Patents

Literature

267results about How to "Less deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

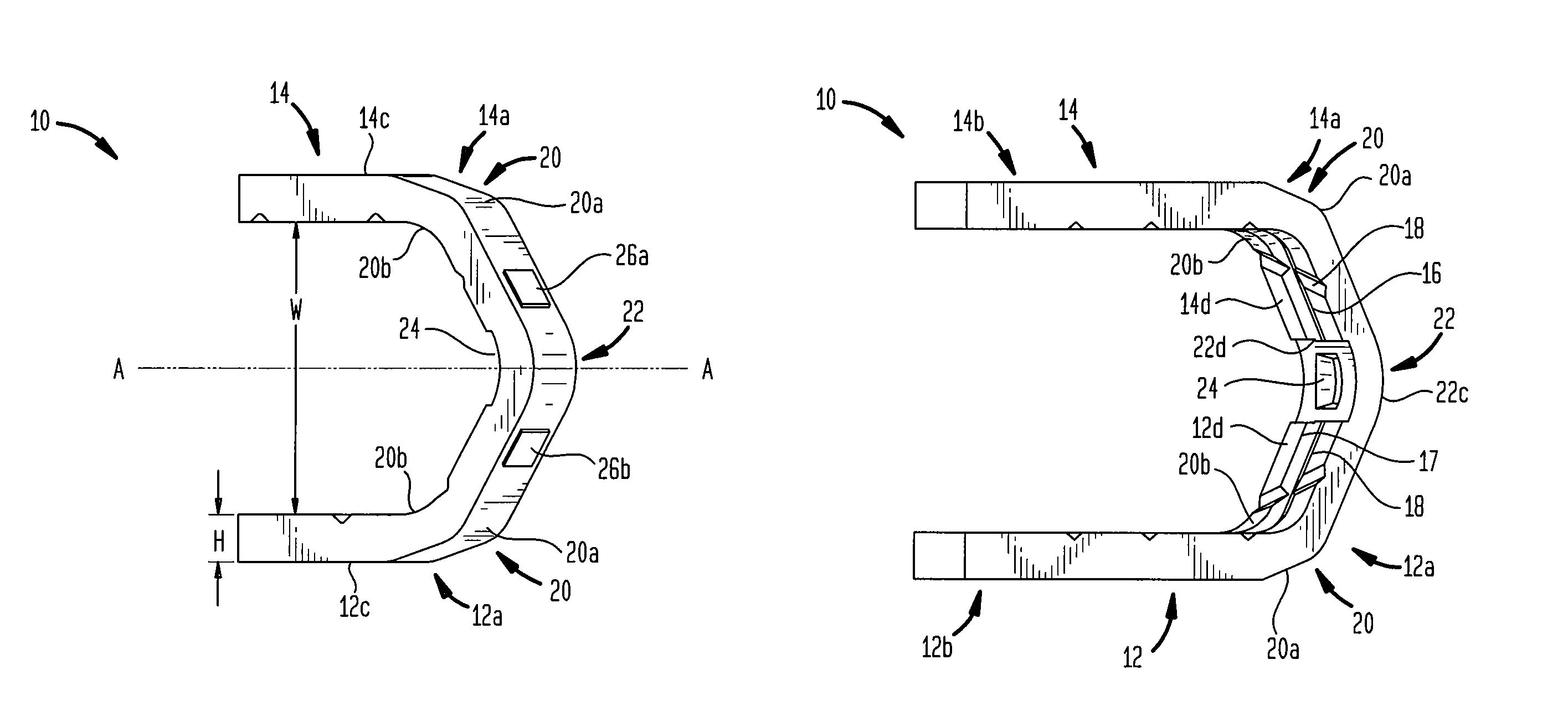

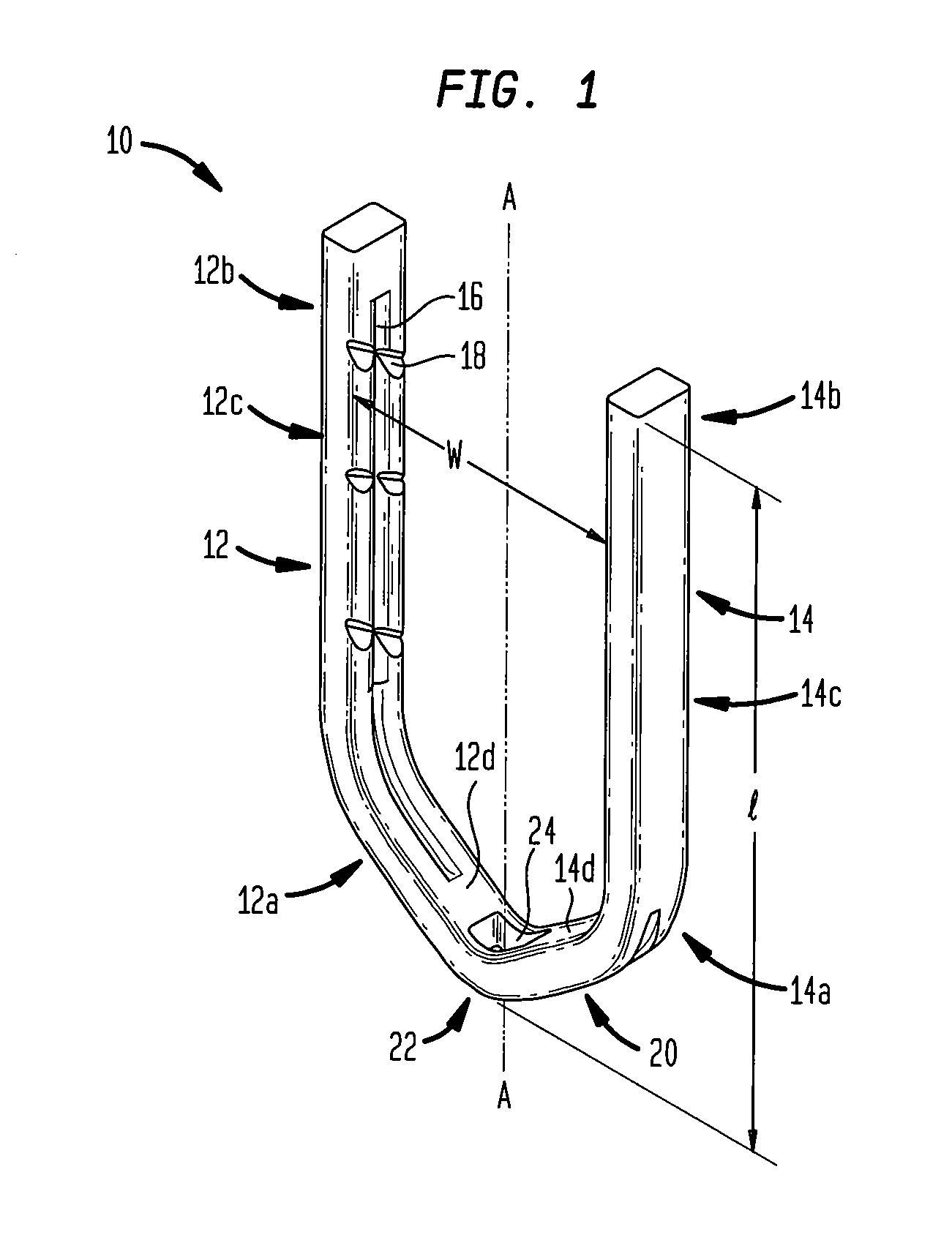

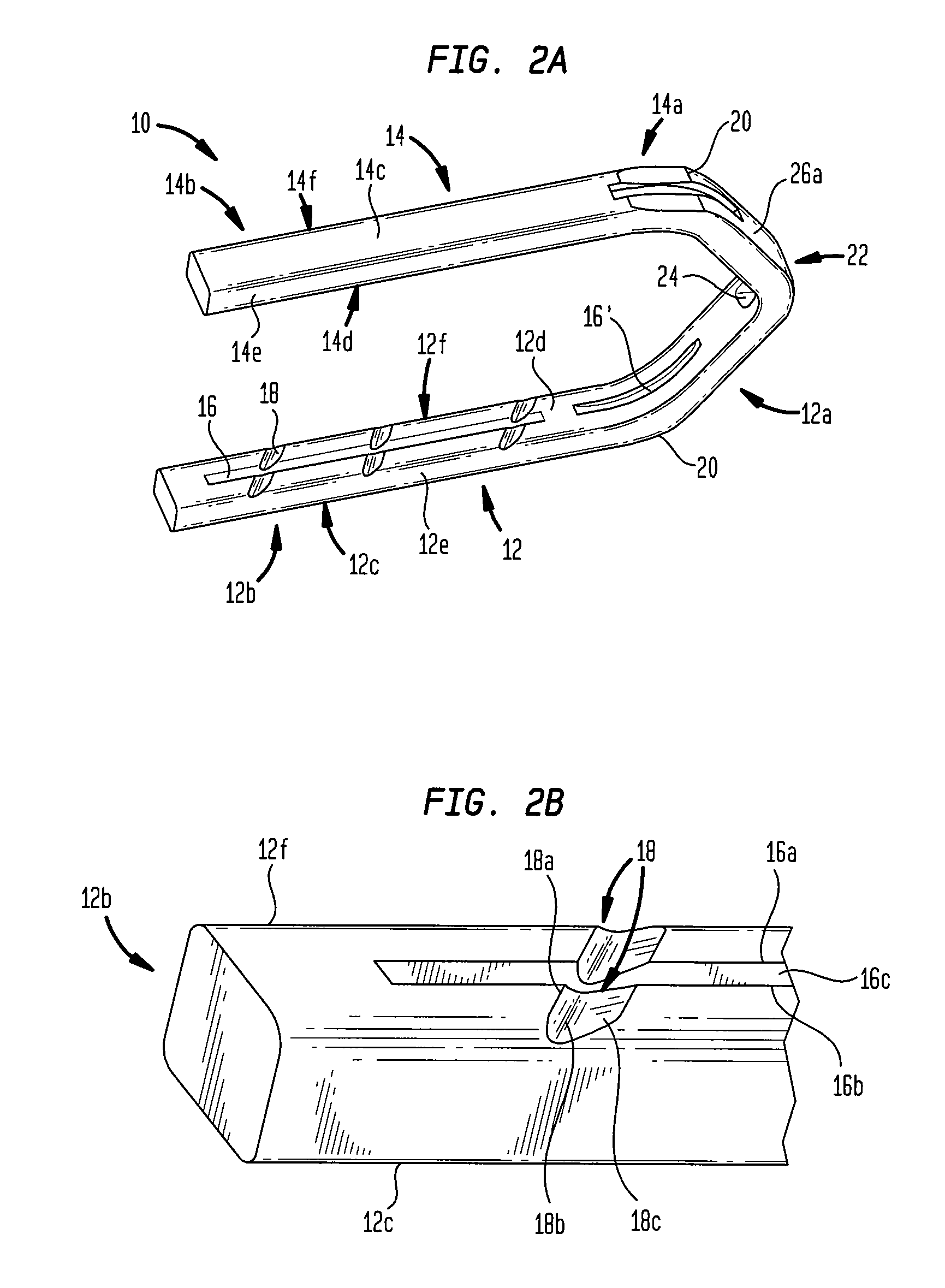

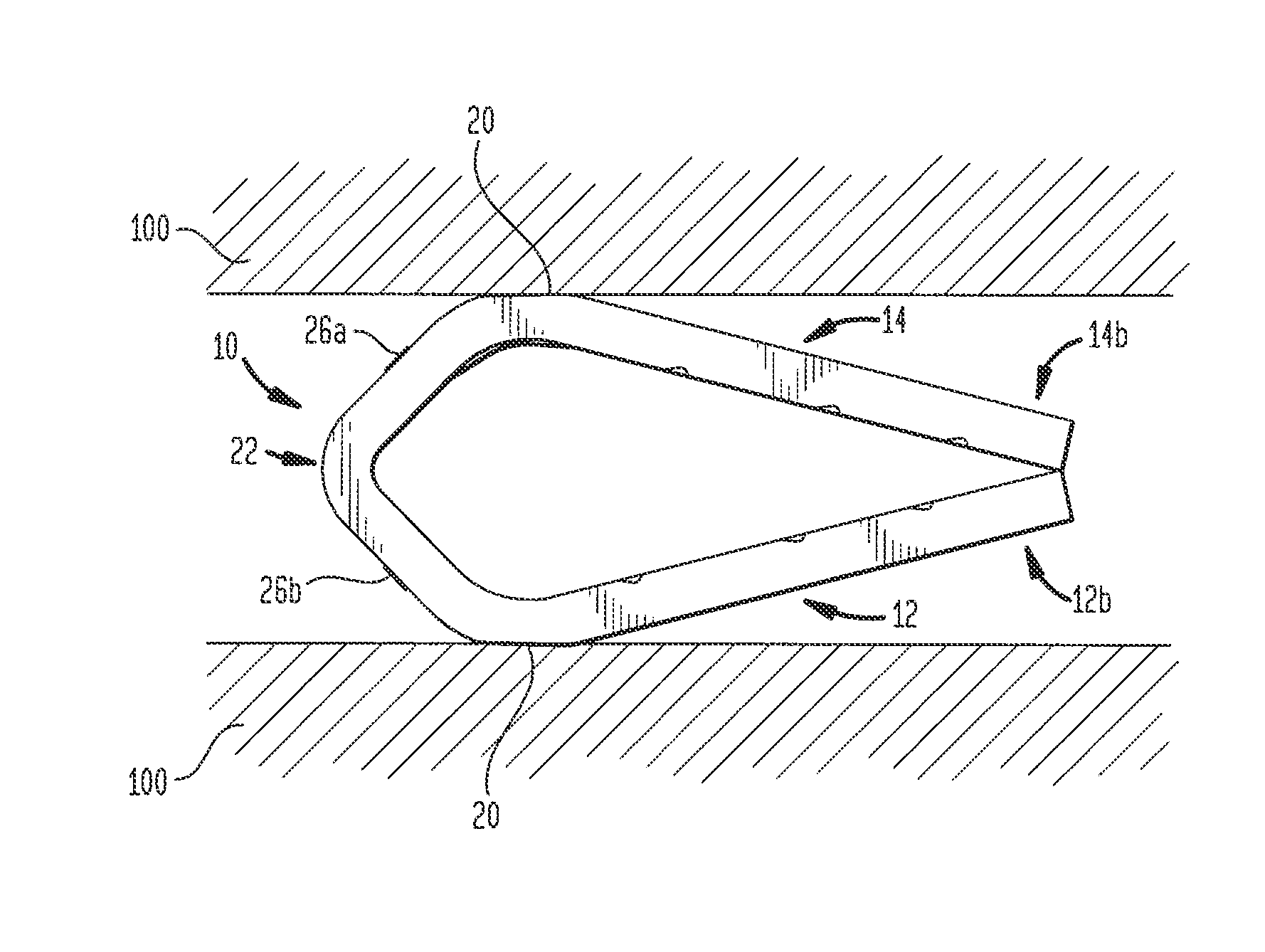

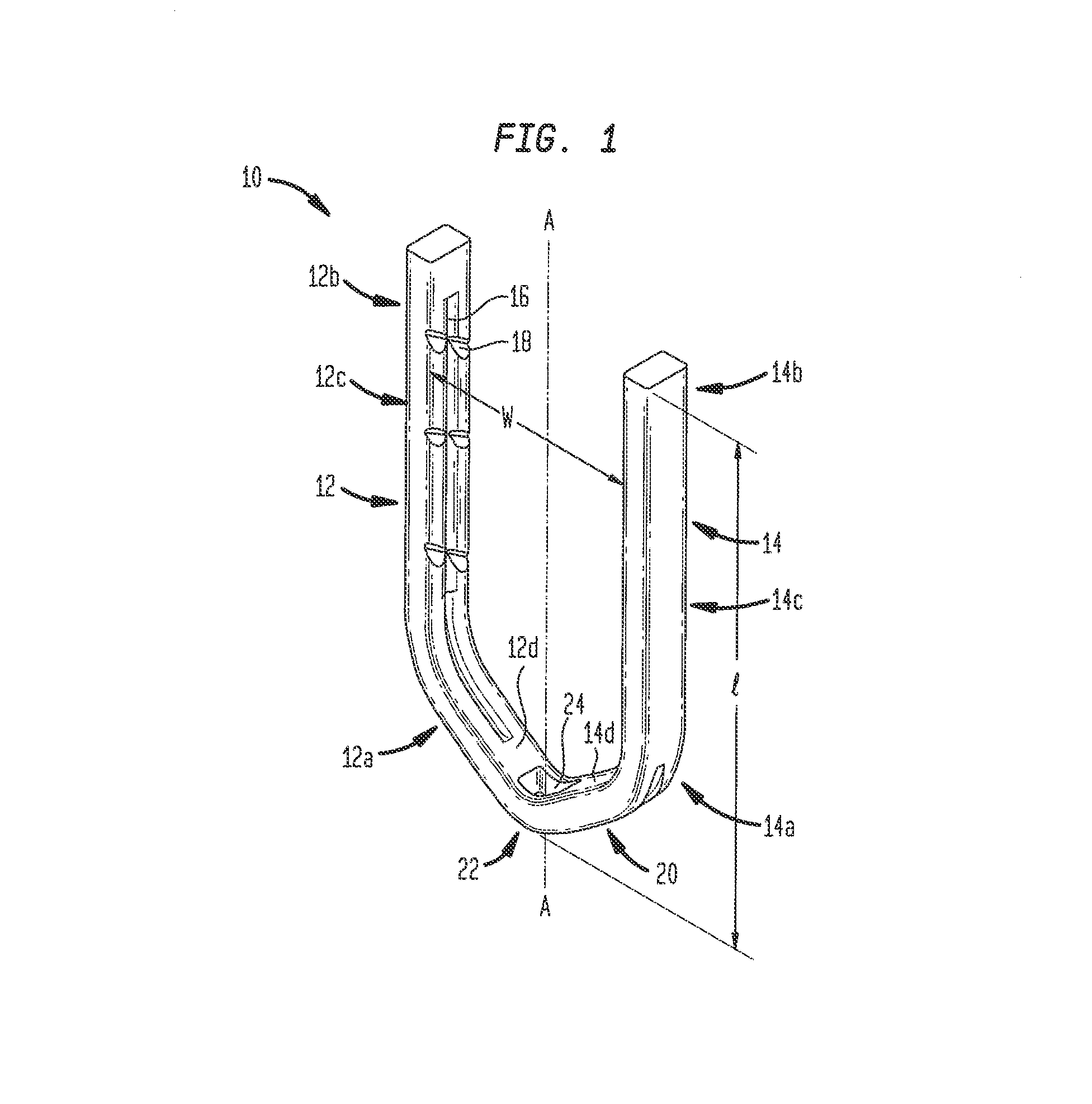

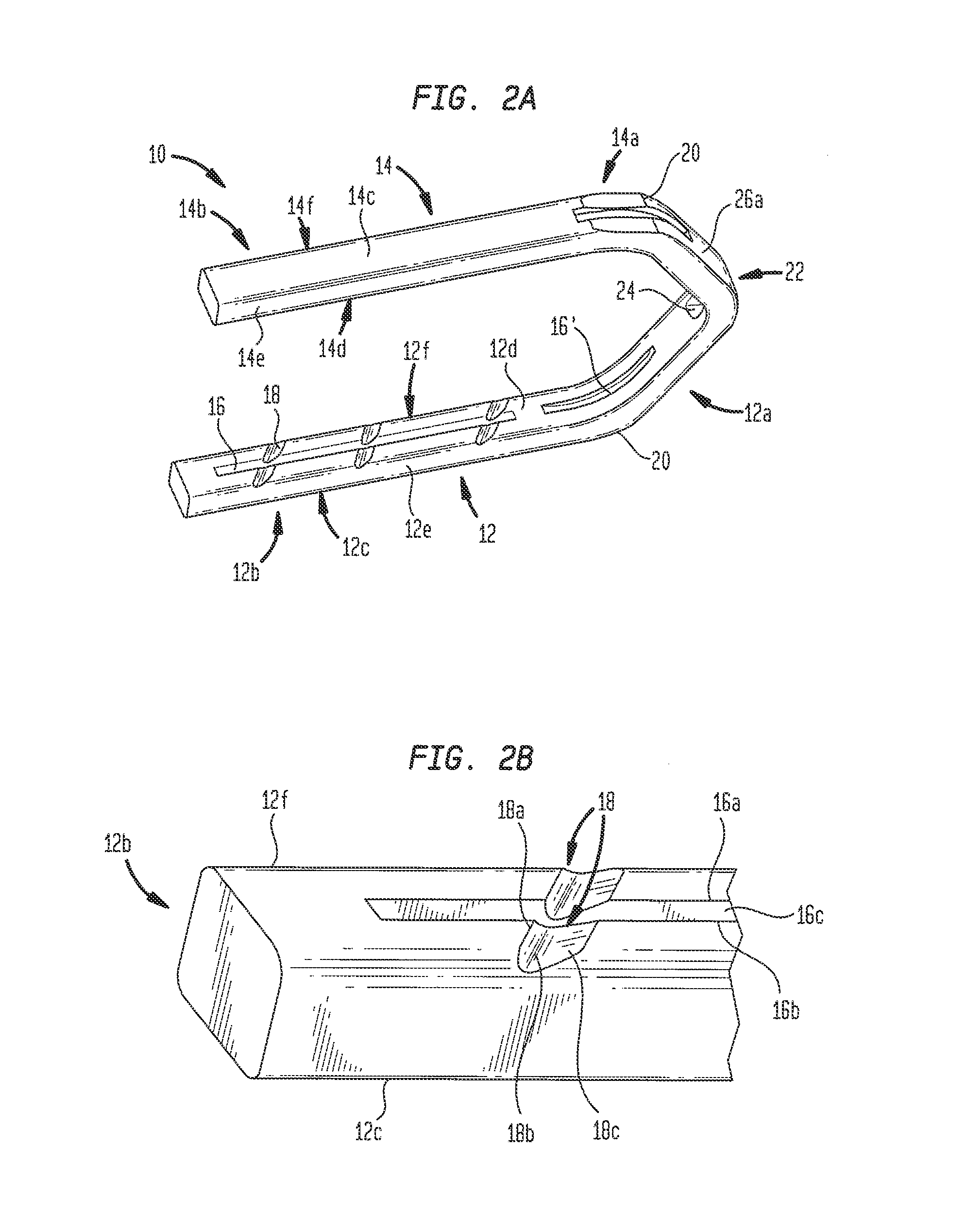

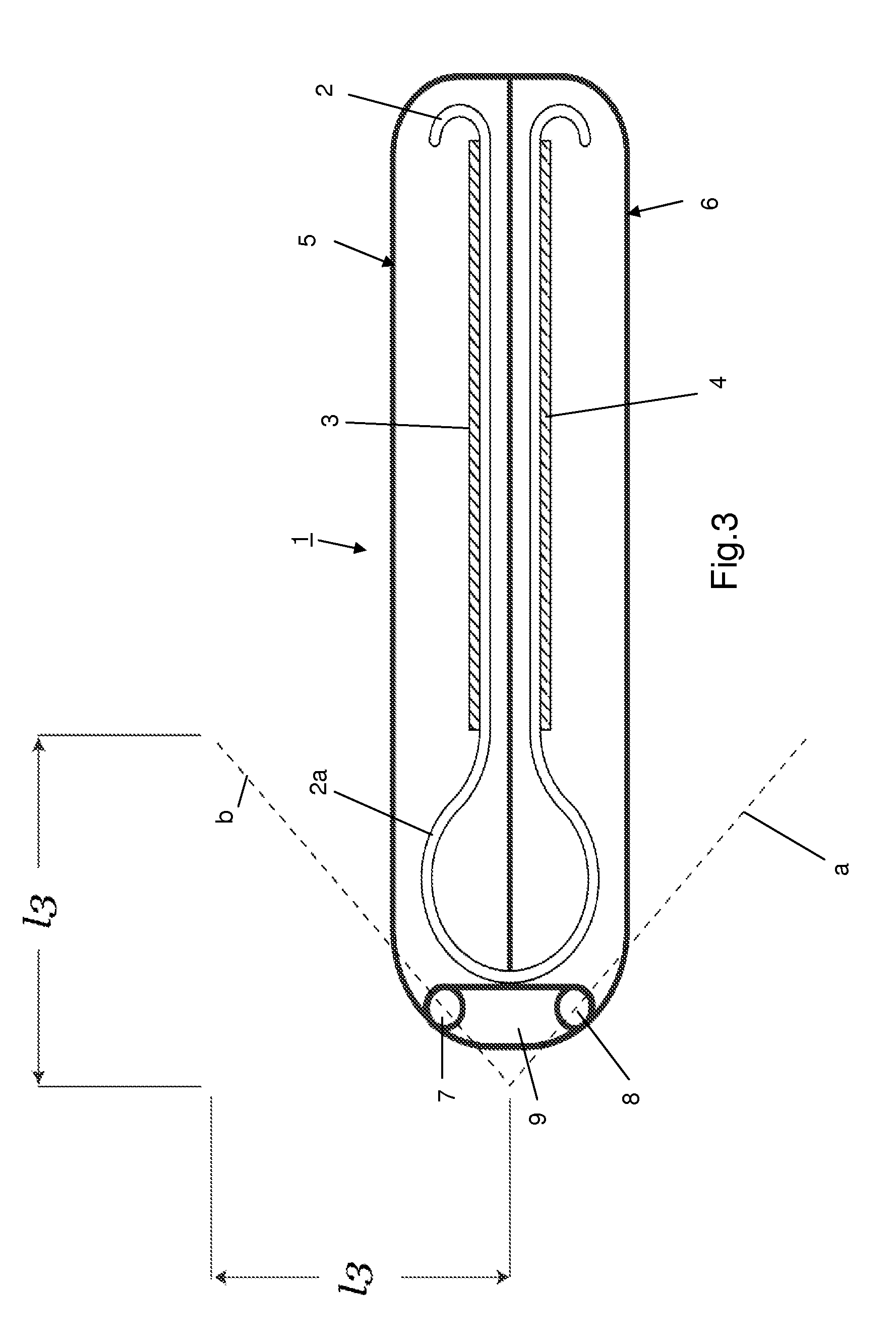

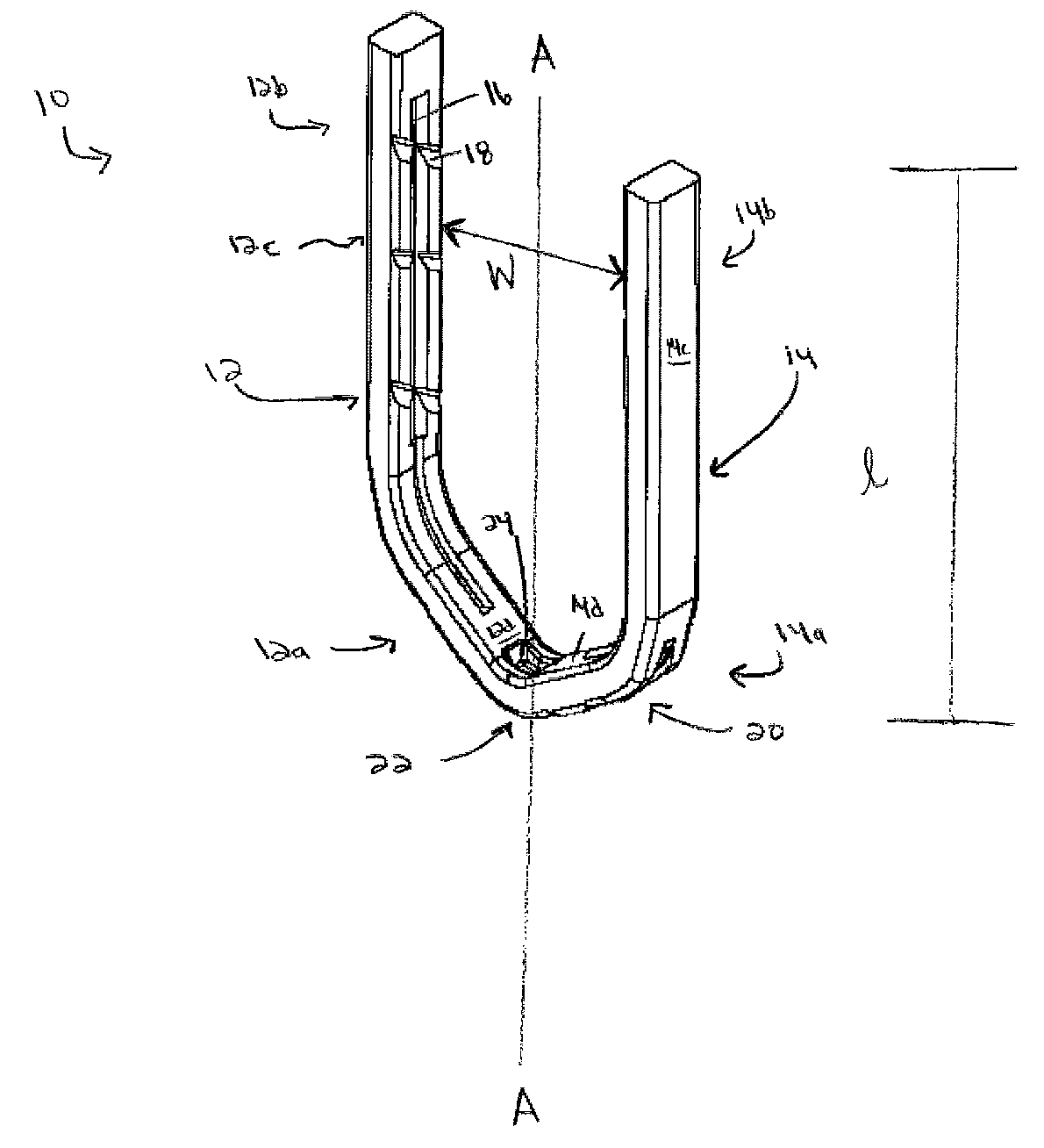

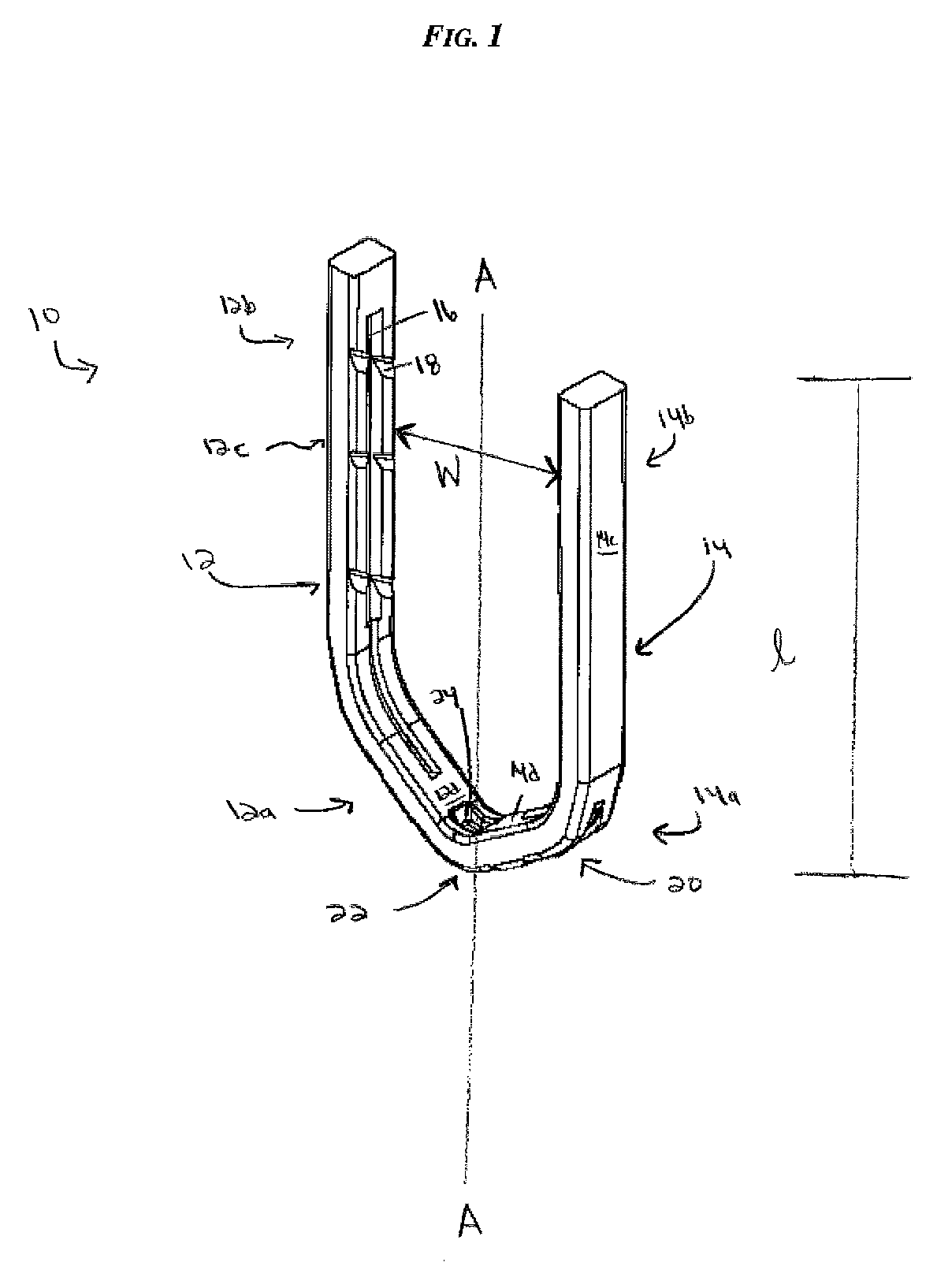

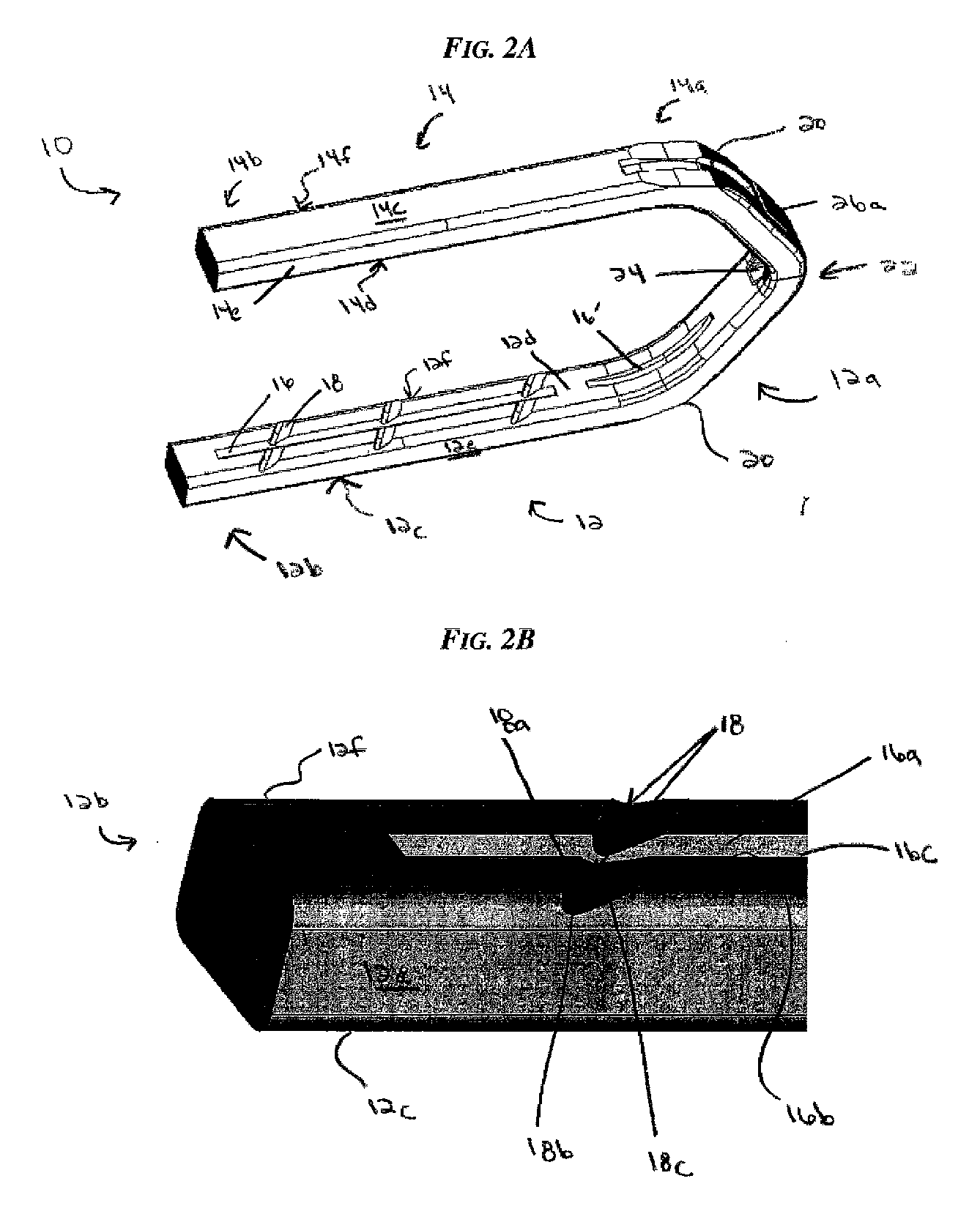

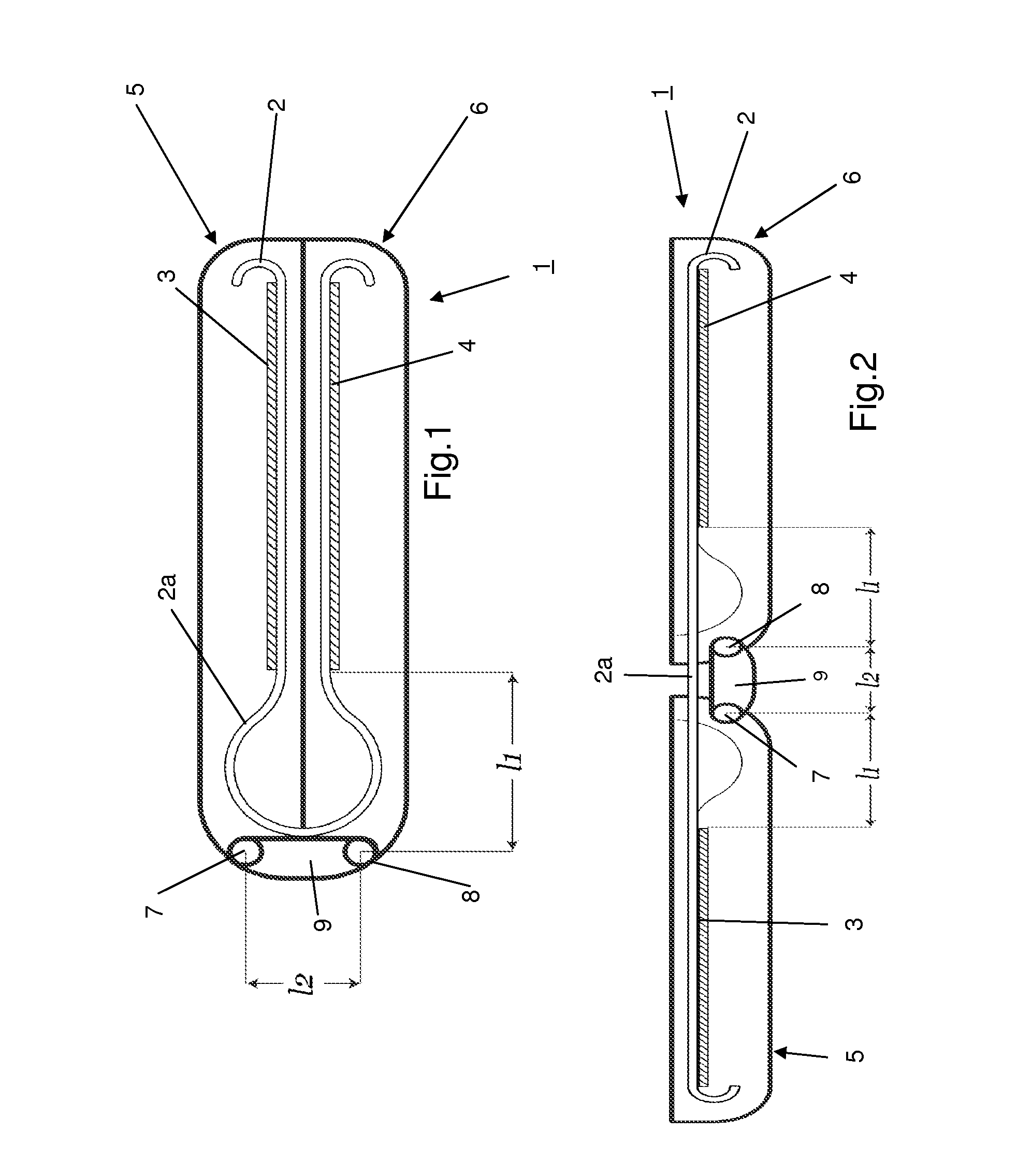

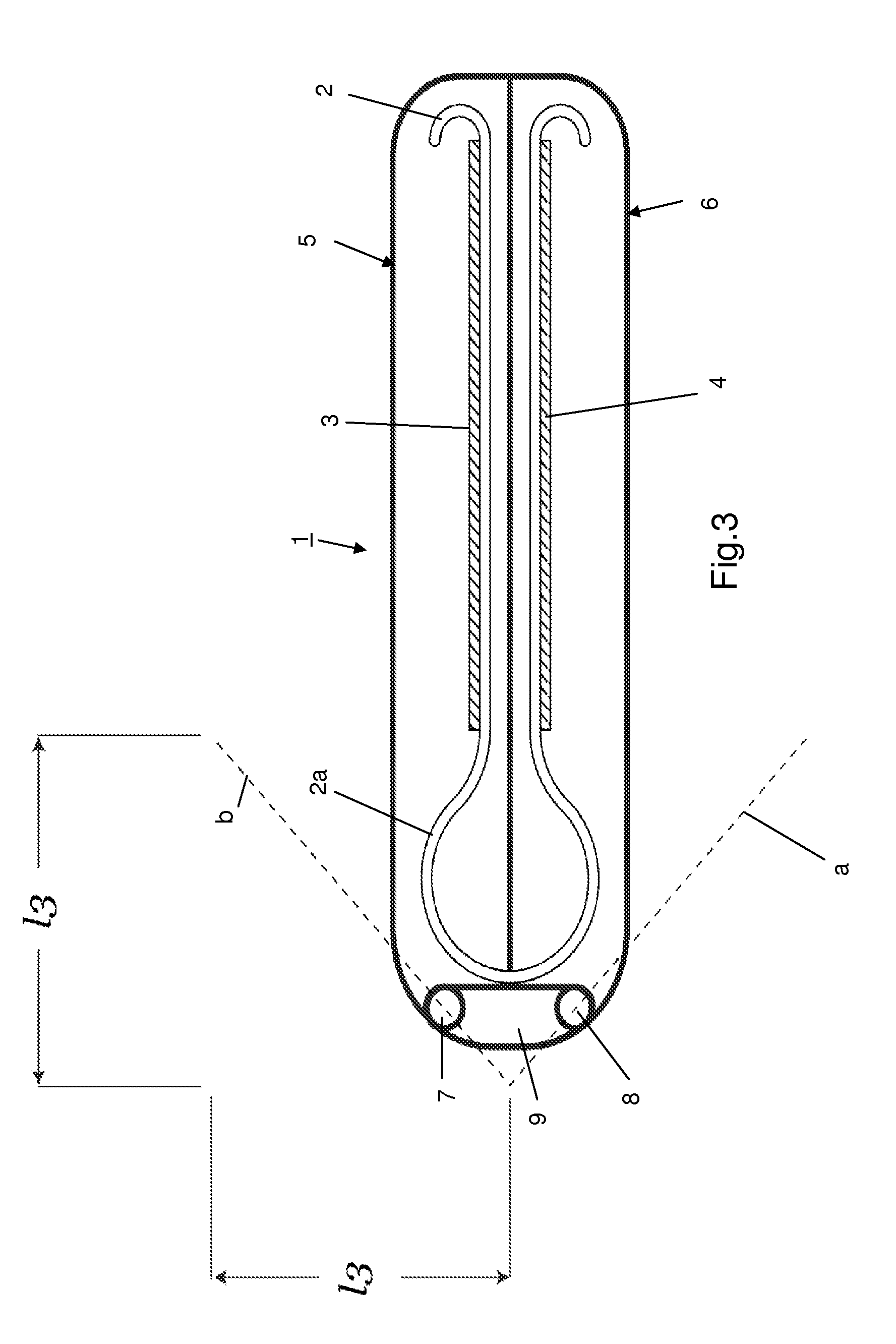

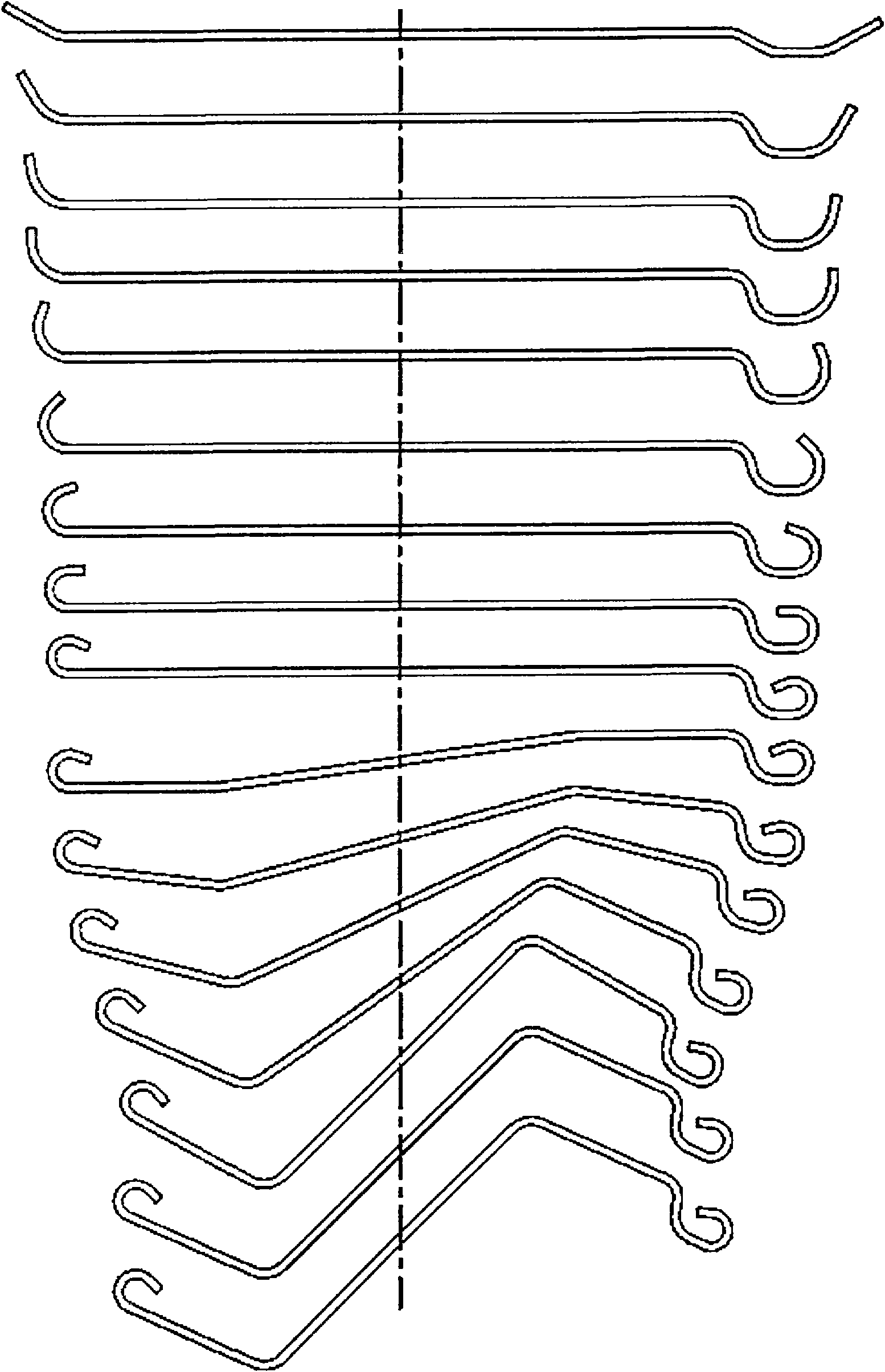

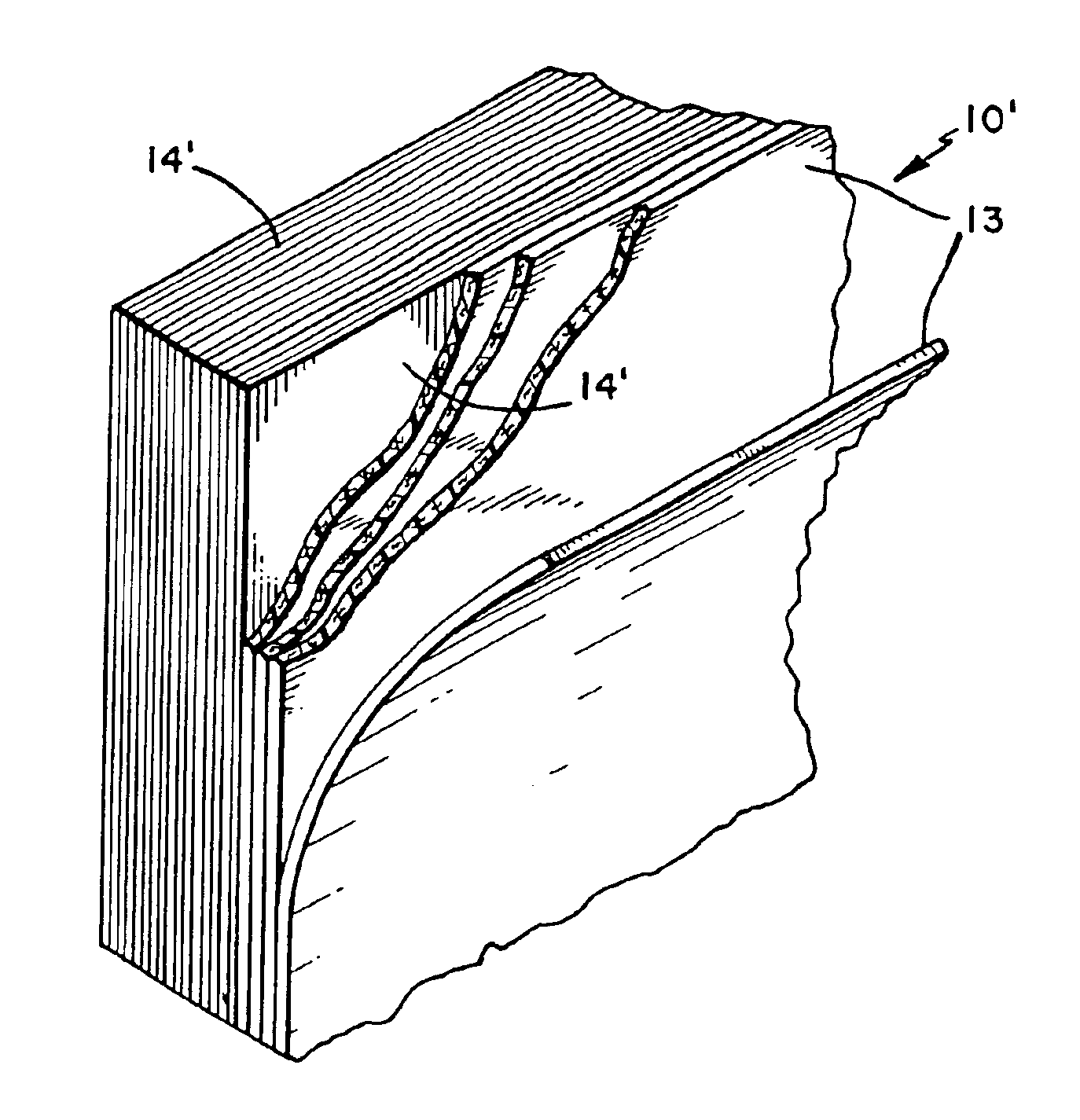

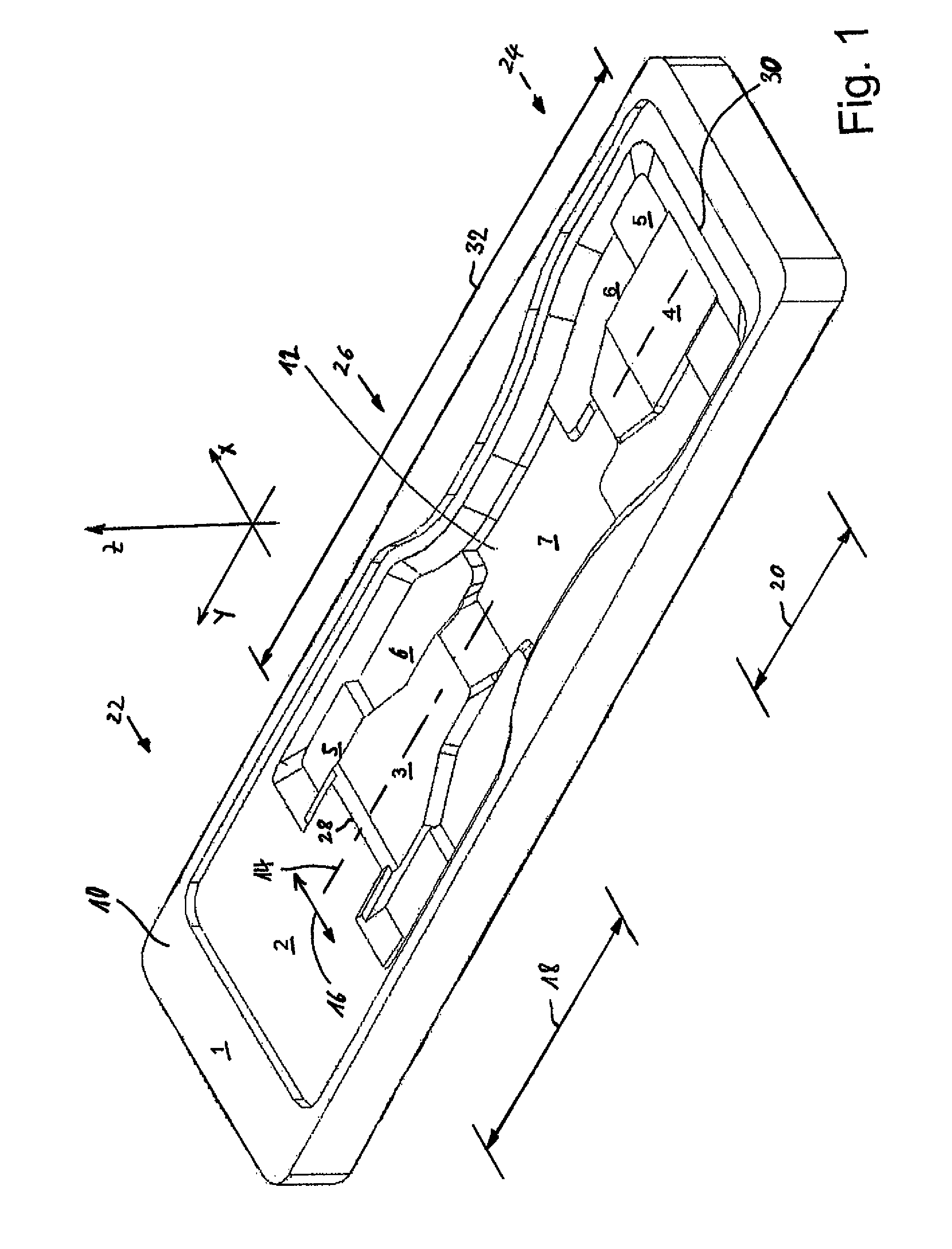

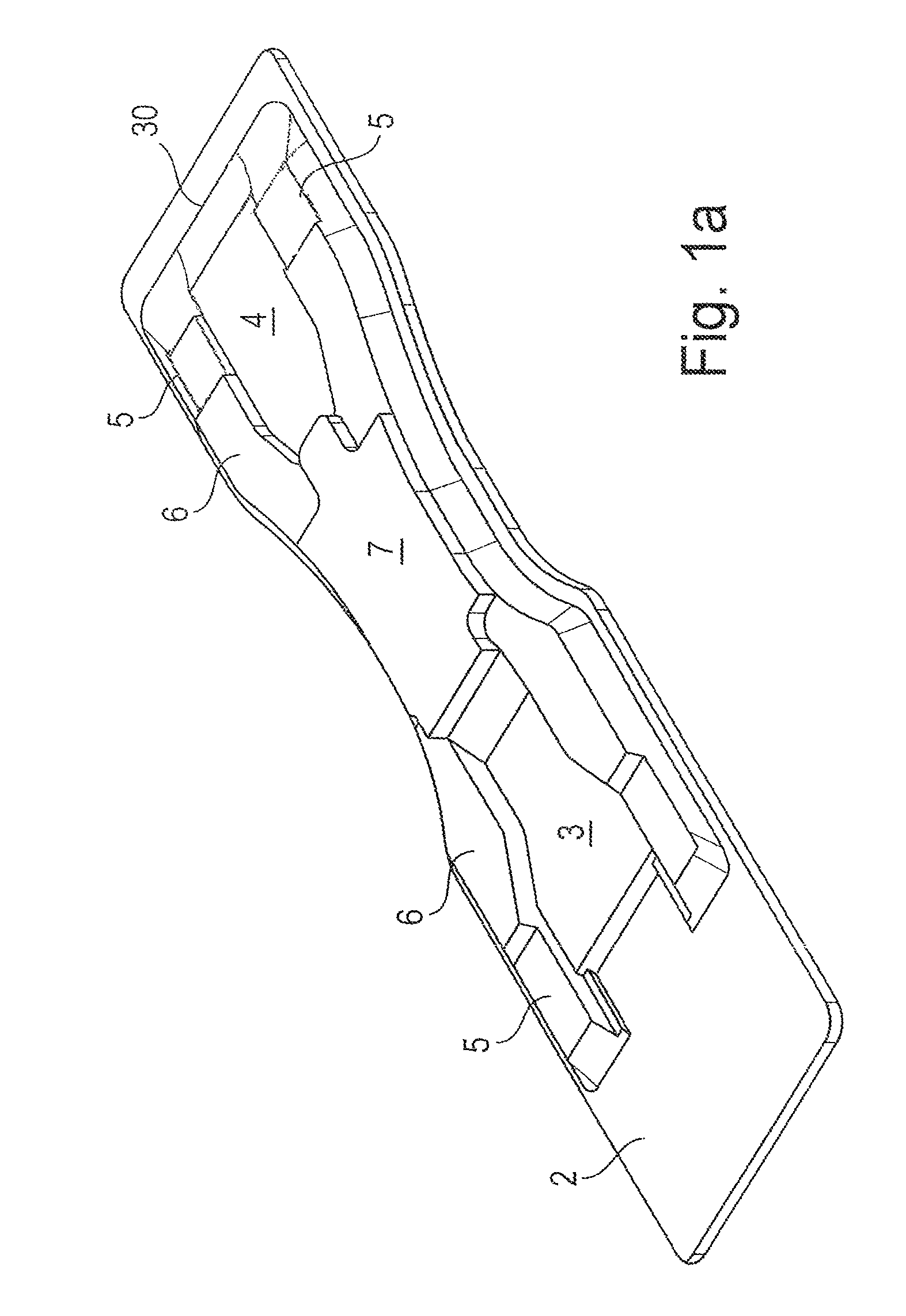

Surgical clip

ActiveUS7699860B2Less deformationElasticitySuture equipmentsSurgical veterinarySurgical ClipsBlood vessel

A clip is provided that can be used for ligating tissue, such as vessels, other tubular ducts, and the like. The clip has opposed first and second leg members having proximal and distal ends. The proximal end of each leg member is connected by an apex having a notch formed therein. Moreover, each leg member has an inner tissue-contacting surface and an outer compression-receiving surface, both of which include features to provide a more secure ligation of the vessel or duct. A method of ligating vessels is also provided.

