Patents

Literature

54results about How to "Shorten heating and cooling time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

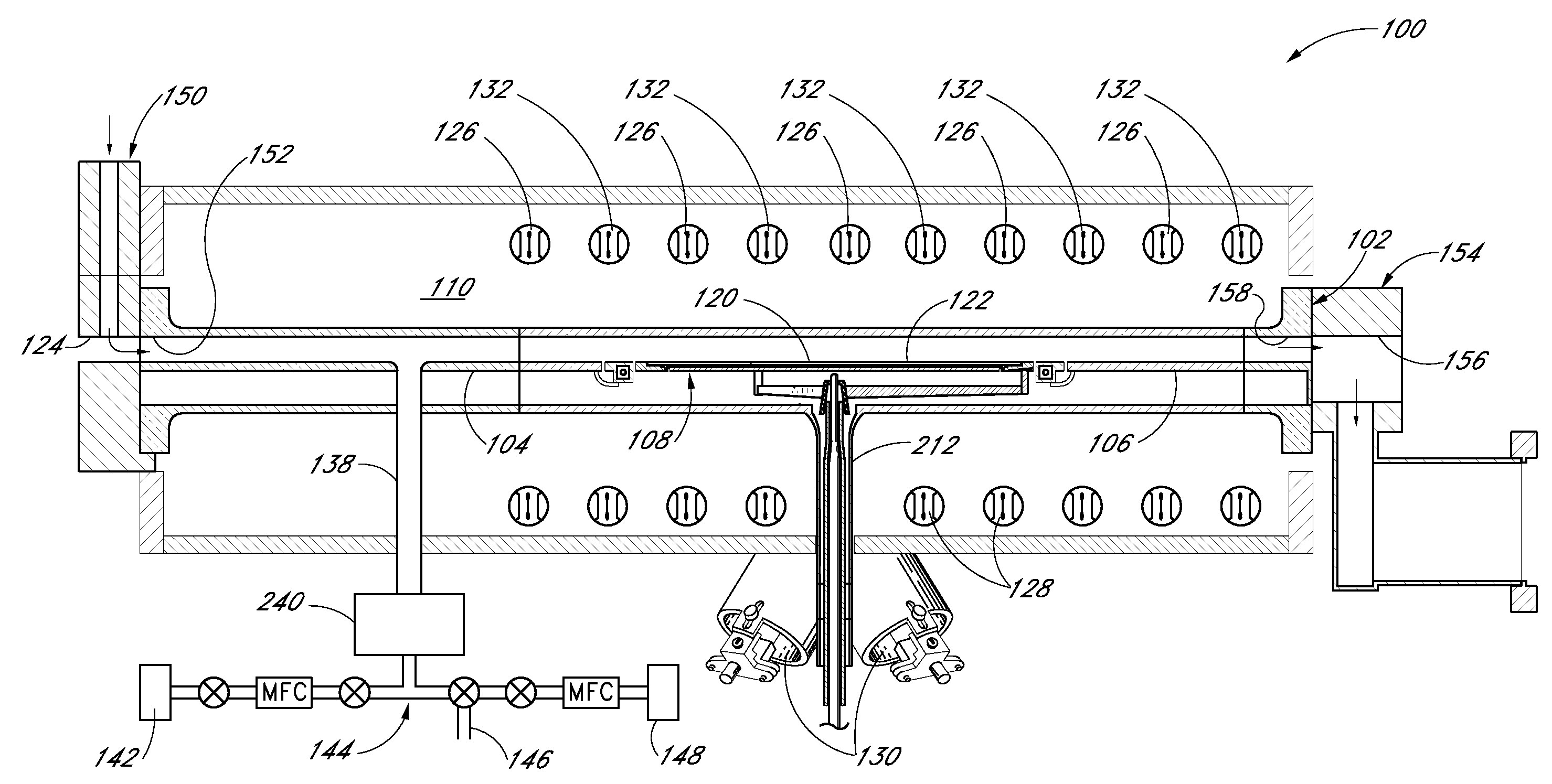

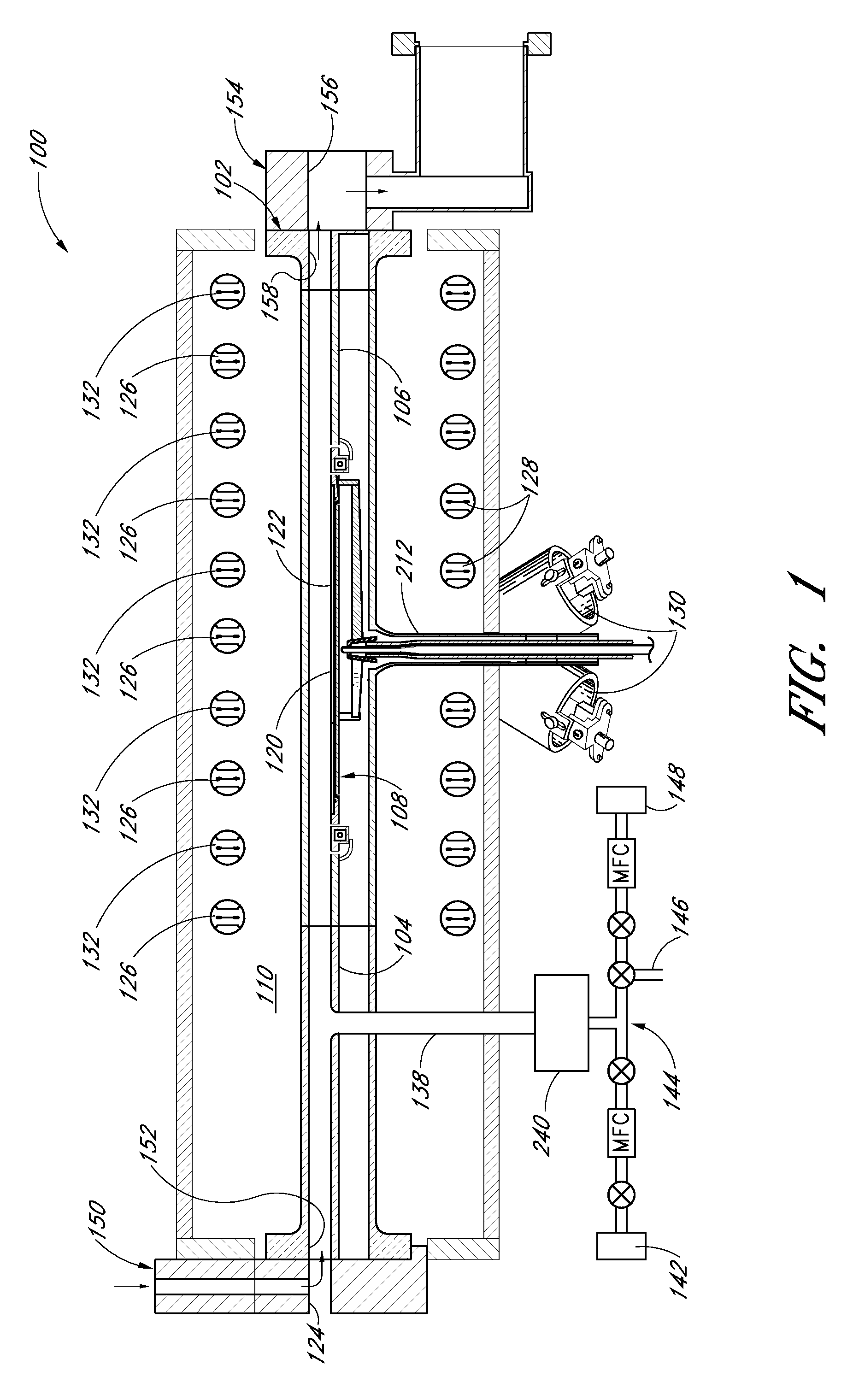

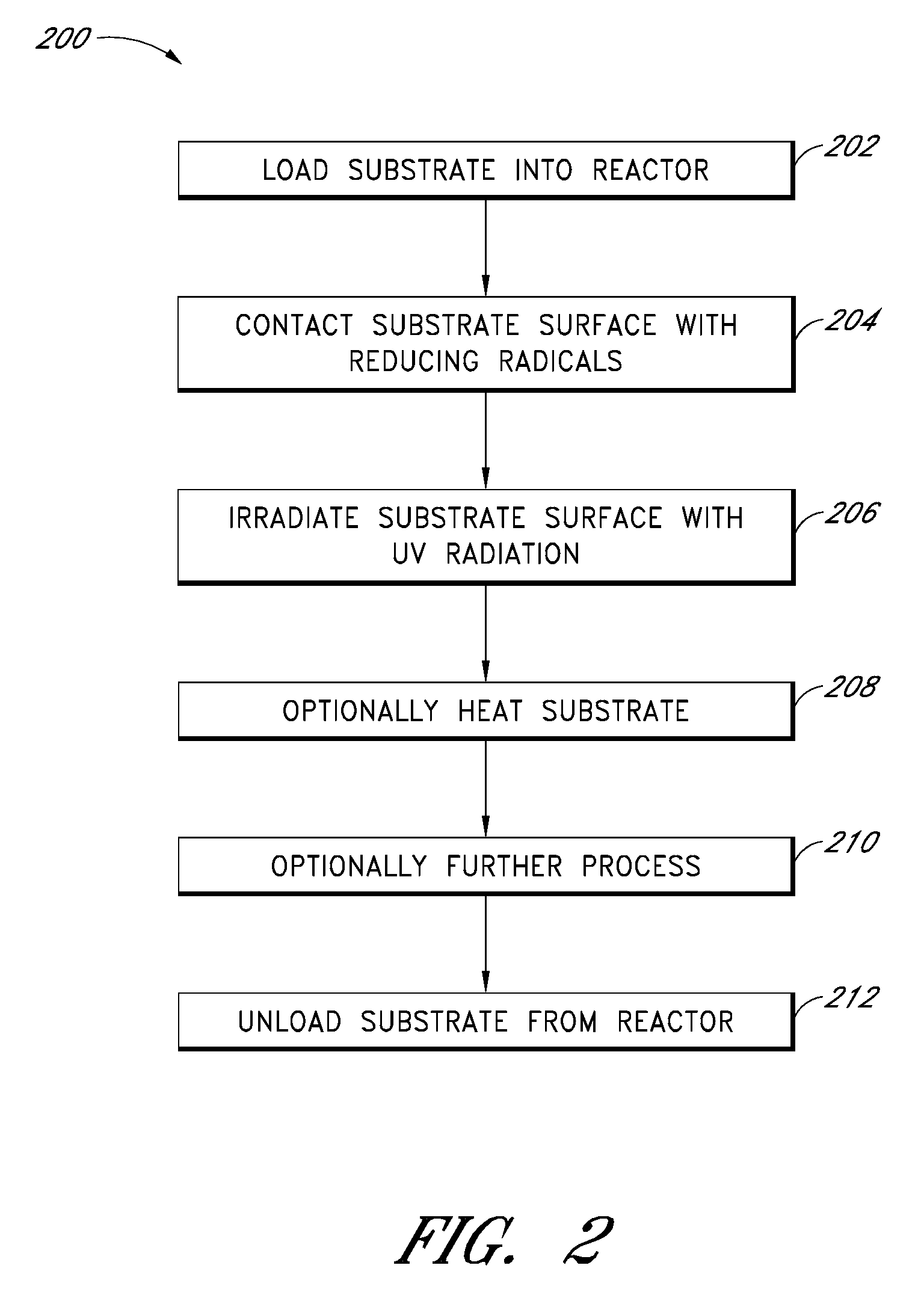

Low-temperature cleaning of native oxide

InactiveUS20080289650A1Reduce vertical sizeReduce device sizeElectrostatic cleaningSemiconductor/solid-state device manufacturingHydrogenSurface cleaning

Disclosed herein is a method of cleaning oxide from a surface in the fabrication of an integrated device using reducing radicals and UV radiation. For silicon surfaces, the cleaning may be performed at a temperature at which a hydrogen-terminated passivated surface is stable, such that the surface remains protected after loading into the chamber until the cleaning is performed. Performing the cleaning at a lower temperature also consumes a reduced portion of the thermal budget of a semiconductor device. Epitaxial deposition can then be performed over the cleaned surface.

Owner:ASM AMERICA INC

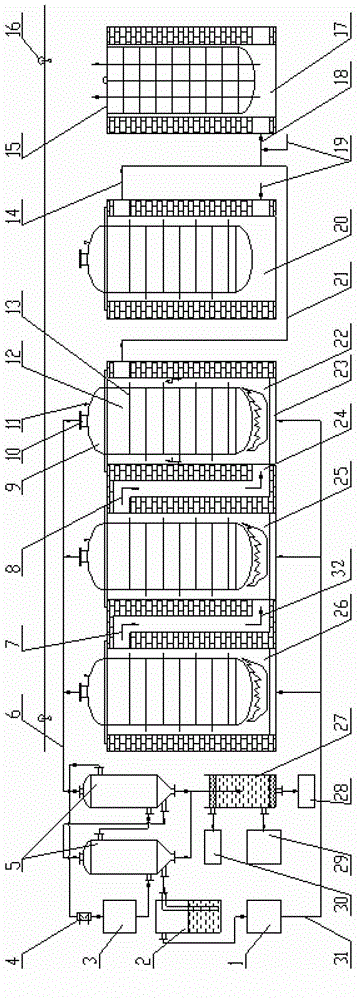

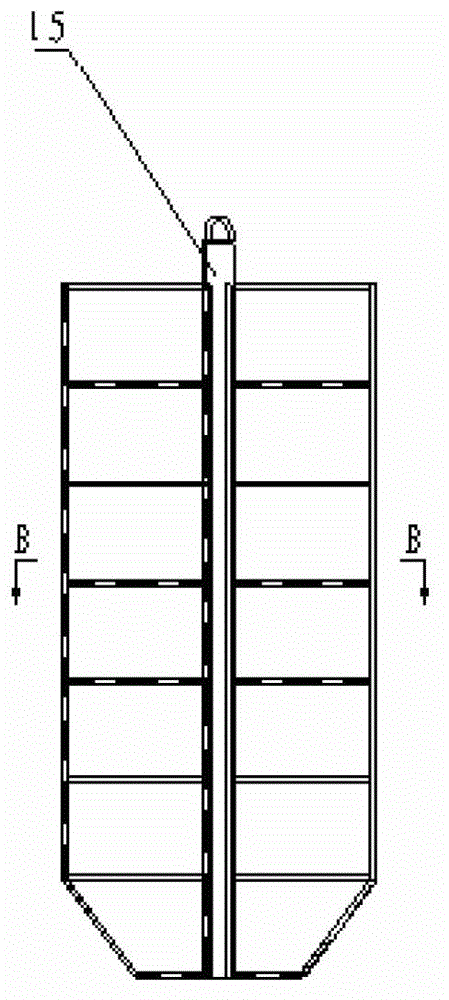

Carbonizing system and carbonizing process of wood materials

ActiveCN102911683AQuality improvementIncrease the heat exchange areaBiofuelsEnergy inputCooling chamberAgricultural residue

The invention discloses a carbonizing system of wood materials. The carbonizing system of wood materials comprises a carbonizing device and a by-product recovery device, wherein the carbonizing device comprises a reaction vessel and a reaction chamber for putting the reaction vessel; the reaction vessel comprises a material shelf and a destructive distillation kettle for putting the material shelf; the destructive distillation kettle is composed of a destructive distillation kettle body and a destructive distillation kettle cover; an exhaust hole and a temperature measuring hole are arranged on the destructive distillation kettle cover; the reaction chamber comprises a calcining chamber with a combustion area, a carbonizing chamber, a pre-heating chamber which are sequentially arranged, a drying chamber and a cooling chamber for pre-treatment and post-treatment of wood materials respectively. The pre-heating chamber, the carbonizing chamber and / or the exhaust hole on the destructive distillation kettle cover in the calcining chamber are connected with the by-product recovery device. The system is suitable for carbonizing production of all wood materials such as tree wood, hard weed tree, bamboo material, forestry and agricultural residues (straw, shell, sawdust and on the like). The invention is scientific and rational in process, none in emission and pollution, short in production period and low in cost, thereby being suitable for popularization and application.

Owner:BLUESTAR BEIJING CHEM MACHINERY

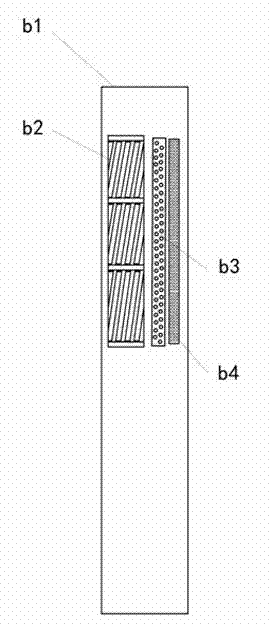

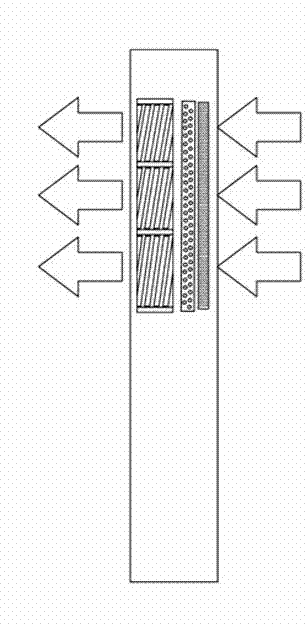

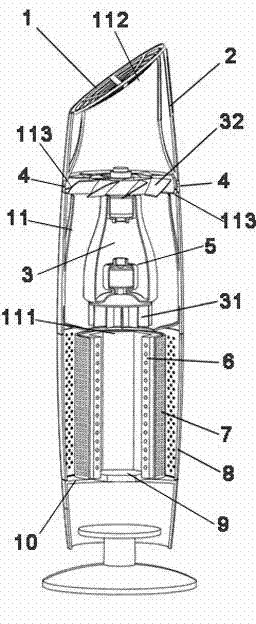

Cabinet type air conditioner

ActiveCN103574777AReduce volumeImprove styling scalabilityDucting arrangementsLighting and heating apparatusCoaxial lineEngineering

The invention relates to a cabinet type air conditioner, in particular to an air supply structure inside the cabinet type air conditioner. The cabinet type air conditioner comprises a cabinet body, a heat exchanger, an air exhaust device and a motor for driving the air exhaust device, wherein the heat exchanger and the air exhaust device are arranged in the cabinet body; an air inlet and an air outlet are formed in the positions, corresponding to the heat exchanger and the air exhaust device respectively, of the cabinet body; a filter screen is arranged between the heat exchanger and the air inlet; the heat exchanger is columnar and longitudinally mounted in the cabinet body; the air exhaust device and the heat exchanger are placed in the coaxial line; the air inlet is formed in the side edge of the heat exchanger; and one end of the air exhaust device is close to the heat exchanger, and the other end of the air exhaust device corresponds to the air outlet. With the adoption of the cabinet type air conditioner, the size of the air conditioner can be reduced, the modelling expansibility of the cabinet type air conditioner is improved, and the heat exchange effect is enhanced.

