiveCN102500740AReduce preprocessing timeIncrease profitRailway componentsMetal-working apparatusProduction rateControl arm

The invention discloses a manufacturing process for a lambdoidal control arm. The manufacturing process comprises the following steps of: sawing an extruded bar; heating the extruded bar; rolling and forging the extruded bar to form a blank; bending to form the blank; preforming a forged die; finally forming the forged die; and trimming the forged die. In the manufacturing process, the extruded bar is taken as a raw material; the blank is heated to 440 DEG C-480 DEG C through electric induction; the blank is rolled and forged twice by a forging roll to realize volume distribution; the processes of bending to form the blank, preforming the forged die and finally forming the forged die are carried in sequence; and the trimming process is carried out in a thermal cutting manner. Compared with the prior art, a repairing process and a secondary heating process are reduced, the processing steps for the lambdoidal control arm are simplified, production cost for the product can be lowered, production rate can be increased, and product performances can be ensured.

Owner:芜湖禾田汽车工业有限公司

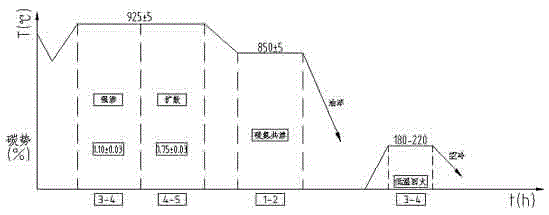

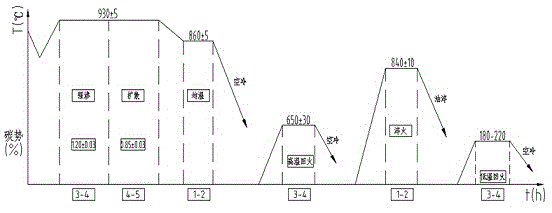

Automobile transmission gear heat treatment method

ActiveCN104894506AAvoid early crackingAlleviate the problem of bulky carbidesSolid state diffusion coatingFatigue IntensityHigh carbon

The invention discloses an automobile transmission gear heat treatment method. The method includes the steps of carburization, carbonitriding, quenching, cleaning, low temperature tempering and air cooling. The carburization technique is combined with the carbonitriding technique, abrasion resistance, fatigue strength and corrosive resistance are improved by a layer of highly hard nitride layer obtained on the carburized layer on the surface of a gear, and comprehensive performance of a product is good; meanwhile, the problems of massive carbide appearing under the high carbon potential state and network carbide appearing in the cooling process are avoided, and early-age cracking of the surface of the gear is avoided; moreover, by the method, the technological process is simplified, heating and cooling links and discharge links are reduced, carburization deformation and quenching deformation are reduced, generation of black structures is reduced as well, and anti-fatigue performance is guaranteed; finally, by the method, production cycle is shortened greatly, energy consumption is lowered, and production efficiency is improved highly.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Method for preparing hollow steel ingot for protection ring of large power generator by adopting electroslag remelting

ActiveCN104164574AIncrease profitReduce heating timesCasting parameters measurement/indication devicesTransformerProtection ring

The invention discloses a method for preparing a hollow steel ingot for a protection ring of a large power generator by adopting electroslag remelting. The method comprises the following steps: (1) preparing consumable electrode groups; (2) melting slag into liquid molten slag; (3) inserting the consumable electrode groups into an electroslag remelting hollow ingot crystallizer; (4) starting two transformers; (5) injecting the liquid molten slag into the electroslag remelting hollow ingot crystallizer; (6) when the consumable electrode groups are in contact with the liquid molten slag, forming an electrifying loop among fake electrodes, the consumable electrode groups and a bottom water tank; (7) when the liquid molten slag is in contact with an upper section, forming a loop among the upper section, the bottom water tank and the transformers connected with the bottom water tank; (8) adjusting the output currents and voltages of the two transformers; (9) when a metal melt is in contact with a molten steel liquid level detection device, starting an ingot stripping device for ingot stripping; (10) exchanging the consumable electrode groups; and (11) inserting subsequent consumable electrode groups into the liquid molten slag, and repeating the steps (8 to 10) until the ingot stripping is finished.

Owner:NORTHEASTERN UNIV LIAONING

Circulating tin plating process and device

The invention relates to the technical field of tin plating of copper wires, in particular to a circulating tin plating process and device. The circulating tin plating process comprises the following steps of: setting speed and stabilizing speed and tension in a tension buffer area; annealing in a high-temperature annealing area at high temperature; initially cooling in an annealing and cooling area; pre-plating tin in an inlet tin heating area; finally plating tin in an outlet tin heating area; scraping residual tin by using a tin plating mold for sizing; protecting reducing gas to deoxidize liquid tin and protecting a wire rod from being oxidized; cooling a hot plated tin wire with water; scraping water on the tin-plated wire with rubber; scraping water and possible tin beads by using a mold; drying residual water by using a drier; cooling the tin-plated wire to room temperature by using a cooling wind scoop; and rolling into a finished product, and the like. By adopting the circulating tin plating process, the product quality of the tin-plated wire is ensured, use of a soldering flux causing pollution can be avoided, noble rare earth metals are avoided or reduced, a large amount of electric energy is saved, waste of tin dross is reduced, operation is simplified and concealed danger of quality is reduced.