Owner:ETHICON ENDO SURGERY INC

Method For Applying A Surgical Clip Having A Compliant Portion

Owner:CILAG GMBH INT +1

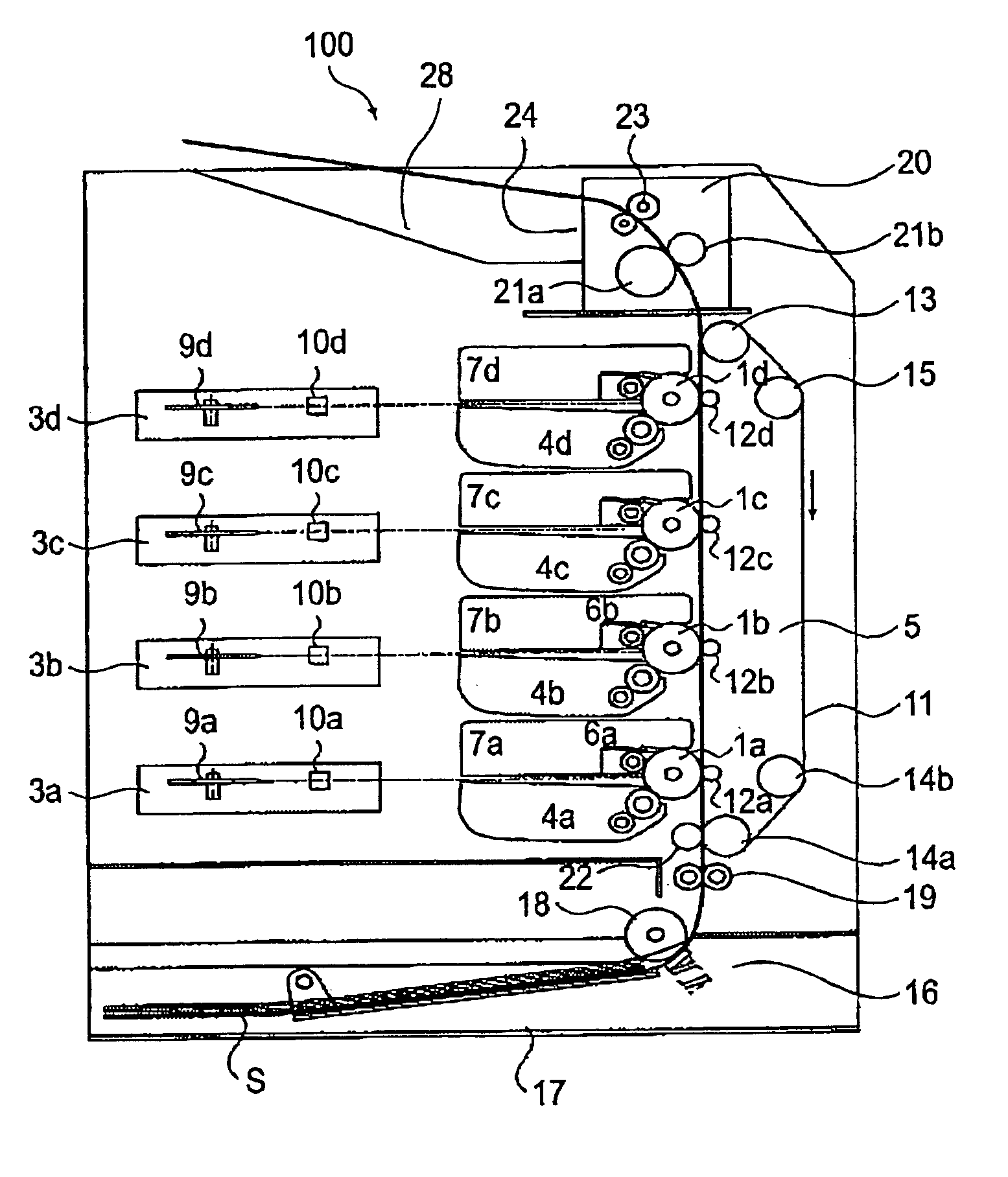

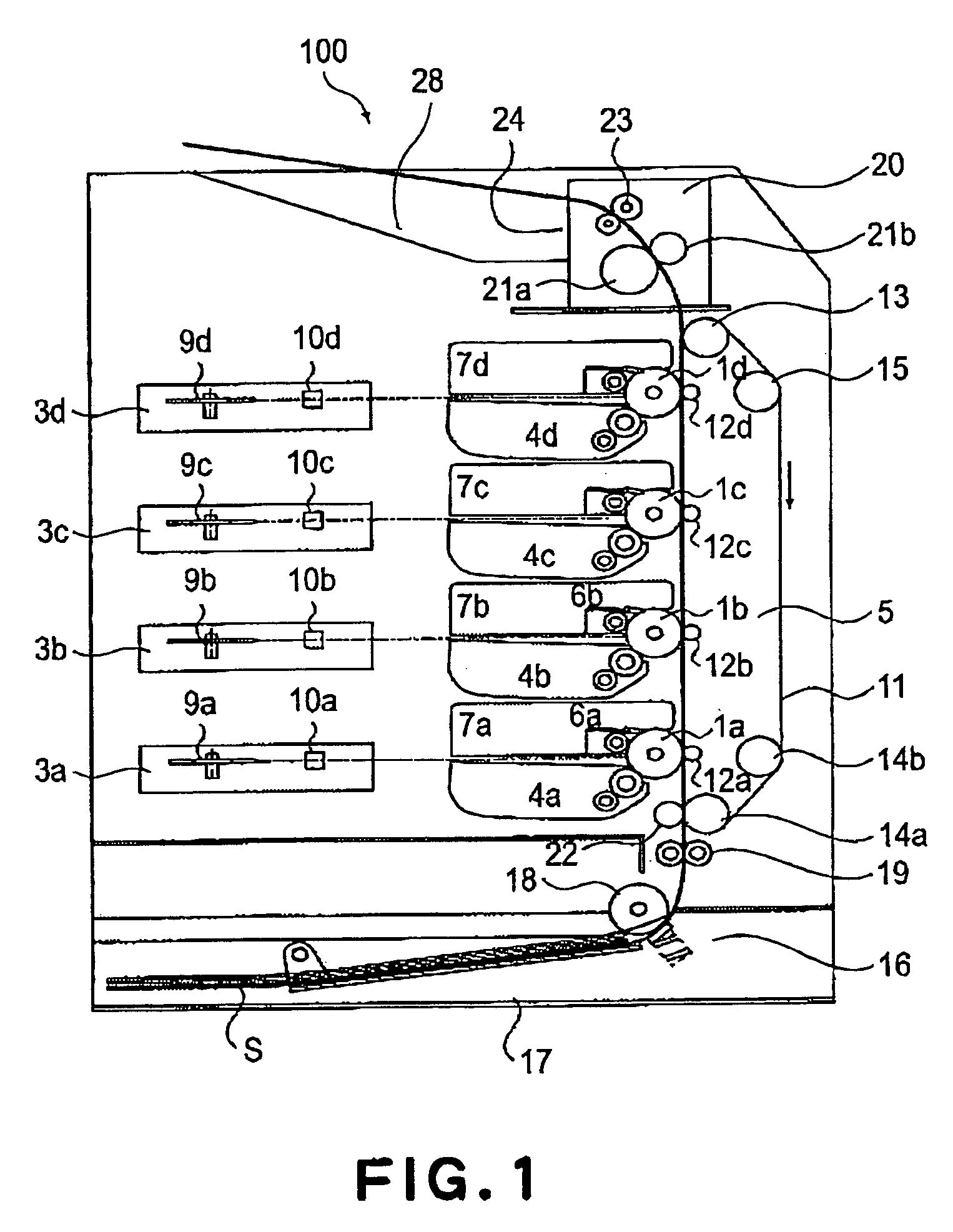

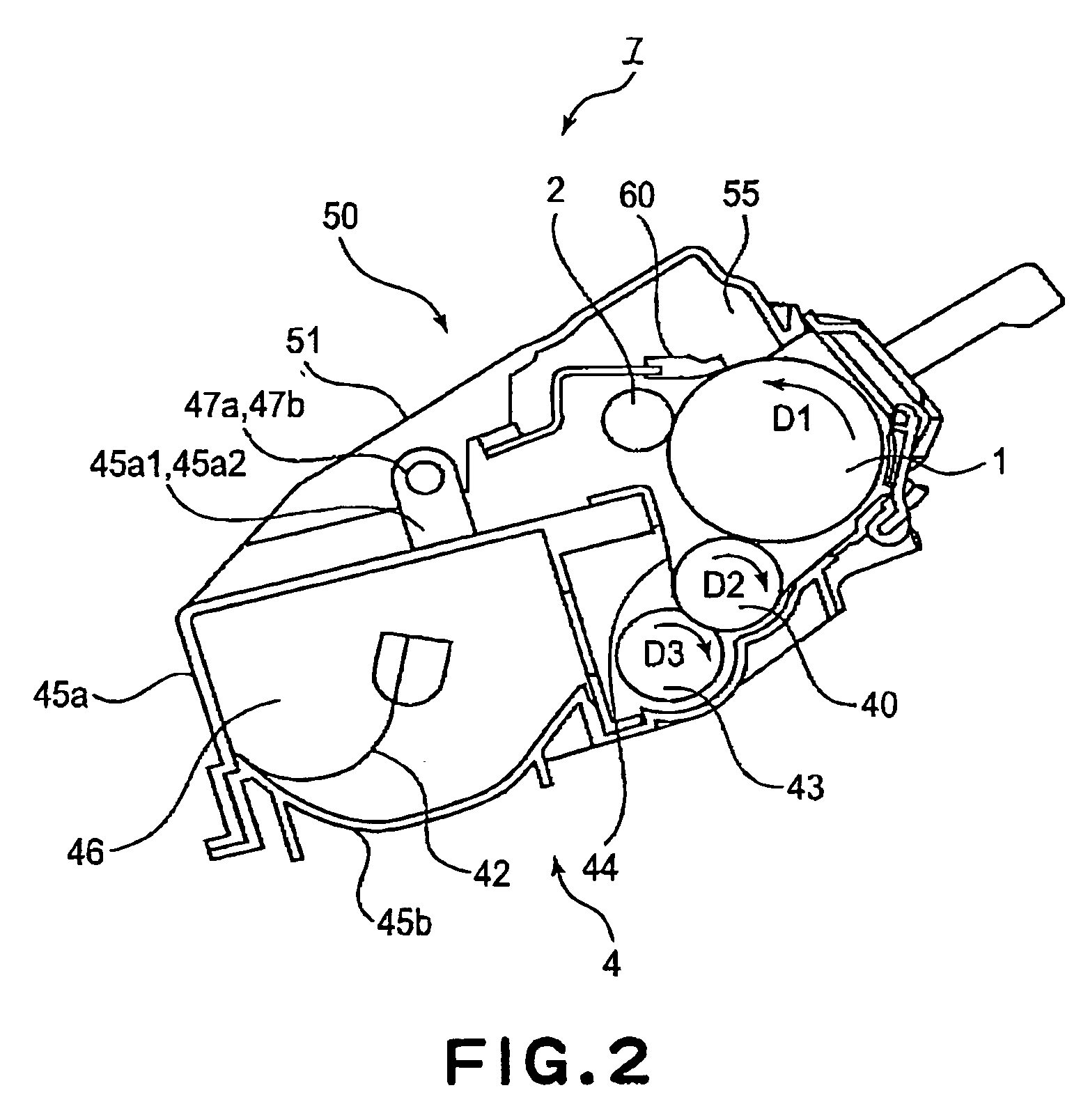

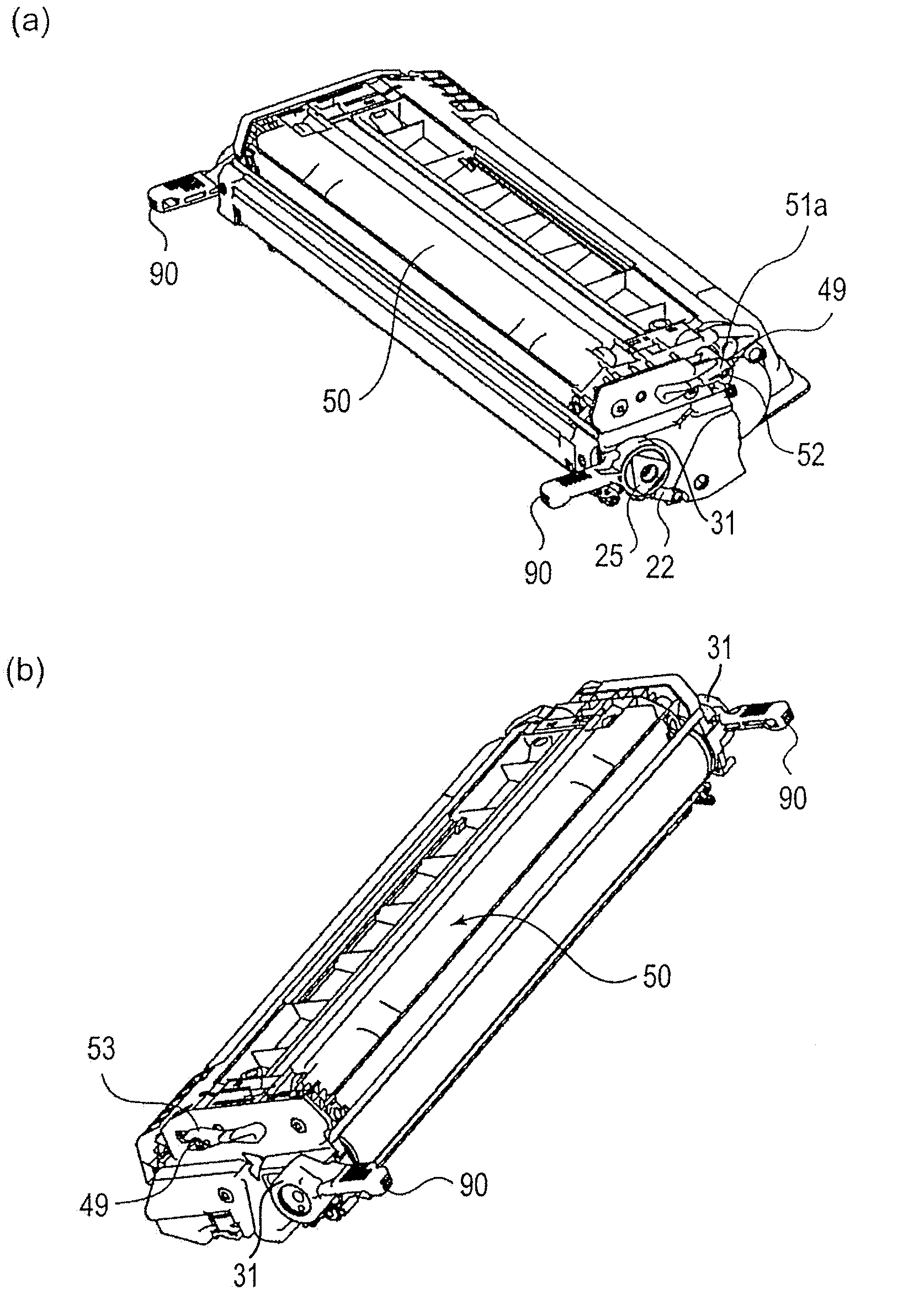

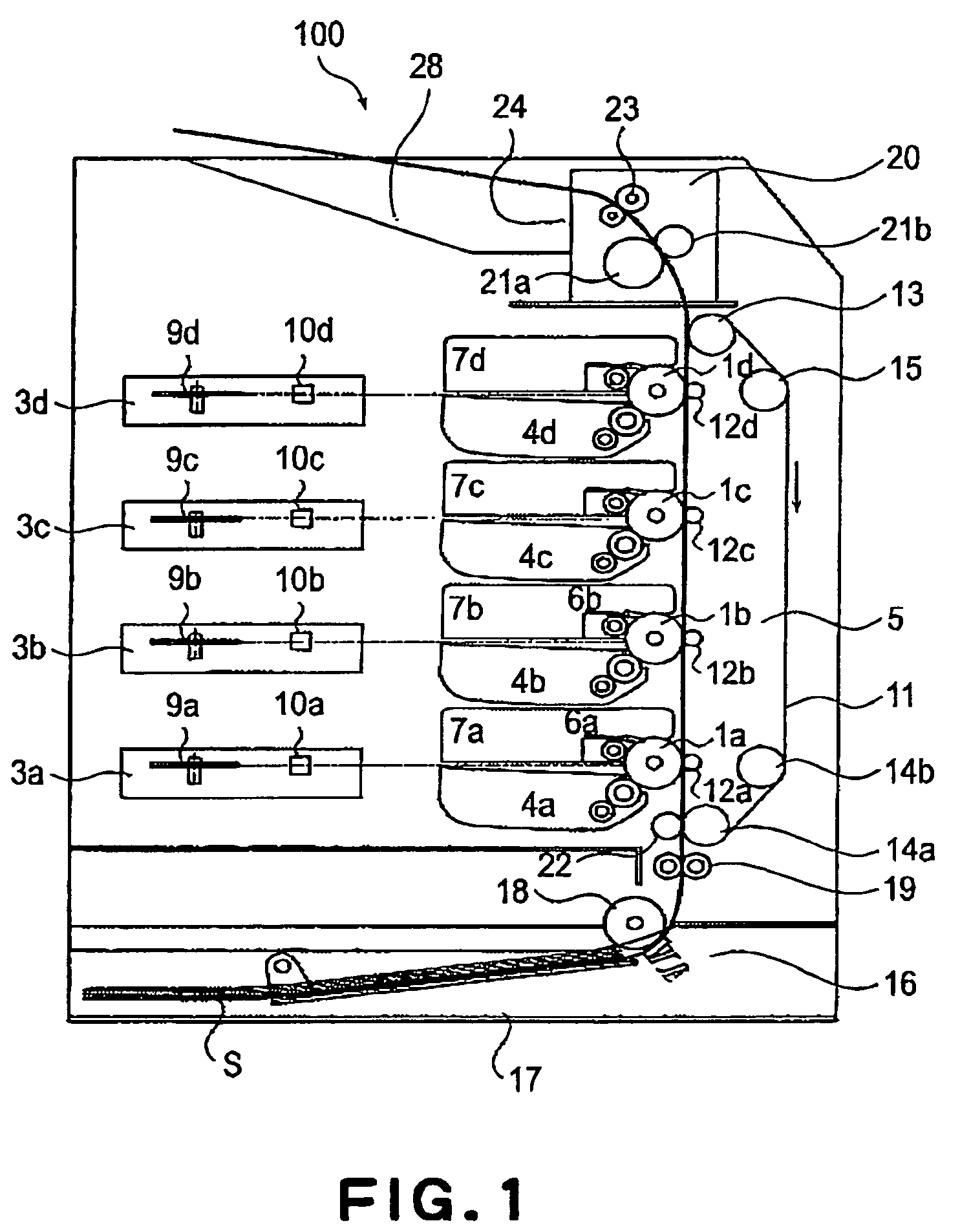

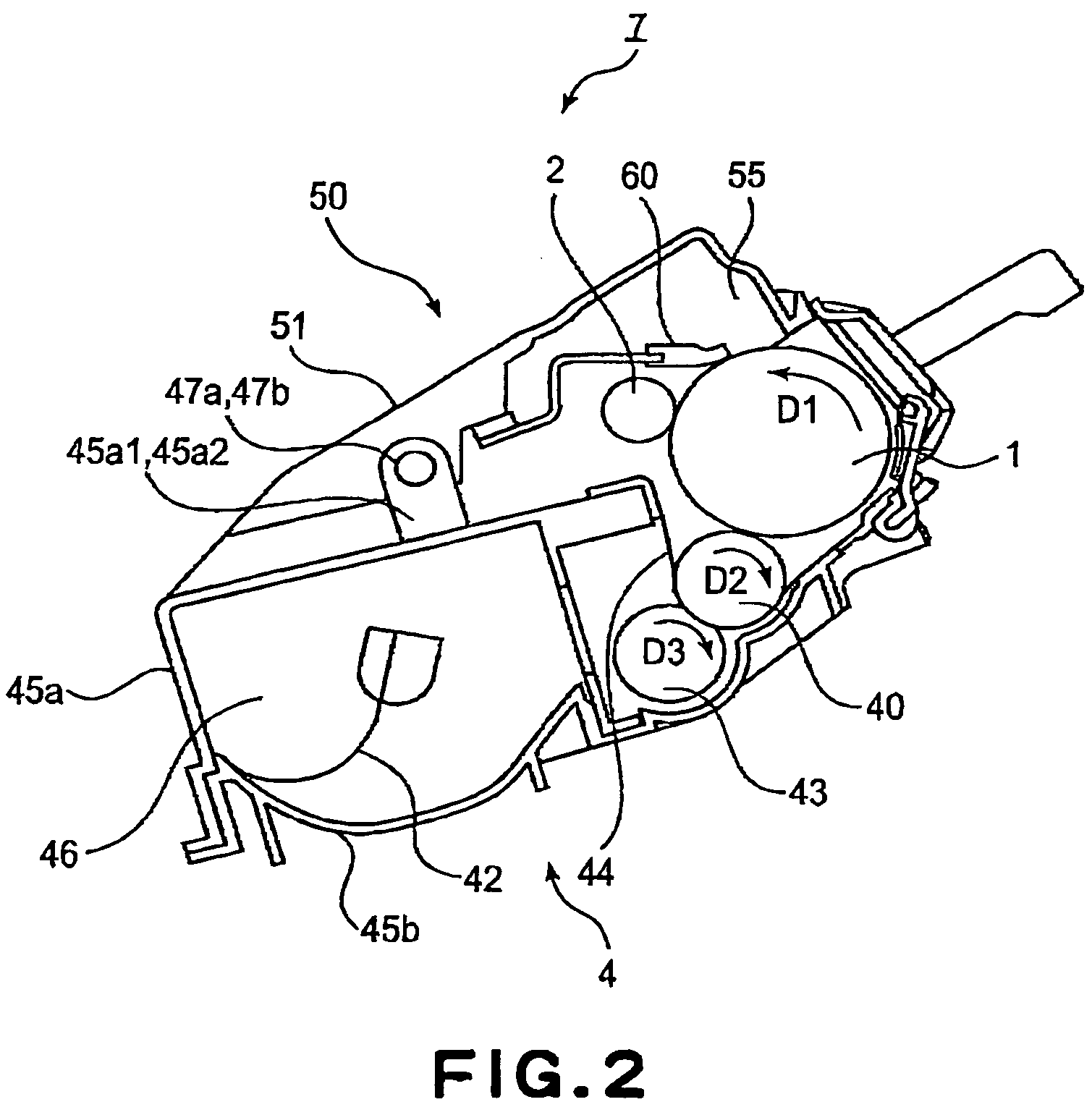

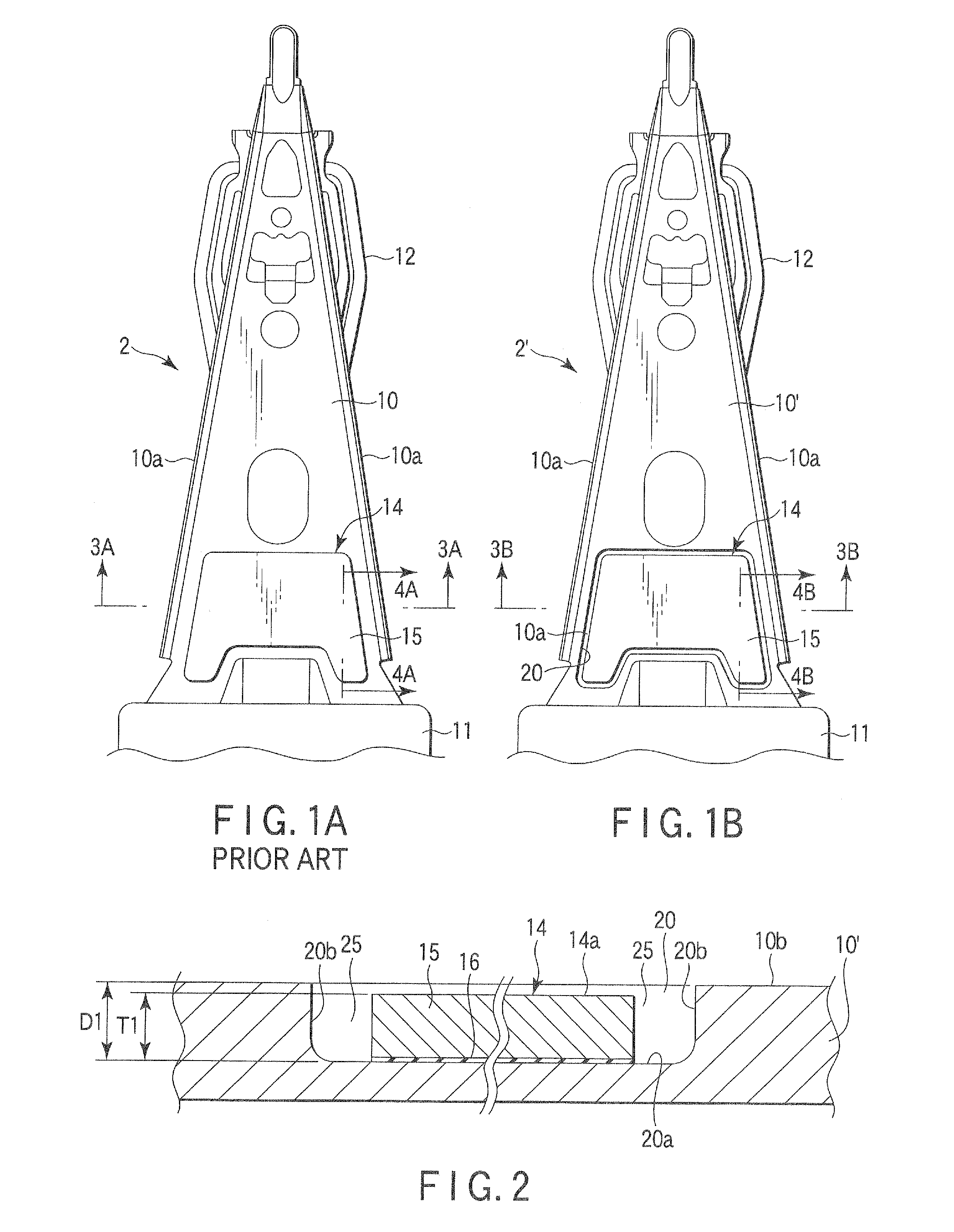

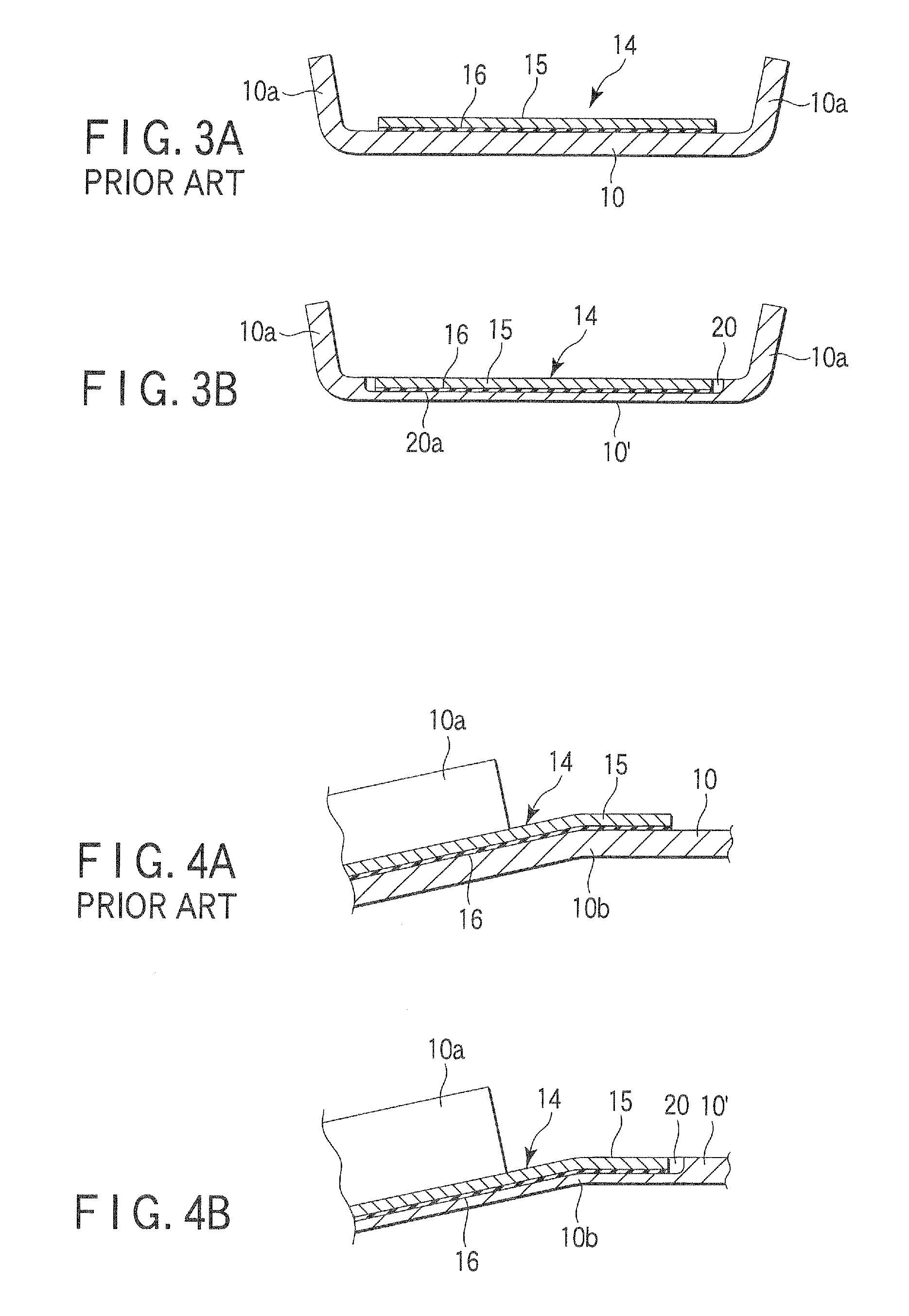

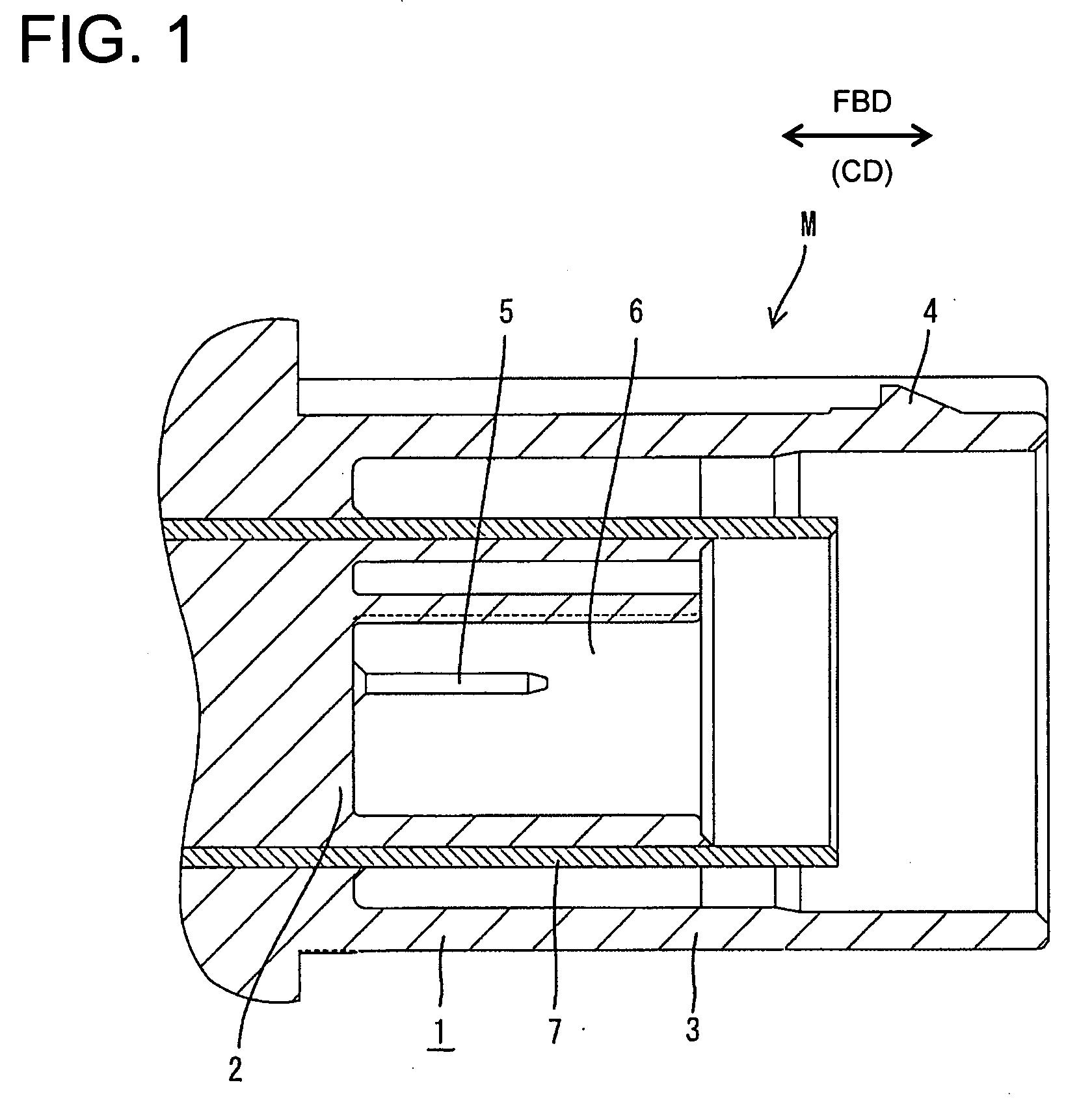

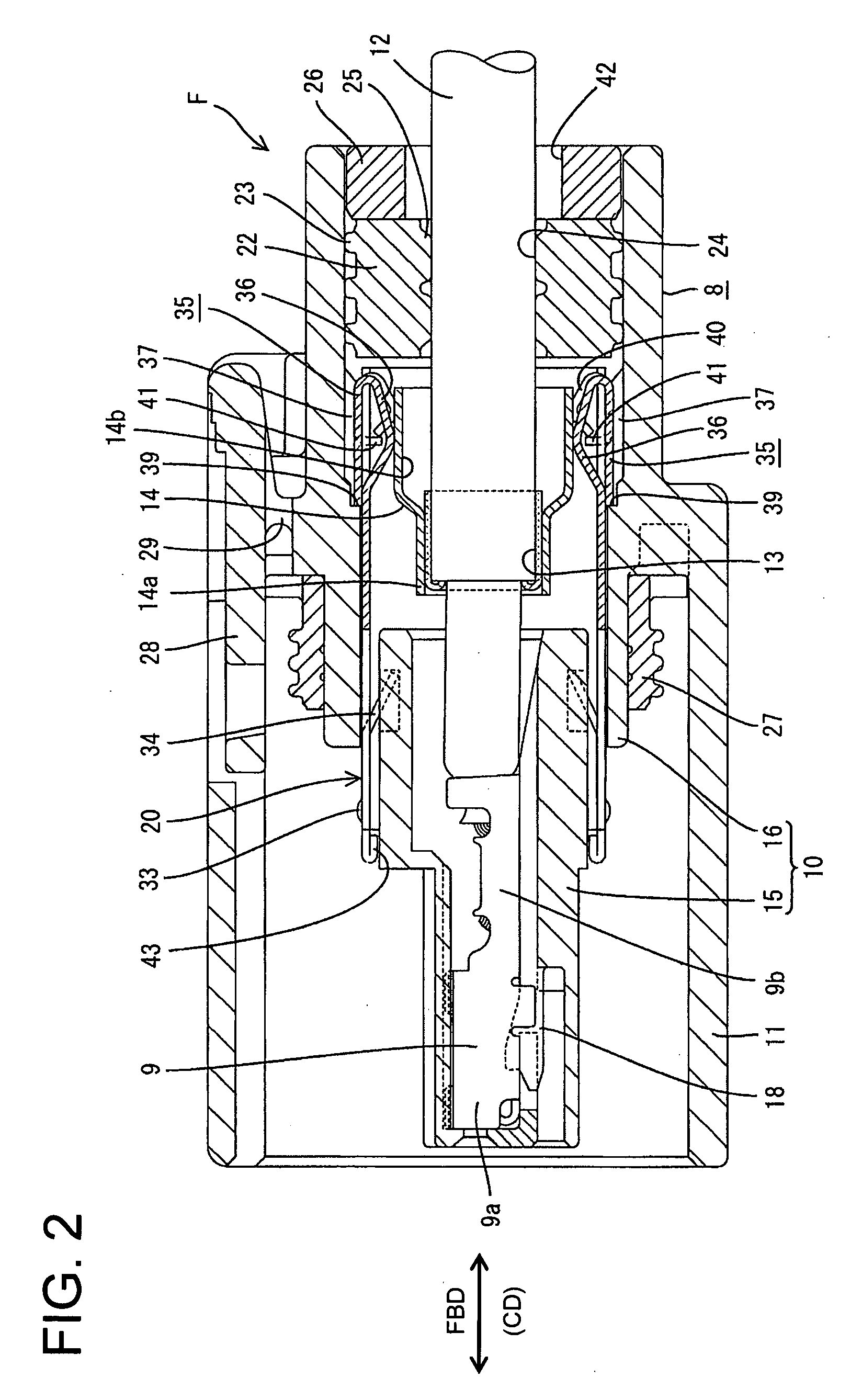

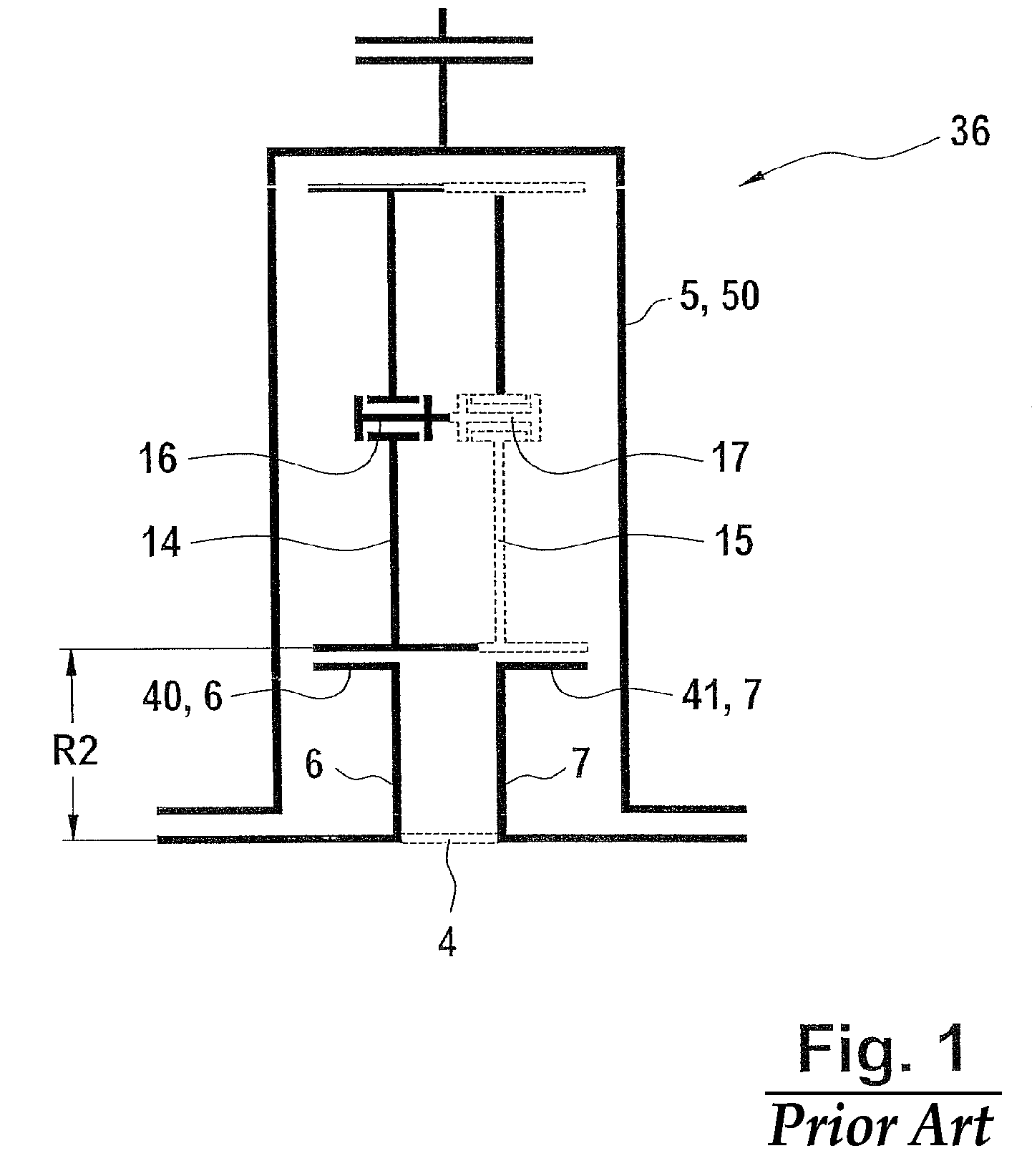

Process cartridge having first and second rotatably coupled frames and electrophotographic image forming apparatus mounting such process cartridge

ActiveUS7158736B2Less bending momentLess deformationElectrographic process apparatusEngineeringImaging equipment

A cartridge detachably mountable to an apparatus includes a drum, a developing roller, first and second frames supporting the drum and roller, a coupling member rotatably connecting the frames, a first cartridge positioning portion abuttable to a first main assembly positioning portion positioning the cartridge with respect to a direction crossing the drum axis when the cartridge is mounted to the apparatus, a drive input gear engaging a main assembly driving gear, and a second cartridge positioning portion abuttable to a second main assembly positioning portion limiting cartridge rotation about the first cartridge positioning portion. When the cartridge is in the apparatus, the coupling member crosses a phantom line perpendicular to the second main assembly positioning portion and which passes through the second positioning portion, as seen from one end with respect to the axis.

Owner:CANON KK

Process cartridge and electrophotographic image forming apparatus

ActiveUS7212768B2Less bending momentLess deformationElectrographic processImaging equipmentMechanical engineering

A process cartridge detachably mountable to an electrophotographic image forming includes an electrophotographic photosensitive drum; a developing roller; a first cartridge positioning portion abuttable to a first main assembly positioning portion provided in a main assembly of the apparatus to position the cartridge with respect to a direction crossing the longitudinal direction, when the cartridge is mounted to the main assembly; a second cartridge positioning portion abuttable to a second main assembly positioning portion provided in the main assembly to limit rotation of the cartridge about the first cartridge positioning portion, when the cartridge receives a rotational driving force for rotating the roller from the main assembly; and a first drive input gear, for engagement with a main assembly driving gear to transmit a rotational driving force to the roller.