Owner:HISENSE HOME APPLIANCES GRP CO LTD +1

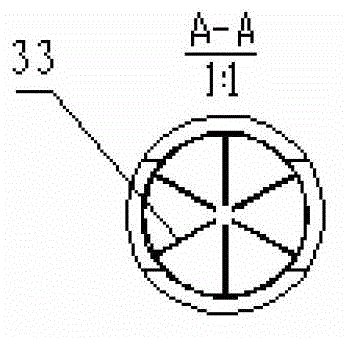

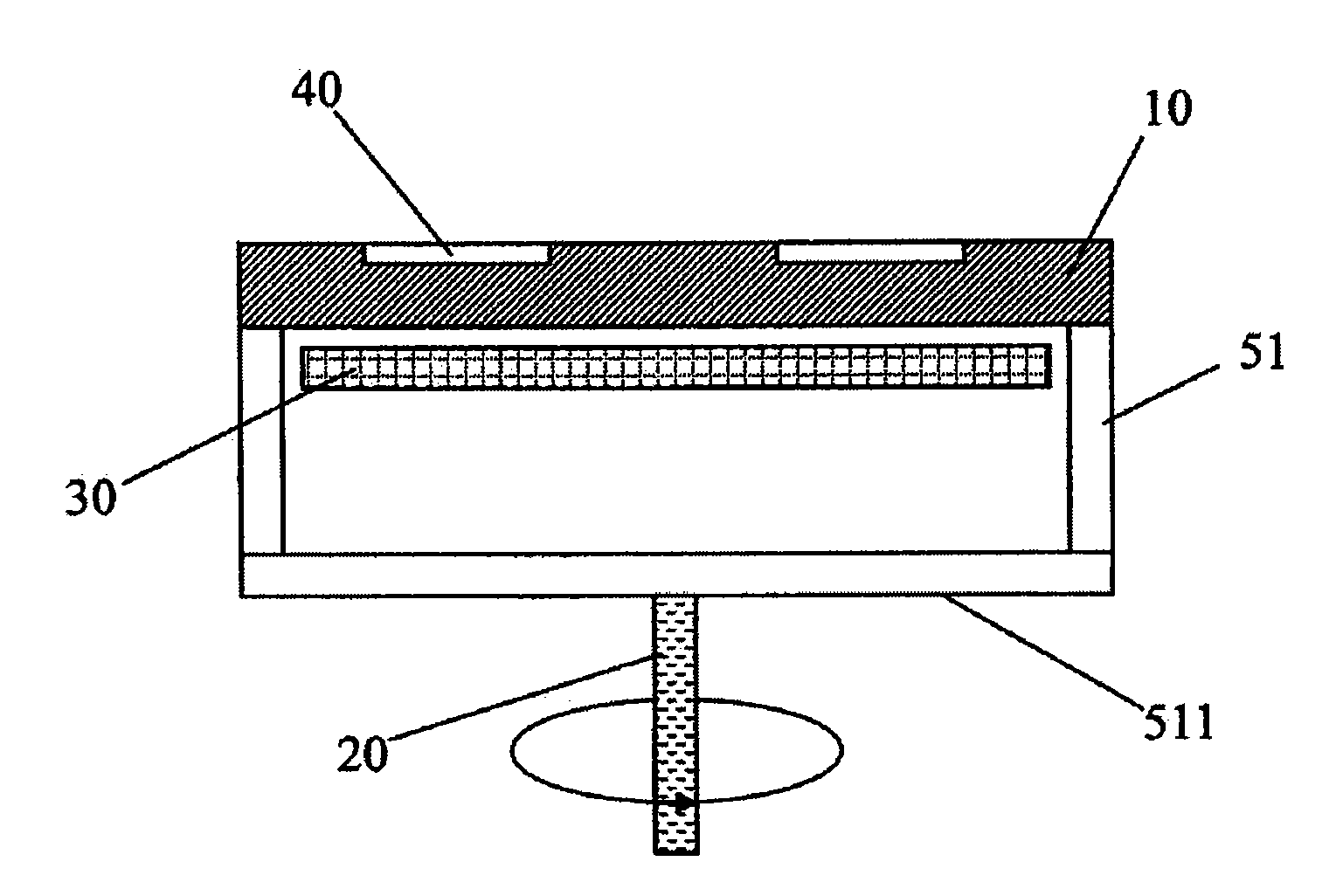

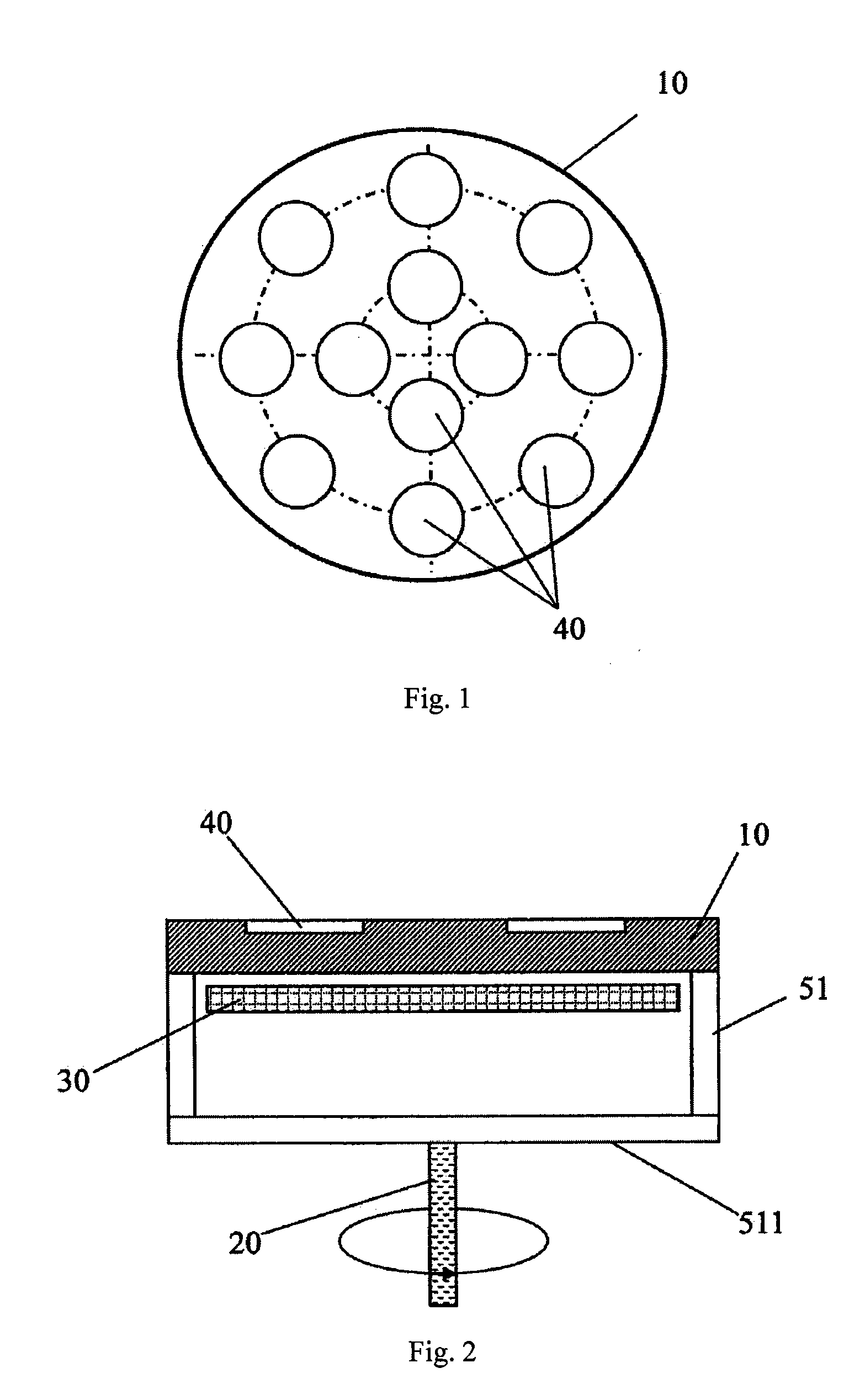

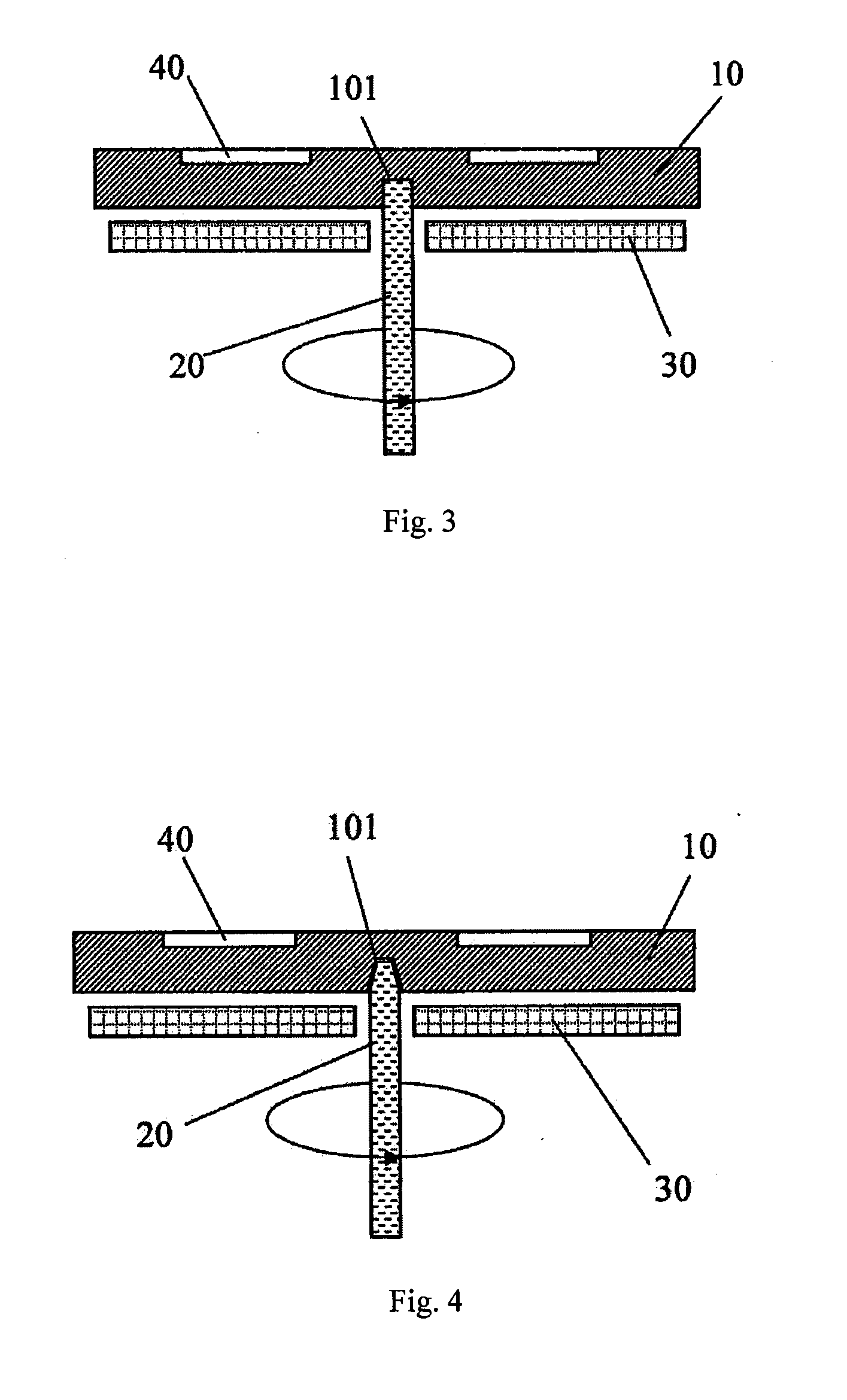

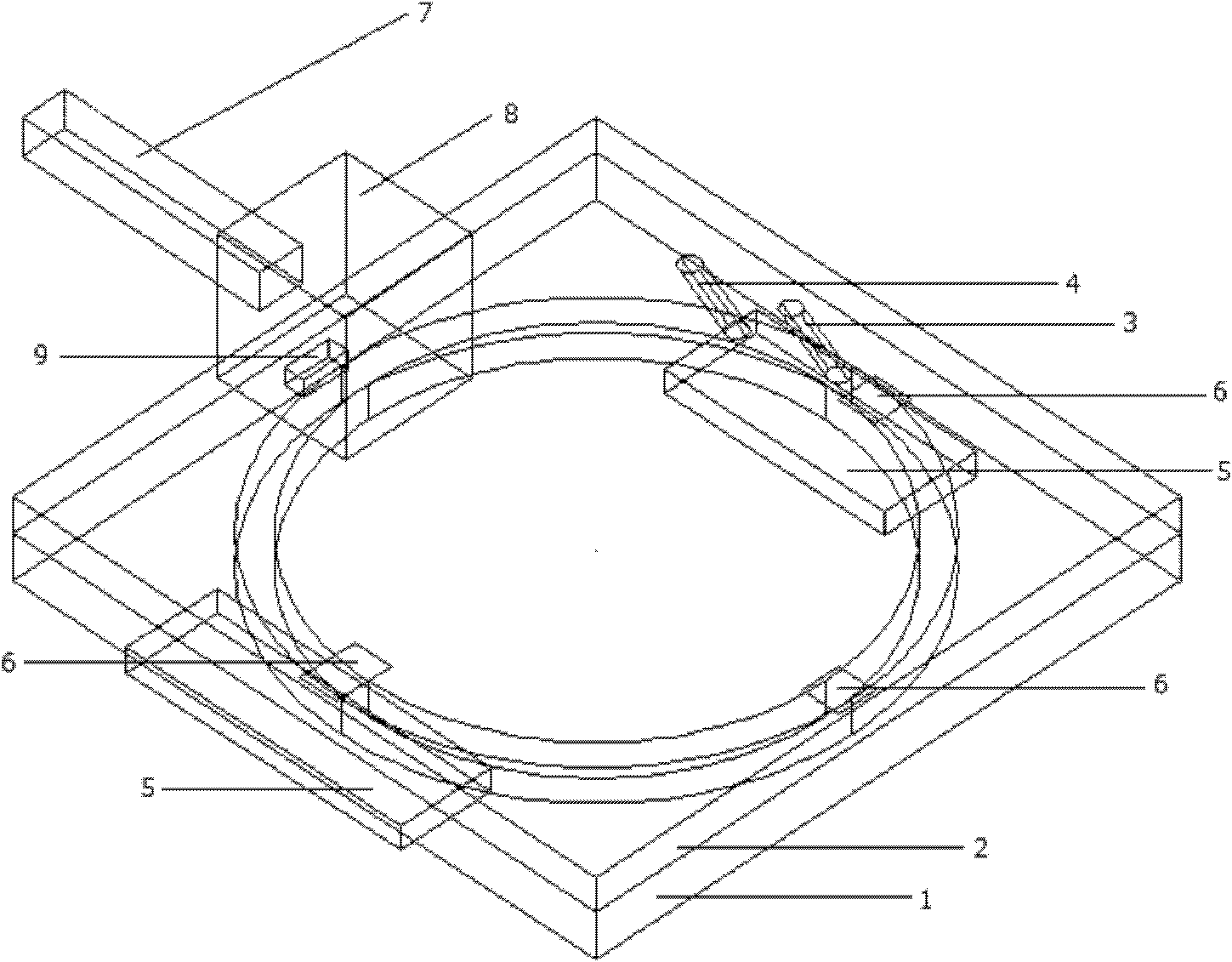

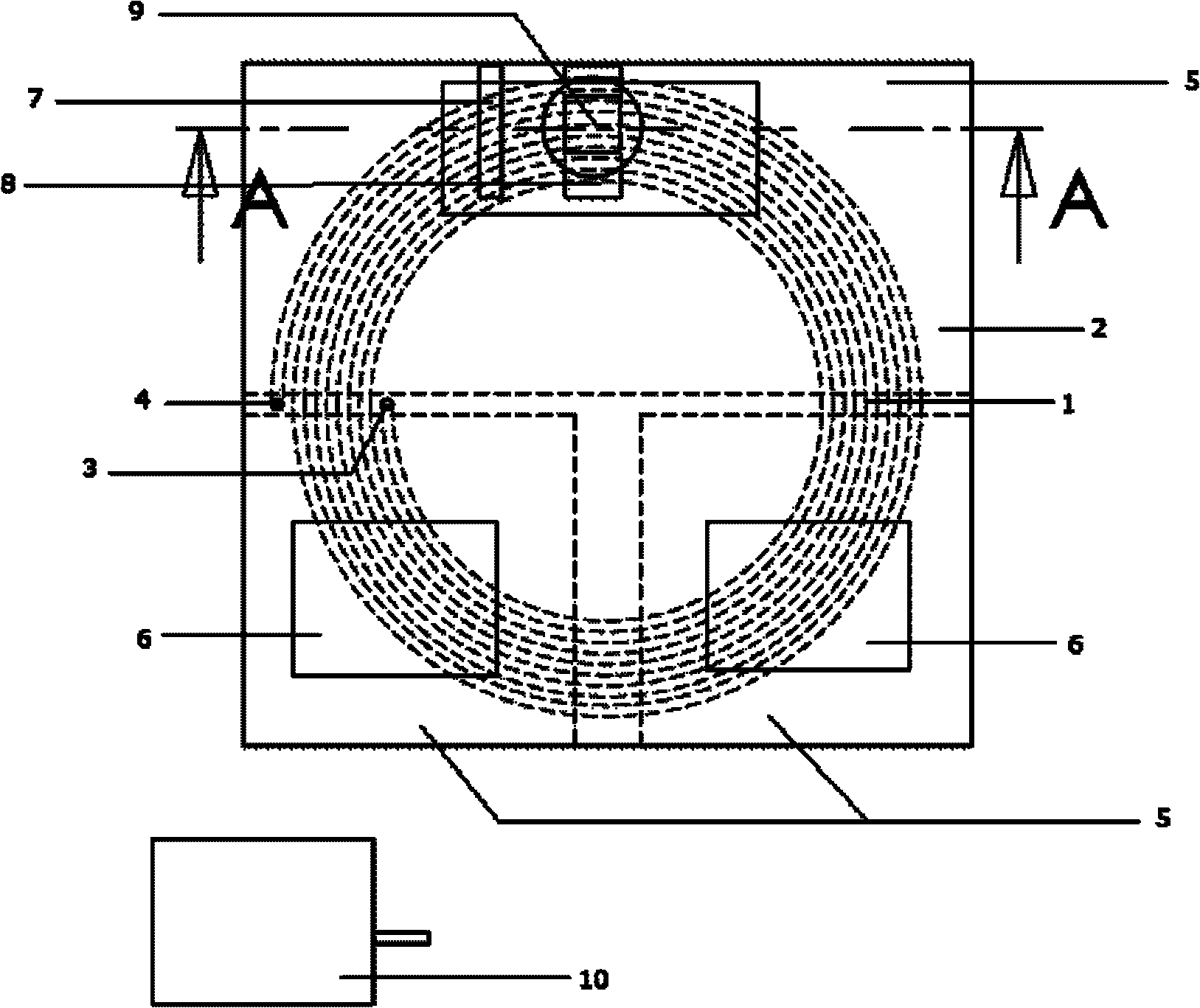

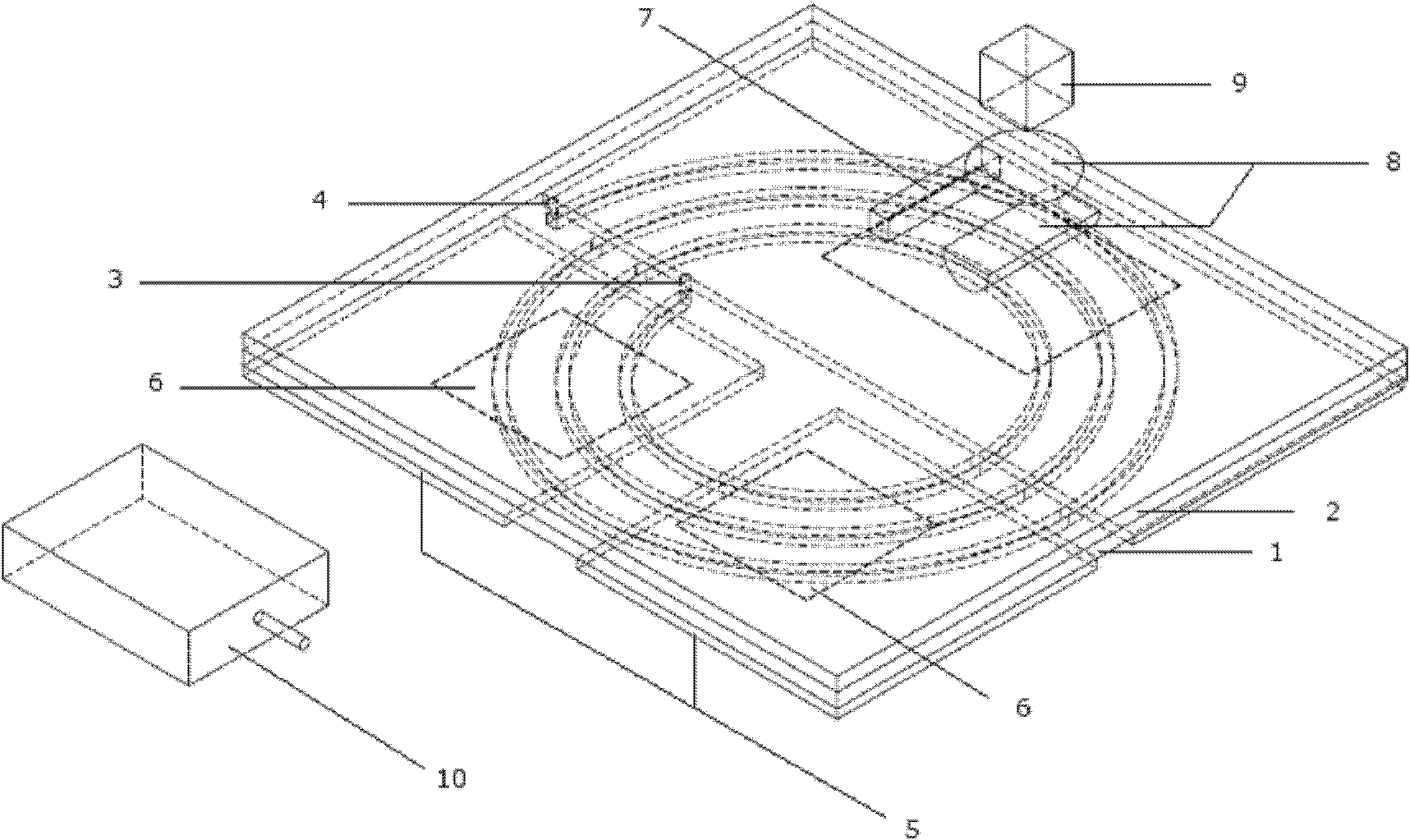

Epitaxial wafer susceptor and supportive and rotational connection apparatus matching the susceptor

InactiveUS20130061805A1Heating evenlyLow production costSemiconductor/solid-state device manufacturingFrom chemically reactive gasesSusceptorDrive shaft

Disclosed is an epitaxial wafer susceptor and a supportive and rotational connection apparatus matching the susceptor used for an MOCVD reaction chamber. The susceptor comprises a top surface and a susceptor rotating shaft protruding downward. A vertical driving shaft is coupled to the susceptor. The driving shaft comprises a counter bore inside an upper end of the driving shaft. At least a part of the susceptor rotating shaft is inserted into the counter bore if the susceptor is loaded. The susceptor is positioned and supported in the reaction chamber via coupling and connection between a contact surface of the susceptor rotating shaft and a corresponding contact surface of the counter bore. The susceptor is driven to rotate by the driving shaft if the driving shaft rotates. Reactant gases are introduced into the reaction chamber for an epitaxial reaction or a film deposition on the epitaxial wafers placed on the susceptor.

Owner:JIANGSU ZHONGSHENG SEMICON EQUIP

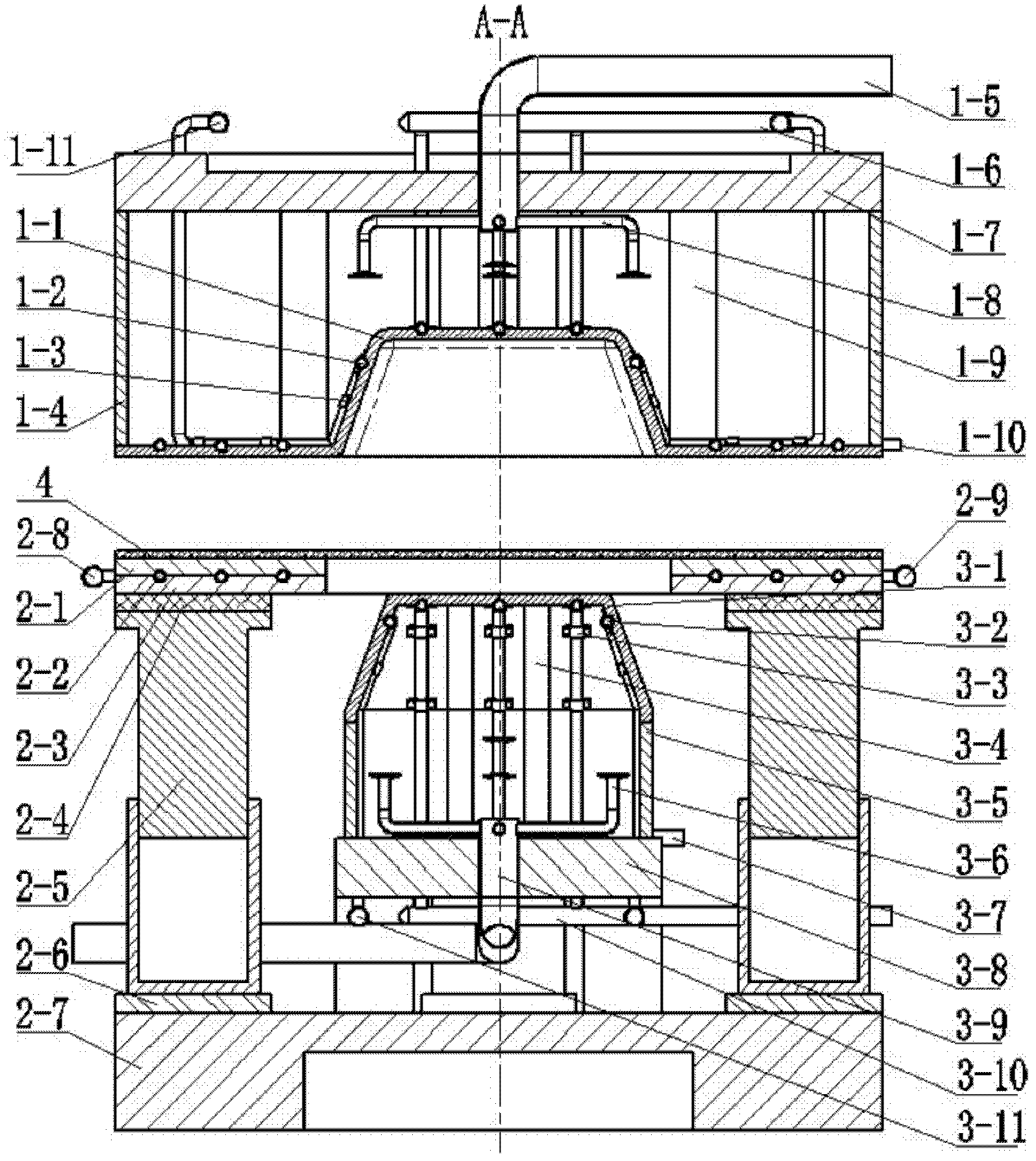

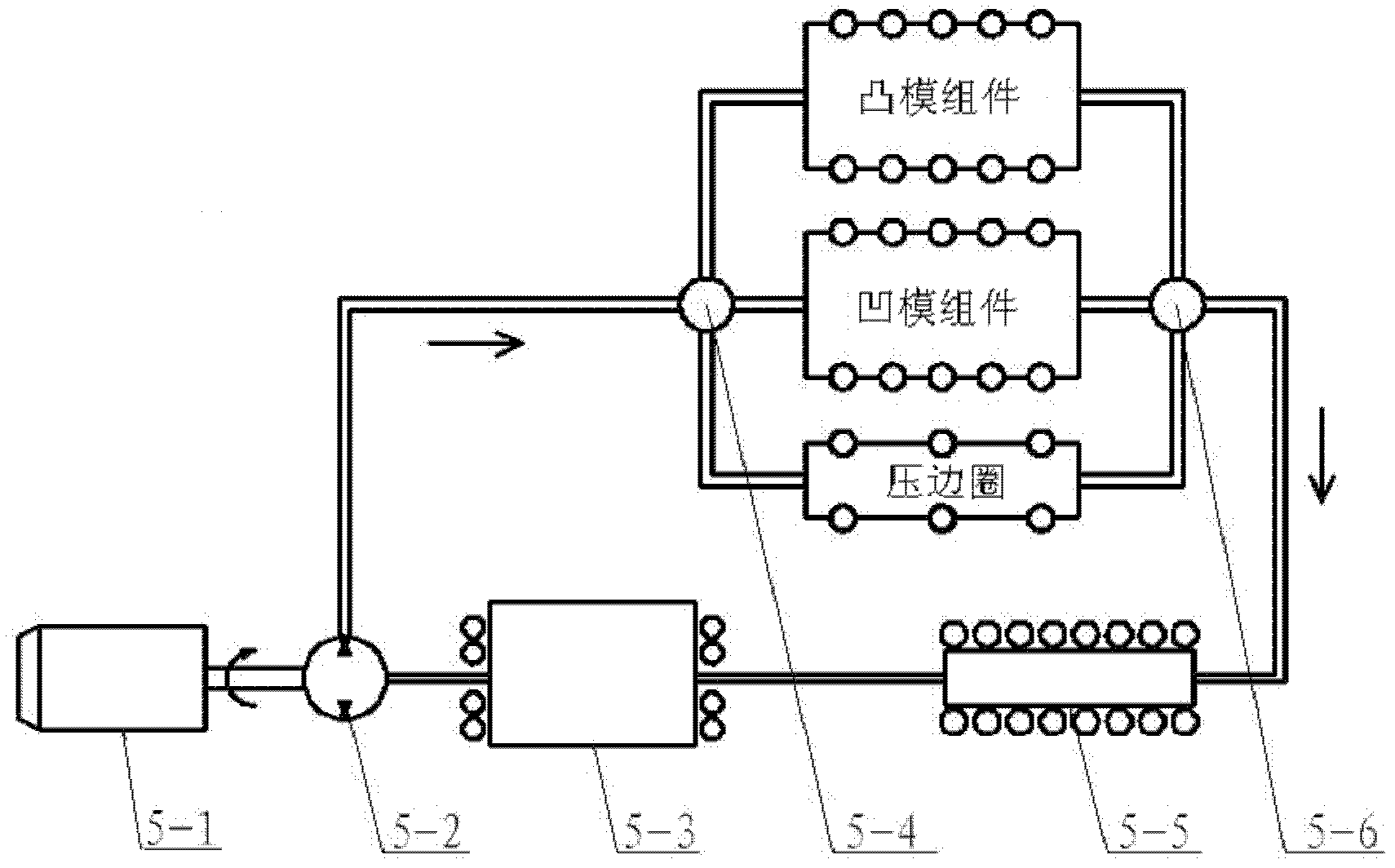

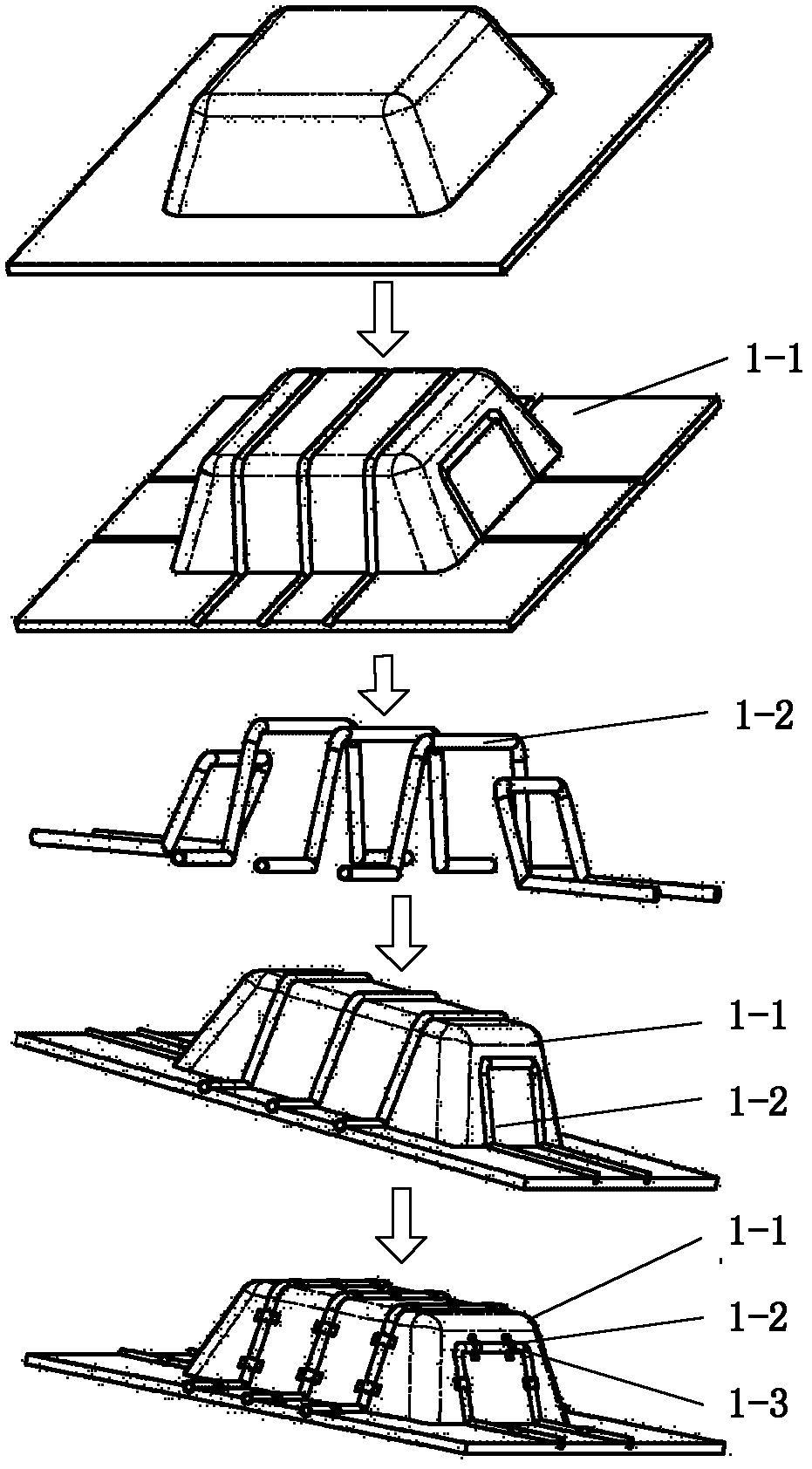

Device and method for forming fiber reinforced resin-based composite material plate through hot stamping

The invention relates to a device and a method for forming a fiber reinforced resin-based composite material plate through hot stamping. The device comprises a female die component, a male die component, a blank holder, a supporting device, a hot oil heating system and a die water spray cooling system, wherein the female die component is connected with a sliding block of a press; the male die component is arranged on a pedestal; and the blank holder and the supporting device are arranged on the pedestal. The forming method comprises the following steps: placing a plate material on the surface of the blank holder; starting the hot oil heating system to heat a female die, a male die and the blank holder to the set temperature; starting the press; driving the female die to move close to and contact with the plate materials; suspending operation; heating the plate material to the softening temperature of a resin matrix through contact heat transfer of the female die, the male die and the blank holder; continuously operating the press; descending a nitrogen cylinder; adjusting the nitrogen cylinder to obtain the proper blank holder force; and gradually forming the plate material. By the device and the method, the fiber reinforced resin-based composite material plate can be formed through hot stamping and formation efficiency and quality are guaranteed.

Owner:XI AN JIAOTONG UNIV

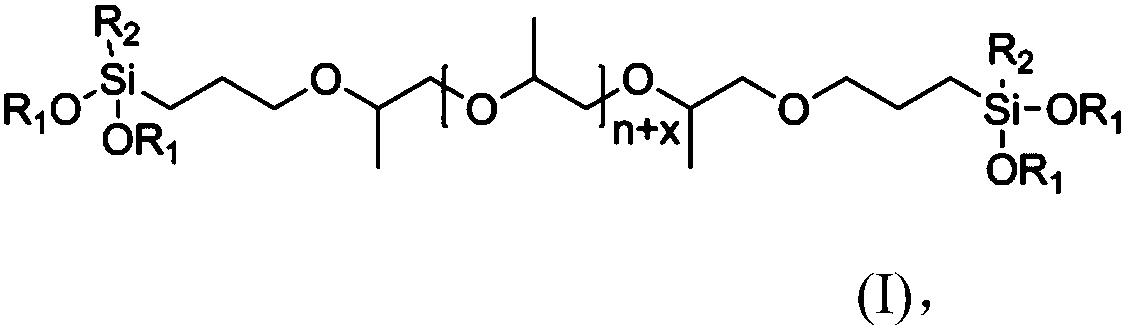

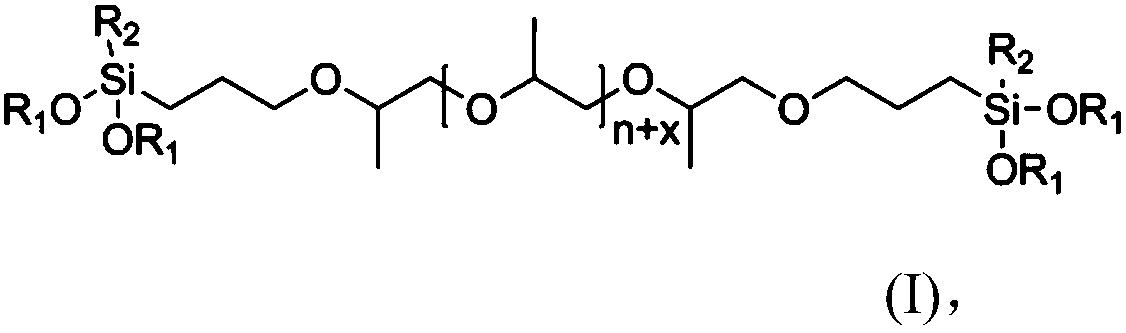

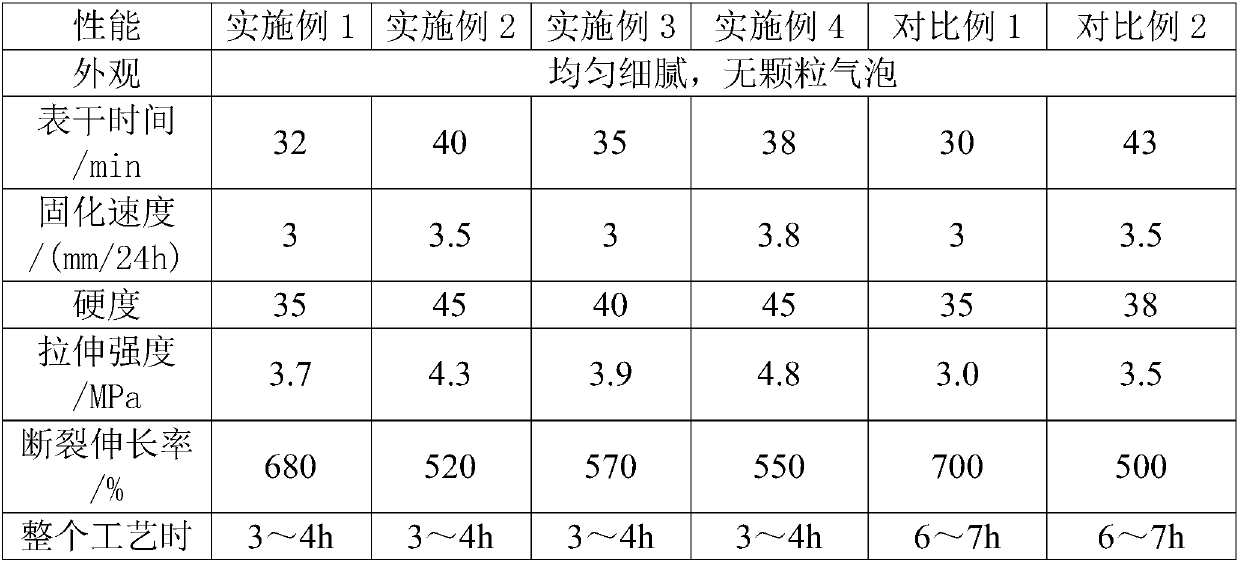

Preparation method of silane-modified polyether sealant

ActiveCN109251711AImprove stabilityShorten heating and cooling timeNon-macromolecular adhesive additivesMacromolecular adhesive additivesScavengerSilanes

The invention relates to a preparation method of a silane-modified polyether sealant, comprising the following steps: drying a filler, a thixotropic agent and a 3A molecular sieve respectively while the process conditions include: drying temperature 50-60 DEG C and drying time 40-60h; mixing the filler, the thixotropic agent and the 3A molecular sieve, and then adding silane-modified polyether resin, a plasticizer, a ultraviolet absorber, a light stabilizer and an antioxidant in sequence, uniformly mixing at a temperature of 50-60 DEG C, carrying out vacuum dehydration for 0.3-0.8 h and at thevacuum degree of 0.08-0.2 MPa; removing the vacuum, adding neutral alumina to obtain a mixed system, heating the mixed system to 70-75 DEG C, continuing vacuum stirring for 1-2h and at the vacuum degree of -0.08 to -0.2 MPa until the water content of the mixed system is reduced to 0.4%-1%; cooling the mixed system treated in the Step 3) to below 50 DEG C, adding a catalyst, a moisture scavenger and an adhesion promoter, uniformly mixing, and carrying out vacuum defoamation. The above preparation method can help prolong the shelf life of the silane-modified polyether sealant.