Owner:周开勇

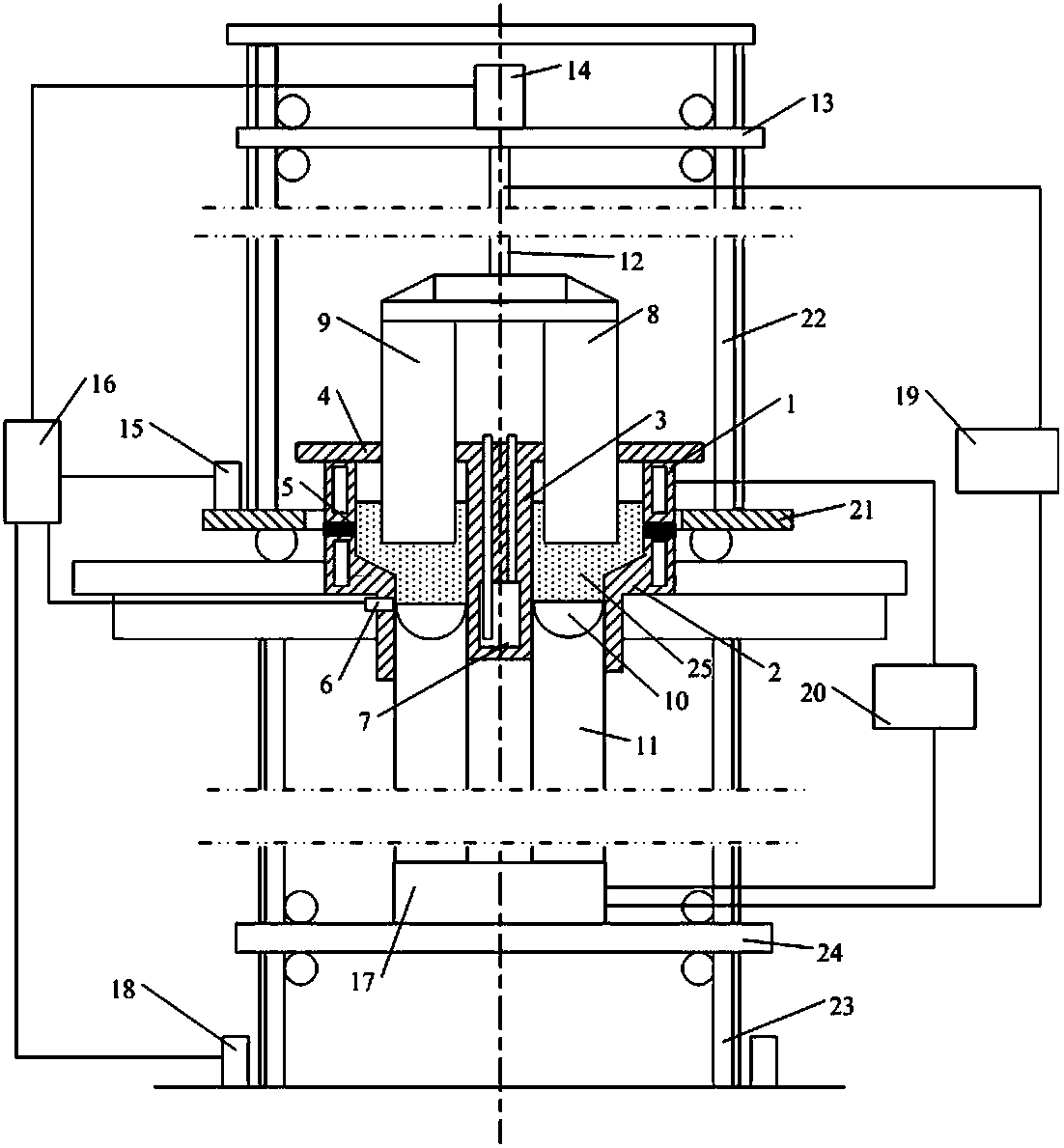

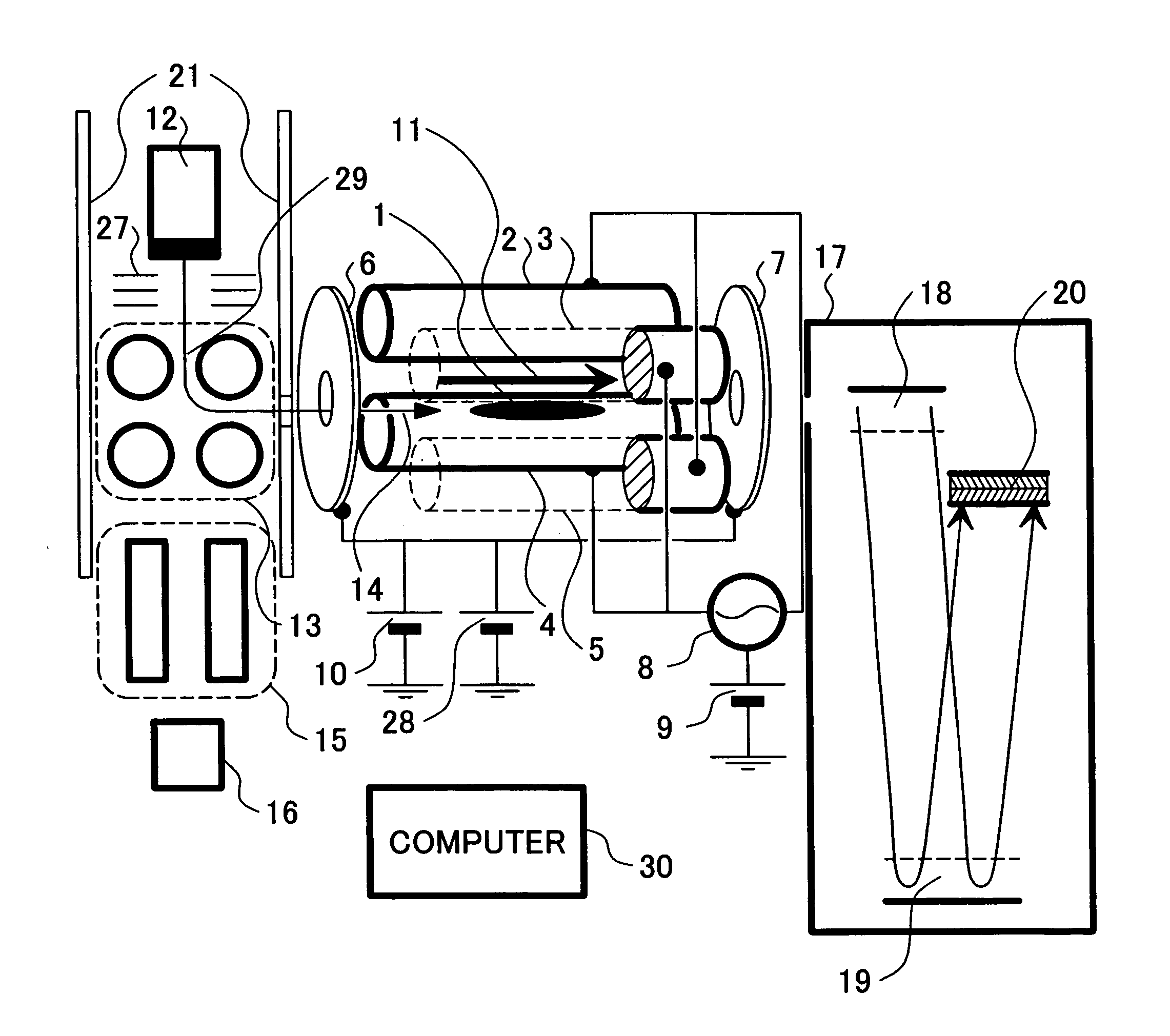

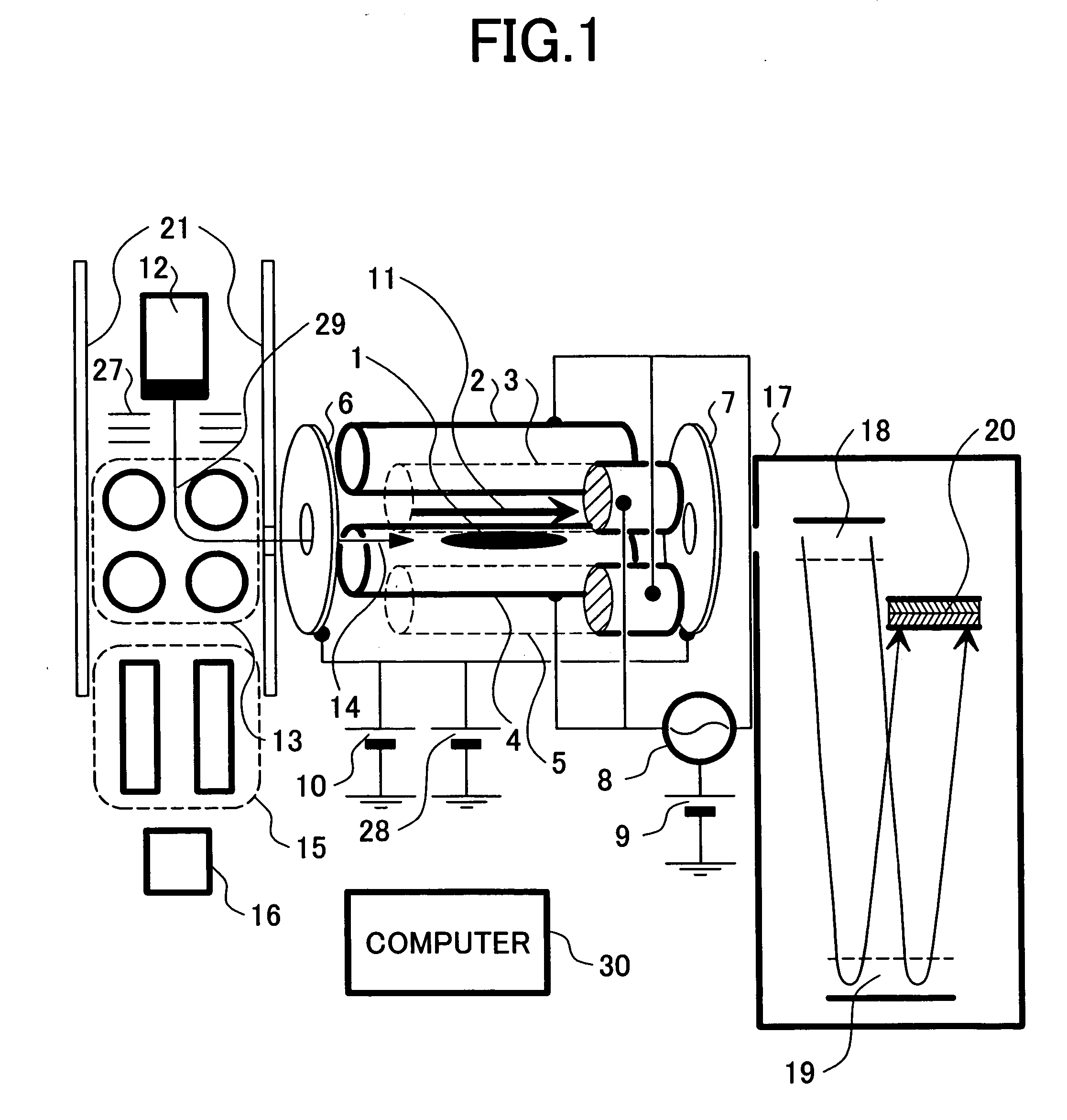

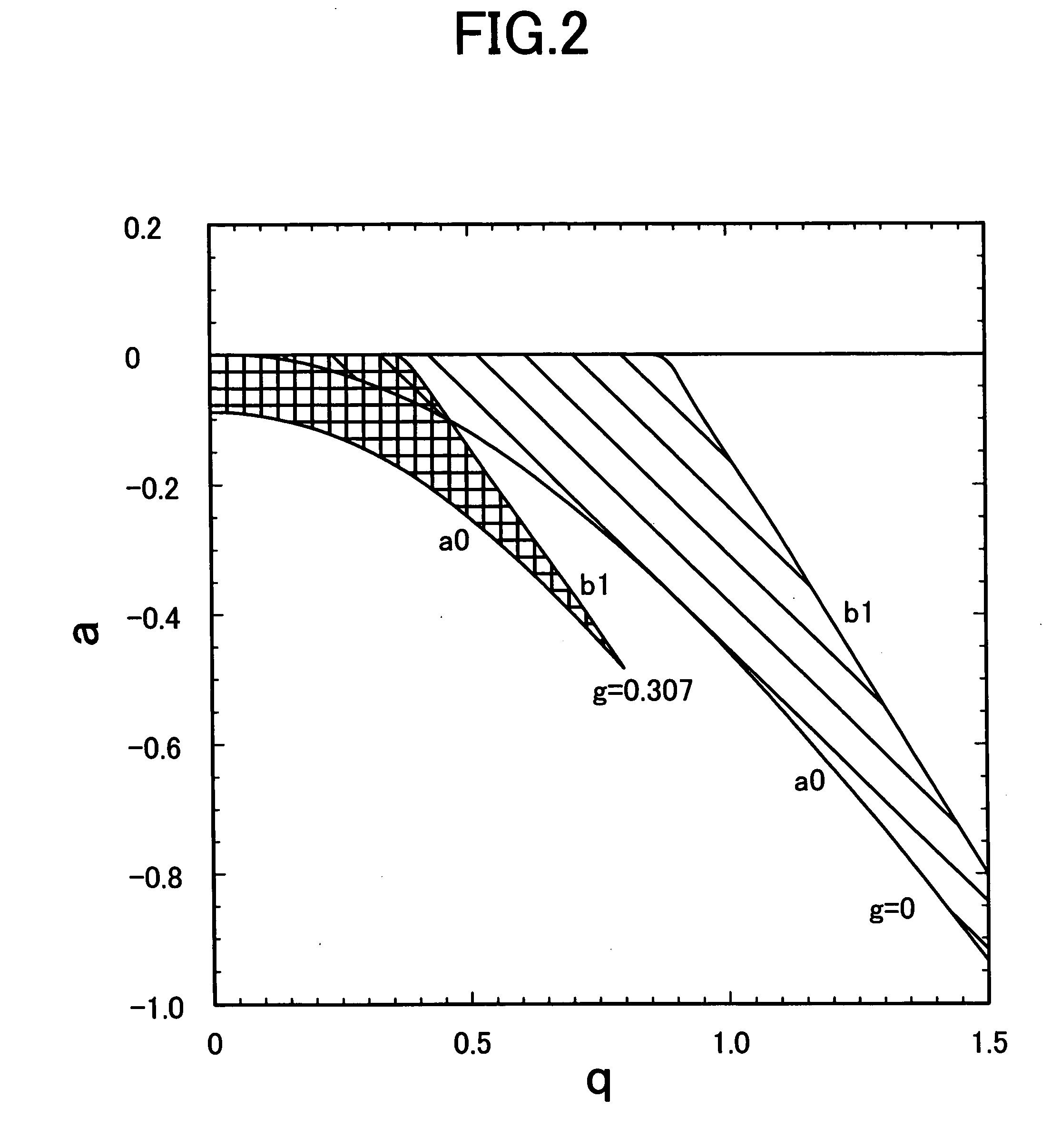

Mass spectrometer

ActiveUS20050178955A1Reduce radio frequency amplitudeReduce heating effectStability-of-path spectrometersTime-of-flight spectrometersRadio frequencyIon trap mass spectrometry

The present invention provides a mass spectrometry capable of high-efficiency and high-throughput ECD. An electron source and a two-dimensional combined ion trap in which a magnetic field along and generally parallel to a central axis is applied are used, thereby to achieve the foregoing object. First, precursor ions are trapped. By adopting the two-dimensional combined ion trap, it is possible to obtain a high ion trapping efficiency upon being injected and trapping. Subsequently, electrons are made incident thereon in such a manner as to be wound along the central axis to which no radio frequency is applied by using a magnetic field. For this reason, it is possible to allow energy-controlled electrons to reach the precursor ions. It is possible to implement a mass spectrometer capable of avoiding heating due to a radio frequency electric field, and effecting high-throughput / high-efficiency ECD.

Owner:HITACHI HIGH-TECH CORP

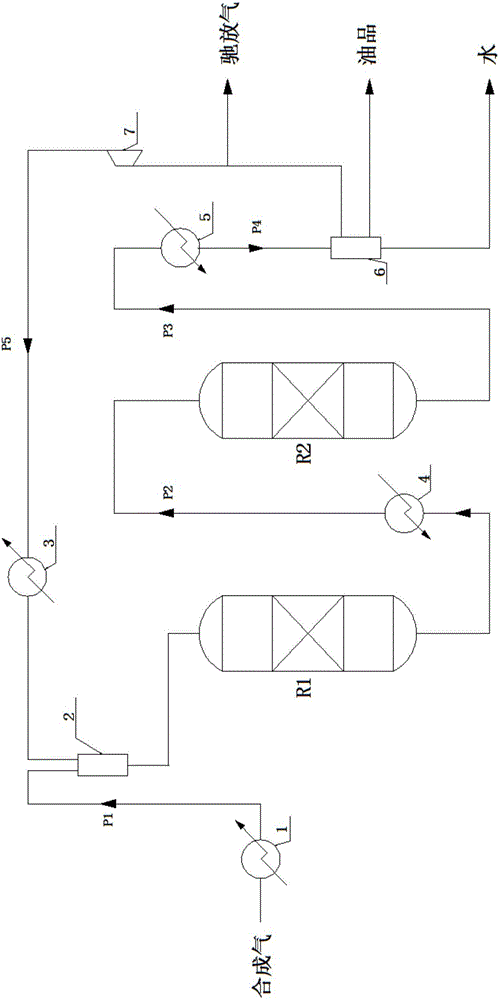

Combination process for producing aromatic hydrocarbon from synthetic gas

ActiveCN106518591AWith characteristicsHave made significant progressOrganic compound preparationMolecular sieve catalystGas phaseOil phase

The invention relates to a combination process for producing aromatic hydrocarbon from synthetic gas. According to the combination process, synthetic gas is pre-heated, the pre-heated synthetic gas enters a buffer tank and is mixed with circulation gas, the obtained mixed gas enters a fixed bed reactor R1, a methanol synthesis reaction is performed, the outlet gas is cooled and then enters a fixed bed reactor R2, an aromatization reaction is performed, the outlet gas is cooled with a cooler and then enters a gas-oil-water three-phase separator, the separated water phase is discharged and enters a wastewater system, the oil phase is collected as the product, one part of the gas phase is pressurized through a circulation compressor, the pressurized gas phase is heated and then enters the buffer tank, and the other part of the gas is adopted as the Chi-deflated gas. The combination process of the present invention has advantages of low energy consumption, easy operation, and low equipment investment.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI +1

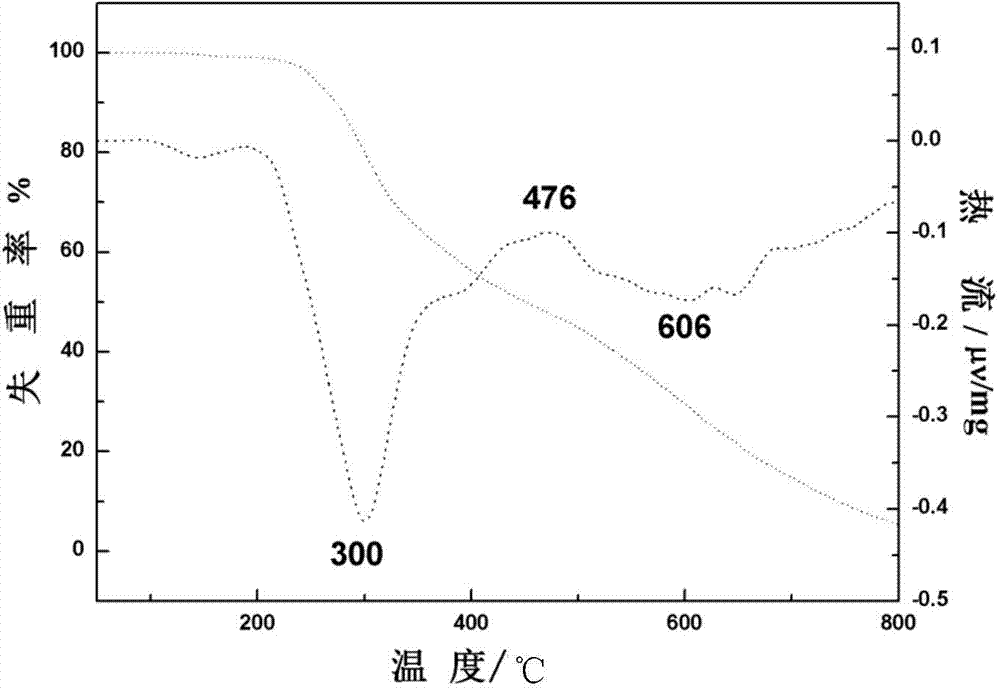

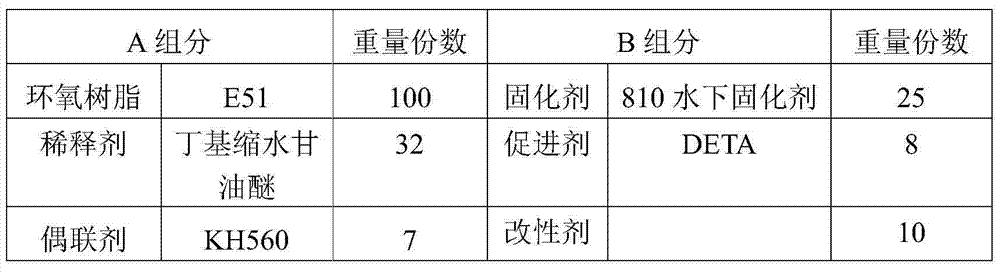

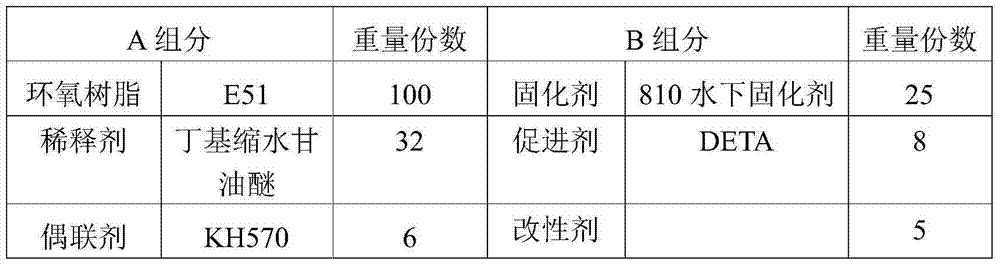

Room-temperature cured high-temperature-resistant epoxy resin plugging material and preparation method thereof

InactiveCN104726047AHigh tensile strengthImprove shear performancePolyureas/polyurethane adhesivesEpoxy resin adhesivesExtensibilityAccelerant

The invention discloses a room-temperature cured high-temperature-resistant epoxy resin plugging material and a preparation method thereof, and belongs to the technical field of material preparation. The plugging material is composed of a part A and a part B, wherein the part A comprises epoxy resin, a diluent, a coupling agent, and packing; the part B comprises a curing agent, an accelerant, and a modifying agent, and the modifying agent is a polyurethane prepolymer prepared by reacting isocyanate with polyether polyol. The preparation method comprises the following steps: uniformly mixing the epoxy resin with the reactive diluent and the coupling agent so as to obtain the part A; uniformly mixing the curing agent with the compound accelerant, adding the modifying agent, and uniformly stirring, so that the part B is obtained; and when in use, pouting the part B into the part A, uniformly mixing at room temperature, and curing the obtained product to plug a position required to be plugged. The plugging material prepared according to the invention is simple in preparation process, strong in operability, wide in application, good in shearing property and high in tensile strength at high temperature, short in curing time at room temperature, and good in extensibility and toughness, and the maximum thermal decomposition temperature can reach 275 DEG C.