Owner:CANON KK

Display system having a continuous flexible display with display supports

InactiveUS20130342094A1Relieve stressKeep displayStatic indicating devicesAdvertisingDisplay deviceSpring force

A display system comprises a continuous flexible display and two main display supports being hingeably connected with respect to each other between a closed storage position and a planar open position for fixing the flexible display in an open position. Each of the supports is structurally configured to support respectively a first and a second portion of the flexible display, a segment of the flexible display is located between the said respective portions of the flexible display in the open position. The display system comprises a spring force biased mechanism operative in either the open or closed position or both the open and closed positions of the flexible display, biasing said segment of the flexible display in the respective position.

Owner:SAMSUNG ELECTRONICS CO LTD

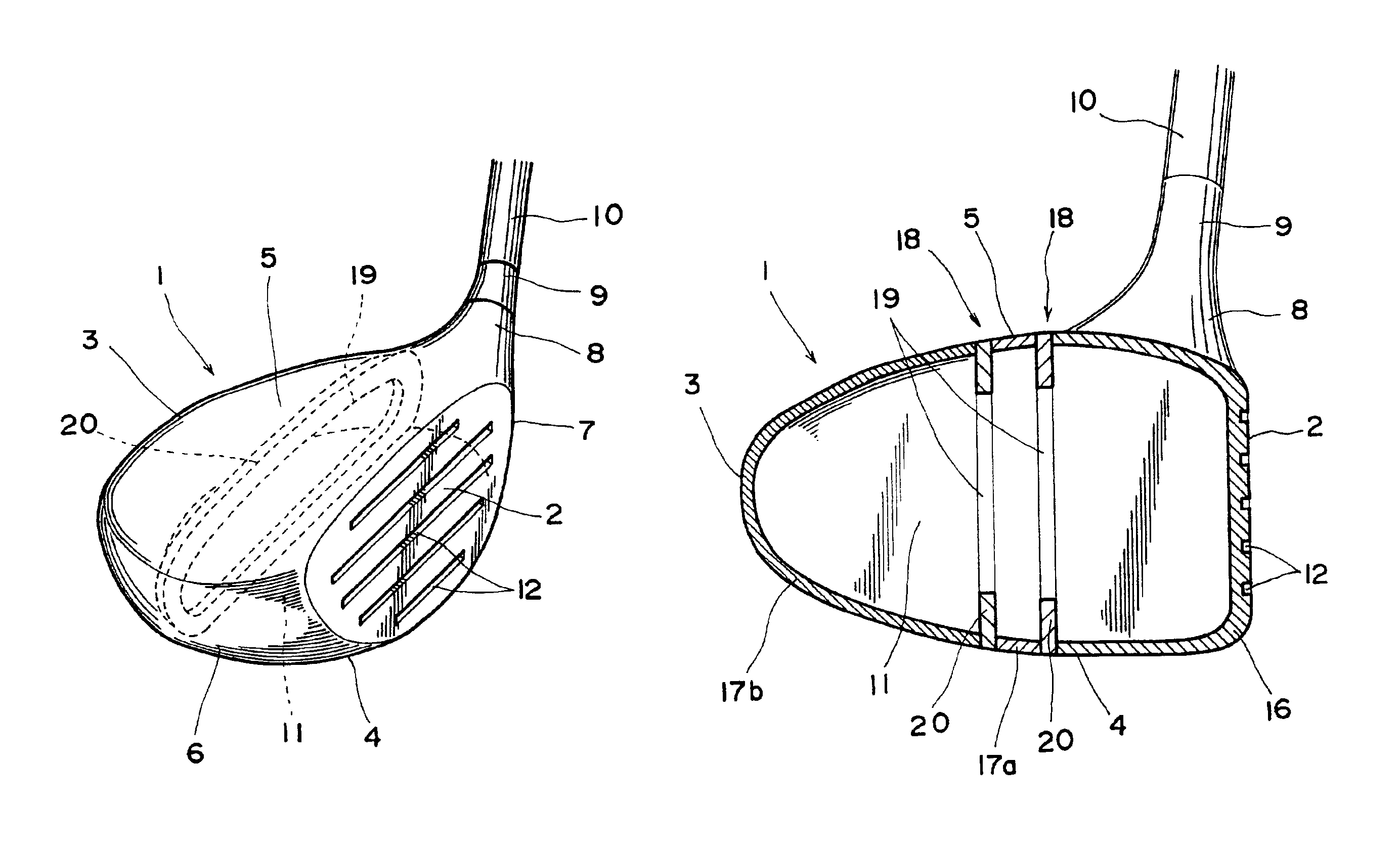

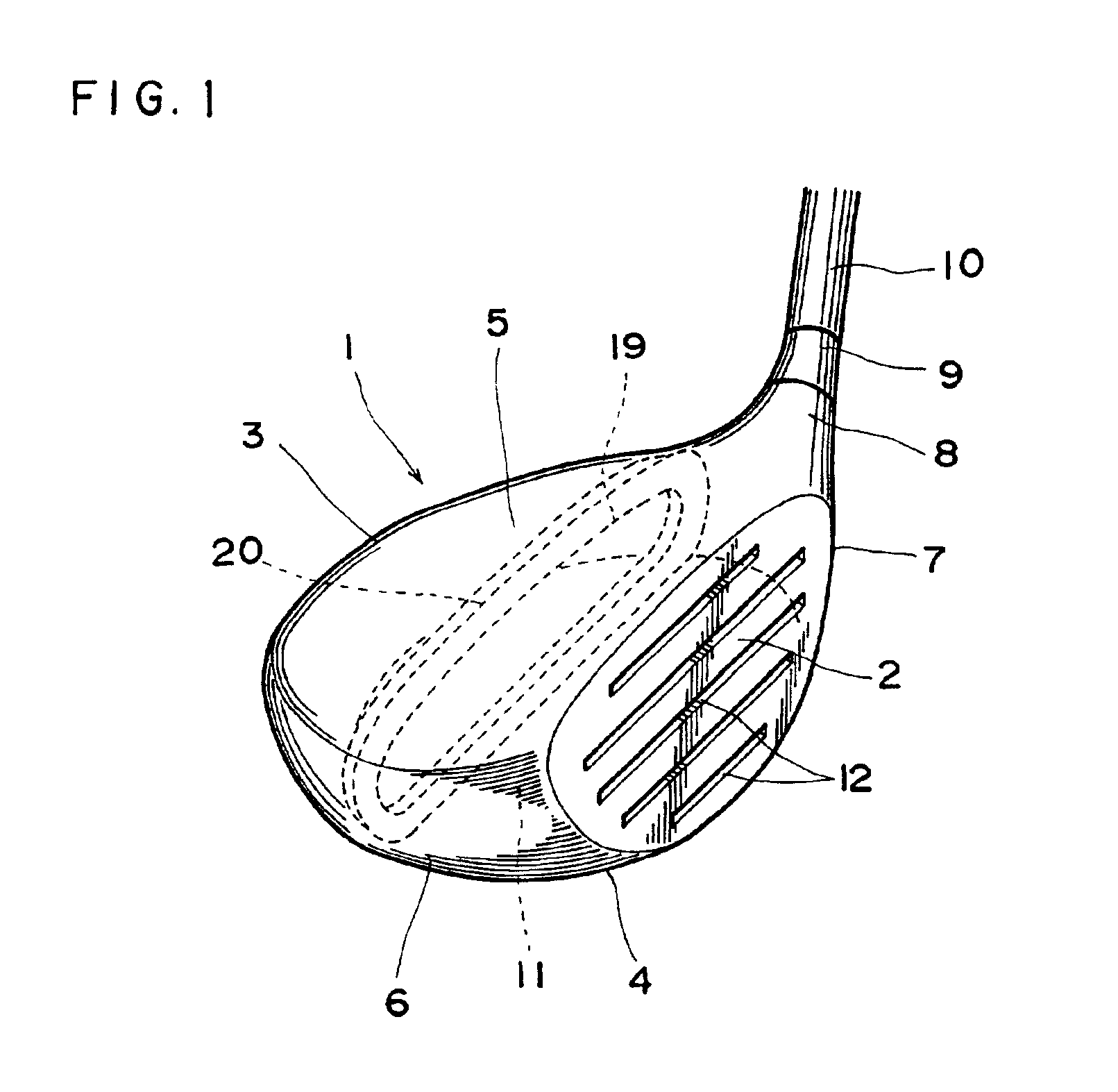

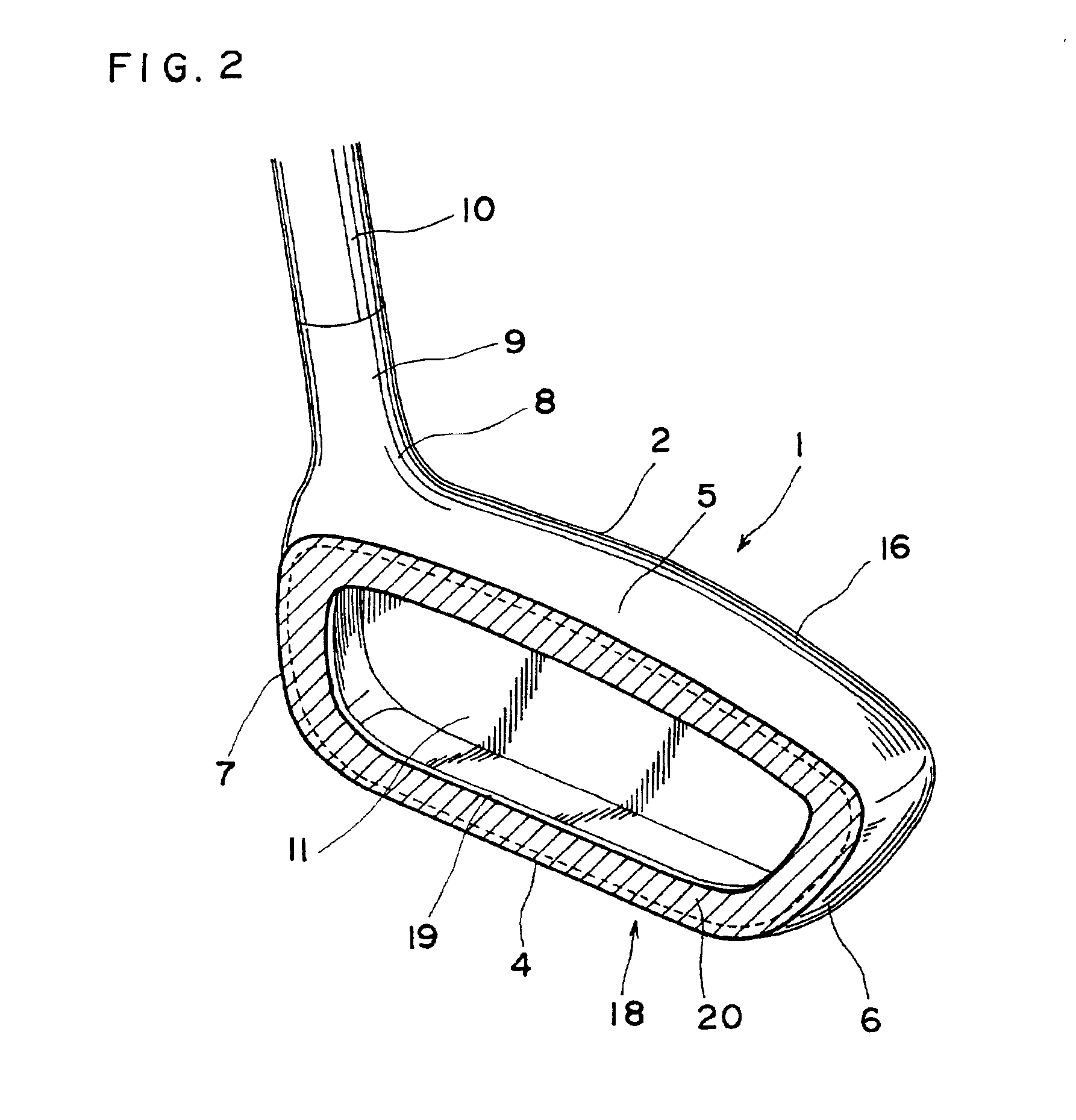

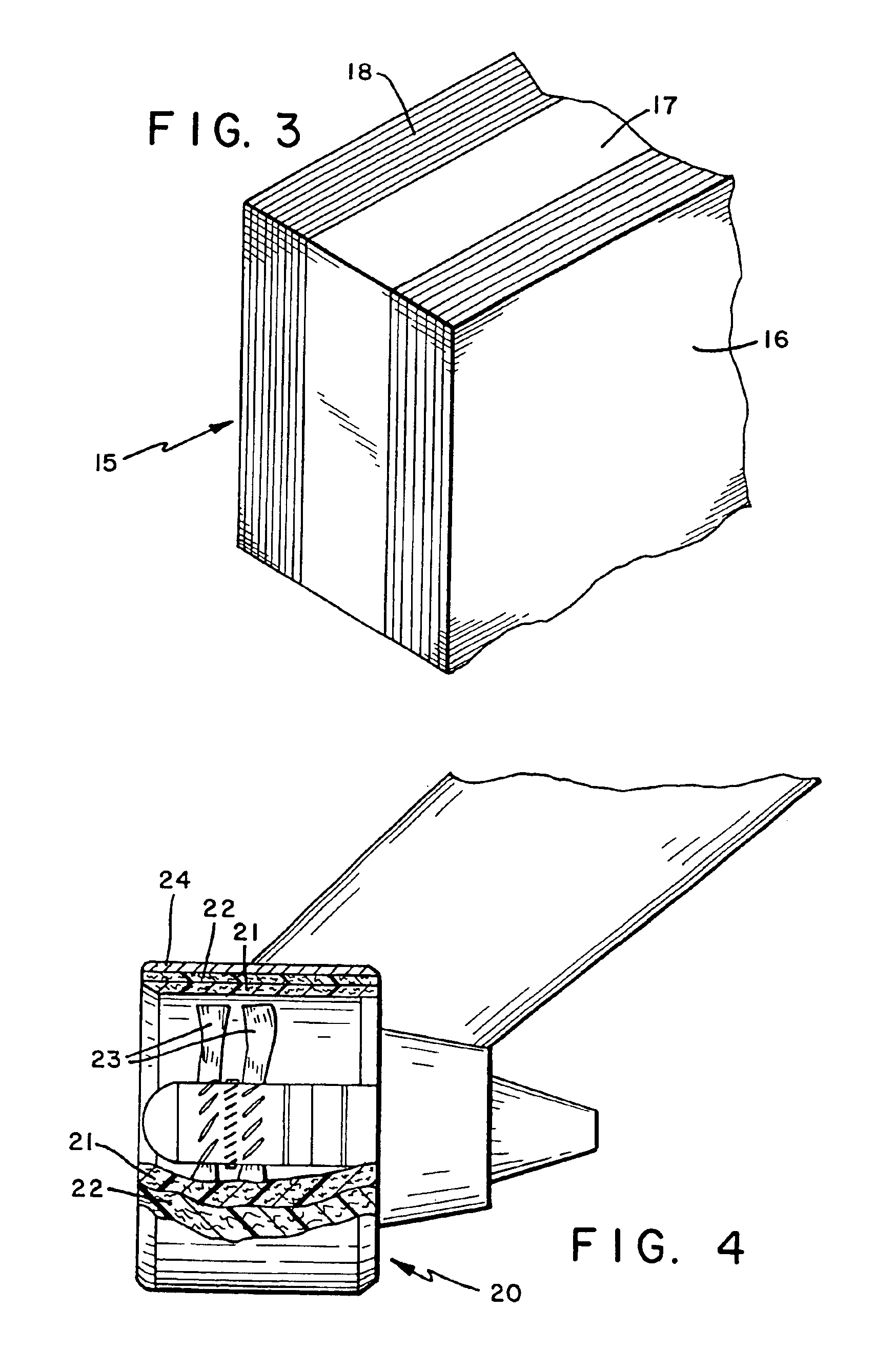

Wood golf club

InactiveUS6878073B2Effectively elastically deformedPrevent excessive deformationGolf clubsRacket sportsEngineeringGolf Ball

A wood golf club called a metal wood which suppresses the deformation of a head body at the time of impact, thereby effectively elastically deforming a face to thereby elongate a travelling distance of a ball. An outer shell of a head 1 is constructed of metallic shell members, thus defining a hollow interior 11 inside the head 1. A tabular reinforcing member 20 is provided nearly along a cross-sectional area of the hollow interior 11 defined in a toe-to-heel direction, a preset distance away from the face 2. Thus, the deformation of a sole 4 and a crown 5 can be suppressed, while permitting the sufficient elastic deformation of the face 2.

Owner:ENDO MFG COMPANY

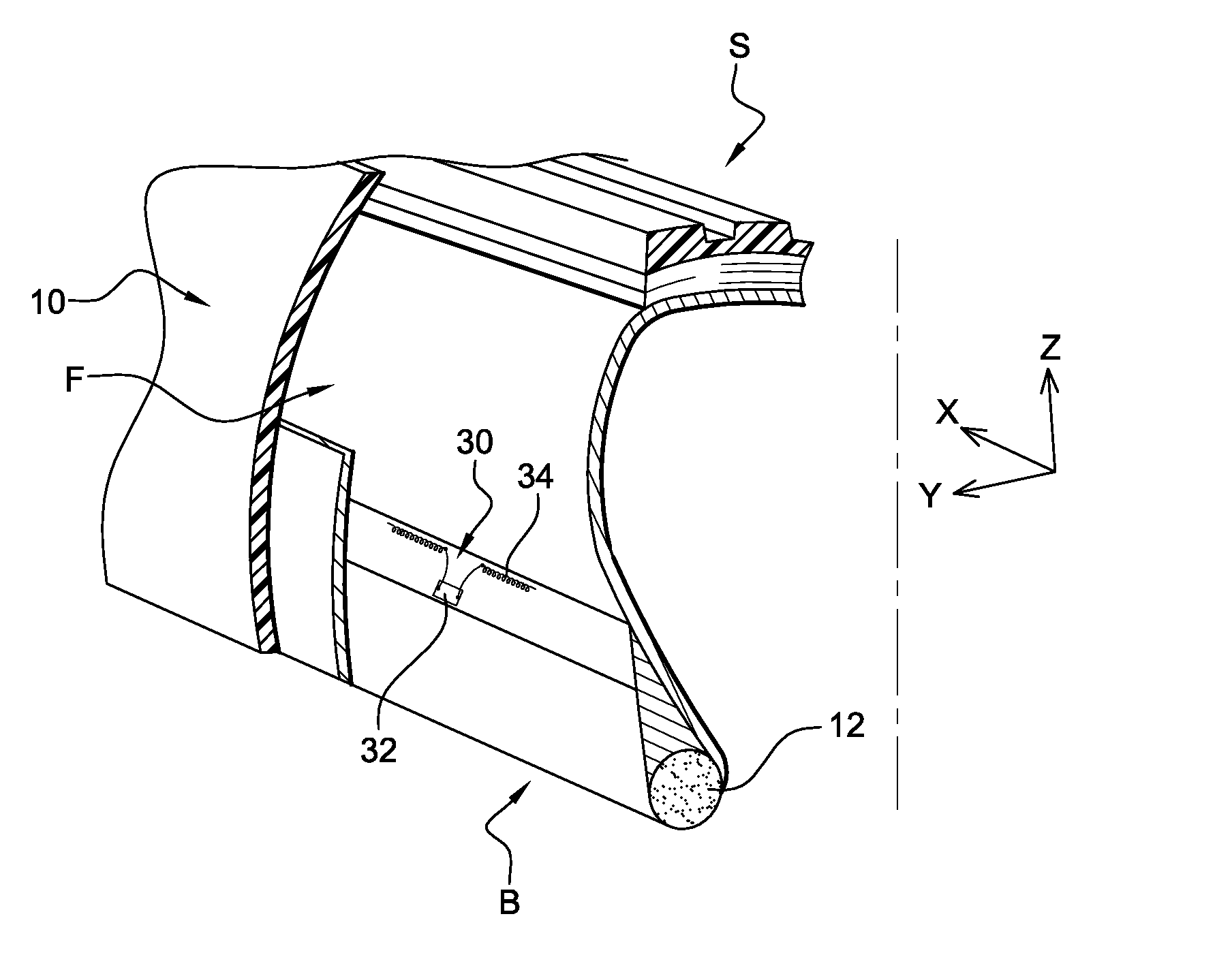

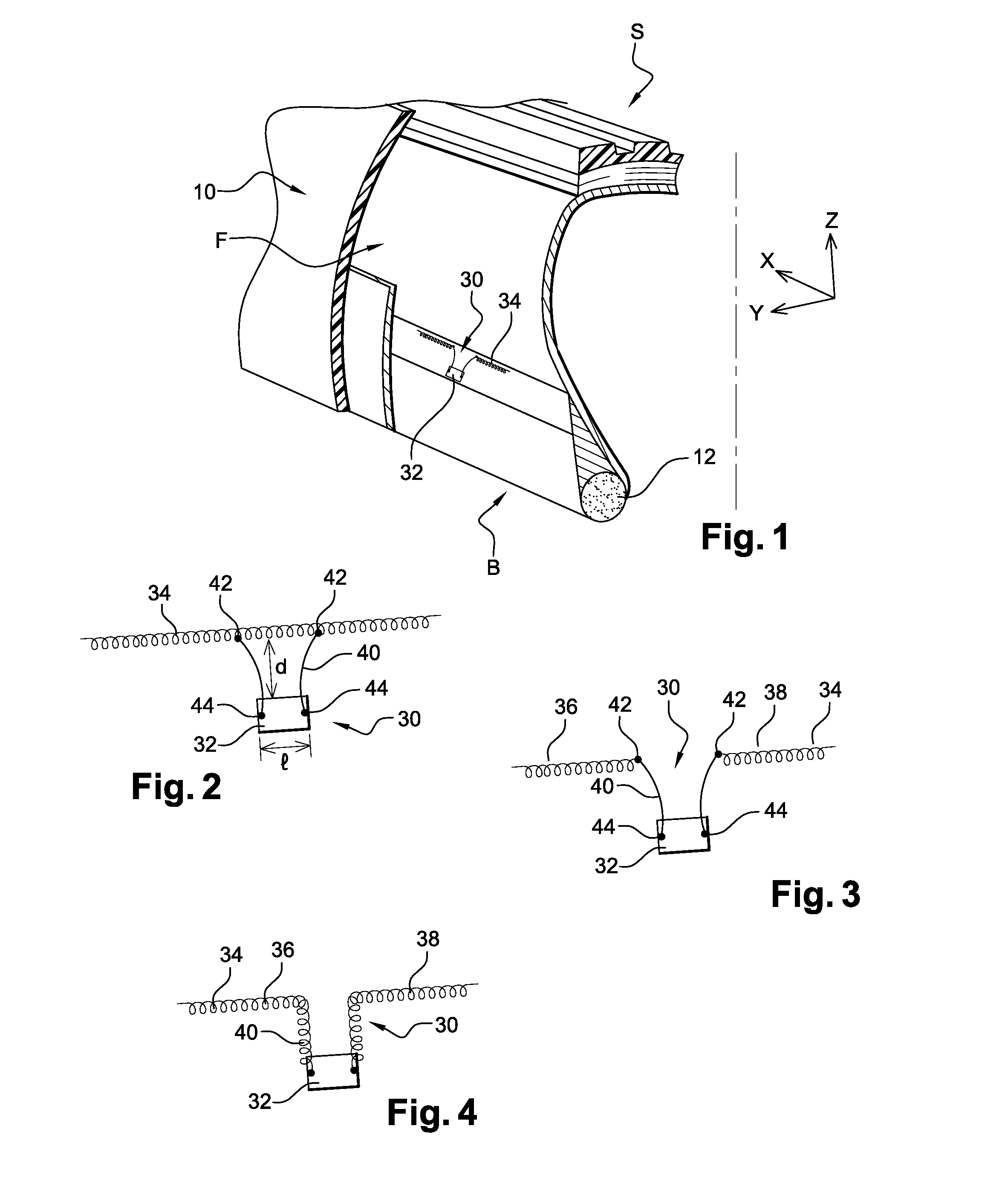

Tyre having a member with an offset antenna

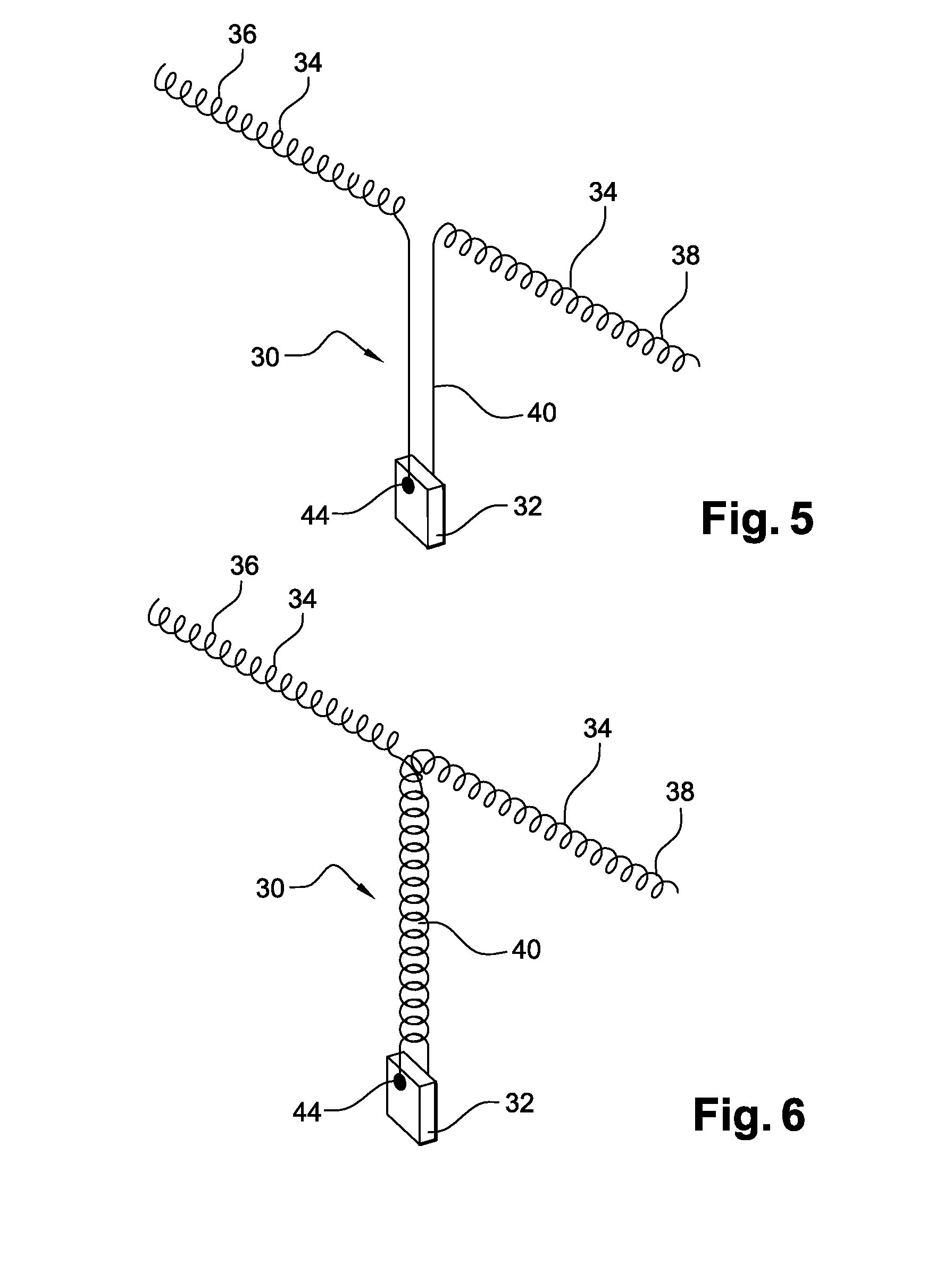

ActiveUS20110175778A1Mitigate such drawbackWithstanding stressAntenna adaptation in movable bodiesTyresElectrical connectionWire antenna