Owner:GUANGDONG LIANCHENG RESIDENTIAL EQUIP INFORMATION TECH CO LTD

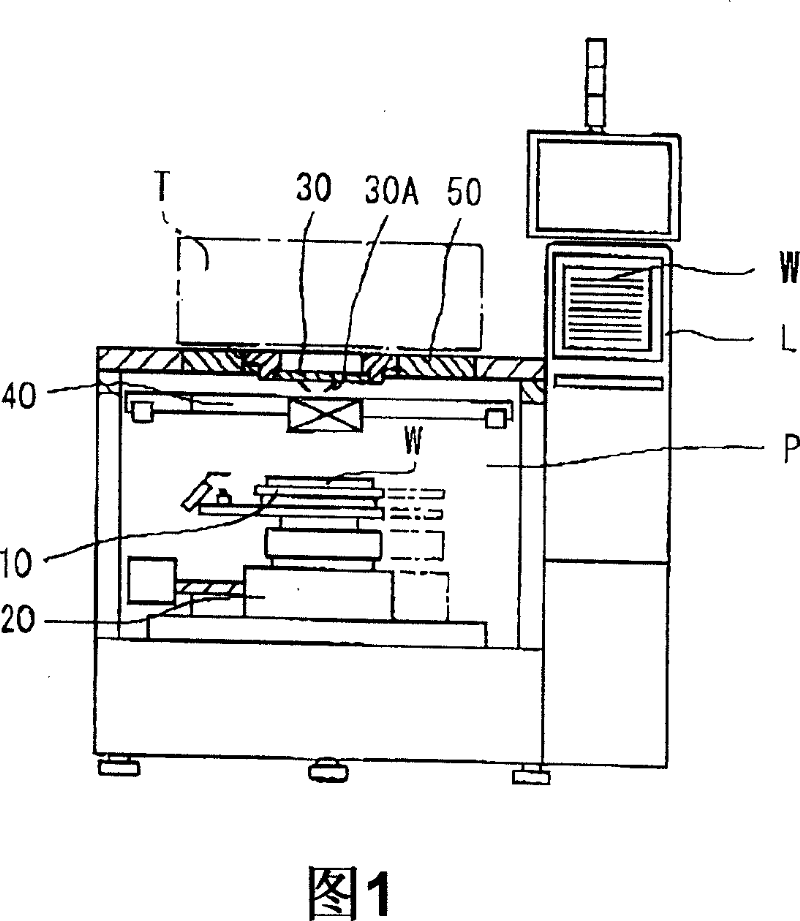

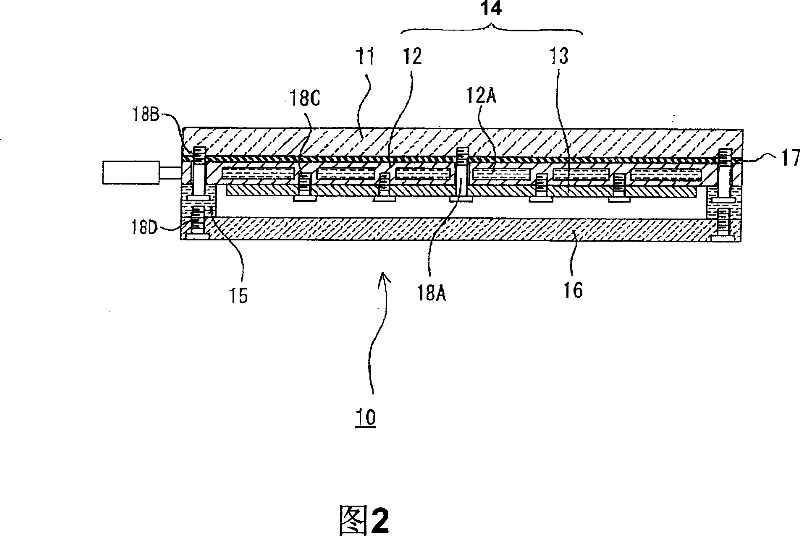

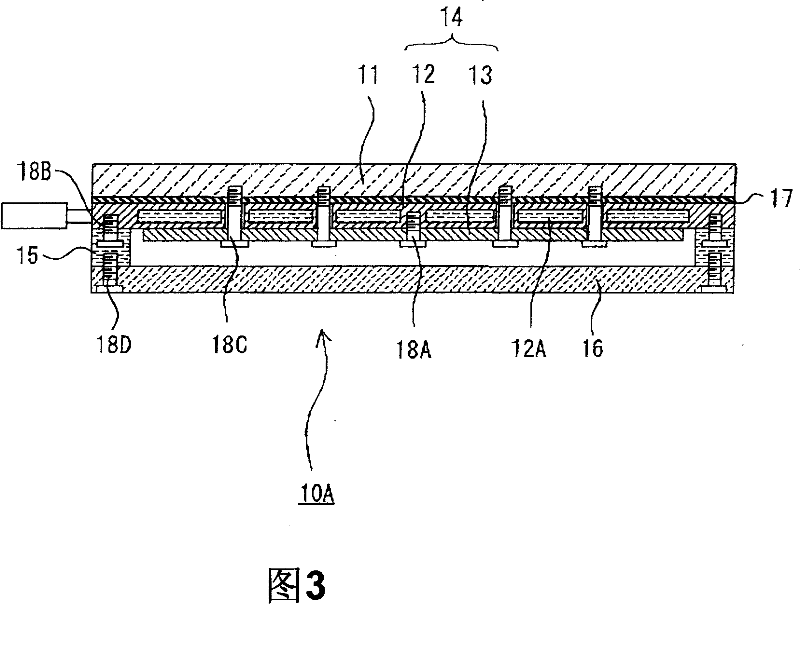

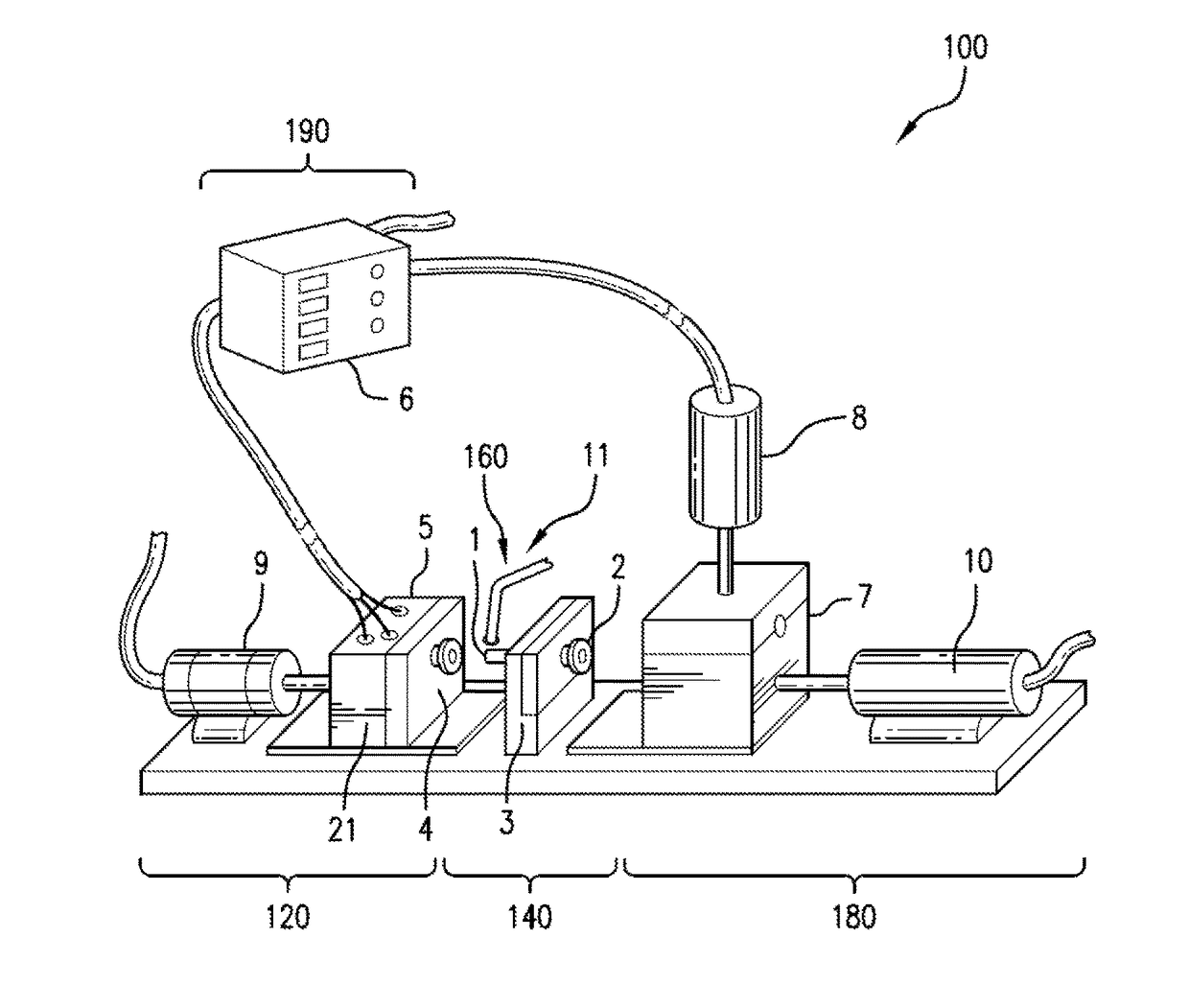

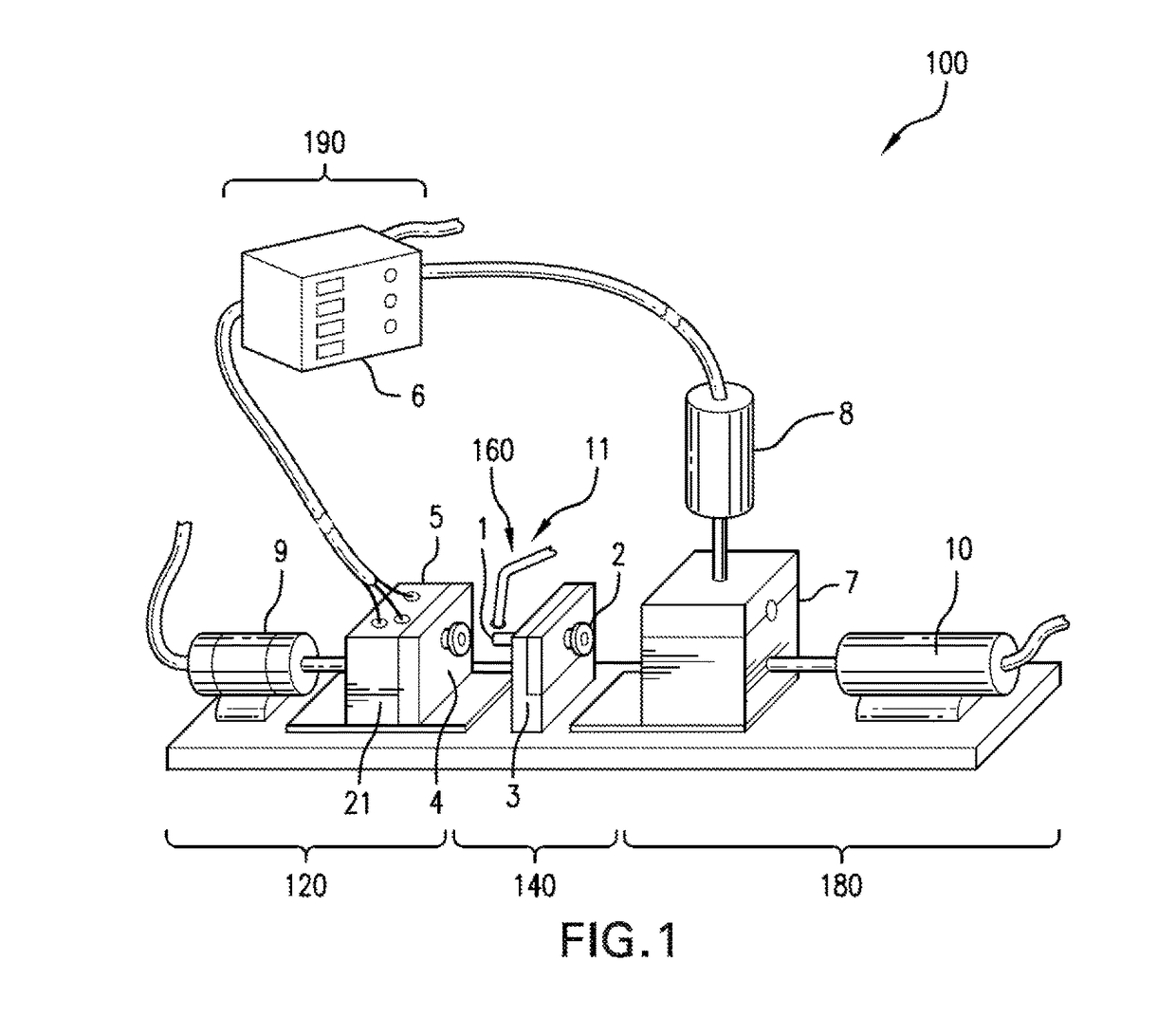

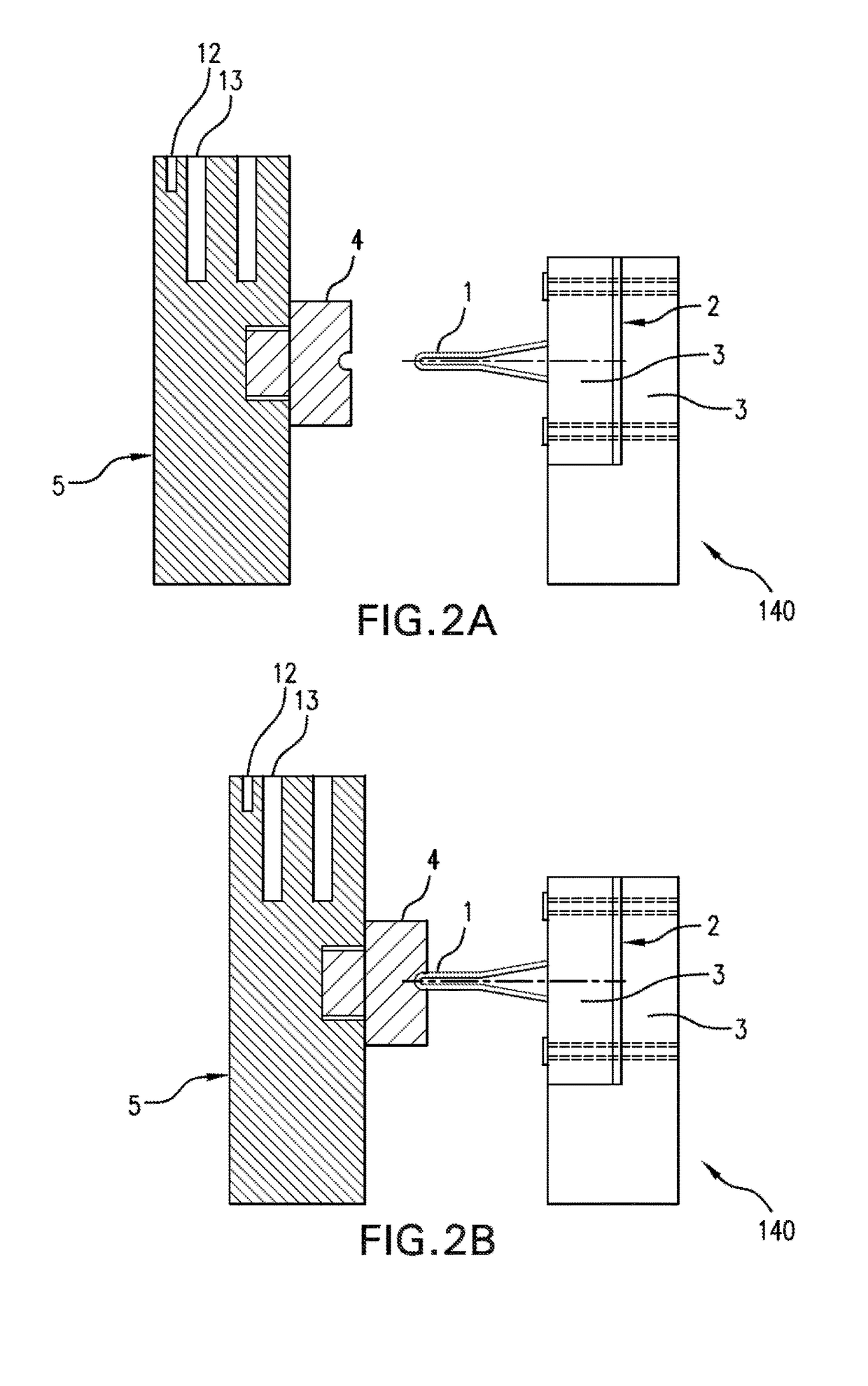

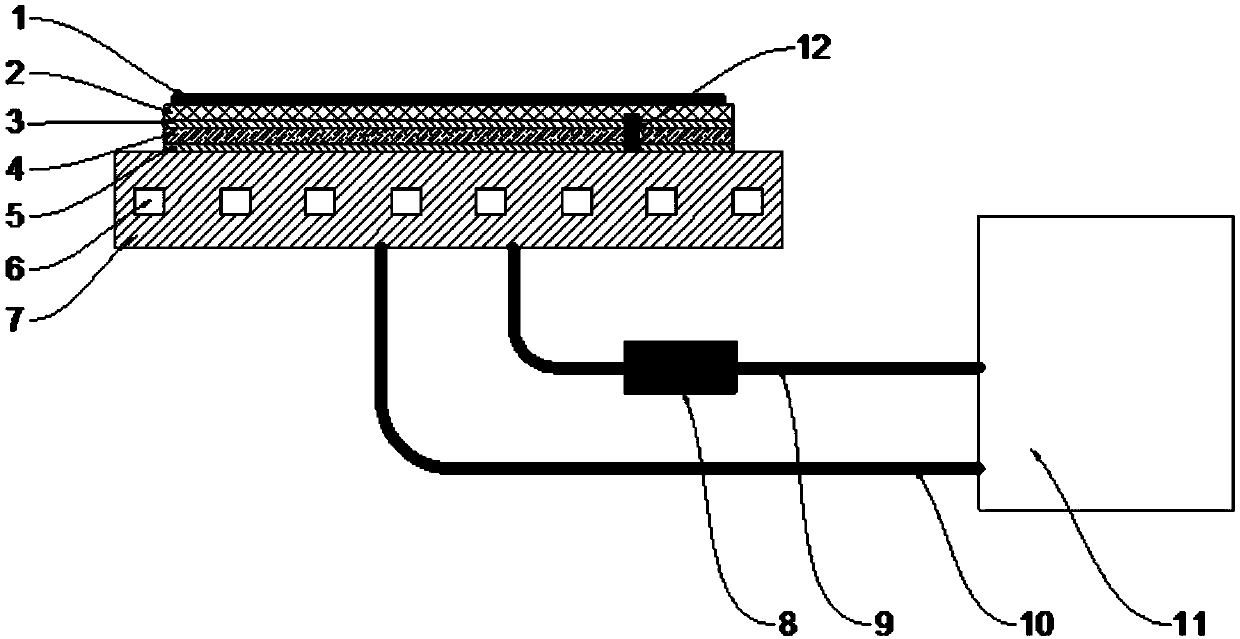

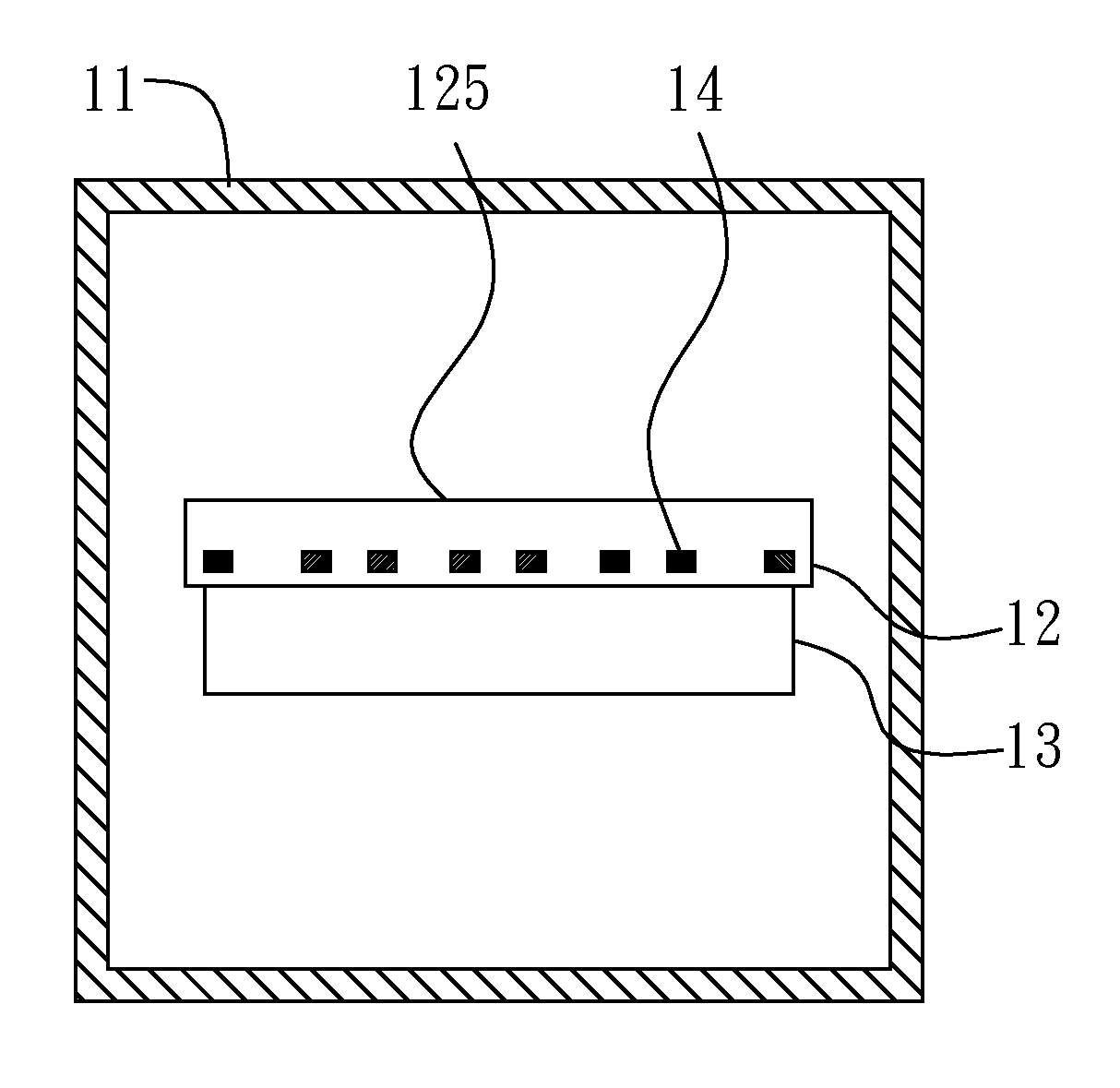

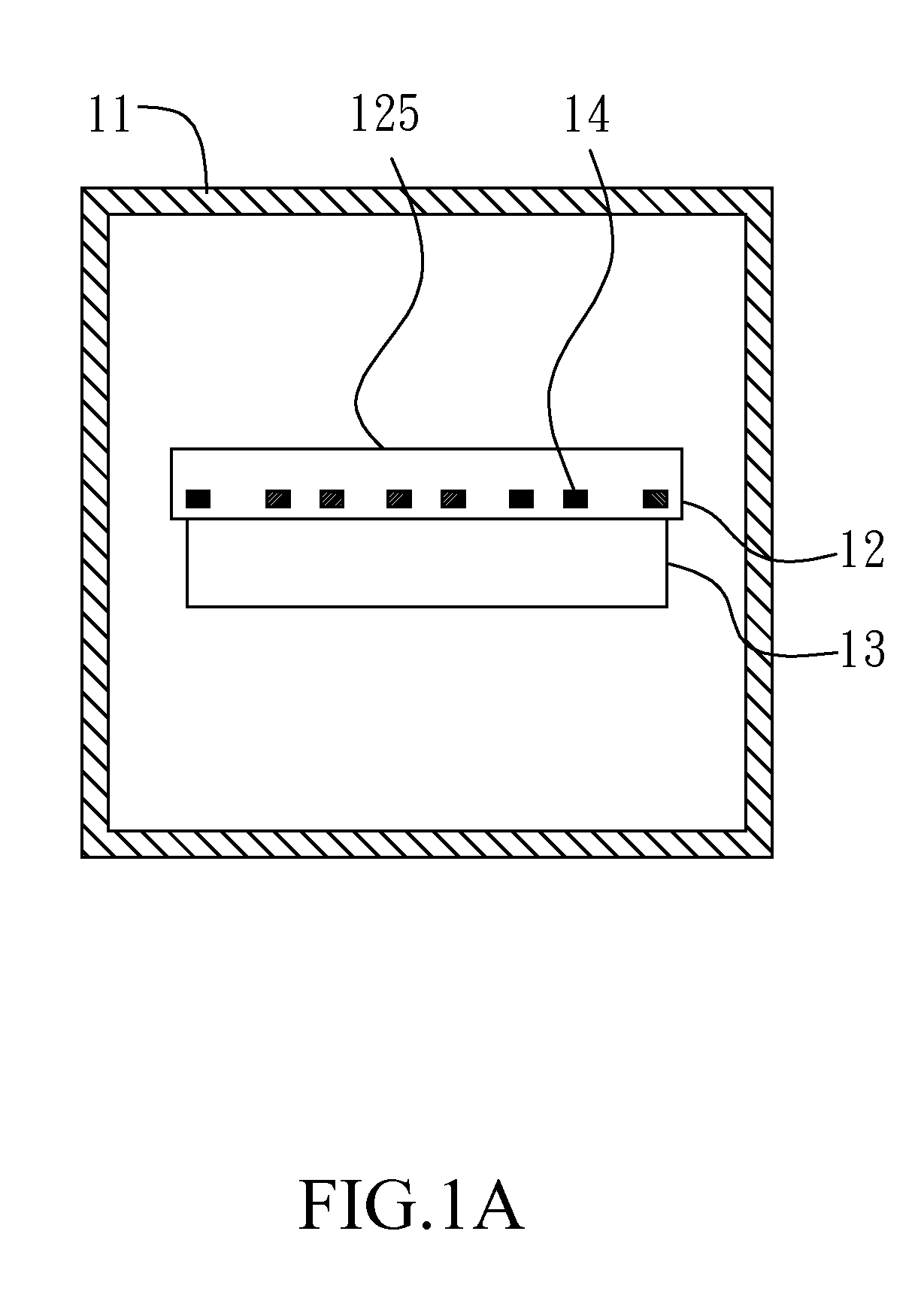

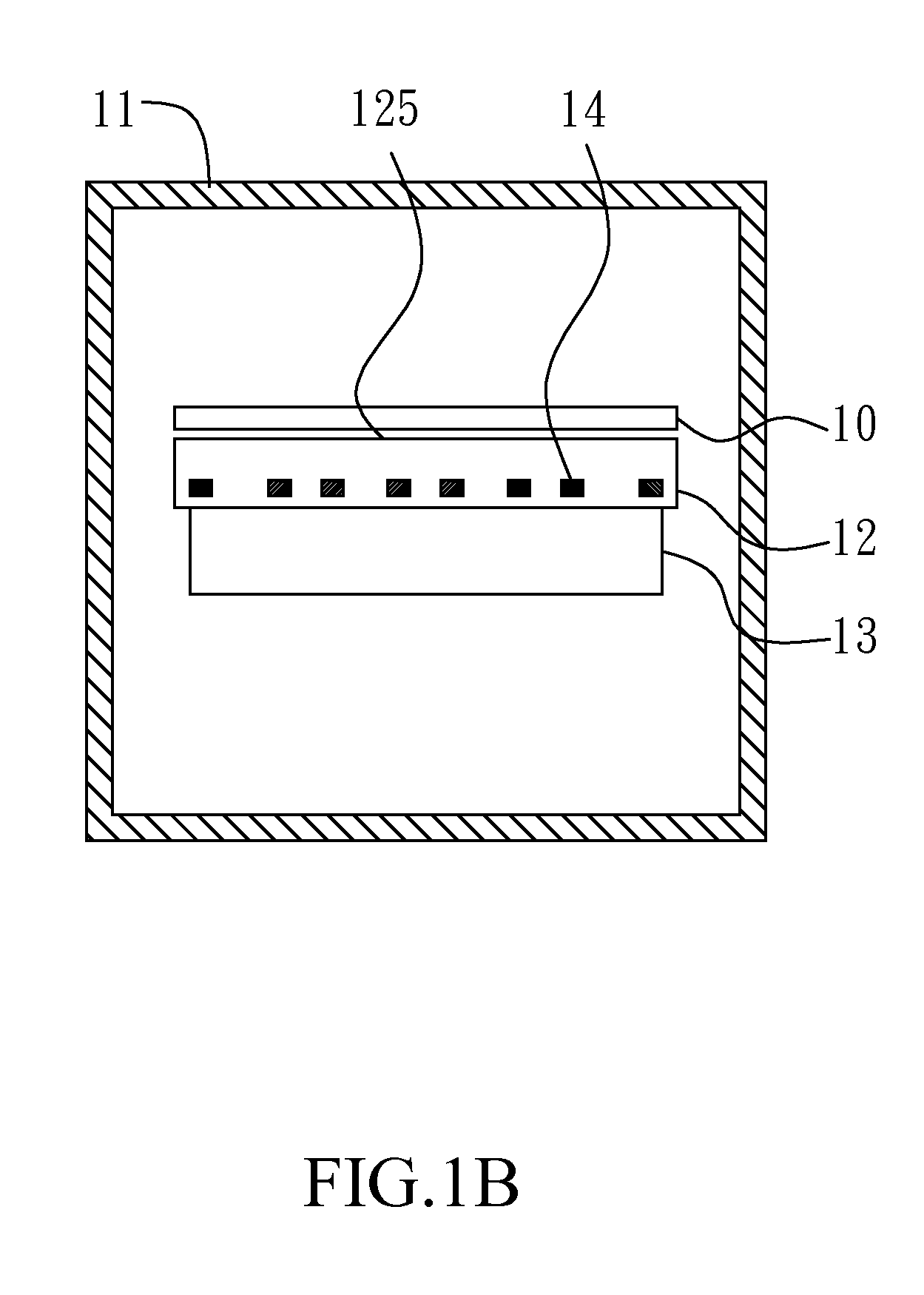

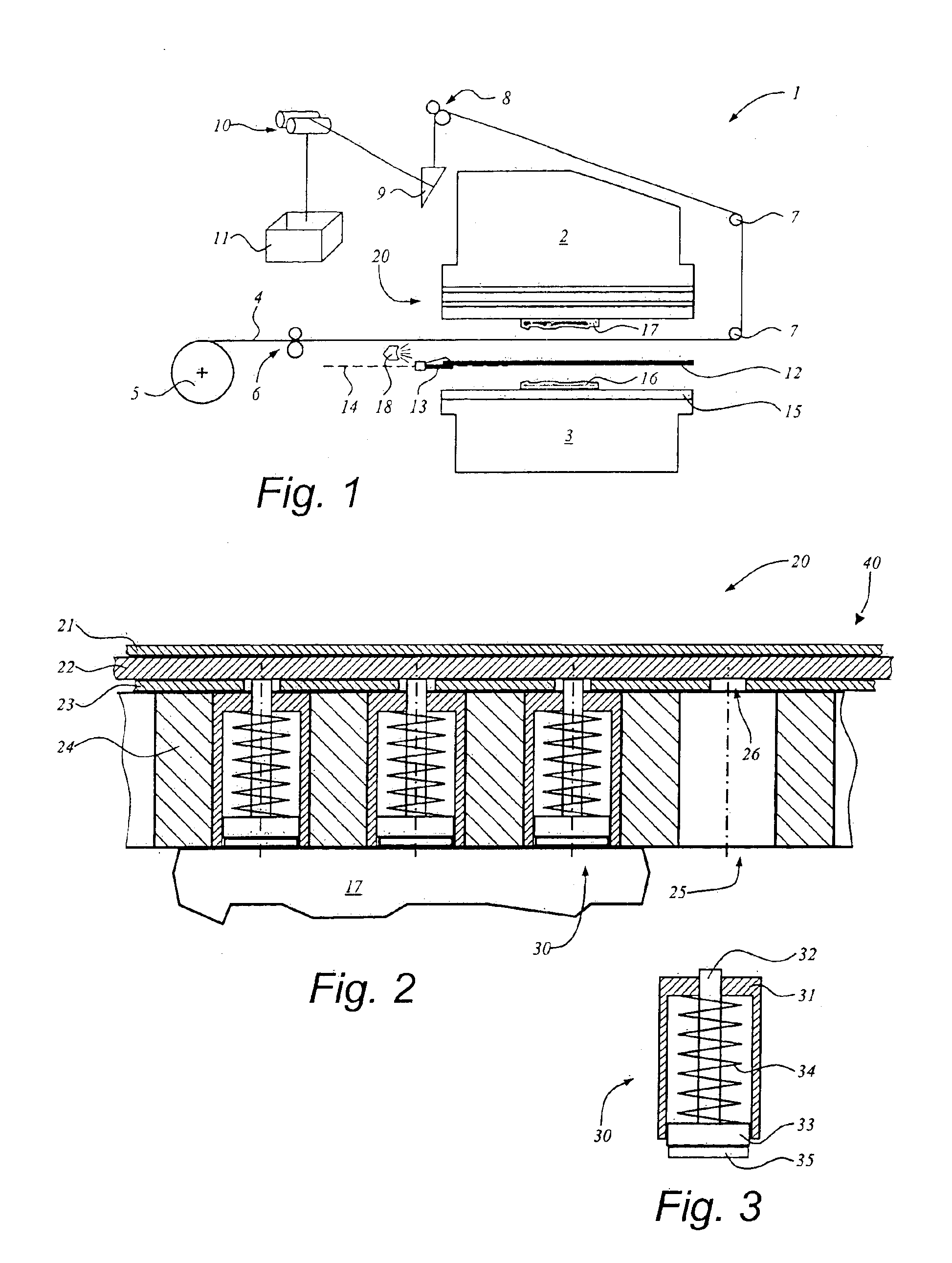

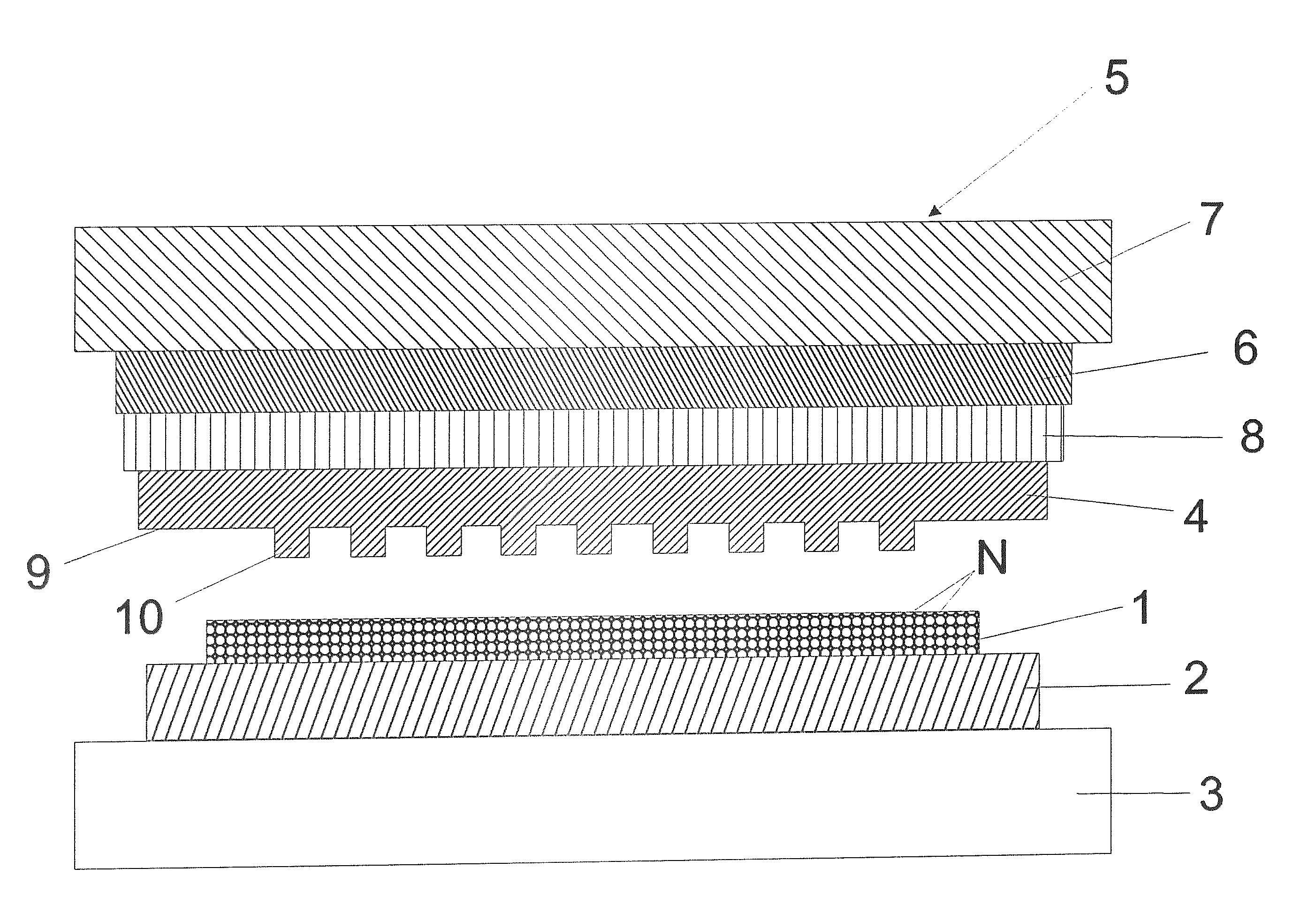

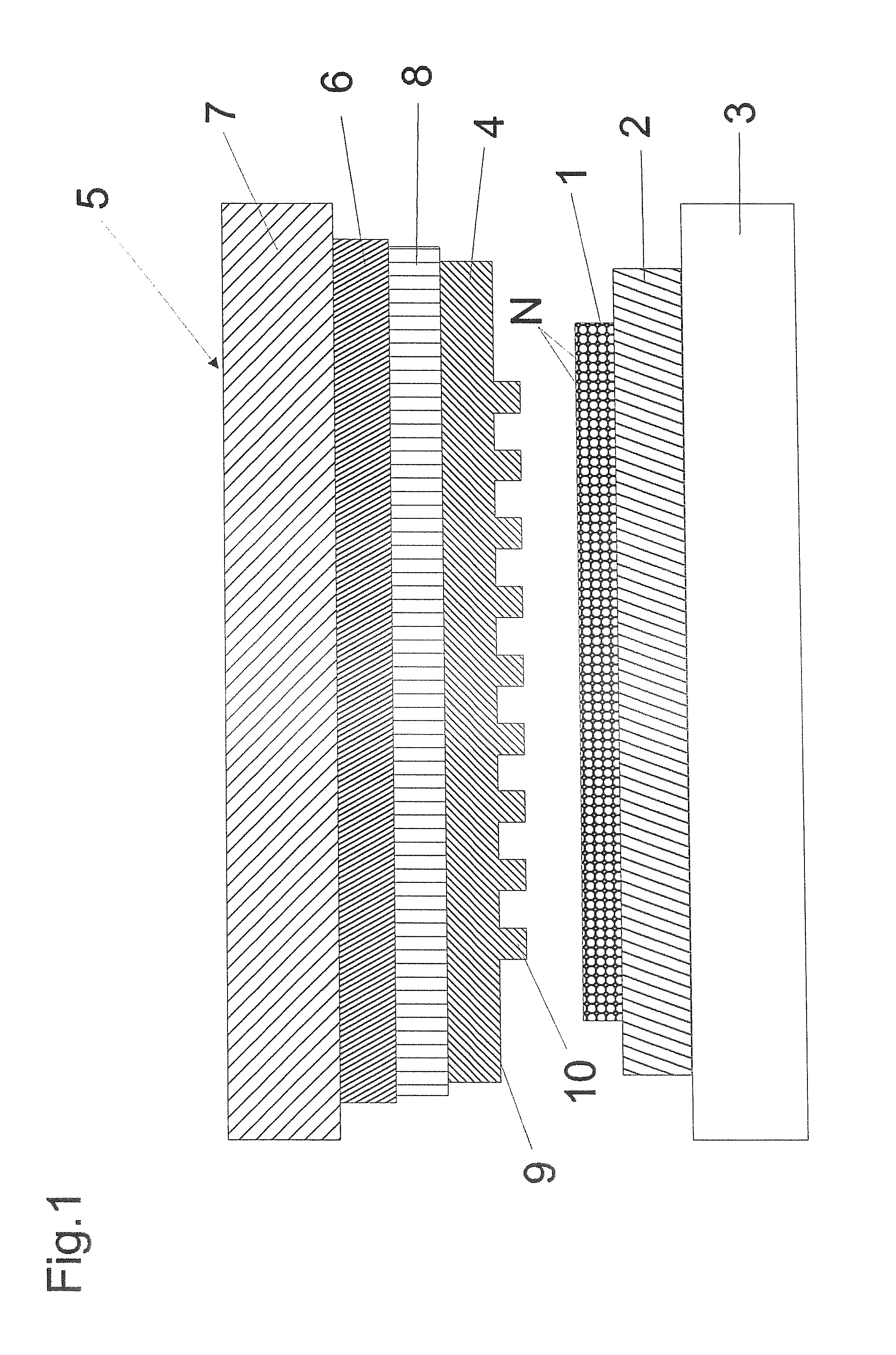

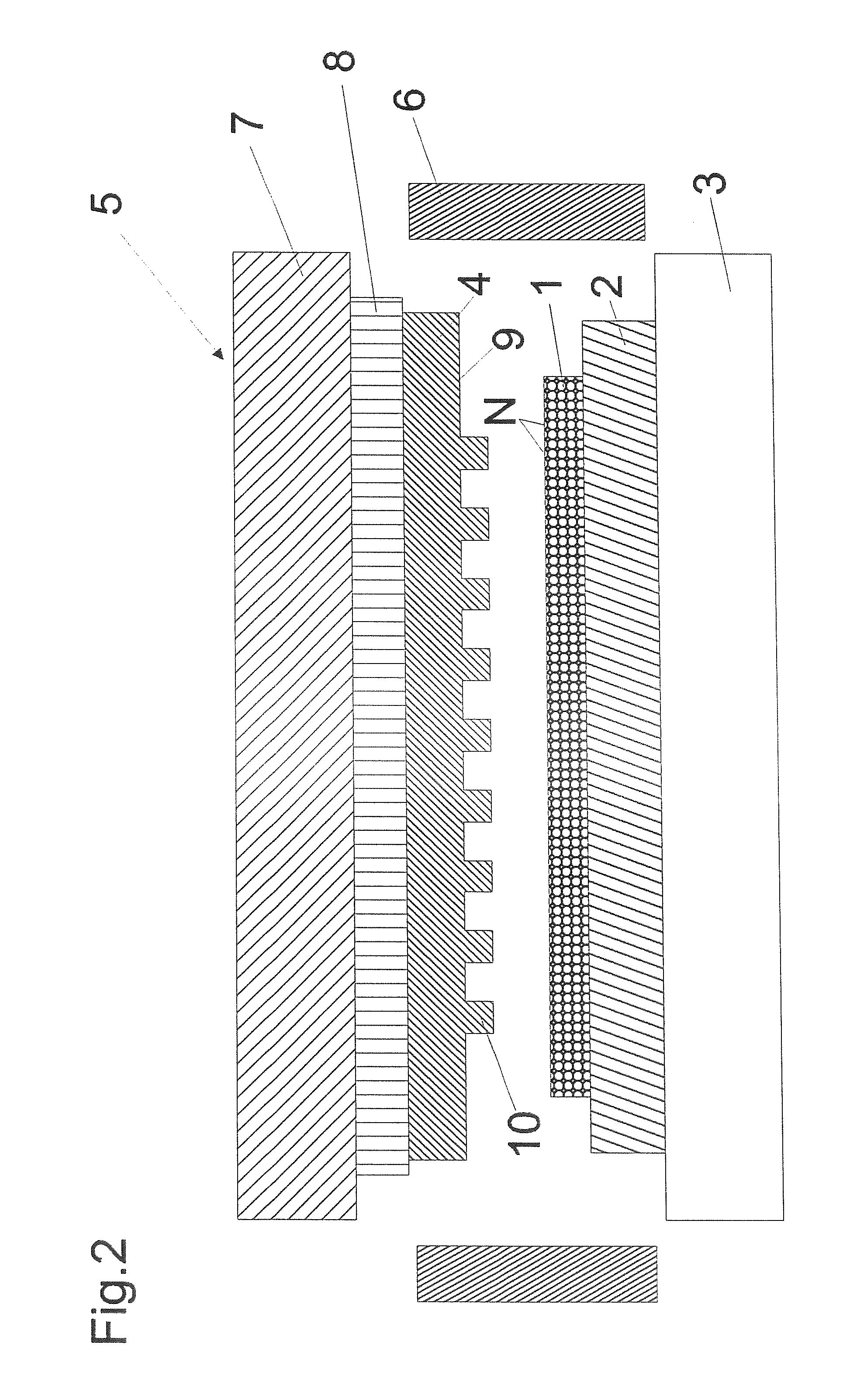

Mounting apparatus

ActiveCN101038888AImprove flatnessInhibit deteriorationSemiconductor/solid-state device manufacturingIndirect heat exchangersTemperature controlEngineering

To provide a mounting apparatus capable of shortening time required for raising and lowering a temperature of a target object by way of improving the flatness of an assembled top plate and at the same time suppressing the deterioration of the flatness of the top plate by the temperature variation from a low temperature to a high temperature.A wafer chuck 10A includes a top plate 11, a temperature control unit 14 formed of a cooling jacket 12 and a plate heater 13 integrated with the top plate 11, and a heat insulation plate 16 integrated with the temperature control unit 14 through a heat insulation ring 15, the top plate 11 being formed of ceramic. The top plate 11, the cooling jacket 12, and the plate heater 13 are coupled to each other by a third bolt 18C at each portion thereof except for each peripheral portion thereof such that the peripheral portion of the top plate 11 being not coupled thereto, and the cooling jacket 12 and the heat insulation ring 15 are coupled together by a second bolt 18B.

Owner:TOKYO ELECTRON LTD

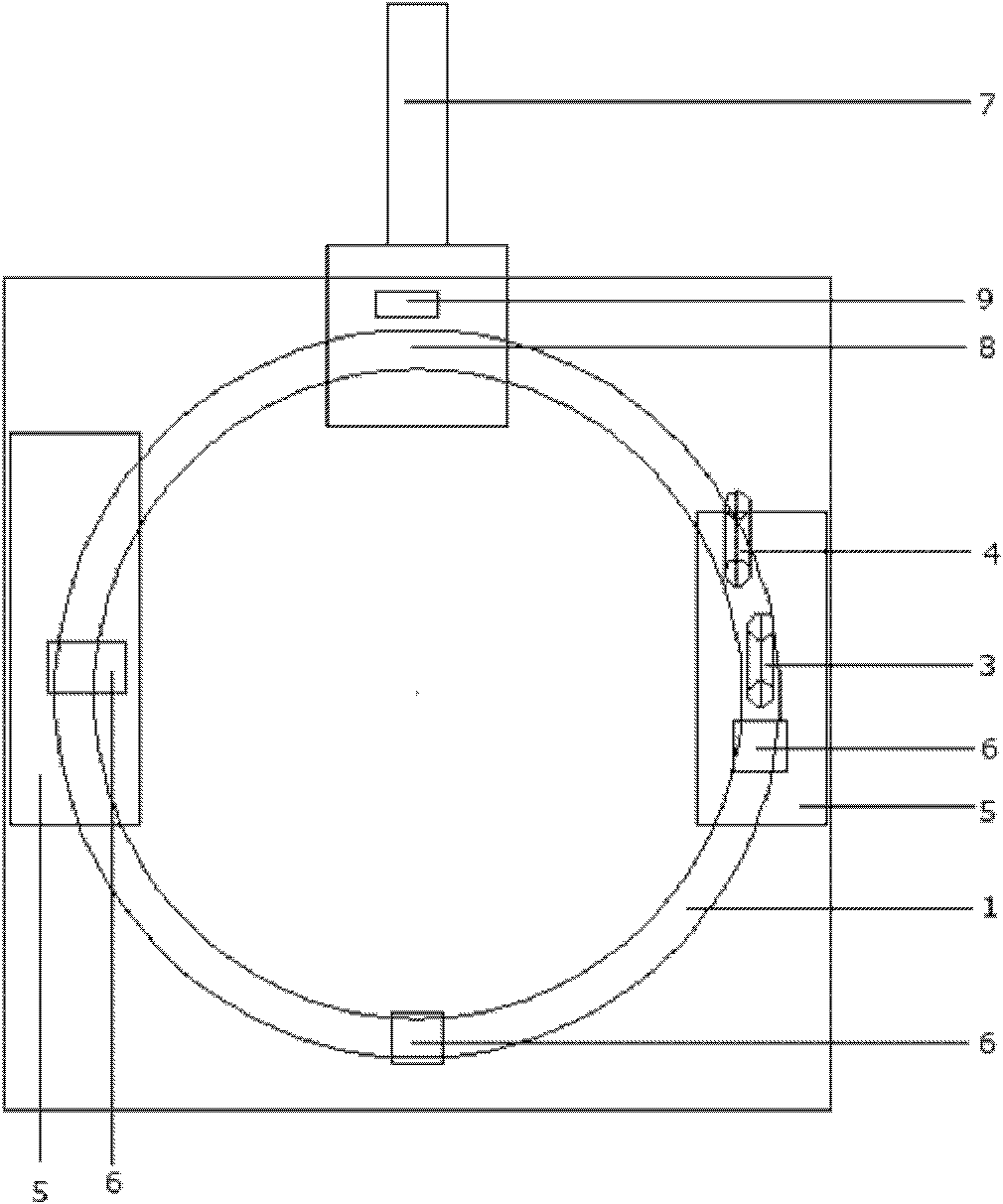

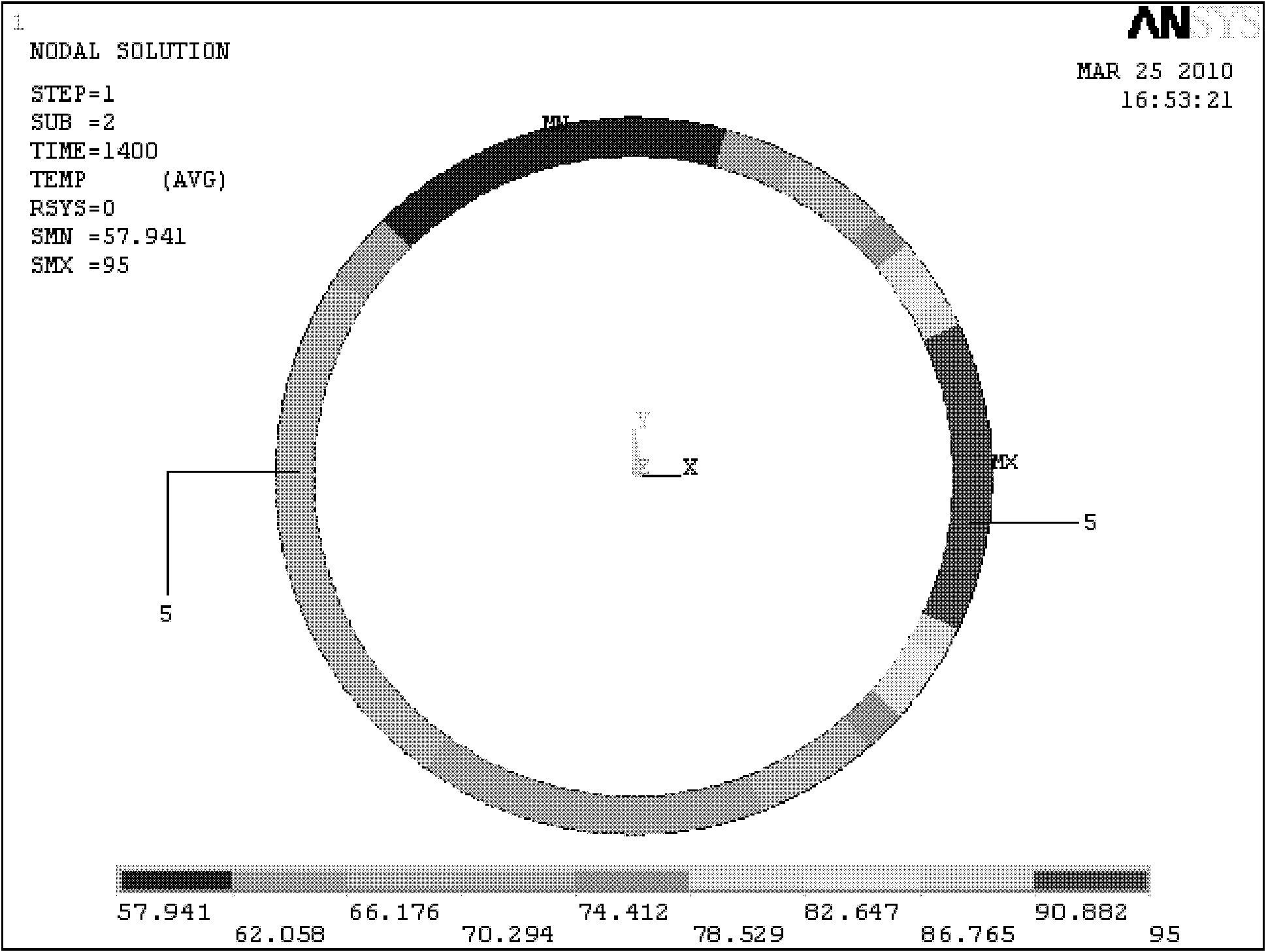