Owner:JILIN UNIV

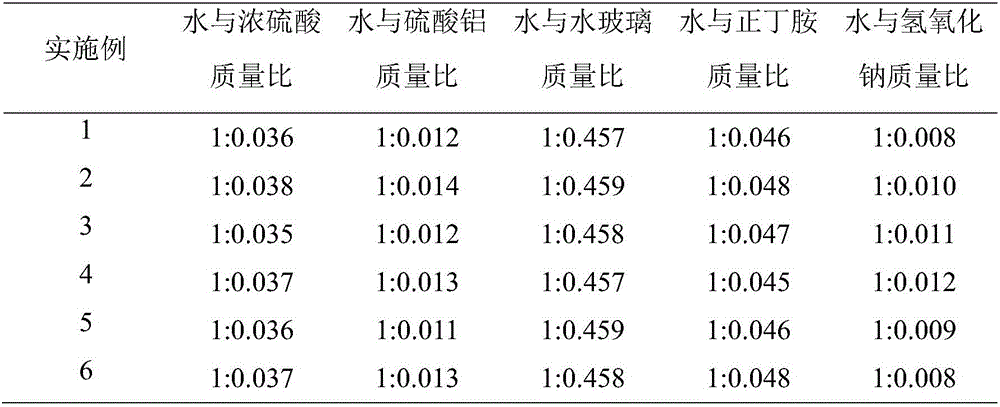

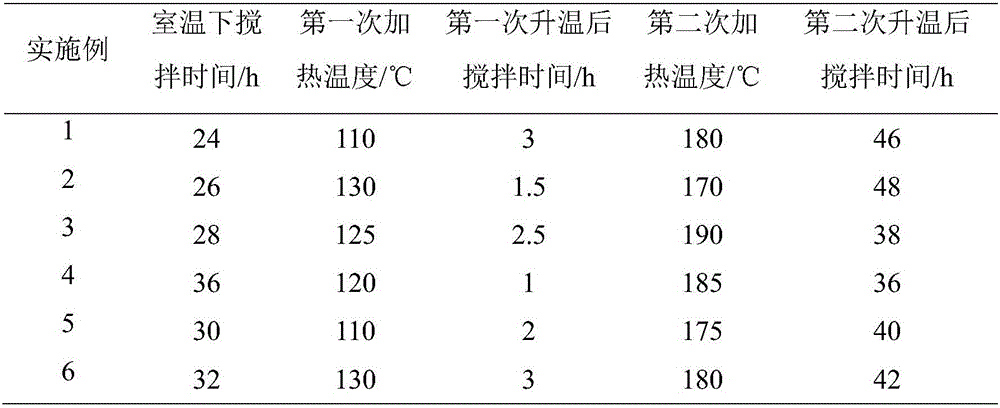

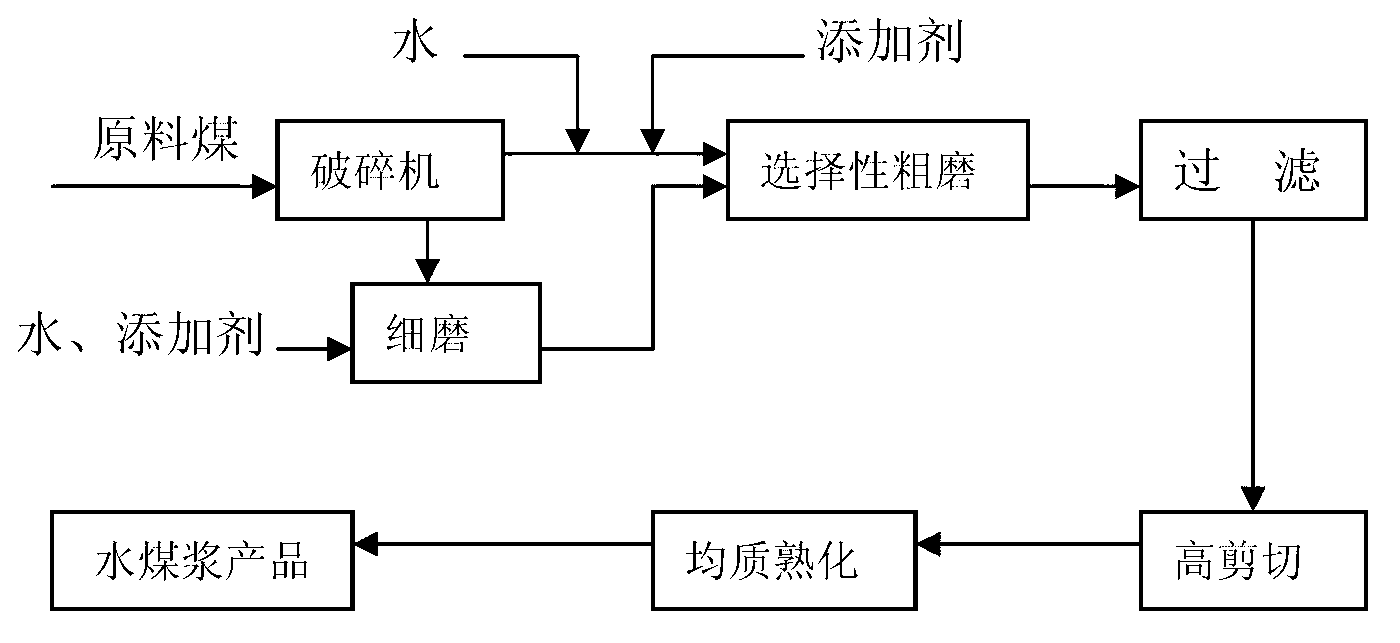

Gasified water-coal-slurry and preparation method thereof

ActiveCN103305297AOptimize particle size distributionImprove stacking efficiencyLiquid carbonaceous fuelsCoal slurryHigh concentration

The invention discloses a preparation method of gasified water-coal-slurry. The method comprises the following steps: (1) crushing low-rank coal to pulverized coal, wherein the grain diameter of the pulverized coal is less than 13mm; (2) inputting pulverized coal a to a roughing machine, and adding an additive and water to carry out high concentration pulping; (3) inputting pulverized coal b to an atomizer mill, adding an additive and water and grinding to prepare water-coal-slurry, wherein the mass concentration of the water-coal-slurry is 40-45% and the granularity of the water-coal-slurry is less than 40 mu m; and (4) inputting the water-coal-slurry prepared in the step (3) to the roughing machine in the step (2), and grinding to obtain the gasified water-coal-slurry. According to the preparation method disclosed by the invention, the original graded grinding process, i.e., after all coal passing through the crusher enters into the roughing machine to carry out ore grinding, part of crushed coal is directly fine-grinded and then enters into the roughing machine carry out mixed ore grinding is changed, so that not only is coal slurry granularity distribution of the atomizer mill more suitable for granularity distribution of gasified coal slurry, but also the grinding load increased by 10-30% caused by repeated grinding of the roughing machine is reduced. Therefore, the grinding energy consumption is further reduced.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

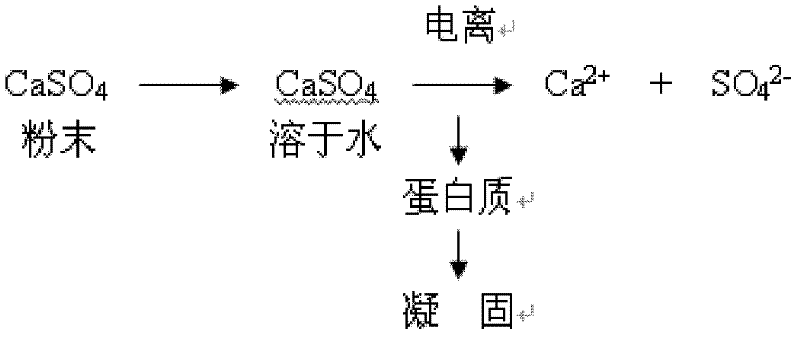

Production method for boxed bean curd and boxed bean curd

ActiveCN102550698AEnergy savingReduce energy consumptionCheese manufactureMilk substitutesChemistrySoybean oil

The invention discloses a production method for boxed bean curd and the boxed bean curd. The production method for the boxed bean curd comprises the following steps of: boiling soybean milk by taking soybeans as raw materials; controlling the temperature of the boiled soybean milk to be above 85 DEG C; mixing the boiled soybean milk with a coagulating agent; and filling the mixture into a packing container; keeping the temperature of mixed milk of the soybean milk and the coagulating agent in the packing container for 10 to 30 minutes; and solidifying to form the boxed bean curd. The production method has a scientific process and simple steps. According to the production method, defects in the prior art are overcome, a solidification process of the soybean milk can be more effectively controlled, industrialized production can be really realized, and the aims of reducing energy consumption to a great extent, simplifying equipment and diversifying varieties are fulfilled, and boxed lactone bean curd and boxed southern bean curd and northern bean curd which fit conventional taste can be prepared.