A motor-vehicle tyre includes a sidewall and a member with an electronic device, a generally and substantially linear-shaped rectilinear wire antenna, and means of electrical connection between the wire antenna and the electronic device. The member is embedded in the sidewall in an arrangement such that the antenna is oriented circumferentially with respect to the tyre and the connection means is oriented in a radial direction of the tyre. The wire antenna is integrally offset radially on one side of the electronic device.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

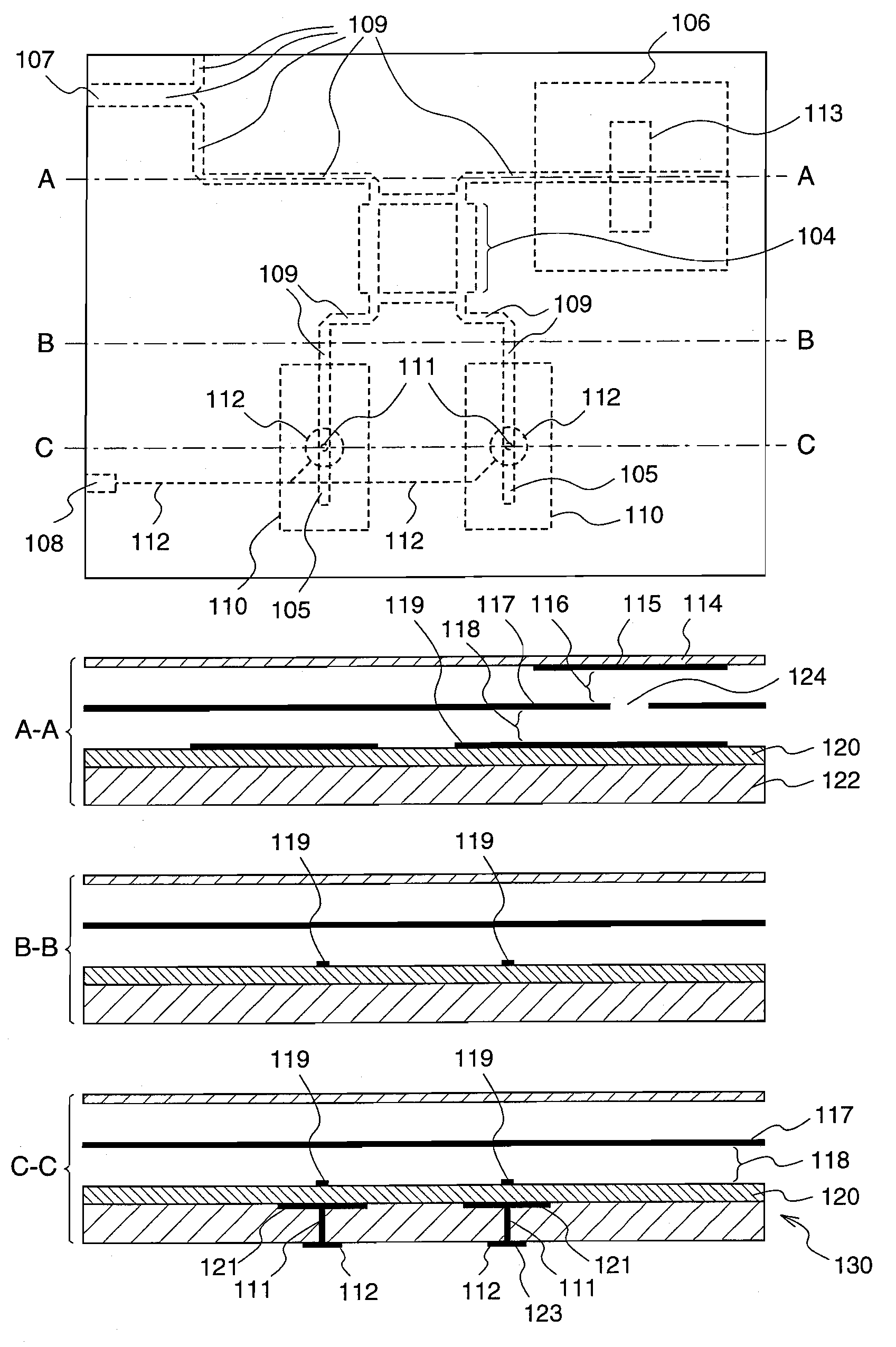

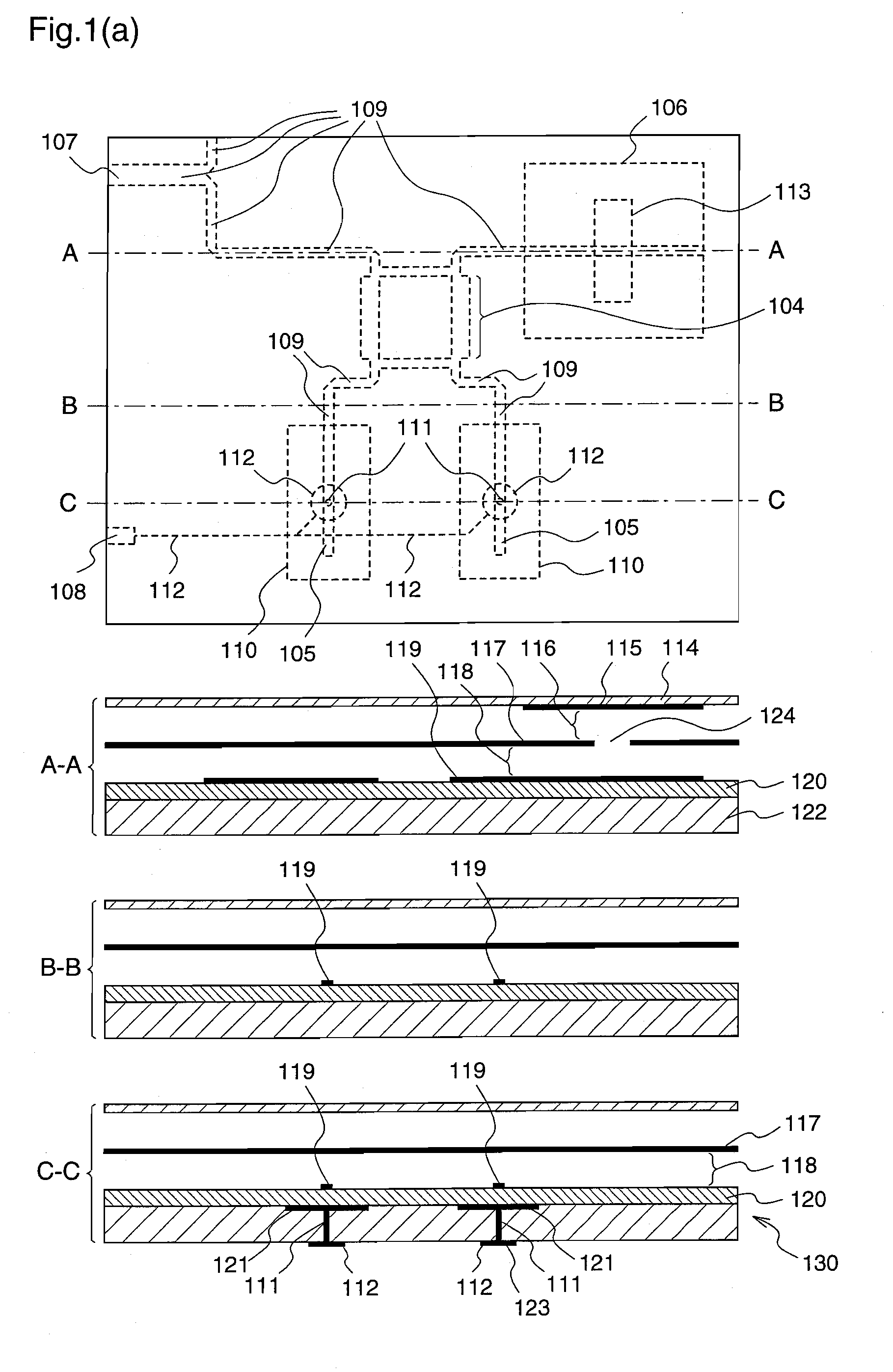

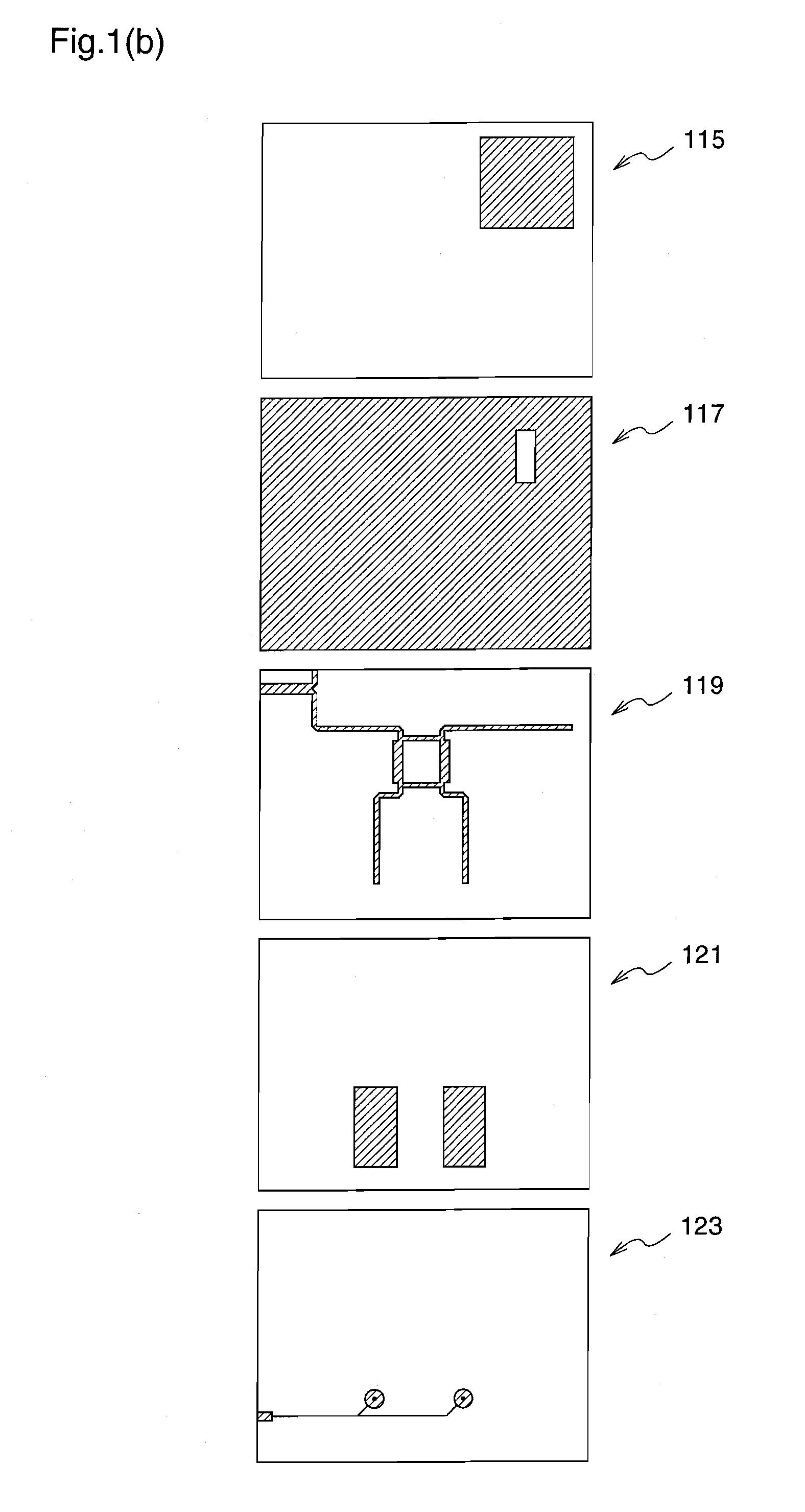

Phased array antenna

InactiveUS20090278744A1High directional gainLess deformationSimultaneous aerial operationsRadiating elements structural formsPhase shiftedElectrical conductor

There is provided a phased array antenna having variable phase shifters constituted by using a variable dielectric-constant dielectric substance whose dielectric constant varies according to an applied electric field, which antenna can dispense with a DC blocking element that causes mismatch, and reduce deformation of the beam shape even when beam tilt occurs, in the case where the variable phase shifters are divided into those for right-side tilt and those for left-side tilt and the phase shift amounts thereof are independently controlled.The phased array antenna is provided with a feeding phase shift unit (130) having a laminated structure obtained by laminating at least a ground conductor layer (117), an insulator layer (118), a main conductor layer (119), a variable dielectric-constant dielectric layer (120), and a sub conductor layer (121) in this order, and a propagation characteristic variable line (105) having a line on the sub conductor layer in an area which planarly overlaps a line on the main conductor layer is provided on the feeding phase shift unit. By applying a bias voltage between the main conductor layer and the sub conductor layer, the dielectric constant of the variable dielectric-constant dielectric substance in the propagation characteristic variable line area is varied to control the propagation characteristics. Thereby, a DC blocking element to be inserted in series into the feeding line can be dispensed with.

Owner:PANASONIC CORP

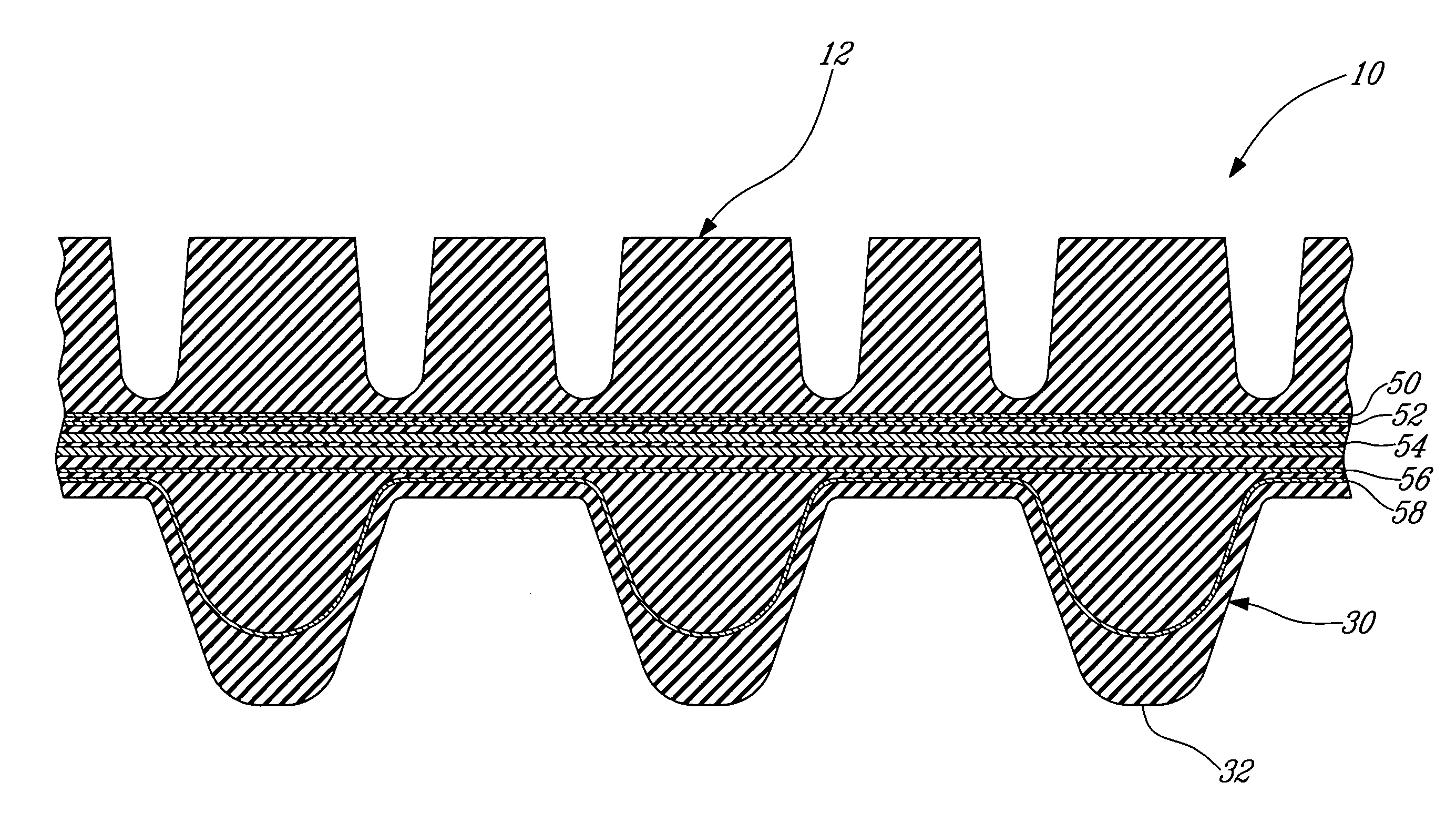

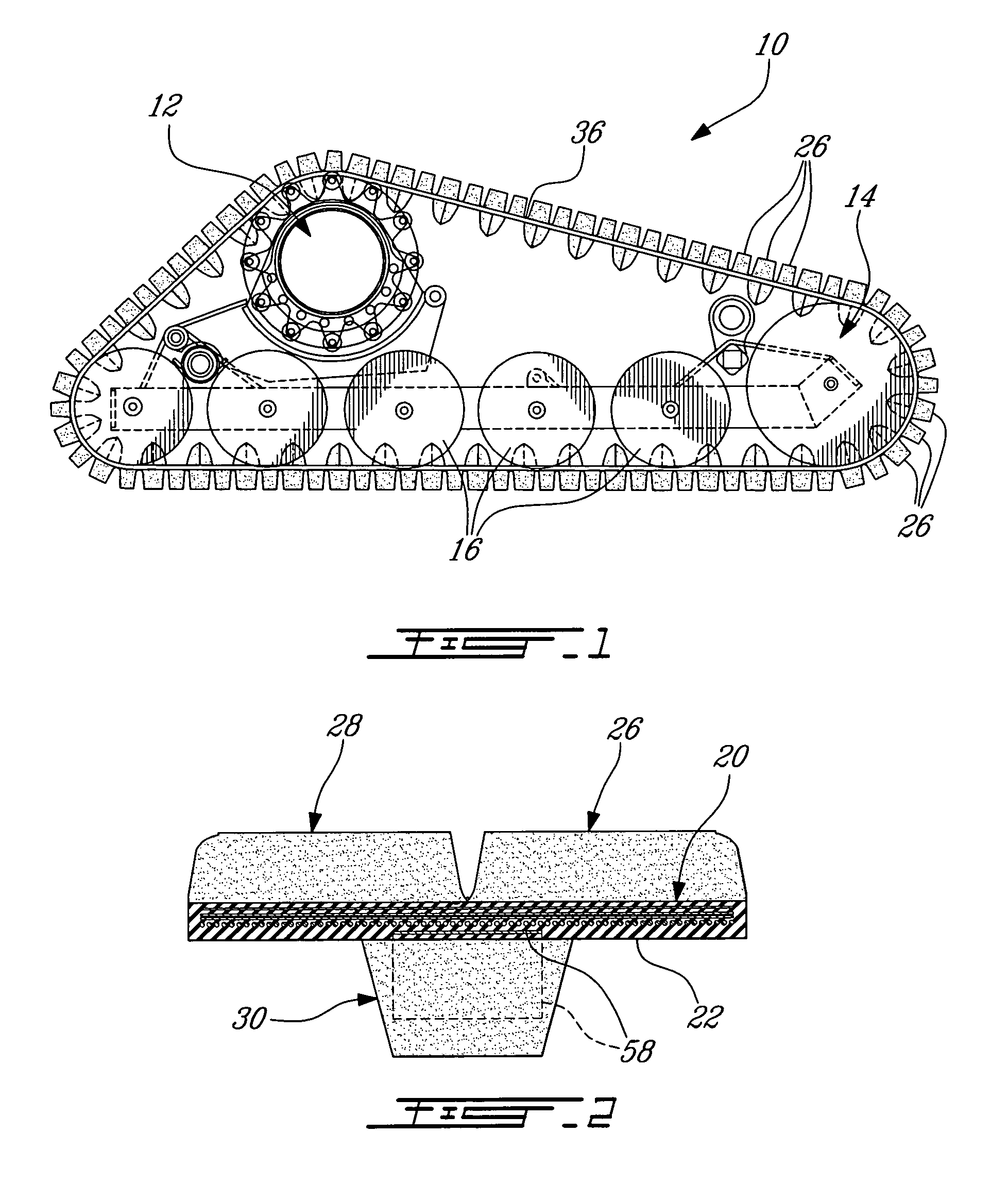

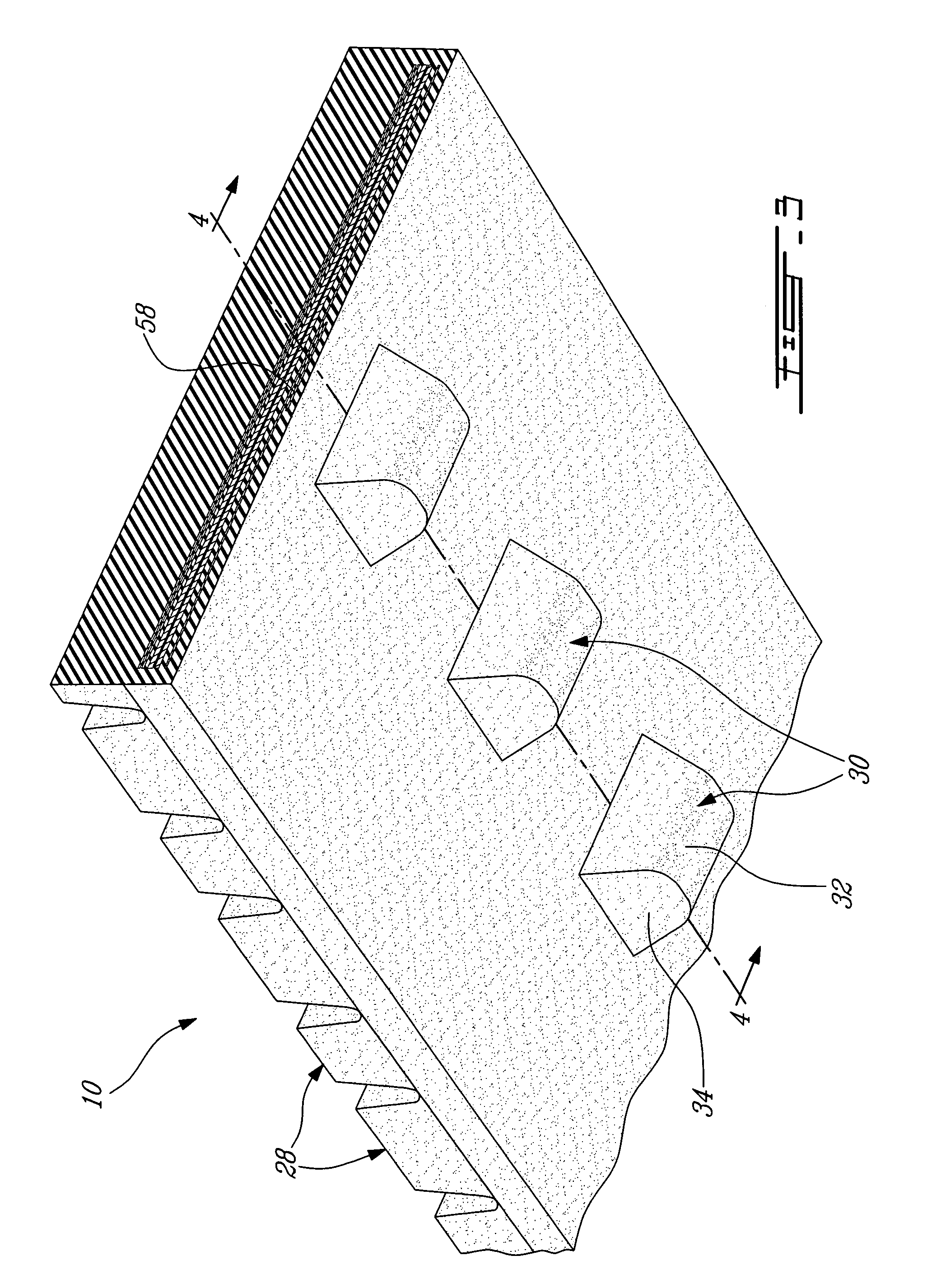

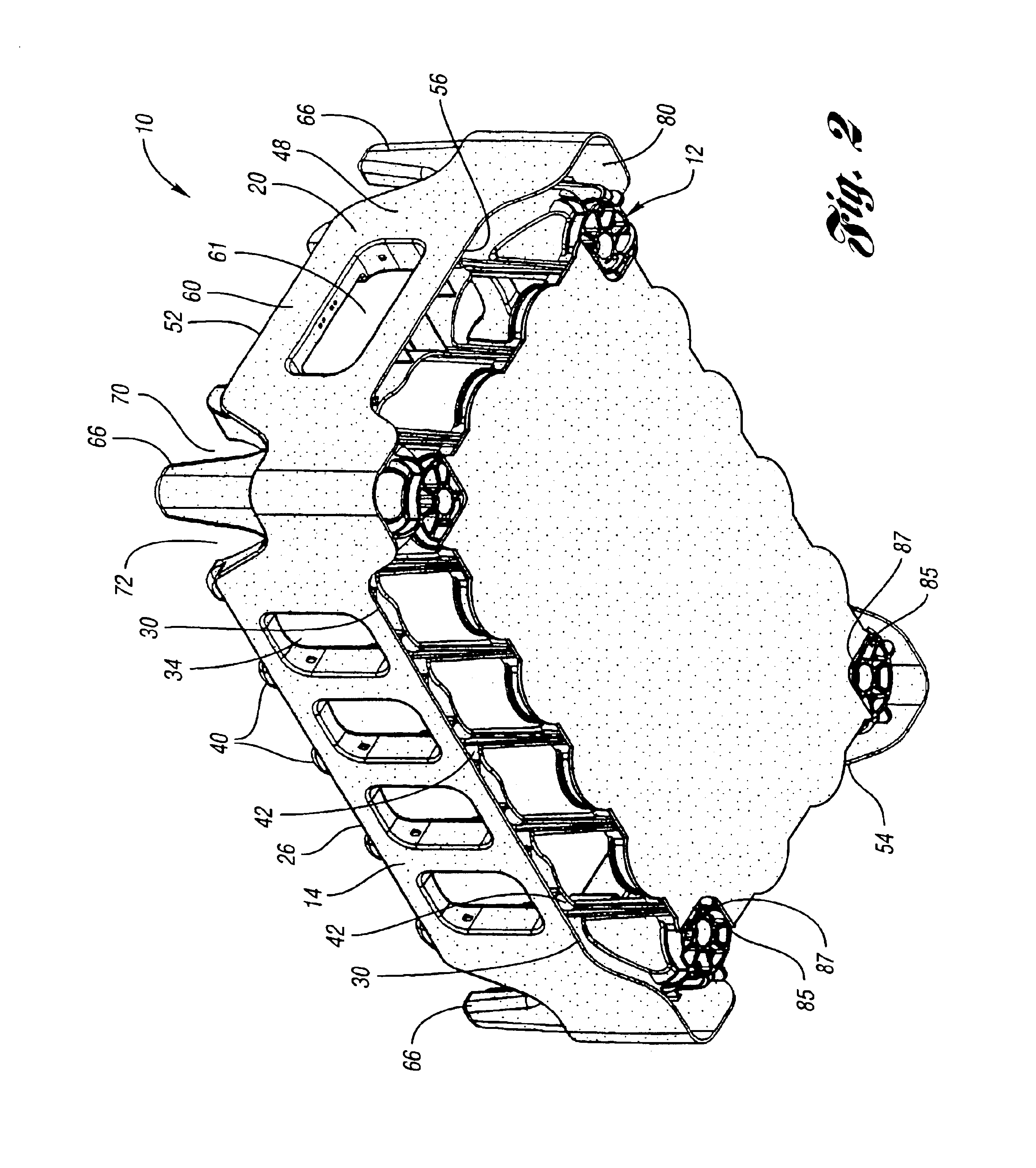

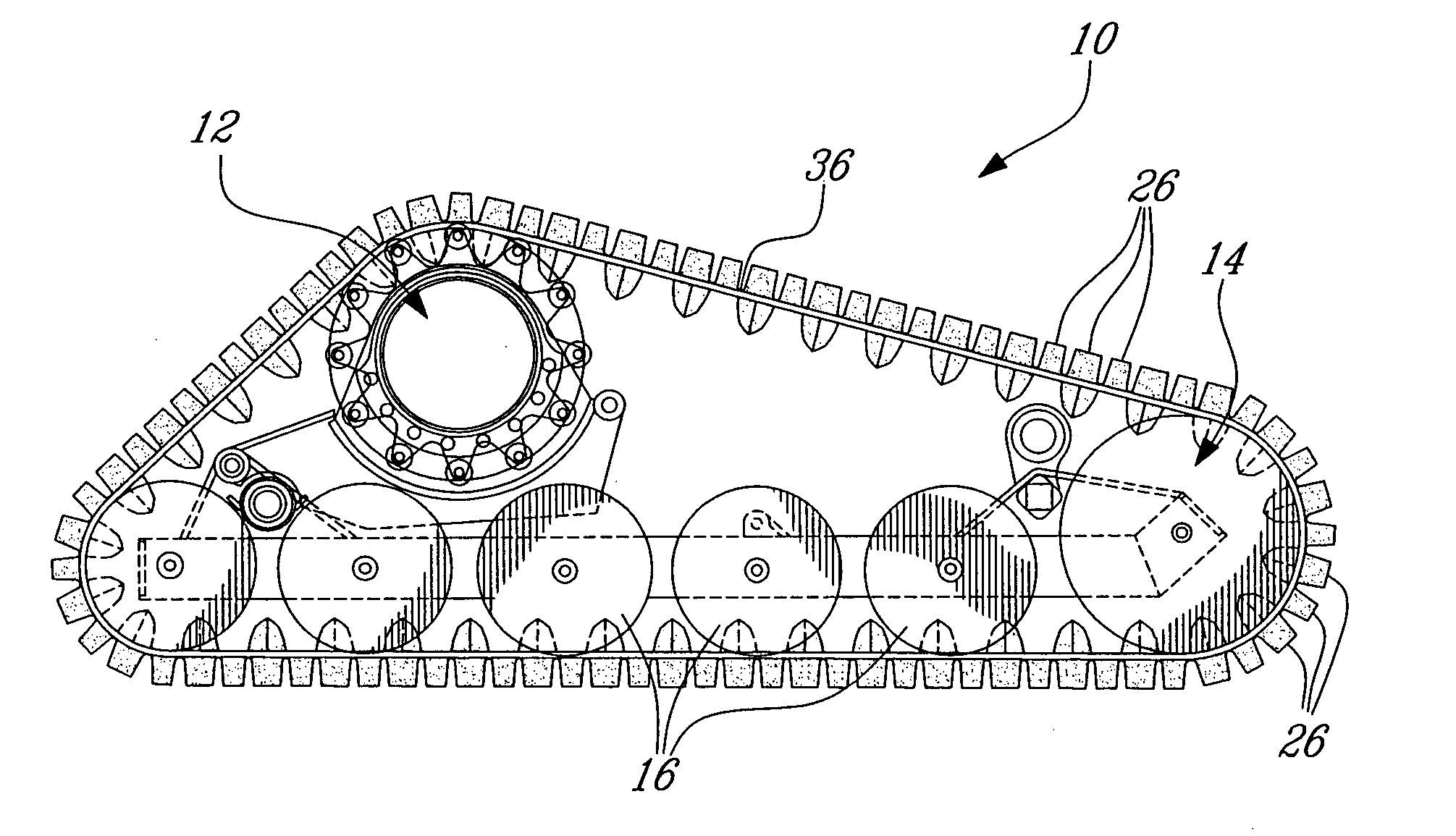

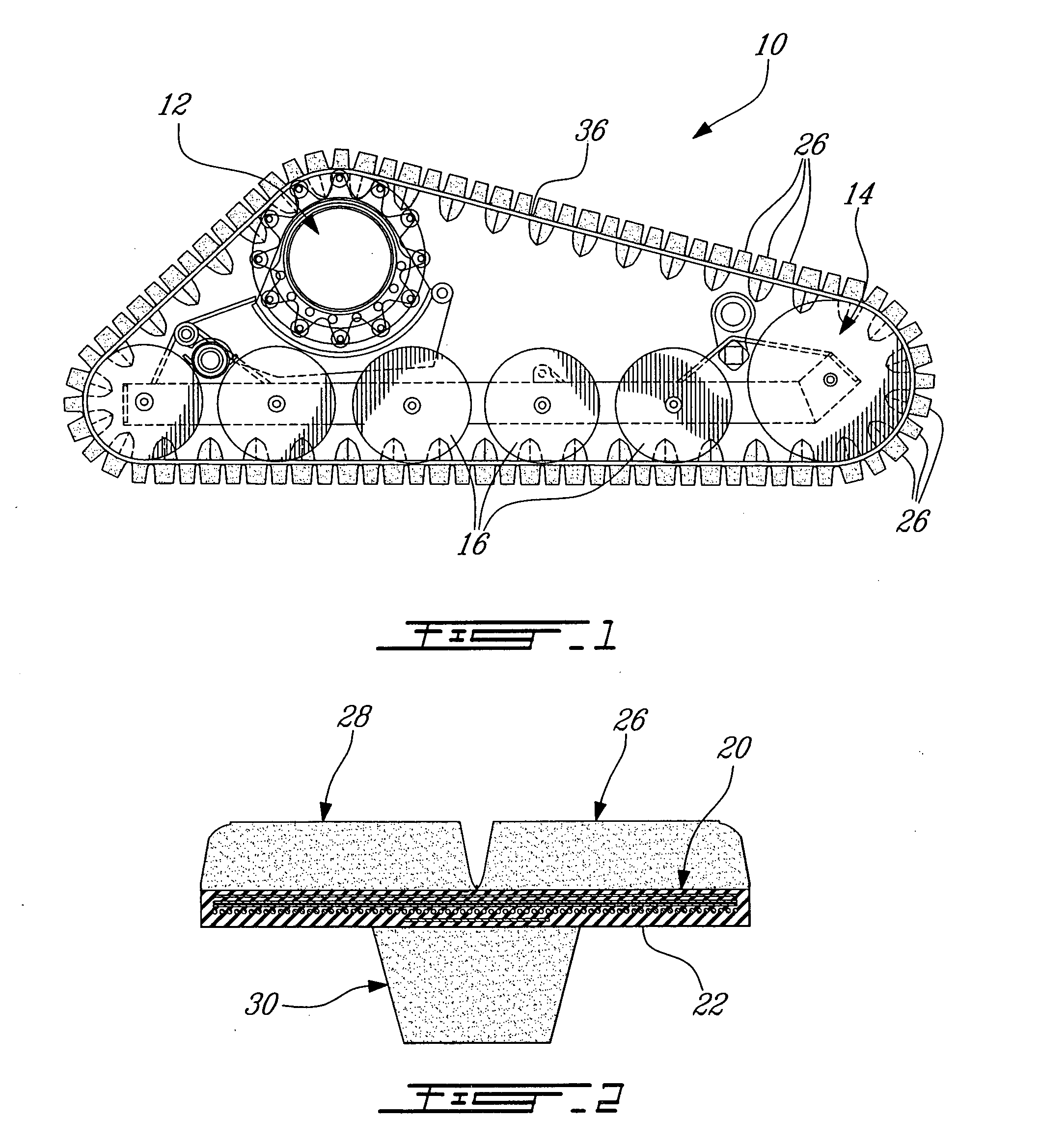

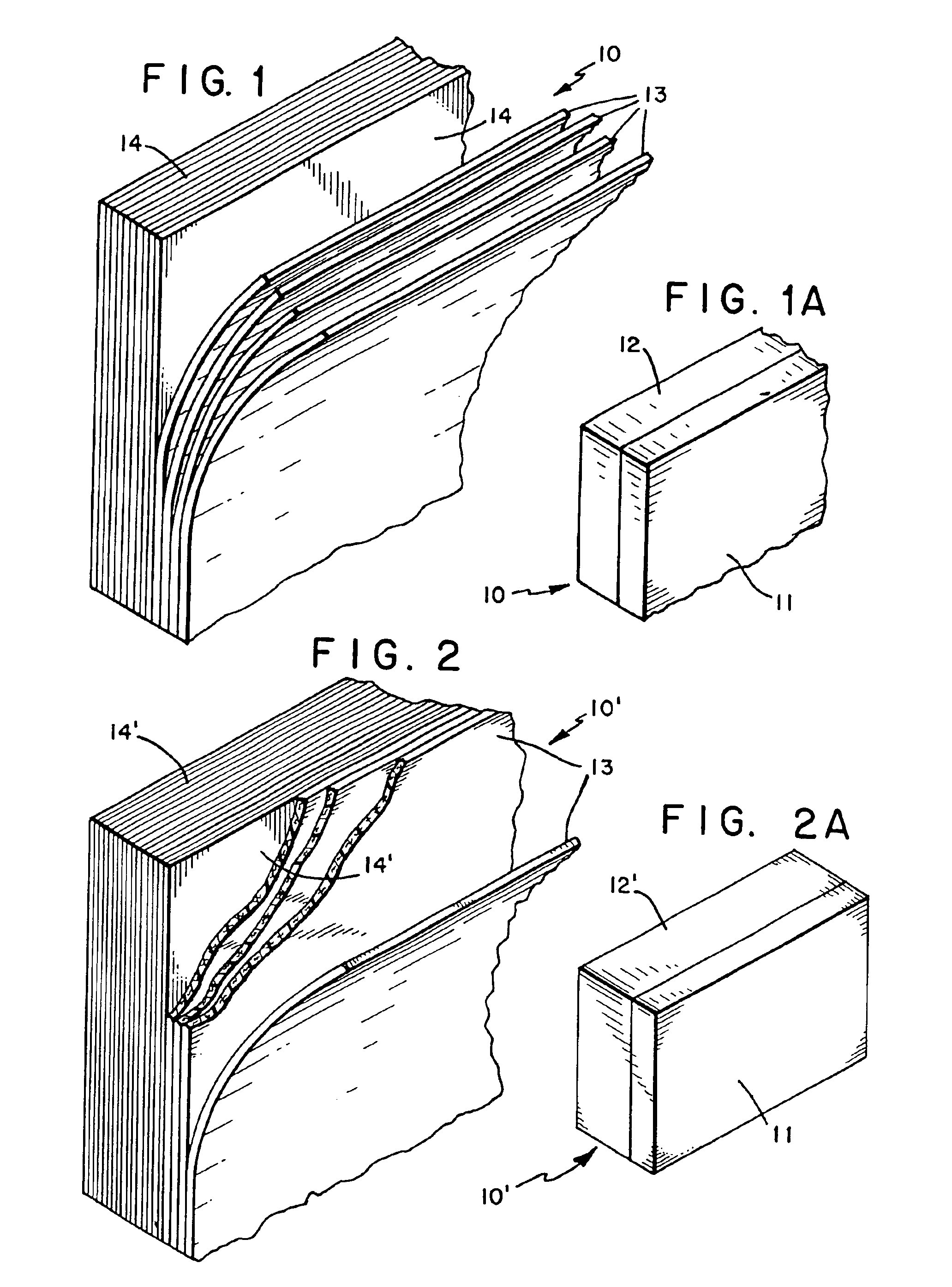

Endless track for industrial or agricultural vehicles

Described is an endless track for an industrial or agricultural vehicle consisting of a body formed of a rubber material having an outer surface displaying a series of ground engaging profiles longitudinally spaced along the surface and an inner surface displaying a series of longitudinally spaced drive lugs adapted to be engaged by drive sprockets on the vehicle driving assembly. The body of the endless track is fabric reinforced. One layer of fabric longitudinally extends at a distance from the inner surface of the track and has a width slightly less than the width of the drive lugs so that the fabric may extend inside the drive lugs to increase their rigidity.