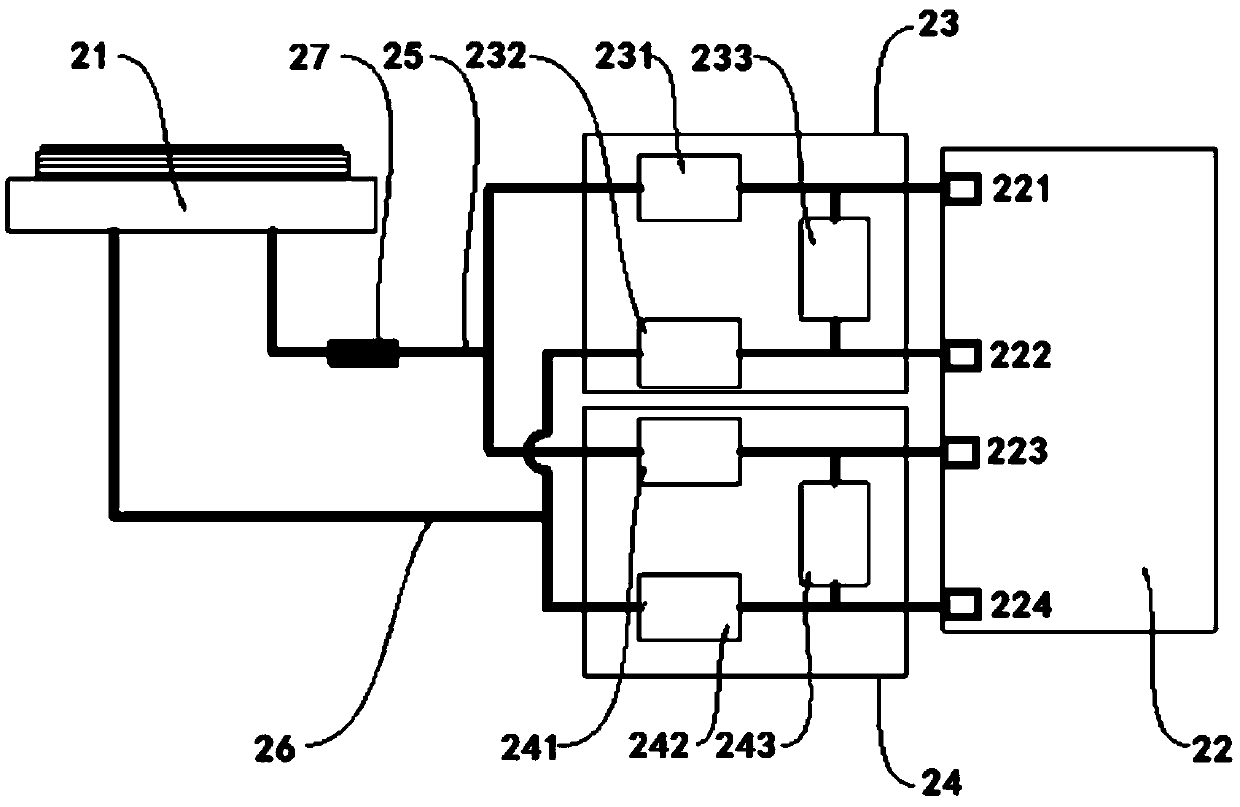

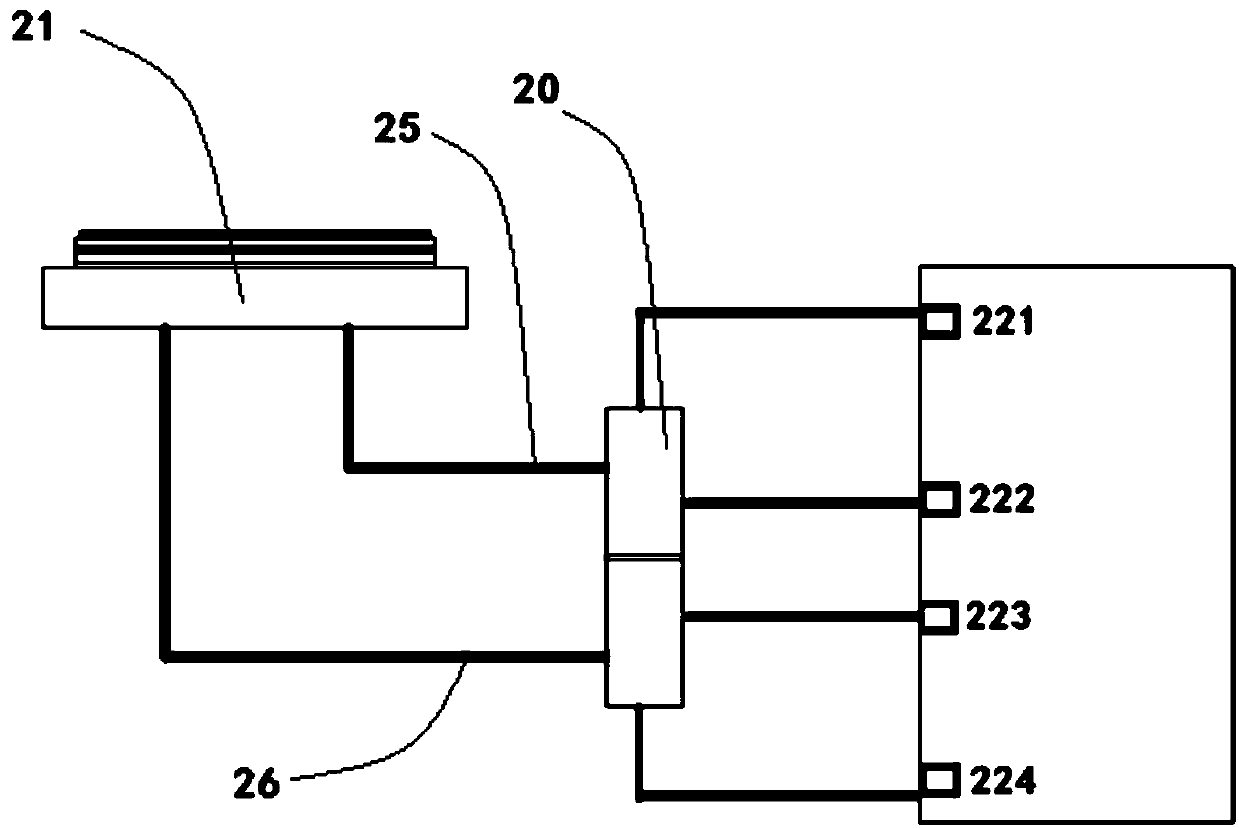

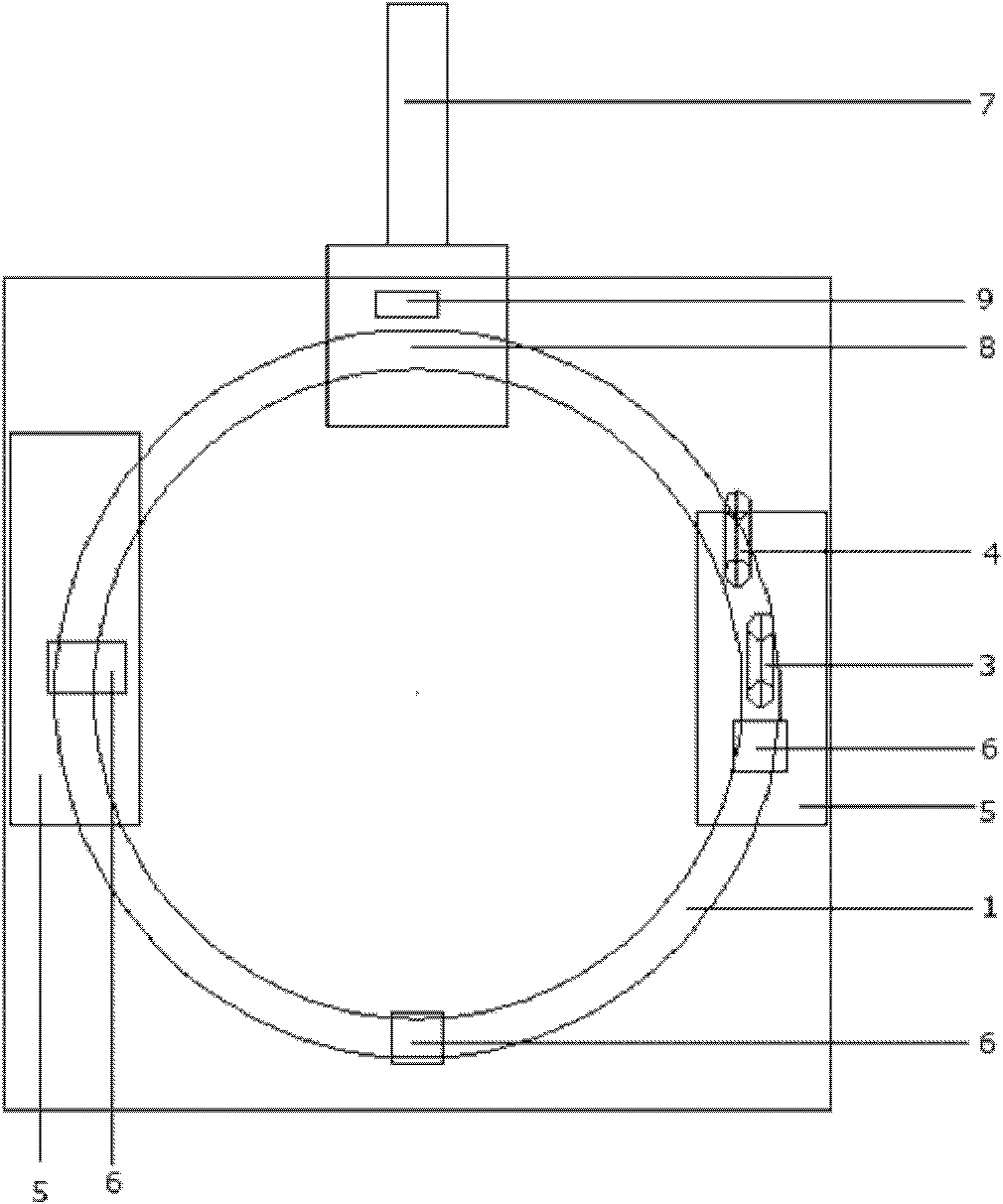

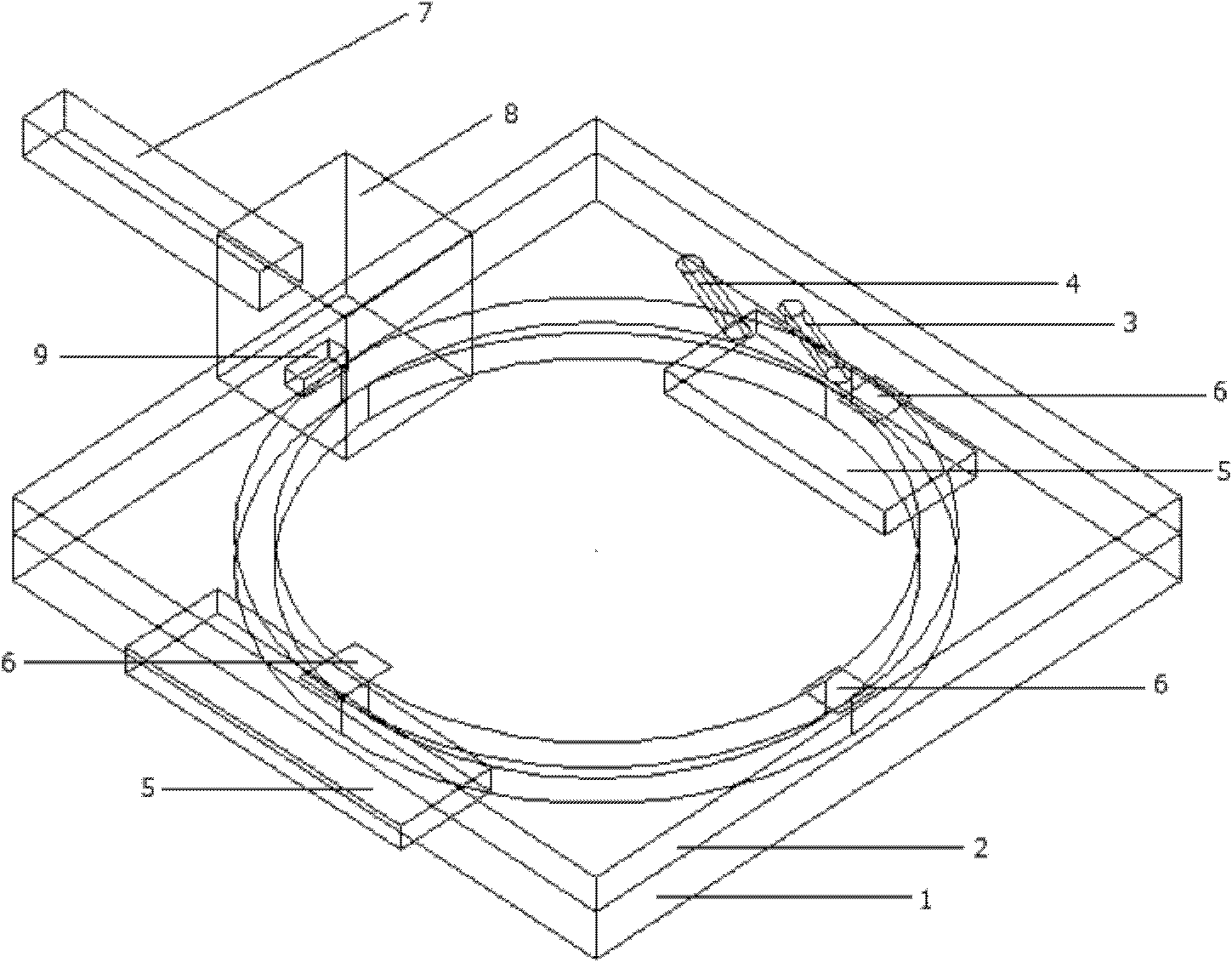

Two-path temperature control polymerase chain reactor and real-time detection device

InactiveCN102220226AShorten the timeExtended service lifeBioreactor/fermenter combinationsBiological substance pretreatmentsMicrofluidic chipMicrofluidic channel

The invention relates to a two-path temperature control polymerase chain reactor and a real-time detection device, which are applied in the field of biochemical reaction and medical detection. The two-path temperature control polymerase chain reactor comprises a base layer with a ring-shaped microfluidic channel structure, wherein the base layer is sealed with a cover board layer to form a microfluidic chip, the cover board layer is provided with a sample incoming hole and a sample outgoing hole, a microprocessor is adopted to control two semi-conductor heating and refrigerating devices, a whole microfluidic channel area forms three constant temperature areas, namely a degeneration area, an annealing area and an extension area needed by polymerase chain reaction, the semi-conductor heating and refrigerating devices are arranged under the microfluidic chip, and a platinum resistance temperature sensor manufactured by a semi-conductor process is arranged among the microfluidic chip and the two semi-conductor heating and refrigerating devices, so that temperature feedback signals are provided to the microprocessor, and closed ring control can be formed. The real-time detection systemcomprises a light source, a photoelectric detector and a fluorescence signal acquisition processing system. In the invention, by controlling the two semi-conductor heating and refrigerating devices, the whole microfluidic channel area forms the three constant temperature areas, and the heating and refrigerating device is simplified.