Owner:FOODSTUFF INST BEIJING

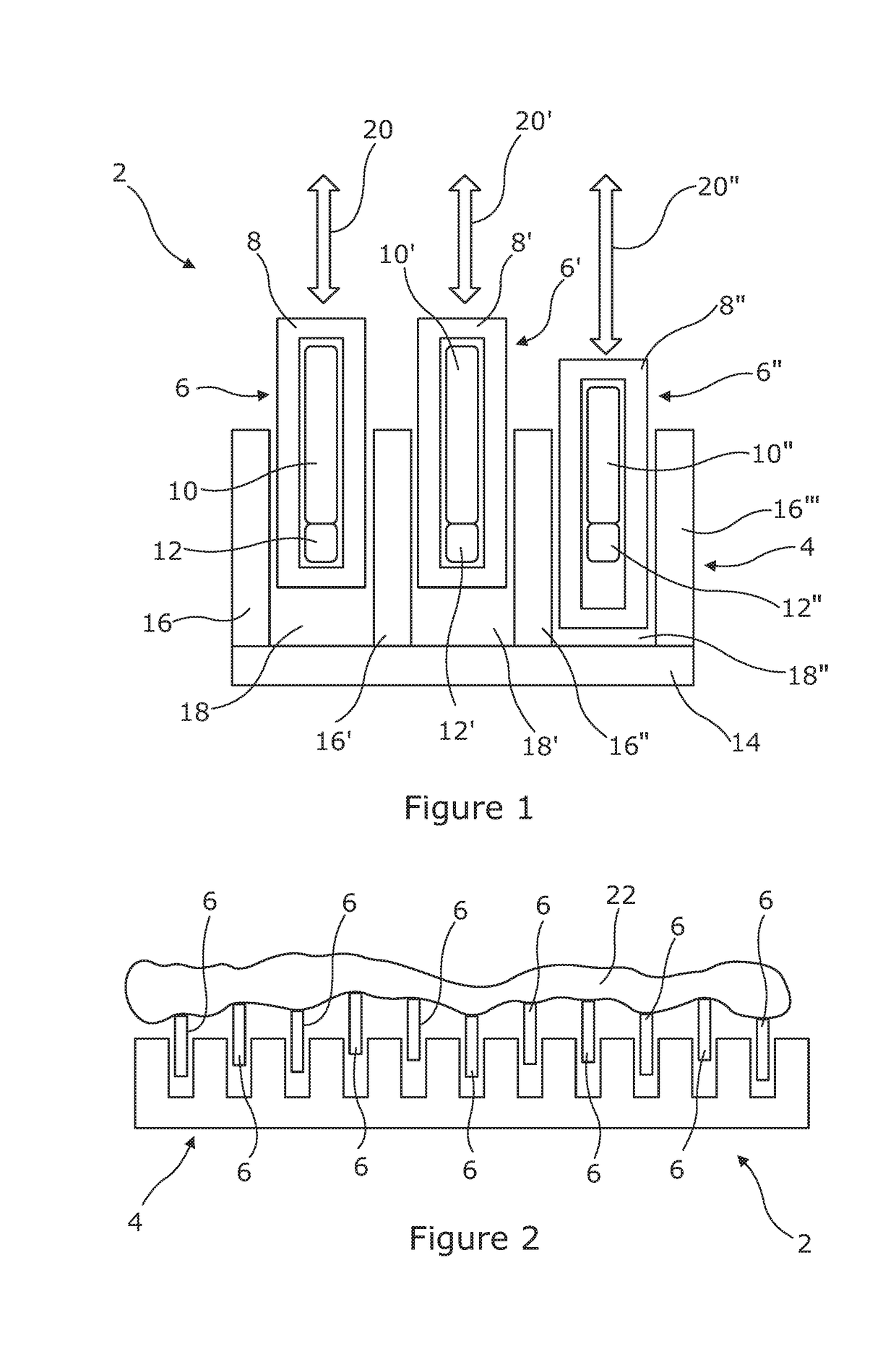

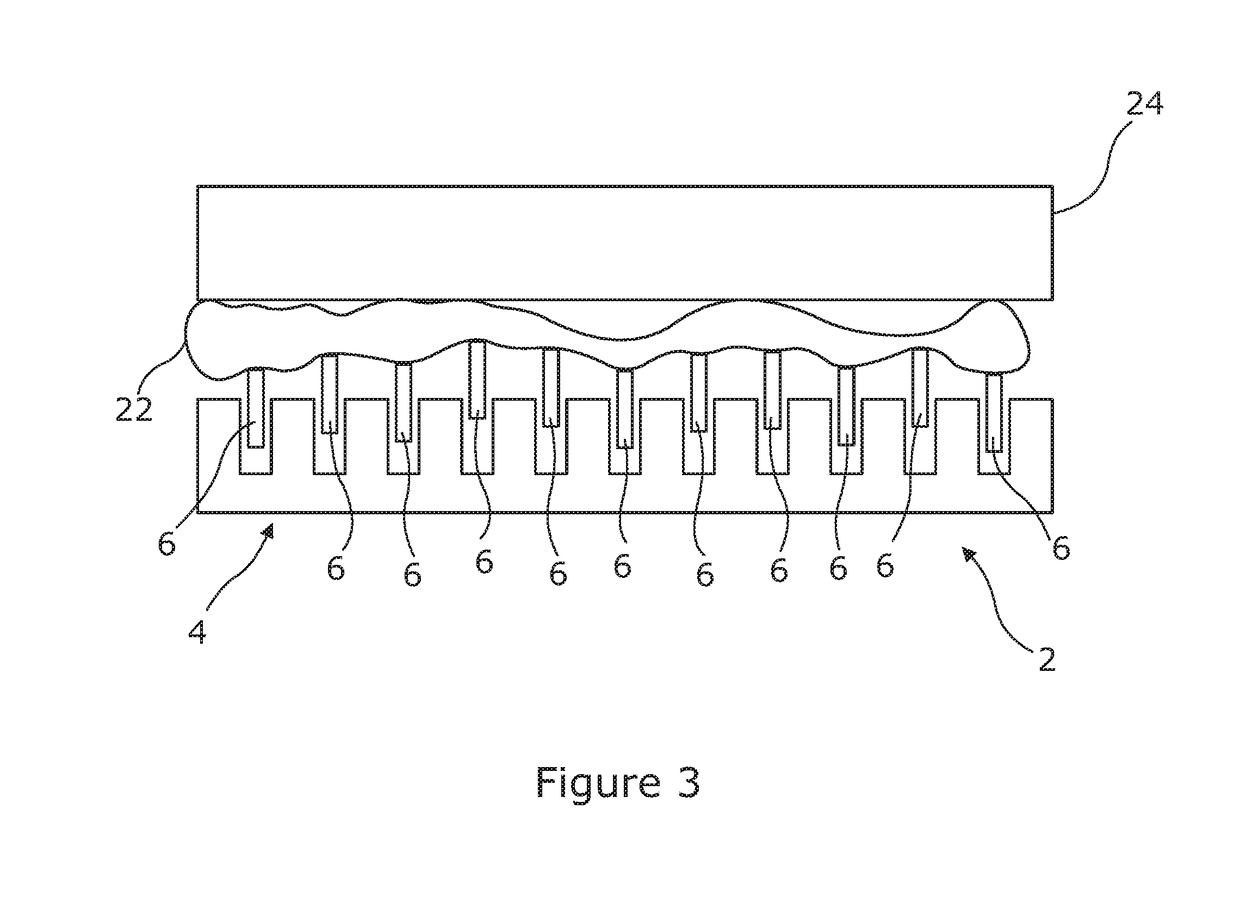

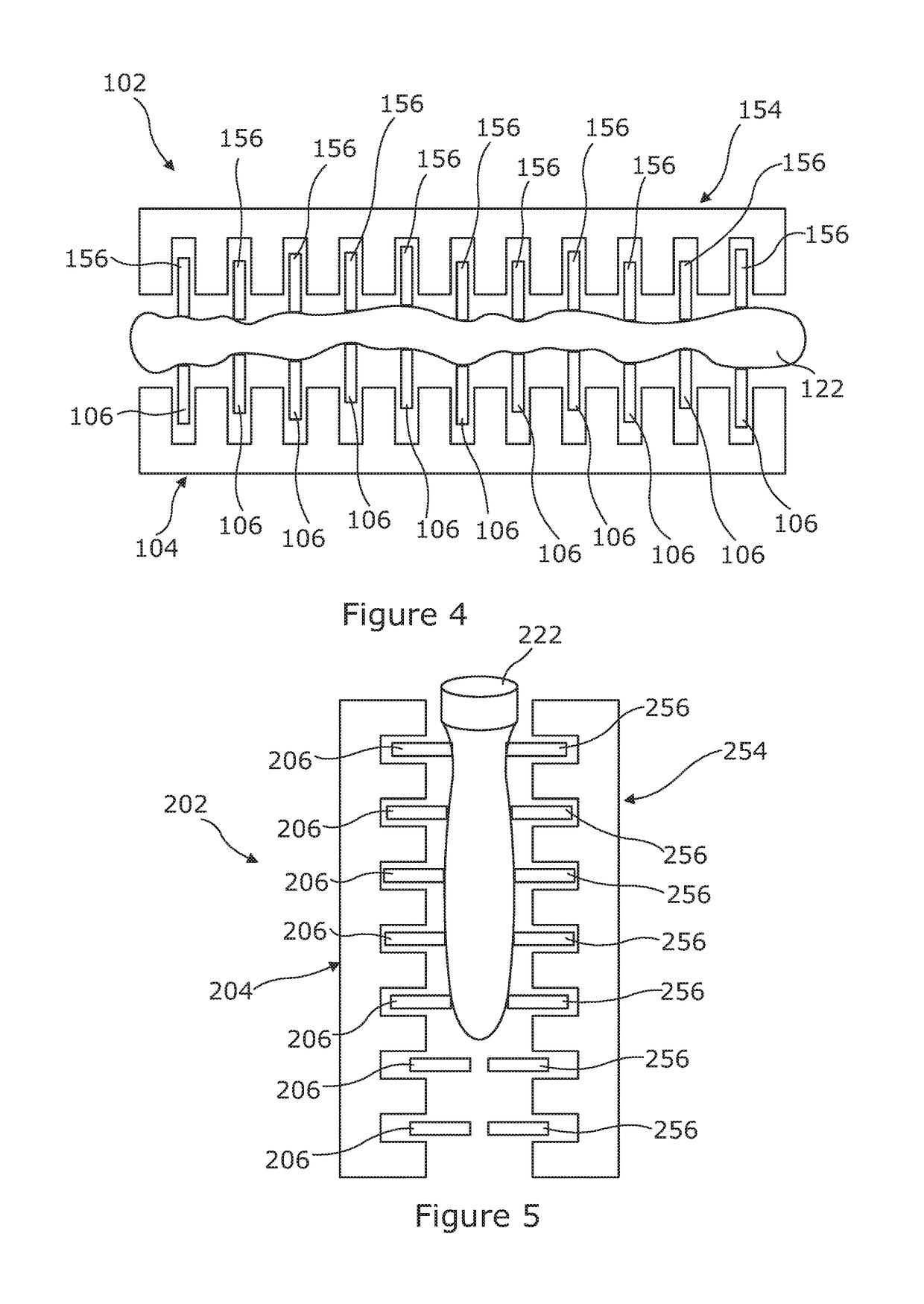

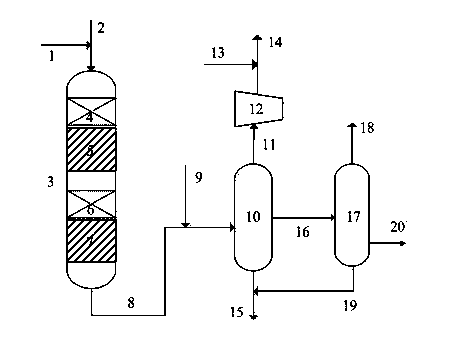

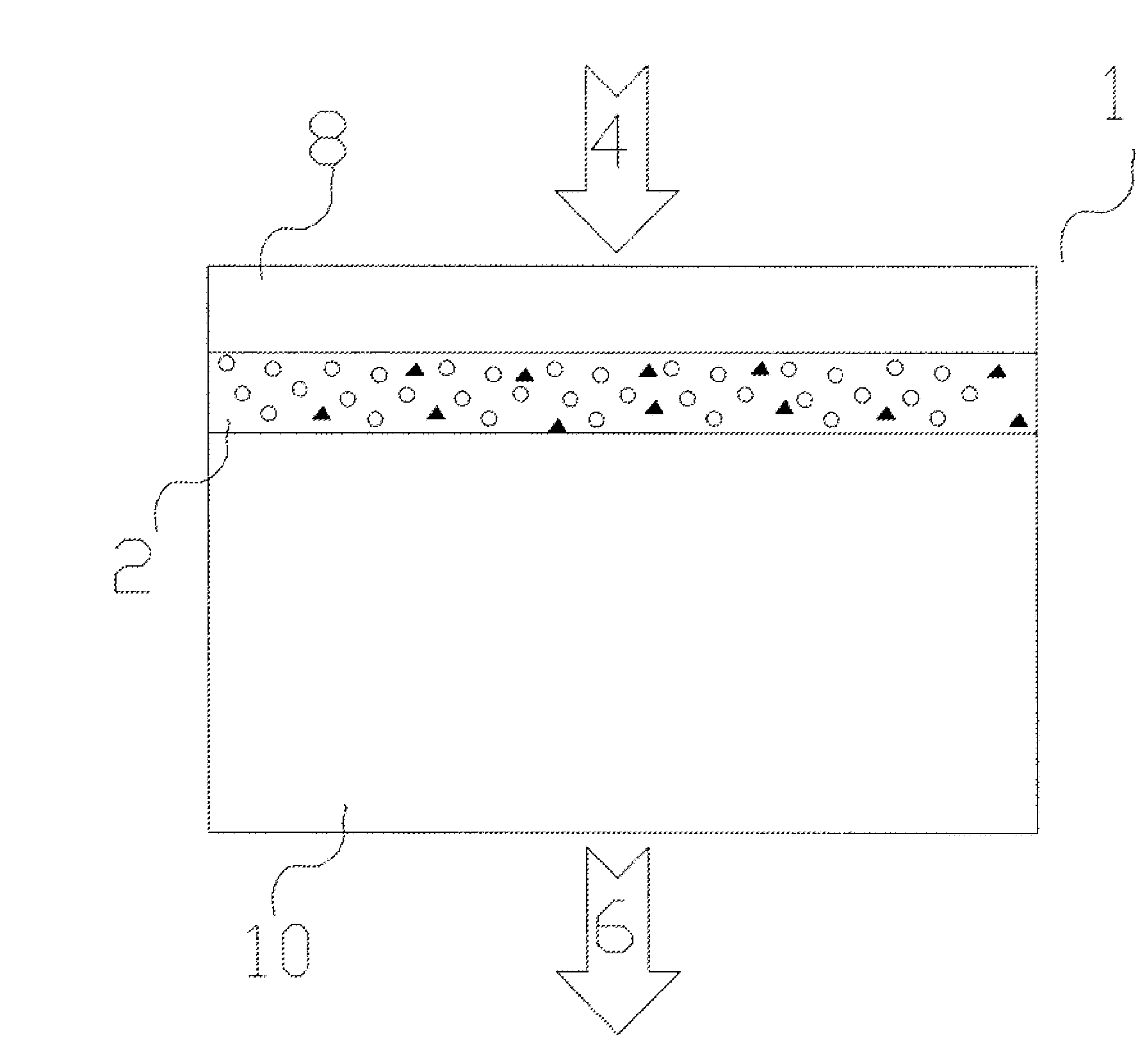

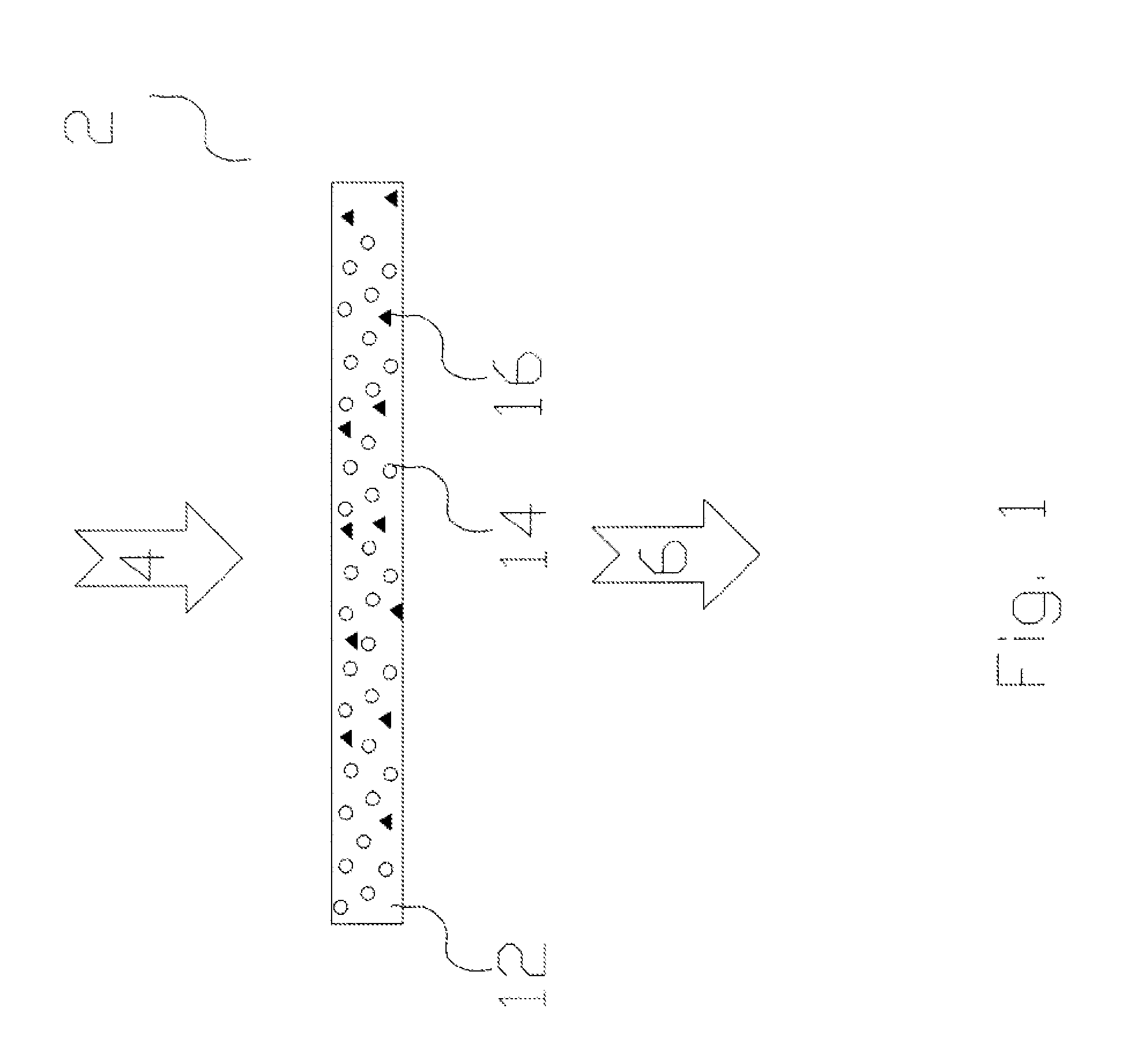

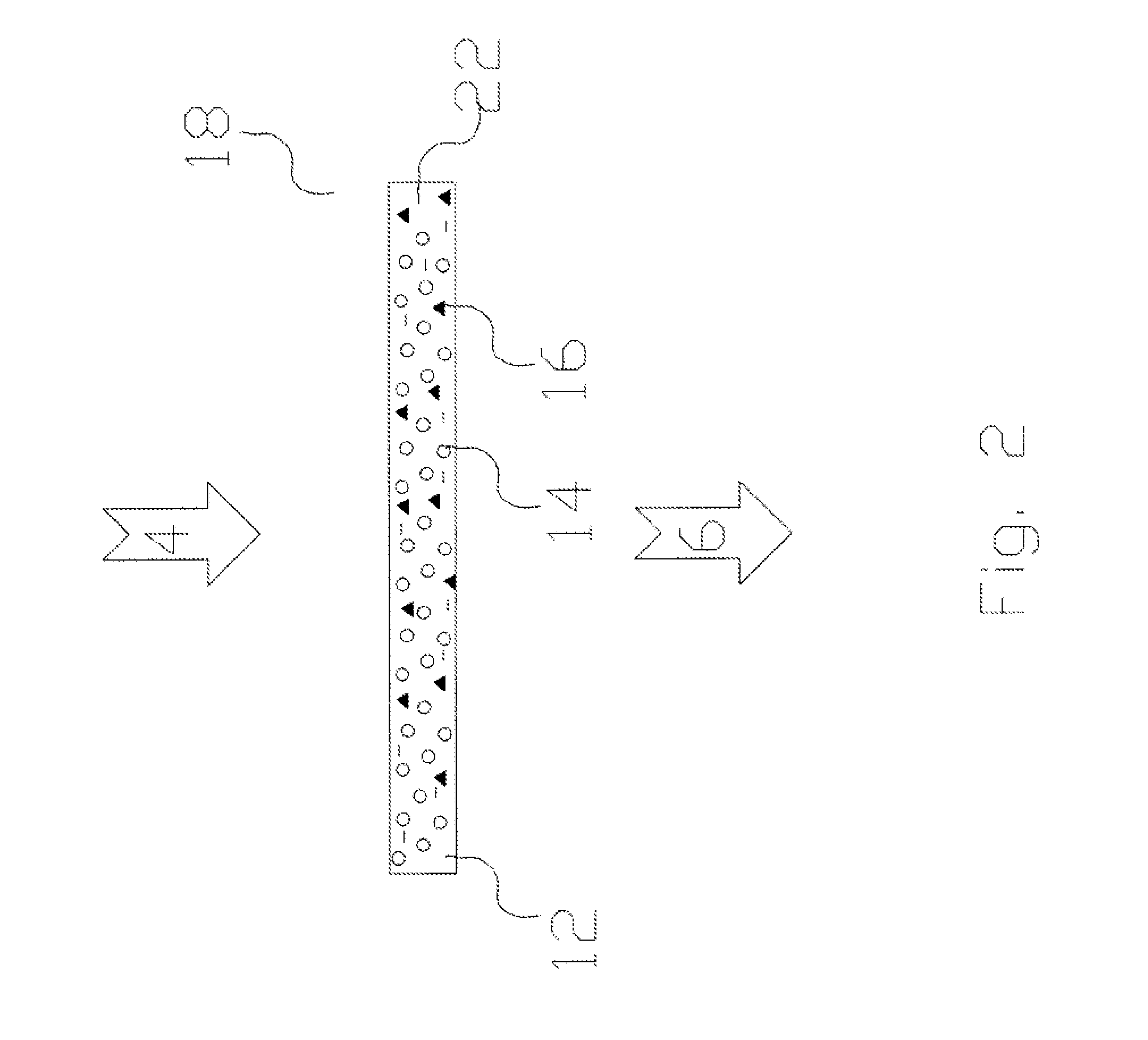

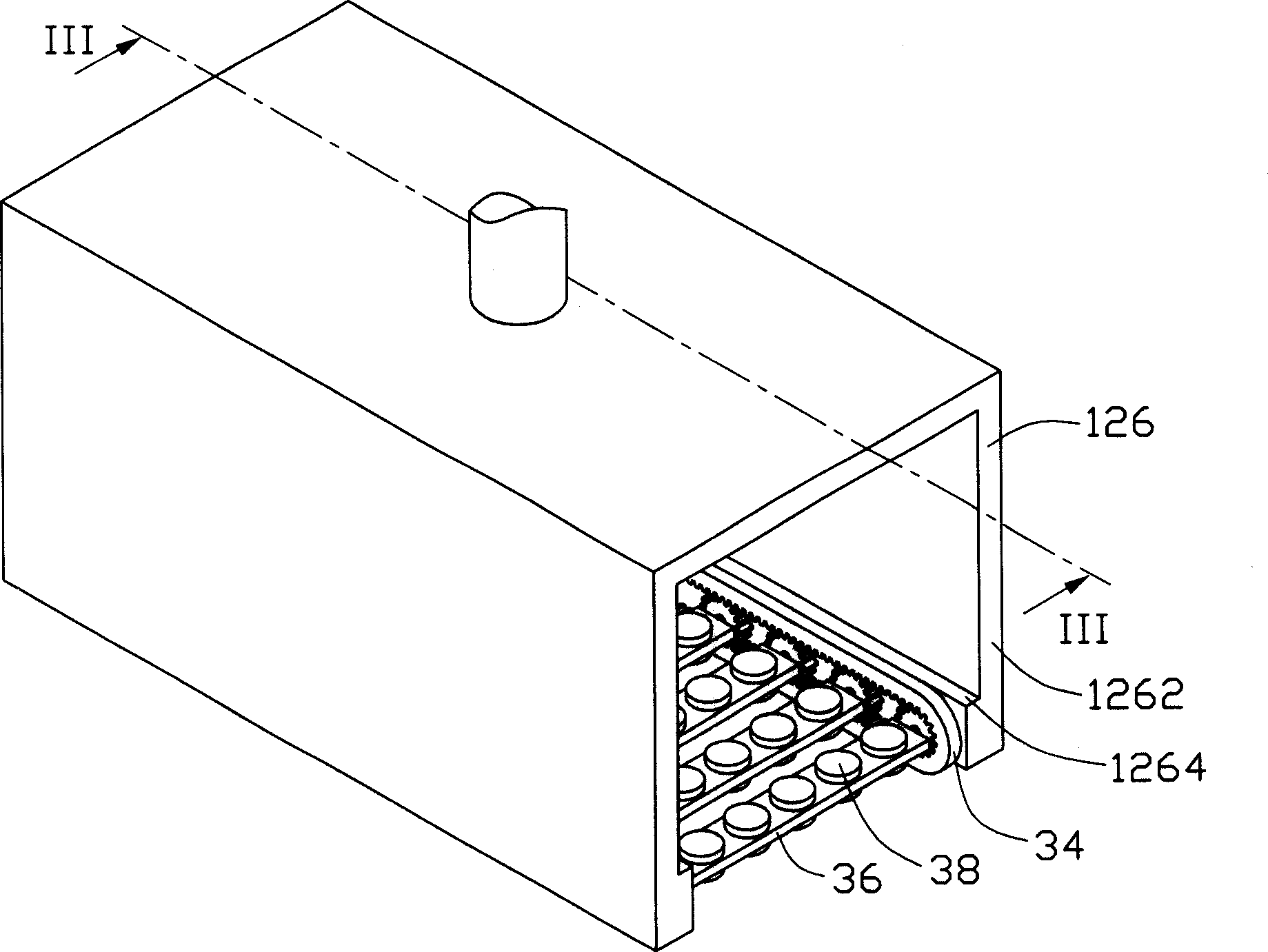

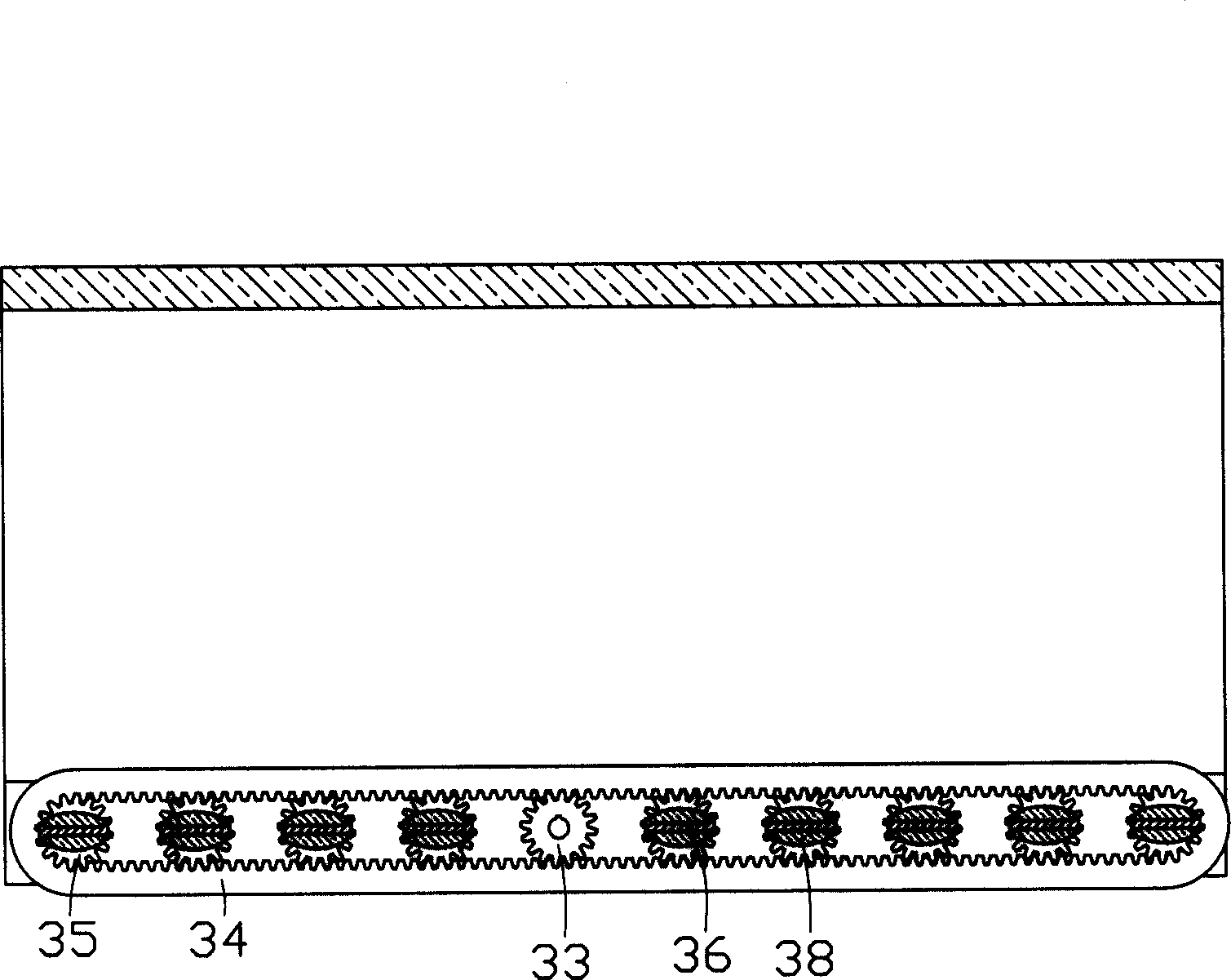

A device and method for heating or cooling a sample

ActiveUS20190075786A1Enhanced agitationImprove the heating effectHeating or cooling apparatusBiological substance pretreatmentsThermal energyCooling curve

A sample heating / cooling device comprises a plurality of members operable in use to heat and / or cool one or more samples. Each member has a sample contact surface and is biased towards a resting position under the operation of a biasing means. The members are movable independently of one another against said bias under