Owner:CAMOPLASY INC

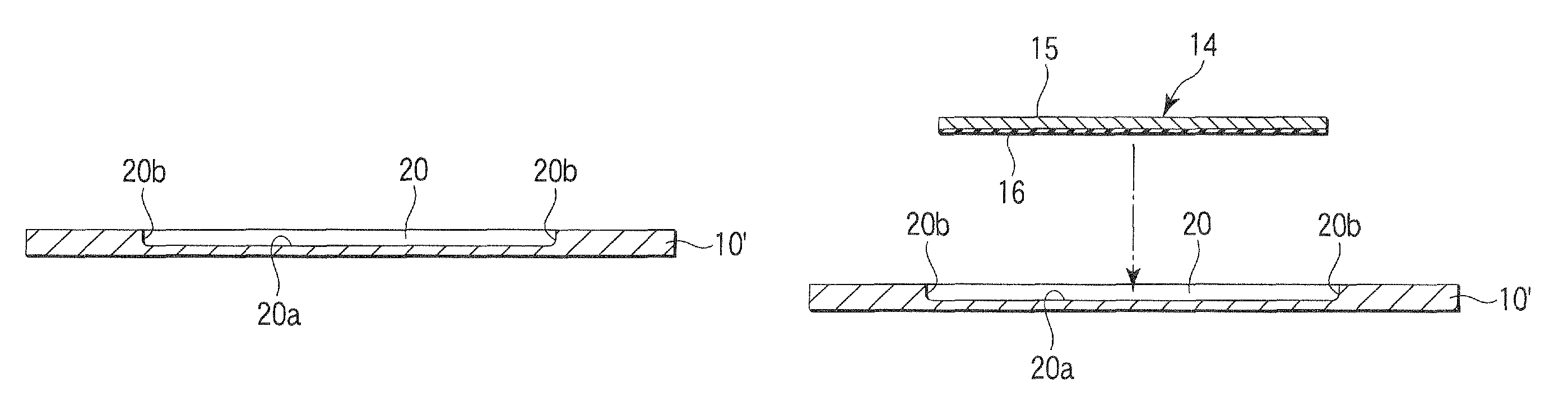

Method for manufacturing a suspension

ActiveUS8161626B2Maintain stable propertiesLess deformationElectrical transducersDecorative surface effectsControl theoryThin sheet

Owner:NHK SPRING CO LTD

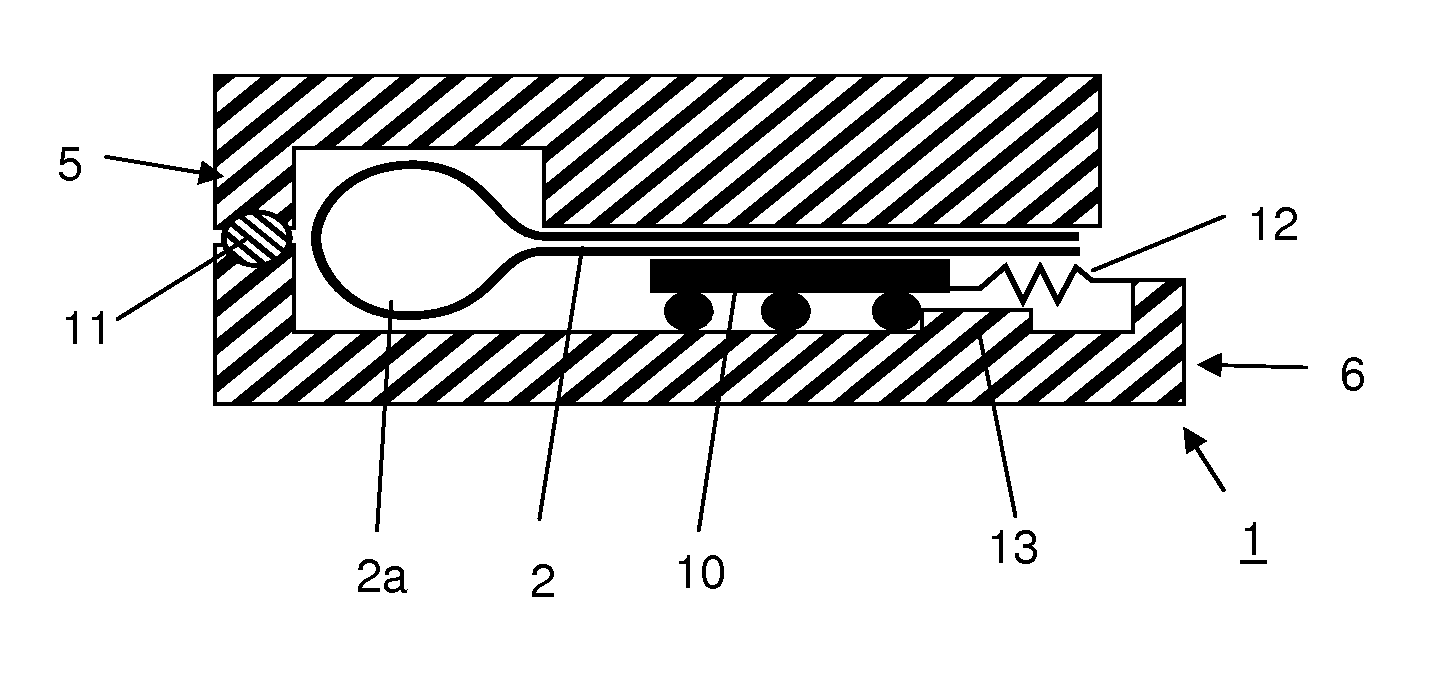

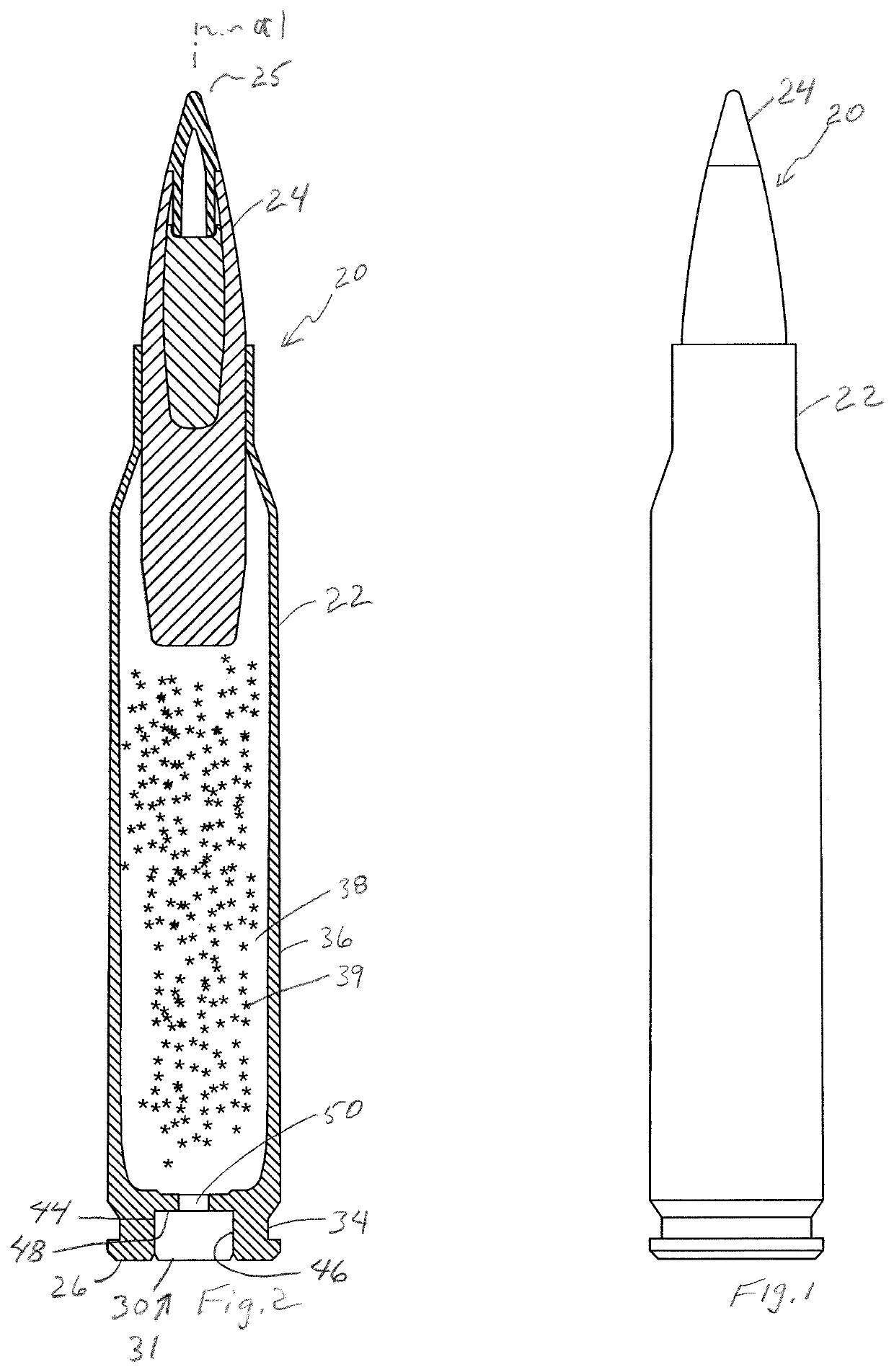

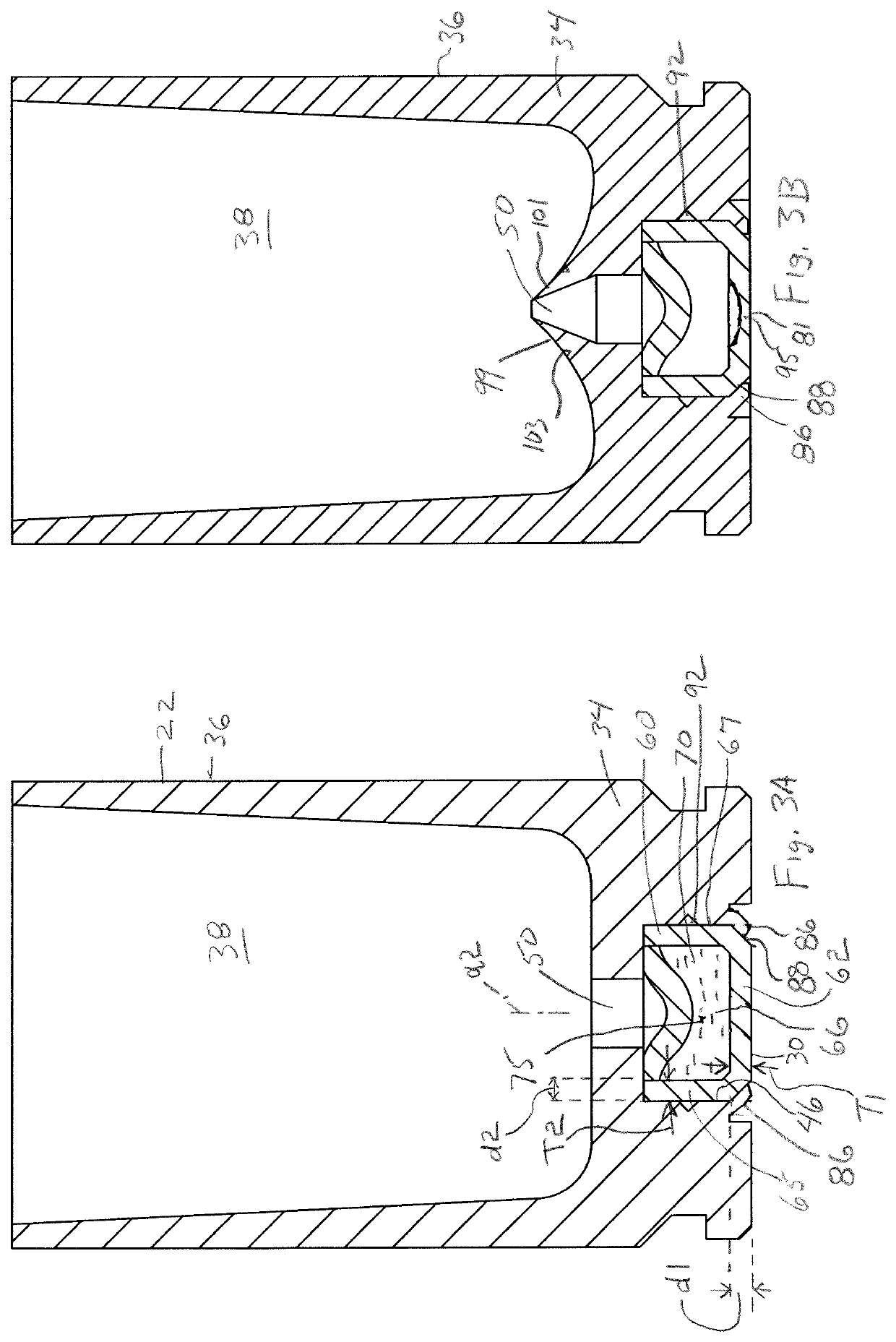

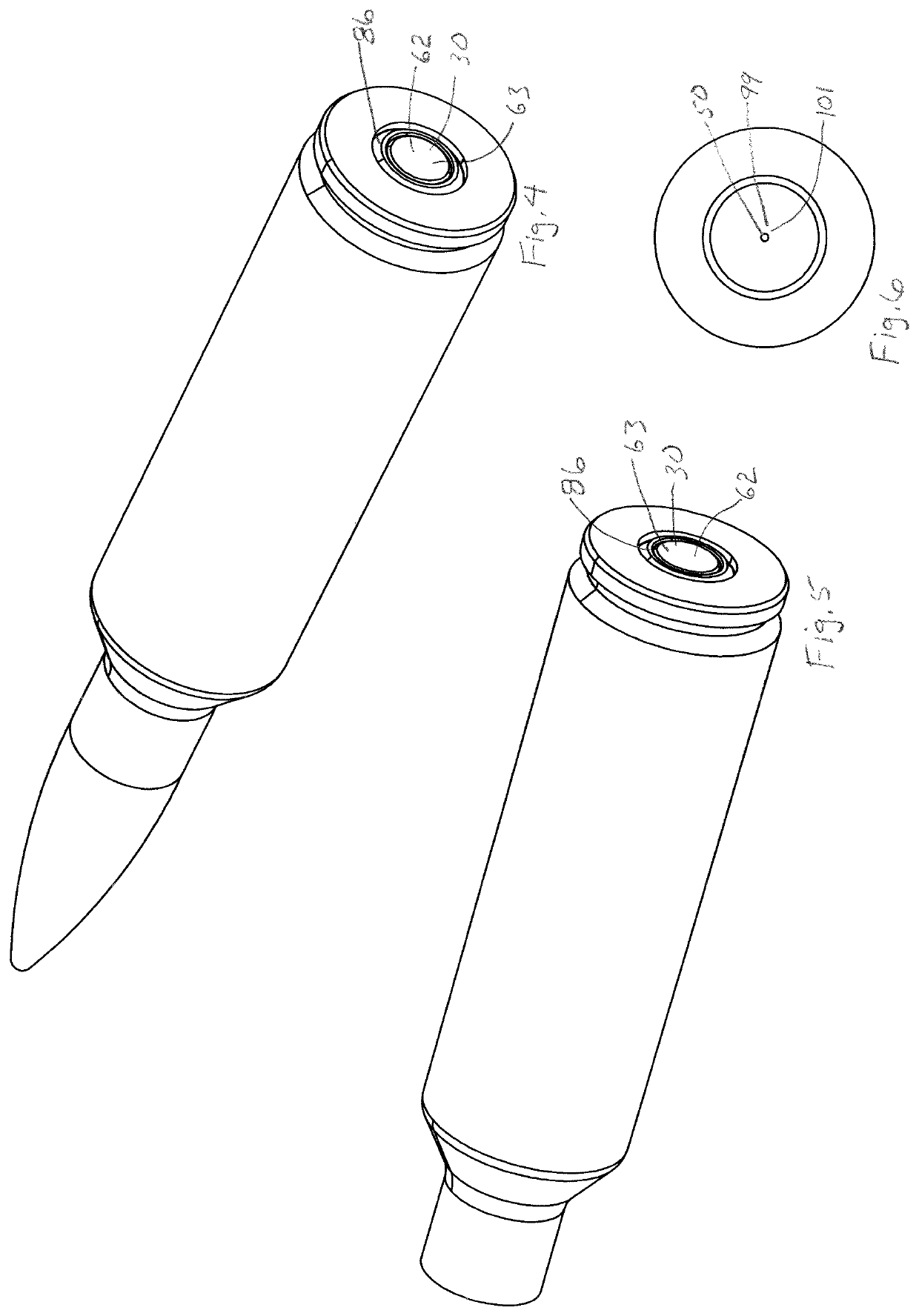

High pressure rifle cartridge with primer

ActiveUS10976144B1Increase pressureHigh strengthAmmunition fuzesStructural engineeringChamber pressure

A cartridge that generates higher than typical chamber pressures has an enhanced means of primer retention for retaining the primer in the primer recess of the casing. The means may be a lip folded onto a conical surface, a annular groove to receive deformed primer wall portion material upon detonation, a concavity in the rearward facing wall of the primer, a check valve in the flash tube to inhibit propellant gases from reaching the primer recess, or specifically configured primers with a greater length than diameter and with greater wall thicknesses.

Owner:FEDERAL CARTRIDGE

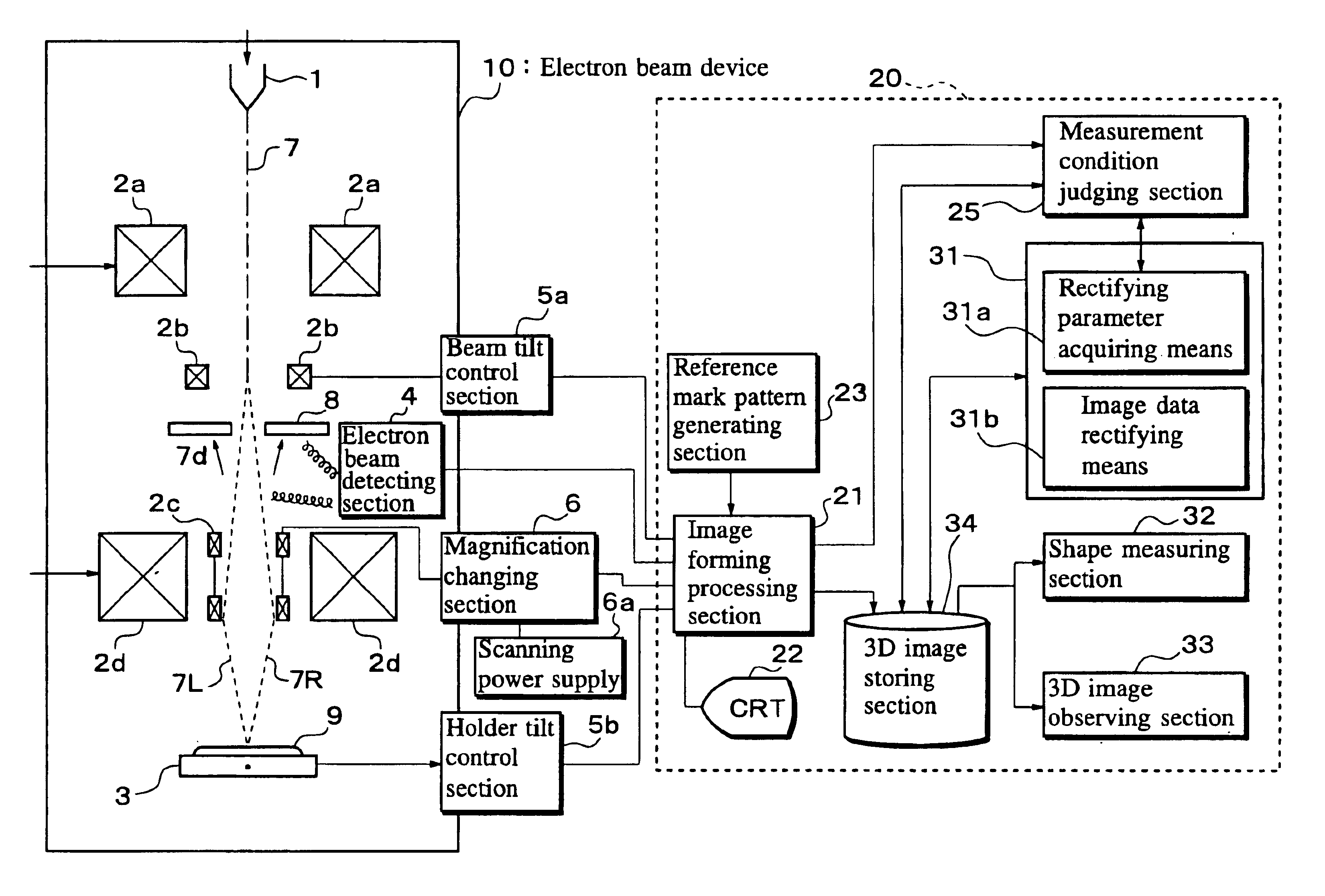

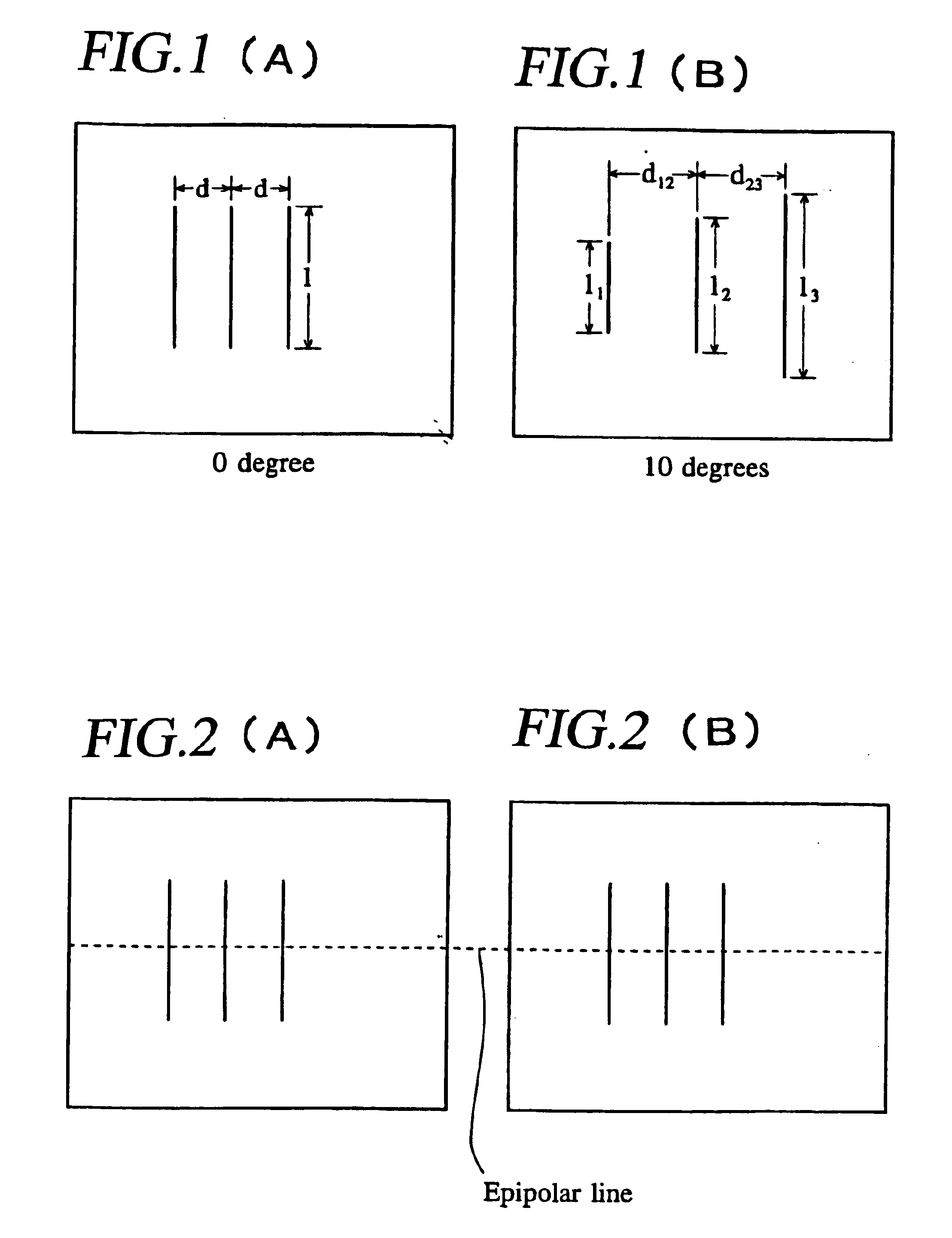

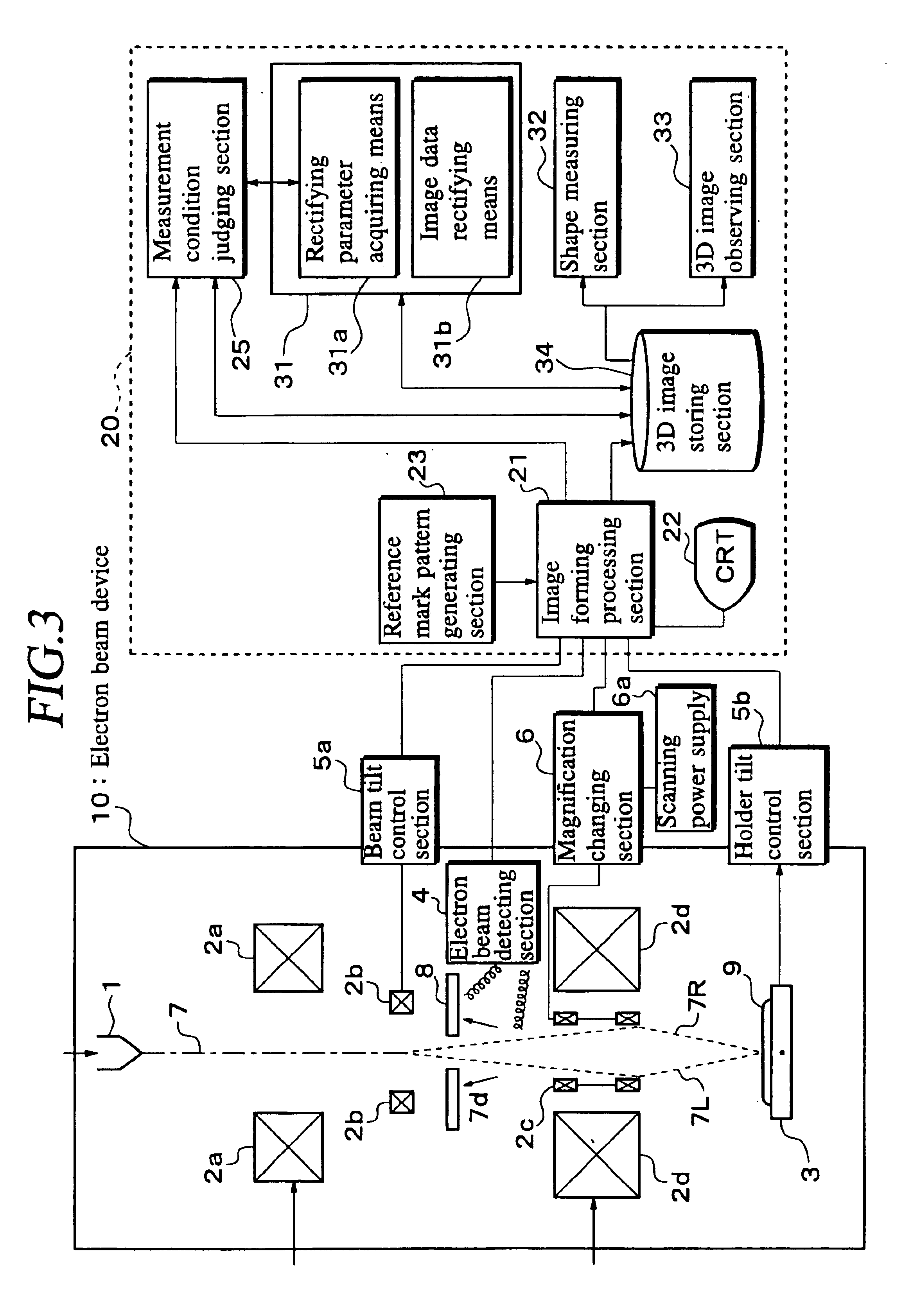

Electron beam device and method for stereoscopic measurements

InactiveUS6852974B2Improve accuracyImage recognition of the reference mark can be carried out smoothlyMaterial analysis using wave/particle radiationMicrobiological testing/measurementBeam sourceAtomic physics

An electron beam device according to the present invention is made up of an electron beam source for emitting an electron beam, an electron optical system for irradiating the electron beam onto a specimen, a specimen holder for holding the specimen, a specimen tilting section for producing relative tilt angles between the specimen holder and the electron beam, an electron beam detecting section for detecting electron beam emitted from the specimen, and a data correcting section for correcting the three-dimensional detection data to have specified relationship under the condition of a relative tilt angle between the specimen holder and the electron beam.

Owner:KK TOPCON

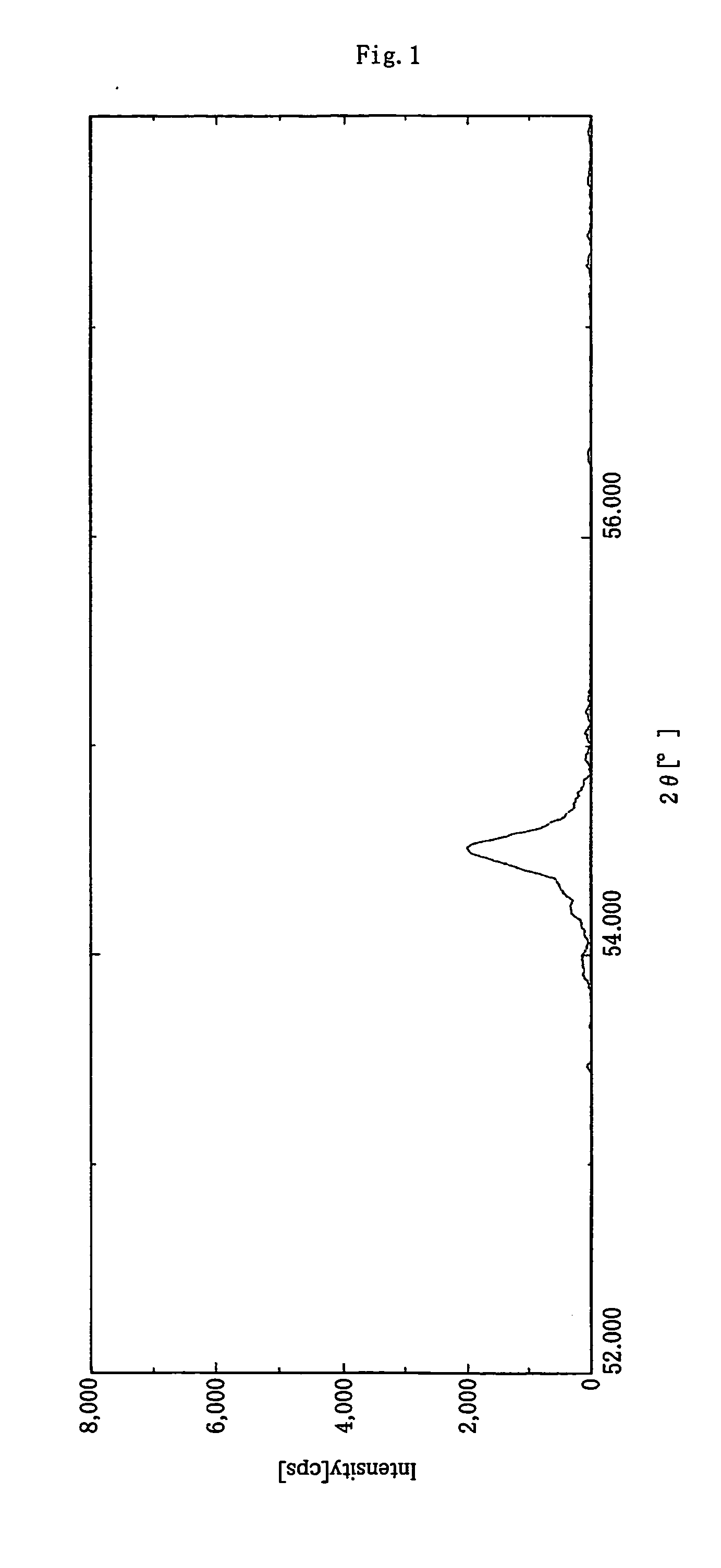

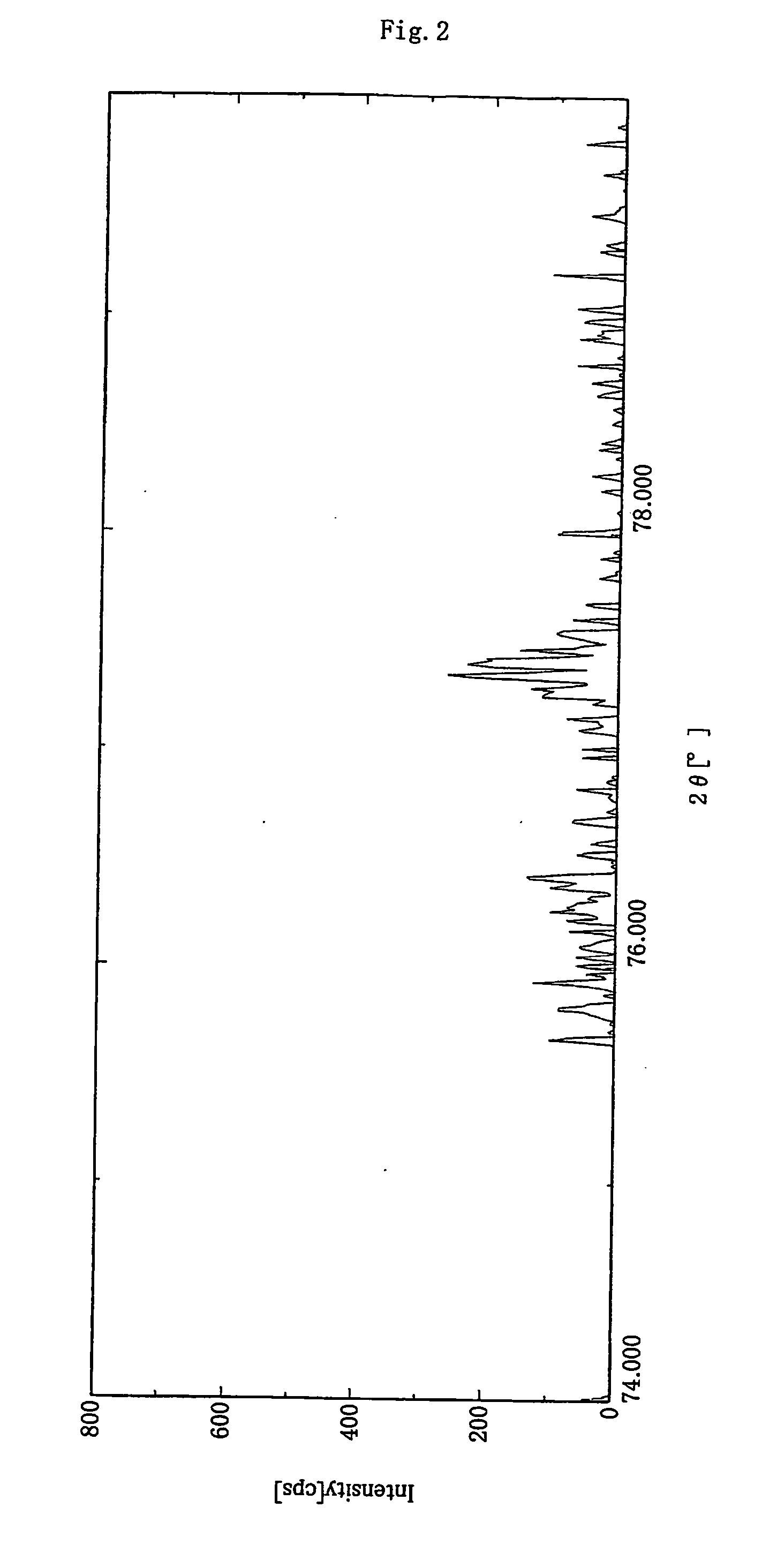

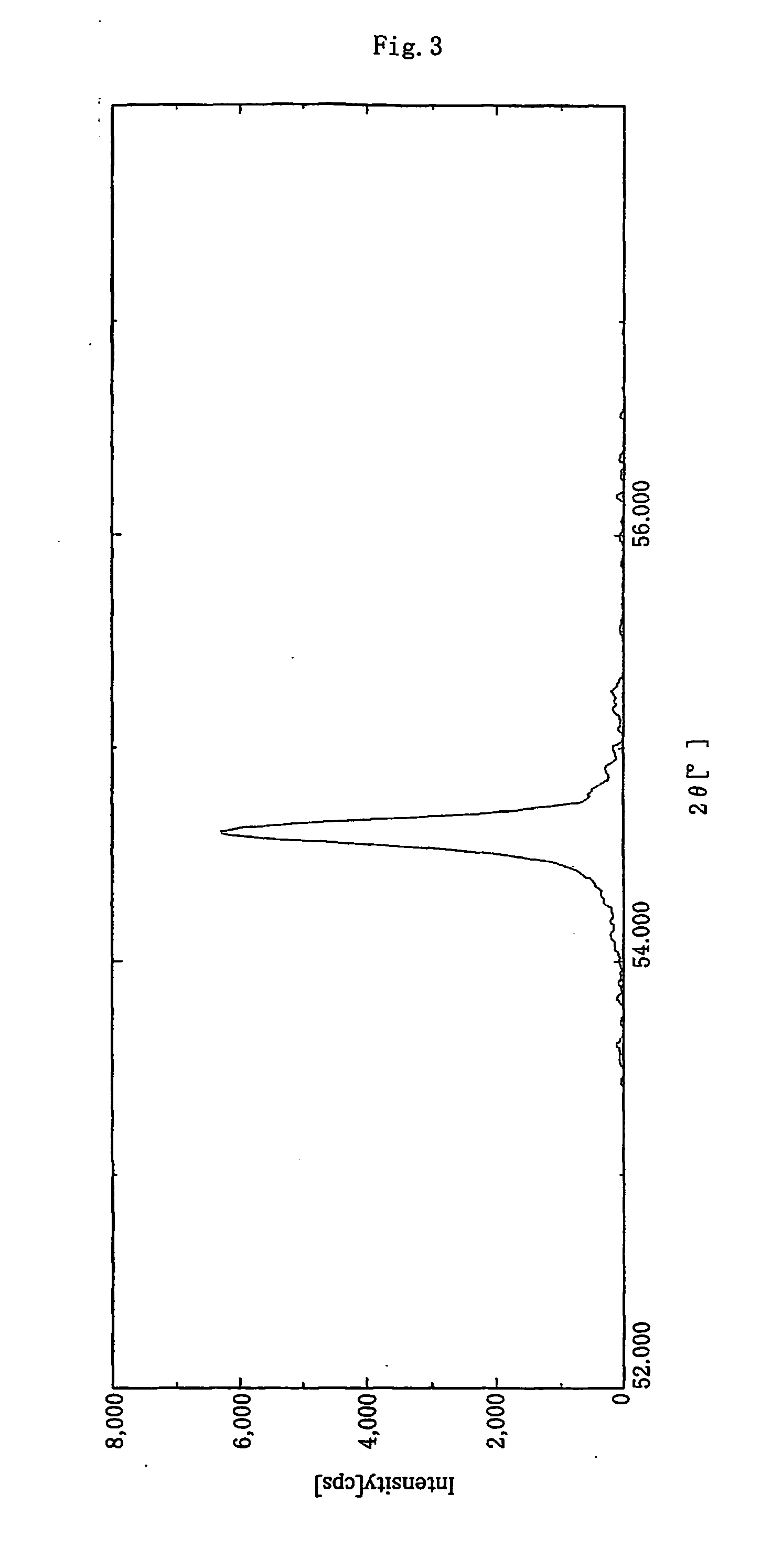

Carbon material for battery electrode and production method and use thereof

InactiveUS20070092428A1Less deformation/orientationLarge discharge capacityGraphiteSecondary cellsPolymer scienceSource material

The invention provides a carbon material for a battery electrode, which comprises a carbon powder material as a composite of carbonaceous particles and an a carbon material derived from an organic compound prepared by allowing the organic compound serving as a polymer source material to deposit onto and / or permeate into the carbonaceous particles to thereby polymerize the polymer material and then heating at 1,800 to 3,300° C., and which has an intensity ratio of 0.1 or more for peak intensity attributed to a (110) plane to peak intensity attributed to a (004) plane determined through X-ray diffraction spectroscopic analysis on a mixture of the carbon material and a binder resin when pressed at 103 kg / cm2 or higher. The carbon material which undergoes less deformation / orientation due to application of pressure, has high discharge capacity and small irreversible capacity and exhibiting excellent coulombic efficiency, cycle characteristics and leakage-current load characteristics.

Owner:SHOWA DENKO KK

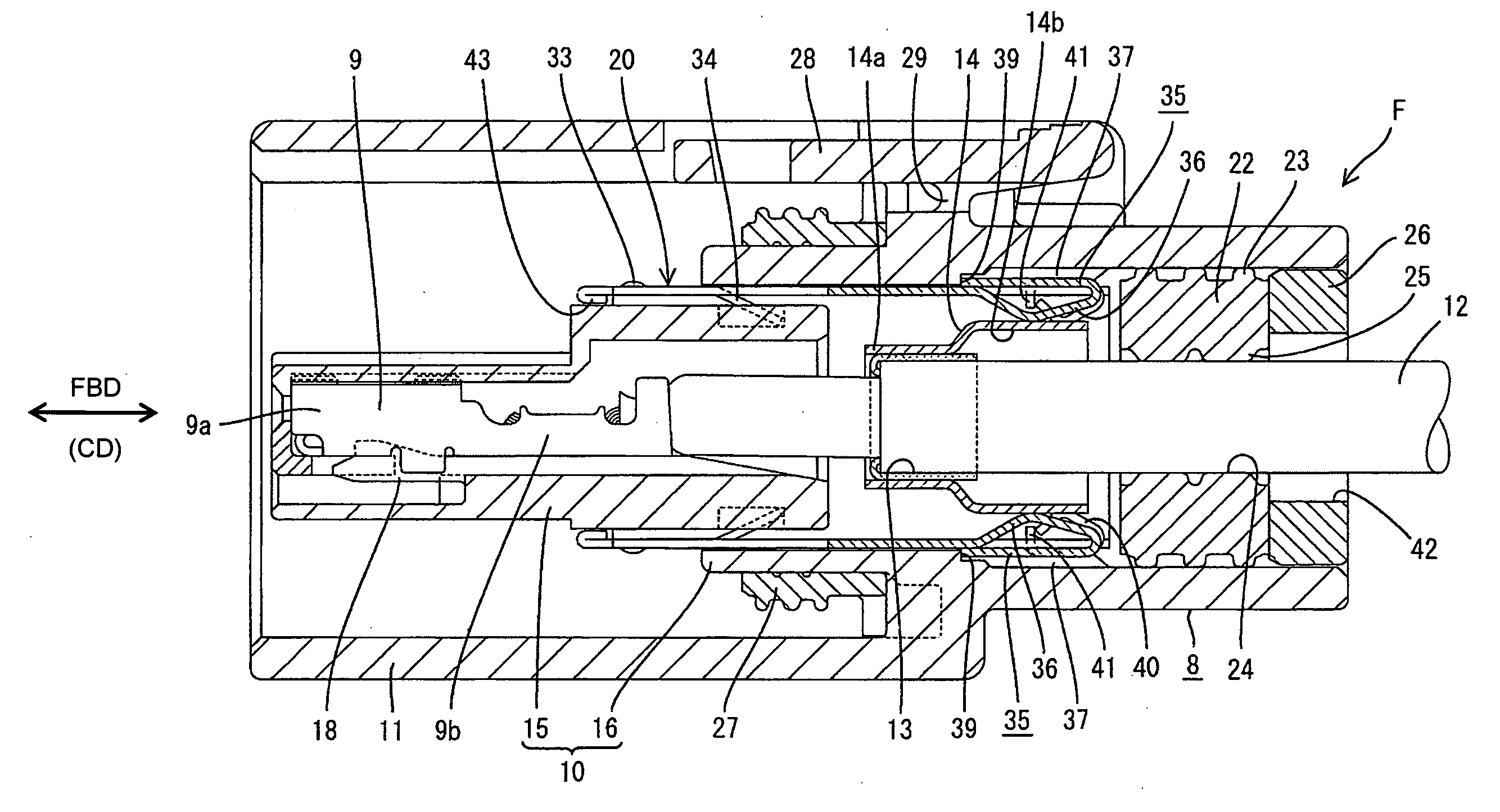

Shielded connector

InactiveUS20090035993A1ShortShielding shell can be shorterCoupling protective earth/shielding arrangementsConnection contact member materialEngineeringMechanical engineering

A crimp ring (14) is mounted on a braided wire (13) of a shielded cable (12). On the other hand, a shielding shell (20) connectable with a large diameter portion (14b) of the crimp ring (14) is mounted in a housing (8). Entire touching portions (35) are formed at both upper and lower surfaces of the shielding shell (20) by being bent inward to form mountain-shaped resilient contact pieces (36) that can resiliently contact the large diameter portion (14b) and then being folded back outward near the rear edge of the shielding shell (20). Displacement restricting portions (40) are arranged between the touching portions (35) adjacent in width direction to protect the other touching portions (35) from the interference of the shielded cable (12) being inserted or withdrawn.