Owner:BEIJING UNIV OF TECH

Moldable material shaping systems and methods of use

A moldable material shaping system for shaping a moldable material, the system comprising a thermal transfer mold having an internal cavity configured to receive a moldable material, the internal cavity further comprising an internal mold shape, a thermally controlled heat source subsystem configured to heat the thermal transfer mold and the moldable material received in the thermal transfer mold thereby reshaping the moldable material to a deformed moldable material shape conforming to the internal mold shape. Some embodiments further comprise a cooling source subsystem configured to cool the thermal transfer mold and stabilize the moldable material inside the thermal transfer mold to maintain the deformed moldable material shape. Methods of molding a moldable material are also disclosed.

Owner:CATHETER DYNAMICS INC

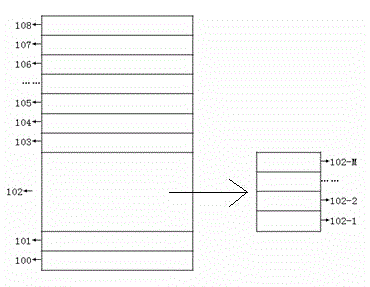

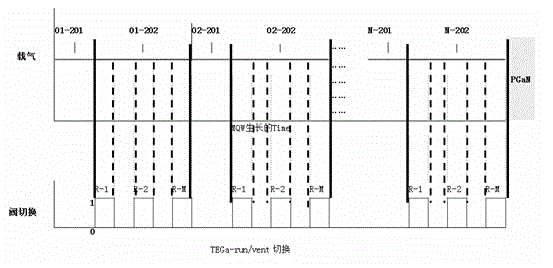

Intermittent-annealing isothermal-growth multi-quantum well LED extension structure and manufacturing method thereof

InactiveCN104319321AUniform crystal plane orientationImprove lattice qualitySemiconductor devicesHydrogen atmosphereCrystal orientation

The invention discloses a manufacturing method of an intermittent-annealing isothermal-growth multi-quantum well LED (light-emitting diode) extension structure, and the manufacturing method comprises the following steps of: preparing a substrate, and treating it at high temperature under hydrogen atmosphere; successively growing a buffer layer and a n-GaN layer on the treated substrate surface; periodically growing a MQW (multiple quantum well) active layer on the n-GaN layer; successively growing a p-GaN contact layer and a P-type contact layer on the MQW active layer; the MQW active layer is composed of at least two MQW layers, each MQW layer includes an InGaN MQW layer, a GaN protection layer and a GaN quantum barrier layer, and each MQW layer is grown at the same temperature. In the manufacturing method, through intermediate intermittent annealing, the extension structure has more uniform crystal orientation and higher crystal lattice quality; through the method, a high-quality MQW structure layer can be manufactured, the luminous efficiency is improved by more than 10%, much original heating and cooling time is saved in the MQW and the capacity is also obviously increased. The surface of low-temperature GaN material is smoothed to achieve uniform two-dimensional growth of the barrier so as to obtain a high-quality MQW material.

Owner:SUZHOU NANOJOIN PHOTONICS

Polymerase chained type reactor and real-time micro-optics detection device

InactiveCN102220227AExtended service lifeLow costBioreactor/fermenter combinationsBiological substance pretreatmentsFluorescenceClosed loop

The invention discloses a polymerase chained type reactor and a real-time micro-optics detection device thereof, relating to the field of biochemical reaction and medicine detection. The real-time micro-optics detection device comprises a basal layer with a helical micro-channel structure, and the basal layer is sealed with a cover plate layer. Semiconductor heating refrigerators are arranged below a microfluidic chip; and a microprocessor is used for controlling the three semiconductor heating refrigerators to ensure that a whole micro-channel area is divided into a denaturation area, an annealing area and an extending area which are required for polymerase chained type reaction. Three platinum resistor temperature sensors are arranged between the microfluidic control chip and the three semiconductor heating refrigerators to form a closed-loop temperature control. A real-time fluorescence detection system comprises a light source, a photoelectric detector and a fluorescent signal acquiring and processing system, wherein a linear array light-emitting diode is used as the light source, and a photoelectric photomultiplier is used as the photoelectric detector; and the linear array light-emitting diode and the photoelectric photomultiplier are fixed above the extending area of the microfluidic control chip by an optical stand. According to the polymerase chained type reactor and the real-time micro-optics detection device disclosed by the invention, temperature rise and fall time is omitted, the time of polymerase chained type reaction is shortened and the service life of thesemiconductor heating refrigerators is prolonged.

Owner:BEIJING UNIV OF TECH

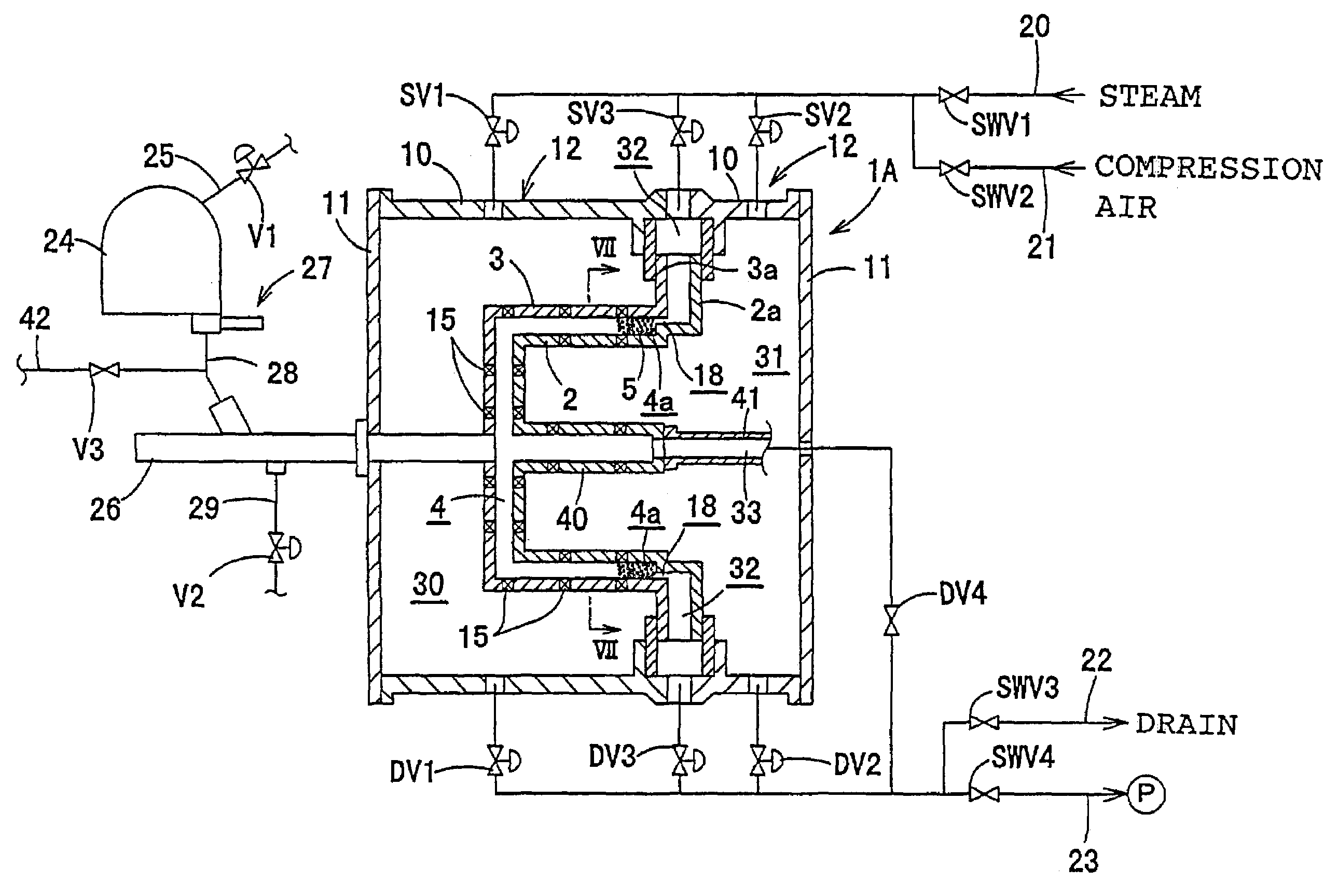

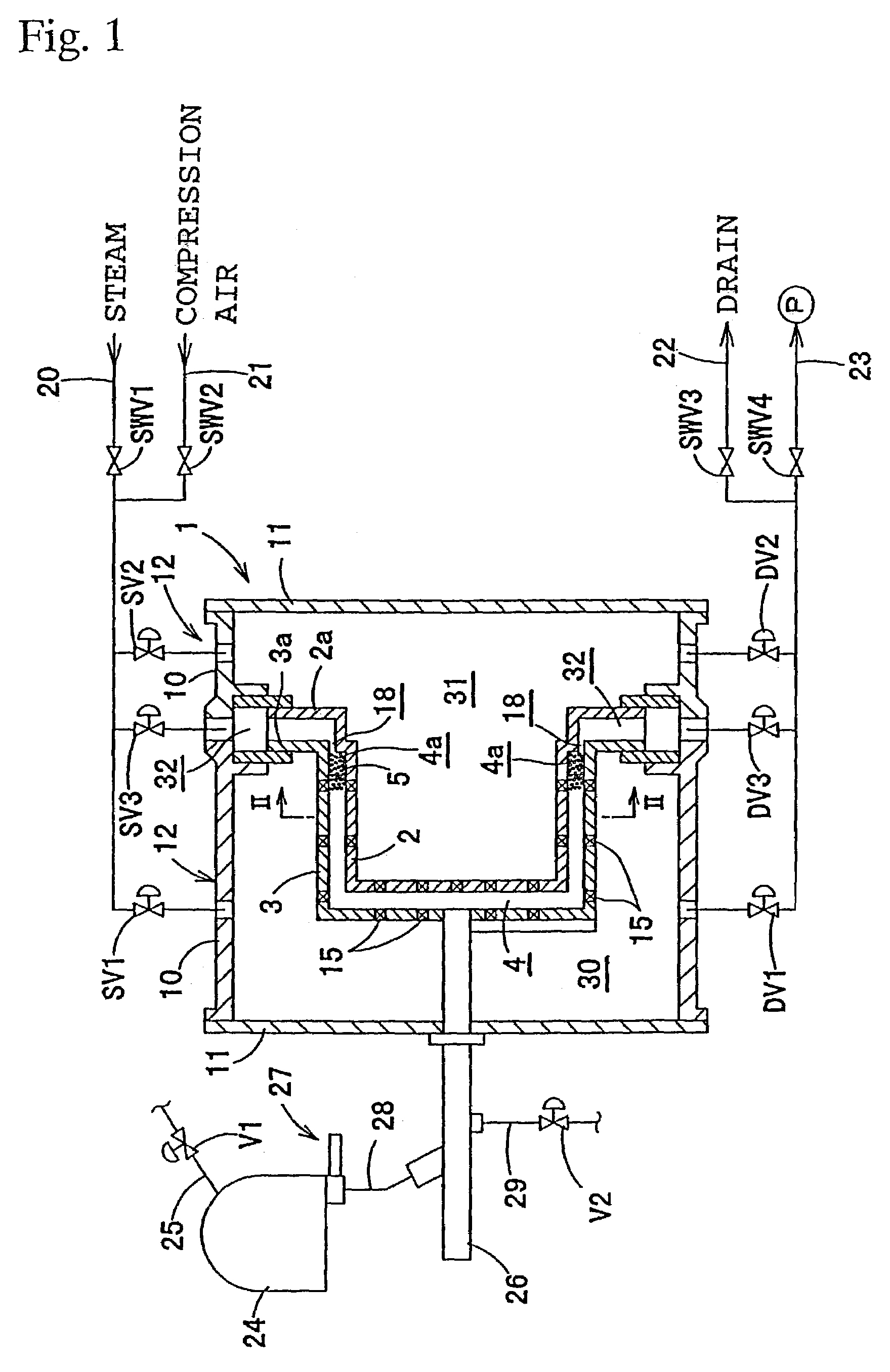

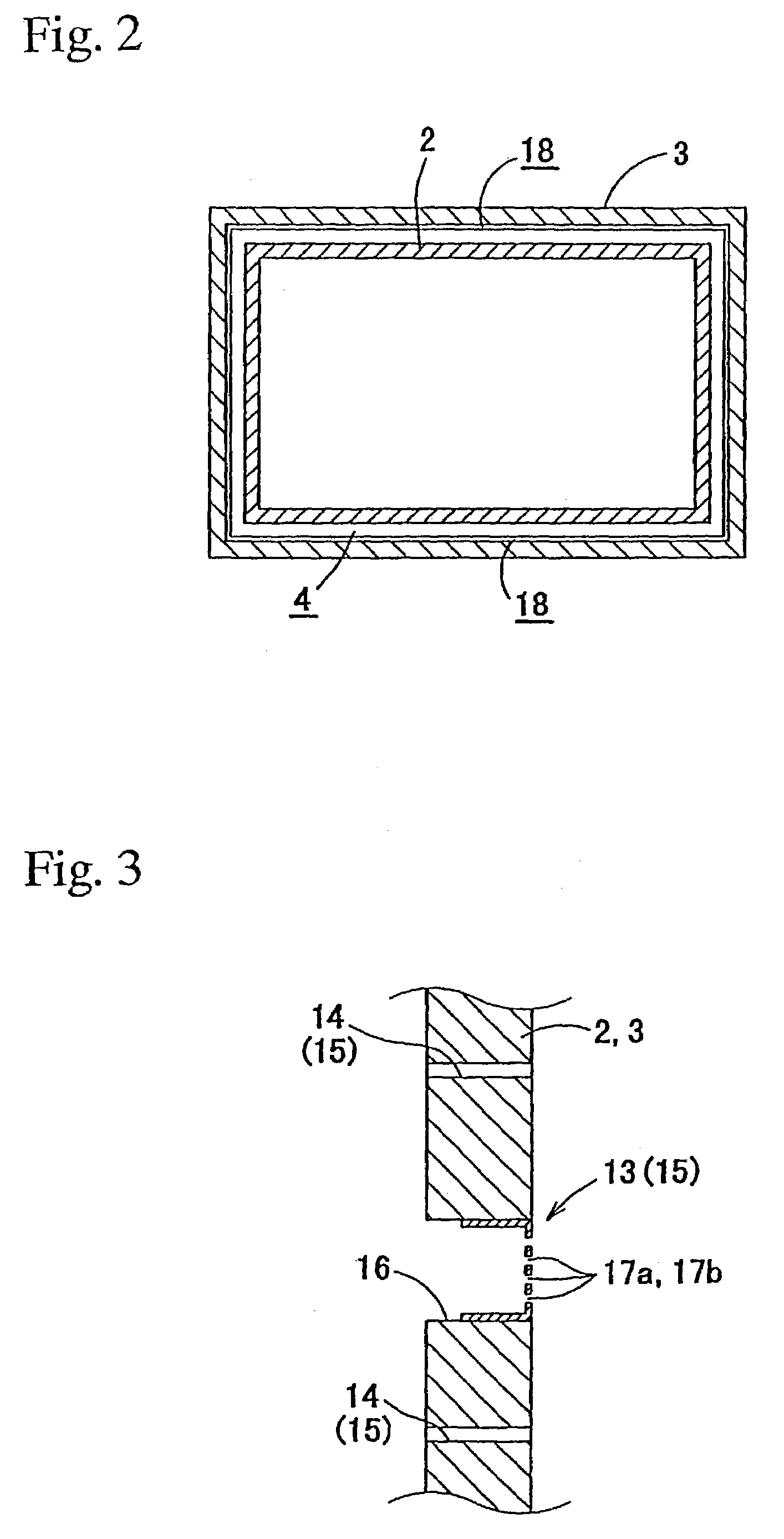

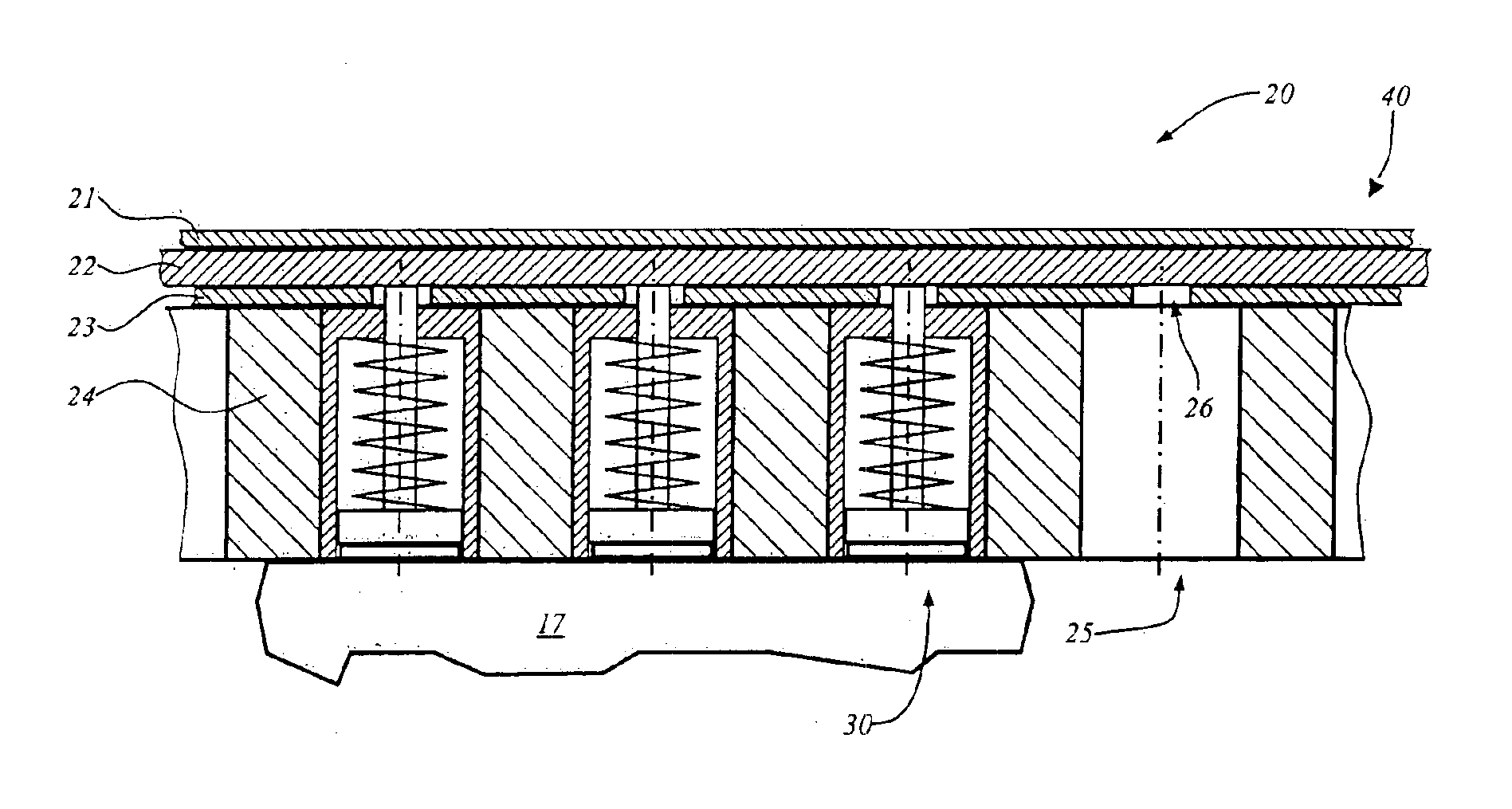

Die-expanded molding apparatus and method for synthetic resin, and die-expanded molded foam obtained thereby

InactiveUS7070720B2Shorten heating and cooling timeSatisfy the rigidity requirementWood working apparatusFlat articlesEngineeringAtmospheric pressure

A die-expanded molding apparatus comprising starting material bead supply for supplying beads on a current of air from a tank through a packer into a cavity formed by a core and cavity molds; a plurality of air expulsion devices having air pressure-adjusting components communicating with the cavity, a dual-system air expulsion device being such that steam chambers on the back side of the core mold and the cavity mold are used as the air pressure-adjusting components, each communicating with the cavity through through-holes formed in the core and cavity molds, respectively; an air expulsion device having one or more air pressure-adjusting components communicating with a clearance between the core and cavity molds; and a control for controlling the air pressure in each of the air pressure-adjusting components to be pressurized less than the pressure in the tank.

Owner:DAISEN IND CO LTD +1

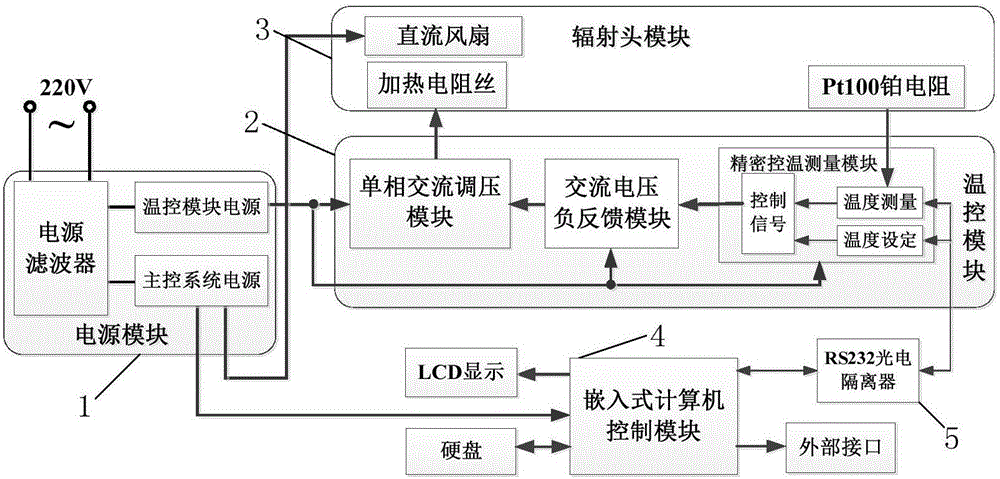

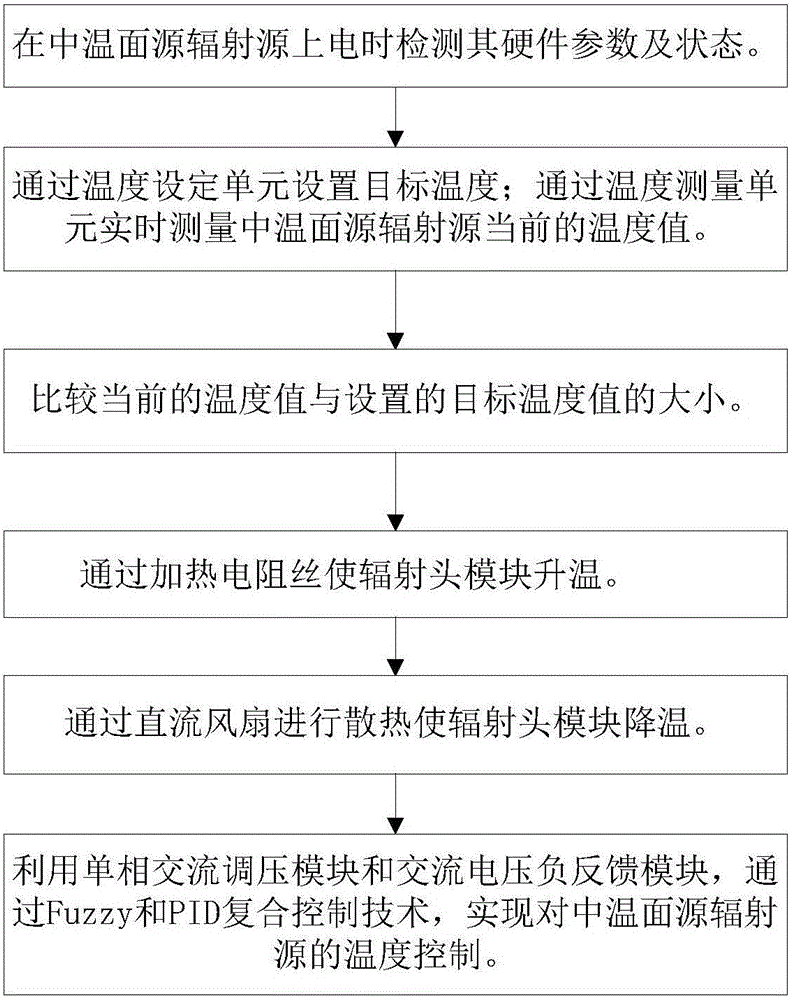

Temperature control device and method for medium temperature surface radiation source

InactiveCN105929872AImprove stabilityImprove uniformityAuxillary controllers with auxillary heating devicesTemperature controlEngineering

The invention discloses a temperature control device and method for a medium temperature surface radiation source, and belongs to the technical field of temperature control. The device comprises a power module, a temperature control module, a radiation head module, an embedded computer control module, and an optoelectronic isolator. The device employs a precise temperature control measurement module to precisely control a radiation panel of the medium temperature surface radiation source, employs the technologies of dynamic adjustment temperature control power and multipoint nonlinear correction, achieves the large-area and broadband infrared radiation output, and improves the temperature stability, uniformity and temperature rise and fall time.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

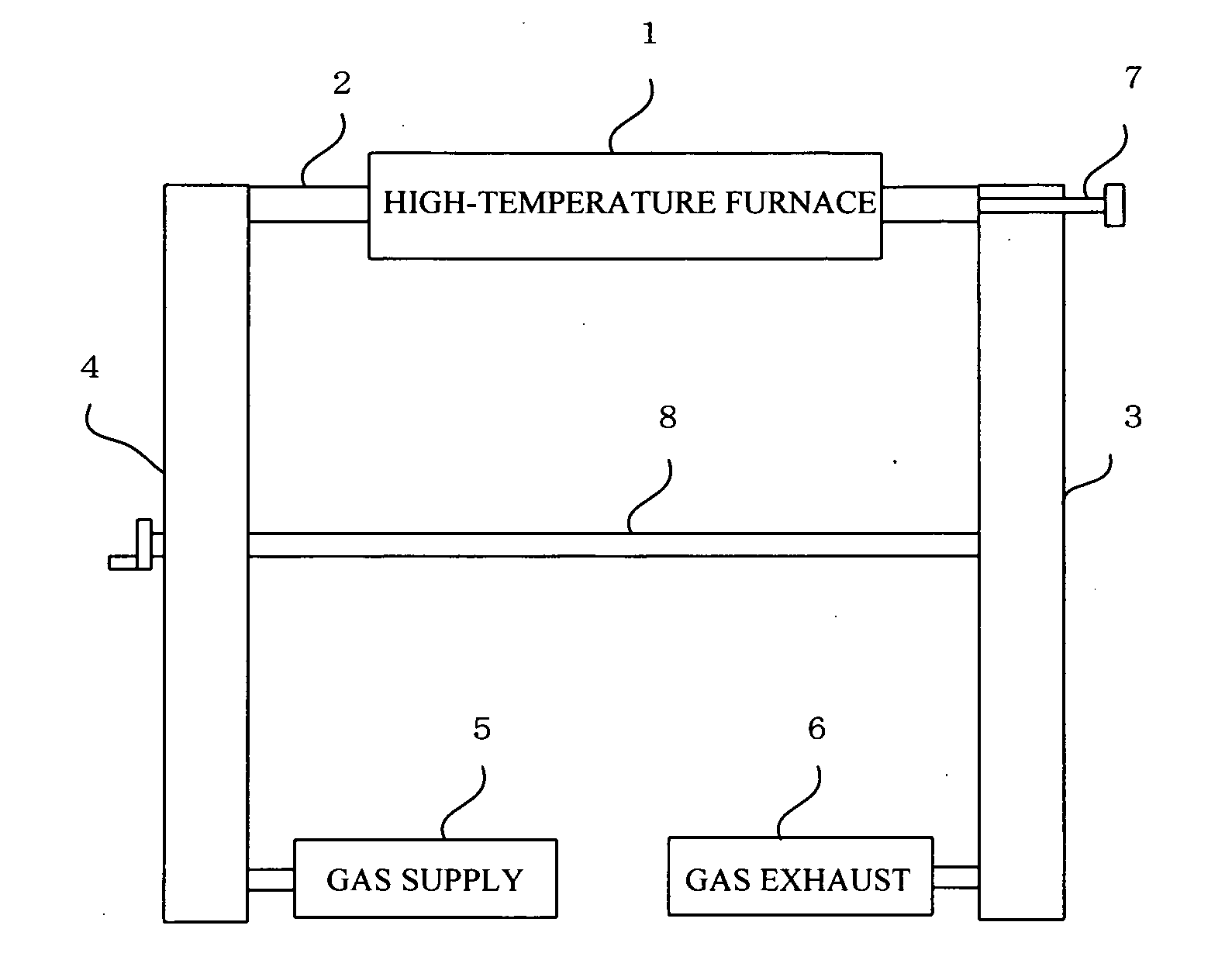

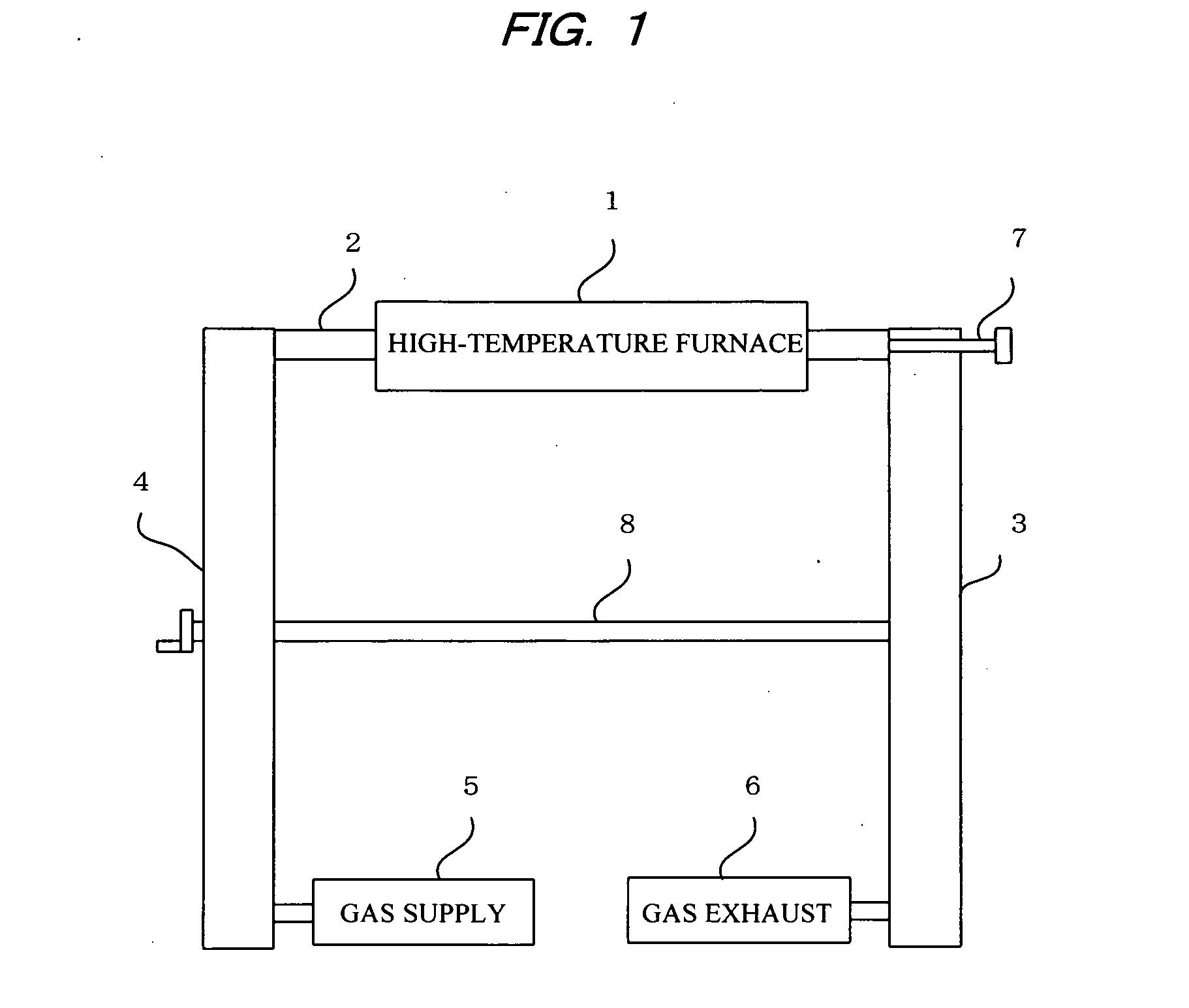

Continuous-atmosphere high-temperature furnace apparatus, method of continuous production of nanocarbon, and method of burning and graphitizing nano-material

InactiveUS20080241779A1Shorten cooling timeShorten heating timeMaintainance of heating chambersFurnace typesEngineeringProduct gas

A continuous-atmosphere high-temperature furnace apparatus comprises a high-temperature furnace section, a mechanism for continuously supplying substrates or samples to the high-temperature furnace section, and a mechanism for continuously discharging treated substrates or samples from the high-temperature furnace section. Gas is exhausted from the high-temperature furnace section and ambient gas is supplied thereto for reaction to produce carbon materials and various other nanomaterials or to burn and graphitize the nanomaterials. The substrates or samples are sequentially moved for heat treatment, thereby improving the work efficiency of the high-temperature furnace.