the application of a force on the sample contact surface and so are able to conform to the shape of a sample placed on the members to provide a uniform heating / cooling profile. The members may be mounted in a heating / cooling element and adapted to conduct thermal energy between the sample and the element. The device is particularly suitable for thawing frozen sample bags having an irregular shape. A corresponding method is also described.

Owner:CELL THERAPY CATAPULT

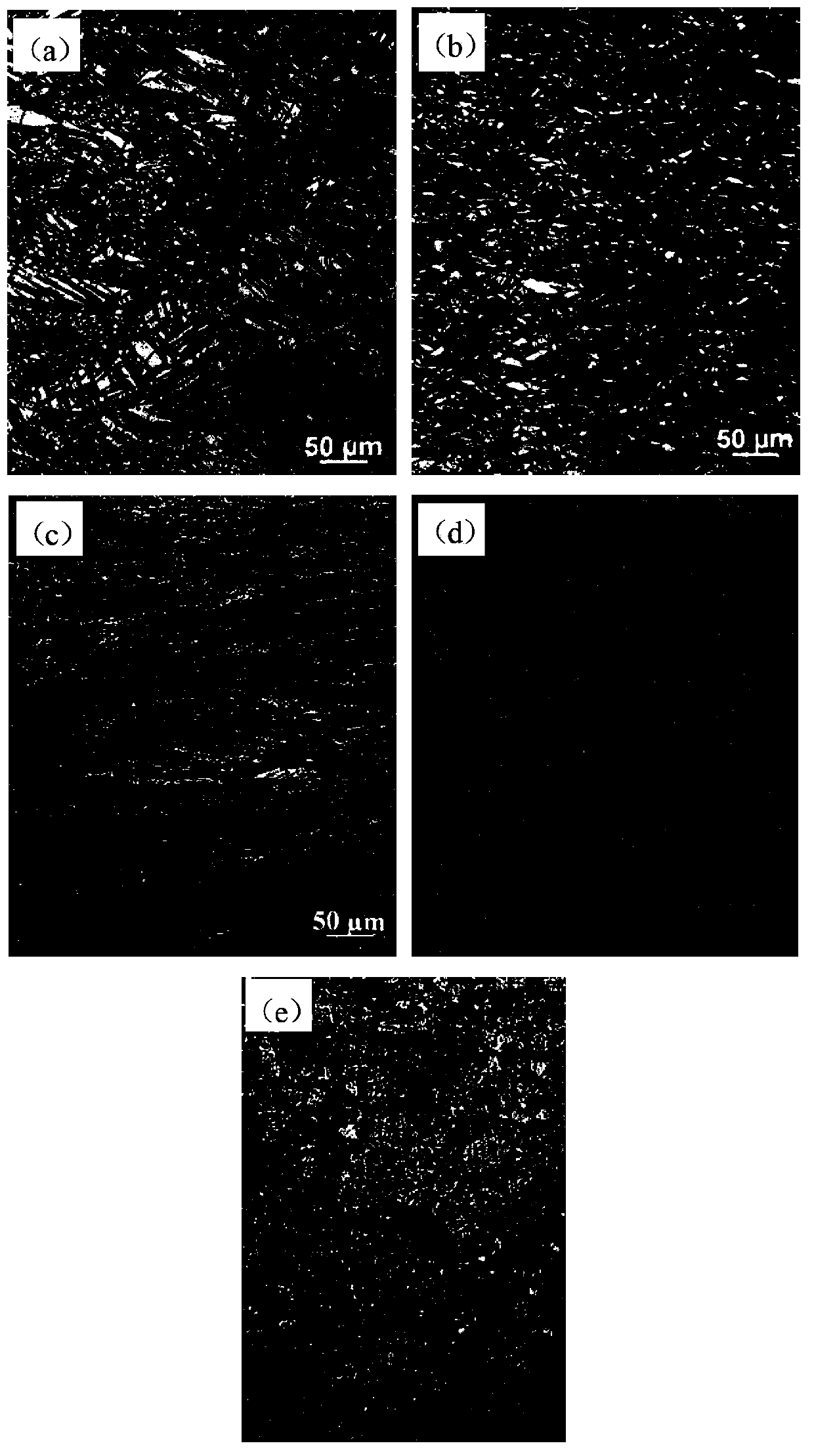

Magnesium alloy sheet with low Gd content and high ductility and malleability, and hot rolling technology thereof

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

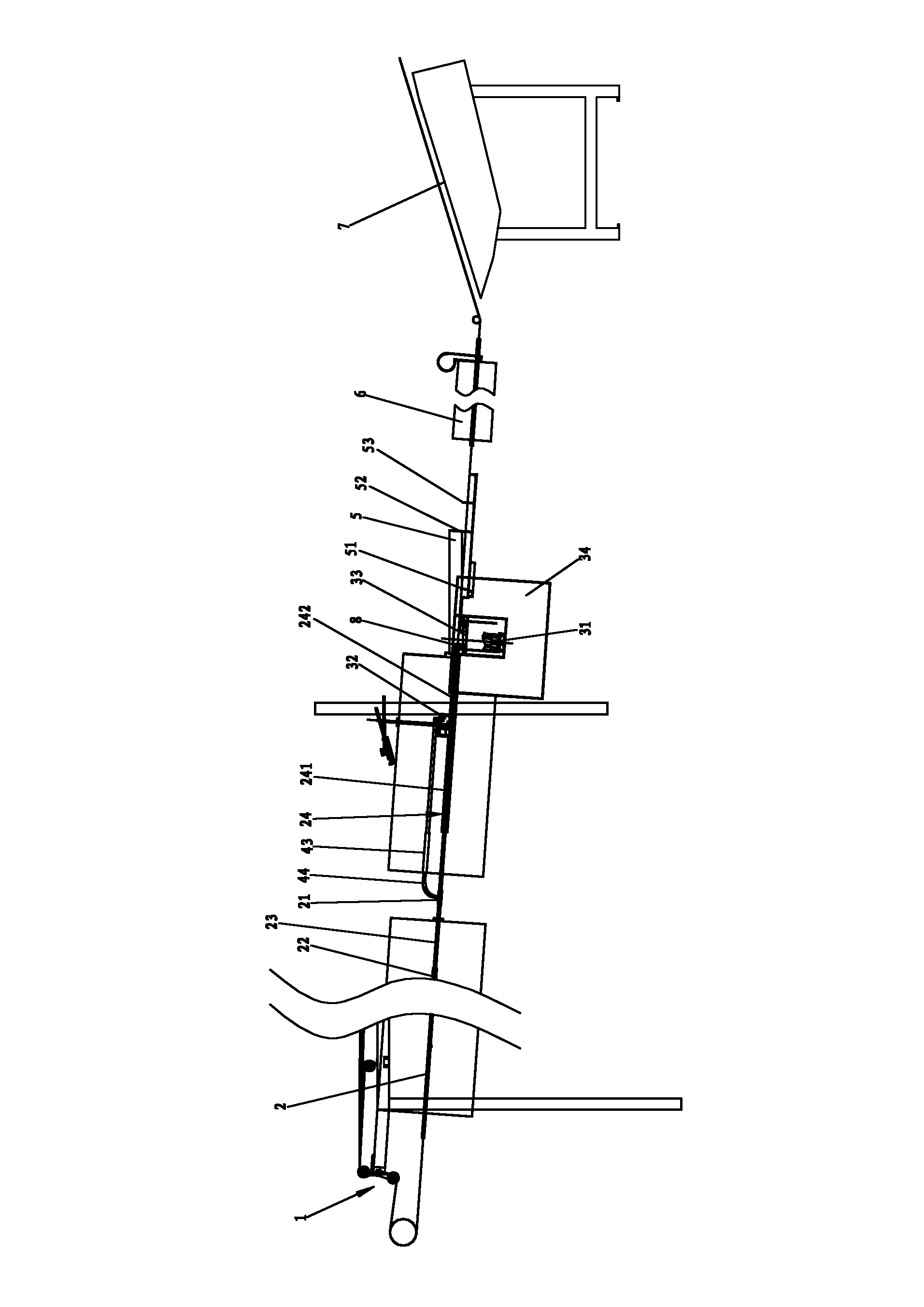

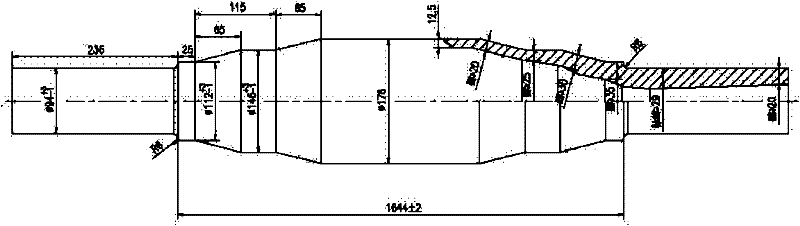

Method for forming rear axle whole by rapid extrusion

ActiveCN102240688AReduce the number of heating times and forming stepsSimple processSteel tubeIntermediate frequency