Owner:SUMITOMO WIRING SYST LTD

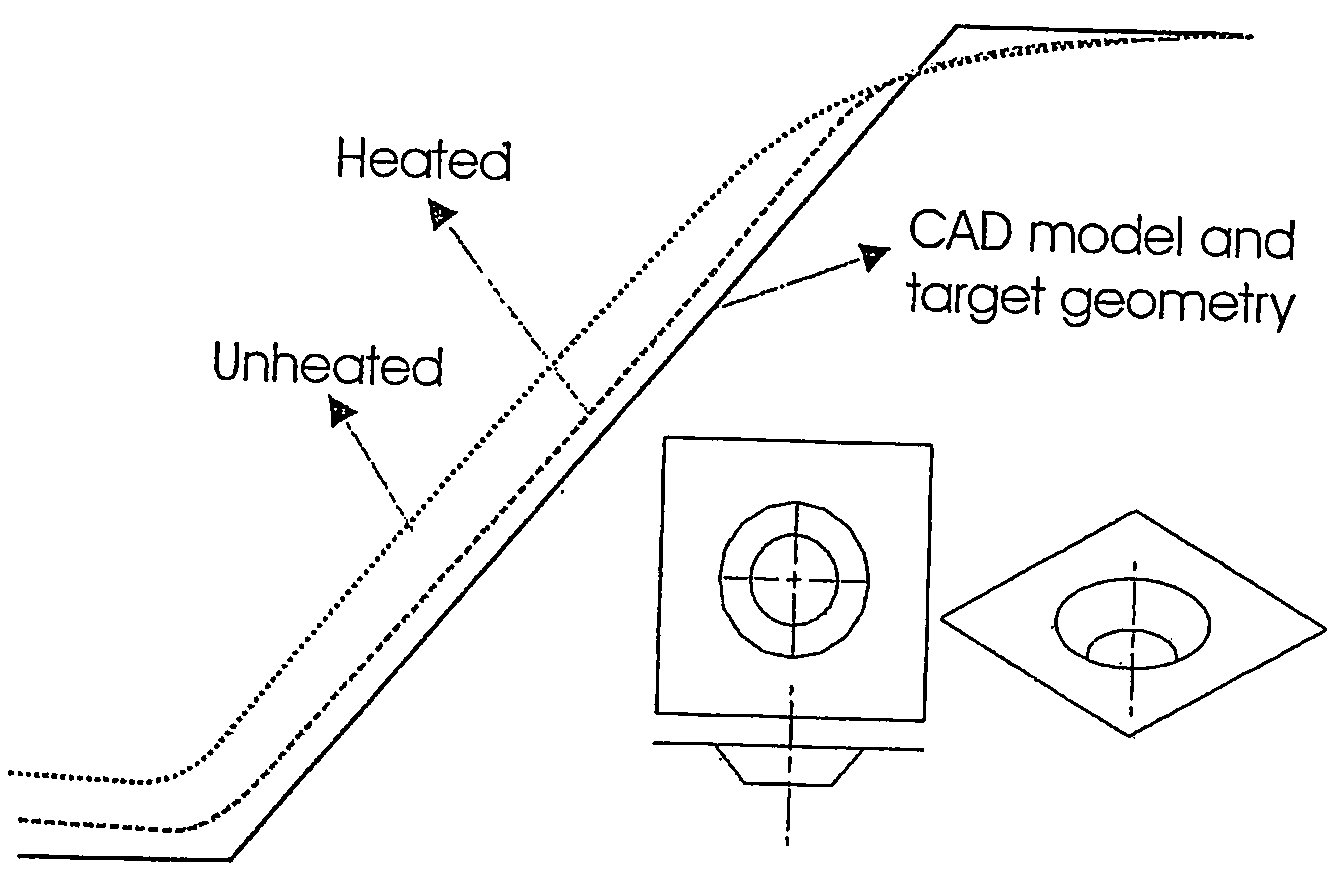

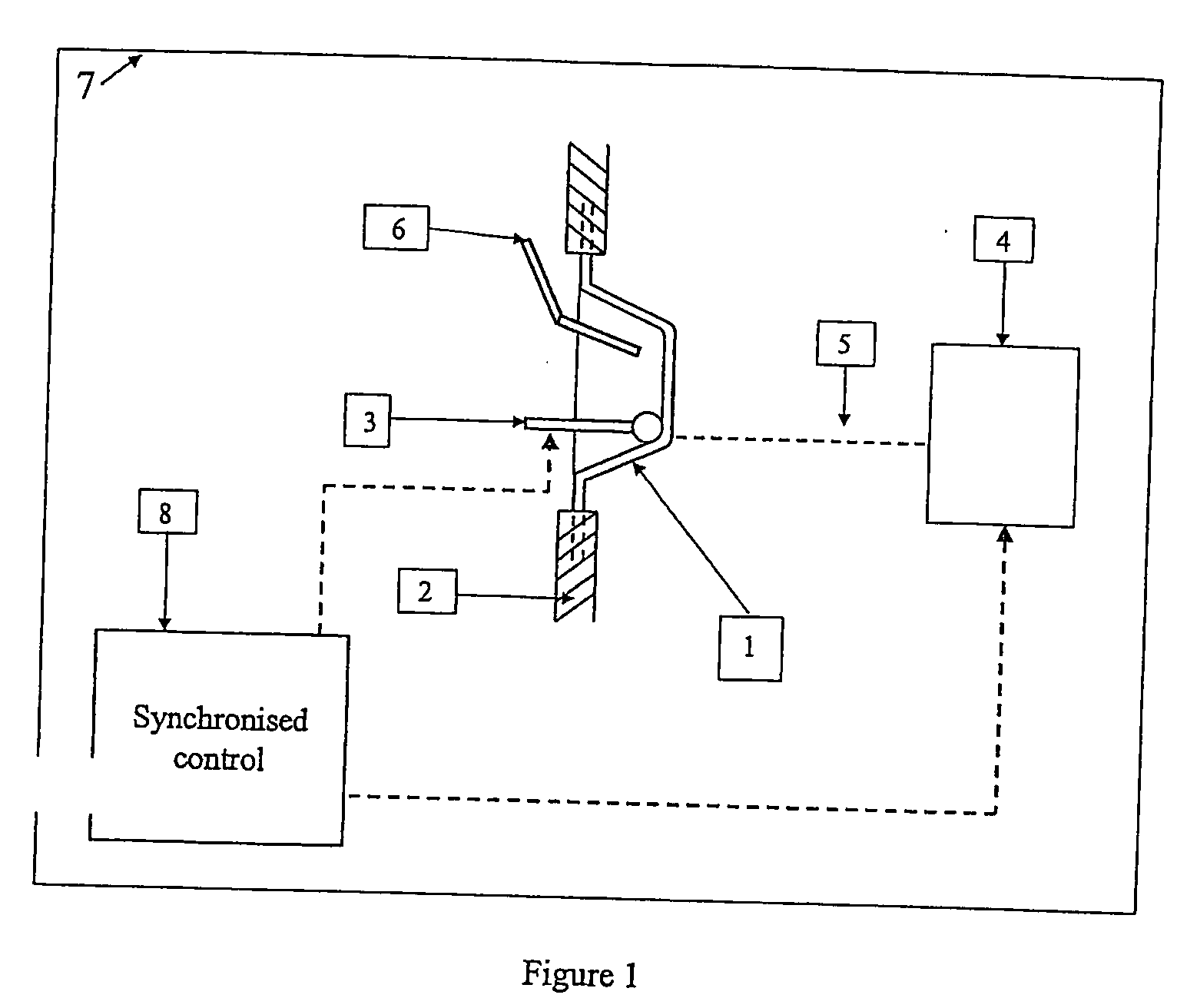

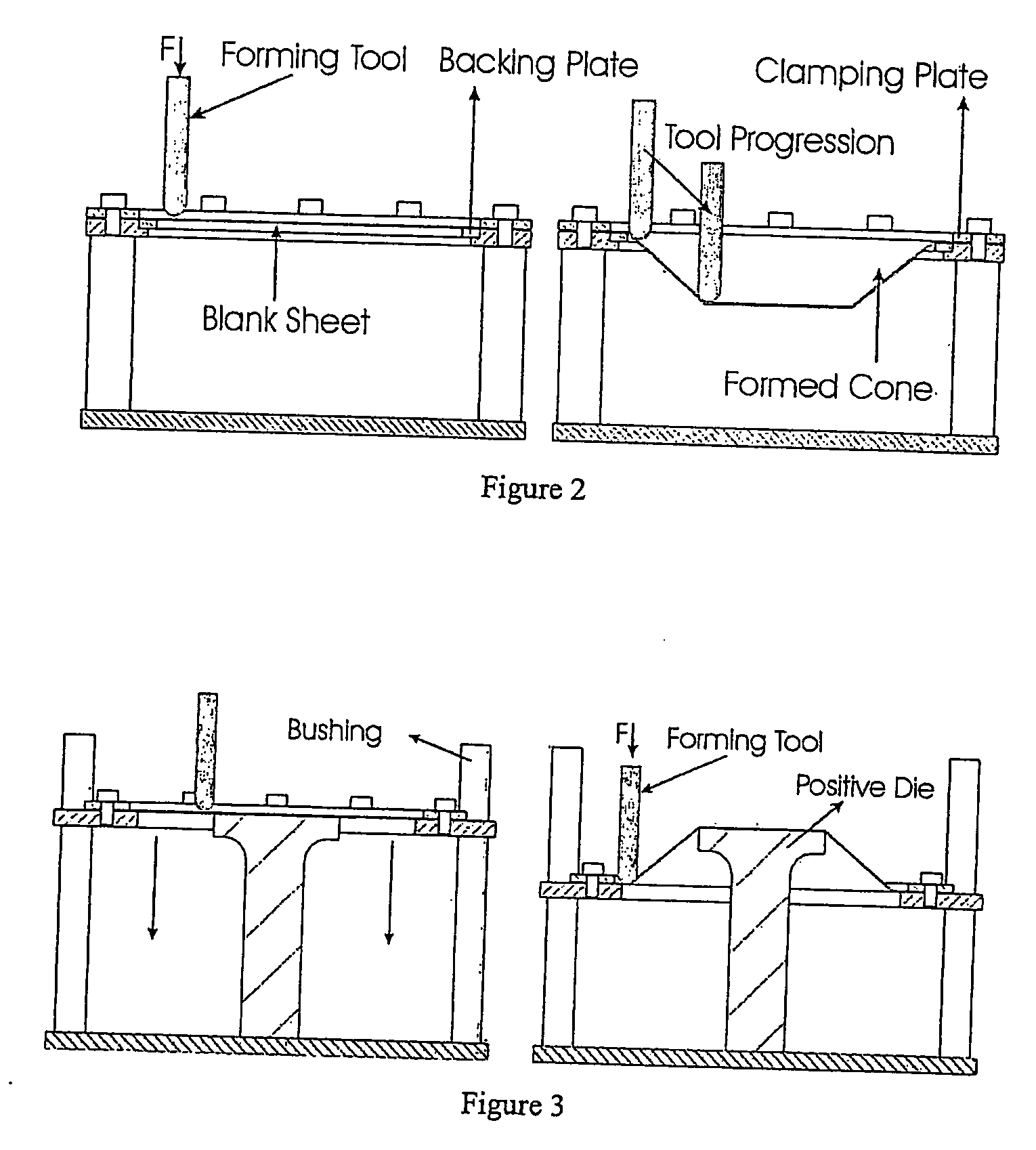

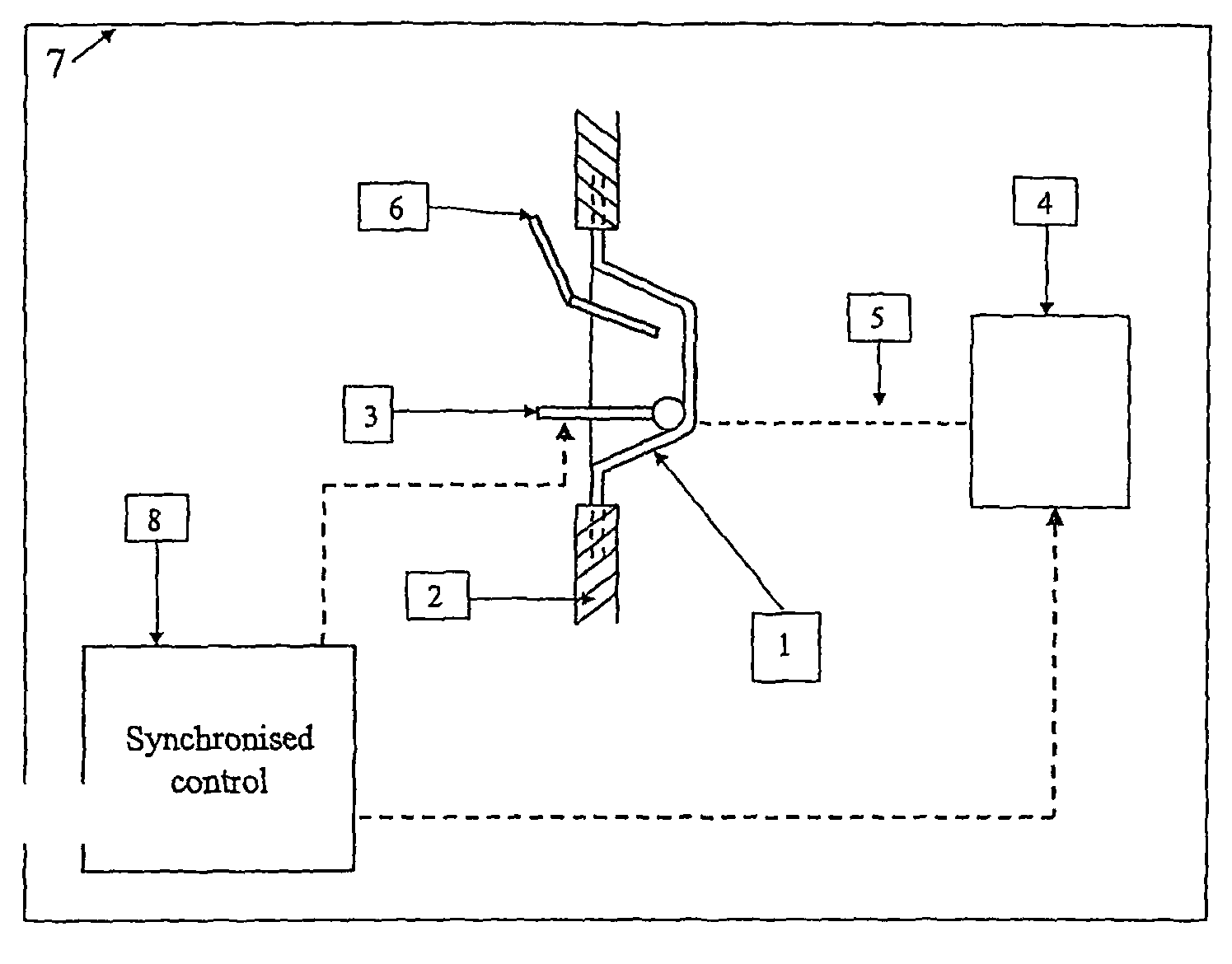

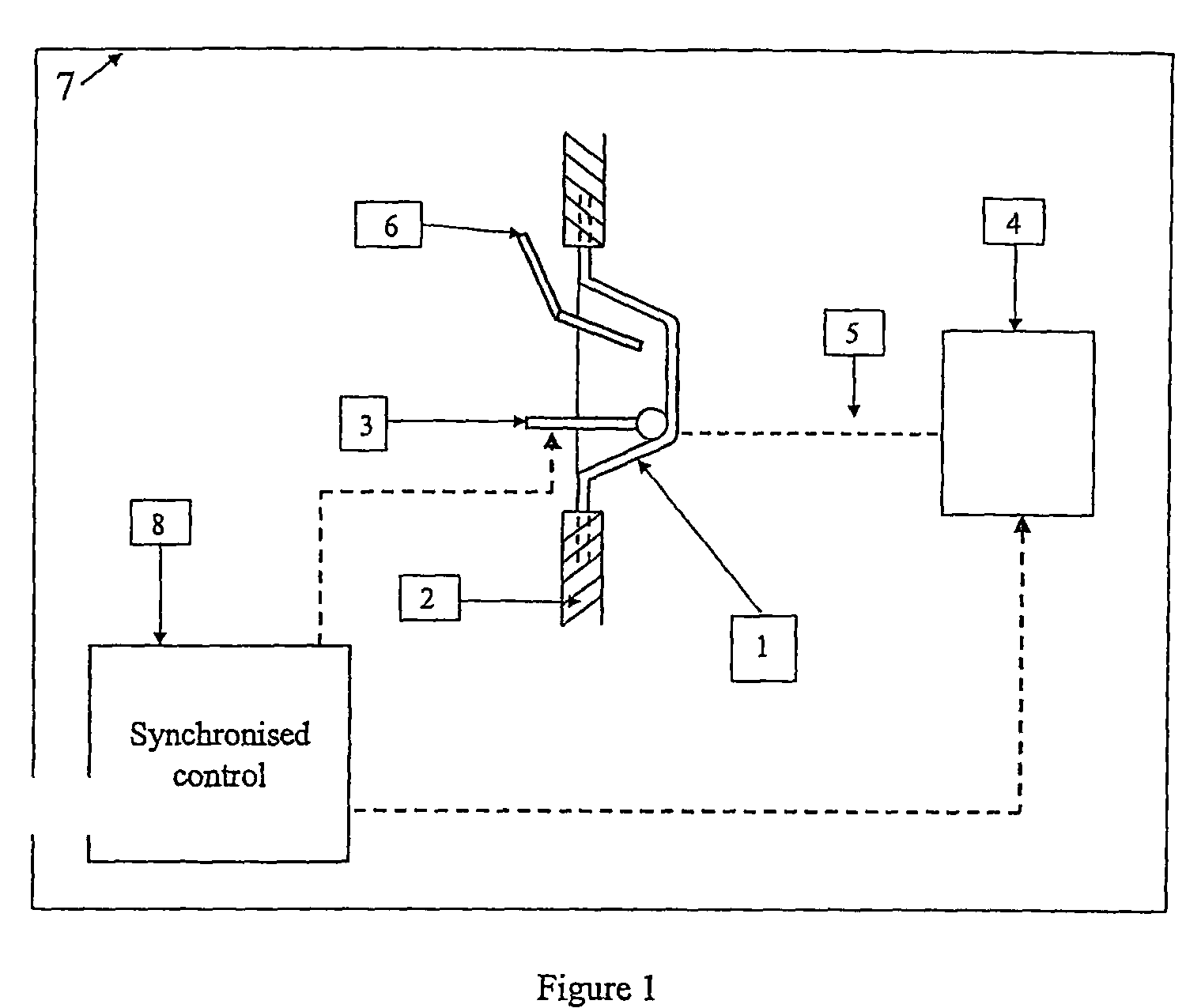

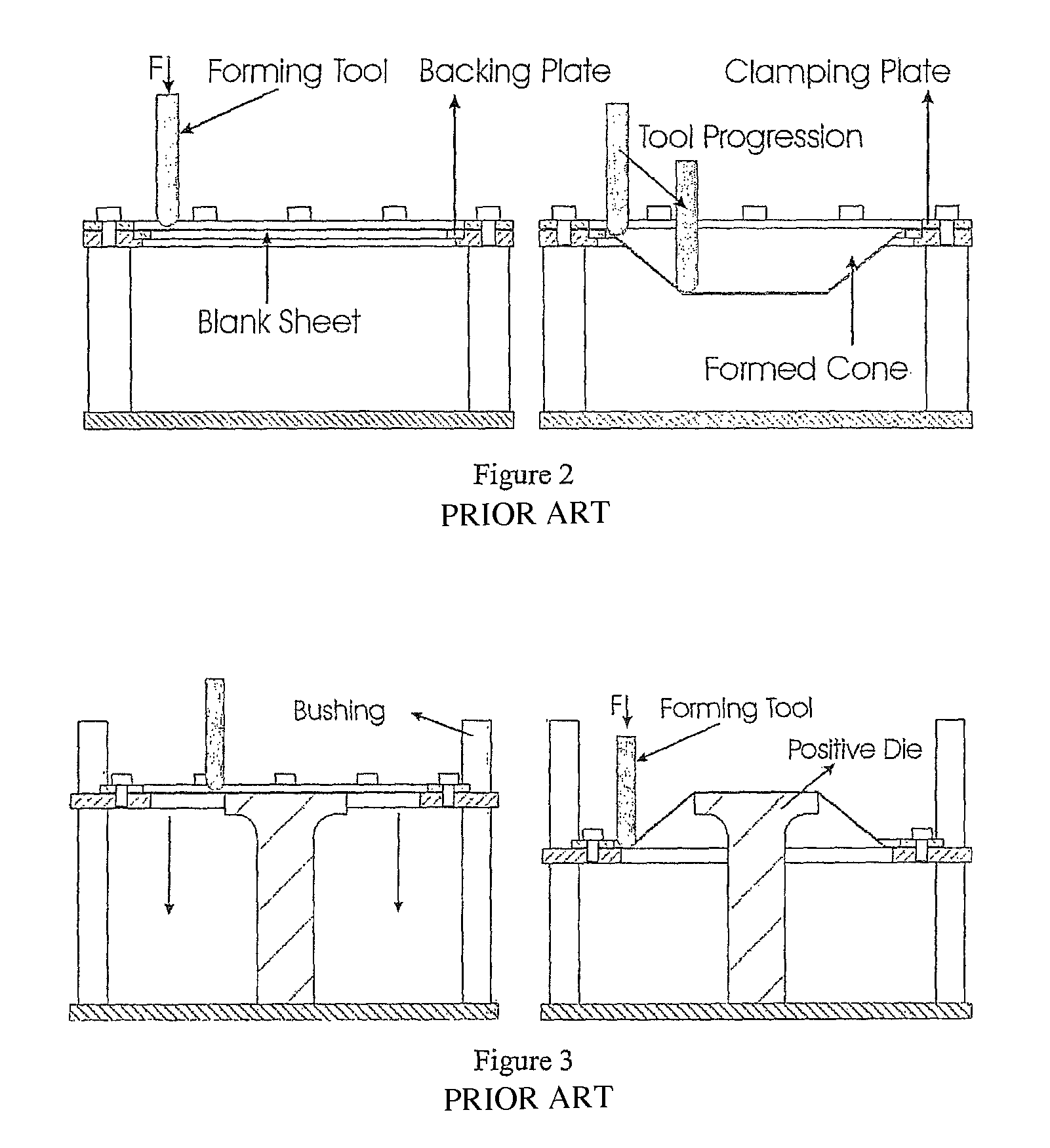

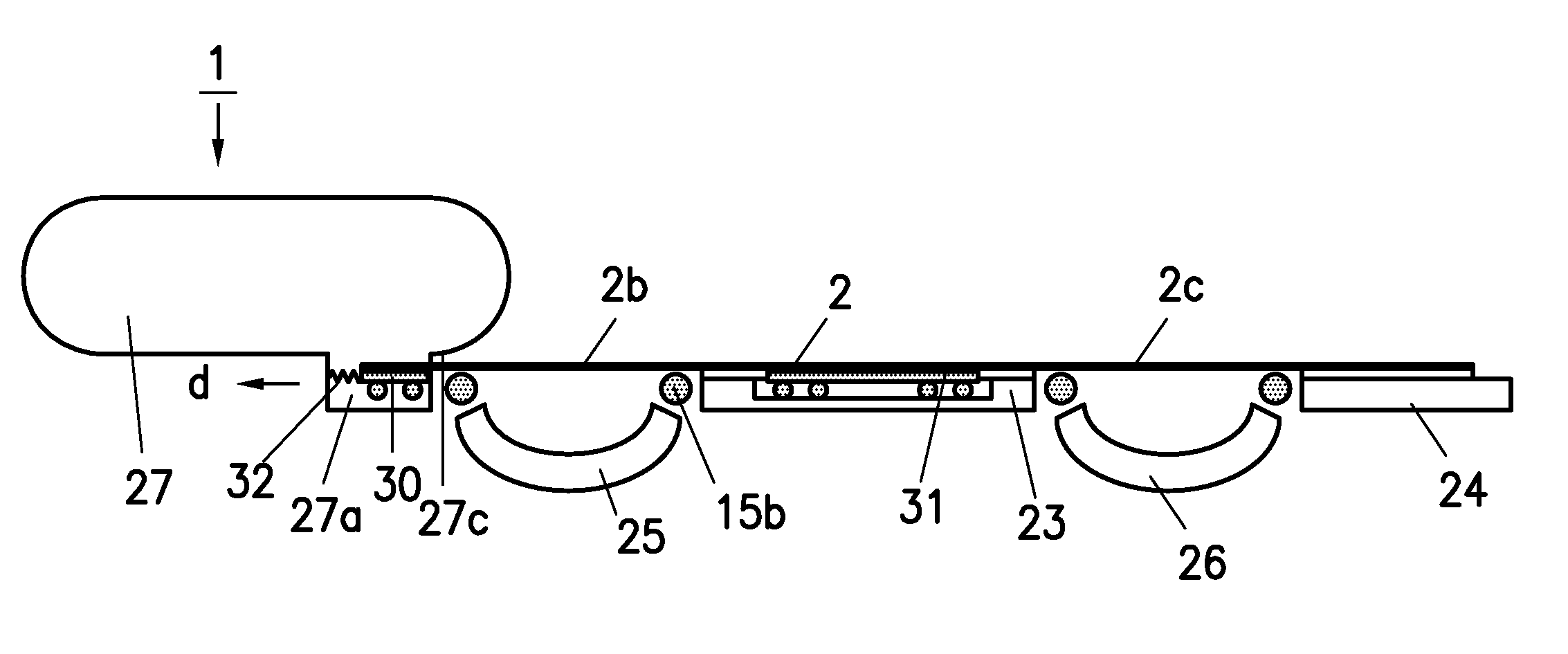

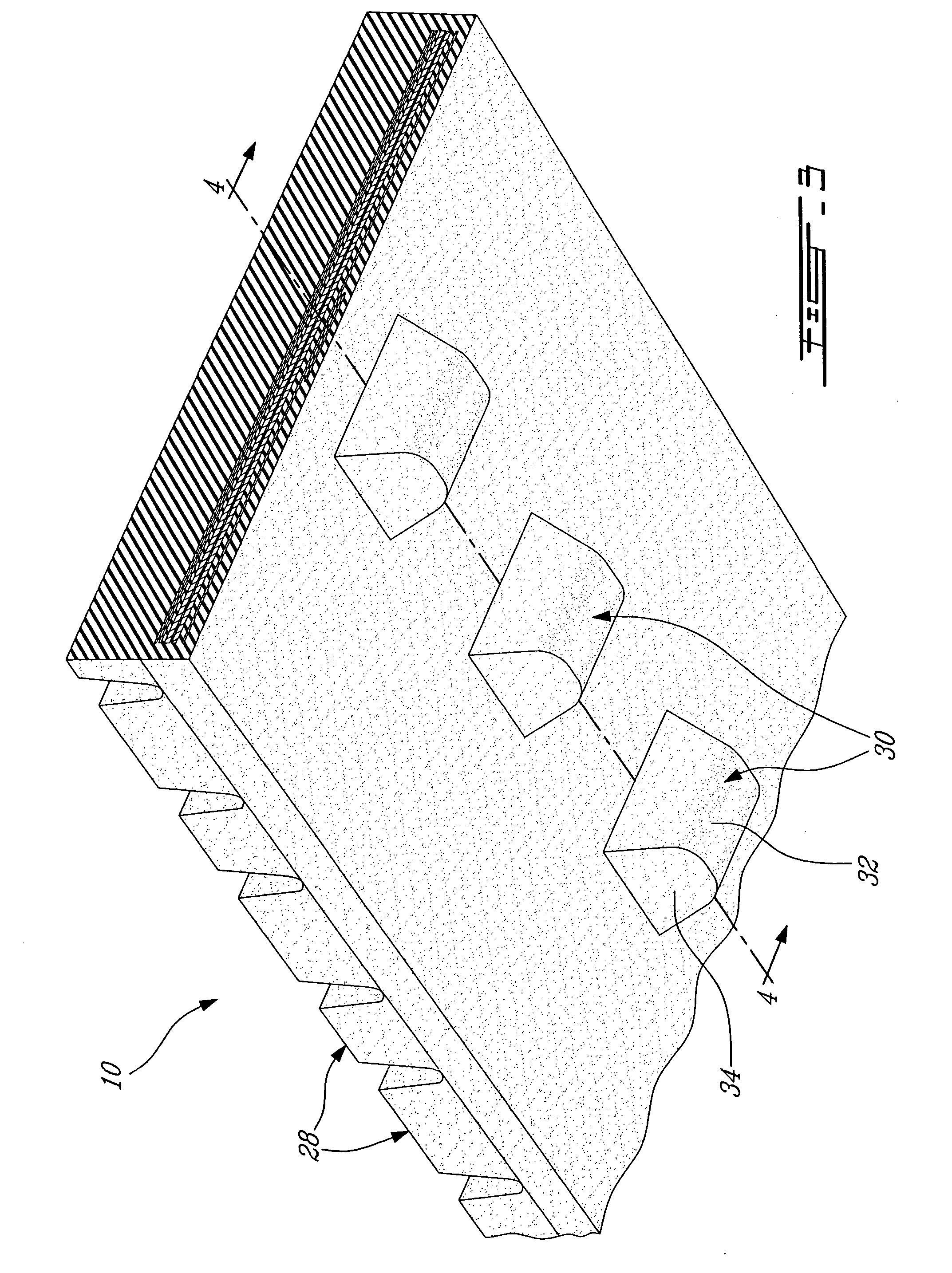

Asymmetric incremental sheet forming system

ActiveUS20090158805A1Good molding effectLimited strainabilityShaping toolsMechanical propertyBiomedical engineering

The present invention relates, in general, to sheet material forming technology and the forming of structures there from. The invention relates to incremental forming of sheet material (1) with localised heating (5) and more particularly to a system and method for incrementally forming a sheet blank (1) that is at the same time heated by a dynamically moving heating source (5). This dynamic and localised heating locally changes the mechanical properties of the sheet material (1), thus facilitating the forming process.

Owner:K U LEUVEN RES & DEV

Asymmetric incremental sheet forming system

ActiveUS7984635B2Reduce forceGood molding effectShaping toolsMechanical propertyBiomedical engineering

The present invention relates, in general, to sheet material forming technology and the forming of structures there from. The invention relates to incremental forming of sheet material (1) with localised heating (5) and more particularly to a system and method for incrementally forming a sheet blank (1) that is at the same time heated by a dynamically moving heating source (5). This dynamic and localised heating locally changes the mechanical properties of the sheet material (1), thus facilitating the forming process.

Owner:K U LEUVEN RES & DEV

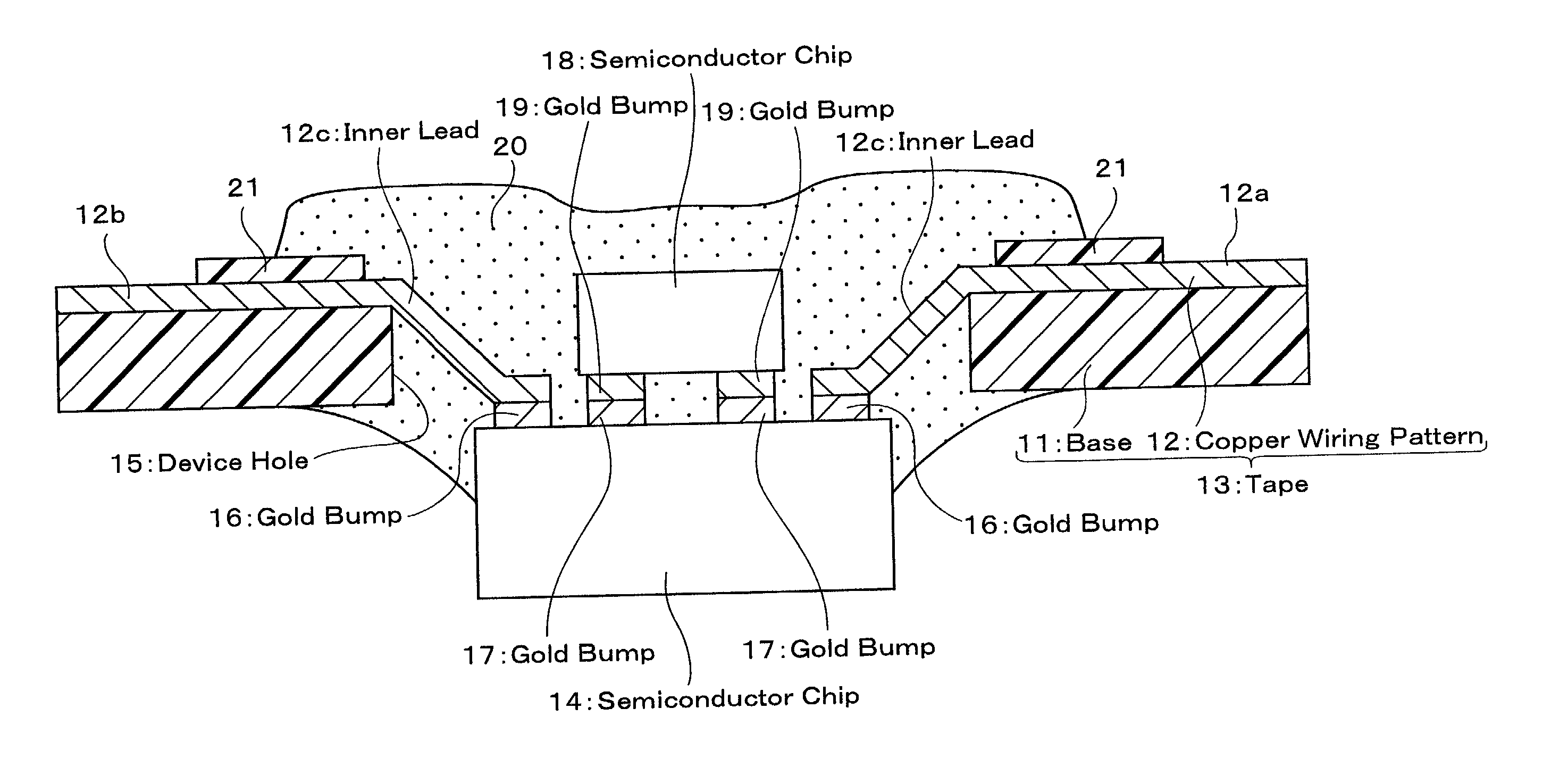

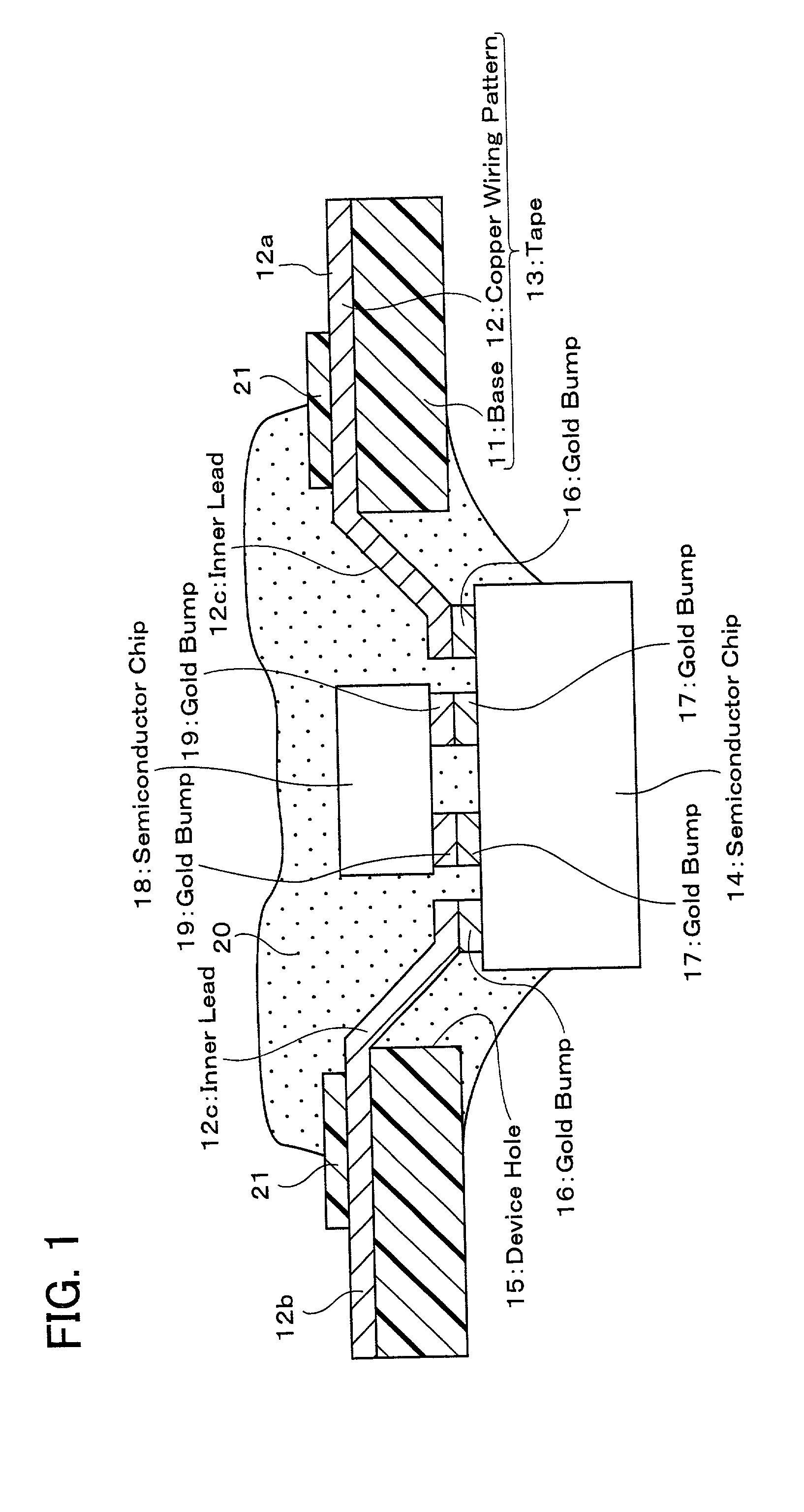

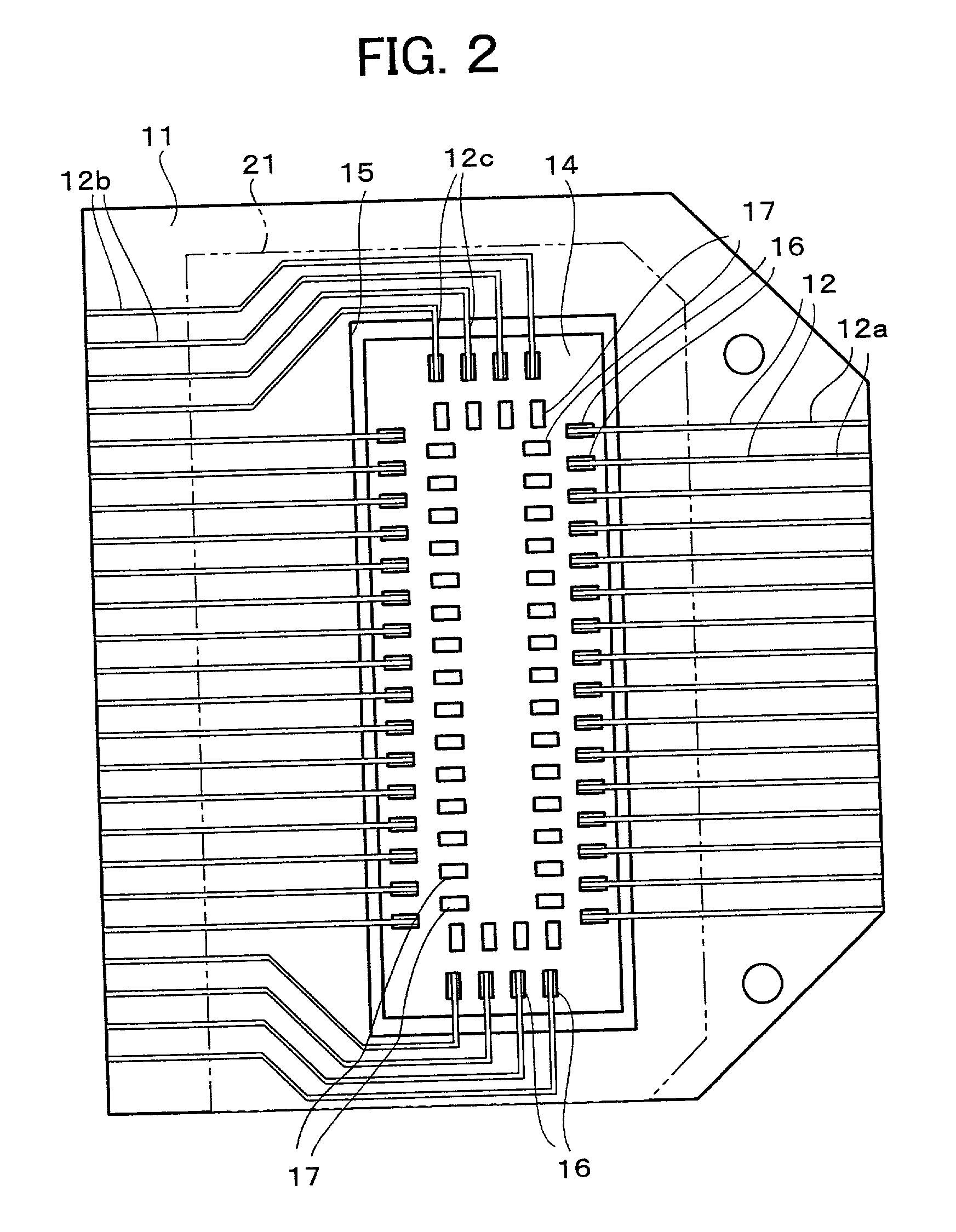

Semiconductor device and liquid crystal module using the same

InactiveUS20020096781A1Terminal pitch can be shortenedLess deformationSemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor chip

A semiconductor device in accordance with the present invention is a semiconductor device using TCP structure, including a first semiconductor chip mounted on a tape carrier by ILB and a second semiconductor chip mounted on the tape carrier via the first semiconductor chip. The first semiconductor chip is arranged so that a first electrode, formed on a surface of the first semiconductor chip for an electrode, is connected to an inner lead via a gold bump, whereas the second semiconductor chip is arranged so that an electrode thereof is connected to a second electrode formed on that surface via a gold bump. On this account, it is possible to reduce a terminal pitch of the semiconductor device on which more than one semiconductor chip are mounted.