Owner:SHONAN GOSEI JUSHI SEISAKUSHO KK

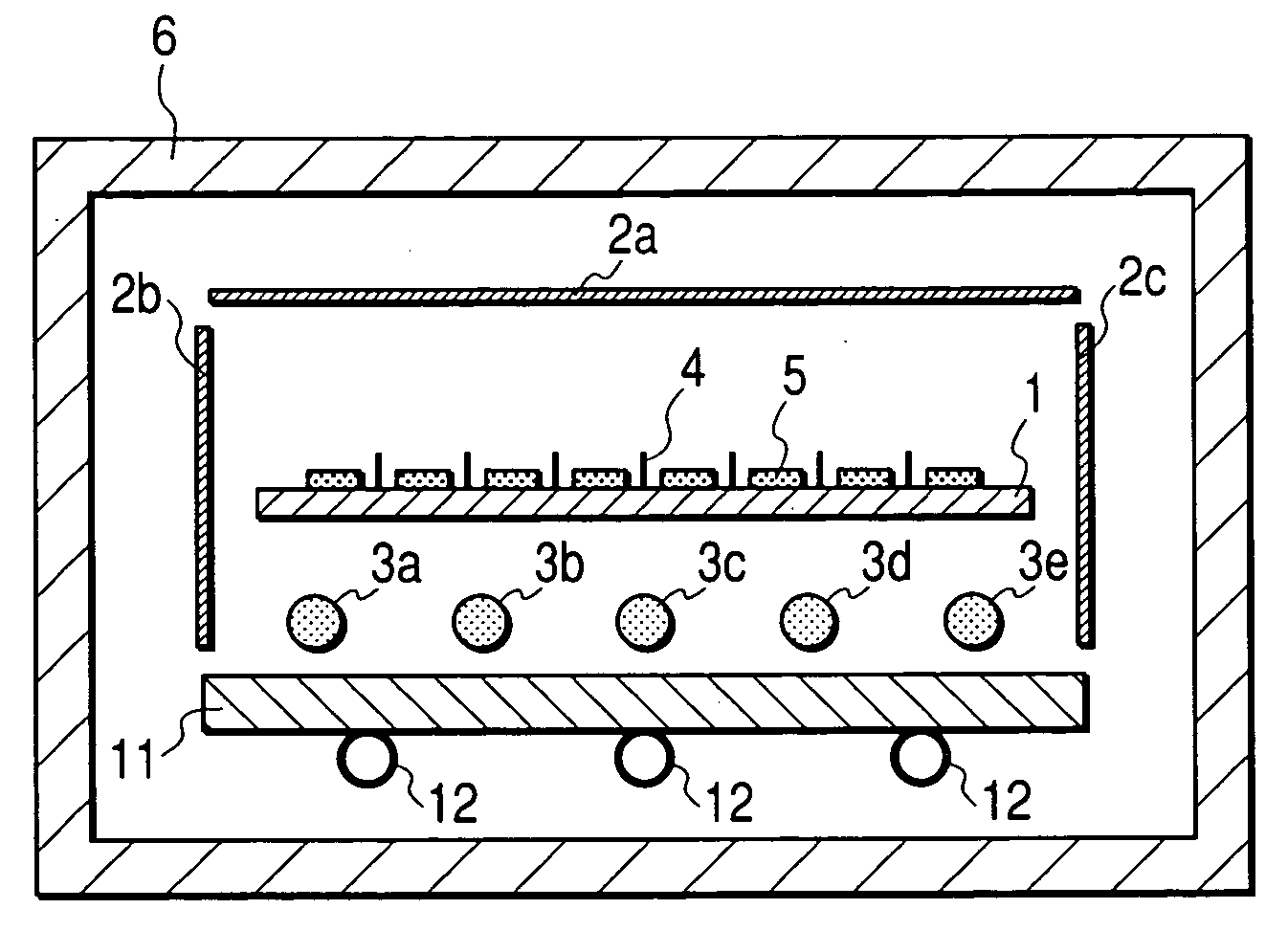

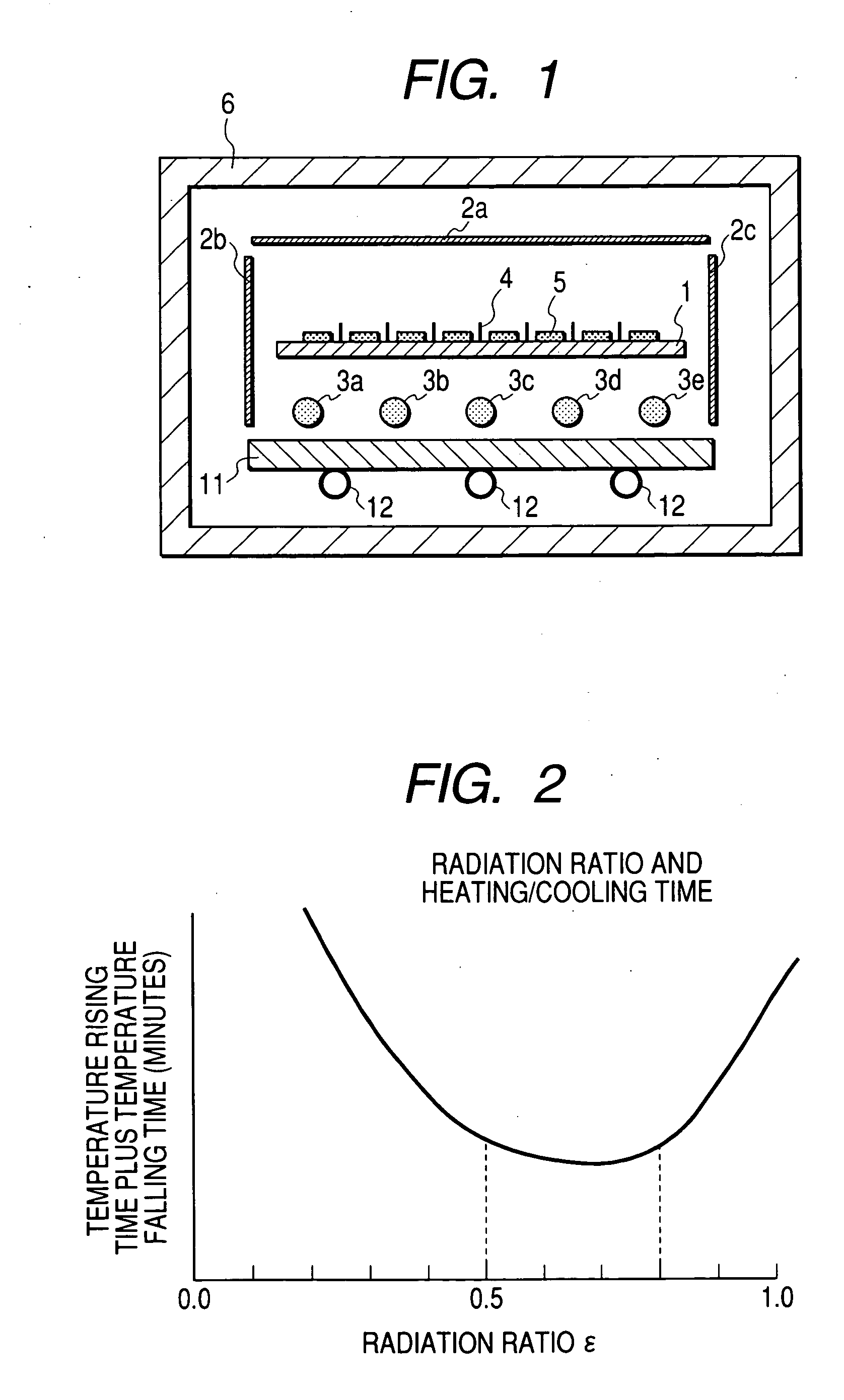

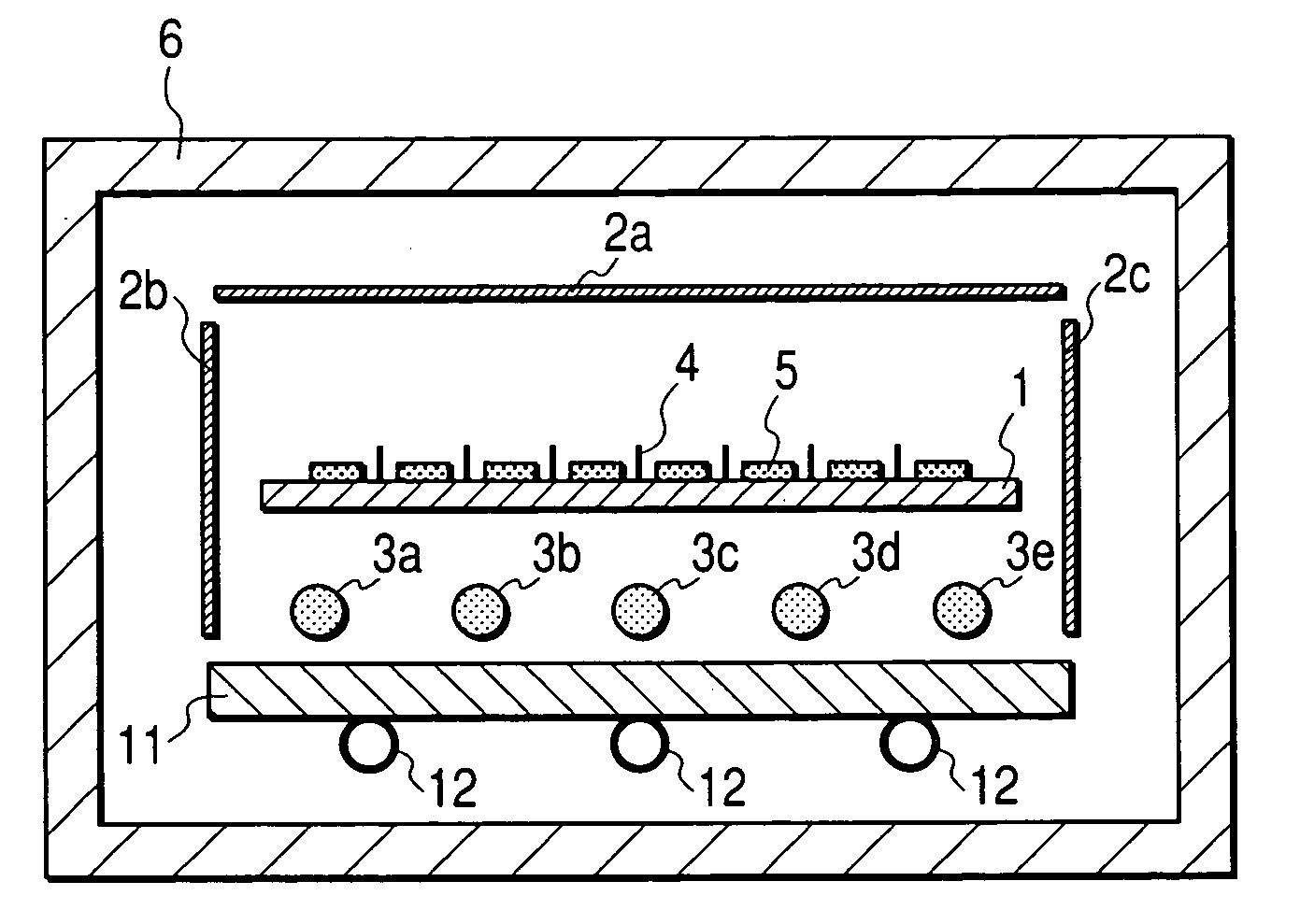

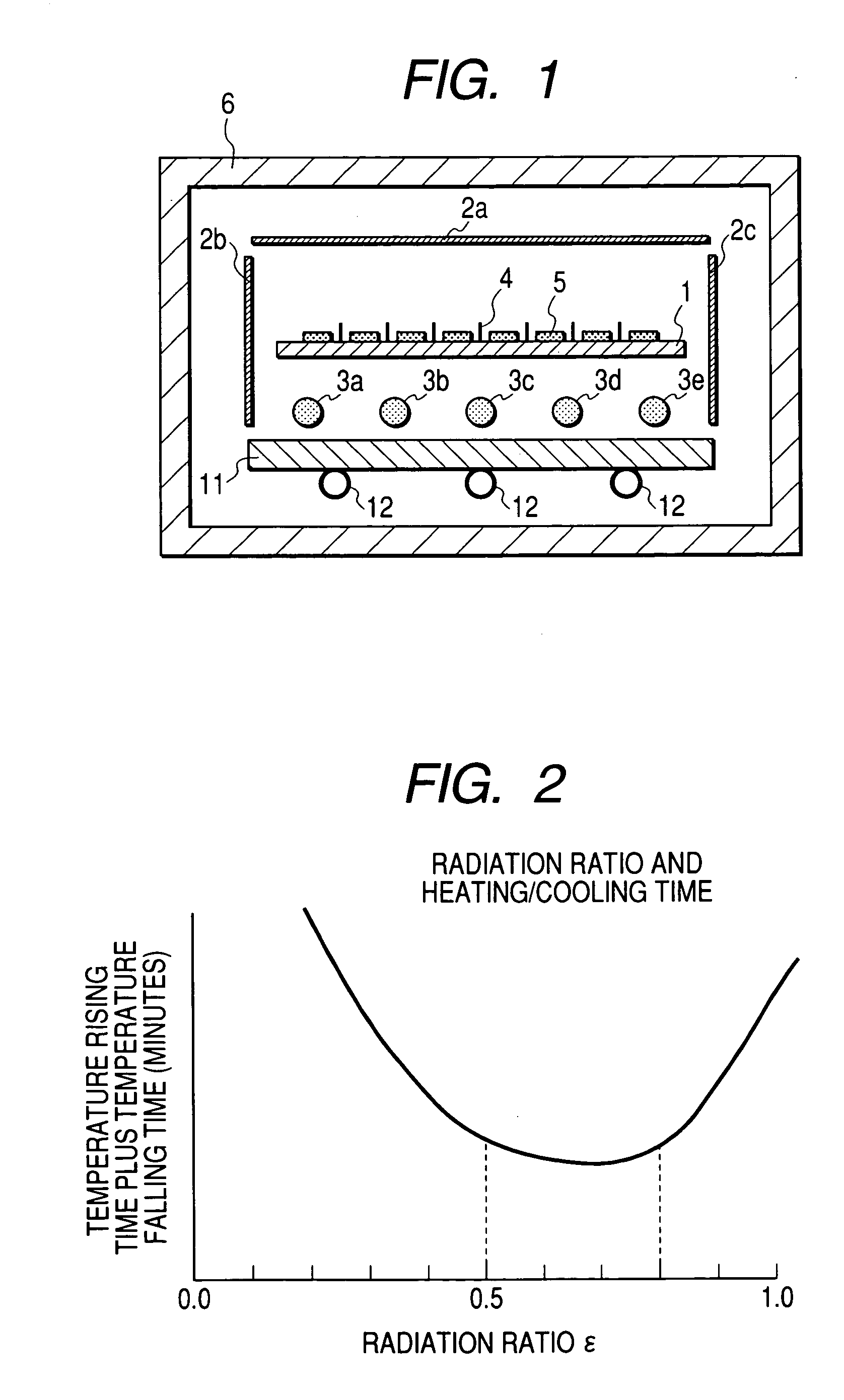

Method of effecting heating and cooling in reduced pressure atmosphere

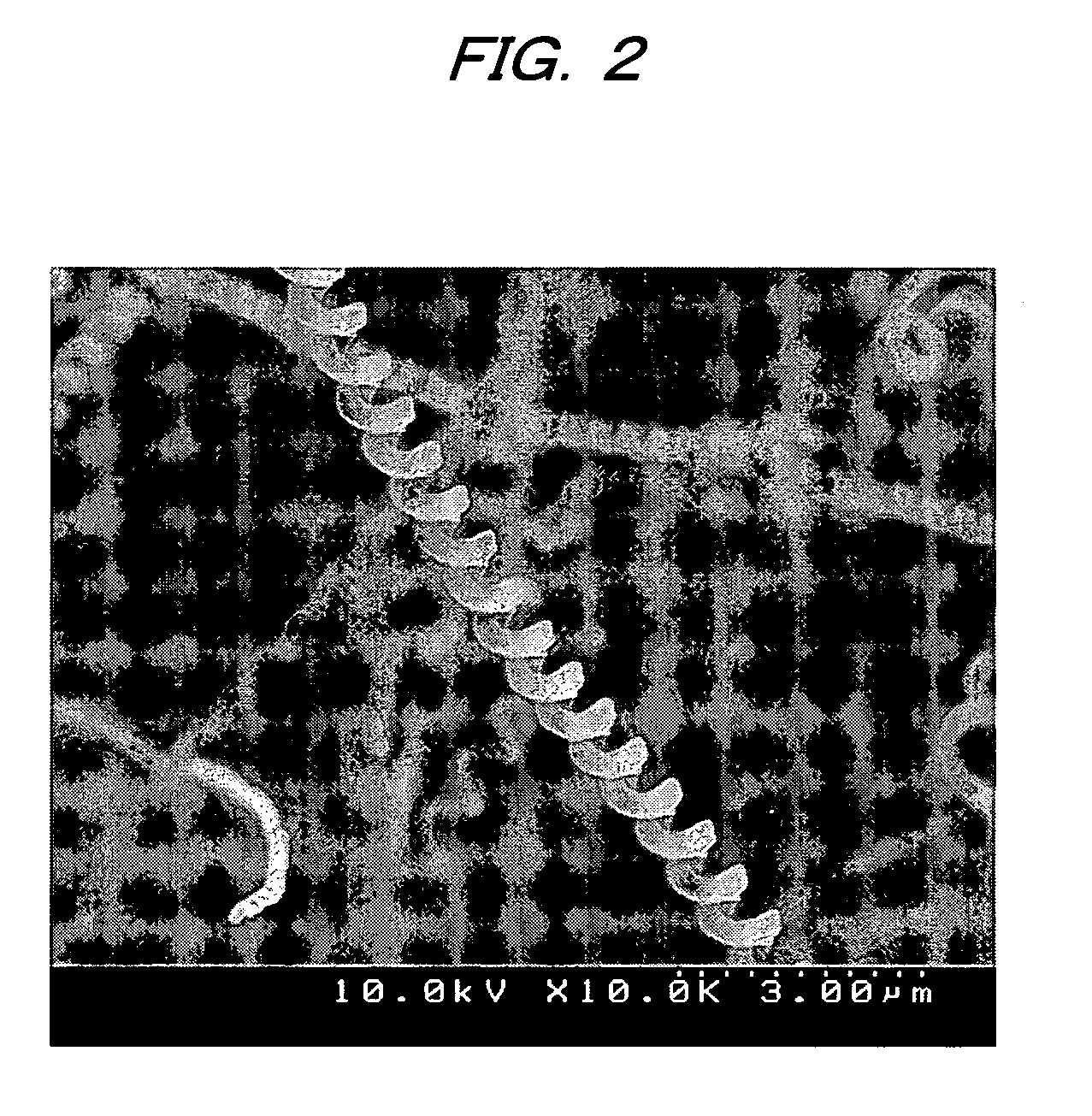

InactiveUS20050029243A1Shorten cooling timeShorten heating timeDrying solid materials with heatMuffle furnacesIn planeEmissivity

The present invention provides a method of effecting high temperature vacuum heating and cooling suitable for conducting heat treatment to be performed on components used in a display apparatus. The present invention's heating / cooling method comprises the steps of: heating a plate-like member placed in a reduced pressure atmosphere in a chamber by heating means opposed to the plate-like member; and cooling the plate-like member by a cooling plate which is opposed to the plate-like member, with the heating means therebetween, the cooling plate having a heat reflecting function. In one aspect of the present invention, the cooling plate is designed to have a emissivity of not less than 0.50 but not more than 0.80 so as to minimizes a sum of a requisite time for the heating step and a requisite time for the cooling step. In another aspect of the present invention, the plate-like member to be heated has two main surfaces differing from each in an in-plane distribution of emissivity and the heating means is opposed to one of the two main surfaces, which has a smaller distribution ratio, thereby realizing uniform and efficient heating / cooling.

Owner:CANON KK

Method of effecting heating and cooling in reduced pressure atmosphere

InactiveUS7126087B2Minimize sumShorten heating and cooling timeDrying solid materials with heatMuffle furnacesEmissivityPressure Atmosphere

Owner:CANON KK

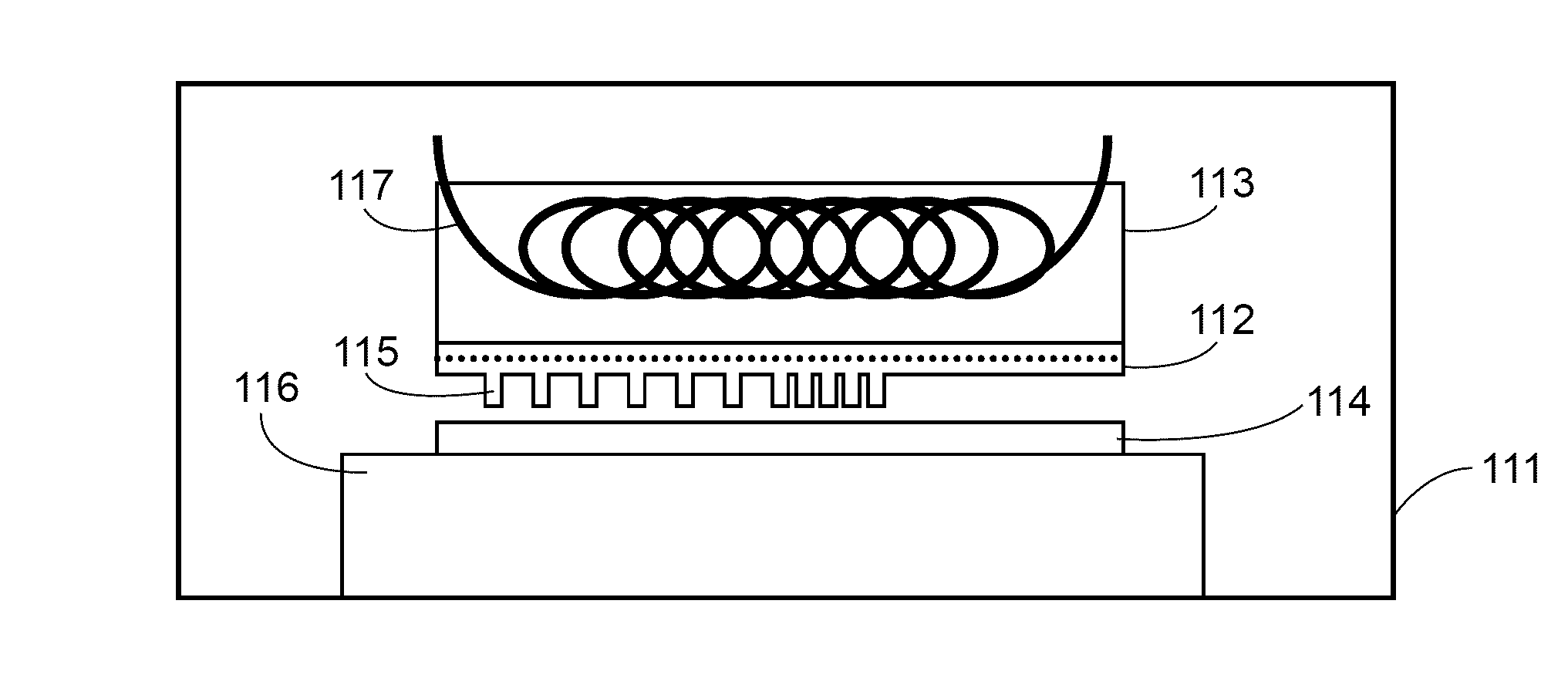

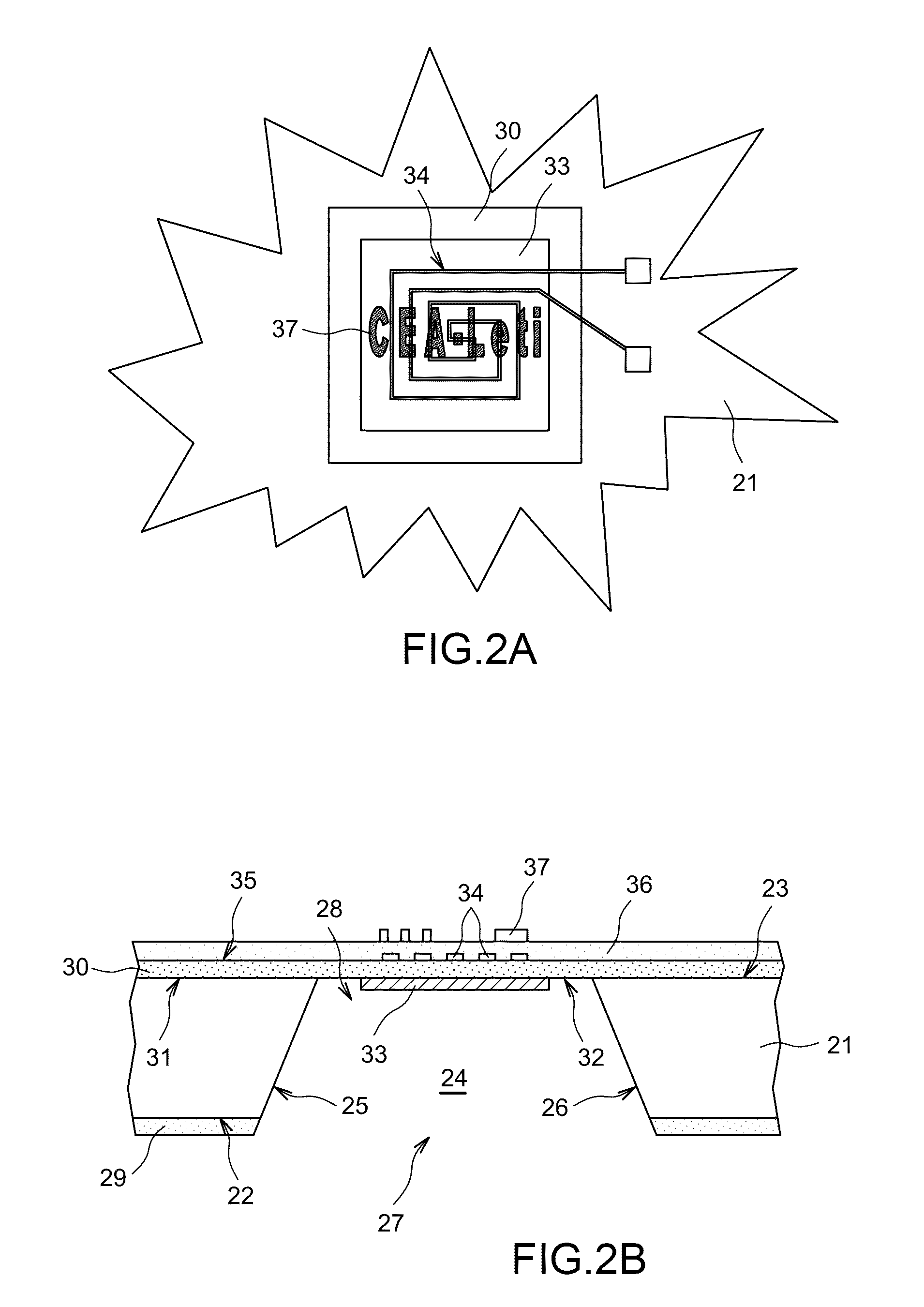

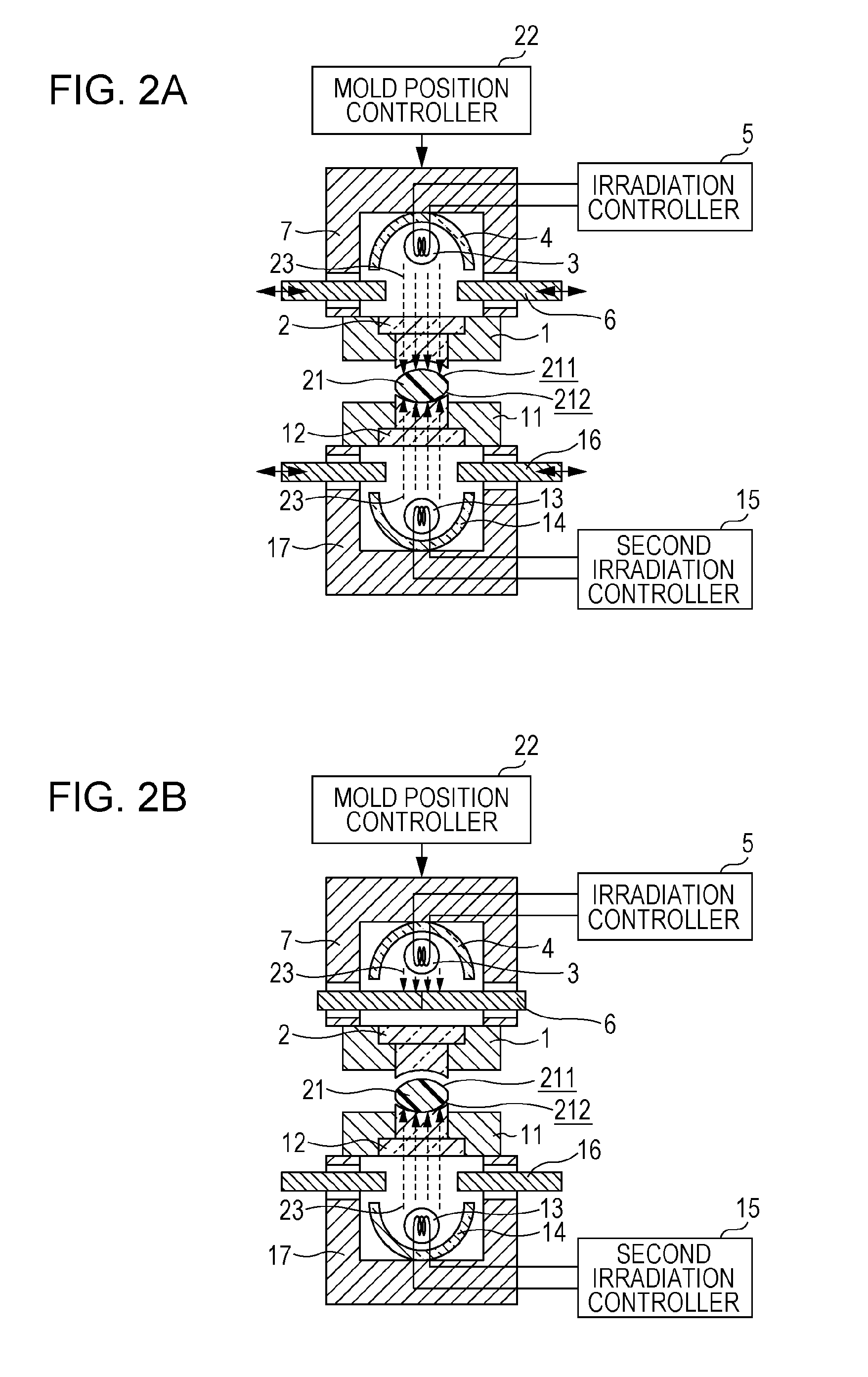

Mold for thermal nanoimprint lithography, process for fabricating the same, and nanoimprint process using the same

ActiveUS8974215B2Less deformationEasy to manufactureConfectioneryNanoinformaticsElectromagnetic fieldEngineering