The invention discloses a method for forming a rear axle whole by virtue of rapid extrusion. The method comprises the following steps of: firstly simultaneously heating the two ends of a seamless steel tube blank in an intermediate frequency heating furnace, wherein the heating temperature is gradually reduced from the end part of the blank to the middle part of the blank; then carrying out extrusion forming on the heated tube blank twice to reach required deflection, thus the shape of the end part of the blank and the wall thickness meet requirements of a drawing, a once-heating and twice-extrusion process is realized, the number of times for heating the blank and the forming procedures are reduced, the technological process is simplified, the quality of a forge piece is improved, and the efficiency of a production line is improved. Quantity of production equipment of the production line is reduced, the investment is saved, and the energy consumption is reduced.

Owner:BEIJING RES INST OF MECHANICAL&ELECTRICAL TECH

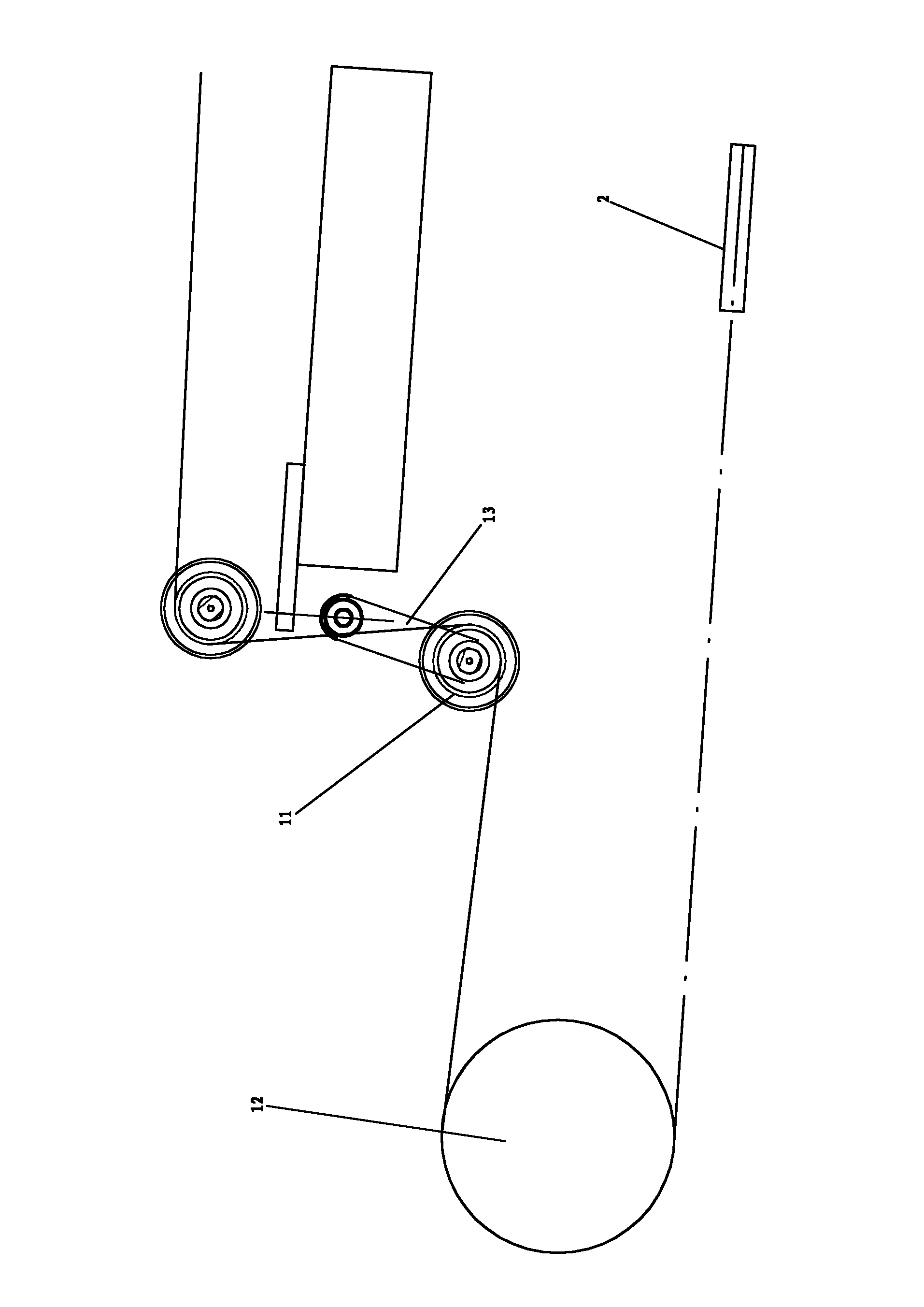

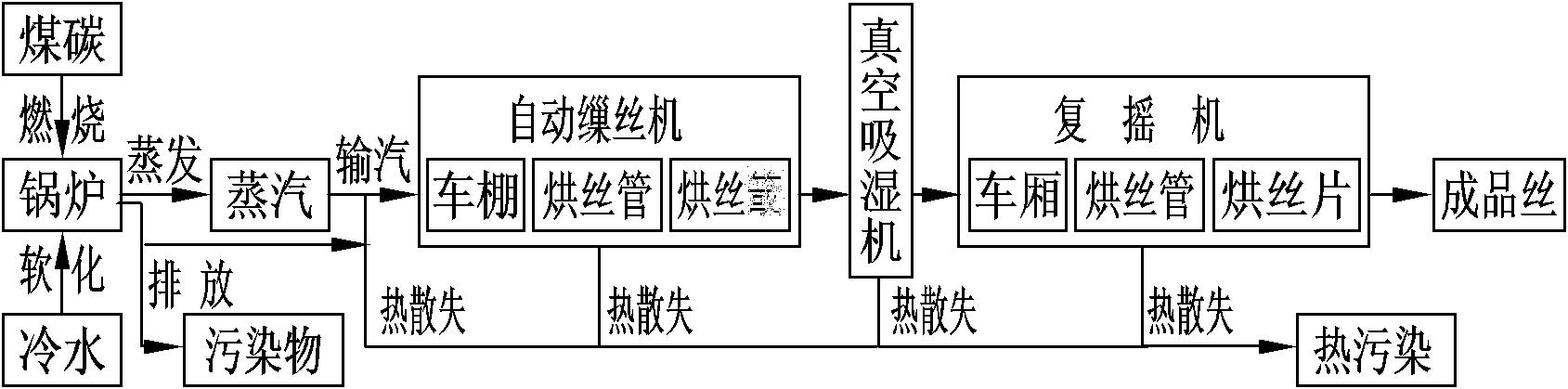

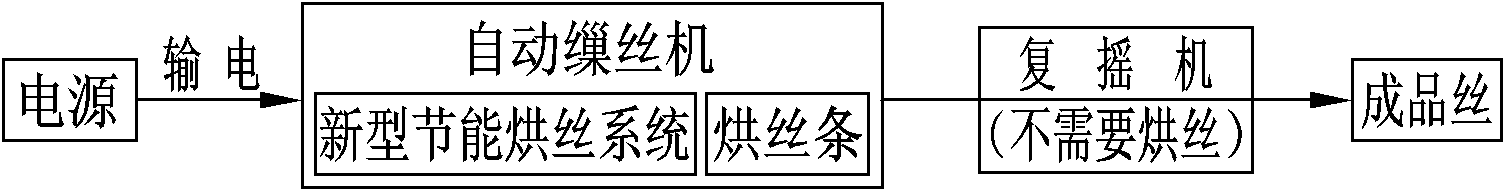

Novel energy-conservation silk drying system of automatic silk reeling machine

ActiveCN101984156AImprove production efficiency and product qualityReduce manufacturing costArtificial filament washing/dryingSilk reelingProcess engineeringEnergy loss

The invention relates to an automatic silk reeling machine in the technical field of raw silk production in the silk reeling industry, in particular to a novel energy-conservation silk drying system of an automatic silk reeling machine. The novel energy-conservation silk drying system comprises a compensation drum wheel, a traverse rod, a silk arranging drum wheel and a small silk-collecting tool. The technical scheme of the invention is as follows: a silk drier inlet drum wheel is arranged at the silk outlet of the compensation drum wheel, a far infrared silk drier is arranged adjacent to the silk drier inlet drum wheel, a photoelectric automatic silk moving mechanism is arranged at the silk outlet of the far infrared silk drier, and the silk outlet of the photoelectric automatic silk moving mechanism is provided with the silk arranging drum wheel. In the invention, less air is heated to heat wet raw silks, the raw silks are evenly dried at a high speed, and silk drying can be finished in the silk reeling machine once, thus the novel energy-conservation silk drying system not only saves energy, but also is favorable for lowering the workshop temperature, the silk reeling operation environment is improved, the problems of multiple working procedures, large energy loss and high workshop temperature of the traditional silk steam drying system for silk reeling production can be thoroughly solved, and according to incomplete statistics, the silk reeling energy consumption is greatly reduced compared with the silk coal-fired steam drying process.

Owner:SICHUAN RES INST OF SILK SCI

Method of extracting rosemary as matural antioxidant

InactiveCN1441030AHigh yieldReduce heating effectBulk chemical productionChemical inhibitorsOrganic solventFreeze-drying

The present invention relates to method of extracting rosemary natural antioxidant from rosemary plant. The extraction process incldues distilling fresh rosemary plant to obtain resemary oil and material containing resemary antioxidant; crushing the material and adding food level organic solvent in a diffuser to extract rosemary leaching liquid; concentrating the resemary leaching liquid, supercritical extracting and high pressure separation to obtain extractive liquid; recovering solvent; spray or freeze drying to obtain yellowish antioxidant product. The said process obtains rosemary oil and antioxidant separately and has high yield and quality of antioxidant product.