Owner:SHARP KK

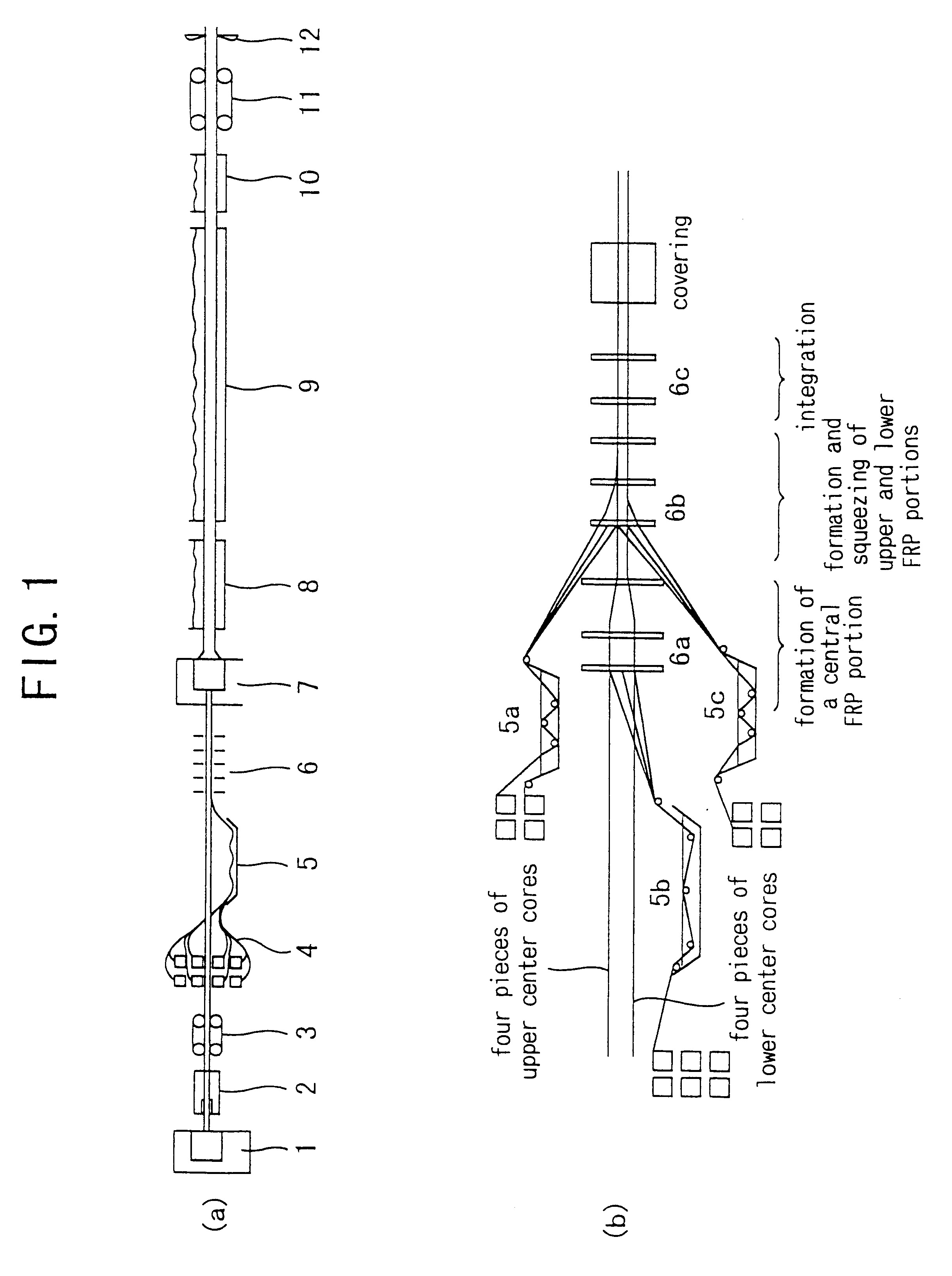

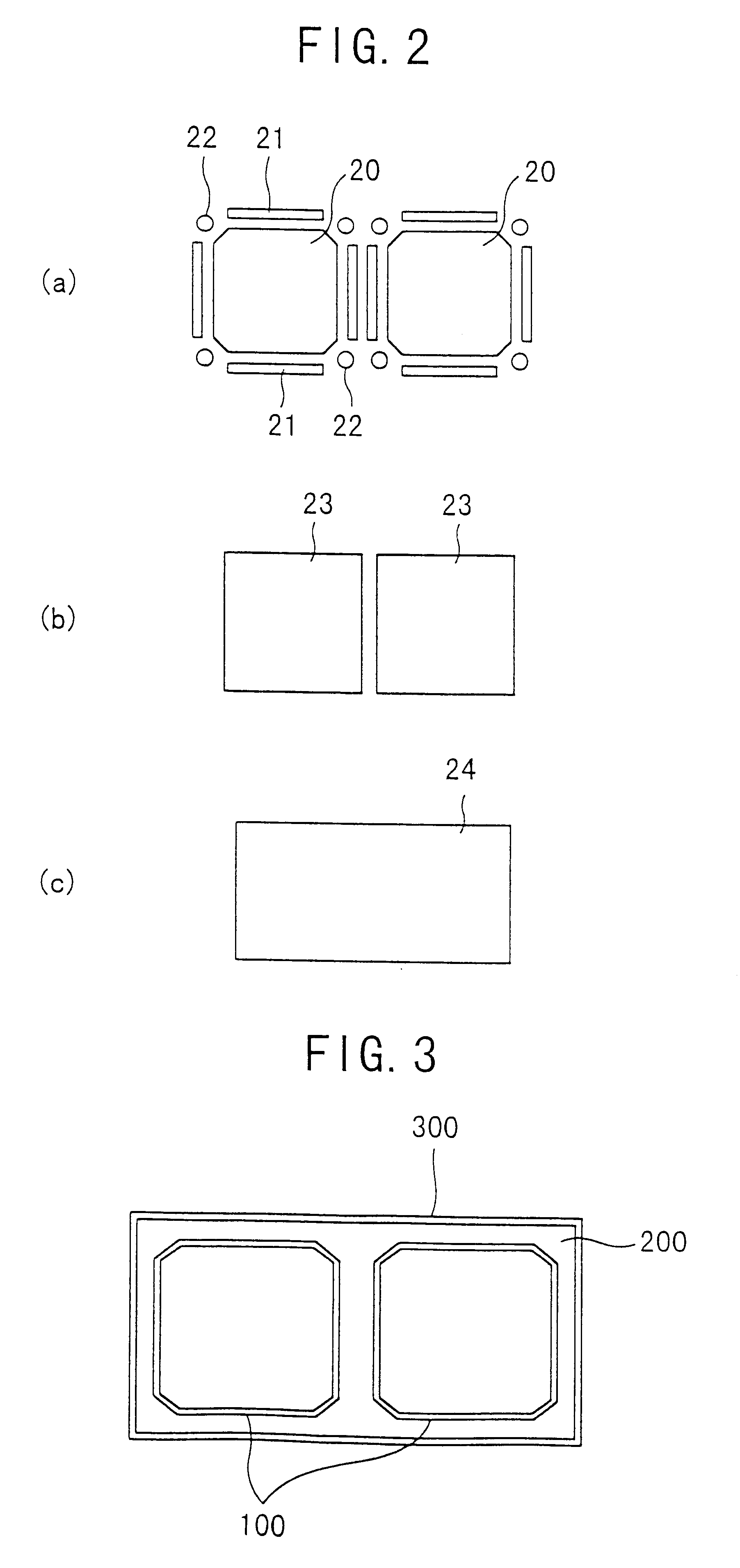

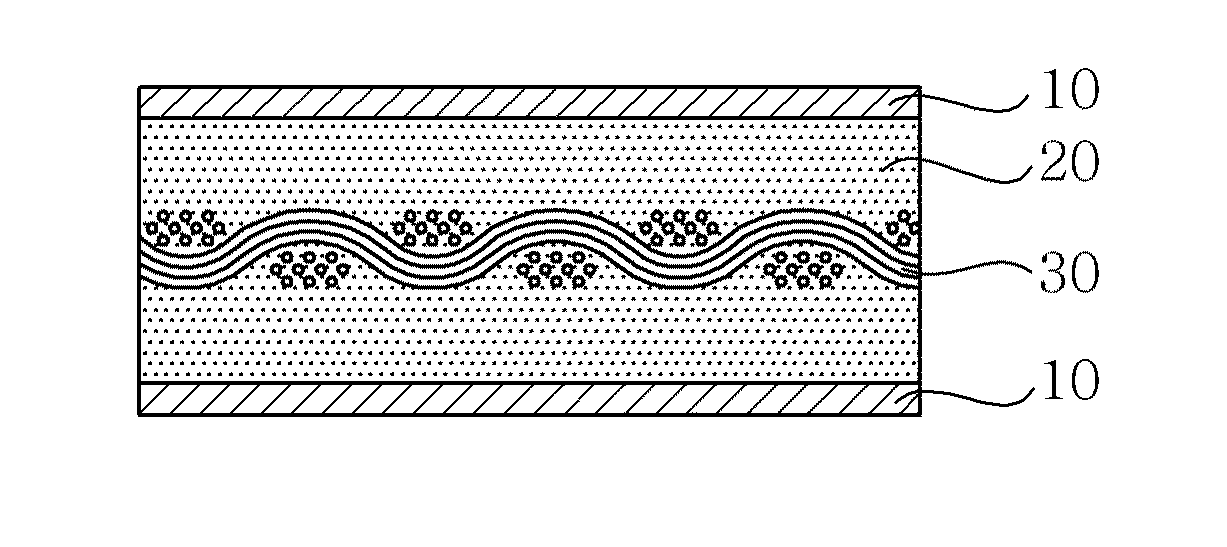

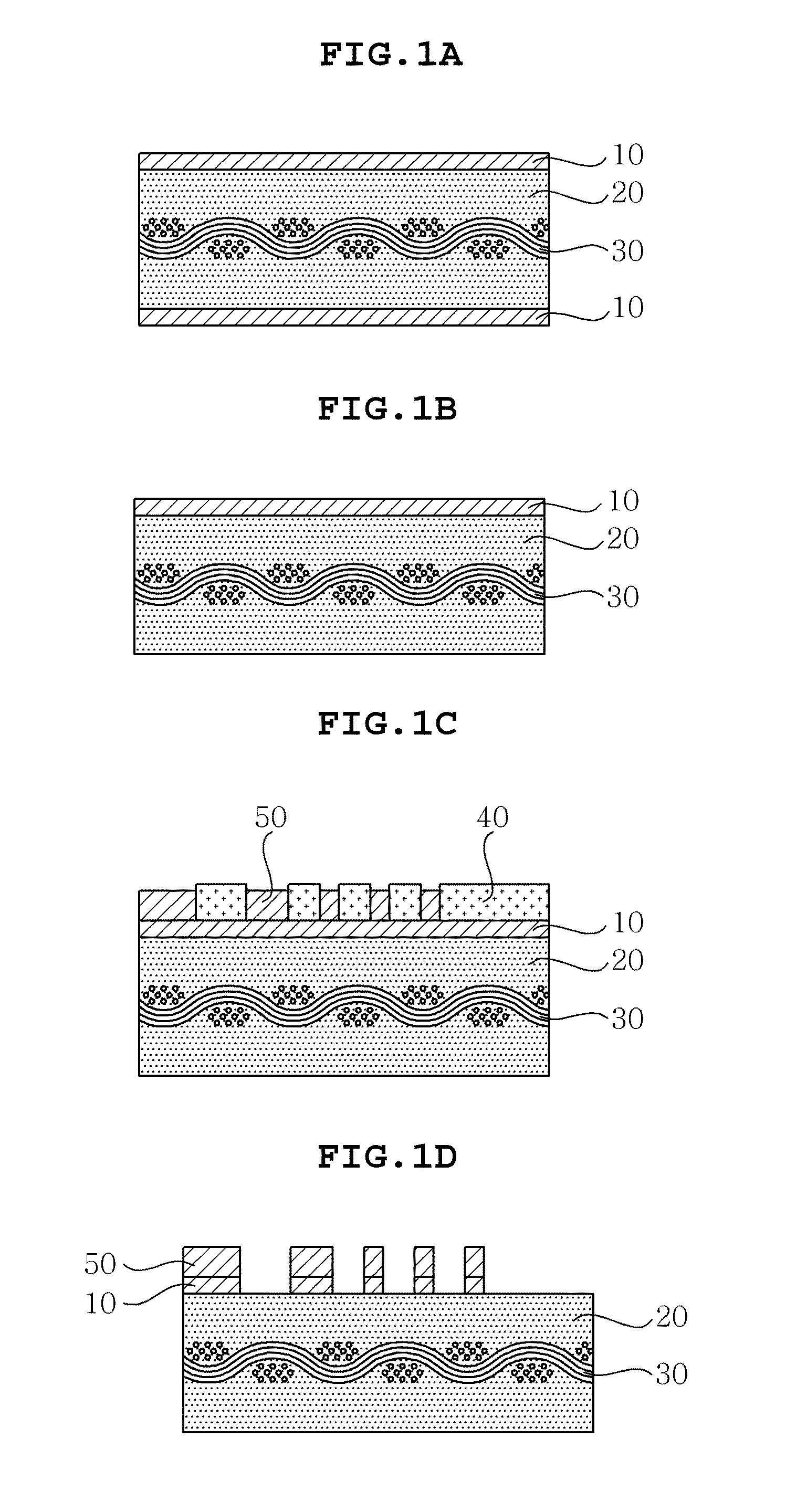

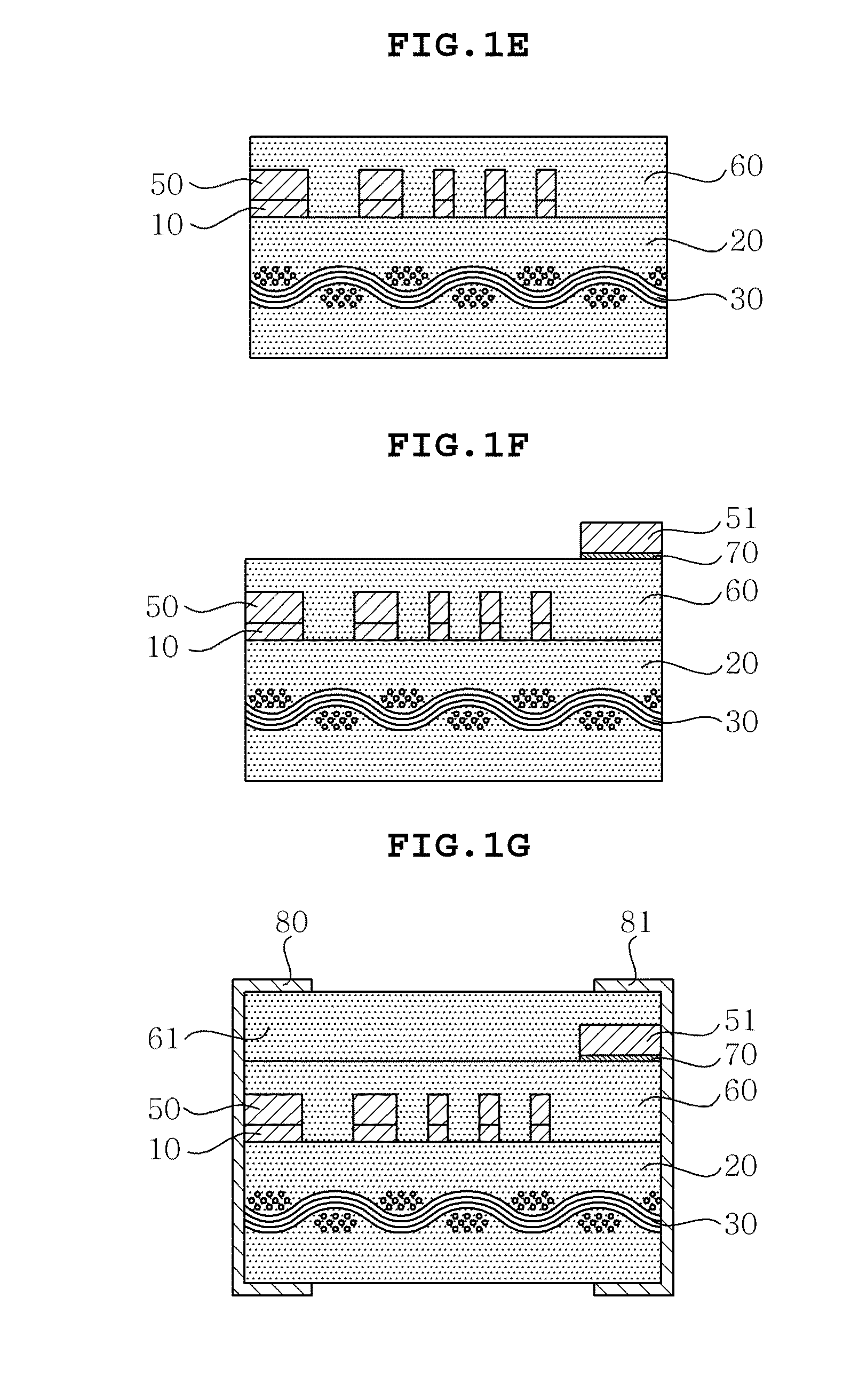

Fiber-reinforced composite hollow structure, method for production thereof, and apparatus therefor

InactiveUS6607798B1Prevent saggingUniform coverageEnvelopes/bags making machineryWrappers shrinkageEngineeringFiber-reinforced composite

Center cores are formed by extrusion-molding ABS resin. Seven pieces of the center cores, which are juxtaposed to each other in the horizontal direction, are supplied by a pultruder, and reinforcing long-fibers impregnated with an unsaturated polyester resin are allowed to pass through dispersion guides and squeezing nozzles, to thus squeezing-mold a fiber-reinforced composite hollow structure having FRP made legs. A final squeezing nozzle is disposed in a cross head die through a cooling jacket, and the hollow structure thus molded is allowed to pass therethrough to be covered with the ABS resin in a state in which the outer periphery of the hollow structure is heated. The hollow structure thus covered is subjected to cooled-sizing through a plurality of horizontal and vertical pairs of rollers, and then cured in a hot curing tank. The surface covered with the ABS resin is subjected to a surface-treatment of imparting irregularities for giving an antislipping function to the surface. A thermoplastic resin-made protective cap is fitted to an end of the center core. The apparatus for manufacturing a composite hollow structure has a plurality of pairs of rotatable and heat-resisting sizing rollers. The plurality of pairs of the sizing rollers are disposed in the pultruding direction while being gradually cooled in the order from those positioned on the upstream side to those positioned on the downstream side for sizing the softened outer layer covering the outer periphery of the intermediate layer.

Owner:UBE NITTO KASEI CO LTD

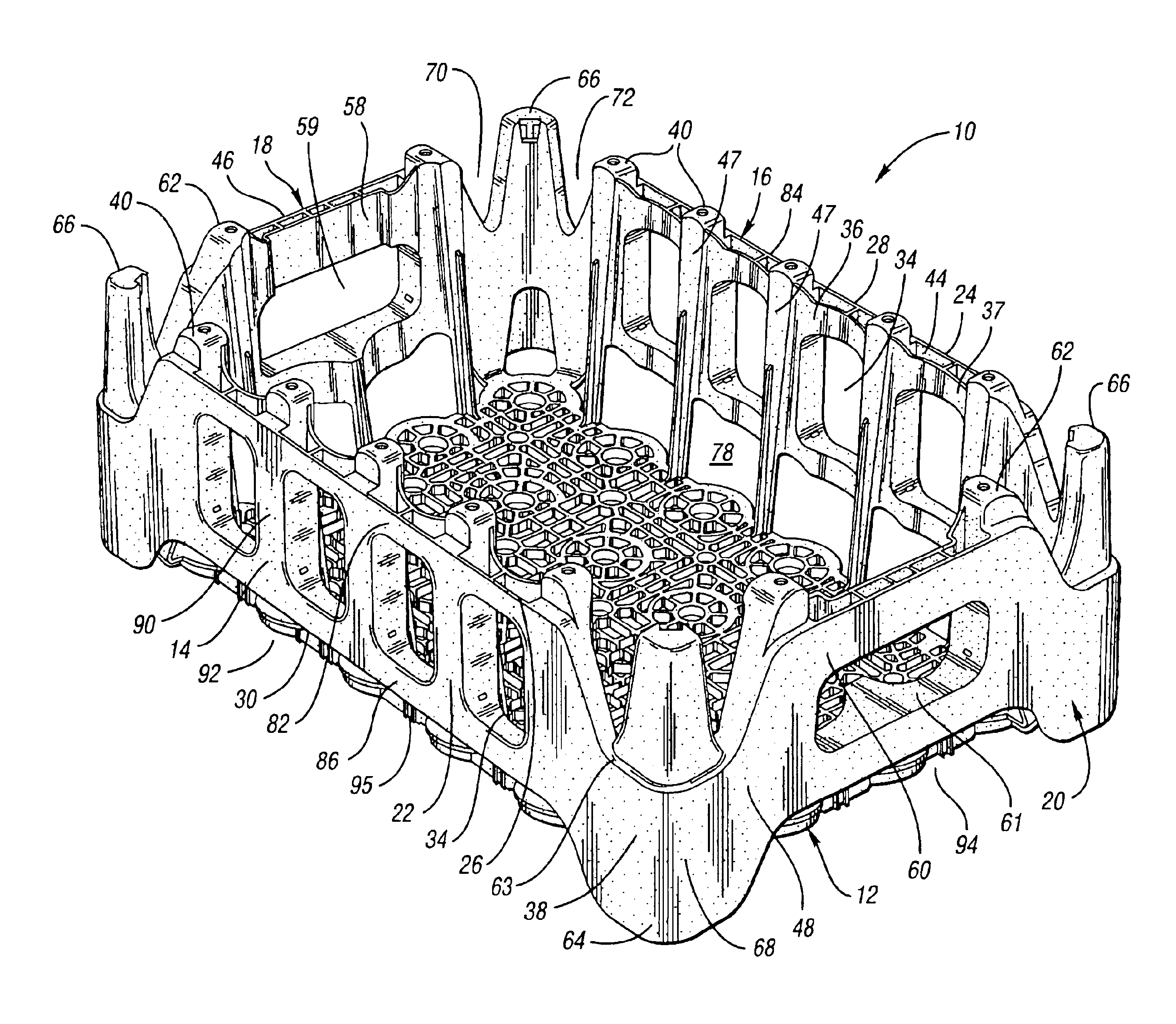

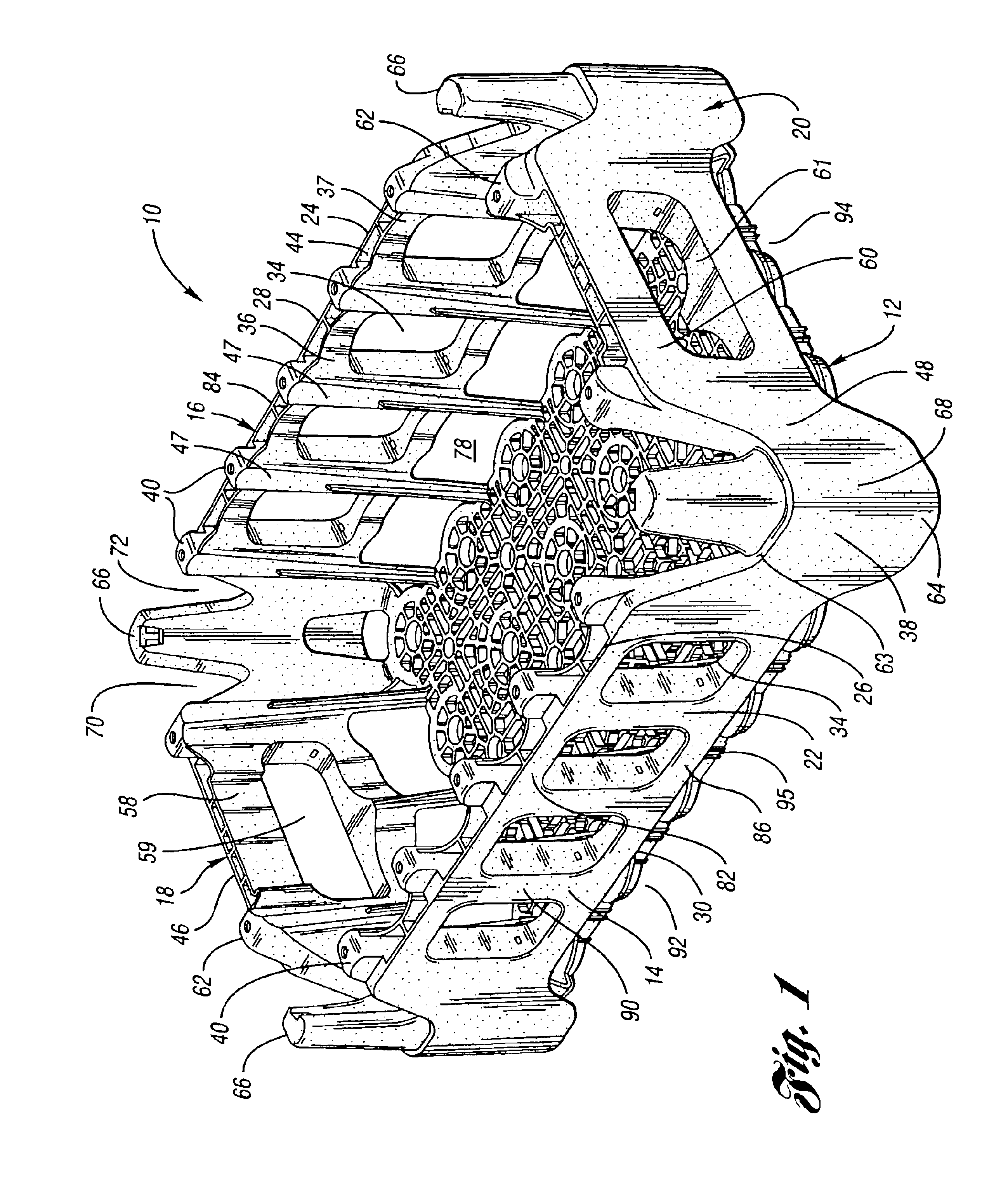

Bottle crate

A nestable crate for bottles which includes a floor member and first and second pairs of opposed sidewalls integrally formed with the floor member. Each sidewall includes a side band member which is defined by a centrally disposed upper edge and lower edge. The lower edge is spaced above the floor member by a predetermined distance to define a sidewall nesting area therebelow. The upper and lower edges each contoured downwardly to form a corner band portion having a corner upper edge and corner lower edge, wherein each nesting area matingly receives a corresponding side band member of a crate nested subjacent thereto.

Owner:REHRIG PACIFIC CO INC

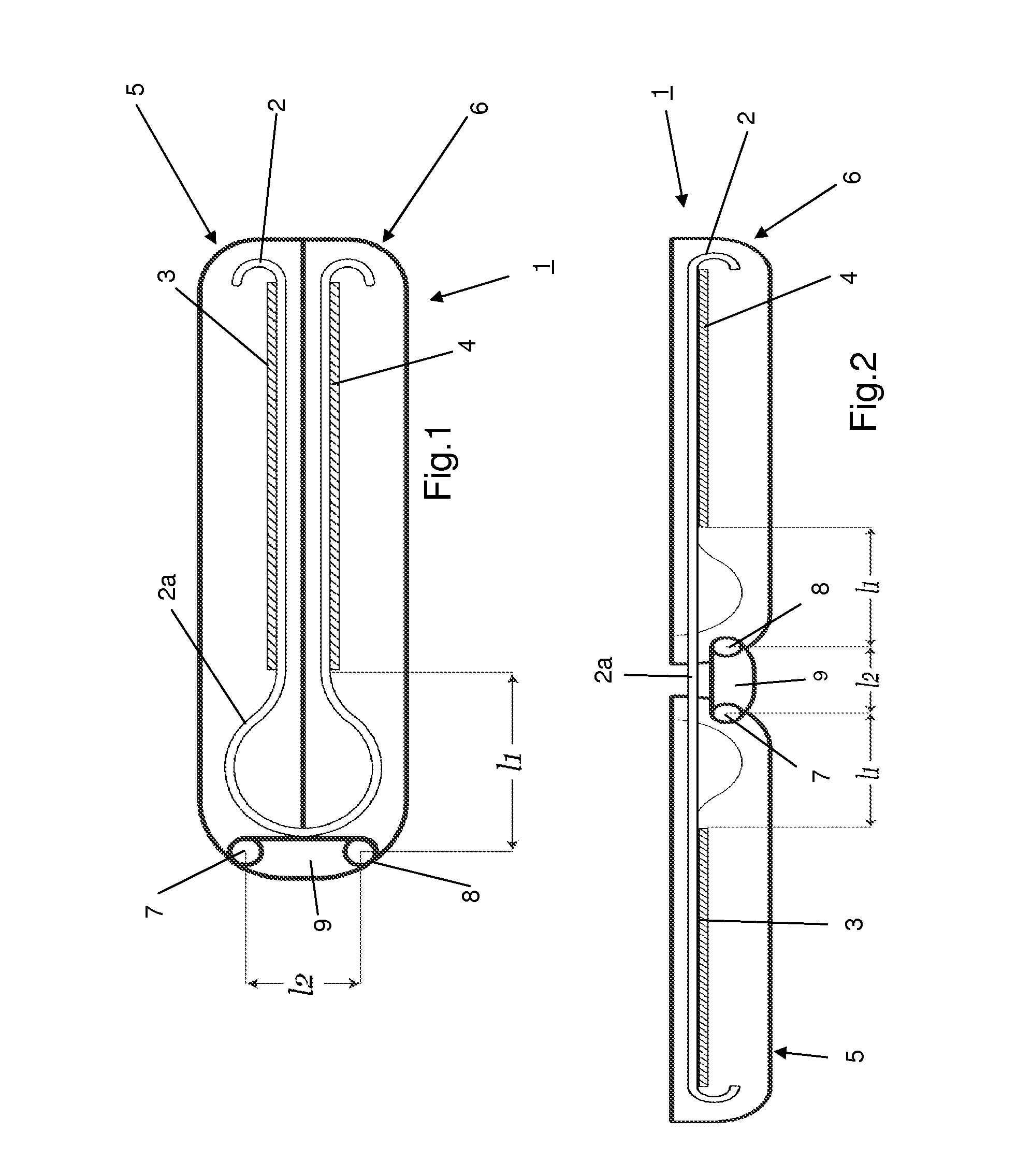

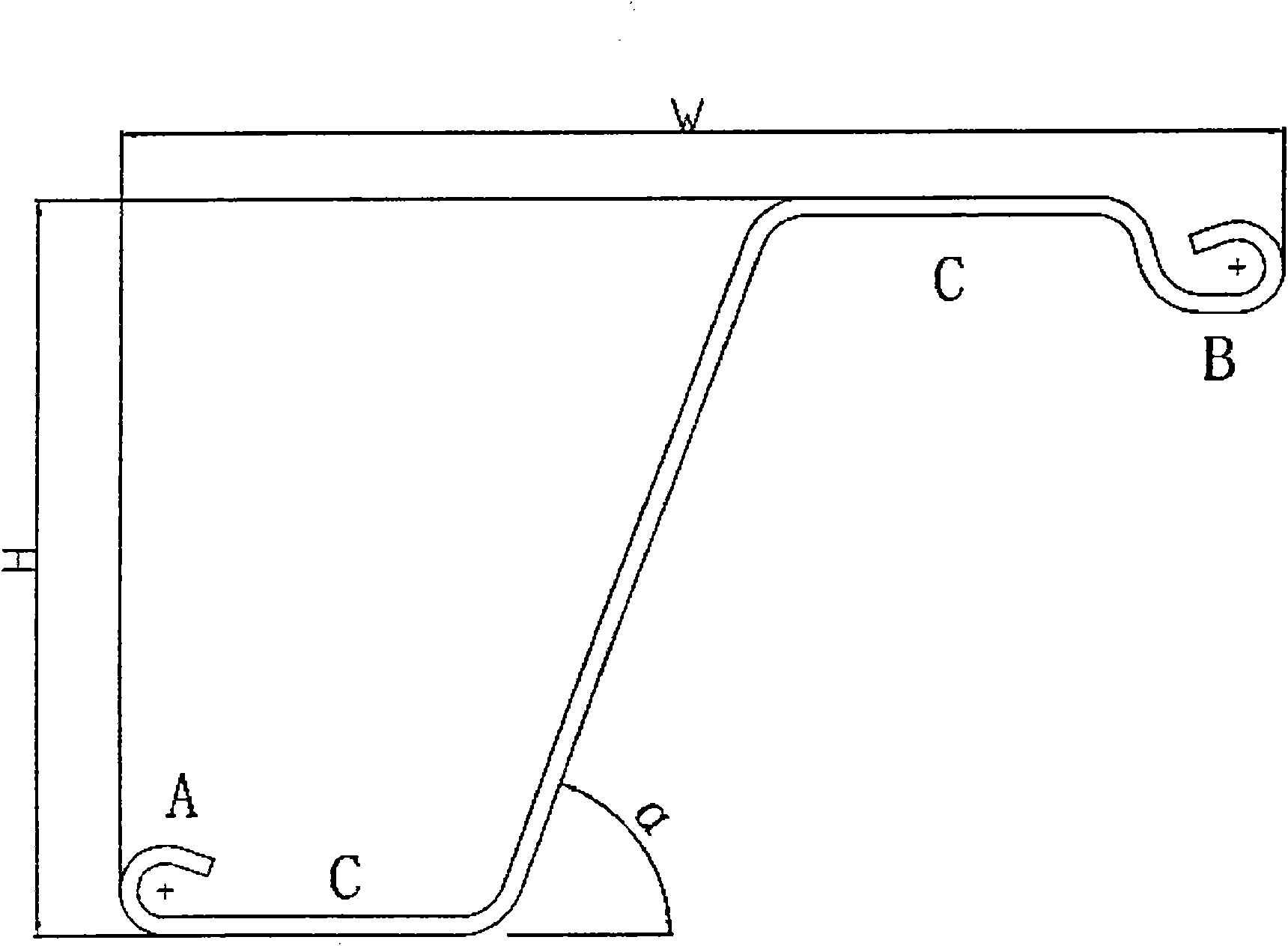

Surgical clip

ActiveUS20060235468A1Less plastic deformationElasticitySurgical veterinaryHaberdasherySurgical ClipsBiomedical engineering

A clip is provided that can be used for ligating tissue, such as vessels, other tubular ducts, and the like. The clip has opposed first and second leg members having proximal and distal ends. The proximal end of each leg member is connected by an apex having a notch formed therein. Moreover, each leg member has an inner tissue-contacting surface and an outer compression-receiving surface, both of which include features to provide a more secure ligation of the vessel or duct. A method for ligating vessels is also provided.

Owner:ETHICON ENDO SURGERY INC

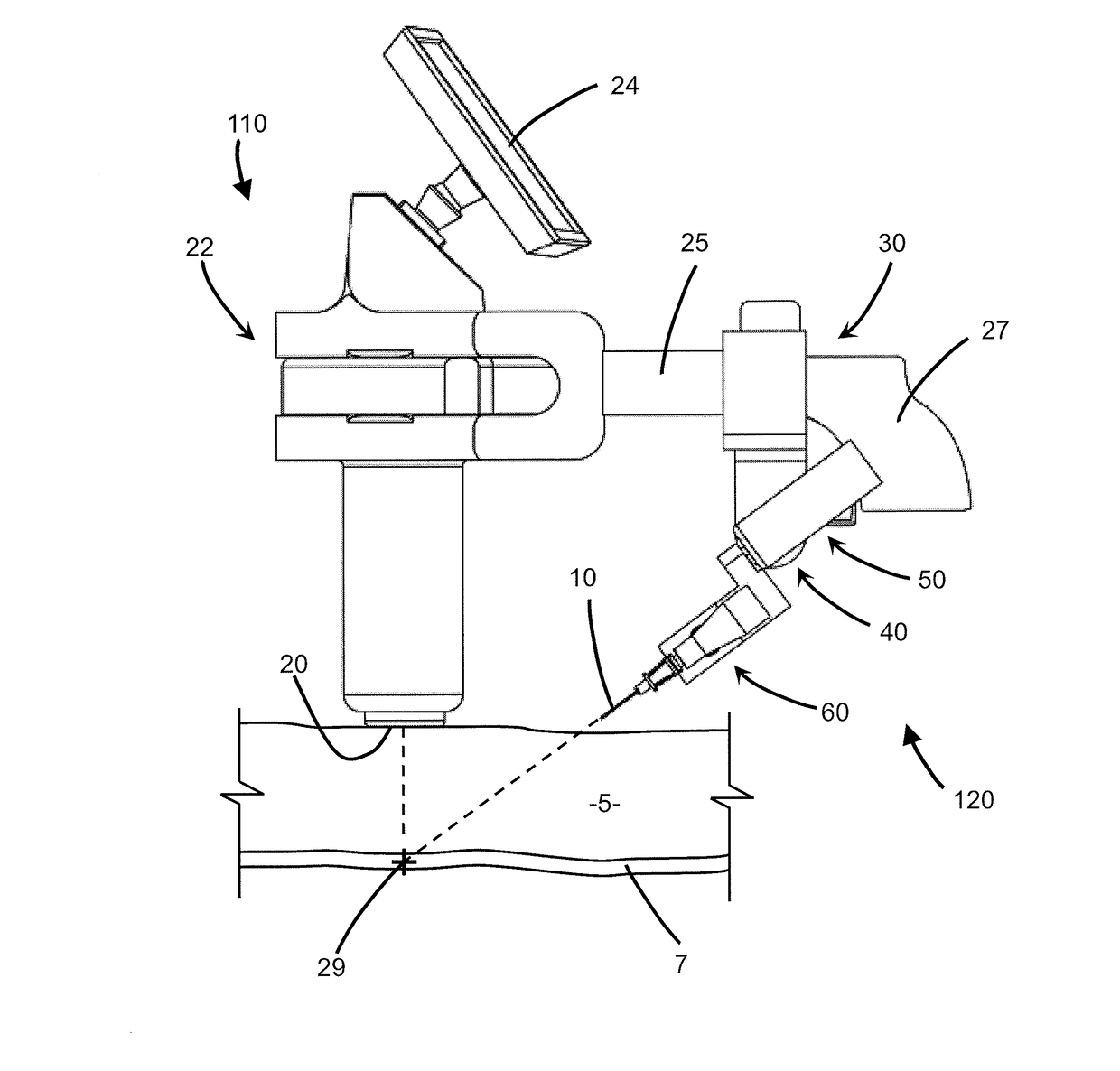

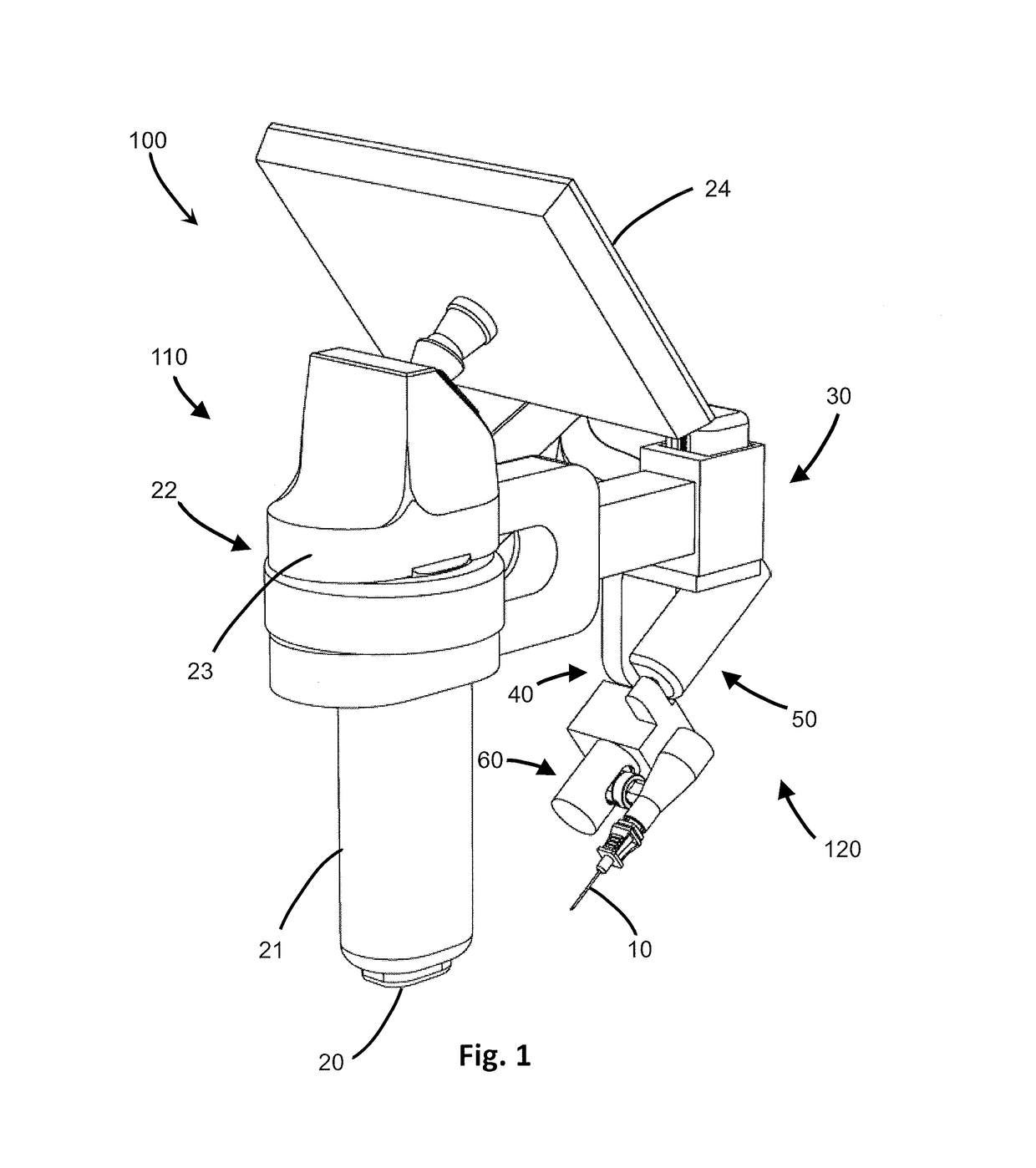

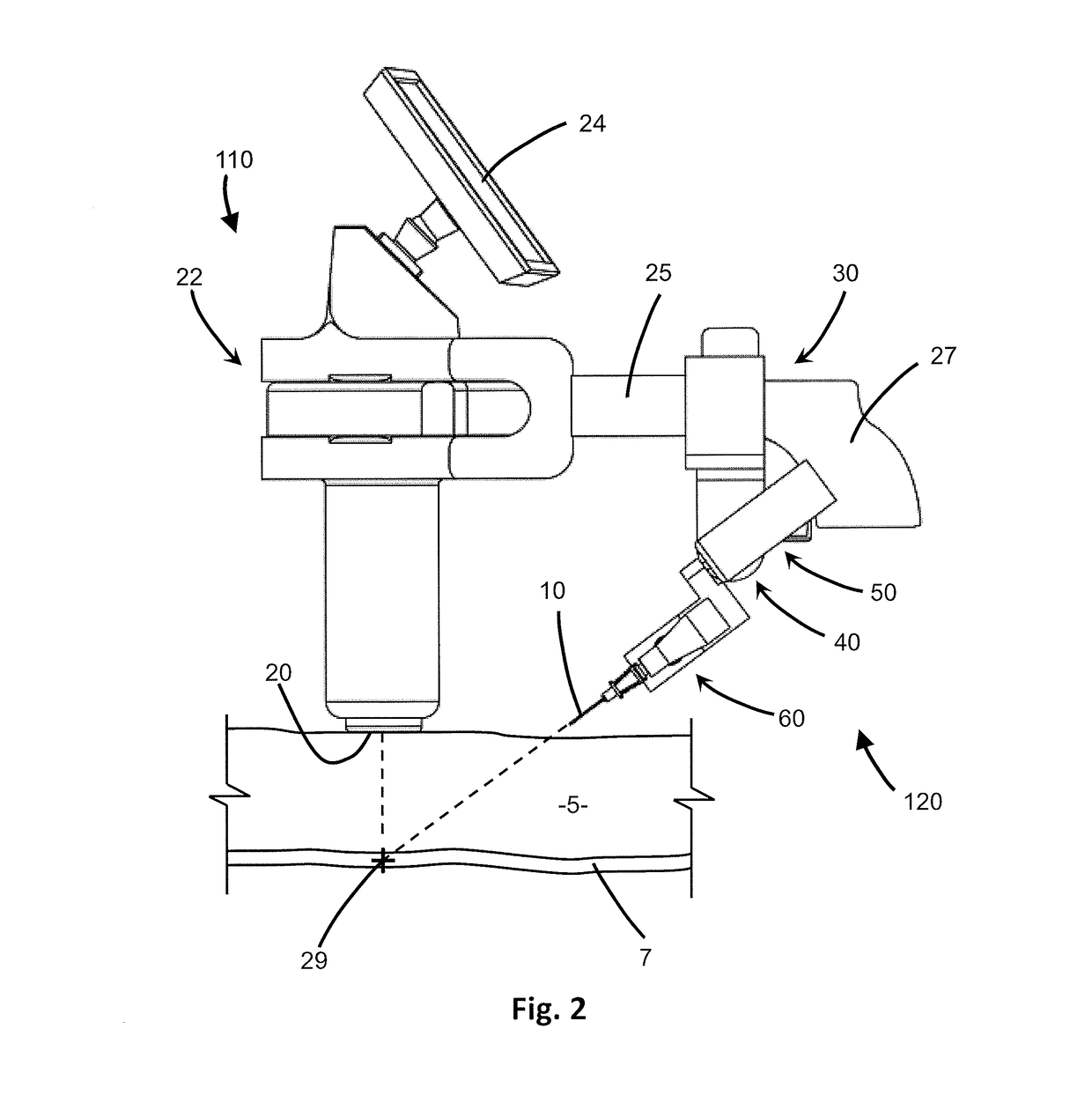

Device and System for Insertion of Penetrating Member

A system, device and method for insertion of a penetrating member into tissue is disclosed, which may be handheld and automated. A detector obtains data regarding subdermal locations of tissue structures, including cavities such as blood vessels. A processor calculates the distance between a preselected target point below the tissue surface, such as within a blood vessel, and the tissue surface, and adjustment data for vertical, angular and extension adjustment of the penetrating member. Vertical, angular and extension actuators carry out the adjustments in real-time as calculated and directed by the processor. Changes in the location of the target point result in automatic recalculation and adjustment by the processor and various actuators. A vibrational actuator induces vibration to the penetrating member during insertion, overcome tissue deformation and vein rolling. A guidewire may be inserted through or by the device, for dilator and catheter insertion once the penetrating member is removed.