A heating mold for thermal nanoimprint lithography is disclosed. According to one aspect, the mold includes a resistive heating element and collecting element for collecting the electromagnetic energy of a variable electromagnetic field emitted by a source located outside the mold. The collecting element being connected to the resistive heating element in which the electromagnetic energy is dissipated. A method for manufacturing the mold, a thermal nanoimprint lithography device including the mold, and a a method for preparing a substrate including a surface nanostructured by a thermal nanoimprint lithography technique using the mold is applied are also disclosed.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Circulating fluid system for electrostatic adsorption chuck

InactiveCN110544663AShorten heating and cooling timeRapid temperature controlSemiconductor/solid-state device manufacturingTemperature controlLiquid temperature

The invention discloses a circulating fluid system for an electrostatic adsorption chuck. The base body of the electrostatic adsorption chuck contains a cooling liquid circulating water path. The circulating fluid system includes a cooler connected to the cooling liquid circulating water path, and the cooler is configured to be capable of simultaneously pumping a first circulating fluid and a second circulating fluid having different temperatures, wherein when one of the circulating fluids circulates through the cooling liquid circulating water path, the other circulating liquid circulates outside the electrostatic adsorption chuck. By introducing a dual-channel cooler with two independent circulating liquids of two temperatures, the temperature-stabilizing circulating liquids entering thebase body of the electrostatic adsorption chuck can be switched between the circulating liquids of two temperatures, which shortens the circulating liquid temperature increasing and decreasing time between high and low temperature processes, achieving rapid temperature control of the electrostatic adsorption chuck in different temperature processes, and avoiding damage to the electrostatic adsorption chuck due to excessive heating power of the electrostatic adsorption chuck.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

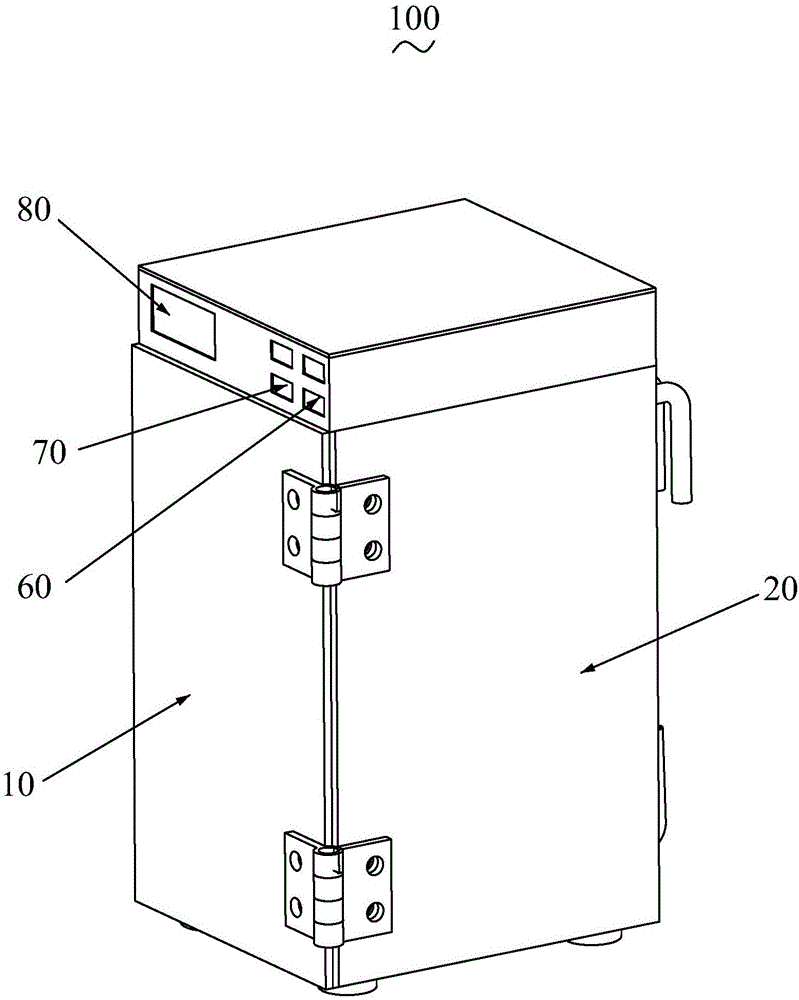

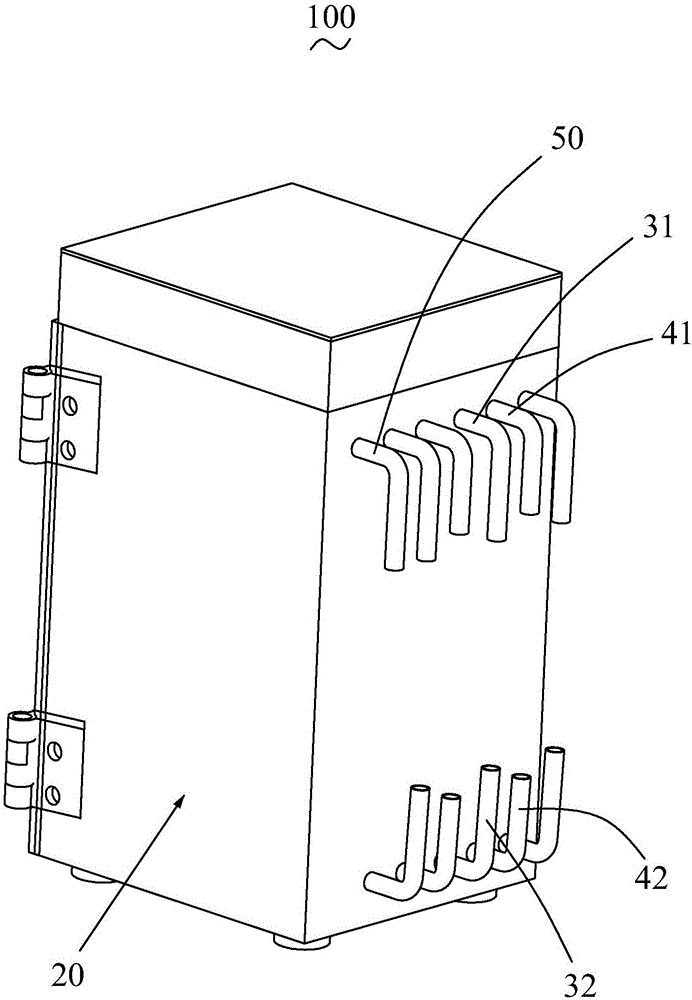

Oven

InactiveCN106679350ASolve uneven temperatureShorten heating and cooling timeDrying gas arrangementsDrying chambers/containersInterior spaceEngineering

The invention provides an oven. The oven comprises an oven body with an opening in one side, an oven door, an upper liquid delivery pipe, a lower liquid delivery pipe, an upper ventilation pipe, a lower ventilation pipe and a vacuum pipe, wherein the oven body comprises an outer wall, an inner wall arranged in the outer wall in a sleeving manner, and a sandwich layer which is located between the outer wall and the inner wall and is spaced from the outer wall and the inner wall; an airtight outer hollow layer is enclosed by the outer wall and the sandwich layer, and an airtight inner hollow layer is enclosed by the sandwich layer and the inner wall; one side of the oven door is movably connected with the oven body, the oven door can be in seal fit with the oven body, and an inner space is formed by the oven door and the inner wall; the upper liquid delivery pipe and the lower liquid delivery pipe are separately located at the two ends of the oven body and communicate with the inner hollow layer; the upper liquid delivery pipe, the lower liquid delivery pipe and the inner hollow layer are used for the circulation of heat conducting liquid; the upper ventilation pipe and the lower ventilation pipe are separately located at the two ends of the oven body and communicate with the inner space, and the upper ventilation pipe, the lower ventilation pipe and the inner space are used for the circulation of dry air; and the vacuum pumping pipe communicates with the outer hollow layer.

Owner:OPTIMUM BATTERY CO LTD

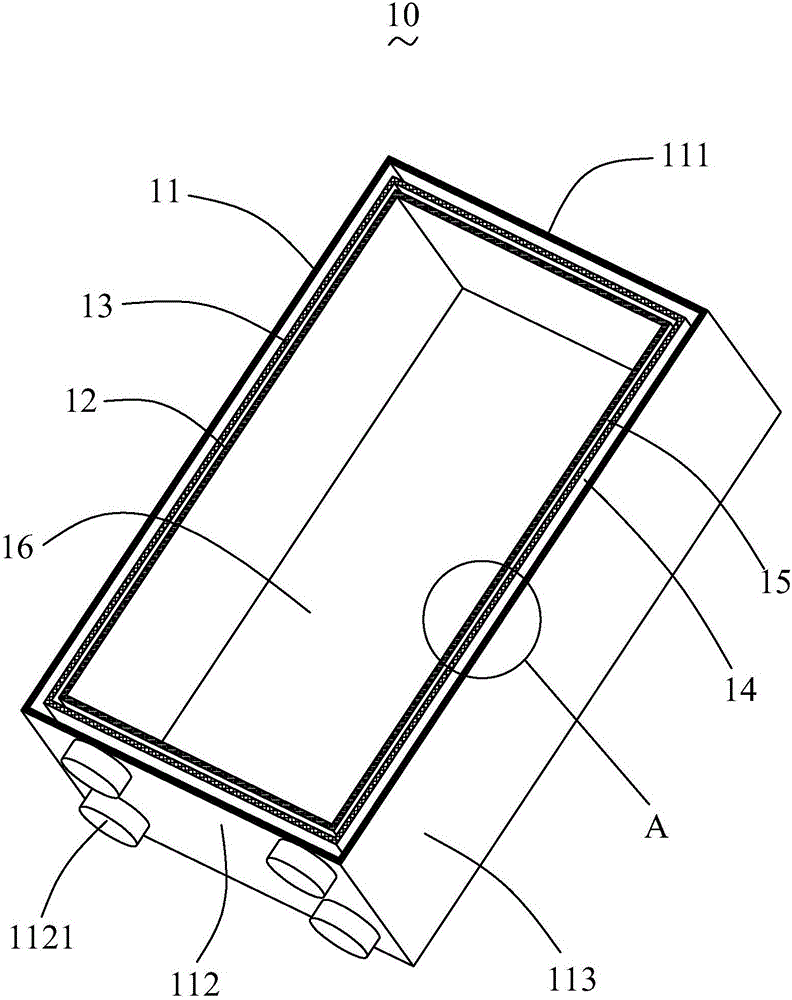

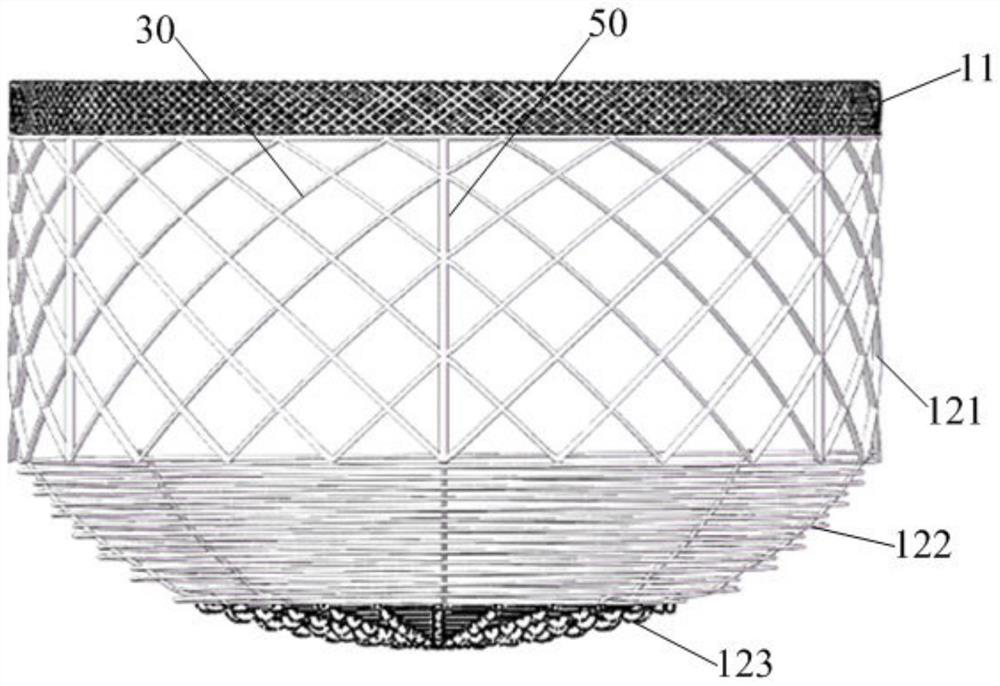

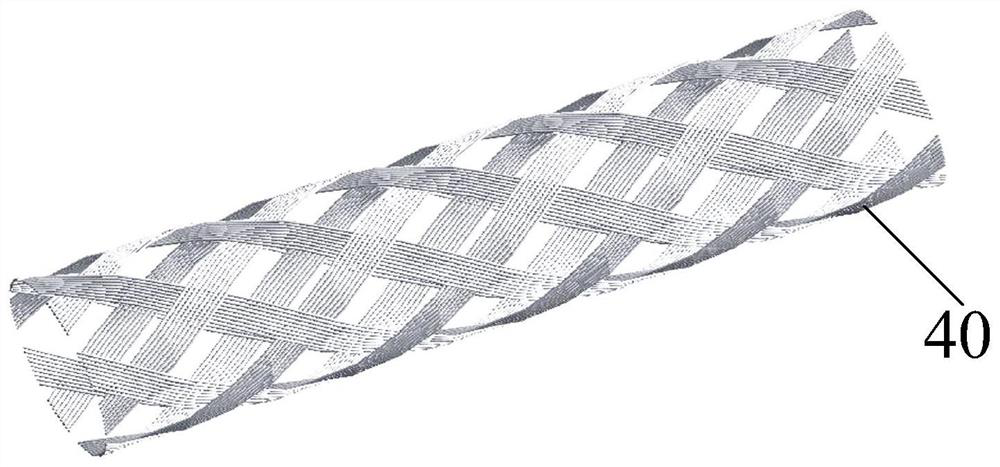

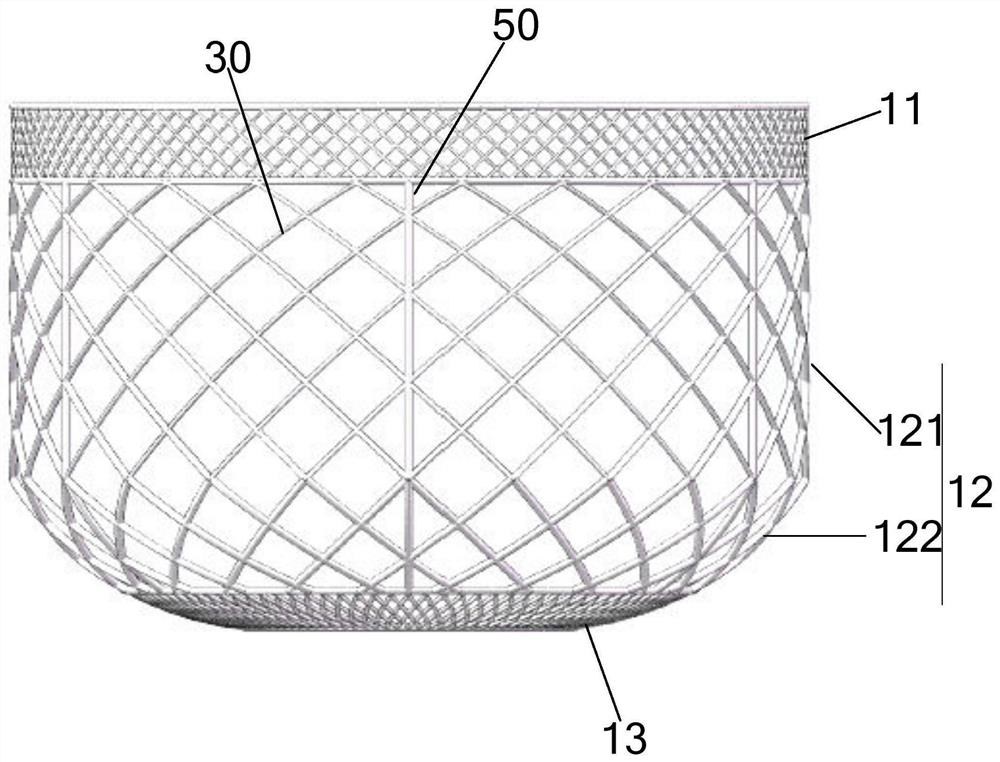

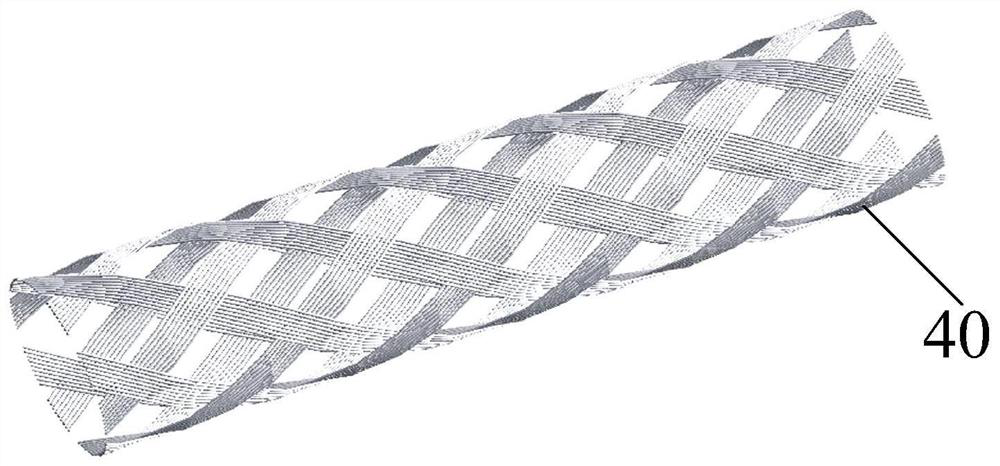

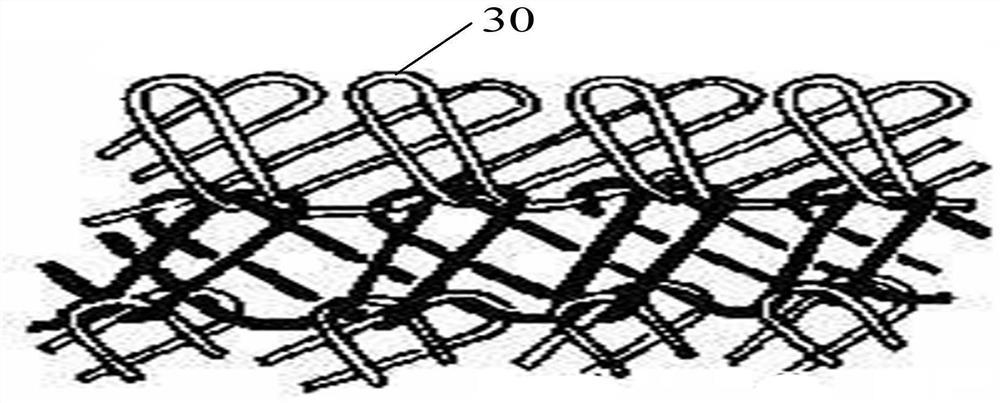

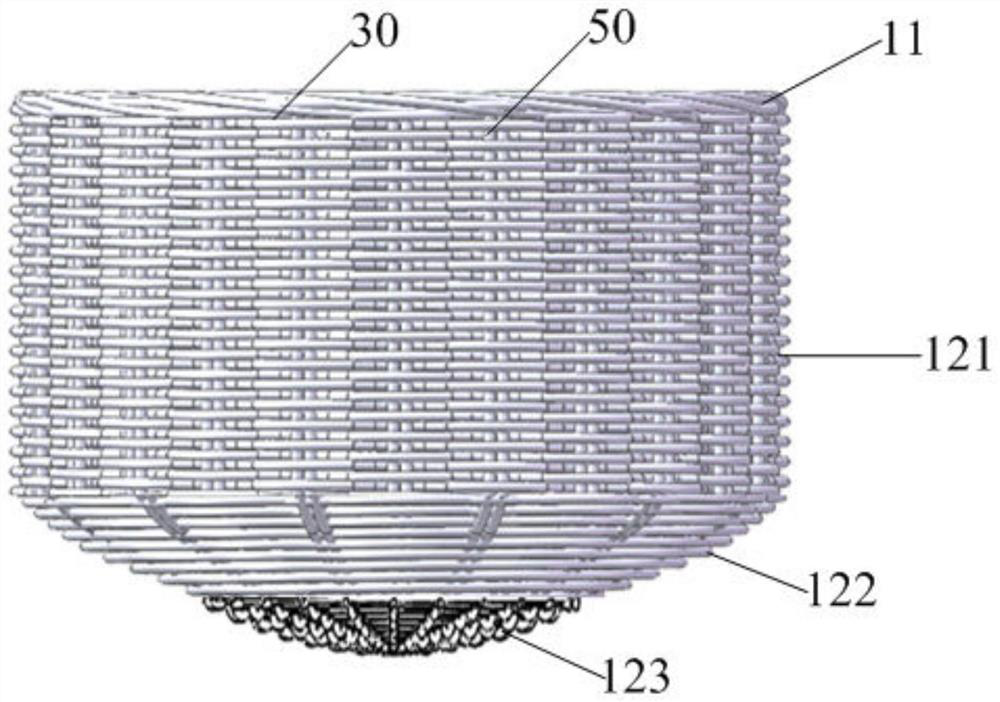

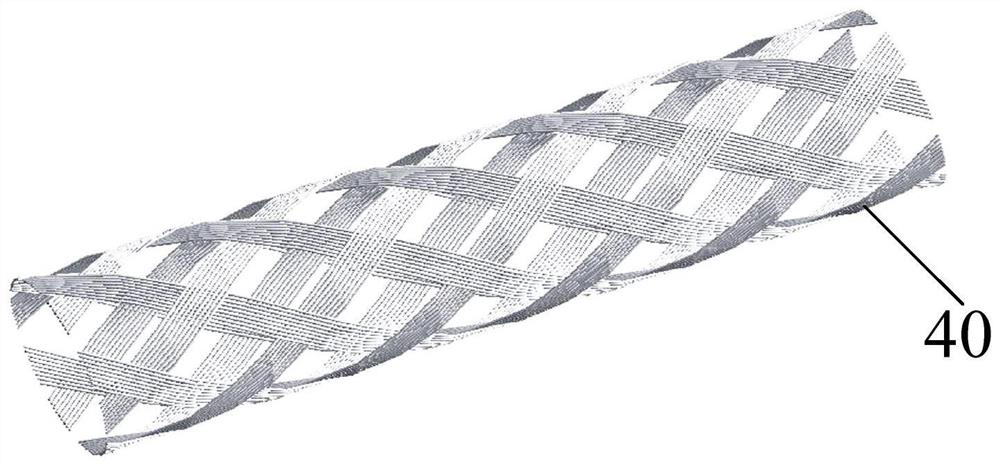

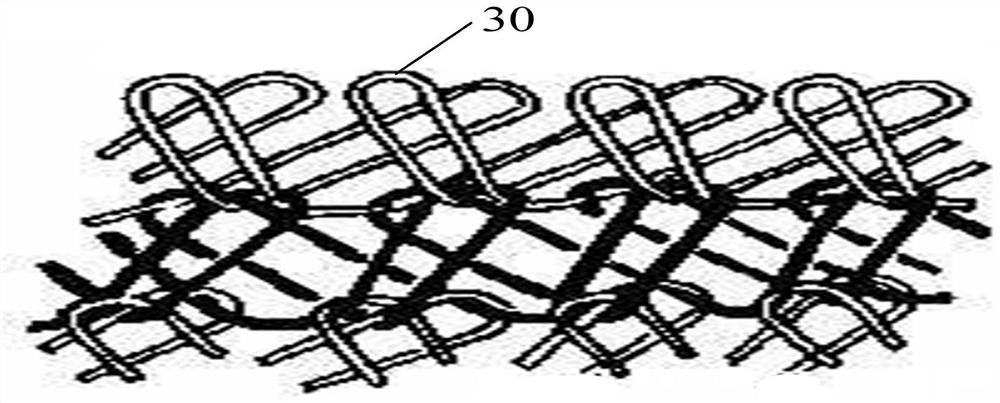

Integrally woven crucible preform and coated crucible prepared from same

PendingCN112176403AReduce processing wasteImprove plasticityPolycrystalline material growthBy pulling from meltFiberCarbon fibers

The invention provides an integrally-woven crucible prefabricated body which is a net-shaped body formed by weaving one or more carbon fiber ropes, and the crucible prefabricated body is formed by densely weaving an opening in the upper end and a compact weaving at the lower end. The crucible is formed by weaving one carbon fiber rope or a plurality of carbon fiber ropes, so that a prefabricated body is unnecessary and working hours are reduced. According to the crucible, straight carbon fiber ropes are adopted for weaving, so that a blank body does not need to be manufactured, the shape plasticity is high, limitation of the blank body is avoided, flexible design and batch production can be achieved, the delivery period is shortened, and material machining waste is little.

Owner:SHANGHAI QI JIE CARBON MATERIALS

Apparatus and method for controlling workpiece temperature

InactiveUS20120317993A1Shorten cooling timeShorten heating timeFinal product manufactureSemiconductor/solid-state device manufacturingProduct gasMechanical engineering

An atmospheric controlled chamber includes a support assembly capable of holding a workpiece over a specific surface of the support assembly, a heat-transfer assembly located close to the support assembly and capable of transferring heat to and from the exterior of the chamber, and at least one thermopile device disposed in the support assembly. The thermopile device(s) is configured to transfer heat between the specific surface (or viewed as the held workpiece) and the heat-transfer assembly. A gas assembly is optionally surrounded by the chamber wall and capable of ensuring the existence and controlling the pressure of an essentially static gas between the held workpiece and the specific surface, wherein the gas is used as a thermal medium for conducting heat. The thermopile device acts as an efficient heat pump, so as to provide extra lower / higher workpiece temperature, a greater cooling / heating rates, and more flexible rate control.

Owner:ADVANCED ION BEAM TECHNOLOGY INC

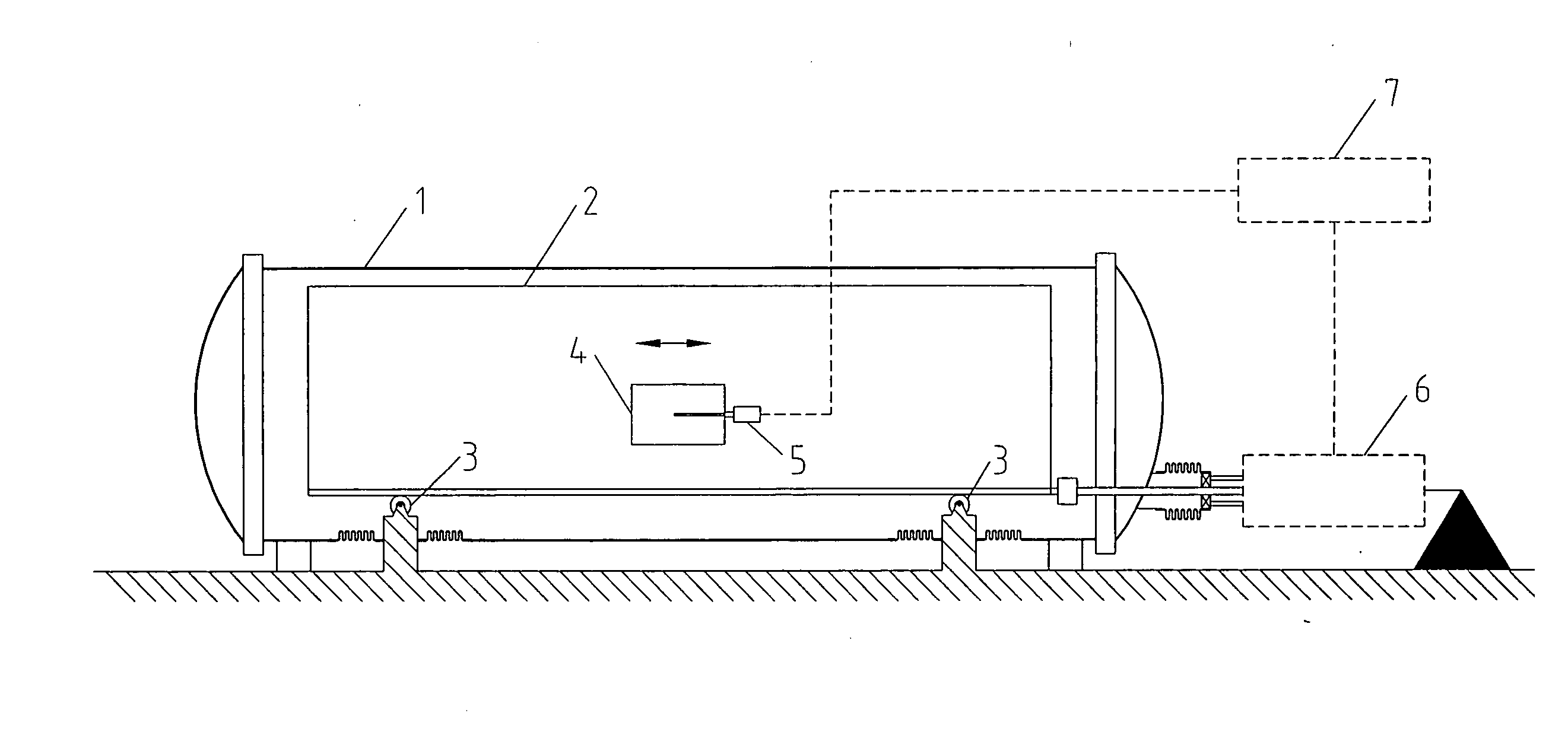

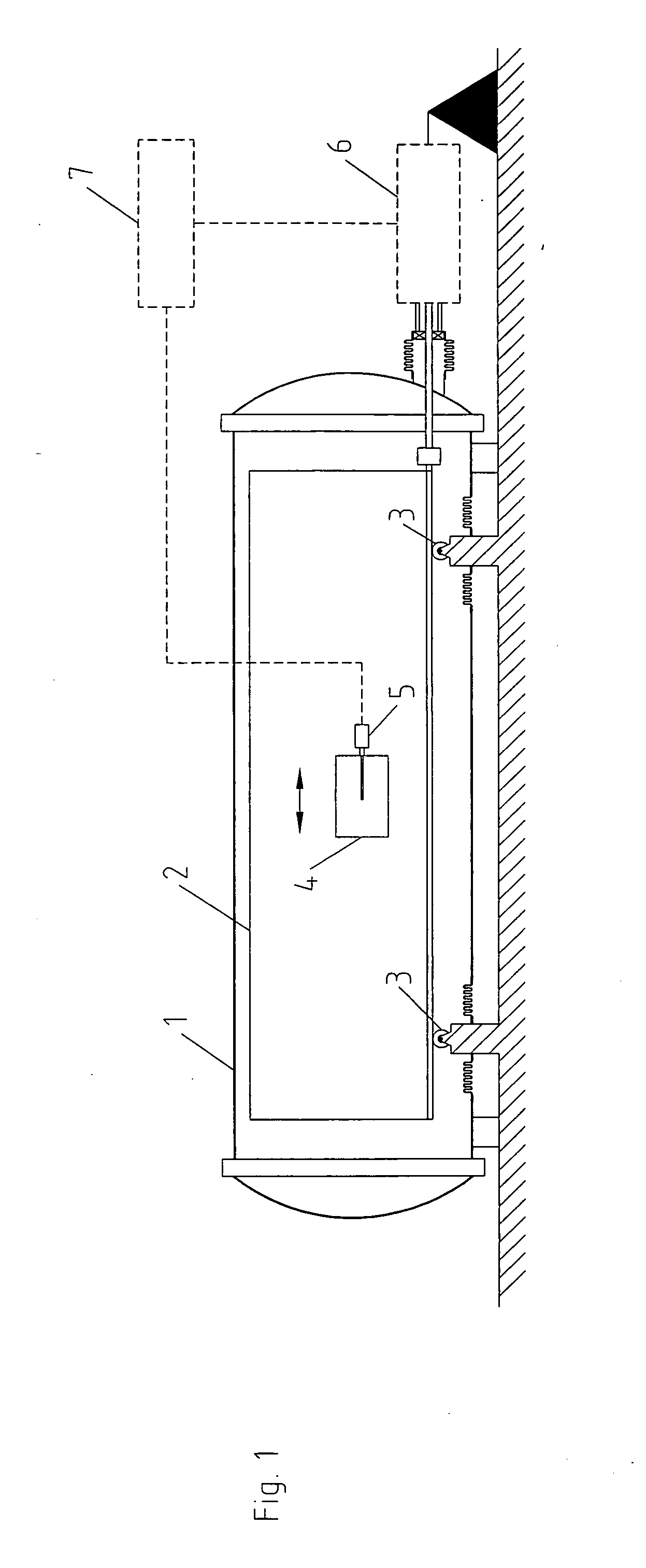

Method for heating or cooling material in a container

InactiveUS20100155217A1Shorten heating and cooling timeShorten the timeDistillation regulation/controlFood preservationEngineeringMechanical engineering

The present invention relates to a method for heating or cooling material in a container inside a pressurized retort, in which the container is moved and heated or cooled. A temperature sensor disposed in or on the container is connected to a control means, which control means is connected to a drive, to move the container in the retort and the control means controls the drive and / or the movement of the container on the basis of the container temperature measured, and a pressurized retort suitable for that purpose is also included.