Owner:马文彬

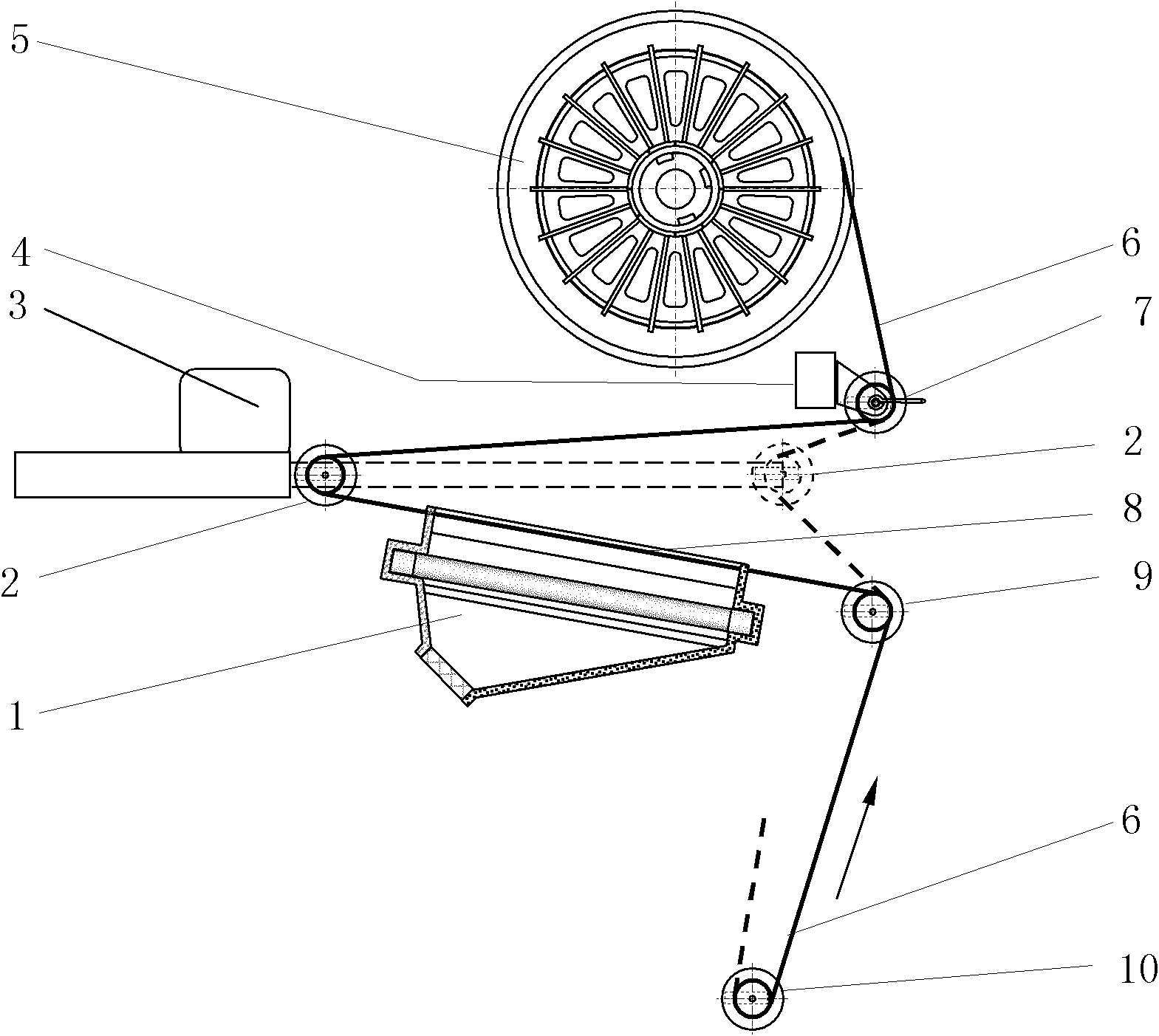

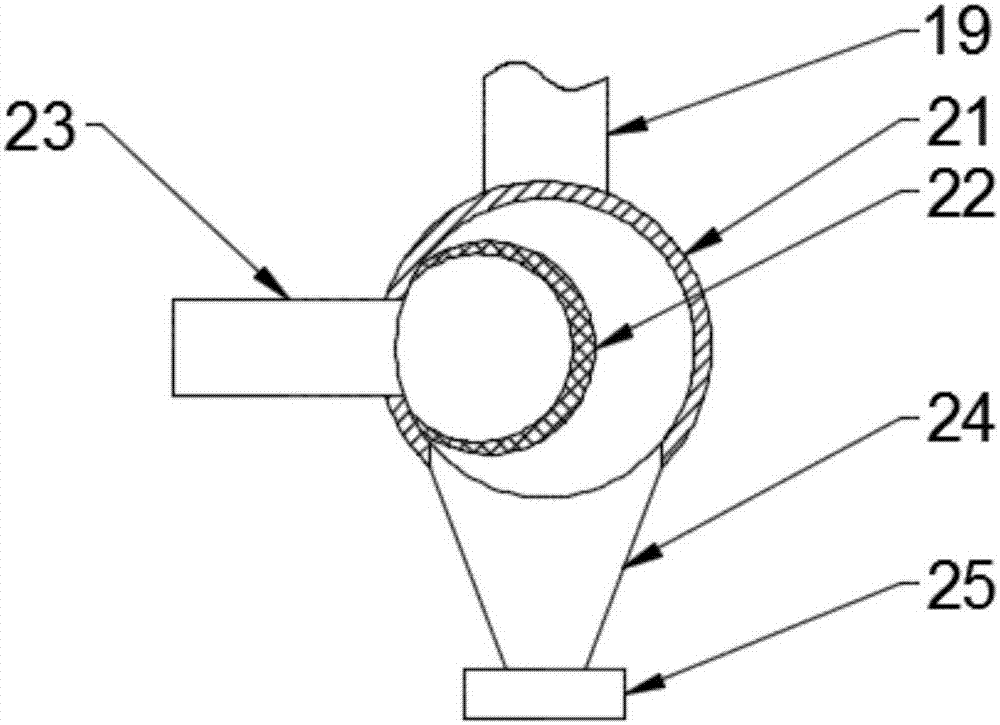

Traditional Chinese medicine extracting and filtering device

InactiveCN107158743AEvenly heatedAvoid burnsSolid solvent extractionStationary filtering element filtersBiochemical engineeringHeating effect

The invention discloses a traditional Chinese medicine extracting and filtering device which comprises a reaction kettle and an inner container. The inner container is arranged in an inner cavity of the reaction kettle, a heating cavity is formed between the reaction kettle and the inner container, the top end of one side face of the heating cavity is penetratingly connected with an air incoming pipe, an air shift box is arranged at the top wall of an inner cavity of the inner container, a stirring rod is arranged in the inner cavity of the inner container, the top end of the stirring rod penetrates the top walls of the air shift box and the reaction kettle and is fixedly connected on a motor shaft of a motor, a plurality of stirring pipes are uniformly arranged on the stirring rod, the bottom end of the inner container is penetratingly connected with an agent discharging pipe, the other end of the agent discharging pipe penetrates the bottom wall of the reaction kettle and is penetratingly connected with a filter, and a plurality of supporting legs are arranged at the bottom end of the reaction kettle uniformly. By arranging the heating cavity to wrap the whole inner container to enable the outside of the same to be heated uniformly, lowering of quality of medicine liquid due to charring of traditional Chinese medicine caused by local overheating can be prevented effectively; the medicine liquid is heated from the inside of the same through the stirring rod and the stirring pipes, so that heating effect of the medicine liquid is further improved, and extraction speed and quality of traditional Chinese medicine are improved substantially.

Owner:贵港市鼎金电子产品有限公司

Combined process method for producing clean diesel oil with low condensation point

ActiveCN103805258AGuaranteed yieldRealize comprehensive utilizationTreatment with hydrotreatment processesFractionationLiquid gas

The invention discloses a combined process method for producing clean diesel oil with a low condensation point. The method comprises the following steps: mixing a diesel oil raw material with hydrogen, orderly passing through at least two hydrogenation reaction zones connected in series, wherein in the material flowing direction, each hydrogenation reaction zone orderly comprises a hydro-upgrading catalyst bed layer, and a hydrodewaxing catalyst composite bed layer filled with a mixture of a hydrodewaxing catalyst and a hydro-refining catalyst; performing separation and fractionation of the reaction effluent from the last hydrogenation reaction zone to obtain the clean diesel oil product with a low condensation point, and a few light naphtha and liquefied gas products. The method of the invention reasonably combines and utilizes the temperature decrease of the hydrodewaxing process with the temperature increase of the hydro-refining and hydro-upgrading process, improves the diesel oil yield while producing diesel oil with a low condensation point and low sulfur, reduces the hot-spot temperature of the device, prolongs the running period, also reduces the cold hydrogen consumption or the combustion gas loss of a heating furnace, and saves operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

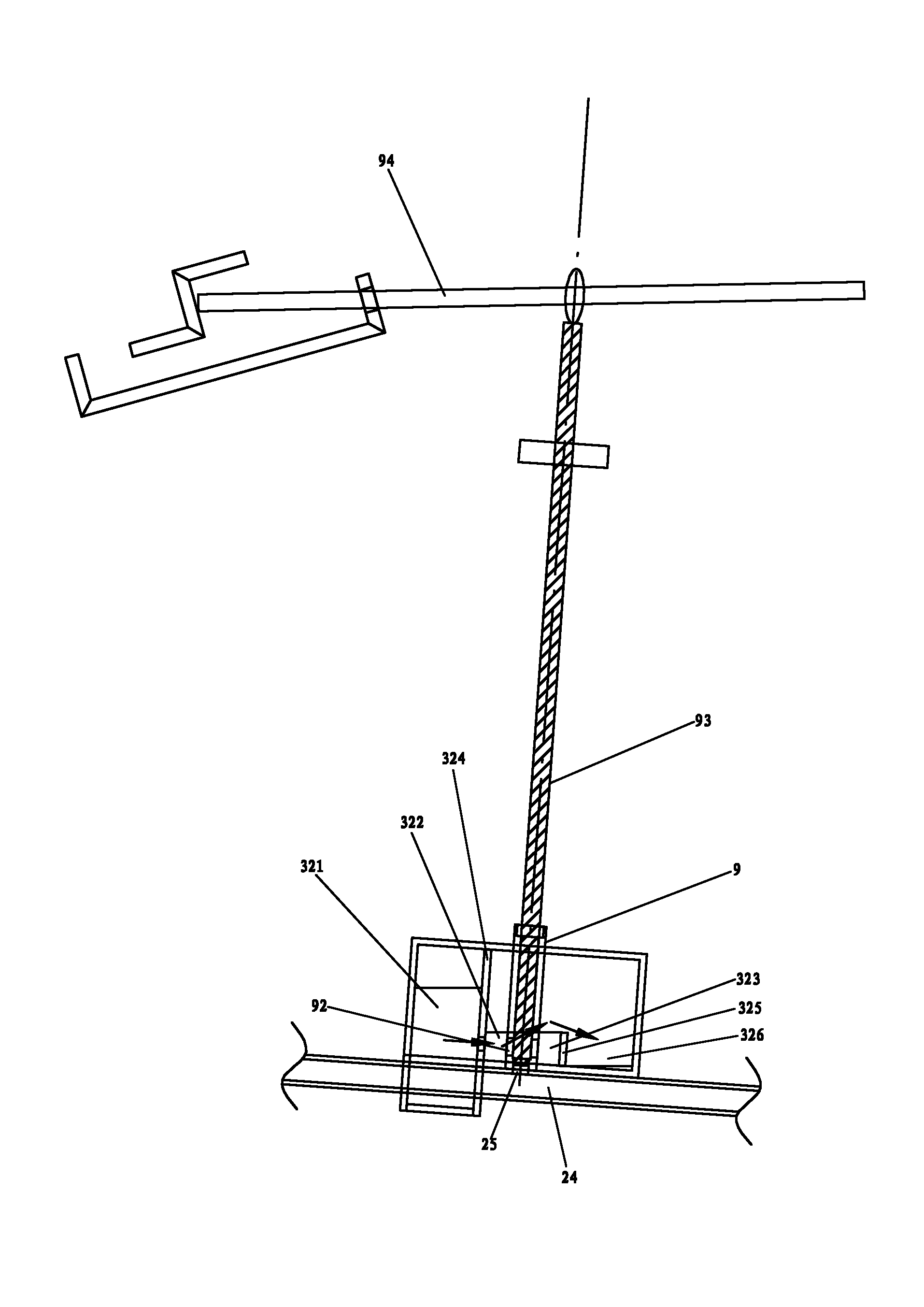

Automatic film coating device

InactiveCN101597749AGuaranteed fixed effectReduce heating effectSpraying apparatusVacuum evaporation coatingDrive shaftEngineering

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Fast response photochromic composition and device

InactiveUS20130242368A1Quick changeQuick responseNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesOptical powerEngineering

The present invention relates to optical power-limiting device, and more particularly, to an optical power-limiting passive device and to a method for limiting optical power transmission in lenses and windows, using absorption changes in a photochromic material with a fast response, featuring under a millisecond rise time and one to five seconds return / decay time.

Owner:KILOLAMBDA TECH

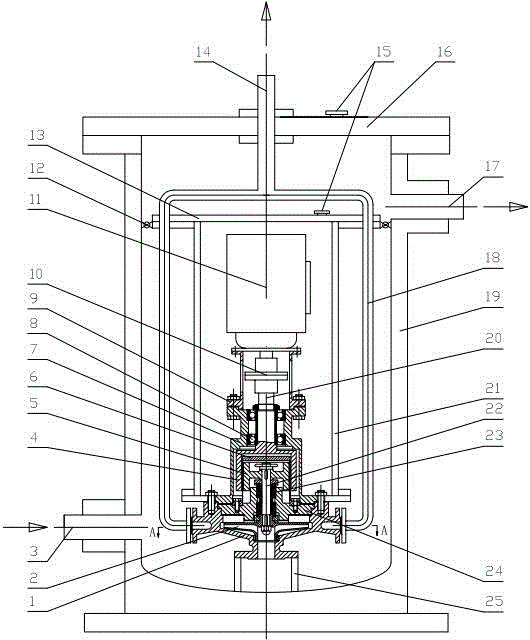

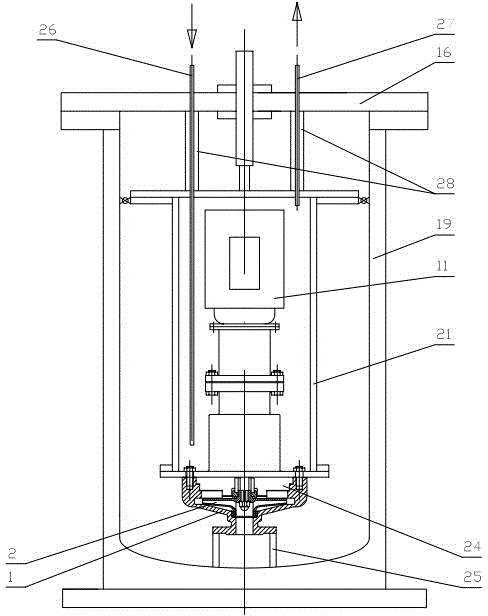

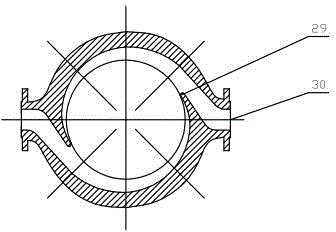

Submerged double-discharging magnetic driving pump for conveying liquefied natural gas

ActiveCN104564711ACompact structureReasonable structurePump componentsPump installationsImpellerEngineering

The invention provides a submerged double-discharging magnetic driving pump for conveying liquefied natural gas. The submerged double-discharging magnetic driving pump for conveying the liquefied natural gas comprises an external high vacuum heat insulation container which is that an evaporated gas outlet is formed in the upper part of one sidewall and while a liquefied natural gas inlet is formed in the lower part of the other sidewall, and an outer sealing cover is mounted on the top part through a flange; an internal high vacuum heat insulation container is mounted inside, and an inner sealing cover is mounted on the top part of the internal high vacuum heat insulation container through the flange; a liquefied natural gas outlet is formed in the center of the inner sealing cover; an impeller housing is fixed to the inner wall of the bottom part of the external high vacuum heat insulation container by axial supporting, and an impeller is mounted to the impeller housing through a central shaft; the upper part of the impeller housing is fastened to the bottom part of the internal high vacuum heat insulation container through a fastening part; a connecting seat is mounted in the impeller housing; a central shaft is mounted in the middle part of the connecting seat through a sliding bearing and extends into the internal high vacuum heat insulation container; a submerged double-discharging magnetic part is mounted at the central shaft. The submerged double-discharging magnetic driving pump is compact and reasonable in structure, convenient to operate, high in sealing performance, safe and reliable to use, and low in vibration noise.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

Manufacturing method of toughened vacuum glass

The invention relates to a manufacturing method of toughened vacuum glass, which comprises the following steps: (1) after drying the pre-treated glass, arranging a support on the glass; (2) spraying or steeping chemical liquid medicine on the surface of the glass, the chemical liquid medicine is of metal oxide chemical glass toughened liquid medicine sold on the market, and the concentration of the chemical liquid medicine is controlled to the solution saturation; (3) arranging two pieces of glass which is coated or steeped with chemical liquid medicine on a platform for combining, sealing the edge of the glass, and heating the glass in a heating furnace, wherein the temperature inside the furnace is 200 to 800 DEG C, and the time is 1.5 to 10 hours; and at the same time completing the ventilation, vacuum pumping, edge sealing and sealing, and reducing the temperature to obtain the finished product. The manufacturing method breaks through the international and the domestic blank that the ordinary glass and the toughened glass cannot be directly utilized to manufacture the vacuum glass, so the manufacturing and the application cost of the safety glass in the fields such as the building can be greatly reduced, the heating times and the heat loss of the glass can be greatly reduced, and the strength and the service life of the glass can be improved.