Owner:BAYLOR COLLEGE OF MEDICINE +1

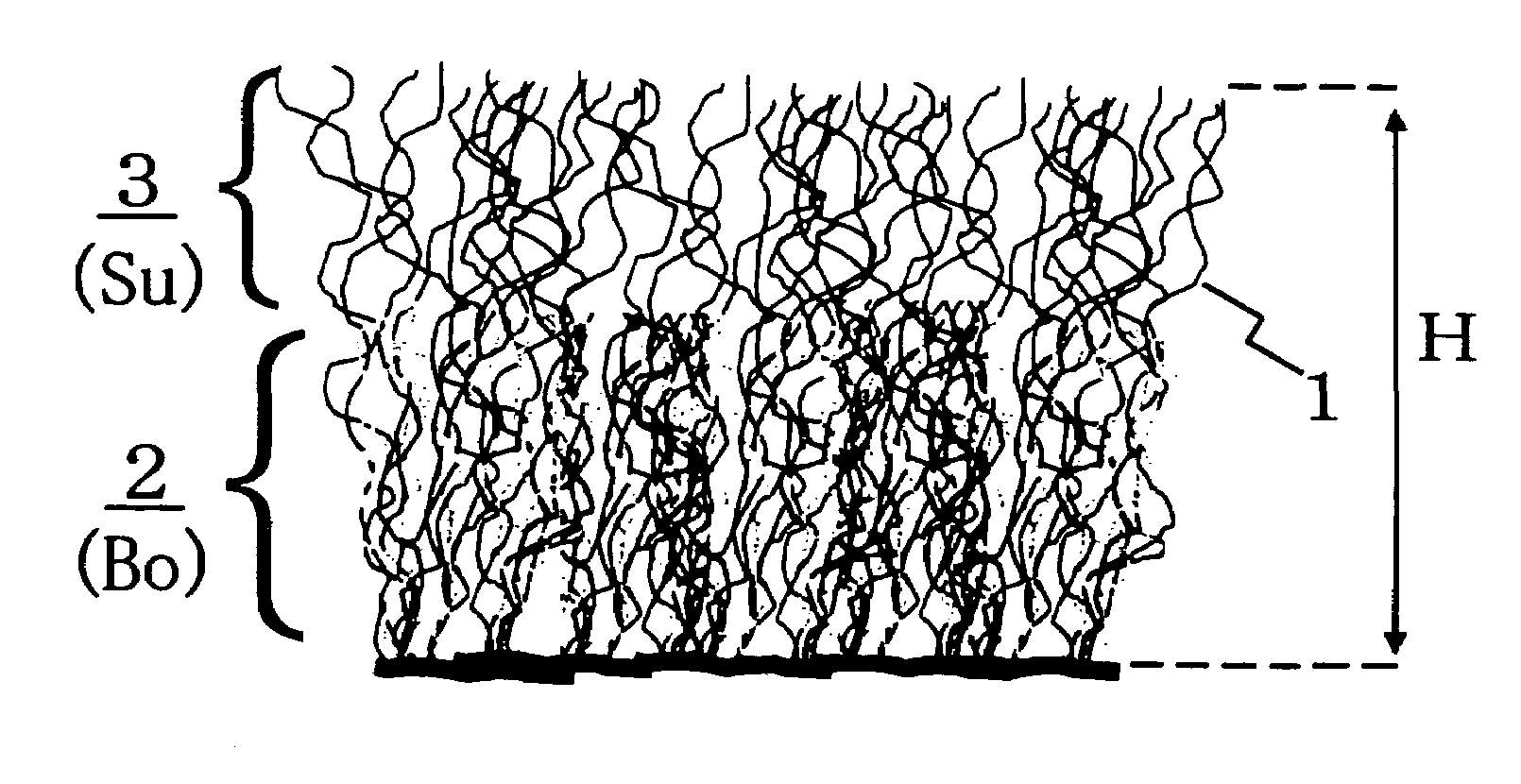

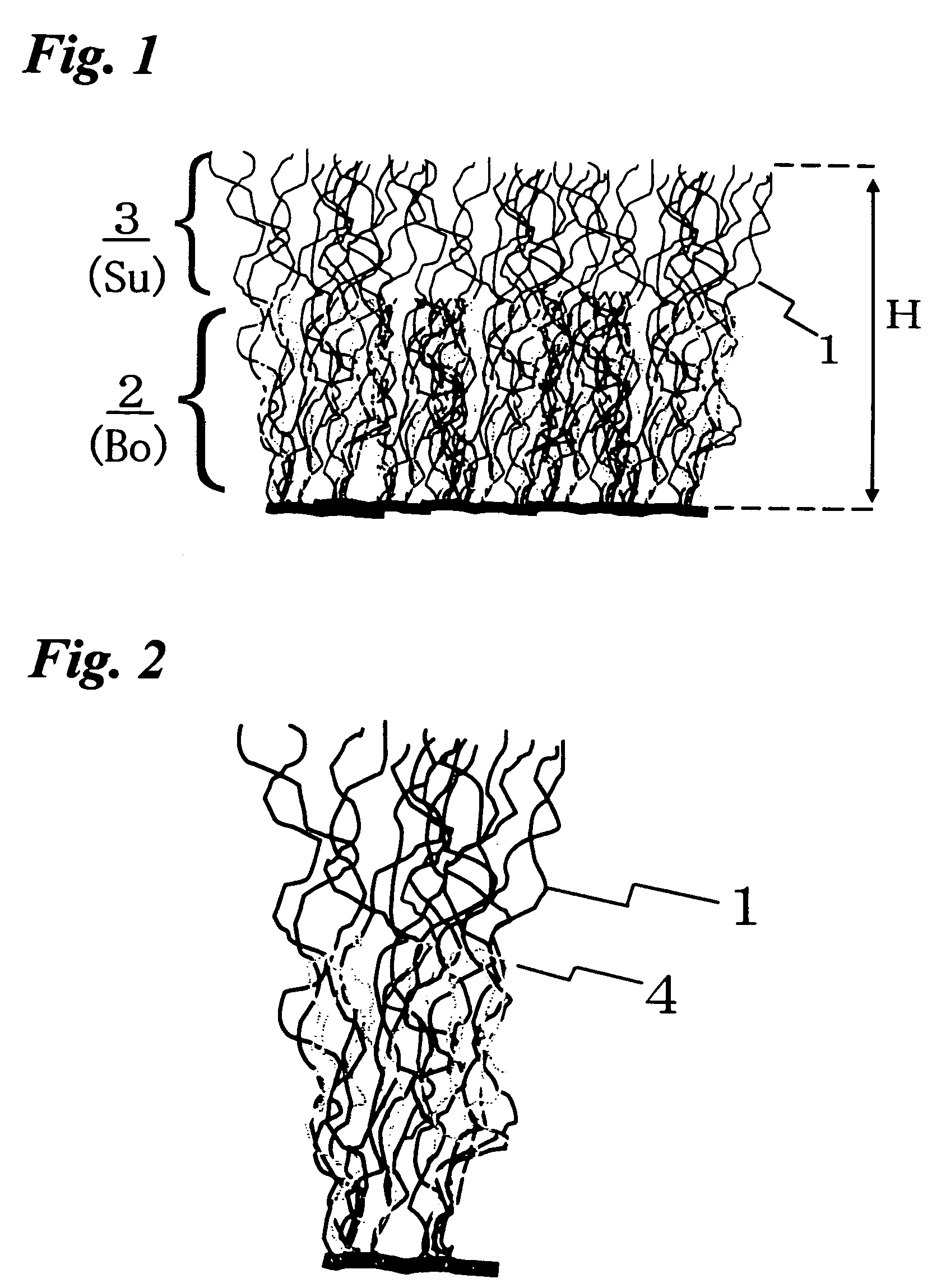

Silver-knit material

InactiveUS6993941B2Less deformationReduce fatigueLiquid surface applicatorsCircular knitting machinesFiberComposite material

A sliver-knit material causing less buckling fatigue or deformation during compression and improved with shedding, in which a pile thread contains 30% or more of staple fibers having steric crimps, and a dense layer (Bo) and a bulky layer (Su) on the side of the upper layer in contact with the dense layer (Bo) are formed, where the ratio of height between the dense layer (Bo) and the bulky layer (Su) in the sliver-knit material is from 2:5 to 1:1, and at least a portion of fibers present in the dense layer (Bo) are folded back.

Owner:KURARAY CO LTD

Display system having a continuous flexible display with display supports

InactiveUS8908365B2More roomPrevent saggingStatic indicating devicesAdvertisingDisplay deviceSpring force

A display system comprises a continuous flexible display and two main display supports being hingeably connected with respect to each other between a closed storage position and a planar open position for fixing the flexible display in an open position. Each of the supports is structurally configured to support respectively a first and a second portion of the flexible display, a segment of the flexible display is located between the said respective portions of the flexible display in the open position. The display system comprises a spring force biased mechanism operative in either the open or closed position or both the open and closed positions of the flexible display, biasing said segment of the flexible display in the respective position.

Owner:SAMSUNG ELECTRONICS CO LTD

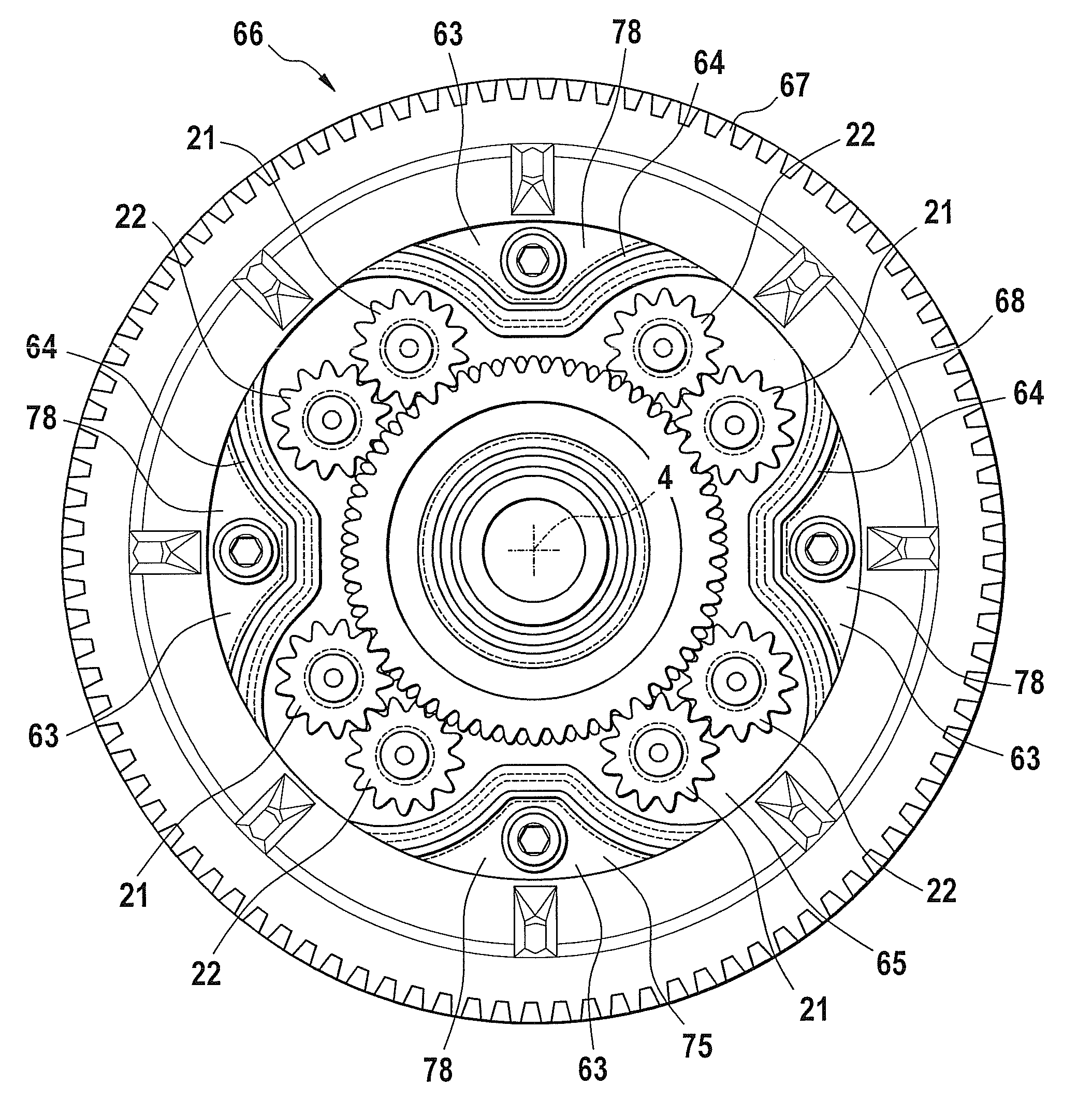

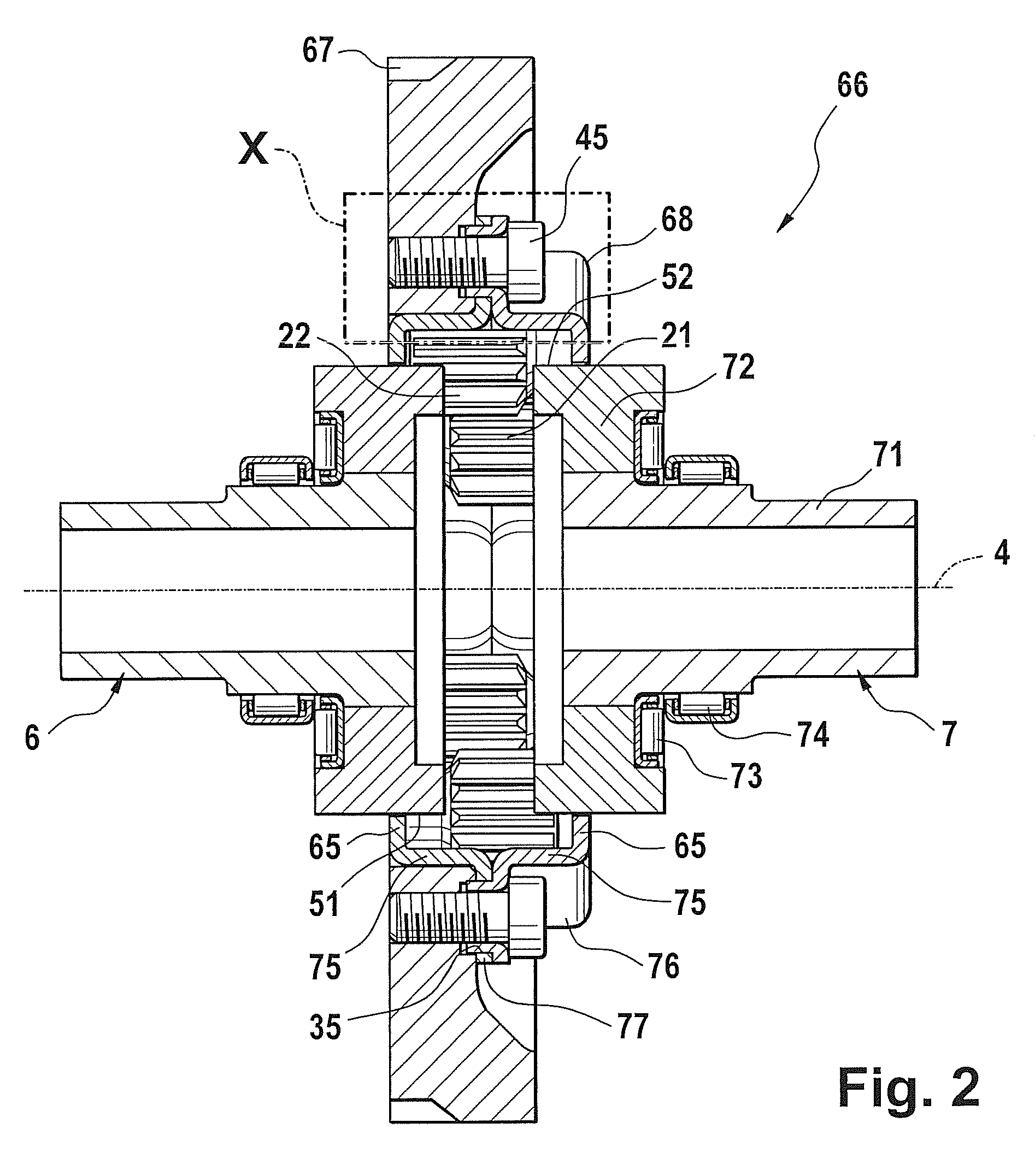

Spur gear differential

The invention relates to a spur gear differential (66) comprising a housing (68) that is embodied as a sum wheel (50) and that rotates around a longitudinal rotational axis (4), at least three planet gears (21, 22) disposed on the periphery at a distance in relation to each other around the rotational axis (4), and a drive wheel (67) at the housing (68), withthe housing (68) comprised of at least two housing sections (75) fixed to each other,each of the planet gears (21, 22) mounted longitudinally on both sides in the housing sections (75),at least one of the housing sections (75) formed in the shape of a pot, with the housing section (75) formed from a pot (76) having a base (65) arranged on the front side of the housing, a wall starting from the base (65) and extending around the rotational axis (4).

Owner:SCHAEFFLER TECH AG & CO KG

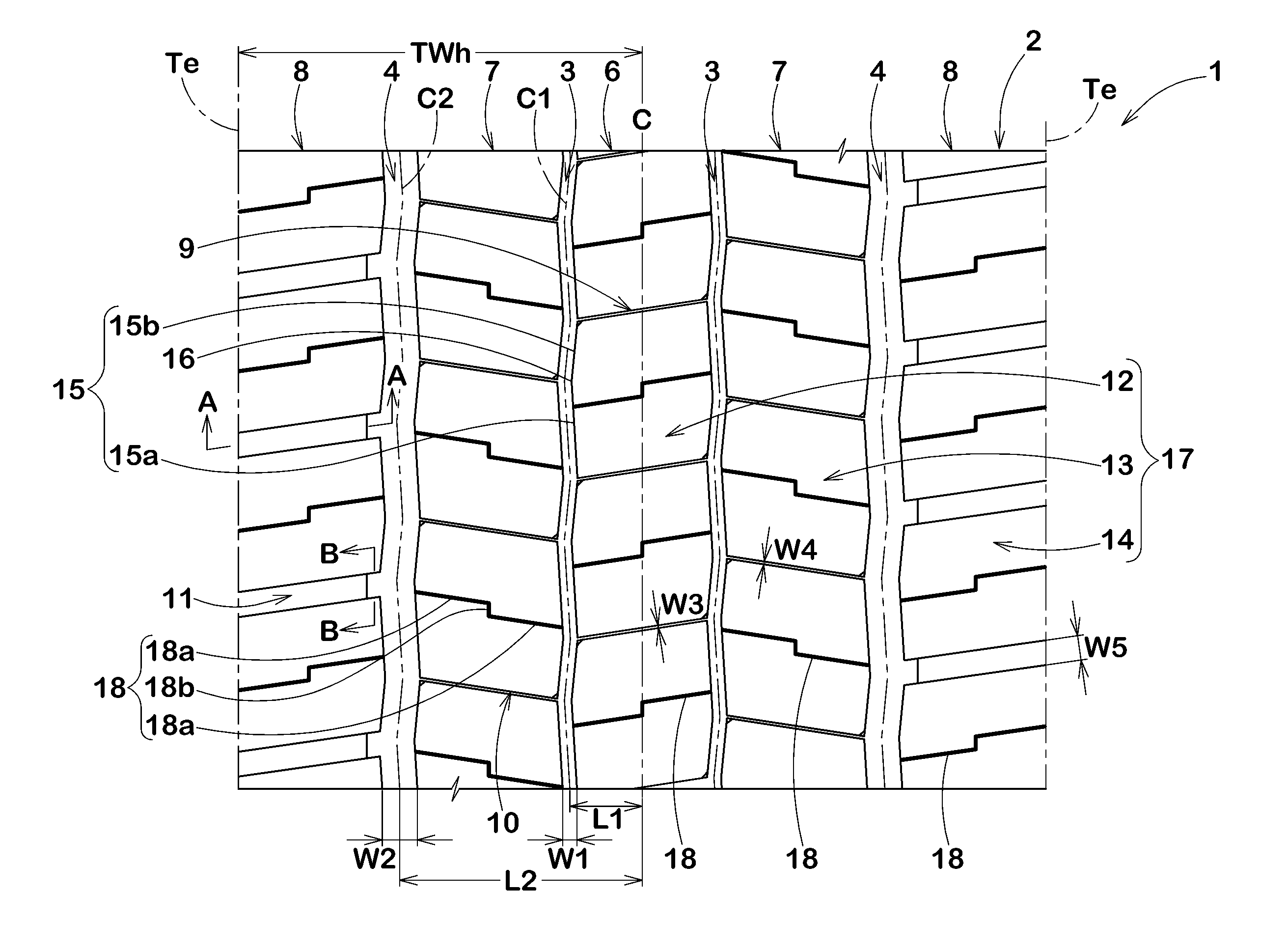

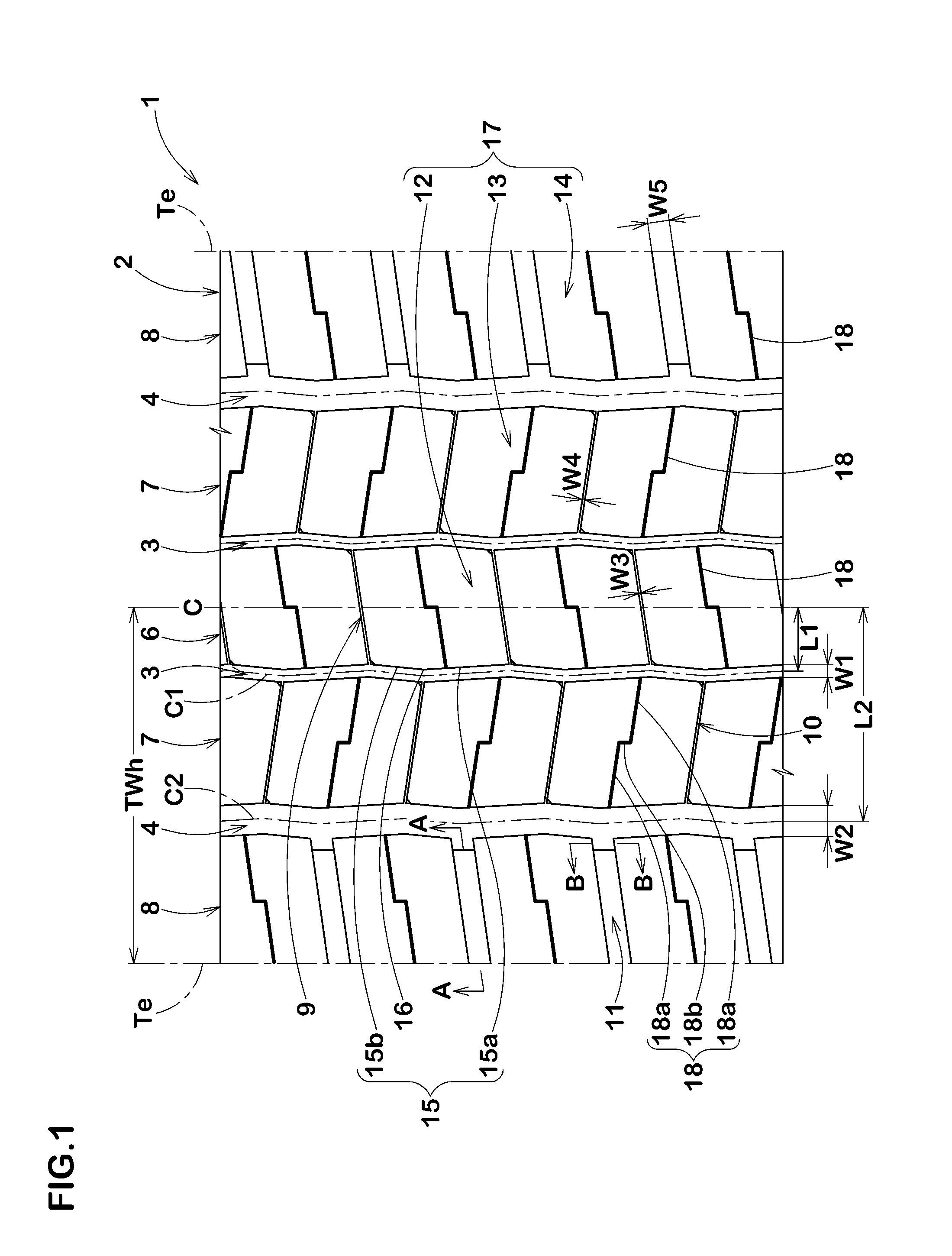

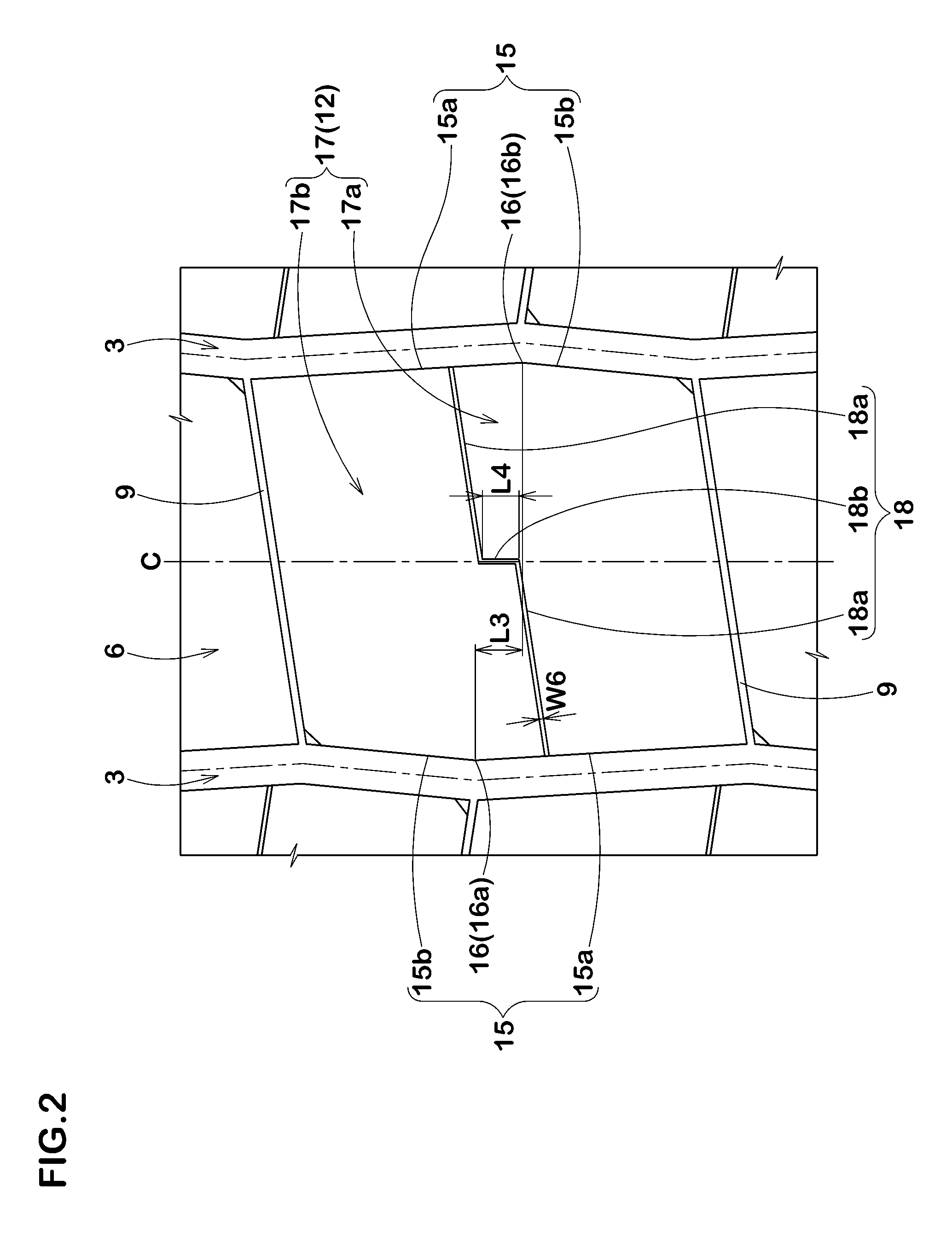

Heavy duty tire

ActiveUS20130098519A1Improve fuel efficiencySmall overall deformationHeavy duty tyresHeavy duty vehicleGroove widthEngineering

Owner:SUMITOMO RUBBER IND LTD

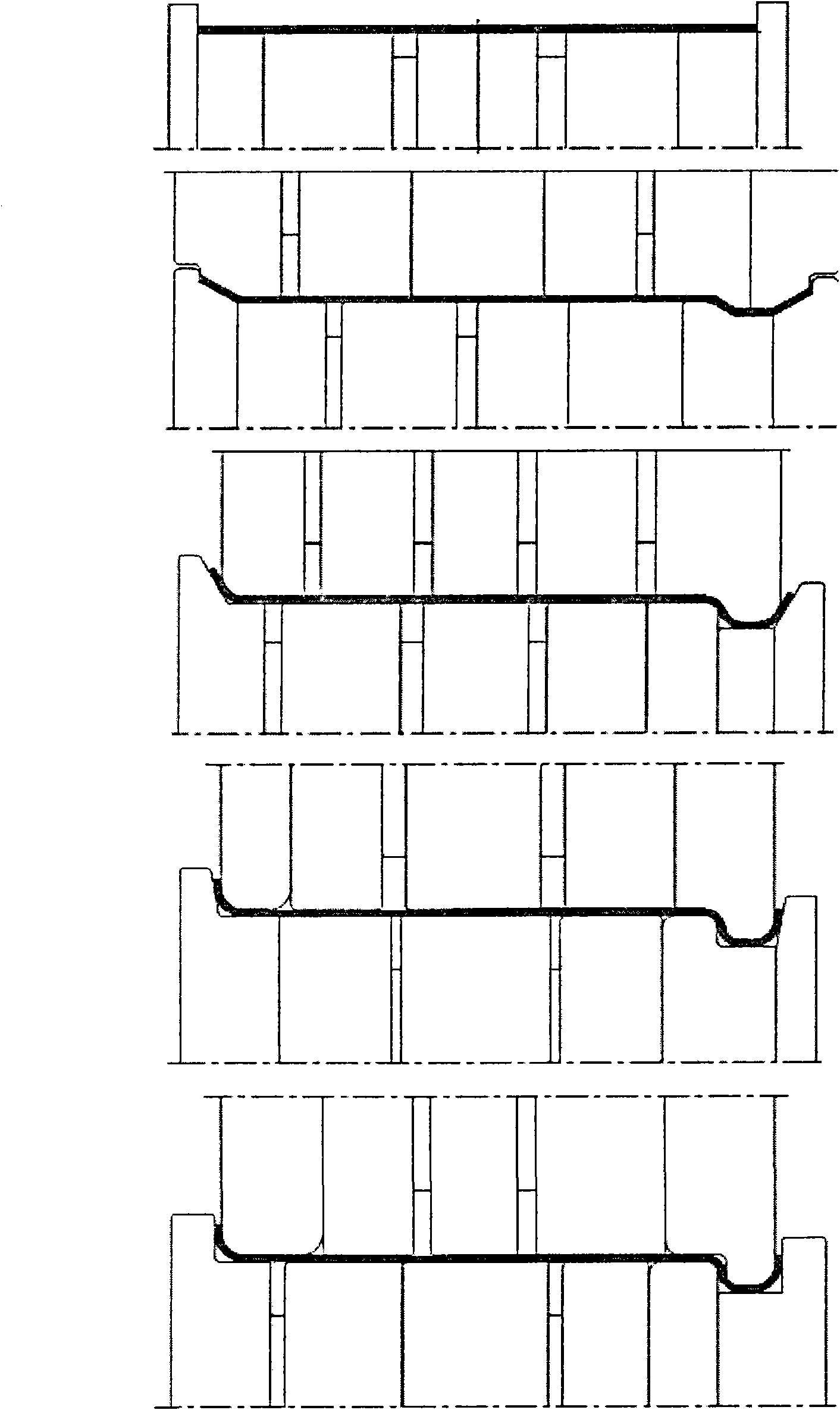

Manufacture method of Z-shaped steel sheet pile through continuous cold roll forming

The invention discloses a manufacture method of a Z-shaped steel sheet pile through continuous cold roll forming by continuously rolling and forming with a cold bending unit and distributing preliminary shafts at both sides of a central shaft. Web plates are continuous so as to greatly improve the modulus and the flexible rigidity of a cross section and fully exert the mechanical characteristic of the cross section. The manufacture process takes great effects in aspects, such as controlling the quality of the cold-bent Z-shaped steel sheet pile, improving the matched accuracy and the connection strength of the preliminary shafts of the steel sheet pile, and the like. The invention controls the product size and overcomes the defects generated in the processing process by performing the preliminary shafts of the cold-bent Z-shaped steel sheet pile and wholly forming the Z-shaped steel sheet pile.

Owner:NANJING WANHUI STEEL SHEET PILING

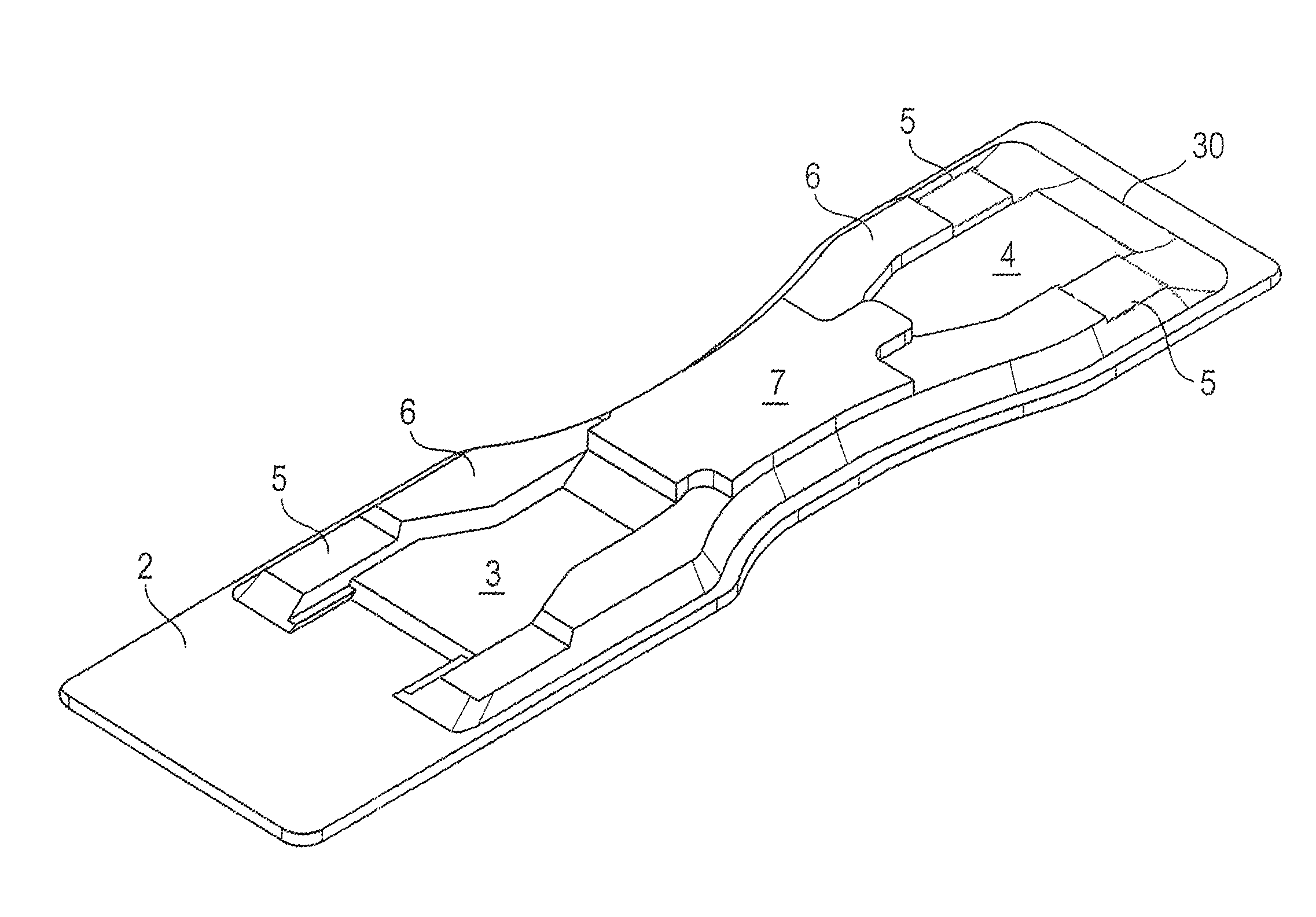

Endless track for industrial or agricultural vehicles

ActiveUS20050104450A1Less deformationSimple structureV-beltsDriving beltsSurface displayRubber material

Described is an endless track for an industrial or agricultural vehicle consisting of a body formed of a rubber material having an outer surface displaying a series of ground engaging profiles longitudinally spaced along the surface and an inner surface displaying a series of longitudinally spaced drive lugs adapted to be engaged by drive sprockets on the vehicle driving assembly. The body of the endless track is fabric reinforced. One layer of fabric longitudinally extends at a distance from the inner surface of the track and has a width slightly less than the width of the drive lugs so that the fabric may extend inside the drive lugs to increase their rigidity.

Owner:CAMOPLASY INC

Armor systems

InactiveUS6945155B2Improve performanceExcellent high velocity impact and ballistic resistanceLayered productsProtective fabricsEngineeringBallistic resistance

An armor system useful, for example, as a shroud, comprising a first pliable, cut resistant fibrous layer and a second pliable fibrous layer is disclosed. The first layer is arranged to receive an impact from a large projectile prior to the second layer and engages the projectile to slow its velocity. The second layer is substantially coextensive with the first and dissipates the incoming energy of the impact to resist complete penetration of the second layer by the projectile, preferably by deforming in response to the impact. Both layers comprise fibers having a tensile modulus of at least about 200 g / d, and an energy-to-break of at least about 8 J / g and a tenacity equal to or greater than about 10 g / d. In another embodiment, the layers are reversed relative to the impact face of the system so that the second layer becomes the first layer and is resistant to projectiles impacting the system, while the first layer becomes the second layer and resists deformation of the system by projectile impacts. Any projectile which completely penetrates the first layer is engaged by the second layer to slow its velocity and prevent complete penetration of the second layer. This armor system provides excellent ballistic resistance with enhanced deformation control.

Owner:HONEYWELL INT INC

Inductor and method of manufacturing the same

InactiveUS20140002226A1Low dielectric lossQ-factor can be increasedTransformers/inductances detailsCable/conductor manufactureInductorLiquid crystal

Disclosed herein are an inductor and a method of manufacturing the same. More specifically, in the inductor according to the present invention, a coil with a fine pattern may be formed, and an insulating resin composite including liquid crystal oligomer for reducing occurrence of deformation of the coil may be used for an insulating substrate.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Disposable hygiene article

A disposable hygiene article has an absorbing element component (12) which is used for storing body liquids and can also contain superabsorbent materials. The absorbing element component (12) is provided with a first area (18, 20), an absorbent material of which has a mass per unit area that increases towards the lateral edges in the transversal direction (16) of the hygiene article. The storage capacity of a section (44) which extends along 40 to 90 percent of the length of the absorbing element component (12) in the longitudinal direction (14) is substantially constant relative to the longitudinal direction (14).

Owner:PAUL HARTMANN AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com