Owner:MARS INC

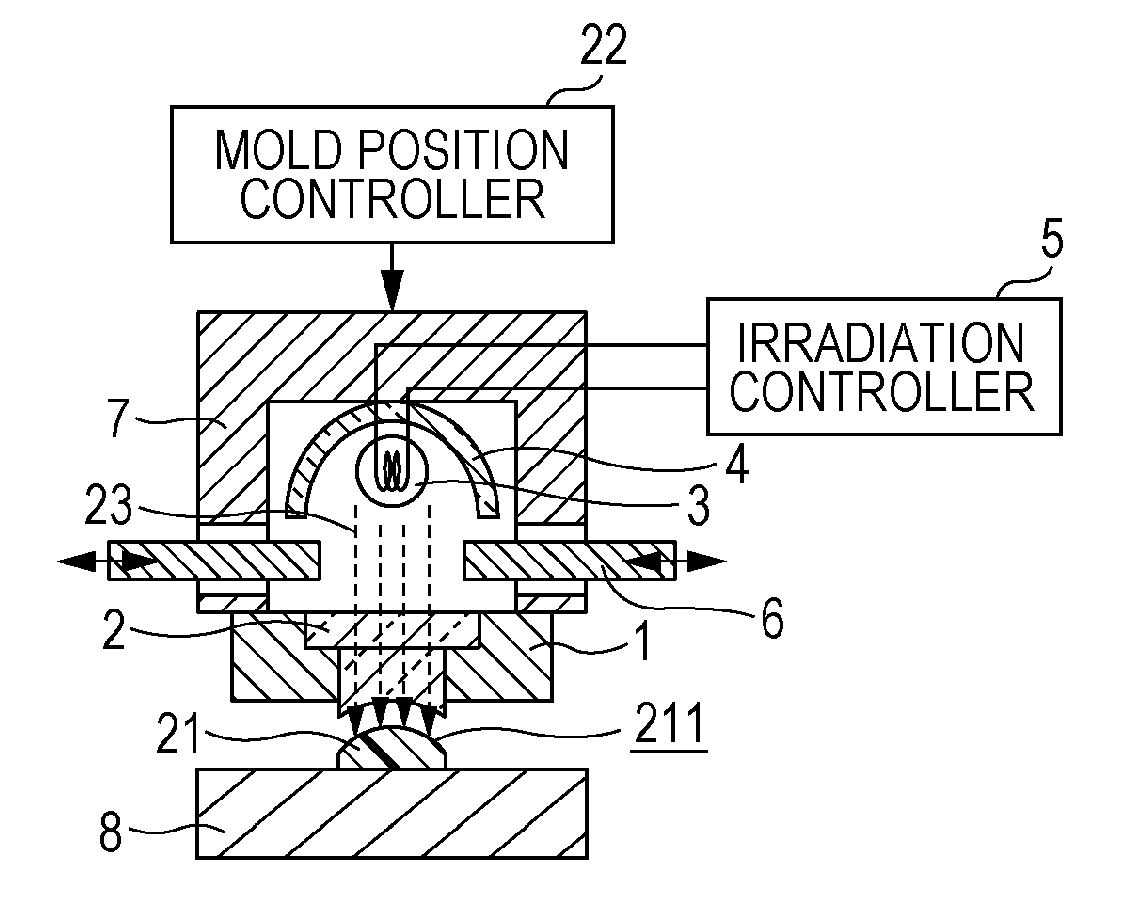

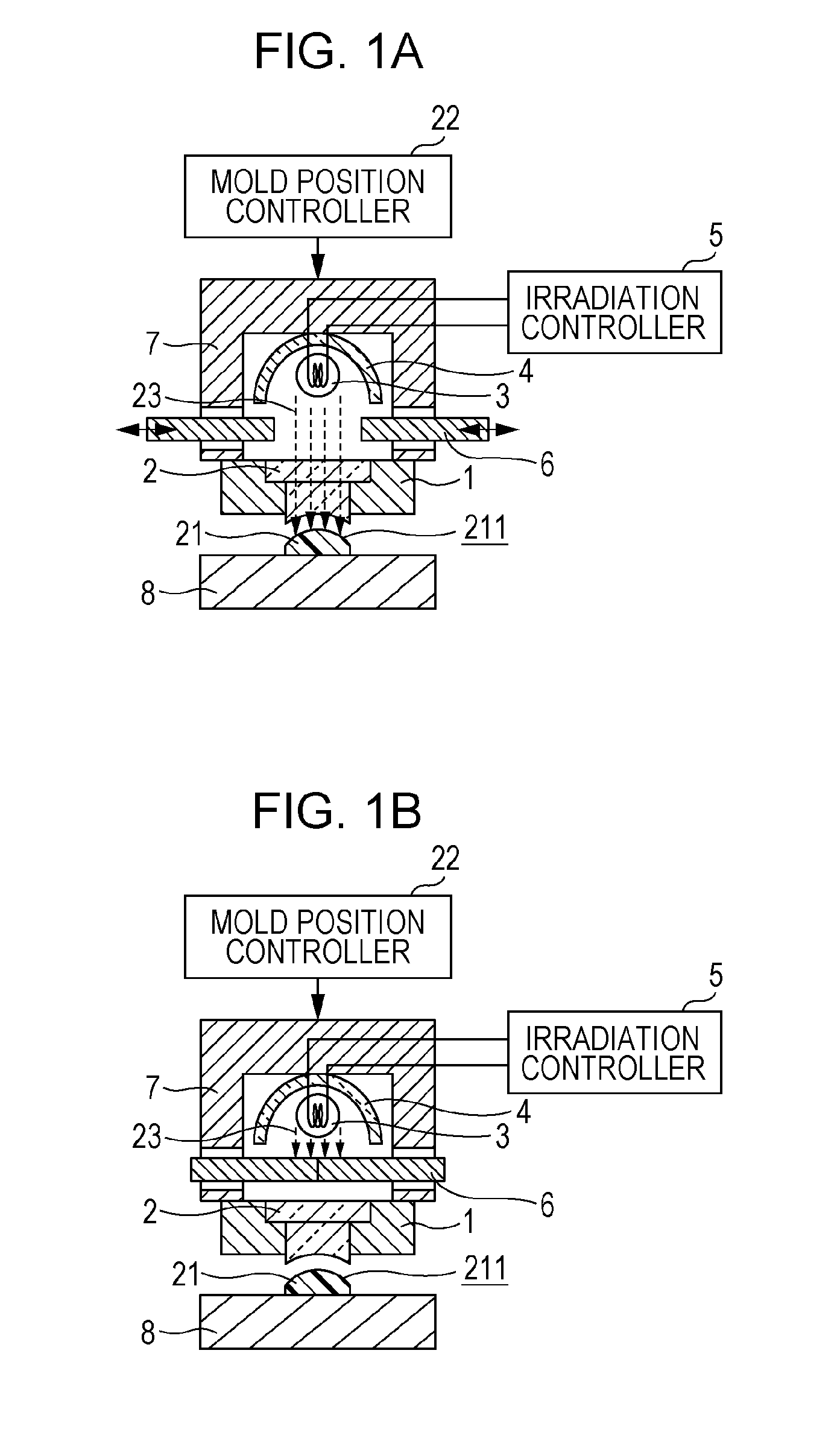

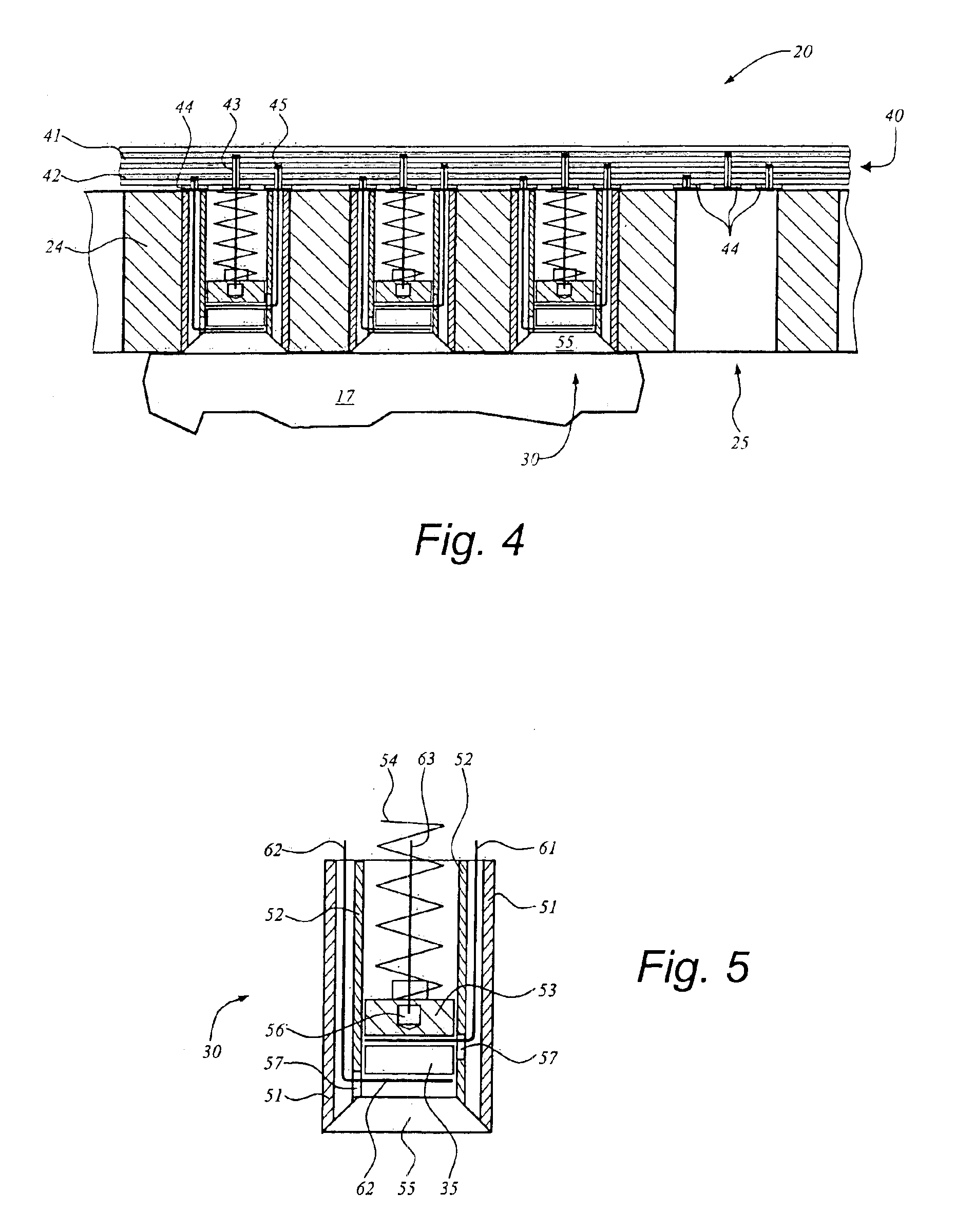

Method of manufacturing optical component and apparatus for manufacturing optical component

ActiveUS20120061865A1Shorten molding timeGood optical performanceOptical articlesAuxillary shaping apparatusOptoelectronicsMaterials science

A method of manufacturing an optical component includes, bringing a mold including at least one portion made of an infrared transmitting material into tight contact with a substrate, heating the substrate by irradiating the substrate with an infrared ray in a state that a gap is present between the substrate and the mold, and placing the mold and the substrate into tight contact with each other.

Owner:CANON KK

Tools supporting and heating device

InactiveUS6892633B2Fast convivial adaptabilityEasy to removeTransfer printingMechanical working/deformationHoneycombEngineering

Tools supporting and heating device for tools like printing plates, used for diecutting and hot pressure transfer of portions of metallic films on a substrate. This device comprises a base plate applied against one of the sides of the honeycomb chase. This base plate is made of a sequence of at least one insulating surface and of at least one conducting surface enabling to feed at least one heating device intended to be inserted inside each one of said apertures in order to heat a printing plate fastened against a second side of the honeycomb chase.

Owner:BOBST SA

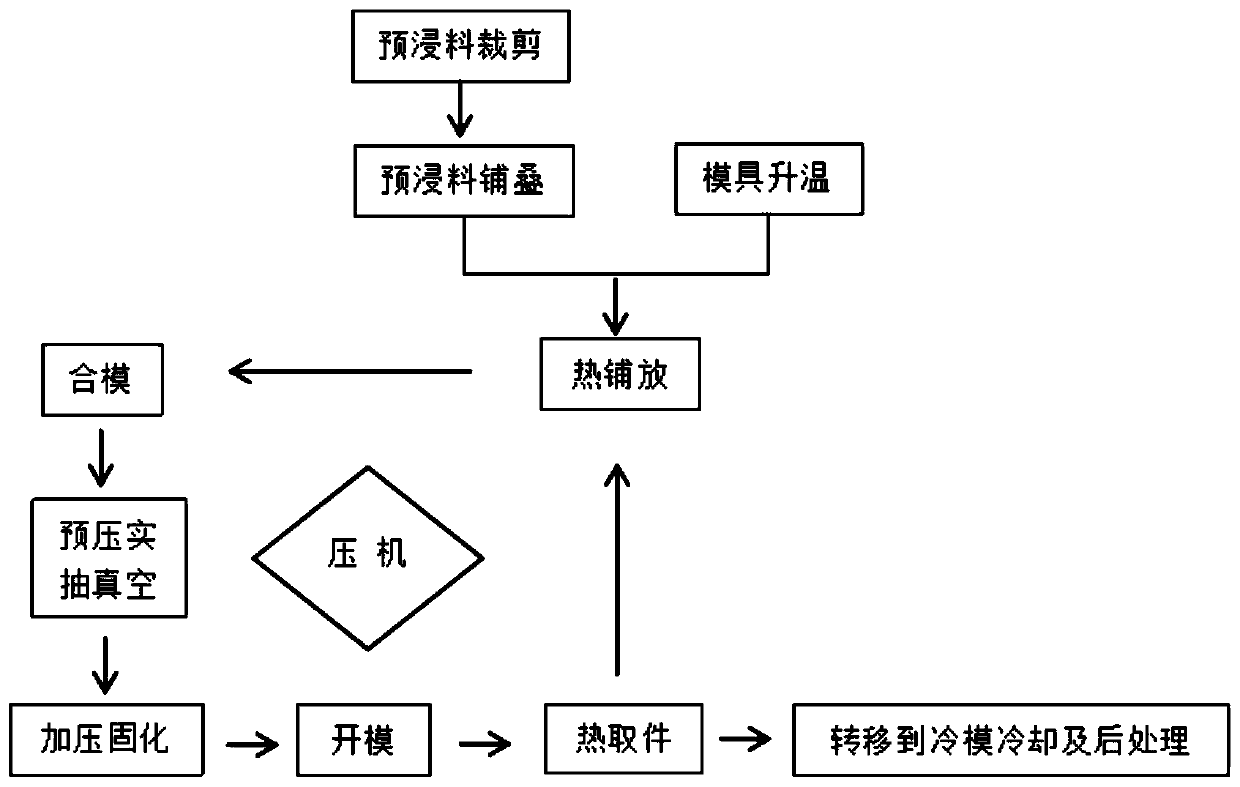

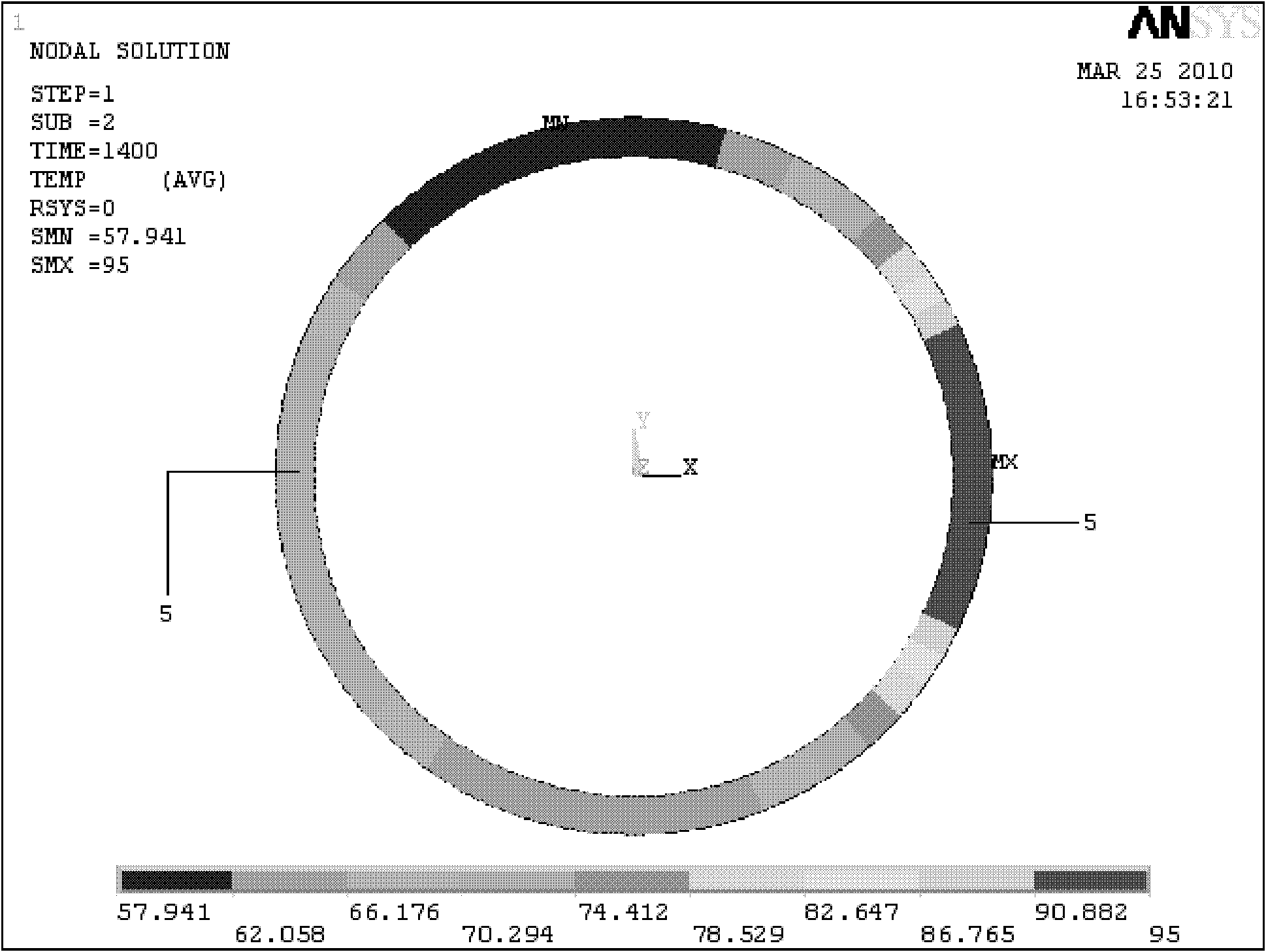

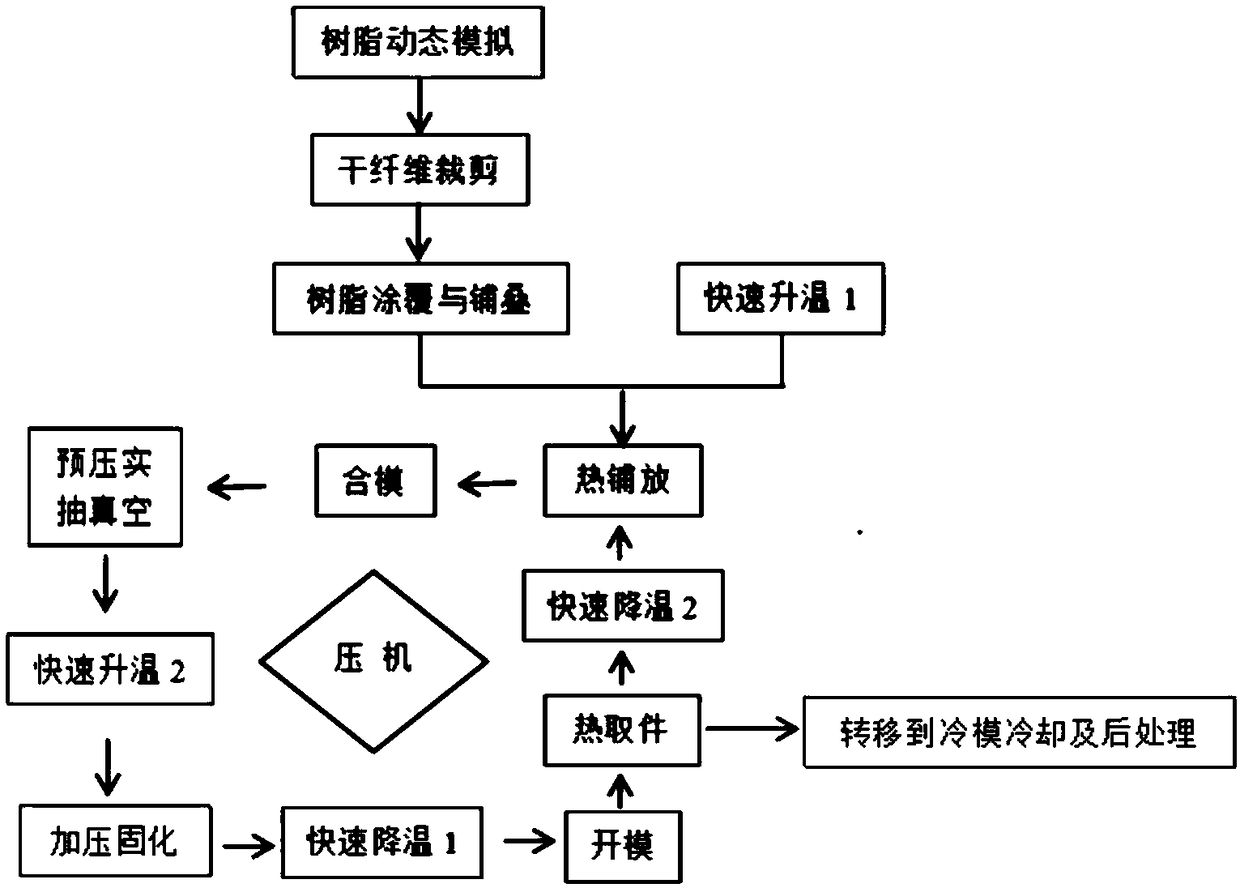

A rapid compression molding process of carbon fiber prepreg

The invention discloses a rapid compression molding process for carbon fiber prepreg. The carbon fiber prepreg is used as a forming material, a prepreg molding process is used as a foundation, an online molding and curing process, a next-period thermal laying process and a previous-period product cooling aftertreatment process can be carried out simultaneously, and finally, buckling deformation of the product does not exist. In the whole process, steps of preforming, coating of a release agent and mold cleaning are not required, the mold heating and cooling time in every forming period is saved, therefore, the forming time is greatly saved, the production efficiency is improved, power consumption costs for heating and cooling are reduced, and a forming environment is improved; and the shortest final forming period can be controlled within 5 minutes, the quality of formed products is good, and requirements of automobile parts and requirements of the production trend can be met.

Owner:JIANGSU ZHAOJUN NEW MATERIAL CO LTD

Integrally-woven crucible prefabricated body with bottom holes and coating crucible made of integrally-woven crucible prefabricated body

PendingCN112195508AReduce processing wasteImprove plasticityPolycrystalline material growthBy pulling from meltFiberCarbon fibers

The invention provides an integrally-woven crucible prefabricated body with bottom holes, the crucible prefabricated body is an annular hollow net-shaped body formed by weaving one or more carbon fiber ropes, and the diameter of an opening in the upper end of the crucible prefabricated body is larger than that of an opening in the lower end of the crucible prefabricated body. The crucible prefabricated body is formed by weaving one carbon fiber rope or a plurality of carbon fiber ropes, needling of a prefabricated body is not needed, and working hours are saved; straight carbon fiber ropes areadopted for weaving, a blank body does not need to be manufactured, the shape plasticity is high, limitation of the blank body is avoided, flexible design and batch production can be achieved, the delivery period is shortened, and material machining waste is little.

Owner:SHANGHAI QI JIE CARBON MATERIALS

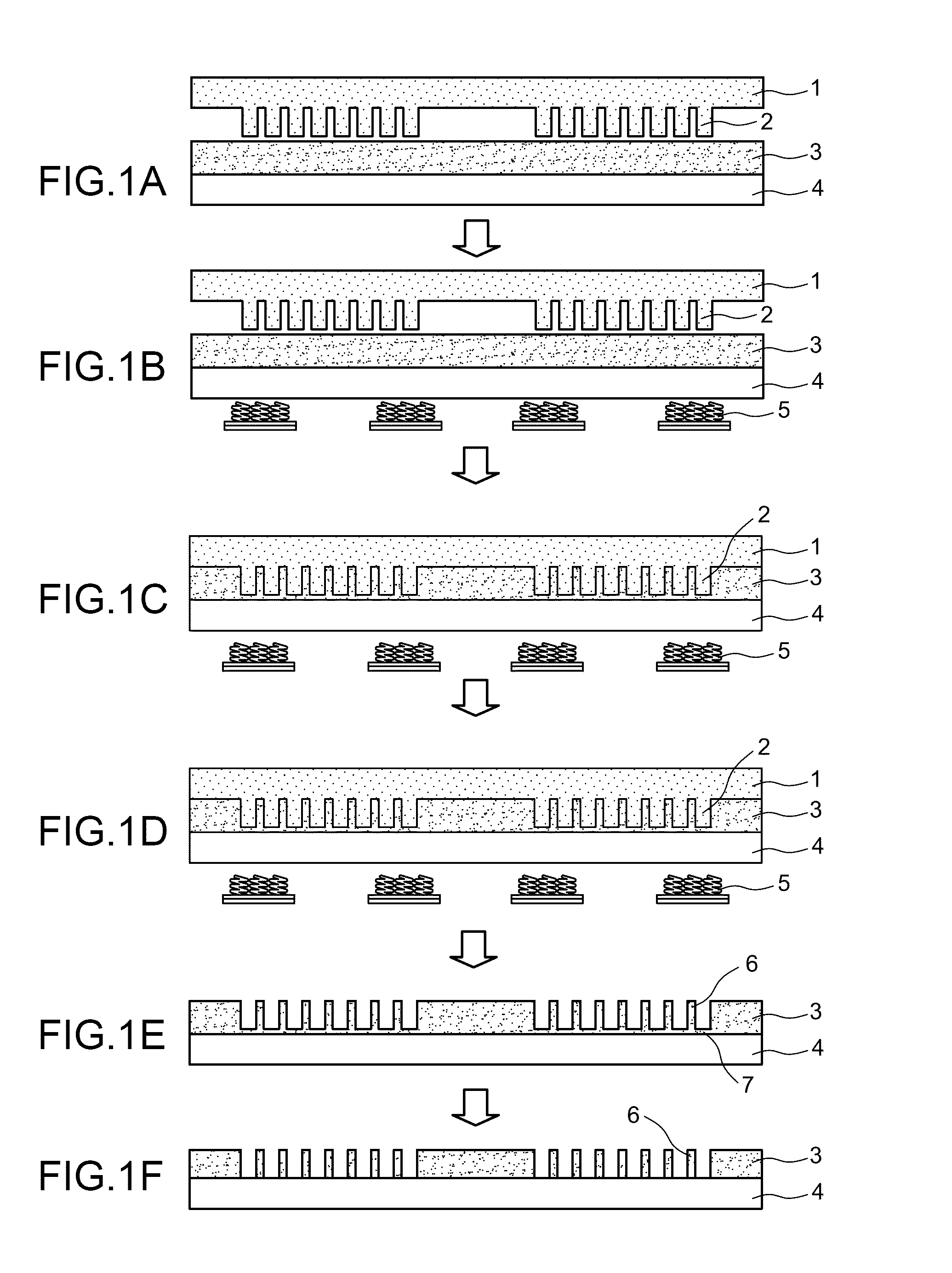

Device and method for hot embossing of a polymer layer

ActiveUS8741204B2Improve throughputReduce energy useElectric discharge heatingInduction heatingPolymer scienceMagnetite Nanoparticles

The invention relates to a device for hot embossing of a magnetic nanoparticle (N)-containing polymer layer and a method for hot embossing of a magnetic nanoparticle-containing polymer layer.

Owner:EV GRP E THALLNER GMBH

Integral spiral woven crucible prefabricated body and coated crucible prepared from same

PendingCN112195509AReduce processing wasteImprove plasticityPolycrystalline material growthBy pulling from meltFiberCarbon fibers

The invention provides an integral spiral woven crucible prefabricated body which is a net-shaped body formed by spirally weaving one or more carbon fiber ropes, and a crucible which is woven in a net-shaped hollowed-out mode with the upper end open and the lower end closed. The crucible is formed by weaving one carbon fiber rope or a plurality of carbon fiber ropes, needling of a prefabricated body is not needed, and working hours are saved; straight carbon fiber ropes are adopted for weaving, a blank body does not need to be manufactured, the shape plasticity is high, limitation of the blankbody is avoided, flexible design and batch production can be achieved, the delivery period is shortened, and material machining waste is little.

Owner:SHANGHAI QI JIE CARBON MATERIALS

Two-path temperature control polymerase chain reactor and real-time detection device

InactiveCN102220226BExtended service lifeLow costBioreactor/fermenter combinationsBiological substance pretreatmentsFluorescencePolymerase L

The invention relates to a two-path temperature control polymerase chain reactor and a real-time detection device, which are applied in the field of biochemical reaction and medical detection. The two-path temperature control polymerase chain reactor comprises a base layer with a ring-shaped microfluidic channel structure, wherein the base layer is sealed with a cover board layer to form a microfluidic chip, the cover board layer is provided with a sample incoming hole and a sample outgoing hole, a microprocessor is adopted to control two semi-conductor heating and refrigerating devices, a whole microfluidic channel area forms three constant temperature areas, namely a degeneration area, an annealing area and an extension area needed by polymerase chain reaction, the semi-conductor heating and refrigerating devices are arranged under the microfluidic chip, and a platinum resistance temperature sensor manufactured by a semi-conductor process is arranged among the microfluidic chip and the two semi-conductor heating and refrigerating devices, so that temperature feedback signals are provided to the microprocessor, and closed ring control can be formed. The real-time detection systemcomprises a light source, a photoelectric detector and a fluorescence signal acquisition processing system. In the invention, by controlling the two semi-conductor heating and refrigerating devices, the whole microfluidic channel area forms the three constant temperature areas, and the heating and refrigerating device is simplified.

Owner:BEIJING UNIV OF TECH

A Simulated Coating Rapid Prototyping Wet Molding Process

The invention discloses a coating-simulating rapid-forming wet mold pressing technique. Simultaneous conducting of the solidifying forming technique in a pressing machine, the coating-simulating and hot laying technique outside the pressing machine in the next cycle and the treatment technique after last-cycle product cooling is achieved, and final products are protected against buckling deformation. Through coating simulating, the optimum coating position and using quantity are determined, the resin using quantity is effectively reduced, no resin overflows in mold assembly, and mold pollution is avoided; resin coating is conducted outside the pressing machine, site environmental friendliness is achieved, the steps of pre-forming, mold-release agent coating and mold clearing and using of rapid heating and cooling equipment are not needed for the whole technique, and the mold temperature rising-falling time of each forming cycle is omitted, so that the forming time is greatly saved, production efficiency is improved, the temperature rising-and-falling power consuming cost is reduced, the forming environment is improved, the final shortest forming cycle can be controlled to be within 5 min; and the quality of a formed product is good, and the requirements of car parts and the production tendency can be met.

Owner:JIANGSU ZHAOJUN NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com