Owner:沃卡姆(山东)真空玻璃科技有限公司

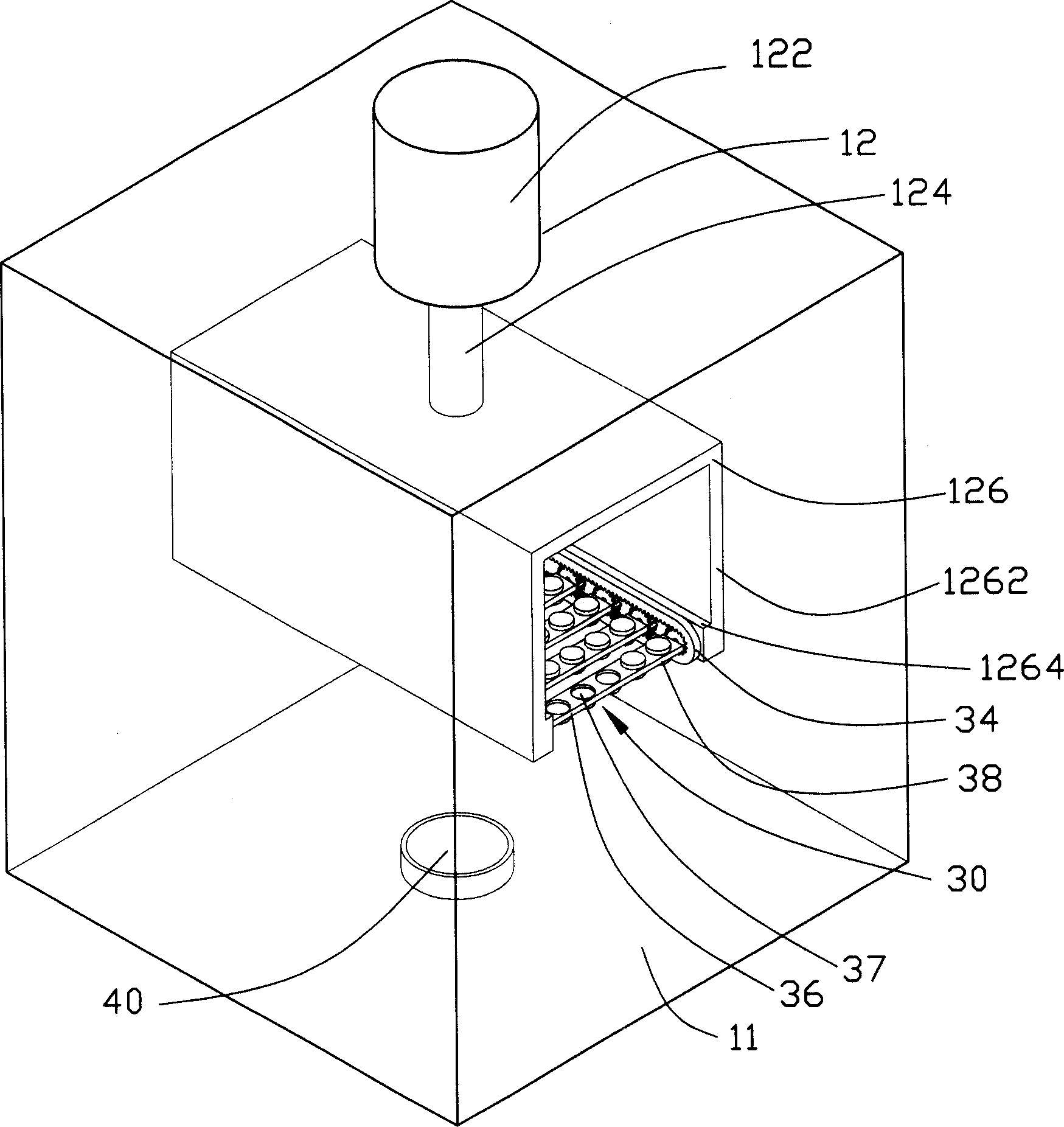

Vacuum coating device

InactiveCN1690244AGuaranteed constant vacuum parametersReduce heating effectVacuum evaporation coatingSputtering coatingEngineeringVacuum chamber

The invention relating to a vacuum plating device, which contains a vacuum chamber, a rotation supporting assembly, a substrate support lying in vacuum chamber and containing a few substrates and also connected to rotation supporting assembly, and a deposition source lying in the vacuum chamber and opposite the substrate support, further contains a turning device lying in the vacuum chamber and connected to substrate support, and a turning control device out of the vacuum chamber, with the turning device and turning control device, several substrates rotating horizontally in the vacuum chamber. With the invented plating device, no need of cooling and breaking vacuum after one surface of the substrate is coated, the heat-up and pump-down times decrease.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

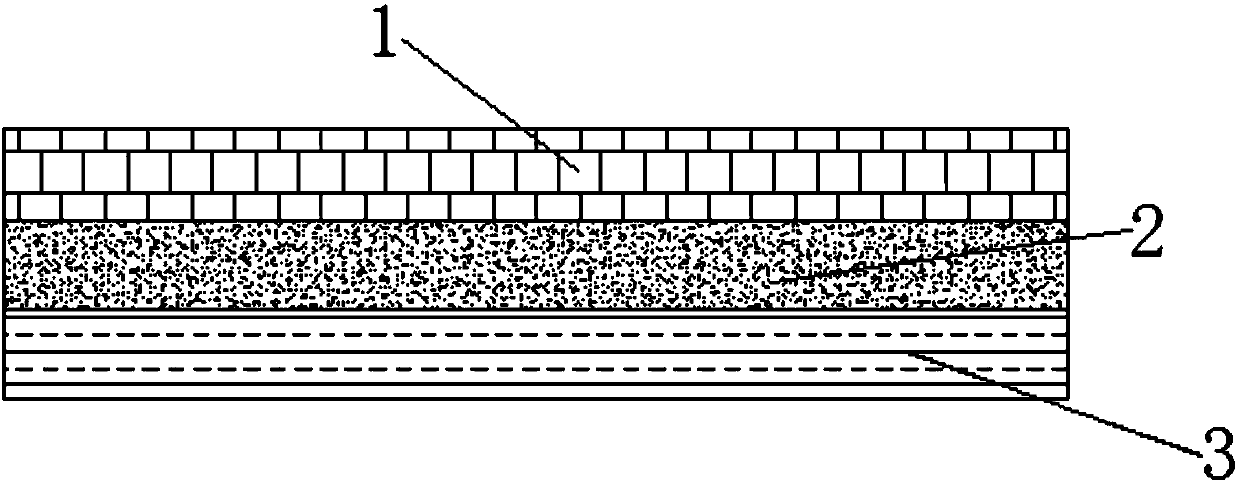

Protective film for chip cutting as well as preparation method and use method thereof

InactiveCN107815257AHigh strengthNo risk of precipitation of small moleculesNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsTectorial membranePolypropylene

The invention discloses a protective film for chip cutting. The protective film sequentially comprises a releasing layer, a substrate layer and an adhesive layer, wherein the substrate layer is made of modified PO (propylene epoxide) material; the modified PO material is prepared by copolymerizing PP (polypropylene) and PE (polyethylene); the modified PO material is prepared from the following components in parts by weight: 50 to 70 parts of PP, 20 to 40 parts of PE, and 5 to 10 parts of talcum powder. The protective film has the characteristics that the substrate layer adopts the modified POmaterial, so that the mechanical strength is high, the halogen is avoided, and the environment-friendly requirement is met; the heat-resistant property is better, and the certain high-temperature operation requirement is met; the plasticizer is not contained, so that the risk of micromolecule segregation is avoided for the material; the material strength is high, the ductility is good, the uniformshrinkage rate in each direction is maintained under the condition of 140% of elongation rate, and the uniform strength in each direction is realized at the premises of certain elongation rate; the adhesive layer uses pressure-sensitive adhesive to replace the photo-sensitive adhesive and thermo-sensitive adhesive, the transparency degree is high, the weather-resistant property is high, TG is about -20 DEG C, and the procedures are simple (no UV (ultraviolet) furnace passing or reheating procedure); by performing simple laminating and separating, the product application requirement can be met, the change of viscosity duration is small and is less than 20%, and the residual adhesive is avoided.

Owner:CYBRID TECHNOLOGIES INC

Particle additive suitable for bituminous pavement and preparation and using methods thereof

InactiveCN102086279AImprove thermal stabilityImprovement and ruttingBuilding insulationsWaxPitch blende

The invention relates to a particle additive suitable for a bituminous pavement and preparation and using methods thereof. The particle additive is mainly prepared from 40-80 parts of high polymers, 5-30 parts of rubber powder and 5-10 parts of wax; and the preparation method comprises the following steps of: uniformly stirring the components, then carrying out mixing, extruded granulation and air drying on mixtures by using a rubber refining machine to obtain the rubber-powder particle additive. The particle additive is directly added when mixed and stirred without special equipment so that the preparation method is simple in process and convenient to operate; the particle additive can comprehensively raise and improve the quality of bituminous mixtures and has excellent low-temperature crack resistance, water stability and high-temperature track resistance as well as favorable economic and social benefits so that the integral durability of bituminous concrete is improved.

Owner:北京新桥技术发展有限公司

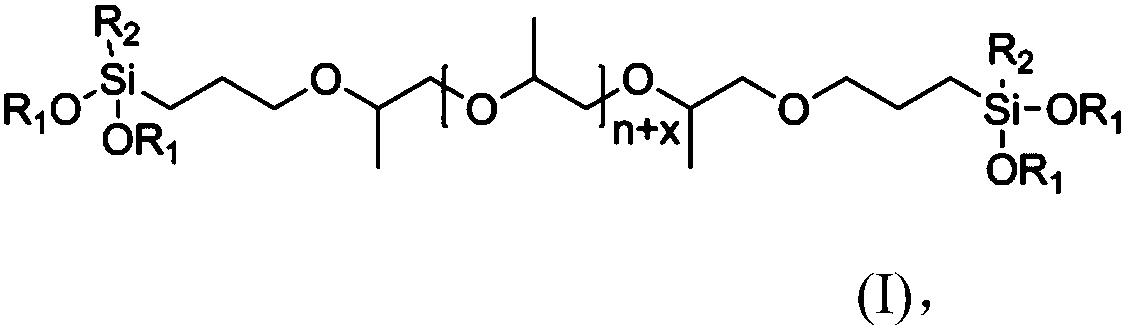

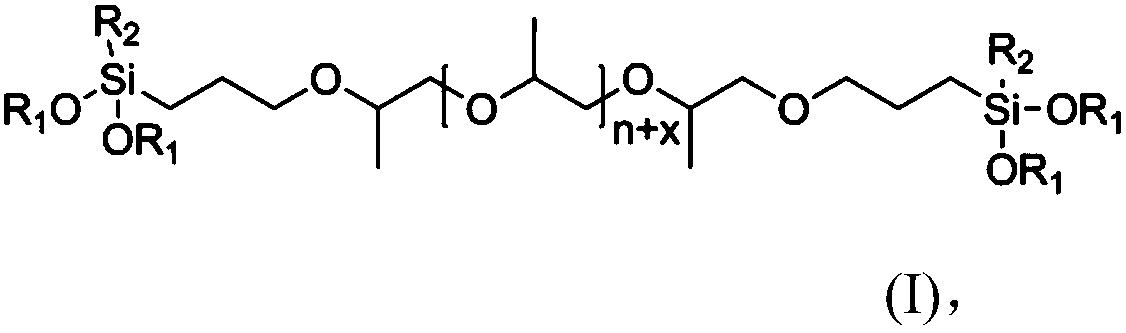

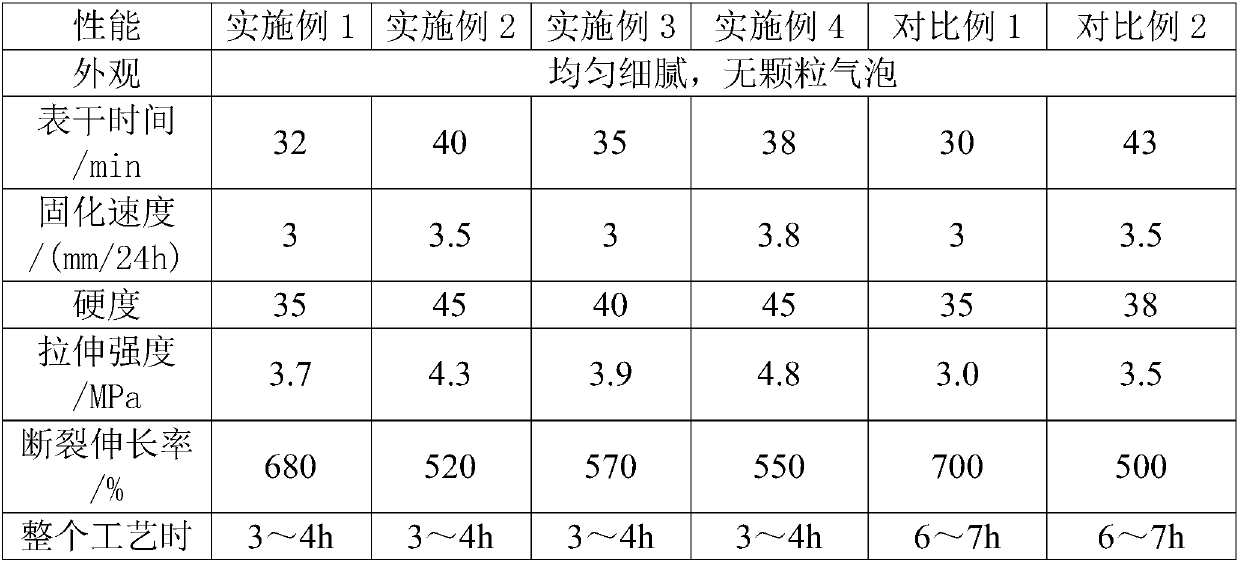

Preparation method of silane-modified polyether sealant

ActiveCN109251711AImprove stabilityShorten heating and cooling timeNon-macromolecular adhesive additivesMacromolecular adhesive additivesScavengerSilanes

The invention relates to a preparation method of a silane-modified polyether sealant, comprising the following steps: drying a filler, a thixotropic agent and a 3A molecular sieve respectively while the process conditions include: drying temperature 50-60 DEG C and drying time 40-60h; mixing the filler, the thixotropic agent and the 3A molecular sieve, and then adding silane-modified polyether resin, a plasticizer, a ultraviolet absorber, a light stabilizer and an antioxidant in sequence, uniformly mixing at a temperature of 50-60 DEG C, carrying out vacuum dehydration for 0.3-0.8 h and at thevacuum degree of 0.08-0.2 MPa; removing the vacuum, adding neutral alumina to obtain a mixed system, heating the mixed system to 70-75 DEG C, continuing vacuum stirring for 1-2h and at the vacuum degree of -0.08 to -0.2 MPa until the water content of the mixed system is reduced to 0.4%-1%; cooling the mixed system treated in the Step 3) to below 50 DEG C, adding a catalyst, a moisture scavenger and an adhesion promoter, uniformly mixing, and carrying out vacuum defoamation. The above preparation method can help prolong the shelf life of the silane-modified polyether sealant.

Owner:GUANGDONG LIANCHENG RESIDENTIAL EQUIP INFORMATION TECH CO LTD

Hydroisomerization pour-point-depressing deep-coupling process for producing low-pour-point diesel oil

ActiveCN105087063AImprove combustion effectRealize cleaner productionTreatment with hydrotreatment processesIsomerizationHydrogenation reaction

The invention discloses a hydroisomerization pour-point-depressing deep-coupling process for producing low-pour-point diesel oil. The process comprises the following steps: mixing a diesel oil raw material and hydrogen; then successively allowing the mixture to pass through at least two tandem hydrogenation reaction zones, wherein each hydrogenation reaction zone successively includes a composite catalyst bed layer filled by a mixture of a hydrodewaxing catalyst and a hydro-upgrading isomerization pour-point-depressing catalyst, and a hydrofining catalyst bed layer according to a flow direction of the materials; and finally, subjecting an obtained reaction effluent of the last hydrogenation reaction zone to separation and fractionation so as to obtain the low-pour-point diesel oil. The method provided by the invention reasonably utilizes temperature rise in upgrading pour-point-depressing process and temperature drop in hydrodewaxing process, so clean low-pour-point diesel oil is produced; meanwhile, the yield and cetane number of the diesel oil are improved; hot-spot temperature of a device is reduced; and operation cycle is prolonged; moreover, consumption of cooled hydrogen and fuel gas loss of a heating furnace are reduced, and operation cost is saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com